Patents

Literature

141 results about "Drainage rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing, and permeability increasing

InactiveCN101644166AImprove flow statusEasy to extractUnderground miningSurface miningHigh pressure waterHigh pressure

The invention discloses a method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing and permeability increasing, comprising the following steps: whena drill is drilled into a predetermined position of the coal seam, coal bodies at both sides of a drill hole are cut in the drill hole by high pressure water jet with a certain pressure and flow; a flat slot is formed at both sides of the drill hole; the cut coal bodies is led out the hole by the high pressure water jet. The exposed area of the coal body at the slotted part in the drill hole aregreatly increased, namely that an extremely thin protective layer is exploited with local scope of the flat slot, which enlarges effective influential range of pressure releasing, permeability increasing and gas discharging of the coal bodies in the drill hole, thus the air permeability of the coal bodies is increased about 200-300 times, the average amount of single-hole gas extraction reaches 0.3m<3> / min, the concentration of the gas extraction is 30-60%, gas drainage rate of working face of coal extraction is more than 50%, the number of drill holes for gas drainage is reduced by 10-20% after slotting, pressure releasing and permeability increasing. The method realizes the safety, high efficiency and uniform extraction of the gas from the high gas low permeability outburst coal seam, and changes high gas coal seam with outburst danger into low gas coal seam without outburst danger.

Owner:CHINA UNIV OF MINING & TECH

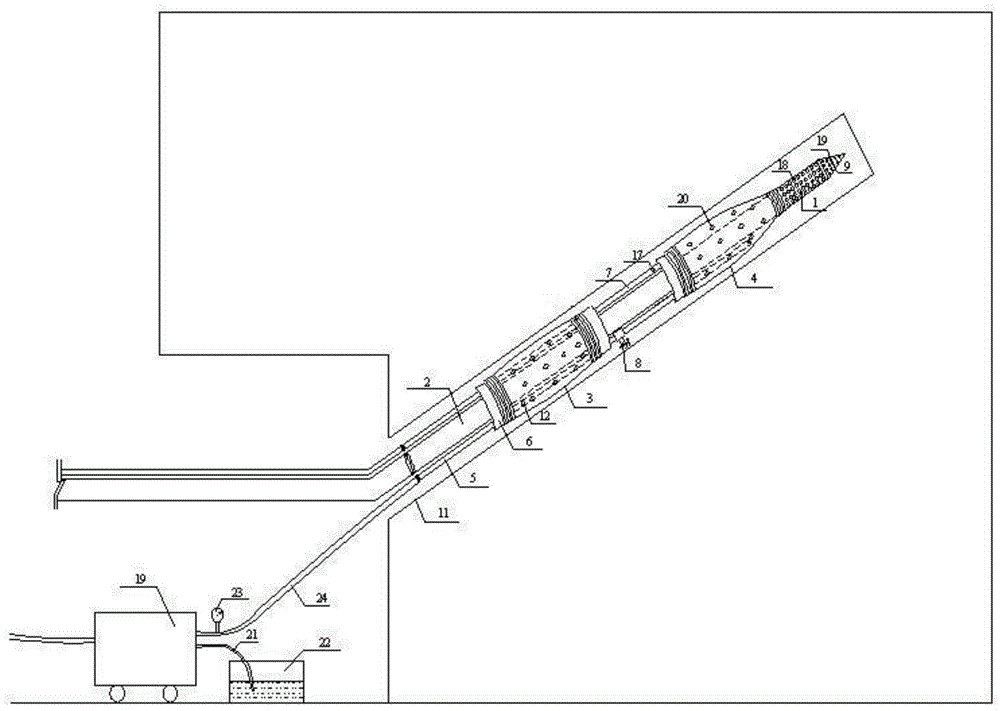

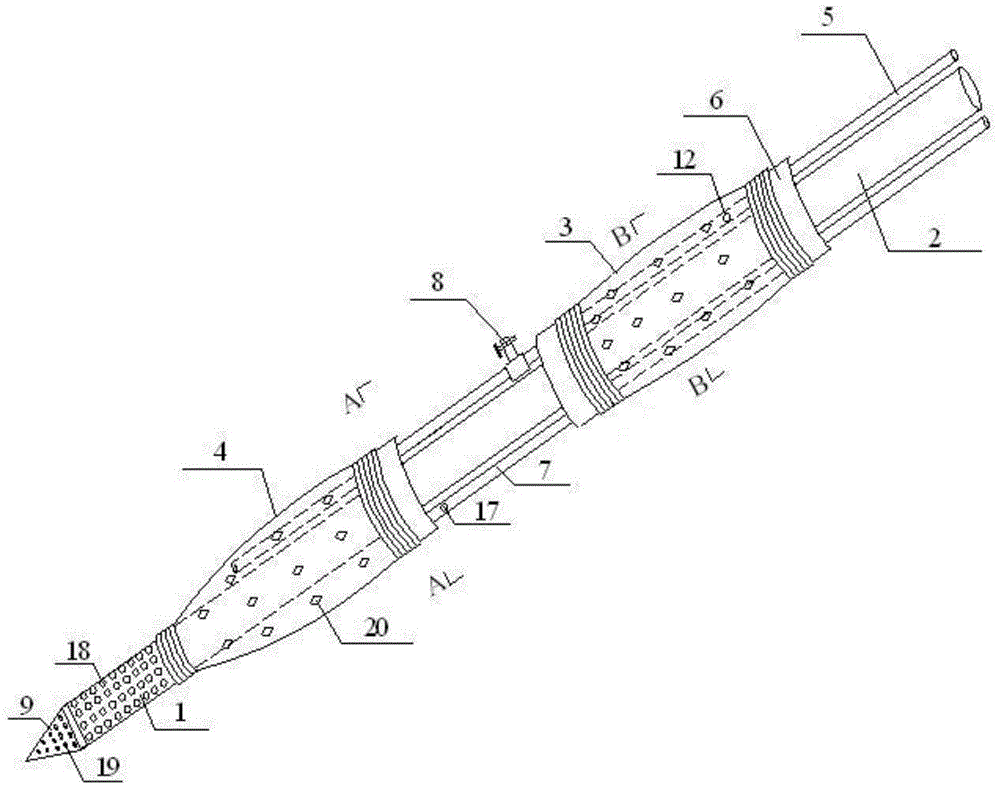

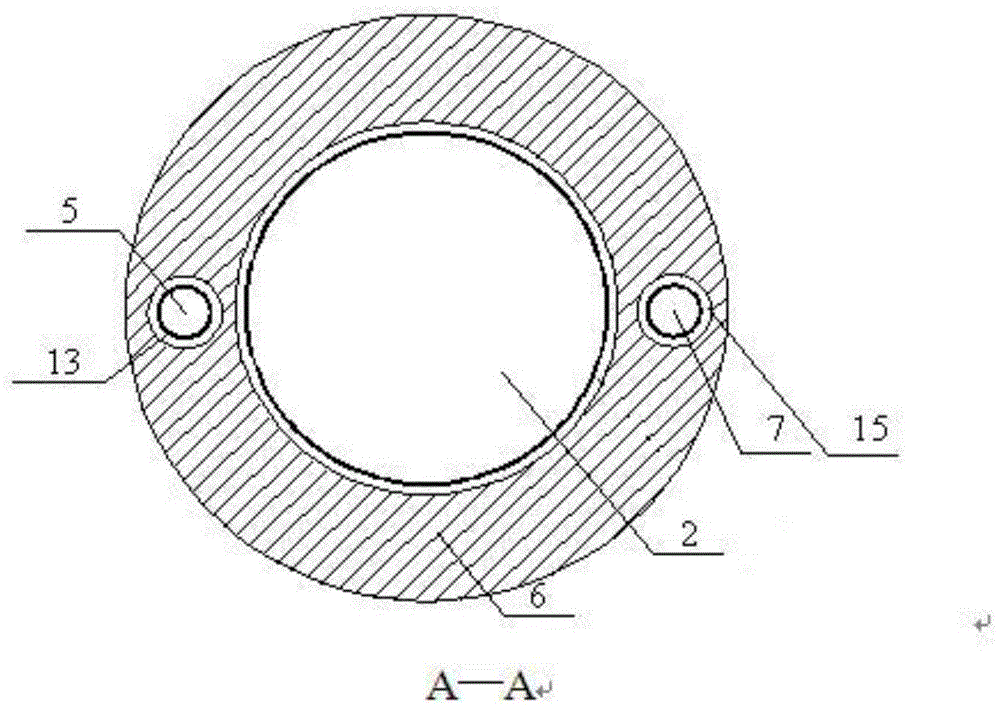

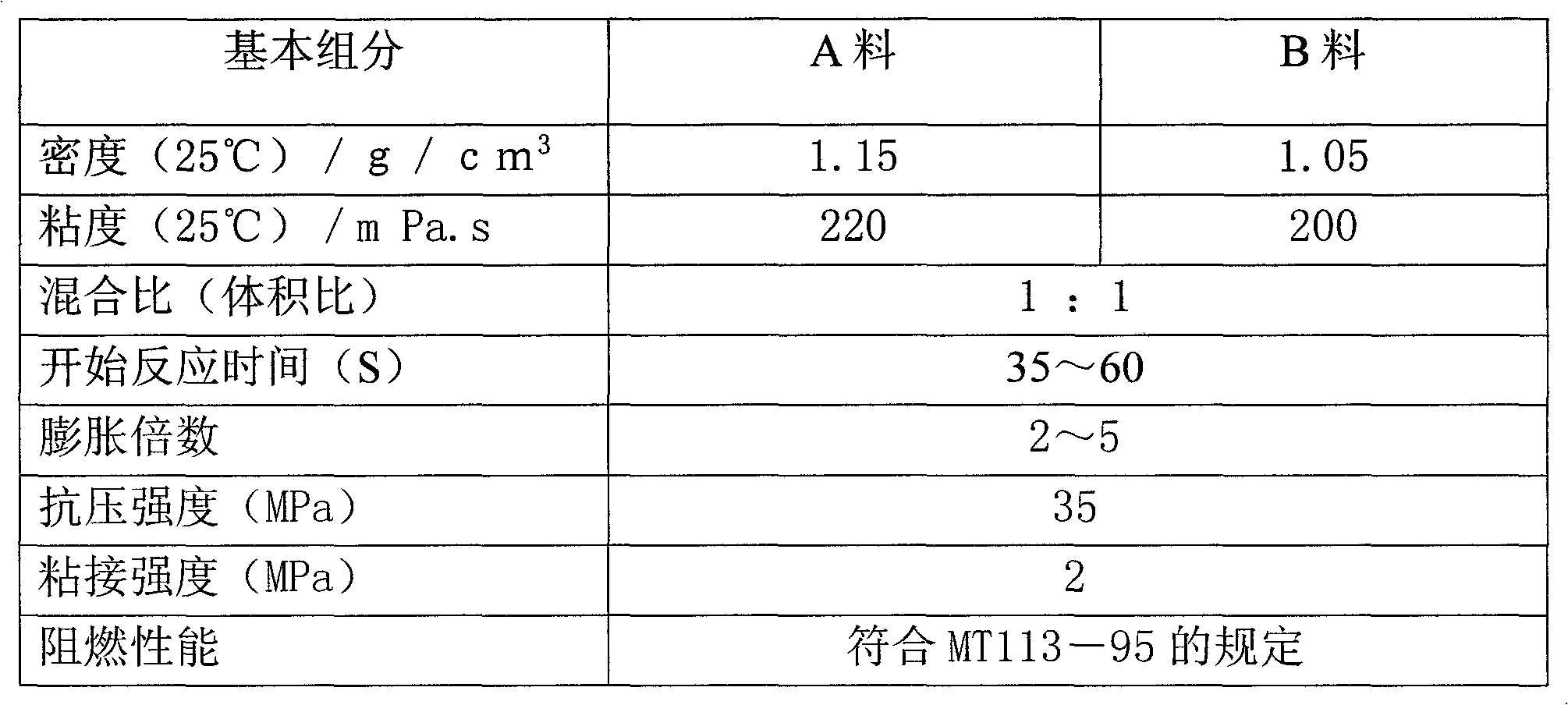

Directional fracturing permeability improvement outburst elimination method in coal mine and device thereof.

InactiveCN101575983AImprove breathabilityRapid and relatively long-lasting releaseFluid removalGas removalUltrasound attenuationFracturing fluid

The invention relates to a directional fracturing method in the coal mine and a fracturing permeability improvement outburst elimination device to ensure the coal-bed gas to release rapidly and continually in the coal mine. The method comprises the following steps: fracturing and drilling a bore on a preparing working face along the dip direction and strike direction of a coal bed, fixing a fracturing hole packer with an outer diameter matching with the pore diameter of a fracturing drilling bore into the fracturing drilling bore; connecting a fluid reservoir with a sand mixing machine, connecting the sand mixing machine with a fracturing pump package, and then connecting the fracturing pump package with the fracturing drilling bore; pumping formation fracturing fluid and proppant into the fracturing drilling bore to fracture the formation and sealing the fracturing drilling at above formation fracturing pressure, and completing directional fracturing permeability improvement outburst elimination in the coal mine, thus ensuring that the coal-bed gas discharges rapidly and continually relatively and solving the problems that drainage in low air permeability coal bed can only influence a limited range and the drainage attenuation period is short, improving the drainage rate by over 50% on primary base, decreasing the coal body dynamic phenomenon after fracturing and reginal stress influenced by fracturing, and having a significant effect for eliminating outburst.

Owner:河南省煤层气开发利用有限公司

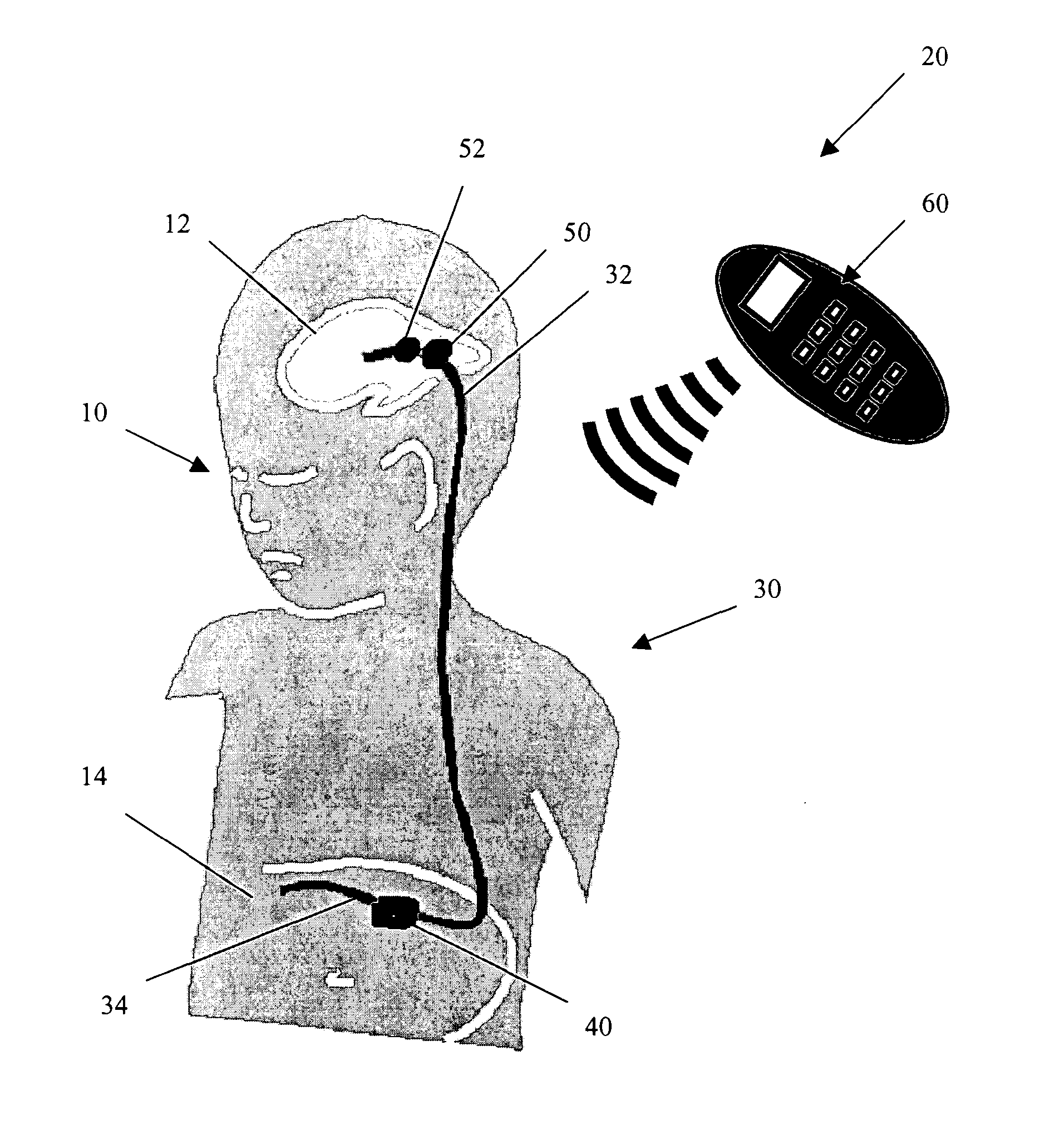

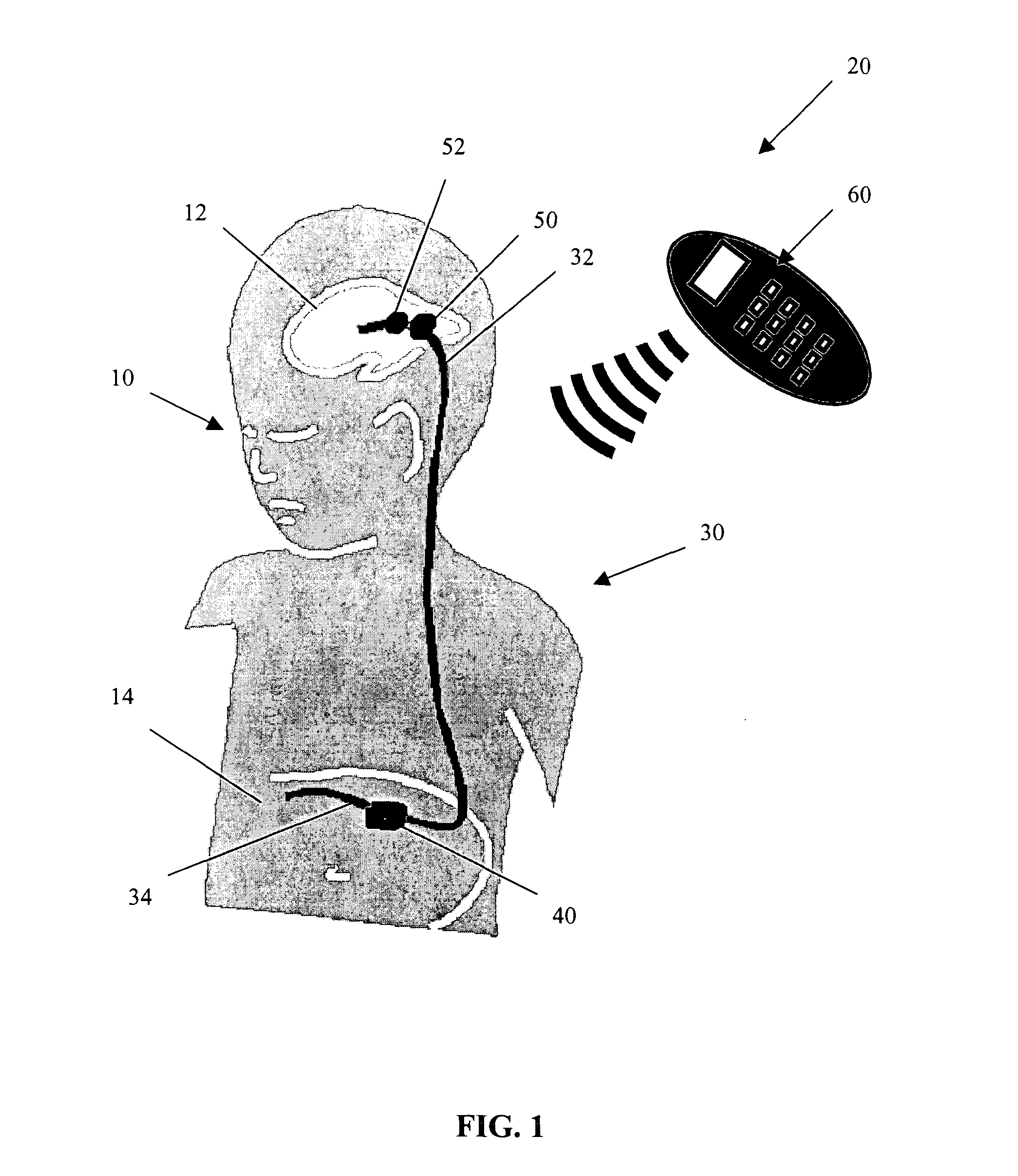

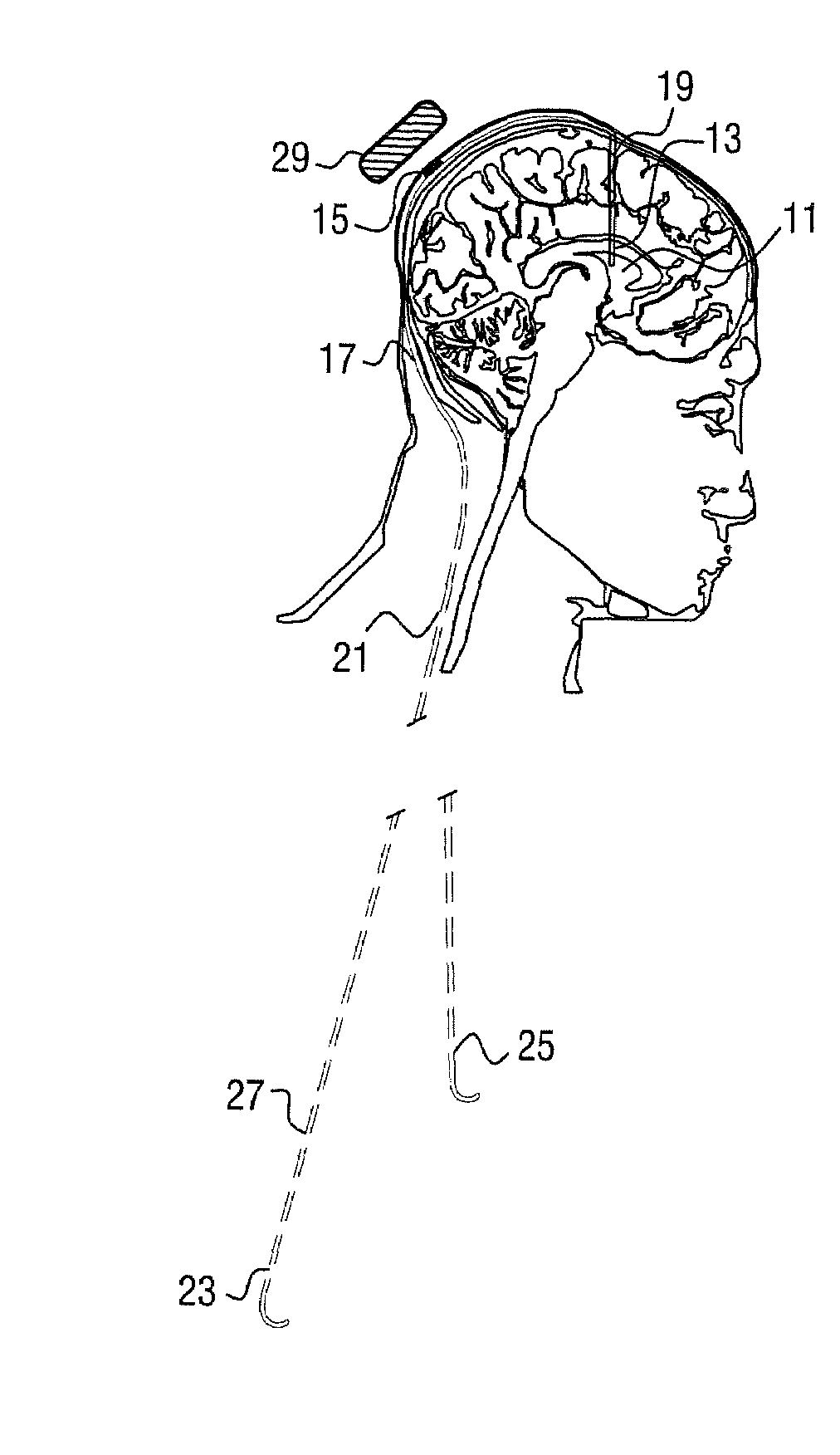

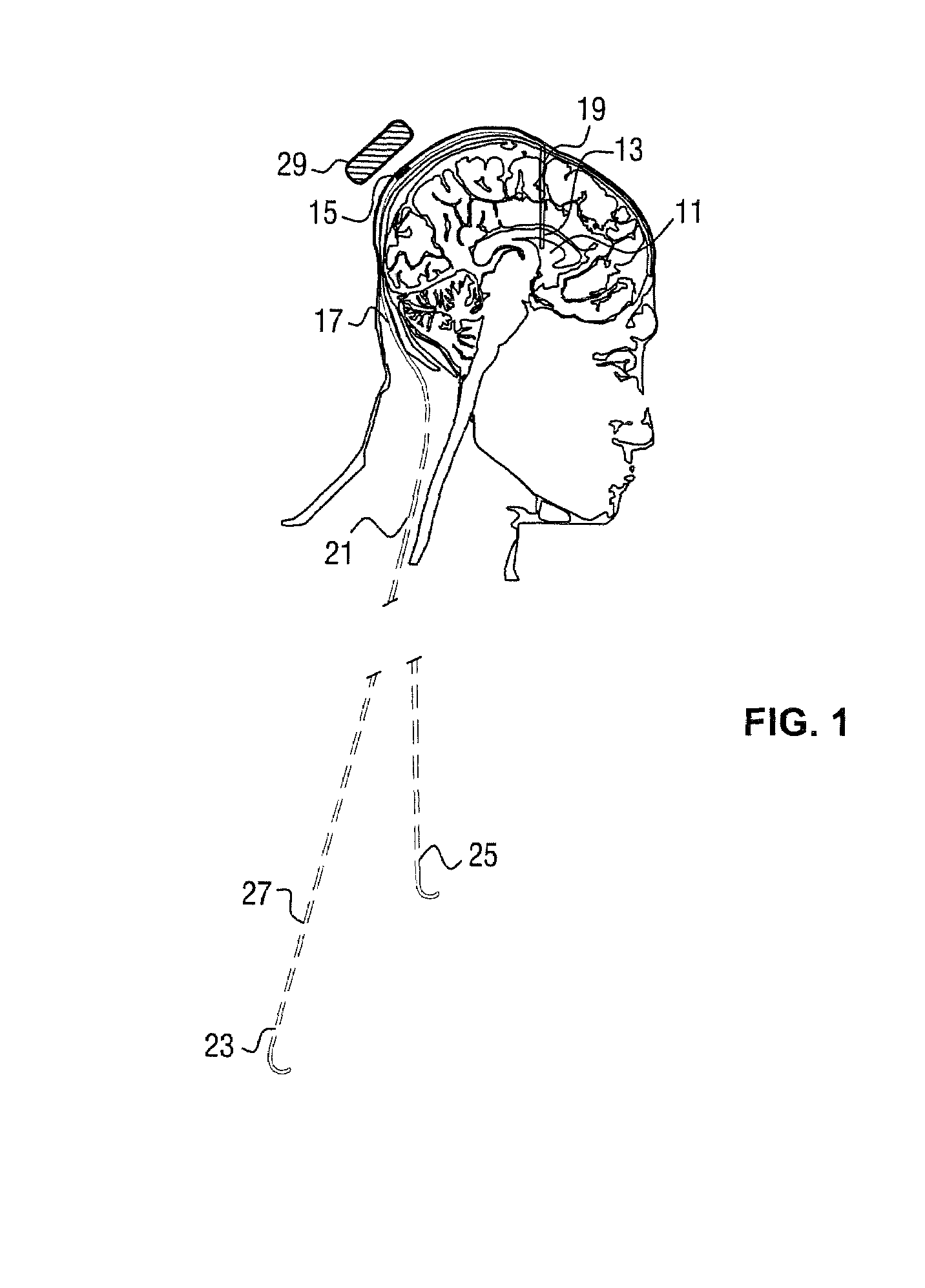

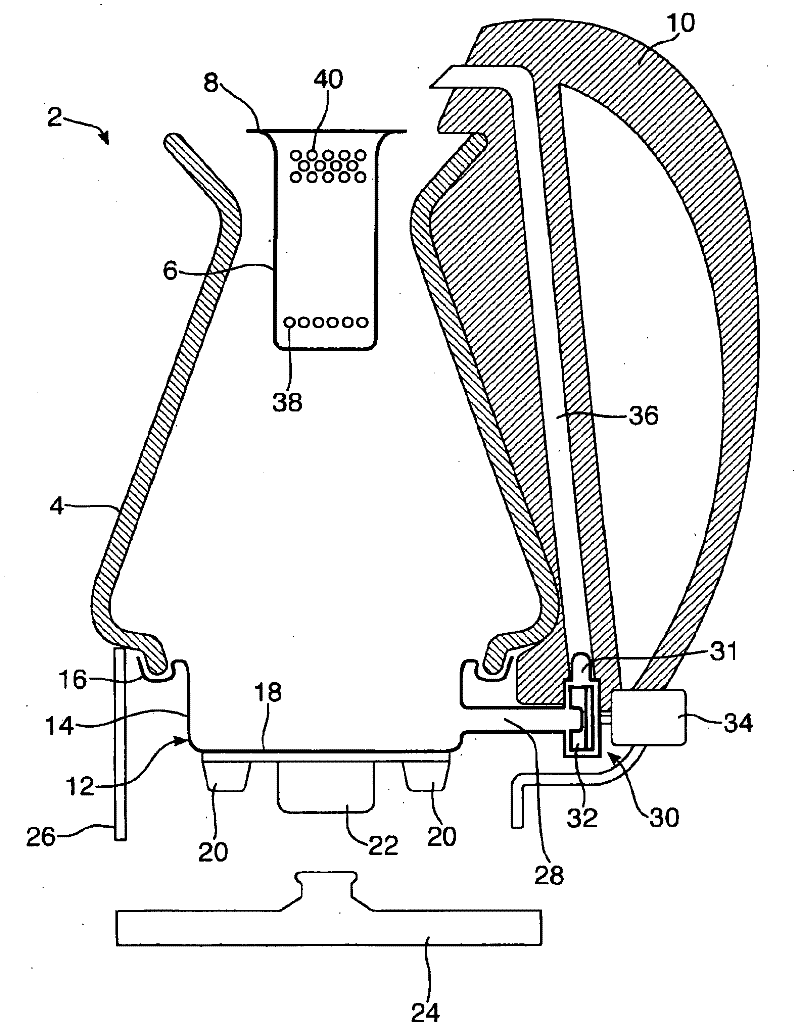

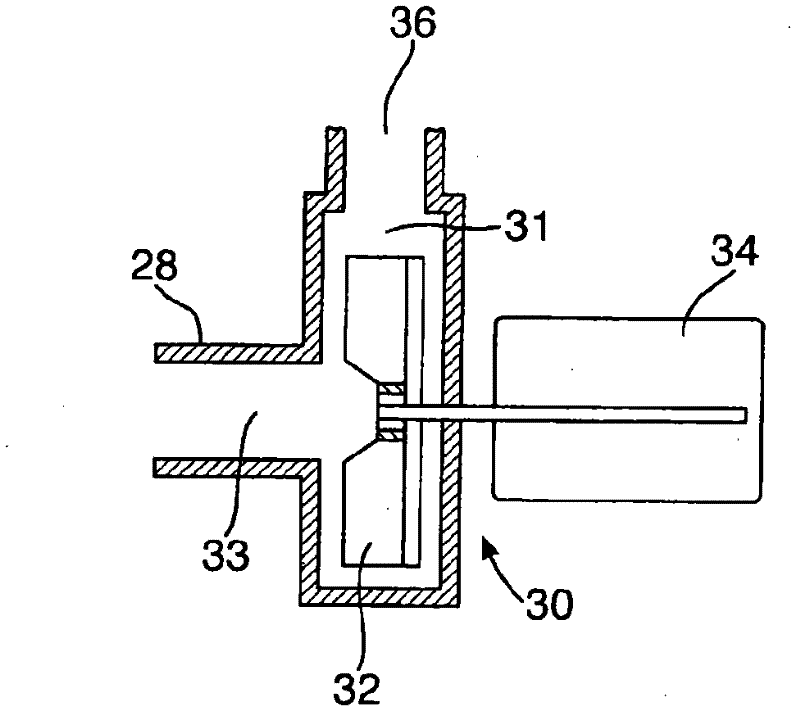

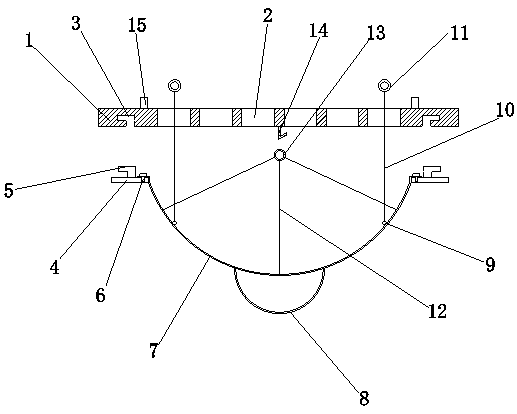

Method and apparatus for managing normal pressure hydrocephalus

InactiveUS20050055009A1Increased and decreased resistanceReduce resistanceWound drainsMedical devicesVentricular volumePhysician attending

An adjustable drainage system for regulating cerebrospinal fluid flow in a hydrocephalus patient where the drainage rate is adjusted in response to ventricular volume variations in the patient. The system includes an adjustable valve and a volume sensor that can be periodically energized with an external system controller device by the patient or attending physician to determine when, or if, a change in the ventricular volume has occurred. The system enables the user to adjust the valve's resistance in response to changes in the ventricular volume using the controller device so that a target ventricular volume can be achieved. Also provided is a method of continuously draining cerebrospinal fluid from the cranial cavity of the patient using the system of the present invention.

Owner:CODMAN & SHURTLEFF INC

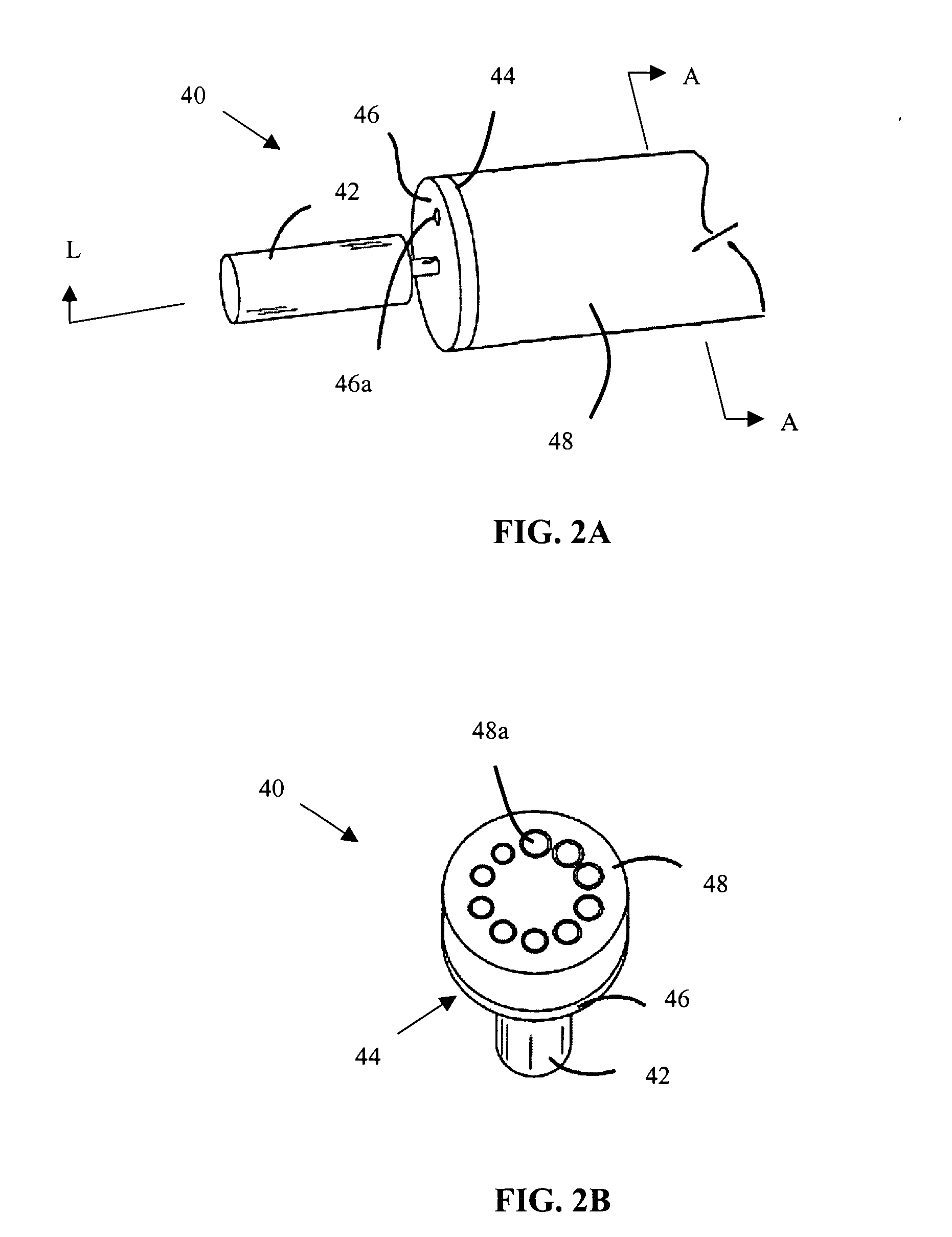

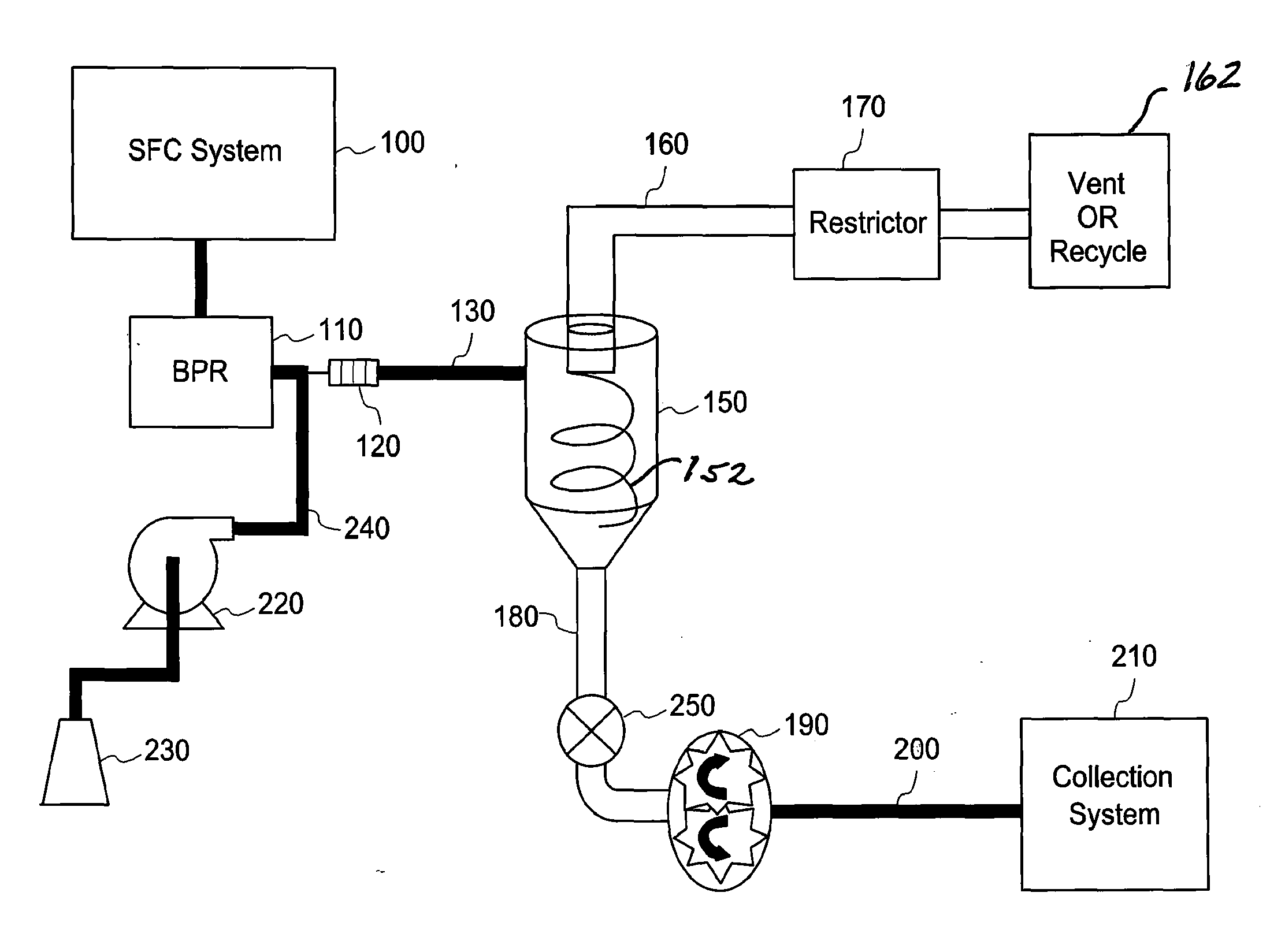

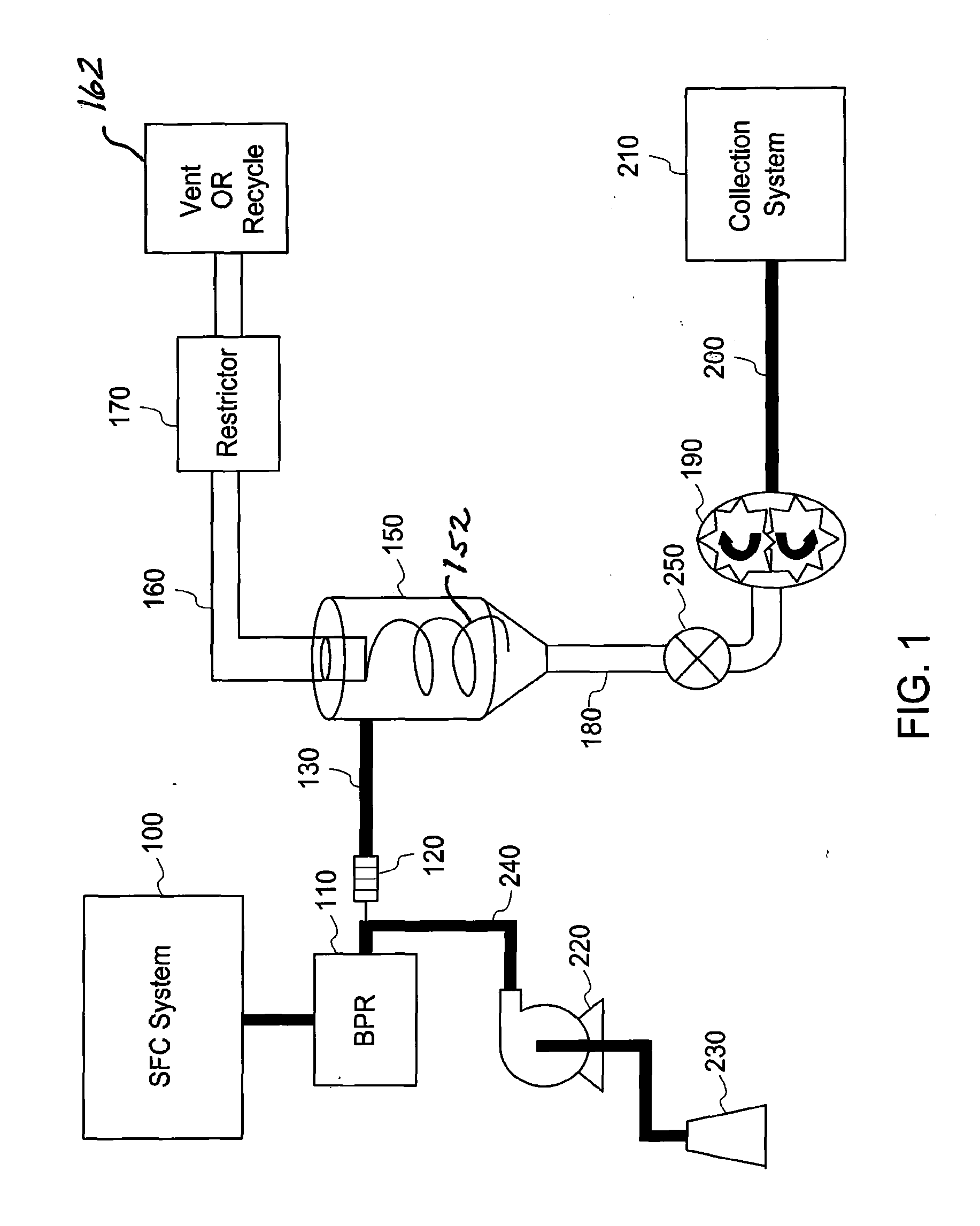

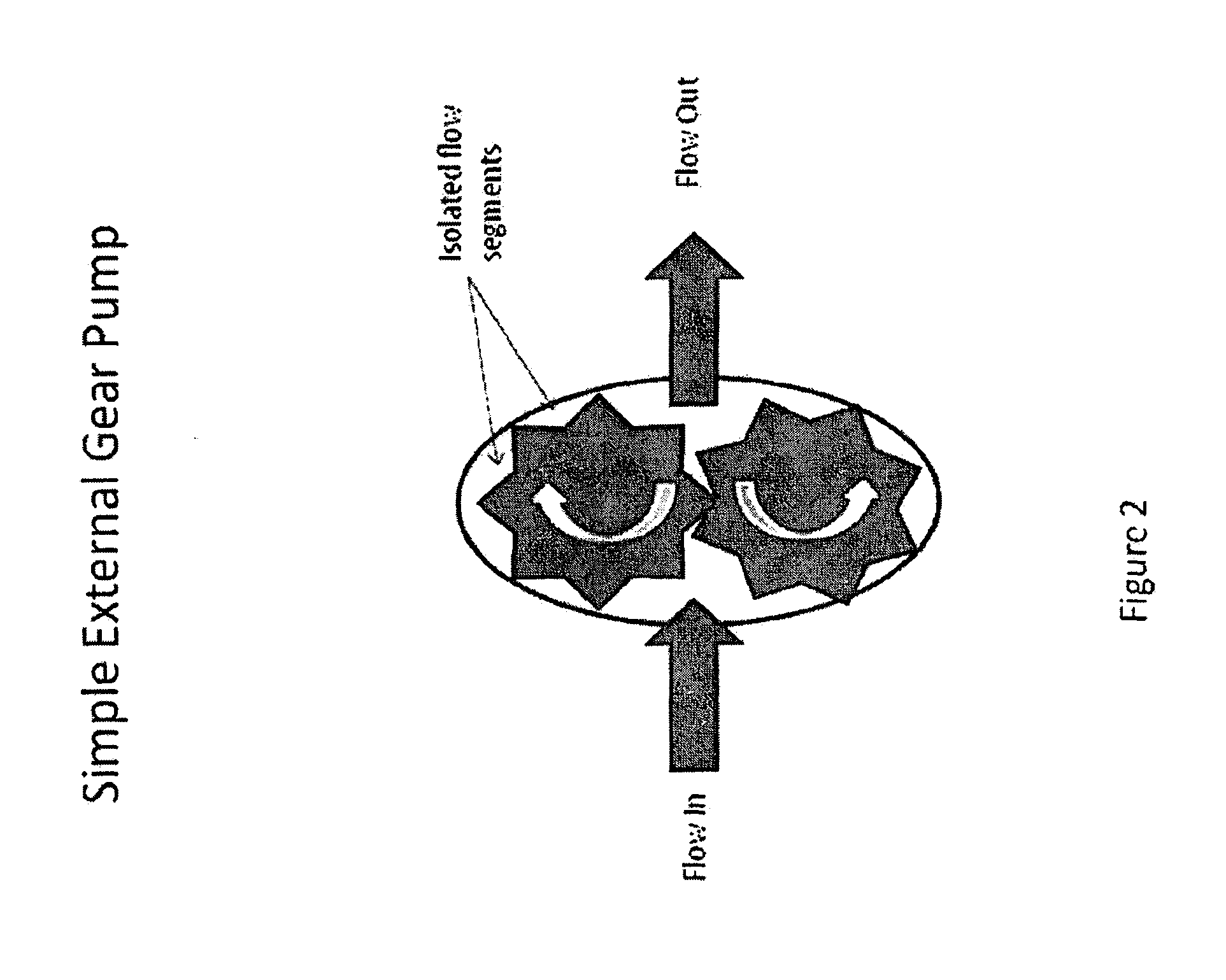

System and process for an active drain for gas-liquid separators

ActiveUS20130180404A1Deterministic drainingSolid sorbent liquid separationLiquid degasification regulation/controlIsolation valveVapor–liquid separator

An apparatus and process to effectively create an active drain for high and low pressure gas-liquid separator. The invention accomplishes a deterministic drainage rate of variable volume and viscosity liquid fractions from the separator. The mechanisms and methods thereof create a flow path from the separator that dramatically favors controlled liquid flow over a wide range of flow rates and viscosities while restricting gas flow. The invention is a superior method of drainage over conventional systems that employ pressure, vacuum, isolation valves and / or passive flow restrictors to achieve drainage of the separators. The embodiments are primarily directed to the fields of preparative supercritical fluid chromatography (SFC) and supercritical fluid extraction (SFE). An advantage of one embodiment allows the economical conversion of typical HPLC systems to state of-the-art supercritical fluid chromatography (SFC) systems with minimal modification to system components.

Owner:AGILENT TECH INC

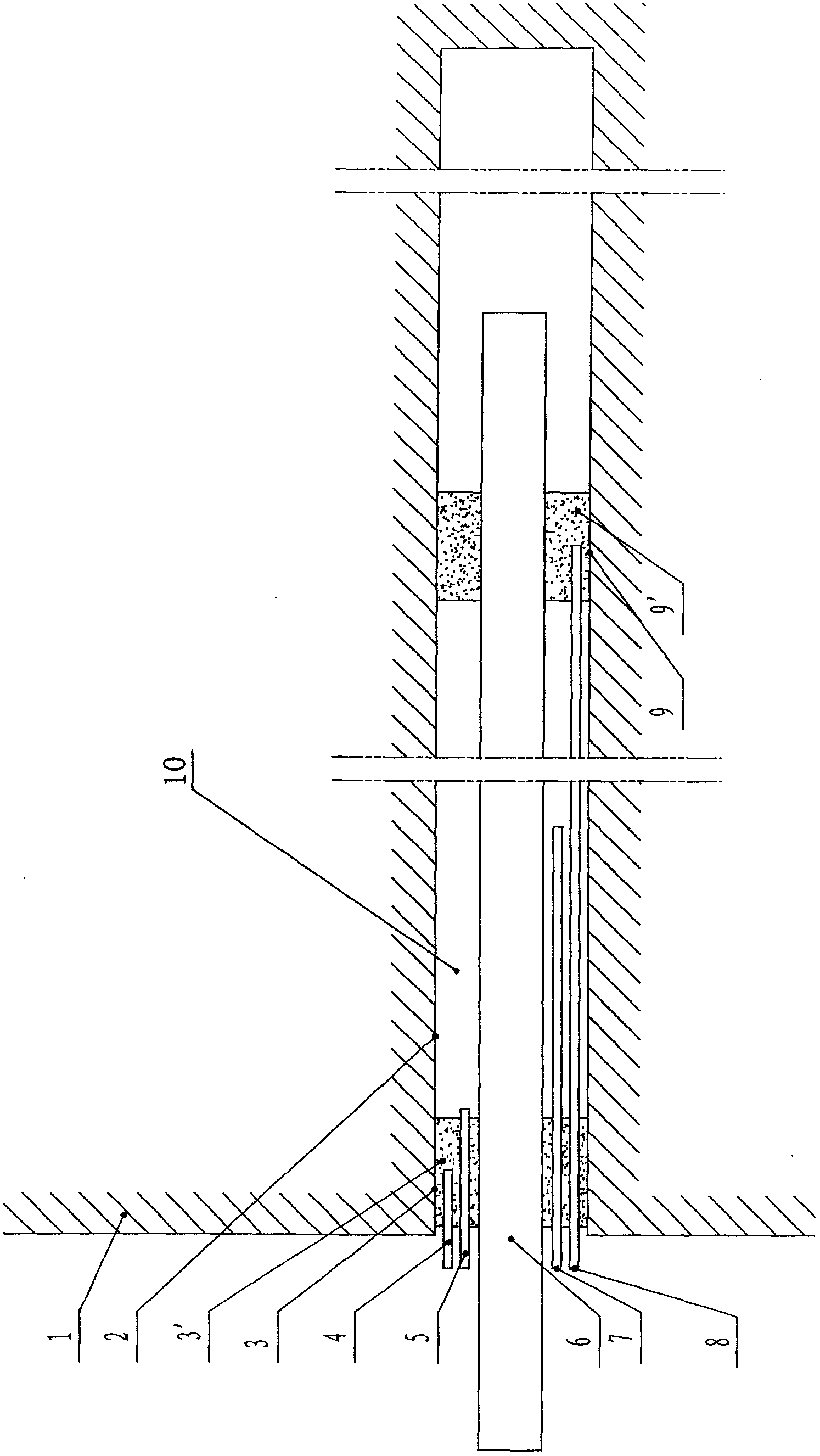

Hole sealing method for coal bed gas drainage drill hole

InactiveCN104314508ASolve the blockageIncrease the pumping rateGas removalSealing/packingHigh densityCoal dust

The invention discloses a hole sealing method for a coal bed gas drainage drill hole, which is suitable for tightly closing the gas drainage drill hole in a high-gas coal mine. The hole sealing device mainly comprises a main pumping pipe, an auxiliary pumping pipe, a front bag, a rear bag, a grouting pipe, a perforated pipe, a connecting piece, a grout return pipe and an explosion valve. The method can greatly increase the hole sealing depth, solve the coal dust blocking problem during the gas extraction process, ensure high density and strength of the filled clearance between the drill hole wall and the pumping pipe groups by the grout coagulation body, avoid the phenomena that the drill hole is not tightly sealed or the gas is leaked from the hole, and greatly increase the drill hole gas drainage rate.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY +1

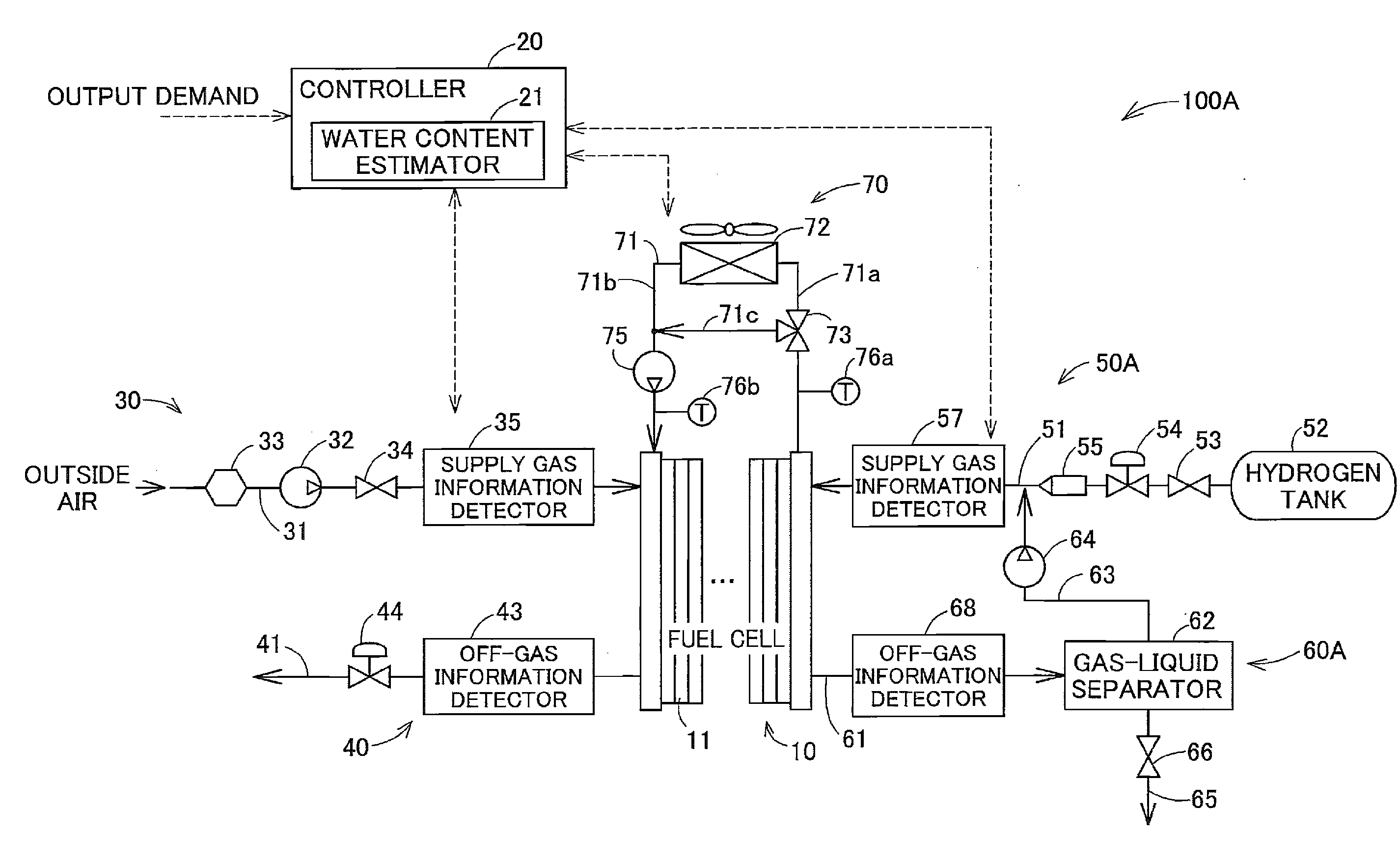

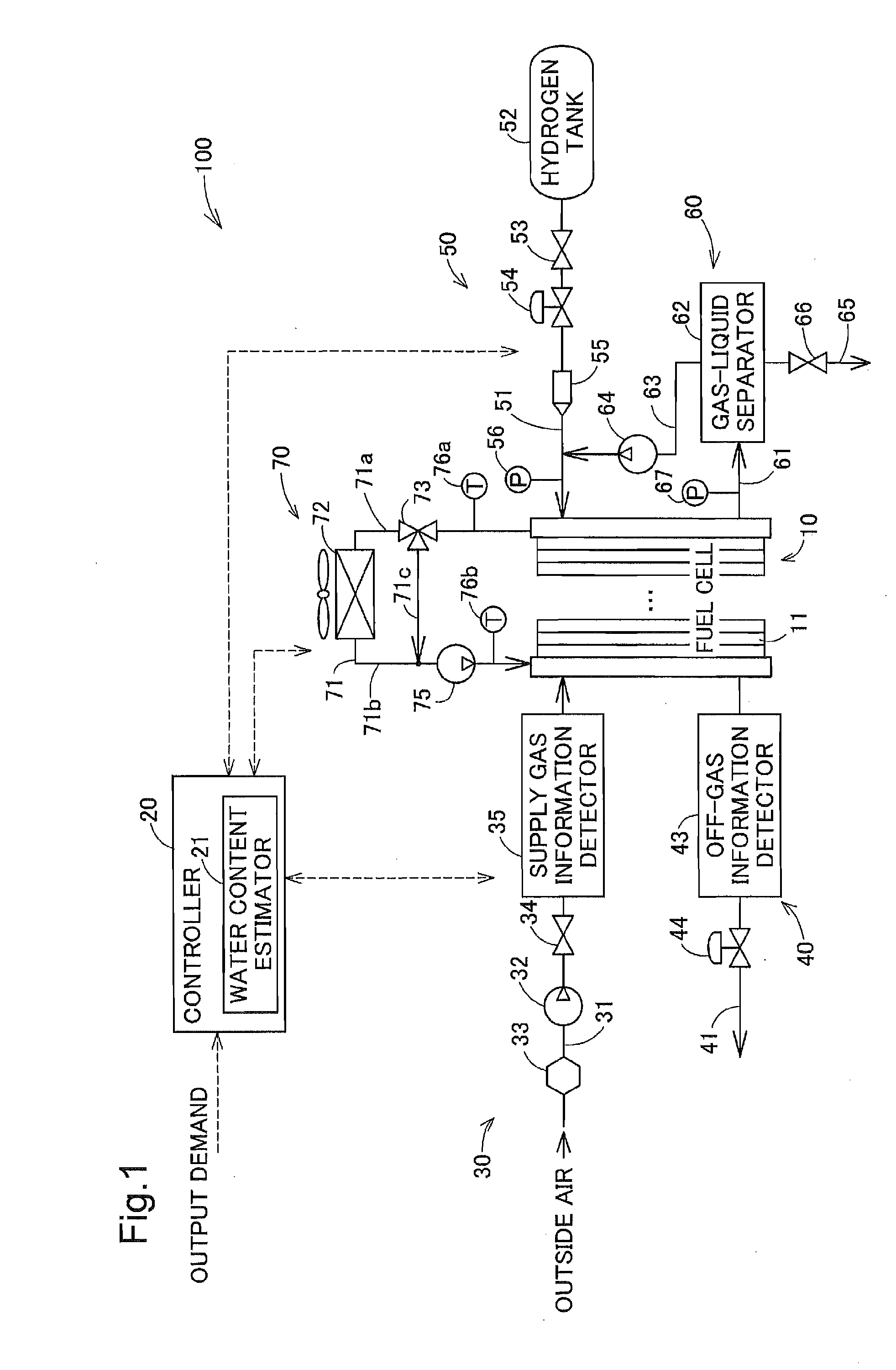

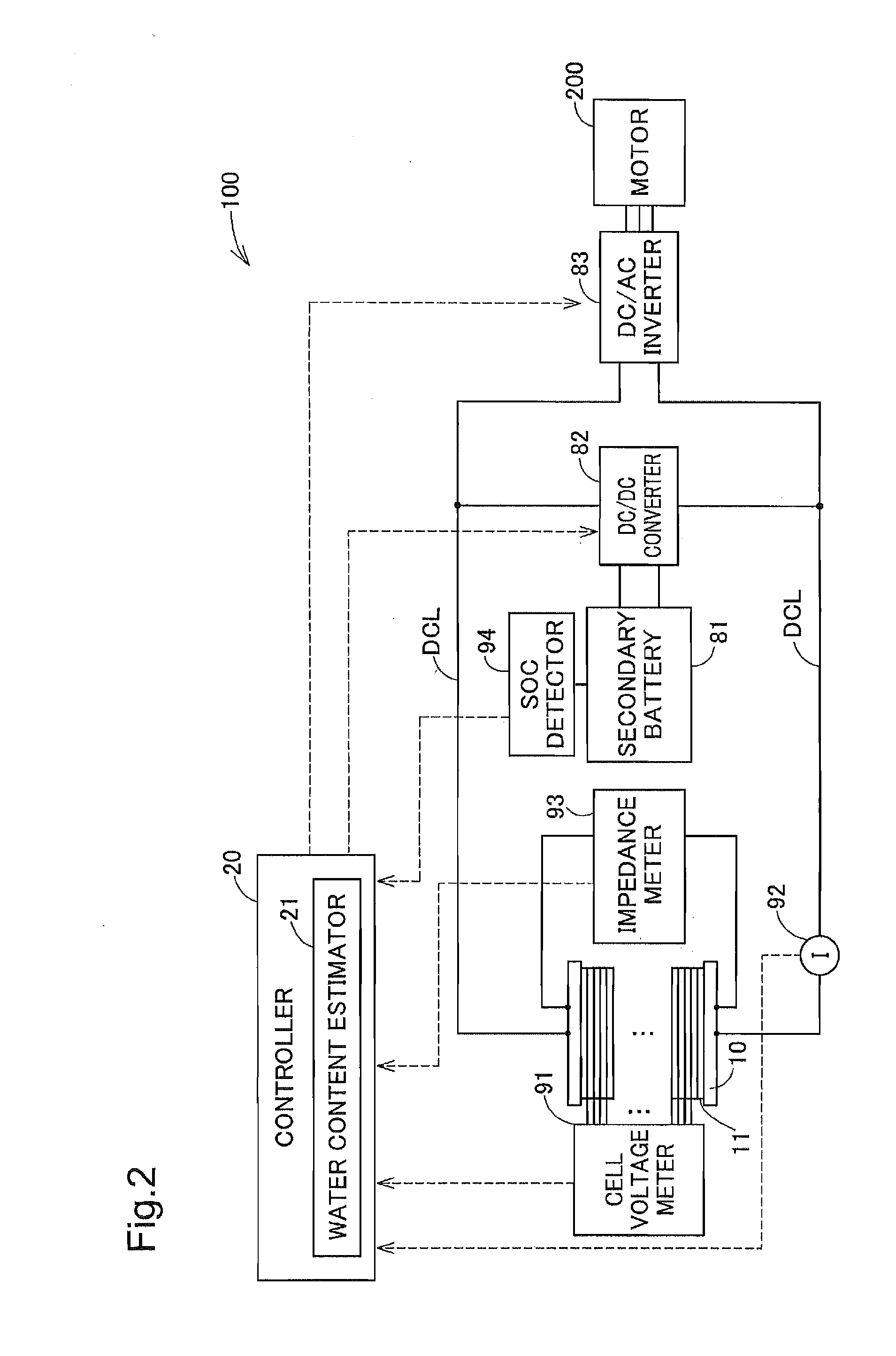

Method of estimating amiount of liquid water in fuel cell, method of estimating amount of liquid water discharged from fuel cell, estimation apparatus of liquid water amount in fuel cell and fuel cell system

The procedure of the invention successively obtains an estimated value of amount of liquid water in a fuel cell during operation in each specified period by the following steps (a) to (d), thereby improving the detection accuracy of the water condition inside the fuel cell. The step (a) obtains a previous estimated value. The step (b) obtains a drainage rate that represents an amount of liquid water discharged from the fuel cell per unit time, based on the previous estimated value and a value representing a current flow rate of a reactive gas in the fuel cell. The step (c) multiplies the drainage rate by a period of obtaining the estimated value, so as to calculate an amount of liquid water discharged from the fuel cell for a specified duration. The step (d) determines a current estimated value, based on the amount of liquid water discharged from the fuel cell for the specified duration.

Owner:TOYOTA JIDOSHA KK

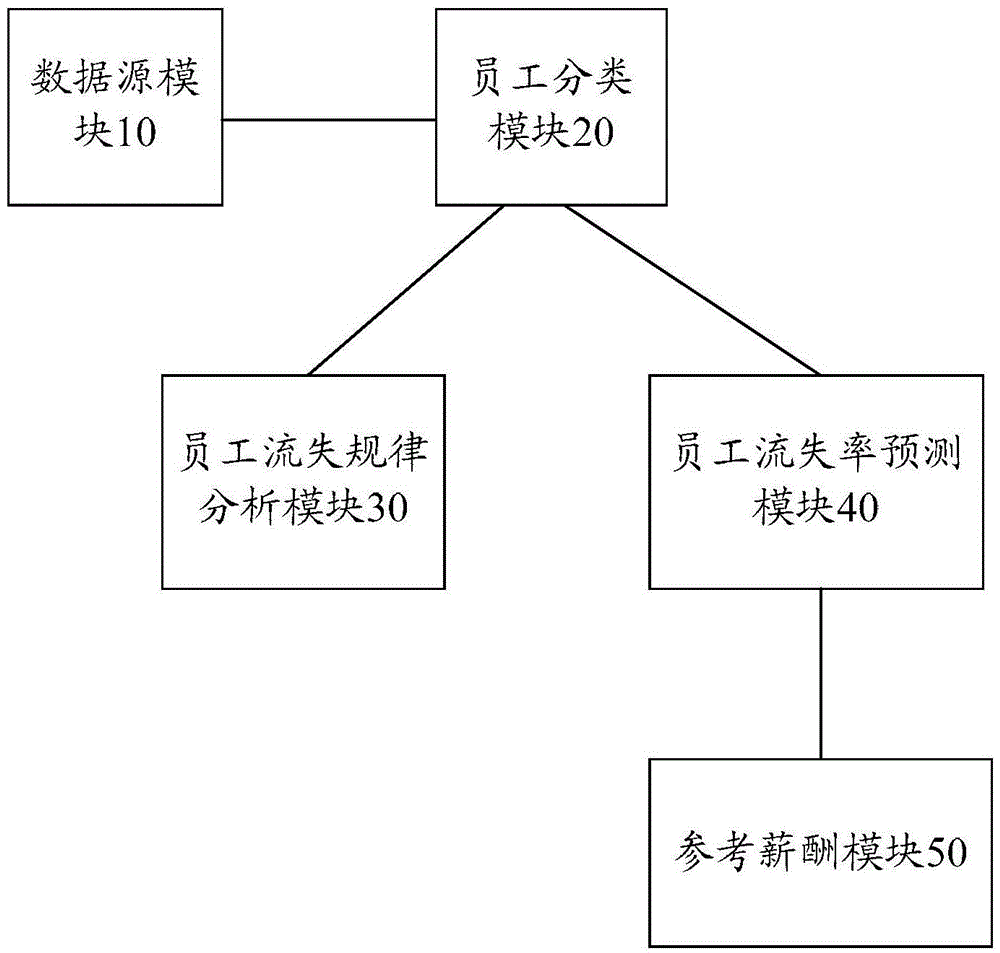

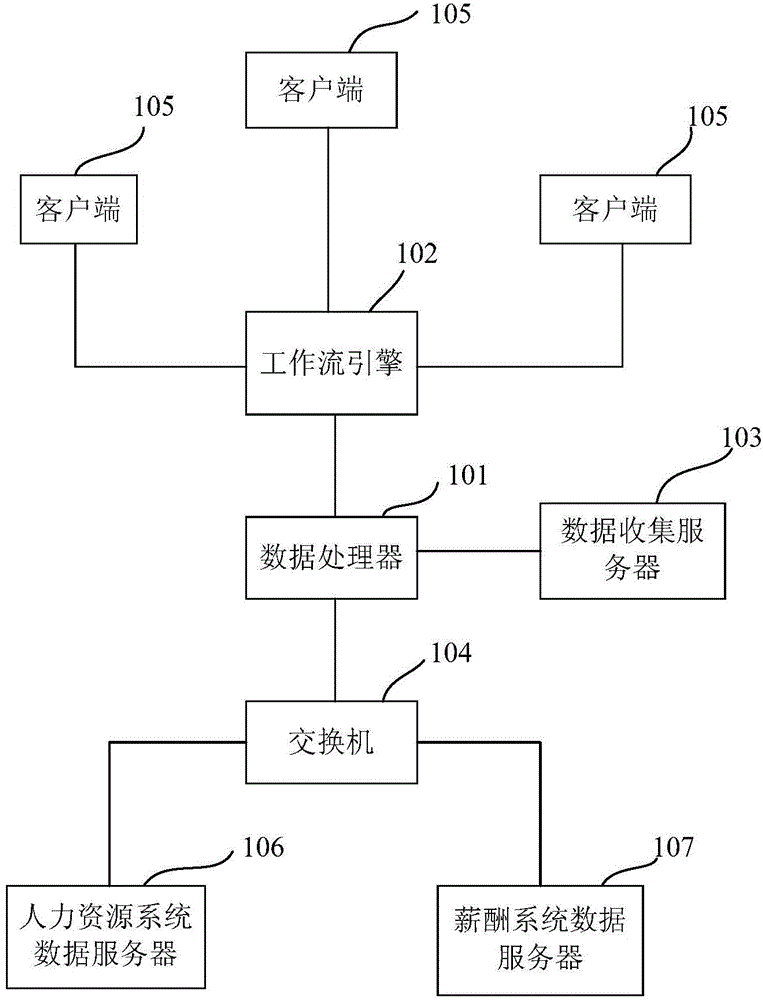

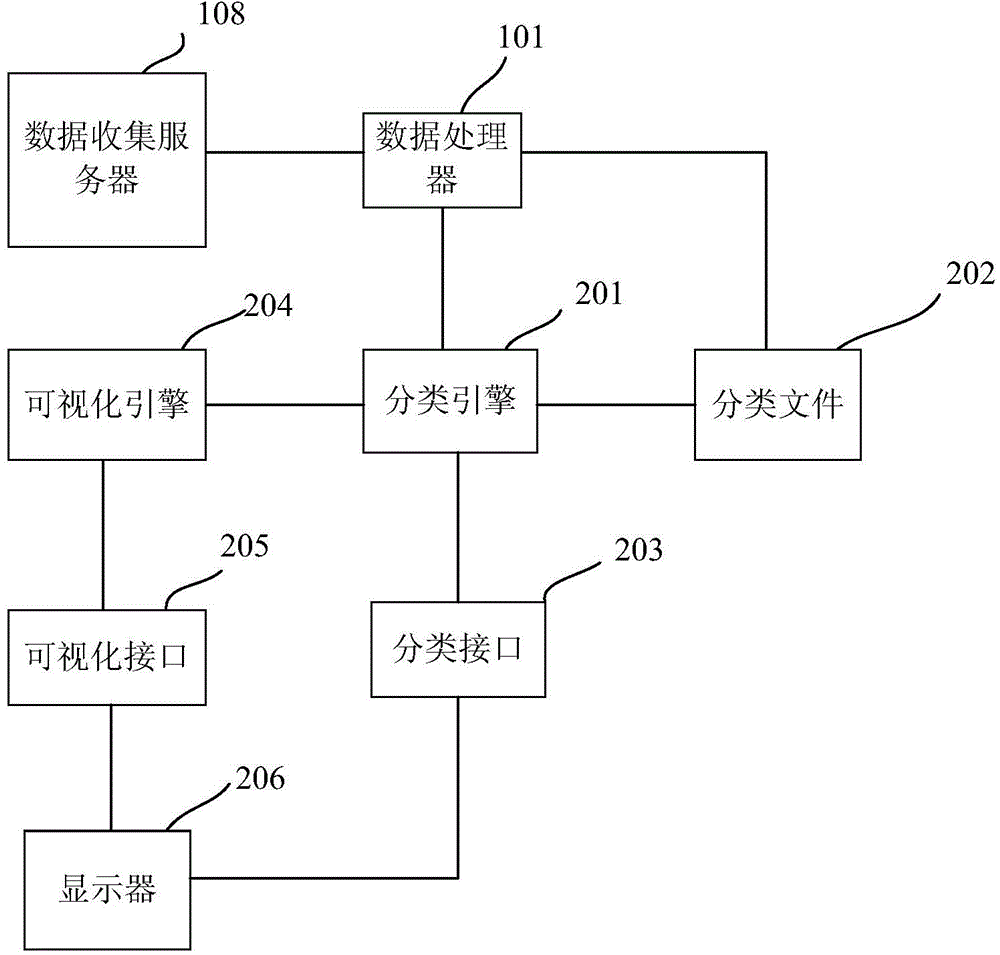

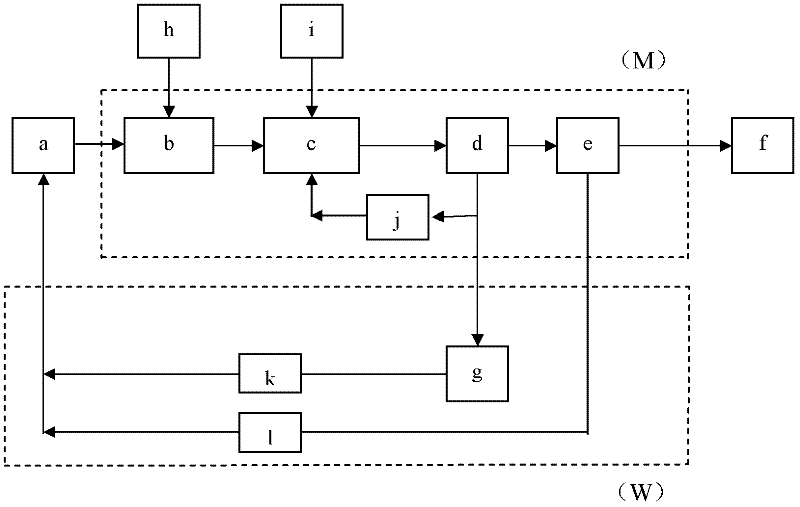

Enterprise talent drainage data mining analysis method and device

The invention discloses an enterprise talent drainage data mining analysis method and device. The device at least comprises a data source module, an employee classification module and an employee drainage rule analysis module, wherein employee information data collected by an enterprise remuneration system and a human resource system is preprocessed, cleared, integrated and converted by the data source module, and is stored into a data collecting server, the employee classification module uses a cluster classification analysis method for carry out cluster analysis on the data of the data source module, the employee clustering is carried out, and the employee clustering result is obtained; the employee drainage rule analysis module utilizes an employee-drainage-analysis-oriented association rule model for associating the employee classification information and the on-job and drainage state according to the clustering analysis result, and carries out causal relationship analysis on factors causing the employee drainage. The method and the device have the advantages that the mold enterprise talent drainage can be analyzed and predicted to obtain the talent drainage rule, meanwhile, the drainage rate of each employee can be obtained, and the reference remuneration of the employee is worked out for the employees with the high drainage rate.

Owner:GUANGDONG UNIV OF TECH

Pressure-controlled hole sealing method for gas drainage hole

InactiveCN102704986AEasy to closeImprove seal qualityGas removalSealing/packingMolecular materialsEngineering

The invention relates to a pressure-controlled hole sealing method for a gas drainage hole. Two hole sealing cloth bags, which serve as two separation sections, are arranged at the two ends of a hole sealing section of the gas drainage hole, and a macromolecular material is injected to the hole sealing section between the two separation sections until a certain pressure is reached, so that the macromolecular material can be fully filled in the hole sealing section and can permeate into cracks in a hole wall. Thus, the pressure-controlled hole sealing method for the gas drainage hole has the advantages of excellence in sealing of a borehole pipe, good quality in hole sealing, and high labor efficiency, and the gas drainage rate is increased from the original 30% to 80%.

Owner:HEBEI TONGCHENG MINING TECH

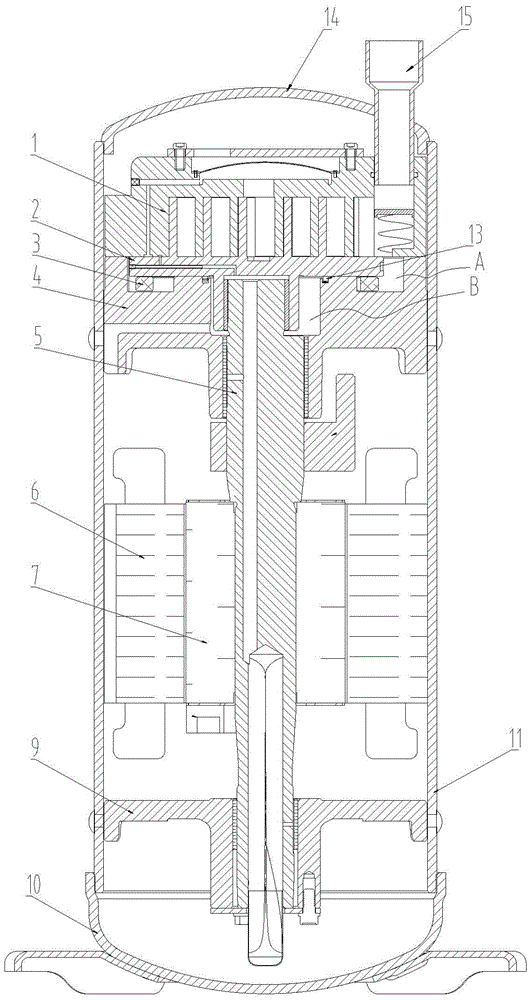

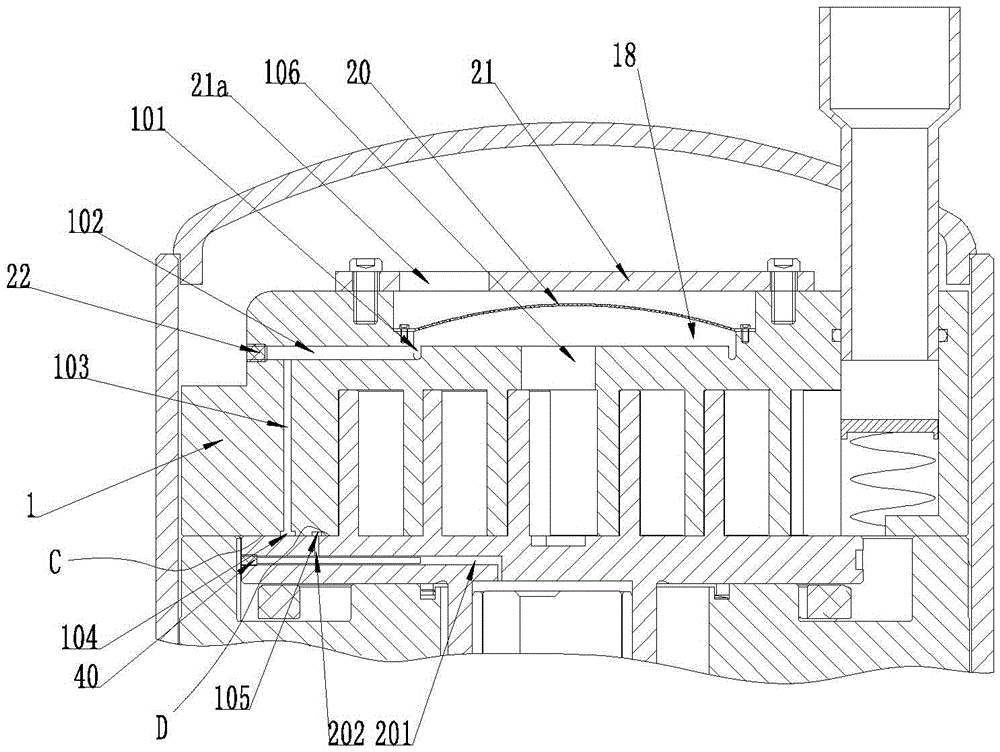

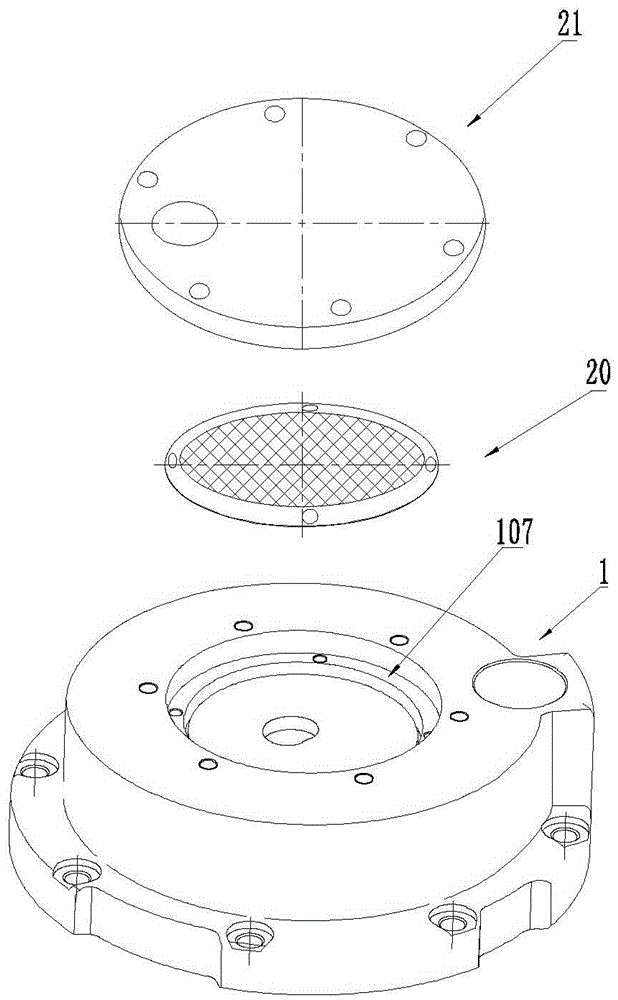

Scroll compressor

ActiveCN105587662AReduce friction and wearSuppresses oil discharge rate riseRotary piston pumpsRotary piston liquid enginesMechanical engineeringScroll compressor

The invention relates to the technical field of compressors, in particular to a scroll compressor. The scroll compressor comprises a fixed scroll and an orbiting scroll, wherein an exhaust buffering cavity which is connected with a compressing cavity is formed in an exhaust region of the fixed scroll; an oil-gas separating device is arranged in the exhaust buffering cavity; at least one first oil groove and at least one second oil groove are formed in an end plate surface, which is attached to the orbiting scroll, of the fixed scroll and are positioned in the periphery of the compressing cavity; the first oil grooves are connected with the bottom of the exhaust buffering cavity through a first channel; and the second oil grooves are connected with a bearing hole of the orbiting scroll through a second channel. By the scroll compressor, the problem that low oil drainage rate cannot be realized while the end plate surface between the orbiting scroll and the fixed scroll is lubricated in the prior art is solved effectively.

Owner:GUANGDONG MIDEA ENVIRONMENTAL TECH CO LTD +1

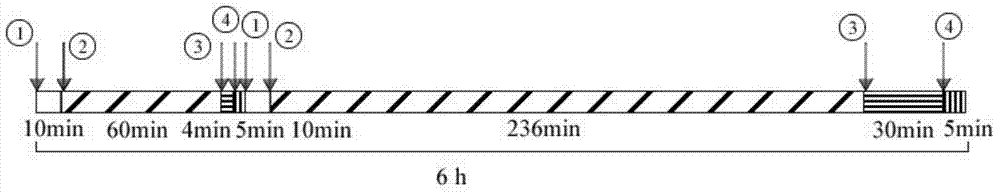

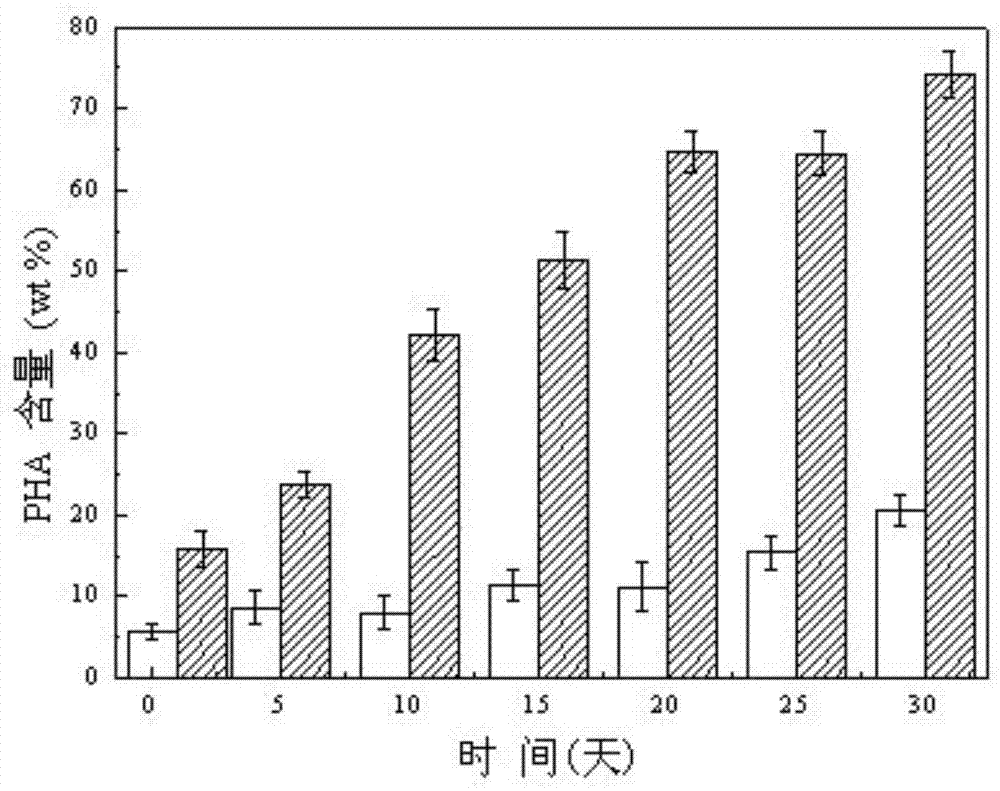

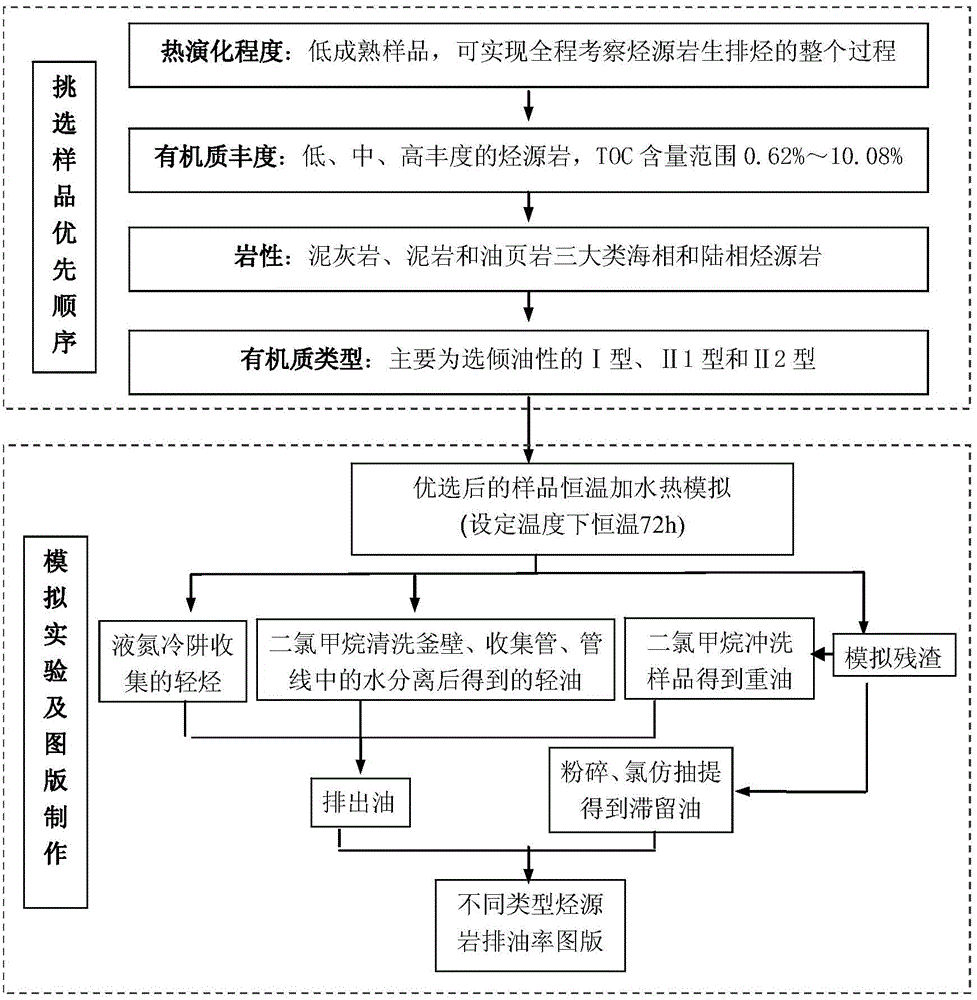

Method for quickly acclimatizing active sludge mixed flora to prepare polyhydroxyalkanoate (PHA) by using aerobic dynamic drainage method

ActiveCN103667376ARealize resourcesQuick domesticationFermentationSequencing batch reactorActivated sludge

The invention discloses a method for quickly acclimatizing active sludge mixed flora to prepare polyhydroxyalkanoate (PHA) by using an aerobic dynamic drainage method and relates to a method for preparing the PHA. The invention solves the problems that the acclimatization time for synthesizing PHA through active sludge mixed flora is long, a reactor works unstably and the synthesized PHA is low in content in the prior art. The method comprises the following steps: 1, active sludge is put into a sequencing batch reactor (SBR); 2, 6-12 hours are taken as a cycle of operation, in the cycle of operation, two-time water introduction, precipitation and drainage are carried out, the drainage rate is 1:1, during the first water introduction, a carbon source and various nutrients are introduced, and during the second water introduction, only the supplement of nitrogen nutrient is carried out; 3, 2-4 cycles are operated every day, the sludge detention time is 1-10 days and sludge-water mixed liquid is collected; 4, batch experiments are carried out, half supernatant is discharged, equivalent carbon source is supplemented, aeration, precipitation and drainage are carried out, and the process is repeated for 6 to 8 times. The invention belongs to the field of biodegradable plastic synthesis.

Owner:HARBIN INST OF TECH

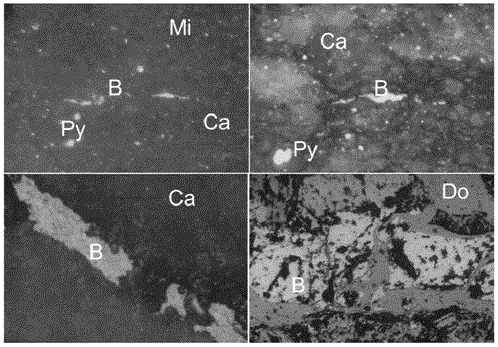

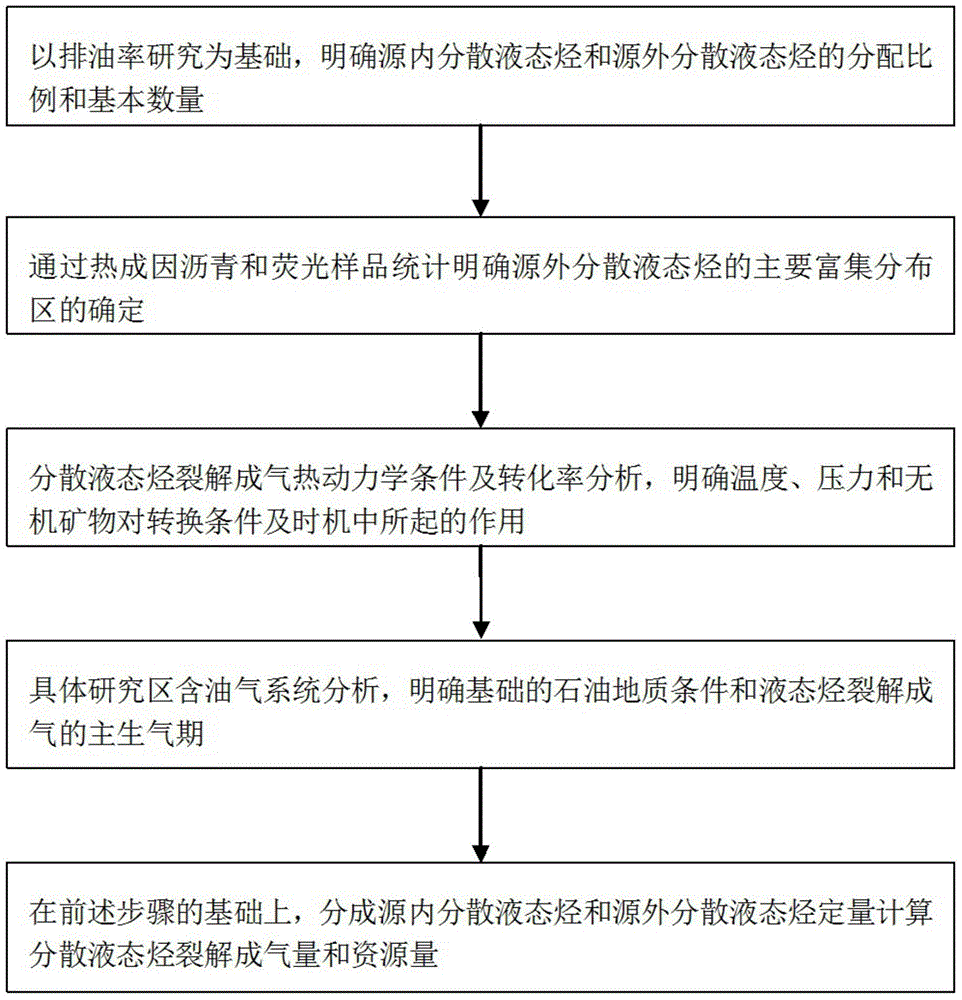

Quantitative evaluation method of cracking of disperse liquid hydrocarbon into gas

ActiveCN104950080AOvercome limitationsThe amount of resources is quickly and clearlyMaterial analysisSystems analysisFluorescence

The invention provides a quantitative evaluation method of cracking of disperse liquid hydrocarbon into gas. The evaluation method comprises the steps of selecting various hydrocarbon source rock of a major end member, determining a distribution ratio and basic amount of in-source disperse liquid hydrocarbon and out-source disperse liquid hydrocarbon in the various hydrocarbon source rock based on an oil drainage rate study, determining a major enrichment distribution area of out-source disperse liquid hydrocarbon via statistics of thermogenic pitch and fluorescence samples, analyzing a thermodynamic condition and a conversion rate of cracking of disperse liquid hydrocarbon into the gas, determining an effect of temperature, pressure and an inorganic mineral medium of the cracked gas on a conversion effect and an opportunity, carrying out oil gas system analysis on a particular study area, determining a basic petroleum geology condition and a main gas generation period of the cracking of liquid hydrocarbon into the gas, dividing disperse liquid hydrocarbon into in-source disperse liquid hydrocarbon and out-source disperse liquid hydrocarbon, and quantitatively calculating gas amount cracked by disperse liquid hydrocarbon. The method can quantity the gas cracked by disperse liquid hydrocarbon in the ancient hydrocarbon source rock in a marine superimposed basin.

Owner:PETROCHINA CO LTD

Aerobic particle sludge method for treating town sewage and aerobic particle sludge thereof

InactiveCN101229947ACompact structureIncreased drainage ratioSustainable biological treatmentBiological water/sewage treatmentSludgeSewage

The invention provides an aerobic granular sludge method for treating city sewage and the aerobic granular sludge, characterized in that a reactor adopts 8-15 ratio of height-to-diameter and 50-80 percent of drainage rate; air is compressed and filled into the bottom of the reactor; after flocculent sludge is inoculated, the drainage rate increases from 40 percent to 60 percent to 80 percent with the increase of 5 percent to10 percent per month; the operation cycle time shortens from 4-6 hours to 2-3 hours with the shortness of 1 hour per mouth; the sedimentation time decreases from 30-40 minutes to 15-20 minutes with the decrease of 1-2 minutes per week; the stable operation is carried out until the aerobic granular sludge takes 50-85 percent of reaction region volume of the reactor; the obtained aerobic granular sludge has large-sized particle, rapid sedimentation speed, compact structure and strong resistance to the environmental change. The invention overcomes the defects of expanded sludge, floated sludge, giant structure of an aeration tank as well as large occupied area, high investment and operation cost and unstable system operation in the prior art.

Owner:UNIV OF SCI & TECH OF CHINA

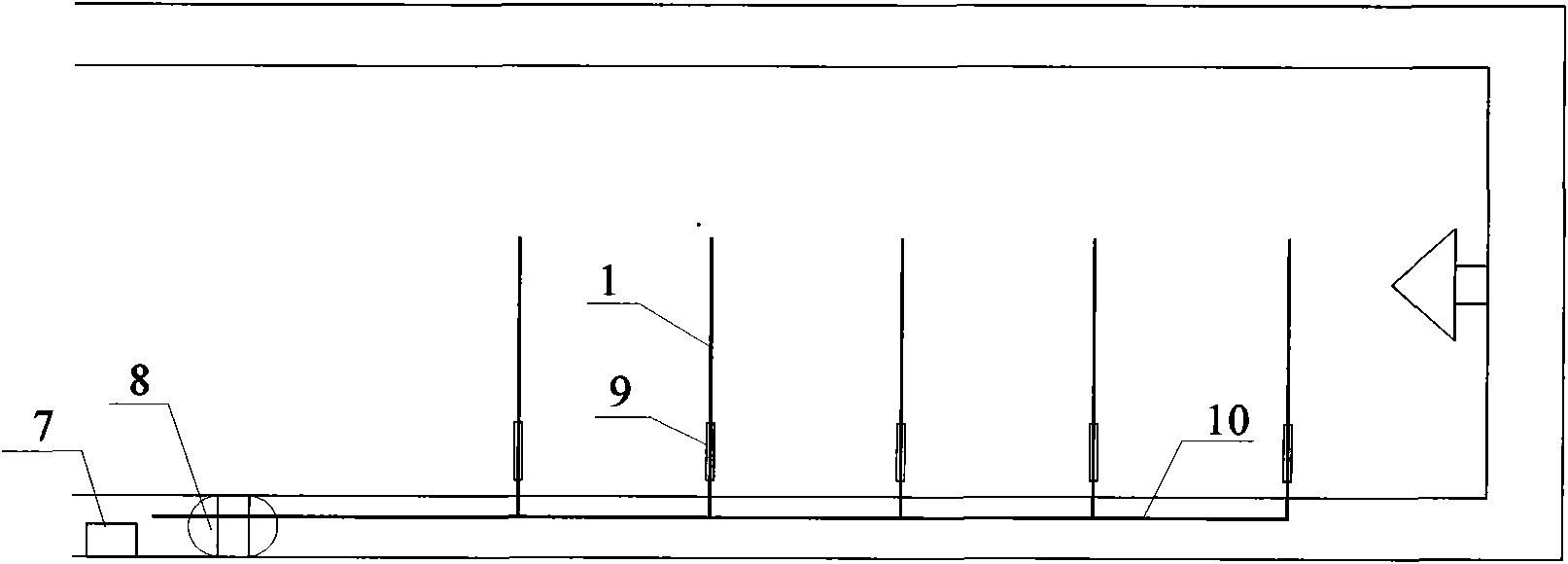

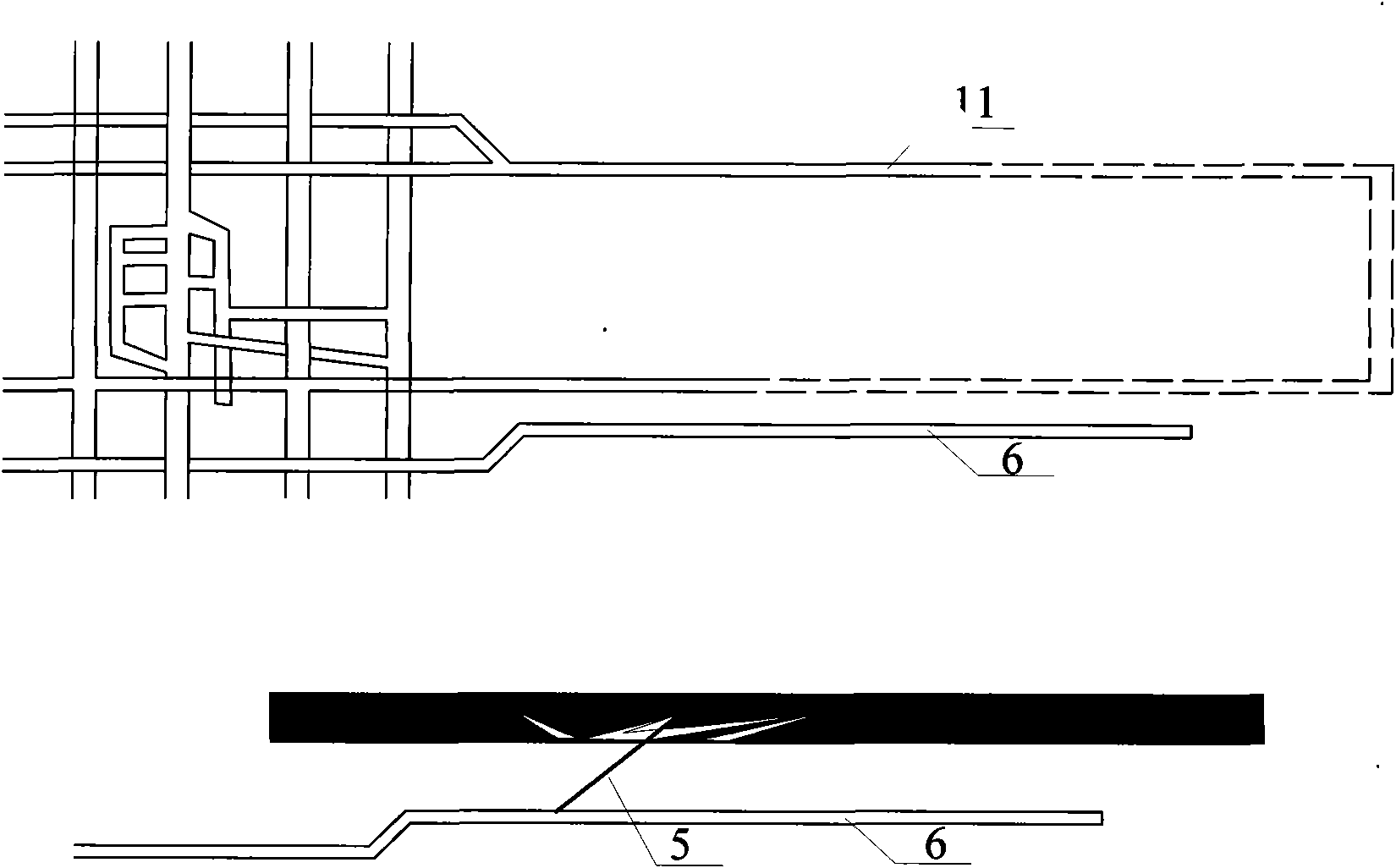

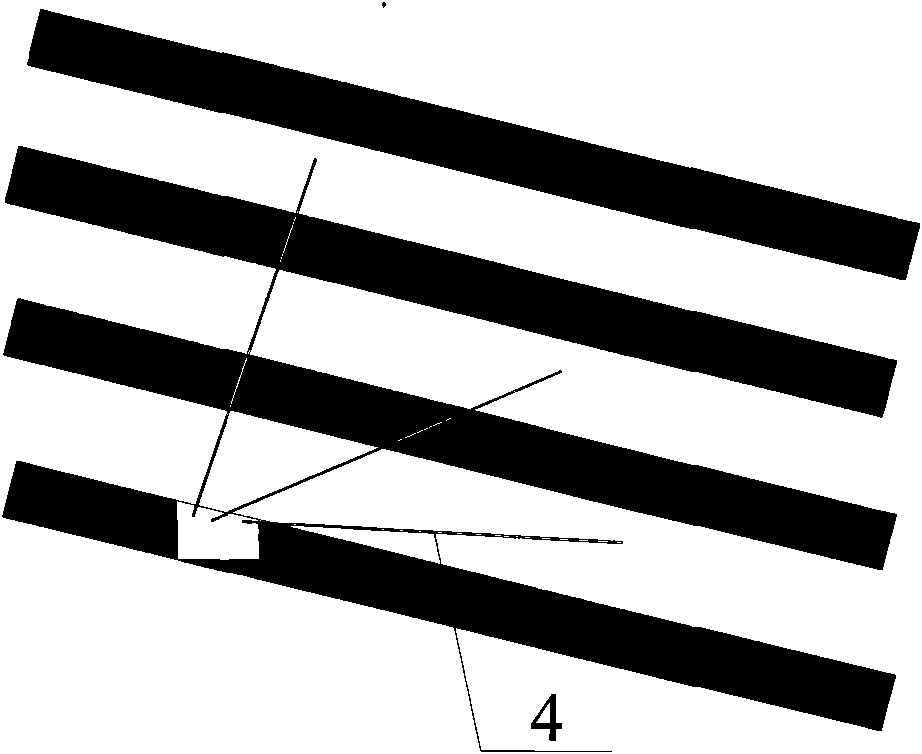

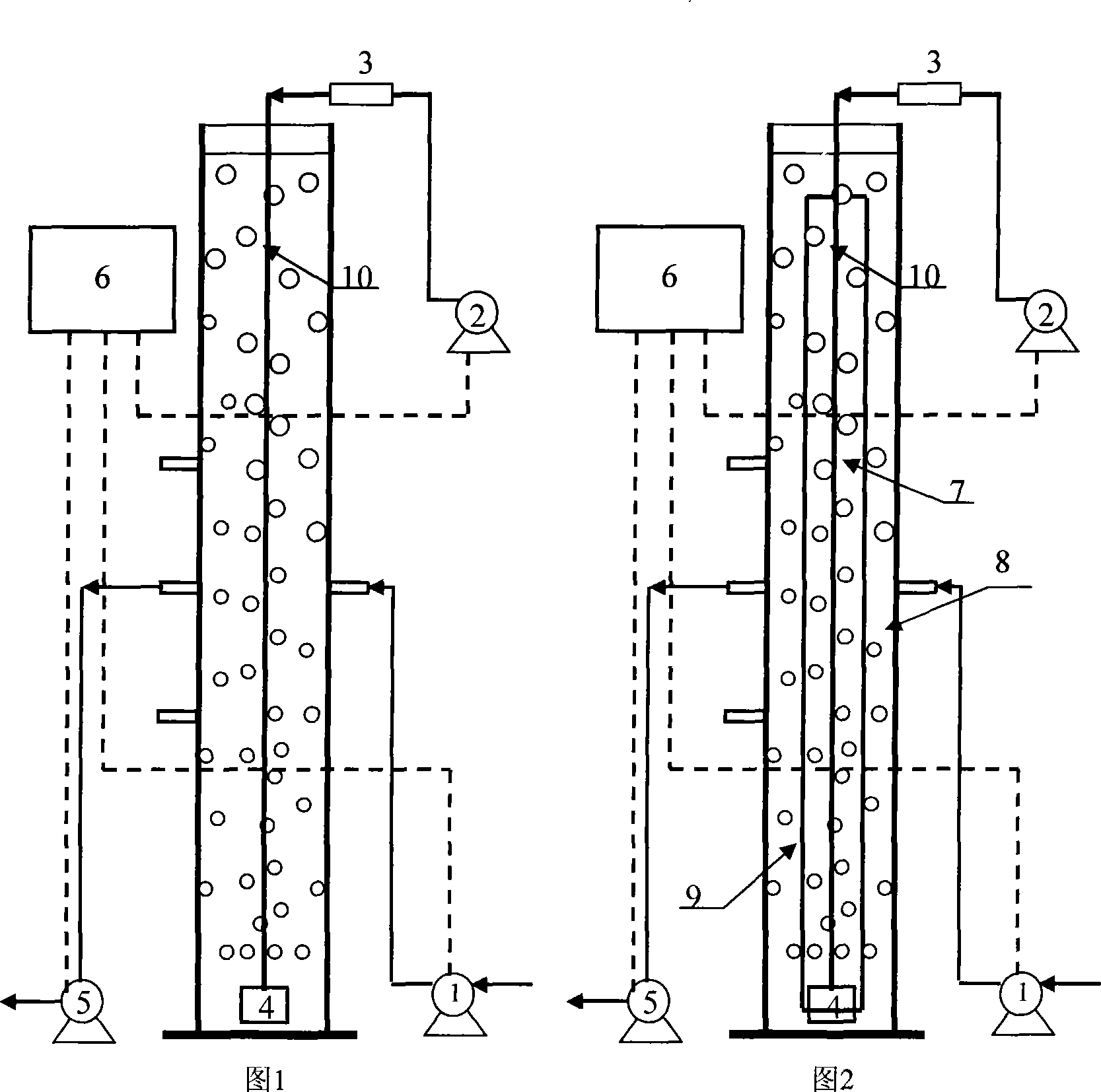

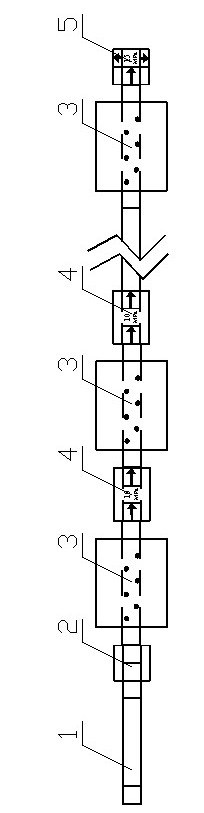

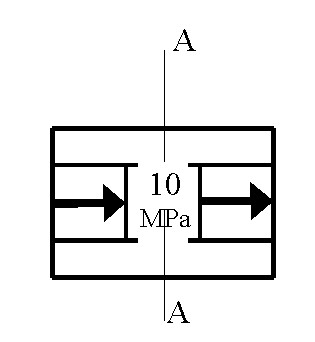

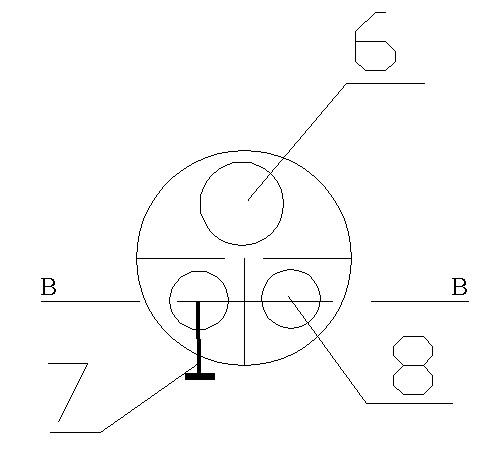

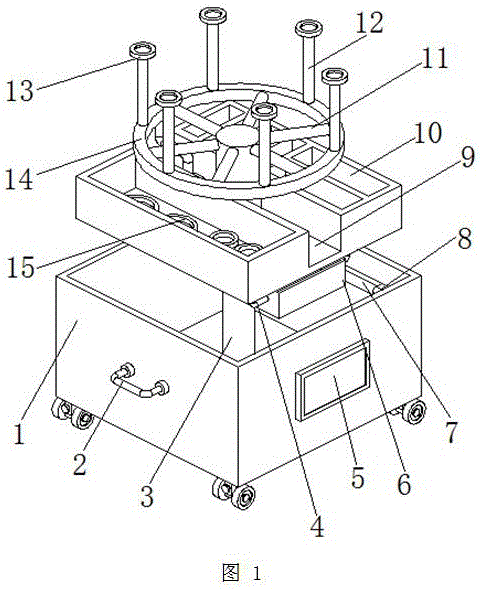

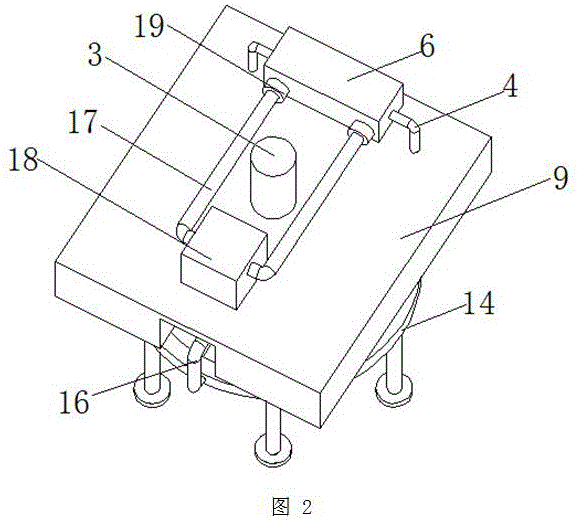

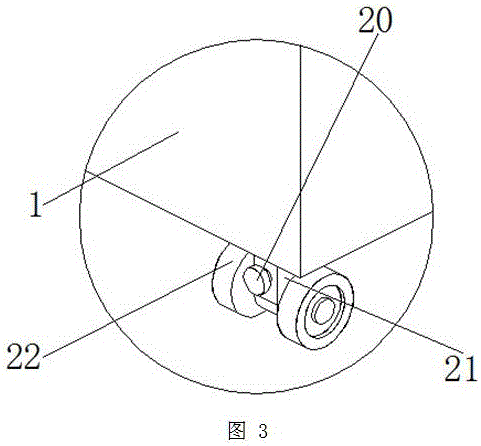

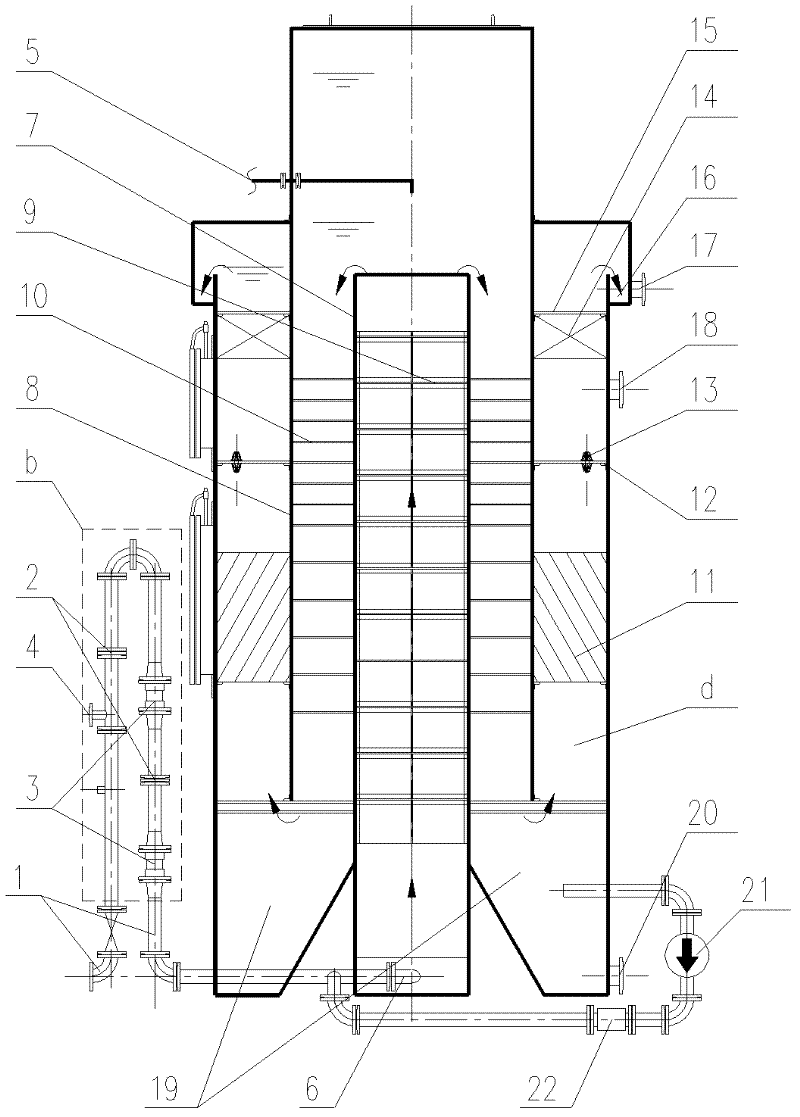

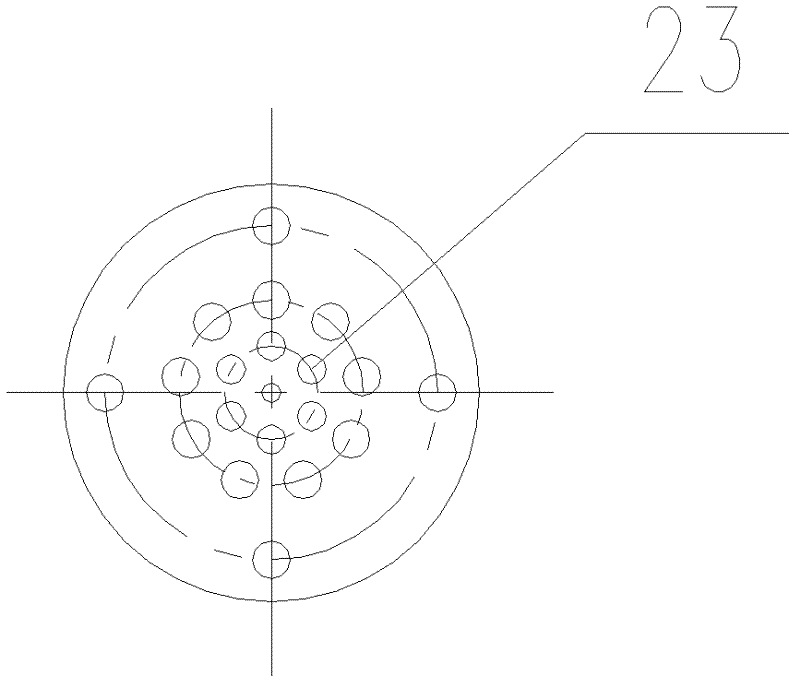

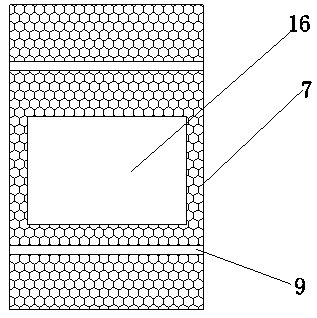

Device and method for enhancing coal seam fracturing effect

InactiveCN102434192ASolve the problem of difficult pumpingIncrease the pumping rateFluid removalGas removalPulse loadHydrostatic pressure

The invention discloses a device and method for enhancing a coal seam fracturing effect. The device comprises four parts, namely, a connecting rod, a connecting sleeve, an expandable sleeve and a constant-pressure switch; a drilling site is arranged according to a full mechanized mining face and coal seam occurrence conditions, all parts are assembled into a system in sequence according to a figure 1 based on drilling site parameters and the coal seam occurrence conditions, the system is arranged between two hole packers and is connected with a water injection pipe, and then, a high-pressure water injection fracturing process is started. According to the device, the number of hole wall cracks can be increased, the device can be used for changing hydrostatic pressure into pulse loads for injected high-pressure water, so that the crushing degree of rocks is enhanced, the crack density is increased, and the hydrostatic pressure can be used for increasing the lengths of the cracks. The invention aims to increase the air permeability of the coal seam, solve the problem of difficult drainage in low-air-permeability coal seams, and increase the gas drainage rate of the coal seams. The device has the advantages of simplicity, clear concept and convenience in operation.

Owner:ZHONGYUAN ENGINEERING COLLEGE

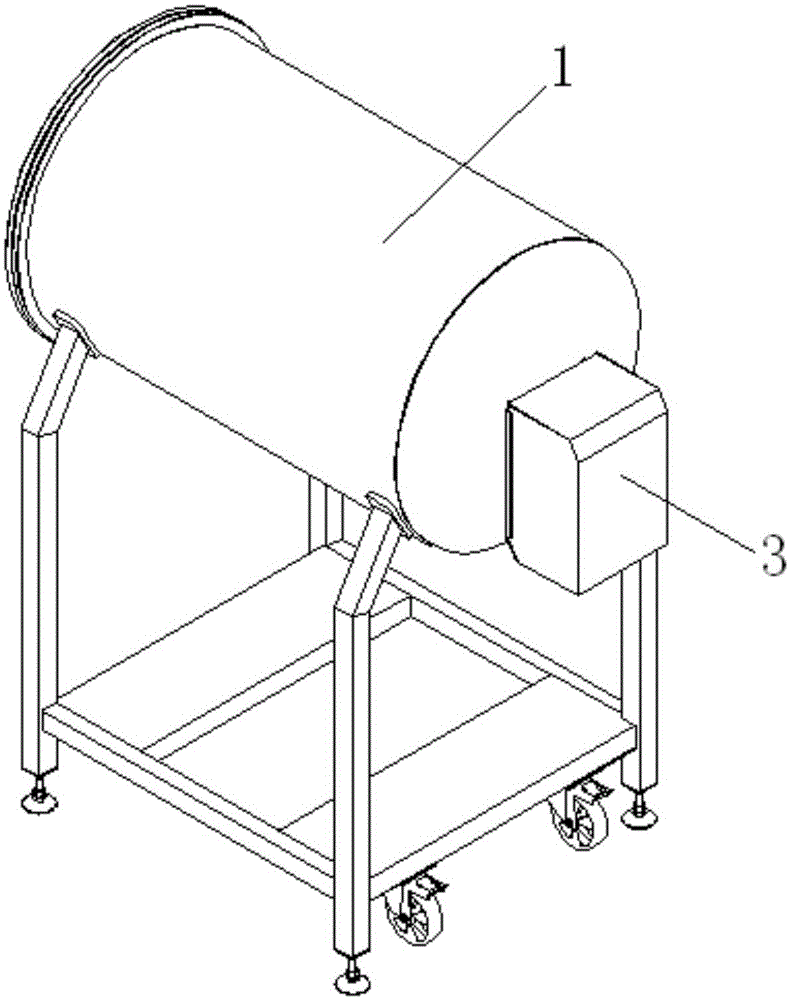

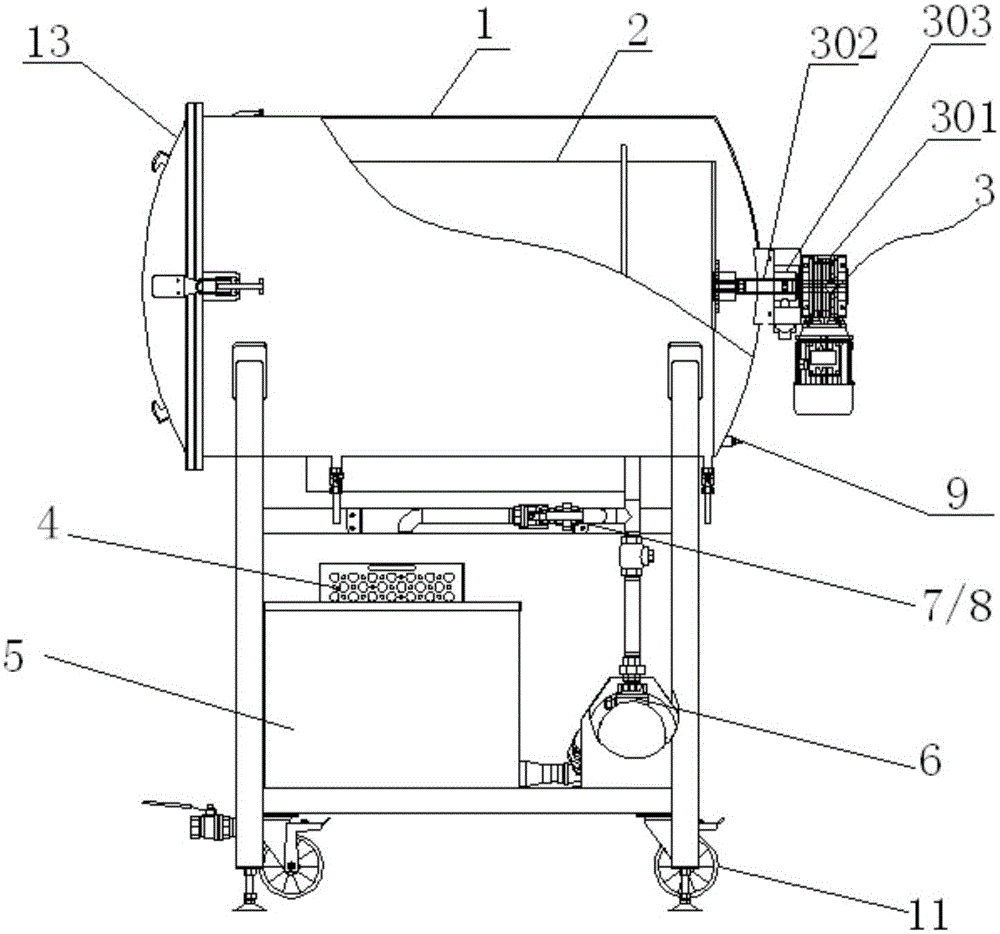

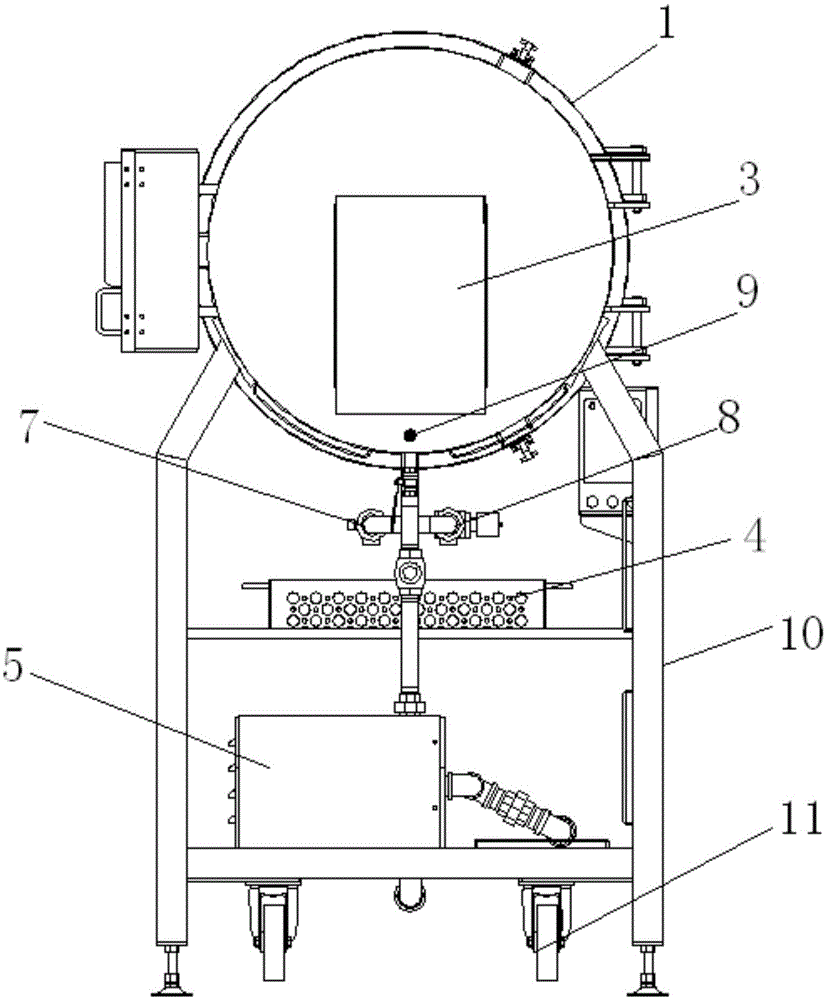

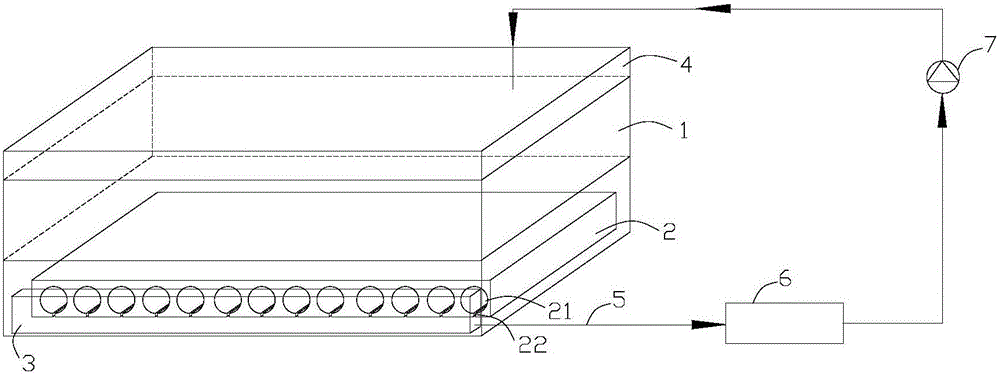

Drum-type economical washing machine

The invention discloses a drum-type economical washing machine which comprises an outer drum, a rotary drum, a power device, a filter, a water tank and a water pump. The rotary drum is rotationally arranged in the outer drum. The power device is arranged outside the outer drum. A power output shaft of the power device penetrates into the outer drum in a sealed manner and can drive the rotary drum to rotate relative to the outer drum. The water pump pumps washing water in the water tank into the outer drum. The washing water drained from the outer drum is filtered through the filter and then stored in the water tank. Therefore, the washing water drained after washing operation can be recycled, the washing effect is guaranteed, the washing water and a detergent are greatly saved, the drainage rate of sewage is decreased, the food washing time is shortened, and sanitation, durability and the economical efficiency are greatly improved. Heating steam can be injected into the outer drum as well, the washing effect is improved, and meanwhile the sterilization effect is achieved.

Owner:KUSN HAOKAOKE FOOD MACHINERY

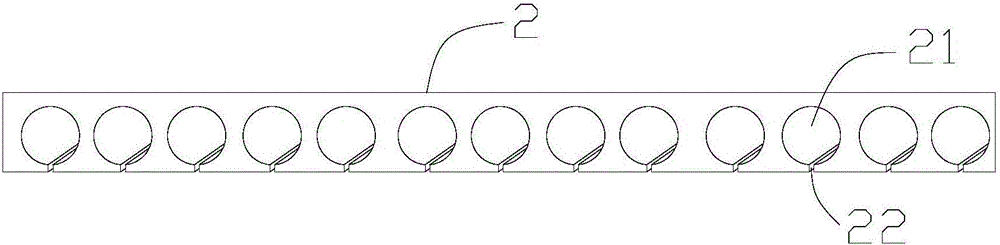

Device and method for removing heavy metals in soil

InactiveCN105750318AGood removal effectEnhanced mass transferContaminated soil reclamationPeristaltic pumpEngineering

The invention discloses a device for removing heavy metals in soil. The device comprises a capillary through drainage belt buried at the bottom of a contaminated soil layer, a water collecting pipe which is communicated with the capillary through drainage belt, a heavy metal adsorption device connected with the outlet of the water collecting pipe, and a peristaltic pump connected with the water outlet of the heavy metal adsorption device, wherein the peristaltic pump is used for sending eluents back to the contaminated soil layer through a water inlet pipe, the capillary through drainage belt is provided with multiple capillary aqueducts which are arranged at intervals and have big insides and small outsides, and the capillary aqueducts are communicated with the water collecting pipe. A method for removing the heavy metals in the soil comprises the following steps: arranging the capillary through drainage belt at the bottom of heavy metal contaminated soil, rapidly discharging the eluents by the capillary through drainage belt, then discharging water of the eluents containing the heavy metals and reusing in the soil after being subjected to adsorption treatment, leaching the soil again, repeating and recycling for several times and then discharging the eluents. The device and the method for removing the heavy metals in the soil realize rapid separation of the eluents and the soil, improve the removal efficiency of the heavy metals and have a high drainage rate, high efficiency and low probability of blockage.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

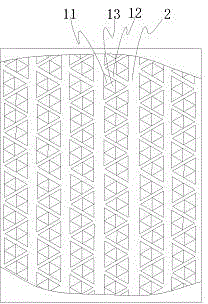

Anti-slip sole and shoe employing same

The invention relates to a sole and provides an anti-slip sole and a shoe employing the same, which can not only improve the drainage rate of a liquid in drainage gaps but also give the anti-slip property of a patterned structure into full play. The anti-slip sole comprises an undersole, wherein a plurality of anti-slip bulge rows are uniformly distributed in the length direction of the undersole; a linear drainage gap is formed between every two adjacent anti-slip bulge rows; each anti-slip bulge row consists of a plurality of triangular anti-slip bulges, every two adjacent triangular anti-slip bulges can together form a parallelogram-shaped structure, and a communication gap communicated with the corresponding drainage gaps is formed between every two adjacent triangular anti-slip bulges; and a triangular groove is formed in the surface of each triangular anti-slip bulge, and each triangular groove is internally connected with the corresponding triangular anti-slip bulge.

Owner:茂泰(福建)新材料科技有限公司

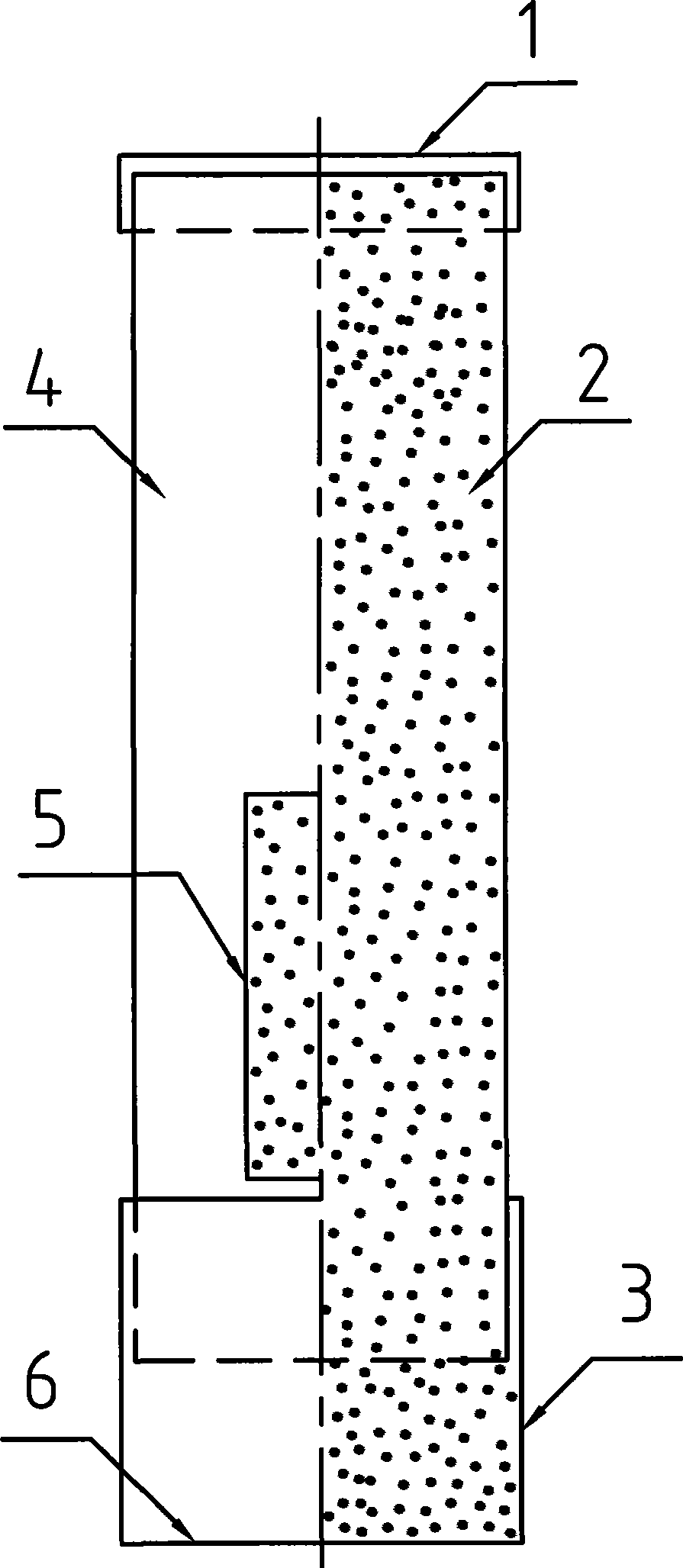

Automatic ladle drainage device

The present invention discloses an automatic ladle drainage device applied in a steel making system. The aim of the invention is to greatly reduce the dosage of draining sand, simplify the operating program and simultaneously obtain the purpose of automatic ladle drainage. The technical essential is that a circular barrel with a closed end is composed through inserting one circular cylinder into another circular cylinder with a larger diameter. The side surface of barrel body is provided with one or a plurality of side openings. Draining sand is filled in the barrel body. The side openings are closed by a sheet or a film with temperature of 40 DEG C to 1200 DEG C. In using, the automatic drainage device is inserted along the opening of ladle. Along with the erection of ladle, the draining sand in the barrel automatically fills the space in the filling pipe end and brick cup. The automatic ladle drainage device of the invention is suitable for the using of ladle in all technical conditions of steel making, and has the advantages of simple operation, dust pollution reduction, cost saving, shortened working procedure time, stable automatic drainage rate.

Owner:石宏帅 +1

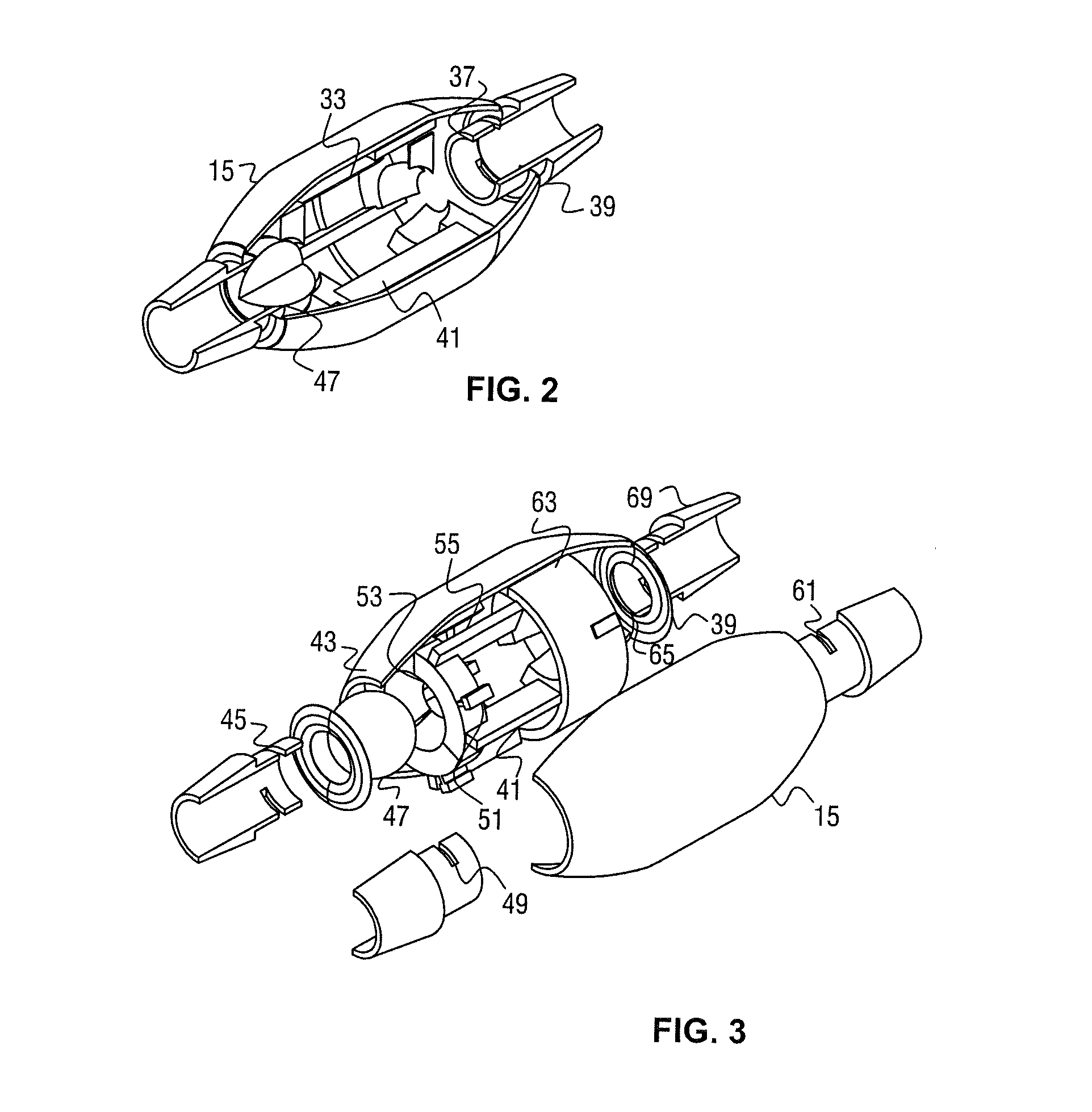

Electroactive polymer actuated cerebrospinal fluid shunt

InactiveUS20080125690A1Reduce in quantityAvoid possibilityWound drainsMedical devicesInternal pressureVentricular catheters

A cerebrospinal fluid (CSF) shunt comprises a ventricular catheter and an electroactive polymer actuated valve for regulating the drainage rate of CSF from the brain ventricle of a patient. The shunt system also comprises a distal catheter for discharge of the CSF to a separate location in the patient's body such as the peritoneal cavity or atrium of the heart. The electroactive polymer actuated valve regulates the flow rate of CSF through a predetermined threshold pressure, which can be adjusted and programmed externally from the patient's body by means of an external control unit signal, as well as through a signal indicated by an internal sensor or an electroactive polymer transducer. The sensor also communicates a signal to the external control unit for indicating the internal pressure at a single location or multiple locations throughout the fully implanted shunt assembly.

Owner:ANITEAL LAB

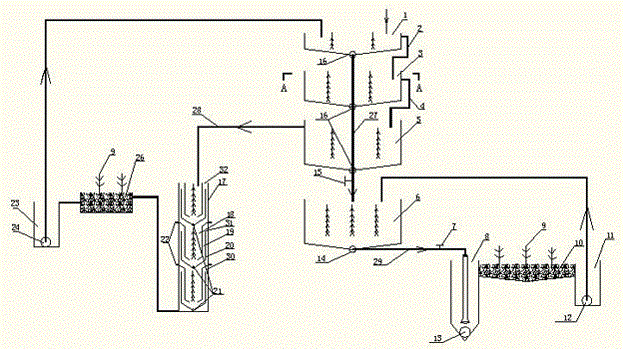

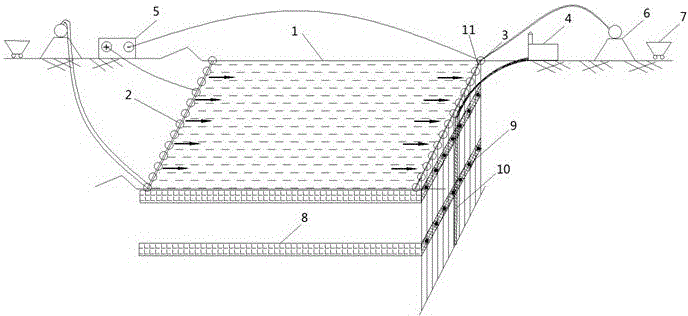

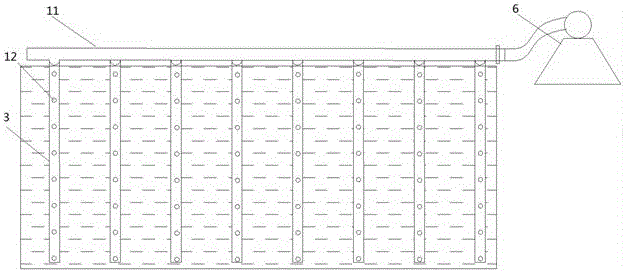

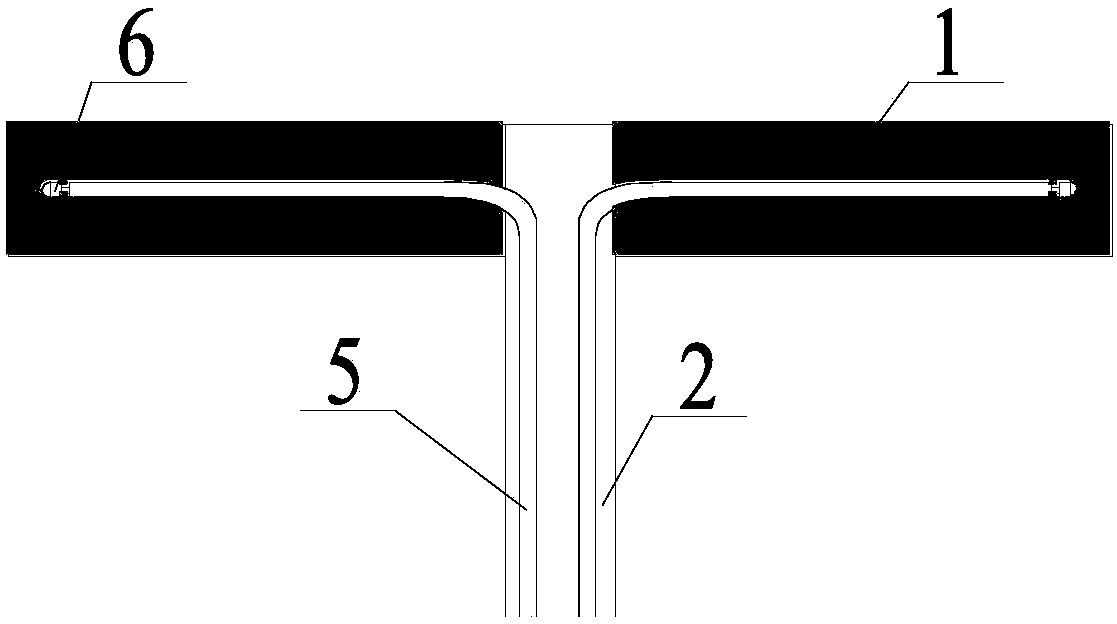

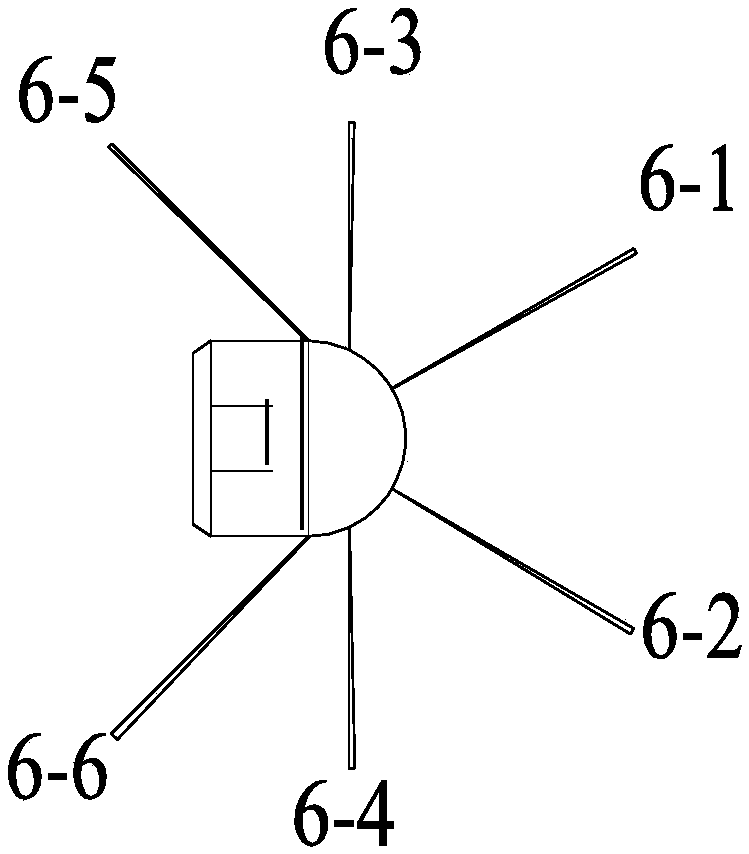

Layered fish and shrimp circulating water polyculture system

InactiveCN105724304AReduce self-harm ratesAchieving zero emissionsClimate change adaptationPisciculture and aquariaPolycultureHigh density

The invention discloses a layered fish and shrimp circulating water polyculture system. The system is composed of a culture pond I (1), a culture pond II (3), a culture pond III (5), a culture pond IV (6), a settling pond I (8), a purifying pond I (10), a clear water pond I (11), a settling pond II (17), a purifying pond II (26) and a clear water pond II (23), wherein the culture pond I (1), the culture pond II (3), the culture pond III (5), the settling pond II (17), the purifying pond II (26) and the clear water pond II (23) are connected in series to form a penaeus monodon culture system, and the culture pond IV (6), the settling pond I (8), the purifying pond I (10) and the clear water pond I (11) are connected in series to form a tilapia mossambica culture system. The system mainly has the advantages that high-density culture of penaeus monodon is achieved; water purifying capacity is high, and drainage rate is low; synchronous culture of penaeus monodon and carnivorous fishes is achieved; separate control of fish and shrimp circulating water can be conducted easily.

Owner:CHONGQING UNIV OF ARTS & SCI

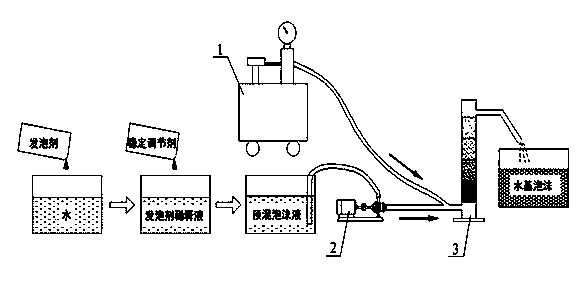

Electric infusion beverage makers

An electric infusion beverage maker (2) comprises a liquid heating chamber (4) having electric heating means (12) associated therewith for heating liquid in the chamber (4). An infusion chamber (6) receives in use a beverage to be infused. A pump (30) transfers heated liquid from the liquid heating chamber (4) to the infusion chamber (6) at a transfer rate. The infusion chamber (6) has outlet means (38) arranged such that beverage-infused liquid drains out of the infusion chamber (6) and into the liquid heating chamber (4) at a drainage rate which is lower than the transfer rate. This means that liquid cannot pass straight through the infusion chamber (6).

Owner:STRIX LTD

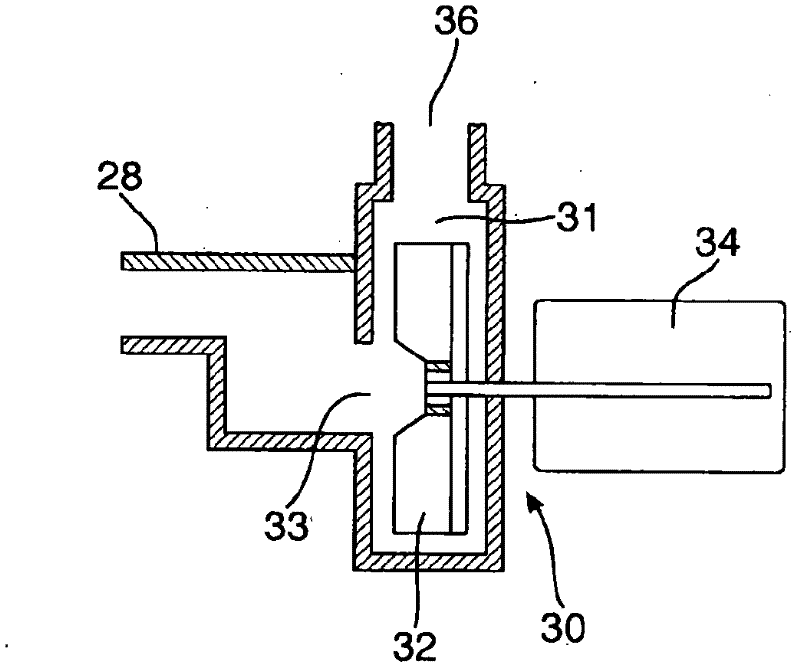

Mining water base foam preventing coal spontaneous combustion and manufacturing method thereof

InactiveCN103967512AHigh foaming ratioLong stable timeDust removalFire preventionWater basedHydrolysate

The invention discloses mining water base foam preventing coal spontaneous combustion. The mining water base foam comprises, by weight, 10-20 parts of lauryl sodium sulfate, 0.5-4 parts of cattle hoof and horn hydrolysate, one to two parts of hydroxypropyl methyl cellulose, two to four parts of dodecanol, one to two parts of cationic guar gum, 0.1-0.5 part of polystyrene-acrylic based emulsion particles, 0.5-2 parts of sodium chloride and 700-1500 parts of water. A manufacturing method of the water base foam comprises the steps that foaming agents are diluted by the water, stable adjusting agents are added to the foaming agents to form premixed foam liquid, compressed air with the pressure intensity of 100 kPa to 200 kPa is guided to a foam maker, after stable air flow exists on an outlet of the foam maker, the diluted premixed foam liquid is injected into the foam maker, the compressed air and the premixed foam liquid generate turbulent vortex in the foam maker, and the turbulent vortex is enhanced constantly to form the water base foam. The water base foam is high in foaming time, long in stable time and low in liquid drainage rate, the performance needs of foam materials are fully met, and meanwhile the water base foam can independently carry out oxygen isolation and cooling on a high-temperature fire source point.

Owner:CHINA UNIV OF MINING & TECH

Portable neurosurgical surgical drainage system

InactiveCN106344974AImprove securityEasy to useIntravenous devicesSuction devicesEngineeringLiquid tank

The invention discloses a portable neurosurgical surgical drainage system equipped with disinfect box. The disinfect box is set with wheel brackets on the four corners at the bottom. The wheel bracket is equipped with wheels on the two sides. The inner cavity of the disinfect box has motorized support rods in the middle of the bottom. The support rods are connected with a placing tray by sleeve connection. The bottom of placing tray is set with the L-shaped connecting rod and flow rate control valve. The two L-shaped are connected with rods. This portable neurosurgical surgical drainage system works by the drainage tube equipped with a sucking pump to drain the waste liquid like the blood of the patient, which is collected by a waste liquid tank. The drainage rate is controlled by the flow rate control valve to improve the safety during the drainage process. After the drainage, the drainage system is placed into the disinfect box for overall disinfection treatment. The portable neurosurgical surgical drainage system has complete functions, high safety performance, simple operation and easy application to save time and labor.

Owner:段祺峰

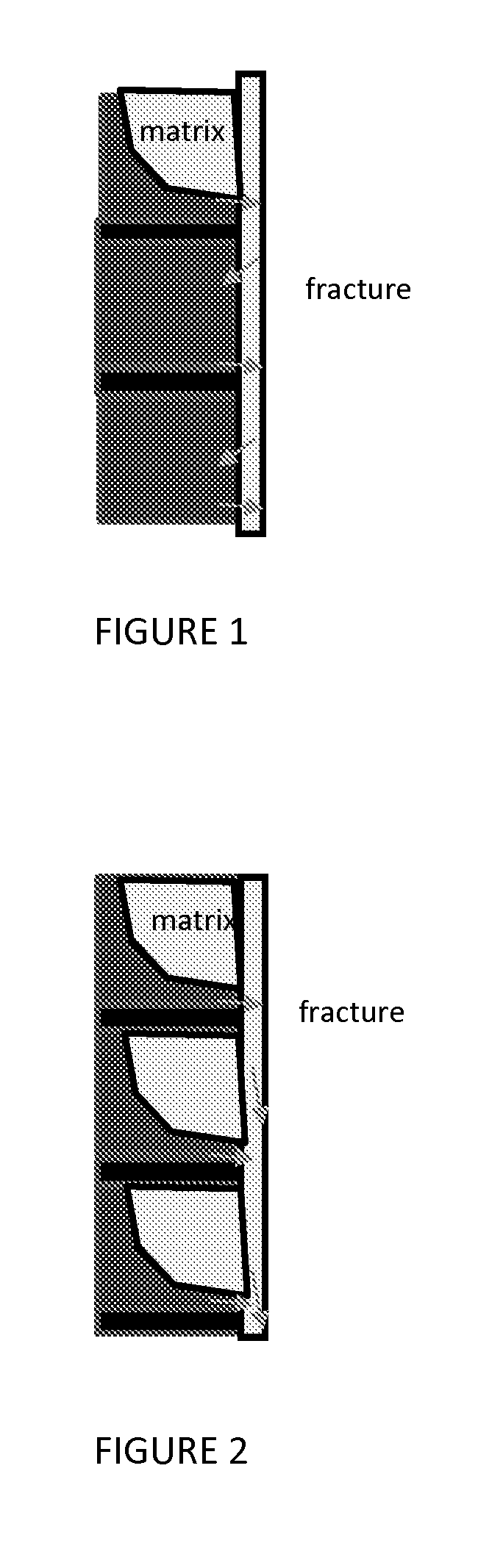

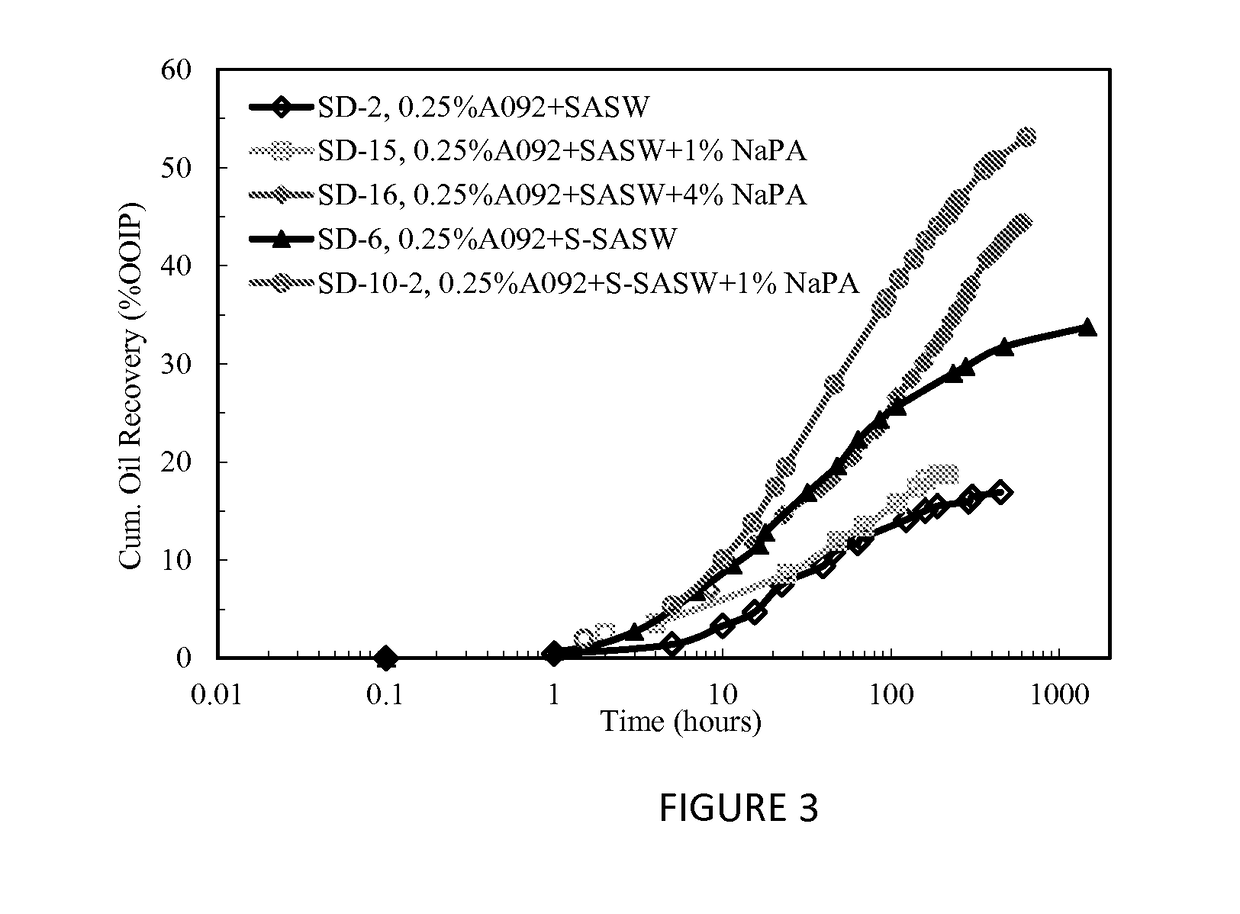

Method to increase gravity drainage rate in oil-wet/mixed-wet fractured reservoir

InactiveUS20170137696A1Increase oil drainage rateOil reimbibition can be preventedFluid removalDrilling compositionGravitationIncreased Gravity

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

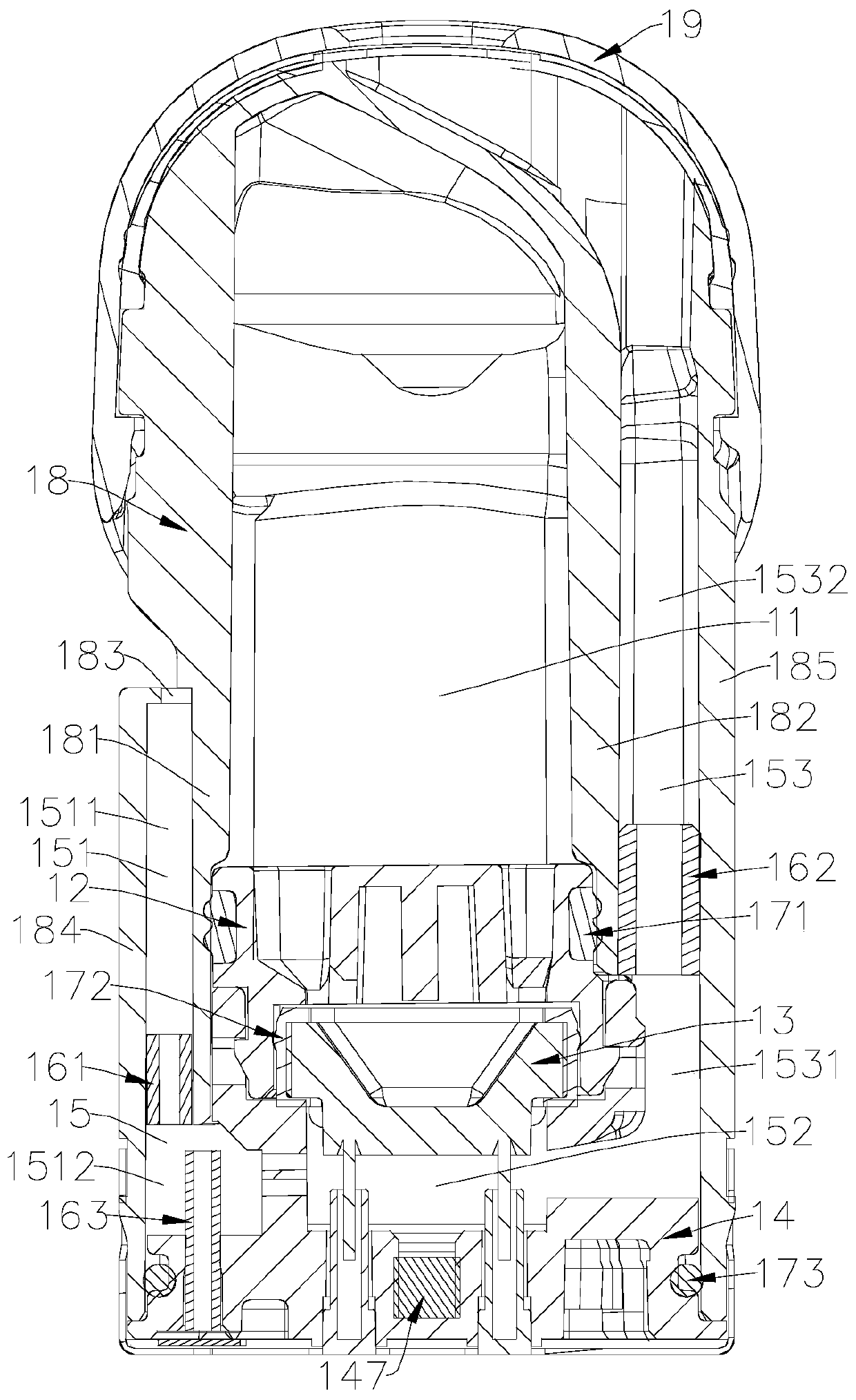

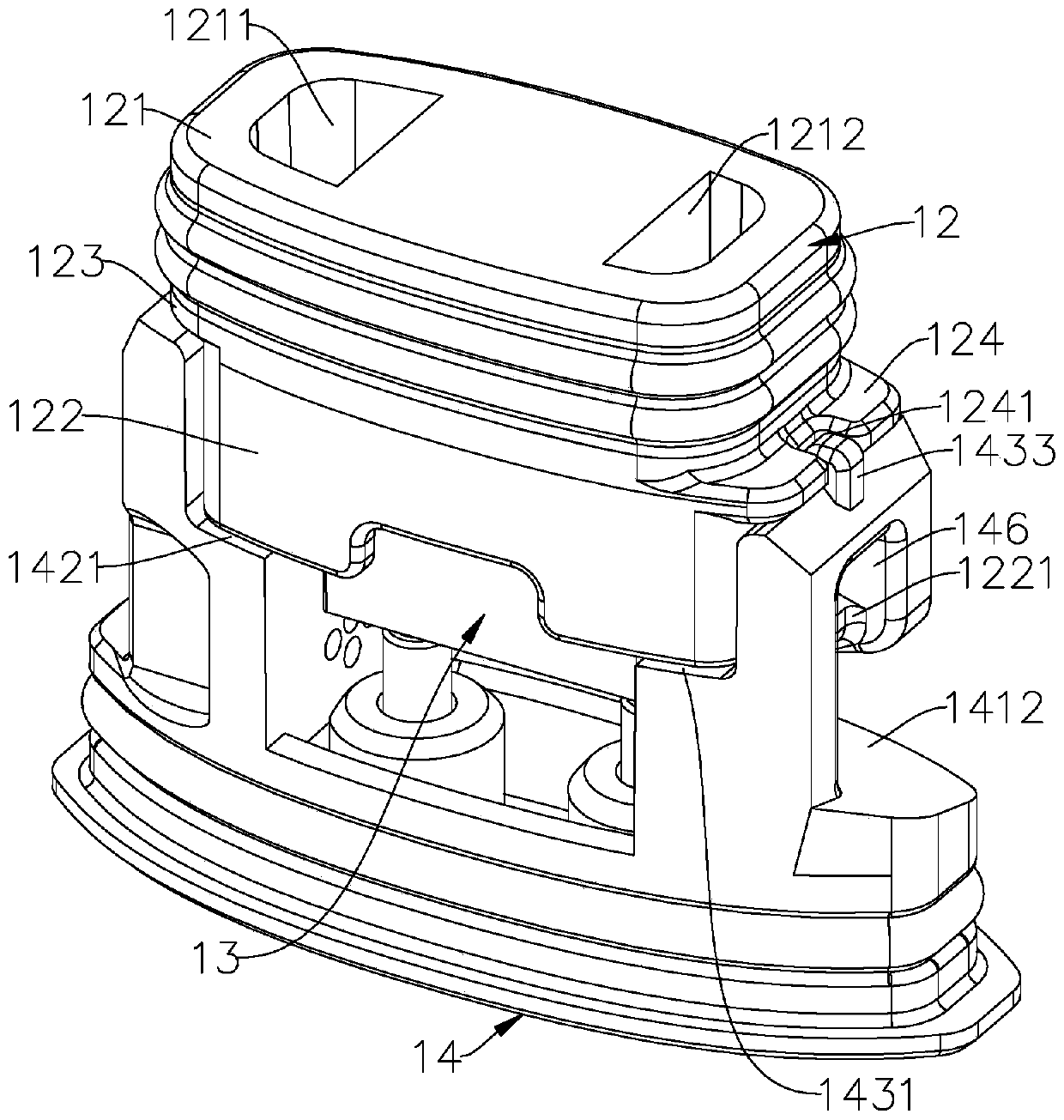

Electronic atomizing device and atomizer thereof

PendingCN110623308ARelieve dry feverAvoid formingTobacco devicesMedical atomisersAir exchangeEngineering

The invention relates to an electronic atomizing device and an atomizer thereof. A liquid storage cavity is formed in the atomizer; the atomizer comprises a heating component and an upper seat at least partially surrounding the upper part of the heating component; the upper seat comprises a first liquid inlet and at least one second liquid inlet communicating the liquid storage cavity with the heating component; and the area of the cross section of the inner hole of the first liquid inlet is more than that of the inner hole of the at least one second liquid inlet. The liquid drainage rate / liquid flow of the first liquid inlet is more than the liquid drainage rate / liquid flow of the at least one second liquid inlet, the first liquid inlet is mainly used for draining liquid, and the at leastone second liquid inlet can be used for helping air exchange, so that dry burning caused by insufficient air exchange of the heating component is relieved, and a lot of bubbles are prevented from being formed in the liquid storage cavity.

Owner:SHENZHEN SMOORE TECH LTD

Water-saving clarification and purification system and process thereof

ActiveCN102515383AReduce own water rateReduce consumptionMultistage water/sewage treatmentWater savingFlocculation

Provided is a water-saving clarification and purification system and a process thereof. Chemicals are added to to-be-treated raw water in a raw water tank and mixed through a multi-section type pipe mixer, the water enters a flocculation reactor with vanes having variable bore diameters for flocculation through rotational flows, then enters a sediment separator for solid-liquid separation, and finally is filtered through a filter, and output water enters a clean water tank to be used. Mud slag separated through the sediment separator is concentrated through a mud accumulation bucket, after concentration, a part of active mud slag flows back to the flocculation reactor through a circulation device, the remaining mud slag is pressed and filtered through a pressing and filtering device, and filtrate flows to the raw water tank, and filter backwashing drain water flows back to the raw water tank. The steps of mixing, flocculation, sediment and filtering are achieved in an integrated high-efficiency clarification and purification device. By means of concentration, circulation and backwashing of the mud slag, water content of the remaining mud slag is reduced. The filtrate of the pressing and filtering device and backwashing water of the filter are recycled to the raw water tank so that exterior drainage rate of the clarification and purification process is greatly decreased and water saving performance of the water-saving clarification and purification system is improved. Compared with a traditional coagulation clarification process, the process has good water saving performance.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION

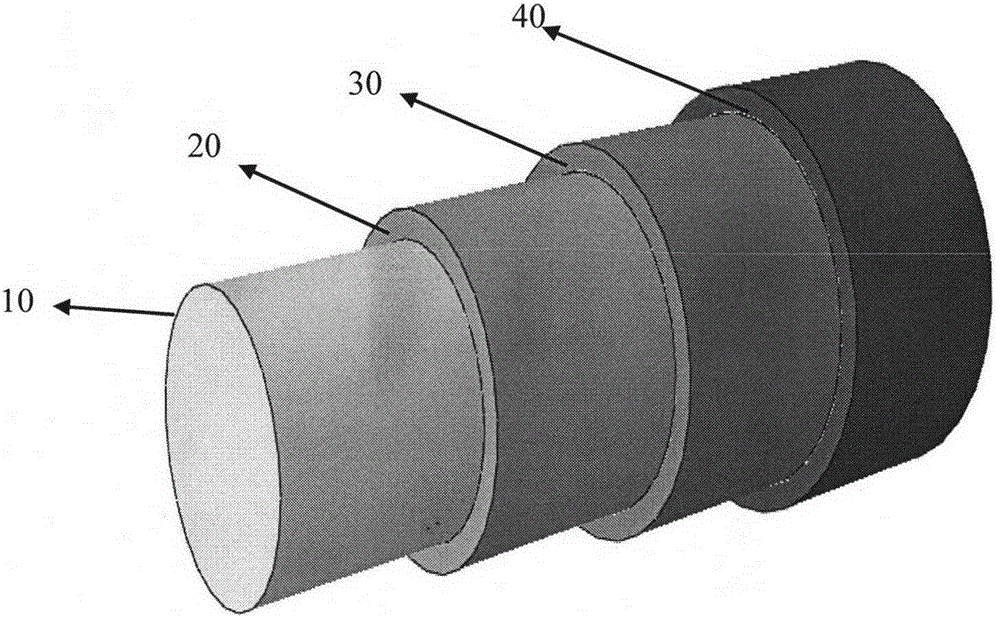

Functionally gradient glass cotton felt for high-temperature pipelines

ActiveCN105202314ABlock deliveryAvoid accumulationThermal insulationPipe protection by thermal insulationGlass fiberEconomic benefits

The invention discloses functionally gradient glass cotton felt for high-temperature pipelines. The functionally gradient glass cotton felt is characterized in that the functionally gradient glass cotton felt comprises a superfine ceramic fiber paper layer, a superfine glass fiber paper layer and hydrophobic flame-resistant glass fiber cotton felt, wherein zirconium silicate and silicon carbide hollow ceramic powder are arranged between every two pieces of paper of the superfine ceramic fiber paper layer in a filling manner from inside to outside, and a 1-3 mu m thick stainless steel film is arranged every 1 mm; aerogel is arranged between every two pieces of paper of the superfine glass fiber paper layer in a filling manner, the volume content is 15%-25%, and a 2-4 mu m thick aluminum foil is arranged every 5 mm; according to the hydrophobic flame-resistant glass fiber cotton felt, the weight content of organic matters in the cotton felt is 10%-20%, and the drainage rate is 20 g. The functionally gradient glass cotton felt can be used for a long time at the temperature about 500 DEG C, the temperature of the junction of the ceramic fiber paper layer and the glass fiber paper layer doesn't exceed 400 DEG C, the temperature of the junction of the glass fiber paper layer and the glass cotton fiber felt doesn't exceed 150 DEG C, the overall heat conductivity coefficient is about 0.045 W / m*K, the overall thickness of the material is greatly reduced, mounting and dismounting are facilitated, meanwhile, the construction period is shortened, and the economic benefits are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Geogrid combined grouting electro-osmosis construction method for ultra-soft soil

ActiveCN105649005AImprove integrityImproving the effect of electroosmotic drainage reinforcementSoil preservationSoil horizonGuide tube

The invention discloses a geogrid combined grouting electro-osmosis construction method for ultra-soft soil. The geogrid combined grouting electro-osmosis construction method for ultra-soft soil comprises the following steps: carrying out hydraulic reclamation of mud soil by using hydraulic reclamation construction machinery, performing reinforcement on the mud soil layer at the surface layer of the mud by using a geogrid, and paving geotextile on the surface layer; arranging grouting iron pipes as a positive electrode and a negative electrode; connecting a grouting pump and a horizontal grouting guide pipe by means of a connecting valve, and connecting the horizontal grouting guide pipe with top ends of the grouting iron pipes of the positive electrode and the negative electrode; arranging a drainage main pipe and pumping equipment in an ultra-soft soil place on one side where the cathode is arranged; and switching on the power for electro-osmosis. The geogrid combined grouting electro-osmosis construction method for ultra-soft soil is capable of changing the present situation of separation of electrodes and soil mass, effectively increasing the effective electric potential at the later stage of electro-osmosis, increasing the overall current intensity, and also correspondingly increasing the drainage rate; compared with treating ultra-soft soil by using a conventional electro-osmosis method, the integrity of the soil mass is enhanced by the geogrid, and the efficiency at the later stage of electro-osmosis is improved by the grouting technology; in addition, by means of void filling, differential settlement can also be effectively reduced.

Owner:ZHEJIANG UNIV

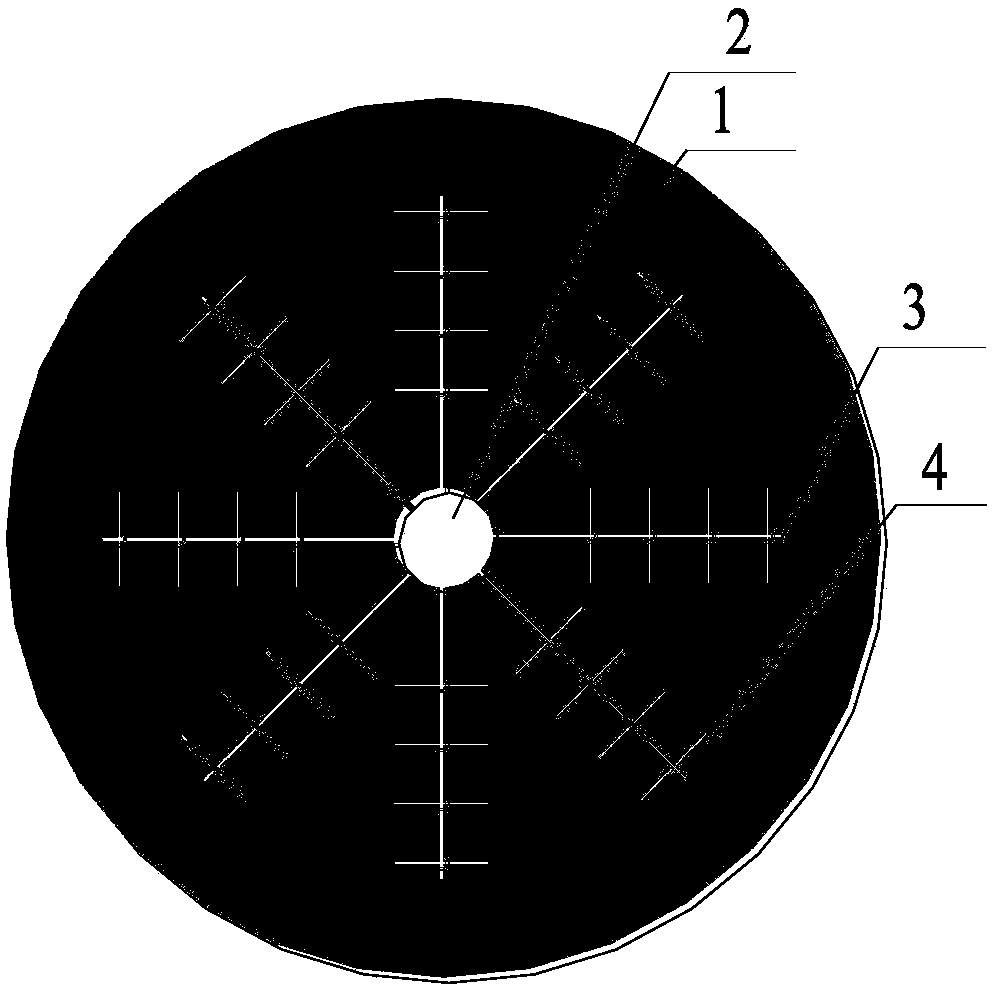

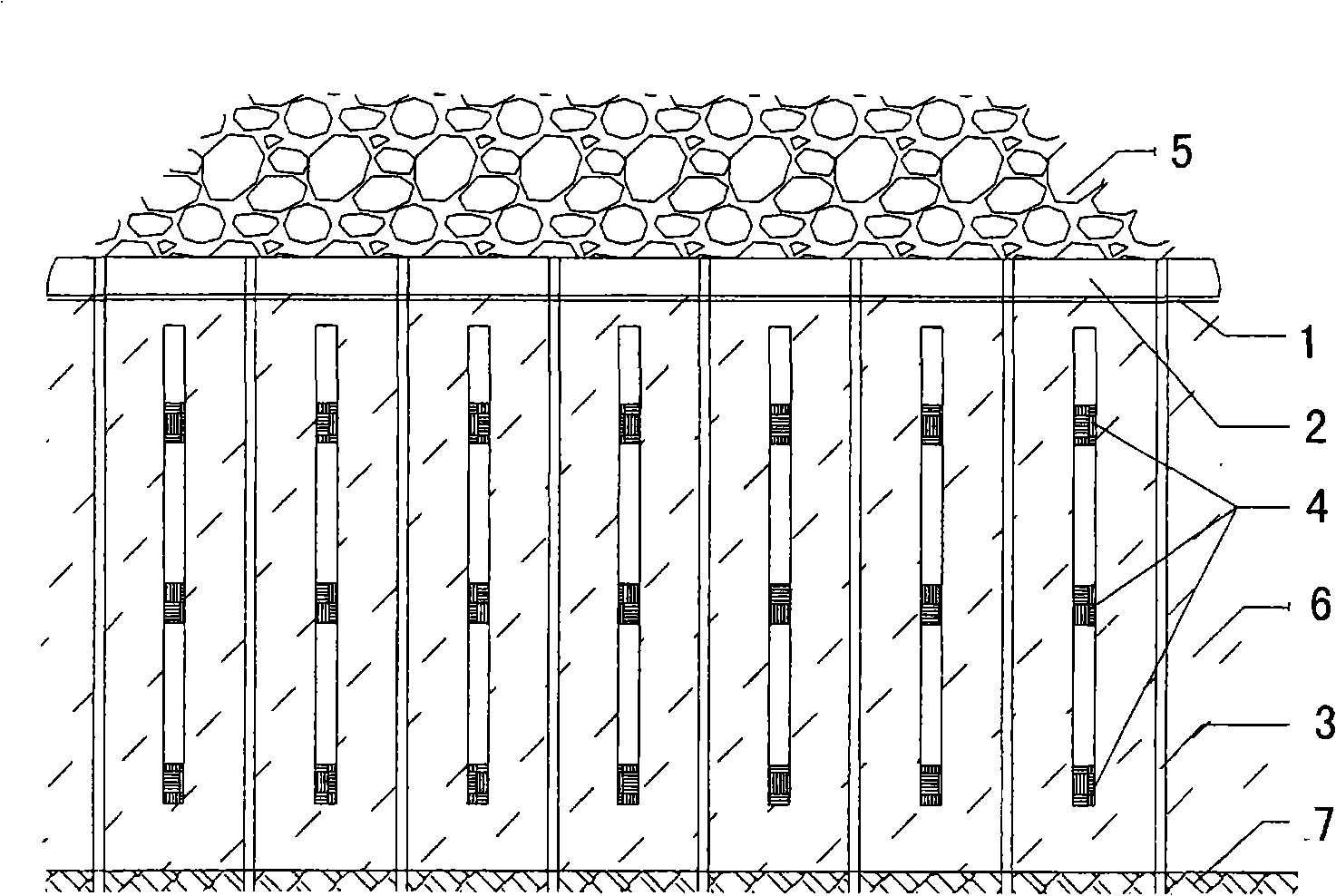

Crossing hole mesh slotting and permeability increasing method

InactiveCN108086901AReduce the number of drilled holesIncrease the effective range of influenceDisloding machinesUnderground miningEconomic benefitsEngineering

The invention relates to a crossing hole mesh slotting and permeability increasing method. The method includes the following steps of S1, constructing crossing holes by a design depth in a to-be-excavated or to-be-mined working face by means of a drilling machine; S2, retreating a drilling stem, assembling a self-advancing type high-pressure hose in the drilled hole, introducing medium-pressure water in the self-advancing type high-pressure hose, bending the self-advancing type high-pressure hose by 90 degrees when the self-advancing type high-pressure hose advances to a designated position ofthe crossing holes, and constructing along-coal-seam drill holes distributed in the radial direction of the crossing holes around the crossing holes; S3, introducing high-pressure water into the self-advancing type high-pressure hose in the retreating process of the self-advancing type high-pressure hose after the along-coal-seam drill holes are constructed to cut a coal body around the along-coal-seam drill holes so as to generate a radial crack; S4, repeating the steps S2 and S3 to complete the mesh slotting and permeability of the crossing holes. The method is simple and convenient to operate and has wide application and popularization value, the effective influence range of the crossing holes is enlarged, the gas drainage rate is increased, the number of the crossing holes is greatlyreduced, and economic benefits are improved.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

Method for consolidating mud soft base by explosion and piling prepressing united drainage

The invention relates to a method for exploding, piling-loading, preloading, combining, draining and consolidating muddy soft ground. The method comprises the following steps that: a vertical drainage channel is arranged in the soft ground first; a plane of the drainage channel is arranged according to grids; explosive packages are buried in silt in the center of the grid; stone is loaded on a sand cushion; the amount of the loaded stone cannot cause the shear failure and sideslip of the silt; and the drainage rate and consolidation rate of the muddy soft ground are improved by utilizing the explosion of the explosive packages and the functions of piling-loading, combining, squeezing silt and draining. The method is implemented, which solves the technical problems that: a single explosion-drainage-consolidation method for treating the muddy soft ground is poor in drainage-consolidation effect due to depending on the dead weight of a matrix during the later period of explosion, and is long in construction period. After the explosion, the drainage of the matrix is speeded up through layering, piling-loading and preloading, which improves consolidation rate.

Owner:北京中科力爆炸技术工程有限公司

Pipeline orifice device for municipal engineering drainage pipeline

The invention discloses a municipal engineering drainage pipe crossing device, which is mainly composed of a drainage board, and the drainage board is uniformly provided with drain holes penetrating up and down, and the sewage is discharged down by using the drain holes; the drainage board There are slots on both sides of the lower surface, and the slots are horizontally oriented forward and backward, and the two ports of the slots communicate with the outside of the drainage plate; in the present invention, when the surface of the filter screen has accumulated too much residue and affects the drainage, the fixing ring Take it off, and at the same time lift up to adjust the pull rope, then one side of the filter can be lifted to form a structure with one end high and one end low, and the residue accumulated on the surface of the filter can be partly shaken by the operator under the action of gravity. The residue shakes off into the slag collecting net bag, which can reduce the amount of residue attached to the surface of the filter screen, thereby improving the overall drainage speed, and this method helps to increase the service life of the filter screen.

Owner:成都阡陌九城网络科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com