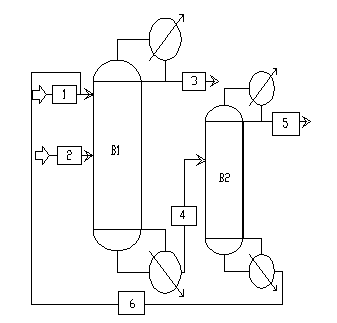

Continuous extractive distillation separation method of dimethyl carbonate-methanol azeotropic mixture

A technology of dimethyl carbonate and azeotropic mixture, which is applied in the field of continuous extraction, rectification and separation of dimethyl carbonate-methanol azeotropic mixture, can solve problems such as difficulty in obtaining high-purity dimethyl carbonate, and achieve environmental protection and good Economical and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

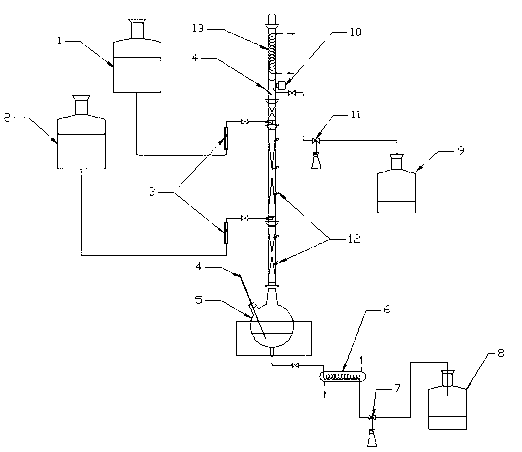

[0021] by figure 2 In the process device shown, the extractive distillation tower has an inner diameter of 29mm, a stainless steel θ mesh ring of 3mm×3mm inside, a packing height of 1.5m, and the number of theoretical plates is about 30. The top of the tower is a condenser, and the tower kettle is equipped with an electric heating jacket. Heating, discharge at the top of the tower, and reflux at the top of the tower are adjusted with electromagnetic rods. The tower has 3 and 2 tower body sampling ports in the rectification section and the stripping section of the extractive distillation tower, respectively, so as to facilitate the detection of the mass fraction of the liquid phase composition.

[0022] Operate under normal temperature and pressure, separate the dimethyl carbonate-methanol azeotropic mixture, wherein the mass content of dimethyl carbonate is 70%, the solvent ethylene glycol is fed on the third board, and the raw materials are fed on the 20th board, The solven...

Embodiment 2

[0024] by figure 2 In the process device shown, the extractive distillation tower has an inner diameter of 29mm, a stainless steel θ mesh ring of 3mm×3mm inside, a packing height of 1.5m, and the number of theoretical plates is about 30. The top of the tower is a condenser, and the tower kettle is equipped with an electric heating jacket. Heating, discharge at the top of the tower, and reflux at the top of the tower are adjusted with electromagnetic rods. The tower has 3 and 2 tower body sampling ports in the rectification section and the stripping section of the extractive distillation tower, respectively, so as to facilitate the detection of the mass fraction of the liquid phase composition.

[0025] Operate under normal temperature and pressure, separate the dimethyl carbonate-methanol azeotropic mixture, wherein the mass content of dimethyl carbonate is 70%, the solvent ethylene glycol is fed on the third board, and the raw materials are fed on the 20th board, The solven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com