Patents

Literature

2325 results about "Aluminium chlorohydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum chlorohydrate is a group of specific aluminum salts having the general formula AlₙCl₍₃ₙ₋ₘ₎(OH)ₘ. It is used in cosmetics as an antiperspirant and as a coagulant in water purification. In water purification, this compound is preferred in some cases because of its high charge, which makes it more effective at destabilizing and removing suspended materials than other aluminum salts such as aluminum sulfate, aluminum chloride and various forms of polyaluminum chloride (PAC) and polyaluminum chlorisulfate, in which the aluminum structure results in a lower net charge than aluminum chlorohydrate. Further, the high degree of neutralization of the HCl results in minimal impact on treated water pH when compared to other aluminum and iron salts.

Sludge curing agent and application thereof

ActiveCN101081718AGood boardIncreased durabilitySludge treatment by de-watering/drying/thickeningSolid waste managementSludgeSlag

The present invention is sludge curing agent and its application, and belongs to the field of soil treating chemicals technology. The sludge curing agent includes powdered components and liquid components, the powdered components include cement clinker 30-60 weight portions, slag 30-60 weight portions, lime 3-8 weight portions, gypsum 1-7 weight portions and other sulfates 1-7 weight portions; and the liquid components include polyacrylamide 5-30 weight portions, polyaluminum chloride 0-20 weight portions, mannitol 0-30 weight portions, lignosulfonate 20-80 weight portions, lignosulfonate-iron or chromium ion complex 0-30 weight portions, alkylphenol ethoxylate 0.2-2 weight portions, tannin 0-10 weight portions, humate 0-10 weight portions, and alpa-olefin sulfonate 0.2-2.5 weight portions. The sludge curing agent has low cost, small consumption, high cumulate strength and high cumulate water tolerance, and may be applied widely.

Owner:BEIJING ZHONGYONGJI FIRMING AGENT TECH DEV

Chitosan graft ternary polymerization polymeric flocculant and its preparation method and use

InactiveCN1654497AImprove performanceWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateNon ionic

The present invention discloses one kind of chitosan-grafting ternary copolymer flocculant and its preparation process and application. Chitosan is first dissolved in acid solution and made to produce grafting polymerization with non-ionic monomer, cationic monomer and non-ionic surfactant under the action of initiator at 30-75 deg.c for 2-6 hr; and the reaction product is then added with alkali to regulate the pH value to 3.5-5.5, so as to obtain the chitosan-grafting ternary copolymer flocculant. The produced flocculant is used in sewage treatment, and has treating effect higher than available marketable flocculants, small use amount, wide application pH range, large flocculated product, fast deposition and other advantages.

Owner:SOUTH CHINA UNIV OF TECH

Flocculating agent for sludge dewatering and sludge dewatering method

InactiveCN101367597AImprove rigidityImprove toughnessSludge treatment by de-watering/drying/thickeningAluminium chlorohydrateSewage

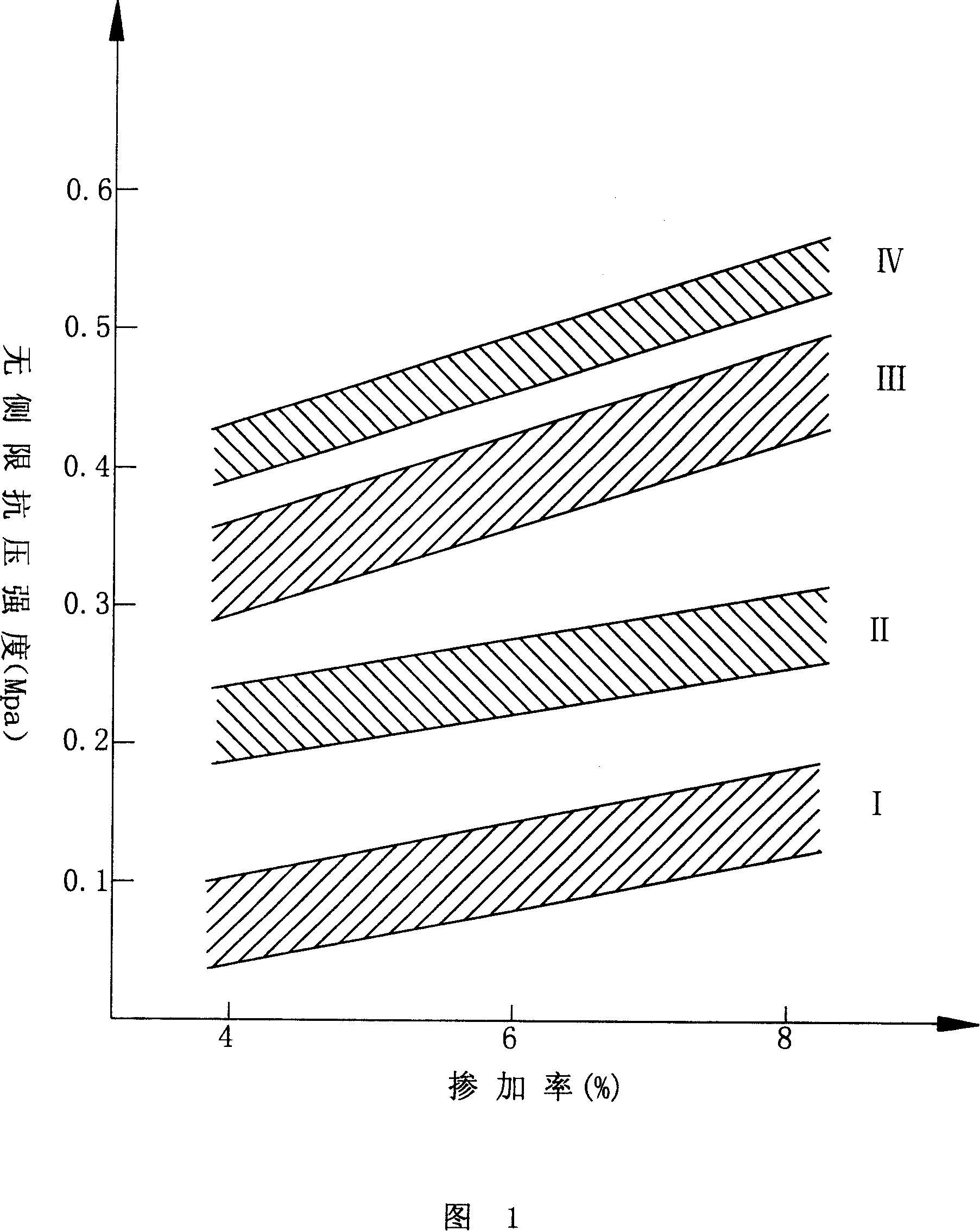

is the invention discloses a flocculating agent for filthy mud dehydration, which is composed of polyaluminium chloride and polyacrylamide. The flocculating agent addition is 4.92 percent to 10.18 percent by weight of the solid content of the filthy mud; and the polyaluminium is 4.38 percent to 5.33 percent by weight of the flocculating agent. The flocculating agent has the advantages of low specific impedance value of the filthy mud and high solid content of filter mass after dehydration. The method of filthy mud dehydration and the method of flocculating agent adding are as follows: polyaluminium chloride is added first, then is fast stirred at the speed of 32.0 r / m for two minutes and slowly stirred at the speed of 10.0 r / m for three minutes, and the pH value of sewage mud is regulated to 6 to 8; and the polyacrylamide is added, is fast stirred at the speed of 32.0 r / m for three minutes and then is slowly stirred at the speed of 10.0 r / m for seven minutes. The methods have the advantages that the flocculating agent can fully contact solid grains to facilitate the flocculating agent to trap colloid grains, so that the concentration distribution of the flocculating agent is uniform; large grains can not be stirred into small grains, precipitated grains can not be stirred into non-precipitated grains, so that the flocculation effect is improved.

Owner:广州中滔绿由环保科技有限公司

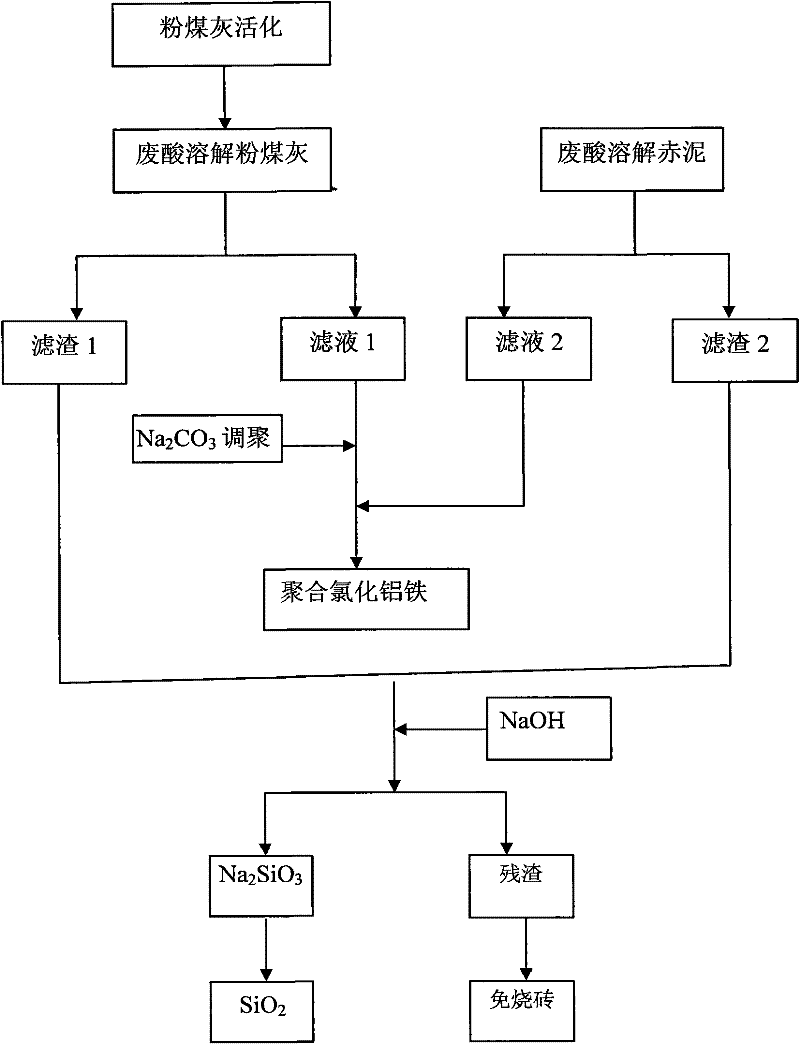

New method for resource comprehensive utilization of red mud and fly ash

InactiveCN102344171AAchieve recyclingAchieve near-zero emissionsSilicaSolid waste disposalAluminium chlorideRed mud

The invention discloses a new method for resource comprehensive utilization of red mud and fly ash, and relates to a comprehensive utilization of industrial waste, specifically to a preparation method for a flocculating agent of aluminum ferric chloride and white carbon black. The method comprises the following steps: (1) acid leaching: the red mud and the activated fly ash are adopted as raw materials, and react with HCl, wherein the leaching temperature is 70-90 DEG C, a solid-liquid ratio is 10:1-10:3, the HCl concentration is 3-6 mol.L<-1>, the leaching time is 4-10 hours; (2) polymerization: Na2CO3 is added to a dissolution solution 1 to carry out telomerization, a dissolution solution 2 is added to the dissolution solution 1 until the dissolution solution 1 is stable, then the polymerization reaction is performed to obtain the polyaluminum ferric chloride, wherein the temperature is 60-70 DEG C, the pH value is 2.5-3.0, the aging time is 12-24 hours; (3) white carbon black preparing: a NaOH solution is adopted to carry out alkali dissolution to dissolve the filter residue, then treatments of acidification and calcination are performed to obtain the powder SiO2, wherein the alkali dissolution temperature is 80-100 DEG C, the time is 4-8 hours.

Owner:孙建之

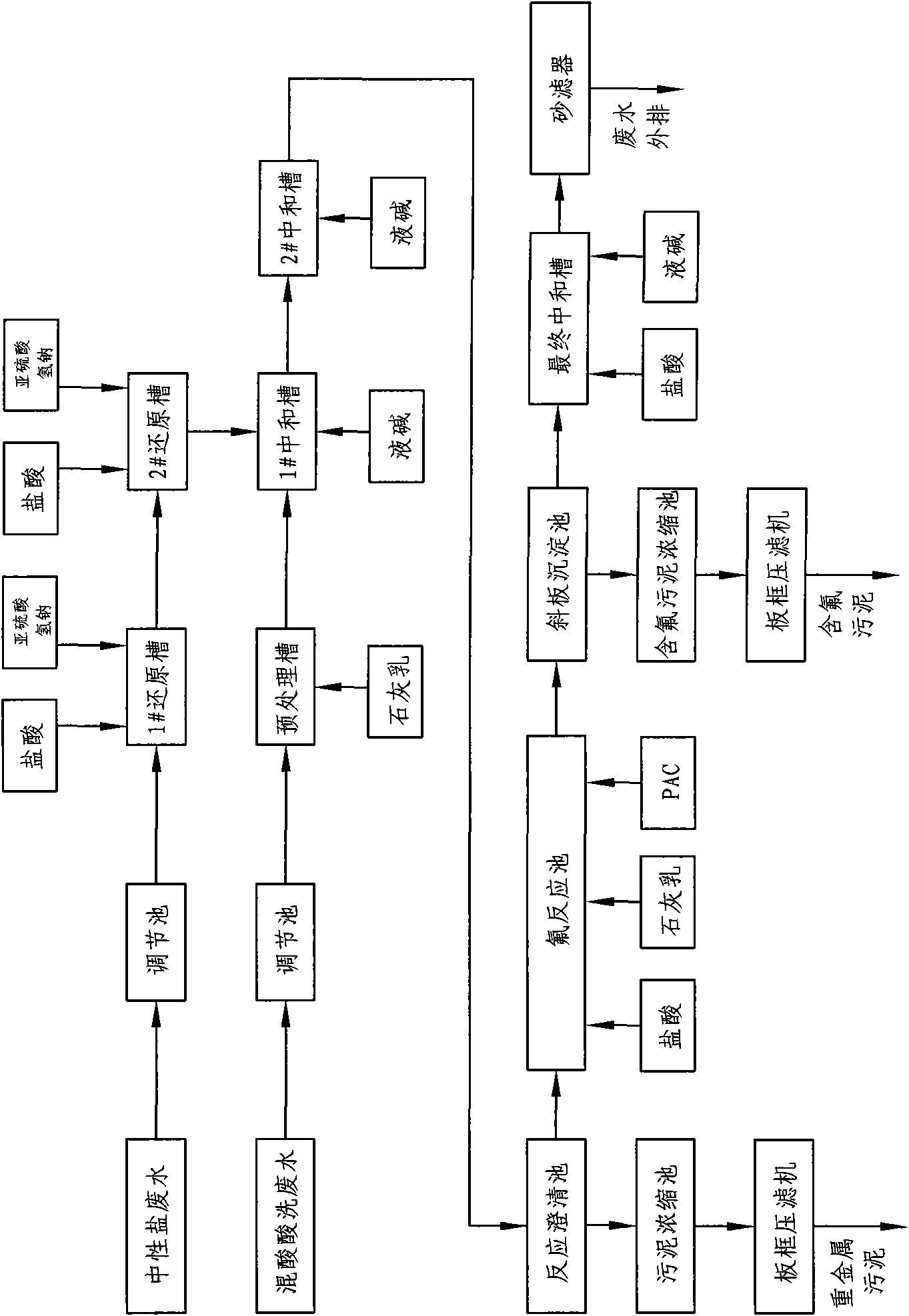

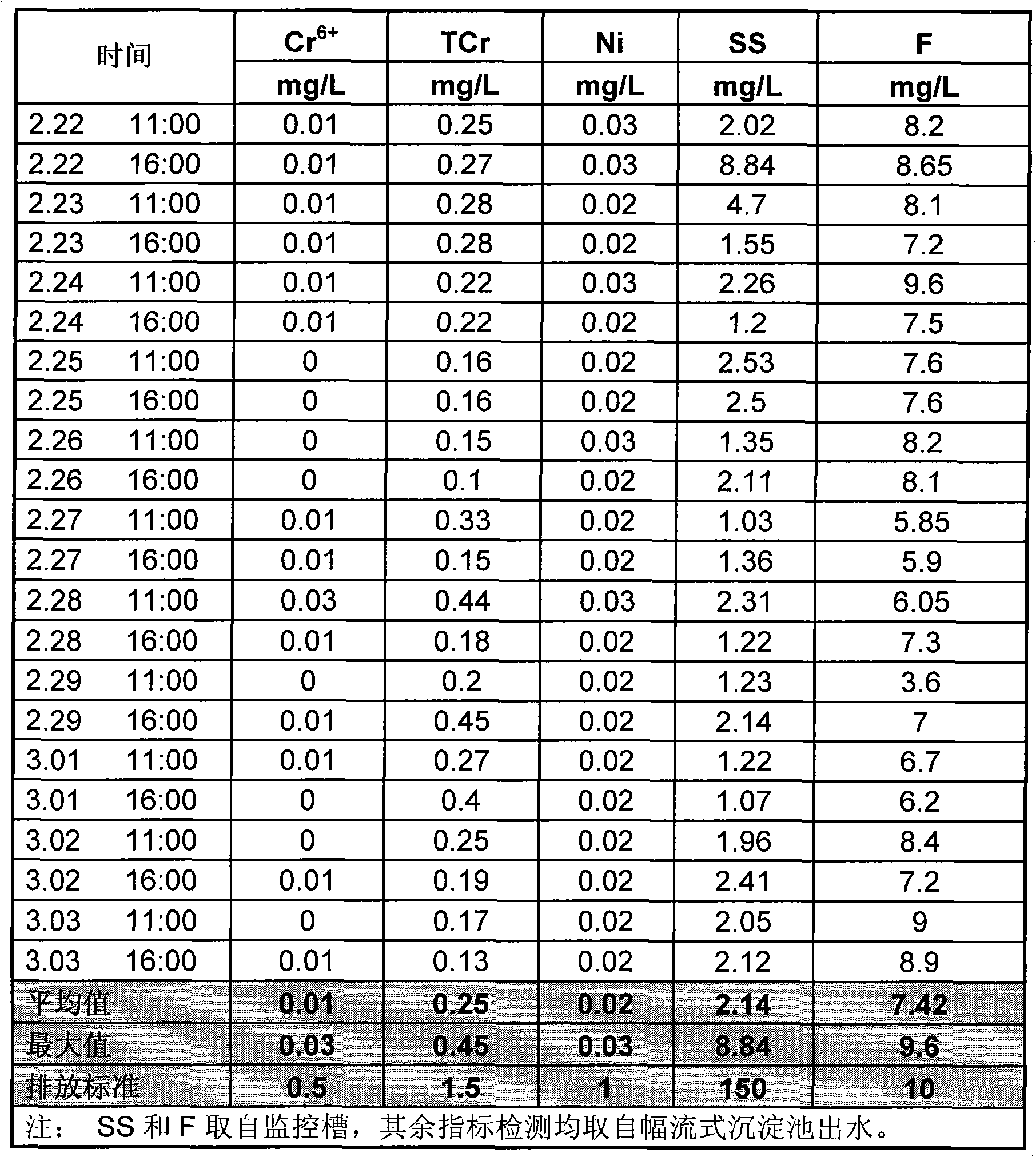

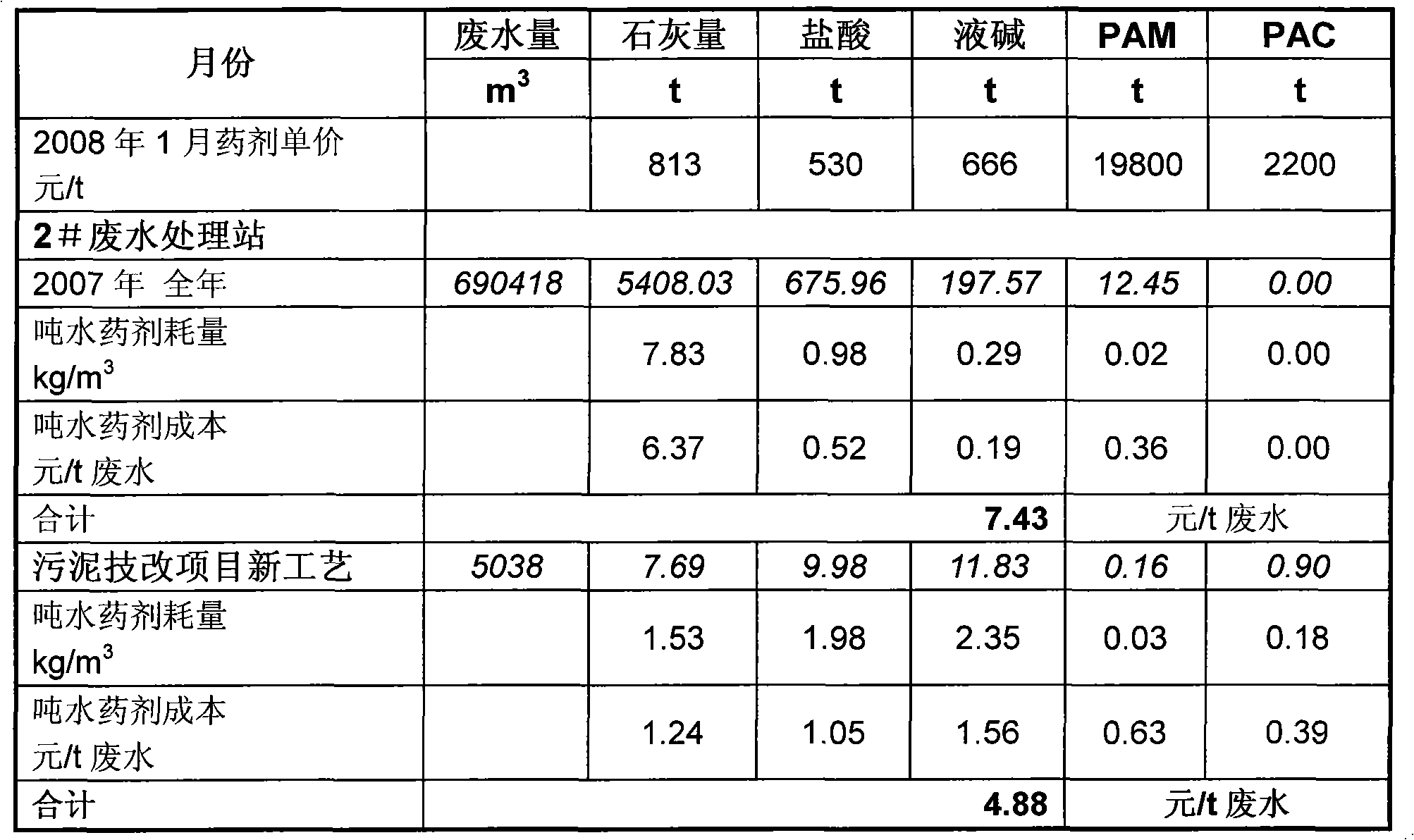

Method for treating stainless steel cold rolling pickling waste water

InactiveCN101993158AReduce consumptionStable fluoride ion concentrationIron oxides/hydroxidesWater contaminantsAluminium chlorohydrateSludge

The invention discloses a method for treating stainless steel cold rolling pickling waste water, which adopts a lime milk pretreatment process and a waste water segmental treatment process and comprises the following steps of: firstly, performing lime milk pretreatment on the waste water to control the pH value between 5 and 6; secondly, adding liquid caustic soda to remove heavy metal ions in the waste water so as to form a metal oxide precipitate; and finally, treating fluorine ions, namely adding polyaluminium chloride and lime milk to remove the fluorine ions, and filtering and discharging the waste water after adjusting the pH. The treatment method has good using effect, the waste water reaches the required standard and is stable, the sludge quantity is small, and the cost is low.

Owner:NINGBO BAOXIN STAINLESS STEEL

Water purifier for treating production wastewater of rubber accelerator NOBS and wastewater treatment method

ActiveCN104529062AHigh transparencyImprove water purification effectMultistage water/sewage treatmentNature of treatment waterPectinaseDesorption

The invention belongs to the technical field of environmentally water treatment and particularly relates to a water purifier for treating production wastewater of a rubber accelerator NOBS and a wastewater treatment method. The water purifier comprises a flocculating water purifier, a microbial water purifier and an enzyme preparation, wherein the flocculating water purifier consists of polyaluminum ferric chloride, polyacrylamide, ferrous sulfate and aluminum sulfate; the microbial water purifier consists of nitrobacteria powder, paracoccus denitrificans powder, thiobacteria powder, aniline degradation bacteria powder, flocculating bacteria powder, bacillus siliceous powder and bacillus subtilis powder; the enzyme preparation consists of pectinase, cellulose, oxidordeuctase, xylanase, alkaline protease and monoamine oxidase. The water purifier for treating sewage provided by the invention is good in water purification effect, quick in water purification speed, high in safety and free of secondary pollution. By using a material with a desorption capacity as a raw material, sewage is treated by being assisted by microorganisms, so that the water purifier is wide in application range, and the treated water is extremely high in transparency and can be recycled.

Owner:安徽优盾信息科技有限公司

Multifunctional sewage treatment agent and preparation method thereof

ActiveCN103708631AOvercome deficienciesReduce flocculation costScale removal and water softeningWater/sewage treatment by ion-exchangeCross-linkSodium Bentonite

The invention relates to the technical field of water treatment agents and particularly relates to a multifunctional sewage treatment agent. The multifunctional sewage treatment agent comprises the following raw materials in parts by weight: 10-20 parts of sepiolite powder, 30-40 parts of bentonite, 30-40 parts of starch xanthate, 0.1-0.5 part of sodium hydroxide caustic soda, 1-5 parts of polyaspartic acid, 0.1-0.5 part of amino trimethylene phosphonic acid, 25-50 parts of cross-linked rectorite, 20-50 parts of aluminum polychlorid, 5-30 parts of chitosan and 10-30 parts of deionized water. The multifunctional sewage treatment agent provided by the invention is high in purity, free of impurity and dustless, the aqueous solution is clear, transparent, non-toxic and free of effect on operation workers, and the treated water is free of problems such as secondary pollution.

Owner:WENZHOU HONGJIAN CONSTR ENG

Dyeing wastewater treatment agent and preparation method thereof

InactiveCN103708593ASustainable processingHigh chromaWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionDyeing wastewaterPollution

The invention relates to the technical field of wastewater treatment, and particularly relates to a dyeing wastewater treatment agent and a preparation method thereof. The dyeing wastewater treatment agent comprises the following raw materials in parts by weight: 2-10 parts of ferrous sulfate, 20-30 parts of magnesium sulfate, 0.5-2 parts of polyacrylamide, 10-20 parts of iron nitrate, 1-5 parts of nickel nitrate, 40-60 parts of polyaluminum chloride, 10-20 parts of modified kieselguhr, 8-22 parts of meerschaum powder, 10-20 parts of crosslinked rectorite, 5-10 parts of chitosan-graphene composite material and 1-3 parts of graphene nano layer / MnO2 compound. The dyeing wastewater treatment agent provided by the invention has the advantages of convenient production method, low investment, quick effect taking and no secondary pollution.

Owner:HANDAN COLLEGE

Papermaking wastewater treating agent and preparation method thereof

ActiveCN103641245ASustainable processingIncrease concentrationWater/sewage treatment by ion-exchangeWaste water treatment from plant processingStarch xanthatePolyacrylamide

The invention relates to the technical field of wastewater treatment, and in particular relates to a papermaking wastewater treating agent and a preparation method thereof. The papermaking wastewater treating agent comprises the following raw materials in parts by weight: 2-10 parts of ferrous sulfate, 10-20 parts of magnesium sulfate, 0.5-1.5 parts of polyacrylamide, 15-25 parts of ferric nitrate, 1-5 parts of nickel nitrate, 35-50 parts of polyaluminum chloride, 15-30 parts of starch xanthate, 2-5 parts of tetrasodium 2-phosphonobutane-1, 2, 4-tricarboxylate, 0.5-1 part of zinc sulfate, 1-3 parts of benzotriazole, 16-30 parts of modified kieselguhr, 5-20 parts of cross-linked rectorite and 5-8 parts of a chitosan-graphene composite material. The papermaking wastewater treating agent disclosed by the invention is wide in using range, simple in treatment process, small in drug consumption, good in treatment effect, stable in performance and good in effluent quality and is capable of effectively reducing the cost of water treatment, so that the papermaking wastewater treating agent has a very good economic benefit and a wide social benefit.

Owner:SHANTOU LONGHU DISTRICT YUEAN PAPER

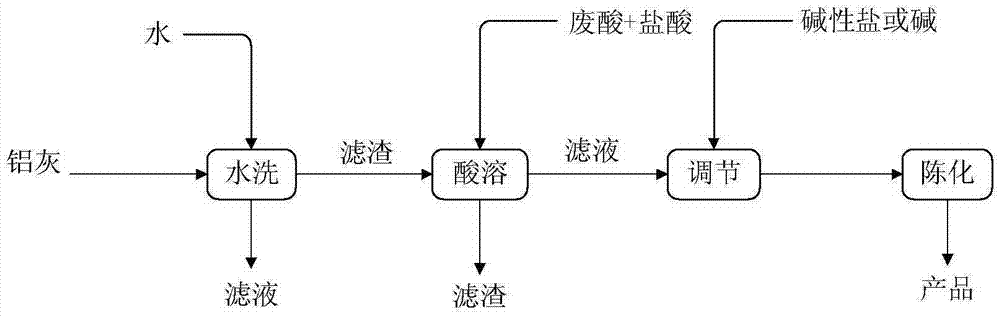

Method for producing aluminum polychlorid water purifying agent from waste hydrochloric acid and aluminum ash

InactiveCN106892444AQuick buildGuaranteed stabilityAluminium chloridesWater/sewage treatment by flocculation/precipitationLiquid productResource utilization

The invention relates to a method for producing an aluminum polychlorid water purifying agent from waste hydrochloric acid and aluminum ash. The method comprises the following steps: carrying out dissolving reaction on the solid waste aluminum ash produced in an aluminum electrolysis process and waste hydrochloric acid produced in a resource utilization process of high-aluminum coal ash, so as to obtain an aluminum-containing solution; adding alkaline salt or alkali into the aluminum-containing solution, and carrying out polymerization reaction, so as to obtain a primary product; and ageing the primary product, so as to obtain an aluminum polychlorid liquid product. By utilizing the method, the problems of solid waste pollution and wastewater emission can be solved, and the aluminum polychlorid product meeting the index requirements of national standard (GB15892-2009) can be prepared; and the method has good economic and social values.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Stabilized antiperspirant compositions containing soy products

InactiveUS20070009459A1Reducing and stopping perspirationDeodorizing skinCosmetic preparationsHair removalAluminium chlorohydrateSoy product

This invention relates to antiperspirant compositions comprising soy products, one ore more antiperspirant agents such as aluminium chlorohydrate and a stabilizing system, which additionally influence hair growth.

Owner:JOHNSON & JOHNSON CONSUMER FRANCE SAS

Decolorization flocculating agent for printing and dyeing waste water

InactiveCN101085688ADosage controlGood decolorization effectWater/sewage treatment by flocculation/precipitationRefluxAluminium chlorohydrate

The invention provides a method for preparing decolouring flocculating agent for printing and dyeing wastewater. It comprises following steps: adding 6- 9 units dicyandiamide, 4- 1 units urea, 20 -26 units formaldehyde and 3.5- 7.5 untis ammonium chloride into autoclave equipped with reflux condensing unit, reacting at 40 -50 Deg. C for 1- 2 hours, heating to 80- 85 Deg. C and reacting for another 1.5- 2 hours, adding 66.5- 56.5 units newly prepared polymeric aluminum chloride solution (Al2O3%=12), cooling to 40- 50 Deg. C and reacting for 0.5- 1 hour, curing 24 hours and getting final product. The invention is characterized by good decoloring and flocculating effect, simple device and process, and low production cost.

Owner:GUANGZHOU GELONG ENVIRONMENTAL PROTECTION TECH DEV

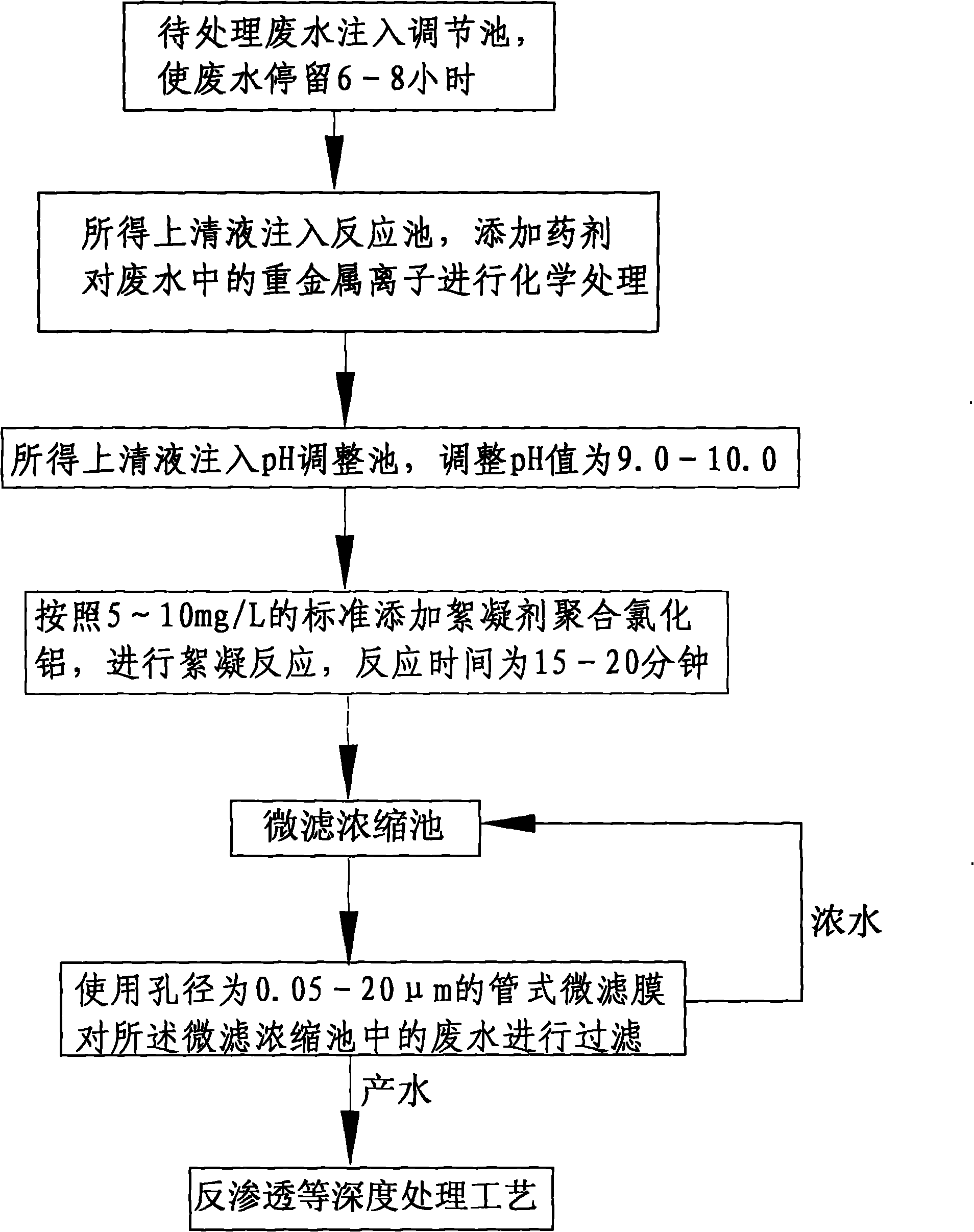

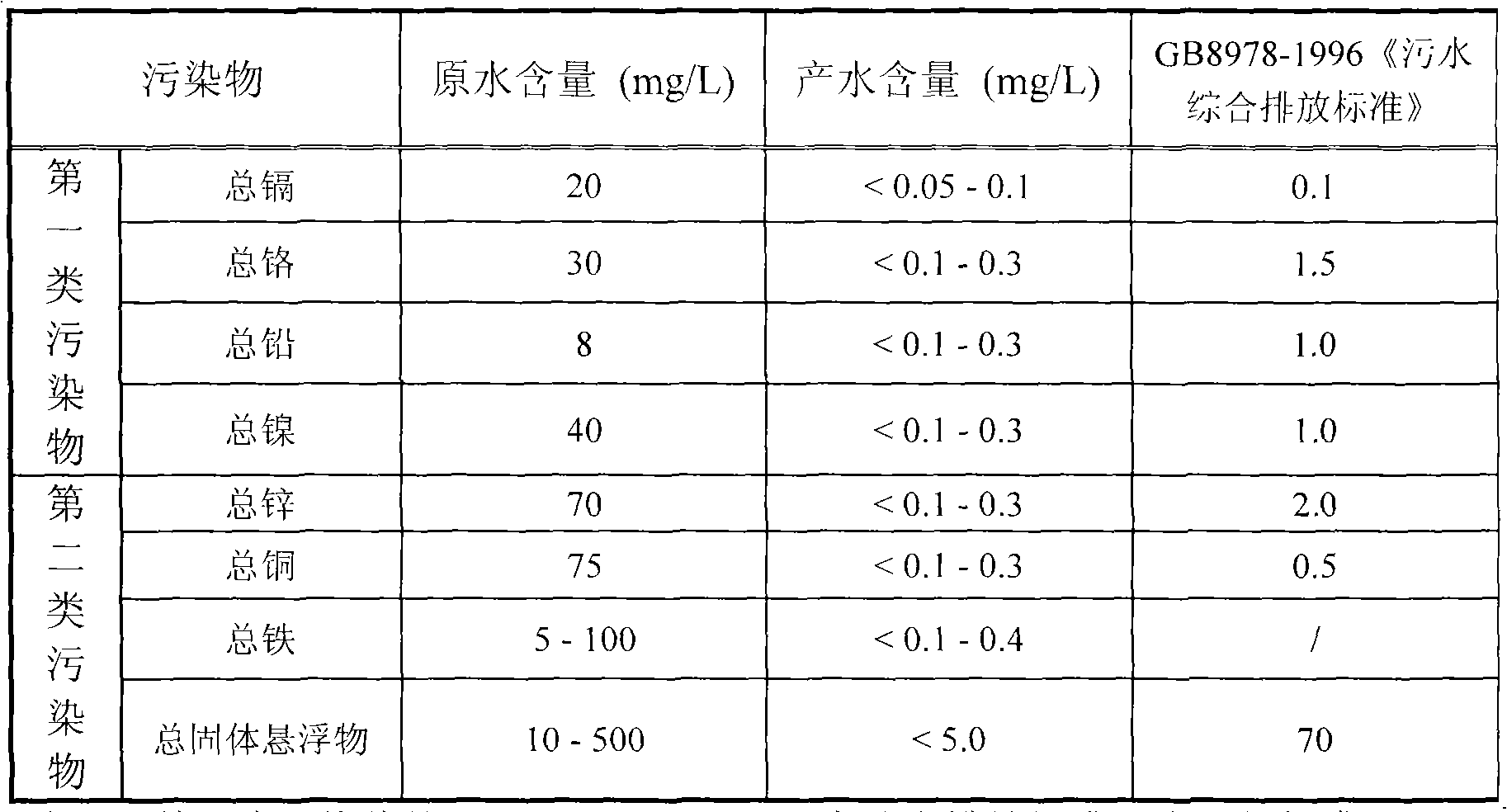

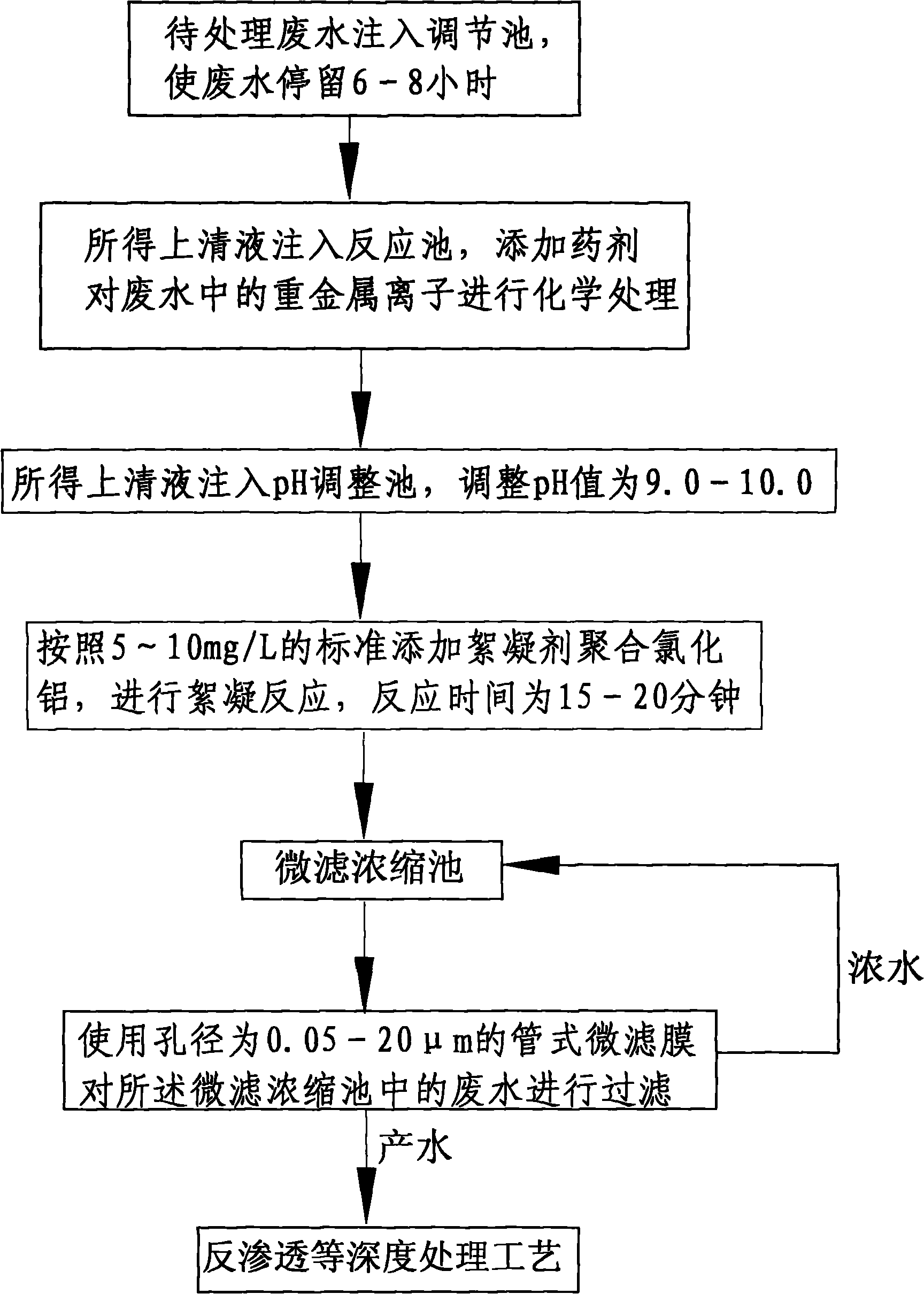

Method for treating heavy metal industrial sewage

InactiveCN101830581ASmall footprintLess investmentWaste water treatment from metallurgical processMultistage water/sewage treatmentHigh concentrationChemical treatment

The invention discloses a method for treating heavy metal industrial sewage, sequentially comprising the following steps of: a, infusing sewage to be treated to a regulating tank, and staying for 6-8 hours; b, infusing supernate obtained in the step a to a reaction tank, adding medicament to perform chemical treatment for heavy metal ions; c, infusing supernate obtained in the step b to a pH adjusting tank and adjusting pH value to 9.0-10.0; d, infusing sewage obtained by the step c to a flocculation tank, adding aluminum polychlorid based on the standard of 5-10mg / L, reacting for 15-20 minutes to perform flocculoreaction; after introducing the supernate to the concentration tank, infusing the sewage in the tank at the flow rate of 3-5m / s by using a centrifugal pump to a pipe-type microfiltration membrane with the aperture of 0.05-20 microns, filtering the sewage and performing advanced treatment for the effluent obtained by entering a reverse osmosis system, and guiding the concentrated sewage back to the microfiltration concentration tank for circular filtration. The method has simplified steps and is particularly suitable for pre-treatment of high-concentration heavy metal ion sewage.

Owner:JIANGXI JDL ENVIRONMENTAL PROTECTION CO LTD

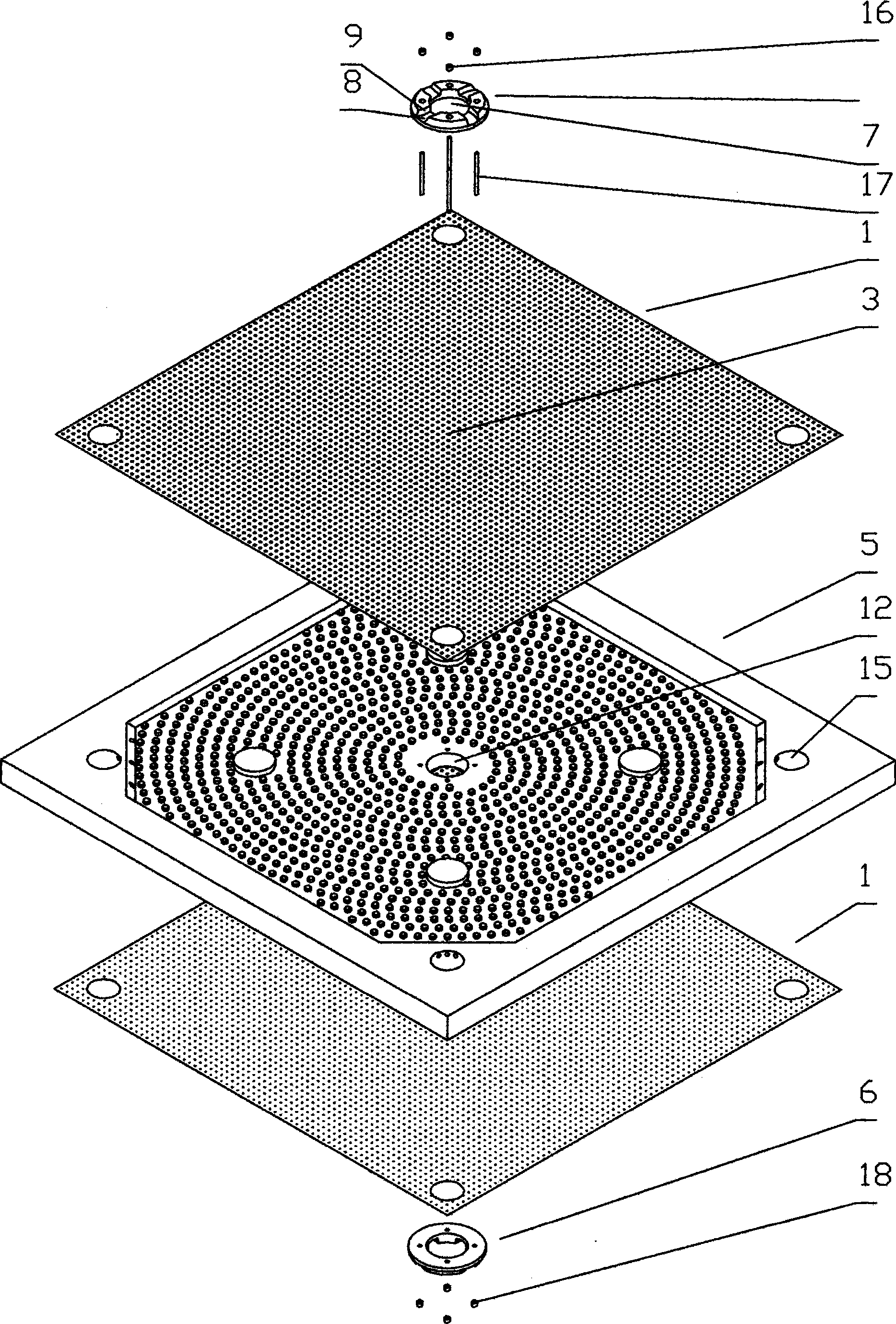

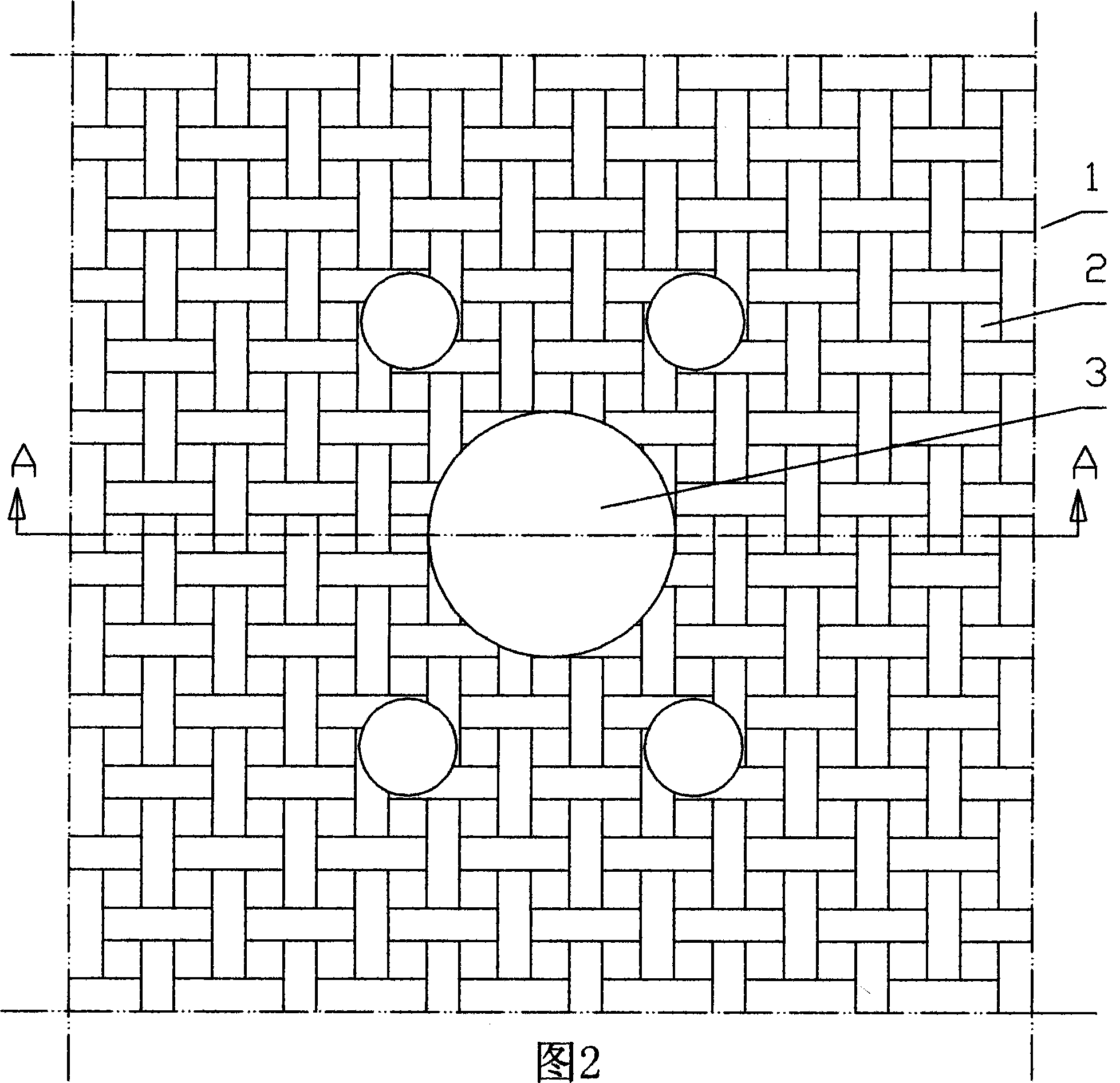

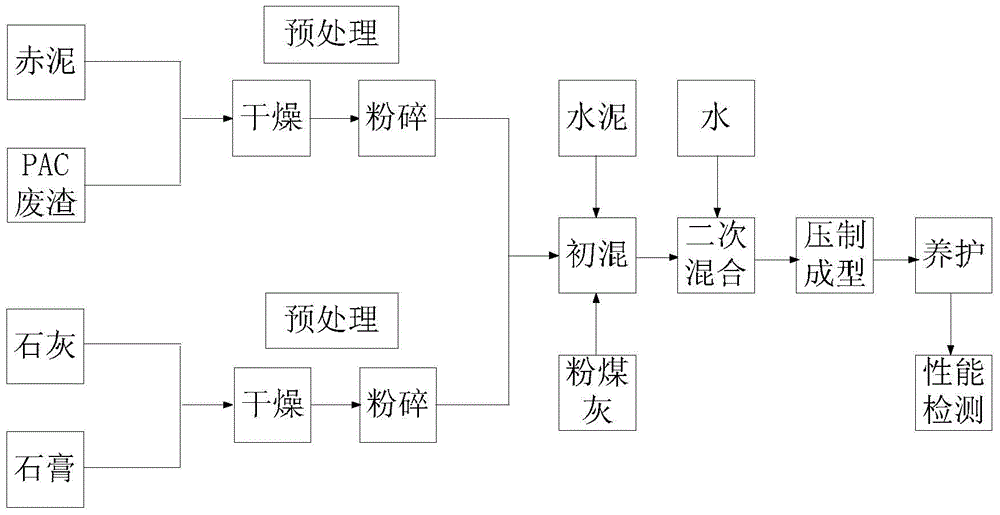

Braking-free brick mainly prepared from polyaluminum chloride waste residues and red mud and preparation method thereof

The invention relates to a braking-free brick mainly prepared from polyaluminum chloride waste residues and red mud and a preparation method thereof. Raw materials for preparing the braking-free brick comprise the red mud, the polyaluminum chloride waste residues, an active mineral material, lime and gypsum. The preparation method comprises the following steps: uniformly mixing the raw materials in proportion, adding 8-12 parts of water, stirring, mixing, carrying out compression molding, sprinkling water and curing. The preparation method has the advantages that the red mud and the PAC (polyaluminum chloride) waste residue are used as the main raw materials, pulverized fuel ash, cement, the lime and the gypsum are added, so that the using amount of an excitant is reduced, the strength of the brick is improved, the usability of the braking-free brick can be improved, meanwhile the national standard requirements are completely satisfied, a gel material does not need to be added in a production process, the heat energy does not need to be consumed, the accumulation of the red mud and the PAC is reduced in a larger sense, and the pollution to environments due to the emission of the red mud and the PAC waste residues is solved.

Owner:SHANDONG UNIV

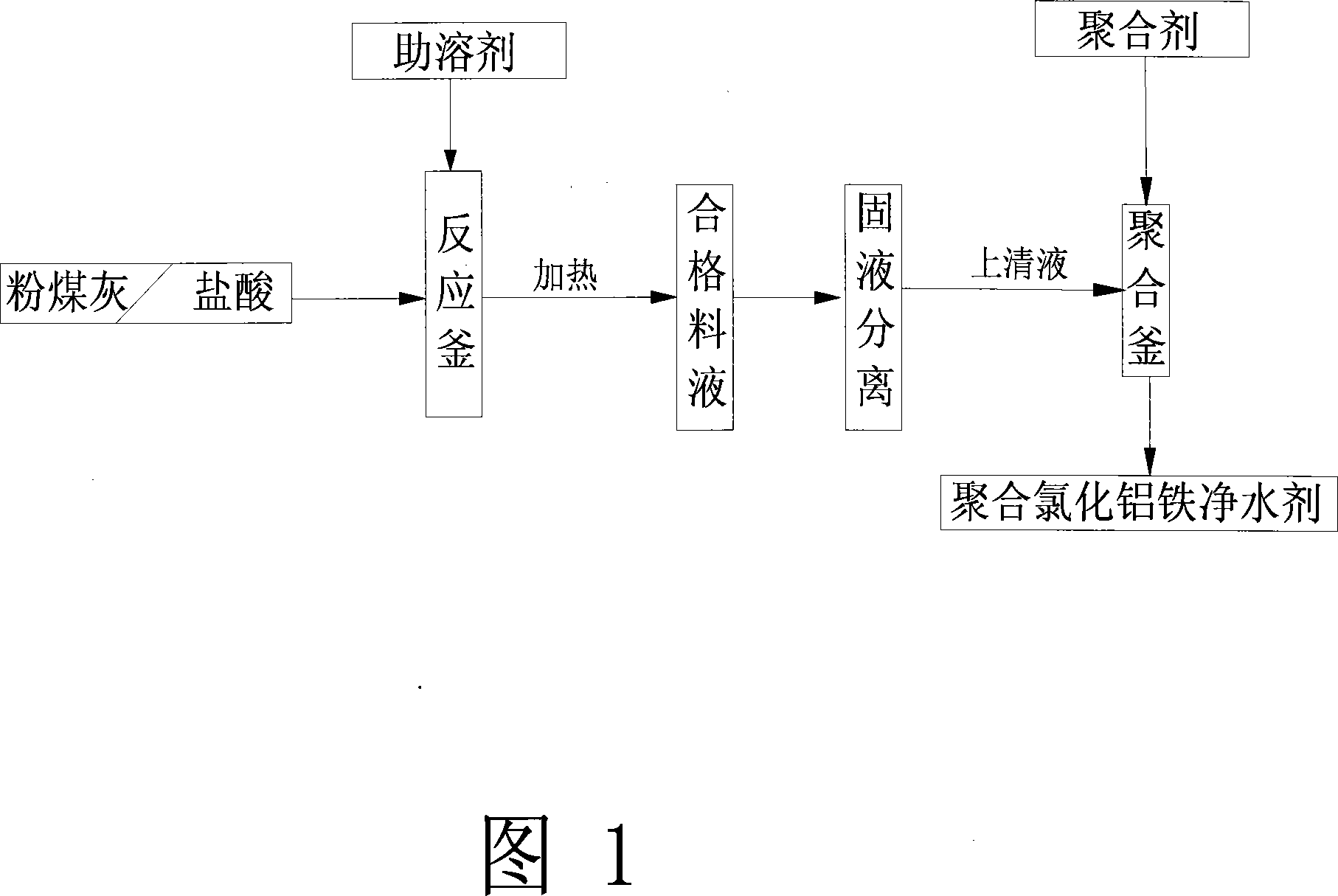

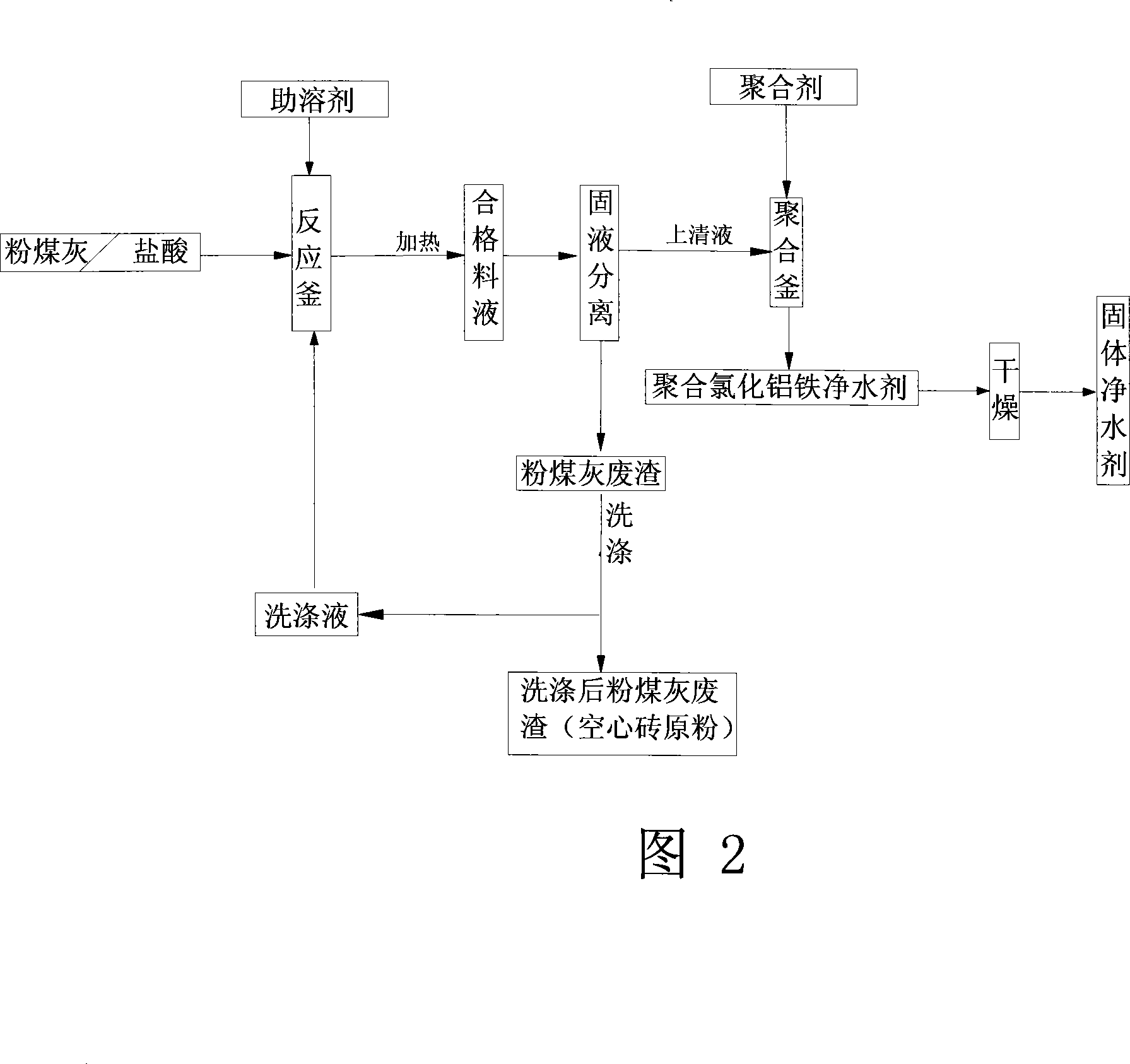

Method for industrial production of polymeric aluminum ferric chloride water purification agent with coal ash

InactiveCN101172684AReduce use costHigh dissolution rateWater/sewage treatment by flocculation/precipitationDissolutionCoal

The invention discloses a method for industrially producing polyaluminum ferric chloride water purifying agent by utilizing fly ash. , put the obtained qualified feed liquid into the clarifier for solid-liquid separation, the separated supernatant liquid is injected into the polymerization kettle, add the polymerization agent, fully stir, and obtain the polyaluminum ferric chloride liquid water purifier through the polymerization reaction. The production process flow is short, the operation is simple, the production cost is low, the economic performance is good, the use cost of the raw material is reduced, the reaction time is shortened, and the reaction energy consumption is reduced. The aluminum dissolution rate in fly ash is high, the raw material cost is low, and industrial production is realized. Adding a cosolvent in the reaction process promotes the cleavage of the silicon-aluminum bond, increases the dissolution rate of aluminum, shortens the reaction time, reduces the consumption of hydrochloric acid, reduces the production cost, and improves the economic benefit of the product. The industrialization of using fly ash to produce polyaluminum ferric chloride has been realized.

Owner:王贵明 +1

Recovery processing process for fracturing return liquid

ActiveCN101475290AAchieving zero emissionsNo pollutionMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationEmulsionAluminium chlorohydrate

The invention relates to a process for reclaiming and treating fracturing backflow fluid. The process comprises the following steps: a, feeding the fracturing backflow fluid into a dirty oil reclaiming pool, and reclaiming dirty oil; b, after natural degradation, adding gel breaker active polyaluminium chloride into sewage, and pumping the sewage into an electric flocculator; c, further breaking gel and emulsion in the sewage through the electric flocculator; and d, after electric flocculation treatment, feeding water purifying agent nano-scale clay and flocculating agent polyaluminium chloride into the sewage, adding coagulant aid polyacrylamide after the sewage is pumped by the pump, feeding the sewage into a suspended silt filter and then conveying the sewage into an oilfield sewage treatment station to be treated and recycled. The process for treating the fracturing backflow fluid has the advantages of low cost, safe production and stable treating effect, and is not limited by environmental conditions.

Owner:DAQING OILFIELD CO LTD +1

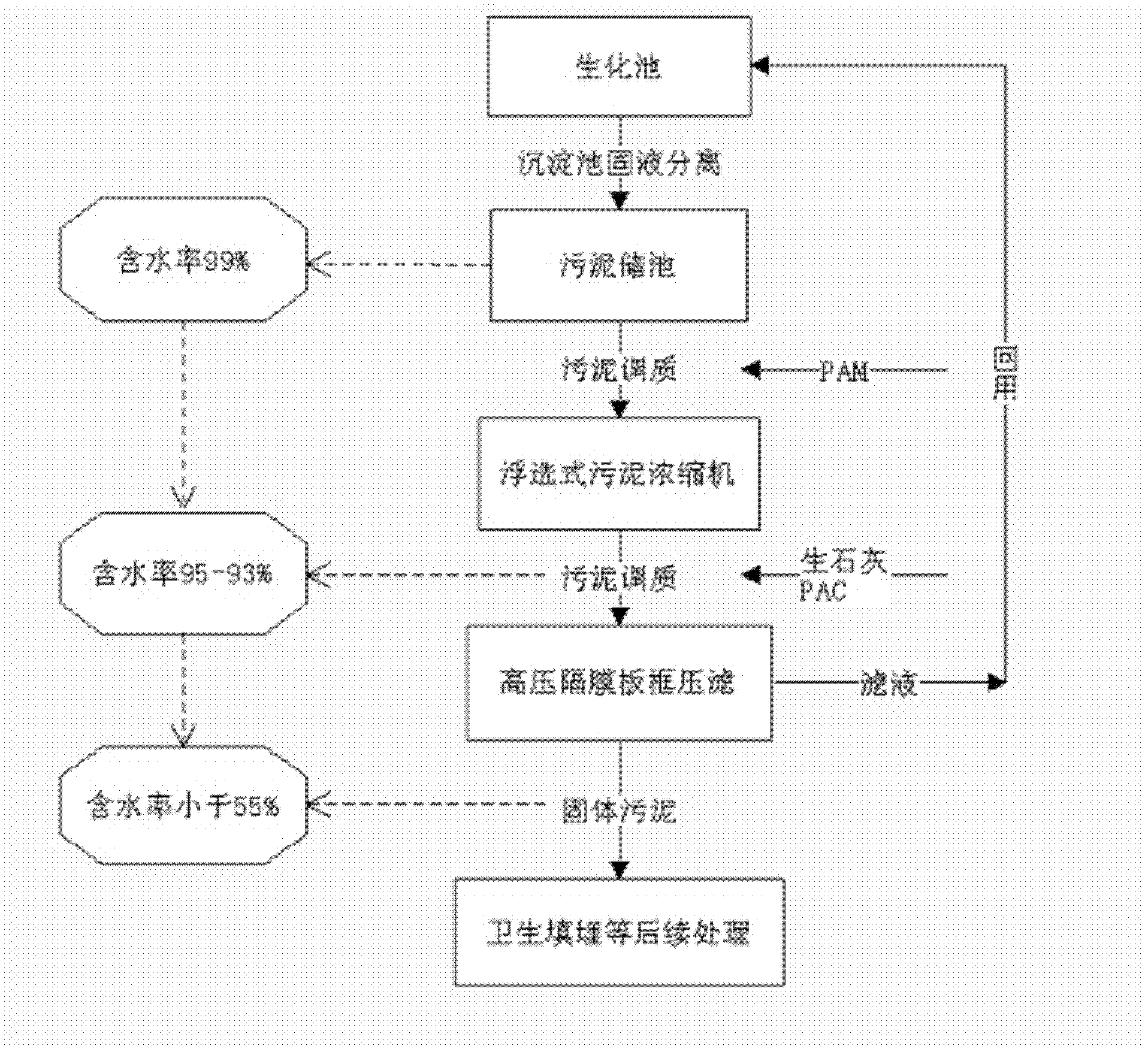

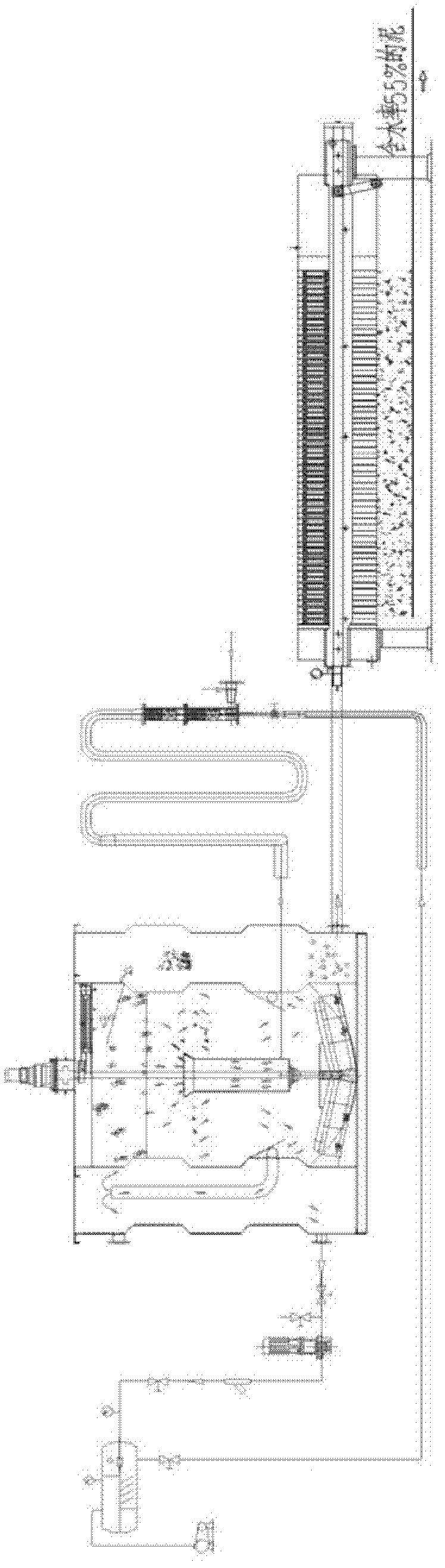

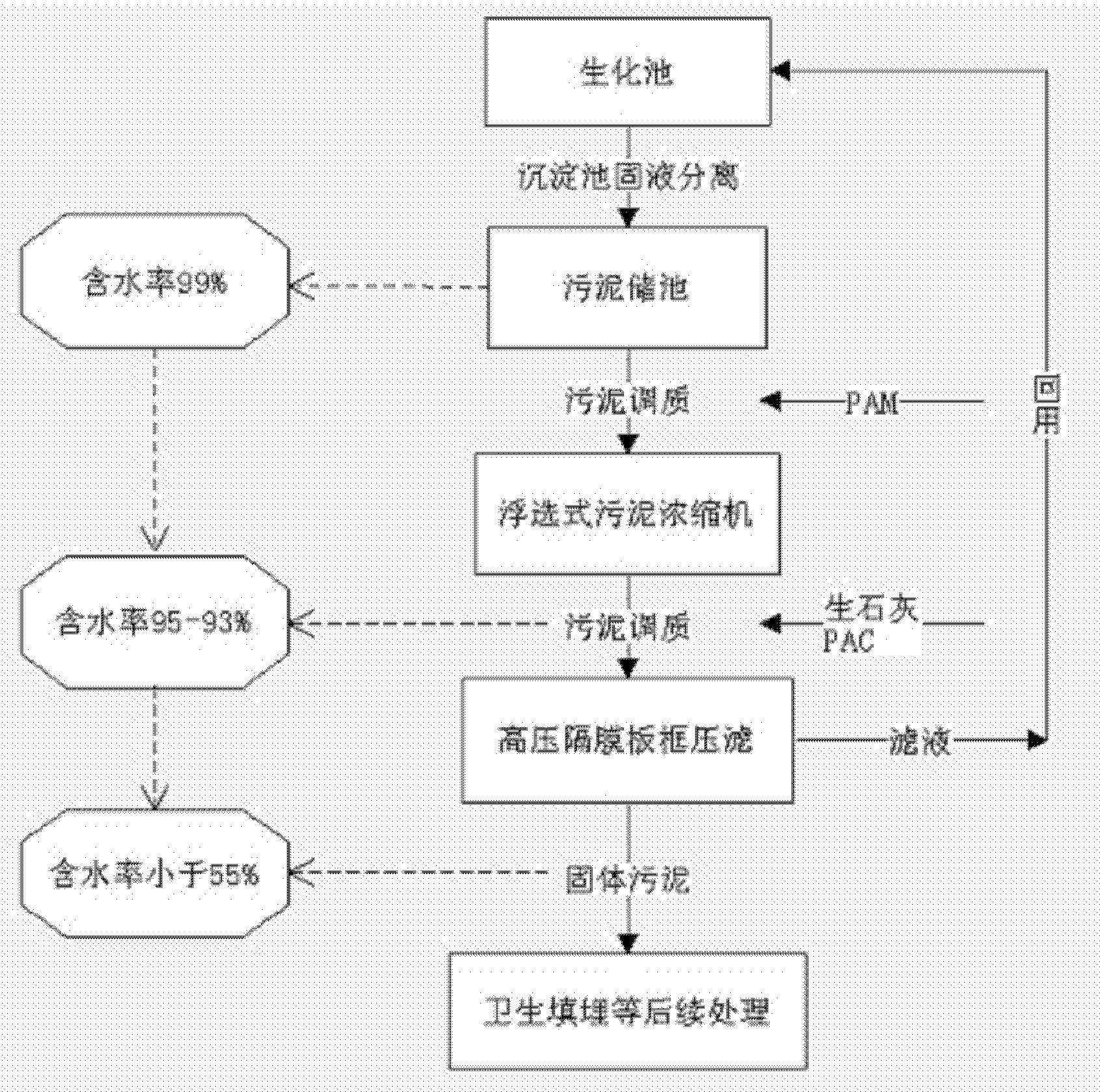

Method for concentrating and dehydrating sludge

InactiveCN102617013AReduce moisture contentHigh degree of automationSludge treatment by de-watering/drying/thickeningFiltration separationHigh concentrationAluminium chlorohydrate

The invention discloses a method for concentrating and dehydrating sludge. The method is characterized by comprising the following steps of: adding polyacrylamide into residual sludge of which the moisture content is 99 percent in an amount of 0.3 percent based on the mass of absolutely dry sludge for hardening and tempering the sludge; feeding the hardened and tempered sludge of which the moisture content is 99 percent into a flotation sludge concentrator through a pump for concentrating; feeding the concentrated sludge into a sludge hardening and tempering tank through a pump, adding caustic lime in an amount of 15 percent based on the mass of the absolutely dry sludge and polyaluminium chloride in an amount of 5 percent of based on mass of the absolutely dry sludge for further hardening and tempering; and performing filter pressing on the further hardened and tempered sludge by adopting a high-pressure diaphragm plate filter press. The method has the advantages of high system automatic degree, high concentration efficiency, low energy consumption, low mud moisture content and capability of making obtained sludge directly meet a filling requirement.

Owner:ZHEJIANG HI TECH ENVIRONMENTAL TECH

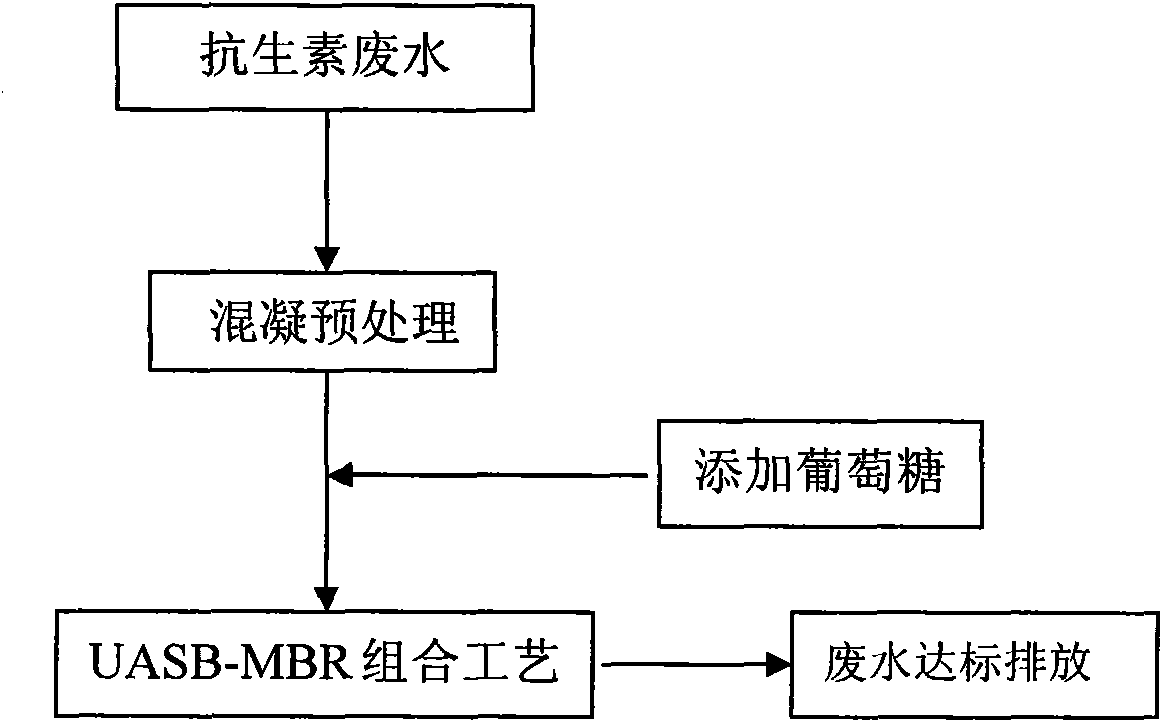

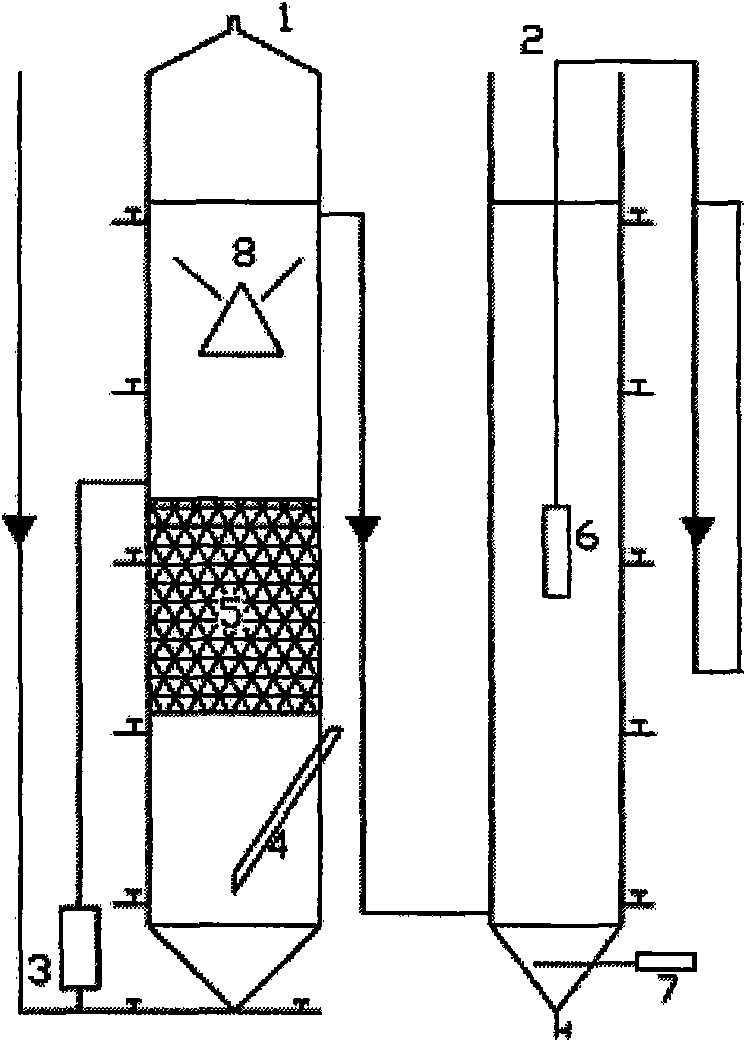

New method for processing antibiotic wastewater

InactiveCN101654311AChemical structure changePromote degradationTreatment with anaerobic digestion processesWater/sewage treatment bu osmosis/dialysisTurbidityWater processing

The invention relates to a method for processing antibiotic wastewater, belonging to the technical field of water processing of environmental engineering. The invention uses an up anaerobic sludge blanket-aerobic membrane bioreactor (UASB-MBR) integrated device to perform biological process on the antibiotic wastewater. Firstly, aluminum polychlorid is put in antibiotic wastewater for coagulationpreprocess; COD concentration of the wastewater is lowered by 30.8%, and turbidity is smaller than 10 NTU; then the UASB-MBR integrated device is used to further deep process to control the hydraulicretention time of the system to be 20.5 hours, COD average removal ratio can reach 86.56%, and mixed liquor suspended solid (MLSS) is 3000-4000mg / l; the effective removal ratio of the integrated device is 80-85%. Water yielding COD can reach the National Bio-pharmaceutical Industrial Wastewater Discharge Standard (GB8978-1996) after being processed by the integrated device, and the discharge standard is 300mg / l.

Owner:SHANGHAI UNIV

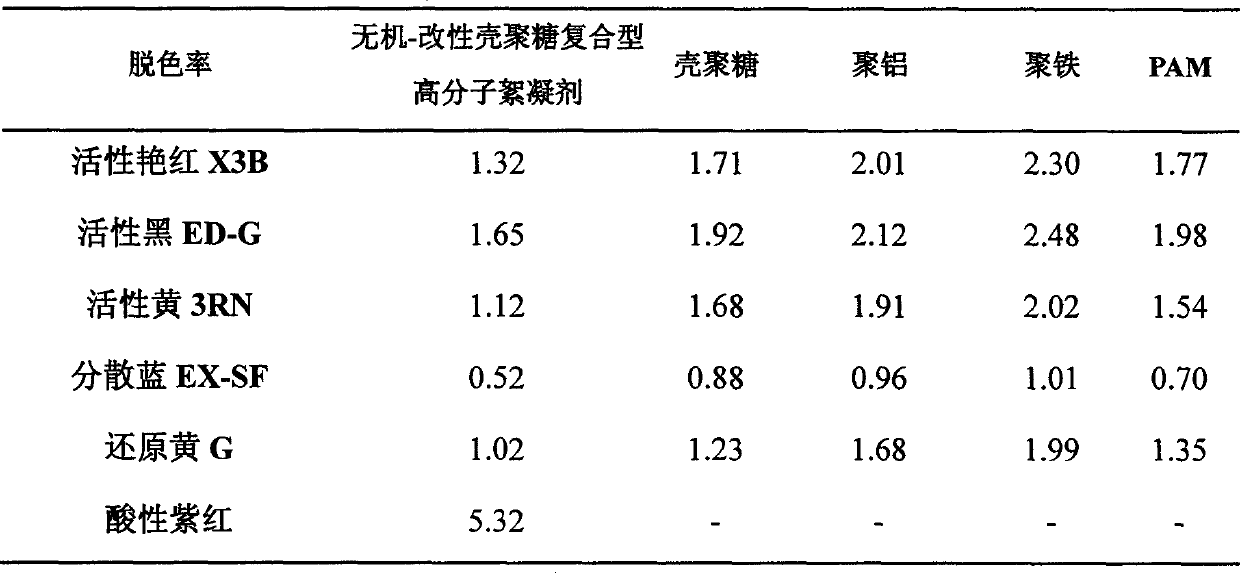

Inorganic-modified chitosan composite type polymeric flocculant

InactiveCN103121742ASimple structureRich sourcesWater/sewage treatment by flocculation/precipitationAluminium chlorideMeth-

The invention relates to an inorganic-modified chitosan composite type polymeric flocculant. The inorganic-modified chitosan composite type polymeric flocculant is characterized in that a method for preparing the composite type polymeric flocculant comprises the following steps of: taking polyacrylamide-modified chitosan as a raw material and methacryloyloxyethyl trimethyl ammonium chloride, maleic acid and ceric ammonium nitrate as initiators, synthesizing a modified chitosan copolymer under a faintly acidic condition and blending the modified chitosan copolymer with polymerized ferric chloride and polymerized aluminium chloride to obtain the inorganic-modified chitosan composite type polymeric flocculant. According to the steps, the mass ratio of modified starch to the chitosan is (1-2): 1, the reaction temperature is 50-60 DEG C, the reaction time is 2-3 hours, and the use amount of the initiators accounts for 0.02 part of the total mass of the system. The inorganic-modified chitosan composite type polymeric flocculant prepared by using the method has the characteristics of high efficiency, low cost and low secondary pollution to environment; and aiming at different sludges, compared with a conventional flocculant, the inorganic-modified chitosan composite type polymeric flocculant disclosed by the invention has the advantages that the wastewater decoloring rate and the wastewater deturbidity rate can reach more than 99 percent under the condition of low use amount.

Owner:WUHAN SLOAN ELECTRIC

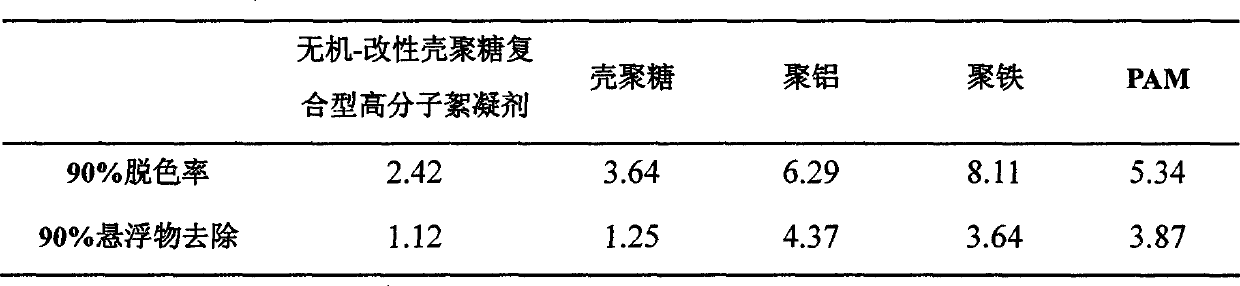

Coproduction method of potassium dihydrogen phosphate, sulfur base composite fertilizer and aluminium polychloride

InactiveCN100999312AReduce in quantityReduce the precipitation rateAluminium chloridesPhosphorus compoundsDecompositionPhosphate

Owner:宜昌市欣龙化工新材料有限公司

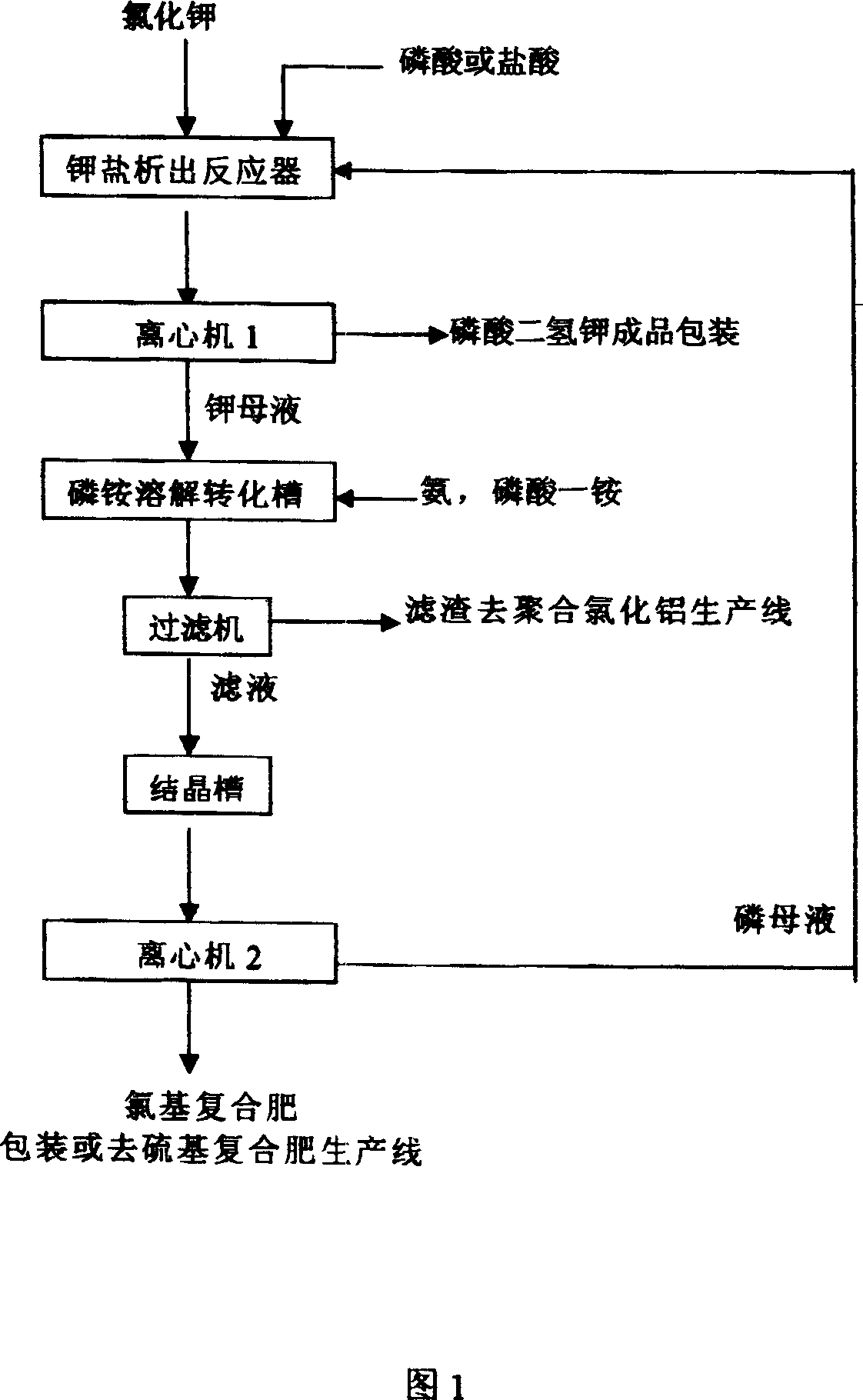

Aqueous ink waste water disposal process

InactiveCN1765762ASatisfy the requirement of complete decolorizationAchieve emission standardsWater/sewage treatment by irradiationWater/sewage treatment by neutralisationSludgeUltraviolet lights

The invention discloses a treatment for ink sewage, which comprises: adding proper PAC as flocculant in sewage, mixing round quickly, and adding proper ferrous sulfate as coagulant aid; mixing, depositing; using the supernatant for UV / Fenton oxidation under ultraviolet light; before oxidation, using hydrochloric acid to regulate solution pH value to optimal, adding given superoxol and ferrous sulfate; after reaction, adjusting solution to neutrality with superoxol and get rid of iron ion; depositing, and separating out water. The treated water has 97-100% transmittance with total removal rate to COD more than 93% that are between highest limit of second and third class discharge standard (GB 8978-1996).

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Oil-containing wastewater treatment agent and preparation method thereof

ActiveCN103864177AReduce CODReduce BODFatty/oily/floating substances removal devicesLiquid separationTherapeutic effectPollution

The invention belongs to the technical field of sewage treatment agents, and in particular relates to an oil-containing wastewater treatment agent and a preparation method thereof. The oil-containing wastewater treatment agent disclosed by the invention comprises the following raw materials in parts by weight: 35-45 parts of polyacrylamide, 15-25 parts of polymeric aluminium, 12-18 parts of expanded graphite, 15-20 parts of zeolite mineral, 20-30 parts of hydrolyzed tannin, 3-5 parts of organic acid, 5-10 parts of TiO2, and 3-5 parts of chitosan-graphene composite material. The oil-containing wastewater treatment agent disclosed by the invention has the advantages of being good in treatment effect, low in production cost, high in purity, free from toxicity, influence to operators and secondary pollution after treatment; the preparation method is simple and easy for popularization.

Owner:广州小众环保科技有限公司

Extraction of Sulfate from Water

InactiveUS20120031850A1Reduce metal contentLess soluble in waterSedimentation separationRadioactive contaminantsAluminium chlorideAluminite

Sulfate anions and divalent metal ions, such as magnesium, strontium and barium, in water are removed by treating the water with polyaluminum chloride, usually together with lime, to form ettringite and similar crystalline species which are readily removable by settling, filtration and the like. Iron is also removed by oxidation in a variation of the process. The process is particularly useful for treating aqueous solutions used in well treatment, where flowback fluids can provide some of the divalent metal ions necessary to form the ettringite-like materials, thus reducing the amount of lime otherwise necessary and further facilitating recycling of the fluid.

Owner:SMART CHEM SERVICES LP

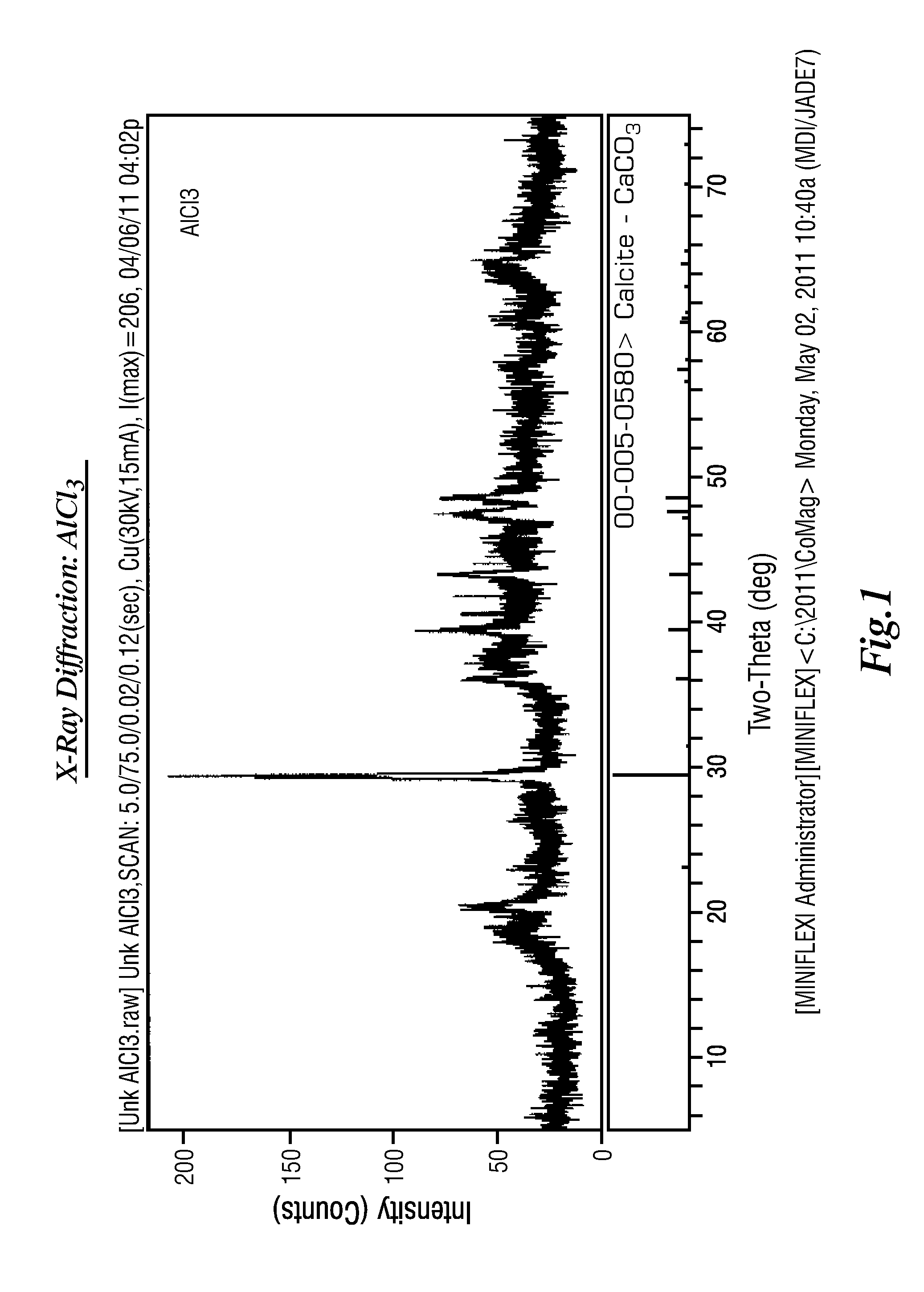

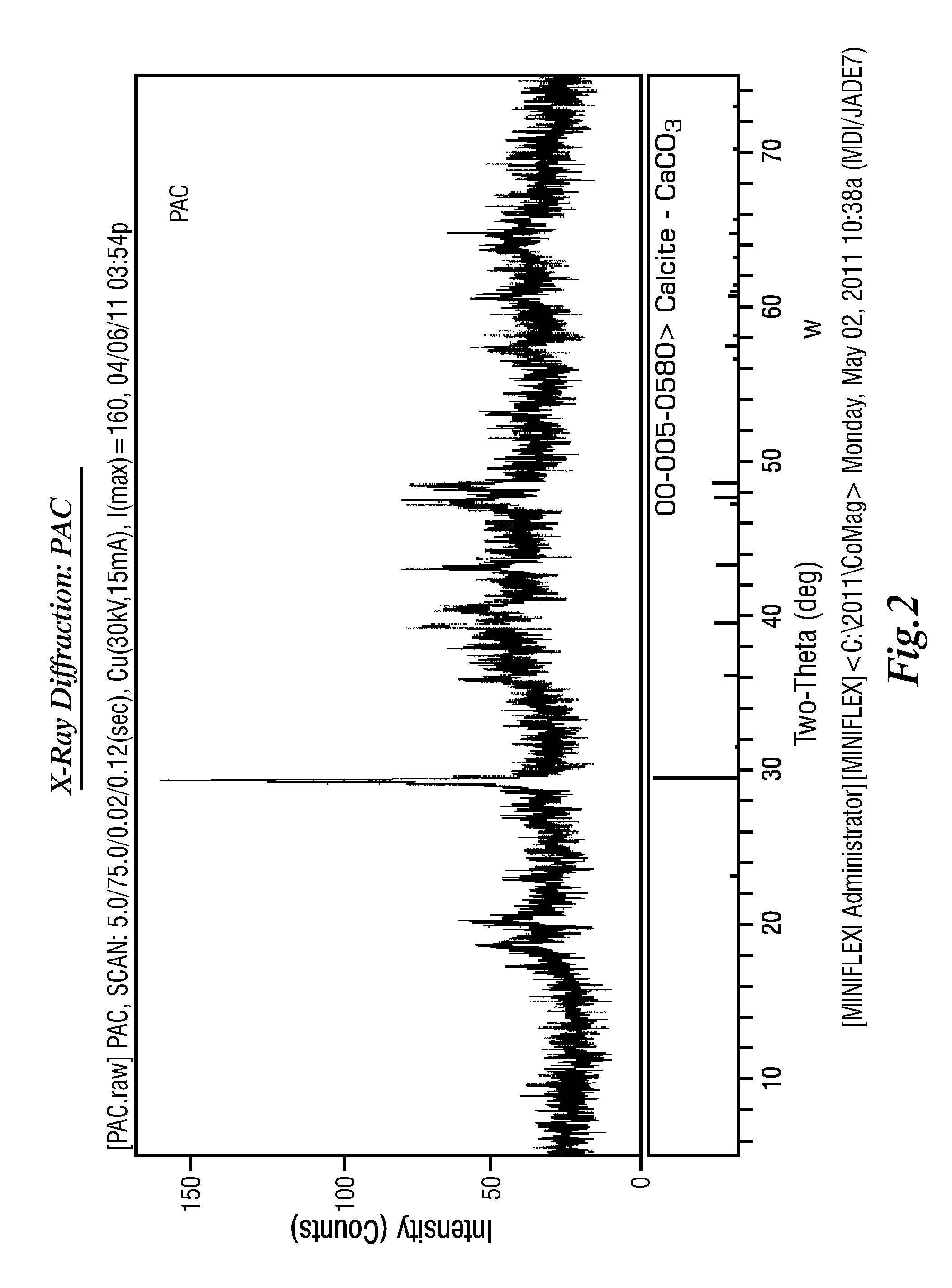

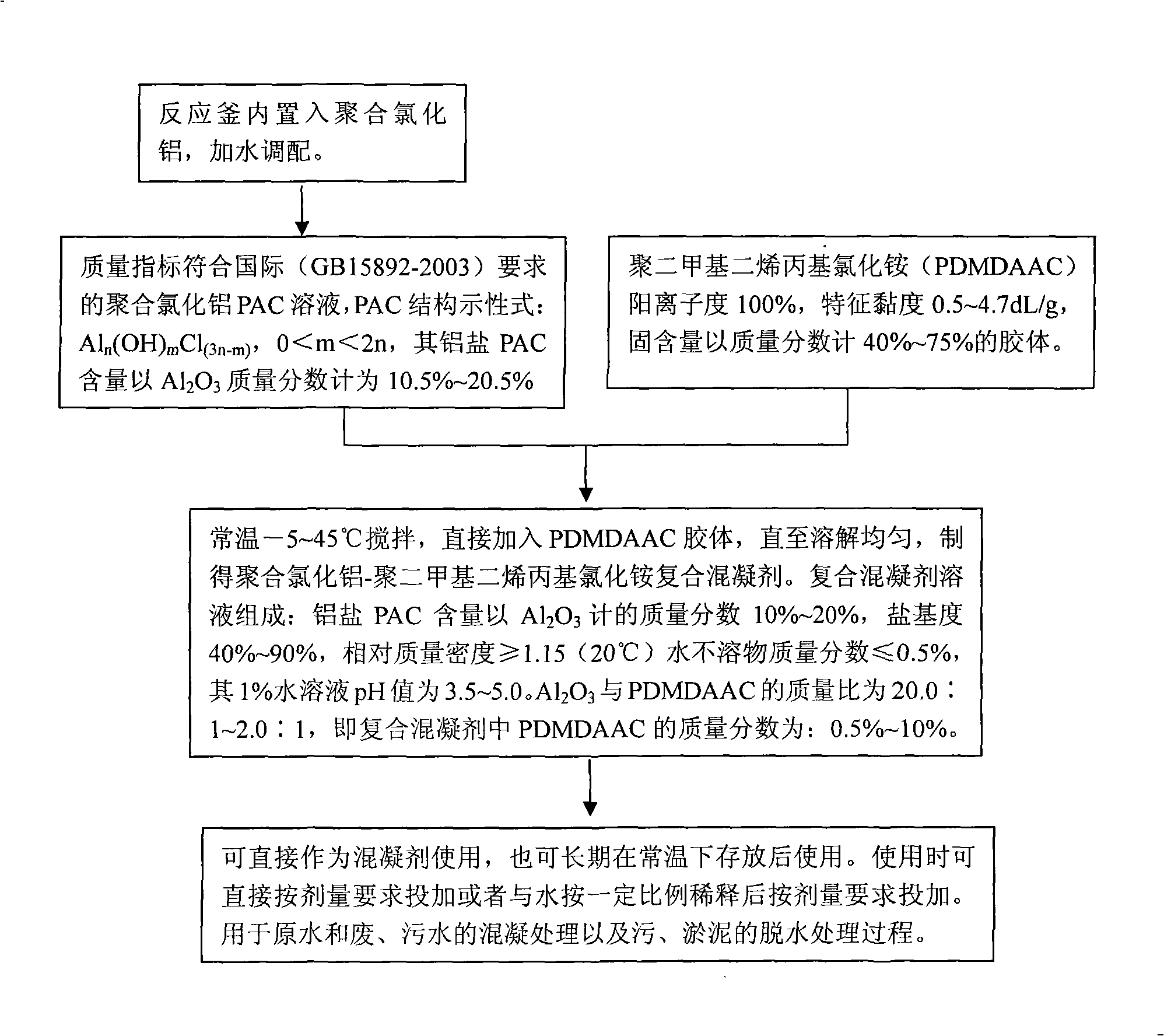

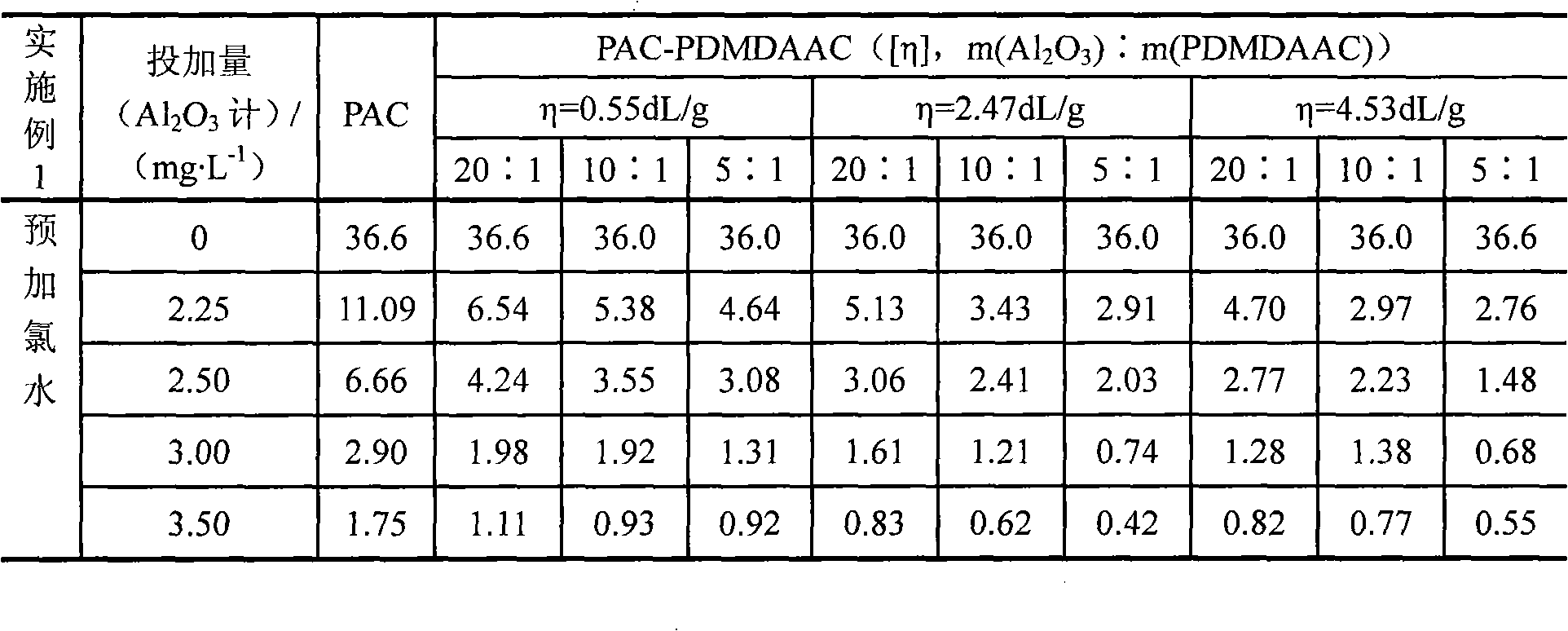

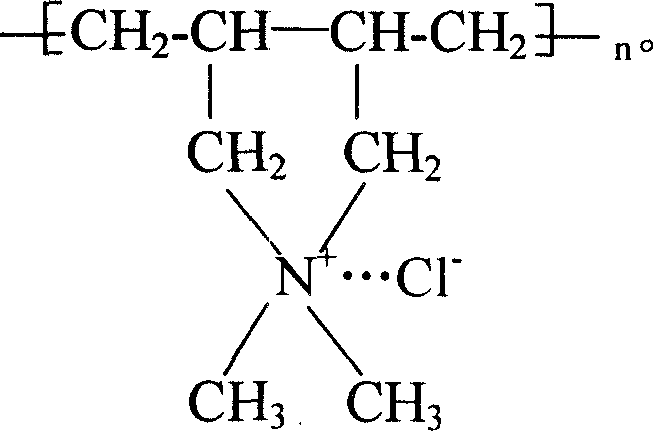

Polyaluminium chloride e-poly-dimethyl-diallyl-ammonium chloride composite flocculent, preparation and use method thereof

InactiveCN101323473AGuaranteed performanceGuaranteed stabilityWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateWater quality

The invention discloses a PAC-PDMDAAC compound coagulant, a corresponding preparation method and an application method. The PAC-PDMDAAC compound coagulant is prepared as the following steps: the PAC dry powder or solution is arranged in a mixing reactor, and water is added to obtain a PAC solution which is stirred under normal temperature and a PDMDAAC colloid is added into the solution; the mixed solution is stirred under normal temperature till the PDMDAAC colloid is completely dissolved to obtain a stable PAC-PDMDAAC. The application of the PAC-PDMDAAC compound coagulant is to adopt the PAC-PDMDAAC compound coagulant for the coagulation treatment to raw water and waste water and sewage and the dehydration treatment to sludge or silt directly or after dilution with water by any proportion. The component structure and content scope of the invention are distinct to guarantee the capability and stability of the obtained PAC-PDMDAAC compound coagulant, and the materials on industrial manufacturing are available. The various functions of the PAC-PDMDAAC compound coagulant can be adjusted during water treatment with high adaptability so as to reduce cost, reinforce coagulation effect and dramatically enhance the quality of obtained water.

Owner:NANJING UNIV OF SCI & TECH

Composite flocculating agent for printing and dyeing waste water treatment

InactiveCN1654348AImprove decolorization efficiencyReduce dosageWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateSludge

The composite flocculant for treating printing and dyeing effluent consists of natural high molecular water soluble chitosan and polyaluminium chloride. The usage of the composite flocculant in treating printing and dyeing effluent includes regulating effluent to pH 6-8, and throwing composite flocculant in the amount of chitosan in 1-2 ppm and polyaluminium chloride in 100-250 ppm to result in printing and dyeing effluent decolorizing rate up to 91 %. The composite flocculant of the present invention has simple compounding process, easy use, low cost, small thrown amount, excellent decolorizing performance, fast deposition, small sludge amount, easy biodegradation, less secondary pollution of water and thus wide application foreground.

Owner:SHANGHAI NORMAL UNIVERSITY

Compound dust suppression agent for coal mine and preparation method of compound dust suppression agent

InactiveCN102465711AGood dust suppression effectWide range of raw materialsDust removalFire preventionAluminium chlorohydrateRespirable dust

The invention discloses a compound dust suppression agent for a coal mine and a preparation method of the compound dust suppression agent. The compound dust suppression agent comprises the following components in percent by mass: 0.05-1.00 percent of fatty alcohol-polyoxyethylene ether (JFC), 0.05-1.00 percent of sodium dodecyl benzene sulfonate (SDBS), 0.01-0.50 percent of polyacrylamide (PAM), 0.02-0.50 percent of polymeric aluminium (PAC) and the balance of water. The compound dust suppression agent disclosed by the invention has the advantages that the components are water-soluble materials, can be directly sprayed by using the original water spraying system of the mine, have wide sources, do not generate any harmful gases, and are non-toxic and tasteless; and the compound dust suppression agent is convenient for construction, and has better dust suppression effect of respirable dust in comparison that of the prior art.

Owner:SHANDONG UNIV OF SCI & TECH

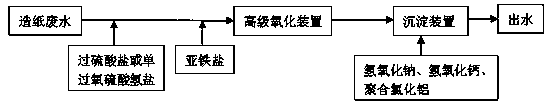

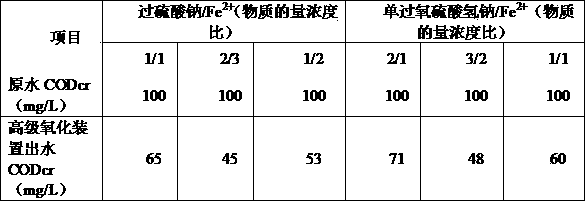

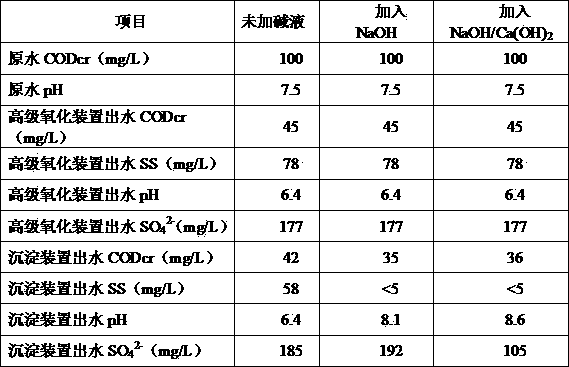

Method for processing papermaking wastewater by advanced oxidation treatment of activating persulfate or monoperoxy-hydrosulfate with ferrous salt

InactiveCN103818993AImprove applicabilityStrong oxidation abilityWater treatment parameter controlSpecific water treatment objectivesAluminium chlorideSulfate radicals

The invention discloses a method for processing papermaking wastewater by an advanced oxidation treatment of activating persulfate or monoperoxy-hydrosulfate with ferrous salt. The method is divided into two phases, namely an oxidation phase and a precipitation phase; wherein the oxidation phase is carried out in advanced oxidation equipment where wastewater is prone to mix, the hydraulic retention time is more than 0.5 hour, then persulfate or monoperoxy-hydrosulfate is subjected to carry out reactions with ferrous salt to generate sulfate free radicals with a strong oxidizing property, the sulfate free radicals can degrade organisms in the wastewater; the precipitation phase is carried out in precipitation equipment, the hydraulic retention time is more than 1.5 hours, and an alkaline solution or polymerized aluminum chloride is added so as to promote the flocculation and sedimentation of iron mud. The papermaking wastewater processing method is based on sulfate free radical advanced oxidation treatment, and the processed wastewater is clear and has a low COD value and a low Cr content. The method has the advantages of high efficiency, easy operation, and wide applicable pH range, and is especially suitable for processing papermaking wastewater having complicated components and high requirements on advanced treatment.

Owner:SOUTH CHINA UNIV OF TECH

Industrial wastewater treating agent

InactiveCN104591362AGood effectImprove water qualityWater/sewage treatment by flocculation/precipitationSodium bicarbonateIron sulfate

The invention relates to the technical field of sewage treatment and particularly relates to an industrial wastewater treating agent. The industrial wastewater treating agent comprises the following components in parts by mass: 0.8-3 parts of polyacrylamide, 25-35 parts of aluminium polychlorid, 25-55 parts of alums, 3-8 parts of iron trichloride, 0.8-3.4 parts of polymeric ferric sulfate, 1.2-2.5 parts of a coagulant aid, 2-10 parts of plant fiber, 10-30 parts of coal ash, 0.8-2.5 parts of sodium silicate, 2.5-5 parts of sodium sulfite, 0.5-3.5 parts of sodium hypochlorite, 5-10 parts of hydrogen peroxide, 8-15 parts of a sodium carbonate-sodium bicarbonate buffer system and 10-20 parts of sodium-based bentonite. The treating agent has the beneficial effects of wide treated pollutant range, good effect, wide production raw material source, environmental friendliness, no toxicity, good discharged water quality, short process flow, and high process operating safety. The treating agent disclosed by the invention can treat various kinds of wastewater such as chemical wastewater produced in oil fields, mining, steel, electroplating wastewater, dyes, pesticides, wine-making and chemical engineering, and sanitary sewage, papermaking wastewater, river and lake water, rubbish seeping water, leather-making wastewater, and the like; and the treating agent is good in treatment effect.

Owner:湖北源绿高科技节能环保有限公司

Process for producing polymeric aluminum ferric chloride coagulating agent by using pickling waste water containing iron

ActiveCN102372308AReduce manufacturing costImprove performanceIron halidesWater/sewage treatment by flocculation/precipitationLiquid wasteWater treatment

The invention relates to a process for producing a polymeric aluminum ferric chloride coagulating agent by using pickling waste water containing iron, wherein the pickling waste water and the raw material containing aluminum are adopted to produce the product. The preparation method is characterized by: adding the raw material containing the aluminum, industrial hydrochloric acid and the pickling waste water to a reactor according to a certain ratio; carrying out a reaction for 4 hours under pressure of 0.24-0.26 Mpa; evacuating the liquid inside the reactor; after settling for 4 hours, injecting the supernatant back to the reactor; adding an oxidant at a temperature of 50-60 DEG C; after reacting for 1 hour, heating to the temperature of about 80 DEG C; adding an aluminate, and continuously stirring for 2 hours; discharging the resulting liquid into a sedimentation tank, and settling for 1 hour, wherein the resulting supernatant is the polymeric aluminum ferric chloride finished product. The product of the present invention concurrently has the advantages of the iron-based coagulating agent and the aluminum-based coagulating agent, and is a widely applicable high quality coagulating agent for drinking water treatment and sewage treatment. The process of the present invention provides a feasible approach for the comprehensive utilization of the pickling waste water, and provides good economic benefits, social benefits and environmental benefits.

Owner:北京万水净水剂有限公司 +1

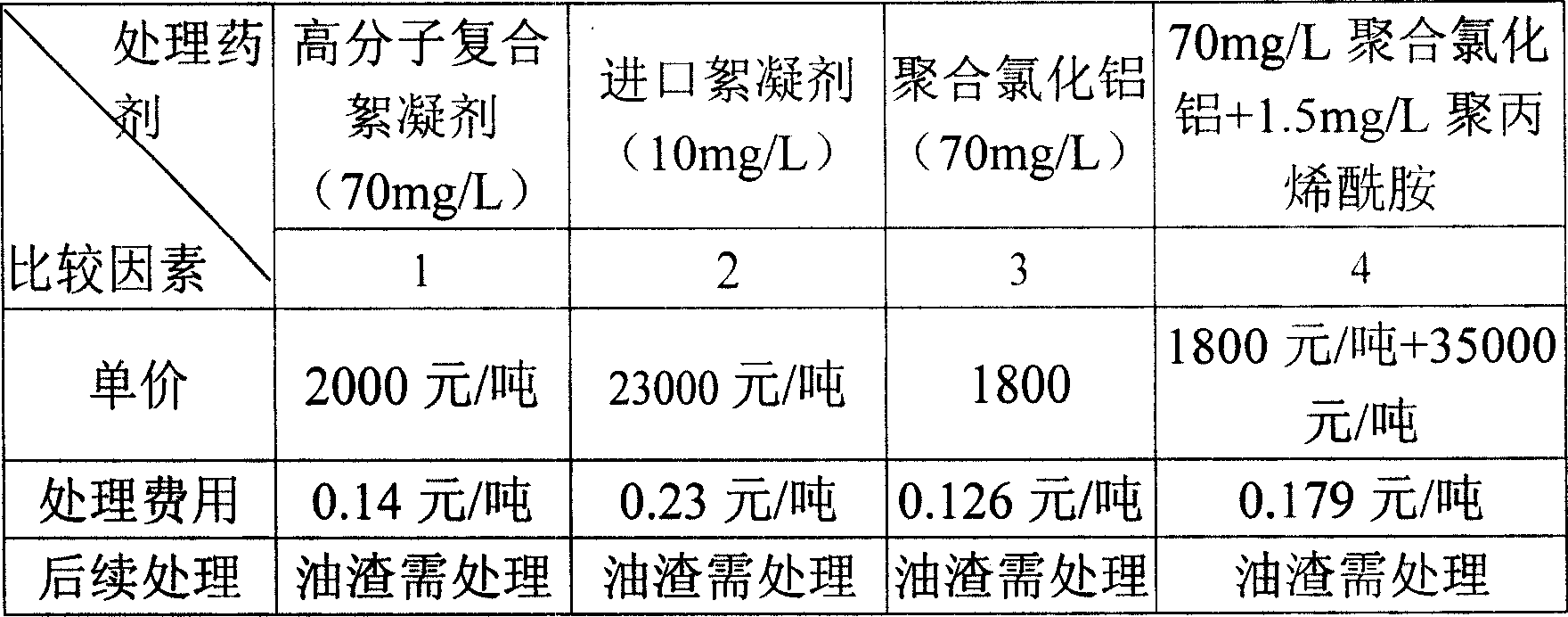

High polymer composite coagulant for treatment of oily waste water and making method thereof

InactiveCN101041495AEasy to handleLess one-time investmentWater contaminantsWater/sewage treatment by flocculation/precipitationAluminium chloridePolymer science

The invention discloses a high polymer composite coagulant for disposing oily wastewater and preparing method, which comprises the following steps: setting ingredient and weight ratio of high polymer composite coagulant with polymeric aluminium chloride : polymeric ferric sulfate : soluble glass : polydiene propyl dimethyl amchlor : water = 39.00:(1.90-2.10):(0.26-0.31):(1.04-1.52):(57.80-57.10); setting 0.02% basic ion polyacrylamide in polydiene propyl dimethyl amchlor; preparing finite density water solution with raw material as first step; preparing flocculant intermediate with polyaluminium chloride, polymeric ferric persulfate and sodium silicate as second step; proceeding mixed reaction with flocculating agent intermediate of the second step and polydiene propyl dimethyl amchlor of 0.02% positive ion polyacrylamide; controlling condition as temperature at 70-90 deg.c, pH value at 4-7; stirring intensity at 50-70r / min and ripening time at 6-24h.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com