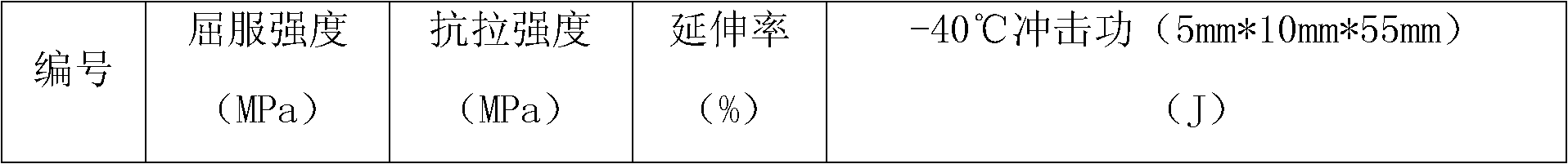

Patents

Literature

1209results about How to "Ease of industrial implementation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

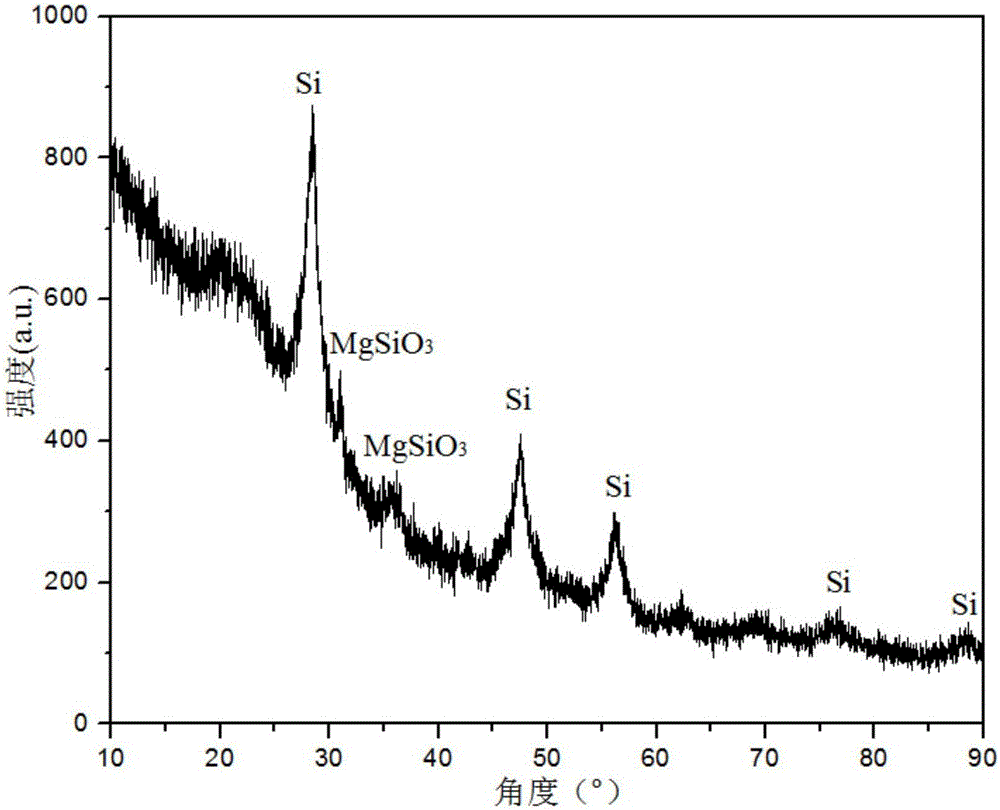

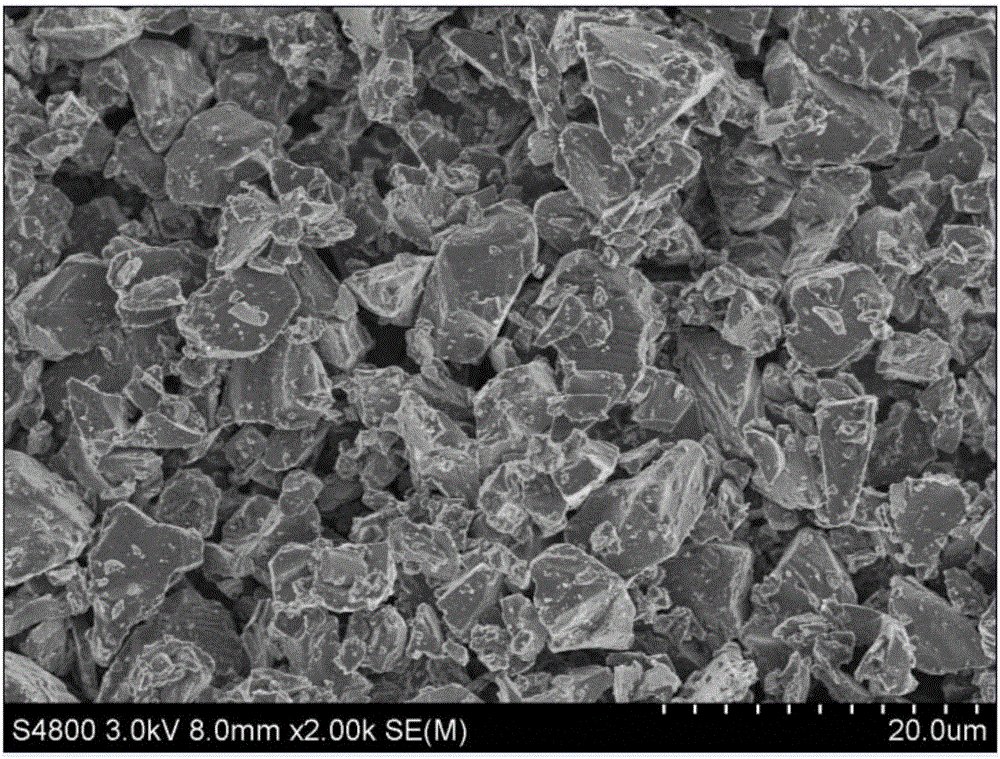

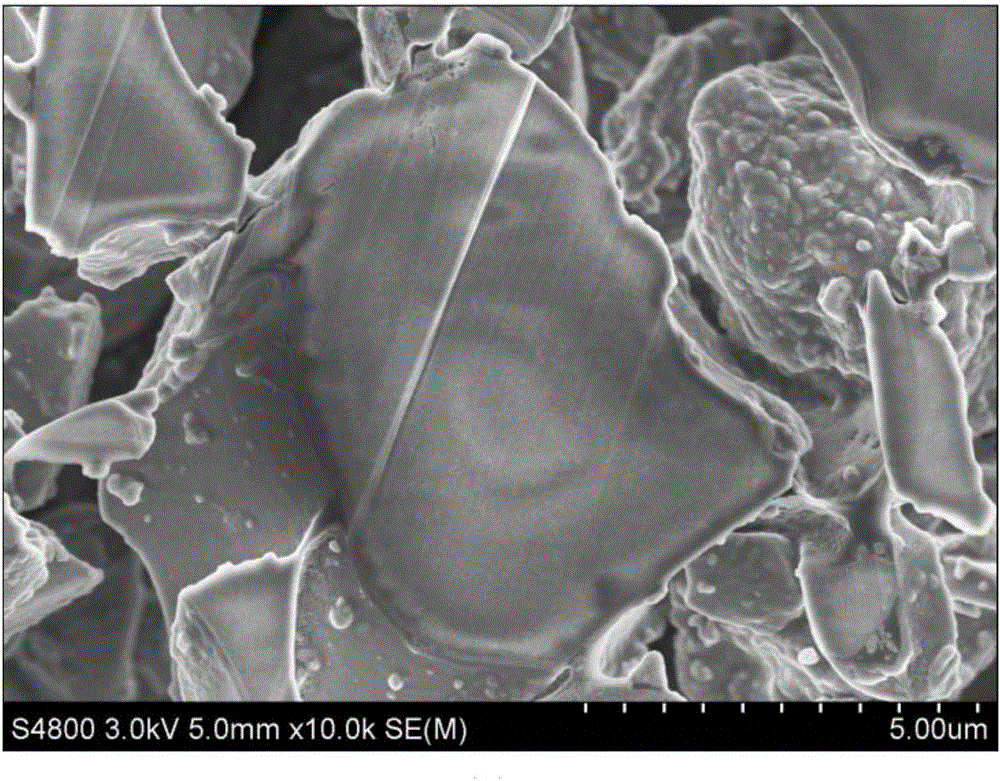

Compound and preparation method thereof as well as negative electrode prepared by adopting compound and lithium ion battery

ActiveCN106356508AImprove consistencyImprove dispersion uniformityCell electrodesSecondary cellsElectrical batterySilicon oxygen

The invention relates to a compound and a preparation method thereof as well as a negative electrode prepared by adopting the compound and a lithium ion battery. The compound comprises silicon, silicon oxide SiOx (x is greater than 0 and is less than or equal to 2) and silicate, wherein positive ion elements of the silicate are reductant elements, and Si, O and the reductant elements in the compound are uniformly distributed. Reductants used in the compound are heated and insulated in the environment of negative pressure, so that SiO steam reacts with reductant steam in the form of a gas phase so as to condense to obtain the compound, and then the compound is further used as a raw material so as to prepare a modified silica negative electrode material. The negative electrode material is suitable for the lithium ion battery, the prepared lithium ion battery has high charge and discharge specific capacity and excellent first coulombic efficiency, the charge capacity is 1447 mAh / g or above, the discharge capacity is 1213 mAh / g or above, and the first coulombic efficiency is 83.8% or above.

Owner:BTR NEW MATERIAL GRP CO LTD

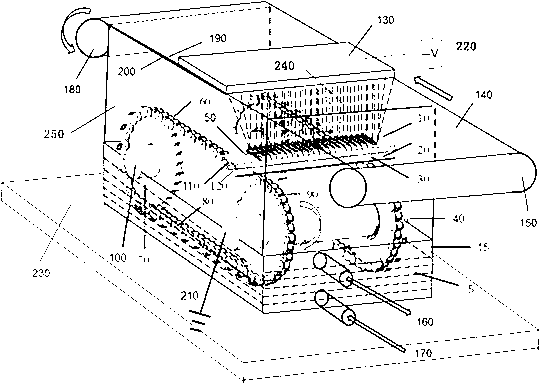

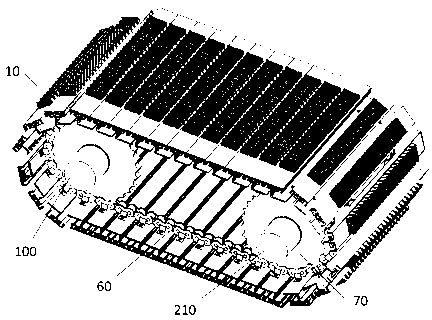

Tip-end type needle-free electrostatic spinning equipment

ActiveCN103255485AImprove uniformityTake advantage ofFilament/thread formingSpinningHigh-voltage direct current

The invention discloses tip-end type needle-free electrostatic spinning equipment which comprises a spinning solution storage box, base cloth, a spinning device and a negative-high-voltage direct-current power source, wherein the spinning device comprises a spinning box body, a needle plate, a chain, a negative electrode and a connecting device. The spinning box body is fixedly connected at the top end of the spinning solution storage box, and the chain is connected on the inner wall of the spinning box body. The connecting device is connected with a transmission device to achieve rotation of the chain, a lowermost link of the chain is submerged in spinning solution of the spinning solution storage box, and the needle plate is fixedly connected on the chain. The base cloth covers the top end of the spinning box body. The spinning solution storage box, the spinning box body and the base cloth form an enclosed spinning space. The negative electrode is attached to the top surface of the base cloth. The spinning device is earthed, the negative electrode is connected with the negative-high-voltage direct-current power source, and a high-voltage electrostatic field is formed between the negative electrode and metal card clothing. The tip-end type needle-free electrostatic spinning equipment can improve the yield and the uniformity of nanofiber products, the fineness of nanofiber manufactured through the tip-end type needle-free electrostatic spinning equipment is small, and the variation of the fineness is less.

Owner:JIANGSU FILTERTEX FILTER MATERIAL +1

Oil absorbing fibre and perparing method thereof

InactiveCN1584148ABroaden the fieldLarger specific surface area for oil absorptionWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberBenzoyl peroxide

The invention relates to a kind of oil-absorbed fiber and its producing method. Its prescription is: 100% polymer monomer, 10-40% of potential gemel agent, 0.1-0.5% solicitation, 0.5-1% dispersant. Moreover the water-like body is 3-4 times more in volume than polymer monomer. The polymer monomer is methacrylate monomer involving butyl methacrylate, the potential gemel agent is 2-hydroxyethyl methacrylate, the solicitation is benzoyl peroxide, and dispersant is poly-vinyl-alcohol. The process is (1) use water-suspending polymerization to produce butyl methacrylate under 70-80 deg.C for blending and polymerizing for 8-10 hours. (2) dissolve the polymer into proper solvent to deploy 20-25% liquid and then insert potential gemal agent and solicitation to polymerize for 3-5 hours under 75-80 deg.C to obtain the original liquid. (3) take off dunking. (4) spin using one of wet or dry method or both, (5) treat with fibre for 10-60 minutes under 120-165 deg.C to obtain the production. The solvent discussed above is one of DMF, DMAC or dimethoxysulfoxide.

Owner:TIANJIN POLYTECHNIC UNIV

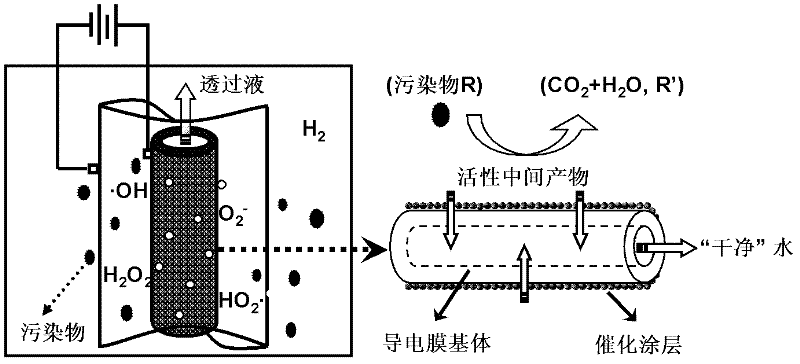

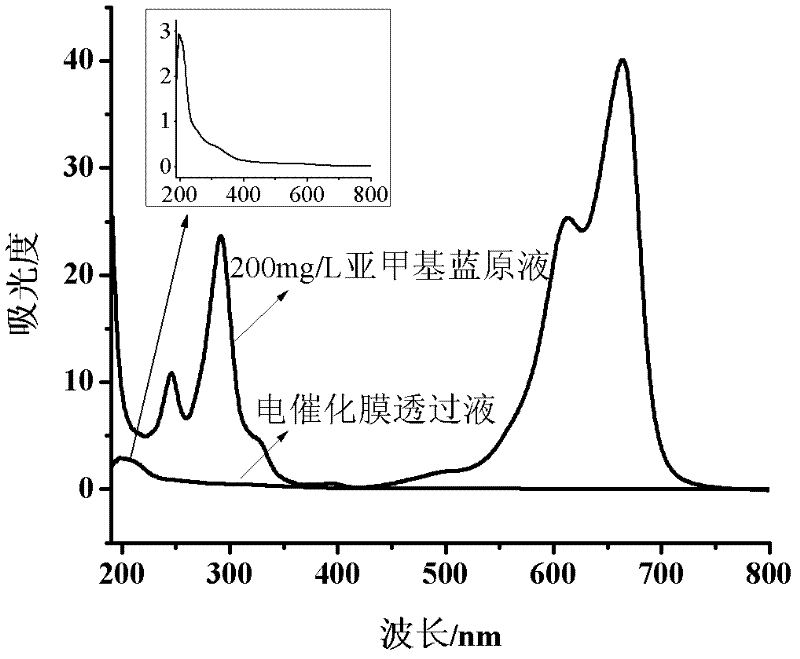

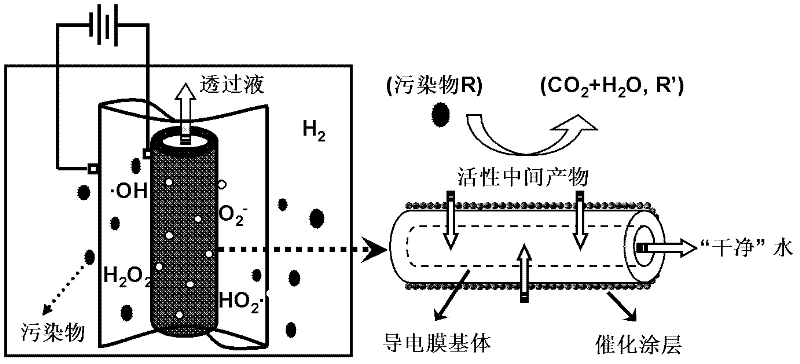

Nano loaded titanium-based electric catalytic film and preparation method thereof

InactiveCN102350228AImprove degradation efficiencyHigh electrode strengthSemi-permeable membranesDispersed particle separationAcid etchingCatalytic oxidation

The invention discloses a nano loaded titanium-based electric catalytic film comprising a conductive microporous separating titanium film matrix and a catalytic coating. Furthermore, the invention also discloses a preparation method of the nano loaded titanium-based electric catalytic film, which comprises the following steps of: (1) preprocessing the titanium film matrix by sand blasting, alkali washing, and acid etching: soaking the matrix after sand blasting in an NaOH solution for 0.5 to 2h, then processing for 1 to 2h in an oxalic acid solution with the mass percent concentration of 10 percent after washing to a neutral state, washing with water and drying at 100 to 120 DEG C; and (2) preparing and loading a catalytic coating: preparing the catalytic coating by adopting a sol-gel method, a thermal decomposition method, an electrodeposition method or a chemical vapor deposition method and loading at the surface of the titanium film matrix and in a hole. Furthermore, the invention also discloses a film reactor comprising the nano loaded titanium-based electric catalytic film. According to the nano loaded titanium-based electric catalytic film, the defects on material strength, range limitation of working voltage, catalytic oxidation efficacy and the like in the prior art are solved.

Owner:SHANGHAI CAS ADVANCED RES INST

Flame-retarding polymer foam material and preparation method thereof

ActiveCN102127269AIncrease the amount addedAddition changeLaminationLamination apparatusPolymer sciencePolystyrene

The invention discloses a flame-retarding polymer foam material which is characterized by comprising polymer foam plastic, wherein the surface of the polymer foam plastic is provided with an organic flame retardant layer; and the organic flame retardant layer is formed by attaching a molten organic flame retardant to the surface of the polymer foam plastic through a spraying, coating or soaking way. The invention also discloses a preparation method of the flame-retarding polymer foam material. In the invention, a flame-retarding variety which is effective to the polymer foam plastic, in particular to extrusion foamed polystyrene foam plastic, is selected from numerous flame retardants, and the polymer foam product with excellent flame-retarding property is prepared by adopting a simple and feasible method. Through the invention, an effective method for increasing the addition amount of the flame retardant is obtained on the premise of not influencing the foaming property of the foam products and not reducing the strength and the insulation and thermal preservation property of foams, and different flame-retarding requirements can be met by flexibly changing the attaching amount of the flame retardant.

Owner:连云港传奇阻燃科技有限公司

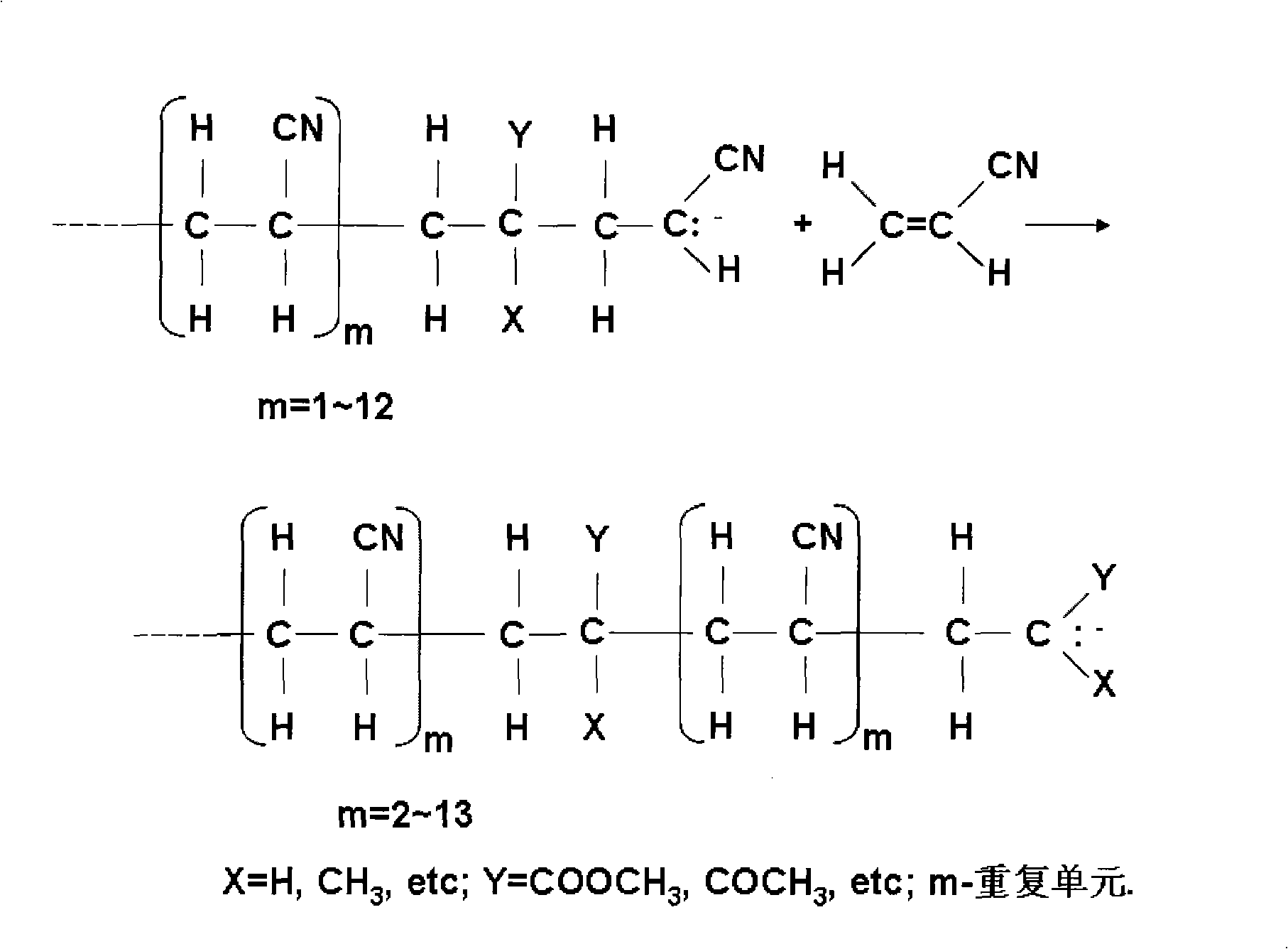

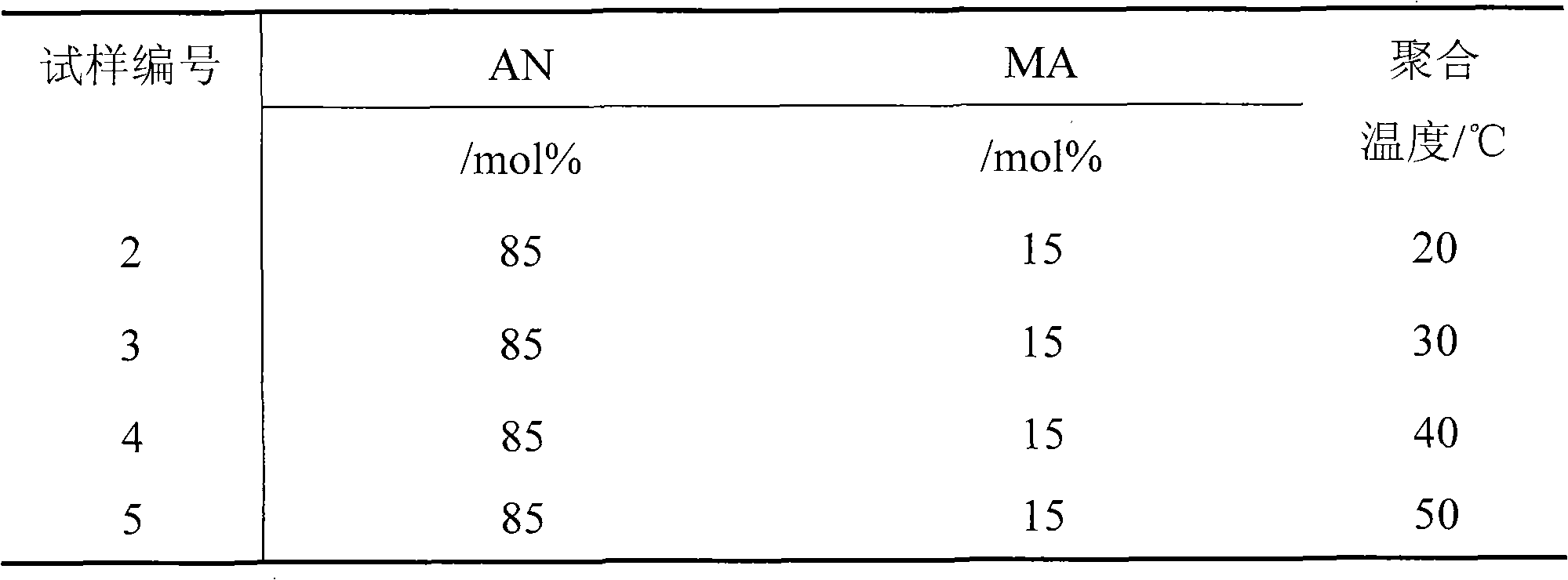

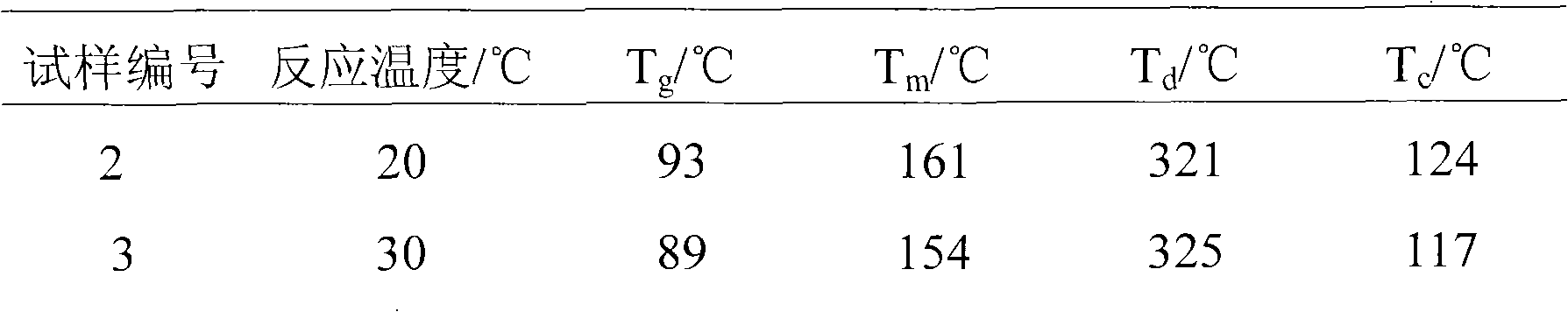

Acrylonitrile copolymer, preparation and use thereof

InactiveCN101323656AReduce pollutionLow costMonocomponent synthetic polymer artificial filamentMelt spinning methodsPolymer scienceNitrogen

The invention relates to an acrylonitrile copolymer and a preparation method and an application thereof, wherein, the mole ratio of an acrylonitrile on a molecular chain of the acrylonitrile copolymer to a second monomeric unit is 2:1 to 19:1; the formula of the acrylonitrile copolymer is that: 70.0 mol percent to 90.0 mol percent of the acrylonitrile monomer, 10.0 mol percent to 30.0 mol percent of the second monomeric unit, an evocating agent and a chain-transferring control agent respectively taking up 0.1 mol percent to 16.2mol percent and 0.05 mol percent to 5.0mol percent of the total quantity of monomers. The preparation method adopts the formula of the acrylonitrile copolymer and the following technique: a proper amount of deionized water is put in a reaction vessel and cleaned with nitrogen for 5 minutes to 400 minutes at a temperature of 0 DEG C to 70 DEG C; the evocating agent and the chain-transferring control agent are added in one time; the acrylonitrile monomer and the second monomer are put into a blending container, evenly blended and the dropped slowly into the reaction vessel; and then all reactants continue to be stirred for 20minutes to 40 minutes and the product is obtained after being filtered, cleaned with the deionized water for three times and dried in vacuum. The acrylonitrile copolymer of the invention can be produced into acrylic fiber or film with good performance through a fusion processing method.

Owner:TIANJIN POLYTECHNIC UNIV

Powder embedding calorizing agent and embedding caloriation method

InactiveCN1425796AEasily control aluminum contentSimple processSolid state diffusion coatingIron powderAluminium powder

The present invention relates to powder embedding calorizing agent and embedding calorization process. The powder embedding calorizing agent is composite comprising aluminium powder 2-10 wt%, iron powder 5-10 wt%, ammonium chloride 0.5-2.5 wt% and alumina 82-86 wt%. The embedding caloriation process includes the following steps: setting well mixed calorizing agent and iron or steel part to be calorized inside sealed tank, heating to 650-1100 deg.c and maintaining for 2-8 hr. measurement results shows that the treated surface is mainly FeAl phase and Fe3Al phase with aluminium content of 23-50at%. The present invention can result in high calorization quality, and can control the aluminum content on the surface of calorized layer.

Owner:EAST CHINA UNIV OF SCI & TECH

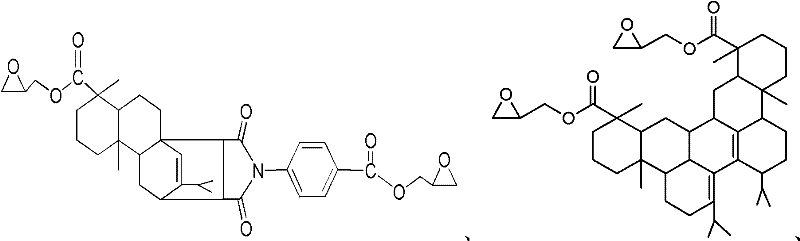

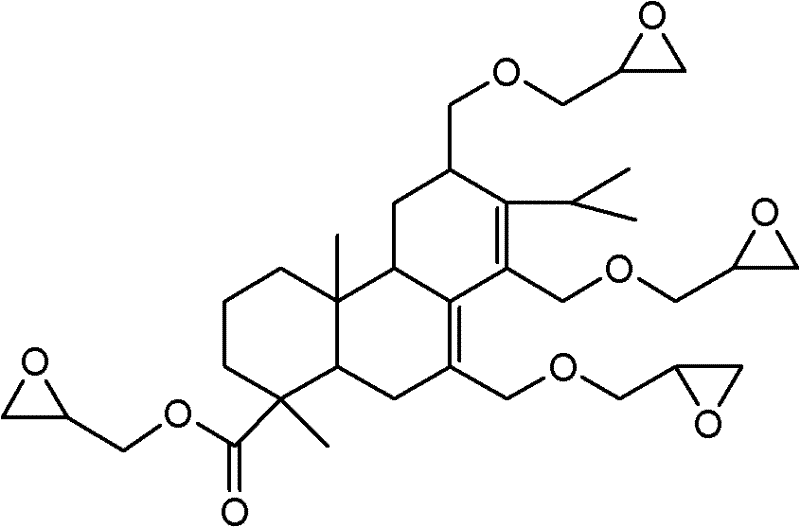

Full-biobased epoxy resin composition and condensate

ActiveCN102206324AGood environmental benefitsImprove flexibilityPlastic/resin/waxes insulatorsEpoxy resin adhesivesAging resistanceResin coating

The invention discloses a full-biobased epoxy resin condensate. The condensate is prepared by the following components in part by weight: 100 parts of abietyl-based epoxy resin base material, 50 to 300 parts of tung oil anhydride and 1 to 15 parts of catalyst, has the characteristics of higher mechanical property, high ultraviolet resistance, high aging resistance and the like and is particularlysuitable for preparing biobased composite material matrix resin and outdoor electric insulation materials. The invention also discloses a preparation method for the full-biobased epoxy resin condensate. The preparation method has a simple preparation process, is high in operability and process controllability and is easy to implement industrially. The invention also discloses a full-biobased epoxy resin composition and application thereof. The full-biobased epoxy resin composition is suitable for preparing a weather resistant epoxy adhesive, epoxy resin paint and an epoxy resin coating and has a good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for making PH value-sensitive polyvinylidene fluoride hollow fibre intelligent film and products thereby

InactiveCN1594405ASimple processEase of industrial implementationSemi-permeable membranesWater bathsHollow fibre

Disclosed is a method for making pH sensitive PVDF hollow fiber intelligent film and products made thereby, wherein the making process comprises the steps of, (1) steeping the film in pure water for 24 hours, (2) preparing 10-20% alkali solution, and charging 3-4gl / L of tetrabutylammonium bromide, charging immersed film in alkali solution, heating by water bath, (3) preparing 1-2 mol / L of AAC solution, charging dimethyl formamide solution by 40-50ml / L, mixing uniformly, charging alkali-treated film in the mixed solution, steeping 10-20 minutes at room temperature, preparing solution of crosslinking agent 0.01-0.09mol / L and K2S2O3 0.1-0.3g, charging the readily made film into the solution, filling N2 and sealing, water-bathing, heating and washing with deionized water, the crosslinking agent is MBAA or diacrylic acid ethylene glycol ester.

Owner:TIANJIN POLYTECHNIC UNIV

A dicyclopentadiene hydrogenation special-purpose catalyzer and its preparing method

InactiveCN101157029AGood dispersionHigh activityMetal/metal-oxides/metal-hydroxide catalystsMolecular sieveUnsaturated hydrocarbon

The invention relates to dicyclopentadiene hydrogenation special catalyst and the preparation method thereof; a catalyst active component is abstracted from Pd or Pt, the percentage content of the weight can be Pd 0.3 to 1.3 percent or Pt 0.5 to 1.2 percent, carriers can be porous inorganic materials of aluminum oxide, silicon oxide, molecular sieves, kaolin, etc. By adopting the novel noble metal colloid method process, the prepared catalyst has the advantages that the grain size of active component particles is concentrated, the dispersion degree is high, the surface area is large, etc., thus the catalyst activity is higher, and the operating pressure of a hydrogenation device can be notably reduced. The preparation method provided by the invention effectively reduces the quantity of noble metals, the catalyst is used for the dicyclopentadiene petroleum resin hydrogenation device with poor color phase in the carbon five fraction, the content of unsaturated hydrocarbon key can be obviously reduced, and the color phase of the resin is improved to be of a water white color.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Weather resistant halogen-free flame retardant ABS resin and preparation process thereof

The present invention discloses a weather-proof anti-flaming ABS resinoid. The compositions and the weight percentage thereof are as follows: 45 to 75 percent of ABS resinoid, 5 to 30 percent of polyester, 10 to 20 percent of fire retardant, 1 to 10 percent of plasticizer, 0.3 to 5 percent of photo-thermal stabilizer, 0.2 to 5 percent of nucleating agent, and 1 to 5 percent of processing accessory ingredient. The weather-proof anti-flaming ABS resinoid obtains largely improved fire retardancy and weatherability because polyester components are added, can be applied to the occasions such as electric switches, transformer cases, control panels of various electric appliances, and the like which directly contact light ray, have higher requirement on appearance and environment, can not use PVC alloy, and have strict requirement on the fire retardancy of the material. The resinoid has wide application prospect. In addition, the adopted twin-screw extrusion preparation process has the advantages of simple flow, high production efficiency, stable product quality, low cost, environment protection, easy industrial implementation, and the like.

Owner:SHANGHAI KINGFA SCI & TECH +1

Environment responding aquogel copolymer and its prepn

The present invention relates to one kind of environment responding aquogel copolymer and its preparation process. The aquogel consists of: N-isopropyl acrylamide 10-90 wt% and methacrylate dextran derivative 10-90 wt%. The preparation process of the environment responding aquogel copolymer includes chemical modification of dextran with GMA to synthesize methacrylate dextran derivative, MA-Dex, with reaction activity; and subsequent copolymerization of MA-Dex and NIPA to obtain the said environment responding aquogel copolymer P(NIPA-co-MA-Dex). The aquogel copolymer has high temperature sensitivity and quick responding speed as well as high strength and excellent biocompatibility. The preparation process is simple, needs no special apparatus and is easy to realize in industry.

Owner:TIANJIN POLYTECHNIC UNIV

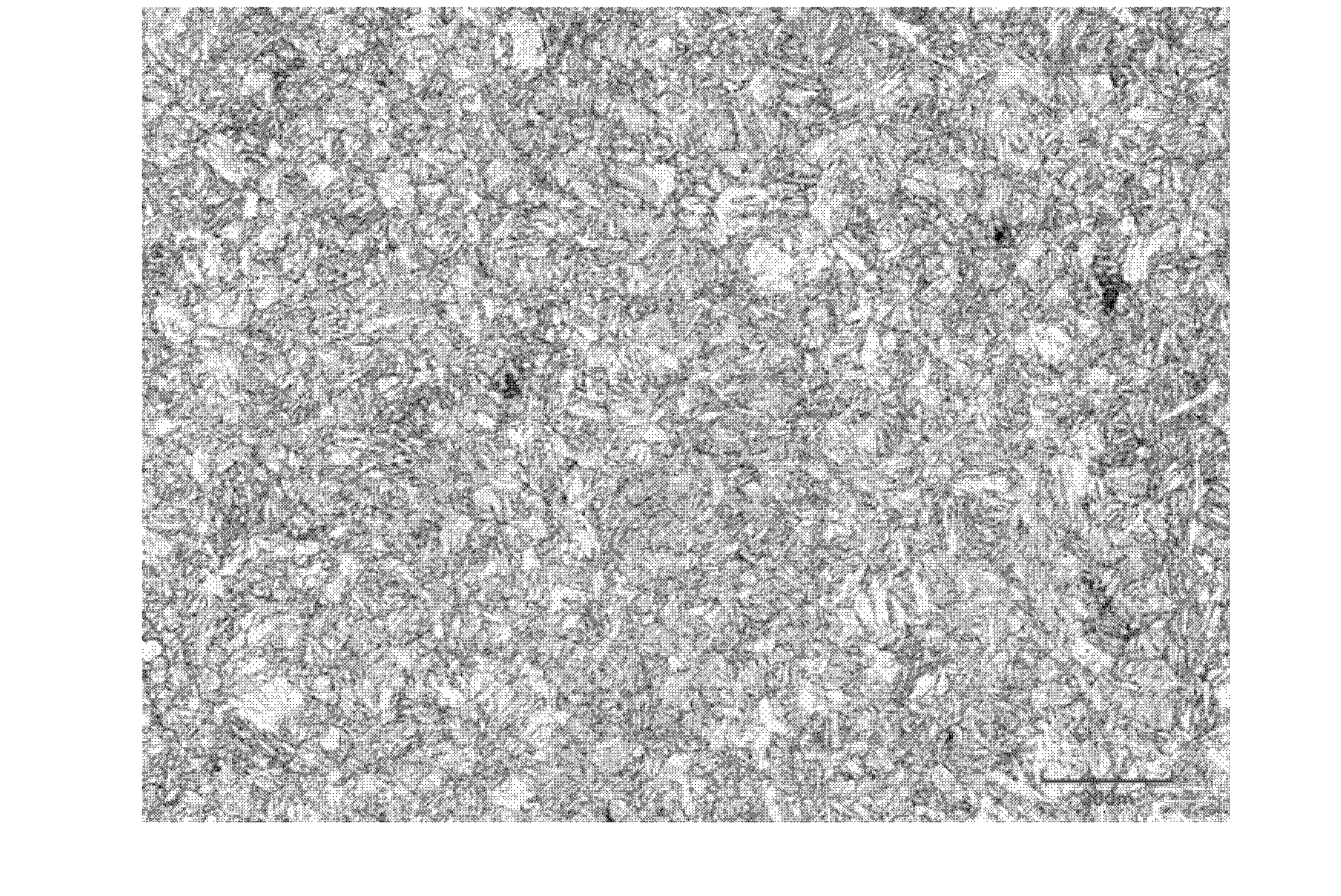

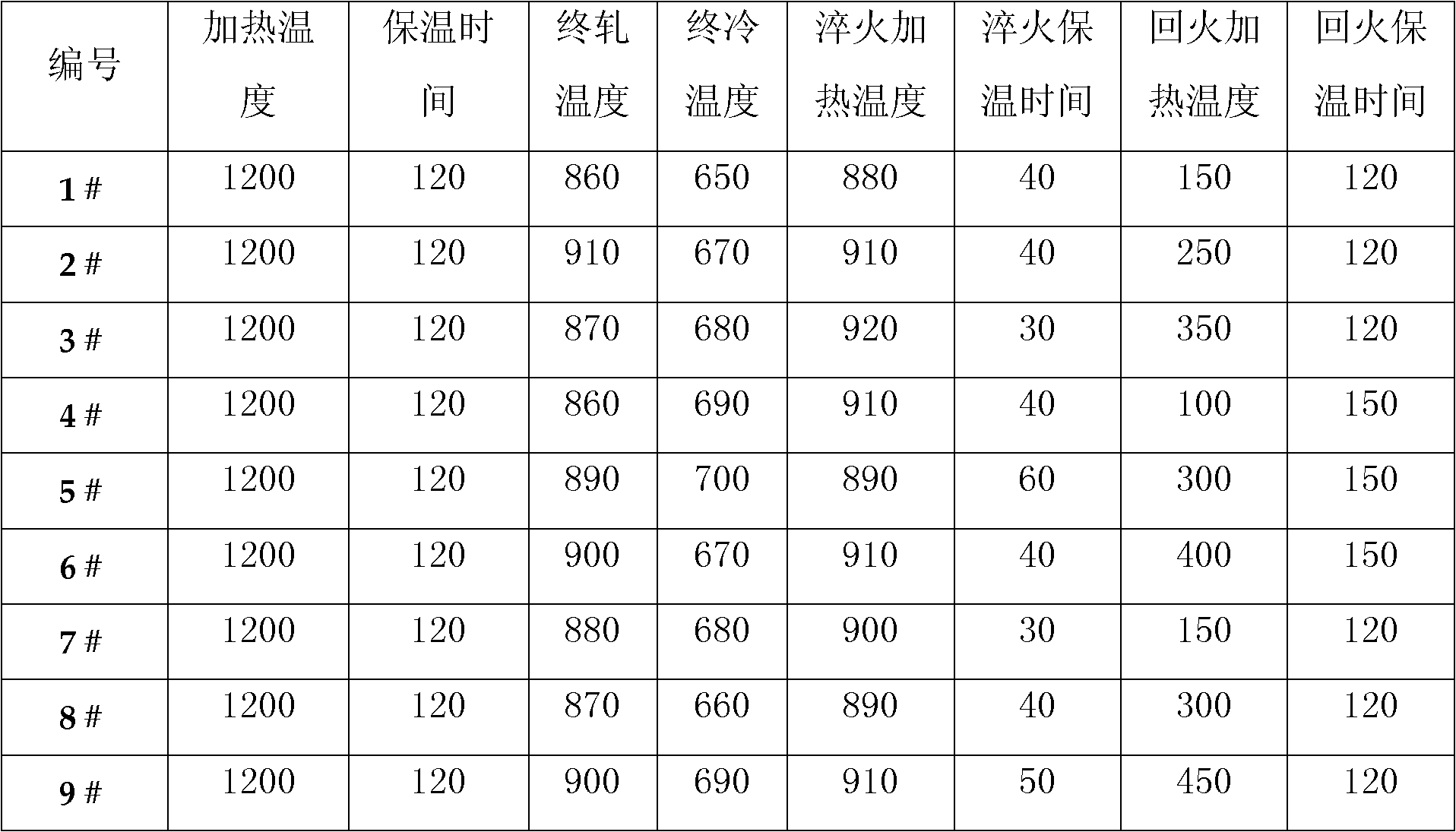

Ultra-high strength steel with yield strength level of 1100MPa-1200MPa and production method of steel

The invention provides ultra-high strength steel with yield strength level of 1100MPa-1200MPa and a production method of the steel. The chemical constituents (weight percentage) include: 0.15-0.18% of C, 0.20-0.25% of Si, 0.85-1.25% of Mn, 0.20-0.60% of Cr; and 0.45-0.65% of Mo, 0.035-0.060% of V, 0.015-0.020% of Nb, 0-0. 55% of Ni, 0-0.035% of Cu, 0.01-0.06% of Al, no more than 0.015% of P, no more than 0.01% of S, no more than 0.008% of N, the balance of Fe and unavoidable impurities. The production method includes: smelting and casting into casting blank; and heating the casting blank to 1150-1250 DEG C, wherein the final rolling temperature is 860-920 DEG C, the coiling temperature is 650-750 DEG C, the quenching heating temperature is 880-930 DEG C, the thermal insulation time is 20-90min, the tempering heating temperature is 100-450 DEG C, the thermal insulation time is over 90min. Slow cooling or air cooling is conducted to room temperature. For the steel plate produced with the constituents and the technology, the yield strength is 1150-1230MPa, the tensile strength is 1250-1340MPa, the elongation is 11-13.5%, and the impact power value at minus 40 DEG C is 21-34J.

Owner:SHOUGANG CORPORATION

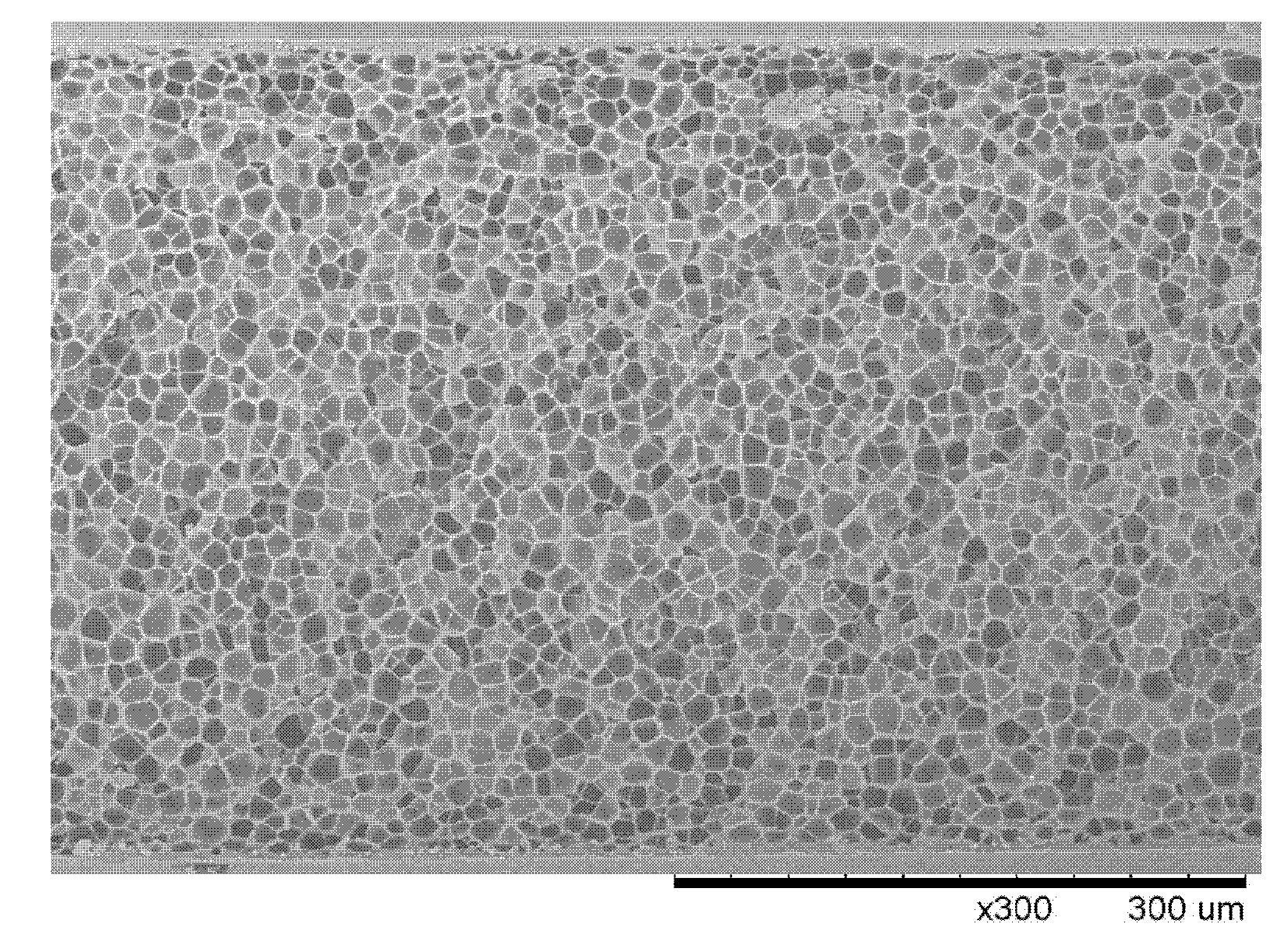

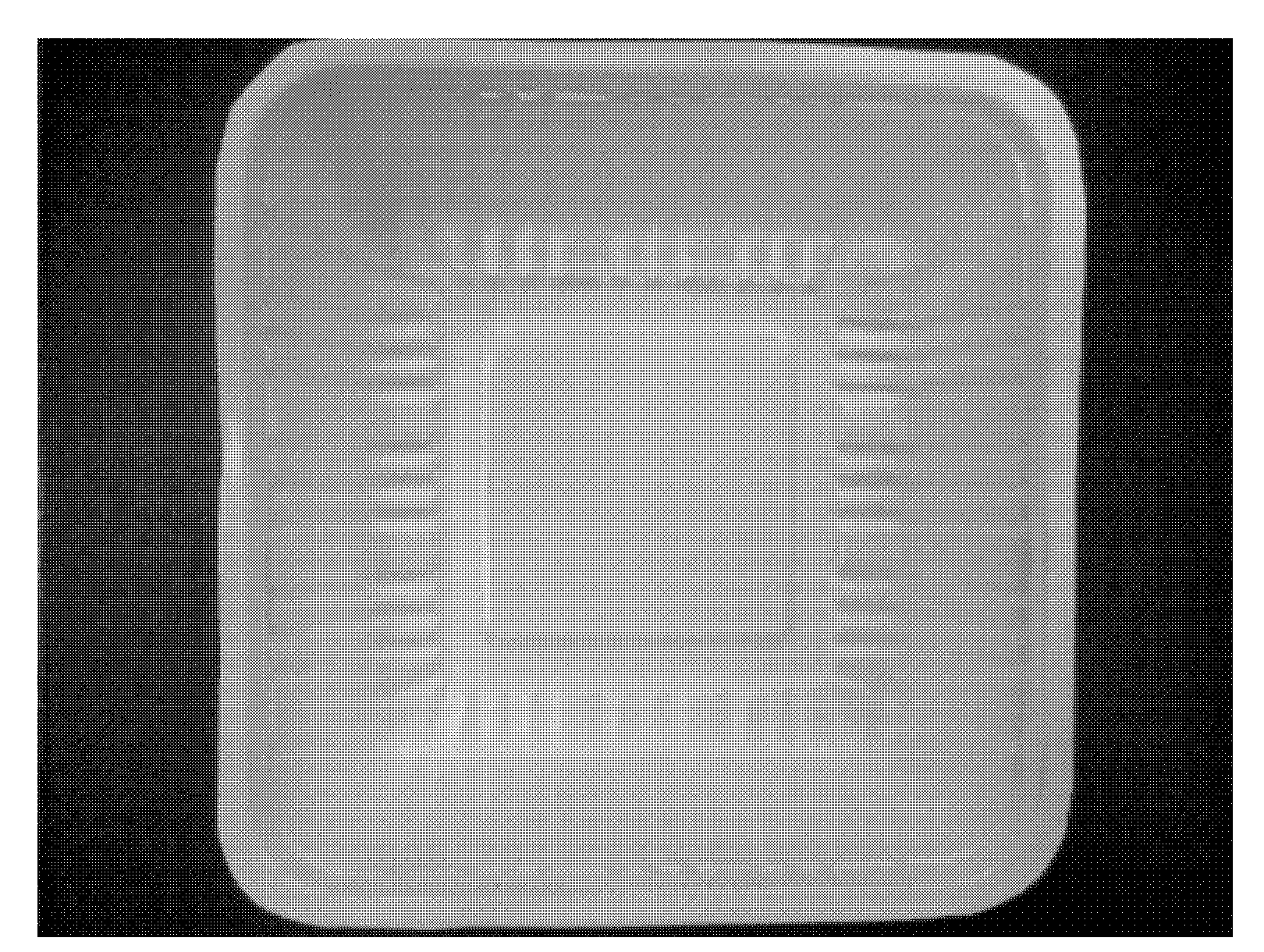

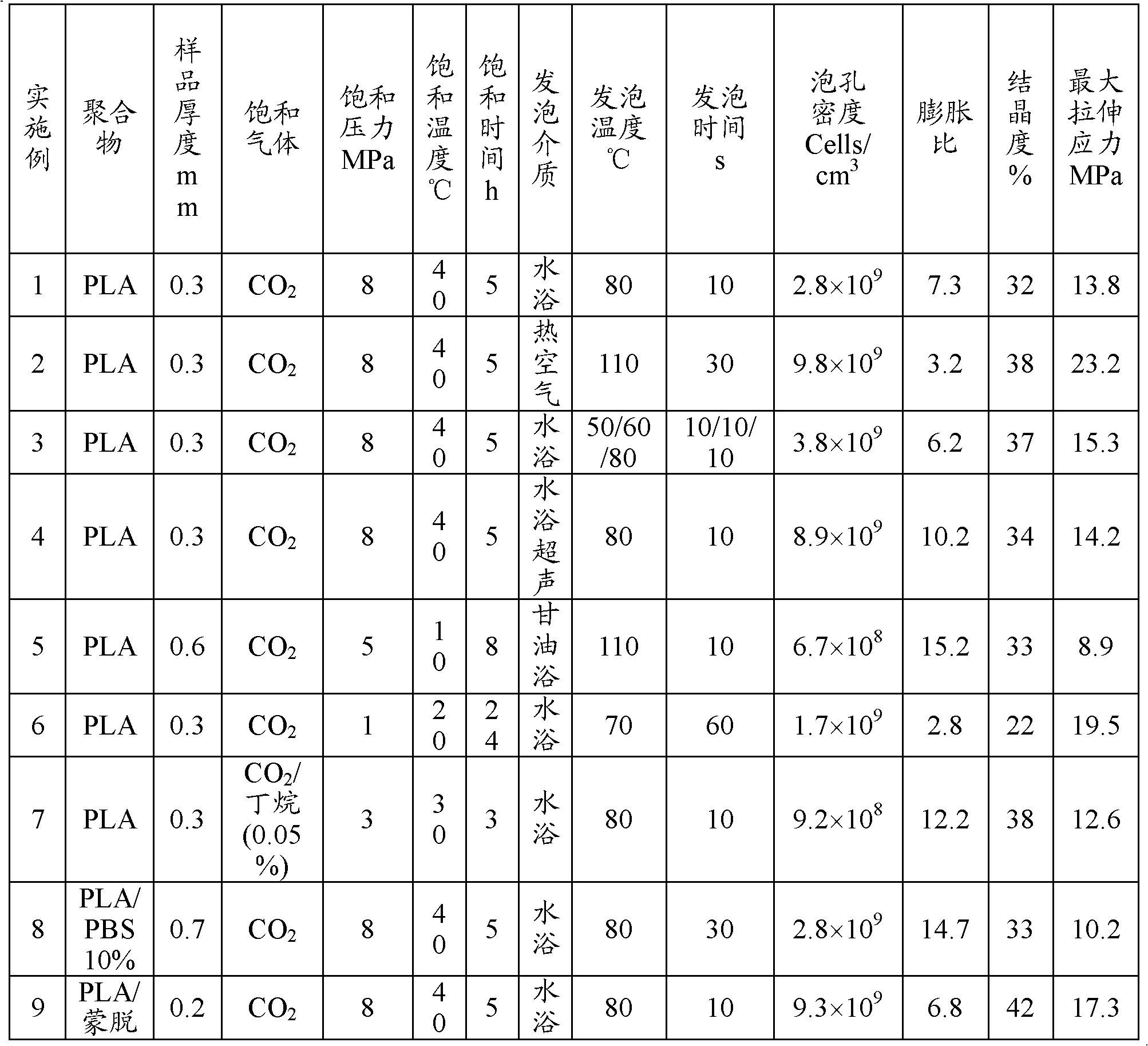

Preparation method of biodegradable polymer foamed sheet product

The invention discloses a preparation method of a biodegradable polymer foamed sheet product, comprising the following steps of: putting a polymer sheet into high-pressure fluid with the pressure of 0.5-10MPa to saturate the polymer sheet; then putting the saturated polymer sheet into a hot medium with the temperature of 40-140 DEG C for foaming for 2-300 seconds to obtain a polymer foamed sheet; and forming the polymer foamed sheet by heat treatment to obtain the biodegradable polymer foamed sheet product, wherein the polymer sheet is made of polylactic acid or the blend of polylactic acid and a polymer with an ester group or ether bond, and the thickness of the sheet is 0.1-2.0mm. The process disclosed by the invention is simple to operate, easy to control and favorable for industrial implementation, and the product has the advantages of bright and clean surface, light weight, uniform closed pore structure with the pore size of 5-50 micrometers, high tensile modulus and strength, excellent temperature tolerance and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Special resin with high melt strength for foaming of polylactic acid and preparation method thereof

The invention relates to special resin with high melt strength for foaming of polylactic acid and a preparation method thereof, and belongs to the technical field of macromolecules. The special resin is prepared from the following raw materials in parts by weight: 60 to 95 parts of polylactic acid, 1 to 20 parts of biodegradable copolymer, 0.1 to 1 part of chain expander, 1 to 5 parts of melt enhancer, 0.1 to 5 parts of nucleating agent, and 0.5 to 2 parts of lubricant. The special resin has the advantages and beneficial effects that by improving the melt strength of the polylactic acid and enhancing the adsorbing ability of polylactic acid on CO2 (carbon dioxide), the foaming property of the polylactic acid is enhanced. The used devices are universal devices in the technical field of macromolecules, such as a double-screw extruder, a crystallizing drier and a plastic extrusion foaming machine. The special resin has the advantages that the operation is simple and convenient, the control is easy, the industrialized implementing is easy, and the economic benefit is high.

Owner:JILIN COFCO BIOCHEM

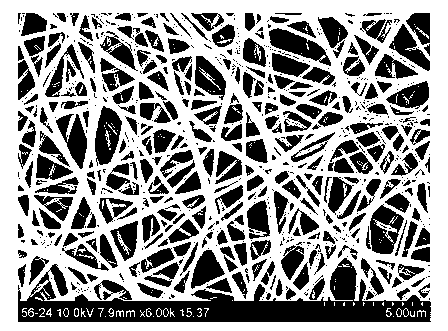

Nanofiber membrane and membrane adsorbing assembly for extracting uranium from seawater and brine water and application of nanofiber membrane and membrane adsorbing assembly

InactiveCN105080509AImprove adsorption efficiencyHigh mechanical strengthOther chemical processesProcess efficiency improvementIndustrial waste waterSpinning

The invention discloses a nanofiber membrane and a membrane adsorbing assembly for extracting uranium from seawater and brine water and application of the nanofiber membrane and the membrane adsorbing assembly. The nanofiber membrane is prepared by the steps: preparing polyacrylonitrile into a spinning solution; depositing polyacrylonitrile nanowires on a macromolecular non-woven fabric through an electrostatic spinning process to obtain a polyacrylonitrile nanofiber membrane; and then carrying out amidoximation on the polyacrylonitrile nanofiber membrane to obtain the nanofiber membrane. The membrane adsorbing assembly is prepared by the steps: preparing the nanofiber membrane into a rolled membrane assembly; and then carrying out amidoximation on the rolled membrane assembly to obtain the nanofiber membrane adsorbing assembly. The membrane adsorbing assembly disclosed by the invention is high in adsorption capacity, great in adsorption rate, stable in recycling performance and high in mechanical strength. The membrane adsorbing assembly not only is suitable for extracting uranium element from water bodies such as seawater or brine water and the like, but also is suitable for separating and recovering other noble metal or heavy metal ions from industrial wastewater, underground water and drinking water separately as well as removing metal ions from an organic phase.

Owner:和晶(上海)新能源科技有限公司

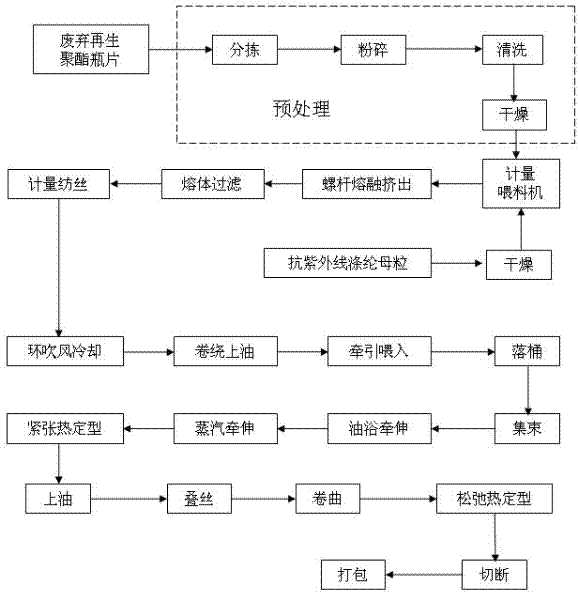

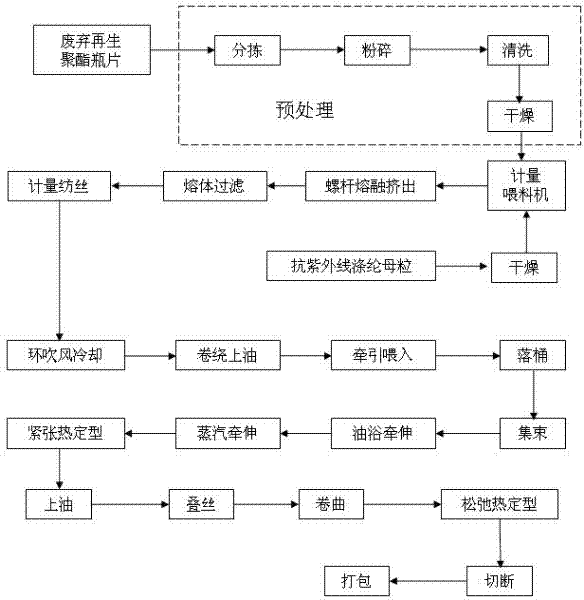

Method for preparing functional ultraviolet-resistant polyester staple fiber from waste renewable polyester bottle chips

InactiveCN102505182APromote environmental protectionReduce manufacturing costFilament forming substance formingPlastic recyclingPolyesterFiber

The invention discloses a method for preparing functional ultraviolet-resistant polyester staple fiber from waste renewable polyester bottle chips. The method comprises the following steps of: pre-treating and drying recovered waste renewable polyester bottle chips; drying ultraviolet-resistant polyester master batch; conveying the dried polyester bottle chips and ultraviolet-resistant polyester master batch into a special metering feeder to quantitatively feed and mix the polyester bottle chips and the ultraviolet-resistant polyester master batch to obtain a mixture; performing screw fusion extrusion on the mixed mixture with a certain concentration to obtain melt; filtering the melt, metering and spinning, cooling through circular blowing, winding and oiling, drawing and feeding, and holding filaments and falling into a barrel; bundling the filaments in the barrel; and performing oil water bath drawing and steam drawing, tense thermal forming, oiling, filament lamination, curling, loose thermal forming, cutting and packing to obtain an ultraviolet-resistant polyester staple fiber product. The method has the advantages of rational preparation process and high operability; and the product has lower cost than a new material and has good economic benefit and social benefit.

Owner:东莞市粤盛纤维制品有限公司

Method for preparing nano particle modified chemical fibre

The method of preparing nano particle modified chemical fiber features that nano particles after surface treatment in certain proportion is added into and dispersed in solidifying bath, preheating bath or extracting bath for wet spinning or wet-dry spinning via high speed stirring to form bathing liquid with homogeneously dispersed nano particles. After eliminating solvent and drawing, nano particles are diffused into fiber pores, and the nano particle modified chemical fiber possesses raised drawing performance. The said method is simple, low in cost and suitable for industrial production.

Owner:DONGHUA UNIV

Functional fiber and the multifunctional fiber thereof

InactiveCN1811021AEasy to prepareLow costMonocomponent synthetic polymer artificial filamentAlkali metal oxides/hydroxidesFiberPolymer science

The present invention relates to one kind of functional fiber and the multifunctional fibers thereof. The functional fiber includes basic fiber polymer and functional additive in the weight ratio of 60-96 to 4-40, the basic fiber polymer may be wet spun and the functional additive is superfine adsorbent of average diameter of 0.01-20 microns. The multifunctional fibers are produced with the functional fiber of the present invention and through further ionizing treatment, and include strong acid ion exchange multifunctional fiber, weak acid cation exchange multifunctional fiber, multiple-functional group ion exchange multifunctional fiber and alkali anion exchange multifunctional fiber. The functional fiber has excellent physical adsorption property; and the multifunctional fibers have both physical adsorption effect and chemical adsorption effect, and may be used in treating electroplating effluent, treating food industry waste water, purifying automatic tail gas, etc.

Owner:TIANJIN POLYTECHNIC UNIV

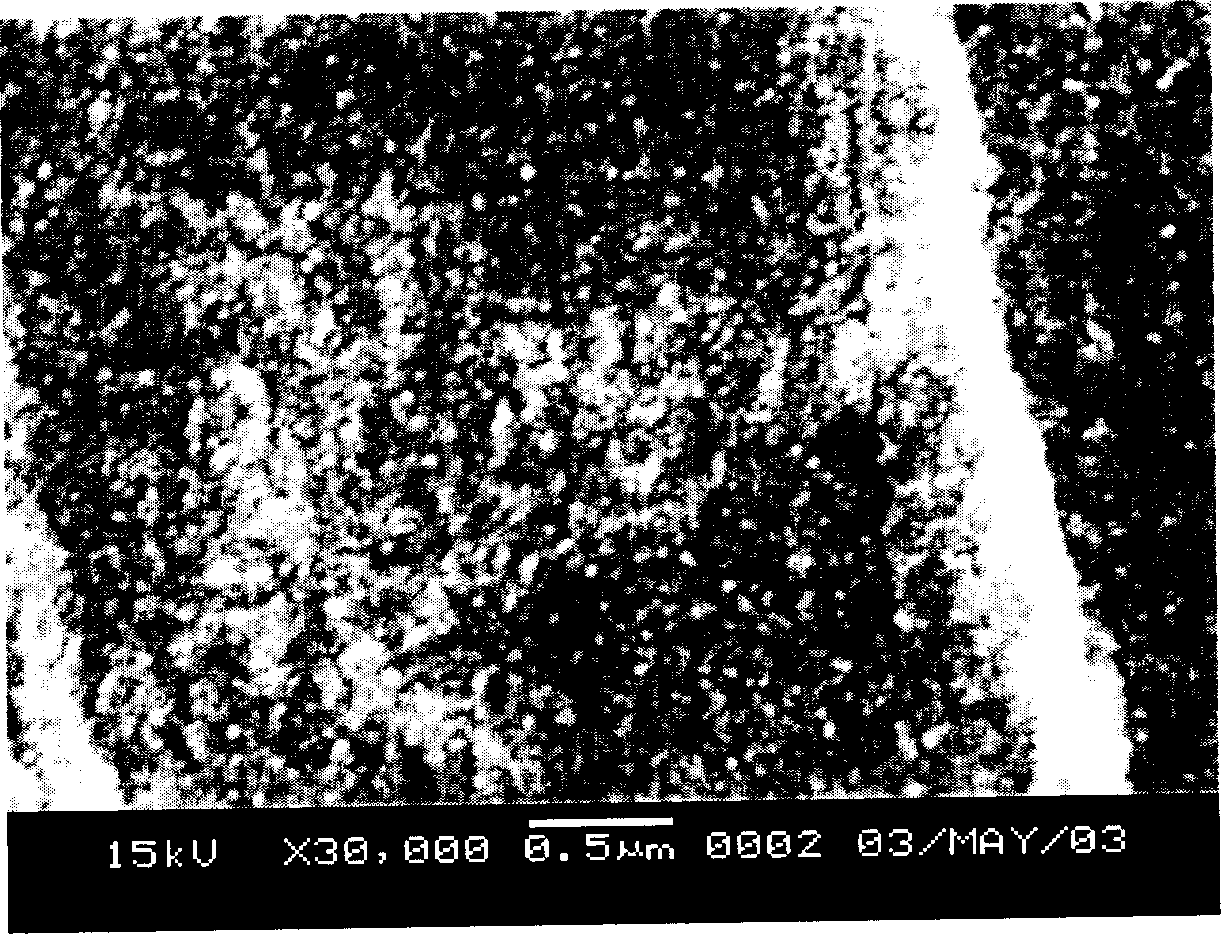

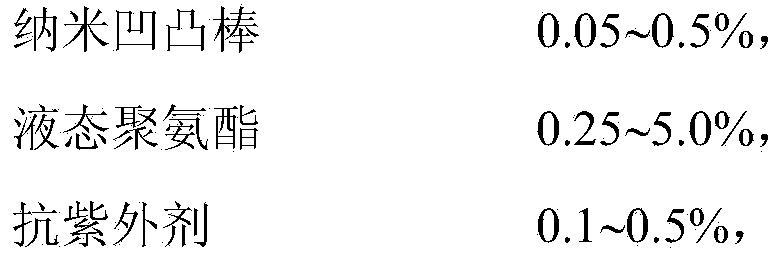

High-resilience urethane elastic fiber as well as preparation method thereof

ActiveCN103436983AHigh reboundImprove the degree of microphase separation of soft and hard segmentsMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberEthylenediamine

The invention relates to a preparation method of a high-resilience urethane elastic fiber. The preparation method comprises the following steps: (1) mixing raw materials, namely, polytetramethylene ether glycol (PTMEG) and 4, 4-diphenylmethane diisocyanate (MDI) to carry out reaction so as to obtain a prepolymer; (2) adding a certain amount of a mixed diamine chain extender into the prepolymer to form polymer liquor; (3) quickly adding polyamine (the number of functional groups is greater than 2) into the polymer liquor while stirring to carry out reaction so as to form polyurethaneurea liquor; (5) carrying out reaction on MDI and polyether polyhydric alcohol and blocking with ethanediamine to prepare oligomers; (6) blending nano attapulgite with the oligomers to prepare a prepreg; and (7) mixing the polyurethaneurea liquor with the prepreg to prepare a spinning dope, and spinning to form the high-resilience urethane elastic fiber. The preparation method of the high-resilience urethane elastic fiber provided by the invention satisfies the demands on the high-resilience urethane elastic fiber in certain special fields, and the resilience of the urethane elastic fiber is improved.

Owner:ZHEJIANG HUAFENG SPANDEX

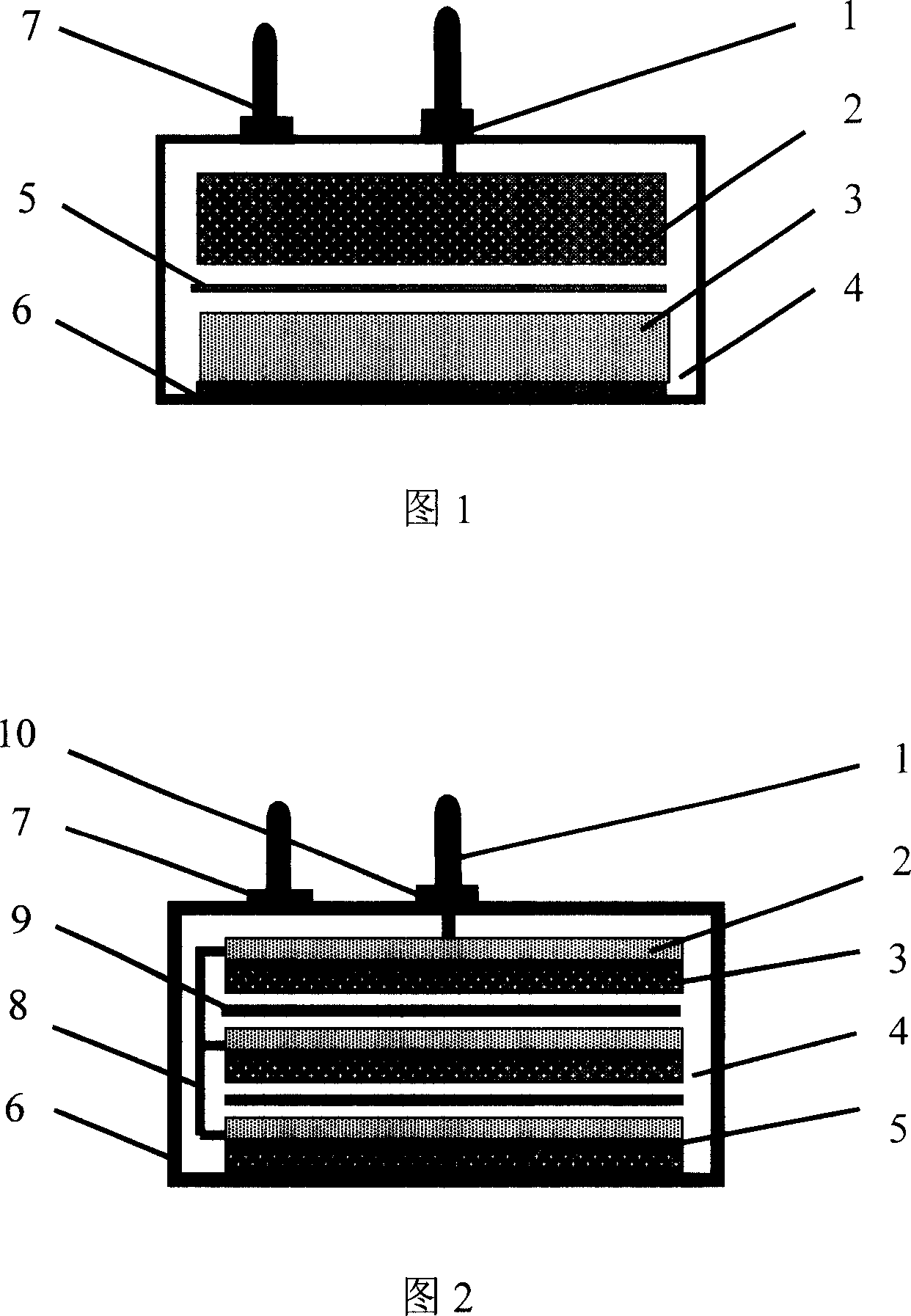

A mixed super capacitor

InactiveCN1963966AIncrease working voltageHigh capacity densitySecondary cellsCapacitor electrodesElectrolysisEngineering

The related mixed super capacitor comprises: using Ta and RuO2 as the anode and cathode respective; filling H2SO4 electrolyte to form the electrolytic capacitor with anode and the electrochemical capacitor with cathode in series, respectively. This invention increases working voltage and energy storage density, overcomes defects in prior art, and can be used in the impulse power system.

Owner:DALIAN UNIV OF TECH

Method for preparing temperature-sensitive polyvinylidene fluoride intelligent membrane material and its product

This invention relates to a method for prparing temperature-sensitive polyvinylidene flourine intelligent membrane. The method is: NIPA as grafted monomer, PVDF as macromelocular initiator, cuprous chloride as catalyst,4,4 demethyl 2,2 bipyridine as ligand, using atom transfer free radical process, preparation of temperature-sensitive polyvinylidene flourine intelligent membrane comprising: in reaction kettle, adding 7-13% PVDF(WT%) and solvent N-methyl-2-pyrrolidone,heating to 50 deg. C to make it solve completely; then adding grafted monomer NIPA, its mol ratio with cuprous chloride is 2000:1-2500:1,filling nitrogen gas 30mins. at stirring, and separately adding 0.20-025g ligand 4,4-dimethyl 2,2-bipyridine and 0.04-0.06g catalyst cupous chloride, stirring and heating to 80-120deg.C,constant reaction 19-25 hrs; then washing reaction product using pure water to obtain light brown solid, filtering and 80 C degree drying to obtain finish product.

Owner:TIANJIN POLYTECHNIC UNIV

Method for secondary aluminum ash harmless use

InactiveCN109052445AHigh alumina contentIncrease contentAluminium chloridesCeramic materials productionBrickAluminium chlorohydrate

The invention discloses a method for secondary aluminum ash harmless use. The method comprises the following steps: mixing water with secondary aluminum ash, heating, stirring, leaching, and carryingout solid-liquid separation after water leaching so as to obtain primary filtrate and primary filter residues; heating and evaporating the primary filtrate so as to obtain a soluble salt; mixing the primary filter residues with an acid, heating and stirring to achieve leaching; after acid leaching, and carrying out solid-liquid separation so as to obtain secondary filtrate and secondary filter residues; manufacturing bricks with the secondary filter residues; adjusting the pH value of the secondary filtrate within 2.5-3.0; heating and aging the secondary filtrate after the pH value is adjusted, thereby obtaining aluminum polychlorid. By adopting the method, the aluminum element in secondary aluminum ash can be utilized to the maximum extent, aluminum nitride which is hard to react with theacid can be converted into aluminum hydroxide which is easy to react with the acid through high-temperature water leaching, dissolution of the aluminum element in the secondary aluminum ash can be improved, and the content of aluminum oxide in a prepared aluminum polychlorid product can be increased; in addition, a salt solvent and a nitrogen element in the secondary aluminum ash can be recycled,and damage of leaching residues upon the environment can be reduced.

Owner:CENT SOUTH UNIV

Heavy metal ion adsorption type polyvinylidene fluoride (PVDF) hollow fiber membrane

ActiveCN102527261AReduce dosageLow priceSemi-permeable membranesOther chemical processesFiberMass ratio

The invention discloses a heavy metal ion adsorption type polyvinylidene fluoride (PVDF) hollow fiber membrane. The invention belongs to the technical field of membranes and in particular relates to a preparation technology for an organic-inorganic hybrid hollow fiber membrane. The heavy metal ion adsorption type PVDF hollow fiber membrane comprises modified attapulgite, wherein the mass ratio of the PVDF to the modified attapulgite is (1:0.01)-(1:0.1). The heavy metal ion adsorption type PVDF hollow fiber membrane has the advantages that high pressure resistance is achieved, a supporting body is not required, a membrane component has any sizes and shapes and large filling density, and unit volume membrane area and flux are large. In addition, the hybrid membrane is high in spinning performance, the spinning membrane-forming process is simple in process, and cost is low.

Owner:TIANJIN POLYTECHNIC UNIV

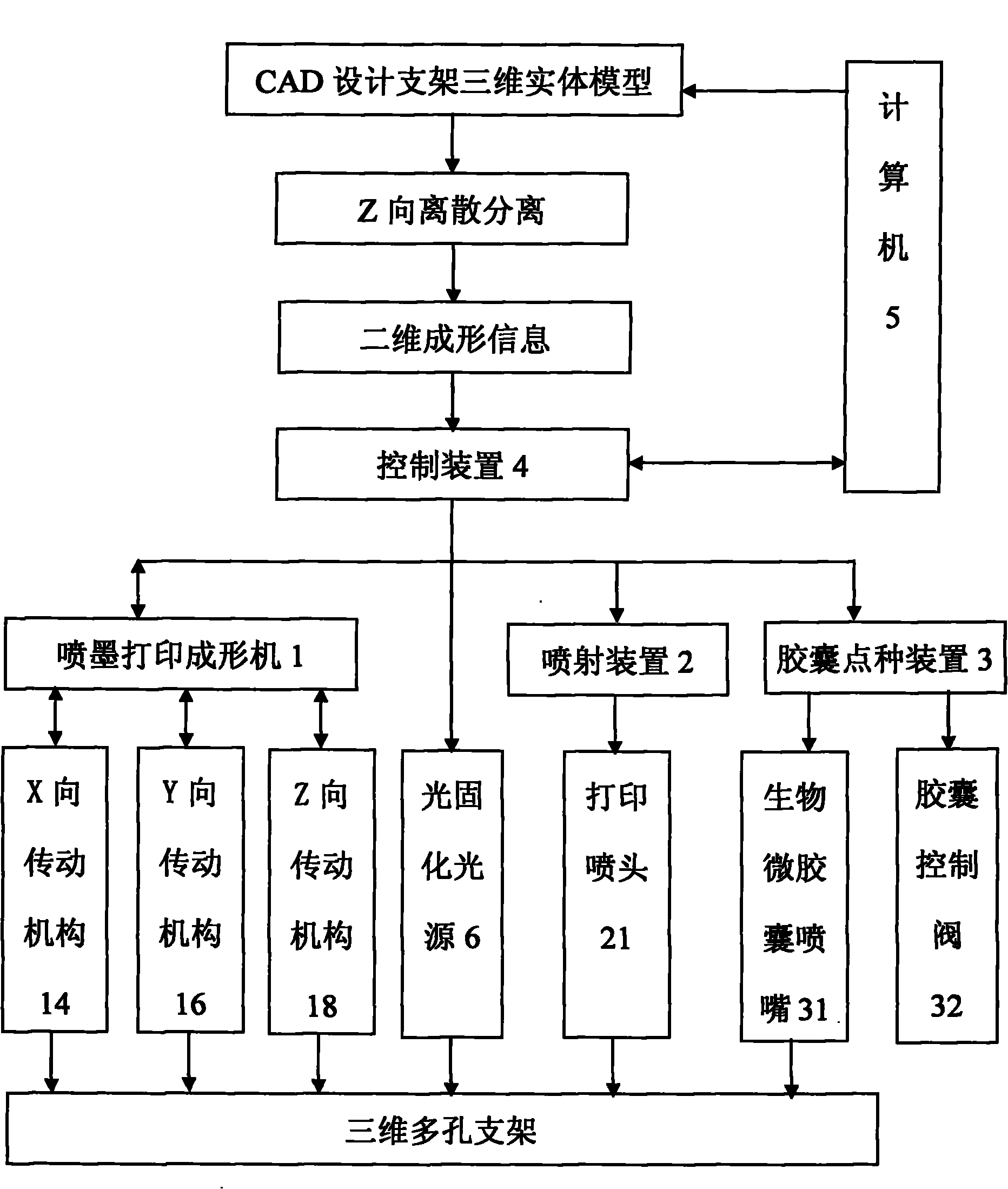

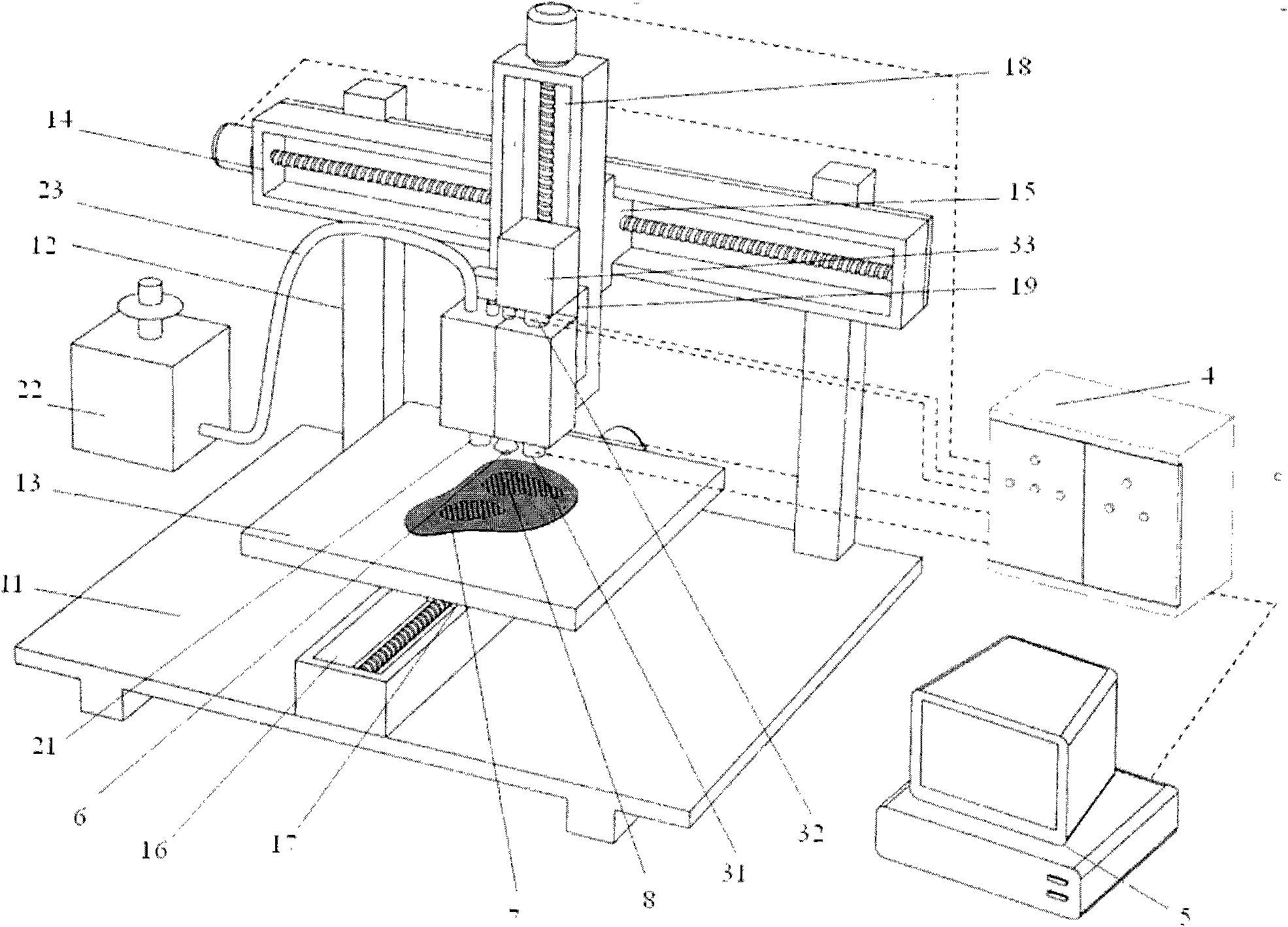

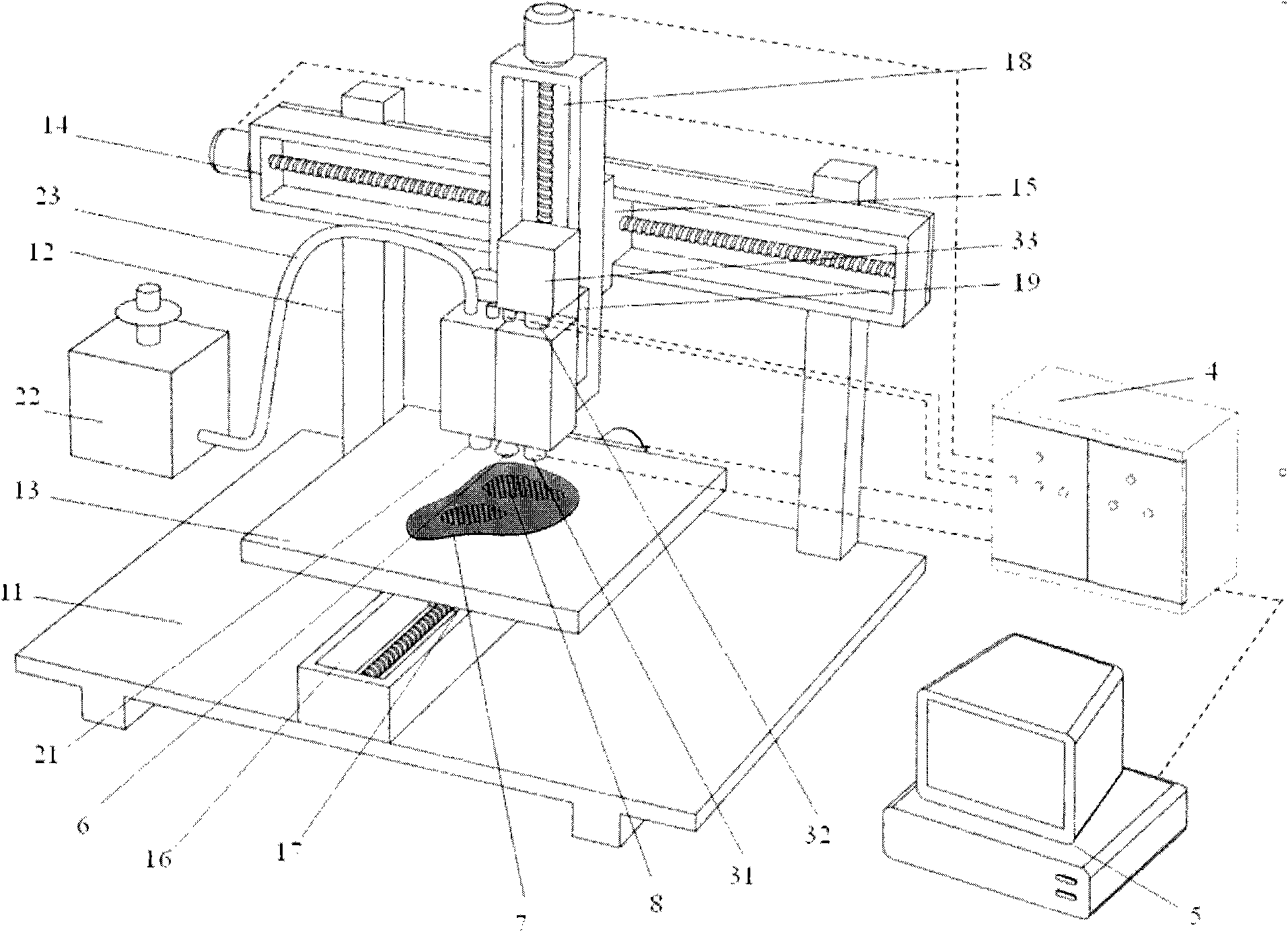

Method and device for preparing three-dimensional porous support for tissue engineering

InactiveCN101884574APosition is easy to controlControllable Aperture SizeStentsProsthesisControl systemLayer wise

The invention discloses a method and device for preparing a three-dimensional porous support for tissue engineering. The preparation method comprises the following steps of: 1, slicing and layering a support according to a certain thickness firstly to obtain two-dimensional cross section information of each layer of the support; 2, preparing a first layer slice of the support by using a three-dimensional inkjet printing spray head under the control of CAD software, dibbling microcapsule particles on the first layer slice of the support by using a bio-microcapsule preparation nozzle, and stacking the microcapsule particles to form gaps required by a support design; 3, moving the three-dimensional inkjet printing spray head and the bio-microcapsule preparation nozzle for the height of one layer slice of the support to finish the forming preparation of a second layer of the support; and 4, repeating the method layer by layer until the three-dimensional porous support is prepared. The device for preparing the three-dimensional porous support is suitable for the preparation method, and comprises a three-dimensional inkjet printing forming machine, a jetting device, a bio-microcapsule dibbling device and a control system.

Owner:HEBEI UNIV OF TECH

Method for making temperature-sensitive polyvinylidene fluoride hollow fibre intelligent film and products thereby

InactiveCN1594404ASimple processEase of industrial implementationSemi-permeable membranesFiberHollow fibre

Disclosed is a method for making temperature-sensitive PVDF hollow fibre intelligent film and products made by chemical grafting and copolymerization of NIPA on PVDF film surface, and the making process comprises the steps of, (1) steeping the film in pure water for 24 hours, (2) preparing 10-20% alkali solution, and charging 3-4gl / L of tetrabutylammonium bromide, charging immersed film in alkali solution, water-bathing, heating and washing for later use, the alkali solution is one of KOH, NaOH or LiOH, (3) preparing 1-2 mol / L of NIPA solution, charging dimethyl formamide solution by 40-50ml / L, mixing uniformly, charging alkali-treated film in the mixed solution, steeping at room temperature, preparing solution of crosslinking agent 0.01-0.09mol / L and K2S2O3 0.1-0.3g, charging the readily made film into the solution, filling N2 and sealing, water-bathing, heating and washing with deionized water, the crosslinking agent is MBAA or diacrylic acid ethylene glycol ester.

Owner:TIANJIN POLYTECHNIC UNIV

Antibacterial spandex fiber and preparation method thereof

InactiveCN104726961AWith antibacterial functionEasy to useWet spinning methodsConjugated synthetic polymer artificial filamentsAntioxidantAntibacterial agent

The invention discloses an antibacterial spandex fiber and a preparation method thereof. The antibacterial spandex fiber is prepared by combining a wrapper and a core part, wherein the section of the fiber is solid; the material of the core material is a polyurethane slice for melt spinning; the wrapper comprises the following raw materials in percentage by mass: 0.1-0.2% of a silver ion compound, 0.1-0.5% of an ultraviolet screening agent, 0.1-0.55 of an antioxidant,0.2-1.0% of a lubricant, 0.1-0.5% of a matting agent and 97.3-99.4% of fiber forming aggregate. The preparation method of the antibacterial spandex fiber comprises the following steps: 1 manufacturing an antibacterial spandex core part by a melt spinning technique according to the formula ratio; 2 manufacturing an antibacterial spandex wrapper by a wet-dry spinning technology according to the ratio; and 3 spinning by wet-dry spinning equipment and process through a special spinneret assembly, and thus preparing the antibacterial spandex fiber by a special coagulating bath. The preparation method of the antibacterial spandex fiber is simple in process; the antibacterial agent is low in amount, economical and practical; and the prepared antibacterial spandex fiber is stable and uniform in performance, broad-spectrum antibacterial and lasting in antibacterial effect.

Owner:ZHEJIANG HUAFENG SPANDEX

Hepatic targeted temperature sensitive microsphere and preparation method therefor

InactiveCN103709323AControlled release rateControl concentrationPowder deliveryPharmaceutical non-active ingredientsCross-linkTemperature response

The invention discloses a hepatic targeted temperature sensitive microsphere and a preparation method therefor, and belongs to the functional polymer material field, and especially relates to a drug sustained release and targeted drug delivery material and a preparation method therefor. The temperature response range of the material is 25 DEG C-37 DEG C, and the particle size of the microsphere is about 500nm. The microsphere can be prepared through the following method: glycyrrhetinic acid (GA) is modified by ethylene diamine and acrylic acid (AAc) and vinyl monomers are generated; ammonium persulfate (APS) is employed as an initiator, N,N-methylene bisacrylamide (MBA) is employed as a cross-linking agent, hepatic targeted temperature sensitive microspheres are prepared through a semicontinuous soap-free emulsion polymerization method. The preparation method has simple technological processes, and mild experiment conditions, needs no special devices, has a low investment cost, and has good operability. The reagents are all common reagents. The reaction residues are easy to remove. The preparation method is convenient for industrial implementation.

Owner:TIANJIN POLYTECHNIC UNIV

Method for oxidizing fluorene to 9-fluorenone

ActiveCN1754867AIncrease profitHigh yieldOrganic compound preparationCarbonyl compound preparationWastewaterOxygen

The invention discloses a method to prepare 9-fluorenone with fluorene. Wherein, using dimethyl sulfoxide as solvent, sodium hydroxide as catalyst, oxygen as oxidant and tower filling reactor; cooling and filtering the reacted liquid to obtain 93% coarse fluorenone; distilling liquid and recycling 94% solvent and some coarse fluorenone; refining with oriented crystallization method and obtaining yellow piece 99.8% fluorenone. This method is simple, needs short reaction time, produces no waste water, and convenient to produce in industry.

Owner:SHANGHAI HUAYI ENERGY CHEM

PET (polyethylene glycol terephthalate) fiber/polyacrylonitrile fiber composite sound absorbing cotton and preparation method of PET fiber/polyacrylonitrile fiber composite sound absorbing cotton

InactiveCN102965847AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsSound producing devicesPolymer scienceAntioxidant

The invention discloses PET (polyethylene glycol terephthalate) fiber / polyacrylonitrile fiber composite sound absorbing cotton, which is prepared from the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of polyacrylonitrile fibers, 10 to 15 parts of emulsifying agents OP-20, 5 to 10 parts of peregal O-15, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of SEBS (styrene ethylene butylene styrene), 15 to 20 parts of calcined clay, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of diisooctyl phthalate, 4 to 6 parts of tricresyl phosphate, 2 to 3 parts of polyethylene wax, 1 to 2 parts of vinyl (beta-methoxyethoxy) trisilane, 2 to 3 parts of calcium stearate, 1 to 2 parts of dimethyl dimercapto isooctyl acetate tin, 0.5 to 1.5 parts of anti-aging agents ODA (octyl decyl adipate) and 1 to 2 parts of antioxidants 1035. The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com