Method of preparing full-fluorine alkyl iodide

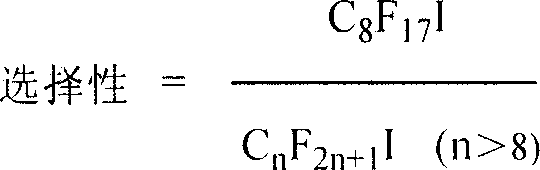

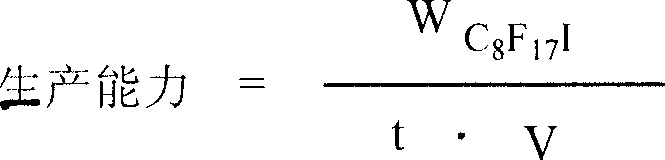

A perfluoroalkyl iodide and catalyst technology, which is applied in chemical instruments and methods, halogenated hydrocarbon preparation, organic chemistry, etc., can solve the problem of low selectivity of target products and low production capacity of reaction, and can not control high carbon number well By-products and molecular weight distribution, etc., to reduce time, avoid cyclopolymerization, and improve production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Volume is 10L Hastelloy stainless steel vertical reaction kettle except moisture content, adds active palladium powder catalyst 15g. The kettle was sealed and evacuated, replaced with nitrogen several times to remove oxygen, and the oxygen content reached below 10ppm. Add C to the kettle with an auxiliary pump at room temperature 2 f 5 I 1500g, turn on the stirring, heat to 50°C, and pretreat the catalyst for 2 hours. Then slowly feed 15g of TFE monomer. When the temperature rises to 100°C, the pressure is about 2.0MP. When the pressure in the kettle drops to a certain level, 15g of TFE is fed again, and the TFE is repeatedly and slowly fed until the total mass of TFE is 450 grams, react until the pressure no longer changes, cool down, reclaim unreacted C 2 f 5 I, to obtain the product C 2 f 5 (CF 2 CF 2 ) n I total 874.5 grams, n≥1. Product is through alkaline washing, after dehydration treatment, see Table 1 with the ratio of each component in the product of...

Embodiment 2

[0025] 90g of active tantalum powder catalyst was added to a Hastelloy stainless steel horizontal reaction kettle with a volume of 10L except water. The kettle was sealed and evacuated, replaced with nitrogen several times to remove oxygen, and the oxygen content reached below 10ppm. Add CF to the kettle with an auxiliary pump at room temperature 3 I 900g, turn on the stirring, heat to 50°C, and activate the catalyst for 4 hours. Then slowly feed 25g of hexafluoropropylene monomer. When the temperature rises to 140°C, the pressure is about 2.5MP. Fluoropropylene until the total mass of hexafluoropropylene is 600 grams, react until the pressure no longer changes, lower the temperature, and reclaim unreacted CF 3 I, to obtain the product CF 3 (CFCF 3 CF 2 ) n I total 861.2 grams, n≥1. Product is through alkaline washing, after dehydration treatment, see Table 2 with the ratio of each component in the product of chromatographic analysis:

[0026] Chain length

Embodiment 3

[0028] The capacity is 10L Hastelloy stainless steel vertical reaction kettle except moisture content, add the active palladium powder catalyst 40g of load and alumina upper carrier. The kettle was sealed and evacuated, replaced with nitrogen several times to remove oxygen, and the oxygen content reached below 10ppm. Add C to the kettle with an auxiliary pump at room temperature 3 f 7 I 1800g, turn on the stirring, heat to 50°C, and activate the catalyst for 4 hours. Then slowly feed 20g of vinylidene fluoride monomer. When the temperature rises to 160°C, the pressure is about 2.5MP. When the pressure in the kettle drops to a certain level, 20g of vinylidene Vinyl fluoride until the total mass of vinylidene fluoride is 1000 grams, react until the pressure no longer changes, cool down, and reclaim unreacted C 3 f 7 I, to obtain the product C 3 f 7 (CH 2 CF 2 ) n I total 1235.8 grams, n≥1. Product is through alkali washing, after dehydration treatment, see Table 3 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com