Method for improving properties of rubbering track shoe rubber via compounding and modified cerium oxide

A technology of cerium oxide and rubber-mounted shoes is applied in the field of compounding modified cerium oxide to improve the rubber properties of rubber-mounted track shoes. The effect of increasing strength and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

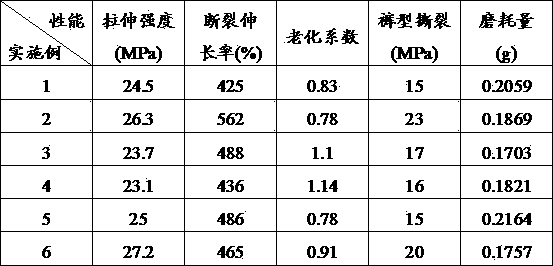

Examples

Embodiment 1

[0024] Weigh 5g of cerium oxide, add 1200ml of deionized water, and stir in a water bath at 70°C for 20min with a speed rating of 20. Weigh 0.1g of sodium lauryl sulfate, add a small amount of ethanol, and add deionized water to make a 600ml solution, add the solution dropwise to cerium oxide with a peristaltic pump, let it settle after 3 hours of reaction, take the upper layer solution, and suction filter drying to obtain sodium dodecyl sulfate modified cerium oxide. Stearic acid-modified cerium oxide was prepared by the same method, wherein the amount of stearic acid was 0.2 g, the reaction time was 1 h, and the rotational speed grade was 15.

[0025] Cerium oxide modified with sodium lauryl sulfate and stearic acid is added to the track shoe rubber in the plasticizing stage at a ratio of 1:1.

[0026] The surface of cerium oxide was organically modified with two modifiers. On the basis of keeping the original production formula and technological process of the rubber trac...

Embodiment 2

[0028] Weigh 5g of cerium oxide, add 1200ml of deionized water, and stir in a water bath at 70°C for 20min with a speed rating of 20. Weigh 0.1g of sodium lauryl sulfate, add a small amount of ethanol, and add deionized water to make a 600ml solution, add the solution dropwise to cerium oxide with a peristaltic pump, let it settle after 3 hours of reaction, take the upper layer solution, and suction filter drying to obtain sodium dodecyl sulfate modified cerium oxide. Stearic acid-modified cerium oxide was prepared by the same method, wherein the amount of stearic acid was 0.2 g, the reaction time was 1 h, and the rotational speed grade was 15.

[0029] Cerium oxide modified with sodium lauryl sulfate and stearic acid is added to the glued track shoe rubber together with other small rubber materials in an internal mixer at a ratio of 1:1.

[0030] The surface of cerium oxide was organically modified with two modifiers. On the basis of keeping the original production formula ...

Embodiment 3

[0032] Weigh 5g of cerium oxide, add 1200ml of deionized water, and stir in a water bath at 70°C for 20min with a speed rating of 20. Weigh 0.1g of sodium lauryl sulfate, add a small amount of ethanol, and add deionized water to make a 600ml solution, add the solution dropwise to cerium oxide with a peristaltic pump, let it settle after 3 hours of reaction, take the upper layer solution, and suction filter drying to obtain sodium dodecyl sulfate modified cerium oxide. Stearic acid-modified cerium oxide was prepared by the same method, wherein the amount of stearic acid was 0.2 g, the reaction time was 1 h, and the rotational speed grade was 15.

[0033] Cerium oxide modified with sodium lauryl sulfate and stearic acid is added to the rubber of track shoes on the open mill together with sulfur at a ratio of 1:1.

[0034] The process of this example is different from that of Example 2 in that the compounded modified cerium oxide is added together with sulfur on the mill, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com