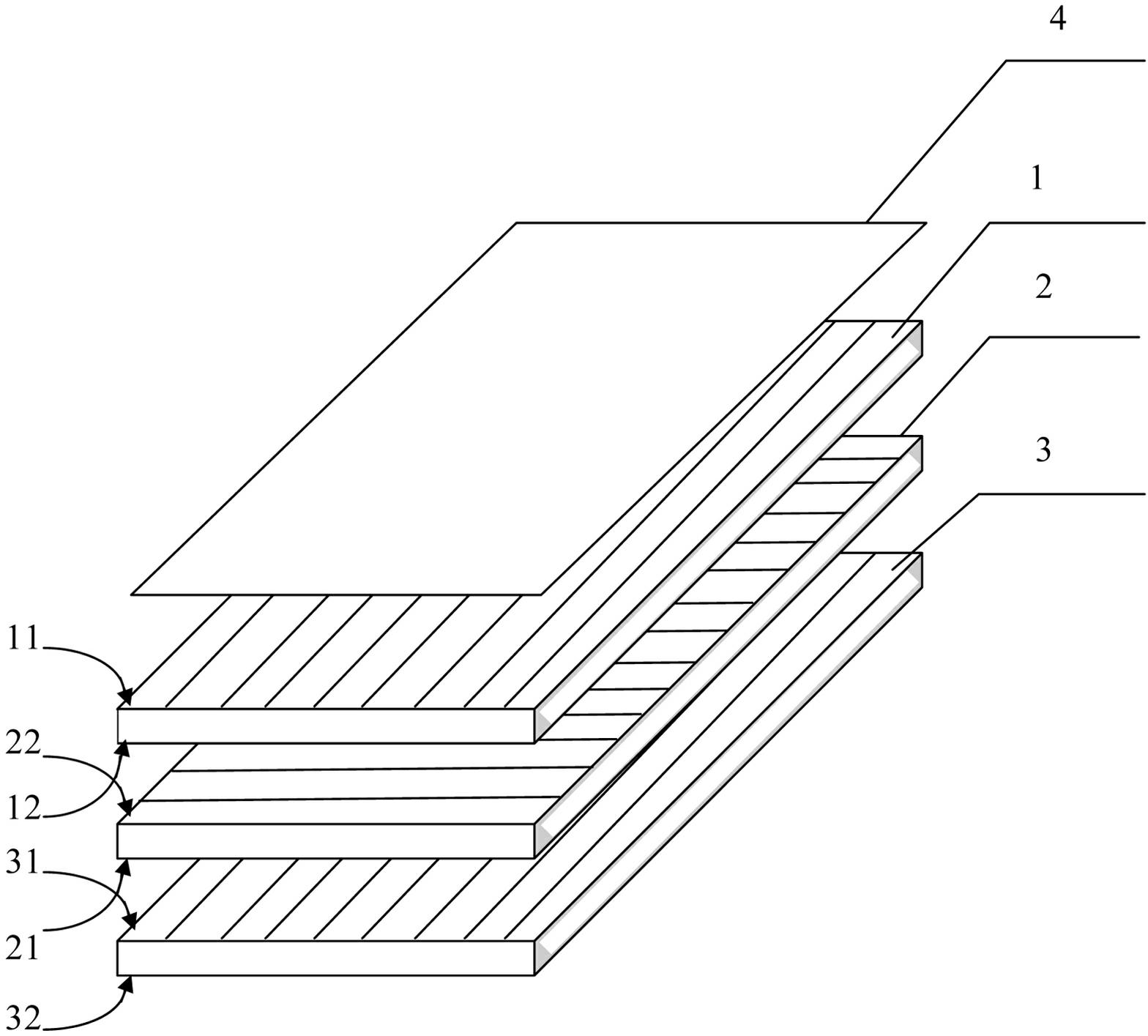

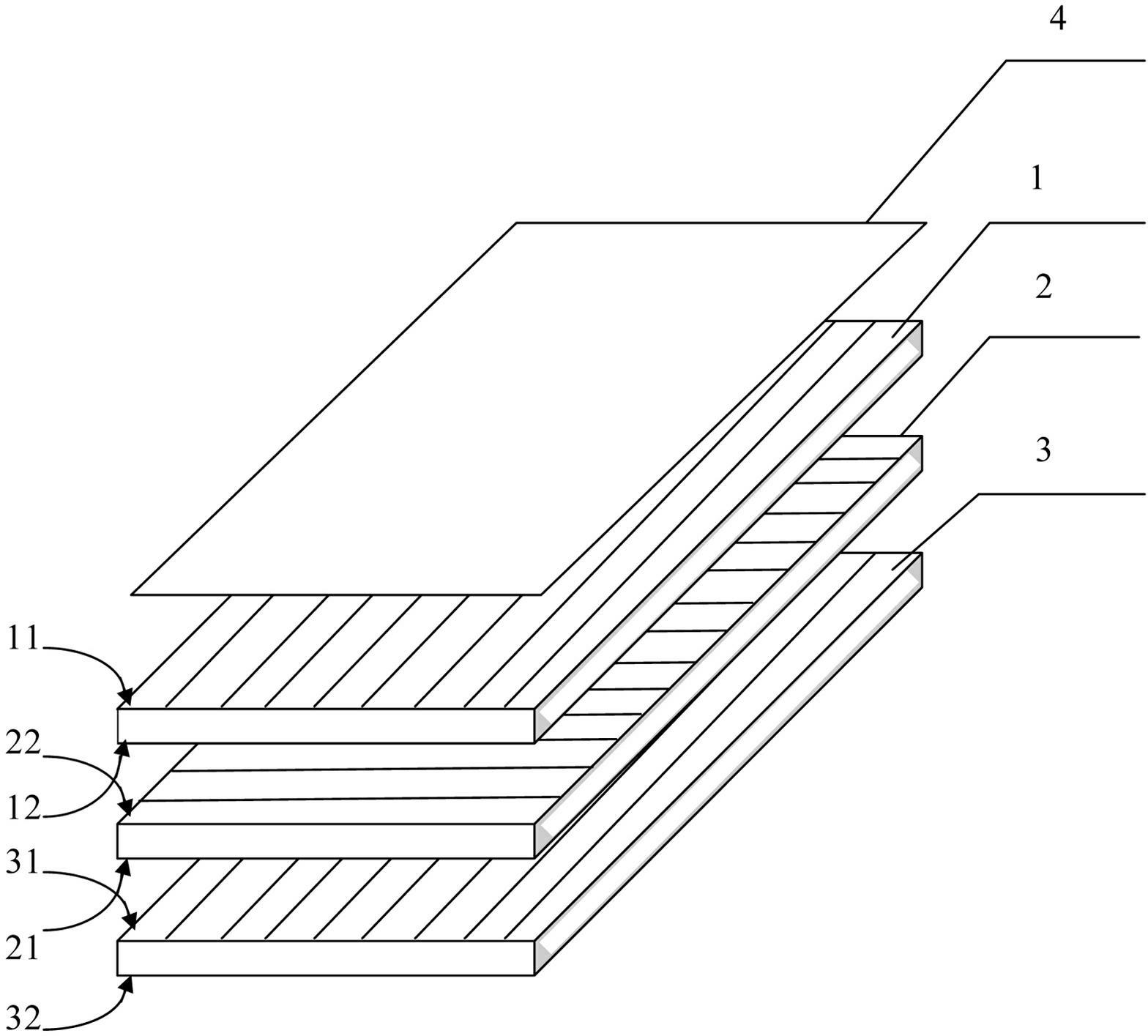

Non-formaldehyde solid wood composite floor using low-density cottonwood veneers as base materials and manufacturing method thereof

A technology of solid wood composite flooring and poplar veneer, which is applied in the direction of manufacturing tools, wood layered products, wood processing equipment, etc., can solve the problems of high production speed, low density, and large proportion of young wood in poplar, and achieve high efficiency The effect of resource utilization, enhanced dimensional stability, and efficient value-added utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The present invention utilizes the existing solid wood composite floor processing and production technology and equipment, uses recycled HDPE (high-density polyethylene) plastics as the bonding material, adopts the 0.6mm thick oak veneer veneer process, and takes the following steps:

[0056] 1. Select poplar logs with a diameter of 15-20 cm, cook at a low temperature of 20°C for 30 hours, then peel or slice them into poplar veneers (choose ones with a thickness of 1.5 mm or more), and then dry the veneers until they contain moisture Rate 15%;

[0057] 2. Slice the precious logs into decorative veneers, and place the veneers in the atmosphere to dry naturally to reduce the moisture content to below 25%;

[0058] 3. Sorting recycled plastics into HDPE, crushing and cleaning, and then granulating and blowing the scraps to make plastic films;

[0059] 4. Coat the dried poplar veneer with silane coupling agent; the amount of silane coupling agent selected is 10% of the wei...

Embodiment 2

[0065] In the production, the new HDPE is used as the production raw material, and the 0.6mm thick oak veneer veneer process is adopted, and the equipment and steps are similar to those of Example 1;

[0066] It’s just that the recycled plastic described in step 3 in Example 1 becomes the direct purchase of HDPE particle blown film; step 4 in Example 1 is used as a coating polyurethane coupling agent, and the coating amount is 1 to 20% of the weight of the film. After 15 minutes, all the other steps, equipment and parameters were the same as in Example 1.

Embodiment 3

[0068] In the production, recycled PP is used as the bonding material, and the 2mm thick oak veneer veneer process is adopted. The equipment and steps are the same as in Example 1, except that the production process parameters are changed, as follows:

[0069] Step 3: Sorting the recycled plastics into PP, crushing and cleaning, and then granulating the scraps and blowing them into plastic films. The remaining parameters are the same as in Example 1, except that the extrusion temperature is changed to 150-240°C, and the blown film temperature is changed to 160-250°C;

[0070] Step 5: Assemble the low-density poplar veneer and plastic film, and then heat-press and shape the poplar board to obtain the poplar board. The other parameters are the same as in Example 1, except that the hot pressing temperature is changed to 150-220°C.

[0071] Other steps, equipment and process parameter are all identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com