Directional fracturing permeability improvement outburst elimination method in coal mine and device thereof.

A directional fracturing and coal mine technology, applied in safety devices, mining equipment, earthwork drilling, etc., can solve the problems of decreased extraction volume, unimproved permeability of the original coal seam, complicated construction procedures, etc., to increase the desorption ratio. The surface area, the dynamic phenomenon of coal body are weakened, and the effect of eliminating outburst is obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

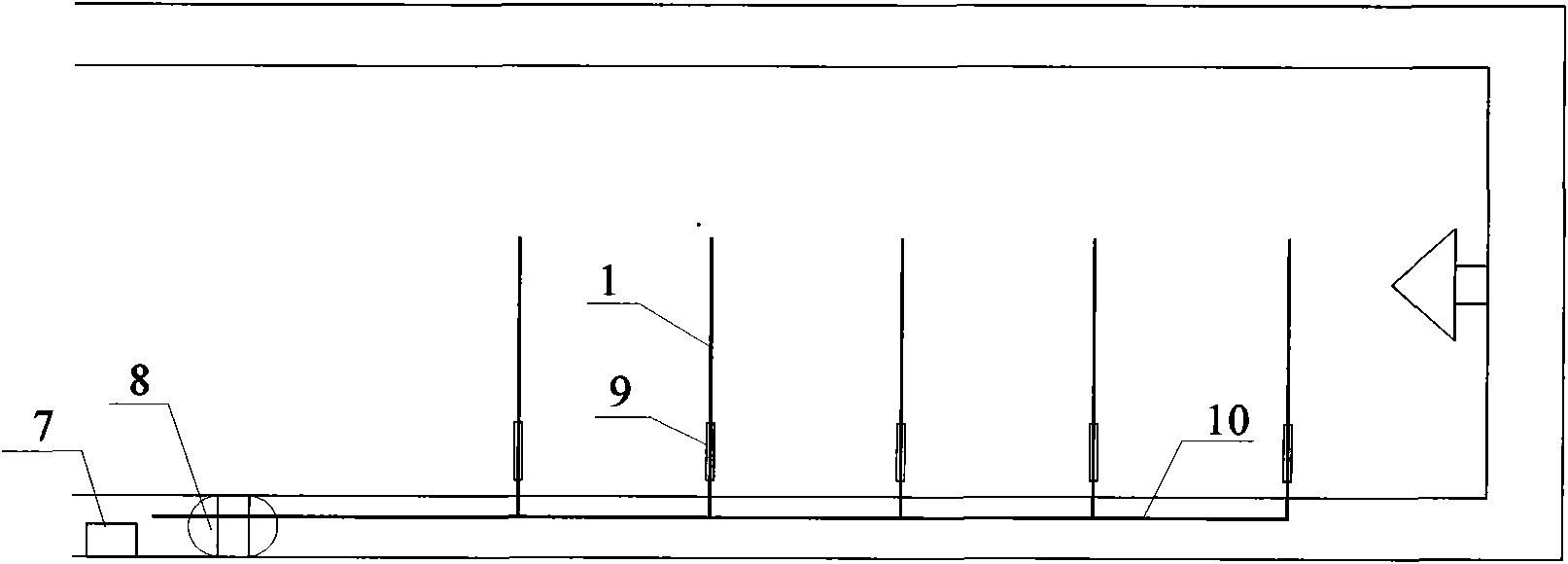

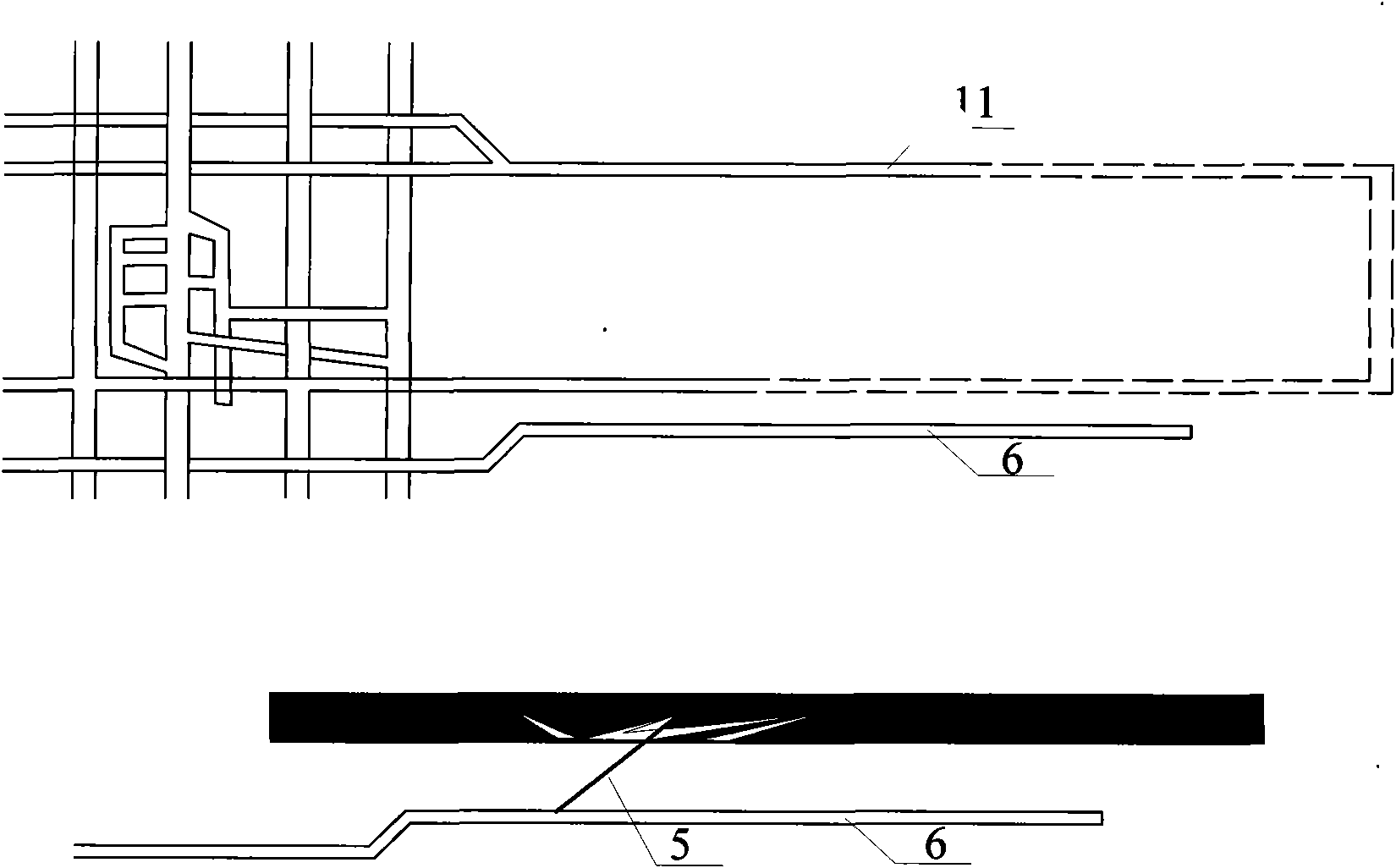

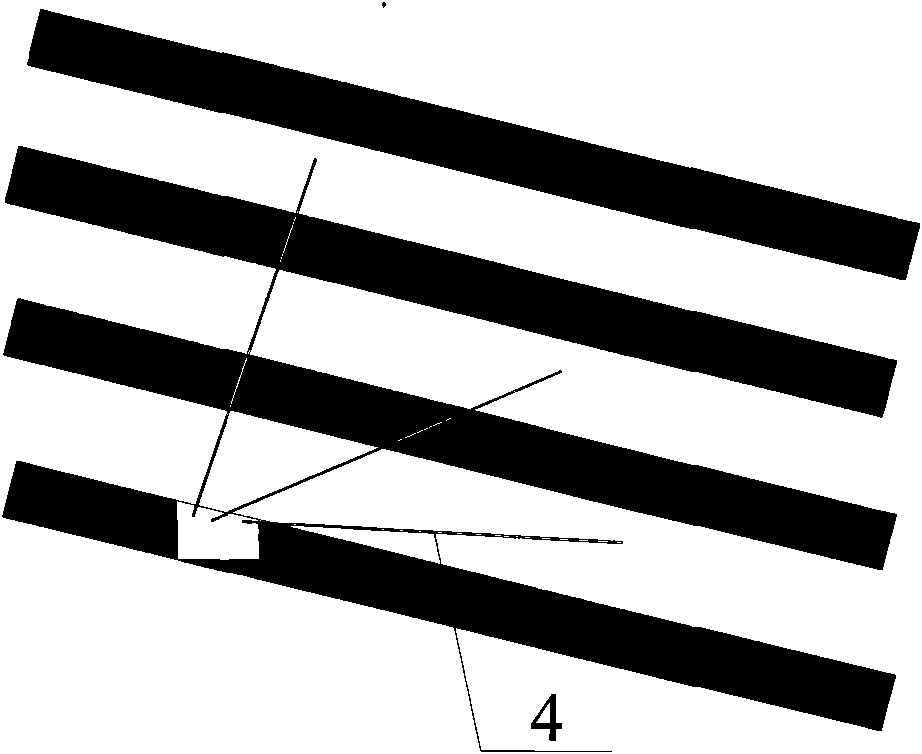

[0025] As shown in the figure, the technical solution of the present invention is carried out according to the following steps:

[0026] In the first step, in the roadway closest to the fracturing target area, that is, in the air inlet roadway 11 of the fracturing target coal seam, excavate the working face and the upper side, and construct the bedding fracturing drilling holes 1, 2. The depth is 60m, and the fracturing hole sealer tool whose outer diameter matches the fracturing borehole diameter is installed in the fracturing hole, that is, the fracturing special hole sealer 9 and other tools are lowered;

[0027] The second step, such as figure 1 As shown, the fracturing equipment 7 is placed outside the nearest anti-draft door 8 in the roadway of the fracturing target area, and the fracturing equipment 7 is connected to the orifice through a high-pressure pipeline 10; the fracturing equipment 7 includes a liquid storage tank 12, a mixer Sand device 13 and fracturing pump ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com