Patents

Literature

228results about How to "Improve separation quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

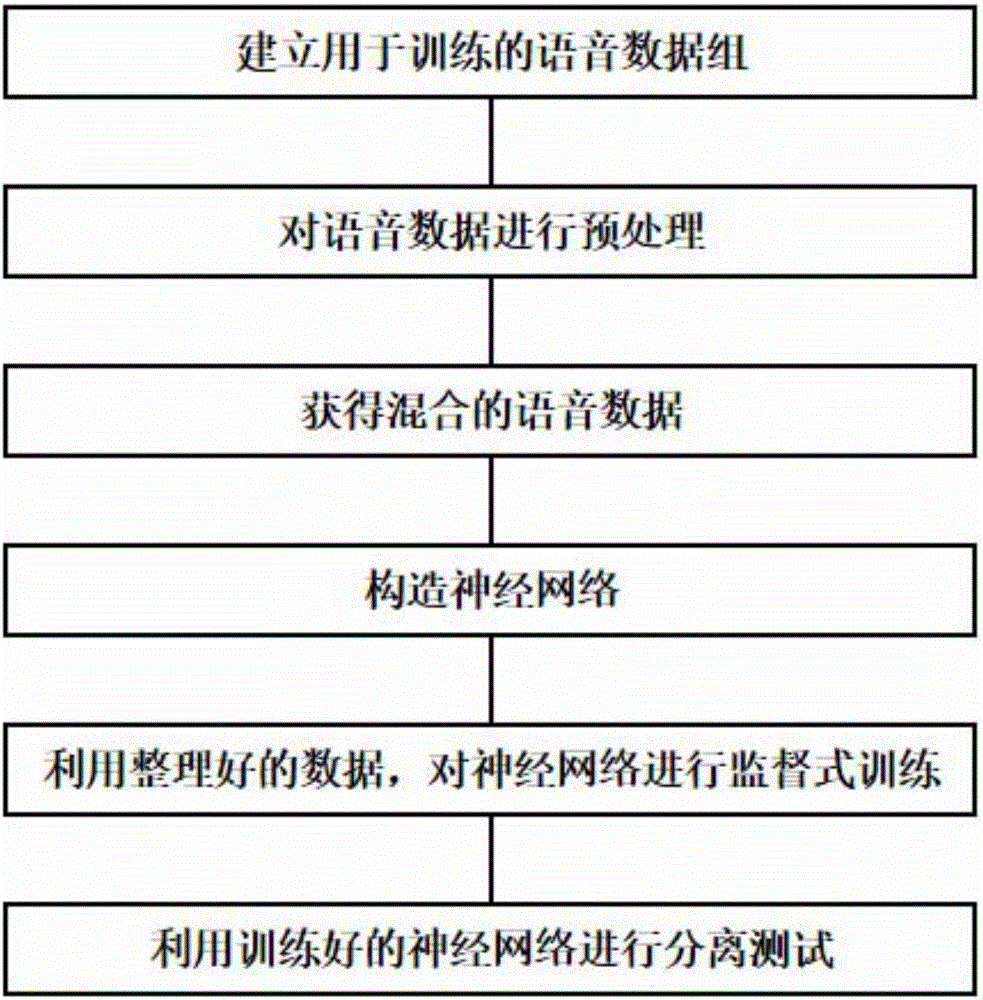

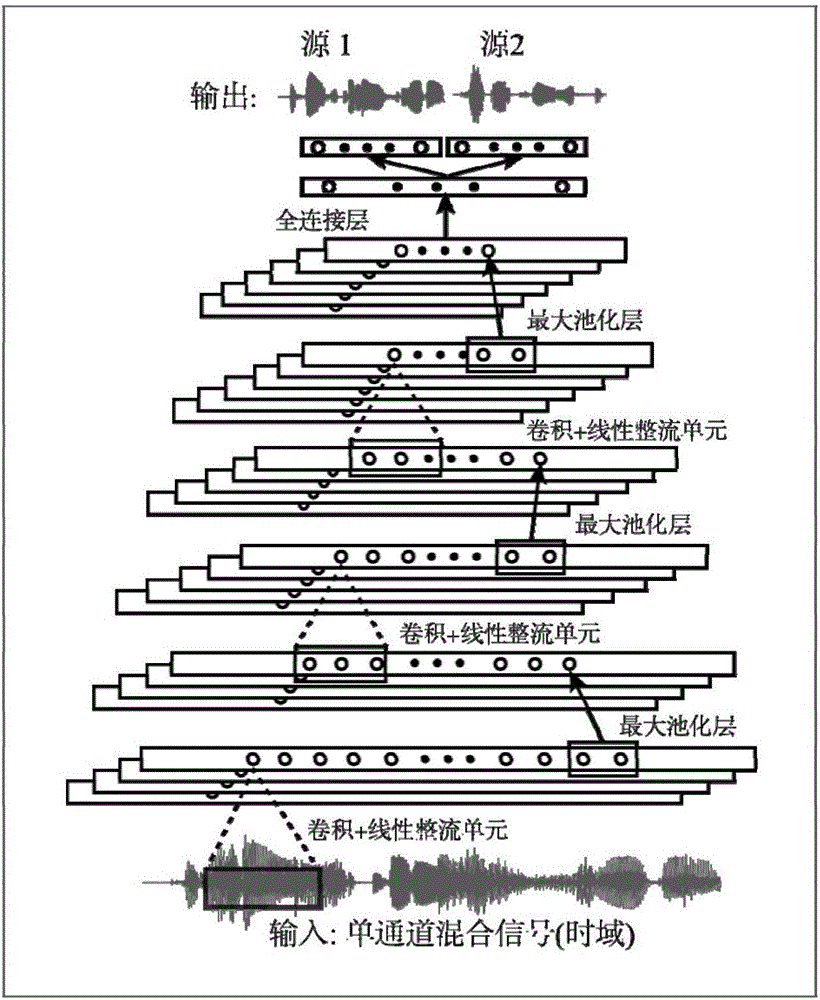

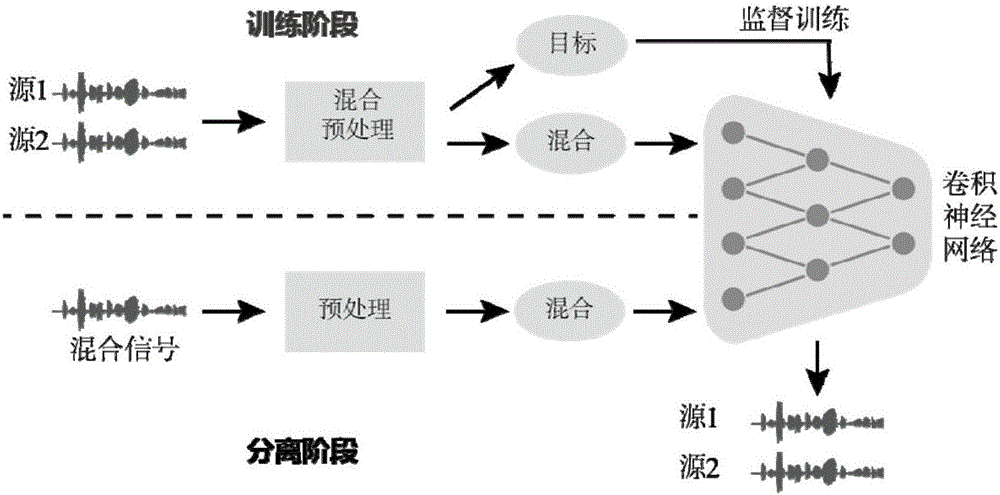

Single channel mixed speech time domain separation method based on Convolutional Neural Network

The invention relates to a single channel mixed speech time domain separation method which is the single channel mixed speech time domain separation method based on a Convolutional Neural Network. The method comprises the following steps of 1, constructing a speech data set for training, 2, preprocessing speech data, 3, obtaining hybrid speech data, 4, constructing a neural network structure, 5, using data organized to train a neural network in a monitoring mode, and 6, using the trained neural network to carry out a separation test. According to the single channel mixed speech time domain separation method based on the Convolutional Neural Network, time domain speech signals serve as input and output of the Convolutional Neural Network, single channel hybrid speeches are separated, and therefore estimation for two source signals is obtained. The method does not need to deal with the problem of phase retrieval, and the separation quality of a single channel speech is improved.

Owner:DALIAN UNIV OF TECH

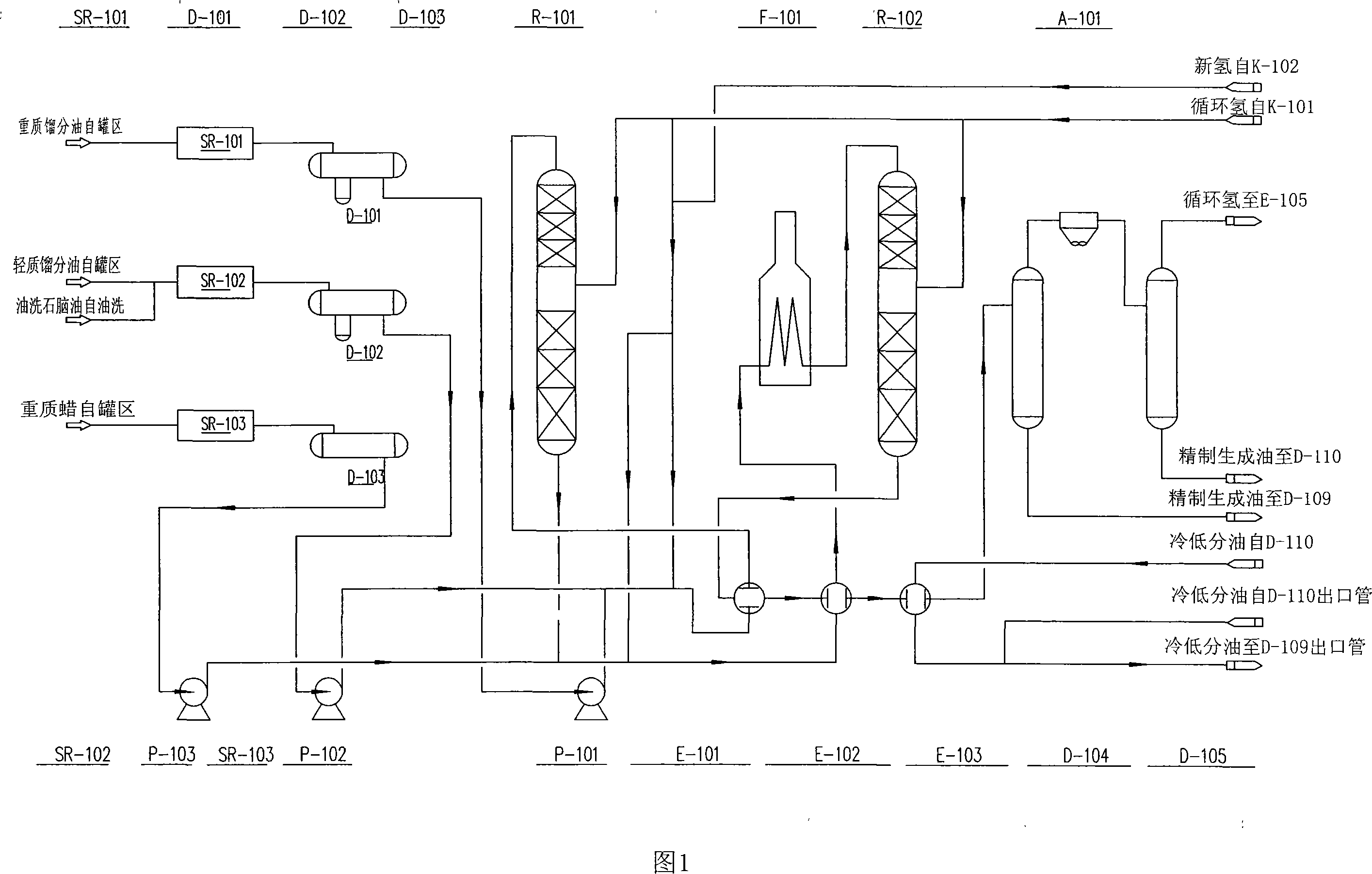

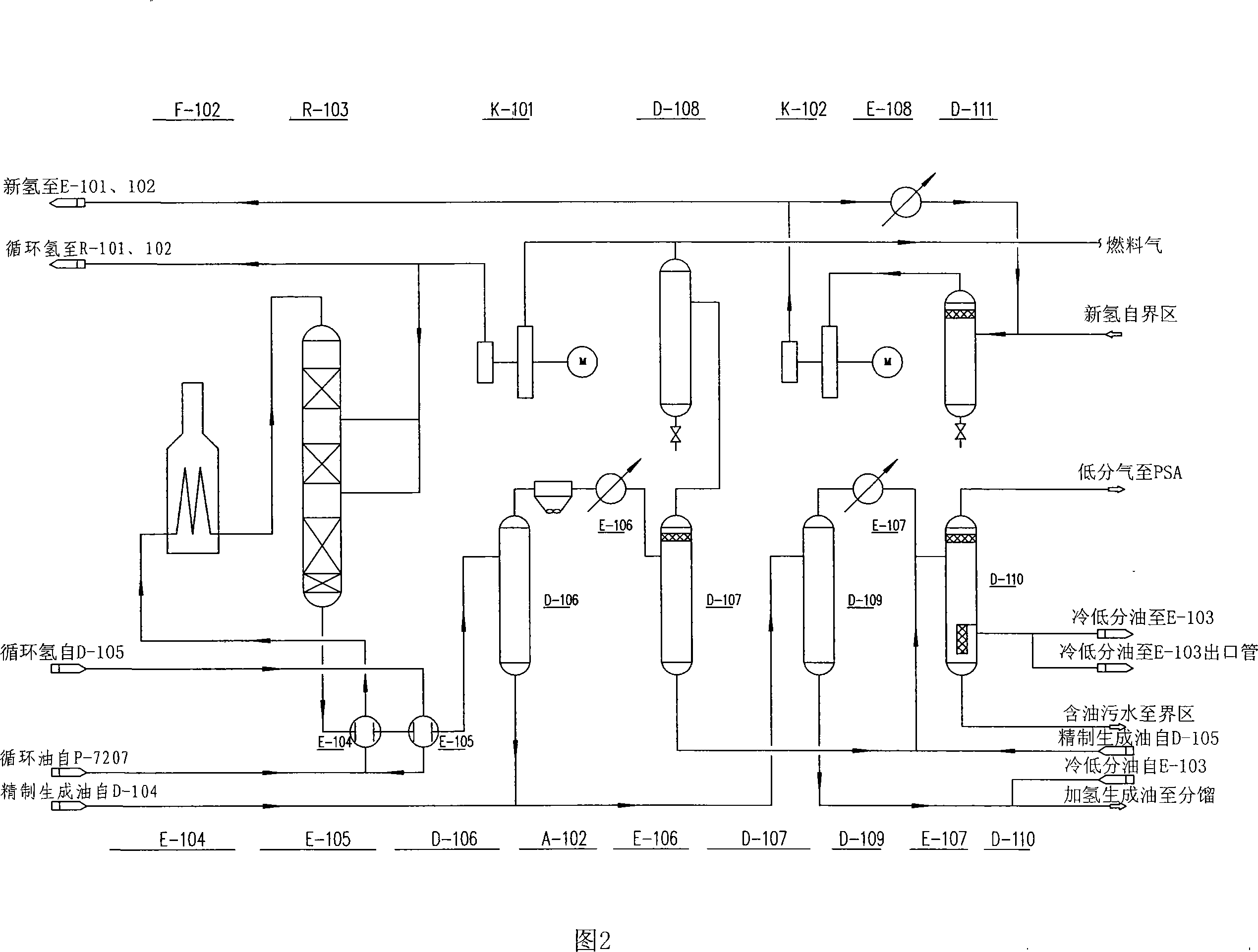

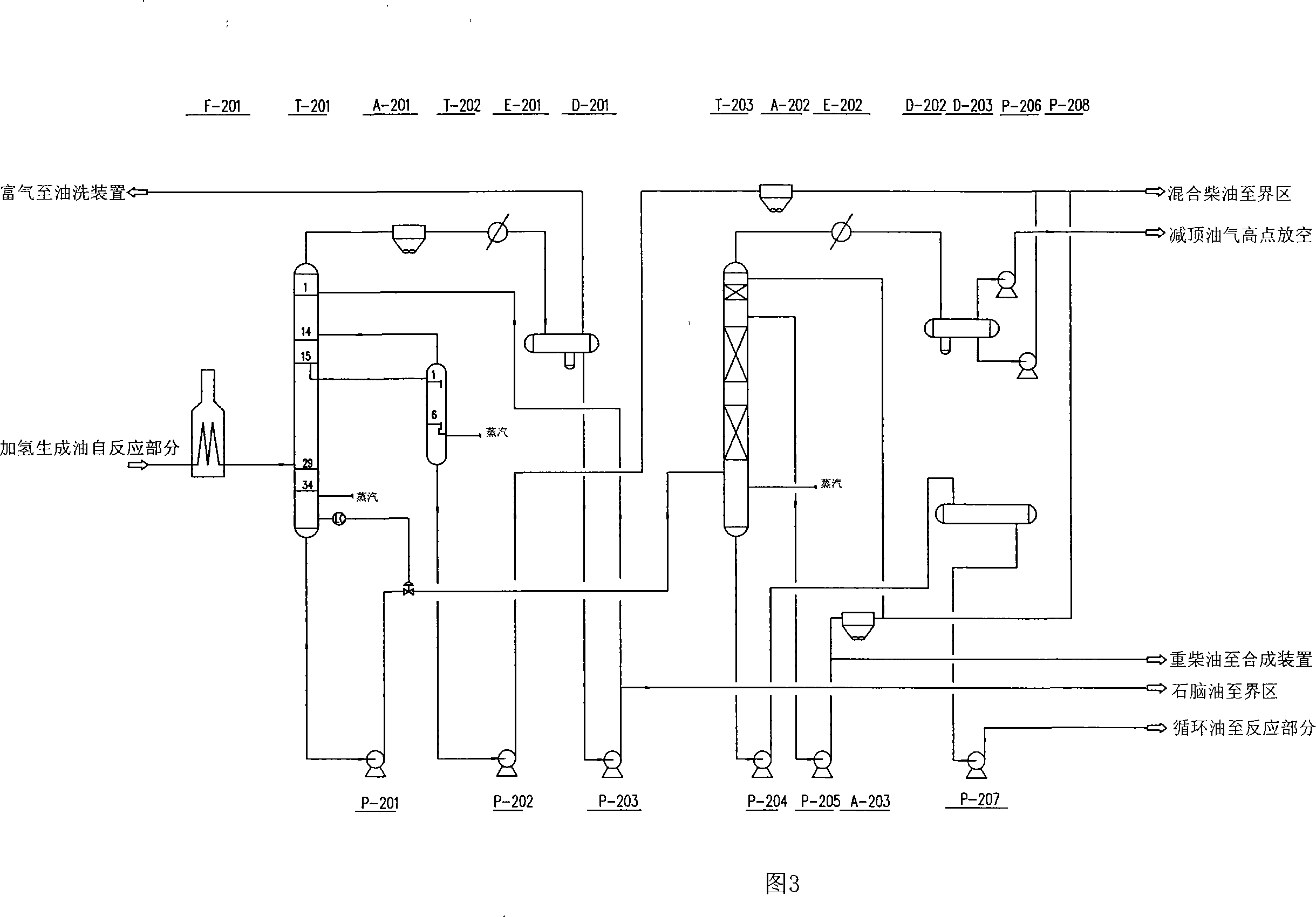

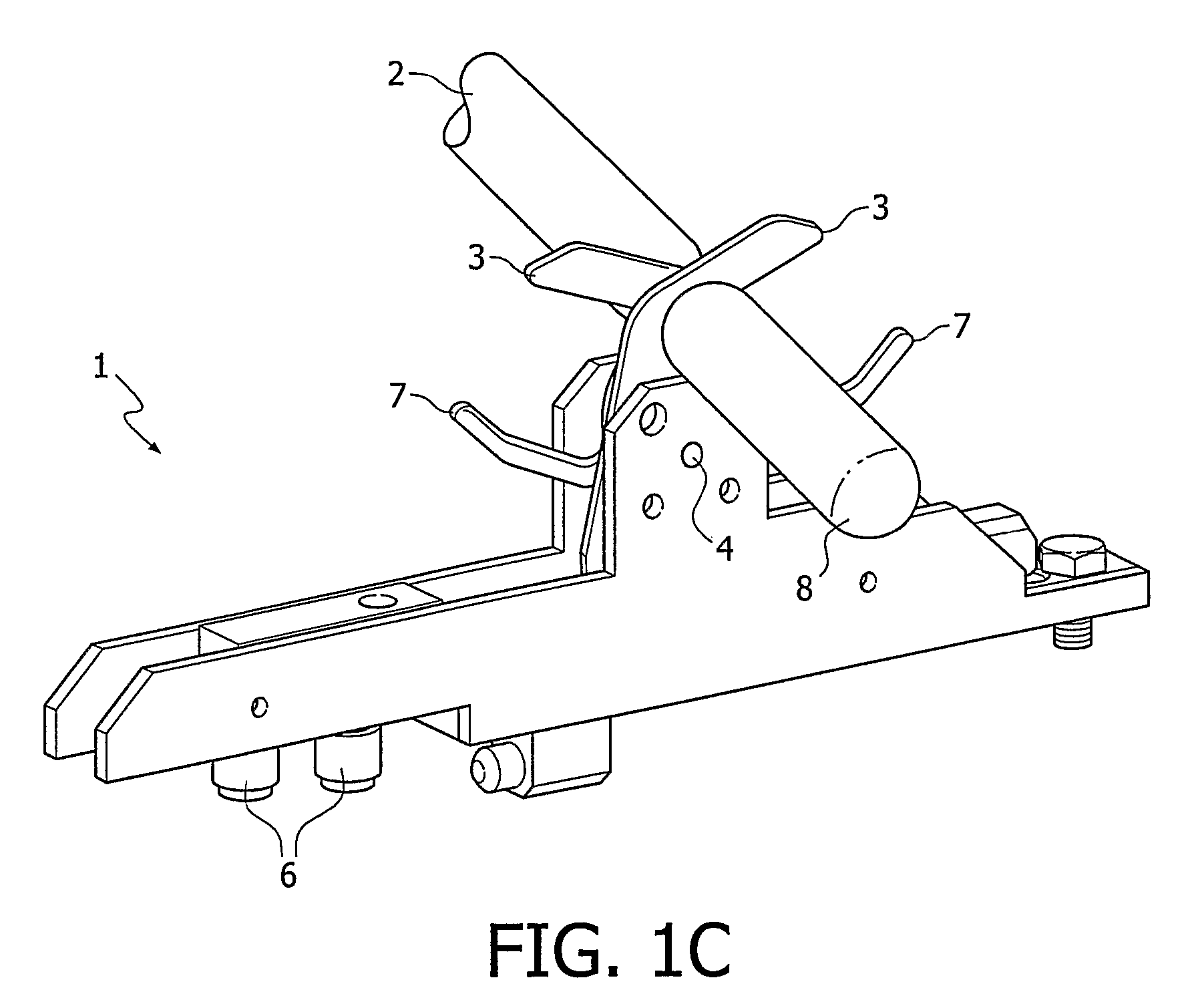

Feito synthetic oil processing line

ActiveCN101173190AReduce design flowStable temperature controlTreatment with hydrotreatment processesGas phaseMetal impurities

The invention relates to a processing flow of FT synthetic oil, which comprises hydrogenation, low-temperature oil washing, decarburization and PSA. The invention is characterized in that the synthetic oil is mixed with hydrogen via a filter, and enters a hydrogenated prerefining reactor after heat exchange, then enters a hydrogenated refining reactor after the synthetic oil is heated to 300 to 380 DEG C by a heating furnace; oxygen-containing compounds, unsaturated hydrocarbons and metal impurities in the raw material are extracted; the hydrogenated refined product enters a high thermal separator for separation of oil phase and gas phase after heat exchange, and enters a hydrocracking reactor for hydrocracking after heat exchange and heating of the heating furnace; the cracked product and the refined product are mixed to enter a fractionation system; a combined flow with two stages connected in series is adopted for the hydrogenated refining reactor and the hydrocracking reactor which share a recycle hydrogen system; a fractionation system is shared by the hydrogenated refined oil and the hydrocracked oil; and a three-column process flow is adopted for the fractionation system. The invention has the advantages of low gas consumption of the low-temperature oil washing process, high recovery of light hydrocarbons, less matching investment, and reduction of energy consumption and improvement of hydrogen recovery rate due to the decarburization process.

Owner:中国石油集团工程设计有限责任公司抚顺分公司

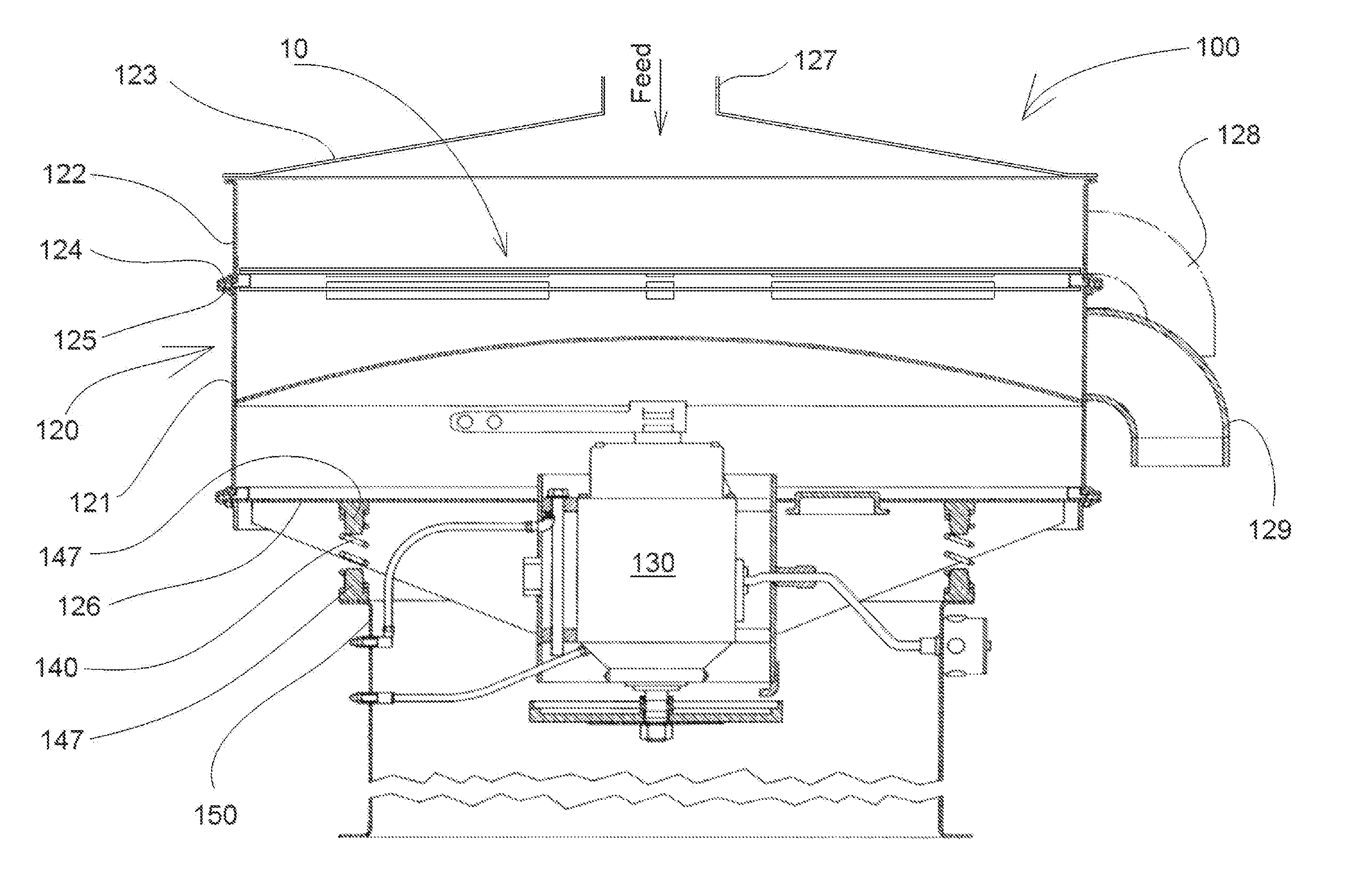

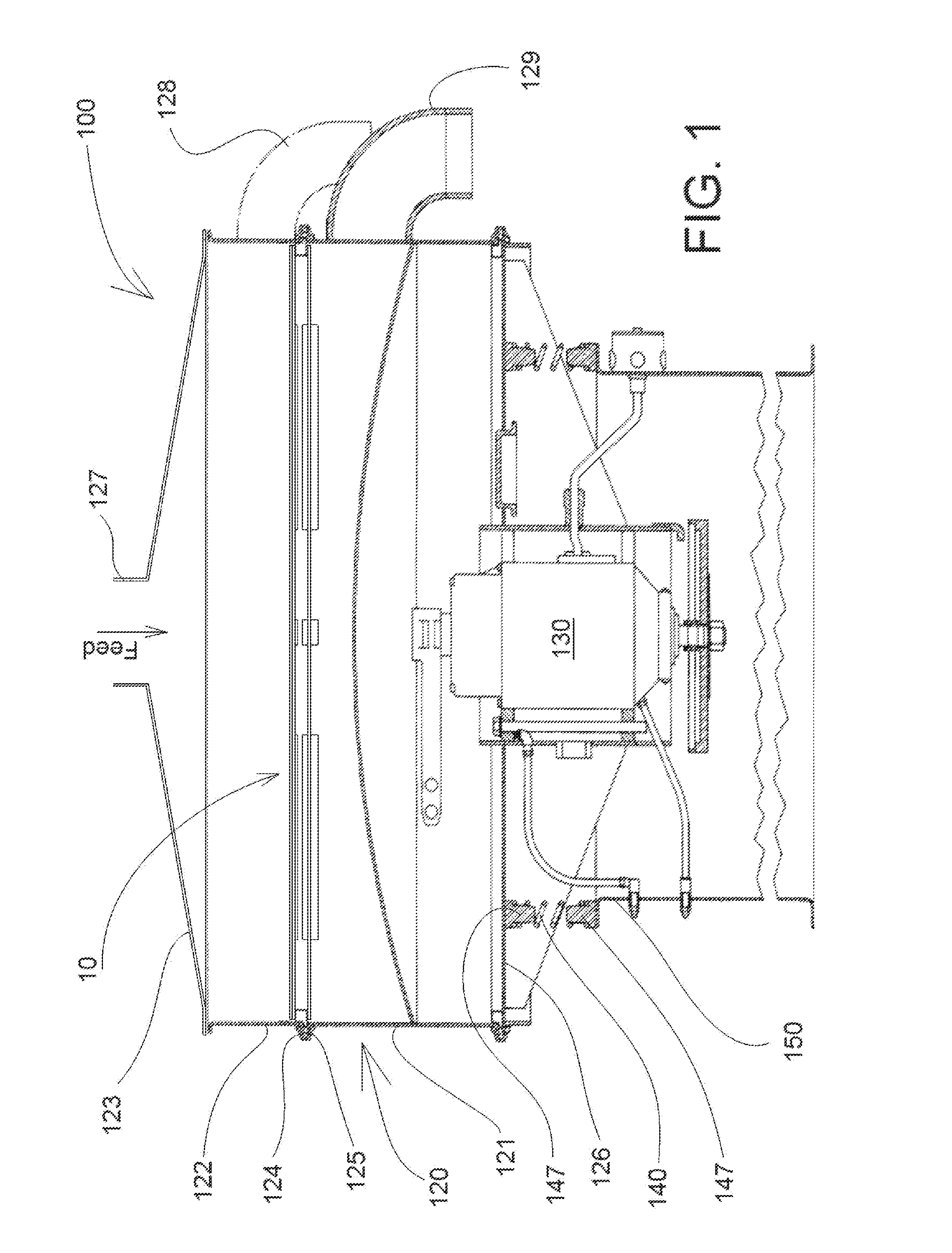

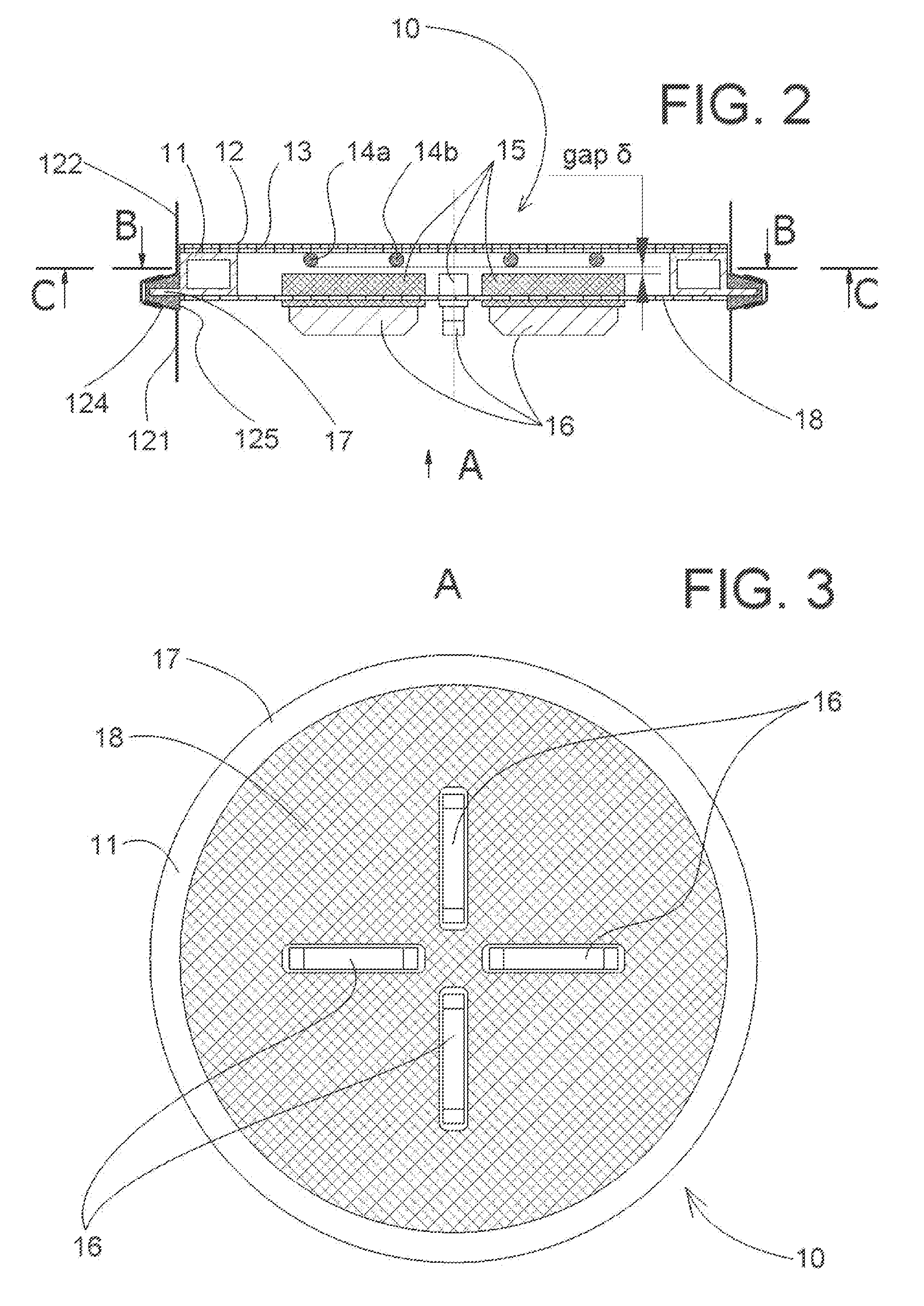

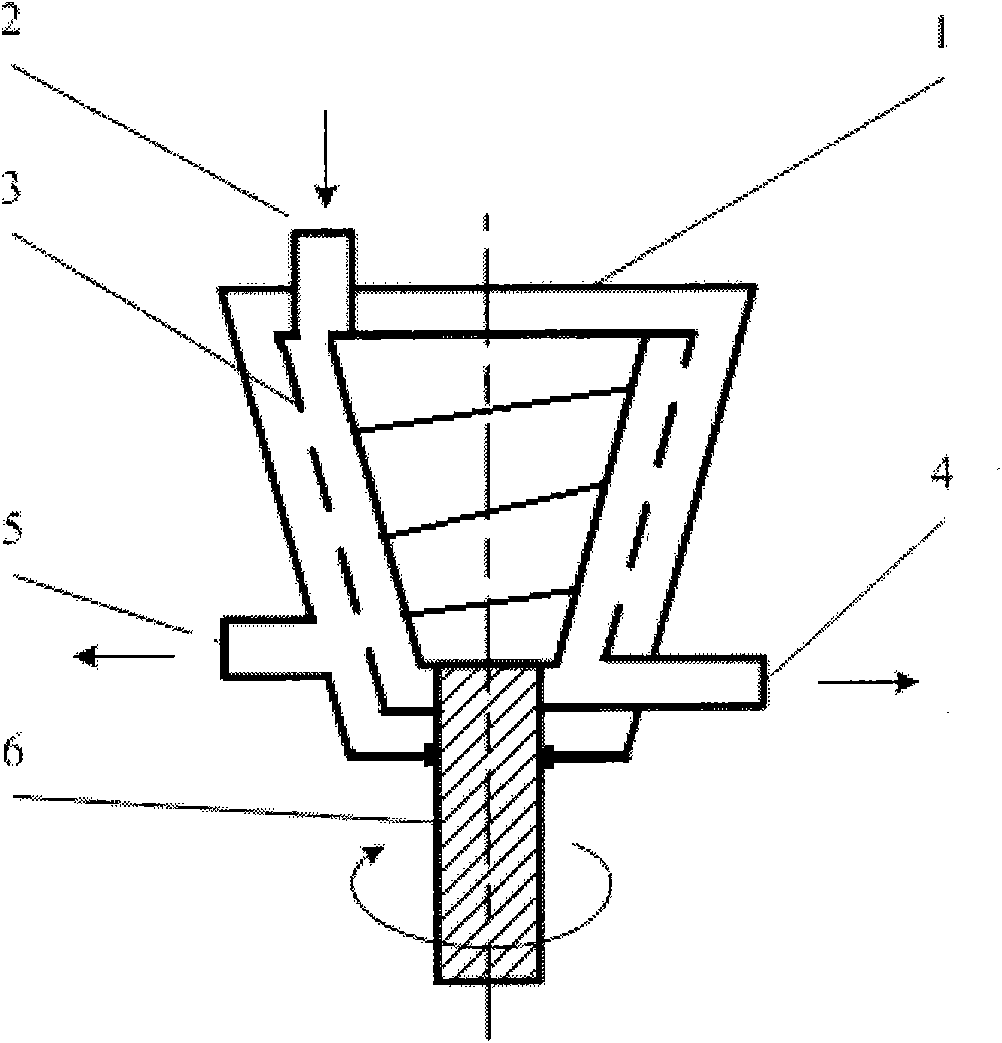

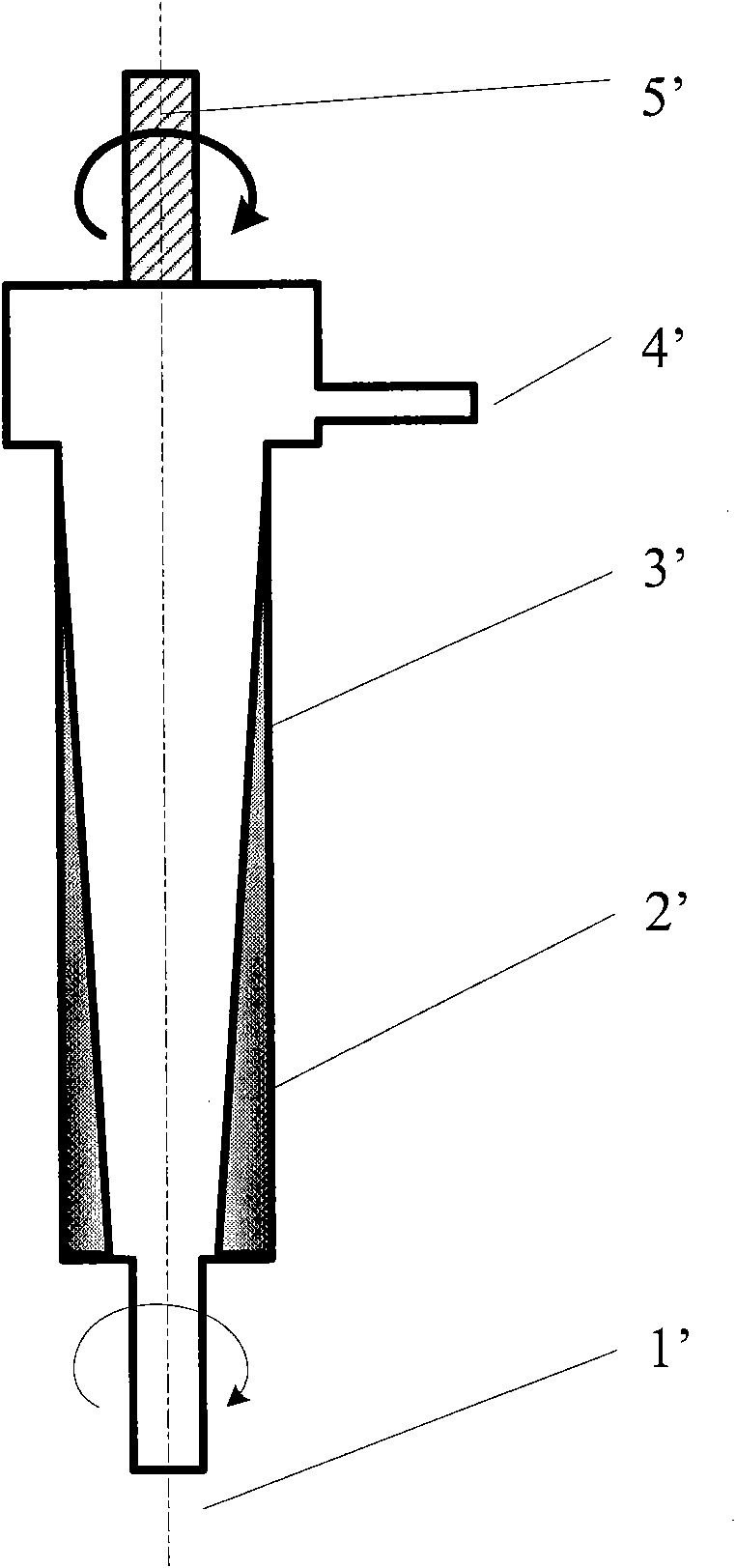

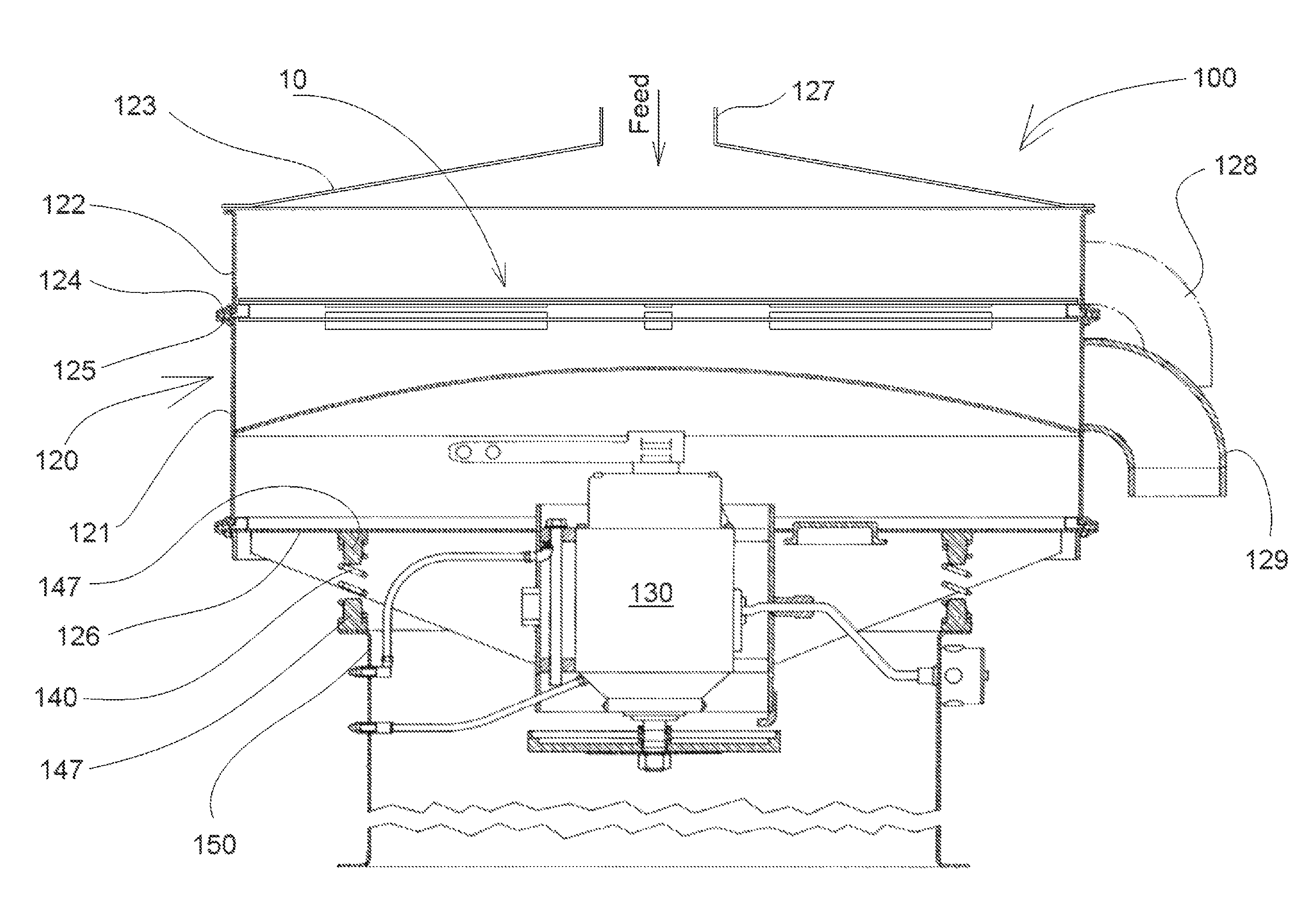

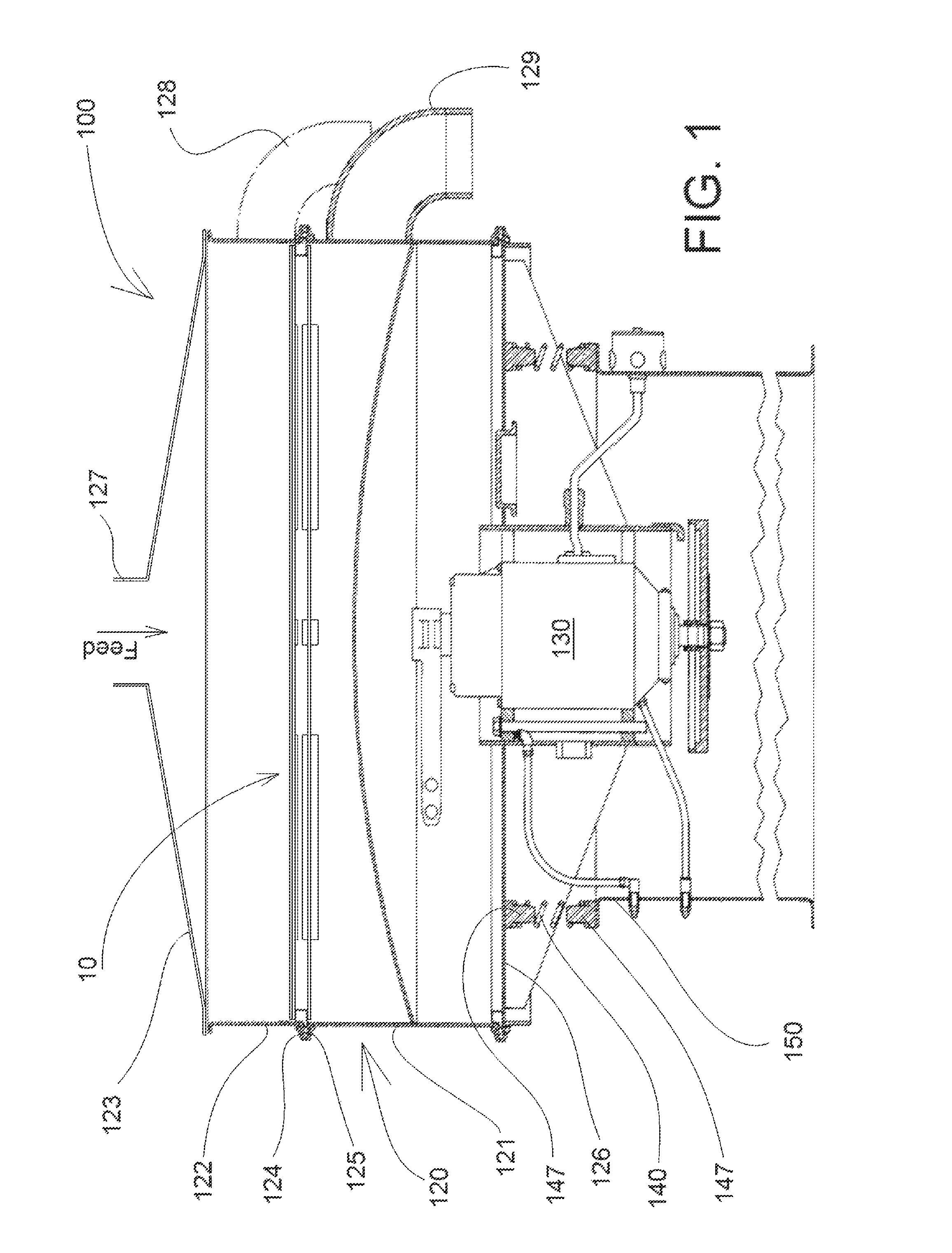

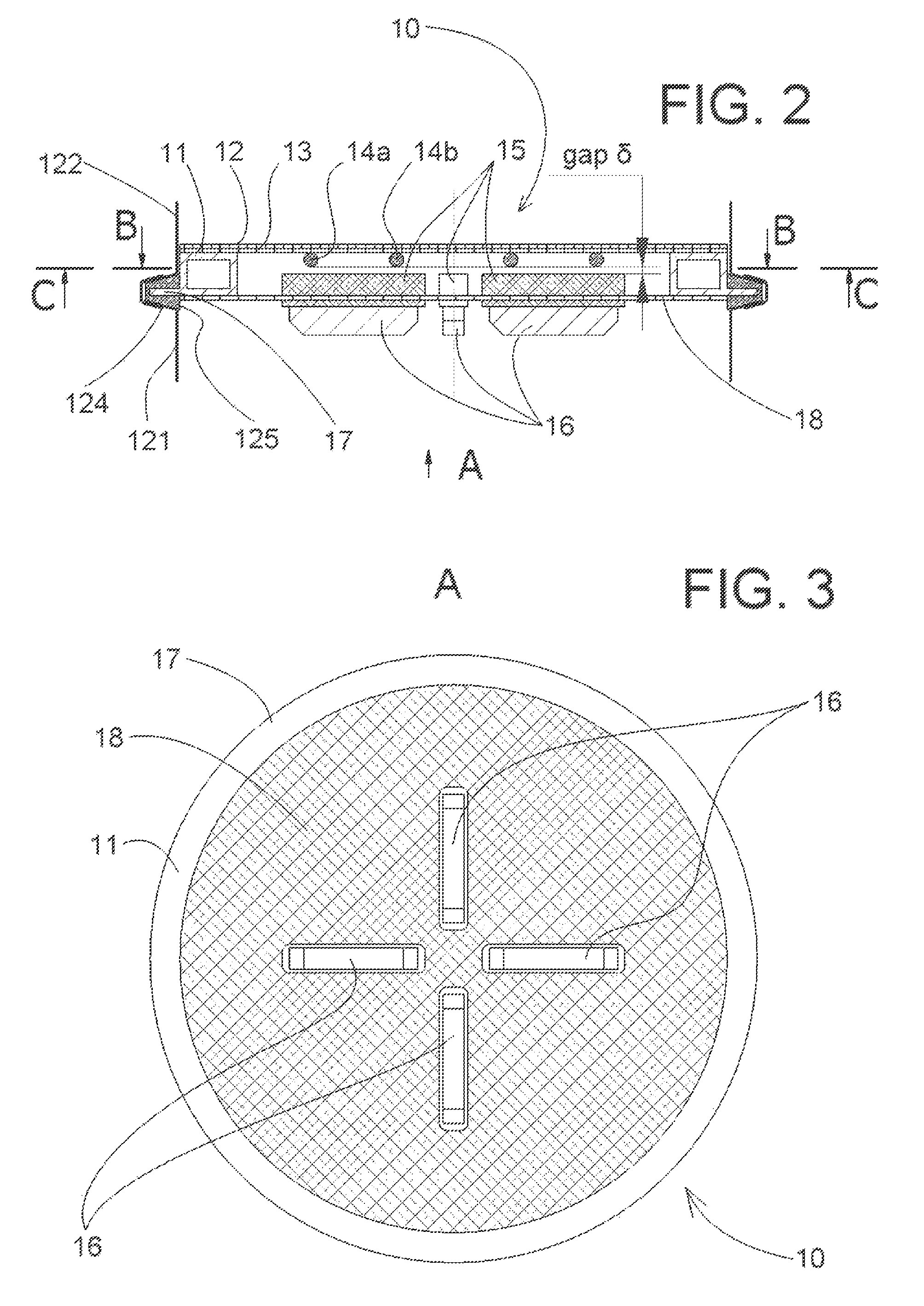

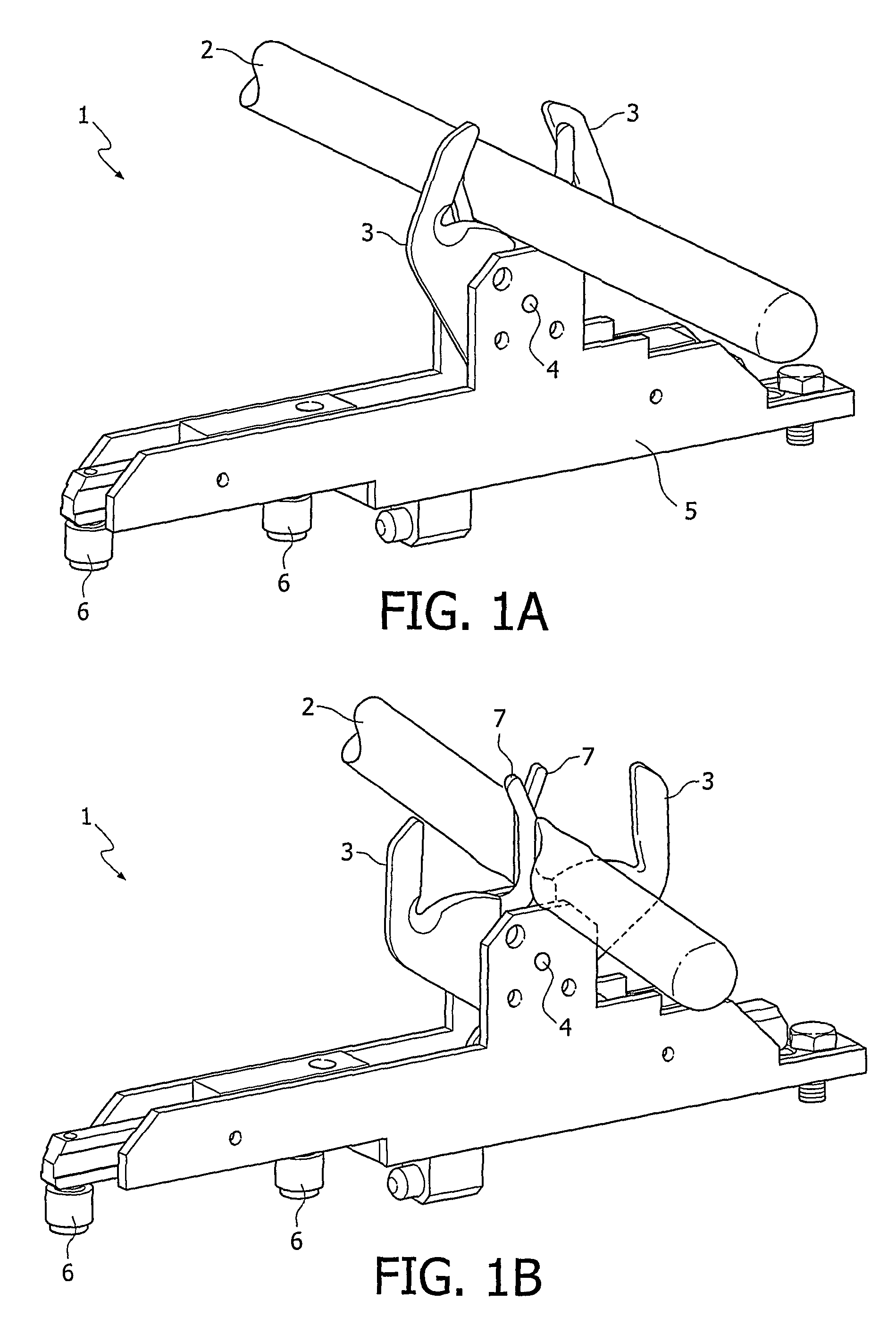

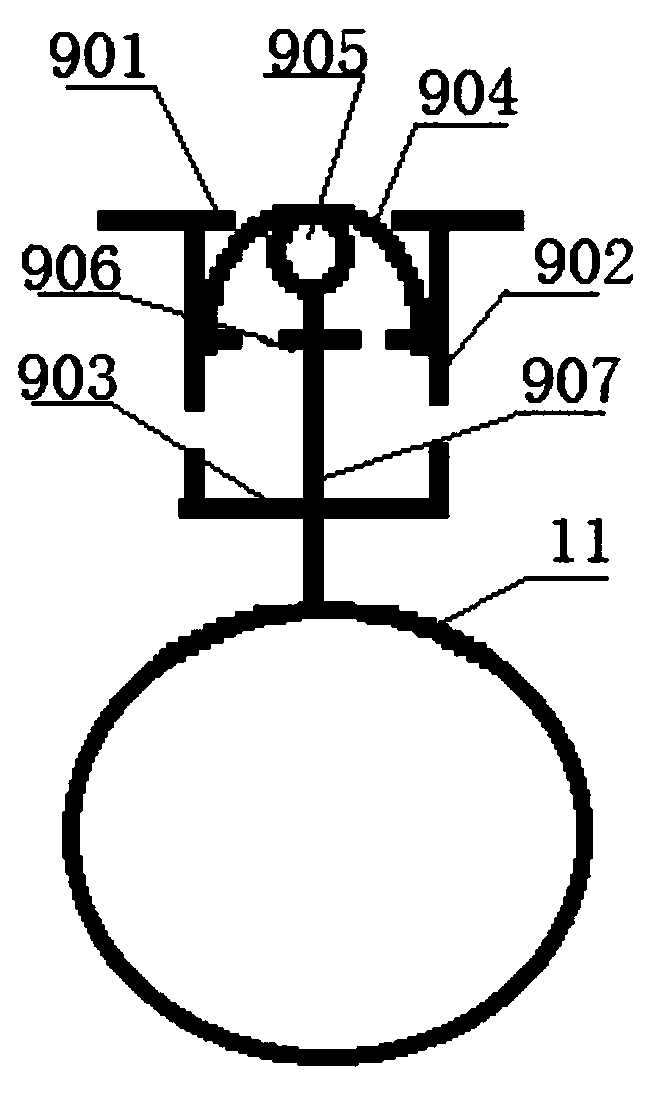

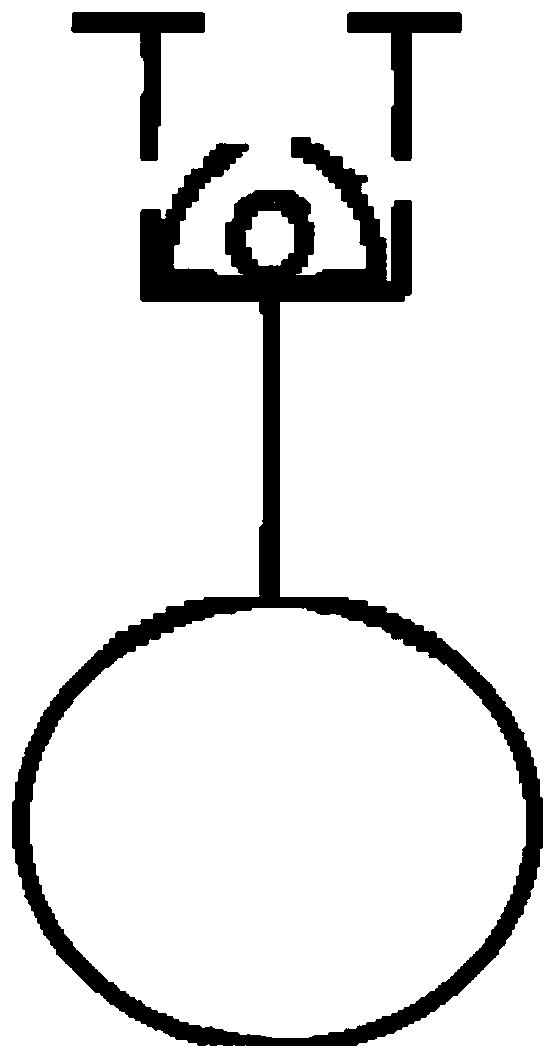

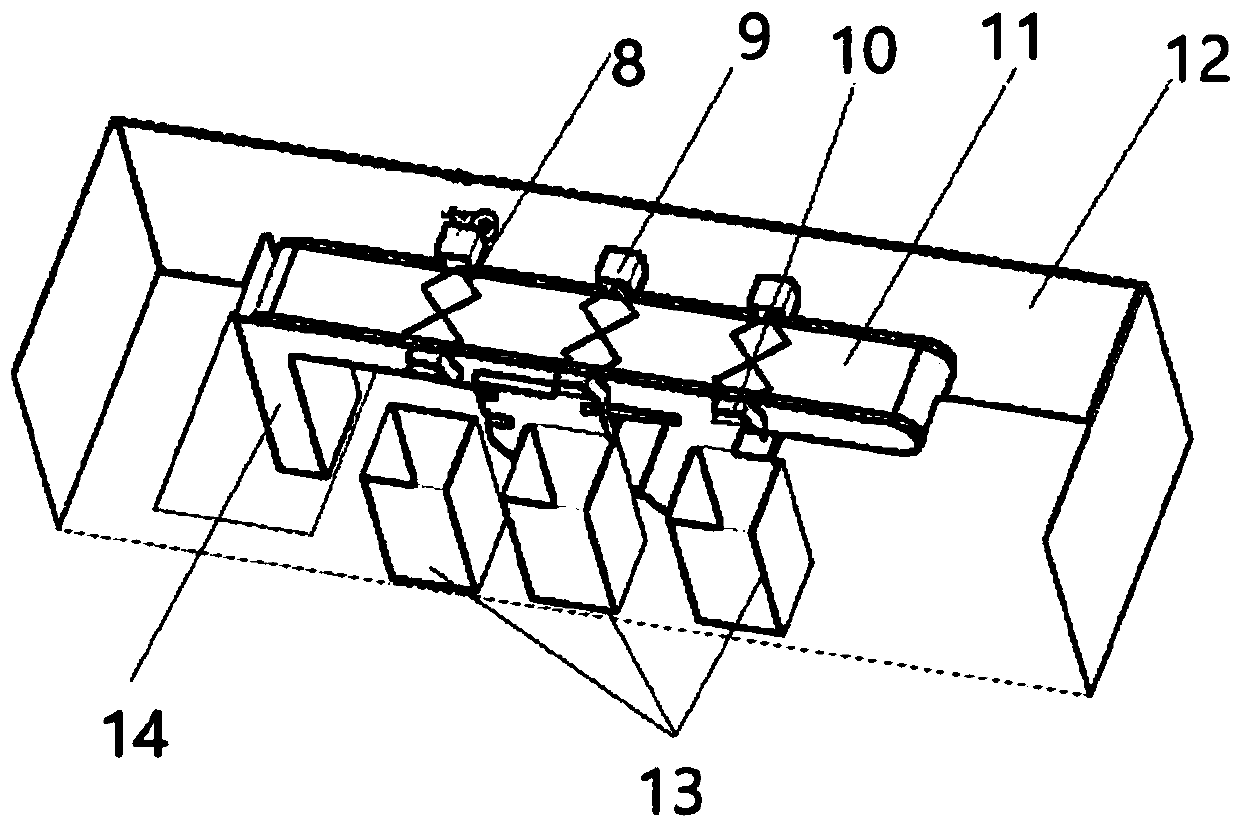

Multifrequency Sieve Assembly for Circular Vibratory Separator

ActiveUS20120024764A1Improve filtering effectImprove separation qualitySievingScreeningSlurryEngineering

The invention is intended for sizing separation of difficult-to-screen powder materials and slurries. A sieve assembly includes a rigid frame, attached inside the separator housing, and upper and bottom sieves, stretched on the frame. The interface apparatuses are connected to the upper sieve, while actuator means—to the bottom sieve. The forced frequency of the vibrator is close to one of the natural frequencies of the bottom sieve. When the vibrator is operated, the actuator means interact with interface apparatuses, thus generating repeated collisions therebetween and mechanical impulses, which provide multifrequency excitation of the interface apparatuses and upper sieve. This ensures continuous self-cleaning of the upper sieve, intense loosening of the material bed and disintegration of the particle agglomerates. Separation capacity and products' quality substantially rises. In other embodiments presented sieve assembly includes buffer elements and inertial apparatuses, connected to the upper sieve.

Owner:KROOSH TECH

Method for producing stabhyose, and method for producing stabhyose and catalpol by using rehmannia root

ActiveCN101003551APrevent spoilageImprove the breaking effectSugar derivativesChemical industryFiltrationIon-exchange resin

This invention provides a method for separating and extracting high-purity stachyose product from Rehmannia glutinosa and Stachys sieboldii. This invention also provides a method for continuously separating and extracting stachyose and catalpol from Rehmannia glutinosa. The method comprises: separating and purifying the extract by passing through continuous pressure-filtration, microfiltration, ultrafine filtration and nanofiltration membranes, and active carbon column, macroporous adsorption resin column, cation exchange resin column, and anion exchange resin column chromatography to obtain stachyose and catalpol. The method has scuh advantages as increased product quality, low wnwegy consumption, and increased raw material utility.

Owner:GUANGDONG APOLLO GRP

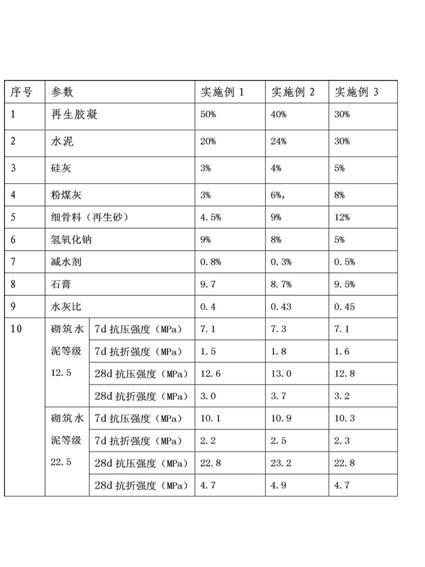

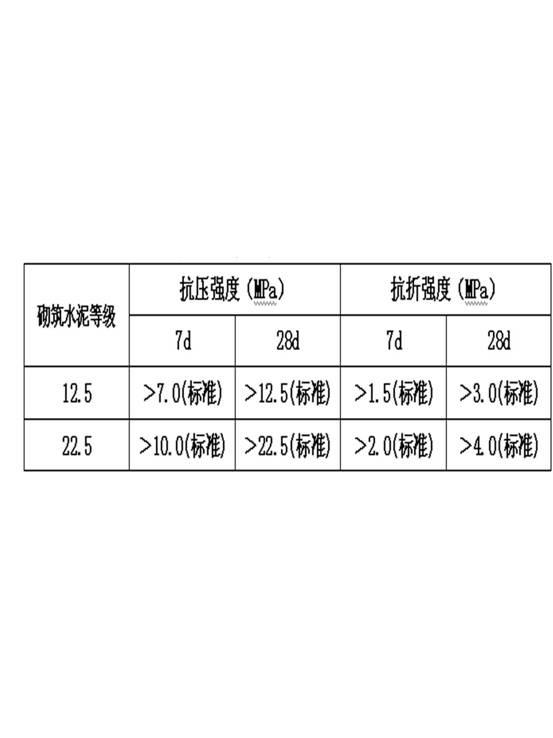

Construction regenerated binding material prepared from construction garbage and preparation method thereof

InactiveCN102432207AGreat renewable valueLarge specific surface areaCement productionSlagPre treatment

The invention discloses a construction regenerated binding material prepared from construction garbage, prepared by the following steps: putting the construction garbage in a reclamation machine to rub, impact, activate, and modify, using a micro powder extraction device to obtain regenerated micro powder, adjusting the proportion. The invention also discloses a preparation method of the material, comprising the following steps: pretreating construction garbage, reserving waste concrete, waste bricks, waste lime-sand mortar, and waste slag as raw materials; crushing and sieving raw materials to obtain particles; putting the particles in the reclamation machine for processing, removing inert membranes on sand grains, and activating the surface activity of particles; extracting micro powder by a dust collector, sieving the micro powder, and taking undersized parts to obtain regenerated micro powder; continuously crushing the unextracted particles, and extracting the regenerated micro powder when crushing; examining, and adjusting the components to obtain the construction regenerated binding material, wherein, the particles in the reclamation machine are regenerated sand. The construction regenerated binding material is used for replacing 50-70 % of ordinary portland cement to be as masonry cement.

Owner:云南华威废弃物资源化有限公司

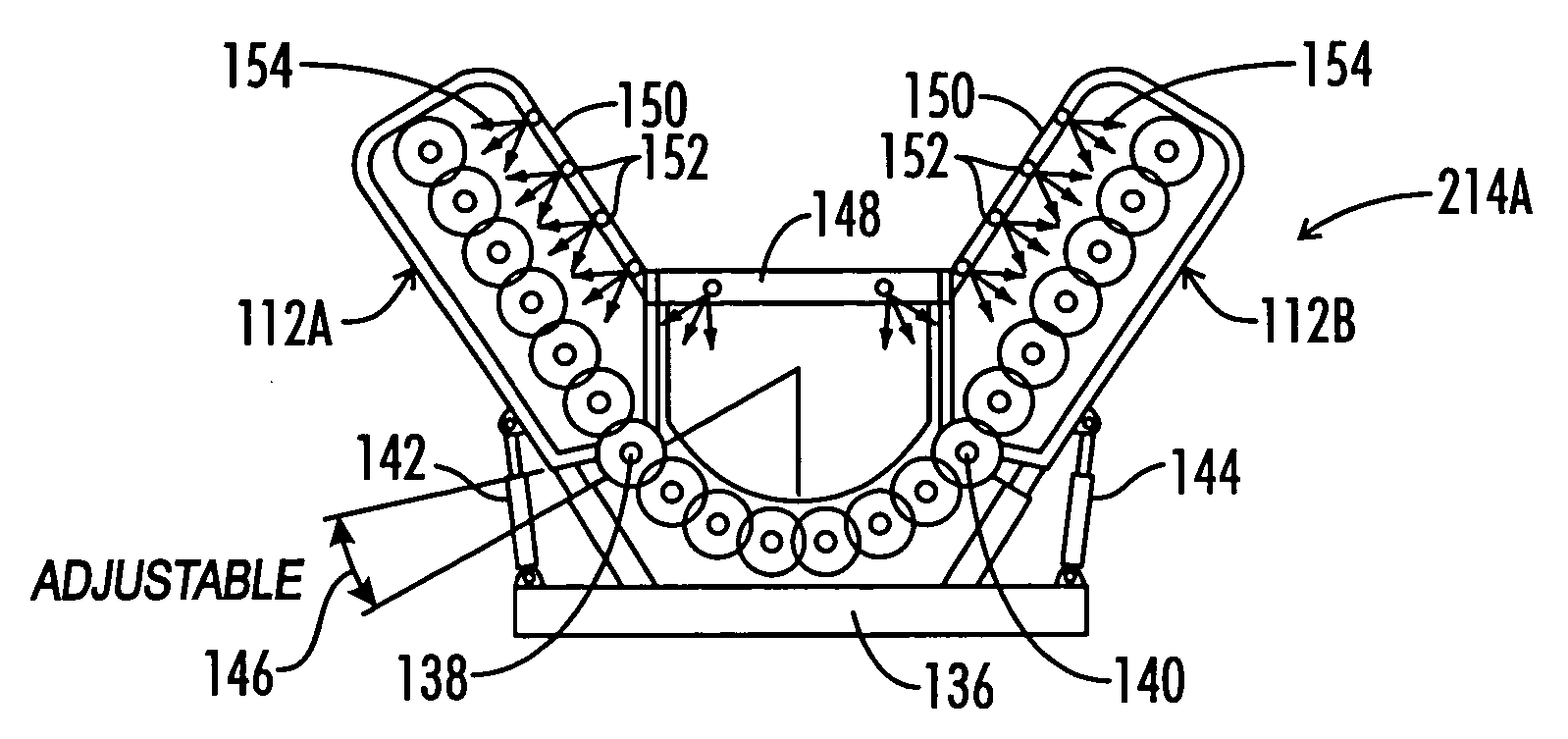

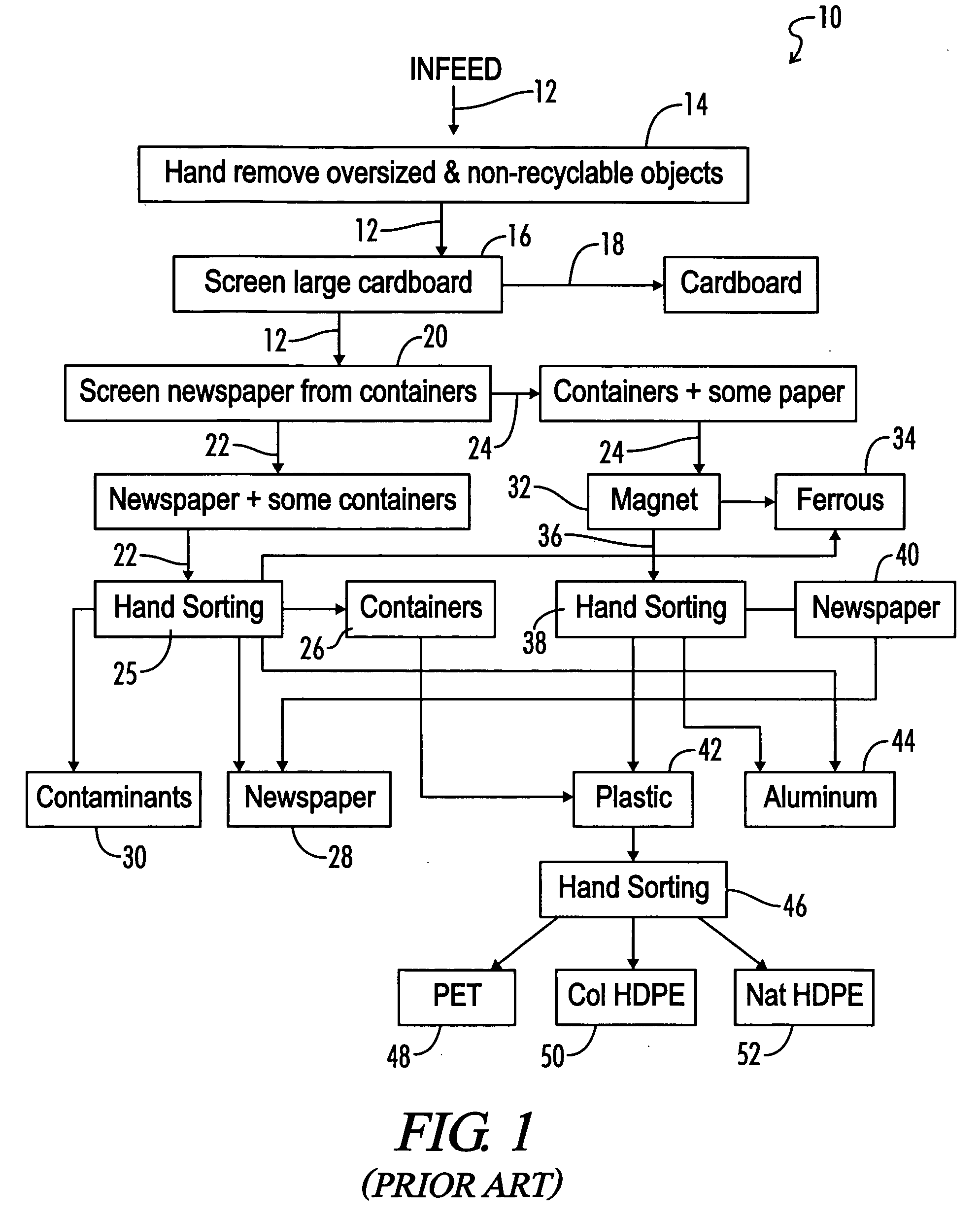

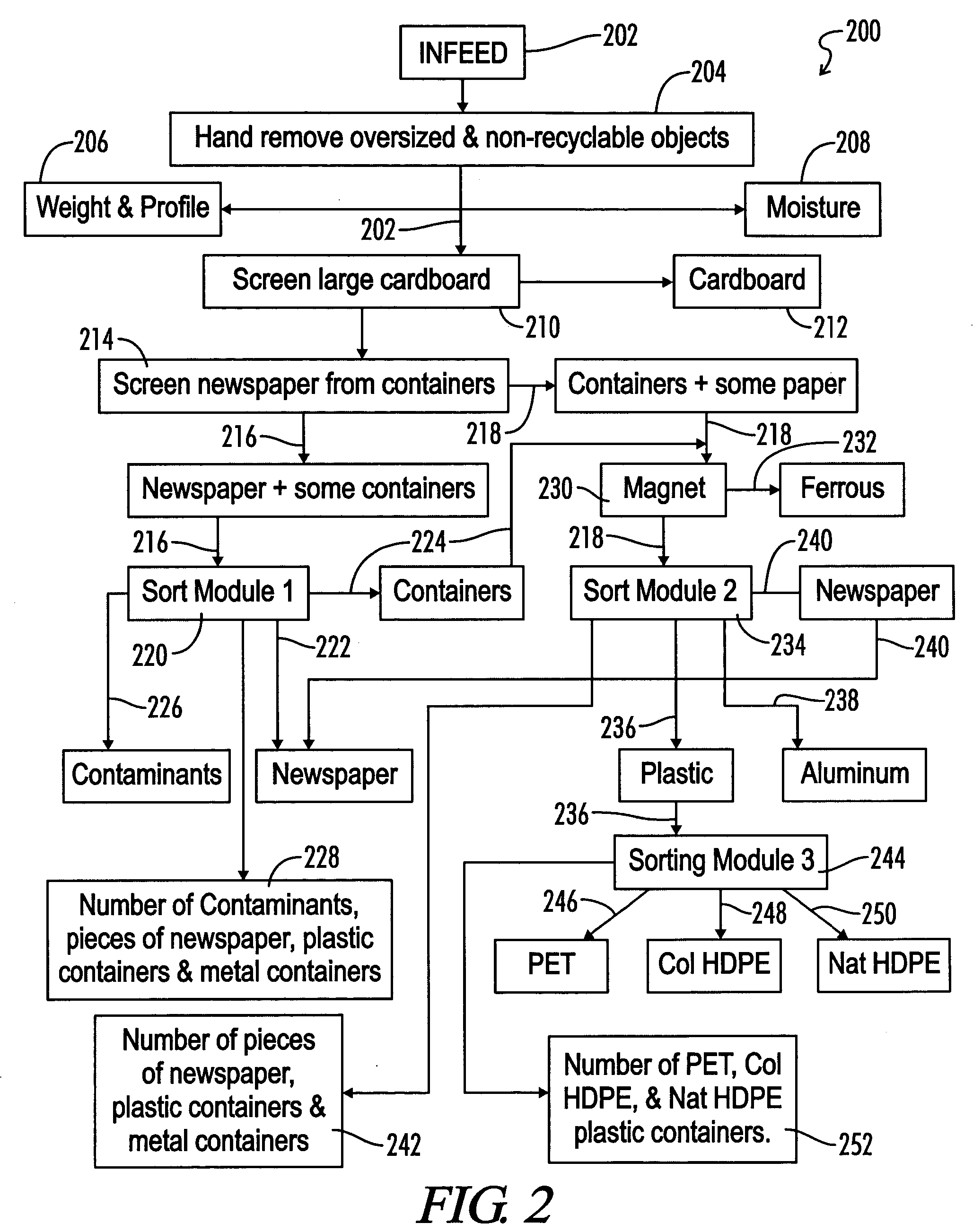

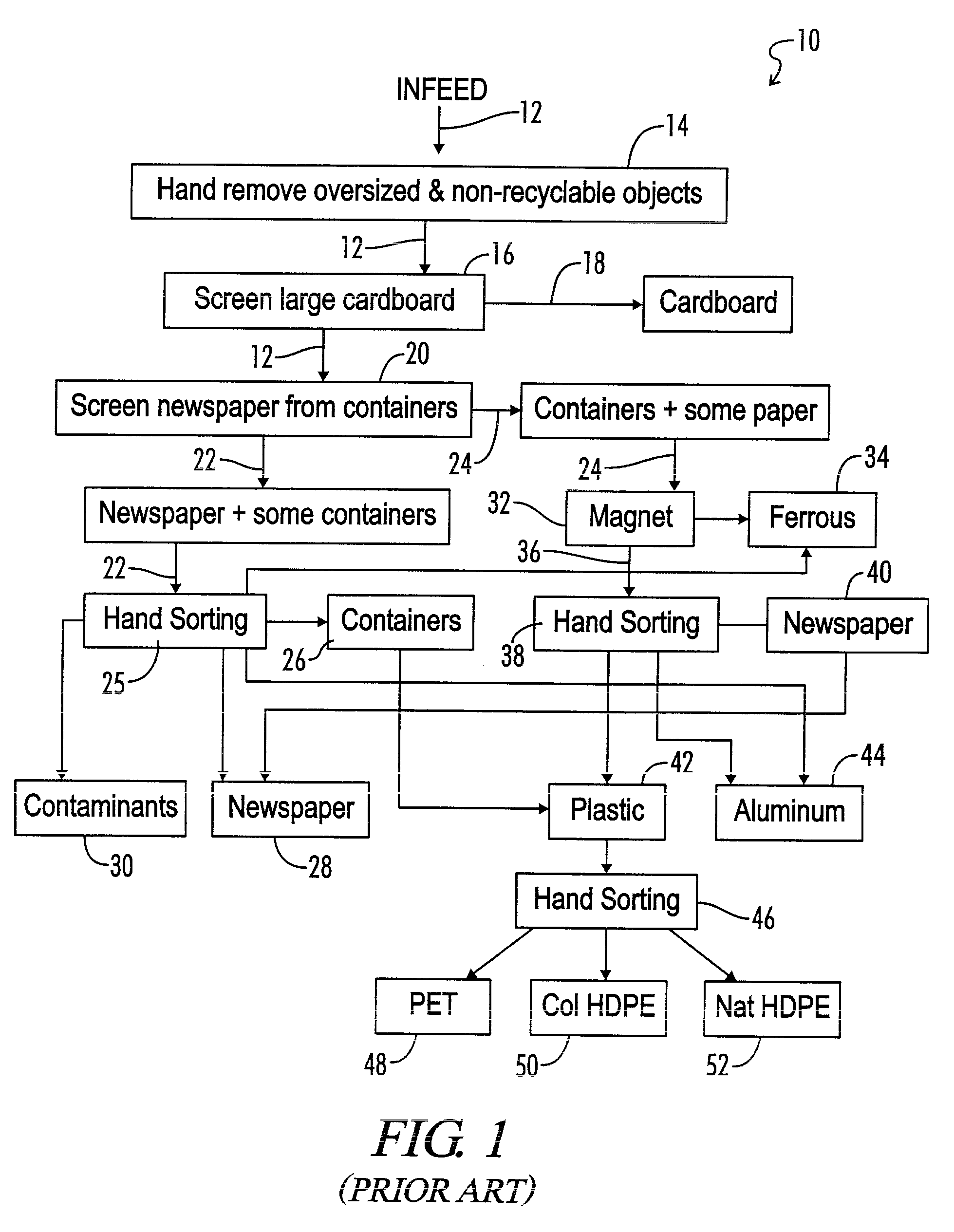

Sorting recycle materials with automatically adjustable separator using upstream feedback

InactiveUS20060081513A1Improve operational efficiencyImprove separation qualitySievingGas current separationProcess engineeringWaste material

Methods and systems are provided for controlling an automatic separator apparatus of a Materials Recovery Facility. An input stream of recycled materials is provided, wherein the composition of the input stream is subject to variation during a time interval. At least one characteristic of the input waste material stream is measured. An initial value is selected for an adjustable parameter of the automatic separator apparatus based upon the measured characteristic of the input stream.

Owner:KABUSHIKI KAISHA MSS

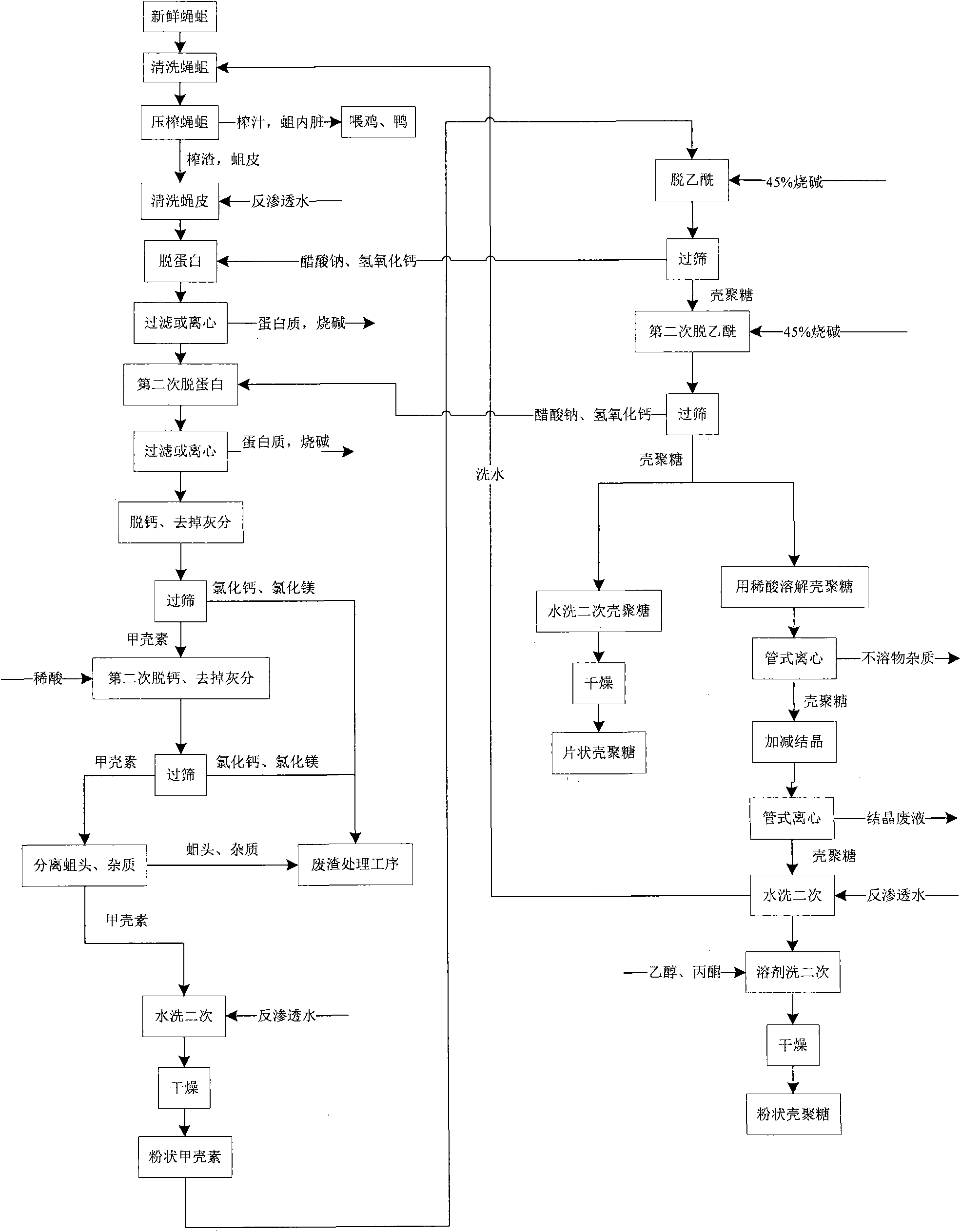

Preparation method of fly maggot chitosan

The invention relates to a method of preparing chitosan by using fly maggots, which comprises the followings steps that: firstly, the skin of a maggot is separated from entrails by pressing the fly maggot, an alkali solution is used to remove protein, a dilute acid solution is used to de-ash, and the impurities of the head of the maggot are removed by a physical method to obtain chitin; secondly, the chitin is deacetylated by 40-55% (W) of caustic soda solution, and then is separated to obtain a filter cake chitosan; and the chitosan is repeatedly washed until the PH value is equal to 7; thirdly, the cleaned chitosan adopts two processing methods: one method is to obtain flaky chitosan by drying, and the other method is that the chitosan is dissolved in dilute acid and centrifugally separated by a tube type centrifuge to obtain filtrate a chitosan solution; alkali is added in the filtrate until the PH value is equal 7-7.5, the chitosan is precipited and is separated by the tube type centrifuge to obtain a filter cake chitosan, and powdery chitosan is obtained after drying. The invention has the characteristics that: water can be saved, the chitosan product has low heavy metal content, low toxic content and stable product quality, the productivity is high and the production cost is low.

Owner:ZHEJIANG PUJIANG CHENGYUE PLANTATION +1

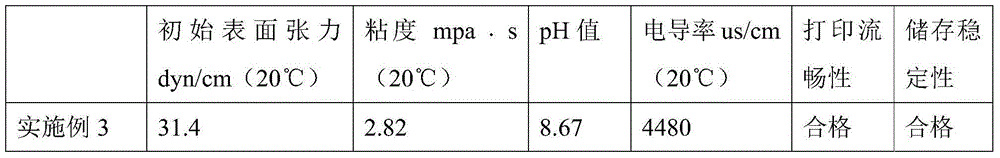

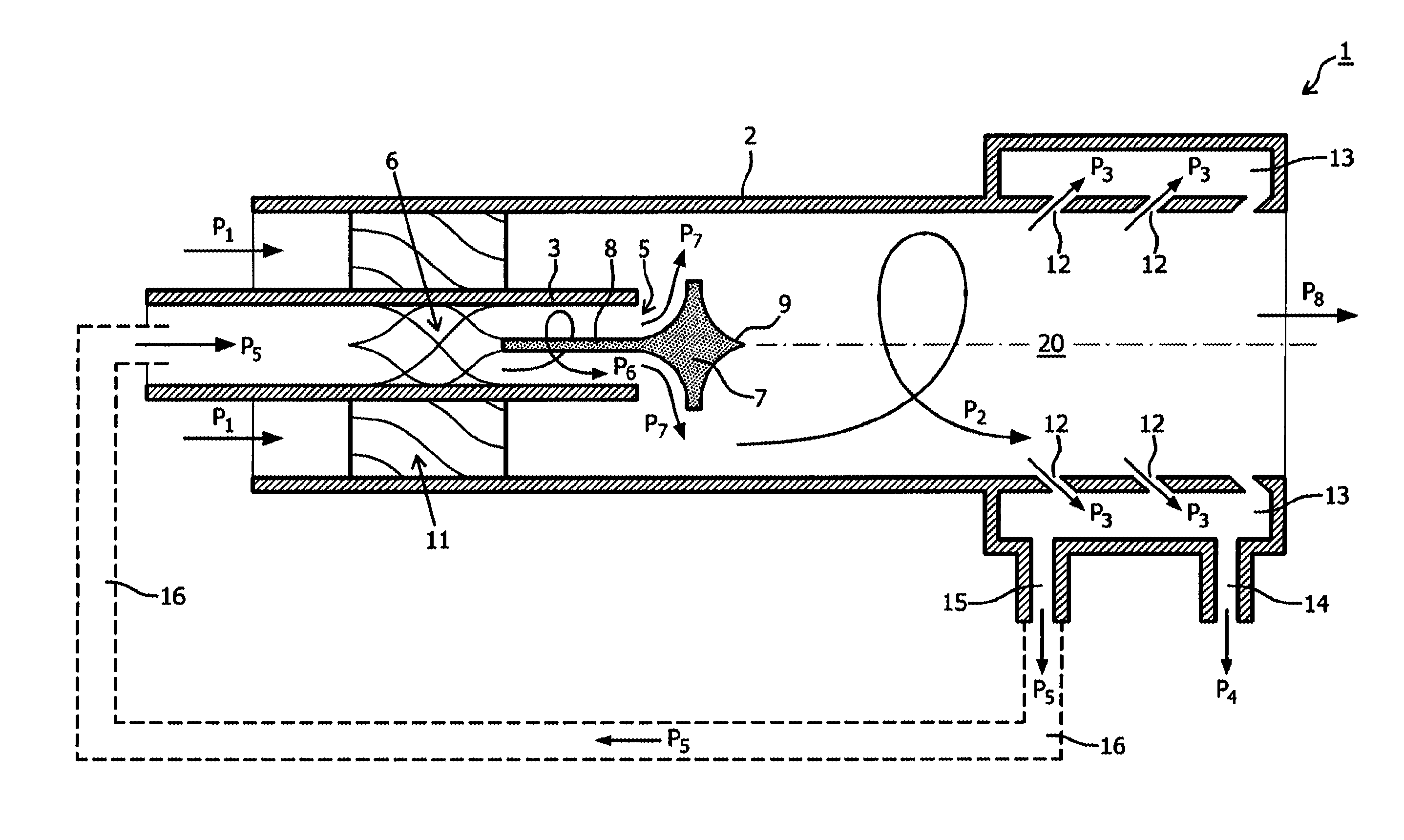

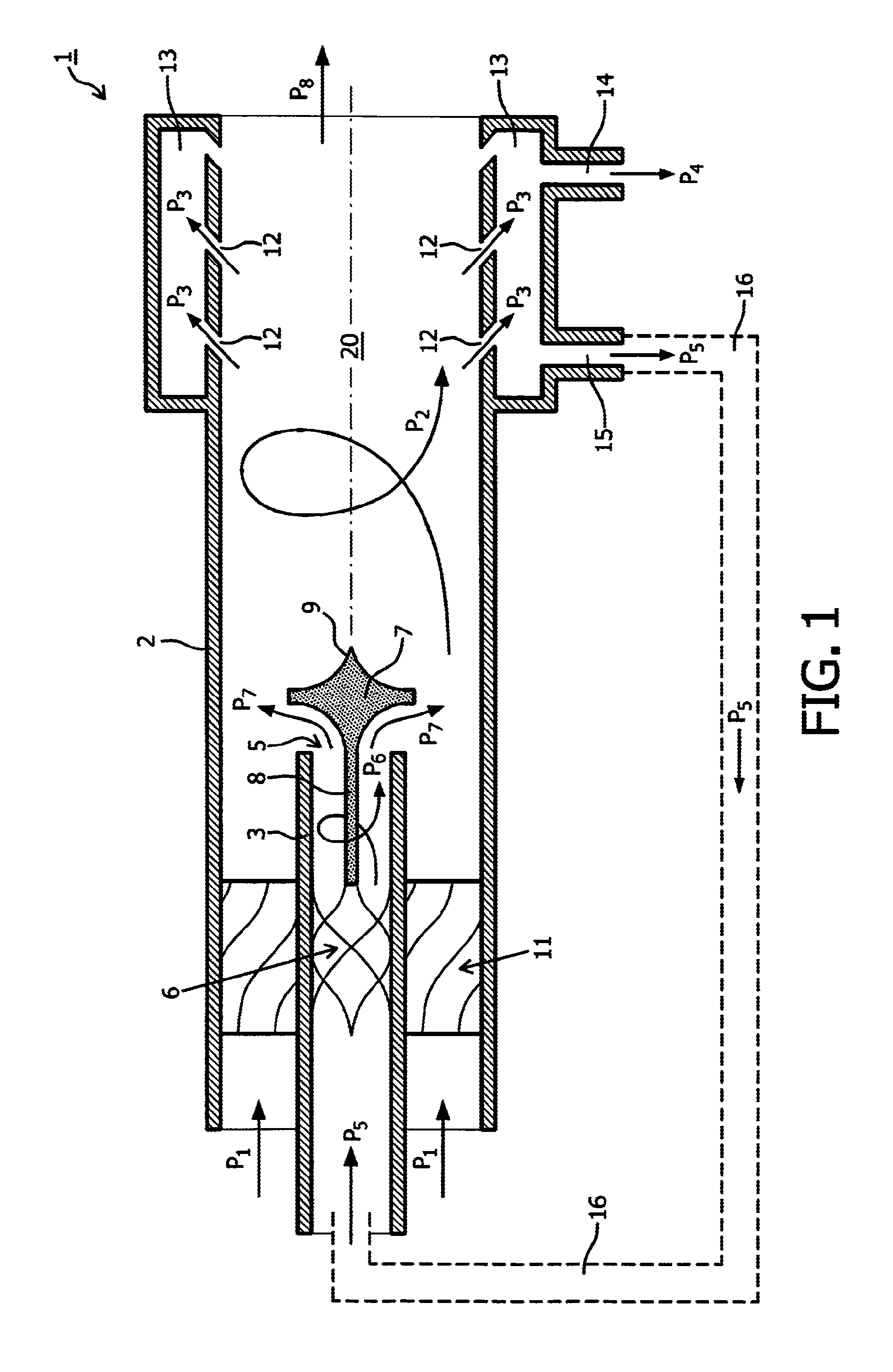

Multifrequency sieve assembly for circular vibratory separator

ActiveUS8485364B2Improve filtering effectImprove separation qualitySievingScreeningSlurryEngineering

The invention is intended for sizing separation of difficult-to-screen powder materials and slurries. A sieve assembly includes a rigid frame, attached inside the separator housing, and upper and bottom sieves, stretched on the frame. The interface apparatuses are connected to the upper sieve, while actuator means—to the bottom sieve. The forced frequency of the vibrator is close to one of the natural frequencies of the bottom sieve. When the vibrator is operated, the actuator means interact with interface apparatuses, thus generating repeated collisions therebetween and mechanical impulses, which provide multifrequency excitation of the interface apparatuses and upper sieve. This ensures continuous self-cleaning of the upper sieve, intense loosening of the material bed and disintegration of the particle agglomerates. Separation capacity and products' quality substantially rises. In other embodiments presented sieve assembly includes buffer elements and inertial apparatuses, connected to the upper sieve.

Owner:KROOSH TECH

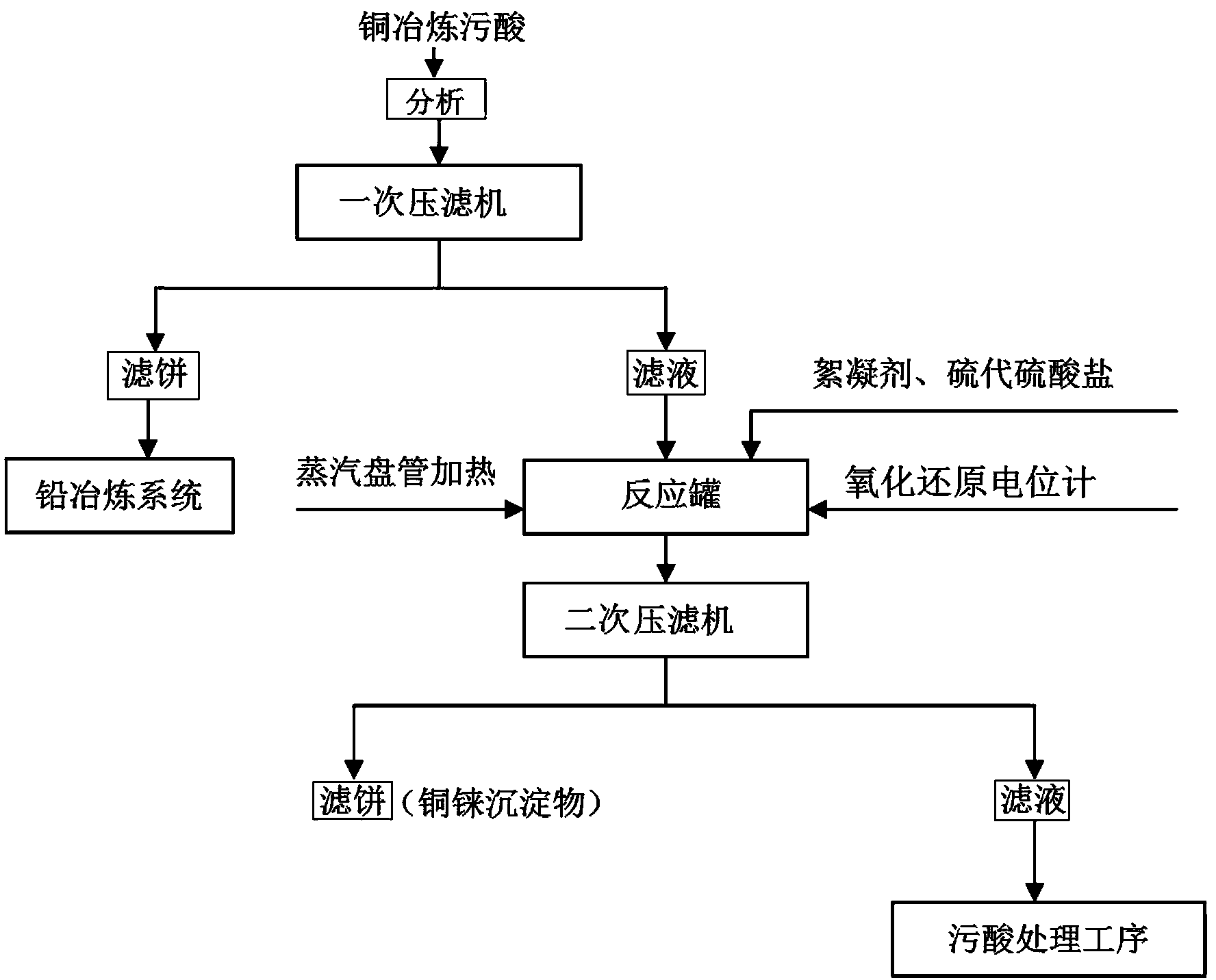

Method for efficiently recovering copper and rhenium from copper smelting waste acid

ActiveCN103773963AImprove precipitation effectStrong water separationProcess efficiency improvementOxidation reductionBismuth

The invention relates to the field of metal smelting and particularly relates to a method for efficiently recovering copper and rhenium from copper smelting waste acid. The method comprises the steps: filtering copper smelting waste acid serving as a raw material for the first time, heating the filtered copper smelting waste acid in a reaction tank, and detecting the initial oxidation reduction potential by using an oxidation reduction potentiometer; then, sequentially adding a flocculant and thiosulfate for reaction, and controlling the reaction time through discontinuously detecting the oxidation reduction potential in the reaction process; and finally, carrying out secondary filtration to obtain a filter residue, i.e., a copper and rhenium precipitate. By using the method, copper and rhenium in the waste acid can be thoroughly settled, the sedimentation effect is improved under the action of the flfocculant, and thus, the recovery rates of the copper and the rhenium are increased; the recovery rate of copper is higher than 95%, the recovery rate of rhenium is higher than 98%, the sedimentation rate of arsenium is relatively low and is only about 10%, and the obtained filter cake contains 2-4% of rhenium and 10-20% of copper; and meanwhile, silver and bismuth are also recovered, and the silver content is up to 2-5%, and the bismuth content is up to 6-10%.

Owner:BAIYIN NONFERROUS GROUP

Distillation method of oxime

The present invention relates to a distillation method of oxime. Tower bottom materials are usually heated by still distillation, a U-shaped outer tube or a rotary film evaporator, long-term operation of the tower bottom is easy to coking, and the distillation efficiency is low. The invention is characterized in that: in the distillation and separation section of oxime, at least one high boiling point solvent is added in the distillation process, the content of the high boiling point solvent in the tower bottom is maintained in proportional to that of oxime, and finally oxime is effectively separated by distillation. Oxime is fed into a rectifying tower, and is distilled at an absolute pressure of 0-0.4 MPa and at 20-300 DEG C to collect fractions. The unevaporated liquid left in the tower bottom is subjected to the processes of removing water and impurities, and is recycled to the rectifying tower as a high boiling point solvent. The present invention can reduce total production costs, simplify operation processes, prevent the product from coking in the tower bottom or decomposing due to overheating, ensure product distillation to be efficient, continuous, safe and stable, and improve product quality.

Owner:ZHEJIANG SAINON CHEM

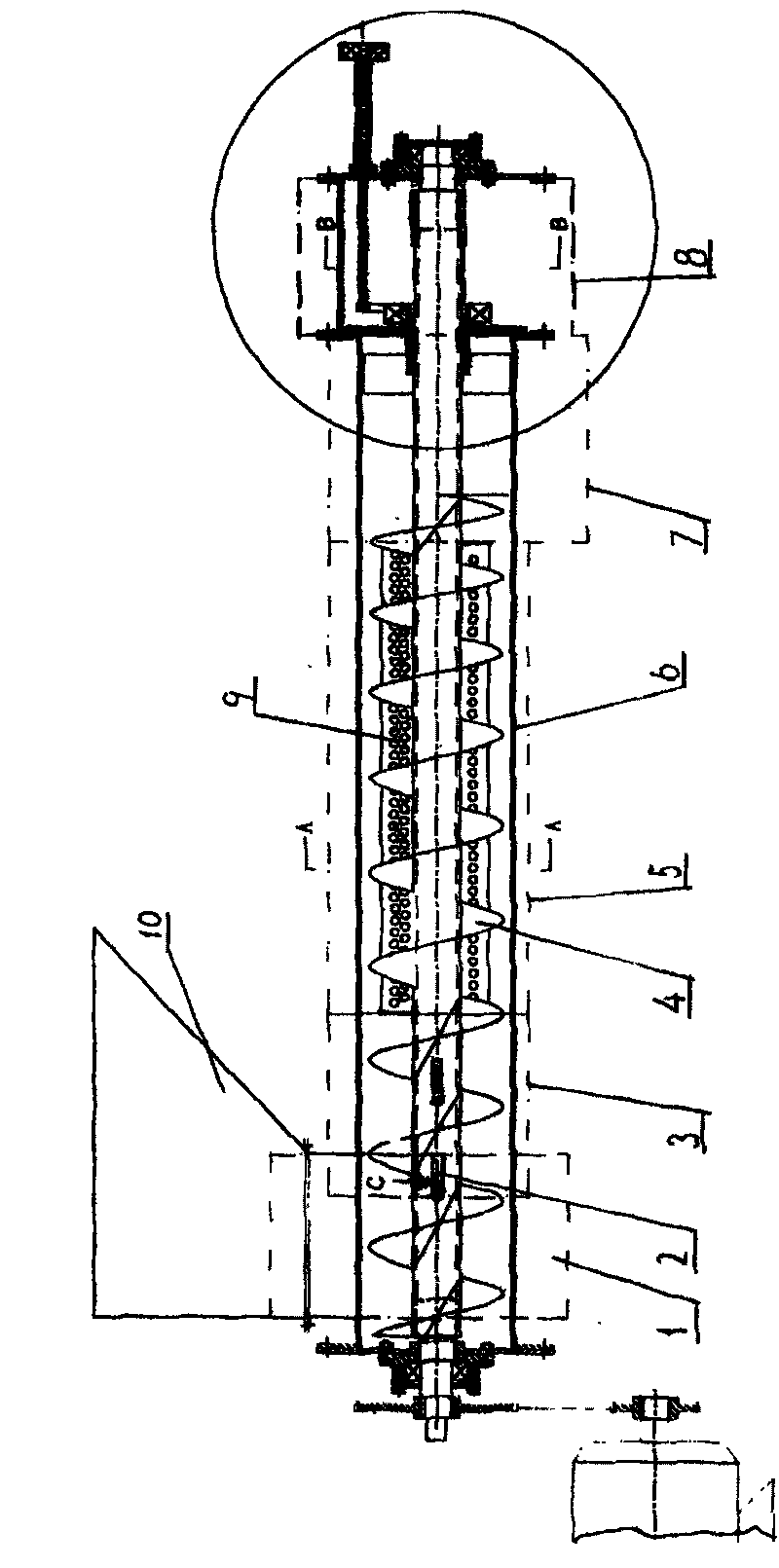

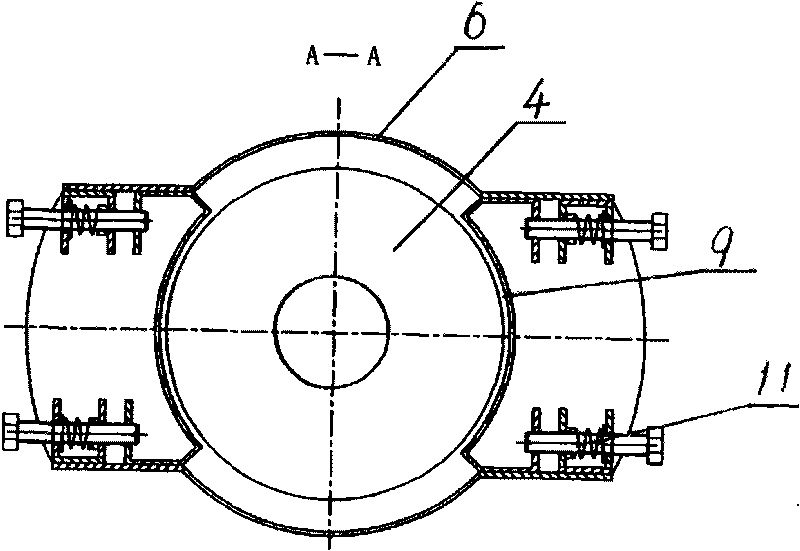

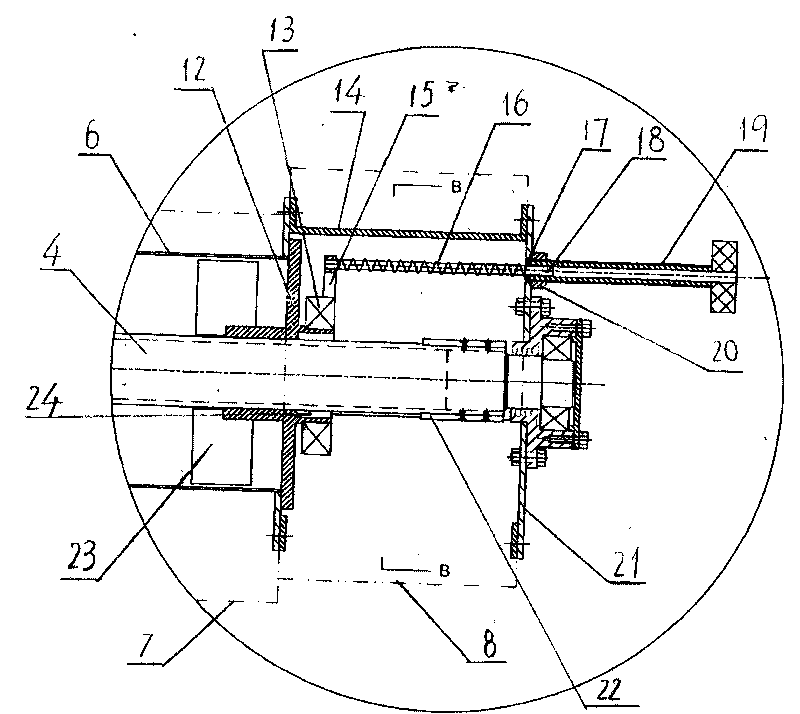

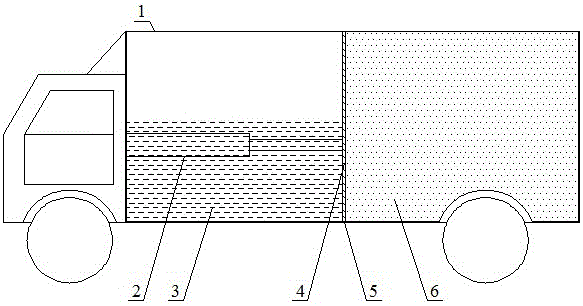

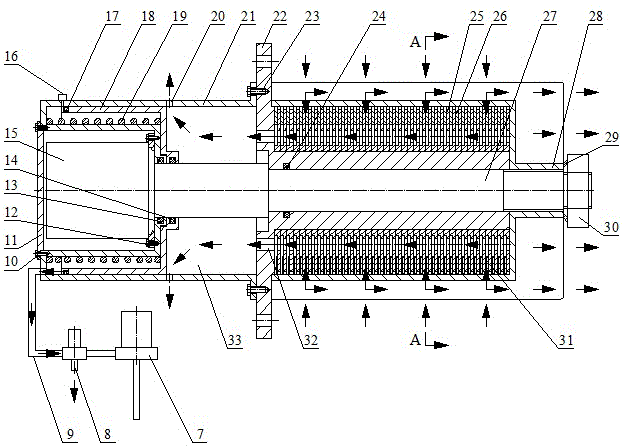

Solid-liquid separator for separating livestock-poultry dung, biogas fluid and biogas dregs

InactiveCN101722666ANovel structural designScientific and reasonable operation processPressesHelical bladeAnimal feces

The invention relates to a solid-liquid separator for separating livestock-poultry dung, biogas fluid and biogas dregs, which belongs to a device for treating the livestock-poultry dung, the biogas fluid and the biogas dregs. The solid-liquid separator is provided a feeding section, a stirring section, a separating section, a solid material stockpiling section and a solid material discharging section which are arranged in turn along the axial direction of a helical blade auger assembly and are matched with a shell, wherein an auger shaft in the stirring section is provided with a stirring knife or a stirring rod; a separation screen assembly matched with the helical blade auger assembly is arranged on two relative lateral parts in the range of the separating section on the shell respectively; an elastic float positioning assembly is arranged on the shell, and is fixedly connected with the separation screen assembly on the same side; and the blade pitch of the helical blade auger assembly is gradually reduced from the rear lateral part of the separating section to the front part of the solid material stockpiling section. The solid-liquid separator has the advantages of scientific and reasonable operation process flow, novel structure, small resistance for separation operation, high separation efficiency, good separation quality, convenient operation, reliable use and fewer faults.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

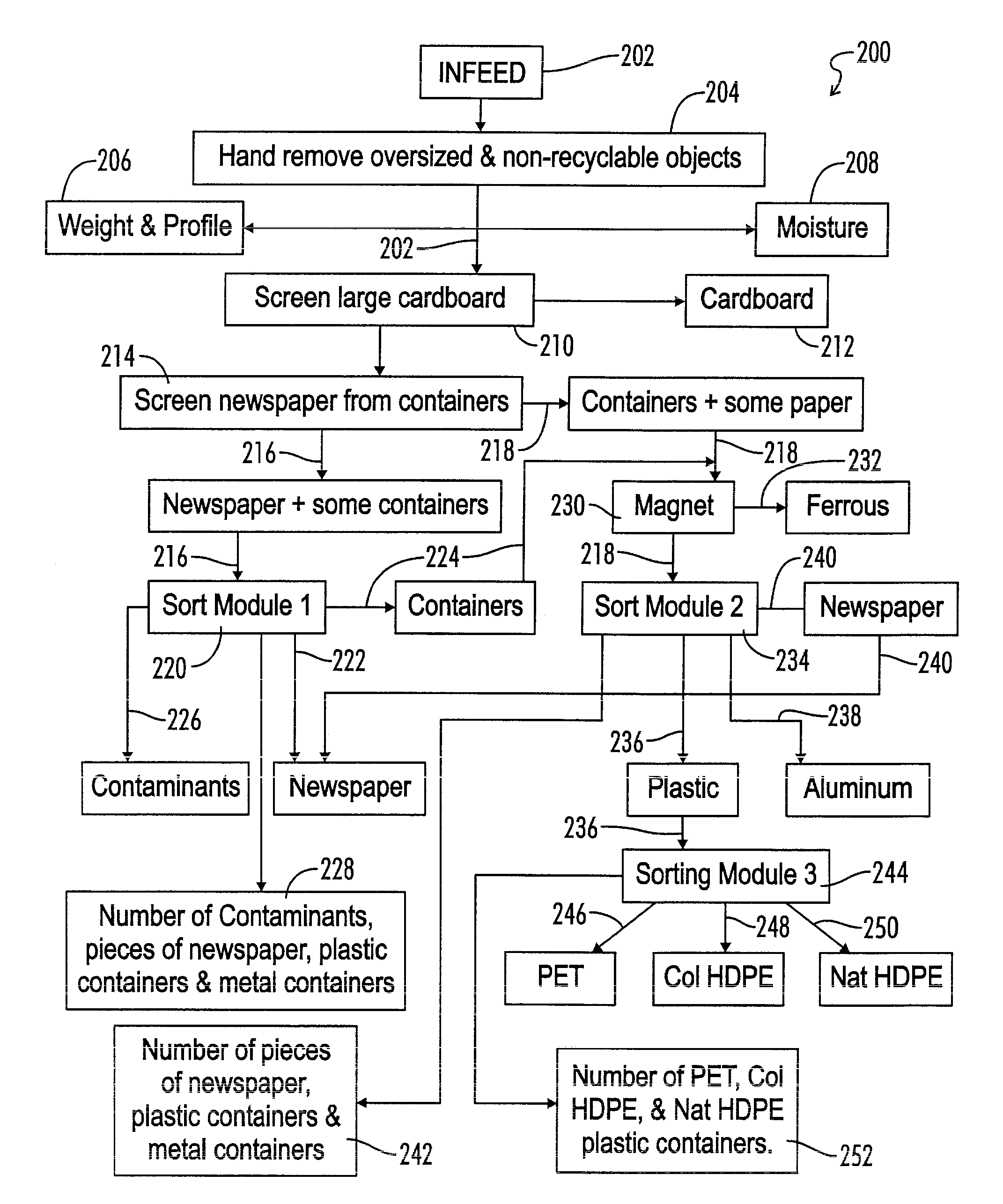

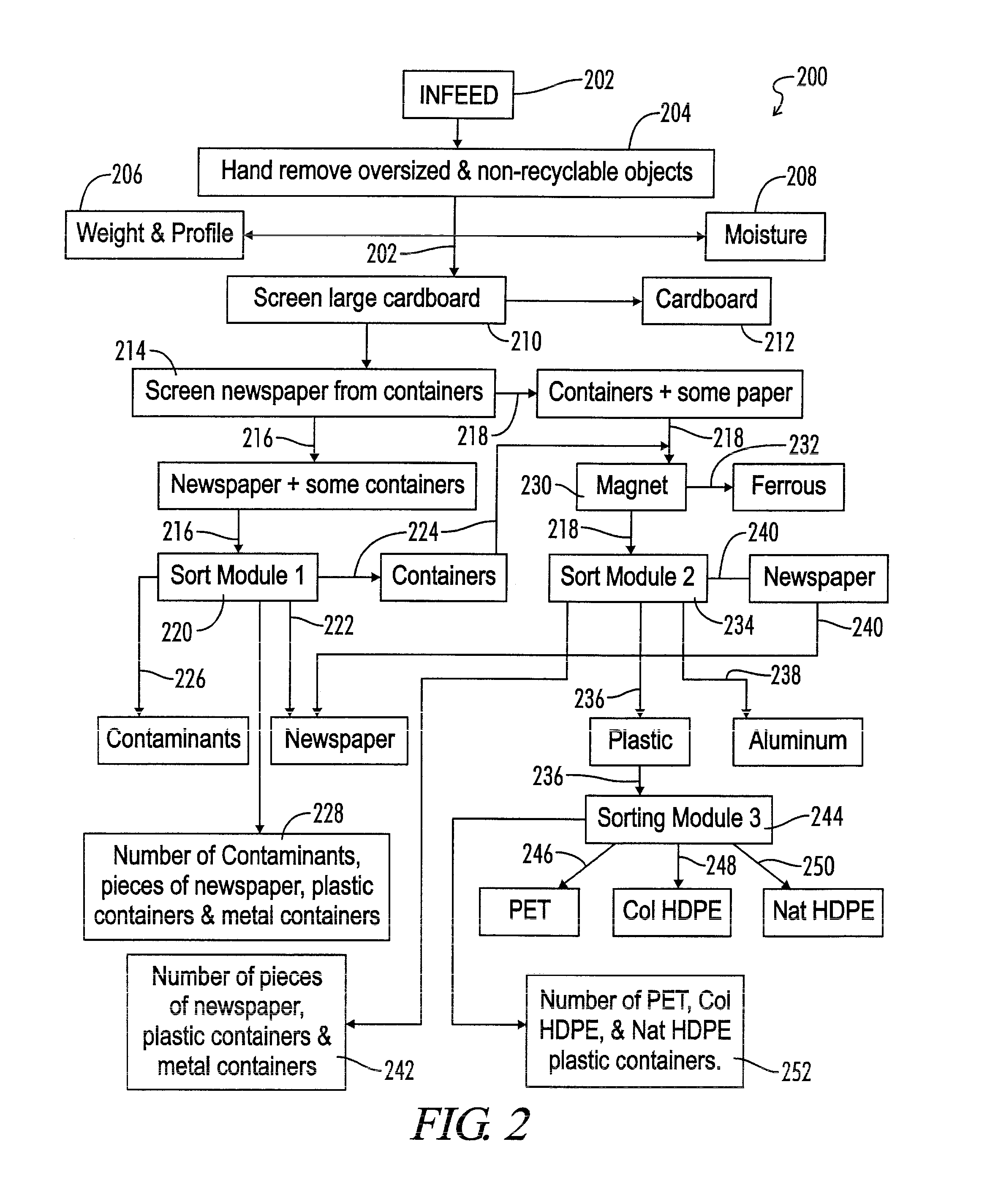

Sorting Recycled Materials With Automatically Adjustable Separator Using Upstream Feedback

InactiveUS20080156703A1Improve separation qualitySimple methodSievingGas current separationProcess engineeringControl material

Methods and systems are provided for controlling an automatic separator apparatus of a Materials Recovery Facility. The separator apparatus has a plurality of adjustable machine operating parameters. An input stream of recycled materials is provided, wherein the composition of the input stream is subject to variation during a time interval. Historical data is provided representative of a set of historical values of the operating parameters corresponding to improved quality of separation for given values of a characteristic of the input stream. A present value of the characteristic of the input stream is sensed. A plurality of machine operating parameters is automatically adjusted in response to the sensed present value of the characteristic.

Owner:KABUSHIKI KAISHA MSS

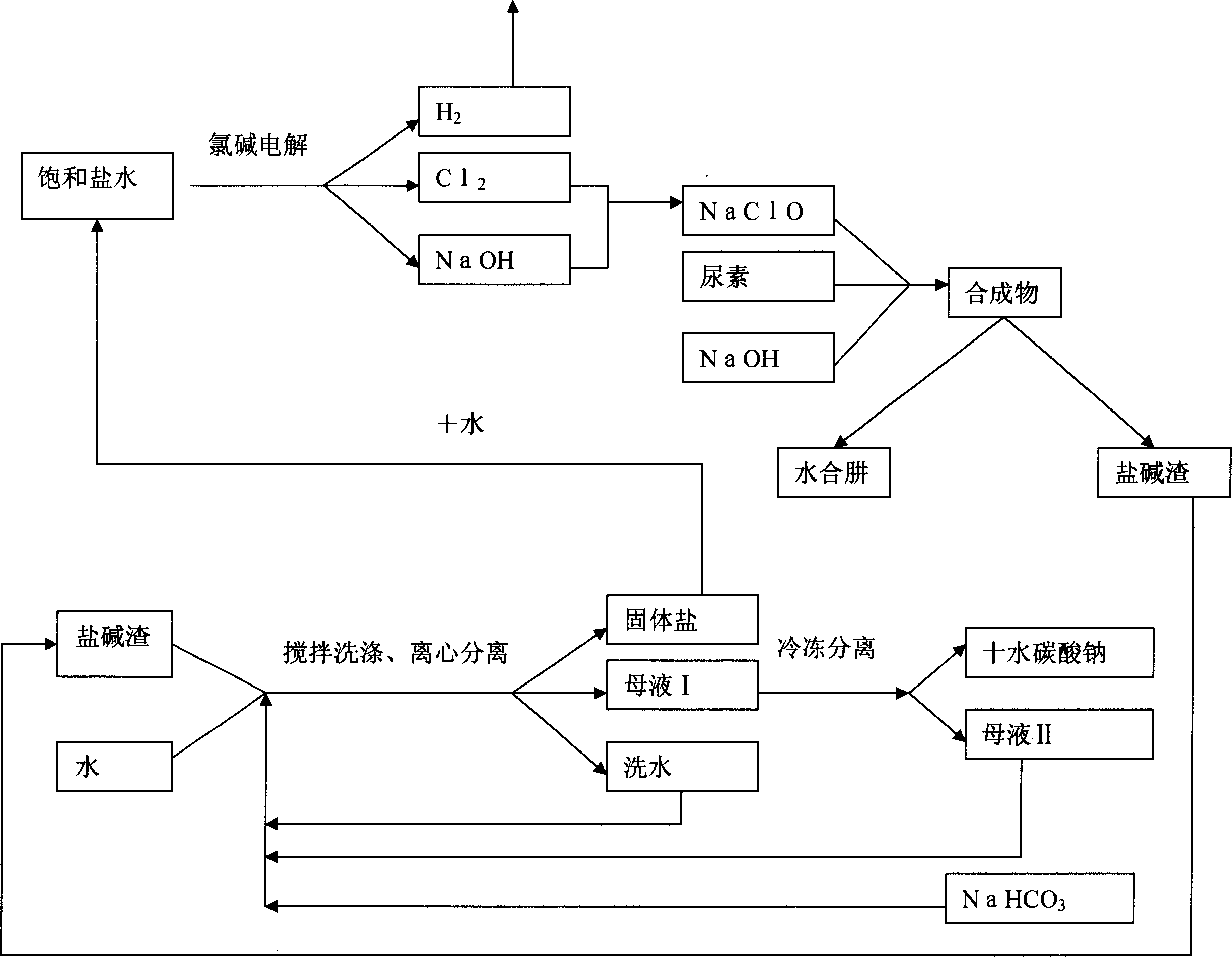

Separation of salt and alkali from waste salt and alkali residue in production of hydrazine hydrate and technique of cyclic utilization

InactiveCN1796280ANo pollutionNo need for external dischargeHydrazineAlkali metal chloridesSodium bicarbonateHydrazine compound

This invention describes a process for the recovery and recycle of industrial waste solids, especially the salt-alkali separation and recycle of the waste salt-alkali solids from the manufacturing of hydrated nitriles. This invention uses water, mother liquid and sodium bicarbonate to wash the waste salt-alkali solids from the manufacturing of hydrated nitriles, so that Na2CO3 and NaOH in the waste salt-alkali solids are washed into the solution. The washing solution is then cooled to 0-5deg.C, and filtrated and separated to obtain solid sodium carbonate decahydrate, which can be commercialized after washing. The mother liquid, after separating the solid alkali, is directed to the next process for washing the waste salt-alkali solids without discharge. During the circulatory washing of the waste salt-alkali solids, the table salt keeps in the solid state. After centrifugal separation, the table salt containing 3% of alkali can be obtained and used for sodium carbonate industry. The said table salt NaCl, after washing and separation to remove a small amount of hydrazine and amine, can be used for chlorine-alkali industry. Chlorine Cl2 and sodium hydroxide NaOH are raw materials for sodium hypochlorite NaClO, which is a raw material for producing hydrazine hydrate. In addition, sodium hydroxide is directly involved in the reaction for producing hydrazine hydrate N2H4íñH2O, thus constituting an internal recycling system of a manufacturing plant without discharging, which not only is environmentally friendly but also reduces transportation load and production cost. This invention describes a rational process for large-scale hydrazine hydrate manufacturing plants.

Owner:陈大元

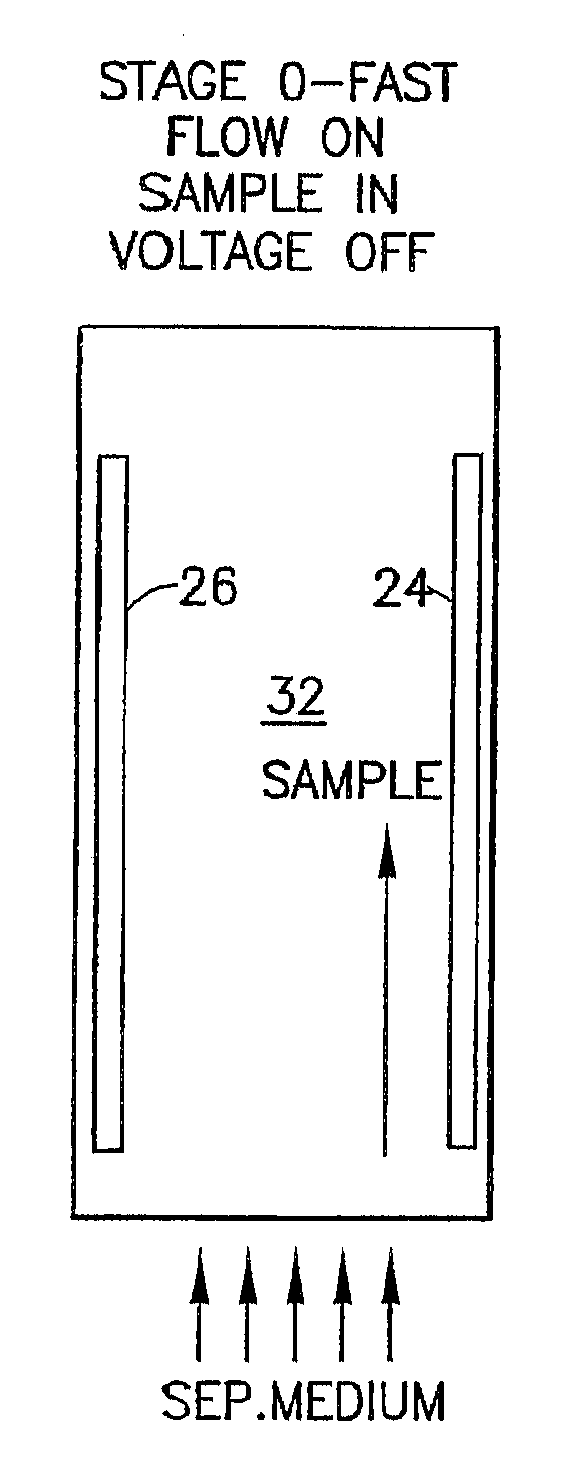

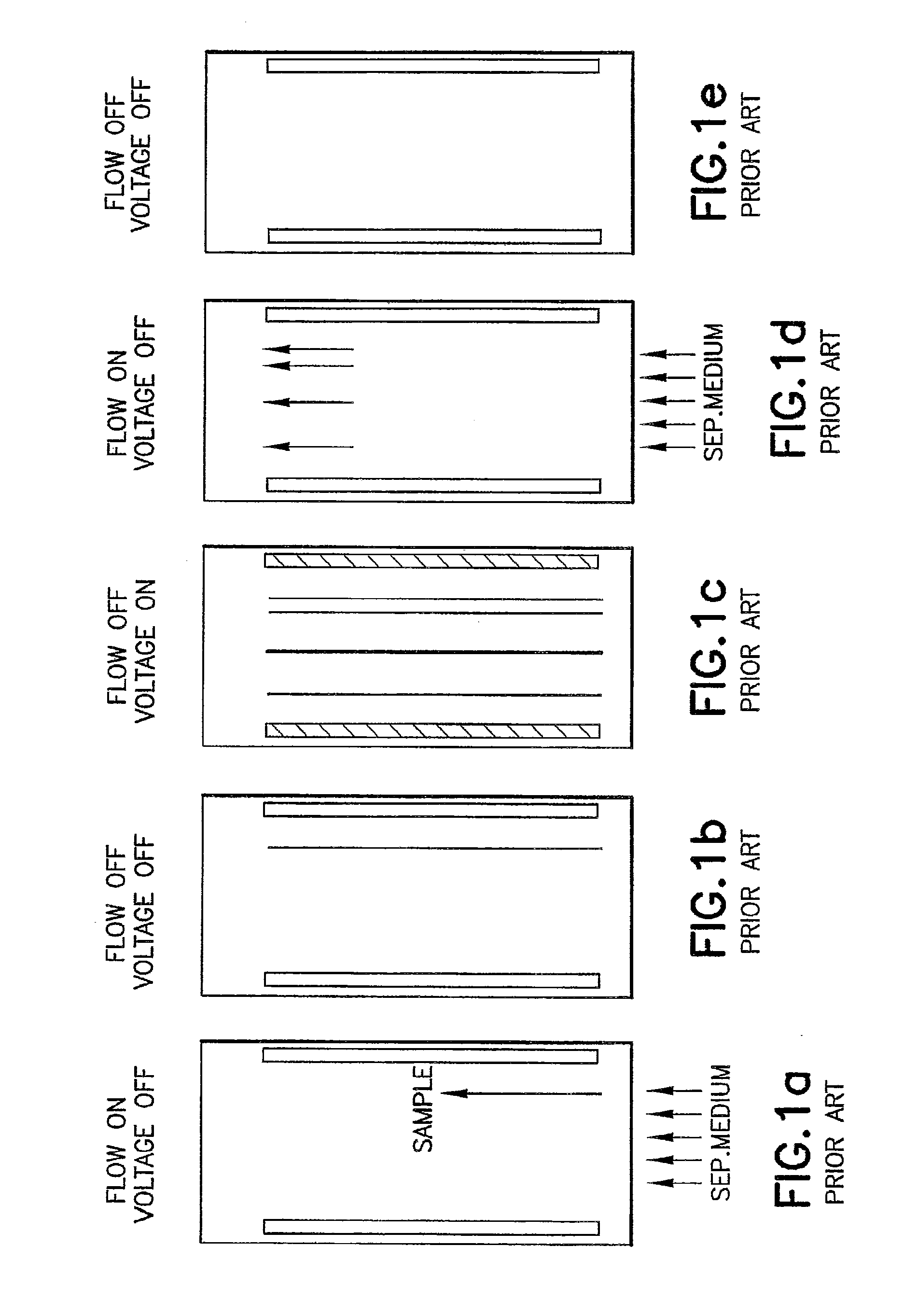

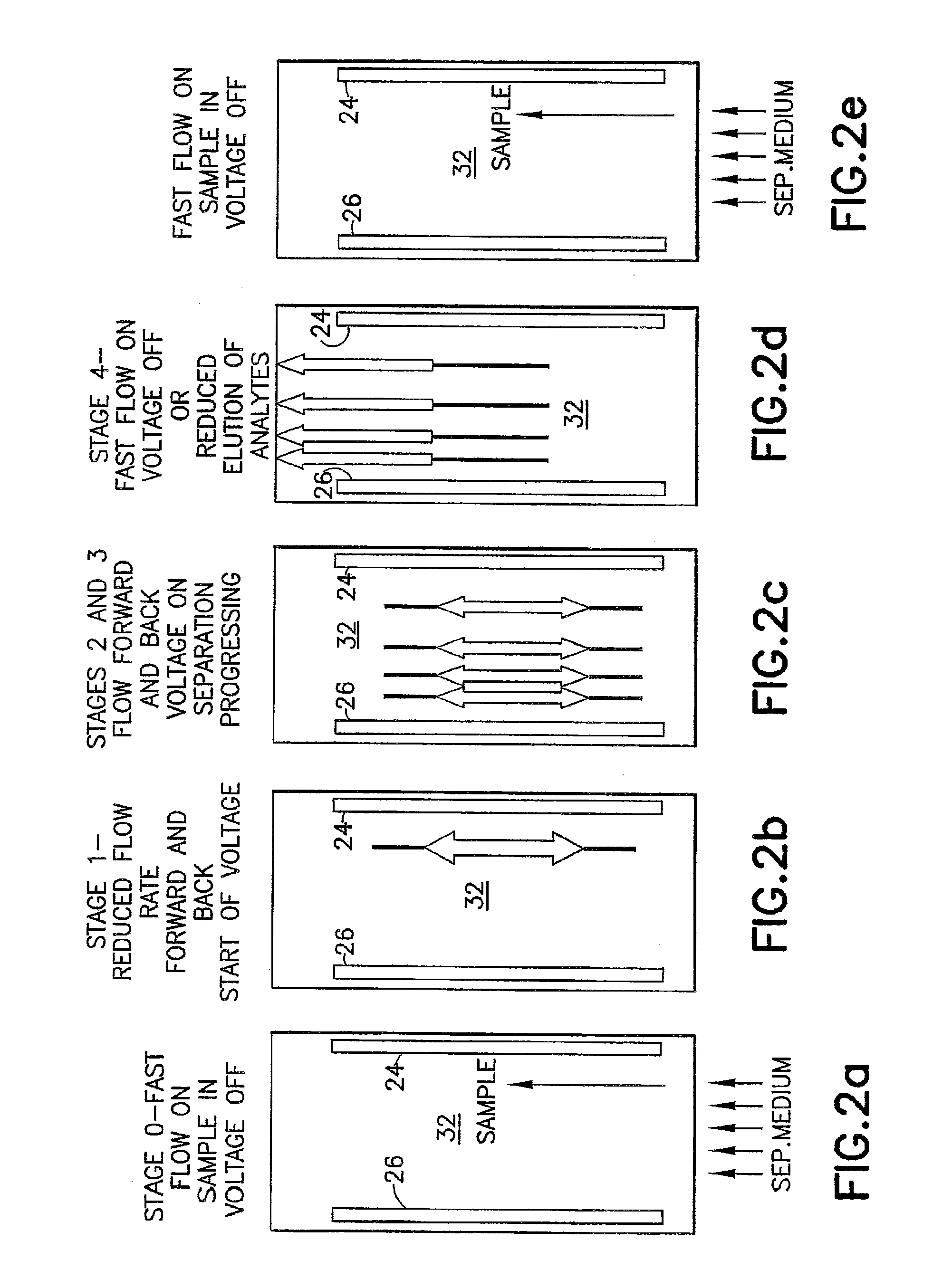

Methods and Apparatus for Carrier-Free Deflection Electrophoresis

ActiveUS20110174624A1Exclude influenceImprove separation qualitySludge treatmentVolume/mass flow measurementElectricityIsotachophoresis

Owner:BECTON DICKINSON & CO

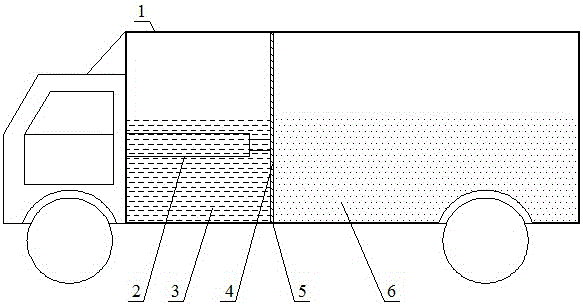

Pressure-control two-way self-cleaning slit-type sewage separation system

ActiveCN106422465AFast separationGuaranteed stable workSewer systemsStationary filtering element filtersSolenoid valveMotor shaft

The invention discloses a pressure-control two-way self-cleaning slit-type sewage separation system. A filtering piece (25) and a base (22) are connected, a scraper (26) and an impeller (28) are connected, the filtering piece (25) and the scraper (26) are stacked in a spaced mode, a motor shaft (27) is connected with the impeller (28), a water outlet cylinder (21), a speed reduction motor (15) and the base (22) are connected, a one-way valve (18) is disposed in the water outlet cylinder (21), a spring (19) is disposed between the one-way valve (18) and the water outlet cylinder (21), a three-way electromagnetic valve (8) is connected with a water outlet of the water outlet cylinder (21) and an outlet of a water pump (7) through water pipes (9) respectively, a water inlet of the water pump (7) extends into separation water (3) through a water pipe (9), a position switch (16) is installed on the water outlet cylinder (21), and a pressure switch (40) is installed on a piston (4). The system is used for separating sewage in a sewage box of a sewer dredging vehicle, increasing sewage separation speed and improving sewage separation quality.

Owner:JIANGSU JIHONGTE SPECIAL PURPOSE VEHICLE MFG CO LTD

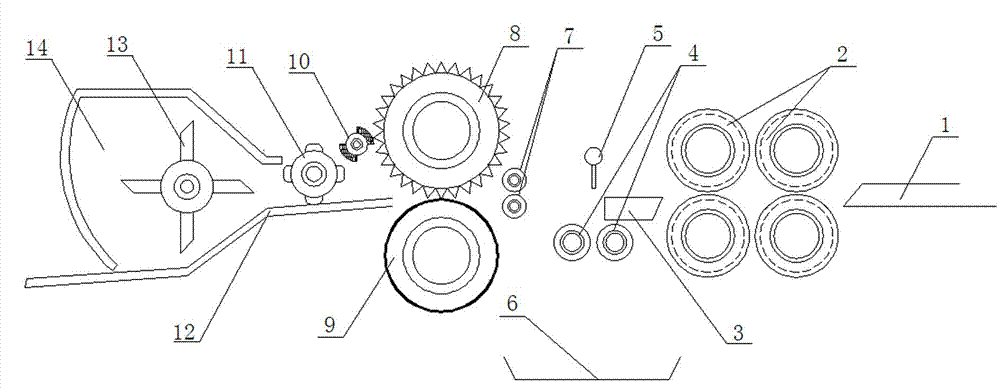

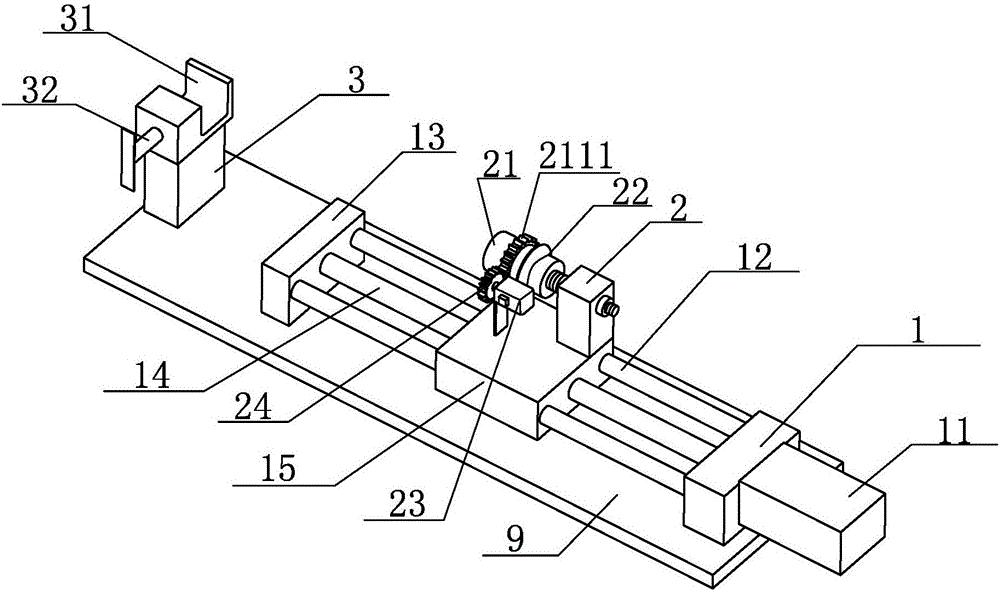

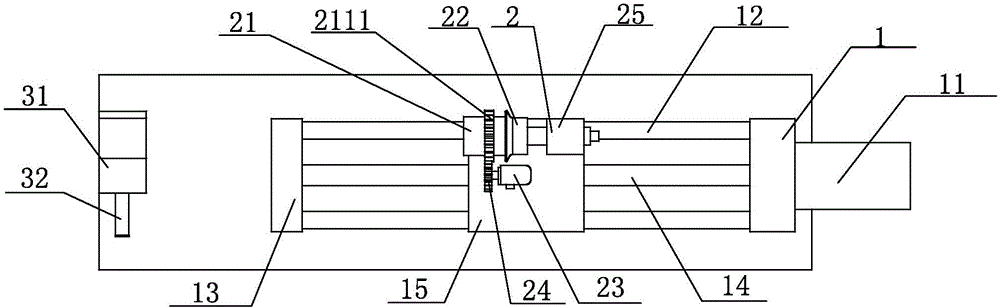

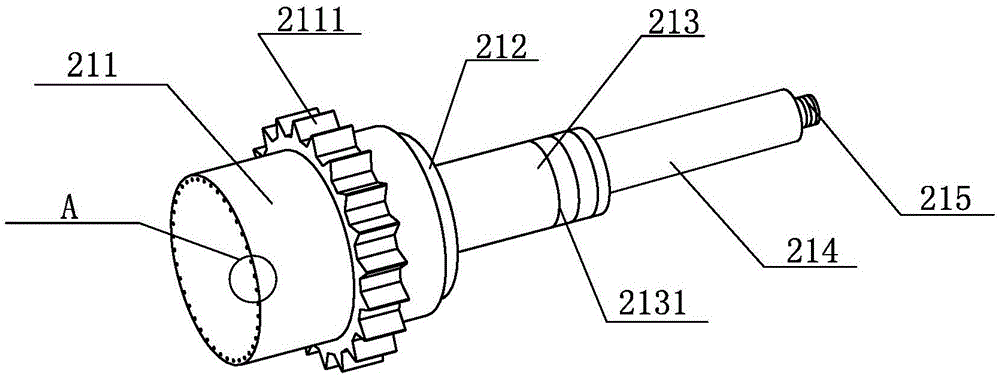

Mulberry twig bark and core separation and granulation combined machine

A mulberry twig bark and core separation and granulation combined machine comprises a bark and core separation device and a mulberry twig granulation device, wherein a transferring roller is arranged between the bark and core separation device and the mulberry twig granulation device. The mulberry twig bark and core separation and granulation combined machine is good in bark and core separation quality, the separation rate can reach 90%, separated mulberry barks are complete in shape, is small in damage to fibers and contains few impurities like wood chips, manufactured core rod aggregate particles are uniform in size, contain a little dust and a few large-particle materials, and can meet the process requirements on raw materials when mulberry extraction fibers and core rod aggregates are directly used for producing mulberry twig fiber boards, paper and fungus culture media, and the comprehensive utilization rate of the mulberry twigs is high. The mulberry twig bark and core separation and granulation combined machine is high in mechanical continuity degree, only the mulberry twigs are fed manually, product transportation, mulberry twig bark and core separation, mulberry bark collection, core rod granulation and collection and links between the work procedures are all automatically and continuously finished by equipment, a little work time is used, and production efficiency is high.

Owner:SICHUAN RES INST OF SILK SCI +1

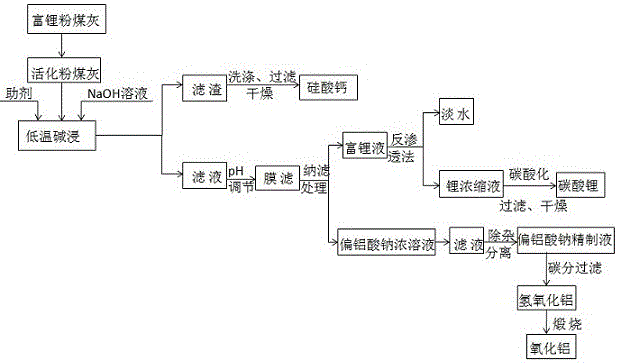

Method for separating and enriching lithium, aluminum and silicon from fly ash

ActiveCN106745016AEasy to recycleImprove leaching rateAlkaline-earth metal silicatesLithium carbonates/bicarbonatesCalcium silicateReverse osmosis

The invention discloses a method for separating and enriching lithium, aluminum and silicon from fly ash. The method comprises the following steps: (1) pretreating fly ash; (2) carrying out low-temperature alkali dip reaction on the treated fly ash, aids and a sodium hydroxide solution, and filtering; (3) washing the filter residue, removing the impurities, filtering, and drying to obtain calcium silicate; (4) regulating the pH value of the filtrate to alkalinity, separating the lithium / aluminum-containing filtrate to obtain a sodium metaaluminate concentrated solution and a lithium-rich solution, carrying out reverse osmosis on the lithium-rich solution to obtain a lithium concentrated solution, and mixing the sodium metaaluminate concentrated solution with the lithium / aluminum-containing filtrate to obtain a refined solution; (5) precipitating the sodium metaaluminate refined solution, filtering to obtain aluminum hydroxide, and calcining to obtain the aluminum oxide finished product; (6) treating the lithium-rich solution to obtain a lithium-rich concentrated solution and fresh water; and (7) carrying out carbonating precipitation on the lithium-rich concentrated solution, filtering, and drying to obtain the lithium carbonate finished product. The method is a short-stage extraction process, reduces the lithium loss, and implements separation, enrichment and extraction of calcium silicate, aluminum oxide and lithium carbonate.

Owner:HEBEI UNIV OF ENG

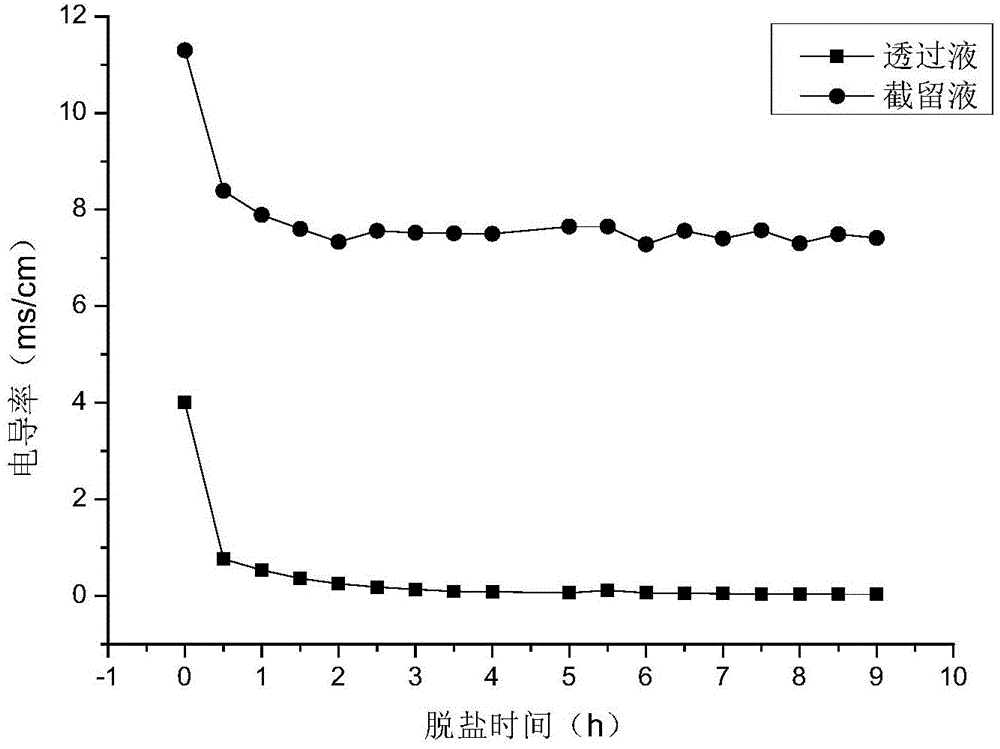

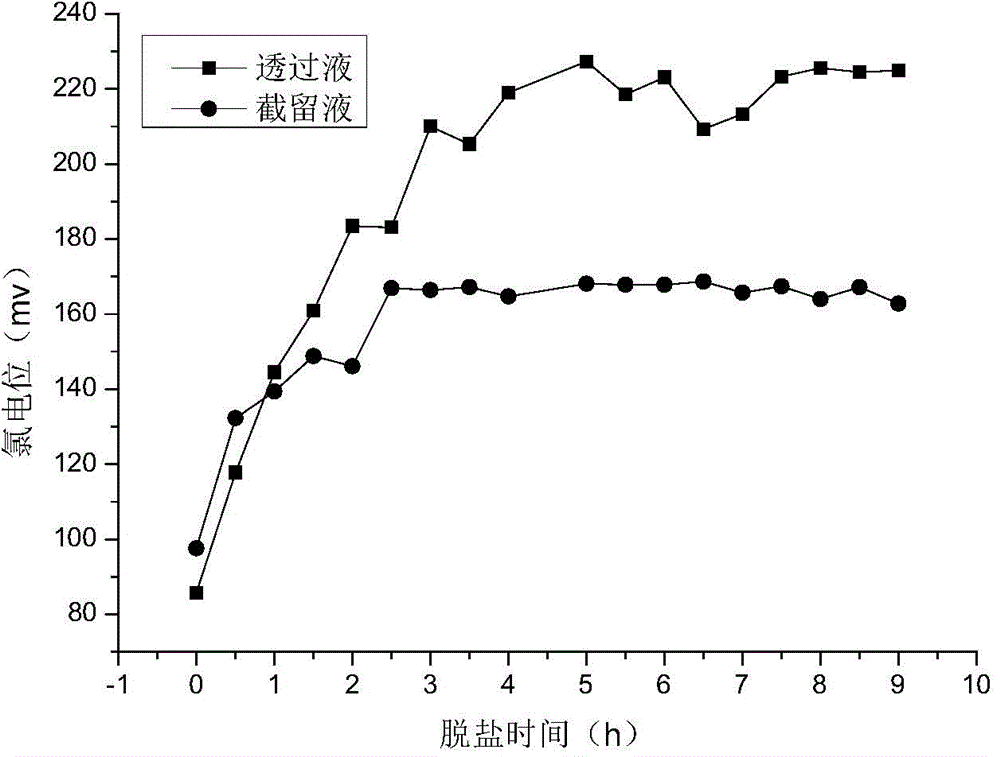

Process for purifying reactive dye for ink jet printing and reactive dye ink

The invention discloses a process for purifying reactive dye for ink jet printing. The process comprises the following steps: (1) precipitation reaction, namely preparing a crude dye aqueous solution by using the reactive dye and deionized water, then mixing to react by adding barium chloride in the crude dye solution under the condition of mixing to enable barium chloride and sulfate ions in the crude dye solution to fully react and produce precipitates; (2) centrifugal treatment, namely performing the centrifugal treatment of the reactive dye solution after the precipitation reaction of step (1); (3) desalting concentration treatment, namely performing desalting concentration treatment of the reactive dye solution through a nanofiltration membrane; (4) drying, namely drying the reactive dye solution after desalting concentration treatment to obtain high-purity reactive dye. The invention also discloses a reactive dye ink made of the reactive dye obtained by purification according to the purification process. The sulfate ions are effectively removed through the precipitation reaction and nanofiltration, the process is simple and feasible, the production cost is low, and the separation quality and the efficiency are high.

Owner:HONGSAM DIGITAL SCI & TECH

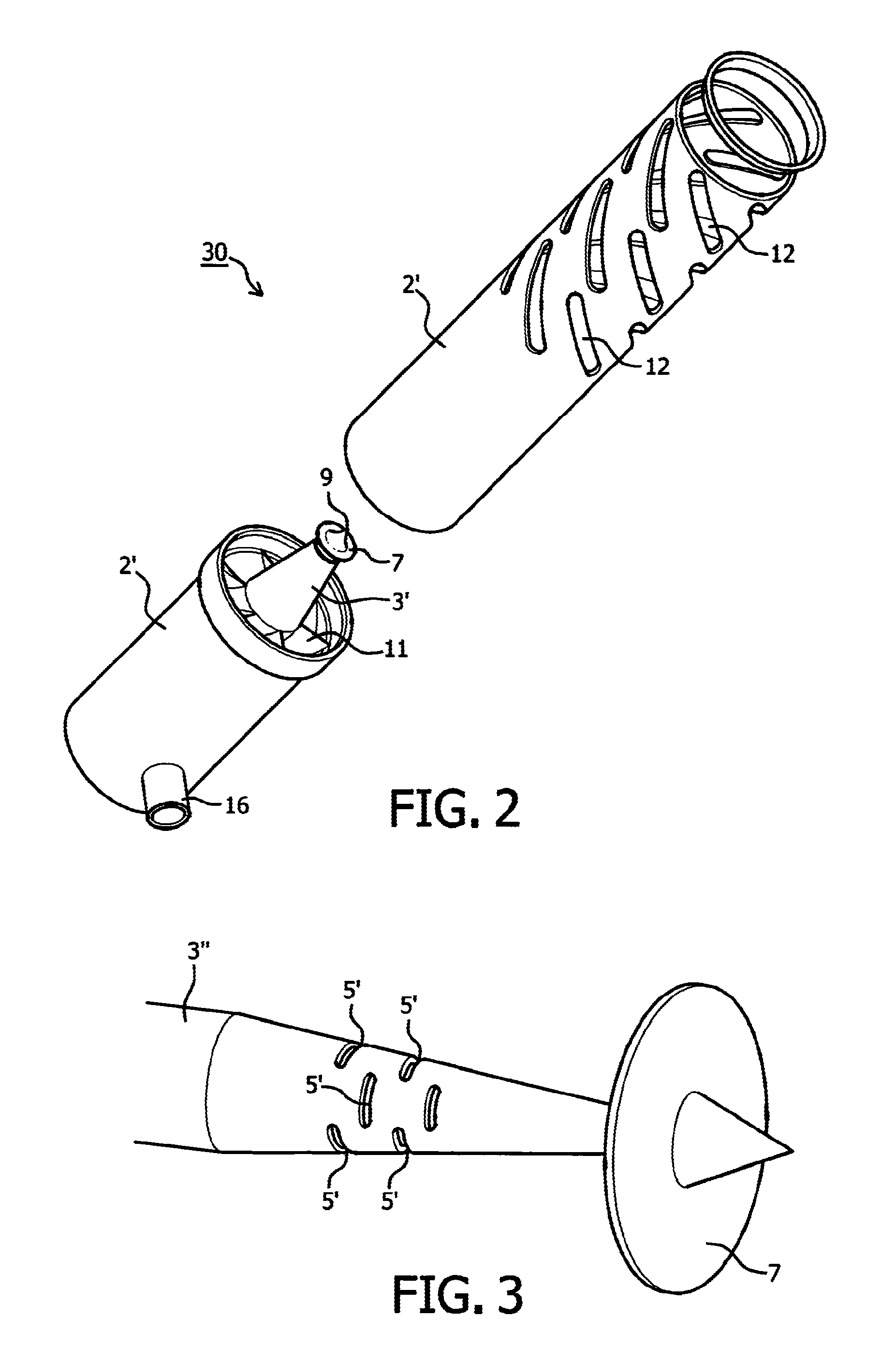

Method for phased separation of a sausage strand, separating element and assembly of separating elements

ActiveUS7625266B2Sufficient separating capacitySimple and inexpensive drivingLinked sausage separationSausage skin tying apparatusEngineeringControl manner

A method for phased separation of a sausage strand, a separating element for phased separation of a sausage strand, and an assembly of a plurality of such separating elements. In the production of sausages it frequently occurs that a sausage strand must be divided into smaller segments, and the result of this division is achieved in controlled manner by the present invention.

Owner:STORK TOWNSEND BV

Method and device for refining sulfoxide chloride

ActiveCN104591099AExport of finished products is flexibleEfficient cycleThionyl chlorideChemistryLiquid phase

The invention relates to a method and a device for refining sulfoxide chloride. The method comprises the following steps: after rectifying a crude product generated in a sulfoxide chloride synthesis step, performing overvulcanization and condensation on the rectified light component, putting a liquid-phase component obtained through gas-liquid separation into a rectification cycle and putting a gas-phase component obtained through gas-liquid separation into a synthesis step cycle; condensing the gas-phase component generated after the rectified light component is subjected to first vacuum distillation and then putting the condensed gas-phase component into the synthesis step cycle, and performing second vacuum rectification on a heavy component; performing overvulcanization and condensation on the light component obtained by virtue of the second vacuum rectification, returning the liquid-phase component obtained through gas-liquid separation to the second vacuum rectification step cycle, and returning the heavy component to the rectification step cycle; putting the gas-phase components obtained in the two stages of vacuum rectification steps into the synthesis step cycle, respectively. According to the method, a tower system sequence is arranged reasonably, the easily decomposable components are separated under vacuum and at a controlled temperature, and the components difficult to separate are cyclically rectified, and therefore, the separation accuracy and the product quality are improved; after multi-stage rectification, the purity of sulfoxide chloride is above 99.9%.

Owner:QINGDAO UNIV OF SCI & TECH

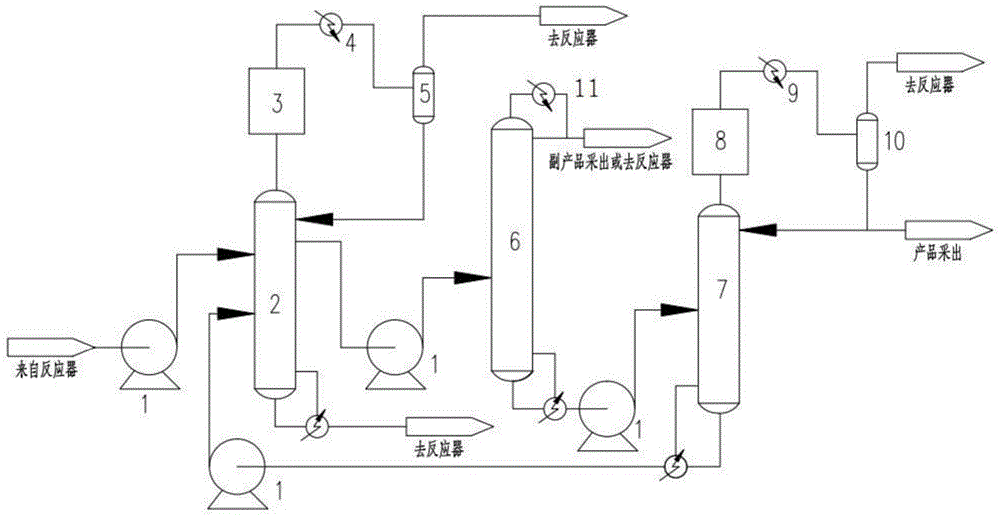

Three-phase separator system used in gas well liquid discharging process and using method

PendingCN110578510AOutgas preventionImprove separation qualityOperating means/releasing devices for valvesFluid removalEngineeringThree-phase

The invention relates to the technical field of gas and liquid separation, in particular to a three-phase separator system used in a gas well liquid discharging process and a using method. Different from an existing control method, 1, a liquid level is not controlled to run at a certain height in a separator, but the liquid level is controlled to run between a liquid outlet and a gas outlet; 2, the two gas and liquid outlets adopt pneumatic pressure adjusting valves of the same model and the same parameter for control, so that the two outlets are equal in adjusting pressure, and it is guaranteed that the separator is steady in work pressure; 3, the gas pressure adjusting values of the two gas and liquid outlets are controlled through one pressure adjusting valve, so that the two pneumaticadjusting valves are equal in control gas pressure, and therefore the pressure is equal, that is, the pressure in a separator tank is smooth and steady, and good separating is guaranteed; and 4, whenthe gas outlet contains liquid drops, it is only needed to adjust the control gas pressure of the pressure adjusting valve high, and then gas and liquid separating can be achieved; and if the liquid outflow and gas outflow amounts are both very small, the control gas pressure of the pressure adjusting valve is adjusted small to lower return pressure on a well opening, and then normal liquid discharging of a gas well can be achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

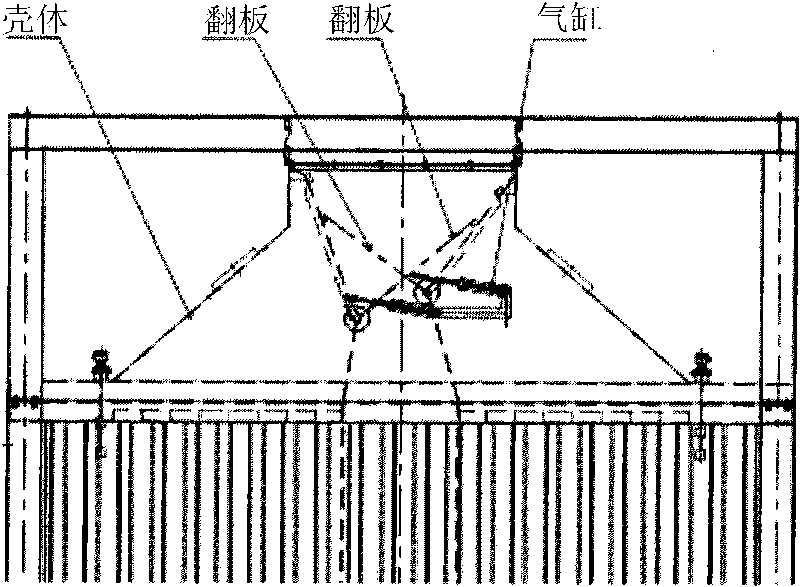

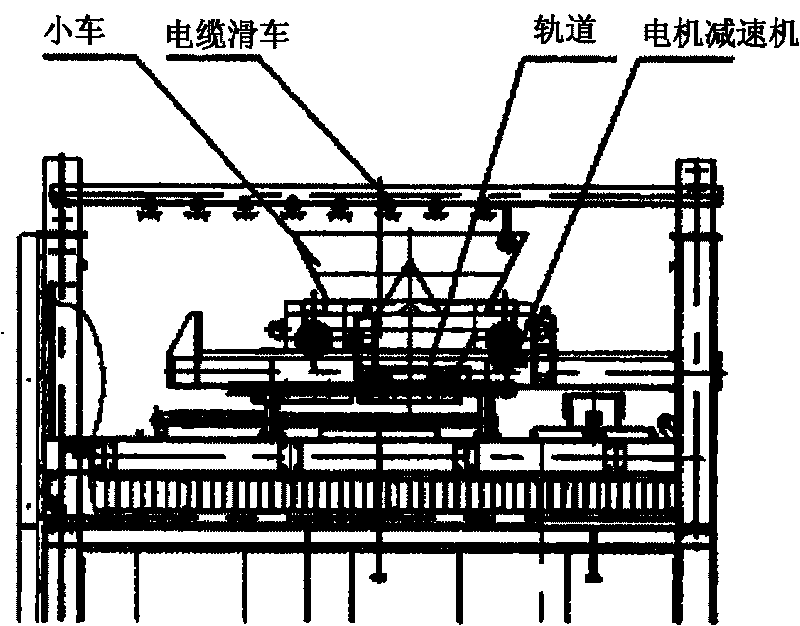

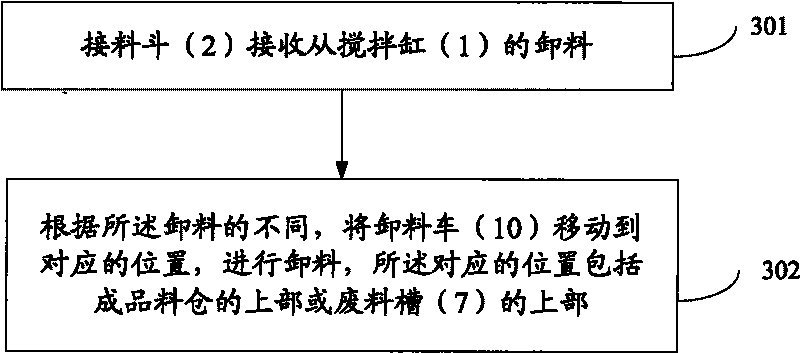

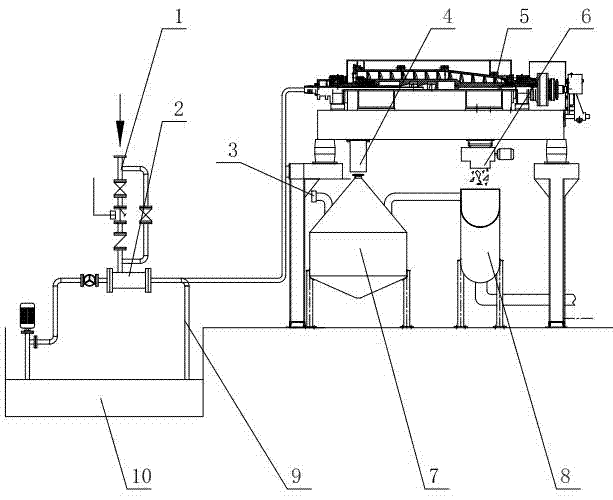

Unloading method, device and underlying bin type mixing station with device

ActiveCN101723185AEasy to separateReduce complexityCement mixing apparatusLoading/unloadingWaste materialEngineering

The embodiment of invention discloses an unloading method, an unloading device and an underlying bin type mixing station with the unloading device. The method and the device are applied to the underlying bin type mixing station. The method comprises the following steps: receiving an unloaded material from a stirring tank (1) by a material receiving hopper (2); and moving an unloading car (10) to a corresponding position for unloading according to the difference of unloaded materials, wherein the corresponding position comprises the upper part of a finished product material bin or the upper part of a waste material groove (7). The unloading method, the unloading device and the underlying bin type mixing station of the invention simply separate waste materials from finished product materials, decrease the complexity of the unloading device and improve the separation quality.

Owner:SANY HEAVY IND CO LTD (CN)

Kitchen waste oil-water-solid separation device of kitchen waste

InactiveCN103086557AIncrease pressureGuaranteed to workFatty/oily/floating substances removal devicesMultistage water/sewage treatmentProduction lineInjection port

The invention discloses a kitchen waste oil-water-solid separation device consisting of a steam mixing section, a solid-liquid separation section and an oil-water separation section, wherein the steam mixing section is provided with a steam-water mixer; high-temperature steam is input from the steam inlet of the steam-water mixer; the absorption inlet of the steam-water mixer is communicated with a slag-liquid mixing groove; the injection port of the steam-water mixer is communicated with the input end of a solid-liquid separation machine; and the liquid exhaust port of the solid-liquid separation machine exhausts to an oil-water separator. According to the invention, the steam-water mixer for heating directly on a pipeline mixes high-temperature steam in crushing slag liquids, not only can the operation continuity be ensured, but also the whole treatment can be operated in a production line, continuity and scale mode, and moreover, mixed liquids output from the injection port has high temperature and high pressure, and enter the solid-liquid separator directly for solid-liquid separation, and additional delivery equipment is not required; and the efficiency is high, and the separation quality is good.

Owner:WUXI SAIYA ENVIRONMENTAL PROTECTION TECH

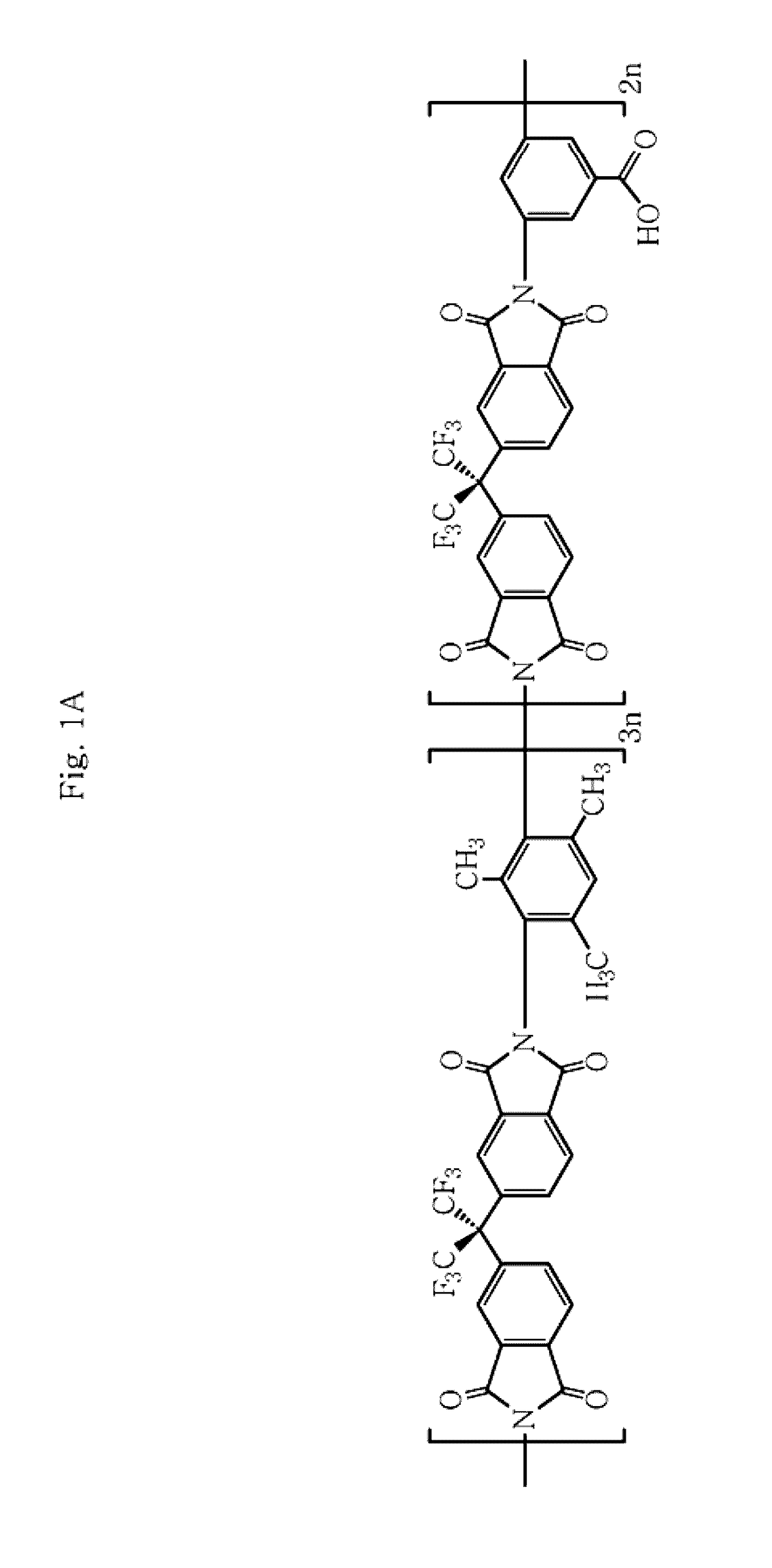

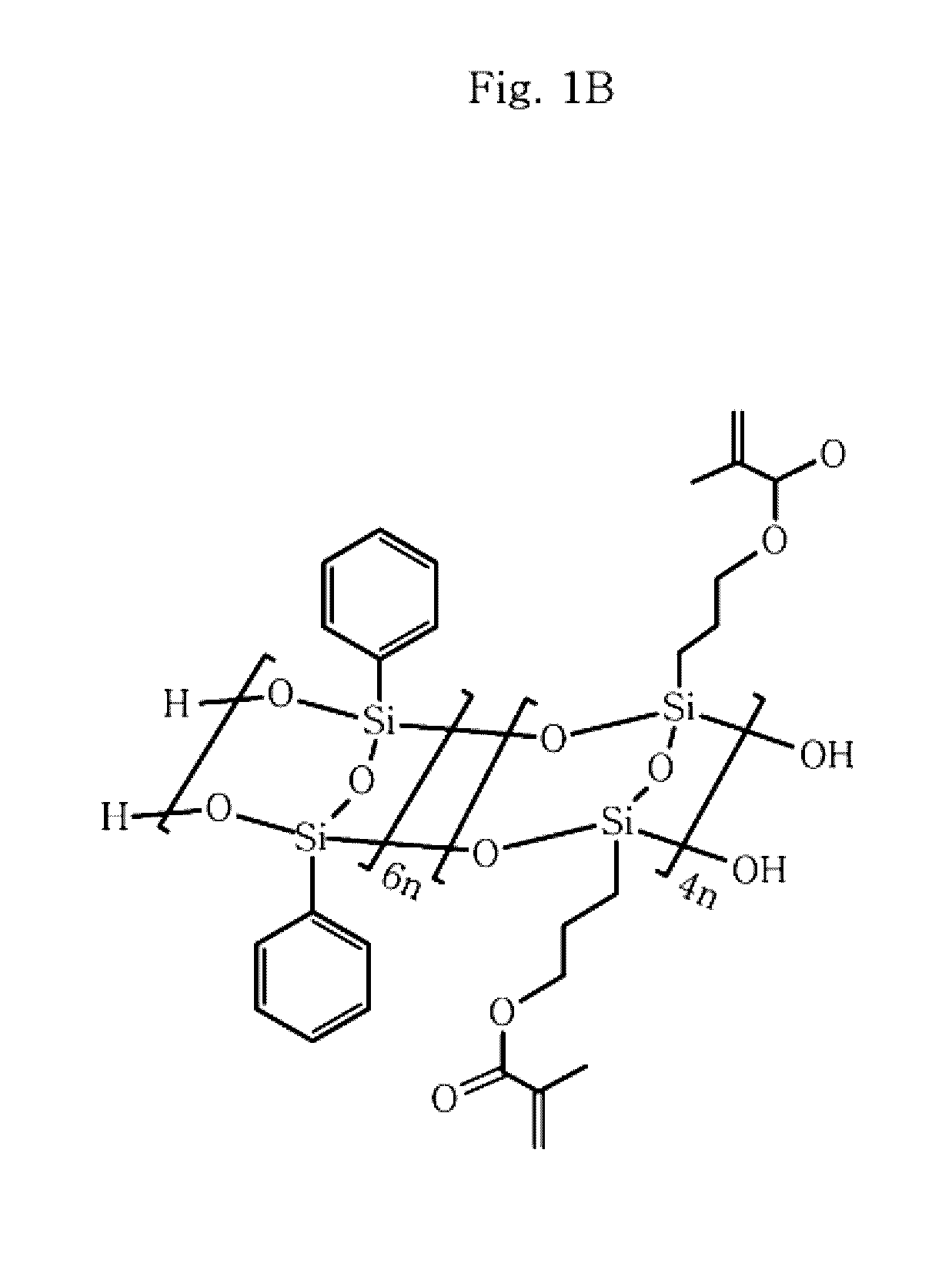

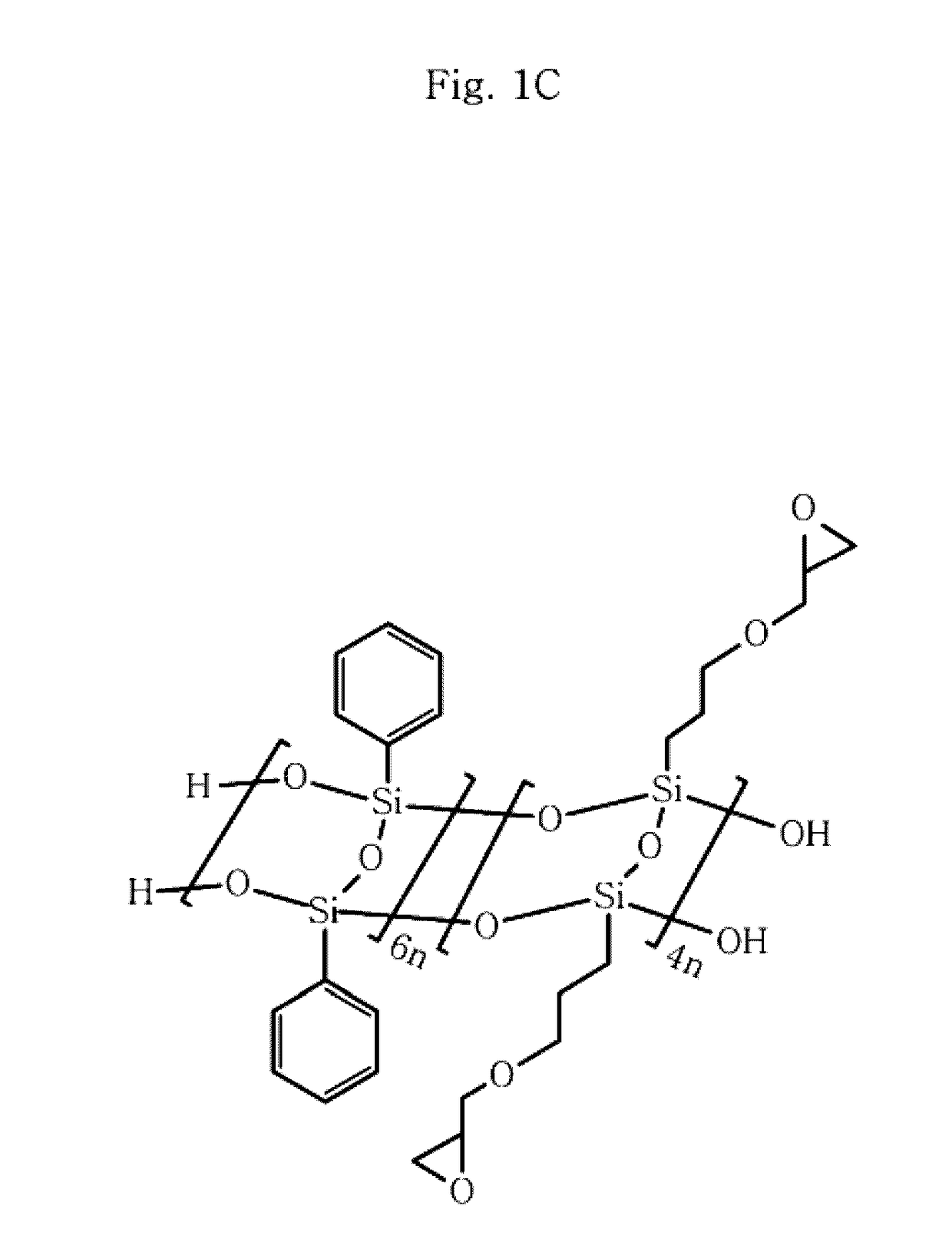

Carbon molecular sieve membranes based on fluorine-containing polymer/polysilsesquioxane blending precursors and method for fabricating the same

ActiveUS20170120200A1Improve selectivityHigh free volumeMembranesSemi-permeable membranesChemistryMolecular sieve

Provided is a composition for use in fabricating a carbon molecular sieve membrane, including a fluorine-containing polymer matrix and polysilsesquioxane. The composition shows high selectivity to the gas to be separated and high separation quality by controlling the mixing ratio of the fluorine-containing polymer matrix with polysilsesquioxane as well as the type of fluorine-containing polymer matrix and polysilsesquioxane. Ancillary selective pore formation is enhanced by a so-called “autogenous fluorinated gas induced siloxane etching” (A-FISE) mechanism of fluorine-containing polymer / polysilsesquioxane blend precursors during carbonization. Therefore, it is possible to effectively separate gases having a small difference in particle size, which, otherwise, are difficult to be separated with the conventional polymer membranes.

Owner:KOREA INST OF SCI & TECH

Small automatic garbage sorting device

InactiveCN108672326AImprove sorting efficiency and qualitySpeed up reuseSortingElectromagnetic inductionGravitation

The invention discloses a small automatic garbage sorting device which is a box structure formed by connecting a plurality of garbage sorting and recycling units. The garbage sorting and recycling units comprise conveying mechanisms, screening mechanisms, sliding mechanisms, recycling mechanisms, and post-processing mechanisms. Wherein the screening mechanisms are sequentially an electromagnetic induction screening mechanism, a photosensitive induction screening mechanism and a gravity sensing screening mechanism; the screening mechanisms and the recycling mechanisms respectively correspond tobe matched through sliding mechanisms. The box-type structure of the ''upper, middle and lower'' are used for separating different kinds of garbage accurately through three circular sorting in a garbage classification device for the first time, and the defect that the garbage classification device can only sort garbage one-time can be filled. In addition, the sorting efficiency and the quality are improved on the basis of guaranteeing the separation precision, and therefore the resource reuse speed is accelerated.

Owner:SHANGHAI DIANJI UNIV

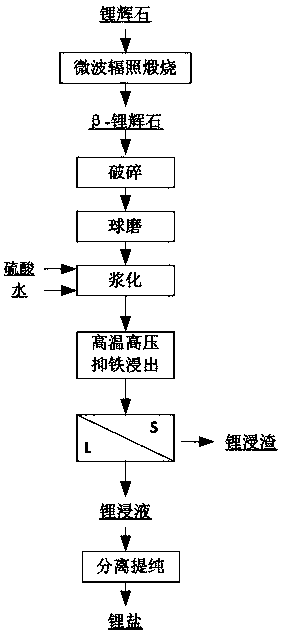

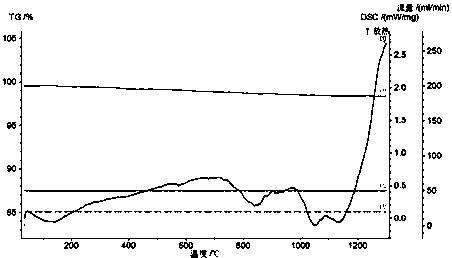

Method for leaching spodumene based on combination of microwave and pressure field

ActiveCN108165767AEmission reductionAvoid pollutionProcess efficiency improvementLithium sulphateIrradiation

The invention discloses a method for leaching spodumene based on combination of a microwave and a pressure field, and belongs to the production technology field of lithium salt extracted from spodumene in chemical metallurgy. The method comprises the steps of (1) grinding ore; (2) transforming an out-field irradiation crystal form; (3) pressure leaching; and (4) separating and purifying. Accordingto the technical scheme, microwave irradiation is adopted on the spodumene, so that a crystal form transformation temperature range is expanded; and then a direct sulfuric acid leaching process is carried out on the irradiated spodumene, valuable metals such as lithium are leached into lithium sulfate under the conditions of heating and pressurizing, then the lithium sulfate is separated and purified, a solution is recovered, and a final product i.e. the lithium salt is obtained, so that an application range of a complicated spodumene raw material is further expanded. The technical scheme hasthe advantages of short flow, energy conservation, emission reduction, excellent current joining process and the like.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Separating device and method with a return flow of heavy fraction

ActiveUS8991622B2Excellent separation propertyLess creepDispersed particle separationCentrifugal force sediment separationMain channelReturn channel

The invention relates to a device for separating a heavy fraction from a fluid, comprising: a main channel; swirl means in the main channel; collecting means adjoining the main channel for collecting the discharge heavy fraction; a concentric additional supply conduit with an outlet and extending into the cylindrical housing; a return channel connecting the collecting means with the additional supply conduit, and deflection means wherein the outlet is encircling the circumference of the additional supply conduit. The invention also relates to a method for separating a heavy fraction from a fluid using such a device.

Owner:SULZER MANAGEMENT AG

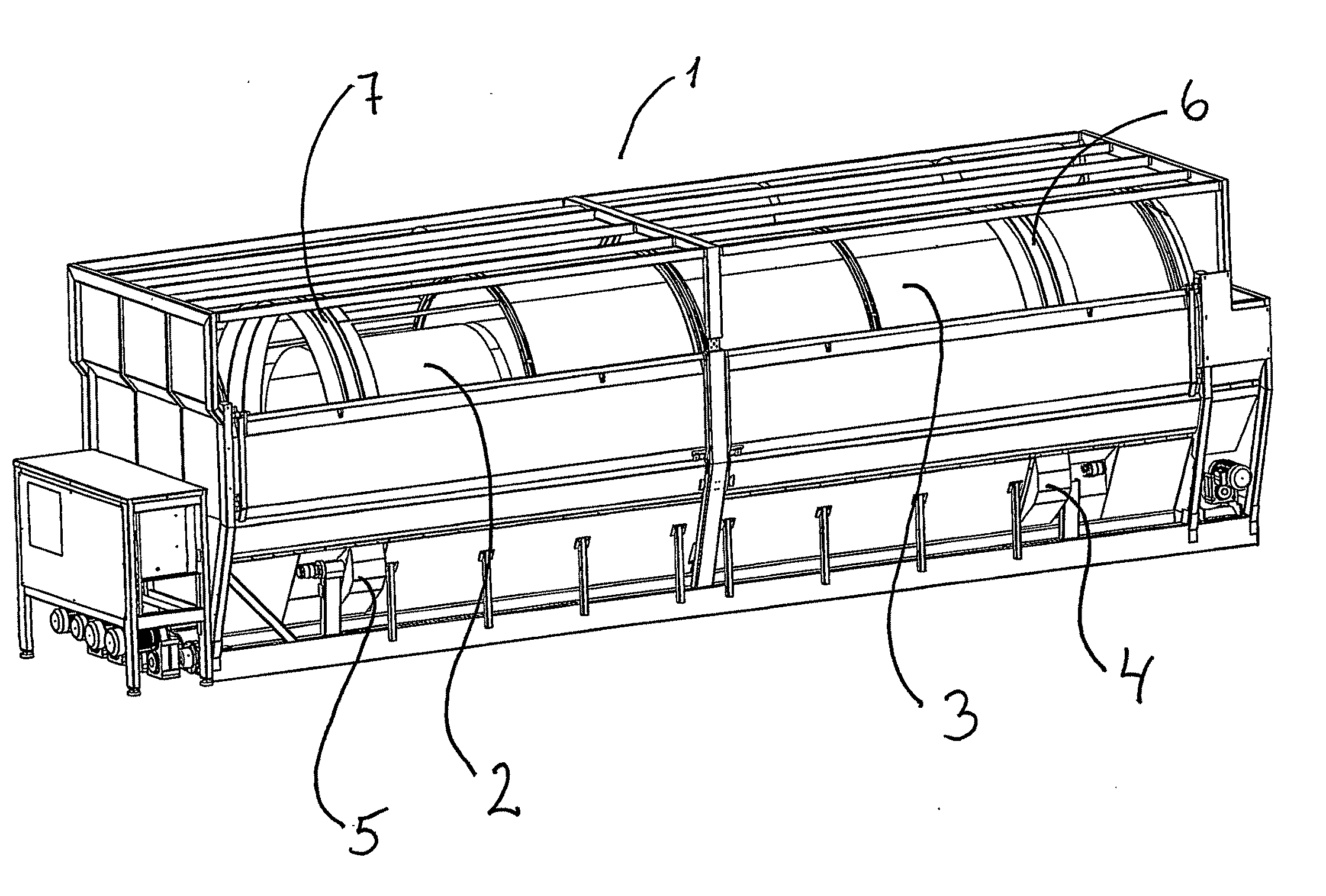

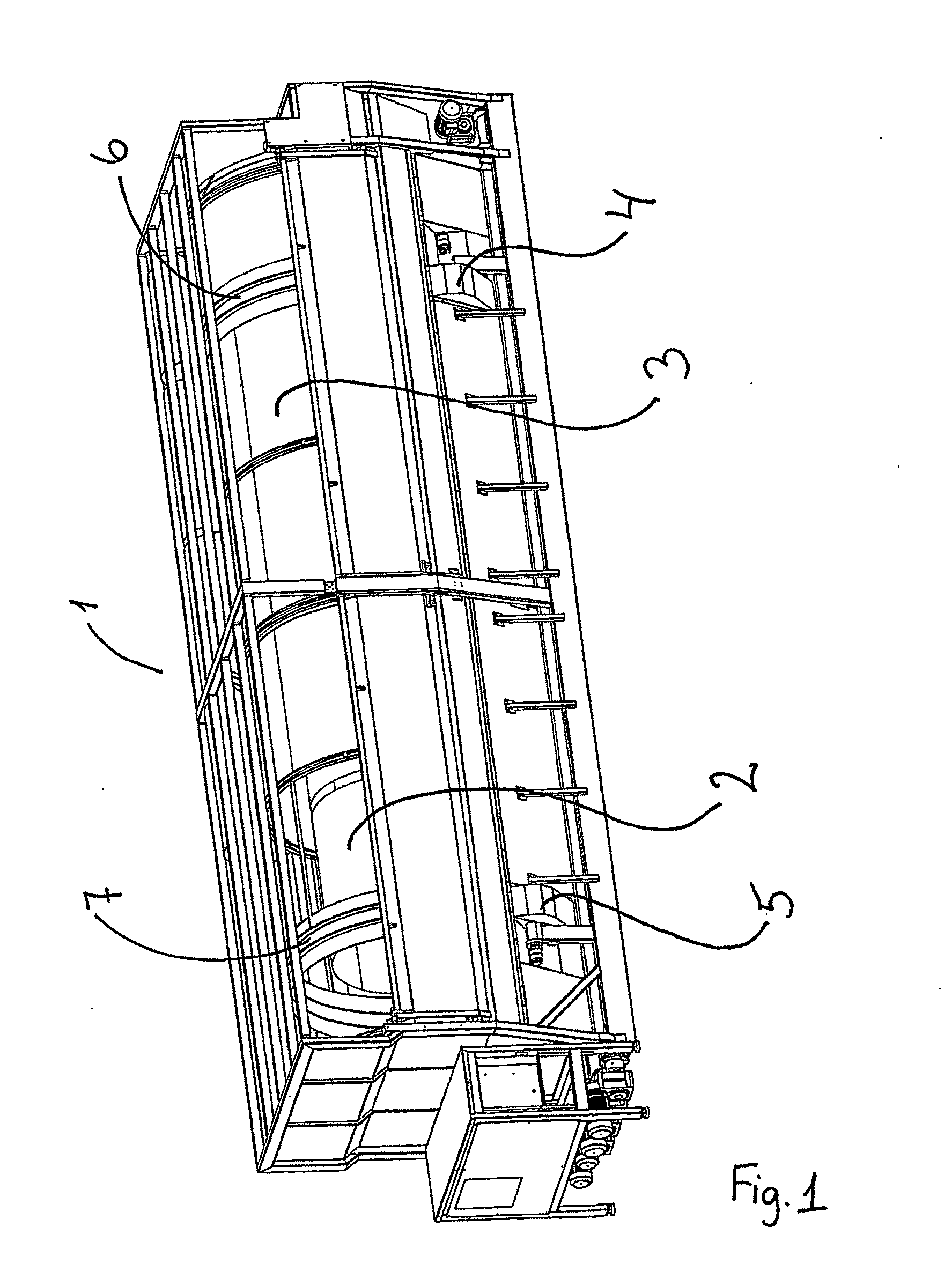

Double Wall Separating Drum

InactiveUS20090218256A1Improve separation qualityIncrease the amount of materialSievingConstruction waste recoveryDouble walledMechanical engineering

Separating device, comprising a rotatable double walled separating drum, where a first wall of the drum constituting the inner drum (2) is arranged concentrically inside and space from a second wall constituting the outer drum (3) of the separating drum, and that a plurality of apertures are provided in said drum walls, where the apertures in the first wall have larger openings than the apertures in the second wall, and that the axis about which the drum rotates may be arranged at an inclined angle in relation to a horizontal plane.

Owner:GIPS RECYCLING

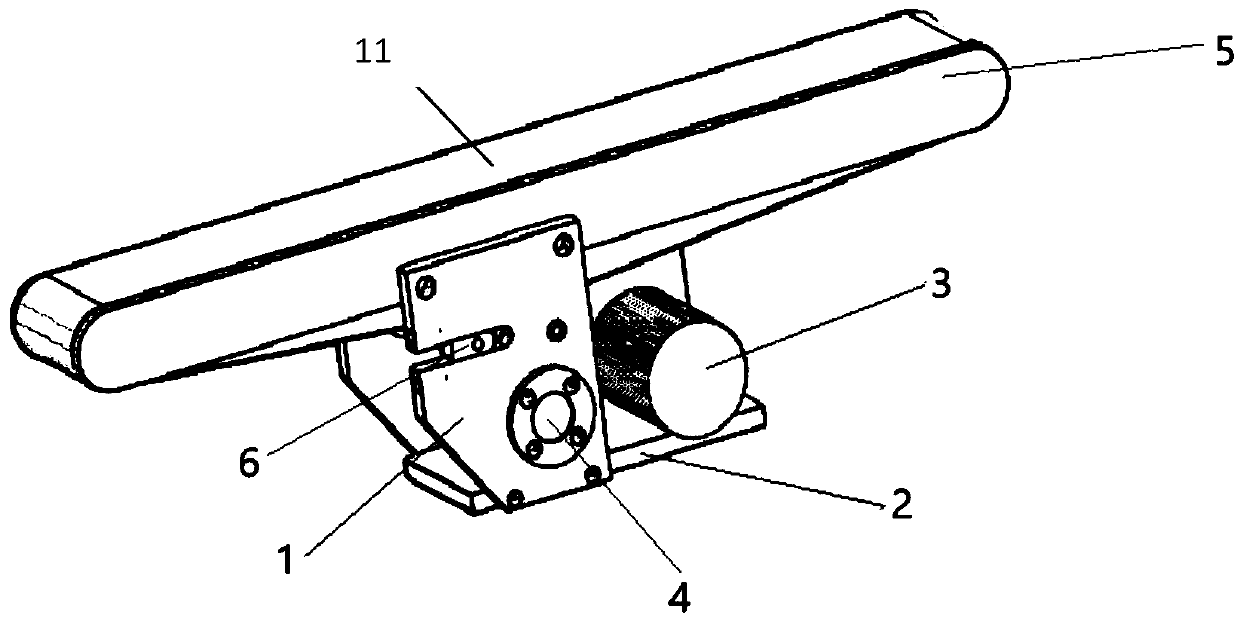

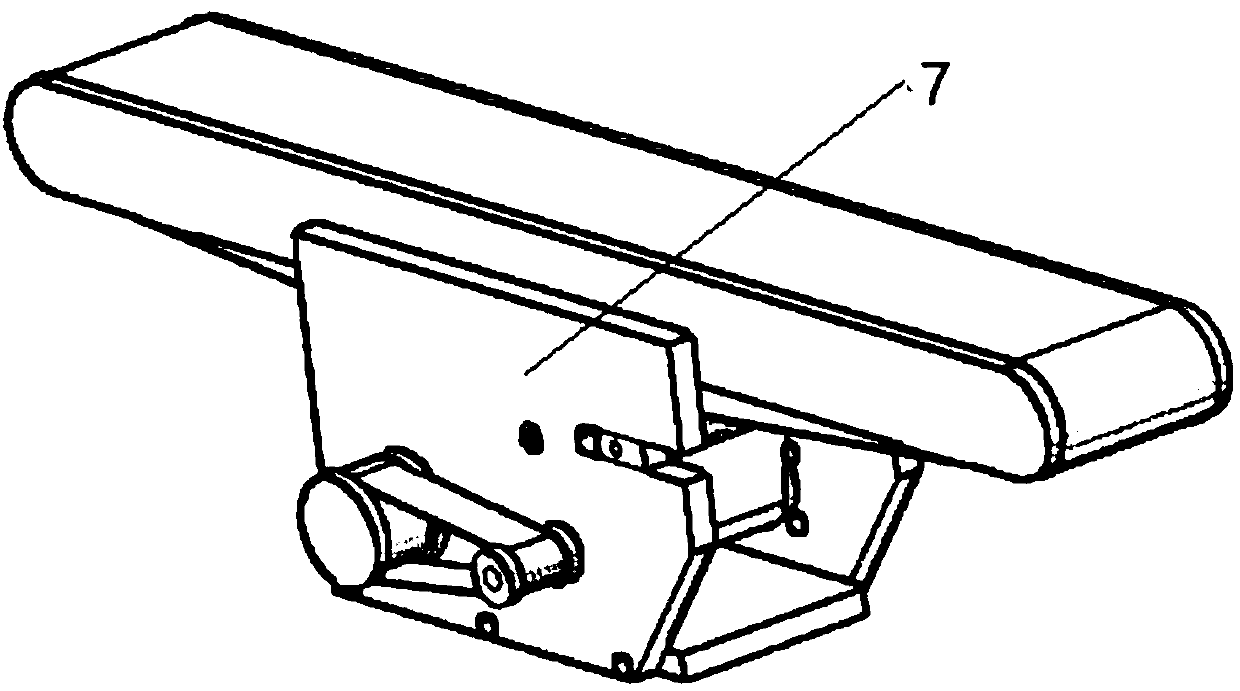

Cable synchronous separating and tensioning device

ActiveCN106270298AAchieve tensionPrevent rewinding phenomenonApparatus for overhead lines/cablesScrew threadEngineering

Owner:SHANGHE COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

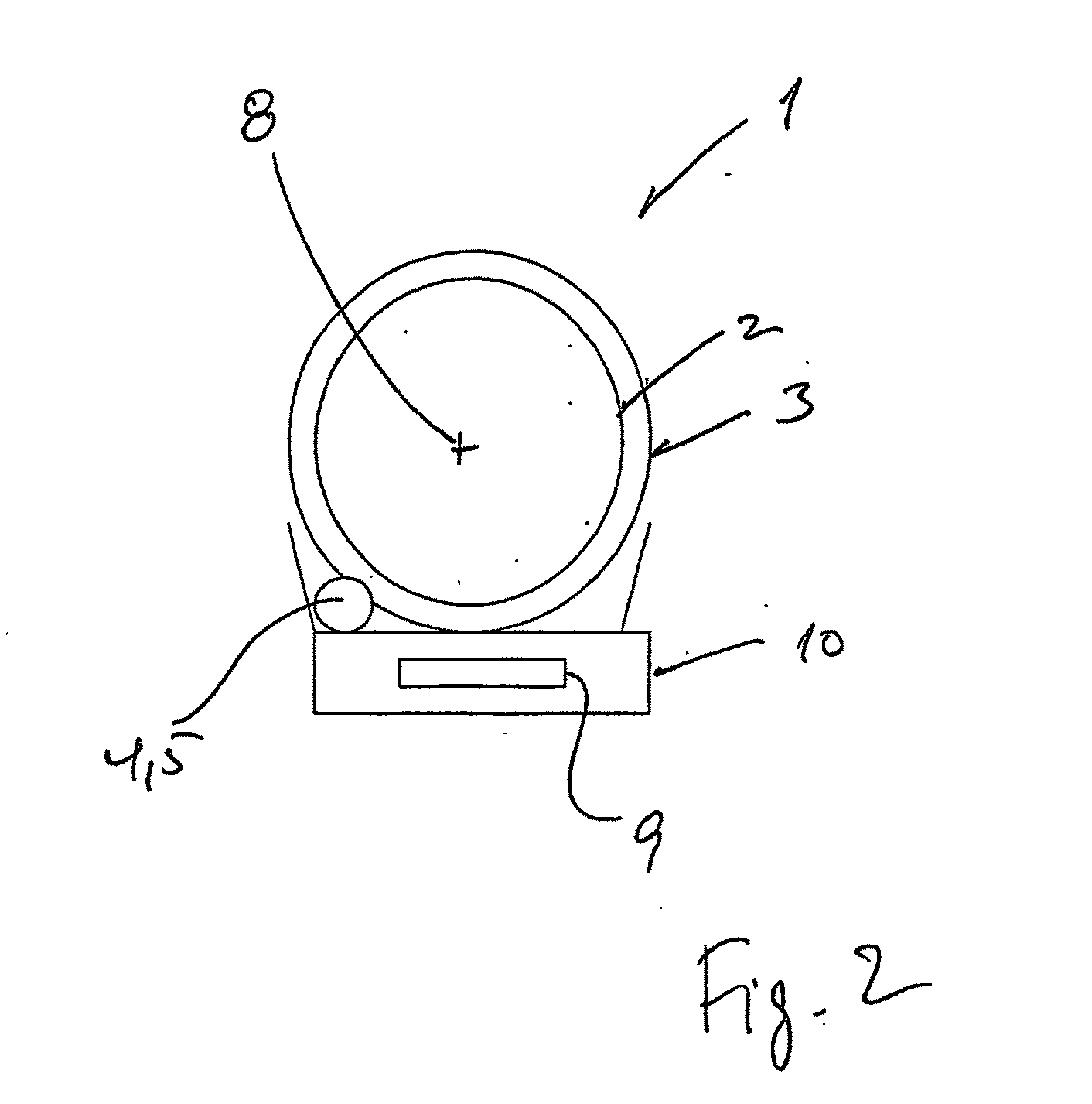

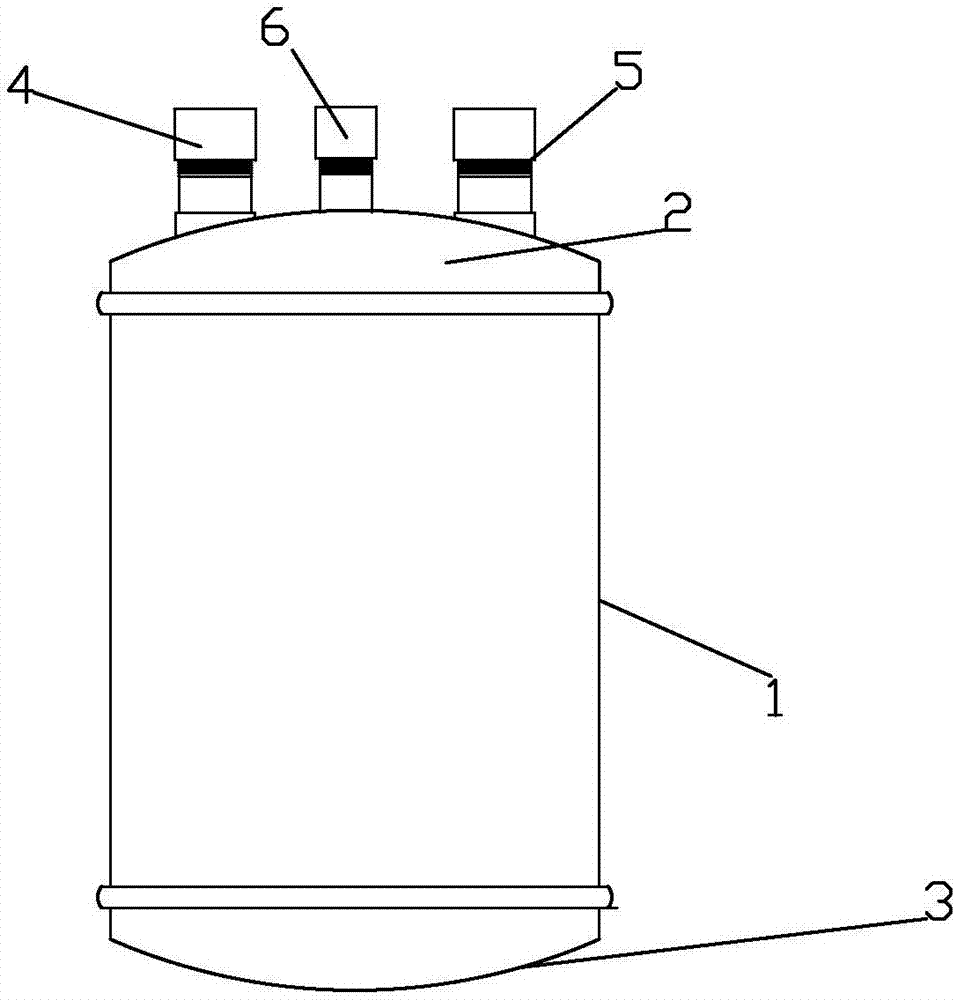

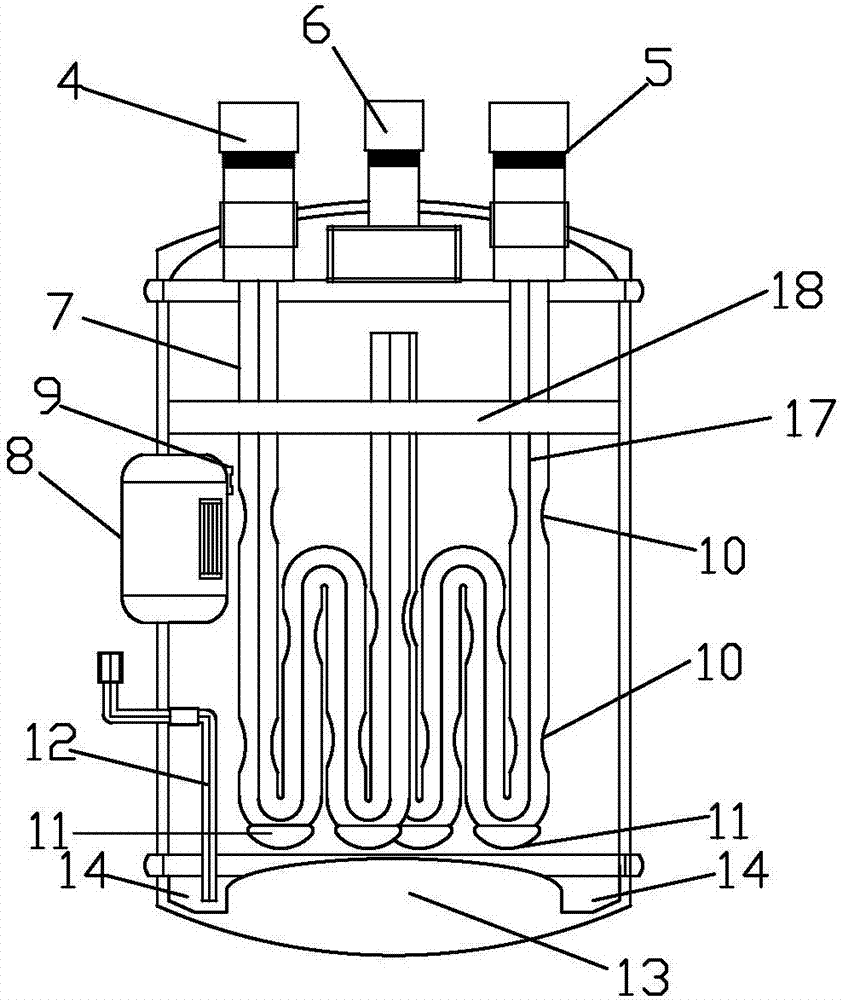

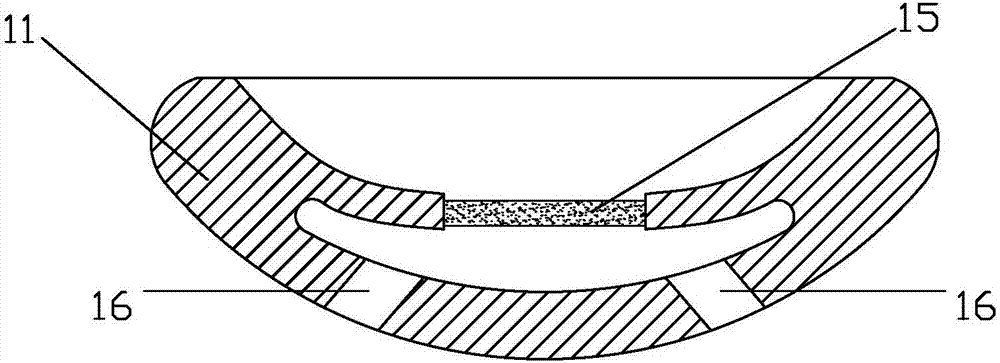

Gas-liquid separator for multi-connected heat pump and manufacturing method of gas-liquid separator

ActiveCN107388649AFast forming rateReduce defective rateRefrigeration componentsMaterials preparationVapor–liquid separator

The invention discloses a gas-liquid separator for a multi-connected heat pump and a manufacturing method of the gas-liquid separator. The gas-liquid separator comprises a barrel, a gas inlet pipe, a gas outlet pipe and a liquid outlet pipe, a gas-liquid separation coiler is connected to the gas inlet pipe, the other end of the gas-liquid separation coiler faces the gas outlet pipe, and a liquid pocket is connected to the lower end of the gas-liquid separation coiler; and a thermostatic controller is installed on the barrel and is used for maintaining the temperature in the device. The manufacturing steps of the gas-liquid separator include that (1) physical design of the gas-liquid separator is carried out; (2) sample testing of the gas-liquid separator is carried out; (3) material preparation is made; (4) part machining is carried out; (5) part assembling is carried out; (6) welding is carried out; and (7) aftertreatment is carried out. According to the manufacturing method, the molding rate is high, the inferior-quality product rate is low, the product quality is high, and huge economic benefits can be brought to enterprises; and the gas-liquid separator is high in separation efficiency, thorough in gas-liquid separation and long in service life.

Owner:青岛开拓隆海智控有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com