Patents

Literature

1279 results about "Mass content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energy Efficient Methods to Produce Products

InactiveUS20080193989A1Improve energy efficiencyEnergy efficiencyBiofuelsWaste based fuelBiomassChemistry

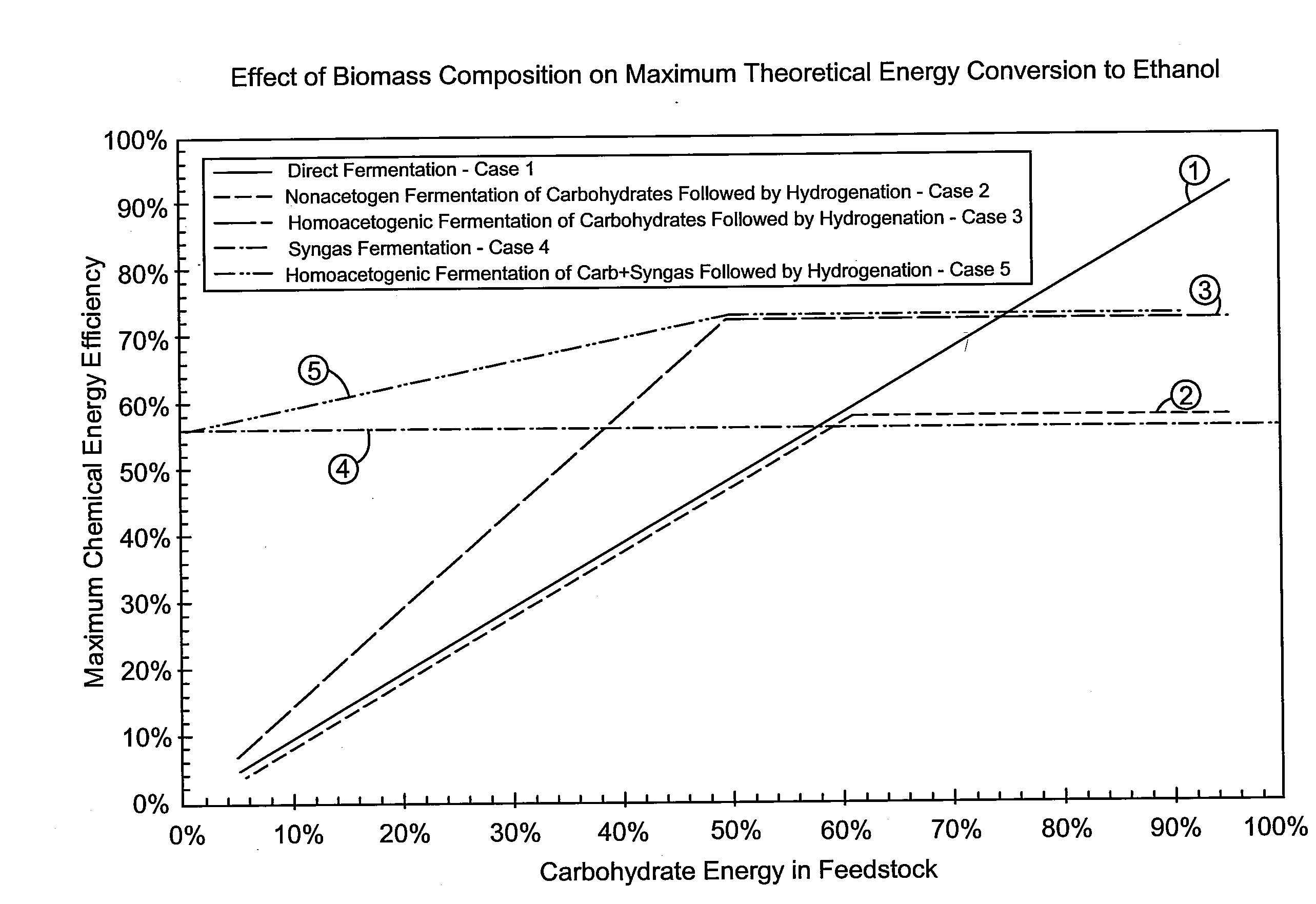

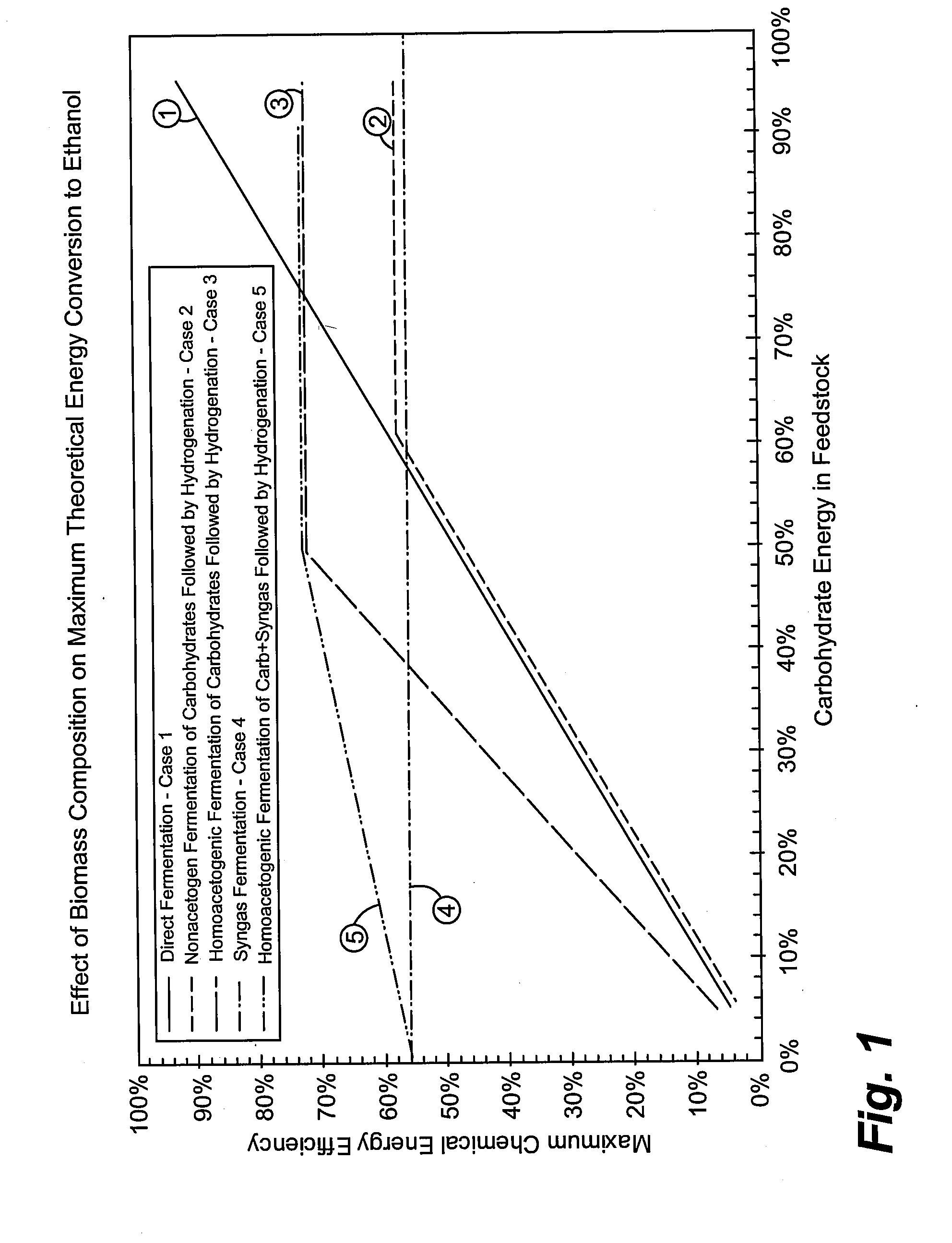

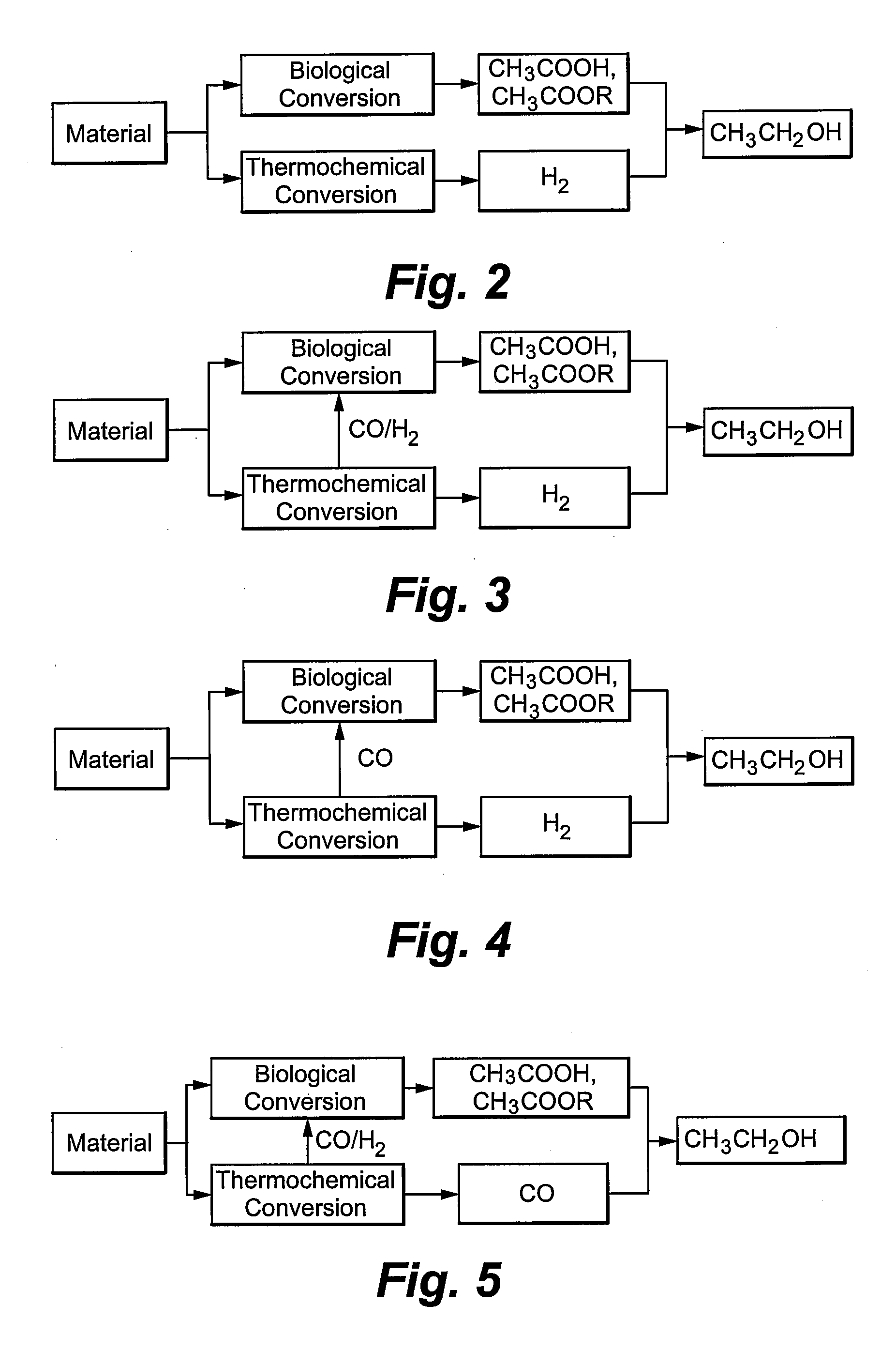

The invention relates to processes that efficiently convert carbon-containing materials, such as biomass, into products in such a manner that the energy, carbon, and mass content of the materials are efficiently transferred into such products. Such methods include converting the materials into at least one intermediate by a biological conversion process and at least one intermediate by a thermochemical conversion process and reacting the intermediates to form the product. Such methods have a chemical energy efficiency to produce the product that is greater than the chemical energy efficiency of a solely biological conversion process to produce the product and that is greater than the chemical energy efficiency of a process in which all of the material is initially subjected to a thermochemical conversion step as part of the process to produce the product.

Owner:ZEACHEM

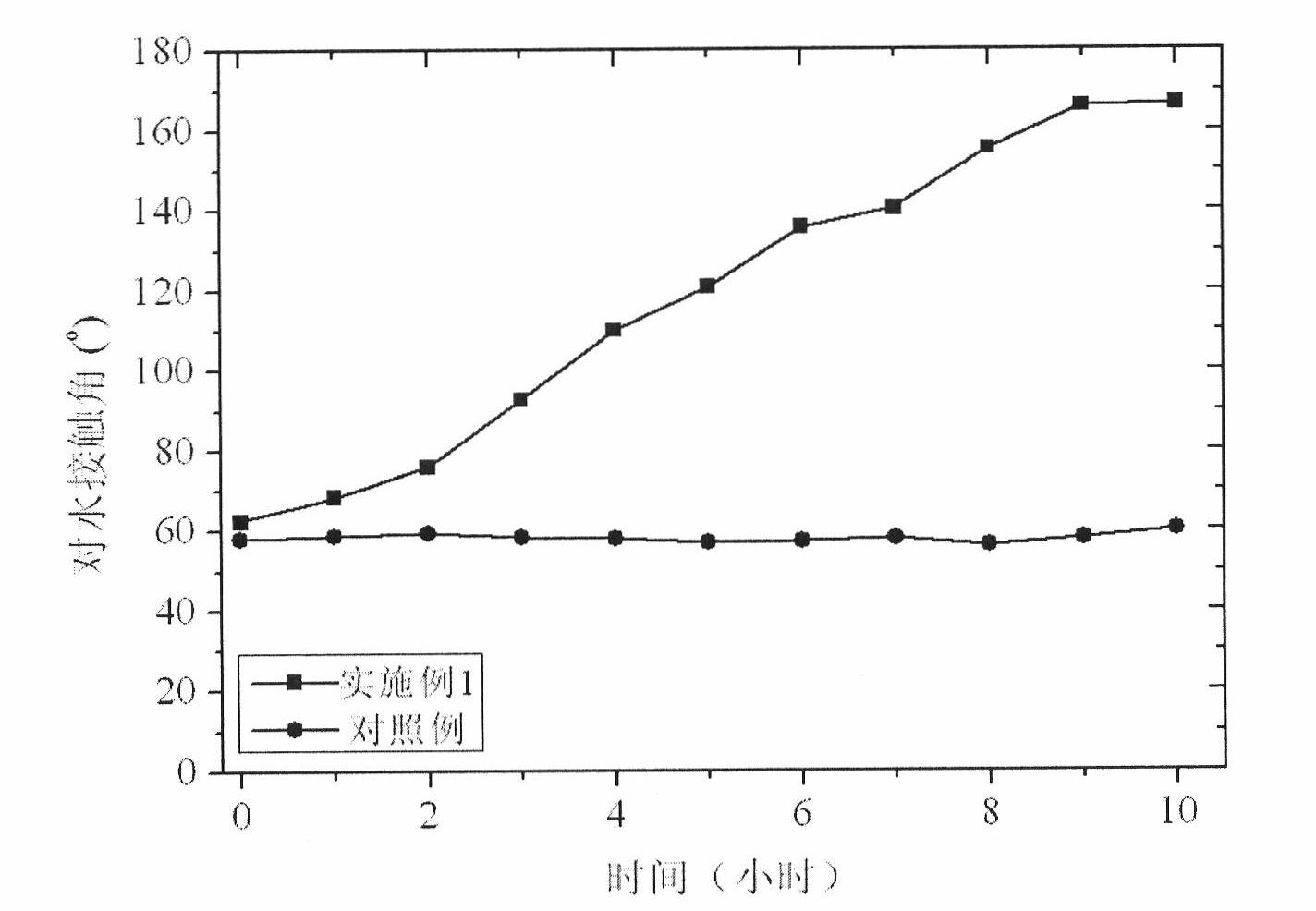

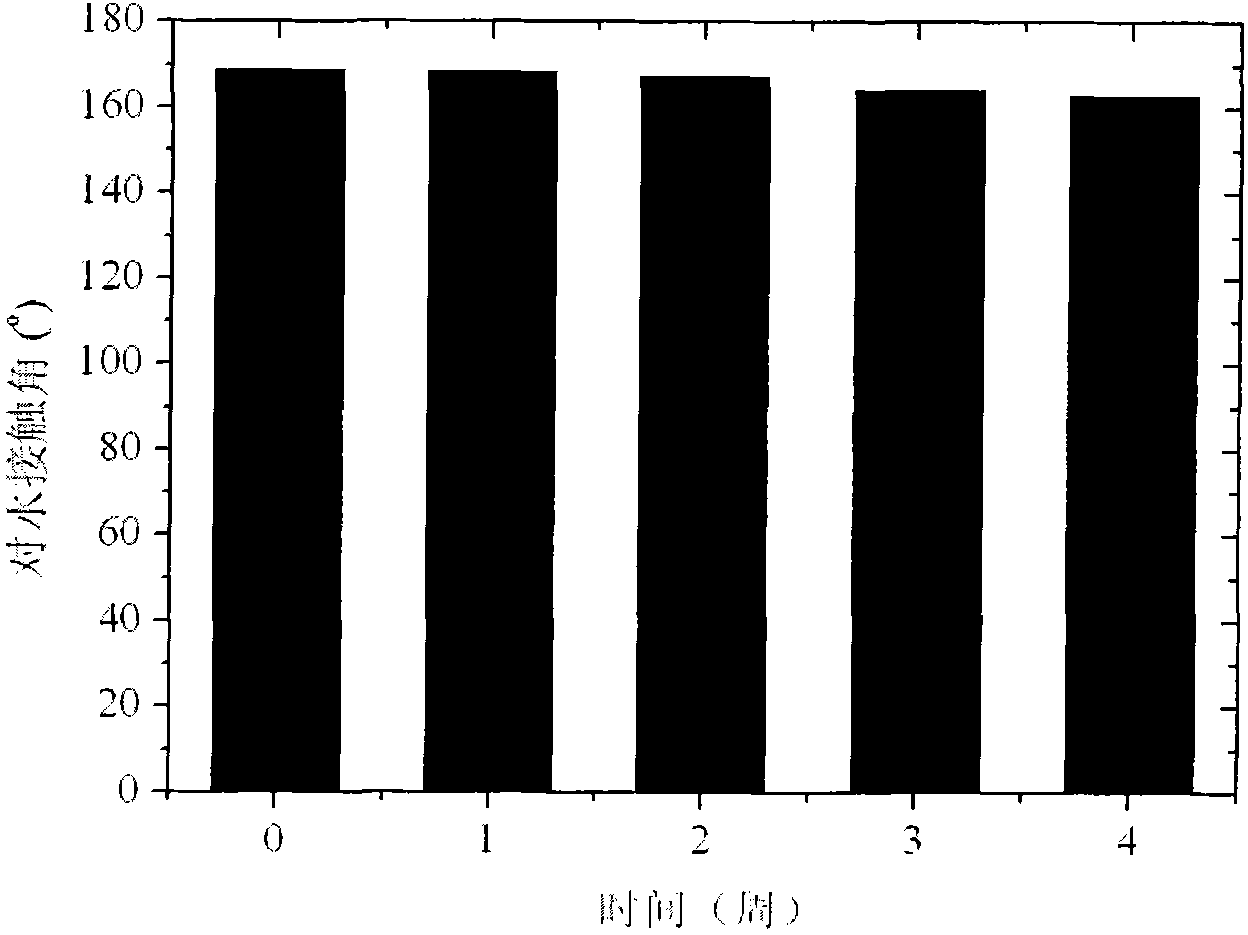

High-durability super-hydrophobic self-cleaning coating material and preparation method thereof

InactiveCN101962514AHas the following advantages: (1) cleanlinessHas the following advantages: (1) has the functionAntifouling/underwater paintsPaints with biocidesDouble bondDimethyl siloxane

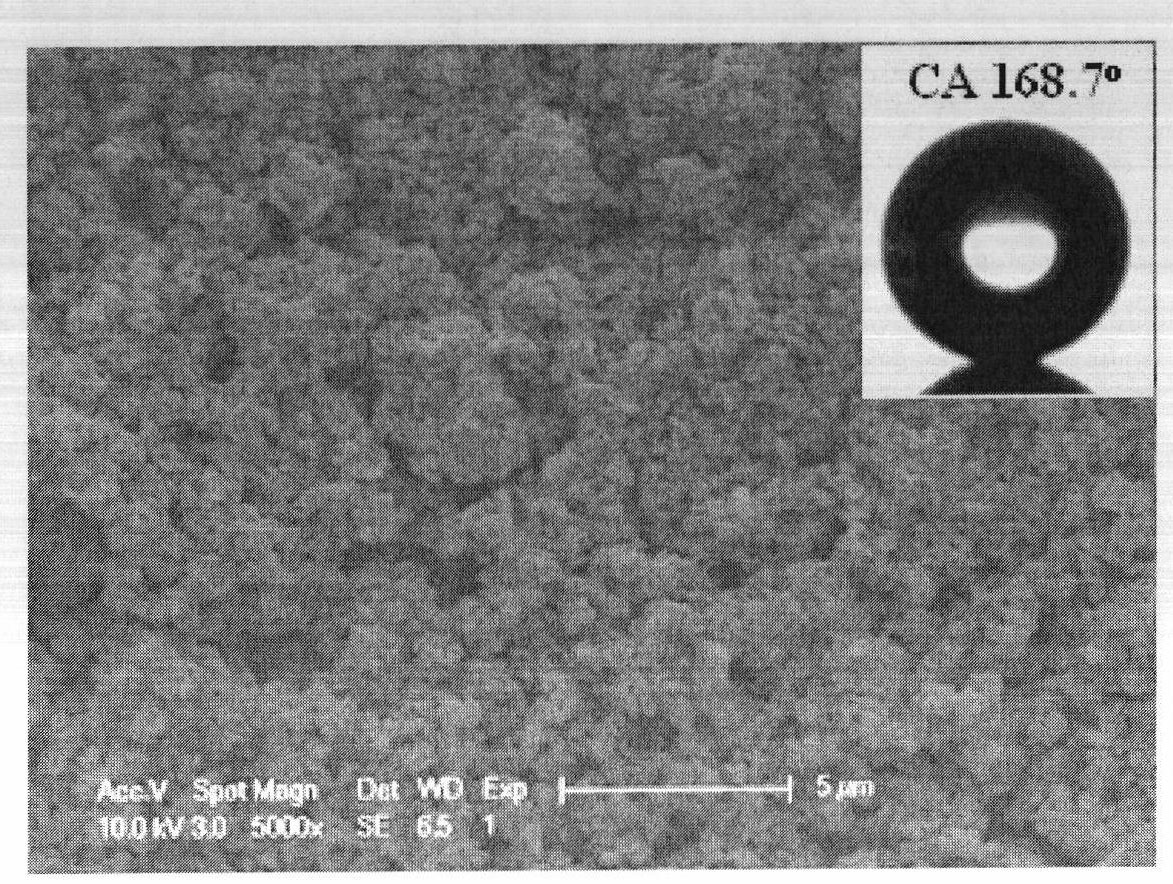

The invention belongs to the technical field of a new chemical material, and in particular relates to a high-durability super-hydrophobic self-cleaning coating material and a preparation method thereof. The coating material of the invention is prepared by curing and drying nanoparticles with photo-catalytic activity, a low-surface-free-energy polymer and a cross-linking agent at the room temperature, wherein the low-surface-free-energy polymer consists of one or more of polysiloxane fluoride, dimethyl silicone polymer and polyphenylene methyl siloxane, which contain active groups, such as hydroxyl alkoxy group, carbon-carbon double bond, silanol group, siloxy group, and the like; the cross-linking agent is hydrogen-containing silicone oil or aminosilane; and the mass content of the photo-catalytic nanoparticles in the coating ranges from 10 to 60 percent. The coating is formed into a micro-nanostructure by nanoparticle self-organization; a super-hydrophobic self-cleaning coating with lotus effect is prepared from the coating and a cross-linked filming matrix with low surface energy; the persistence of a lotus-shaped super-hydrophobic characteristic of the coating is realized by using the photo-catalytic decomposition characteristic of an organic pollutant for the nanoparticles; and thus the material is suitable for large-area construction and has high weathering resistance andprominent self-cleaning characteristic.

Owner:FUDAN UNIV

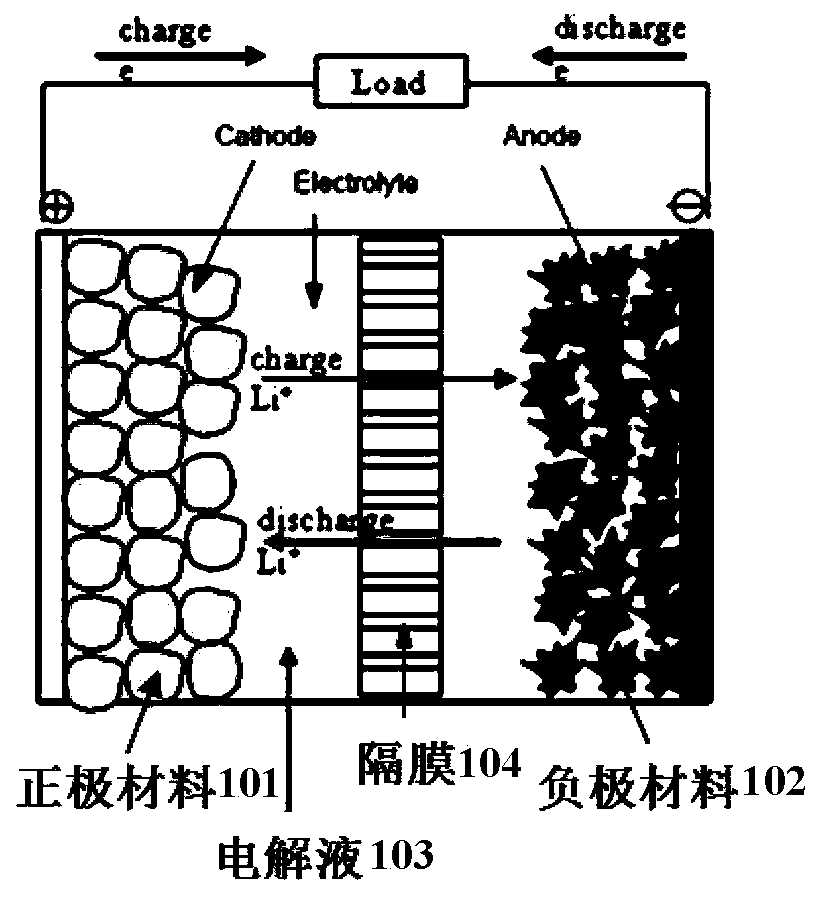

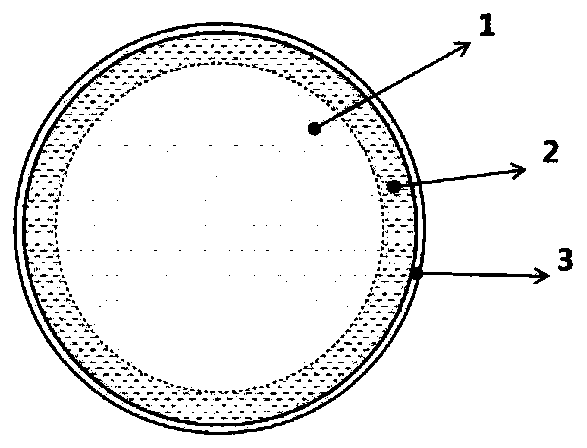

Silicon-oxygen composite negative electrode material and manufacturing method thereof

ActiveCN109755500AImprove electronic conductanceReduce lossCell electrodesLi-accumulatorsSilicon oxygenMetallurgy

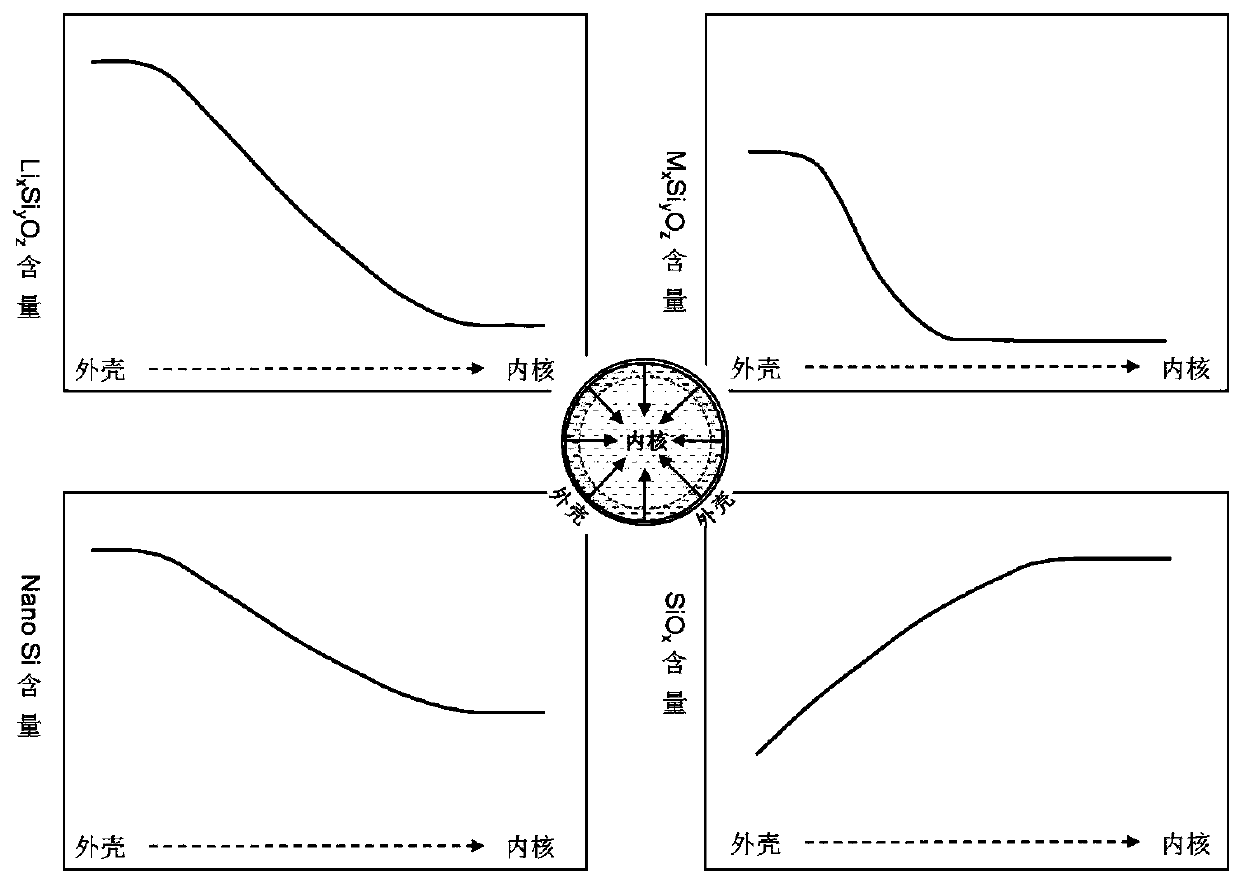

The invention discloses a silicon-oxygen composite negative electrode material which is used for manufacturing a negative electrode of a lithium battery; the negative electrode material comprises an inner core, a coating layer and a middle layer, wherein the coating layer wraps the inner core, and the middle layer is positioned between the inner core and the coating layer, wherein the middle layercomprises non-lithium silicate, and the non-lithium silicate refers to non-lithium silicate, wherein the mass content of the non-lithium silicate in the middle layer is gradually decreased from the middle layer to the inner core. The decrementing comprises a gradient reduction from the middle layer to the inner core, and the gradient reduction refers to the fact that the mass-duty ratios on the circumference parts which have the same central distance from the inner core are the same, and when the distance from the center of the inner core is reduced, the mass-duty ratio is reduced step by step. The non-lithium silicate is generated in situ on the outer layer of the inner core, and has a non-water-soluble or non-alkaline or weakly alkaline compact structure, so that the dissolution of theinternal water-soluble lithium silicate can be effectively relieved; and the pH value of the ghost-eye composite negative electrode material can be lowered.

Owner:HUAWEI TECH CO LTD

Preparation of supported catalyst for 1,4-butynediol

InactiveCN103157500AImprove stabilityHigh activityMolecular sieve catalystsOrganic compound preparationMolecular sievePtru catalyst

The invention relates to preparation of a supported catalyst for 1,4-butynediol. The supported catalyst used is characterized in that a mesoporous molecular sieve is used as a carrier, and soluble copper salt and bismuth are loaded on the carrier by an impregnation method so that the mass content of copper in the catalyst is 15-30%, and the mass content of bismuth is 1-6%. In the prepared catalyst, the particle size of copper oxide is 10-80nm, and the bismuth oxide is amorphous powder; the copper oxide and the bismuth oxide are uniformly distributed on the carrier and interact with the carrier; and the catalyst has high activity and high selectivity in producing 1,4-butynediol through an alkyne hydroformylation reaction, is more stable and wear-resistant than similar catalysts, and saves copper resources.

Owner:XINJIANG UNIVERSITY

Glass fiber

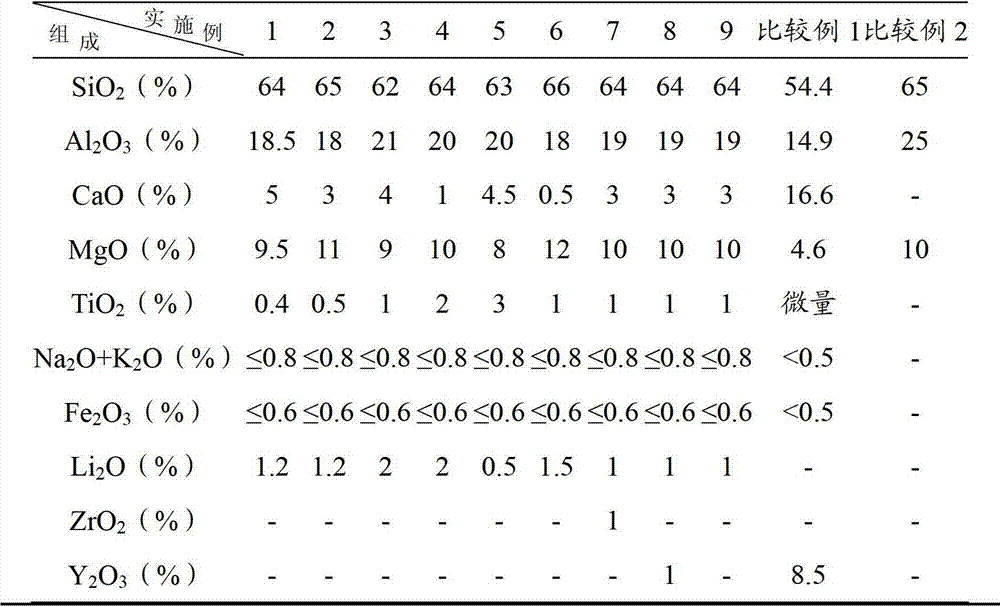

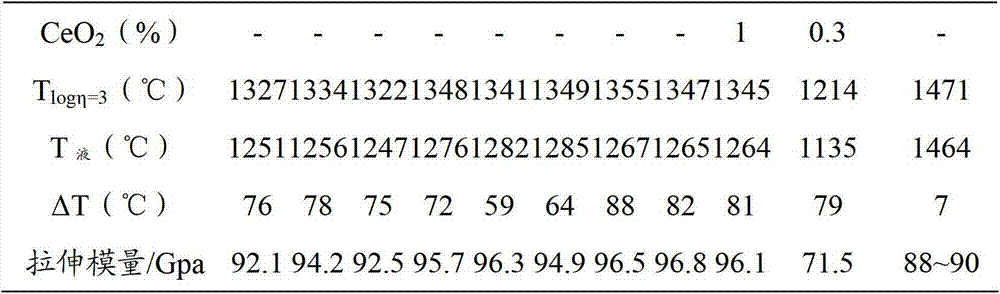

InactiveCN103086605AHigh tensile modulusLow molding temperatureGlass fiberCrystallization temperature

The invention provides a glass fiber which comprises 62-66 wt% of SiO2, 18-21 wt% of Al2O3, 0.5-5 wt% of CaO, 8-12 wt% of MgO, 0.5-2 wt% of Li2O, 0.4-3 wt% of TiO2, 0.1-0.6 wt% of Fe2O3 and 0.1-0.8 wt% of Na2O and K2O. The total mass content of the Na2O, K2O and Li2O is 0.5-3 wt%. Therefore, the glass fiber provided by the invention has low forming temperature and upper limit crystallization temperature on the premise of having high tensile modulus, so that the glass fiber is applicable to large-scale industrial production.

Owner:CHONGQING POLYCOMP INT

Low noble metal mercury-free catalyst for acetylene hydrochlorination reaction, preparation method and application thereof

ActiveCN103894208AHigh catalytic activityImprove stabilityPreparation by halogen halide additionCatalyst activation/preparationActive componentMass content

This invention relates to a low noble metal mercury-free catalyst for a vinyl chloride synthesis reaction through an acetylene hydrochlorination reaction, a preparation method and an application thereof. The catalyst comprises an active carbon carrier and a mixed active component comprising one or a plurality of noble metal compounds and one or a plurality of general metal compounds according to a certain ratio, wherein the mass content of the noble metal is 0.01-0.04%, and the mass content of the general metal is 0.1-1%. The low noble metal mercury-free catalyst has characteristics of low noble metal content, low catalyst cost, high catalyst activity and long service life.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

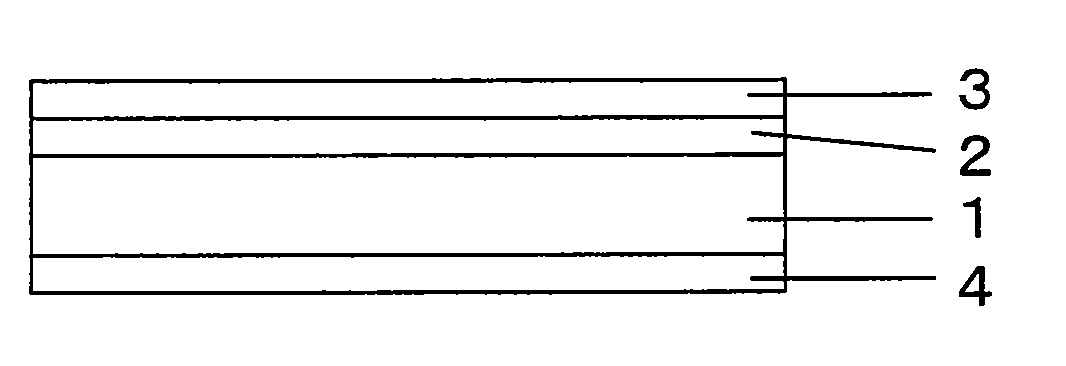

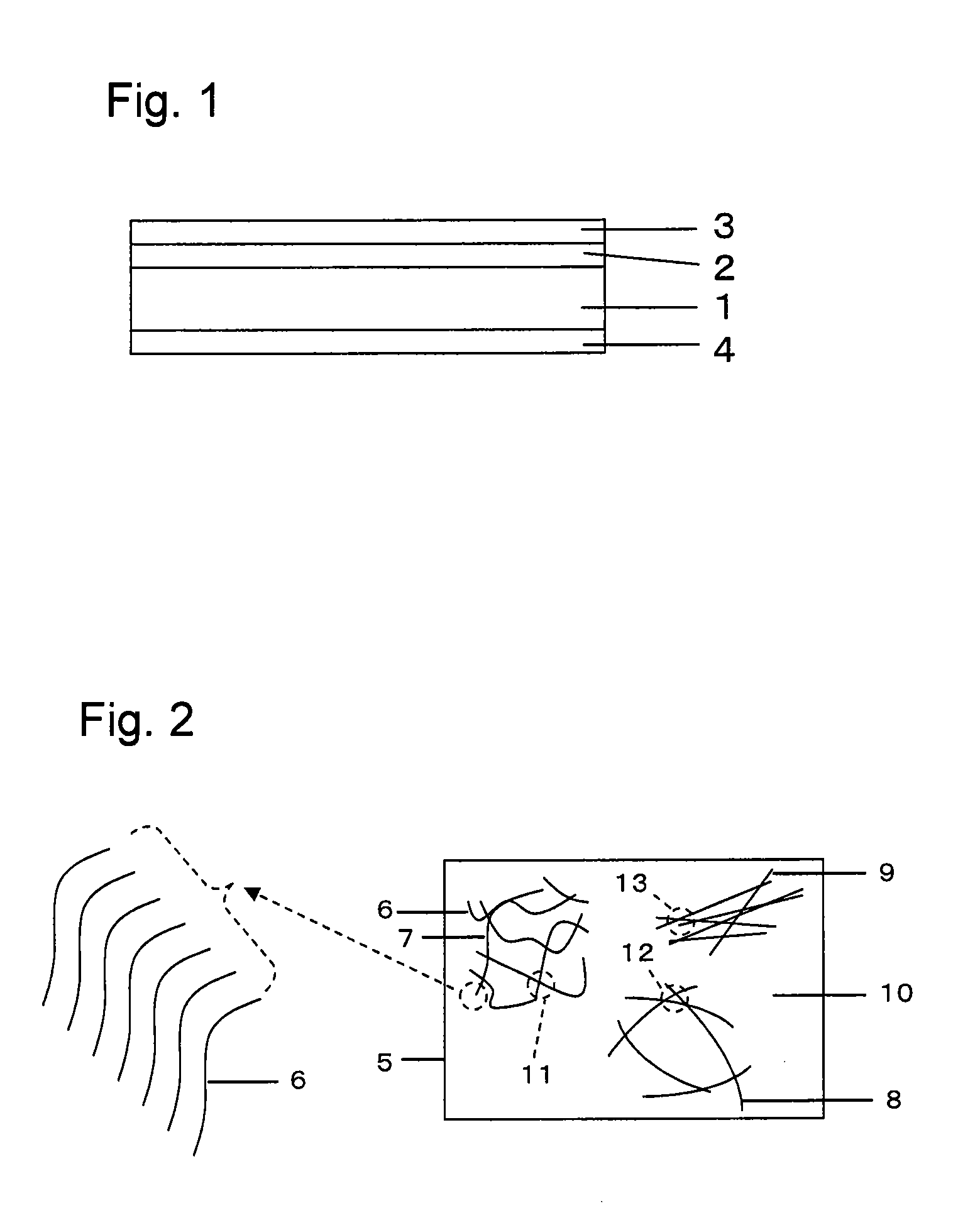

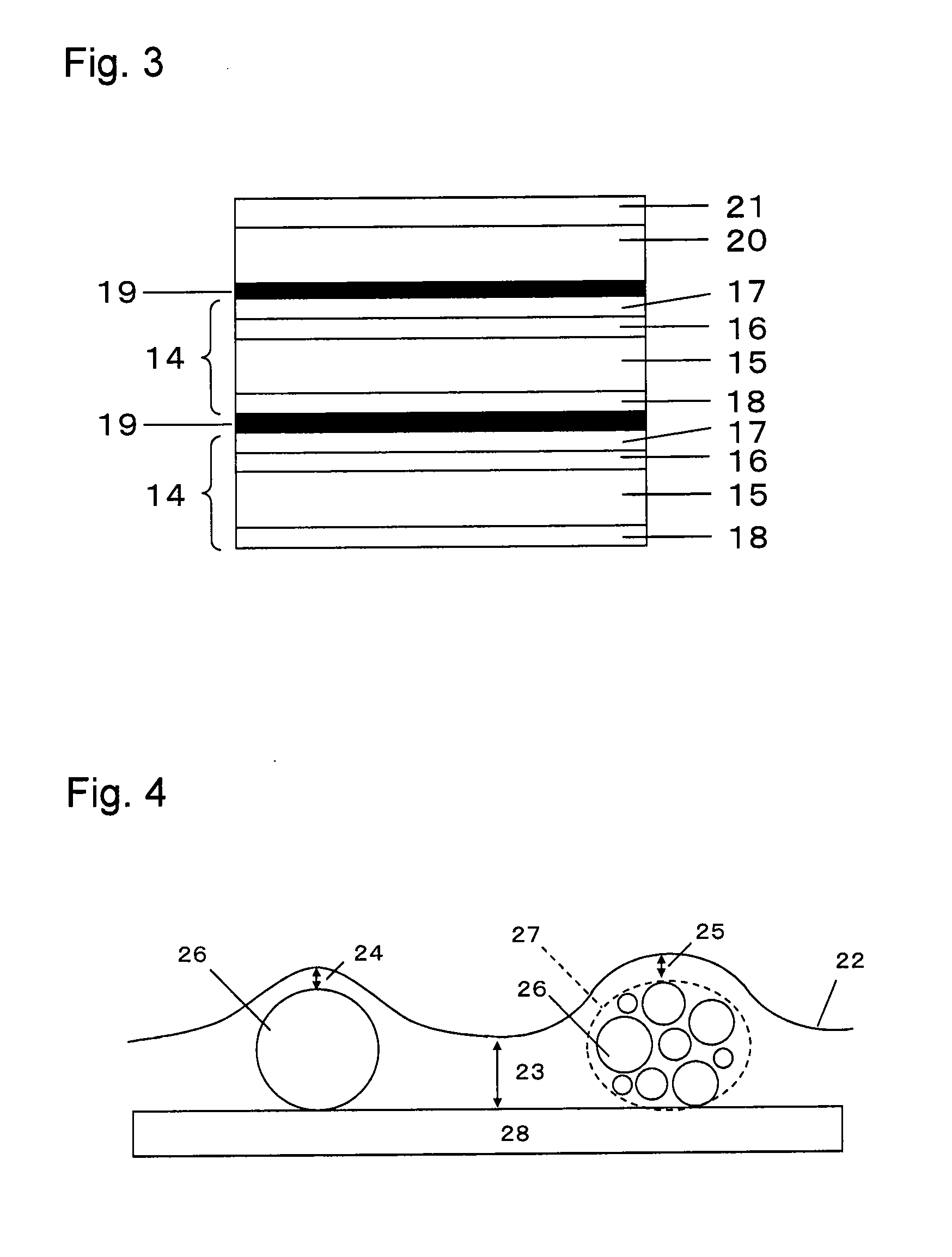

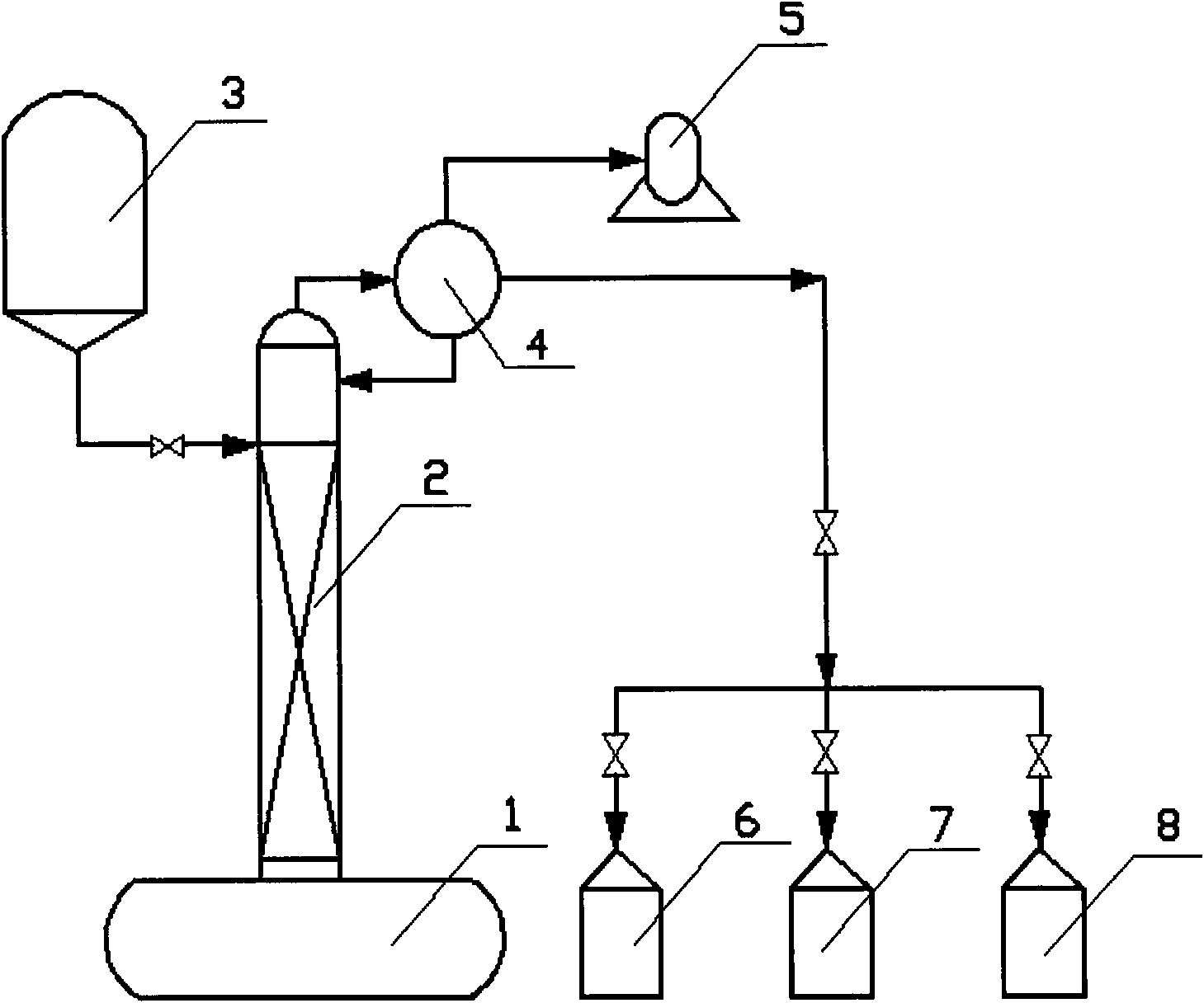

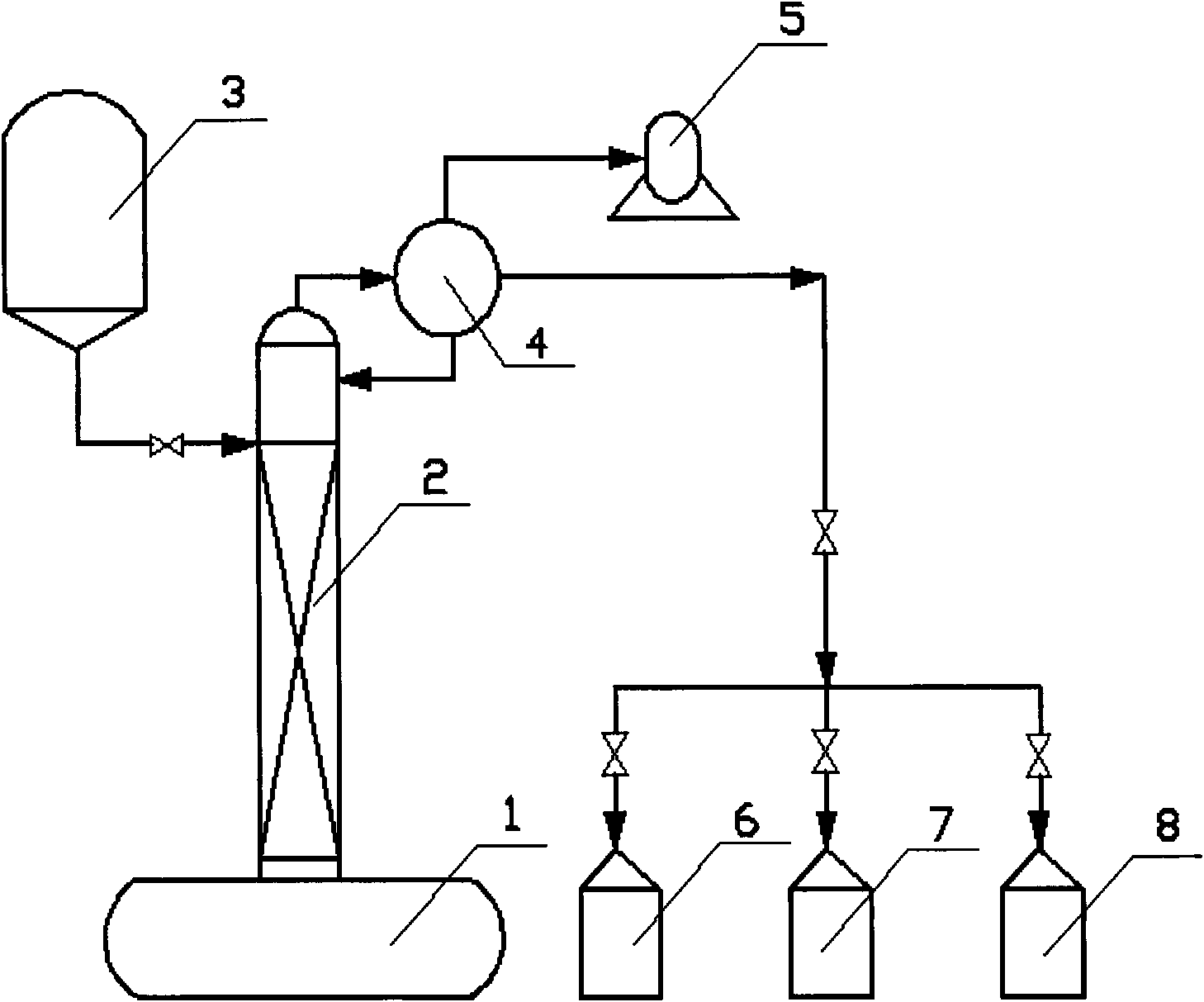

Conductive laminate and touch panel

InactiveUS20140008115A1Poor durabilityAdverse influence on optical properties or electrical properties of the electrode memberConductive layers on insulating-supportsPrinted circuit detailsConductive polymerNetwork structure

A conductive laminate includes a substrate, a crosslinked layer, and a conductive layer and a protective layer, wherein (i) the crosslinked layer is composed of a crosslinked polymer including a structure in which compounds, each having two or more carbon-carbon double bond groups contributing to a polymerization reaction, are subjected to the polymerization reaction, and also the mass content of a unit structure portion of the carbon-carbon double bond group in the structure derived from the carbon-carbon double bond group is from 9 to 26% by mass relative to the total mass of the crosslinked layer; (ii) the crosslinked layer has a thickness of 50 nm to 1 μm; (iii) the conductive layer contains a conductive component having a network structure composed of linear structures; and (iv) the protective layer has an average thickness (t) of 70 nm to 1 μm.

Owner:TORAY IND INC +1

Method for separating methyl acetate-methanol mixture by ionic liquid intermittent extractive rectification

InactiveCN102180791AIncrease relative volatilityNo pollution in the processOrganic compound preparationCarboxylic acid esters preparationMethyl acetateMass content

The invention discloses a method for separating a methyl acetate-methanol mixture by ionic liquid intermittent extractive rectification, which is realized in a way that: a rectifier of an extractive rectification tower is adopted, an ionic liquid 1-ethyl-3-methyl imidazolyl acetate is used as an extractant, and the operation is carried out intermittently, so the top of the extractive rectification tower sequentially produces a methyl acetate product of which the mass content is up to 98-99.9%, a methyl acetate-methanol transitional fraction and methanol of which the mass content is 97-99%; and finally, the extractant of which the mass percent is 99% is left in the heating kettle. The invention has the following advantages: the extractant is adopted to enhance the relative volatility of the methyl acetate-methanol system, the purity of the separated methyl acetate product is high, and the ionic liquid used as the extractant is easy to recover and does not pollute the environment; and only one single tower needs to be operated, so that operation is flexible and the equipment investment is low.

Owner:TIANJIN UNIV

Feed for lean meat fattening pigs

InactiveCN102669492AImprove qualityProtect healthFood processingAnimal feeding stuffPhytaseLean meat

The invention relates to feed, in particular to feed for lean meat fattening pigs. The feed consists of a major material part and an auxiliary material part, wherein the mass content of the major material part is 98 percent, the mass content of the auxiliary material part is 2 percent, the major material part consists of the following ingredients in parts by weight: 300 to 500 parts of corn, 200 to 300 parts of wheat, 150 to 200 parts of dehulled soybean meal, 0 to 100 parts of American distillers dried grains with solubleb (DDGS), 0 to 50 parts of rice bran, 30 to 100 parts of wheat bran, 6 to 10 parts of mountain flour and 5 to 10 parts of calcium hydrophosphate, the auxiliary material part consists of the following ingredients in percentage by weight: 2 to 5 percent of choline, 1 percent of antioxidant, 3 percent of mould inhibitors, 2 percent of composite vitamins, 15 to 30 percent of synthetic amino acid, 20 to 30 percent of electrolyte, 15 percent of composite trace elements, 0.5 percent of phytase, 1 percent of composite zymin, 3 to 10 percent of meat modifiers and 5 to 30 percent of carriers. The feed for the lean meat fattening pigs provided by the invention has the advantages that 1) the growth speed and the lean meat percentage of the lean meat fattening pigs can be improved; 2) the pork quality can be improved, and in addition, no toxic residue exists; and 3) the heath of consumers is ensured, and the competitiveness of the pig product exportation is enhanced.

Owner:GUANGZHOU PANYU DACHUAN FEED +5

Method for preparing monohydric alcohol or dihydric alcohol through organic acid hydrogenation

ActiveCN103288596AOrganic compound preparationHydroxy compound preparation3-Hydroxypropionic acidPropanoic acid

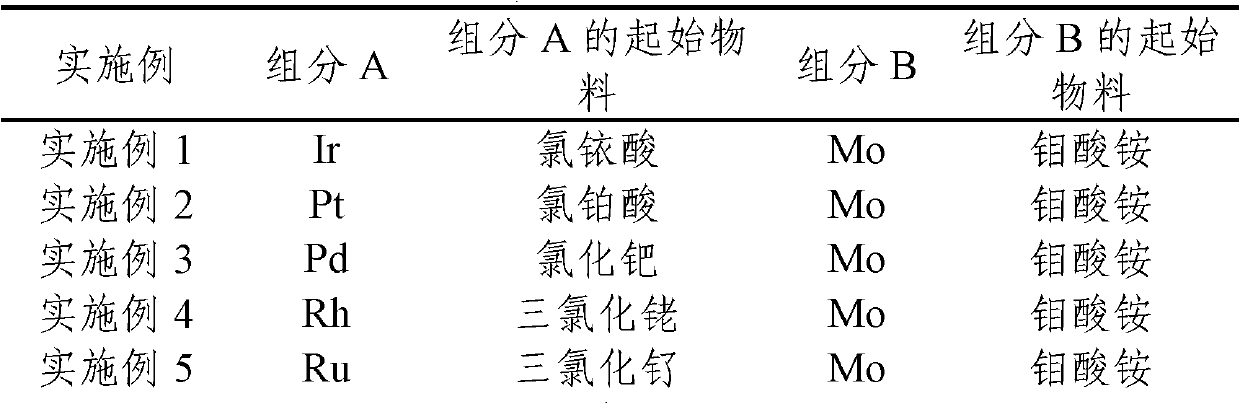

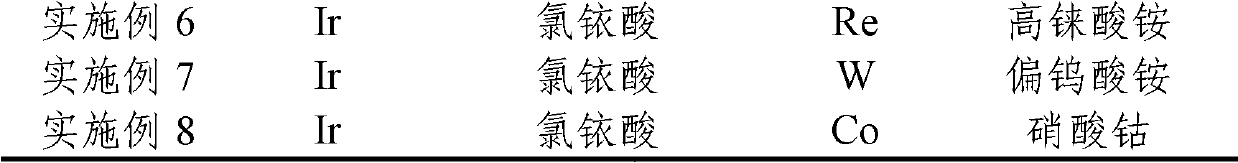

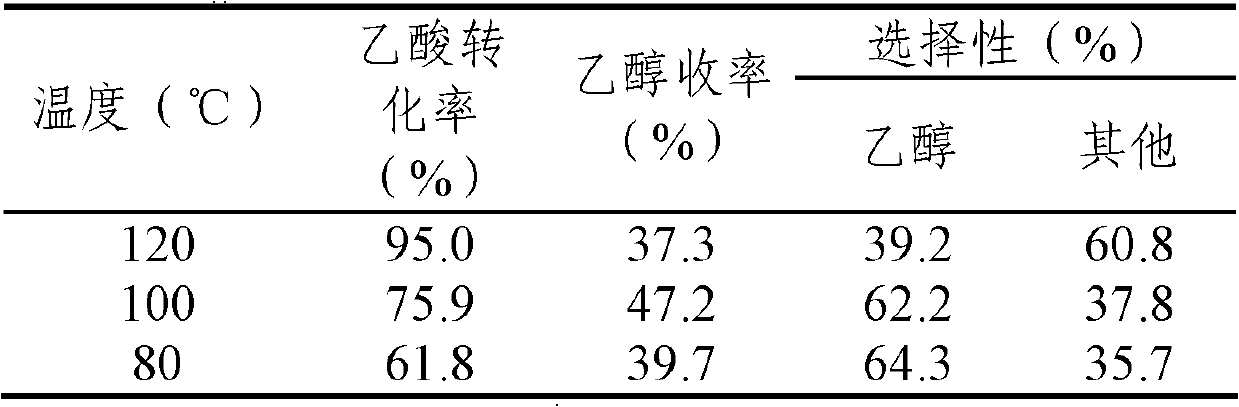

The invention relates to a method for preparing monohydric alcohol or dihydric alcohol through organic acid hydrogenation. According to the method, any one of acetic acid, propionic acid, valeric acid, stearic acid, oleic acid, palmitic acid, levulinic acid, lactic acid, succinic acid, 3-hydracrylic acid and other organic acids is taken as a reactant, and an A-B / X supported catalyst is adopted, wherein the component A is any one or more than two from Ir, Pt, Pd, Rh and Ru, the assistant B is any one or more than two from Mo, Re and W, the carrier X is any one in SiO2, activated carbon, titanium oxide, zirconium oxide, SiO2-Al2O3 (the mass content of Al2O3 accounts for 17 percent) and molecular sieves, the mass load amount of A in the catalyst is 0.5-10 percent, the molar ratio of the assistant B to A is 0.01-1.0, the reaction pressure is 2-20 MPa, and the reaction temperature is 40-180 DEG C. The catalyst has the characteristics of mild reaction conditions, high reaction activity and good selectivity, and a novel effective way for preparing monohydric alcohol or dihydric alcohol from biomass is provided.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Nano cerium oxide polishing liquid composition

The invention provides a cerium oxide polishing liquid suitable for polishing rock crystals, photomask quartz glass, semiconductor devices and glass-prepared hard disks and polishing low-dielectric-constant materials for interlayer insulating films of semiconductor devices of siloxane and the like. The polishing liquid contains surface modified nano cerium oxide, silicon dioxide, a dispersing agent, an oxidizing agent, an alkaline compound, an alcohol compound and water. Preferably, stearic acid treated nano cerium oxide is selected, the particle size is preferably 10-100 nm, and the mass content is 1-10%; preferably, the particle size of the colloidal silicon dioxide is 40-100 nm, and the mass content is 0.1-5%; preferably, the polishing liquid contains 0.01-5% of the high-molecular dispersing agent, 1-10% of the hydrogen peroxide oxidizing agent, and the balance an alcohol-water mixture, wherein the pH value of a slurry is 8-10. The nano cerium oxide polishing liquid selects the surface modified nano cerium oxide, has addition of a proper amount of the silicon dioxide, thereby reducing the grinding trigger time and improving the processing stability.

Owner:天津西美半导体材料有限公司

Ultra-supercritical novel ferrite heat-resistant steel welding electrode

The invention discloses an ultra-supercritical novel ferrite heat-resistant steel welding electrode, consisting of an H08Cr9WMo special core wire and a coating, wherein the content of each of sulfur, phosphorous, arsenic, stannum and the like in the H08Cr9WMo special core wire is low; the coating is wrapped on the surface of the core wire; and the covering components and the mass contents thereof are as follows: 28-40% of marble, 18-28% of fluorite, 5-10% of rutile, 3-8% of ferrotitanium, 4-10% of silica powder, 2-5% of silicoferrite, 1-1.8% of ferrovanadium, 0.4-0.8% of ferrocolumbium, 1-1.8% of nickel powder, 0.4-0.8% of sodium carbonate, 0.4-0.8% of CMC (Carboxymethyl Cellulose), 0.2-0.6% of amorphous graphite powder, 0.6-1.5% of ferrochrome nitride and 1.5-3% of electrolytic manganese. The welding electrode provided by the invention is used for the welding of ultra-supercritical heat-resistant steel T / P92 in a matching way; and in the course of welding, the electric arc is stable, the splashing is little, the slag detachability is good, the all-position operability is good, the formed welding line is attractive and the welding line wettability is moderate.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Solvent-free polyurethane composition for synthetic leather

The invention discloses a solvent-free polyurethane composition for synthetic leather. The composition consists of a component A and a component B, wherein the component A comprises polyetherester polyol, polyester polyol, a crosslinking agent, a chain extender, a foam stabilizer, a catalyst, a foaming agent and the like; the component B comprises polyol, micromolecule alcohol and isocyanate; the mass content of -NCO is 10%-25%. The component A and the component B are subjected to moment mixing through a low pressure foaming machine or a high pressure foaming machine, and then the mixture is sprayed or poured onto release paper coated with surface polyurethane resin, uniformly scraped to be 1-2 mm in thickness with a scraper, and fed to a baking channel to be heated till the resin is semi-solidified, the semi-solidified is laminated with base cloth to be fed to a rear passage oven for curing. The composition is low in viscosity, good in flowability after being sprayed or poured onto the release paper, easy for scraper coating, and high in strength after formation.

Owner:李善军

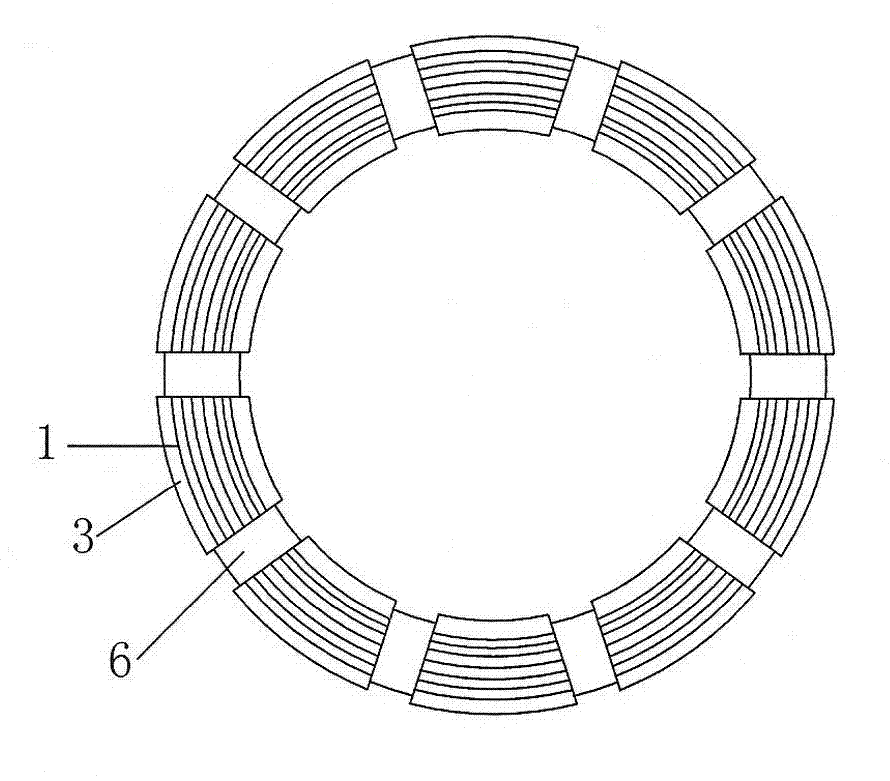

Iron-based diamond-impregnated bit for drilling in hard slipping foundation

The invention discloses an iron-based diamond-impregnated bit for drilling in a hard slipping foundation. An iron-based substrate mixed material provided by the invention is formed by sintering an iron-based matrix and a diamond; the diamond is impregnated in the iron-based matrix; the volume percentage of the content of the diamond is 45-75%, and the grain size is 35-45mu; the iron-based matrix comprises the following components in percentage by mass: 65-72% of iron powder, 10-14% of zinc powder, 14-18% of 663 bronze powder, 1% of manganese powder and 2% of nickel powder; according to the invention, the iron powder with the mass content of about 70% is used for replacing the common tungsten carbide powder, and therefore, the cost of the diamond-impregnated bit is greatly reduced, the sintering temperature is reduced, and the heat damage rate of the diamond is reduced; the iron-based matrix is few in component, less in variable and easy to control; and the iron-based diamond-impregnated bit has higher pertinence and mainly aims to the hard slipping foundations.

Owner:JILIN UNIV

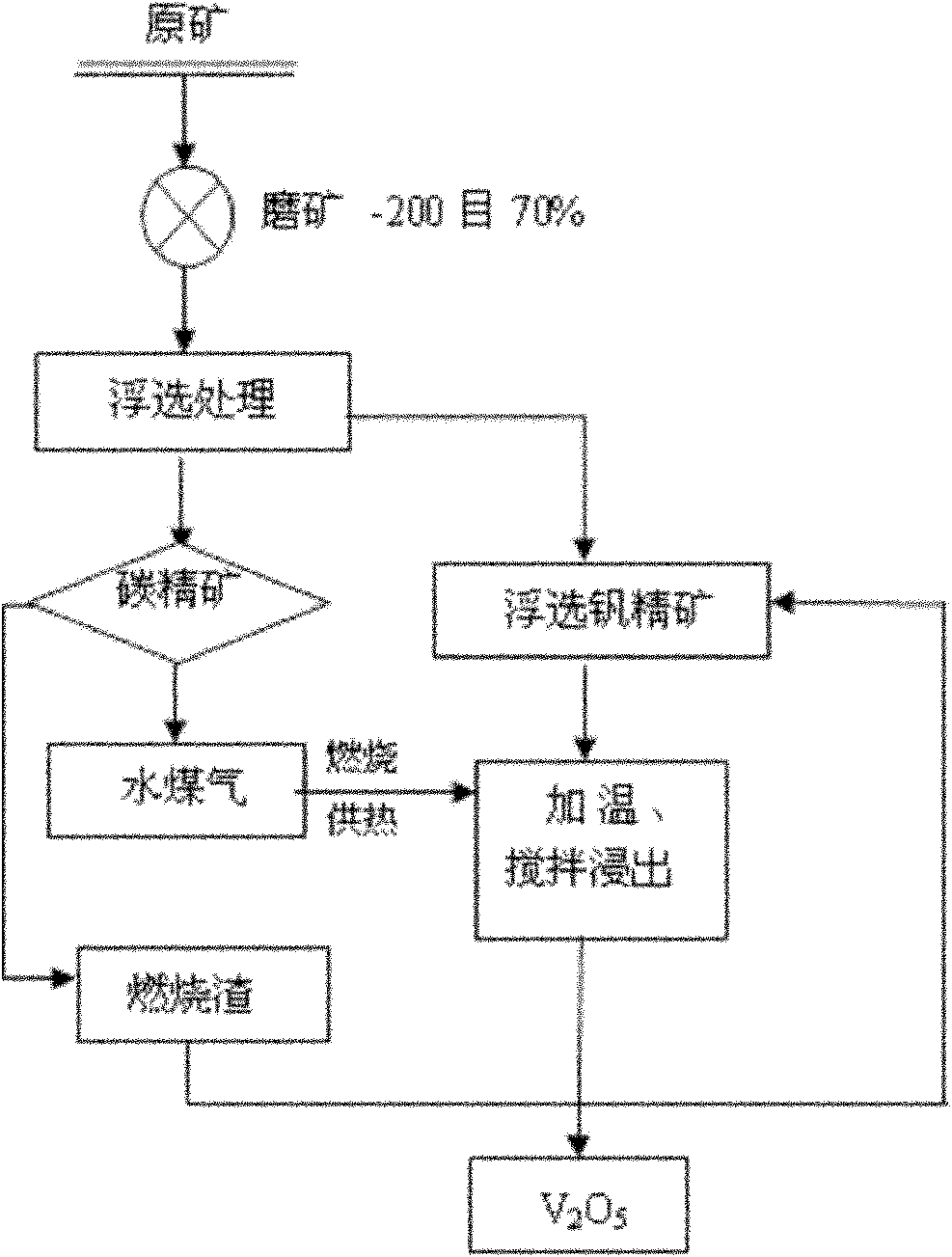

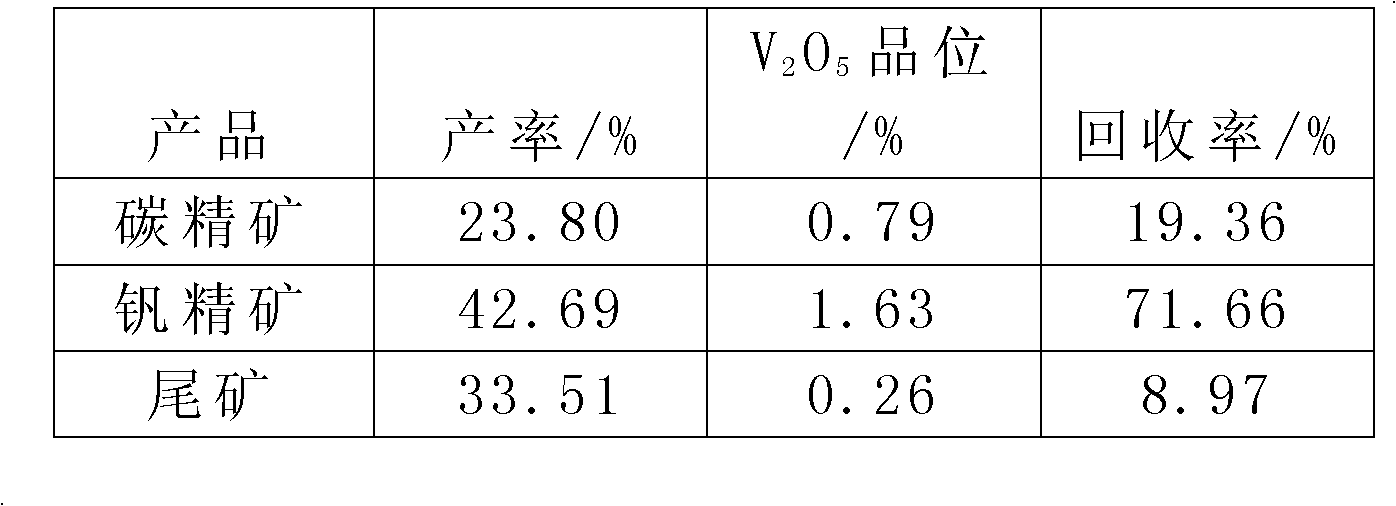

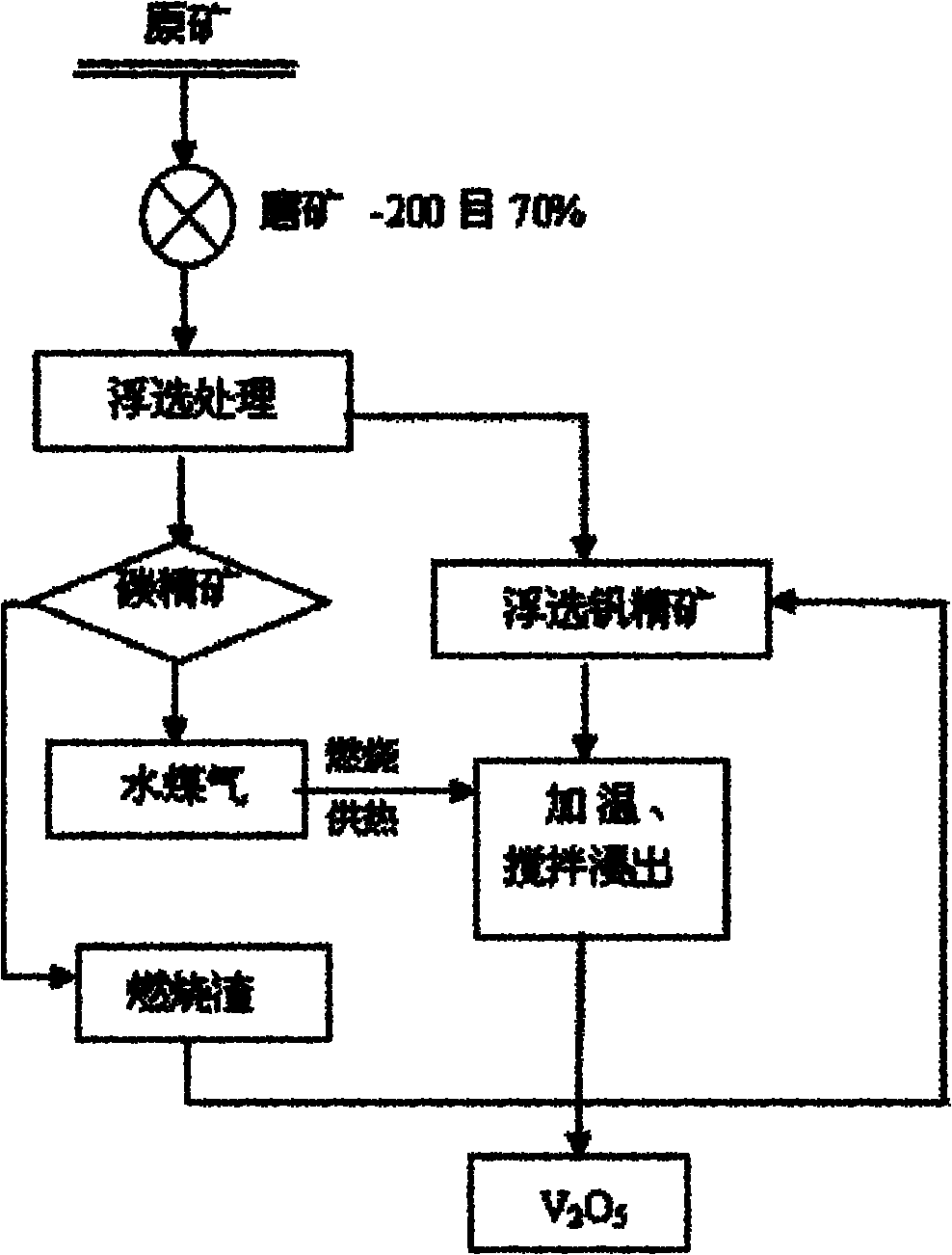

Method for enrichment of vanadium from stone coal mine in a manner of low consumption and high efficiency

InactiveCN102168190ASimple processGood effectFlotationProcess efficiency improvementCombustionMass content

The invention discloses a method for enrichment of vanadium from stone coal mines in a manner of low consumption and high efficiency The method comprises the steps of crushing the stone coal mines, grinding before flotation, first selecting coal and de-carboning to pick out carbon concentrate and then pick out vanadium concentrate, wherein grinding fineness of the stone coal mines is -200 meshes, mass content is more than 70% and mass concentration of flotation pulp is 35 to 45%; preparing water gas by a gas generator, with the carbon concentrate being a raw material; supplying heat by the heat generated from combustion of the water gas to the vanadium concentrate for vanadium leaching; and mixing residues from the combustion of the carbon concentrate for preparing the water gas with flotation vanadium concentrate to leach the vanadium. By utilizing the carbon concentrate from the flotation of original mines to generate the water gas for heat supplying, the method has the advantages of environment protection, low energy consumption, high recovery rate, etc.

Owner:CENT SOUTH UNIV

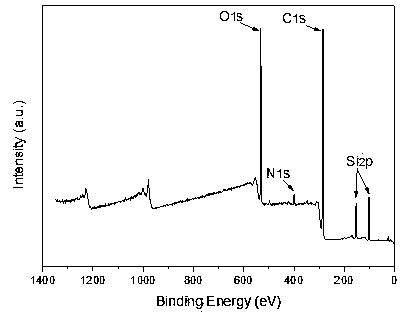

Preparation method for graphene/polyimide composite material

The invention discloses a preparation method of a graphene / polyimide composite material. The preparation method adopts composite materials in percentage by weight and the processes, wherein the composite material comprises the following components in in percentage by weight: 80 to 99.99 percent of polyimide and 20 to 0.01 percent of Si-modified graphene; the preparation method particularly comprises the following steps: (1), preparing graphite oxide; (2), preparing Si-modified graphene: performing ultrasonographic treatment on the obtained graphite oxide powder in an aprotic organic solvent for 0.5 to 2 hours to obtain dispersion liquid with the concentration of 0.5 to 5mg / mL, adding an siloxane modification reagent into the dispersion liquid for reaction for 1 to 24 hours at a temperature of 30 to 180 DEG C, and performing washing and drying to obtain the powder of Si-modified graphene , wherein the mass content of Si is 2 to 13 percent;(3), preparing a precursor of Si-modified graphene / polyimide; (4), preparing the Si-modified graphene / polyimide composite material.

Owner:TIANJIN POLYTECHNIC UNIV

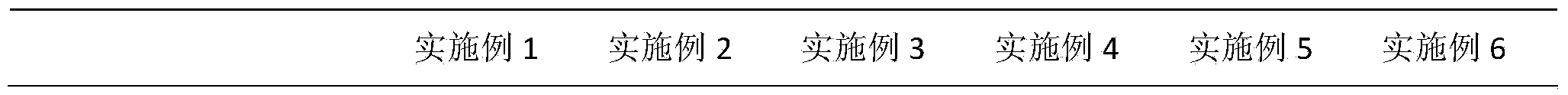

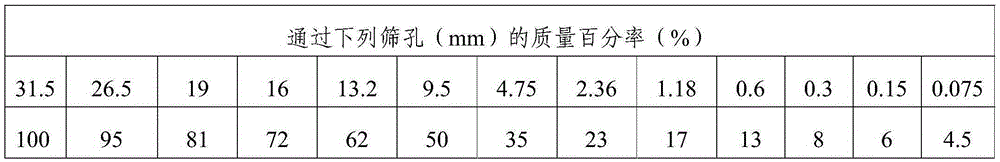

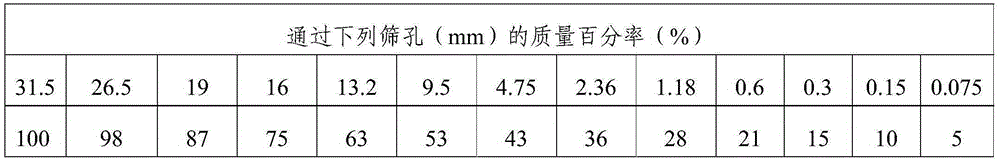

Warm-mixing recycled asphalt mixture preparation method

ActiveCN105293996AEmission reductionImprove road performanceClimate change adaptationMass contentAsphalt

The invention discloses a warm-mixing recycled asphalt mixture preparation method which comprises the following steps: I, preparing a compound regenerant; II, preparing a compound warm-mixing agent; III, measuring the mass content and natural gradation of old asphalt in an RAP material and respectively determining mass ratios of novel aggregate and novel mineral powder which are required for preparing the warm-mixing recycled asphalt mixture to the RAP material; IV, preparing a warm-mixing recycled asphalt mixture sample and determining an optimum asphalt-aggregate ratio of the warm-mixing recycled asphalt mixture; V, under the condition of the optimum asphalt-aggregate ratio, preparing the warm-mixing recycled asphalt mixture. According to the invention, the recycling rate of the RAP material reaches 70% or above, meanwhile, secondary aging of the asphalt mixture is avoided, the advantages of energy saving and carbon emission and harmful gas emission reduction are realized and the warm-mixing recycled asphalt mixture prepared through the preparation method has good pavement performance.

Owner:CHANGAN UNIV

Catalyst for preparing methyl glycolate through dimethyl oxalate hydrogenation and synthetic method of catalyst

ActiveCN103785408AHigh selectivitySimple preparation processOrganic compound preparationCarboxylic acid esters preparationCopperBULK ACTIVE INGREDIENT

The invention discloses a catalyst for preparing methyl glycolate through dimethyl oxalate hydrogenation and a synthetic method of the catalyst, belonging to the technical field of preparation of methyl glycolate catalysts. The catalyst is prepared by taking NaOH as a precipitator, wherein Cu is a main active ingredient of the catalyst, alkaline silica sol serves as a carrier, one or more base metals in Mn, Zr and Zn serve as aids, the mass content of metal copper is 10-40 percent, the content of the other base metal aids is 5-10 percent, and the carrier content is 60-80 percent. According to the catalyst, the preparation method is simple, raw materials are readily available, preparation repeatability is high, high reaction activity is achieved in a methyl glycolate preparation reaction through the dimethyl oxalate hydrogenation, and the catalyst stability and the selectivity of the methyl glycolate are high.

Owner:CHANGZHOU UNIV

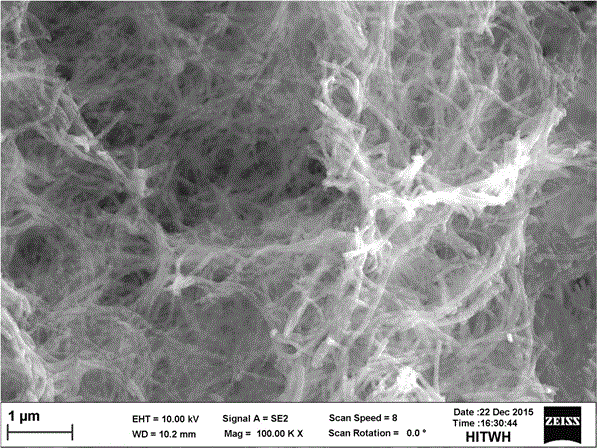

Preparation method of nitrogen and phosphorus doubly-doping porous carbon nanofiber material for air electrode

The invention discloses a preparation method of a nitrogen and phosphorus doubly-doping porous carbon nanofiber material for an air electrode. The preparation method comprises the following steps of adding 2.8ml aniline solution to 50ml phytic acid solution with certain mass content; heating and stirring the mixed solution to generate an aniline-phytic acid salt solution; cooling the aniline-phytic acid salt solution to a certain temperature; weighing and dissolving 1.716g ammonium persulfate in 6ml deionized water; cooling the mixed solution to a certain temperature; rapidly mixing the two solutions; allowing the mixed solution to stand in ice-water bath for a certain time; immersing synthesized hydrogel; carrying out freeze-drying on the hydrogel for 72 hours to generate aerogel; and carbonizing the aerogel at a certain temperature and under the protection of Ar, thereby obtaining the porous carbon nanofiber material.

Owner:HARBIN INST OF TECH AT WEIHAI

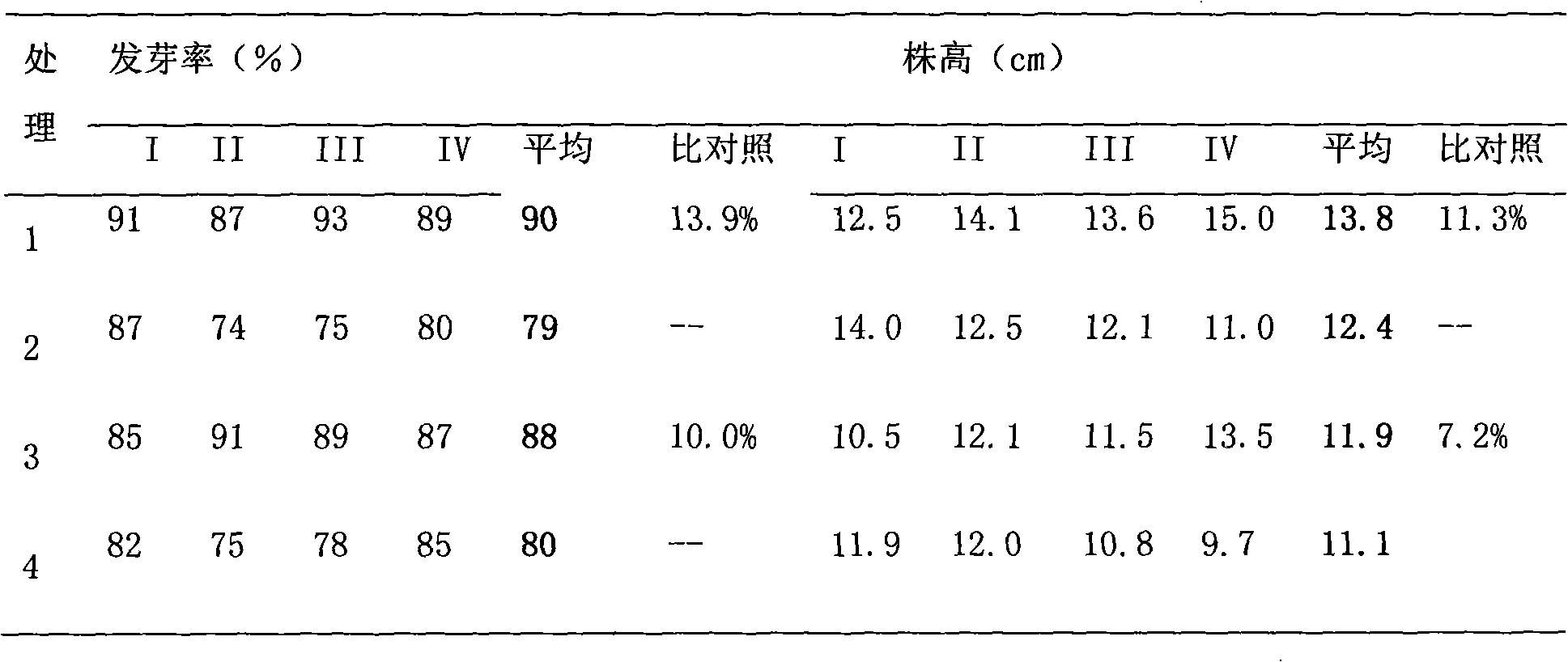

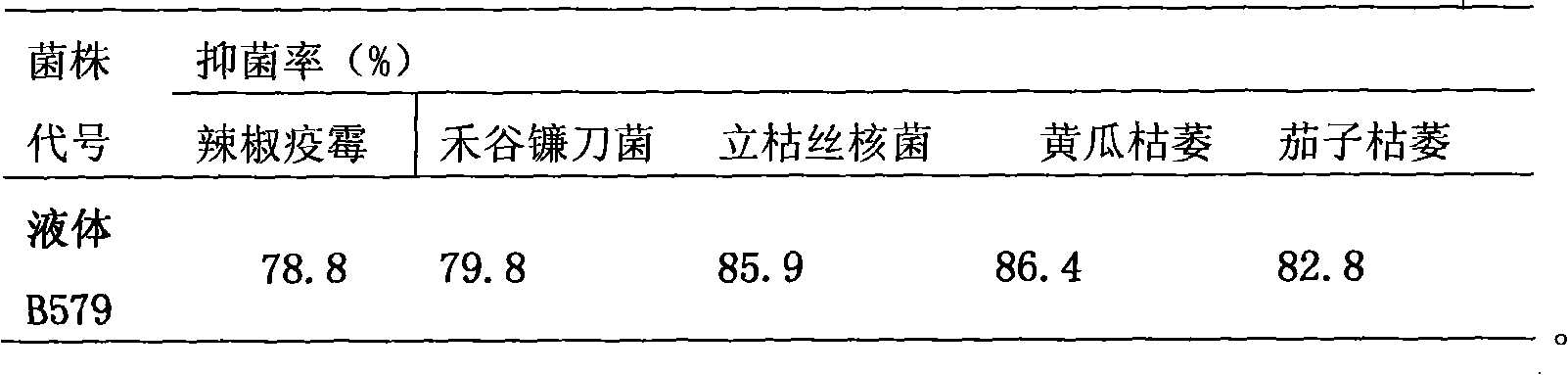

Bacillus subtilis formulation for preventing and controlling soil-borne disease and method of preparing the same

InactiveCN101401587AImprove efficacyImprove practicalityBiocideFungicidesDiseaseEcological environment

The invention relates to a bacillus subtilis preparation for preventing and controlling soil-borne diseases, as well as a preparation method thereof. The bacillus subtilis preparation is prepared by taking the thalli and metabolites of bacillus subtilis B579 with preservation number of CGMCC No.2270 as an effective active constituent which are matched with agriculturally acceptable carrier and a heat-resistant protective agent; the thalli content of the effective active constituent is 8 to 80 billion thalli per gram; and the mass content of the heat-resistant protective agent is 3 to 5 percent. The bacillus subtilis preparation can effectively prevent and control cucumber drooping diseases, cucumber wilt, eggplant root rot, eggplant damping-off, pepper blight, tomato basal stalk rot, grape botrytis cinerea and banana anthracnose. The bacillus subtilis preparation has a control efficiency more than 70 percent, has obvious effect of promoting plant growth, and is characterized in high efficiency, wide antimicrobial spectrum, simple use, low cost, no environmental pollution and improvement on the micro-ecological environment of soil.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

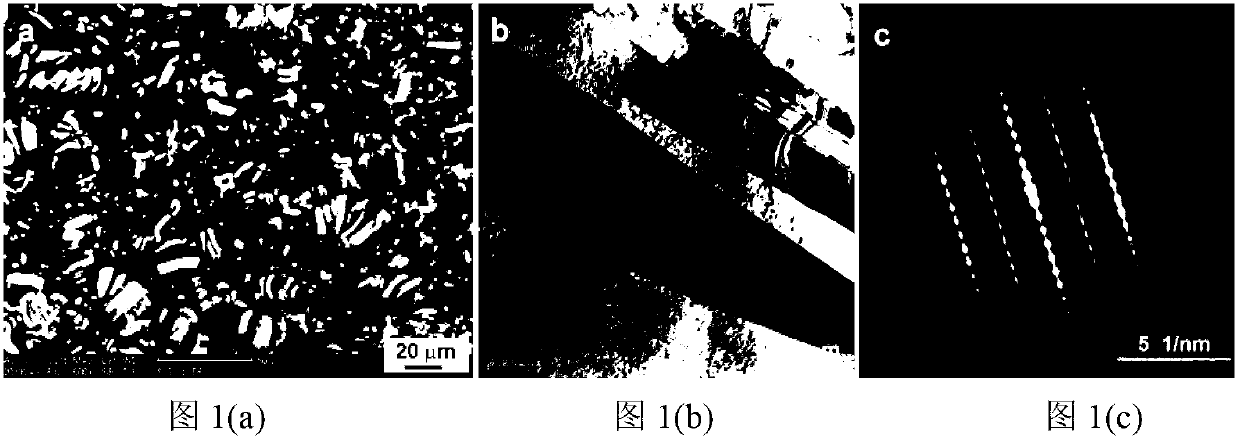

Magnesium-lithium alloy with enhanced long-period structure phase and preparation method thereof

ActiveCN103122431AMeet the requirements of various applicationsHigh strengthAlloy substrateMass content

The invention provides a magnesium-lithium alloy with an enhanced long-period structure phase and a preparation method thereof. The method adopts pure Mg, pure Li, pure Zn and Mg-Y intermediate alloy as raw materials and comprises the following steps of: proportionally putting the raw materials into a vacuum induction melting furnace, filling a protective gas, heating and smelting, and casting the smelted melt into a metal die to obtain an as-cast alloy; performing heat treatment at 490-510 DEG C for 5-10 hours to obtain a casting alloy with an LPSO structure phase through phase transformation; and performing extrusion deformation processing at 260-280 DEG C to obtain a magnesium-lithium alloy which comprises the following components in percentage by mass: 5.5-10% of Li, 4-10% of Y, 1-4% of Zn, less than 0.03% of inevitable impurities Fe, Cu, Ni and Si in total and the balance of Mg, wherein the mass content ratio of Y to Zn is 1-6. According to the invention, by reasonably selecting the alloy elements, the LPSO structure phase is introduced into a magnesium-lithium alloy substrate, and a magnesium-lithium alloy material with low density, high strength, high plasticity and good heat resistance is prepared.

Owner:HARBIN ENG UNIV

Internal olefin sulfonate composition and cleansing composition containing same

Provided is an internal olefin sulfonate composition which is capable of exerting good foamability together with good volume of foam, foaming speed, foam dissipation property, foam quality, foam durability in the presence of sebum, and volume of foam in the presence of sebum at high levels, and a cleansing composition containing the same. The internal olefin sulfonate composition of the present invention comprises (A) an internal olefin sulfonate having 16 carbon atoms and (B) an internal olefin sulfonate having 18 carbon atoms, wherein a mass content ratio (A / B) of component (A) to component (B) is from 75 / 25 to 90 / 10, and wherein a mass ratio (hydroxy form / olefin form) of a content of a hydroxy form in the internal olefin sulfonate of the component (A) and the component (B) to a content of an olefin form in the internal olefin sulfonate of the component (A) and the component (B) is from 75 / 25 to 100 / 0.

Owner:KAO CORP

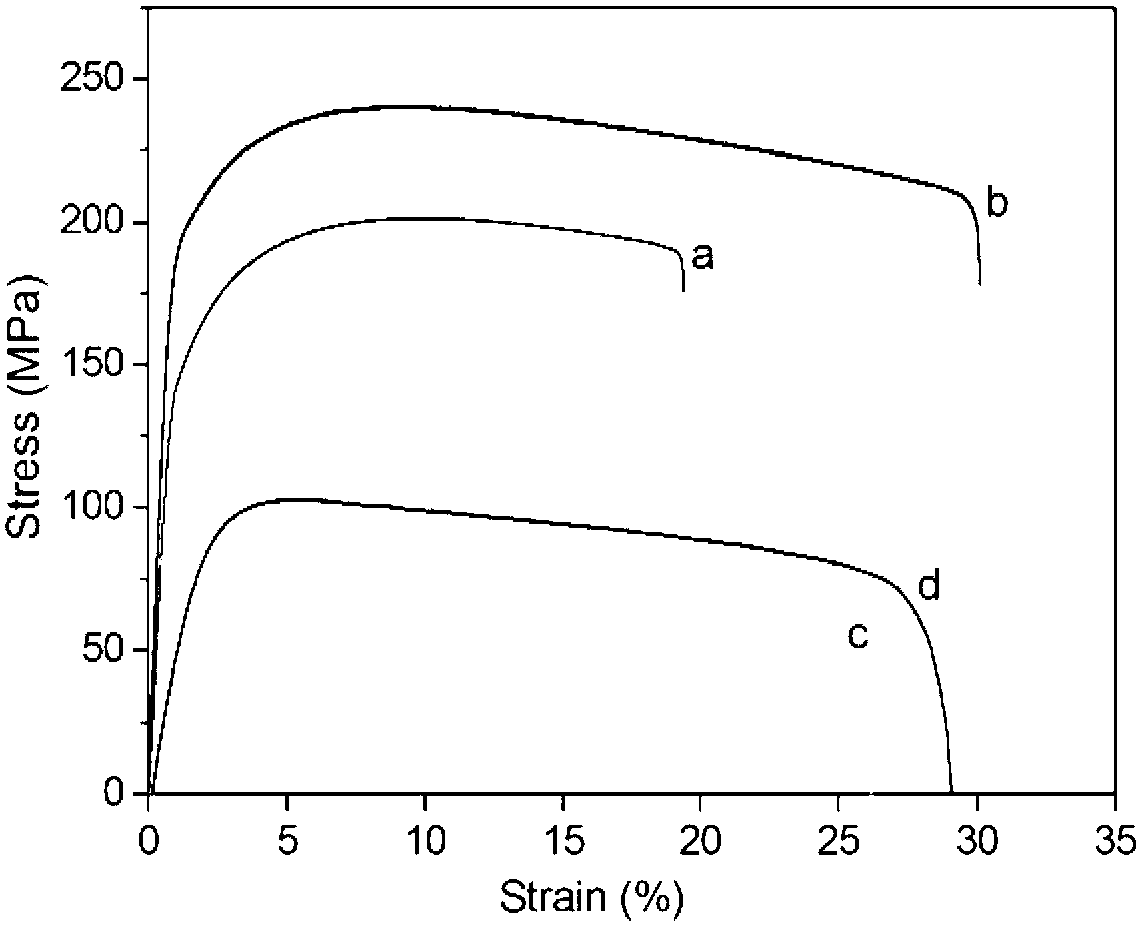

Polypropylene composite and preparation method thereof

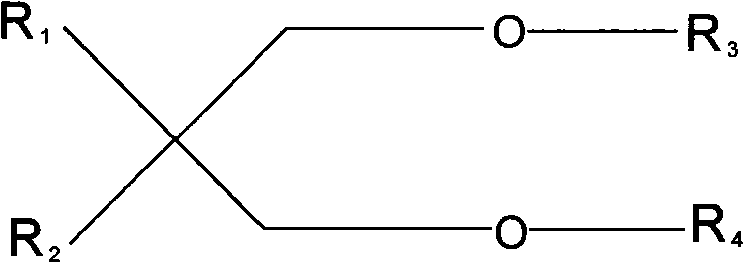

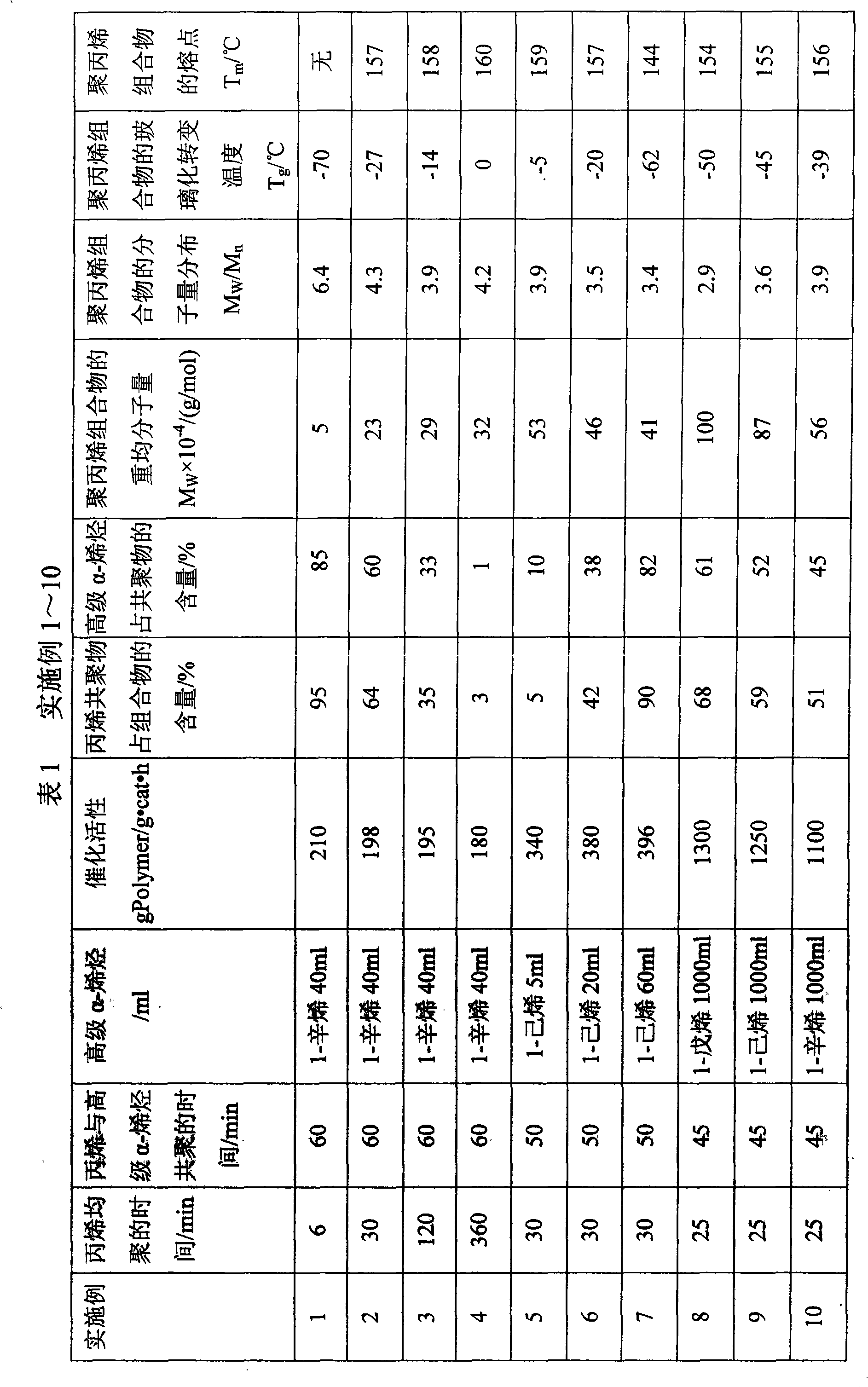

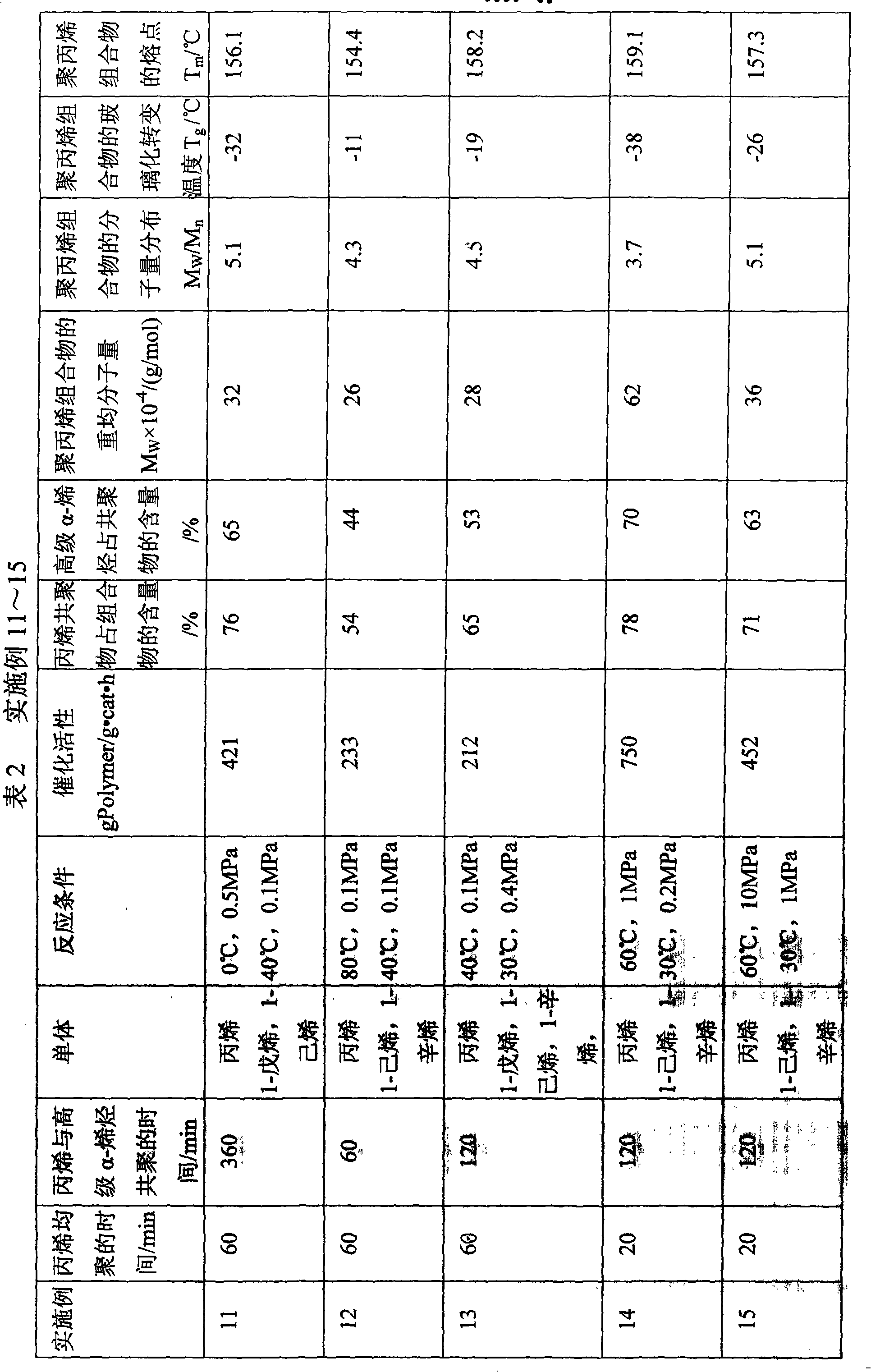

The invention belongs to the polyolefin material field, in particular relates to a preparation method of polypropylene composite and the polypropylene composite obtained by the preparation method. The invention adopts single heterogeneous Ziegler-Natta catalyst to carry out staging polymerization in a kettle, so as to prepare polypropylene composite, and homopolymerization time of propylene and copolymerization time of propylene and high grade alpha-olefin as well as monomer charging ratio are controlled to regulate content of propylene and high grade alpha-olefin copolymer in polypropylene composite, thus obtaining polypropylene composite with adjustable structure and property. The polypropylene composite is composed of propylene homopolymer and propylene copolymer; wherein the propylene copolymer is obtained by propylene and high grade alpha-olefin by copolymerization, the mass content of high grade alpha-olefin in the propylene copolymer is 1-85%, and propylene copolymer accounts for 3-95% of total mass of polypropylene composite.

Owner:INST OF CHEM CHINESE ACAD OF SCI

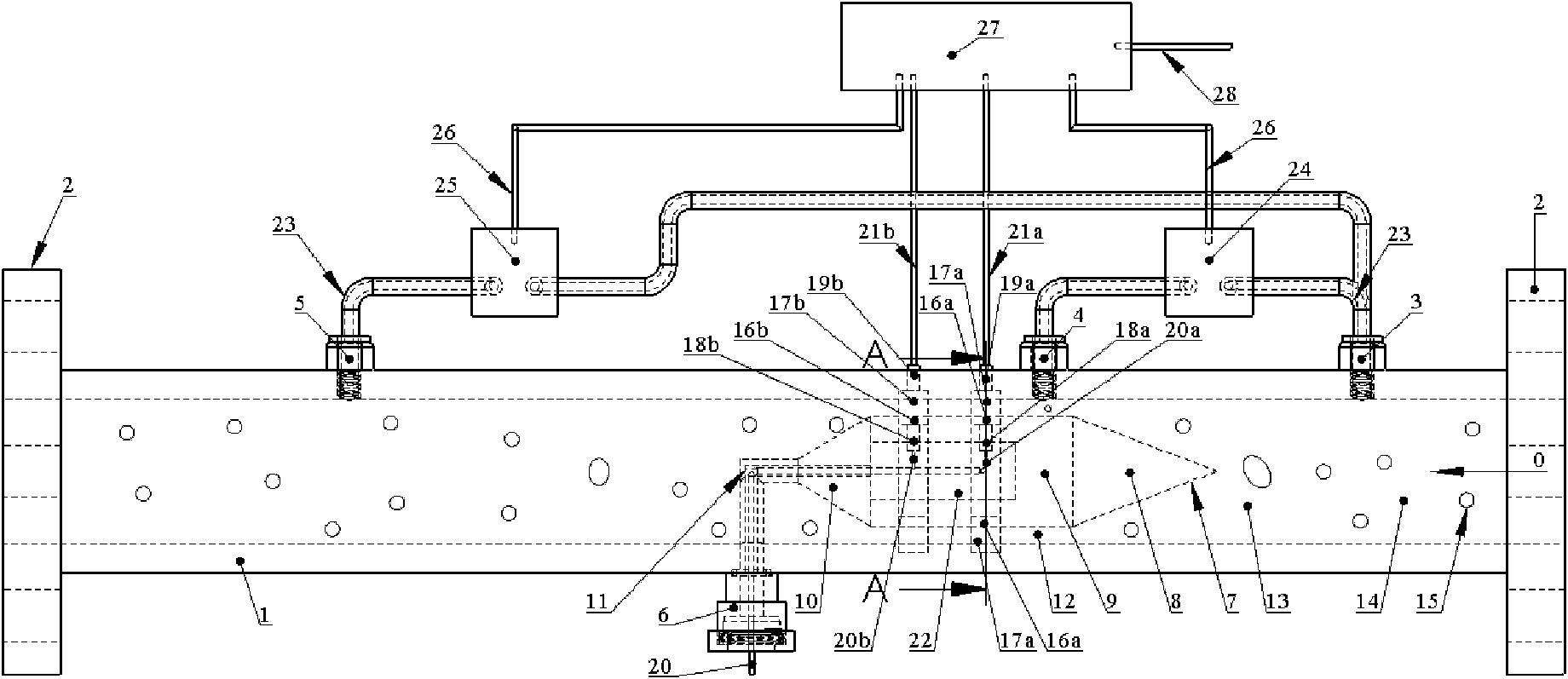

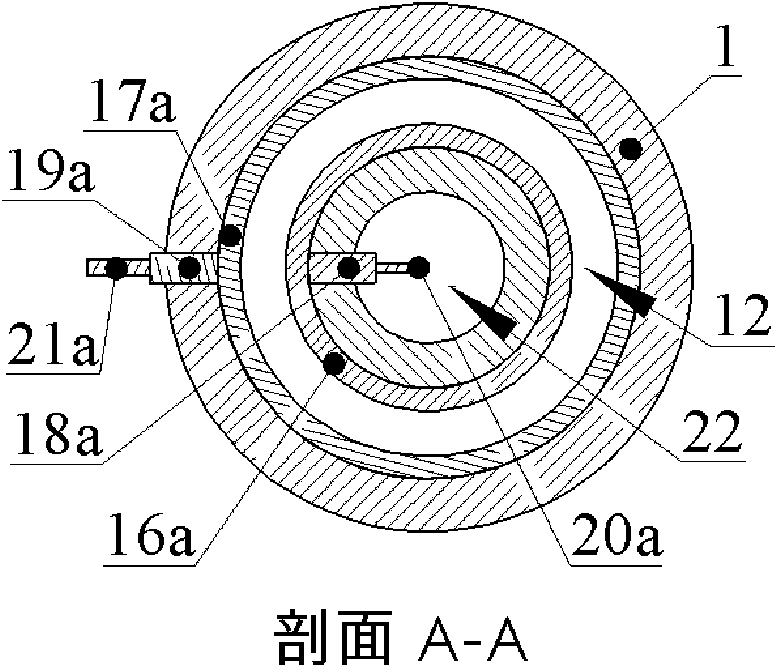

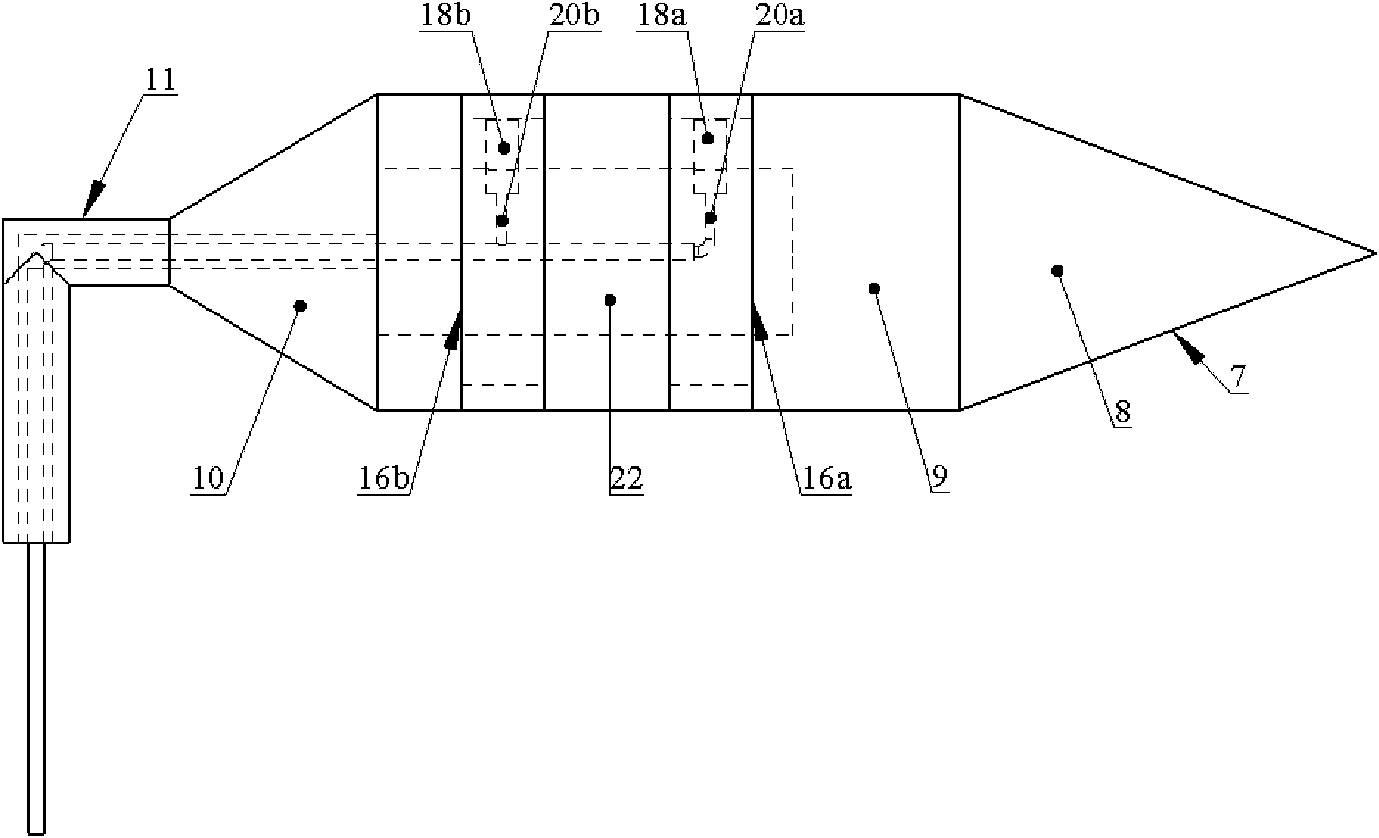

Multiphase flow measurement method based on double-section impedance type long waist cone sensor

InactiveCN102116754AGood repeatabilityHigh precisionResistance/reactance/impedenceFluid speed measurementCapacitanceDifferential pressure

The invention belongs to the fluid measurement technology field and relates to a multiphase flow measurement method based on a double-section impedance type long waist cone sensor. The adopted sensor comprises a cone throttling element, a systolic blood pressure drop differential pressure transmitter, a permanent pressure loss differential pressure transmitter and an electrical sensitive sensor. The method comprises the following steps: collecting two pairs of differential pressure signals generated by the cone throttling element; utilizing the electrical sensitive sensor to collect an electrical signal; calculating the total mass flow rate, the each-phase mass flow rate and the each-phase mass content according to a double-differential pressure model of a single throttling element; utilizing a support vector machine to realize classify, identify and pre-judge a flow pattern according to the measurement data of the differential pressure signals and the electrical signal; adopting a capacitance model to measure a mixed fluid dielectric constant; adopting a conductivity model to measure the mixed fluid conductivity; and calculating the procedure parameter of oil-gas-water three-phase flow. The multiphase flow measurement method is not influenced by the fact that whether a multiphase flow continuous phase is conducted or not, has the characteristics of high measurement precision,high reliability and the like and can obtain more measurement information.

Owner:TIANJIN UNIV

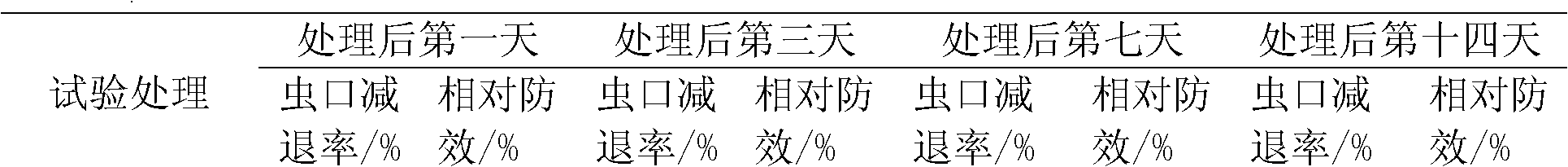

Thrip pest trapping-killing device

The invention relates to a thrip pest trapping-killing device mainly used in the fields of pest trapping. The chemical substance components of thrip insect pheromone are as follows by mass content percent: 0.1-50% of 8-eucalyptol, 0.5-20% of anise aldehyde, 20-50% of hexenal, 1-15% of eugenol, 4-25% of hexenol, 0.1-40% of phenethyl alcohol, 0.01-5% of carvone, 0.1-10% of linalool and 0.1-60% of methyl isonicotinate. The mixture prepared by the above components is dissolved in n-hexane or dichloromethane dichloromethane dissolvent which is then added on a rubber carrier; and after the dissolvent volatilizes completely, a thrip insect pheromone bait is prepared. The thrip insect pheromone bait is placed on a pest trapping plate which is made from sticky insect glue and substrates. The thrippest trapping-killing device is mainly used for preventing and controlling thrips and has the advantages of being convenient to use, excellent in trapping effect, long in duration time, safe, environment-friendly, free from pollution and the like.

Owner:北京依科曼生物技术股份有限公司

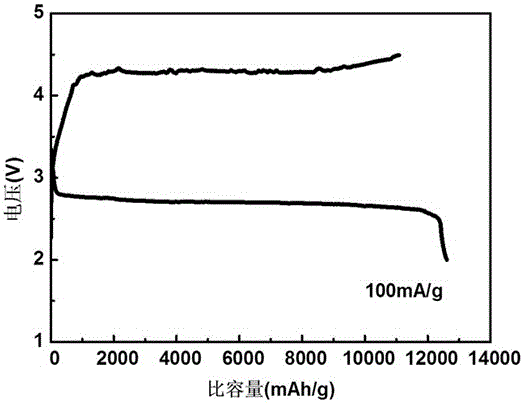

Carbon/sulfur composite positive material having long cycle life, and preparation method thereof

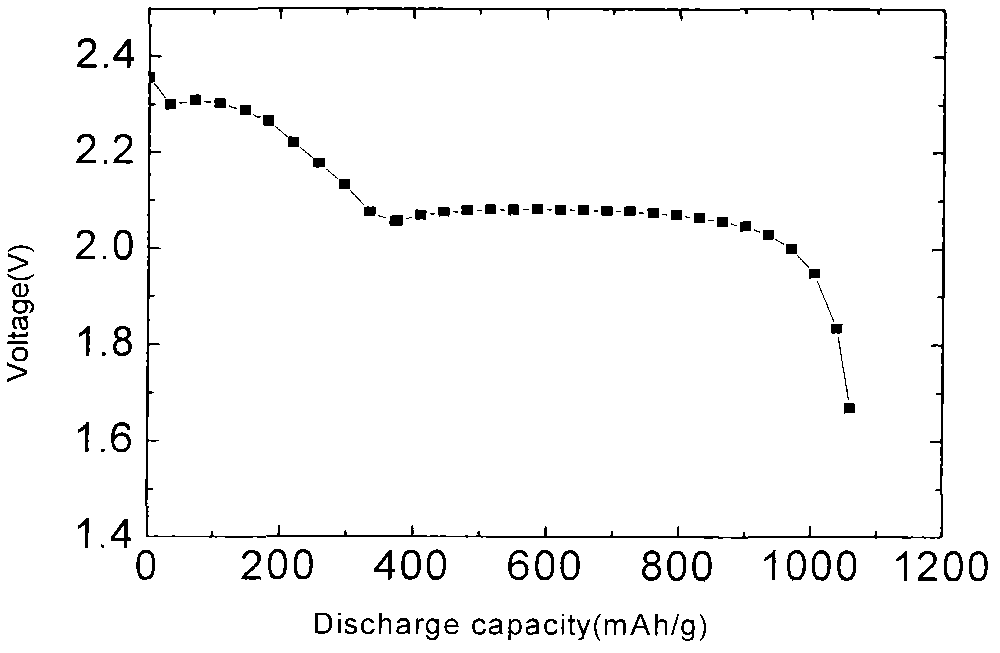

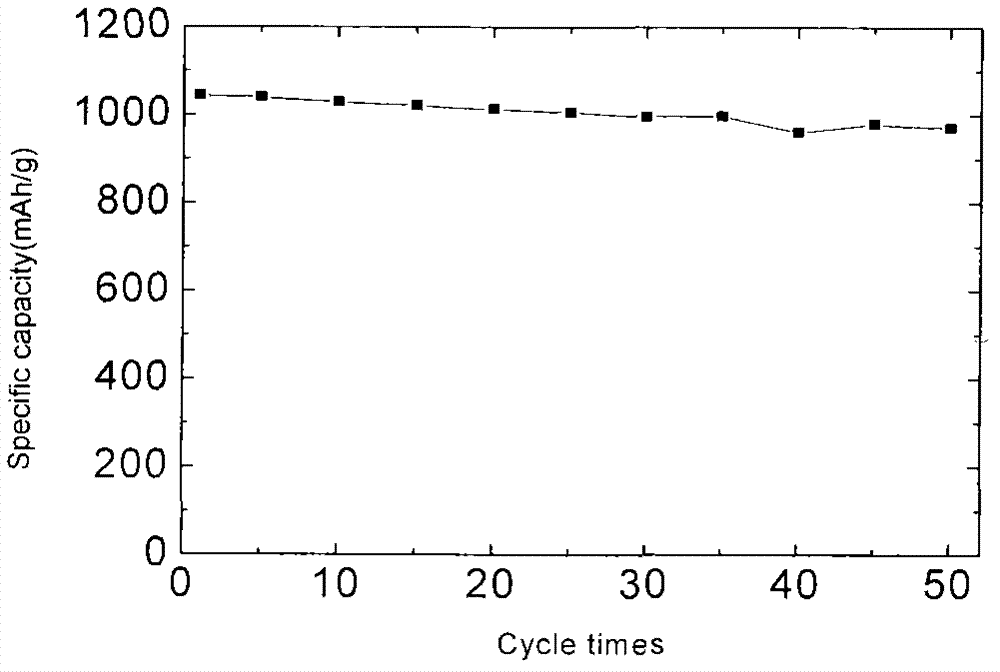

InactiveCN103247799ARich cross-linked network structureSimple structureCell electrodesCarbon fibersSulfur

A grafted carbon nanofiber / sulfur composite material having a high specific capacity and a long cycle life and applied in a lithium sulfur battery is obtained through carrying out melt compounding of grafted carbon nanofibers having an outstanding conductive performance and a network structure and elemental sulfur at a reaction temperature of 110-380DEG C for 2-60h, and the mass content of sulfur in the composite material is 40-85%. The initial discharge specific capacity of the composite positive electrode material is 1186mAh / g, and the discharge specific capacity of the composite positive electrode material after 50-time cycle still maintains 948mAh / g, so the composite positive electrode material has a good cycle stability.

Owner:NO 63971 TROOPS PLA

Method for adsorbing and purifying oil tea polyphenols by adopting macroporous resin

InactiveCN103393845AHigh purityHigh quality contentCosmetic preparationsToilet preparationsOrganic solventDesorption

The invention discloses a method for adsorbing and purifying oil tea polyphenols by adopting macroporous resin, belonging to the technical field of purification and separation of the oil tea polyphenols. The method comprises the following processes of: taking oil tea seeds and oil tea fruit shells after deoiling as raw materials for extracting the oil tea polyphenols, drying, then crushing, adopting an organic solvent for extracting to obtain a crude extract of the oil tea polyphenols, dissolving the crude extract of the oil tea polyphenols in water to prepare a water solution of the crude extract of the oil tea polyphenols, performing macroporous resin adsorption and desorption on the water solution of the crude extract of the oil tea polyphenols, and then performing rotary evaporation on a desorption solution to obtain a product of the oil tea polyphenols. According to the method disclosed by the invention, the oil tea polyphenols are obtained by adopting the macroporous resin to perform separation and purification, the processes are relatively simple, the using amount of the solvent is small, the obtained oil tea polyphenols have high purity, and the mass content can be as high as above 78%.

Owner:TIANJIN UNIV

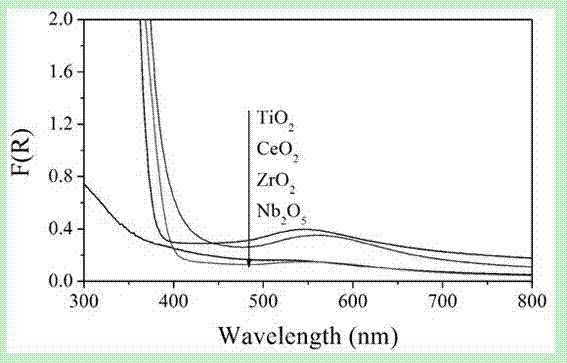

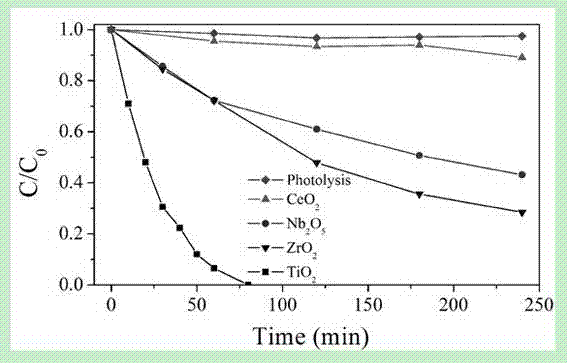

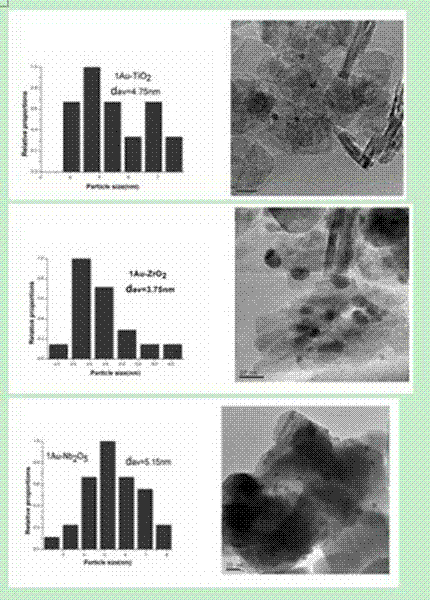

Preparation method of visible light catalyst with surface plasmon effect and application thereof

InactiveCN102350346AEfficient depositionControllable sizeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActive componentNanoparticle

The invention relates to a preparation method of a visible light catalyst with a surface plasmon effect and application thereof. The active component of the visible light catalyst is a precious metal Au, and the carrier is one of TiO2, CeO2, Nb2O5, SiO2, Ta2O5, Al2O3 and ZrO2, wherein, Au accounts for 0.2-5% in mass content, and the particle size of Au particle is 2-20nm. Preparation of the catalyst consists of two steps: the first step is to prepare a carrier; the second step is to prepare an Au / TiO2 (CeO2, SiO2, Al2O3, Nb2O5, Ta2O5, ZrO2) visible light catalyst with a plasmon effect througha sol precipitation method. Au nanoparticles prepared by the method of the invention have good dispersibility, easily controllable size, high active component utilization rate, as well as the effect of high efficiency photocatalytic degradation of organic pollutants by visible light.

Owner:FUZHOU UNIV

Low sugar high dietary fiber composite fruit and vegetable paste and preparation method thereof

InactiveCN102919813ARich in nutrientsMeet the requirements of a high dietary fiber dietFood preparationFiberMass content

The invention belongs to the technical field of food deep processing and particularly relates to a low sugar high dietary fiber composite fruit and vegetable paste and a preparation method thereof. Fruits and vegetables subjected to sugaring, acidity regulators, thickening agents, coloring matters and essence are subjected to scalding treatment, pulping, blending, concentrating, homogenizing, canning and sterilization to form the composite fruit and vegetable paste, the mass content of soluble solids is in a range from 26% to 31%, and the mass content of total sugar is in a range from 35.23% to 39.53%. According to the low sugar high dietary fiber composite fruit and vegetable paste and the preparation method thereof, the fruits and vegetables subjected to sugaring are used as main raw materials, the use ratio of the raw materials is improved, the production costs are lowered, types of jams are enriched, the preparation method is simple, the operation is simple, convenient and easy to control, the prepared composite fruit and vegetable paste has comprehensive nutritions, low sugar and high dietary fiber, health care and edible effects are integrated, the effect of balancing human nutrition can be achieved, simultaneously the taste is good, the low sugar high dietary fiber composite fruit and vegetable paste has low price and fine quality, the process is simple, the cost is low, the environment is not polluted, and the industrialized production is facilitated.

Owner:JILIN AGRICULTURAL UNIV

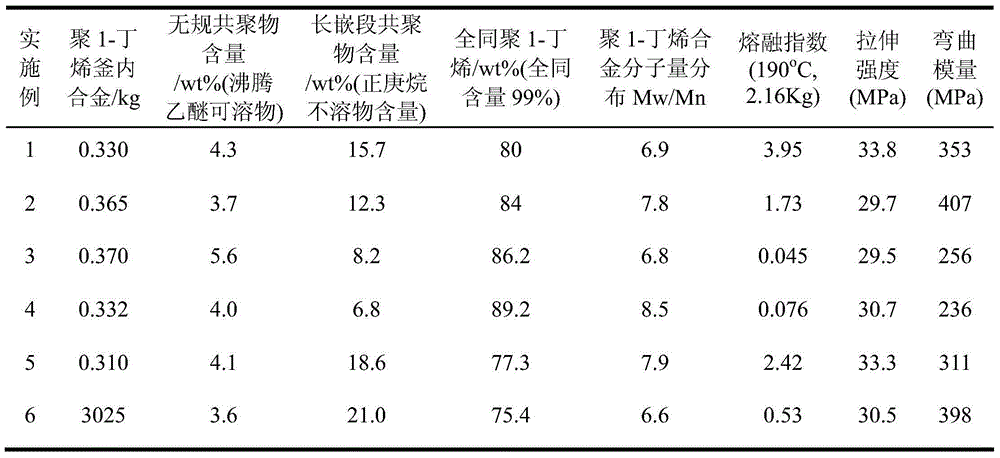

Poly 1-butene/1-butylene-propylene copolymer in-reactor alloy and preparation method thereof

ActiveCN103951898AImprove crystal transformation rateStrong impact resistancePolymer sciencePolyolefin

The invention discloses a poly 1-butene / 1-butylene-propylene copolymer in-reactor alloy material and a preparation method thereof, belongs to the field of polyolefin material, and relates to poly 1-butene in-reactor alloy, and a preparation method and applications thereof. According to the poly 1-butene / 1-butylene-propylene copolymer in-reactor alloy material, a poly 1-butene homopolymer is taken as a main ingredient, and the poly 1-butene / 1-butylene-propylene copolymer in-reactor alloy material comprises a small amount of a 1-butylene / propylene copolymer, wherein molar content of propylene monomer unit ranges from 2 to 25%, molar content of 1-butene monomer unit range from 75 to 98%, mass content of poly 1-butene ranges from 65 to 89%, and mass content of the 1-butylene / propylene copolymer ranges from 35 to 11%. The poly 1-butene / 1-butylene-propylene copolymer in-reactor alloy material is prepared by adopting a high-efficient loaded Ti catalytic system and via two-stage bulk in-suit polymerization. The polybutene alloy material possesses excellent shock resistance and thermal creep resistance, and low shrinking rate of the poly 1-butene homopolymer; is capable of increasing crystal transfer rate of poly 1-butene, and shortening shaping and curing time at the same time; and can be used for replacing a part of polyethylene and polypropylene for preparation of tubular products or for toughening modification of polypropylene.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com