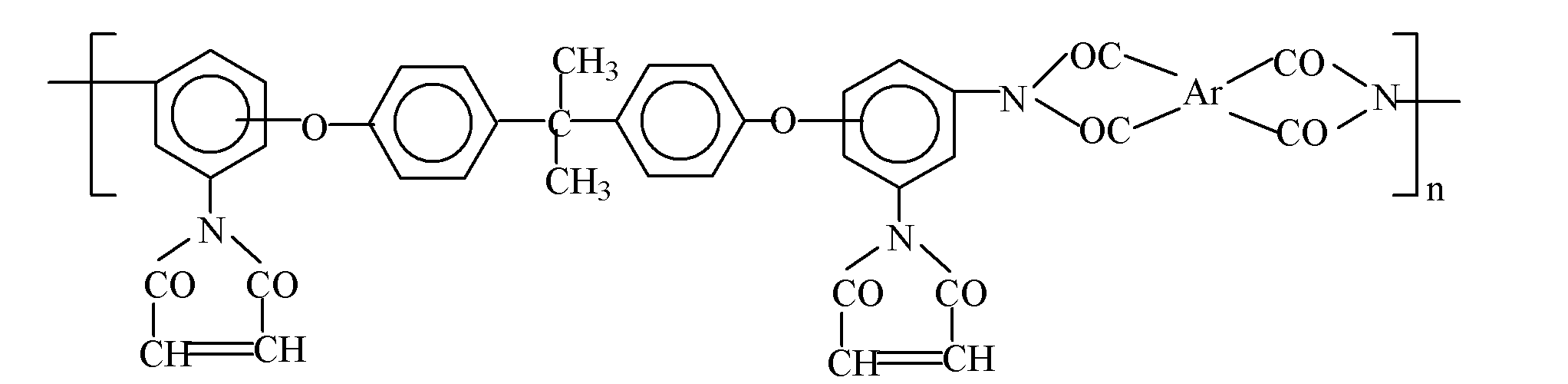

Thermosetting polyimide resin and preparation method thereof

A technology of polyimide resin and maleimide-based polyimide resin, applied in the direction of adhesives, etc., can solve the problems that have not yet been published in literature or patent reports, and achieve low cost, easy molecular weight, and good reaction conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

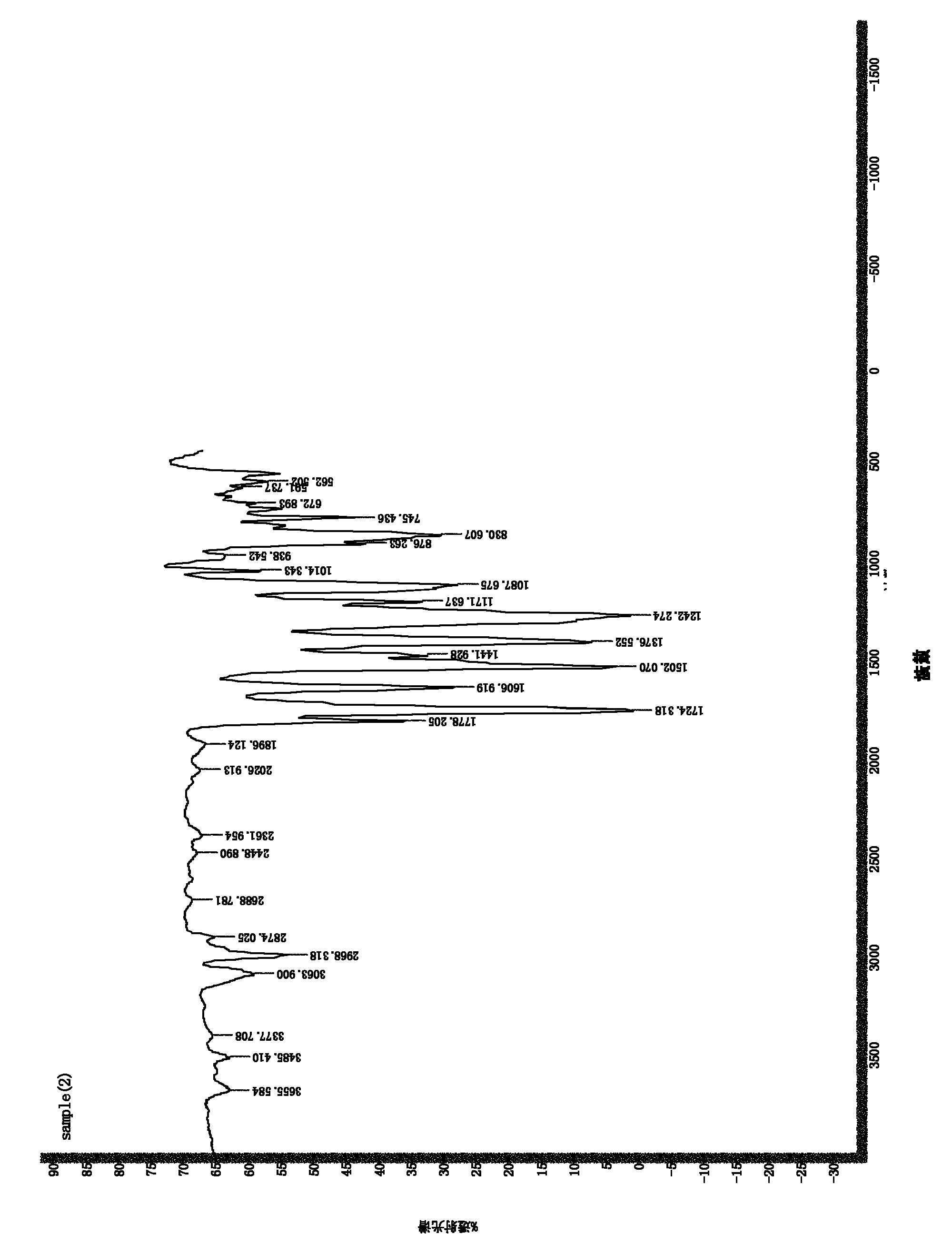

Image

Examples

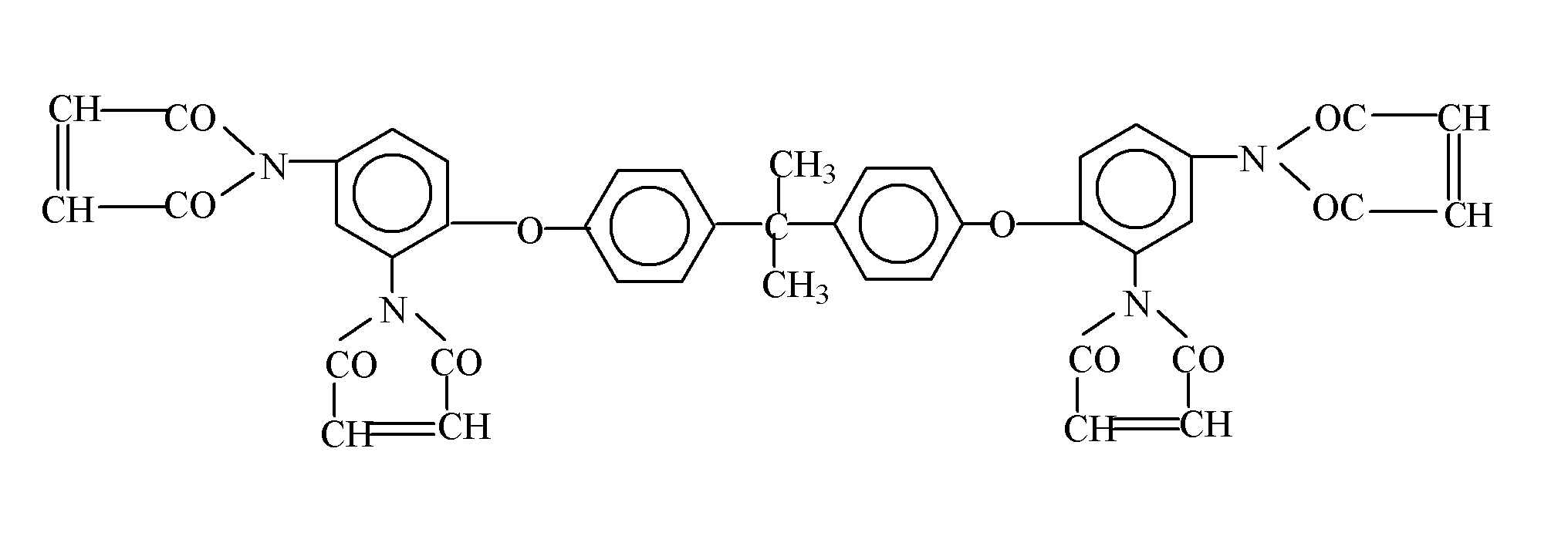

Embodiment 1

[0057] Put 44.1 grams (0.1 moles) of 2,2-bis[4-(2,4-diaminophenoxy)phenyl] propane and 285.0 grams of N-methyl-2-pyrrolidone organic solvent into the reaction kettle, room temperature After stirring and dissolving completely, add 19.6 grams (0.2 moles) of maleic anhydride solid powder, stir at room temperature until completely dissolved, continue stirring for 0.5 hours, add 31.0 grams (0.1 moles) of 3,3',4,4' -Tetracarboxydiphenyl ether dianhydride, stirring and reacting at room temperature for 5-8 hours to obtain a homogeneous transparent viscous resin solution, adding 142.5 grams of toluene azeotropic dehydrating agent, azeotropic reflux, water separation and stirring for 6-8 hours , Separate the toluene azeotropic dehydrating agent to obtain a homogeneous transparent viscous maleimide-based polyimide resin liquid with a solid content of 25 wt%, namely component A.

[0058] 264.3 grams (0.6 moles) of 2,2-bis[4-(2,4-diaminophenoxy)phenyl]propane and 750.0 grams of N-methyl-2-...

Embodiment 2

[0064] 48.5 grams (0.11 moles) of 2,2-bis[4-(2,4-diaminophenoxy)phenyl]propane and 1004.0 grams of N,N-dimethylacetamide organic solvent are put into the reactor, At room temperature, after stirring and dissolving completely, add 21.6 grams (0.22 moles) of maleic anhydride solid powder, stir at room temperature until completely dissolved, continue stirring for 0.5 hours, then add 15.5 grams (0.05 moles) of 3,3', 4,4 '-Tetracarboxydiphenyl ether dianhydride and 26.0 grams (0.05 moles) of 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl]propane dianhydride, stirred at room temperature for 5-8 hours , to obtain a homogeneous transparent viscous resin solution, add 502.0 grams of toluene azeotropic dehydrating agent, azeotropic reflux, water separation and stirring reaction for 6-8 hours, separate the toluene azeotropic dehydrating agent to obtain a homogeneous transparent viscous The maleimide-based polyimide resin liquid has a solid content of 10wt%, that is, component A.

[0065] 264.3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com