Patents

Literature

190 results about "Telomerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Telomerization is a radical polymerization reaction where a chain transfer limits the size of the oligomer molecule product—the telomer. Telomerization requires a telogen to react with at least one unsaturated taxogen molecule. Fluorotelomers are an example.

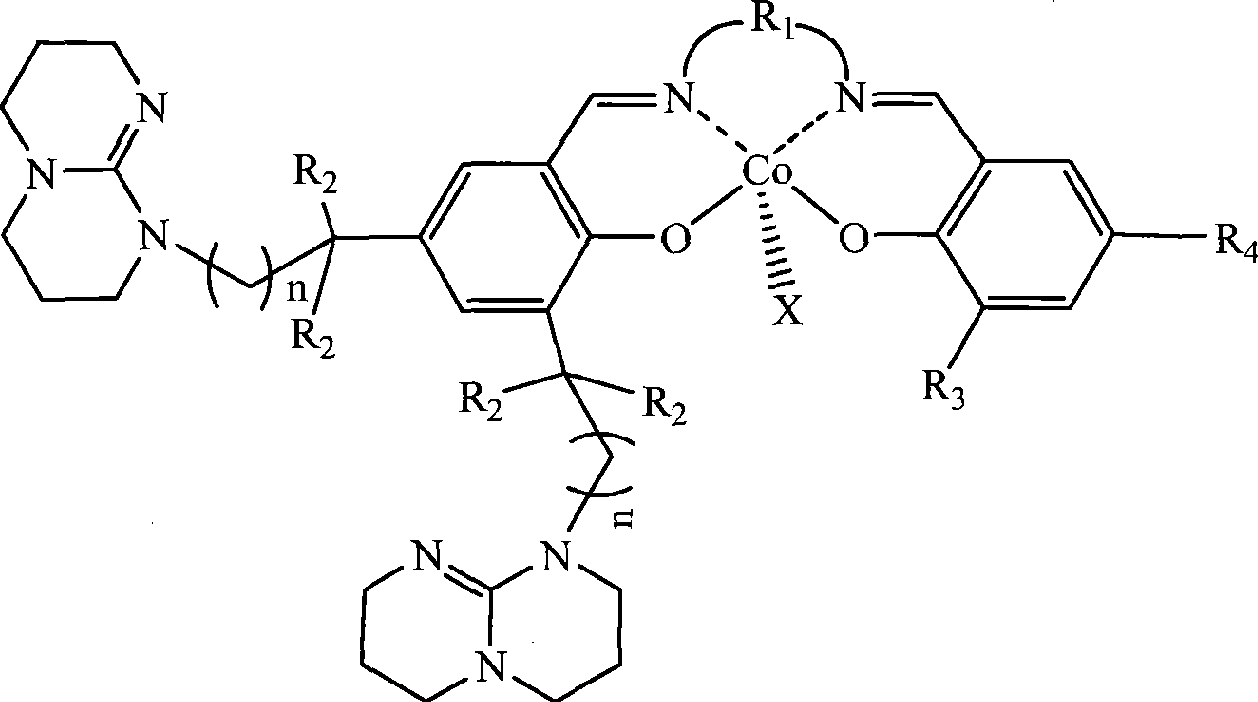

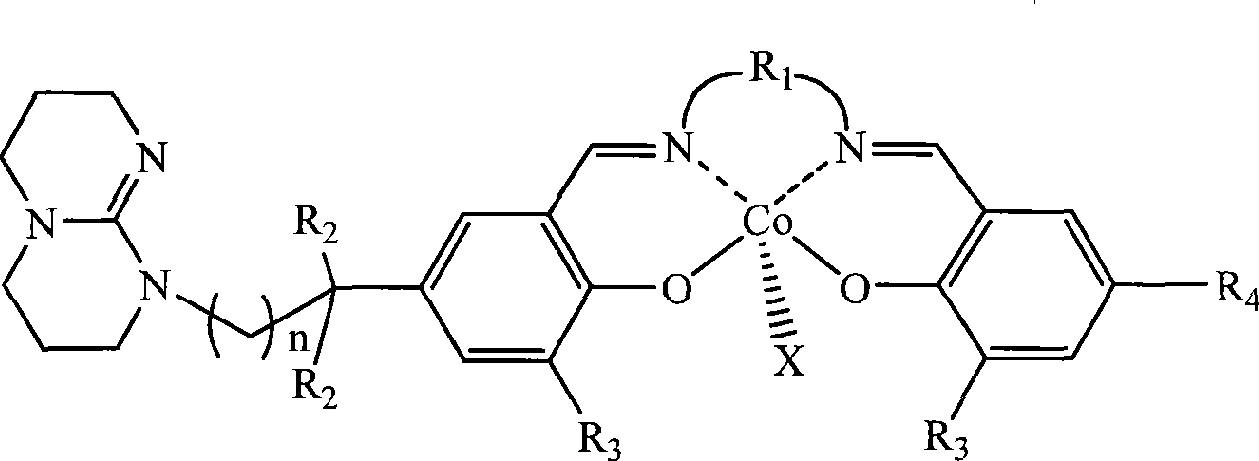

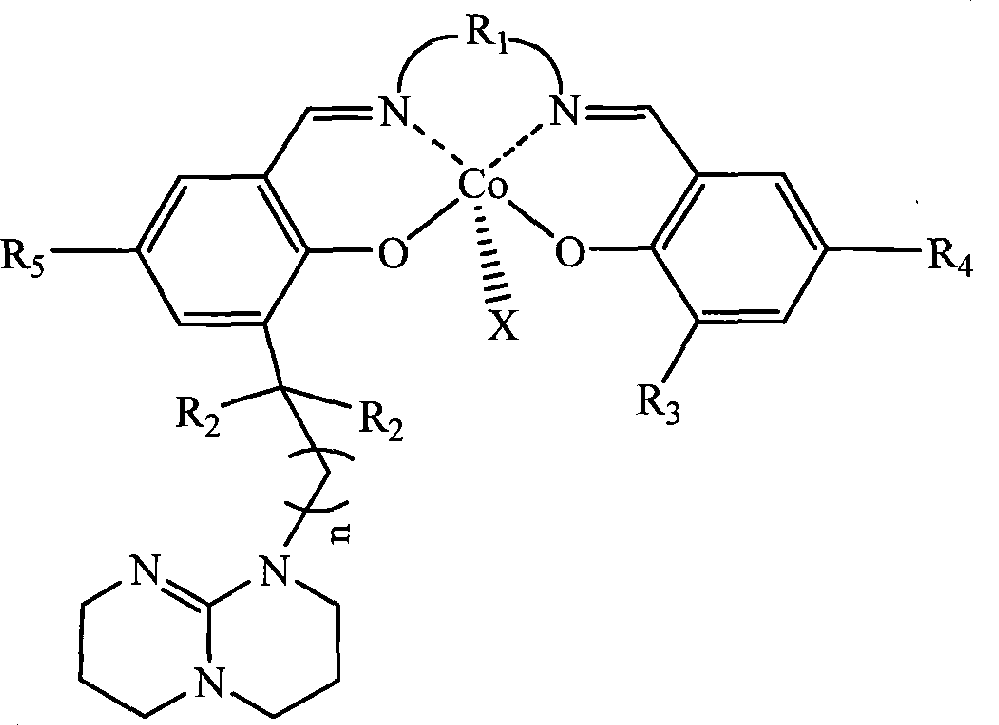

Single site catalyst for synthesizing polycarbonate

The invention discloses a high-activity catalyst which catalyzing and activating carbon dioxide to perform the copolymerization reaction with alkylene oxide to synthesize polycarbonate. The catalyst is characterized in that the catalyst is a tetradentate schiff base complex contains one or two organic base groups and has single active site initiation and controllable polymerization. The catalyst has the advantages that under milder conditions and at lower concentration of the catalyst, the catalyst can highly and efficiently catalyze the carbon dioxide to make the copolymerization reaction with the alkylene oxide to prepare the polycarbonate, the catalytic efficiency is 10<6>g polymer / mol catalyst, the polymer molecular weight is adjusted in the range of between 5,000 and 500,000, the molecular weight distribution is less than 2, the alternating structure is over 97 percent, and the catalyst can be degraded into small molecule compounds under certain condition. By utilizing the catalyst, the telomerization reaction between the carbon dioxide and two or more than two types of alkylene oxide can be catalyzed to synthesize a polycarbonate telomer with adjusting glass transition temperature.

Owner:DALIAN UNIV OF TECH

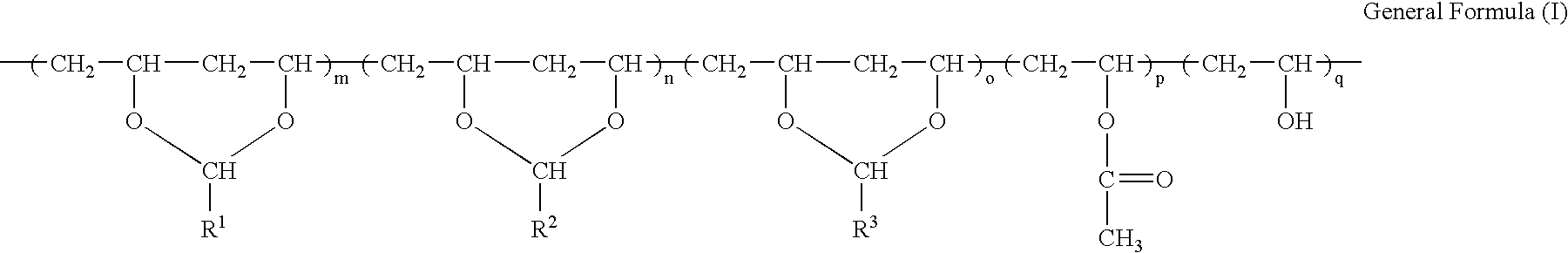

Light-sensitive lithographic printing plate

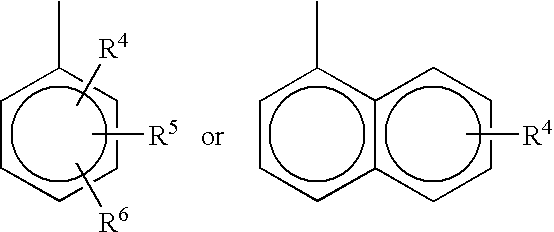

InactiveUS20050214678A1High developing latitudeExcellent printing durabilityPhotosensitive materialsLithographySide chainTelomerization

A light-sensitive lithographic printing plate comprises a hydrophilic substrate provided thereon with an infrared light-sensitive layer which comprises (A) an acetal polymer having a specific structure; (B) a polymeric compound carrying, on the side chains, fluorinated aliphatic groups in which the fluorinated aliphatic groups are those derived from fluorinated aliphatic compounds prepared by the telomerization or oligomerization; and (C) a light-heat conversion substance. The light-sensitive lithographic printing plate is excellent in the both printing durability and the developing latitude.

Owner:FUJIFILM CORP +1

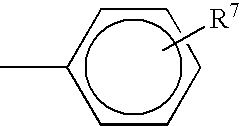

New method for resource comprehensive utilization of red mud and fly ash

InactiveCN102344171AAchieve recyclingAchieve near-zero emissionsSilicaSolid waste disposalAluminium chlorideRed mud

The invention discloses a new method for resource comprehensive utilization of red mud and fly ash, and relates to a comprehensive utilization of industrial waste, specifically to a preparation method for a flocculating agent of aluminum ferric chloride and white carbon black. The method comprises the following steps: (1) acid leaching: the red mud and the activated fly ash are adopted as raw materials, and react with HCl, wherein the leaching temperature is 70-90 DEG C, a solid-liquid ratio is 10:1-10:3, the HCl concentration is 3-6 mol.L<-1>, the leaching time is 4-10 hours; (2) polymerization: Na2CO3 is added to a dissolution solution 1 to carry out telomerization, a dissolution solution 2 is added to the dissolution solution 1 until the dissolution solution 1 is stable, then the polymerization reaction is performed to obtain the polyaluminum ferric chloride, wherein the temperature is 60-70 DEG C, the pH value is 2.5-3.0, the aging time is 12-24 hours; (3) white carbon black preparing: a NaOH solution is adopted to carry out alkali dissolution to dissolve the filter residue, then treatments of acidification and calcination are performed to obtain the powder SiO2, wherein the alkali dissolution temperature is 80-100 DEG C, the time is 4-8 hours.

Owner:孙建之

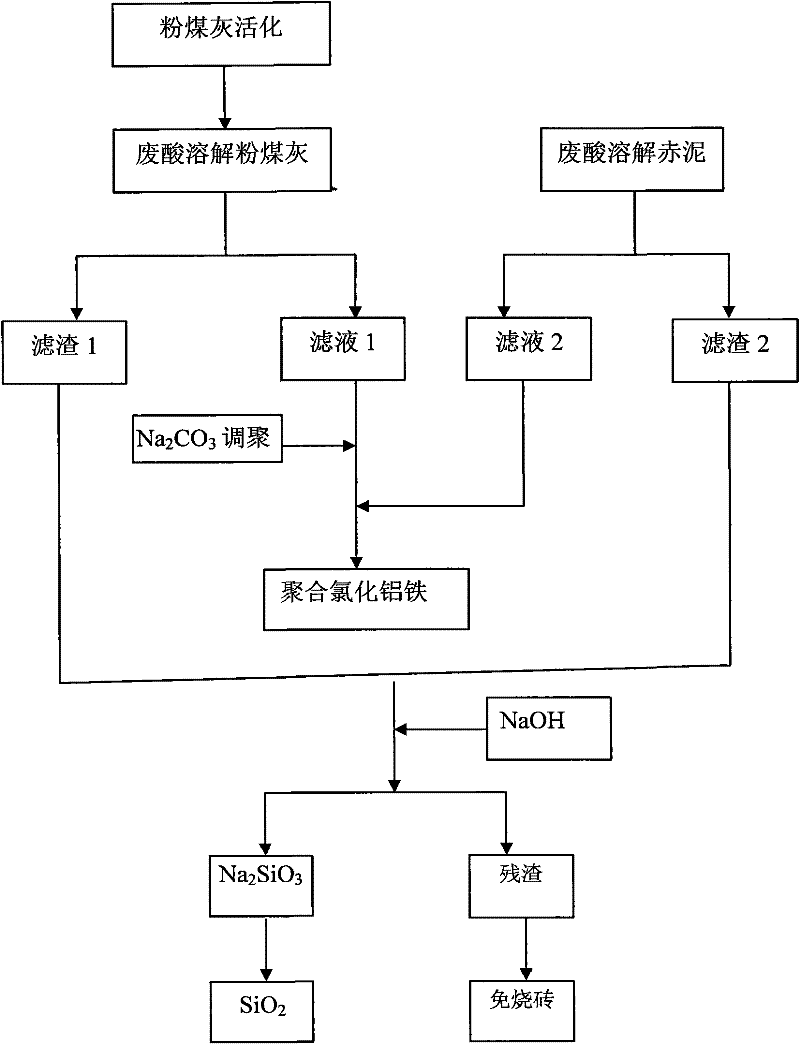

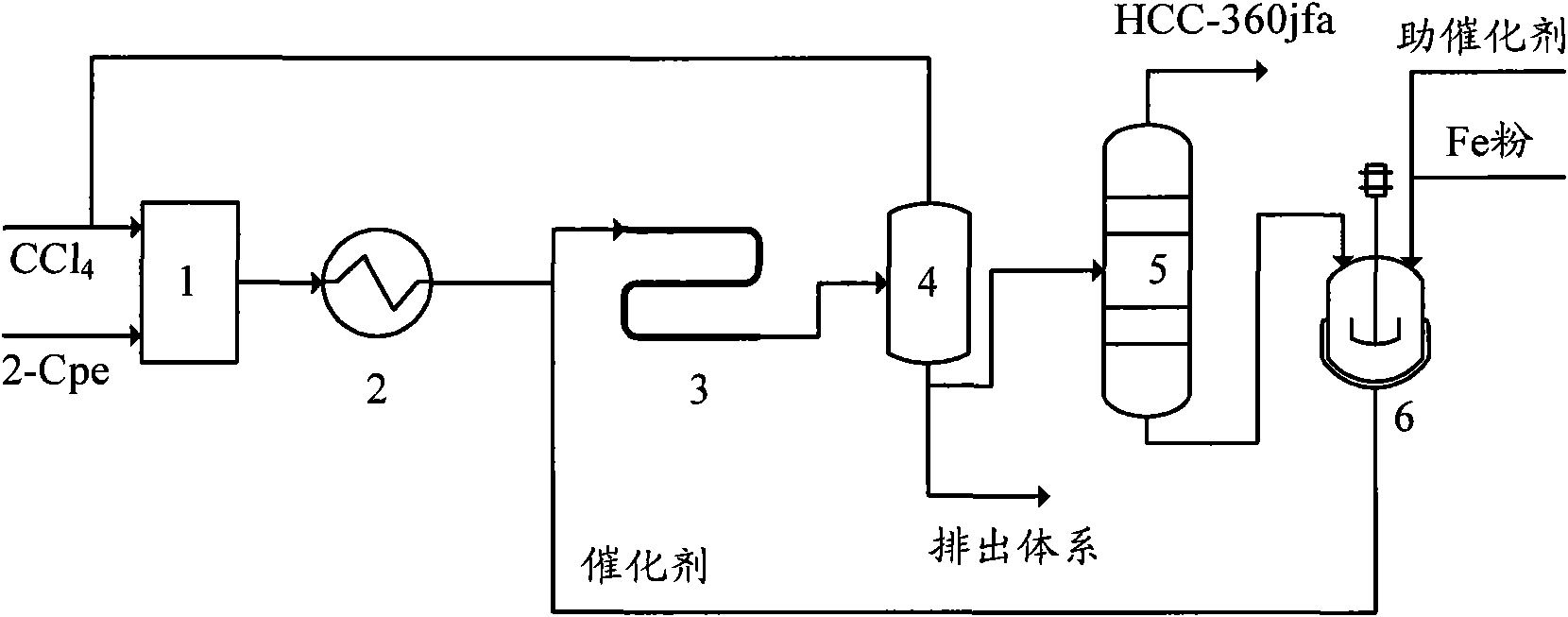

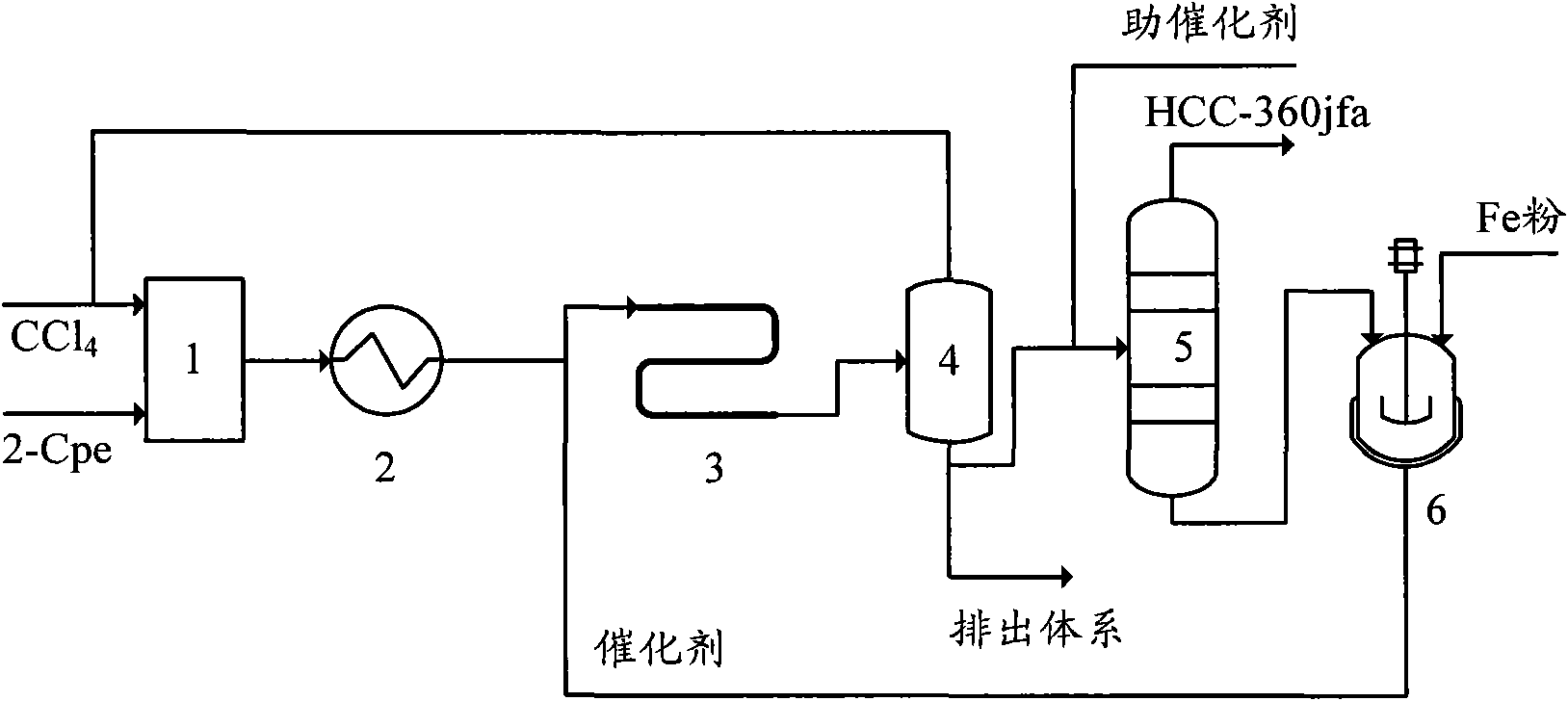

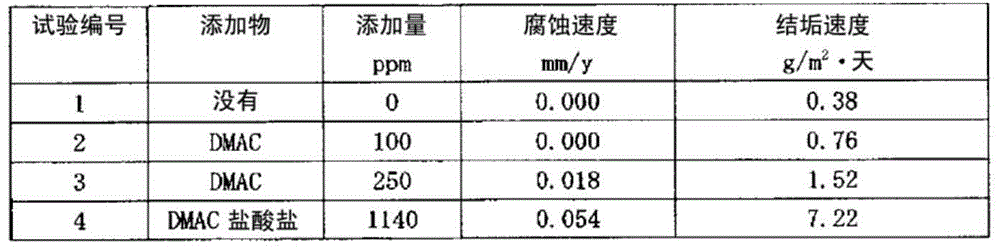

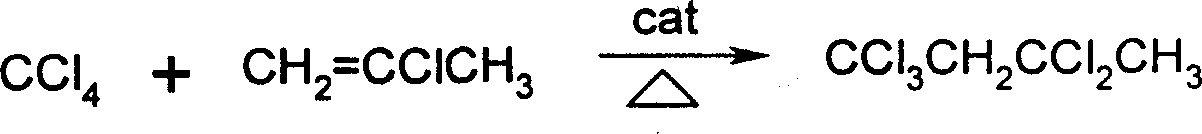

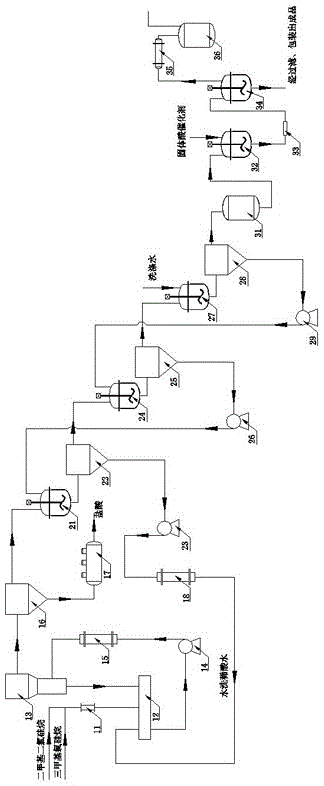

Production method of 1,1,1,3,3-pentachlorobutane

InactiveCN101913979ASuitable for continuous productionEasy to useOrganic-compounds/hydrides/coordination-complexes catalystsChemical recyclingReaction temperatureTelomerization

The invention provides a production method of 1,1,1,3,3-pentachlorobutane (HCC-360jfa), in which carbon tetrachloride and 2-chloropropene are taken as raw materials for continuous reaction in a tubular reactor to synthesize the 1,1,1,3,3-pentachlorobutane. In the method, the carbon tetrachloride and 2-chloropropene are firstly mixed and preheated to reaction temperature; the carbon tetrachloride and 2-chloropropene enter the tubular reactor with a catalyst for telomerization; a product undergoes flash evaporation to remove the un-reacted tetrachloride and 2-chloropropene and then is further distilled to obtain the HCC-360jfa product; the un-reacted tetrachloride and 2-chloropropene are recycled; and the catalyst undergoes activating treatment for recycle. The catalyst used by the invention is liquid, no solid exists in the reaction product, and the tubular reactor is used for reaction, so that the invention is convenient for operation and easy for continuous production.

Owner:XIAN MODERN CHEM RES INST

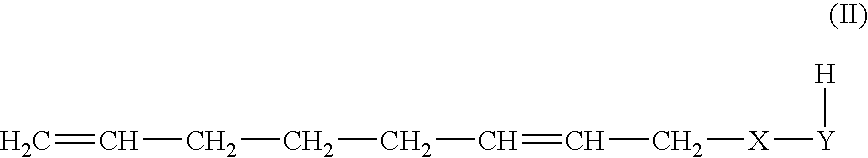

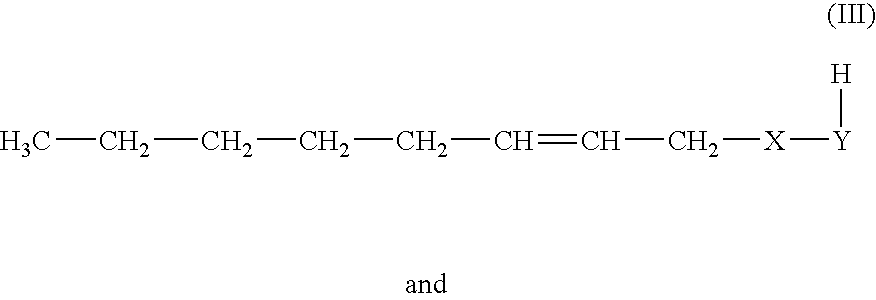

Method for producing 1-octene

InactiveUS7030286B2High purityHigh yieldOrganic compound preparationOrganic chemistry methods1-OcteneOctene

The invention relates to a process for preparing 1-octene by reacting 1,3-butadiene with a telogen of the formula H—X—Y—H, where X is O, N, S or P and Y is C, N or Si and X and Y bear, depending on their valence, further substituents, in the presence of a telomerization catalyst to form a telomer of the formula H2C═CH—CH2—CH2—CH2—CH═CH—CH2—X—Y—H, partially hydrogenating the telomer to form a 1-substituted 2-octene of the formula H3C—CH2—CH2—CH2—CH2—CH═CH—CH2—X—Y—H and dissociating the 1-substituted 2-octene to give 1-octene.

Owner:OXENO OLEFINCHEMIE GMBH

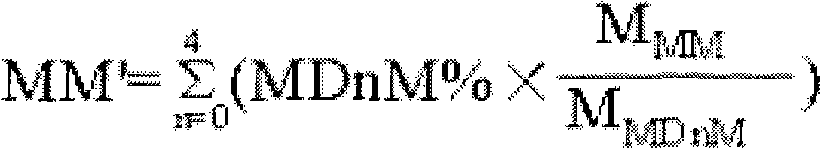

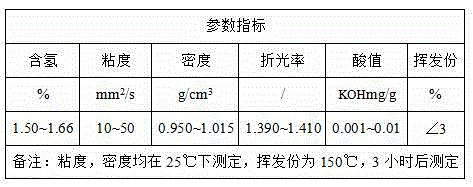

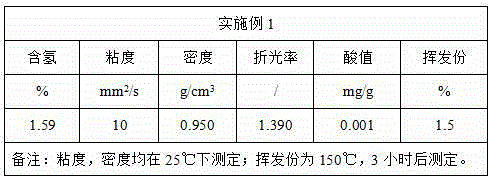

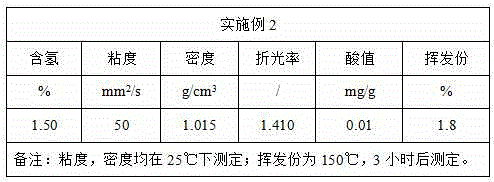

Preparation method for low hydrogen-containing silicon oil

The invention relates to the technical field of chemical engineering, in particular to a preparation method for low hydrogen-containing silicon oil. The preparation method adopts high hydrogen-containing silicon oil (202) and dimethylcyclosiloxane (DMC) as raw materials and hexamethyldisiloxane (MM) as an end-capping agent, under the catalysis of a solid superacid, the temperature is increased to 50-140 DEG C for a telomerization, and the low hydrogen-containing silicon oil is prepared. Compared with the prior art for preparing the low hydrogen-containing silicon oil under the catalysis of vitriol, the preparation method adopts the solid superacid as a catalyst, the catalyst has a good catalysis effect and can be reused, neutralization and washing are not required during the preparation method, and short time is taken by the whole preparation process, continuous method industrial production is likely to be achieved, and the production efficiency is high.

Owner:蓝星安迪苏股份有限公司

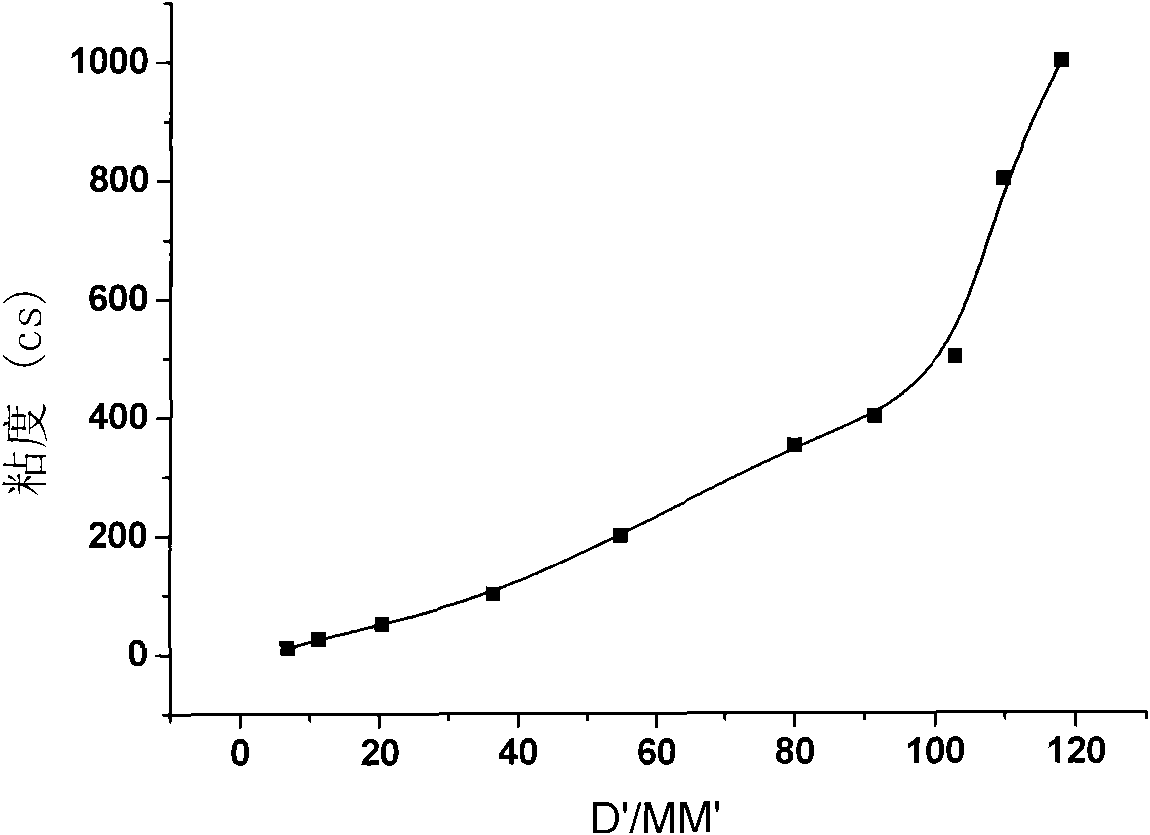

Method for preparation of silicon oil by silicon oil byproduct

The invention relates to a method for the preparation of silicon oil by silicon oil byproduct, in which dimethyl silicon oil byproduct in acid method production is used as raw material to prepare low-viscosity dimethyl silicone coil under the catalysis of solid acid catalyst. The method comprises the steps: calculating the constitution of raw materials in the silicon oil byproduct and drawing a proportion-viscosity relationship curve of the raw materials to set a feeding ratio, controlling reaction temperature between 50 and 110 DEG C under the catalyst of 3%-15% of solid catalyst, and implementing telomerization for 2 to 6 hours. By reutilizing the silicon oil byproduct, the method solves the problem of warehouse occupation of the silicon oil byproduct and lowers production cost. Using the solid acid catalyst can directly prepare neutral equilibration reaction product without neutralization and water washing procedures, the reaction process is simple, the viscosity of the product is easy to control and the regenerated byproduct can still be used repeatedly.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

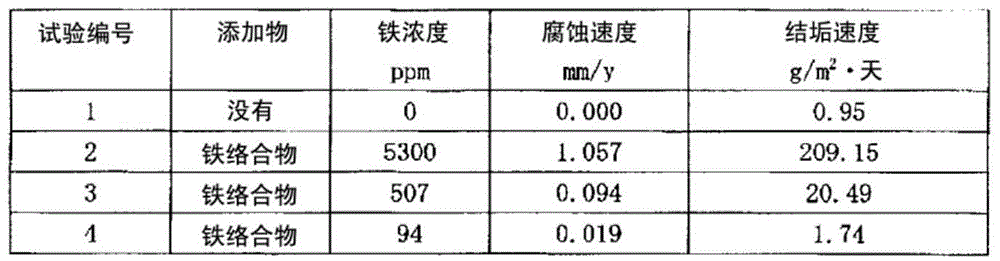

Improved preparing process for 1,1,1,3,3-pentachloro propane

ActiveCN1986507AReduce decompositionIncrease productivityHalogenated hydrocarbon preparationPhosphoric Acid EstersIron salts

The improved 1, 1, 1, 3, 3-pentachloro propane preparing process includes the telomerization of carbon tetrachloride and chloroethylene in the presence of iron powder catalyst and phosphoric acid ester cocatalyst, settlement separating the reaction product to eliminate coarse iron powder and un-reacted material, water treating the product to eliminate fine iron powder, iron ion complex dissolved in the product and iron salt, and final decompression rectifying to obtain target product. The technological process of the present invention has greatly reduced scaling, decomposition and blocking during product rectification, and is favorable to industrial production.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH

Hexafluoropropylene-2-butyne synthesizing method

ActiveCN105348034AHigh yieldConvenient sourcePreparation by halogen replacementHexachlorobutadieneHexafluoropropylene

The invention discloses a hexafluoropropylene-2-butyne synthesizing method. Hexachlorobutadiene (CCl2=CCl-CCl=CCl2) is taken as the raw material to generate hexafluoropropylene-2-butyne under the action of a catalyst, the raw material hexachlorobutadiene is easy to obtain and low in cost. The gaseous-phase circulating fluorination method is adopted, the discharge level of three industrial wastes is low, the yield of products is high, and production cost is reduced greatly; the gaseous-phase circulating fluorination method is conducted at normal temperature, the traditional high-pressure telomerization process route is avoided, and risks in industrial safety production are reduced greatly; meanwhile, the method has the advantage that operation is easy and is totally suitable for industrial production.

Owner:TIANJIN MEDICAL UNIV

Method for the production of 1-octene by reductive telomerisation

InactiveUS7115790B2High selectivityHigh yieldHydrocarbon by hydrogenationSolid fuels1-OctenePartial hydrogenation

The invention relates to a process for preparing 1-octene by telomerization of 1,3-butadiene using a reducing agent in the presence of a telomerization catalyst and partial hydrogenation of the octadiene obtained in this way.

Owner:OXENO OLEFINCHEMIE GMBH

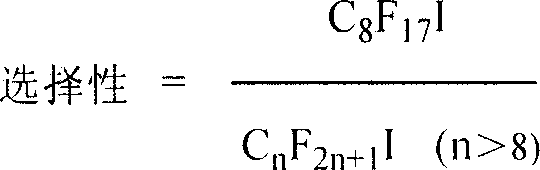

Method for continuous production of perfluoroalkyl iodide telomer

InactiveCN1535258AEfficient productionReduce generationOrganic chemistry methodsHalogenated hydrocarbon preparationTetrafluoroethyleneHydrogen

The present invention relates to a process for continuously producing a perfluoroalkyl iodide represented by the general formula Rf(CF2CF2)nI, wherein Rf is a C1-6 perfluoroalkyl and n is an integer from 1 to 4, the method comprising continuously supplying a perfluoroalkyl iodide as a telogen represented by the general formula RfI, wherein Rf is as defined above, and tetrafluoroethylene as a taxogen to a tubular reactor packed with a metal catalyst comprising a powdery spherical metal or a sintered metal; and conducting telomerization at a temperature of 60 to 160 DEG C. under a pressure of 0.1 to 5 MPa (gauge pressure). According to the present invention, medium-chain perfluoroalkyl iodides can be continuously and efficiently produced with little generation of impurities, such as hydrogen-containing organic compounds and the like.

Owner:DAIKIN IND LTD

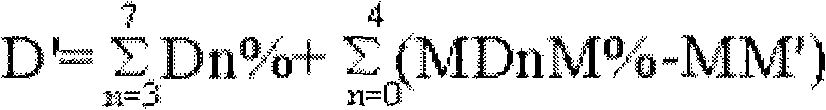

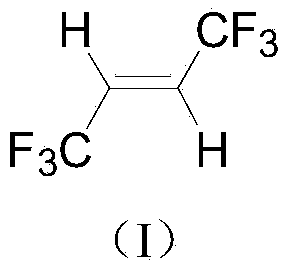

Synthetic method of trans-1, 1, 1, 4, 4, 4-hexafluoro-2-butene

ActiveCN104370690ALow costWide variety of sourcesPreparation by hydrogen halide split-offPreparation by halogen replacementGas phase2-Butene

The invention provides a method for synthesizing trans-1, 1, 1, 4, 4, 4-hexafluoro-2-butene by three steps by taking 1, 1, 1-triflluoro-2, 2-dichloroethane and chloroethylene CH2=CX2 as raw materials. The method comprises the following steps: (a) in the presence of a telomerization catalyst and a catalytic addictive, carrying out reactive synthesis on 1, 1, 1-triflluoro-2, 2-dichloroethane and CH2=CX2 to obtain CF3CHClCH2CClX2; (b) carrying out photochlorination on CF3CHClCH2CClX2 to synthesize CF3CHClCH2CCl3; and (c) in the presence of a fluorination catalyst, carrying out gas phase fluorination on CF3CHClCH2CCl3 to synthesize trans-1, 1, 1, 4, 4, 4-hexafluoro-2-butene, wherein CH2=CX2 is ethylene, chloroethylene and 1, 1-dichloroethylene. The method provided by the invention has the characteristics of high trans-selectivity and low price of raw materials.

Owner:XIAN MODERN CHEM RES INST

Method for continuous production of a perfluoroalkyl iodide telomer

InactiveUS6919490B2Less impuritiesContinuous and efficient productionOrganic chemistry methodsMetal/metal-oxides/metal-hydroxide catalystsTetrafluoroethyleneHydrogen

The present invention relates to a process for continuously producing a perfluoroalkyl iodide represented by the general formula Rf(CF2CF2)nI, wherein Rf is a C1-6 perfluoroalkyl and n is an integer from 1 to 4, the method comprising continuously supplying a perfluoroalkyl iodide as a telogen represented by the general formula RfI, wherein Rf is as defined above, and tetrafluoroethylene as a taxogen to a tubular reactor packed with a metal catalyst comprising a powdery spherical metal or a sintered metal; and conducting telomerization at a temperature of 60 to 160° C. under a pressure of 0.1 to 5 MPa (gauge pressure).According to the present invention, medium-chain perfluoroalkyl iodides can be continuously and efficiently produced with little generation of impurities, such as hydrogen-containing organic compounds and the like.

Owner:DAIKIN IND LTD

Method for preparing hydroxy terminated high-boiling silicone oil through low-temperature continuous hydrolysis technology

InactiveCN106432732ASignificant progressSignificant positive effectEnvironmental resistanceHydrolysis

The invention belongs to the technical field of organic silicon production, and particularly relates to a method for preparing hydroxy terminated high-boiling silicone oil through a continuous hydrolysis technology in the condition of low temperature of organosilicon high-boiling components. The method comprises the following steps: performing rectifying treatment on chlorosilane compound with the boiling point of byproducts being greater than 70.5 DEG C during the synthesis of methyl chlorosilane through a rectification device and a direct method; collecting the fraction with the boiling range being 70.5 to 180 DEG C in a standard condition; performing low-temperature hydrolysis reaction through a hydrolysis assistant solution with certain concentration. According to the method, the technical problem that organosilicon high-boiling component hydrolysis is easy to cause crosslinking and emulsification through the steps of continuous hydrolysis, water washing, alkali washing, telomerization and filtering, hydroxy terminated high-boiling silicone oil products are produced, and the fact that hydrogen chloride produced through high-boiling component hydrolysis is directly applied to methyl chloride synthesis after being subjected to purification is realized. The method has the advantages that the production automation degree is high, the product quality is stable, active silicon hydroxyl at the molecular chain end of a product is wide in application range, three waste discharge does not exist in the whole technology, and clean and environment-friendly continuous production is realized.

Owner:TANGSHAN SANYOU SILICON IND

Method for synthesizing trans-1,1,1,4,4,4-hexafluoro-2-butene

ActiveCN109553506AHigh catalytic activityThe reaction conditions are mild and controllablePreparation by hydrogen halide split-offPreparation by halogen replacementActive componentGas phase

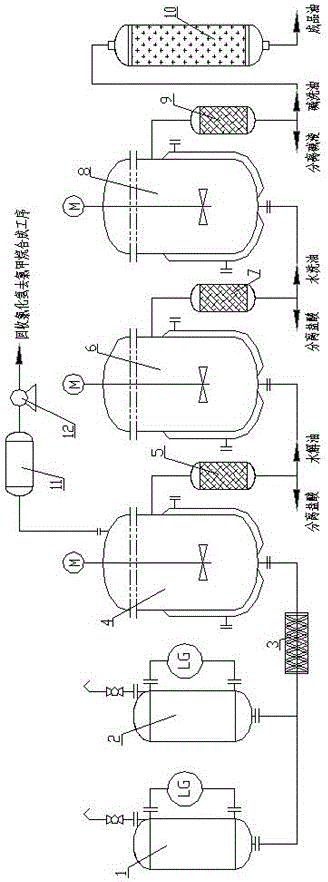

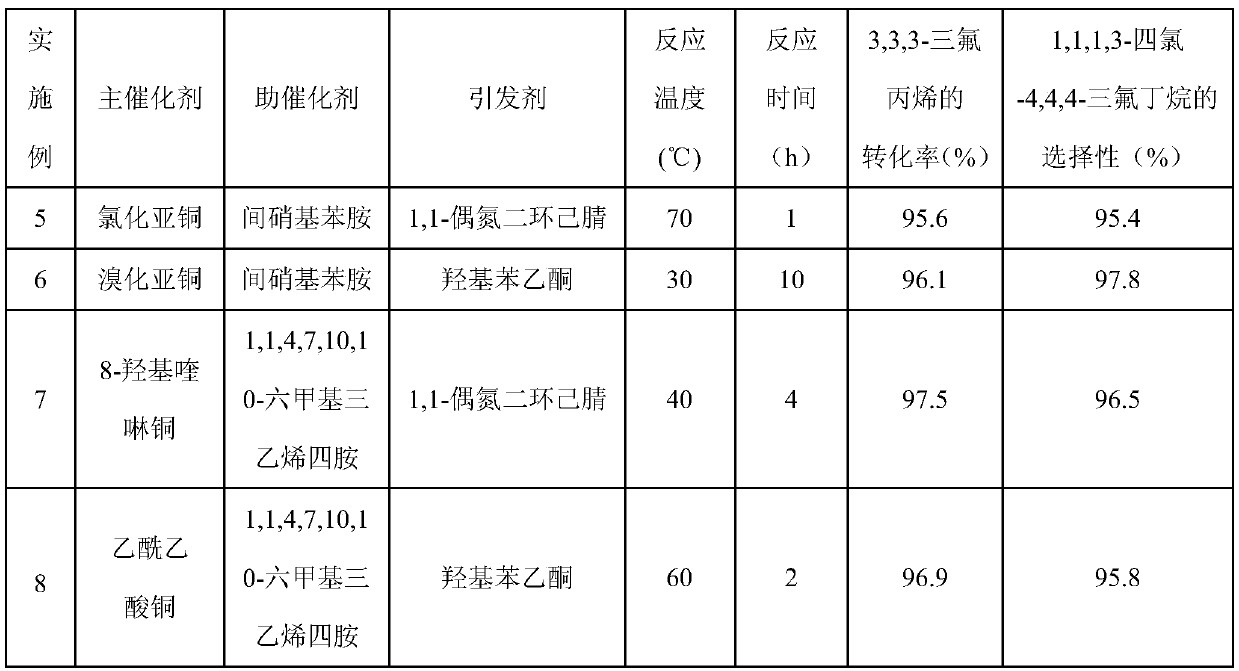

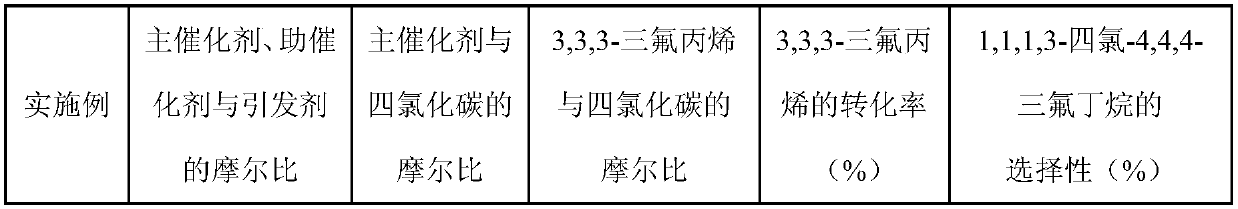

The invention discloses a method for synthesizing trans-1,1,1,4,4,4-hexafluoro-2-butene. The method comprises the following steps: (a) in the presence of a telomerization catalyst, performing a reaction on 3,3,3-trifluoropropene and carbon tetrachloride to synthesize 1,1,1,3-tetrachloro-4,4,4-trifluorobutane, wherein the reaction temperature is 30-70 DEG C, and the reaction time is 1-10 h; and (b)under the action of a fluorination catalyst, performing gas phase fluorination on the 1,1,1,3-tetrachloro-4,4,4-trifluorobutane and HF to synthesize the trans-1,1,1,4,4,4-hexafluoro-2-butene, whereinthe reaction temperature is 200-300 DEG C, a molar ratio of the HF to the 1,1,1,3-tetrachloro-4,4,4-trifluorobutane is (5-50):1, the telomerization catalyst is composed of a main catalyst, a cocatalyst and an initiator, the main catalyst is a monovalent or divalent copper salt, the cocatalyst is an organic amine, and the initiator is p-hydroxyacetophenone or 1,1-azobis(cyanocyclohexane); and thefluorination catalyst is a supported catalyst with a composition of Nx / MgF2, N is an active component and selected from one of Al, Cu, Zn and Co, x is a molar ratio of N to MgF2, and a value of x satisfies the relationship of 0.05 <= x <= 0.15. The method provided by the invention is mainly used for synthesizing the trans-1,1,1,4,4,4-hexafluoro-2-butene.

Owner:XIAN MODERN CHEM RES INST

Solvent-free process method for continuously producing methyl hydrogen silicone oil

The invention discloses a solvent-free process method for continuously producing methyl hydrogen silicone oil. The process method is a production method which uses an organosilicone monomer production by-products-methyldichlorosilane and chlorotrimethylsilane as raw materials and sequentially comprises the steps of hydrolysis, layering, washing extraction, telomerization and oiling so as to prepare methyl hydrogen silicone oil finished products. By means of the solvent-free process method, the defect that an existing traditional intermittent method enables the product efficiency to be low and the quality to be unstable during production and introduces an organic solvent in the traditional production and the like is changed, and the purposes of saving energy and reducing consumption can be achieved. The solvent-free process method has characteristics of environmental pollution reduction and the like, further has the advantages of reducing the production cost, shortening a production period, improving the product quality, increasing finished product yield, being high in industrial operation safety and the like and has good industrial operability.

Owner:成都博达爱福科技有限公司

Method of preparing full-fluorine alkyl iodide

ActiveCN1927788AImprove efficiencyHigh selectivityHalogenated hydrocarbon preparationCarbon numberIodide

The present invention relates to the telomerization process of perfluoro alkyl iodide in the general expression of Rf(CF2CF2)nI. By using fluoric olefin as the taxogen and RfI as the telogen, at the temperature of 60-160 deg.c and the system generated pressure, the present invention performs the telomerization reaction in perfluoro solvent under the initiation of the active Pd, Nd, Ta or their alloy catalyst. The active metal catalyst is prepared through activating the metal nitrate attached to carrier with hydrogen, and can control the carbon number of the product, raise selectivity on target product, raise the reaction rate and reduce the reaction period. The reaction is performed at relatively low temperature to avoid cyclopolymerization of tetrafluoroethylene and in a kettle type or tubular reactor for high production capacity of the target product.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

Preparation method of 1,3,3,3-tetrafluoropropylene

ActiveCN102211974AReaction conditions are easy to controlImprove reaction efficiencyPreparation by halogen replacementReaction temperatureReactions stress

The invention relates to a preparation method of 1,3,3,3-tetrafluoropropylene, and belongs to the field of refrigerants. Carbon tetrachloride, vinyl chloride and hydrogen fluoride are used as raw materials in the preparation method. The preparation method comprises the following steps of: performing telomerization on CC14 and chloroalkene to generate CCl3CH2CHCl2, performing fluorine-chlorine exchange and hydrogen chloride removal to obtain CF3CH=CHCl, and performing fluorine-chlorine exchange to obtain a final product HFO-1234ze. The raw materials are low in price and easily obtained in the method, so the raw material cost in the HFO-1234ze production process is reduced; and the reaction temperature is low, the reaction pressure is low, the whole reaction process is operated in a tubularreactor in a continuous phase mode, and the reaction conditions are easily controlled, so the method has great industrialized application prospect.

Owner:泉州宇极新材料科技有限公司

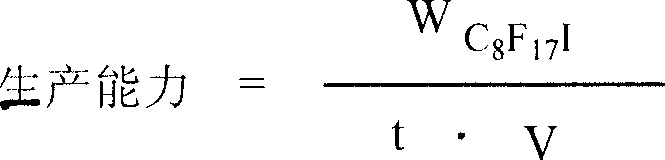

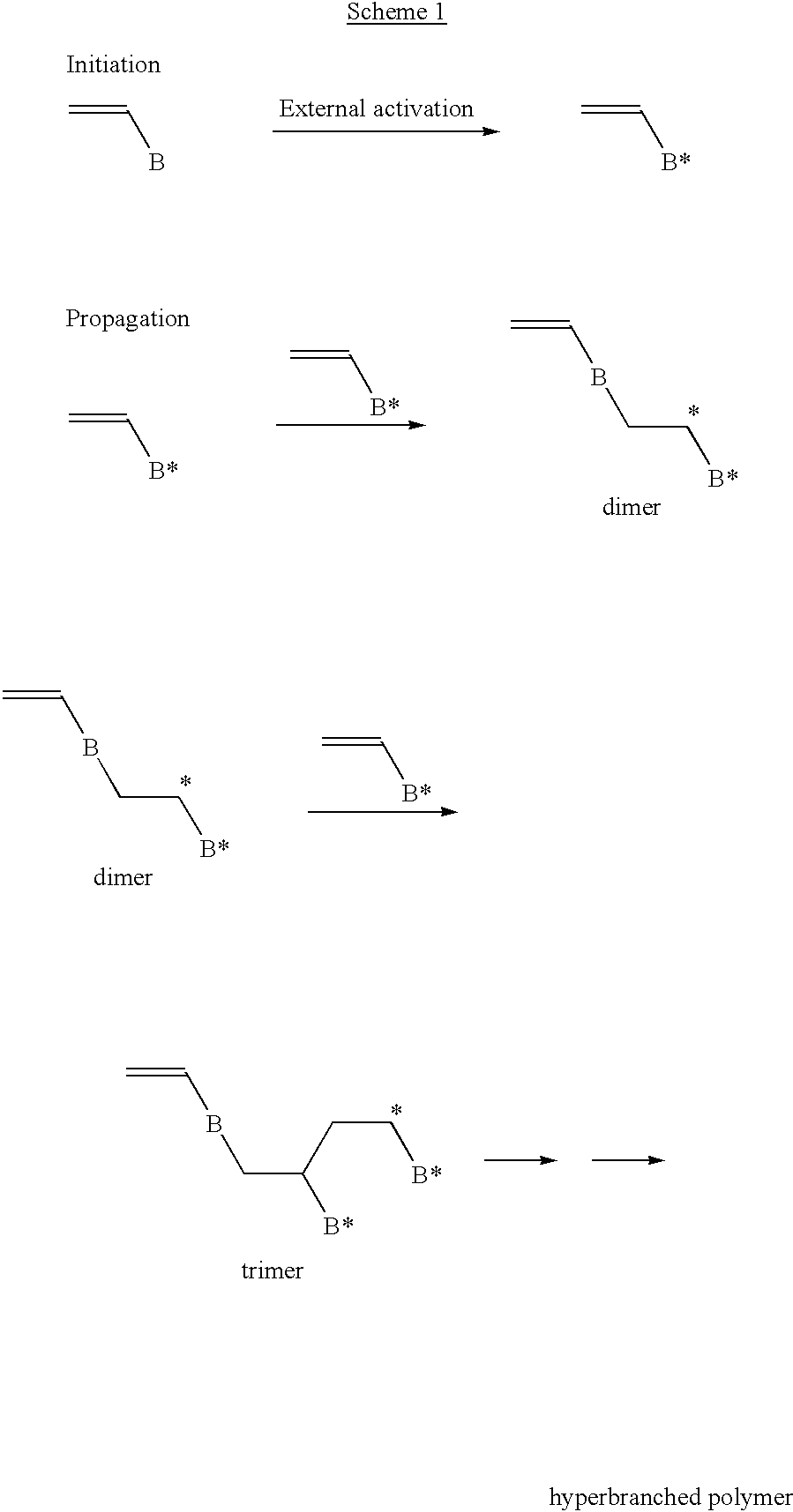

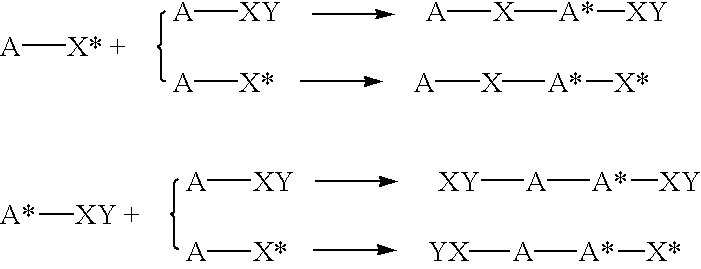

Highly branched polymer from telomerization

A process for making hyperbranched polymers from An-Lz(XY)m type monomers wherein A is a polymerizable group moiety, XY is a telogen group moiety in which Y is a transferable atom or group which can participate in a transfer reaction with the formation of reactive X*, L is a linkage between A and XY, z is 0 or 1, and n and m are integers of at least 1, comprising: (a) initiating reaction by forming activated species from reaction between either an A or an XY group of the An-Lz(XY)m type monomer and an external stimulus to form activated monomer species with an activated polymerizable group moiety A* or an activated moiety X* derived from the telogen group moiety XY; and (b) polymer segment chain growth by (i) propagation reaction between the polymerizable group A moieties of the An-Lz(XY)m type monomers with the activated moieties A* and X* of activated species, and further reaction between the polymerizable group moieties with the activated moieties of the reaction products thereof, and (ii) chain transfer reaction between the activated A* polymerizable group moieties of activated species or of polymer segments formed in (b)(i) with XY telogen group moieties of the An-Lz(XY)m type monomers or of polymer segments formed in (b)(i), whereby activated X* moieties and inactive A-Y moieties are formed by transfer of transferable atom or group Y of the telogen group moiety XY to the activated A* moiety.

Owner:EASTMAN KODAK CO

Mixture containing 1,3-butadiene and process for producing the same

InactiveUS20070123738A1Cost-effectiveEasy to makeOrganic compound preparationHydrocarbon by hydrogenationButeneEther

To provide a C4 fraction that contains significantly reduced amounts of butynes and methylallene and to provide a process for low-cost and effective production of ethers in which the C4 fraction is used as the starting material for a telomerization process. A mixture containing 25 to 80 mass % 1,3-butadiene, 13 to 68 mass % butenes and 2 to 15 mass % butanes with butynes and methylallene being contained in amounts of 50 ppm or less and 5 to 800 ppm, respectively

Owner:KURARAY CO LTD

Technology for preparing methyl hydrogen silicone oil

The invention discloses a technology for preparing methyl hydrogen silicone oil.The methyl hydrogen silicone oil is prepared through saturated acid hydrolysis, secondary hydrolysis, telomerization reaction, devolatiligation reaction and decoloring reaction.According to the technology for preparing methyl hydrogen silicone oil, frozen saline water is not needed for cooling in the hydrolysis process, energy consumption is greatly reduced, production cost is reduced, HCl generated through the hydrolysis reaction overflows in a gas state mode, the concentration of prepared hydrochloric acid can be increased to be 31% or above, the standard of industrial hydrochloric acid of the state is achieved, selling is facilitated, and by means of the method, continuous production can be achieved, the productivity is high, and the middle process can be controlled easily.

Owner:JIANGXI PINHAN CHEM IND CO LTD

Method for preparing chlorohydrocarbon

ActiveCN1762933AImprove reaction efficiencyShort reaction timePreparation by halogen halide additionAlkaneMetal catalyst

The present invention relates to chlorohydrocarbon preparing process, and is especially one telomerization process of preparing chlorohydrocarbon in the molecular expression CCl3CH2CHnClm, where n is 0, 1 or 2, and m=3-n, inside a tubular reactor, with chloroalkane or chloroalkene as main material and in the presence of composite Fe, Cr and Ni metal catalyst and dimethyl formamide as co-catalyst. The reacted mixture may be distilled to recover un-reacted material and co-catalyst and is decompression distilled to obtain final chlorohydrocarbon product. The telomerization process is simple, high in reaction efficiency and suitable for continuous industrial production.

Owner:BEIJING YUJI SCI & TECH +1

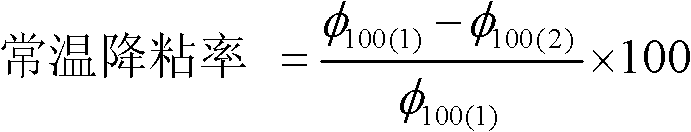

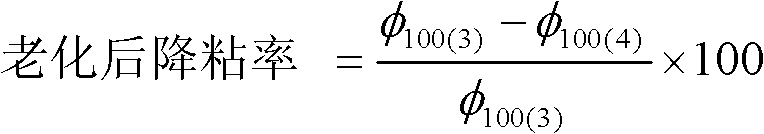

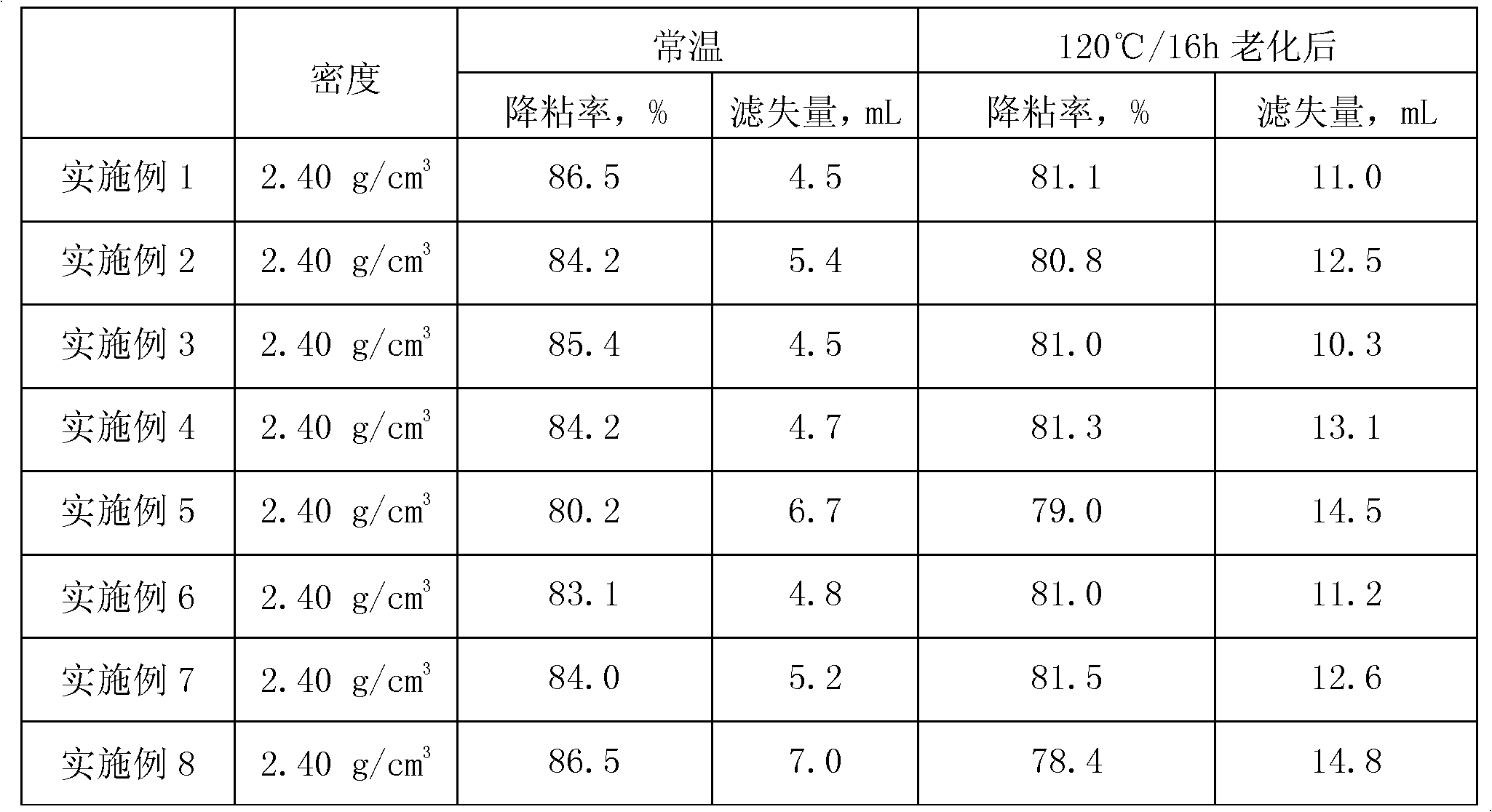

Dispersant for ultra-high-density drilling fluid, preparation method and application thereof

The invention discloses a dispersant for ultra-high-density drilling fluid, a preparation method and application thereof. The dispersant is prepared through the reaction of raw materials containing the following components in parts by weight: 10-40 parts of lignin, 1.5-20 parts of phenols, 2.5-15 parts of sulfonating agent, 0.5-5 parts of telomerization agent, 0.5-4 parts of catalyst and 100 parts of water. The method comprises the steps of mixing the components uniformly, carrying out reaction for 6-10 hours at the temperature of 160-180 DEG C, and then obtaining the dispersant for the ultra-high-density drilling fluid. The dispersant disclosed by the invention is applied to the ultra-high-density drilling fluid, and the surface properties of solid-phase weighting agents, such as barite and the like, can be remarkably improved; the hydration film formation for the surfaces of weighting agent particles is prompted, and the agglomeration role and frictional resistance among the weighting agent particles are reduced, so that the viscosity and shearing force of the prepared high-density drilling fluid are reduced, and the fluidity of the high-density drilling fluid is improved; and the dispersant is non-toxic and efficient, and the preparation method is simple and easy in operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Metallic copper catalyst for polyfluoroalkylethyl iodide production and process for producing polyfluoroalkylethyl iodide

InactiveCN1662302AEfficient manufacturingOrganic compound preparationOrganic chemistry methodsPtru catalystIodide

A metallic copper catalyst which is for use in the addition of ethylene to a polyfluoroalkyl iodide; and a process for efficiently producing a polyfluoroalkylethyl iodide, which comprises using the metallic copper catalyst to conduct the addition of ethylene to a polyfluoroalkyl iodide. Also provided is a process for efficiently producing a polyfluoroalkylethyl iodide from a polyfluoroalkyl iodide, which comprises using the same metallic copper catalyst to conduct a telomerization reaction and a subsequent ethylene addition reaction.

Owner:DAIKIN IND LTD

Preparation method of terminal hydrogen-containing silicone oil

The present invention discloses a preparation method of terminal hydrogen-containing silicone oil. The method comprises the following steps: using 1,1,3,3-tetramethyl-1,3-dihydrogen disiloxane (MHMH) as a capping agent, and dimethylcyclosiloxane (DMC) or octamethyl cyclotetrasiloxane (D4) as a raw material, under the catalysis of a solid super acid, heating to 50-100 DEG C to perform a telomerization reaction, and performing a reflux reaction for 4 to 8 h to prepare and obtain the terminal hydrogen-containing silicone oil. Compared with a conventional preparation method of the terminal hydrogen-containing silicone oil by using H2SO4 as a catalyst, a solid super acid is adopted as a catalyst, the catalytic effect is good and the catalyst can be repeatedly used, neutralization and washing are not required in the preparation method, the time used in the whole preparation process is short, continuous industrial production is expected to be achieved, and the production efficiency is high.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Production method for 1-chloro-3,3,3-trifluoropropene

ActiveCN104039745AInhibit deteriorationAvoid corrosionPreparation by hydrogen halide split-offOrganic chemistry methodsHydrogen fluorideSolvent

This invention is characterized by the catalyst component of a 1,1,1,3,3-pentachloropropane, which is the raw material substrate, being limited to no more than a fixed concentration, in a method in which hydrogen fluoride is reacted with the 1,1,1,3,3-pentachloropropane, and 1-chloro-3,3,3-trifluoropropene is produced. By limiting impurities such as the catalyst component, etc., to no more than a fixed concentration in the 1,1,1,3,3-pentachloropropane, issues during production of 1-chloro-3,3,3-trifluoropropene, such as shortened catalyst life, reaction inhibition, and device scaling or corrosion, can be improved. In addition, 1,1,1,3,3-pentachloropropane can be generated with a high yield and selectively, by causing a telomerization reaction of carbon tetrachloride and vinyl chloride in the presence of a specific metal solubilizing agent, using a catalyst having as the main component thereof elemental metal. As a result, this invention is useful as an industrially predominant production method that obtains a high yield of 1-chloro-3,3,3-trifluoropropene.

Owner:CENT GLASS CO LTD

Method for preparing 1,1,1,3,3 - pentachlorobutane from materials of chloropropene and carbon tetrachloride under tempering and polymerizing catalyst

ActiveCN1958541AEasy to operateReduce security risksOrganic-compounds/hydrides/coordination-complexes catalystsHalogenated hydrocarbon preparationOrganic solventReaction temperature

This invention relates to a method for preparing 1, 1, 1, 3, 3-pentachorobutane from 2-chloropropylene and tetrachloromethane in the presence of telomerization catalyst. The major catalyst is selected from Fe (II) salts, Fe and Fe (III) salts. The assistant catalyst is selected from alkyl phosphites and / or alkyl phosphates. This invention solves the problems of high catalyst toxicity, uneasy washing and recovery of viscous semi-solid catalyst, low conversion rate of the raw materials, low yield of the product, and large quantities of solvents needed faced by present techniques. The method in this invention does not need organic solvent, and can easily control the reaction temperature and pressure. The catalyst can be easily separated from the product, and can be recycled.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH

Titanium dioxide acid hydrolysis modified high efficiency multifunctional decoloring agent and preparation method thereof

InactiveCN101391830APromote degradationAccelerated settlementWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationTitanium sulfateSodium hydroxide

The invention relates to a modified and high-efficiency multi-function decolorizer of titanium dioxide acid hydrolysis waste residue and a preparation method thereof. Acid hydrolysis waste residue containing titanium sulfate is successively and respectively added with sodium hydroxide, peroxide, waste acid and calcium and magnesium powder according to the weight rate of the materials, therefore, the acid hydrolysis waste residue containing titanium sulfate generates nanometer titanium dioxide by nutralization, hydrolysis and acidification; added ferrous iron and iron in the acid hydrolysis waste residue are dehydrated at the temperature of 100-200 DEG C, oxidized at the temperature of 400-500 DEG C and then generate polymerization ferrous sulfate after natural cooling, telomerization and aging. The organic pollutants in wastewater are rapidly degraded by nano TiO2 and directly converted into non-toxic and harmless CO2, H2O and inorganic matters. Without changing the pH value of original sewage, the coagulation speed is fast, alumen ustum is big, settlement is quick, and the decolorizer has the functions of decolorization, degerming, removing radioactive elements and heavy metal ions, reducing COD and BOD, small feeding amount and strong adaptability.

Owner:朱文新

Continuous preparing technology for low-viscosity simethicone

The invention relates to a production technology for simethicone, in particular to a continuous preparing technology for low-viscosity simethicone. The continuous preparing technology comprises the following steps that hydrolysis is carried out, wherein trimethylchlorosilane and dimethyldichlorosilane are preliminarily mixed according to a mass ratio and then enter a tubular hydrolysis reactor to carry out a reaction; washing is carried out, wherein hydrolysate is washed to be neutral through three levels of washing step by step; telomerization is carried out, wherein under the condition that a catalyst is added, an equilibration reaction is carried out on siloxane; hydroxyl is removed, wherein a hydroxyl scavenging agent is added in the filtered simethicone to remove silicon hydroxyl remaining in silicon oil; low molecules are desorbed, wherein the low molecules are desorbed through an inert gas bubbling device, and the silicon oil with the low molecules desorbed is filtered and stored. The production technology has the advantages that the problems that washing acid water is large in discharging amount and contains much organic manner, and waste water is difficult to treat are solved, the product yield and the quality of the simethicone are improved, the low molecule desorbing time is shortened, cost is lower, and efficiency is higher.

Owner:TANGSHAN SANYOU SILICON IND

Method for preparing chlorohydrocarbon

ActiveCN100361944CImprove reaction efficiencyShort reaction timePreparation by halogen halide additionAlkaneMetal catalyst

Owner:BEIJING YUJI SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com