Patents

Literature

830 results about "Acrylic adhesive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

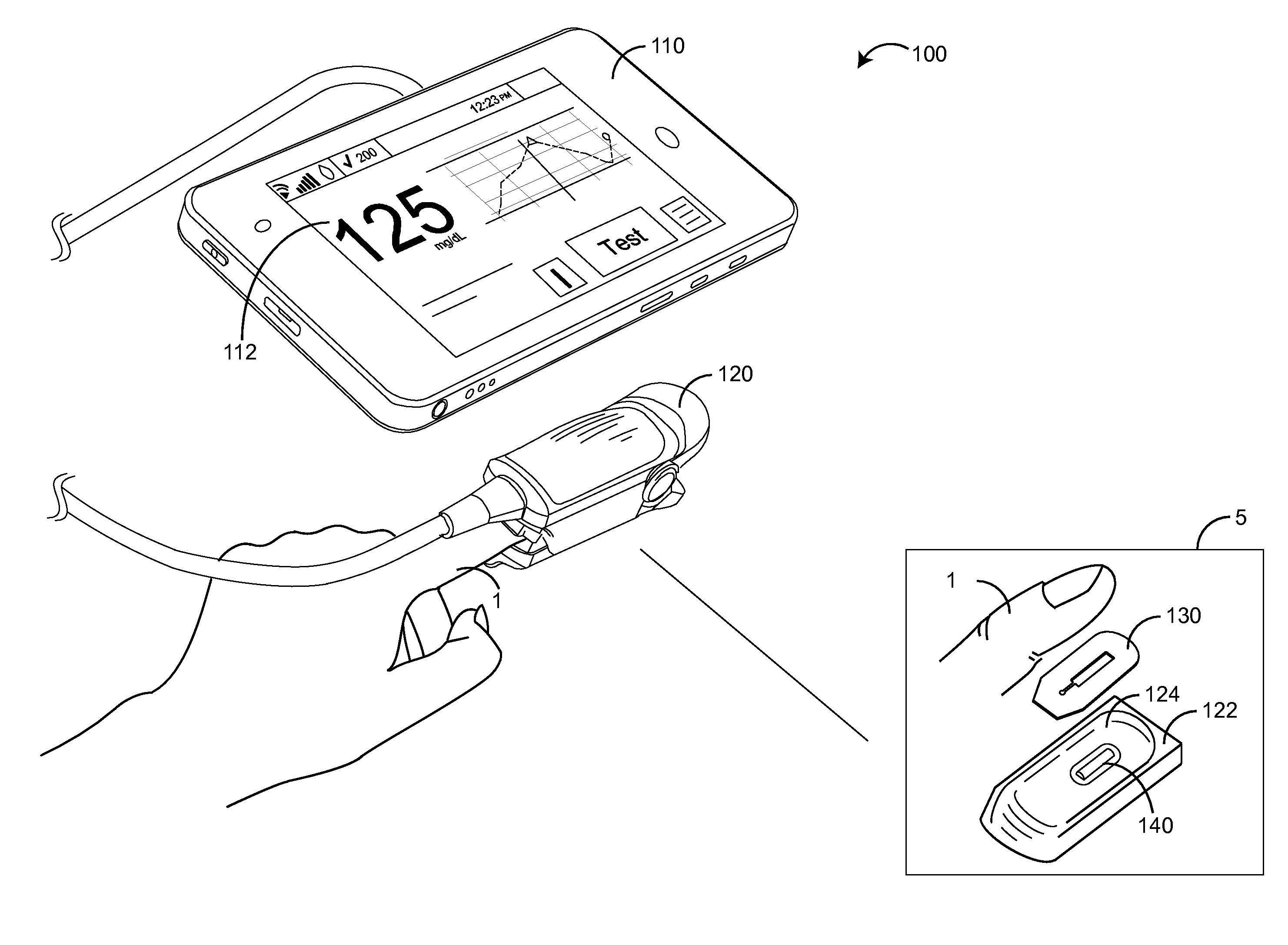

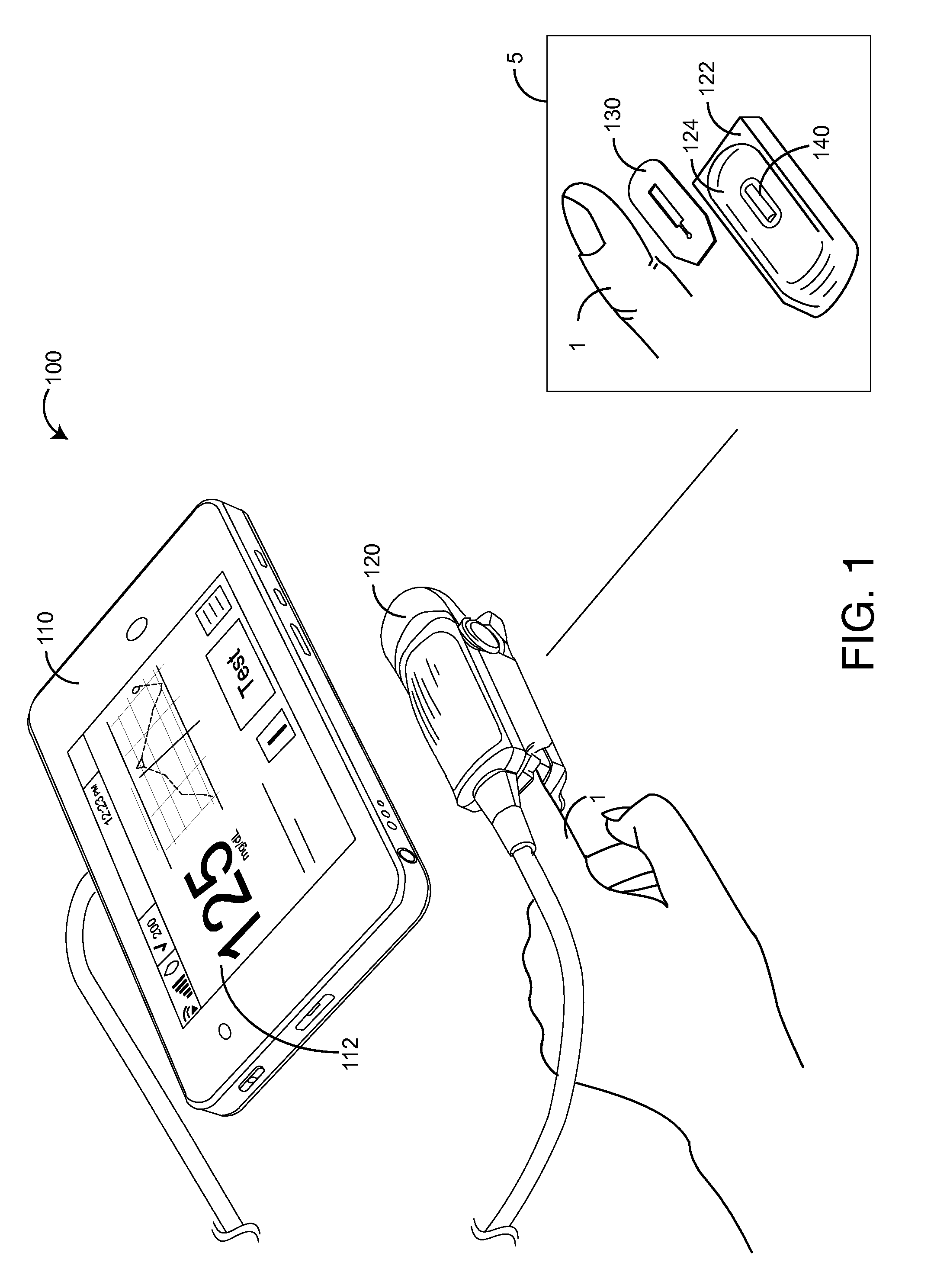

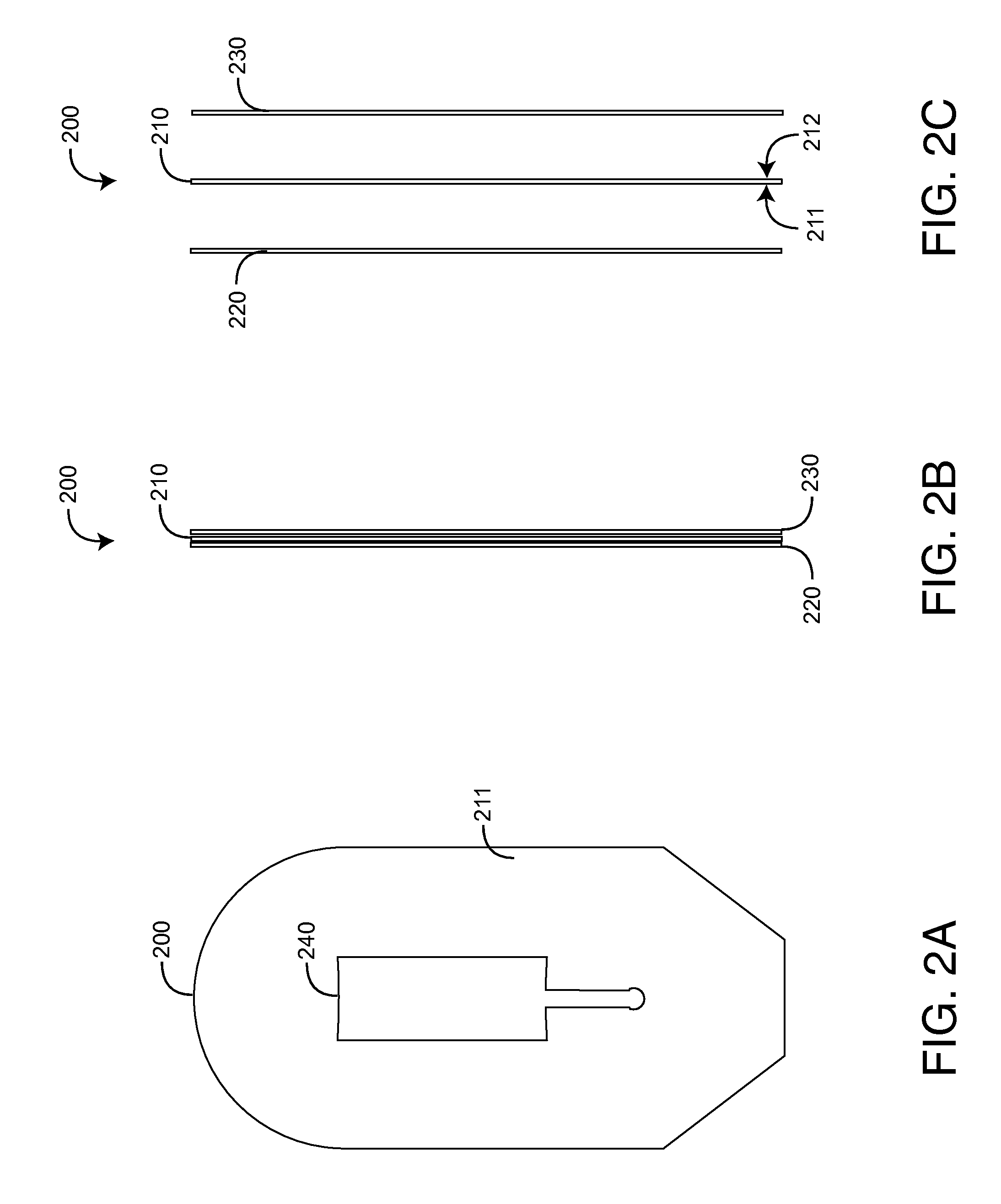

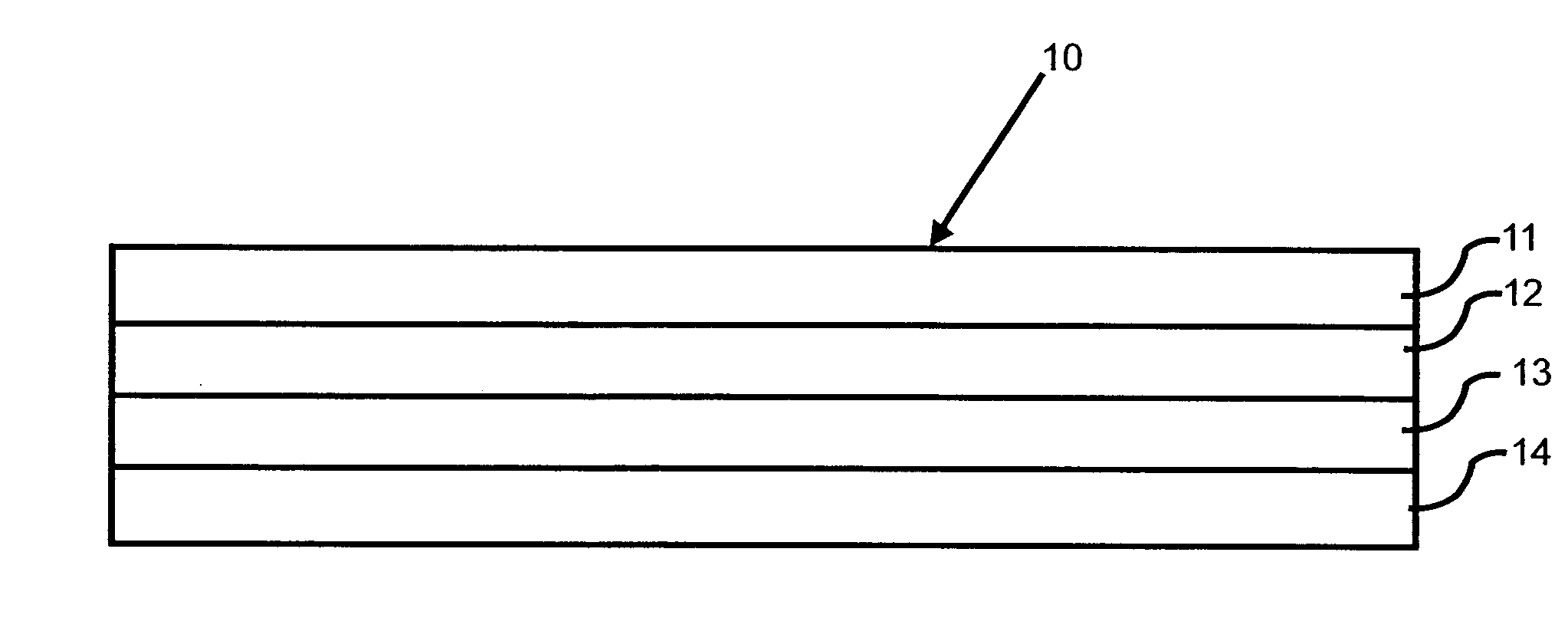

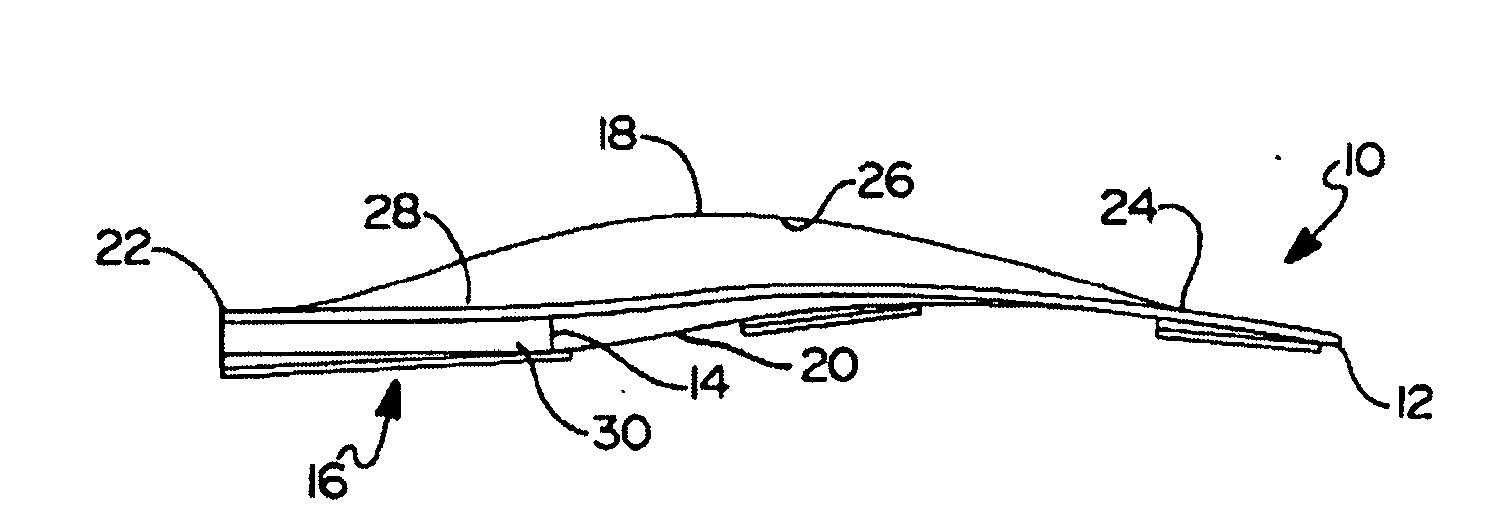

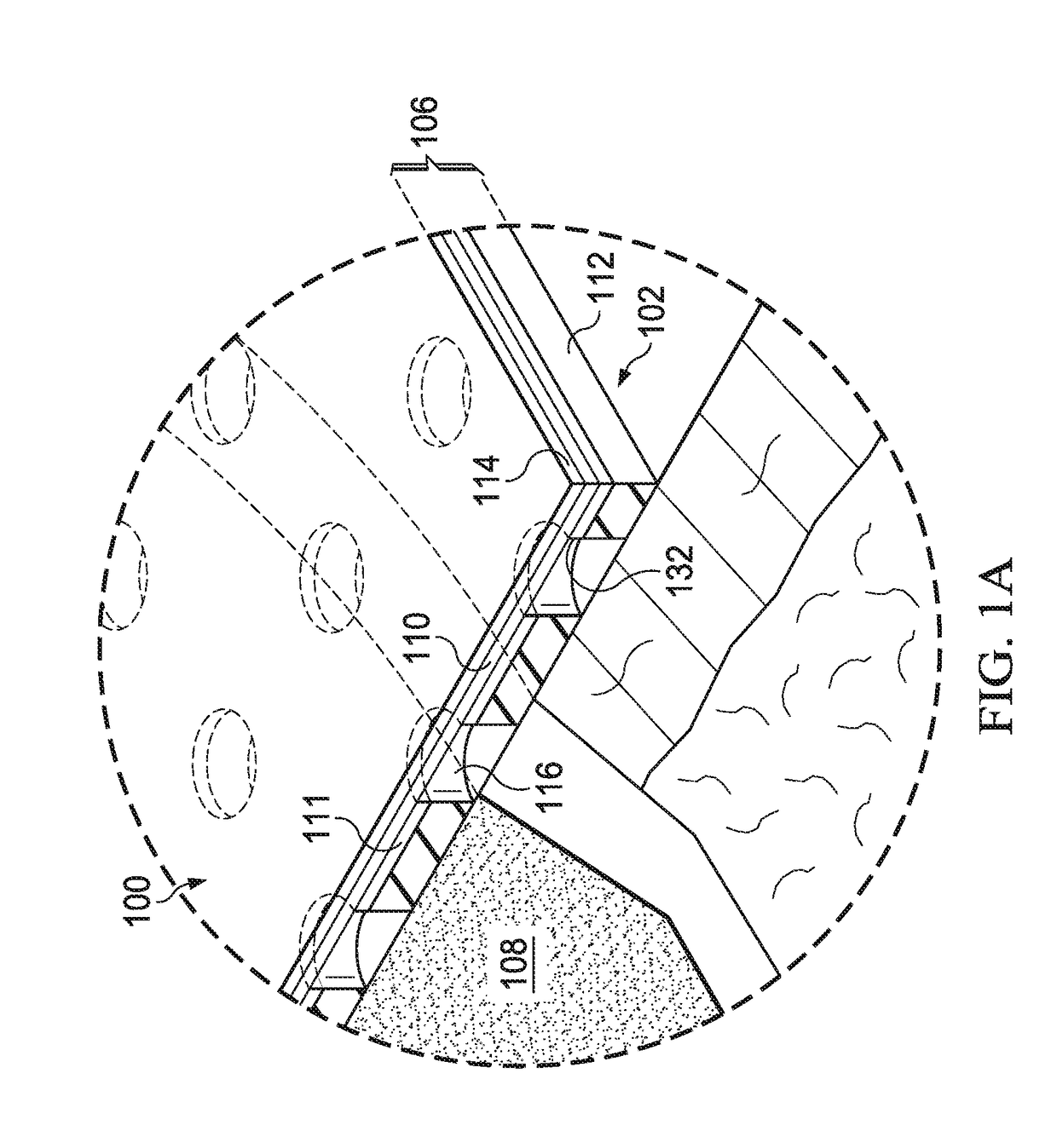

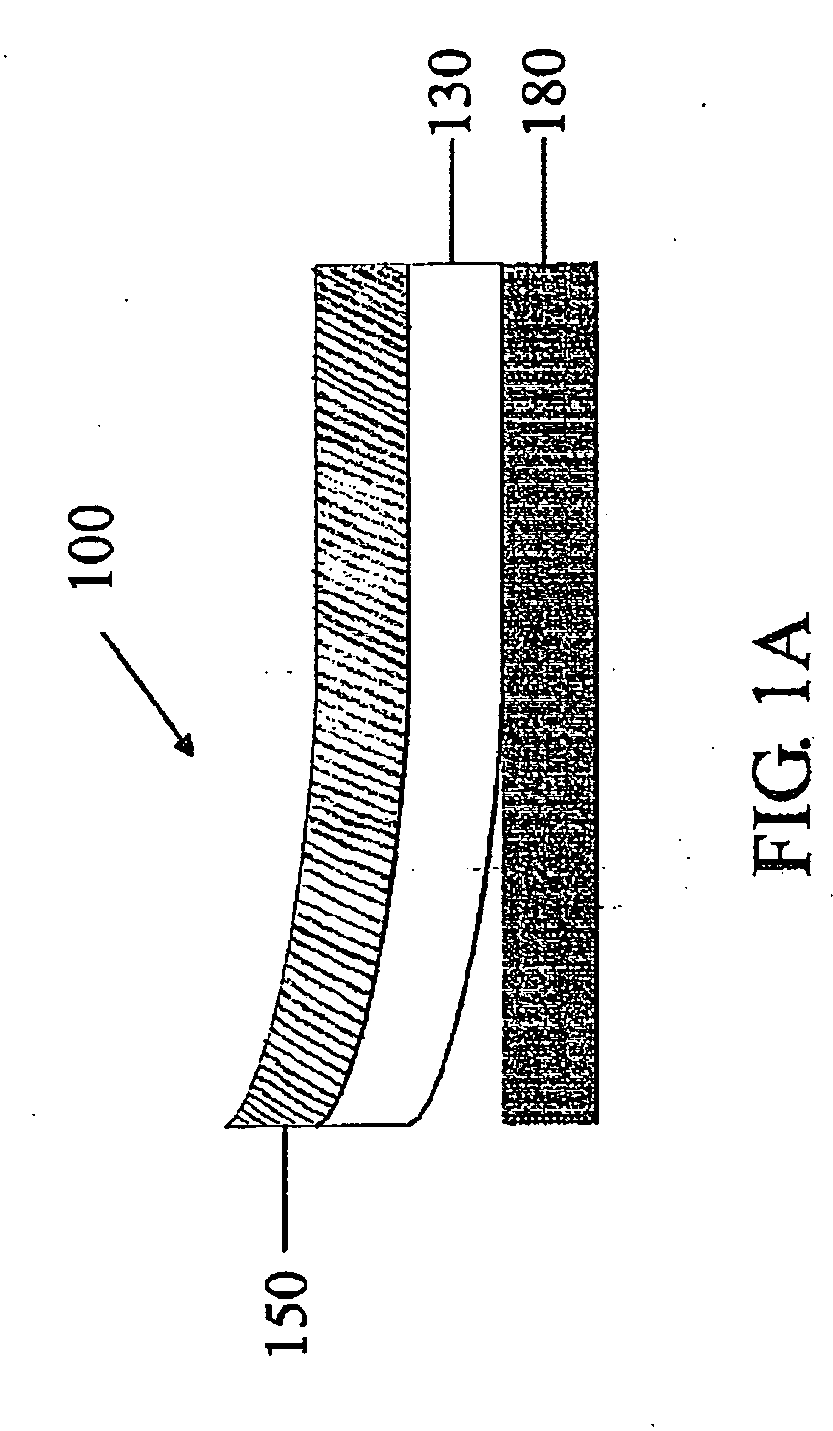

Finger-placement sensor tape

InactiveUS20150005600A1Easy to disassembleEasy to installSensorsBlood characterising devicesEngineeringAcrylic adhesive

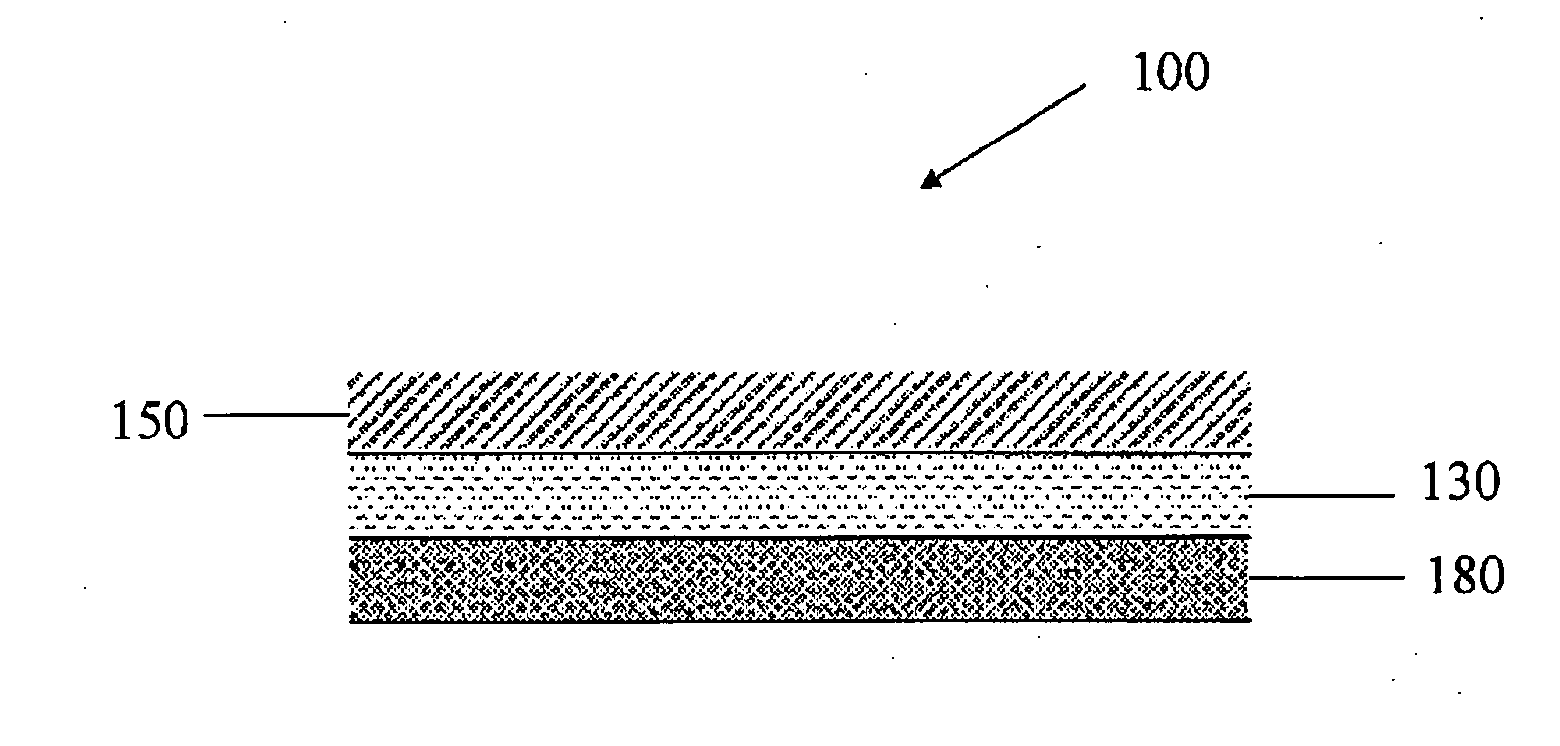

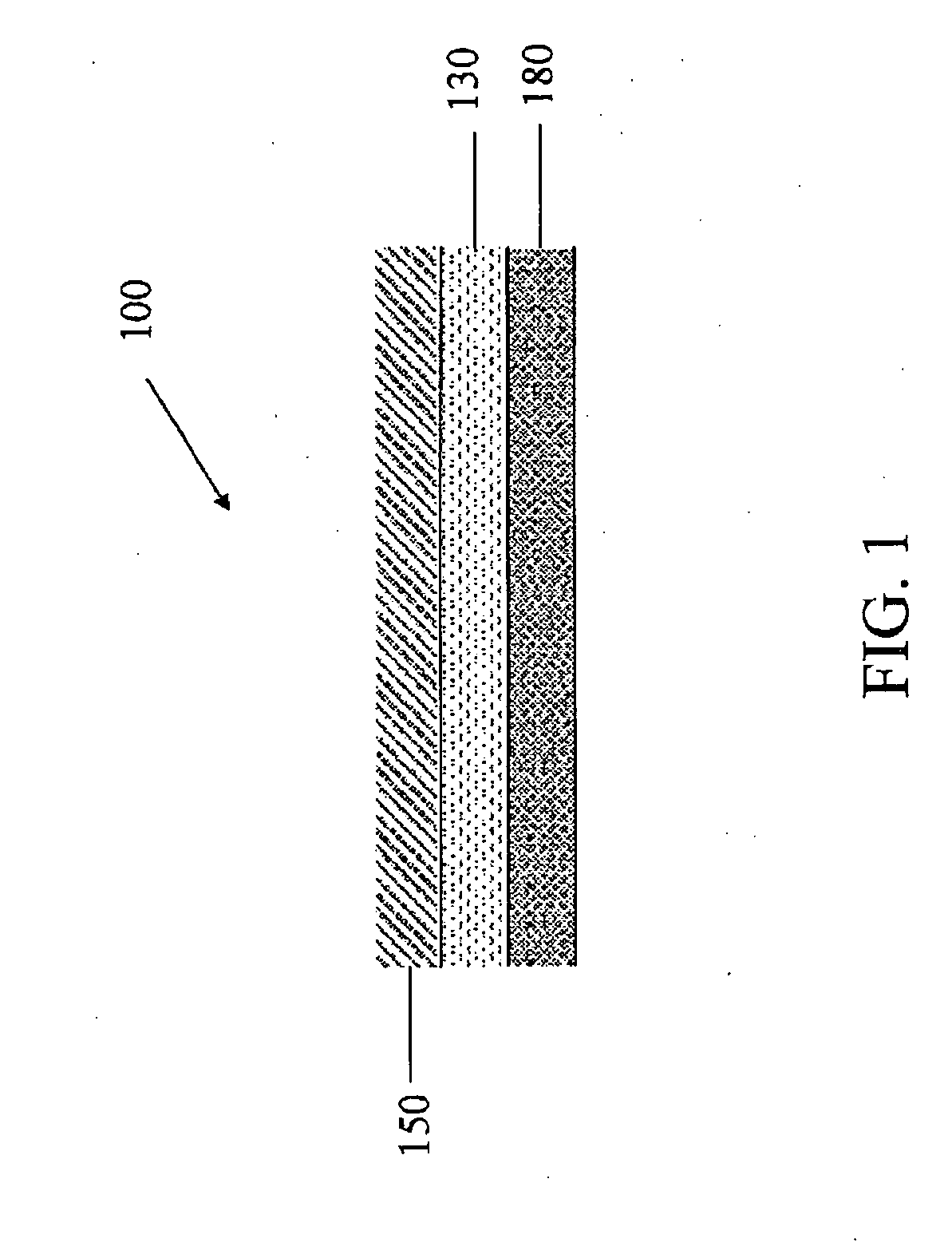

A finger-placement sensor tape aligns and removably secures a finger to a sensor pad of a reusable finger-clip optical sensor so as to assure the finger is repeatably aligned between the sensors emitters and detectors and that the finger stays aligned during a test procedure. The sensor tape has a double-sided tape layer having a silicon-based adhesive on a finger side and an acrylic adhesive on a sensor-side. An aperture is defined in the tape layer so as to allow emitters disposed in a top sensor pad to emit light through the tape layer to detectors disposed in a bottom sensor pad. A finger-side release layer is removably disposed over the silicon-based adhesive. A sensor-side release layer is removably disposed over the acrylic adhesive.

Owner:MASIMO CORP

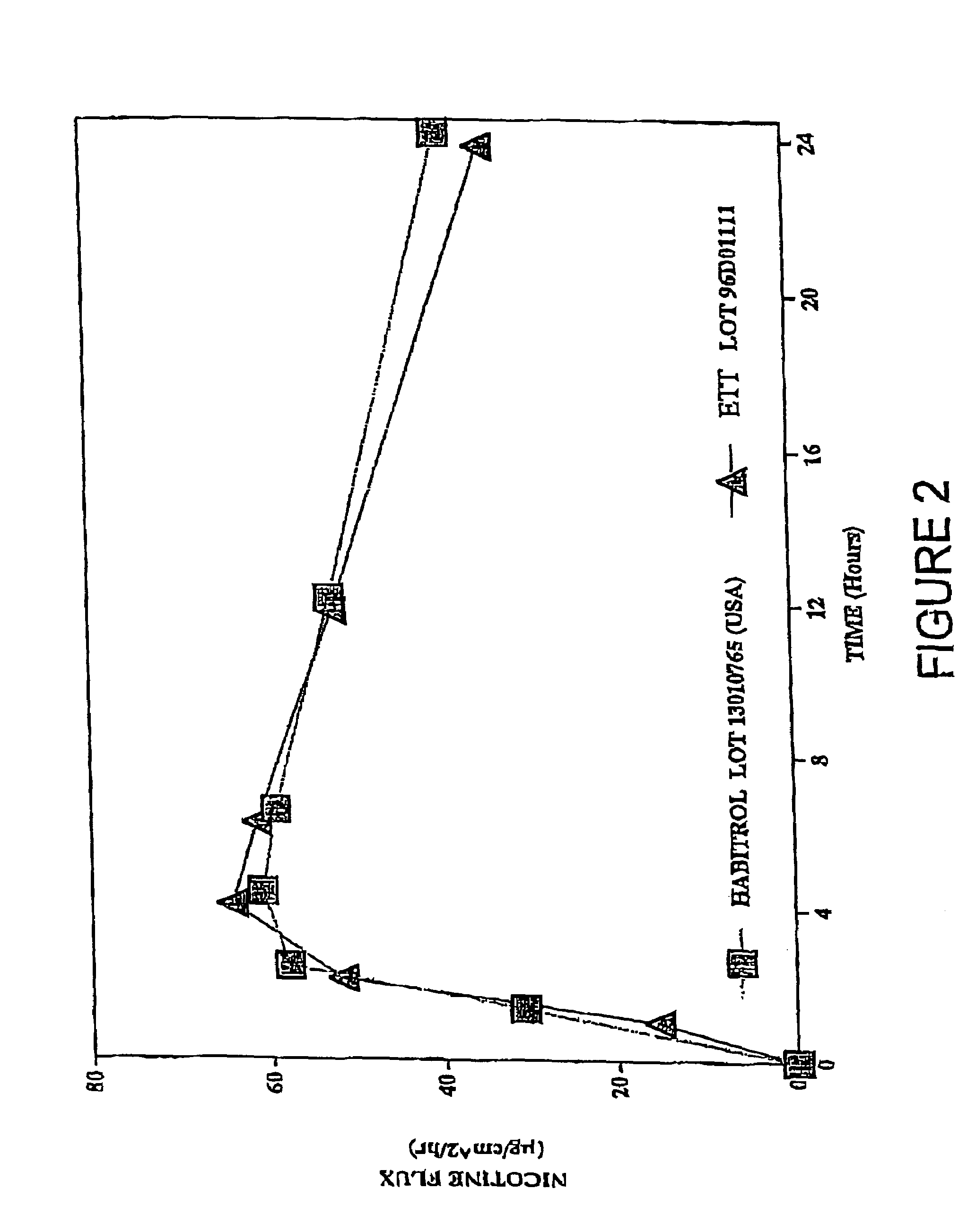

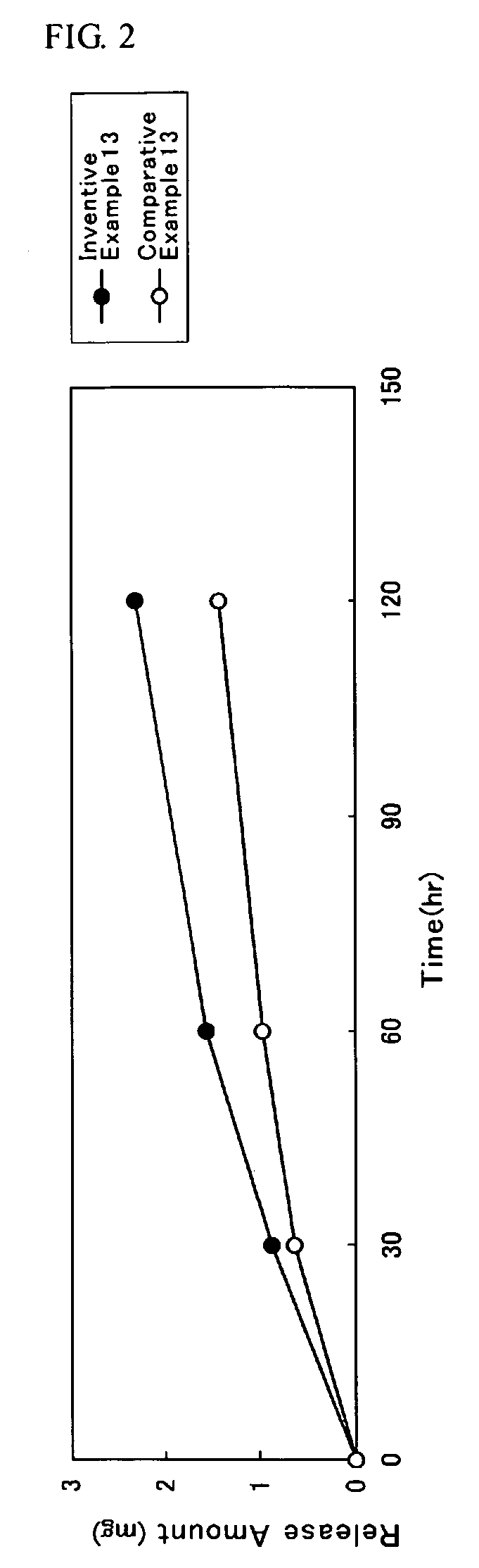

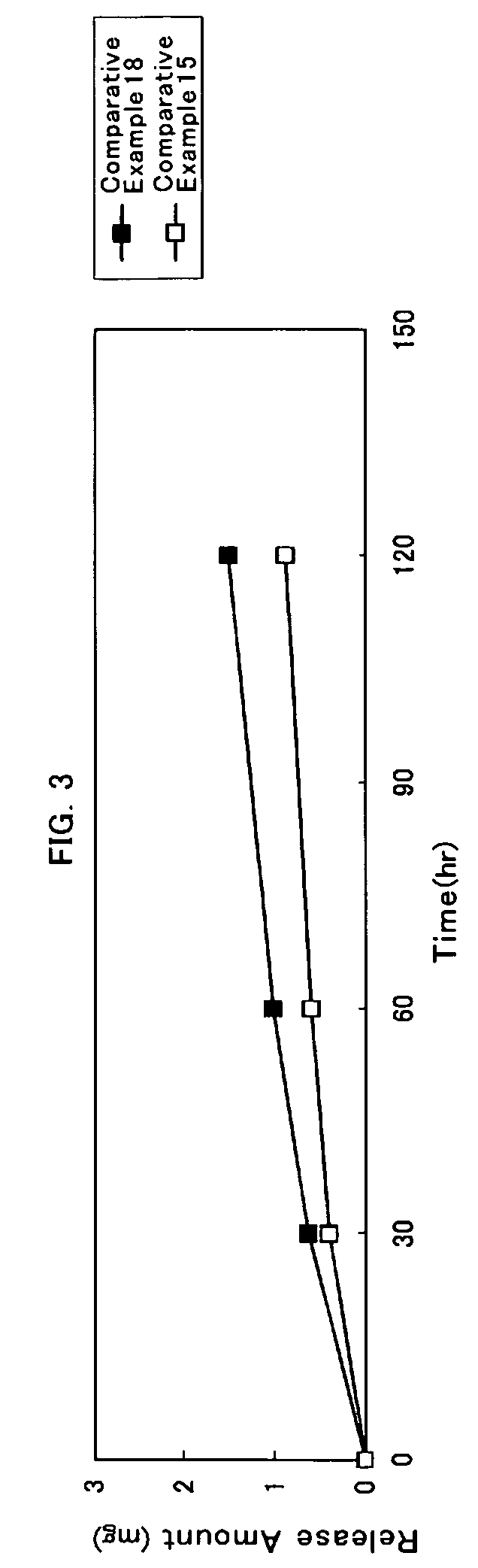

Transdermal patch for delivering volatile liquid drugs

A transdermal patch for administering a volatile liquid drug, such as nicotine, transdermally to a patient comprising a four-layer laminated composite of: a top drug impermeable backing layer; a pressure sensitive silicone adhesive layer containing the drug; a pressure sensitive acrylic adhesive layer also containing the drug; and a removable siliconized release liner layer. Also disclosed is a method for treating a person for nicotine dependence and particularly for treating a woman for nicotine dependence.

Owner:ELAN PHRMA INT LTD +1

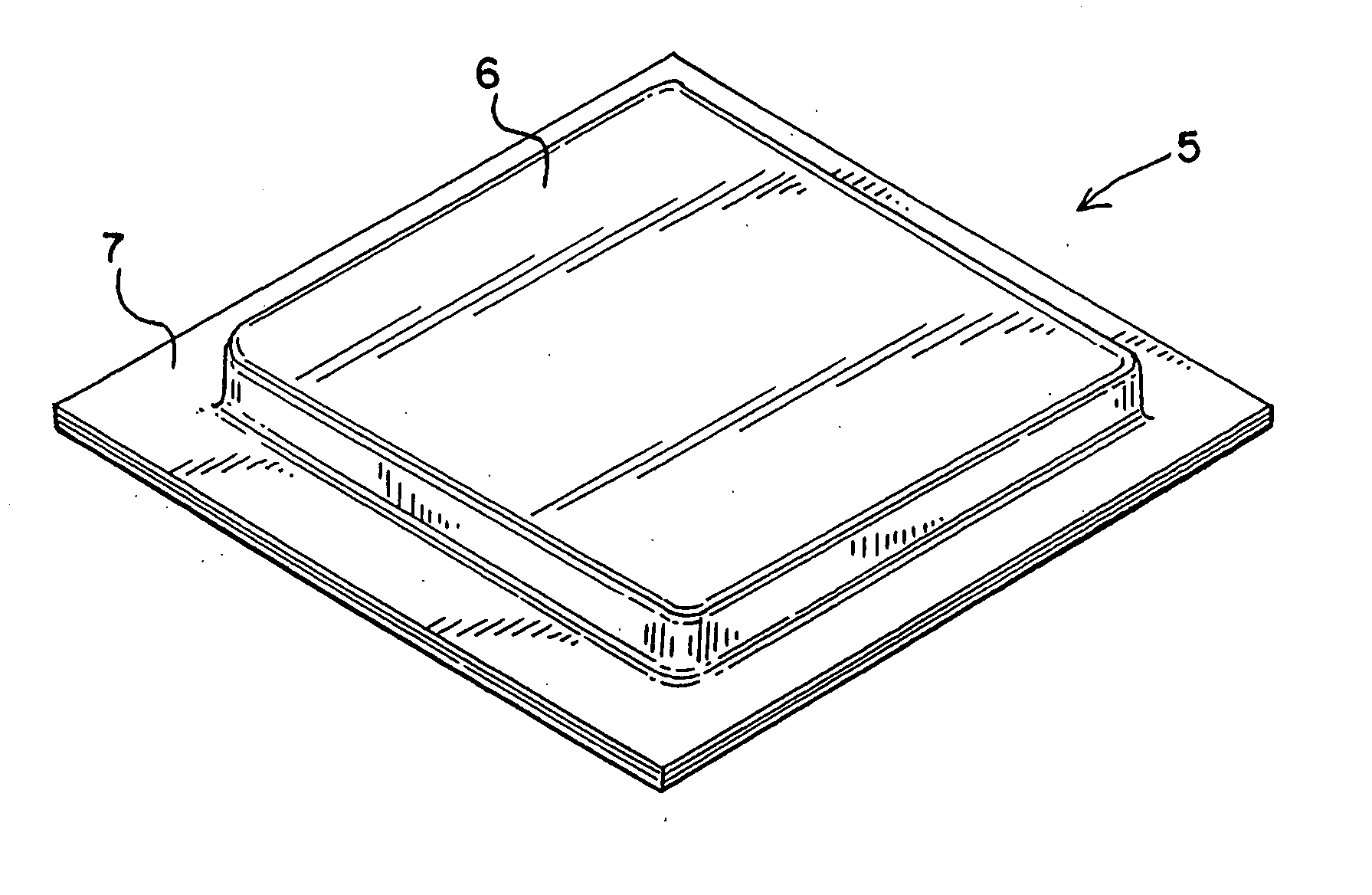

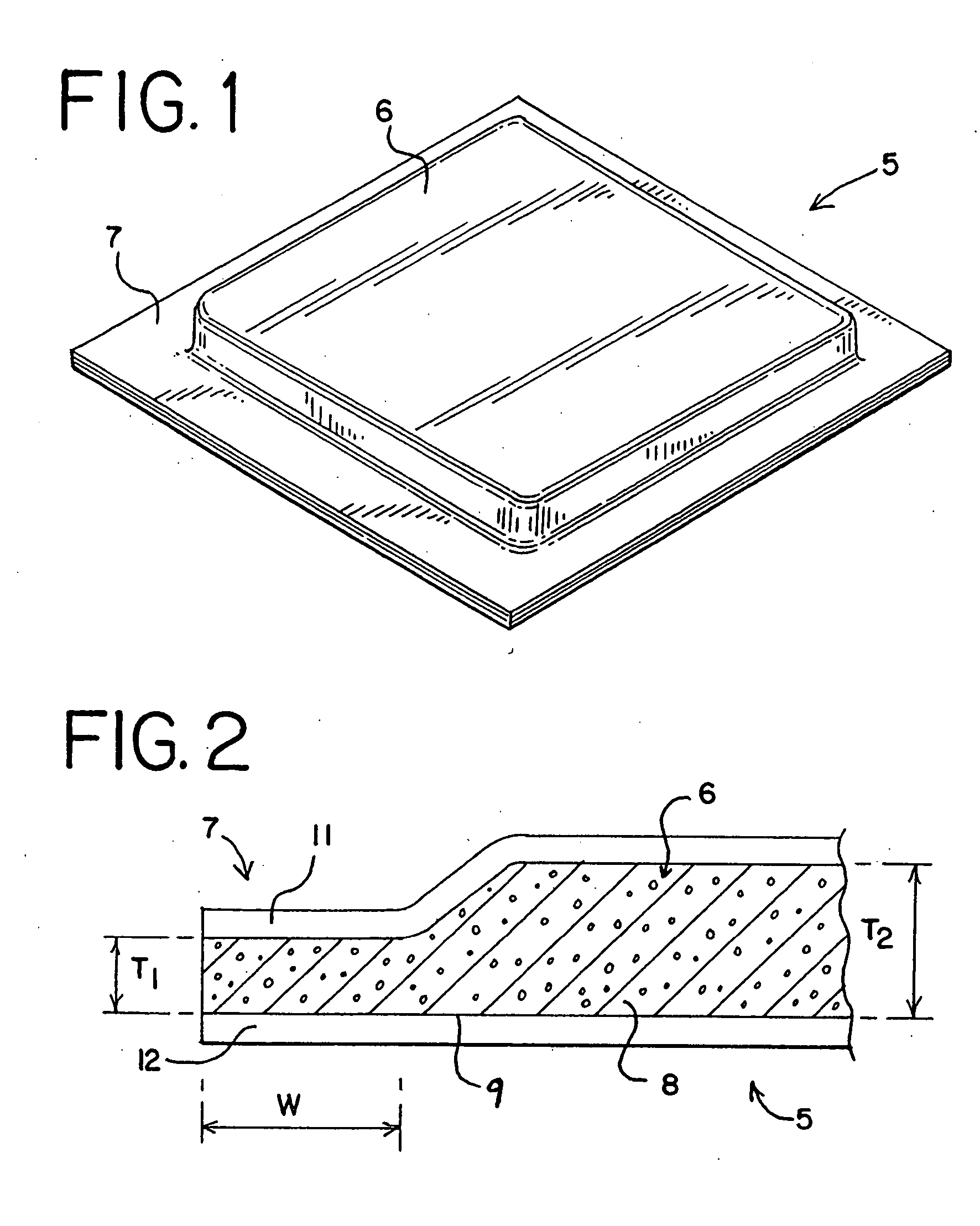

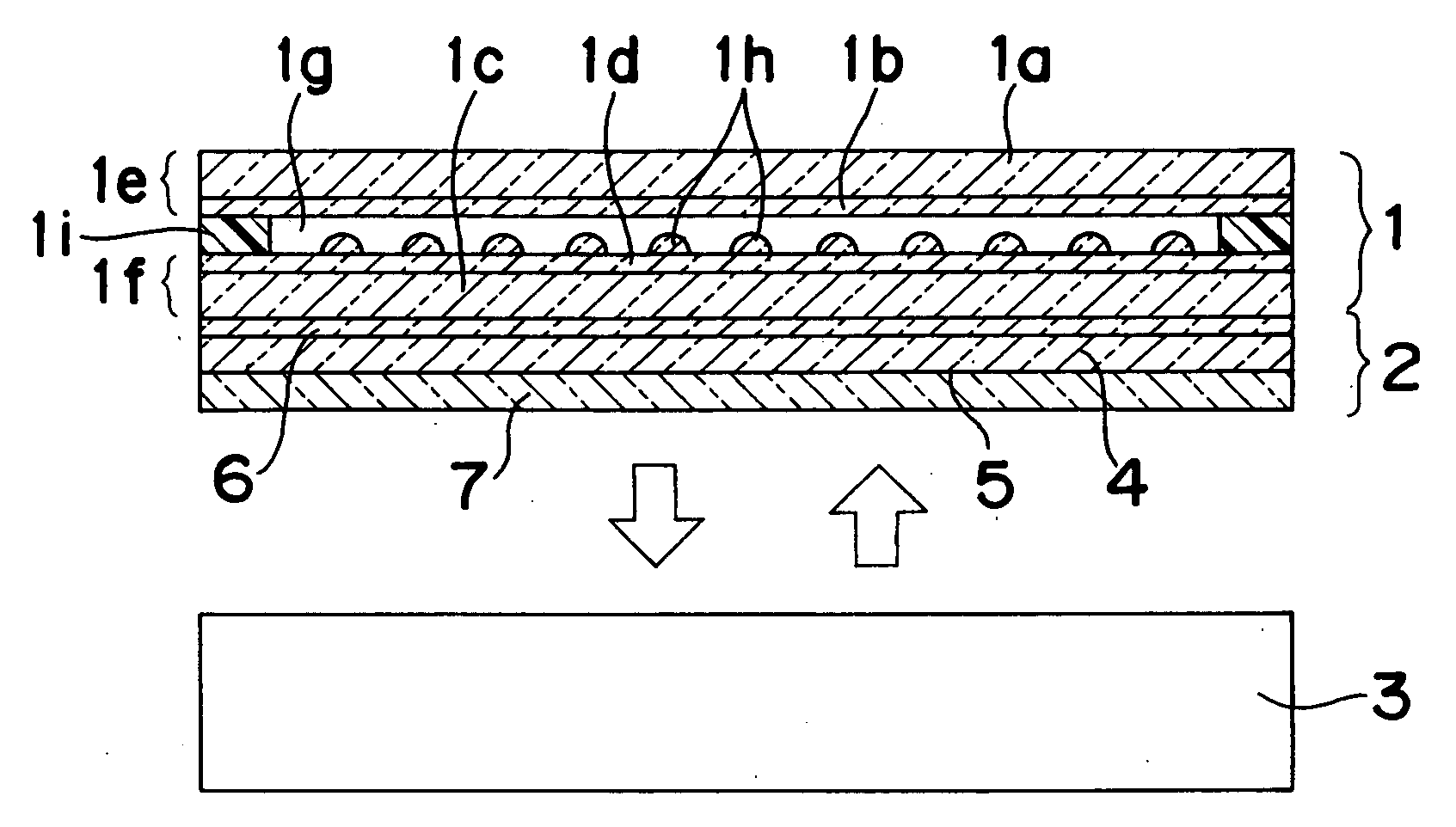

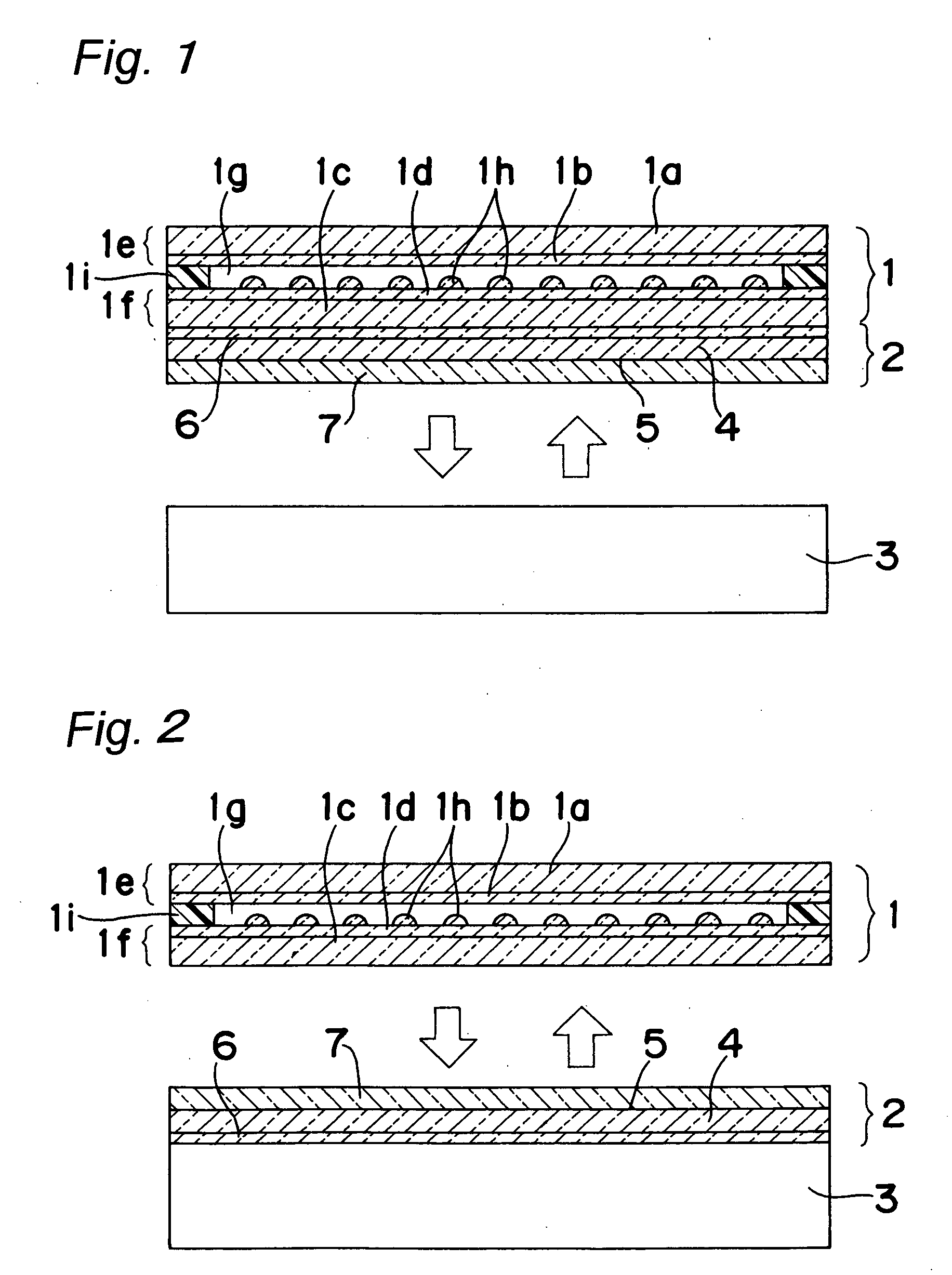

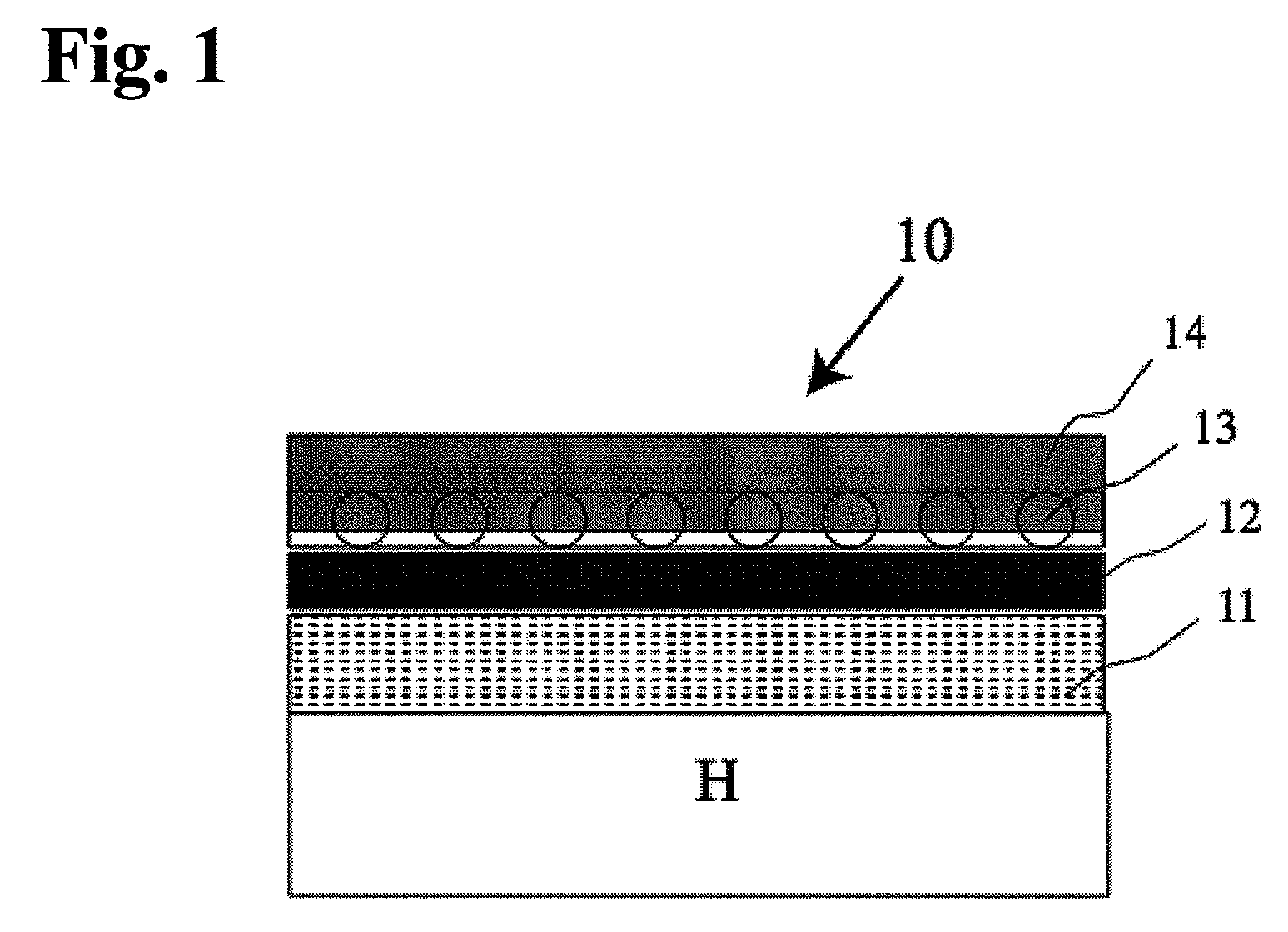

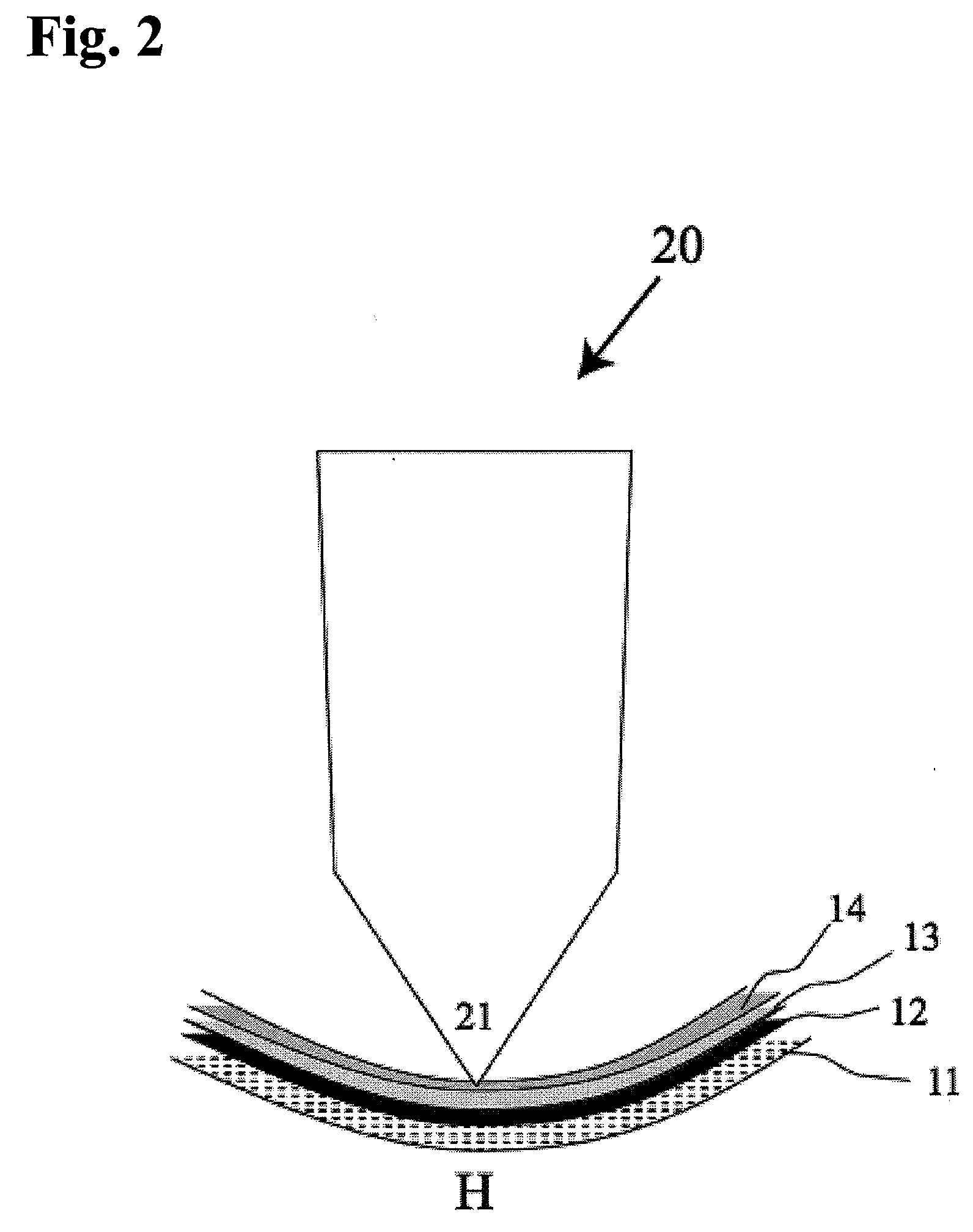

Mounting structure of re-peelable protective panel and mounting sheet using the same

InactiveUS20090087655A1Improve buffering effectAvoid elevationDetails for portable computersElectrical equipmentDisplay deviceEngineering

A transparent mounting sheet has a structure in which a one-sided re-peelable sheet, provided with a core member of a plastic film, a silicone rubber sheet that is laminated on a primer treated surface formed by one surface of the core member having been subjected to a primer treatment, and an acrylic adhesive agent layer that is laminated on the other surface of the core member, is bonded to at least one of surfaces of a gel sheet by the acrylic adhesive agent layer, and this transparent mounting sheet is used so that a protective panel for an electronic apparatus display window is mounted on a surface of a display in a manner so as to be re-peelable.

Owner:NISSHA PRINTING COMPANY

Composition for pressure sensitive adhesive film, pressure sensitive adhesive film, and dicing die bonding film including the same

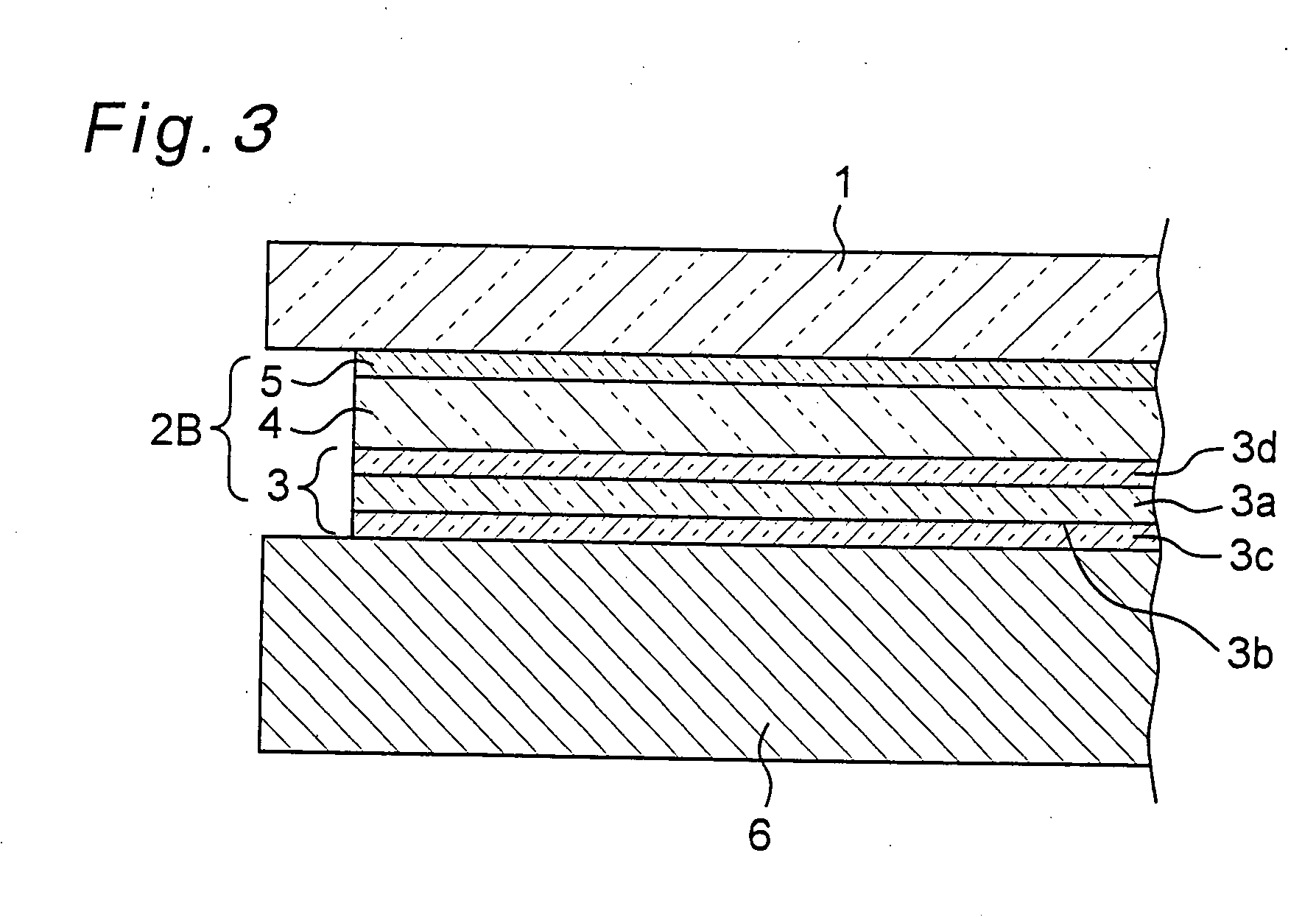

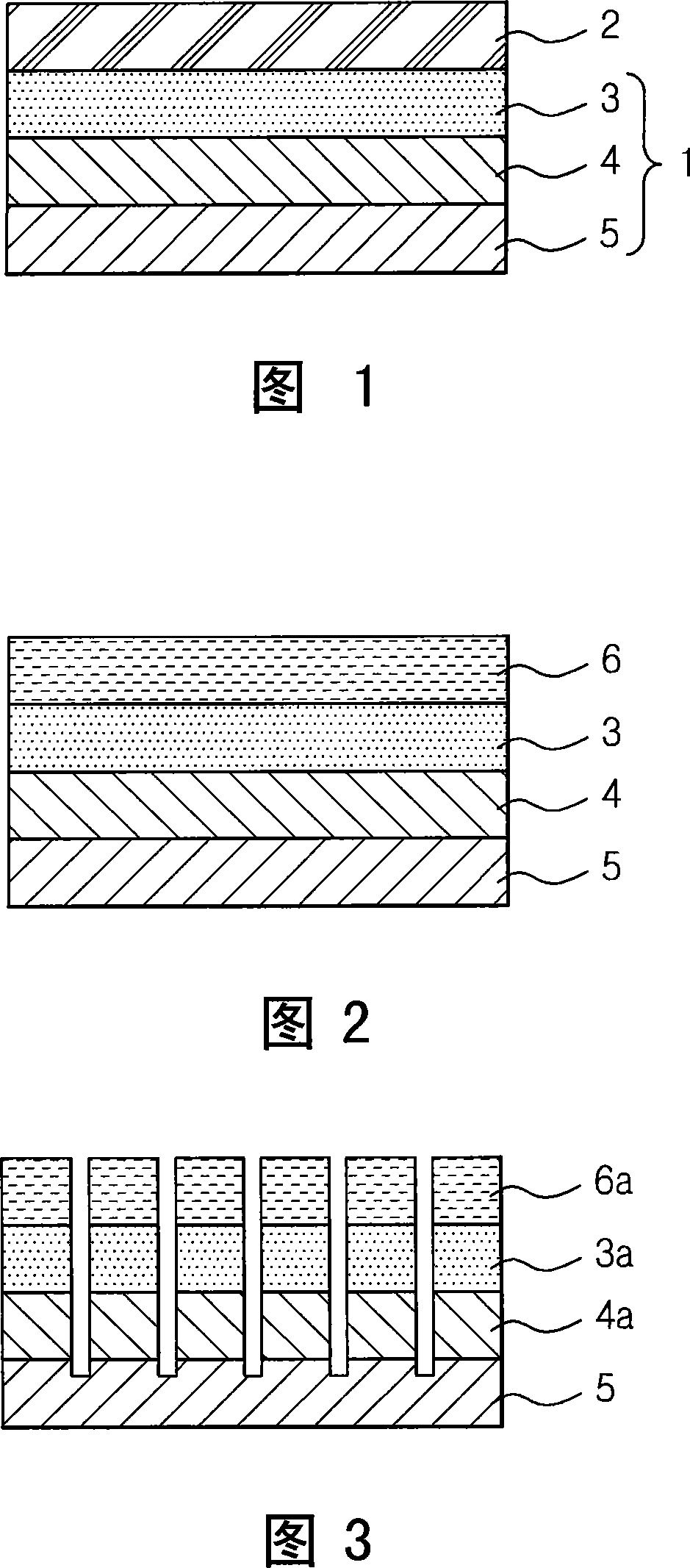

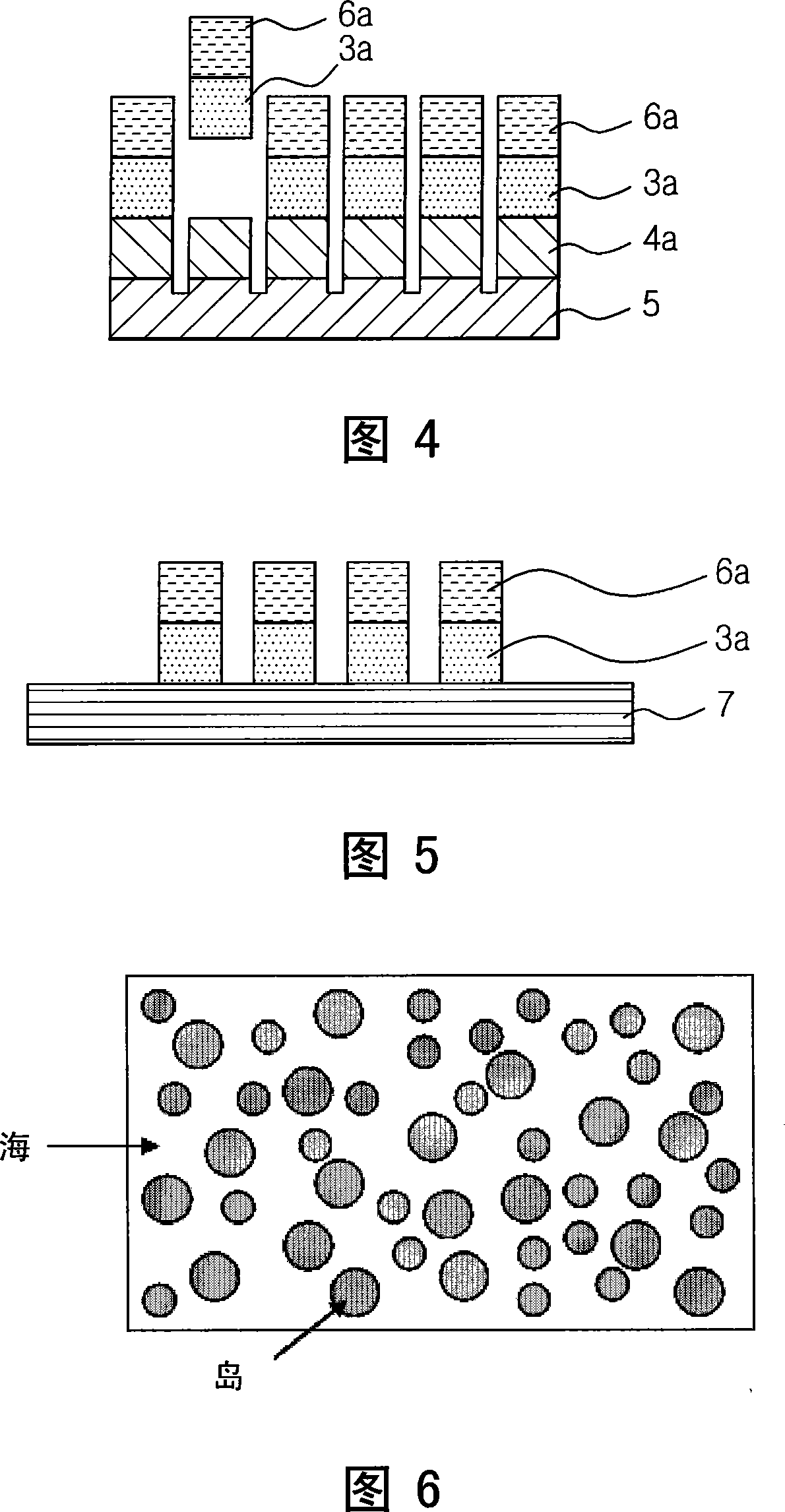

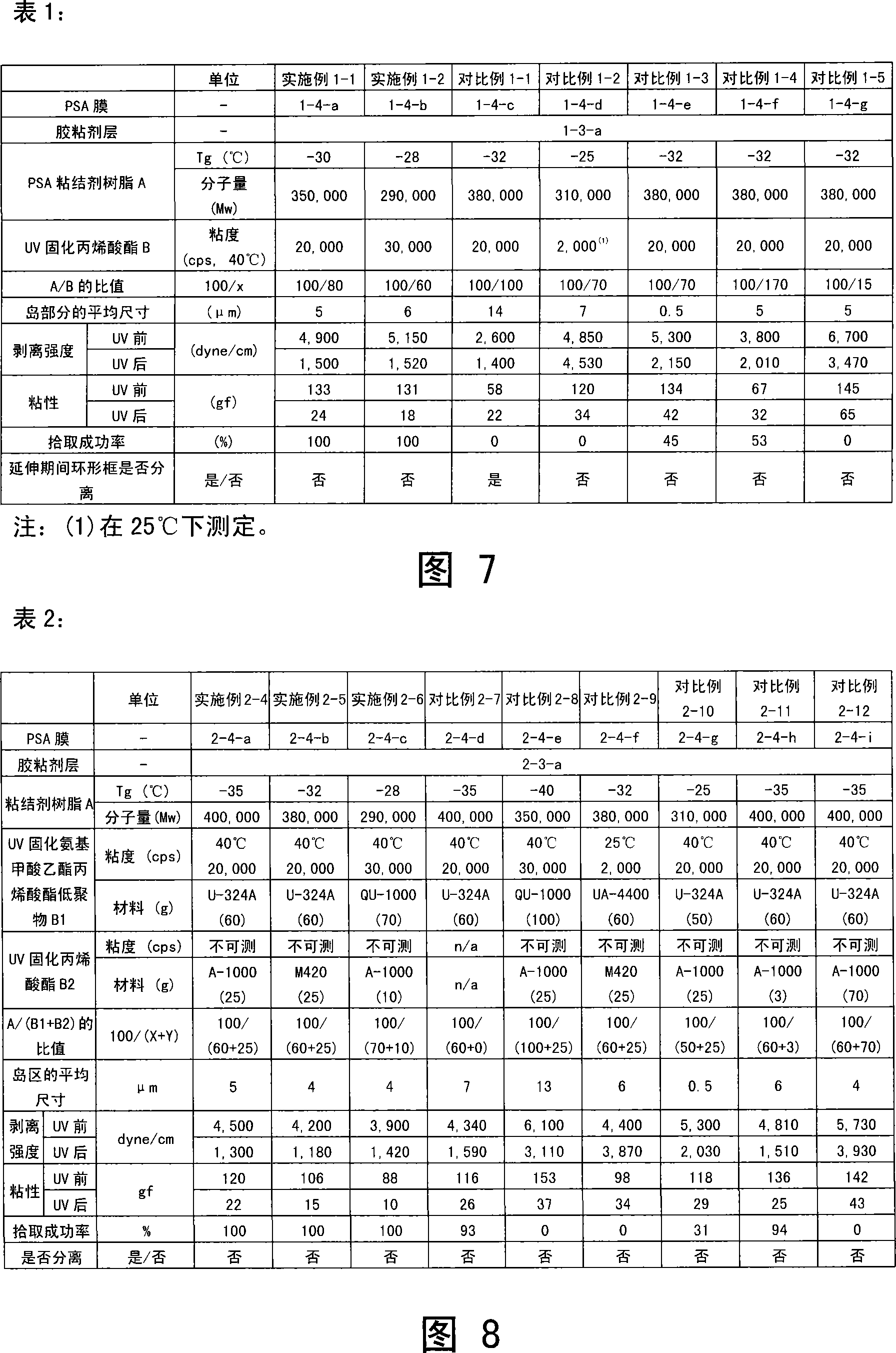

A composition for forming an adhesive film is provided to prevent an acrylic adhesive binder and UV curable acrylate from being transferred to an adhesive layer when used in a dicing die bonding film, and to realize high pick-up property even in large chips greater than 10 mm X 10 mm after UV irradiation. A composition for forming an adhesive film comprises: (A) 100 parts by weight of a polymer binder resin; (B) 20-150 parts by weight of a low-molecular weight UV curable acrylate; (C) 0.1-10 parts by weight of a thermal curing agent; and (D) 0.1-5 parts by weight of a photopolymerization initiator based on 100 parts by weight of the UV curable acrylate. The adhesive film formed by the composition has a sea-island surface structure, wherein the island region has an average size of 1-10 micrometers.

Owner:CHEIL IND INC

Extended stay-on wound dressing

A wound dressing having a dressing layer covered by protective cover layer and a release sheet. The dressing has an adhesive composition on a skin-contacting surface. The adhesive composition comprises a highly water-absorbable material (e.g. hydrocolloid), an acrylic adhesive and a tackifier. The composition provides extended stay-on capabilities. The composition also provides an adhesive that is removed from the skin with little pain to the on the skin.

Owner:JENTEC

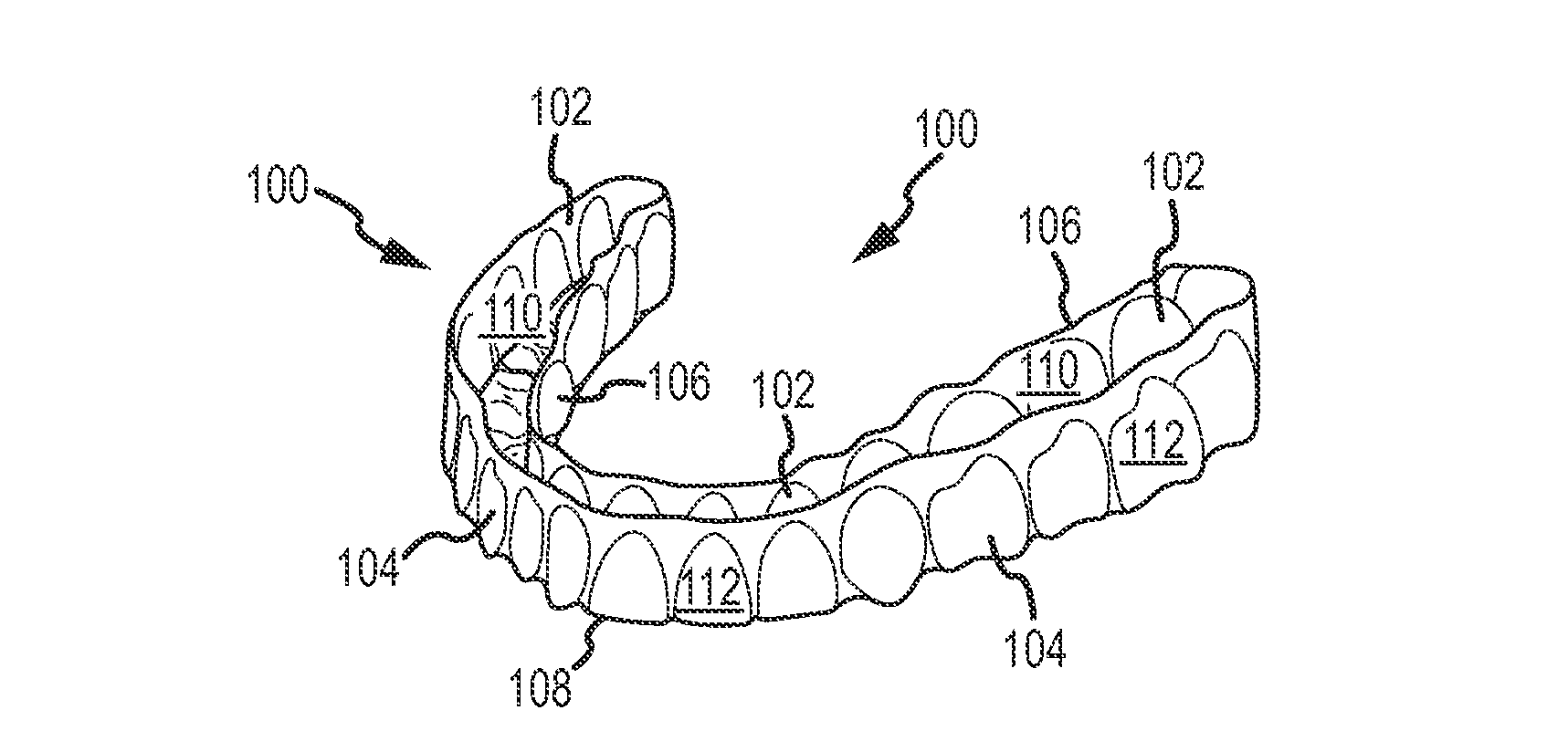

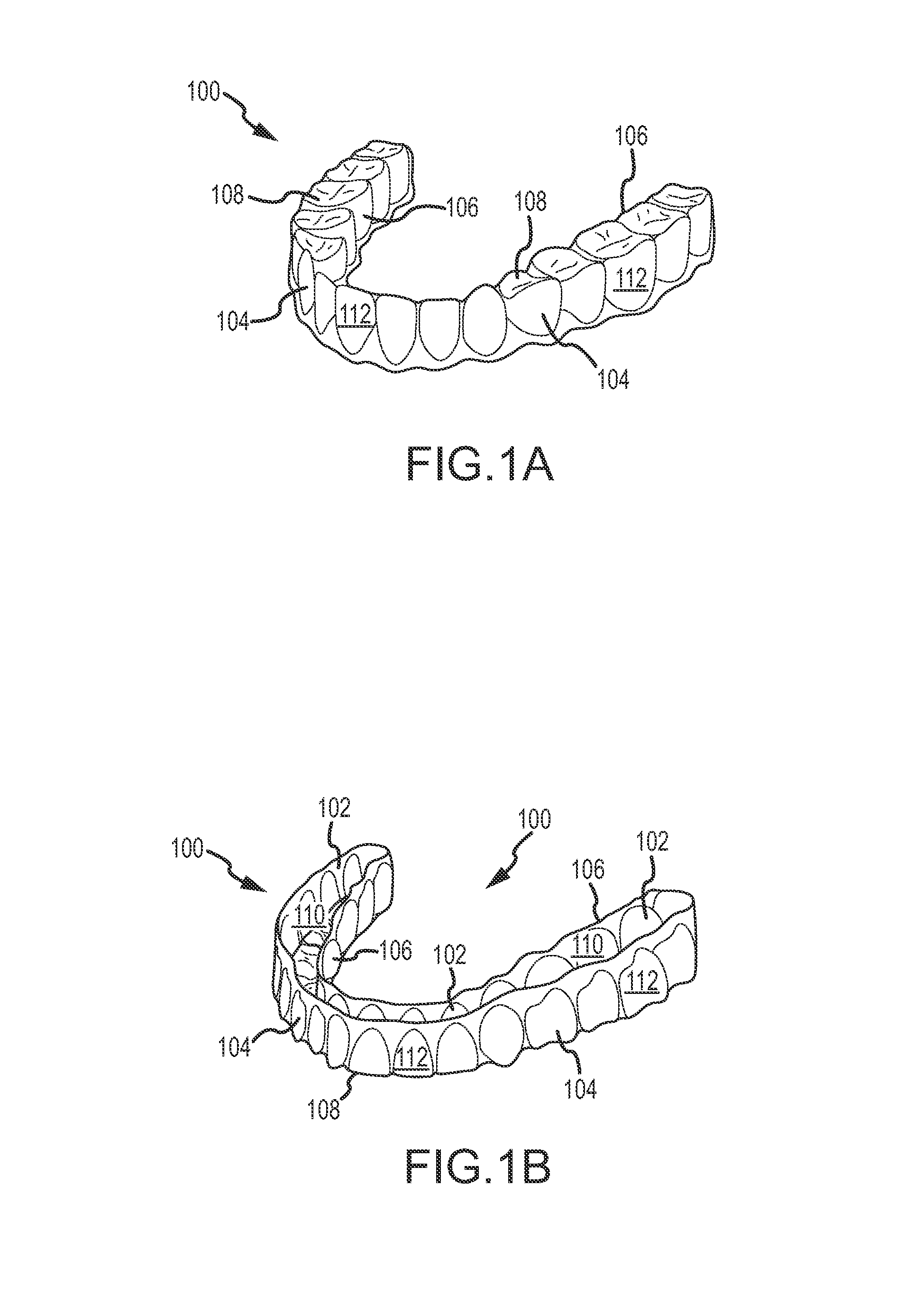

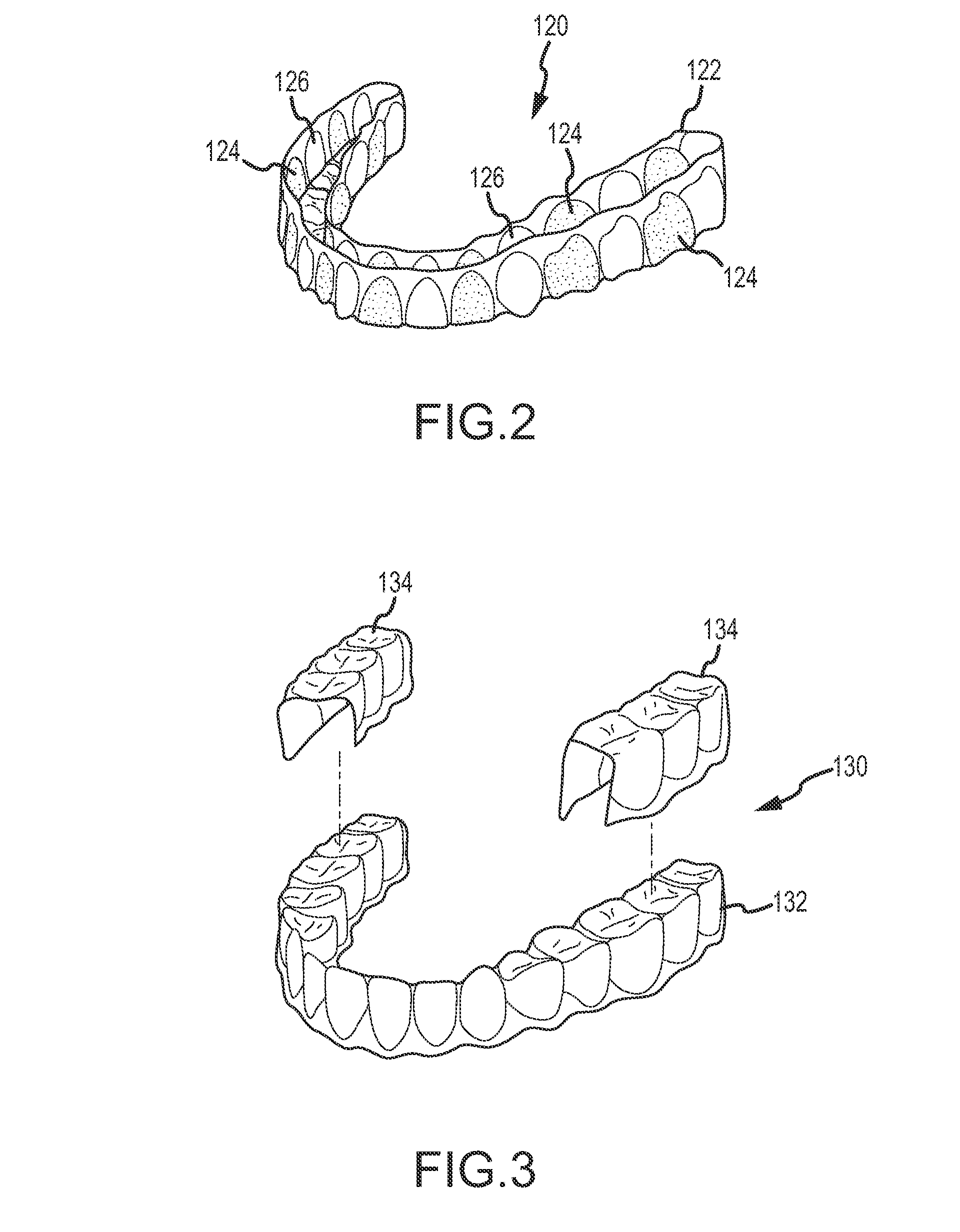

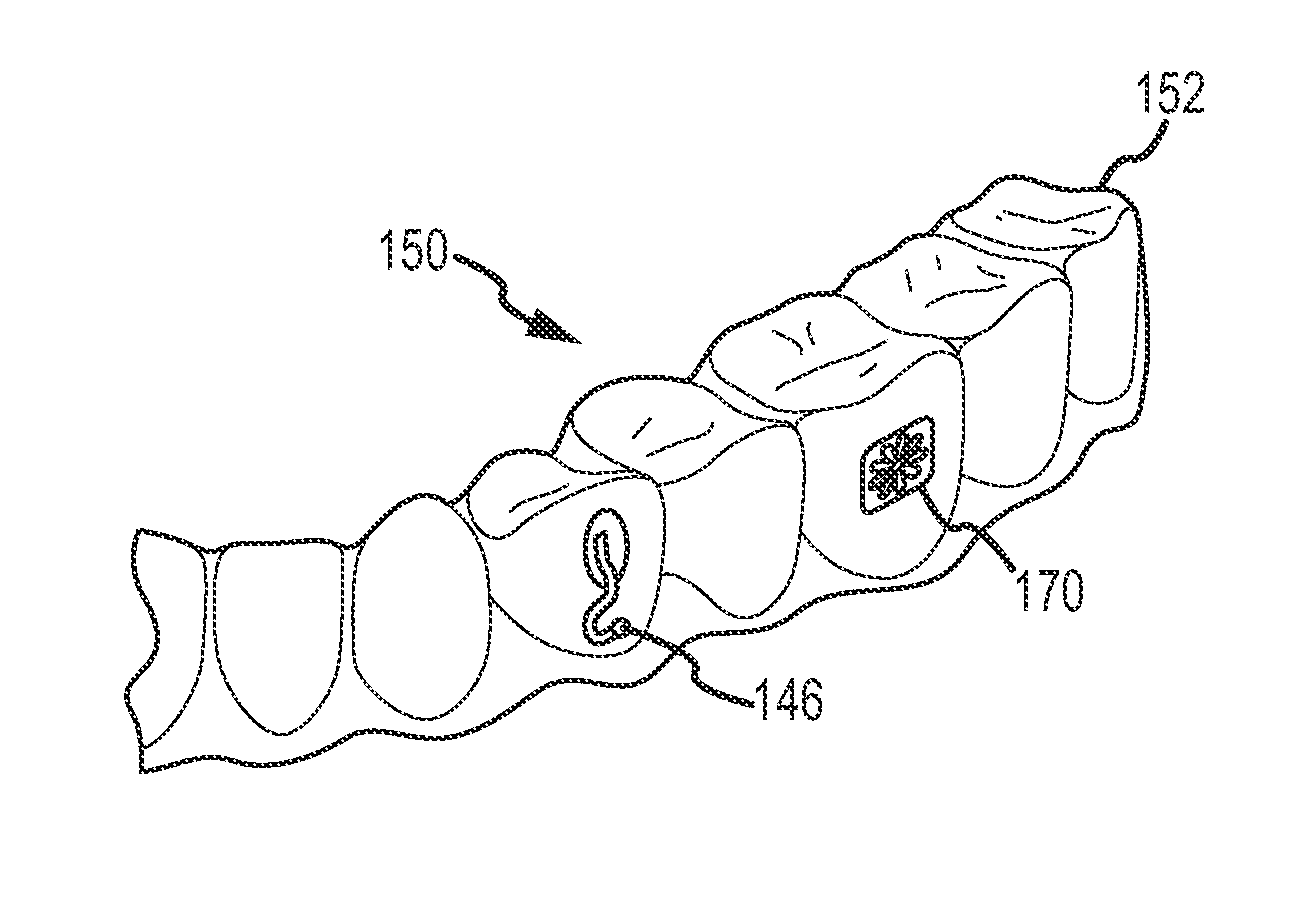

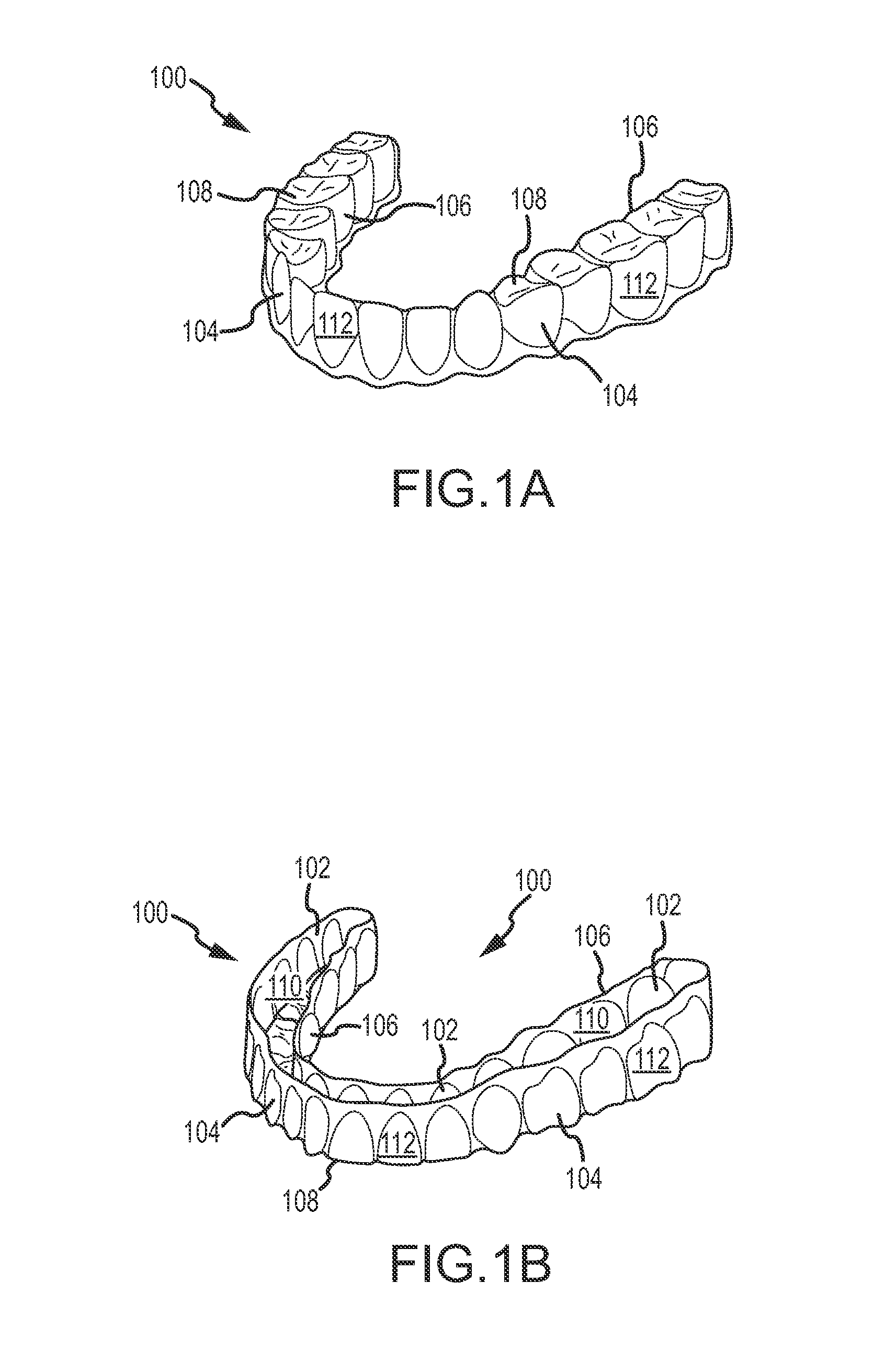

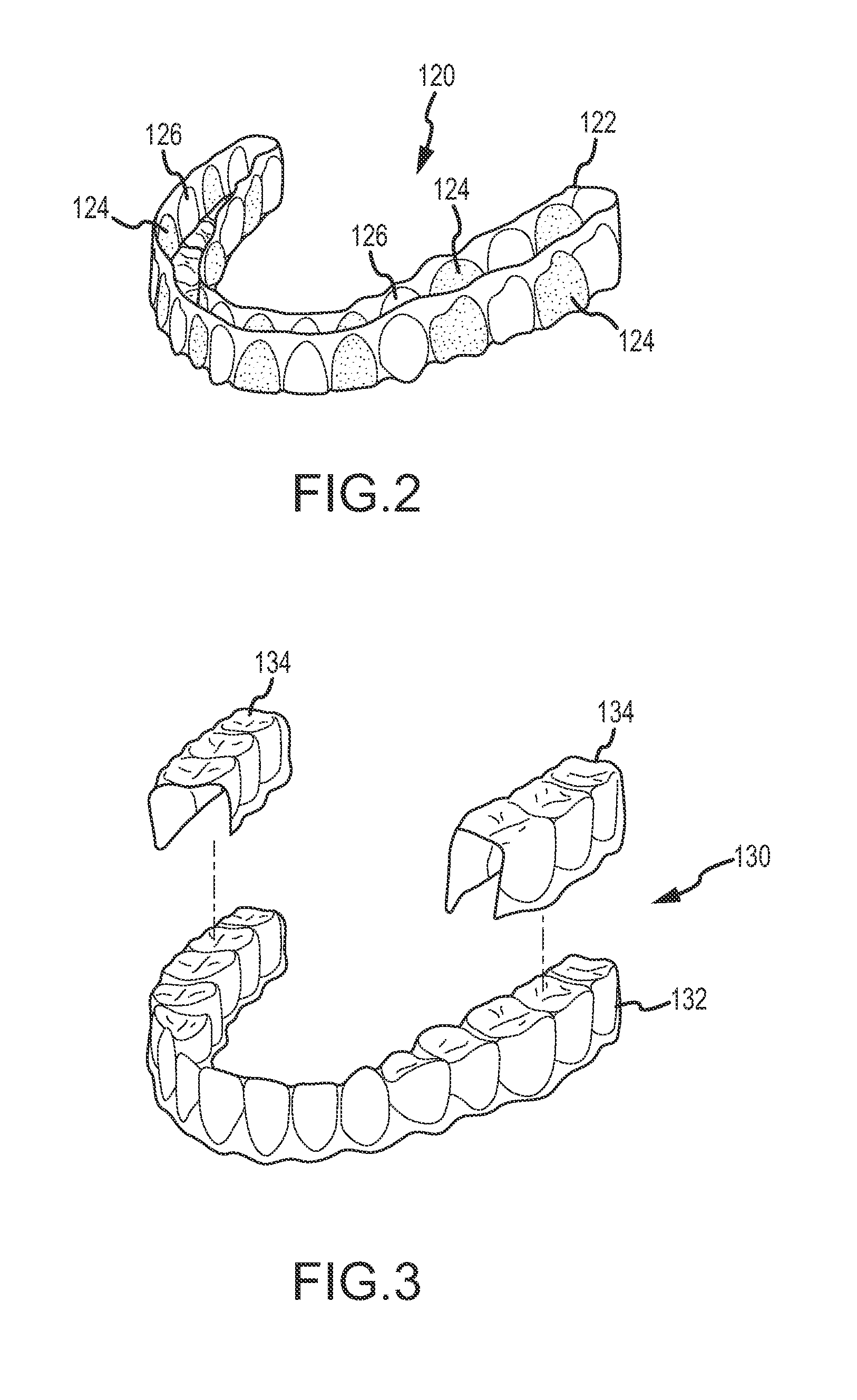

Dental appliance, dental appliance adhesive and related methods and uses

ActiveUS20130078594A1Stay interestedImprove complianceImpression capsGum massagePolymeric surfaceThiol

A dental appliance has an auxiliary feature bonded to a polymeric surface of a shell body with a compartment for receiving teeth. The auxiliary feature is bonded with a light-curable acrylic adhesive comprising acrylate base material and photoinitiator. Auxiliary features include colored layers and, decals, reinforcing features and auxiliary dental devices. A light-curable acrylic adhesive may include a thiol monomer and / or a pigment. A dental appliance may have a shell body with a bonding surface adapted for attachment of an auxiliary feature, such as prepared by a pretreatment to mar the surface of to impregnate the surface with a reactive adhesion promoter.

Owner:SYMDENT

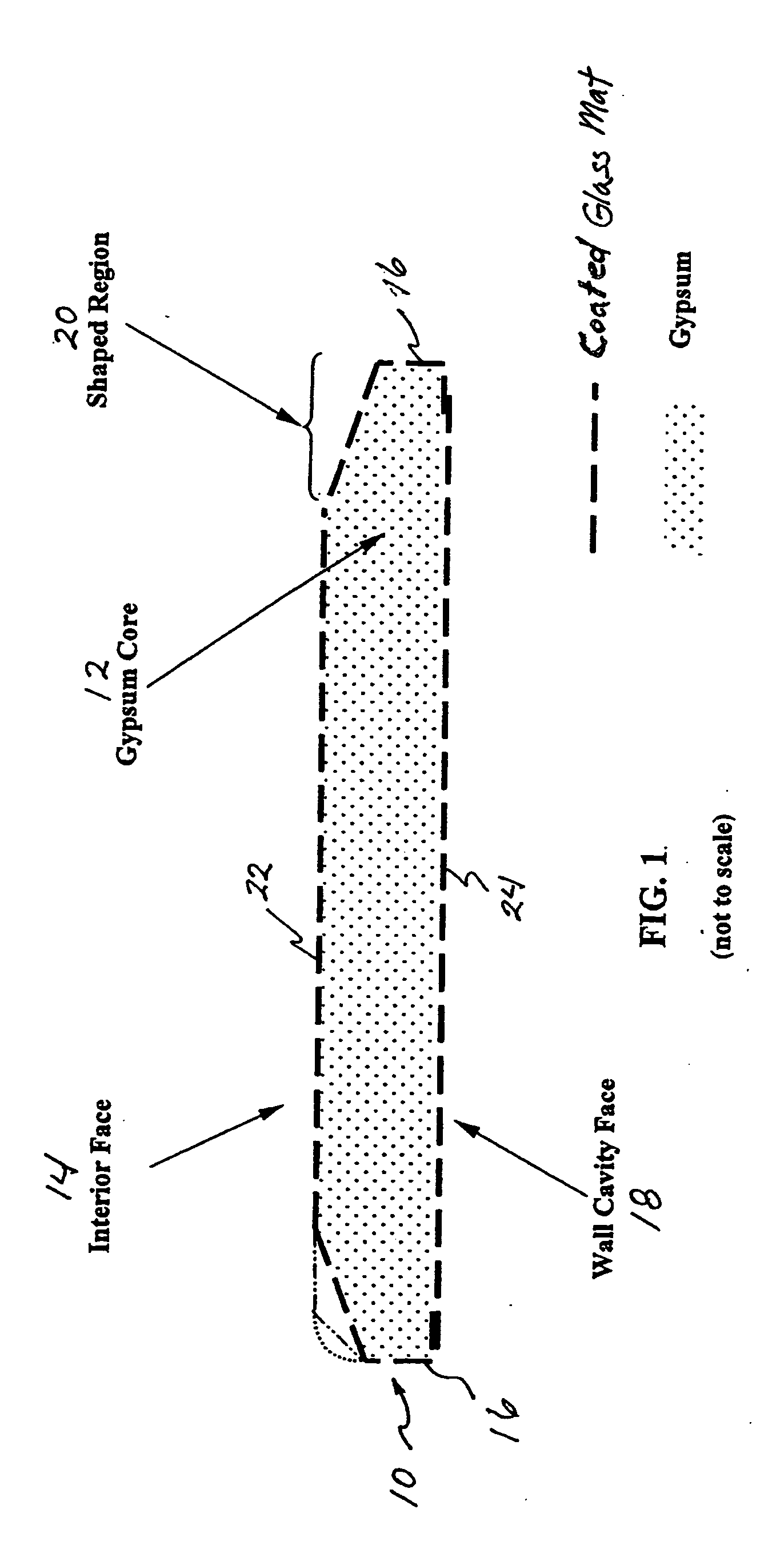

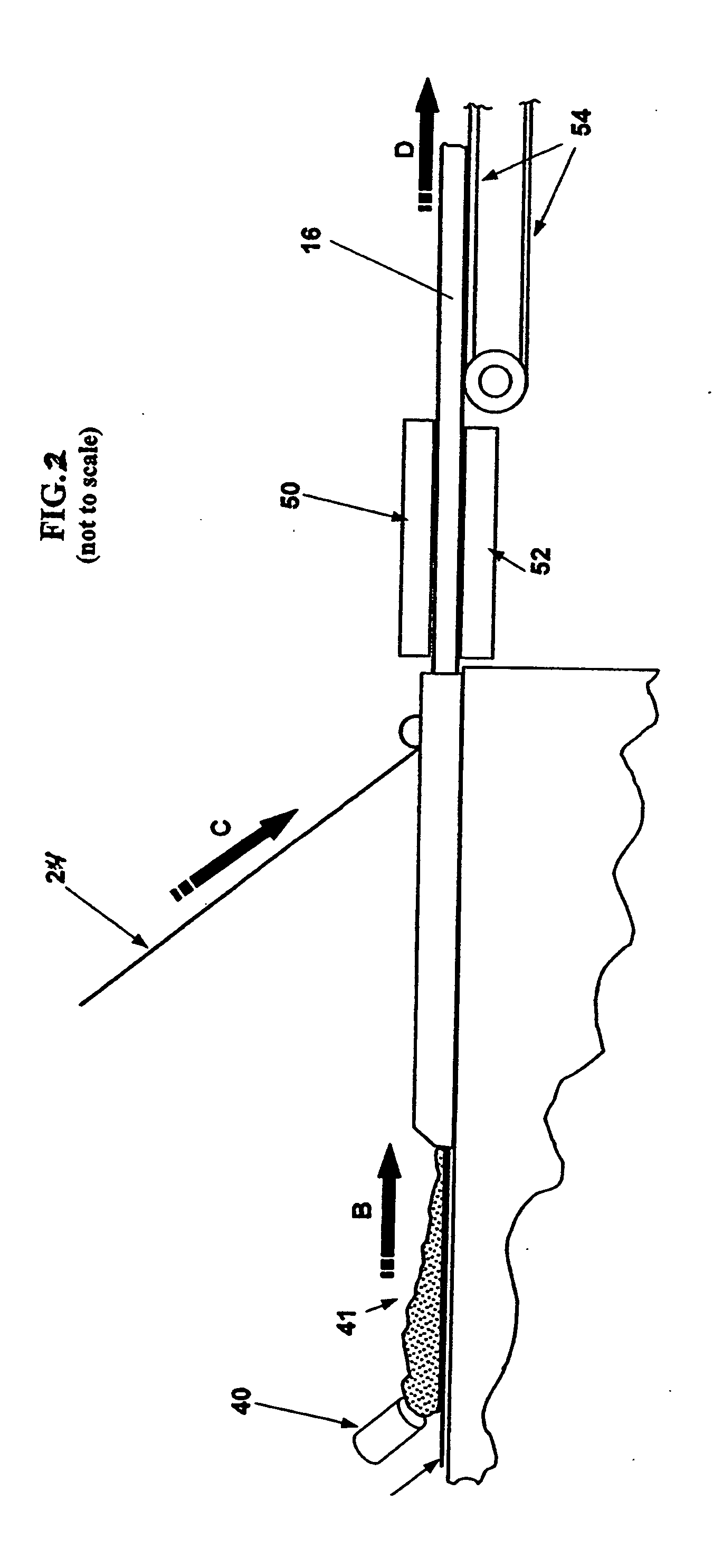

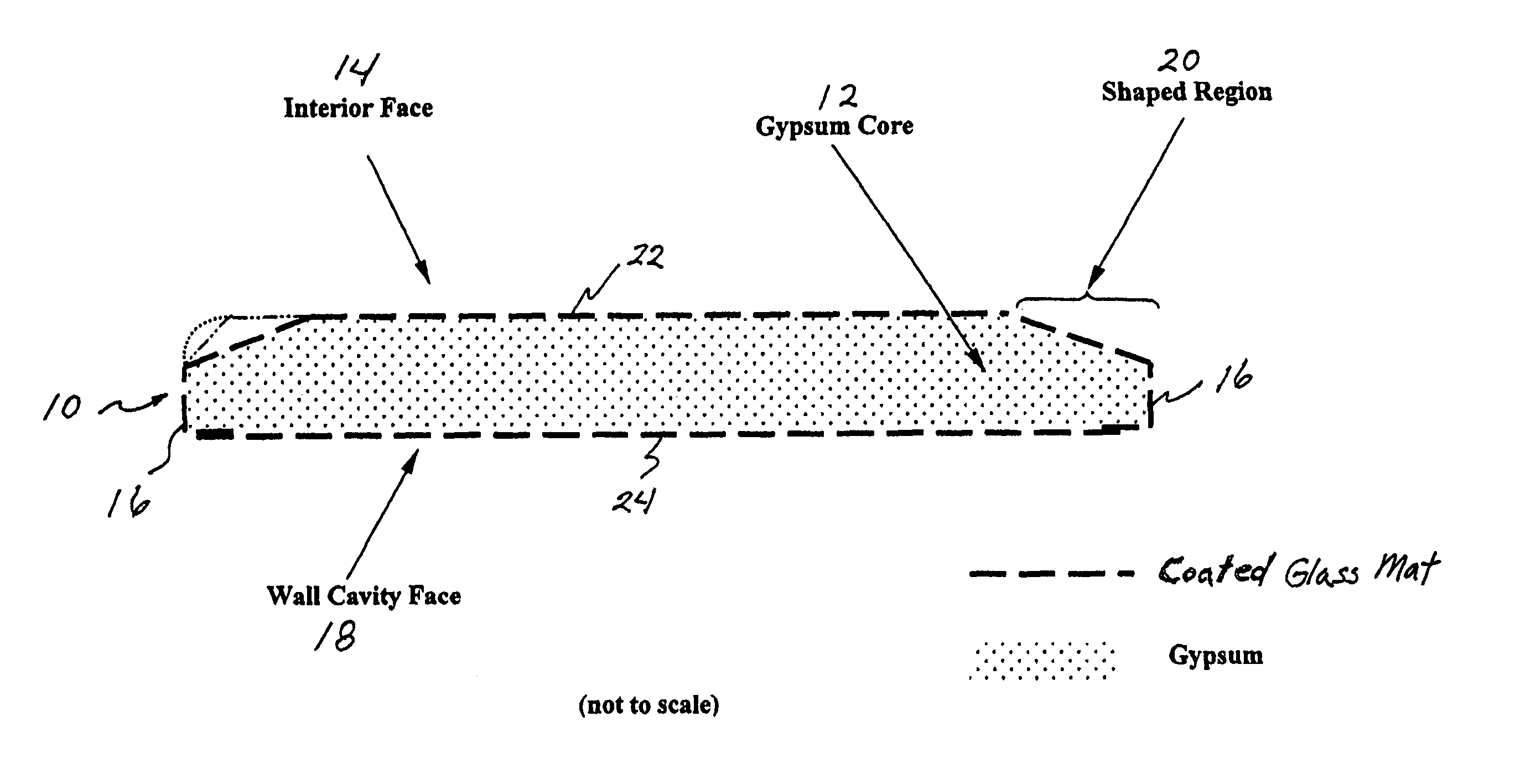

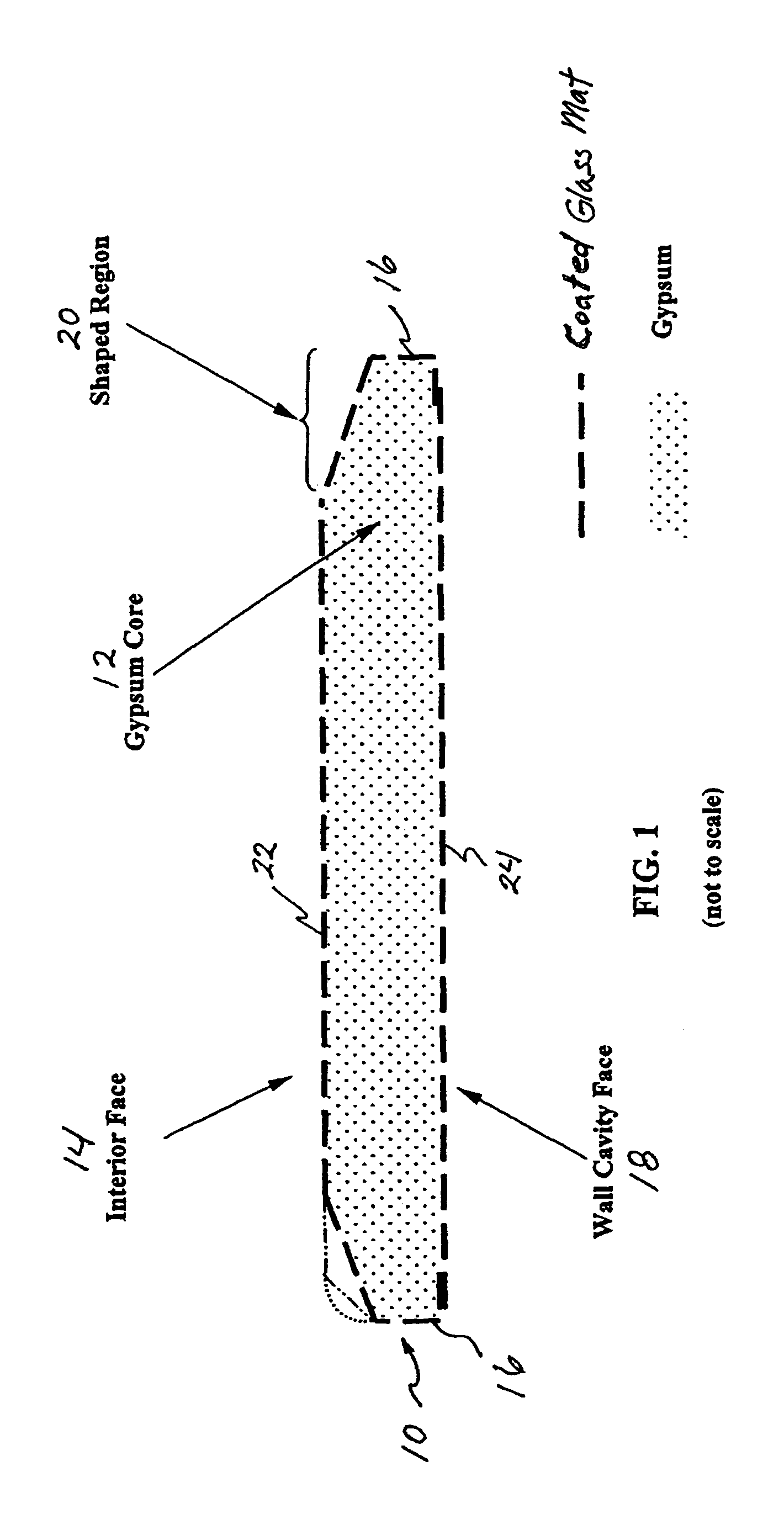

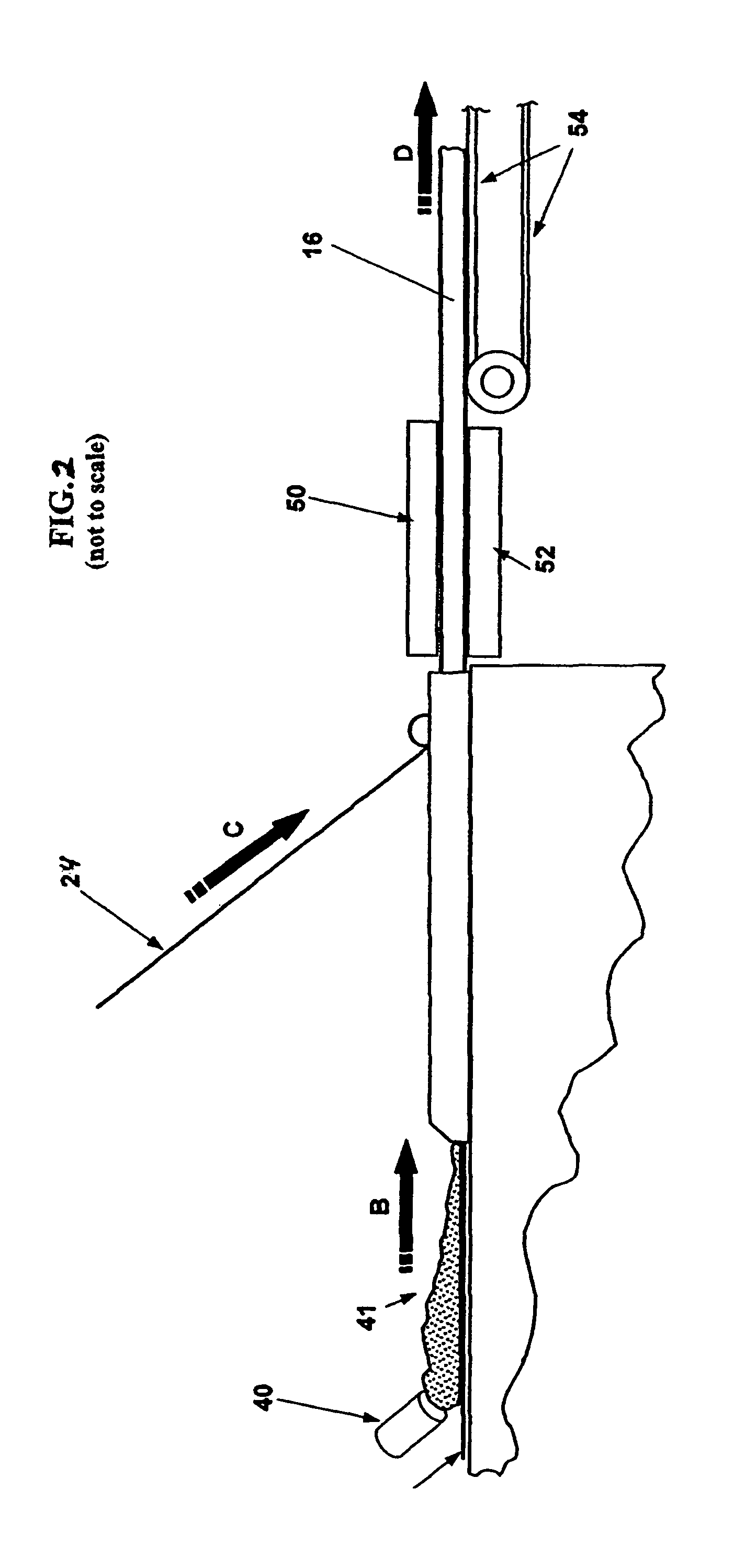

Interior wallboard and method of making same

A gypsum wallboard suitable for Level 4 finishing having a coated non-woven glass fiber mat facing material where the glass fiber mat has a majority of fibers of a fiber diameter between 8 and 11 microns and a fiber length between ¼ and ¾ inch and preferably between ¼ and ½ inch and preferably has a basis weight between about 0.8 lb. / 100 ft.2 and about 2.2 lb. / 100, and wherein the fibers in the non-woven glass fiber are bound together with an acrylic adhesive binder and wherein the non-woven glass mat has a coating of a dried aqueous mixture of (i) a mineral pigment, (ii) a polymer latex adhesive binder and optionally (iii) an inorganic adhesive binder such that the coated non-woven glass mat facing material has a porosity which allows water to evaporate through said coated mat from the gypsum core during preparation of the wallboard.

Owner:GEORGIA PACIFIC GYPSUM LLC

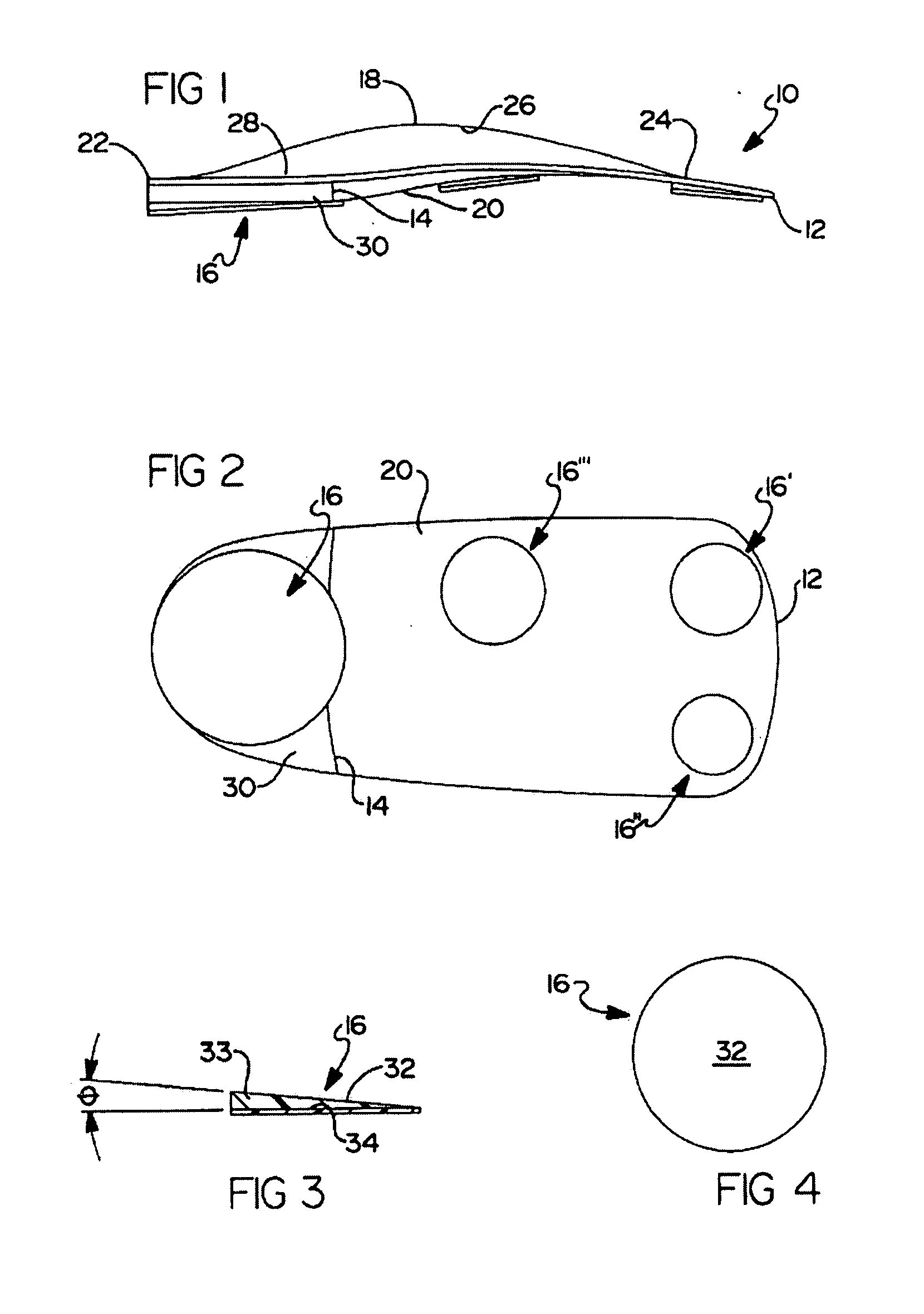

Orthotic device

An adhesive strip for use with a balancing disc for balancing the gait of the user comprises a medial polyester sheet having an upper surface and a lower surface. An acrylic adhesive is the disposed on both the upper and lower surfaces. A silicone release sheet is disposed atop the upper layer of acrylic adhesive and a circular polyester sheet is disposed over the lower layer of adhesive. The overlying polyester sheet is scored to facilitate removal of at least a portion thereof in order to expose a portion of the acrylic adhesive for immediate adherence to a surface of an associated balancing disc. After emplacement, the other portion of the polyester sheet is removed to secure the adhesive to the disc. When the silicone release sheet is removed, the disc can then be readily applied to an insole or to a footwear item.

Owner:EPSTEIN MEREL

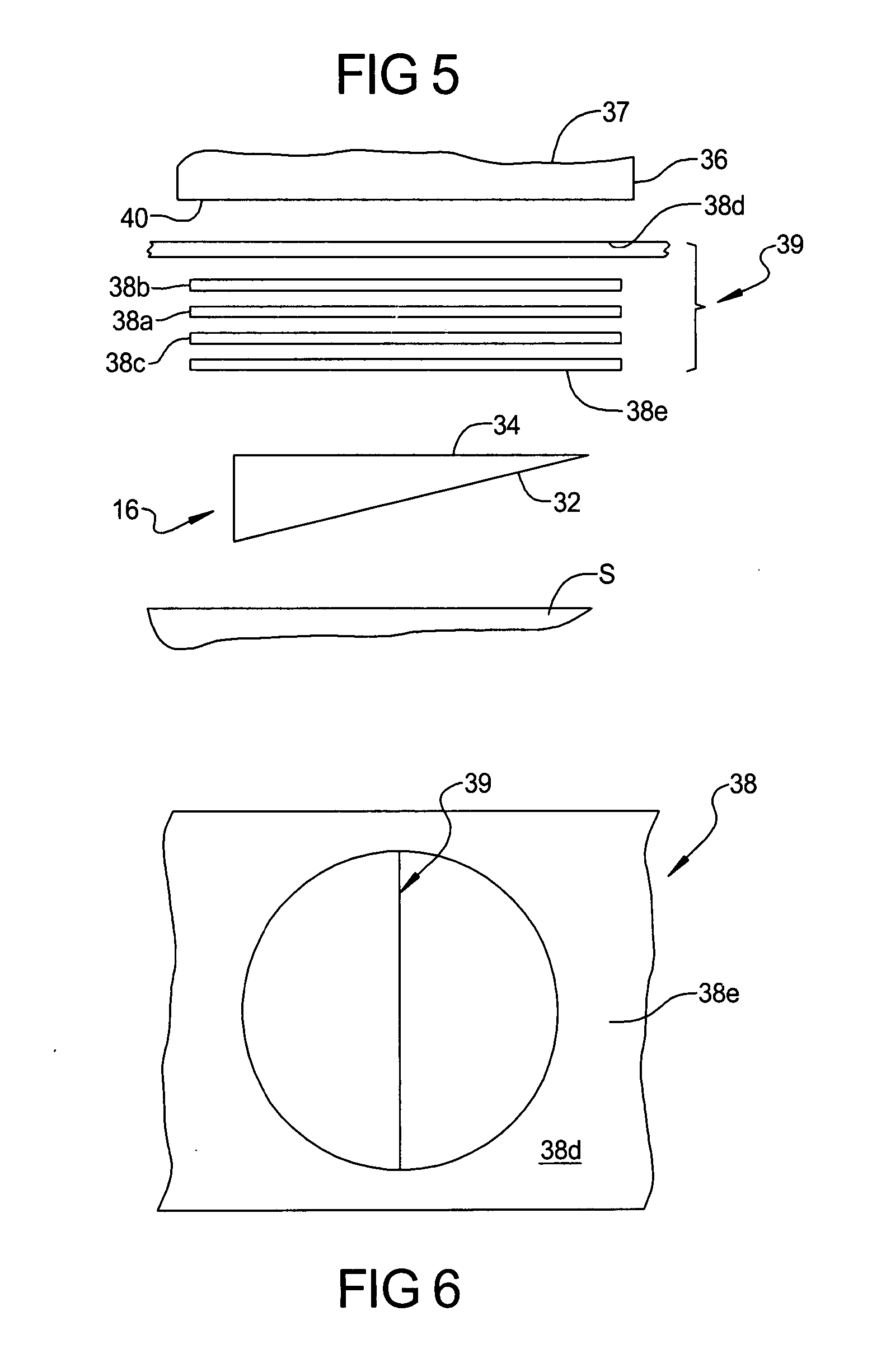

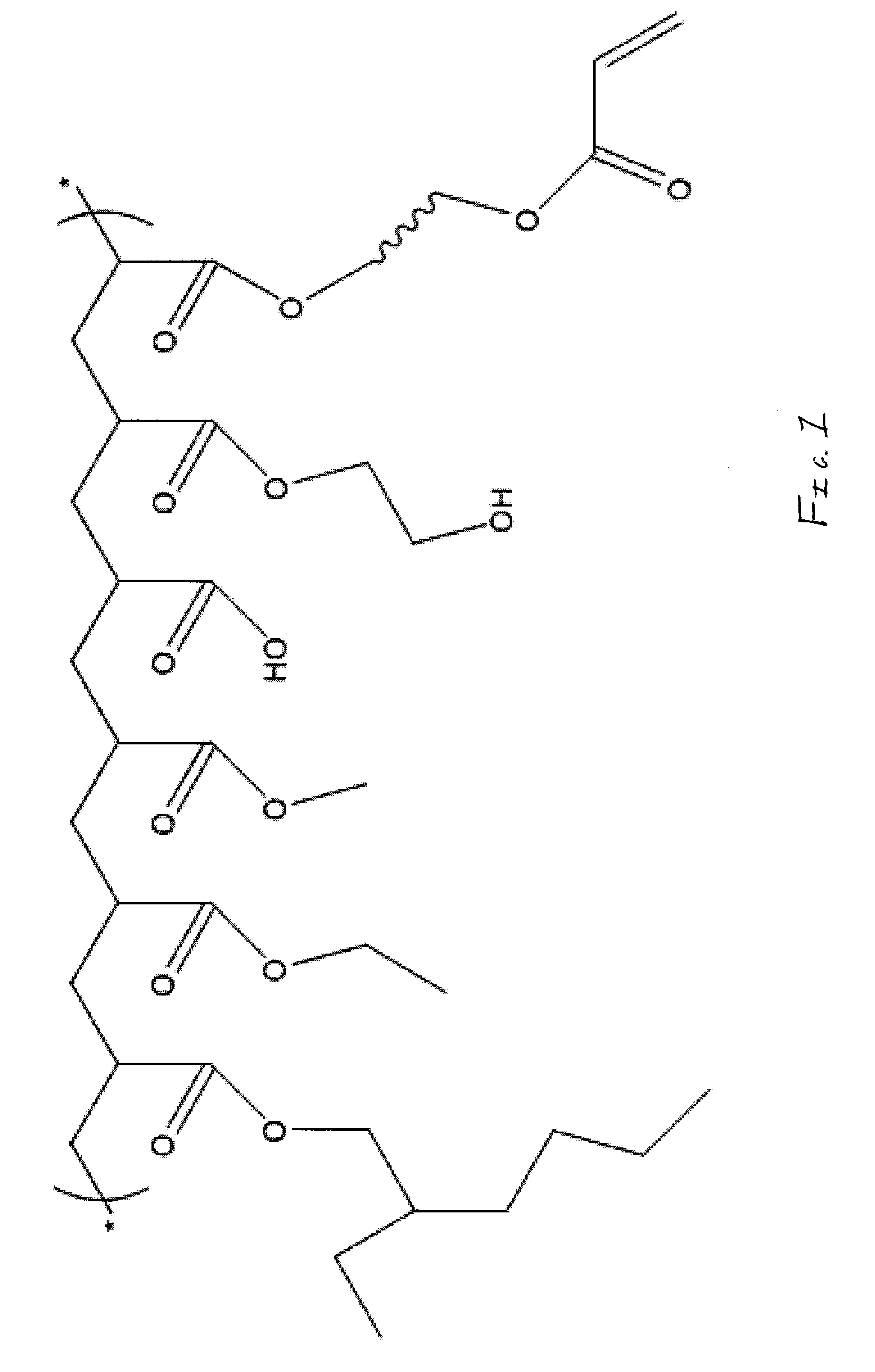

Ultraviolet radiation curable pressure sensitive acrylic adhesive

ActiveUS20100255239A1Adhesive processesLamination ancillary operationsPolymer scienceUltraviolet radiation

A process for making UV curable pressure sensitive adhesive compositions by derivatizing an acrylic polymer with a derivatizing agent prepared from a hydroxy-functional acrylate monomer and a diisocyanate. The derivatizing agent typically has a ratio of hydroxy-functional acrylate monomer to diisocyanate greater than about 1:1. Also disclosed are UV curable pressure sensitive adhesives made with the derivatizing agent and methods for adhering substrates with pressure sensitive adhesive compositions.

Owner:ARKEMA FRANCE SA

Mounting structure of re-peelable transparent touch panel and mounting sheet used for it

InactiveUS20040263481A1Improve adhesionSimple treatmentEmergency casingsDigital data processing detailsDisplay deviceEngineering

A transparent sheet for mounting that has an acrylic adhesive layer laminated on one surface of a core of plastic film and that has a silicone rubber sheet laminated on a primer-treated surface formed by primer treatment on the other surface is bonded overall onto a reverse face of a transparent touch panel with the acrylic adhesive layer, and the transparent touch panel provided with the sheet for mounting is mounted on a front surface of the display.

Owner:NISSHA PRINTING COMPANY

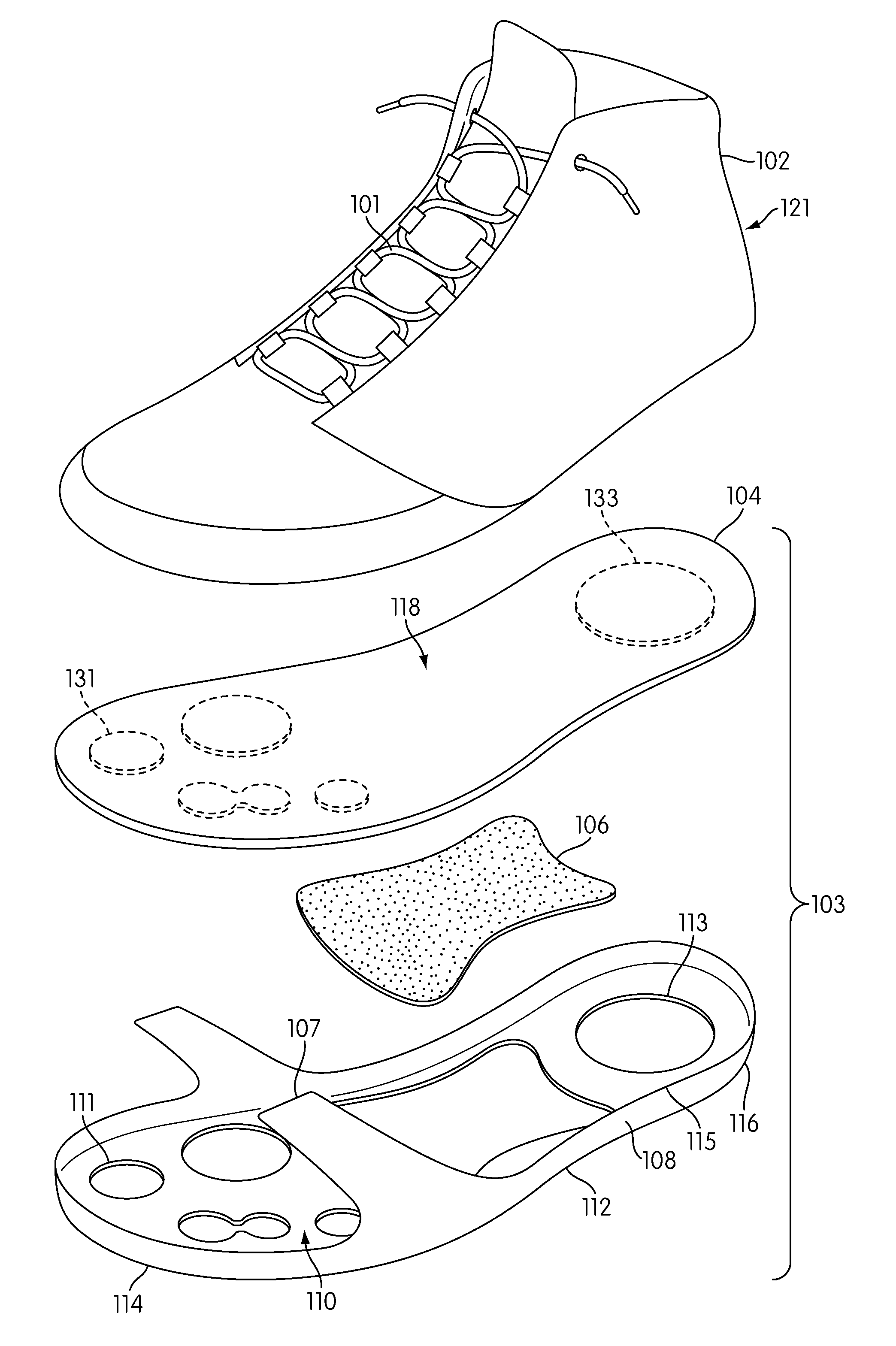

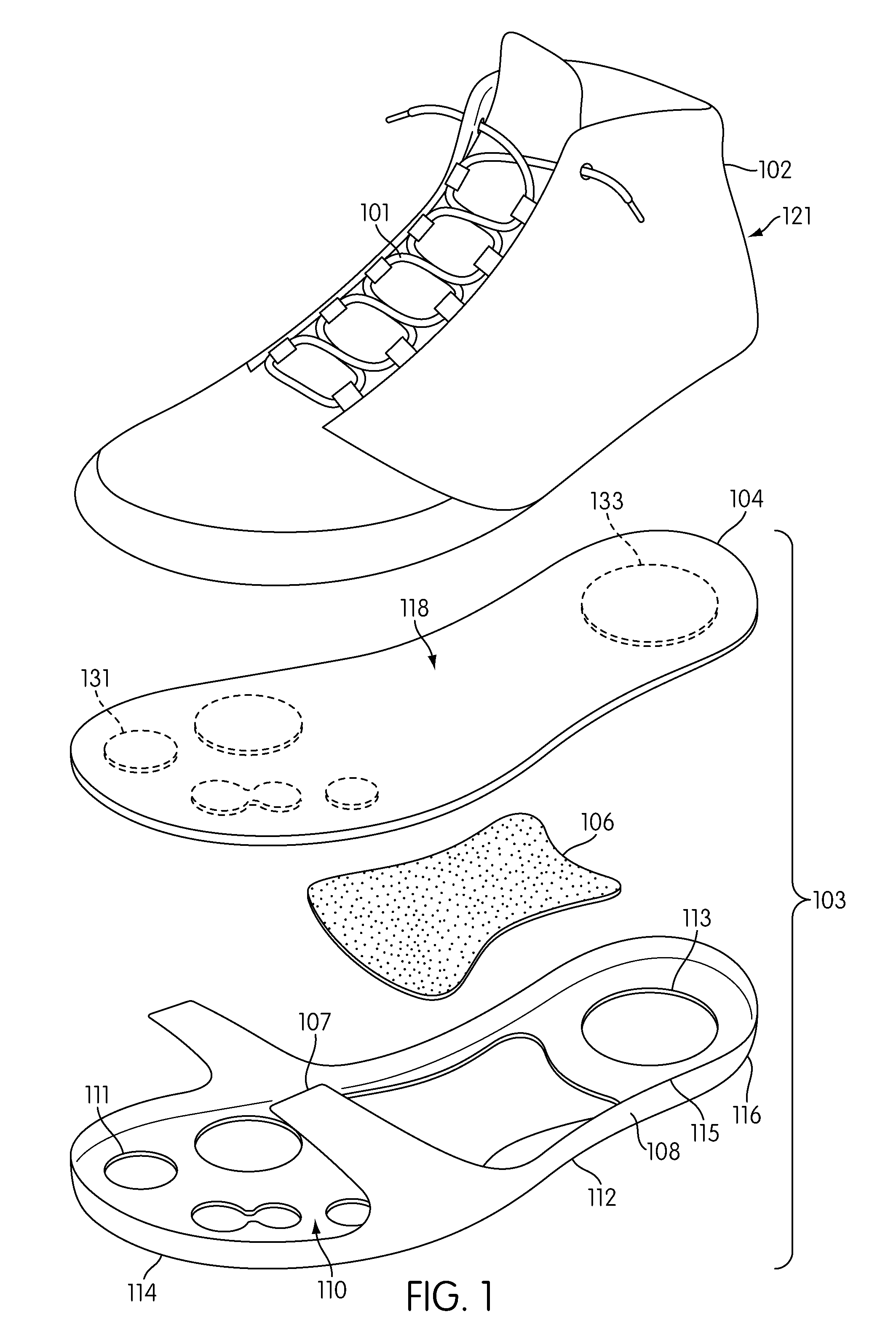

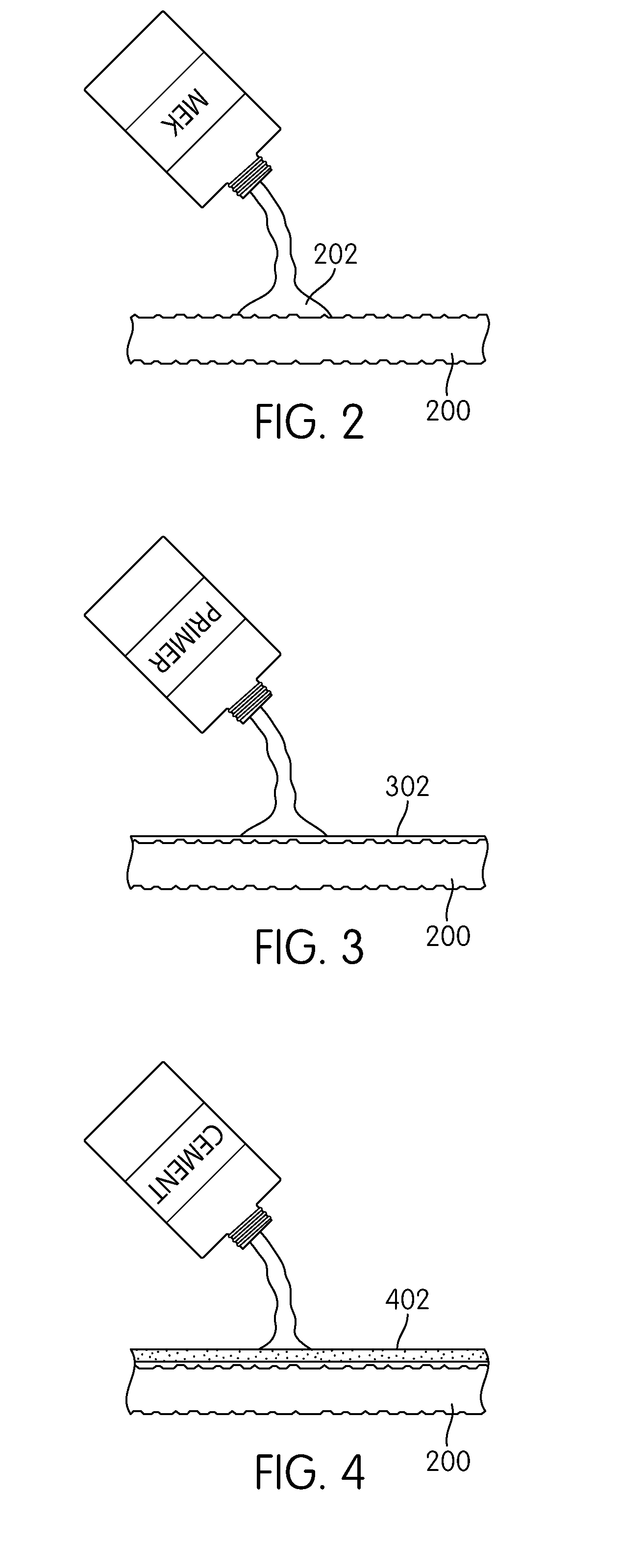

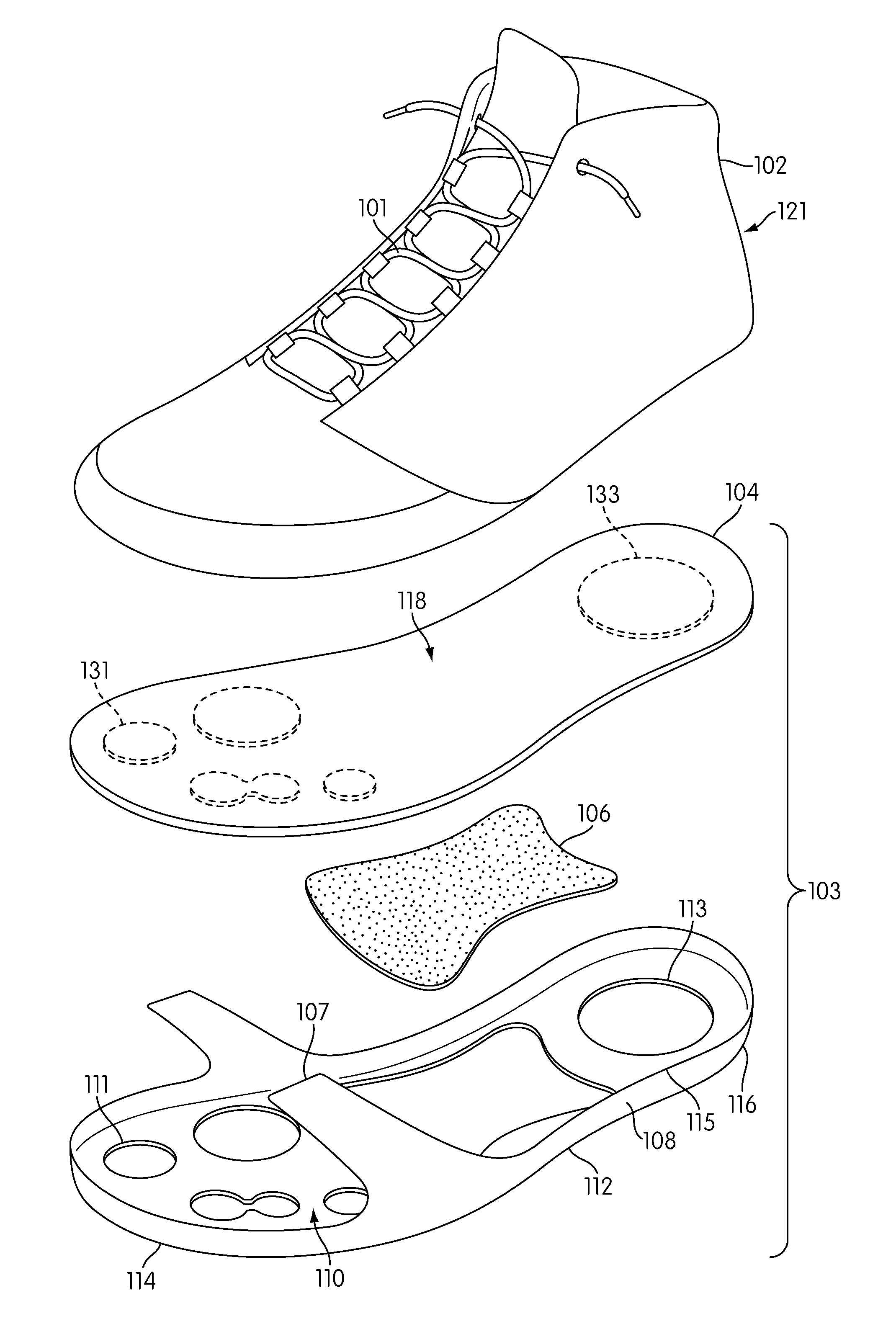

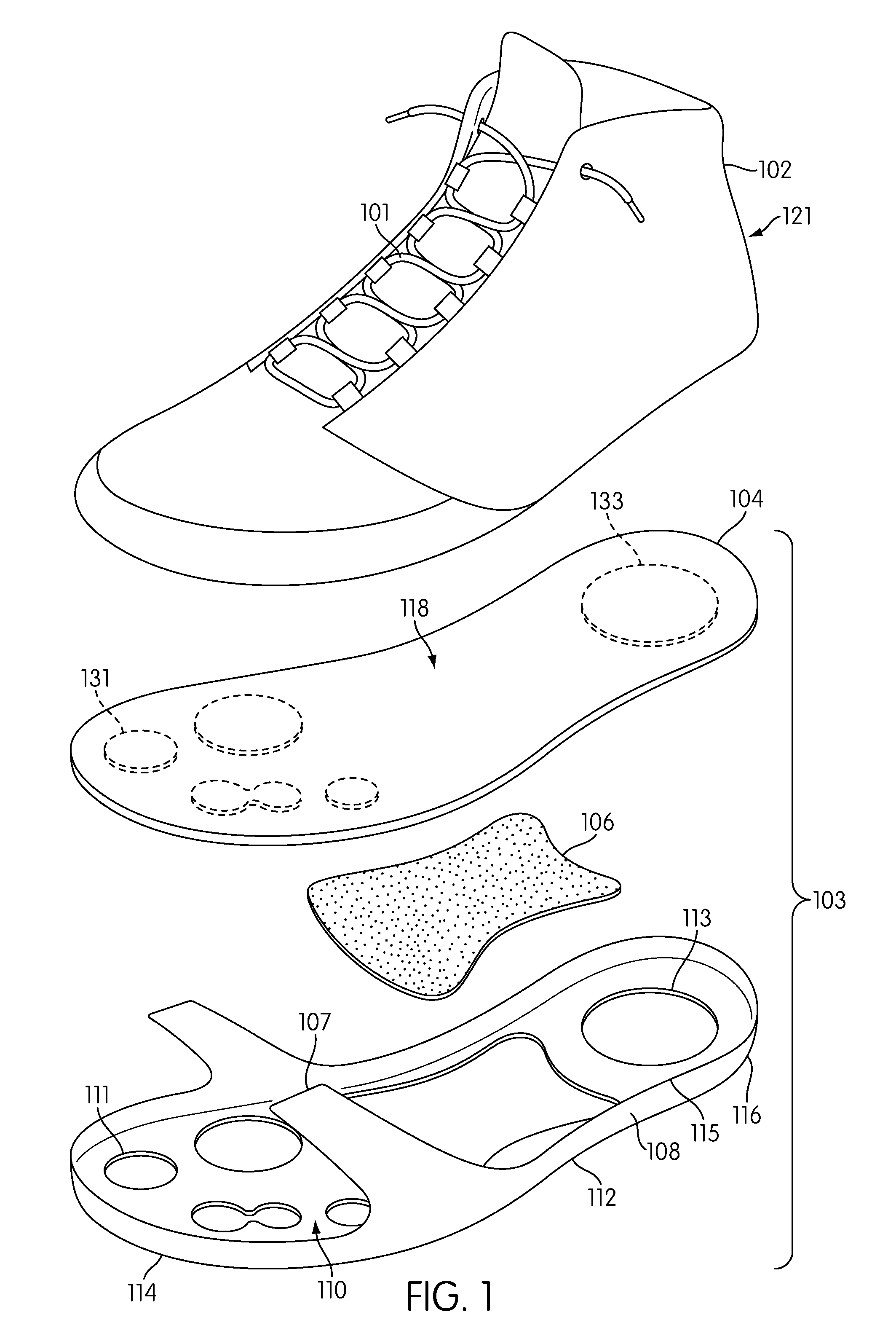

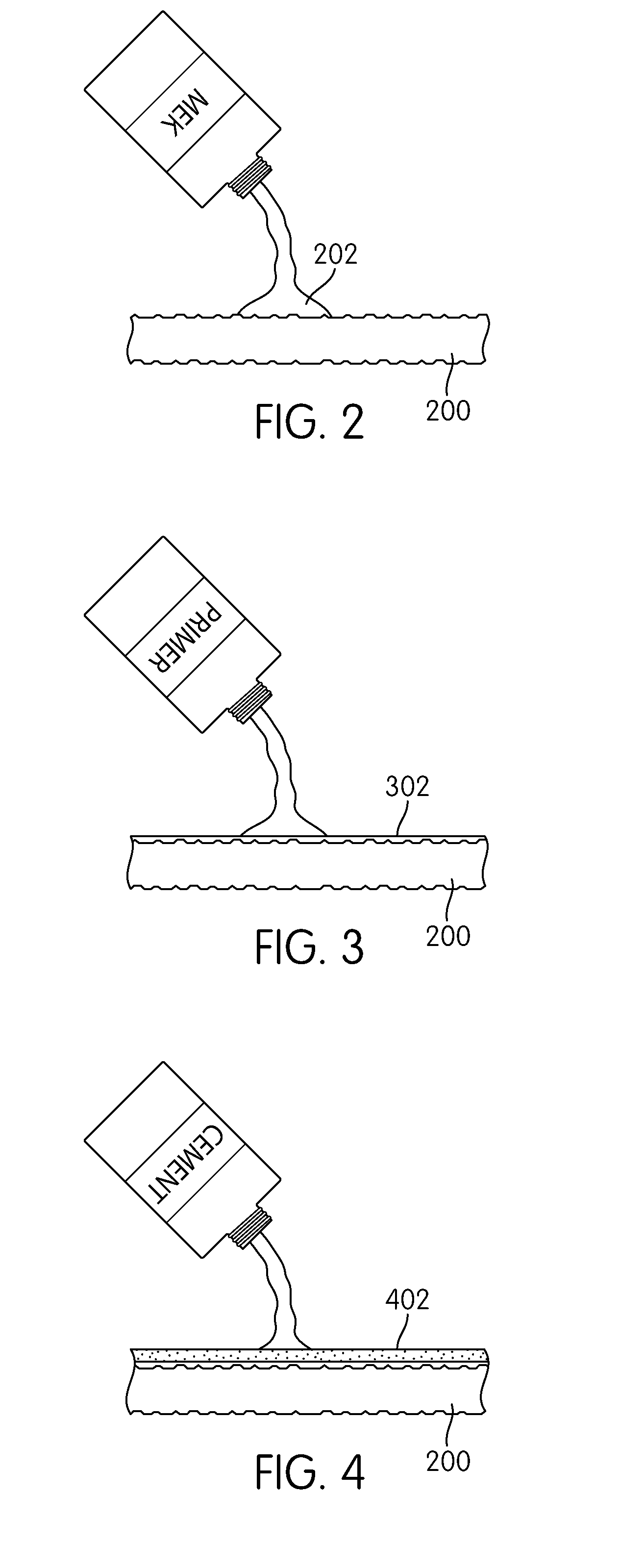

Method of Making an Article of Footwear and An Article of Footwear and apparatus

A method of making a sole for an article of footwear is disclosed. The method includes steps of attaching a double sided acrylic adhesive film to a composite plate. The composite plate is then attached to an outer member of the article of footwear using the acrylic adhesive film.

Owner:NIKE INC

Chemical Resistant Glove Having Cut Resistant Properties

InactiveUS20090077713A1Low shear strengthReduces cut stress intensityGlovesThin material handlingLatex gloveChemical treatment

A cut resistant chemical handling glove that is flexible and lightweight comprises a cured, liquid-impervious polymeric latex shell. A tacky acrylic adhesive with low shear strength can be used. A cut resistant liner is slipped on the tacky adhesive coating and is infiltrated with a polymeric latex coating and cured to integrally attach the cut resistant liner with the cured polymeric coating. When the latex glove is worn on a hand and a cutting edge, such as a knife edge, contacts the glove, a crease is formed due to slip at the tacky adhesive-cut resistant liner interface creating a geometry that reduces cut stress intensity at the knife-edge thereby increasing the cut resistance of the glove. Processes for making and using these gloves are also described.

Owner:ANSELL HEALTHCARE PRODS

Hybrid silicone and acrylic adhesive cover for use with wound treatment

Sealing members and methods of manufacturing the same are described. A first film layer and a second film layer each having a first side and a second side can be provided. A first adhesive can be coupled to the second side of the first film layer to form a first adhesive layer. A second adhesive can be coupled to the second side of the second film layer to form a second adhesive layer, and a third adhesive can be coupled to the first side of the second film layer to form a third adhesive layer. One or more perforations can be formed through the third adhesive layer, the second film layer, and the second adhesive layer. A first side of the third adhesive layer can be coupled to a second side of the first adhesive layer.

Owner:3M INNOVATIVE PROPERTIES CO

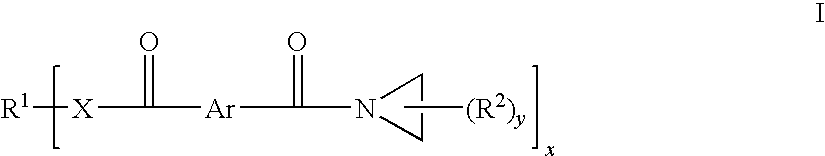

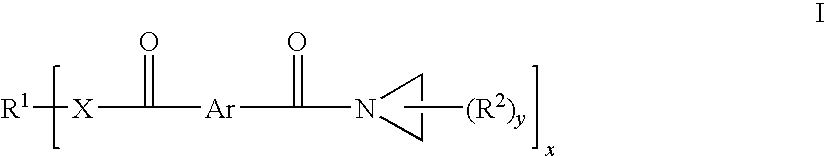

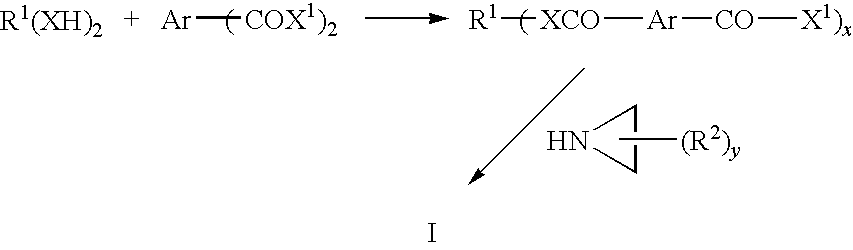

Aziridine crosslinking agents for acrylic adhesives

InactiveUS20100227969A1Reduce sensitivityGood shear propertyOrganic chemistryNon-macromolecular adhesive additivesMeth-Aziridine

Owner:3M INNOVATIVE PROPERTIES CO

Acrylic adhesive compositions for polarizing film and the polarizer film using the same

InactiveUS20030054166A1Liquid crystal compositionsPlastic/resin/waxes insulatorsPolarizerOptical coefficient

The present invention provides an acrylic pressure sensitive adhesive composition having an element with a positive stress optical coefficient for a polarizing film and a polarizing film using the same.

Owner:SHANJIN OPTOELECTRONICS SUZHOU CO LTD

Transdermal patch

InactiveUS20090258063A1Diffusibility is increasedSufficient amountOrganic active ingredientsUrinary disorderTransdermal patchCarbon number

The present invention provides a transdermal patch having excellent preservation stability and transdermal absorbency of DMAEs. The patch has a support and a plaster layer integrally laminated on one surface of the support, and the plaster layer includes: DMAEs; an acrylic adhesive prepared by copolymerizing monomers respectively containing 30 to 99% by weight of alkyl methacrylate having an alkyl group with a carbon number of 6 to 22 and 1 to 70% by weight of alkyl acrylate having an alkyl group with a carbon number of 2 to 20; and fatty acid ester prepared by dehydro-condensing saturated fatty acid having an alkyl group with a carbon number of 10 to 20 and saturated aliphatic monohydric alcohol having an alkyl group with a carbon number of 2 to 20, wherein solubility of the DMAEs is 0.05 to 5 g at 25° C. with respect to the fatty acid ester.

Owner:SEKISUI CHEM CO LTD

Dental appliance, dental appliance adhesive and related methods and uses

A dental appliance has an auxiliary feature bonded to a polymeric surface of a shell body with a compartment for receiving teeth. The auxiliary feature is bonded with a light-curable acrylic adhesive comprising acrylate base material and photoinitiator. Auxiliary features include colored layers and, decals, reinforcing features and auxiliary dental devices. A light-curable acrylic adhesive may include a thiol monomer and / or a pigment. A dental appliance may have a shell body with a bonding surface adapted for attachment of an auxiliary feature, such as prepared by a pretreatment to mar the surface of to impregnate the surface with a reactive adhesion promoter.

Owner:SYMDENT

Method of making an article of footwear and apparatus

Owner:NIKE INC

Waterproof and anti-corrosion repair mortar for polymer cement-based concrete structure

The invention relates to a waterproof and anti-corrosion repair mortar for a polymer cement-based concrete structure, in particular to a cement concrete repair material for a cement concrete structure, which is used for carrying out bonding reinforcement and repair on defects of municipal roads, municipal services, bridges and water conservancy projects (dams and gates). The waterproof and anti-corrosion repair mortar is prepared by mixed materials and water, and the mixed materials comprise the following components in parts by weight: 20-30 parts of portland cement, 0.01-0.05 part of high-performance water-reducing agent, 1-5 parts of high-aluminum cement, 15-30 parts of quartz sand, 25-60 parts of gravel and 1-3 parts of acrylic adhesive powder, 1-3 parts of fiber material, while the using amount of water accounts for 5-14% of the total parts of the mixed materials. Due to the adoption of the technical scheme, the waterproof and anti-corrosion repair mortar has the characteristics of good pressure resistance, high flexural strength, high bonding strength, good durability, convenient and fast construction, fast setting and early strength shrinkage control, and can greatly shorten the repair time and quickly resume the traffic in particular to roads.

Owner:卢建华

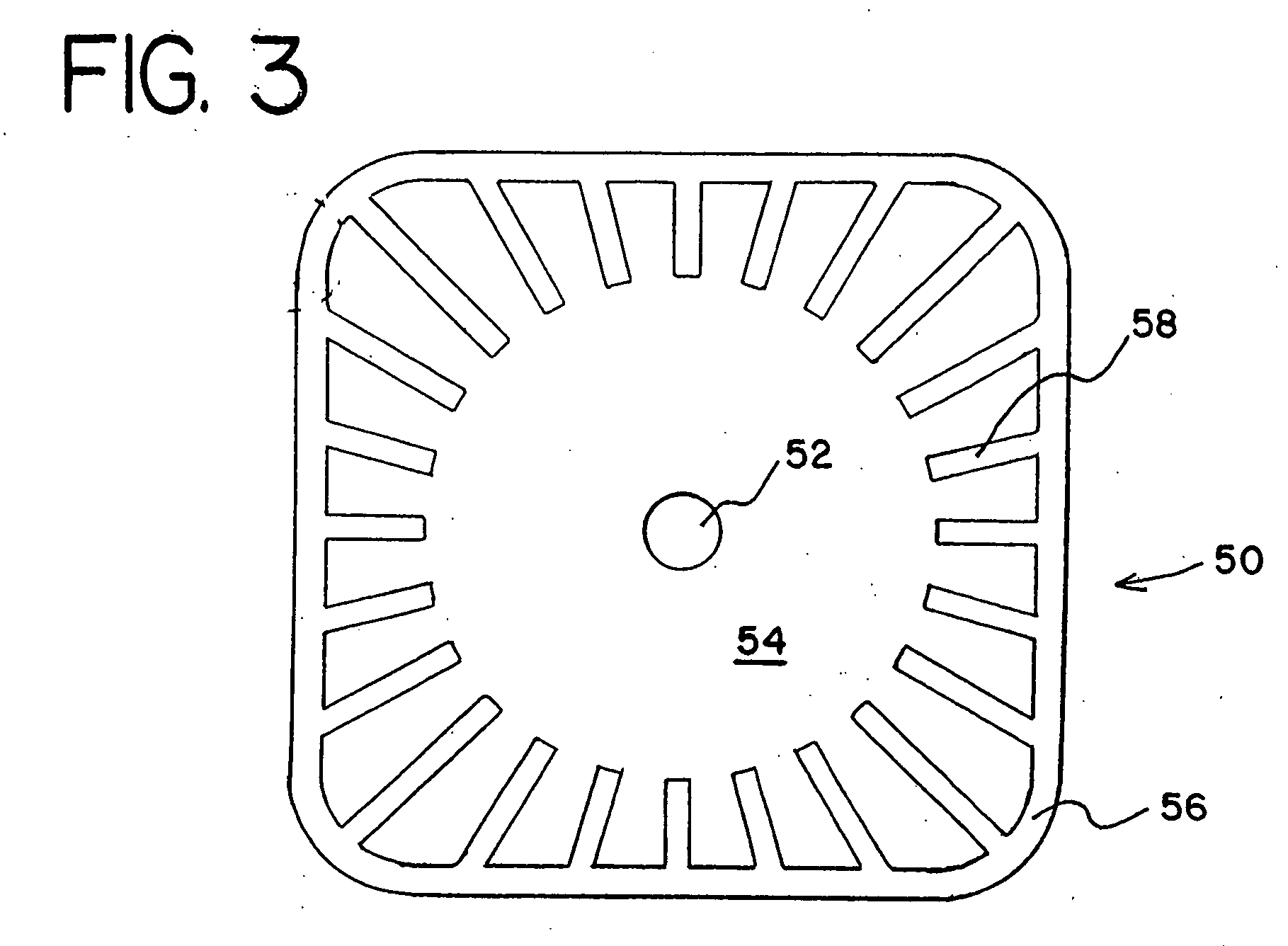

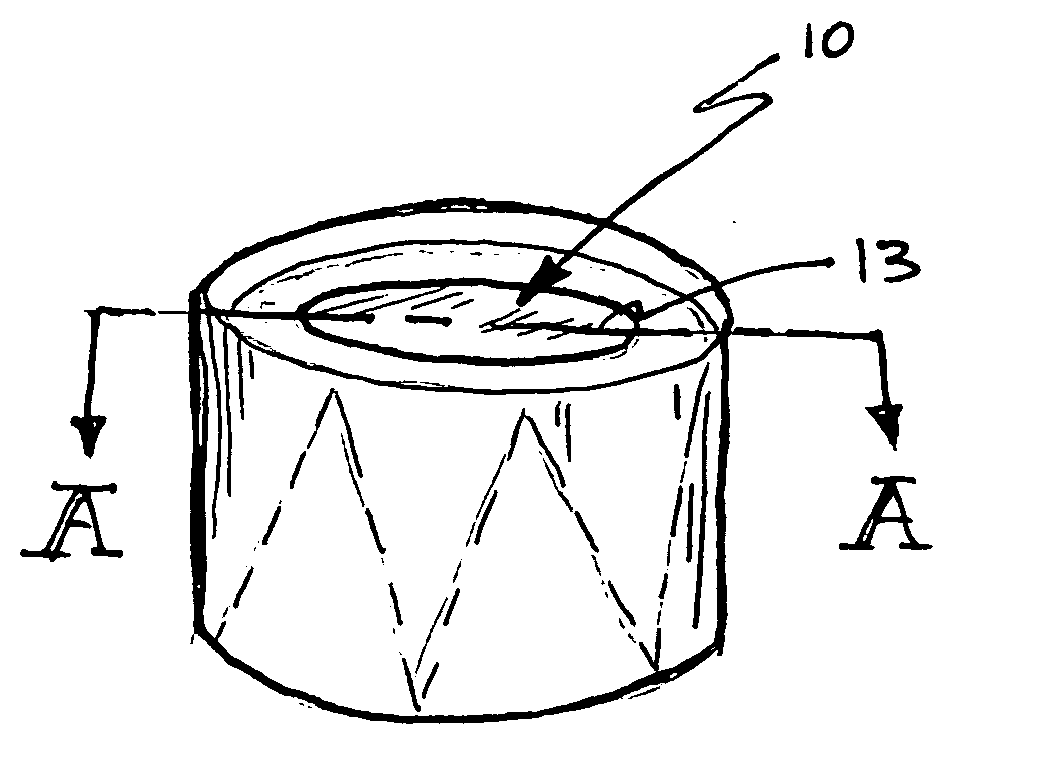

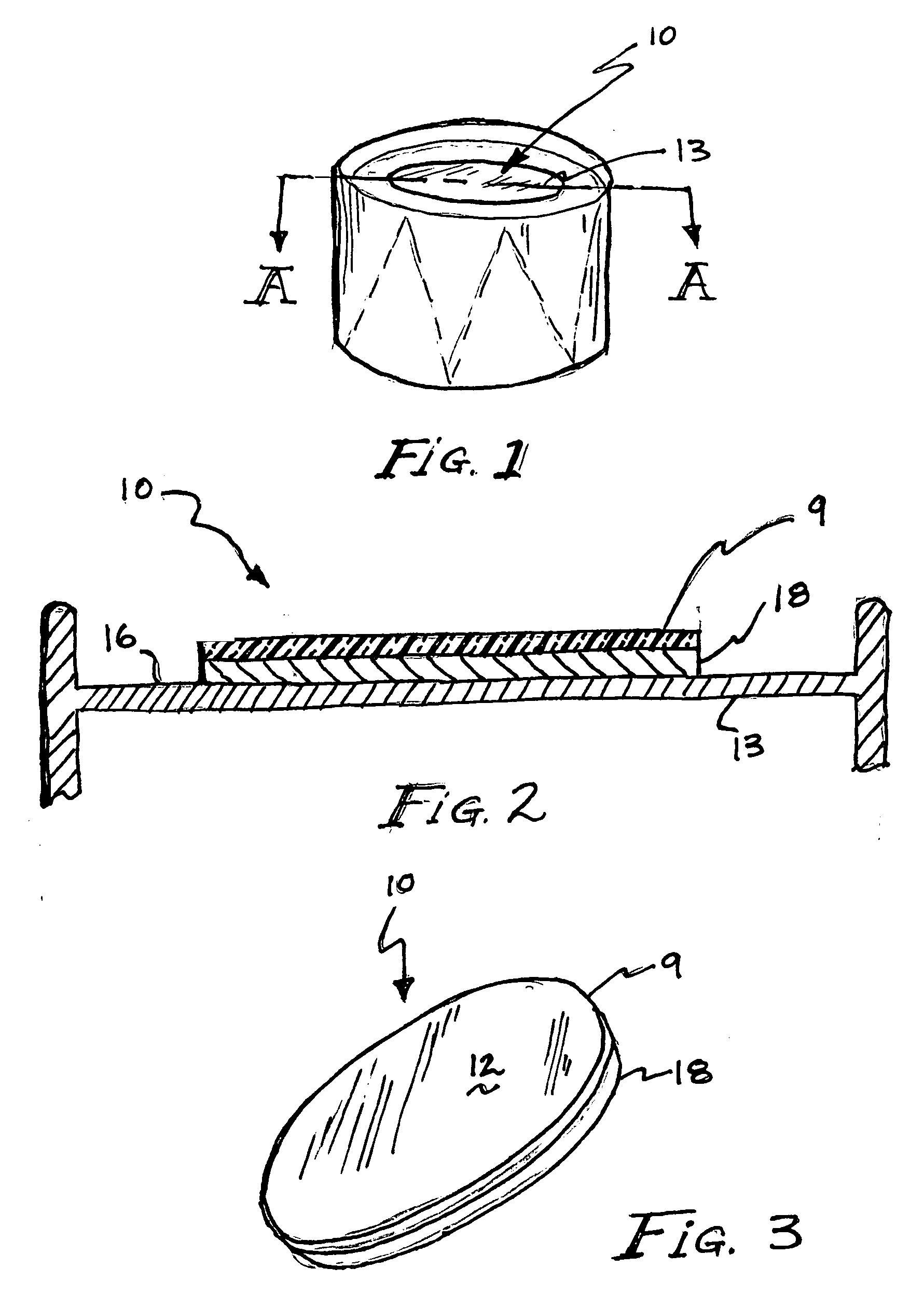

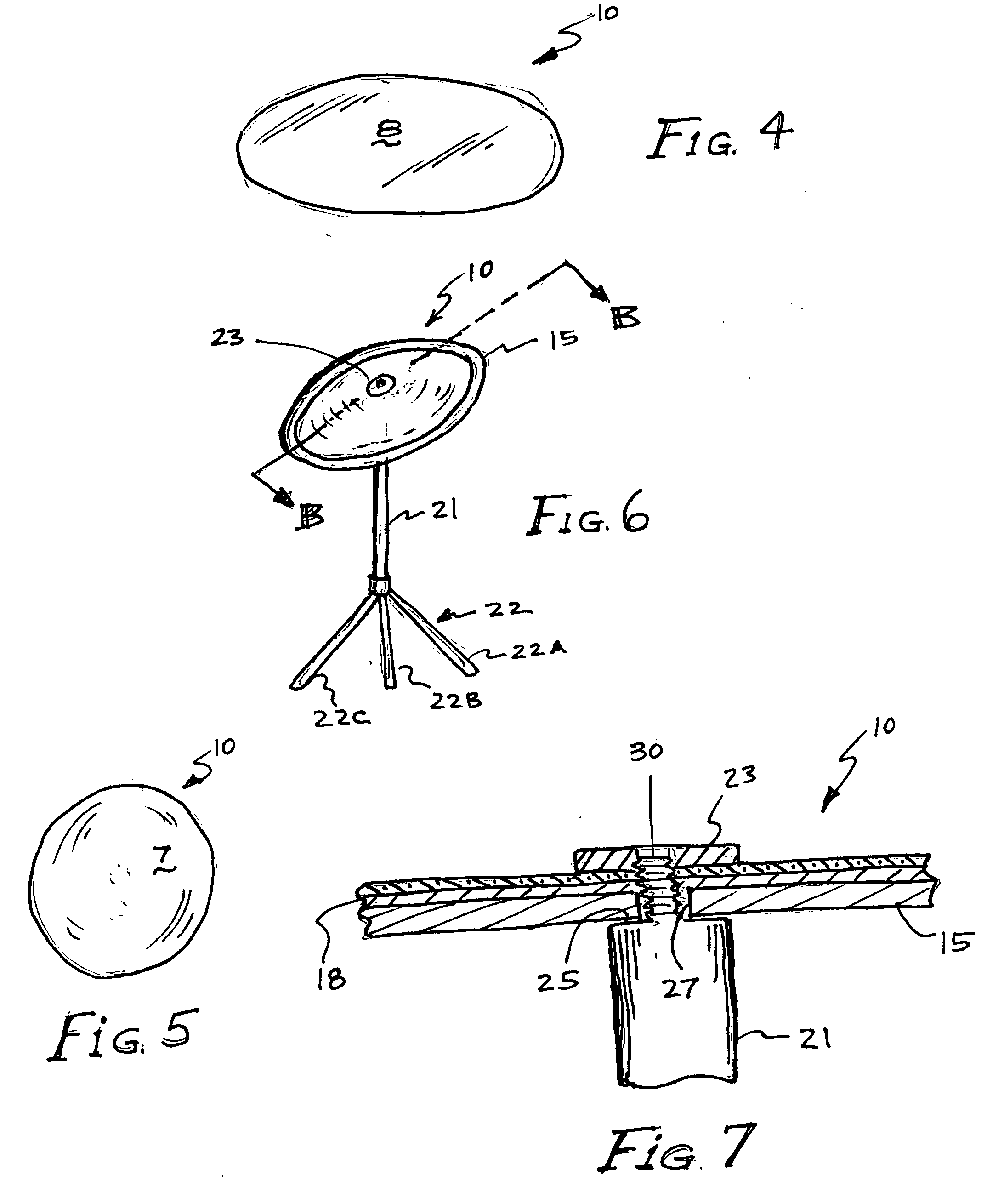

Removable muting device for drums, cymbals and the like

InactiveUS20060065099A1Reduce peelingIncrease shearPercussion musical instrumentsRubber materialEngineering

A removable muting device for drums, cymbals, and the like, including a new and innovative layered combination formed of a pad of sponge rubber material having a top portion and a bottom portion, the bottom portion having a layer thereon of TYCO Adhesive No. 1724D which is a removable Acrylic adhesive having low peel, low tack, high shear and non-residue properties to allow the entire combination to be adhesively and removably affixed by pressure to a surface such as the drumstick-struck portions of drums and cymbals to mute the sound thereof when struck by a drumstick or the like.

Owner:ANDERSON JAMES MARTIN

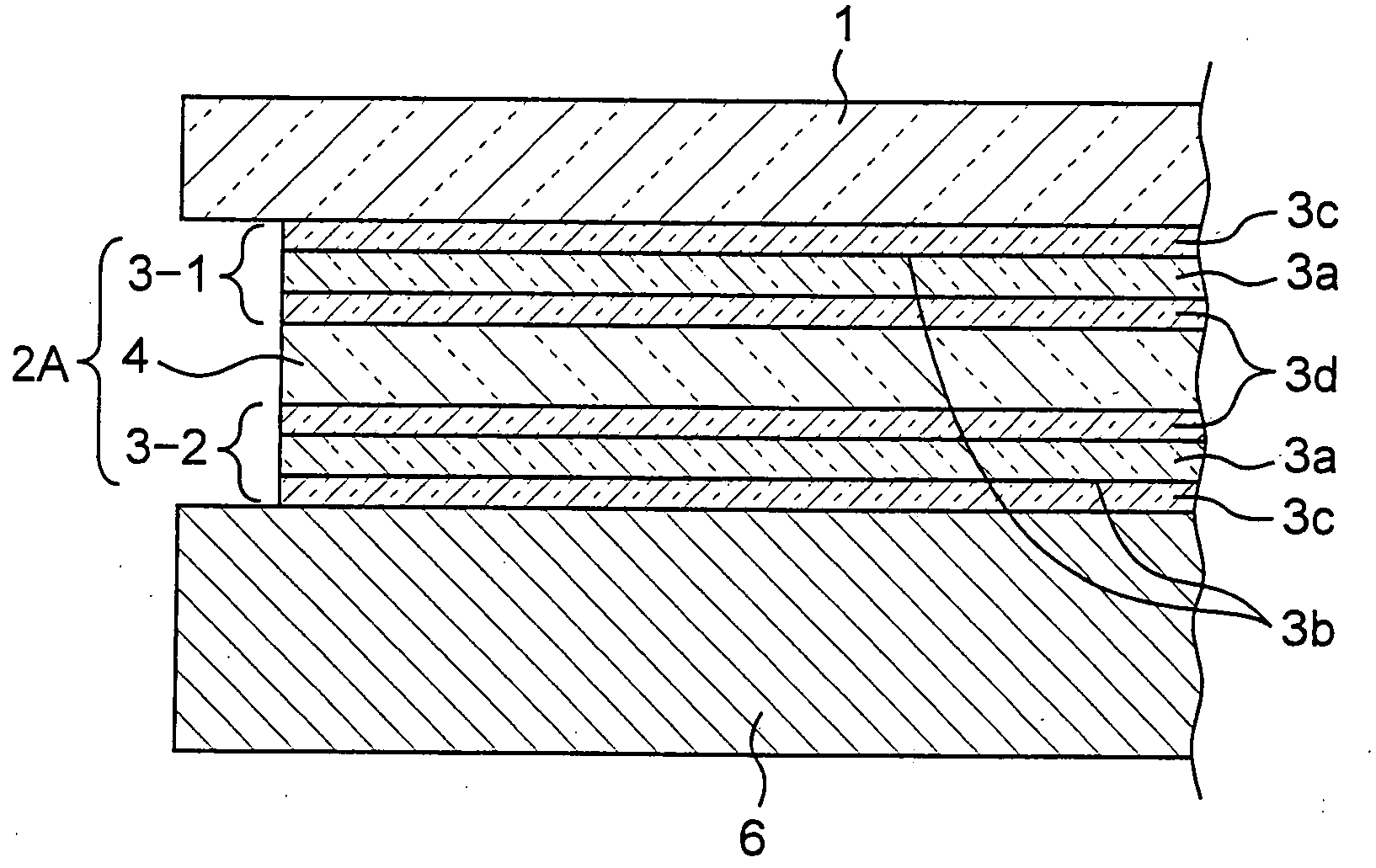

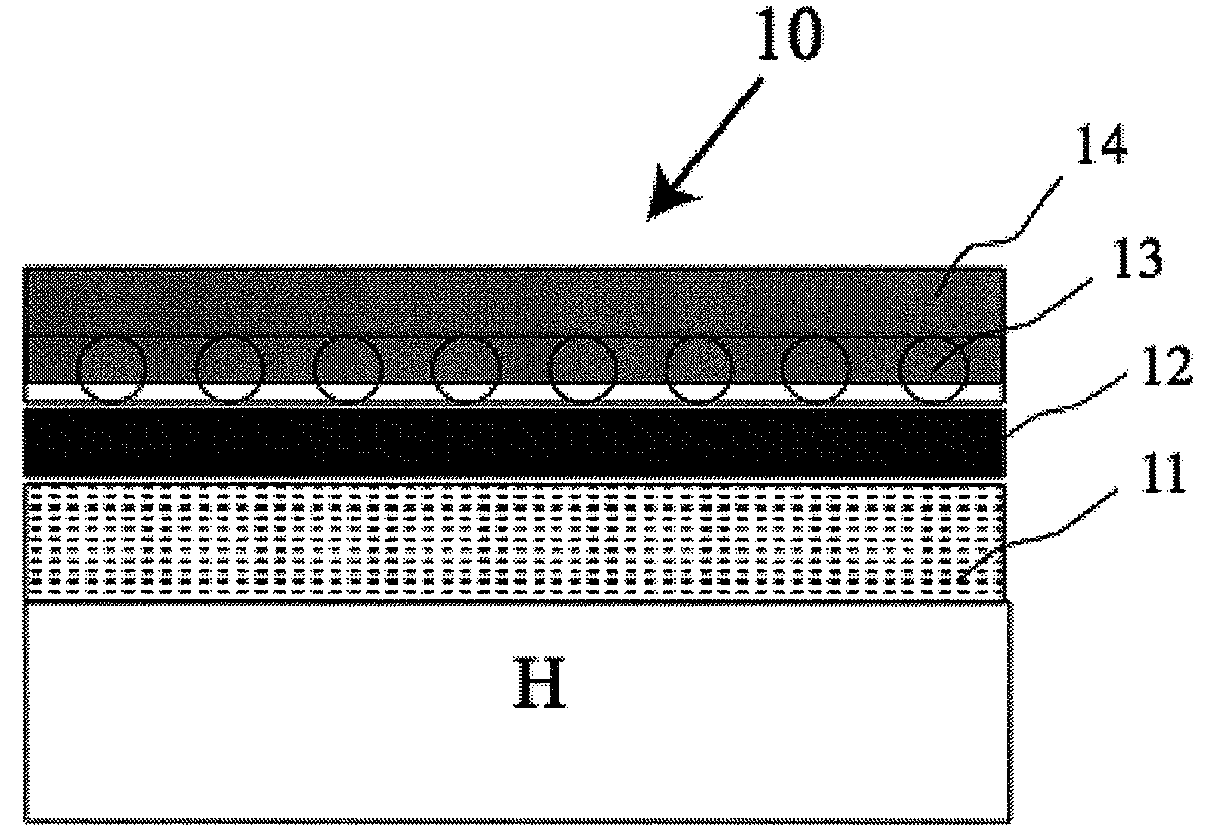

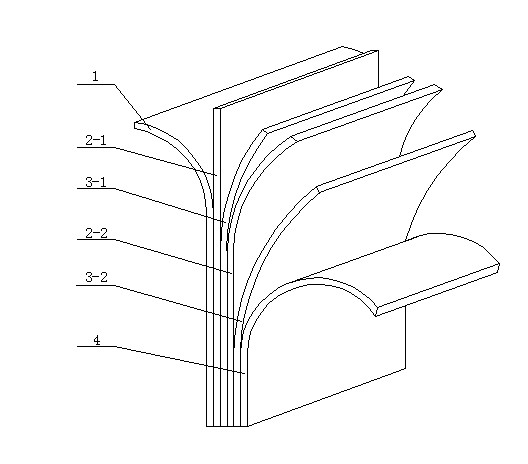

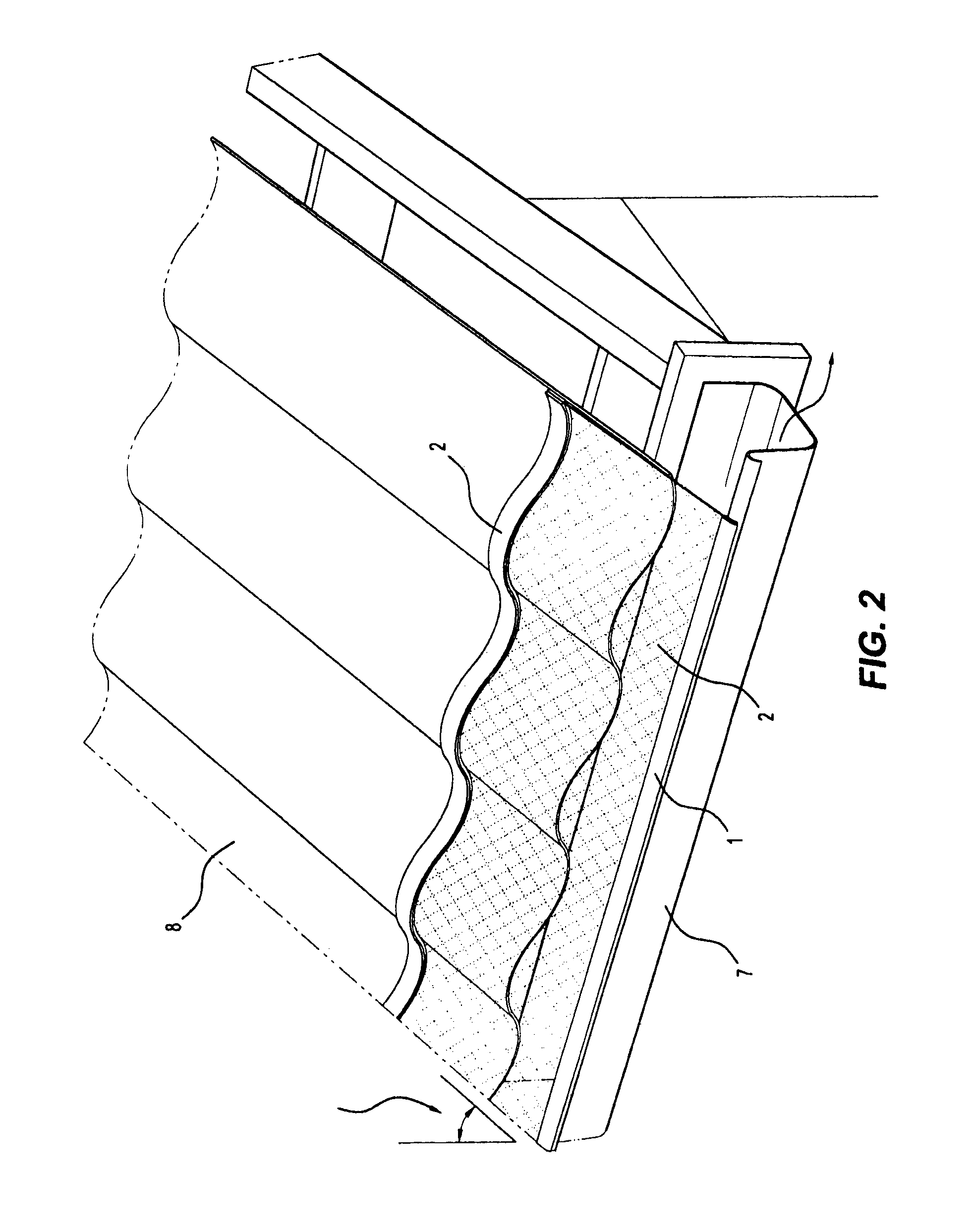

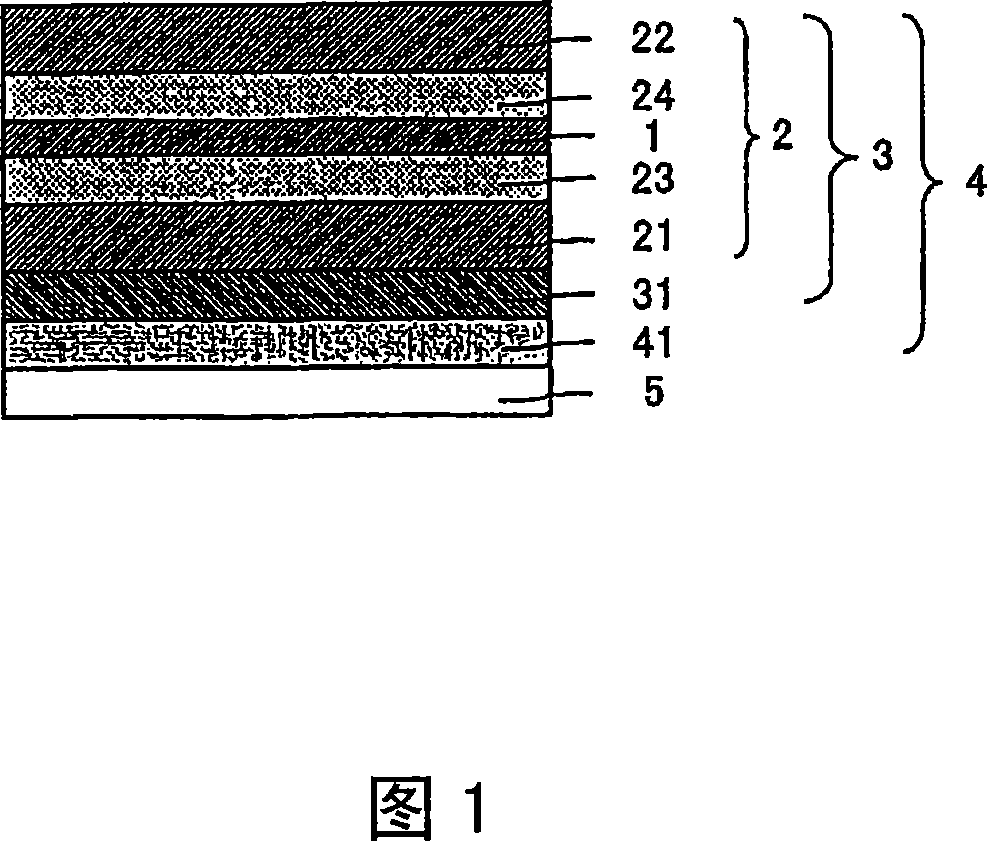

Anti-fogging agent composition and anti-fogging insulation window film formed thereby

InactiveCN102604460AGood anti-fog durabilityEasy to prepareFilm/foil adhesivesSynthetic resin layered productsPolyesterMonomethyl ether

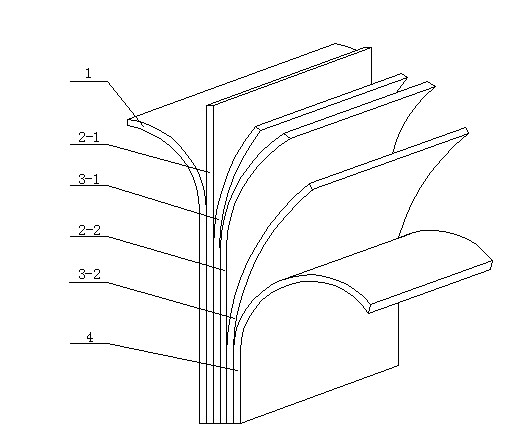

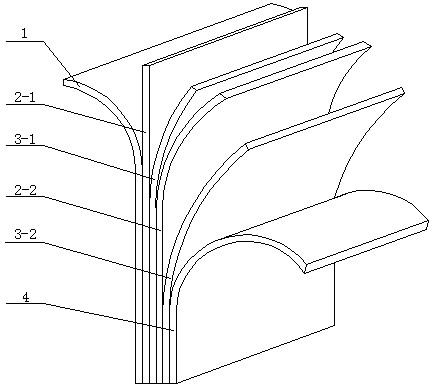

The invention relates to an anti-fogging agent composition and an anti-fogging insulation window film formed thereby, wherein the anti-fogging agent composition comprises 9 to 14 wt% of hydrophilic resin, 55 to 76 wt% of propylene glycol monomethyl ether, 3 to 10 wt% of dimethyl methylamine, 1 to 5 wt% of triethylene diamine, 1 to 5 wt% of leveling agent, 5 to 26wt% of isopropanol and 5 to 24wt% of ethanol; the anti-fogging insulation window film comprises a first transparent polyester film or transparent polyethylene film substrate (2-1), a heat insulation acrylic adhesive layer (3-1), a second transparent polyester film or transparent polyethylene film substrate (2-2), an acrylic adhesive layer (3-2) and a release film (4), which are composited as a whole, wherein the anti-fogging coating (1) is formed by the anti-fogging agent composition; and the heat insulation acrylic adhesive layer (3-1) contains a specific insulation material. According to the invention, the anti-fogging insulation window film is anti-fogging, insulating and safe.

Owner:西安航天三沃化学有限公司

Process for preparing a semiconductor wafer

InactiveUS6297076B1Reliable manufacturingImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesFluenceWafer dicing

Disclosed is a process for preparing a semiconductor device comprising the steps of adhering a back surface of a wafer, a front surface of which has been formed a circuit, onto the radiation curable adhesive layer, dicing the wafer into chips, rinsing, drying, irradiating the adhesive layer with radiation to cure said adhesive layer, expanding the adhesive sheet if necessary to make the chips apart from each other, then picking up the chips, mounting the picked chips on a lead frame, bonding, and molding to give such a structure that the back surfaces of the chips are partially or wholly in contact with a package molding resin, wherein the radiation curable adhesive layer comprises 100 parts by weight of an acrylic adhesive composed of a copolymer of an acrylic ester and an OH group-containing polymerizable monomer and 50-200 parts by weight of a radiation polymerizable compound having two or more unsaturated bonds, and the radiation curable adhesive layer has an elastic modulus of not less than 1x109 dyn / cm2 after curing by irradiation with radiation.

Owner:LINTEC CORP +1

Prepn of water-base composite acrylic adhesive

The water-base composite acrylic adhesive is prepared through first pre-emulsifying partial deionized water, partial emulsifier and partial reaction monomer to obtain the pre-emulsion I; pre-emulsifying the rest deionized water, emulsifier and reaction monomer to obtain the pre-emulsion II; adding partial initiator to the pre-emulsion II for emulsion polymerization to prepare seed, adding molecular weight regulator, dropping the pre-emulsion I, adding rest initiator, and controlling the pH value in the required range to complete the reaction and to obtain the water-base composite acrylic adhesive. The preparation process has low emulsifier consumption and stable emulsion reaction, and the product has high stability and high adhesion strength, and may be used in the adhesion of plastic film and aluminum film.

Owner:BEIJING COMENS NEW MATERIALS

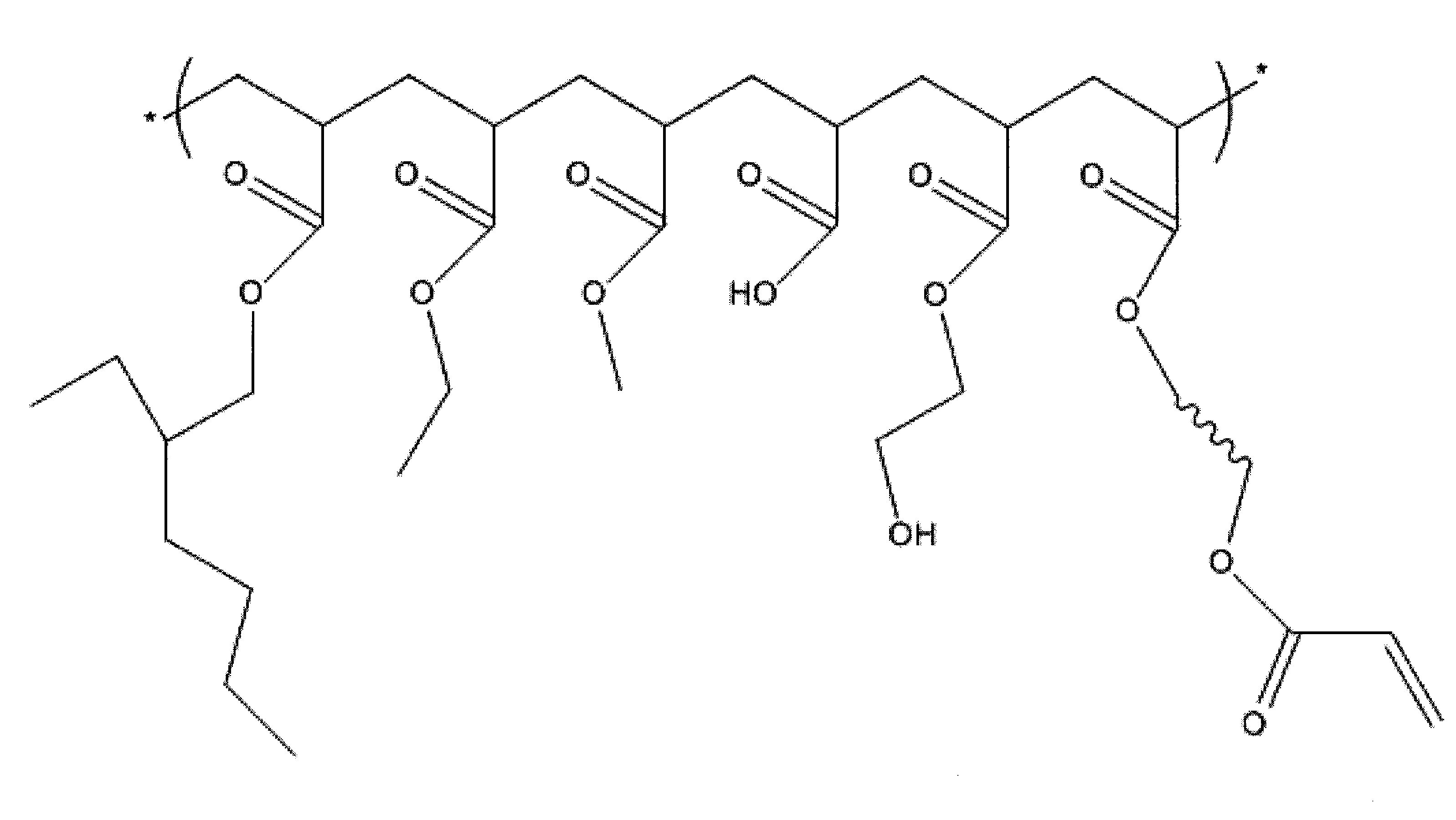

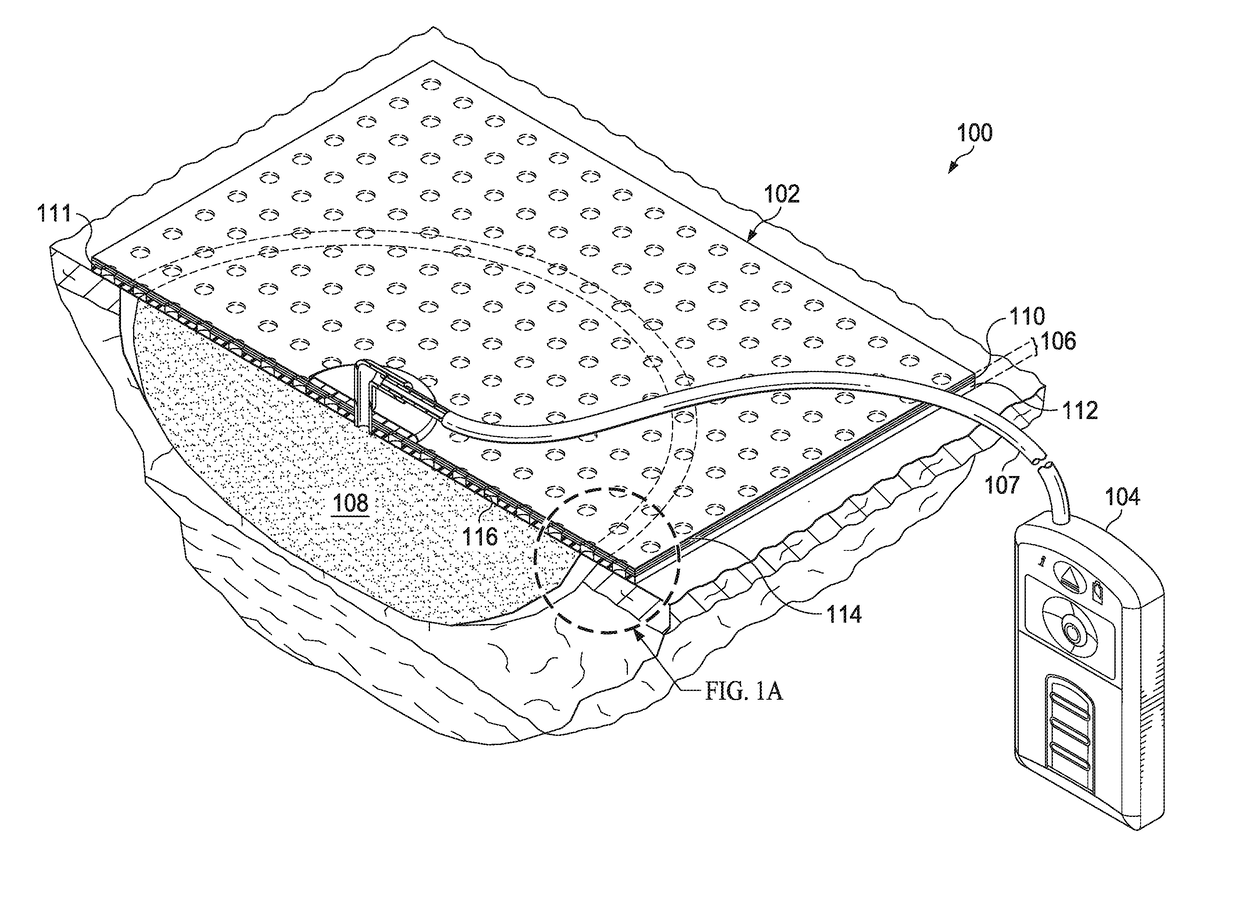

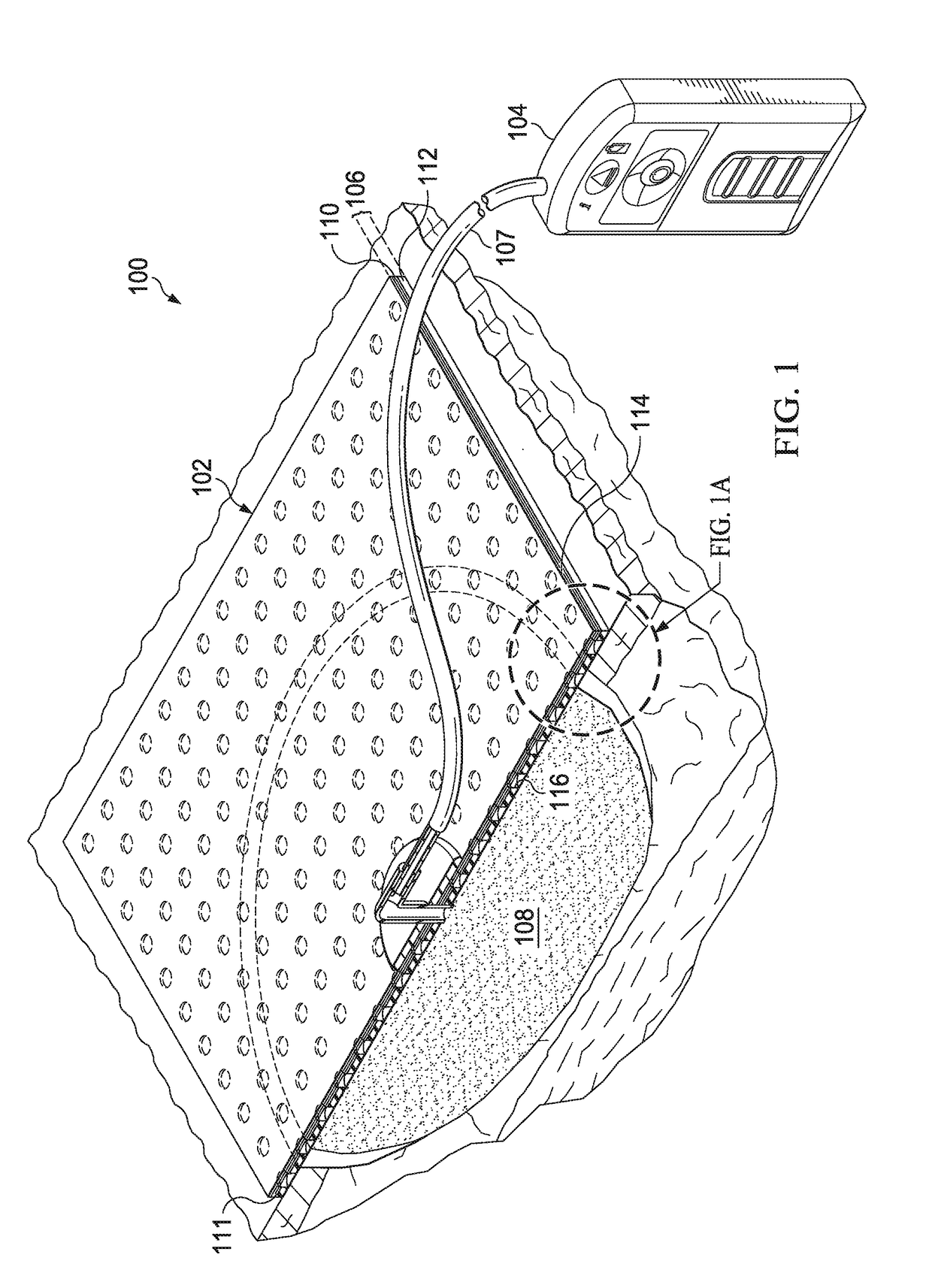

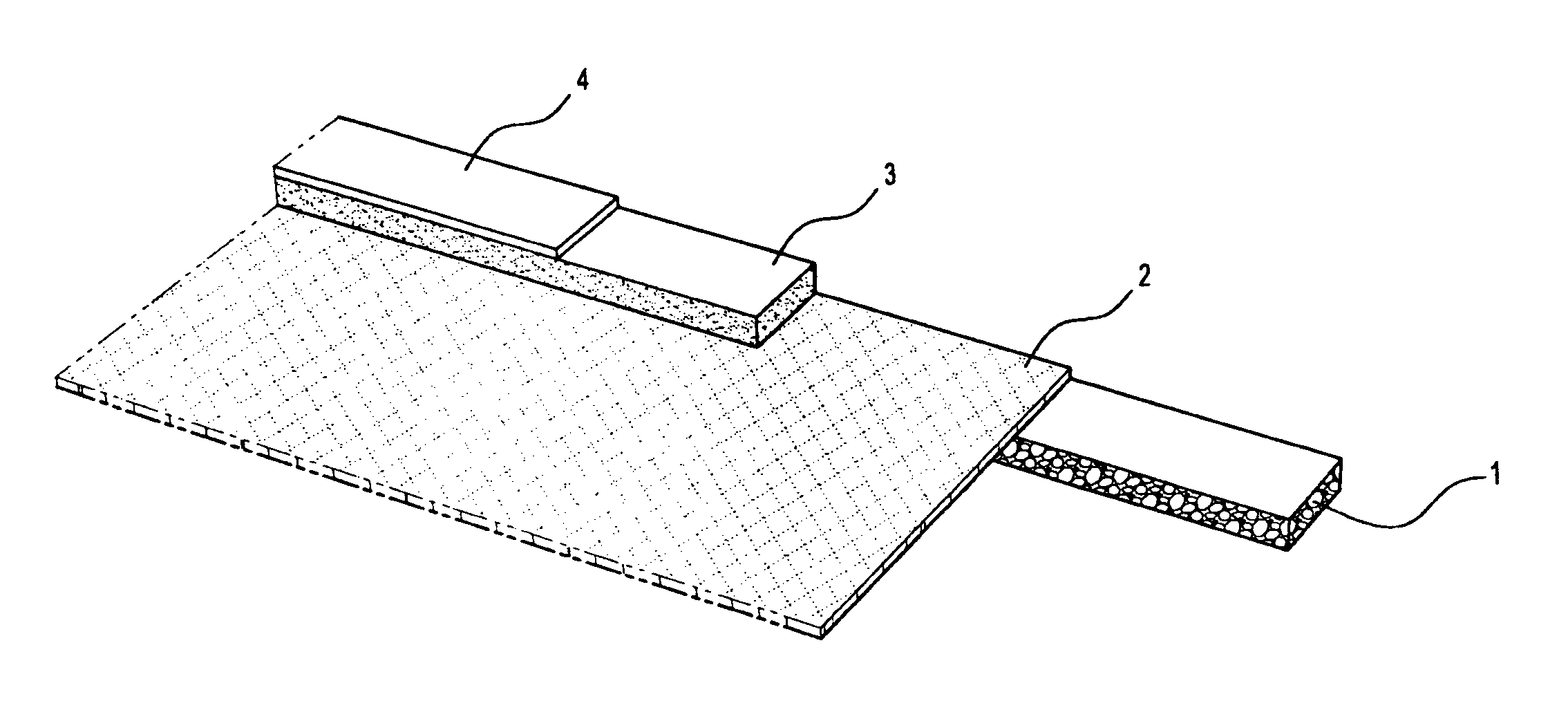

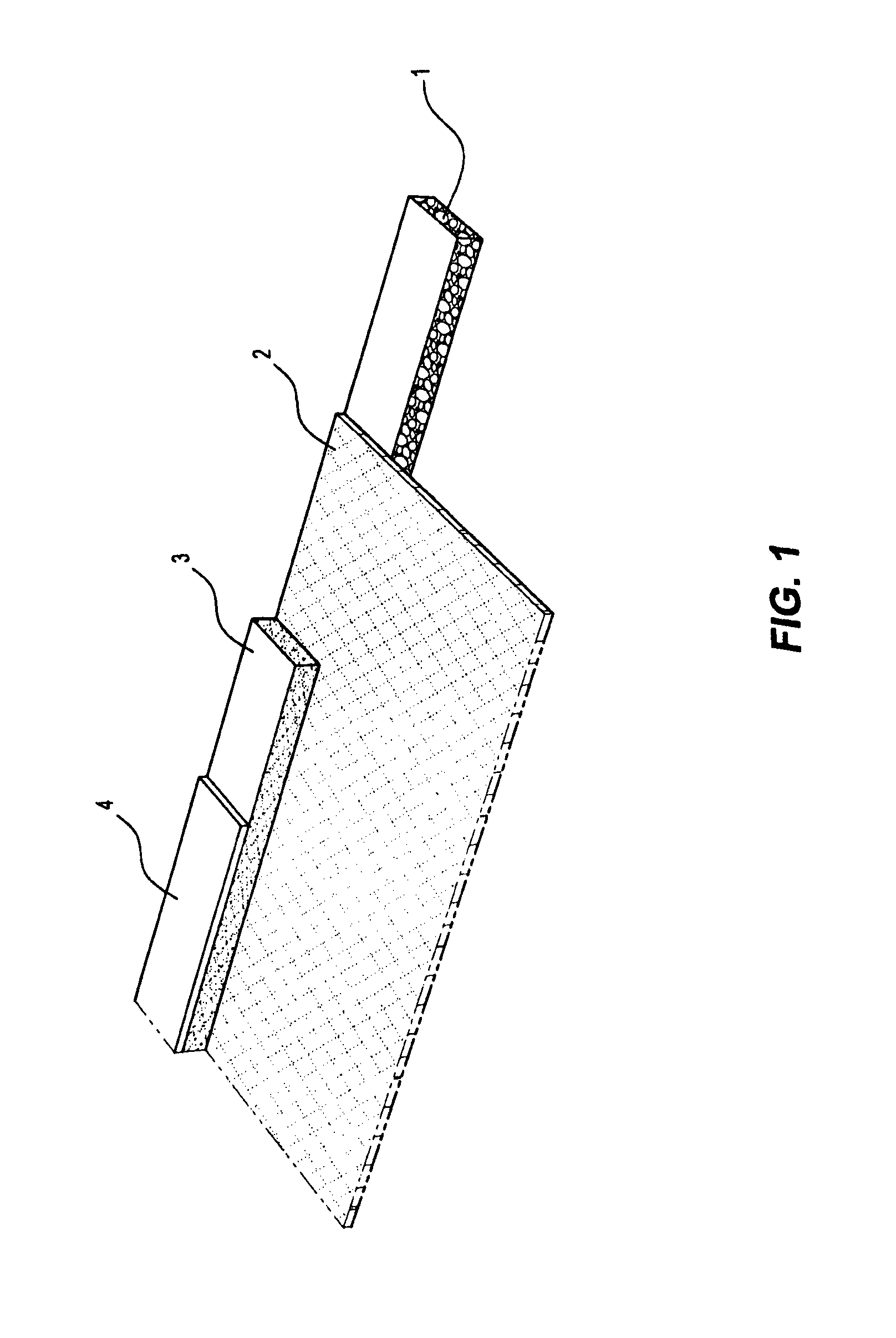

Gutter guard mesh secured using adhesive

ActiveUS8572899B1Minimise traversalProvide protectionRoof coveringThin material handlingAcrylic adhesiveProtection layer

A gutter guard mesh for application to the gutter / roof interface of a roof includes a length of woven mesh or the like having an array of apertures dimensioned to maximize traversal by rain water and minimize traversal of accumulated debris from the roof wherein at least a first edge of the mesh is fitted on a first side with a double sided acrylic foam closed cell tape having acrylic adhesive on both sides and on a second opposing side with a double sided butyl tape wherein the free side of the foam tape is available for adherence to the gutter via the acrylic adhesive and the free side of the butyl tape is available for adherence of a protective laminate.

Owner:LEAF FREE

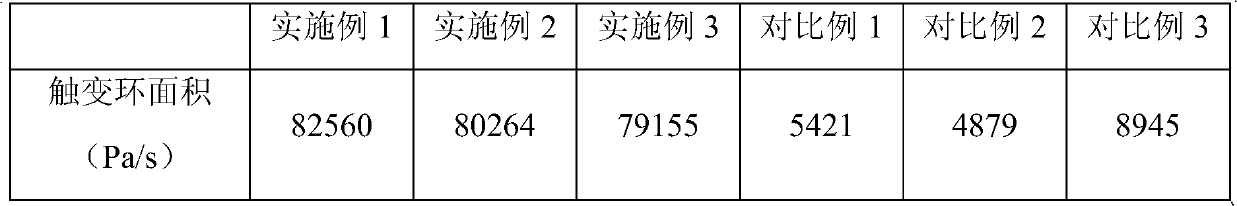

Preparation method of medium/low-viscosity high-thixotropy nano calcium carbonate for aqueous system

InactiveCN102167915AHigh whitenessSmall particle sizeNon-macromolecular adhesive additivesCoatingsCompatibilizationParticle-size distribution

The invention relates to a preparation method of nano calcium carbonate, particularly a preparation method of medium / low-viscosity high-thixotropy nano calcium carbonate for an aqueous system, which comprises the following steps: carbonizing a calcium hydroxide suspension and carbon dioxide in a reactor to generate nano calcium carbonate; and carrying out mixed coating on the obtained nano calcium carbonate by liquid-phase coating treatment and surface treatment to obtain highly-dispersed surface-activated nano calcium carbonate powder. The nano calcium carbonate prepared by the method provided by the invention can obviously enhance high thixotropy and low viscosity properties of the aqueous system. After the modified nano calcium carbonate is added into acrylic adhesive, the thixotropic value of the system is greatly enhanced by 290 times, but the viscosity is only enhanced by 10 times. In addition, the nano calcium carbonate prepared by the method has the advantages high whiteness, small average particle size, narrow particle size distribution, high compatibility with the aqueous system, and high stability, and is applicable to the fields of aqueous adhesive, aqueous paint, other aqueous polymers and the like.

Owner:淄博嘉泽纳米材料有限公司

Pressure-sensitive adhesive type polarizer with retardation layer, process for producing the same, optical film, and image display

ActiveCN101080657AEasy to identifySuppresses changes in optical propertiesPolarising elementsAcid polymer adhesivesPolyvinyl alcoholPotassium

The present invention provides a pressure-sensitive adhesive type retardation-layer-possessing polarizer (4) obtained by forming a polarizer (2) comprising an iodine-containing polarizing element (1) and transparent protective films superposed respectively on both sides thereof, disposing a retardation layer on at least one of the transparent protective films of the polarizer (2) to produce a retardation-layer-possessing polarizer (3), and further superposing a pressure-sensitive acrylic adhesive layer on the retardation layer side. In the iodine-containing polarizing element (1), the ratio of the content of potassium (K) (wt.%) to the content of iodine (I) (wt.%), (K / I), is 0.200-0.235. In the polarizer (2), the iodine-containing polarizing element (1) has been laminated to the transparent protective films through an adhesive layer formed from a water-soluble adhesive comprising a polyvinyl alcohol resin having acetoacetyl groups and a crosslinking agent. The retardation-layer-possessing polarizer (3) has a degree of shrinkage in the absorption axis direction, as measured after 24-hour standing at 80 DEG C and expressed by the following equation, of 0.5% or lower. The pressure-sensitive adhesive type retardation-layer-possessing polarizer (4) by itself has a transmittance of 41.0-43.2%. This pressure-sensitive adhesive type retardation-layer-possessing polarizer can be inhibited from changing in optical properties even under high-temperature high-humidity conditions and can keep visibility high.

Owner:NITTO DENKO CORP

Interior wallboard and method of making same

A gypsum wallboard suitable for Level 4 finishing having a coated non-woven glass fiber mat facing material where the glass fiber mat has a majority of fibers of a fiber diameter between 8 and 11 microns and a fiber length between ¼ and ¾ inch and preferably between ¼ and ½ inch and preferably has a basis weight between about 0.8 lb. / 100 ft.2 and about 2.2 lb. / 100, and wherein the fibers in the non-woven glass fiber are bound together with an acrylic adhesive binder and wherein the non-woven glass mat has a coating of a dried aqueous mixture of (i) a mineral pigment, (ii) a polymer latex adhesive binder and optionally (iii) an inorganic adhesive binder such that the coated non-woven glass mat facing material has a porosity which allows water to evaporate through said coated mat from the gypsum core during preparation of the wallboard.

Owner:GEORGIA PACIFIC GYPSUM LLC

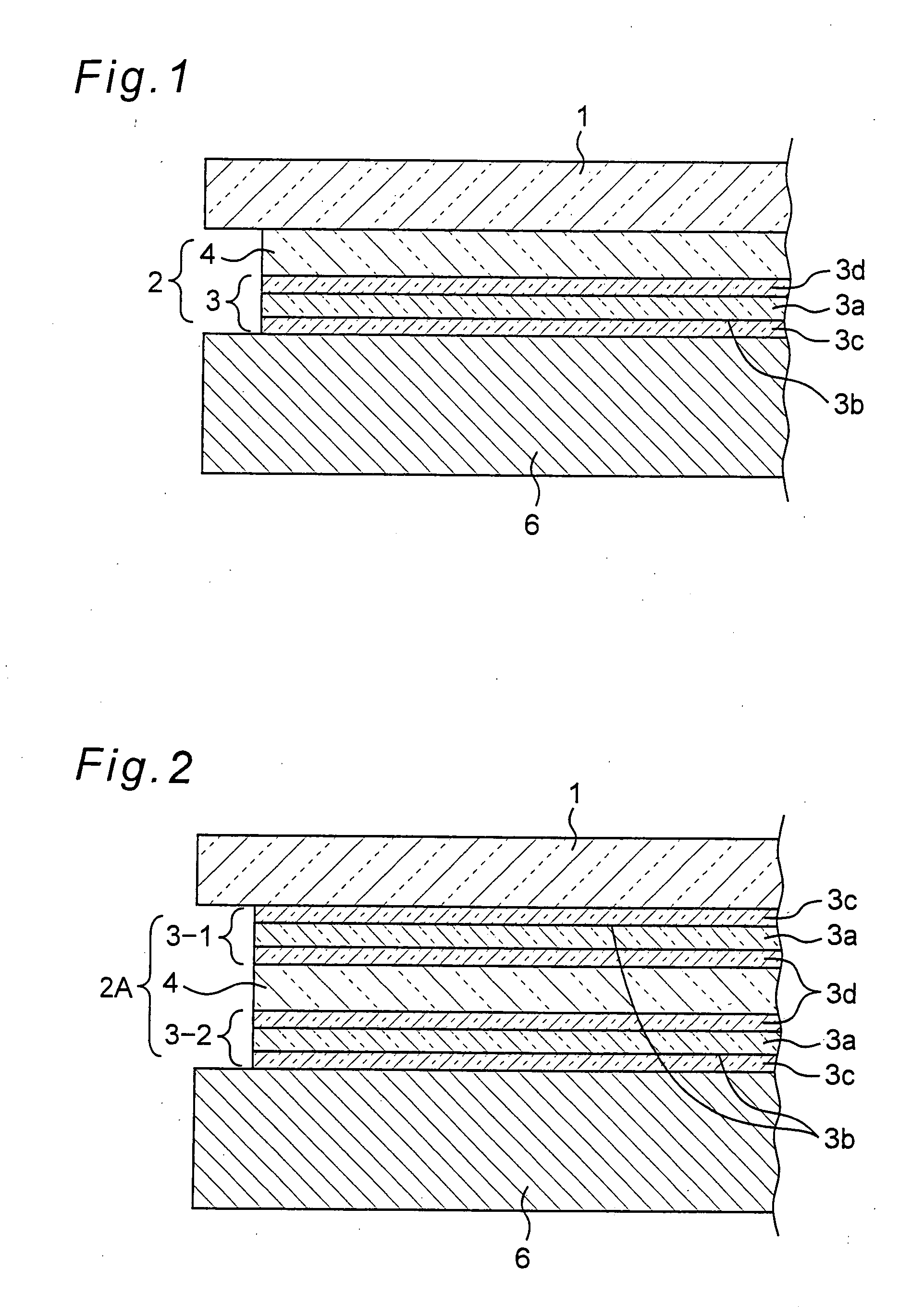

Antifogging agent composition and antifogging colored window film formed by same

ActiveCN102618102AEasy to prepareReduce manufacturing costOther chemical processesSynthetic resin layered productsPolyesterDiamine

The invention relates to an antifogging agent composition and an antifogging colored window film formed by the same. The antifogging agent composition comprises 9-14wt% of hydrophilic resin, 55-76wt% of propylene glycol methyl ether, 3-10wt% of dimethyl methylamine, 1-5wt% of triethylene-diamine, 1-5wt% of leveling agent, 5-26wt% of isopropanol and 5-24wt% of ethanol. The antifogging colored window film comprises an antifogging agent coating layer (1), a first transparent polyester film or transparent polyethylene film substrate (2-1), a dyed acrylic acid adhesive layer (3-1), a second transparent polyester film or transparent polyethylene film substrate (2-2), an acrylic acid adhesive layer (3-2) and a releasing film (4) which are integrally composited, wherein the antifogging agent coating layer (1) is formed by the antifogging agent composition. The antifogging colored window film is antifogging, attractive, transparent and safe.

Owner:CHANGZHOU SANYOU DISSAN PROTECTIVE MATERIAL MFG

Surface coating system and method of using surface coating system

InactiveUS20120276381A1Tensile strengthFew organic volatileLiquid surface applicatorsSynthetic resin layered productsEpoxyEmulsion

A coating system for a surface (such as a floor) including an adhesive layer composition including a dispersible adhesive that forms an adhesive layer upon application to a surface, and a maintenance layer composition comprising a dispersible polymer that forms a maintenance layer upon application to the adhesive layer. The dispersible adhesive may include at least one of a styrene-butadiene latex, an acrylic latex material, a polyurethane latex, a polyvinyl acetate emulsion, and a combination thereof. The maintenance layer may include at least one of a UV-cured polymer, a nylon, an epoxy, a polyacrylate, a polystyrene acrylate, a polyurethane, a polyurea, and a combination thereof. The adhesive layer and the maintenance layer may form a finished coating having a peel strength greater than about 50 gf / 25 mm.

Owner:JOHNSONDIVERSEY INC

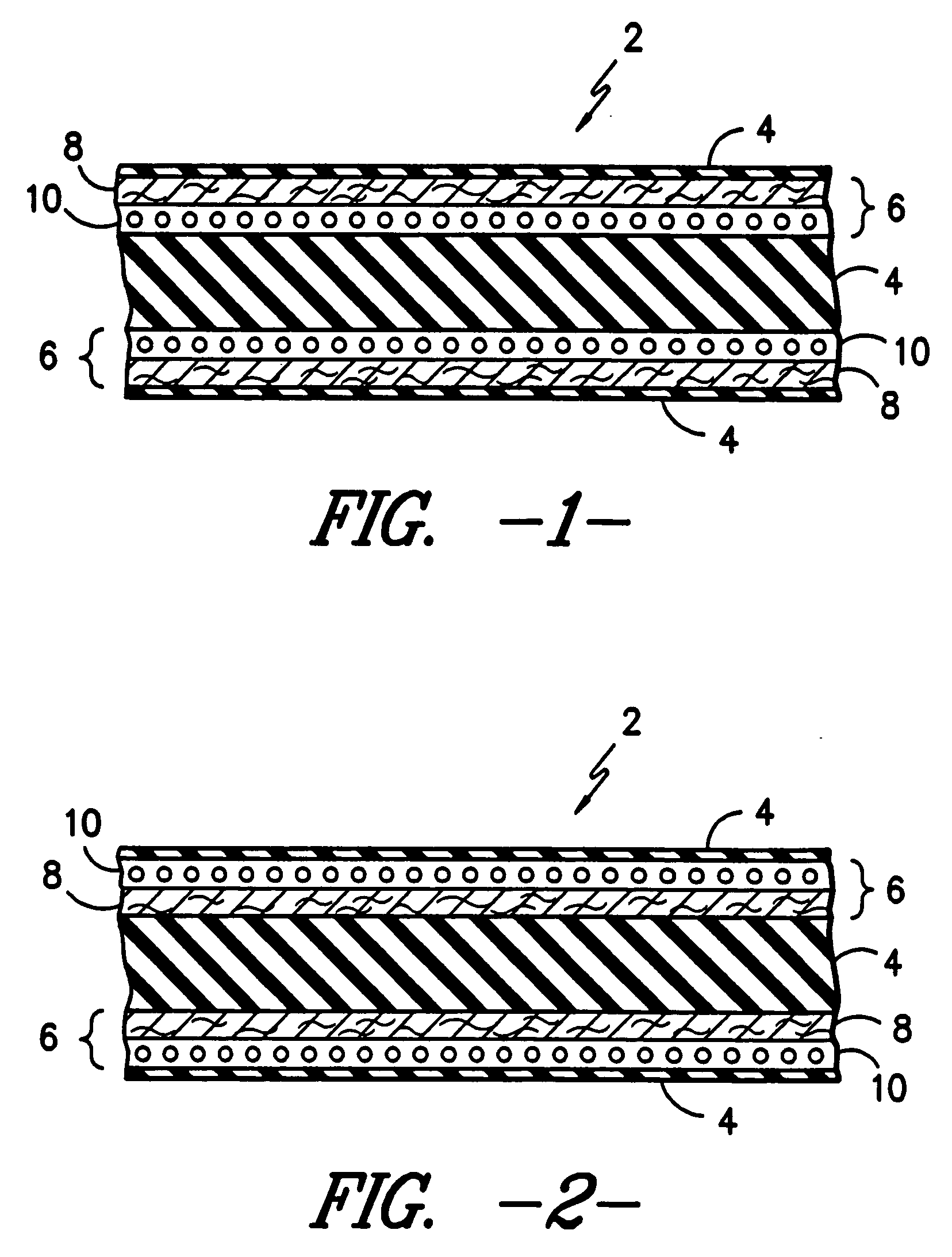

Composite facer for wallboards

InactiveUS20040033749A1Improves strength and fire resistance and water resistanceMedical devicesPressure infusionPolyesterGlass fiber

A composite facer material for use with cementitious wallboards, where the composite facer is embedded in a top and bottom face thereof. The composite facer material, in a most preferred embodiment, comprises two layers. The first layer is preferably a carded polyester nonwoven mat, which is bonded to a second layer comprising preferably a tri-directional laid scrim fabric reinforcement layer made of continuous glass fibers. The two layers are preferably bonded together using an acrylic adhesive, which offers superior adhesion between the layers as well as superior adhesion between the composite facing material and the cementitious core.

Owner:SMITH ROBERT M +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com