Patents

Literature

3847 results about "Well control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Well control is the technique used in oil and gas operations such as drilling, well workover and well completion for maintaining the hydrostatic pressure and formation pressure to prevent the influx of formation fluids into the wellbore. This technique involves the estimation of formation fluid pressures, the strength of the subsurface formations and the use of casing and mud density to offset those pressures in a predictable fashion. Understanding pressure and pressure relationships is important in well control.

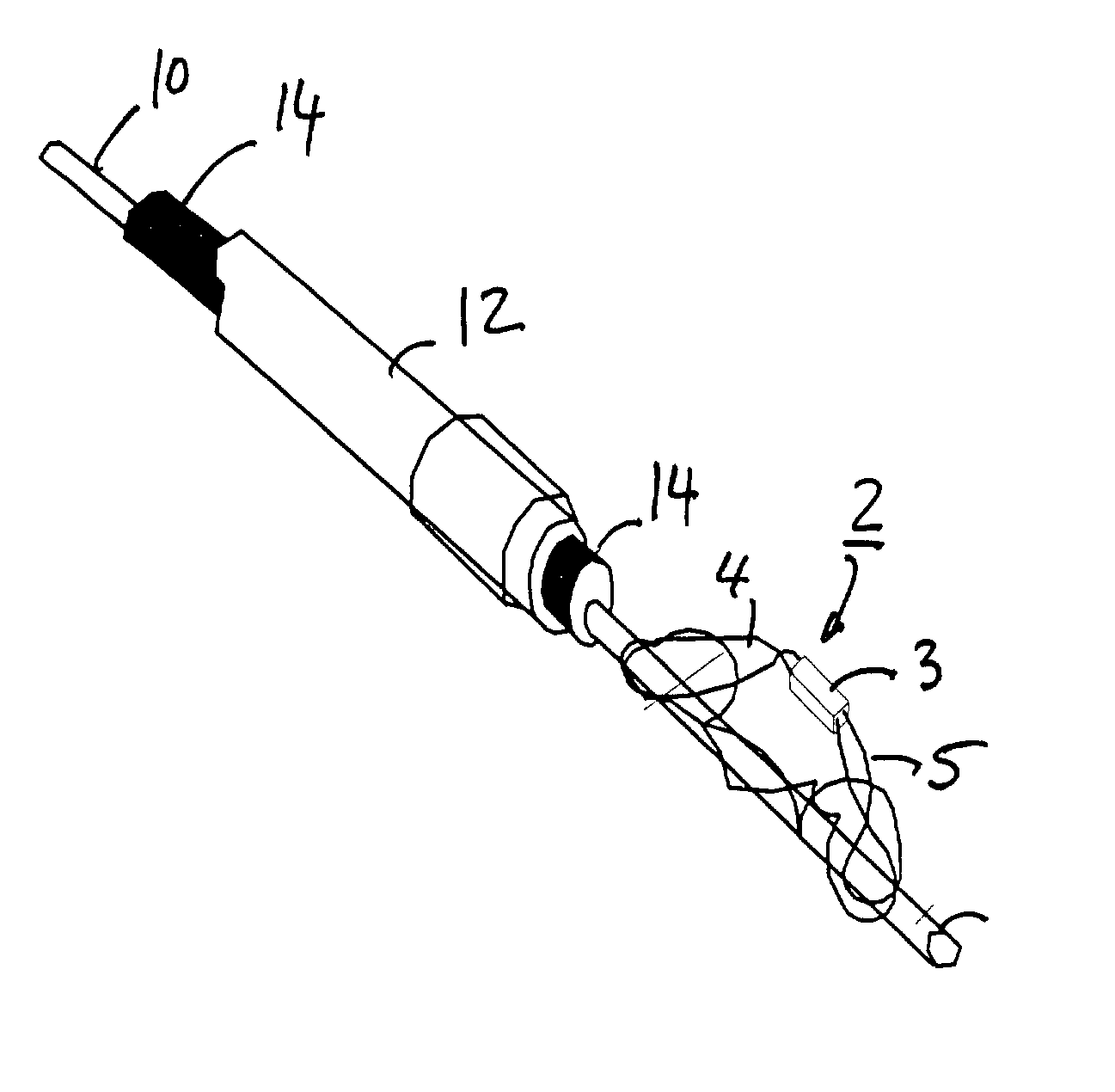

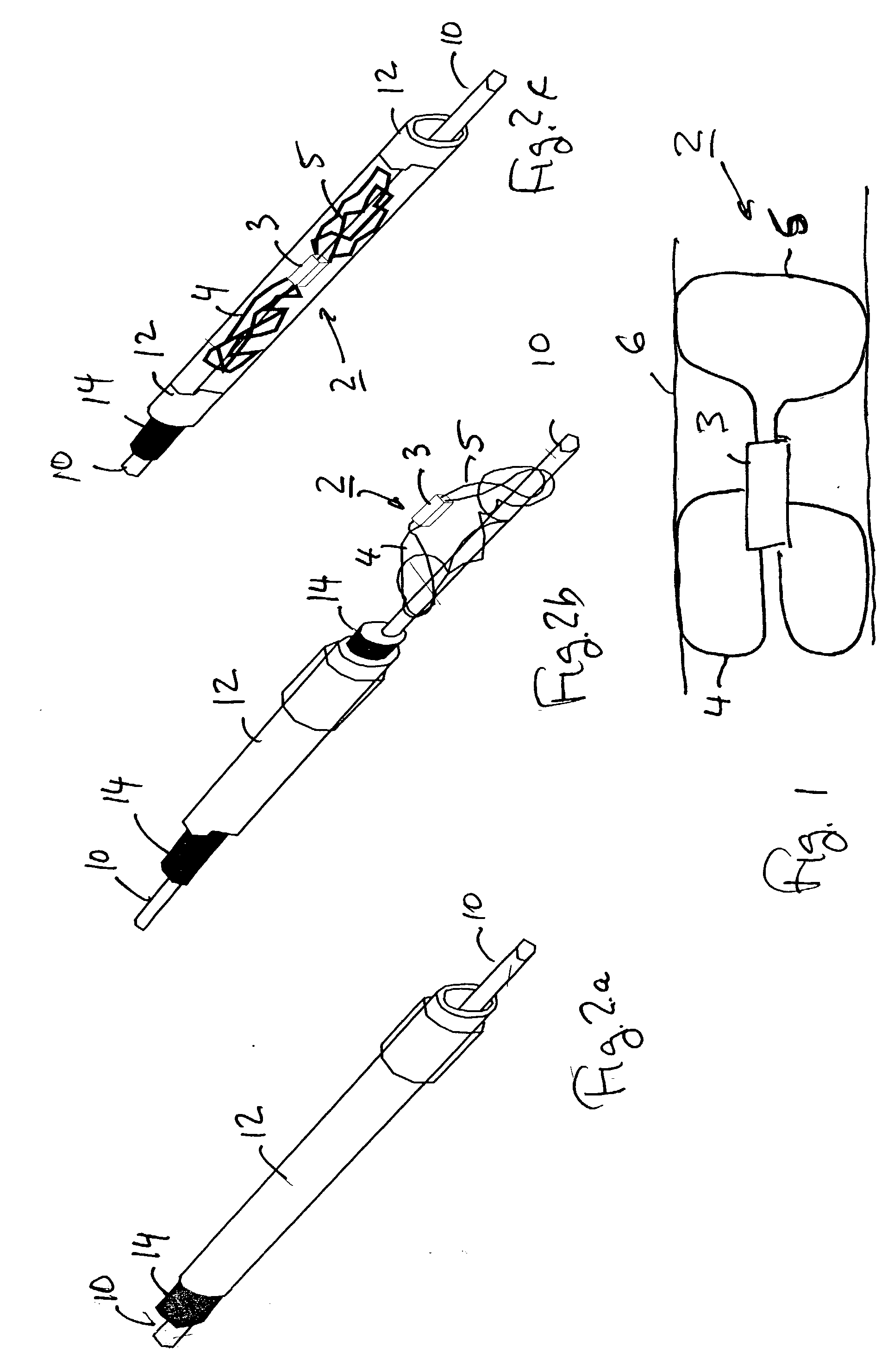

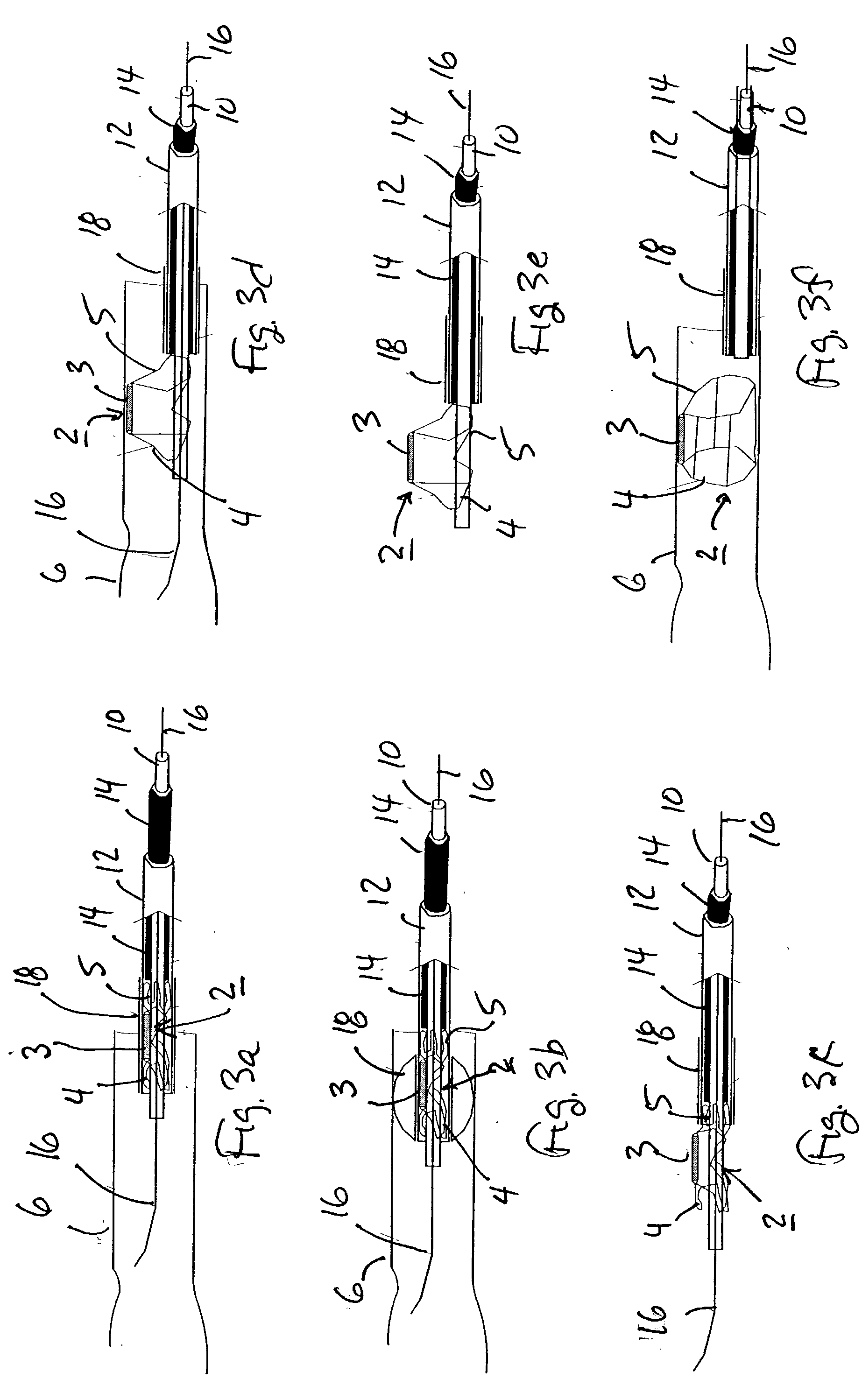

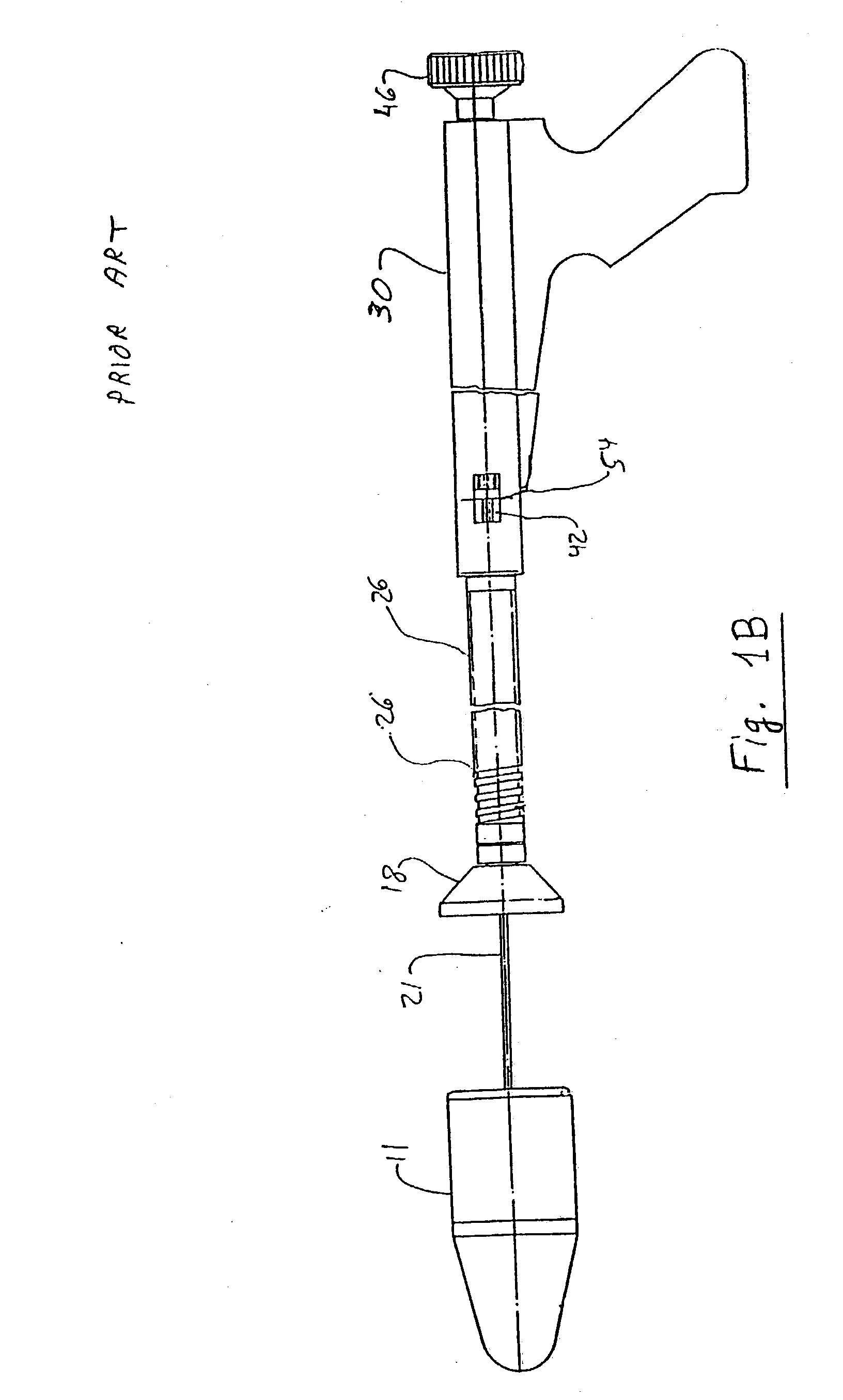

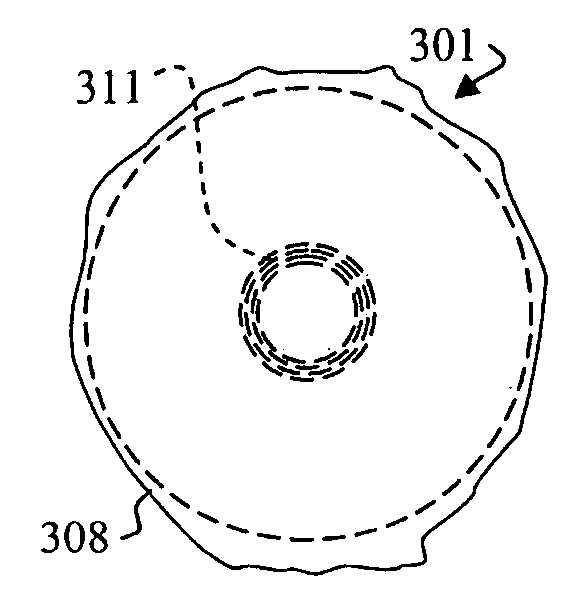

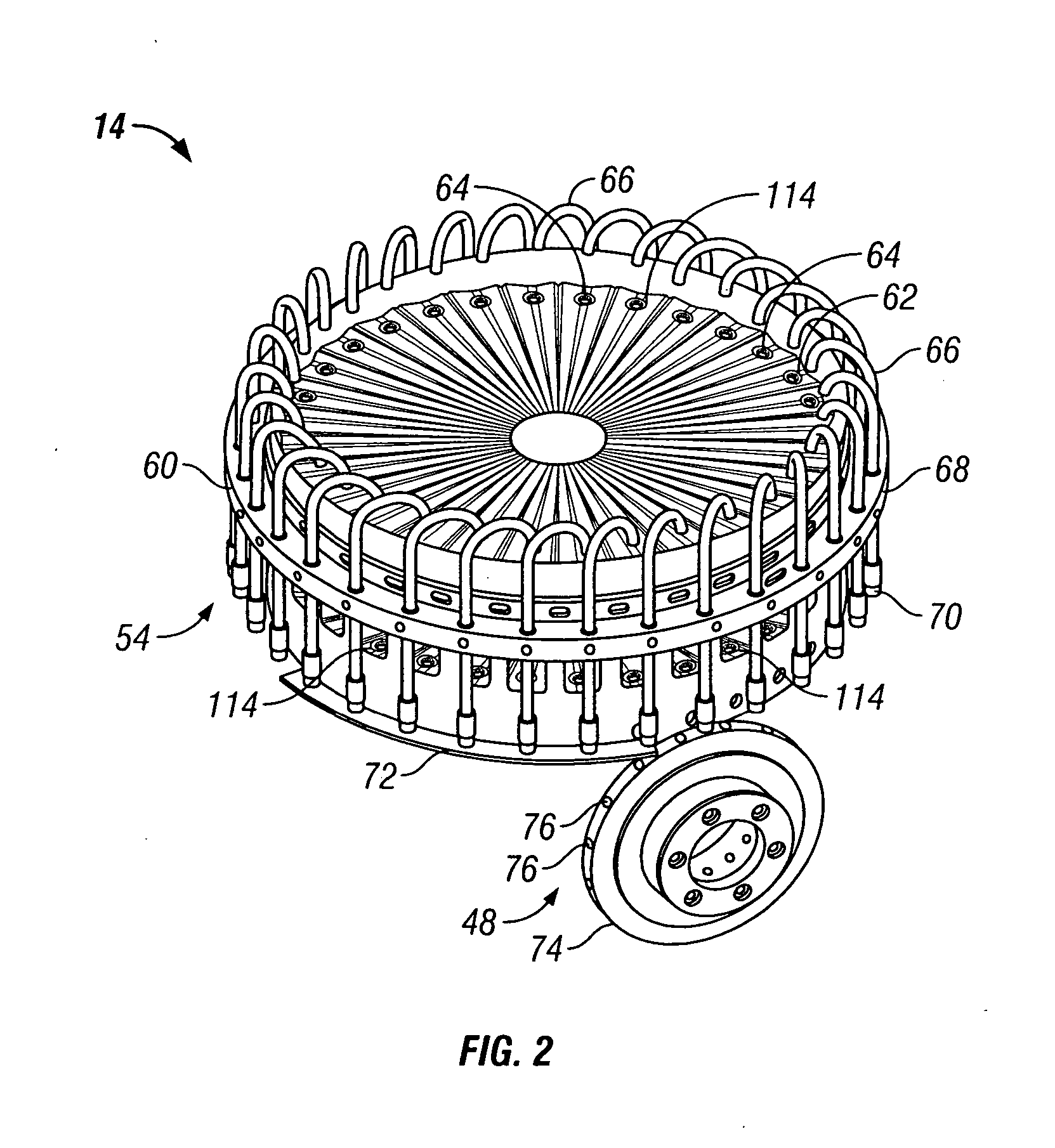

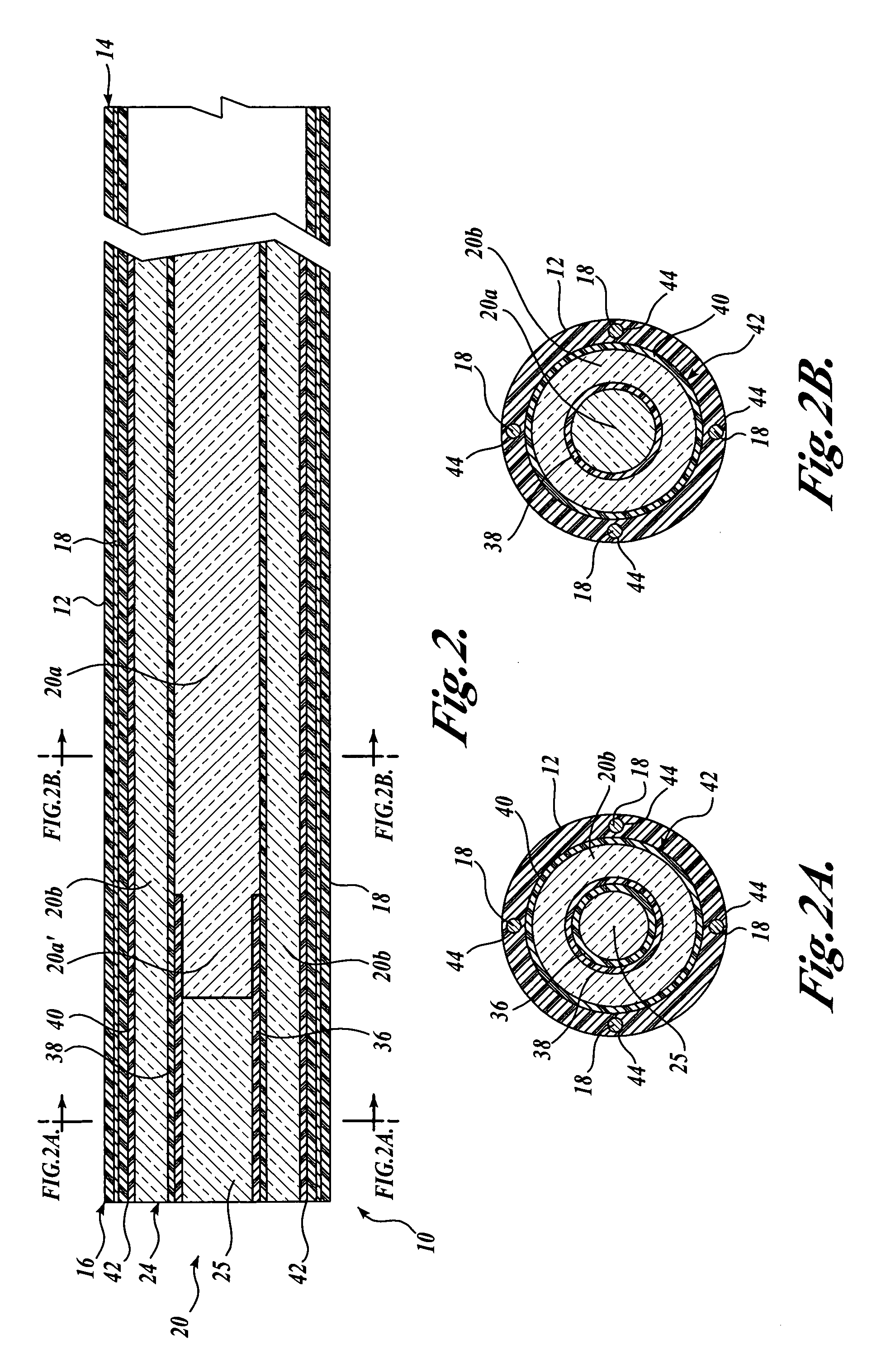

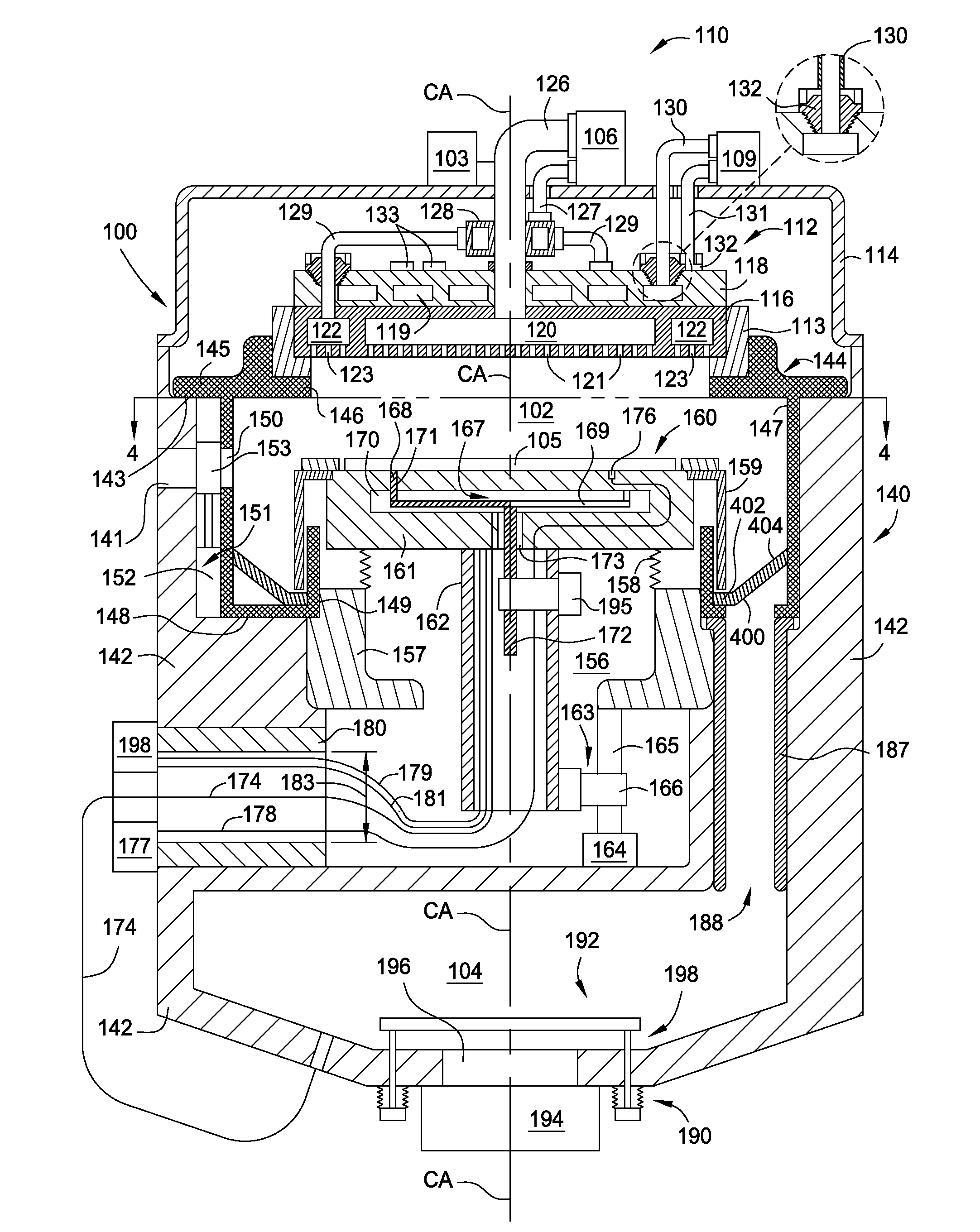

Deployment device, system and method for medical implantation

A deployment device for deploying a self-expansible medical implant at a target location in a body cavity, is provided. While generally, the expansion of self-expansible structures tends to be abrupt, and the impact of expansion may cause injury, a two-stage expansion process of the present invention minimizes the impact of exapnsion. Additionally, an ability to manuever the medical imlant into position, after the first stage of expansion, provides for accurate positioning. Thus the present invention is of a deployment device for precise and well-controlled manner of deployment, so as to minimize damage to the cavity wall and to position the implant accurately at the target location. The deployment device includes: an inner tube; an outer tube; and an implant received on the inner tube and enclosed by the outer tube. The implant has a self-expansible anchoring element which is in a contracted condition when enclosed by the outer tube, expands to a partially-expanded condition when the outer tube is retracted, and expands to a fully-expanded condition when the inner tube is removed.. The implant is deployed by introducing the deployment device to the target location in the body cavity; retracting the outer tube with respect to the implant such that the anchoring element self-expands from its contracted condition to its partially-expanded condition; and withdrawing the inner tube from the implant such that the anchoring element self-expands from its partially-expanded condition to its fully-expanded condition to firmly fix the implant at the target location within the body cavity.

Owner:REMON MEDICAL TECH

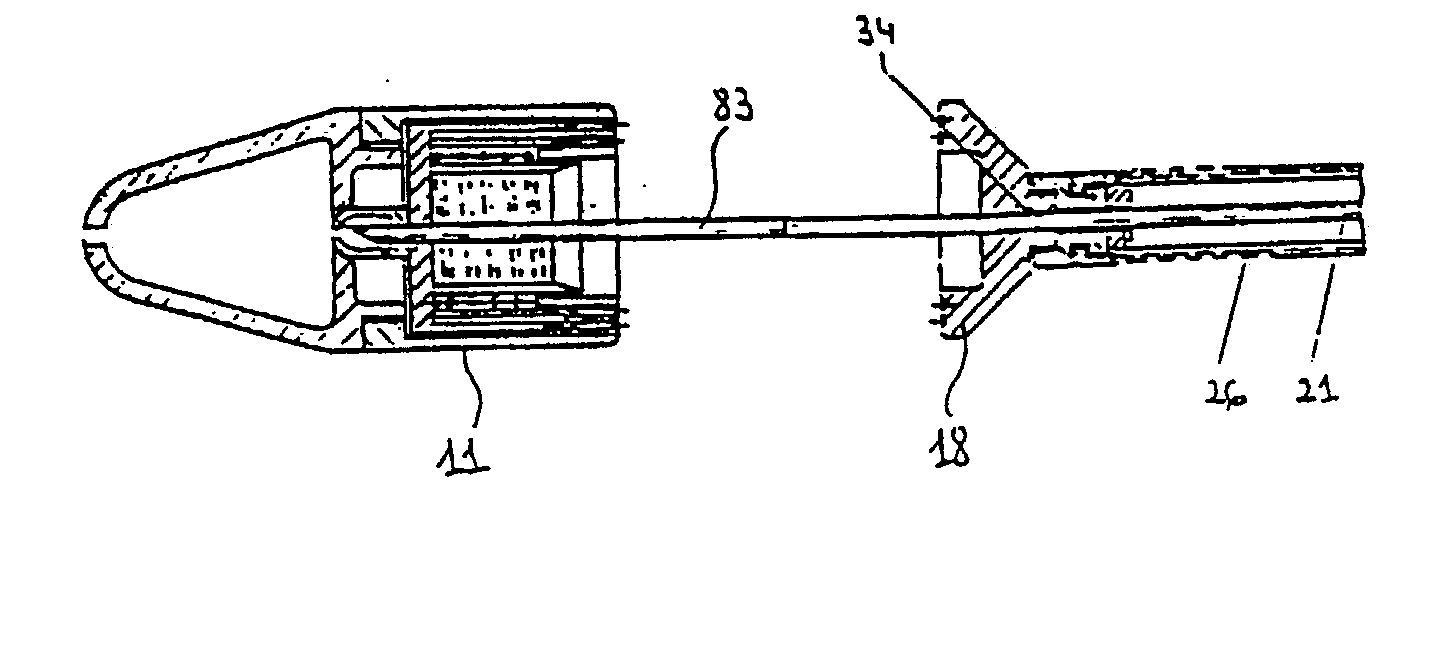

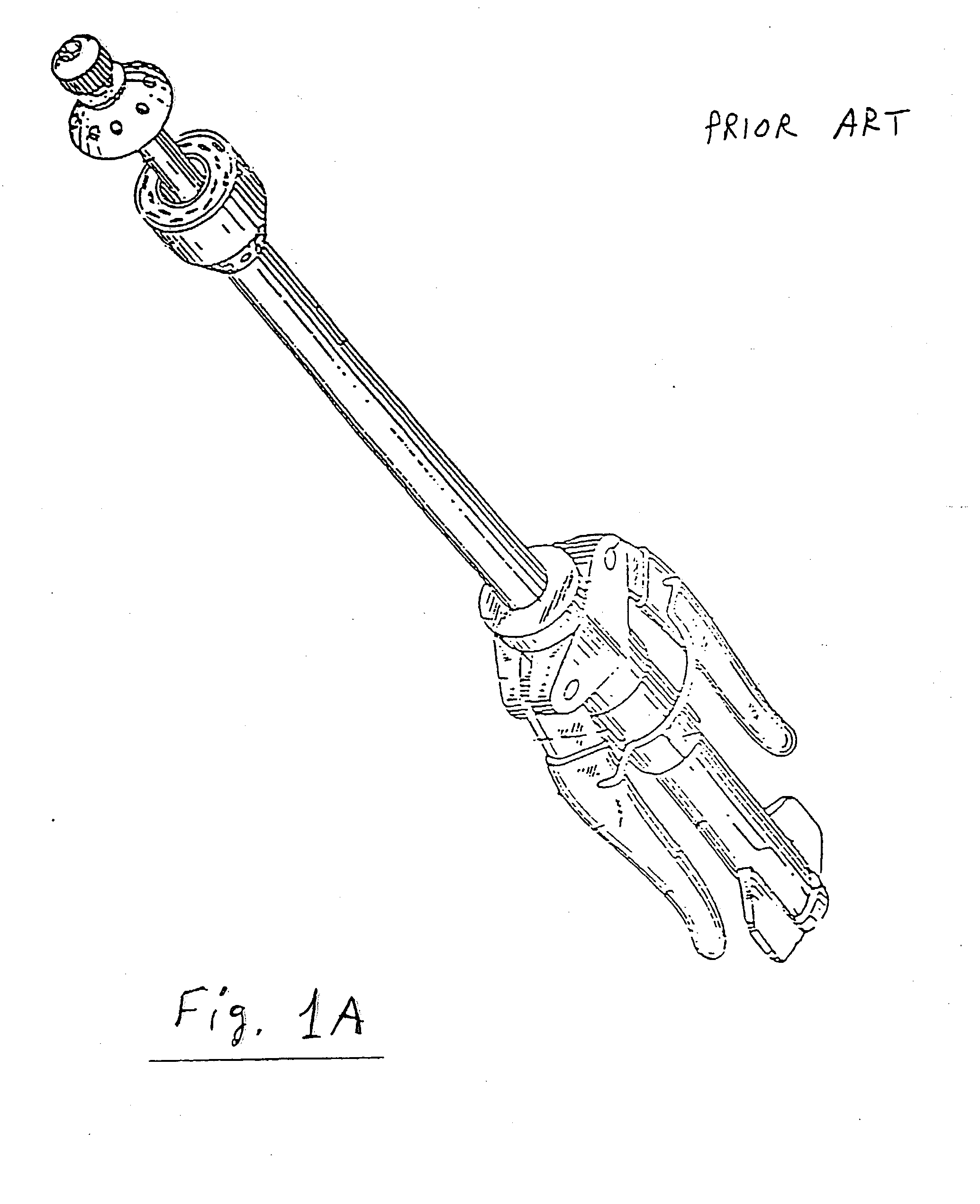

Flexible annular stapler for closed surgery of hollow organs

InactiveUS20050051597A1Reduce traumaLess complicatedSuture equipmentsStapling toolsEngineeringSurgery procedure

A improved flexible annular stapler for joining annular organs (163, 164) is disclosed. The novel stapler features greater accuracy of operation and better control by the operator, as well as additional functions, such as internal illumination (76) and viewing facility (82), and accommodation of a large number of accessories, such as fibroscopes (90) and catheters. The novel stapler features easy attachability of both stapling jaws (18, 25) and easy detachability of the head (11). The novel features of the flexible stapler, and associated methods performed thereby, are particularly useful for closed surgery.

Owner:TOLEDANO HAVIV

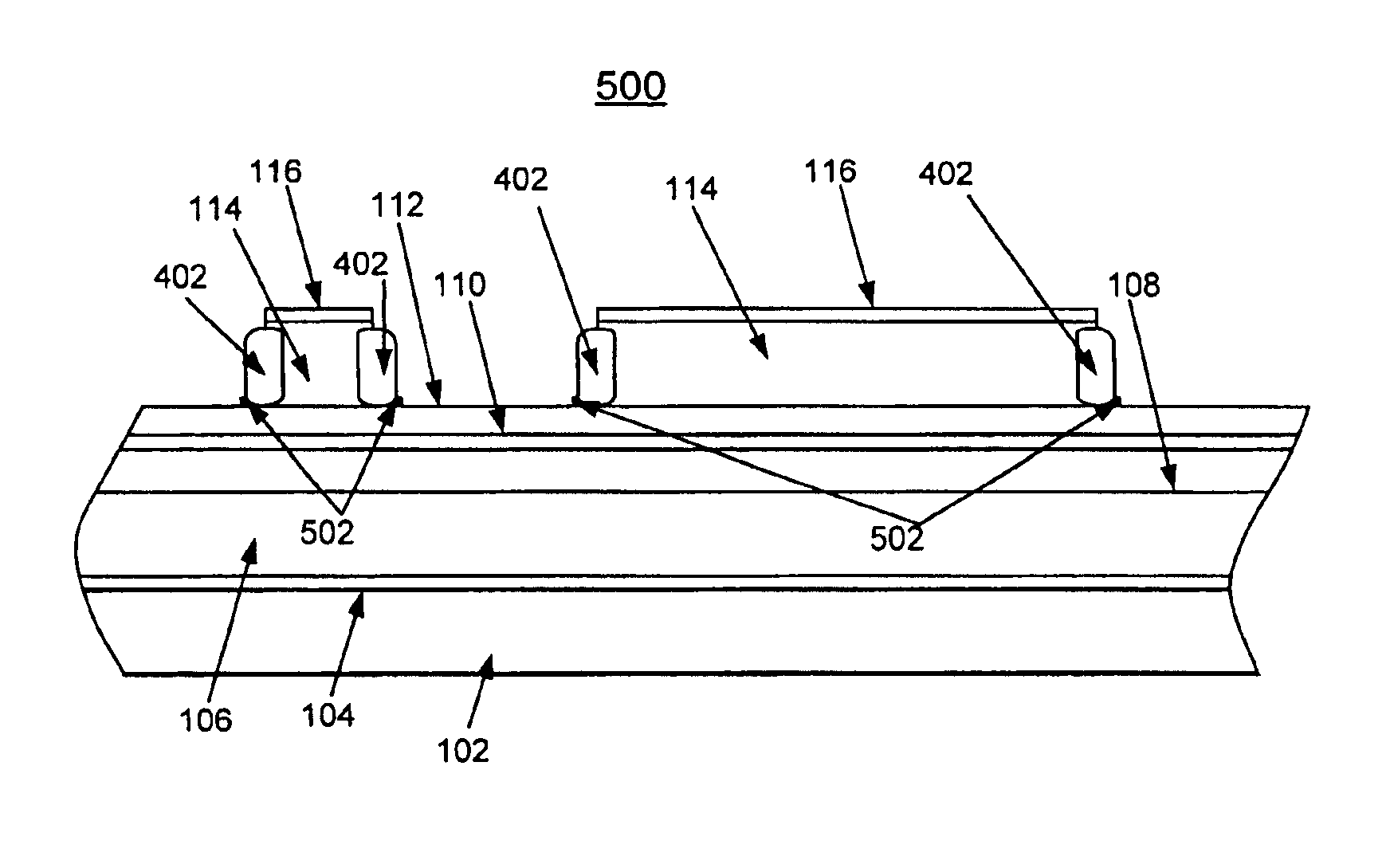

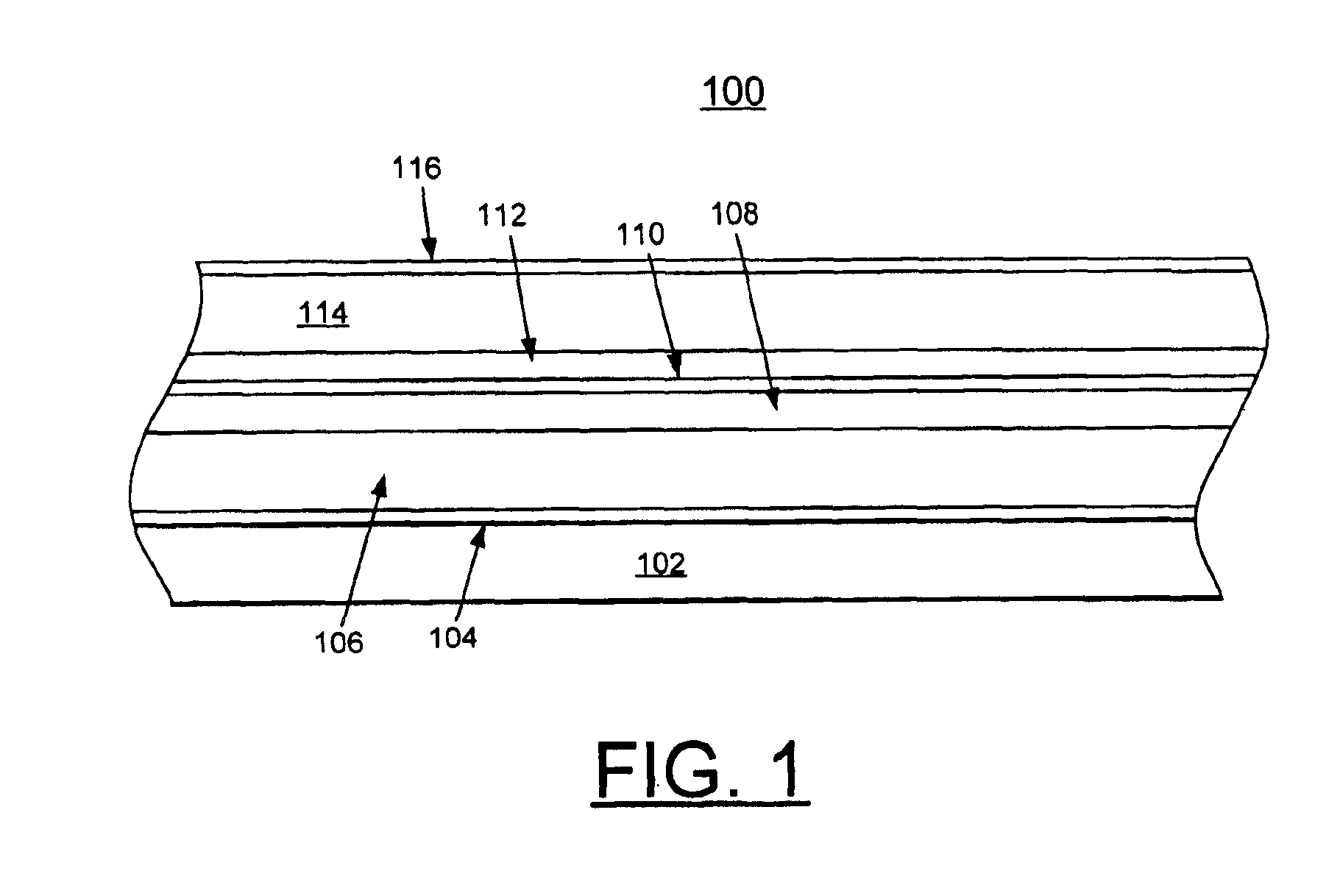

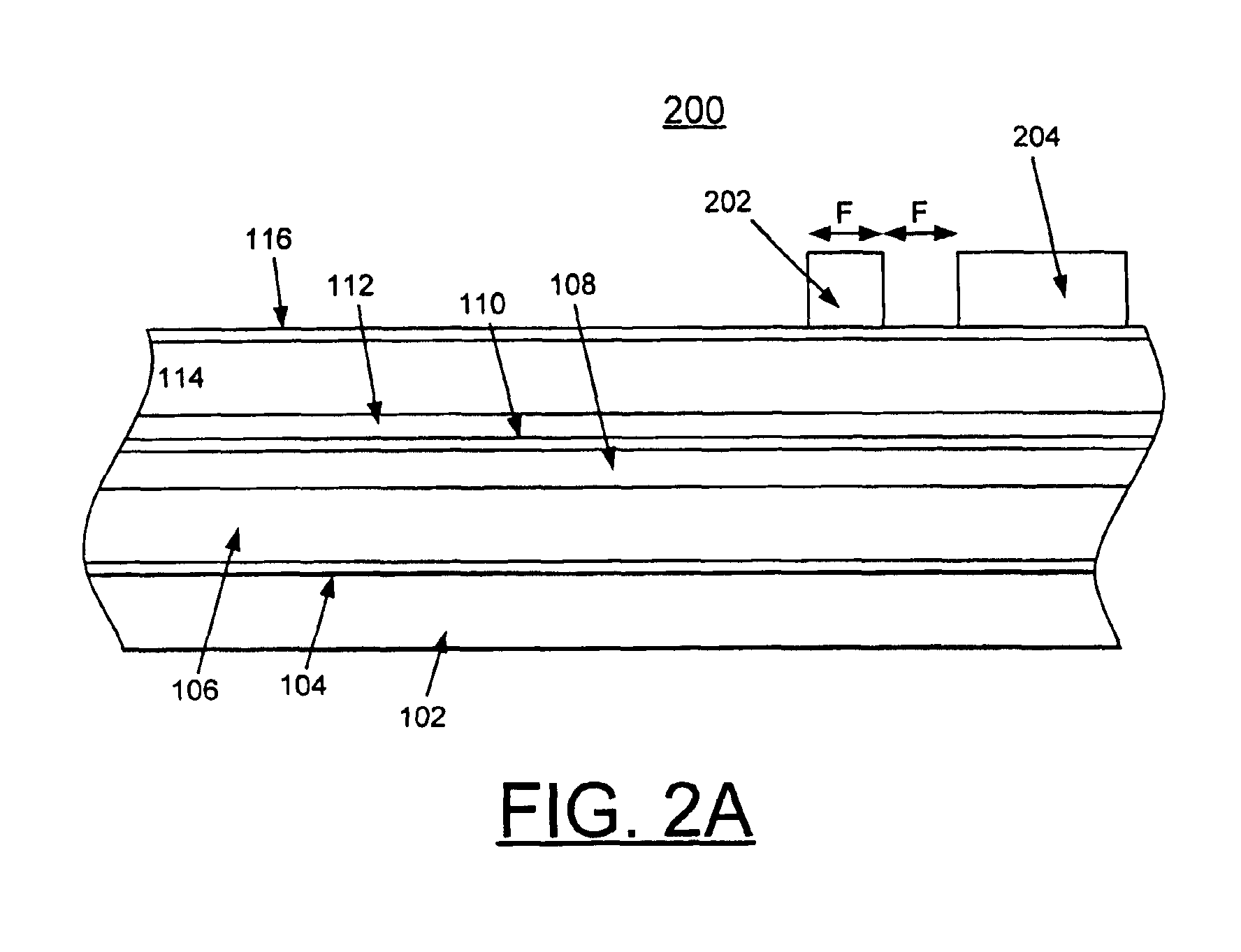

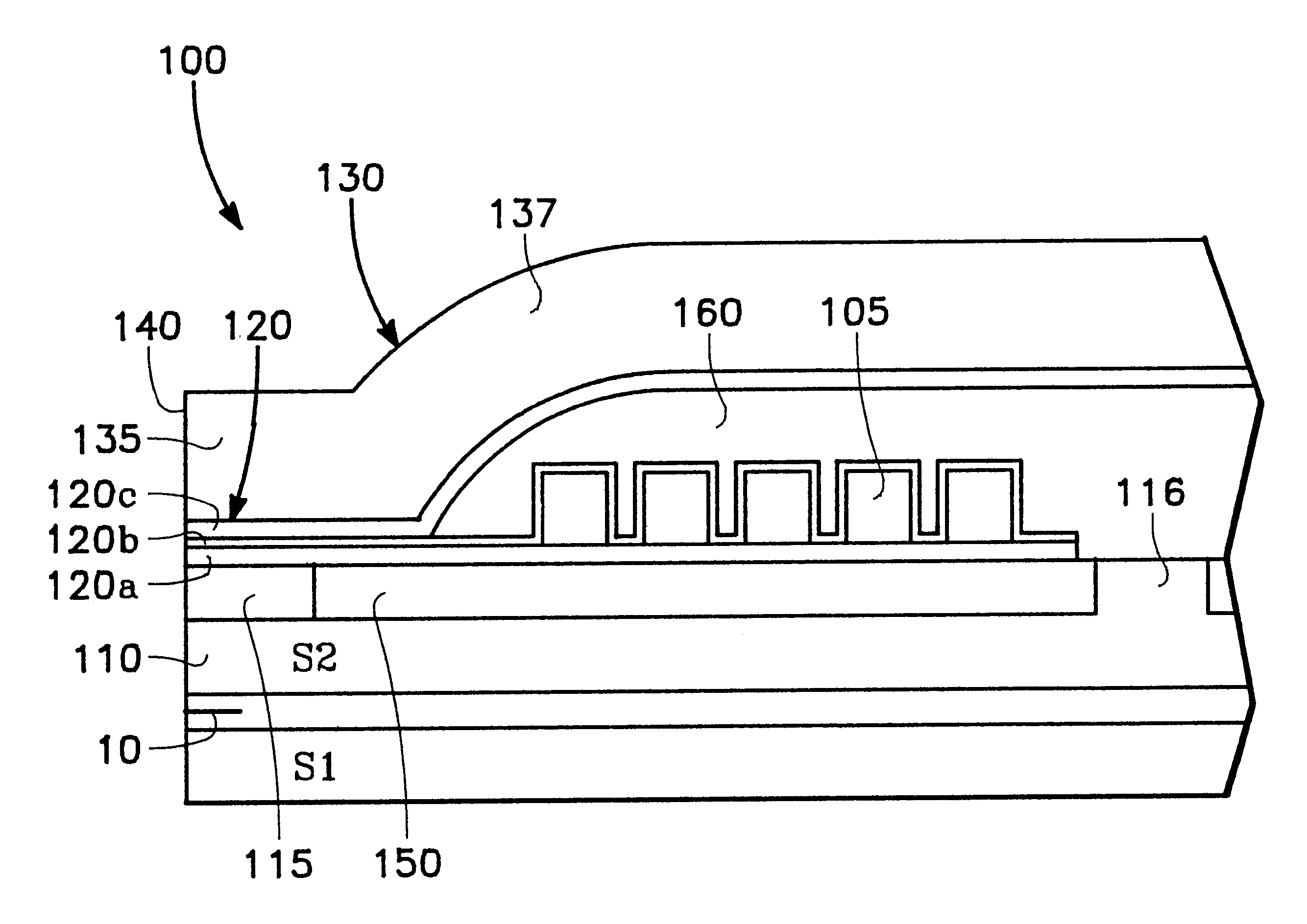

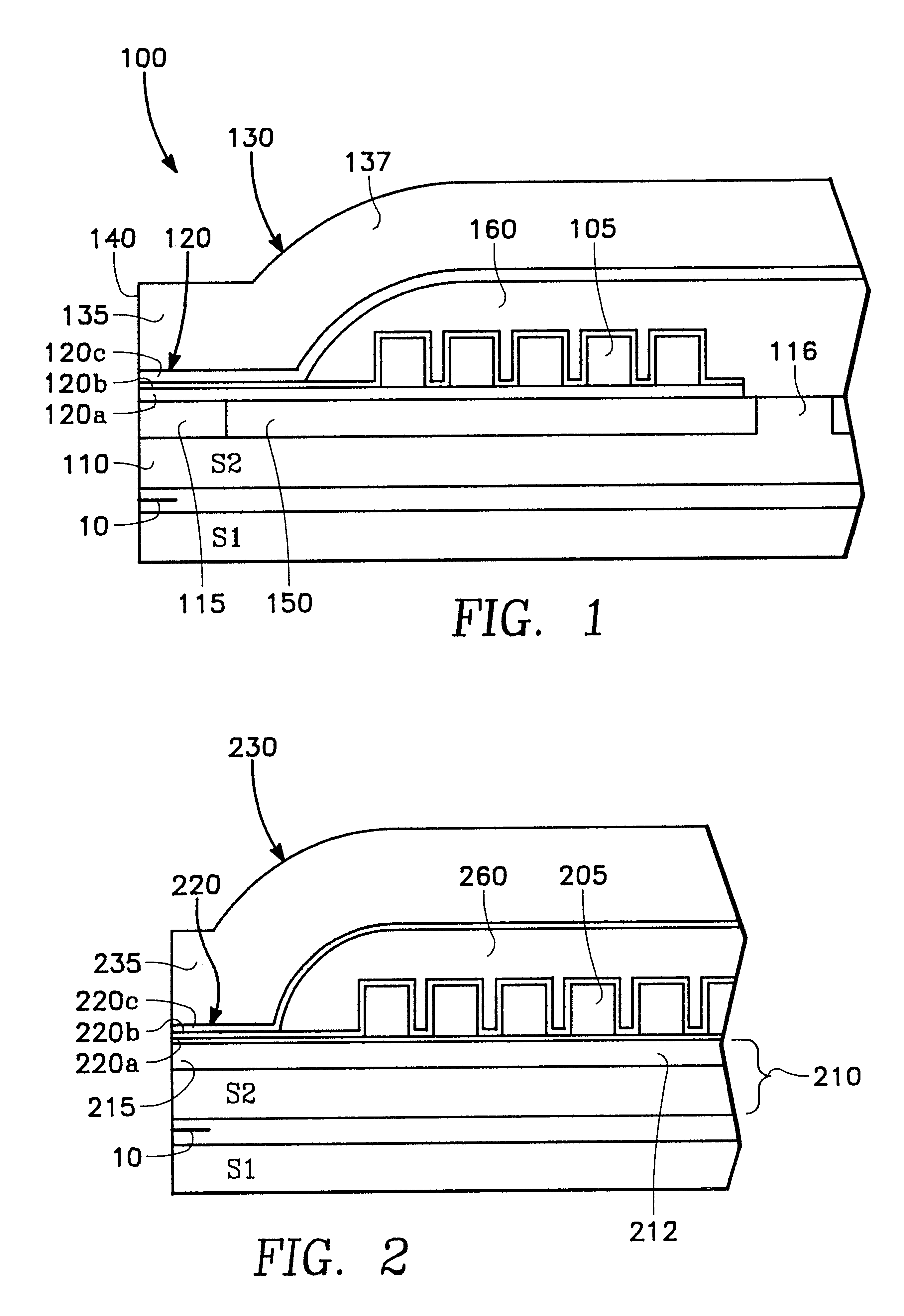

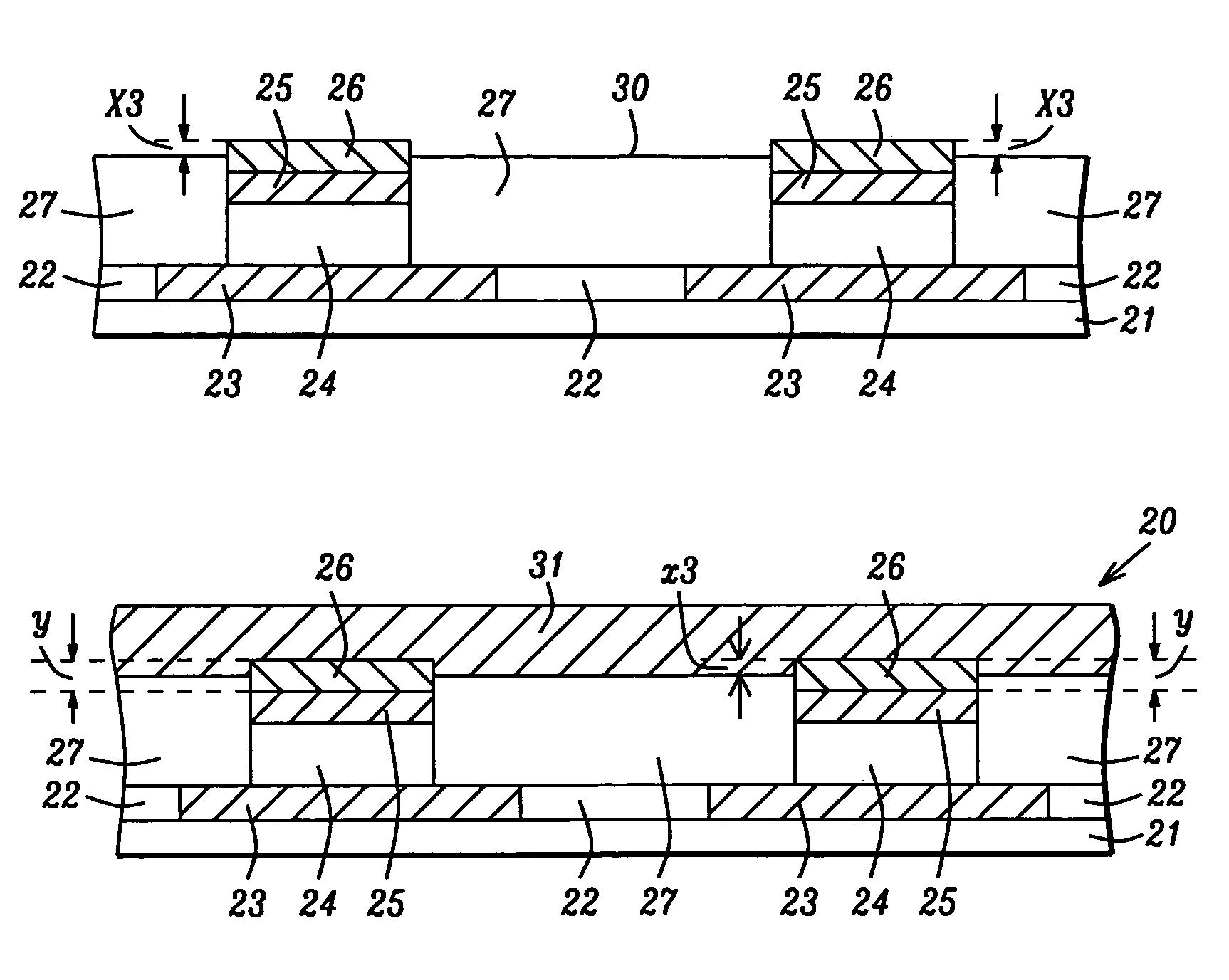

Method for forming quadruple density sidewall image transfer (SIT) structures

InactiveUS6875703B1Small sizeSemiconductor/solid-state device manufacturingSemiconductor devicesImage transferEngineering

A method is provided for forming a quadruple density sidewall image transfer (SIT) structure. Oxide spacers are formed on opposite sidewalls of a first mandrel. The oxide spacers form a second mandrel. Then sidewall spacers are formed on opposite sidewalls of the oxide spacers forming the second mandrel. A pattern of the sidewall spacers is used to form the quadruple density sidewall image transfer (SIT) structure. The method of the invention enables formation of four well-controlled lines for each lithographically minimum pitch dimension.

Owner:IBM CORP

Radiation shield

ActiveUS20190051544A1Reduce heat fluxQuality improvementGaseous chemical processesElectric discharge tubesSusceptorHeat flux

A radiation shield and an assembly and a reactor including the radiation shield are disclosed. The radiation shield can be used to control heat flux from a susceptor heater assembly and thereby enable better control of temperatures across a surface of a substrate placed on a surface of the susceptor heater assembly.

Owner:ASM IP HLDG BV

Electrocatalyst powders, methods for producing powders and devices fabricated from same

Electrocatalyst powders and methods for producing electrocatalyst powders, such as carbon composite electrocatalyst powders. The powders have a well-controlled microstructure and morphology. The method includes forming the particles from an aerosol of precursors by heating the aerosol to a relatively low temperature, such as not greater than about 400° C.

Owner:CABOT CORP

Method and apparatus for incorporating objects into cigarette filters

Owner:R J REYNOLDS TOBACCO COMPANY

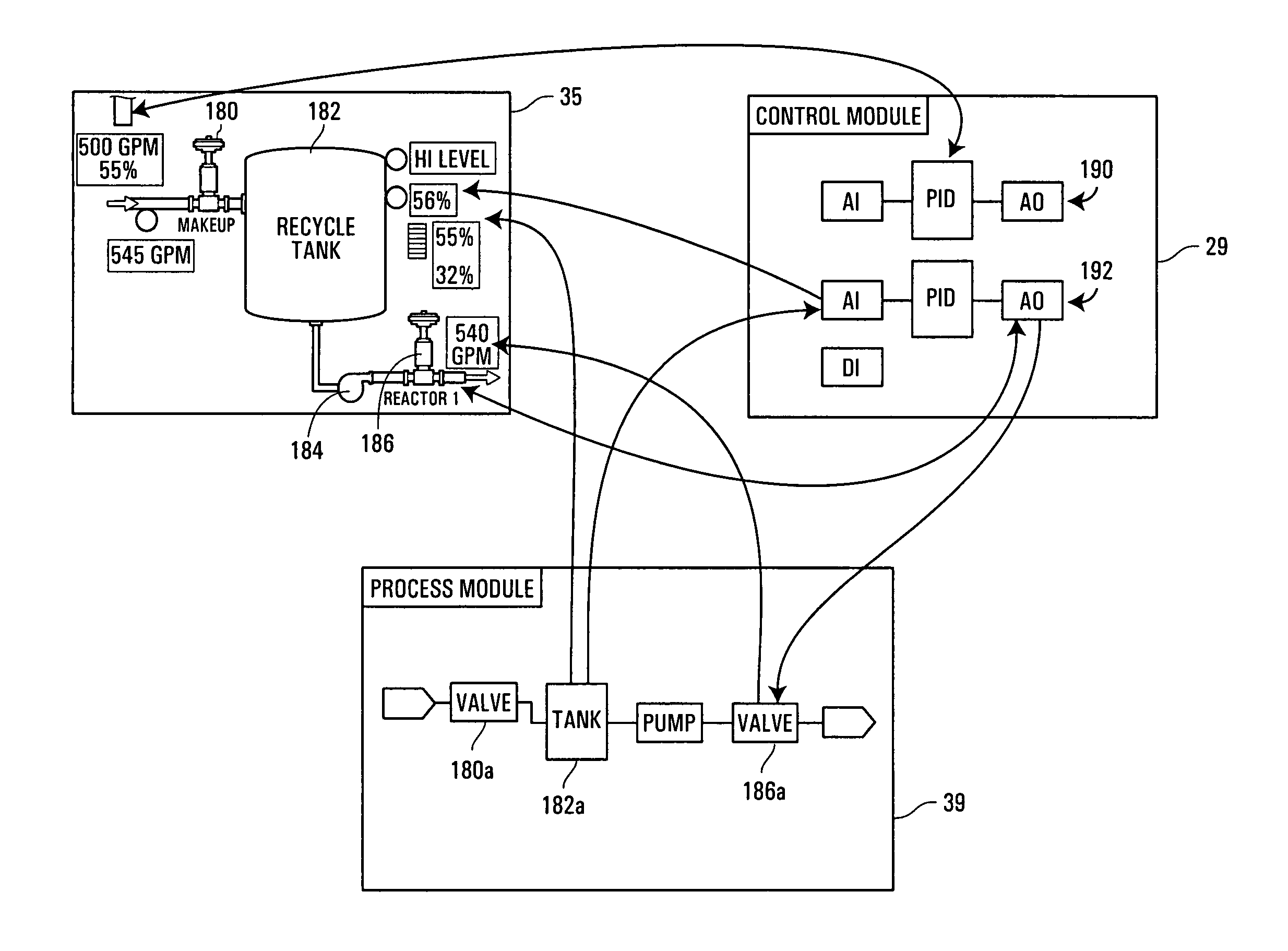

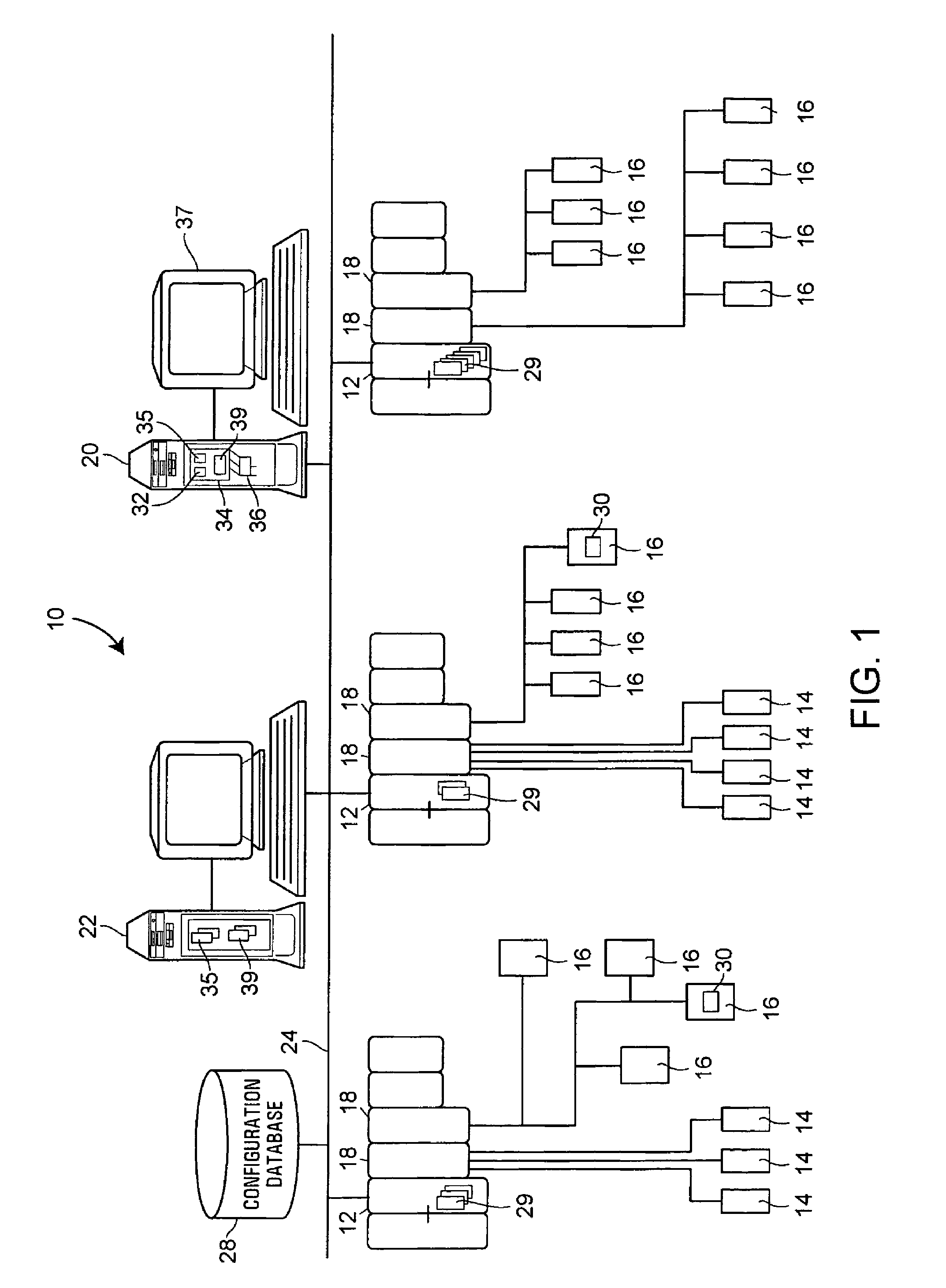

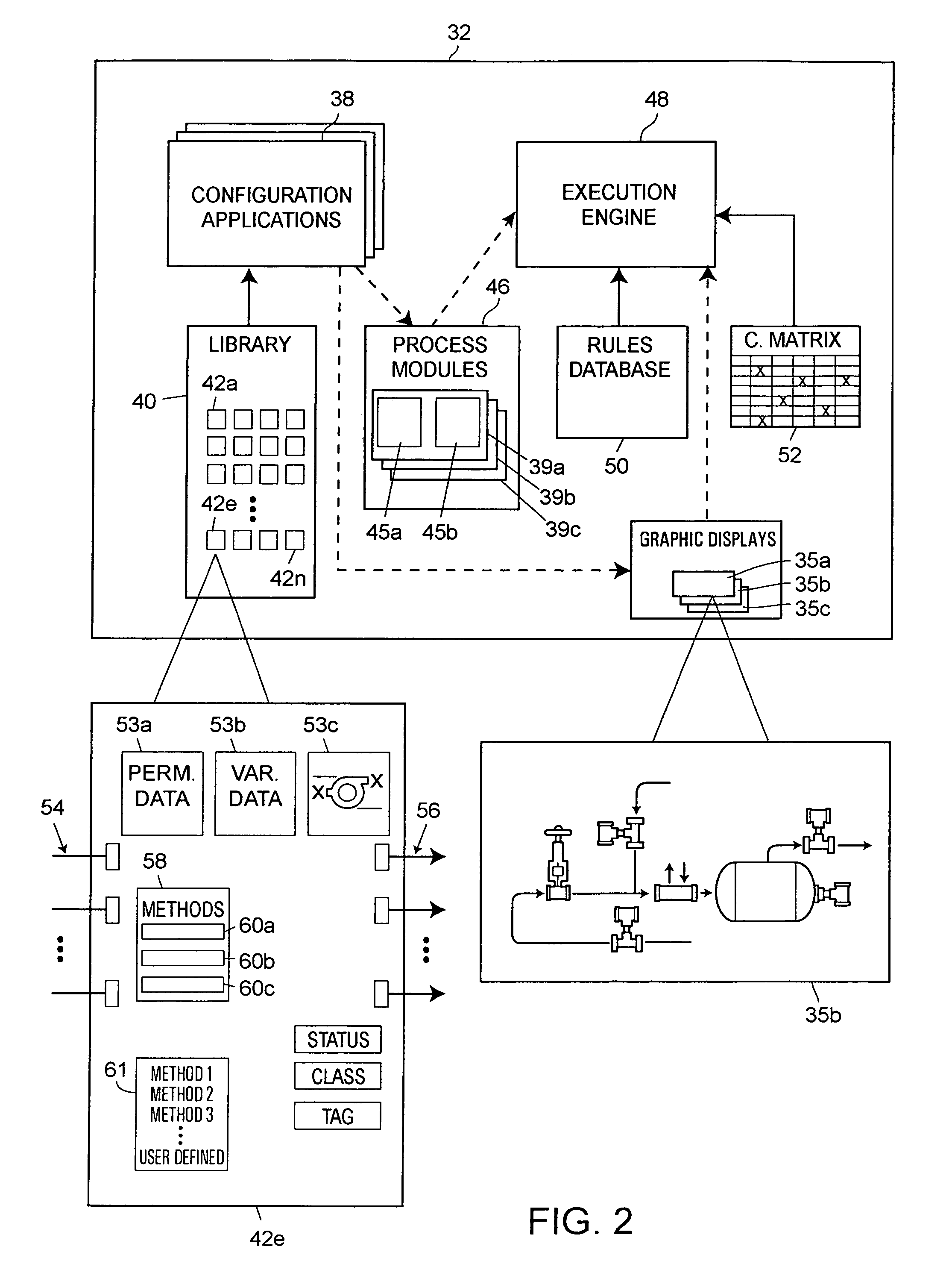

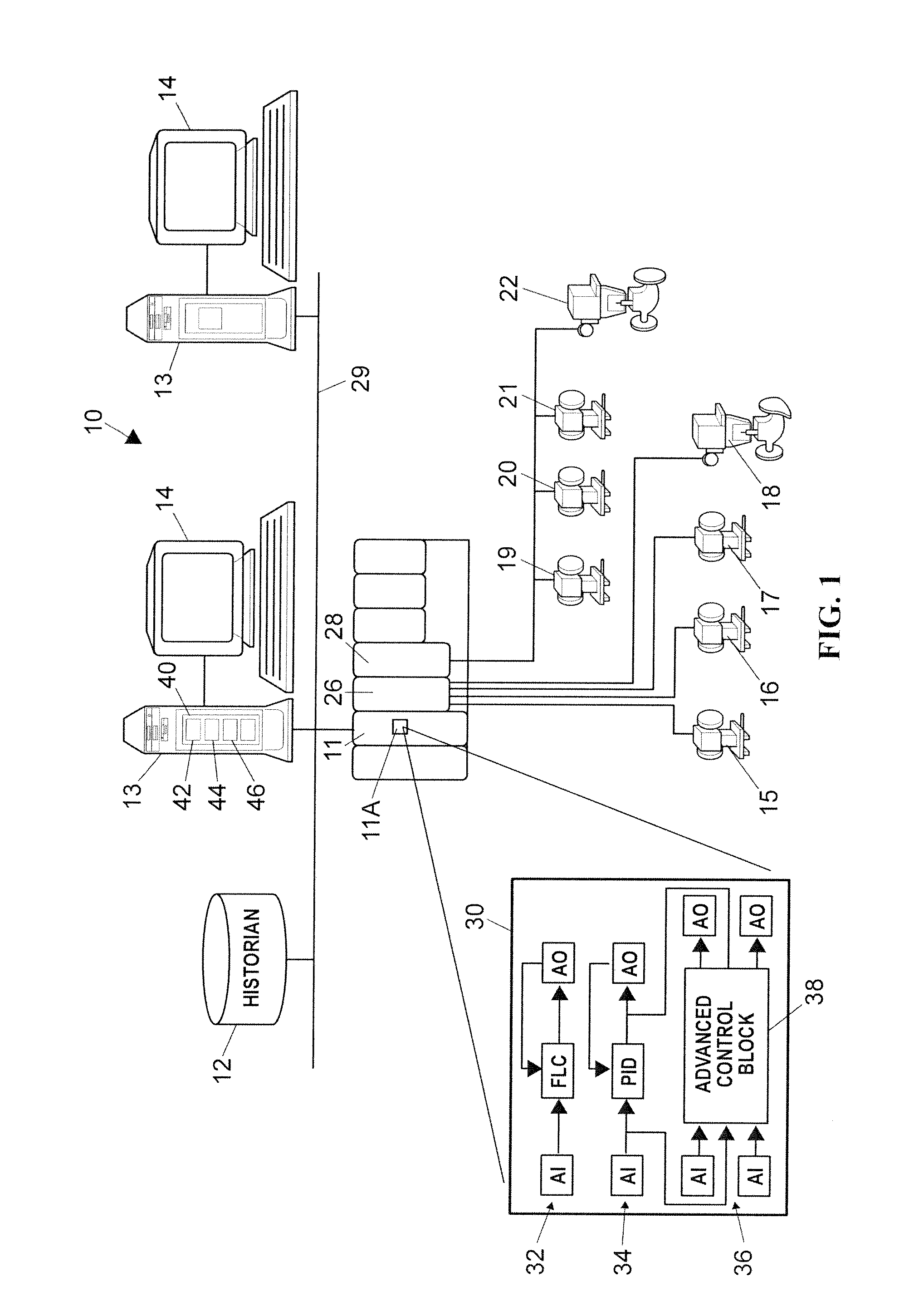

Integration of graphic display elements, process modules and control modules in process plants

InactiveUS7110835B2Easy to useEasy to implementSpace heating and ventilationDomestic heating detailsGraphicsProcess module

Graphic displays, which display information about process elements and the manner in which these elements are connected within a process, process modules, which simulate the operation of the elements depicted within the graphic displays and control modules, which perform on-line control activities within a process, may be communicatively connected together to provide a combined control, simulation and display environment that enables enhanced control, simulation and display activities. Smart process objects, which have both graphical and simulation elements, may used to create one or more graphic displays and one or more process simulation modules, each having elements which may communicate with one another to share data between the graphic displays and the process modules. Additionally, function blocks within control modules executed in the process plant may reference the elements within the graphic displays and the process modules (and vice versa) so that control modules may use simulated data developed by the process modules to perform better control, so that process modules may perform better simulation using actual pant data from the control modules, and so that the graphic displays may be used to illustrate actual process data and / or simulated process data as developed by the control modules and the process modules.

Owner:FISHER-ROSEMOUNT SYST INC

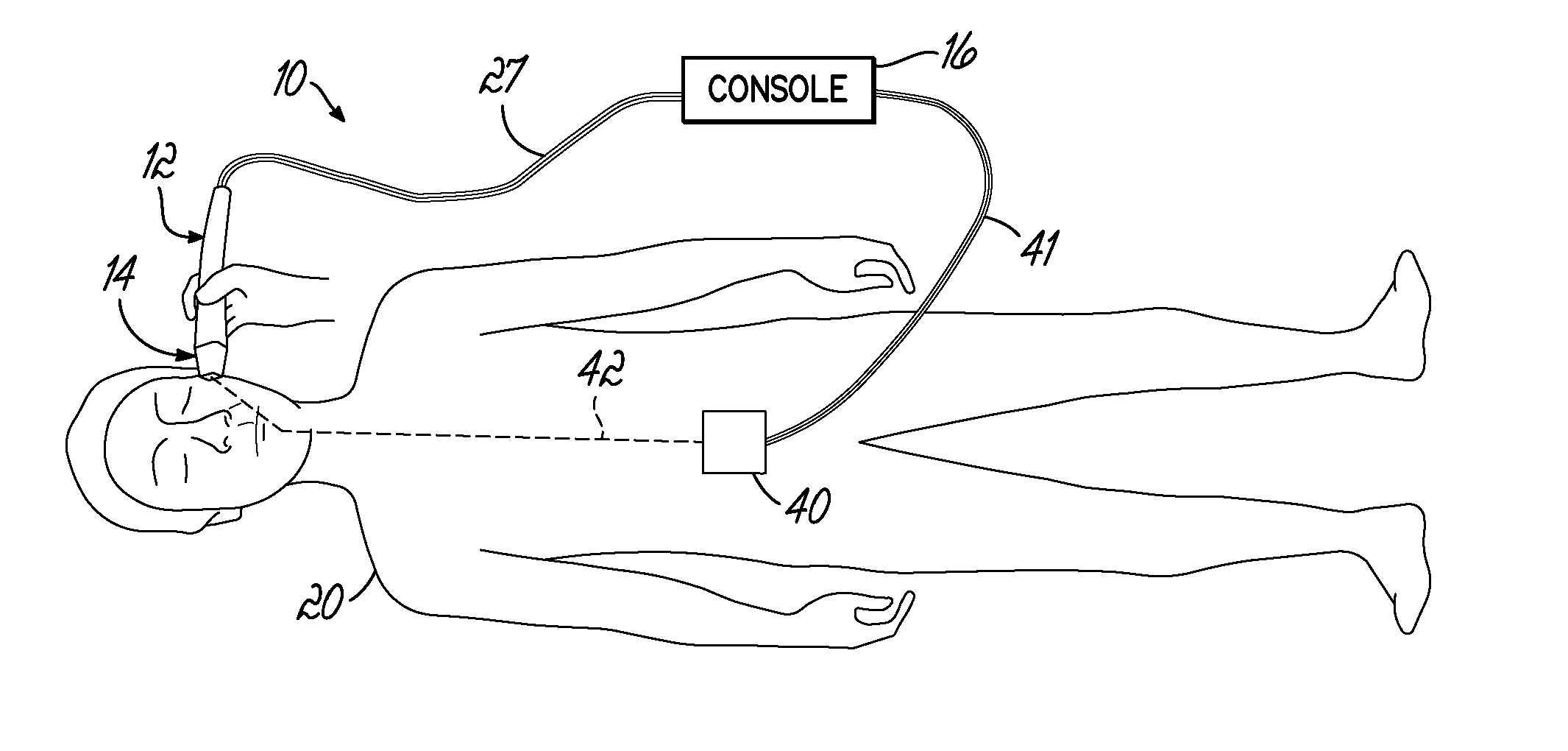

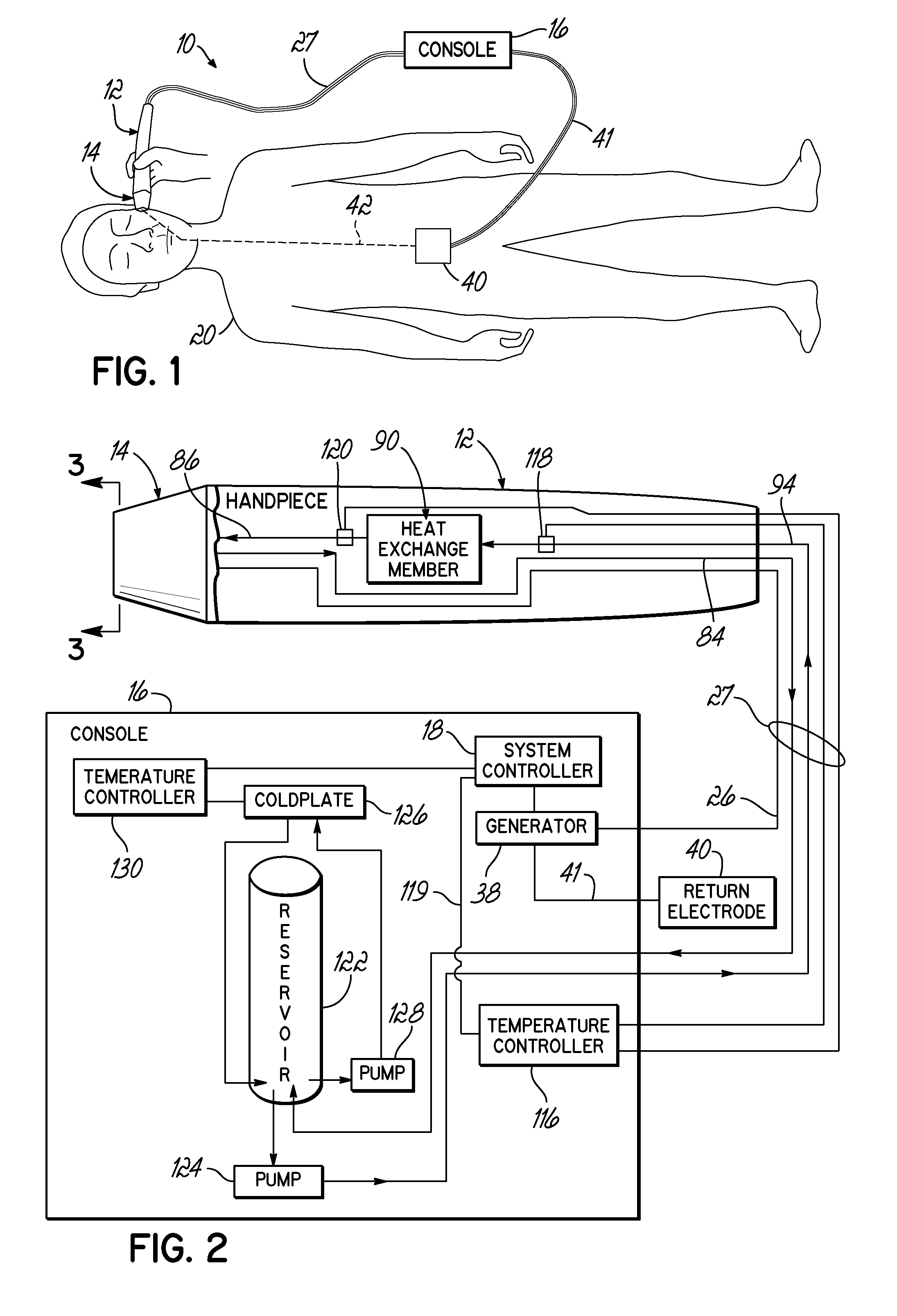

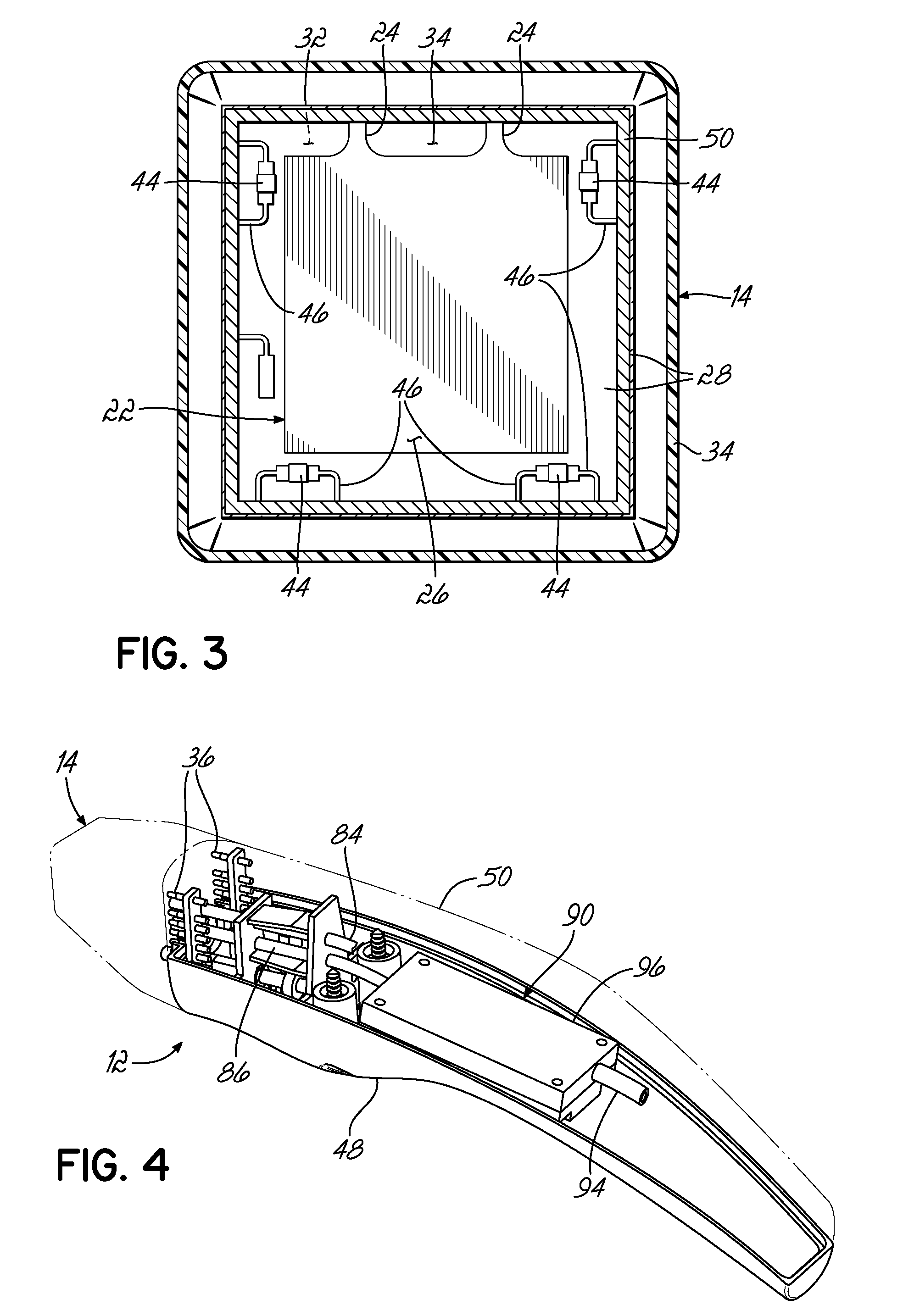

Apparatus and methods for cooling a treatment apparatus configured to non-invasively deliver electromagnetic energy to a patient's tissue

InactiveUS20090149930A1Surgical instruments for heatingLight therapyClosed loopElectromagnetic shielding

Apparatus and methods for delivering electromagnetic energy to a patient's tissue. The treatment apparatus includes a closed-loop cooling system that cools the energy delivery device. The fluid forced to flow in the closed-loop cooling system is chilled to a first temperature at a location remote from the energy delivery device and is warmed to a higher second temperature near the energy delivery device. This promotes better control over the fluid temperature at the energy delivery device.

Owner:THERMAGE INC

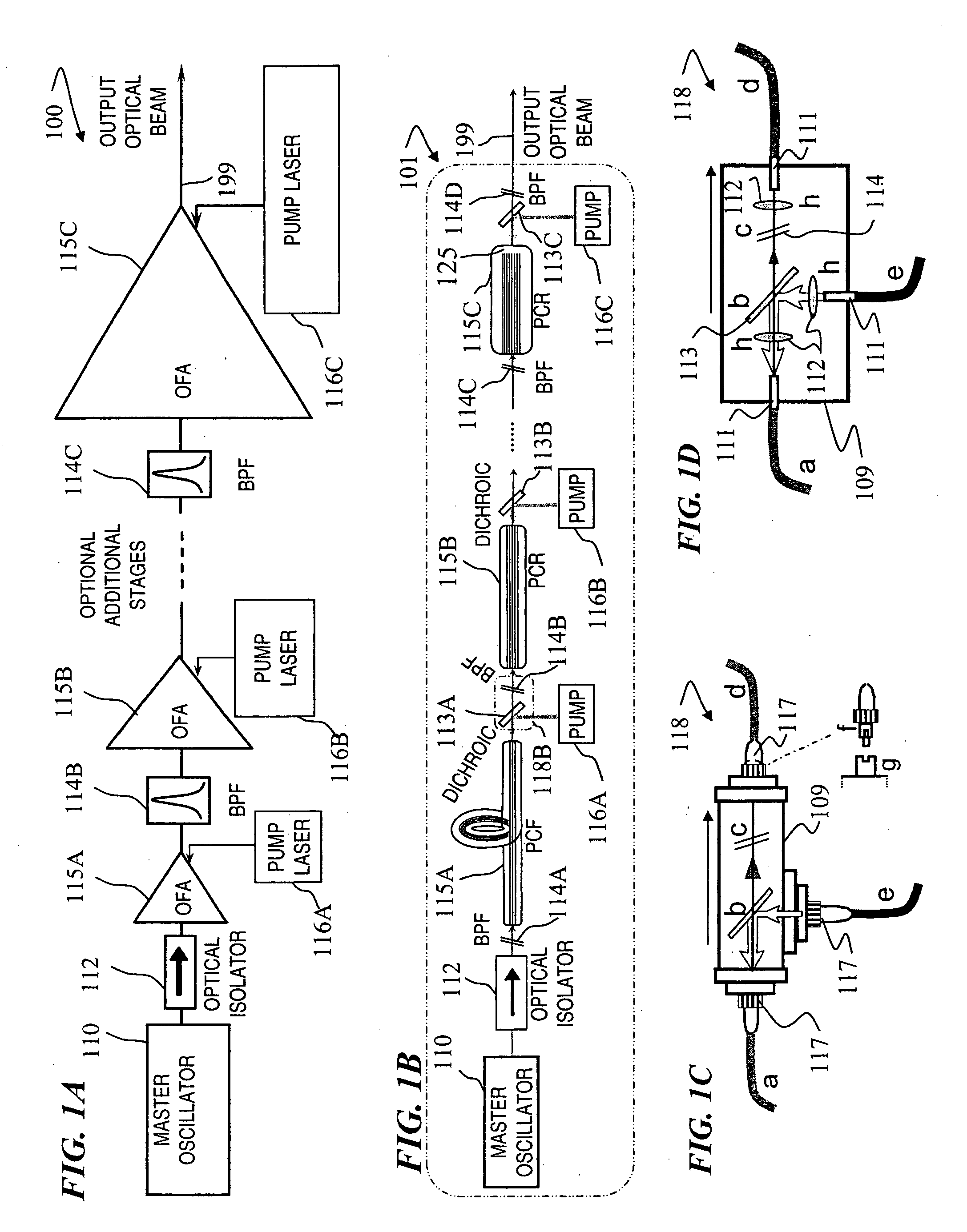

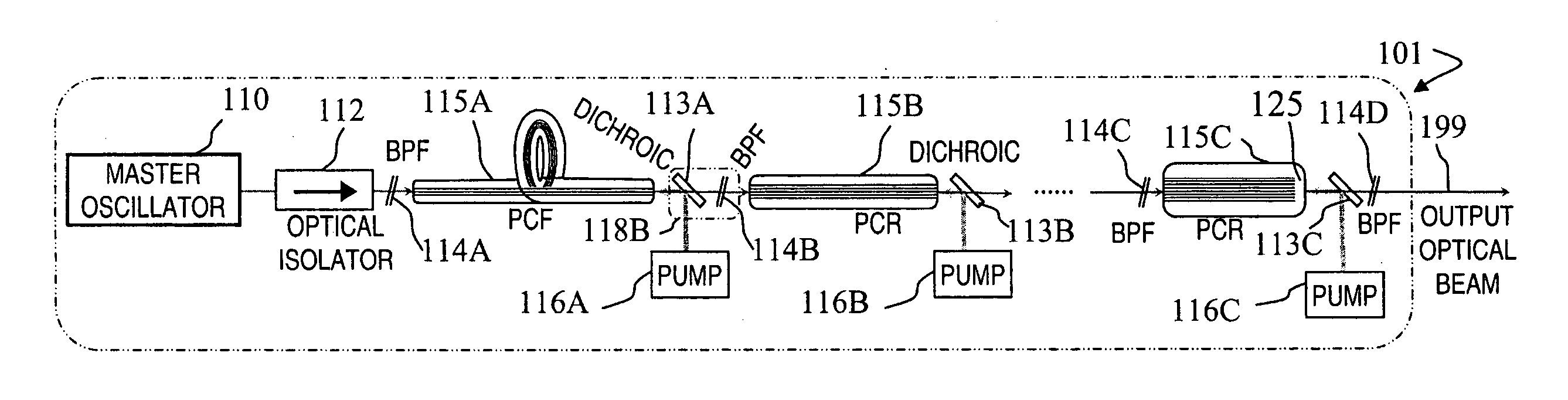

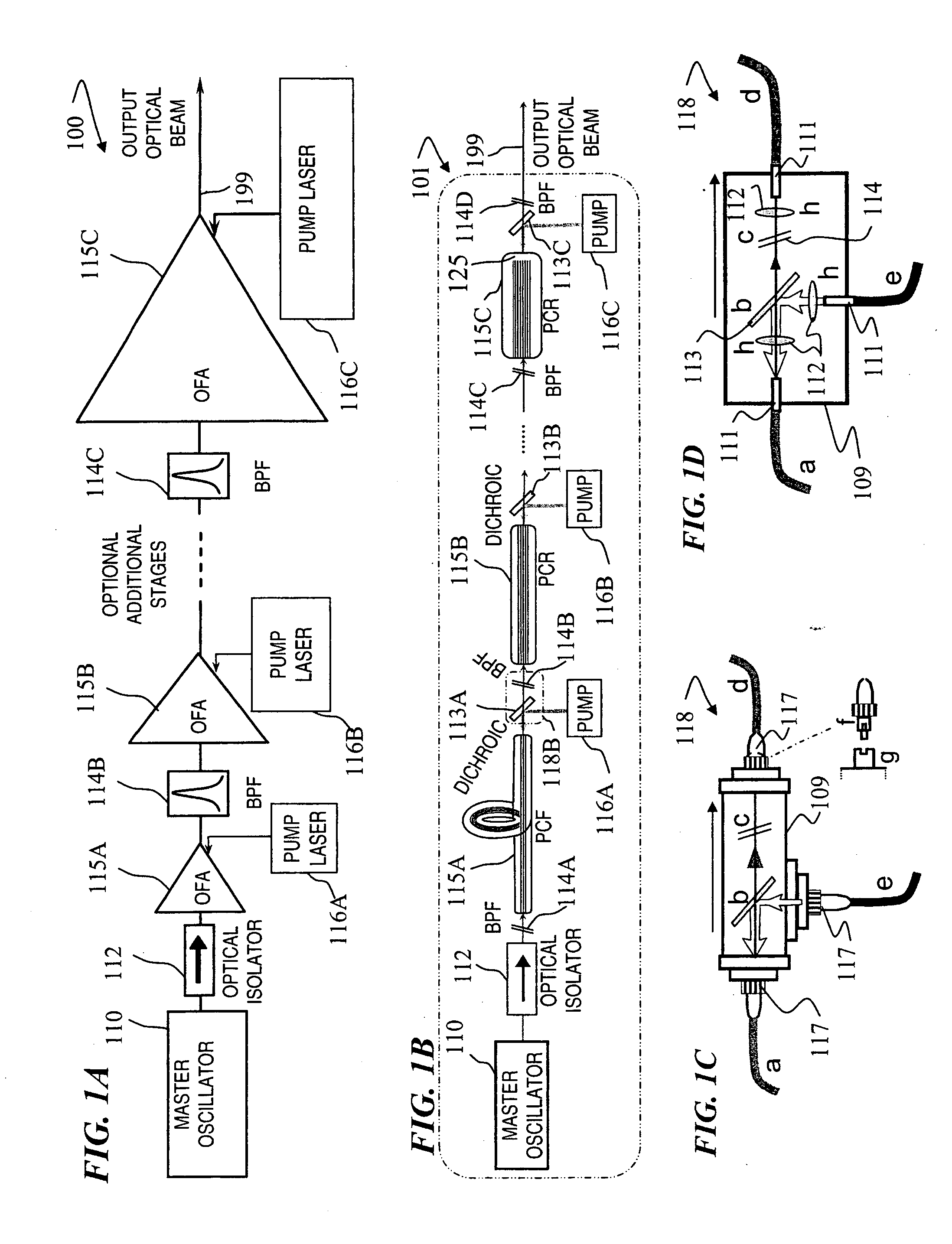

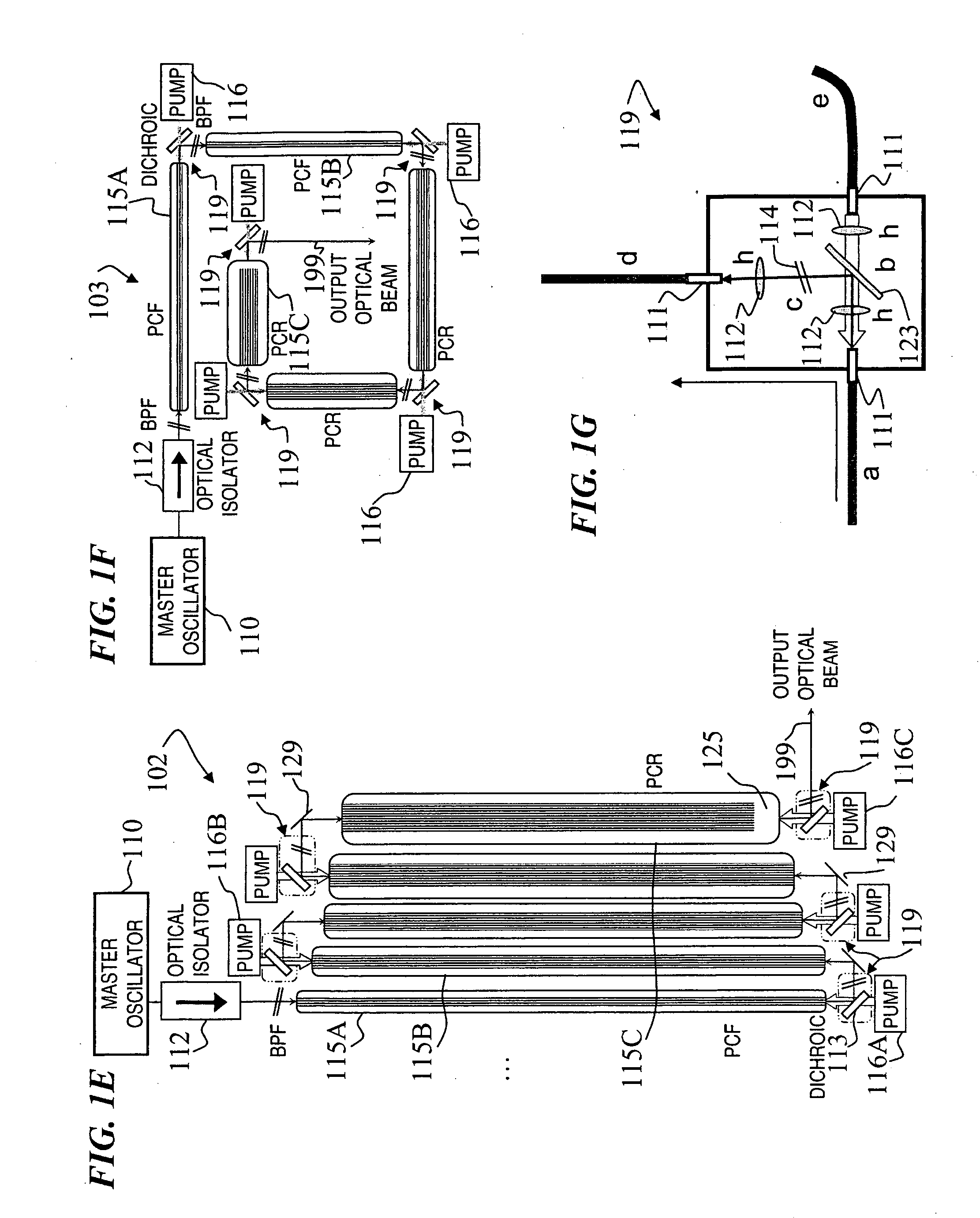

Fiber- or rod-based optical source featuring a large-core, rare-earth-doped photonic-crystal device for generation of high-power pulsed radiation and method

ActiveUS20070041083A1High peak powerHigh pulse energyGlass making apparatusOptical fibre with multilayer core/claddingRare earthEngineering

A method and apparatus use a photonic-crystal fiber having a very large core while maintaining a single transverse mode. In some fiber lasers and amplifiers having large cores problems exist related to energy being generated at multiple-modes (i.e., polygamy), and of mode hopping (i.e., promiscuity) due to limited control of energy levels and fluctuations. The problems of multiple-modes and mode hopping result from the use of large-diameter waveguides, and are addressed by the invention. This is especially true in lasers using large amounts of energy (i.e., lasers in the one-megawatt or more range). By using multiple small waveguides in parallel, large amounts of energy can be passed through a laser, but with better control such that the aforementioned problems can be reduced. An additional advantage is that the polarization of the light can be maintained better than by using a single fiber core.

Owner:LOCKHEED MARTIN CORP

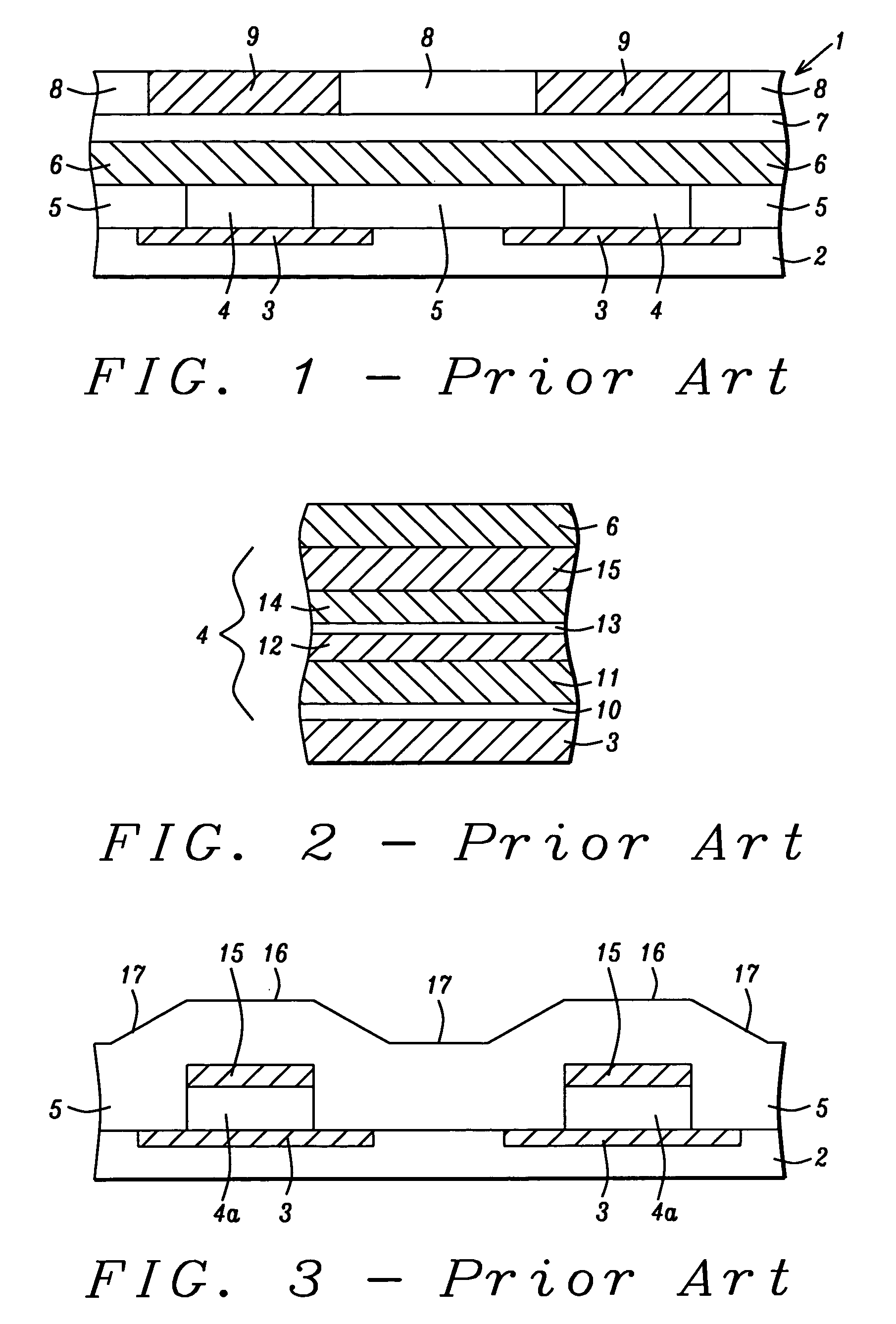

Thin film writer with multiplayer write gap

InactiveUS6724569B1Easy to controlControl performanceConstruction of head windingsManufacture head surfaceElectrical conductorLower pole

Embodiments in accordance with the thin film write head of the present invention have a lower pole structure, an upper pole structure, and a multilayer write gap extending from an air bearing surface between the upper and lower pole structures. In preferred embodiments, the write gap comprises at least two of: (a) a first layer covering a lower pole tip portion of the lower pole structure, (b) a second layer covering turns of a semiconductor winding, or (c) a third layer covering a winding insulation stack. In more preferred embodiments, the write gap is formed of the first, the second, and the third write gap layers. An advantage of a write head with a multilayer write gap is that it allows better control of write gap thickness. As such, loss of write gap thickness can be compensated for by deposition of the second write gap layers, or by deposition of the third write gap layer. Some embodiments have one or more additional advantages in providing increased corrosion prevention, improving the integrity of conductor insulation, and / or improving the top pole magnetic material characteristics.

Owner:WESTERN DIGITAL TECH INC

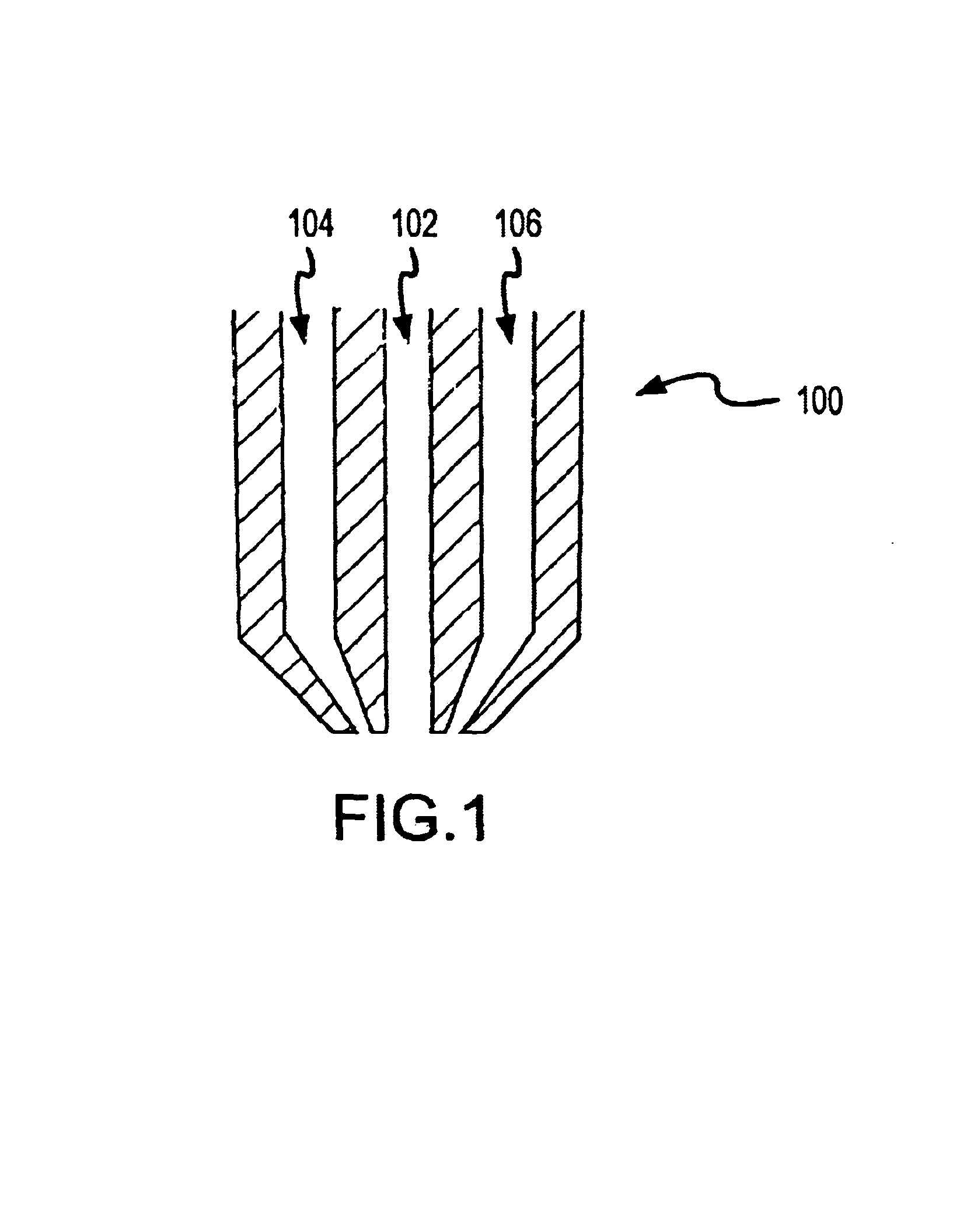

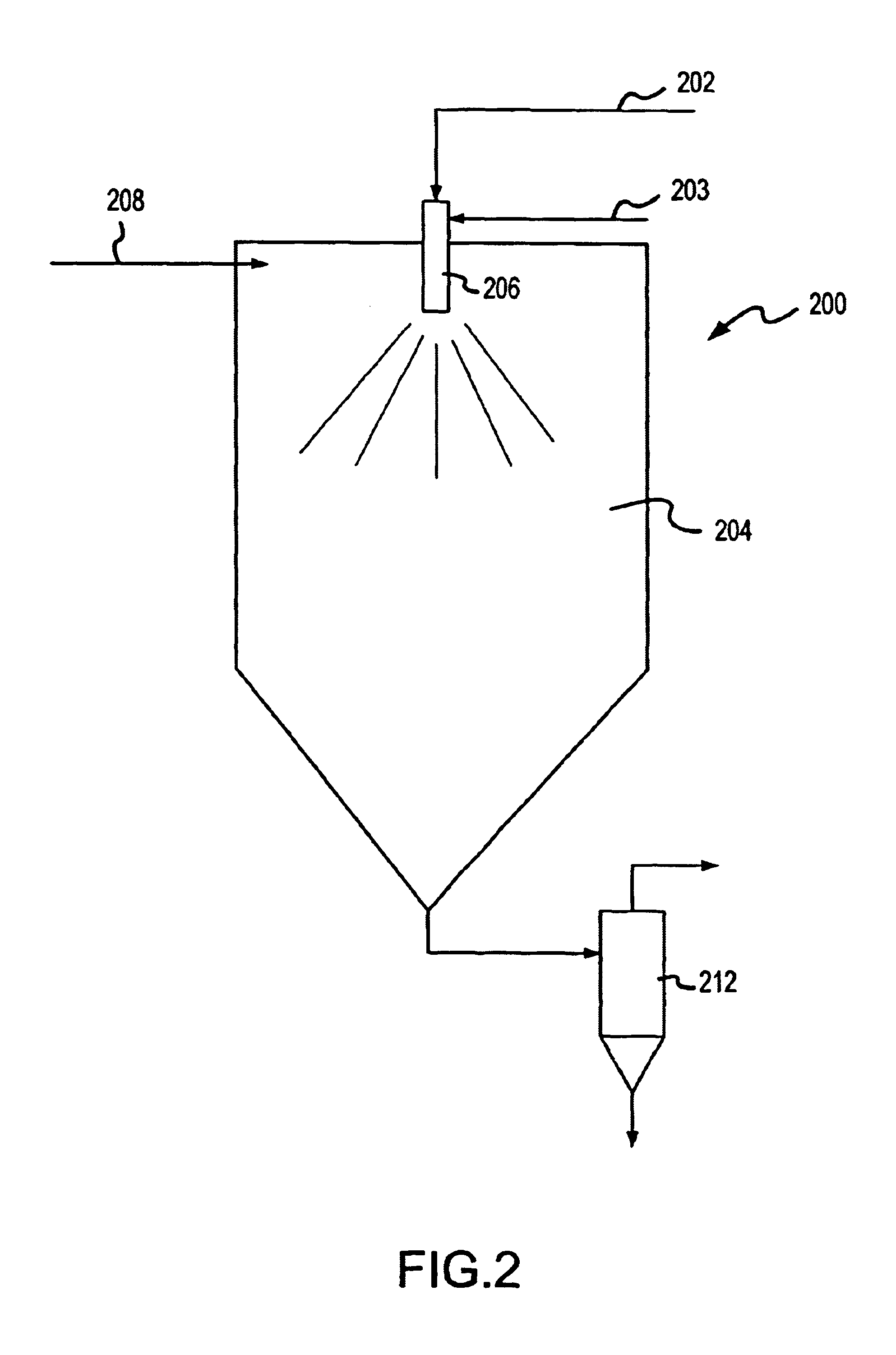

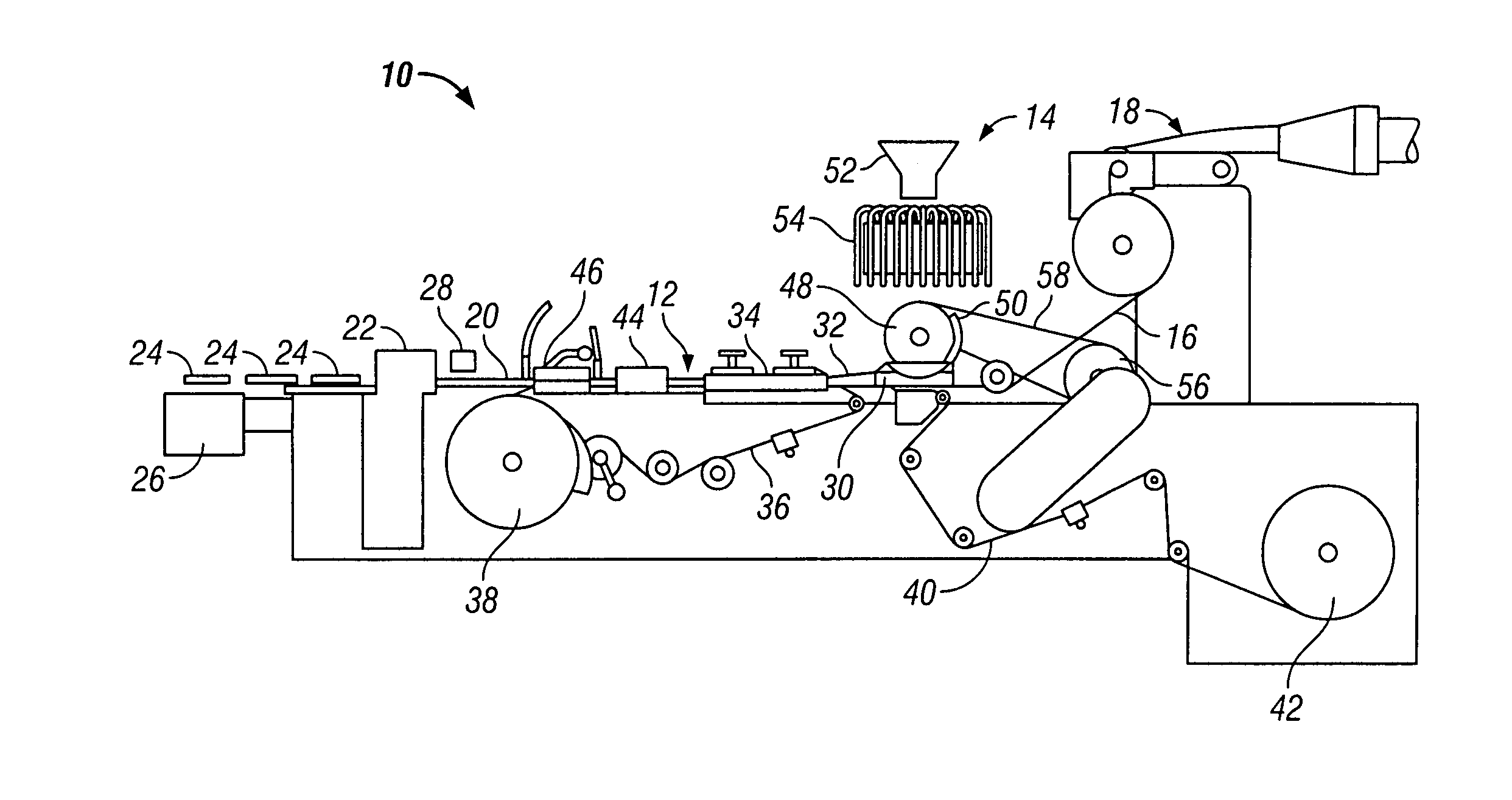

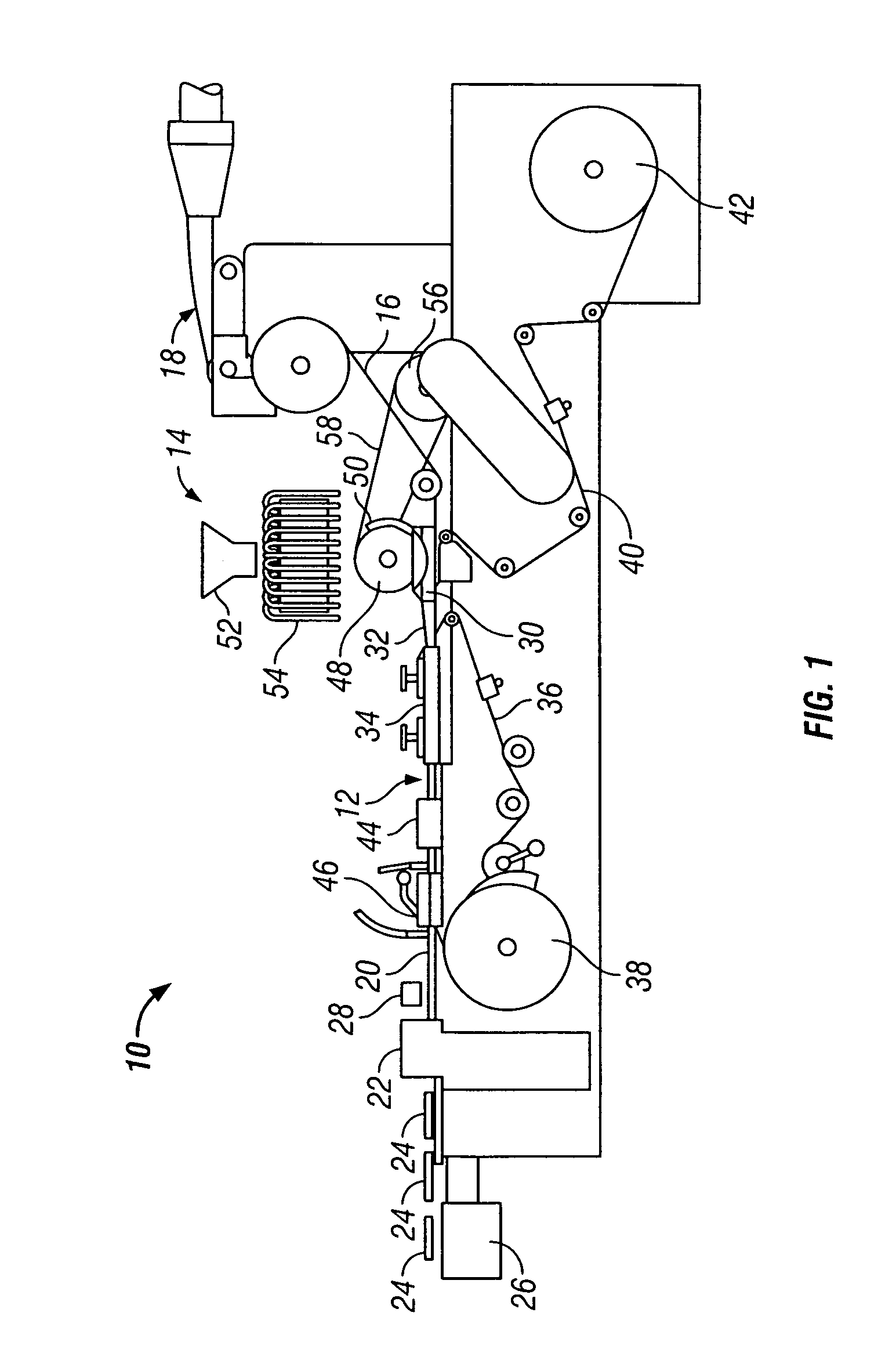

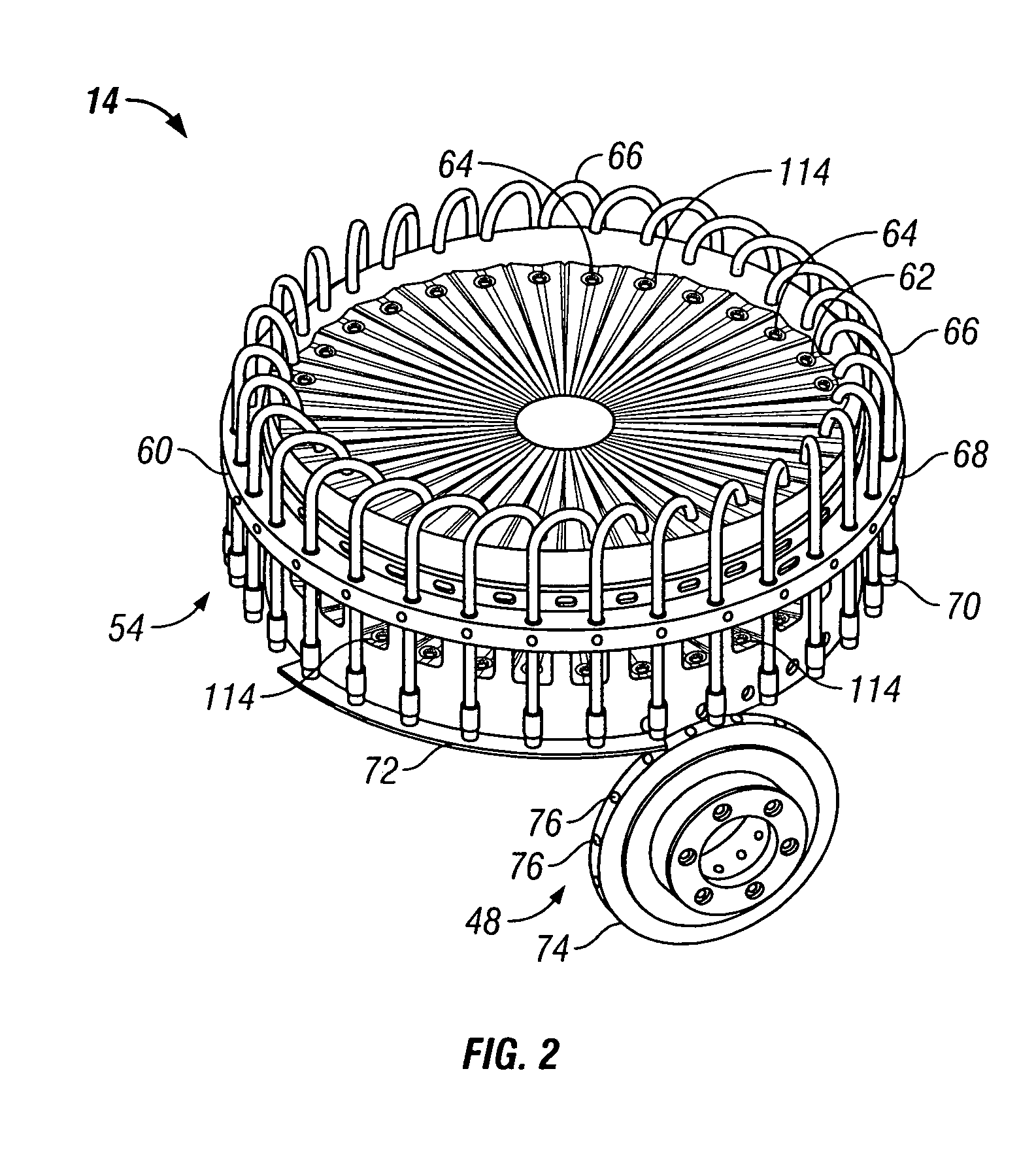

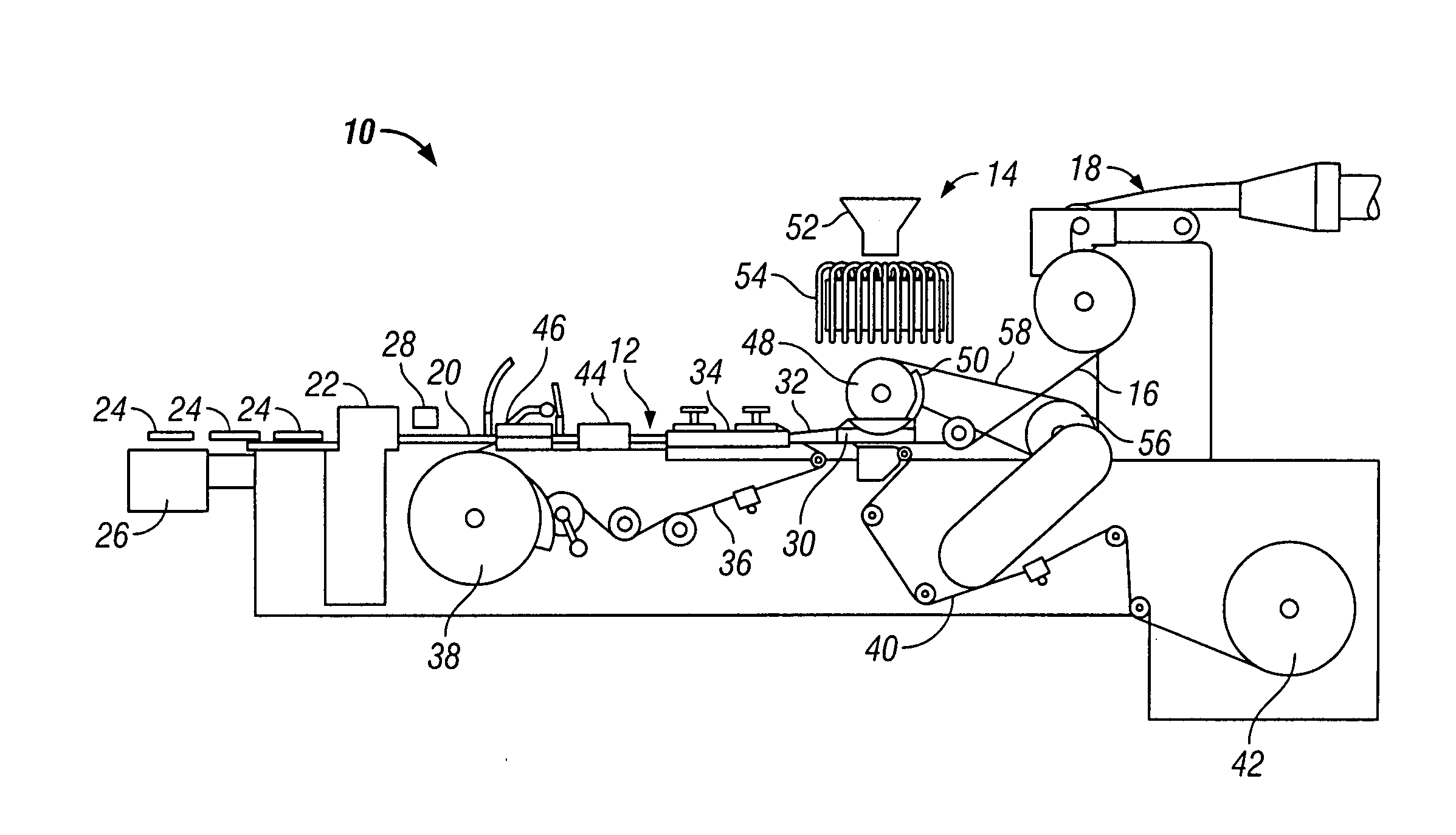

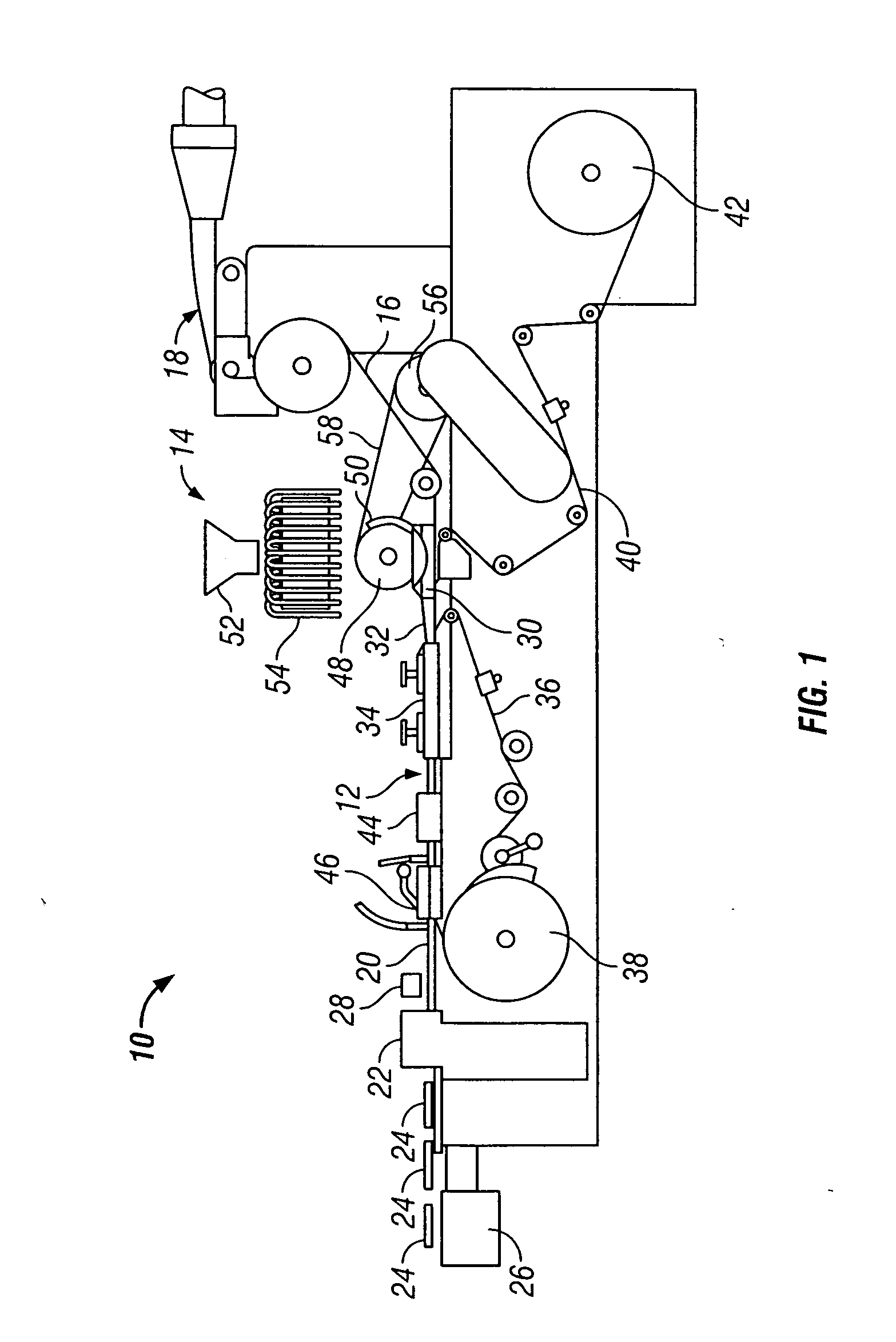

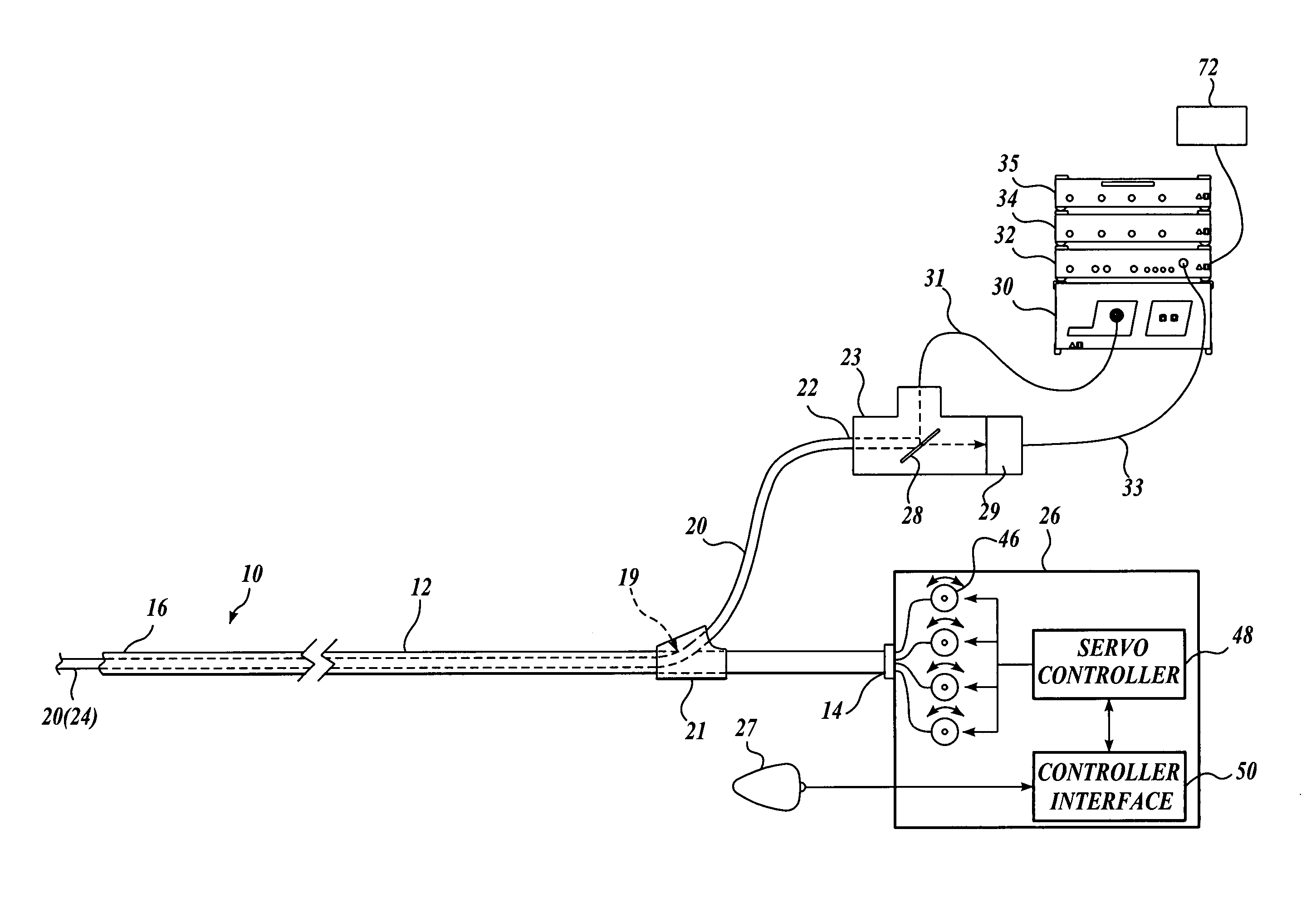

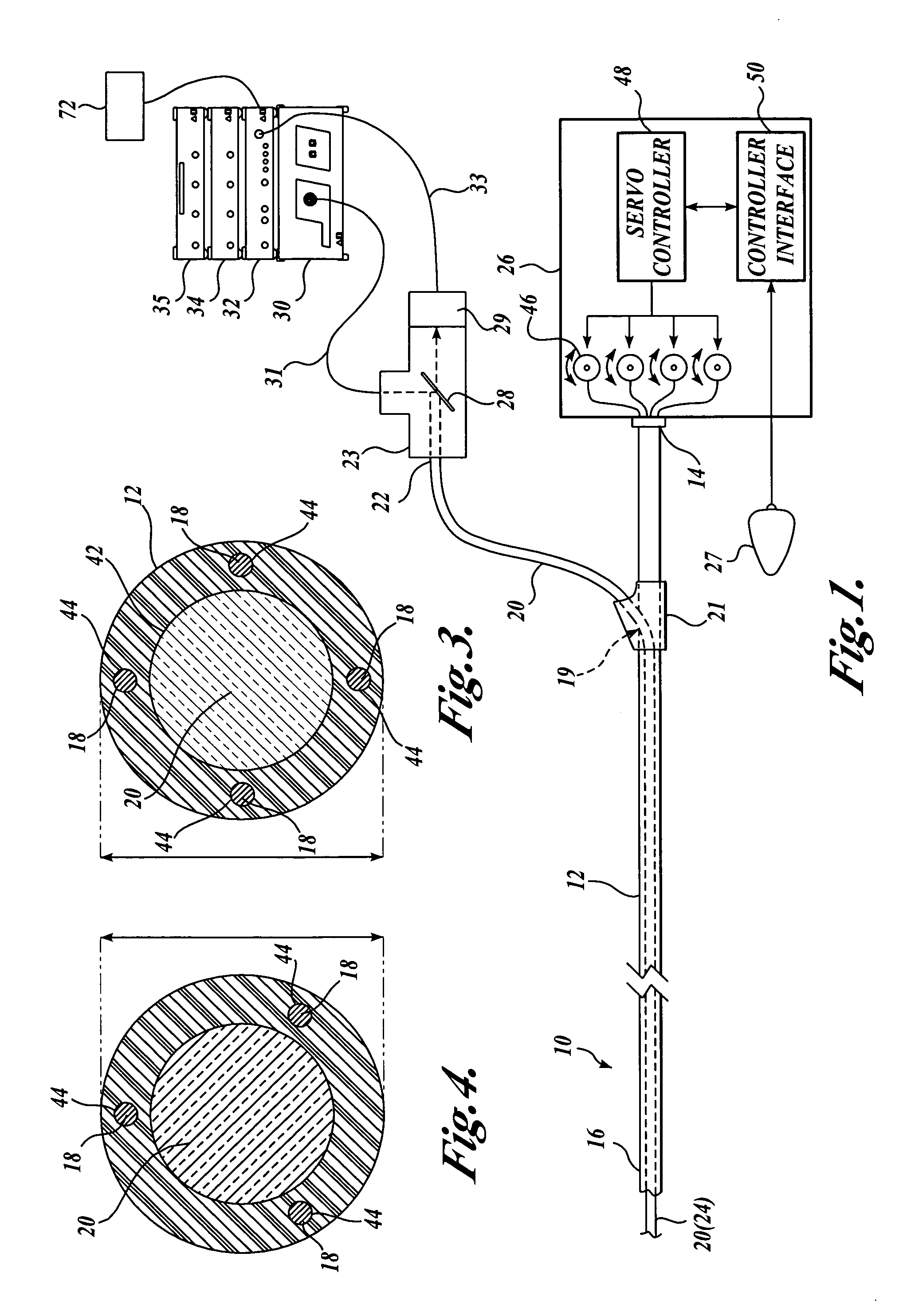

Method and apparatus for incorporating objects into cigarette filters

ActiveUS20050070409A1Tobacco treatmentPaper/cardboard wound articlesFilter materialMechanical engineering

Cigarette filter rods having individual objects positioned at predetermined intervals therein are prepared by transferring the individual objects from a rotating horizontal pan to a rotating vertical wheel and then depositing the object into a web of filter tow. Each object is positioned within the moving web of tow. The web filter material and the objects positioned within the web are introduced into a rod-forming unit wherein the rod is formed. The rate of feed of the filter tow, the rate of rotation of the horizontal pan and the vertical wheel are controlled relative to one another such that objects are positioned at predetermined intervals along the rod. Cigarette filter elements having well controlled amounts of flavorant contained therein can be made from the rods.

Owner:R J REYNOLDS TOBACCO COMPANY

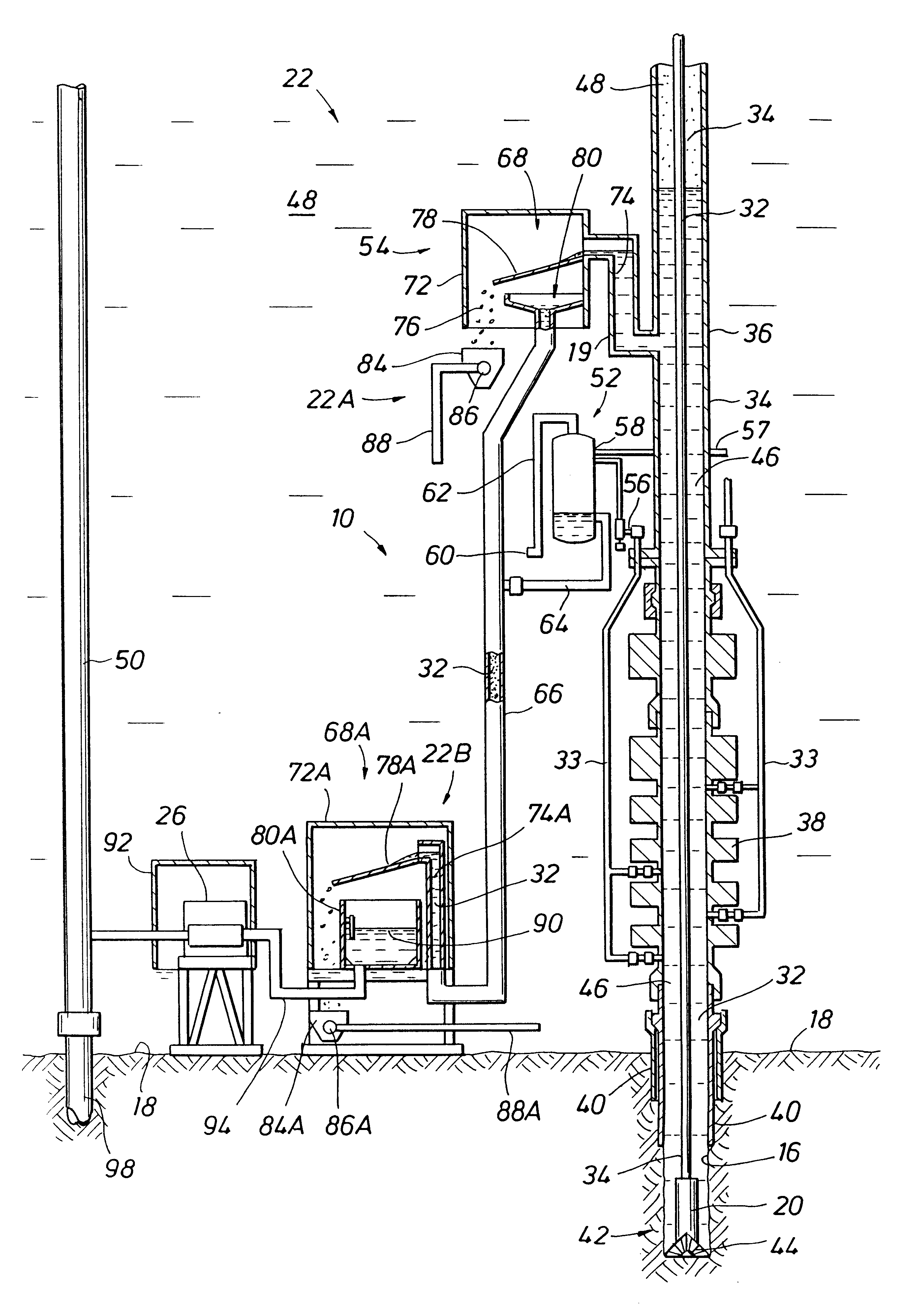

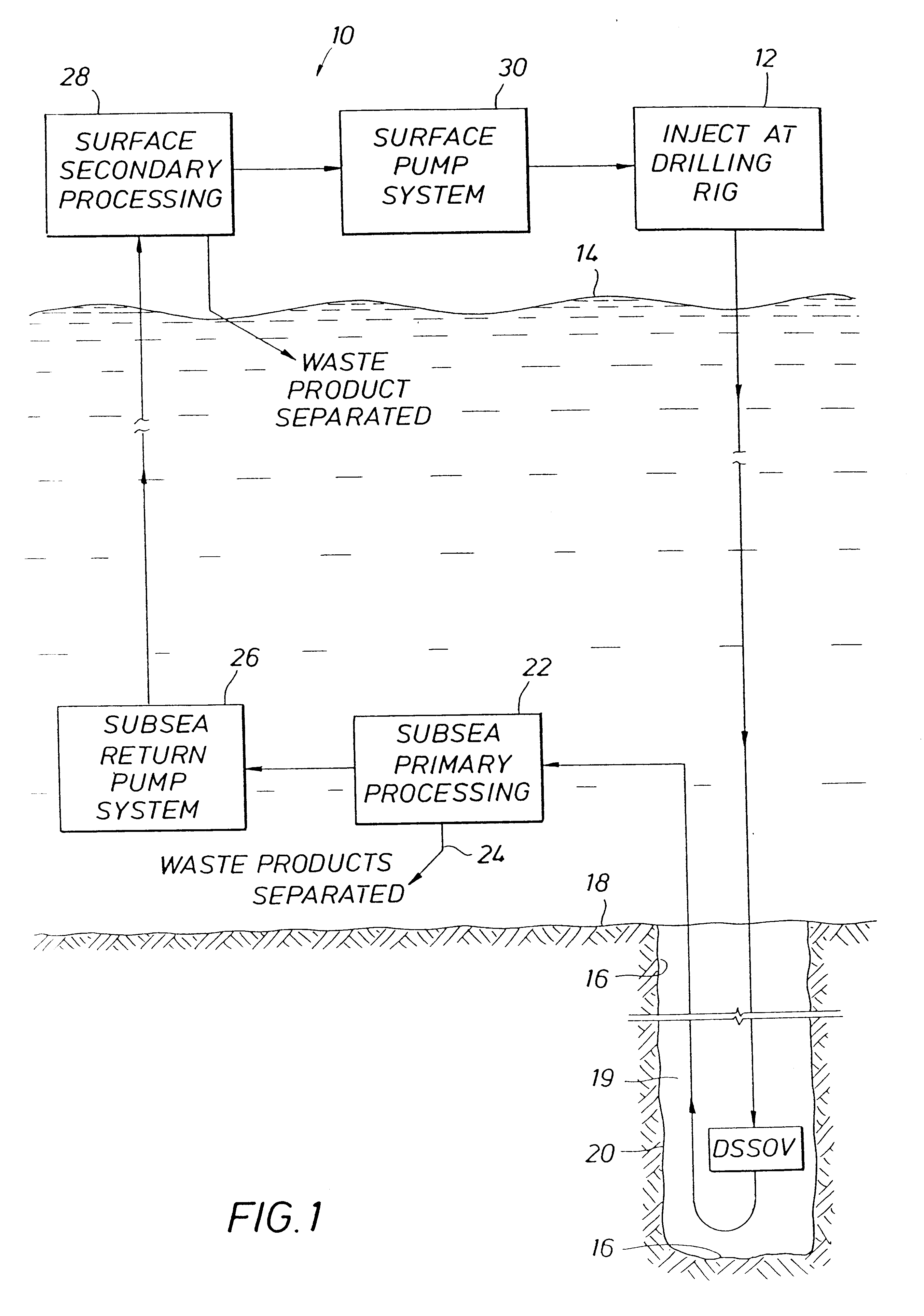

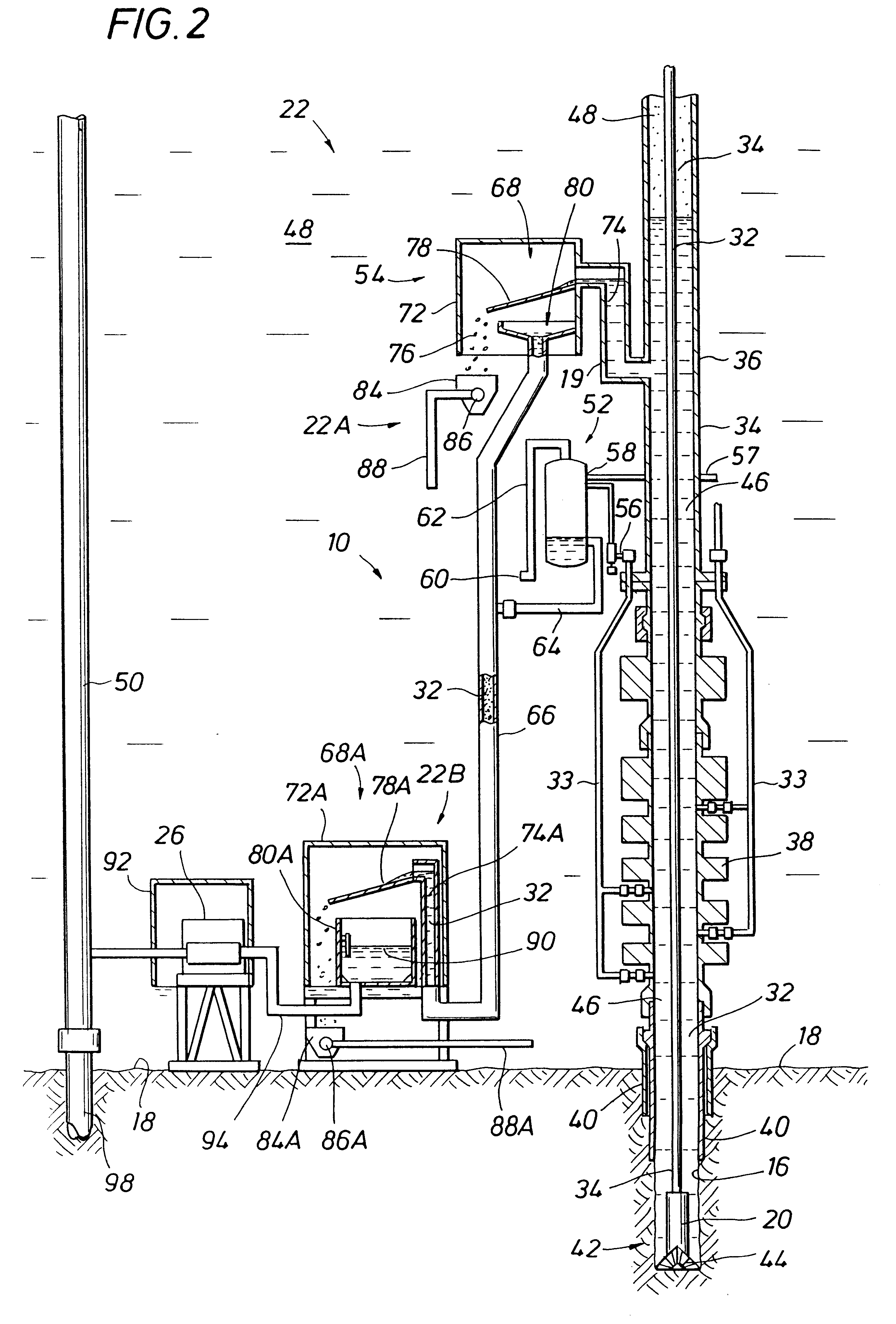

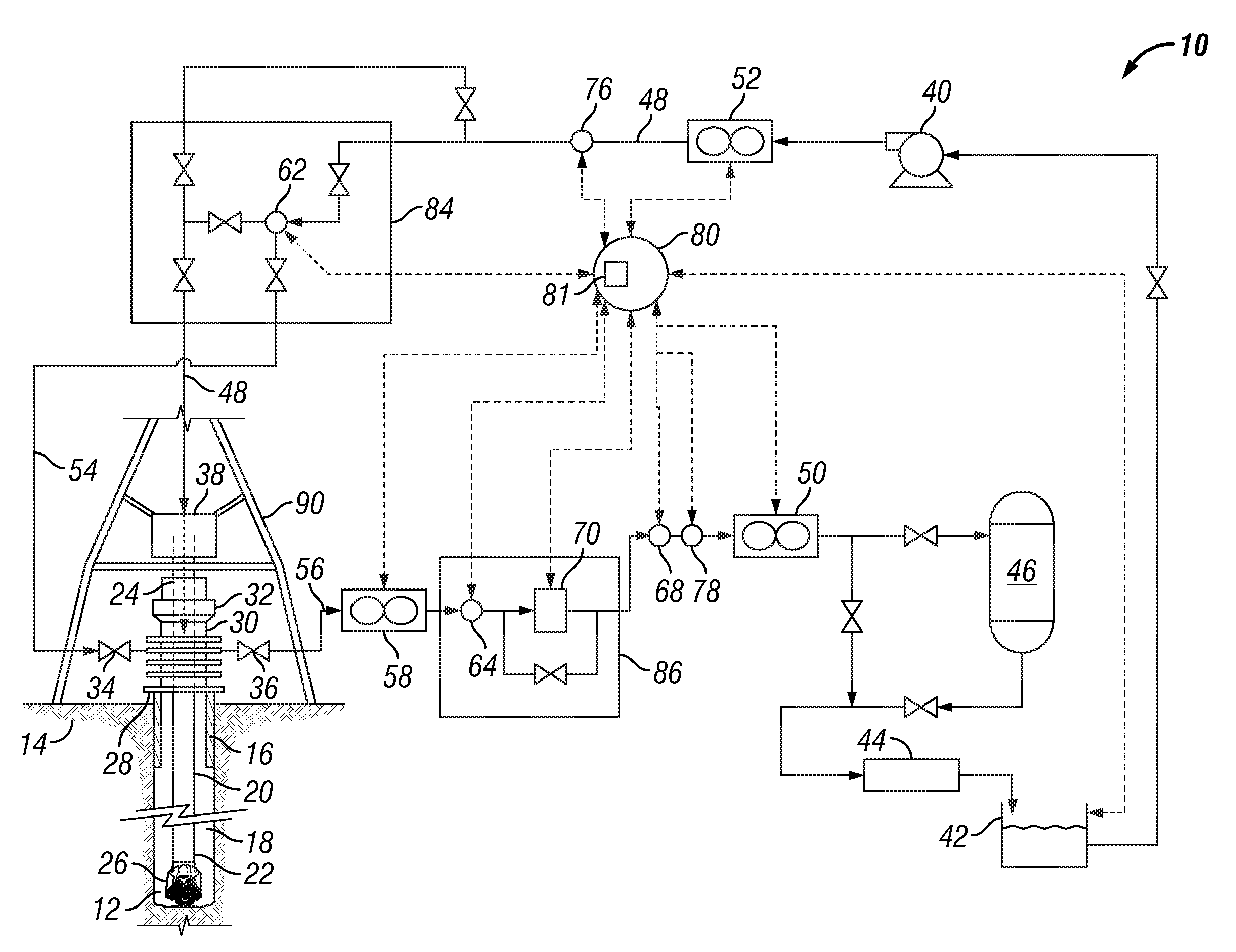

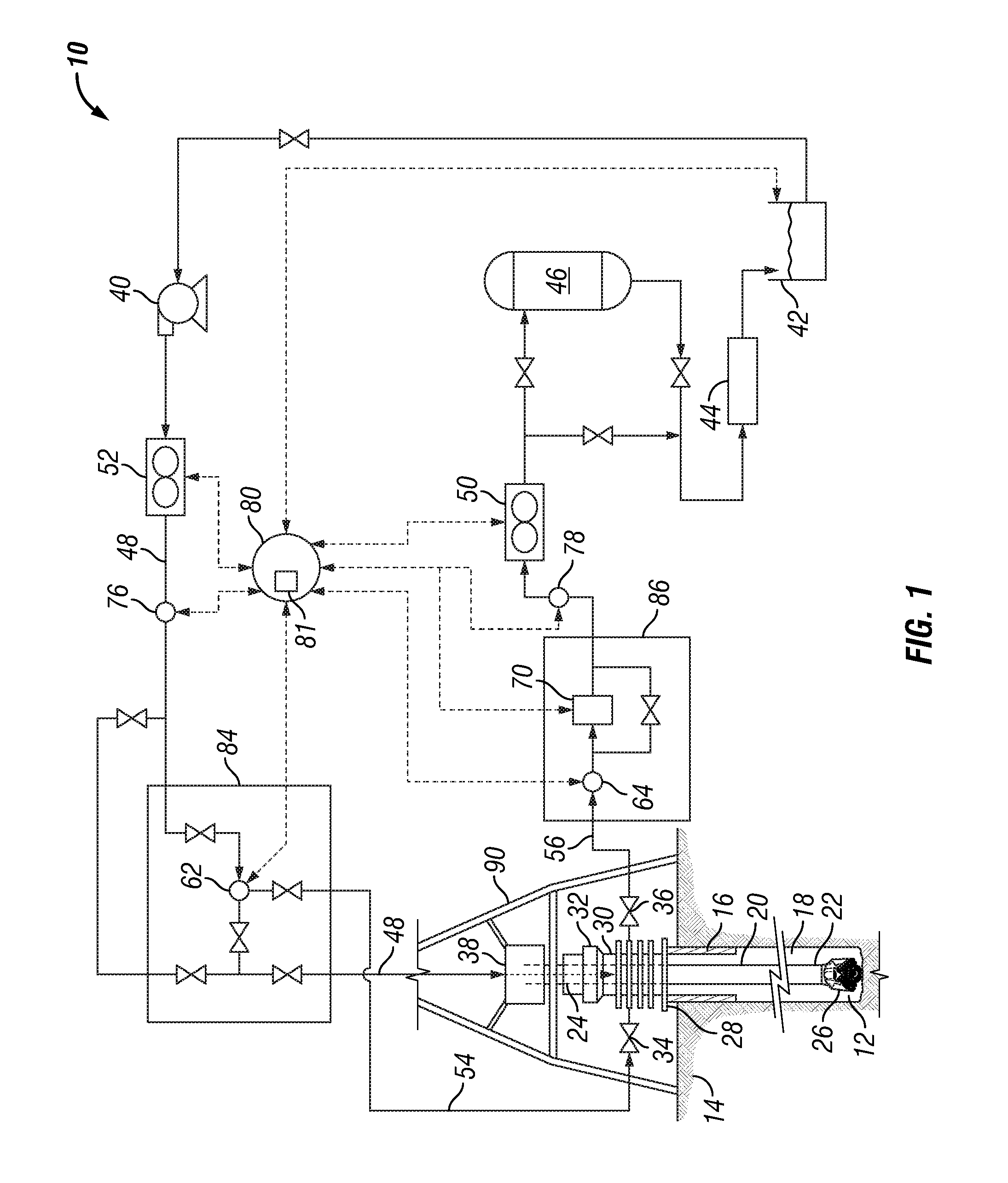

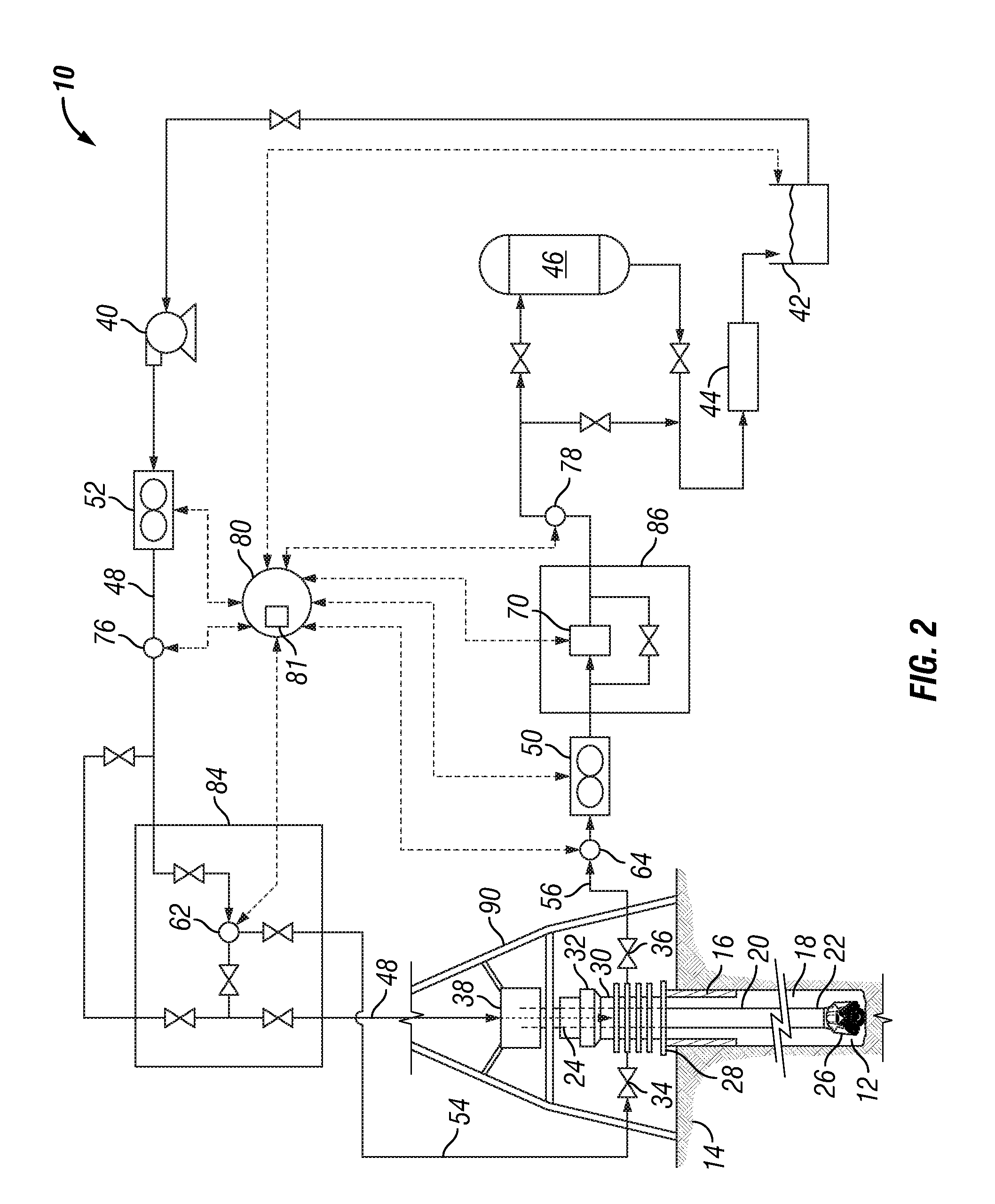

Subsea gas separation system and method for offshore drilling

A subsea gas separation system use in drilling an offshore well includes a subsea blowout preventor connected to the well and a gas separator connected to the blowout preventor near the seafloor. Gas released into the well bore during a well control event is removed at the separator and not returned with the drilling mud recirculated to the surface. A method offshore drilling includes a mud circulation circuit established leading down the drill string, through the drill bit, up the borehole, through a subsea pump, and to the surface through a return riser. The subsea pump is protected during critical well control events by removing gas released into the mud at a gas separator located upstream of the subsea pump and in communication with the blowout preventor.

Owner:SHELL OFFSHORE

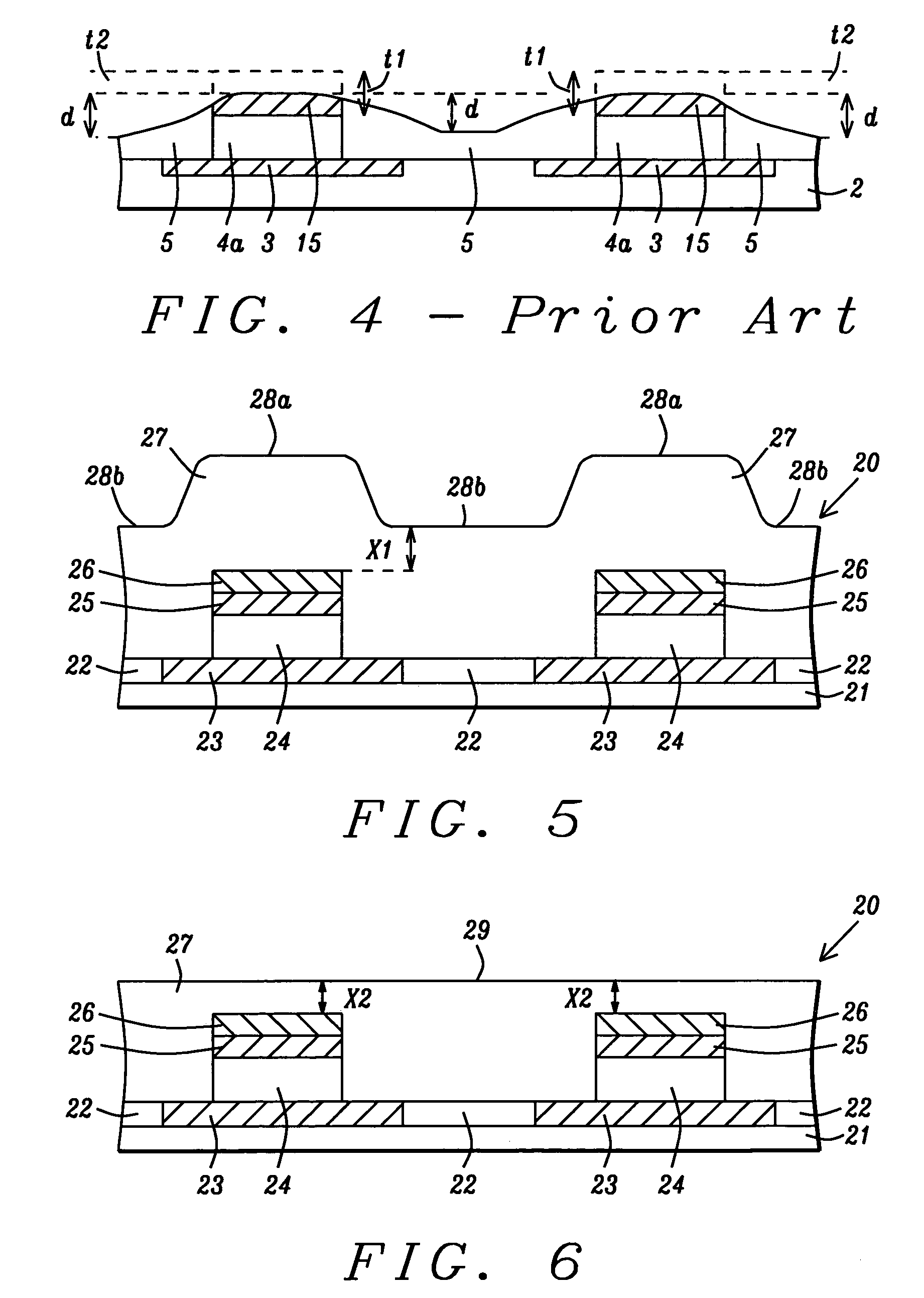

MRAM cell structure and method of fabrication

ActiveUS7045368B2Solid-state devicesSemiconductor/solid-state device manufacturingBit lineInsulation layer

An MRAM structure is disclosed where the distance from a bit line or word line to an underlying free layer in an MTJ is small and well controlled. As a result, the bit line or word line switching current is reduced and tightly distributed for better device performance. A key feature in the method of forming the MRAM cell structure is a two step planarization of an insulation layer deposited on the MTJ array. A CMP step flattens the insulation layer at a distance about 60 to 200 Angstroms above the cap layer in the MTJ. Then an etch back step thins the insulation layer to a level about 50 to 190 Angstroms below the top of the cap layer. Less than 5 Angstroms of the cap layer is removed. The distance variation from the free layer to an overlying bit line or word line is within + / −5 Angstroms.

Owner:TAIWAN SEMICON MFG CO LTD

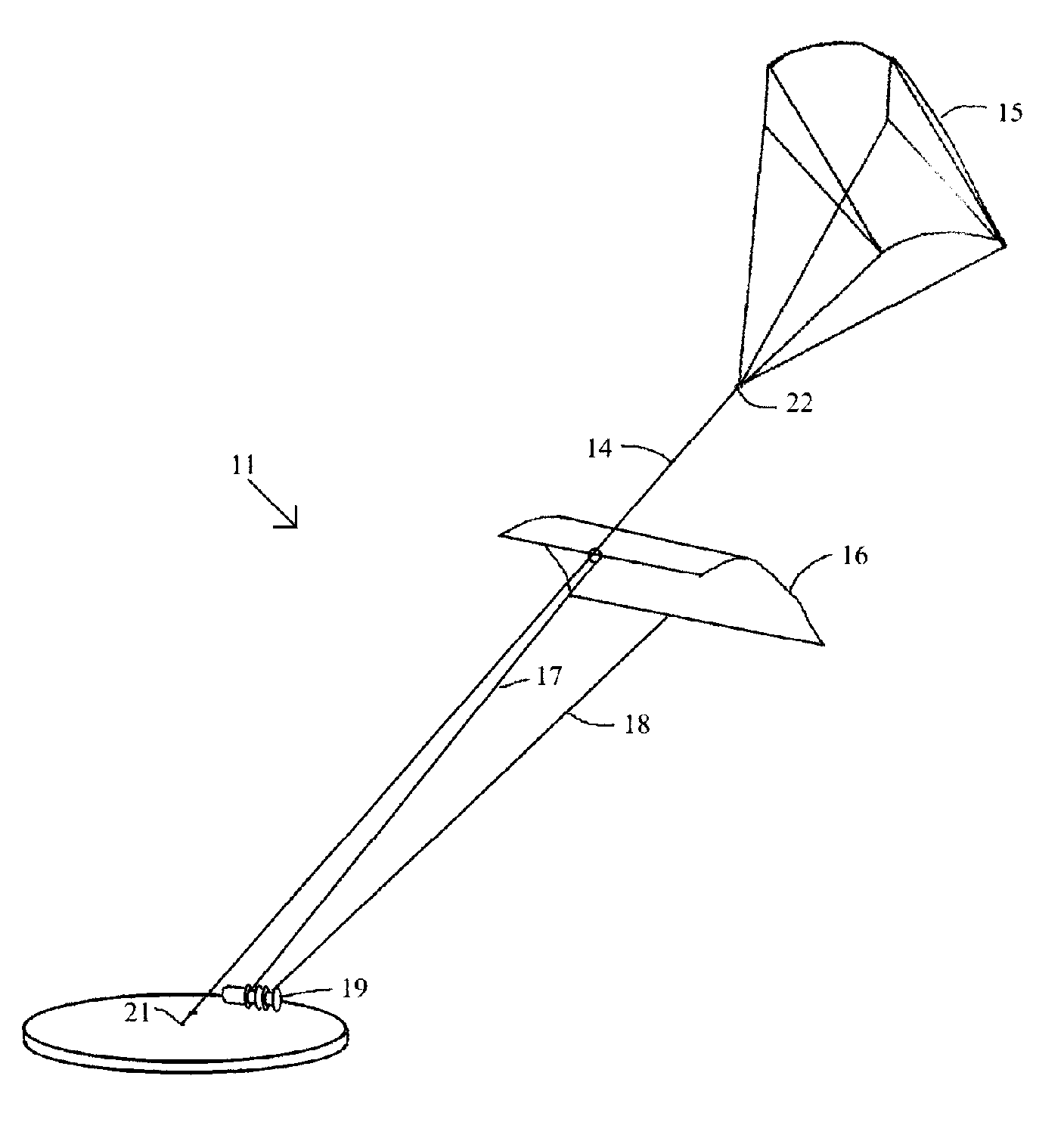

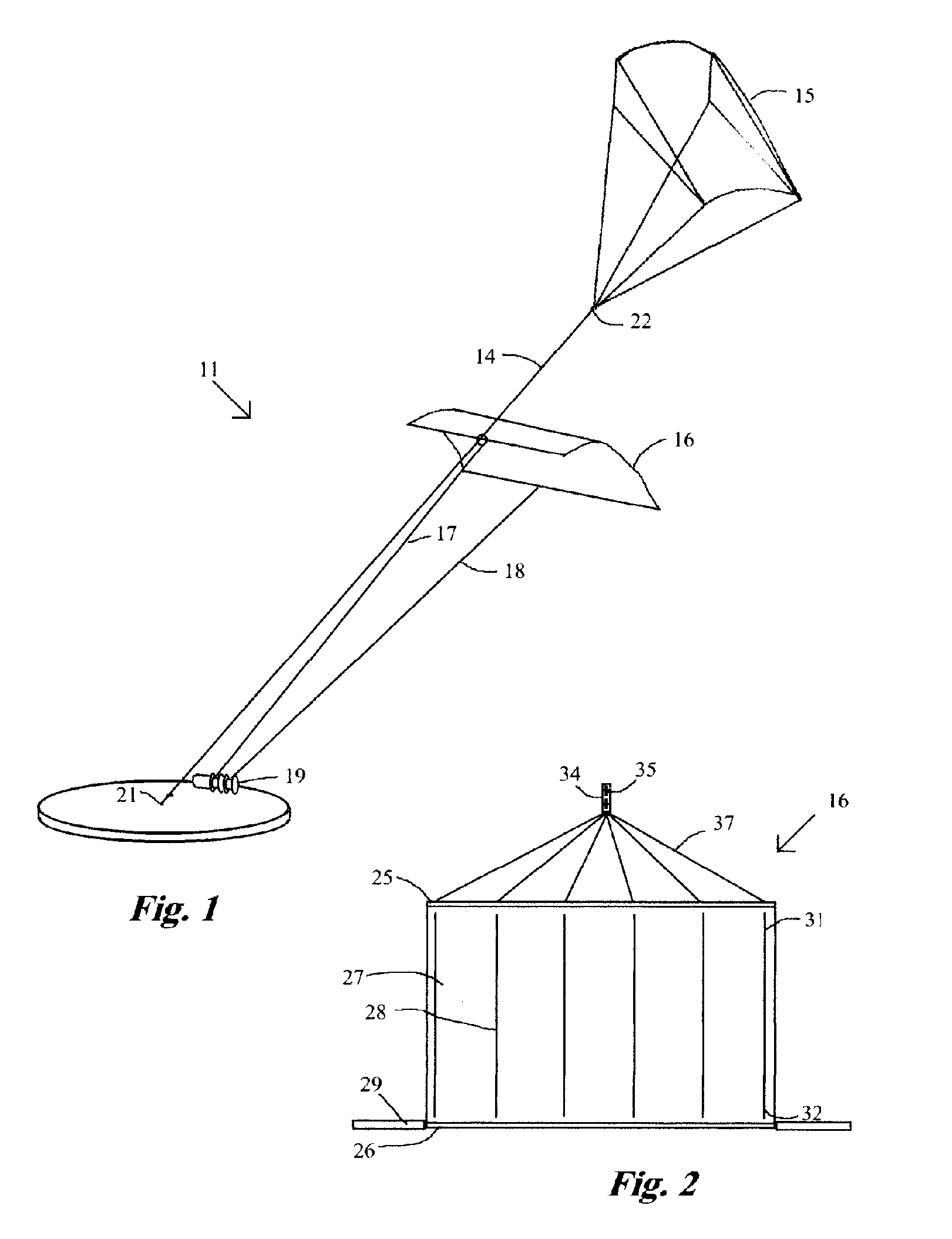

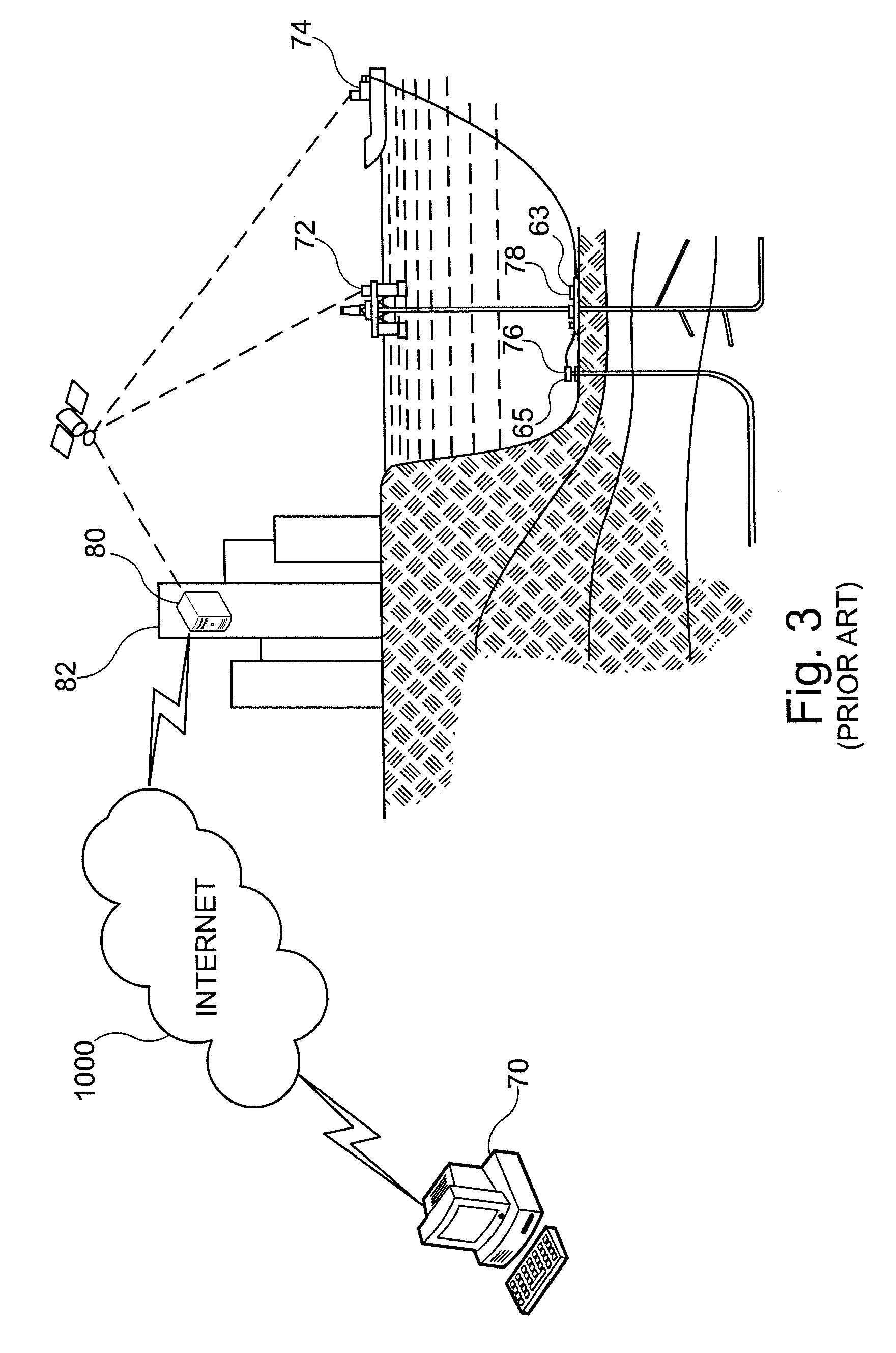

Aerialwind power generation system and method

InactiveUS7188808B1Increase power generationWind motor combinationsMachines/enginesWind drivenAngular orientation

An aerial power generation system includes a guide line supported by a support body. Wind driven elements are configured and shaped to provide maximum force from both lift and drag during the downwind phase of operation and minimum force during the upwind phase. The guide lines add stability to the system and provide better control over angular orientation and direction of motion. Power transfer is through one or more tow lines connected from the driven elements to power generation devices on the ground. Another embodiment of the aerial power generation system includes a revolving apparatus and two or more wind powered driven elements connected by tow lines to the revolving apparatus. The method includes changing the driven elements between high and low force configurations for downwind and upwind operation, and flying the driven elements in a selected pattern perpendicular to the tow line.

Owner:OLSON GAYLORD G

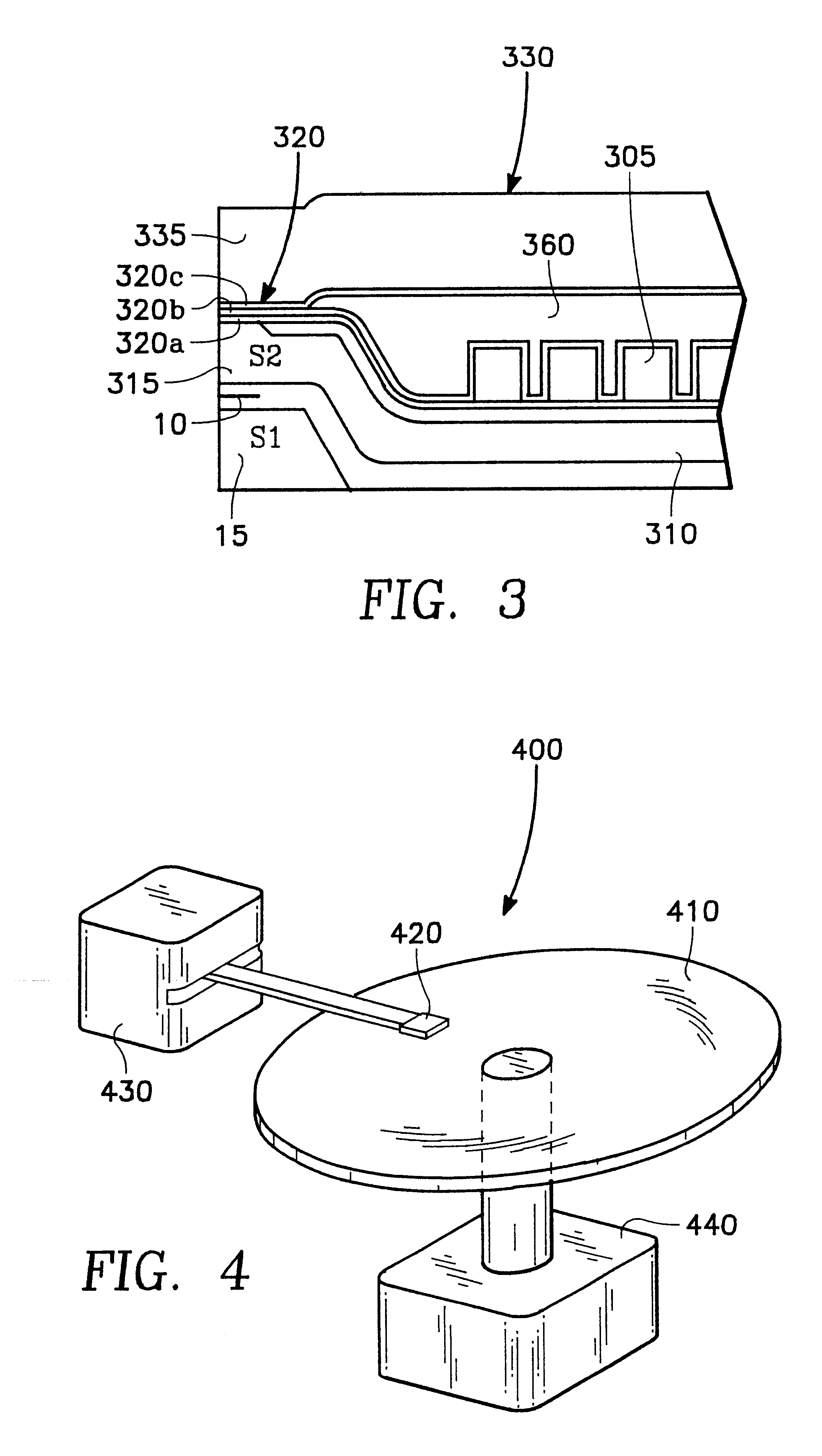

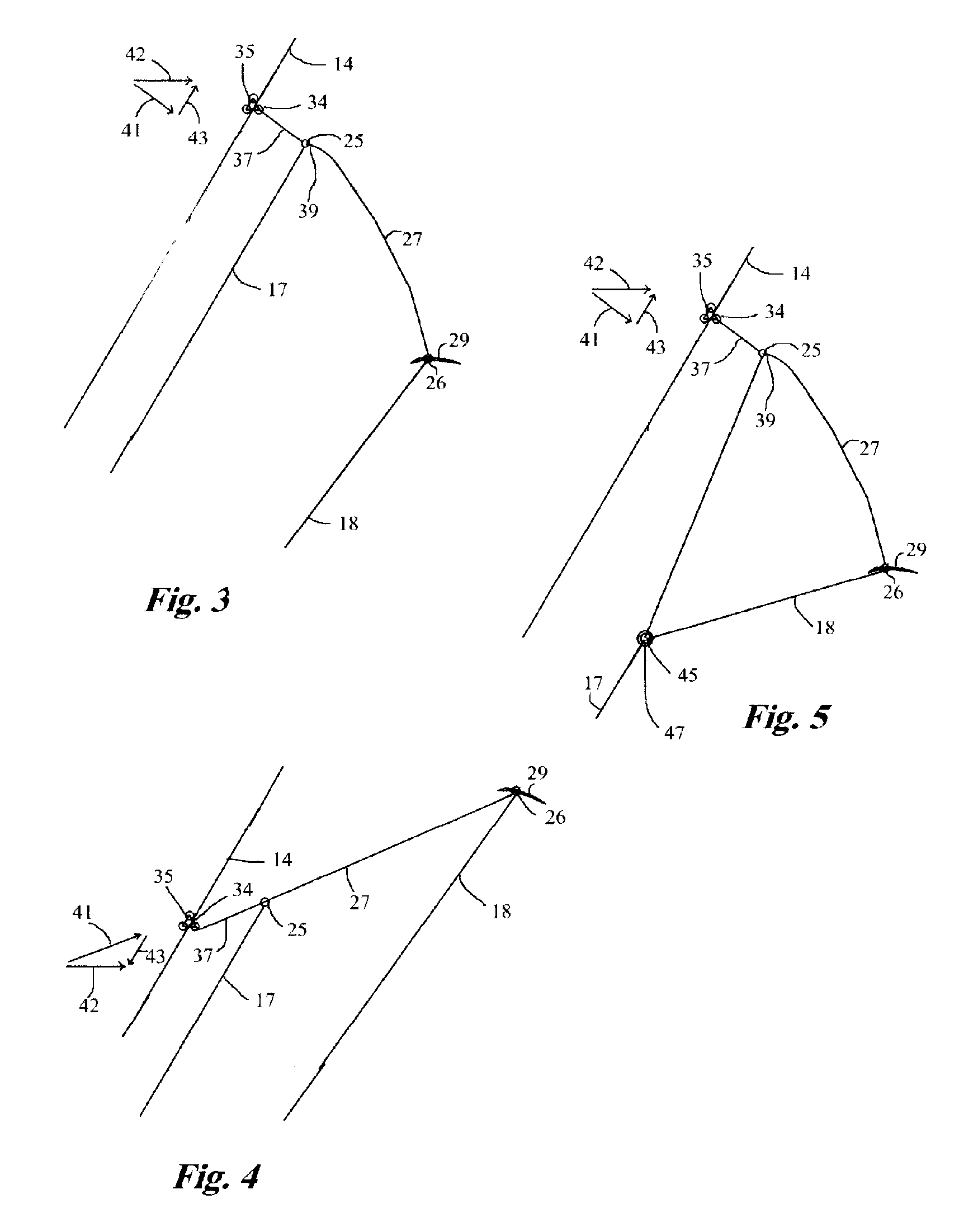

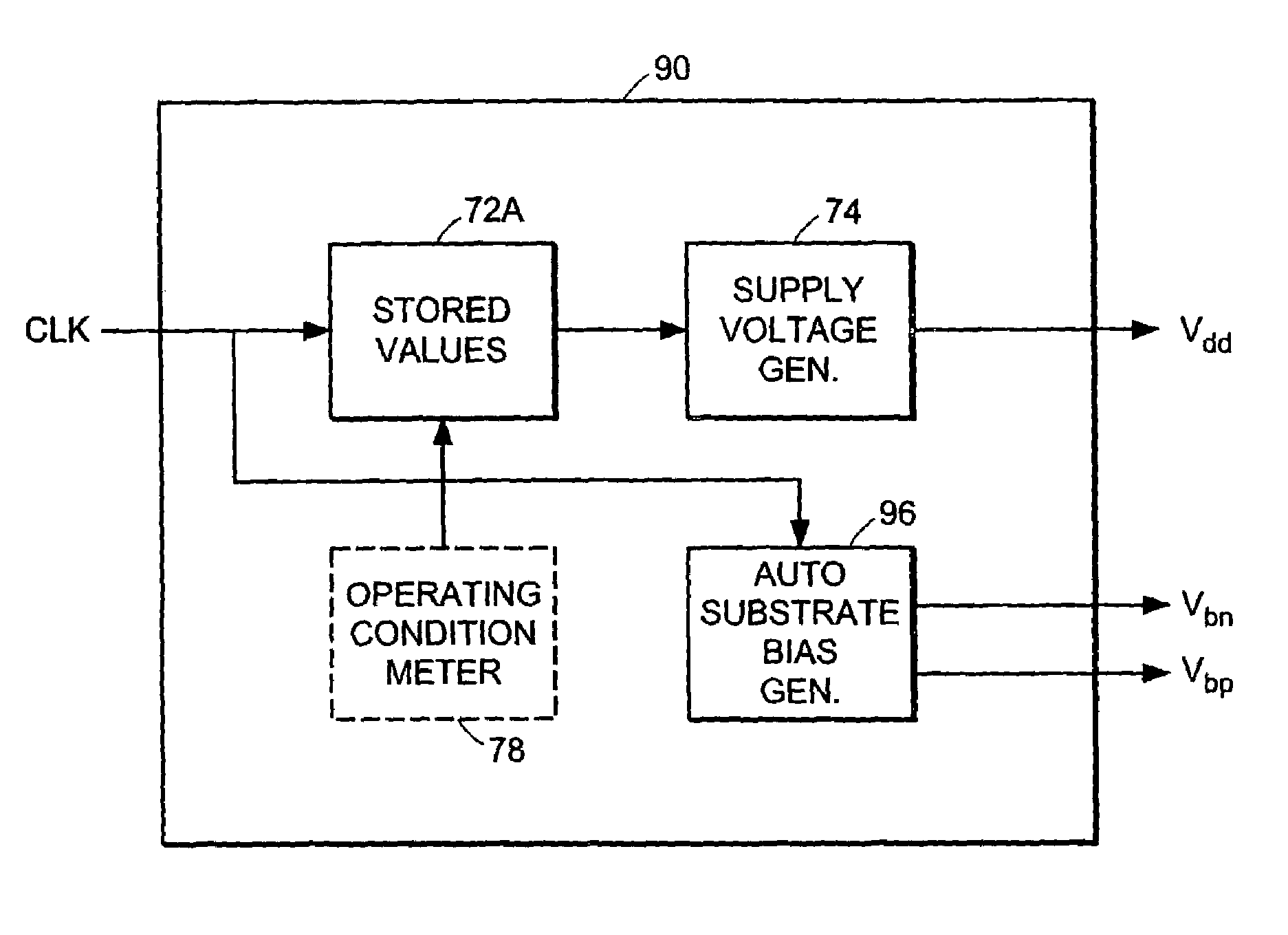

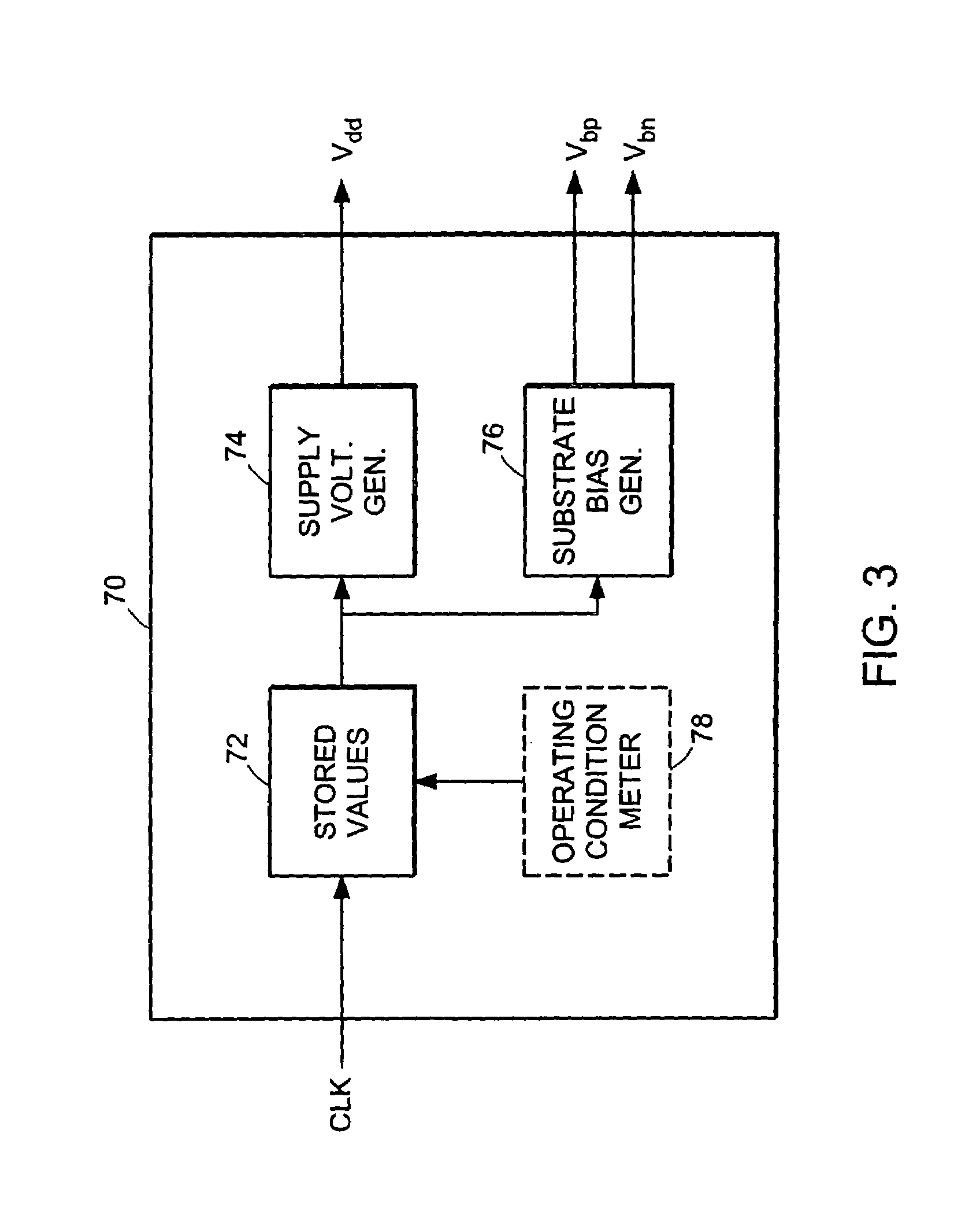

Adaptive power supply and substrate control for ultra low power digital processors using triple well control

InactiveUS6967522B2Improve power efficiencyMinimize power consumptionElectric pulse generator detailsElectric variable regulationEngineeringSelf adaptive

A system for improving the power efficiency of an electronic device includes a threshold voltage selector and a supply voltage selector. The threshold voltage selector selects a value of a threshold voltage for operation of the device in response to a present operating condition of the device. The supply voltage selector selects a value of a supply voltage to be applied to the device in response to the present operating condition of the device. The value of the threshold voltage and the value of the supply voltage control a power consumption of the device.

Owner:MASSACHUSETTS INST OF TECH

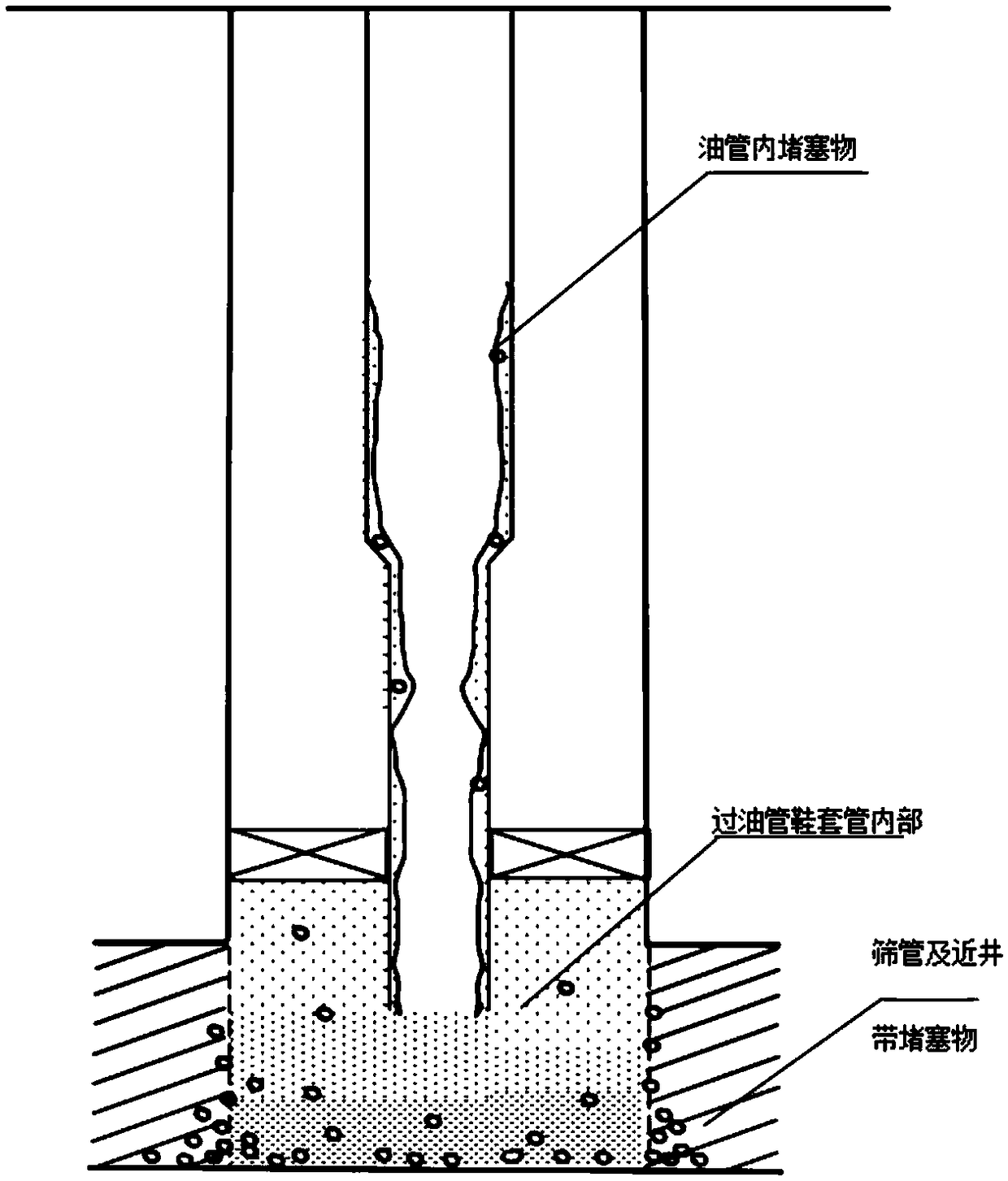

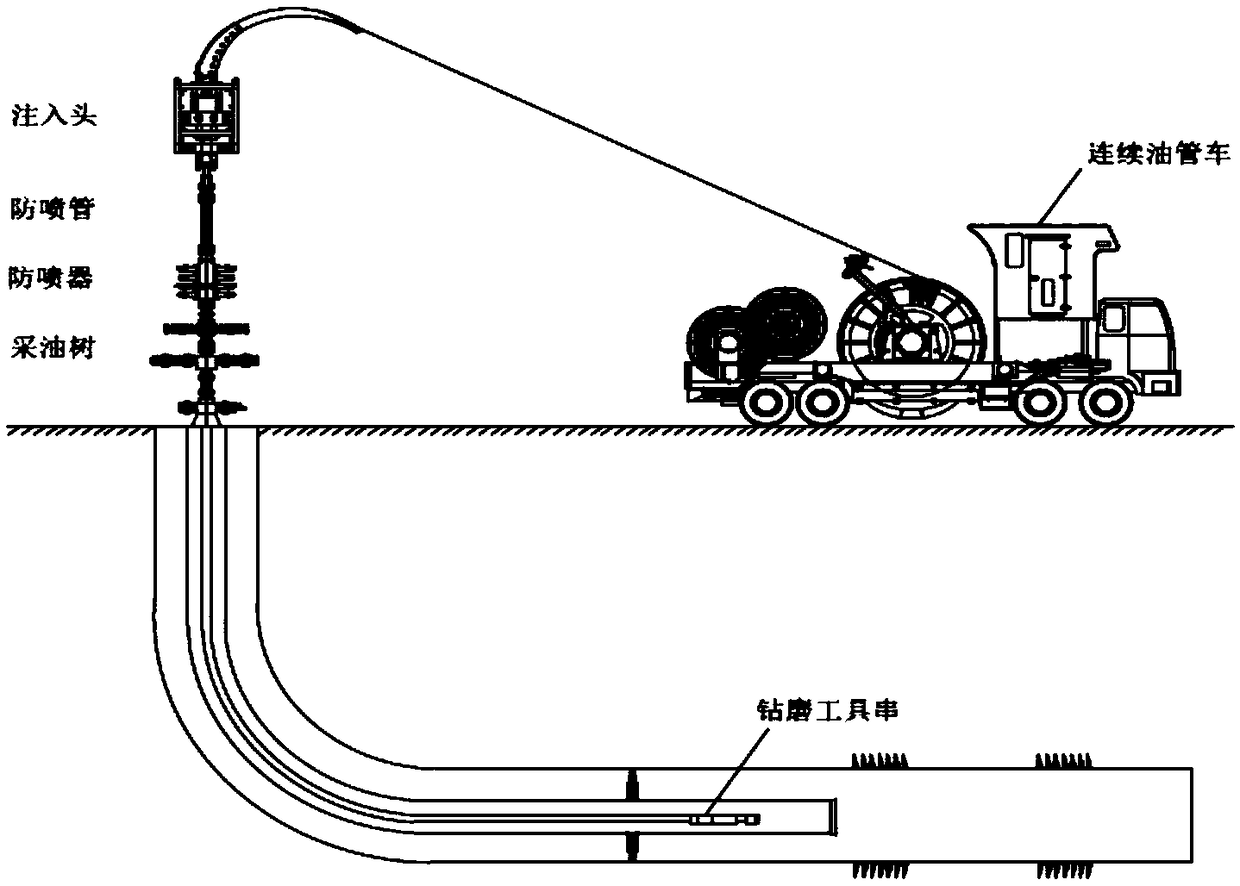

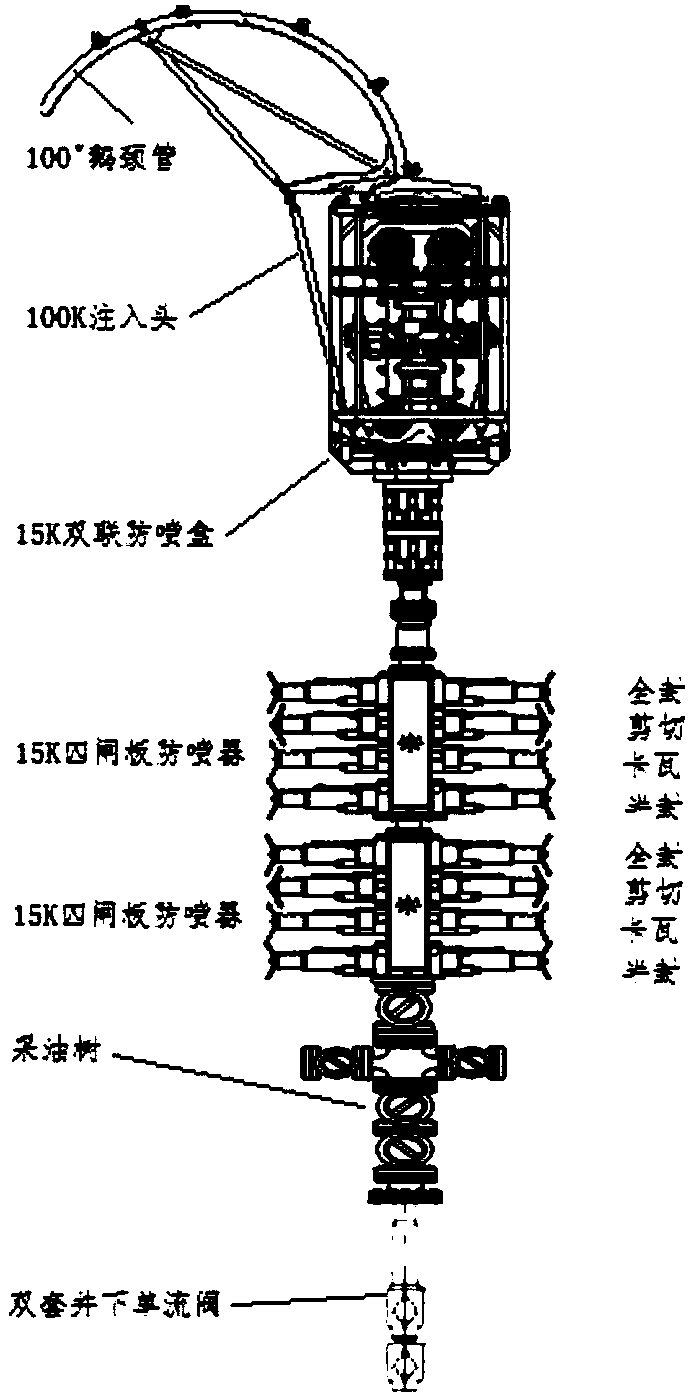

Method for three-layer unblocking for immovable string

InactiveCN108979569AEasy constructionLow costCleaning apparatusFluid removalCoiled tubingEngineering

The invention relates to the technical field of unblocking of oilfield gas wells, in particular to a method for three-layer unblocking for an immovable string. The three-layer unblocking includes oiltube internal unblocking, through-tubing casing internal unblocking and unblocking of immediate vicinity of a wellbore. The method comprises the following specific steps: arranging coiled tubing wellcontrol equipment at the position of an inlet of a high-pressure gas well; arranging a circulating working liquid sand removal system on the ground; and carrying downhole tools and delivering unblocking liquid by coiled tubing to realize three-layer unblocking. The method is proposed for a blocked gas well of an oilfield, the coiled tubing is used as a carrier of unblocking tools, and used as a deliverer for unlocking liquid. The method is simple to construct, the cost is saved, well control is safe, reservoir protection is implemented, occupied area is small, the method runs safely and reliably, and the requirements for unblocking operation of a high-pressure gas well of an oilfield can be met completely.

Owner:JEREH ENERGY SERVICES

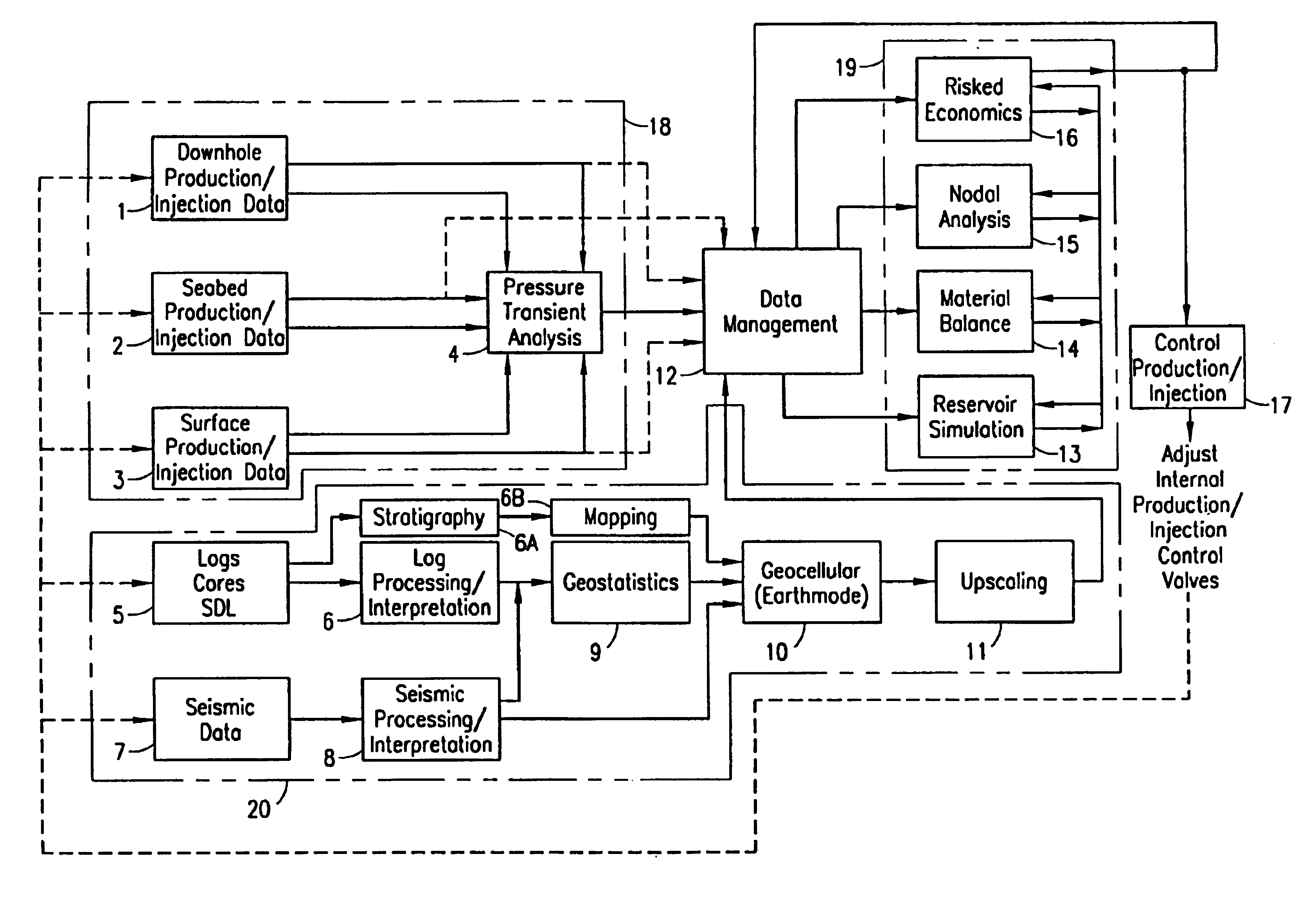

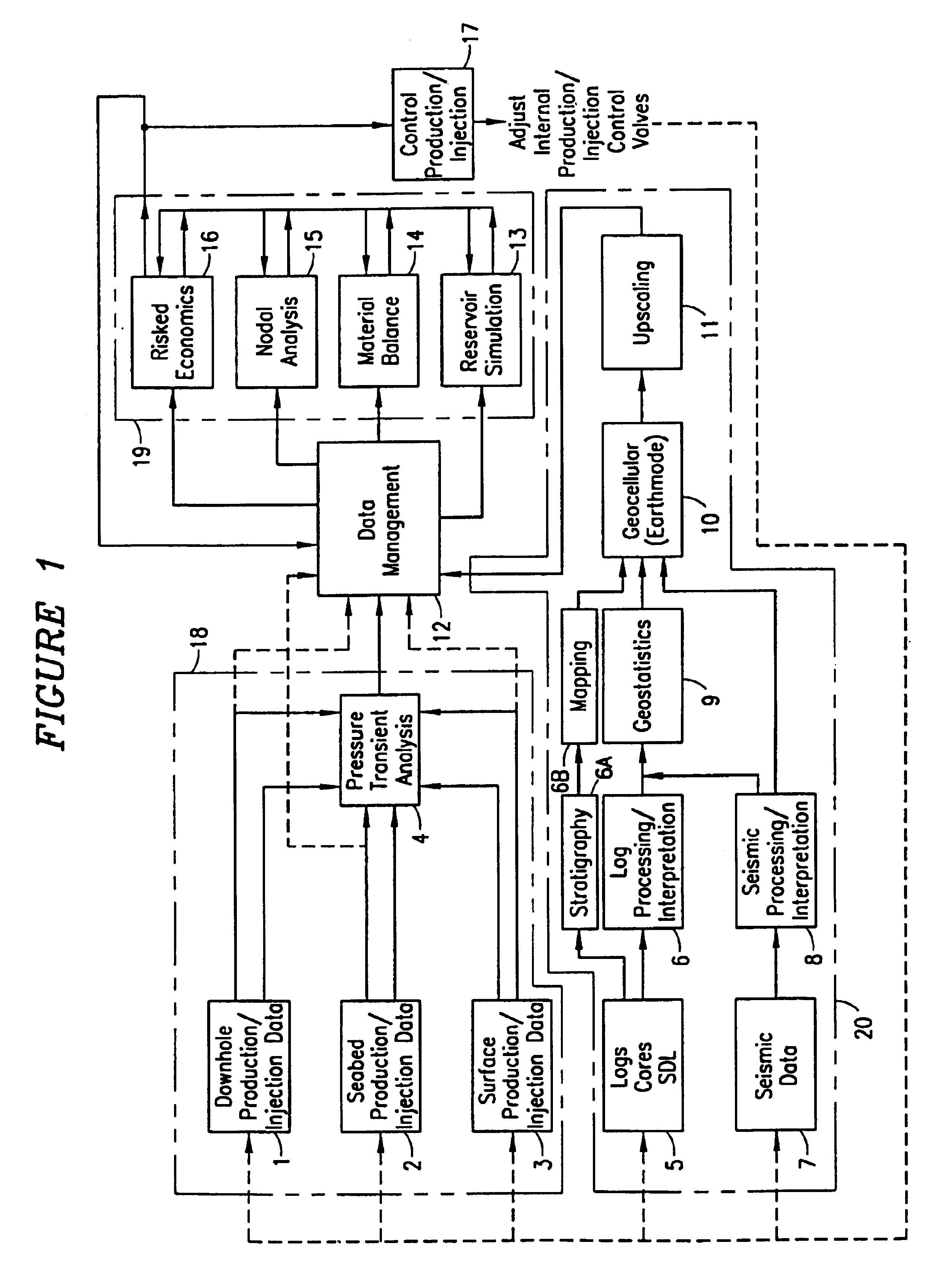

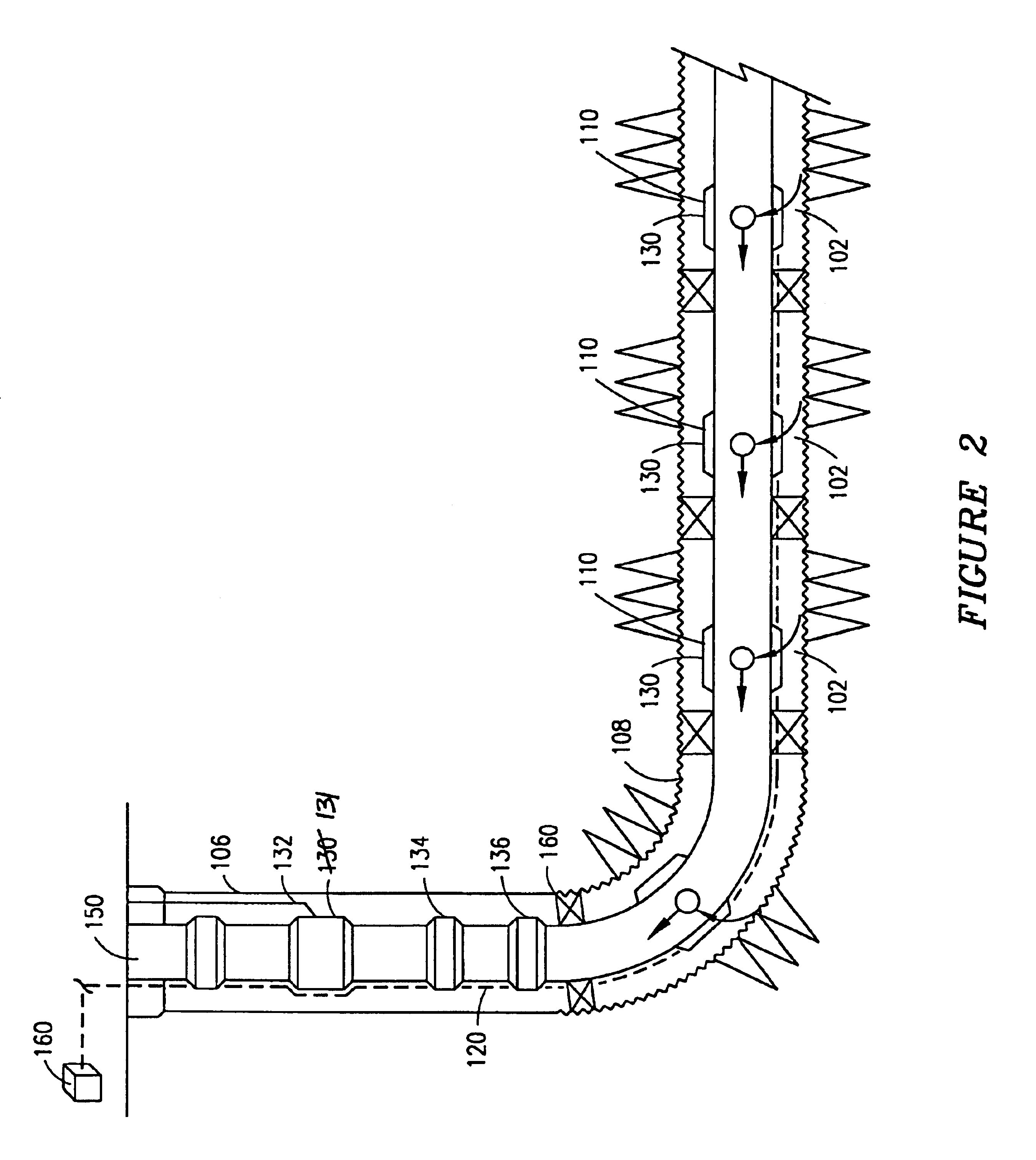

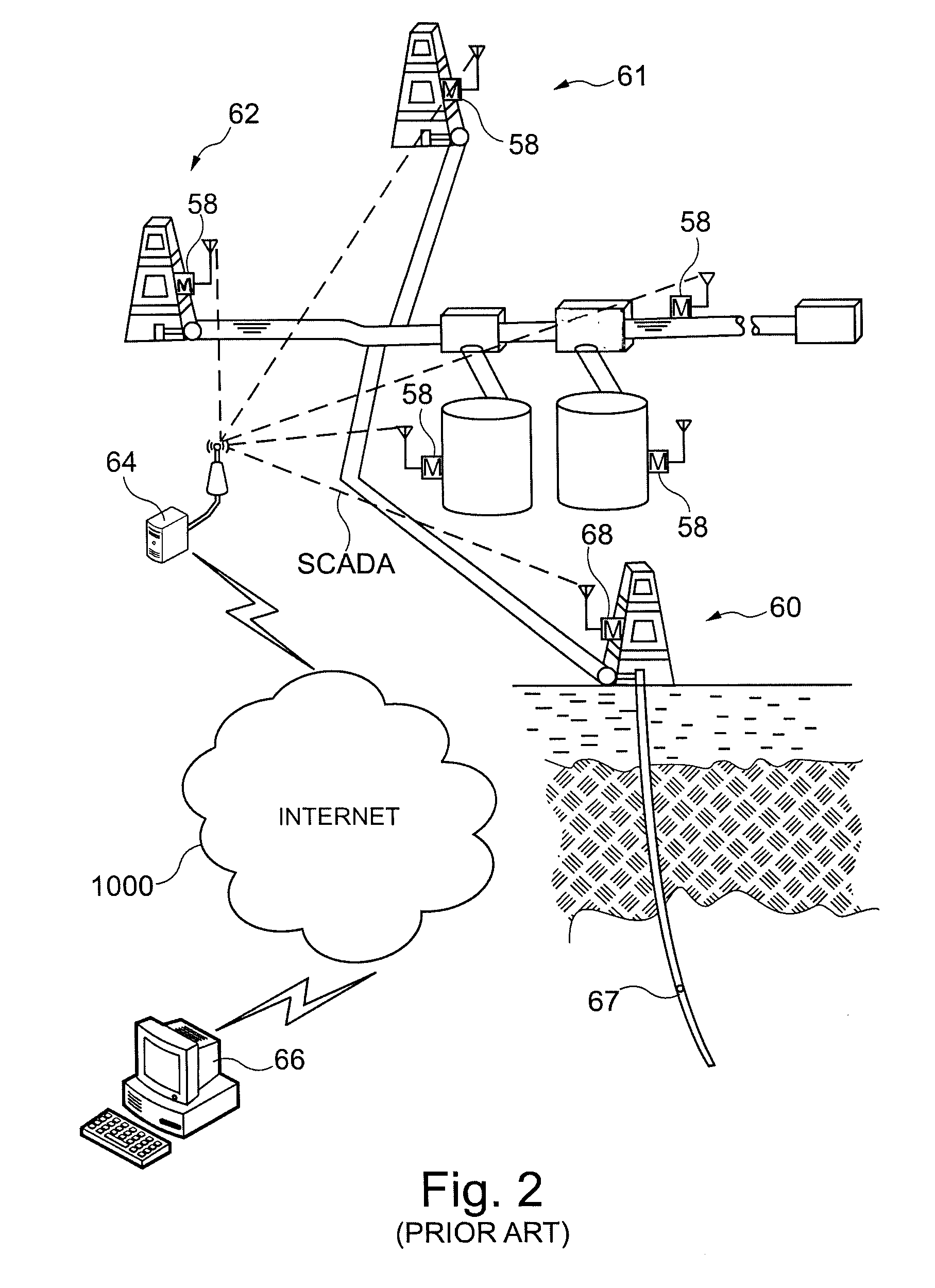

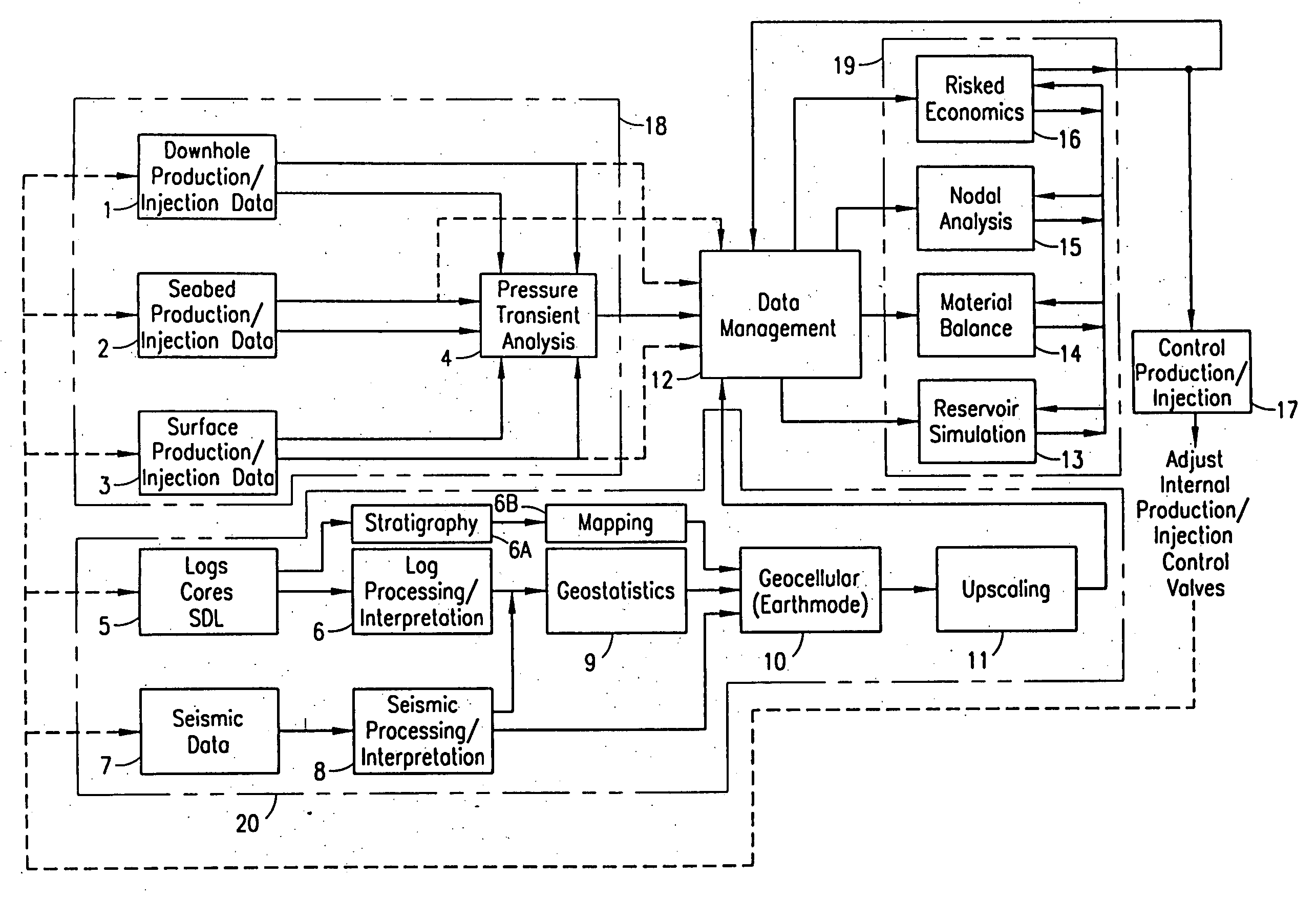

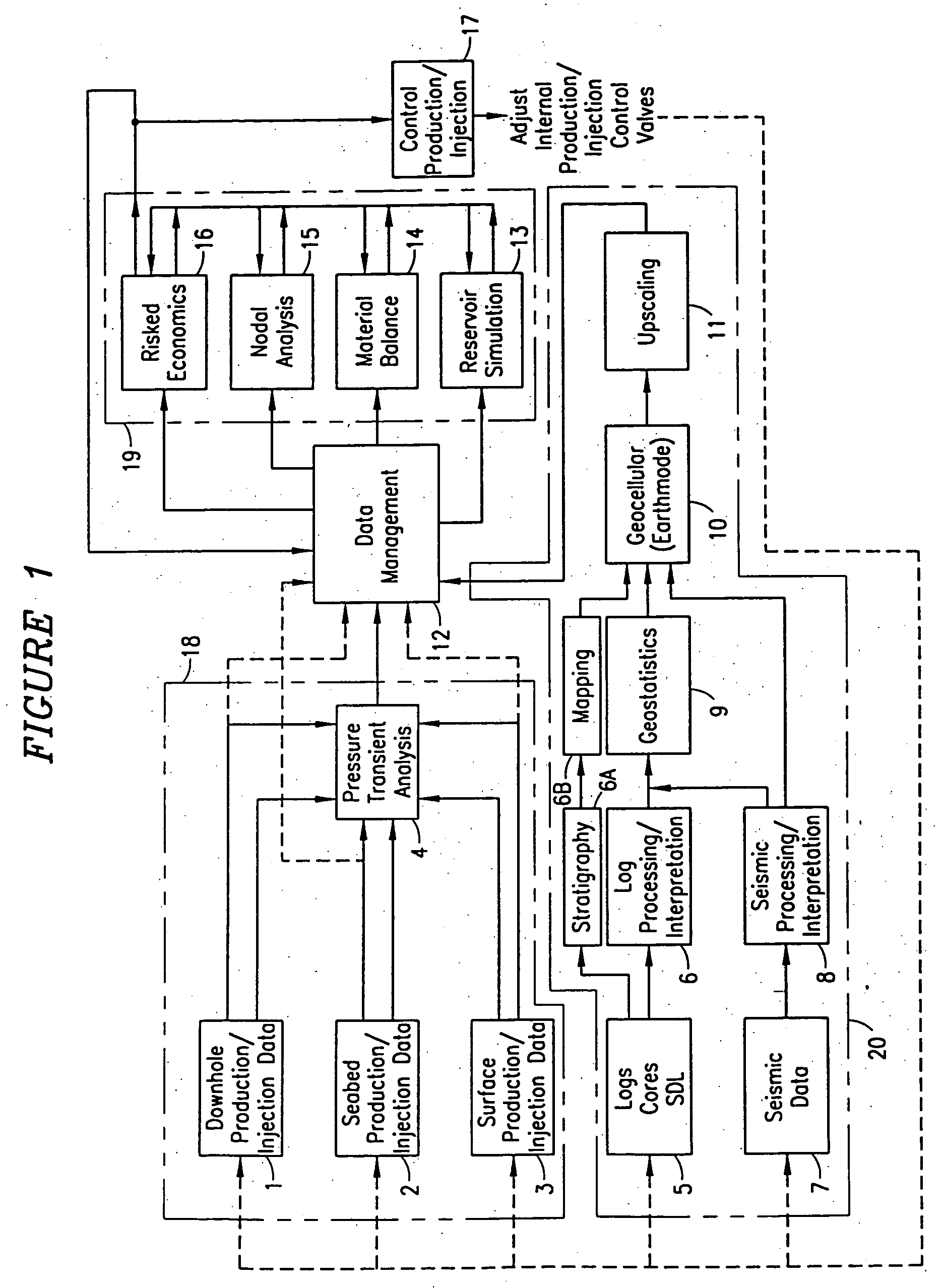

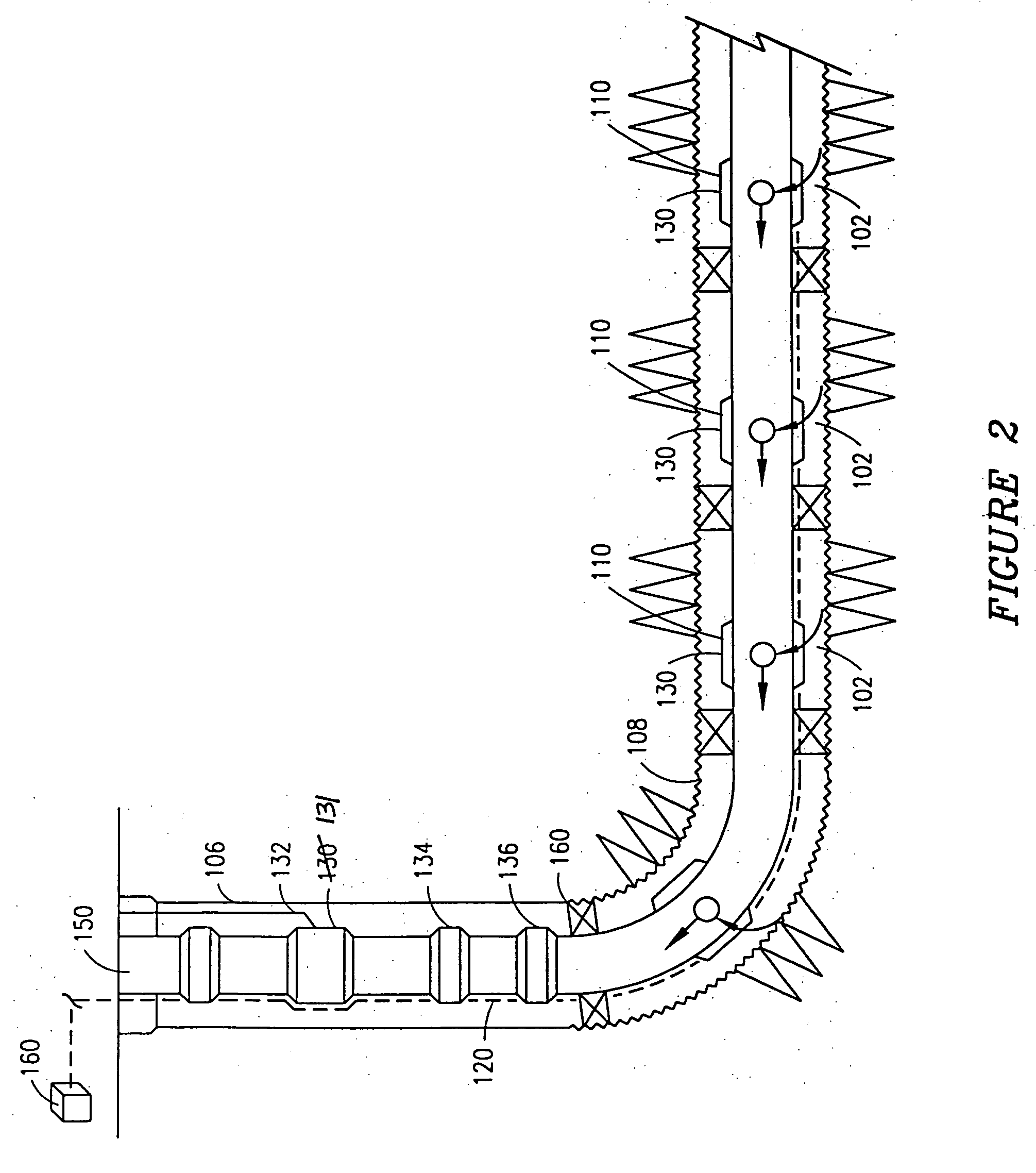

System and method for real time reservoir management

InactiveUS6853921B2Maximizing value of assetEasy to manageElectric/magnetic detection for well-loggingFluid removalProduction rateEngineering

A method of real time field wide reservoir management comprising the steps of processing collected field wide reservoir data in accordance with one or more predetermined algorithms to obtain a resultant desired field wide production / injection forecast, generating a signal to one or more individual well control devices instructing the device to increase or decrease flow through the well control device, transmitting the signal to the individual well control device, opening or closing the well control device in response to the signal to increase or decrease the production for one or more selected wells on a real time basis. The system for field wide reservoir management comprising a CPU for processing collected field wide reservoir data, generating a resultant desired field wide production / injection forecast and calculating a target production rate for one or more wells and one or more down hole production / injection control devices.

Owner:HALLIBURTON ENERGY SERVICES INC

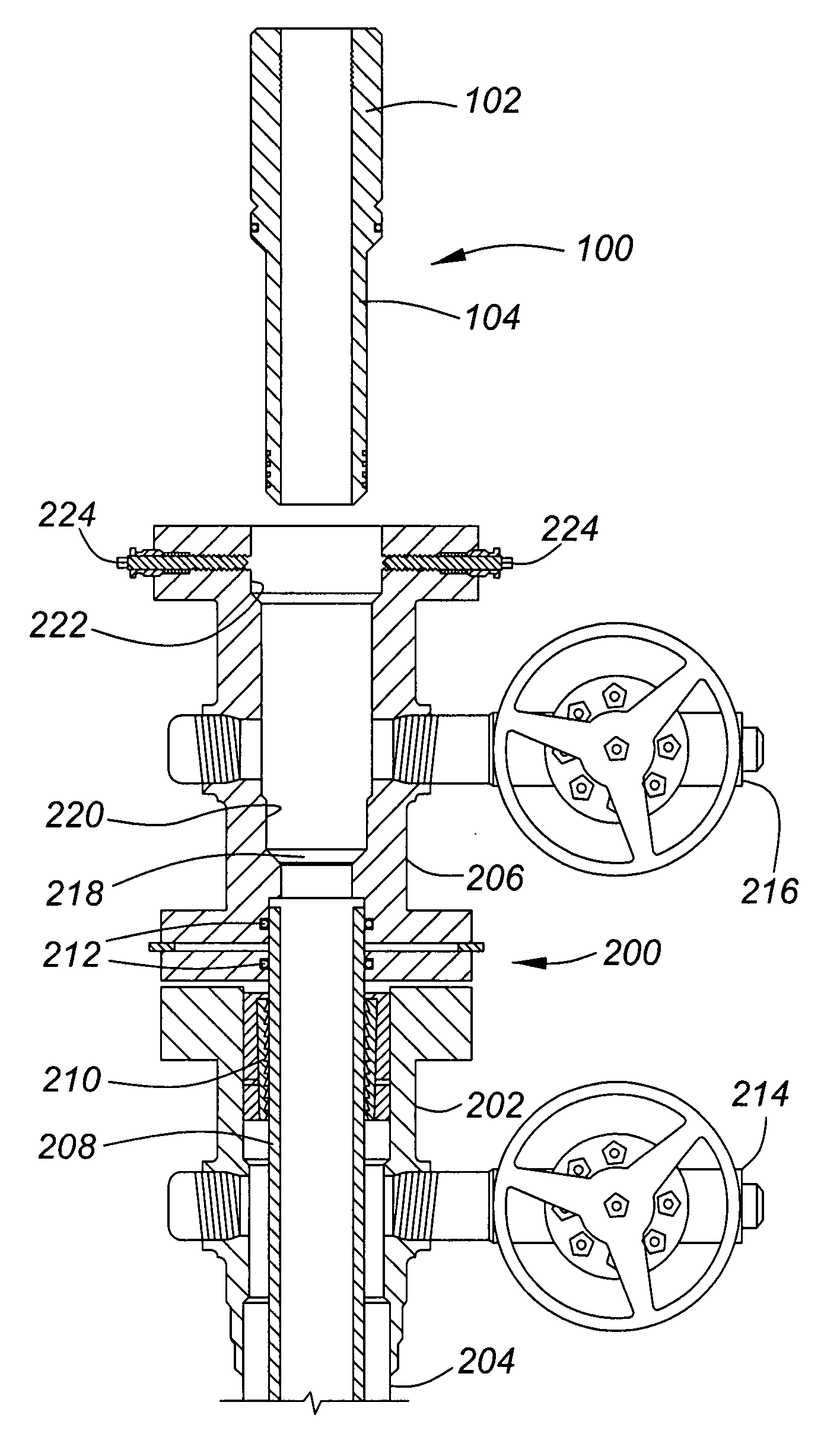

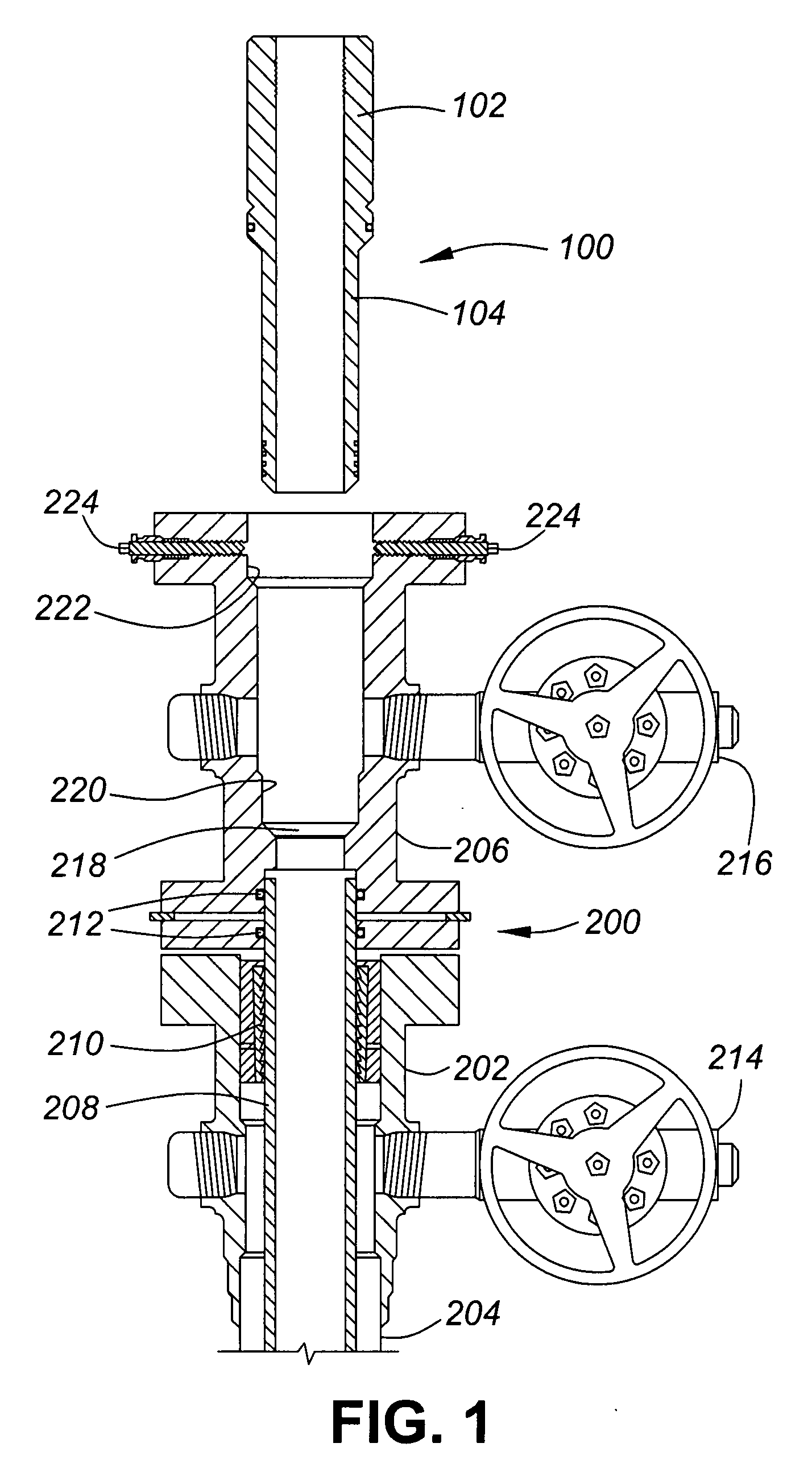

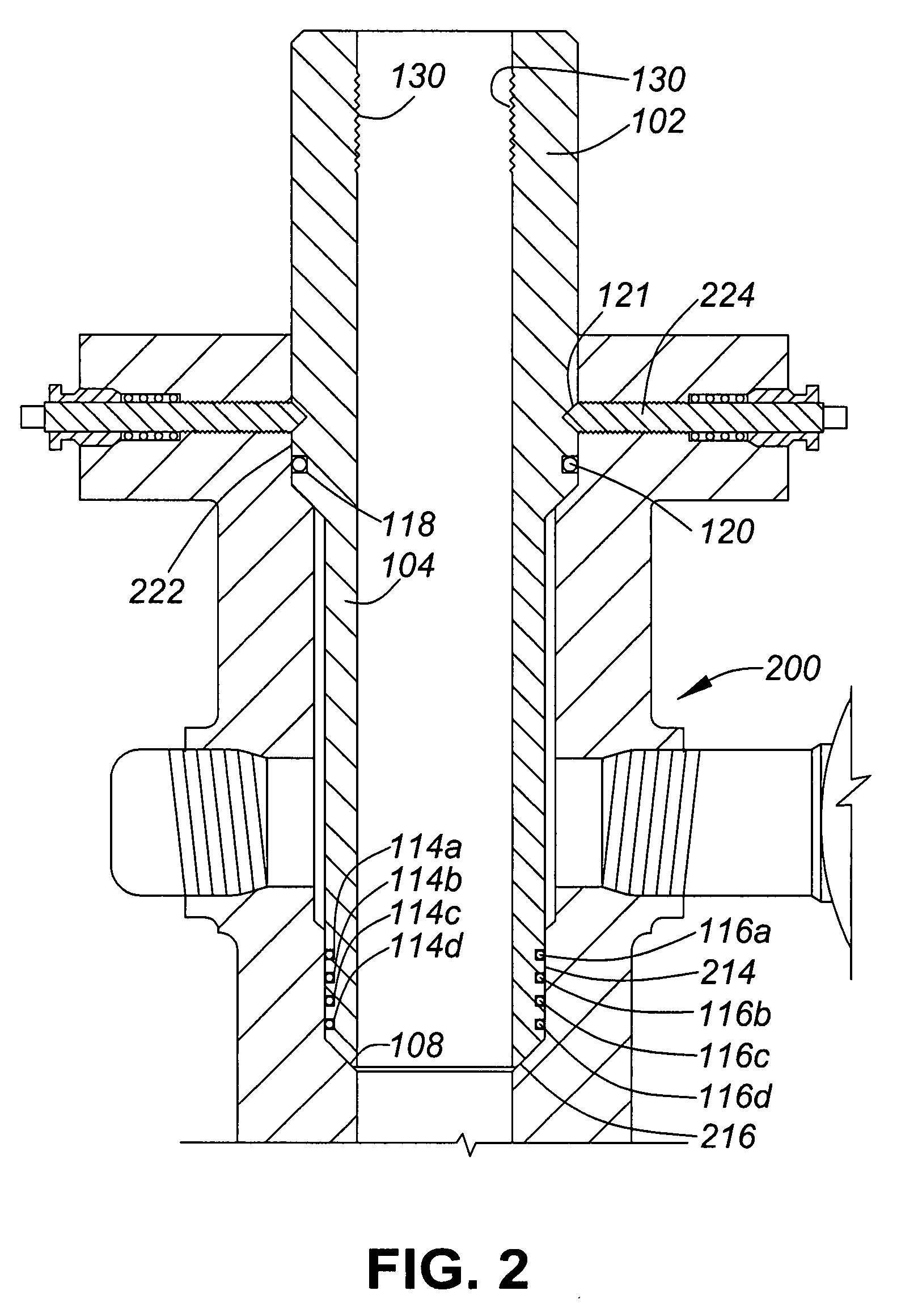

Retrievable frac mandrel and well control stack to facilitate well completion, re-completion or workover and method of use

A retrievable frac mandrel and a well control adapter are used to efficiently accomplish well completion, re-completion or workover. The retrievable frac mandrel is inserted in a tubing head spool of a well to be completed, re-completed or re-worked. The well control adapter is mounted to a top of the tubing head spool and seals off against a top of the retrievable frac mandrel. After well completion, re-completion or workover is completed, the frac mandrel can be retrieved from the tubing head spool without killing or plugging the well.

Owner:WELLS FARGO BANK NAT ASSOC +1

Fiber optic imaging catheter

InactiveUS20060030753A1Minimize applicationMinimizes unduly twisting and damagingSurgeryEndoscopesFiberOptical fiber cable

A steerable imaging catheter is provided, including an elongated catheter tube, at least one steering cable extending along the catheter tube to control the movement of the distal end thereof, and a fiber optic cable extending along the catheter tube. The fiber optic cable transmits illumination light from its proximal end to its distal end and transmits an image from its distal end to its proximal end. In one embodiment, two or more steering cables are used, and the catheter tube is configured to have greater flexibility near its distal end than its proximal end so as to concentrate the movement (flexing) of the catheter tube at its distal end. The use of two or more steering cables, together with the catheter tube having varying flexibility, permit better control of the distal end of the catheter tube while reducing undue twisting of the remainder of the catheter tube.

Owner:BOSTON SCI SCIMED INC

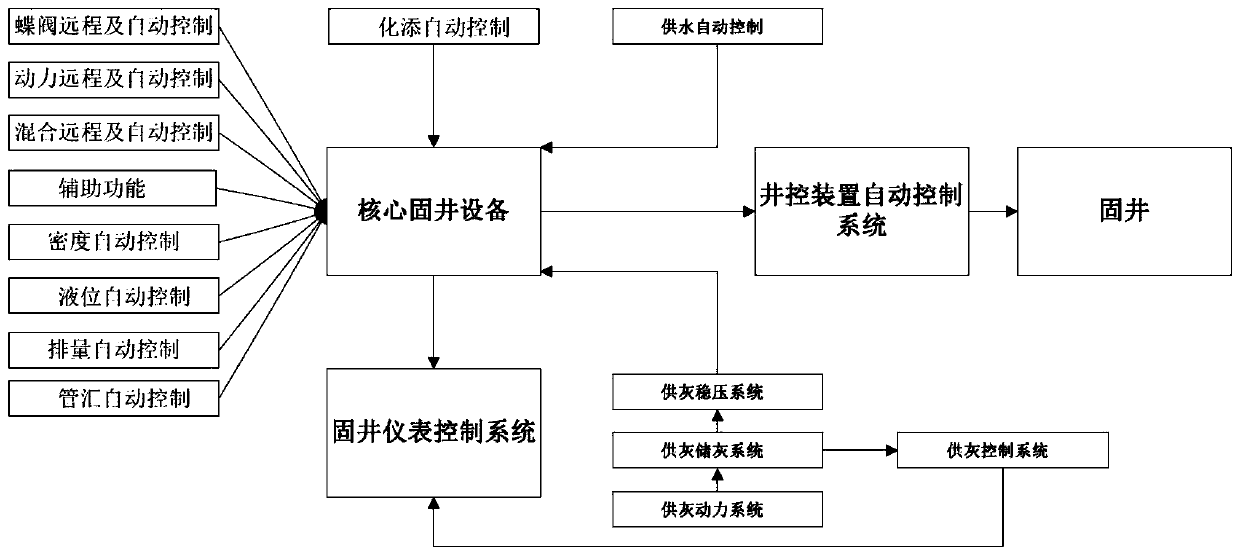

Full-automatic cementing complete set control method

InactiveCN110159225ARaise the advanced levelSolve labor shortageSealing/packingTotal factory controlAutomatic controlControl system

The invention discloses a full-automatic cementing complete set control method, and relates to the related technical field of petroleum equipment. The method comprises the steps of intelligent full-automatic cementing key control, matching control, an automatic power control system, a slurry mixing control system, an automatic premixing function, automatic liquid level control, automatic manifoldcontrol, a hydraulic pneumatic control system, a lime supply automatic control system, a chemical additive automatic control system, a water supply automatic control system and a well control device automatic control system. According to the operating method, intelligent full-automatic control over cementing operation is achieved, and breakthrough of the automatic manifold control technology is achieved successfully; through the lime supply automatic control technology and the full-automatic control technology, the advanced level of equipment and technologies of the company is improved greatly; a new mode of future cementing operation is created, and a new era of a smart oil field is started; through achievement of the intelligent full-automatic cementing operation technology, the problems, that customers face at present, of shortage of labor forces and labor resources can be solved; and the intelligent operation is achieved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

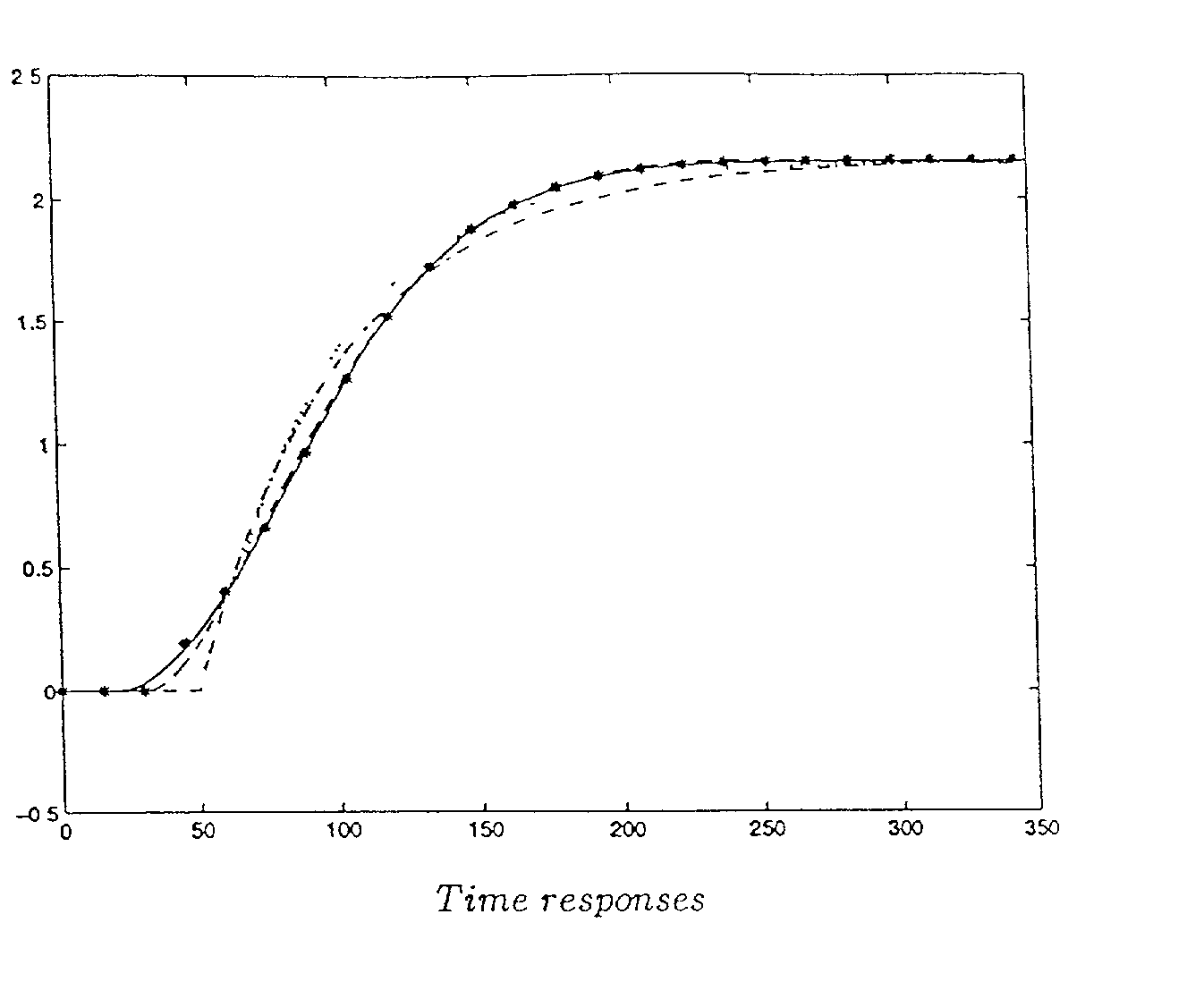

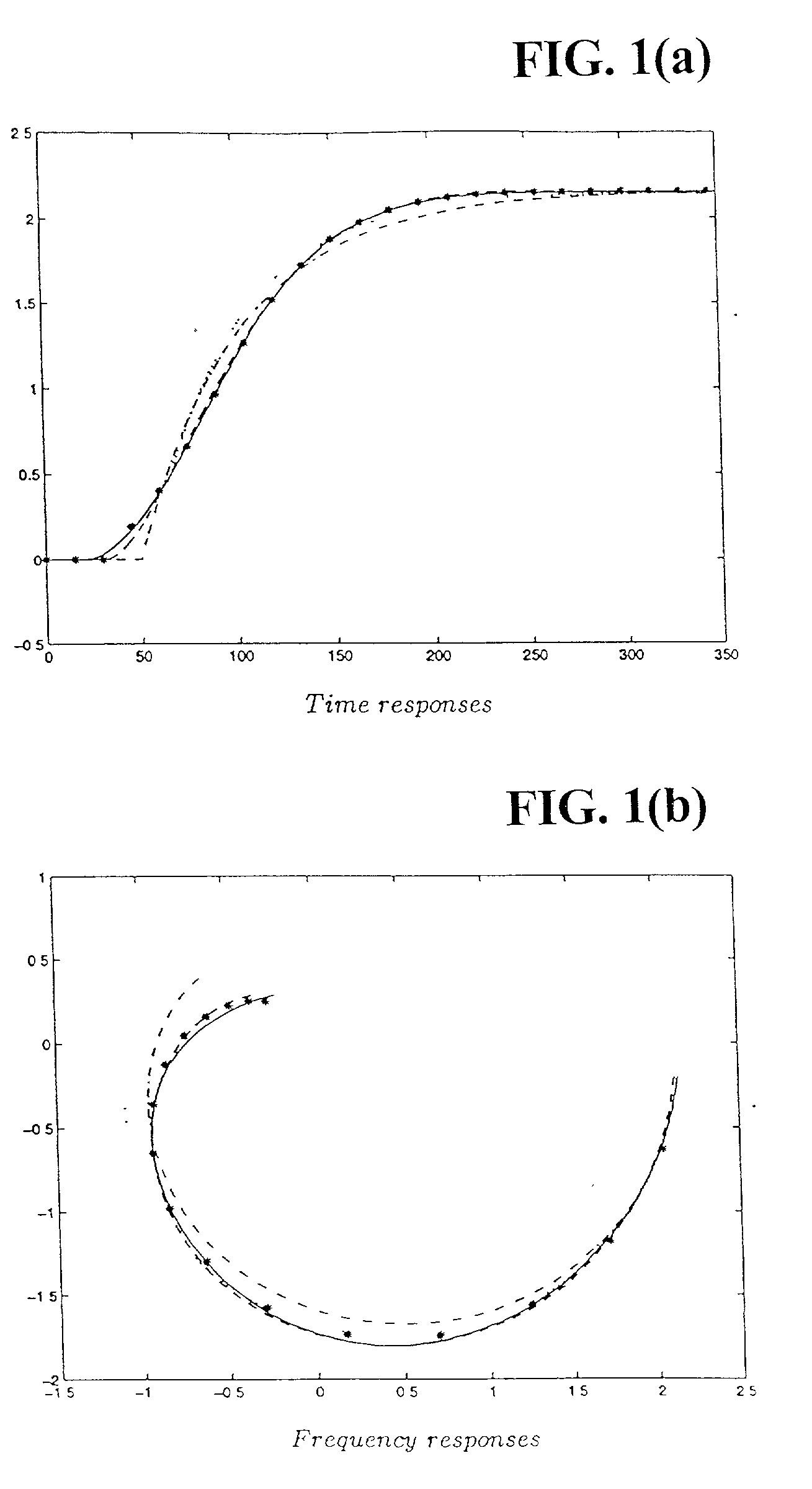

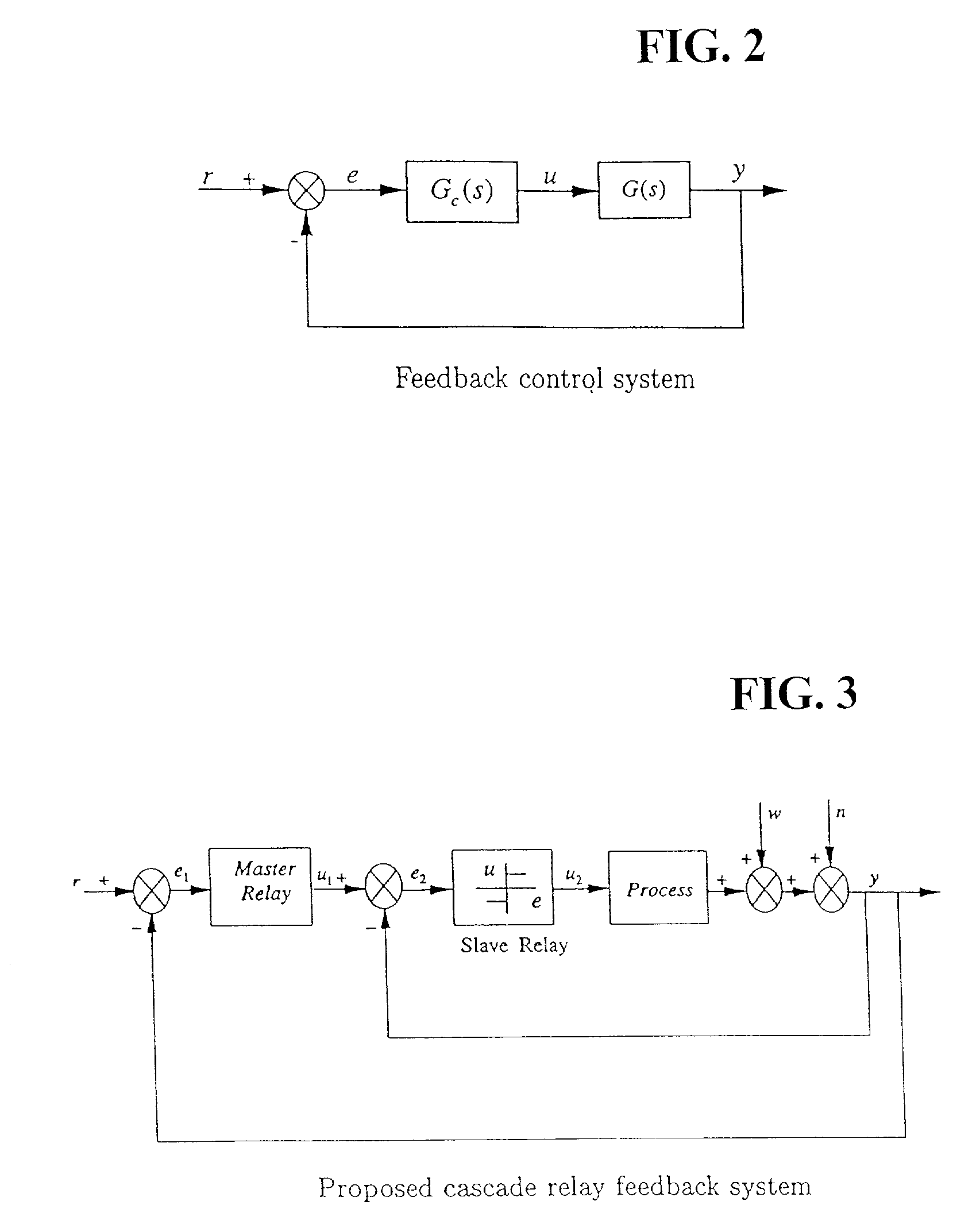

Robust process identification and auto-tuning control

InactiveUS20020111758A1Accurate estimateImprove performanceAmplifier modifications to reduce noise influenceVoltage-current phase angleGuidelineTime delays

A simple yet effective and robust identification method is presented using process step responses for process identification that can provide a continuous transfer function with time-delay without iteration. A cascade relay provides accurate and reliable more points on the process frequency response. The internal model principle is employed to design single-loop controller of PID or high-order types with best achievable control performance for controller tuning, e.g. both single and multivariable cases are covered. The process identification and control design portions can be easily integrated into a control system auto-tuning package. Further, a general control scheme for disturbance rejection is given which can significantly improve disturbance rejection performance over conventional feedback systems with time delays. Practical issues such as noises, real-time implementation and tuning guidelines are also provided. The present invention provide general, systematic, effective, and applicable methods for process identification and control for a wide range of industries such as process and chemical plants, food processing, waste water treatment and environmental systems, oil refinery, servo and mechatronic systems, where a system model is needed for analysis, prediction, filtering, optimization and management, and / or where control or better control is required for their systems.

Owner:NAT UNIV OF SINGAPORE

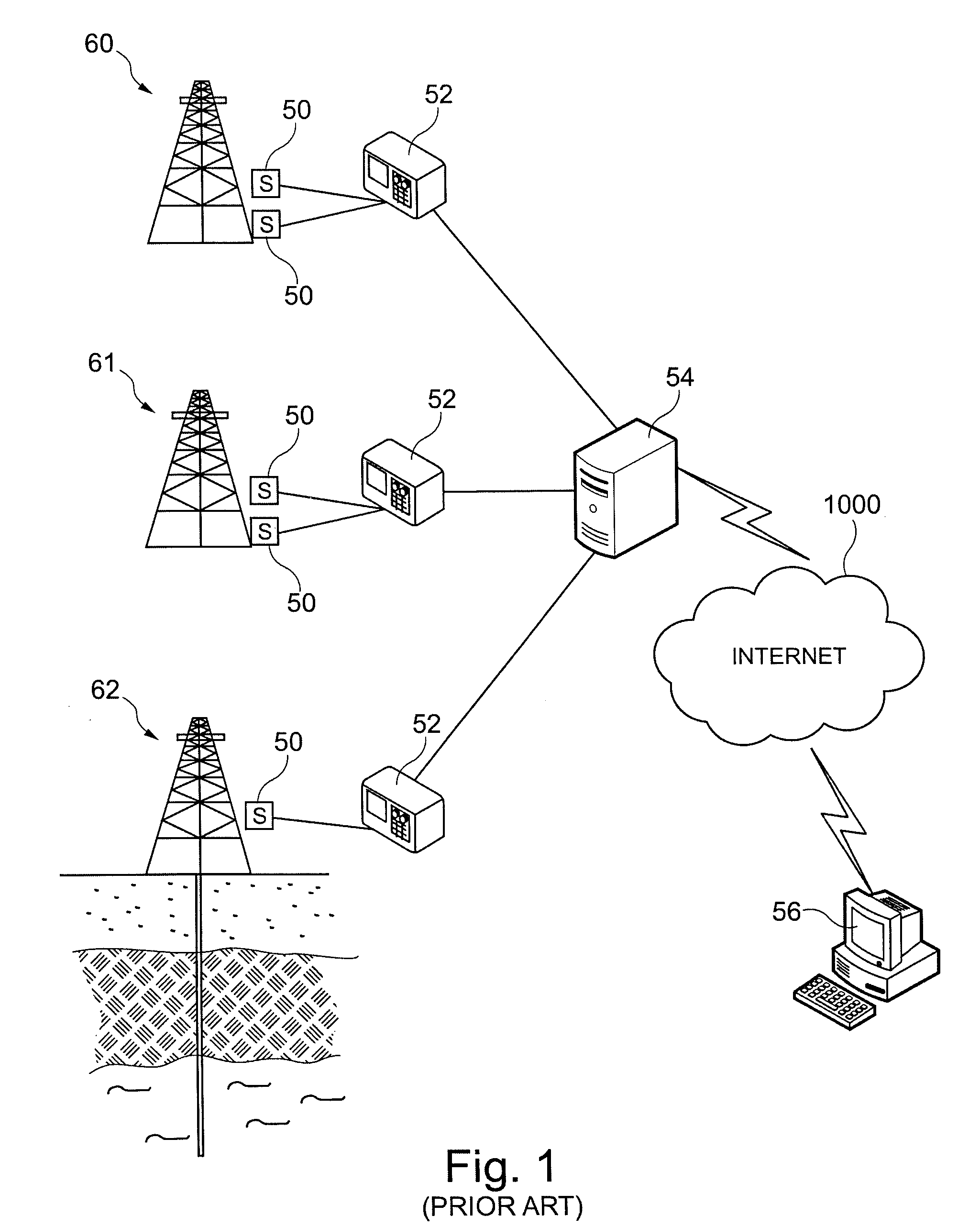

Real-time onsite internet communication with well manager for constant well optimization

ActiveUS20090055029A1Eliminate needSurveyTesting/monitoring control systemsInternet communicationTTEthernet

An apparatus and method for well control and monitoring including an independent web server computer integrated with a pump controller located at each well in an oil field. The well controller locally controls the well pump, processes well and pump data, generates surface and downhole cards, and communicates production reports, recommendations for production improvements, and production statistics to remote sites via the internet. The controller can be queried remotely to provide production reports, etc. Furthermore, the controller can initiate alerts via email, text messaging, or internet messaging, for example, during fault conditions.

Owner:LUFKIN INDUSTRIES

System and method for real time reservoir management

InactiveUS20050038603A1Value maximizationElectric/magnetic detection for well-loggingFluid removalProduction rateEngineering

A method of real time field wide reservoir management comprising the steps of processing collected field wide reservoir data in accordance with one or more predetermined algorithms to obtain a resultant desired field wide production / injection forecast, generating a signal to one or more individual well control devices instructing the device to increase or decrease flow through the well control device, transmitting the signal to the individual well control device, opening or closing the well control device in response to the signal to increase or decrease the production for one or more selected wells on a real time basis. The system for field wide reservoir management comprising a CPU for processing collected field wide reservoir data, generating a resultant desired field wide production / injection forecast and calculating a target production rate for one or more wells and one or more down hole production / injection control devices.

Owner:HALLIBURTON ENERGY SERVICES INC

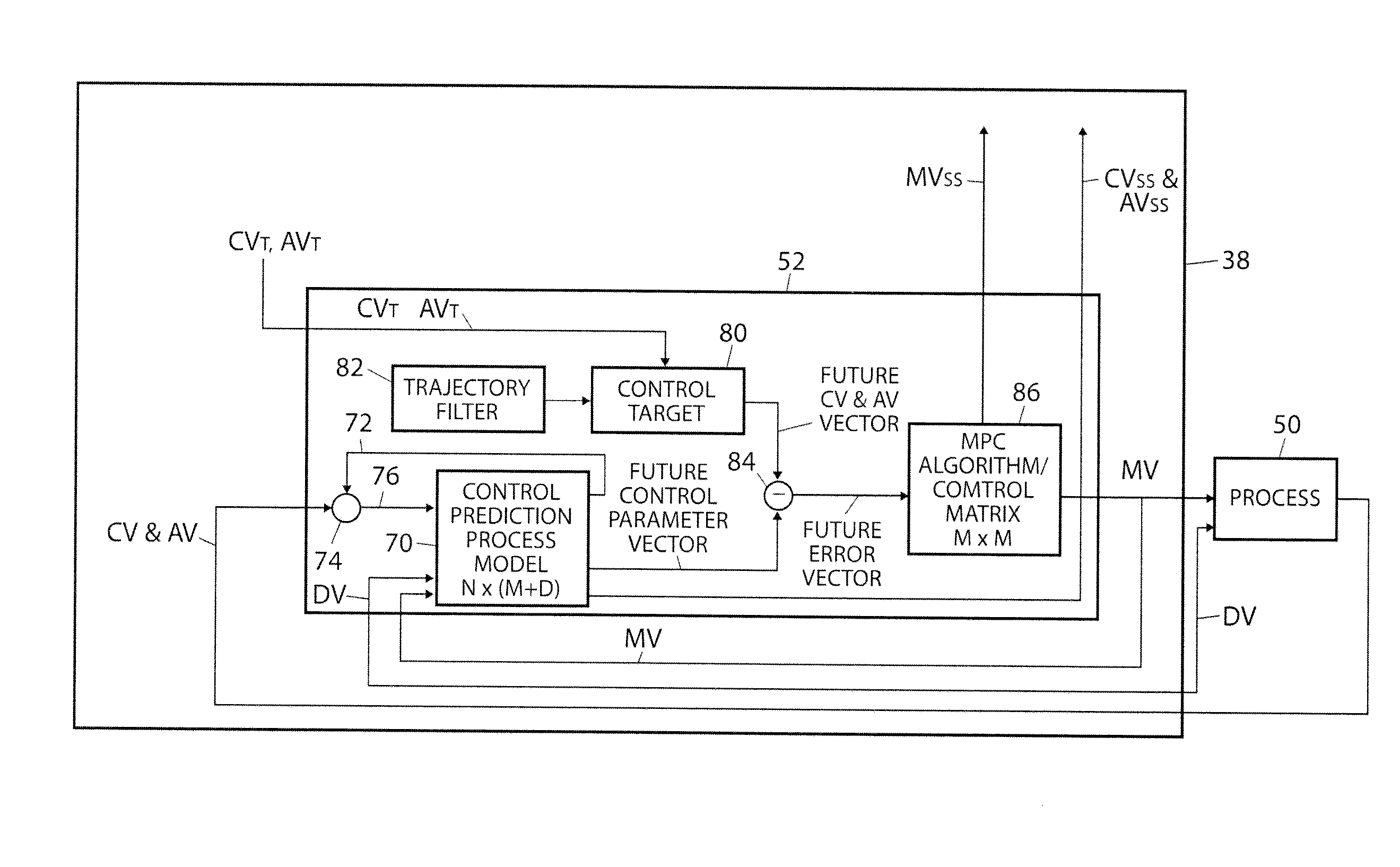

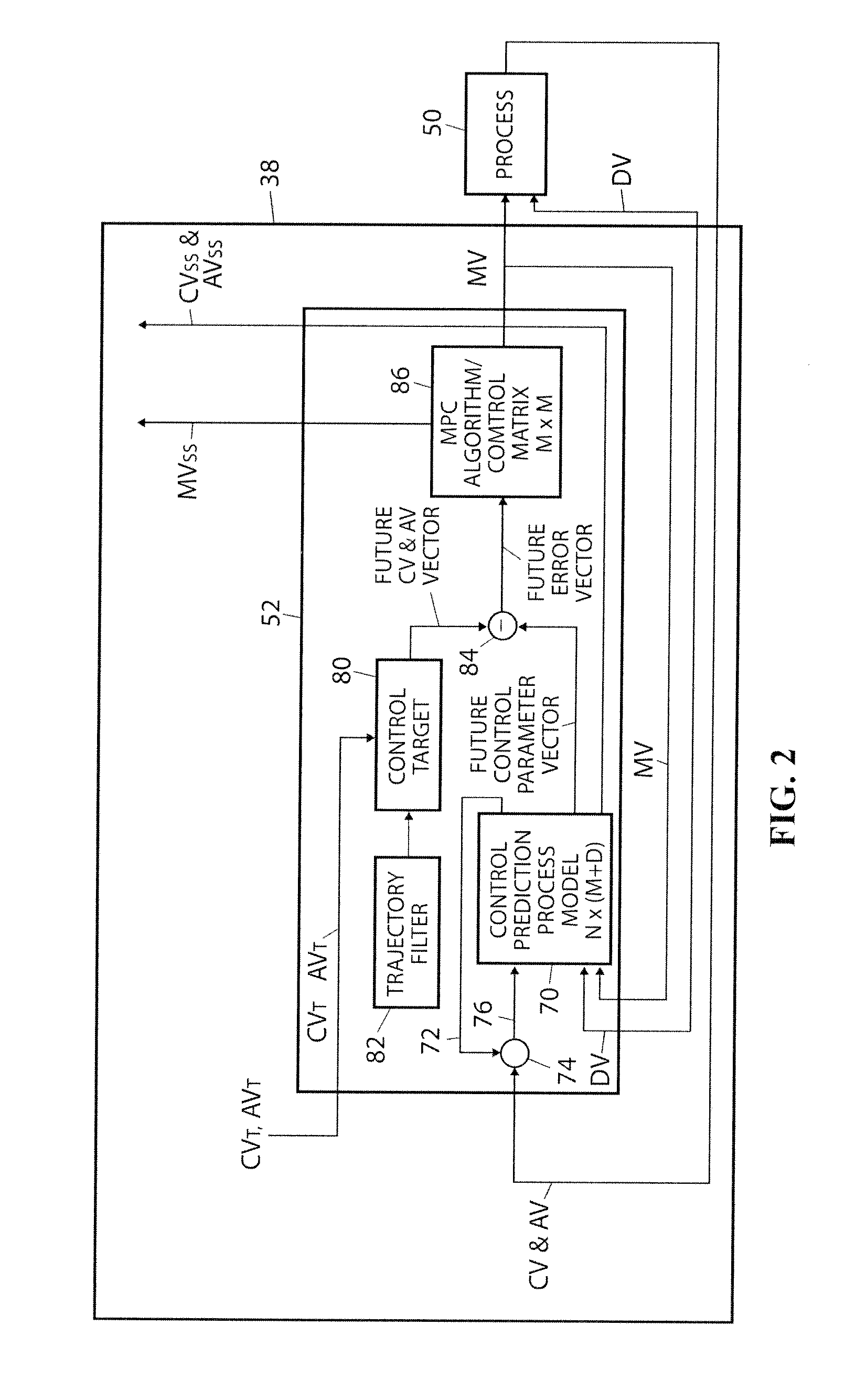

Model predictive controller with tunable integral component to compensate for model mismatch

ActiveUS20100204808A1Low robustnessImprove performanceProgramme controlSimulator controlPredictive controllerFeedback control

An MPC controller technique integrates feedback control performance better than methods commonly used today in MPC type controllers, resulting in an MPC controller that performs better than traditional MPC techniques in the presence of process model mismatch. In particular, MPC controller performance is enhanced by adding a tunable integration block to the MPC controller that develops an integral component indicative of the prediction or other control error, and adds this component to the output of an MPC controller algorithm to provide for faster or better control in the presence of model mismatch, which is the ultimate reason for the prediction error in the first place. This technique enables the MPC controller to react more quickly and to provide better set point change and load disturbance performance in the presence of model mismatch, without decreasing the robustness of the MPC controller.

Owner:FISHER-ROSEMOUNT SYST INC

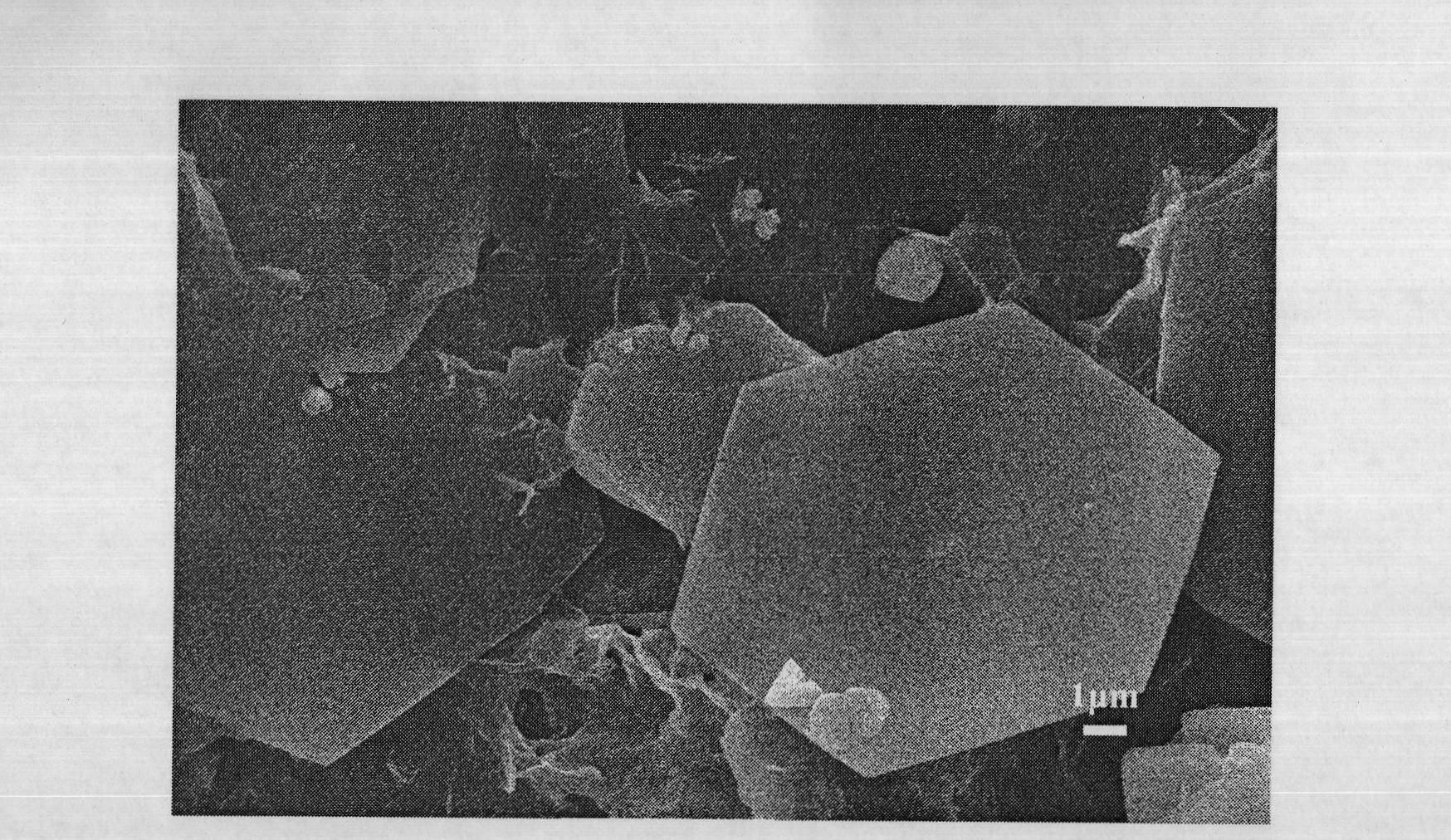

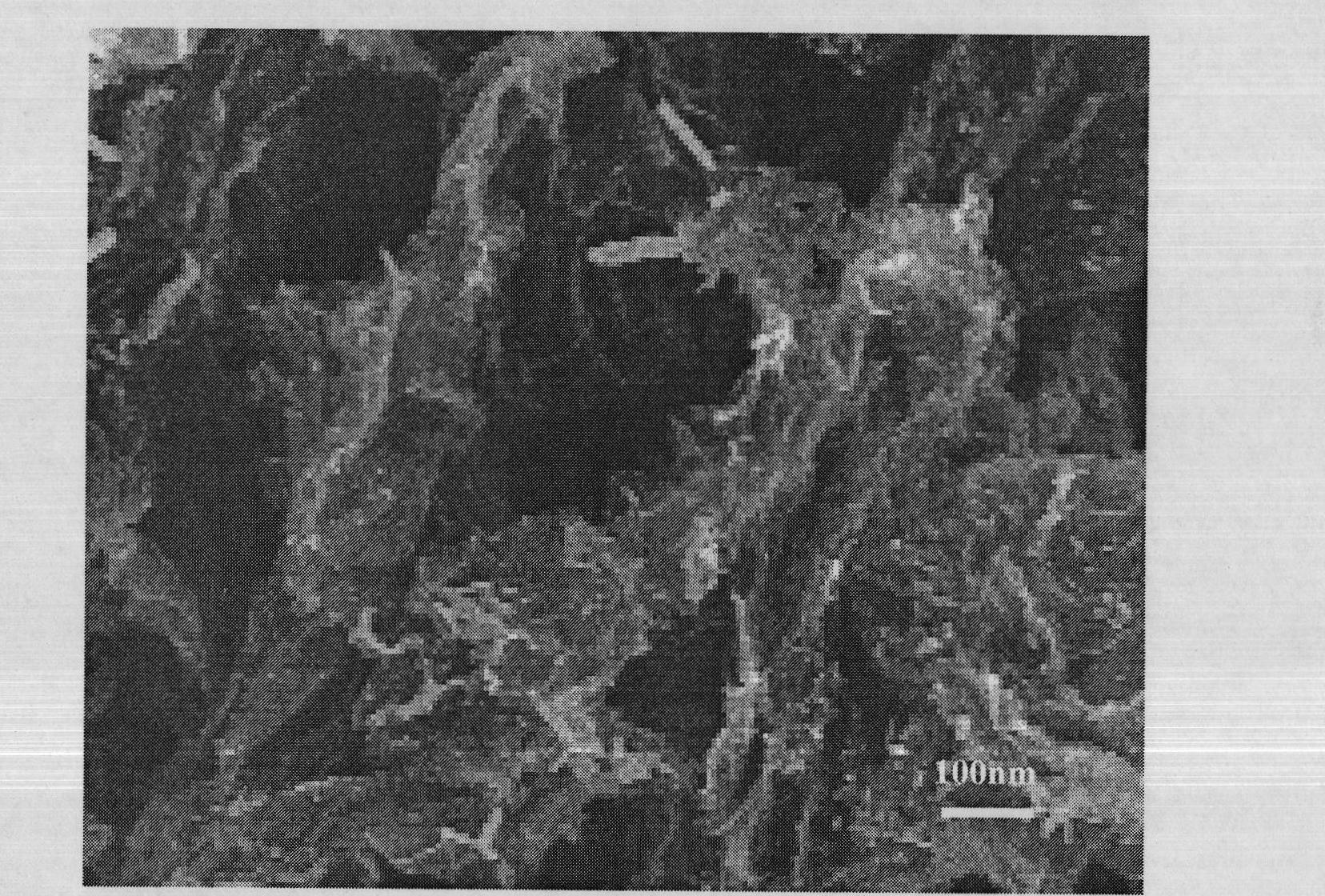

Preparation method of large-area and continuous graphen/zinc oxide composite structure

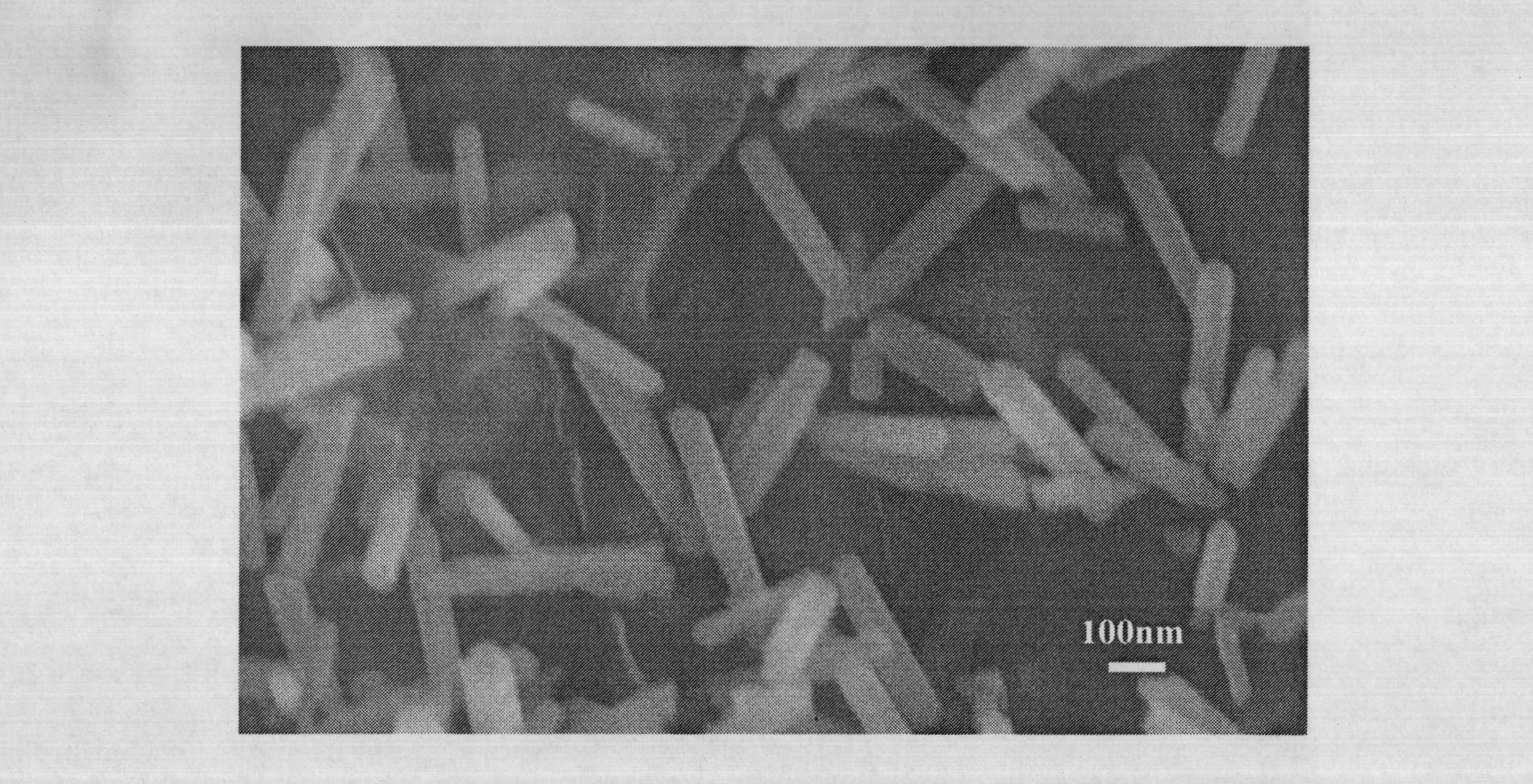

ActiveCN101857222AThickness is easy to controlSimple processZinc oxides/hydroxidesNanoparticleThree-dimensional space

The invention relates to a method for preparing continuous graphen / zinc oxide composite structure in large area, which belongs to the preparation field of the novel nanometer material, and is applicable to the fields such as sensor, solar panel, novel nanometer part and the like. The method comprises the following three steps that: first step: uniformly dispersing graphen or graphene oxide in liquid phase; second step: utilizing a hydrothermal process to ensure the zinc oxide nanometer structure and the graphen two-dimensional sheet to form a continuous structure in a three-dimensional space; third step: transferring the prepared composite structure onto a substrate to be dried. The method has simple process and low device requirement since the composite structure is synthesized in the solution; the process repeatability is strong, and the process parameter can be well controlled; the prepared graphen / zinc oxide composite structure has large area and is continuous, the generated zinc oxide nanometer sheet layer, nanometer particle and nanometer line are connected with each other and intersected with each other under the effect of the graphen so as to form a continuous porous structure in the three-dimensional space.

Owner:如东文园投资开发有限公司

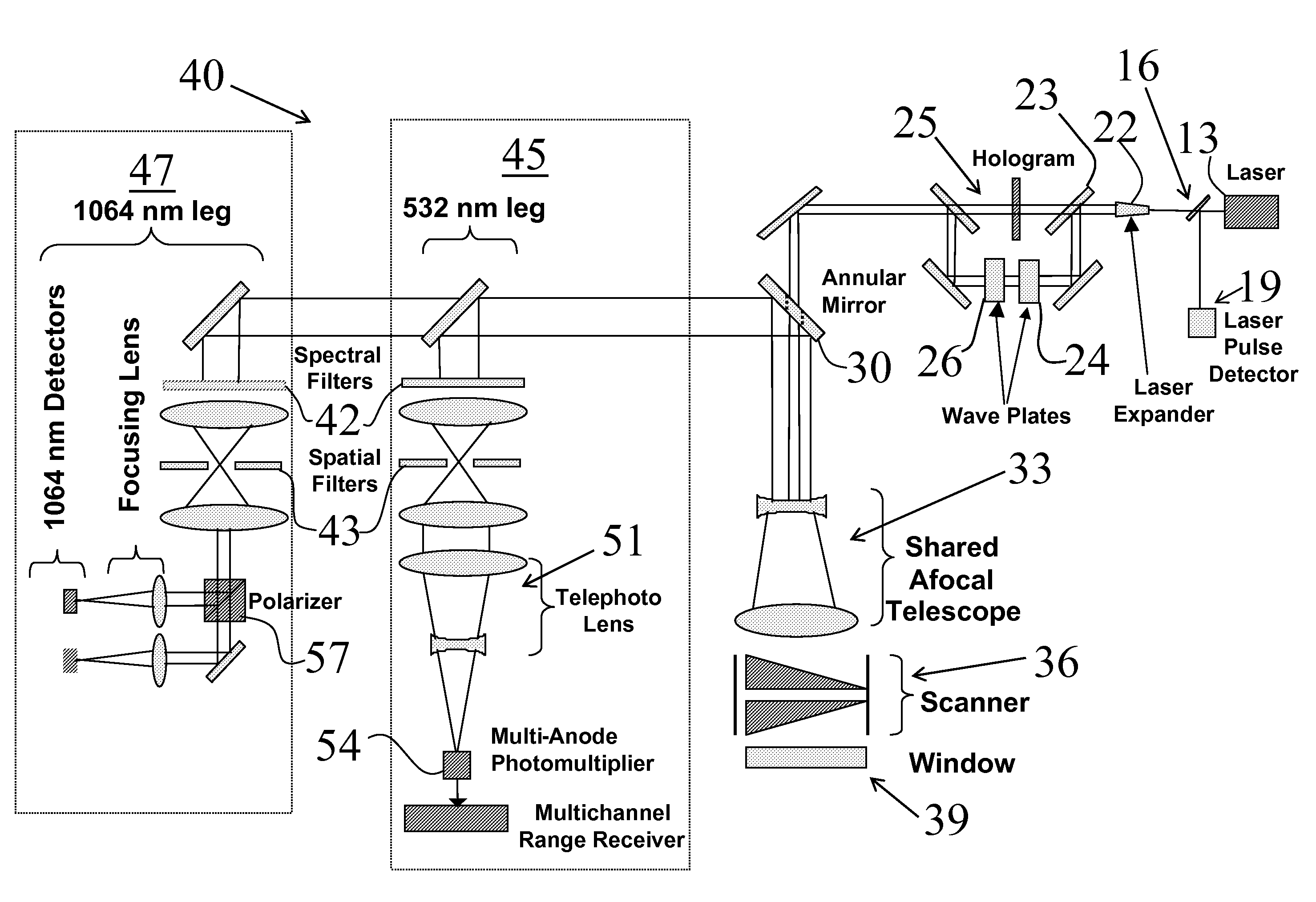

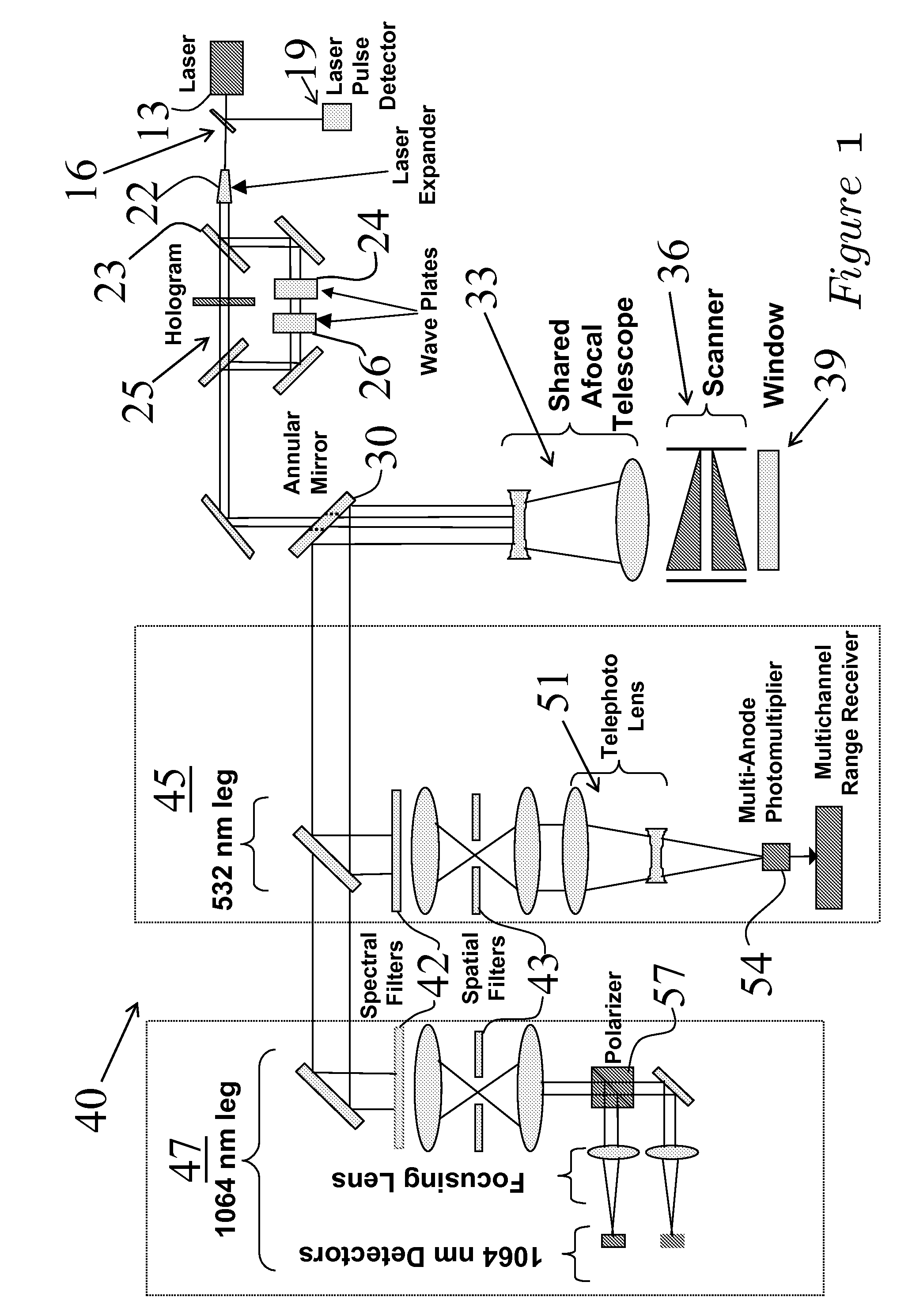

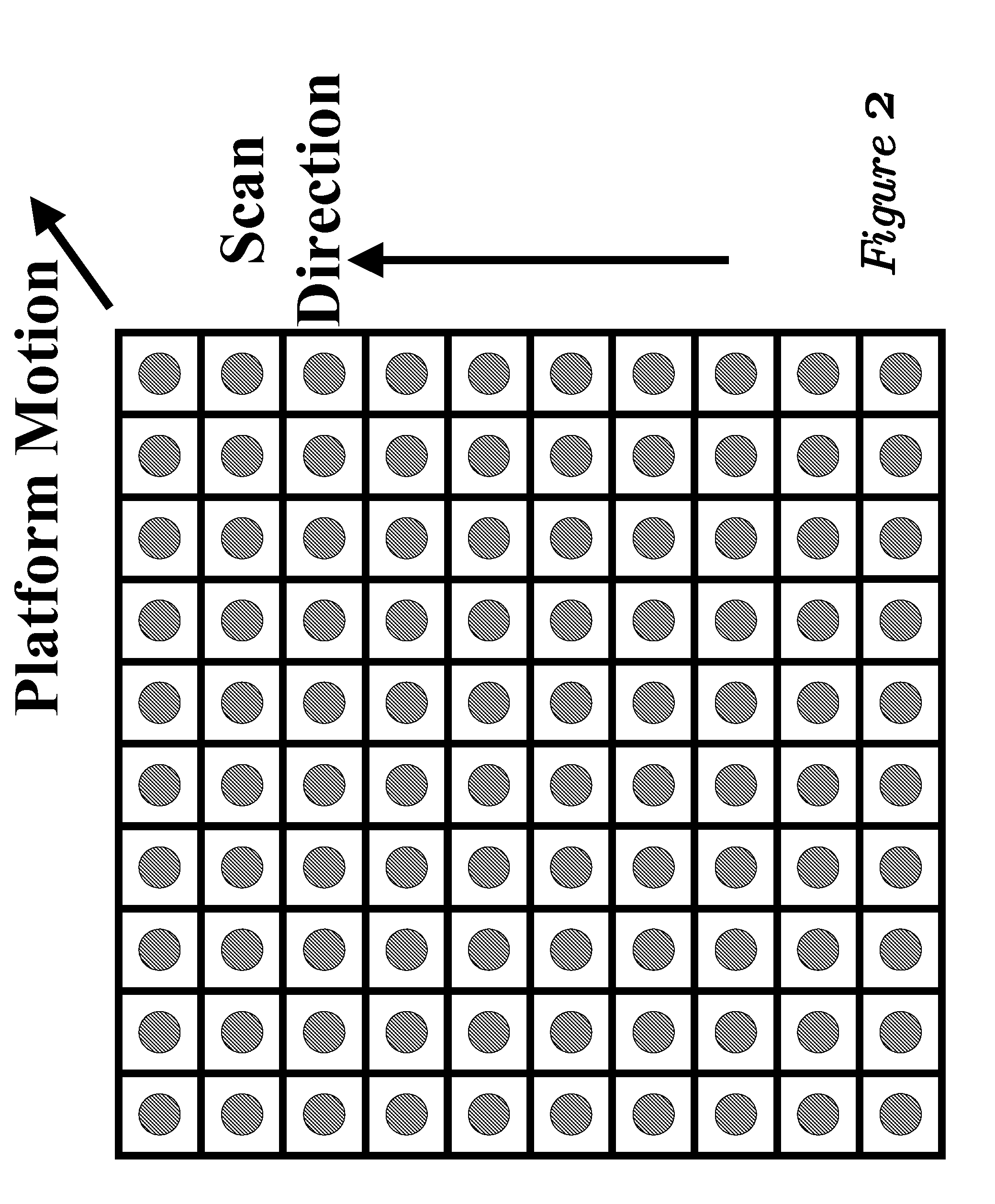

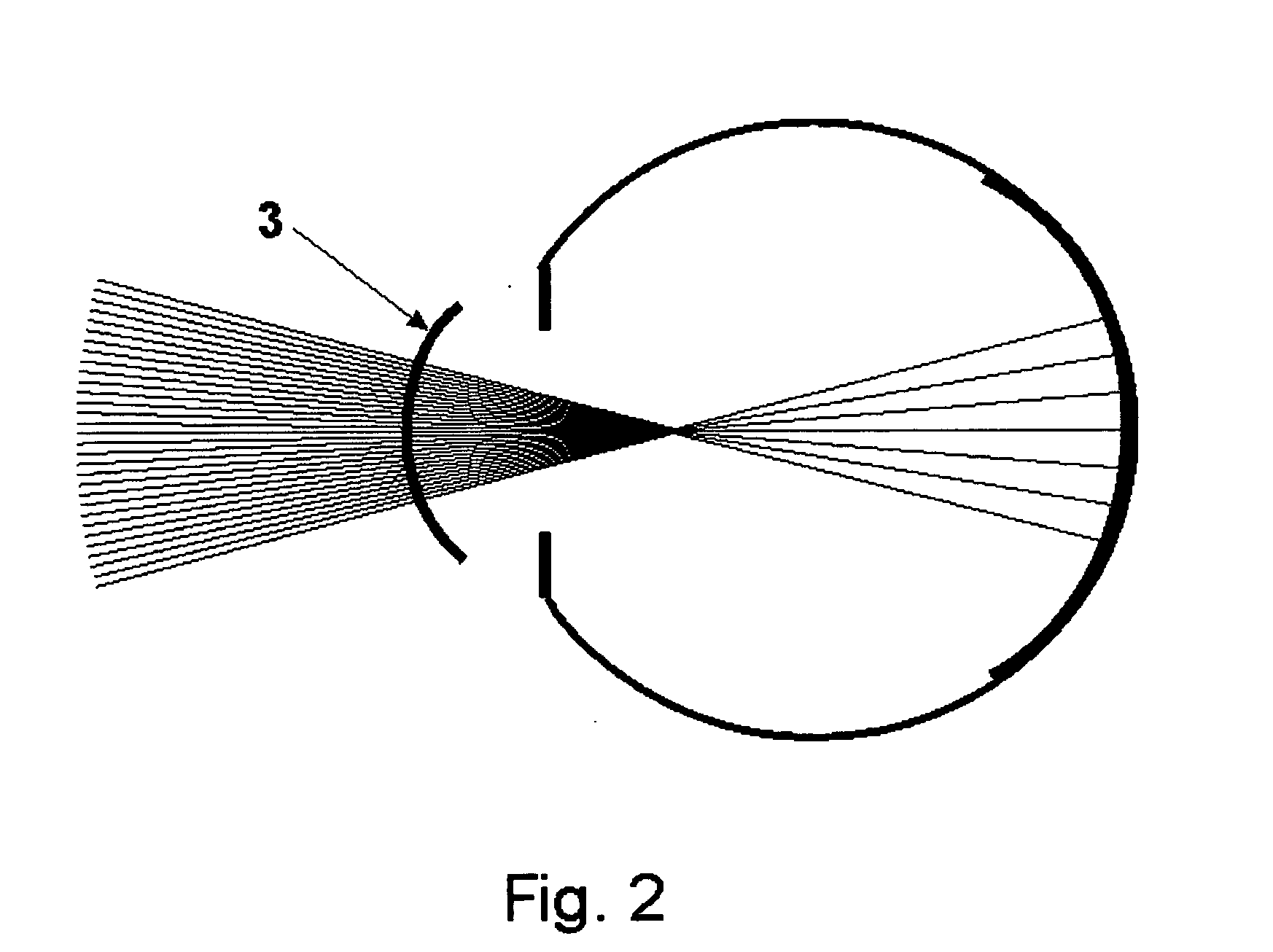

Scanner/optical system for three-dimensional lidar imaging and polarimetry

ActiveUS20070279615A1High repetition rateReduce solar background noiseOptical rangefindersColor television detailsOptical scannersLaser beams

An optical scanner system for contiguous three-dimensional topographic or volumetric imaging of a surface from an aircraft or spacecraft is disclosed. A servo controller synchronizes the rotation rates of a pair of wedge scanners with high precision to the multi-kilohertz laser fire rate producing an infinite variety of well-controlled scan patterns. This causes the beam pattern to be laid down in precisely the same way on each scan cycle, eliminating the need to record the orientations of the wedges accurately on every laser fire, thereby reducing ancillary data storage or transmission requirements by two to three orders of magnitude and greatly simplifying data preprocessing and analysis. The described system also uses a holographic element to split the laser beam into an array that is then scanned in an arbitrary pattern. This provides more uniform signal strength to the various imaging detector channels and reduces the level of optical crosstalk between channels, resulting in a higher fidelity three-dimensional image.

Owner:INTERGRAPH

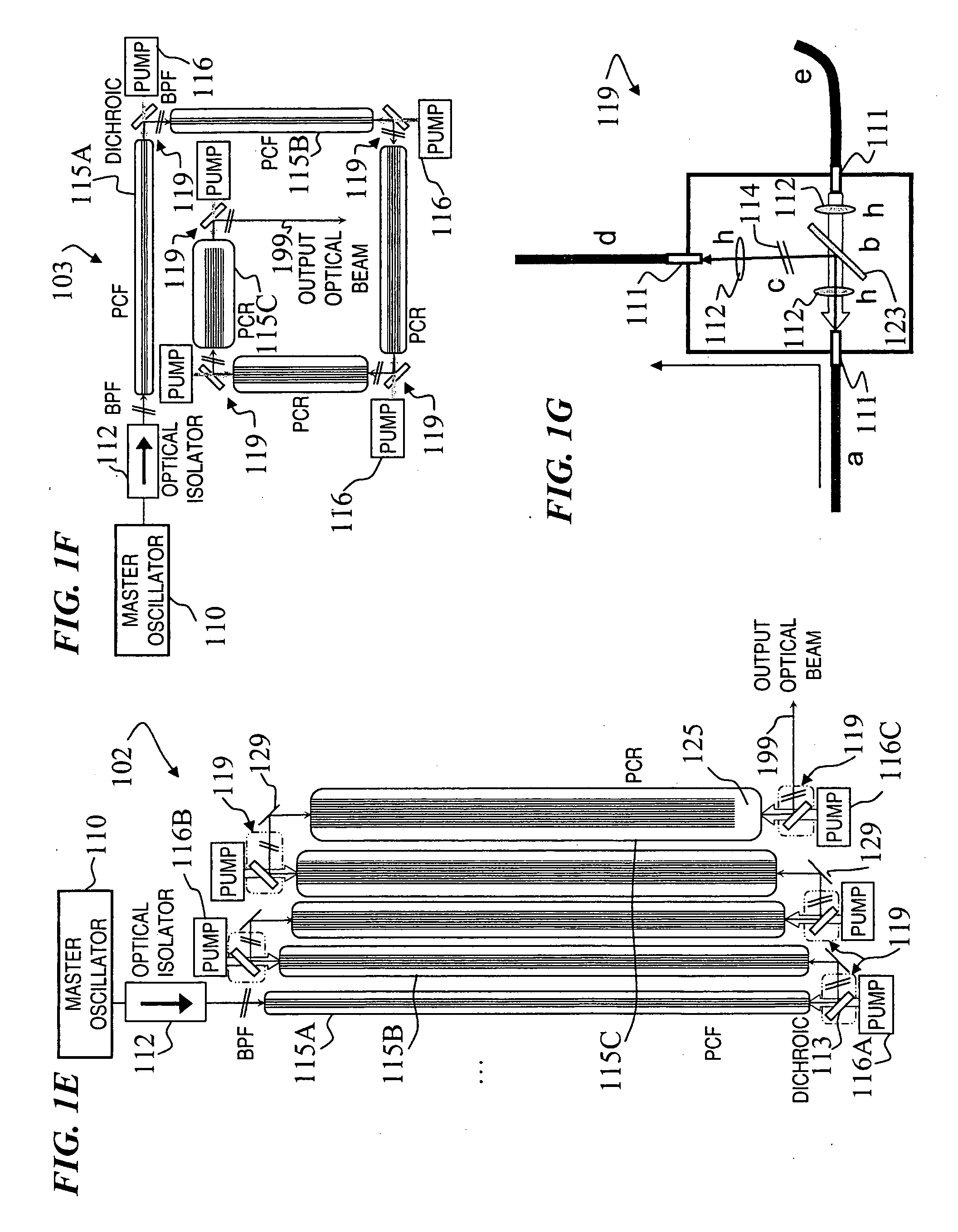

Multi-segment photonic-crystal-rod waveguides for amplification of high-power pulsed optical radiation and associated method

InactiveUS20070104431A1High peak powerHigh pulse energyLaser detailsCladded optical fibreOptical radiationPromiscuous behaviour

A method and apparatus use a photonic-crystal fiber having a very large core while maintaining a single transverse mode. In some fiber lasers and amplifiers having large cores problems exist related to energy being generated at multiple-modes (i.e., polygamy), and of mode hopping (i.e., promiscuity) due to limited control of energy levels and fluctuations. The problems of multiple-modes and mode hopping result from the use of large-diameter waveguides, and are addressed by the invention. This is especially true in lasers using large amounts of energy (i.e., lasers in the one-megawatt or more range). By using multiple small waveguides in parallel, large amounts of energy can be passed through a laser, but with better control such that the aforementioned problems can be reduced. An additional advantage is that the polarization of the light can be maintained better than by using a single fiber core.

Owner:LOCKHEED MARTIN CORP

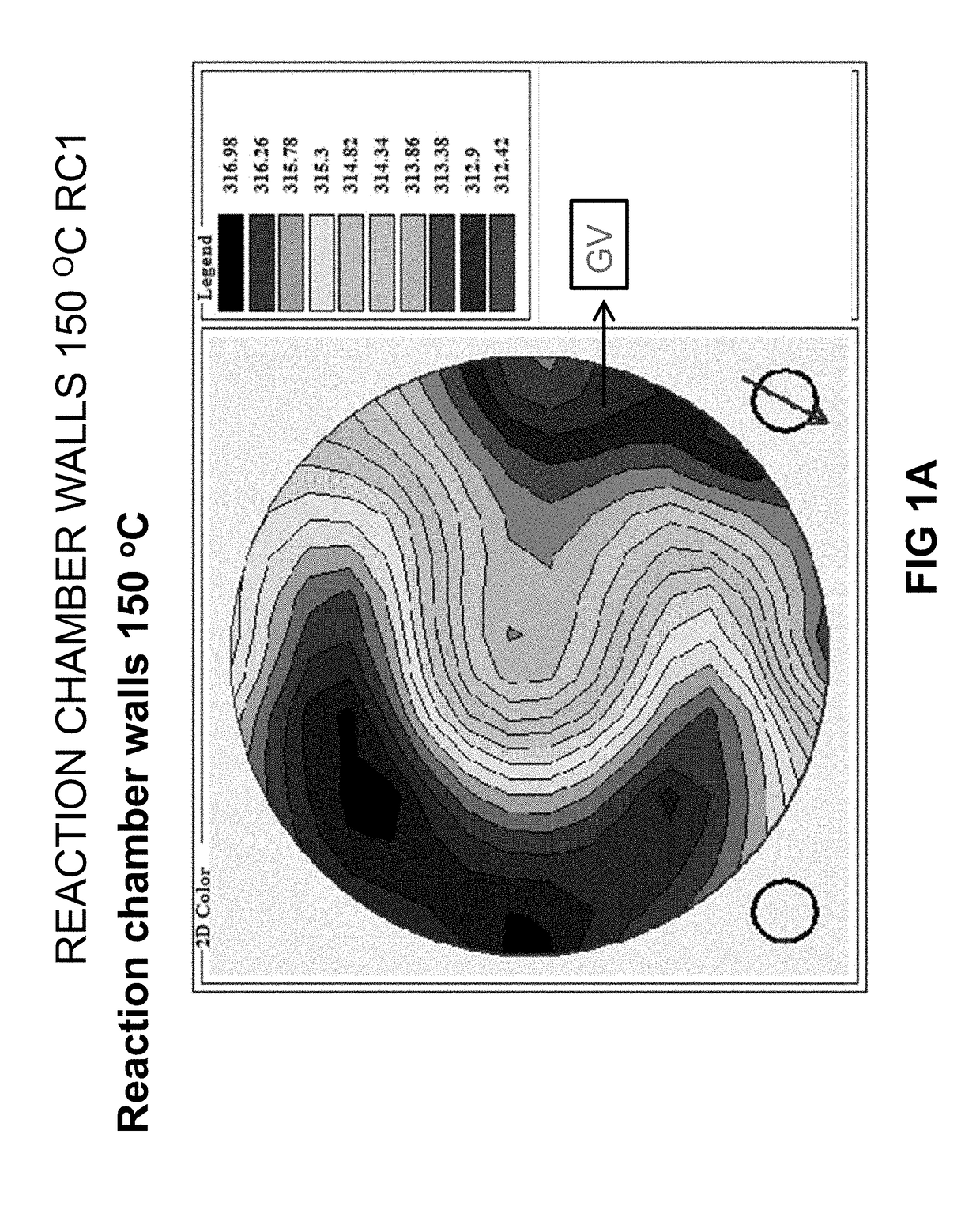

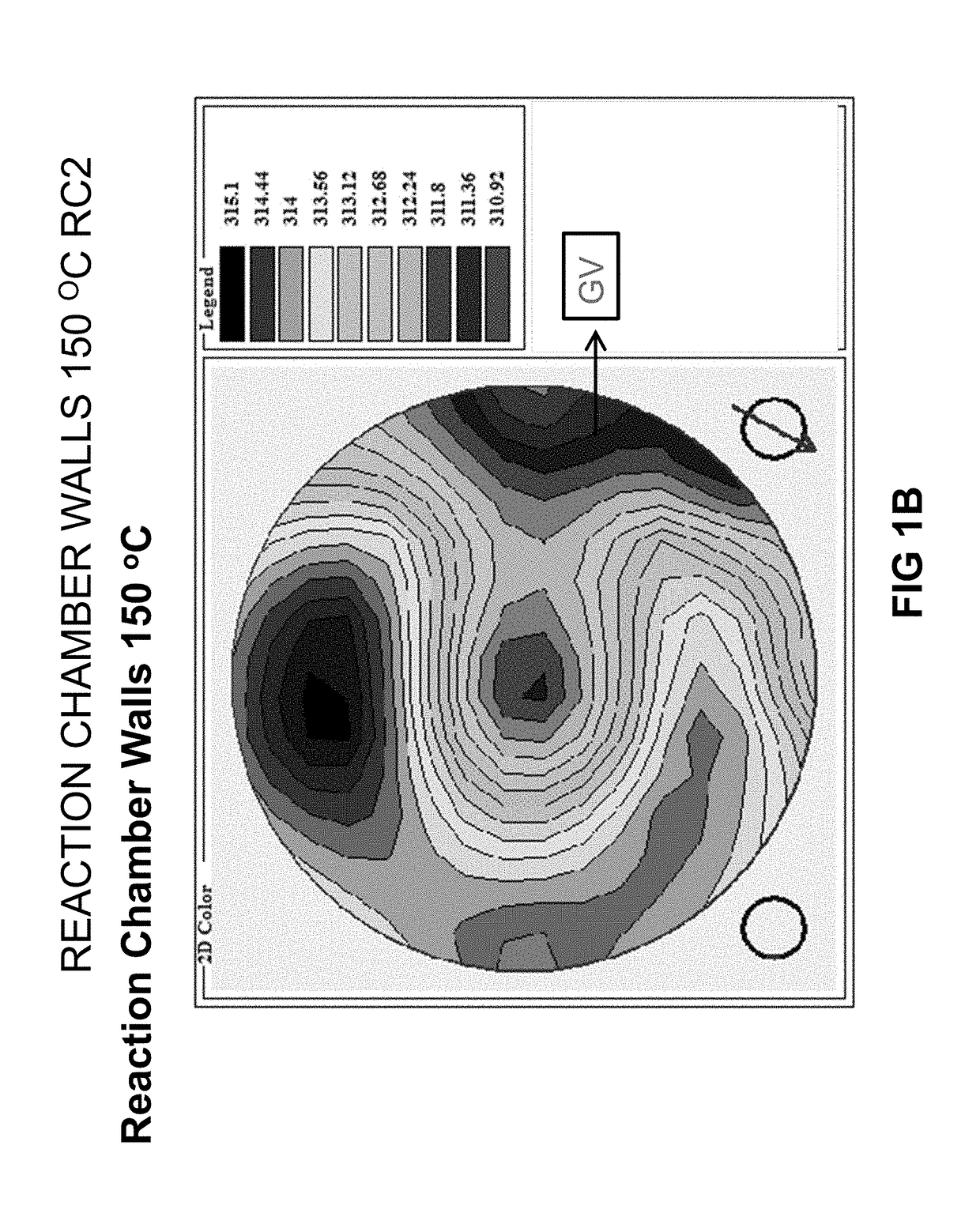

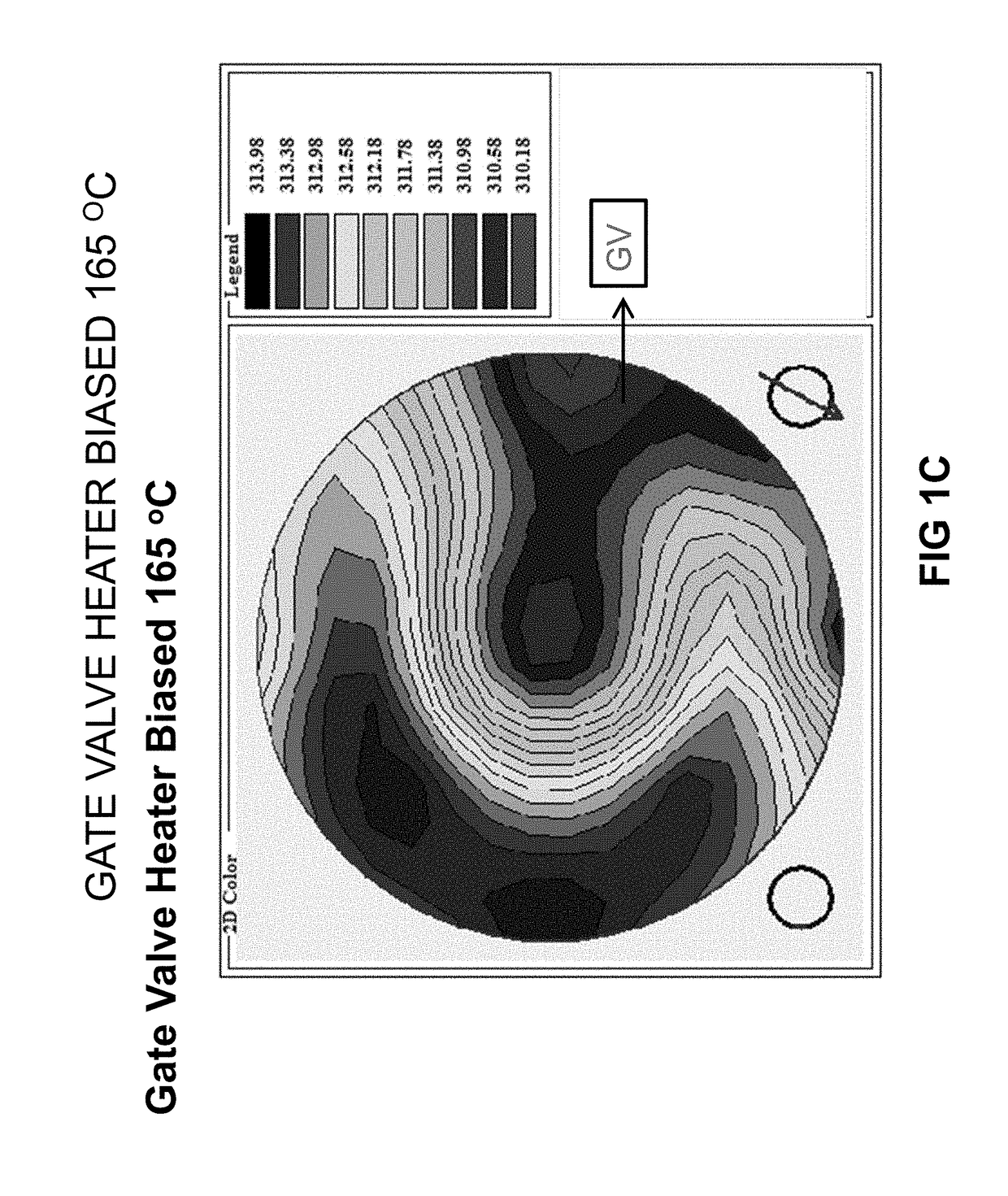

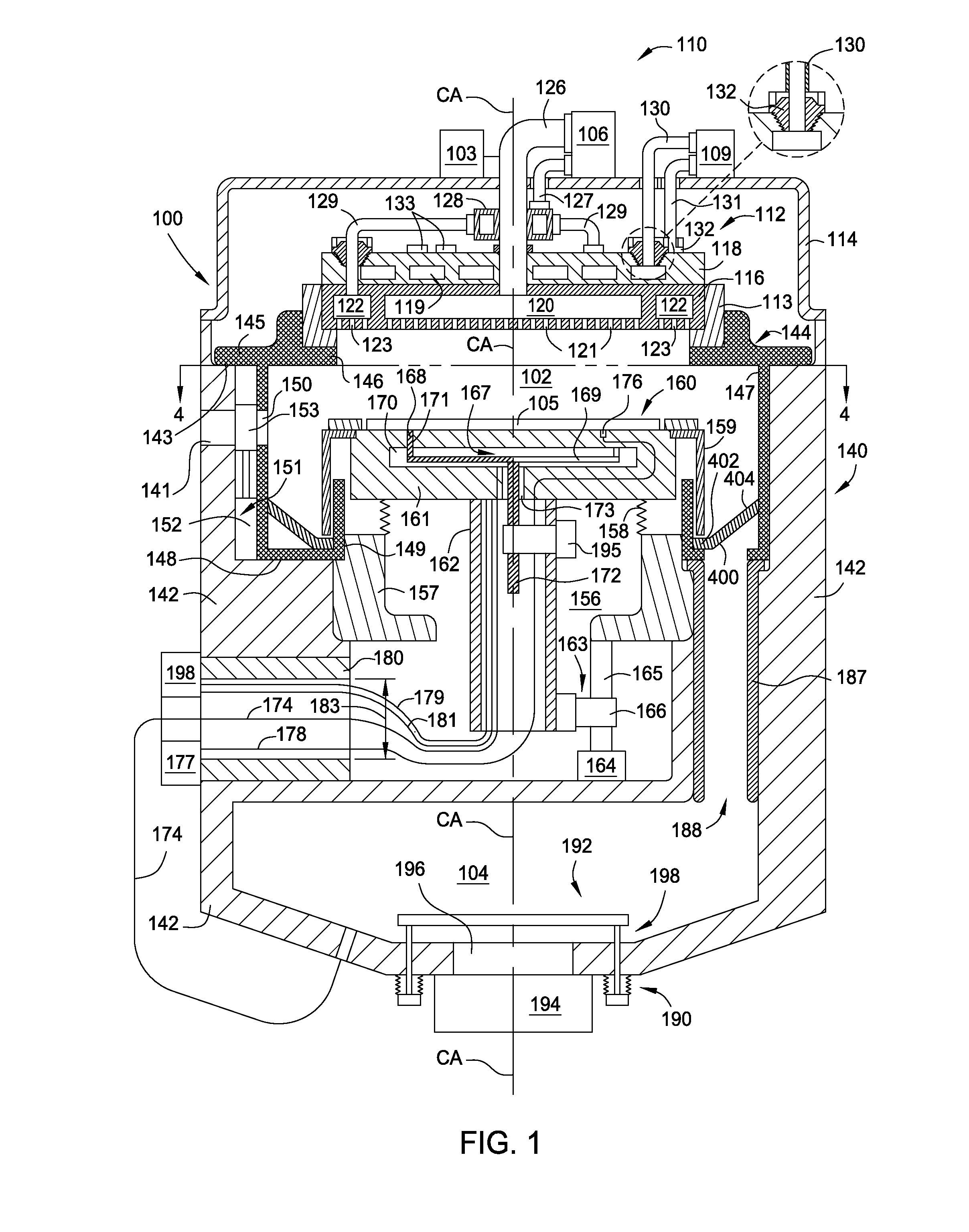

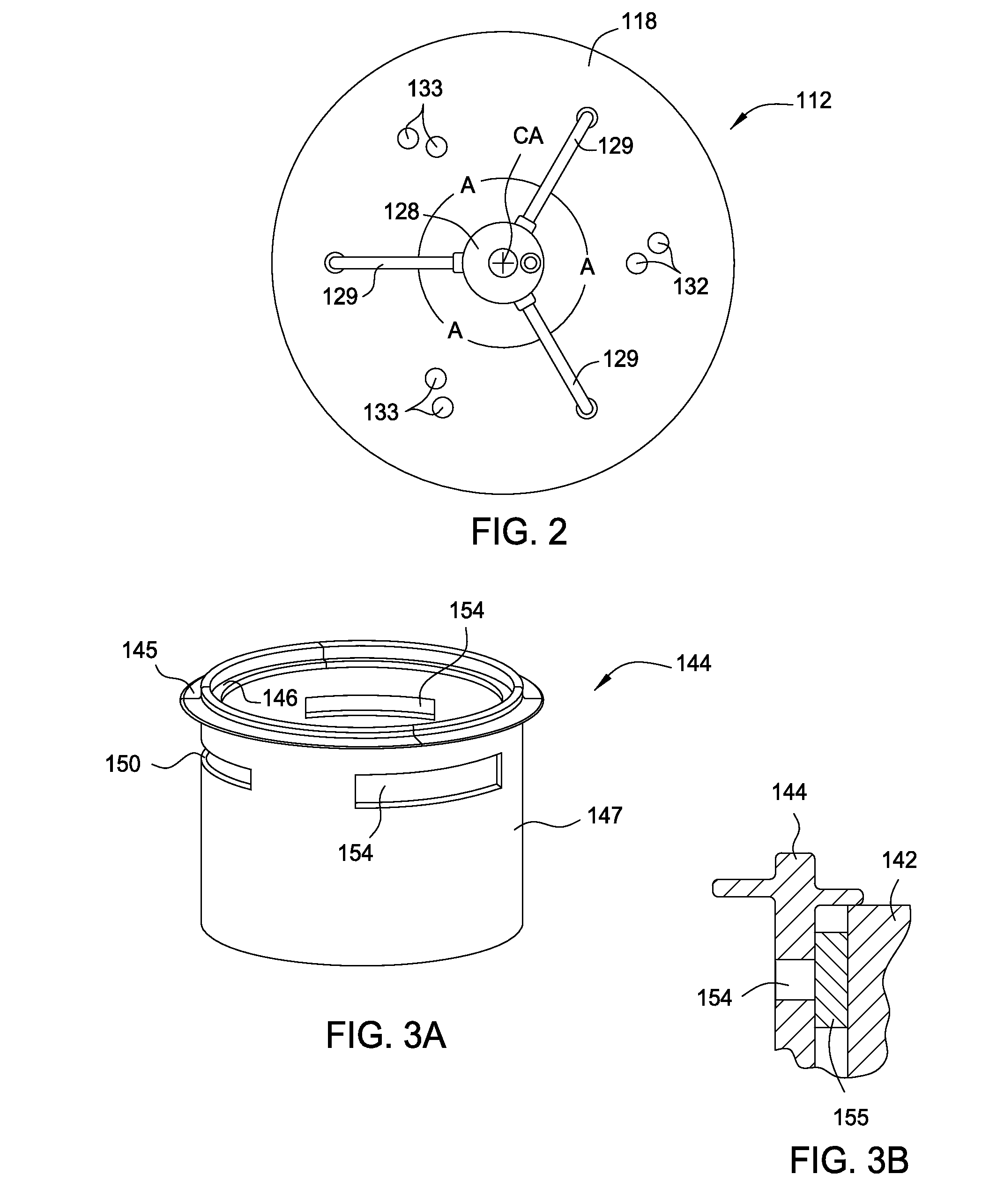

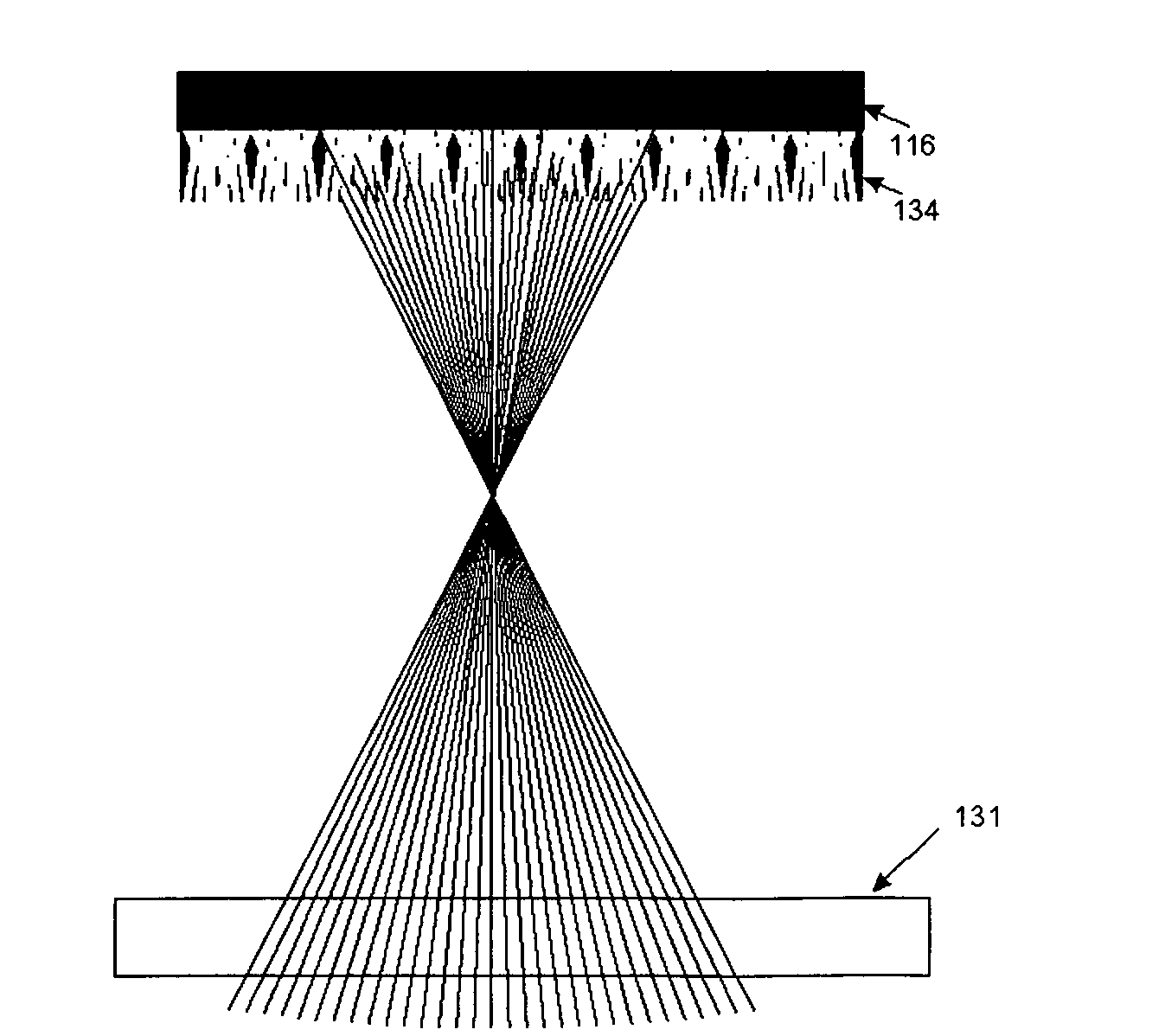

Symmetric plasma process chamber

ActiveUS20130087286A1Electric discharge tubesSemiconductor/solid-state device manufacturingProcess regionEngineering

Embodiments of the present invention provide a plasma chamber design that allows extremely symmetrical electrical, thermal, and gas flow conductance through the chamber. By providing such symmetry, plasma formed within the chamber naturally has improved uniformity across the surface of a substrate disposed in a processing region of the chamber. Further, other chamber additions, such as providing the ability to manipulate the gap between upper and lower electrodes as well as between a gas inlet and a substrate being processed, allows better control of plasma processing and uniformity as compared to conventional systems.

Owner:APPLIED MATERIALS INC

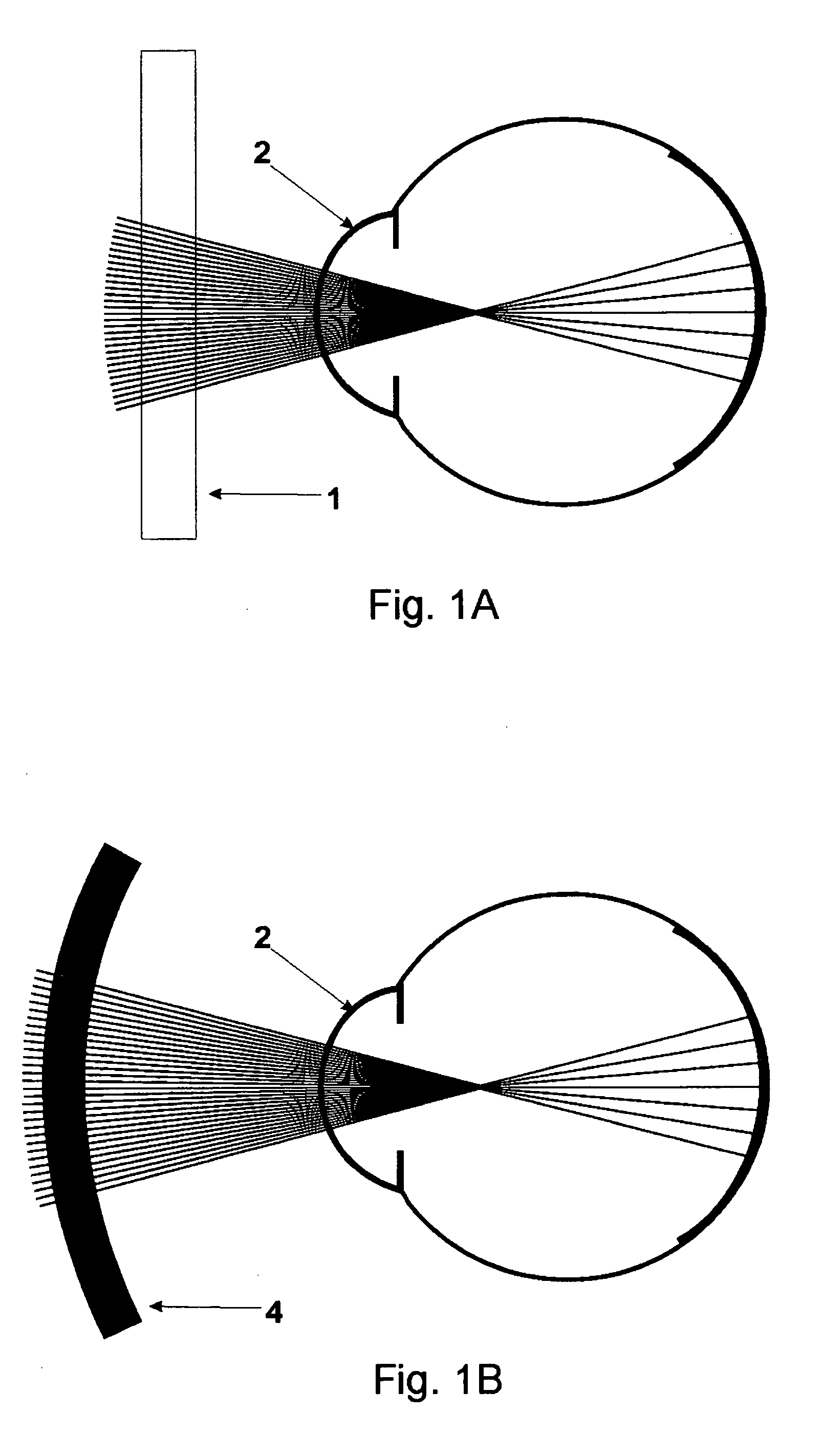

Specially coherent optics

ActiveUS20060244907A1Improve accuracyLow costCharacter and pattern recognitionOptical partsComputer graphics (images)Depth of field

A refinement in optics providing images with improved sharpness, better control of depth of field, vision-improvement applications, and 3-D capture and display.

Owner:SIMMONS JOHN CASTLE

System and method for safe well control operations

ActiveUS20110214882A1Facilitate well control operationFacilitates hands-on trainingDrilling rodsFluid removalLine tubingWell drilling

A system and method for safely controlling a well being drilled or that has been drilled into a subterranean formation in which a conventional blow-out preventer operates to close the well bore to atmosphere upon the detection of a fluid influx event. Fluid pressures as well as fluid flow rates into and out of the well bore are measured and monitored to more accurately and confidently determine the fracture pressure and pore pressure of the formation and perform well control operations in response to a fluid influx event. During a suspected fluid influx event, one or more of the fluid flow and pressure measurements are used to confirm the fluid influx event and to safely regain well control by circulating the fluid influx out of the well through a choke line while maintaining the pressure inside the well between specified, selected limits, such as between the fracture and pore pressures.

Owner:SAFEKICK AMERICAS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com