Patents

Literature

52results about How to "Tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

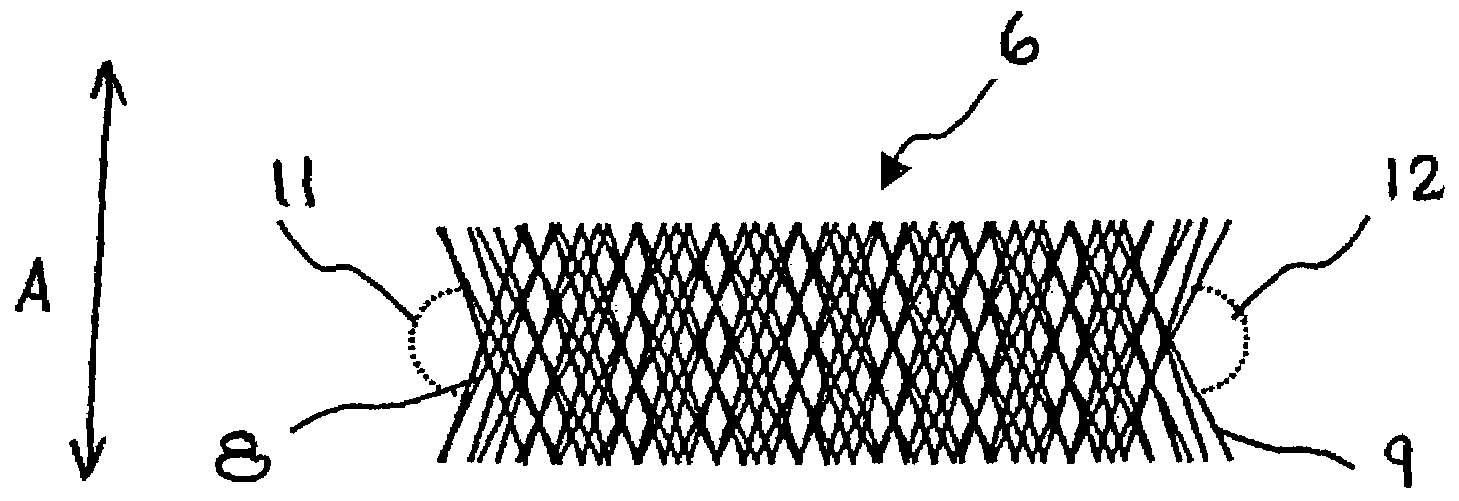

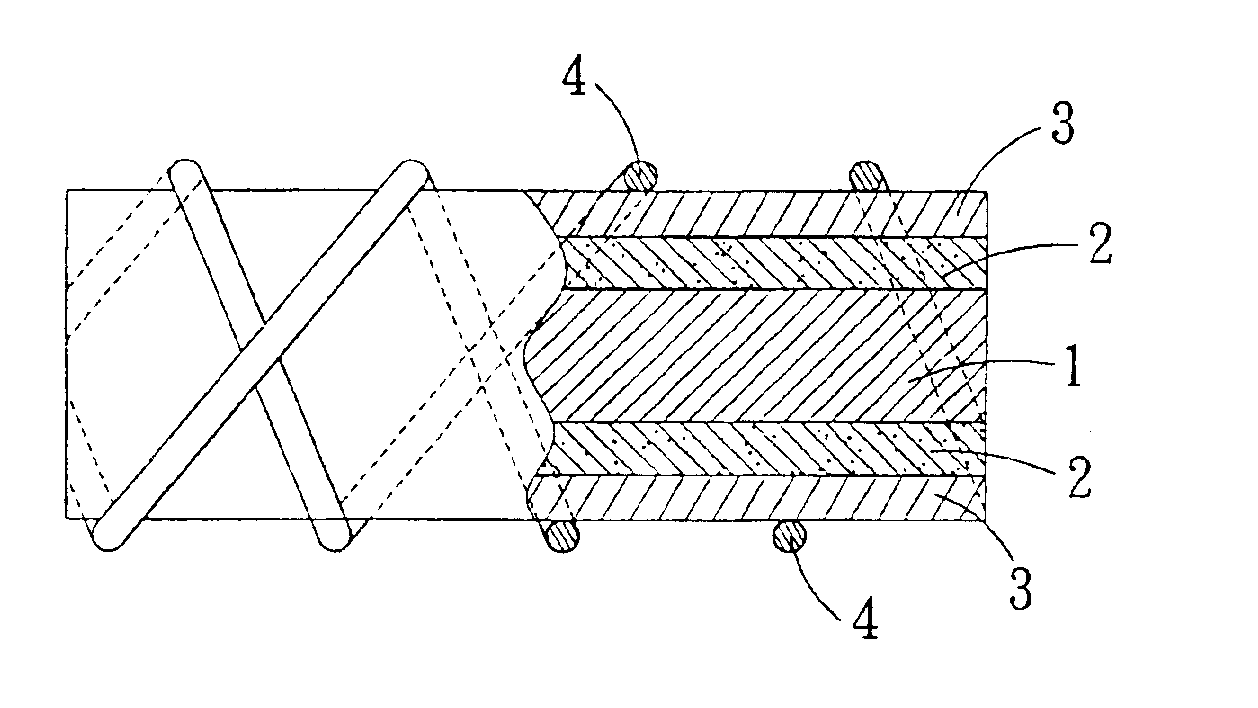

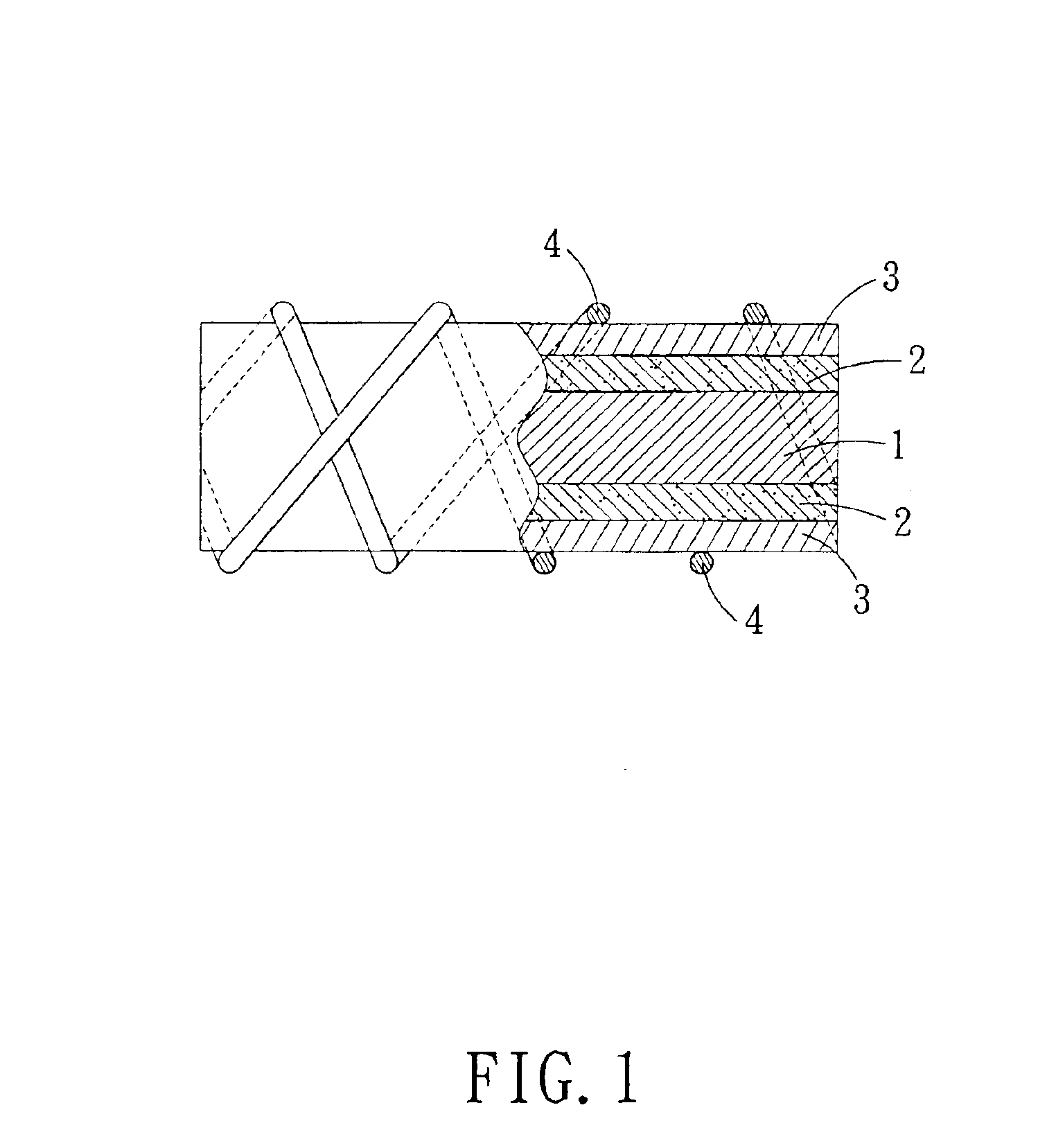

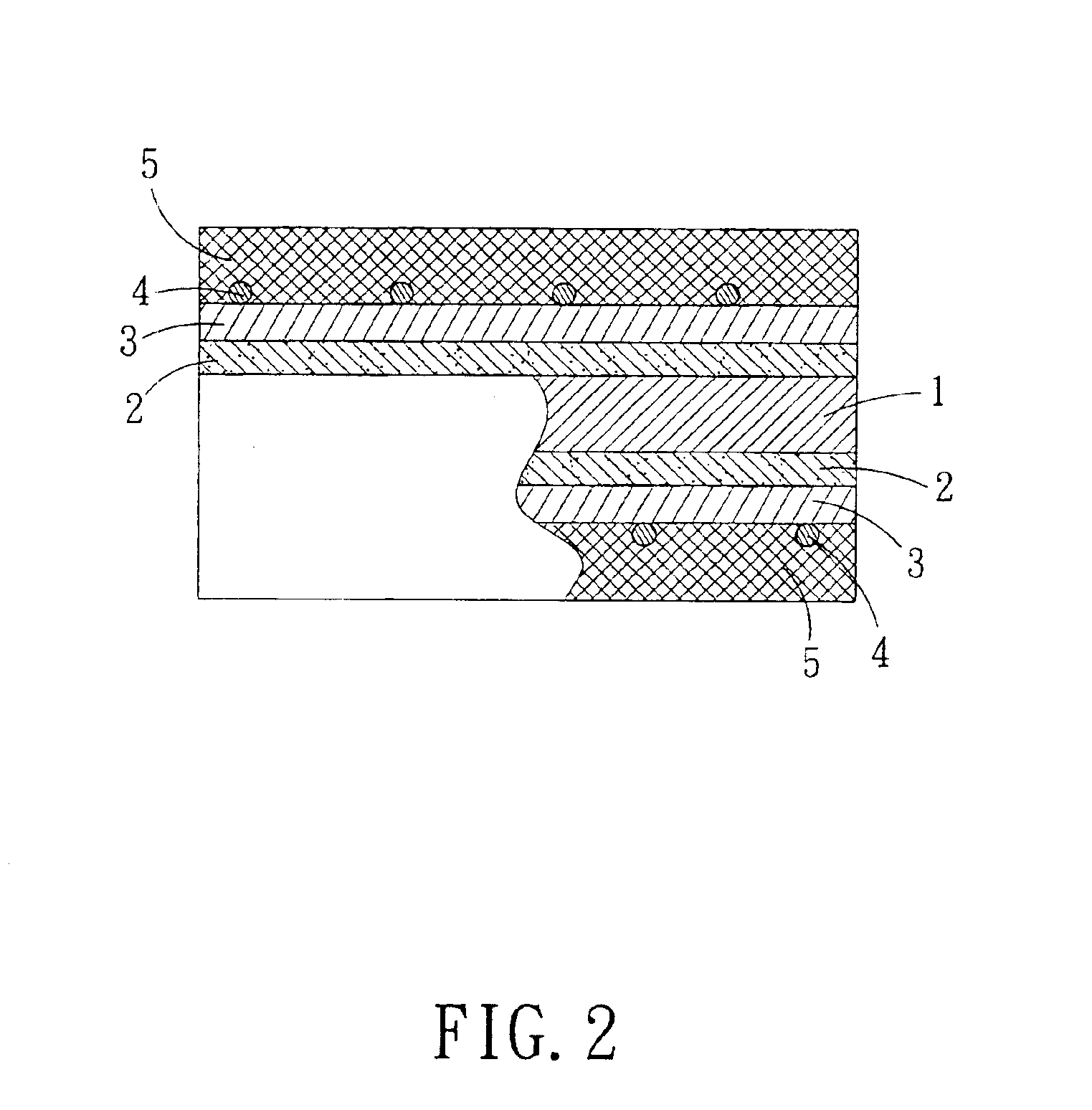

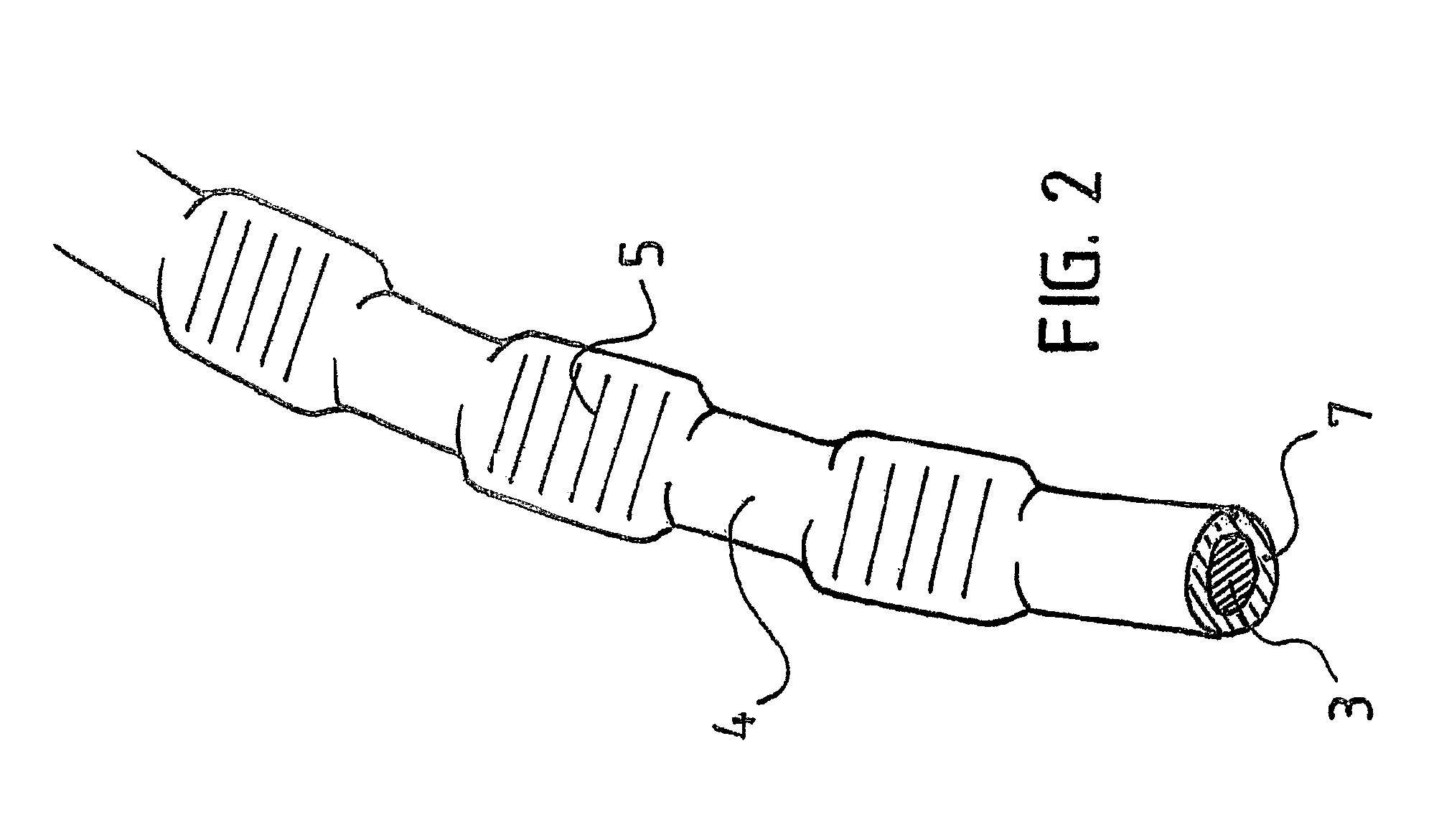

Multi-braid exterior tube

InactiveUS7438712B2Reduce frictional contactAvoid abrasionsGuide needlesStentsCompound structureUltimate tensile strength

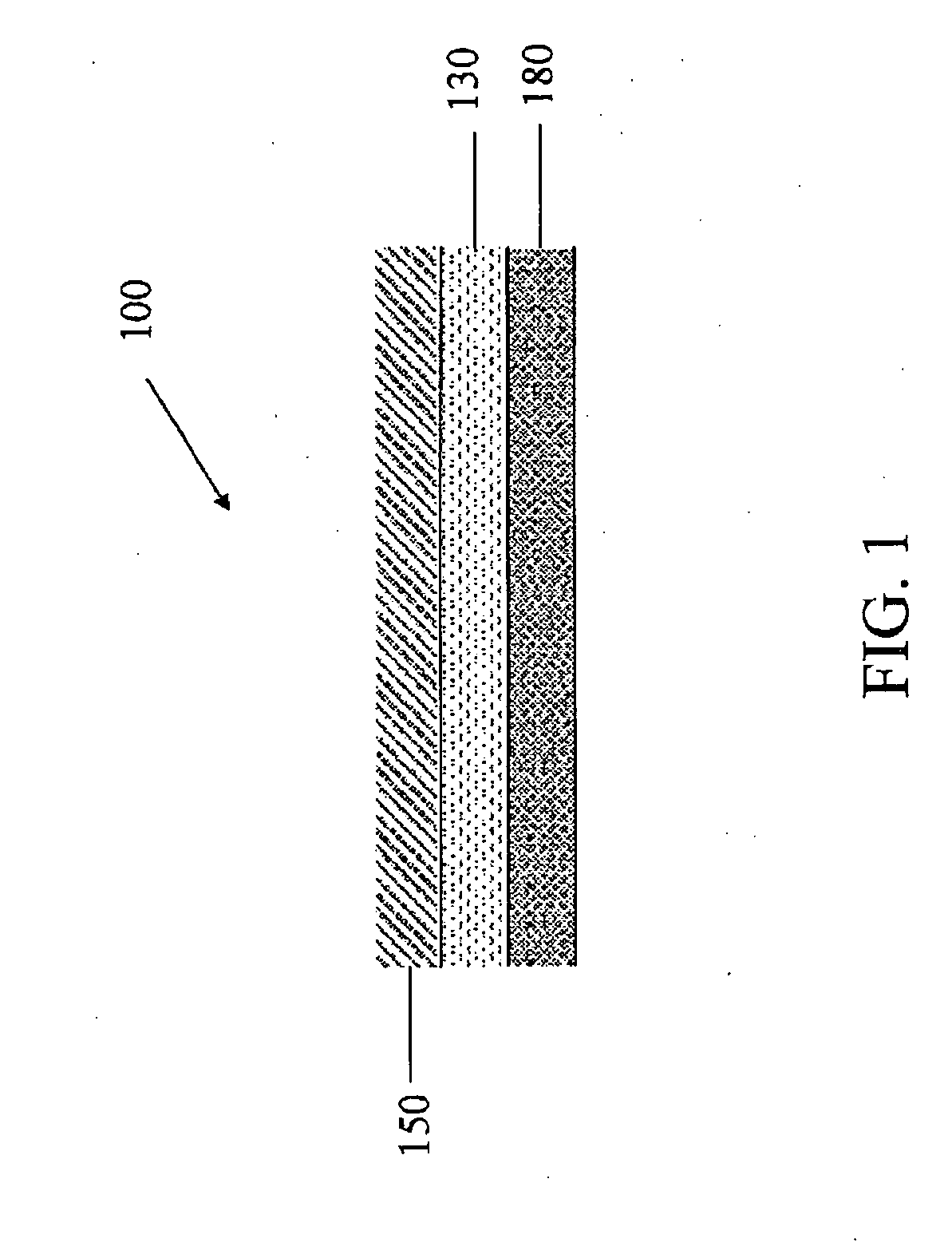

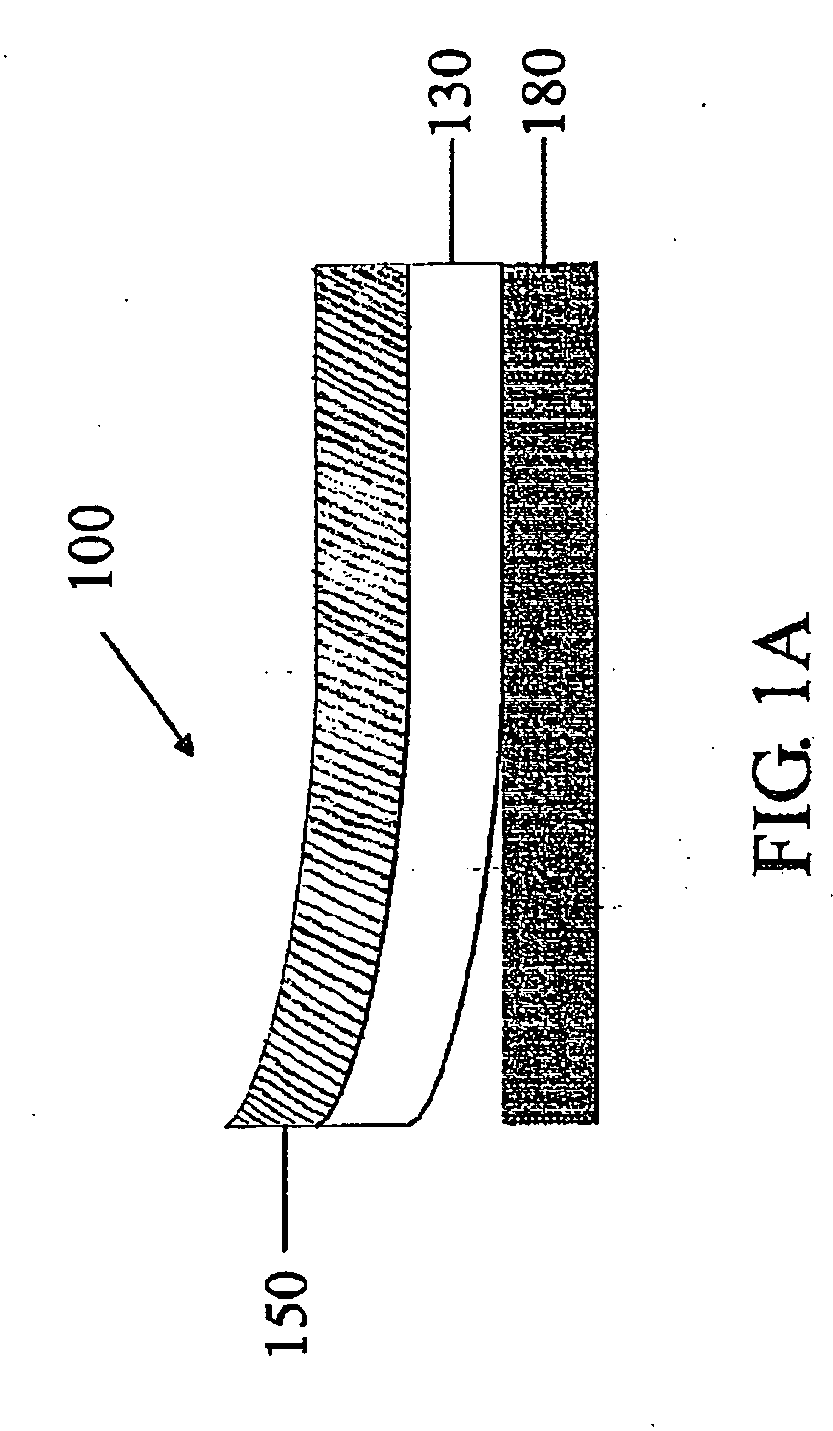

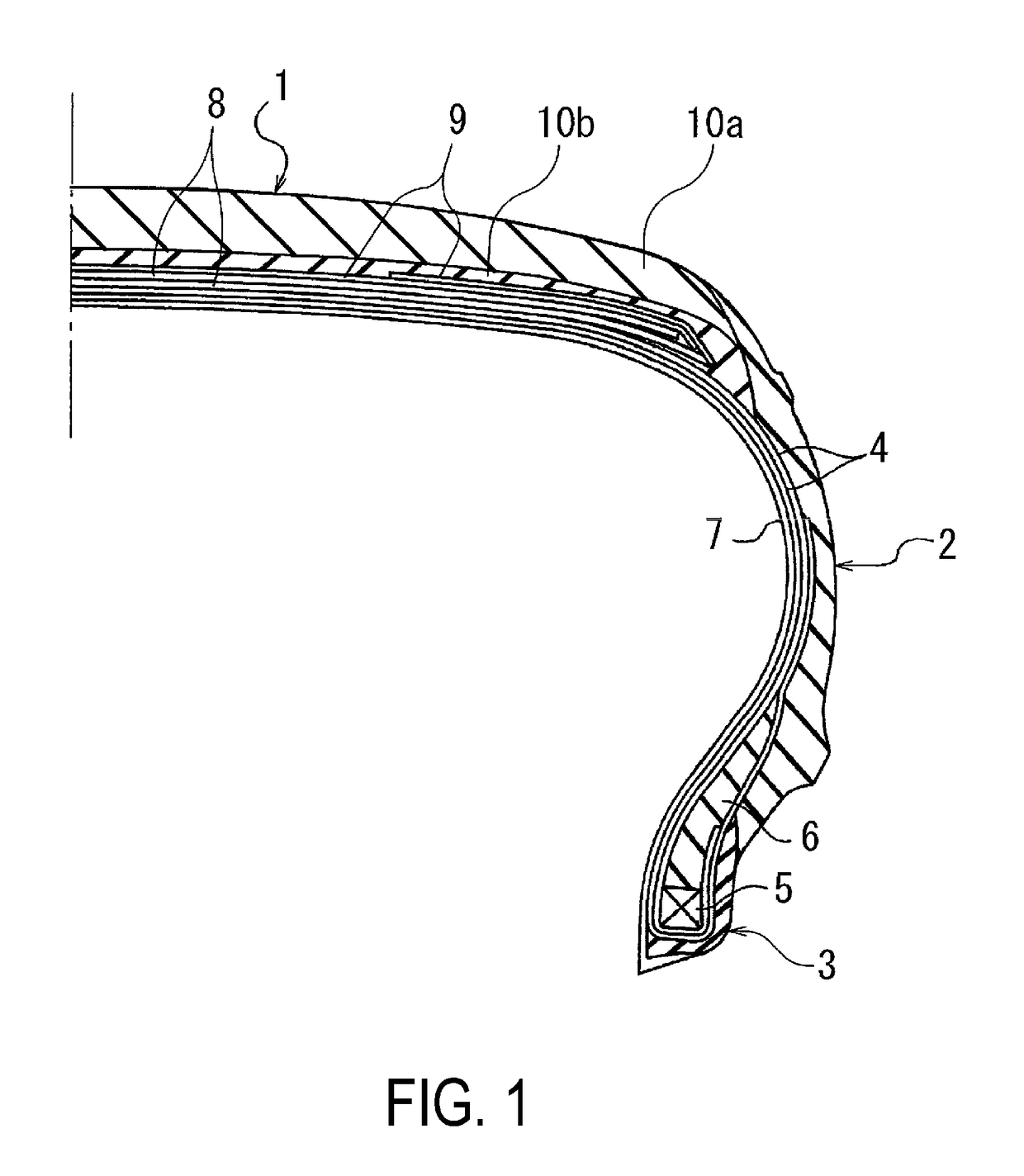

A multiple braid exterior tube having a composite structure which includes an inner tubular layer, reinforcing layers and a polymer matrix layer. The exterior tube is formed with polymeric materials and metallic reinforcing braiding configured to provide greater tensile strength and stiffness. The exterior tube is used for a variety of medical devices such as a sheath component for intravascular devices and catheters.

Owner:LIFESHIELD SCI

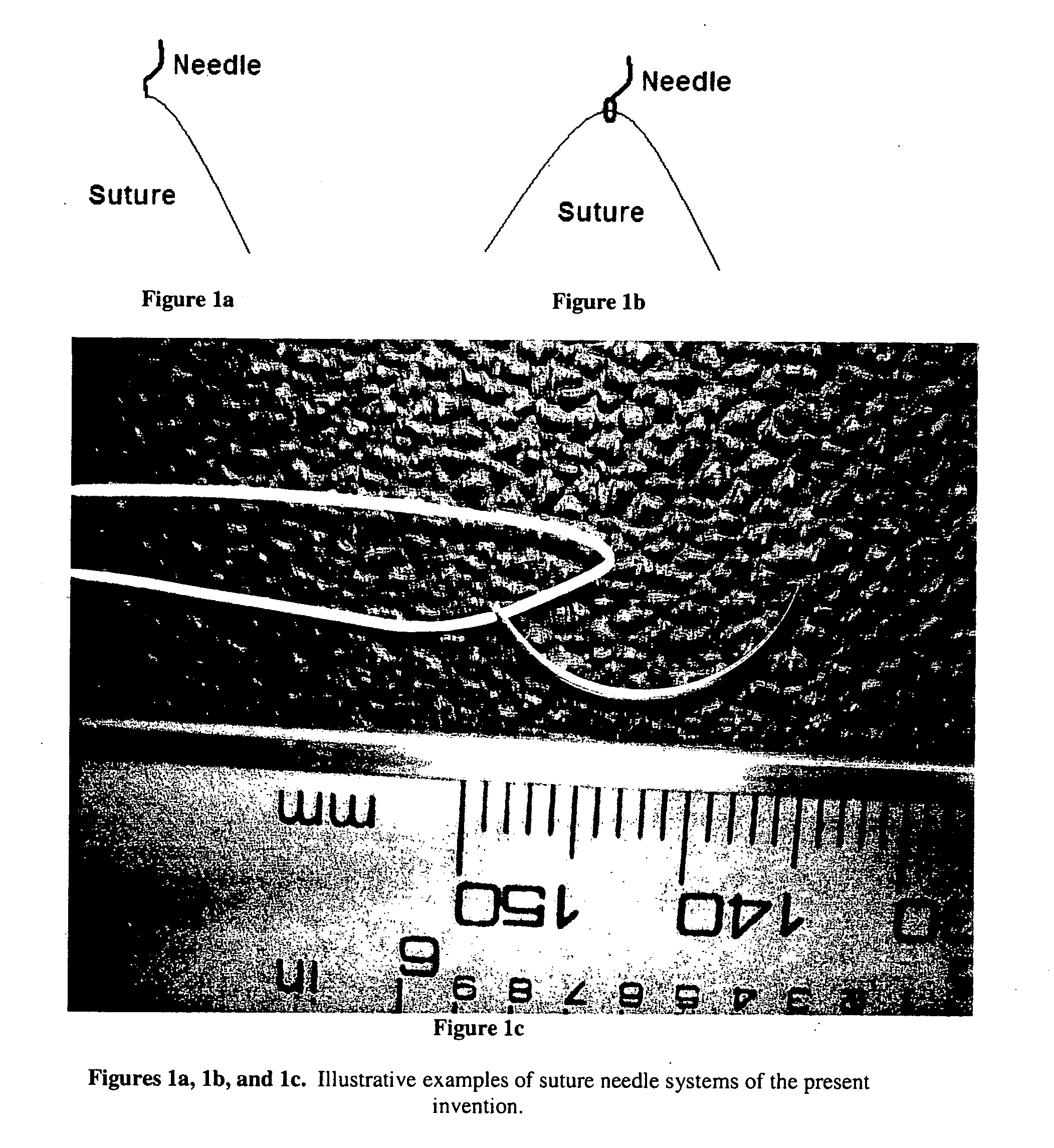

Biodegradable drug-polymer delivery system

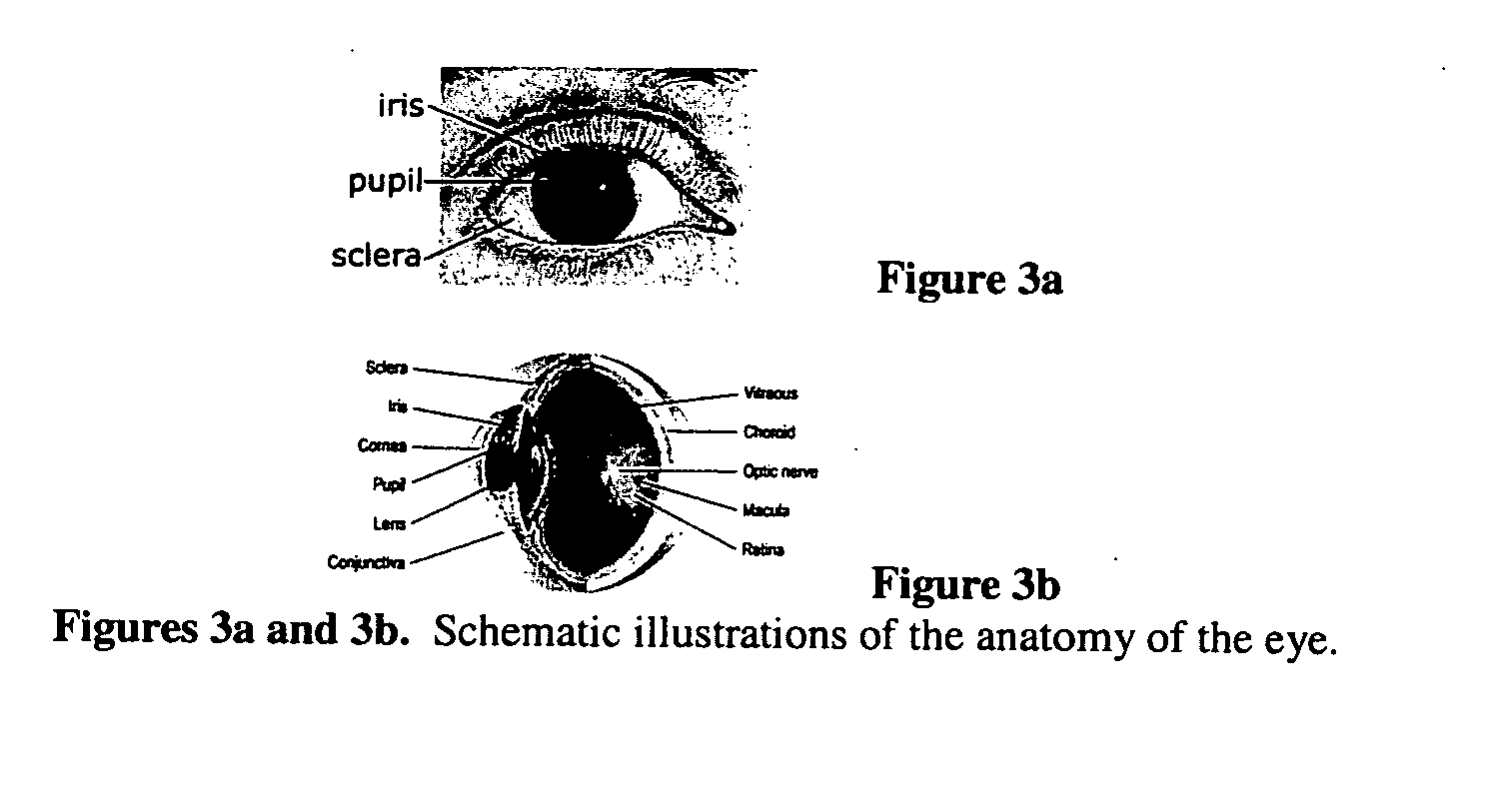

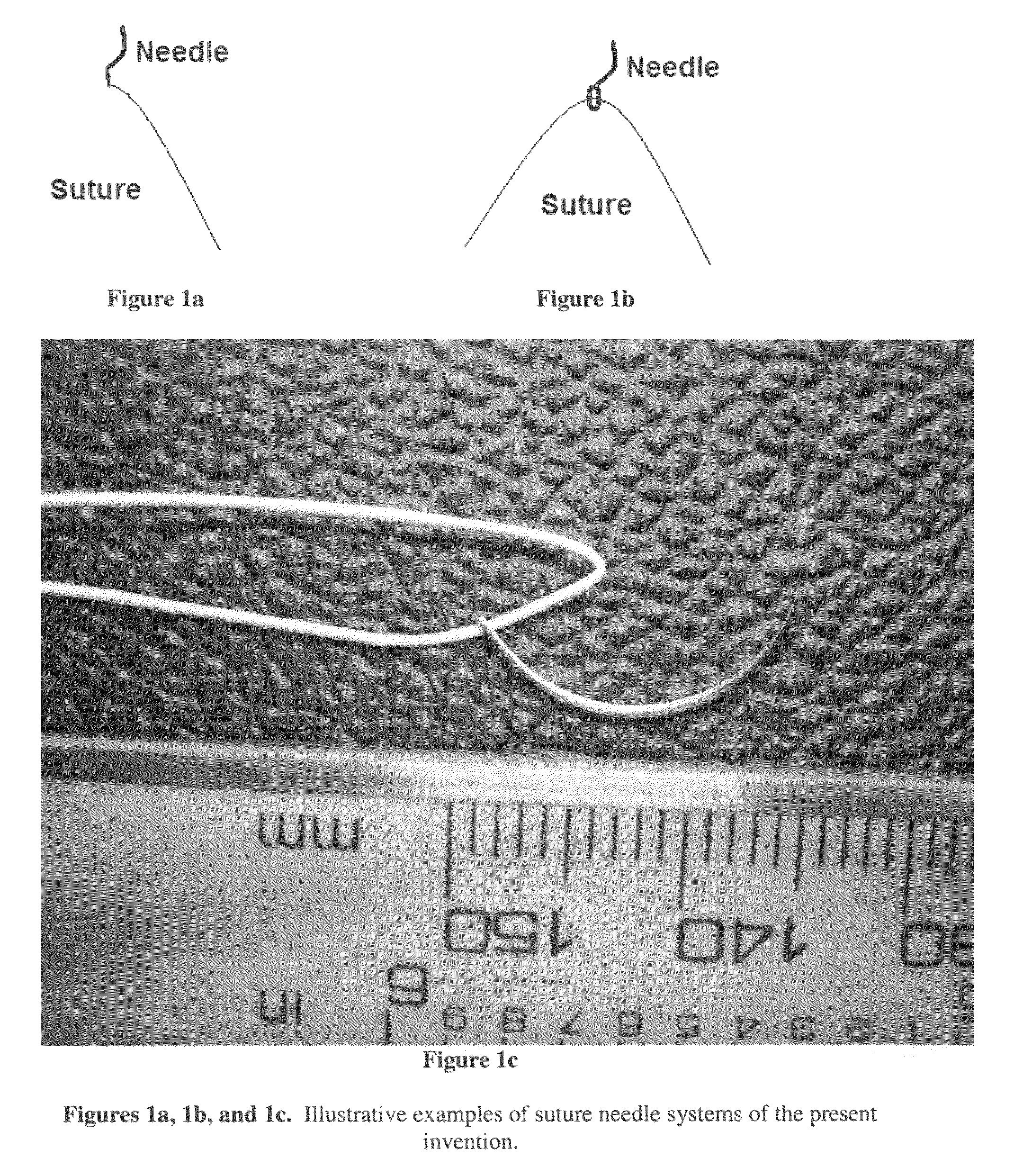

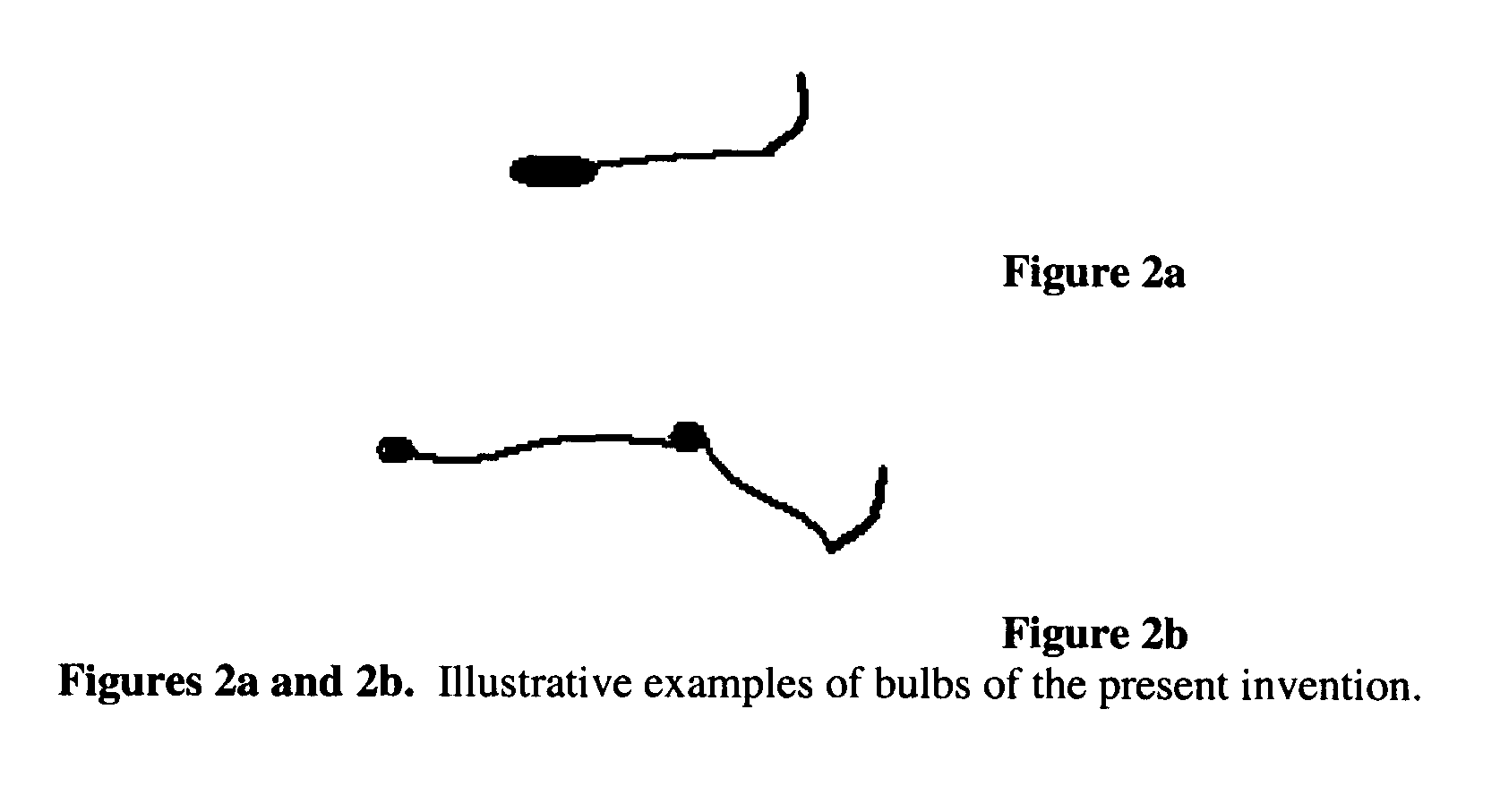

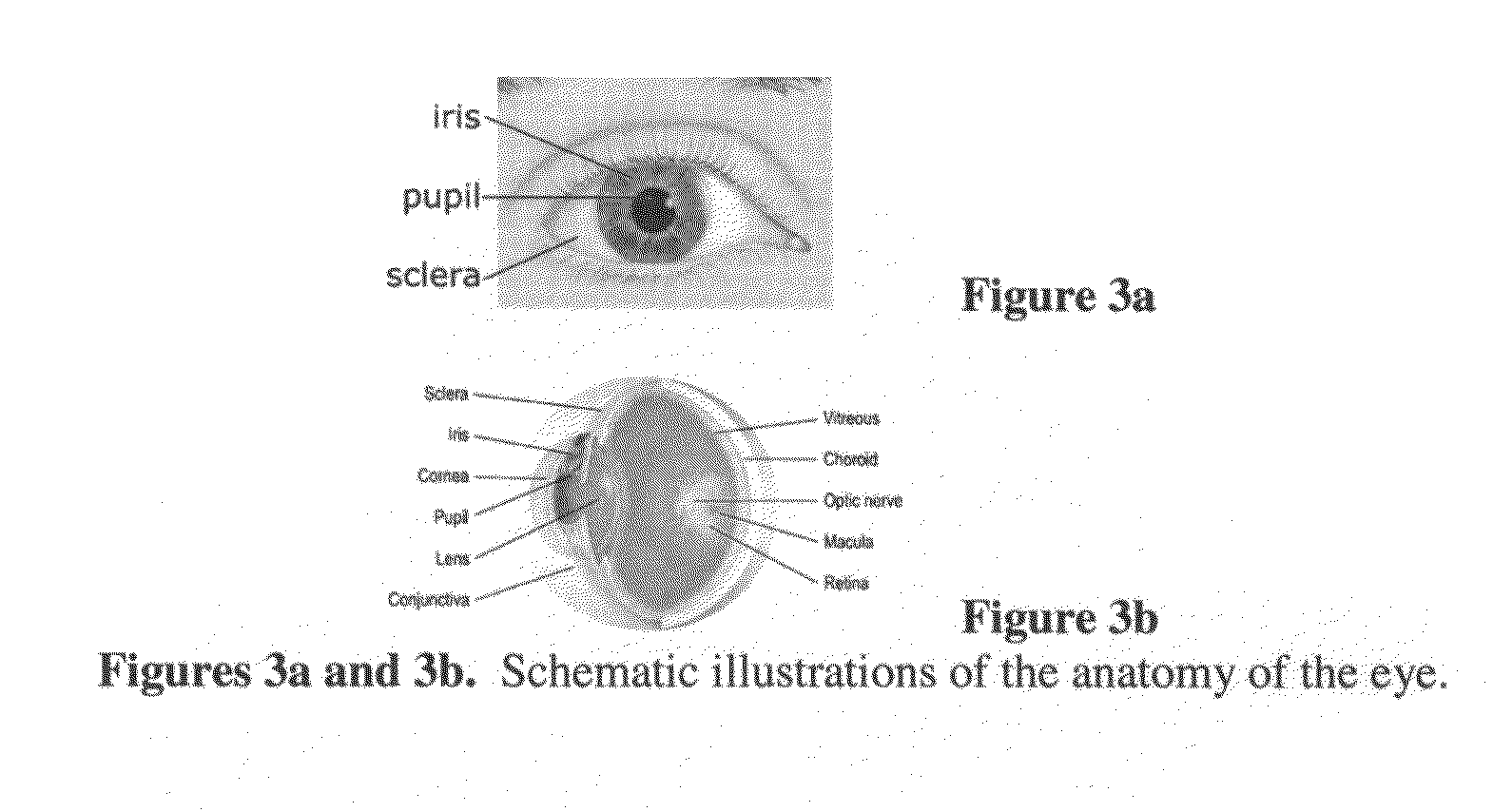

ActiveUS20050276841A1Low tensile strengthTensile strengthOrganic active ingredientsBiocideTherapy medicationDisease

A sustained-release biodegradable polymeric drug-eluting fiber is disclosed. In some embodiments, the therapeutic drug is complexed with cyclodextrin. In certain embodiments, the polymeric component of the fiber comprises cyclodextrin. The fiber may be fabricated to provide a thread and / or suture. The fiber may be used for treatment of ocular diseases or disorders.

Owner:CALIFORNIA INST OF TECH

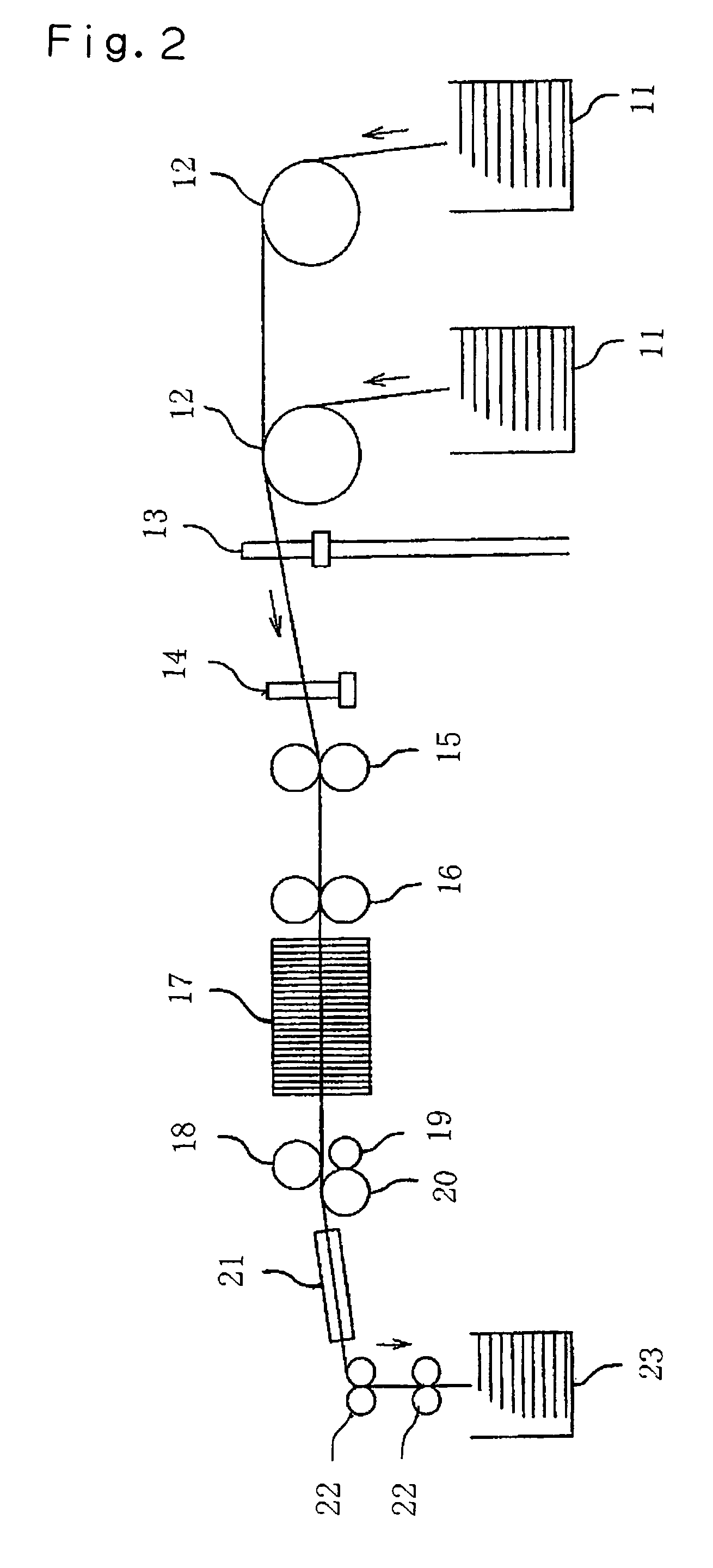

Polyacrylonitrile polymer, method of producing the same, method of producing precursor fiber used for producing carbon fiber, carbon fiber and method of producing the same

ActiveUS20100003515A1Stable productionModulus improvementLayered productsMonocomponent synthetic polymer artificial filamentCarbon fibersPolymer science

A polyacrylonitrile-based polymer, containing a polymer of which main component is acrylonitrile, which satisfies at least one kind requirement selected from the following [a] to [d].[a] Z-average molecular weight (Mz) determined by gel-permeation chromatograph is 800,000 to 6,000,000 and degree of polydispersity (Mz / Mw) (Mw denotes weight average molecular weight) is 3.0 to 10.0.[b] Z+1-average molecular weight (Mz+1) determined by GPC method is 3,000,000 to 10,000,000 and degree of polydispersity (Mz+1 / Mw) is 6.0 to 25.0.[c] Mzm determined by gel-permeation chromatograph multi-angle laserlight scattering photometry is 400,000 to 1,000,000 and degree of polydispersity (Mzm / Mwm) is 3.0 to 10.0.[d] Z-average radius of gyration (Rz) determined by gel-permeation chromatograph multi-angle laserlight scattering photometry is 25 to 45 nm and its ratio to weight average radius of gyration (Rz / Rw) is 1.3 to 2.5.

Owner:TORAY IND INC

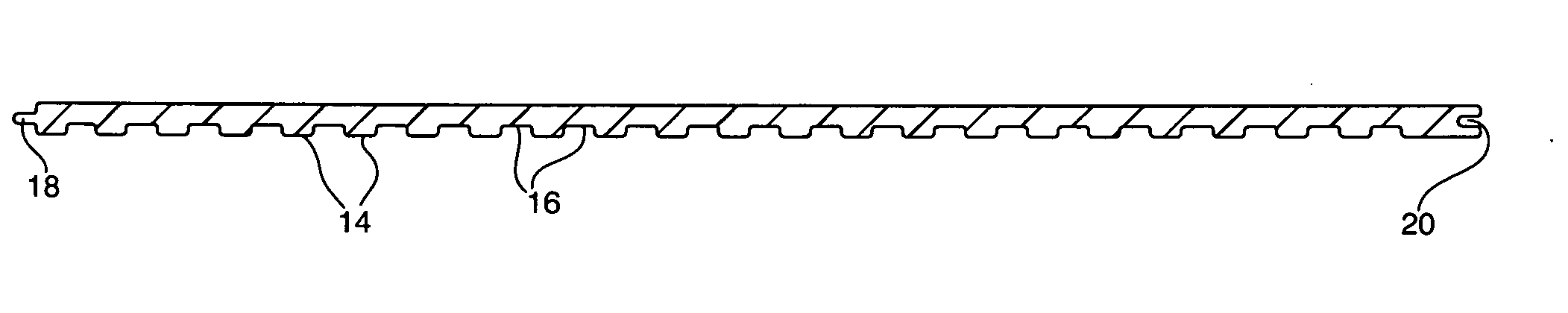

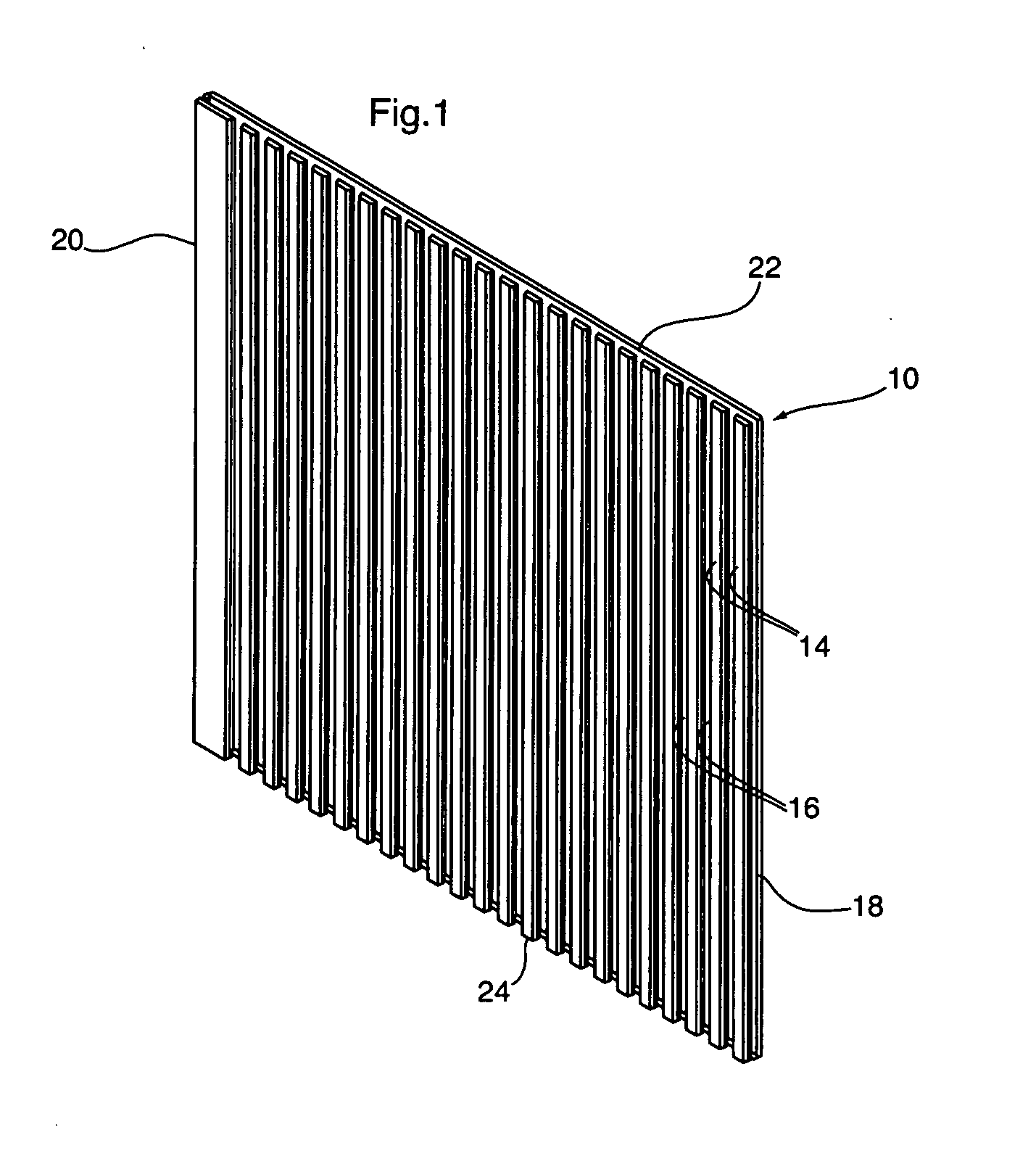

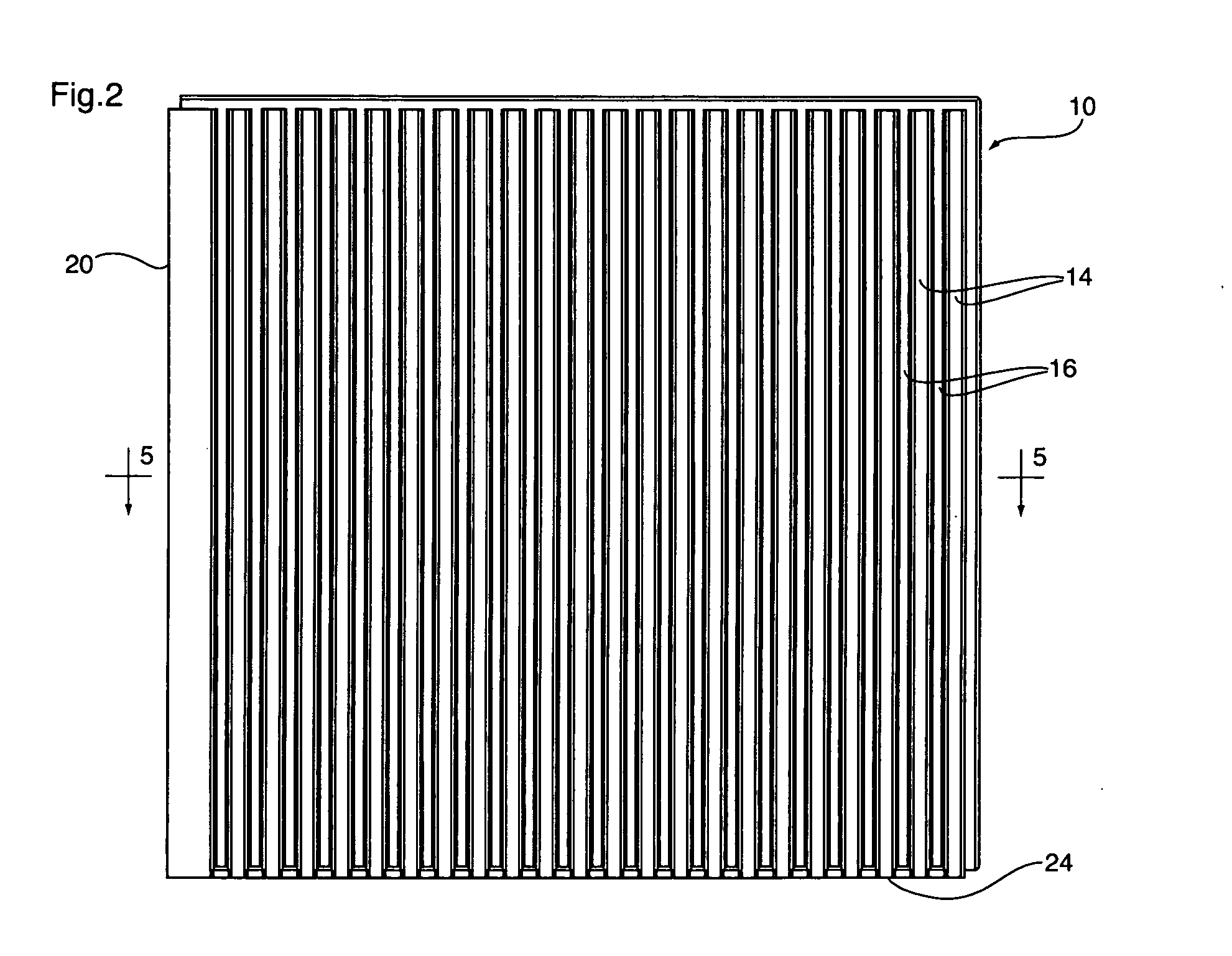

Extrusion process and product

InactiveUS20110045250A1Enhance thermal insulation and vapour barrierExcellent supportLayered productsWood treatment detailsThermoplasticPolypropylene

A thermal insulating and substantially moisture impermeable rigid extrusion comprising 40 to 75 wt % rice husks, a coupling agent, a lubricant, a plasticizer, and the balance a thermoplastic plastic, preferably a thermoplastic polyolefin plastic selected from the group consisting of high density polyethylene, low density polyethylene; linear low density polyethylene, homopolymer polypropylene, copolymer polypropylene, and combinations thereof. The rigid extrusion may be an elongated strip in the shape of a panel, a sheet, a board, a stud, a door frame jamb, a door frame header, an I-beam, a hollow post or beam with partially or fully encapsulated glass fibre reinforcing, a baseboard, a quarter-round, a cove molding, a fascia or a soffit. A preferred rigid extrusion has longitudinal tongue and groove side edges and longitudinal ribs and recesses formed across a face thereof substantially from one side edge to the other. The extrusion may be cut transversely to form a rectangular floor panel having a transverse tongue formed in one end and a mating groove formed in the other end for assembly of abutting panels together side-by-side and end-to-end to produce a continuous floor surface adapted for assembly with the ribbed surface facing downwardly.

Owner:DE ZEN VIC

Core sample testing protocol

The invention relates to the dividing up and testing of bulk samples from cores of rock. The method involves the extraction of several plugs for triaxial testing which are derived from exactly the same level in the core, and also Brazilian test samples and samples for compositional and textural analysis from the same level. Triaxial tests with different confining pressures may be performed to destruction on separate triaxial plugs, allowing a reliable full Mohr-Coulomb analysis to be performed. Mechanical properties may be related more reliably to composition and texture of rock. The technique is especially useful for non-conventional rock such as shale.

Owner:CONOCOPHILLIPS CO

Biodegradable drug-polymer delivery system

Owner:CALIFORNIA INST OF TECH

Surface coating system and method of using surface coating system

InactiveUS20120276381A1Tensile strengthFew organic volatileLiquid surface applicatorsSynthetic resin layered productsEpoxyEmulsion

A coating system for a surface (such as a floor) including an adhesive layer composition including a dispersible adhesive that forms an adhesive layer upon application to a surface, and a maintenance layer composition comprising a dispersible polymer that forms a maintenance layer upon application to the adhesive layer. The dispersible adhesive may include at least one of a styrene-butadiene latex, an acrylic latex material, a polyurethane latex, a polyvinyl acetate emulsion, and a combination thereof. The maintenance layer may include at least one of a UV-cured polymer, a nylon, an epoxy, a polyacrylate, a polystyrene acrylate, a polyurethane, a polyurea, and a combination thereof. The adhesive layer and the maintenance layer may form a finished coating having a peel strength greater than about 50 gf / 25 mm.

Owner:JOHNSONDIVERSEY INC

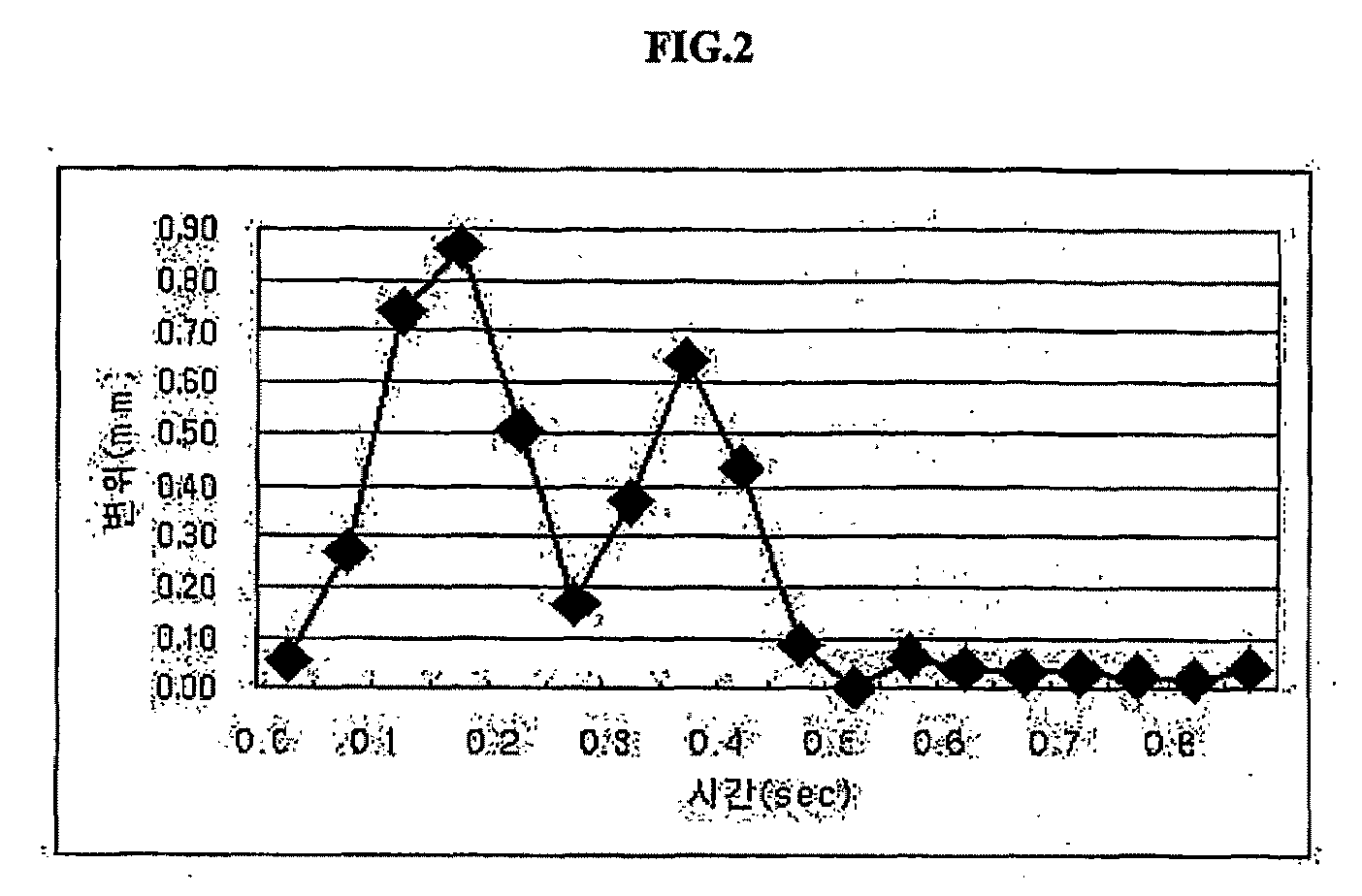

Collagenous matrix with improved porosity and tensile strength and preparation method therefore by using mechanical stimulation system

InactiveUS20090209020A1High porosityHigh tensile strengthEpidermal cells/skin cellsArtificial cell constructsPorosityMedicine

The present invention relates to a method of preparing a collagen matrix with increased porosity and tensile strength by using mechanical stimulation system. More specifically, in the present invention, the cell-populated gel is being cultured under the condition that the physical forces is loaded for causing the matrix to move periodically and discontinuously. Resulting collagen matrix can be used for preparing an artificial skin or organs. Furthermore, this collagen matrix can be used as fillers for esthetic or therapeutic purposes.

Owner:WELSKIN

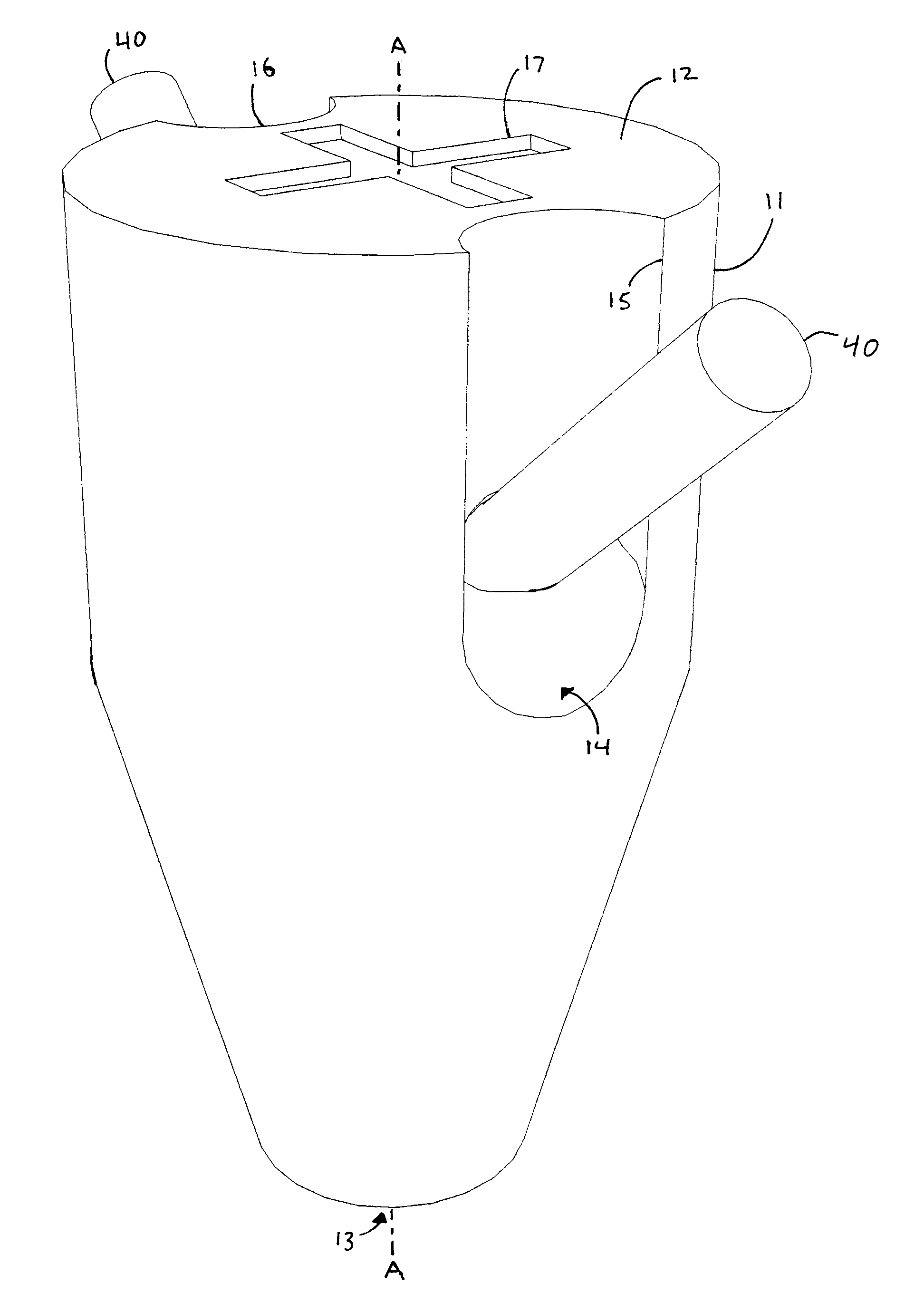

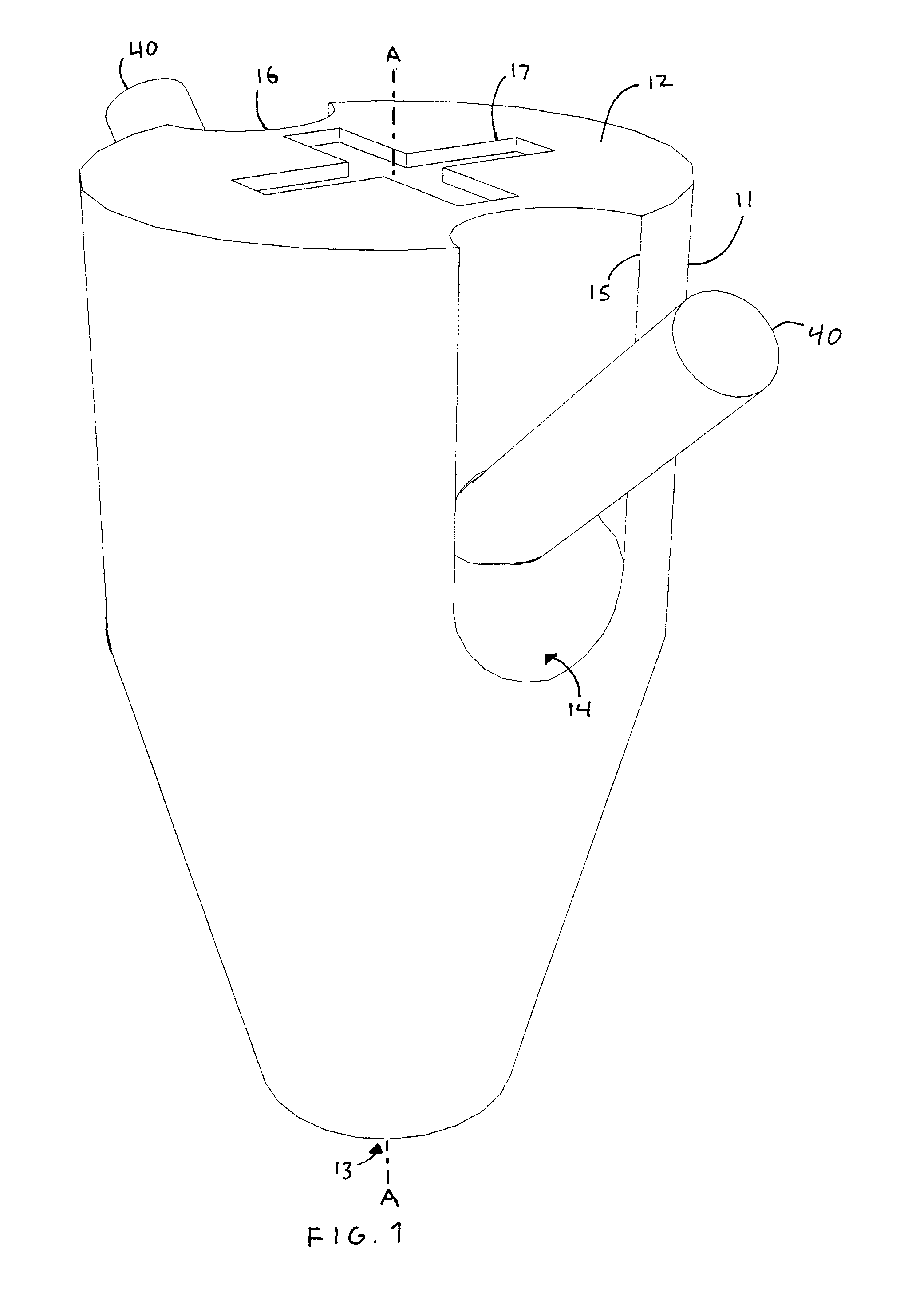

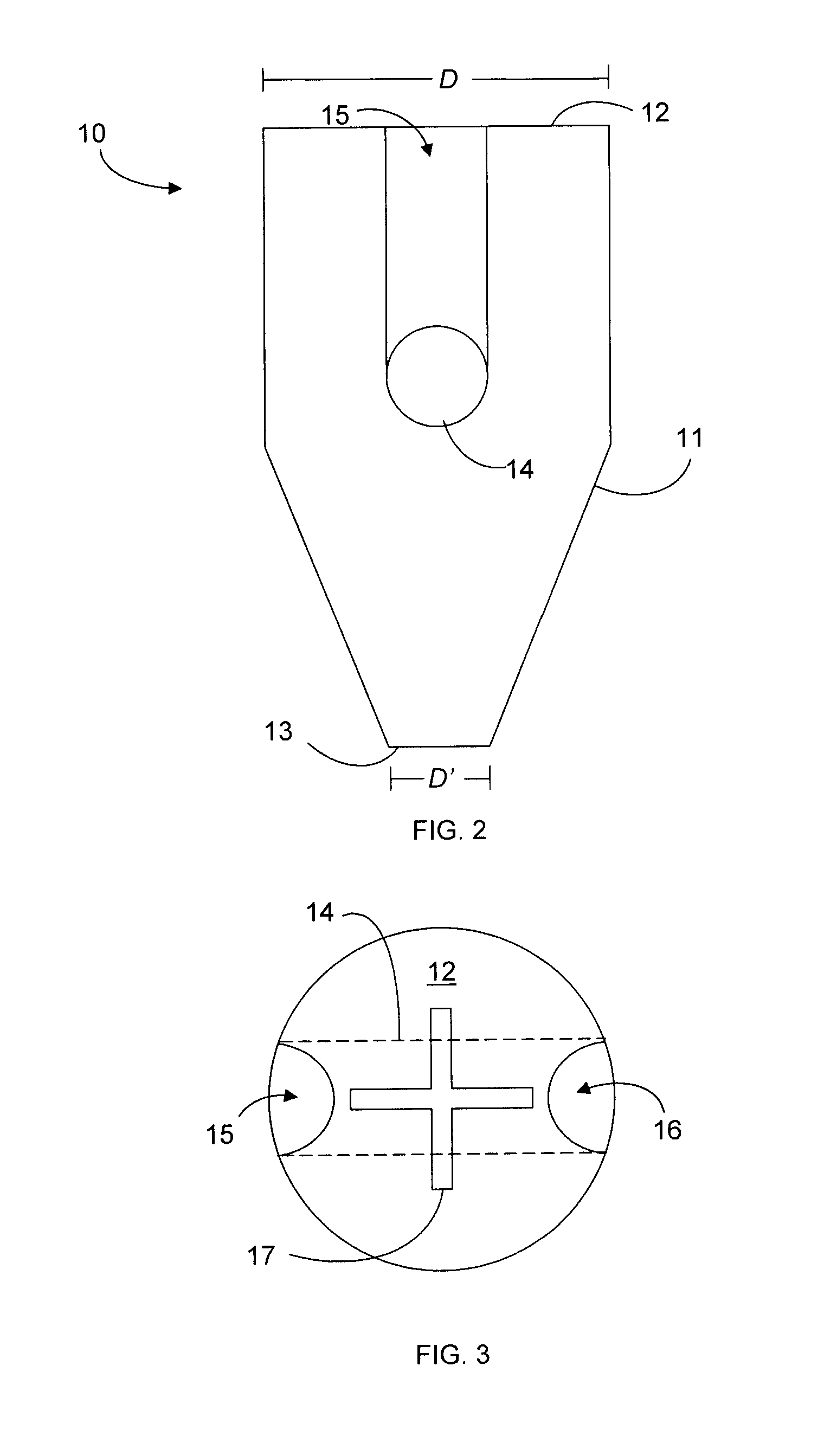

Surgical System Including Suture Anchor and Insertion Device and Method for Using

InactiveUS20120053622A1Tensile strengthSuture equipmentsOsteosynthesis devicesFilling materialsAdhesive

An improved suture anchor has one or more channels formed into the exterior surface of the anchor body. The channels may be used to inject a compound, such as filler material or an adhesive, into the implant site. Preferably, the channels connect to a retainer in the anchor body for a suture to pass through, preventing the suture from being compressed and allowing removal and adjustment of a suture retained by the anchor after the anchor is installed in a bone. The retainer is preferably a slot formed into the distal end of the anchor body. In a method of securing tissue to bone, an insertion tool is used to insert the suture into the anchor and install the anchor into an implant site in the bone. If the suture later fails, the channels may be used to fill the implant site with bone cement for redrilling. Preferably, the suture anchor is made of human cortical bone or a similarly bioabsorbable and osteoconductive material.

Owner:SCHULMAN DANIEL S

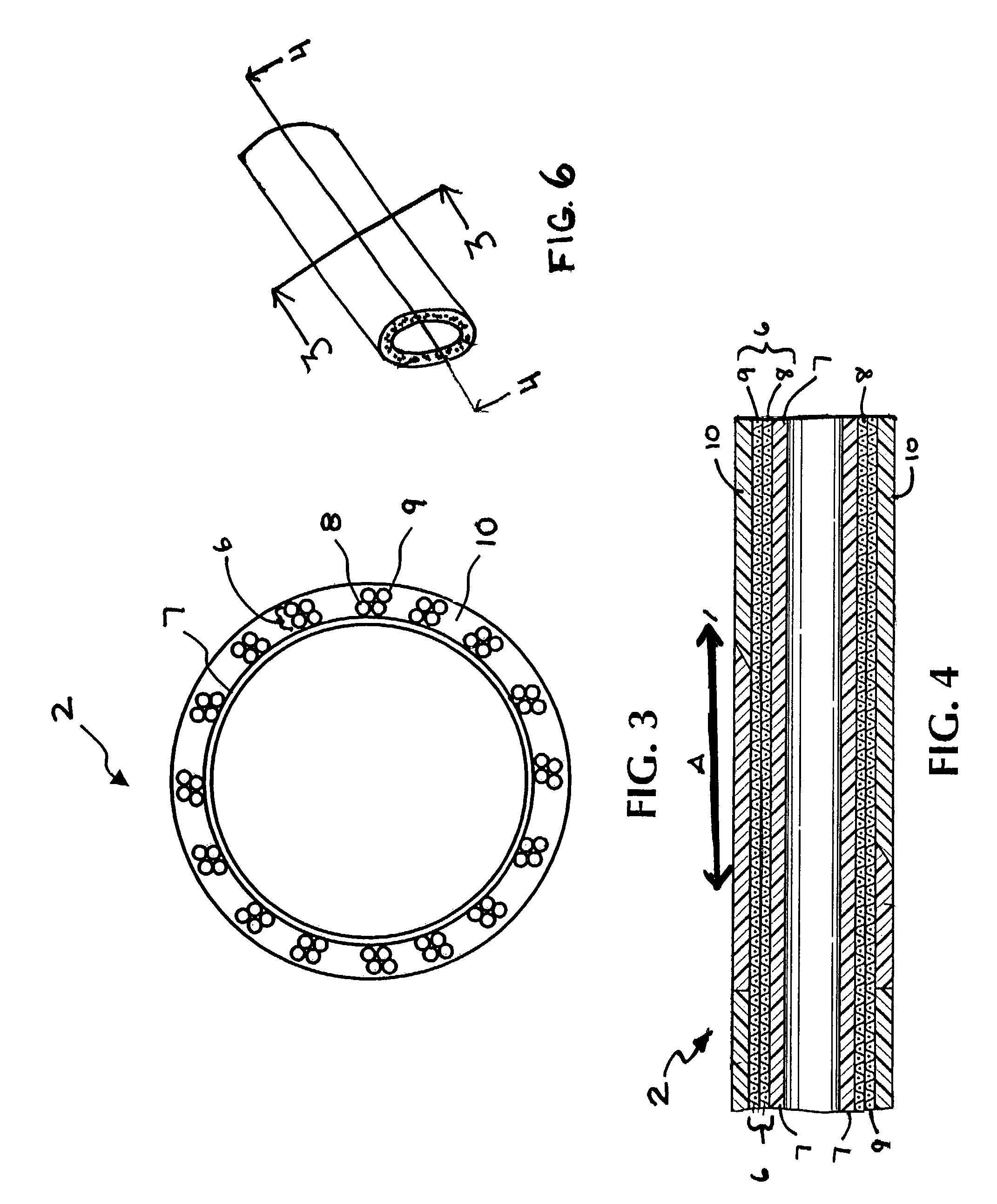

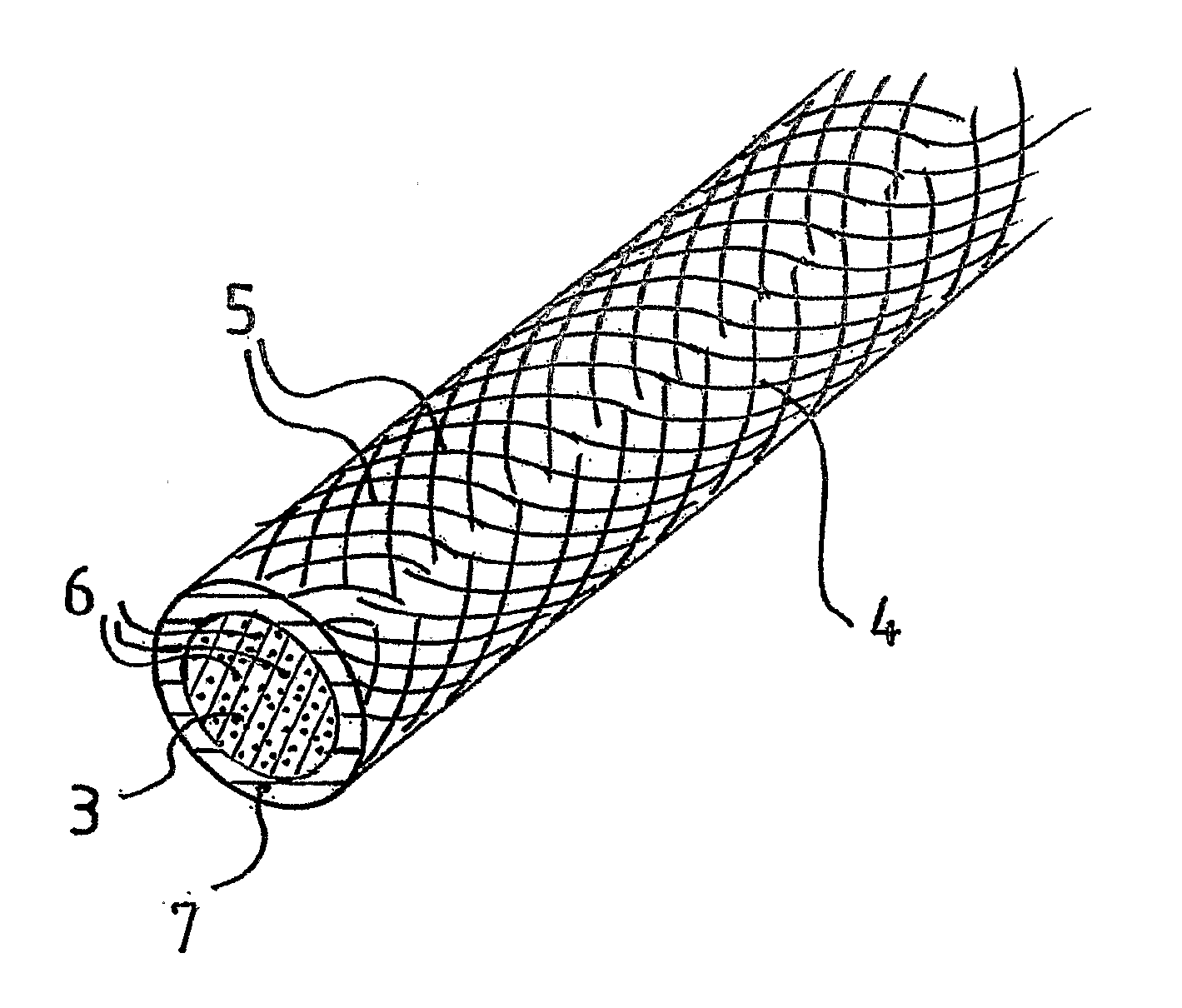

Electroluminescence (EL) tube and wire and manufacturing method

InactiveUS6960725B2Increase the areaSimple manufacturing processElectroluminescent light sourcesPower cables with screens/conductive layersSynthetic resinElectroluminescent wire

An electroluminescent wire core having a flexible central electrode, a luminescent layer and a transparent, conductive layer. An outer surface of the central electrode is coated with the luminescent layer and the transparent, conductive layer respectively. In the transparent, conductive layer is disposed luminescent power which is covered by thermoplastic macromolecular polymer and synthetic resin.

Owner:SHENZHEN EL LIGHTING TECH CO LTD

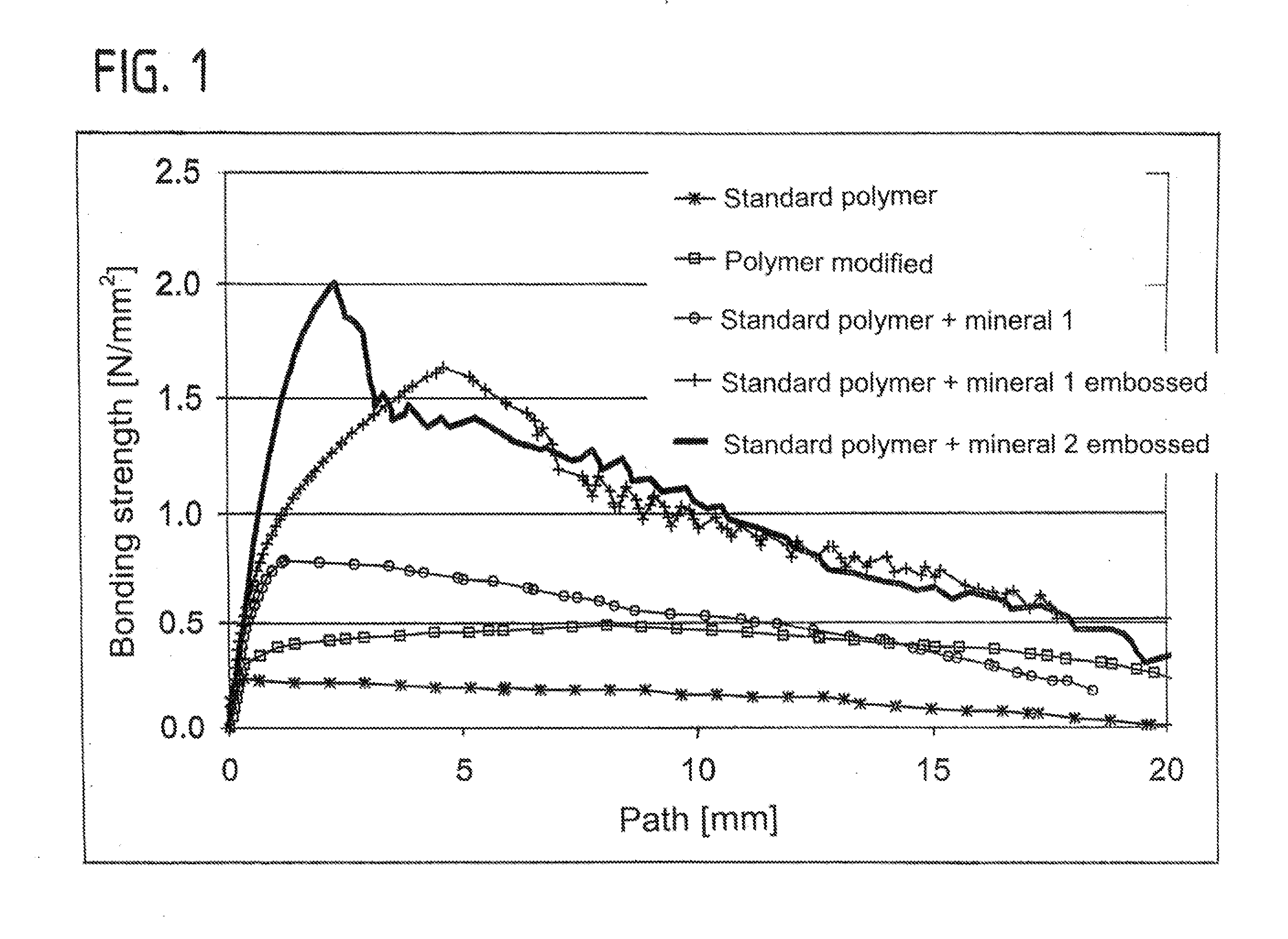

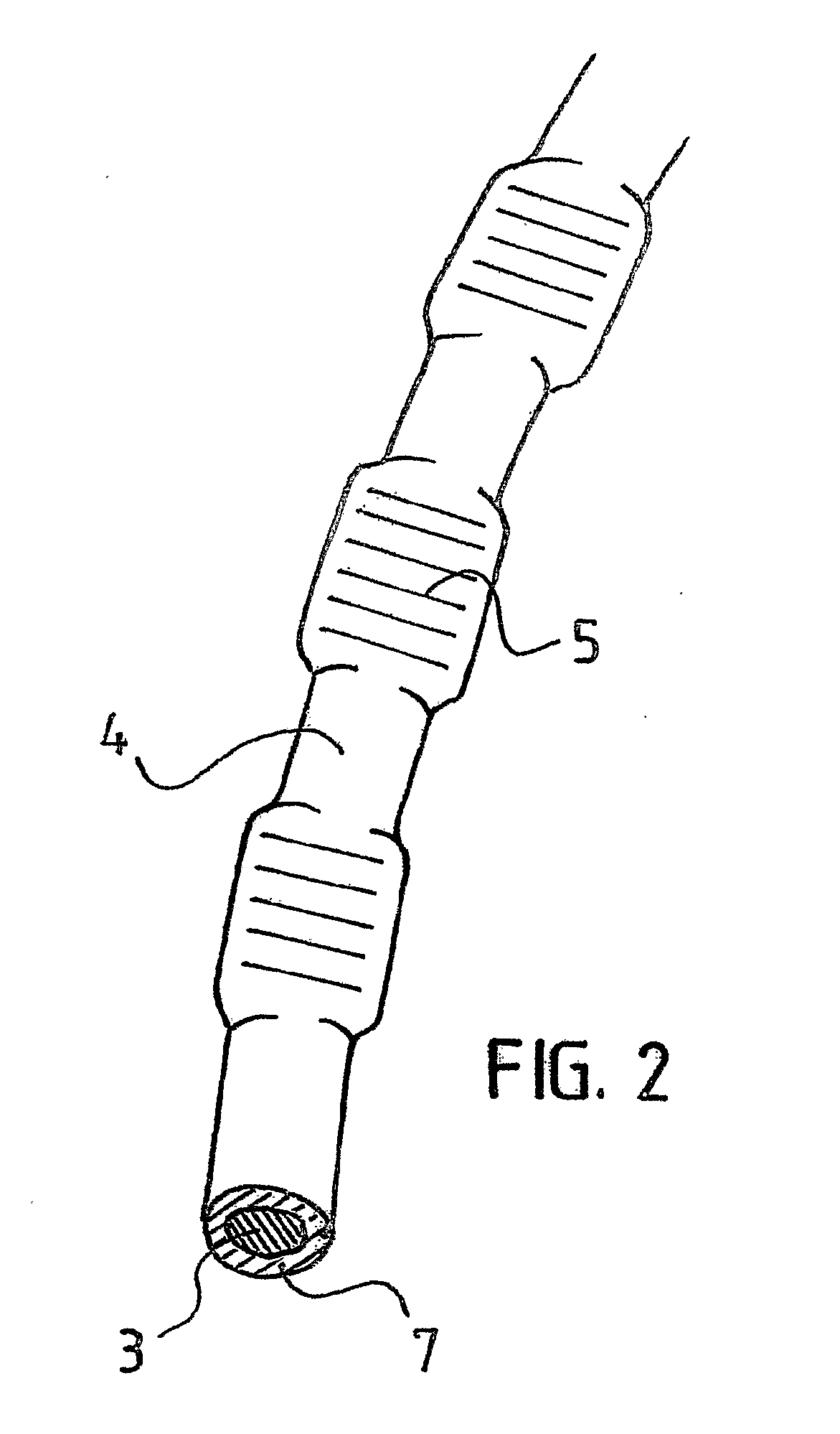

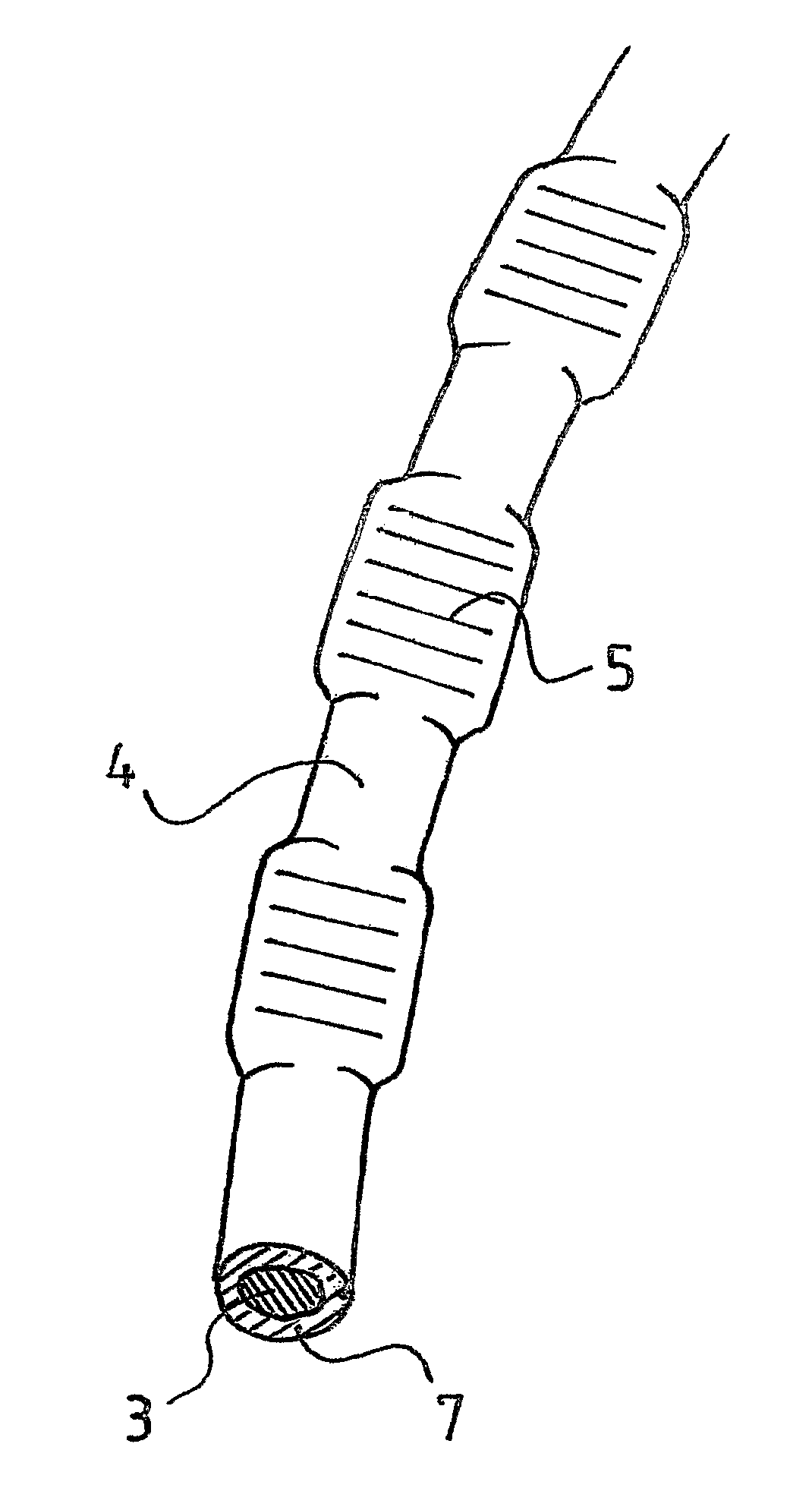

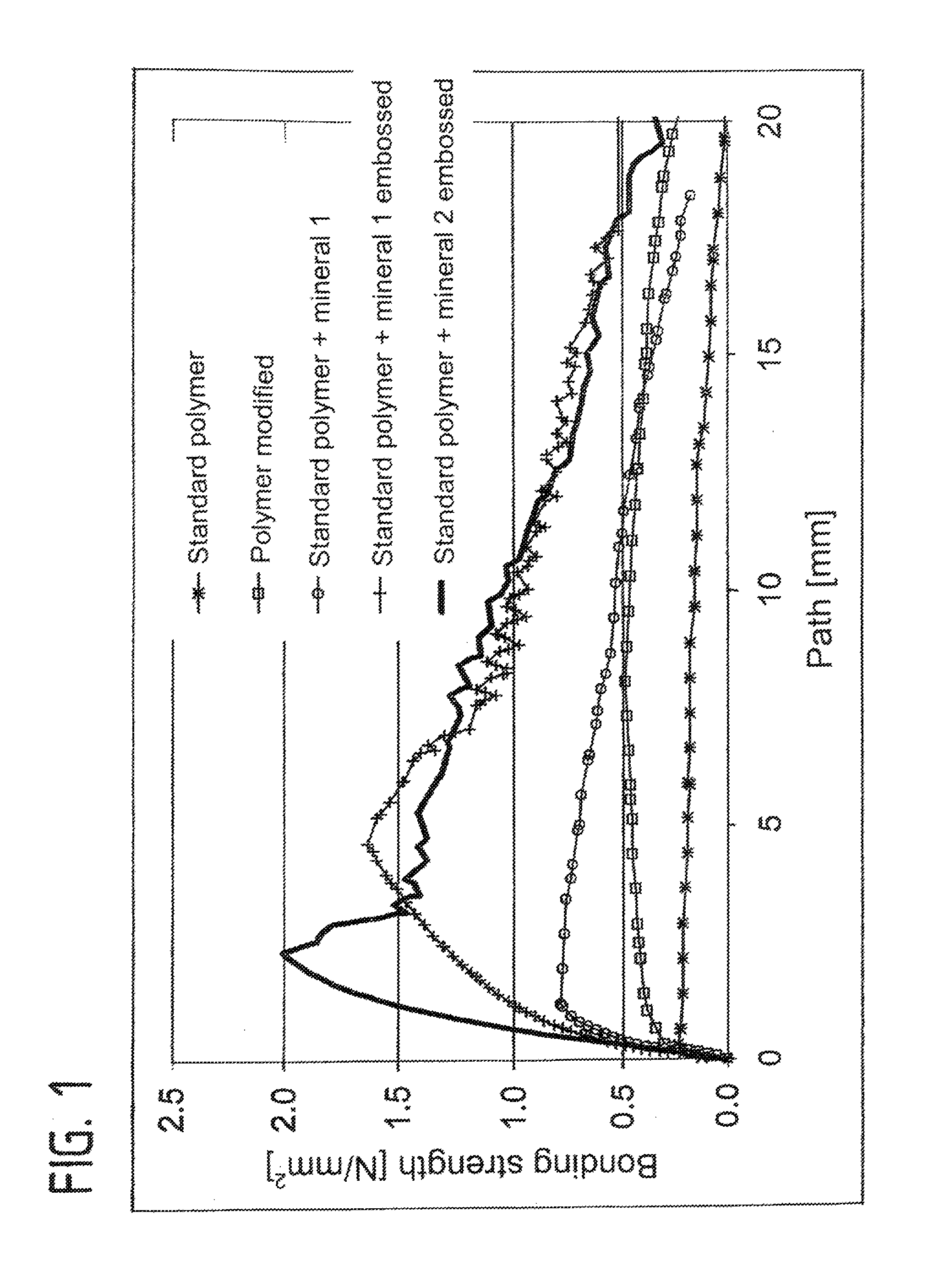

Bi-Component Plastic Fibers For Application in Cement-Bonded Building Materials

InactiveUS20120146254A1Low costHigh tensile strengthSynthetic resin layered productsBuilding reinforcementsPolymer scienceFiber diameter

Method for making plastic fiber for application in concrete with largest grain diameters >4 mm, with an average diameter of 0.15 to 2 mm, corresponding to approximately 160 to 28,000 dtex. Using a co-extrusion process, a bi-component fiber is formed having a central core and a casing around the central core, the central core and the casing contain different pure polymers or polymer mixtures, and then the co-extruded bi-component fiber is stretched by a factor of 5 to 15, and thereafter a structured or grooved surface is embossed onto the co-extruded stretched bi-component fiber. The embossing is performed such that a depth of the embossing is more than 10% of an average fiber diameter, and a maximal distances of structure tips within incorporated structures of the embossing in an axial direction lie in a region between 0.5 mm and 3 mm.

Owner:EMPA EIDGENOESSISCHE MATERIALPRFUNGS & FORSCHUNGSANSTALT +1

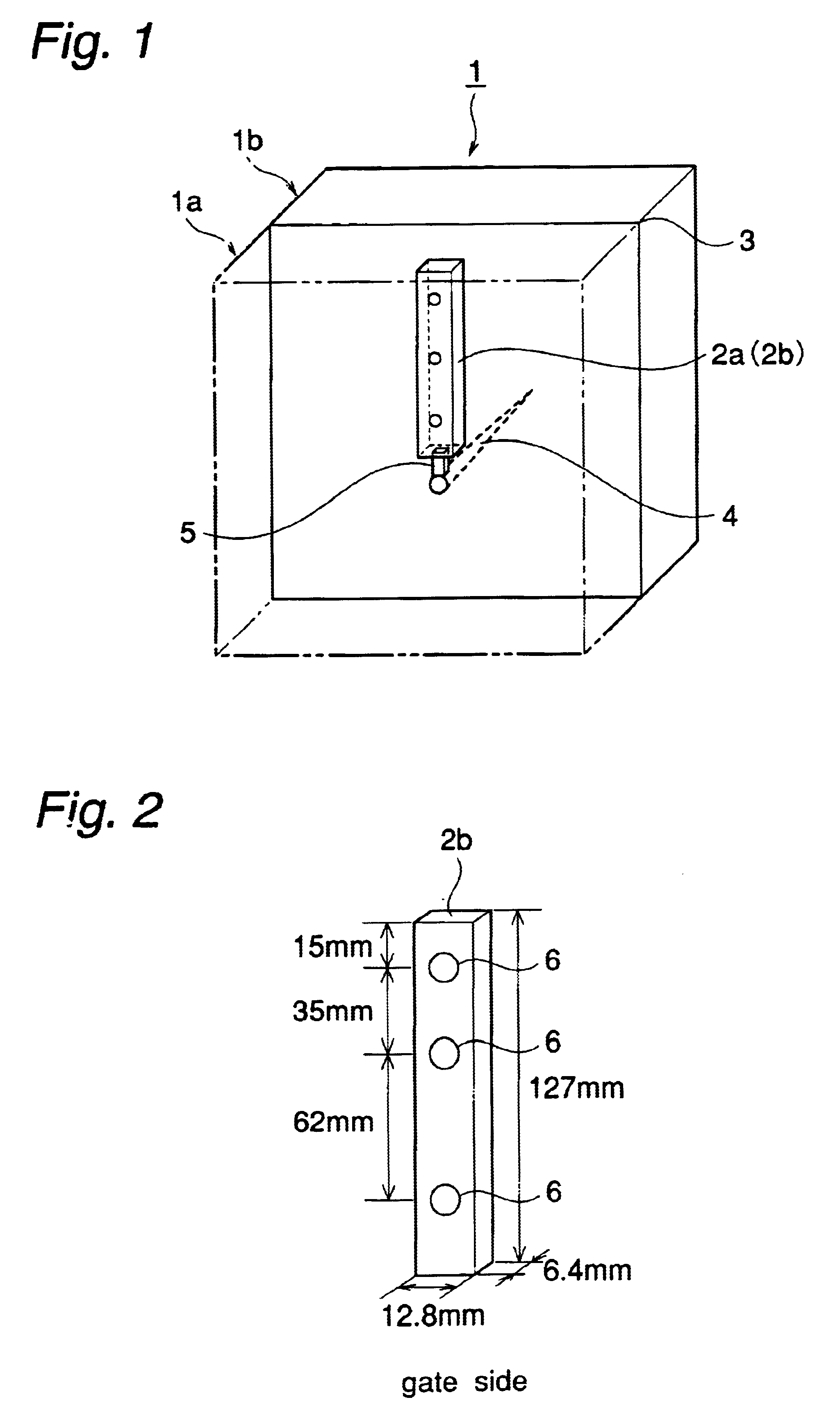

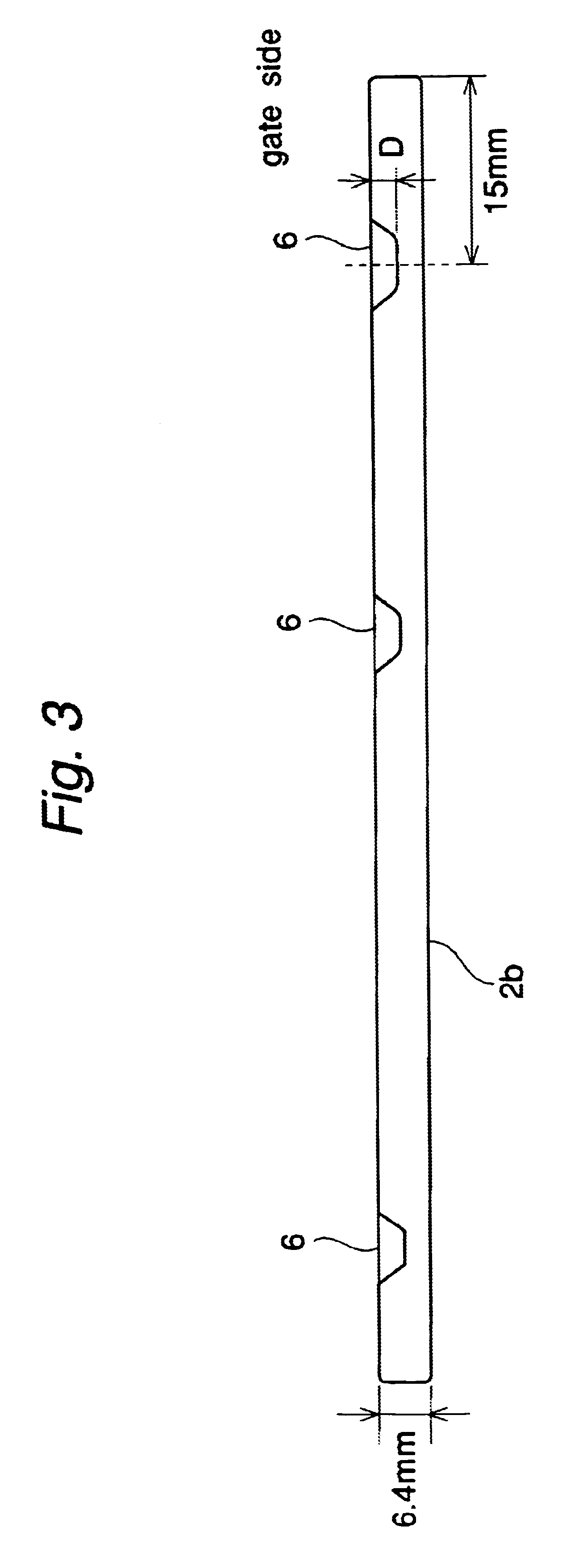

Injection molding soft resin composition and users thereof

The injection molding soft resin composition of the invention comprises (A) an ethylene / alpha-olefin copolymer using an alpha-olefin of 3 to 10 carbon atoms as a comonomer and (B) a thermoplastic elastomer composition obtained by dynamically heat treating a crystalline polyolefin resin and an olefin copolymer rubber in the presence of a crosslinking agent, in a specific ratio. The component (A) has a Shore A hardness of 40 to 95, MRF2.16 of 1.0 to 100 g / 10 min and a density of 855 to 900 kg / cm<3>, and the component (B) has a gel content of 30 to 100% and a Shore A hardness of 40 to 95. The injection molded article of the invention comprises the soft resin composition and may have been subjected to painting on its surface. Each of the toy and the daily use miscellaneous article of the invention comprises the injection molded article. According to the invention, there can be provided an injection molding soft resin composition, from which injection molded articles having softness and being excellent in low gloss, mechanical properties such as tensile strength and appearance can be produced with high productivity, and a molded article of the composition, such as a molded article employable as a soft toy or a daily use miscellaneous article. Further, a painted article of an injection molded article, which has excellent adhesion of coating, can be provided.

Owner:MITSUI CHEM INC

Fluororesin tube and method for producing the same

InactiveUS20090097890A1Excellent abrasion resistanceHigh tensile strengthClosuresPaper/cardboard wound articlesEngineeringUltimate tensile strength

Owner:JAPAN GORE TEX INC

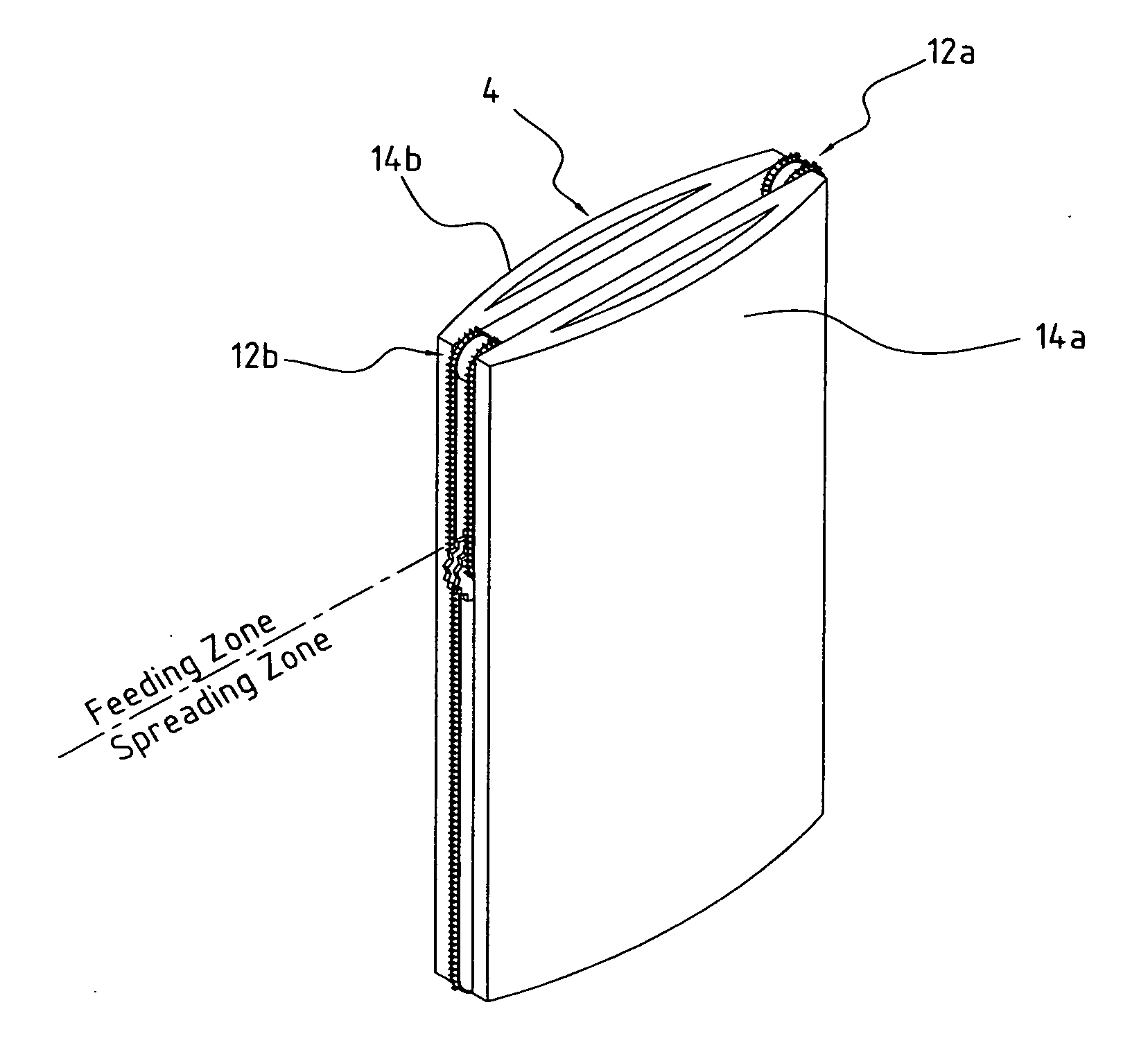

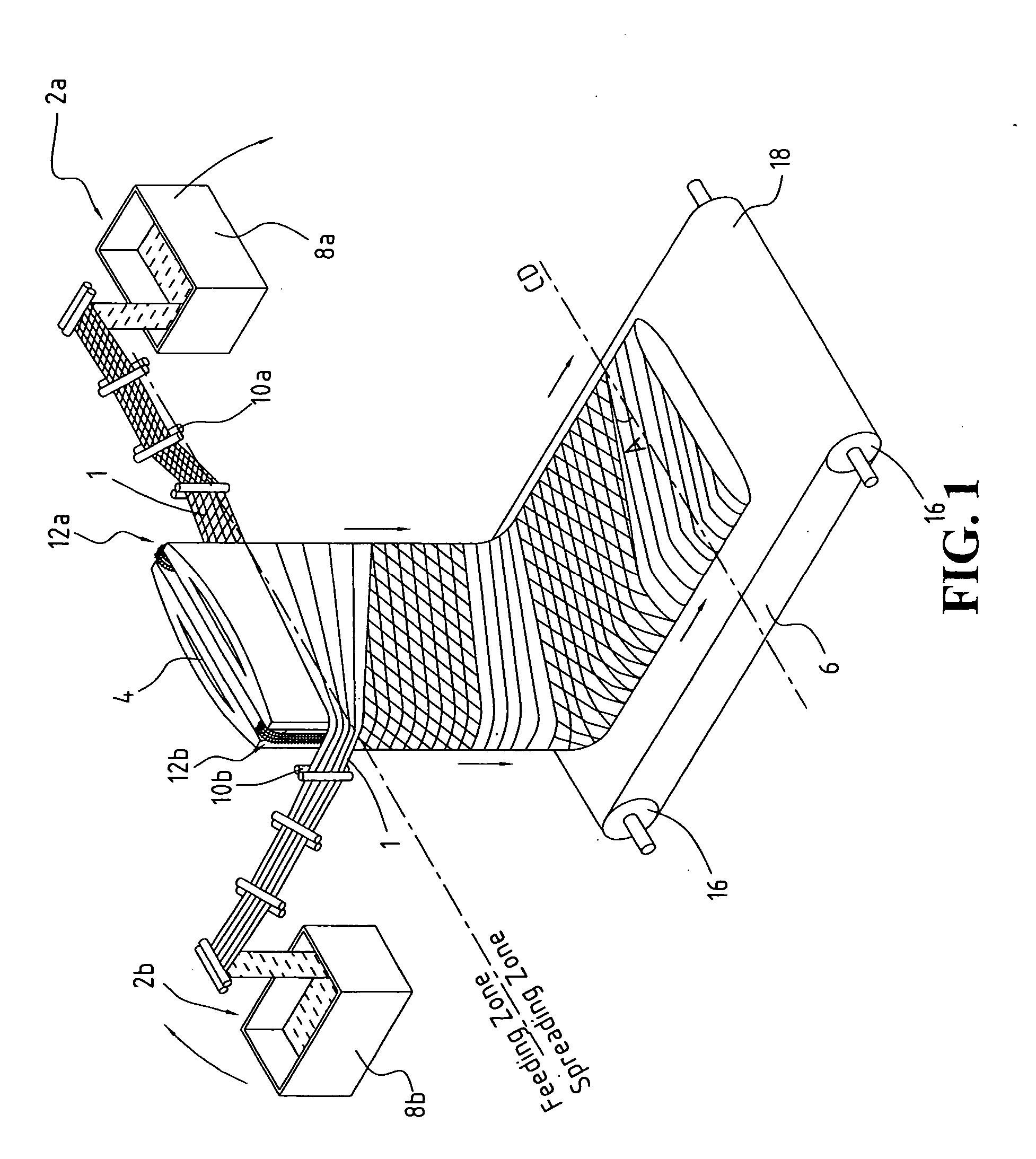

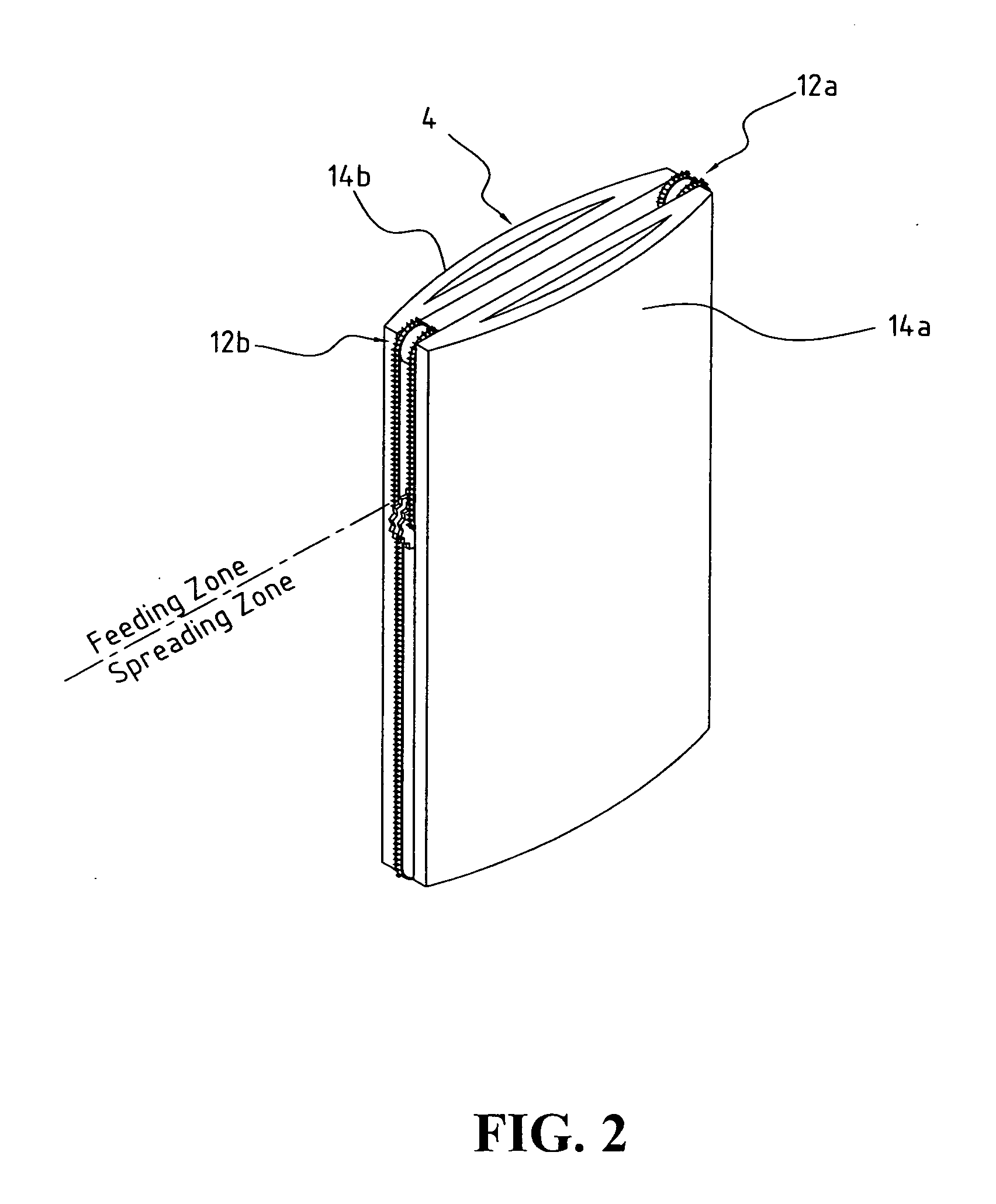

Stretchable high-loft flat-tube structure from continuous filaments

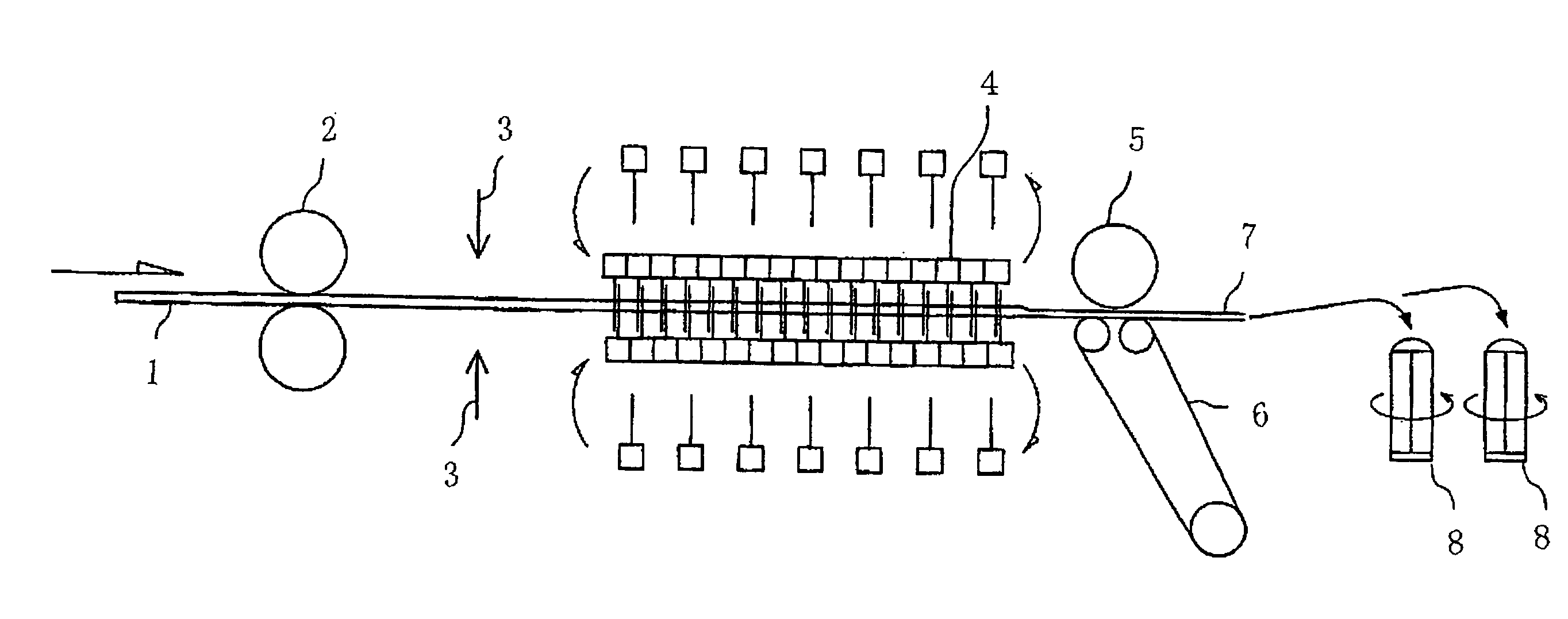

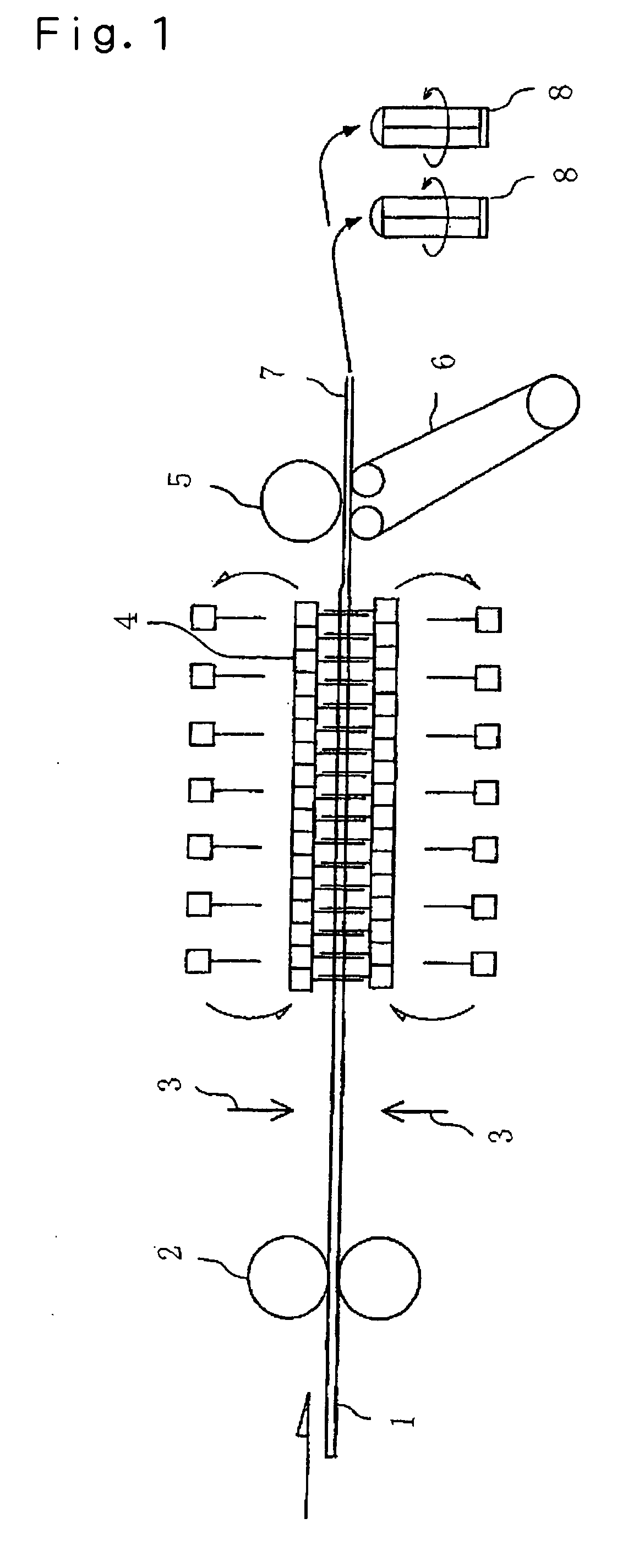

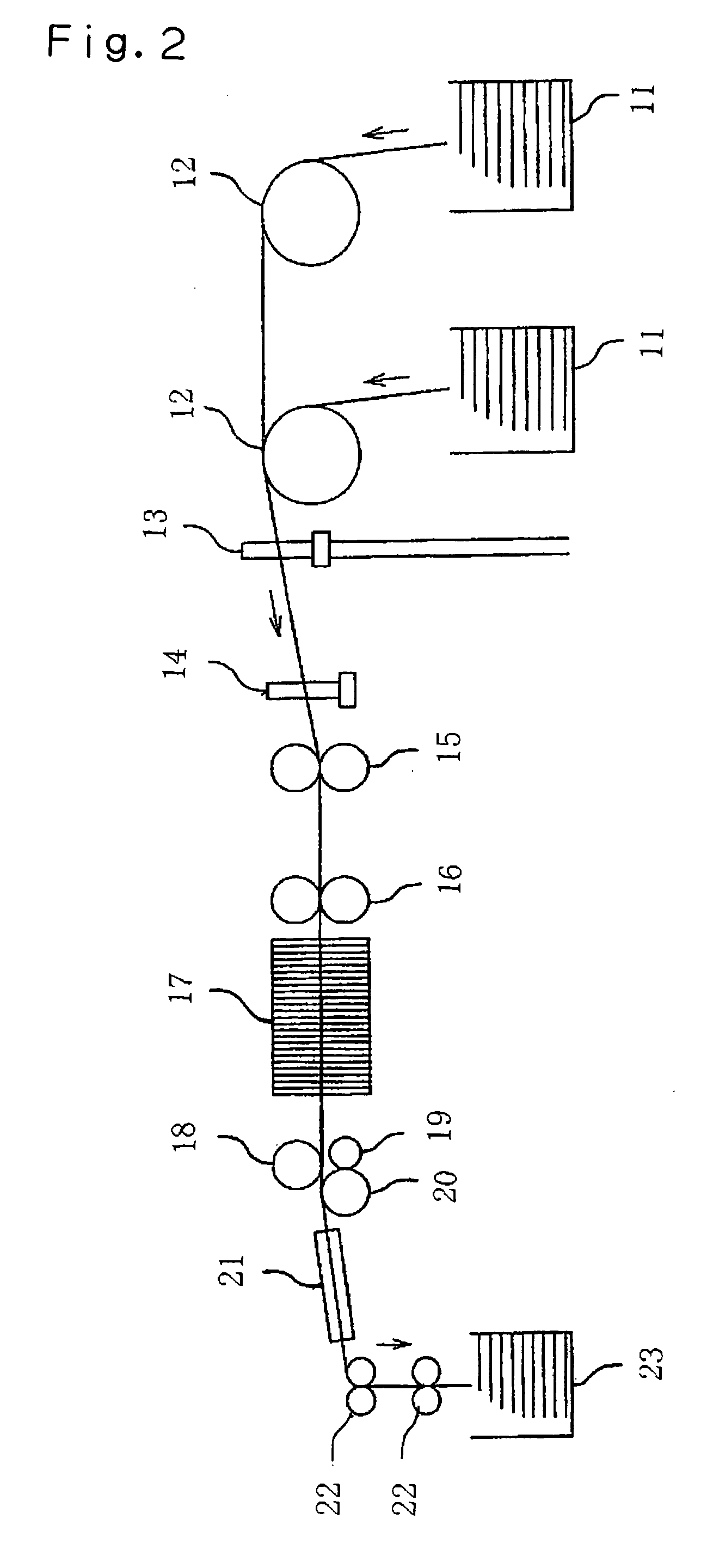

ActiveUS20050147775A1Maintain good propertiesImprove stabilityEnvelopes/bags making machineryPreformed elementsEngineeringUltimate tensile strength

Improved batts for sleeping bags, insulated apparel, bedding, and other uses are made from a tow of crimped continuous filaments by a machine and process which spreads, extends, and cross-laps the tow into an endless flat-tube structure with desired uniformity, balanced tensile strength, dimensional stability, stretchability, and high loft.

Owner:V F T

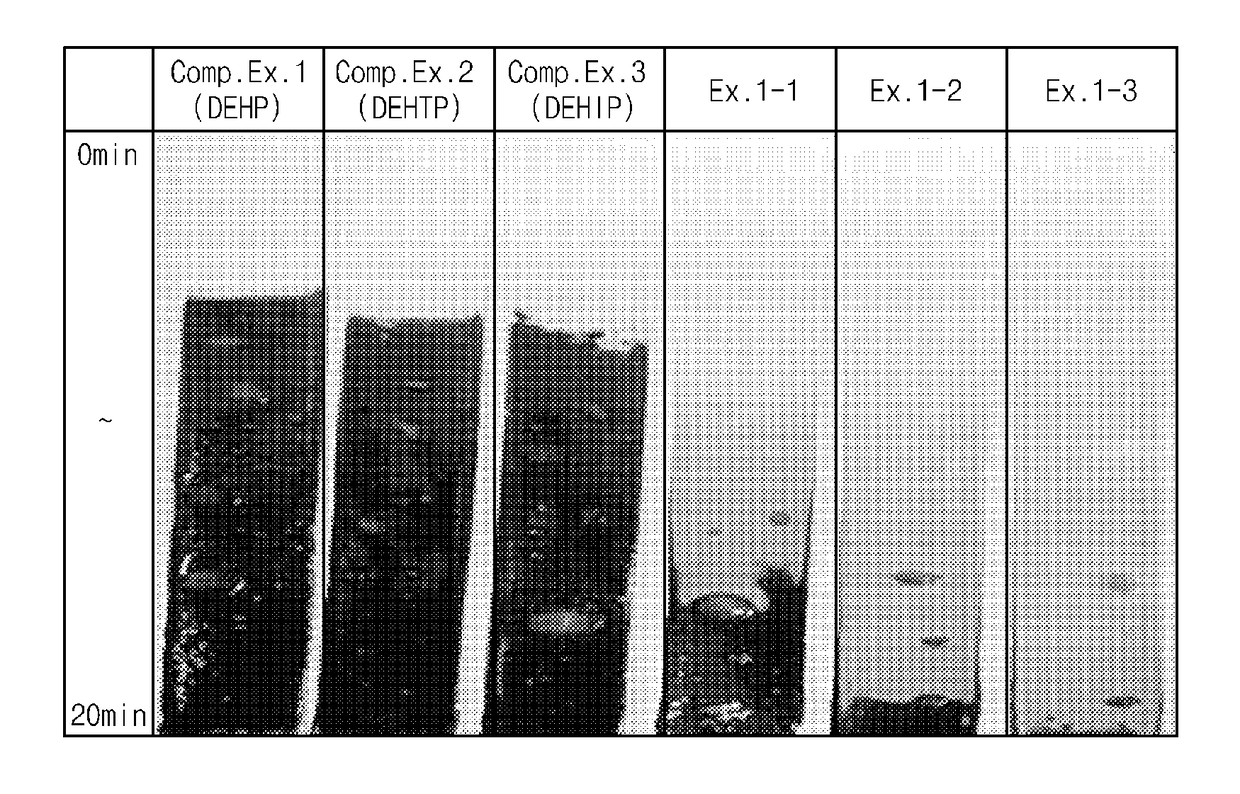

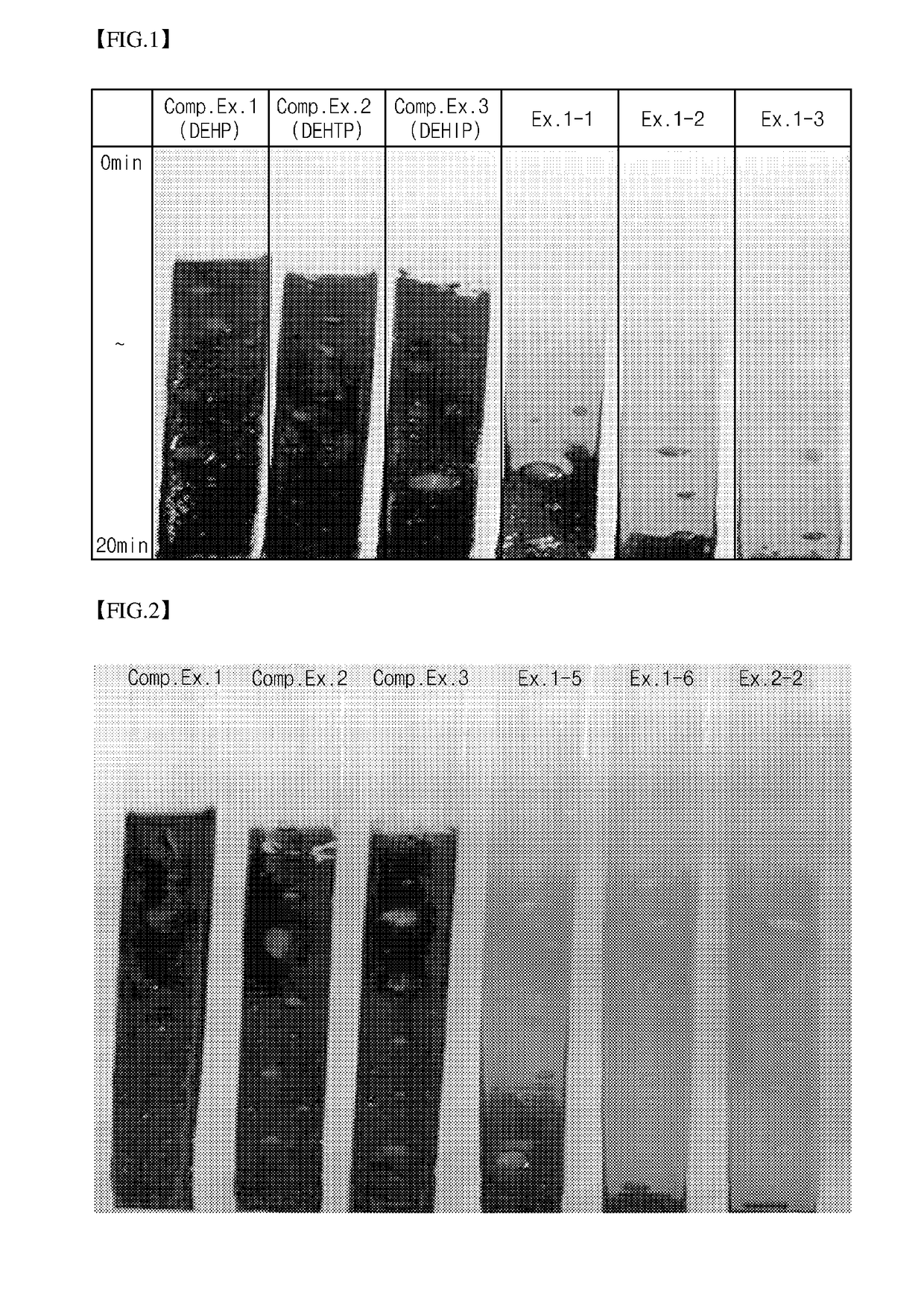

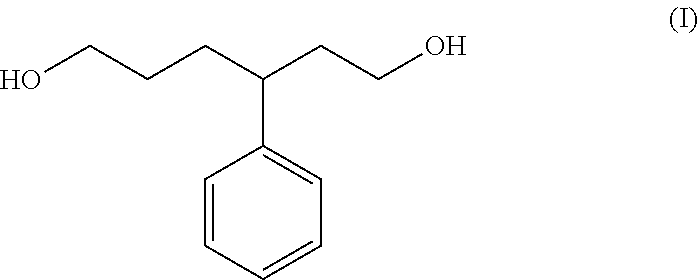

Plasticizer composition, resin composition and method of preparing the same

ActiveUS20180066124A1Maintain good propertiesHigh plasticizing efficiencyOrganic chemistryPlasticizerPolymer chemistry

The present invention relates to a plasticizer composition, a resin composition, and a method of preparing the plasticizer composition. A plasticizer composition capable of improving properties such as tensile strength, migration resistance, volatile loss and the like, which are required when used as a plasticizer of a resin composition, by improving poor properties occurring due to structural limitations, and a resin composition including the same may be provided.

Owner:LG CHEM LTD

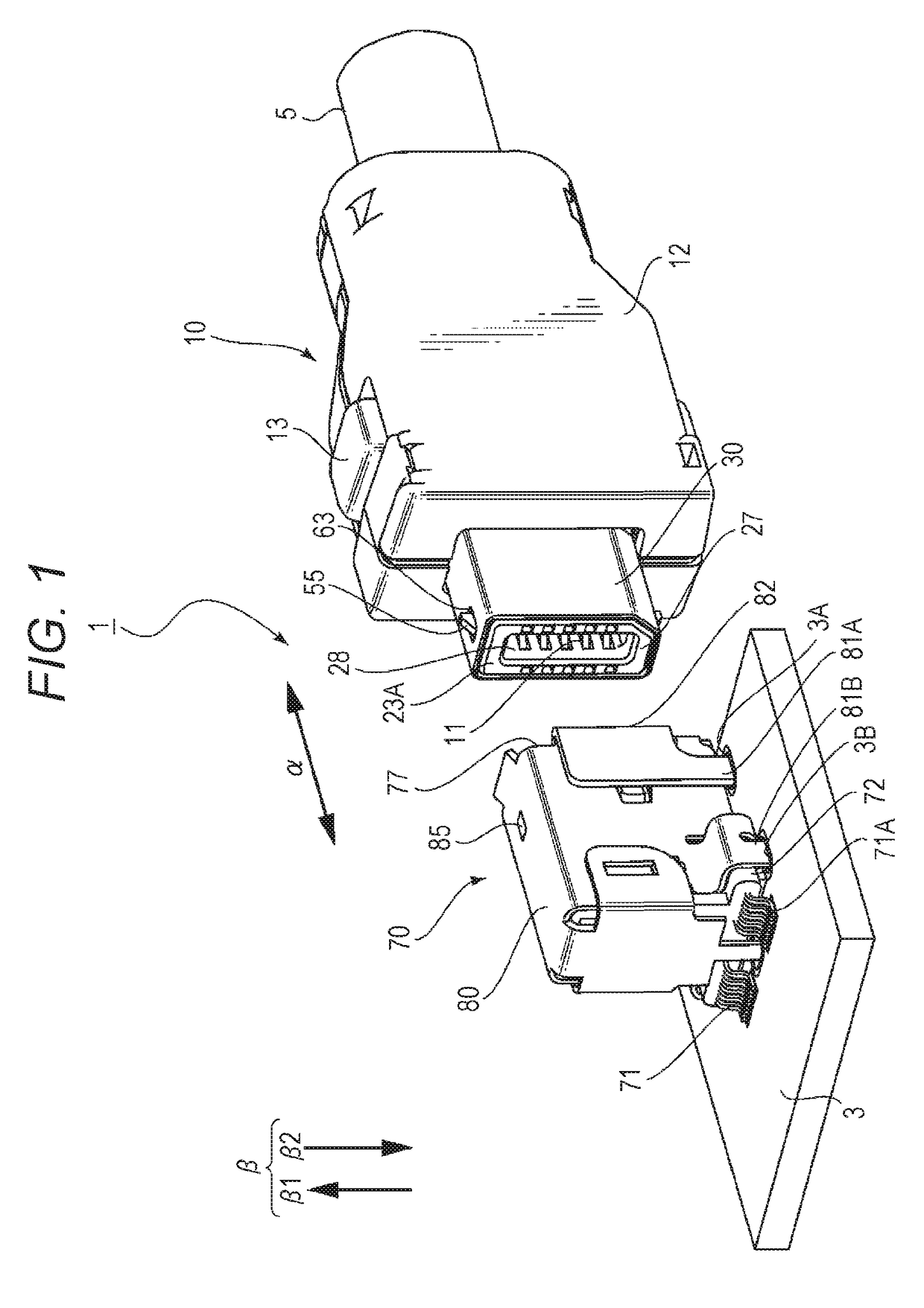

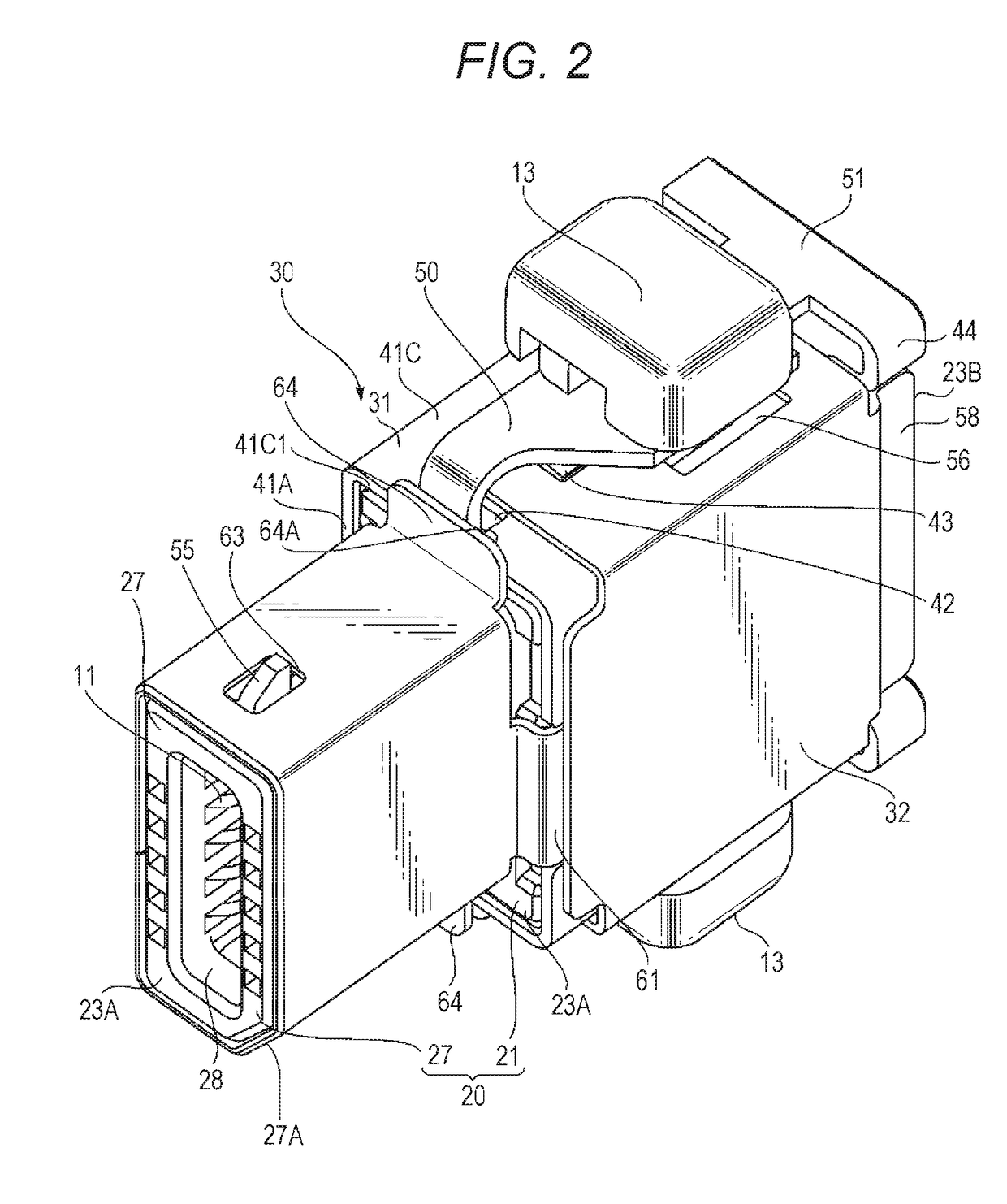

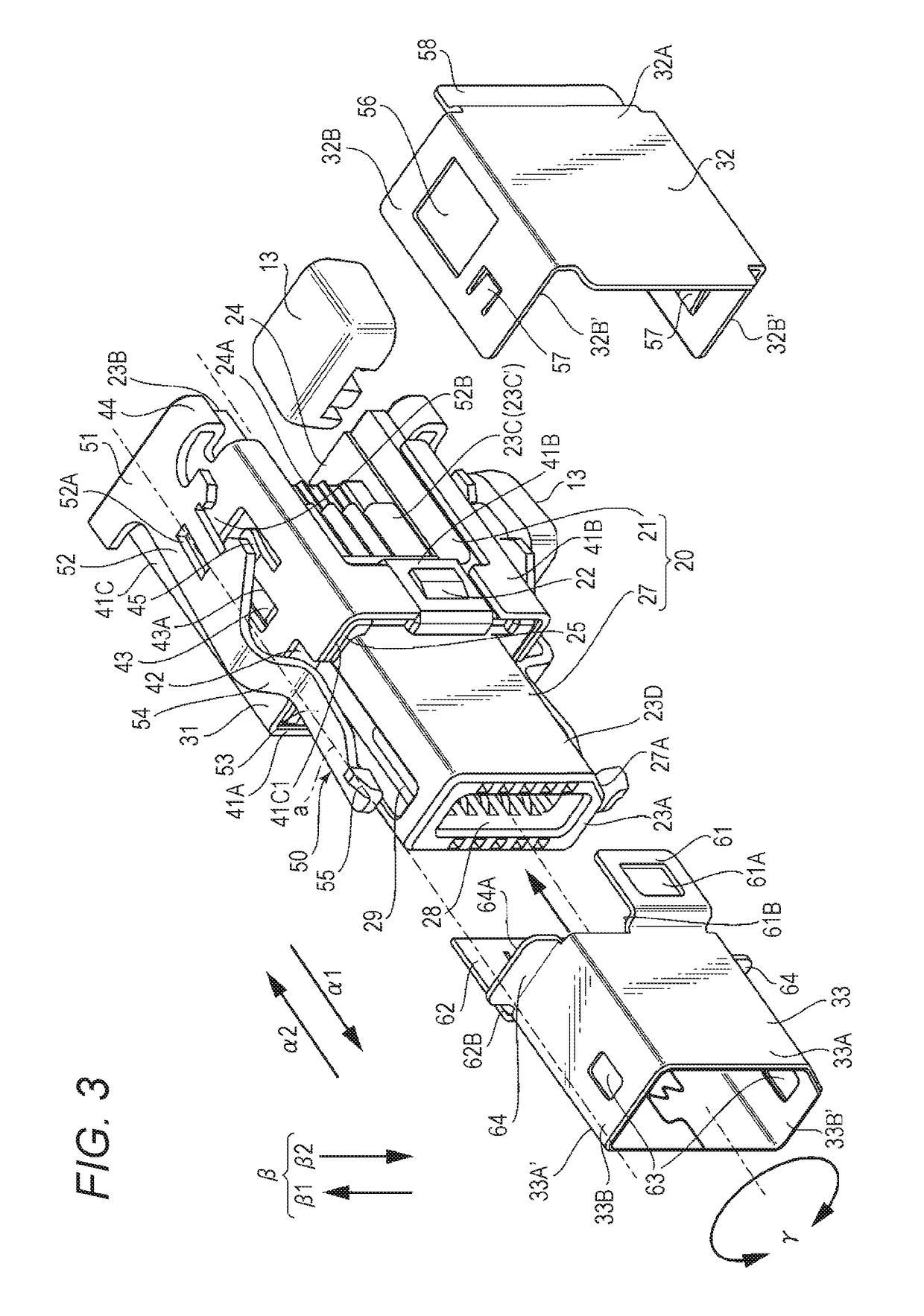

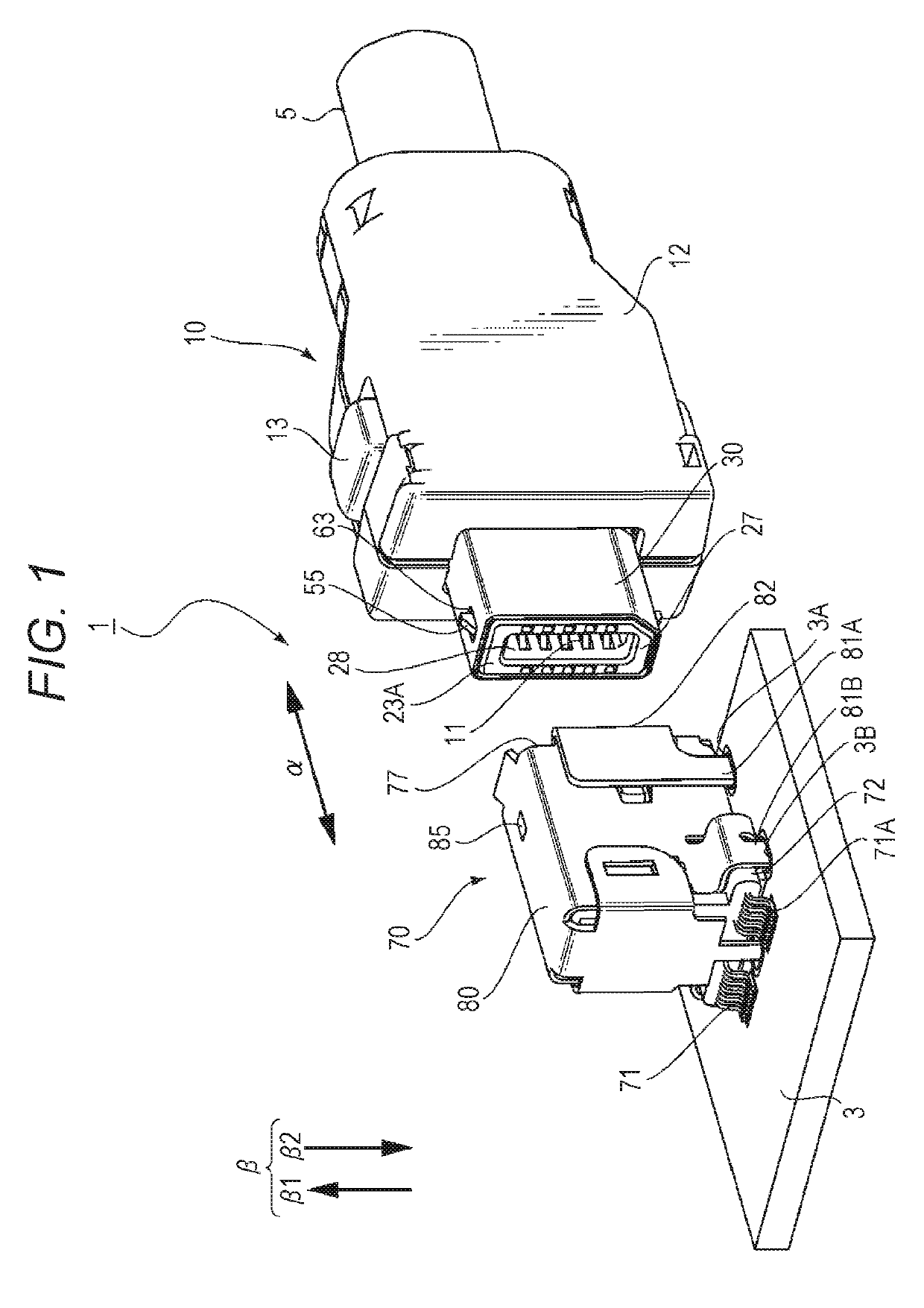

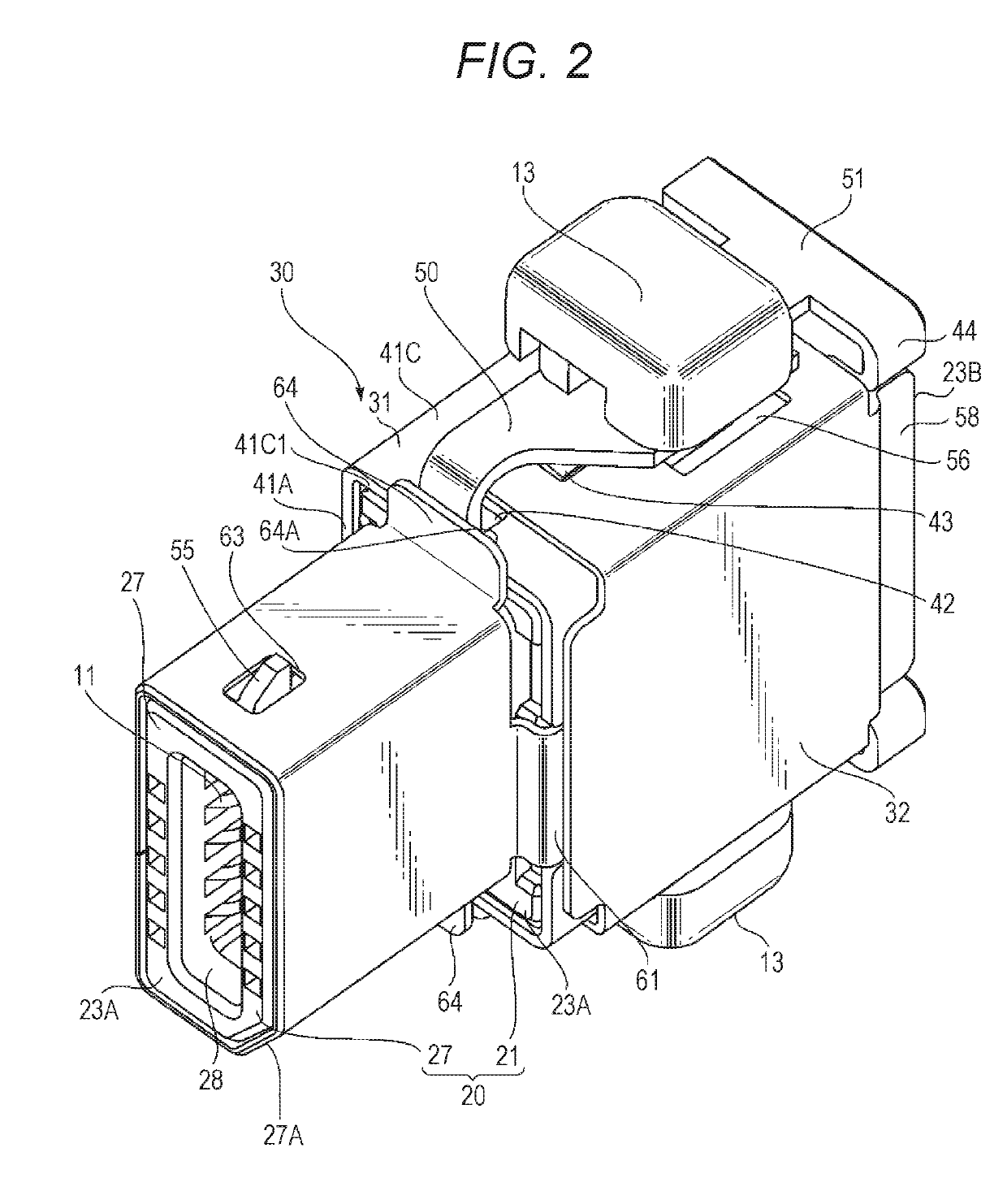

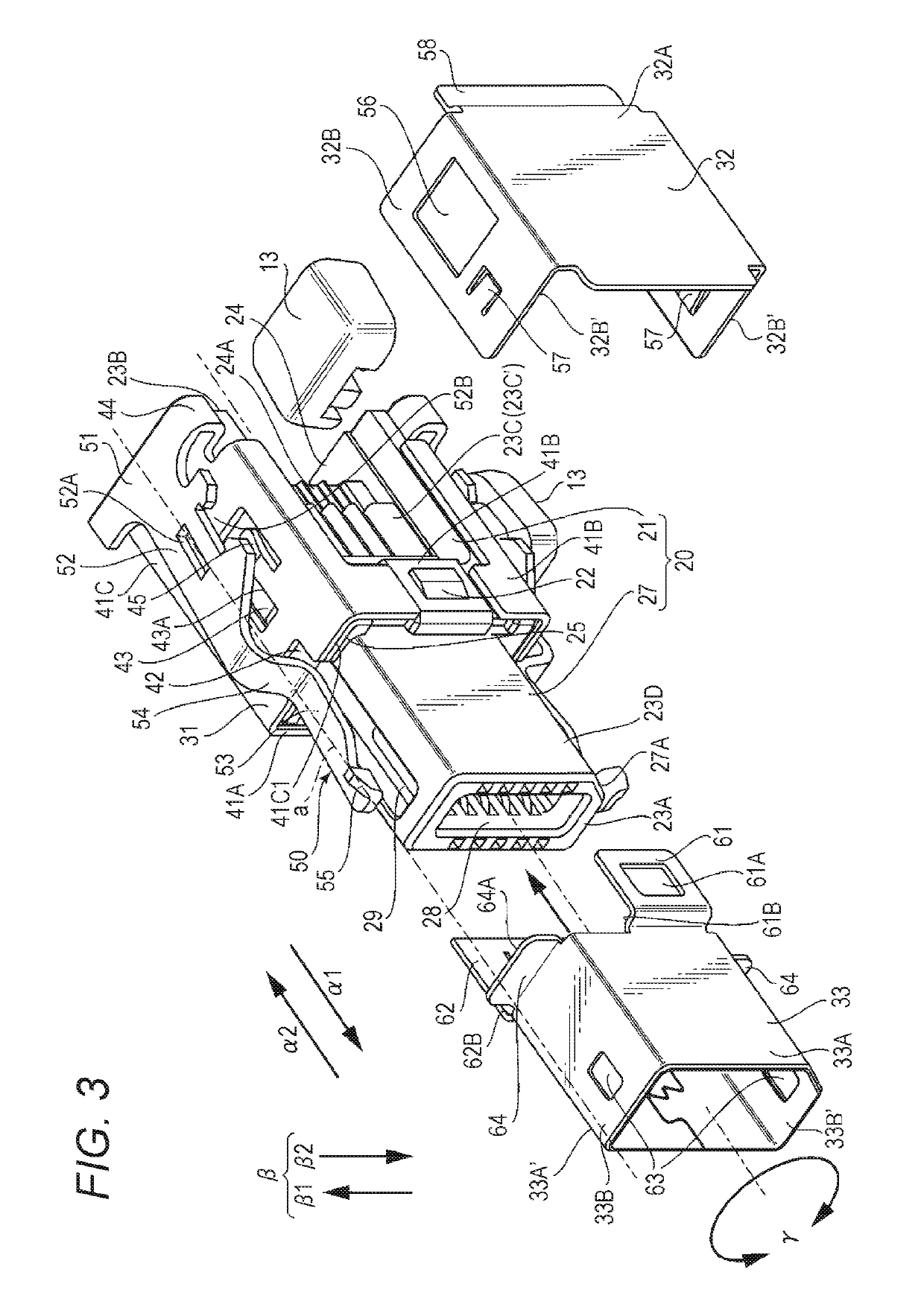

Connector having shell and connector device

ActiveUS20190058289A1Tensile strengthCoupling device detailsTwo-part coupling devicesMating connectionCantilever

Provided is a connector configured so that tensile strength when an attempt is made to forcibly detach the connector from a partner connector can be enhanced. A housing includes a body portion and a fitting target portion extending to the side of fitting to the partner connector. The diameter of a side portion outer peripheral surface of the fitting target portion is, at at least part thereof, smaller than that of the body portion. A conductive shell includes a first shell and a second shell. The first shell includes a cover portion configured to cover at least part of an outer peripheral surface of the housing, an elastic arm having a free end on the side of fitting to the partner connector, and a support portion elastically connecting the cover portion and the elastic arm and configured to support the elastic arm in a cantilever manner. The elastic arm has a lock portion configured to lock fitting to the partner connector, and has a stepped portion corresponding to a stepped surface of the housing provided using a difference in the diameter. The second shell includes a portion facing the stepped portion at a position closer to the side of fitting to the partner connector than the stepped portion of the elastic arm.

Owner:HIROSE ELECTRIC GROUP

Hybrid Carbon Fiber Spun Yarn and Hybrid Carbon Fiber Spun Yarn Fabric Using the Same

ActiveUS20080152906A1High tensile strengthReduce adhesionFinal product manufactureLayered productsYarnCarbon fibers

A hybrid carbon fiber spun yarn comprising a core region which comprises carbon fibers as a main component, and a surrounding region which comprises carbon fibers as a main component and covers an outer peripheral surface of the core region;wherein 20% by mass or more of fibers forming the core region are long carbon fibers having a fiber length of 500 mm or longer,80% by mass ormore of fibers forming the surrounding region are short carbon fibers having a fiber length of less than 500 mm, anda mass ratio between the long carbon fibers and the short carbon fibers (long carbon fibers:short carbon fibers) is in a range of 20:80 to 80:20.

Owner:KUREHA KAGAKU KOGYO KK

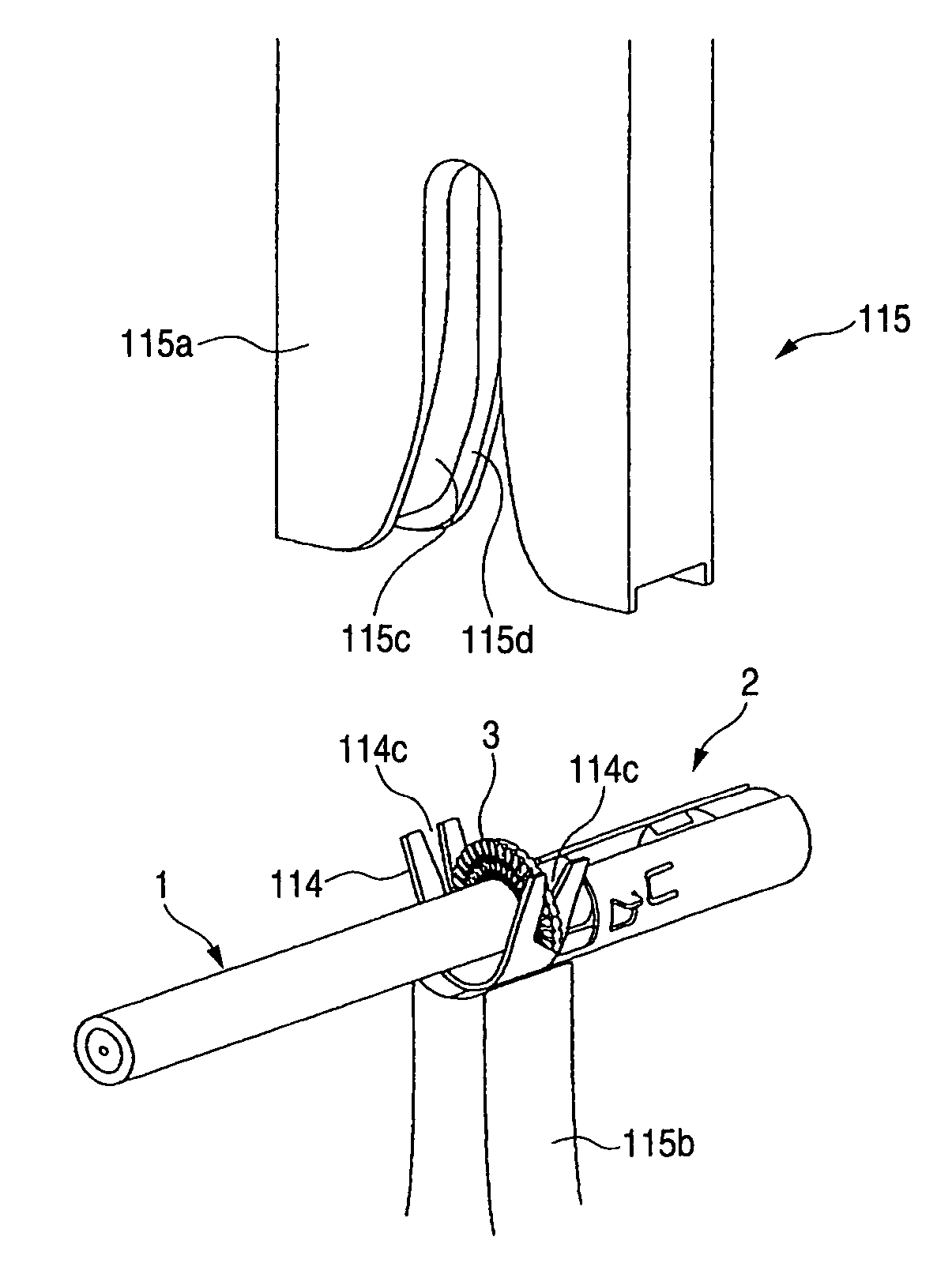

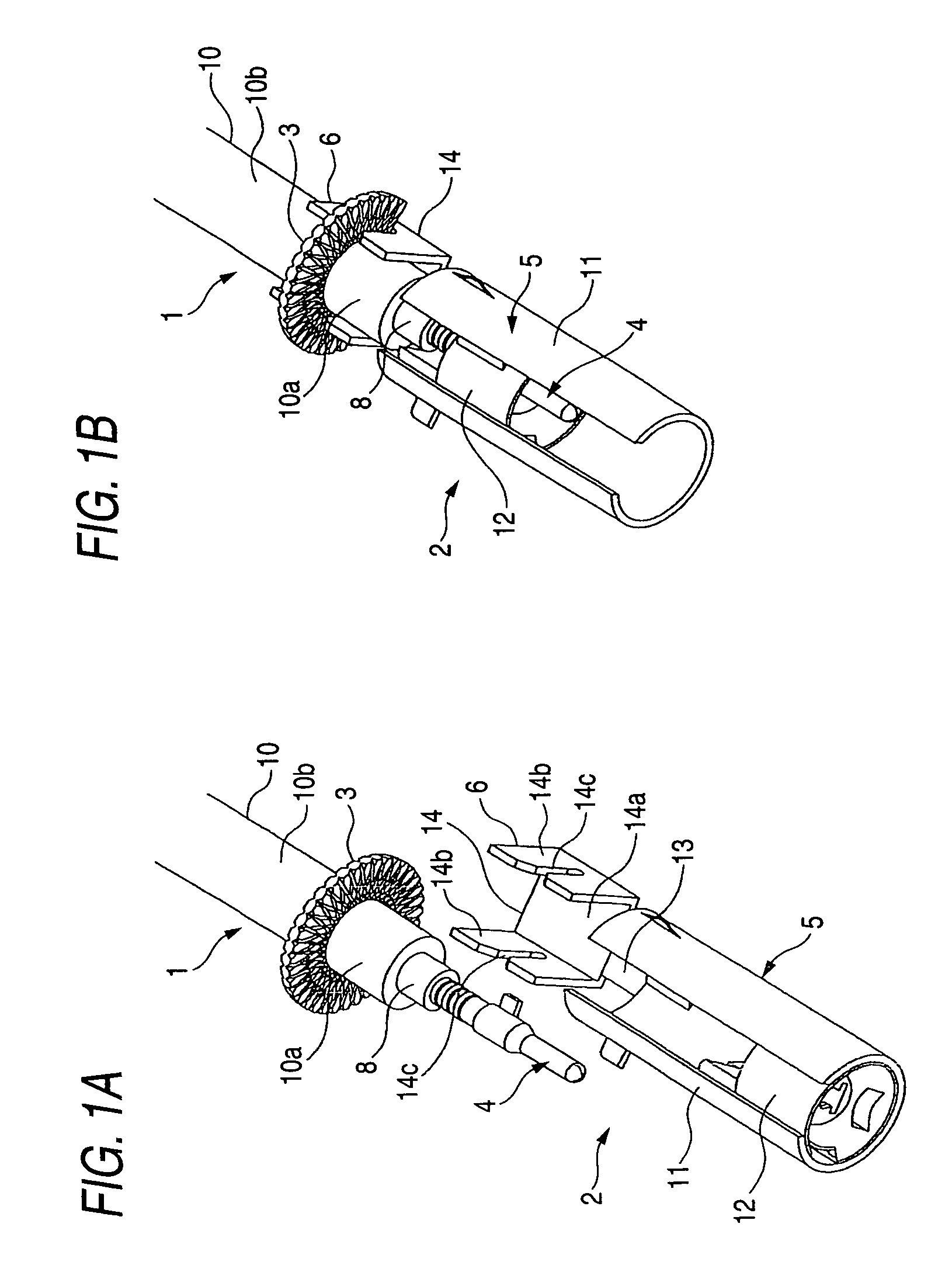

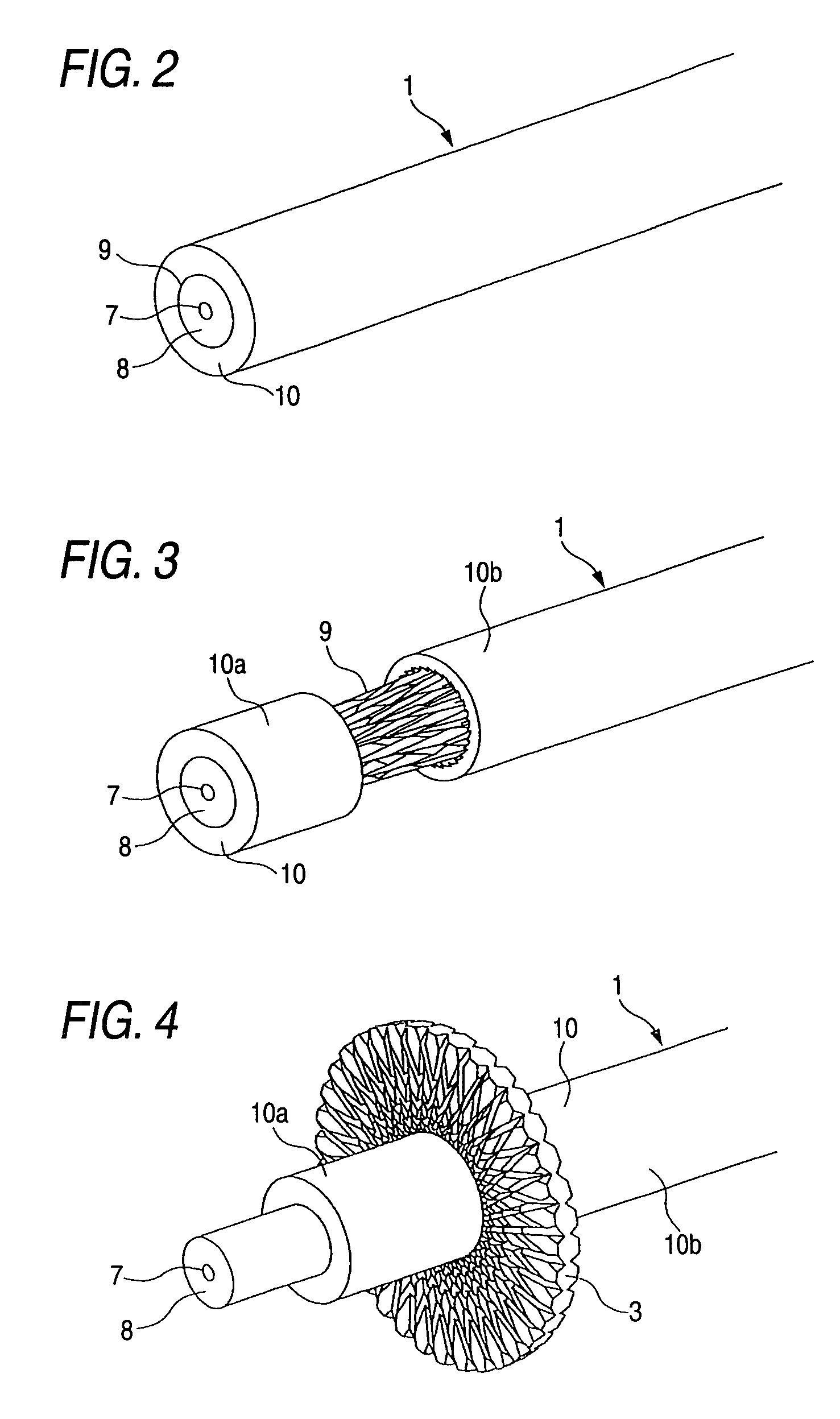

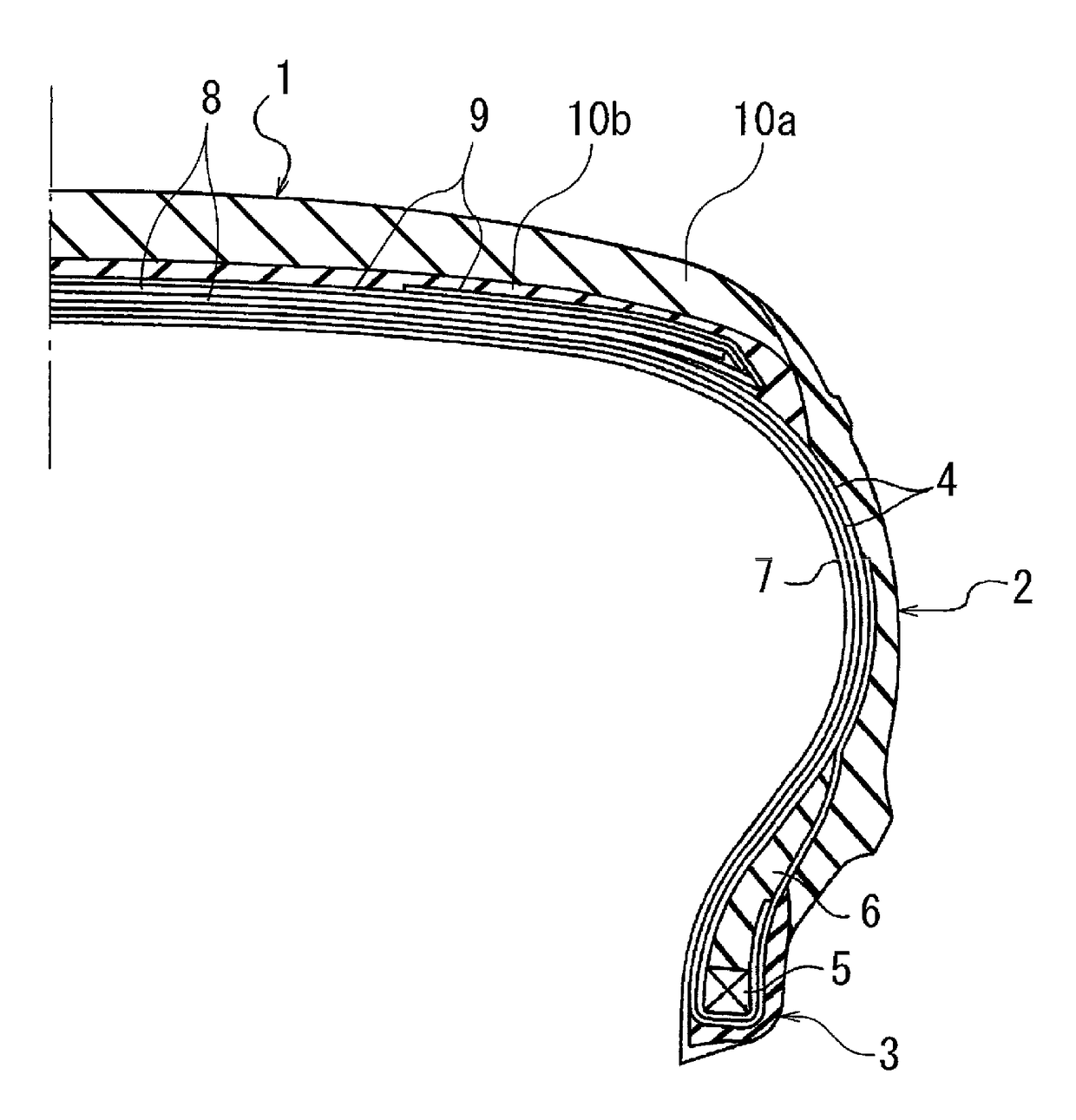

Coaxial cable end-processing structure, coaxial cable shielding terminal and press-fastening apparatus

InactiveUS7425161B2Easy to carryReduce the number of partsAntenna connectorsConnections effected by permanent deformationCoaxial cableElectrical and Electronics engineering

An intermediate portion of an insulating sheath of a coaxial cable is removed, and a first insulating sheath portion is drawn toward a second insulating sheath portion, so that a braid is projected into an annular shape outwardly from an interval between opposed ends of the first and second insulating sheath portions to form an annular projecting braid portion, and this annular projecting braid portion is fixed so as to be connected to a portion (that is, a braid fixing portion) of a coaxial cable shielding terminal for connection to an end portion of the coaxial cable. This connecting and fixing operation is effected by press-contacting or press-clamping.

Owner:YAZAKI CORP

Alkaline phenolic resole resin compositions and their use

InactiveUS20100252226A1Reduce odorTensile strengthFoundry mouldsDetergent compounding agentsPolymer sciencePolyol

Owner:ASK CHEM LP

Rubber Composition and Pneumatic Tire Using Same

ActiveUS20180186975A1Improve wear resistanceHigh tensile strengthSpecial tyresPolymer scienceButadiene-styrene rubber

The present technology provides a rubber composition containing a diene rubber including a styrene-butadiene copolymer component including at least one type of styrene-butadiene copolymer and a reinforcing filler. The bonded styrene content is from 5 to 50 wt. %. The total amount of styrene of an ozone decomposed component S1 including one styrene-derived unit and an ozone decomposed component S1V1 including one styrene-derived unit and one 1,2-bonded butadiene-derived unit is less than 80 wt. % of the amount of bonded styrene. The total amount of styrene of the decomposed component S1V1 is less than 10 wt. % of the amount of bonded styrene. The integrated intensity of an ozone decomposed component S1V2 including one styrene-derived unit and two 1,2-bonded butadiene-derived units is less than 15% of the integrated intensity of all decomposed components including styrene-derived units. The vinyl content of a butadiene portion is not less than 50%.

Owner:YOKOHAMA RUBBER CO LTD

Process for making plastic fibers for application in concrete

InactiveUS8496861B2Improve mechanical propertiesTensile strengthBuilding reinforcementsThin material handlingPolymer scienceFiber diameter

Owner:EMPA EIDGENOESSISCHE MATERIALPRFUNGS & FORSCHUNGSANSTALT +1

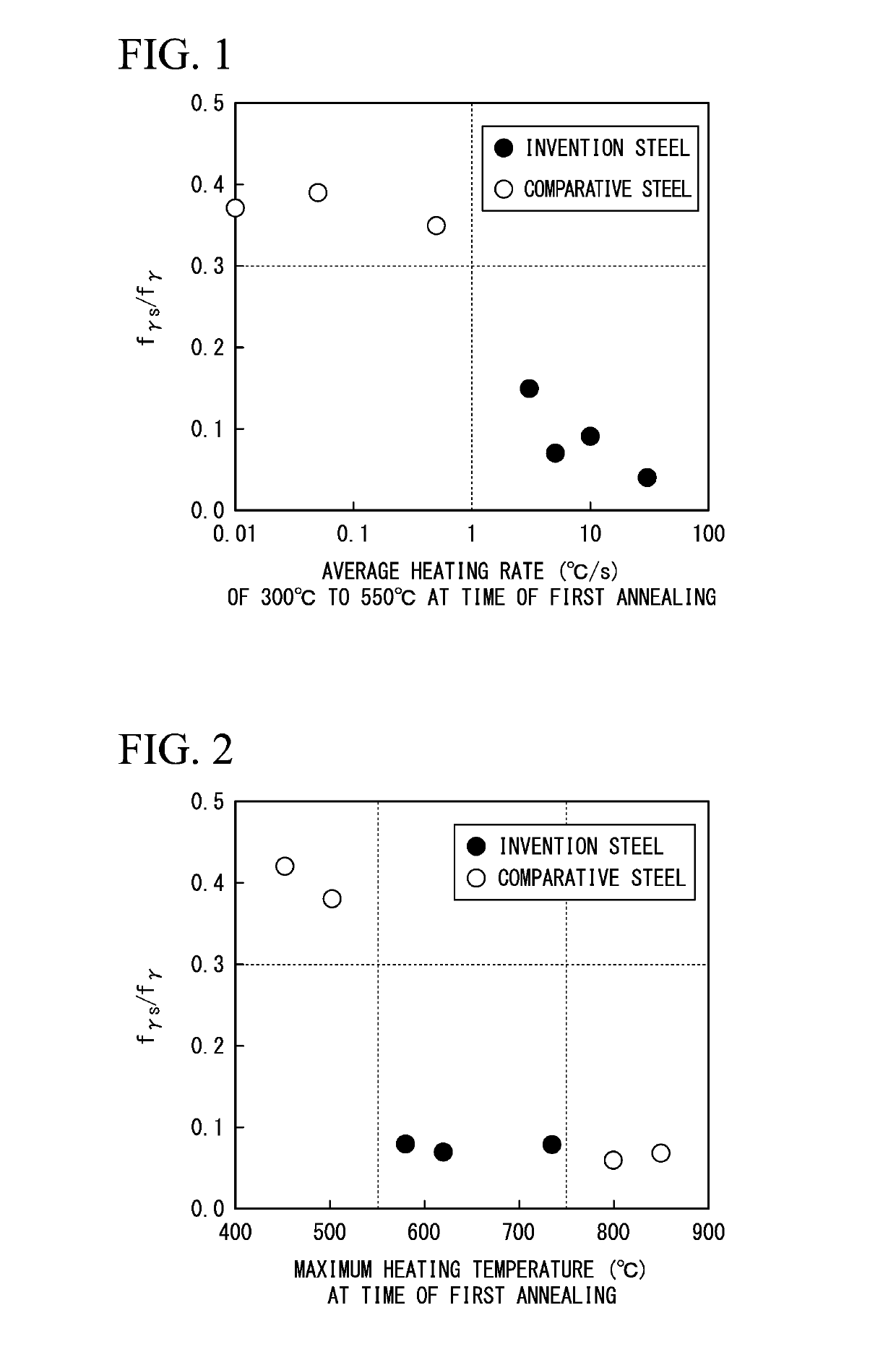

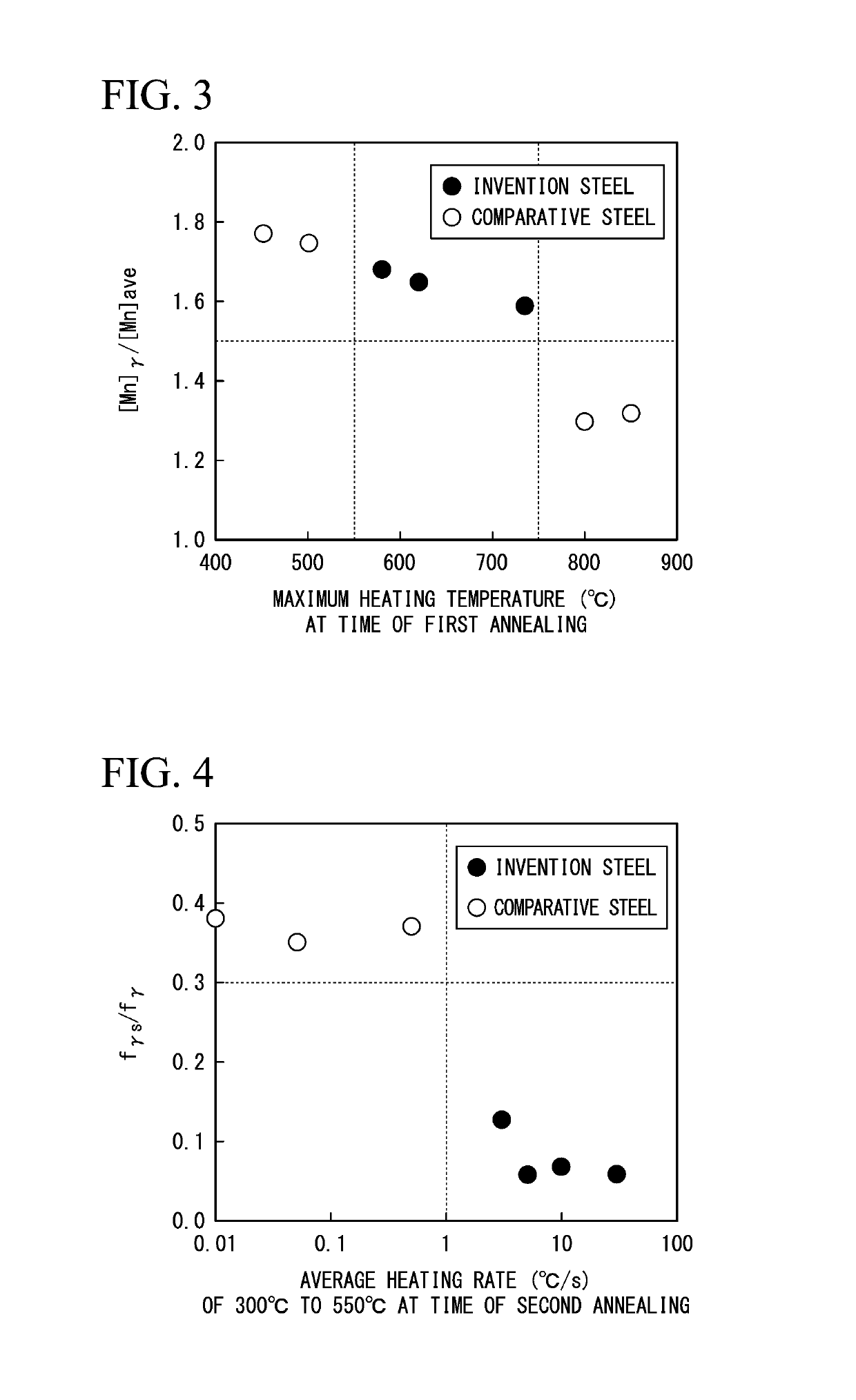

Steel sheet

InactiveUS20190211427A1Improve solderabilityTensile strength highHot-dipping/immersion processesFurnace typesChemical compositionSheet steel

A steel sheet according to an aspect of the present invention includes a predetermined chemical composition; in which a metallographic structure in a ¼ t portion contains residual austenite of 4 volume % to 70 volume %; [Mn]γ / [Mn]ave>1.5 is satisfied in the ¼ t portion; fγs / fγ≤0.30 and [C]×[Mn]≥0.15 are satisfied in the ¼ t portion.

Owner:NIPPON STEEL CORP

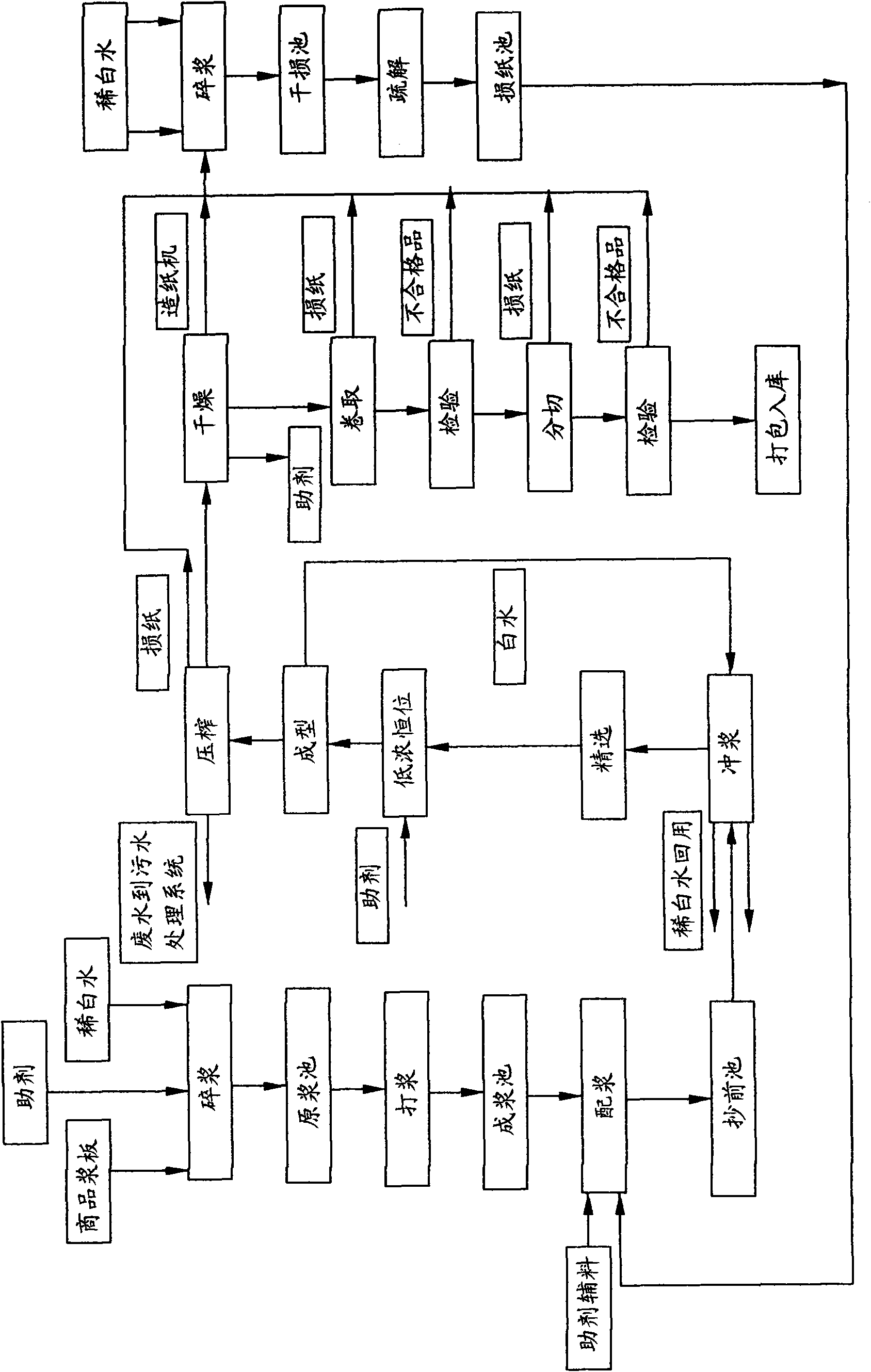

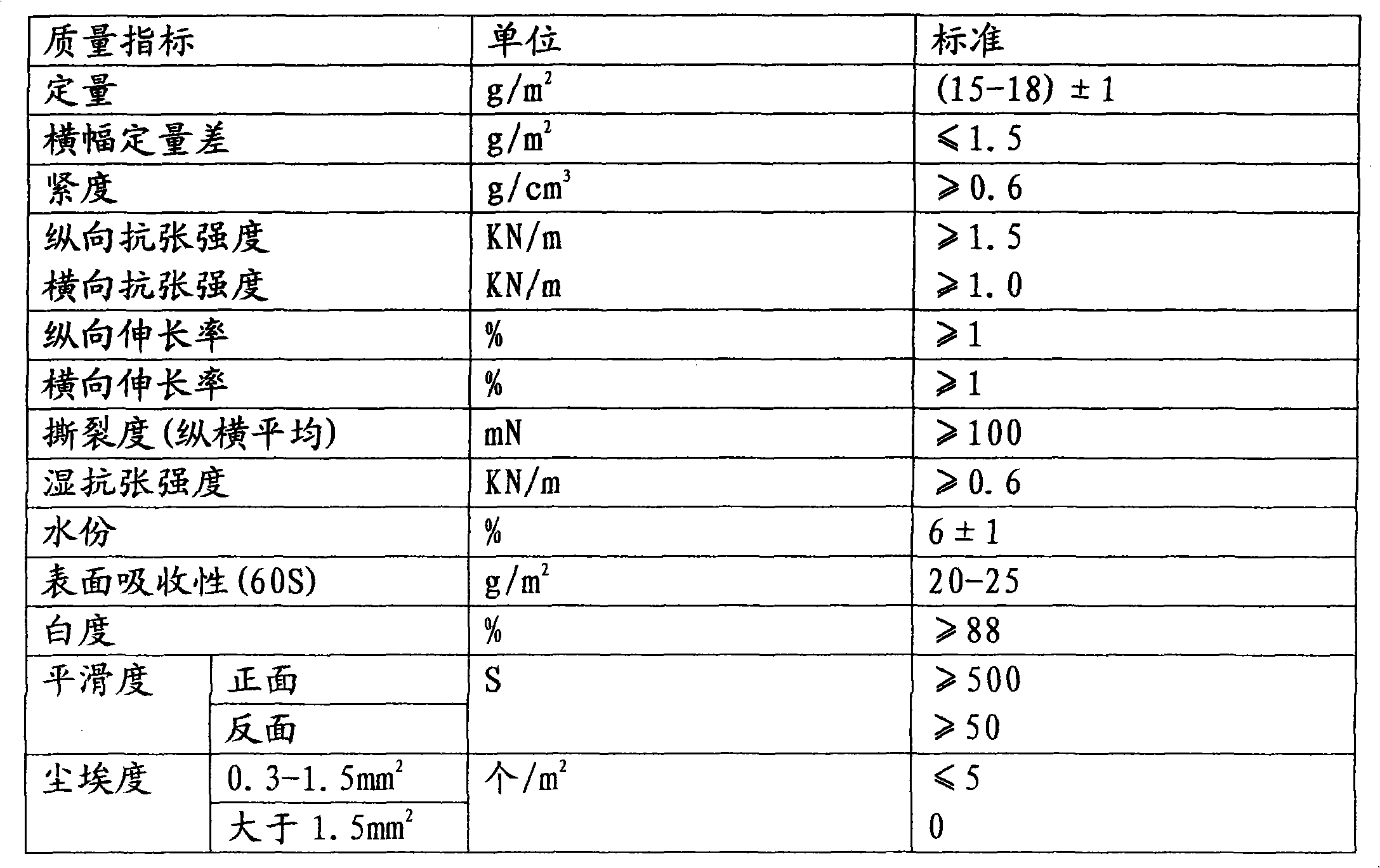

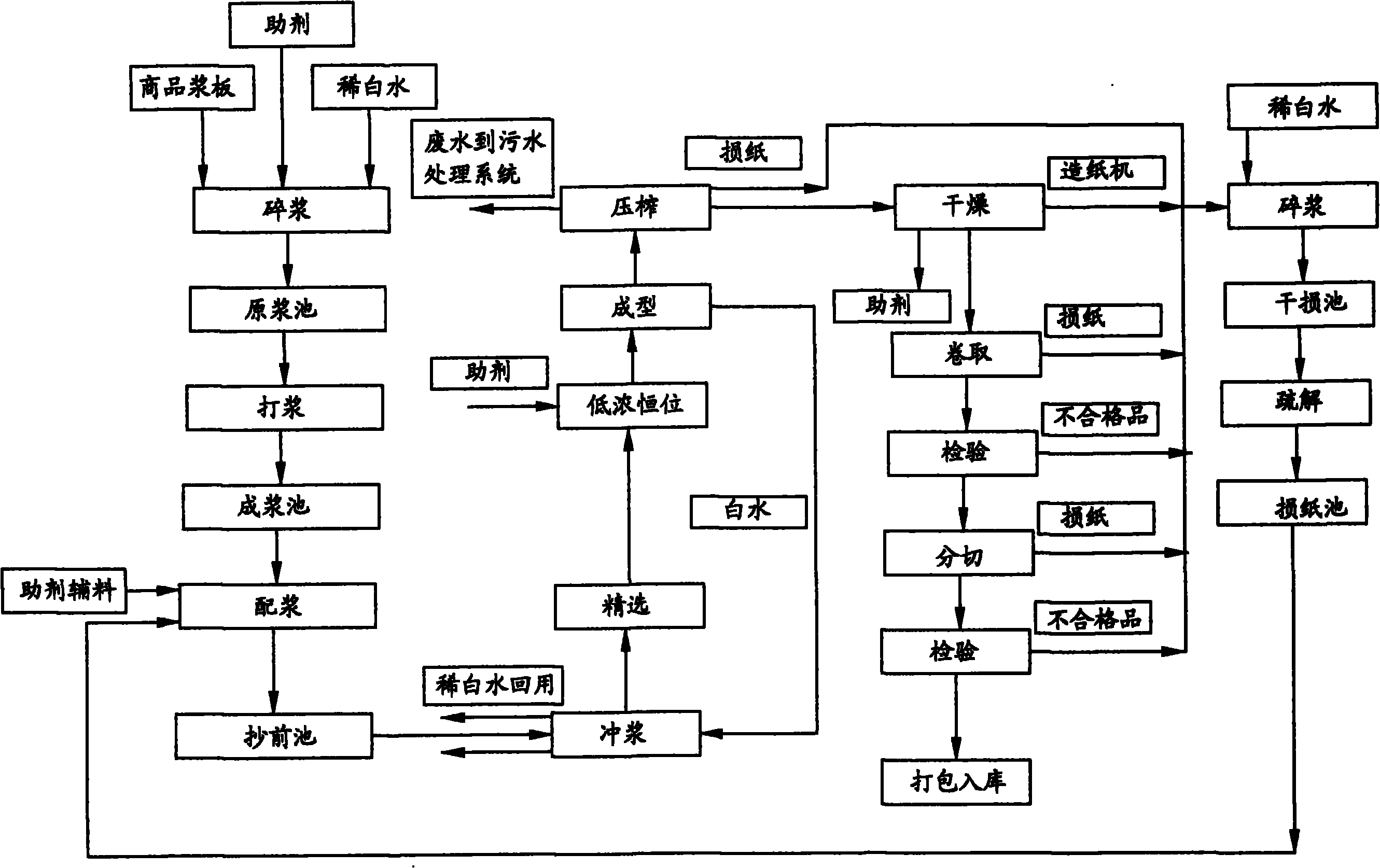

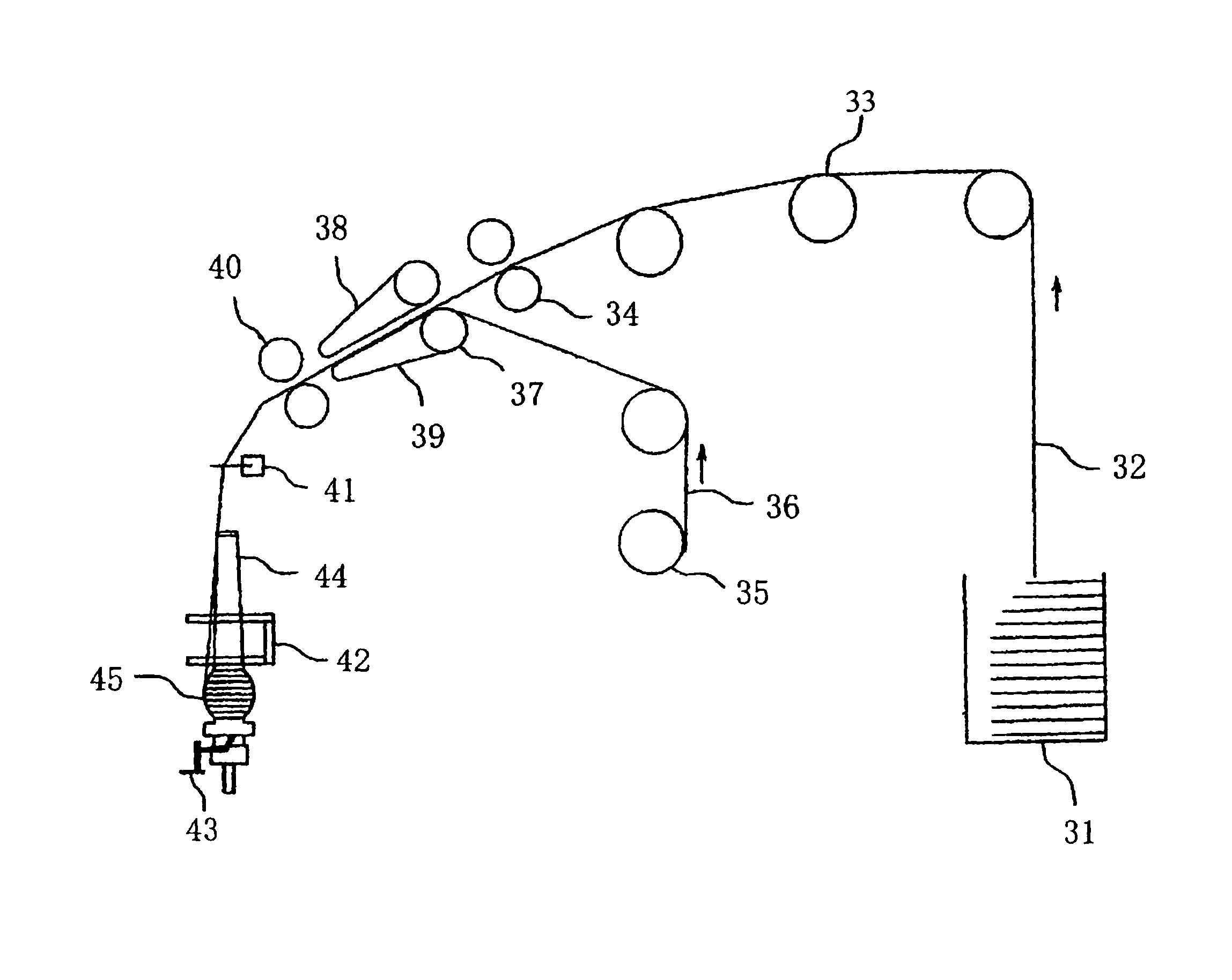

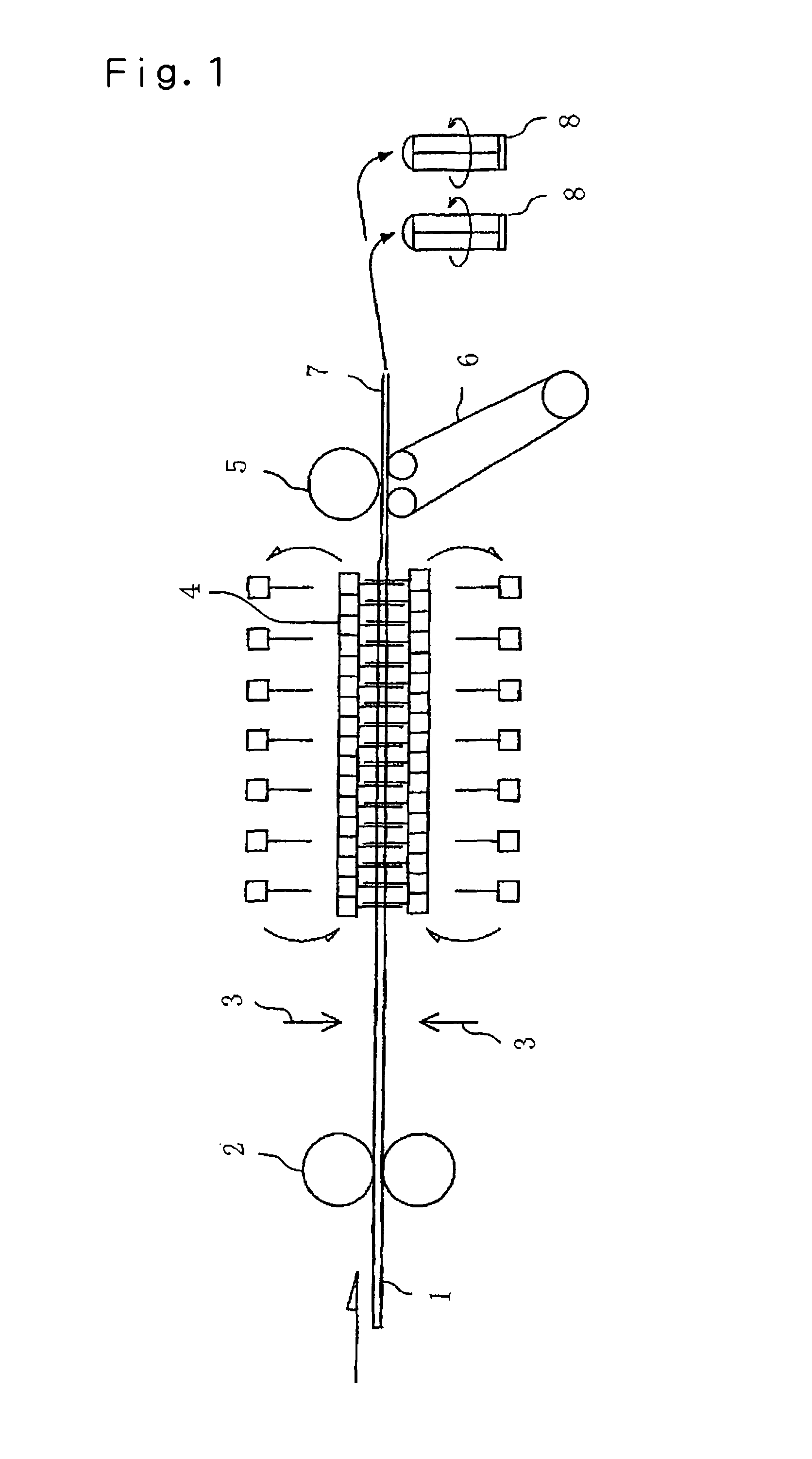

Production process for cotton paper

InactiveCN101914862AImprove toughnessImprove water and moisture absorption performanceCellulose material pulpingFiberCotton paper

The invention discloses a production process for cotton paper, which comprises the following steps of: digesting long fibered wood pulp by using a hydraulic breaker, and adding chemical aids to prepare primary pulp; serially connecting a fluted disc type deflaker and a fiberizer, pulping in a semi-cohesive state at low current, wherein the pulping concentration of the fiberizer is 4.2 to 5.5 percent and the pulping ampere is 46 to 58A; compounding the pulp after the pulping is finished, adding 1 percent of brightener, filtering with a 90-mesh screen, and uniformly compounding with the pulp; and performing papermaking on the mixed pulp, drying, reeling by using a re-reeling machine, detecting broken paper in the drying and reeling procedures, digesting and defibering the detected broken paper, and refluxing the broken paper to the pulp compounding procedure. The cotton paper prepared by the process has the advantages of uniform fibrous tissues, flat and smooth paper surface and small aspect ratio.

Owner:FUJIAN NAOSHAN PAPER IND GROUP

Hybrid carbon fiber spun yarn and hybrid carbon fiber spun yarn fabric using the same

ActiveUS8171711B2High tensile strengthReduce adhesionLayered productsFinal product manufactureYarnCarbon fibers

A hybrid carbon fiber spun yarn having a core region with carbon fibers as a main component, and a surrounding region with carbon fibers as a main component and covers an outer peripheral surface of the core region. 20% by mass or more of fibers forming the core region are long carbon fibers having a fiber length of 500 mm or longer. 80% by mass or more of fibers forming the surrounding region are short carbon fibers having a fiber length of less than 500 mm. A mass ratio between the long carbon fibers and the short carbon fibers (long carbon fibers:short carbon fibers) is in a range of 20:80 to 80:20.

Owner:KUREHA KAGAKU KOGYO KK

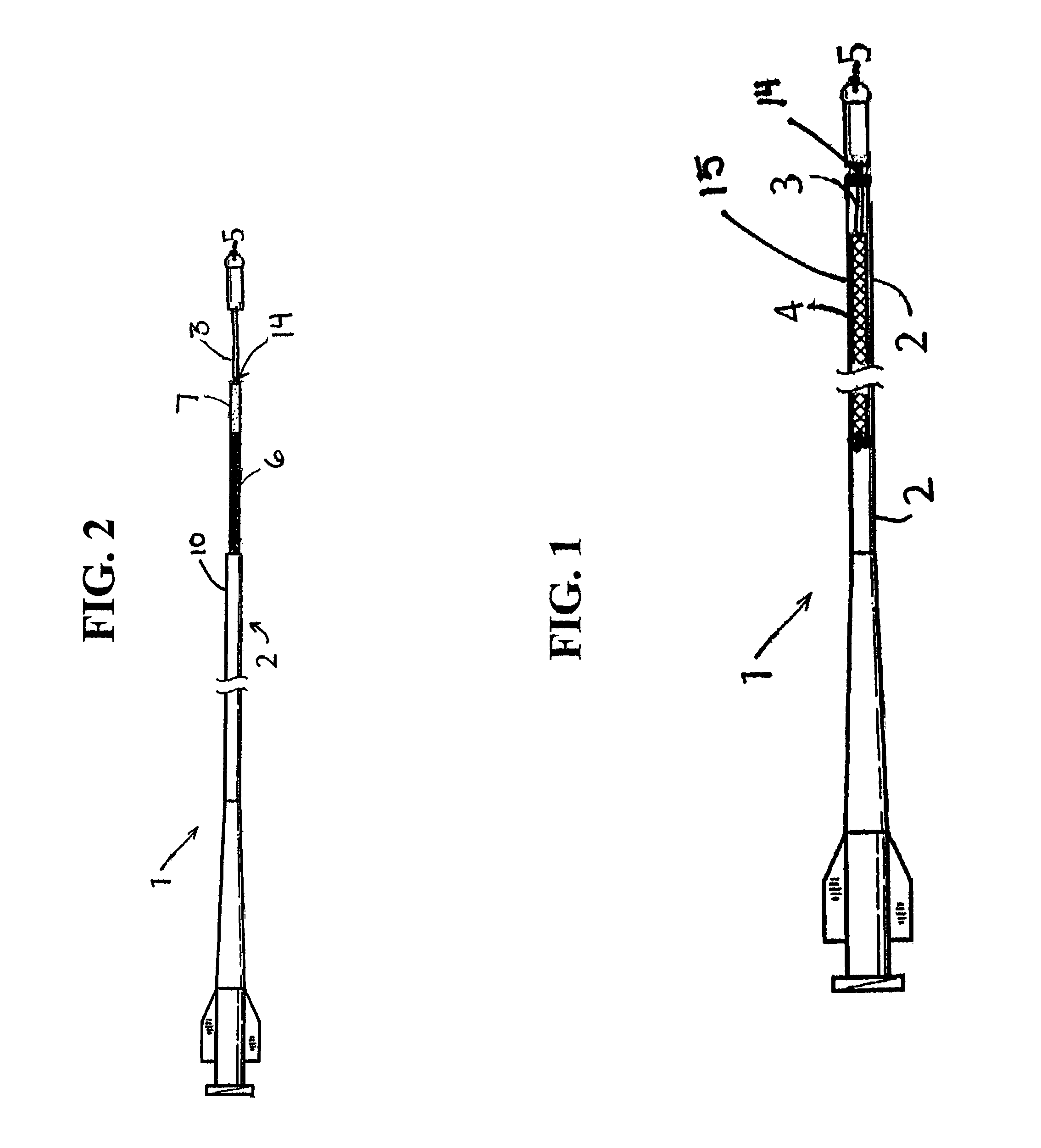

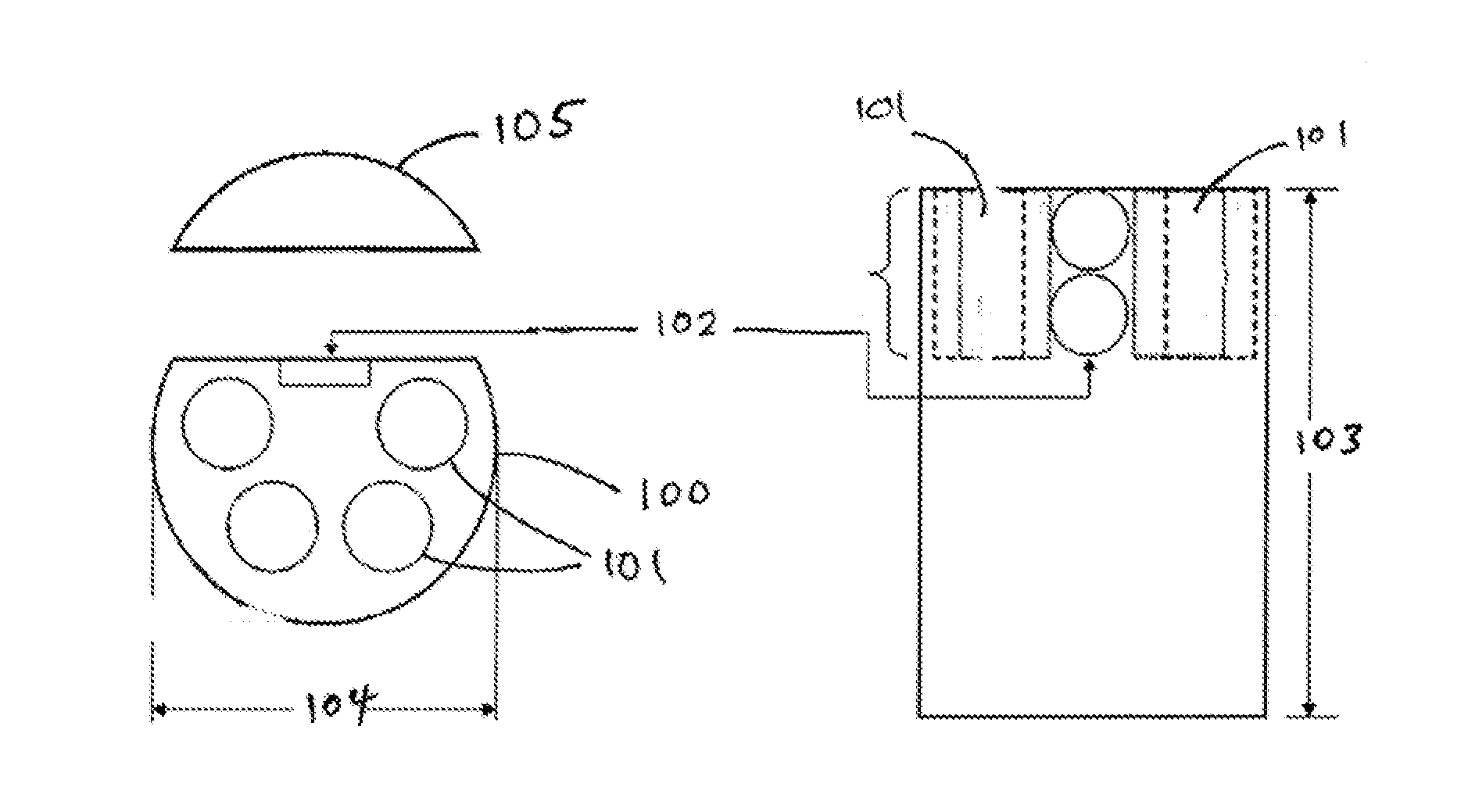

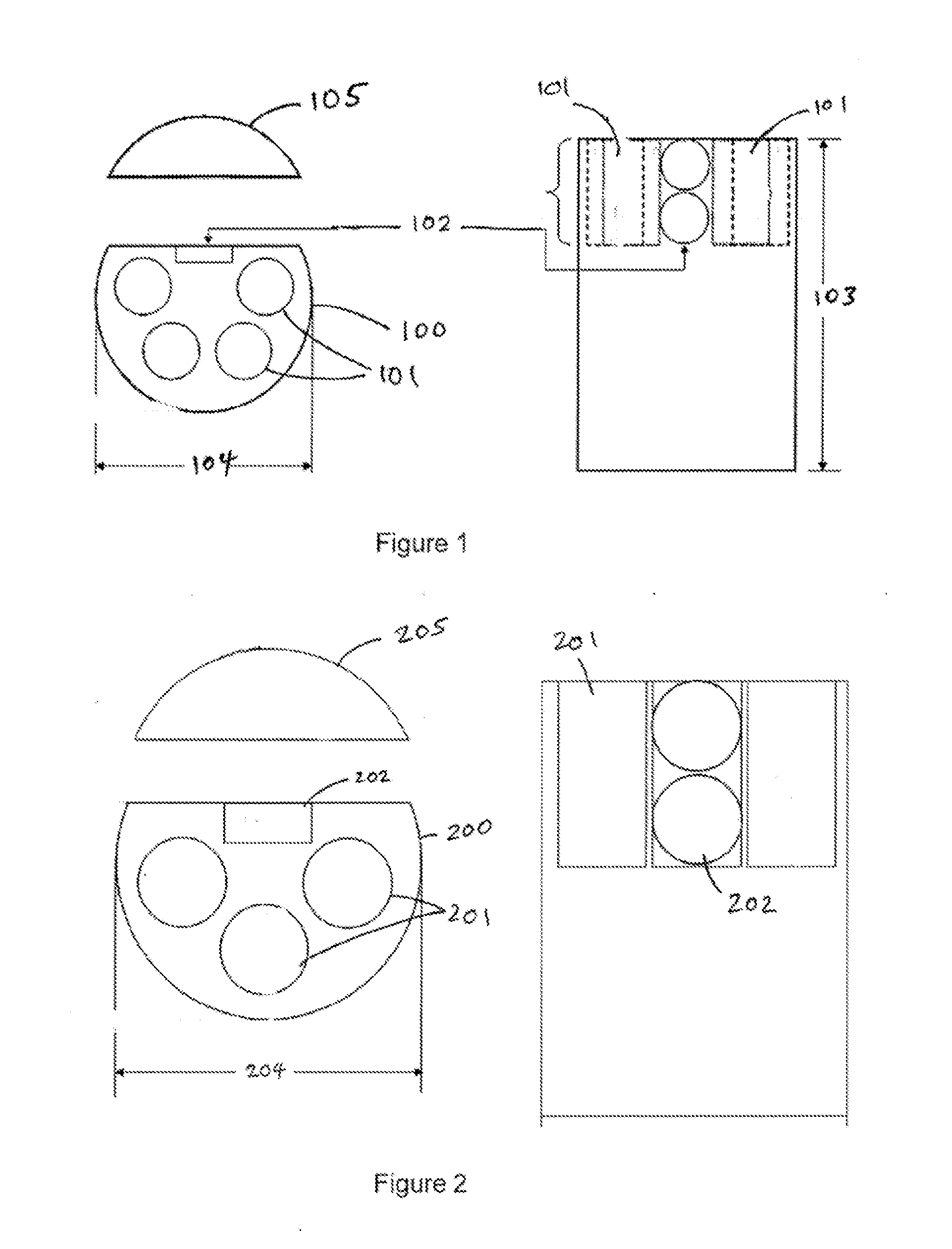

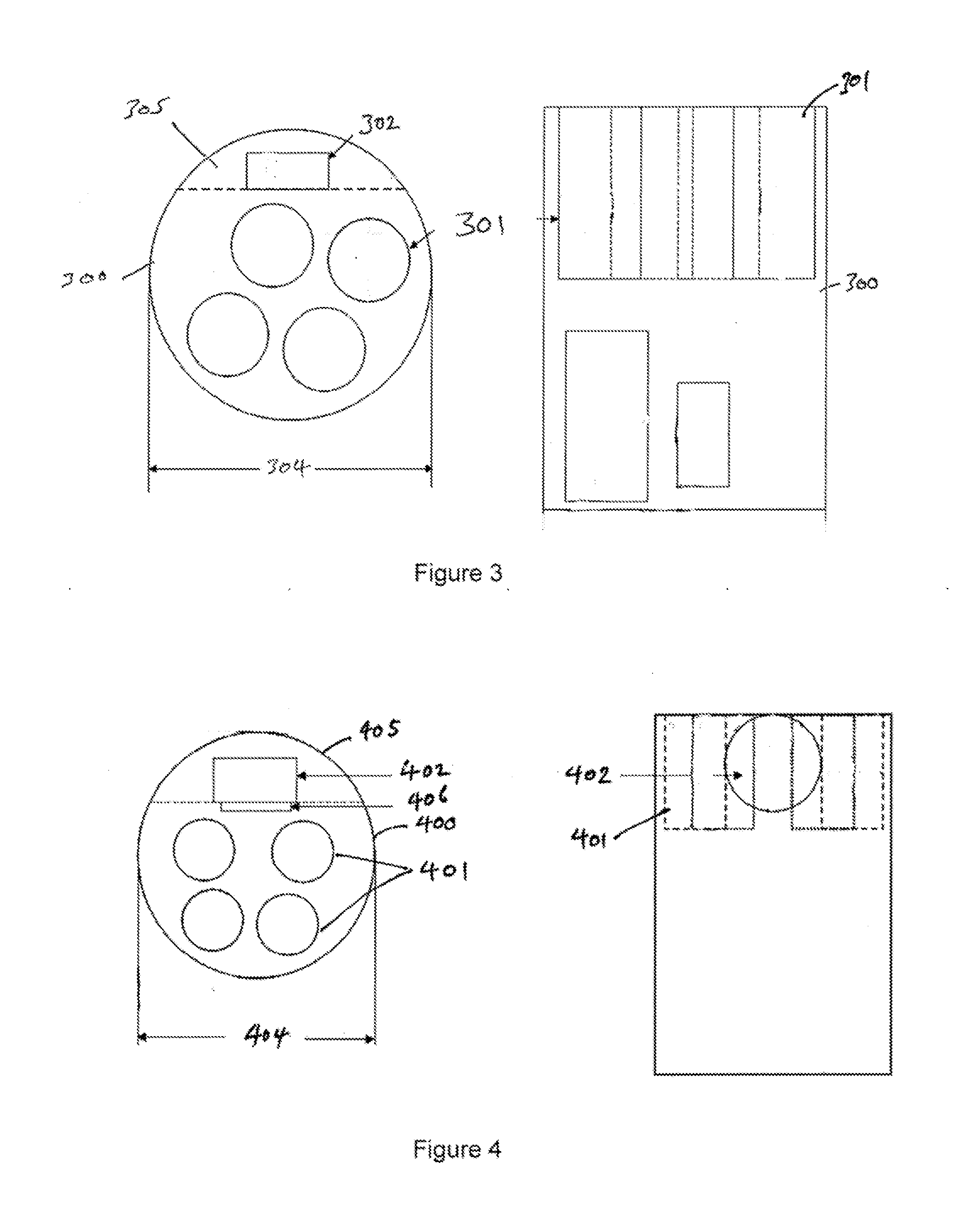

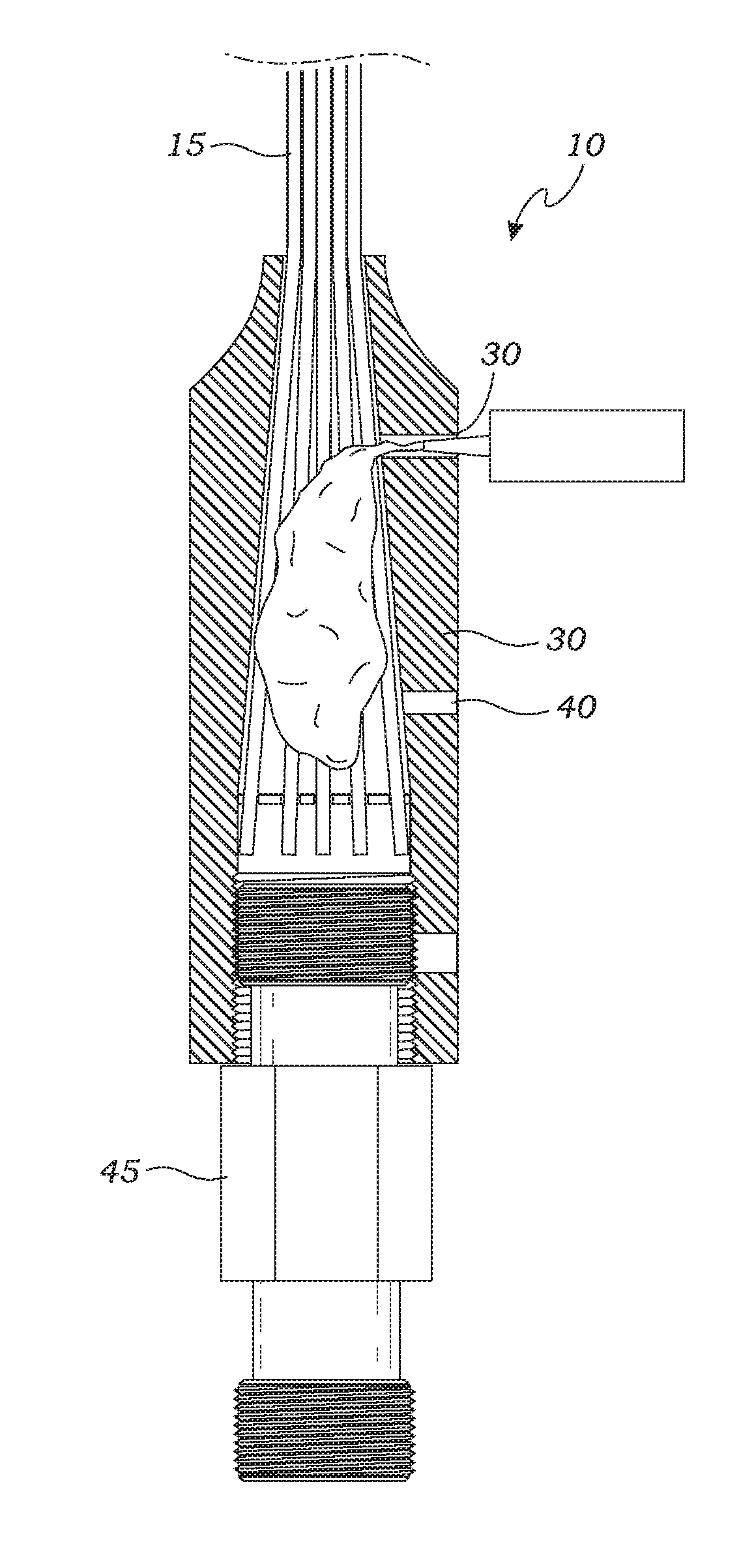

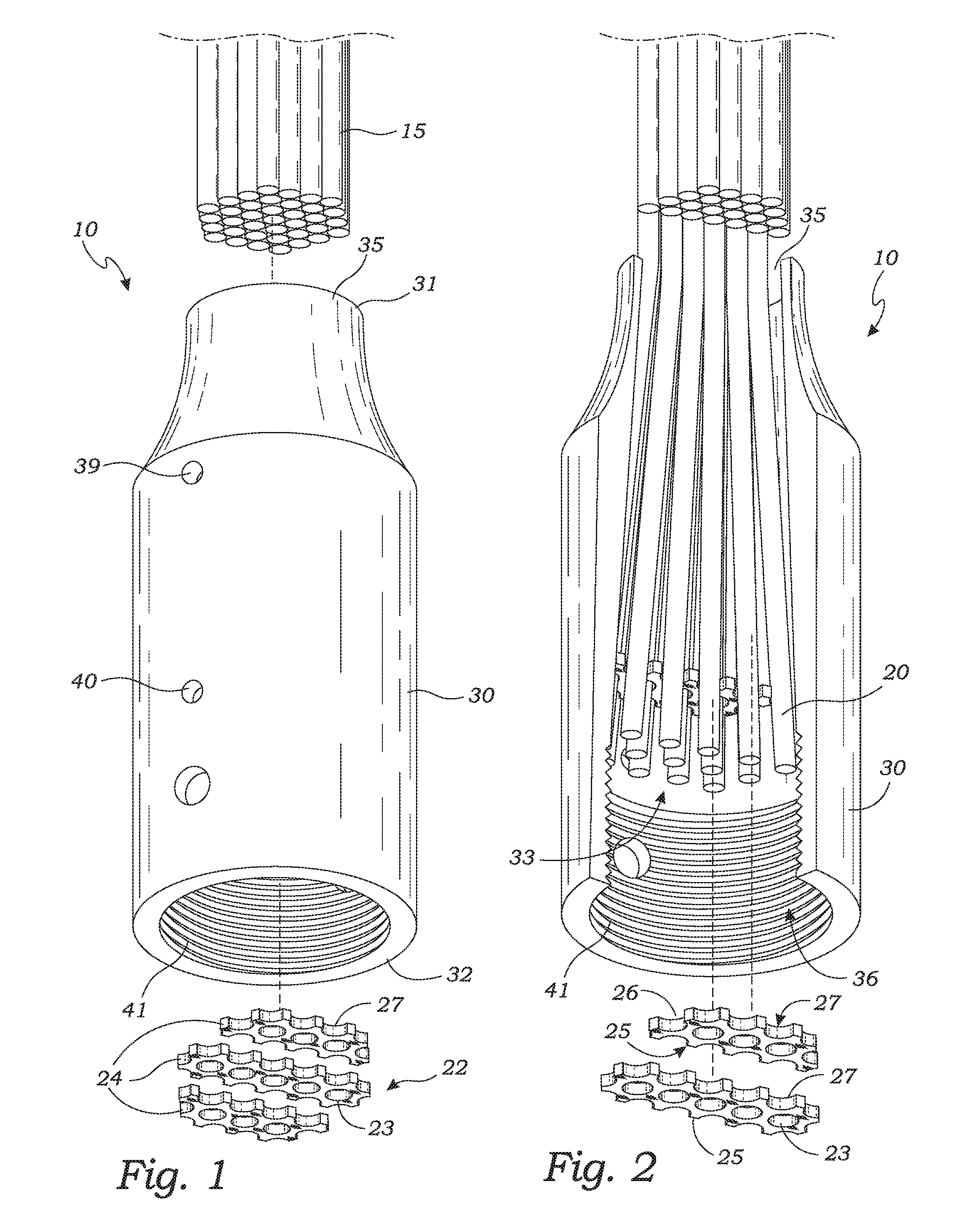

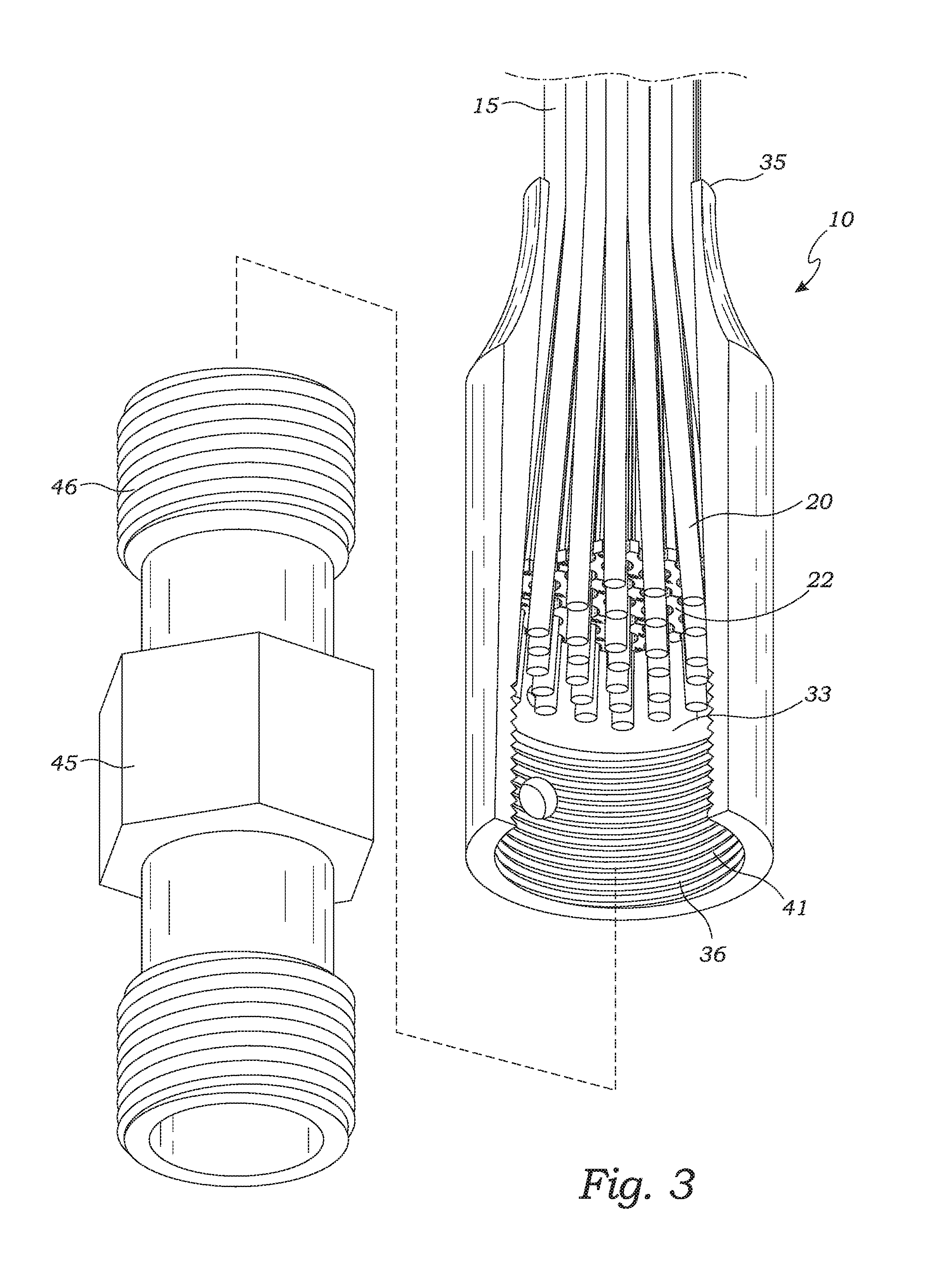

Composite sucker rod assembly for underground wells

InactiveUS20160362939A1Increase stiffnessPrevent wearDrilling rodsConstructionsEngineeringMechanical engineering

A composite sucker rod assembly is provided for use in down-hole wells. The sucker rod assembly includes a plurality of parallel composite strands forming an elongate rod. Preferably, both ends of the rod are fitted with metallic terminus fittings. Each terminus fitting has a tapered cavity with a proximal opening to receive a rod end. The cavity is tapered so as to flare outwardly from said cavity's proximal opening toward the cavity's distal end. The sucker rod assembly further includes a spreader plate, preferably made up of a plurality of pieces, which has holes to receive and splay out the plurality rod strands. A hardened material, such as a hardened resin, is introduced into the cavity and allowed to harden to affix the rod to the terminus fitting. Preferably the hardened resin is compressed by a connection member.

Owner:ELEVATORING SOLUTIONS USA INC

Connector having shell and connector device

ActiveUS10461478B2Tensile strengthTwo-part coupling devicesCoupling protective earth/shielding arrangementsEngineeringCantilever

Provided is a connector configured so that tensile strength when an attempt is made to forcibly detach the connector from a partner connector can be enhanced. A housing includes a body portion and a fitting target portion extending to the side of fitting to the partner connector. The diameter of a side portion outer peripheral surface of the fitting target portion is, at at least part thereof, smaller than that of the body portion. A conductive shell includes a first shell and a second shell. The first shell includes a cover portion configured to cover at least part of an outer peripheral surface of the housing, an elastic arm having a free end on the side of fitting to the partner connector, and a support portion elastically connecting the cover portion and the elastic arm and configured to support the elastic arm in a cantilever manner. The elastic arm has a lock portion configured to lock fitting to the partner connector, and has a stepped portion corresponding to a stepped surface of the housing provided using a difference in the diameter. The second shell includes a portion facing the stepped portion at a position closer to the side of fitting to the partner connector than the stepped portion of the elastic arm.

Owner:HIROSE ELECTRIC GROUP

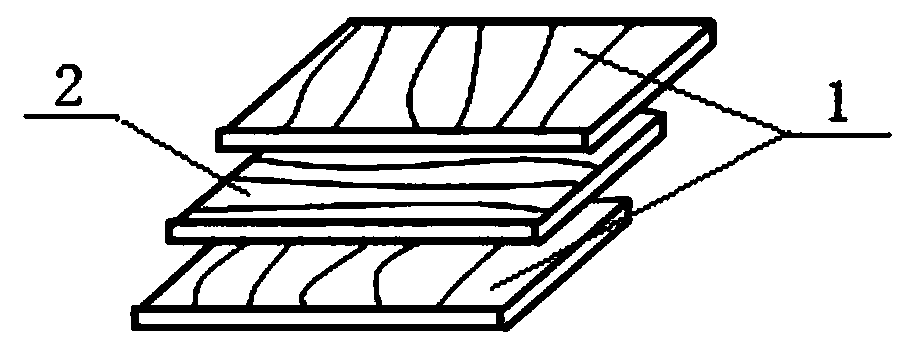

Palm wood plywood and preparation method thereof

InactiveCN108818785AImprove physical and mechanical propertiesGood dimensional stabilityOther plywood/veneer working apparatusWood veneer joiningMelamine resinEngineering

The invention discloses palm wood plywood and a preparation method thereof. The plywood comprises a surface board and a core board, a high-density palm impregnated wood single board formed by the impregnating of impregnated resin is adopted as the surface board, a low-density palm impregnated wood single board formed by the impregnating of the impregnated resin is adopted as the core board, the content of the impregnated resin in the high-density palm impregnated wood single board is 20-55%, and the content of the impregnated resin in the low-density palm impregnated wood single board is 30-65%, the solid content of the impregnated resin is 30-50%, urea-formaldehyde resin, phenol formaldehyde resin, melamine resin or melamine modified urea-formaldehyde resin is adopted, and the preparationmethod of the plywood is further disclosed. The palm wood plywood has the advantages that the mechanical performance and the dimensional stability are excellent and can meet related national standards.

Owner:NANJING FORESTRY UNIV

Insulation layer for cable conductors

InactiveCN106832798AWith insulationMoisture-proofPlastic/resin/waxes insulatorsInsulation layerPolyvinyl alcohol

The invention discloses an insulation layer for cable conductors. The insulation layer for cable conductors is composed of the following raw materials in parts by weight: 12-18 parts of polytetrafluoroethylene, 100-150 parts of epoxy acrylic resin, 50-60 parts of chlorosulfonated polyethylene rubber, 8-15 parts of aluminum chloride, 18-25 parts of hydroxy silicone oil, 6-10 parts of plasticizer, 8-12 parts of phenolic aldehyde-polyvinyl acetal and 4-8 parts of silicon dioxide. The insulation layer for cable conductors has the advantages of thermal insulation, moisture resistance, high flexibility, high tensile resistance, high tear resistance and the like.

Owner:ANHUI YUANZHENG CABLE TECH

Biodegradable aliphatic polyester fiber and method for producing the same

ActiveUS10760183B2Improve crystallization speedImproved threadingMonocomponent copolyesters artificial filamentNon-woven fabricsPolyesterFiber

An objective is to improve the spinnability and the productivity and increase the tensile strength of a polyester fiber containing polyhydroxyalkanoate. Disclosed is a biodegradable aliphatic polyester fiber containing a polyhydroxyalkanoate, a nucleating agent, and a lubricant, wherein the nucleating agent contains pentaerythritol, and the lubricant contains at least one of behenic amide, stearic acid amide, erucamide, oleic amide, and a combination thereof.

Owner:TOKYO INST OF TECH +1

Biodegradable aliphatic polyester fiber and method for producing the same

ActiveUS20190003082A1Improve crystallization speedImproved threadingMonocomponent copolyesters artificial filamentNon-woven fabricsPolyesterFiber

An objective is to improve the spinnability and the productivity and increase the tensile strength of a polyester fiber containing polyhydroxyalkanoate. Disclosed is a biodegradable aliphatic polyester fiber containing a polyhydroxyalkanoate, a nucleating agent, and a lubricant, wherein the nucleating agent contains pentaerythritol, and the lubricant contains at least one of behenic amide, stearic acid amide, erucamide, oleic amide, and a combination thereof.

Owner:TOKYO INST OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com