Patents

Literature

934results about How to "Improve physical and mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite material of polypropylene in low smell and preparation method

InactiveCN1727390AGood physical and mechanical propertiesSimple preparation processMolecular sieveChemistry

A polypropene composition with low odor is proportionally prepared from polypropene, talc powder, molecular sieve (powdered silicoaluminate of alkali-metal), toughening agent poe, and thermal stabilizer.

Owner:SHANGHAI PRET COMPOSITES

Composite material of polypropylene in low smell and volatile matter

A polypropene composition with low odor and low volatile components is proportionally prepared from polypropene, talc powder, fine-porous silica gel, toughening agent poe, thermal stabilizer DSTP, thermal stabilizer 3114 and thermal stabilizer 618 through mixing, dual-screw extruding out and granulating.

Owner:上海天原集团胜德塑料有限公司

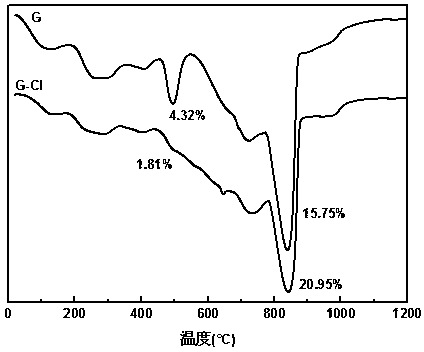

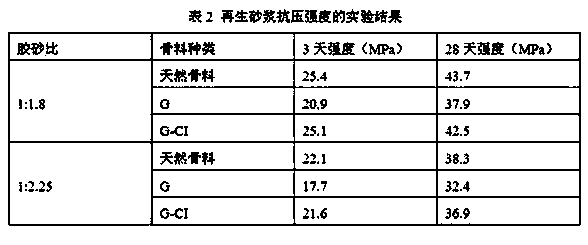

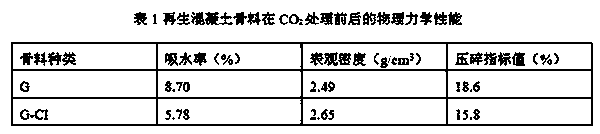

Method for carbon dioxide strengthening of recycled concrete aggregate

ActiveCN104045251AImprove physical and mechanical propertiesImprove early strengthSolid waste managementCarbonizationAbsorption rate

A method for carbon dioxide strengthening of a recycled concrete aggregate comprises the following steps: (1) crushing and sieving waste concrete; (2) placing the sieved recycled concrete aggregate in a sealed container, controlling the relative humidity of 30-90% and the CO2 concentration of 5-90%, and carrying out carbonization treatment; and (3) making the treated recycled concrete aggregate particles into recycled mortar and concrete. Compared with mortar prepared from a recycled concrete aggregate without treatment, the mortar prepared from the obtained recycled concrete aggregate after CO2 strengthening treatment enables the mortar early strength to be improved by 20.1%-22.0% and the later strength to be improved by 12.1%-13.9%; the 28 d drying shrinkage value can be reduced by 7.8%-16.7%; and the 28 d water absorption rate can be reduced by 7.7%-13.3%.

Owner:HUNAN UNIV

Low-odour polypropylene composite

The invention relates to a low-odour polypropylene compound, the compound comprises (by weight ratio) polypropylene 55-95, talcum powder 0-40, fatty acid ester compound 0.5-3, nano zinc oxide 0.5-3, nano titanium oxide 0.5-3, heat stabilizer DSTP 0.1-1.0, heat stabilizer 3114 0.1-1.0, heat stabilizer 618 0.1-0.5, wherein the fatty acid ester compound being C25-C45 long-chain fatty acid ester, the heat stabilizer DSTP being octadecyl thiodipropionate, the heat stabilizer 3114 being 3,obtaining 5-ditert-butyl-4-hydroxy benzylphosphonate diethylate, the heat stabilizer being dioctadecyl pentaerythritol diphosphite.

Owner:SHANGHAI PRET COMPOSITES +1

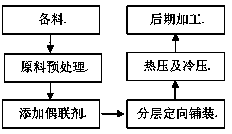

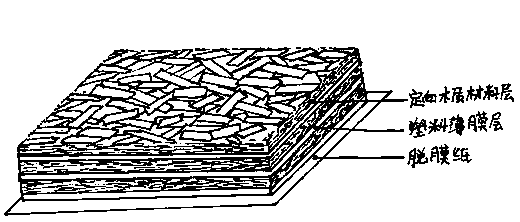

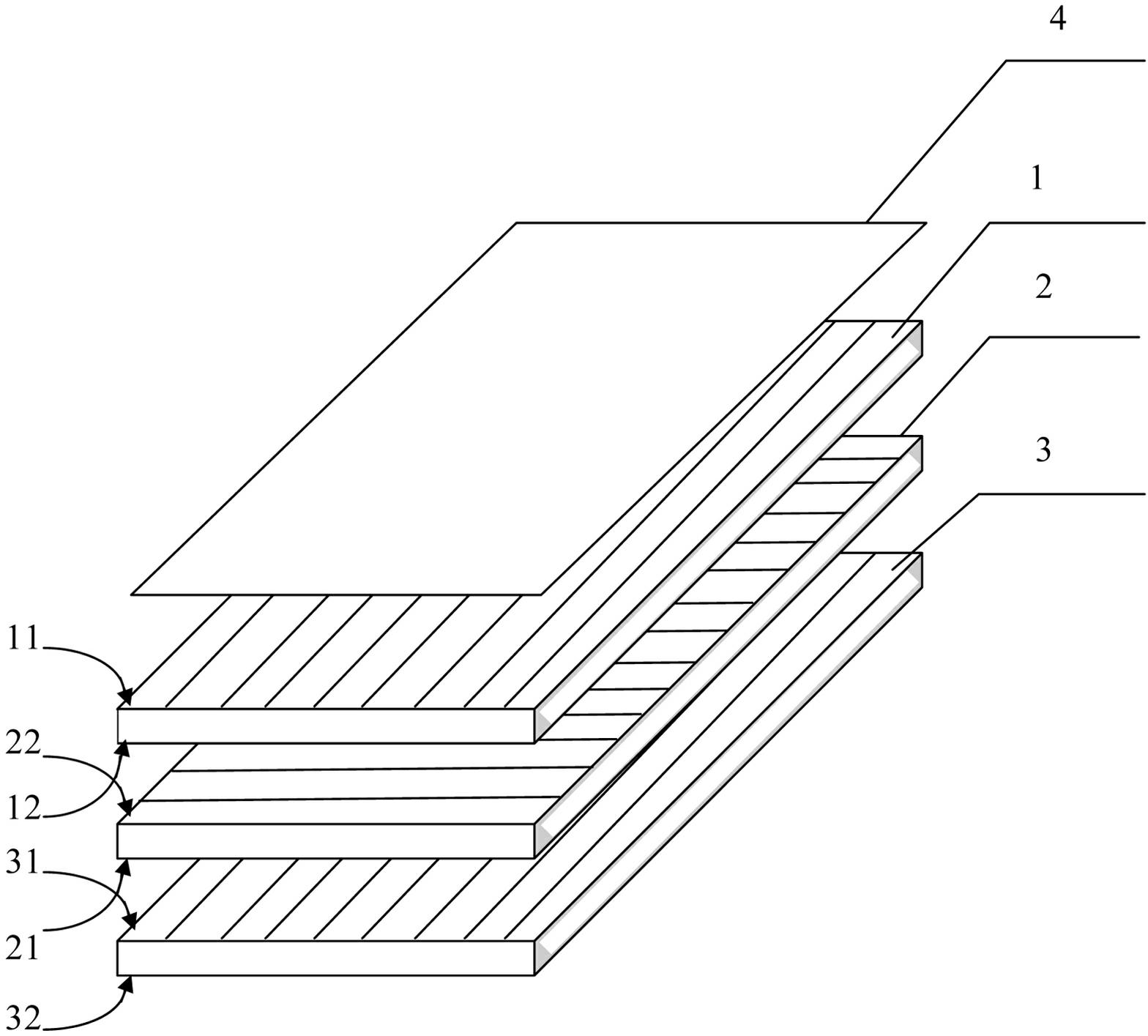

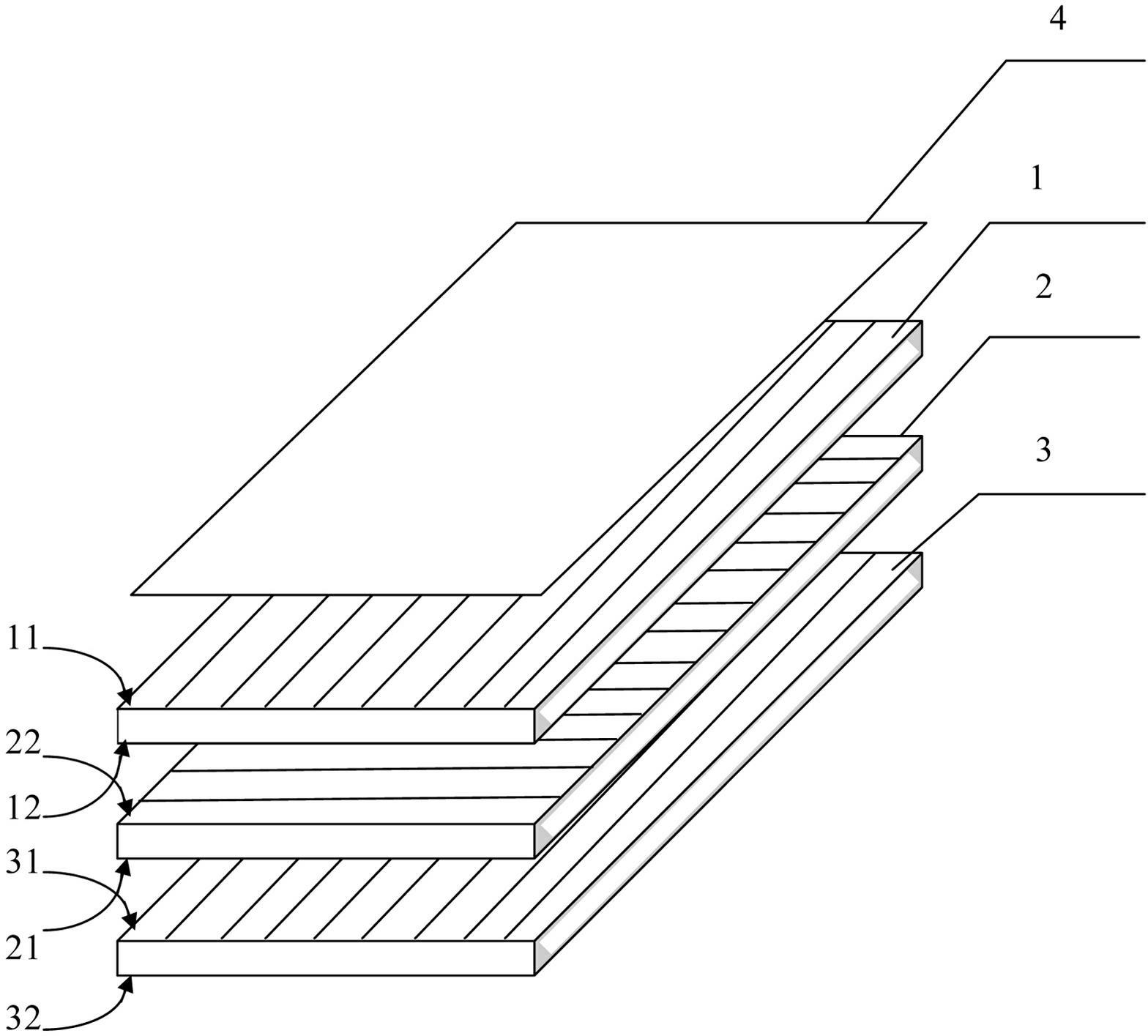

Directional wood-plastic composite plate and manufacturing method thereof

InactiveCN103659946ASmall sizeIncrease contentSynthetic resin layered productsLaminationThermoplasticPulp and paper industry

The invention relates to a directional wood-plastic composite plate and a manufacturing method thereof. The problem that large-slenderness-ratio wood raw materials are used for manufacturing wood-plastic composite materials is solved. The directional wood-plastic composite plate comprises the following ingredients in percent by weight: 70-95% of wood raw materials, 5-30% of thermoplastic plastics and 0.5-4% of coupling agents. The manufacturing method for the directional wood-plastic composite plate comprises the following steps of preparing raw materials; pre-treating the raw materials; adding the coupling agents in the raw materials; directionally laying the wood raw materials and thermoplastic plastic films in a layered manner; and performing hot pressing, cold pressing and later machining procedures on the materials. The directional wood-plastic composite plate has the advantages that the content of the plastics is low, the physical mechanical performance is high, the width of the directional wood-plastic composite plate is large, and release of harmful gas is avoided; and the directional wood-plastic composite plate is applicable to buildings, furniture and packaging materials.

Owner:BEIJING FORESTRY UNIVERSITY

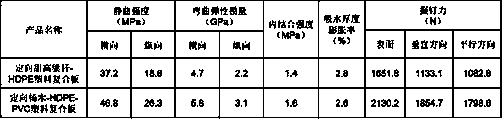

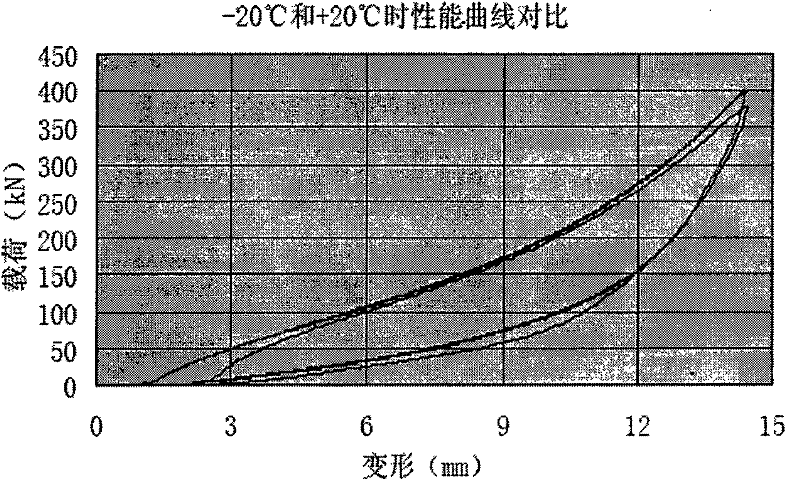

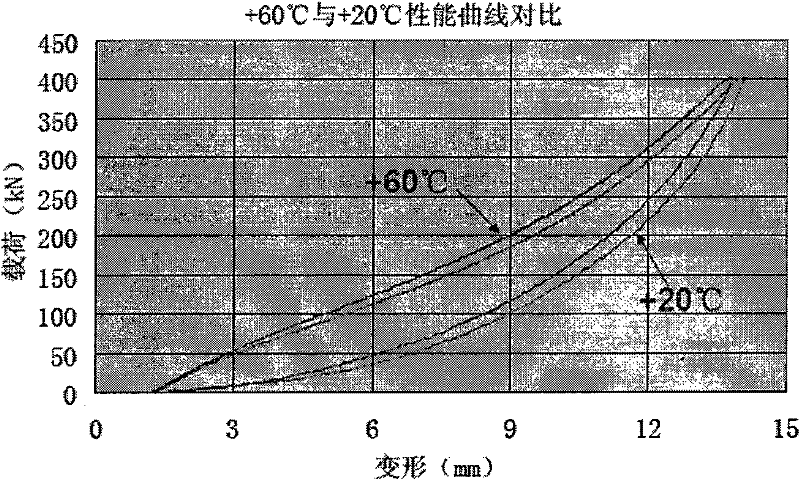

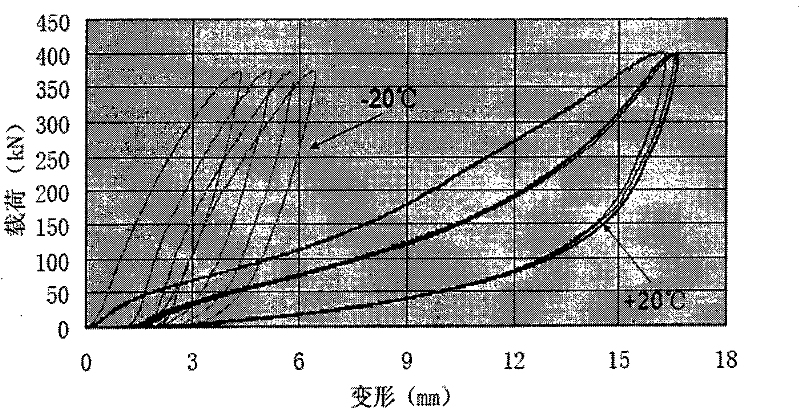

A kind of polyurethane elastomer shock absorber material and preparation method

The invention relates to a polyurethane elastomer shock absorber material and a preparation method. The present invention is formed from the following three components (A), (B) and (C) through a two-step polymerization reaction. This elastomer material has excellent mechanical properties and extremely stable stiffness maintenance over the operating temperature range. Among them (A) polymer polyol, (B) polyisocyanate, (C) low molecular polyol, ammonia chain extension cross-linking agent, (A) uses an optimized combination of polyether and polyester, and the present invention is used for The application of elastomer buffering and shock absorption can greatly reduce the volume and weight of equipment shock absorption system components, and solve the problem of large changes in the stiffness of polyurethane elastomer materials despite temperature. At the same time, the invented material has high rebound, low pressure change, hydrolysis resistance and Biodegradability, thereby expanding the application scope of polyurethane materials in elastomer shock absorption.

Owner:NORTHWEST RUBBER & PLASTIC RES & DESIGN INST CO LTD

High-performance recovered PET/ABS alloy

The invention discloses a high-performance recycled PET / ABS alloy. The alloy comprises the following components in percentage by weight: 30 to 80 percent of recycled PET, 10 to 50 percent of ABS, 1 to 10 percent of reinforcing agent, 2 to 15 percent of compatilizer, 0.5 to 5 percent of flexibilizer, 0.5 to 3 percent of polyhydroxy chemical coupling agent, and 0.1 to 1 percent of antioxidant. The alloy can improve a recycled PET system by using reasonable matching of additives, effects of the polyhydroxy chemical coupling agent, and excellent physical mechanic properties of an ABS system. Therefore, the recycled PET / ABS alloy has the advantages of high compatibility, high tensile strength, high mobility, good machinability and the like, is particularly suitable for producing complicated components and parts and large plates, has a simple process, is suitable for mass production of medium-sized and small enterprises, and has obvious economic benefit and social benefit.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Non-formaldehyde solid wood composite floor using low-density cottonwood veneers as base materials and manufacturing method thereof

ActiveCN102423891AHigh densityEfficient value-added utilizationWood working apparatusWood layered productsSolid woodSurface layer

The invention provides a manufacturing method of a non-formaldehyde solid wood composite floor using low-density cottonwood veneers as base materials. The non-formaldehyde solid wood composite floor is at least a cottonwood base plate assembly manufactured by combining following two raw materials: first, cottonwood veneers formed by stewing cottonwood logs at a low temperature of 10 to 50 DEC C, then rotary-cutting or slicing the cottonwood logs and afterwards drying the cottonwood logs, and second, plastic adhesive films manufactured by adopting thermoplastic resin; the treated cottonwood veneers are coated with coupling agents and are then assembled with the plastic adhesive films, and after hot-pressing and setting treatment, a cottonwood base plate is manufactured; afterwards, decorative thin wood is adopted as a surface layer and is combined with the cottonwood base plate assembly, and after cold-pressing, a floor blank is manufactured; and finally, the floor blank is milled, tenoned, slotted, and subjected to paint curing, and then a product is manufactured. Through using high polymer materials, from which no harmful substance escapes, in both the machining process and the use process, the environmentally friendly solid wood composite floor is produced.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

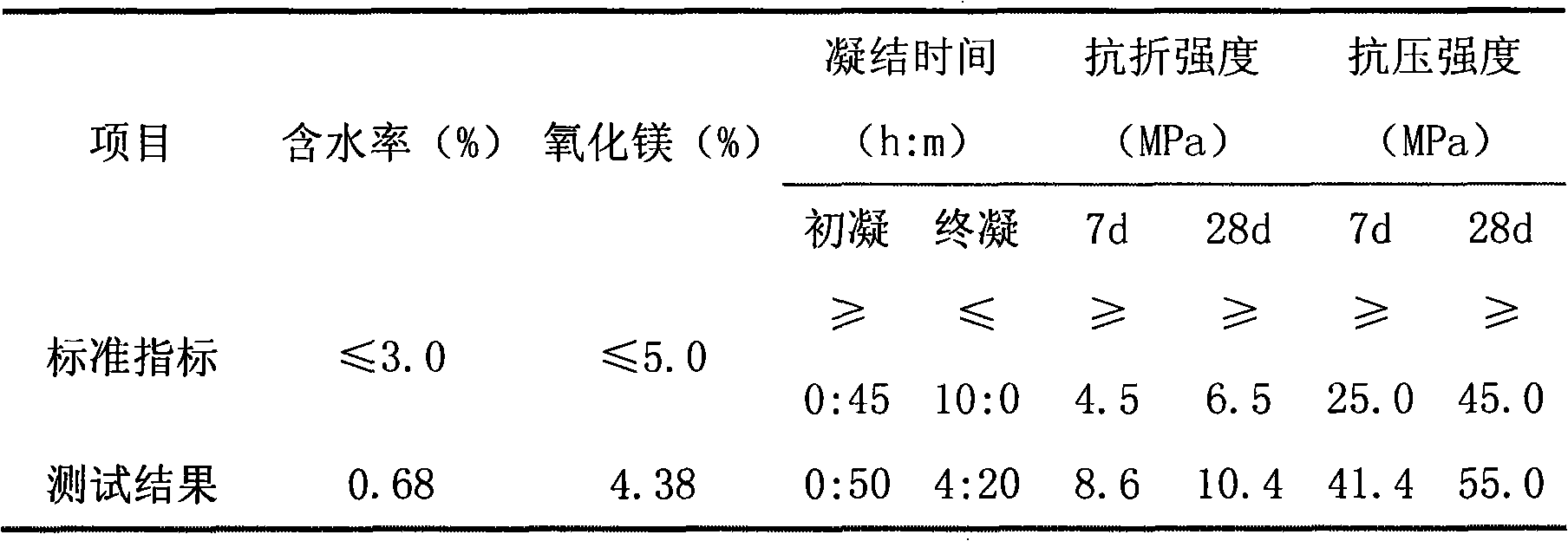

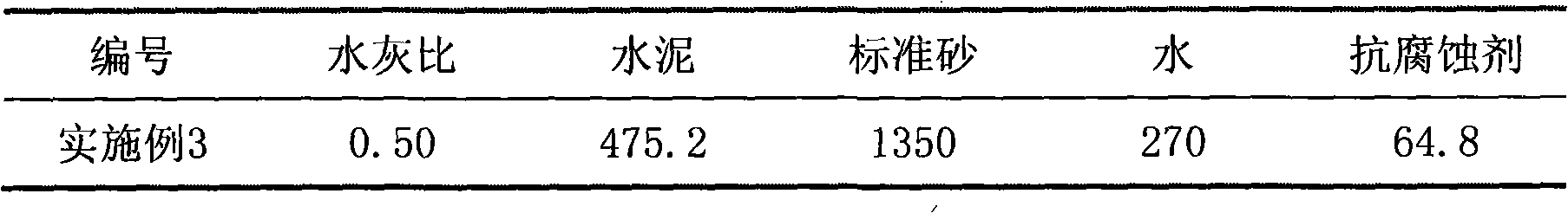

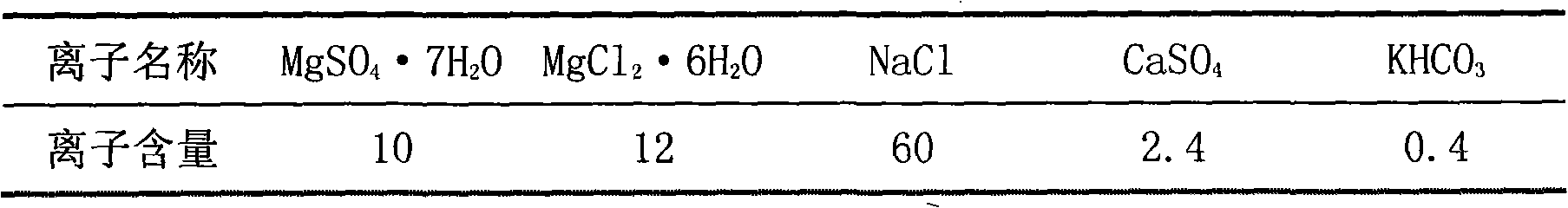

Concrete corrosion resistant additive for sea construction

InactiveCN101337787AAchieve high performanceImprove corrosion resistanceSolid waste managementCrack resistanceHazardous substance

The invention relates to a concrete corrosion proof additive for maritime work. The concrete corrosion proof additive is characterized in that the concrete corrosion-proof additive is prepared with the following components by weight: 40 to 80 percent of a sulfoaluminate micro-expanding agent, 0.1 to 2.0 percent of synthetic fiber, 1 to 10 percent of anticorrosive composition, 10 to 40 percent of fleur, and 0 to 12 percent of a water reducer. In the invention, the sulfoaluminate micro-expanding agent, the synthetic fiber, the anticorrosive composition, the fleur, the water reducer and so on are matched and compounded properly, thus forming the mutual superimposed effect. In this way, the crack resistance and the impermeability of concrete can be significantly improved; and chloride ions, vitriol and other hazardous substance can be effectively prevented from entering the concrete, thus preventing seawater and hazardous substance contained in seawater from eroding the concrete, protecting steel bars from being eroded, and improving the service life of concrete structure in maritime work.

Owner:南京派尼尔科技实业有限公司

High-performance tire containing oxidized graphene

InactiveCN105482201AHigh tensile strengthImprove physical and mechanical propertiesSpecial tyresActive agentCarbon black

The invention relates to a high-performance tire containing oxidized graphene and a preparing method thereof. Tread rubber is basically prepared from, by mass, 80-100 parts of matrix rubber, 50-70 parts of high dispersion white carbon black, 4-6 parts of silane coupling agent, 5-10 parts of carbon black, 0-10 parts of oxidized graphene rubber master batch, 2-8 parts of plasticizer, 1-3 parts of active agent, 1-3 parts of antiager, 1-3 parts of vulcanization accelerator, 1-2 parts of common sulphur and 0-0.3 part of scorch retarder. The oxidized graphene rubber master batch is the compound of oxidized graphene and natural rubber, and the mass of oxidized graphene is 5-15% of the total mass of the rubber master batch. By the adoption of oxidized graphene, the properties, including tensile strength, stress at definite elongation, hardness and wear resistance, of the composite tread rubber material are improved.

Owner:QINGDAO DOUBLESTAR TIRE IND CO LTD

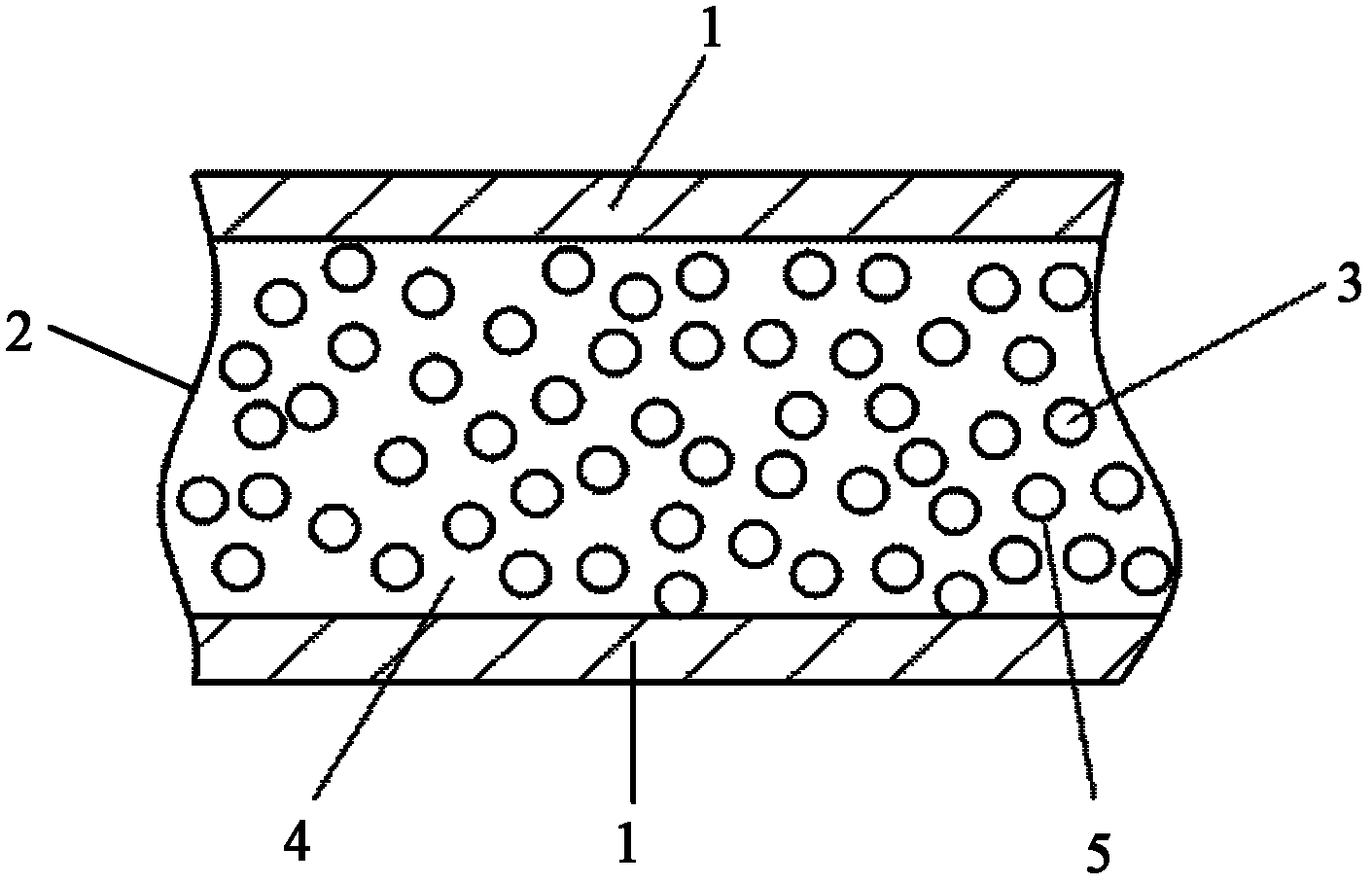

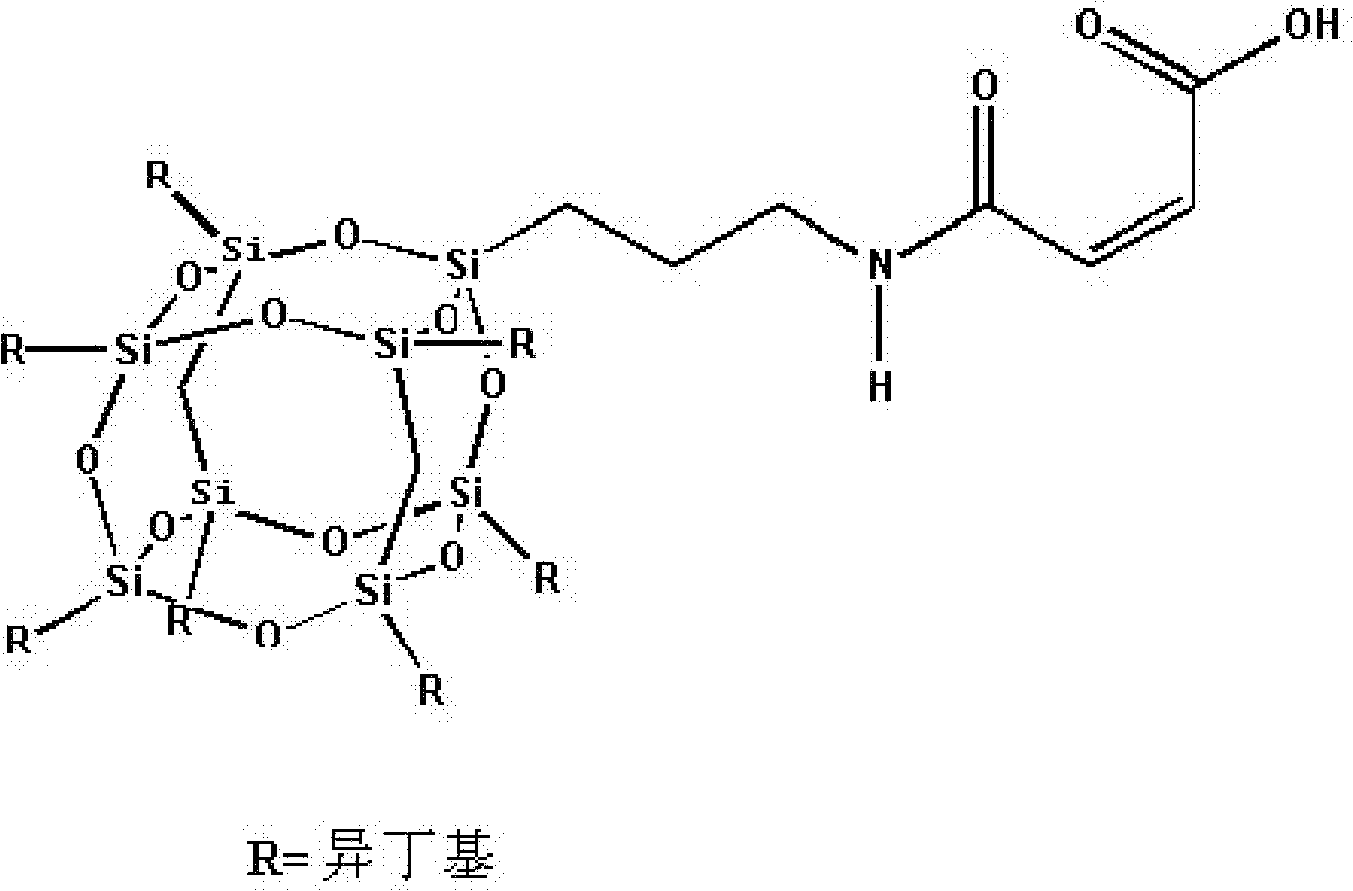

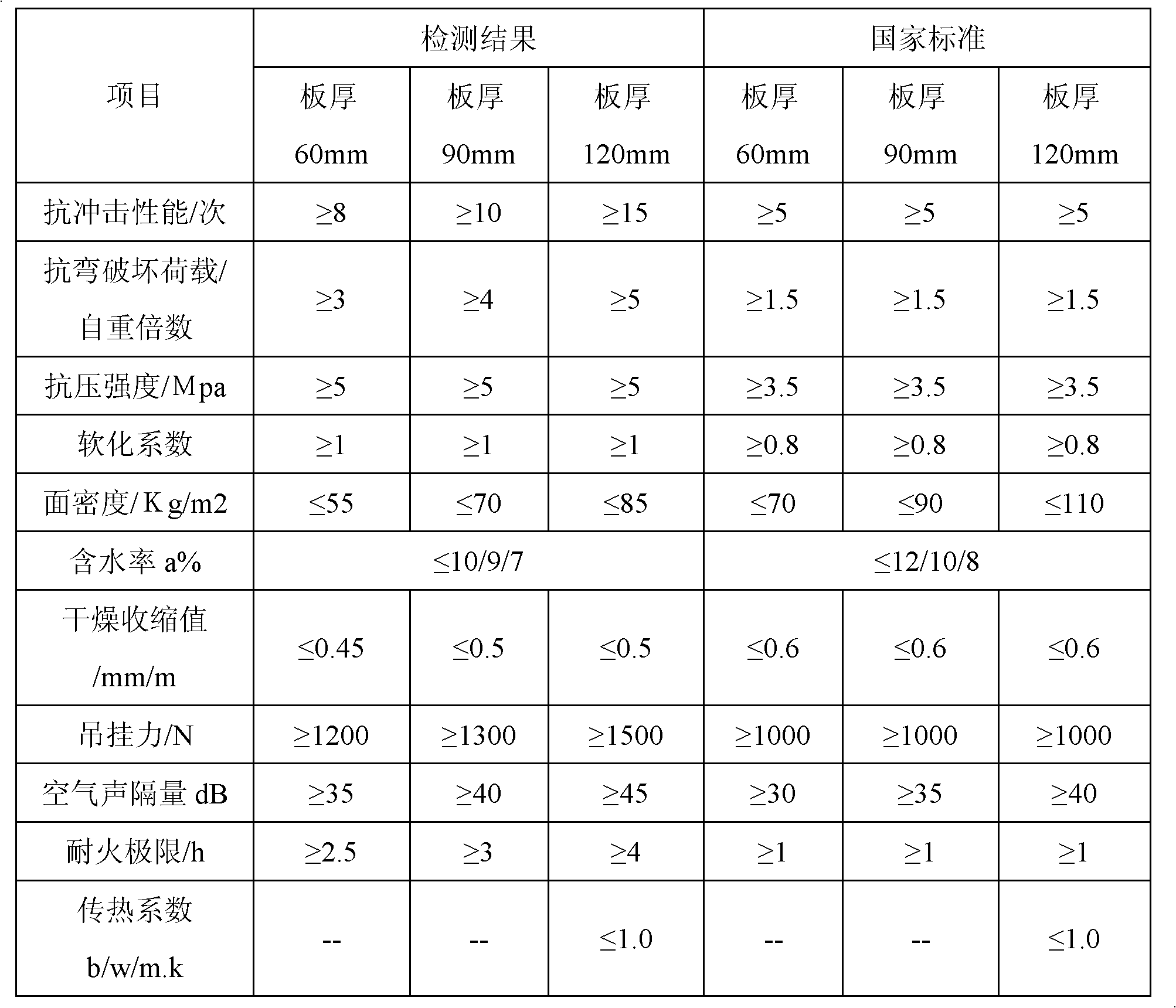

Composite heat-insulating wallboard and preparation method thereof

InactiveCN102505798AImprove interface compatibilityImprove physical and mechanical propertiesClimate change adaptationCeramic shaping apparatusCalcium silicateEmulsion

The invention discloses a composite heat-insulating wallboard and a preparation method thereof and relates to a heat-insulating wallboard. The heat-insulating wallboard is provided with two layers of calcium silicate plates, wherein a heat-insulating core material is clamped between the two layers of calcium silicate plates and is prepared from cement, coal ash, gypsum, expandable polystyrene (EPS), Maleamic Acid-Isobutyl Polyhedral Oligomeric Silsesquioxane (POSS), emulsion powder, a water reducing agent, a foaming agent and an early strength agent. Dry POSS powder is dissolved in normal hexane and then the solution is sprayed onto the surface of EPS particles to obtain substance A; the cement, the coal ash, the gypsum and the emulsion powder are drily stirred, water is added into the mixture, the mixture is stirred into paste, the substance A is added into the paste to form a slurry B; the foaming agent solution is stirred through a stirrer to form foam C; the slurry B and the foam C are mixed to obtain a heat-insulating core material slurry; the surfaces of the calcium silicate plates are brushed and washed, the calcium silicate plates are placed on the two sides of a fixed mold, the heat-insulating core material slurry is poured into the middle of the two calcium silicate plates, and the mold is vibrated to mold the slurry; and the mold is de-molded, and after watering to maintain, the wallboard is obtained.

Owner:XIAMEN UNIV +1

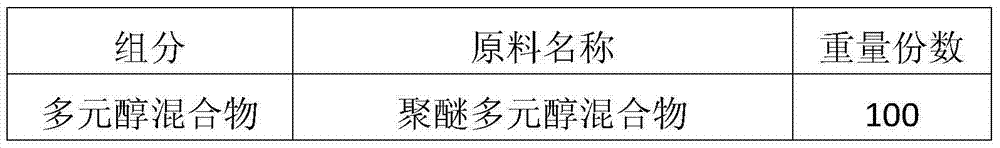

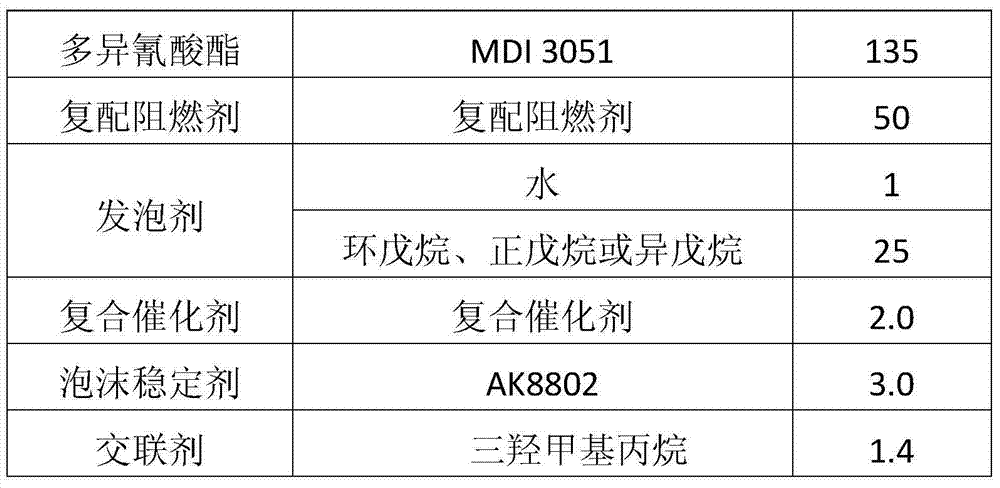

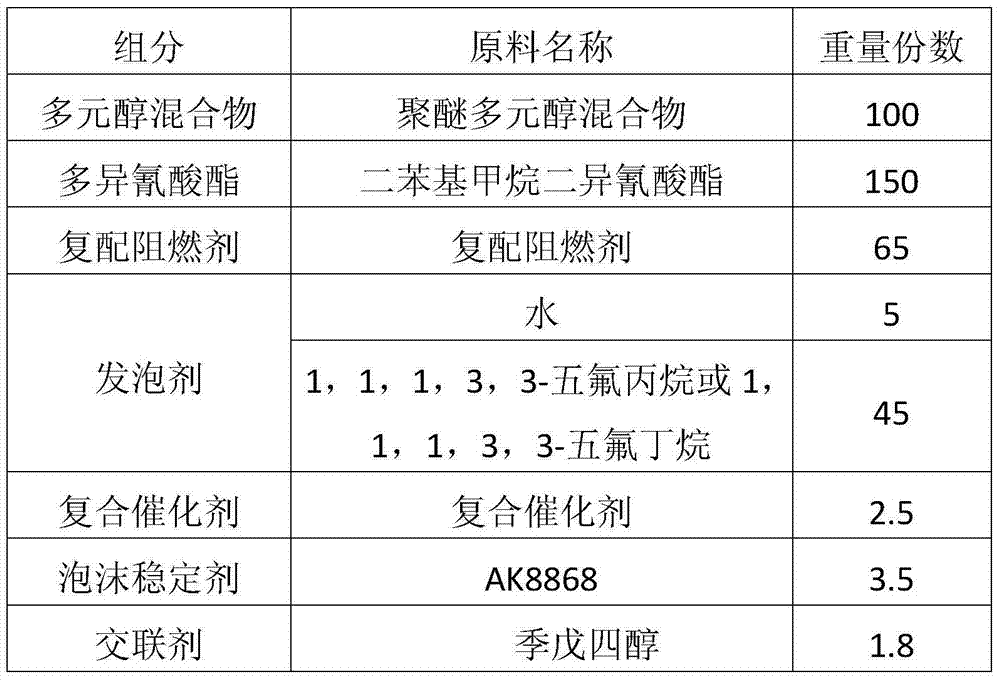

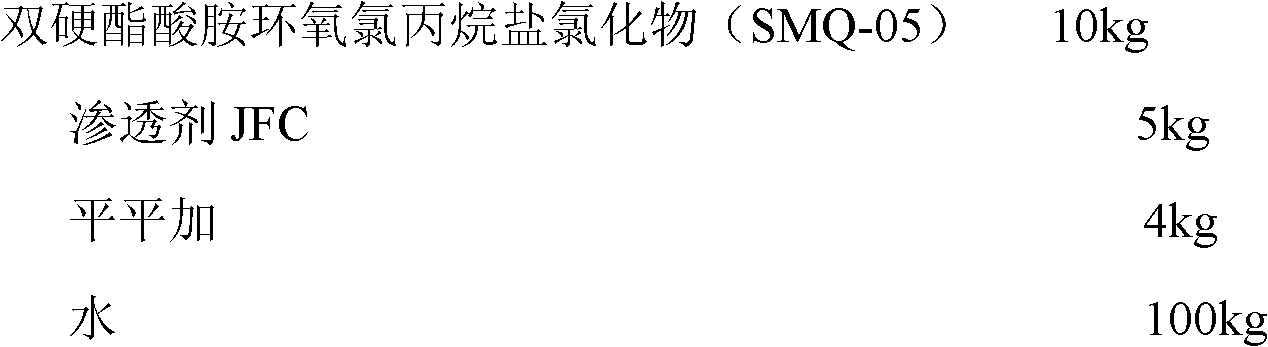

Halogen-free flame-retardant rigid polyurethane foamed plastic and preparation method for same

ActiveCN103694438ALittle impact on physical propertiesGood physical propertiesHydrogen halideToxic gas

The invention discloses halogen-free flame-retardant rigid polyurethane foamed plastic and a preparation method for the same. The polyurethane foamed plastic consists of the following raw materials in parts by weight: 100 parts of polyalcohol mixture, 105 to 180 parts of polyisocyanate, 20 to 80 parts of compound halogen-free flame retardant, 1 to 50 parts of foaming agent, 1 to 3 parts of composite catalyst, 2 to 4 parts of foam stabilizer and 1 to 2 parts of cross-linking agent. An obtained product is high in flame retardance and environment-friendly, the raw materials are free of halogen, and the production of toxic gas such as hydrogen halide during combustion is avoided; the raw materials are readily available and low in cost, so that the preparation cost of the polyurethane foamed plastic is greatly lowered; the polyurethane foamed plastic also has the characteristic of wide application range, and is applied to cold storage and heat-preservation industries of external wall heat-preservation of buildings, heat-preservation of pipelines, refrigerators, freezers and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

PC/PET alloy and manufacture method thereof

The invention discloses a PC / PET alloy and its producing method with a composite weight ratio (%): PC 65-87%; PET5-20%; elasticizer 6-10%; compatilizer 1-3%; antioxidant 0.2-0.6%; other assistant agents 0.1-2%. The inventive material has a high impacting strength, a high module, a high rigidity, a high surface gloss and a low density, which improves the PC resistance to solvent, abrasion resistance, resistance to stress cracking and processing fluidity. The plastic producing method contains following steps: firstly mixing the material according to above proportion, then entering into the plastic extruder at 245-280 DEG C, prilling, getting PC / PET alloy.

Owner:SHENZHEN KEJU NEW MATERIAL

Technical wood and manufacture method thereof

ActiveCN103171014AImprove the utilization rate of solid woodHigh densityWood compressionWood impregnation detailsHot pressHot pressing

The invention relates to technical wood and a manufacture method thereof. The manufacture method comprises the steps of dying and drying eucalyptus and poplar veneers, conducting gum dipping and thickening on the wood veneers by using an ultrasonic vibration method, assembling gum dipping boards, conducting semi-solidification hot-pressing maintaining by using a curve die high-frequency press, conducting square slicing on the technical wood or cutting the technical wood into wood veneers, assembling the wood veneers in the same direction according to needed thickness, and conducting hot pressing and thickening. The thickness of the technical wood veneers or wood square produced by using the manufacture method is as high as 0.8-1.8kg / cm<3>, the thickness of the technical wood is more than 1.5 times of that of common technical wood, a plurality of items of physical and mechanical properties are improved by more than 1.5 times, the technical wood is not easy to crack, product durability improves to more than one time, service life of products is prolonged, and using fields of the products are extended.

Owner:SINO MAPLE JIANGSU CO LTD

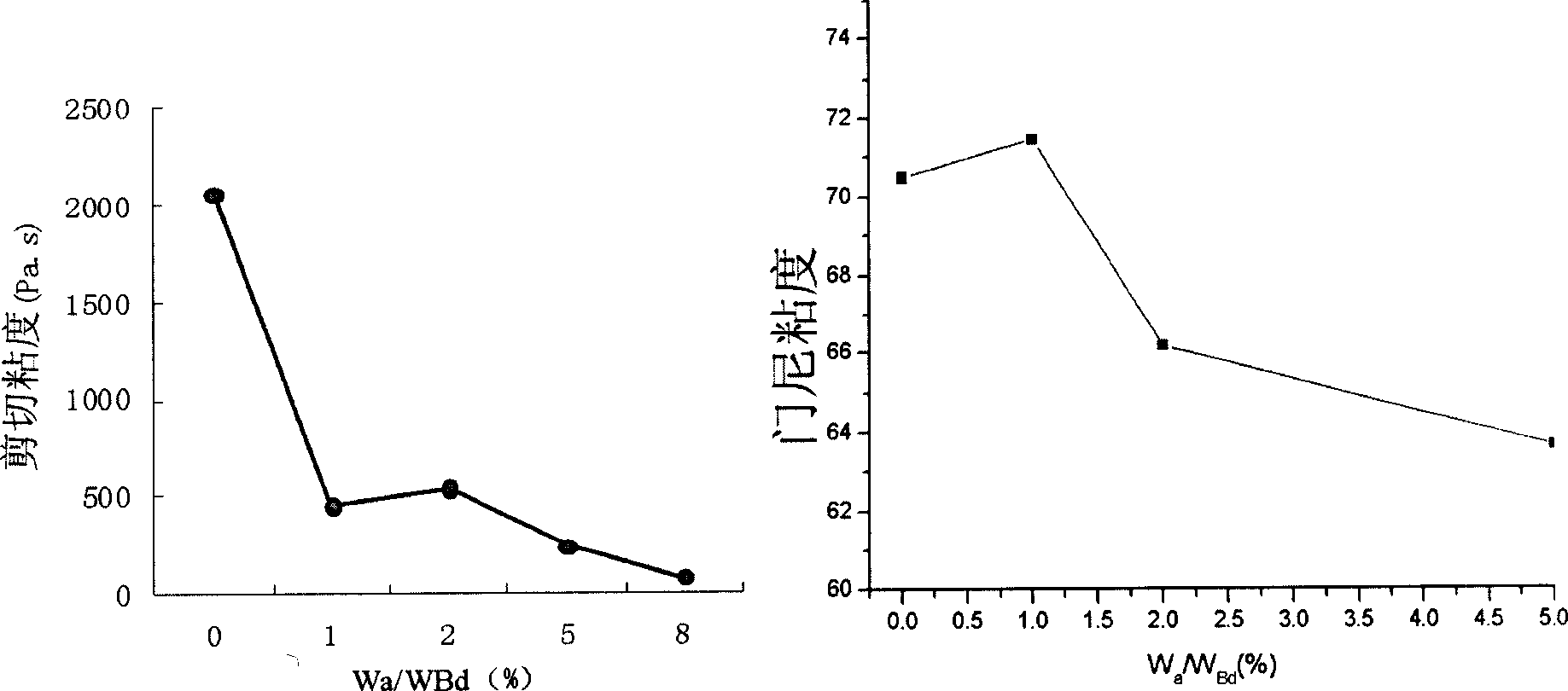

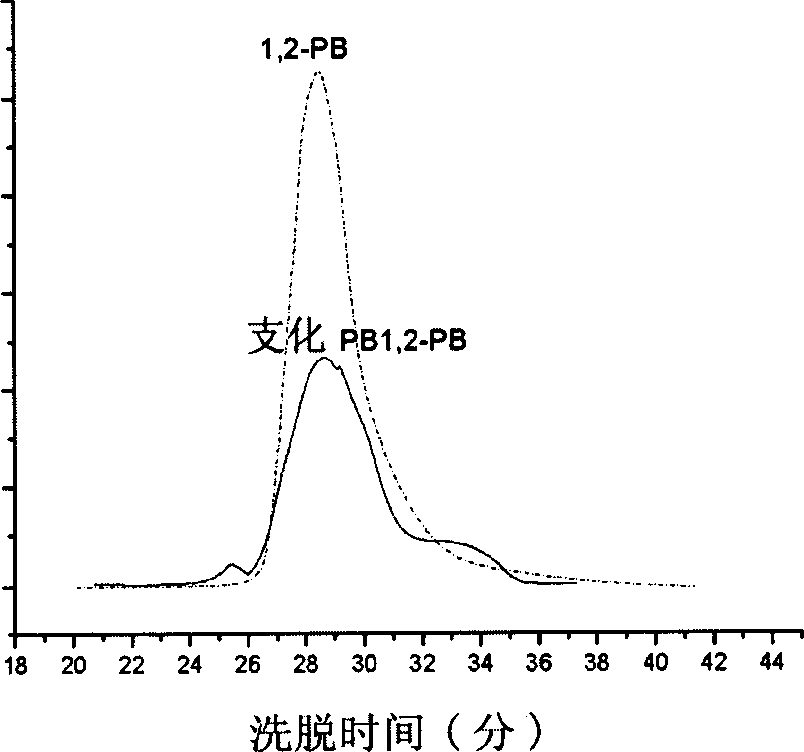

Method for preparing branched high vinyl polybutadiene rubber using molybdenum series catalysis

The invention relates to a method for preparing branched high ethenyl butadiene rubber with molybdenum catalyst, recombining macromolecular monomer prepared through polymerization of molybdenum catalyst butadiene atom free radical or butadiene anion initiated by organic lithium, naphthalene sodium, with coordinate polymerization of butadiene or original position polymerization, to prepare said product with controllable construction. The method is characterized by simple process, special construction of polymer, proper molecular weight and molecular distribution, more than 80% of ethenyl content, controllable property, length, distribution and degree of branching of branch chain in a certain range, good processing behavior and physical mechanics property and low production cost.

Owner:QINGDAO UNIV OF SCI & TECH

PBT/ABS alloy material and preparation method thereof

InactiveCN101215409AGood physical and mechanical propertiesSimple preparation processFire retardantHigh intensity

The invention discloses a PBT / ABS alloy material and a process for preparation, which comprises PBT 10-45%, ABS 10-45%, compatibilizer 1-10%, filling reinforcing agent 10-40%, composite flame retardant 20-30%, lubricating agent 0.1-0.6%, and anti-oxidant 0.1-12%. PBT system and ABS system are welded together through choosing appropriate flame retardant and reinforcing agent, and the invention which is prepared has the character of flame resisting, and which is environment friendly and innocuous, and various physical mechanics properties of the invention are excellent when alloy material is guaranteed to have flame-proof function, and the flame-proof alloy material has the advantages of simple preparation technology, stable sizes, high intensity, aesthetic appearance, high flowability, and drug tolerance and the like.

Owner:SHENZHEN KEJU NEW MATERIAL

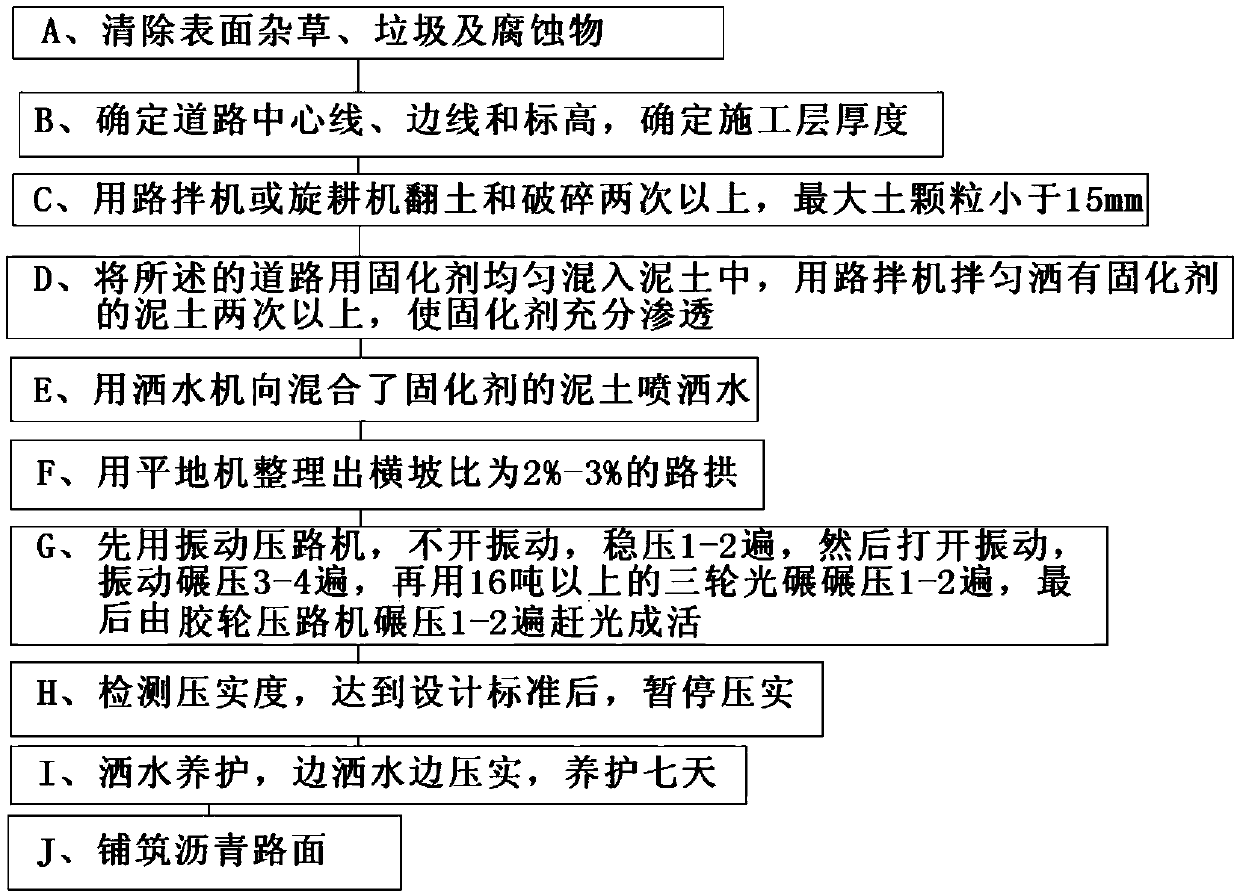

Hardening agent for road and roadbed hardening method

ActiveCN105367010AImprove physical and mechanical propertiesImprove engineering propertiesSolid waste managementEpoxyPhosphate

The invention discloses a hardening agent for a road. The hardening agent is prepared from, by weight, 10-15% of cement, 1-5% of lime, 2-3% of fly ash, 2-3% of gypsum, 1-2% of coal gangue, 1-2% of zeolite, 3-15% of sulfonated oil, 1-2% of phosphate, 1-2% of caustic alkali, 1-2% of potassium permanganate, 2-4% of sodium chloride, 2-4% of sodium carbonate, 2-3% of calcium carbonate, 2-3% of silicon powder, 1-2% of asphalt, 5-10% of sodium silicate, 1-2% of polyacrylamide, 1-2% of polyacrylic acid, 1-2% of magnesium sulfate, 1-2% of calcium carbonate, 7-10% of tar, 0.1-1% of epoxy resin, 0.6-1% of aniline furfural, 0.3-1% of calcium acrylate and 0.5-2% of carboxymethyl cellulose. The invention discloses a roadbed hardening method. The hardening agent for the road is adopted for hardening.

Owner:郑卫忠

Chemical industrial gypsum building materials and method for manufacturing same

InactiveCN101139198AImprove protectionSimple production processSolid waste managementSlurryQuenching

The present invention relates to a chemical gesso building material, which consists of the following components according to weight ratio: 30-60 percent of waste gesso, 15-25 percent of powder coal; 20-30 percent of scoria and 5-20 percent of cement material. The chemical waste stone includes titanium gesso and phosphor gesso. The scoria includes titanium scoria, steel residue, water quenching residue and silicon powder stone. The chemical gesso also includes an assistant agent with the weight ratio of 0-5 percent. The preparation method for the chemical gesso building material includes the following steps: the raw materials are to be prepared according to the corresponding weight ratio for each component; the components are mixed and grinded to prepare the material slurry, and then is to be pressed into a mould; the mould is kept for more than 7 days. The present invention uses the chemical waste residue as the main materials and adopts simple process and equipments; without any calcining, the chemical gesso building products with much better physical force performance can be manufactured. The present invention is with much greater economical benefit and social benefit.

Owner:深圳清研创业投资有限公司

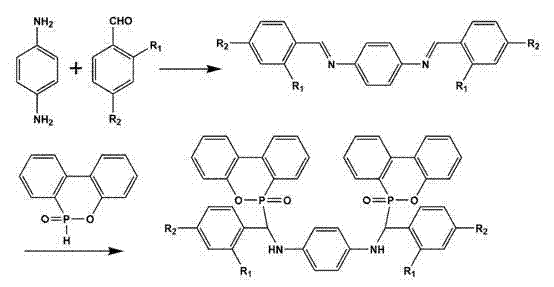

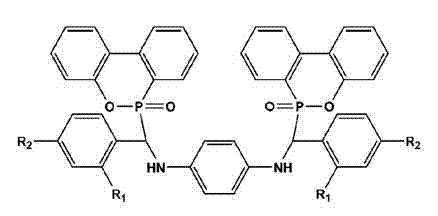

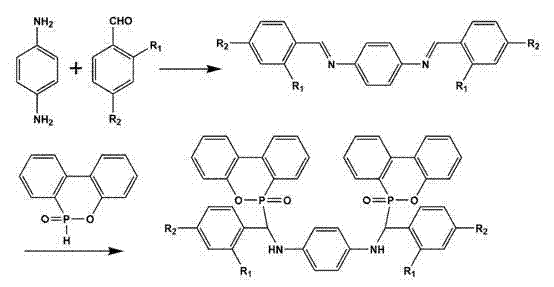

Nitrogen and phosphorus containing flame retardant agent and preparation method thereof as well as application thereof

ActiveCN102391545AHigh yieldSimple post-processingGroup 5/15 element organic compoundsEpoxyPolymer science

The invention relates to a preparation method of a nitrogen and phosphorus containing flame retardant agent, the nitrogen and phosphorus containing flame agent and application thereof. The preparation method comprises the following steps of: carrying out condensation reaction on phenylene diamine and aromatic aldehyde, then carrying out addition reaction with DOPO (9, 10-Dihydro-9-oxa-10-phosphaphenanthrene 10-oxide) to obtain solid nitrogen and phosphorus containing flame retardant agent molecules. The preparation method has the advantages of easiness in control, good repeatability, high yield and suitability for expanded production. The obtained flame retardant agent molecules have amino groups and phenolic hydroxyl active groups and can further react with matters containing expoxy group functional groups. The flame retardant agent molecules contain nitrogen and phosphorus elements and have good expansion char forming characteristic and very good flame retardant effect in the burning process; when the flame retardant agent molecules resist the flaming of the epoxy resin, the flame retardant agent molecules can further undergo cross-linking reaction with resin, thereby increasing the glass transition temperature, the bonding strength, the mechanical property and the like of the resin; meanwhile, the flame retardant agent molecules have good flame retardant property; the limiting oxygen index of the flame retardant agent molecules is substantially increased; and the vertical burning grade of the flame retardant agent molecules reaches a UL-94V-0 grade.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

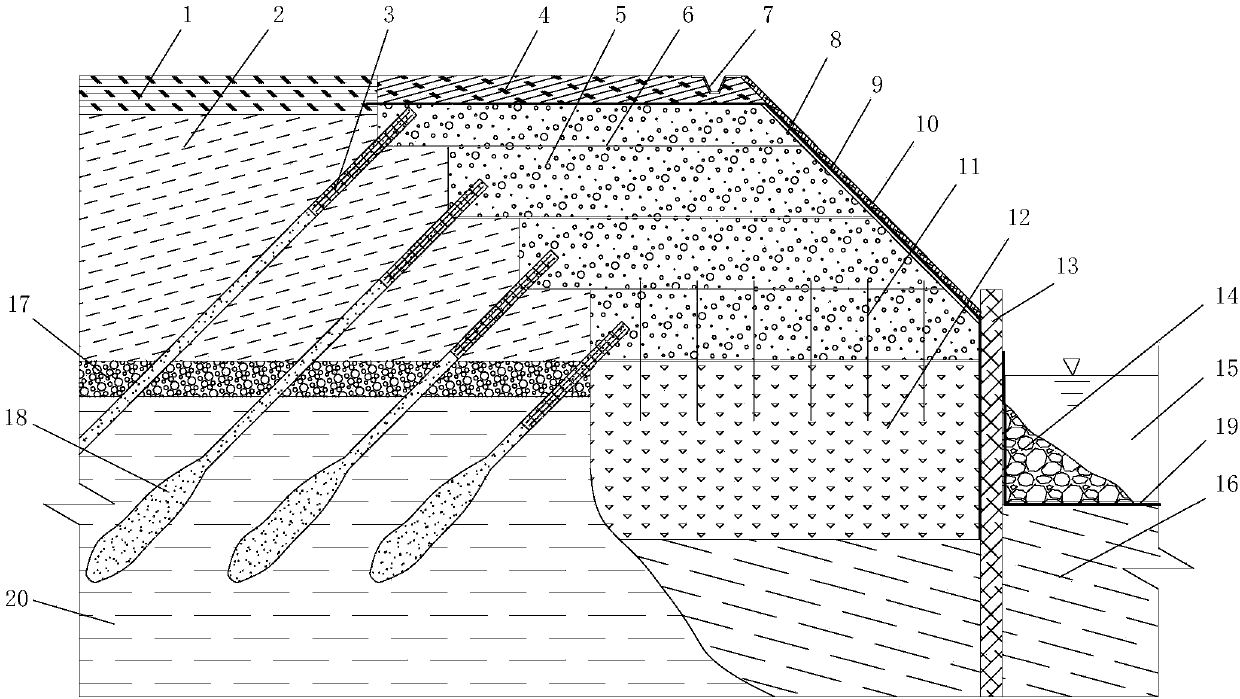

Waterside road broadened embankment structure and construction method thereof

ActiveCN103628378AImprove connection strengthImprove mechanical performanceRoadwaysClimate change adaptationEconomic benefitsStructural engineering

The invention relates to a waterside road broadened embankment structure, which is characterized in that the waterside side of a new embankment is provided with a waterproof maintenance pile, and the outer side of the maintenance pile is provided with a dumping stone weights body; the lower part of the new embankment is a solidified soil layer, the upper part of the new embankment is a lightweight filler layer, and the contact part of the solidified soil layer and the lightweight filler layer is provided with a horizontal reinforced body and a vertical reinforced body; a grouting strengthened body is arranged in an original embankment, and the front end of the grouting strengthened body is a reinforced connecting section; and the side slopes on the top surface and outer side of the new embankment and the two sides of the maintenance pile are respectively provided with a waterproof later, and the bottom of the dumping stone weights body is provided with an impervious blanket. According to the invention, the connection strength and integrity of the new and original embankments can be enhanced, an outside water body is prevented from permeating in the embankments from multiple beddings, and the anti-uplift performance of the embankment can be improved, therefore, the embankment structure has good technical and economic benefits. The invention also provides a construction method of the broadened embankment structure.

Owner:江苏镇江路桥工程有限公司

Preparation of polystyrene/expanded graphite composite foaming material

InactiveCN101891852APhysical and mechanical properties do not deteriorateImprove physical and mechanical propertiesCompression moldingFoaming agent

Owner:SHANGHAI BOTAO ENVIRONMENT PROTECTION SCI & TECH +1

High-strength wear-resistant engineering microcrystalline glass prepared by using granite waste materials and preparation method thereof

InactiveCN102942303AImprove physical and mechanical propertiesSmall sizeChemical industryWear resistant

The invention discloses high-strength wear-resistant engineering microcrystalline glass prepared by using granite waste materials and a preparation method thereof. The microcrystalline glass disclosed herein comprises 10.0-55.0wt% of granite waste materials as the main raw material, and comprises SiO2, CaF2, CaCO3, ZnO, K2CO3, etc. as the auxiliary raw materials. The preparation method comprises the following steps: crushing the granite waste materials, uniformly mixing the crushed granite waste materials with other raw materials in a mixer to obtain a base mixed batch, using a tank furnace to carry out high temperature melting on the base mixed batch to obtain qualified liquid glass, carrying out calendaring, casting or water quenching on the liquid glass to form a base glass plate (or pellets), and carrying out crystallization heat treatment on the base glass plate (or pellets) to obtain the microcrystalline glass. The microcrystalline glass has a density of 2.5-2.8g / cm<3>, a flexural strength of 30.0-103.5MPa, a compressive strength of 70.0-903.0MPa, a Moh's hardness of 5-8, and a wear resistance of 0.063-0.15g / cm<2>, has the advantages of high strength, good toughness, strong wear resistance and corrosion resistance, and excellent cutting machinability, and an be widely applied in the fields of chemical industry, metallurgy, building decoration, petroleum, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

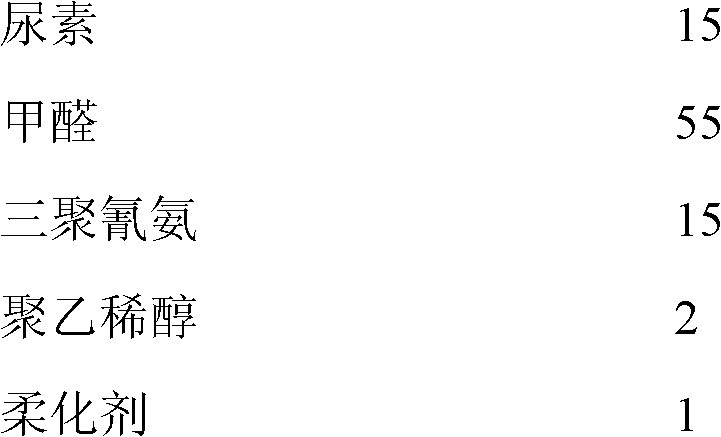

Modified urea-formaldehyde resin adhesive for concrete formwork and production method of adhesive

ActiveCN102391805AImprove performanceEasy to operateAldehyde/ketone condensation polymer adhesivesWood veneer joiningStrong acidsMelamine

The invention discloses a modified urea-formaldehyde resin adhesive for a concrete formwork, which is mainly prepared from the following raw materials in parts by weight: 50 to 60 parts of formaldehyde with the mass concentration of 37 percent, 20 to 30 parts of urea with purity of 98 percent, 6 to 8 parts of melamine, 0.1 to 0.2 part of tackifier and 0.2 to 0.3 part of accelerant. The adhesive has an Uron-ring improved structure, so that the waterproofness of the formwork can be improved. The invention also discloses a production method of the adhesive, which comprises three steps of strong acid, weak acid and weak base. The reaction between the formaldehyde and the urea under a strong acid reaction condition can be effectively controlled by controlling temperature, pH value, charging speed, charging time and molar ratio. Meanwhile, two endpoint control indexes which are simple and convenient and are easy to operate are provided, and therefore processing implementing can be controlled conveniently and accurately.

Owner:GUANGXI UNIV

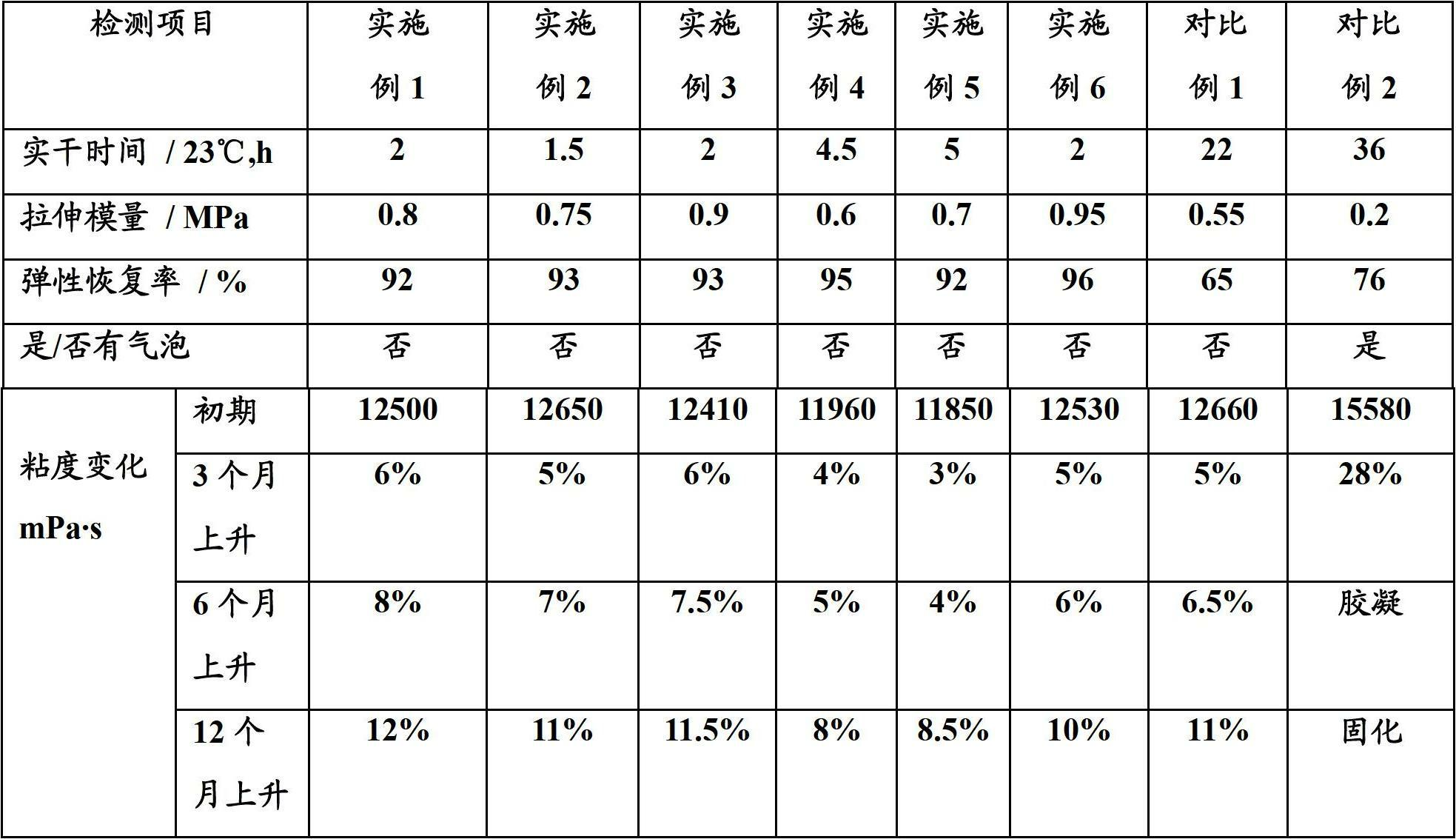

Moisturecured one-component polyurethane paint and preparation method thereof

ActiveCN102676039ASolving Storage Stability IssuesImprove physical and mechanical propertiesPolyurea/polyurethane coatingsPlasticizerMoisture cure polyurethane

The invention relates to moisturecured one-component polyurethane paint and a preparation method thereof. The polyurethane paint comprises the following raw materials in percentage by weight: 10%-20% of polyisocyanate monomer, 20%-40% of polyether polylol, 5%-15% of plasticizer, 30%-50% of modified mineral powder, 1%-5% of latent curing agent, 0.1%-2% of environment-friendly catalyst covered with cyclodextrin, 0.1%-1% of defoamer and 0.1%-1% of mono-isocyanate compound, wherein the modified mineral powder is mineral powder of which the surface is covered with a covered agent by a chemical covering method; and the environment-friendly catalyst covered with the cyclodextrin is in a nanometer cavity of the cyclodextrin, and the cyclodextrin is unmodified cyclodextrin or modified cyclodextrin or the composition of the unmodified cyclodextrin and the modified cyclodextrin. The moisturecured polyurethane paint disclosed by the invention solves the problem in storage stability of a one-component polyurethane product, and the storage life of the moisturecured polyurethane paint can exceed one year.

Owner:苏州中材非金属矿工业设计研究院有限公司 +1

Manufacturing method for microorganism heat-insulation building material

PendingCN108530013ASolve the strength problemSolve insulation problemsBacteriaMicroorganism based processesNutrient solutionMechanical property

The invention discloses a manufacturing method for a microorganism heat-insulation building material. The manufacturing method for the microorganism heat-insulation building material comprises the following steps: taking a bacteria solution which has a mineral deposition function and is prepared from microorganisms and a corresponding nutrient solution as raw materials; directly carrying out mineral deposition on various lightweight aggregates or compounding inorganic or organic cementing materials; and carrying out microorganism inactivation and pore forming to obtain novel microorganism heat-insulation plates, heat-insulation blocks, heat-insulation concrete, heat-insulation mortar and the like. By the method, the physical and mechanical properties of an existing traditional heat-insulation material can further be improved through a microorganism mineralization function and an inactivation process. Microorganism mineral deposition products are used as cementing material manufacturingand modifying building heat-insulation materials, contradiction between strength and heat insulation of the heat-insulation materials can be solved effectively, cementing materials such as cement arereduced and are even prevented from being used, resource consumption are reduced remarkably, mine excavation frequency is reduced, pollution emission is eliminated, and environment stress and haze influence are relieved. The manufacturing method for the microorganism heat-insulation building material is an environmentally friendly building material manufacturing method, and has good economic benefit, environment benefit and social benefit.

Owner:李珠

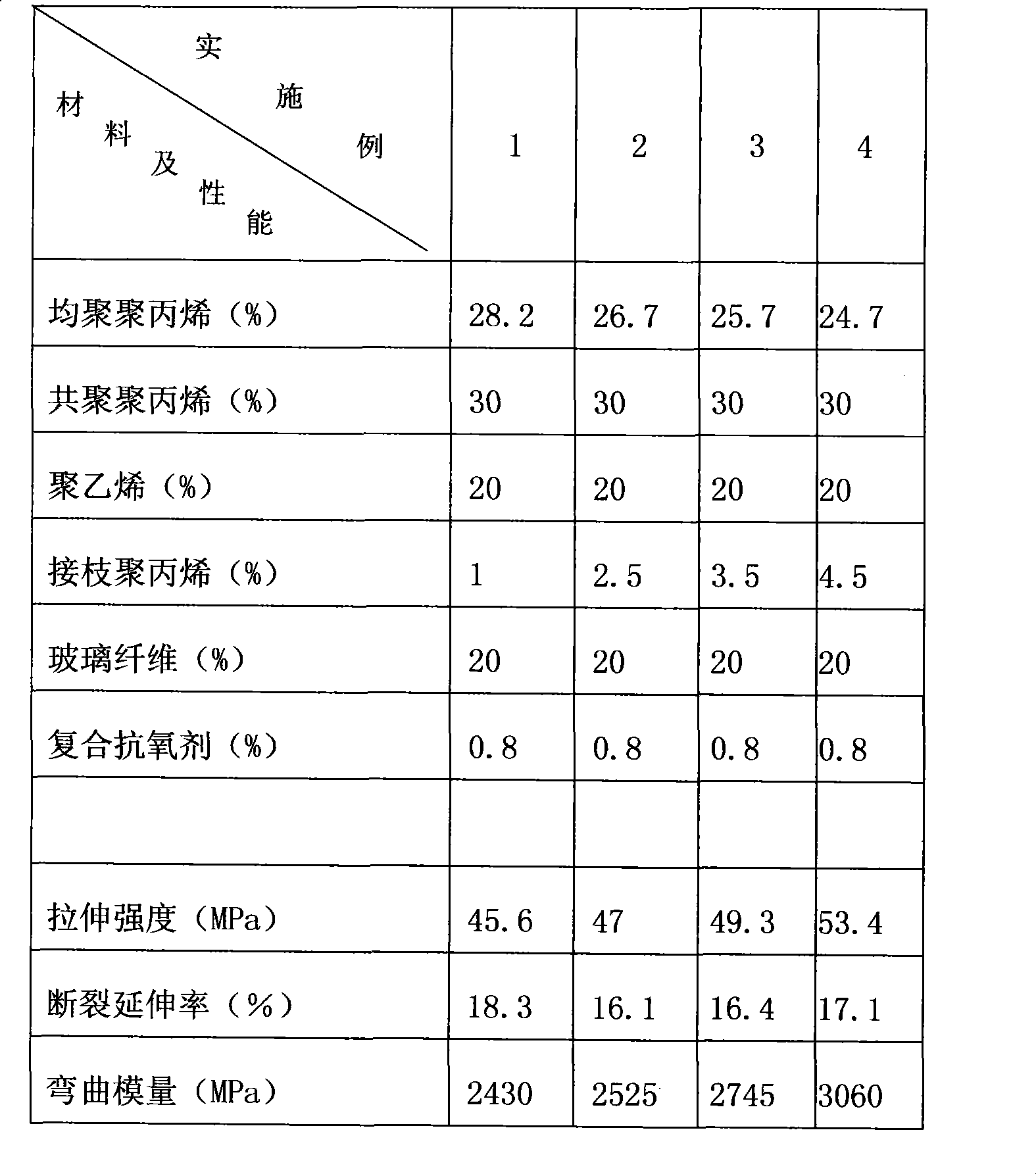

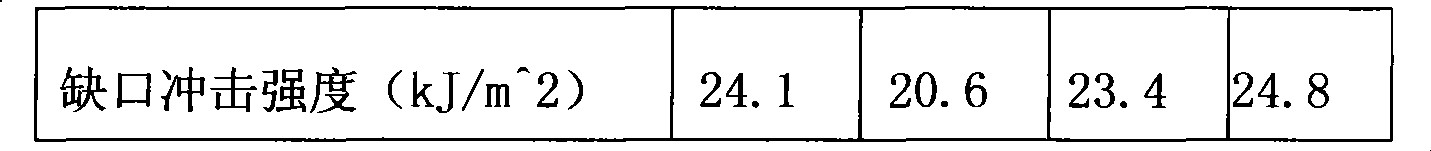

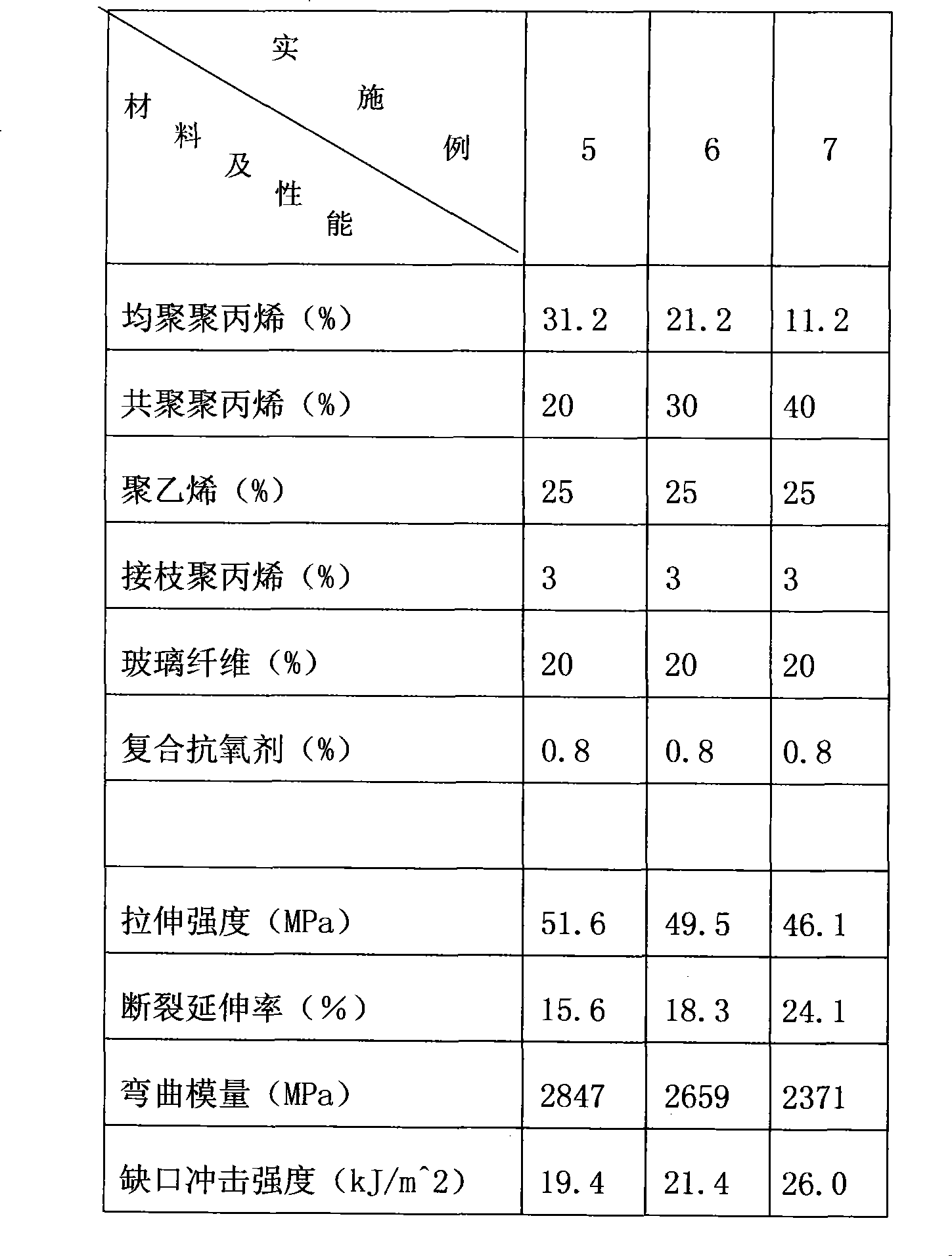

Ultralong unit extension glass fiber reinforced polypropylene composite material

The invention relates to glass fiber reinforced polypropylene composite material with the super-long elongation. The glass fiber reinforced polypropylene composite material is characterized in that the composite material comprises the following components: 10 to 50 percent of homopolymerization polypropylene, 20 to 40 percent of copolymerization polypropylene, 10 to 40 percent of polyethylene, 0.5 to 5 percent grafted polypropylene, 10 to 40 percent of glass fibers, 0.1 to 2 percent of composite antioxidant, and 0.1 to 2 percent of other additives; and a preparation method for the composite material comprises the following steps: dryly mixing the homopolymerization polypropylene, the copolymerization polypropylene, the polyethylene, the grated polypropylene, the composite antioxidant and the other additives in a high speed mixer for 3 to 5 minutes according to the proportion; and then placing the mixed raw materials in a double screw extruder, and carrying out the melted extrusion andgranulation at 160 to 250 DEG C. The prepared composite material has not only the super-long elongation, but also other excellent physical mechanical properties. In addition, the composite material also has the reduced cost.

Owner:SHANGHAI PRET COMPOSITES

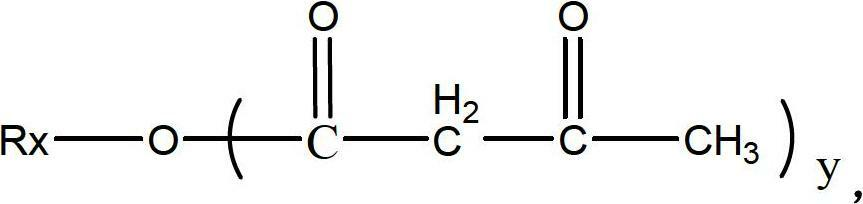

Single-component polyurethane sealant capable of quickly curing moisture and preparation method thereof

ActiveCN102690626AFast curingWon't foamNon-macromolecular adhesive additivesOther chemical processesAcetoacetatesCyclodextrin

The invention relates to a single-component polyurethane sealant capable of quickly curing moisture and a preparation method thereof. The polyurethane sealant comprises the following raw materials in percentage by weight: 10 to 20 percent of polyisocyanate monomer, 20 to 45 percent of polyether polyol, 1 to 10 percent of acetoacetic ester sealed end polyether prepolymer, 5 to 20 percent of plasticizer, 25 to 40 percent of modified mineral powder, 1 to 5 percent of latent curing agent, 0.1 to 2 percent of cyclodextrin wrapped environment-friendly catalyst, 0.1 to 1 percent of defoaming agent and 0.1 to 1 percent of water-removing agent, wherein the water-removing agent is one or more of mono-isocyanate compound or functionalized silane compound. The single-component polyurethane sealant avoids bubble fundamentally, can be quickly cured, is stable in storage, and can be applied to construction on damp interfaces.

Owner:苏州中材非金属矿工业设计研究院有限公司 +1

Formaldehyde-free plywood and fabrication method thereof

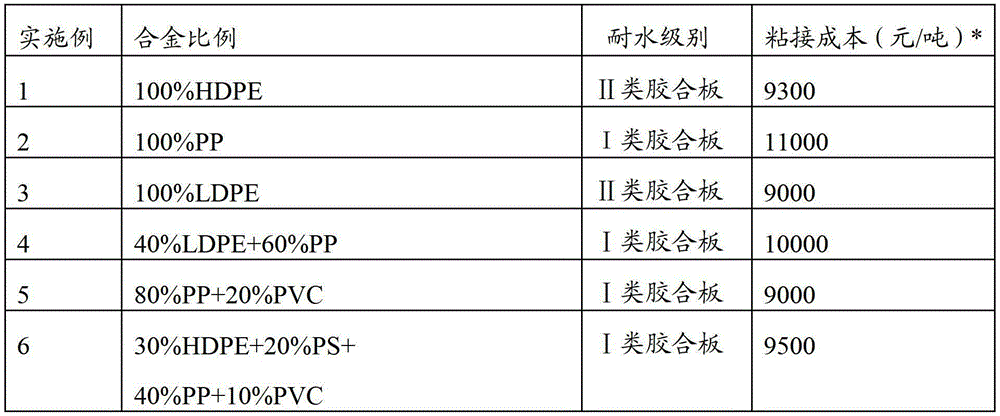

ActiveCN103144152ASolve the hazardImprove physical and mechanical propertiesLayered product treatmentPlastic recyclingEnvironmental resistanceWood veneer

A method for fabricating a formaldehyde-free plywood with waste plastic alloy is used for fabricating the novel plywood without free formaldehyde being released by fabricating a plastic alloy film with different waste plastics and taking the plastic alloy film as a bonding material. The method comprises the steps of smashing and cleaning the different waste plastics, allowing the waste plastics to be independent or mixing the waste plastics to a scale, adding relevant packing and assistant, conducting film blowing and calendering to prepare the plastic alloy adhesive film in certain breadth and thickness, conducting crossed assembly with a wood veneer, conducting hot pressing and cold pressing, and obtaining the formaldehyde-free plywood. The fabrication method for the nontoxic and environment-friendly formaldehyde-free plywood with the waste plastics solves the problem that the free formaldehyde released by the ordinary plywood has a toxic action on an environment and a human body, and a recycling approach for the waste plastics is provided.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Multifunctional protection paste for outside wall

ActiveCN101054492ALight weightReduce shear stressFilling pastesPolyurea/polyurethane coatingsPerliteMultiple function

An outside wall multi-functional protective slurry is composed of A and B components, in which A component contains elastical latex, cellulose aether, crack resistance fiber, lignified fiber, dispersant, anti mildew agent; B A component contains cement, perlite, girasol pearl, pulverized fuel ash, water reducer. The inventive outside wall multi-functional protective slurry has a perfect crack resistance and a high cohesive strength. The slurry matches with the outside wall external heat retaining and has a high cost performance. The invention accords to the industry standards of construction industry of JG / T157-2004 <> and outside wall heat retaining plaster standard and it has a certain heat insulation and heat retaining function.

Owner:南通甜港材料科技有限公司

Green environment friendly flame-proof PA6/PP alloy and method for producing the same

InactiveCN101508840AImprove flame retardant performanceImprove physical and mechanical propertiesGreen environmentAlloy

The invention discloses an environment-friendly flame retardant PA6 / PP alloy and a preparation method thereof. The alloy comprises the components proportioning by weight: 65-76% of PA6, 10-15% of PP, 6-10% of flame retardant, 0.1-0.5% of Anti-dripping agent, 6-10% of toughener, 1-2% of compatilizer, 0.4-0.6% of antioxidizer and 0.3-0.5% of other accessory ingredients. The materials of the invention has excellent combination property, improves the hydroscopicity and processability of the PA6, and enhances the mechanical property, heat resisting property, surface color property and the like of the PP. By being added with the environment-friendly flame retardant, the alloy can reach the requirements of ROSH and WEEE instruction of European Union, thus laying good foundation for the products which are exported into European Union.

Owner:SHENZHEN KEJU NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com