Method for efficiently recovering copper and rhenium from copper smelting waste acid

A technology for copper smelting and copper recovery, applied in the direction of improving process efficiency, etc., can solve the problems of low copper rhenium recovery rate, neglect, waste of secondary resources, etc., to improve the quality of liquid-solid separation, improve the precipitation effect, and increase the recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

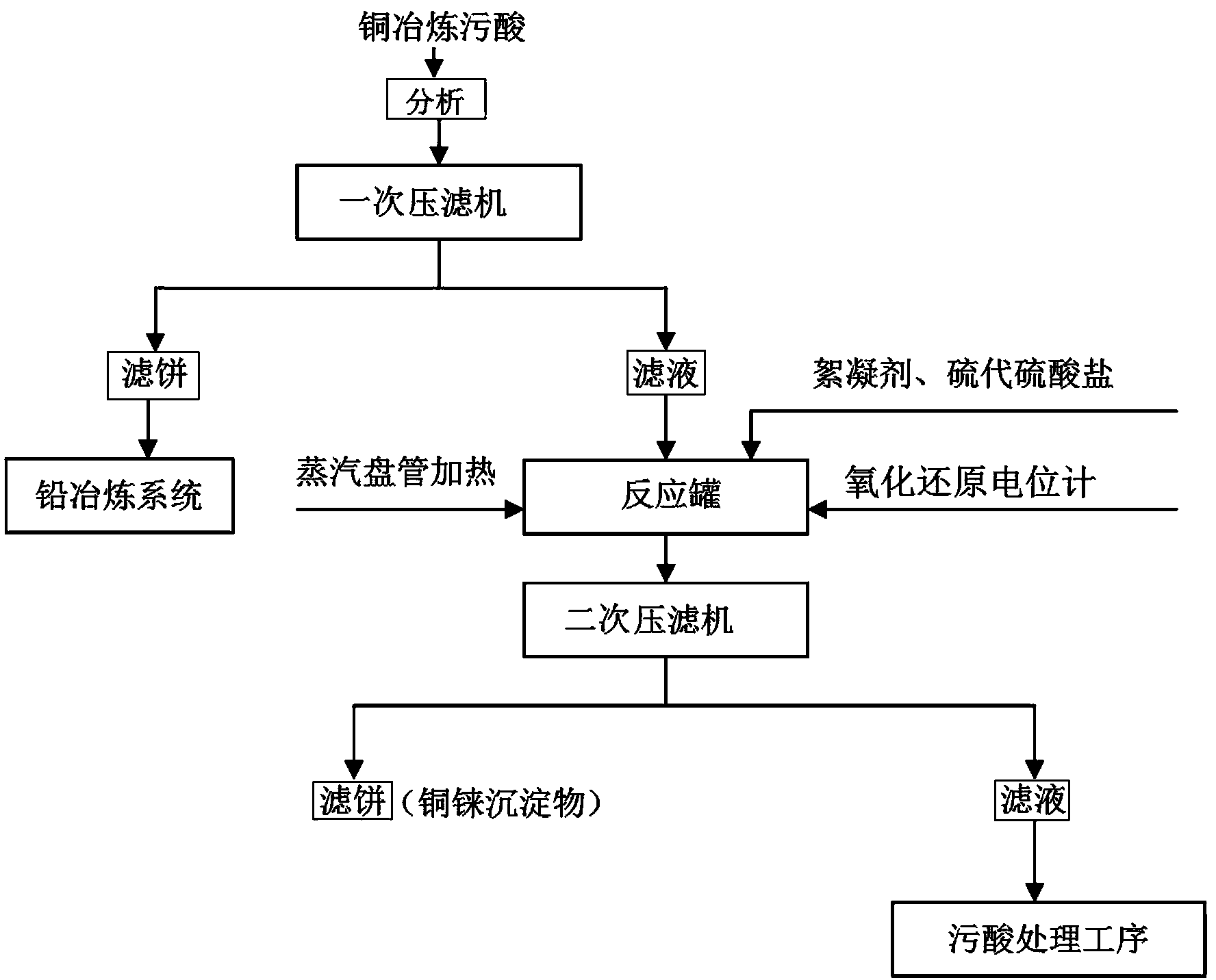

[0021] (1) Take 5 m of copper smelting sewage acid 3 , spent acid composition: H 2 SO 4 : 50 g / L, Cu : 0.2 g / L, As : g / L, Re : 0.01 g / L;

[0022] (2) Add the copper smelting dirty acid in step 1 into a filter press to filter and remove lead in the copper smelting dirty acid, the filtrate is the copper smelting dirty acid purification solution, and the filter cake is returned to the lead smelting system as lead deposits;

[0023] (3) Add the copper smelting sewage acid purification solution in step 2 into the reaction tank and heat it to 60°C with a steam tube coil, turn on the stirrer, control the stirring speed to 80r / min, and use the redox potentiometer to detect the initial oxidation of the reaction solution Reduction potential, detection value is 240 mv;

[0024] (4) Add thiosulfate and flocculant in step 3. Thiosulfate is prepared by dissolving sodium thiosulfate to make a 5%-20% solution, and flocculant is to dissolve polyacrylamide with water to form a glue-like liqu...

Embodiment 2

[0027] (1) Take 5 m of copper smelting sewage acid 3 , spent acid composition: H 2 SO 4 : 102.49 g / L, Cu: 0.280 g / L, As: 4.59 g / L, Re: 0.06695 g / L;

[0028] (2) Add the copper smelting dirty acid in step 1 into a filter press to filter and remove lead in the copper smelting dirty acid, the filtrate is the copper smelting dirty acid purification solution, and the filter cake is returned to the lead smelting system as lead deposits;

[0029] (3) Add the copper smelting sewage acid purification solution in step 2 into the reaction tank and heat it to 70°C with a steam tube coil, turn on the stirrer, control the stirring speed to 100r / min, and use the redox potentiometer to detect the initial oxidation of the reaction solution Reduction potential, detection value is 264 mv;

[0030] (4) Add thiosulfate and flocculant in step 3. Thiosulfate is prepared by dissolving sodium thiosulfate to make a 5%-20% solution, and flocculant is to dissolve polyacrylamide with water to form a gl...

Embodiment 3

[0033] (1) Take 5 m of copper smelting sewage acid 3 , spent acid composition: H 2 SO 4 : 200 g / L, Cu: 0.6 g / L, As: 5 g / L, Re: 0.08 g / L;

[0034] (2) Add the copper smelting dirty acid in step 1 into a filter press to filter and remove lead in the copper smelting dirty acid, the filtrate is the copper smelting dirty acid purification solution, and the filter cake is returned to the lead smelting system as lead deposits;

[0035] (3) Add the copper smelting sewage acid purification solution in step 2 into the reaction tank and heat it to 80°C with a steam tube coil, turn on the stirrer, control the stirring speed to 120r / min, and use the redox potentiometer to detect the initial redox potential at the same time, The detected value is 360 mv;

[0036](4) Add thiosulfate and flocculant in step 3. Thiosulfate is prepared by dissolving sodium thiosulfate to make a 5%-20% solution, and flocculant is to dissolve polyacrylamide with water to form a glue-like liquid , the proportio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com