Patents

Literature

354 results about "Fracture pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

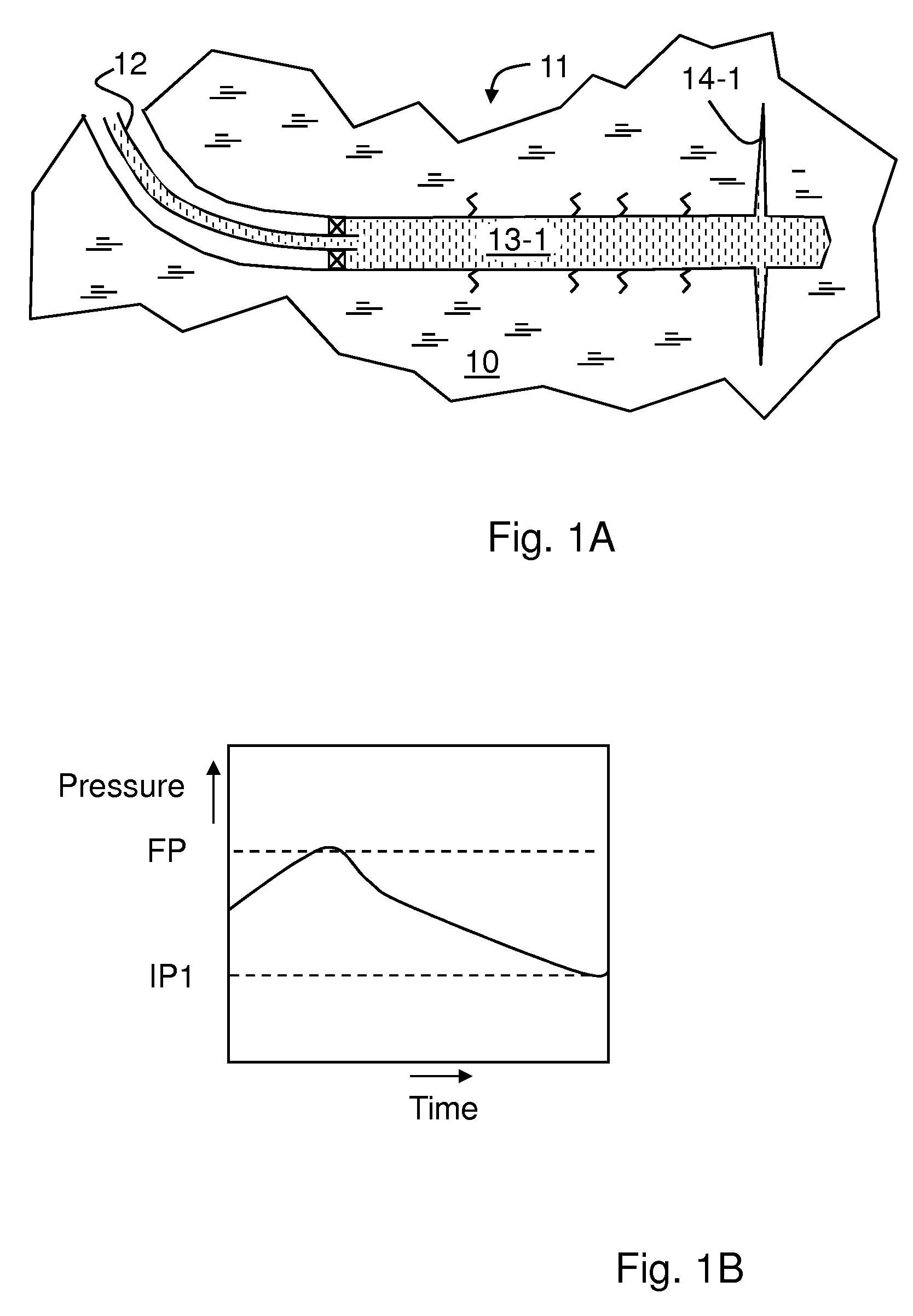

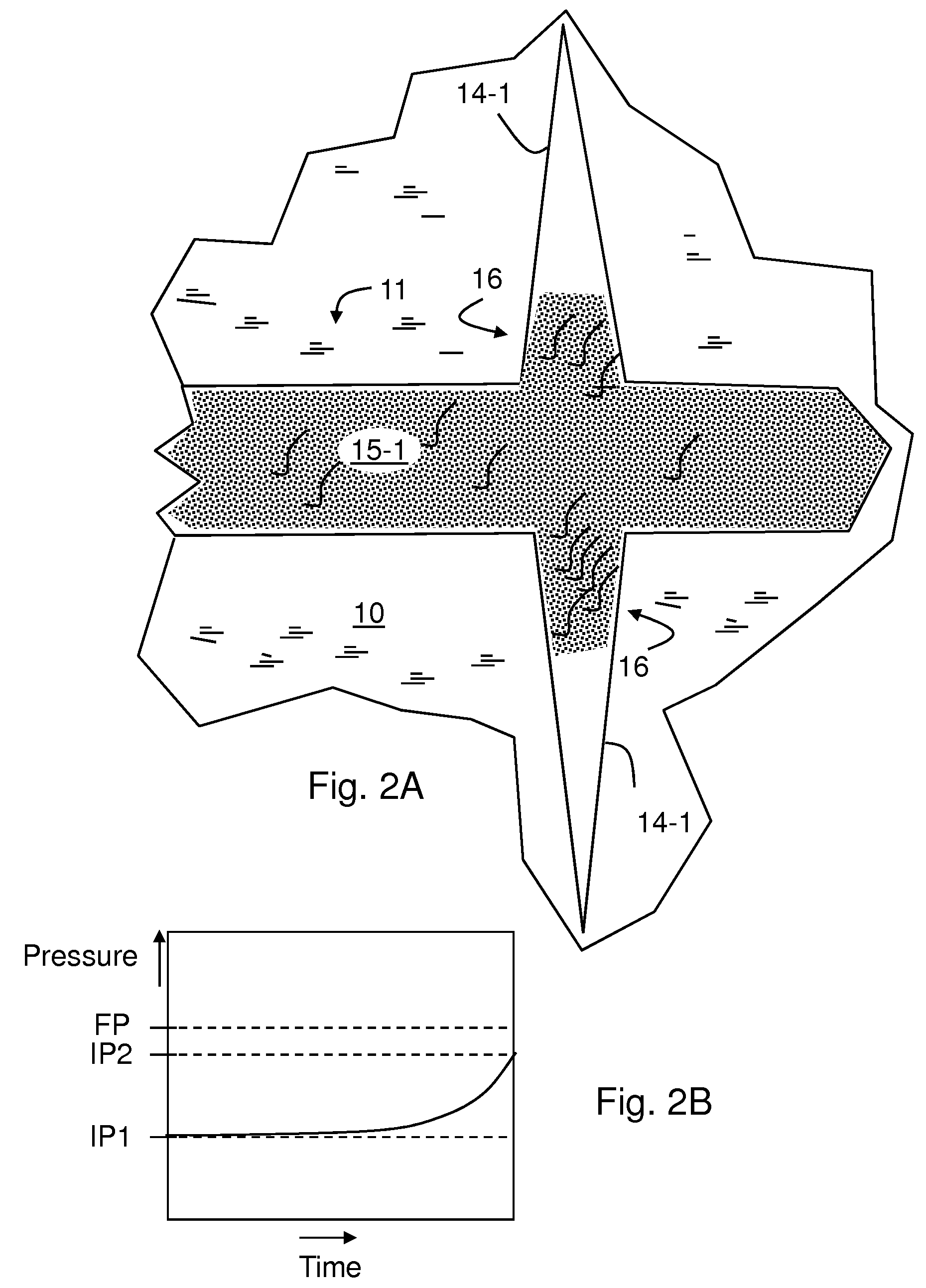

Fracture pressure is the pressure needed to create a fracture in a rock while drilling in open hole. Closure stress is the pressure needed to fracture a rock through perforations in cased hole. ... Closure stress is the pressure at which the fracture closes after the fracturing pressure is relaxed. It is usually between 80 and 90% of breakdown pressure.

Cleanup additive

InactiveUS6242390B1Low viscosityEasy to disassembleOther chemical processesFluid removalSolubilityHydraulic fracturing

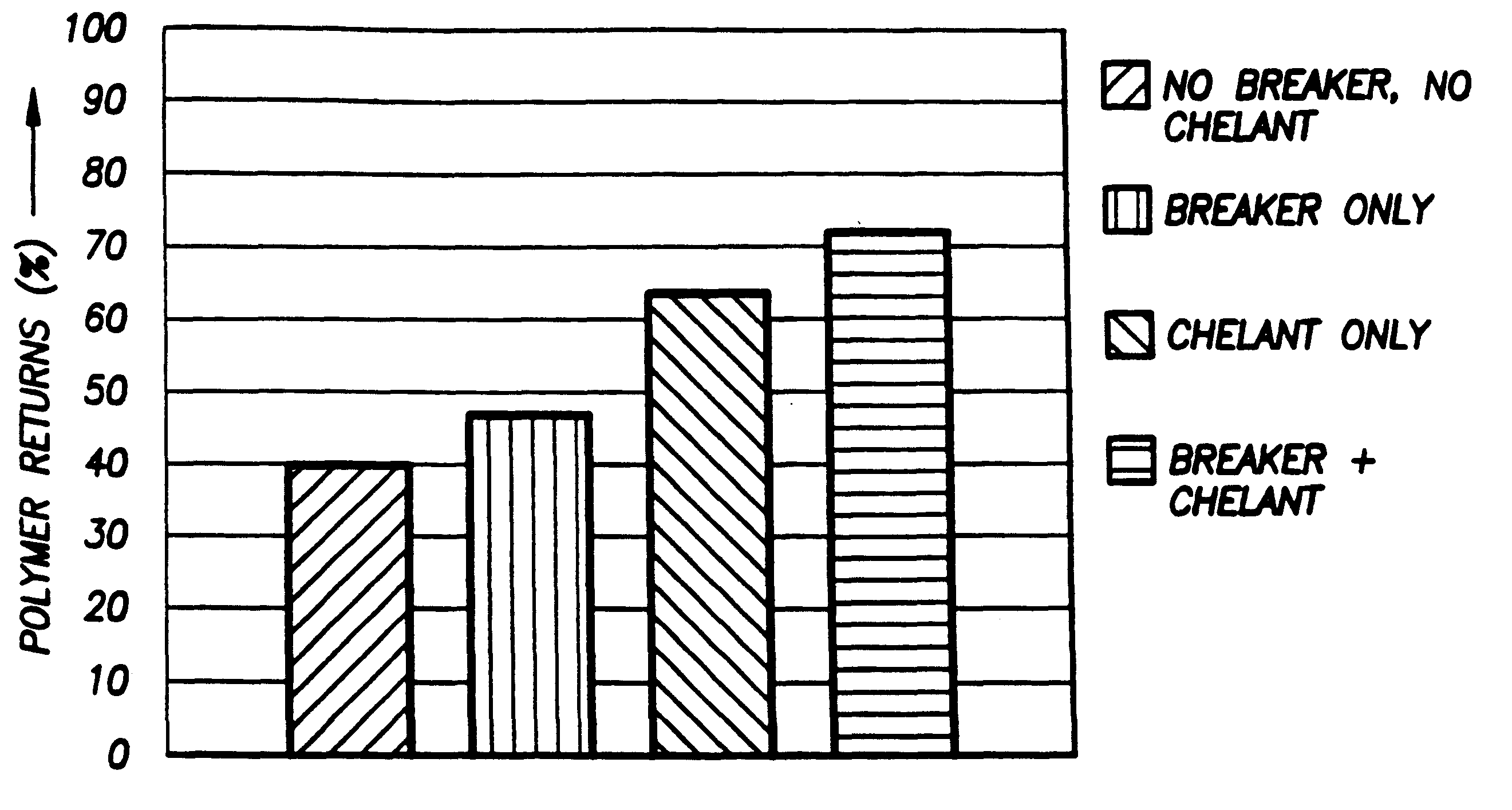

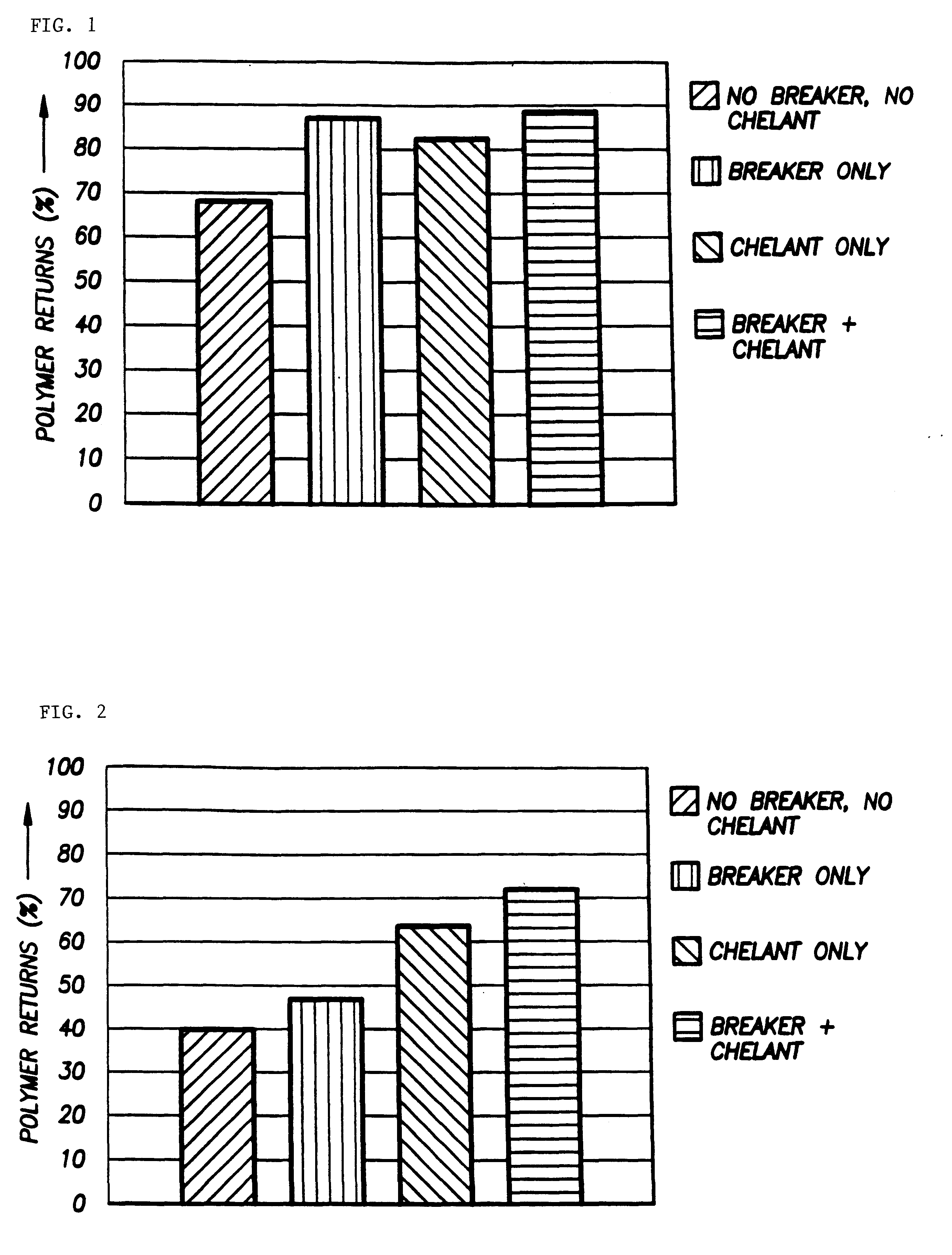

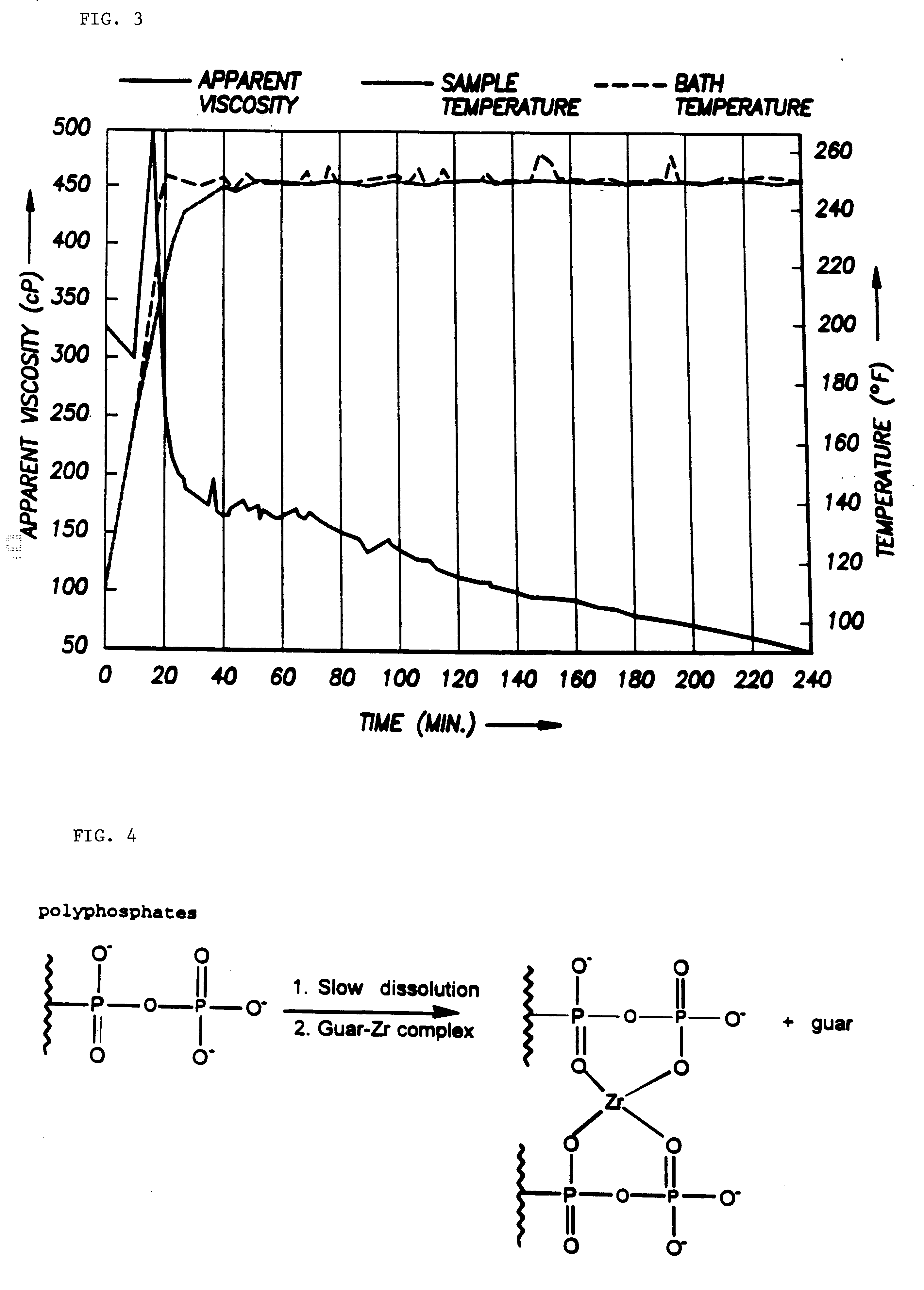

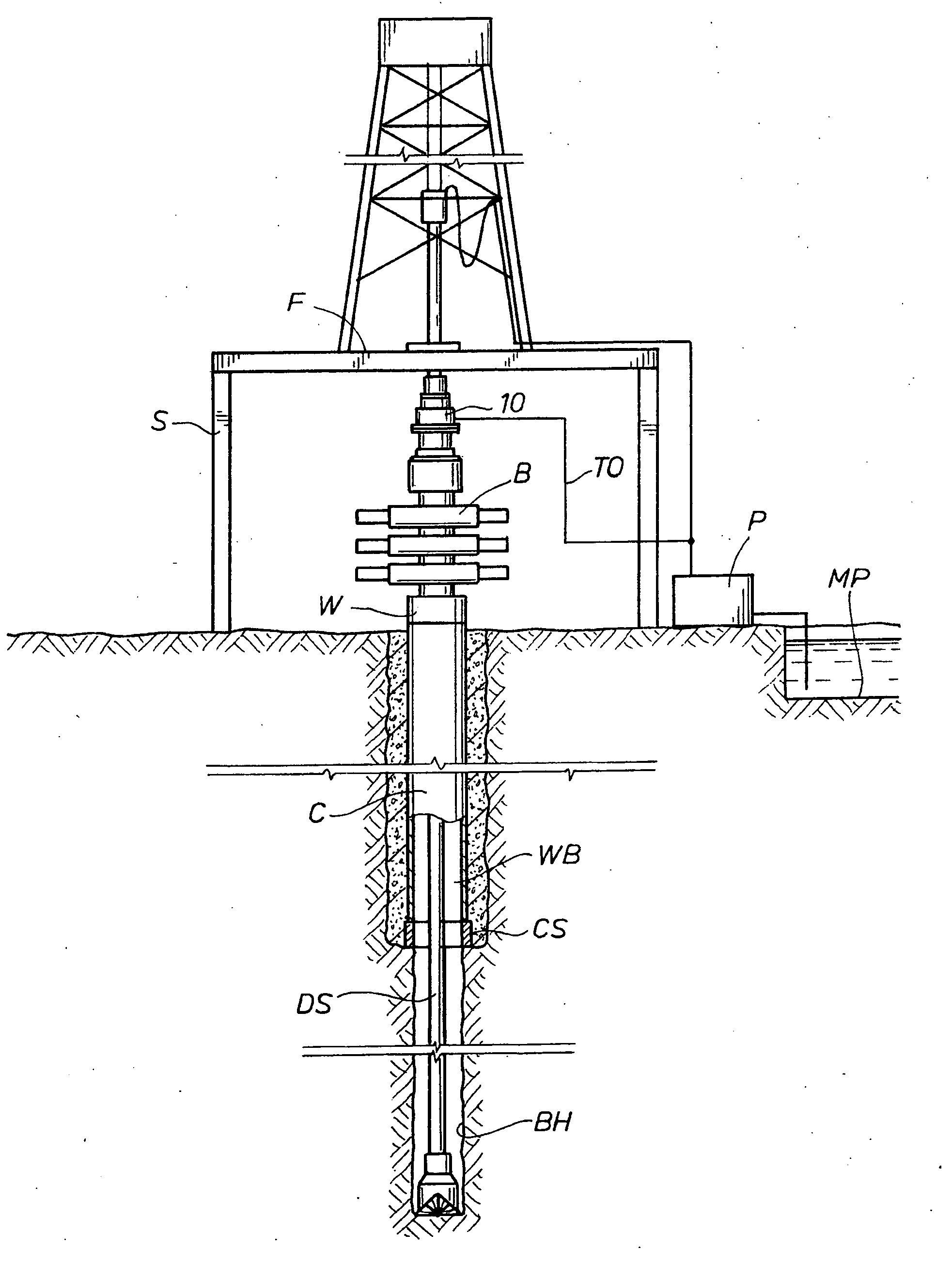

According to the present invention, a composition and method for hydraulically fracturing a subterranean formation is provided. The composition comprises an aqueous mixture of a hydrated polysaccharide, preferably a galactomannan gum, the hydrated polysaccharide having a plurality of bonding sites; a crosslinking agent for crosslinking the hydrated polysaccharide at the bonding sites at the conditions of the subterranean formation with a polyvalent metal ion to form a polyvalent metal crosslink, thereby increasing the viscosity of the hydrated polysaccharide; and a controlled solubility compound for releasing a chelating agent for controllably breaking the polyvalent metal crosslink and bonding with the polyvalent metal ion released by breaking the crosslink, thereby decreasing the viscosity of the hydrated polysaccharide. The method comprises the steps of injecting the above-described composition into the subterranean formation at fracturing pressures; allowing the controlled solubility compound to begin breaking the polyvalent metal crosslink, thereby reducing the viscosity of the hydrated polysaccharide and yielding a lower viscosity fluid; and removing the lower viscosity fluid from the subterranean formation.

Owner:SCHLUMBERGER TECH CORP

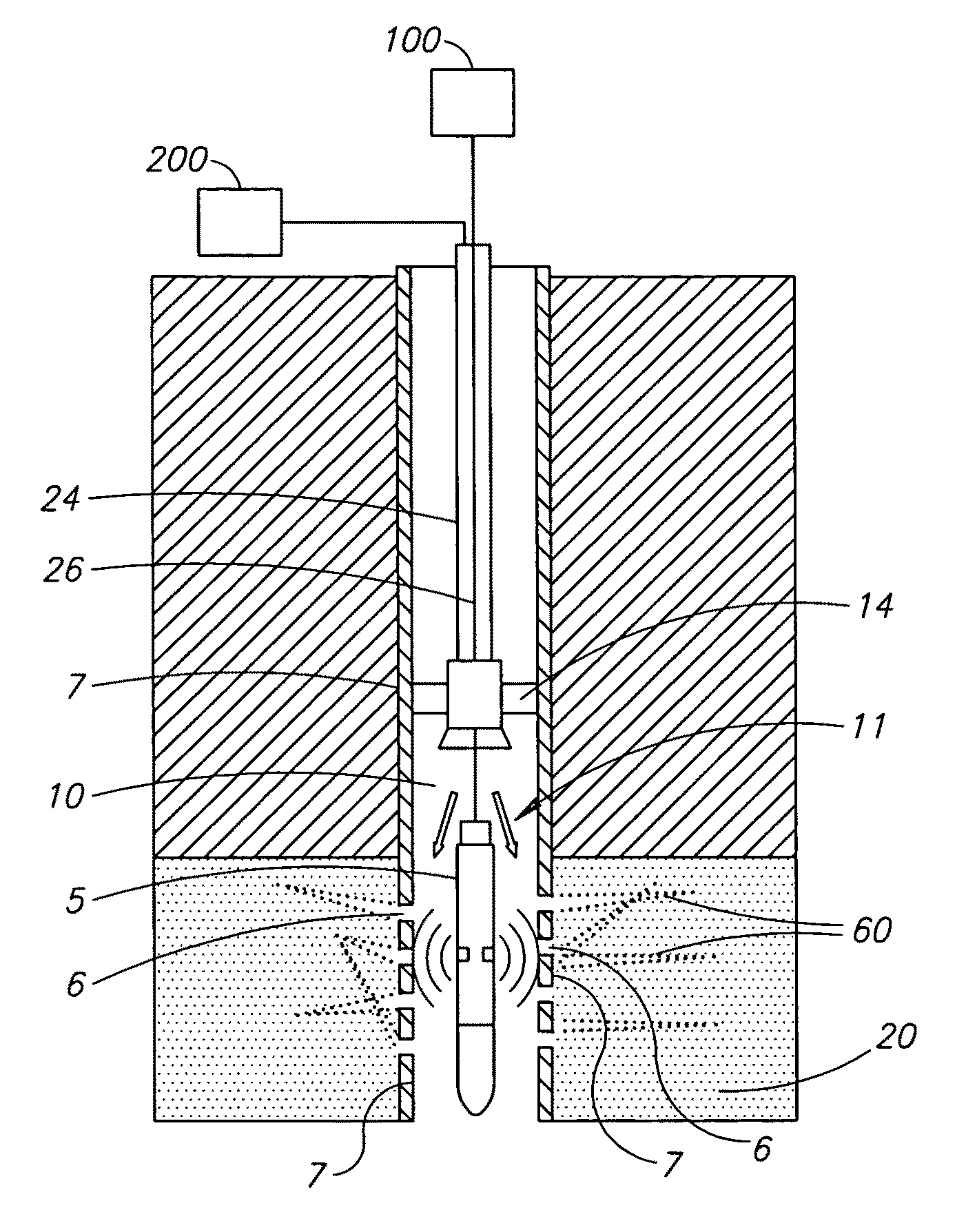

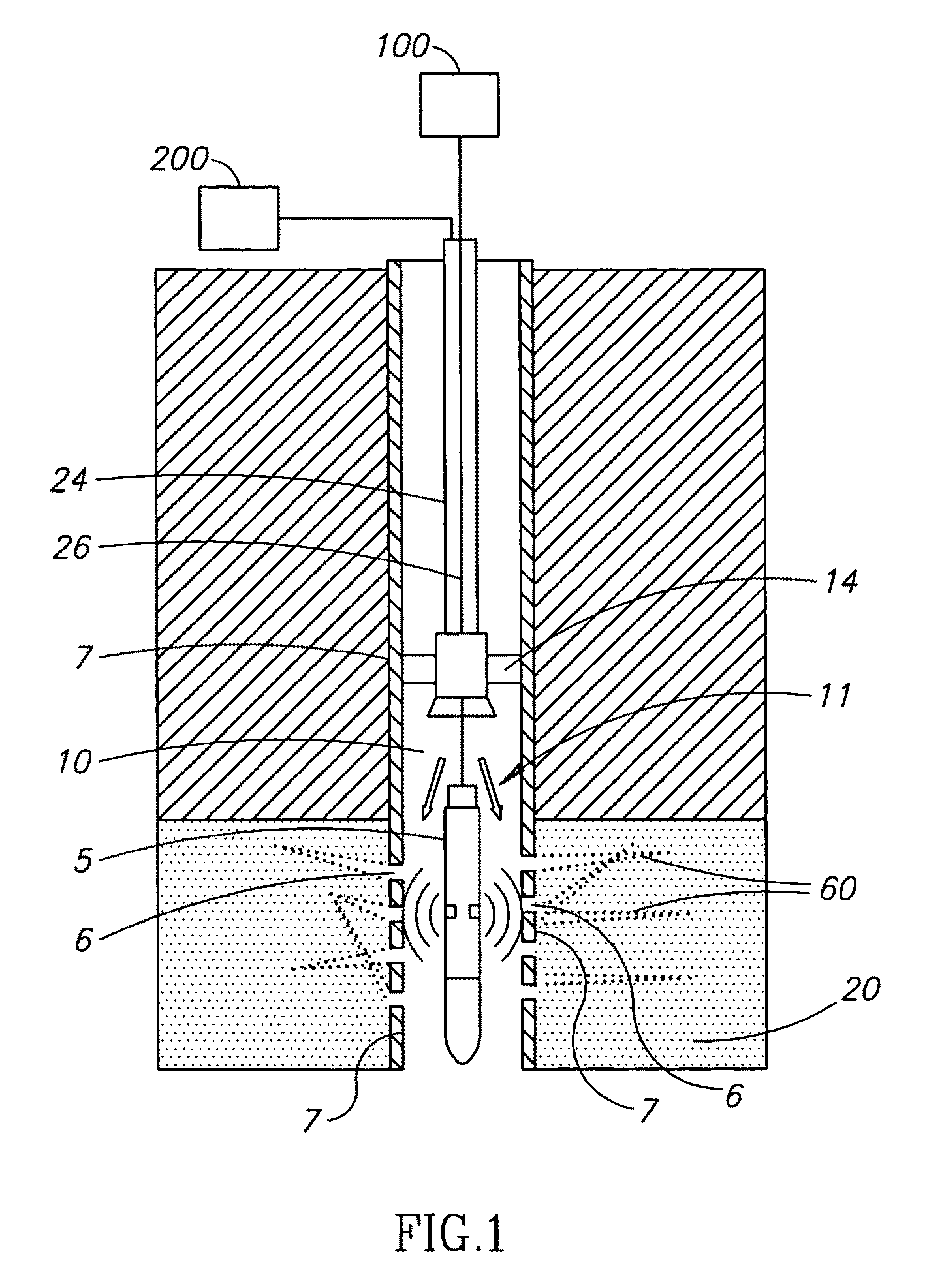

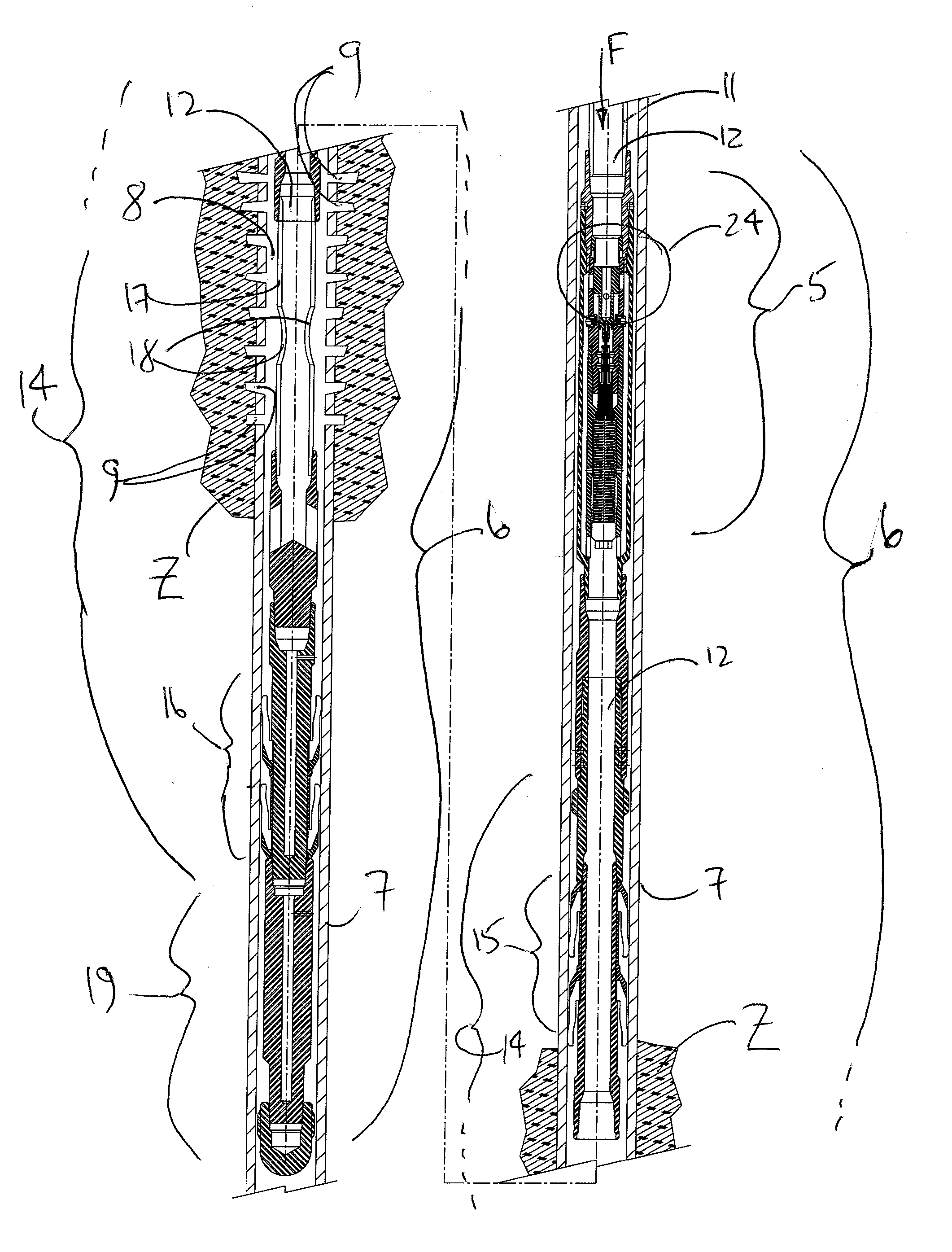

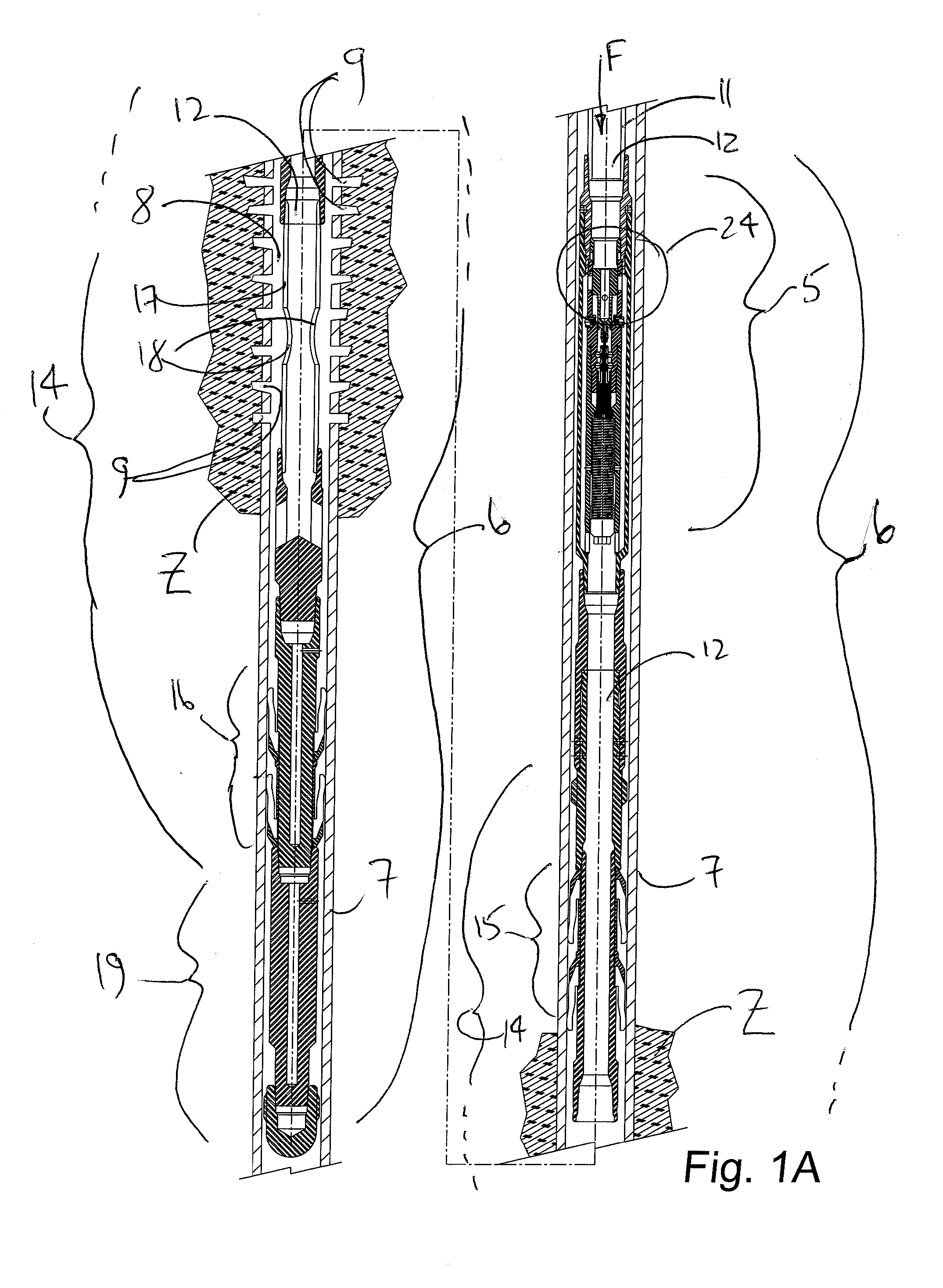

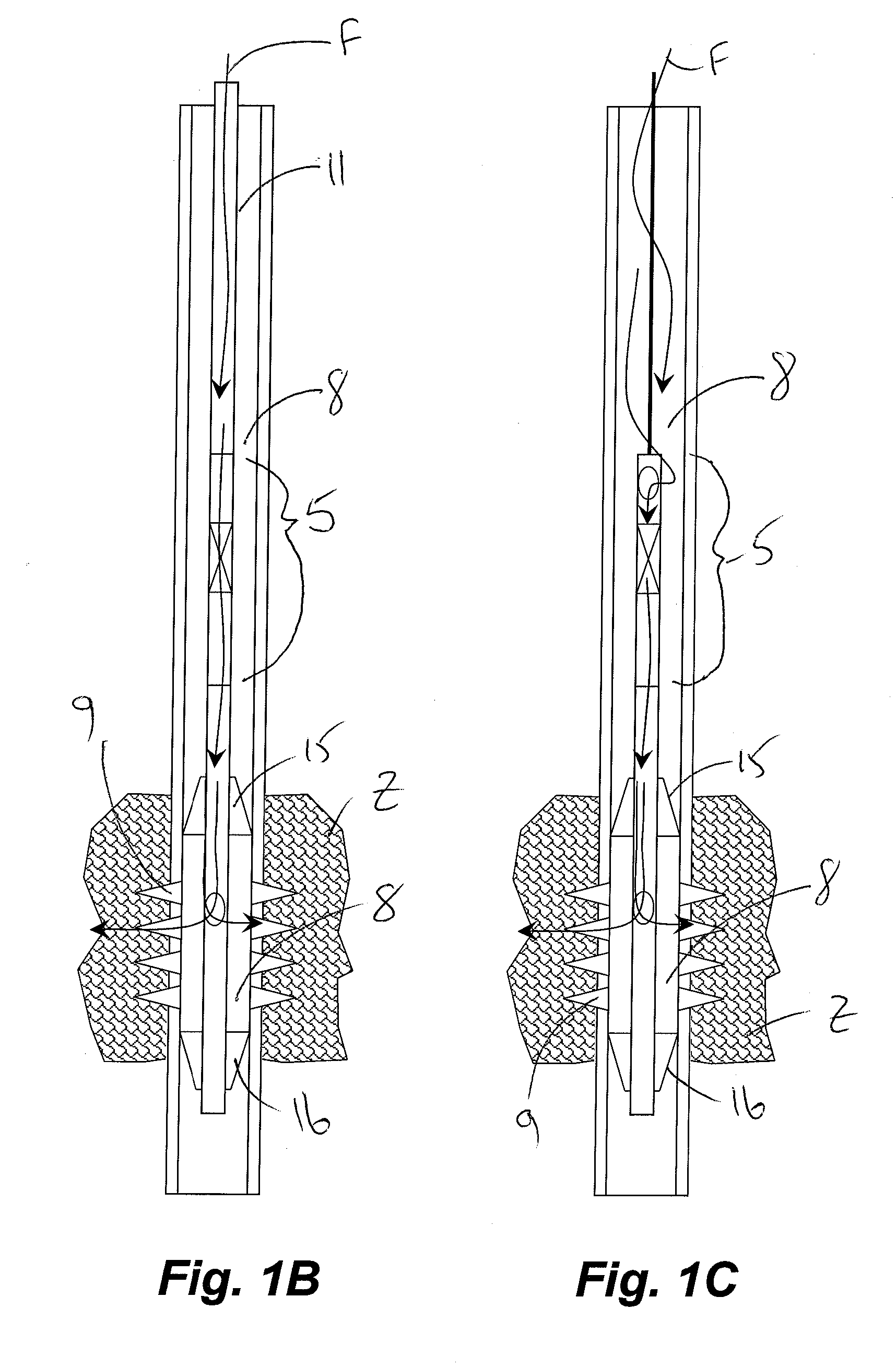

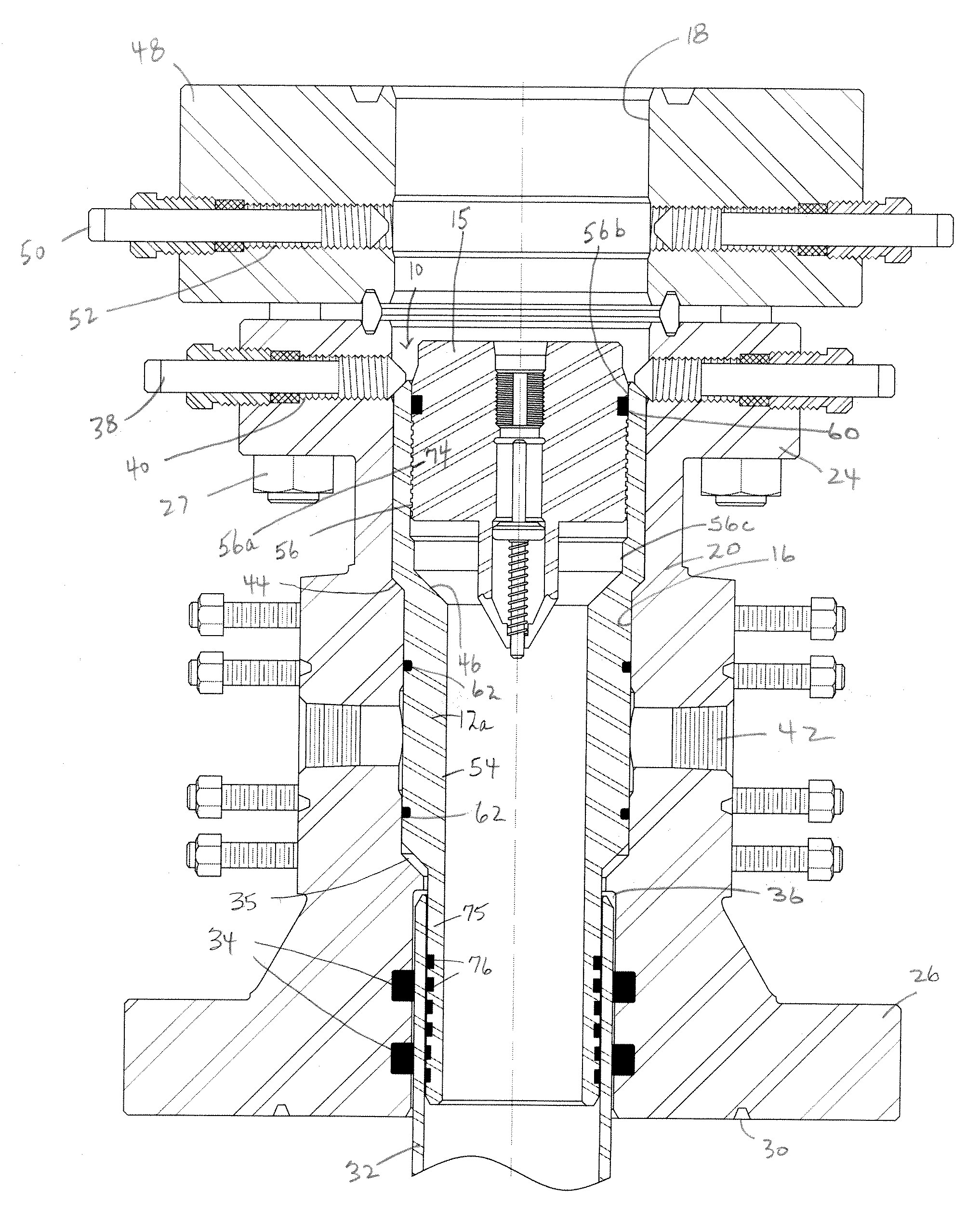

Drilling with a high pressure rotating control device

ActiveUS20110024195A1Operational securityHigh safety factorSurveyDrilling rodsWell drillingControl system

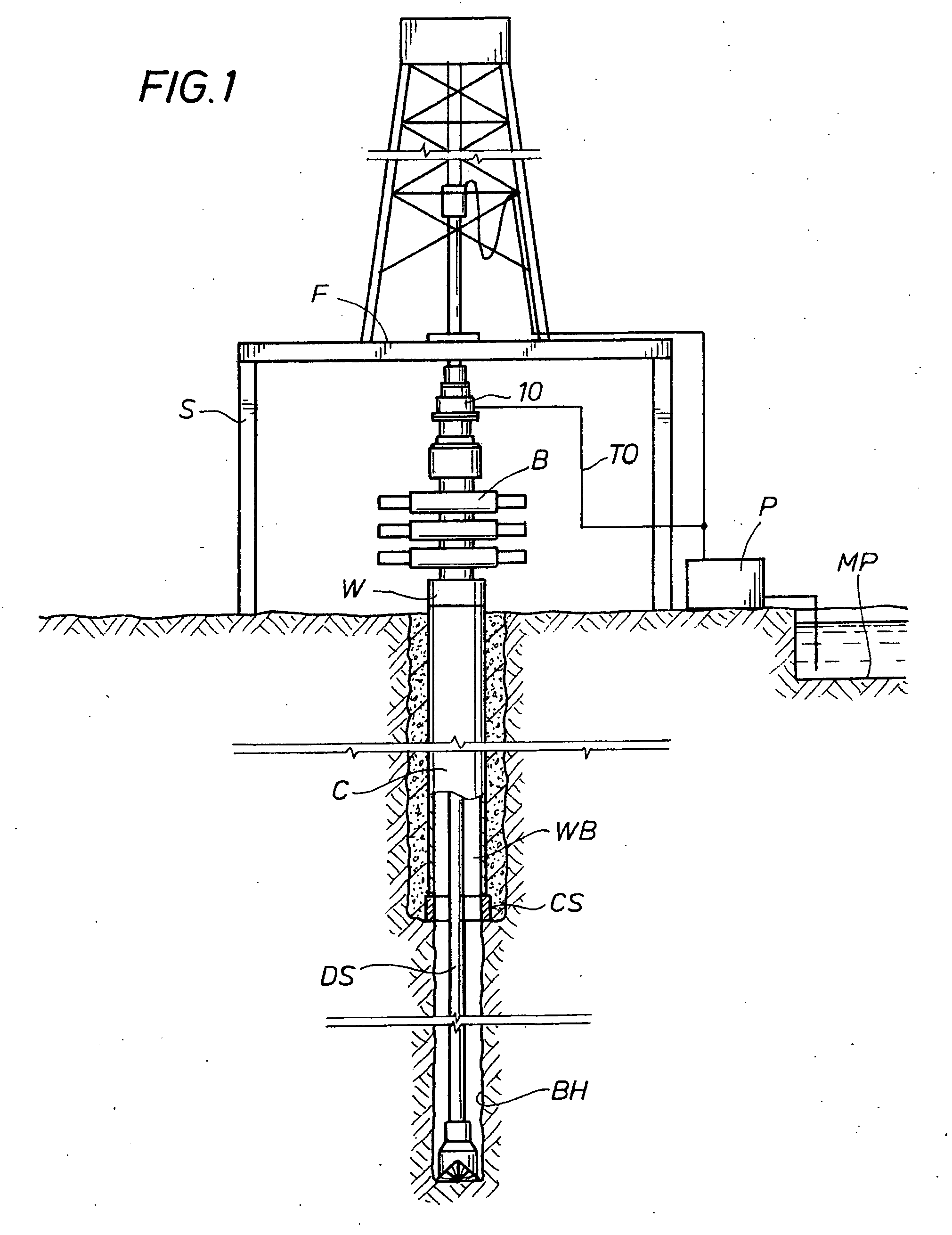

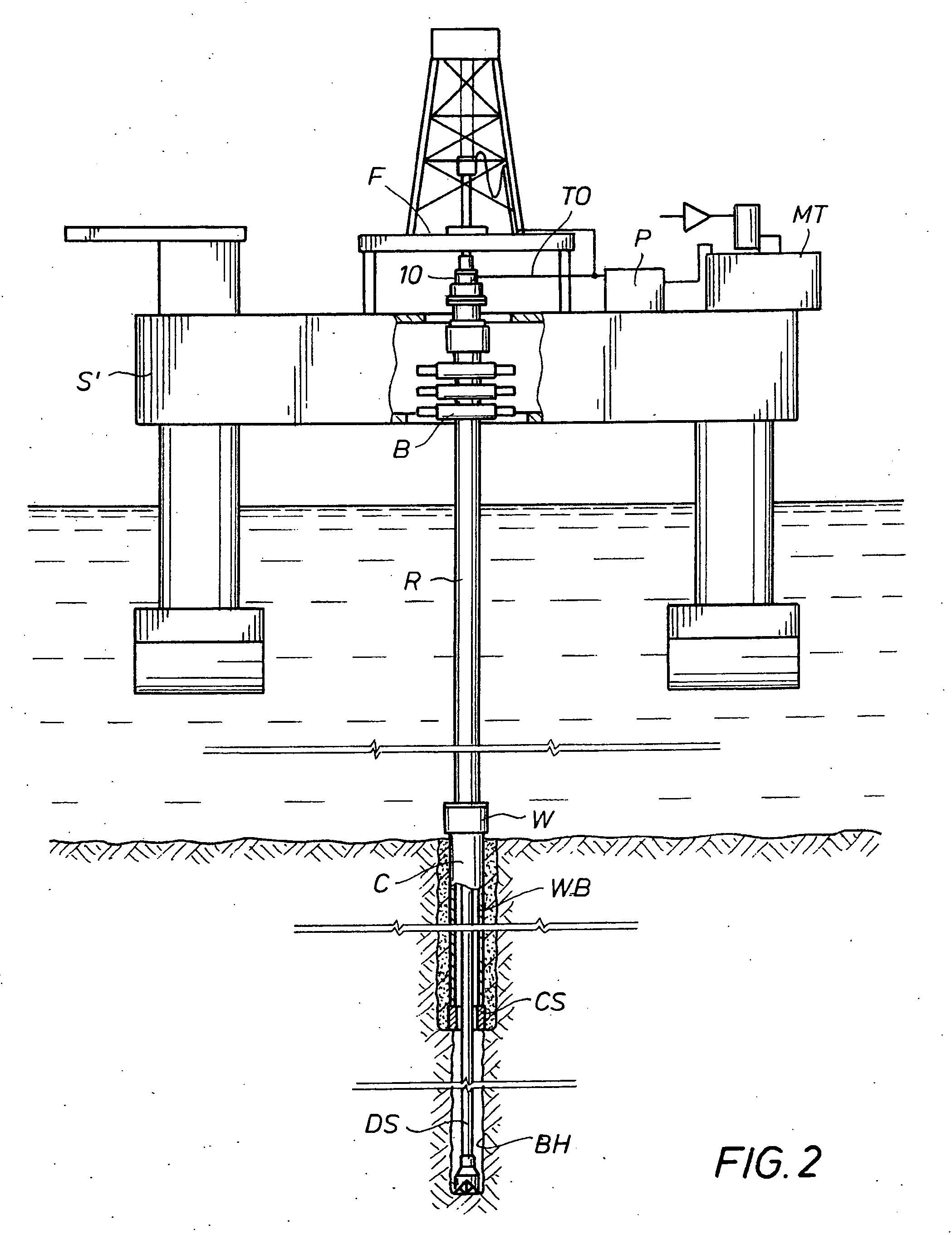

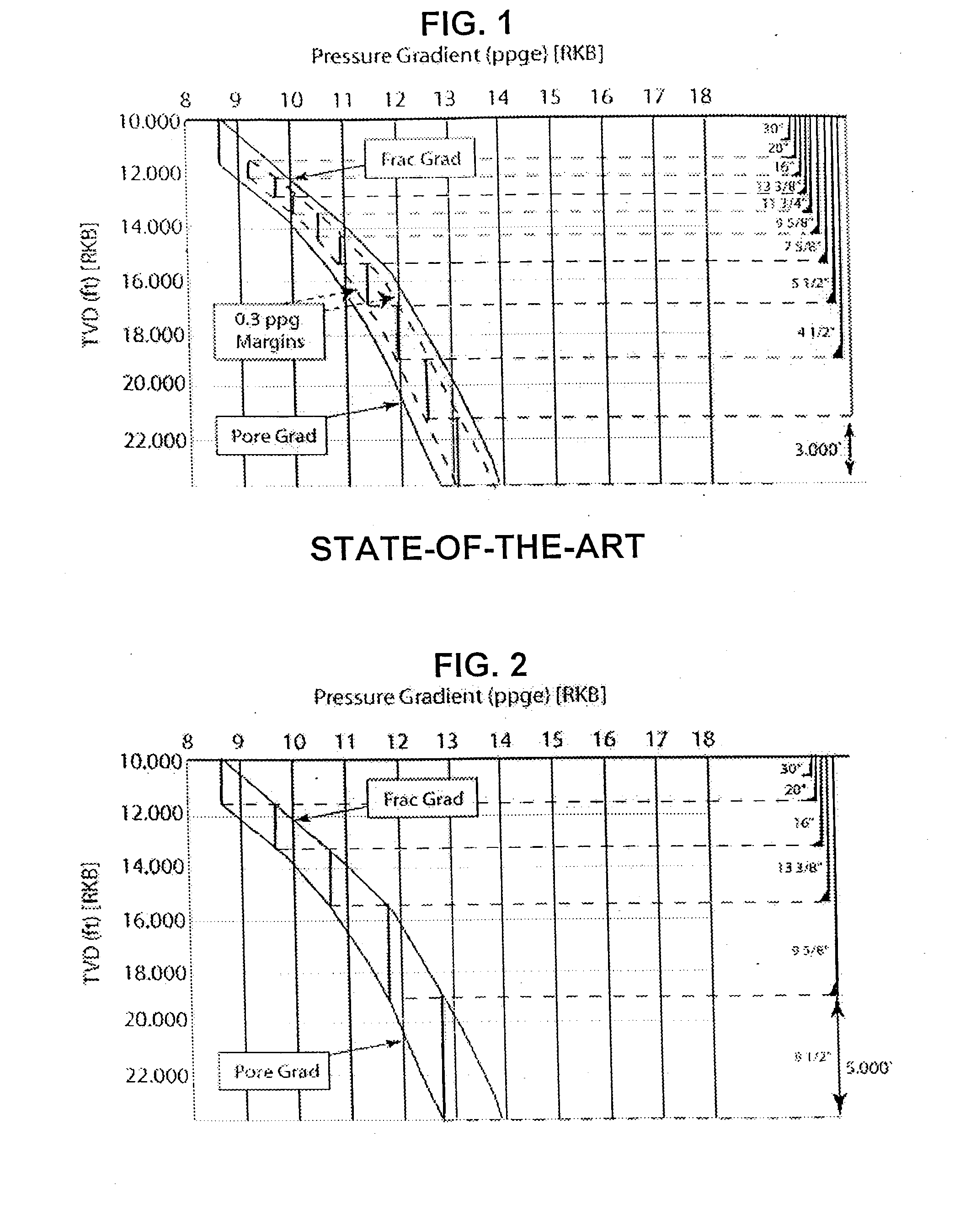

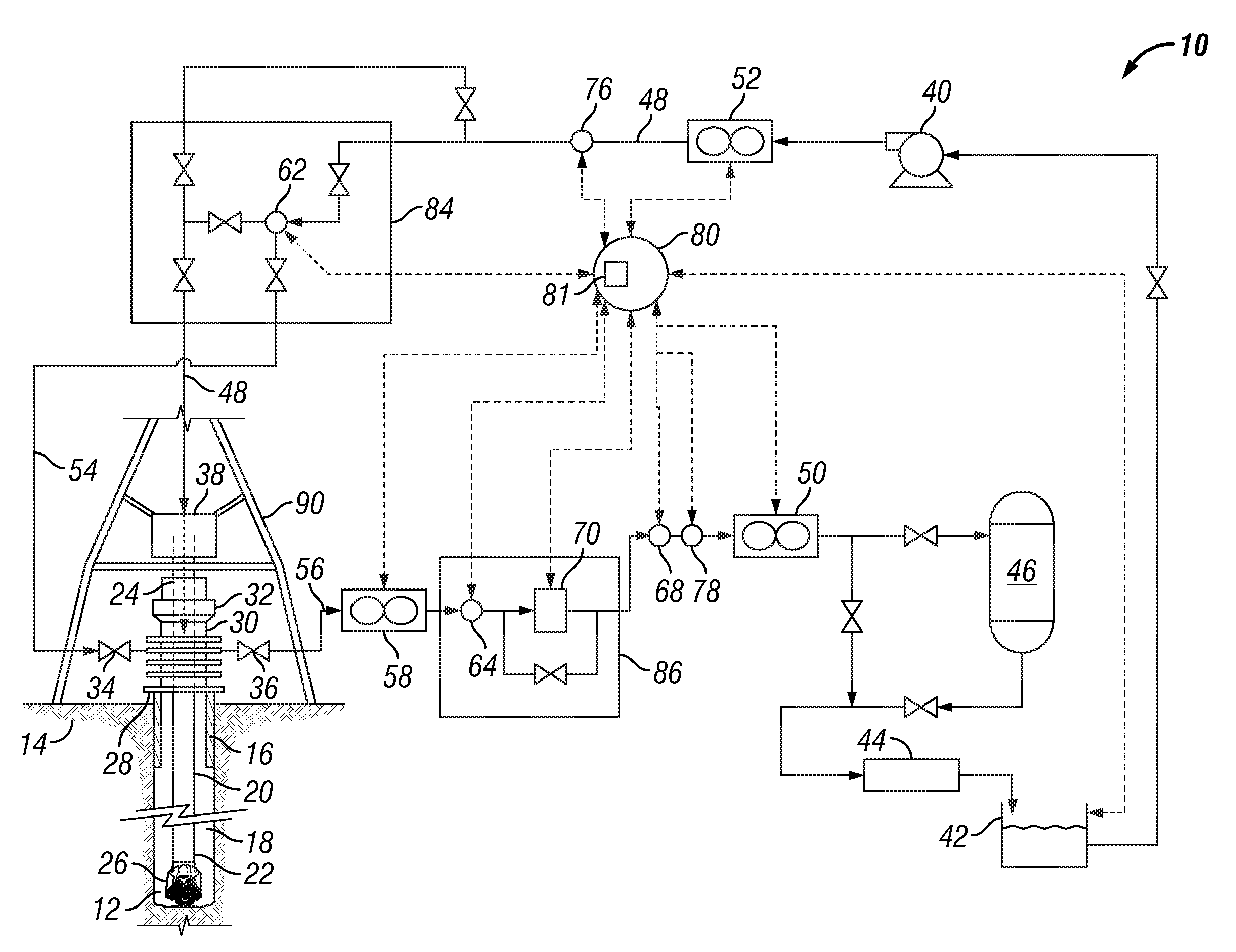

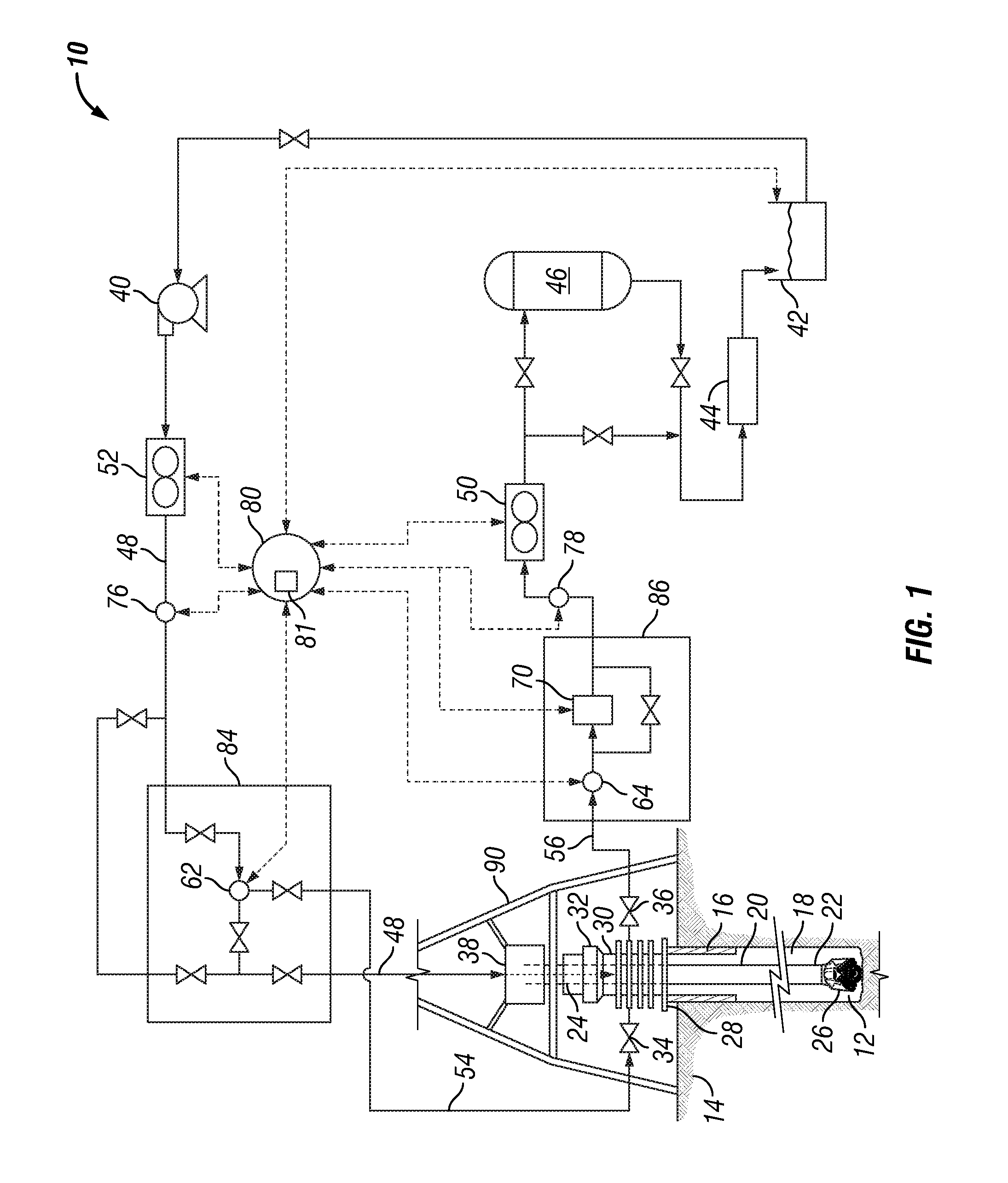

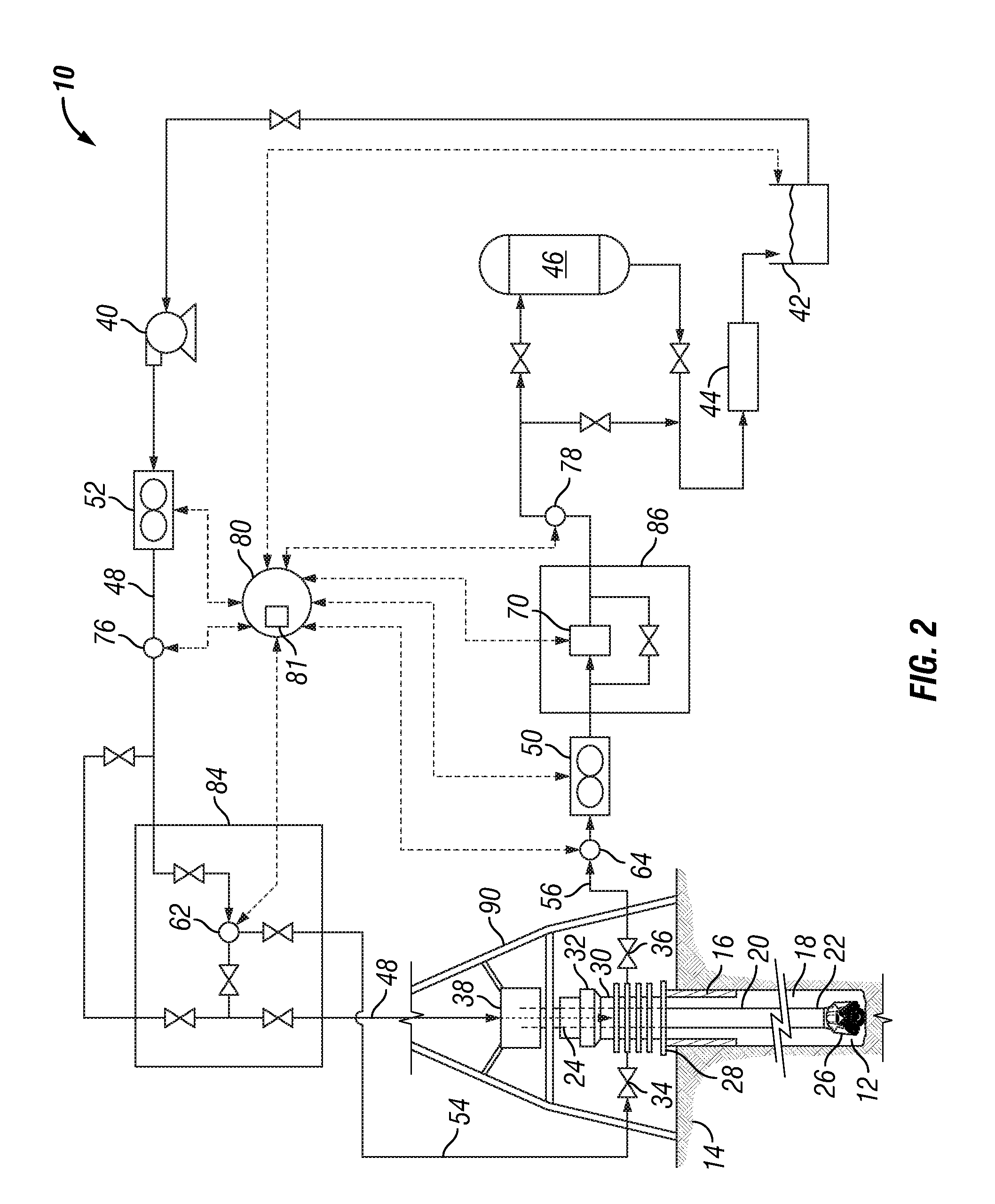

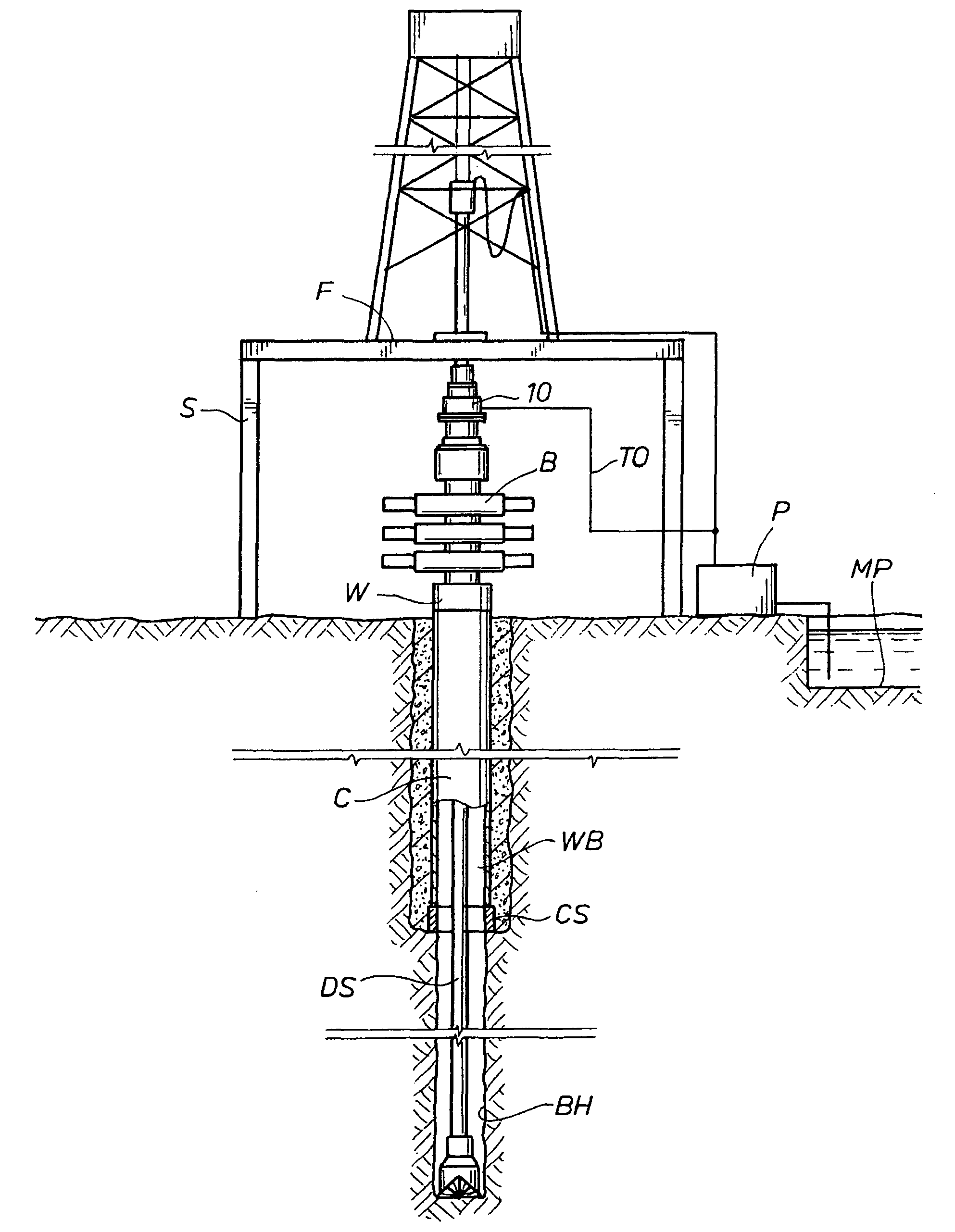

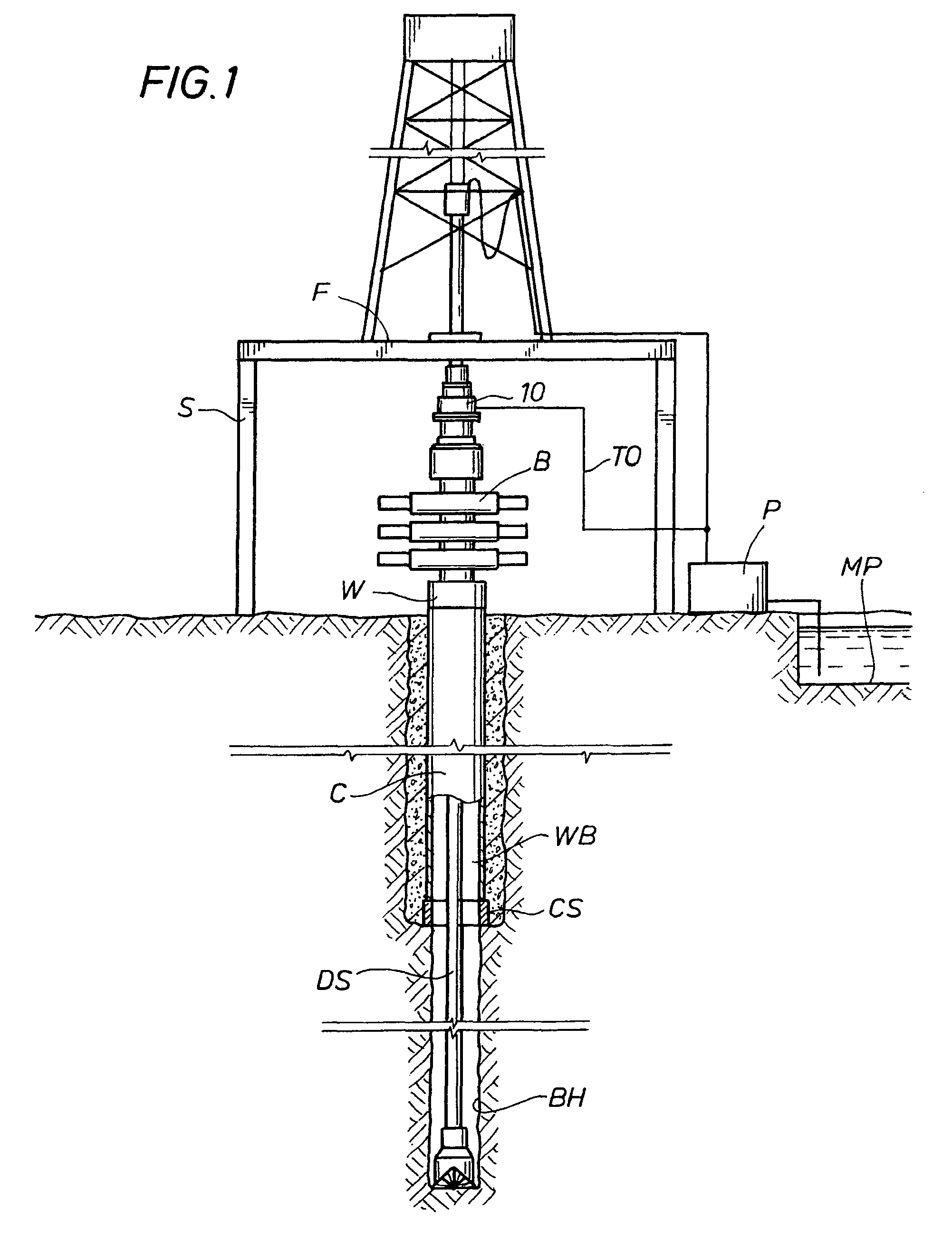

A Drill-To-The-Limit (DTTL) drilling method variant to Managed Pressure Drilling (MPD) applies constant surface backpressure, whether the mud is circulating (choke valve open) or not (choke valve closed). Because of the constant application of surface backpressure, the DTTL method can use lighter mud weight that still has the cutting carrying ability to keep the borehole clean. The DTTL method identifies the weakest component of the pressure containment system, such as the fracture pressure of the formation or the casing shoe leak off test (LOT). With a higher pressure rated RCD, such as 5,000 psi (34,474 kPa) dynamic or working pressure and 10,000 psi (68,948 kPa) static pressure, the limitation will generally be the fracture pressure of the formation or the LOT. In the DTTL method, since surface backpressure is constantly applied, the pore pressure limitation of the conventional drilling window can be disregarded in developing the fluid and drilling programs. Using the DTTL method a deeper wellbore can be drilled with larger resulting end tubulars, such as casings and production liners, than had been capable with conventional MPD applications.

Owner:WEATHERFORD TECH HLDG LLC

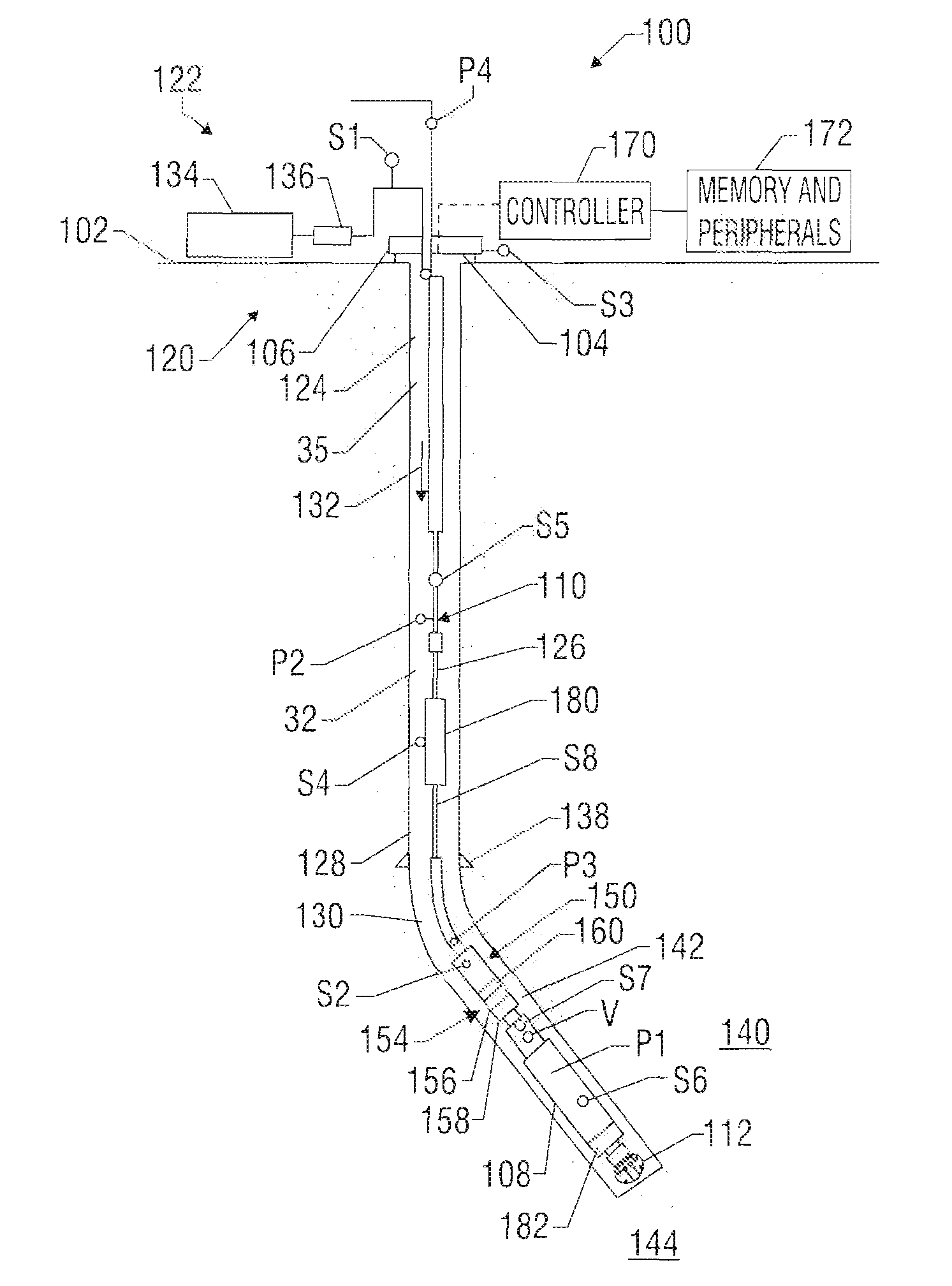

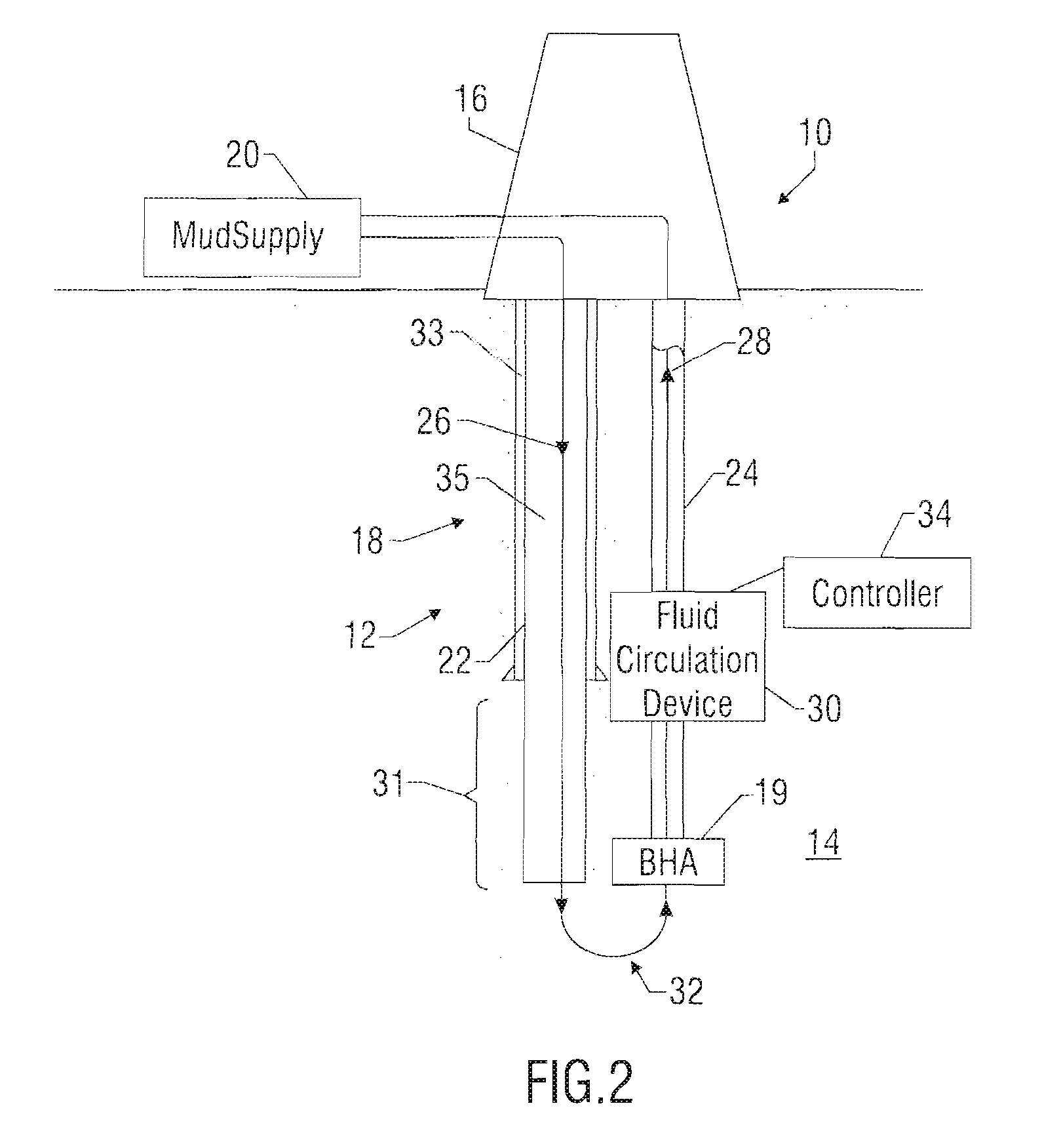

Drilling system and method

InactiveUS20030079912A1Accurate calculationImprove securityConstructionsFlushingWell drillingEngineering

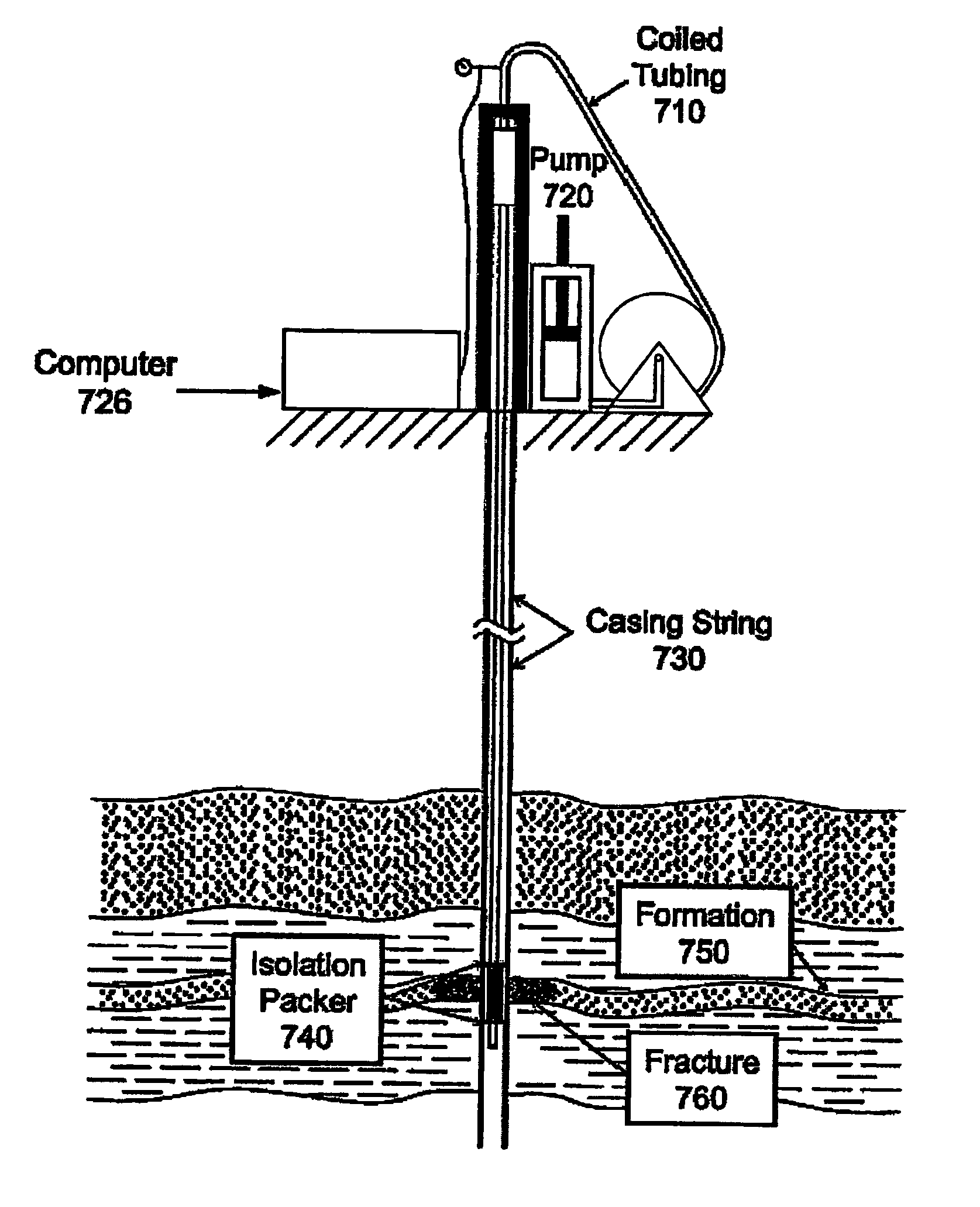

A closed-loop circulating system for drilling wells has control of the flow rates in and out of the wellbore. Kicks and fluid losses are quickly controlled by adjusting the backpressure. Kick tolerance and tripping margins are eliminated by real-time determination of pore and fracture pressure. The system can incorporate a rotating BOP and can be used with underbalanced drilling.

Owner:SECURE DRILLING INT

System and method for safe well control operations

ActiveUS20110214882A1Facilitate well control operationFacilitates hands-on trainingDrilling rodsFluid removalLine tubingWell drilling

A system and method for safely controlling a well being drilled or that has been drilled into a subterranean formation in which a conventional blow-out preventer operates to close the well bore to atmosphere upon the detection of a fluid influx event. Fluid pressures as well as fluid flow rates into and out of the well bore are measured and monitored to more accurately and confidently determine the fracture pressure and pore pressure of the formation and perform well control operations in response to a fluid influx event. During a suspected fluid influx event, one or more of the fluid flow and pressure measurements are used to confirm the fluid influx event and to safely regain well control by circulating the fluid influx out of the well through a choke line while maintaining the pressure inside the well between specified, selected limits, such as between the fracture and pore pressures.

Owner:SAFEKICK AMERICAS LLC

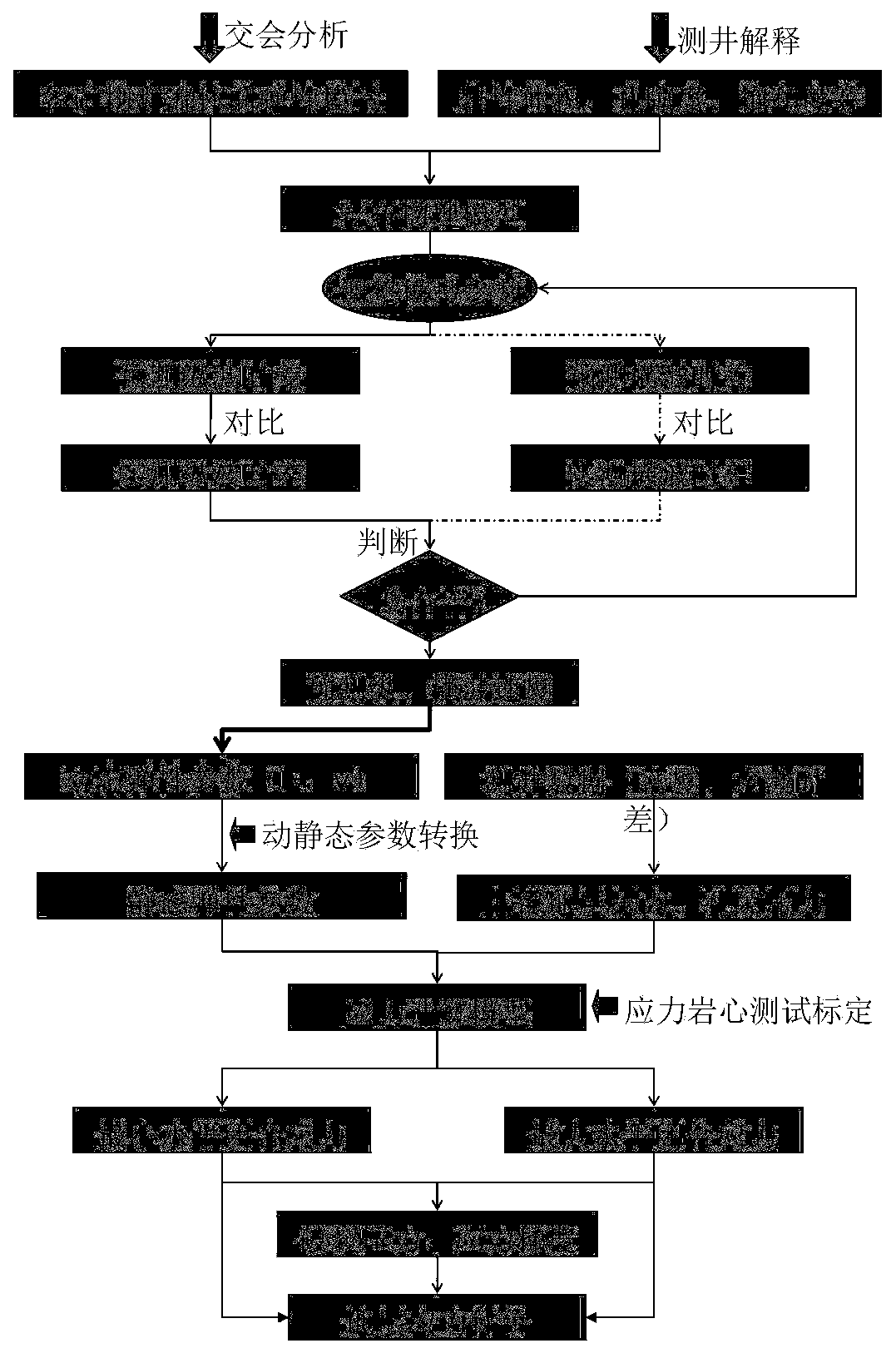

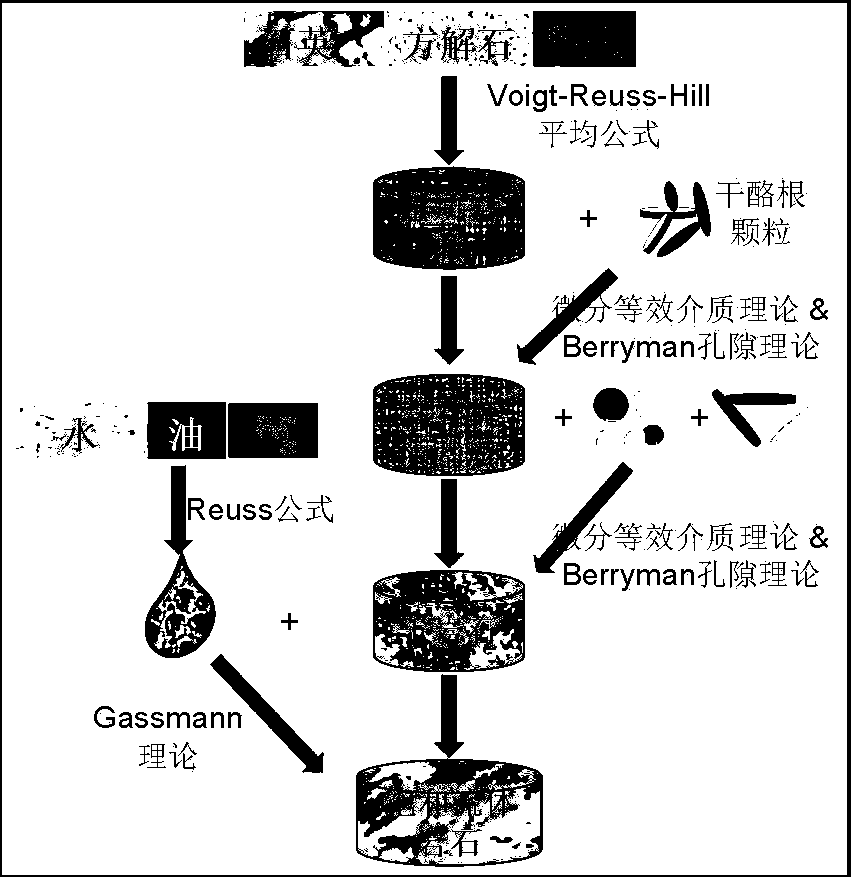

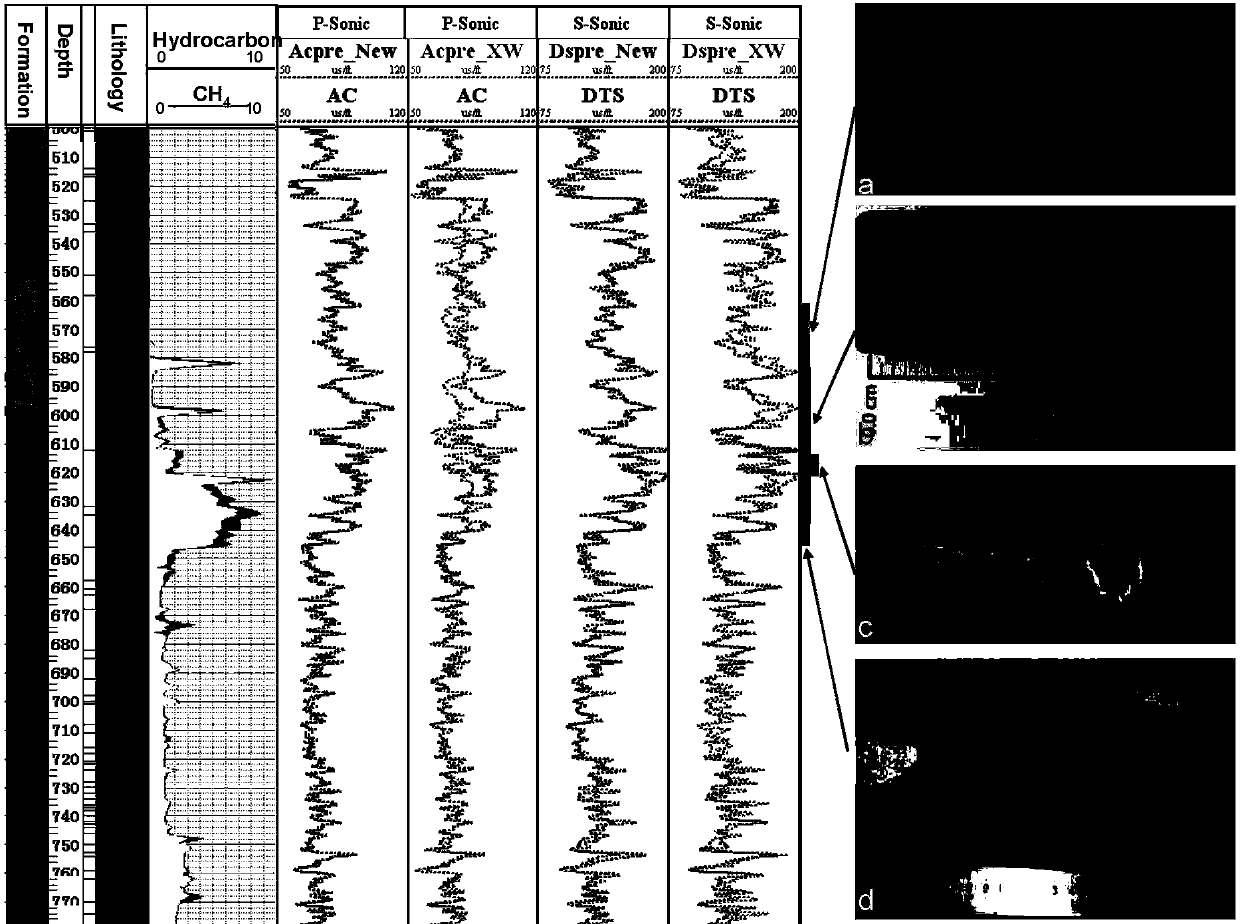

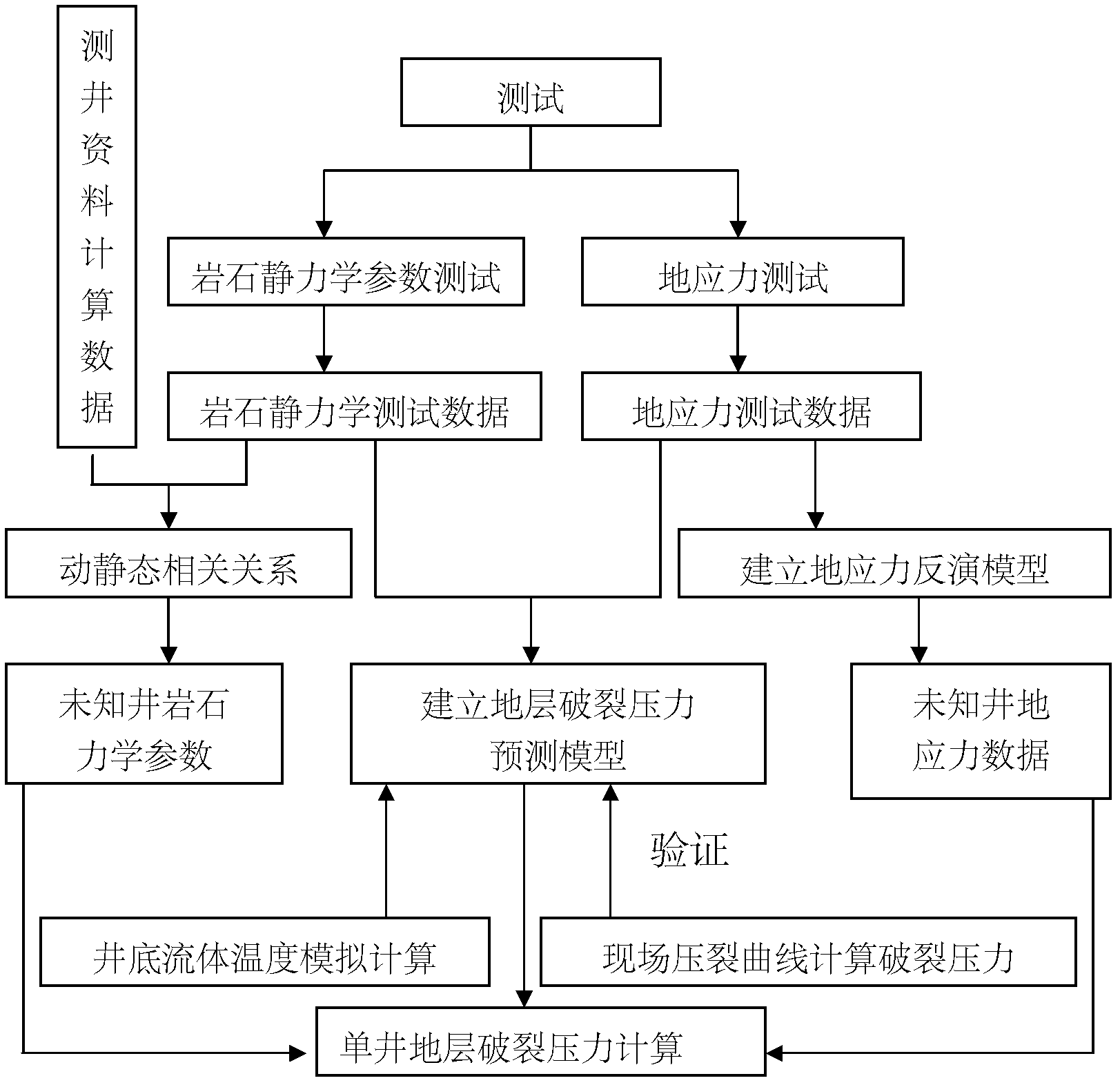

Shale gas reservoir crustal stress logging prediction method based on rock physics model

The present invention relates to a shale gas reservoir crustal stress logging prediction method based on a rock physics model. According to the method, a shale gas reservoir rock physics model which takes kerogen particles into consideration is established, so as to predict a longitudinal and transverse wave velocity of the logging; based on the above, a maximum and minimum horizontal principal stress and a fracture pressure of the reservoir are calculated; and an accurate stress assessment of a shale gas reservoir is carried out while a transverse wave logging is not provided. The beneficial effects of the invention are that: the rock physics model in line with characteristics of the shale gas reservoir is established to improve precision of the prediction velocity; and based on the rock physical model, the maximum and minimum horizontal principal stress and the fracture pressure are obtained, so that while the measured transverse wave logging data are not provided, the underground stress can be predicted on the basis of a conventional logging curve, and the prediction result is high in accuracy.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

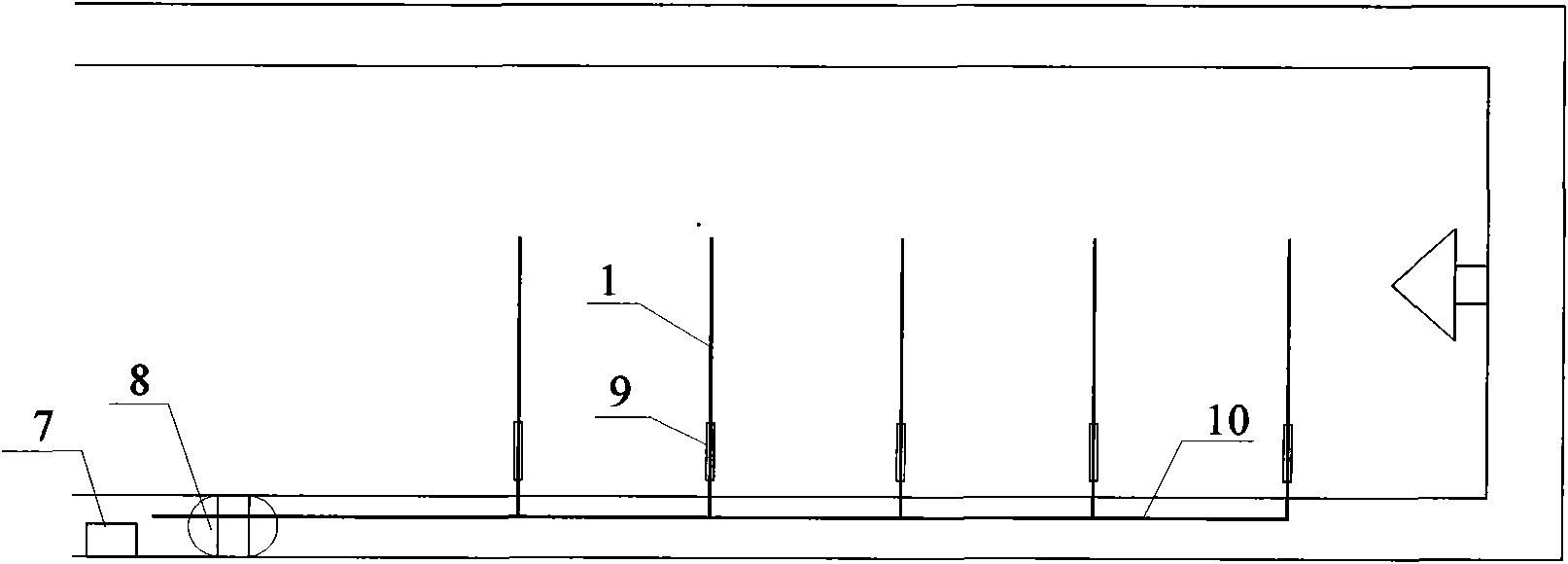

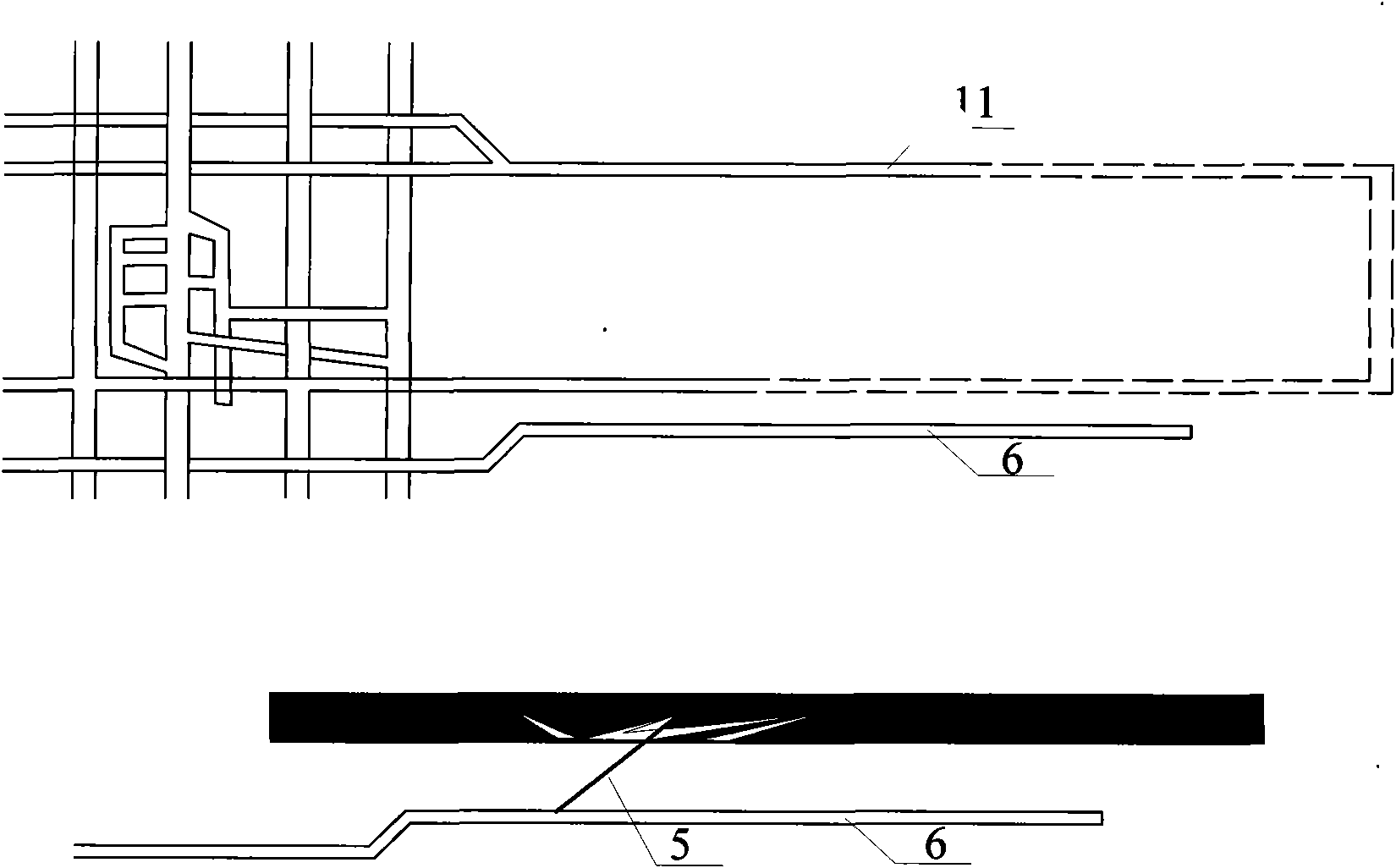

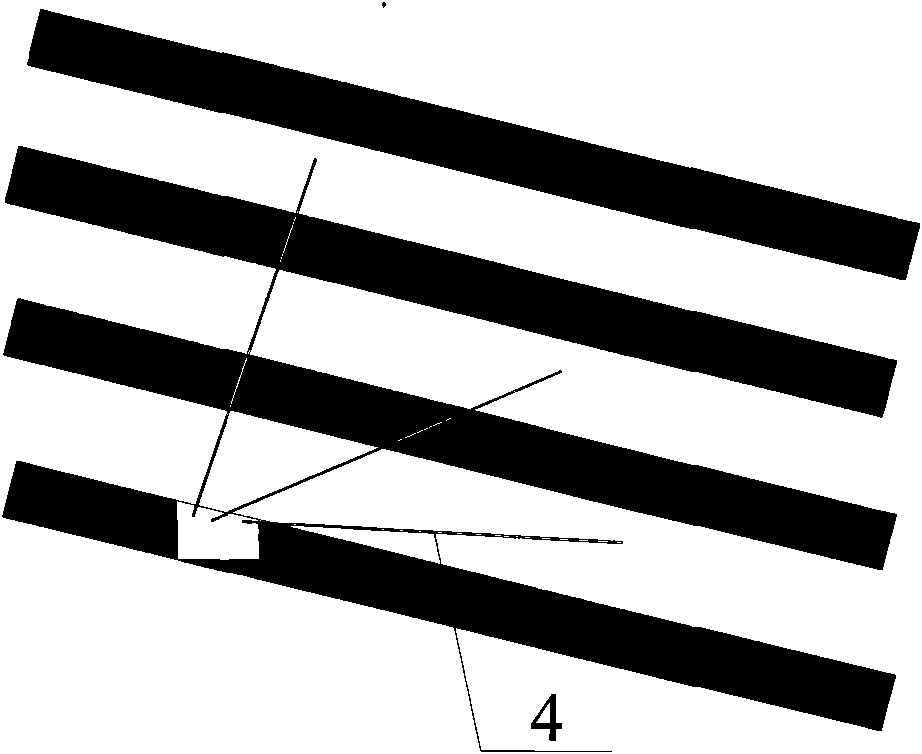

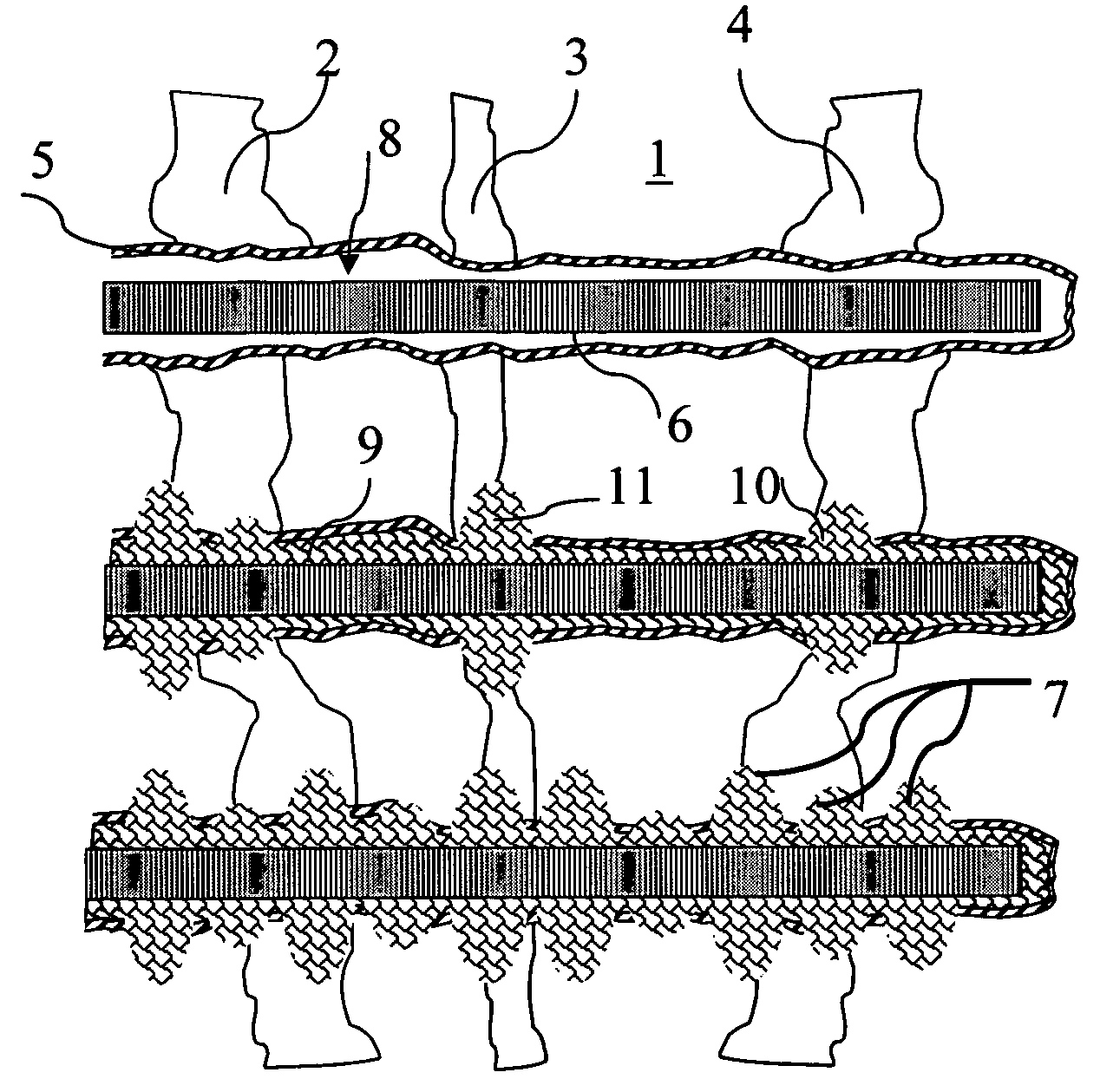

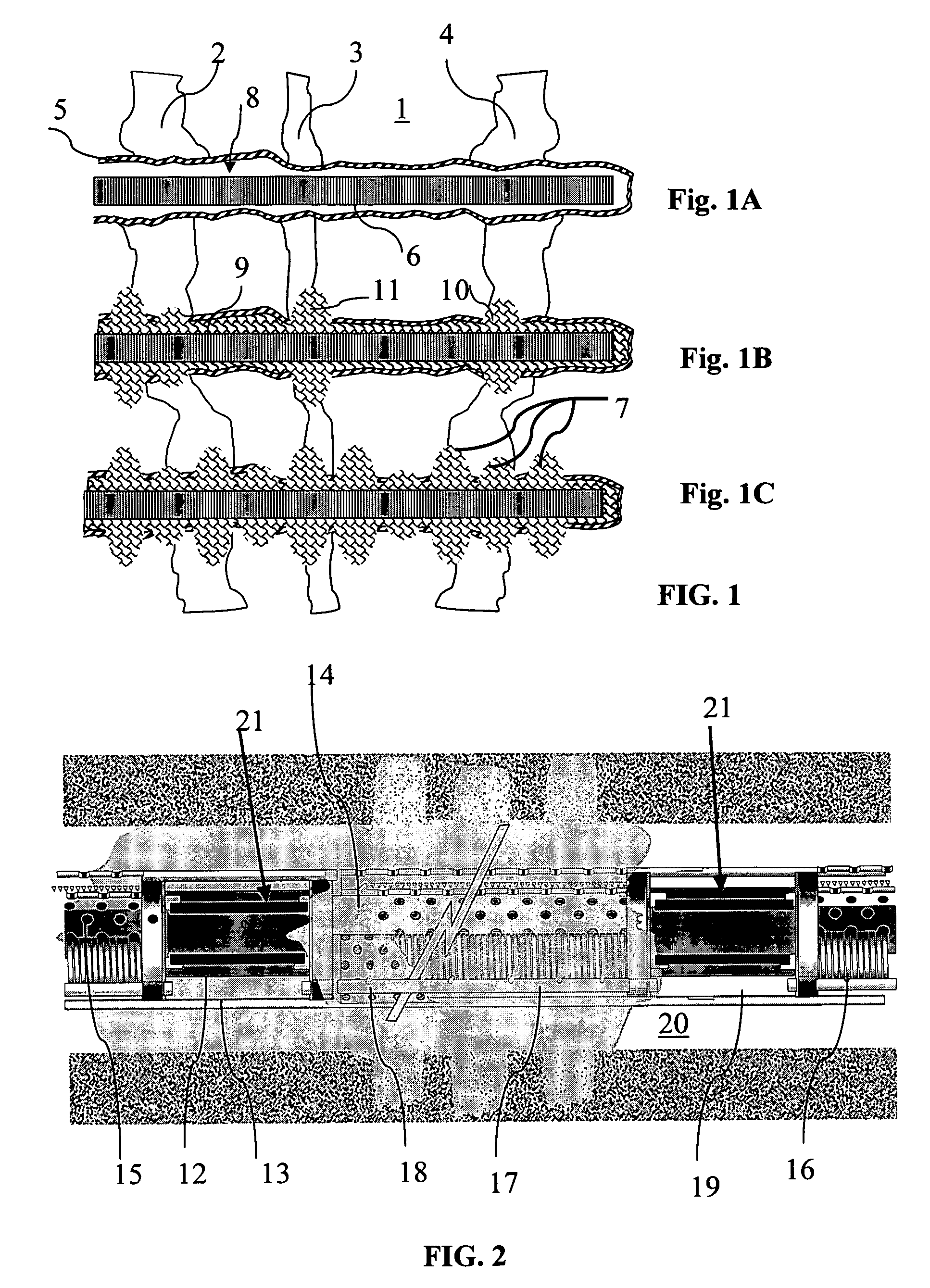

Directional fracturing permeability improvement outburst elimination method in coal mine and device thereof.

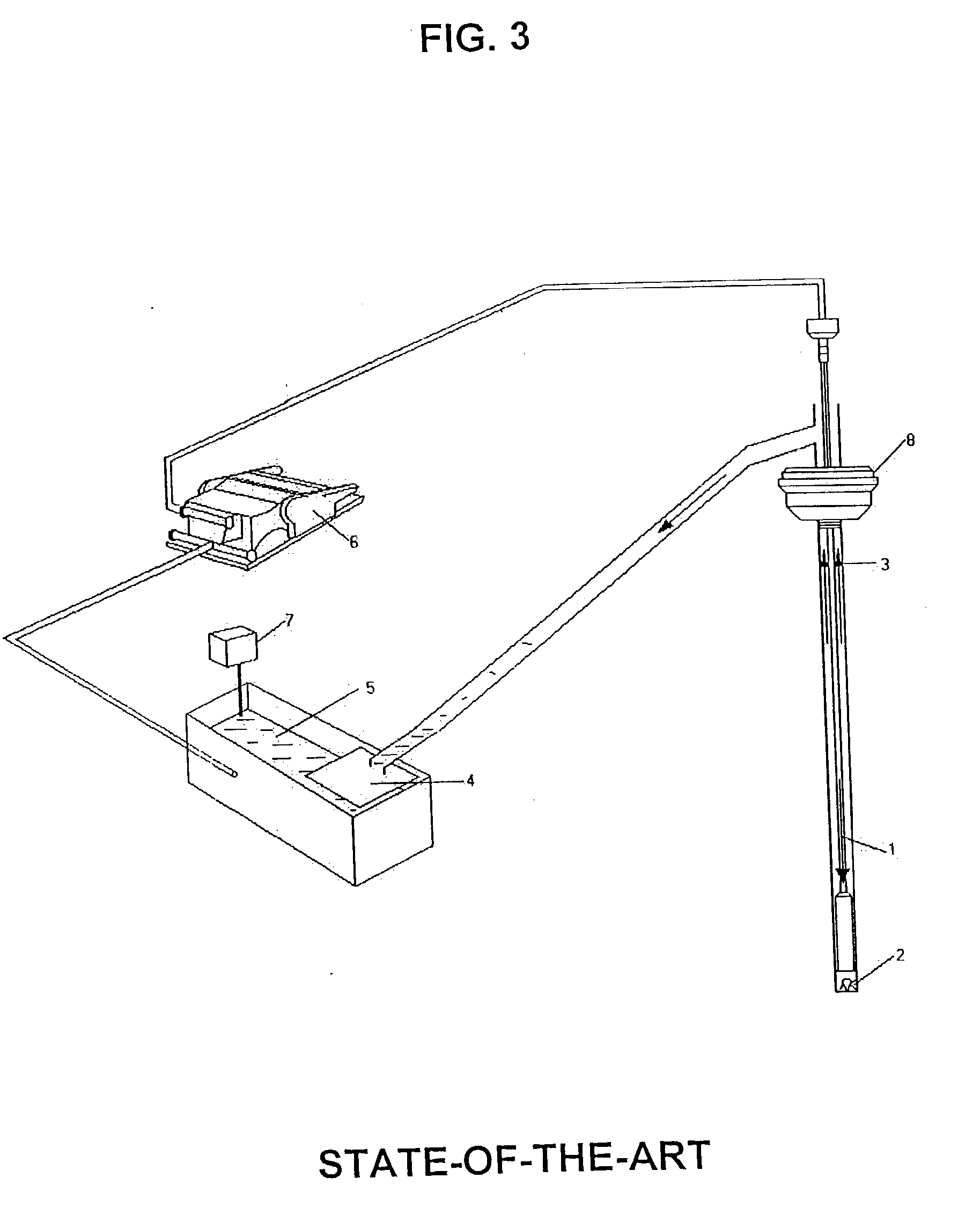

InactiveCN101575983AImprove breathabilityRapid and relatively long-lasting releaseFluid removalGas removalUltrasound attenuationFracturing fluid

The invention relates to a directional fracturing method in the coal mine and a fracturing permeability improvement outburst elimination device to ensure the coal-bed gas to release rapidly and continually in the coal mine. The method comprises the following steps: fracturing and drilling a bore on a preparing working face along the dip direction and strike direction of a coal bed, fixing a fracturing hole packer with an outer diameter matching with the pore diameter of a fracturing drilling bore into the fracturing drilling bore; connecting a fluid reservoir with a sand mixing machine, connecting the sand mixing machine with a fracturing pump package, and then connecting the fracturing pump package with the fracturing drilling bore; pumping formation fracturing fluid and proppant into the fracturing drilling bore to fracture the formation and sealing the fracturing drilling at above formation fracturing pressure, and completing directional fracturing permeability improvement outburst elimination in the coal mine, thus ensuring that the coal-bed gas discharges rapidly and continually relatively and solving the problems that drainage in low air permeability coal bed can only influence a limited range and the drainage attenuation period is short, improving the drainage rate by over 50% on primary base, decreasing the coal body dynamic phenomenon after fracturing and reginal stress influenced by fracturing, and having a significant effect for eliminating outburst.

Owner:河南省煤层气开发利用有限公司

Reverse Circulation Pressure Control Method and System

A system for reverse circulation in a wellbore include equipment for supplying drilling fluid into the wellbore bit via at least an annulus of the wellbore and returning the drilling fluid to a surface location via at least a bore of a wellbore tubular. The system also includes devices for controlling the annulus pressure associated with this reverse circulation. In one embodiment, an active pressure differential device increases the pressure wellbore annulus to at least partially offset a circulating pressure loss. In other embodiments, the system includes devices for decreasing the pressure in the annulus of the wellbore. For offshore application, annulus pressure is decreased to accommodate the pore and fracture pressures of a subsea formation. In still other embodiments, annulus pressure is decreased to cause an underbalanced condition in the well.

Owner:BAKER HUGHES INC

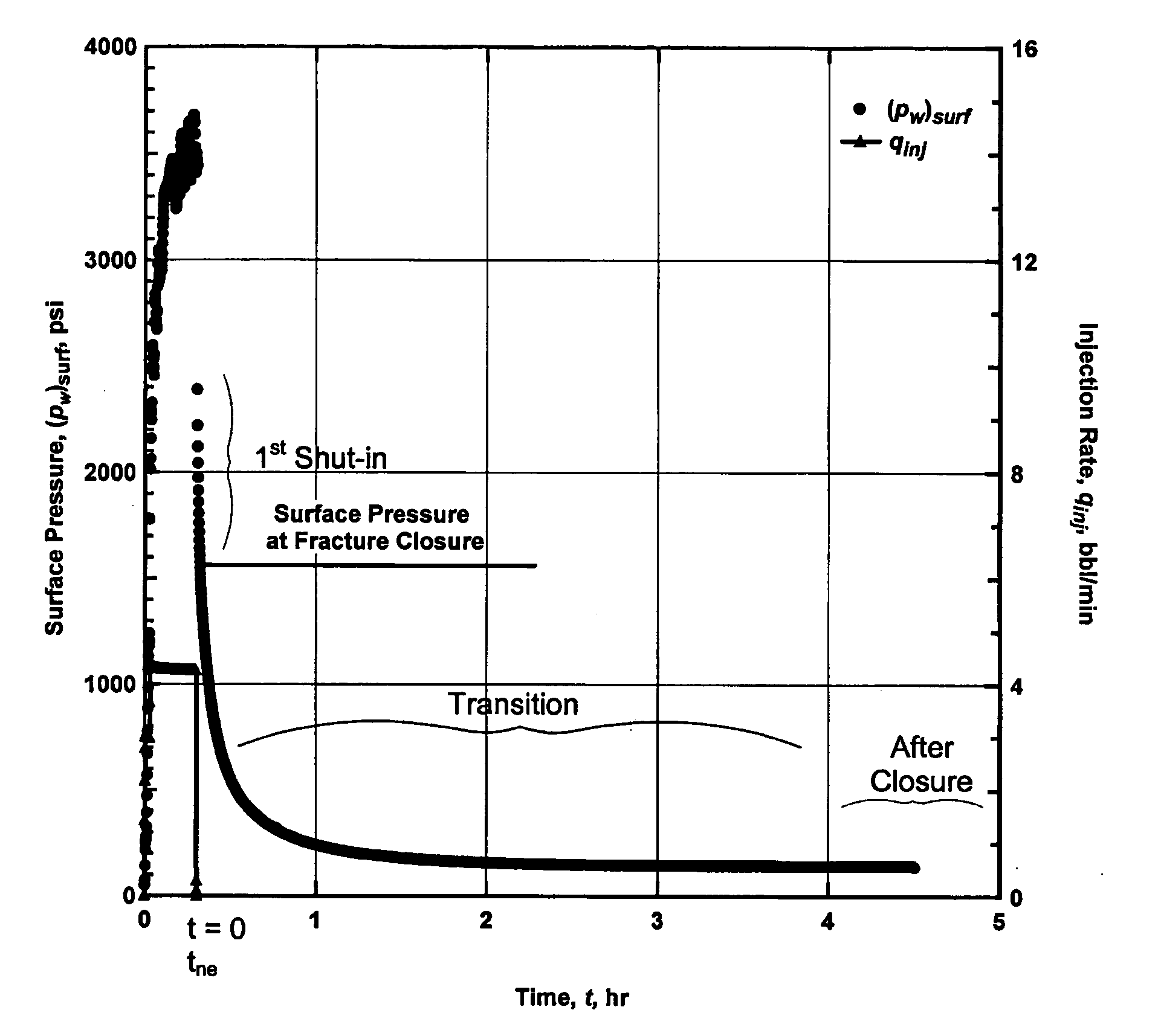

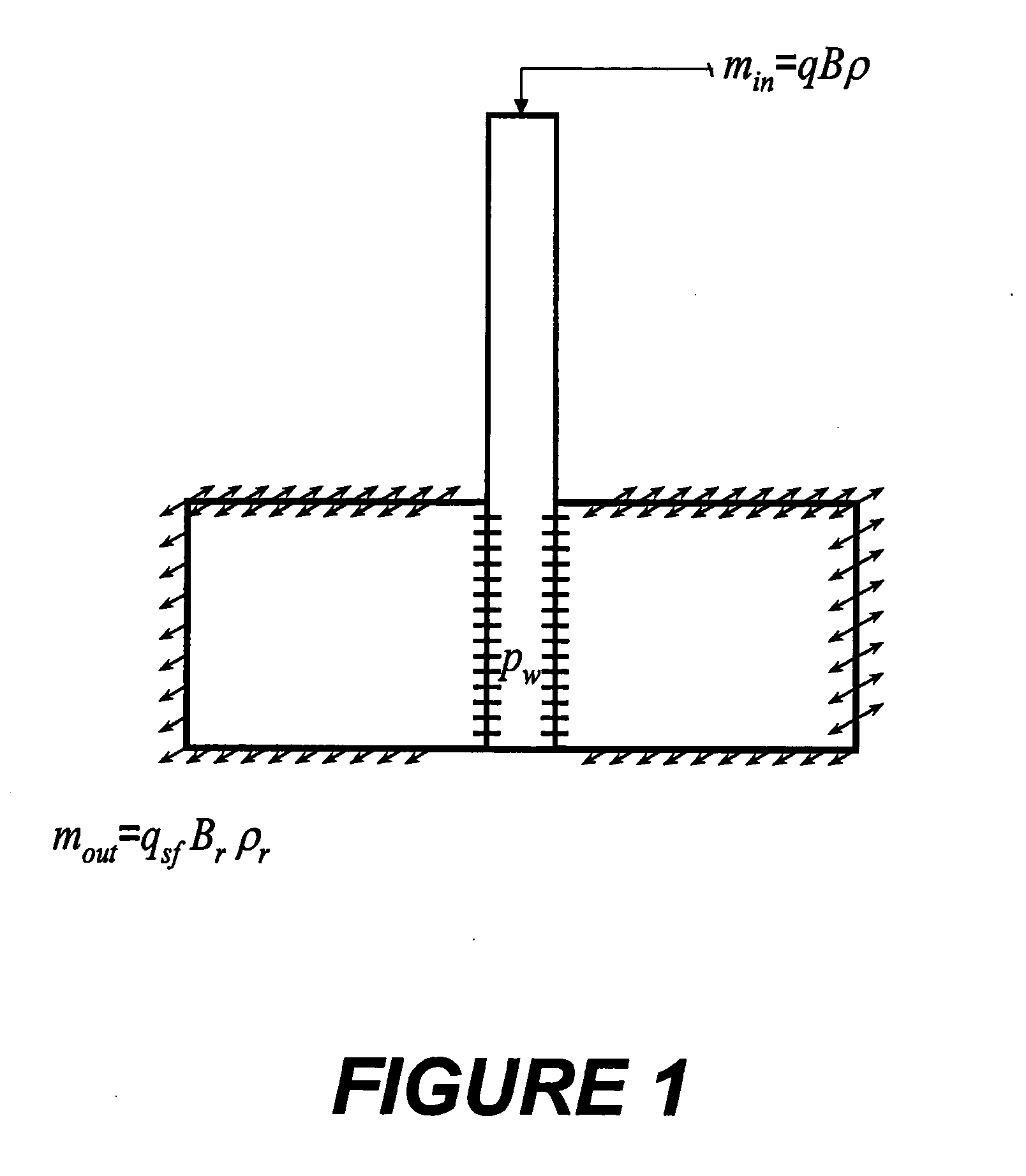

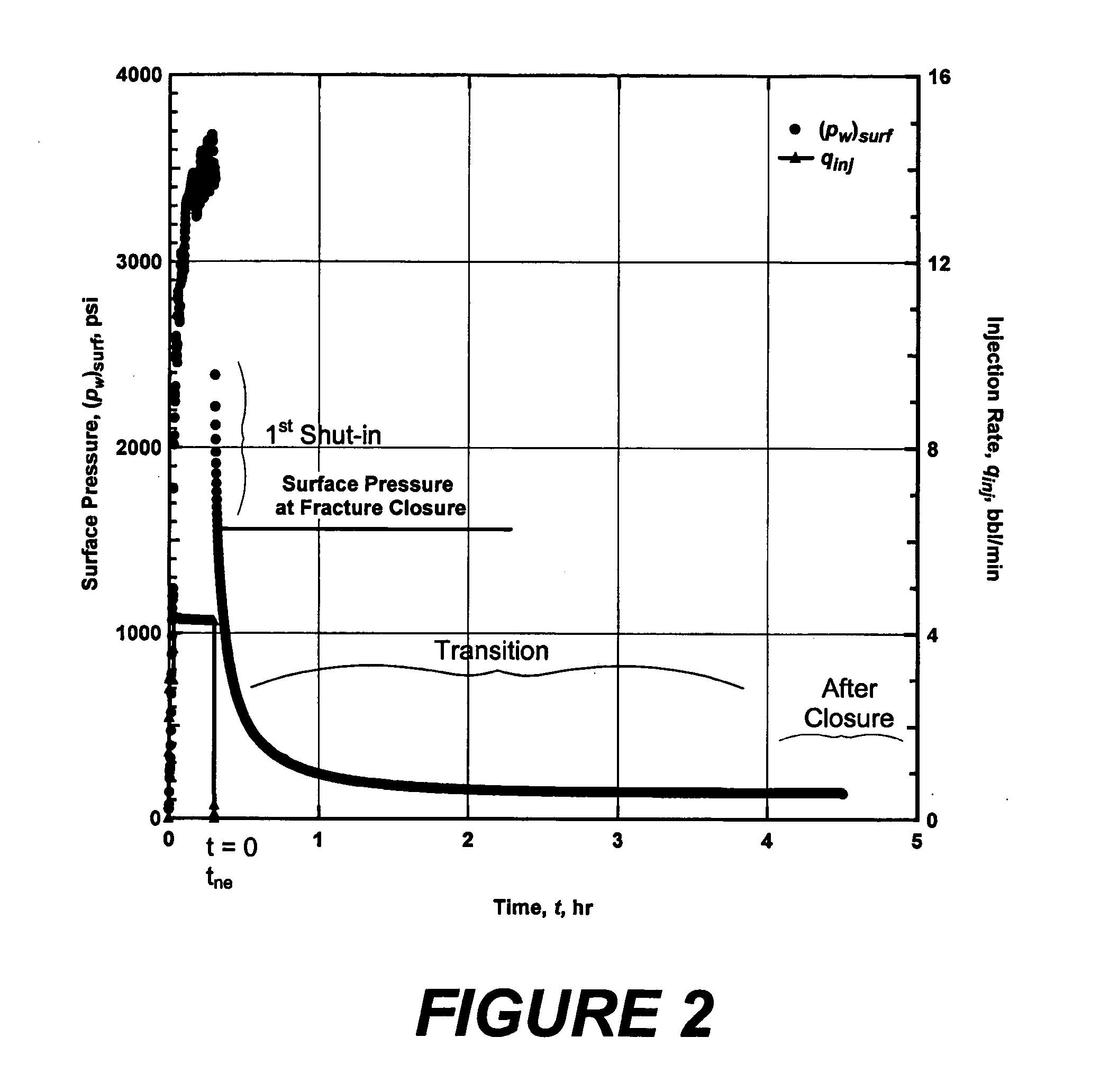

Method and an apparatus for detecting fracture with significant residual width from previous treatments

ActiveUS20050222852A1Rapid determinationElectric/magnetic detection for well-loggingSurveyDual unitMedicine

A refracture-candidate diagnostic test is an injection of compressible or slightly compressible fluid such as liquid, gas, or combination at pressures in excess of minimum in-situ stress and formation fracture pressure with pressure decline following injection test recorded to detect a fracture retaining residual width from previous stimulation treatments. The diagnostic consists of small volume injections with injection time being a small fraction of time required for compressible or slightly compressible reservoir fluid to exhibit pseudoradial flow. The fracture-injection portion of a test can be considered as occurring instantaneously, and the results obtained in an open infinite-conductivity hydraulic fracture with pressures above fracture closure stress during before-closure portion of pressure falloff and with pressures less than fracture closure stress during after-closure portion of pressure falloff. Data measurements are transformed into a constant rate equivalent pressure transformation to obtain adjusted pressures or adjusted pseudovariables which are analyzed to identify dual unit-slope before and after closure periods confirming a residual retaining width.

Owner:HALLIBURTON ENERGY SERVICES INC

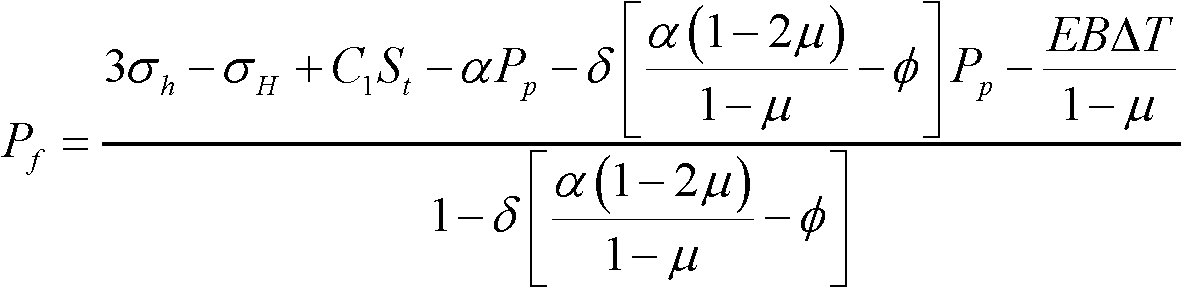

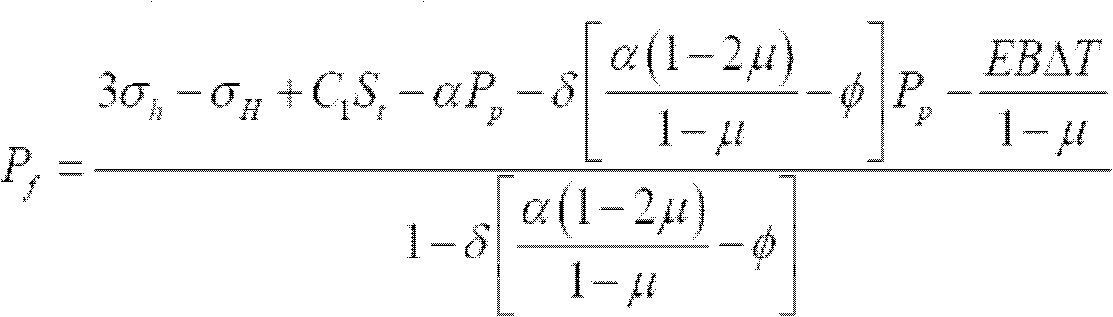

Method for calculating fracture pressure of ultra deep well formations

The invention provides a method for calculating the fracture pressure of ultra deep well formations. The method is based on an elastic theory, a pore elastic theory and a thermoelasticity theory, various factors which can influence the calculation precision are comprehensively taken into consideration, and compared with the calculating method of the prior art, the method is utilized for greatly increasing the calculation precision. The difference between a calculation result obtained by a fracture pressure prediction model of the method and the fracture pressure obtained by calculating according to practical field log data is within 10%. The method is particularly suitable for carbonate rock ultra deep well formations.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fracturing fluid for subterranean formations

A method of fracturing a reservoir comprising the steps of pumping a geopolymer precursor fluid through a wellbore into the reservoir at a fracture pressure, the geopolymer precursor fluid at the fracture pressure generates fractures in the reservoir, wherein the geopolymer precursor fluid is comprised of an amount of aluminosilicate, an amount of alkaline reagent, and a permeability enhancer, allowing the geopolymer precursor fluid to fill the fractures in the reservoir, shutting-in the wellbore at a wellbore pressure, the wellbore pressure maintains the geopolymer precursor fluid in the fractures, allowing the geopolymer precursor fluid to harden for a hardening time to form a geopolymer in the fractures, the geopolymer has a geopolymer matrix, the geopolymer matrix has a permeability, the geopolymer has a compressive strength, and reducing the wellbore pressure allows a reservoir fluid to flow from the reservoir through the geopolymer matrix of the geopolymer to the wellbore.

Owner:SAUDI ARABIAN OIL CO

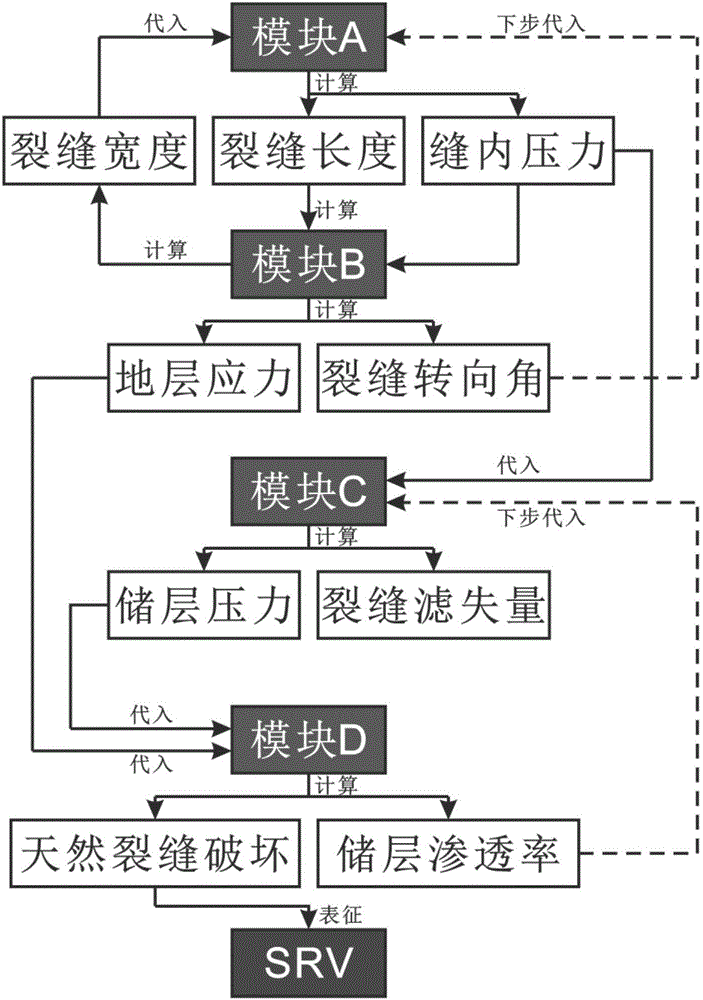

Method for calculating tight reservoir fracturing transformation volume area

ActiveCN106844909AFastSolve the problem of failure to widely promote and apply in the mining fieldGeometric CADDesign optimisation/simulationReservoir pressureChange model

The invention discloses a method for calculating a tight reservoir fracturing transformation volume area. The method comprises the following steps that multiple hydraulic fracture non-planar turning extension models, a formation stress field change model, a reservoir pressure file change model and a natural fracture failure criterion in the tight reservoir horizontal well fracturing process are established, geological parameters, horizontal well fracturing construction parameters and the total fracturing time are obtained, an initial fracture filter loss value, an initial fracture half-length value, an initial in-fracture pressure value, an initial fracture extension turning angle, initial permeability and an initial fracturing time value are endowed, all the models are calculated, and natural fracture failure point coordinate data is calculated; a spatial and numerical integration method is utilized to calculate tension failure transformation area volume and shear failure transformation area volume in a reservoir respectively, and the spaces of the two parts are united and regarded as a total transformation volume area. By adopting the method, accurate, economic and rapid tight reservoir horizontal well fracturing evaluation can be achieved, and the problem that effort, money and time are wasted in the existing tight reservoir horizontal well fracturing transformation volume area calculating process is solved.

Owner:SOUTHWEST PETROLEUM UNIV

Method and gravel packing open holes above fracturing pressure

InactiveUS7152677B2Reduce drillingReduce completion costFluid removalVibration devicesSlurryWellbore

The present invention provides a method for gravel packing a open-hole wellbore having a filter cake, comprising pumping a gravel slurry into a first portion of an annulus between the wellbore and a screen, at a sufficient rate and pressure to form at least a first fracture and diverting the gravel slurry to a second portion of said annulus through alternate flowpaths while providing hydraulic isolation between the first and the second portion of said interval, thereby preventing flowback from said second portion to said first portion and resulting extension of the first fracture, and thereby forming a second fracture in said second portion of said interval.

Owner:SCHLUMBERGER TECH CORP

Building method for artificial dry-hot-rock geothermal reservoir

ActiveCN105696996ALower burst pressureObvious lithofacies structureOther heat production devicesGeothermal energy generationStructure of the EarthHydraulic fracturing

The invention provides a building method for an artificial dry-hot-rock geothermal reservoir and belongs to the field of artificial dry-hot-rock geothermal reservoir building. According to the technical scheme, the method includes the steps that supercritical carbon dioxide fracturing is conducted on the soft weak face or an interlayer formed along the igneous rock phase to generate a major crack, then large displacement of hydrofracturing is conducted on the interior of the major crack to generate secondary fracturing, bulk fracturing or cluster type fracturing of a dry hot rock body is generated under cyclic fracturing, and the artificial geothermal reservoir is built. The building method has the beneficial effects that the characteristics of low viscosity and easy diffusion of the supercritical carbon dioxide and the characteristic that the crack is easy to form due to the fact that the fracturing pressure of igneous rock under supercritical carbon dioxide fracturing is low are fully utilized; and in combination with the characteristics that the igneous rock is of the obvious rock phase structure and thermal fracturing is easy to generate, the problems that current hydrofracturing cannot be implemented to building of the artificial geothermal reservoir in a deep rock mass, the fracturing pressure is large, the crack group or the crack band of an ideal structure is difficult to form, and an artificial geothermal reservoir stratum is particularly difficult to build are solved.

Owner:TAIYUAN UNIV OF TECH

Fracturing fluid for subterranean formations

A method of fracturing a reservoir comprising the steps of pumping a geopolymer precursor fluid through a wellbore into the reservoir at a fracture pressure, the geopolymer precursor fluid at the fracture pressure generates fractures in the reservoir, wherein the geopolymer precursor fluid is comprised of an amount of aluminosilicate, an amount of alkaline reagent, and a permeability enhancer, allowing the geopolymer precursor fluid to fill the fractures in the reservoir, shutting-in the wellbore at a wellbore pressure, the wellbore pressure maintains the geopolymer precursor fluid in the fractures, allowing the geopolymer precursor fluid to harden for a hardening time to form a geopolymer in the fractures, the geopolymer has a geopolymer matrix, the geopolymer matrix has a permeability, the geopolymer has a compressive strength, and reducing the wellbore pressure allows a reservoir fluid to flow from the reservoir through the geopolymer matrix of the geopolymer to the wellbore.

Owner:SAUDI ARABIAN OIL CO

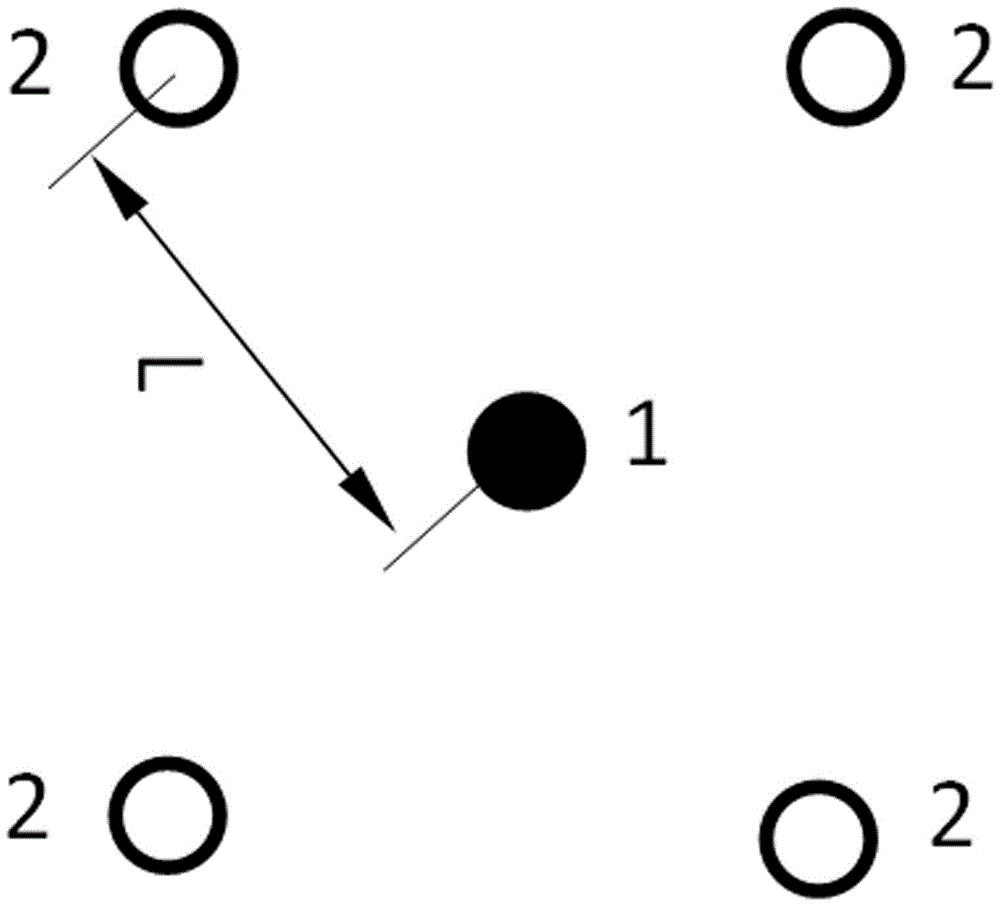

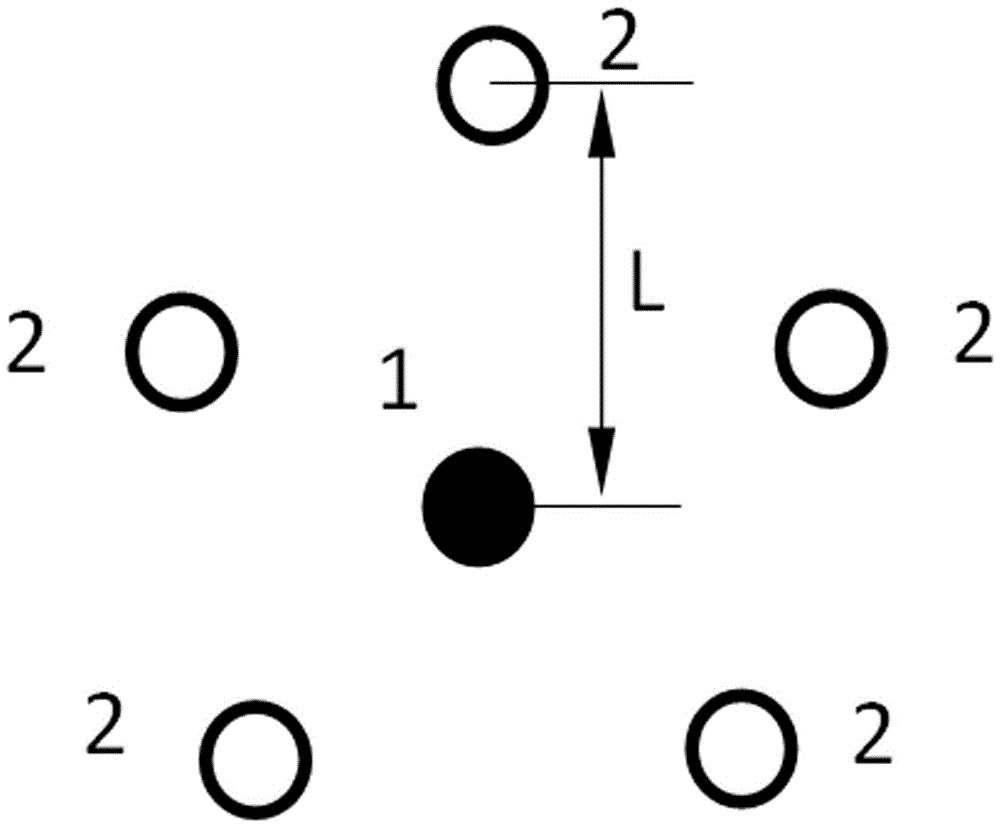

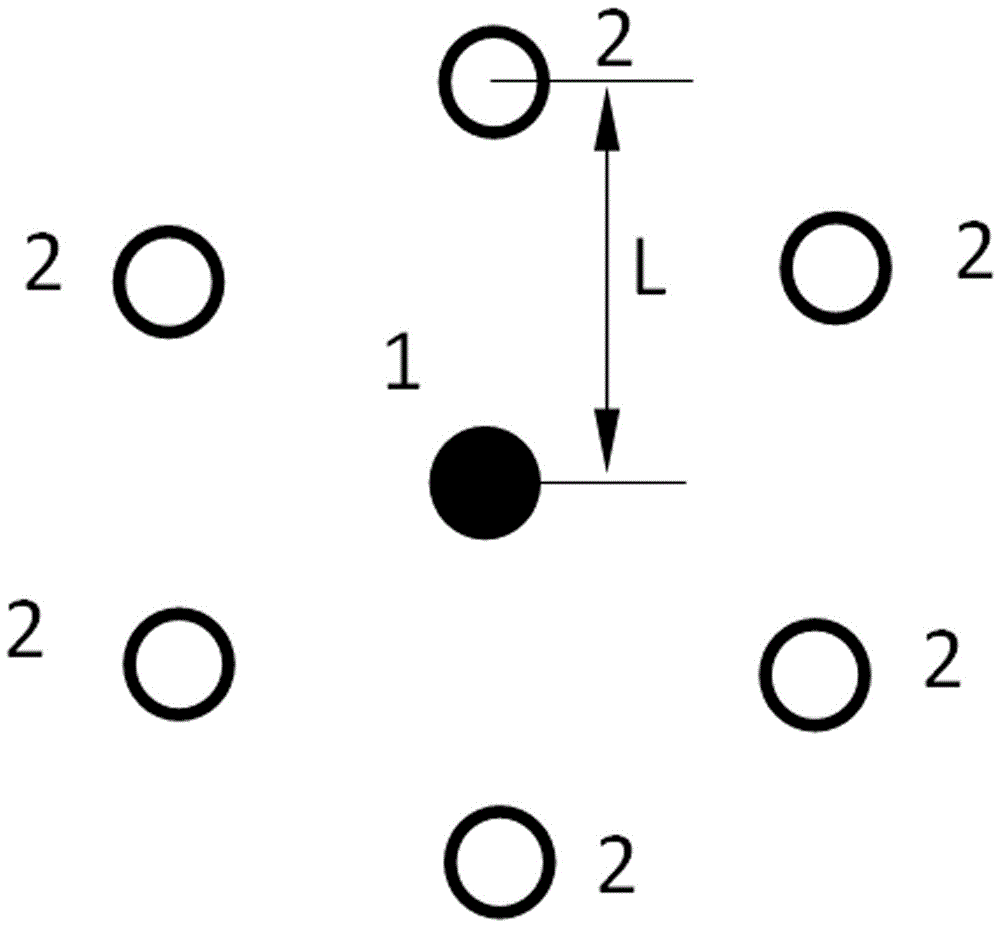

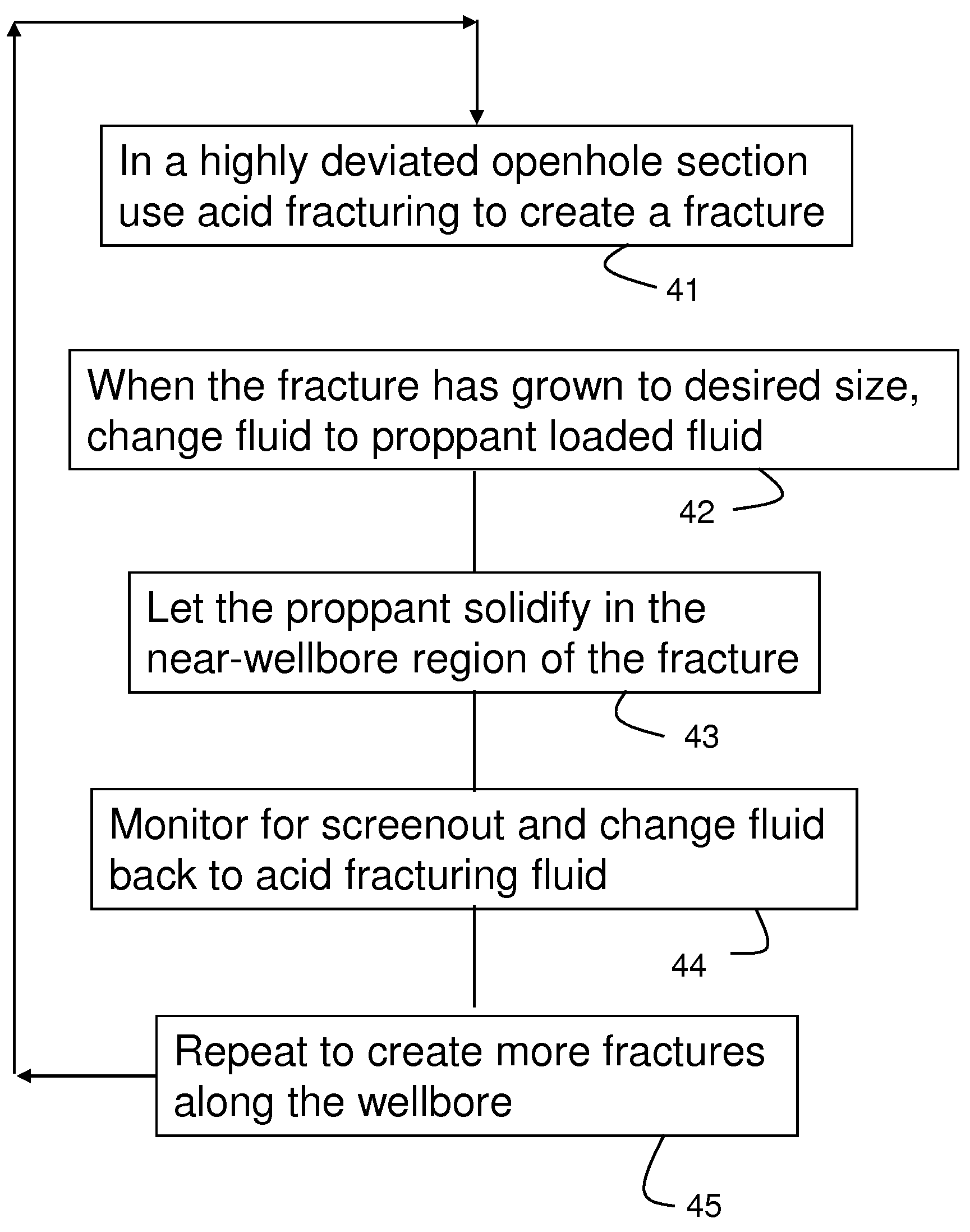

Fracturing method for subterranean reservoirs

A method of creating multiple fractures in a well traversing a formation is described using pressurized fluids in a highly deviated or horizontal section of the well at a pressure above the fracturing pressure of the formation, wherein for creating a fracture the pressurized fluid is alternated between an acid fracturing fluid and a proppant loaded fluid, such that the proppant blocks the flow of pressurized fluid into a fracture created during a previous step of the method and the subsequently pressurized acid fracturing fluid creates a new fracture at a location along the highly deviated or horizontal section different from the location of the previously created fracture.

Owner:SCHLUMBERGER TECH CORP

Drilling with a high pressure rotating control device

A Drill-To-The-Limit (DTTL) drilling method variant to Managed Pressured Drilling (MPD) applies constant surface backpressure, whether the mud is circulating (choke valve open) or not (choke valve closed). Because of the constant application of surface backpressure, the DTTL method can use lighter mud weight that still has the cutting carrying ability to keep the borehole clean. The DTTL method identifies the weakest component of the pressure containment system, such as the fracture pressure of the formation or the casing shoe leak off test (LOT). With a higher pressure rated RCD, such as 5,000 psi (34,474 kPa) dynamic or working pressure and 10,000 psi (68,948 kPa) static pressure, the limitation will generally be the facture pressure of the formation or the LOT. In the DTTL method, since surface backpressure is constantly applied, the pore pressure limitation of the conventional drilling window can be disregarded in developing the fluid and drilling programs.

Owner:WEATHERFORD TECH HLDG LLC

Method for prediction of collapse pressure and fracture pressure of stratum under drill bit while drilling

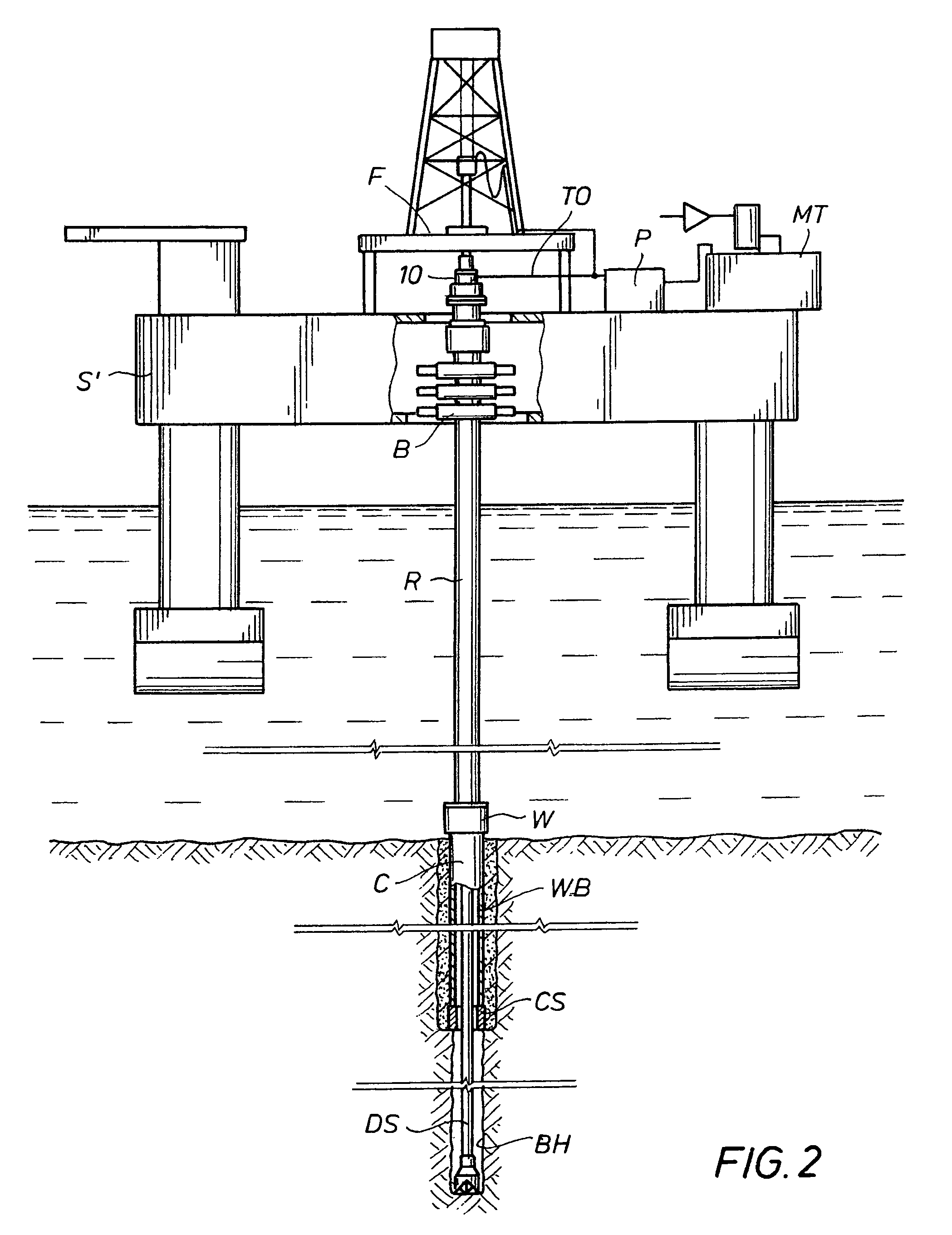

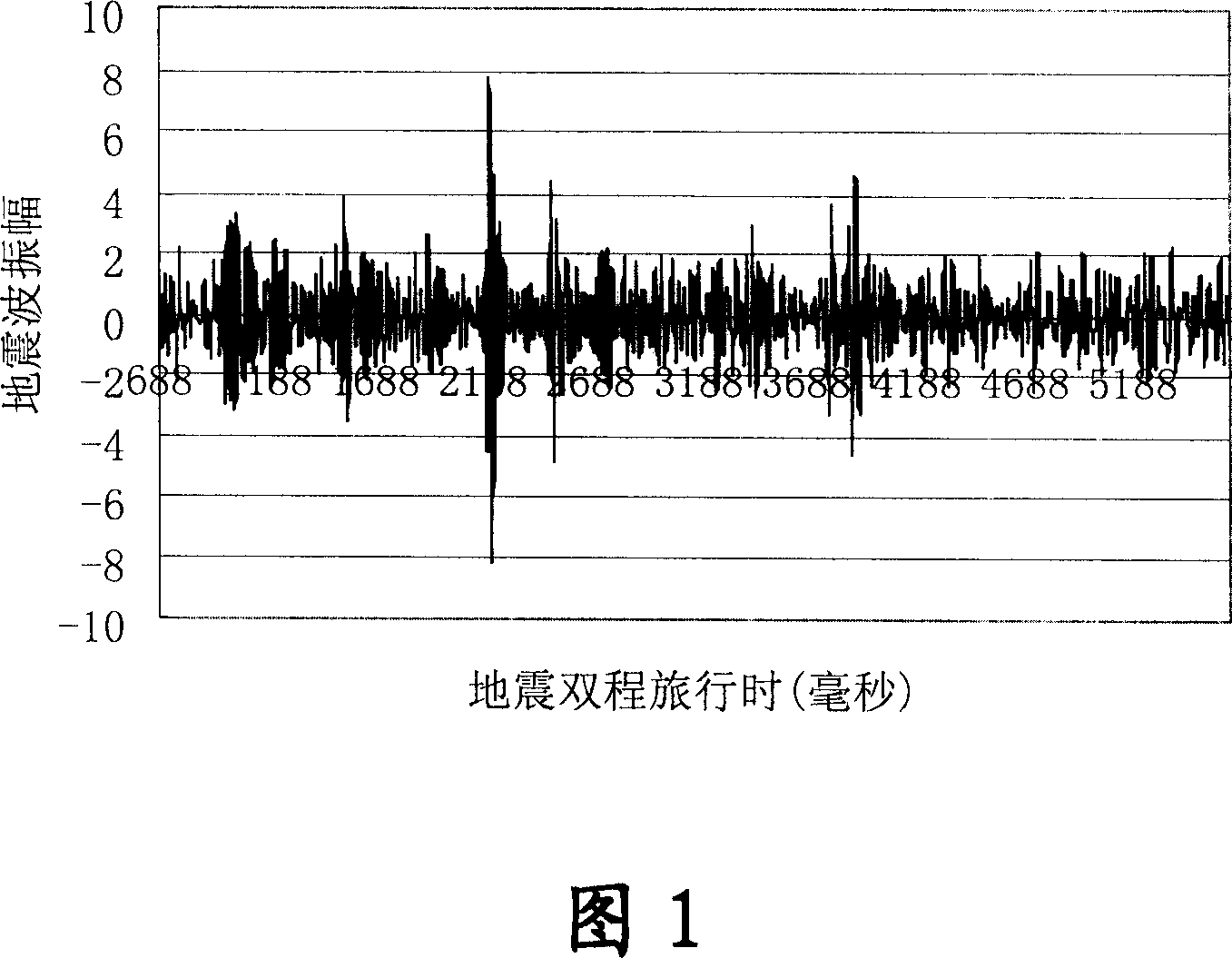

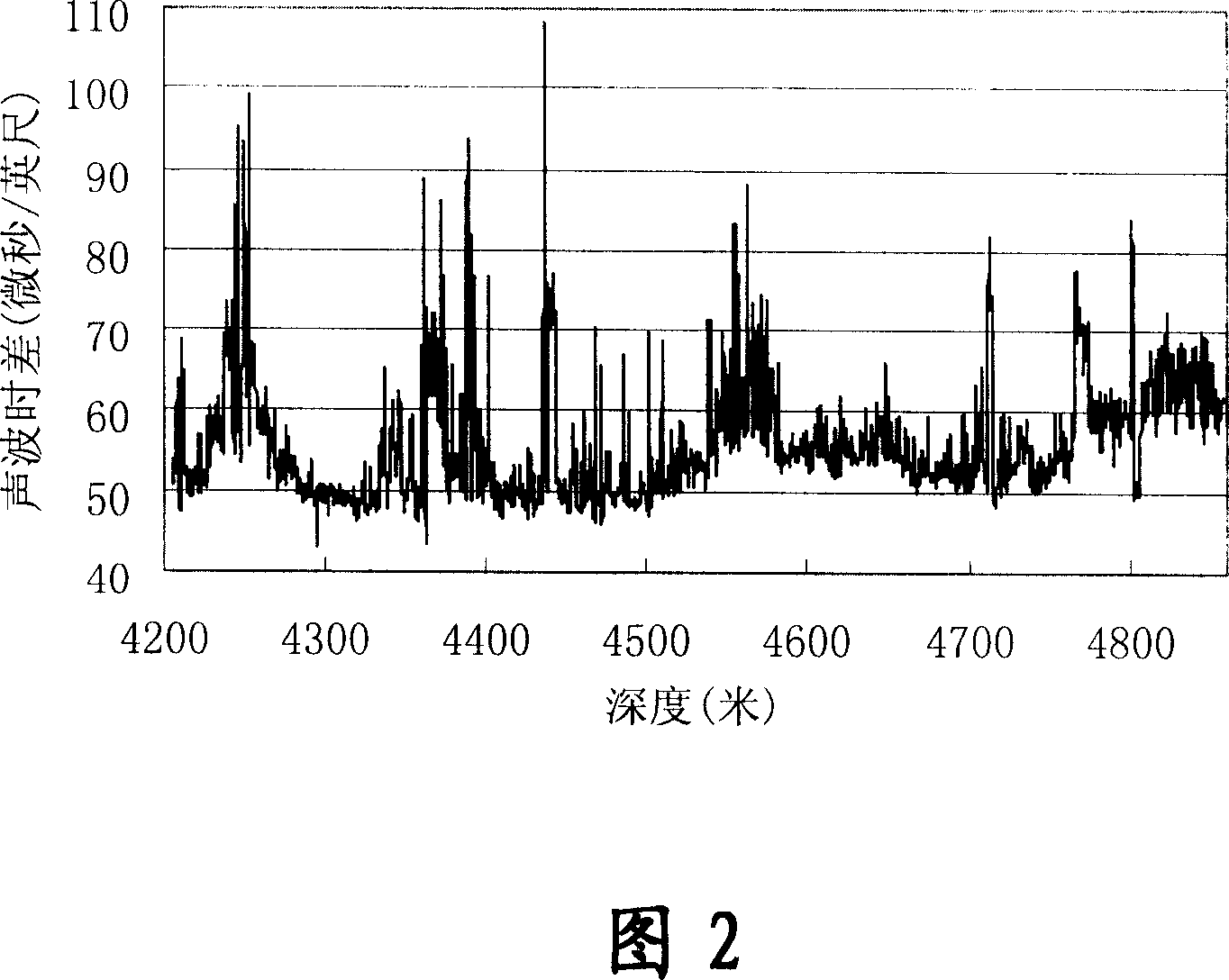

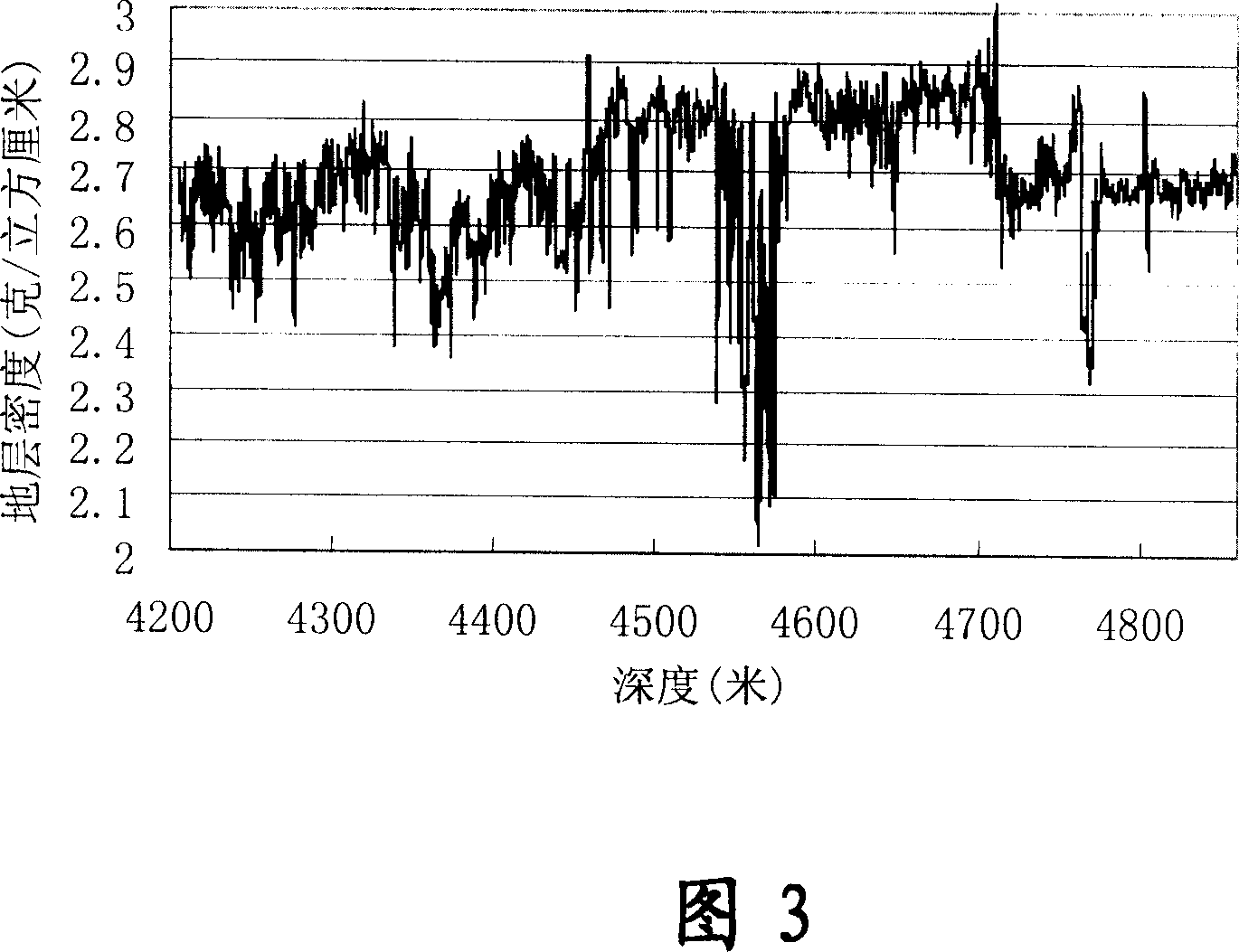

It relates to a method of predicting the collapse and crack pressure underground with the drilling head. Recording the earthquake status of a well to be drilled and several other adjacent drills that have already been drilled, getting the earthquake record of the well to be drill and already drilled through weighting, through sound wave echoing difference and density measuring for the already drilled wells to get the log data of different strata, a hierarchical model can be established to predict the sound wave speed and wave resistance of each strata based on the earthquake record. Through the log curve predicted of the strata of the well to be drilled, the collapse and crack pressure of the strata can be predicted combined with the interpretative model of the well wall stability mechanics logging. It can effectively prevent the collapse of the well wall and accidents occurrence underground.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

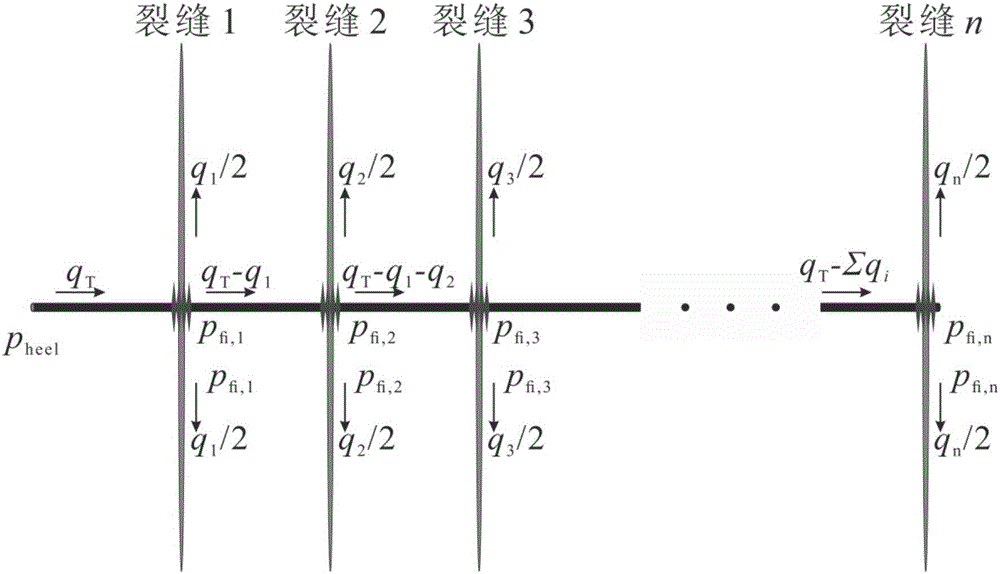

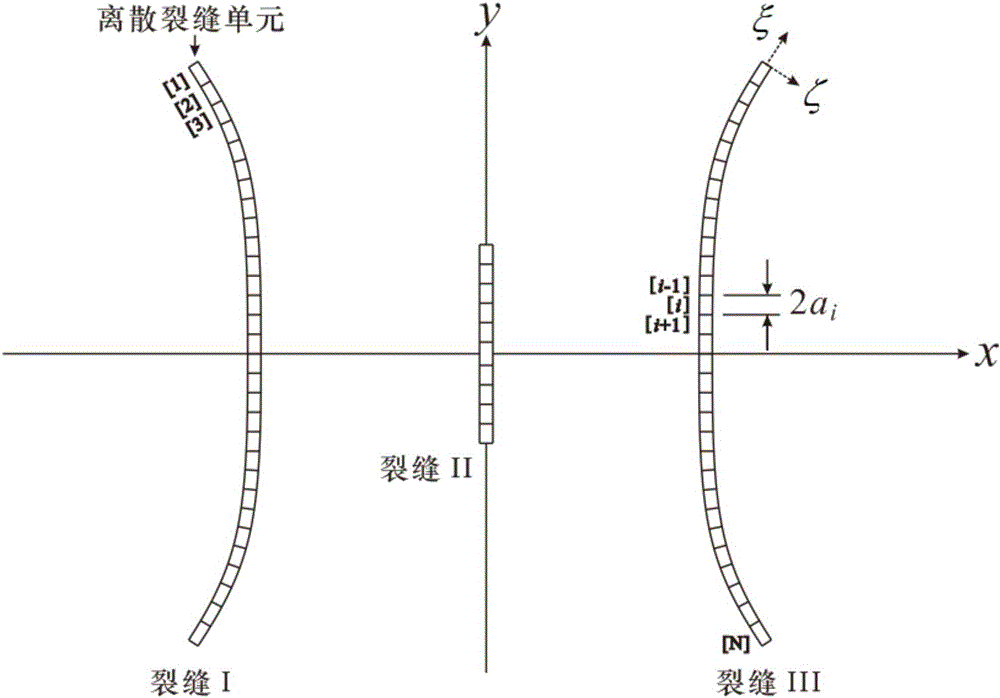

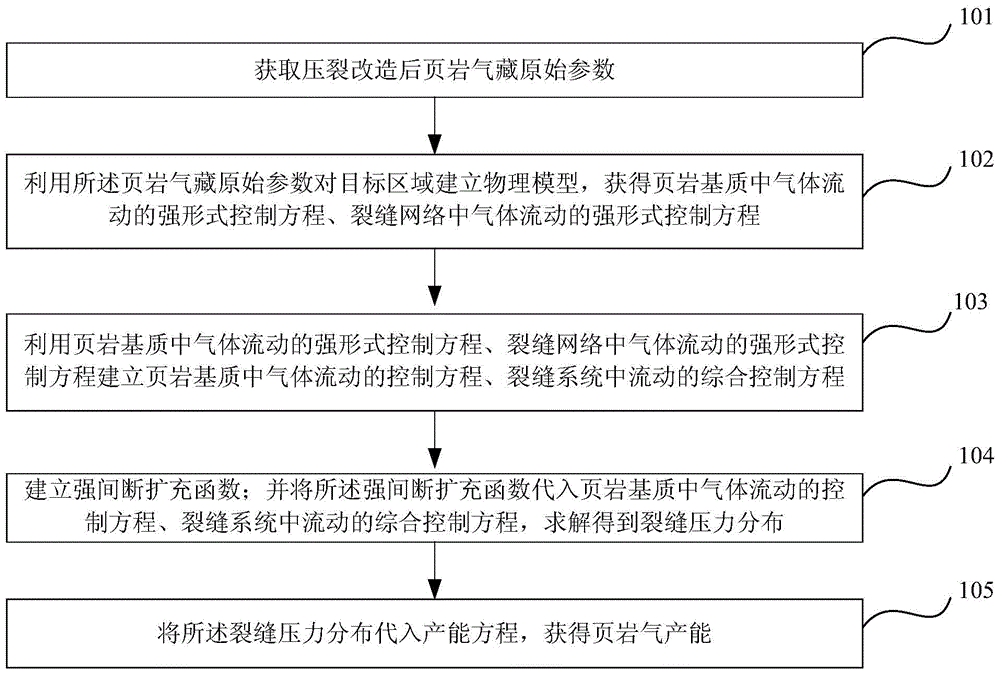

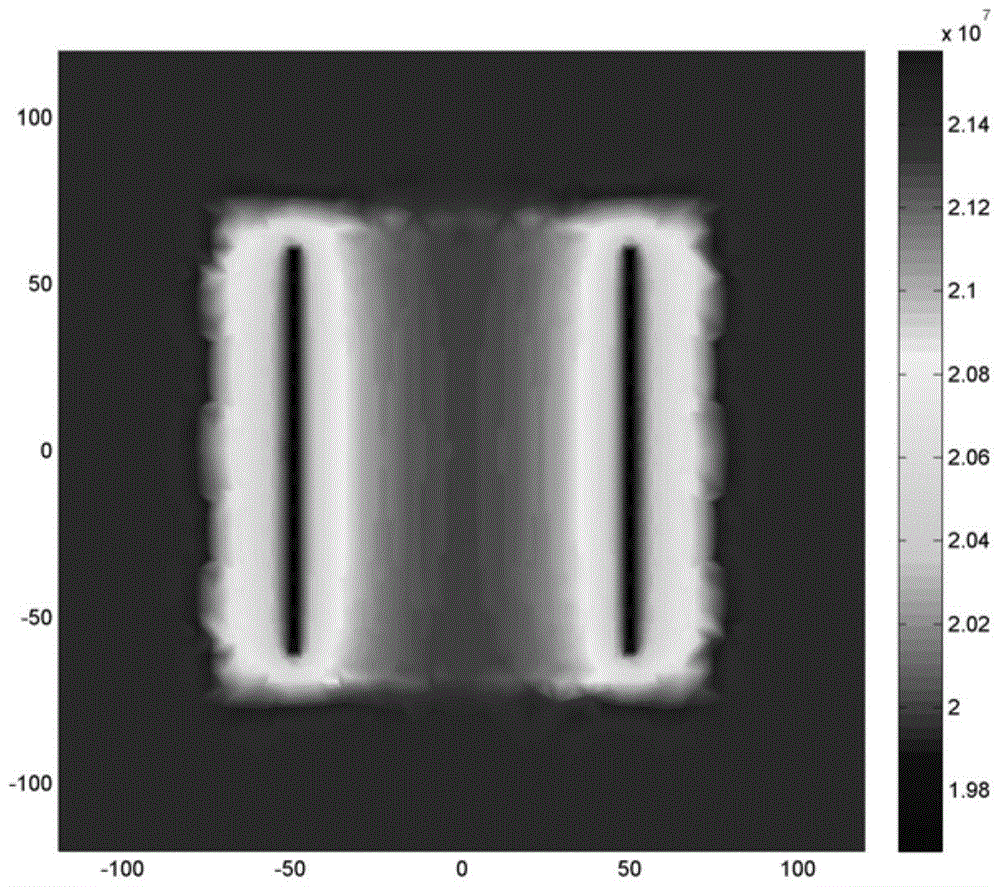

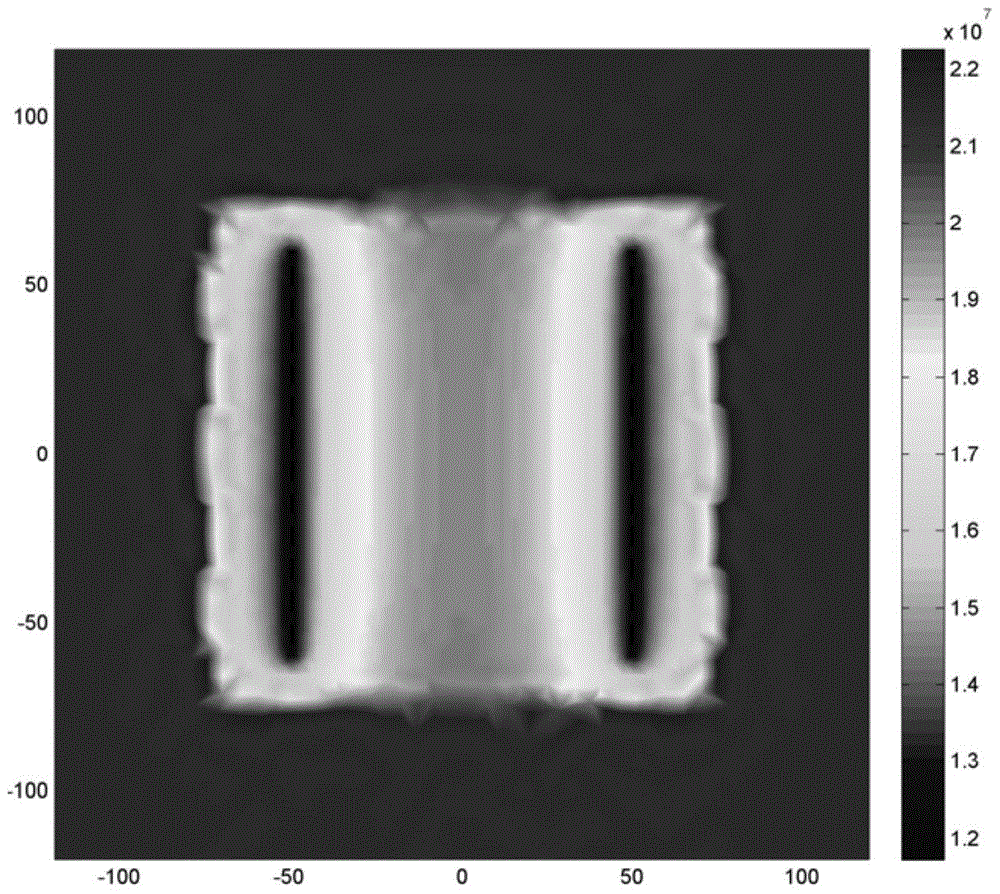

Method and apparatus for predicting multi-section fracturing productivity of shale gas reservoir horizontal well

ActiveCN105046006AReduce computing costAccurate predictionSpecial data processing applicationsPredictive methodsPhysical model

The invention relates to a method and an apparatus for predicting multi-section fracturing productivity of a shale gas reservoir horizontal well. The prediction method comprises: obtaining shale gas reservoir original parameters after fracturing modification; establishing a physical model for a target region by utilizing the shale gas reservoir original parameters, and obtaining a strong form control equation of gas flow in a shale matrix and a strong form control equation of gas flow in a fracture network; establishing a control equation for the gas flow in the shale matrix and a comprehensive control equation for the flow in a fracture system by utilizing the strong form control equation of the gas flow in the shale matrix and the strong form control equation of the gas flow in the fracture network; establishing a strong discontinuous expansion function; substituting the strong discontinuous expansion function to the control equation for the gas flow in the shale matrix and the comprehensive control equation for the flow in the fracture system to calculate fracture pressure distribution; and substituting the fracture pressure distribution into a productivity equation to obtain shale gas productivity.

Owner:PETROCHINA CO LTD

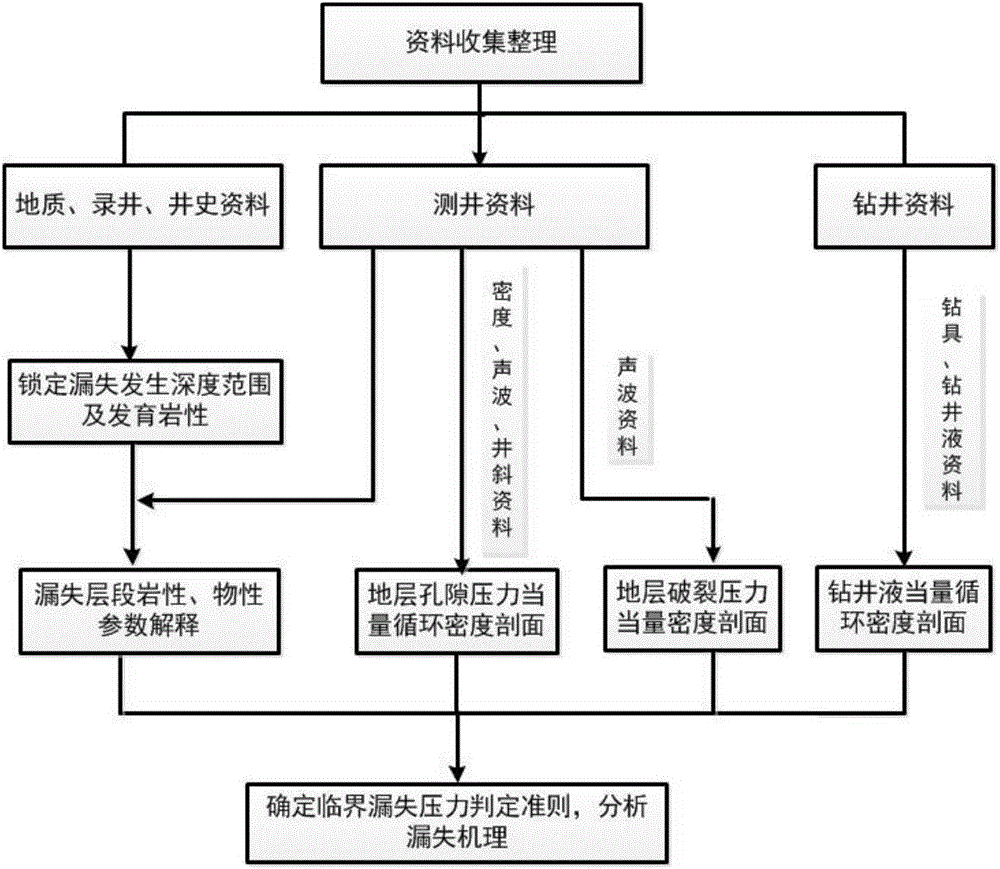

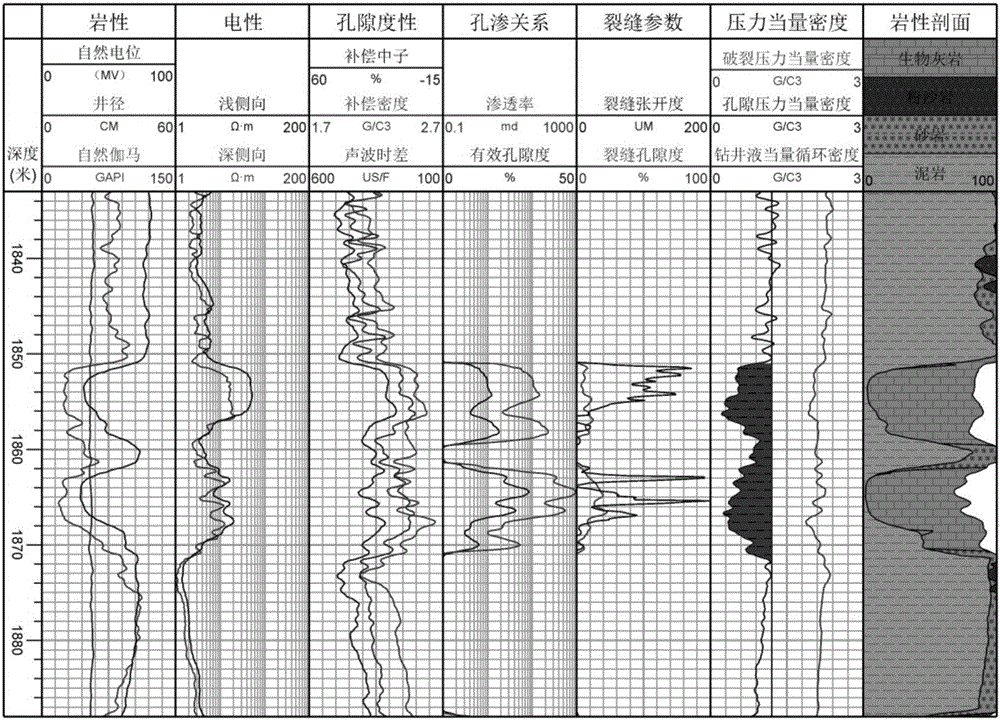

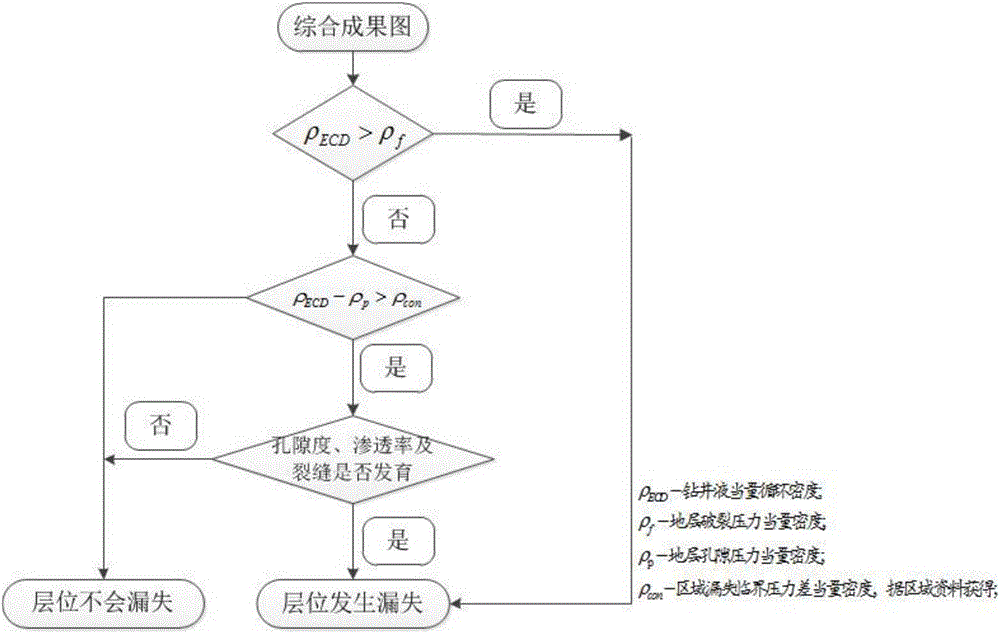

Well drilling thief zone location identification method based on multi-message fusion

The invention provides a well drilling thief zone location identification method based on multi-message fusion, and belongs to the field of well drilling exploration. A thief zone can be accurately determined and thief zone property parameters can be accurately calculated according to essential conditions for leakage. The well drilling thief zone location identification method based on multi-message fusion includes the specific steps that (1) according to drilling fluid summaries and comprehensive logging record data, the leakage depth range is locked, and the developed lithology of a formation within the depth range is locked; (2) lithology and physical property parameters within the leakage depth range locked in the first step are explained and calculated through logging information and geologic information; (3) the equivalent circulating density of drilling fluid, the formation pore pressure equivalent density and the formation fracture pressure equivalent density are calculated according to logging and engineering information; and (4) data obtained in the step (1), the step (2) and the step (3) are sorted to draw a comprehensive result map, thief zone location identification is carried out through the comprehensive result map, and the leakage mechanism is analyzed.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Polyvinylidene fluoride hollow fiber ultrafiltration membrane with permanent hydrophilcity and preparation method thereof

The invention discloses a polyvinylidene fluoride hollow fiber ultrafiltration membrane with permanent hydrophilcity and a preparation method thereof. The preparation method comprises the following steps of: sequentially adding 13 wt% to 25 wt% of polyvinylidene fluoride, 8 wt% to 16 wt% of additives and 0.02 wt% to 3.0 wt% of surface active agents and solvents in a dissolving tank, and then stirring for dissolving for 2 to 16 hours at 15 to 90 DEG C to the fully uniform state to prepare that initial membrane casting liquid; sequentially adding initiating agents accounting for 0.1 wt% to 3.5 wt% of polar monomers and the polar monomers accounting for 0.1 wt% to 5.0 wt% of the membrane casting liquid in the membrane casting liquid, and reacting for 1 to 12 hours at 15 to 90 DEG C to prepare hydrophilic membrane casting liquid; and preparing the hydrophilic hollow fiber ultrafiltration membrane by adopting the traditional dry-wet spinning technology. For the hydrophilic polyvinylidene fluoride hollow fiber ultrafiltration membrane prepared in the preparation method, the pure water permeability coefficient is greater than 230 L / m2*hr*0.1MPa, the retention rate of bovine serum albumin (67000MW) is greater than 95.0%, the breaking elongation rate of fibers is greater than 200%, and the fracture pressure is greater than 0.55 MPa. The polyvinylidene fluoride hollow fiber ultrafiltration membrane with permanent hydrophilcity is especially suitable for deep treatment and recycling of waste water, clarification and separation in the fields of biochemical engineering and medicament, and the like.

Owner:UNIV OF JINAN

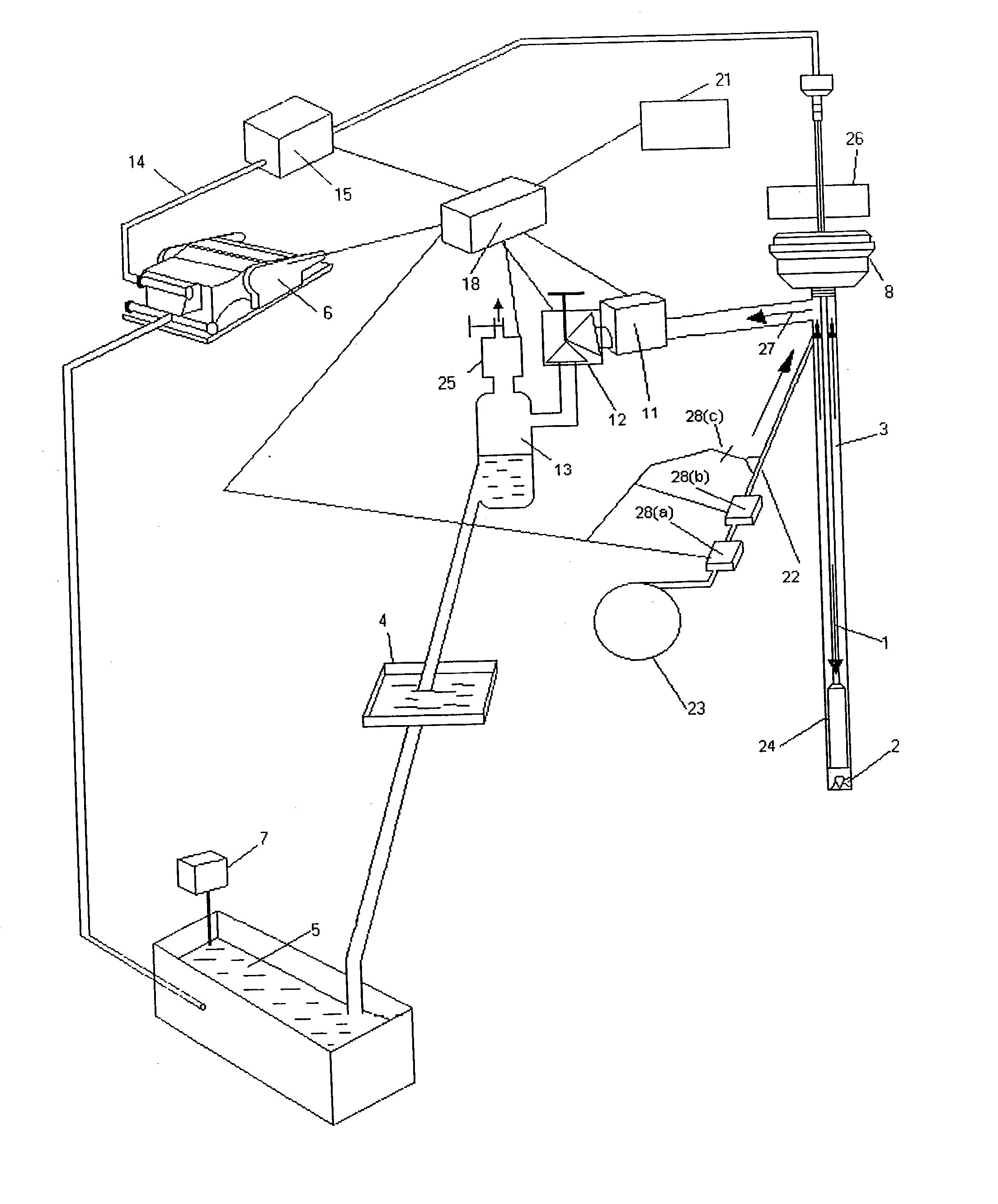

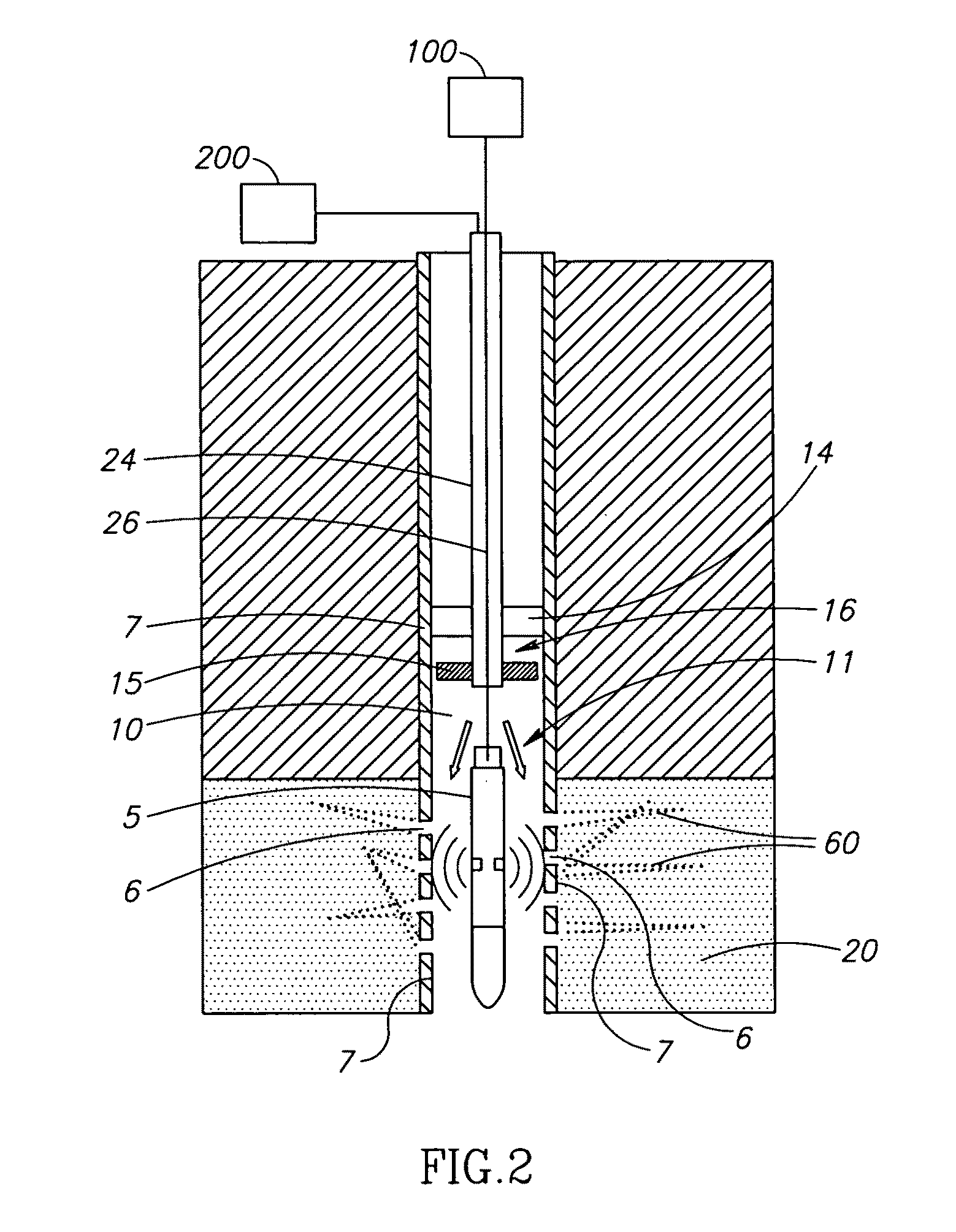

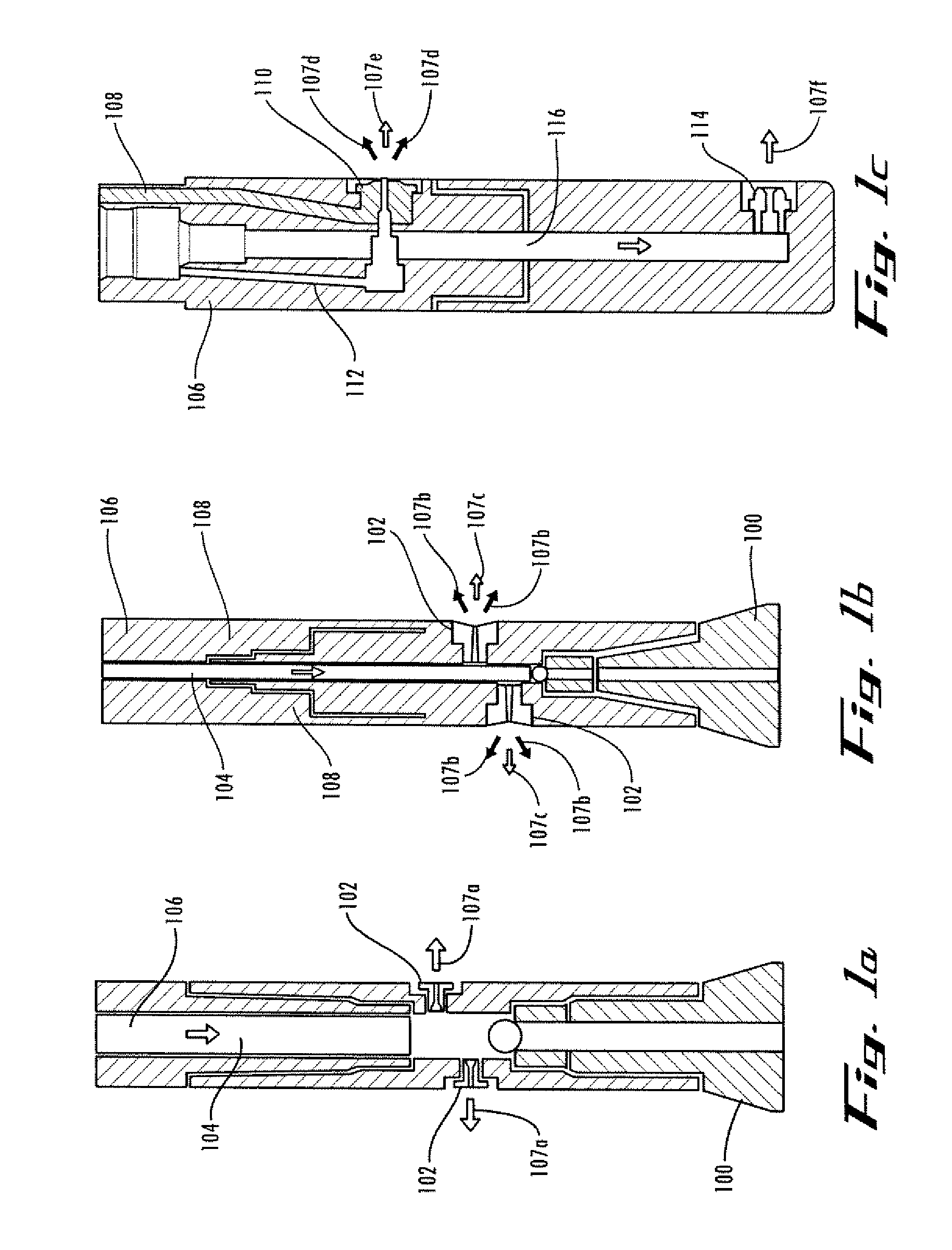

Method for impulse stimulation of oil and gas well production

A method for fracturing an oil or gas formation. The method includes introducing a gas impulse device into a wellbore followed by pumping a pressurized liquid into a wellbore at a pressure equal to or lower than the estimated fracture pressure of the formation. Finally, the method includes firing the gas impulse device periodically so that the device releases high pressure compressed gas impulses. The impulses when expanding through the pumped pressurized liquid substantially instantaneously increases the fracturing liquid flow rate into the oil or gas formation. It causes the total pressure to exceed the actual fracturing pressure of the formation thereby initiating or extending fractures in the formation stimulating the flow of the oil or gas therefrom into the wellbore. Use of the method of the invention in waterflooding and preventing lost circulation is also described.

Owner:FLOW IND INC A WASHINGTON (USA) COPROPORATION

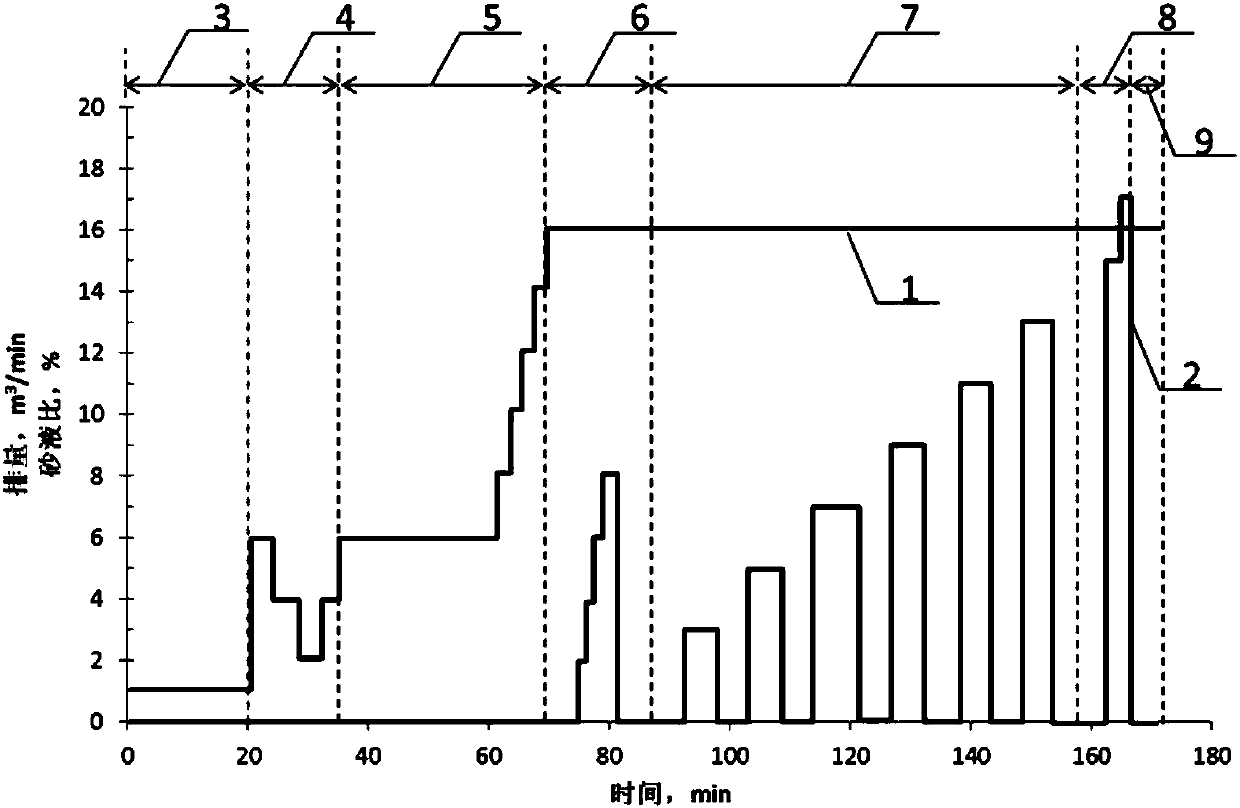

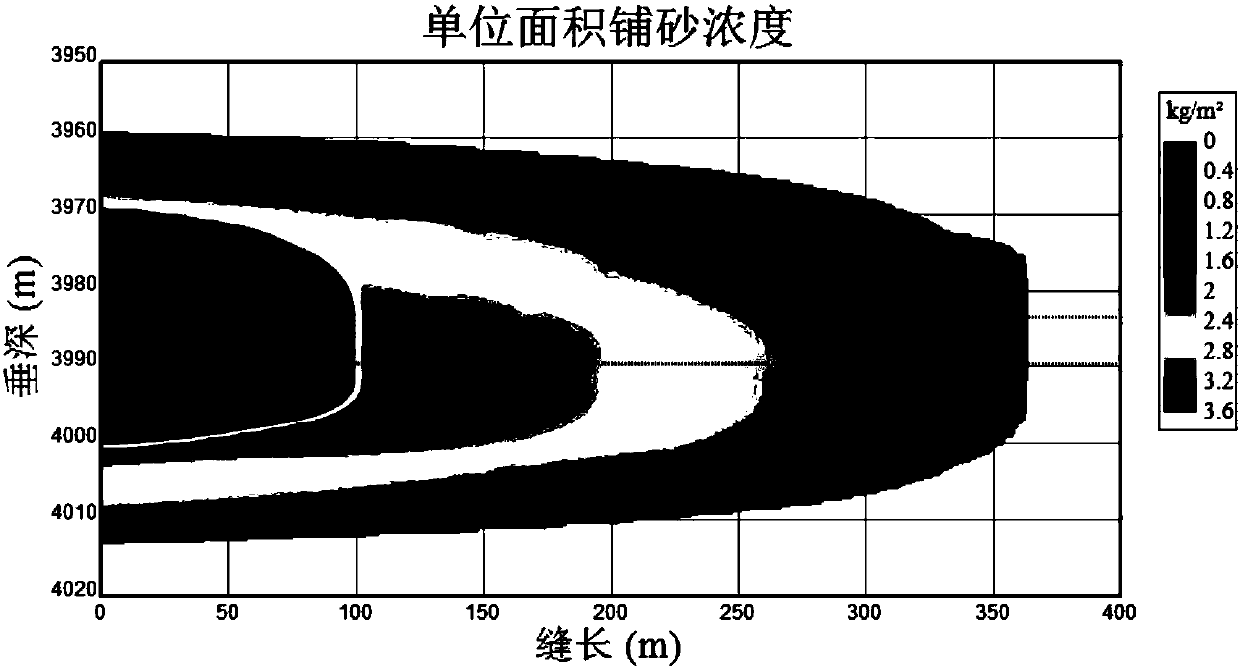

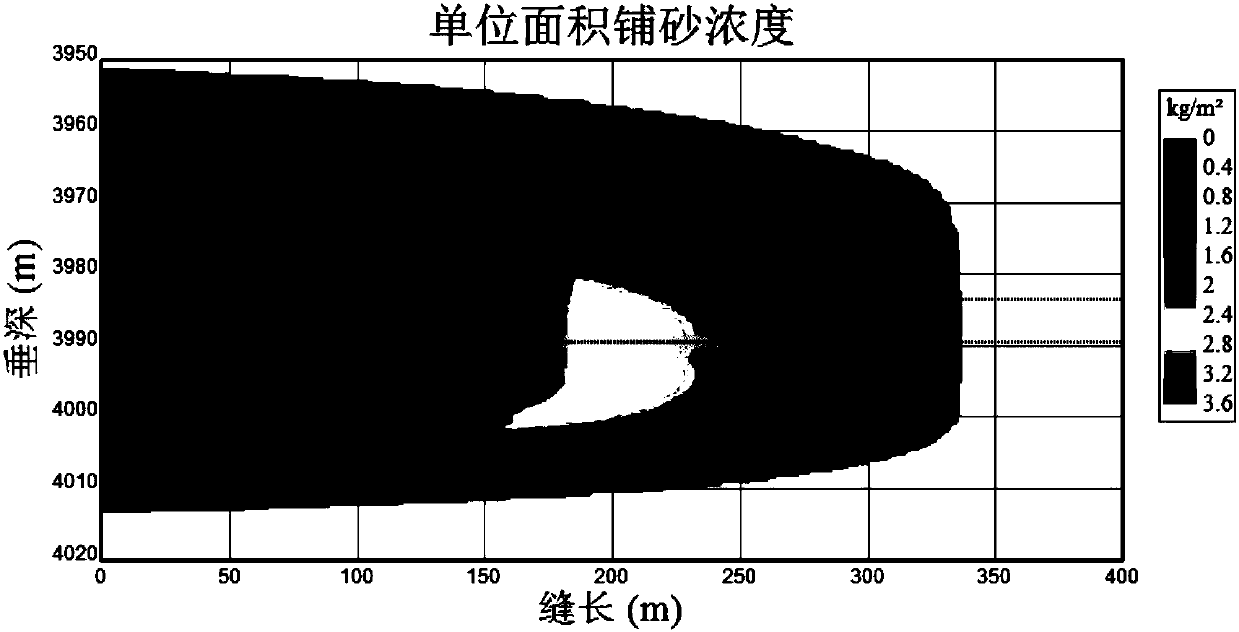

Volume fracturing method of deep shale gas multi-scale proppant packing

The invention discloses a volume fracturing method of deep shale gas multi-scale proppant packing. The volume fracturing method of deep shale gas multi-scale proppant packing comprises the following steps: (1) evaluating key engineering parameters of shale gas; (2) determining a fracturing fluid system and a proppant; (3) optimizing fracture parameters and fracturing construction parameters; (4) determining the position of a fracturing section shower hole and perforating parameters; (5) carrying out acid pretreatment; (6) carrying out low viscosity quick water low-displacement fracture heightcontrolling fracturing; (7) carrying out ultra low density proppant screen-out fracturing; (8) carrying out multi-scale fracture fracturing packing; and (9) according to a hole volume of each fracturing section, carrying out over-displacing operation according to 110-120%. The volume fracturing method of deep shale gas multi-scale proppant packing, disclosed by the invention, has the advantages that the net pressure is effectively increased by combining processes of optimizing acid treatment to reduce a fracture pressure, carrying out low viscosity quick water low-displacement injection fracture height controlling, screening out in a mixed ultra low density proppant fracture and so on, and through full-process small particle size proppant injection construction, the filling degree of the deep shale gas fracture system of small and micro fracture development is enhanced. Therefore, the effective volume of the fracture is further increased, and the long-time fracture flow conductivity isfurther improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

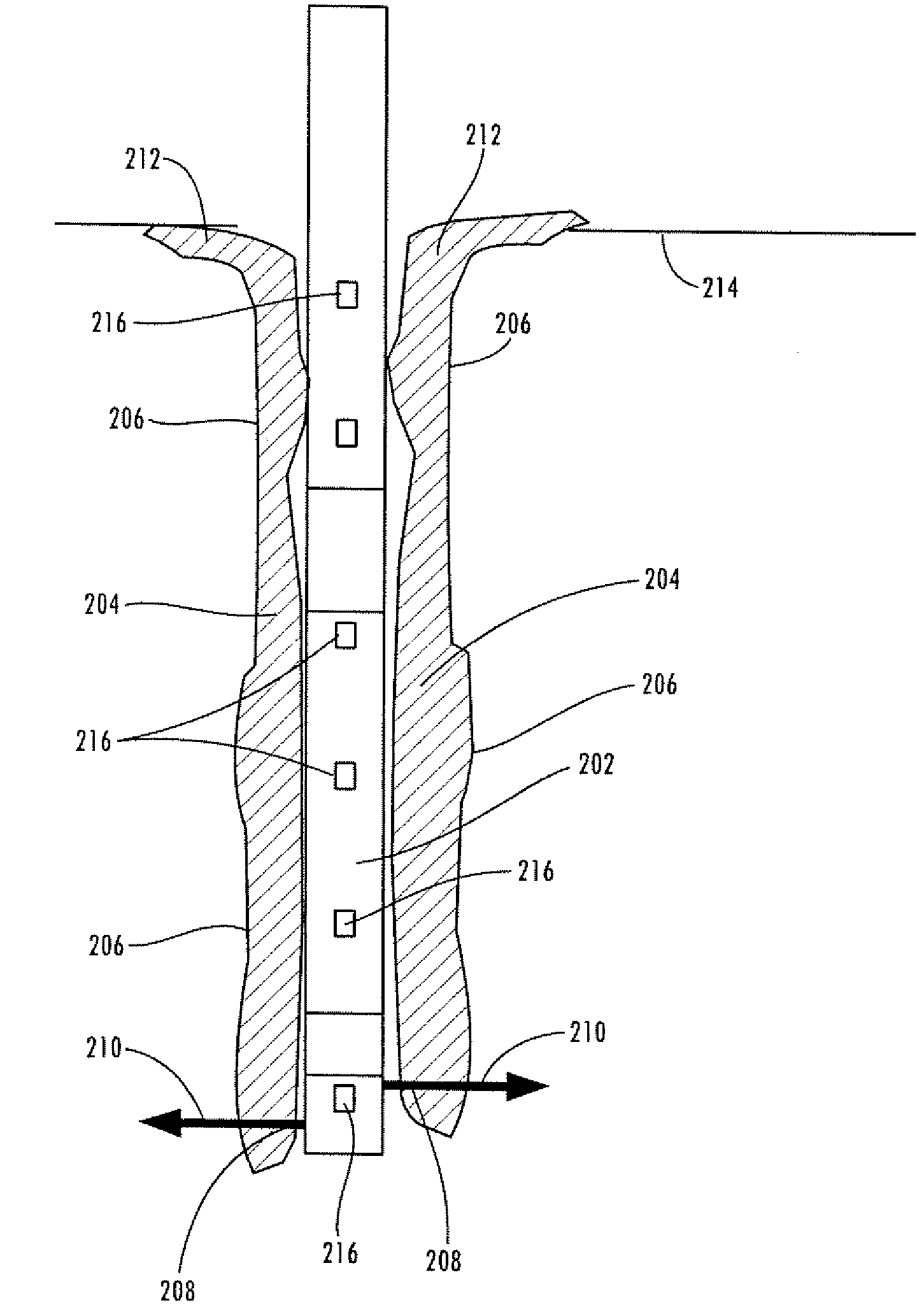

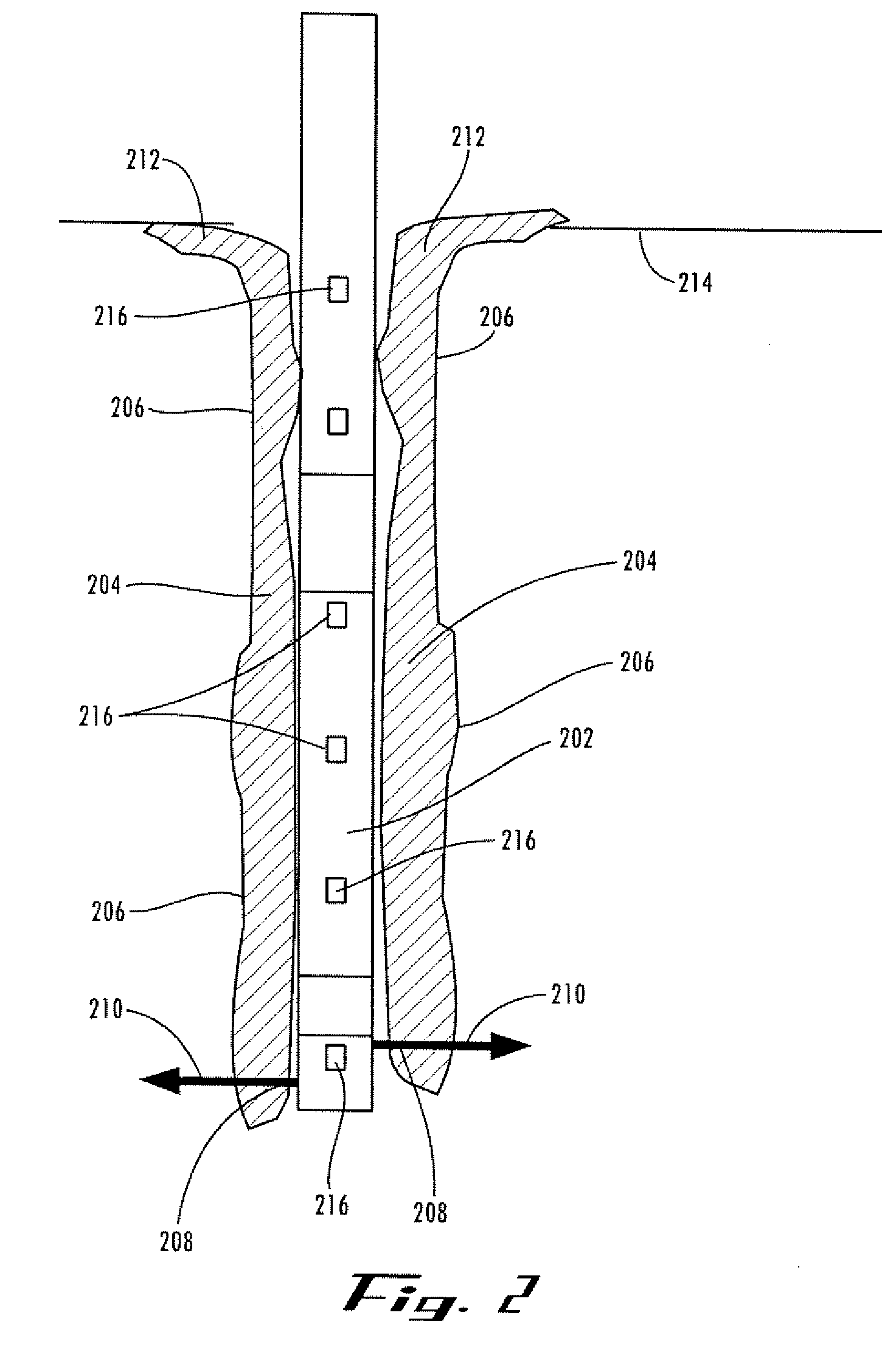

Shock-release fluid fracturing method and apparatus

A shock tool is adapted to a bottom hole tool assembly for isolating a zone in a subterranean formation accessed by a wellbore. Fracturing fluid such as nitrogen is accumulated at fracturing pressures uphole of the shock tool for subsequent and rapid release to the formation. Coal bed methane seams are particularly well suited to such a shock fracturing methodology. The tool assembly can be suspended from a conveyance string in which fluid is accumulated for shock release through a valve of the shock tool and through an injection tool to the zone isolated by the injection tool. After a first zone is shocked, the tool assembly can be moved to a new zone, or multiple shocks can be applied cyclically at the selected zone.

Owner:CALFRAC WELL SERVICES

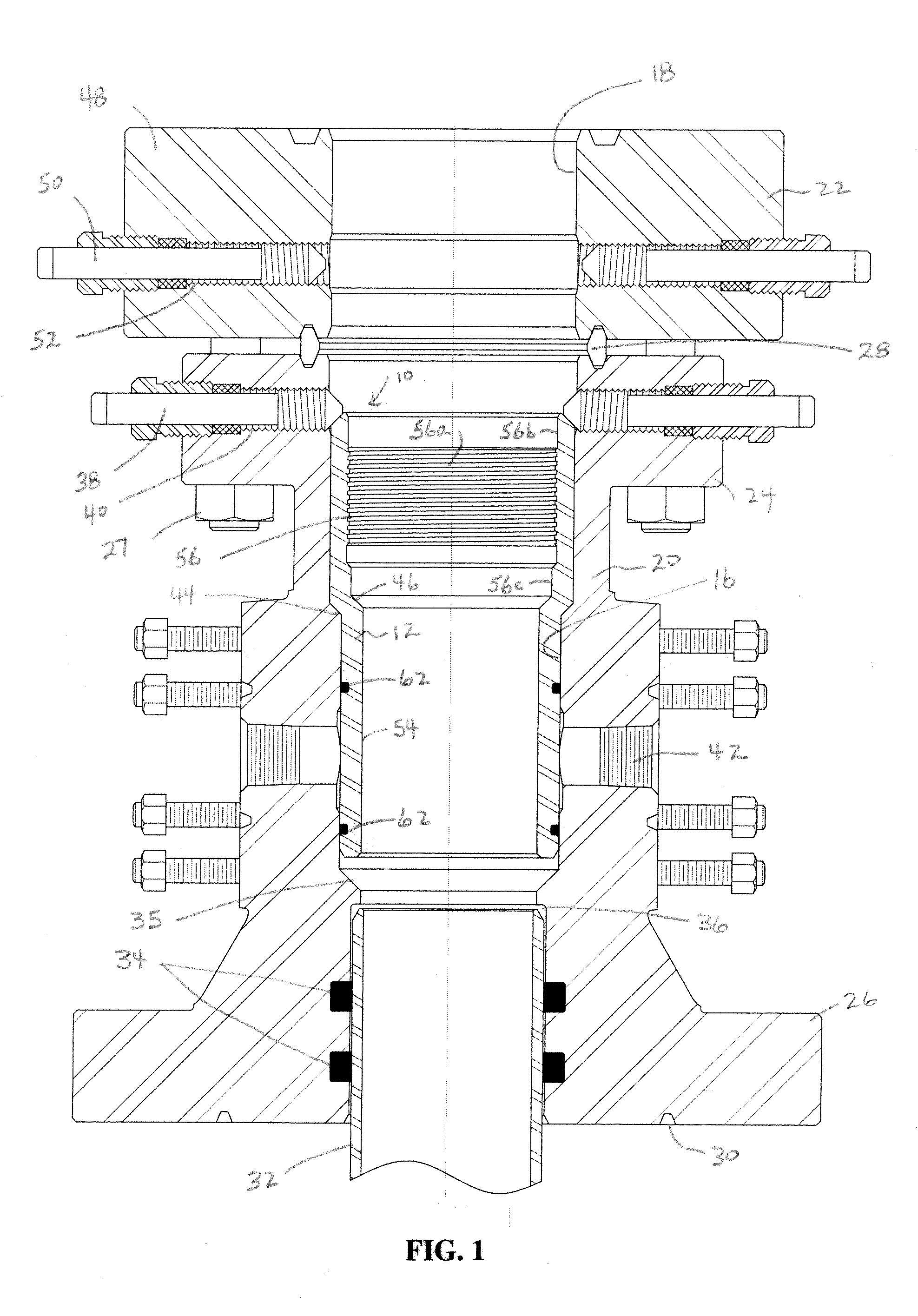

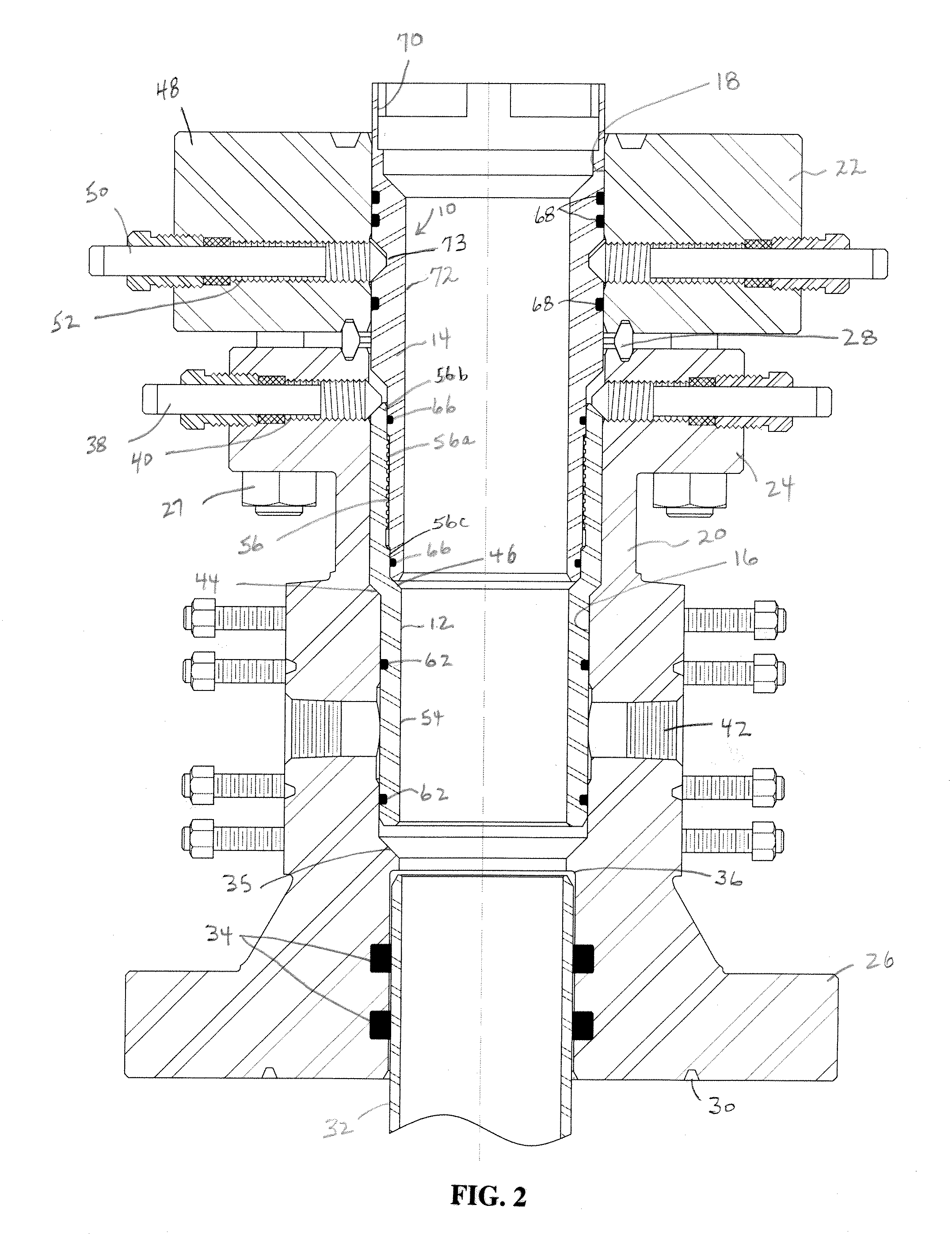

Method and apparatus for isolating a wellhead for fracturing

A welihead assembly to seal to a production casing including one or more pressure-containing wellhead body members defining a vertical bore, with the lowermost of the wellhead body members sealing to the production casing. A fracturing isolation tool is sealed in the vertical bore of the wellhead body members above the production casing, and forms a pressure barrier profile in its internal bore. A removable protector sleeve is located at least partially within the fracturing isolation tool to seal, protect, isolate and cover the pressure barrier profile against a fracturing pressure and a fracturing fluid. After fracturing the protector sleeve is removed and a pressure barrier is sealed in the pressure barrier profile of the fracturing isolation tool. The invention also extends to the method of isolating the wellhead body members and to the fracturing isolation tool assembly which includes the fracturing isolation tool and the protector sleeve.

Owner:STREAM FLO INDS

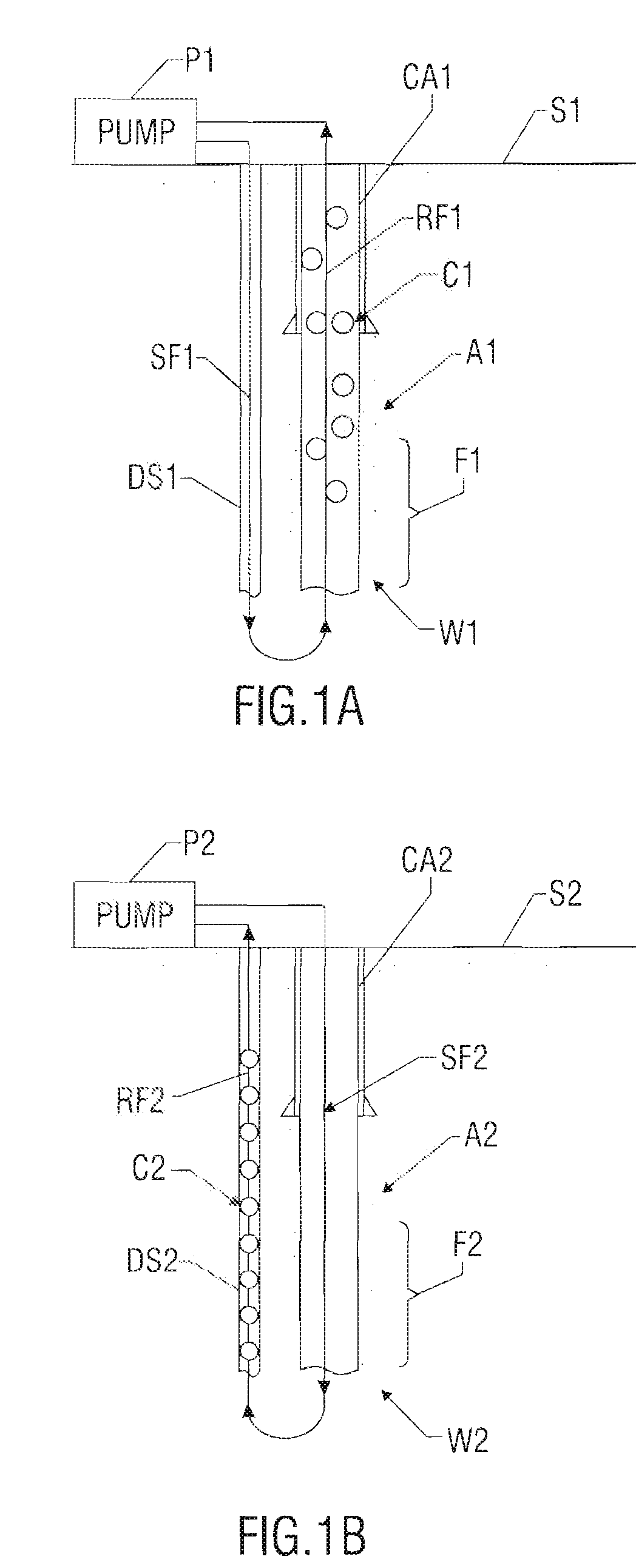

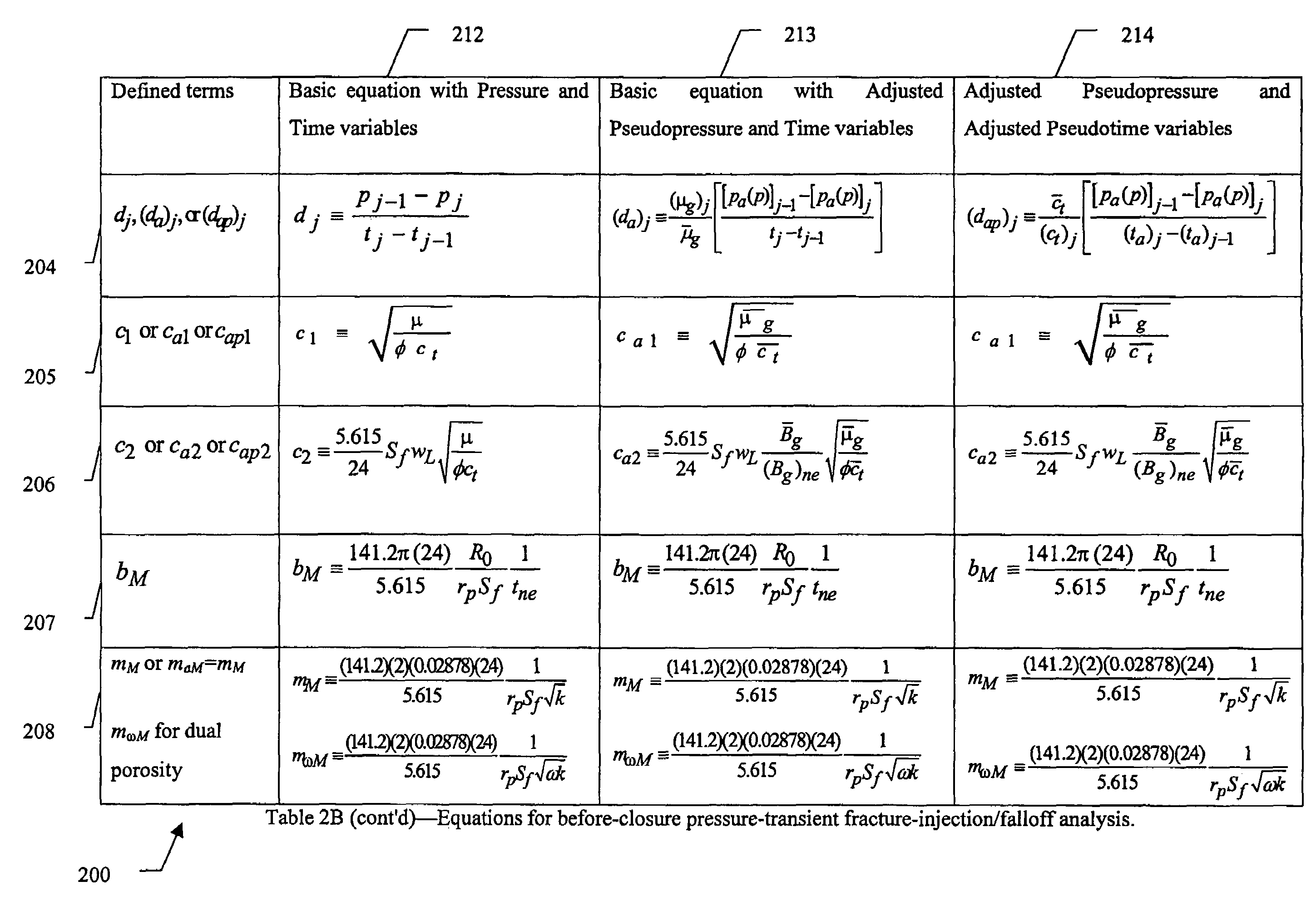

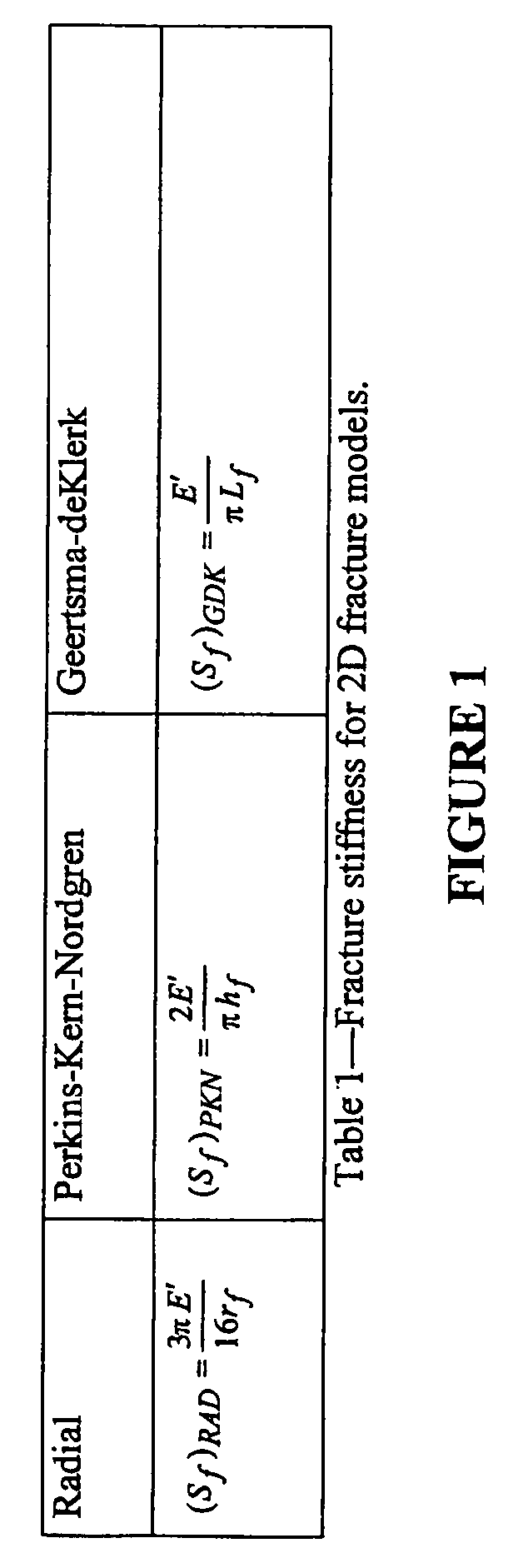

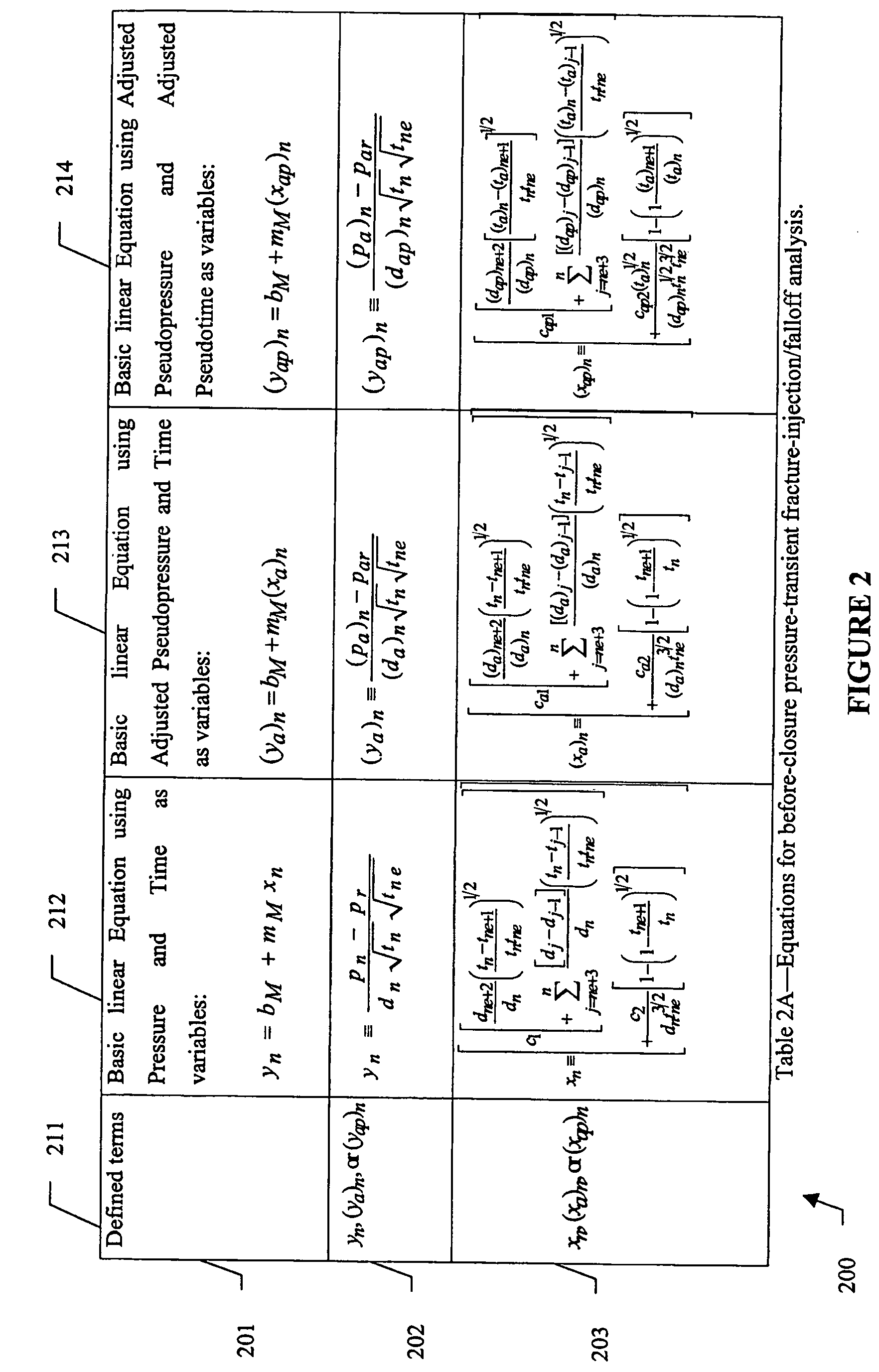

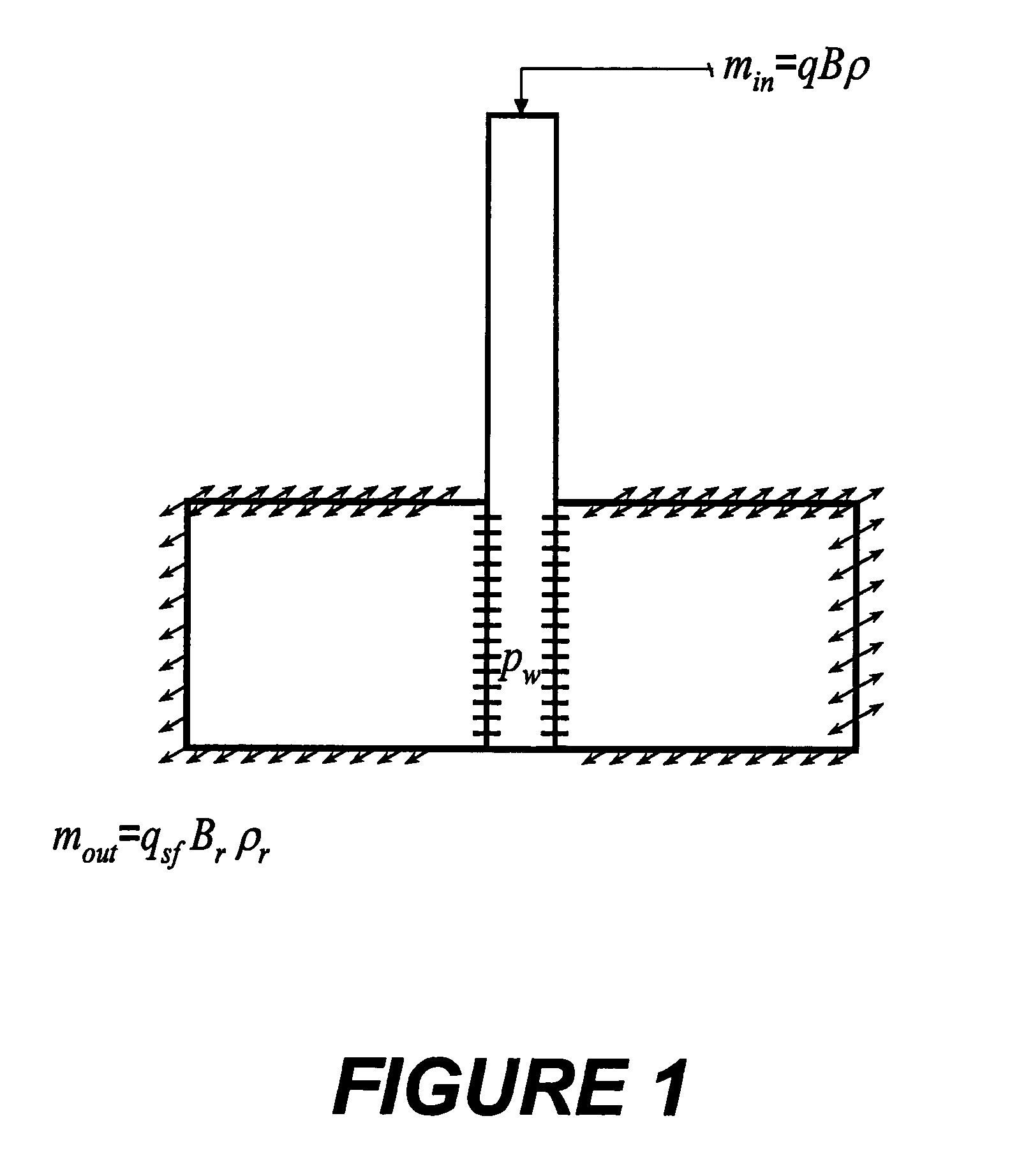

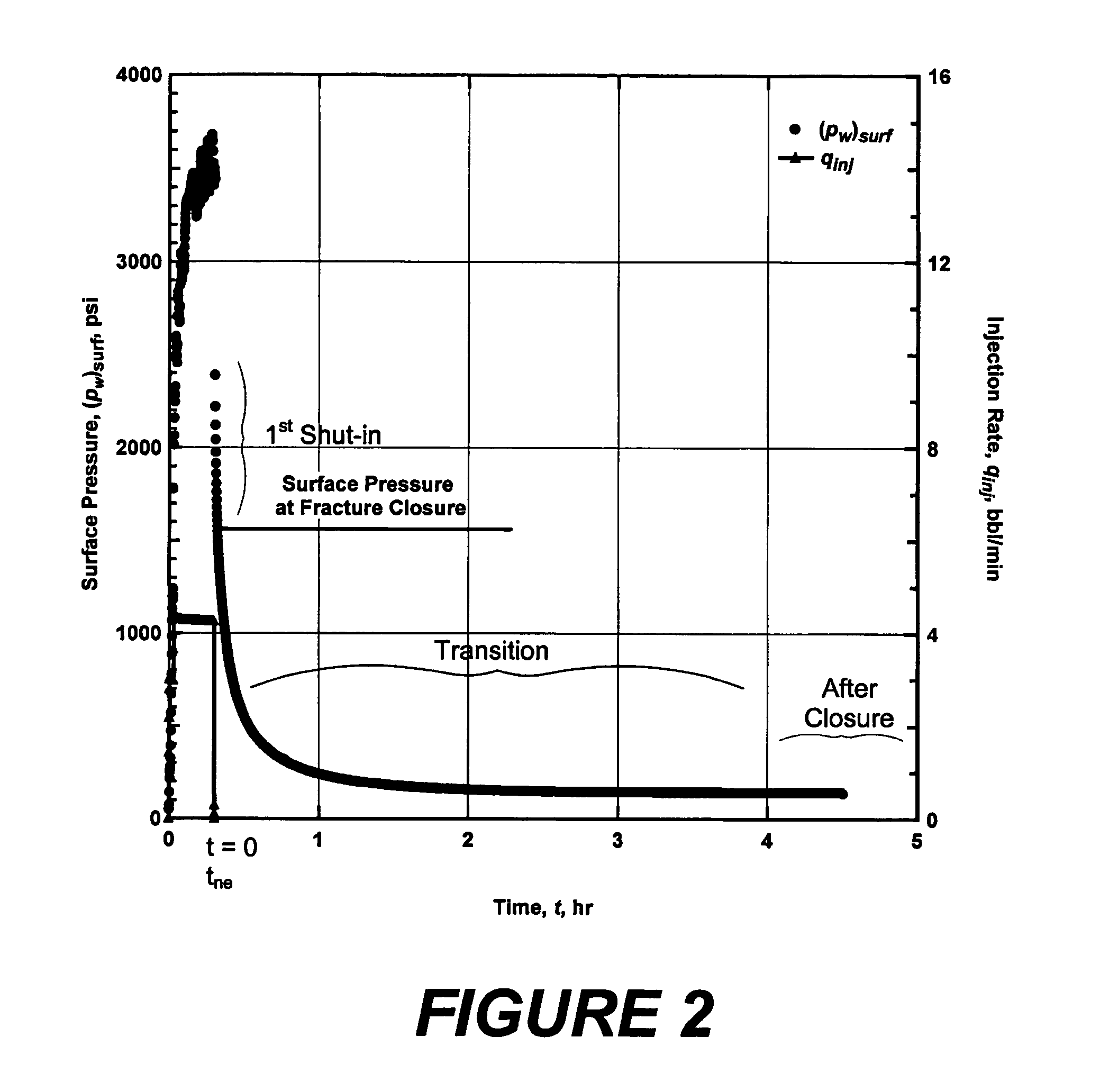

Methods and apparatus for estimating physical parameters of reservoirs using pressure transient fracture injection/falloff test analysis

ActiveUS7054751B2Reduce adverse effectsError minimizationElectric/magnetic detection for well-loggingPermeability/surface area analysisInjection pressureEmulsion

A before-closure pressure-transient leakoff analysis for a fracture-injection / falloff test is used to mitigate the detrimental effects of pressure-dependent fluid properties on the evaluation of physical parameters of a reservoir. A fracture-injection / falloff test consists of an injection of liquid, gas, or a combination (foam, emulsion, etc.) containing desirable additives for compatibility with the formation at an injection pressure exceeding the formation fracture pressure followed by a shut-in period. The pressure falloff during the shut-in period is measured and analyzed to determine permeability and fracture-face resistance by preparing a specialized Cartesian graph from the shut-in data using adjusted pseudodata such as adjusted pseudopressure data and time as variables in a first method, and adjusted pseudopressure and adjusted pseudotime data as variables in a second method.

Owner:HALLIBURTON ENERGY SERVICES INC

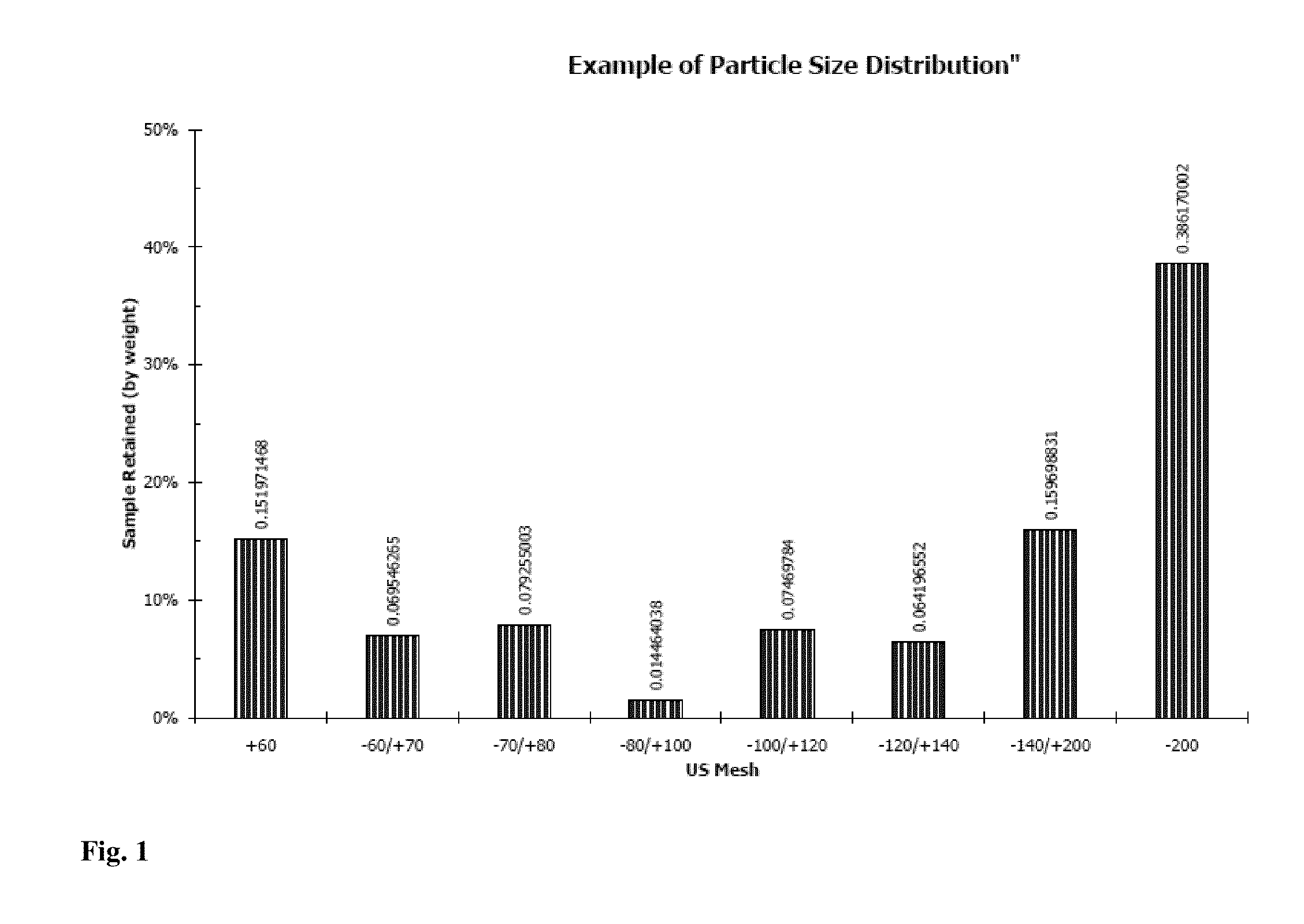

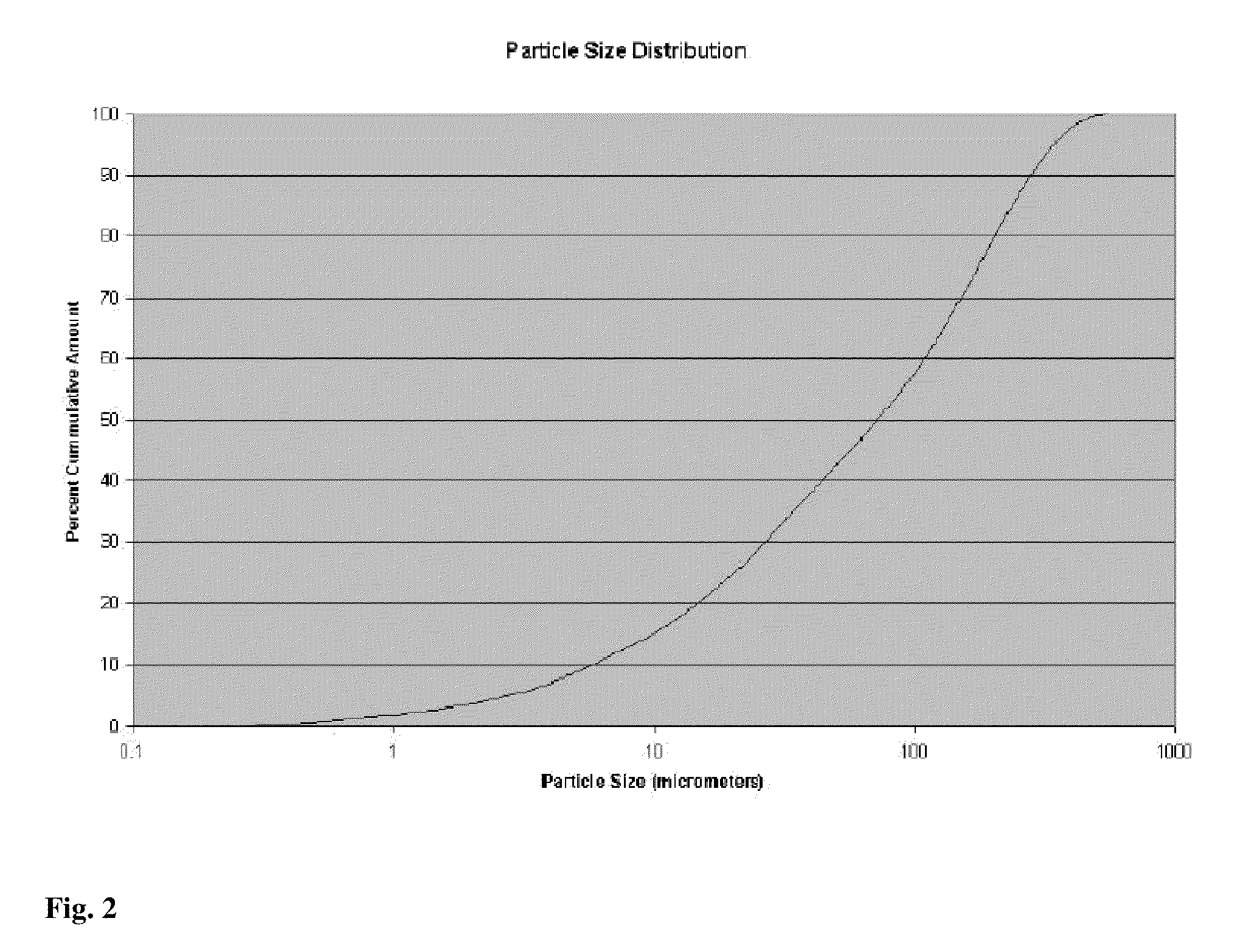

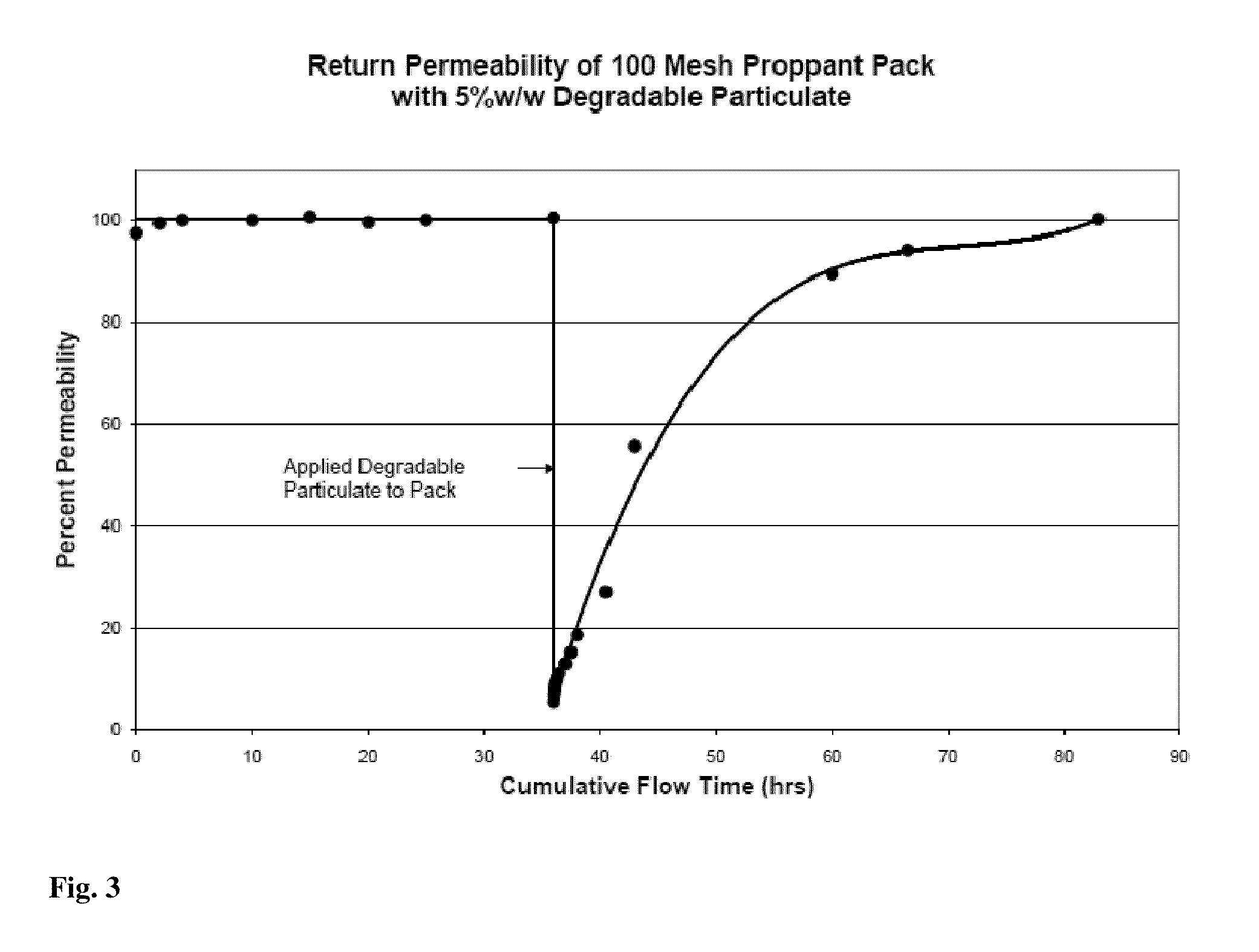

Increasing fracture complexity in ultra-low permeable subterranean formation using degradable particulate

ActiveUS20110120713A1Increasing fracture complexityFluid removalDrilling compositionFracturing fluidSolid particle

A method of increasing the fracture complexity in a treatment zone of a subterranean formation is provided. The subterranean formation is characterized by having a matrix permeability less than 1.0 microDarcy. The method includes the step of pumping one or more fracturing fluids into a far-field region of a treatment zone of the subterranean formation at a rate and pressure above the fracture pressure of the treatment zone. A first fracturing fluid of the one or more fracturing fluids includes a first solid particulate, wherein: (a) the first solid particulate includes a particle size distribution for bridging the pore throats of a proppant pack previously formed or to be formed in the treatment zone; and (b) the first solid particulate comprises a degradable material. In an embodiment, the first solid particulate is in an insufficient amount in the first fracturing fluid to increase the packed volume fraction of any region of the proppant pack to greater than 73%. Similar methods using stepwise fracturing fluids and remedial fracturing treatments are provided.

Owner:HALLIBURTON ENERGY SERVICES INC

Methods and Systems for Monitoring Pressure During Jet Grouting

InactiveUS20070014640A1Preventing soil fractureHigh riskOrganic fertilisersSoil conditioning compositionsFracture pressureEnvironmental geology

A method for preventing soil fracture and / or monitoring borehole pressure during jet grouting that may include monitoring borehole pressure at one or more points in a jet grouting borehole while the jet grouting is being performed and determining whether the borehole pressure exceeds a predetermined limit. The method may further include providing notification to a jet grouting operator that there is a high risk of soil fracture if the borehole pressure exceeds the predetermined limit. The predetermined limit may be the estimated fracture pressure of the soil in which the jet grouting is being performed.

Owner:KAUSCHINGER JOSEPH

Method and an apparatus for detecting fracture with significant residual width from previous treatments

ActiveUS7774140B2Rapid determinationElectric/magnetic detection for well-loggingSurveyDual unitReservoir fluid

Owner:HALLIBURTON ENERGY SERVICES INC

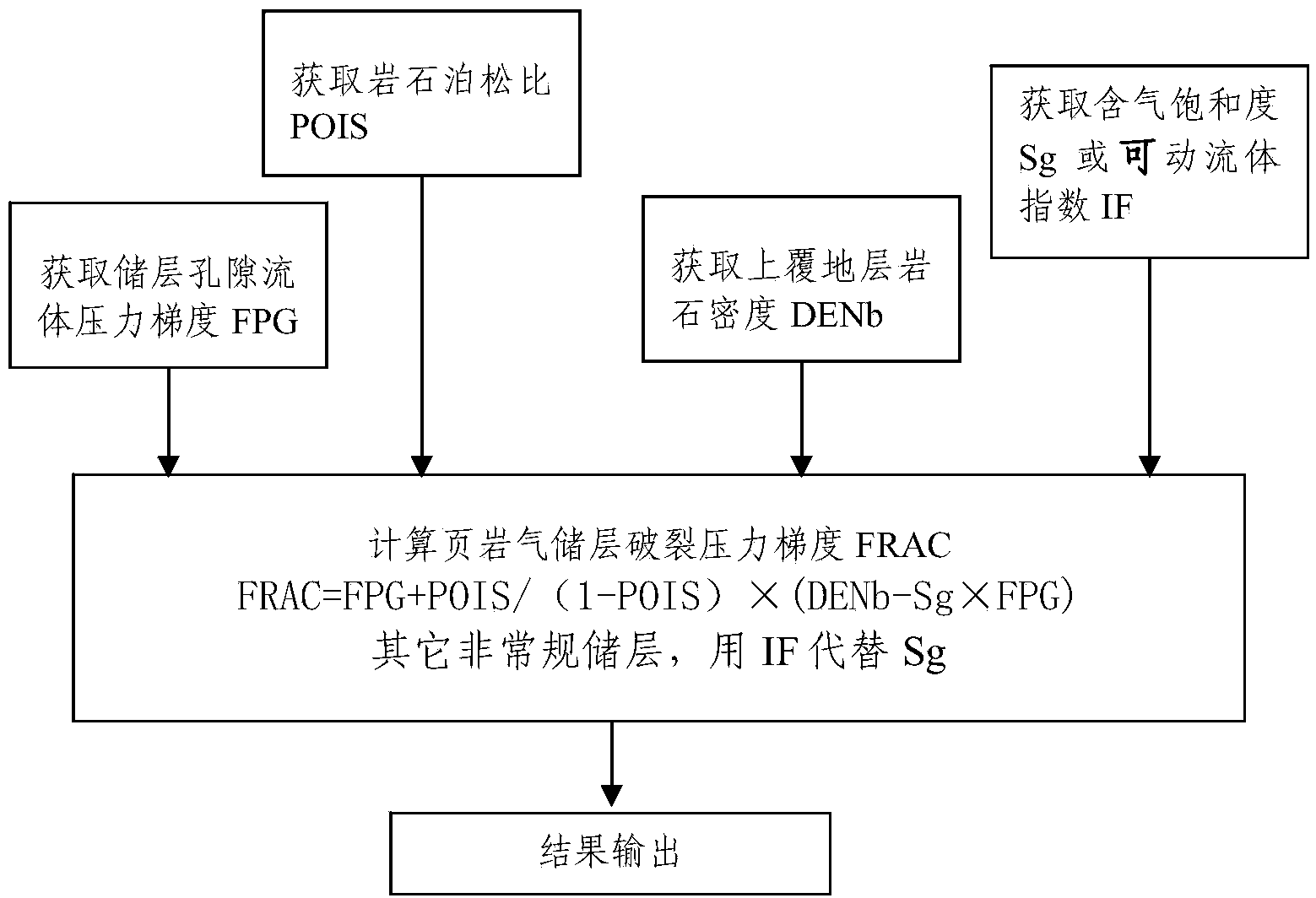

Method for determining formation fracture pressure gradient logging of shale gas reservoir

The invention relates to a method for determining formation fracture pressure gradient logging of a shale gas reservoir. The method comprises the following steps of calculating formation fracture pressure gradient of an objective layer of the shale gas reservoir by evaluating according to layers or according to certain step length in the layers; acquiring formation hole fluid pressure gradient of the objective layer through logging or well measuring information; acquiring the rock poisson ratio of the objective layer through logging or indoor core experimental analysis information; acquiring gas saturation through logging or well measuring information; acquiring overlaying formation lithology density through well measuring information; calculating the formation fracture pressure gradient FRAC of the shale gas reservoir according to the formula: FRAC=FPG+POIS / (1-POIS)*(DENb-Sg*FPG); and outputting a result according to a formula: FP=FRAC*H / 100. The method is applied to 32 shale gas wells in the Jiannan gas field of the middle yangtze region, the shale gas field of the Fuling region, the western Hunan region and the western Hubei region; and the error of a calculated value and the actually acquired formation fracture pressure gradient is &1t;10%.

Owner:CHINA PETROCHEMICAL CORP +2

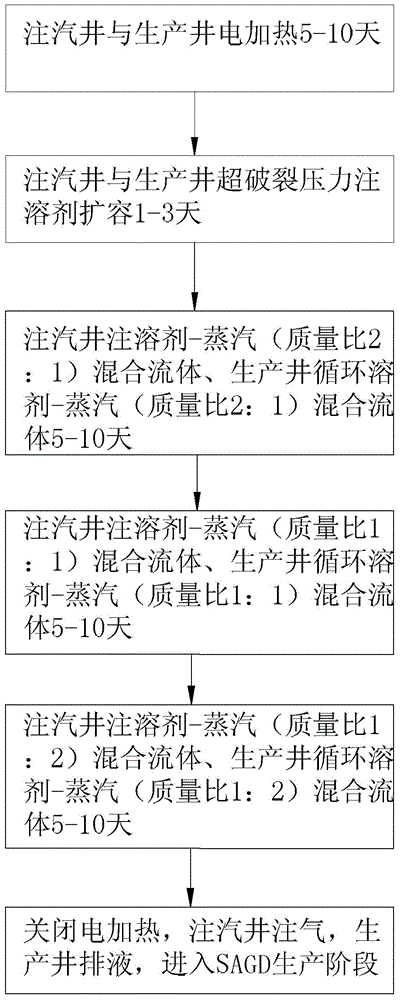

Rapid start method for heavy oil reservoir steam assisted gravity drainage

ActiveCN104453805ABuild pressure connectionIncrease the range of viscosity reductionFluid removalSolventInjection well

The invention discloses a rapid start method for heavy oil reservoir steam assisted gravity drainage. The rapid start method for heavy oil reservoir steam assisted gravity drainage comprises the following steps that (1) a steam injection well and a producing well are electrically heated at a large power; (2) a solvent is injected into a long oil pipe and a short oil pipe of the steam injection well and a long oil pipe and a short oil pipe of the producing well at the same time; (3) a solvent and steam liquid mixture is injected into the long oil pipe and the short oil pipe of the steam injection well at the same time, the solvent and steam liquid mixture is injected into the long oil pipe of the producing well, and the short oil pipe of the producing well discharges liquid; (4) electric heating is stopped, pure steam is injected into the long oil pipe of the steam injection well and the short oil pipe of the seam injection well at the same time, and the long oil pipe and the short oil pipe of the producing well discharge liquid at the same time. Compared with a conventional preheating start method, time is shortened by over two thirds, so that the heat energy utilization rate is greatly increased, rapid preheating start of SAGD can be achieved, and the production speed of SAGD is increased. In addition, through rapid solvent volume expansion and super fracture pressure injection, an even oil drainage channel can be established, and the purposes of increasing the yield and the recovery rate are achieved.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com