Negative pressure air jet deep well dewatering device of foundation pit

A deep well precipitation and air jet technology, which is applied in infrastructure engineering, construction, etc., can solve the problems of reduced precipitation efficiency, slow precipitation speed, waste of human resources, etc., and achieve the effects of easy construction, increased precipitation speed, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

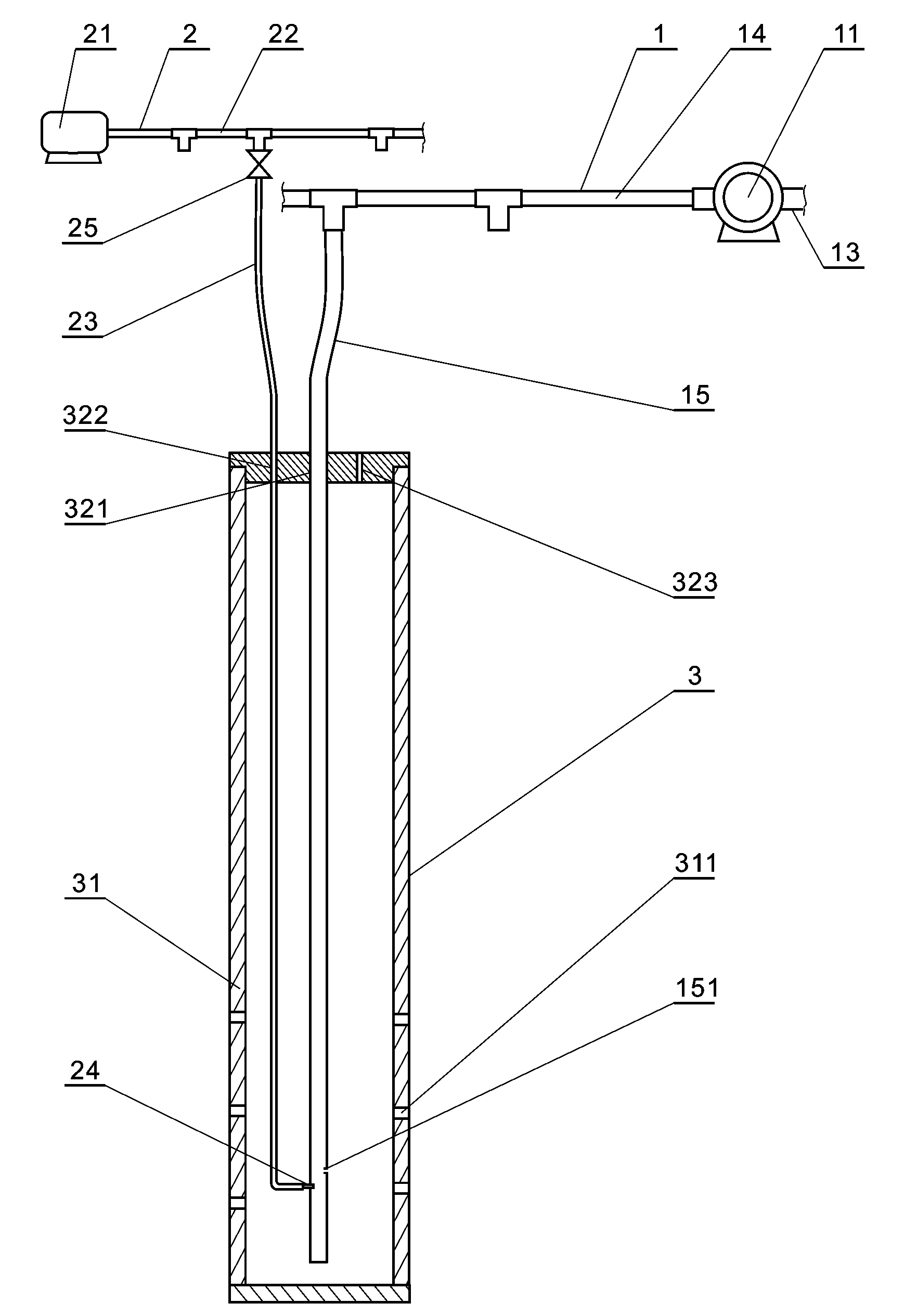

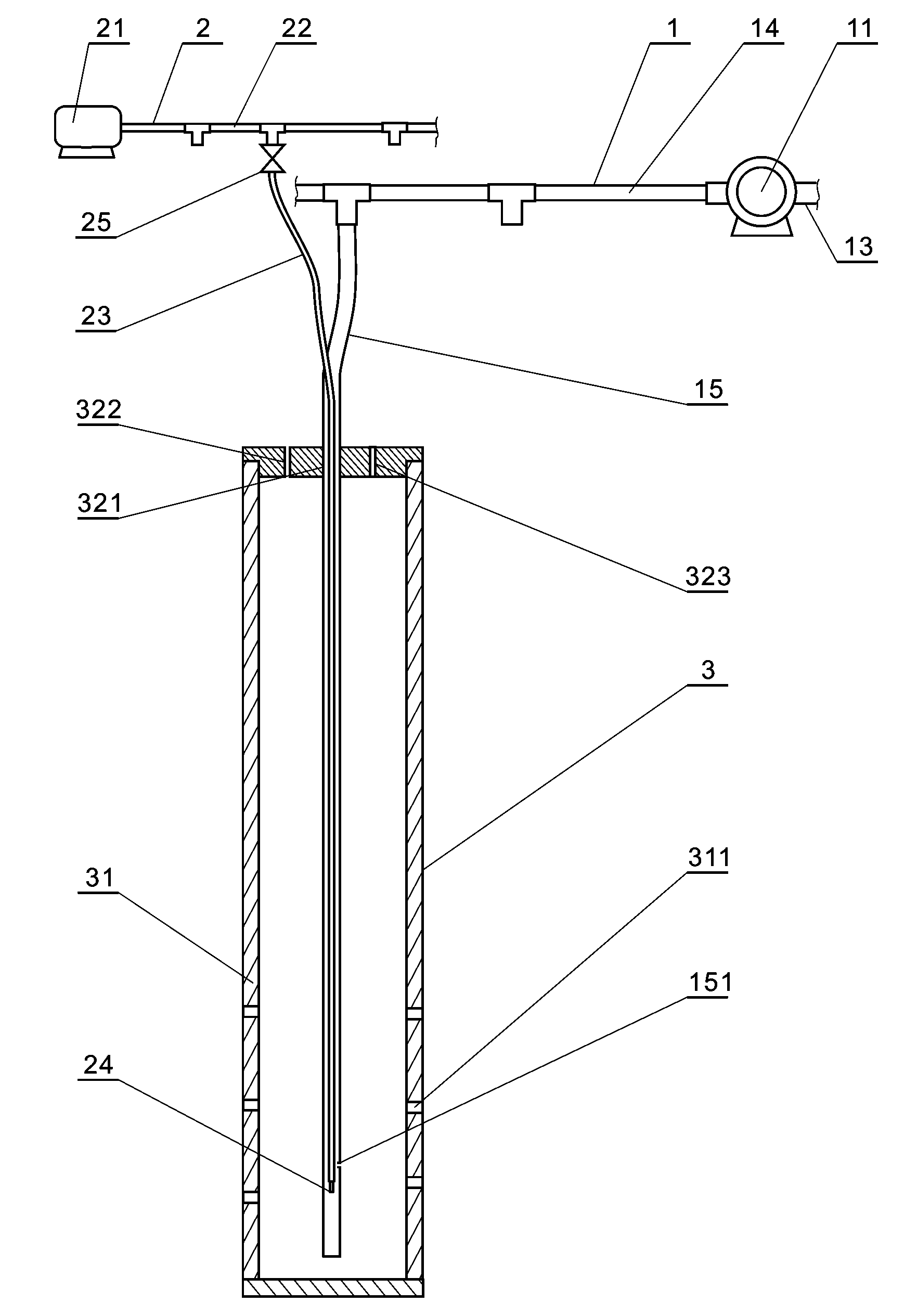

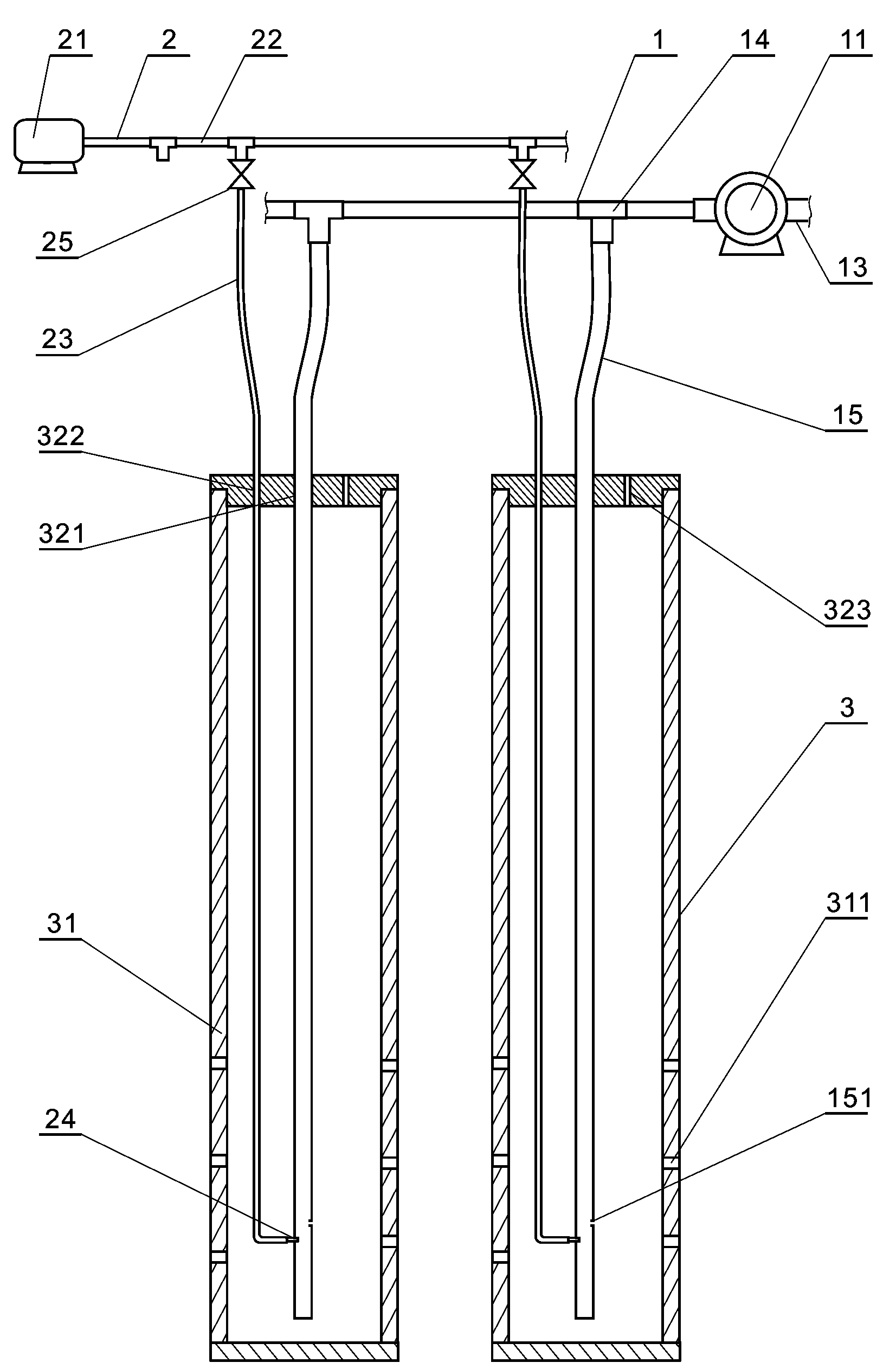

[0012] refer to figure 1 , figure 2 , the present invention includes negative pressure system 1, positive pressure system 2 and deep well pipe assembly 3, described negative pressure system 1 is made up of vacuum pump 11, drainage pipe 13, vacuum main water pipe 14 and vacuum water distribution pipe 15, positive pressure system 2 is made up of empty Compressor 21, air main pipe 22, air branch pipe 23, on-off valve 25 and gas nozzle 24 are composed. Deep well pipe assembly 3 is composed of well pipe 31 and well cover 32. There are vacuum tube holes 321, air tube holes 322 and ventilation holes 323, the bottom of the well tube 31 is closed, and small holes 311 are provided in the tube body;

[0013] The drainage pipe 13 and the vacuum water main pipe 14 of the negative pressure system 1 are respectively connected to the two ends of the vacuum pump 11, the vacuum water distribution pipe 15 is connected to the vacuum water main pipe 14 and extends into the well pipe 31 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com