Patents

Literature

266results about How to "Improve the breaking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A comprehensive extraction, utilization and production method for glossy ganoderma sporocarps and spores

InactiveCN105837700AImprove immunityEasy to separateFatty-oils/fats refiningFatty-oils/fats productionSporePre treatment

The invention relates to a comprehensive extraction, utilization and production method for glossy ganoderma sporocarps and spores. The method includes (1) a step of extracting glossy ganoderma spore oil, namely a step of pretreating the glossy ganoderma spores, performing supercritical extraction, separating under reduced pressure, performing hyperfiltration and homogenizing to obtain a raffinate and the glossy ganoderma spore oil, and (2) a step of extracting glossy ganoderma poIysaccharides, namely a step of smashing the glossy ganoderma sporocarps, mixing with the raffinate, extracting, centrifuging, concentrating, precipitating with ethanol, performing enzymolysis and performing spray drying to obtain the glossy ganoderma poIysaccharides. The poIysaccharide extraction rate is increased by 25-32% than traditional processes. The glossy ganoderma poIysaccharides and the glossy ganoderma spore oil can be prepared into healthcare products, thus increasing production benefit and value.

Owner:JIANGSU JIANGDAYUAN ECOLOGICAL BIOLOGICAL TECH

Method for producing stabhyose, and method for producing stabhyose and catalpol by using rehmannia root

ActiveCN101003551APrevent spoilageImprove the breaking effectSugar derivativesChemical industryFiltrationIon-exchange resin

This invention provides a method for separating and extracting high-purity stachyose product from Rehmannia glutinosa and Stachys sieboldii. This invention also provides a method for continuously separating and extracting stachyose and catalpol from Rehmannia glutinosa. The method comprises: separating and purifying the extract by passing through continuous pressure-filtration, microfiltration, ultrafine filtration and nanofiltration membranes, and active carbon column, macroporous adsorption resin column, cation exchange resin column, and anion exchange resin column chromatography to obtain stachyose and catalpol. The method has scuh advantages as increased product quality, low wnwegy consumption, and increased raw material utility.

Owner:GUANGDONG APOLLO GRP

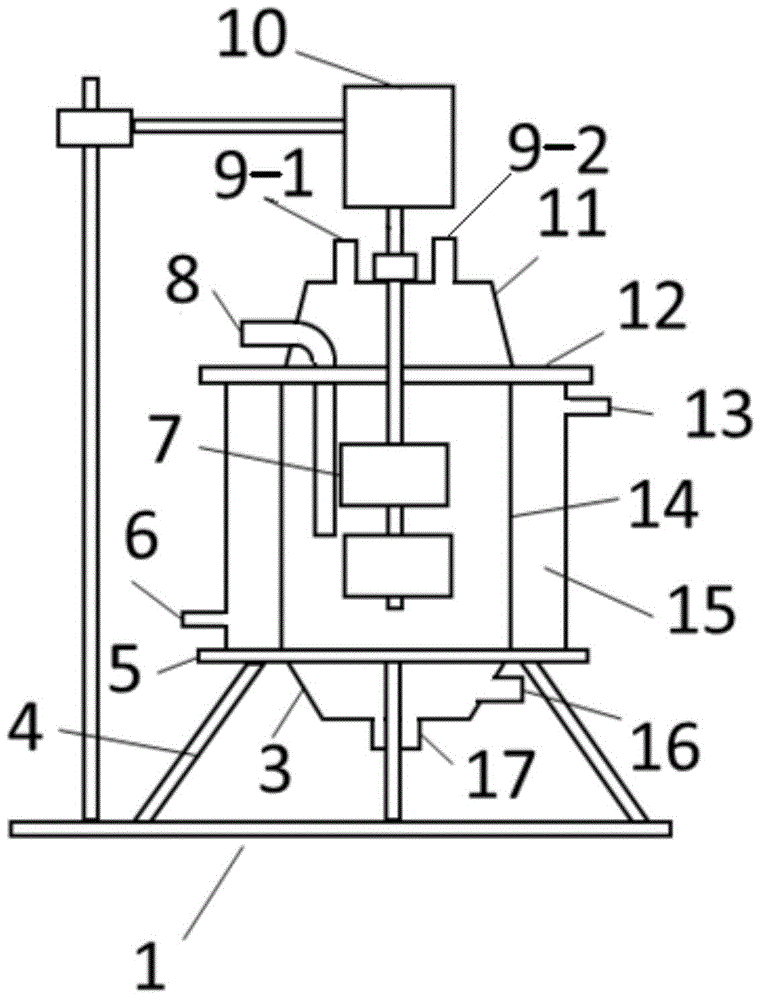

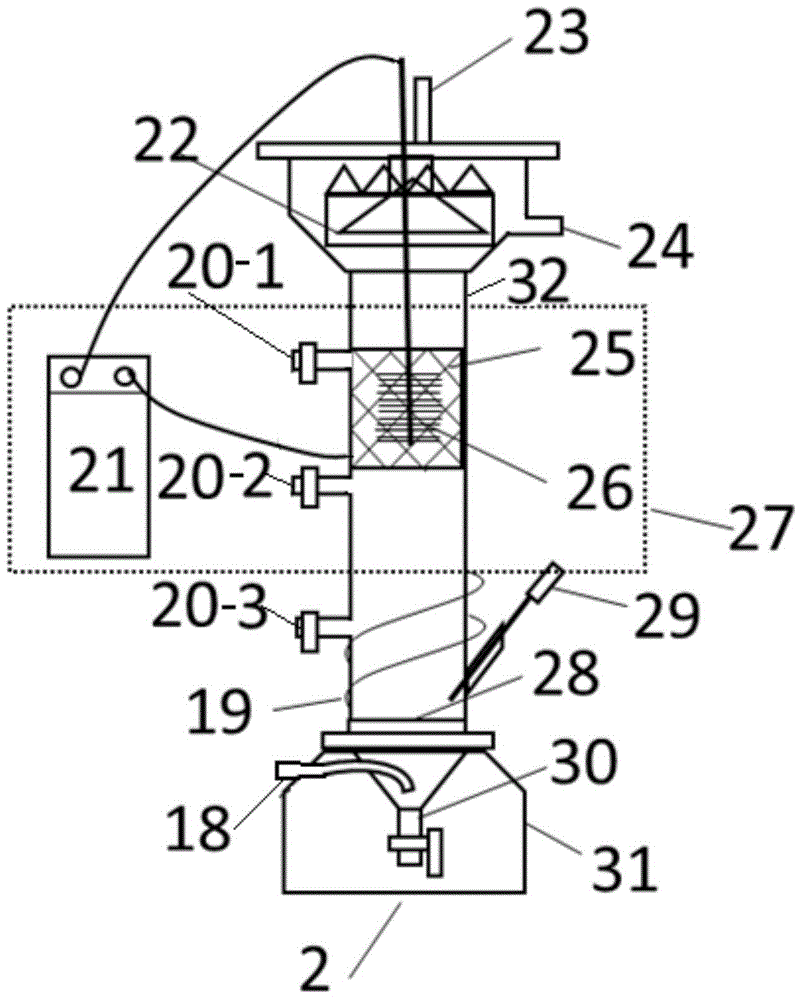

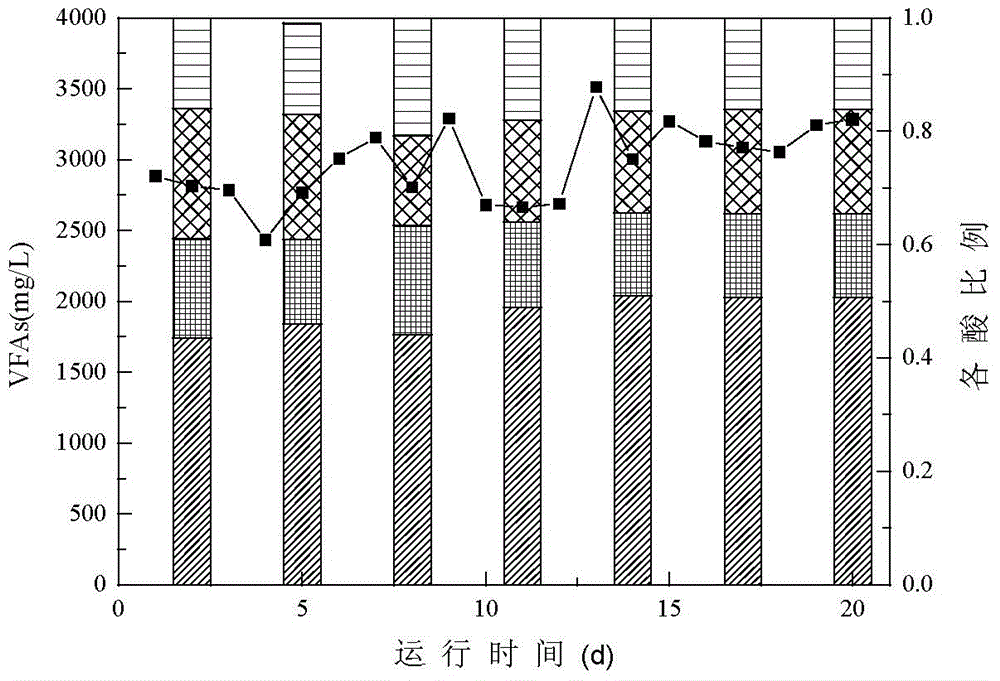

Microbial electrolysis two-section type sludge anaerobic digestion device and method for producing methane by using microbial electrolysis two-section type sludge anaerobic digestion device

ActiveCN104478178AImprove the breaking effectImprove utilization and removal rateSpecific water treatment objectivesWaste based fuelElectrolysisBiomass degradation

The invention discloses a microbial electrolysis two-section type sludge anaerobic digestion device and a method for producing methane by using the microbial electrolysis two-section type sludge anaerobic digestion device, relating to an improved two-section type anaerobic digestion device and a method for producing methanol from sludge. The purpose of the microbial electrolysis two-section type sludge anaerobic digestion device is to solve the technical problems of long fermentation cycle, low methanol yield and difficult biomass degradation and application in an existing residual sludge anaerobic digestion process. The microbial electrolysis two-section type sludge anaerobic digestion device consists of a continuous stirring type acidogenic reactor and a microbial electrocatalysis assisted upflow methane-producing reactor. The method comprises the following steps: starting a microbial catalytic electrolysis unit; producing acid by fermenting the residual sludge; and producing methanol. According to the microbial electrolysis two-section type sludge anaerobic digestion device and method disclosed by the invention, an acid production stage in a treatment process of the residual sludge only needs 5 to 8 days, a methanol production stage adopts continuous flow operation, the hydraulic retention time can be reduced to less than 1 day, and the operation cycle of sludge anaerobic digestion can be greatly shortened by adopting the device and method disclosed by the invention. The device and method disclosed by the invention belong to the field of sludge anaerobic digestion.

Owner:HARBIN INST OF TECH

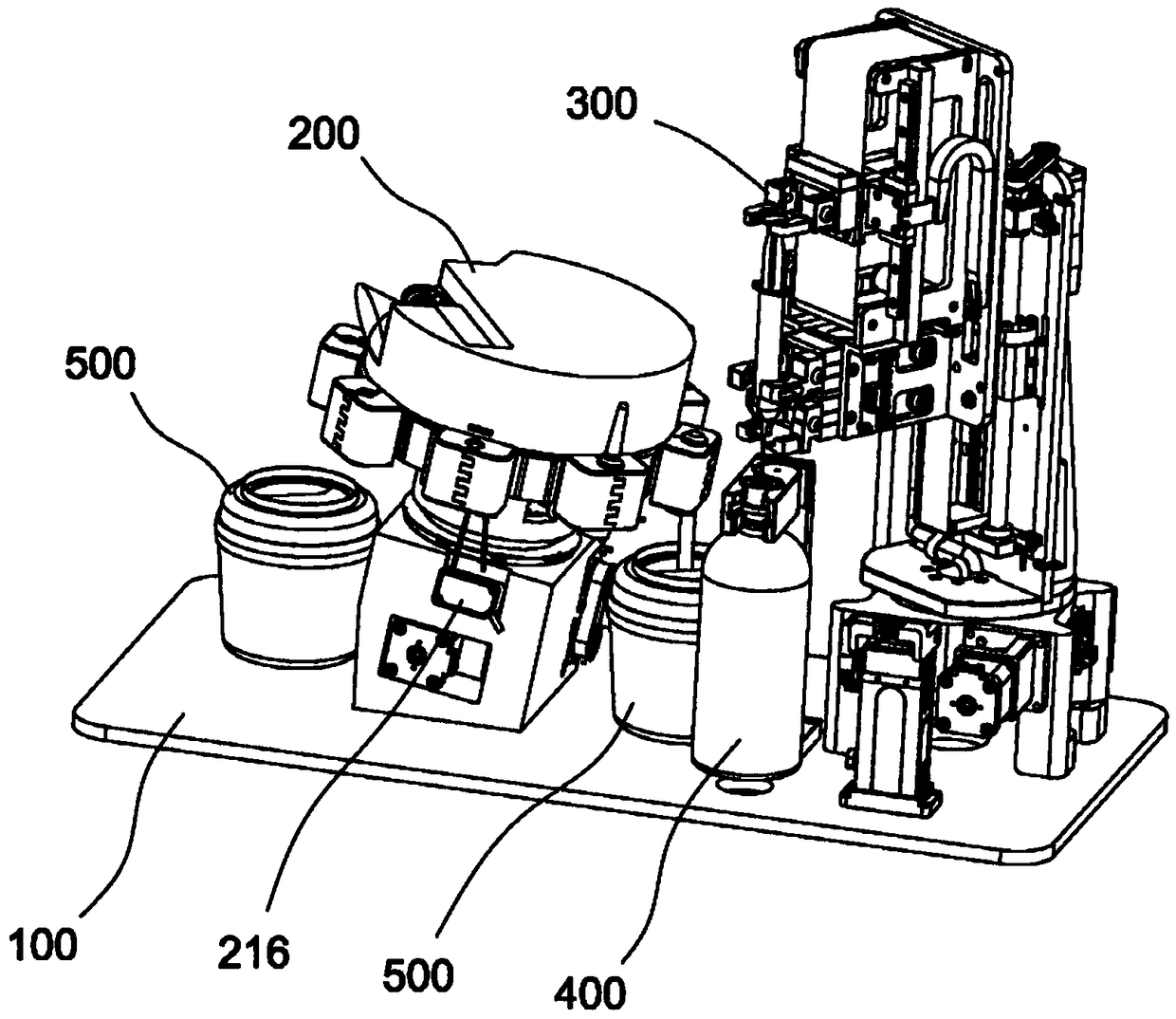

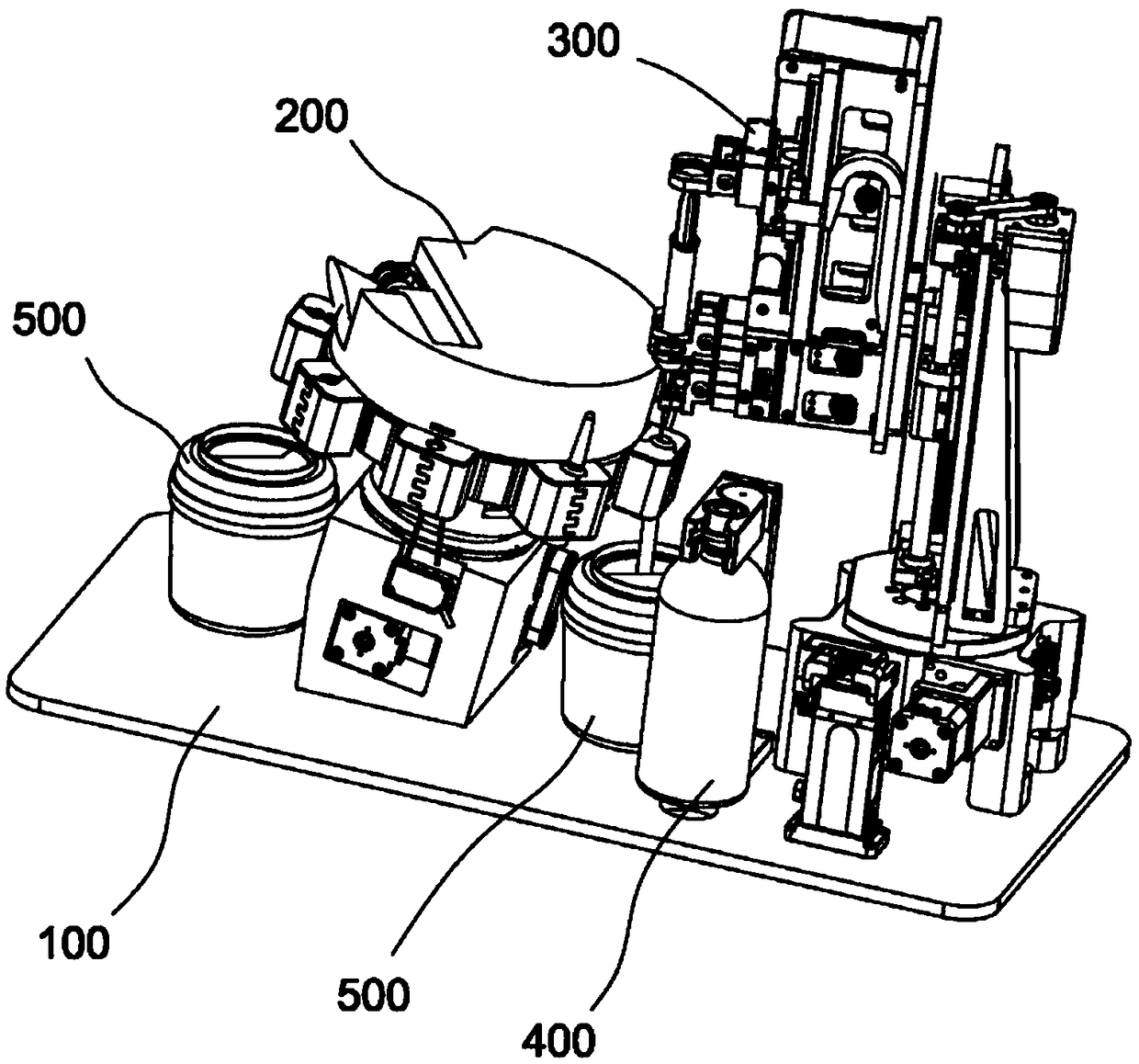

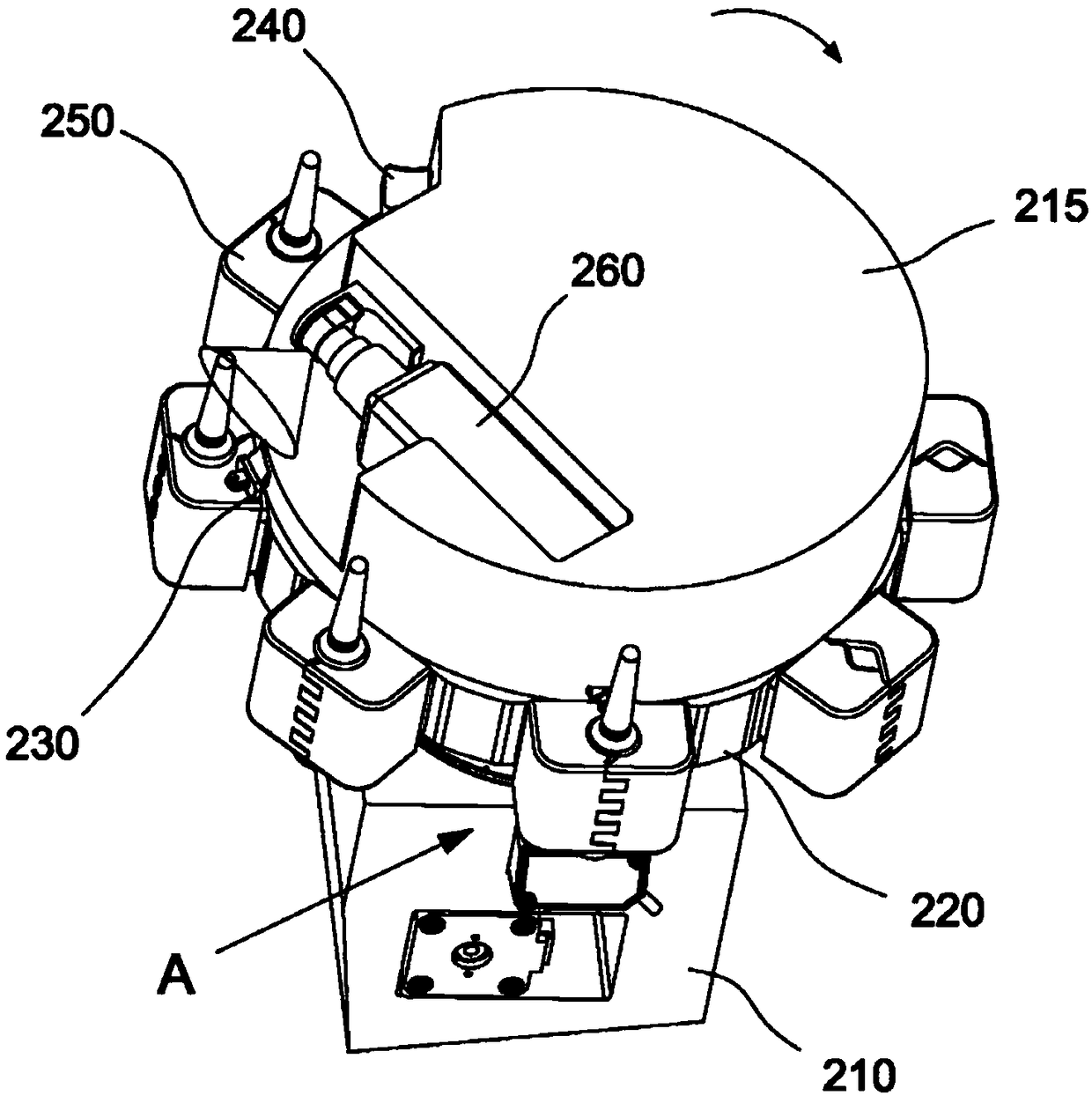

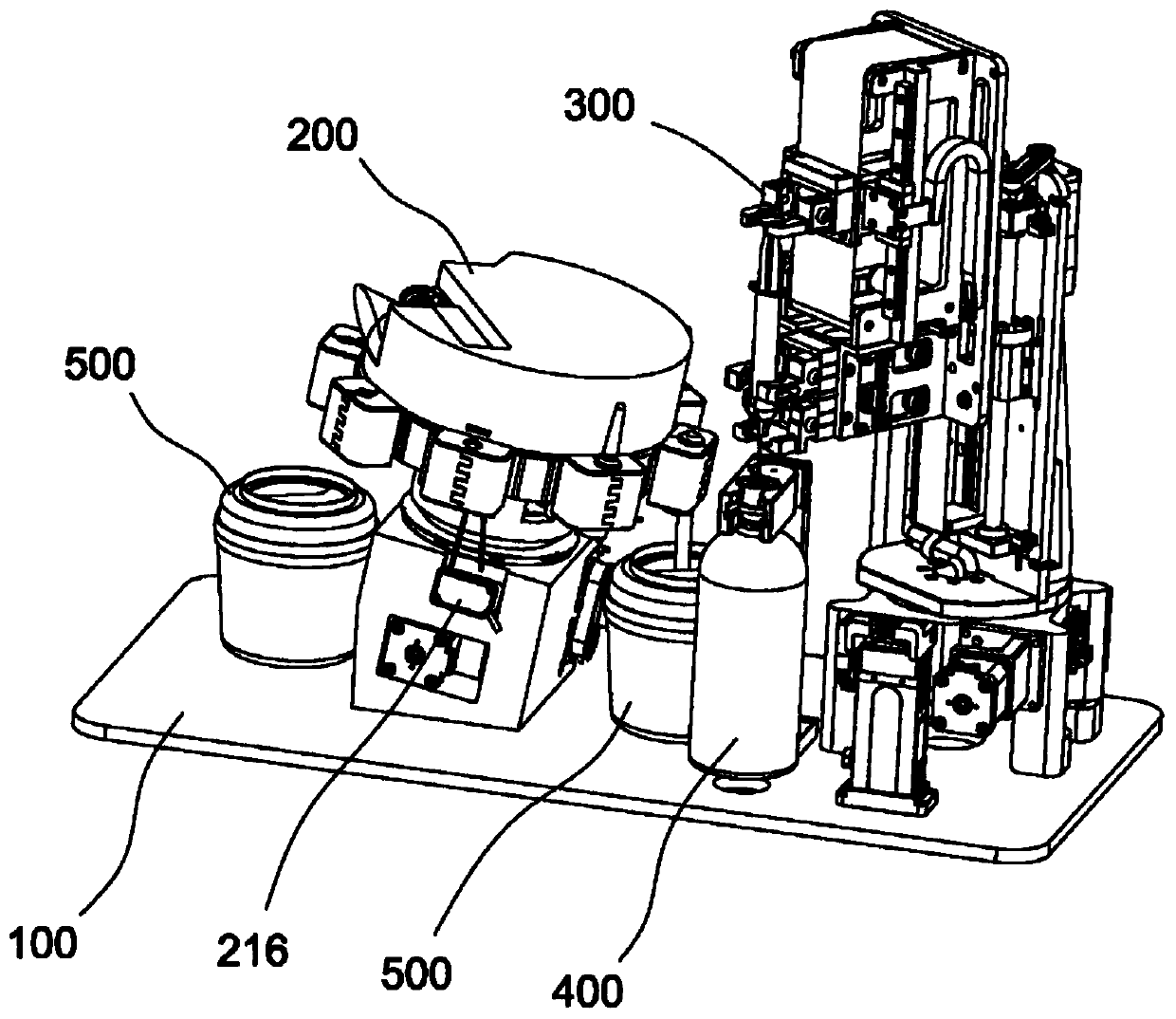

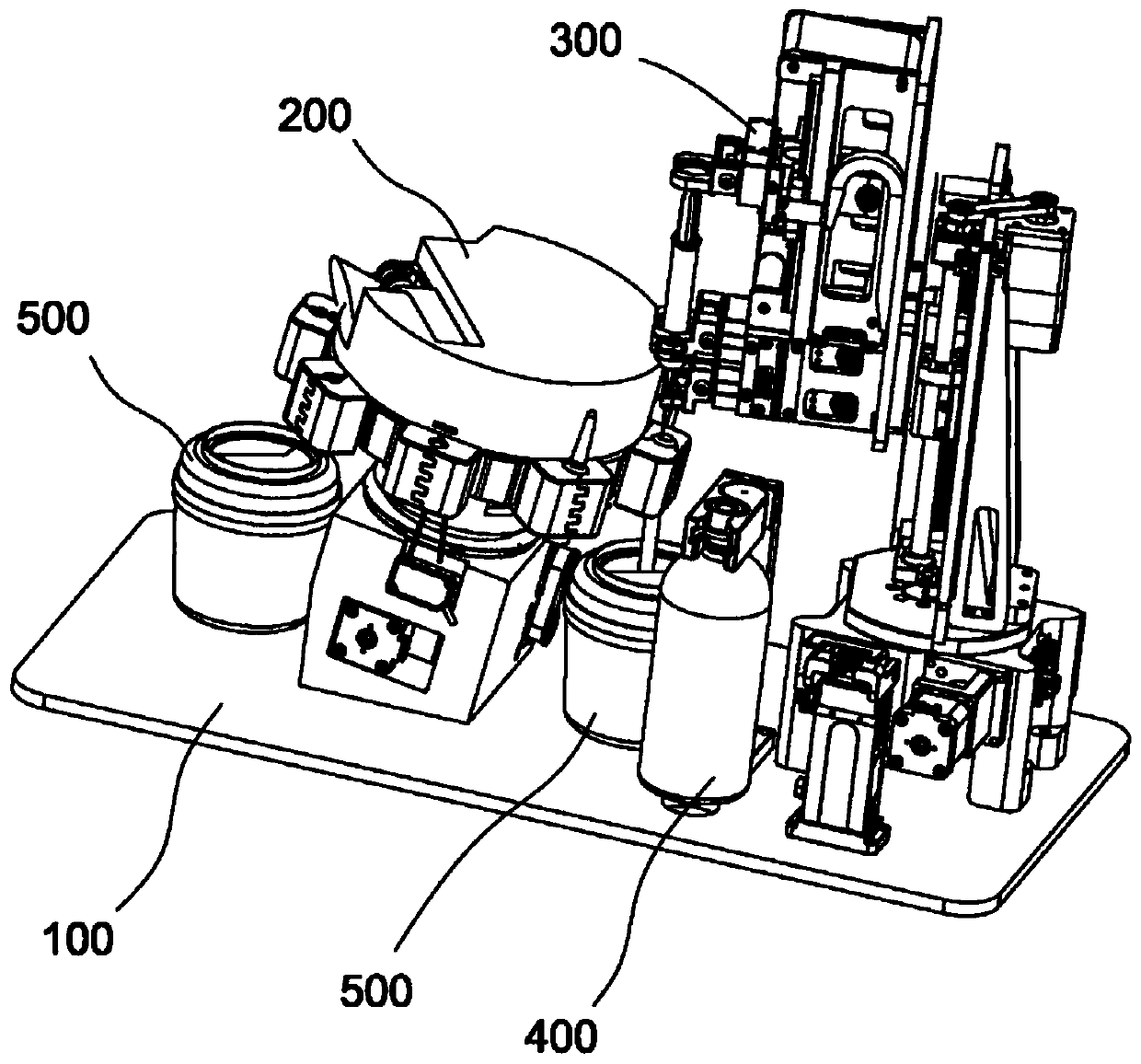

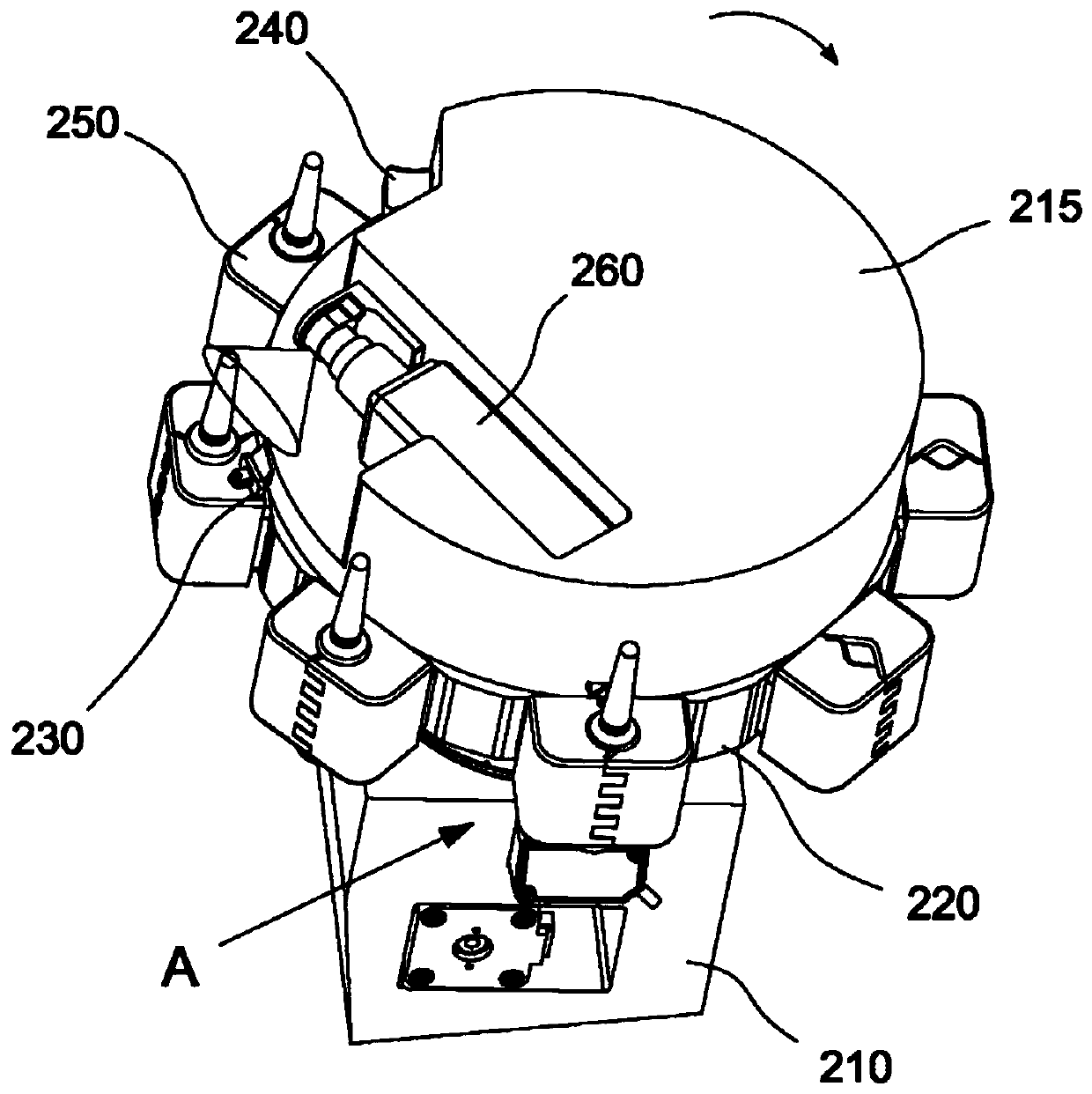

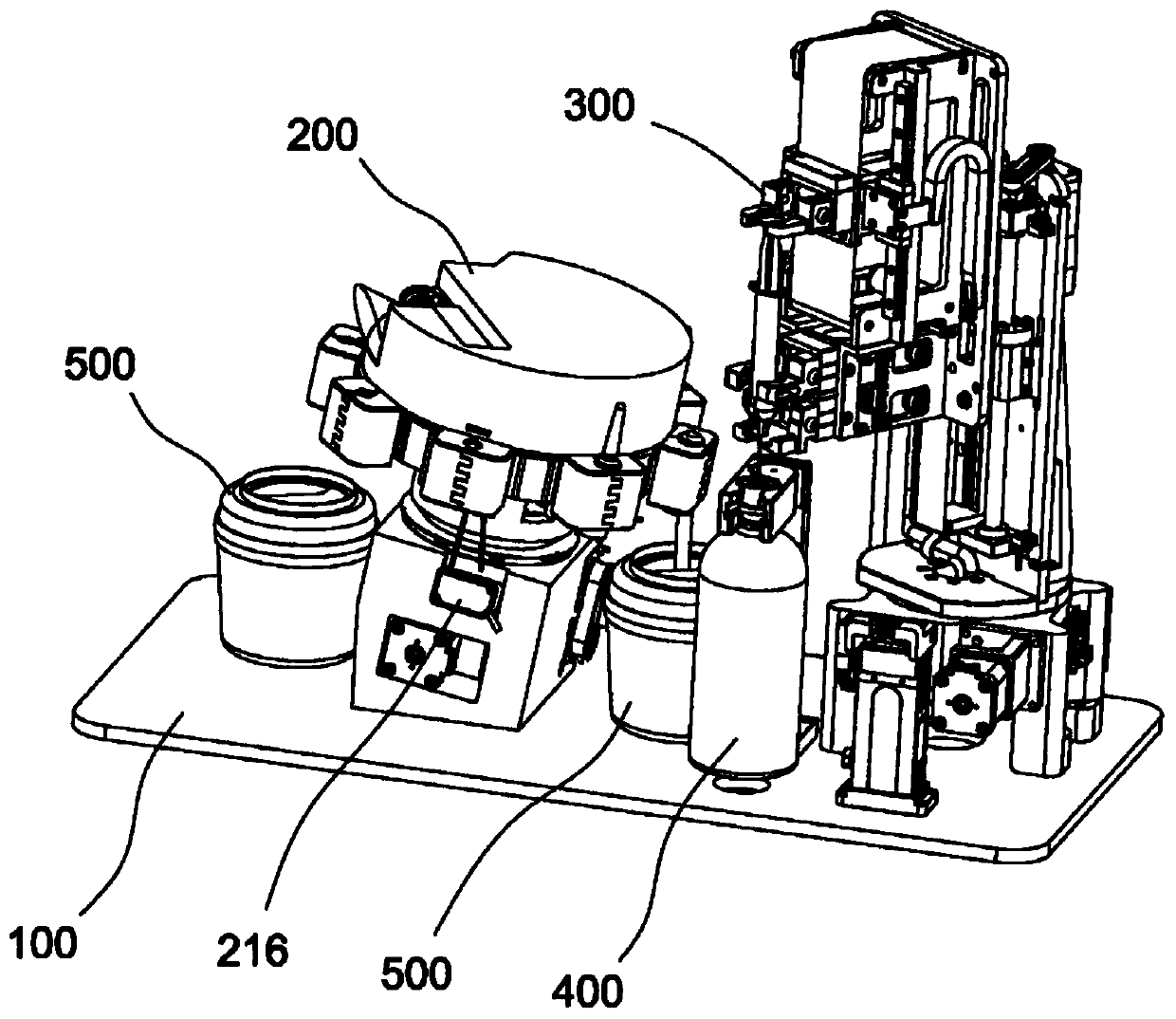

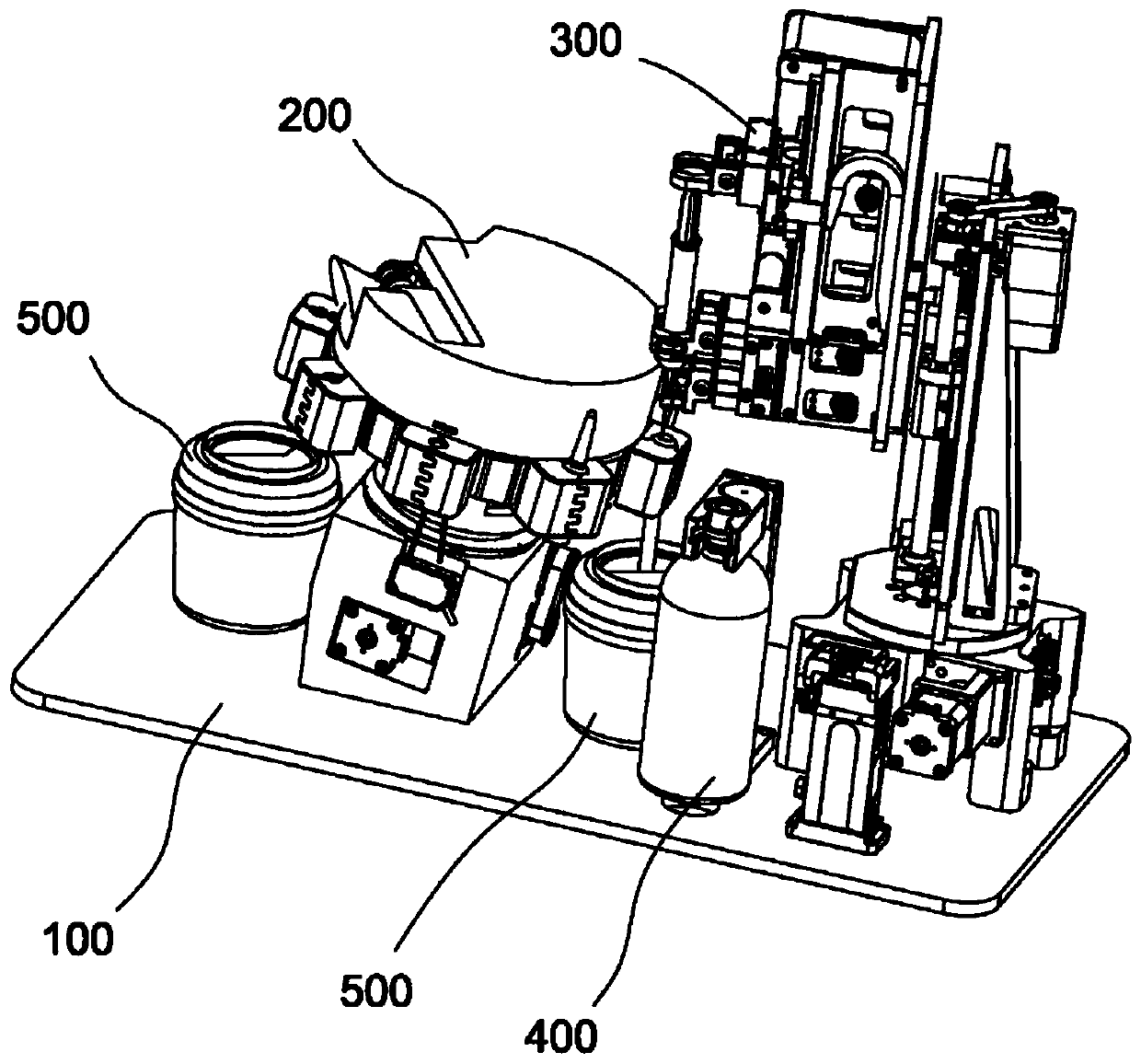

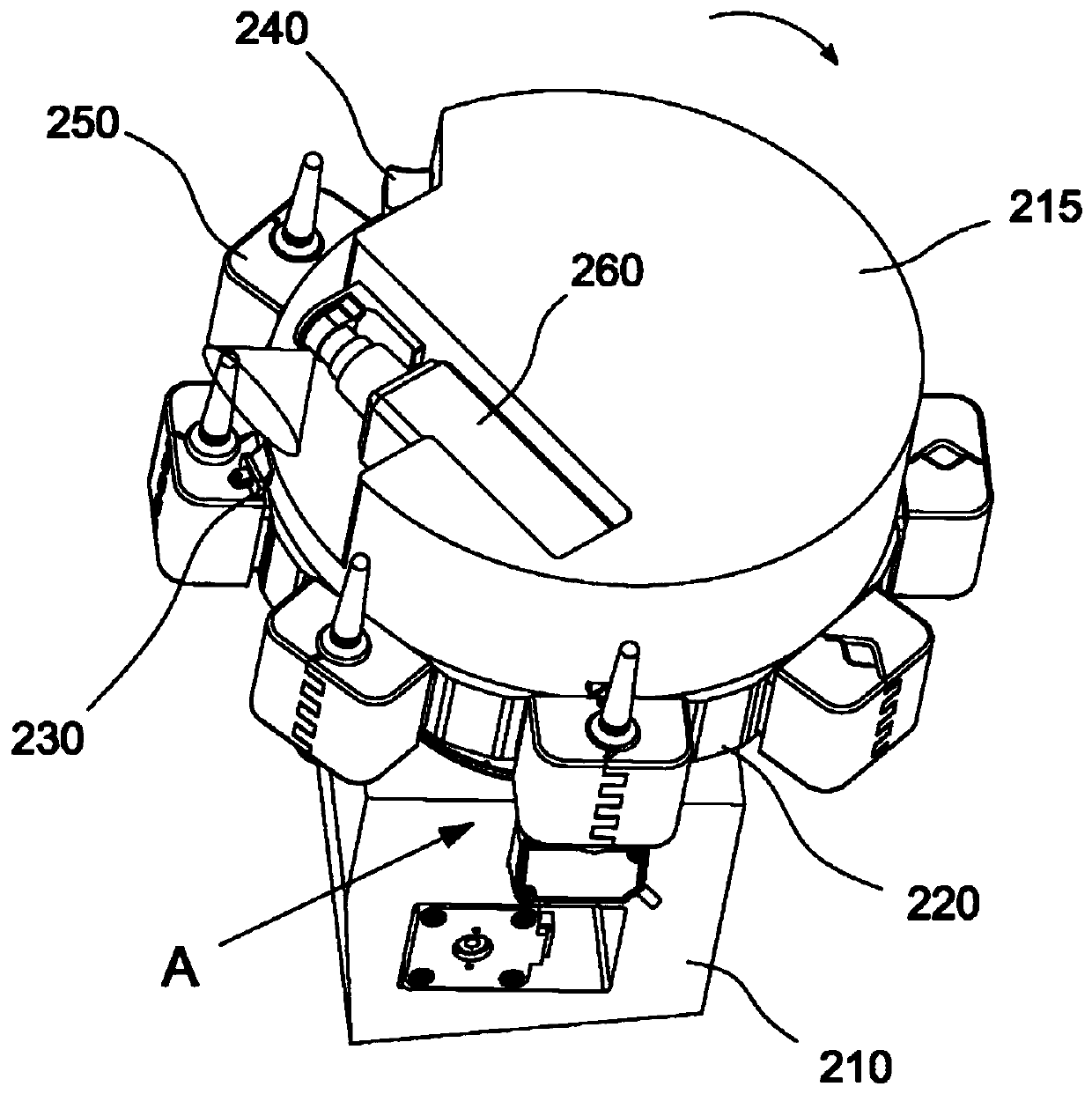

Automatic dispensing robot for ampoule bottles

ActiveCN109394535AUnbreakableImprove the breaking effectBottle/container closurePower operated devicesBottle neckBiomedical engineering

The invention provides an automatic dispensing robot for ampoule bottles. The automatic dispensing robot for the ampoule bottles comprises a base, an automatic bottle opening device, a pipetting device and a solvent clamping device, wherein the automatic bottle opening device, the pipetting device and the solvent clamping device are arranged on the base; the automatic bottle opening device comprises a placing table, a rotating medicine tray, a cutting mechanism and a breaking mechanism; the placing table is fixedly arranged on the base, the rotating medicine tray is rotatably arranged relativeto the placing table, and the rotating medicine tray is provided with a plurality of clamping mechanisms for clamping the ampoule bottles; the ampoule bottles clamped by the clamping mechanisms sequentially passes through the cutting mechanism and the breaking mechanism in the rotating direction of the rotating medicine tray, so that the clamped ampoule bottles are sequentially subjected to bottle neck cutting and bottle head breaking; the solvent clamping device is used for clamping a fixed solvent bag and fixing the solvent bag to one side of the rotating medicine tray; and the pipetting device is used for transferring medicine in the opened ampoule bottles to the solvent bag. The automatic dispensing robot for the ampoule bottles has compact structure, and can automatically complete the dispensing process of the ampoule bottles.

Owner:深圳市博为医疗机器人有限公司

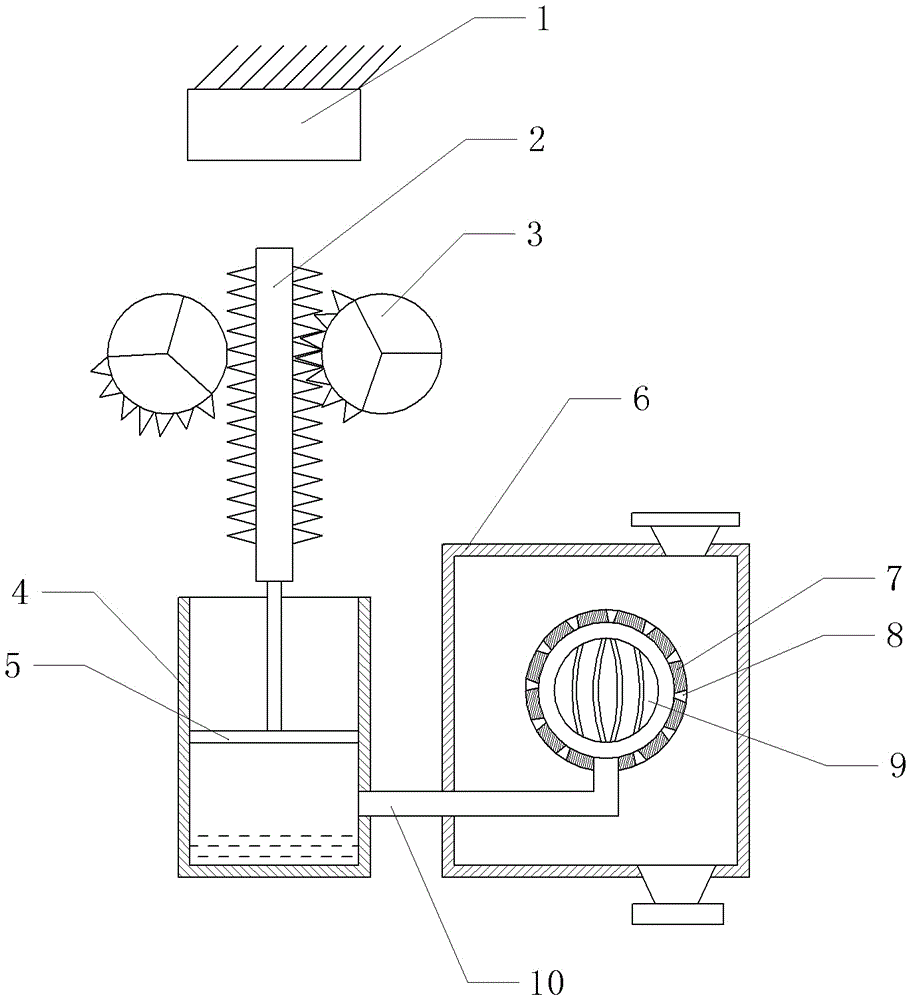

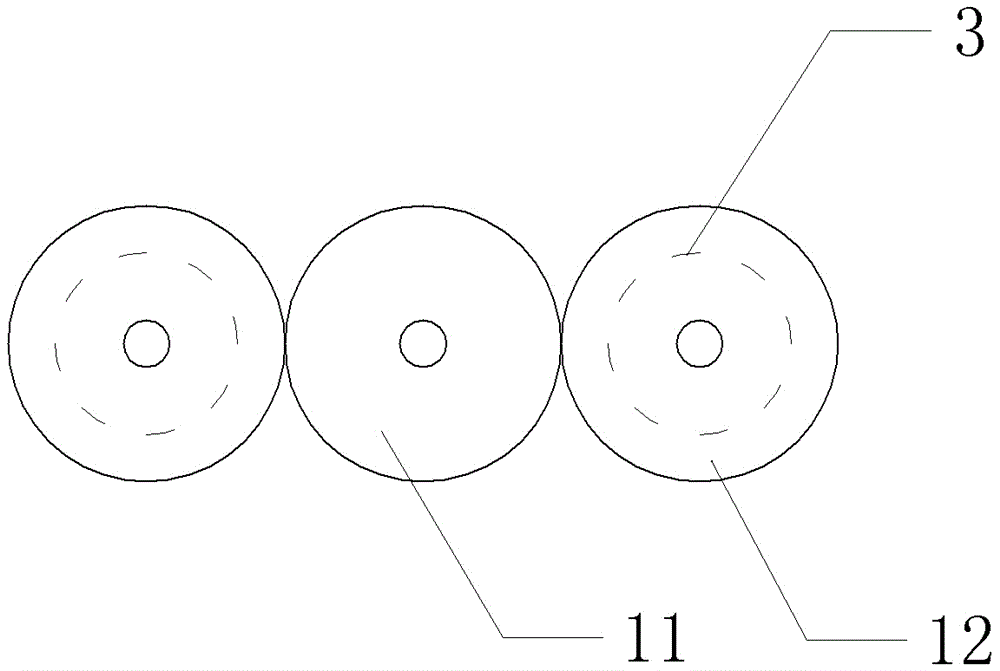

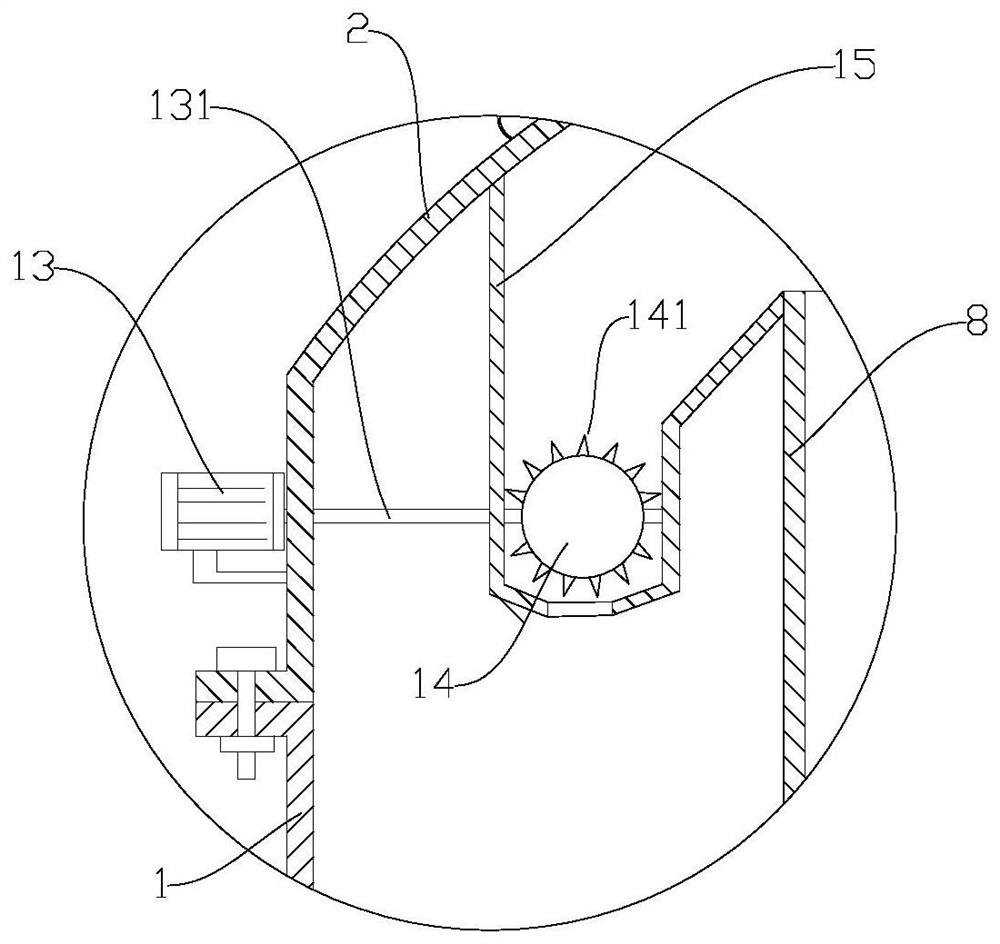

Feedstock scattering device for coir mattress

The invention belongs to the technical field of pretreatment of fiber materials and discloses a feedstock scattering device for a coir mattress. The feedstock scattering device comprises a scattering box and a power case, wherein a hollow scattering ball is arranged in the scattering box, a plurality of scattering holes are uniformly distributed in the sidewall of the scattering ball, the scattering ball communicates with a ventilating pipe, and the ventilating pipe penetrates through the scattering box and communicates with the power case; the power case contains water, a water surface is located below a communicating position of the ventilating pipe and the power case, a piston is arranged in the power case, and a piston rod is arranged at the upper end of the piston; a control device is arranged at the upper end of the piston rod and can drive the piston rod to slide up and down, and the piston rod can stay static during the switching of upward sliding and downward sliding. According to the feedstock scattering device for the coir mattress, the technical problem in the prior art that the feedstock scattering effect is poor during the manufacturing of the coir mattress is solved.

Owner:重庆市永川区植成家俱厂

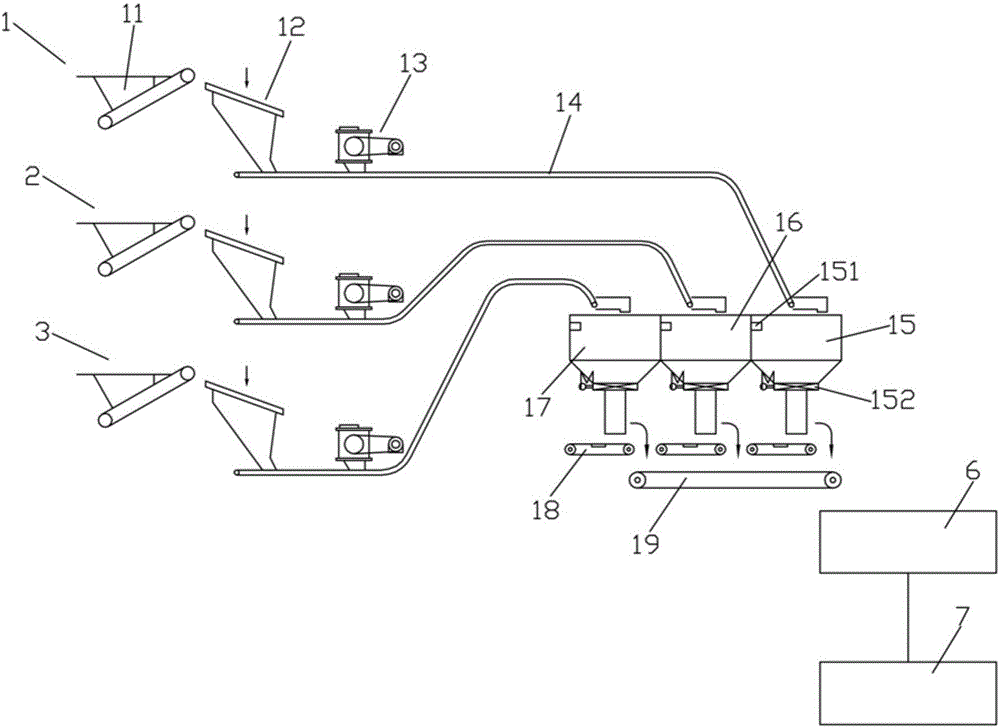

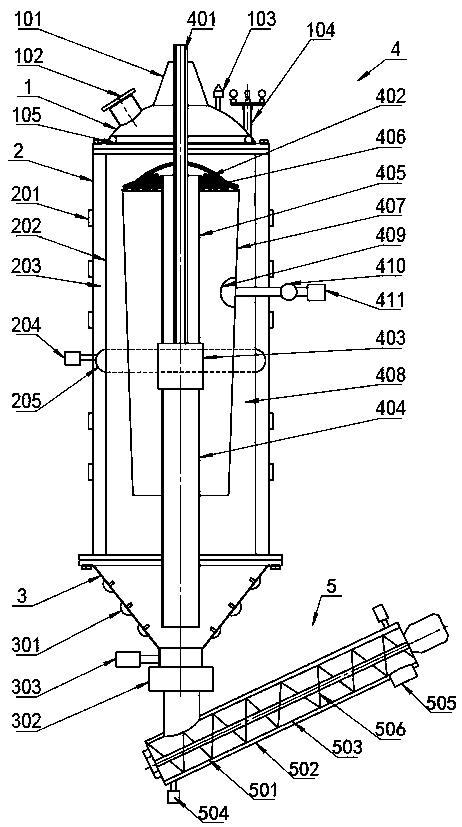

Concrete integral production system

ActiveCN105922438AStir wellAvoid slump lossDischarging apparatusMixing operation control apparatusMaterial supplyBelt machine

The invention discloses a concrete integral production system. The concrete integral production system comprises a dry material supply device, a concrete stirring device, a spiral extrusion conveying device and a control device; the dry material supply device, the concrete stirring device and the spiral extrusion conveying device are joined in sequence, wherein the dry material supply device includes a cement conveying line, a sand conveying line and a bubble conveying line; and cement, sand and bubble are pneumatically conveyed by the dry material supply device to enter a conveying belt machine, and are conveyed to the concrete stirring device by the conveying belt machine. Raw materials are conveyed by using a remote supply system, and are stirred by adding water in scene, so that dry concrete can be transported remotely or even preserved through sealing, the business scope of a concrete mixing plant is widened, the slump loss of concrete in the transportation process is prevented, and the construction while stirring is realized.

Owner:东莞市交港建材有限公司

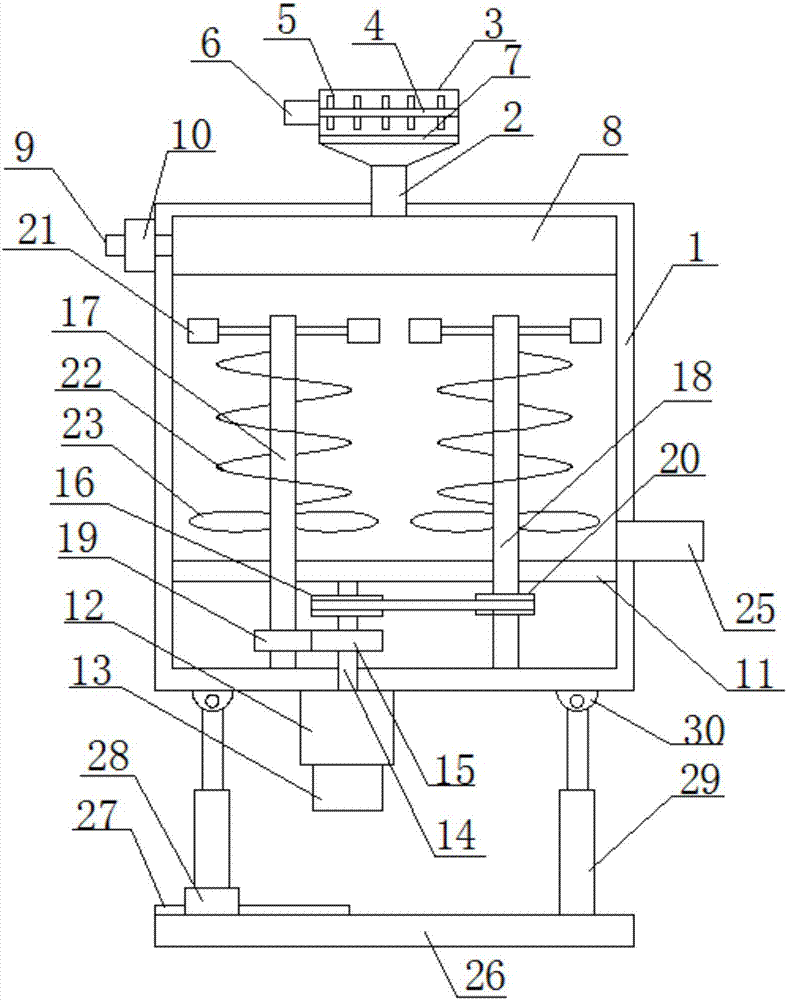

Drink production equipment with good mixing effect

PendingCN107008201AAvoid cloggingGuaranteed cooling effectMixing methodsTransportation and packagingBiochemical engineeringMixing effect

The invention discloses drink production equipment with a good mixing effect. The drink production equipment comprises a tank body and a base, wherein a charging pipe is arranged at the upper end of the tank body; a charging hopper is arranged at the upper end of the charging pipe; a mixing pipe is arranged at the upper end inside the tank body, and comprises an outer pipe, an inner pipe arranged in the outer pipe, a charging cavity is formed between the inner pipe and the outer pipe and a liquid cavity formed inside the inner pipe; a swirling bevel is formed in the inner pipe and is used for communicating the charging cavity and the liquid cavity; a liquid inlet pipe is arranged at the left end of the mixing pipe and is communicated with the liquid cavity; a water pump is arranged on the liquid inlet pipe; the lower end of the charging pipe is communicated with the charging cavity; a plurality of spray holes are formed in the lower end of the outer pipe; a separator is arranged inside the tank body, and is used for separating the tank body into a driving cavity and a mixing cavity; a cooling device is arranged at the lower end of the tank body, and comprises a cover body; and a first motor is arranged at the lower end of the cover body. The drink production equipment is simple in structure and convenient to use, has a good mixing effect, high inspection efficiency and long service life, and is convenient for discharging.

Owner:长沙装研智能科技有限公司

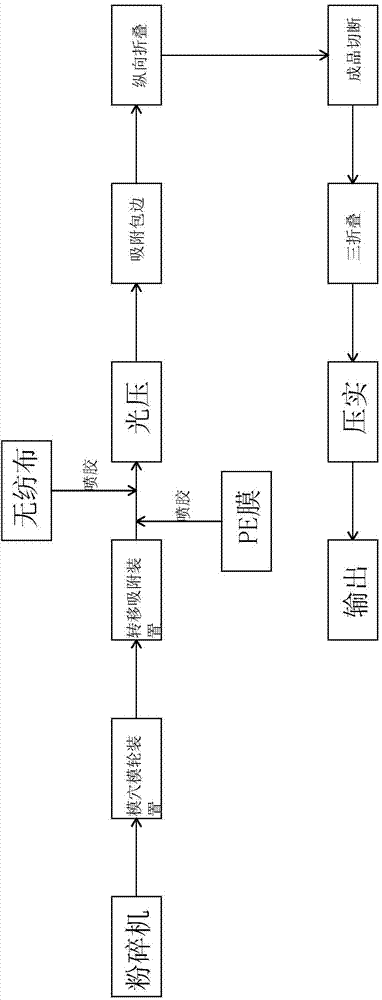

Absorption core production technology

The invention relates to an absorption core production technology which is high in production efficiency and low in production cost, and structures of produced absorption cores are simplified. The absorption core production technology includes the following steps that first, raw materials are conveyed into a pulverizer to be pulverized and then conveyed out; second, pile pulp is conveyed into a mold cavity and mold wheel device, high polymer material is added into the pile pulp, and forming is performed; third, formed cotton cores are adsorbed through a transfer and adsorption device and transferred onto a conveying belt to be conveyed; fourth, in the conveying process, the upper portion of the cotton cores are covered with a layer of non-woven cloth, the bottoms of the cotton cores are covered with a layer of PE film, and the cotton cores are made to adhere to the non-woven cloth and the PE film in an adhesive spraying mode; fifth, the cotton cores are conveyed into a smoothing and pressing device to be pressed and smoothed, and then the cotton cores are conveyed out; sixth, the edges of the cotton cores are coved, and then the cotton cores are longitudinally folded; seventh, the cotton cores are conveyed into a cutting device, and tailoring and edge removing are carried out to obtain finished products; eighth, the cotton cores are folded three times, and the folded cotton cores are compacted through a pressure device and then conveyed out.

Owner:福建培新机械制造实业有限公司

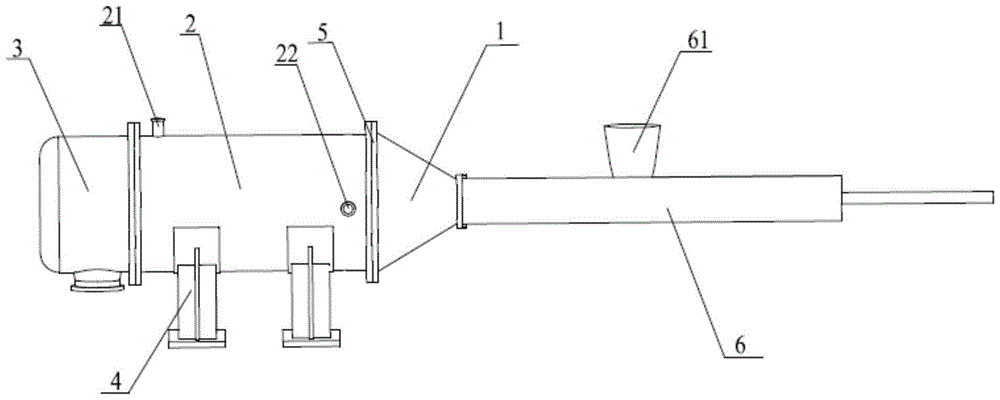

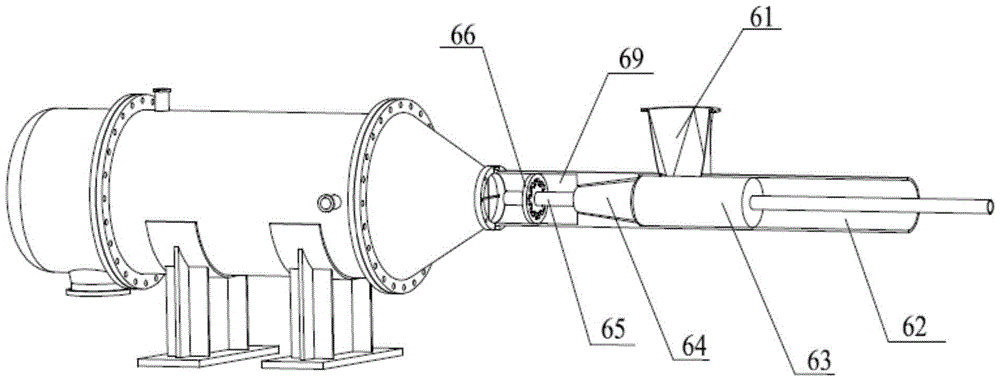

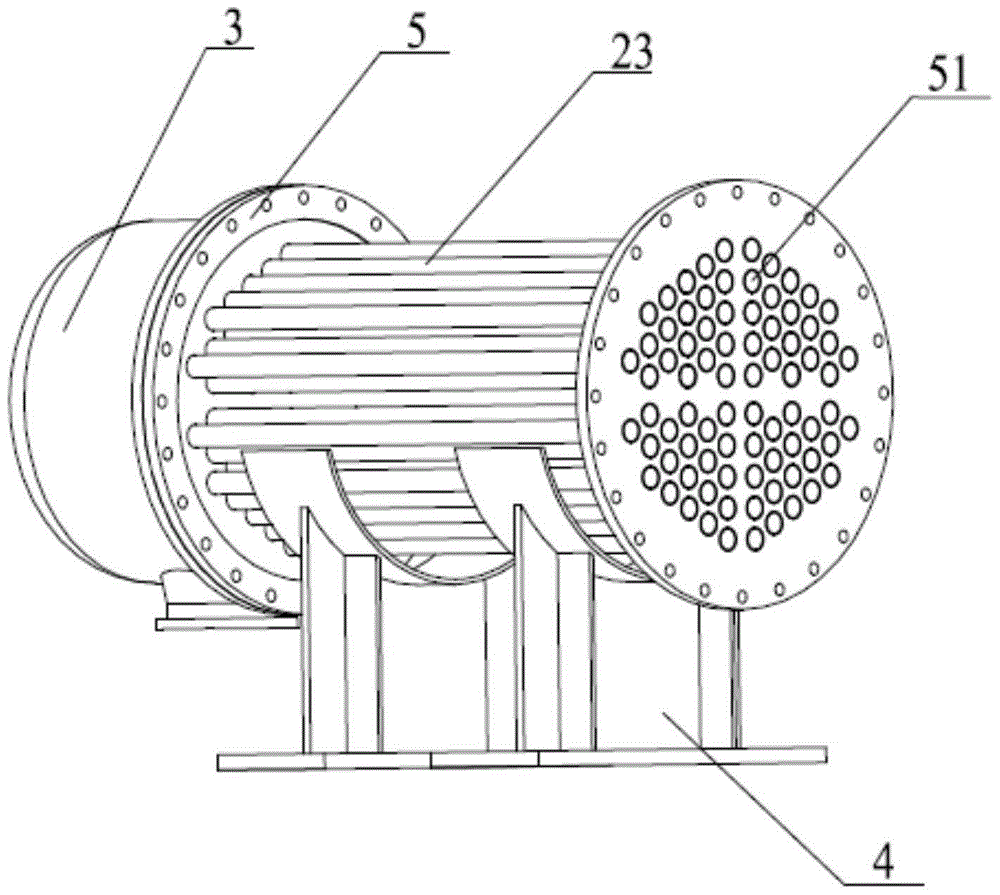

Sewage heat pretreatment wall breaking device and sewage treatment method

ActiveCN105217928ALower specific resistancePracticalSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeHeat pretreatment

The invention discloses a sewage heat pretreatment wall breaking device which is provided with the following parts sequentially in the flowing direction of sewage: a feeding unit, a wall breaking unit, a discharging unit and a support, wherein the feeding unit is provided with a feeding port; the wall breaking unit is connected to the feeding unit, and includes a casing with a heating medium inlet and a heating medium outlet, and a wall breaking pipeline built in the casing; the discharging unit is connected to the wall breaking unit, and is provided with a discharging port; the support supports the bottom of the wall breaking unit; connecting plates are fixedly connected between the feeding unit and the wall breaking unit, as well as between the wall breaking unit and the discharging unit respectively; through holes are formed in the connecting plates; the wall breaking pipeline extends and is fixed to the through holes. The invention further discloses a method for sewage treatment through adopting the wall breaking device, and cell walls of sewage microorganisms and associative keys of matters outside the microbial cells and water can be effectively damaged, follow-up mechanical dehydration efficiency of sewage is increased, and energy consumption in the final drying step of sewage is greatly reduced.

Owner:江苏国翔环保科技有限公司

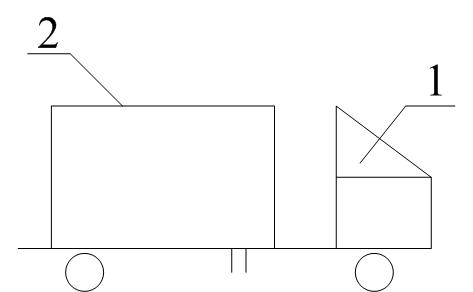

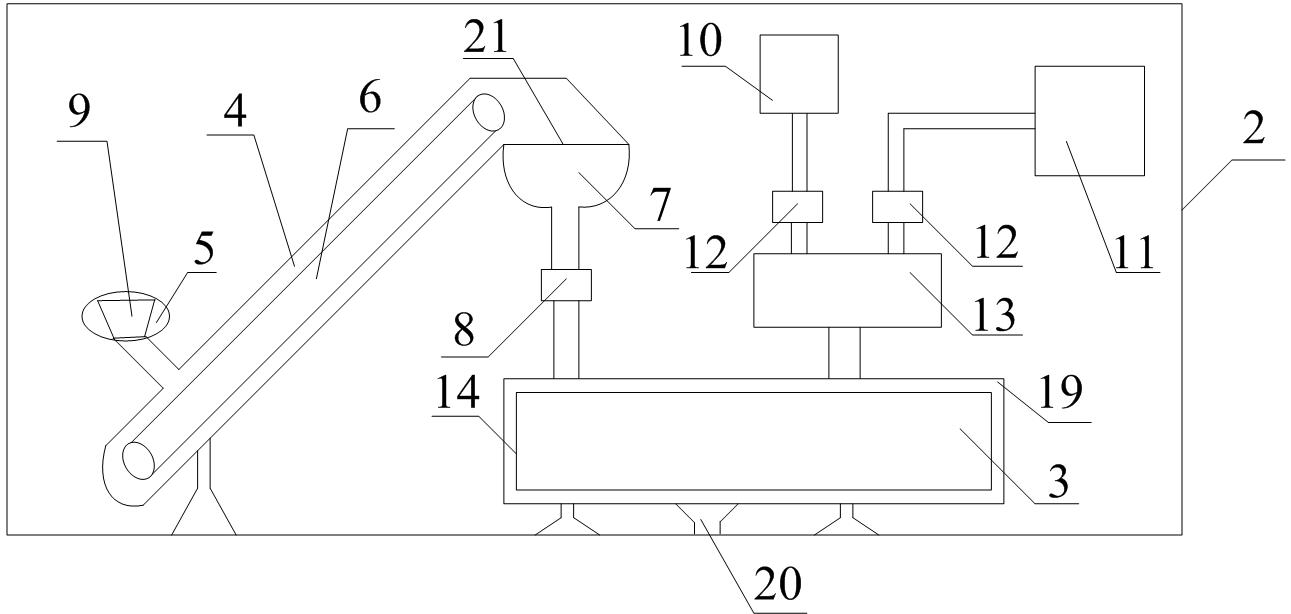

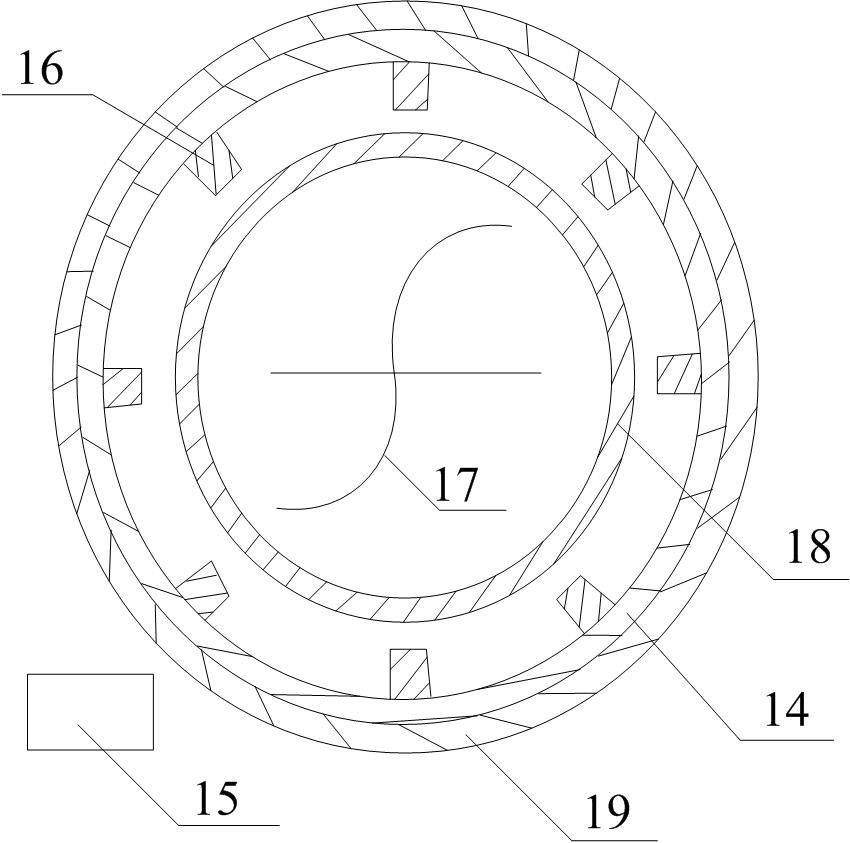

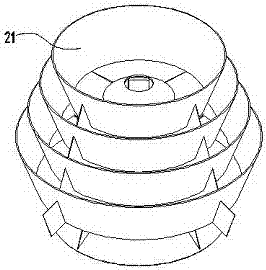

Environmental-friendly vehicle-mounted concrete stirring system and method for carrying out concrete mixing by using same

The invention provides an environmental-friendly vehicle-mounted concrete stirring system which comprises a removable vehicle body, a sealed chamber arranged on the vehicle body, and a concrete stirring system accommodated in the sealed chamber. The concrete stirring system comprises a concrete drier batching device, water and additive batching device and an ultrasound stirrer. Concrete drier, water and additives enter into the ultrasound stirrer after being batched and weighed by the concrete drier batching device and the water and additive batching device respectively. The invention further comprises a method using the environment friendly vehicle-mounted concrete stirring system for concrete stirring. The stirring system expands the business scope of a concrete mixing plant, adapts to conditions of most construction sites, avoids sewage, dust and noise pollution produced by traditionally stirring concrete on sites, enhances the thrashing effect to powder, and ensures that the concrete is uniformly stirred.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

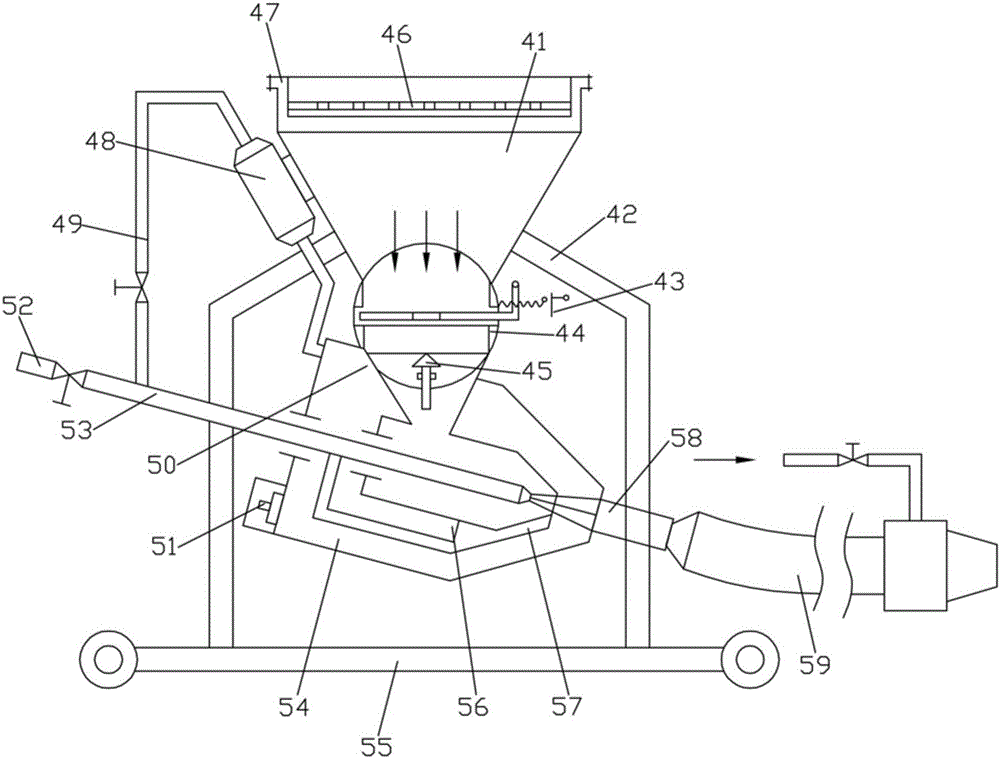

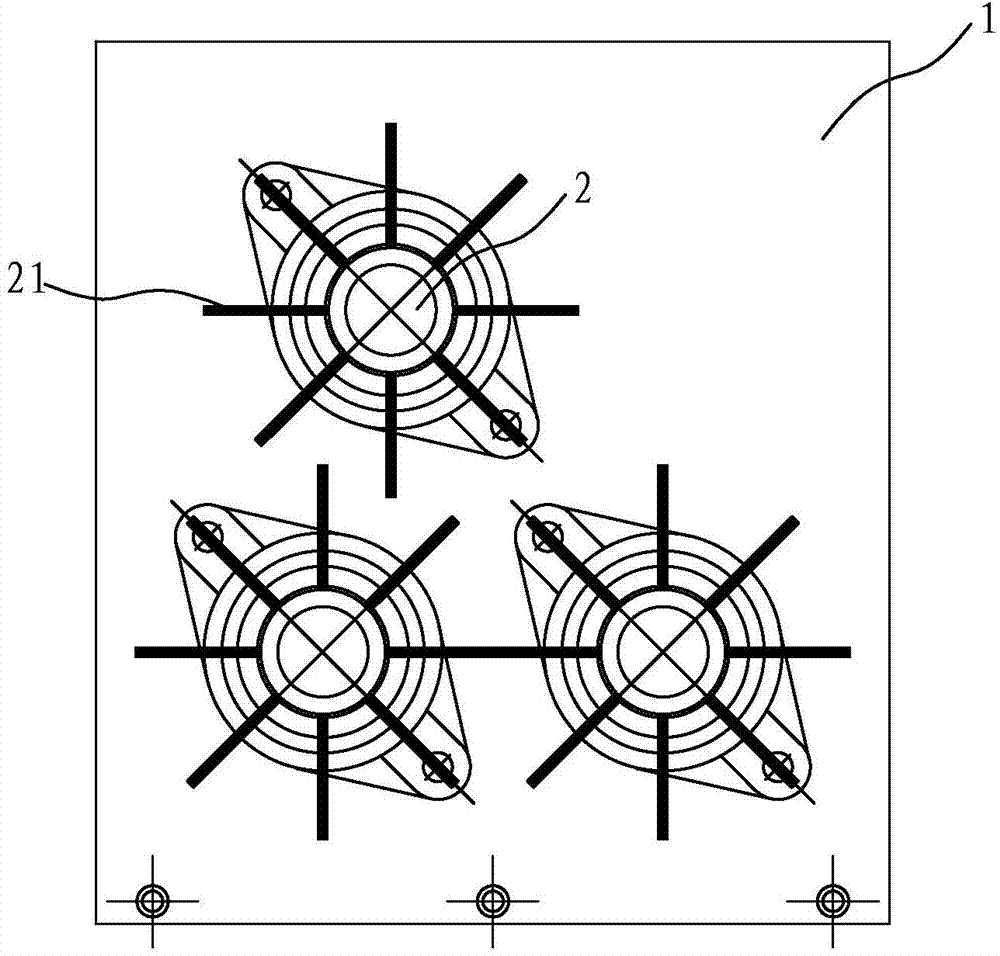

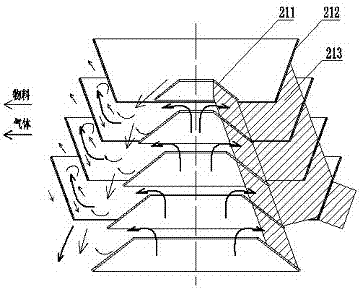

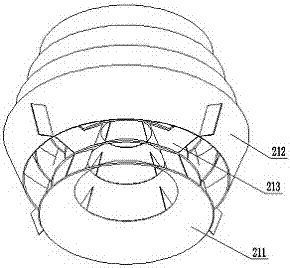

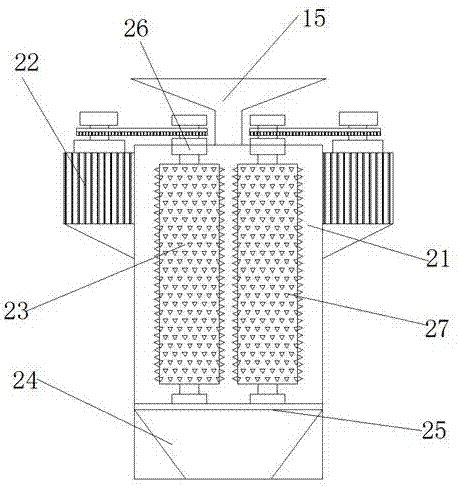

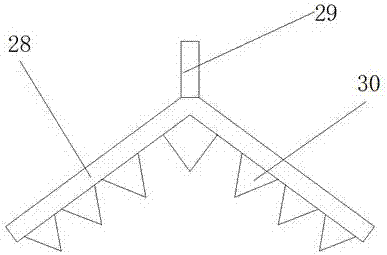

Sorting grid and powder selecting machine for sorting by sorting grid

PendingCN106975609ACompact structureIngenious designGas current separationEngineeringMechanical engineering

The invention discloses a sorting grid. The sorting grid comprises multiple inverted frustum type outer grid plates, multiple forward frustum type inner grid plates, and a sorting grid consisting of multiple grid plates; the outer grid plates and the inner grid plates are coaxially sleeved along the center axis of the sorting grid; and multiple outer and inner grid plates inserted one by one are connected as a whole from top to bottom through the grid plates arranged in the radial direction to form wind ways for enabling wind to pass through and scattering and sorting channels for enabling materials to fall step by step. The invention further discloses a powder selecting machine for sorting by the sorting grid; and the powder selecting machine includes a shell provided with a material sorting cavity inside, a sorting grid mounted in the material sorting cavity, a feed mechanism and a discharge mechanism. The sorting grid is used for enabling the materials to collide by multiple times for full scattering in the natural falling process under the effect of self weight in limited space; and a sorting machine once sorts the materials in the gradual scattering process to effectively improve the sorting efficiency and the sorting rate.

Owner:MIANYANG LANAO HEAVY MACHINERY MFG

Method for wall breaking of oil-containing microalgae and assistant assisted extraction of oil

ActiveCN105176671AHigh extraction rateReduce dosageFatty-oils/fats productionOil and greaseScenedesmus

The invention discloses a method for wall breaking of oil-containing microalgae and assistant assisted extraction of oil. The method comprises the following steps: 1, adjusting the pH value of a suspension of the oil-containing microalgae to 7.5-14, and carrying out hydrothermal treatment; 2, carrying out an enzymatic hydrolysis reaction in the presence of an enzyme; 3, adding an assistant for promoting precipitation of oil in the oil-containing microalgae, and reacting; and 4, adding an organic solvent to extract, and separating the oil. The method has the advantages of high oil extraction rate, mild operation conditions, effective maintenance of nutrition components of the microalgae, small dosage of the organic solvent, environmental protection and low energy consumption, is suitable for Nannochloropsis oceanica, chlorella, diatom, scenedesmus, Monoraphidium sp. and other microalgae, and has a wide application range.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rapid scattering device for recycling rare-earth waste

ActiveCN107321464AImprove the breaking effectThe effect of breaking up is fastGrain treatmentsScrapExtremely good

The invention relates to a scattering device for recycling rare-earth waste, in particular to a rapid scattering device for recycling the rare-earth waste. The rapid scattering device for recycling the rare-earth waste is capable of saving manpower and saving time, high in scattering speed and high in work efficiency. The rapid scattering device for recycling the rare-earth waste comprises a bottom plate, supports, a driving device, a collecting frame and the like; the supports are vertically symmetrically installed on the left side and the right side of the top of the bottom plate in a bolt connection mode, the collecting frame is installed on the top of the part, between the two supports, of the bottom plate in a bolt connection mode, and the driving device is arranged between the collecting frame and the left support. According to the rapid scattering device for recycling the rare-earth waste, a first motor is adopted as a drive to enable first blades to rotate to be matched with second blades, so that the rare-earth waste is extremely good in scattering effect, and therefore the effects of saving manpower, saving time, realizing fast scattering speed and realizing high working efficiency are achieved.

Owner:江苏朗融岩土工程有限公司

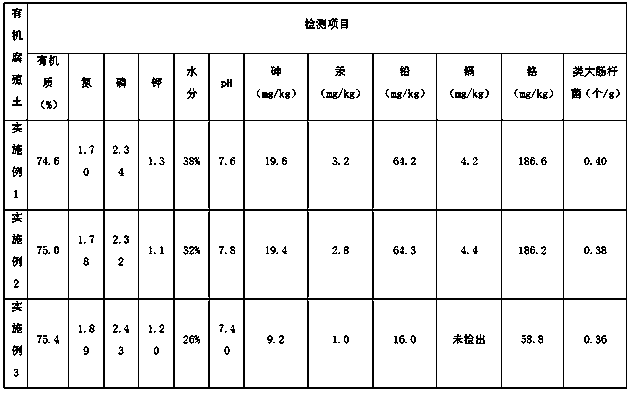

Method for treating sludge by utilizing microbial flocculant and microbial wall breaking

PendingCN110885176ALow investment costPromote fermentationSludge treatment by de-watering/drying/thickeningClimate change adaptationMicroorganismHeavy metal chelation

The invention provides a method for treating sludge by utilizing a microbial flocculant and microbial wall breaking. According to the method, residual sludge is subjected to biological modification with a microbial flocculant, the modified sludge is subjected to biological wall breaking with a microbial wall breaking flora and a heavy metal chelating flora, the content of heavy metals is reduced,and sludge is subjected to aerobic fermentation with a sludge fermentation flora and a biomass fermentation flora, such that the sludge is converted into organic humus. No chemical agent is added in the whole process, no energy is input into the sludge in the dehydration process, only a small amount of mechanical power is used during stacking and turning, the sludge is modified, heated and dried by purely utilizing the activity advantage of microorganisms, and finally reduction, harmlessness, stabilization and recycling of the sludge are achieved. According to the invention, a new method for treating and disposing residual sludge and industrial sludge with high organic matter content in municipal sewage plants is opened up, and the method provided by the invention has the advantages of lowequipment investment, simple operation, safety, no pollution, low energy consumption, and good economic and environmental benefits.

Owner:河南莫大生物科技有限公司

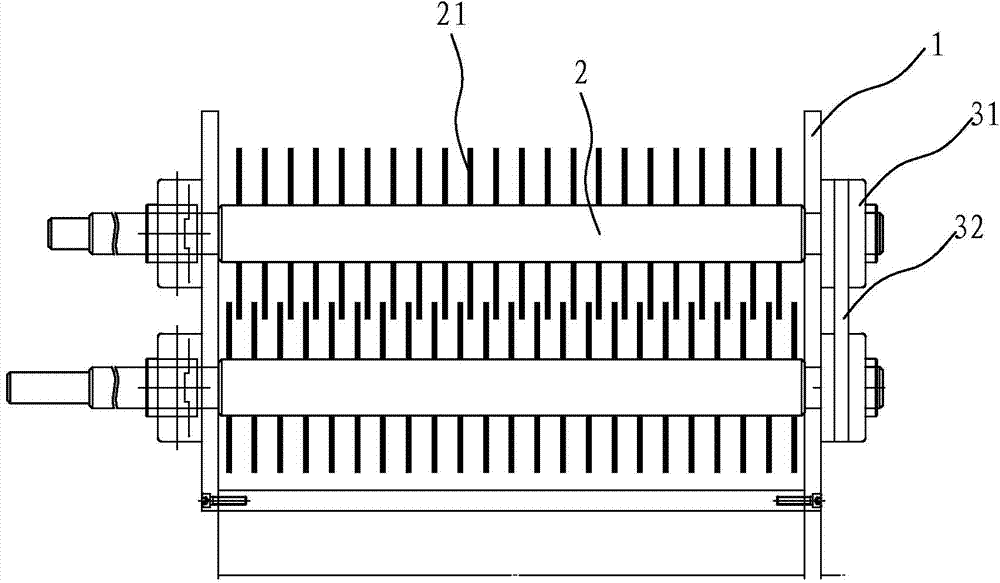

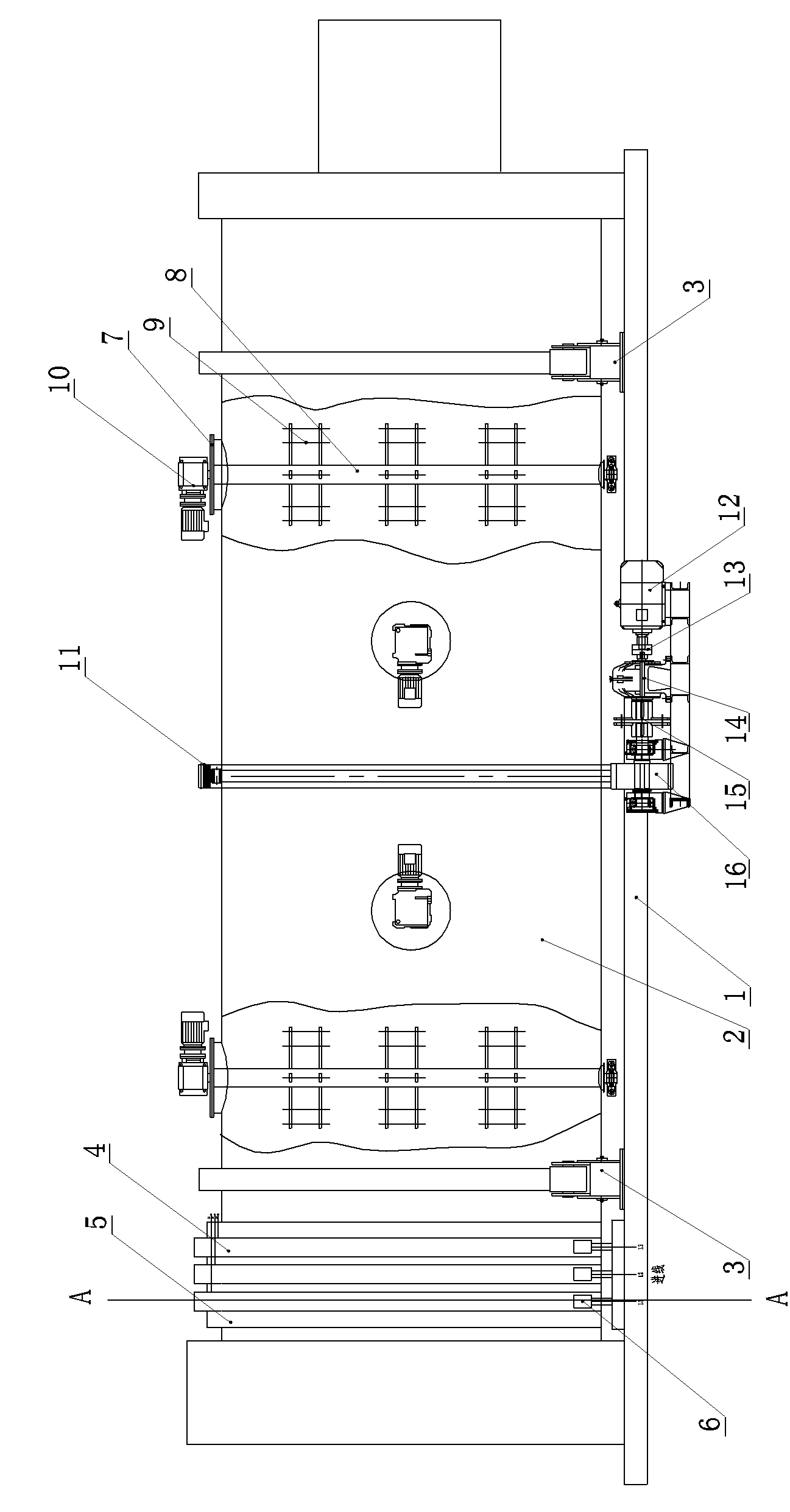

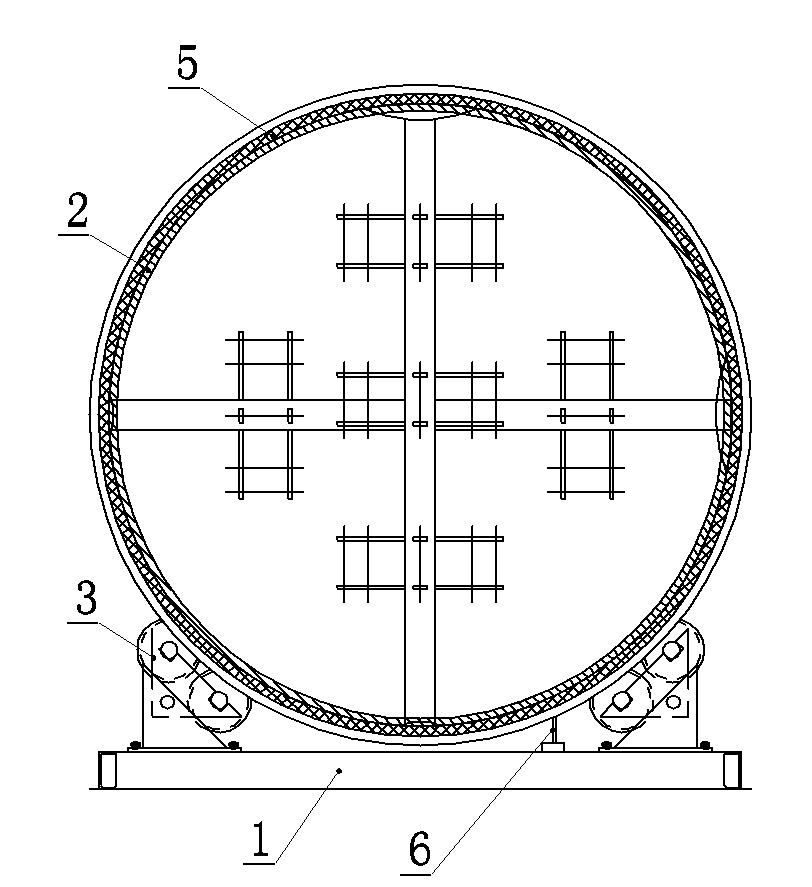

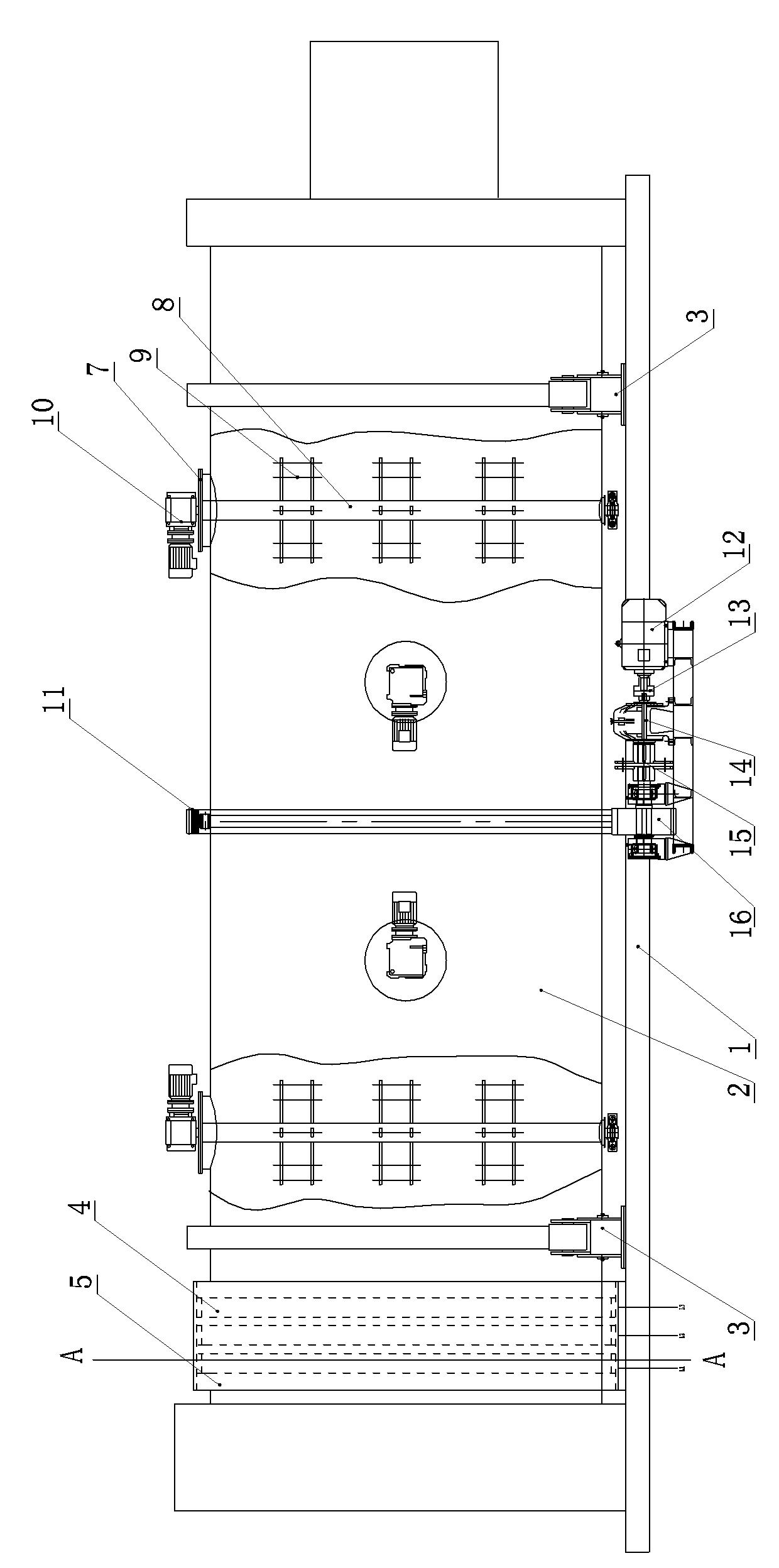

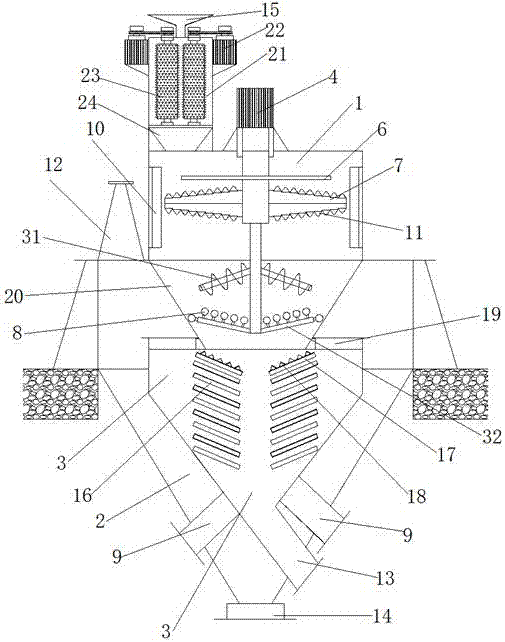

Multi-shaft crushing dryer of rotary drum

ActiveCN103047837AExtended service lifeReduce maintenance rateDrying solid materialsDrying machines with non-progressive movementsFlangeEngineering

A multi-shaft crushing dryer of a rotary drum comprises a dryer big frame, the rotary drum, a driving device and a carrier roller group. The carrier roller group is arranged on the dryer big frame, the rotary drum is supported on the carrier roller group, the driving device drives the rotary drum to rotate, a plurality of vertical crushing shafts transversely penetrating through the drum wall are arranged on the rotary drum, two ends of the vertical crushing shafts are arranged on the drum wall of the rotary drum through flanges, and a plurality of vertical shafts are arranged in crossed mode. One end of each vertical shaft is connected with a crushing motor. At least two rotating linear rings are arranged at the end of the rotary drum, and electric brushes matched with the rotating linear rings are connected with a power supply device. A scattering shaft of the multi-shaft crushing dryer of the rotary drum is arranged in the diameter direction of the rotary drum and transversely penetrates through the rotary drum, the length of the scattering shaft is reduced so that the scattering shaft cannot deform due to over-temperature in the rotary drum, service life of the multi-shaft crushing dryer can be prolonged, and overhaul probability is reduced.

Owner:JIAOZUO ZHENJIENNEG DRYING EQUIP DEV

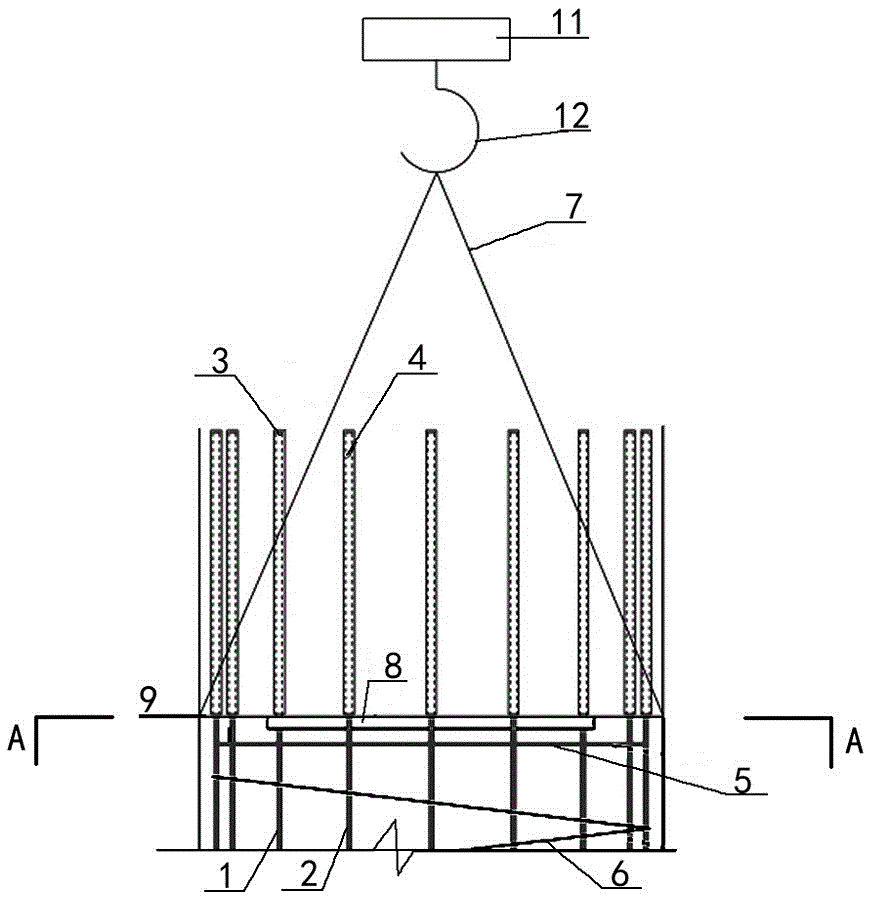

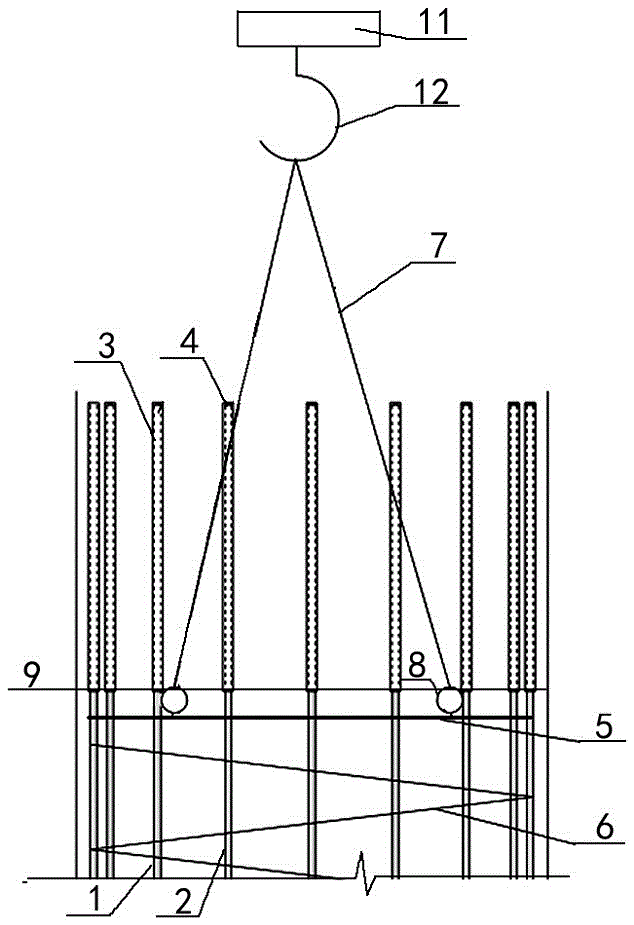

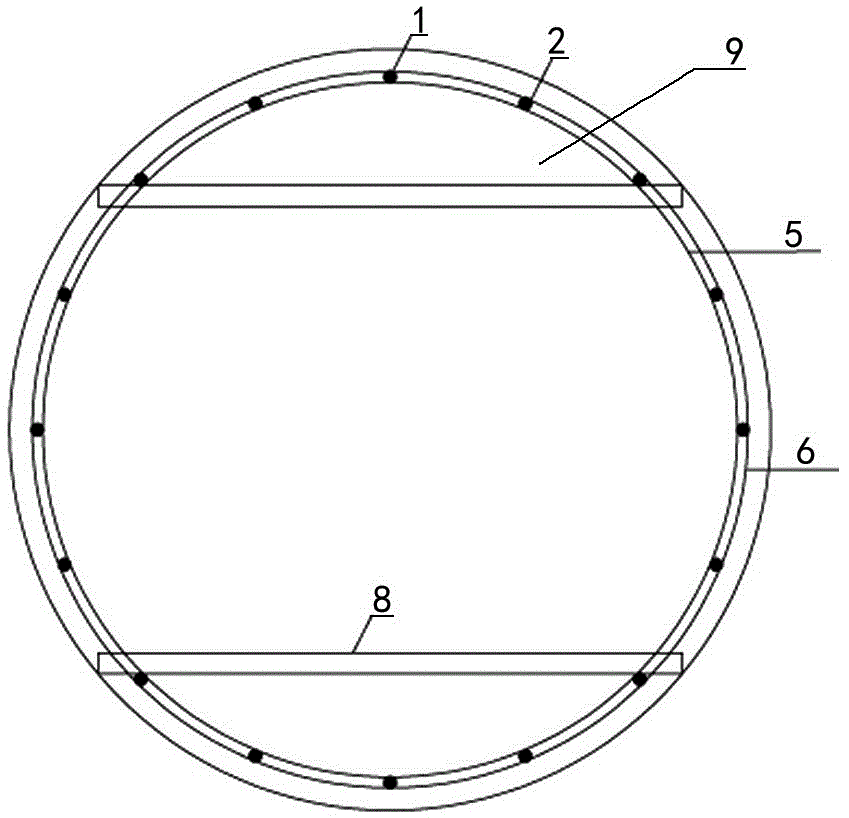

Pile foundation pile head concrete pre-stripping assembly and construction method

The invention provides a pile foundation pile head concrete pre-stripping assembly and a construction method. The assembly comprises a pre-embedded isolation component, a pre-embedded splitting component, splitting equipment and hoisting equipment. The pre-embedded isolation component comprises main reinforcement sleeves and acoustic testing pipe sleeves. The preembedded splitting component comprises a set of horizontal splitting pipes pre-embedded on a fracture surface. The splitting equipment comprises hydraulic splitting machines. The hydraulic splitting machines are inserted into the horizontal splitting pipes from the two sides to conduct splitting to form the fracture surface during breaking and stripping. The hoisting equipment comprises a lifting tool, a lifting hook and a steel wire rope. The steel wire rope penetrates through the split and broken horizontal splitting pipes and is connected with the lifting hook, so that pile head concrete is stripped off from reinforcements and acoustic testing pipes. The pile foundation pile head concrete pre-stripping assembly can be made of engineering leftover materials and is low in cost. During construction, the fracture surface is formed through the hydraulic splitting machines, and then the pile head concrete can be broken and stripped off. The process can be completed only by one person. The hydraulic splitting machines can provide smooth pile head connecting surfaces to facilitate later pile foundation detection and follow-up construction. The pile foundation pile head concrete pre-stripping assembly is easy to operate, low in technical requirement, good in breaking and stripping effect and high in efficiency.

Owner:北京城建七建设工程有限公司

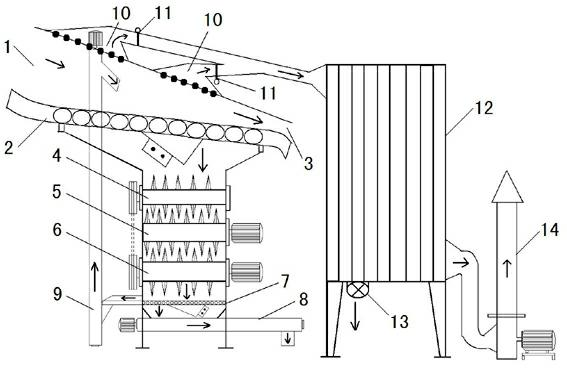

Vibrating dust-collection type scattering machine

InactiveCN102303015AGood removal effectAvoid pollutionSievingGas current separationEngineeringScattering effect

The invention discloses a vibrating dust-collection type scattering machine and relates to a mechanical device for scattering clotted materials. The vibrating dust-collection type scattering machine is characterized in that the upper part of a frame is provided with a feed inlet, the lower part of the feed inlet is provided with a vibrating screen A, and the vibrating screen A is connected with the frame by a spring or a rubber spring; the vibrating screen A is obliquely arranged, the upper part of the vibrating screen A is provided with a dedusting exhaust inlet, the dedusting exhaust inlet is communicated with a dust collection device by a pipeline, and the dust collection device is connected with a draught fan by a pipeline; a rotary roller is arranged below the vibrating screen A, a vibrating screen B is arranged below the rotary roller, and a discharge belt is arranged below the vibrating screen B; one side of the vibrating screen B is provided with a circulatory feeder; and the vibrating screen B is used for screening scattered materials, then conveying qualified materials to the discharge belt, and conveying unqualified materials to the feed inlet to be scattered for the second time circularly. The vibrating dust-collection type scattering machine disclosed by the invention has the advantages of good scattering effect and capability of removing impurities and dust and is suitable for scattering and debonding of various powered materials or granular materials which are clotted because of damp.

Owner:巨锋

Automatic bottle opening device used for ampoule bottle dispensing robot

ActiveCN111453670AUnbreakableImprove the breaking effectBottle/container closurePower operated devicesEngineeringBottle

Owner:深圳市博为医疗机器人有限公司

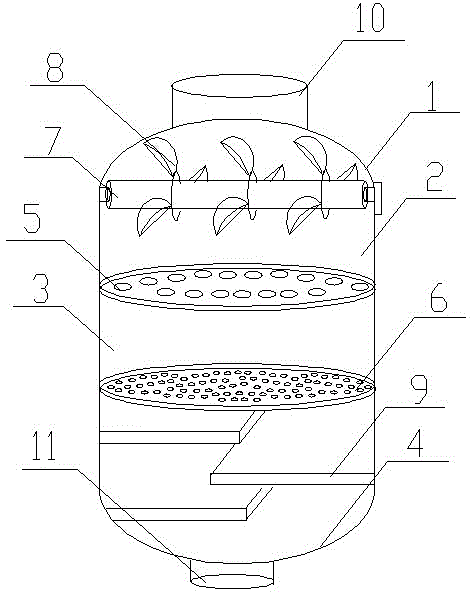

Chemical filtering device

InactiveCN105688472AImprove the breaking effectEasy to cutStationary filtering element filtersLiquid wasteParticulates

The invention discloses a chemical filtering device. The chemical filtering device comprises a filtering tank. The filtering tank is a three-layer structure and comprises a first filtering zone, a second filtering zone and a third filtering zone. A primary filter is arranged between the first filtering zone and the second filtering zone. A re-filter is arranged between the second filtering zone and the third filtering zone. A stirring device is arranged in the first filtering zone. The stirring device comprises multiple propellers. Each one of the propellers comprises multiple blades which can cut and crush particles in the waste liquid so that filter and material outlet blocking is preliminary prevented. Through combination of the primary filter and the re-filter, waste blocks or particles in the waste liquid are well separated from the water liquid and material outlet blocking caused by wastes in the waste liquid is effectively prevented. The chemical filtering device has very good use effects in waste water treatment in the chemical industry.

Owner:丹阳恒安化学科技研究所有限公司

Environment-friendly multi-stage building rubbish crushing treatment device

InactiveCN110215989AAvoid pollutionImprove crushing effectDirt cleaningGrain treatmentsEnvironmental resistanceDrive shaft

The invention relates to the field of environmental protection building equipment, in particular to an environment-friendly multi-stage building rubbish crushing treatment device which comprises a shell, a driving crushing roller and a driven crushing roller; a material throwing hole is formed above the side wall of the shell; an air extractor is fixedly connected to the upper surface of the shell; an air filter is fixedly connected to the side wall of the shell; the shell is internally provided with the driving crushing roller and the driven crushing roller; a second motor is fixedly connected to the lower surface of the shell; a driving shaft is fixedly connected to the shaft extension end of the second motor; and a grinding roller is fixedly connected to the upper end of the driving shaft. For the environment-friendly multi-stage building rubbish crushing treatment device, by arranging a baffle plate and a spring, dust of building rubbish is prevented from escaping; by utilizing a crushing plate to perform preliminary crushing on the building rubbish and the air filter to perform filtering on dust-contained gas, pollution caused by direct emission of the dust-contained gas is avoided; by matching the driving crushing roller with the driven crushing roller, the building rubbish is further crushed; and multi-stage crushing is performed on the building rubbish, and the crushingeffect is greatly improved.

Owner:陈莹

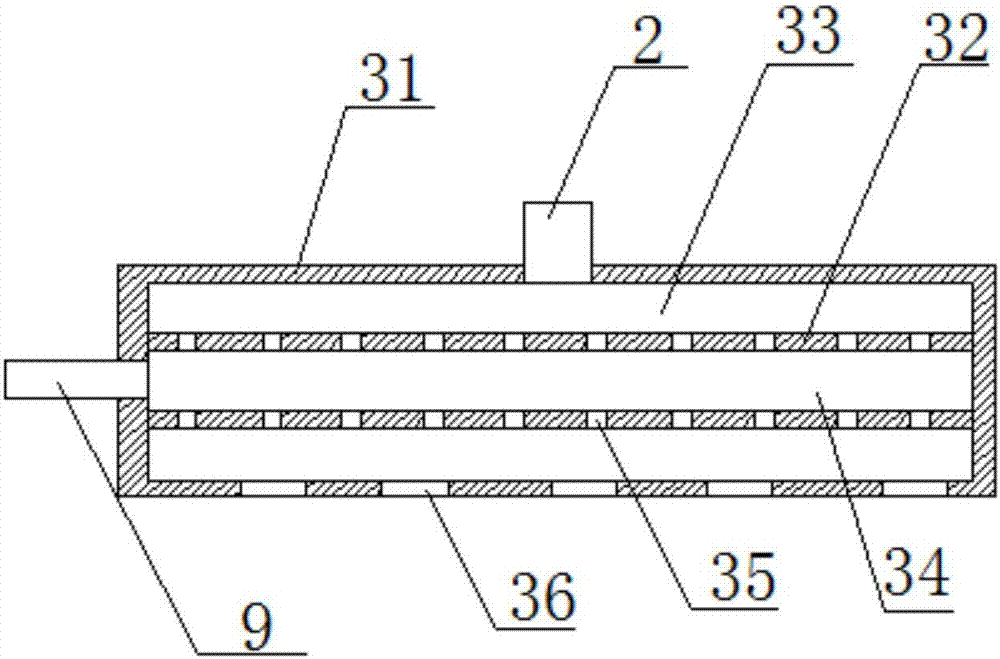

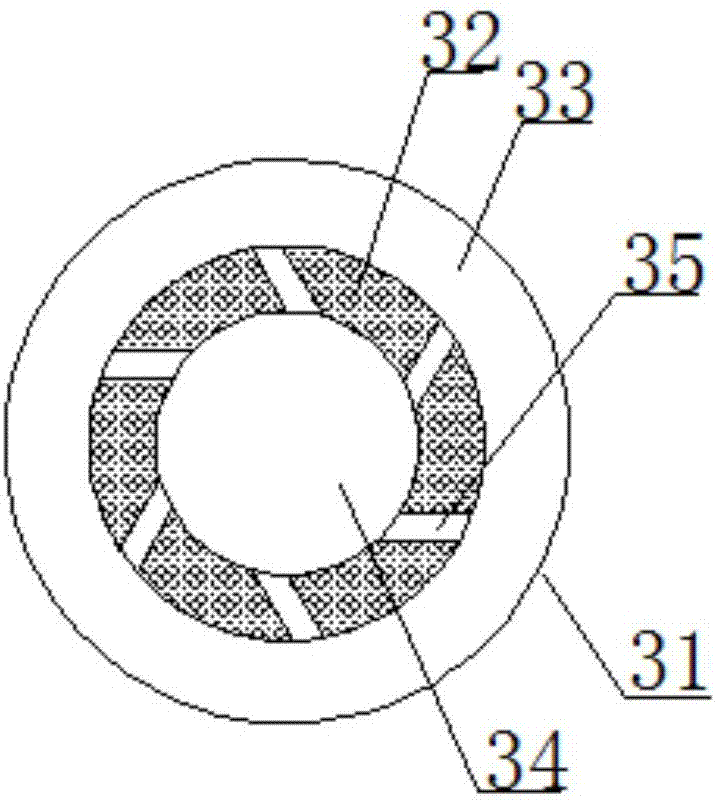

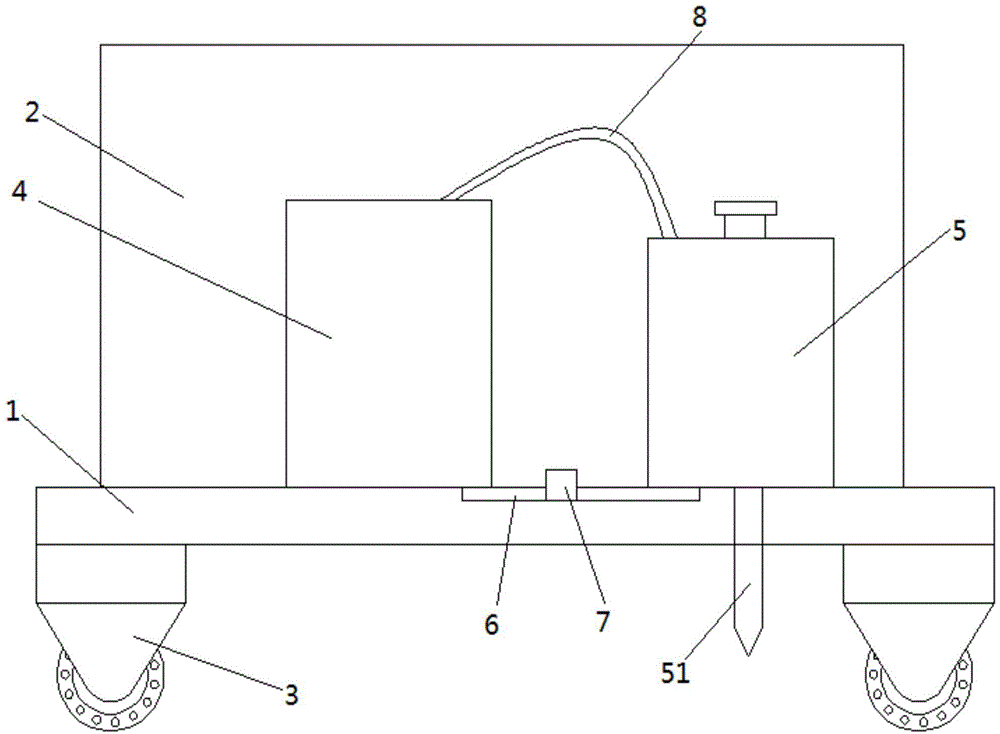

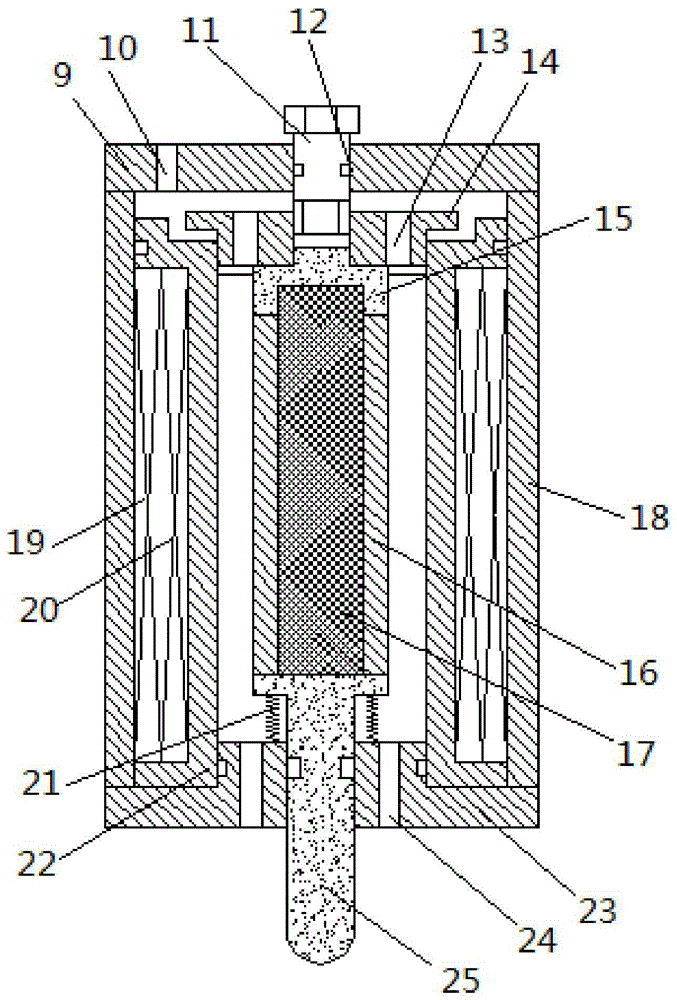

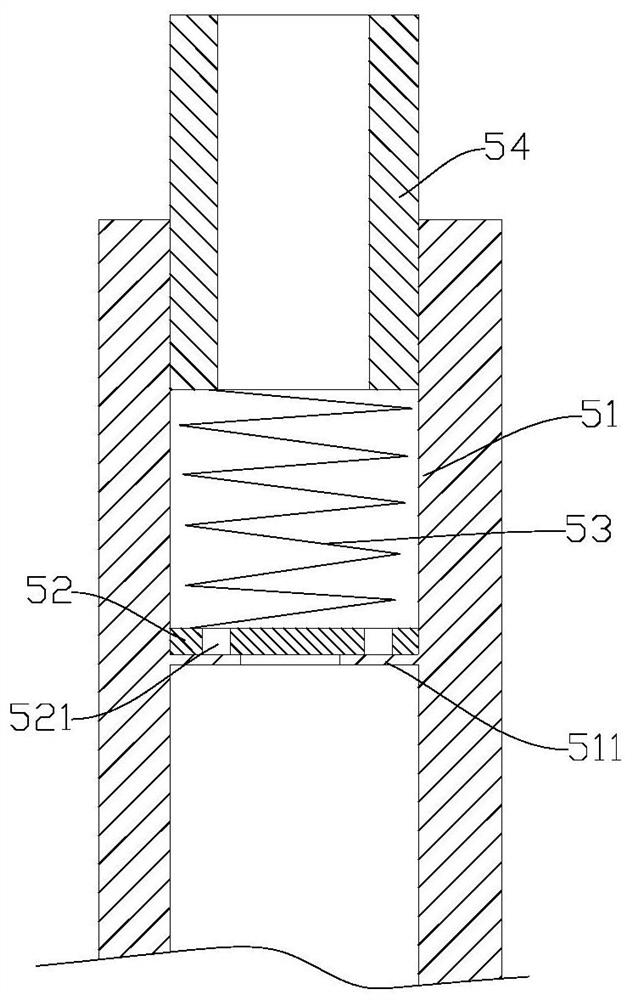

High-speed ice breaking vehicle by utilizing super magnetostrictive devices

ActiveCN104831670AImprove the breaking effectGuaranteed normal passageSnow cleaningReciprocating motionFuel tank

The invention discloses a high-speed ice breaking vehicle by utilizing super magnetostrictive devices. The high-speed ice breaking vehicle comprises a chassis, a compartment, a cooling oil tank and a plurality of super magnetostrictive devices. The compartment is fixedly installed on an upper plane of the chassis, walking wheels are connected with a lower plane of the chassis, the cooling oil tank is installed in the compartment, and the super magnetostrictive devices are transversely installed in the compartment. Each super magnetostrictive device comprises an outer shell, an upper end cap and a lower end cap, wherein the upper end cap is arranged on the upper portion of the outer shell, the lower end cap is arranged on the lower portion of the outer shell, and a coil frame is arranged inside the outer shell. According to the high-speed ice breaking vehicle, the super magnetostrictive devices drive ice breaking nails to reciprocate at a high speed to knock and smash accumulated snow and ice blocks on the ground below the chassis and quickly clear away ice on a road; in addition, through the arrangement of the cooling oil tank, oiling and cooling on the super magnetostrictive devices can be achieved, the service life of the high-speed ice breaking vehicle is prolonged, large-thickness ice layers formed on the road of a cold region can be eliminated well, and normal passage of the city road is effectively guaranteed.

Owner:WEIFANG BAITE MAGNET TECH CO LTD

Construction engineering mud brick and manufacturing method thereof

PendingCN112174635AImprove physical and mechanical propertiesImprove stress resistanceSolid waste managementFiberBrick

The invention discloses a construction engineering mud brick and a manufacturing method thereof, and relates to the technical field of building bricks, the construction engineering mud brick comprisesthe following raw materials by weight: 60-72 parts of mud, 5-10 parts of rubber powder, 2-6 parts of mica powder, 3-7 parts of mine tailings, 2-5 parts of modified composite fiber, 4-8 parts of a modifier, and 1-3 parts of sulfonated lignin. The preparation method comprises the following steps: collecting slurry and dehydrating; adding mica powder, mine tailings and a modifier into the slurry toobtain a mixture A; mixing the modified composite fiber, rubber powder and sulfonated lignin to obtain a mixture B; mixing the mixture A and the mixture B; and paving a glass fiber net on the surfaceof the green brick by using film coating equipment, and maintaining. The mud brick has the beneficial effects that mud is recycled, resources are saved, damage to the environment is reduced, economicbenefits are generated, and the prepared mud brick has good pressure-resistant and fracture-resistant effects and has corrosion resistance.

Owner:江西省建工集团有限责任公司

Wall-breaking and surfactant-assisted method used for extracting grease from microalgae containing oil

ActiveCN105273831AHelps to separate outReduce dosageFatty-oils/fats productionOil and greaseScenedesmus

The invention discloses a wall-breaking and surfactant-assisted method used for extracting grease from microalgae containing oil. The wall-breaking and surfactant-assisted method comprises following steps: (1) pH value of a suspension liquid of microalgae containing oil is adjusted to be 7.5 to 14, and is subjected to hydro-thermal treatment; (2) after hydro-thermal treatment, enzymatic hydrolysis is carried out in the presence of enzymes; and (3) after enzymatic hydrolysis, a surfactant is added for reaction, and an organic solvent is added for extraction and separation of grease. Grease extraction rate of the wall-breaking and surfactant-assisted method is high; operation conditions are mild; nutritional ingredients of microalgae can be maintained effectively; using amount of the organic solvent is small; the wall-breaking and surfactant-assisted method is friendly to the environment, is low in energy consumption, and is suitable for nannochloropsis oculata, chlorella, diatom, scenedesmus, and monoraphidium komarkova-legnerova; and application range is wide.

Owner:CHINA PETROLEUM & CHEM CORP +1

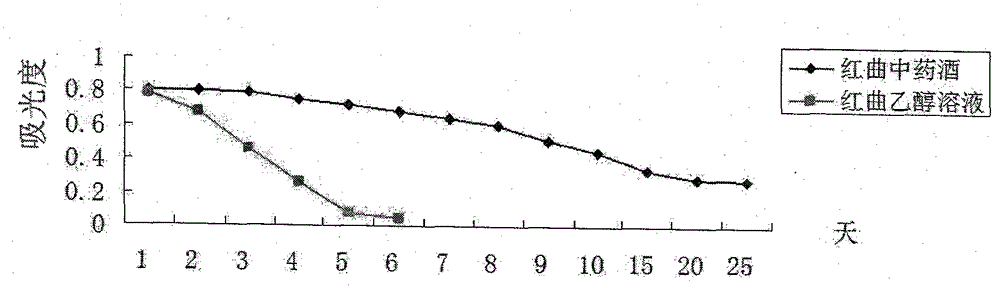

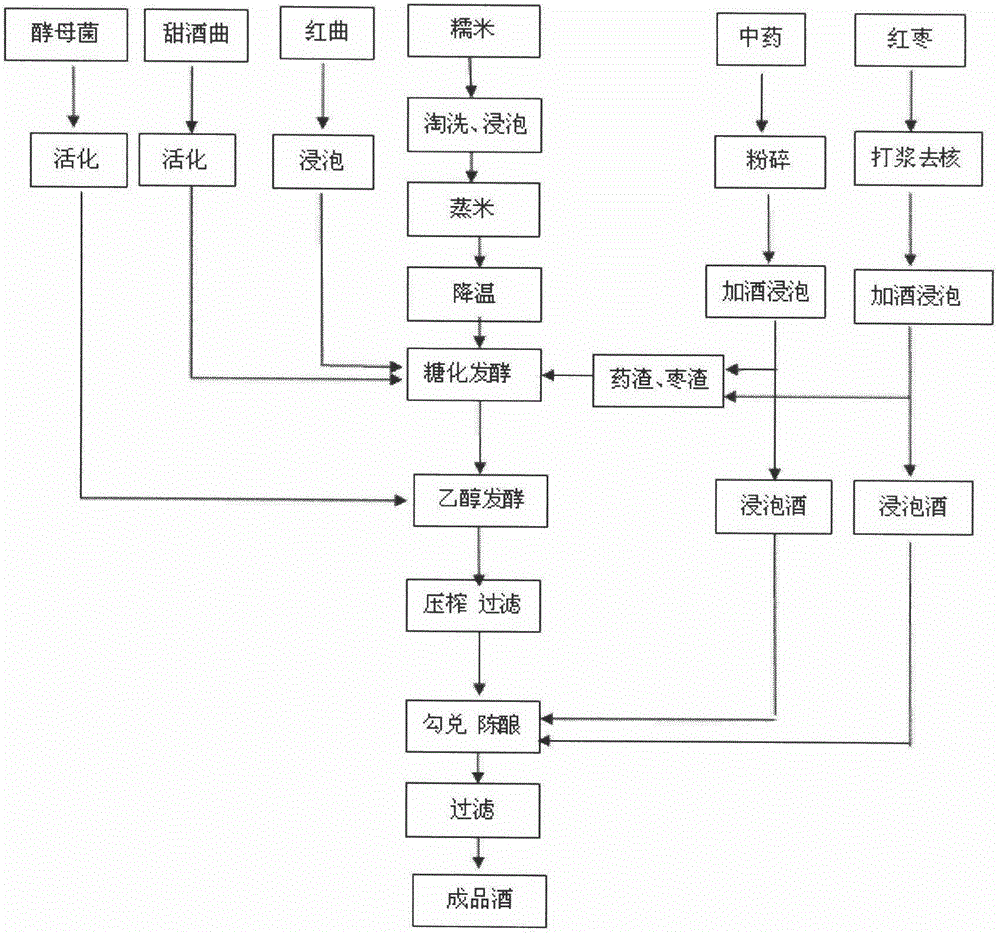

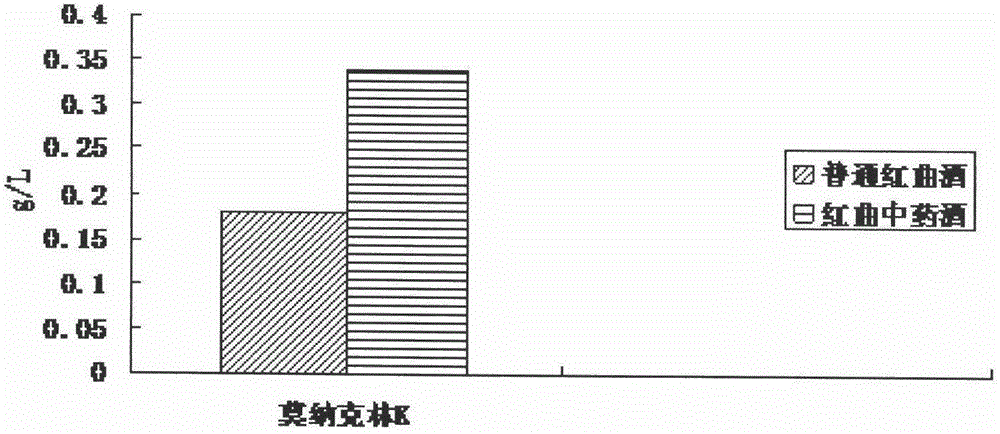

Preparation method of monascus fermentation traditional Chinese medicine health wine with characteristic of no color fading

InactiveCN104830632AHigh extraction rateEasy to useMetabolism disorderAlcoholic beverage preparationAdemetionineChinese herbology

The present invention provides a preparation method of a monascus fermentation traditional Chinese medicine health wine with a characteristic of no color fading. The preparation method is characterized by comprising: a, preparing a seed bacterial liquid for traditional Chinese medicine fermentation, red dates for traditional Chinese medicine fermentation, and a traditional Chinese medicine extraction drug wine for traditional Chinese medicine fermentation; and b, preparing the traditional Chinese medicine fermentation drug wine. The method of the present invention has the following beneficial effects that: the traditional Chinese medicine extraction rate is increased, the drug wine use effect is increased, the drug consumption is reduced, the monascus active component synthesis is increased, the enzyme activity is improved, the obtained wine has characteristics of pleasant color, no color fading, mellow alcohol taste, rich taste, pleasant aroma, no bitter taste, disease prevention, enjoyment feeling, red and bright color, clarified and transparent wine liquid, aroma, mellow taste, concurrent color, aroma and taste provision, perfect health, color and taste integration, health effect, and drinking interest enjoying, the method has characteristics of low equipment investment requirement and low cost, and is suitable for large-scale industrial production, and the obtained product does not contain any chemical additive components and is green and natural.

Owner:LUOYANG NORMAL UNIV

Cutting device used for ampoule bottle dispensing robot

ActiveCN111453671AUnbreakableImprove the breaking effectBottle/container closurePower operated devicesBottle neckDispensing medications

Owner:深圳市博为医疗机器人有限公司

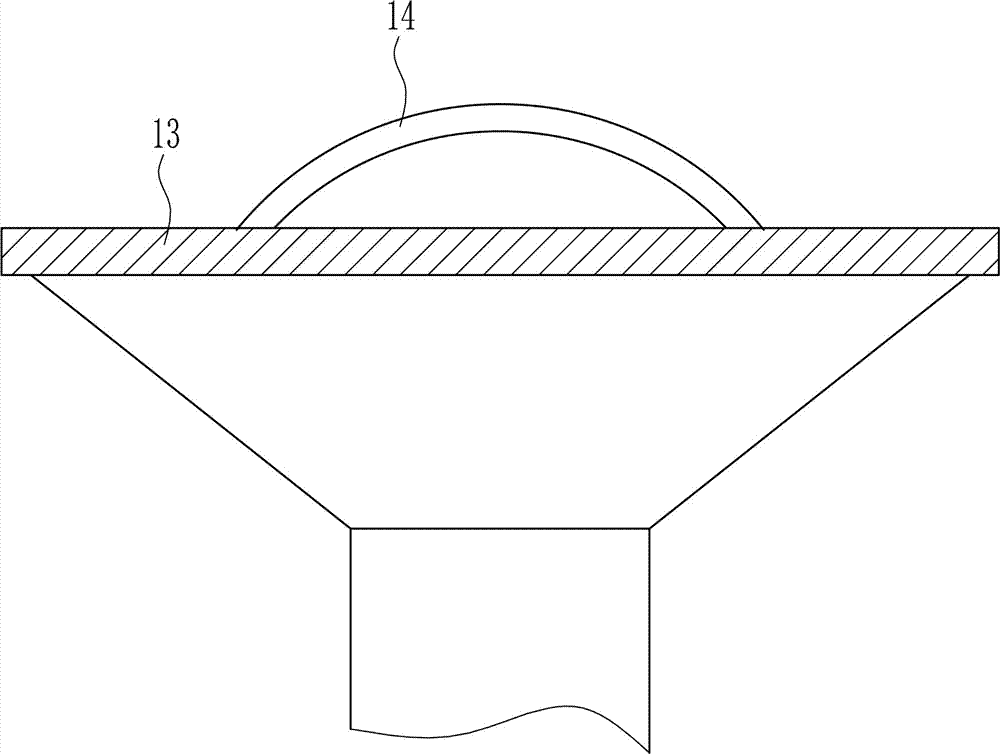

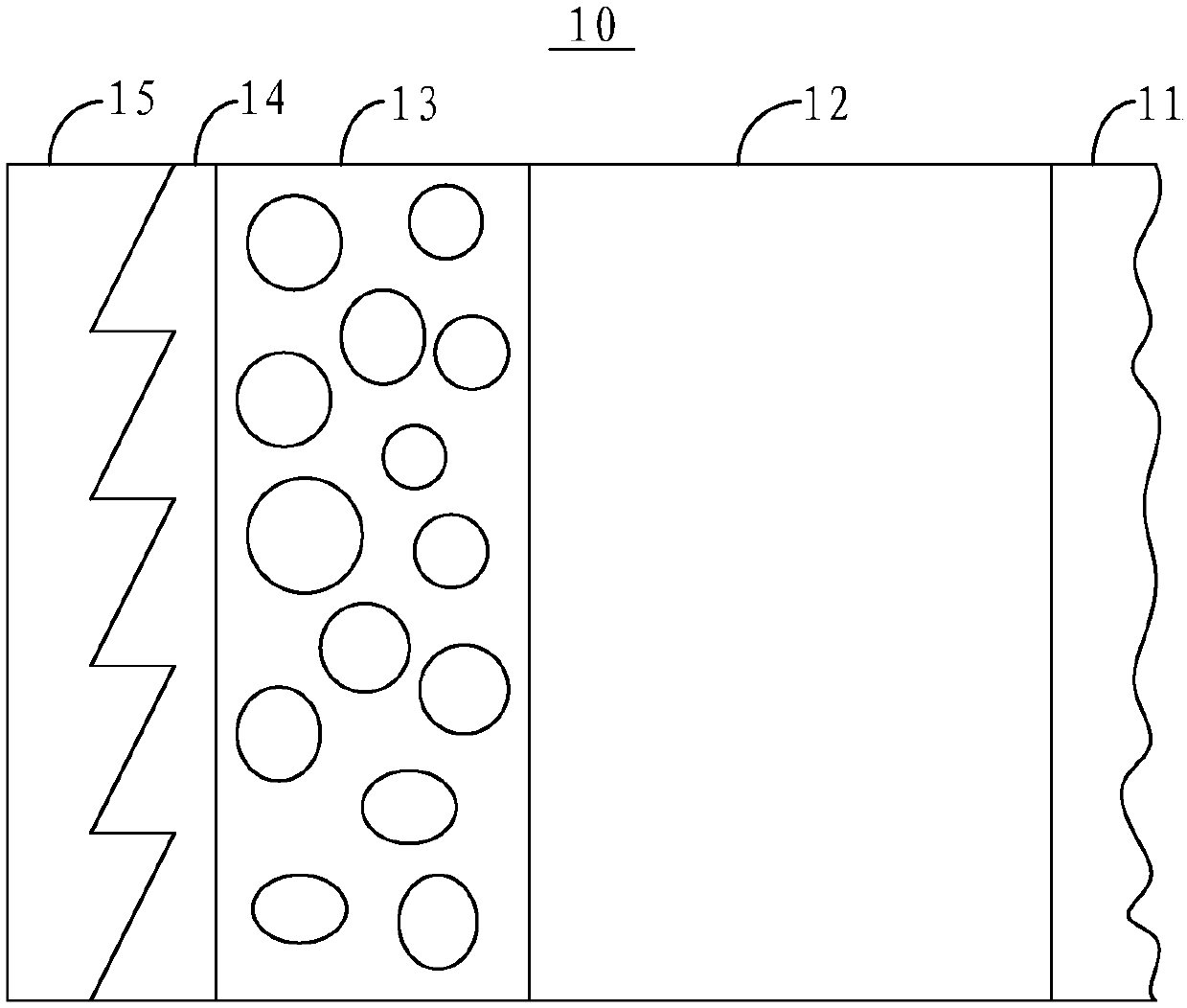

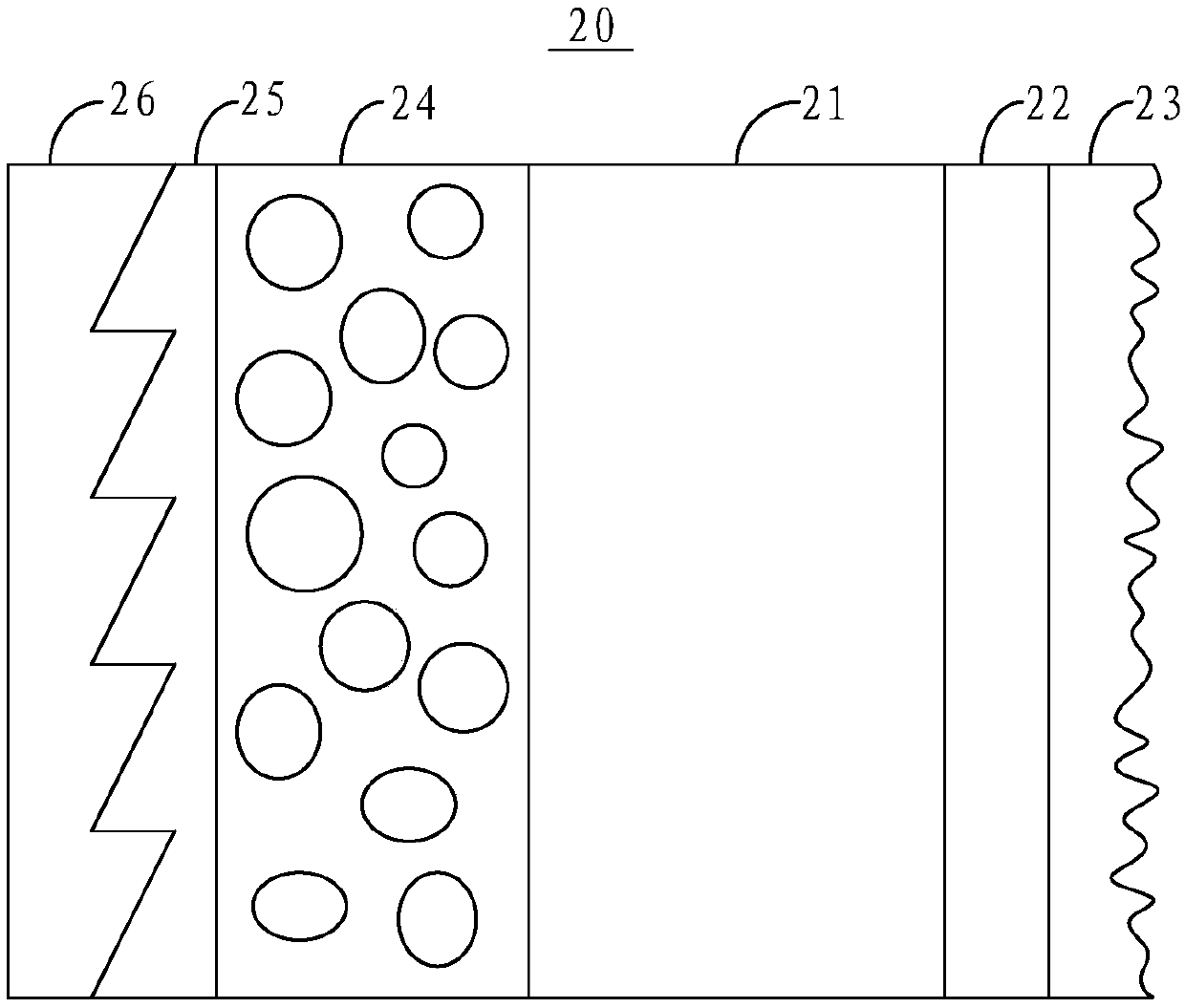

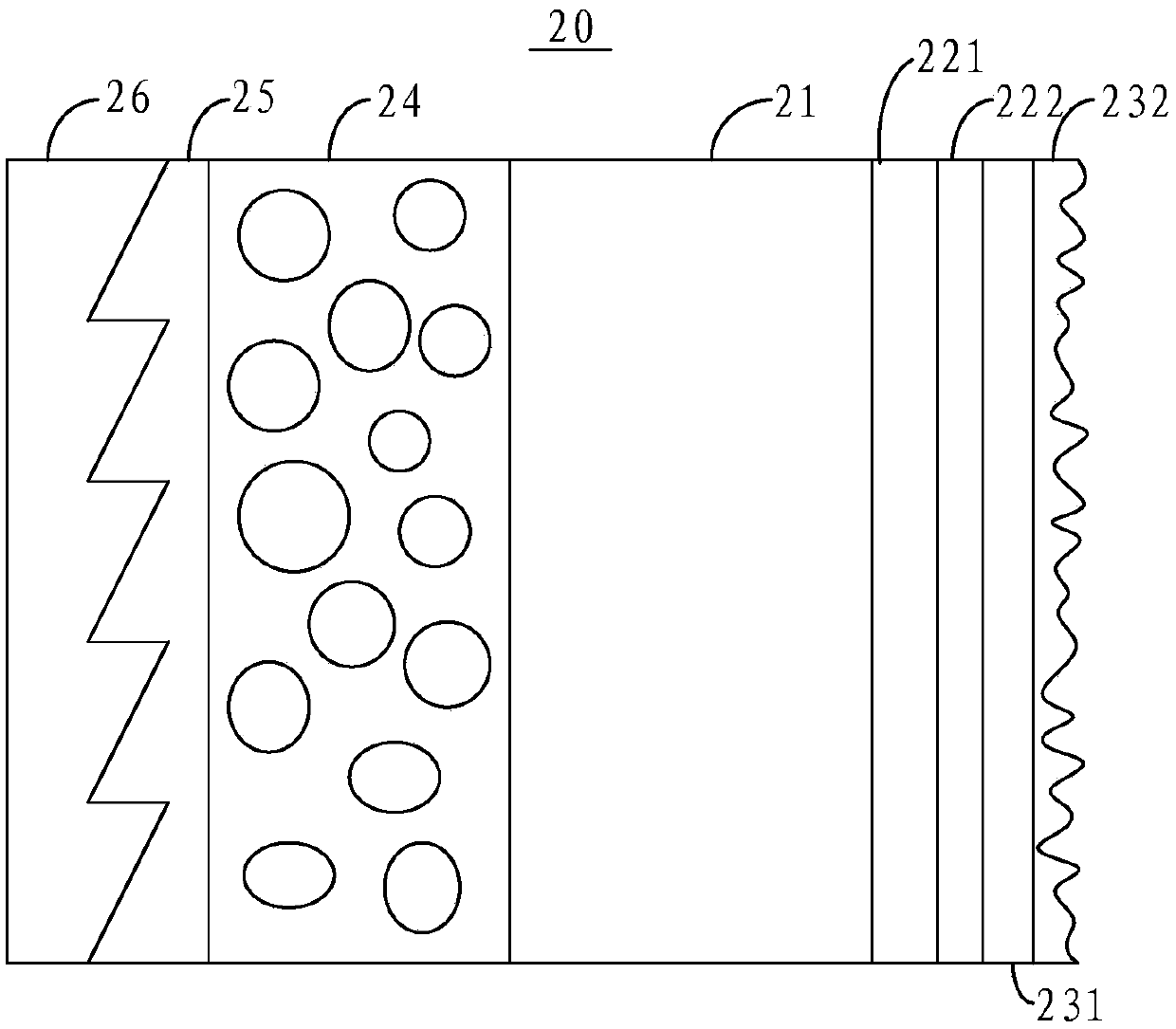

Projection screen and projection system

PendingCN111427229ASuppression of speckleImprove experienceProjectorsOptical elementsProjection imageImage resolution

The embodiment of the invention provides a projection screen and a projection system which relate to the field of projection screens, and can better inhibit the occurrence of a speckle phenomenon on the basis of ensuring the image resolution of a projected image. The projection screen is used for reflecting the projection light beams of a projector, and in the reflection direction of the projection light beams, the projection screen comprises a light gathering layer arranged at the light emitting side of a coloring layer and a surface scattering layer arranged at the light emitting side of thelight condensation layer, wherein the light gathering layer is used for gathering the projection light beams emitted by the coloring layer, the roughness of one surface, far away from the gathering layer, of the surface scattering layer is greater than or equal to the preset roughness, and the surface scattering layer is used for scattering the projection light beams gathered by the light gathering layer and emitting the scattered projection light beams to the human eyes outside the projection screen.

Owner:QINGDAO HISENSE LASER DISPLAY CO LTD

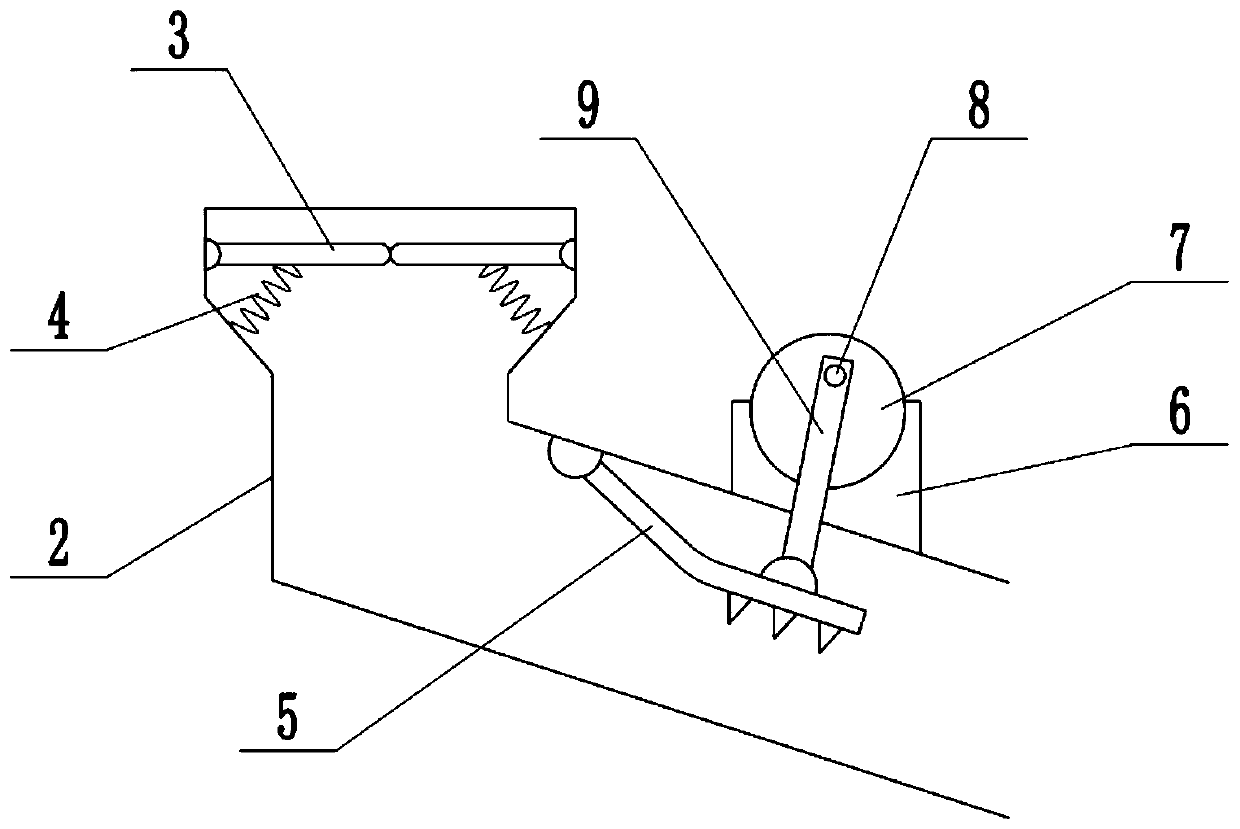

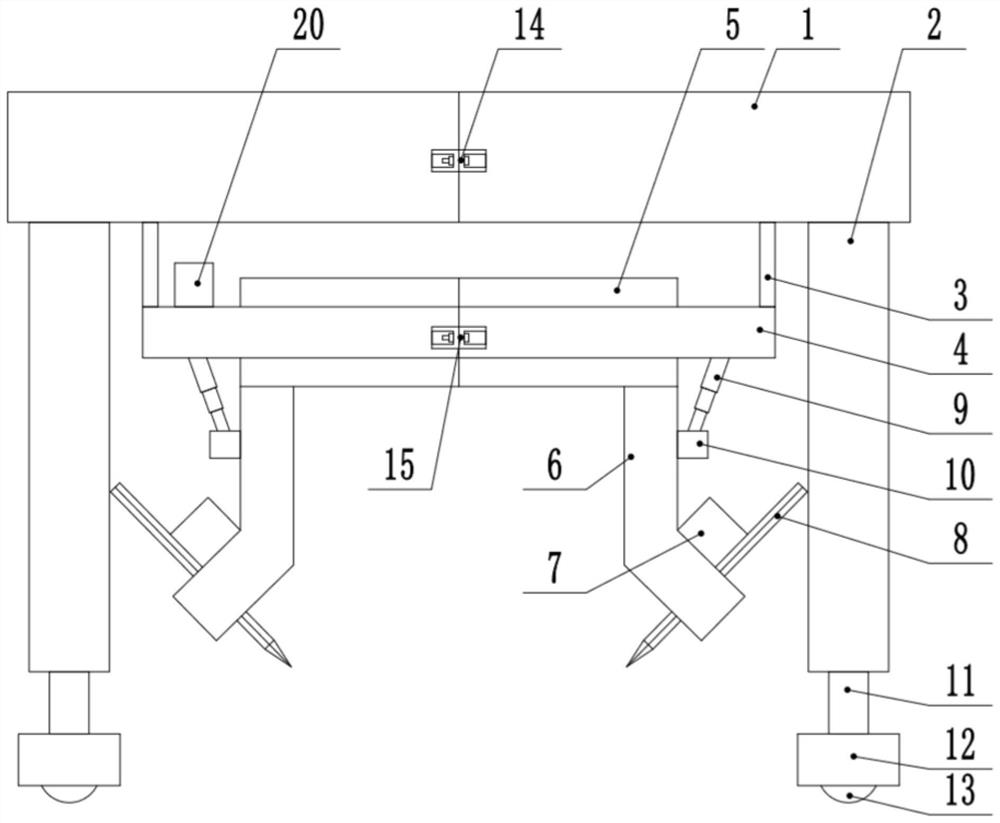

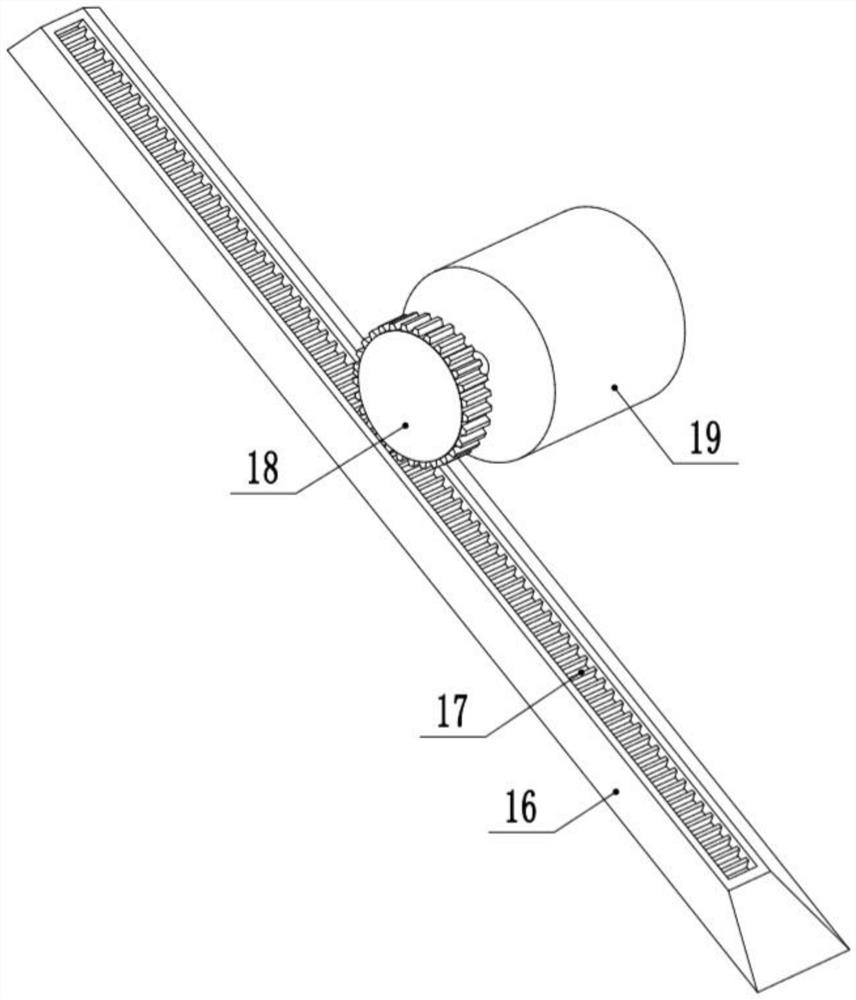

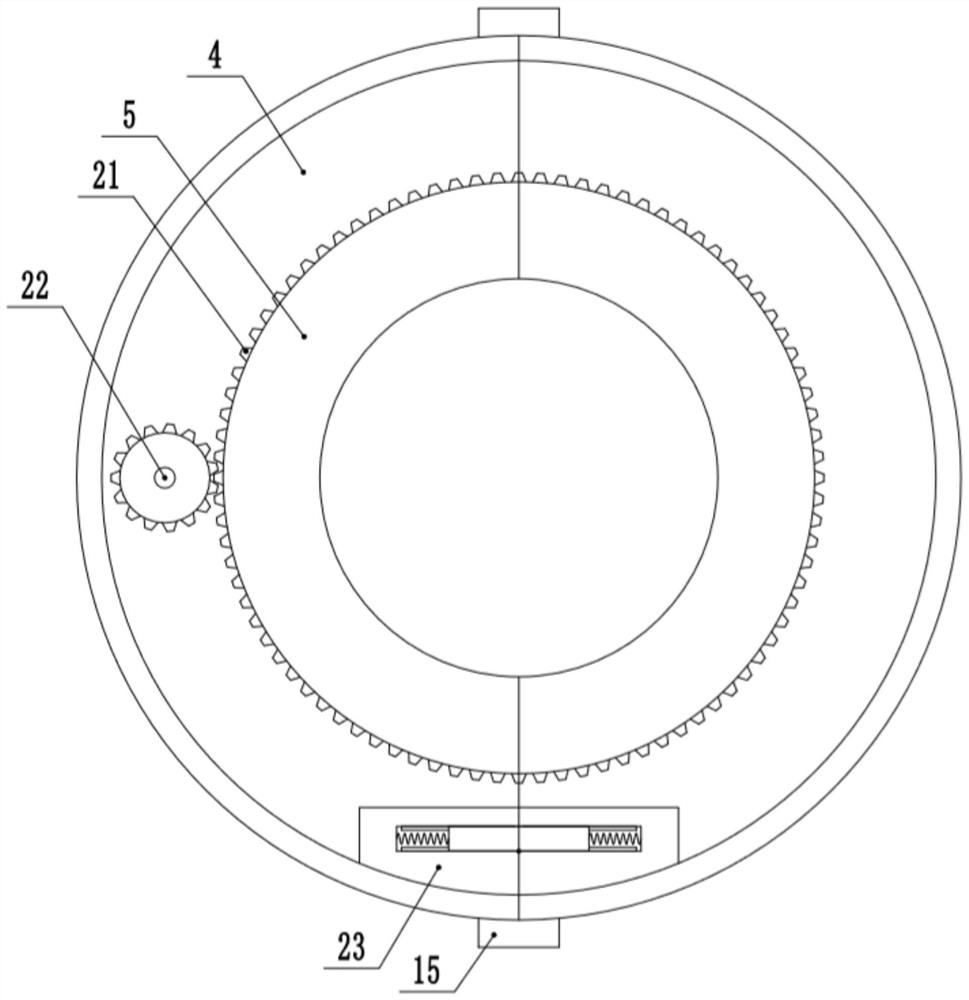

Tea tree transplanting equipment

InactiveCN111631106AGood breaking effectEasy to transplantForestryAgricultural engineeringEnvironmental geology

The invention discloses tea tree transplanting equipment, and relates to the technical field of tea tree planting. The tea tree transplanting equipment comprises top frames, wherein a plurality of support legs are fixedly connected to the bottom of each top frame; the bottom end of each top frame is fixedly connected with a lower pulling rod; the bottom end of each lower pulling rod is fixedly connected with a fixing sleeve; a rotating seat is rotationally connected inside the fixing sleeve; a bottom frame is connected to the bottom of each rotating seat; a driving device and a soil shovelingdevice are arranged on each bottom frame; and an ascending and descending moving device is arranged at the bottom of each support leg. Through the arrangement of the driving devices and the soil shoveling devices, a guide plate can be driven to move; through the arrangement of a second driving motor, a second driving gear and the rotating seat, the guide plate can be driven to rotate; the soil onthe ground can be subjected to shallow-to-deep annular cutting, so that the soil near the root system of a tea tree can be shoveled away; through the arrangement of hydraulic telescopic rods, the angle of the guide plate can also be regulated, so that the soil at different depths can be broken up according to the size of tea tree plants; the soil breaking effect on the soil near the root system ofthe tea tree is good; and the transplantation of the tea trees is convenient.

Owner:郭明星

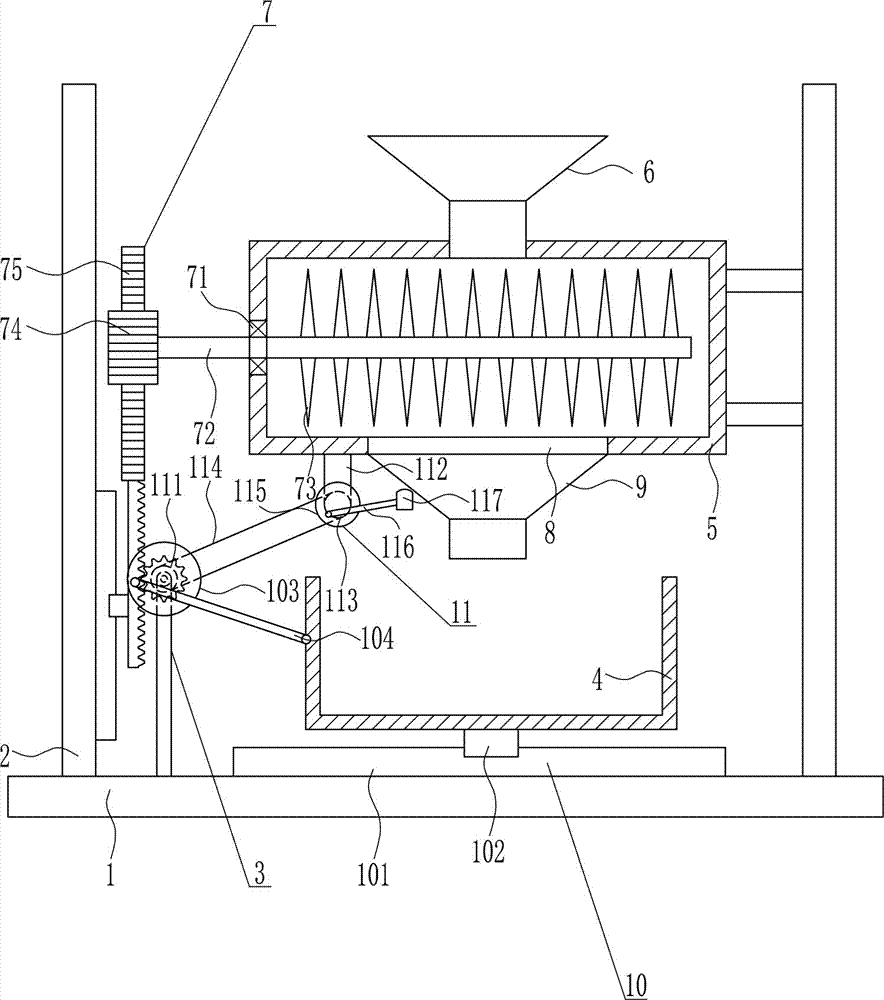

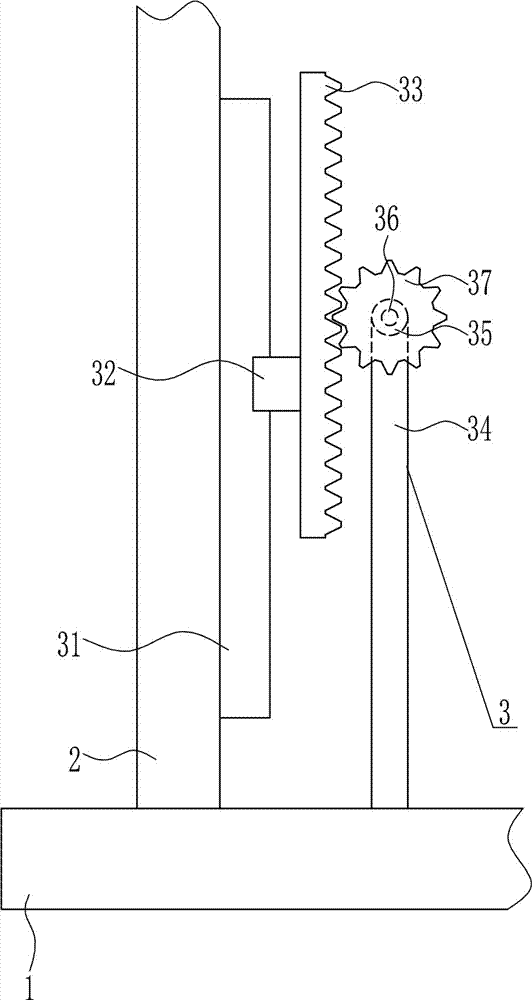

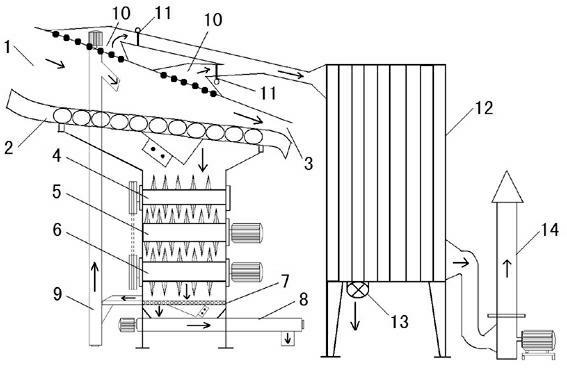

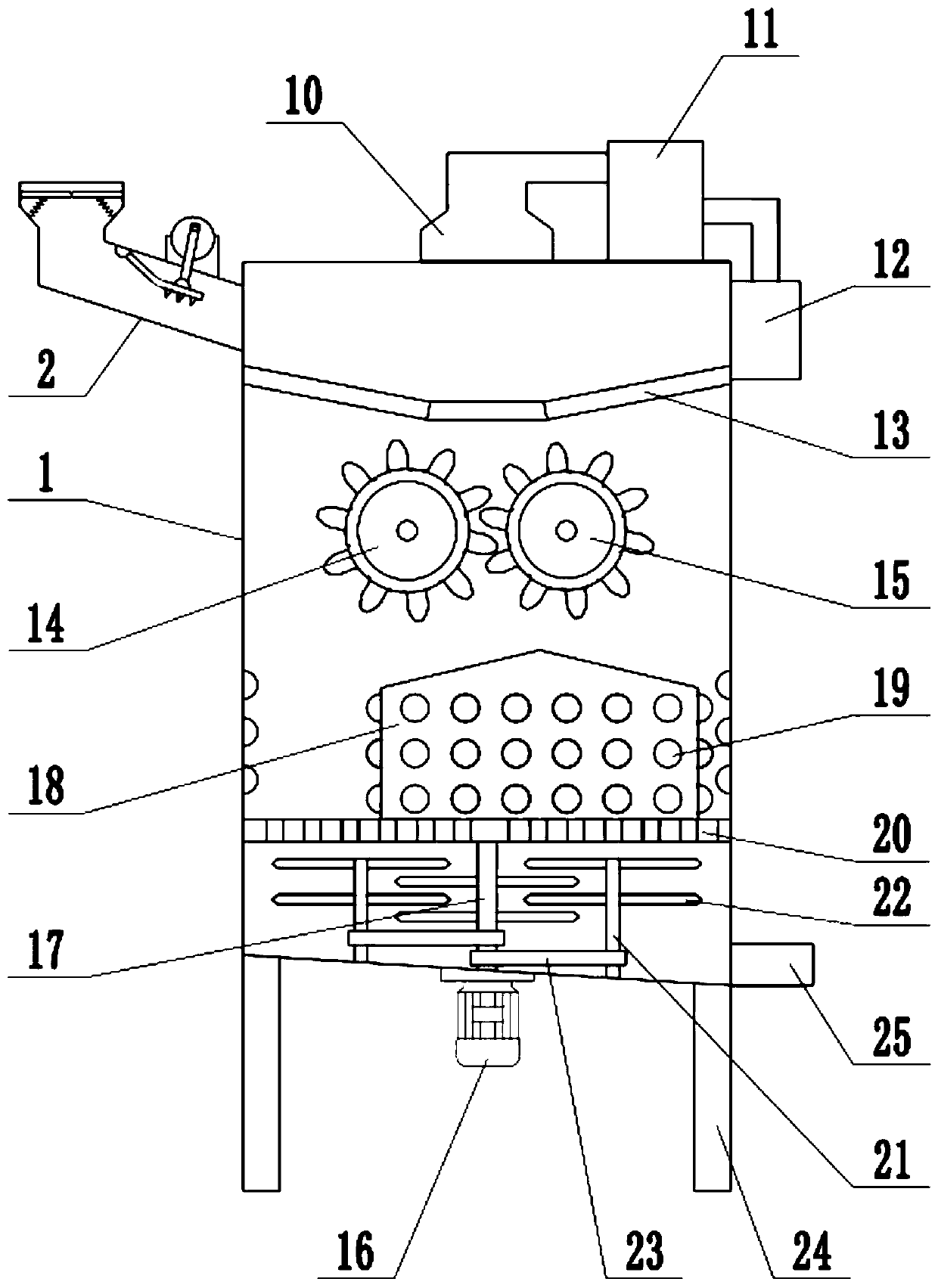

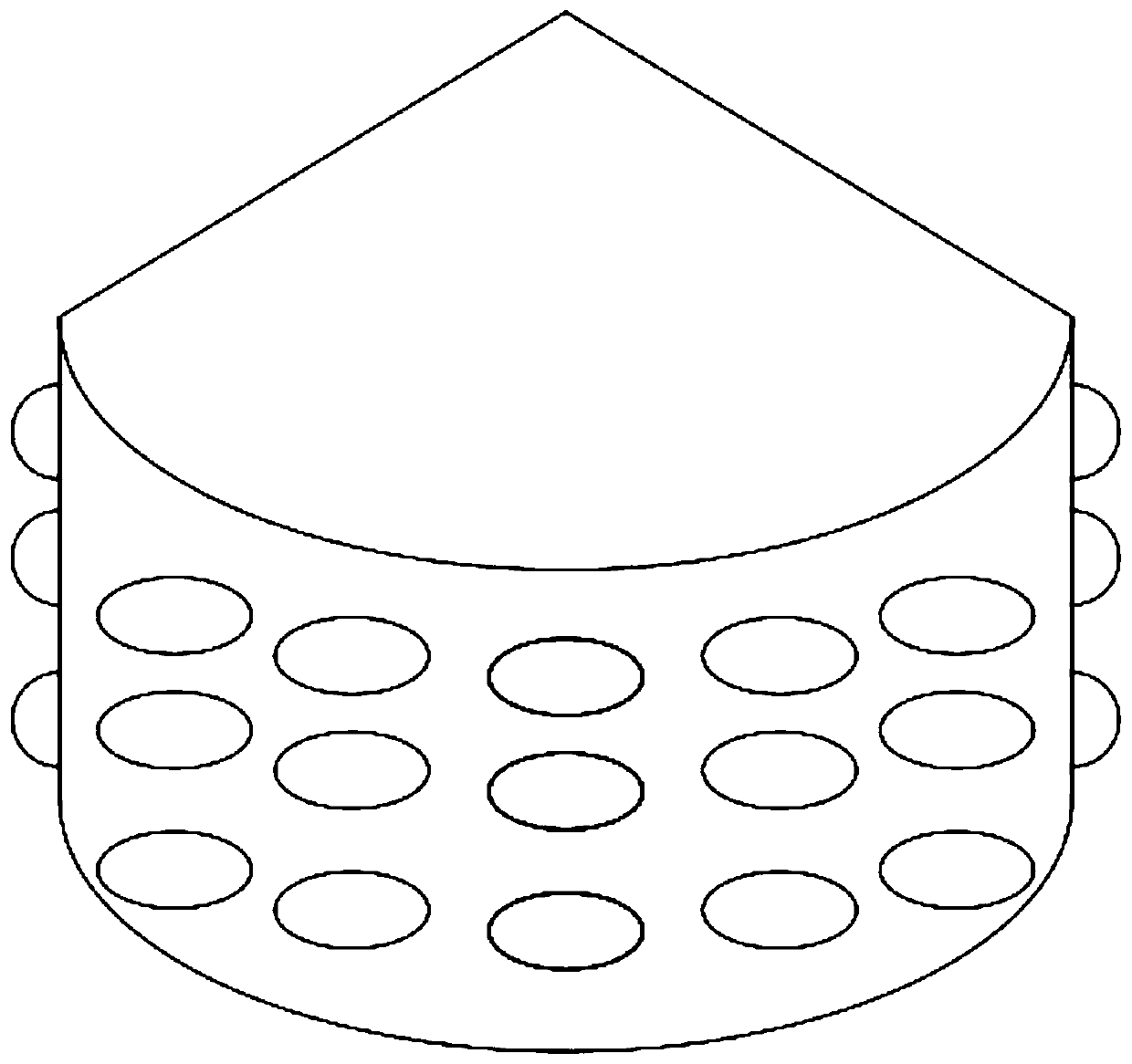

Efficient scattering-grading equipment with multi-stage scattering mechanism for cement processing

InactiveCN106944220ASave the number of loop breaksImprove the breaking effectGrain treatmentsComminutionMechanical engineering

The invention discloses efficient scattering-grading equipment with a multi-stage scattering mechanism for cement processing. The efficient scattering-grading equipment comprises a scattering bin and a grading bin, wherein the scattering bin is arranged at the upper end of the grading bin; a scattering main shaft is arranged in the scattering bin; at least one triangular reverse beating mechanism is arranged on the inner wall of the scattering bin; the lower end of the scattering main shaft extends into the grading bin; a centrifugal disc and a scattering disc are sequentially arranged on the scattering main shaft from top to bottom; a coarse material bin is further arranged in the grading bin in a sleeving manner; a transition bin is arranged between the coarse material bin and the scattering bin; a two-stage secondary scattering mechanism is arranged in the transition bin; a bidirectional air-blasting flow guide device is arranged on the coarse material bin; a secondary beating plate is further arranged at the inlet of the coarse material bin; and a pre-crushing device is further arranged at the charge port of the scattering bin. The scattering-grading equipment is reasonable in structural design; the structural manner of air separation is changed, and the mode of bidirectionally simultaneous air separation is adopted, so that the matching degree of the air separation and scattering is increased; and the pre-crushing device is added, so that the crushing efficiency is increased, the crushing effect is improved, the scattering is more comprehensive and thorough, and the collection amount of a cement powder can be greatly increased.

Owner:JIANGSU XINYE HEAVY IND

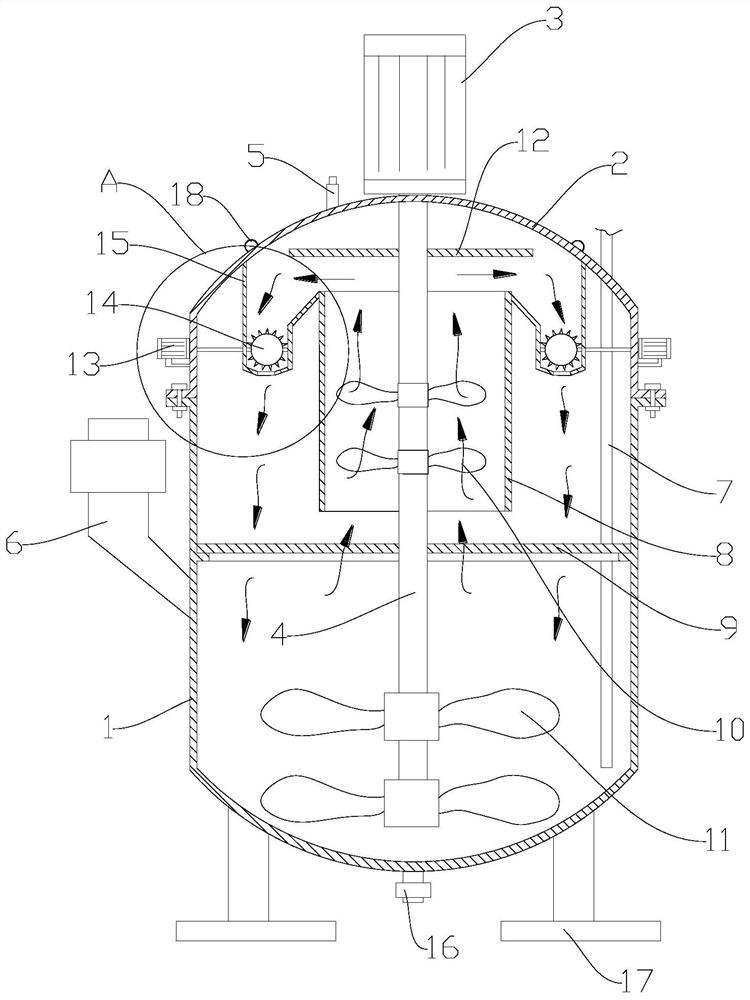

Defoaming chemical reaction tank

InactiveCN112791684AImprove the breaking effectAchieving adjustable deflation pressureLiquid degasification by filtrationChemical/physical/physico-chemical stationary reactorsChemical reactionEngineering

The invention provides a defoaming chemical reaction tank. The reaction tank comprises a tank body, a stirring device, a guide cylinder, a backflow tank and a foam throwing plate, the stirring device comprises a rotating shaft and stirring blades and suction blades arranged on the rotating shaft, the upper end and the lower end of the guide cylinder are open, and the suction blades are located in the guide cylinder. The backflow tank is connected with a tank cover, the guide cylinder is connected with the backflow tank, a backflow opening is formed in the bottom of the backflow tank, and a foam breaking ball is arranged above the backflow opening, so that foam circulation flow is formed in the upper part of the tank body, most of foam is broken in the circulation movement, and the defoaming effect is further enhanced through a foam throwing plate and a foam breaking ball which are arranged in the circulating passage. The mechanical bubble removing mechanism is adopted, so that a good bubble removing effect is achieved, no harmful substance is left, and the problem of bacterial contamination caused by gas backflow is solved.

Owner:重庆市佰恒科技有限公司

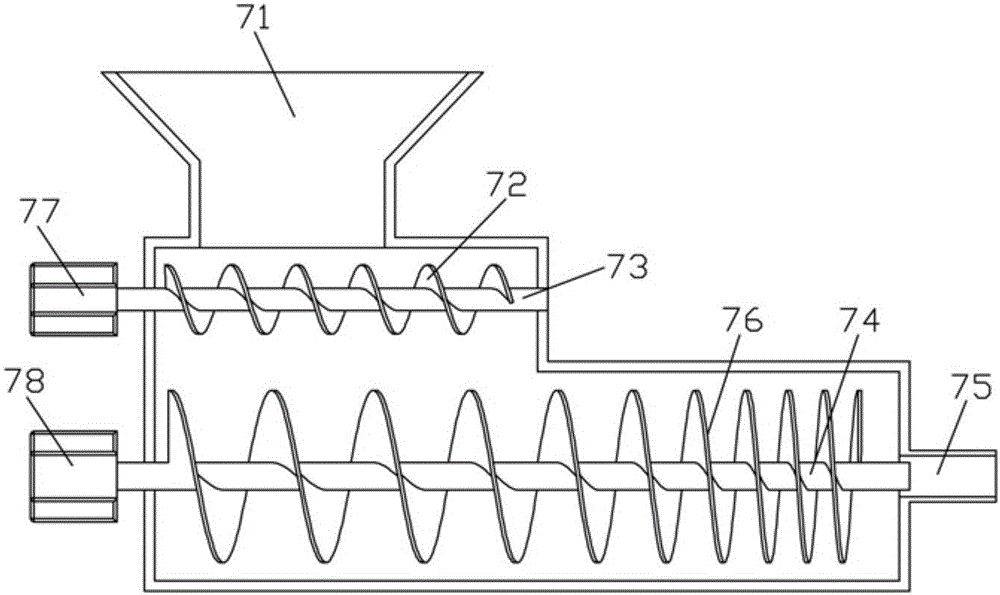

Efficient and energy-saving extraction tank

InactiveCN109045750AImprove extraction efficiencyLow running costSolid solvent extractionUltrasonic generatorEngineering

The invention relates to an efficient and energy-saving extraction tank. The extraction tank comprises a tank body, a microwave ultrasonic generator and a liquid injection overflow mechanism which arearranged on the wall of the tank, a solid and liquid material separating and converging circulation channel in the tank, and a filter type spiral conveyor below the tank. When the tank is operated, the slurry flat turn circulation flow in the tank is changed into solid and liquid material upper-converting and lower-separating ascending and descending flow, so that microwave ultrasonic wave can perform targeted radiation on a solid material but not on a liquid material, the special structure of the tank allows liquid injection overflow and repeated retraction, and operations of liquid discharging and deslagging can be accomplished at the same time during discharging. The tank is obvious in energy-saving and time-saving effect, low in operation cost and high in efficiency, and provides a novel equipment selection for enterprise production.

Owner:李肥生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com