Preparation method for graphene/polyimide composite material

A polyimide and composite material technology, which is applied in the field of graphene/polyimide composite material preparation, can solve the problem that the comprehensive performance of graphene and polyimide composite materials cannot be effectively improved, and the comprehensive performance of composite materials cannot be achieved. Ideal value, poor adhesion between graphene and polyimide matrix, etc., to achieve the effects of easy industrialization, improved stress transfer effect, and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] (1) Preparation of graphite oxide

[0030] Using natural flake graphite as raw material, graphite oxide was prepared by improved Hummer method. The improved Hummer method for preparing graphite oxide is prior art;

[0031] (2) Preparation of Si-modified graphene

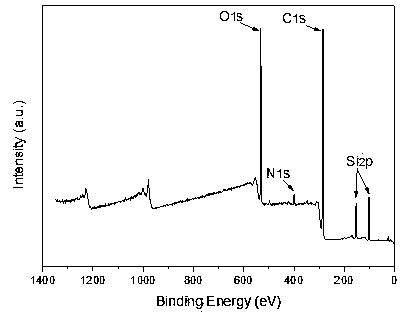

[0032] Ultrasonic the graphite oxide powder prepared in step (1) in an aprotic organic solvent for 0.5 to 2 hours to obtain a 0.5 to 5 mg / mL graphene oxide dispersion; React at 180°C for 1-24 hours; after washing and drying, Si-modified graphene black powder can be obtained; Si-modified graphene obtained through elemental analysis and X-ray photoelectron spectroscopy analysis, wherein the mass content of Si is 2-13 %.

[0033] (3) Preparation of Si-modified graphene / polyimide precursor

[0034] Mixing Si-modified graphene, dianhydride and diamine in the aprotic polar solvent, under the protection of nitrogen, at -10-30°C, in-situ polymerization reaction for 1-36 hours to obtain Si-modified graphene / Polyami...

Embodiment 1

[0047] Step (1) preparation of graphene oxide:

[0048] Using 325 mesh natural flake graphite as raw material, graphite oxide powder was prepared by improved Hummer method.

[0049] Step (2) Preparation of Si-modified graphene:

[0050] Weigh a certain amount of graphite oxide powder prepared in step (1), ultrasonically treat it for 1 hour, and disperse it in N-methylpyrrolidone solvent; add modifier 3-aminopropyltrimethoxysilane in proportion, and the reaction temperature is 50°C, the reaction time is 20 hours, wherein the mass ratio of graphene oxide and siloxane modifier 3‐aminopropyltriethoxysilane is 1:3; after the reaction, the reaction product is washed repeatedly with anhydrous methanol , the black target product was obtained after filtration, and dried in a vacuum oven at 80°C for 24 hours to obtain Si-modified graphene. The thickness of the obtained Si-modified graphene is 0.9 nm, and the particle size is 5-20 μm, detected by the atomic force microscope.

[0051] ...

Embodiment 2

[0057] The difference between this embodiment and Example 1 is that the mass ratio of graphene oxide and siloxane modifier 3-aminopropyltriethoxysilane in step (2) is 1:5, and the others are the same as in Example 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com