Efficient scattering-grading equipment with multi-stage scattering mechanism for cement processing

A technology for dispersing and cementing, which is applied in the field of high-efficiency dispersing and grading equipment for cement processing. It can solve the problems of slow collection of powder, insufficient dispersing, frequent replacement of parts, etc., so as to save the number of cycles of dispersing and improve dispersing. effect, the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

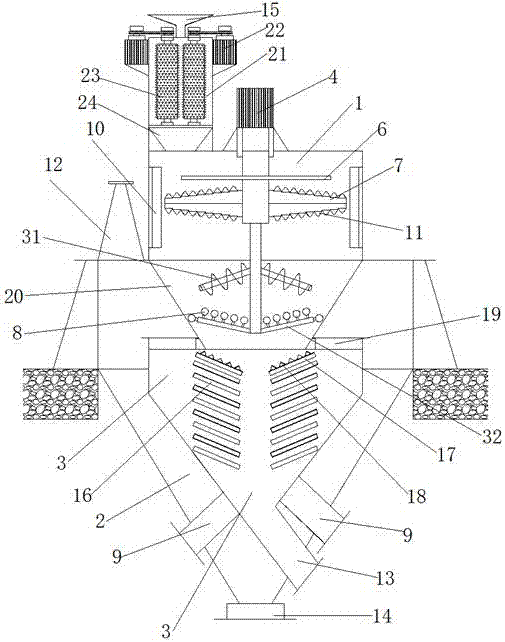

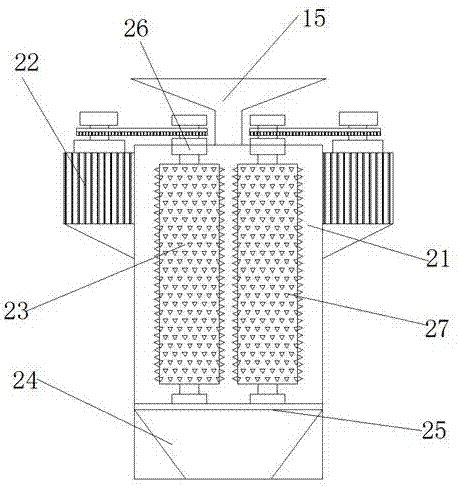

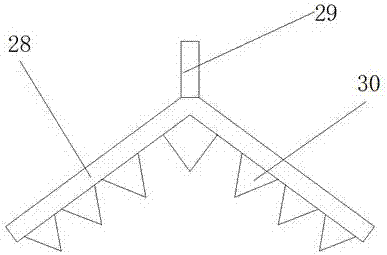

[0025] Refer to attached Figure 1-3 A high-efficiency breaking and grading equipment for cement processing with a multi-stage breaking mechanism is shown, including a breaking bin 1 and a grading bin 2, the breaking up bin 1 is arranged at the upper end of the grading bin 2, and the breaking up bin The bulk bin 1 is arranged through the grading bin 2, the bulk bin 1 is provided with a feed bin 15, the split bin 1 is provided with a split spindle 5, and the inner wall of the split bin 1 is also provided with a triangular The counterattack mechanism 10, the triangular counterattack mechanism 10 includes two fixed vertical plates 28 and an extension plate 29, the ends of the two fixed vertical plates 28 are welded tog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com