Patents

Literature

197 results about "Advanced composite materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Advanced composite materials (ACMs) are also known as advanced polymer matrix composites. These are generally characterized or determined by unusually high strength fibres with unusually high stiffness, or modulus of elasticity characteristics, compared to other materials, while bound together by weaker matrices. These are termed advanced composite materials (ACM) in comparison to the composite materials commonly in use such as reinforced concrete, or even concrete itself. The high strength fibers are also low density while occupying a large fraction of the volume...

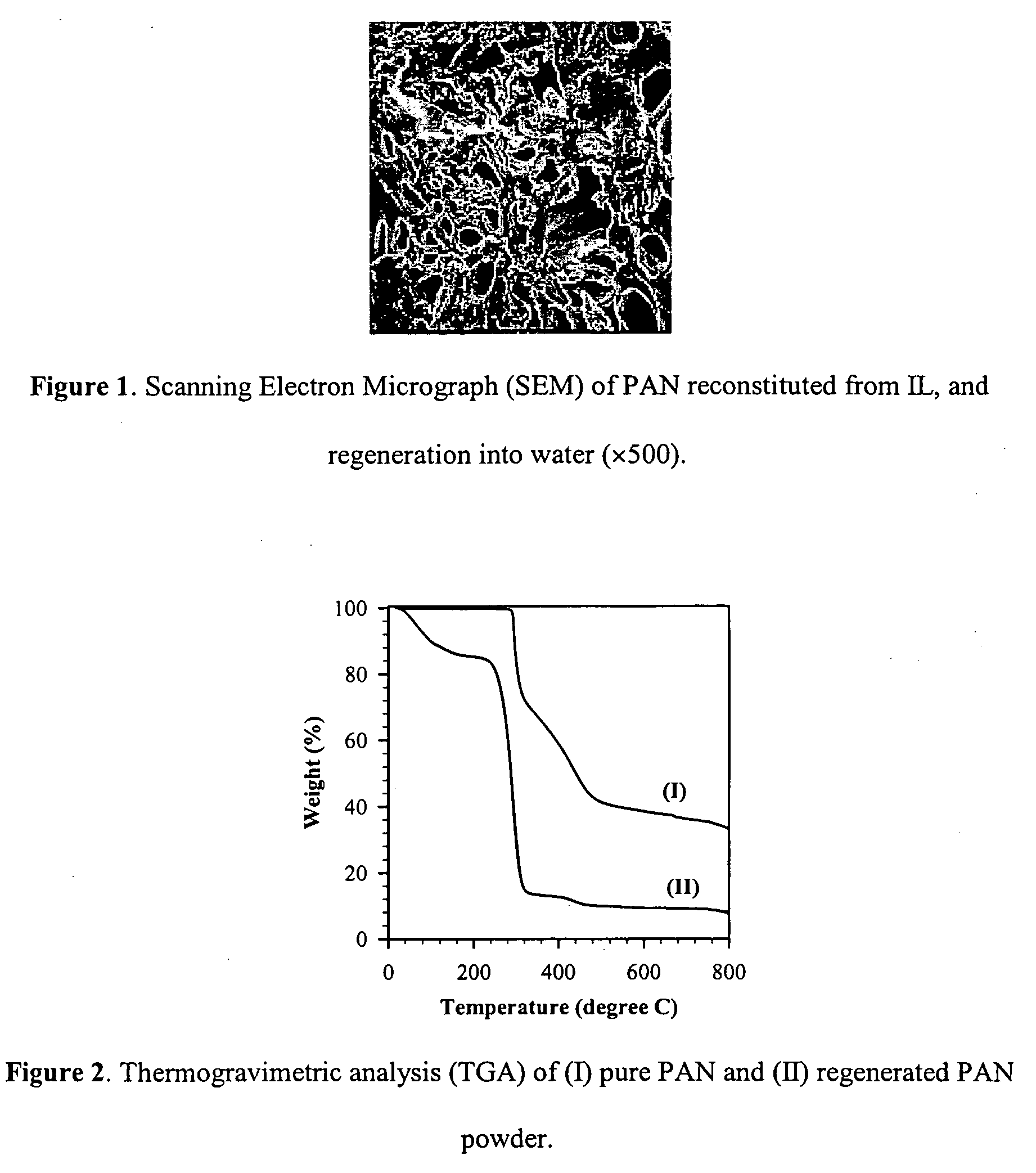

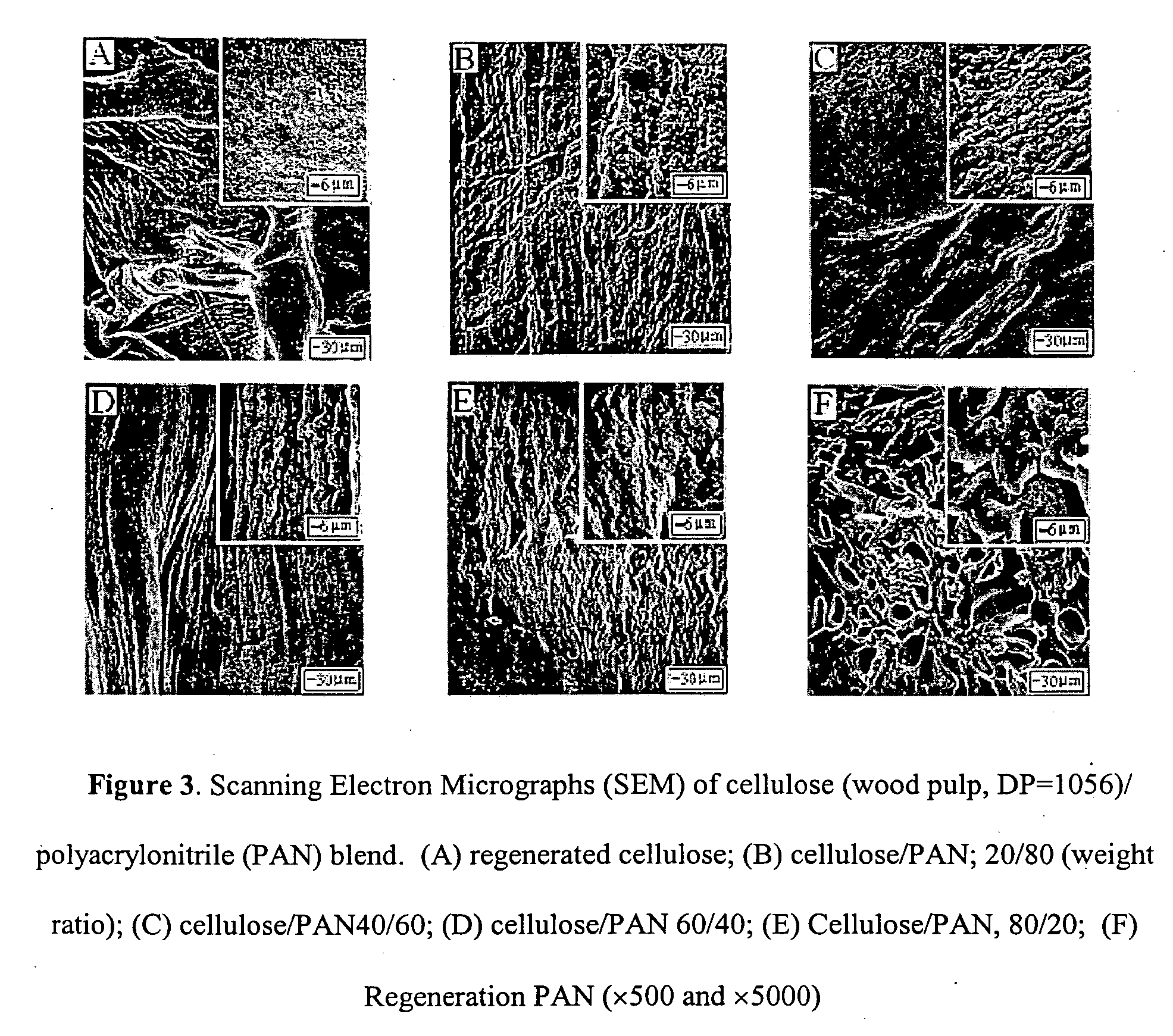

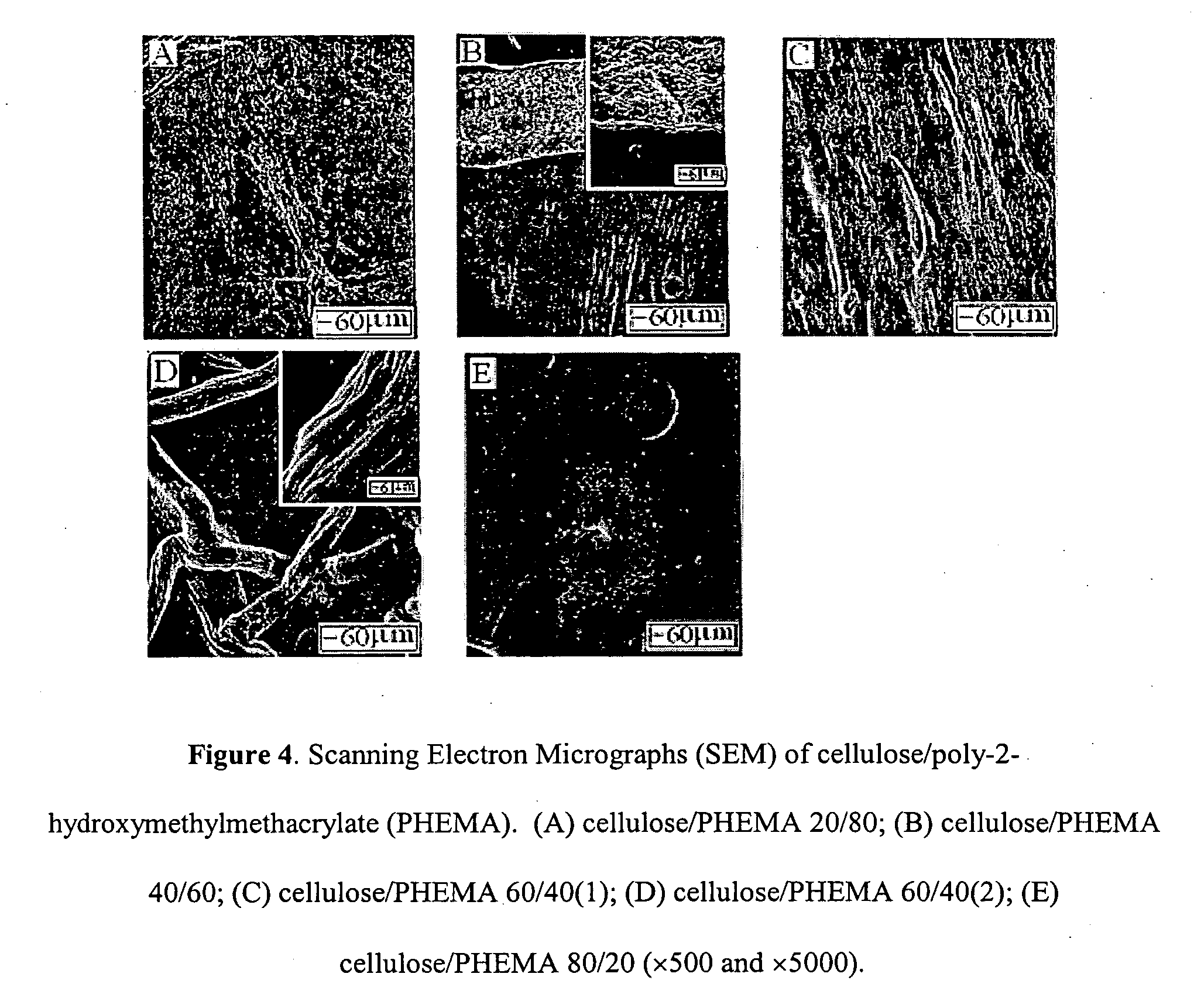

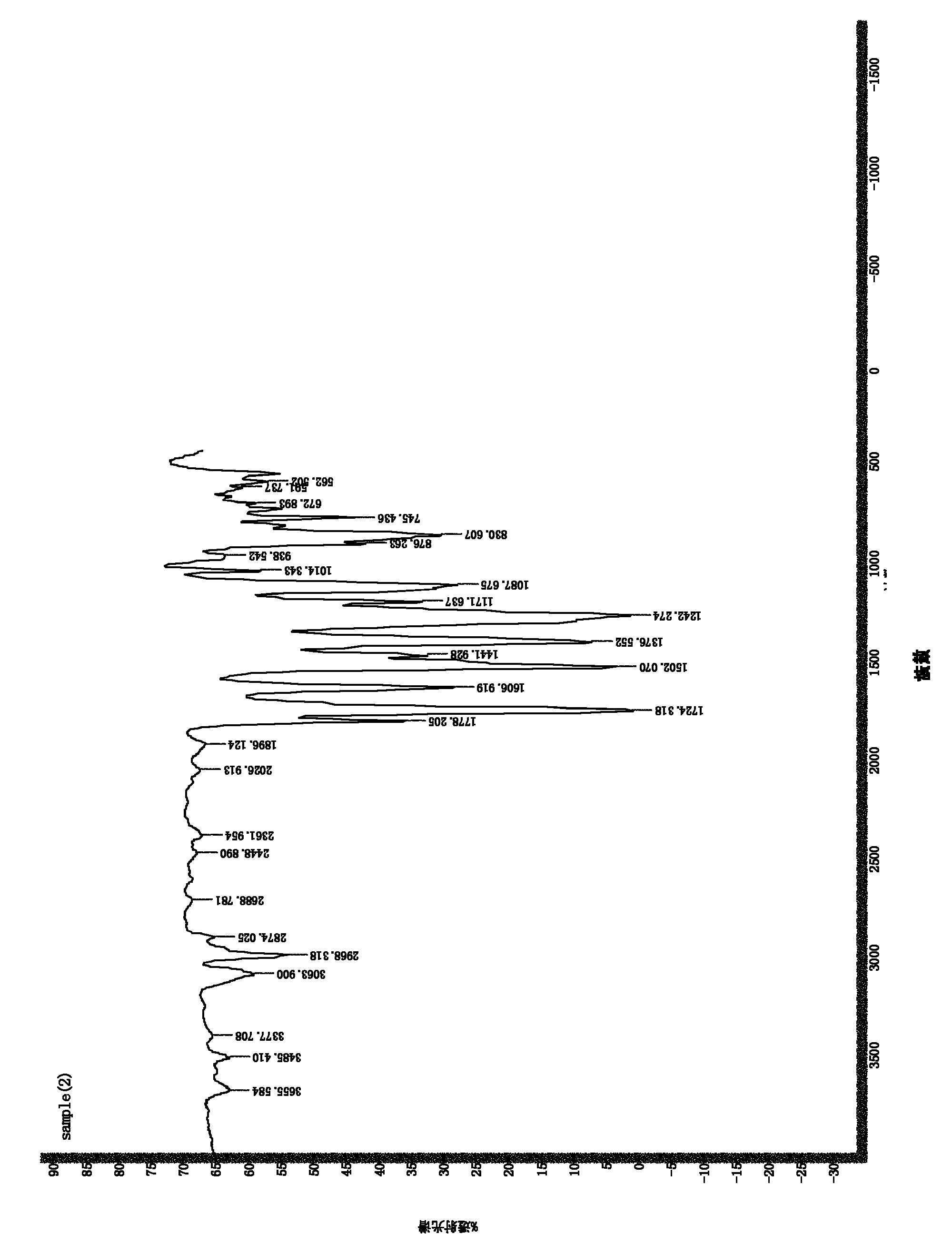

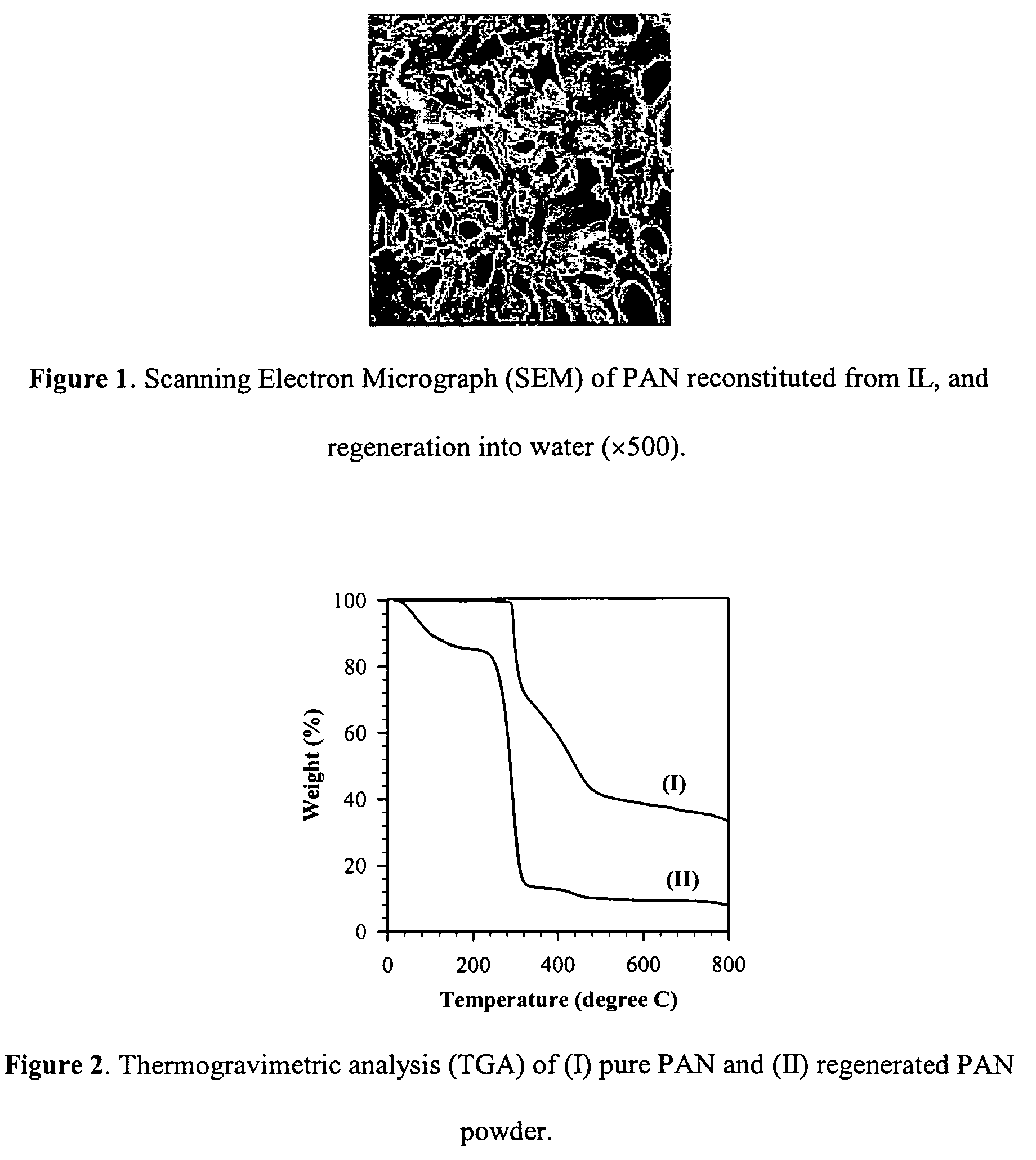

Polymer dissolution and blend formation in ionic liquids

InactiveUS20050288484A1Cosmetic preparationsToilet preparationsPolymer dissolutionAdvanced composite materials

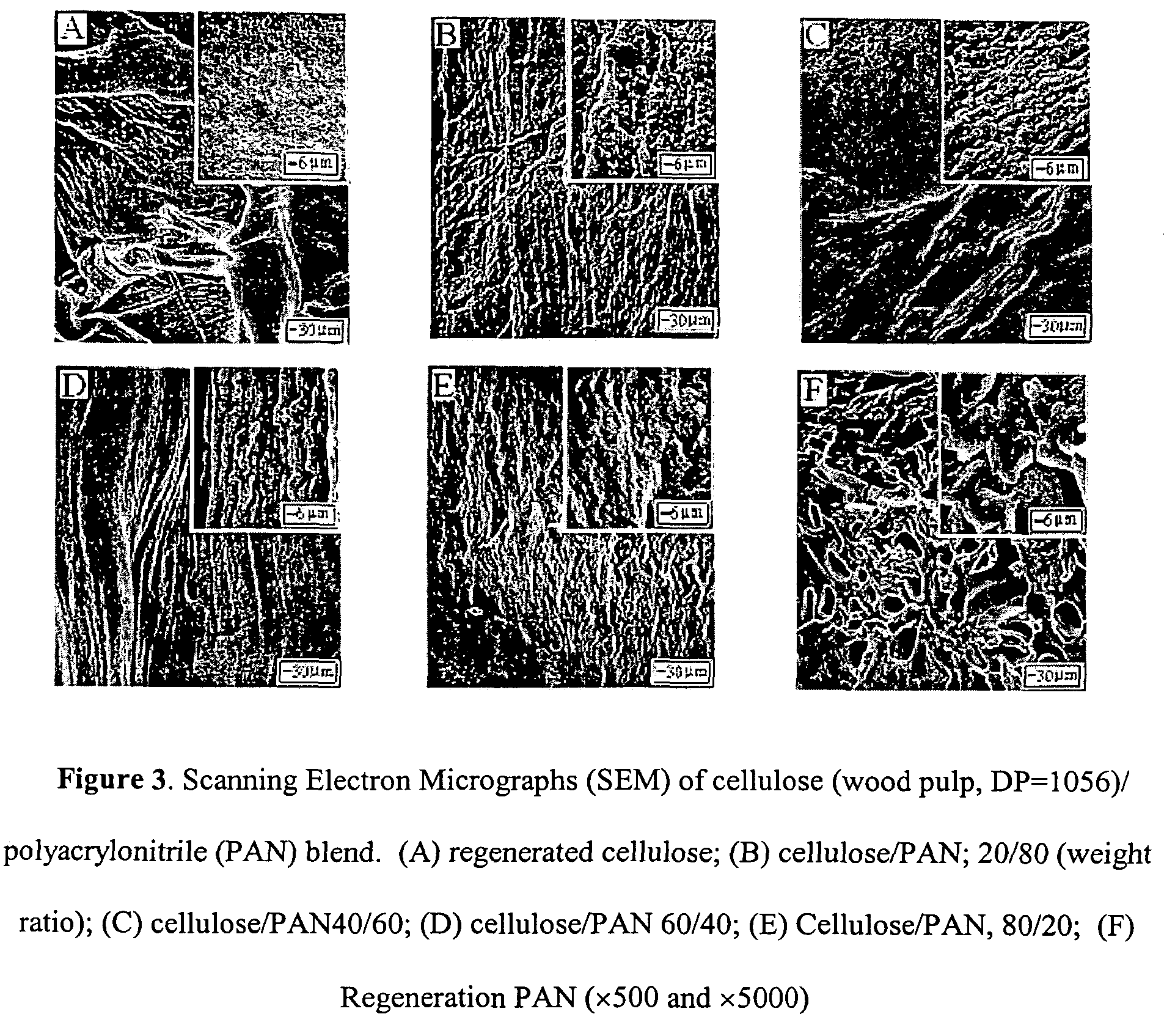

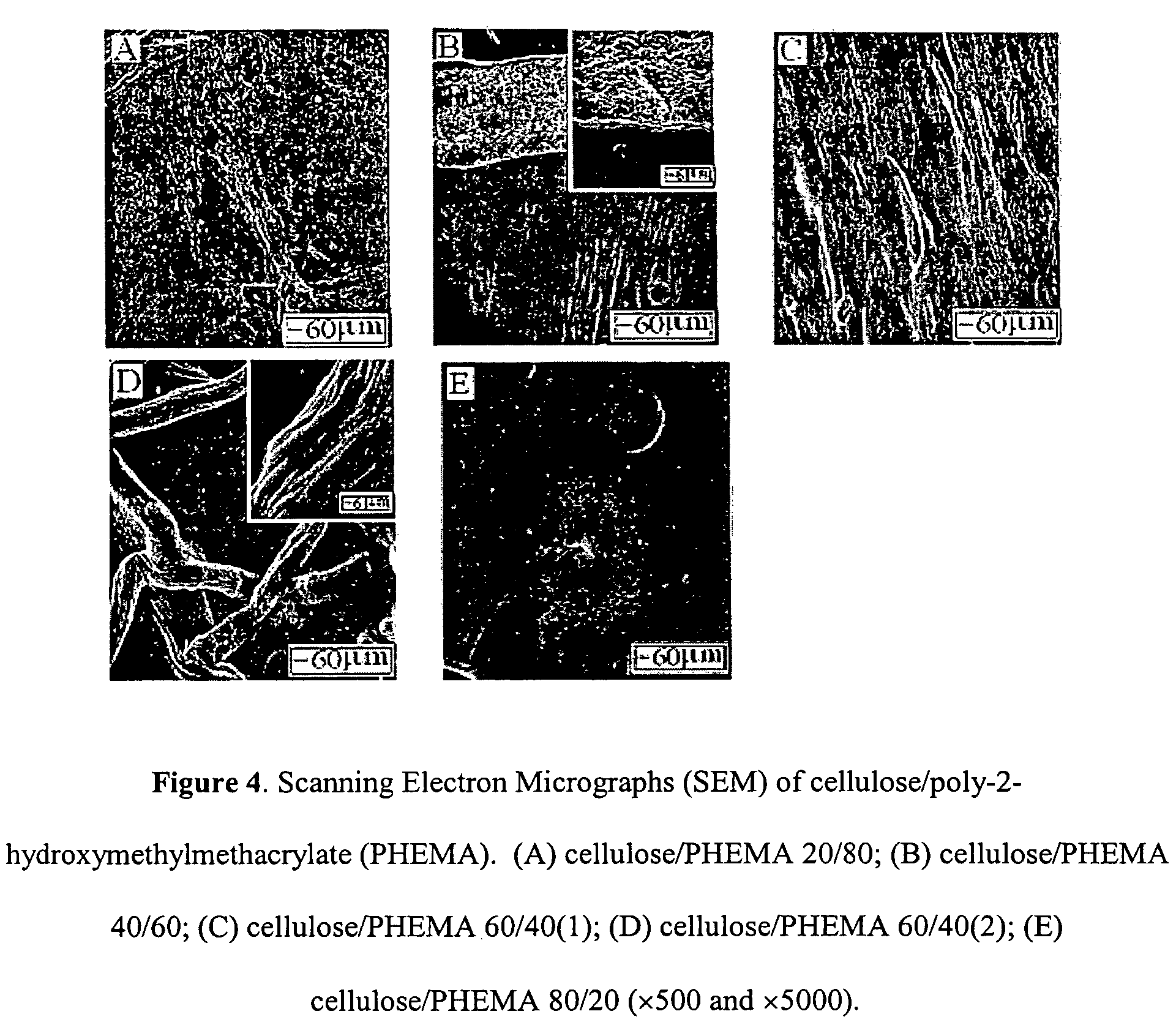

The present invention relates to processes utilizing ionic liquids for the dissolution of various polymers and / or copolymers, the formation of resins and blends, and the reconstitution of polymer and / or copolymer solutions, and the dissolution and blending of “functional additives” and / or various polymers and / or copolymers to form advanced composite materials.

Owner:UNIVERSTIY OF ALABAMA THE

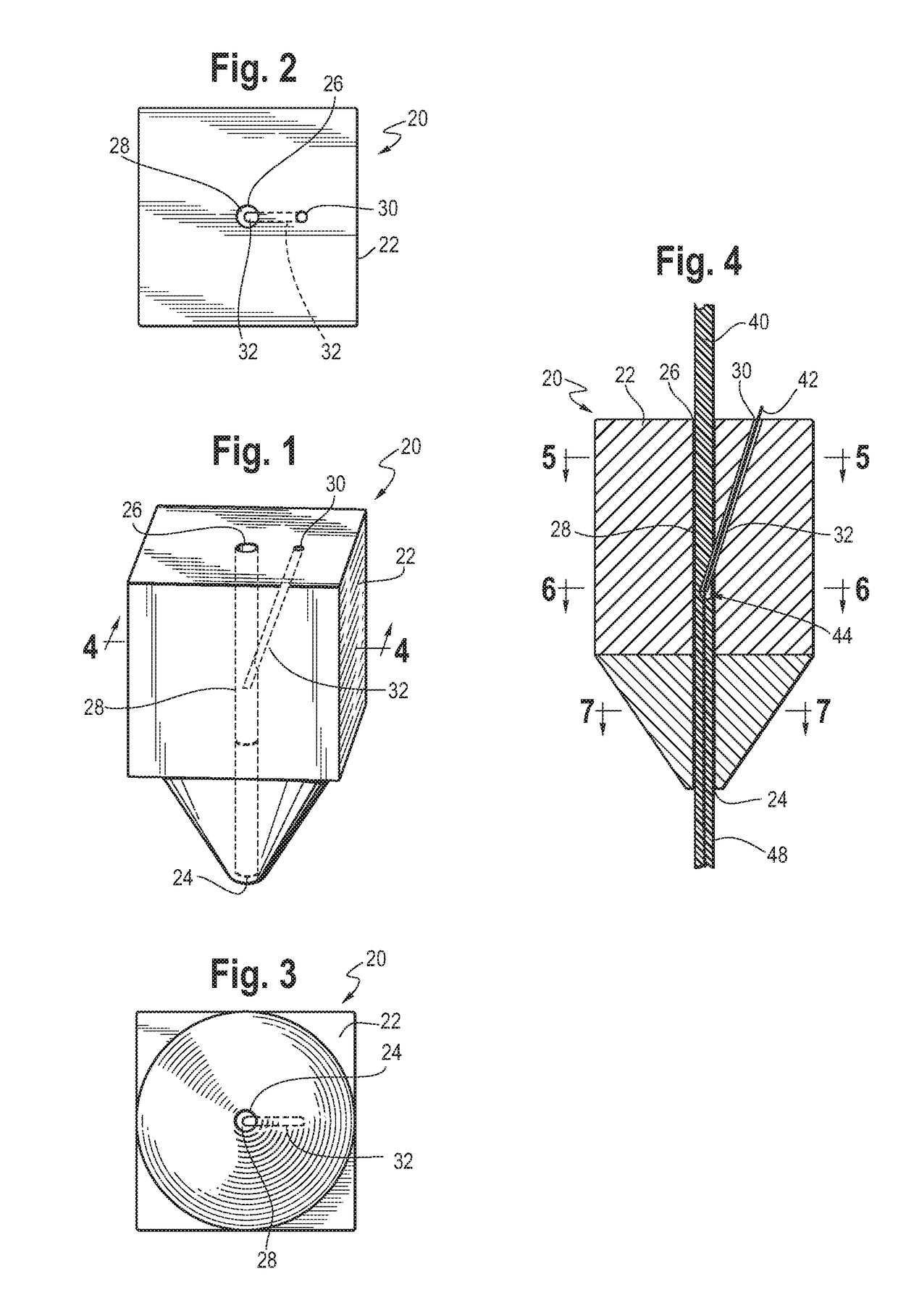

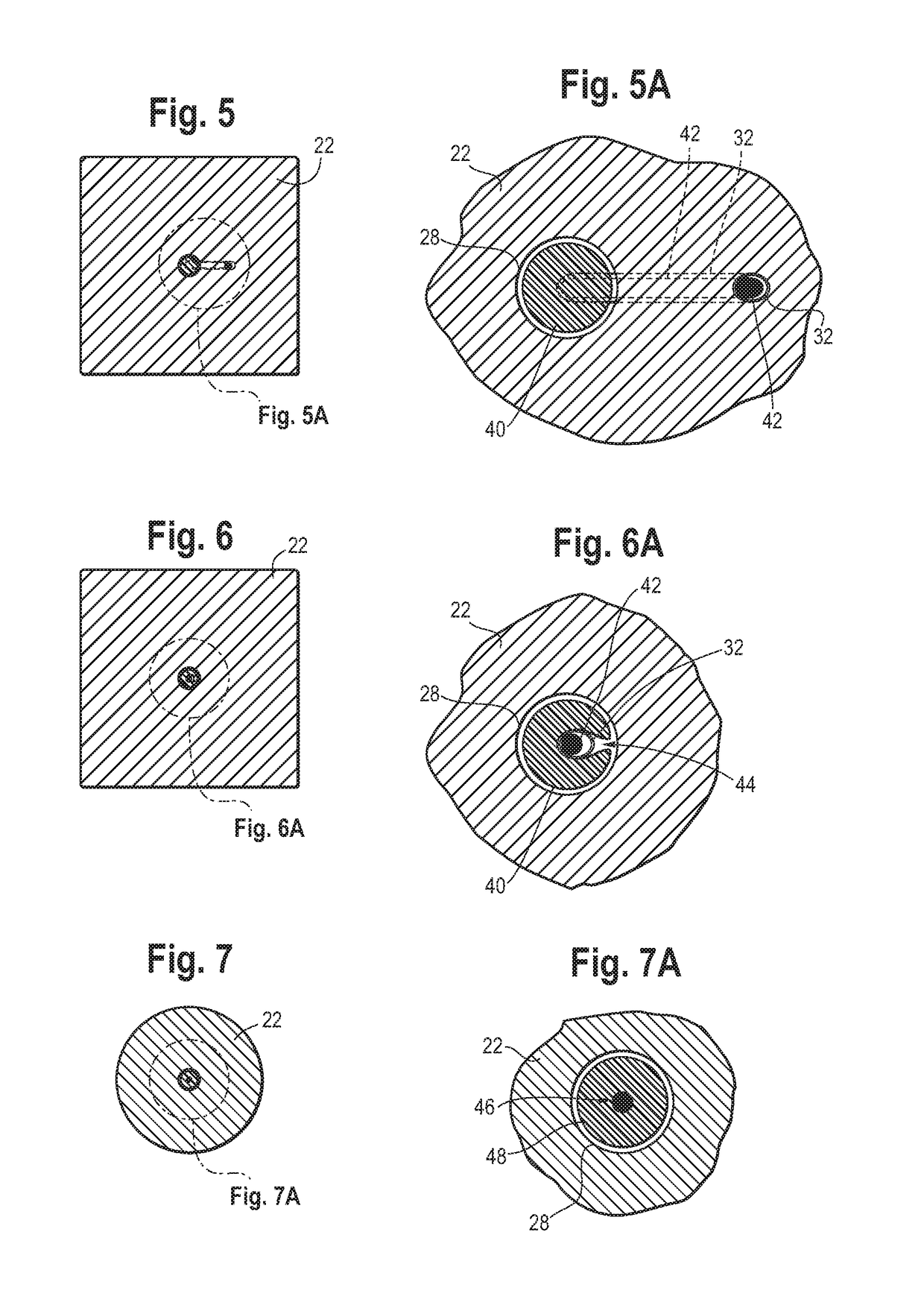

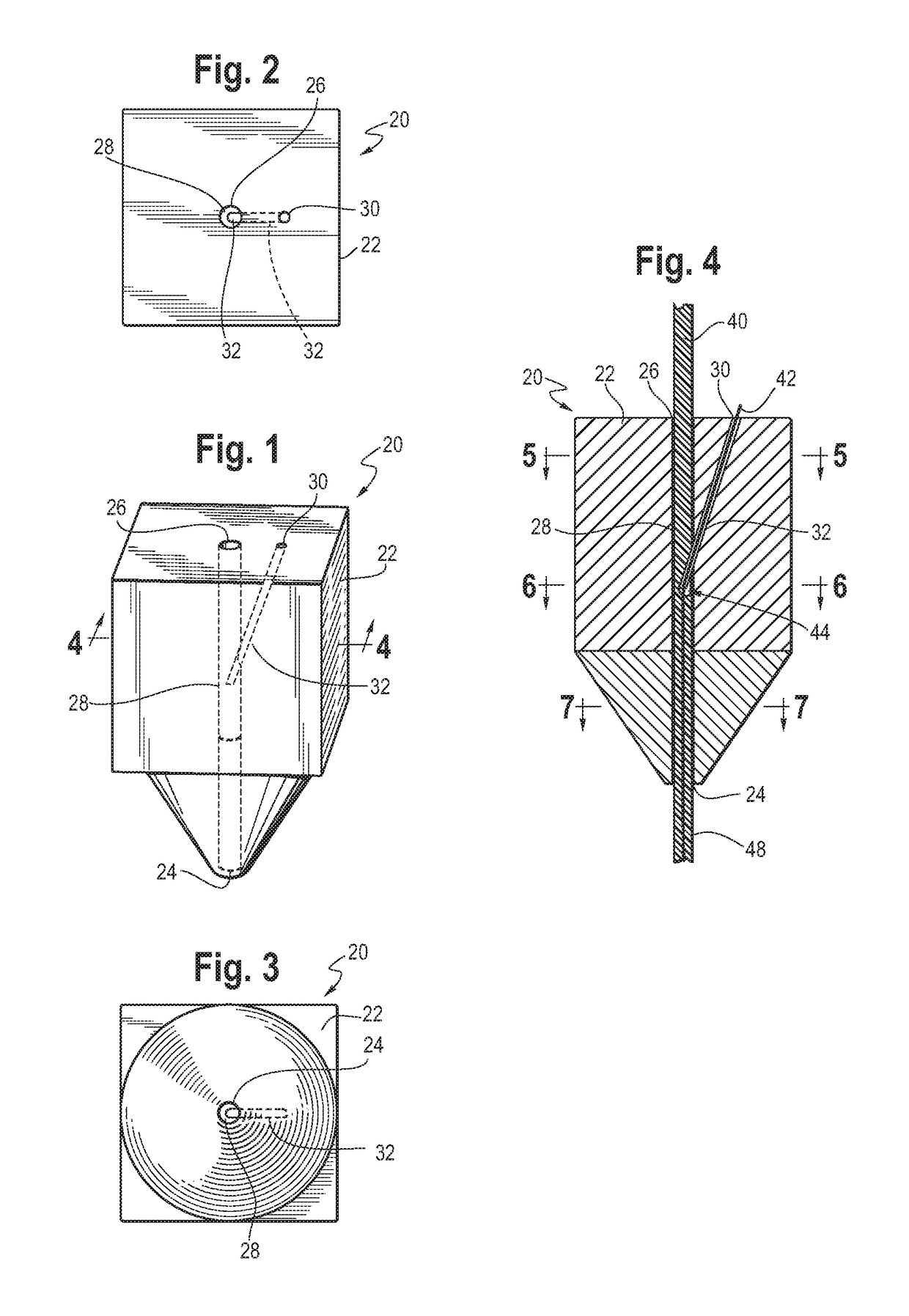

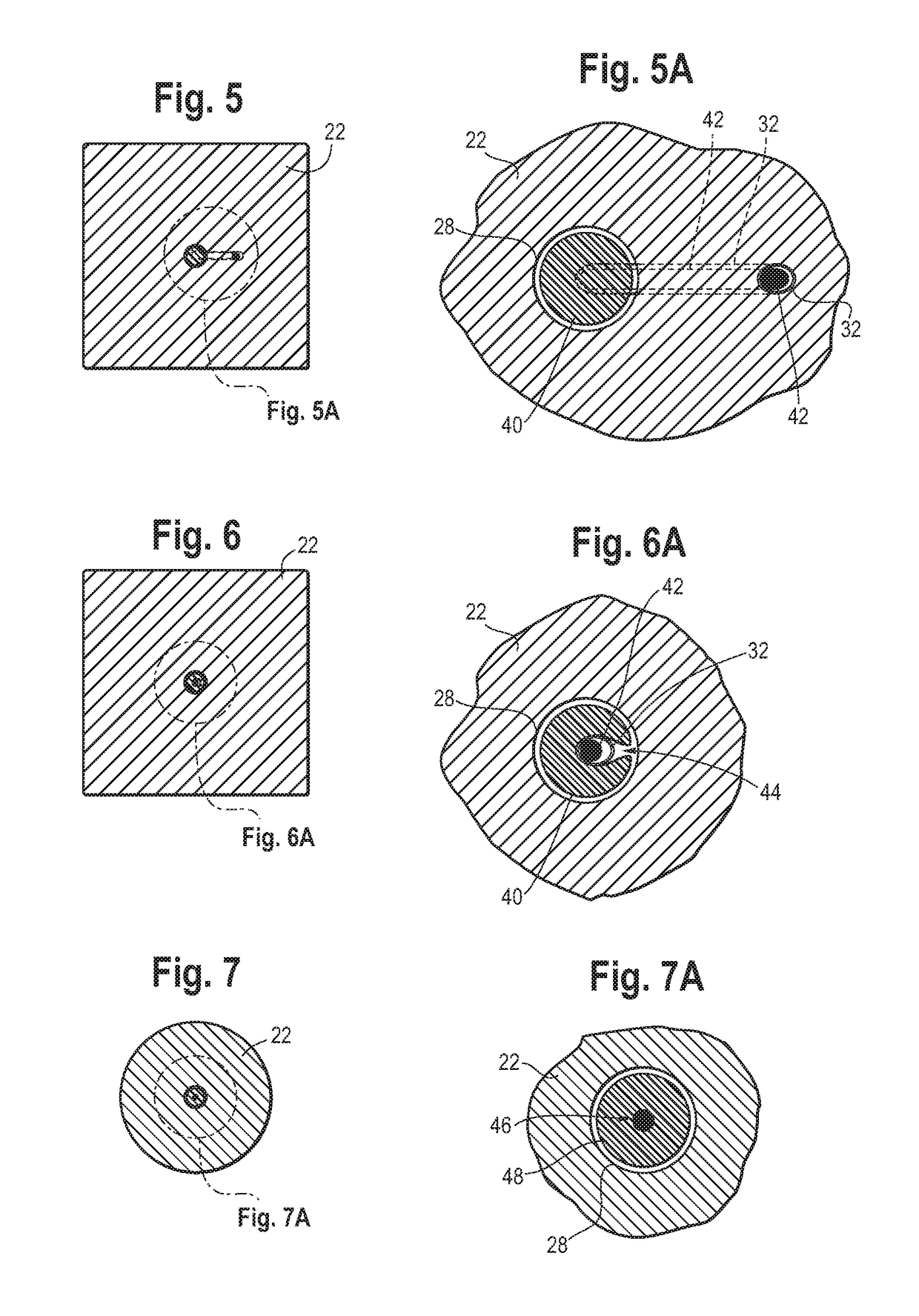

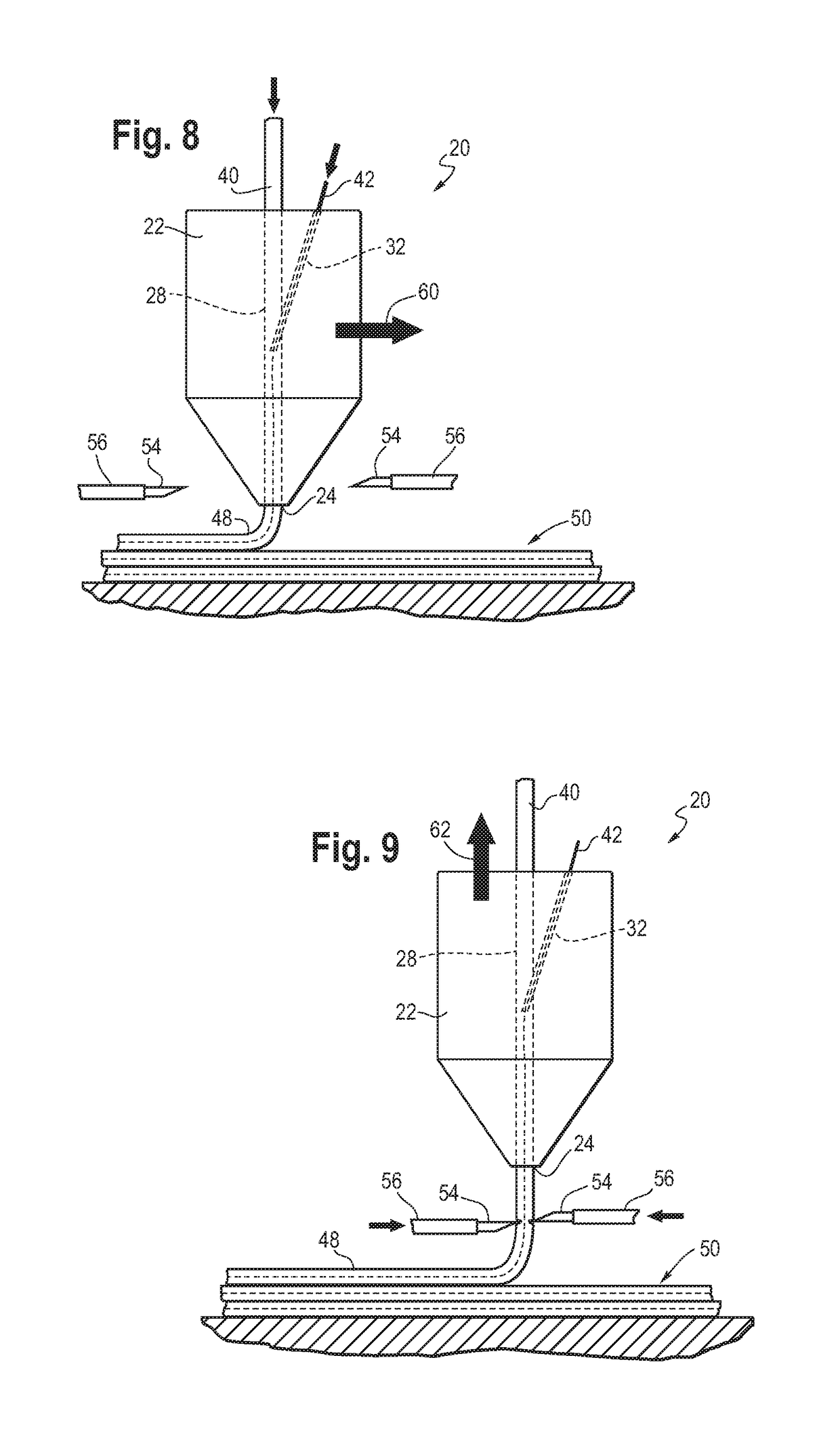

Device and method for 3D printing with long-fiber reinforcement

ActiveUS20170157851A1Eliminate point3D object support structuresAdditive mnaufacturing with solid and fluidAdvanced composite materialsPolymer

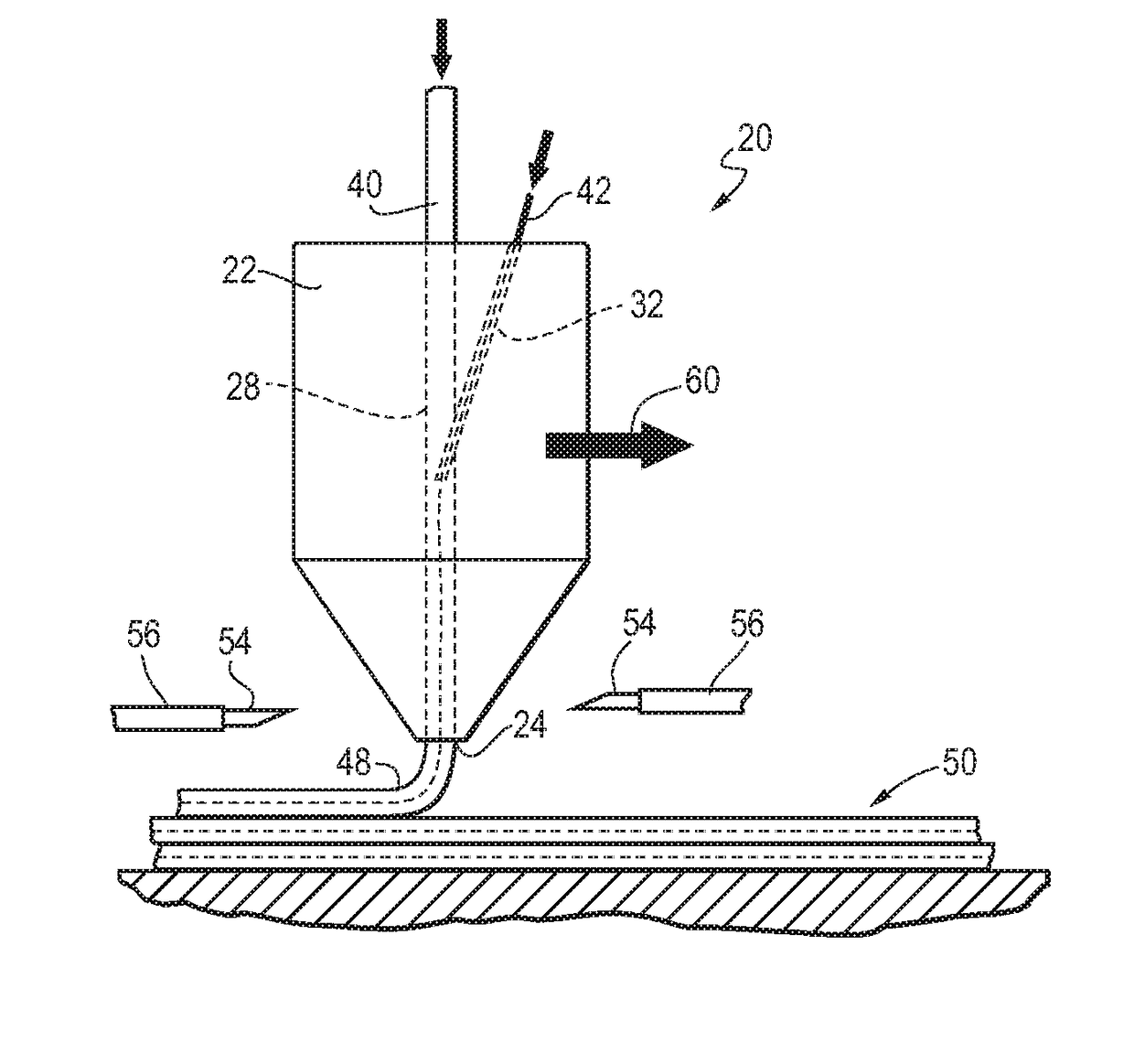

A process and device for 3D printing parts incorporating long-fiber reinforcements in an advanced composite material is disclosed. A nozzle for a 3D printing device receives a polymer material and a reinforcing fiber through separate inlets. A passage from the reinforcing fiber inlet cleaves the passage containing the polymer material, creating an interstitial cavity into which the reinforcing fiber is introduced. The polymer material closes back on itself and encapsulates the reinforcing fiber, then drags the fiber along with the flow and exits nozzle to be deposited on a work surface or part being manufactured.

Owner:NORTHROP GRUMMAN SYST CORP

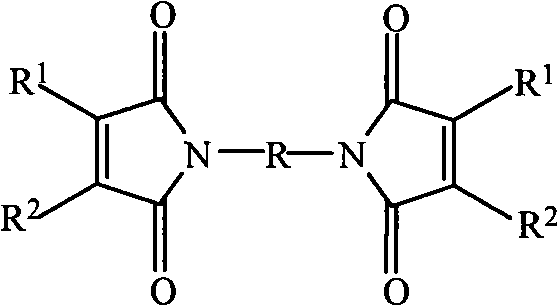

High-temperature-resistant modified polyfunctional epoxy matrix resin for advanced composite material and preparation thereof

The invention relates to high-temperature-resistant modified polyfunctional epoxy matrix resin for an advanced composite material. The resin comprises tetramaleimide resin, carboxy terminated nitrile rubber, polyfunctional epoxy resin, a curing agent and an organic solvent. A preparation method comprises the following steps of: adding the tetramaleimide resin, the carboxy terminated nitrile rubber and the polyfunctional epoxy resin into a reaction kettle and reacting at the temperature of 110 DEG C for one hour; adding the organic solvent and dissolving under stirring to obtain a component A;mixing the curing agent and the organic solvent and dissolving under stirring to obtain a component B; and mixing the component A and the component B and uniformly stirring during use. The high-temperature-resistant modified polyfunctional epoxy matrix resin provided by the invention has the advantages of high room temperature tensile shear strength, high heat resistance, wide application prospect in the fields such as electronics, micro-electronics, printed circuit boards (PCB), motors, aerospace and the like, simple preparation process, low cost and contribution to realizing industrial production.

Owner:DONGHUA UNIV +1

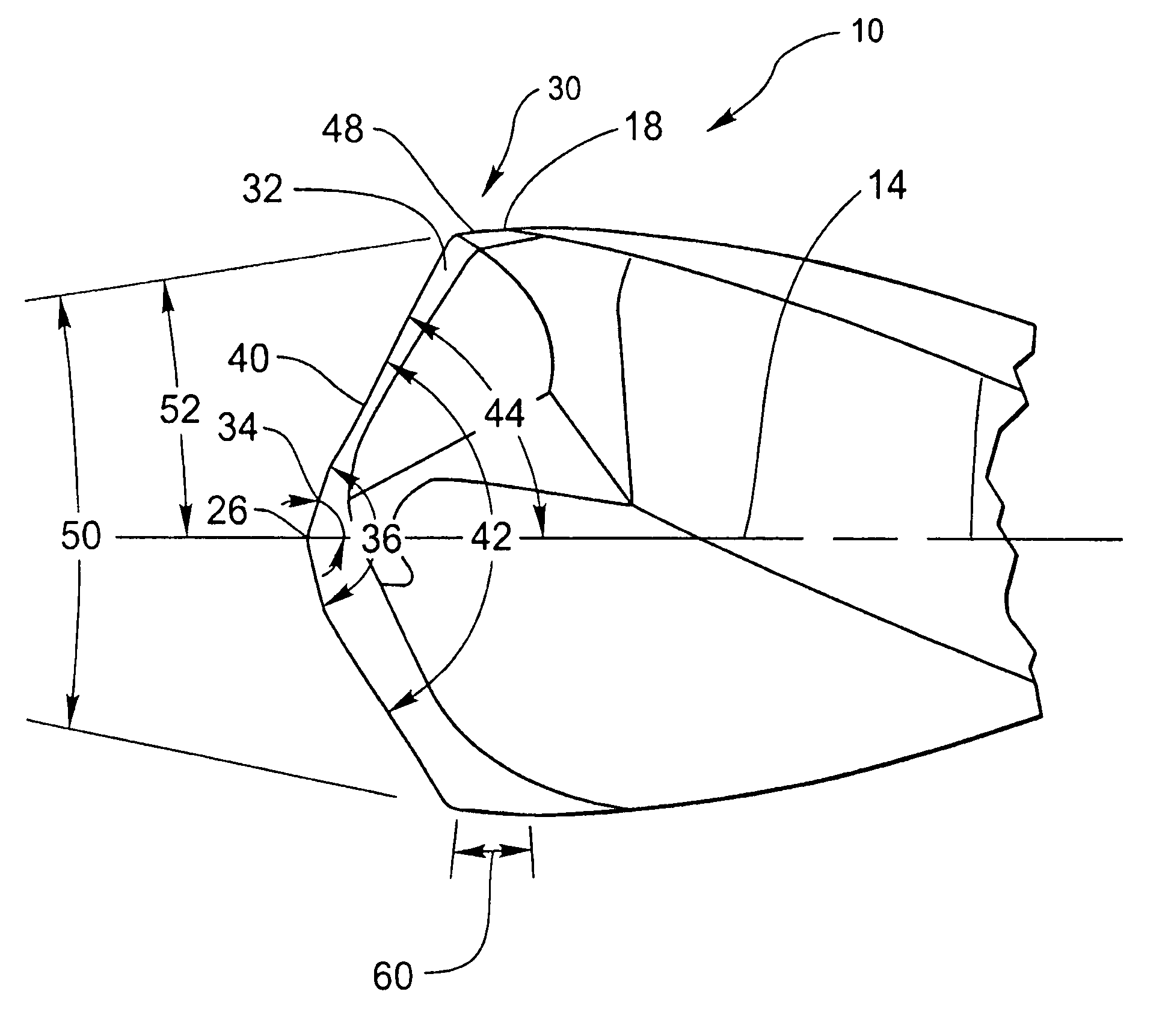

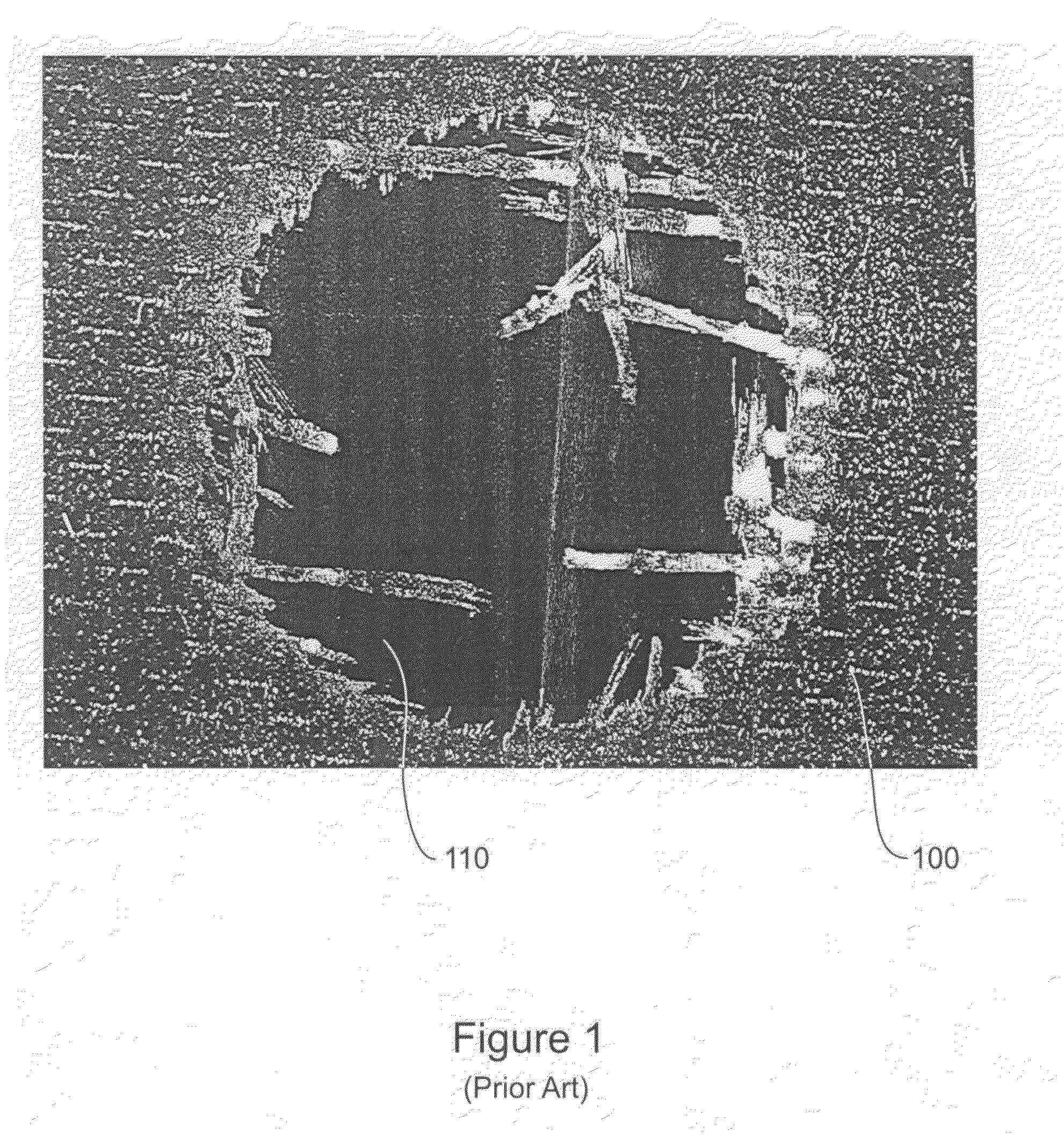

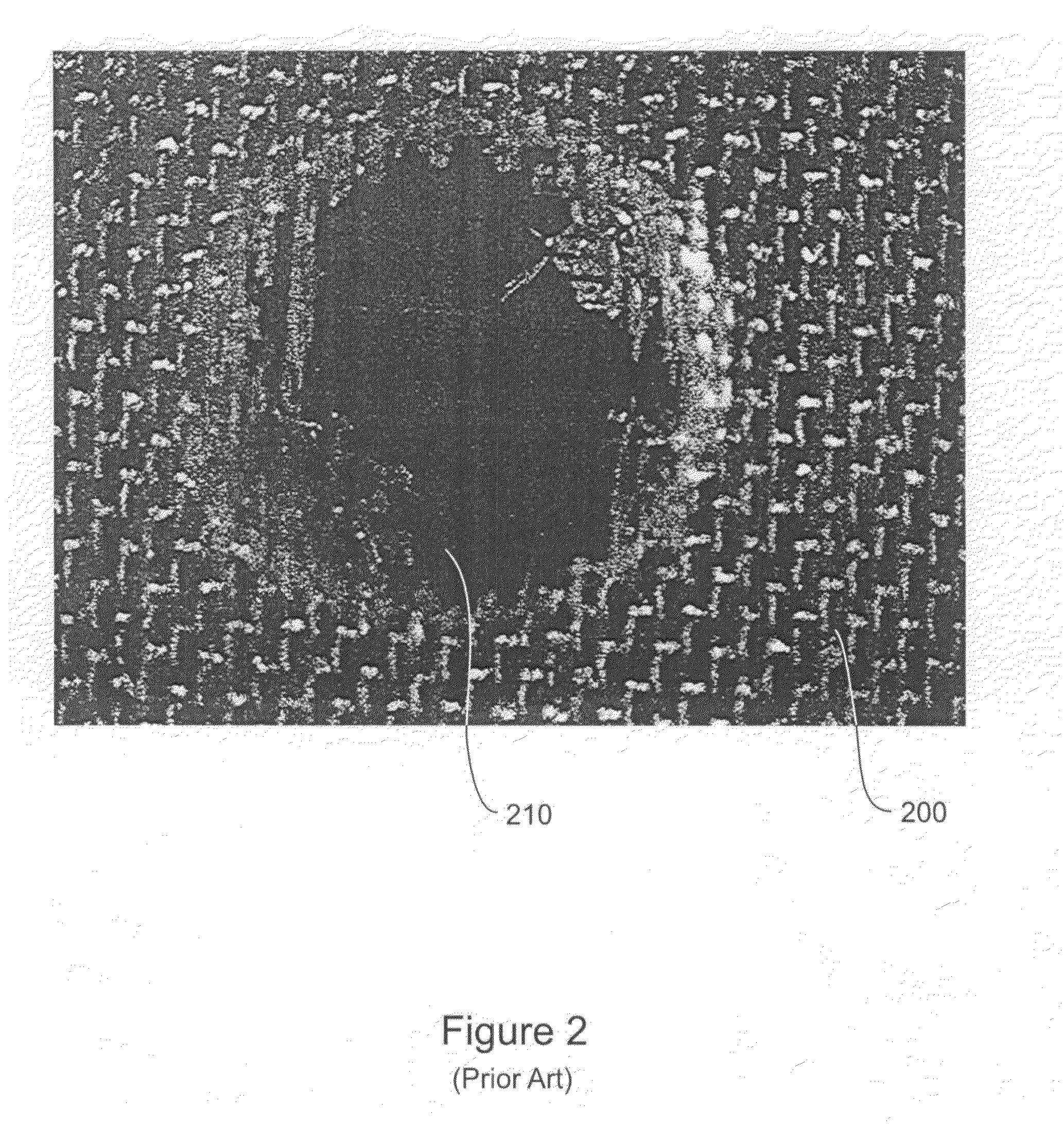

PCD drill for composite materials

ActiveUS7575401B1Increase chanceMinimal delaminationWood turning toolsTransportation and packagingFiberProduction rate

A PCD drill for producing close tolerance holes in multi layer laminates, such as carbon fiber reinforced composites, with minimum fraying of the fibers on both entrance and exit from the hole is provided. The drills provided include a symmetrical cutting point with a self-centering split point and a high shear second cutting lip positioned at the outer diameter of the drill. The drills of the invention may allow for increased cutting speeds and feeds when used with such advanced composite materials, thus increasing tool productivity and providing increased performance.

Owner:PRECORP INC

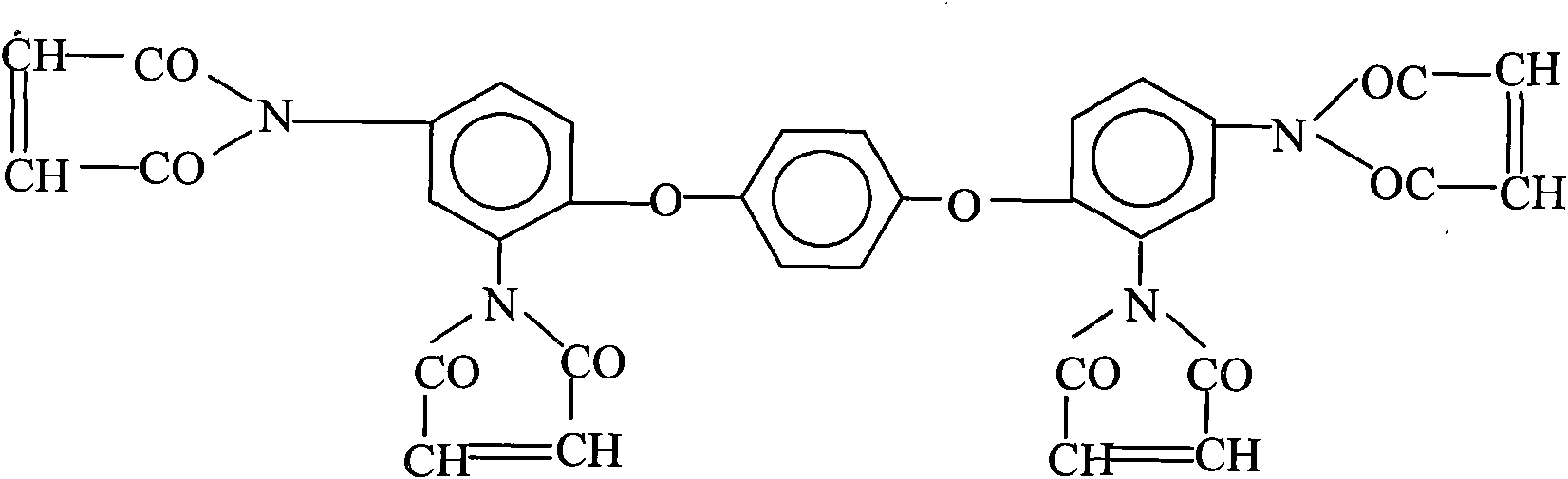

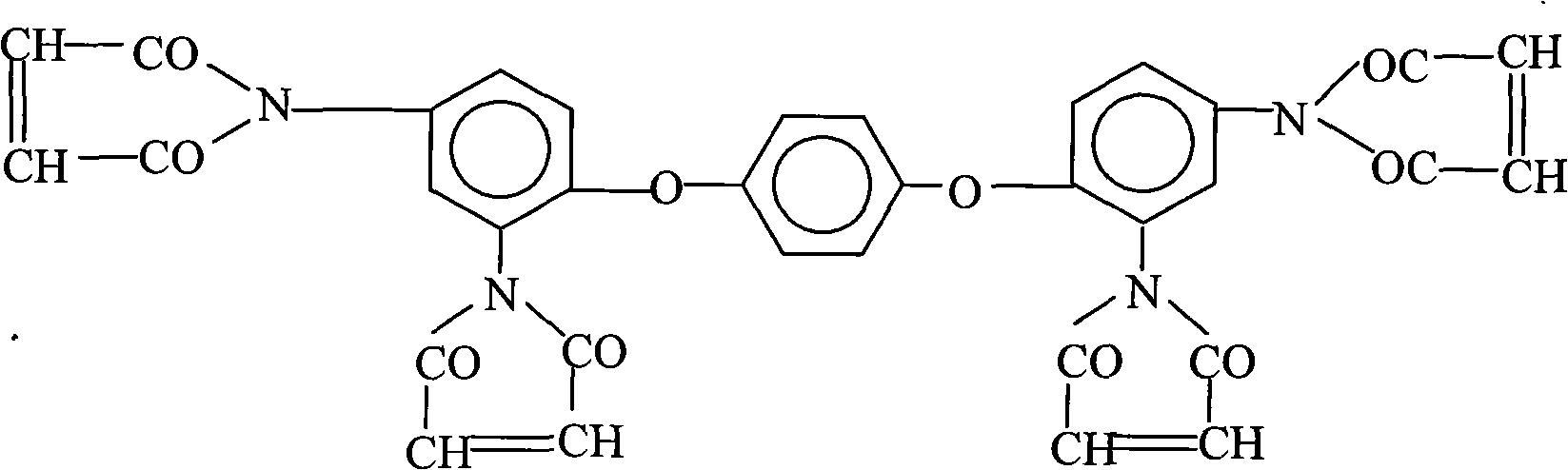

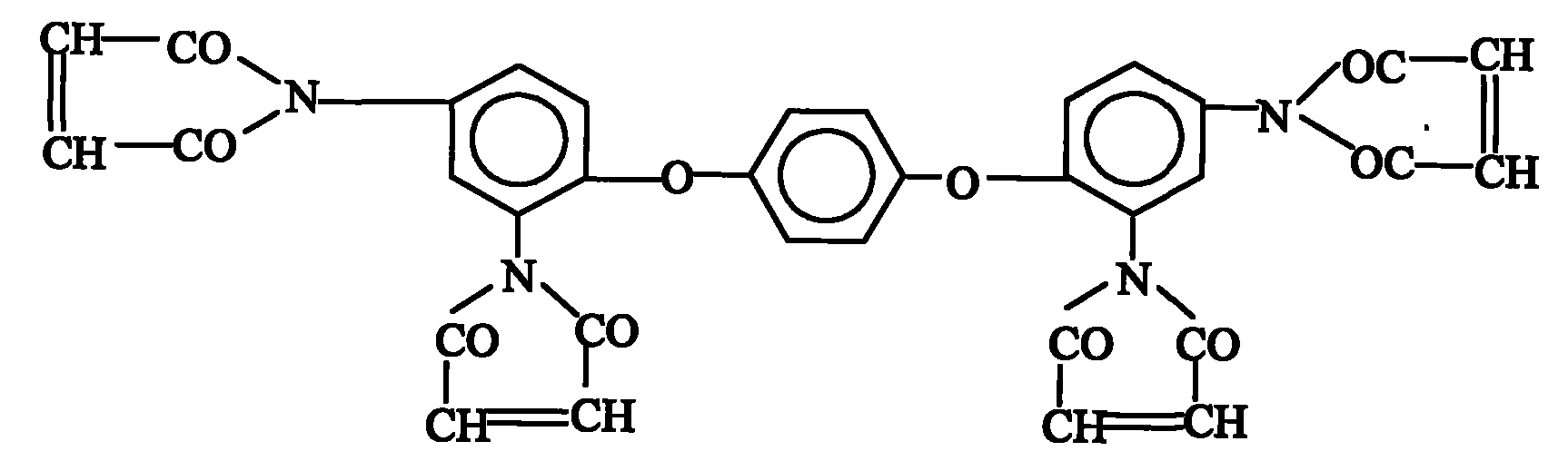

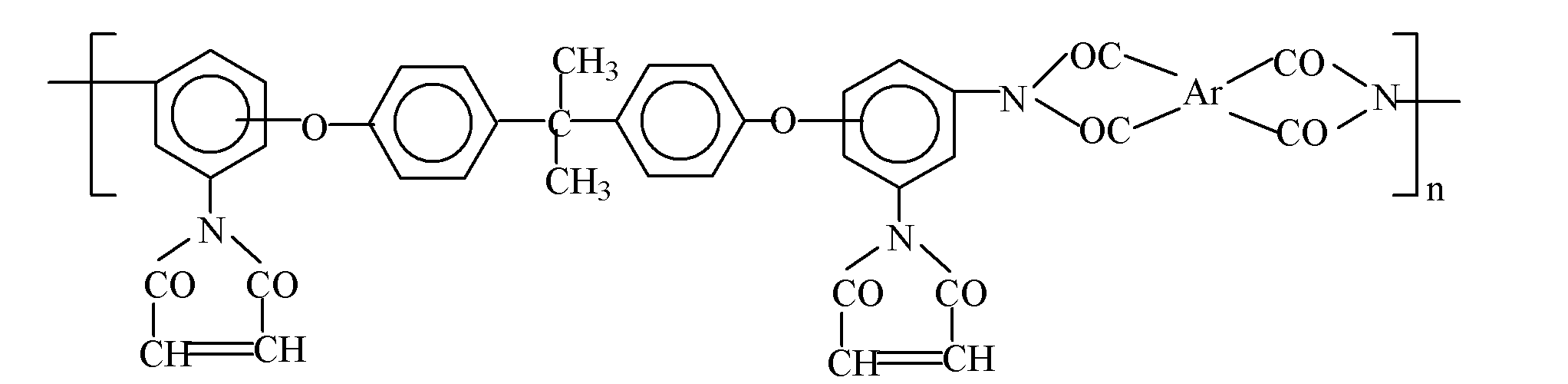

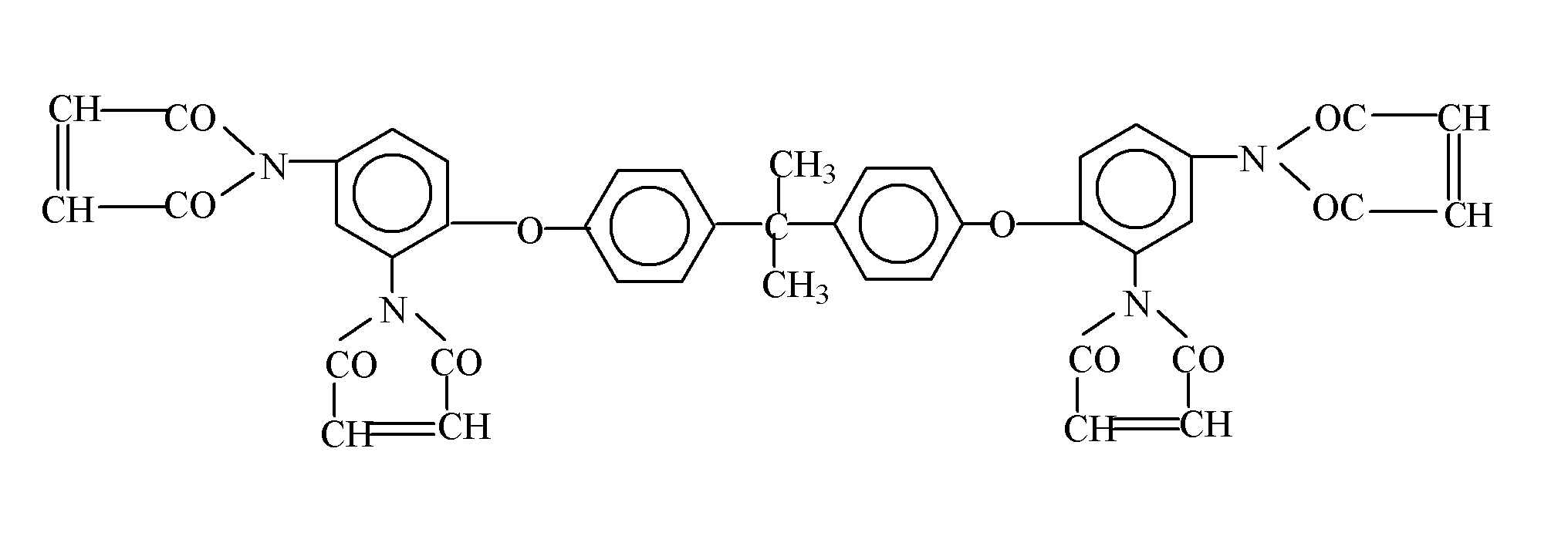

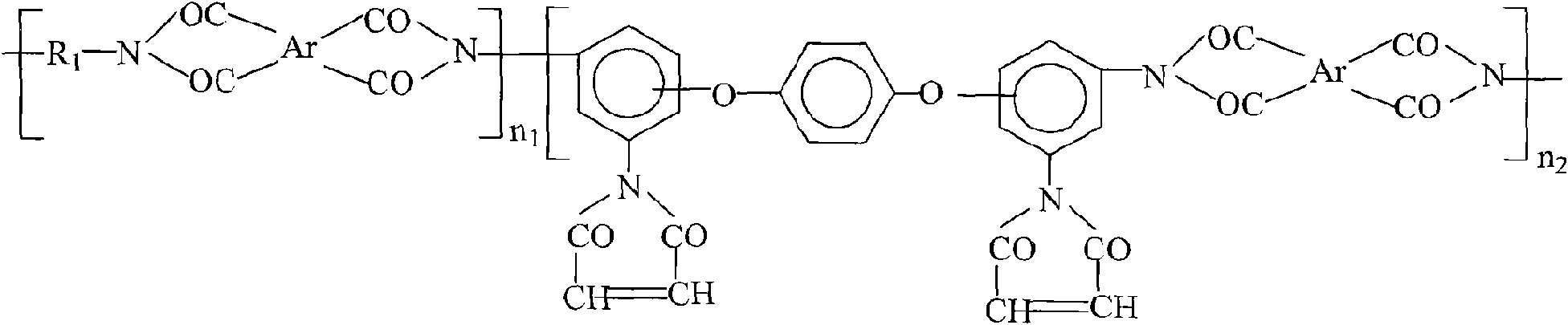

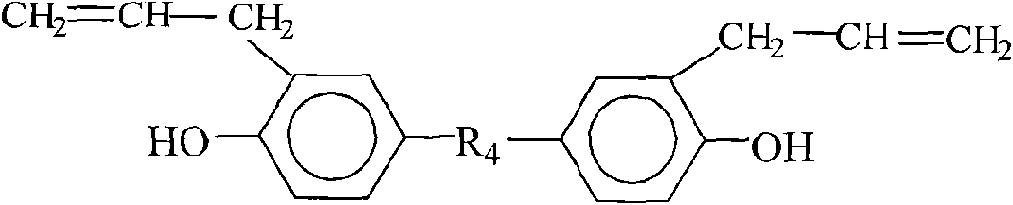

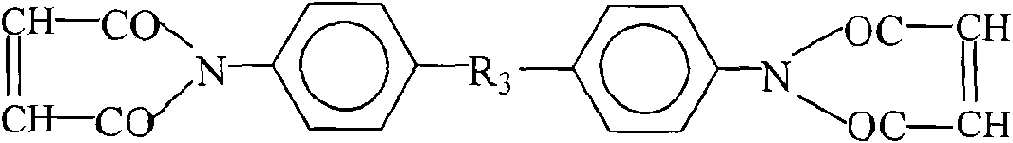

Thermosetting polyimide resin and preparation method thereof

The invention relates to a thermosetting polyimide resin and a preparation method thereof. A homogeneous transparent sticky maleimide-based polyimide resin solution is taken as a component A, and a 4-maleimide-based bisphenol solution A is taken as a component B. The preparation method of the thermosetting polyimide resin comprises the following steps: (1) preparing the maleimide-based polyimide resin solution as the component A; (2) preparing the 4-maleimide-based bisphenol solution A as the component B; and (3) uniformly mixing the component A and the component B at room temperature to obtain the thermosetting polyimide resin. The thermosetting polyimide resin of the invention not only can be applied to the matrix resin of high temperature resistant adhesives and glass fiber reinforced composite materials but also can be applied to the matrix resin of high-performance fiber (carbon fiber, aramid fiber and the like) reinforced advanced composite materials, thus the thermosetting polyimide resin has wide application prospects; and the invention has simple preparation technology, low cost and environmental protection, can finish preparation processes in the general equipment, and is suitable for industrial production.

Owner:DONGHUA UNIV +1

Polymer dissolution and blend formation in ionic liquids

InactiveUS7888412B2Cosmetic preparationsToilet preparationsPolymer dissolutionAdvanced composite materials

The present invention relates to processes utilizing ionic liquids for the dissolution of various polymers and / or copolymers, the formation of resins and blends, and the reconstitution of polymer and / or copolymer solutions, and the dissolution and blending of “functional additives” and / or various polymers and / or copolymers to form advanced composite materials.

Owner:UNIVERSTIY OF ALABAMA THE

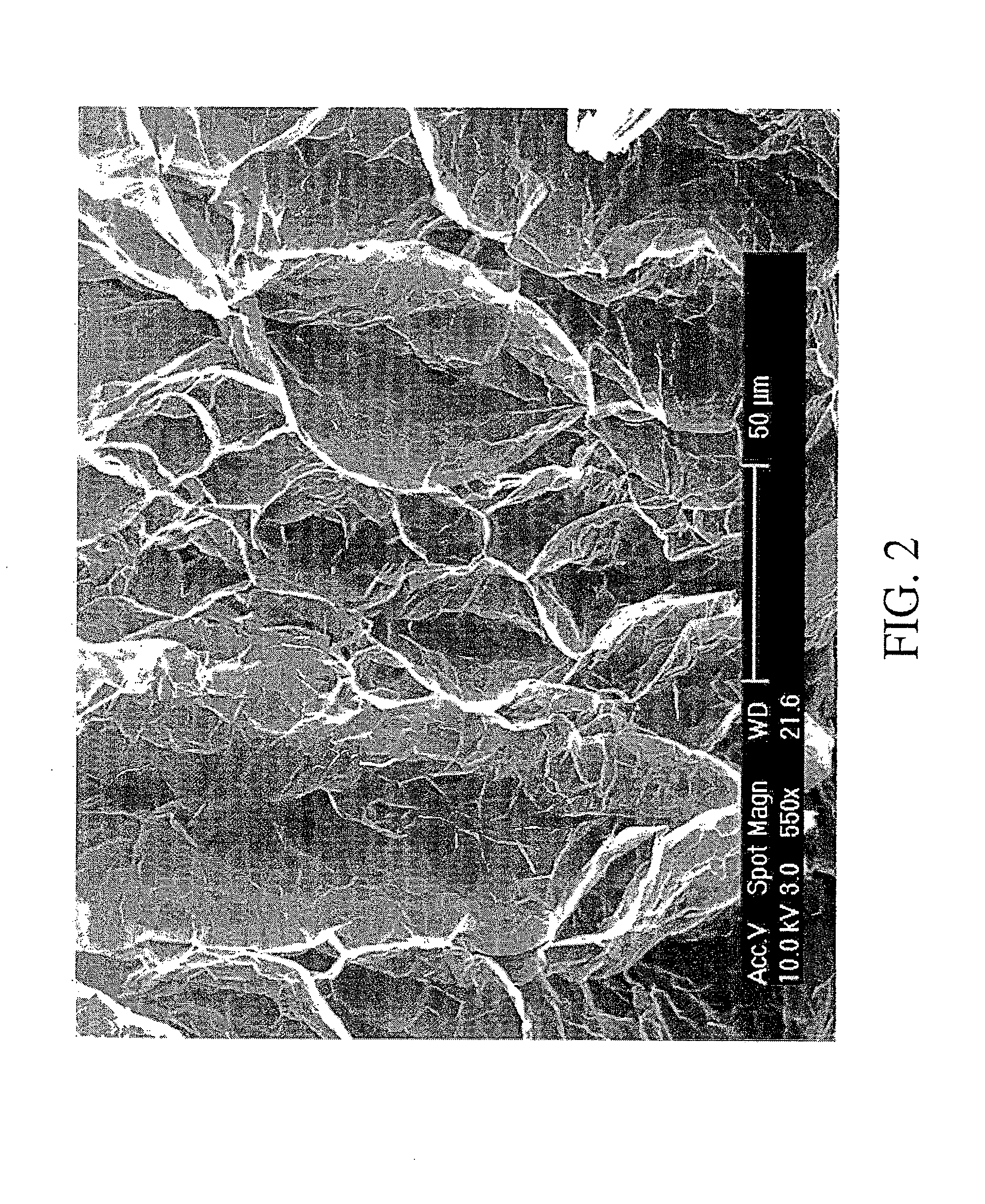

Preparation method for carbon nanotube non-woven fabric interlayer modified fiber reinforced composite materials

InactiveCN102516569AInhibition formationPrevent scalabilityCarbon nanotubeFiber-reinforced composite

The invention belongs to the advanced composite material preparing technology and relates to a preparation method for carbon nanotube non-woven fabric interlayer modified fiber reinforced composite materials. The method includes: enabling carbon nanotube non-woven fabric to enter resin rich areas of the layers of fiber reinforced thermosetting resin base composite materials in direct intercalation mode, using an autoclave molding process or a liquid forming process, and preparing interlayer the interlayer modified composite materials according to an original curing process of matrix resin. The carbon nanotube non-woven fabric can enter weak interlayer areas of the composite materials through direct intercalation mode, has no influence on flow of the resin in the curing process and a liquid forming process of the matrix resin, and simultaneously a network structure formed by carbon nanotubes in an interlayer can effectively prevent interlayer microcracks from being formed and extending, thereby improving strengthening-toughening performance of interlayer of the composite materials, obtaining high impact damage resistance and high damage tolerance, and covering a temperature range of typical aerospace composite structure application, in particular to a more than 300 DEG C high temperature range.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS +1

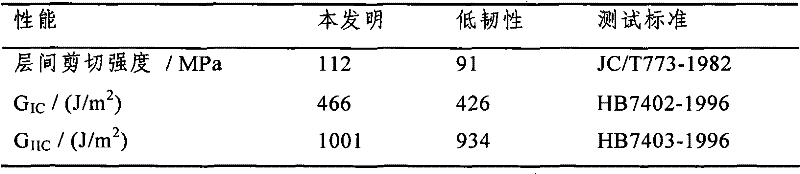

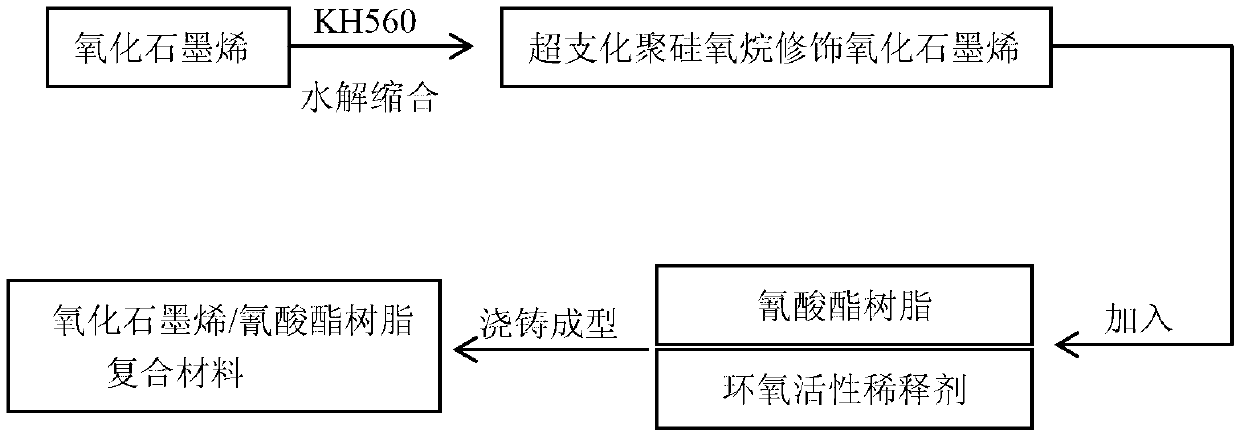

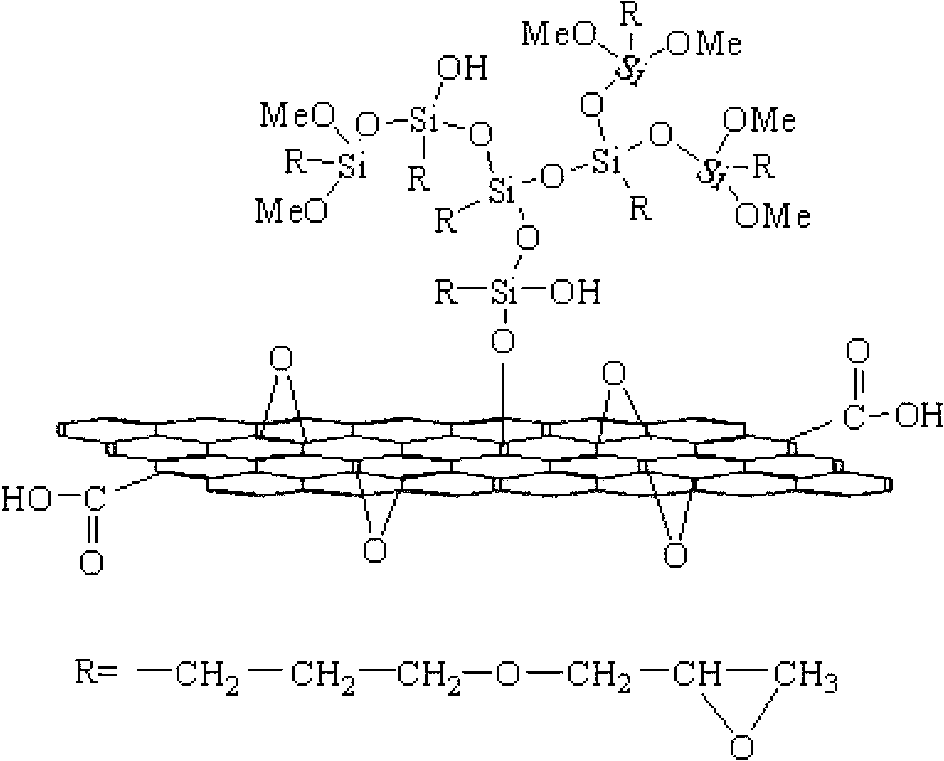

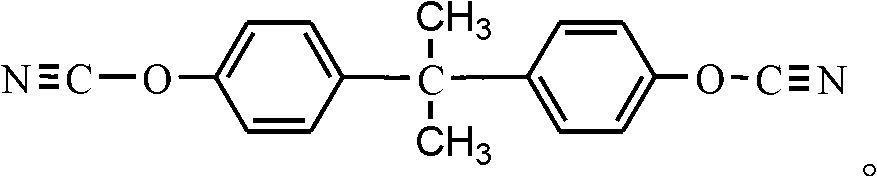

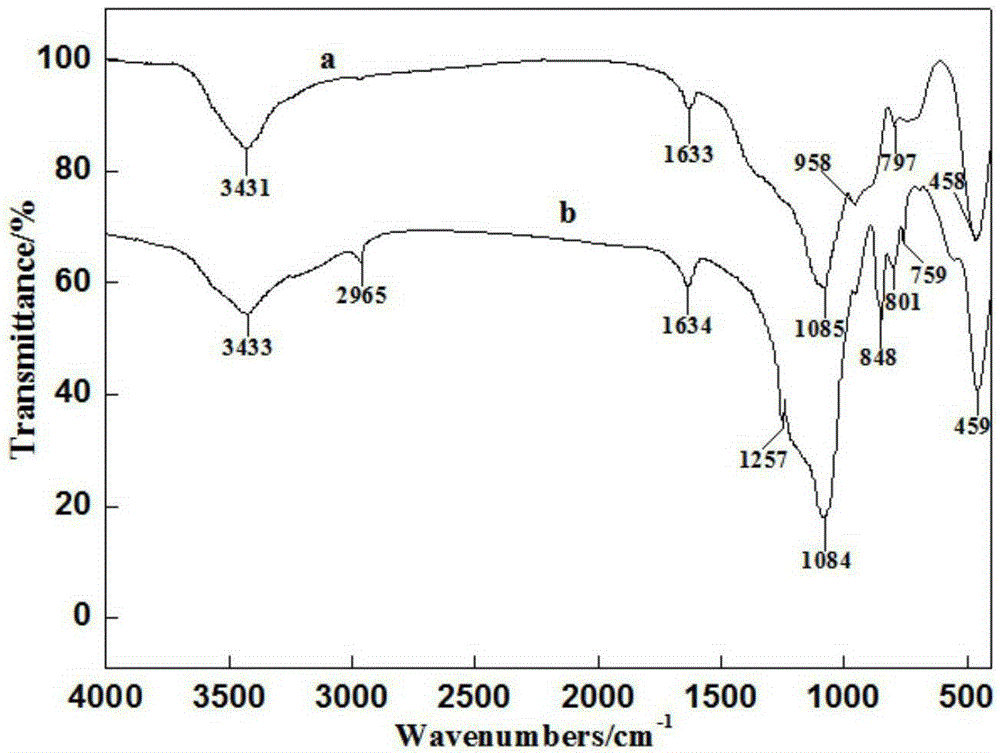

Graphene oxide/cyanate ester composite material and preparation method thereof

InactiveCN102775786AGood dispersionImprove mechanical propertiesChemical reactionAdvanced composite materials

The invention relates to a graphene oxide / cyanate ester composite material and a preparation method of the graphene oxide / cyanate ester composite material, which belongs to the field of advanced composite material technology. The graphene oxide / cyanate ester composite material is prepared by using 0.1-10 parts of hyperbranched polysiloxane-modified graphene oxide, 5-50 parts of epoxy active dilute and 100 parts of bisphenol A cyanate ester prepared by a casting molding method. In order to improve dispersibility of graphene oxide in cyanate ester resin and bonding strength between graphene oxide and cyanate ester resin, hyperbranched polysiloxane is used to modify graphene oxide to introduce active functional group epoxy groups onto the surface of graphene oxide, which can chemically react with the resin. Otherwise, the epoxy active dilute can chemically react with the resin and the epoxy groups on the surface of the graphene. Thus, compatibility and interface adhesion between graphene oxide and the resin are increased on one hand, and low viscosity is helpful to disperse graphene on the other hand. The prepared composite material has excellent performances and can meet the use requirements of cyanate ester resin in various fields.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

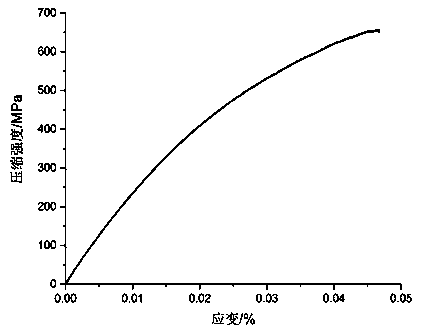

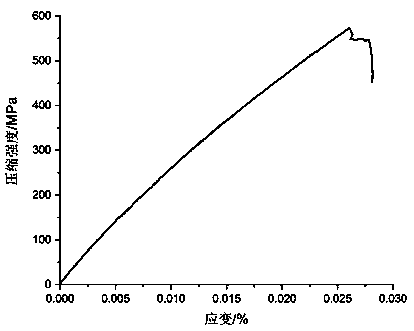

Polyimide foam and preparation method thereof

ActiveCN101812232AHigh temperature for long-term useHigh hardnessSolventAdvanced composite materials

The invention relates to polyimide foam and a preparation method thereof. The raw materials of the polyimide foam include aromatic dianhydride or aromatic tetracid, isocyanate, polar solvent, composite catalyst, surfactant, foaming agent and other assistants. The preparation method comprises: reacting the aromatic dianhydride or aromatic tetracid with the isocyanate to obtain solution of polyimide foam precursor; adding the foaming agent into the solution of the foam precursor to perform a reaction to obtain a foam intermediate by free foaming; and solidifying and setting the foam intermediate by heat treatment. The method is characterized in that: the polyimide foam prepared by the method has uniform cells, hard texture, low density, a glass-transition temperature of 260 to 305 DEG C, a Shore hardness of 40 to 88 HC and a compression strength of 400 to 700kPa; the preparation process is simple; the cost is low; the foaming process is nontoxic and environmentally-friendly; an innovation is made in high-temperature, light, pressure-resistance, sound-absorbing, noise-reducing and heat-insulating polymer foam materials; and an important support is provided for high-temperature advanced composite material technology.

Owner:SHENZHEN HIFUTURE ELECTRIC

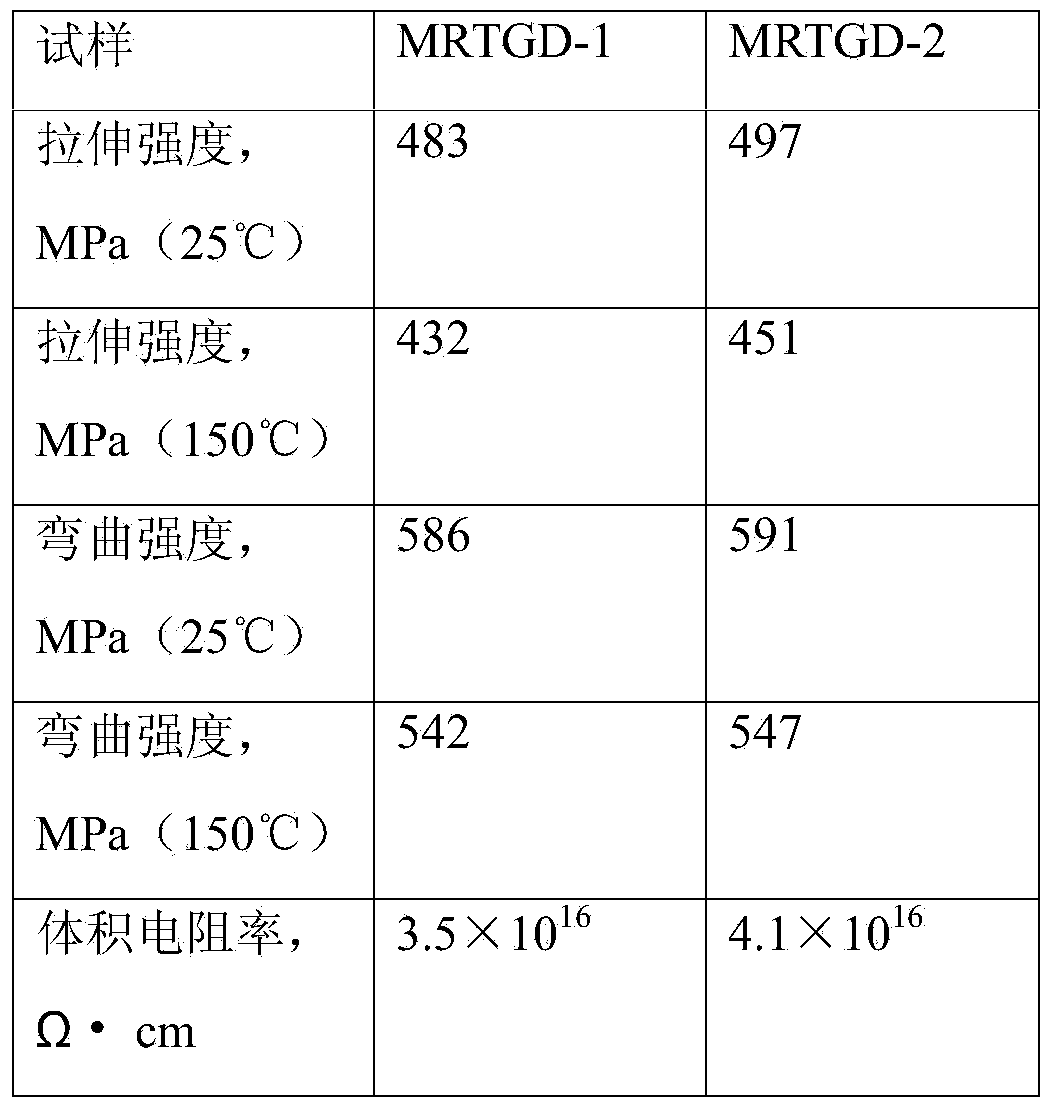

TGDADPE type epoxy matrix resin for advanced composite material and preparation method thereof

InactiveCN103483553AConvenient sourceSimple preparation processSynthetic resin layered productsGlass fiberDiaminodiphenyl ether

The invention relates to a TGDADPE type epoxy matrix resin for an advanced composite material and a preparation method of the TGDADPE type epoxy matrix resin for the advanced composite material. The TGDADPE type epoxy matrix resin for the advanced composite material is prepared from N,N,N',N'-tetraglycidyl-4,4'-diaminodiphenyl ether epoxy resin, aromatic diamine, aromatic binary anhydride, a curing agent and organic solvent, wherein the mass ratio of the N,N,N',N'-tetraglycidyl-4,4'-diaminodiphenyl ether epoxy resin, the aromatic diamine, the aromatic binary anhydride, the curing agent and the organic solvent is 100:5-10:10-20:1-5:80-200. The preparation method of the TGDADPE type epoxy matrix resin is simple in operation technology, the prepared matrix resin is excellent in overall performance and good in wettability to glass fiber, carbon fiber, quartz fiber, basalt fiber and aramid fiber and can be used for preparing the advanced composite material good in overall performance, and the preparation method of the TGDADPE type epoxy matrix resin is suitable for industrial production and has broad application prospects.

Owner:DONGHUA UNIV +1

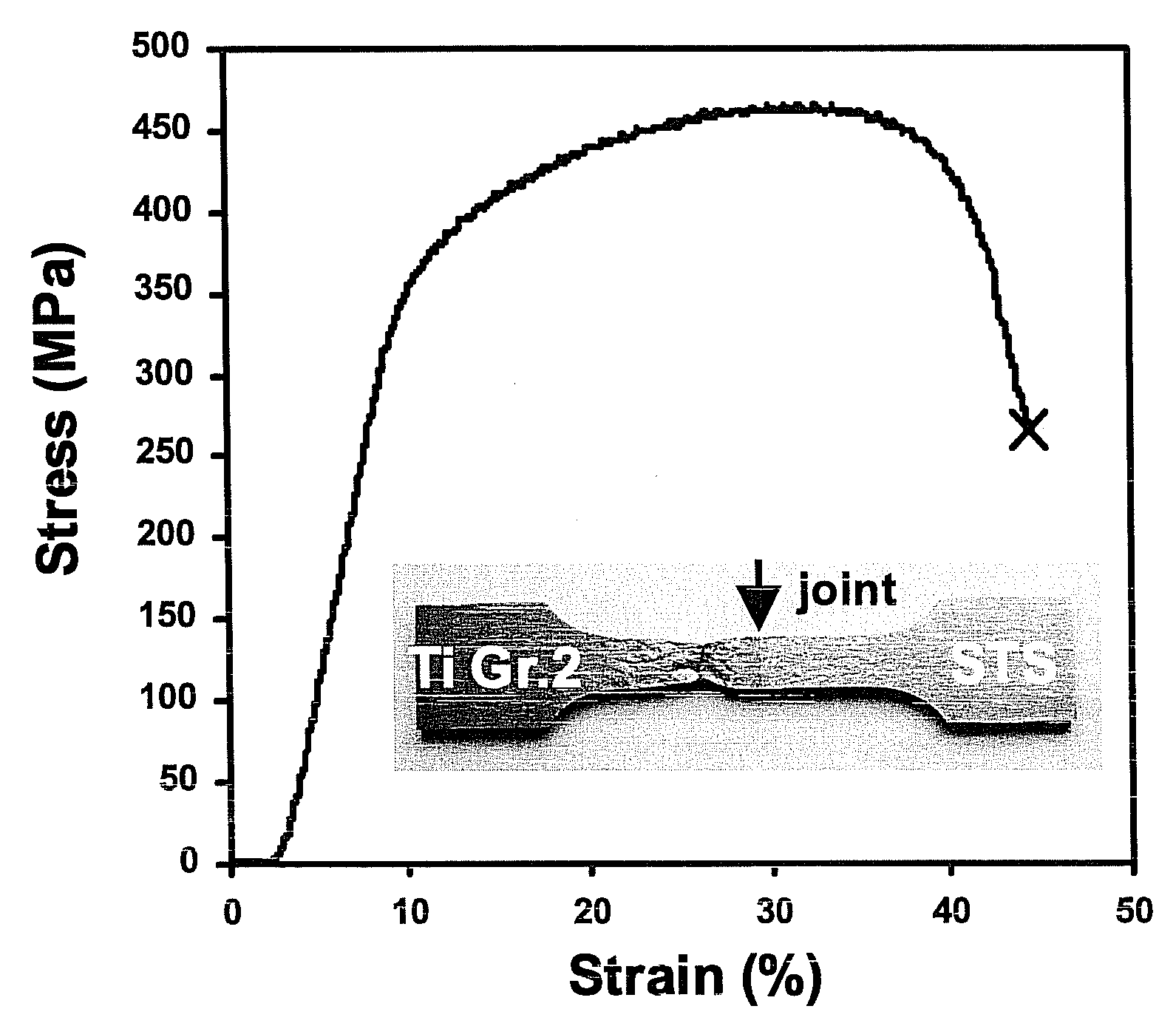

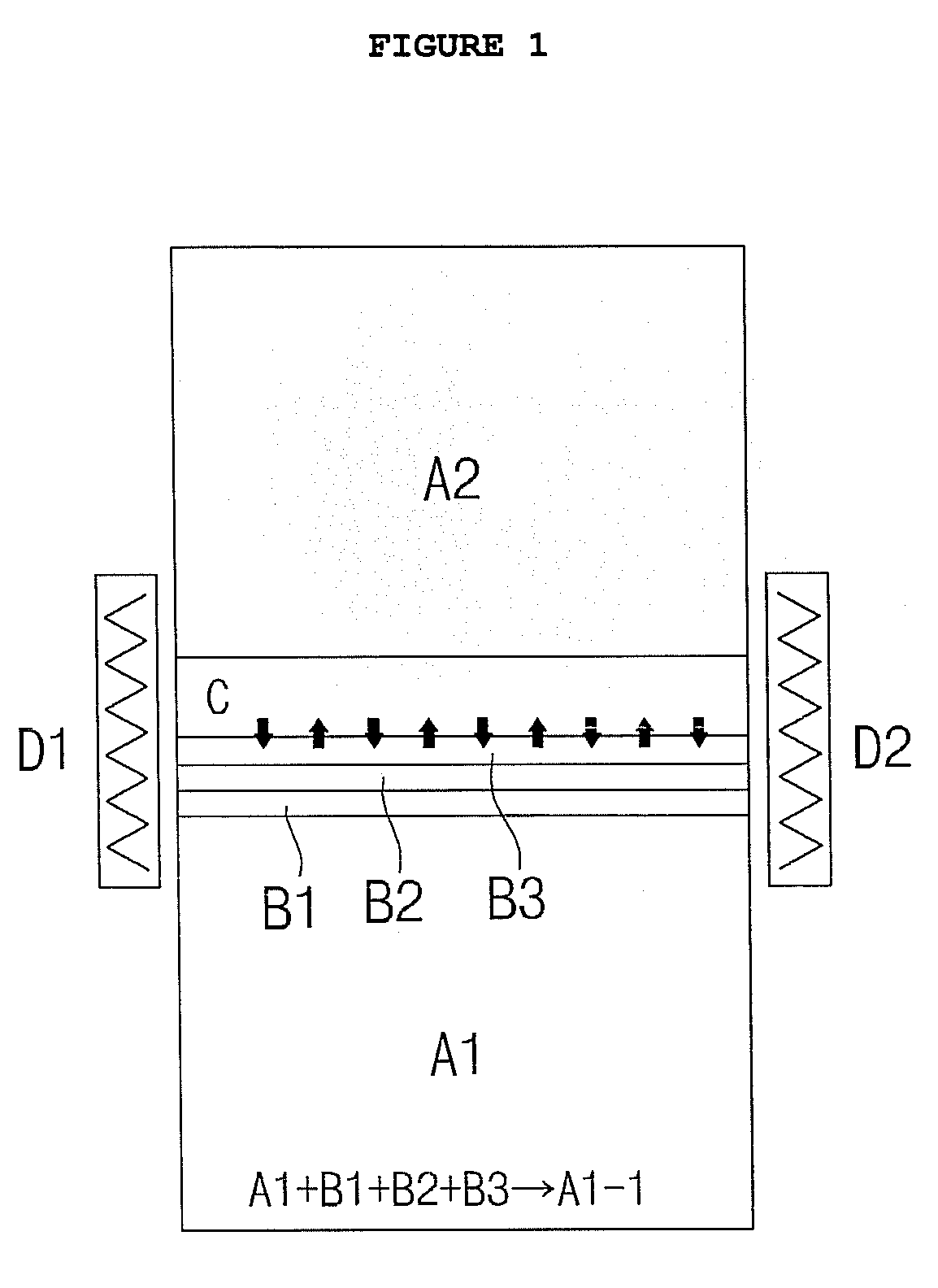

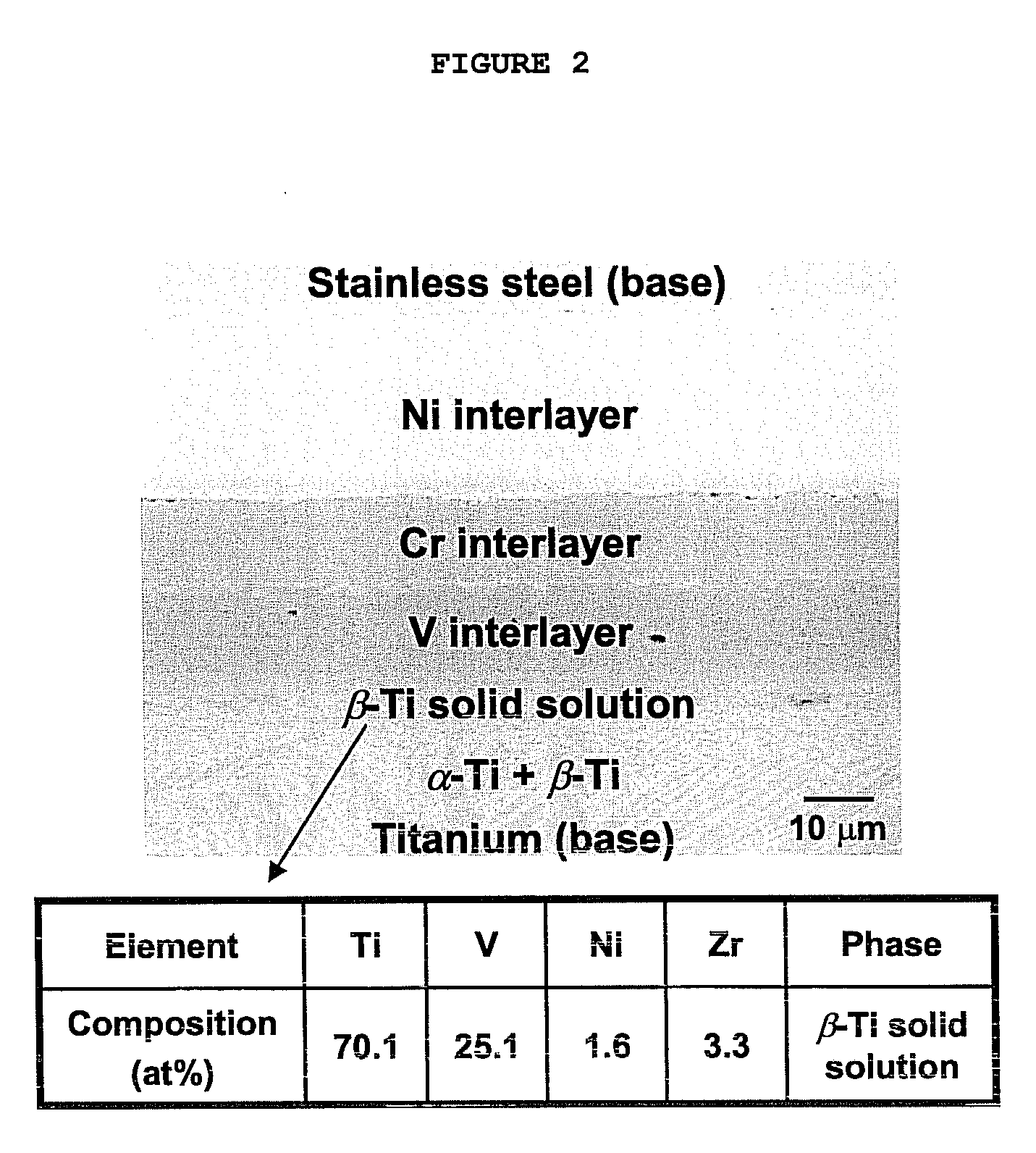

JOINING METHOD BETWEEN Fe-BASED STEELS AND Ti/Ti-BASED ALLOYS HAVING JOINT STRENGTH HIGHER THAN THOSE OF BASE METALS BY USING INTERLAYERS AND THE JOINTS PRODUCED USING THE METHOD

InactiveUS20100124669A1Improve joint strengthAvoid brittleWelding/cutting media/materialsWelding/soldering/cutting articlesHigh intensityAdvanced composite materials

A joining method between Fe-based steel and Ti / Ti-based alloys having a joint strength higher than those of base metals by using interlayers. The production of intermetallic compounds at a joint portion between Fe-based steel and Ti / Ti-based alloys can be prevented using interlayers, and strong interface diffusion bonding can be formed at interfaces between interlayers, thereby producing a high-strength joint. Accordingly, the present disclosure can be used to develop high-strength, high-functional advanced composite materials.

Owner:KOREA ATOMIC ENERGY RES INST +1

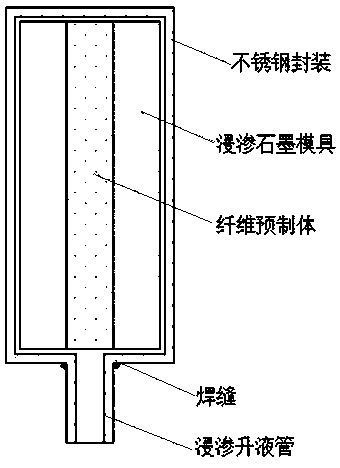

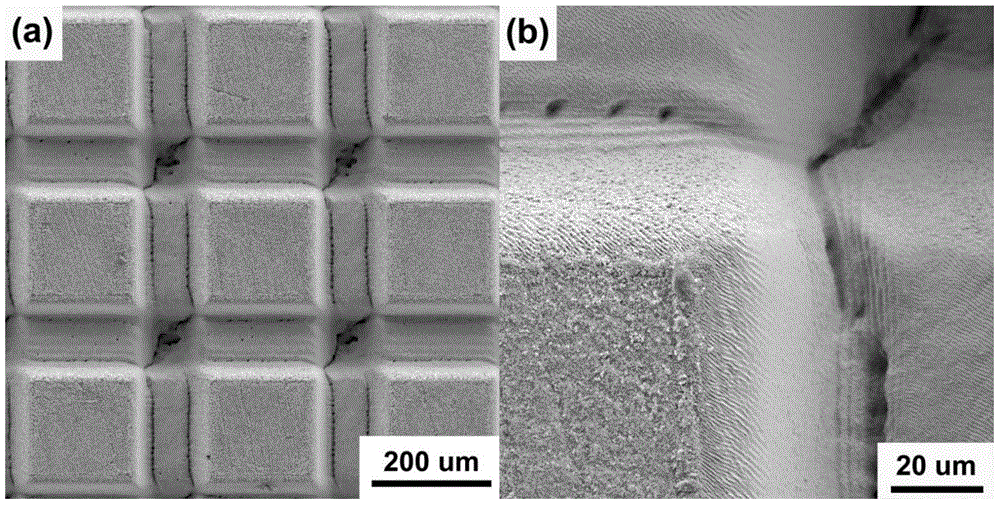

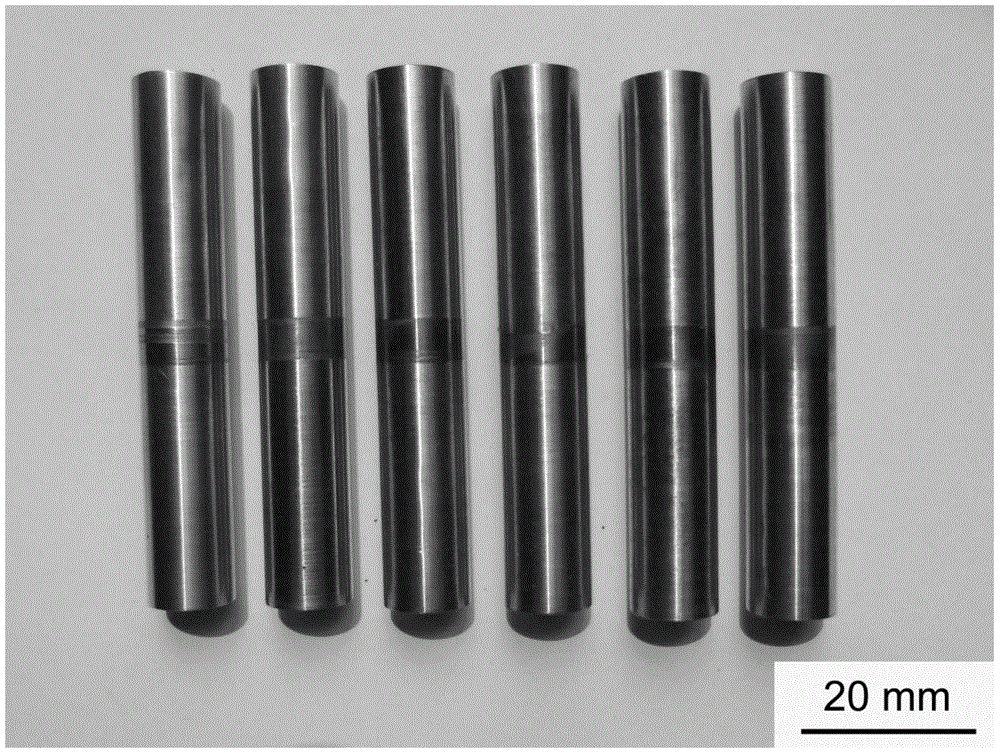

Near-net forming method of 3D braided fiber reinforced metal-based composite material

The invention discloses a near-net forming method of the 3D braided fiber reinforced metal-based composite material, and belongs to the technical field of advanced composite materials. The method is characterized in that a vacuum air pressure infiltration preparation technology based on a liquid binder is adopted to assist in accurately controlling the shape and the size of a 3D braided fiber preform structure; in the 3D weaving process of the fiber preform, a liquid binder is adopted to accurately fix and shape the 3D braided fiber preform, then the size precision of the 3D braided fiber reinforced metal-based composite material is accurately controlled through the impregnated graphite mold of the embedded fiber preform, and deformation and local fiber polarization of the 3D braided fiberpreform in the infiltration process are prevented. The prepared 3D braided fiber reinforced metal-based composite material has high dimensional accuracy and excellent mechanical properties, the near-net forming of the 3D braided fiber reinforced metal-based composite material is realized, batch industrial production can be realized, the near-net forming method has a wide application prospect in the fields of aerospace, national defense, military and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

Quick RTM manufacturing process of resin based advanced composite material

The invention relates to a quick RTM producing method of resin-group advanced composite material, belonging to the composite material producing technique. It comprises following steps: a, using CAD / CAM software and RP technique to prepare needed master mold; b, using said master mold to copy relative room-temperature sulfuration silicon rubber mould; c, plating releasing agent on the inner surface of mould; d, arranging fiber prefabricated element inside the mould, closing mould and sealing; e, using resin to remove gas; f arranging the mould in high-pressure water pot; g, closing high-pressure water pot and filling the water without gas; h, filling resin into mould via high-pressure; I, operating the high-energy focused ultrasonic device to heat and solidify; j, closing the ultrasonic after solidification; k, discharging the water without gas and open the high-pressure water pot; l, removing the mould outside high-pressure water pot and attaining the composite material element from mould; m, cleaning and detecting said element. The inventive method can quickly attain mould, and quickly solidify resin with lower energy consumption, high producing efficiency and high-quality product.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

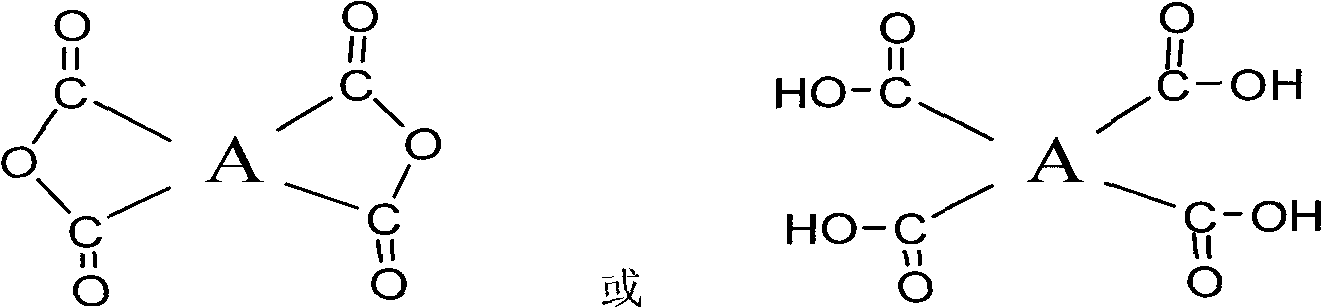

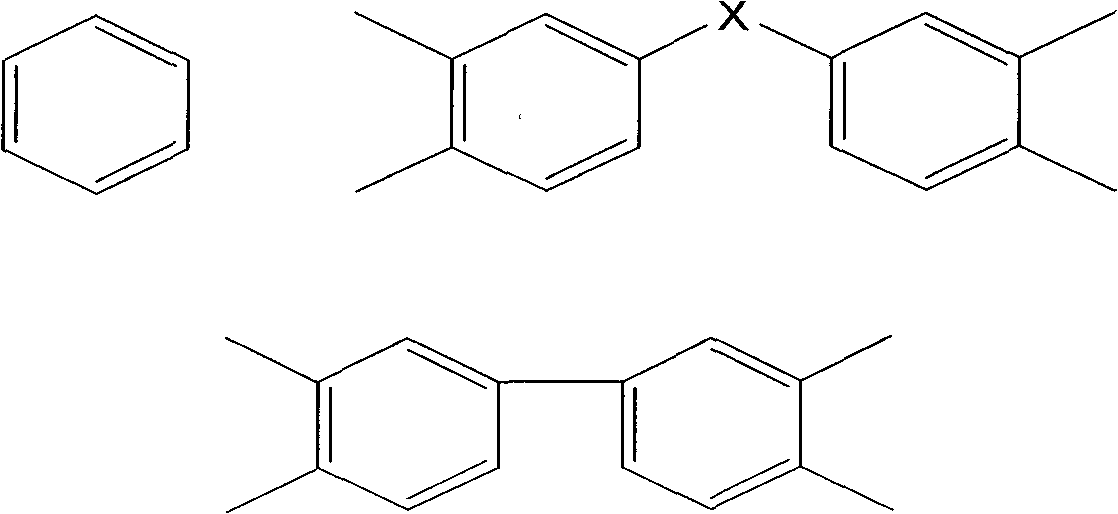

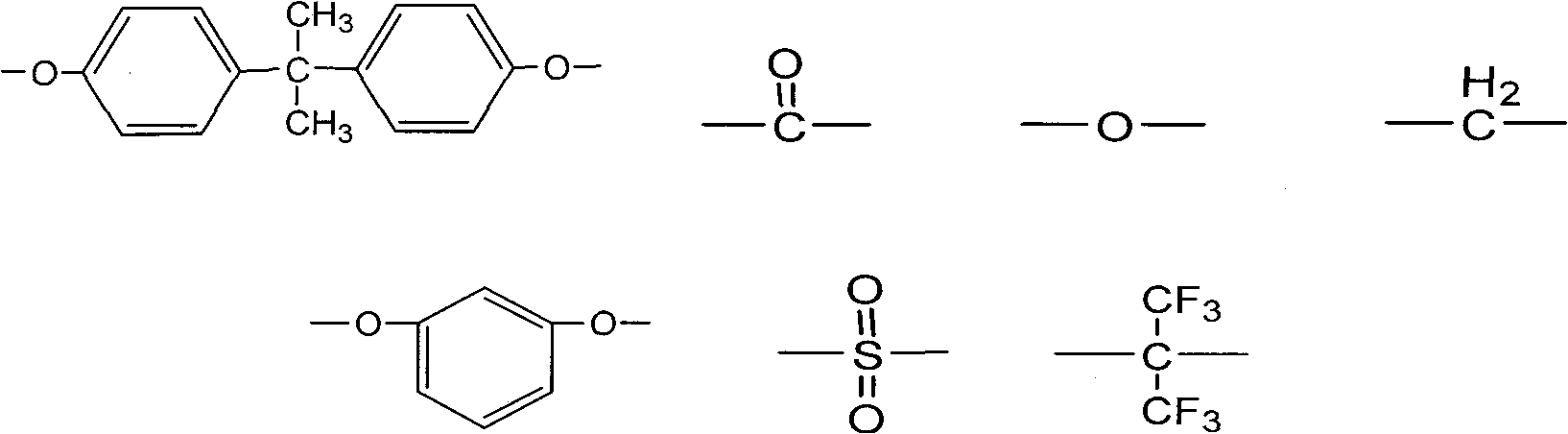

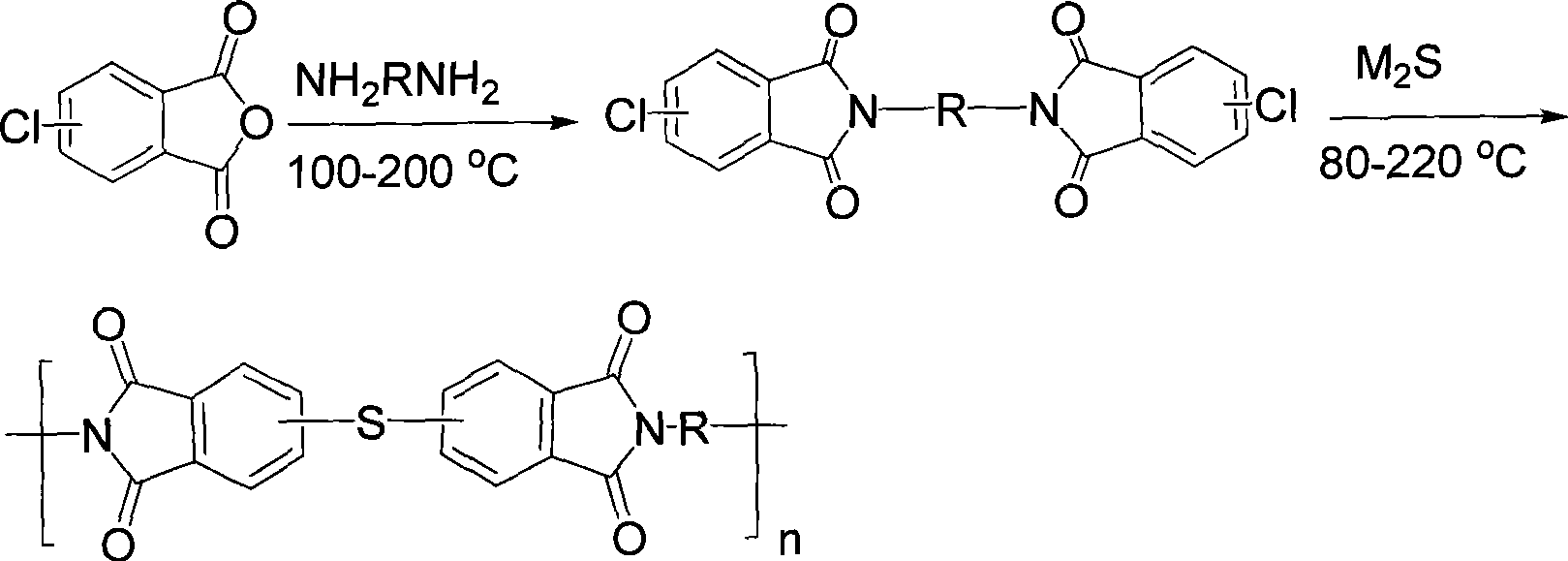

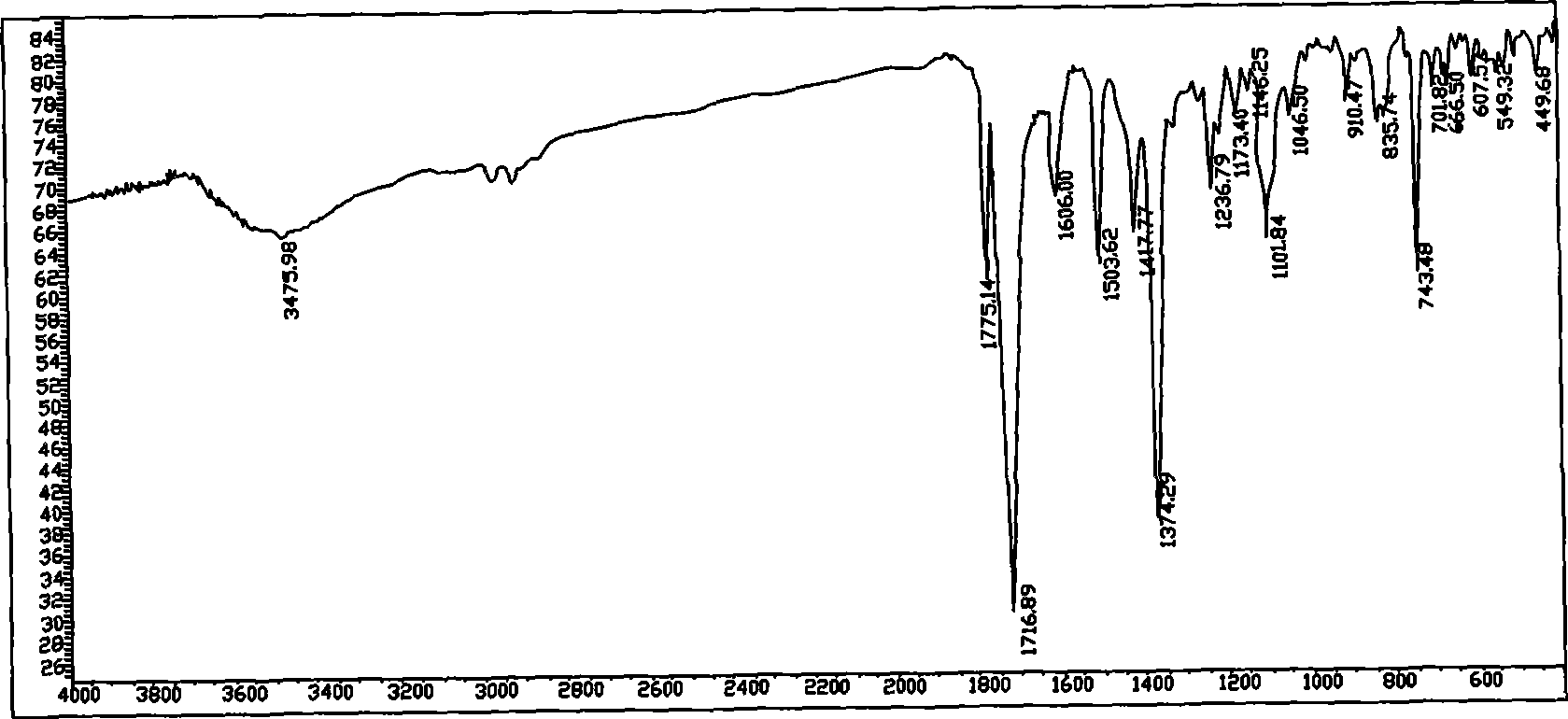

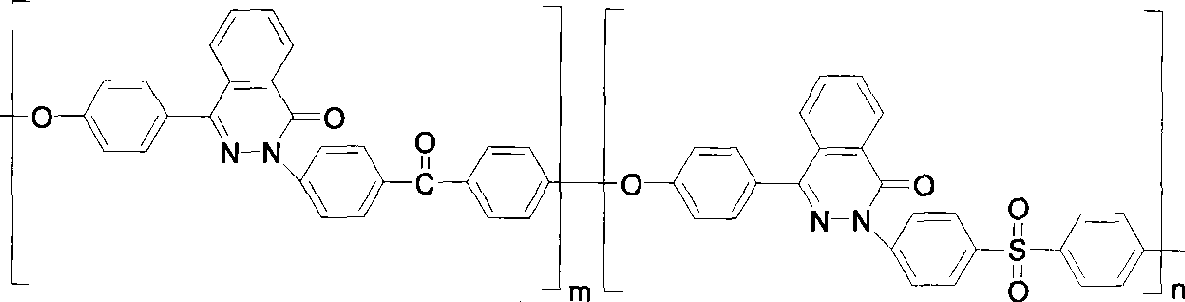

Polythioether acid imide and preparation thereof

The invention discloses a polythioether imide and a preparation method thereof. The method is characterized by comprising the following steps: chlorophthalic anhydride of a structural formula II is taken as a raw material of a reaction, and a half molar equivalent of disubstituted amine NH2RNH2 reacts at the temperature of about 100-200 DEG C to produce dichlorophthalimide; and a coupling reaction occurs between the dichlorophthalimide and alkali metal sulfide of the equal molar equivalent at the temperature of about 80-220 DEG C to produce polythioether imide resin of the structural formula I. The method has the advantages of saving raw materials and preparation cost, reducing reaction steps, having more rational and practical process, obtaining the resin with excellent all round properties such as good heat resistance, mechanical property and melt machining property, being capable of being widely applied to the related fields such as high-temperature resistant engineering plastic, film, adhesive, enameled wire, foam plastic, fiber, advanced composite material and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

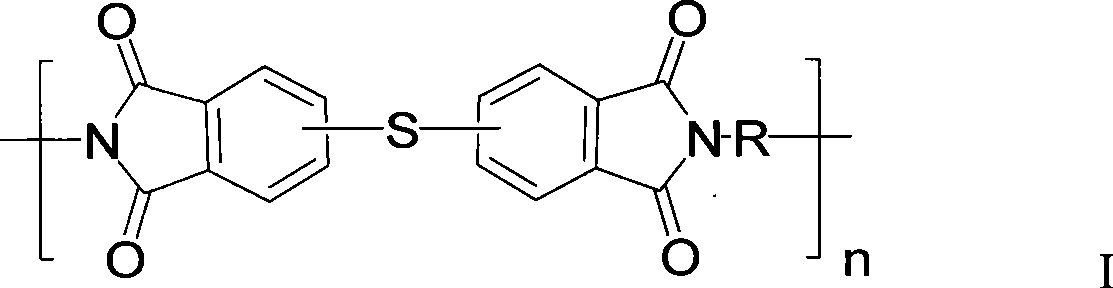

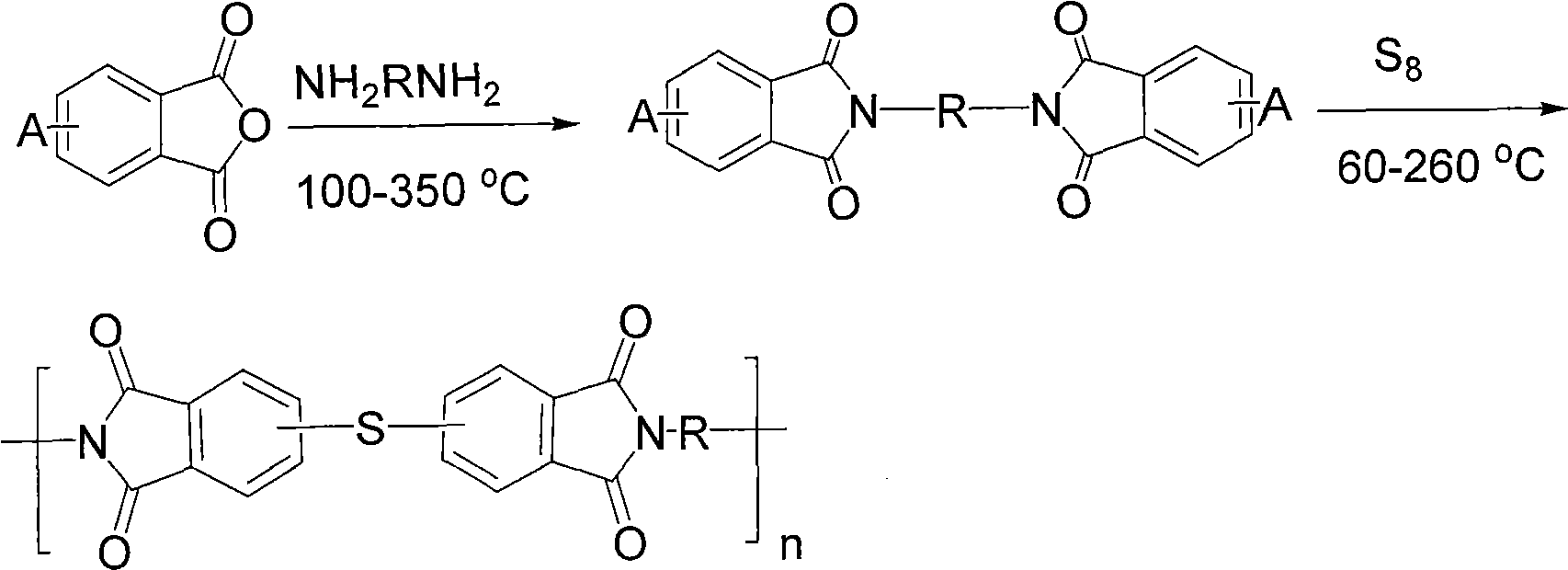

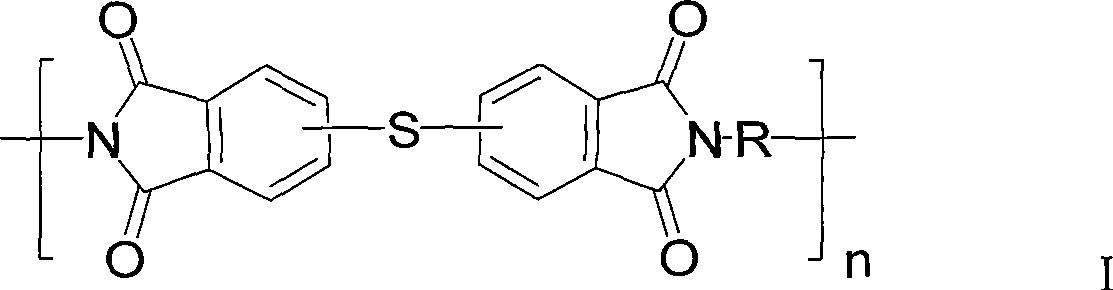

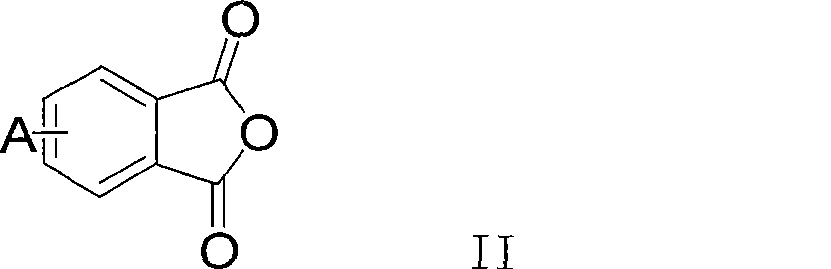

Polythioetherimide and preparation method thereof

The invention relates to polythioetherimide and a preparation method thereof. The method is characterized by comprising the following steps: mono-substituted phthalic anhydride isomer with structural formula II is adopted as a reaction material to react with organic diamine NH2RNH2 with half mol equivalent weight at the temperature of about 100 DEG C to about 350 DEG C to generate binary-substituted phthalimide; then binary-substituted phthalimide and sulfur with about equimolar equivalent weight are subjected to coupling polymerization reaction at the temperature of about 60 DEG C to about 260 DEG C under the existence of reducing agent, catalyst and reaction auxiliary agent to generate polythioetherimide resin with structural formula I; and the molecular weight of the resin can be adjusted by end capping agent. The preparation method can greatly reduce the preparation cost and reaction steps, the whole process is more reasonable and practical, and the obtained resin has superior comprehensive properties such as good heat resistance, mechanical properties, melting processing property and the like, can be widely applied in the related fields such as high-temperature resistant engineering plastics, films, adhesives, enameled wires, foamed plastics, fiber, advanced composite materials and the like; in the structural formula II, A substituent is chlorine atom or nitro at 3-bit or 4-bit; and in the structural formula I, R is substituted or unsubstituted organic group.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

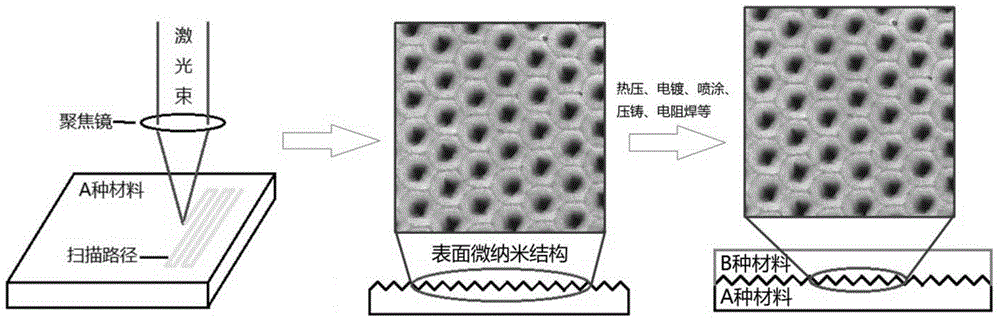

Method for connecting materials difficult to connect through ultrafast lasers

ActiveCN104439956AImprove power densityReduce meltingLaser beam welding apparatusNuclear fusionAdvanced composite materials

The invention discloses a method for connecting materials difficult to connect through ultrafast lasers. The method includes the following steps that firstly, a material A is ablated through ultrashort pulse lasers, removing is achieved through laser ablation, and a nano-micro-meter structure is obtained on the surface of the material A; secondly, impurities on the surface, with the nano-micro-meter structure, of the material A are removed through corrosive liquid; thirdly, in an inert gas or vacuum environment, a material B is deformed and flows to fill the nano-micro-meter structure of the material A, the material A and the material B are combined in a mechanical combination mode, and therefore the material A and the material B are connected, wherein the melting point and the hardness of the material A are higher than the melting point and the hardness of the material B. The method for connecting the materials difficult to connect through the ultrafast lasers is a new method which is flexible, high in efficiency and wide in application range and is used for improving the connecting strength of the materials, and the application of the method includes but is not limited to the development of a nuclear fusion reactor oriented to plasma materials, electric contact materials, heat sink materials, electronic packaging and advanced composite materials.

Owner:TSINGHUA UNIV

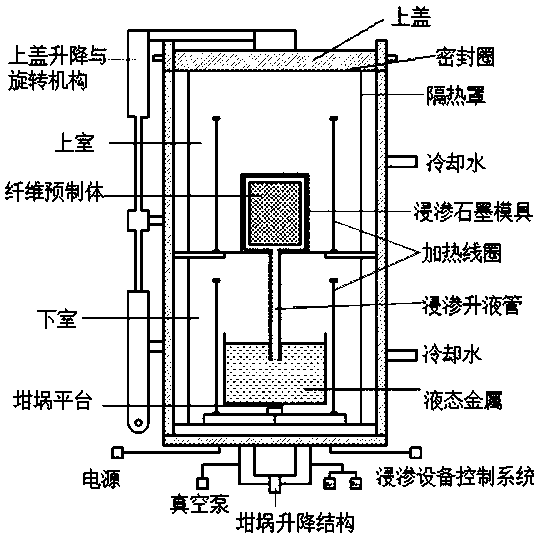

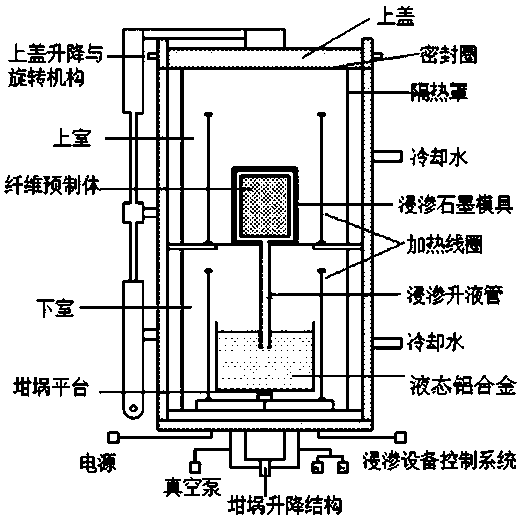

Vacuum air-pressure infiltration forming method of fiber reinforced aluminum base composite material

ActiveCN110230012ASolve the problem of incomplete impregnationEliminate poresVacuum evaporation coatingSputtering coatingGas phaseMetallurgy

The invention discloses a vacuum air-pressure infiltration forming method of a fiber reinforced aluminum base composite material, and belongs to the technical field of advanced composite materials; and the method is to deposit thin-layer metal elements on the surfaces of woven fiber prefabricated bodies in a physical vapor deposition mode and to finally perform hot isostatic pressing on the fiberreinforced aluminum base composite material to realize vacuum air-pressure complete infiltration of the fiber reinforced aluminum base composite material. The difficulty of incapability of realizing complete infiltration in the vacuum air-pressure infiltration forming process of the fiber prefabricated bodies is solved under the condition of the preheating temperature of the fiber prefabricated bodies lower than 450 DEG C; such defects as micro holes and looseness in the composite material are eliminated; the infiltration formation of the high-performance fiber reinforced aluminum base composite material is realized; the industrial batch production can be realized; and the broad application prospect is achieved in such fields as aerospace and national defense and military.

Owner:NANCHANG HANGKONG UNIVERSITY

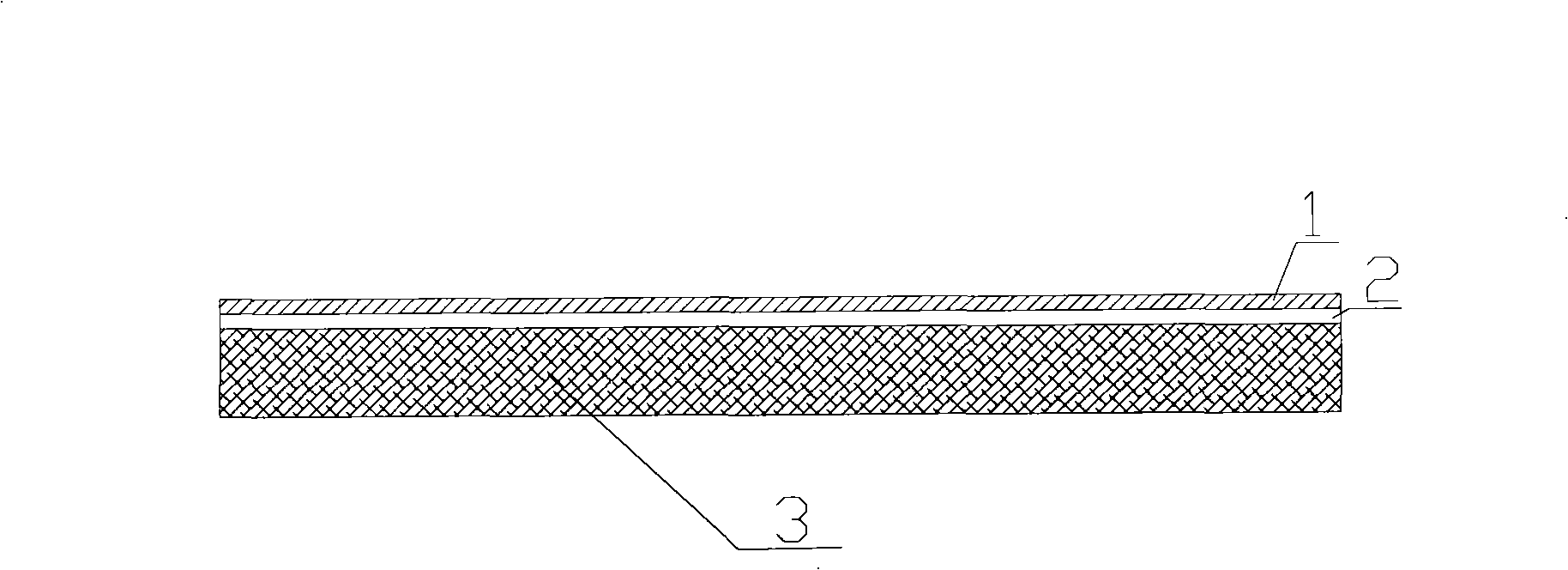

Double-sided metal clad plate and manufacturing method thereof

InactiveCN101513785ALuxurious decorative effectHigh-grade decorative effectLamination ancillary operationsSpecial ornamental structuresNonferrous metalFlexural strength

The invention discloses a double-sided metal clad plate and a manufacturing method thereof. The double-sided metal clad plate is jointly formed by a panel, a substrate and high polymer material in an intermediate layer. The panel chooses a nonferrous metal foil with the thickness of 0.05-1.5mm or a plate as a plane material, the material of which can be red copper, brass, titanium or stainless steel. The substate chooses a common metal plate with the thickness of 0.1mm-3mm as a base material, the material of which can be galvanized steel or antirust aluminum. The high polymer material can be used as an alite paste. A thin nonferrous metal and a thick common metal plate, the middle of which is lined with the higher polymer material, are made into the double-sided metal clad plate by the lamination technique. The metal clad plate has enough shearing strength and bending strength and is a new material which can be further processed by the cold-bending molding technique. The invention has simple manufacturing process and novel structure, is in line with the processing requirement and uses different materials for synthesizing advanced composite material to replace former precious nonferrous metals, thus greatly reducing the cost.

Owner:上海鑫型金属复合材料有限公司

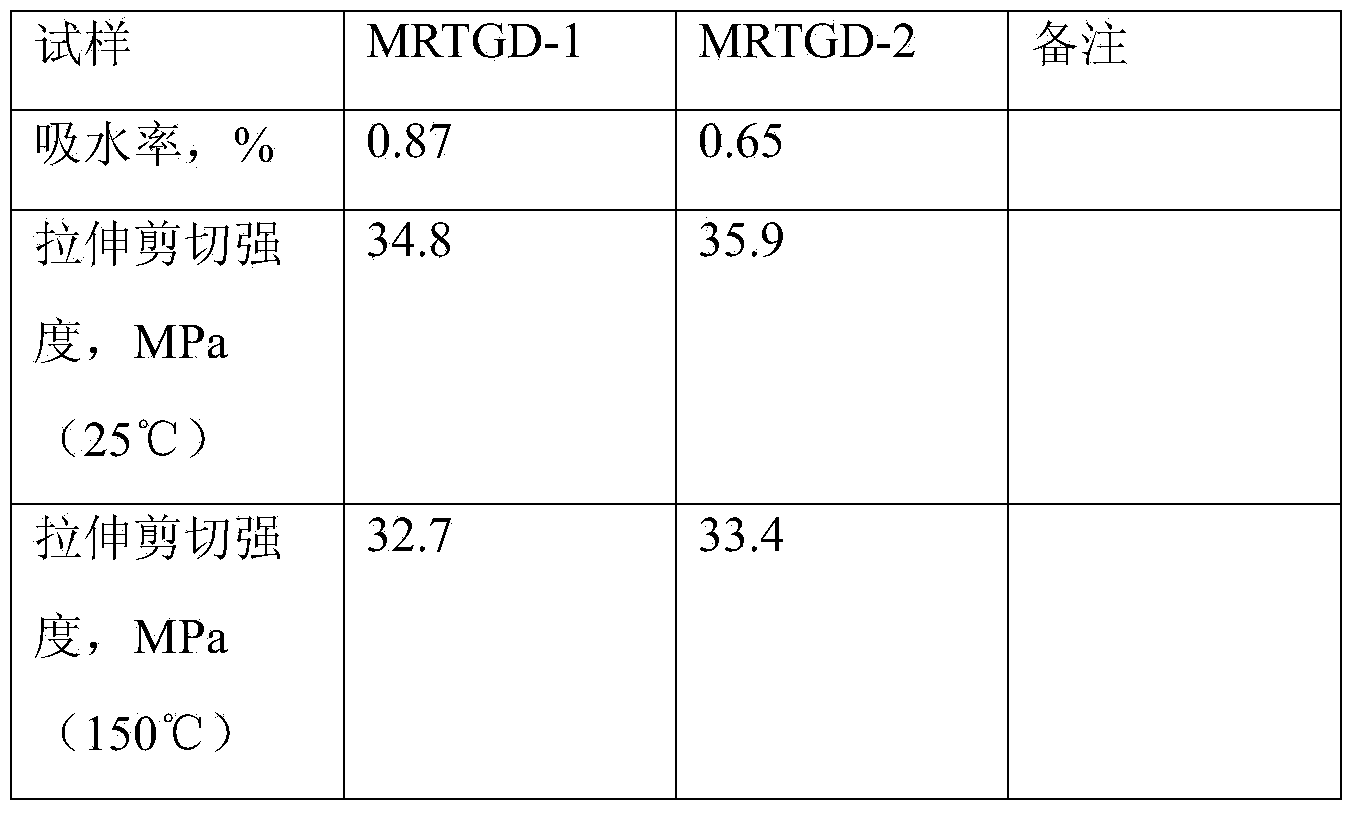

High temperature resistant composite matrix resin and preparation method thereof

The invention relates to a high temperature resistant composite matrix resin and a preparation method thereof. The high temperature resistant composite matrix resin comprises the following components: maleimide-based polyimide powder, diallyl compounds and bismaleimide resin powder. The preparation method of the high temperature resistant composite matrix resin comprises the following steps: mixing 1,4-bis(2,4-diaminophenoxy) benzene with strong polar aprotic organic solvent and adding raw materials such as maleic anhydride, and the like to prepare a resin solution; then adding a dehydrant, a catalyst and a precipitation agent and stirring the mixture to carry out reaction to separate solid powder; and placing the maleimide-based polyimide powder, the diallyl compounds and the bismaleimide resin powder into a reaction kettle to carry out melt polymerization reaction and dissolving the mixture in the organic solvent. The high temperature resistant composite matrix resin can be applied to glass-fiber reinforced composite materials and high-performance fiber-reinforced advanced composite materials such as carbon fiber, aramid fiber, and the like, and has simple process, low cost and no environment pollution, and can be prepared in general equipment, thereby being suitable for industrial production.

Owner:DONGHUA UNIV

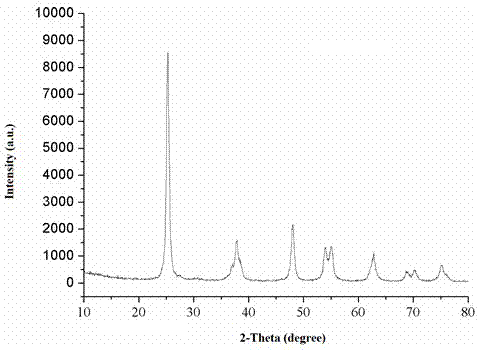

Preparation method of carbon fiber-loaded mesoporous titania

ActiveCN103696235AImprove surface activityHigh porosityCarbon fibresMesoporous materialAdvanced composite materials

The invention discloses a preparation method of carbon fiber-loaded mesoporous titania, and belongs to a carbon fiber surface modification technology. An activated carbon fiber is adopted as a load body, and the mesoporous titania is loaded on the surface of the carbon fiber by sol-gel reaction by virtue of a guiding role of a template. The method has the advantages that titania-modified carbon fiber which has a mesoporous structure, is controllable in load capacity, and uniform in distribution, and has a phase in an anatase structure can be prepared, and high specific surface area of the mesoporous material is beneficial to improvement of interface bonding between a carbon fiber reinforcement and a base material. Thus, the mechanical property of the carbon fiber composite material is improved further. Meanwhile, the preparation method has important significance in expansion of application of the carbon fiber in the structure-energy storage integrated multifunctional composite material. The preparation method can be applied to the technical fields such as an advanced composite material, energy storage, absorption and the like.

Owner:JIANGSU UNIV

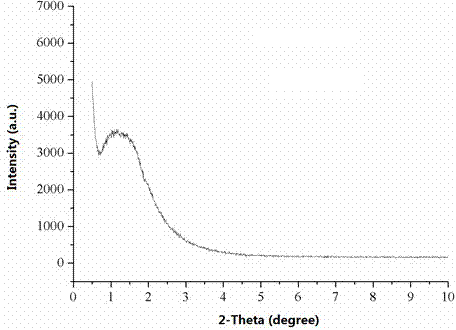

Interface modification method of poly(p-phenylene-benzobisoxazole) fiber-reinforced soluble polyaryl ether resin composite material

InactiveCN101445613AEnhanced interface bindingImprove adhesionPhysical treatmentFibre typesEpoxyFiber

The invention discloses an interface modification method of a poly(p-phenylene-benzobisoxazole) fiber-reinforced soluble polyaryl ether resin composite material, and the interface modification method belongs to the technical field of advanced composite materials. The interface modification method is characterized in that the interface modification method adopts the low-temperature plasma technology to graft epoxy resin and other thermosetting resins on an interface of poly(p-phenylene-benzobisoxazole) fiber and a soluble polyaryl ether resin matrix under the processing power of 10-400W, the processing time of 0.5-30min and the gas pressure of 1-1.01 multiplied by 10<5> Pa in a processing cavity, the content of the epoxy resin and other thermosetting resins by weight percentage is 1-50 percent, and the grafting time is 0.5-24 hours. The interface modification method has the advantages that the prepared composite material has excellent interface binding performance and mechanical performance and can better play the comprehensive performance of the composite material, meet the using requirements of high temperature resistant environments of aerospace, military and other fields and realize batch, continuous and large-scale industrial production.

Owner:DALIAN UNIV OF TECH

High-temperature-resistant matrix resin for high-Tg copper-clad plate and preparation method of high-temperature-resistant matrix resin

InactiveCN104559059AConvenient sourceSimple preparation processSynthetic resin layered productsMetal layered productsEpoxyOrganic solvent

The invention relates to high-temperature-resistant matrix resin for a high-Tg copper-clad plate and a preparation method of the high-temperature-resistant matrix resin. The matrix resin comprises epoxy resin, a polyimide resin liquid, tetrabromophthalic anhydride, DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide), a curing agent and an organic solvent whose mass ratio is 100:50:150: (12-25) : (5-30) : (50-100). The preparation method is as follows: after epoxy resin, DOPO and tetrabromophthalic anhydride are mixed and react, a component A is obtained; after aromatic diamine, aromatic quaternary amine, aromatic dianhydride and maleic anhydride completely react in a strong-polarity nonprotic organic solvent, an azeotropic dehydrating agent and a catalyst are added, and the polyimide resin liquid, namely, a component B is obtained after an azeotropic dehydration imidization reaction; the component A and the component B are mixed, and the curing agent and the organic solvent are added, and the mixture is uniformly mixed to obtain the high-temperature-resistant matrix resin. The product has excellent overall performance, is suitable for manufacturing an advanced composite material, is particularly suitable for manufacturing the high-Tg copper-clad plate and has a good market prospect.

Owner:DONGHUA UNIV +2

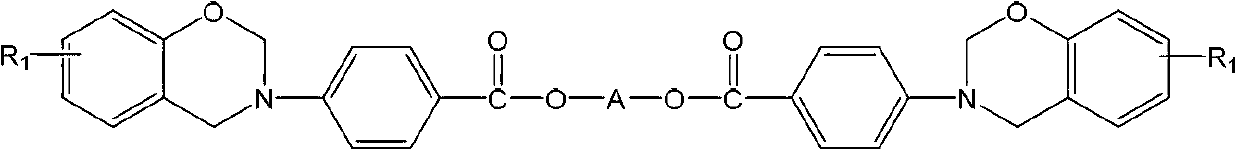

Ester-group-containing diamine type fluorenyl benzoxazine

InactiveCN102702129AImprove toughnessEasy to processOrganic chemistryHydrogenAdvanced composite materials

The invention provides an ester-group-containing diamine type fluorenyl benzoxazine, which comprises the following structure shown as the accompanying drawing, in the formula, A is fluorenyl containing C1 to C4 alkyl groups, fluorenyl containing substituted or unsubstituted aromatic ring or fluorenyl containing phenoxy ethyl, and R1 is one kind of materials from hydrogen, methyl, methoxy group, trifluoromethyl or cyanogroup. The ester-group-containing fluorenyl diamine monomers are used as amine resources for synthesizing the ester-group-containing diamine type fluorenyl benzoxazine. Flexible ester groups are introduced in the benzoxazine monomer molecular structure for improving the toughness and the processing performance of the benzoxazine. The ester-group-containing diamine type fluorenyl benzoxazine prepared by a method provided by the invention can be used in the fields of advanced composite material base resin, electronic encapsulating materials, insulation materials, laminated materials and the like.

Owner:HARBIN ENG UNIV

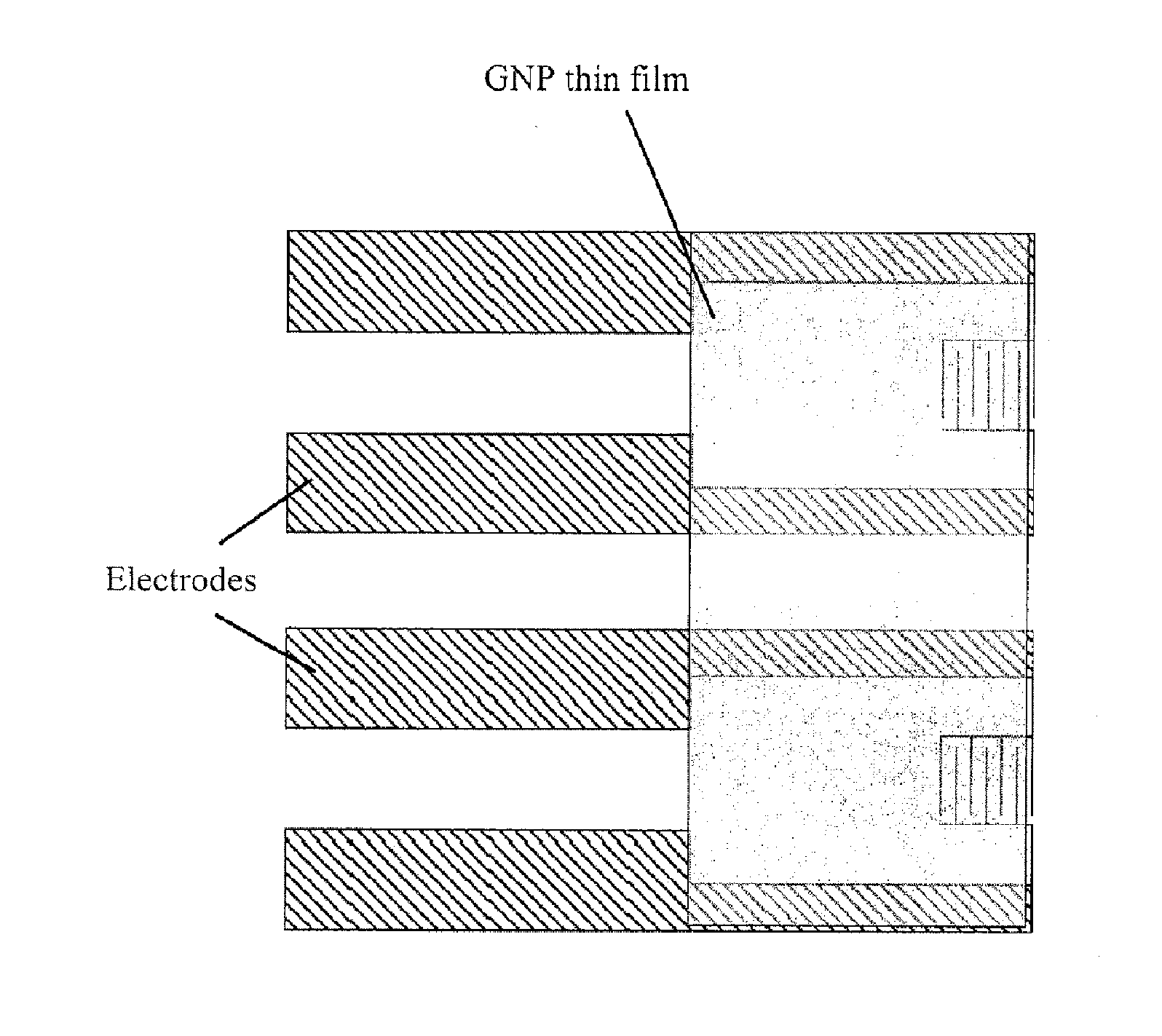

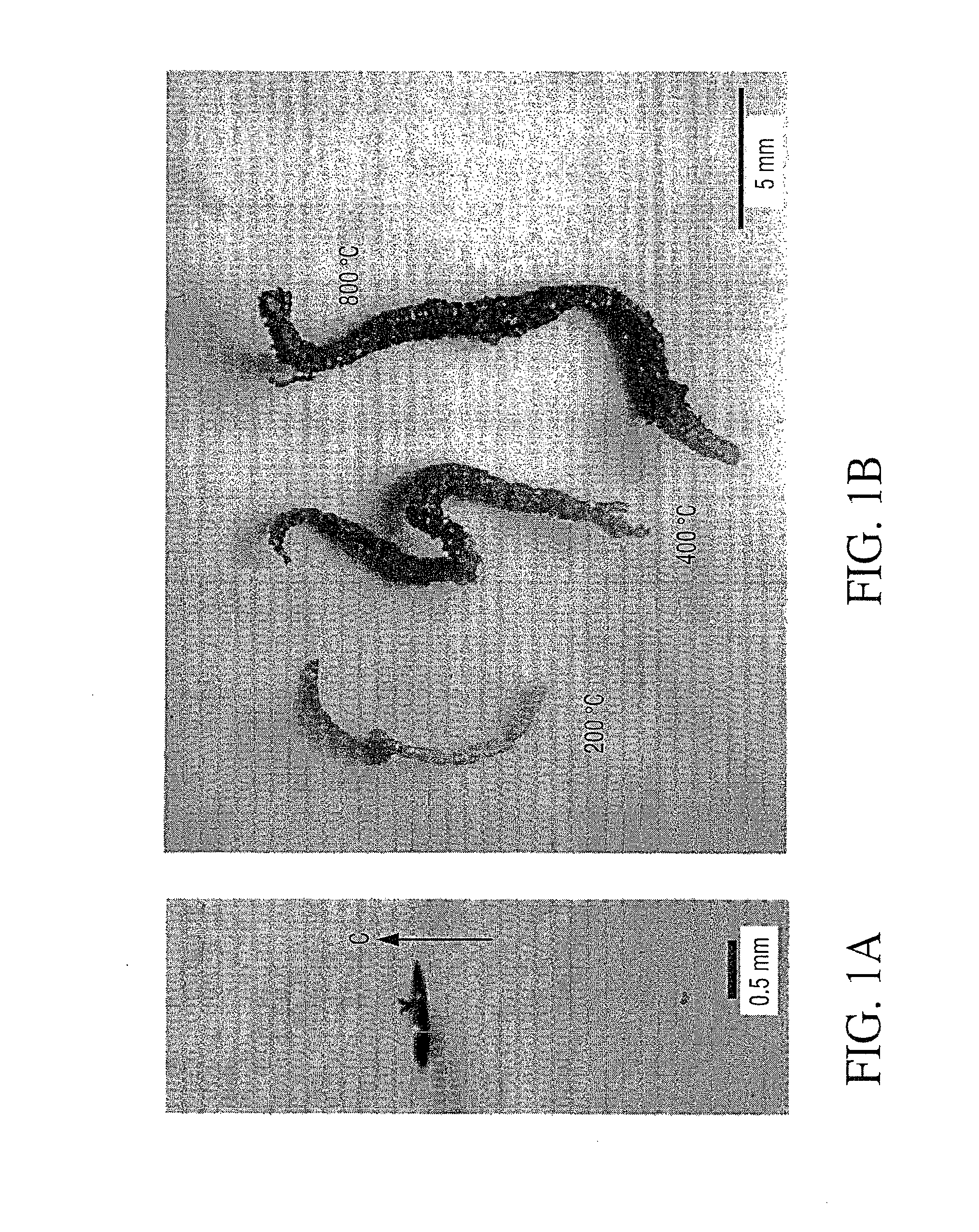

Graphite nanoplatelets for thermal and electrical applications

This disclosure concerns a procedure for bulk scale preparation of high aspect ratio, 2-dimensional nanoplatelets comprised of a few graphene layers, Gn. n may, for example, vary between about 2 to 10. Use of these nanoplatelets in applications such as thermal interface materials, advanced composites, and thin film coatings provide material systems with superior mechanical, electrical, optical, thermal, and antifriction characteristics.

Owner:RGT UNIV OF CALIFORNIA

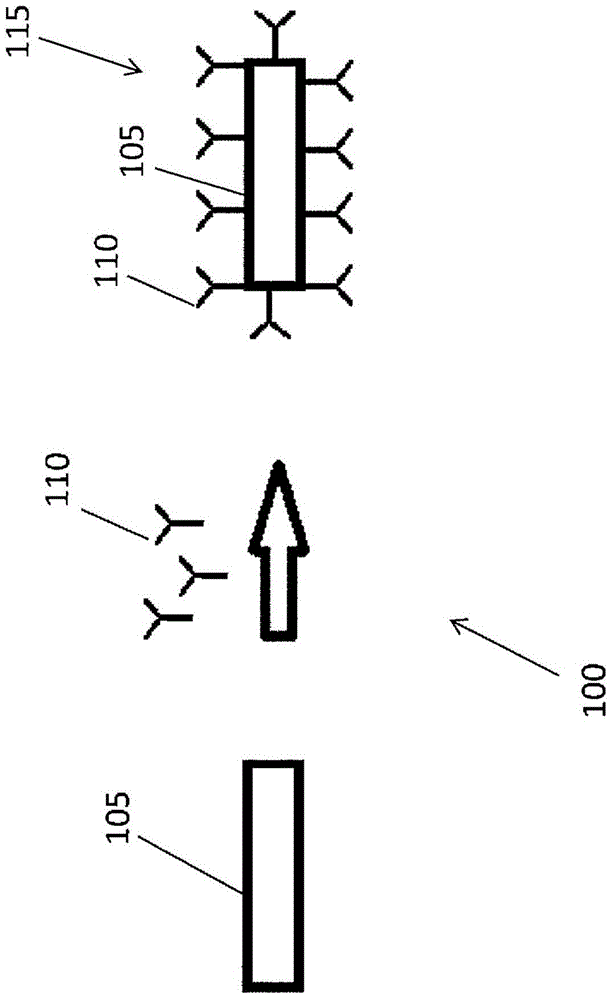

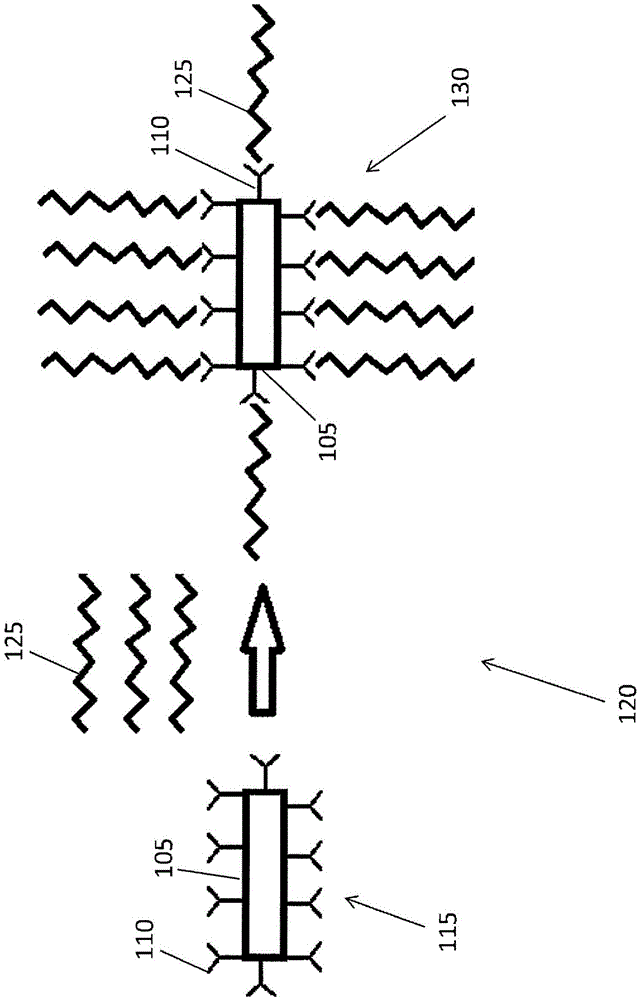

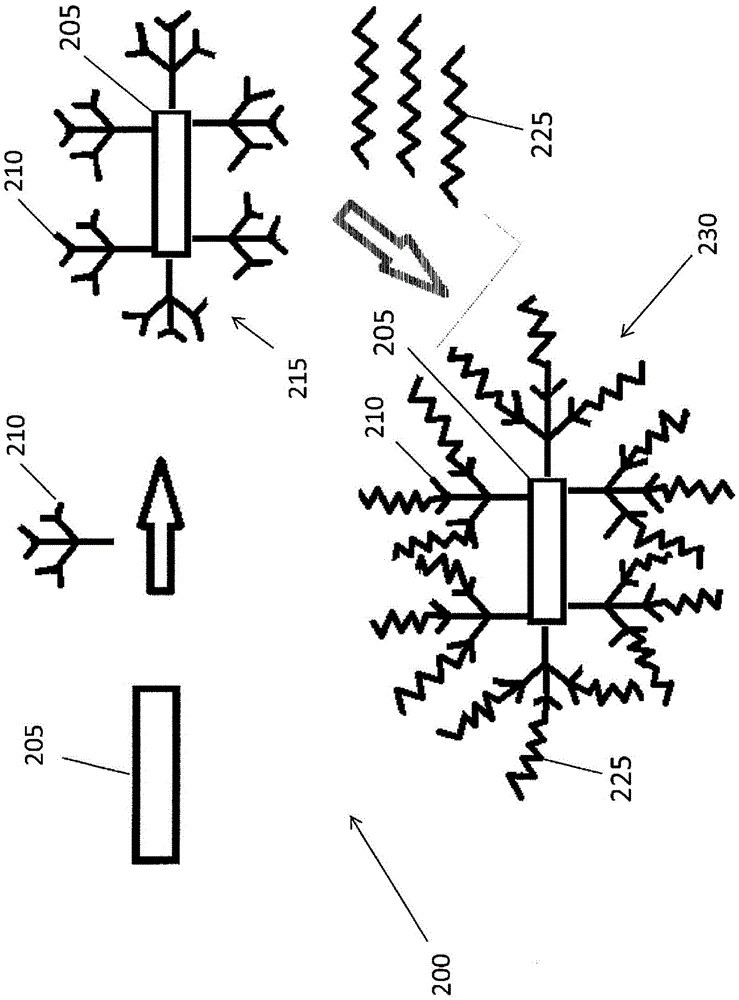

Oligomer-grafted nanofillers and advanced composite materials

InactiveCN105636724APigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPolymer scienceOligomer

Oligomer-grafted nanofiller compositions and composites including oligomer-grafted nanofillers are disclosed. An oligomer-grafted nanofiller composition for disposition in a polymer matrix, the polymeric matrix comprising polymers derived from a plurality of polymerizable units, can include a nanoparticle, one or more coupling groups bonded to the nanoparticle; and one or more oligomers bonded to the one or more coupling groups. In an embodiment the oligomer is derived from two or more polymerizable units, at least one polymerizable unit being at least substantially similar to at least one of the polymerizable units of the polymer matrix. In another embodiment the oligomer comprises two or more polymerizable units and improves dispersion, interfacial strength, or both dispersion and interfacial strength between the nanoparticle and the polymer matrix. Composites and methods are also disclosed.

Owner:ADAMA MATERIALS +1

Device and method for 3D printing with long-fiber reinforcement

ActiveUS10173410B23D object support structuresAdditive mnaufacturing with solid and fluidEngineeringAdvanced composite materials

A process and device for 3D printing parts incorporating long-fiber reinforcements in an advanced composite material is disclosed. A nozzle for a 3D printing device receives a polymer material and a reinforcing fiber through separate inlets. A passage from the reinforcing fiber inlet cleaves the passage containing the polymer material, creating an interstitial cavity into which the reinforcing fiber is introduced. The polymer material closes back on itself and encapsulates the reinforcing fiber, then drags the fiber along with the flow and exits nozzle to be deposited on a work surface or part being manufactured.

Owner:NORTHROP GRUMMAN SYST CORP

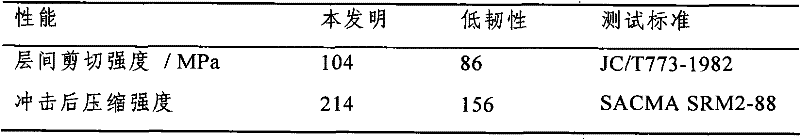

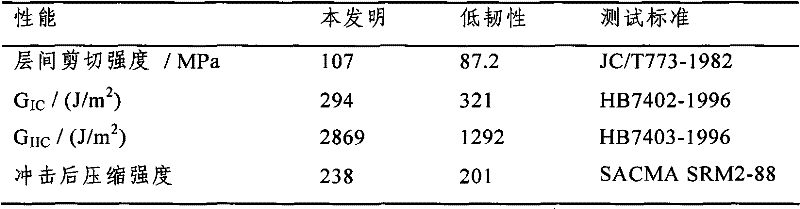

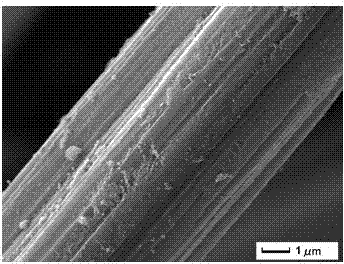

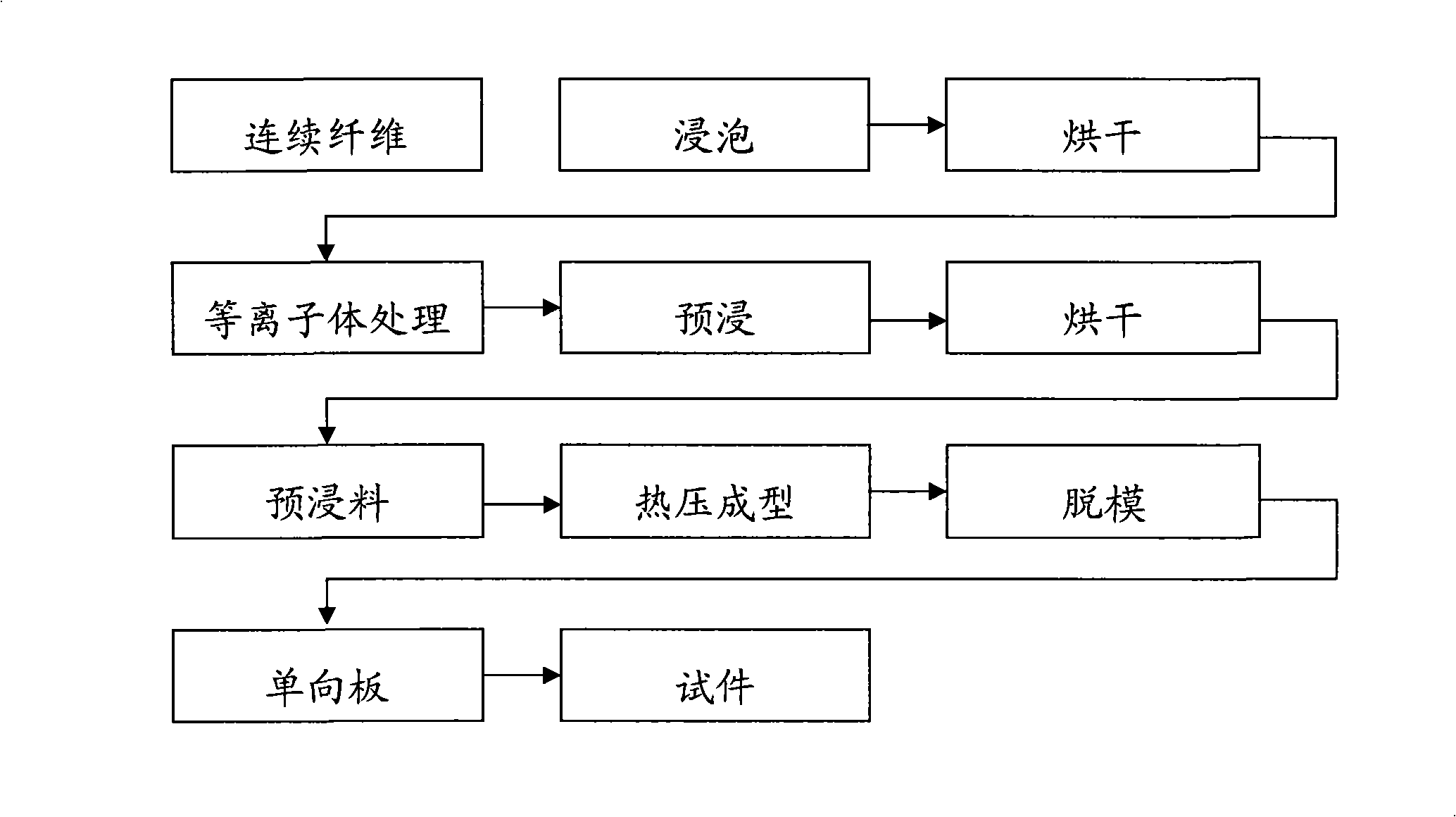

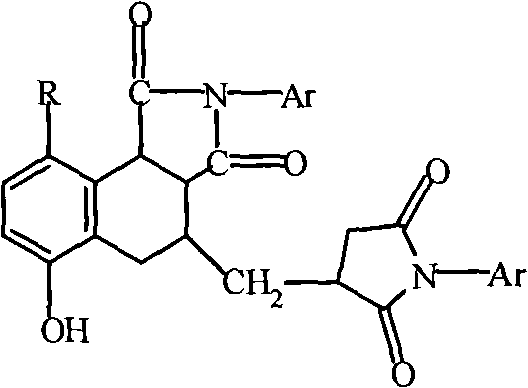

Modification method of continuous PBO fiber for strengthening interface of bimaleimide resin base composite material

InactiveCN101514246AImprove wettabilityImprove adhesionPhysical treatmentFibre typesEpoxyFiber-reinforced composite

The invention relates to a modification method of continuous PBO fiber for strengthening interface of thermosetting BMI resin, belonging to the technical field of advanced composite material. The method is designed for solving the technical problems of the existing fibrous reinforcement resin base composite material that the structural surface thereof is smooth, the active group is few and the cohesiveness of the resin base is weak, the technical proposal is: in a plasma treatment device, the surface of the PBO fiber is modified by adopting the low temperature plasma technology; then the PBO fiber is soaked in bimaleimide resin solution to prepare fibrous reinforcement BMI composite material presoaking material; finally the presoaking material is made into continuous fibrous reinforcement composite material by the high temperature compression molding technique. The adhesiveness of the modified fiber and the resin base is greatly improved, the interface performance is enhanced, the interlaminal shear strength of the composite material is further strengthened and the mechanical property is fine. The product of the invention can meet the increasingly demanding requirements of the modern industry on the composite material, especially the demanding dual requirements of the modern aviation industry on high temperature resistance and mechanical property of the composite material. As the BMI resin has fine electromagnetic performance, thus being capable of replacing epoxide resin as a novel electromagnetic material.

Owner:DALIAN UNIV OF TECH +1

Interface layer reinforced aluminum alloy-silicon carbide double-base fiber composite material and preparation method therefor

ActiveCN109055874AImprove interface compatibilityImprove wettabilityInterface layerAdvanced composite materials

The invention discloses an interface layer reinforced aluminum alloy-silicon carbide double-base fiber composite material and a preparation method therefor. The composite material consists of a fiberpreform, silicon carbide, an interface layer, and an aluminum alloy. The preparation method comprises the following steps of: (1) cleaning and drying the fiber preform; (2) in-situ filling a silicon carbide matrix into the fiber preform by adopting a precursor infiltration and pyrolysis method; (3) preparing the interface layer by adopting a chemical vapor deposition method and an electroless plating technology; (4) and infiltrating the aluminum alloy molten solution into a composite material prepared with the interface layer, so as to obtain the interface layer reinforced aluminum alloy-silicon carbide double-base fiber composite material. According to the interface layer reinforced aluminum alloy-silicon carbide double-base fiber composite material and the preparation method therefor, the interface compatibility problem of the ceramic matrix composite material and the aluminum alloy is solved, the wettability of the aluminum alloy to the ceramic matrix composite material is obviouslyimproved, and the aluminum alloy is fully functioned in toughening and strengthening. The composite material prepared by the invention is excellent in performance and is an important candidate advanced composite material in the aerospace field.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

Composite fiber-reinforced hydrophobic SiO2 aerogel and preparation method thereof

The invention belongs to the field of advanced composite materials and particularly relates to a composite fiber-reinforced hydrophobic SiO2 aerogel and a preparation method thereof. In the method, a proper silicon source is employed as a precursor and a sol-gel method is employed. The method includes the following steps: 1) fully mixing pre-treated composite fibers with sol, performing aging treatment and performing surface modification; 2) connecting a hydrophobic group on the surface of the gel to achieve a hydrophobic effect; 3) replacing the solvent, such as ethanol, water and the like which are high in surface tension, with a low-surface-tension solvent through solvent replacement to reduce capillary tension in the liquid during drying, thereby reducing the phenomenon of gel collapse caused by evaporation of the solvent during a normal-pressure drying process; and 4) performing the normal-pressure drying process to prepare the hydrophobic SiO2 aerogel composite material. The method is simple and quick, is reduced in production cost, can improve both the strength and toughness of the composite aerogel and broadens the application of SiO2 aerogel on surfaces of irregular-shaped objects.

Owner:WUHAN UNIV OF TECH

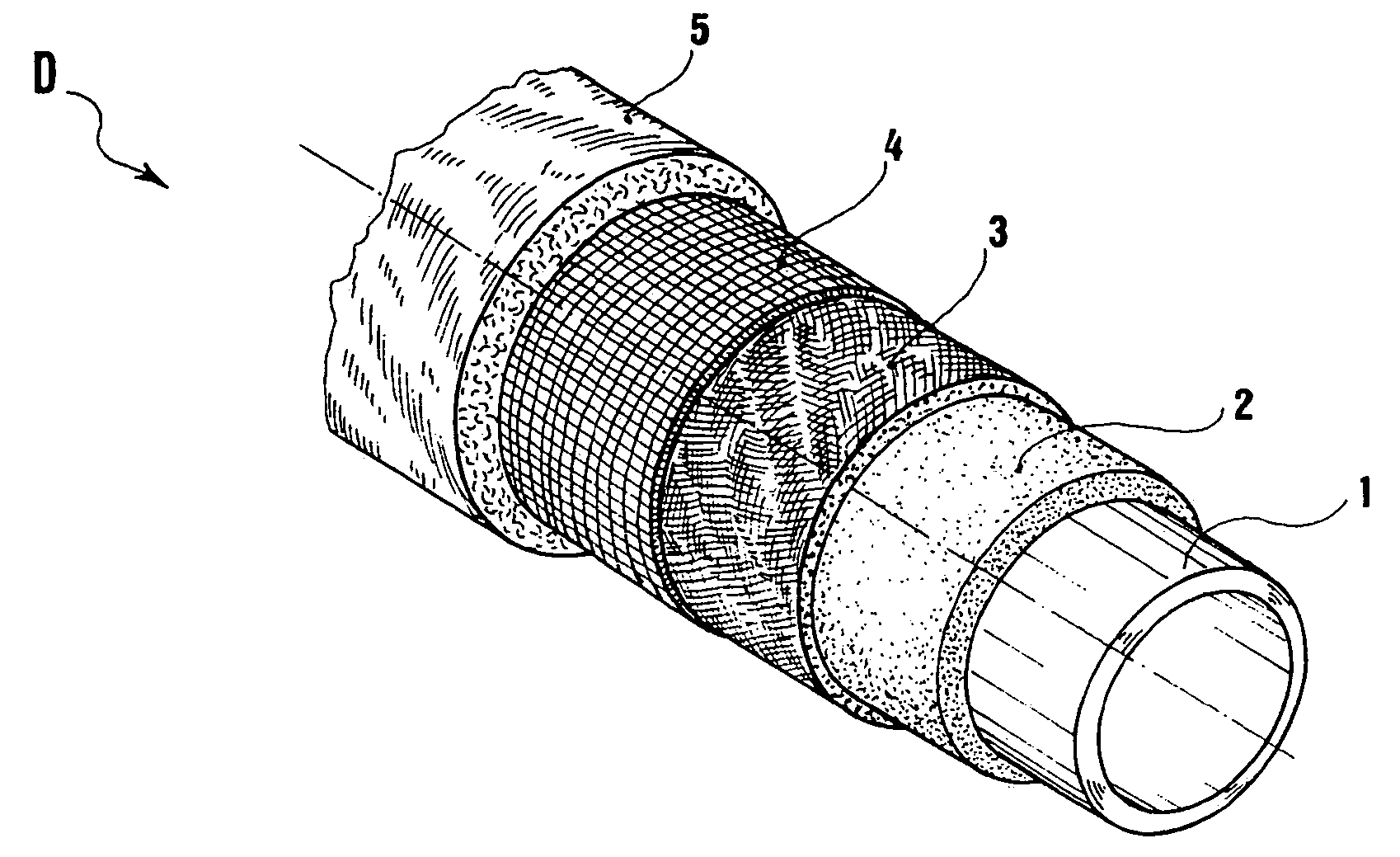

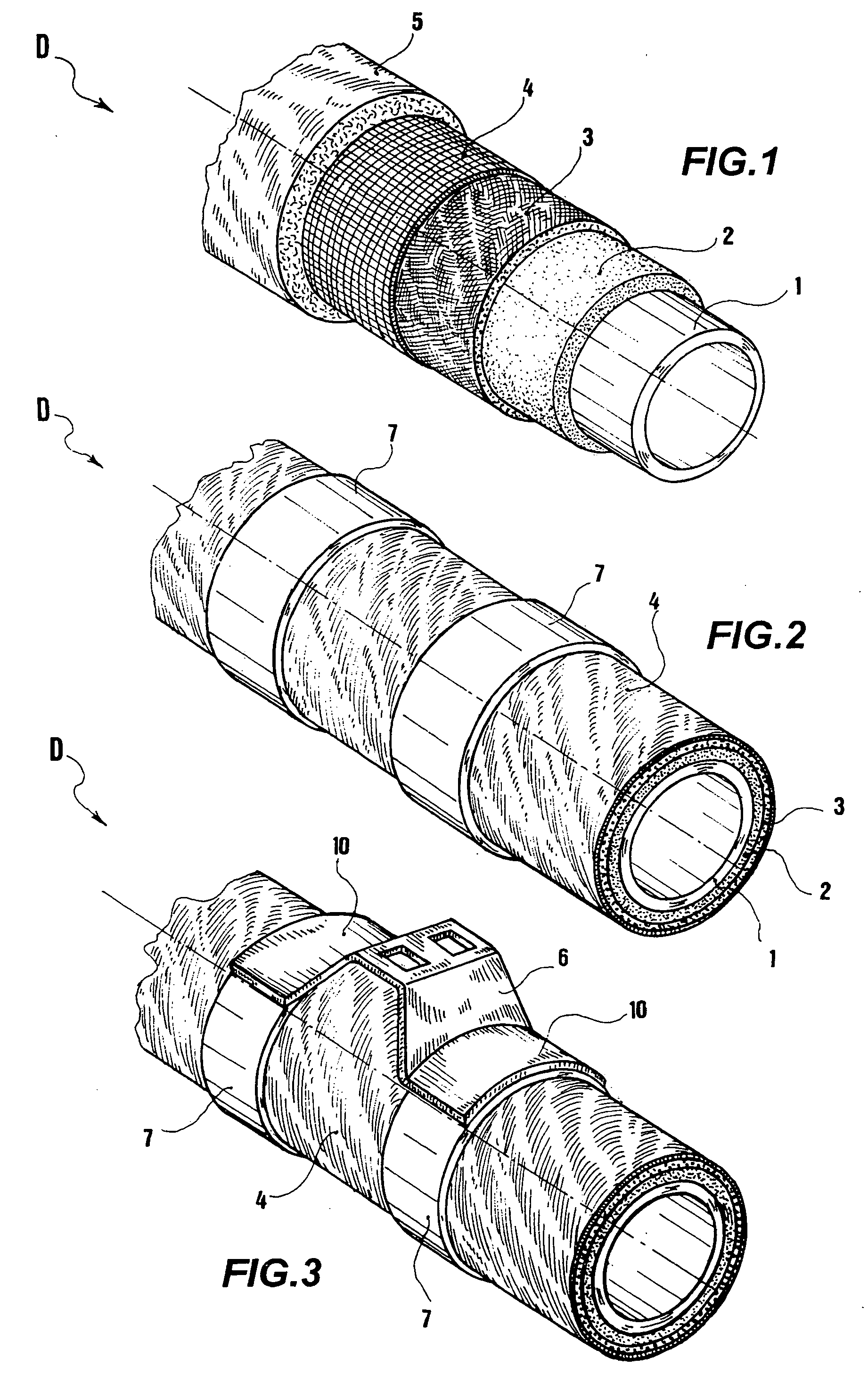

Multi-layer duct and related manufacturing process

InactiveUS20050233129A1Easy to disassembleDecrease of internal roughnessDucting arrangementsSynthetic resin layered productsFiberManufacturing technology

A multi-layer duct for air distribution in air conditioning systems, in particular, yet not exclusively, for aircraft vehicles, is made through a process providing an overlapping of layers of advanced composite materials, comprising: one substantially fluid tight polymer film, defining the inner wall of the duct; at least one stiffening structural layer, formed by a sheet of structural fibres preimpregnated in a polymer matrix of thermosetting resin, enveloping said polymer film; and one or more optional additional functional layers of structural and / or functional fibres, preimpregnated in a polymer matrix of thermosetting resin.

Owner:SALVER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com