Microbial electrolysis two-section type sludge anaerobic digestion device and method for producing methane by using microbial electrolysis two-section type sludge anaerobic digestion device

A technology of microbial electrolysis and anaerobic digestion, which is applied in the field of improved two-stage anaerobic digestion and sludge methane production, can solve the problems of long fermentation period, low methane yield, difficulty in degradation and utilization of biomass, etc. The effect of utilizing the removal rate, increasing the rate of methane production, and shortening the operation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

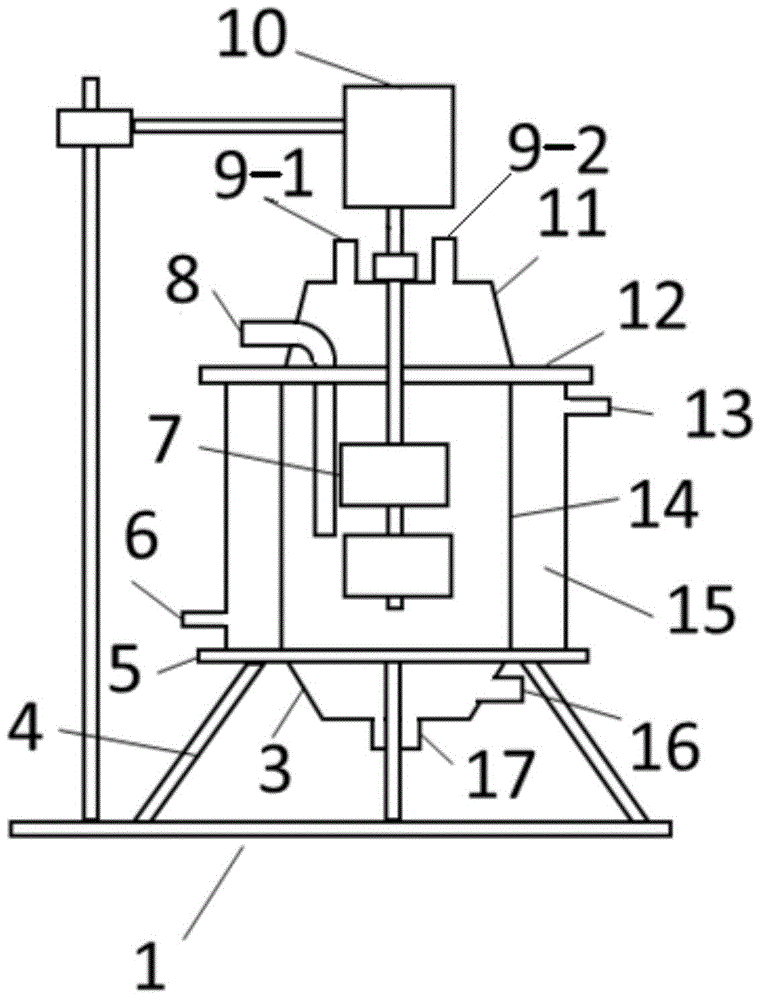

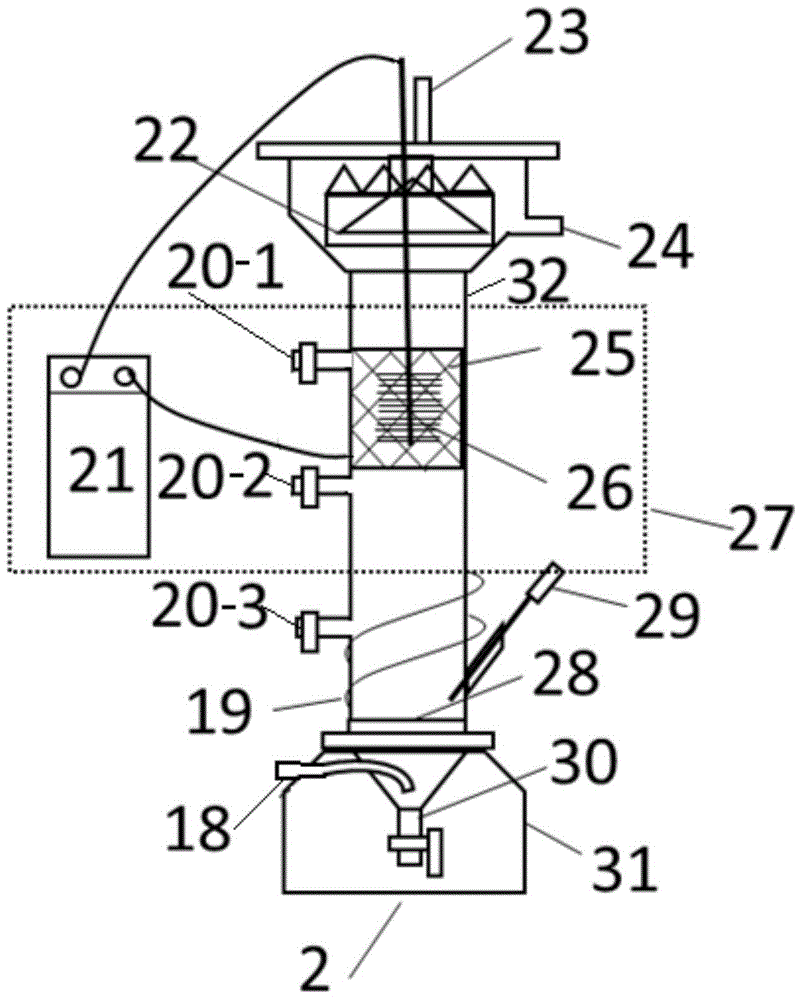

[0026] Specific Embodiment 1: In this embodiment, the microbial electrolysis two-stage sludge anaerobic digestion device is composed of a continuous stirring acid production reactor 1 and an upflow methanogenic reactor 2 assisted by microbial electrocatalysis, and the continuous stirring acid production The reactor 1 is composed of a reactor top cover 11, a reaction inner cylinder 14 and a bottom 3 from top to bottom, and is supported by a bracket 4. Above the reactor top cover 11, there are gas outlet A-19-1 and gas outlet A- 29-2, the top cover 11 and the bottom 3 of the reactor are respectively connected to the reaction inner cylinder 14 through flange A12 and flange B5, the outer wall of the reaction inner cylinder 14 is provided with a water bath insulation interlayer 15, and the lower end of the outer wall of the water bath insulation interlayer 15 is provided with a water bath Interlayer water inlet 6, water bath interlayer water outlet 13 is set on the upper end of the ...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment is different from Embodiment 1 in that the material of the microbial anode 26 is carbon fiber brush, carbon rod, and plate graphite. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the material of the non-biological cathode 25 is stainless steel mesh, carbon fiber, carbon paper, or carbon cloth. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com