Patents

Literature

418results about How to "Efficient resource utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

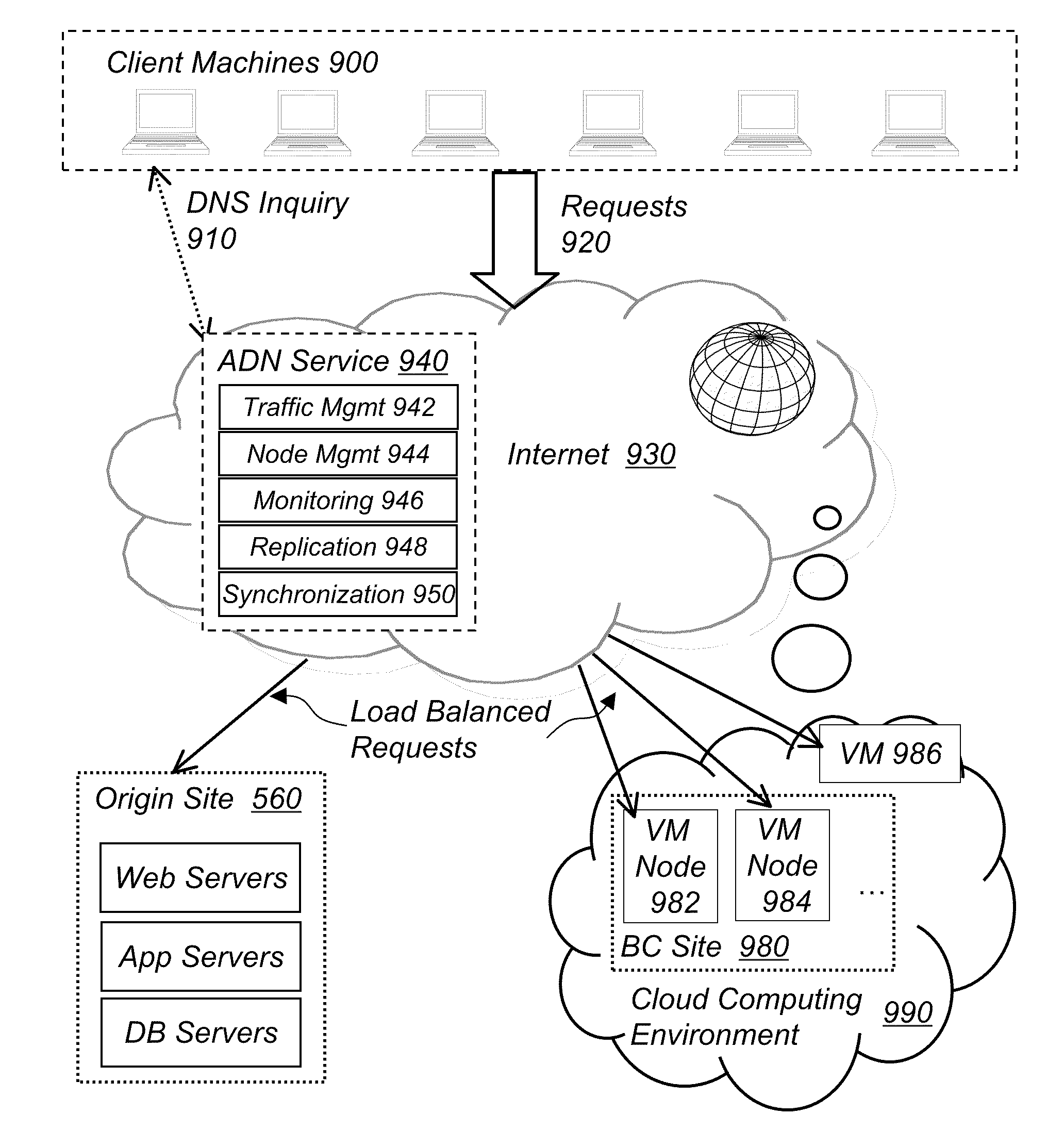

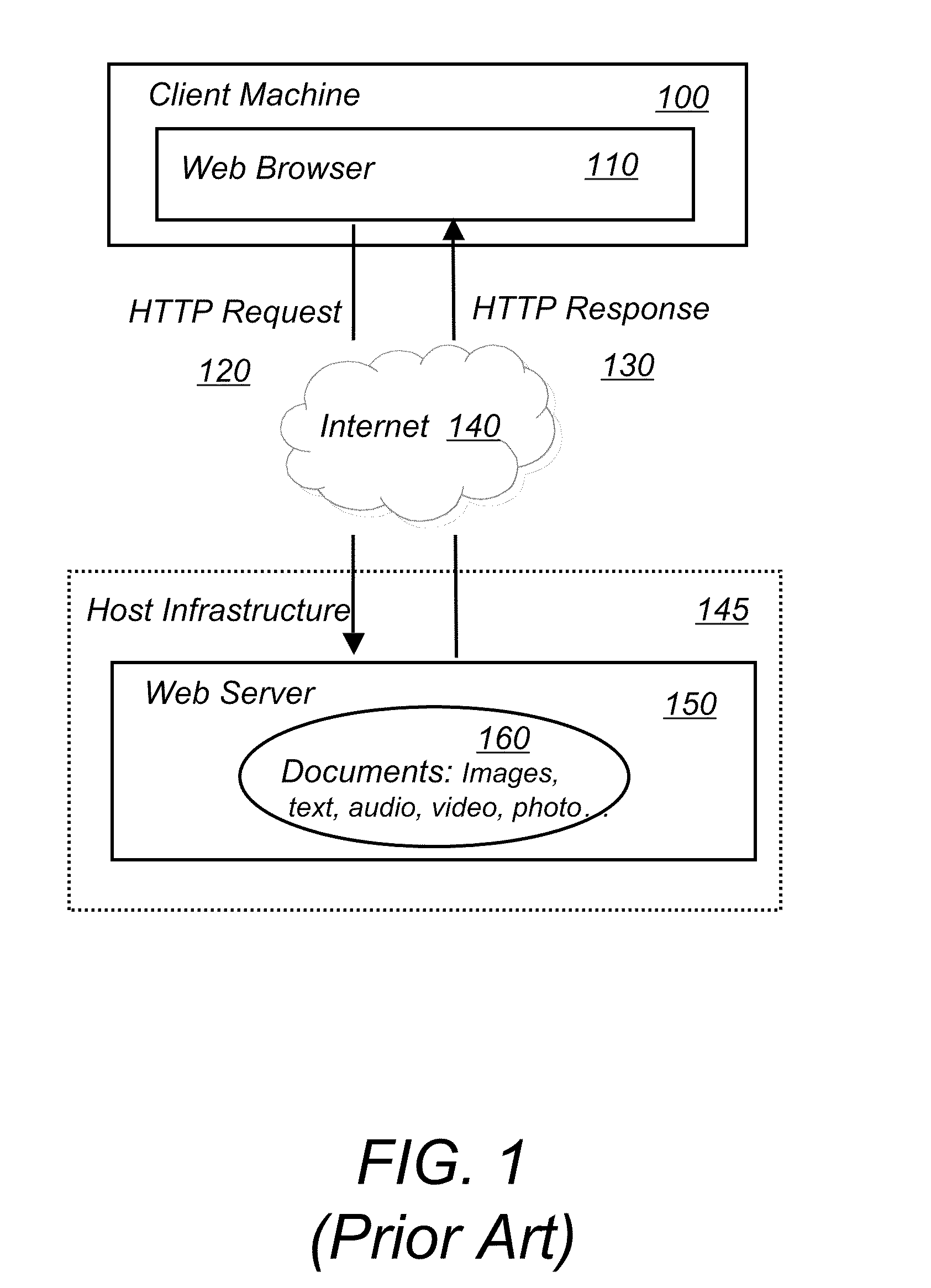

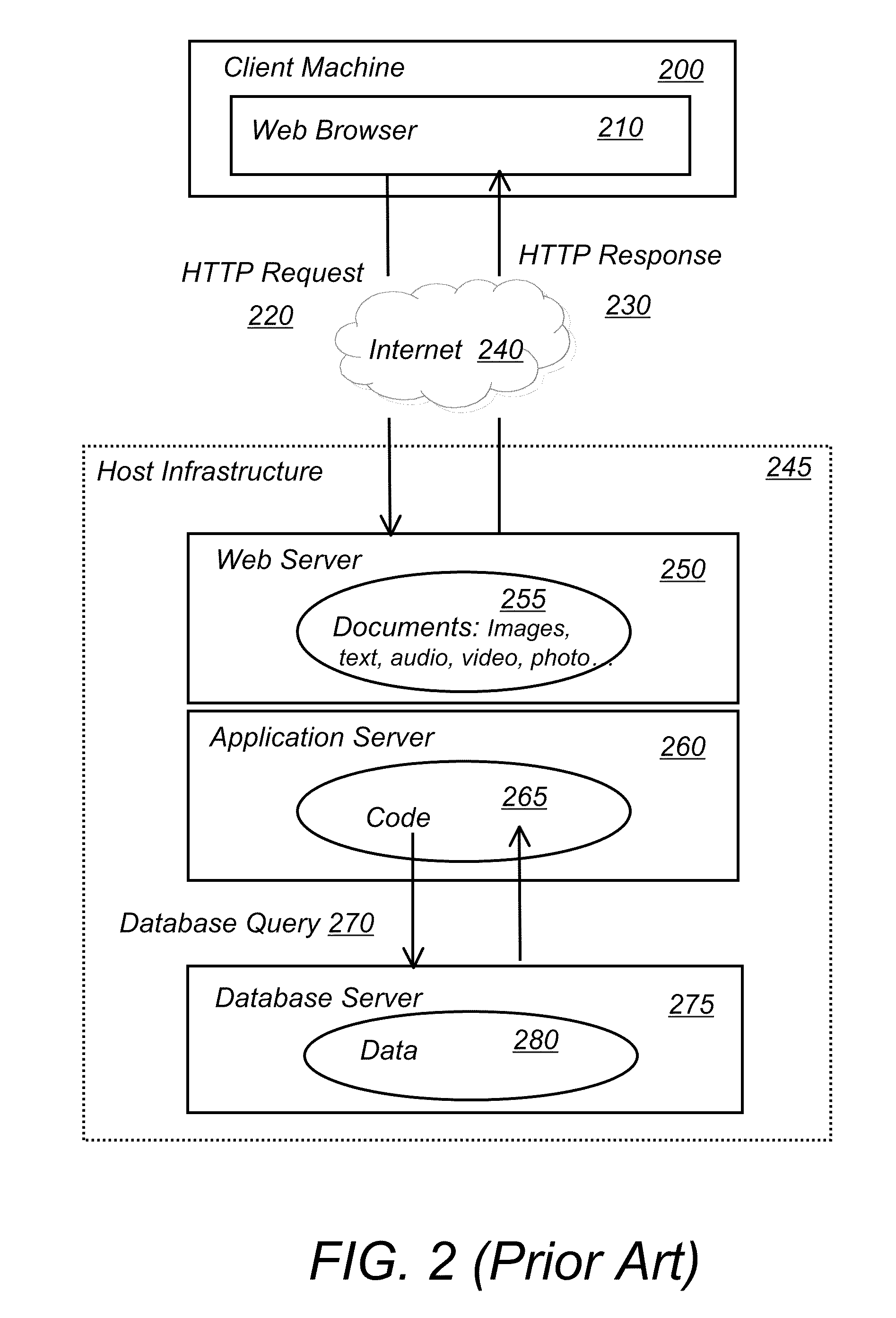

System and method for performance acceleration, data protection, disaster recovery and on-demand scaling of computer applications

InactiveUS20100228819A1Accelerate performanceEfficient resource utilizationMultiple digital computer combinationsTransmissionClient-sideTraffic volume

A method for improving the performance and availability of a distributed application includes providing a distributed application configured to run on one or more origin server nodes located at an origin site. Next, providing a networked computing environment comprising one or more server nodes. The origin site and the computing environment are connected via a network. Next, providing replication means configured to replicate the distributed application and replicating the distributed application via the replication means thereby generating one or more replicas of the distributed application. Next, providing node management means configured to control any of the server nodes and then deploying the replicas of the distributed application to one or more server nodes of the computing environment via the node management means. Next, providing traffic management means configured to direct client requests to any of the server nodes and then directing client requests targeted to access the distributed application to optimal server nodes running the distributed application via the traffic management means. The optimal server nodes are selected among the origin server nodes and the computing environment server nodes based on certain metrics.

Owner:YOTTAA

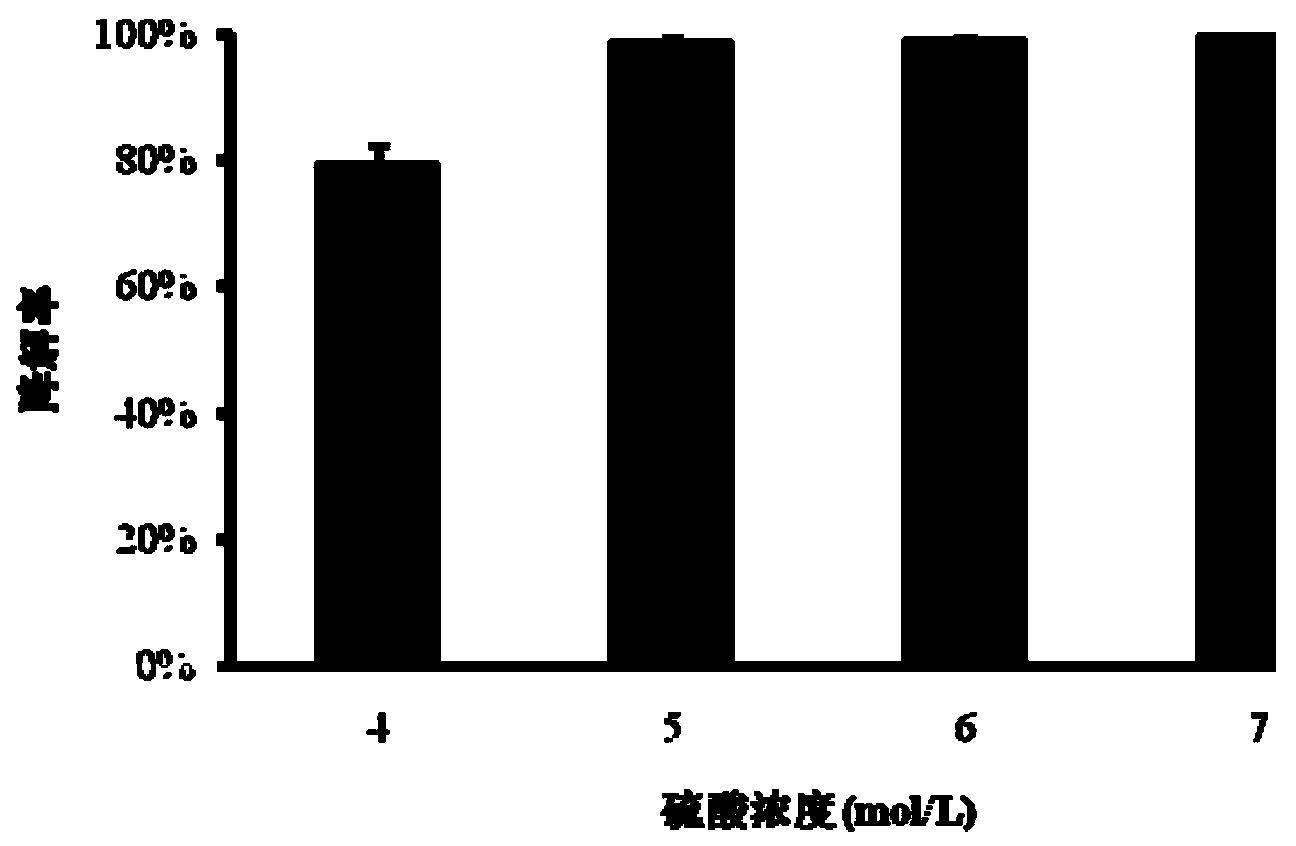

Liquid amino acid compound produced by dead porcine proteins and application thereof

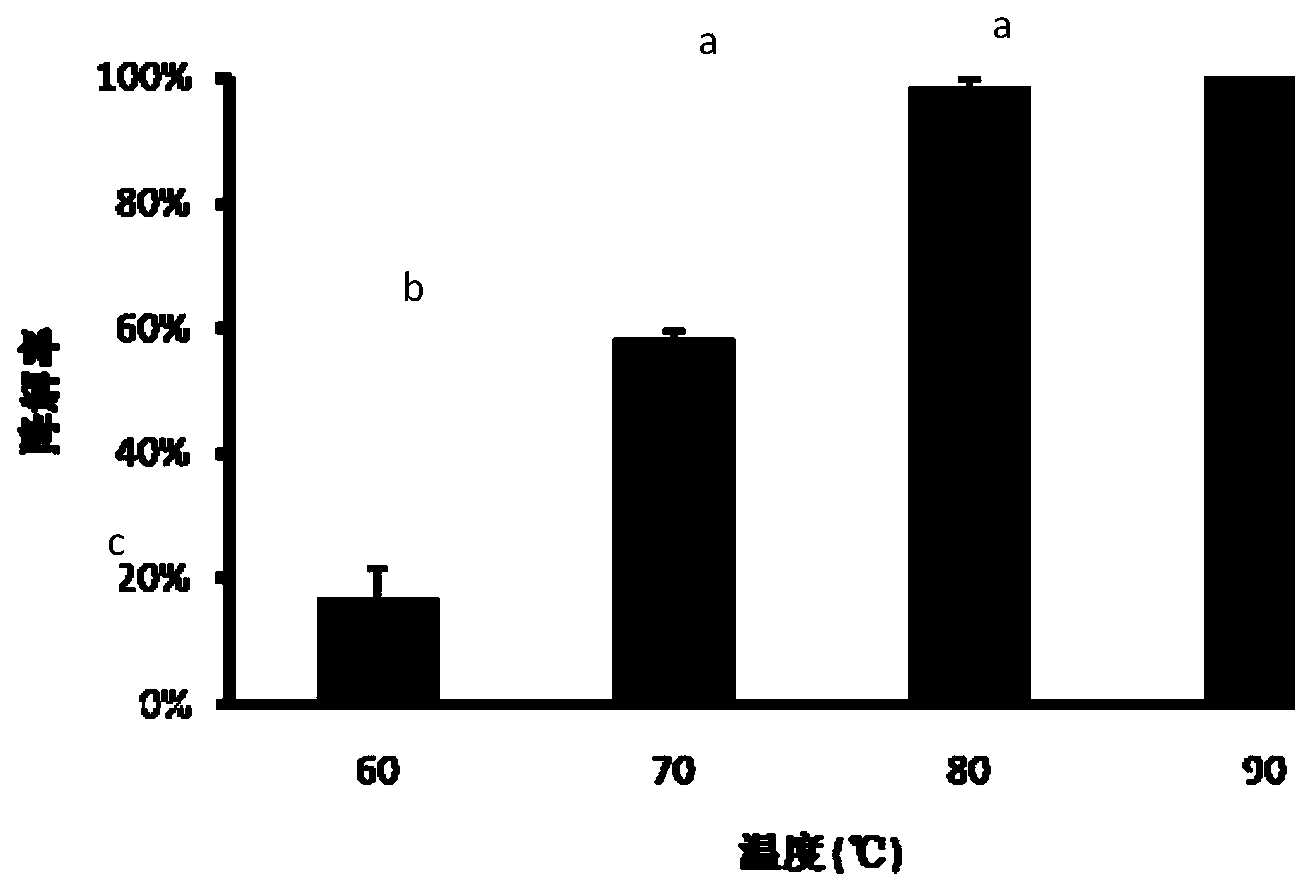

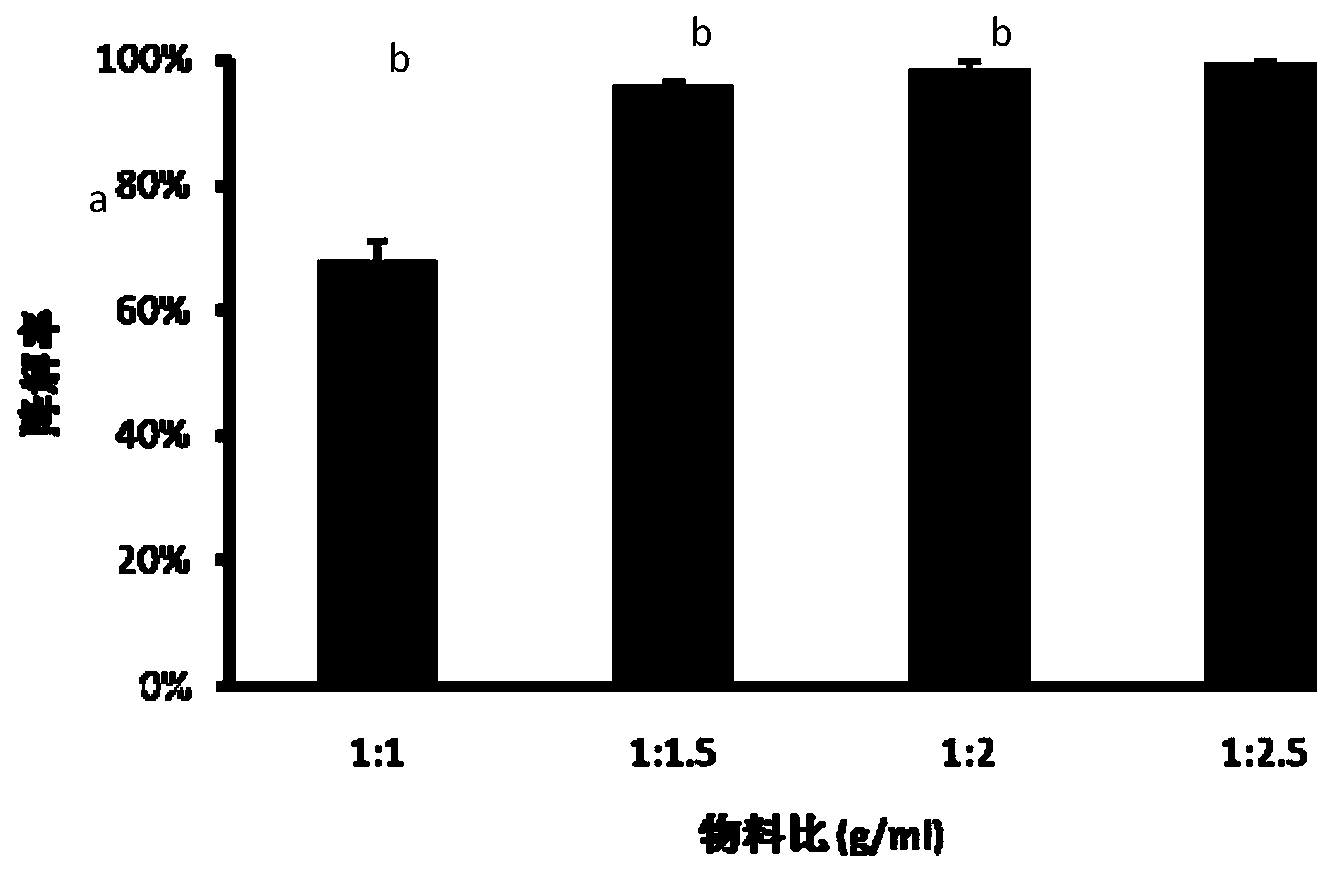

ActiveCN103804032AGood growth promoting effectSimple processAnimal corpse fertilisersClimate change adaptationFertilizerChemistry

The invention discloses a liquid amino acid compound produced by dead porcine proteins and an application of the compound. The liquid amino acid compound is obtained by acidifying lean meat by adding sulfuric acid. The liquid amino acid compound produced by acidifying lean meat by adding sulfuric acid is rich in various free amino acids, and the contents of the free amino acids, soluble polypeptide and soluble albuminous total nitrogen are high. The compound diluted as a liquid agricultural amino acid fertilizer leaf fertilizer is sprayed to cucumber, brassica chinensis and radish plants, so that the compound has a very good growth promoting effect. The invention provides a production method of a liquid agricultural amino acid by acidifying lean meat by adding sulfuric acid. The process is simple and the demand on the equipment is low. Compared with a conventional dead pig treatment process, the production method disclosed by the invention has the characteristics that the produced amino acid as the liquid agricultural amino acid fertilizer has the advantages of low treatment cost, and the porcine lean meat resources can be effectively recycled. The compound disclosed by the invention has importance meaning for preserving the ecological environment, effectively solving the problem of treating dead pigs, protecting physical health of people and improving the additional value of agricultural products.

Owner:NANJING AGRICULTURAL UNIVERSITY

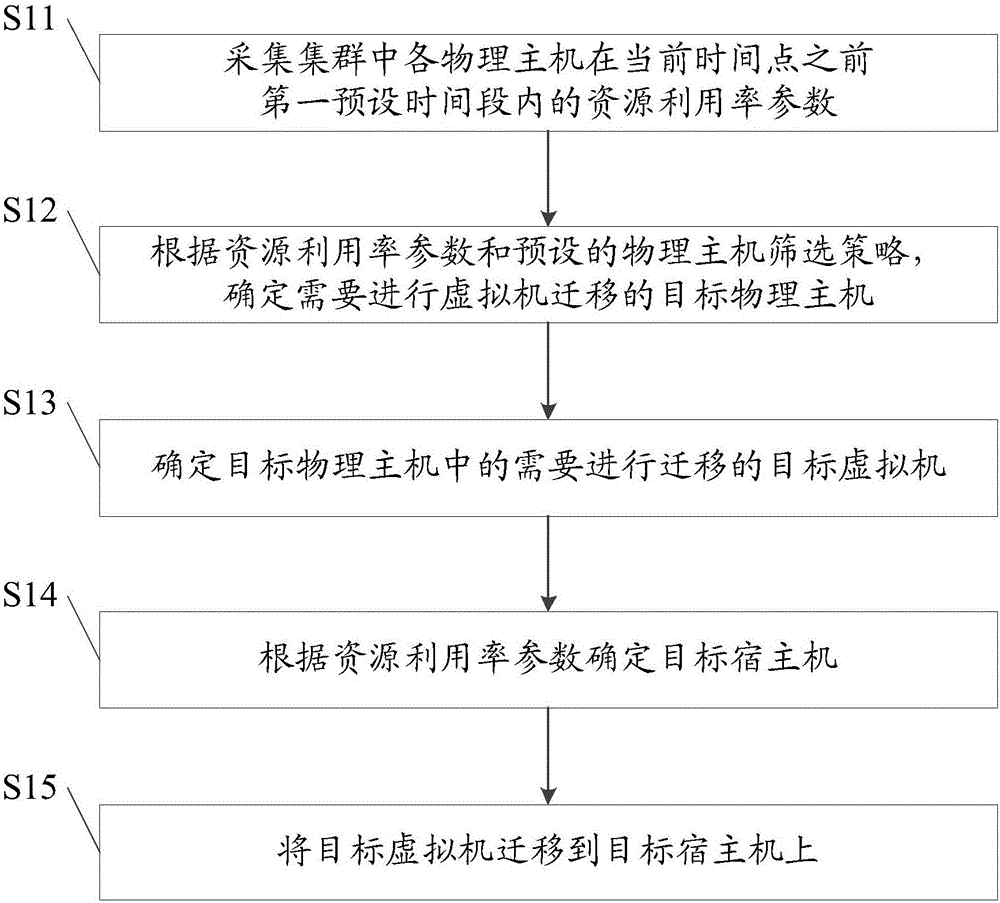

Resource scheduling method of cluster virtual machine

InactiveCN106293871AFix load imbalanceGood resource utilizationProgram initiation/switchingSoftware simulation/interpretation/emulationCurrent timeVirtual machine

The invention discloses a resource scheduling method of a cluster virtual machine. The resource scheduling method comprises the following steps of: acquiring resource utilization parameters of each physical host in the cluster for a first preset time period before the current time point; according to the resource utilization parameter and the preset physical host selection strategy, determining a target physical host having need to migrate the virtual machine; determining a target virtual machine to be migrated in the target physical host; determining a target host machine according to the resource utilization parameter; and migrating the target virtual machine to the target physical host. The target virtual machine in the target physical host is migrated to the target host machine. Through the dynamic migration of the virtual machine, the virtual machine on the target physical host with high resource utilization can be migrated to other physical hosts to realize dynamic load balance of the physical hosts, and fully use a variety of physical resources in the cluster, so that the problem of resource imbalance in the cluster is solved and efficient resource utilization is maintained.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

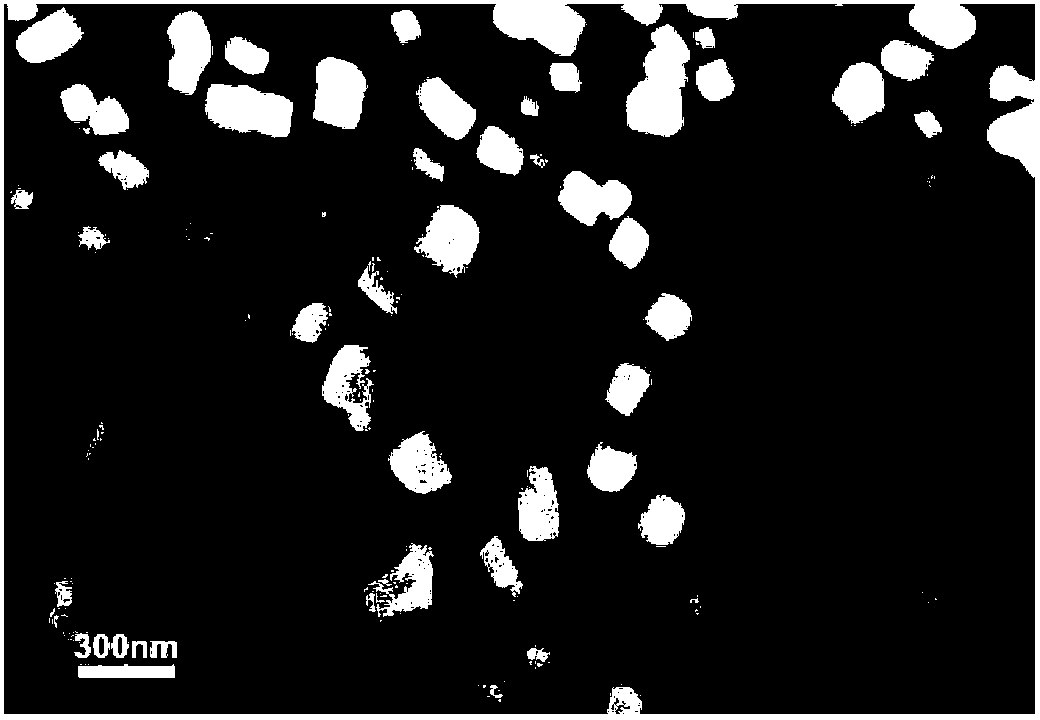

Method for preparing lignin nanoparticles by taking papermaking black liquid as raw material

The invention discloses a method for preparing lignin nanoparticles by taking papermaking black liquid as a raw material and belongs to the field of nanometer material chemistry. The preparation method comprises the following steps of: carrying out acidification or ultra-filtration purification on the papermaking black liquid taken as the raw material so as to remove insoluble impurities and a lower molecular compound; dissolving purified lignin in an alkaline solution; adding sulfuric acid, nitric acid or hydrochloric acid at a certain speed so as to form lignin colloid; and carrying out freeze drying to obtain the lignin nanoparticles, wherein the particle sizes of the lignin nanoparticles are in the range being 50-280 nm. The obtained lignin nanoparticles have good dispersion property and absorption property and are expected to be applied to a dispersing agent for wastewater treatment and systems such as dyes, pesticides and coal-water slurry. The preparation method disclosed by the invention is simple and practicable and has good application prospect; and a solvent used in the method is water which has no negative effect on environments.

Owner:GUANGXI UNIV

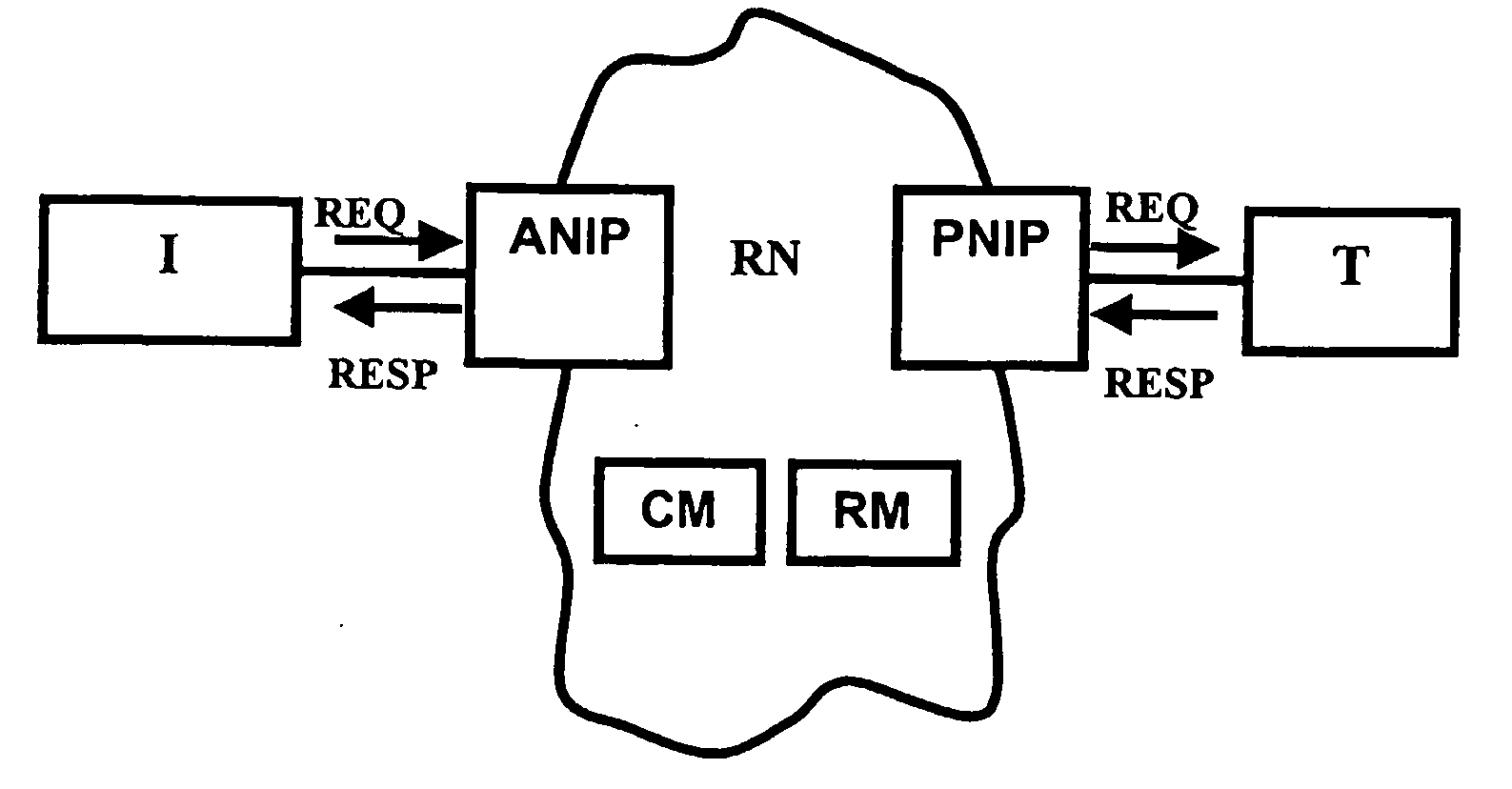

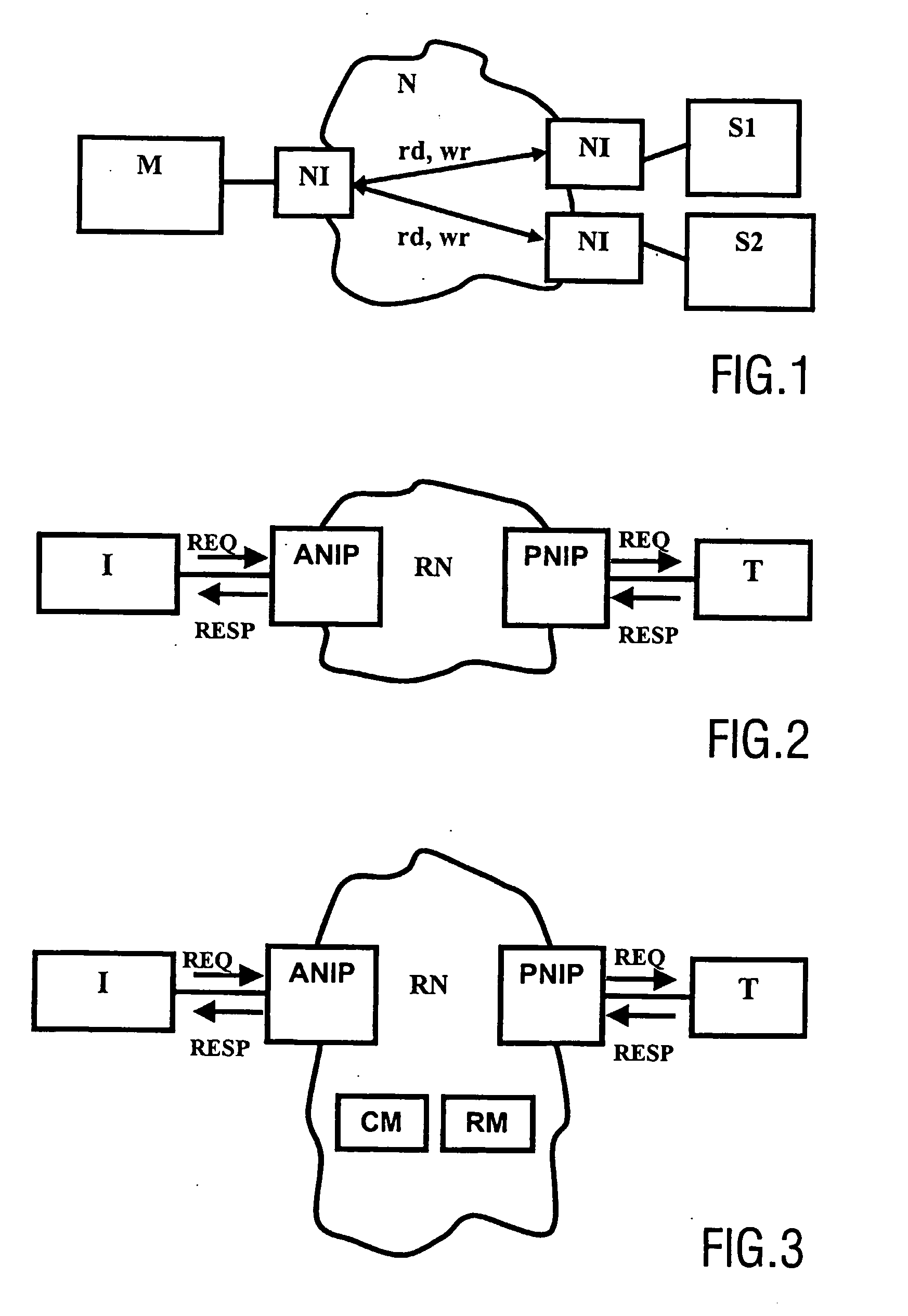

Integrated circuit and method for establishing transactions

ActiveUS20060041889A1Efficient resource utilizationEfficiently utilizedDigital computer detailsMultiprogramming arrangementsIntegrated circuitWeb resource

An integrated circuit comprising a plurality of processing modules (M; I; S; T) and a network (N; RN) arranged for providing at least one connection between a first and at least one second module is provided. Said connections comprises a set of communication channels each having a set of connection properties. Said connection supports transactions comprising outgoing messages from the first module to the second module and return messages from the second module to the first module. The connection properties of the different communication channels of said connection can be adjusted independently. Therefore, the utilization of the resources of a network on chip is more efficient, since the connection between modules can be efficiently adapted to their actual requirement, such that the connection is not over dimensioned and unused network resources can be assigned to other connections.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV +1

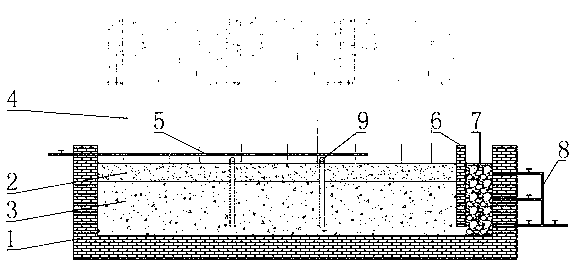

Artificial wetland system taking oyster shell-waste brick-zeolite as composite filler

InactiveCN103304033AIncrease concentrationEasy loadingSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandBrick

The invention discloses an artificial wetland system taking oyster shell-waste brick-zeolite as composite filler. The invention relates to a sewage treatment device, and discloses an artificial wetland ecological treatment device applicable to the treatment of various sewages such as domestic wastewater, livestock and poultry breeding wastewater and landfill leachate. The system disclosed by the invention comprises a vertical undercurrent artificial wetland device and wetland filler, wherein the wetland filler is implemented in a large particle size grading difference 'obverse and reverse particle size mixing' filling mode and taking oyster shell, waste bricks and zeolite which are large in specific surface area, good in nitrogen and phosphorus adsorption capacity and high in volume of organism holding, so that the sustainable, efficient and stable operation of an artificial wetland ecosystem is ensured. The artificial wetland system disclosed by the invention has the advantages of low cost, low energy consumption, high nitrogen and phosphorus removal efficiency, small land-occupied area, simple structure, convenient operation management and the like, is not easy to jam, and can be combined with ecological construction and urban greening functions.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

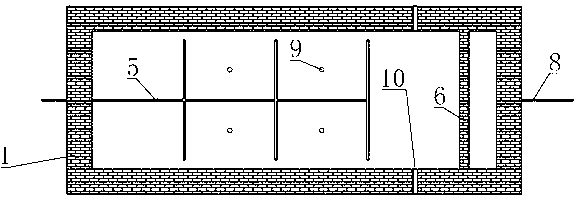

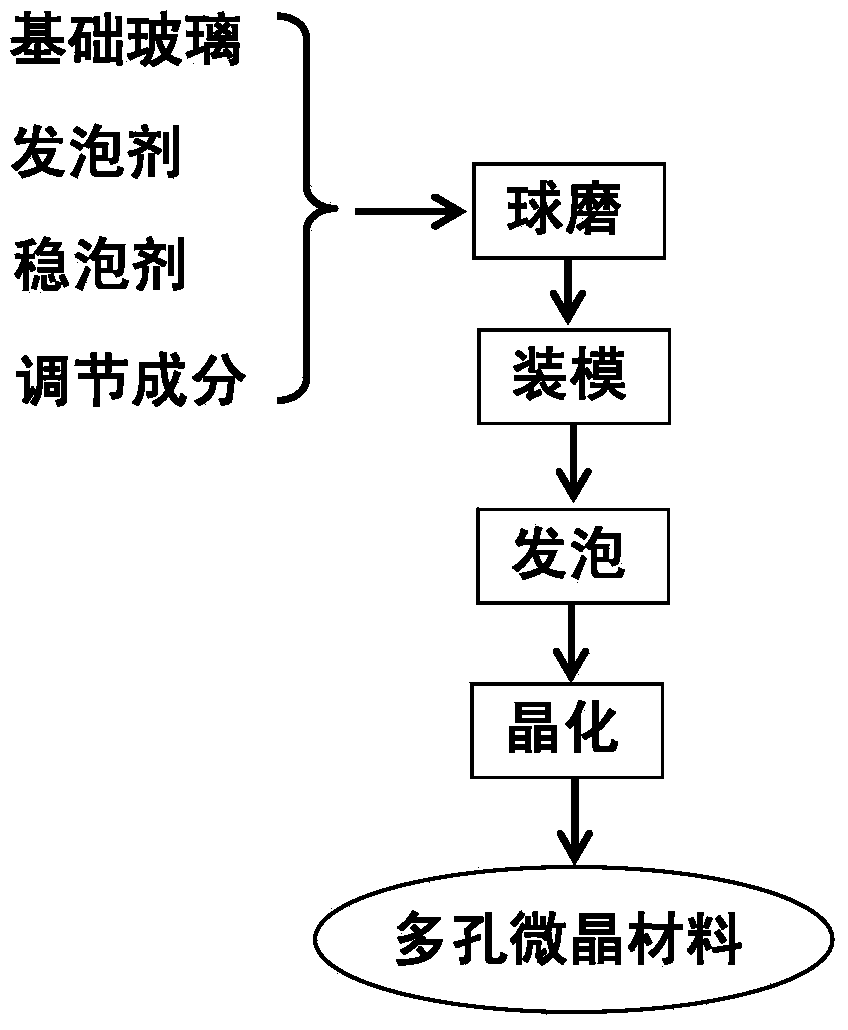

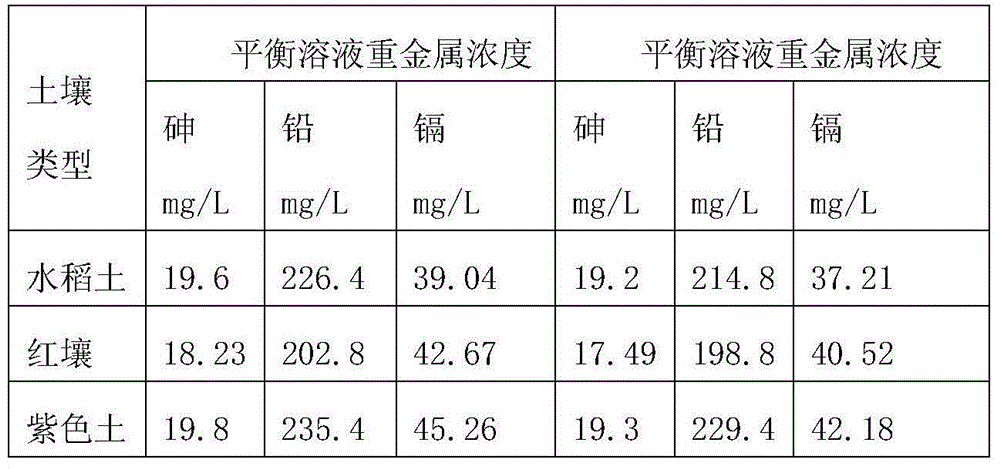

Nickel-slag porous microcrystalline material and preparation method thereof

The invention relates to a nickel-slag porous microcrystalline material and a preparation method of the nickel-slag porous microcrystalline material. Smelting ferro-nickel waste residues are taken as main raw materials, and additives such as SiO2, CaCO3, Na2CO3, ZnO and K2CO3, and a clarifying agent are taken as auxiliary materials. The nickel-slag porous microcrystalline material disclosed by the invention is lightweight, insulating, abrasion-resistant, and resistant to acid and alkali corrosion, has good machinability, can be widely applied to heat insulation and preservation of a pipeline, a storage tank and a heat exchange system in the fields such as chemical engineering, metallurgy, architectural ornament, petroleum, mine and machinery, and a composite heat-insulation system and a soundproof and acoustic absorption system working under a special condition.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

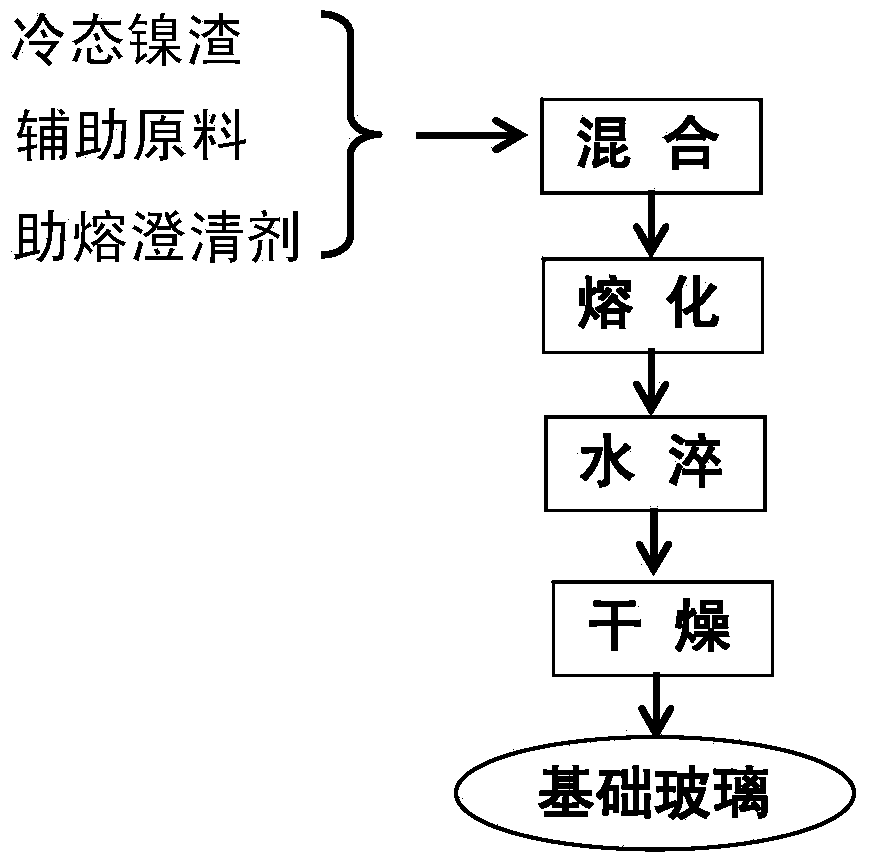

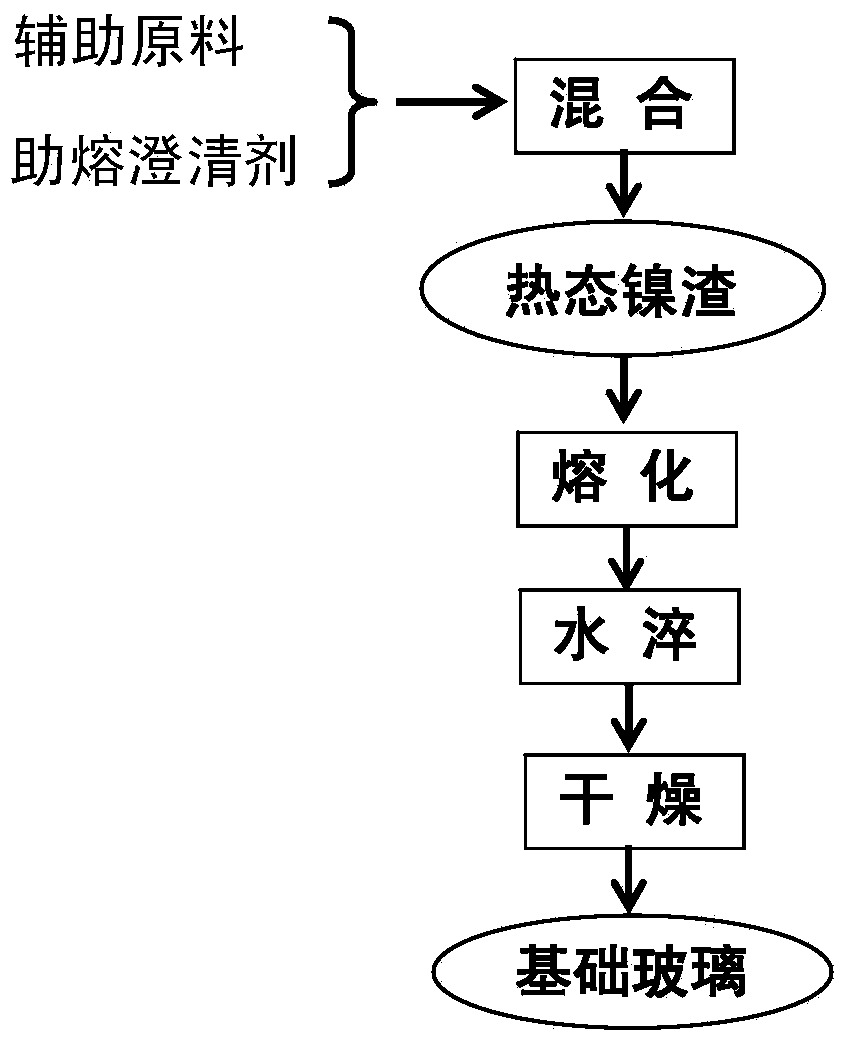

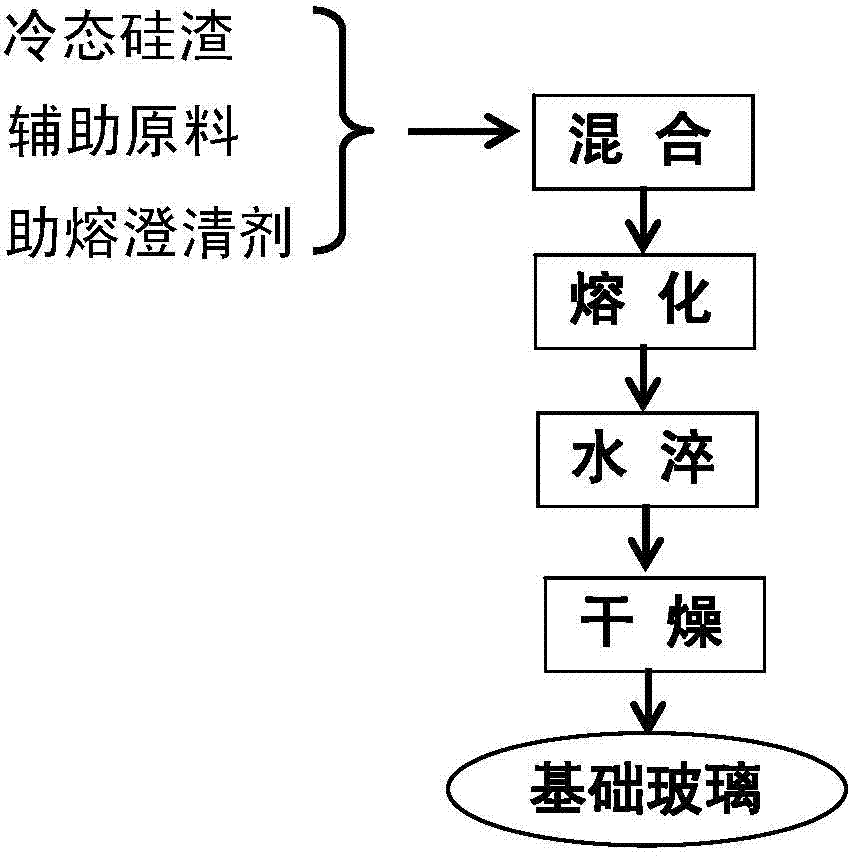

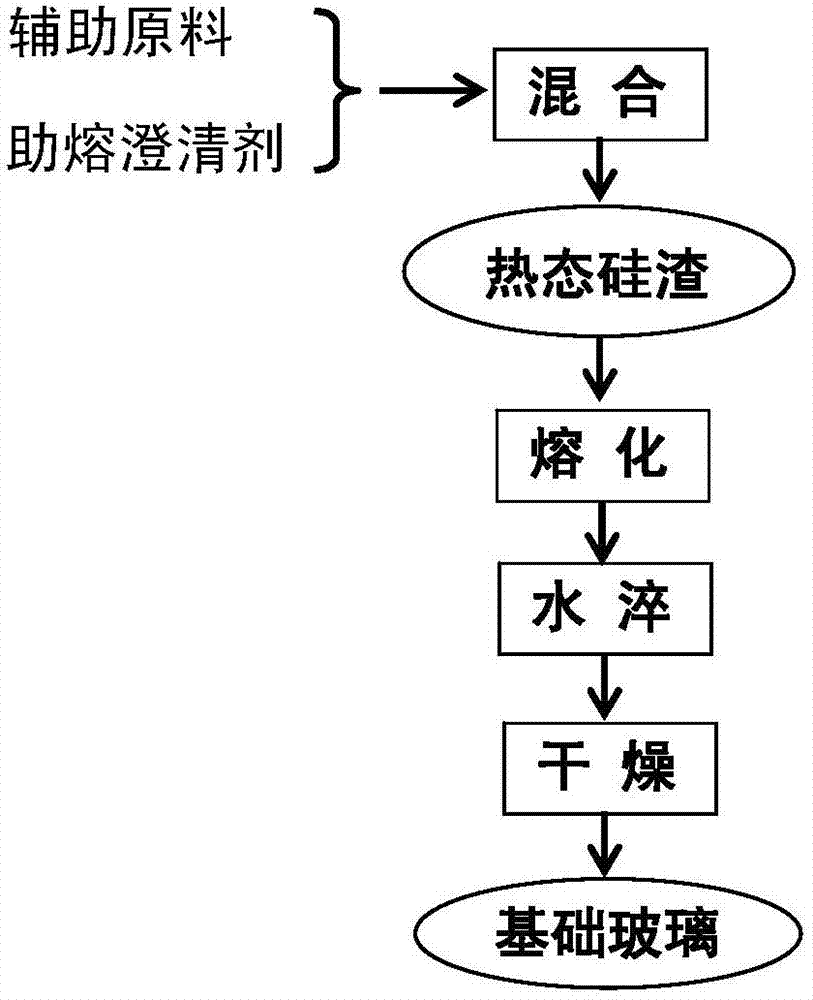

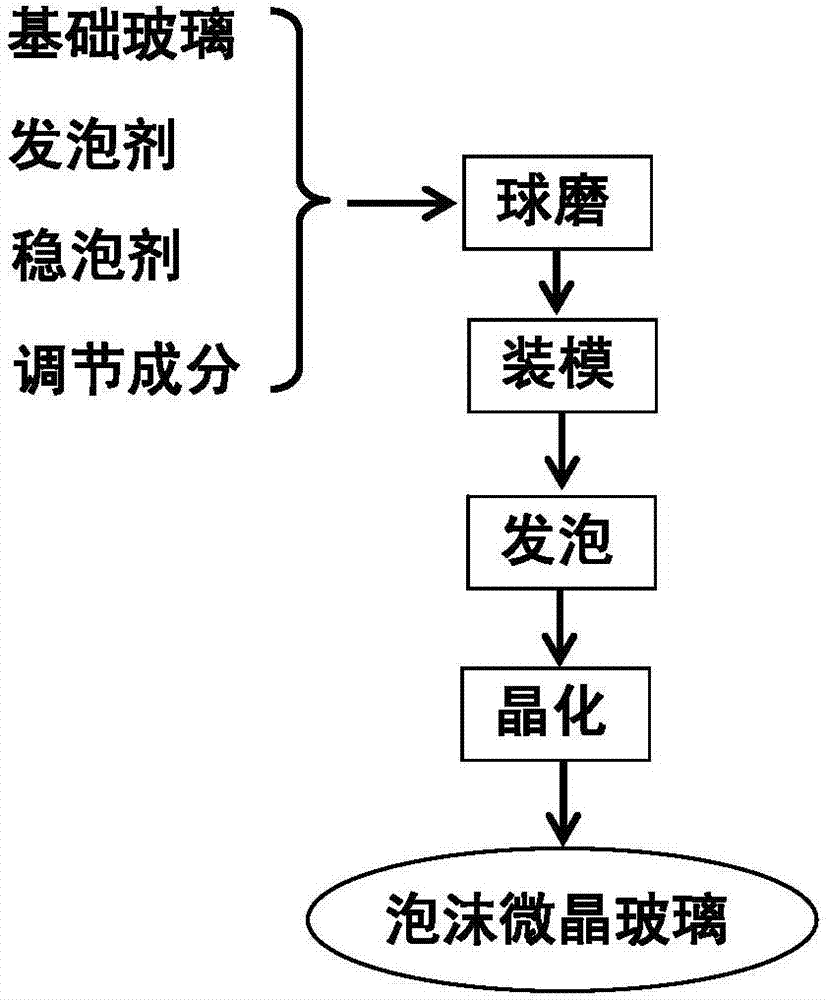

Silicon smelting waste residue foam microcrystalline glass and preparation method thereof

InactiveCN103539360AEfficient resource utilizationReduce manufacturing costChemical industryThermal insulation

The invention relates to silicon smelting waste residue foam microcrystalline glass and a preparation method thereof. The glass takes silicon smelting waste residue as a main raw material, and takes SiO2, CaCO3, Na2CO3, ZnO, K2CO3 and other additives and clarifying agents as auxiliary materials. The preparation method comprises the following steps: uniformly mixing the cold silicon residue and the auxiliary materials in a mixer, and melting at a high temperature in a melting furnace to obtain a qualified glass solution; cooling the glass solution to obtain base glass; smashing the base glass, and thoroughly mixing with a foaming agent, a foam stabilizer and regulation components to form a sintering batch; and feeding the sintering batch into a combined mold, then integrally transferring the sintering batch into a heat treatment kiln together with the mold, firing, annealing, cooling, and demolding to obtain the foam microcrystalline glass. According to the invention, the foam microcrystalline glass is light in weight and resistant to wear and acid / alkali corrosion, can keep warm, has favorable machinability, and can be widely used for heat insulation and warm keeping of pipelines, storage tanks and heat exchange systems in the fields of chemical industry, metallurgy, architectural decoration, petroleum, mines, machinery and the like as well as composite heat insulation systems and sound insulation / absorption systems working under special conditions.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

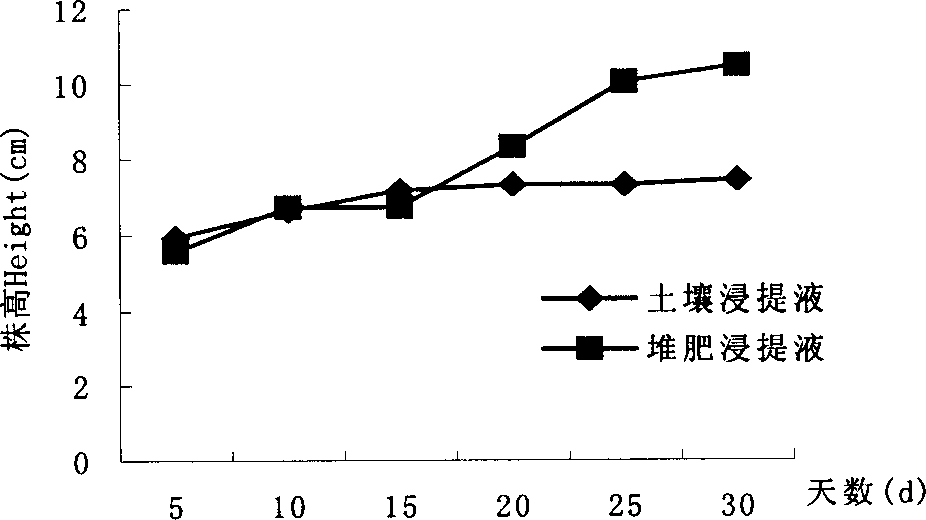

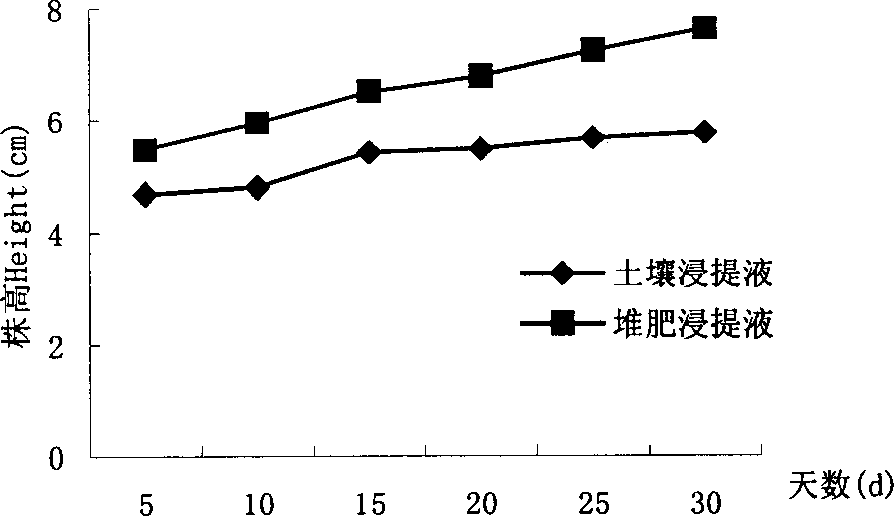

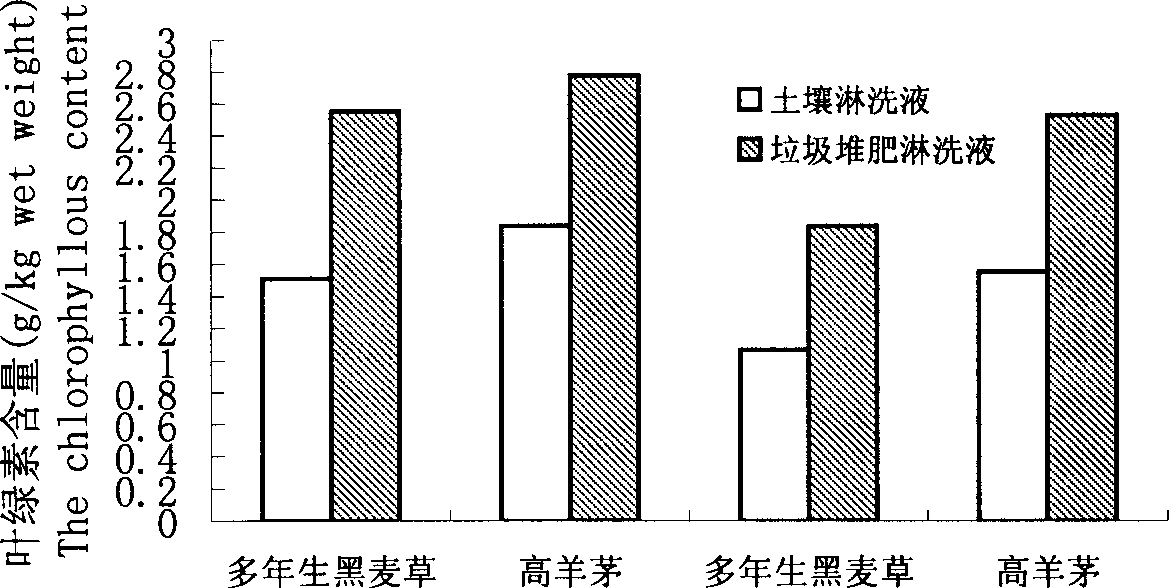

Eluate for compost of domestic waste of city, preprtion method and application

InactiveCN1872802ASafe and effective useBroaden repair pathwaysClimate change adaptationOrganic fertilisersWater useNutrient solution

This invention relates to a method for manufacturing washing solution from domestic waste compost. The method comprises: (1) pulverizing domestic waste compost, sieving with a 2 mm sieve, and collecting the powder; (2) mixing with water at a wt. ratio of 1 :( 1-3), stirring, soaking at room temperature for 24-48 h, and filtering to obtain the final product. The washing solution can be used as the nutrition solution for sod soilless culture. The method can reduce the pollution caused by heavy metals in domestic waste compost, and lower the cost of sod soilless culture.

Owner:TIANJIN NORMAL UNIVERSITY

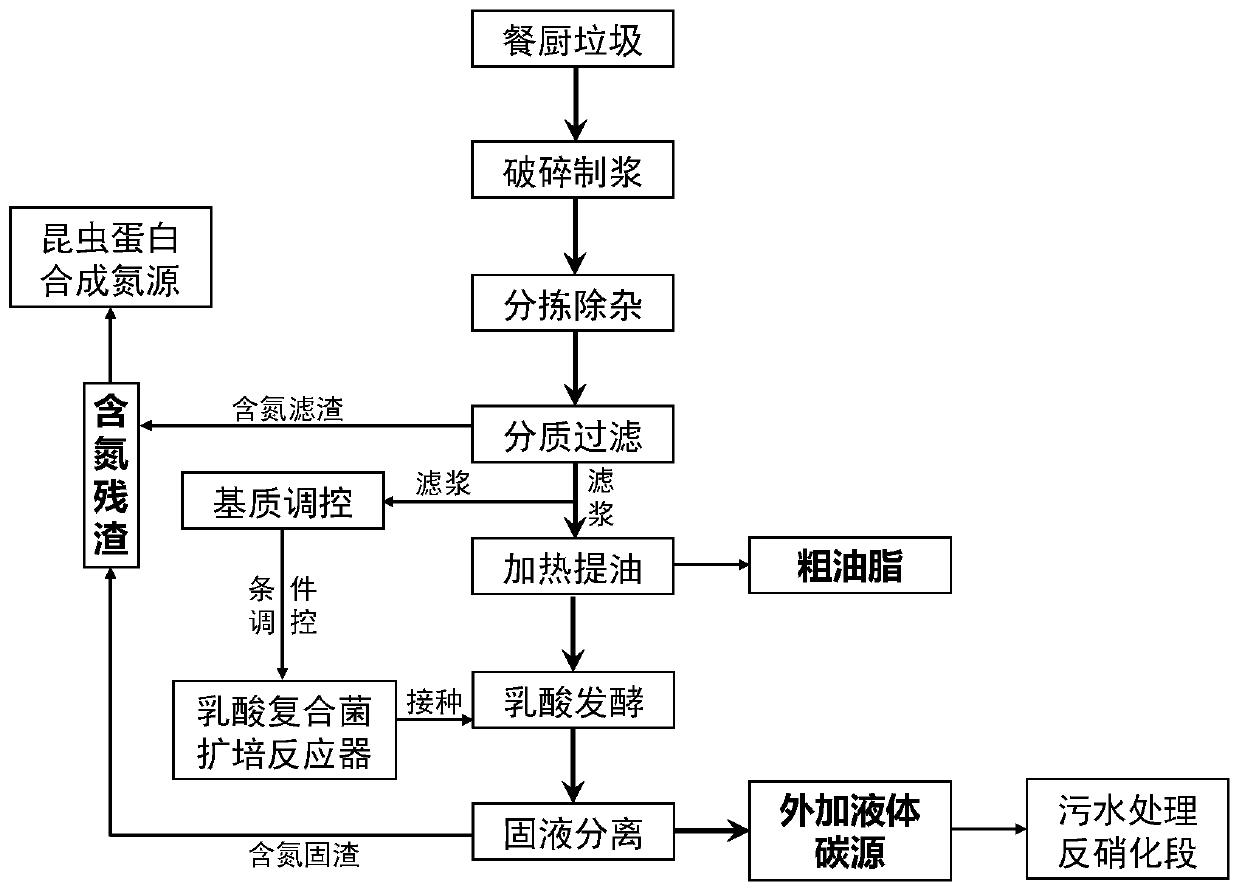

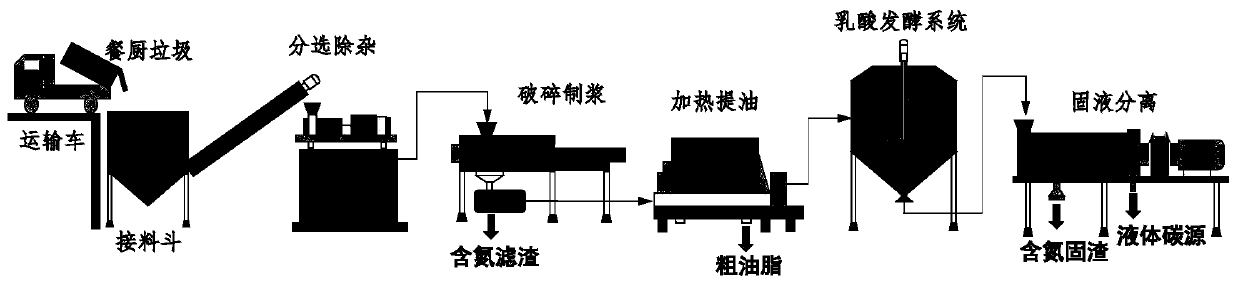

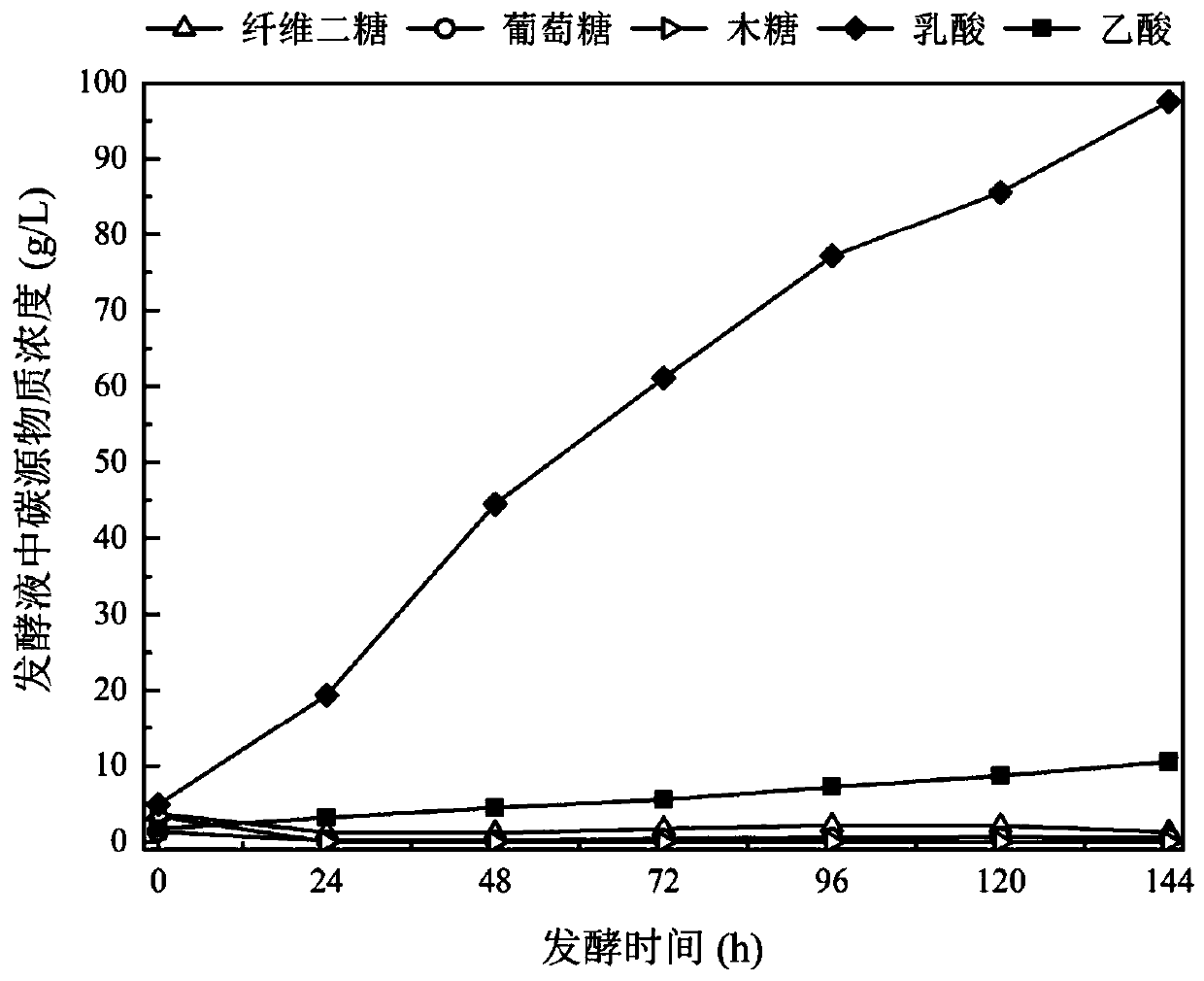

Method for producing wastewater denitrification carbon source through lactic acid fermentation of kitchen waste

ActiveCN111333179ASolve the problem of low COD/TNEfficient resource utilizationWater treatment compoundsTreatment with anaerobic digestion processesNutritionWaste oil

The invention discloses a method for producing a wastewater denitrification carbon source through lactic acid fermentation of kitchen waste, and belongs to the technical field of solid waste resourceful treatment. The method comprises the steps of adopting kitchen waste as a raw material; sorting and impurity removal, controlling the solid-to-liquid ratio, grinding, pulping, and carrying out quality-based and phase-splitting treatment; after the waste oil is heated and recycled, the residual garbage slurry is injected into an anaerobic fermentation tank for batch lactic acid fermentation, after fermentation is finished, solid-liquid separation is carried out, lactic acid-containing supernatant can be directly used as a liquid carbon source in the sewage denitrification stage, a good biological denitrification effect is achieved, nitrogen-containing residues can be collected and recycled, and full recycling is achieved. According to the invention, kitchen waste is directly used for efficient open lactic acid fermentation; according to the method, the indigenous microbial flora in the kitchen waste is fully utilized to hydrolyze the substrate and efficiently and directionally convertthe substrate into lactic acid, exogenous nutrition and industrial enzyme preparations do not need to be added, the process is simple, the production cost is low, a cheap carbon source is provided for a denitrification section of a sewage treatment plant while resource utilization of the kitchen waste is realized, and the biological denitrification efficiency is improved.

Owner:UNIV OF SCI & TECH BEIJING

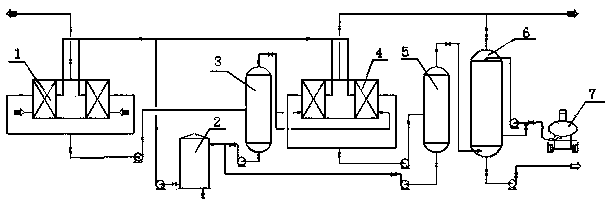

Device and method for producing sodium bisulfide by utilizing refinery dry gas

ActiveCN103754833ARaise the possibilityRealize resource utilizationSulfur compoundsResource utilizationGas composition

The invention relates to a device and method for producing sodium bisulfide by utilizing refinery dry gas. Aiming at the gas composition characteristics of the refinery dry gas, the dry gas refining desulphurization process is processed by utilizing an ultra-high gravity technology, and H2S in acid tail gas after dry gas refining desulphurization is selectively removed, so that the content of the purified H2S is over 99 percent, the purified and refined H2S is absorbed for preparing high-purity NaHS by adopting a continuous alkali liquor cycle, the concentration purity is over 42 percent, the process technology is greatly innovated, the investment is saved, secondary pollution is avoided, a process of a traditional out-dated NaHS product can be replaced, the device has a certain economic benefits and high-efficiency resource utilization rate, the H2S in the acid gas is almost recycled completely, the requirements of environment friendliness and emission are met, high social benefits are achieved, and recycling comprehensive utilization of refinery acid tail gas is realized.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

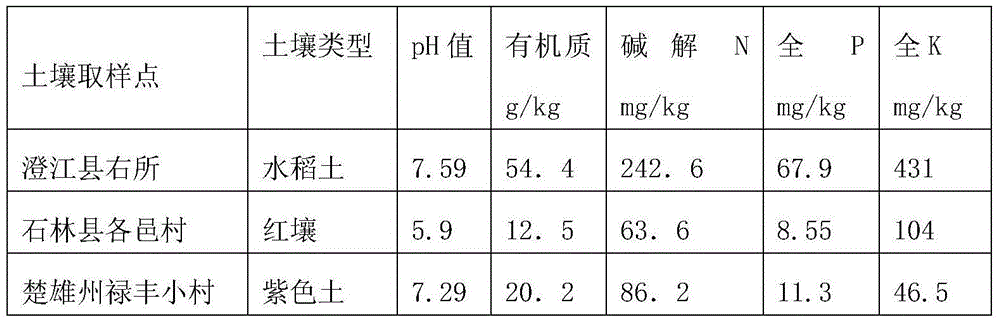

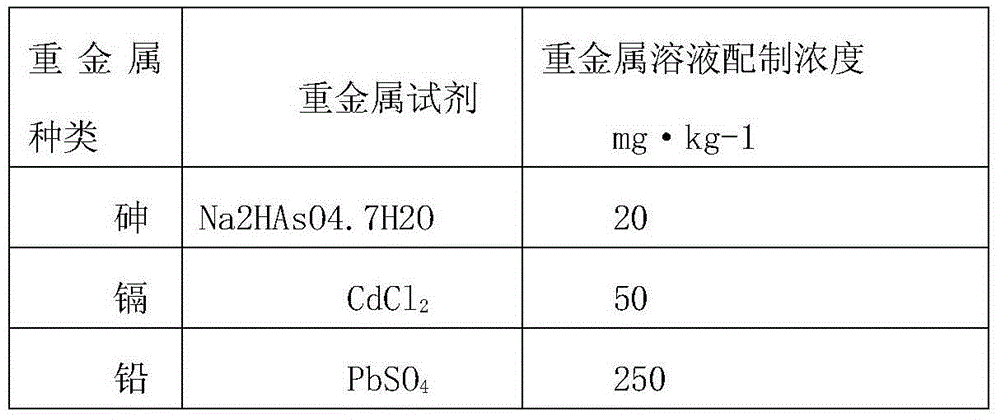

Soil heavy metal ion absorbent and preparation method thereof

InactiveCN104383890AReduce heavy metal contentEnsure safe productionOther chemical processesContaminated soil reclamationMass ratioSorbent

The invention discloses a soil heavy metal ion absorbent and a preparation method thereof. The soil heavy metal ion absorbent is prepared by mixing modified corn straws, modified kaolin and potassium humate in a mass ratio of 2 to 5 to 3; the modified corn straws are mainly formed by drying, alkali treatment, acid treatment and drying; the modified kaolin is mainly formed by adding sodium polyphosphate and then roasting. The soil heavy metal ion absorbent disclosed by the invention can be used for obviously enhancing the absorption capability of soil to heavy metal and reducing the migration of the heavy metal in the soil to crops. Tests show that the average lead reducing rate in corn kernels is 15.63%, the average cadmium reducing rate in the corn kernels is 12.15%, and the average arsenic reducing rate in the corn kernels is 7.62%. The average lead reducing rate in rice is 17.8%, the average cadmium reducing rate in the rice is 17.27%, and the average arsenic reducing rate in the rice is 21.84%, and the quality of edible part of the crops is guaranteed.

Owner:INST OF QUALITY STANDARD & DETECTION TECH YUNNAN ACAD OF AGRI SCI

High-performance concrete admixture in use of waste ceramic powder and implementing method thereof

InactiveCN104817287AThe stability result is qualifiedImprove liquiditySolid waste managementEnvironmental resistanceFiber

The invention discloses a high-performance concrete admixture in use of waste ceramic powder and an implementing method thereof. The high-performance concrete admixture is prepared by the following steps: utilizing waste ceramics as a main material and utilizing active seed crystals and a modified enhancer as auxiliary materials; performing modified treatment and high-temperature smelting on various materials, then putting into a cement mill to mill the materials to be pre-finished products with specific area of 300-450 m2 / kg, and finally, doping mixed fibers. The high-performance concrete admixture comprises the raw materials in parts by weight: 80-100 parts of waste ceramic powder, 6-9 parts of active seed crystal, 2-6 parts of modified enhancer and 5-10 parts of mixed fibers. By adopting mixed ceramic powder, density of cement mortar is effectively increased; strength of concrete is improved and durability of concrete is remarkably improved. Energy problems are solved, and meanwhile, an environmental protection purpose is considered; the high-performance concrete admixture has remarkable technical, economic and social benefits.

Owner:EAST CHINA JIAOTONG UNIVERSITY

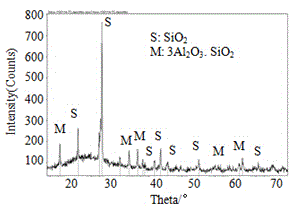

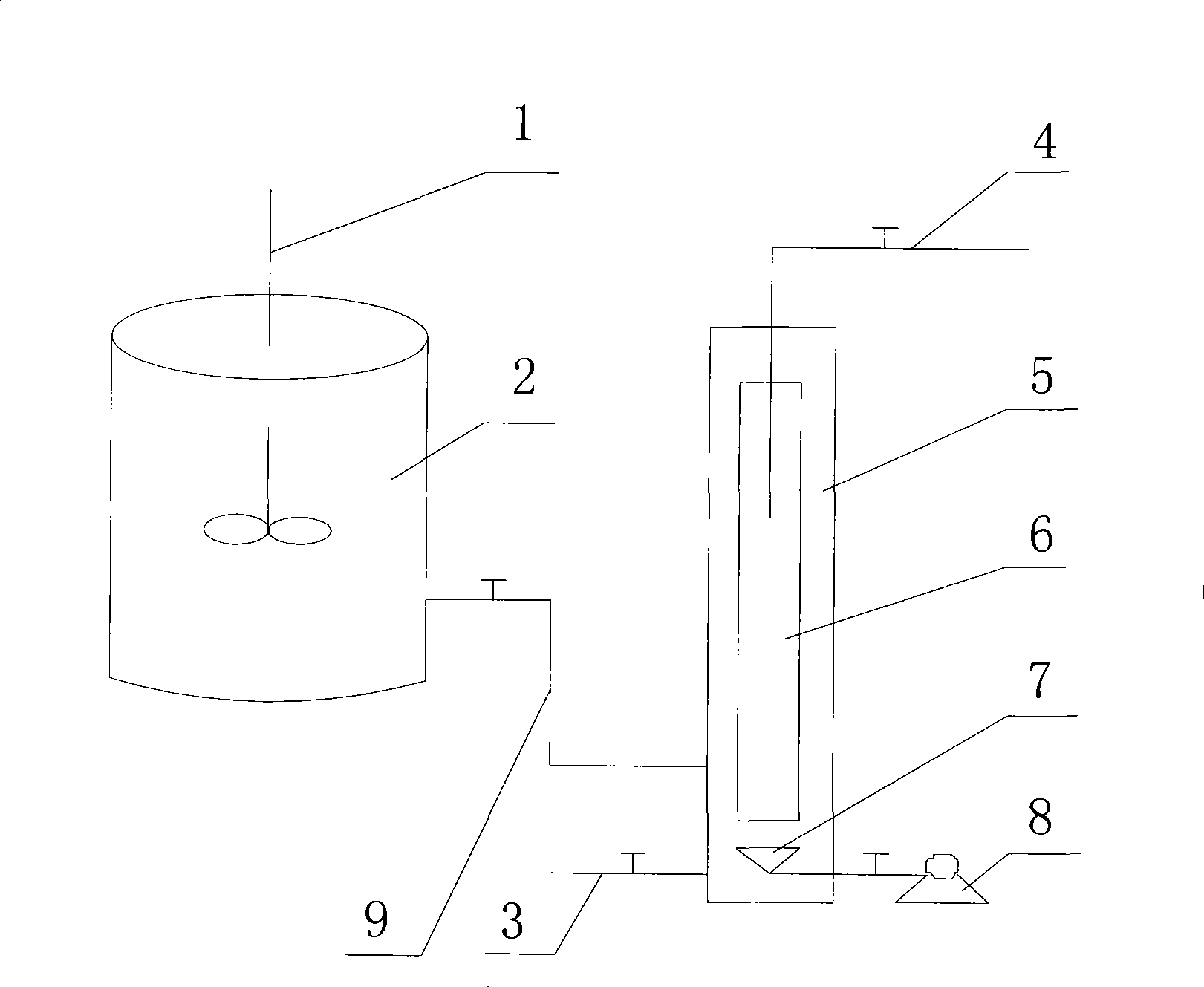

Microbial electrolysis two-section type sludge anaerobic digestion device and method for producing methane by using microbial electrolysis two-section type sludge anaerobic digestion device

ActiveCN104478178AImprove the breaking effectImprove utilization and removal rateSpecific water treatment objectivesWaste based fuelElectrolysisBiomass degradation

The invention discloses a microbial electrolysis two-section type sludge anaerobic digestion device and a method for producing methane by using the microbial electrolysis two-section type sludge anaerobic digestion device, relating to an improved two-section type anaerobic digestion device and a method for producing methanol from sludge. The purpose of the microbial electrolysis two-section type sludge anaerobic digestion device is to solve the technical problems of long fermentation cycle, low methanol yield and difficult biomass degradation and application in an existing residual sludge anaerobic digestion process. The microbial electrolysis two-section type sludge anaerobic digestion device consists of a continuous stirring type acidogenic reactor and a microbial electrocatalysis assisted upflow methane-producing reactor. The method comprises the following steps: starting a microbial catalytic electrolysis unit; producing acid by fermenting the residual sludge; and producing methanol. According to the microbial electrolysis two-section type sludge anaerobic digestion device and method disclosed by the invention, an acid production stage in a treatment process of the residual sludge only needs 5 to 8 days, a methanol production stage adopts continuous flow operation, the hydraulic retention time can be reduced to less than 1 day, and the operation cycle of sludge anaerobic digestion can be greatly shortened by adopting the device and method disclosed by the invention. The device and method disclosed by the invention belong to the field of sludge anaerobic digestion.

Owner:HARBIN INST OF TECH

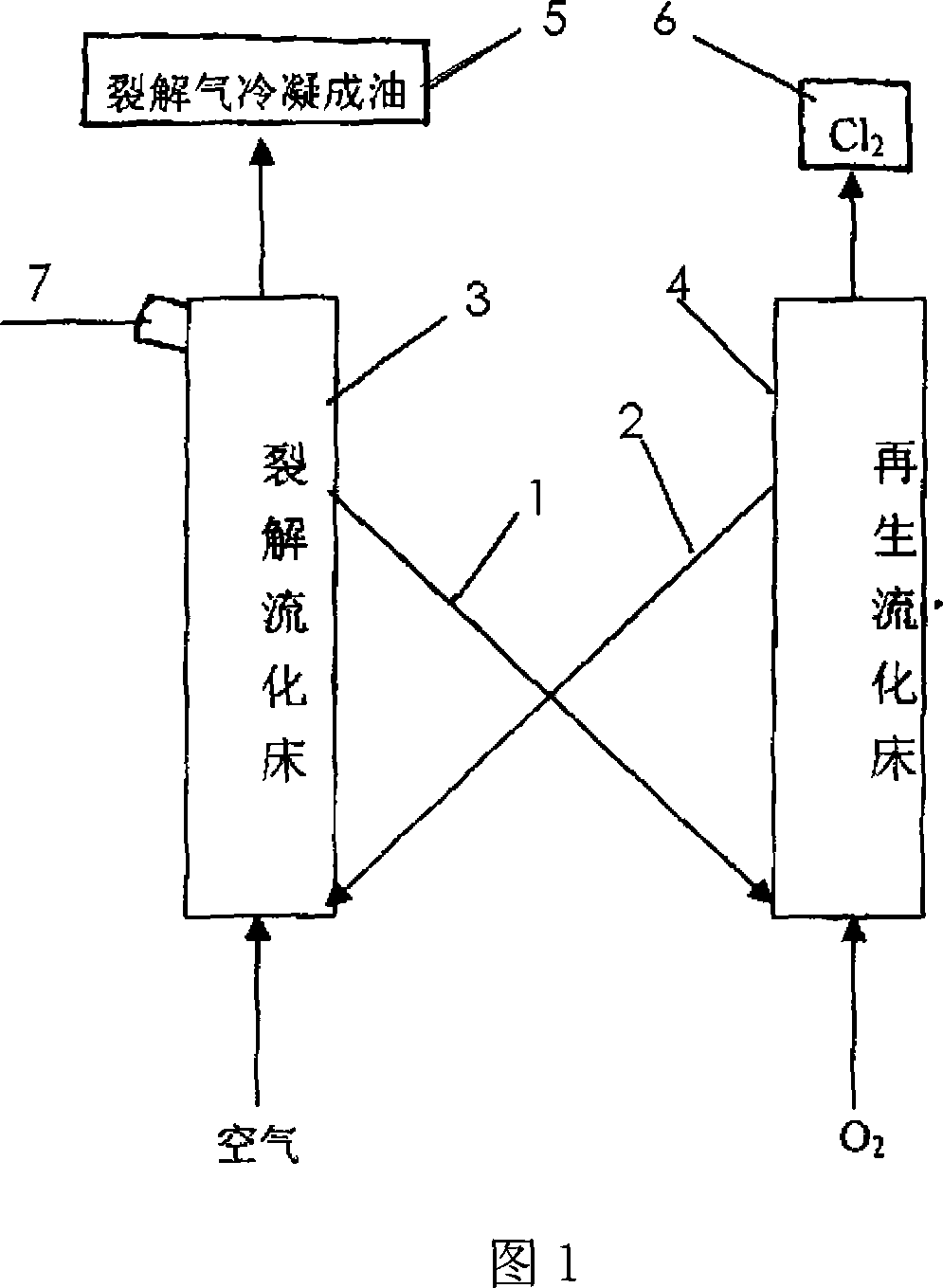

Method for full constituent utilizing resources of wastes of plastic containing chlorine in fluid bed

InactiveCN101050372AEfficient use ofHigh value utilizationLiquid hydrocarbon mixture productionAntichlorFluidized bed

This invention discloses a method for utilizing all components of chloric plastic waste in pyrolysis / regeneration double fluidized beds. The method comprises: removing HCl and pyrolyzing in the pyrolysis fluidized bed, and regenerating antichlor CuO and releasing Cl2 in the regeneration fluidized bed. The two fluidized beds are connected via a connecting pipe, and CuO / CuCl2 are fluidized between the two plastic decomposition, thus can prevent apparatus corrosion and effectively utilize chlorine-free oil product. CuCl2 produced by reaction between HCl and CuO can be regenerated into CuO, and can obtain Cl2 with a high added value.

Owner:TSINGHUA UNIV

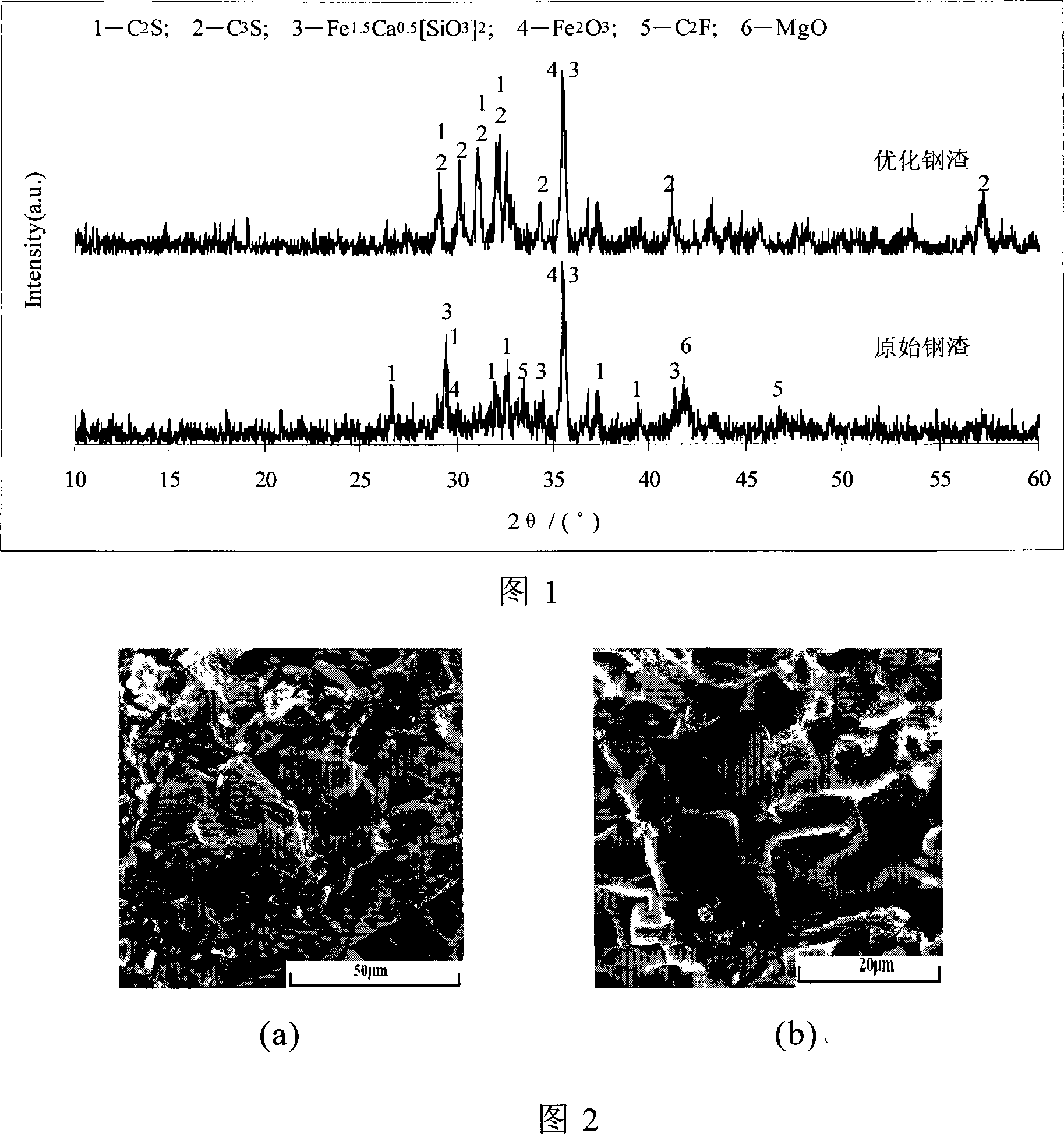

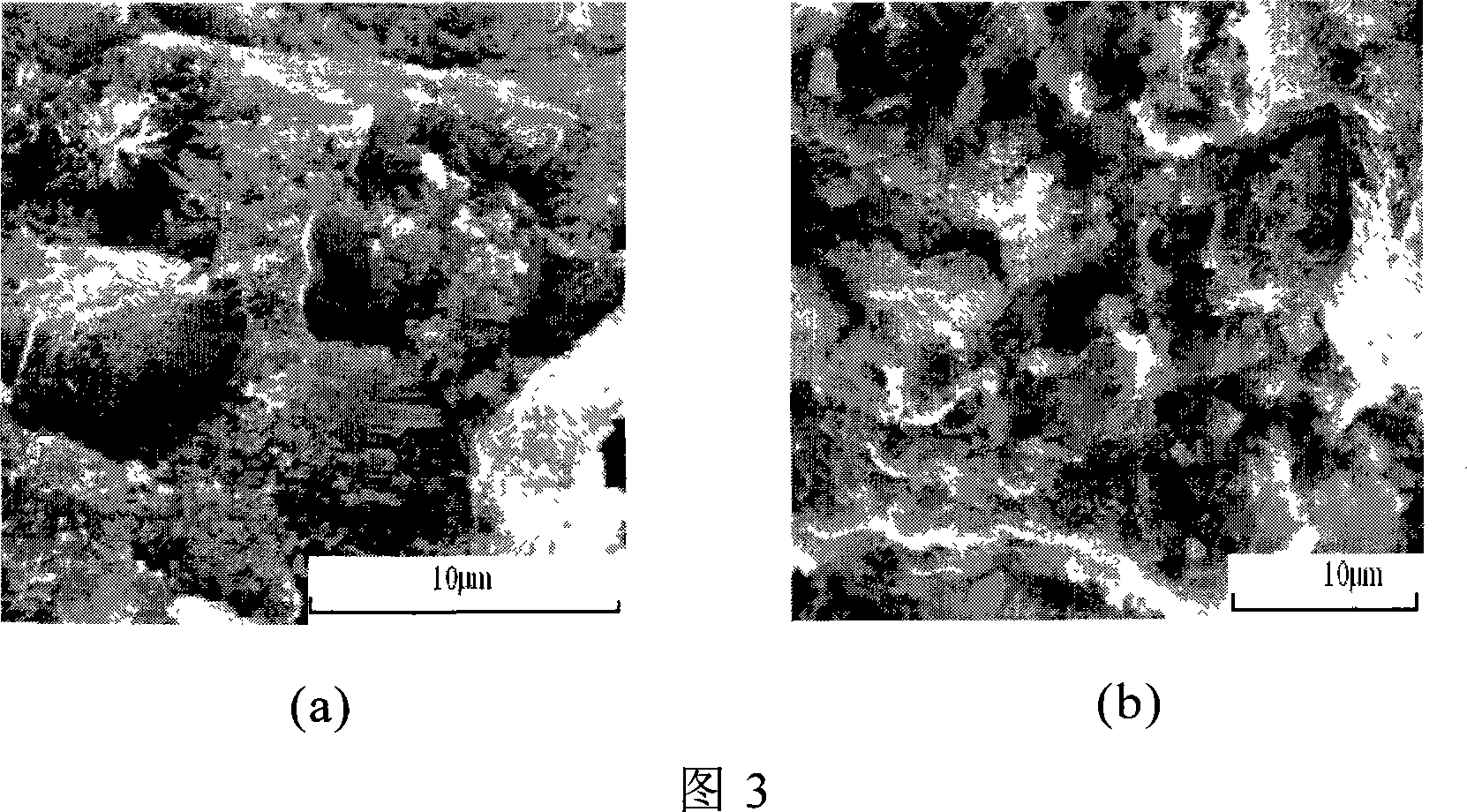

Steel slag property optimized handling method

The invention relates to a steel slag performance optimization treatment method. The following steps are adopted: a certain amount of steel slag is fetched, which is added with 2-10 percent of the weight of the steel slag of calcareous materials (counting in CaO), 1-5 percent of siliceous materials (counting in SiO2) and 1-4 percent of aluminum materials (counting in Al2O3); the slag and the materials are mixed and grinded into fine powders for the calcinations with the sintering temperature of 1200-1550 degree Celsius; after the calcinations, the fast granulation and the grinding are implemented at a slag outlet port through the wind cooling or the water cooling; the optimized steel slag is obtained. The invention has the beneficial effects of optimizing the mineral composition of the steel slag essentially, improving the volume stability of the steel slag and the water hardening activity, effectively utilizing the steel slag as resources, lowering the costs of cement, concrete and other related products and the resource consumption and being beneficial to the environmental protection.

Owner:UNIV OF JINAN

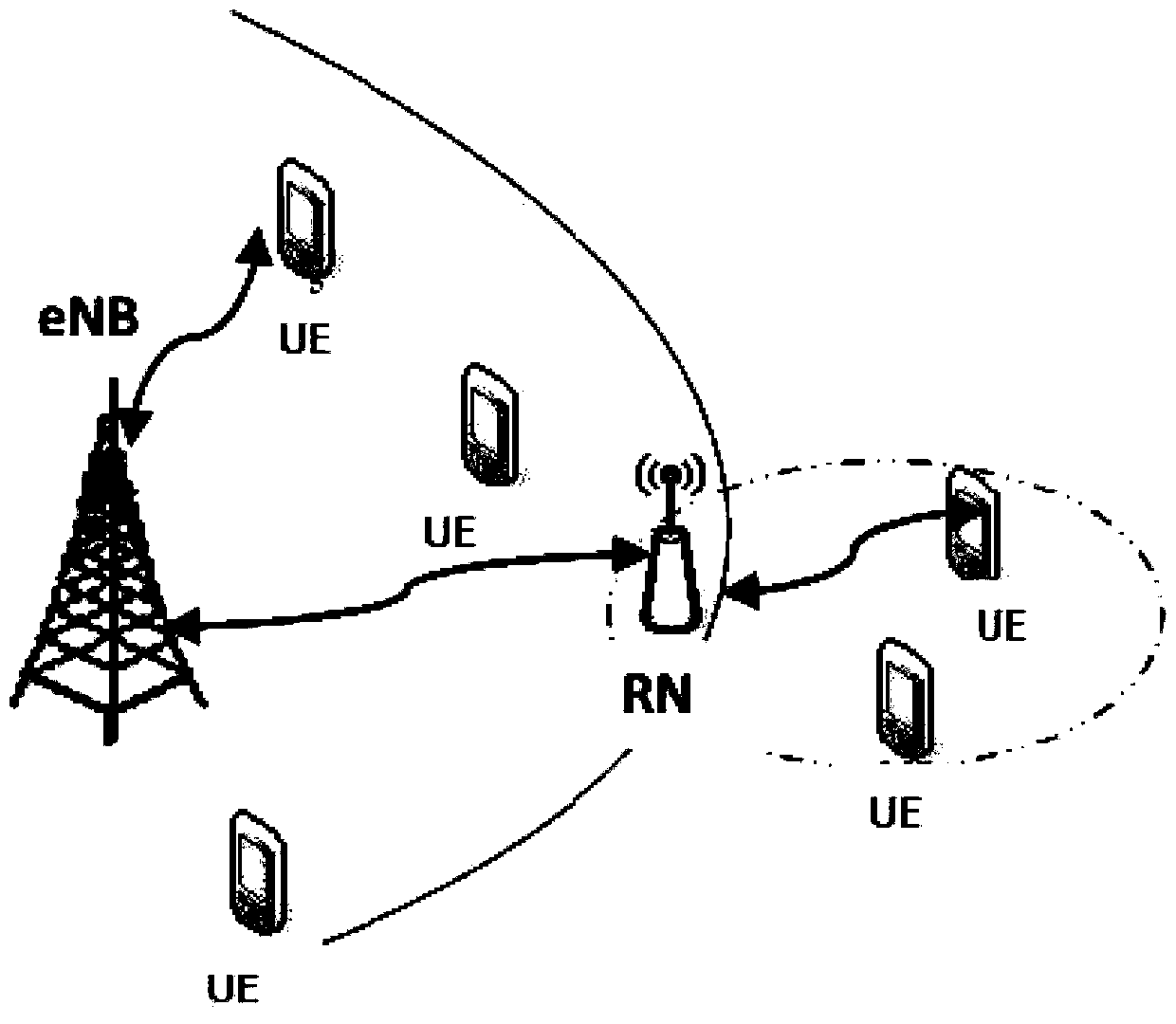

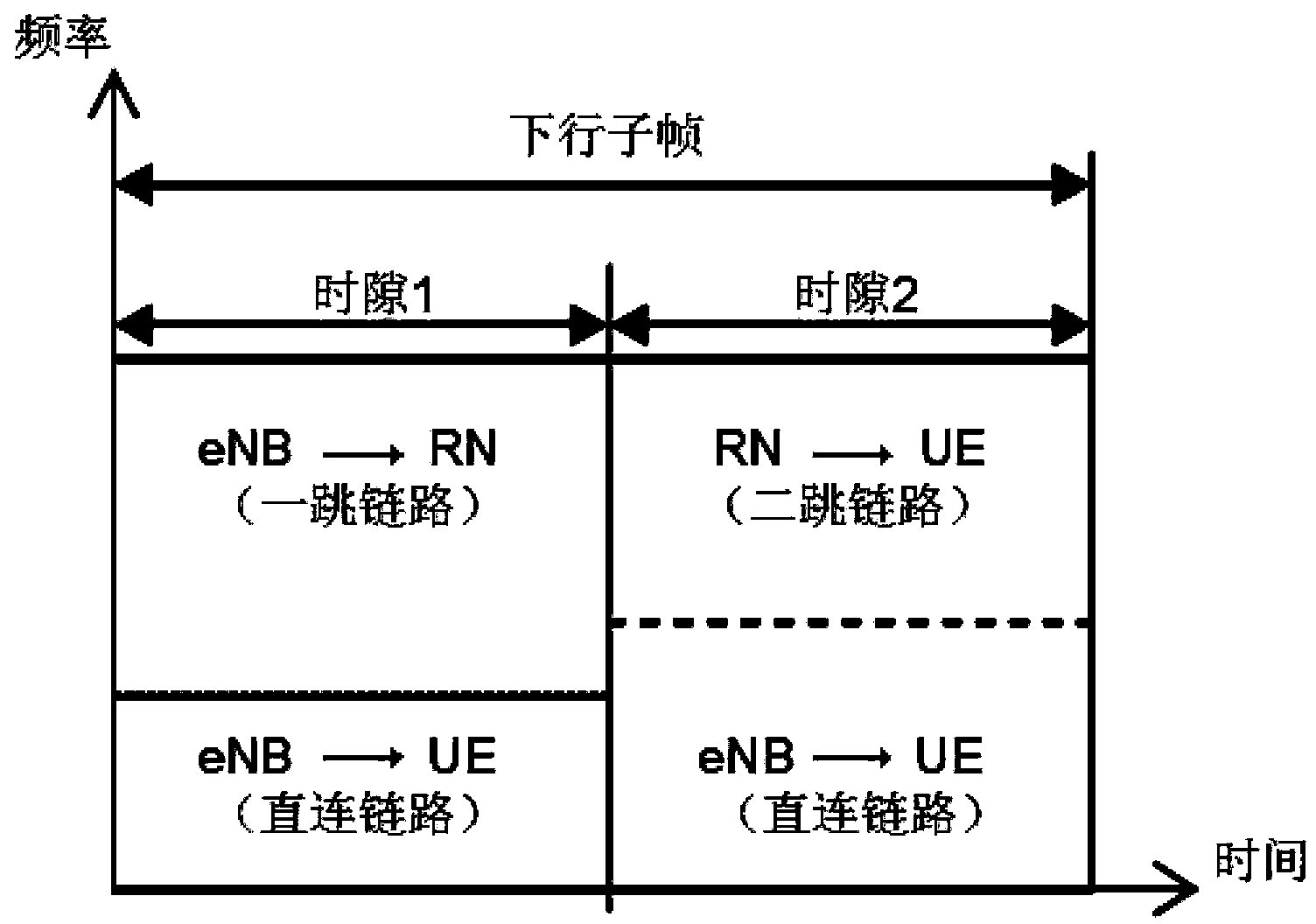

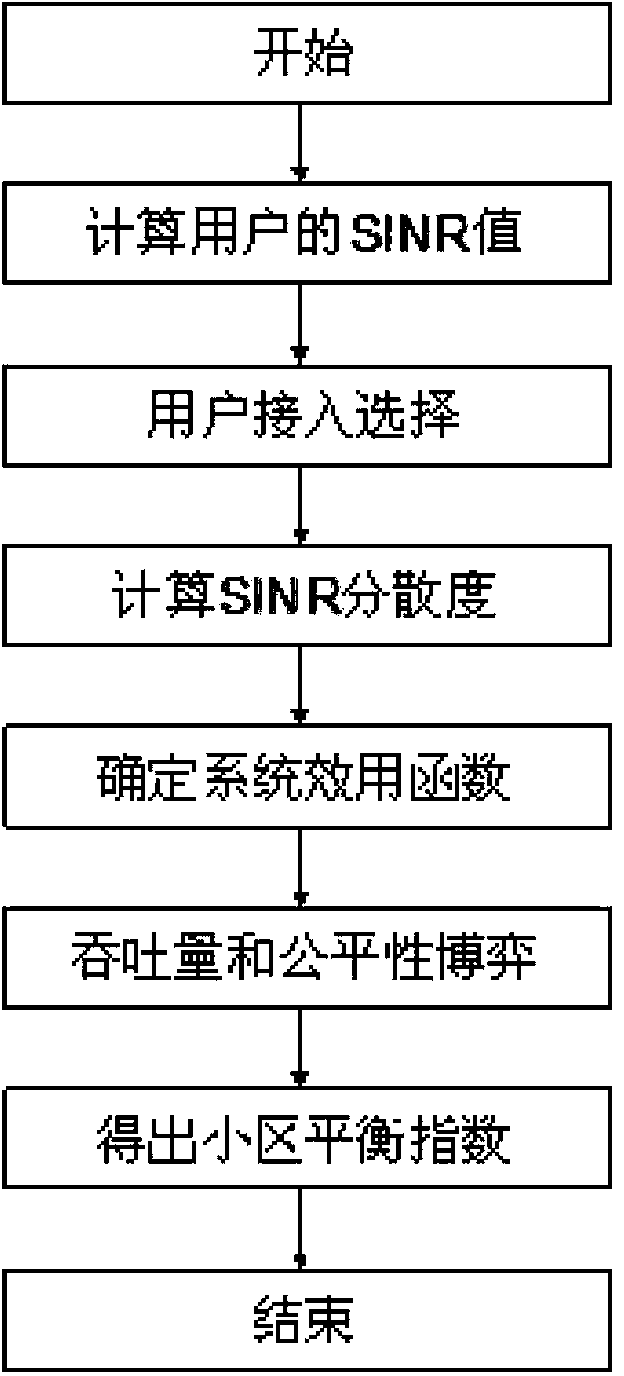

Game theory-based radio resource optimization method in LTE-A relay system

ActiveCN103369568AReduced equity gapEffective throughputNetwork traffic/resource managementDispersityMicro cell

The invention discloses a game theory-based radio resource optimization method in an LTE-A relay system. The method mainly resolves the problem of compromise between system throughput and user fairness when relays are introduced to a cell. The method comprises the steps that SINR values of all users in the cell are calculated, whether the users are connected to a base station or the relays is determined according to the SINR values of the users, the reachable data rate and the minimum required rate of each user are calculated, the SINR dispersity of each micro cell is calculated, and the cell balance index meeting cell throughput maximization and user fairness optimization is obtained through the game theory. According to the game theory-based radio resource optimization method, the SINR dispersity of the users is used as the main parameter of fairness, and fairness of the users in the center of the cell and the users on the edge of the cell are improved obviously; the throughput, the fairness and the game theory are combined, so that system resources are used more effectively, the throughput is maximized under the condition that the fairness is guaranteed, and whole performance of the system is enhanced.

Owner:XI AN JIAOTONG UNIV

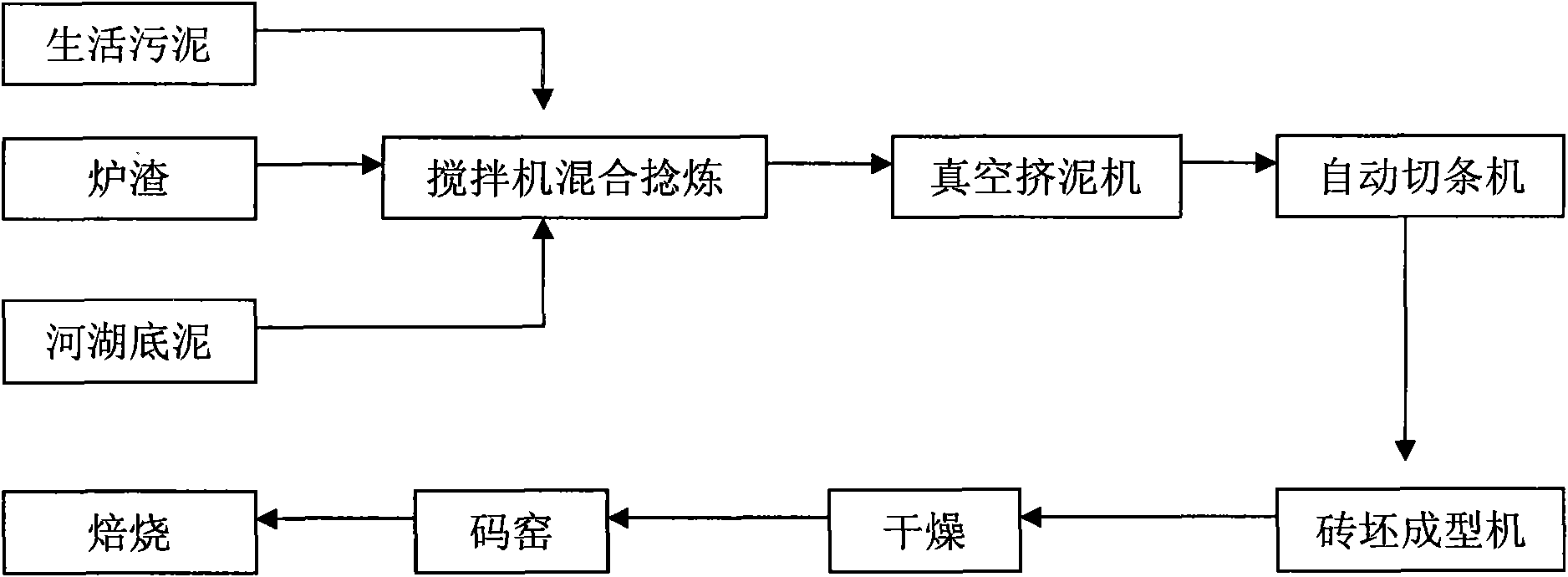

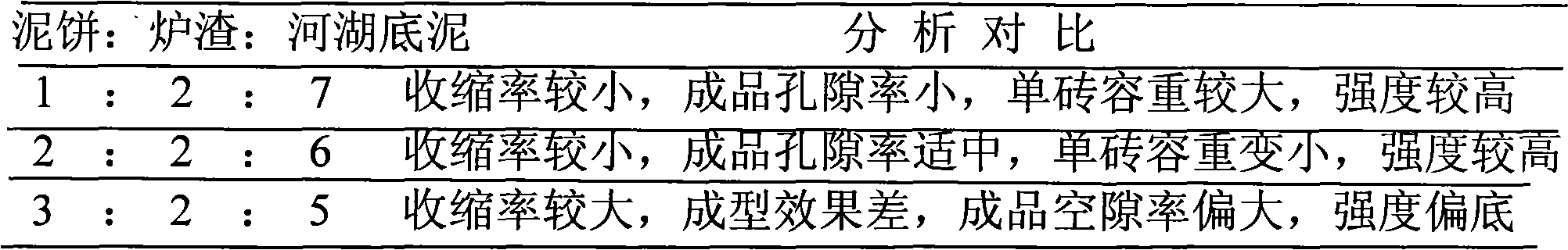

Method for manufacturing bricks by mixing domestic mud and bottom mud of rivers and lakes

InactiveCN101612762ASolve the way outAvoid secondary pollutionSludge treatment by de-watering/drying/thickeningMixing operation control apparatusFlocculationBrick

The invention relates to a method for manufacturing bricks, in particular to a method for manufacturing bricks by mixing domestic sewage sludge and bottom mud of rivers and lakes. According to the technical scheme provided by the invention, the method for manufacturing bricks by mixing domestic sewage sludge and bottom mud of rivers and lakes comprises the following steps: a. processing domestic mud, wherein liquid sludge of sewage treatment plants is made into mud cakes after flocculation, dehydration and filter pressing; b. processing bottom mud of rivers and lakes, wherein muddy water with mud content of 10-15 percent is transferred to a preset drying pool to form settling bottom mud by taking a technology for separating mud and water from the bottom mud of rivers and lakes; and the settling bottom mud becomes river and lake dewatered bottom mud used for manufacturing bricks after being dried for 3-4 months and having mud content of 60-70 percent; c. preparing mixture, wherein the mud cakes, slag and river and lake dewatered bottom mud are prepared according to the mass ratio and are used for making green bricks when the water content of the slag is measured to reach 15-25 percent; during preparation, 1-3 parts by weight of mud cakes are added to every 2 parts by weight of slag, and 5-7 parts by weight of river and lake dewatered bottom mud are added. The invention can better process domestic sewage sludge and improves the environment.

Owner:JIANGSU JIANGDA ECOLOGICAL SCI & TECHCO

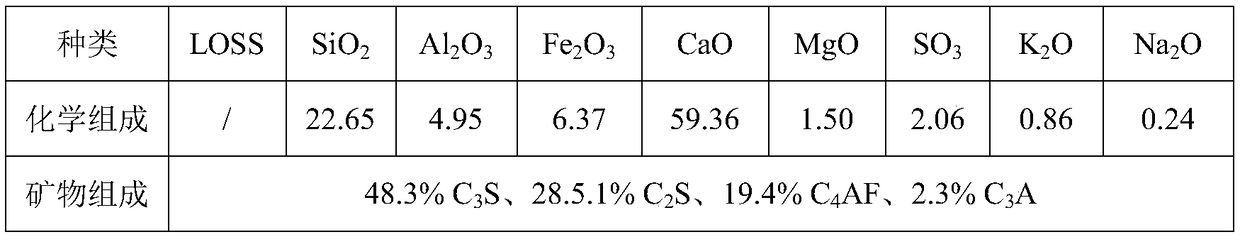

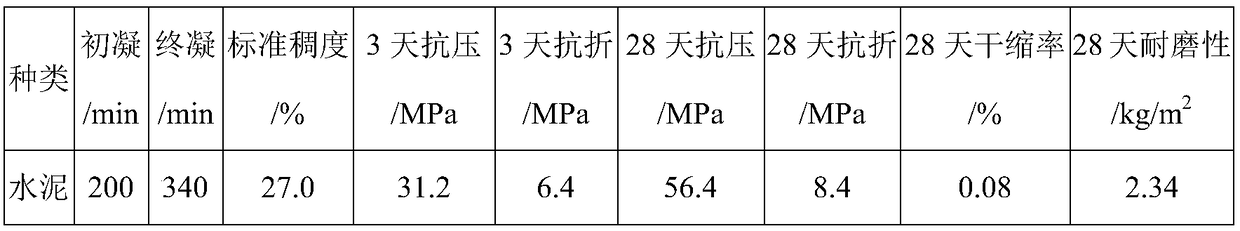

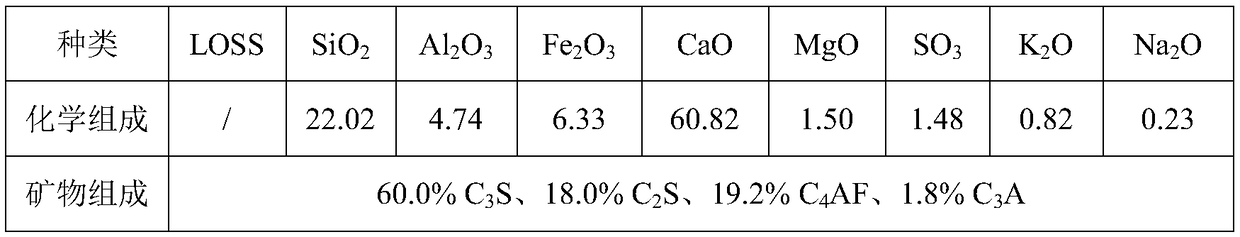

Road delayed-coagulation cement and preparation method thereof

InactiveCN108726904AReduce consumptionReduce calcination temperature and liquid phase viscosityCement productionResource utilizationEconomic benefits

The invention relates to road delayed-coagulation cement and a preparation method thereof. The road delayed-coagulation cement comprises special cement clinker, limestone waste, modified steel slag powder and phosphorus gypsum. According to the road delayed-coagulation cement, a cement raw material is prepared from carbon-containing shale, the phosphorus gypsum serves as mineralizing agents of clinker calcination, steel slag powder is prepared in a crushing, iron removing and grinding manner, the steel slag powder and the limestone waste serve as cement admixtures, and the phosphorus gypsum serves as a cement delayed coagulant. By the aid of the technical scheme, the prepared road delayed-coagulation cement has the advantages that coagulation time is suitable, early strength is high, laterstrength is rapidly increased, breaking strength is high, abrasion resistance is good, dry shrinkage performance is low and the like. Efficient resource utilization of solid waste such as the carbon-containing shale, the limestone waste, steel slag and the phosphorus gypsum is achieved, and the road delayed-coagulation cement has important economic benefits and social benefits.

Owner:GEZHOUBA SONGZI CEMENT

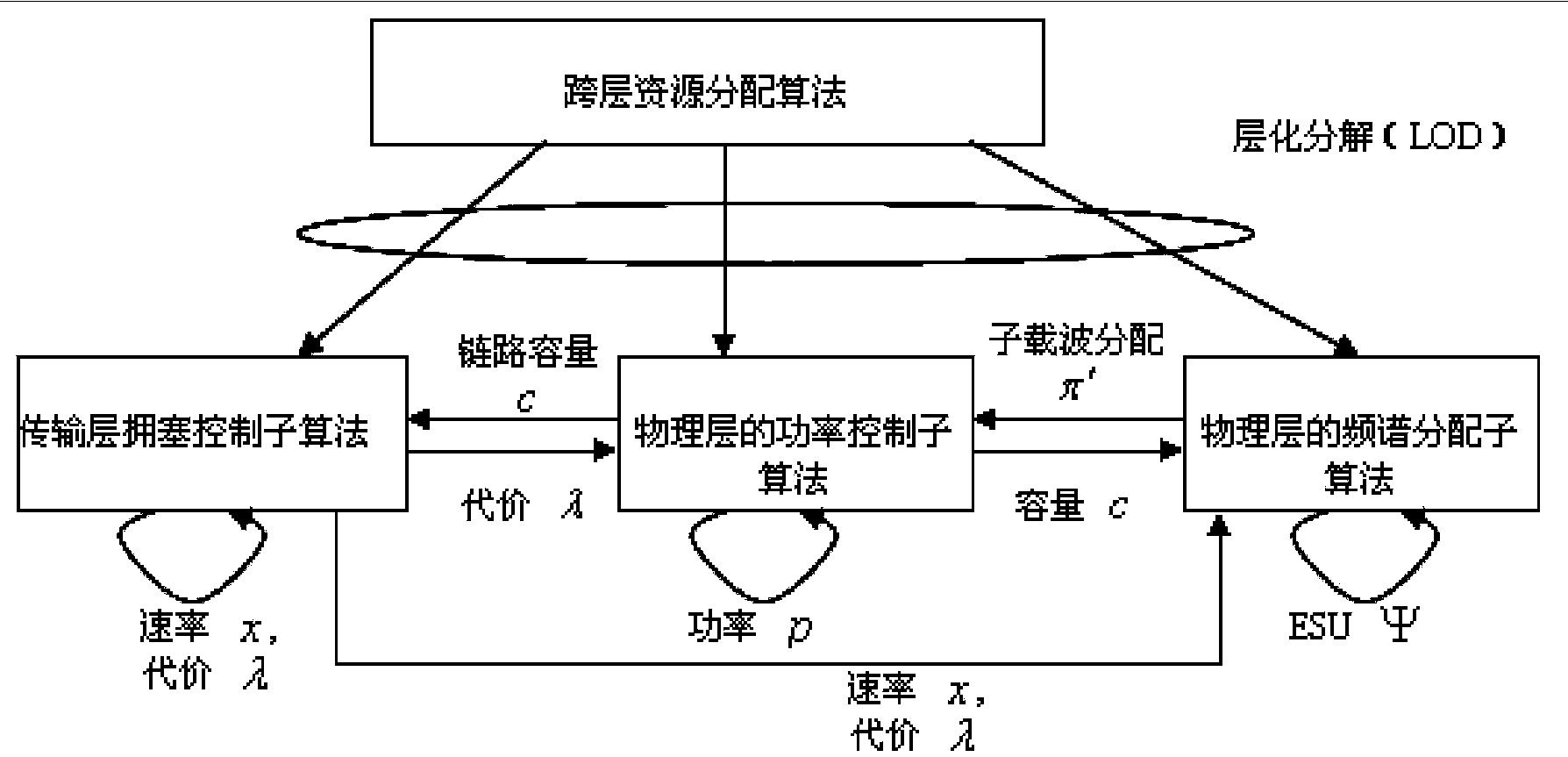

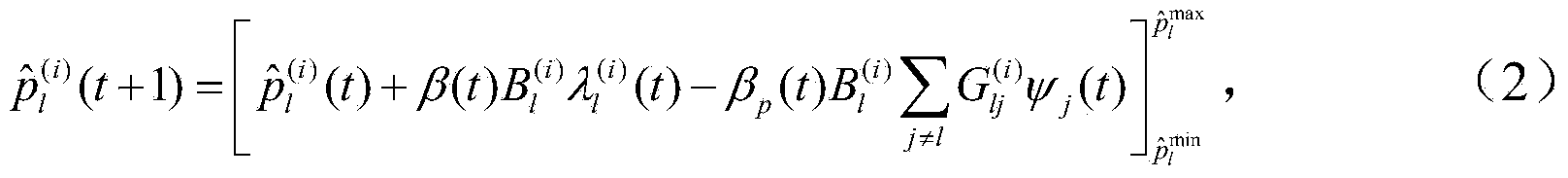

Method for transmitting speeds, sending power and distributing frequency spectra in distributed collaboration mode

InactiveCN103841648AIncrease transfer rateFast convergencePower managementNetwork traffic/resource managementFrequency spectrumResource utilization

The invention discloses a method for transmitting speeds, sending power and distributing frequency spectra in a distributed collaboration mode. The capacity of an elastic link is seen as a function of transmission power, a combined optimization model of congestion control and power control is established, so that a network application with a plurality of optional subcarrier links is optimized, the combined optimization model relates to a non-convex and inseparable optimization problem, and the original optimization problem is converted into a separable and dualization problem by introducing a new variable and a small disturbance secondary item. According to the method, optimal transmission speeds can be provided for all the subcarrier links, moreover, it can be determined that transmission can be achieved by how much power and on which subcarrier, converging can be faster, and larger network utilization, throughput capacity and effective resource utilization can be obtained.

Owner:SOUTHWEST UNIVERSITY

Treatment method and equipment for high phosphorus haematite mineral processing acid wastewater

InactiveCN101423306AGood phosphorus removal effectGood processing effectMultistage water/sewage treatmentWater/sewage treatment by sorptionGramPrecipitation

The invention relates to a method for treating wastewater and equipment thereof. A method for treating acid wastewater generated during high phosphorus hematite ore dressing is characterized in comprising the following steps: 1)a step of preparation of modified red mud is prepared, which comprises the following sub-steps: (1) red mud is dried, crushed and passed through a 20-mesh sieve to obtain red mud powder; (2) according to a red mud powder to hydrochloric acid ratio of between 40 to 60g:1L, the red mud powder is added into the hydrochloric acid, fully stirred in a water bath pot at 60 to 100 DEG C for 1 to 2 hours and cooled to obtain a mixed solution, and (3) the mixed solution is added with ammonia water with stirring, subjected to adjustment pH value to between 7.5 and 8.5 and keeps stand; and the obtained precipitate is washed with distillate water, dried, crushed, passed through a 60-mesh sieve to obtain the modified red mud; and 2) according to a principle of 6 to 23 grams of modified red mud for per litter of acid wastewater generated during the high phosphorus hematite ore dressing, modified red mud is added into a coagulative precipitation tank containing acid wastewater generated during the high phosphorus hematite ore dressing and stirred for 1 to 2 hours to obtain mud-water mixed liquid; and the mud-water mixed liquid flows to a dynamic membrane reactor to obtain reusable acid purified water. The method has the characteristics of good treatment effect, simple process operation, high water flux, low cost, short treatment period, etc.

Owner:WUHAN UNIV OF TECH

Ceramic color sand and preparation method thereof

The invention provides ceramic color sand and a preparation method thereof. The ceramic color sand comprises the following raw materials in parts by weight: 100 parts of solid wastes, 5 to 110 parts of plasticizer, 12 to 28 parts of silica fume, 0.1 to 10 parts of pigment, 0.5 to 2 parts of water reducer and 22 to 39 parts of water. The ceramic color sand has the advantages that the solid wastes are used as the main raw material, and are combined with other ceramic raw materials and pigment, so as to prepare the integral artificial color pottery sand through granulating, drying and sintering; the problem of pollution by the solid wastes is effectively relieved, and the problems of complicated artificial color sand preparation technology, destruction to ecological environment, poor degree of sphericity, easiness in stripping and separation of outer coating layer and inner core, short service life and the like are solved.

Owner:阳江清大环保科技有限公司

Mold bag curing soil for sea filling and cofferdam, preparation method and application method thereof

The invention discloses a mold bag curing soil for sea filling and cofferdam, a preparation method and an application method thereof, and belongs to the technical field of marine materials. The mold bag curing soil is prepared from the following raw materials: waste mud, a composite flocculant, a mud structure agent and biomass fibers, wherein by adopting the dry weight of the waste mud as the reference, the dry weight of the waste mud accounts for 40-60% of the total weight of the slurry during the slurry injection of the mold bag curing soil, the composite flocculant accounts for 6-9% of the dry weight of the waste mud, the mud structure agent accounts for 3-4.5% of the dry weight of the waste mud, and the biomass fibers accounts for 0-2.5% of the dry weight of the waste mud. With the technical scheme of the present invention, the curing effect of the mold bag filling material for the sea filling and cofferdam can be effectively improved, and the product can be directly used for the reclamation project after the curing treatment, and can meet the use requirements of the cofferdam construction project.

Owner:SHENZHEN HONGYEJI GEOTECHNICAL TECH CO LTD +1

Sludge building material and preparation method thereof

InactiveCN101381212ASimple methodReduce manufacturing costSolid waste managementBrickMunicipal sewage

The invention provides a sludge building material and a method for preparing the same, which particularly relates to a fresh sludge building material and a method for preparing the same. The building material consists of sludge, shale and fly ash. In the method, a gravity thickening pond of the prior municipal sewage plant is utilized, the prior gravity thickening process is adopted, the shale and the fly ash are added in the fresh sludge in the pond, and the discharged enriched mixture are directly used as the building material or the discharged enriched mixture is further dewatered to obtain the finished product. The building material has the advantages of few components and large sludge consumption. The method has the advantages of simple method, mature technique and low cost, and provides a new approach for the treatment and the utilization of sludge resources and solves the problems of large land occupation, difficult investment and environmental pollution in the municipal sewage plant. The technical proposal of the invention can be wide applied to the municipal sewage plant adopting the continuous current gravity thickening process. The product prepared by the technical proposal of the invention can be widely applied to the preparation of building bricks, porcelain granules and the like.

Owner:CHONGQING UNIV

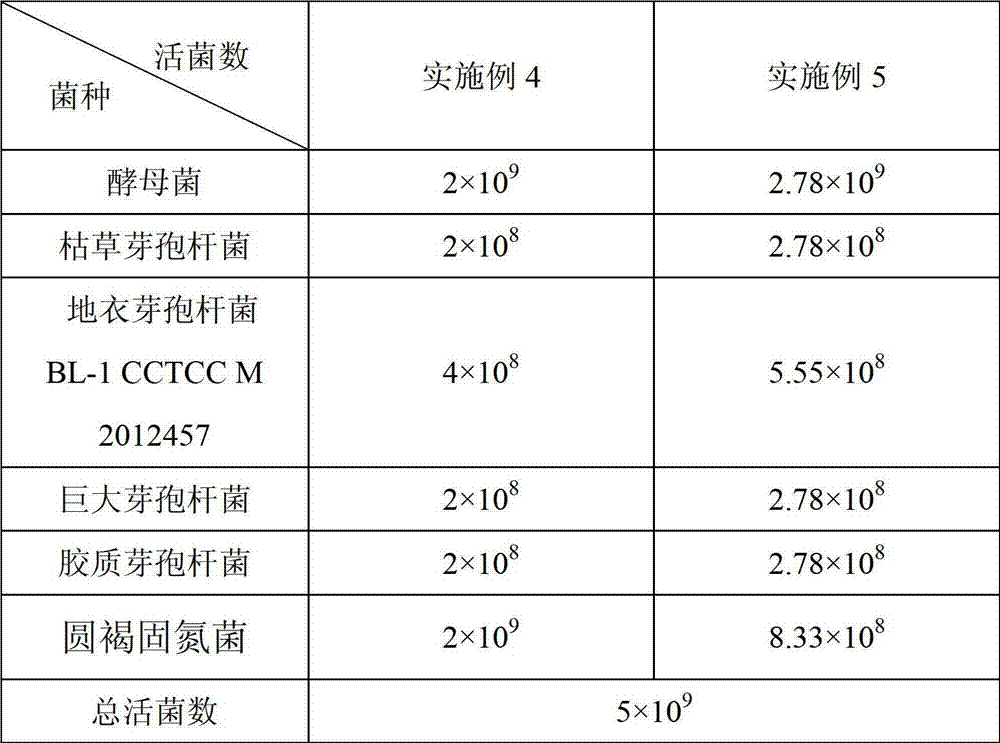

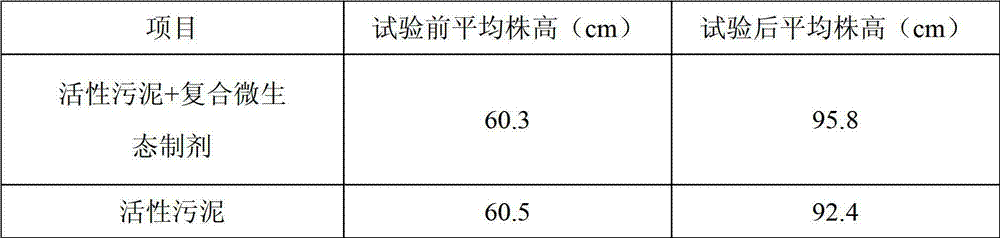

Cellulase production bacillus licheniformis with phosphate-solubilizing and potassium-releasing function and application of same

The invention relates to cellulase production bacillus licheniformis with phosphate-solubilizing and potassium-releasing functions and the application of the cellulase production bacillus licheniformis. The invention discloses the bacillus licheniformis BL-1 with the preserving number of CCTCC No. M 2012457 and the bacterial strain can produce cellulose, which has an excellent phosphate-solubilizing and potassium-releasing function and can be made into composite probiotics through scientific formulation to microzyme, bacillus subtilis, bacillus megatherium, bacillus mucilaginosus and azotbacteria chroococum, and microbial active sludge organic fertilizer added with the composite probiotics in proportion is directly applied to plant growth regions or applied to plant growth regions after compost fermentation, and has excellent soil enriching and yield increasing effects. According to the invention, efficient resource comprehensive utilization to active sludge discarded by fuel ethanol manufacturers can be achieved, meanwhile, environment pollution is avoided, the treatment process is simple, and the application cost is low. Therefore, ecological protection and sustainable development to agriculture can be facilitated.

Owner:江苏华晟知识产权运营有限公司

Light, thermal-insulating and early-strength type cement-based ground self-leveling material and preparation method thereof

ActiveCN105777025AReduce the weight of the structure and effectively reduce the thermal conductivityLow thermal conductivitySocial benefitsPortland cement

The invention relates to a light, thermal-insulating and early-strength type cement-based ground self-leveling material and a preparation method thereof. The material comprises the following components in parts by weight: 40-50 parts of ordinary Portland cement, 5-10 parts of rapid-hardening early-strength cement, 5-15 parts of mineral admixtures, 30-40 parts of lightweight aggregate, 1-5 parts of a toughening agent,0.4-1 part of redispersible latex powder, 0.1-0.3 parts of a water reducing agent, 0.1-0.2 parts of an excitant, 0.1-0.3 parts of a defoaming agent and 0-0.2 parts of a water-retaining agent. The material has the beneficial effects as follows: the construction process is simple, the mobility is good, the early strength is high, no contraction appears in the later period, and cracking is avoided, so that the material has better social benefits and economic benefits, and can be widely applied to projects of ground leveling and broken-ground remolding in new houses.

Owner:WUHAN UNIV OF TECH

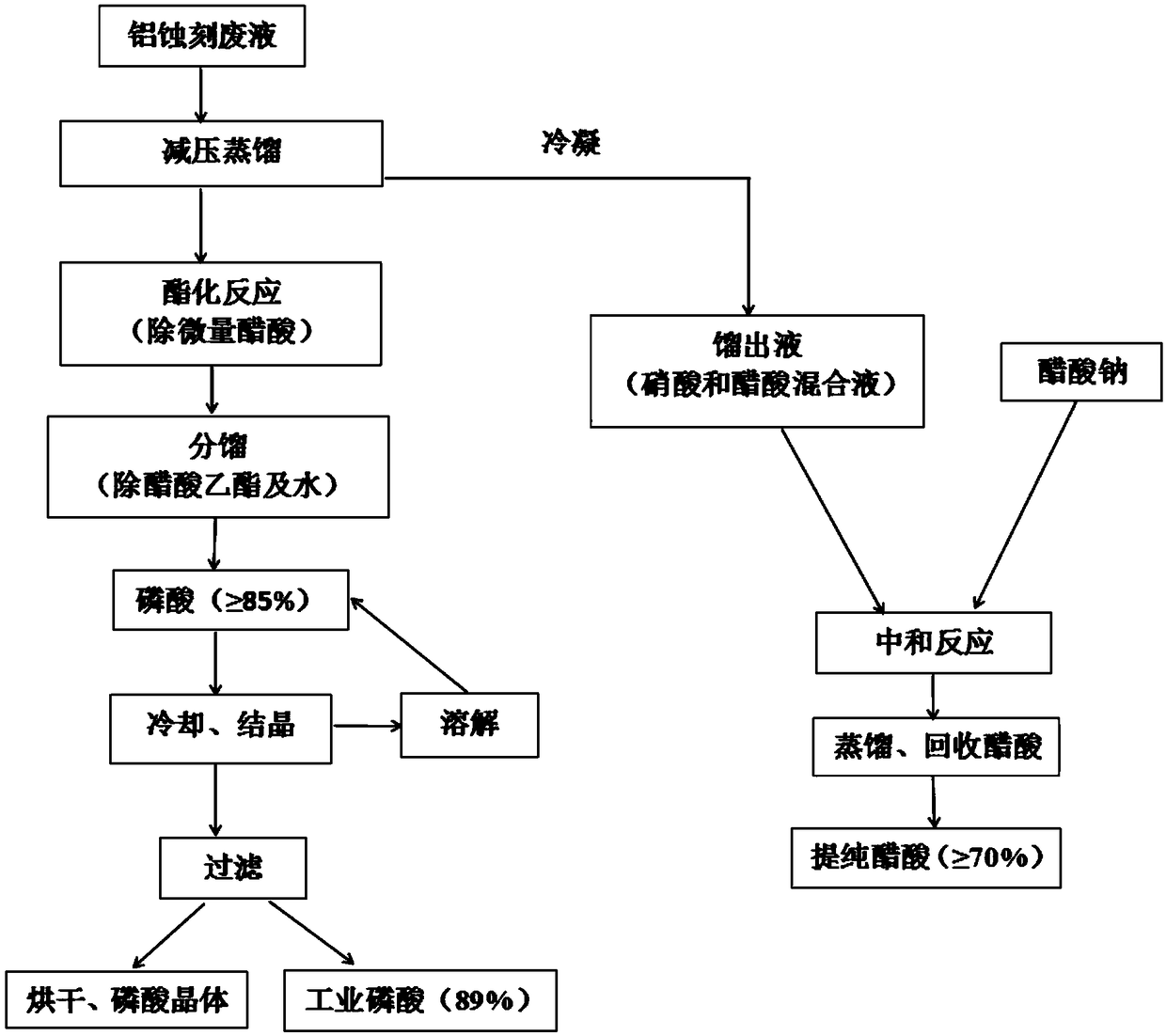

Method for recycling and utilizing phosphoric acid and acetic acid from waste aluminum etching solution

InactiveCN109052355ARealize recycling of resourcesAvoid pollutionPhosphorus compoundsCarboxylic compound separation/purificationHigh concentrationSodium acetate

The invention discloses a method for recycling and reutilizing phosphoric acid and acetic acid from a waste aluminum etching solution. The method comprises the following steps of (1) performing pressure-relief distillation on the waste aluminum etching solution, and removing acetic acid and nitric acid by a fractionation method; (2) treating by ethanol, purifying, and recycling the phosphoric acid; (3) adding sodium acetate into a nitric acid-acetic acid-water mixed solution to react, so as to obtain the acetic acid; applying a water absorbent, so as to obtain the high-concentration acetic acid. A harmless treatment and resource utilization method for recycling and reutilizing of the mixed acid is provided, and has the advantages that the resource recycling and reutilizing of the phosphoric acid and acetic acid can be furthest realized, the raw material is saved, the economic benefit is increased, the amount of wastewater is greatly reduced, and the waste of resource and the pollutionto environment are avoided; the technology process is simple, the operability is good, the effective resource utilization effect is realized, and the method is suitable for the industrial production and waste liquid treatment in the related fields.

Owner:ANQING XINXIANGRUI CHEM CO LTD

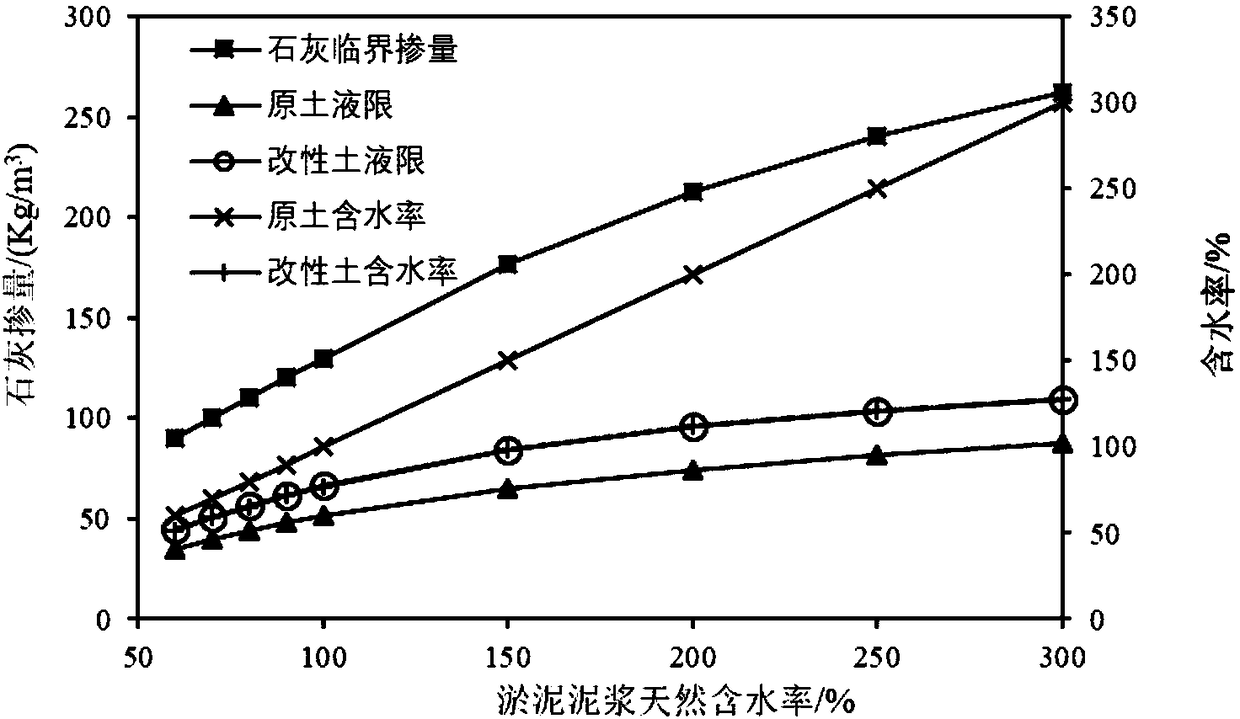

Curing method for waste soil combined treatment

A curing method for waste soil combined treatment comprises the following steps: adding a certain amount of quick lime to slurry to be treated based on the water content of the slurry to be treated, and uniformly stirring, wherein the slurry is alkalinized during being stirred; determining the alkali content of modified soil based on the quantity of doped lime, and setting the alkali content as A%; determining the mixing ratio of a curing material based on the alkali content A% of the slurry modified soil; uniformly stirring based on the ratio of modified soil to industrial solid aluminosilicate waste to flue gas desulfurization gypsum of 100: (3A-4A): (A-2A); and uniformly mixing the obtained mixture and waste soil based on the ratio of 1: 1-1: 6, wherein the finished product is applicable to backfill and soft foundation curing. According to the method, the slurry can be quickly treated, and the problems of dropping, scattering and leaking in transportation can be avoided; the treatedslurry can be used as the soil curing exciting material and matched with the industrial slags to realize combined curing of other waste soil, so that the waste soil can be effectively recycled; the wastes are cured through the wastes; the method is green and environmentally friendly, and meets the requirement of sustainable development.

Owner:FUJIAN CONSTR ENG GRP BUILDING MATERIAL SCI & TECH DEV

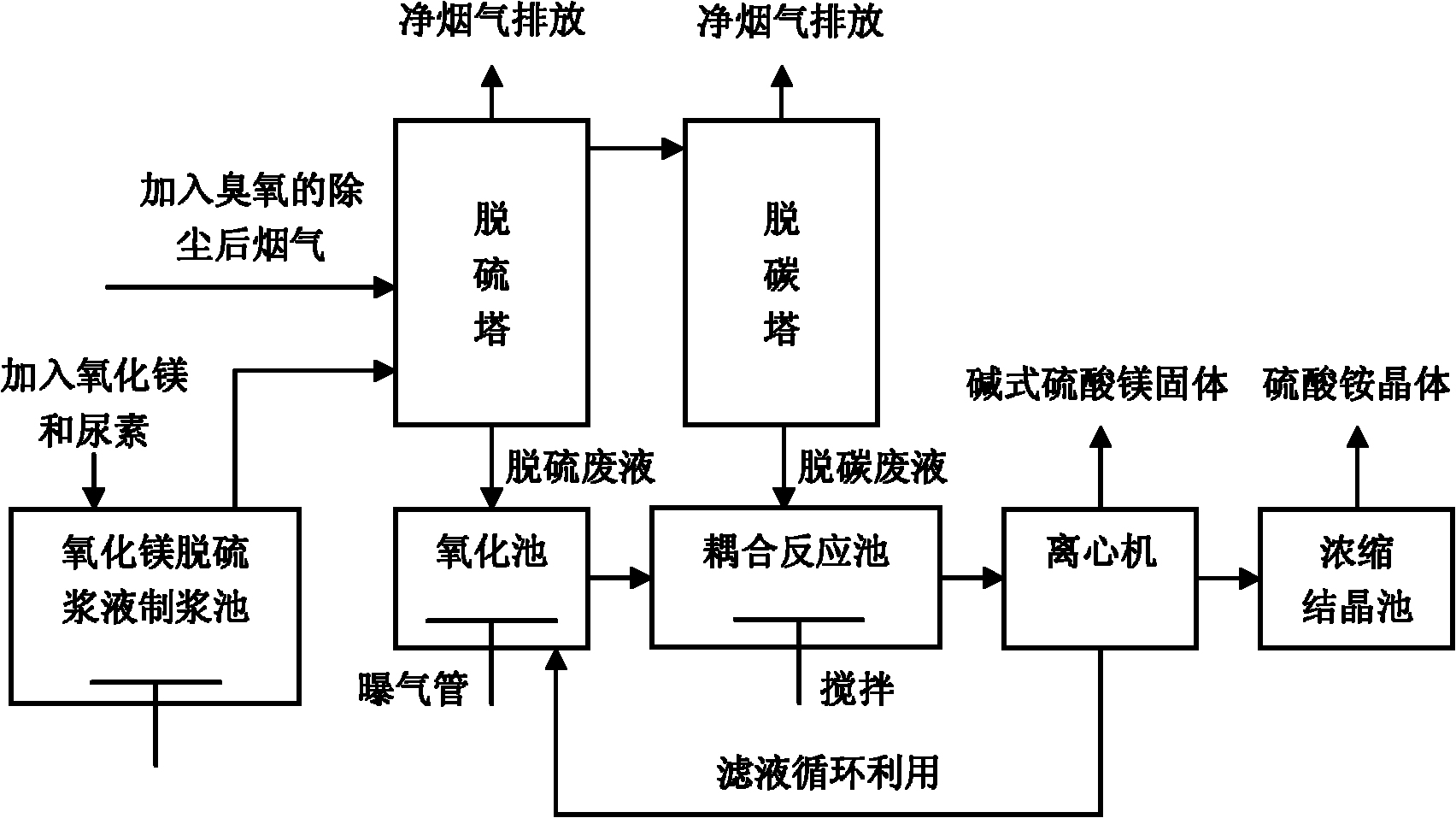

Method for realizing integrated desulfurization and denitrification and product recovery based on magnesium-ammonium method

ActiveCN102008880AEfficient resource utilizationNo secondary pollutionMagnesium carbonatesDispersed particle separationAmmonium sulfateFertilizer

The invention relates to a method for realizing integrated desulfurization and denitrification and product recovery based on the magnesium-ammonium method in the technical field of environment. The method comprises the following steps: firstly adding an oxidant into smoke gas, using magnesium oxide serous fluid containing urea for simultaneously integrated desulfurization and denitrification, andtransforming sulfur dioxide in the smoke gas to magnesium sulfite and magnesium sulfate; and transforming nitrogen oxide to nitrate or nitrogen; and reacting desulfurization waste liquid with ammoniabicarbonate solution after full aeration and oxidation to obtain mixed solution of basic magnesium carbonate precipitate, ammonium sulfate and ammonium nitrate after centrifugation, wherein the basicmagnesium carbonate is used for circulating desulfurization or can be used as an industrial grade product after drying; ammonium sulfate solids containing a small quantity of ammonium nitrate can be obtained after concentrating and crystallizing the centrifuged solution, and the ammonium sulfate solids can be used as fertilizer; and dilute mother liquor is used for preparing magnesium oxide desulfurization serous fluid and can be recycled. By adopting the method, the ammonium sulfate solid fertilizer containing the small quantity of the ammonium nitrate and the industrial grade basic magnesium carbonate can be simultaneously obtained under the premise of ensuring the integrated desulfurization and denitrification efficiency of the smoke gas.

Owner:SHANGHAI JIAO TONG UNIV +2

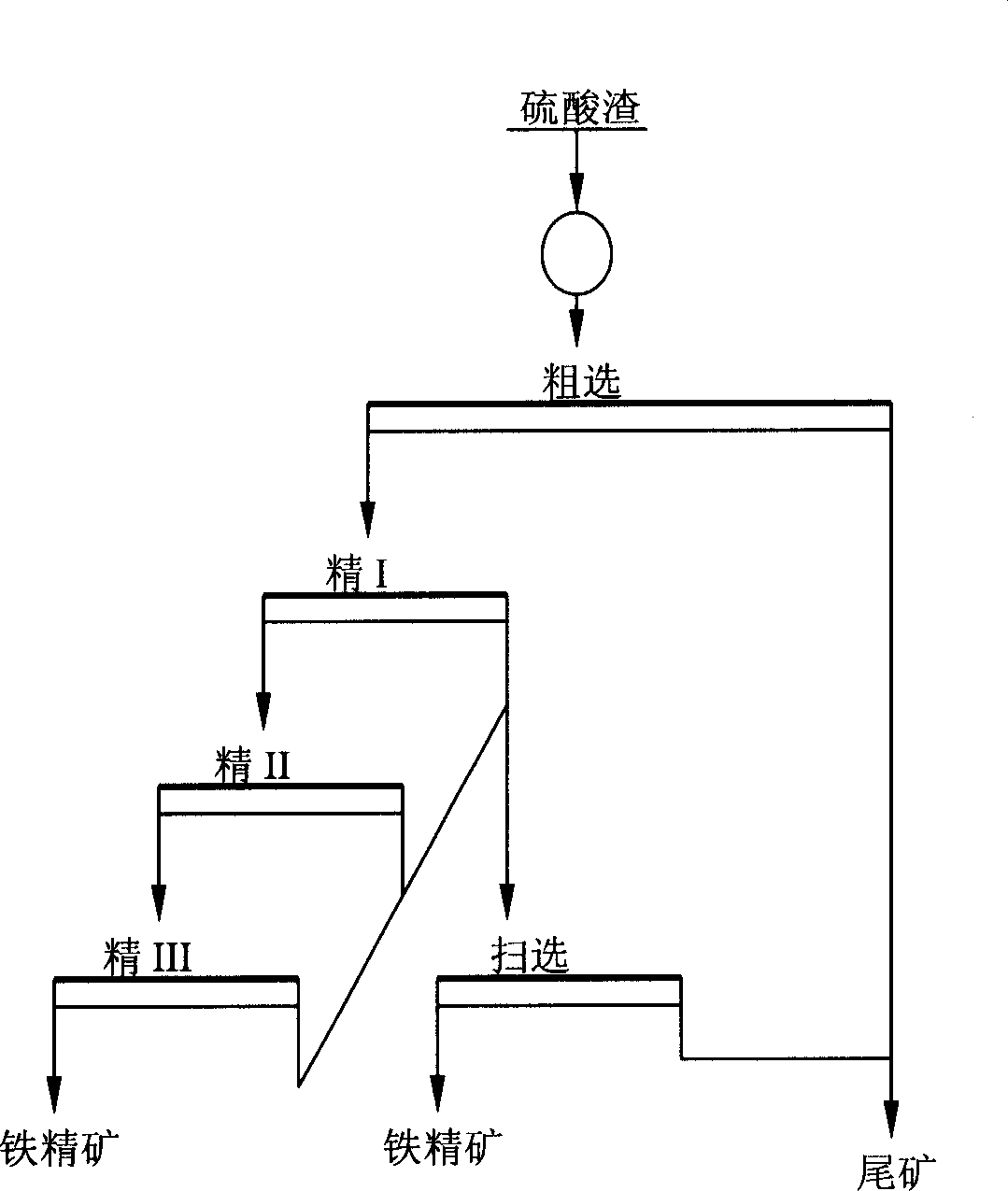

Process for extracting iron concentrate by sulfuric slag flotation

There are many kinds of technological process of extracting sulfuric slag to obtain iron concentrate, and the present invention is one technological process comprising milling sulfuric slag, controlled dispersion and floatation. Compared with other technological processes, the present invention has the advantages of high grade of obtained iron concentrate, high yield, etc. For example, the said technological process can extract sulfuric slag with iron content less than 50 % to obtain iron concentrate with iron content over 60 % and in the iron recovering rate over 70 %. The said technological process is simple, uses conventional apparatus and is easy to use in industrial production.

Owner:杨慧芬 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com