Prediction method for TBM disc cutter wear

A prediction method and hob technology, which are applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as difficulty in predicting hob consumption, and achieve the effect of accurate prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

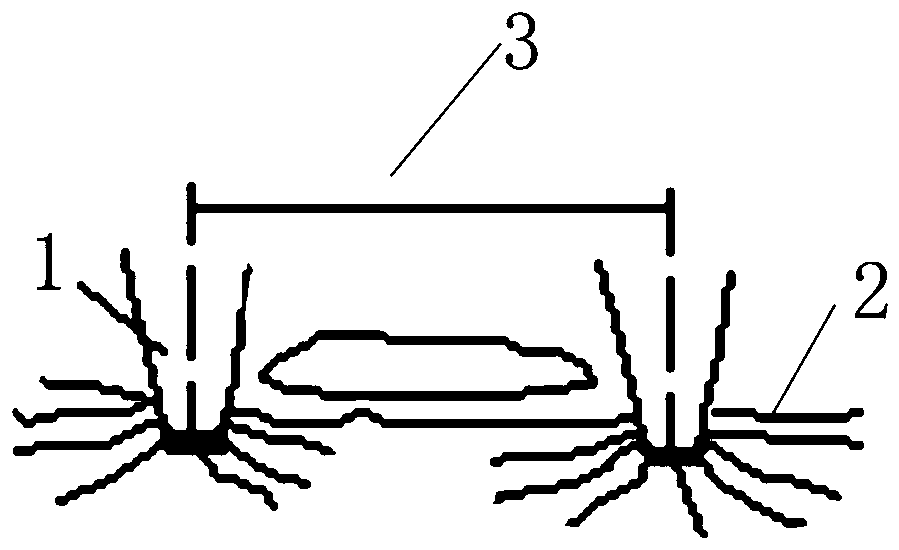

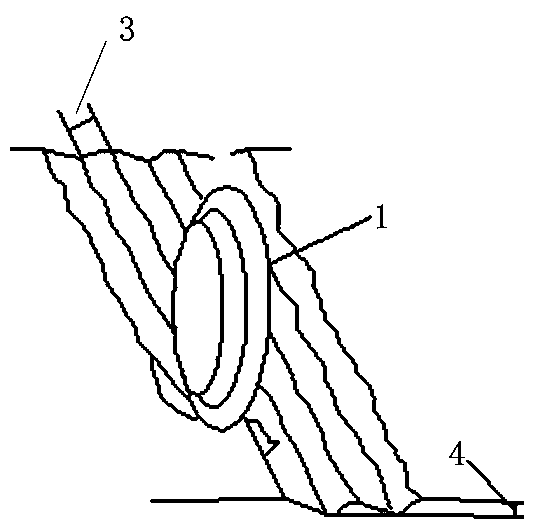

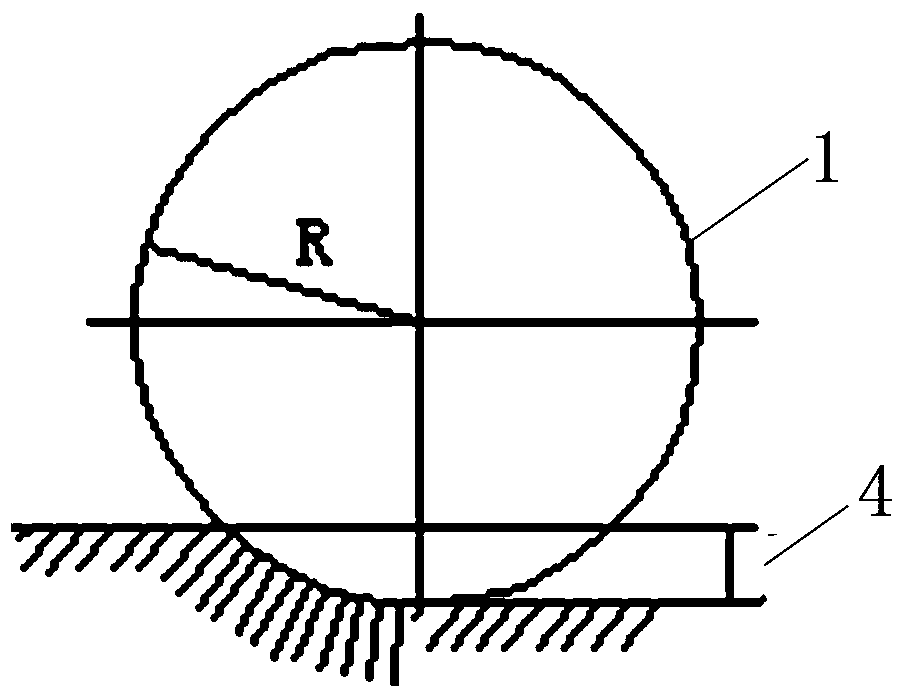

[0044] A kind of TBM hob wear prediction method, comprises the following steps:

[0045] Step 1: Determine the common and easily measurable data information such as the excavation parameters, cutter ring wear and cutter ring characteristics obtained from field measurements and records during the TBM excavation process, as shown in Table 1:

[0046] Table 1. Parameters related to the comprehensive wear coefficient calculation model

[0047]

[0048] Among them, the normal wear and tear replacement standards of each hob are as follows:

[0049]1~6# center cutter, 24~27# front hob, 28~32# side hob allow maximum wear h of 25mm, 7~23# front hob allow maximum wear h of 30mm, 33~35# side The allowable maximum wear h of the hob is 20mm, and the allowable maximum wear h of the 36~37# side hobs is 13mm; in order to avoid overloading of the hob, the height difference of each knife is not greater than 15mm;

[0050] Step 2: Propose the concept of comprehensive wear coefficient, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com