Patents

Literature

227 results about "Wear loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

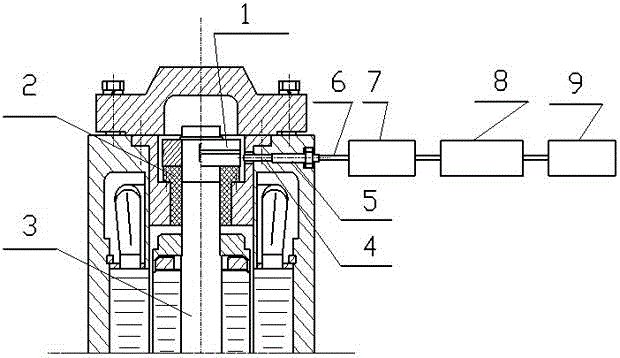

Mechanical scribing apparatus with controlling force of a scribing cutter

InactiveUS20050223570A1Preventing the solar cells from being excessively cutAutomatic control devicesWriting aidsEngineeringMechanical engineering

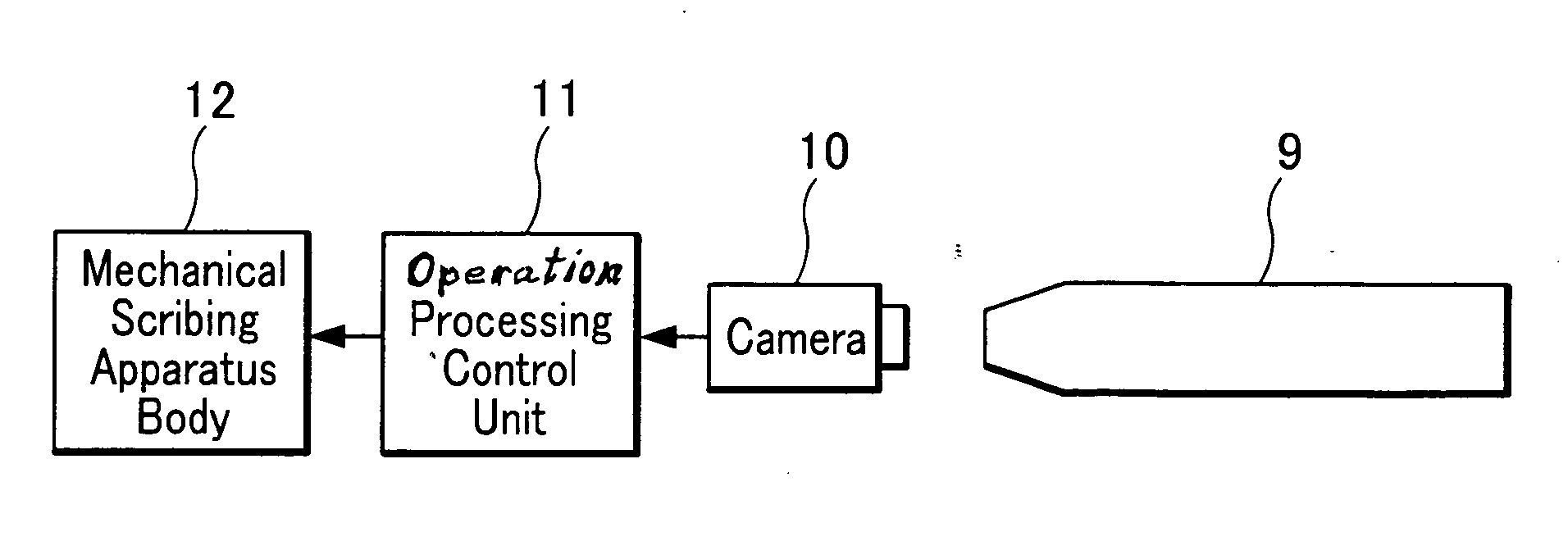

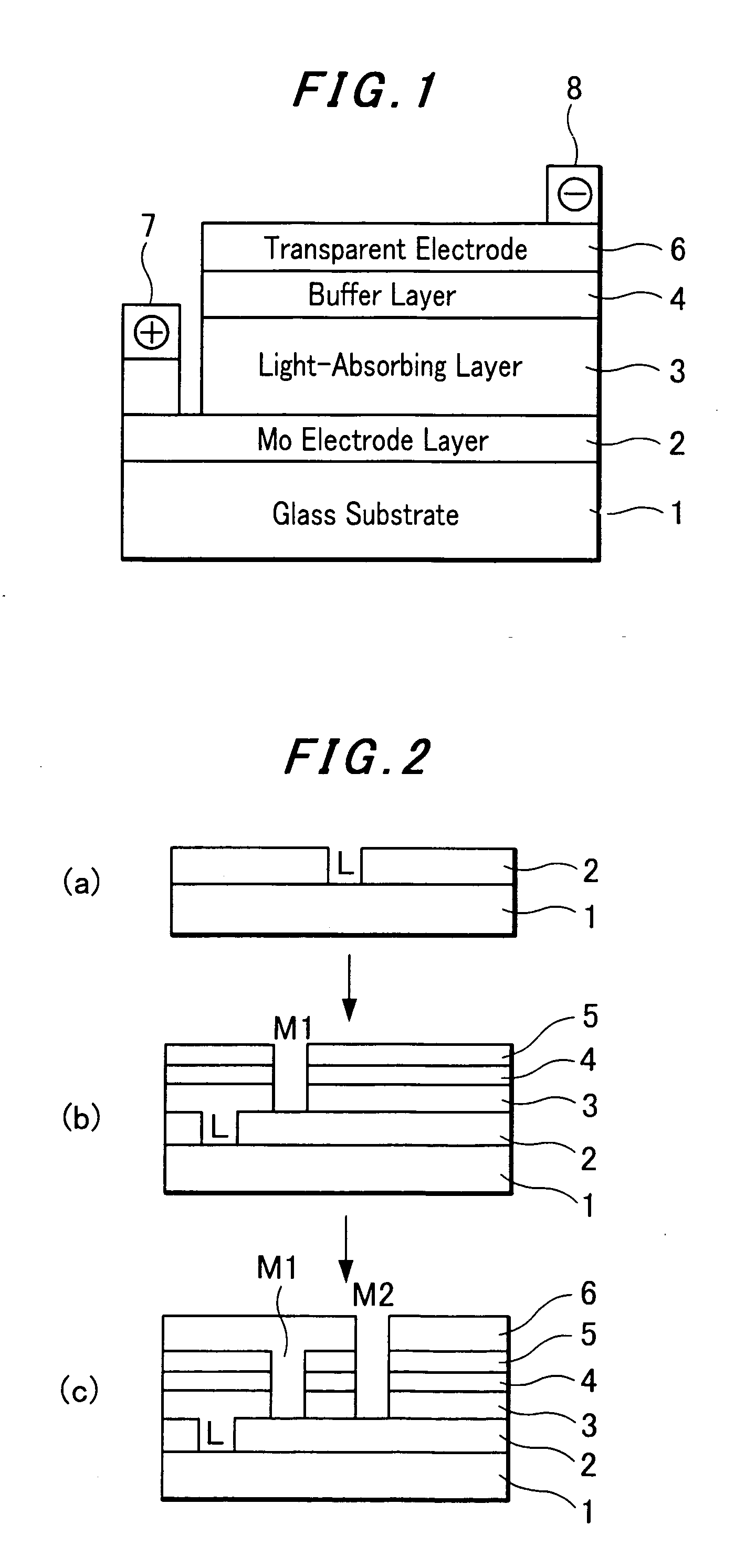

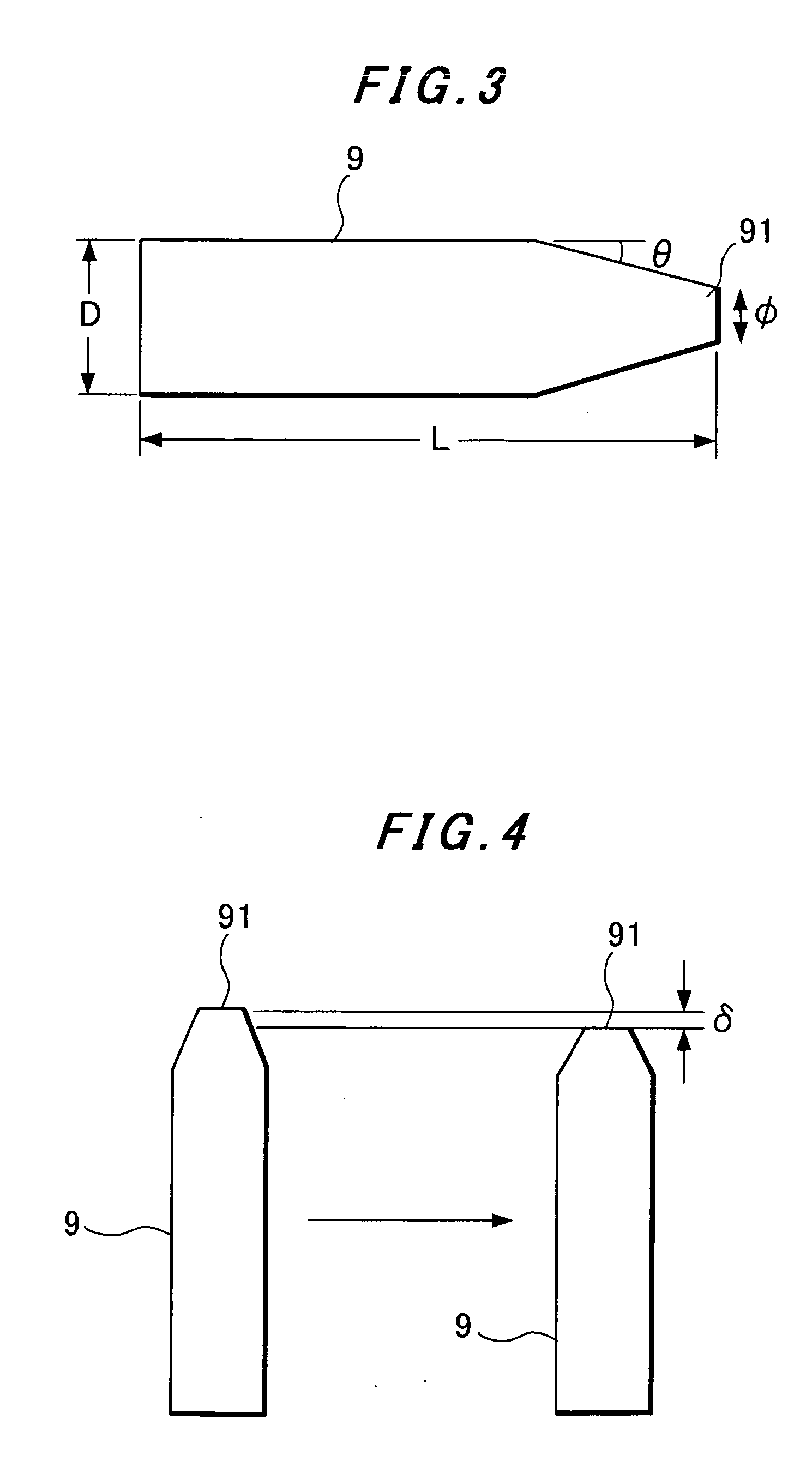

A mechanical scribing apparatus with controlling force of a scribing cutter for adaptively separating each unit of thin film solar cells formed on a single substrate, which is always capable of performing a predetermined minute scribing of a work in accordance with a wear loss of a scribing cutter. This apparatus is provided with a scribing means for placing a scribing cutter having a cylindrical body tapered at a specified tapering angle and having a flat tip face at a specified surface position of the work, pressing the cutter with a specified pressure force to the surface of the work and moving the cutter on the surface of the work, a means for measuring the size of a flat tip face of the scribing cutter and a means for variably controlling the pressure force of the scribing cutter in accordance with the measured size of the flat tip face of the cutter.

Owner:HONDA MOTOR CO LTD

Ultra-wear-resistant alumina ceramic ball and preparation method thereof

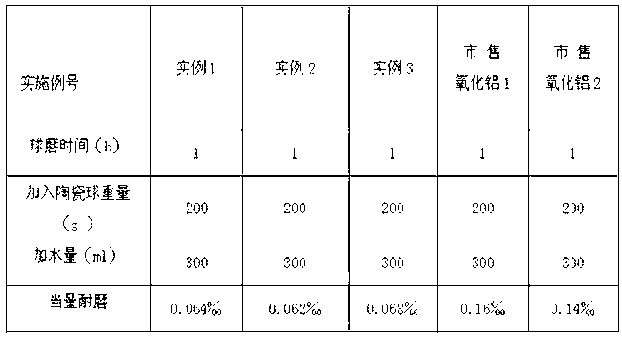

The invention provides an ultra-wear-resistant alumina ceramic ball. The ultra-wear-resistant alumina ceramic ball comprises the following chemical components: 90-95% by weight of Al2O3, 5-8% by weight of SiO2, 0.3-0.5% by weight of CaO, 0.5-0.9% by weight of MgO, 1-2% by weight of ZrO and 0.1-0.5% by weight of La2O3 / Y2O3, wherein the equivalent wear loss is less than 72 per mil. A provided preparation method comprises the following process steps of: adopting alumina powder and other mineral raw materials for burdening, refining mud, drying, calcining, synthesizing, ball-milling, granulating, forming and firing to obtain a product. According to the invention, the wear resistance of the product can achieve the standard of the alumina ceramic ball; and furthermore, the ultra-wear-resistant alumina ceramic ball has the advantages of lower cost of the raw materials, better grinding performance and high performance-price ratio of the product, is more suitable for being applied in production, and can reduce the production cost of an enterprise and improve the production efficiency of the enterprise.

Owner:JINGDEZHEN BETTERWEAR NEW MATERIALS

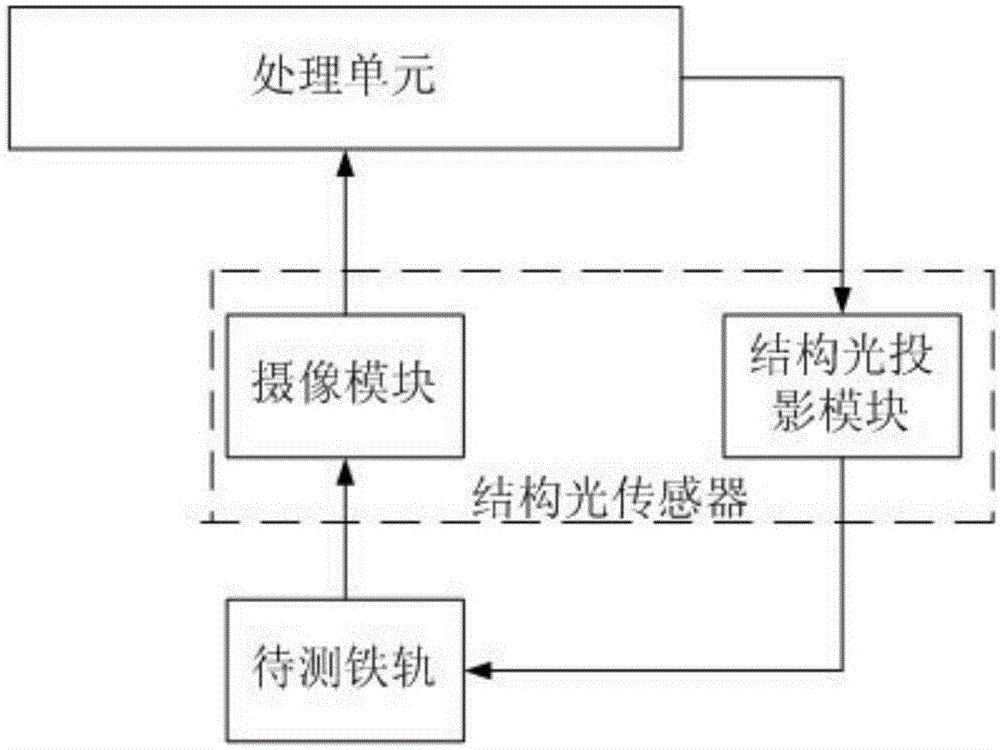

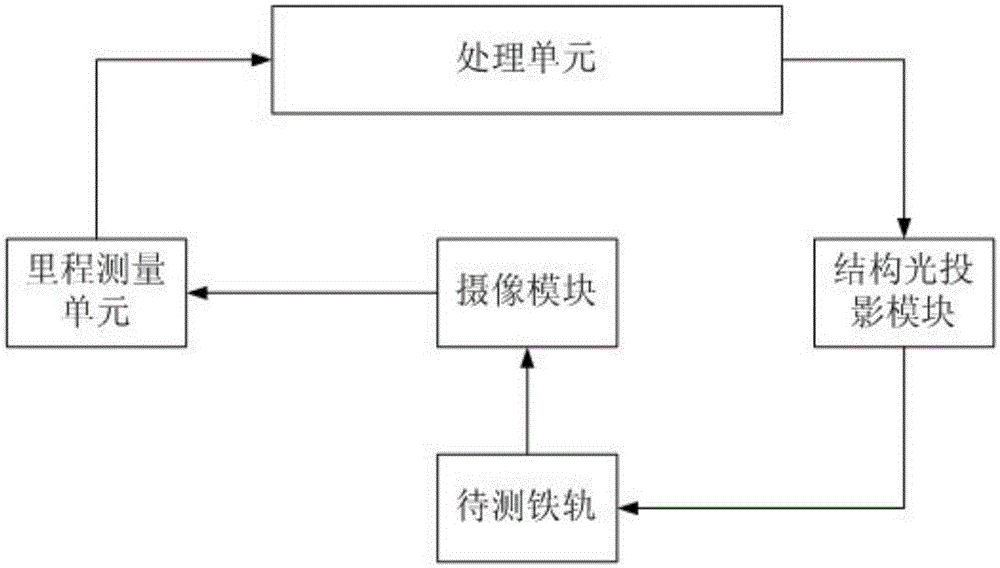

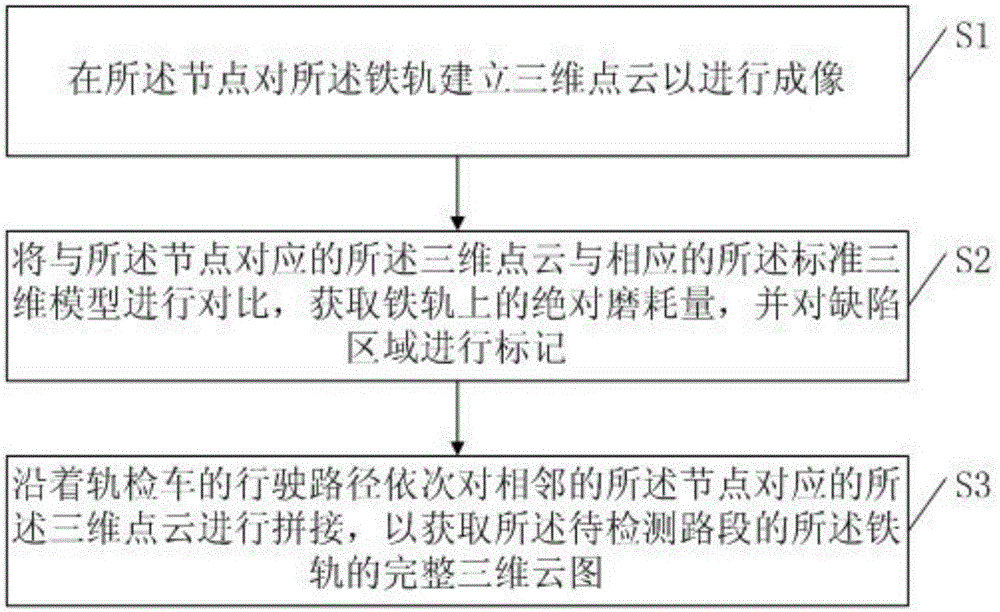

Detection system and method for wear defects of track

ActiveCN105115976AHigh measurement accuracyAdaptableOptically investigating flaws/contaminationPoint cloudEngineering

The invention discloses a detection system and method for wear defects of a track, belonging to the field of wear detection. The detection system and method for wear defects of the track have high measurement precision, high work efficiency and strong adaptive capacity to environments. The system is installed on a track inspection car and used for defect detection of tracks on a to-be-inspected section; a plurality of nodes are arranged on the to-be-inspected section, and each node corresponds to a standard three-dimensional model; three-dimensional reconstruction is carried out on the surface of the tracks by using a structured light sensor; a processing unit compares a three-dimensional point cloud obtained by the structured light sensor with a corresponding standard three-dimensional model, detection is carried out so as to obtain absolute wear loss of the tracks, and a defect area is marked; all the three-dimensional point clouds are spliced via the processing unit so as to obtain a complete three-dimensional cloud picture; so the system has strong adaptive capacity to environments. The detection method for wear defects of the track has the advantages of high measurement precision and low cost.

Owner:成都晟甲科技有限公司 +1

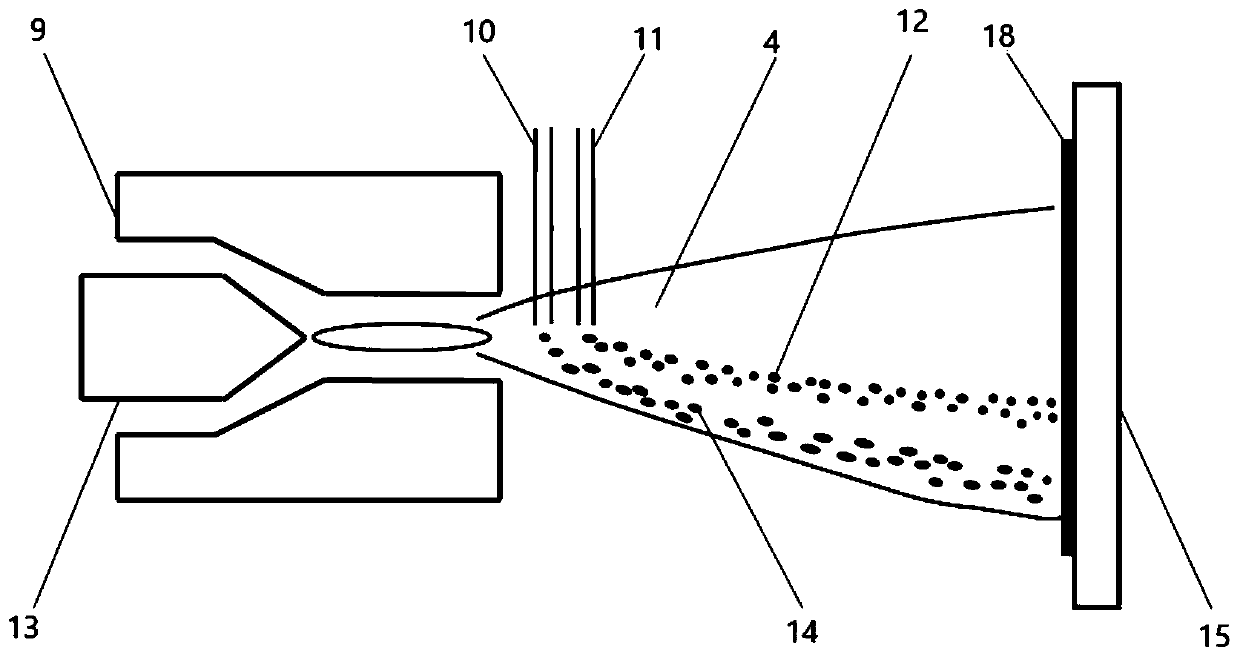

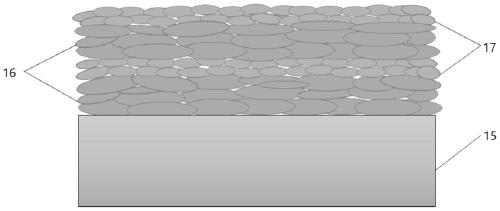

Copper-base crystallizer surface laser cladding method

ActiveCN101532133AHigh hardnessImprove wear resistanceMolten spray coatingSuperimposed coating processHardnessCo2 laser

A copper-base crystallizer surface laser cladding method is characterized in that the method comprises the following steps in sequence: (1) preparing a nickel-base transition layer with thickness of 0.3-0.5mm; (2) melting the transition layer by using a mixing mode CO2 laser beam; (3) preparing a nickel-base or cobalt-base alloy work layer with thickness of 0.6-1.0mm by ultrasonic spraying; (4) melting transition layer by using the mixing mode CO2 laser beam; and (5) processing a laser cladding layer into a smooth surface. By the method of the invention, excellent metallurgically bonded cladding layers are formed on copper-base materials. The hardness and wearing resistance experiments show that the hardness of the work layer is above Hv350, which is improved by more than 3 times compared with the hardness of copper alloy; the wear loss of the laser cladding nickel-base or cobalt-base work layer is about 10mg and the high temperature wearing resistance is over 5 times as high as that of the copper alloy, thus having the effect of strengthening the copper alloy. The method of the invention is suitable for not only strengthening the copper-base crystallizer but also strengthening various copper-base alloy surfaces.

Owner:GUANGDONG INST OF NEW MATERIALS

Ultrahigh-strength wear-resisting plate with cement base and production method thereof

InactiveCN102060479ASmall wear lossSimple production processSolid waste managementCeramic shaping apparatusFiberCompressive strength

The invention provides an ultrahigh-strength wear-resisting plate with a cement base, which comprises the following components: 50-100 weight parts of cement, 0-50 weight parts of mineral blending material, 1-5 weight parts of water reducing agent, 100-400 weight parts of wear aggregate, 0-20 weight parts of steel fiber, 0-10 weight parts of organic fiber and 15-30 weight parts of water. The production method of the ultrahigh strong-wear plate with the cement base provided by the invention comprises the following steps: weighing each component according to the ratio; uniformly stirring the components except the water; continuously stirring the components to a uniform state after the water is added; placing the mixture into a die for artesian molding or vibration molding; arranging a connecting piece or reserving a hole on the molding surface of a plate according to the requirements; carrying out the maintenance for 1 day at the normal temperature after the molding and carrying out thedemolding; and carrying out the maintenance with hot water at the temperature no lower than 50 DEG C for 1-3 days, or carrying out the maintenance with steam for 1-3 days to prepare the strong-wear plate. In the invention, the plate with large compressive strength, large impact strength and small wear loss amount can be obtained, the connecting piece can be installed or the hole is reserved, and the plate has the advantages of simple production process, low cost, and short construction and repair period.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

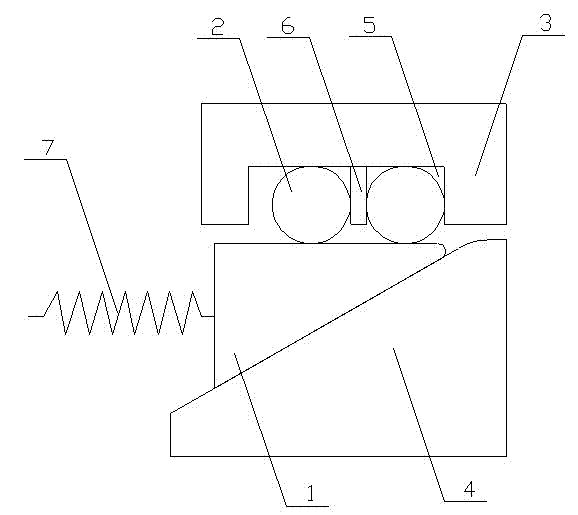

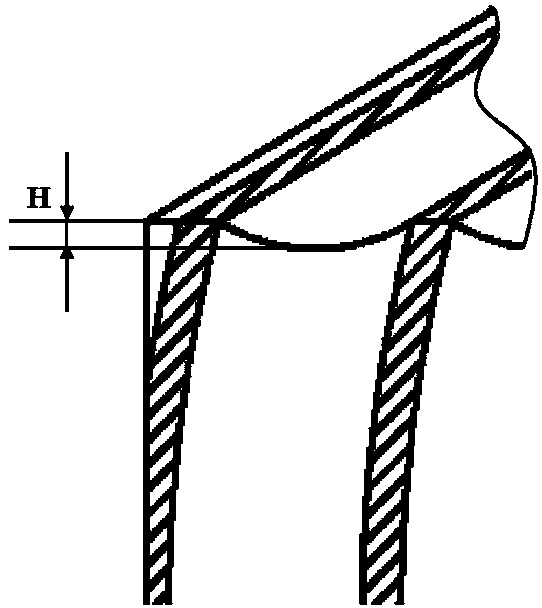

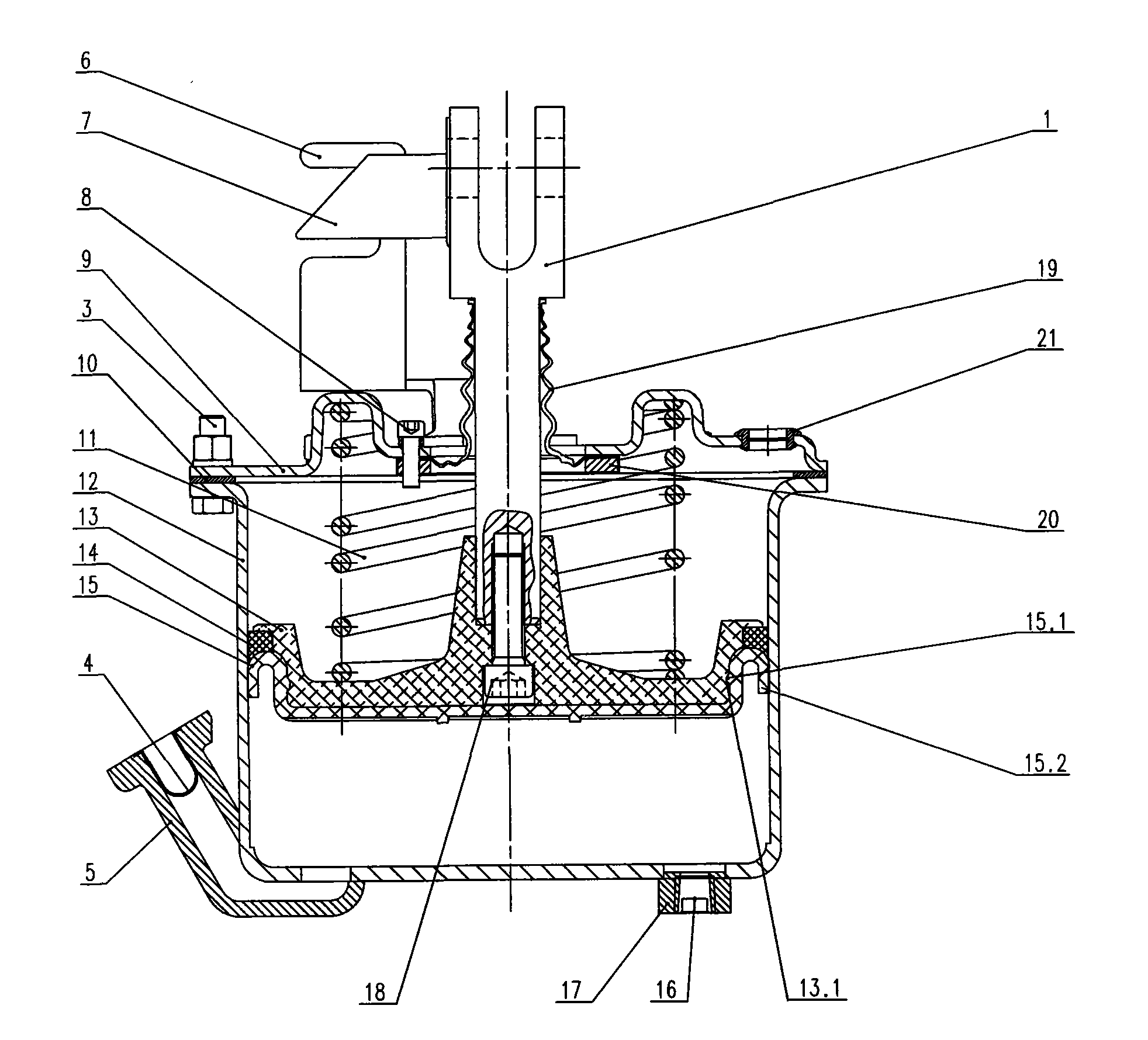

Sealing structure of tapered slip ring with self-compensating property

InactiveCN102410374AIncreasing the thicknessImprove impact resistanceEngine sealsInternal pressureRight triangle

The invention discloses a sealing structure of a tapered slip ring with a self-compensating property, which comprises a tapered slip ring, an O-ring, a cylinder barrel and a shaft sleeve, wherein the O-ring is arranged in a sealing ring groove of the cylinder barrel; a mobile annular retaining ring is arranged between the O-ring; the tapered slip ring is arranged between the cylinder barrel and the shaft sleeve and the cross section is a right triangle; an elastic element is arranged on the end face of the slip ring; the tapered slip ring moves rightward along the inclined plane of the shaft sleeve under the action of the elastic element and the internal pressure; the O-ring is extruded when the slip ring moves rightward; the deformed O-ring reacts on the slip ring as the diameter compression ratio of the cross section changes along with the internal pressure of a sealing cavity; and the contact pressure on the dynamic sealing surface of the slip ring is wavy to form serrated sealing effect. The sealing structure has simple structure, low cost and good sealing performance. The wear loss can be automatically compensated by the tapered slip ring, the problem of wear is fundamentally solved, the stress condition of the O-ring is improved, and the service life of the O-ring is prolonged.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

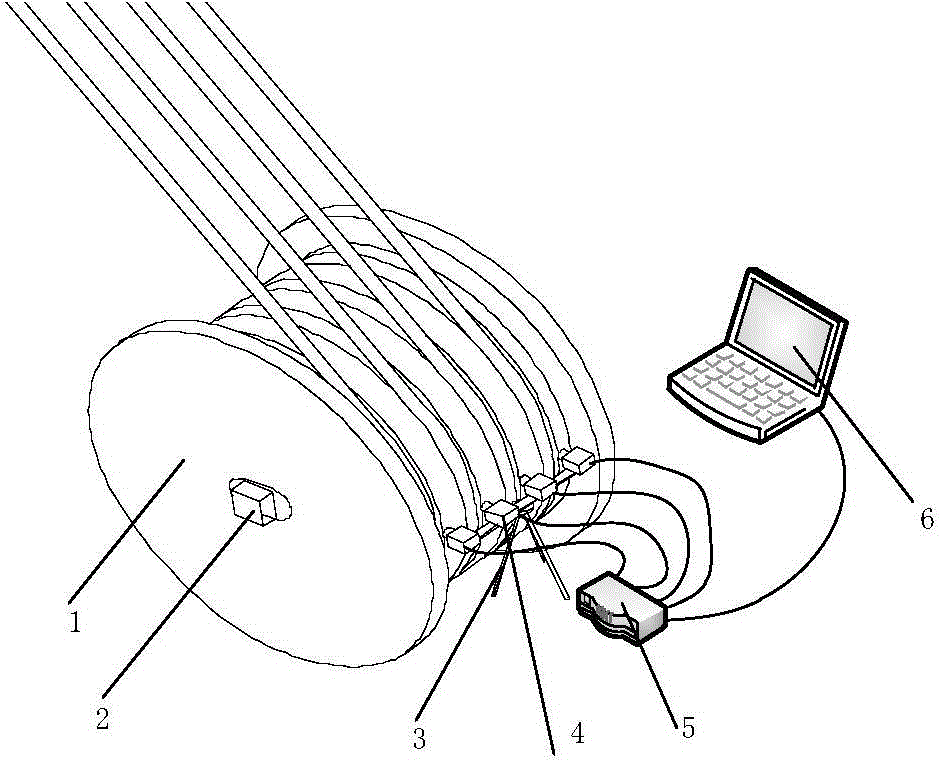

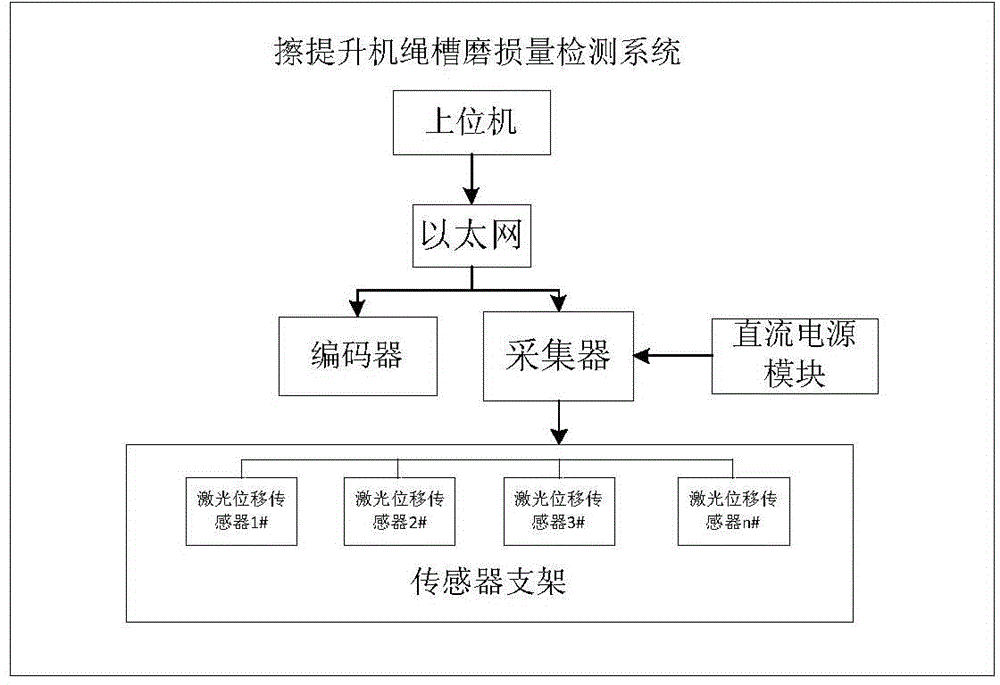

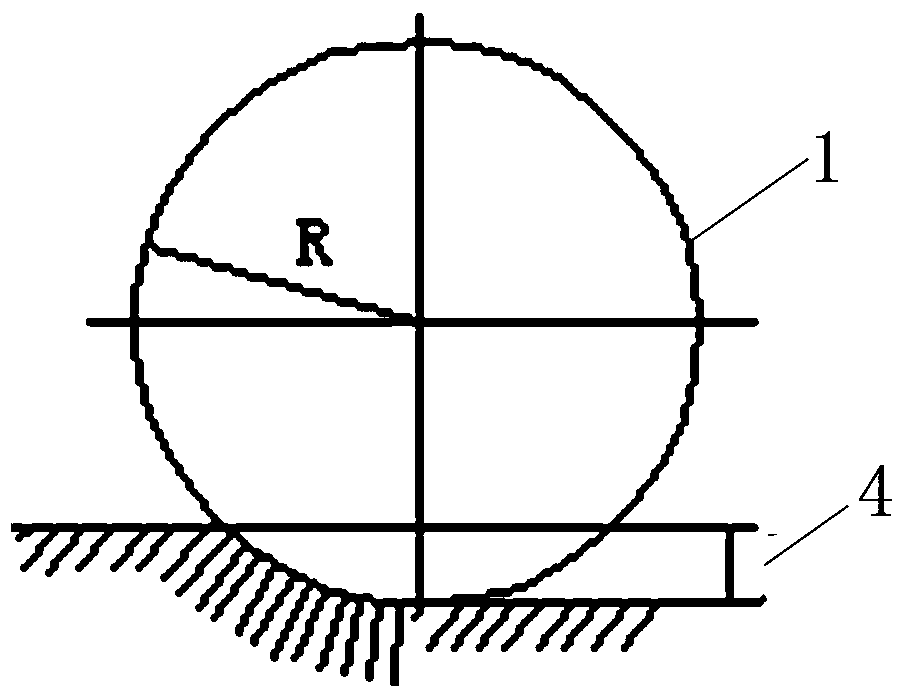

Detection system and detection method of friction elevator rope groove wear loss

InactiveCN104627762AReal-time online detectionReduce labor intensityElevatorsReal time analysisEngineering

The invention provides a detection system and a detection method of friction elevator rope groove wear loss, and belongs to the detection system and the detection method of the elevator rope groove wear loss. The system comprises an upper computer, a laser displacement sensor, a collector, a direct-current power source module and a sensor support. The laser displacement sensor is installed on the sensor support, and the output end of the laser displacement sensor is connected with the collector. An encoder is installed on a roller of an elevator, the output end of the encoder is connected with an Ethernet, and the output end of the collector is connected with the input end of the upper computer through an interface of the Ethernet. The upper computer achieves real-time analysis of the on-line detection of the friction elevator rope groove wear loss and determines the wear loss conditions of different positions according the encoder. The detection system and the detection method have the advantages that the real-time quick on-line detection of the wear loss of a friction liner can be achieved, the friction liner needing to be replaced can be positioned precisely in real time, the working intensity of workers is reduced, the service life of a steel wire rope is prolonged, and the problem that real-time monitoring of the wear loss of the friction line cannot be achieved in a project is solved.

Owner:CHINA UNIV OF MINING & TECH

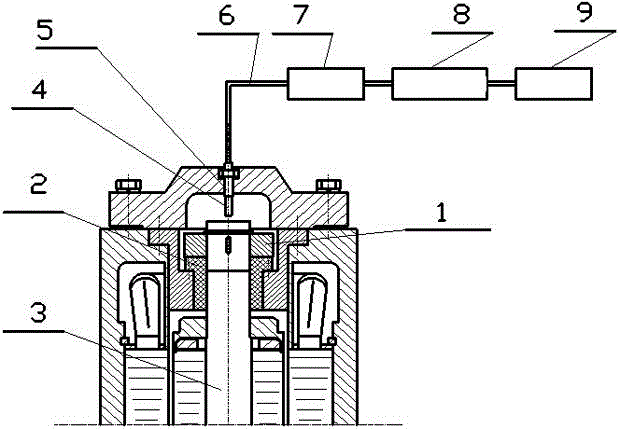

Online monitoring device and online monitoring method for thrust bearing wear loss of fully-sealed pump

InactiveCN104792254AAvoid downtime and other failuresUsing electrical meansAudio power amplifierThrust bearing

The invention discloses an online monitoring device and an online monitoring method for thrust bearing wear loss of a fully-sealed pump. The online monitoring device comprises a rotor, a thrust disc and a graphite bearing bush of the sealed pump, a hole is formed in the sealed pump and faces towards an end face of the rotor or faces towards a lateral side of the thrust disc, a position probe is mounted in the hole and connected with an inductive transducer, the inductive transducer is connected with an amplifier via a signal transmission line, the amplifier is connected with an analog / digital converter via the signal transmission line, and the analog / digital converter is connected with a computer via the signal transmission line. The online monitoring device and the online monitoring method have the advantages that different mounting manners can be selected according to different mounting positions, and moving distance of the thrust disc can be reflected directly and accurately by both measuring methods, so that moving amount of the graphite bearing bush can be obtained, wear conditions of a water-lubricated thrust bearing inside the fully-sealed pump can be reflected directly, and faults like sudden shutdown can be avoided.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Wear resistant material of modified polytetrafluoroethylene resin

InactiveCN101921442AGood self-lubricating performanceSmall average wear coefficientWear resistantHigh pressure

The invention provides a wear resistant material of modified polytetrafluoroethylene resin, which is prepared by fully mixing high polymer polybenzoate serving as a modifier with the polytetrafluoroethylene resin according to a certain ratio and by cold-pressing and sintering or hot-pressing and sintering. The polybenzoate has a high self-lubricating property, so that the problem that common filler polytetrafluoroethylene has high wear loss and particularly damages counter-grinding coupled parts to a large extent can be solved. The wear resistant material can be used as a part in extreme conditions such as high temperature, high voltage, oil-less lubrication, corrosion and the like. The wear resistant material made of the modified polytetrafluoroethylene resin of the invention has a minimum average wear coefficient and has a main characteristic of wear resistance, thereby avoiding damaging the counter-grinding coupled parts. The material can be widely applied in industrial fields such as machinery, aviation, aerospace, electronics and electricity and has a wide application prospect.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

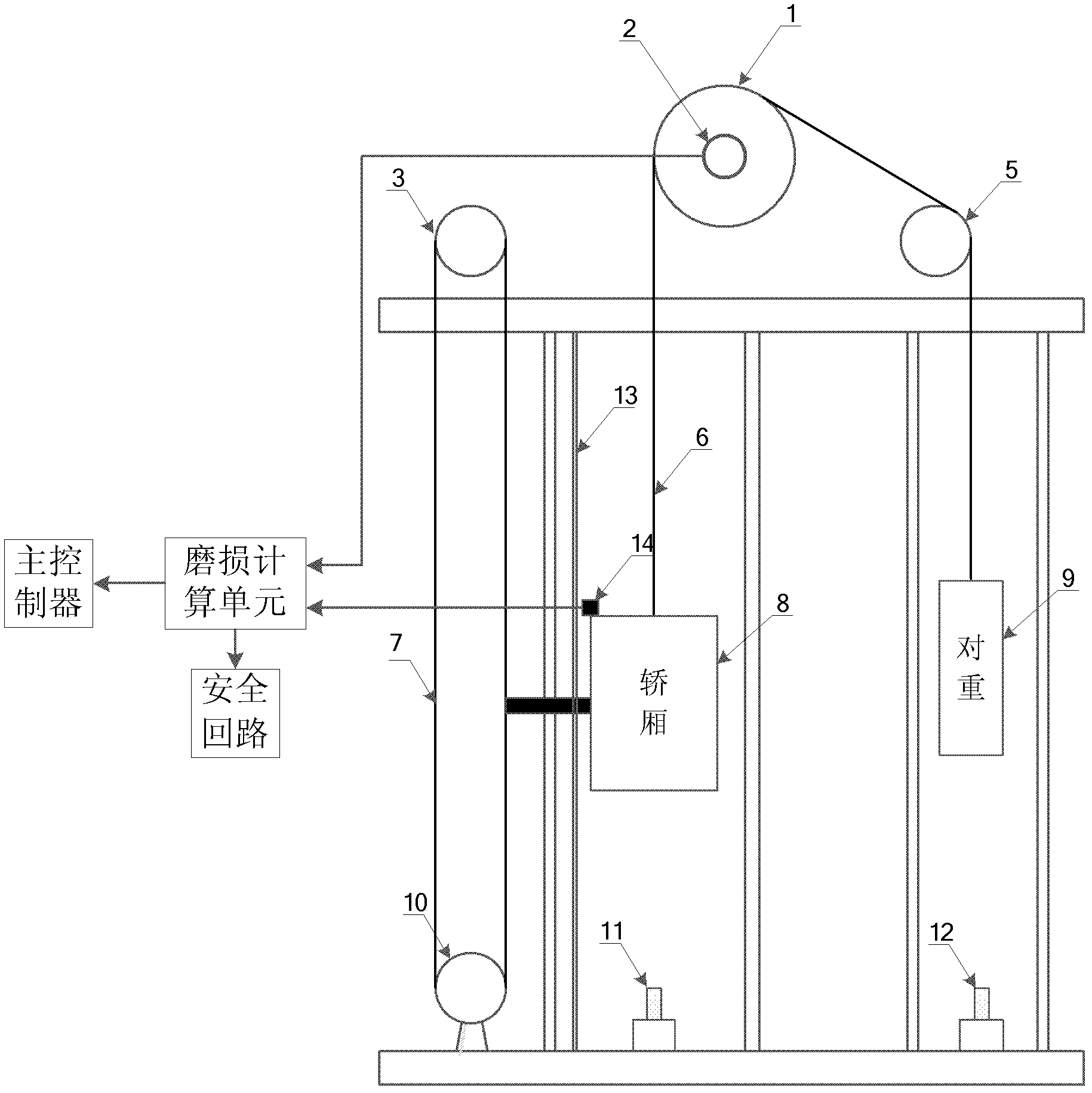

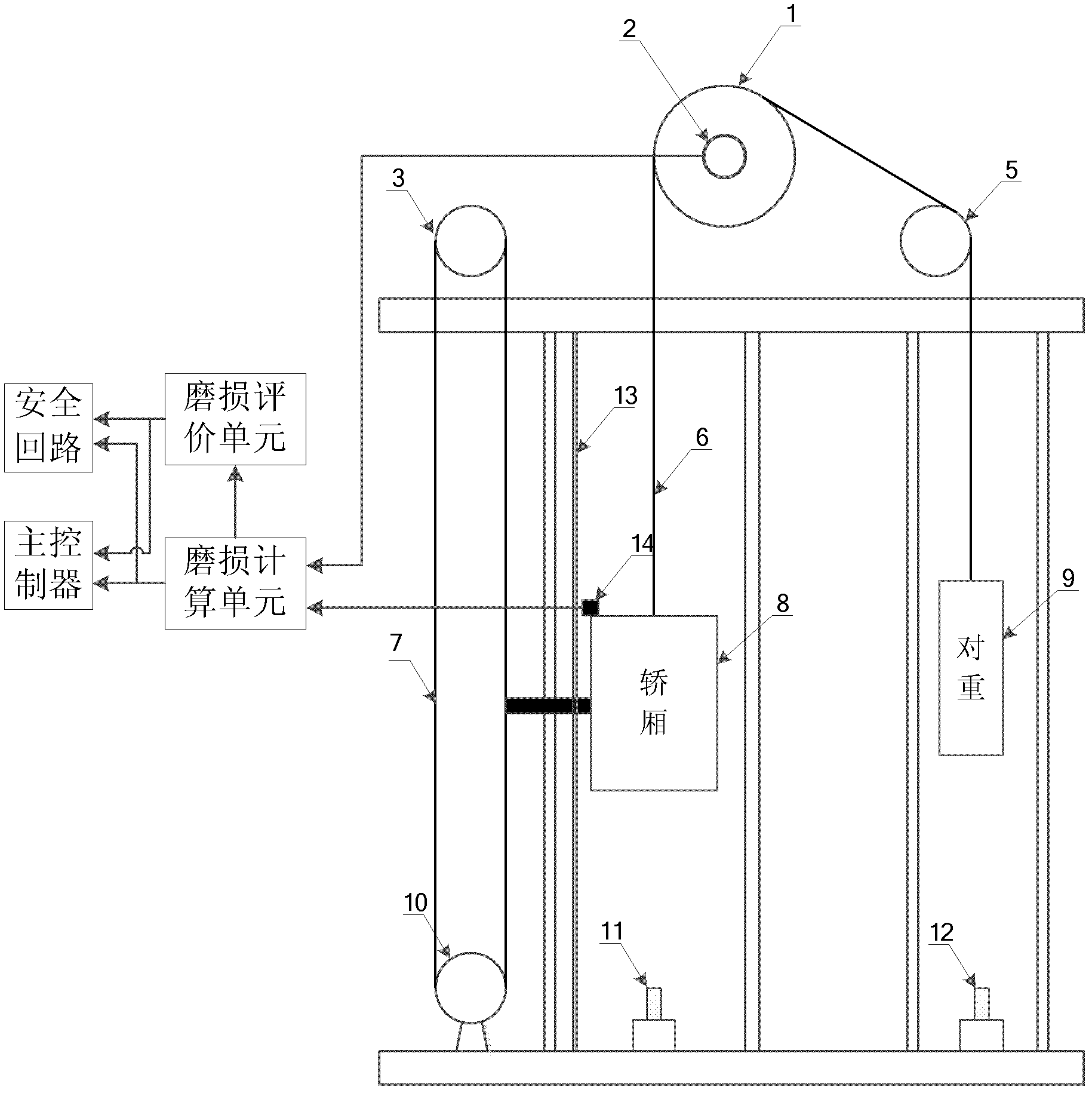

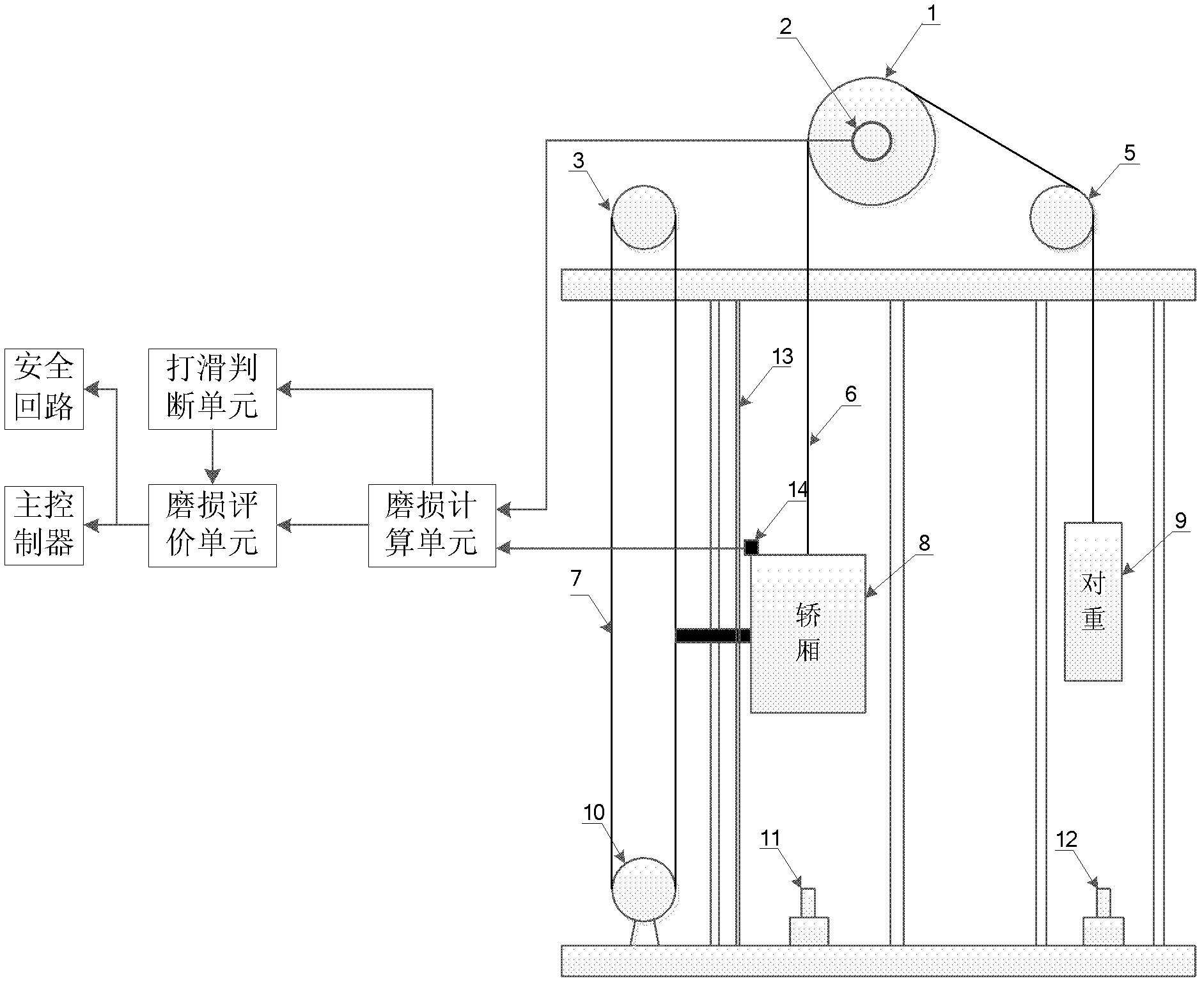

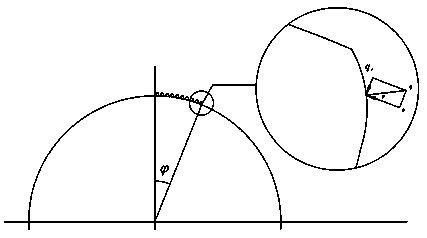

Wear detection device for elevator driving rope sheave and detection method

The invention discloses a wear detection device for an elevator driving rope sheave. The wear detection device comprises an angular displacement detection device, a linear displacement detection device and a wear calculating unit, wherein the wear calculating unit is used for calculating the wear of the elevator driving rope sheave; and the wear calculating unit is used for calculating the practical value of the diameter of the elevator driving rope sheave according to the angular displacement of the elevator driving rope sheave detected by using the angular displacement detection device and the linear displacement of the elevator driving rope sheave detected by using the linear displacement detection device, and is further used for calculating the wear loss of the elevator driving rope sheave according to the practical value of the diameter and the nominal value of the diameter of the elevator driving rope sheave. According to the wear detection device, the linear displacement or angular displacement can be changed as required, slippage between the elevator driving rope sheave and an elevator driving rope can be judged, the wear detection result of the elevator driving rope sheave can be evaluated correspondingly, a specific area where an elevator car is positioned is not limited, and wear of the elevator driving rope sheave can be detected at any time. The invention further discloses a wear detection method for the elevator driving rope sheave.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

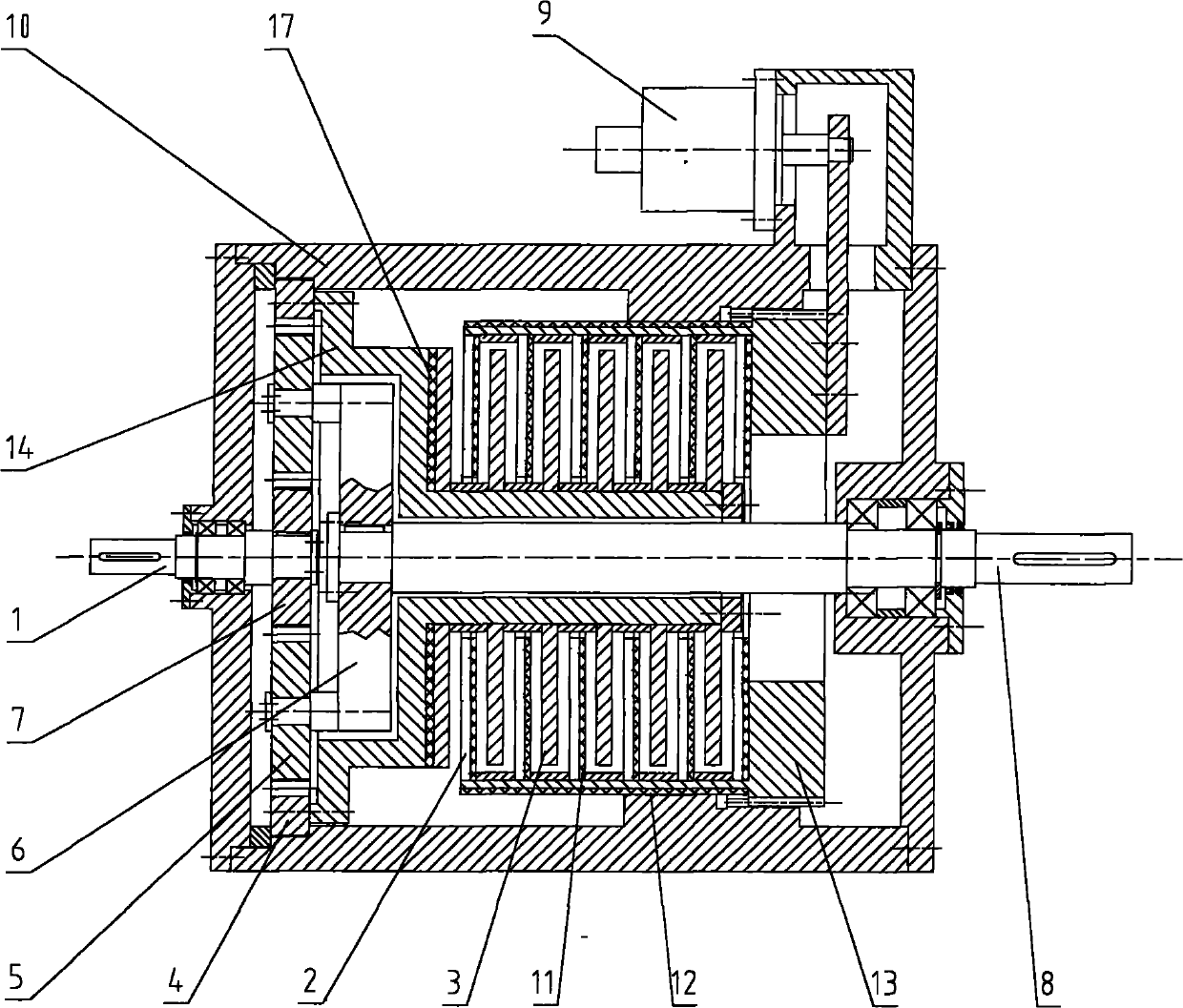

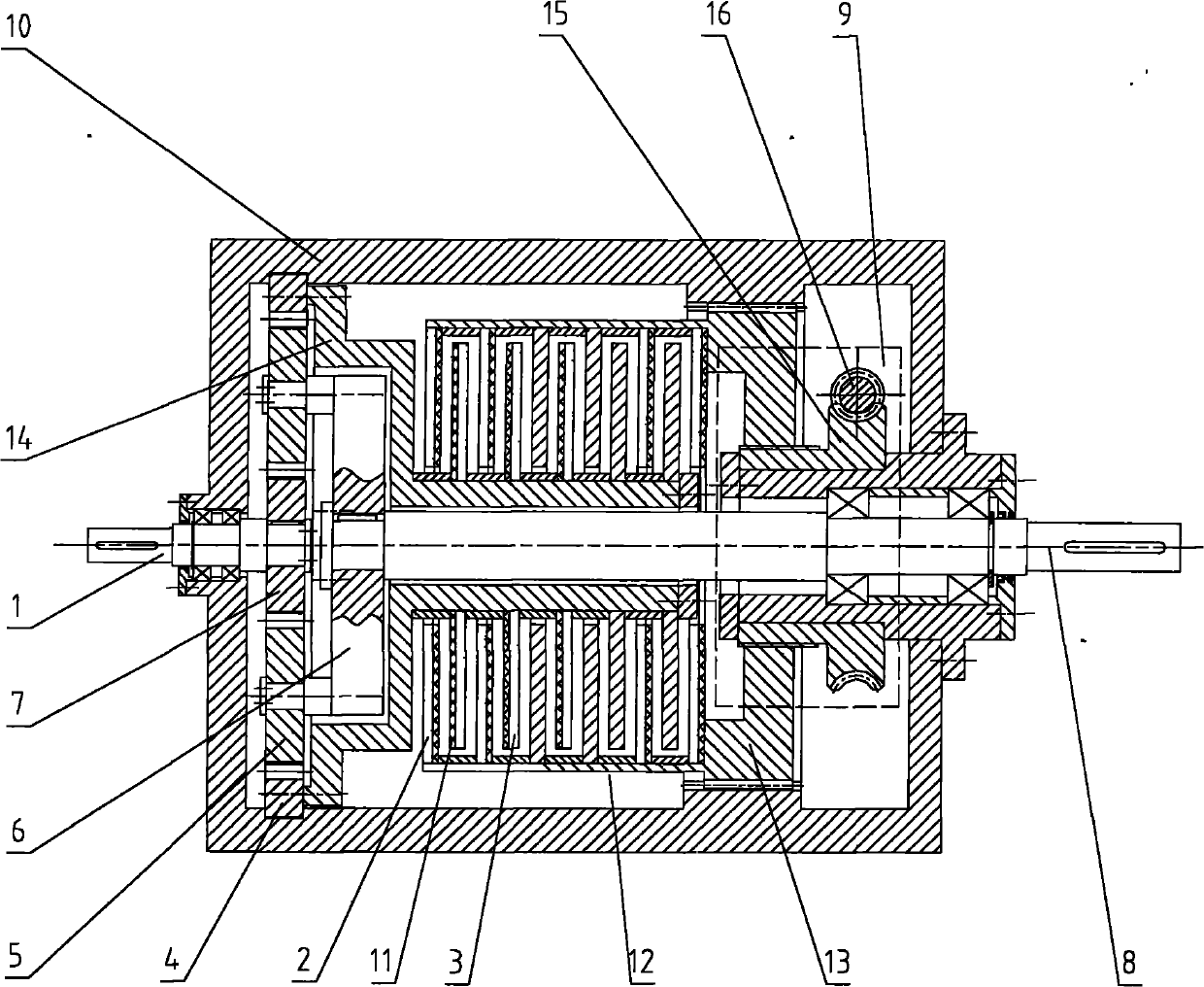

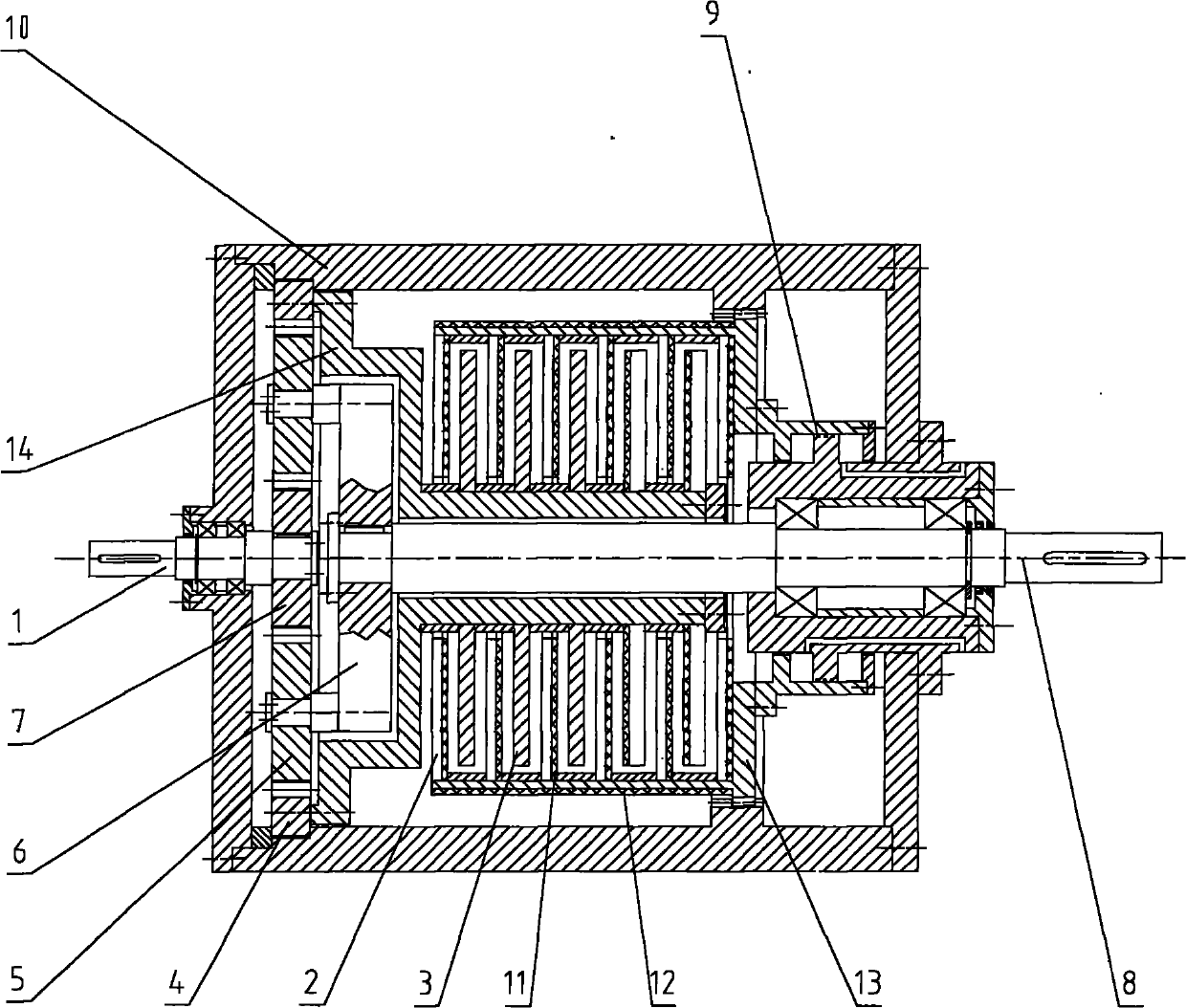

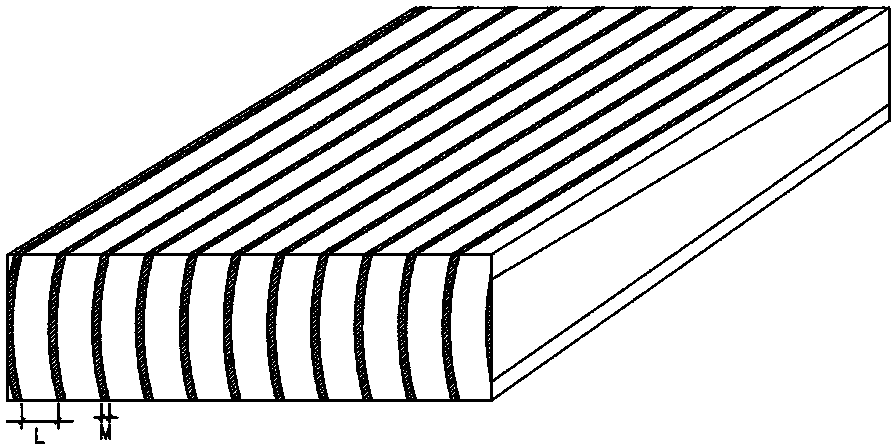

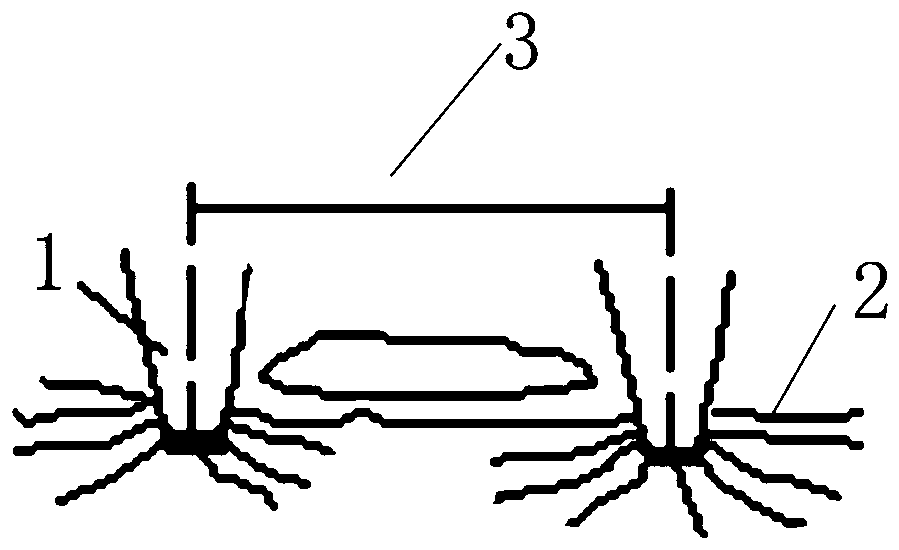

Disc type magnetic control speed governing clutch

InactiveCN102022487AEasy to control the speed by adjusting the distance between the linkage disc and the brake discEasy to control the output torque by adjusting the distance between the linkage disc and the brake discToothed gearingsPermanent-magnet clutches/brakesElectrical conductorMagnetic poles

The invention discloses a disc type magnetic control speed governing clutch which aims at providing a speed governing clutch with small wear loss, long service life, high bearing capacity, overload protection function and speed reduction. The clutch comprises a planet transmission mechanism and a brake mechanism. The planet transmission mechanism is provided with a speed governing input end, a power input end and a power output end, wherein the speed governing input end is directly or indirectly connected with the brake mechanism. The brake mechanism comprises one or more than one brake disc 2, one or more than one linkage disc 3 and a governing mechanism 9, wherein a part of or all brake discs 2 and linkage discs 3 are provided with permanent magnets or permanent magnets showing magnetic poles on disc faces, and the rest are conductors. The brake mechanism carries out braking by means of magnetic force between the brake discs 2 and the linkage discs 3. The invention is applicable to the soft start and the soft braking of mechanical equipment.

Owner:张吉秀 +1

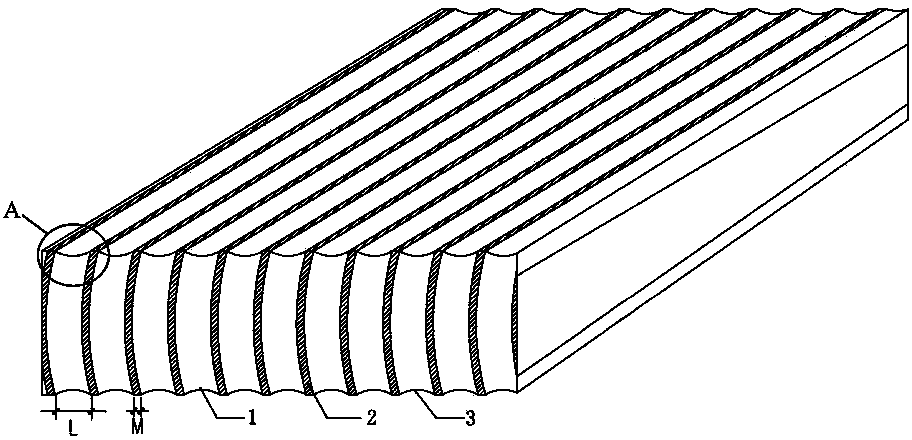

Surface strengthening ancient-Chinese-fir-imitation floor base material and manufacturing method thereof

InactiveCN103522384AGood dimensional stabilityHigh strengthWood treatment detailsPressure impregnationUltimate tensile strengthMachining

The invention discloses a surface strengthening ancient-Chinese-fir-imitation floor base material and a manufacturing method thereof. The surface strengthening ancient-Chinese-fir-imitation floor base material is mainly manufactured by using Chinese-fir converted timbers as raw materials, the surface layer density is 0.6g / cm<3>-0.8g / cm<3>, the hardness is improved by one time to be maximum and is larger than that of the Chinese-fir converted timbers, the wear loss is reduced by 50% to the maximum and is less than that of the Chinese-fir converted timbers, concave-convex grains are arranged on the surface of the base material, the depth of a groove is 1mm-3mm, and the manufacturing method comprises the steps of one-time drying, converted timber fine machining, immersion treatment, secondary drying and sizing treatment. The surface strengthening ancient-Chinese-fir-imitation floor base material is high in surface hardness and strength, has the three-dimensional relief and antiquing effects, and is good in size stability, green and environmentally-friendly. The manufacturing method is easy to operate, small in equipment investment, wide in raw material source, and low in cost.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

Prediction method for TBM disc cutter wear

InactiveCN108710722AAvoid complex internal mechanism research processOvercome the defect of only accurately predicting the hob on the cutter headDesign optimisation/simulationSpecial data processing applicationsPredictive methodsEngineering

The invention belongs to the technical field of TBM disc cutter wear, and particularly relates to a prediction method for TBM disc cutter wear. The prediction method comprises the following steps thattunneling parameters, cutter ring wear losses and cutter ring characteristics in the TBM tunneling process are determined; a cutter ring comprehensive wear coefficient computing model is built; and aTBM effective tunneling distance prediction model based on cutter ring comprehensive wear coefficients is built; and an influence mechanism that the disc cutter ring wear is influenced by various factors on the condition that the geological conditions are the same as the cutter ring properties is analyzed. According to the prediction method, the concept of the cutter ring comprehensive wear coefficients is proposed, a disc cutter wear prediction model is built, and the technical problem that in TBM construction, the disc cutter consumption is difficult to predict is solved.

Owner:ZHENGZHOU UNIV

Super wear-resistant rubber-plastic conveyer belt

InactiveCN102146172AHas hardnessMeet the performance of wear resistanceConveyorsWear resistantEngineering

The invention belongs to the technical field of conveyor belts and particularly discloses a super wear-resistant rubber-plastic conveyer belt. The technical scheme for forming the conveyor belt is as follows: plasticating natural rubber, butadiene rubber, high styrene, high abrasion furnace black, 40# engine oil, an antiager D, antiager A, antiager 4010NA, zinc oxide, stearic acid, an accelerator NOBS and 2.0-2.5 parts by weight of sulphur powder; curing, banburying, performing open mixing, and vulcanizing to produce the super wear-resistant rubber-plastic conveyer belt. The conveyer belt has the advantages of good wear resistance and low temperature performance; and tests prove that the wear loss of the conveyer belt is no more than 120mm<3>, the tensile strength is more than 21MPa, and the elongation rate is more than 440%.

Owner:HENGSHUI QIXING RUBBER

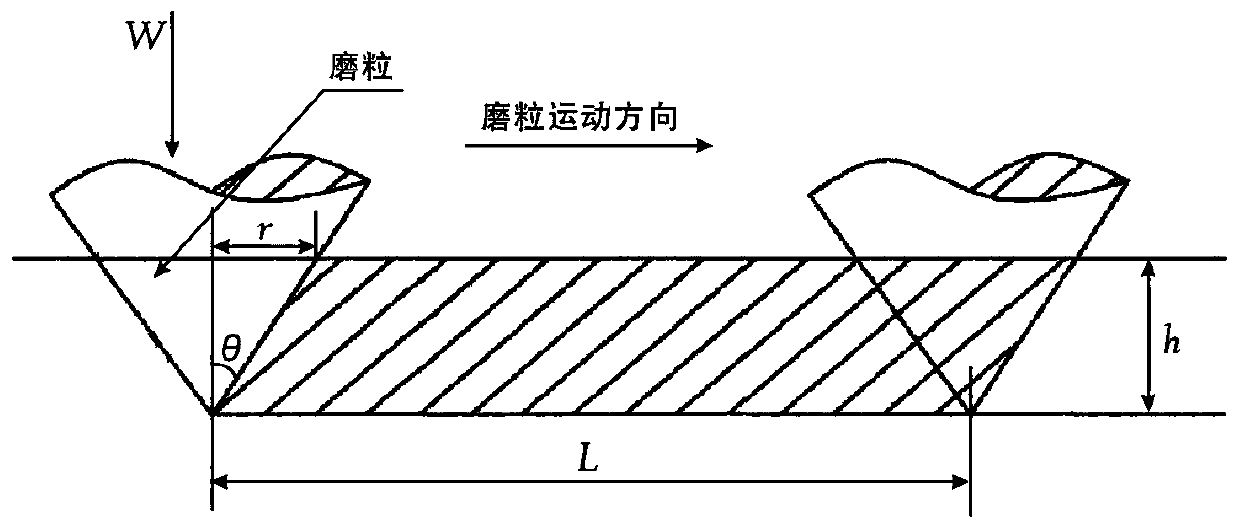

Wear prediction method for shield tunneling hob

InactiveCN111005733APredicted service lifeData processing applicationsMining devicesEngineeringShield tunneling

The invention discloses a wear prediction method for a shield tunneling hob. The wear prediction method for the shield tunneling hob comprises the following steps that a unit displacement wear loss caused by a plastic removal mechanism, a unit displacement wear loss caused by a brittle fracture mechanism, a unit displacement wear loss caused by adhesive wear, a unit displacement wear loss caused by fatigue wear, a rock breaking arc length generated when a point on the front side of the hob rotates by one circle, a spatial rock breaking arc length generated when a point on the side face of thehob rotates by one circle, a normal cutting force of the hob, and a horizontal force borne by the hob are acquired; the radial wear and wear size of the front side of a hob ring caused when the hob rotates by one circle are worked out; the wear loss and wear size of the side face of the hob ring caused when the hob rotates by one circle are worked out; the four wear losses are multiplied by corresponding fitting coefficients, and the products are added to obtain the wear size of the front side and the wear size of the hob ring; and a wear prediction model is generated, and the wear is predicted. By the adoption of the wear prediction method, the service life of the shield tunneling hob can be predicted, the prediction precision can be improved, and the problems of severe wear of the hob and frequency opening of a bin are solved.

Owner:SOUTHWEST PETROLEUM UNIV

Wear-resisting heat-conducting polyurethane bearing as well as preparation method and application thereof

The invention belongs to the field of light-weight wear-resisting materials and discloses a wear-resisting heat-conducting polyurethane bearing as well as an preparation method and an application thereof. The preparation method of the wear-resisting heat-conducting polyurethane bearing comprises the following steps of: soaking a fiber into a copolymer, dispersing ultrasonically, adding a polyurethane prepolymer, a curing agent and a heat-conducting filler, mixing the materials, degassing in vacuum, pouring the degassed mixture into a preheating mold, heating to cure, cooling, and demolding to obtain the wear-resisting heat-conducting polyurethane bearing. The wear-resisting heat-conducting polyurethane bearing prepared by adopting the preparation method has the advantages of light weight, wear resistance (relative volume wear loss of 150mm<3>), good heat conductivity of 4W / m*K, high strength (high modulus of compression of 520Mpa, and notched impact strength of 120J / m), low cost, long service life and the like, is simple in forming process, is suitable for industrial production and can be widely applied to clean-energy power generation equipment.

Owner:JINAN UNIVERSITY

Self-lubricating wear-resisting unsaturated polyester molding compound and preparation method thereof

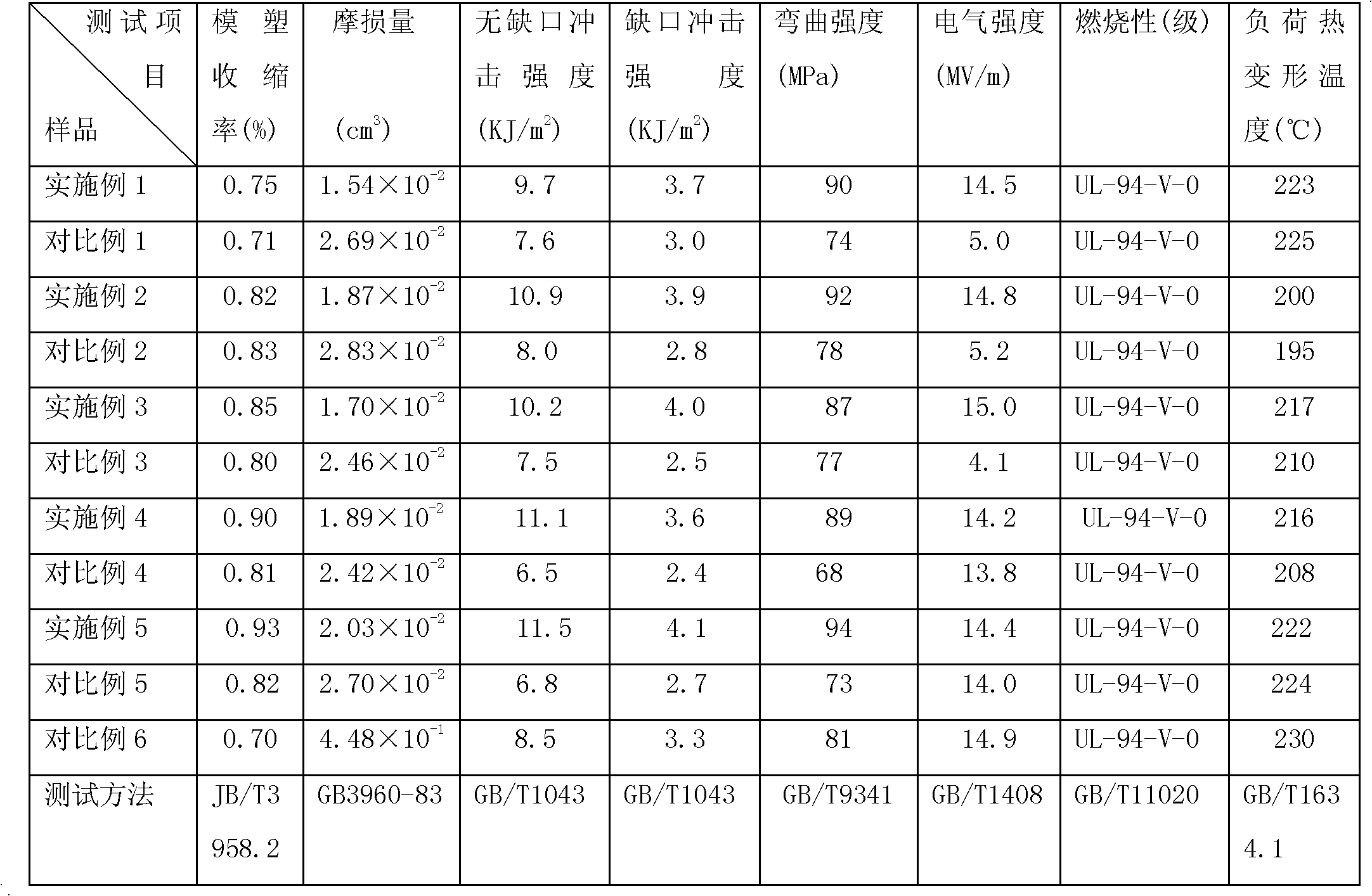

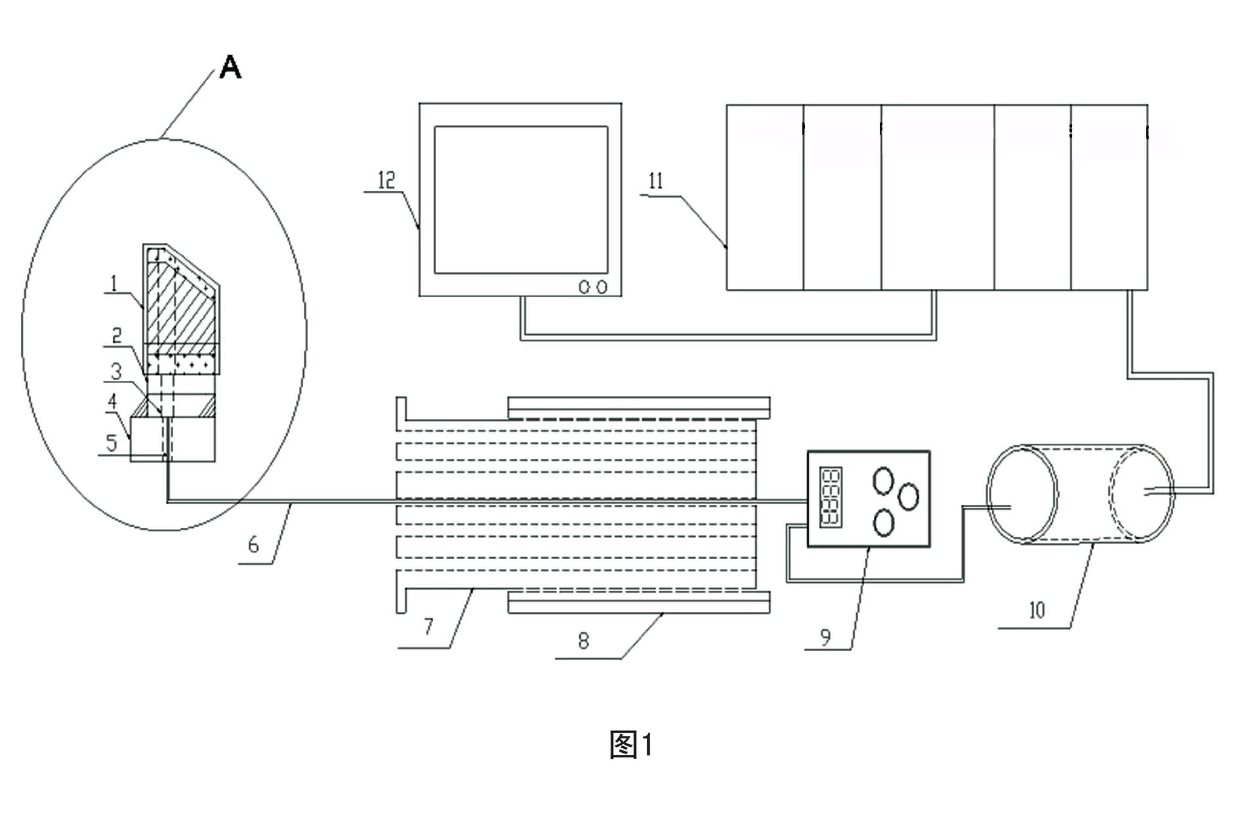

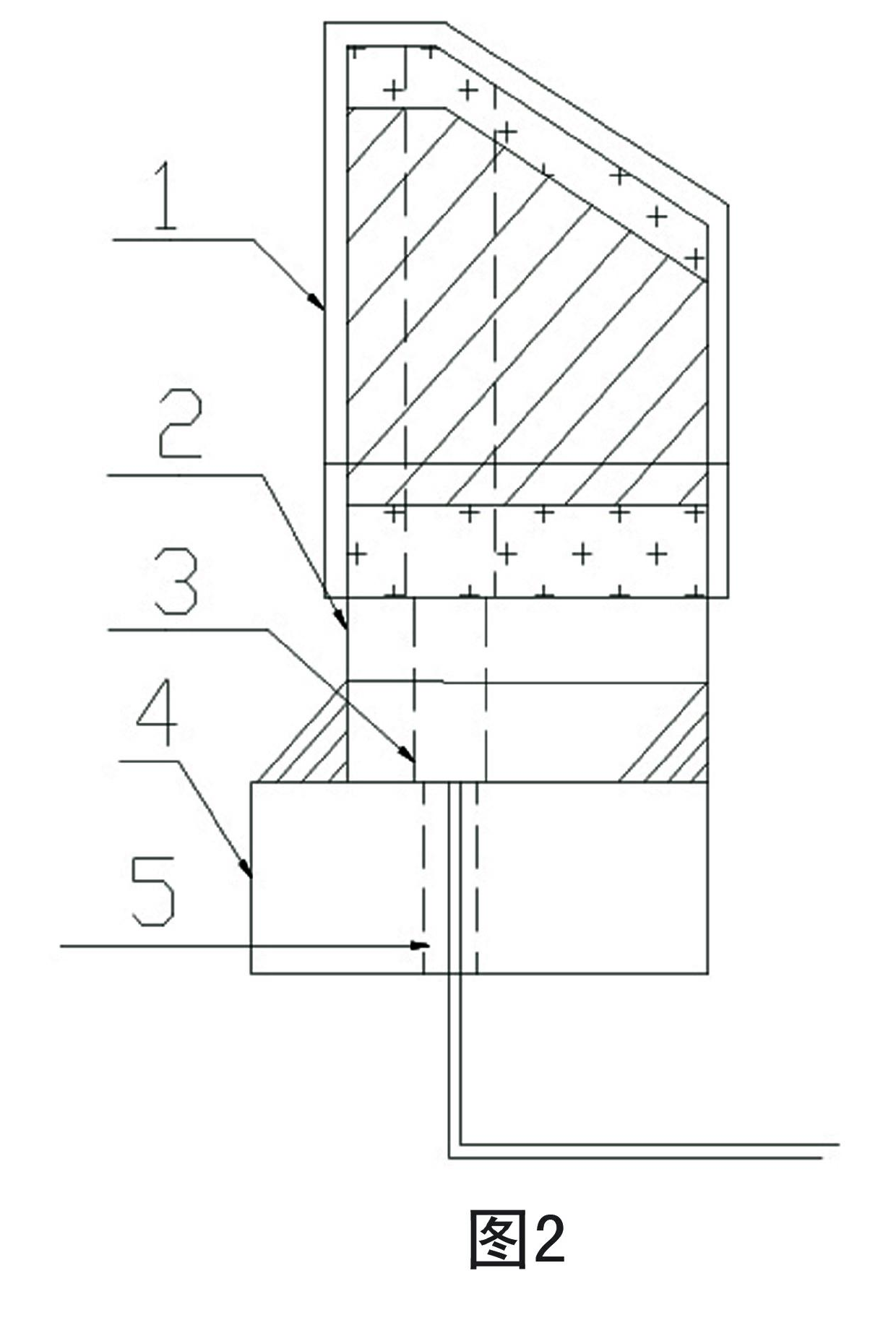

The invention discloses a self-lubricating wear-resisting unsaturated polyester molding compound and a preparation method thereof. The self-lubricating wear-resisting unsaturated polyester molding compound consists of the following components in parts by weight: 25-35 parts of solid unsaturated polyester resin, 2.5-6 parts of a crosslinking agent, 0.3-2 parts of an initiator, 0.01-0.05 part of a polymerization inhibitor, 2-3 parts of an inner demolding agent, 25-35 parts of a flame retardant, 15-30 parts of a reinforced material, 10-15 parts of an organic lubricating agent and 0-2 parts of a pigment, wherein the solid unsaturated polyester resin is any one or a combination of more than two of o-phenylene unsaturated polyester resin, m-phenylene unsaturated polyester resin, m-xylene unsaturated polyester resin and bisphenol A type unsaturated polyester resin; and the organic lubricating agent is any one or a combination of more than two of polytetrafluoroethylene powder, polyamide powder, polyformaldehyde powder and polyamide-imide powder. Compared with the prior art, the unsaturated polyester molding compound has the advantages of low wear loss and high mechanical and electric properties.

Owner:桂林金格电工电子材料科技有限公司

Grease composition

ActiveUS20090270290A1Distinguished lubricabilityDistinguished durabilityLiquid carbonaceous fuelsAdditivesLithiumEther

A grease composition, which comprises a base oil selected from at least one of synthetic hydrocarbon oil, ester-based synthetic oil, and ether-based synthetic oil; a thickening agent selected from at least one of lithium-based soap, lithium-based complex soap, and a urea-based compound; polytetrafluoroethylene resin powders having a number average molecular weight Mn of 20,000-100,000; and zinc dialkyldithiophosphate having straight or branched alkyl groups of at least carbon atoms, preferably 5-13 carbon atoms, and more preferably 8-12 carbon atoms, has not only a distinguished lubricability, when applied to plastic members, but also a distinguished durability as given by change in friction coefficient and wear loss, after the sliding test.

Owner:NOK KLUEBER CO LTD

Vacuum filter bag with odor removing effect

ActiveUS20060137529A1Easy constructionIncrease dust holding capacityGas treatmentSuction filtersEngineeringWear loss

The present invention relates to a vacuum filter bag comprising a layer containing immobilized odor-retaining particles characterized in that the abrasion loss of said odor-retaining particles caused by an air flow of 90 cm / s through a 200 cm2 specimen of said layer for two hours, measured in accordance with DIN 44956 T2, is 0 to 10% by weight of the total odor-retaining particles present before starting the air flow. The vacuum filter bags of the invention have a high dust holding capacity and an excellent long lasting odor removing effect.

Owner:NEENAH GESSNER

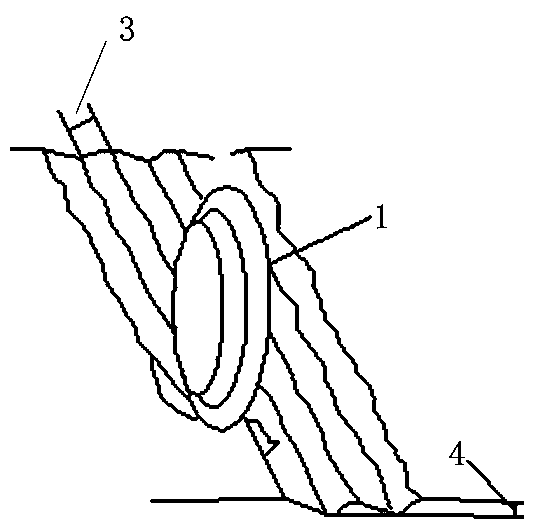

Detection device and detection method for wear loss of shield machine cutter

InactiveCN102607478ASolve the problem of difficult wear detectionHigh measurement accuracyUsing subsonic/sonic/ultrasonic vibration meansOutput deviceAlloy

The invention discloses a detection device and a detection method for the wear loss of a cutter of a shield machine. A detection probe which is connected with an input end of a detector through a data line is arranged in the peripheral foregoing teeth-cutter of the shield machine, wherein the detector is connected with a programmable logic controller (PLC) control system of the shield machine through a signal output device; and the PLC control system of the shield machine is connected with a touch screen and communicates with the touch screen. The detection device has the advantages that the wear loss of the peripheral teeth-cutter is detected through detecting the height of an alloy strip on the peripheral foregoing teeth-cutter of the shield machine, so the defects in a hydraulic limit type detection manner that an alarm can be given only when the cutter is worn to a certain height is overcome, and thereby the detection device can continuously display measured data in time; through welding the peripheral foregoing teeth-cutter on a cutter holder, the problem that a welded type cutter is difficult to detect is solved; meanwhile, data detected through utilizing a conductive slide wire ring can be displayed and recorded in time in a touched manner in an operating room, so the detection device is more convenient to use; and besides, the detection device has high measurement accuracy, great real time performance and high reliability.

Owner:CHINA CONSTR COMM ENG GRP UNITED +2

Method for preparing hard wear-resistant coating

InactiveCN1782126AChange hardnessDensity changePressure inorganic powder coatingWear resistantHardness

The hard wear resistant coating preparing process features that the composite WC-Co / MoS2 powder is used in preparing the hard wear resistant coating by means of exploding spraying technology. The composite WC-Co / MoS2 powder consists of WC-Co in 94-99 wt% and MoS2 in 1-6 wt%. Compared with available technology, the composite wear resistant WC-Co / MoS2 coating of the present invention has high hardness, high compactness, high combination strength, low friction coefficient and very low wear loss and is one kind of excellent composite self-lubricating hard wear resistant coating.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

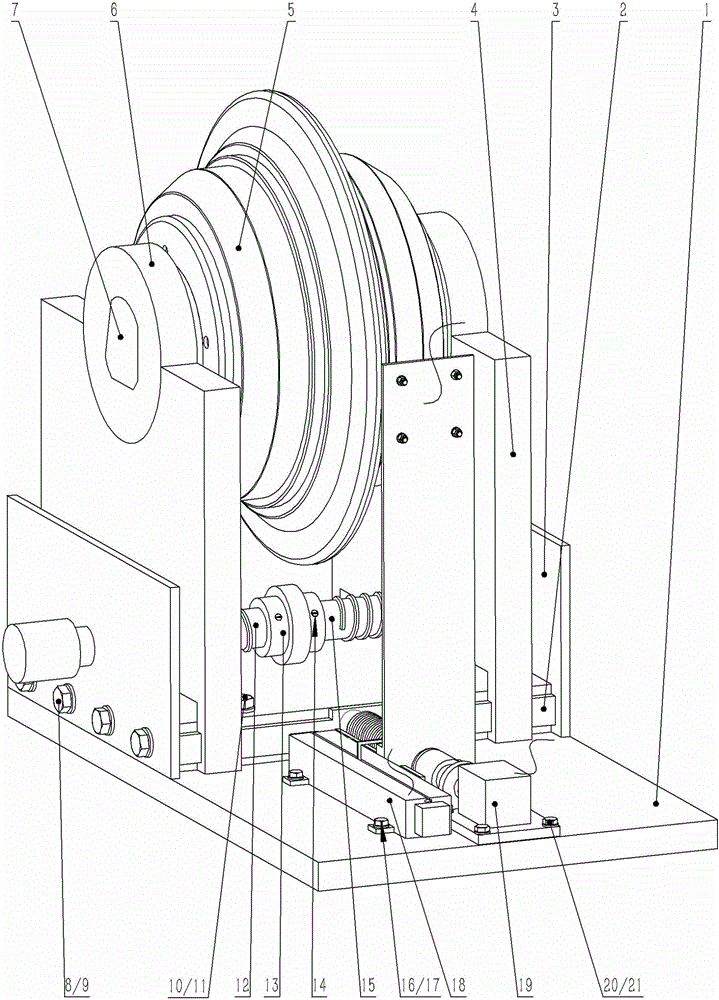

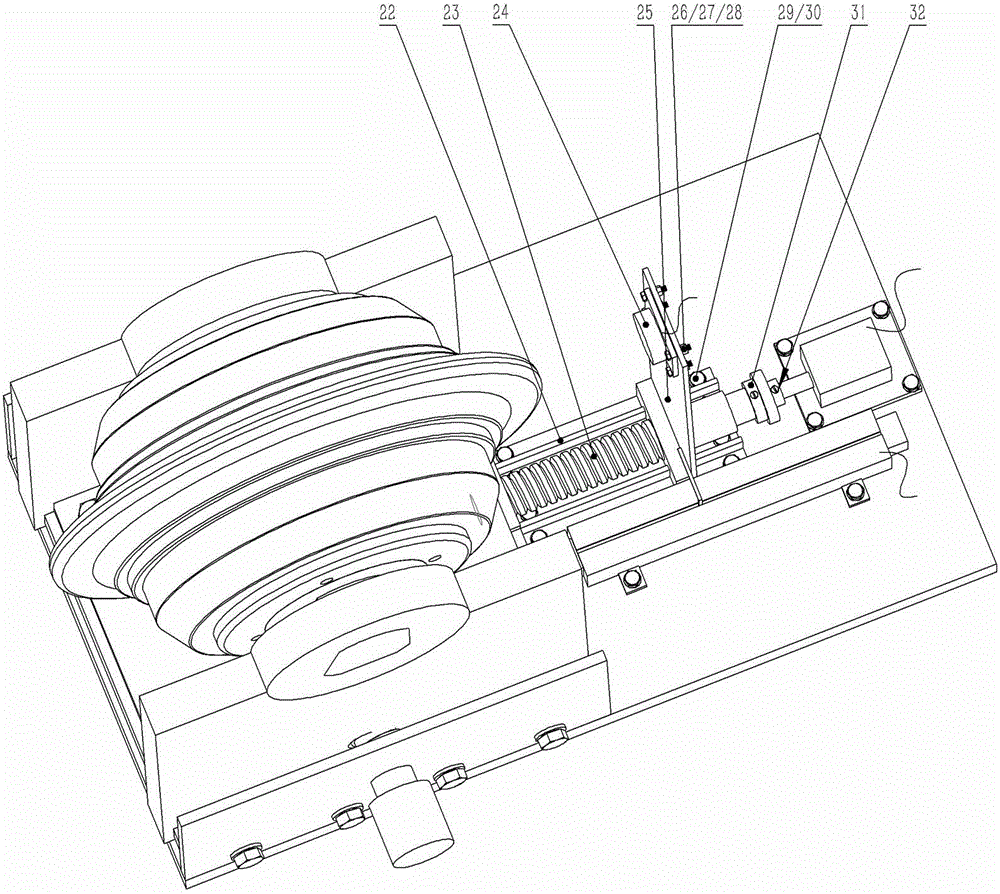

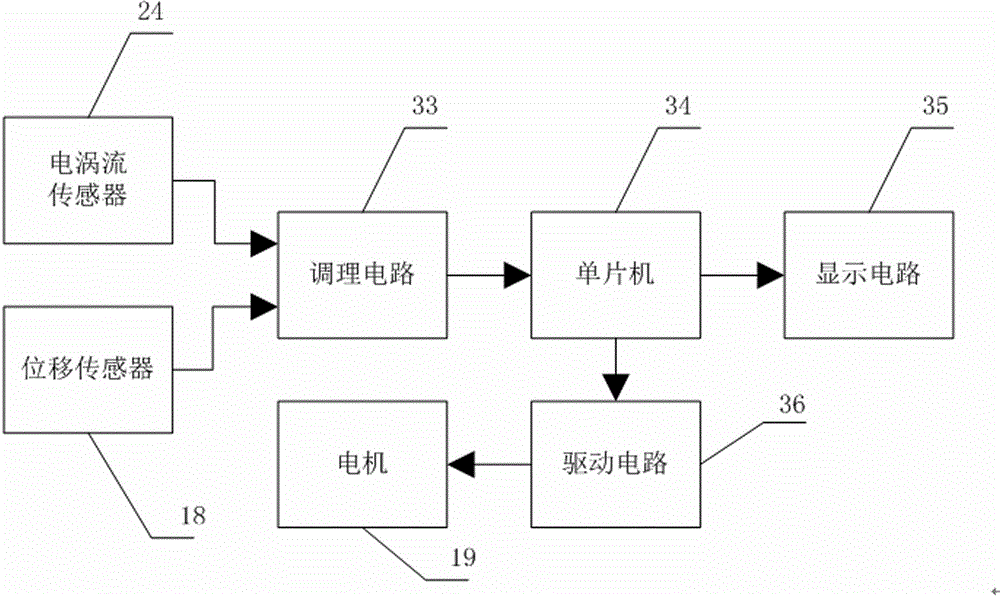

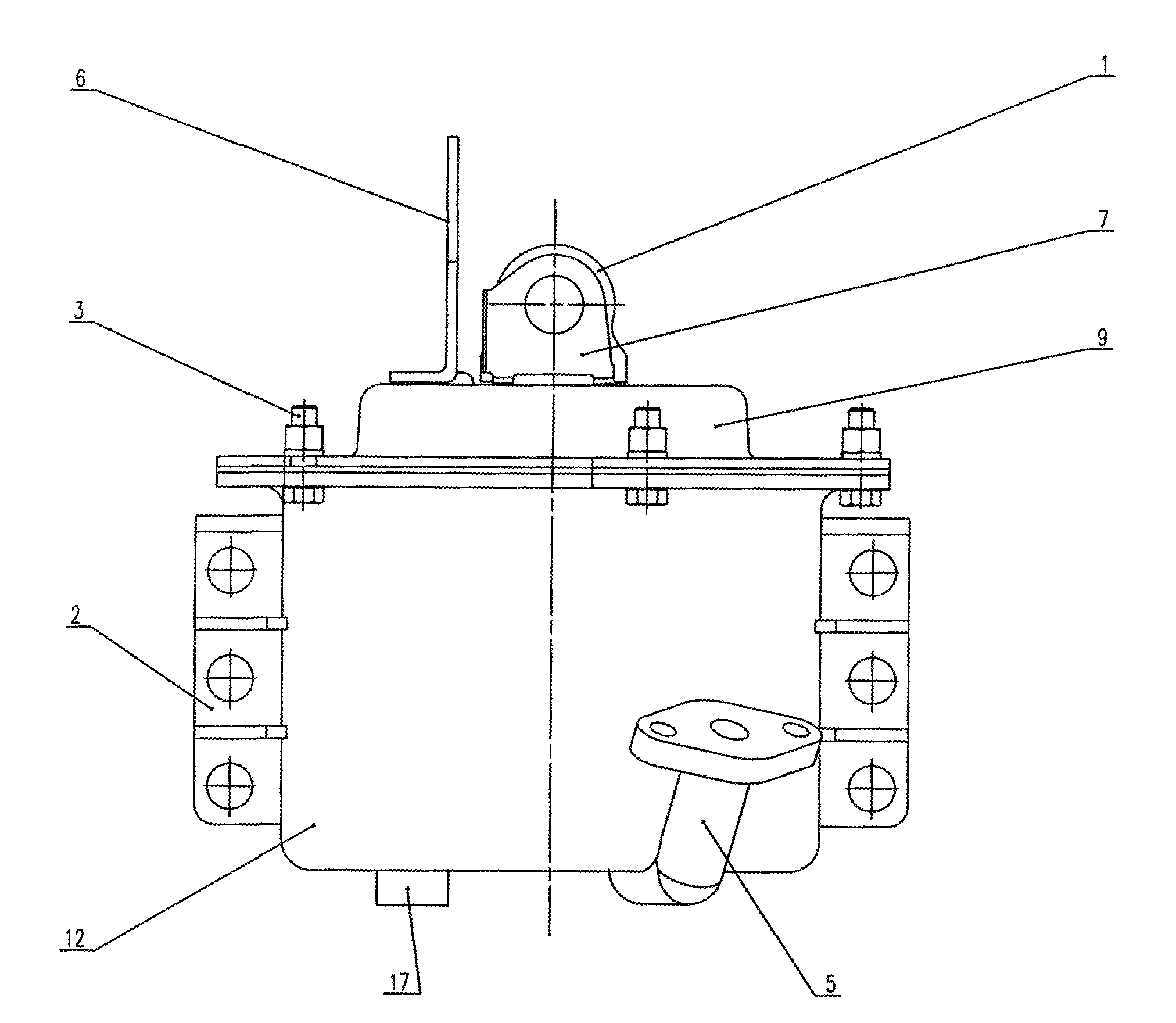

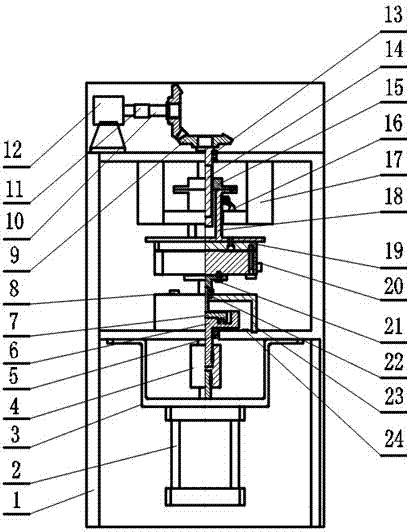

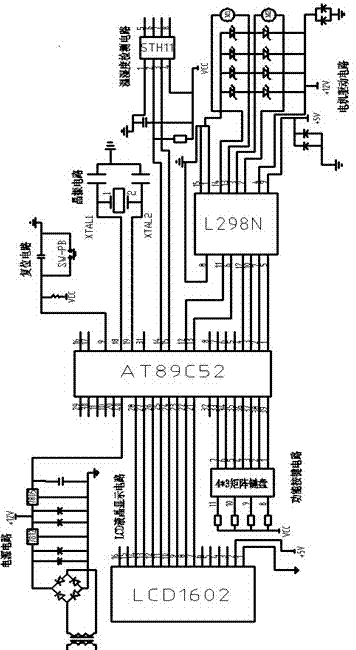

Automatic calibration device for current vortex sensor measuring wear loss of TBM hob

The invention discloses an automatic calibration device for a current vortex sensor measuring the wear loss of a TBM hob. The automatic calibration device is characterized in that convex guide rails on the two sides of a bottom plate match concave grooves on hob brackets, a hob screw coupling connects a left-handed screw and a right-handed screw together, the screws are rotated to drive the hob brackets to move away from or to each other, and therefore, the distance between the hob brackets is applicable to the installation of hobs of different sizes; the shaft of the hob is embedded into fixed blocks, and is mounted on the semicircular grooves of the hob brackets; a single-chip microcomputer controls a drive circuit, a motor drives a sensor screw to rotate, the distance between a sensor vertical plate moving on the T-shaped guide rails and the blade of the hob changes so as to simulate the wear process of the hob; and a voltage signal output by the current vortex sensor and a distance signal output by a displacement sensor are sent to a conditioning circuit for conditioning and then sent to a single-chip microcomputer for processing, a fitting coefficient of wear loss of the hob is fitted out, and data is displayed.

Owner:HUNAN NORMAL UNIVERSITY

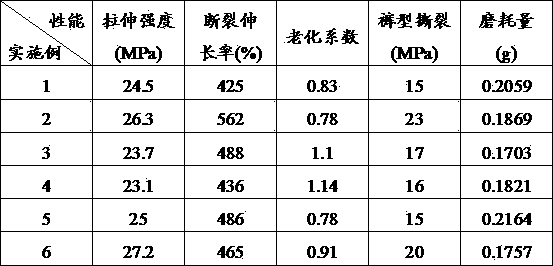

Method for improving properties of rubbering track shoe rubber via compounding and modified cerium oxide

The invention discloses a method for improving the properties of rubbering track shoe rubber via compounding and modified cerium oxide. At least two modifying agents are respectively used for modifying the cerium oxide, on the basis of keeping the original production formula and production process constant, 0.1 to 10% of compounding and modified cerium oxide is added via a mechanical mixing method, and the properties, especially a wear-resisting property and a tearing resistance property, of the rubbering track shoe rubber are improved. The tensile strength and the tearing strength of the rubber obtained via the method are respectively increased by 11% and 41%, and wear loss is reduced by 16%. Therefore, the method is suitable for rubber tracks of large-scale machinery, such as tanks, derrick cranes, agricultural harvesters and the like.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

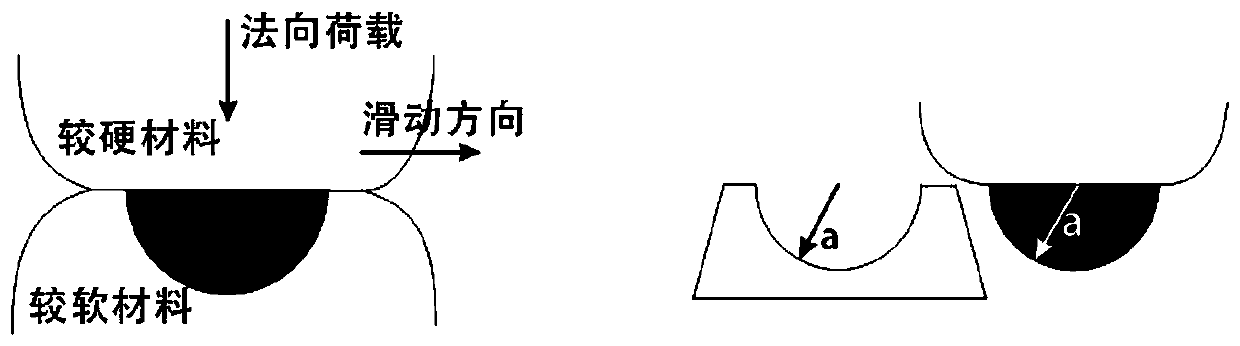

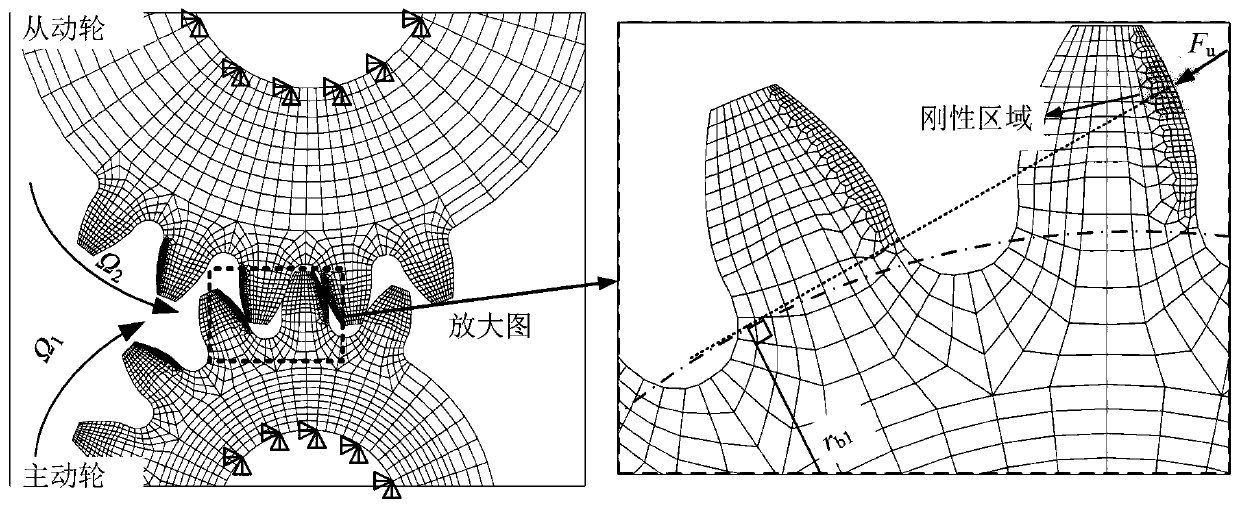

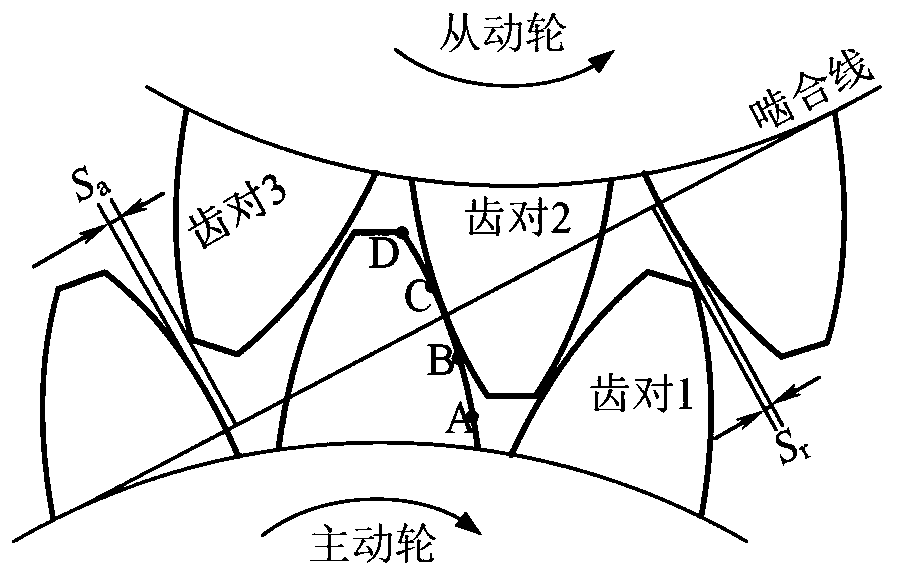

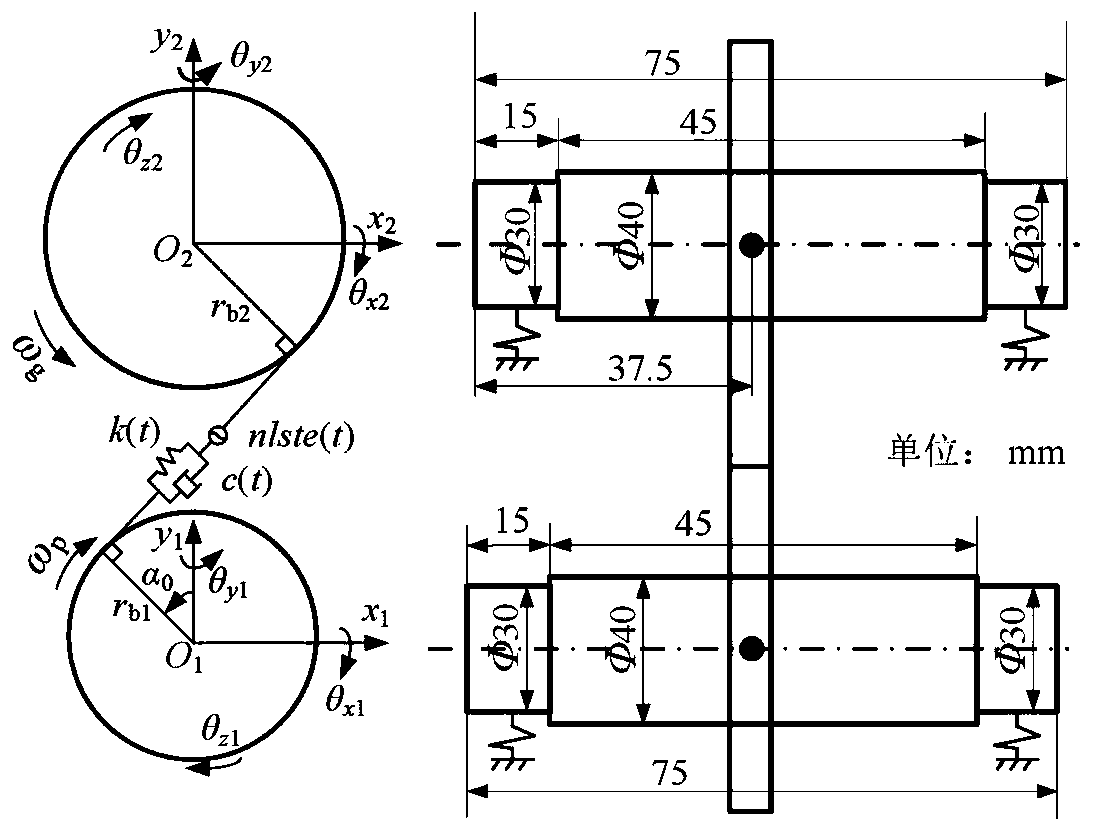

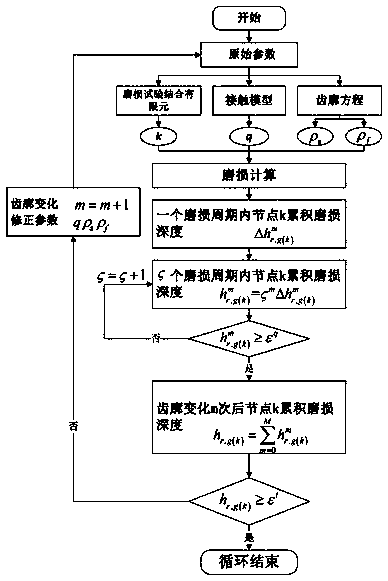

Gear pair abrasion loss prediction method based on dynamic meshing force

ActiveCN109871652ATaking into account efficiencyTaking into account the accuracySpecial data processing applicationsGear wheelEngineering

The invention belongs to the technical field of mechanical dynamics, and particularly relates to a gear pair abrasion loss prediction method based on dynamic meshing force, which comprises the following steps: S1, acquiring basic parameters of a gear pair; S2, calculating the time-varying meshing stiffness and static load distribution coefficient of the worn gear pair according to the acquired basic parameters of the gear pair and a gear tooth bearing contact analysis method; S3, introducing the time-varying meshing stiffness obtained through calculation into a gear rotor system dynamic modelto calculate a dynamic meshing force and a dynamic load distribution coefficient of the gear pair; and S4, adopting an Archard wear theory, a wear coefficient empirical formula, the dynamic meshing force of the gear pair and the dynamic load distribution coefficient to calculate and obtain the tooth surface wear loss of the gear pair. According to the gear pair abrasion loss prediction method based on the dynamic meshing force, prediction efficiency and prediction precision are both considered.

Owner:NORTHEASTERN UNIV

Braking cylinder of braking device of railway wagon

InactiveCN101619748AManufacturing precision requirements are lowStable and reliable self-sealingRailway hydrostatic brakesRailway hydrodynamic brakesEngineeringCylinder block

The invention discloses a braking cylinder of a braking device of a railway wagon, which mainly solves the problem that the traditional braking cylinder has the disadvantages of large wear loss of components, poor sealing performance and poor working stability. The braking cylinder mainly comprises a cylinder body, a piston arranged in the cylinder body and a piston push rod rigidly connected with the piston together, wherein a flange elbow for air intake and air exhaust is arranged at the bottom of the cylinder body; a release spring is arranged between the piston and a cylinder cover; the upper end of the piston push rod extends out of the cylinder cover; an integral type membrane is covered on the working end surface of the piston; and a sealed space is formed between the integral type membrane and the bottom of the cylinder body, thus the braking cylinder has self-sealing performance. The braking cylinder also has the function of automatically marking the stroke of the piston of the braking cylinder by arranging stroke marks. The invention has the advantages of simple structure, good sealing effect, less wear loss, high reliability and long service life.

Owner:CRRC YANGTZE CO LTD +1

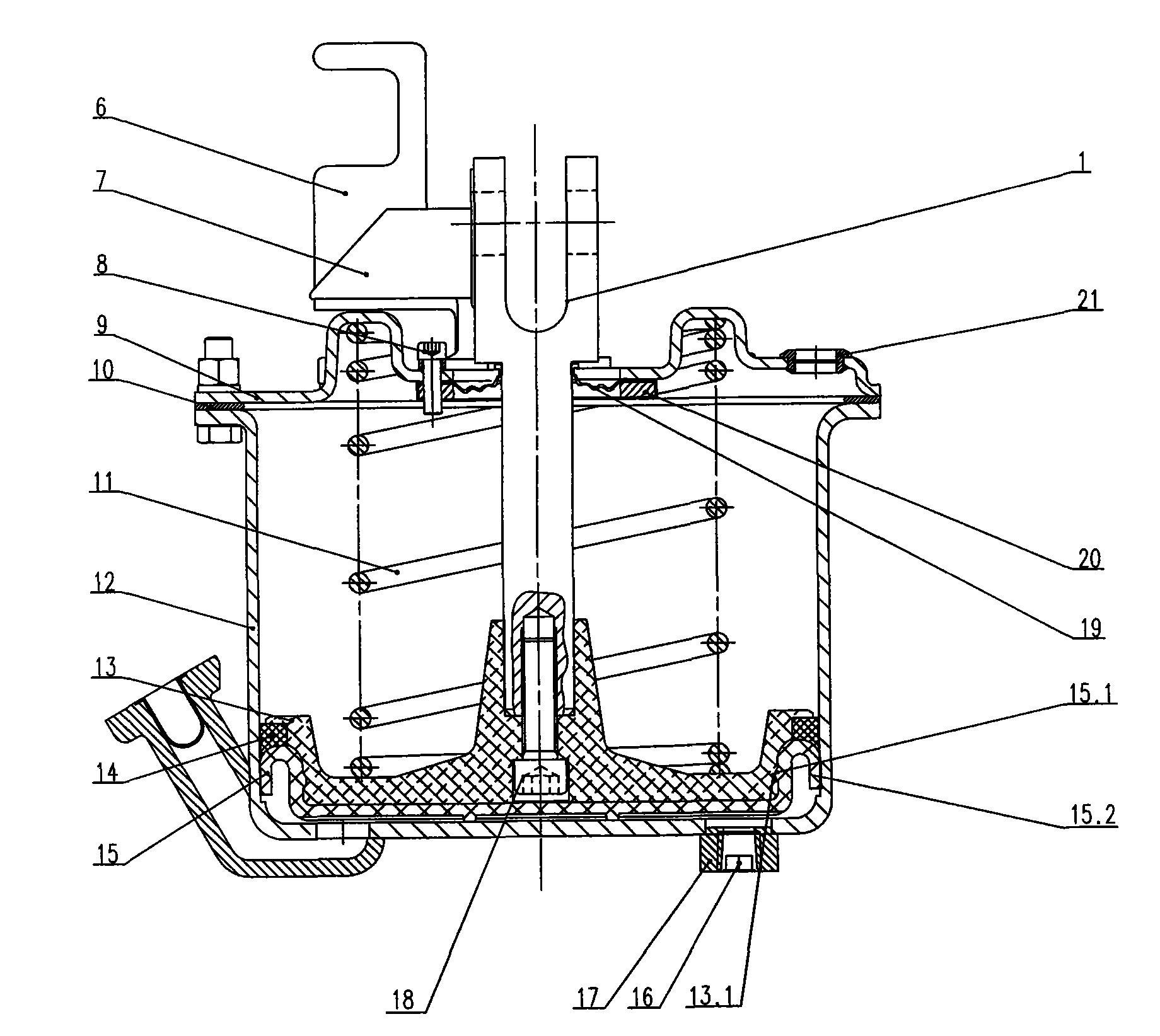

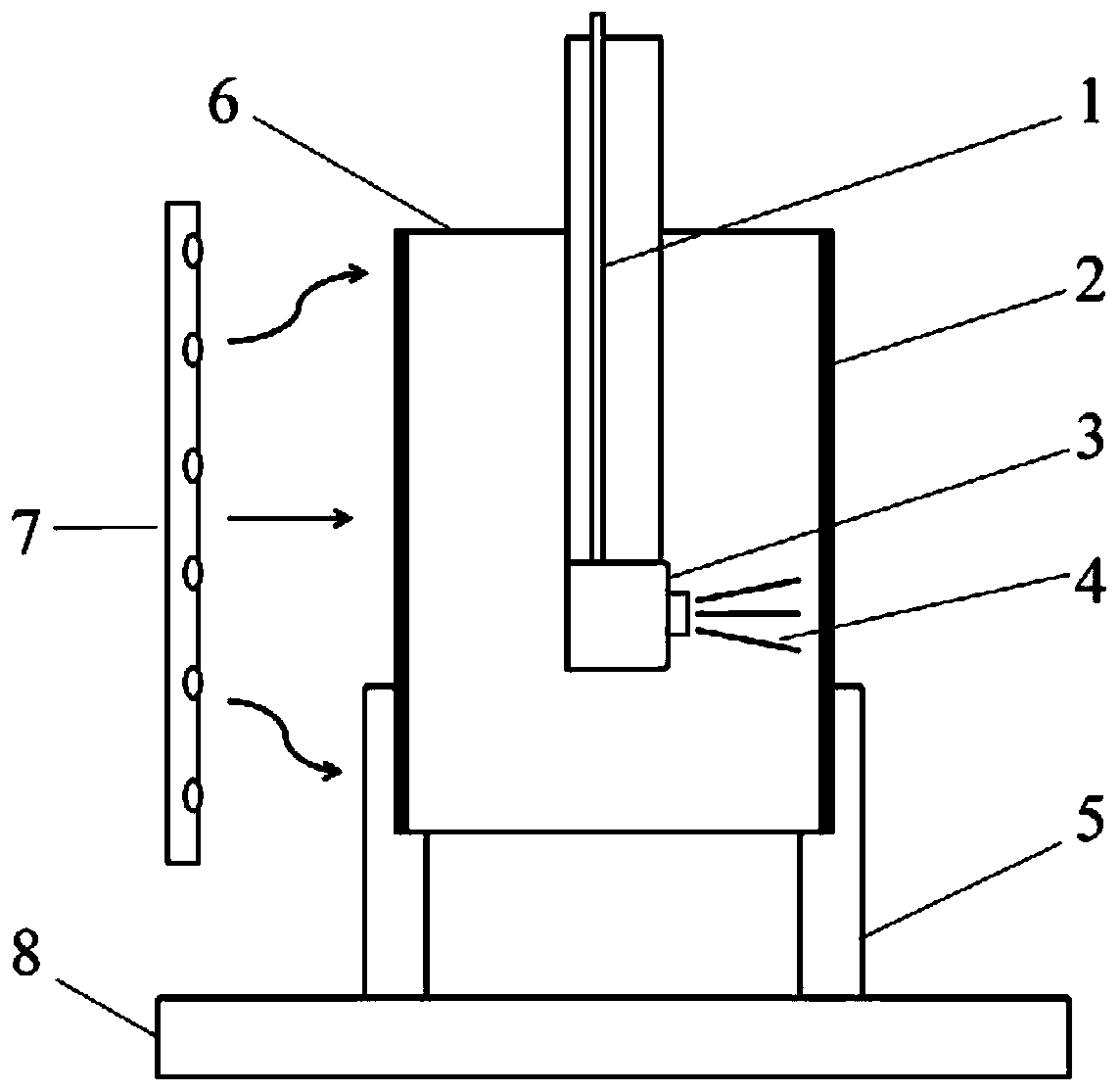

Friction and wear testing machine with controllable humidity

InactiveCN104237041AReduce lossIntelligent humidity controlInvestigating abrasion/wear resistanceBall bearingEngineering

The invention provides a friction and wear testing machine with controllable humidity. The testing machine is provided with a workbench bin, wherein a main shaft motor is fixed in the lower layer of the workbench bin, the main shaft motor is connected with a lower clamp, and a thrust ball bearing is mounted at the joint between the lower clamp and the workbench bin; a lower sample is mounted on the lower clamp, an environmental box is mounted at the periphery of the lower clamp and the lower sample in a covering manner, an embedded boss is arranged at the bottom of the environmental box, a circular hole is formed in the top of the environmental box, an STH11 digital temperature and humidity sensor is mounted at the bottom of the inner side of the environmental box, and a ventilation spring button switch is mounted at the top of the environmental box; an upper sample is fixed on an upper clamp, the upper clamp is connected with a triaxial force sensor, and the triaxial force sensor is connected with a cushion block through bolts; a servo motor is connected with a bevel gear pair, a screw bearing is mounted at the connecting position between a screw shaft and the workbench bin, a screw nut is connected with a loading sleeve, and a column beam is arranged at the periphery of the loading sleeve . Through the adoption of the friction wear testing machine with the controllable humidity, not only the experimental humidity can be intelligently controlled, but also the stability is good, and the friction and wear loss of materials can be reduced.

Owner:CHINA UNIV OF MINING & TECH

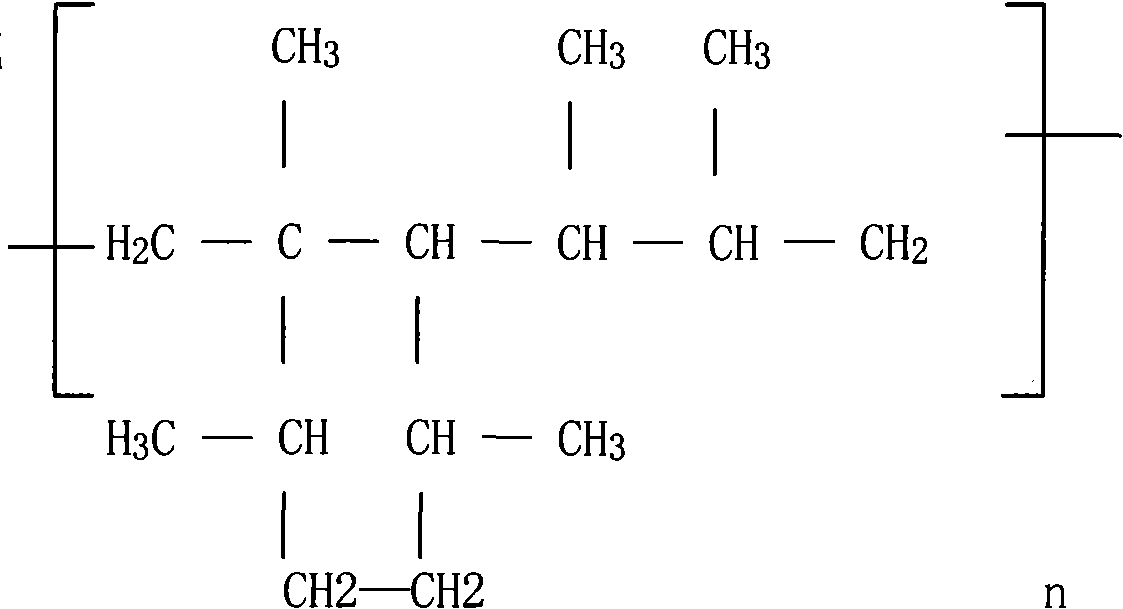

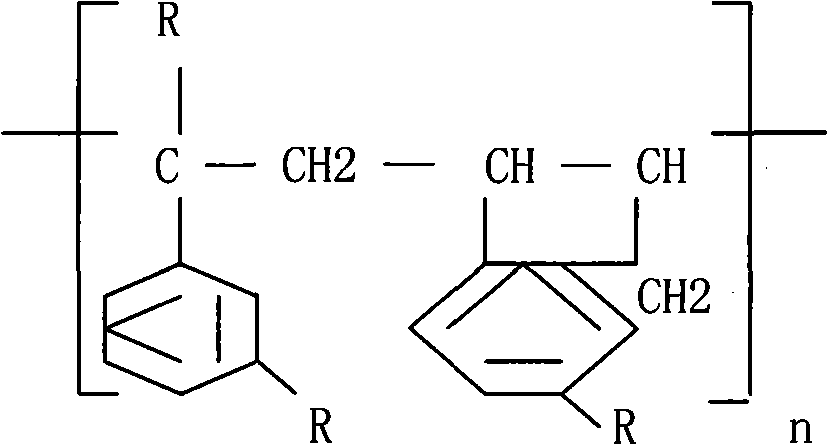

Preparation process of petroleum resin mixed by aliphatic resin and aromatic resin

InactiveCN101358016AImprove mixing uniformityImprove liquidityBuilding insulationsRubber materialPolymer science

Owner:逯大成

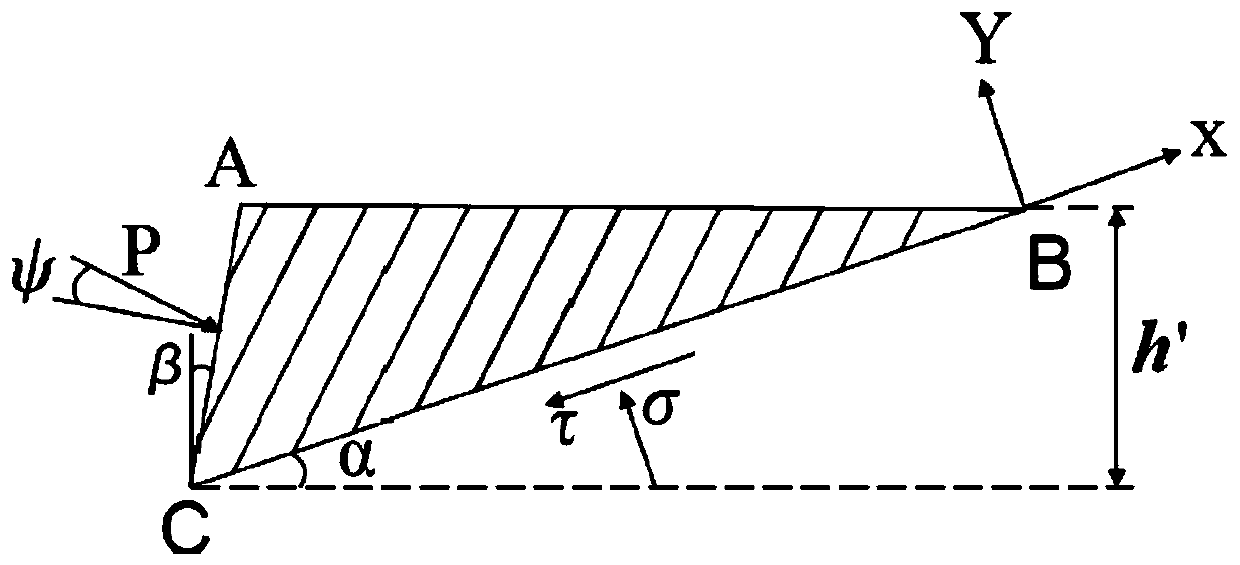

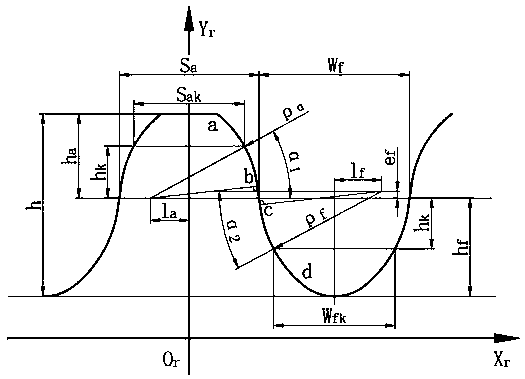

Method for calculating tooth surface wear of double circular arc harmonic reducer

ActiveCN111059255ARealize computingCalculation Precise calculationDesign optimisation/simulationGearing detailsEngineeringWear coefficient

The invention discloses a method for calculating tooth surface wear of a double circular arc harmonic reducer. The method comprises the following steps of, firstly, establishing a tooth profile equation of a flexible gear-rigid gear of the double circular arc harmonic reducer based on original parameters; secondly, determining parameters such as tooth profile parameters, contact positive pressureand wear coefficients; based on an improved Archard wear model, calculating the wear loss of the tooth surface node k of the flexible gear and the rigid gear in a wear period; repeating the wear circulation until the total wear loss of the node reaches a preset threshold value, wherein the contact positive pressure and the tooth profile parameter of the tooth surface are changed due to the tooth surface wear; further, reconstructing the flexible gear-rigid gear tooth profile equation, and recalculating the contact positive pressure; and summing the wear loss of the node k after the tooth profile is changed m times until the wear loss reaches the maximum allowable wear loss. The method for calculating tooth surface wear of the double circular arc harmonic reducer provides a theoretical basis for improving the transmission precision and the accuracy of life prediction of the harmonic reducer.

Owner:TAIYUAN UNIV OF TECH

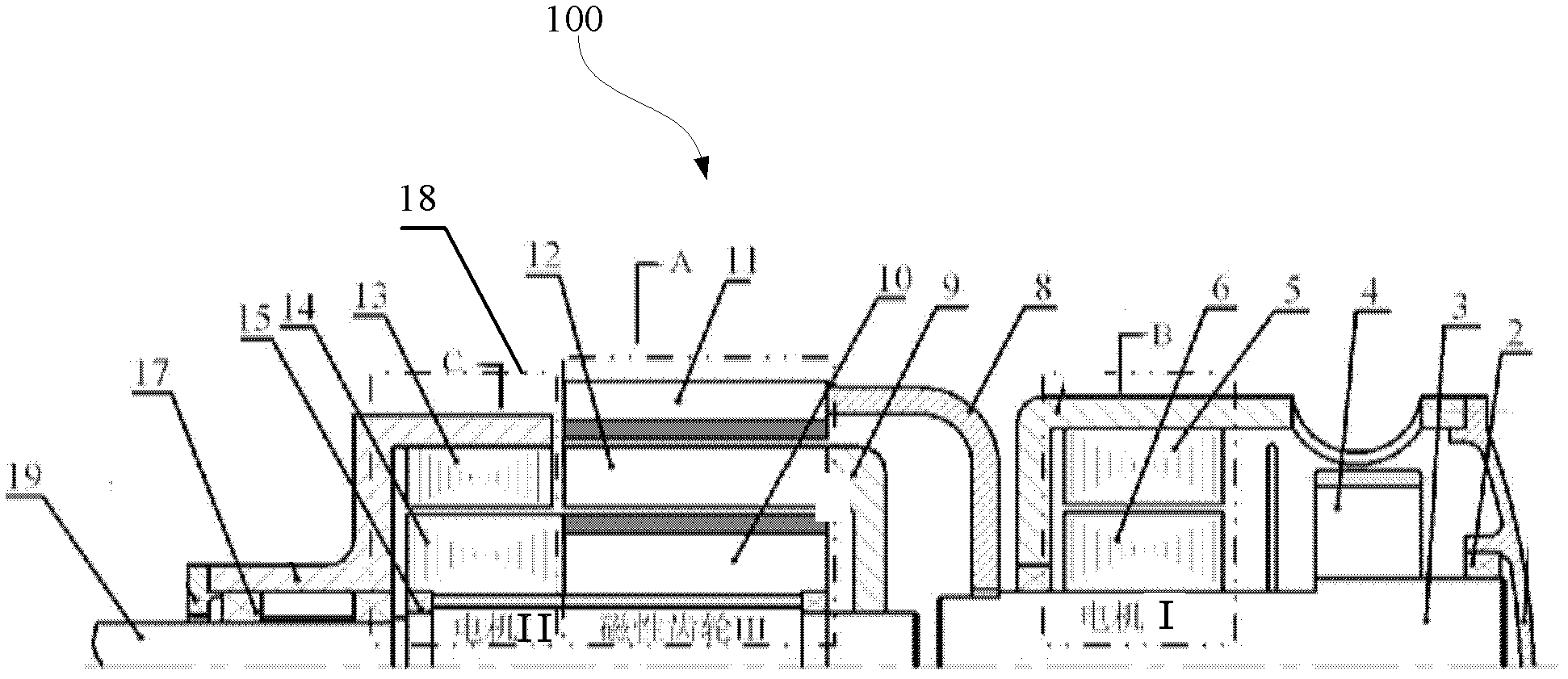

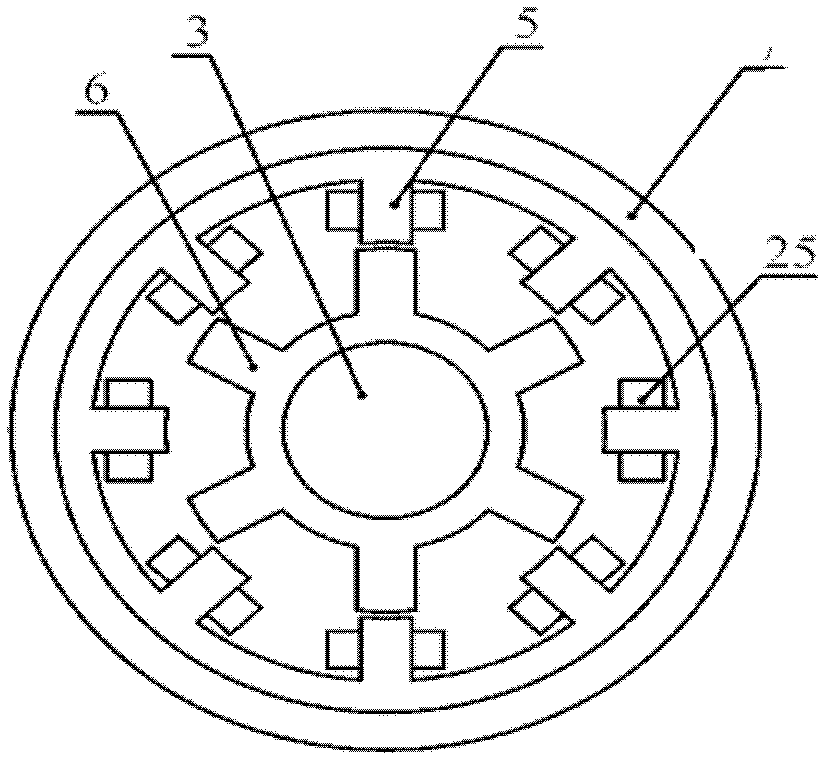

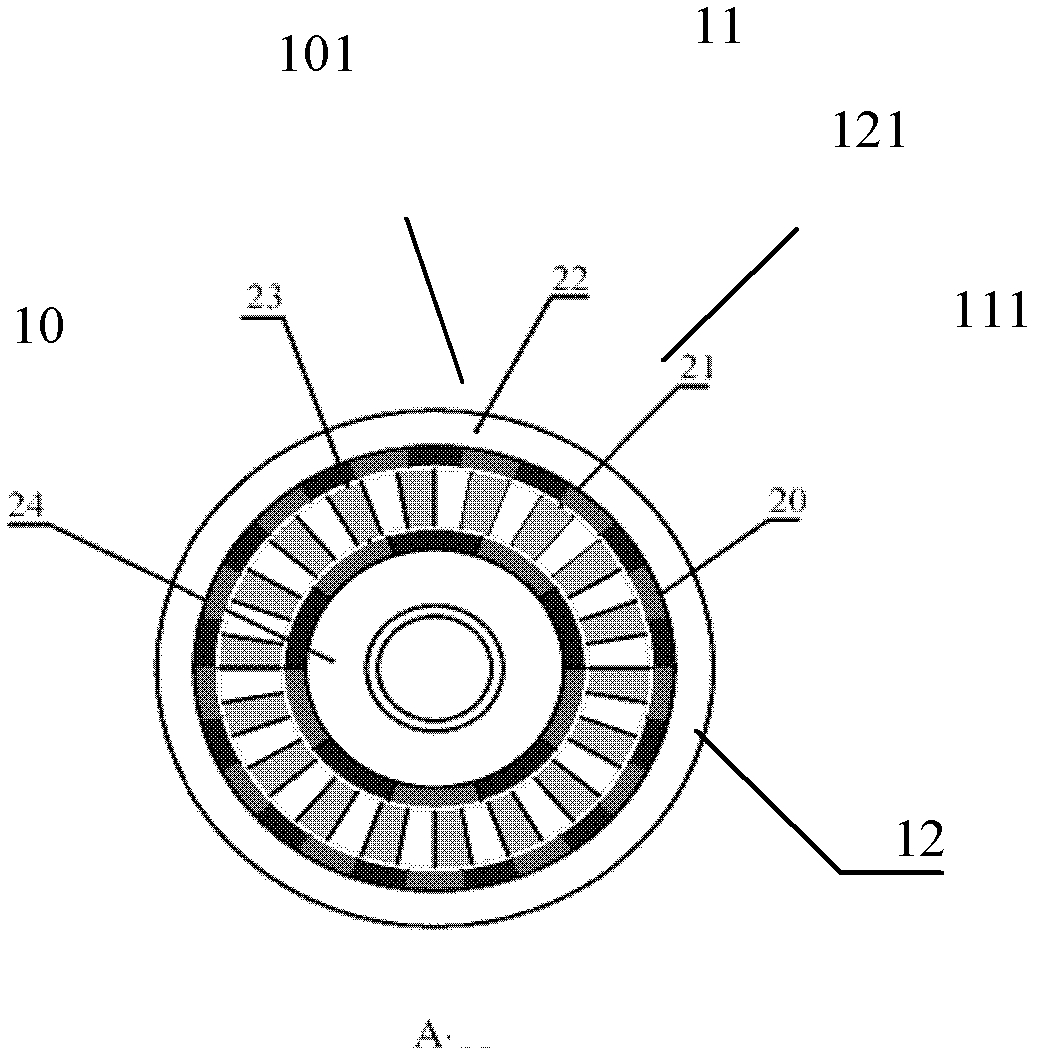

Gear change mechanism

The invention relates to a gear change mechanism comprising a first switched reluctance motor and a second switched reluctance motor, wherein the first switched reluctance motor comprises a first stator and a first rotor which is contained in the first stator; a first rotating shaft and a coaxial magnetic gear are arranged on the first rotor; the coaxial magnetic gear successively comprises an inner rotor, a magnetism adjustment ring and an outer rotor from inside to outside; a permanent magnet pole pair is arranged at one side, near the magnetism adjustment ring, of each one of the inner rotor and the outer rotor; the outer rotor is connected with the first rotating shaft; the magnetism adjustment ring consists of a magnetism adjustment iron block and is provided with an input shaft; the second switched reluctance motor comprises a second stator and a second rotor which is contained in the second stator; and the second rotor is fixedly connected with the inner rotor. In the gear change mechanism, the harmonic drive and the speed regulation are realized depending on the magnetic field modulation effects of an inhomogeneous magnetic circuit. The non-contact variable transmission is realized by using the mutual effect of the permanent magnet by the coaxial magnetic gear, therefore, the defects of wear loss, mechanical noise, vibration and the like which are caused by a mechanical gear can be overcome when the gear change mechanism provided by the invention is applied to automobiles in a hybrid power mode and an electric power mode.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Cylinder sleeve inner wall heat insulation wear-resistant composite coating layer and preparation method thereof

InactiveCN109778104AWith wear resistanceImprove insulation performanceMolten spray coatingInsulation layerWear resistant

The invention belongs to the field of coating layers and particularly relates to a cylinder sleeve inner wall heat insulation wear-resistant composite coating layer and a preparation method thereof. The coating layer is arranged on the inner surface of a cylinder sleeve and comprises ceramic heat-insulation layers and metal wear-resistant layers which are alternately arranged. In the method, an inner hole plasma spraying system with a double-path powder feeder is adopted to perform preparation of the coating layer, metal powder and ceramic powder are sent into a plasma arc flame flow at the same time, the cylinder sleeve rotates around the axis self, an inner hole spray gun head of the inner hole plasma spraying system extends into the cylinder sleeve to move up and down in a reciprocatingmanner through a control program, powder parameters and powder feeding parameters are adjusted, a trajectory is adjusted and controlled, and the composite coating layer with a layered structure is obtained. The alternate layered coating layer is capable of insulating heat and resisting corrosion, enables the cylinder sleeve to perform heat dissipation by conducting the heat to a matrix along thecoating layer and a temperature of the interior of the cylinder sleeve to be maintained within a certain range, so that severe high-temperature wear cannot be caused by heat insulation in a severe high-temperature environment, the abrasion loss of the cylinder sleeve can be effectively reduced, and the heat efficiency of an engine can be improved.

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com