Automatic ladle drainage device

An automatic, ladle technology, applied in the field of ladle drainage device, can solve the problems of affecting the quality of molten steel, disrupting the production rhythm, aggravating the secondary oxidation of molten steel, etc., achieving the effect of shortening the process time, reducing labor intensity and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings.

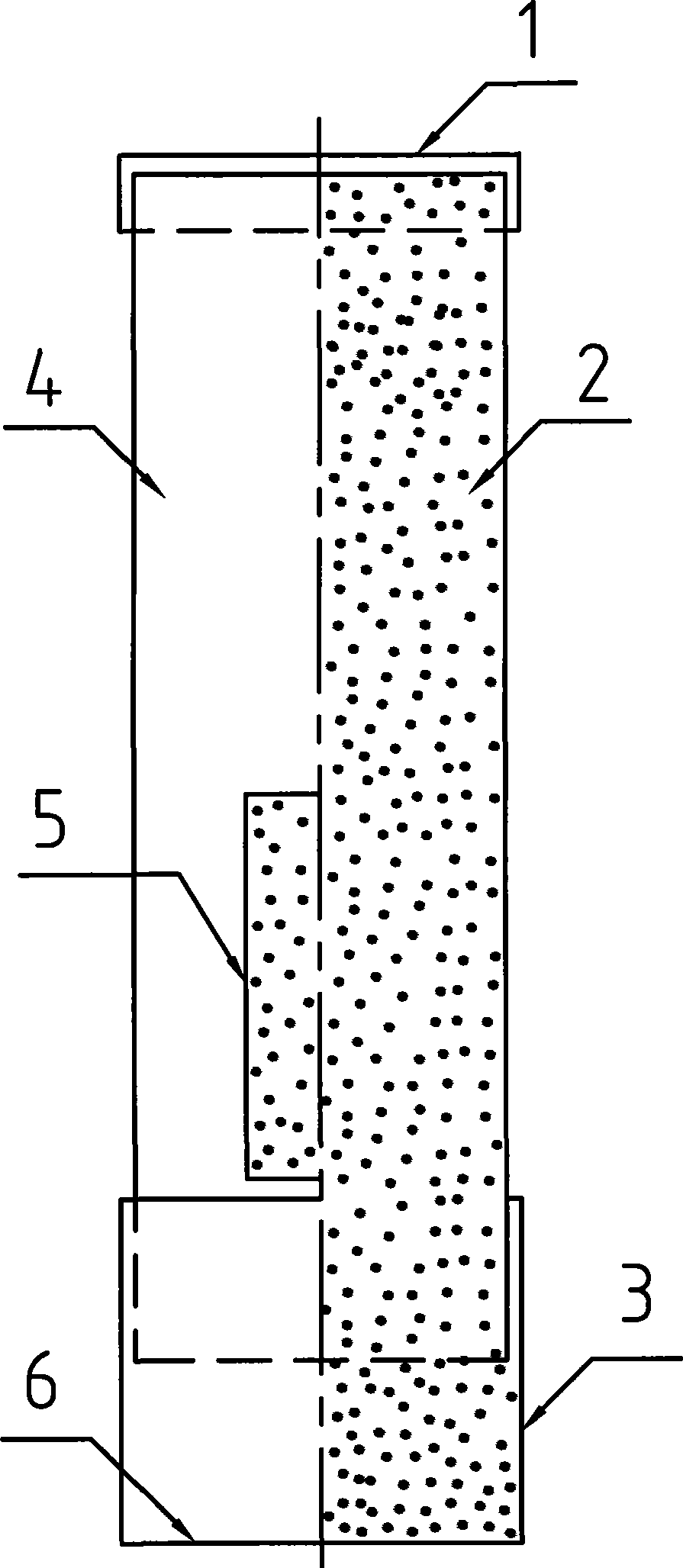

[0018] In the drawings, the present invention is composed of iron sheet sealing end 1, drainage sand 2, lower steel cylinder 3, upper steel cylinder 4, side holes 5 closed with plastic film and lower opening 6 of the steel cylinder closed with plastic film; The cylinder 4 is inserted into the lower steel cylinder 3 and connected with acrylic adhesive; the side hole 5 has a width of 30mm and a length of 300mm.

[0019] The outer diameter of the lower steel cylinder 3 is 2mm smaller than the inner diameter of the ladle slide plate, which is easy to insert; the outer diameter of the upper steel cylinder 4 is 0.5mm smaller than the inner diameter of the lower steel cylinder 3; the space volume in the device should be close to the ladle upper slide plate, upper nozzle, and nozzle block The volume of the enclosed space is used to calculate the length of the entire device. The purpose is to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com