Patents

Literature

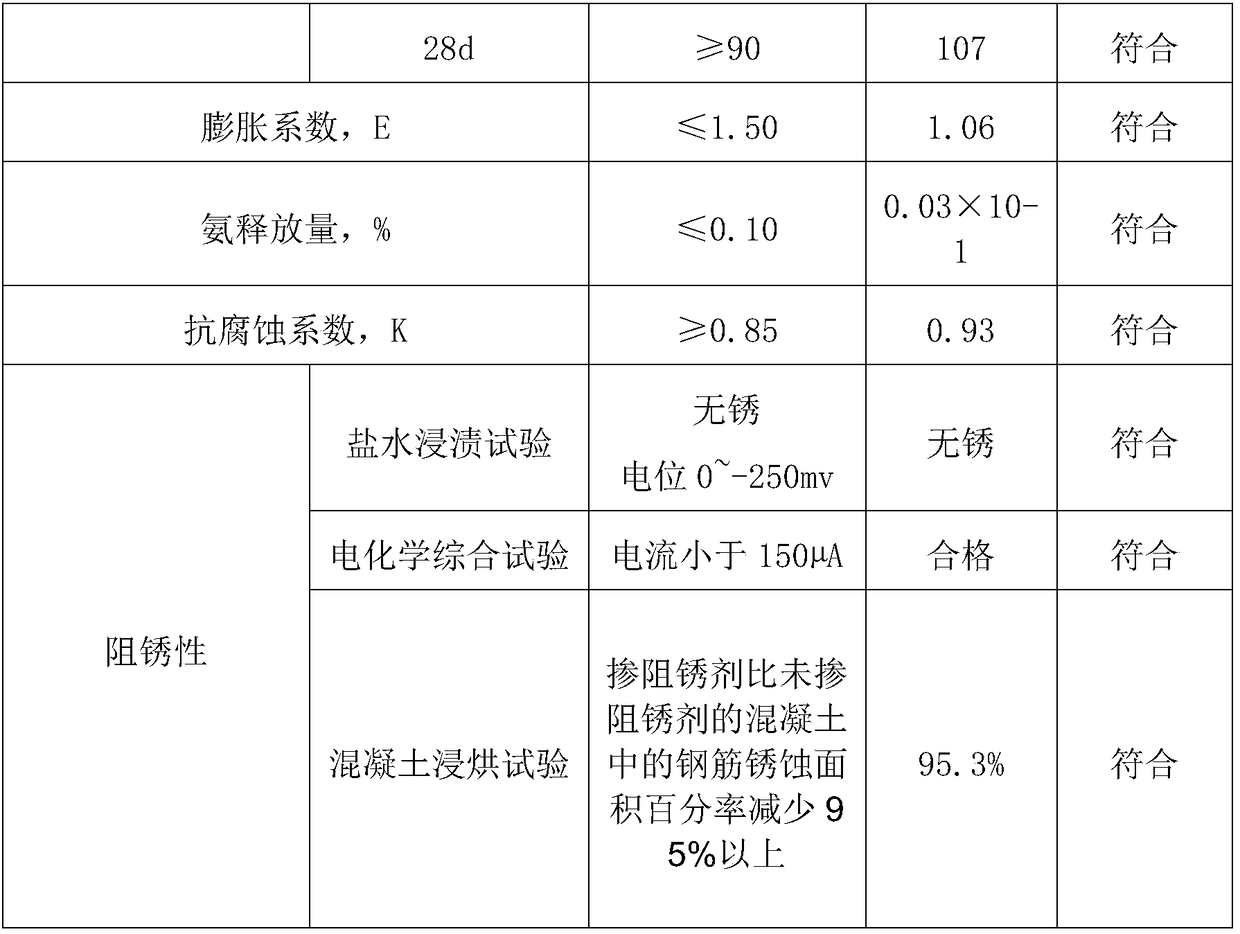

39results about How to "Good flow dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Early strength type polycarboxylate superplasticizer and preparation method thereof

PendingCN109608594AGood early strength development rateGood flow dispersionPolymer scienceSide chain

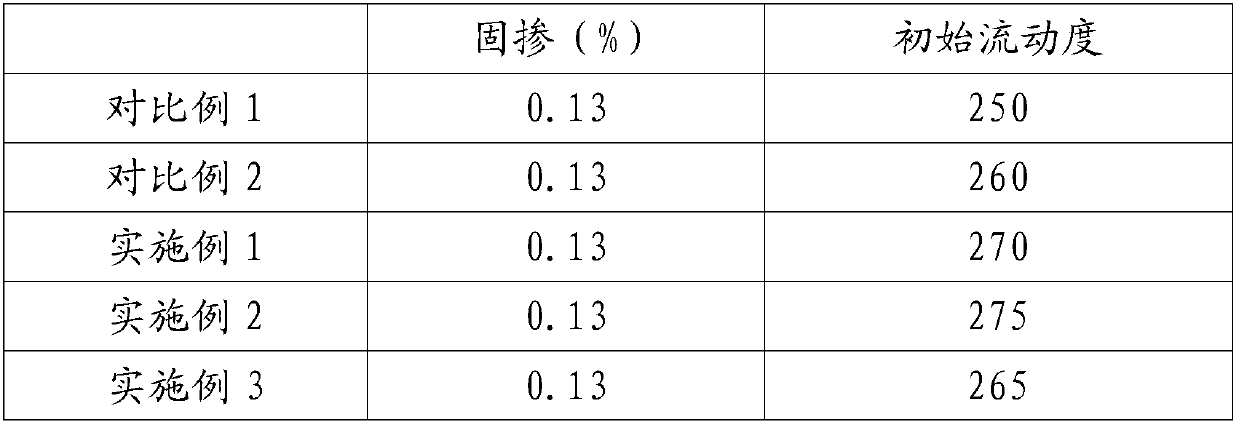

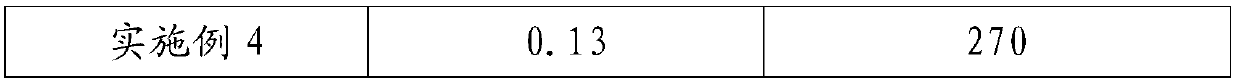

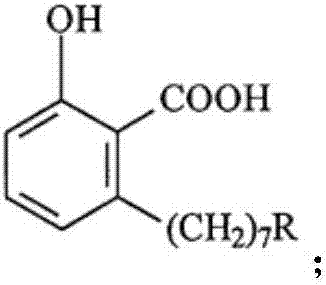

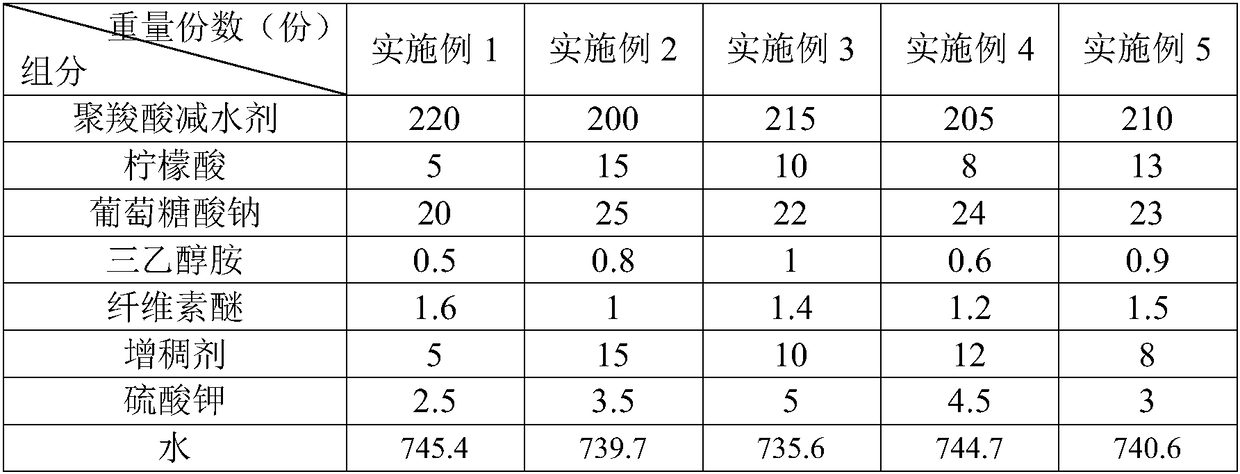

The invention relates to the technical field of concrete additives in building materials, specifically to an early strength type polycarboxylate superplasticizer and a preparation method thereof. Theearly strength type polycarboxylate superplasticizer is prepared from the following raw materials through a polymerization reaction: block unsaturated polyoxyethylene ether, acrylic acid, a functionalmonomer, a chain transfer agent, an oxidative initiator and a reductive initiator. According to the invention, the block unsaturated polyoxyethylene ether is adopted as a raw material, and a macromolecular block polyether side chain can improve the water-reducing rate performance of a superplasticizer, also exerts the performances of early strength, viscosity reduction and shrinkage resistance, greatly reduces the content of air, shortens the setting time of concrete and has excellent working performance and adaptability.

Owner:广东奥克化学有限公司

Coal water slurry additive

InactiveCN106118764AReduce moisture contentGood flow dispersionLiquid carbonaceous fuelsFuel additivesMoistureHeat energy

The invention belongs to the technical field of a concrete additive, in particular to a coal water slurry additive. The problems that the existing coal water slurry has poor flow dispersibility, high moisture content of coal water slurry, large loss of energy consumption and large loss of heat energy are mainly solved. The water coal slurry additive comprises the following components in parts by weight: 35 to 50 parts of naphthalene water reducing agent, 5 to 20 parts of sodium silicate, 1 to 4 parts of sodium hydroxide, 1 to 4 parts of sodium gluconate, 1 to 2 parts of sodium citrate, 1 to 2 parts of sodium lignosulfonate and 5 to 16 parts of water. The additive provided by the invention has the advantages of reducing the moisture content of the coal water slurry, improving the flow dispersibility and suspension property, speeding up the precipitation speed, reducing the used amount, and reducing the nitrogen oxide content after adding urea.

Owner:艾永生

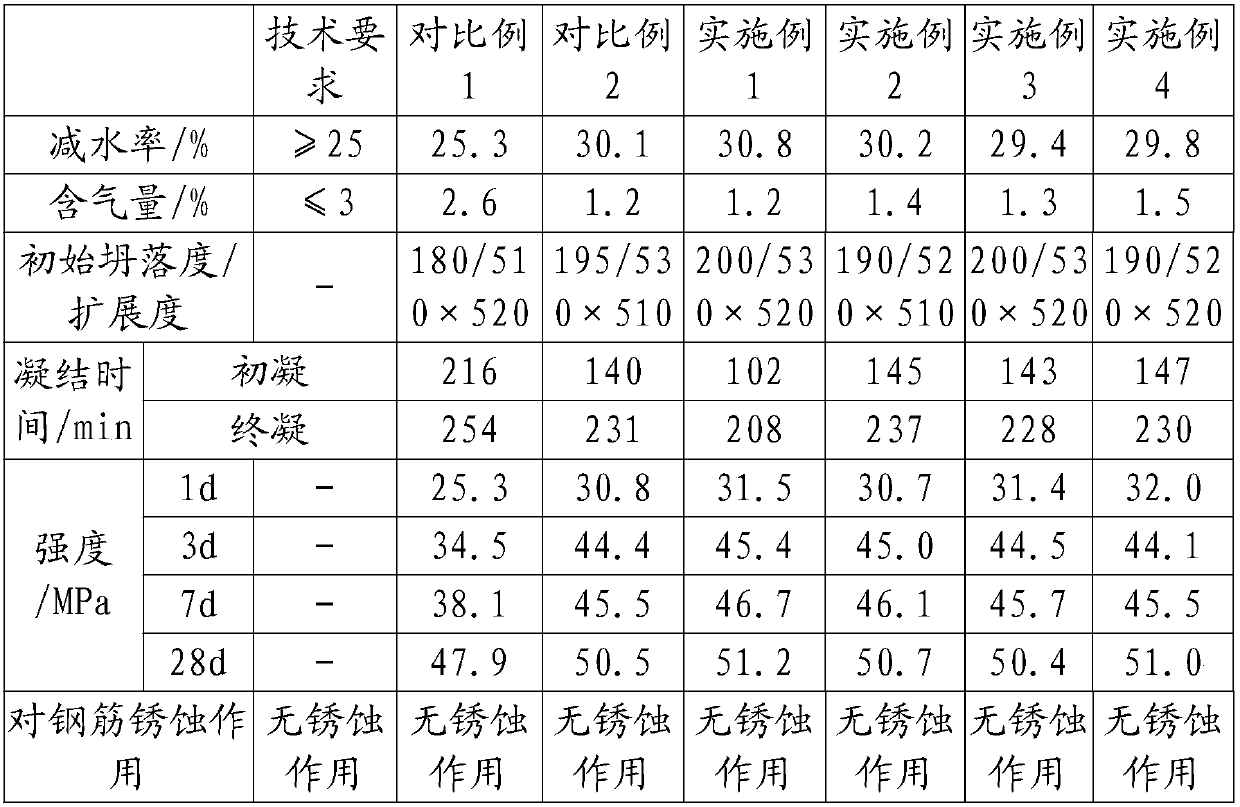

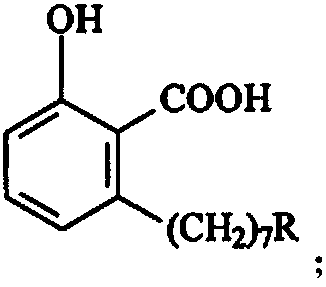

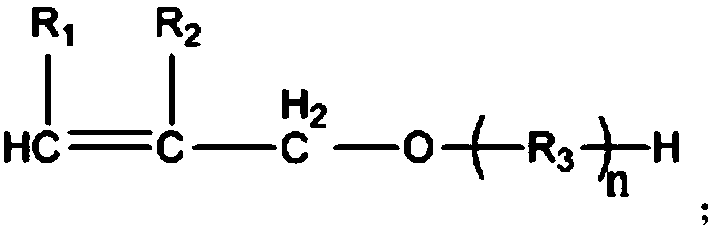

Ginkgolic acid grafted and modified polycarboxylate water-reducer and preparation method thereof

The invention provides a ginkgolic acid grafted and modified polycarboxylate water-reducer and a preparation method thereof. The polycarboxylate water-reducer is a random copolymer prepared by polymerizing ginkgolic acid, unsaturated polyether, unsaturated carboxylic acid or salt thereof. The preparation method comprises the following steps: dissolving ginkgolic acid and unsaturated polyether into water; heating the solution to reach the temperature of 20-80 DEG C; then correspondingly dropwise adding the aqueous solution of unsaturated carboxylic acid and the aqueous solution of an initiator and a chain transfer agent for 2-2.5 hours and 3-3.5 hours; continuously reacting for 1 hour under the temperature of 20-80 DEG C after dropwise adding; cooling; neutralizing the system with liquid caustic soda until the pH is 6-7, so as to obtain the ginkgolic acid grafted and modified polycarboxylate superplasticizer. According to the preparation method, unsaturated ginkgolic acid is extracted from waste ginkgo biloba exocarp; carboxyl, hydroxyl and side chain of ginkgolic acid are introduced into a water-reducer molecular structure, therefore, the wastes are treated into treasure on the premise that the performance of the water-reducer is maintained, and as a result, the environment is protected, and the cost of the polycarboxylate water-reducer is decreased.

Owner:WUHAN UNIV OF TECH

Matting material for BOPP matting film, preparation method thereof, and BOPP matting film

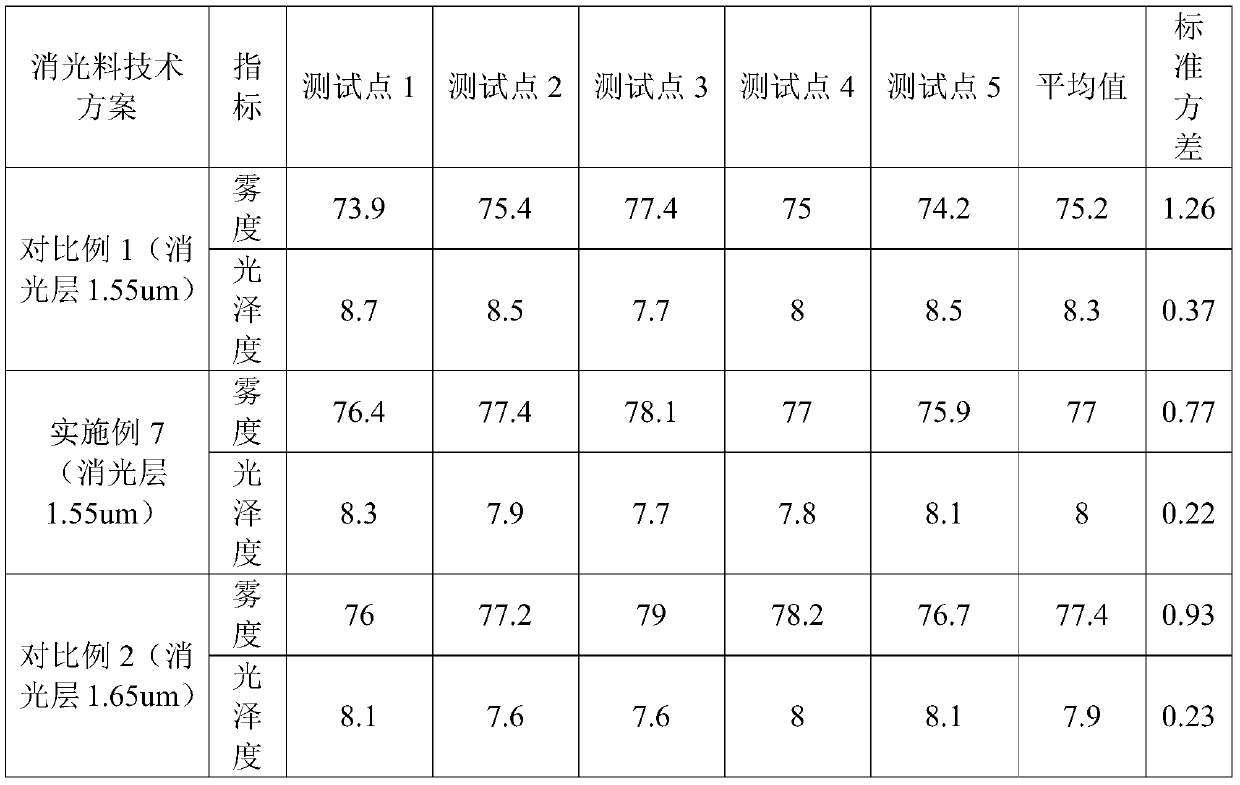

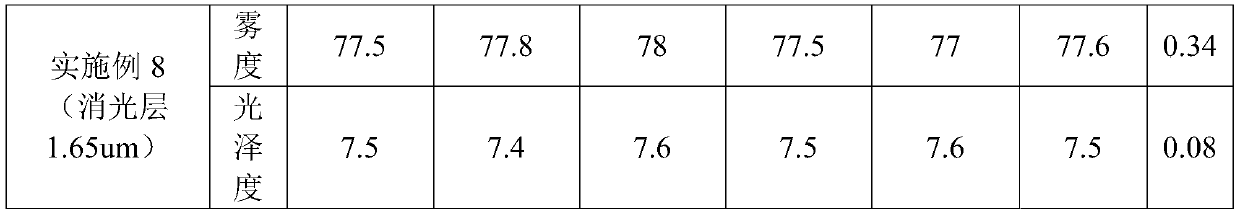

The invention relates to the technical field of biaxially oriented polypropylene extinction films, and concretely relates to a matting material for BOPP, a preparation method thereof, and a BOPP matting film. The matting material for BOPP is prepared from, by weight, 40-60% of co-polypropylene, 35-55% of high-density polyethylene, 5-15% of a master batch A and 0.5-5% of an antioxidant master batch, wherein the master batch A comprises a master batch matrix and hydrogenated petroleum resin or rosin resin, and the master batch matrix is polypropylene. The preparation method of the matting material for the BOPP comprises the following steps: mixing the co-polypropylene, the high-density polyethylene, the master batch A and the antioxidant master batch in a high-speed mixer, and performing extrusion granulation by adopting a double-screw extruder at an extrusion temperature of 225-240 DEG C. The BOPP matting film prepared from the matting material for BOPP is good in overall extinction uniformity, particularly, the glossiness of the two sides of the film is reduced, the haze of the two sides of the film is improved, the thickness of a matting layer is reduced, and the production speedis increased.

Owner:GUANGDONG DECRO PACKAGE FILMS

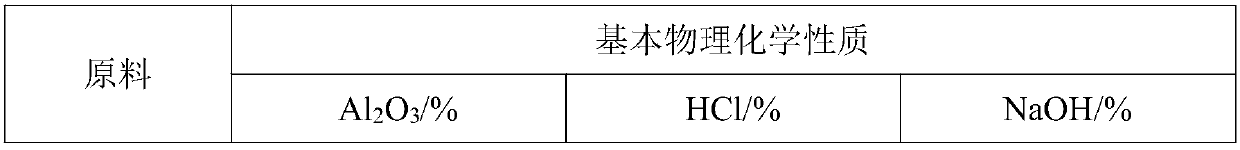

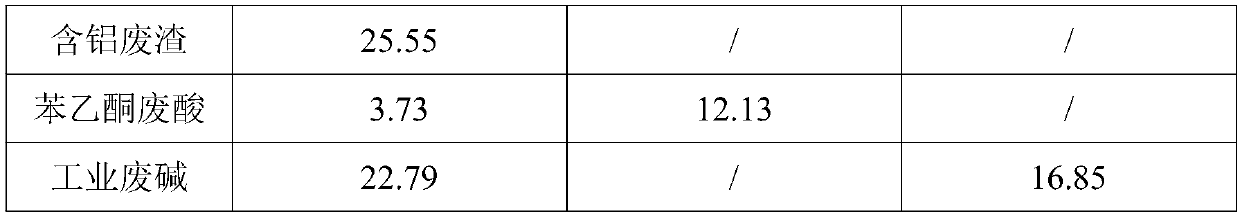

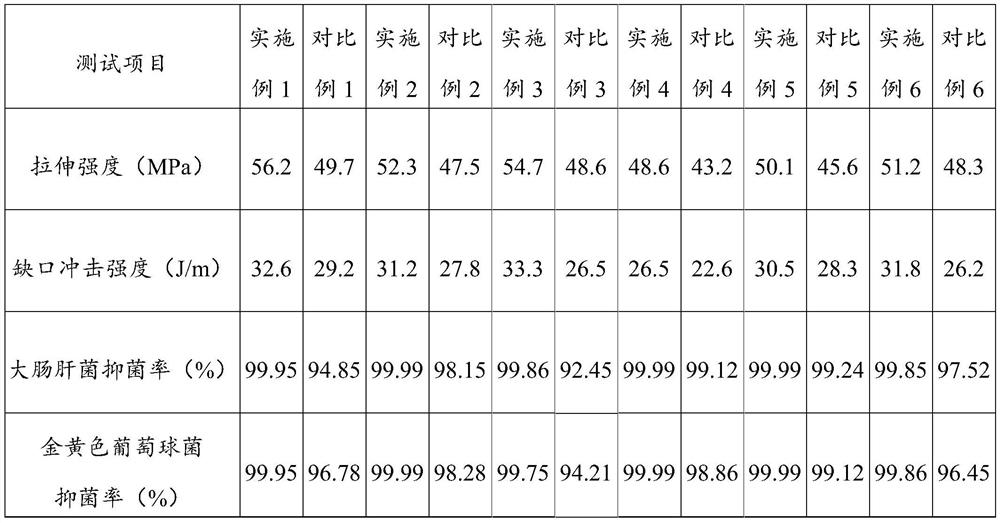

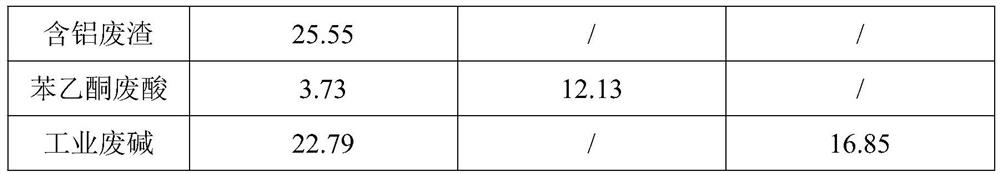

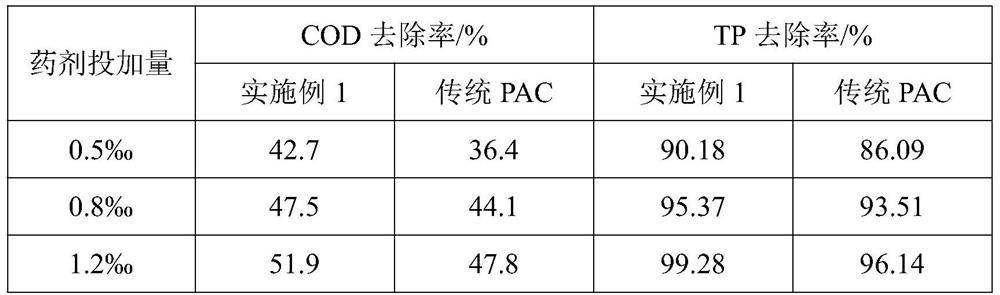

Novel polyaluminum chloride water purifying agent and preparation method thereof

ActiveCN109678232AImprove solubilityPromote aggregationWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateSlag

The invention discloses a novel polyaluminum chloride water purifying agent and a preparation method thereof. Polyaluminum chloride contains 10wt%-12wt% of aluminum oxide, has basicity being 70 wt%-95wt%, contains lower than or equal to 0.1wt% of water insoluble substances and has pH (10g / L aqueous solution) being 4.5-5.0. The preparation method of the polyaluminum chloride water purifying agent comprises the following steps: preparing aluminum-containing mother liquor, and performing high-speed dispersion and homogenization to obtain homogenized mother liquor; adding an alkaline regulator under the condition of high-speed dispersion to adjust the polymerization degree, and performing continuous reaction to obtain the polyaluminium chloride water purifying agent. The novel polyaluminum chloride water purifying agent has the advantages of high aluminum, high basicity, high flow dispersibility, wider pH application range, better coagulation effect, COD removal rate up to 50% or higher and TP removal rate up to about 99%. In the preparation method, the high-speed dispersion technology is adopted to homogenize the aluminum-containing mother liquor and the polymerization degree and adjust reaction procedure, so that the defect of limited polymerization degree adjustment of the traditional alkali adjustment system is overcome, and complete slag-free continuous production of water purifying agent with high polymerization degree is achieved.

Owner:CHANGZHOU WUJIN YOUBANG WATER PURIFICATION MATERIALS

Colloidal nano sulfur and sulfur colloidal nano encapsulation modification method

ActiveCN103709464AGood dispersionFlexible feeding methodMicroballoon preparationMicrocapsule preparationCross-linkElastomer

The invention discloses a colloidal nano sulfur and a sulfur colloidal nano encapsulation modification method. The colloidal nano sulfur comprises the following components: 70 to 80 parts by weight of sulfur, 8 to 10 parts by weight of liquid nitrile rubber, 5 to 7 parts by weight of triglycerin fatty acid ester, 4 to 8 parts by weight of fatty acid monoglyceride and 3 to 5 parts by weight of zinc stearate. The sulfur colloid nano encapsulation modification method comprises steps of mixing, reaction, grinding and cooling. The powder sulfur modified capsule nano colloid provided by the invention can comprehensively improve the dispersion of mixing rubber material and ensure product molding sulfuration to form a homogeneous three-dimensional cross-linked structure elastomer. The feeding mode is flexible and suitable for production processes of different product rubber compounds; and the colloidal nano sulfur is an indispensable crosslinking auxiliary agent for modern rubber formula and efficient production process.

Owner:WUXI NO 2 RUBBER

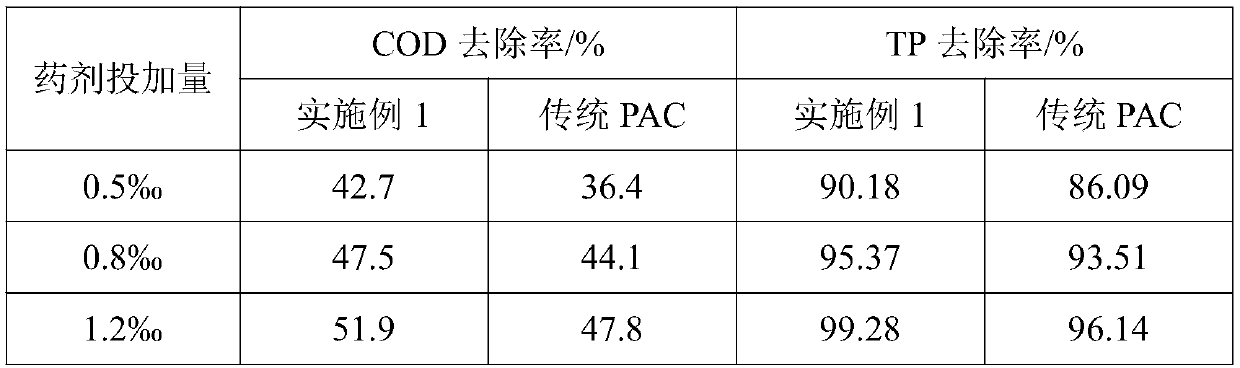

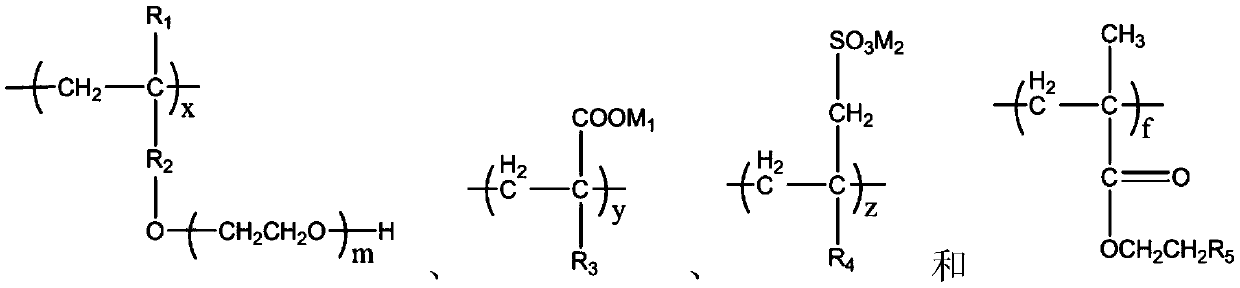

Early-strength polycarboxylate water reducing agent and preparation method thereof

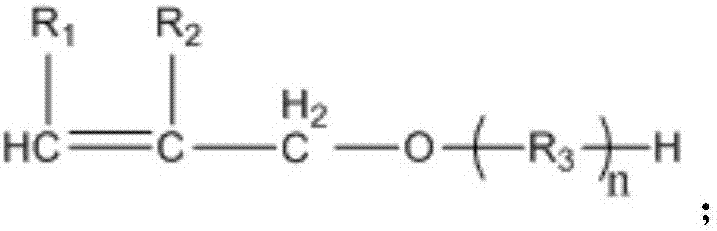

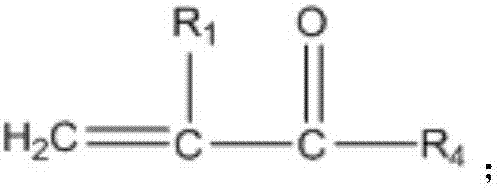

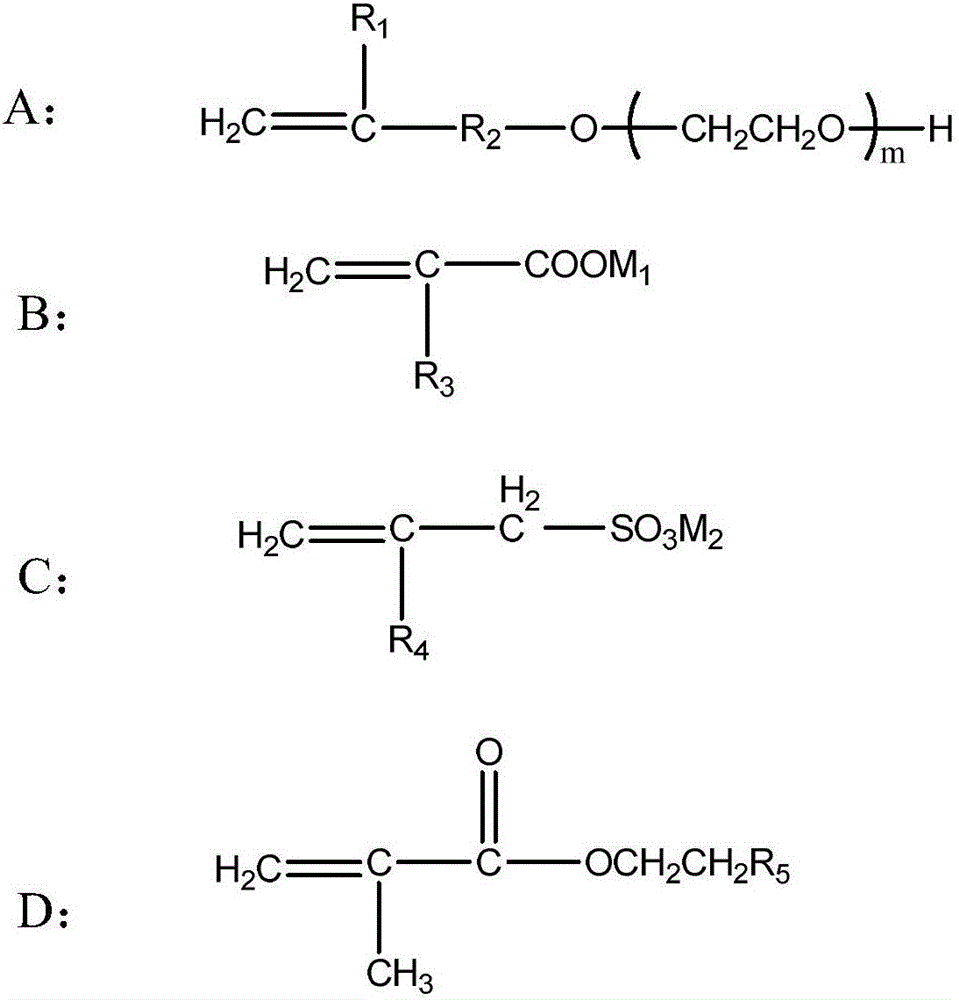

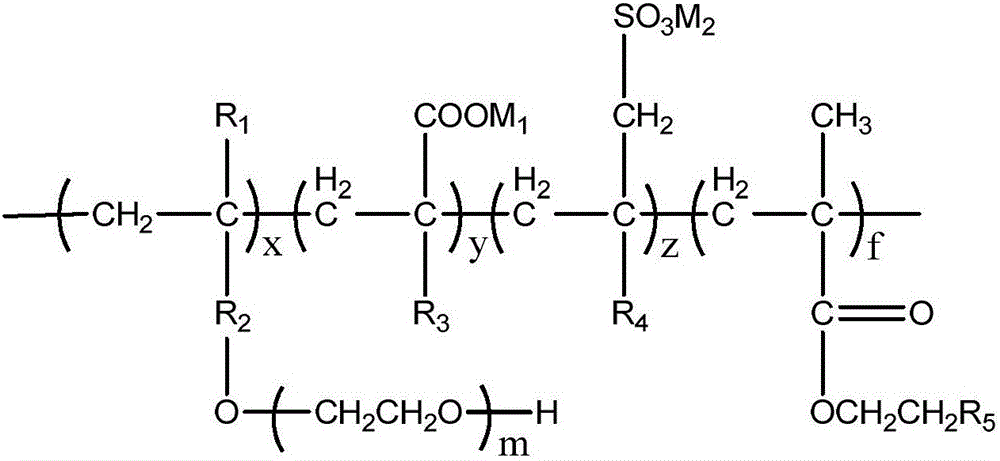

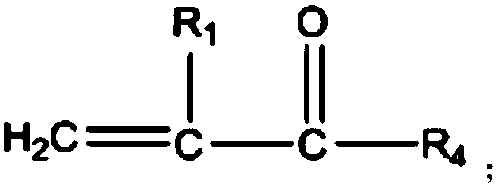

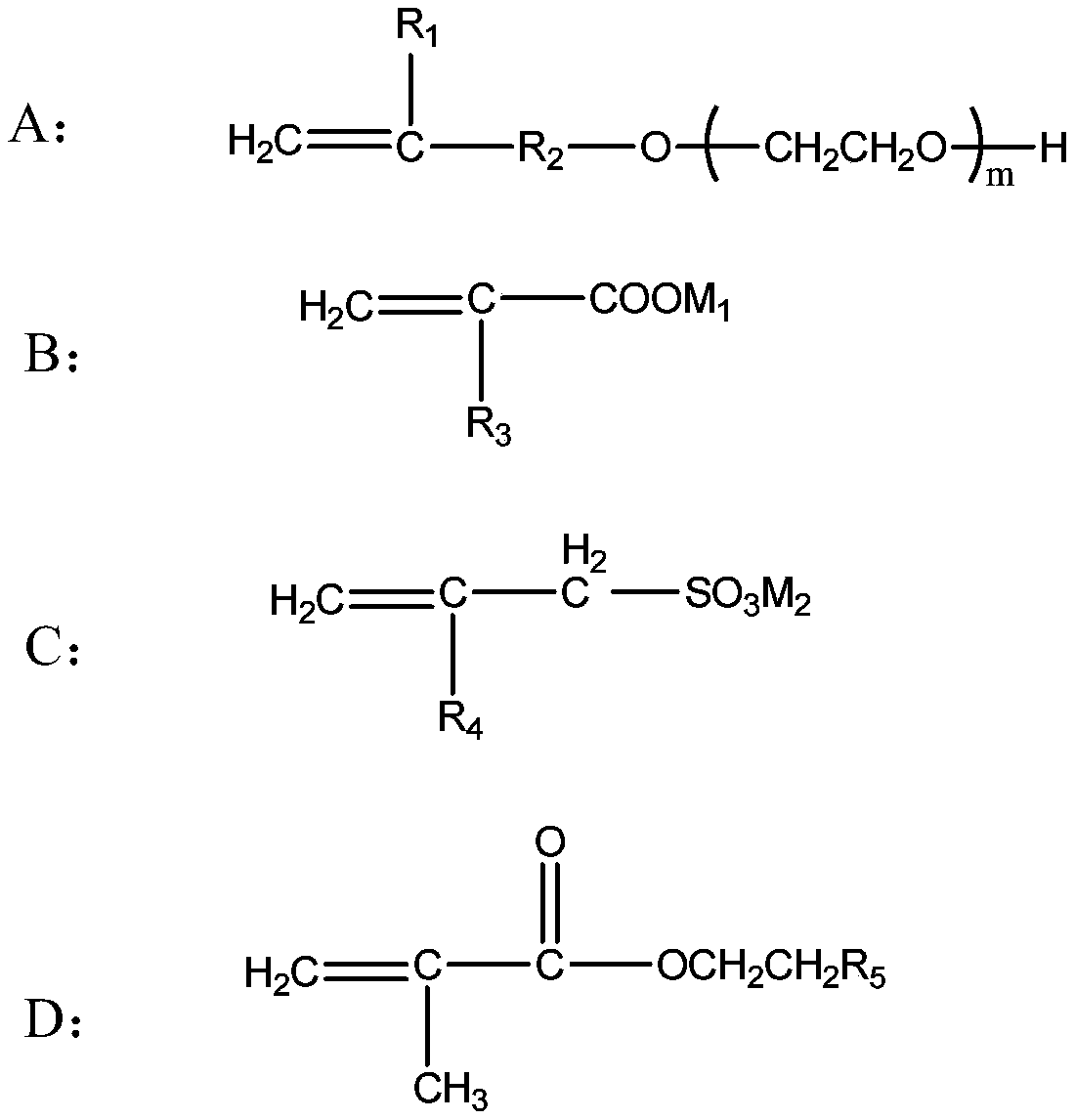

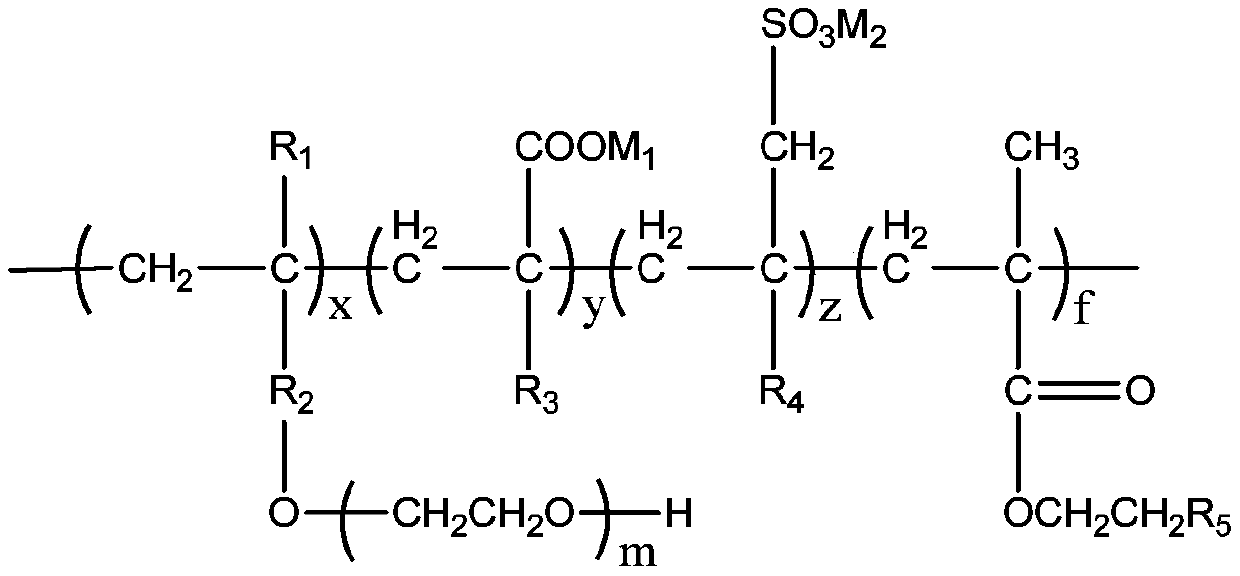

The invention provides an early-strength polycarboxylate water reducing agent and a preparation method thereof. The water reducing agent comprises the following structural units, wherein R1, R3 and R4 represent hydrogen or methyl; R2 represents-CH2-, -CH2CH2- or -O(CH2)4-; R5 represents dimethylamino, diethylamino group, diisopropylamide or morpholinyl; M1 and M2 represent H or Na; the numerical value of m is between 65 and 115; x, y, z and f represent the average mole numbers of each of the structural units. Compared with a common polycarboxylate water reducing agent, the early-strength polycarboxylate water reducing agent of one embodiment of the invention has longer side chains and a relatively shorter main chain, so that the content of carboxyl groups with delayed coagulation effect is reduced; meanwhile, high fluidity and dispersibility of the water reducing agent can be maintained by polyether structure units with large molecular weight, and the water reducing agent has a good water reducing effect.

Owner:JIANGSU OXIRANCHEM CO LTD

Solid microbial agent and preparation method thereof

The invention belongs to the field of agricultural biochemical products, and particularly relates to a solid microbial agent and a preparation method thereof. The solid microbial agent is prepared from the following raw materials in parts by weight: 100 parts of microbial fermentation solution, 150 to 300 parts of absorbent and 40 to 60 parts of coating agent; the coating agent is a mixture of polyethylene glycol and polypropylene glycol according to a weight ratio of (60: 40) to (80:20) or a poly(ethylene glycol-propylene glycol)copolymer with the content of polyethylene glycol being 60 to 80percent; and the coating agent is dissolved in the diol ether solvent to form a film. The microbial agent is provided in a solid form, thereby being convenient to transport, store and use; and meanwhile, the solid microbial agent has the expected sustained-release performance. The invention further relates to a preparation method of the solid microbial agent.

Owner:武汉天度植物科技有限公司 +1

Production process and application of silicon dioxide for choline chloride carrier

PendingCN112694092AImprove liquidityImprove adsorption capacitySilicaAccessory food factorsPhysical chemistrySeed crystal

The invention discloses a production process of silicon dioxide for choline chloride carriers, which comprises the following steps of seed crystal preparation, primary synthesis, secondary synthesis, semi-finished product preparation, final product preparation, screening to remove fine powder with the mesh number of more than 200 after the final product preparation is completed, and packaging in a vacuum negative pressure state to obtain the final product. In addition, the invention also discloses application of the silicon dioxide prepared by the preparation process as a choline chloride carrier. The silicon dioxide product prepared by the process is good in flowability, does not raise dust or cake in the choline chloride adsorption process, has outstanding adsorption performance, adsorbability and manufacturing cost which are obviously superior to those of an existing granular carrier, is good in flowability and dispersibility in premixed feed after adsorbing choline chloride, does not aggregate or cake, and the addition safety and the storage stability of choline chloride products are greatly improved, and the production operation environment is fundamentally improved.

Owner:山东联科卡尔迪克白炭黑有限公司

A kind of polycarboxylate water-reducer modified by gingkgolic acid grafting and preparation method thereof

Owner:WUHAN UNIV OF TECH

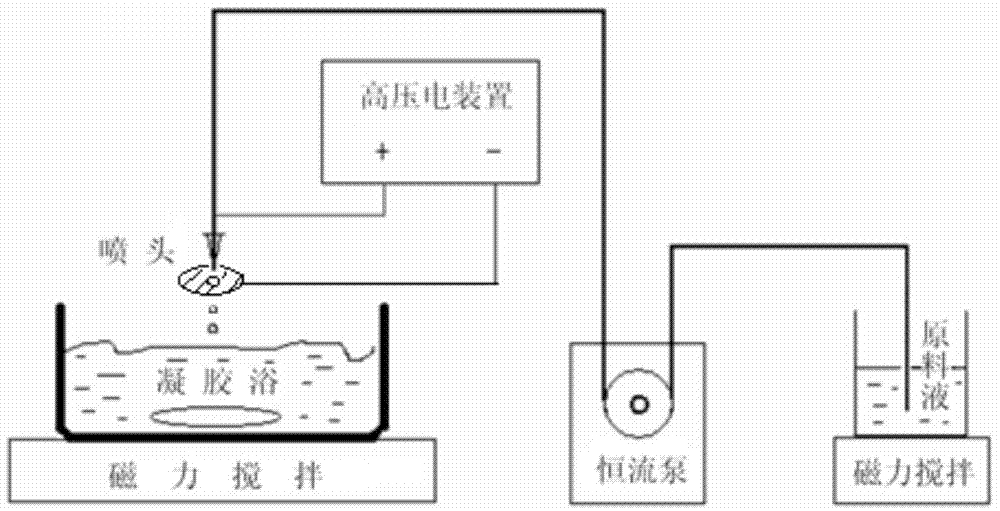

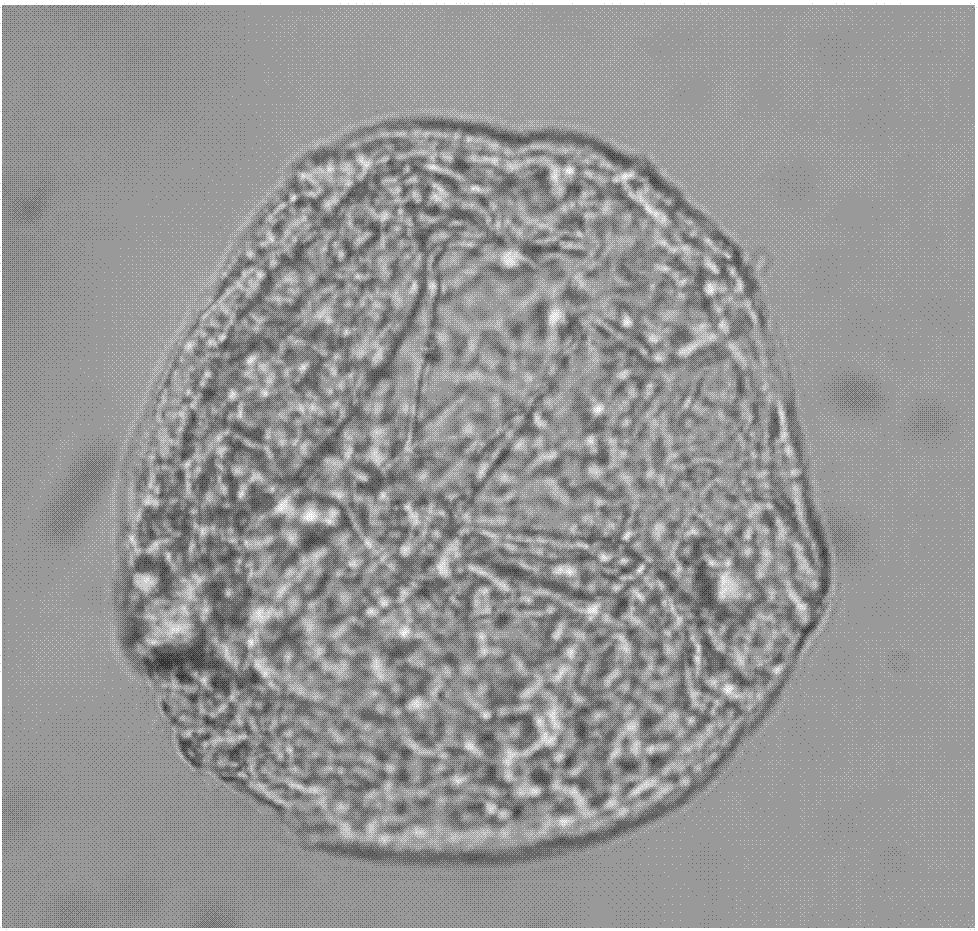

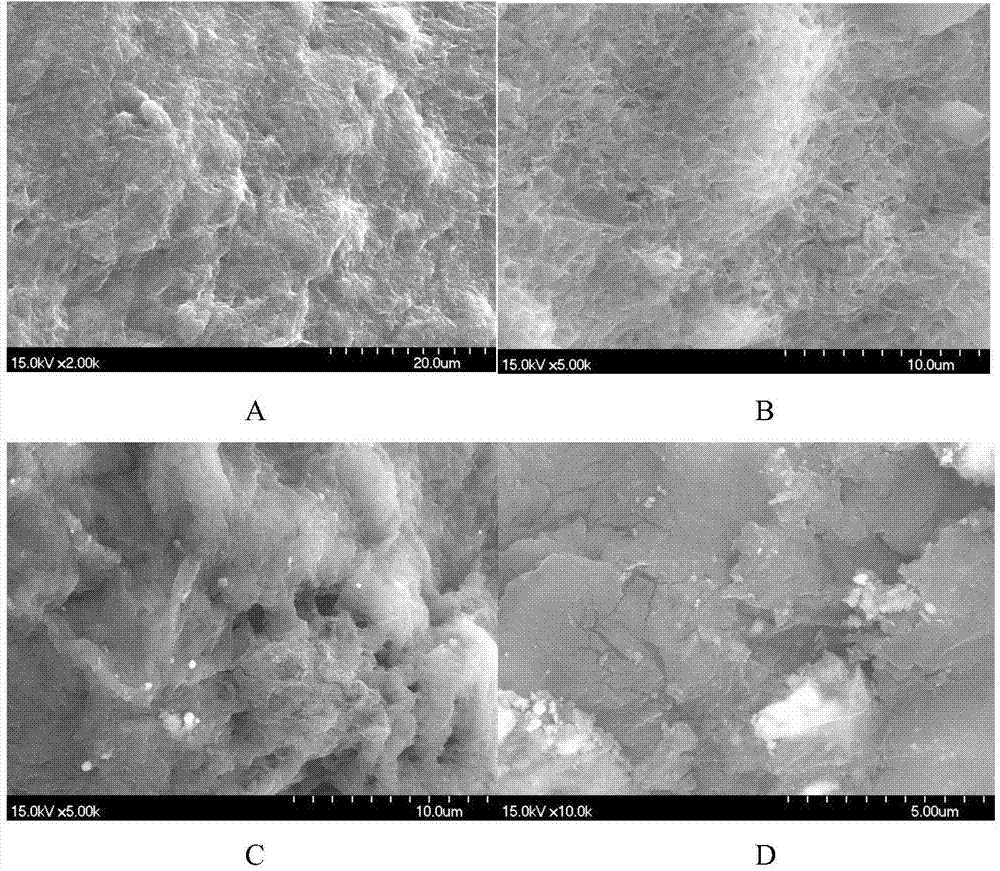

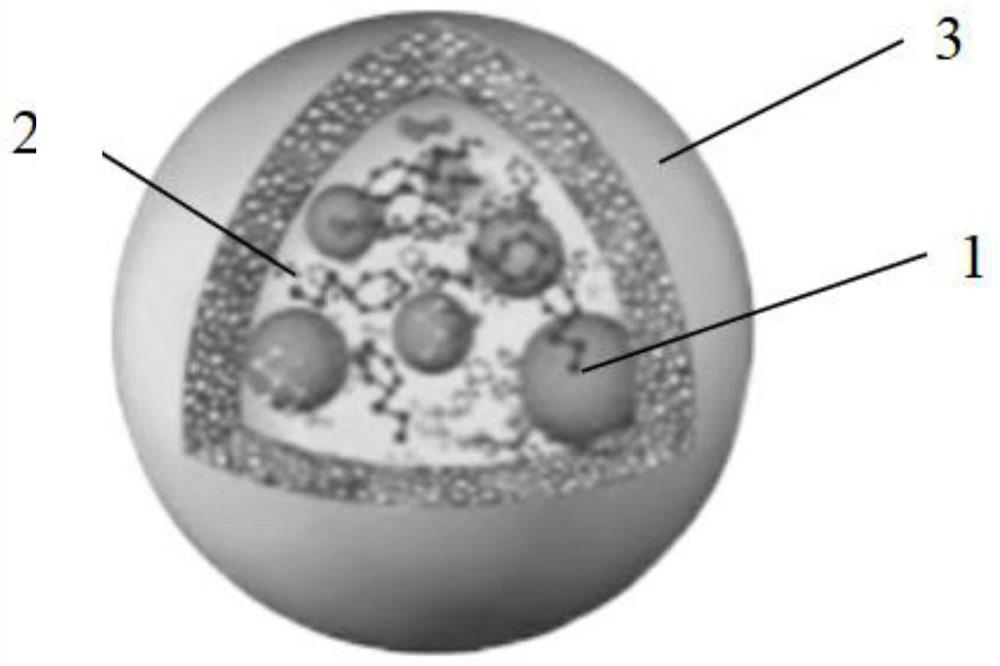

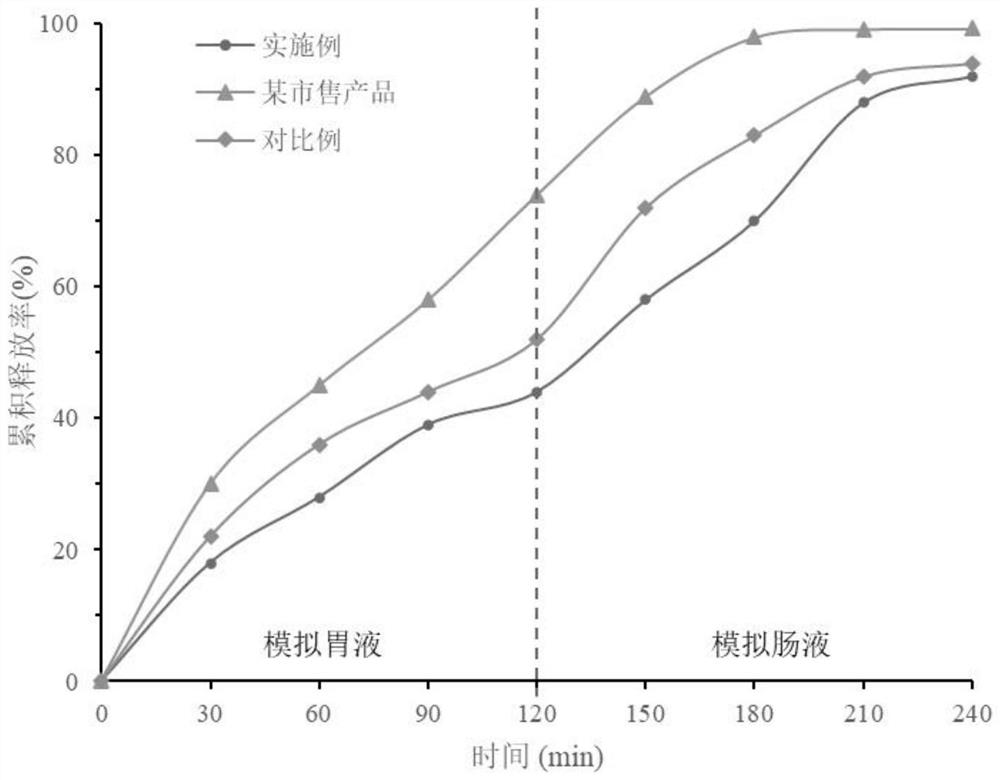

Preparation method of royal jelly microcapsule

ActiveCN103931980AReduce adverse effectsAvoid destructionFood shapingFood electrical treatmentPeristaltic pumpFreeze-drying

The invention discloses a preparation method of a royal jelly microcapsule. The method comprises the following steps: preparing a water solution of sodium alginate with a concentration of 0.015 to 0.025 g / mL and a water solution of loyal jelly with a concentration of 0.15 g / mL, taking the two water solutions as the raw material solution; preparing a mixed solution containing CaCl2 (5-15 mg / mL), chitosan (2.5-7.5 mg / mL), and royal jelly (0.15 g / mL), wherein the pH value of the mixed solution is 4.5 to 6.0, subjecting the mixed solution to a centrifugation treatment, taking the supernate as the gel bath; transporting the raw material solution to the positive pole of a nozzle through a peristaltic pump, arranging a round disc, which is made of stainless steel and is provided with a hole in the center, right under the nozzle and above the gel bath, taking the round disc as the negative pole, spraying the raw material solution into the gel bath from the nozzle to form calcium alginate micro beads in the gel bath, and then subjecting the micro beads to processes of suction filtration, water washing, and freeze-drying so as to obtain the royal jelly microcapsule. The preparation method has the advantages of low temperature and short time. The moisture absorbing property of the freeze-dried powder in the royal jelly microcapsule is reduced, the pungent smell is prominently reduced at the same time, and the microcapsule can tolerate the stomach environment and finally releases freeze-dried powder in the small intestines.

Owner:ZHEJIANG UNIV OF TECH

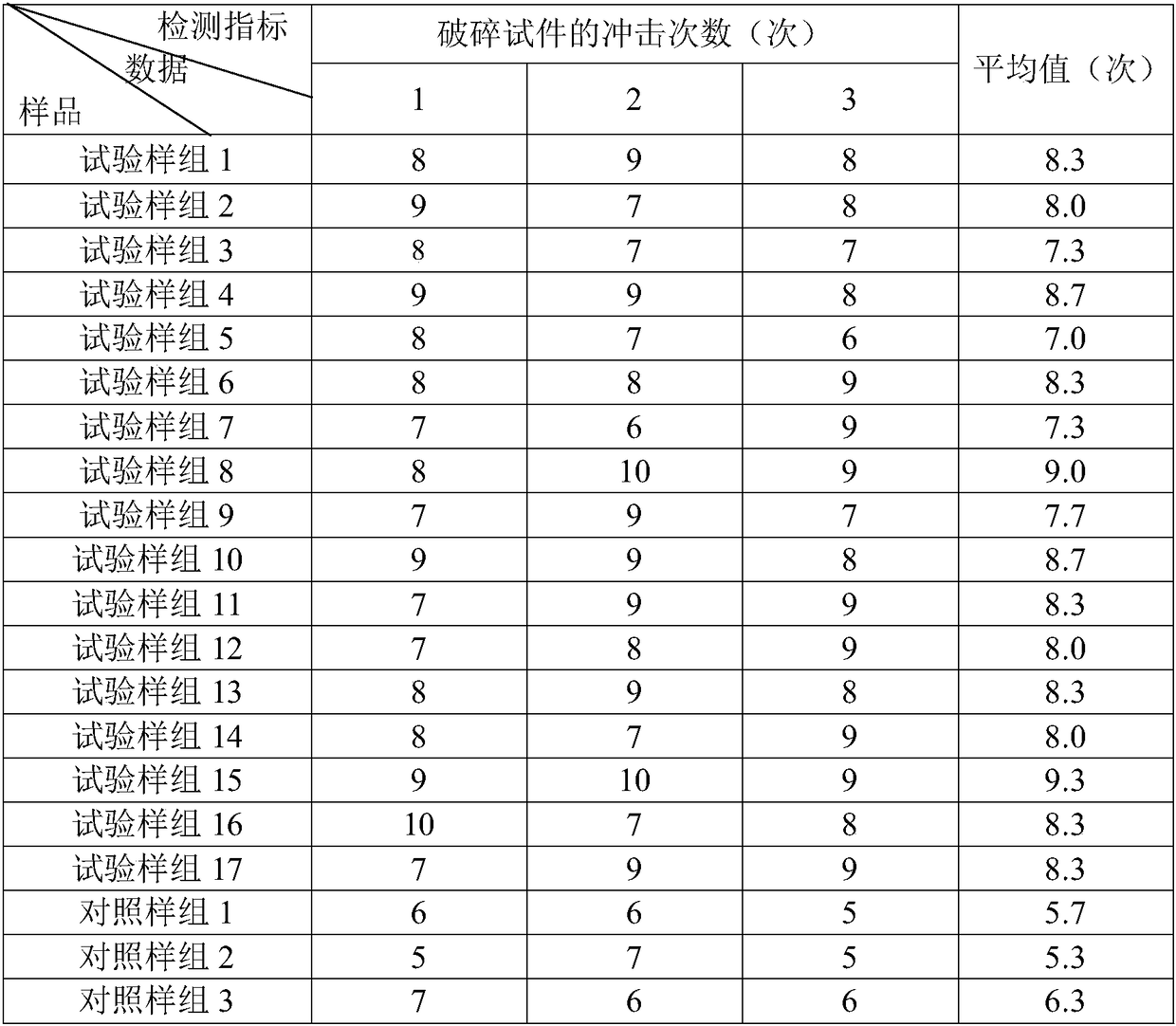

Container wood-plastic bottom plate and preparation method thereof

ActiveCN111546724AHigh strengthExtended service lifeLarge containersDomestic containersGlass fiberFiber

The invention belongs to the technical field of wood-plastic plates, and particularly discloses a container wood-plastic bottom plate and a preparation method thereof. The container wood-plastic bottom plate comprises a core layer and a skin layer wrapping the core layer, a reinforcing layer is arranged between the core layer and the skin layer; the core layer and the skin layer are wood-plastic plates, the core layer is doped with short fibers; the reinforcing layer has a net-shaped structure and is made of glass fibers or metal, and the core layer, the skin layer and the reinforcing layer are integrally formed by adopting a co-extrusion process. By adding short fibers into the wood-plastic material of the core layer and arranging the reinforcing layer, the strength of the wood-plastic plate is remarkably improved, and the strength requirement of a container bottom plate is met. The skin layer wraps and protects the core layer and the reinforcing layer, the service life of the bottomplate is prolonged; the reinforcing layer is designed into a net-shaped structure, and a co-extrusion process is adopted, so that the bonding firmness between layers is greatly improved.

Owner:ANHUI SENTAI WPC GRP CO LTD

Macromolecular nano coating material composite slurry

The present invention relates to one kind of nanometer composite polymer paint slurry, which consists of water 30 wt%, dispersant 0.6 wt%, nanometer polymer assistants 1 wt%, sodium bentonite 2 wt%. heavy calcium carbonate 45 wt%, wollastonite 10 wt%, kaolin 10 wt% and titanium white powder 0-5 wt%, where, the nanometer polymer assistants includes aluminum sulfate 20 wt%, sodium silicate 50 wt%, pentaerythritol 20 wt%, hydroxypropyl methyl cellulose 2.5 wt% and sodium fluosilicate 7.5 wt%. The nanometer composite polymer paint slurry has the crystal structure of the components maintained and narrow size distribution, and can form coating with fire resistance, no smoke in fire, high adhesion to inorganic base material and other advantages.

Owner:赵玉洪

Composite lining paper coating, printing processing technology

The invention discloses a composite lining paper coating, printing and processing technology. The technology comprises the following specific steps of: (1) unwinding: respectively inserting an aluminum foil roll and lining paper into two unwinding devices, simultaneously unwinding the aluminum foil and lining paper, enabling the unwound aluminum foil and lining paper to be parallel to each other,enabling the aluminum foil to be positioned right above the lining paper, and (2) compounding: coating the opposite surfaces of the aluminum foil and the lining paper with an adhesive through an adhesive coating roller, and then simultaneously pressing and forming the aluminum foil and the lining paper coated with the adhesive through a composite pressing roller to obtain the composite lining paper. The printing roller is set to be a micro-concave screen roller; the paper feeding direction of the composite lining paper is opposite to the rotating direction of the micro-concave screen roller; the composite lining paper and the micro-concave screen roller are coated reversely, certain relative friction is generated, so that uniform spreading of coating liquid on the composite lining paper isfacilitated; the liquid transfer amount of the micro-concave screen roller is further large, ink can fully fill fiber gaps and subsurface concave-convex areas of the composite lining paper, and the coating effect of the composite lining paper is guaranteed.

Owner:YUXI DAYING STREET ALUMINUM FOIL PAPER

Recycled pavement paving board and manufacturing technology thereof

The invention discloses a recycled pavement paving board and a manufacturing technology thereof. The recycled pavement paving board comprises a base layer and a surface layer, wherein the base layer comprises the following components in parts by weight: 20-22 parts of cement, 4-6 parts of fly ash, 25-40 parts of reclaimed sand, 21-26 parts of recycled coarse aggregates, 0.1-0.5 part of a recycledfine powder, 0.2-0.4 part of an admixture and 8-10 parts of water; the surface layer comprises the following components in parts by weight: 25-30 parts of cement, 5-8 parts of fly ash, 10-15 parts ofa quartz powder, 33-51 parts of medium sand, 0.2-0.5 part of modified resin, 1-1.5 parts of a waterproof powder, 0.5-1 part of cellulose, 0.4-0.6 part of the admixture and 6-9 parts of water; and therecycled fine powder is prepared by grinding at least one of recycled concrete, recycled bricks, waste sintered red bricks, waste stone materials and waste ceramic. The recycled pavement paving boardhas the advantages of low production cost, good impact resistance, and good water and pollutant resistance.

Owner:成都建工预筑科技有限公司

Plant essential oil inclusion compound and preparation method thereof

PendingCN112450324AReduce lossesImprove stabilityAccessory food factorsWorking-up animal fodderMethyl celluloseSilicon dioxide

The invention relates to a plant essential oil inclusion compound and a preparation method thereof, and belongs to the technical field of microcapsules. The plant essential oil inclusion compound provided by the invention comprises the following raw materials in percentage by mass: 50% -80% of a skeleton, 5% -25% of plant essential oil and 10% -30% of a coating solution, wherein the skeleton consists of a mixture of starch, silicon dioxide, microcrystalline cellulose and dextrin; the coating solution is a hydroxypropyl methyl cellulose solution or an ethyl cellulose solution; the plant essential oil is adsorbed on the surface and in pores of the skeleton; and the plant essential oil and the skeleton are wrapped in a coating layer formed by the coating solution. The plant essential oil inclusion compound disclosed by the invention has the advantages of being easy in obtaining of the raw materials, low in cost, good in fluidity, low in loss, good in stability, excellent in slow release properties and high in bioavailability, and has important significance for application of the plant essential oil in feeds.

Owner:无锡迈莱博生物科技有限公司

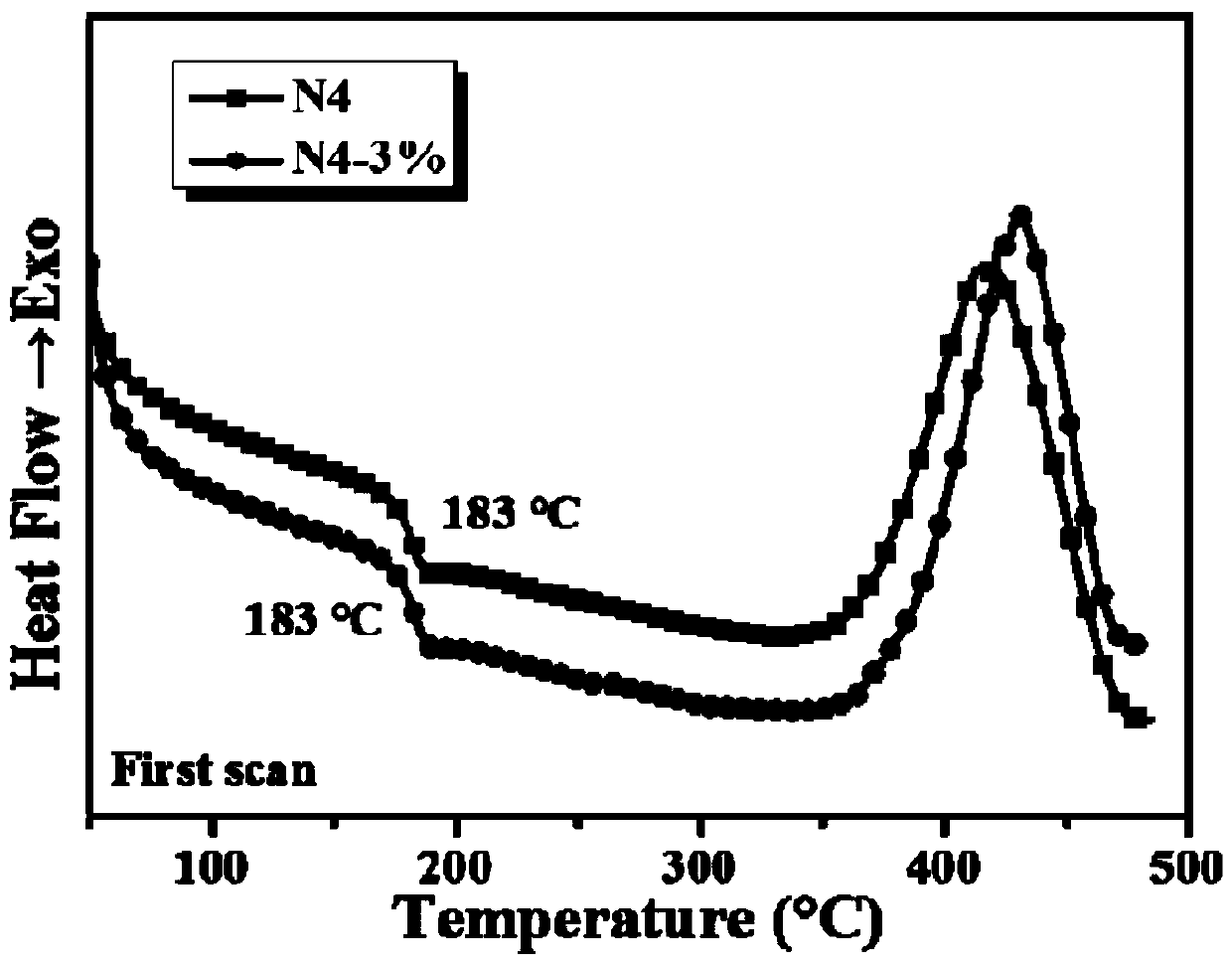

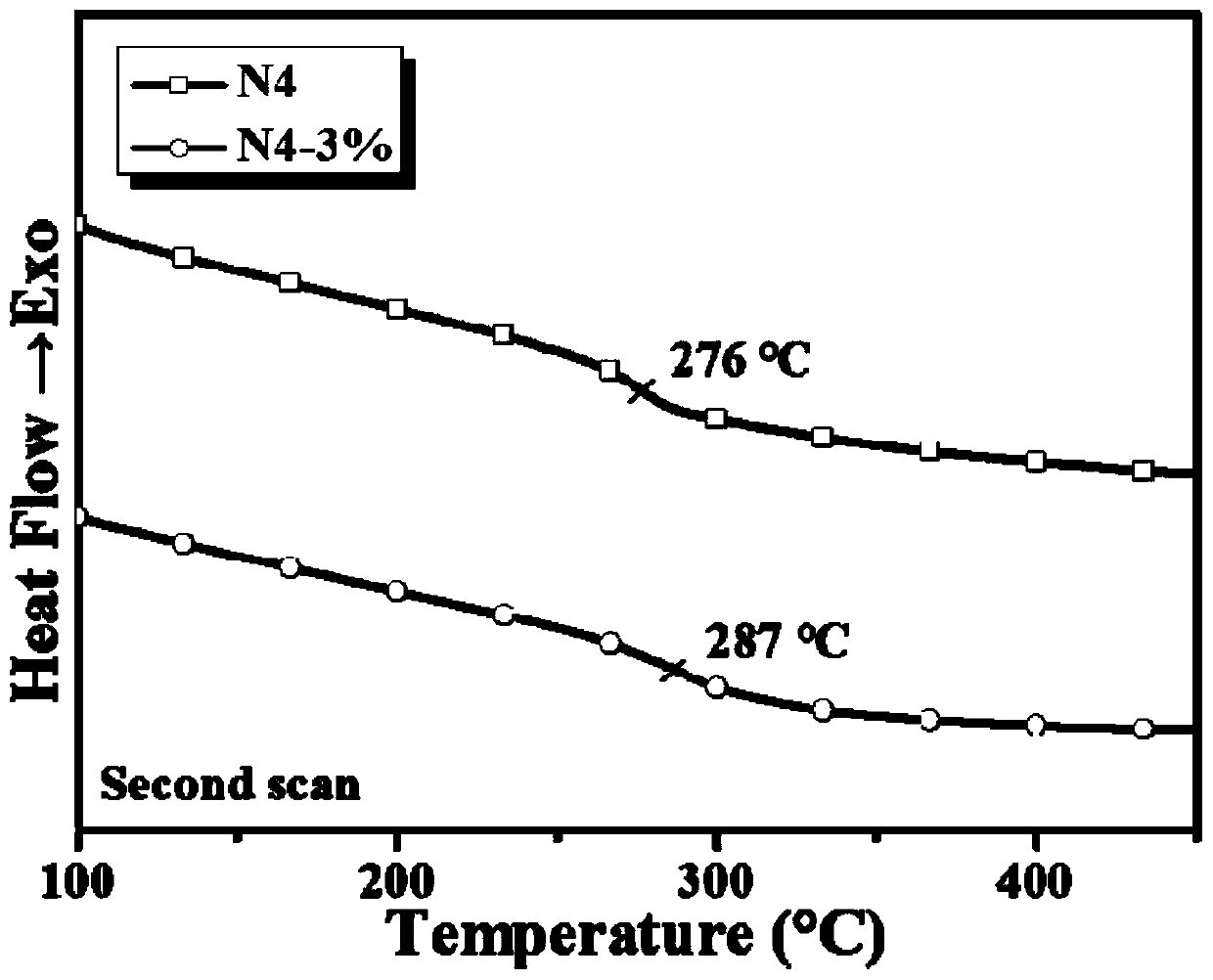

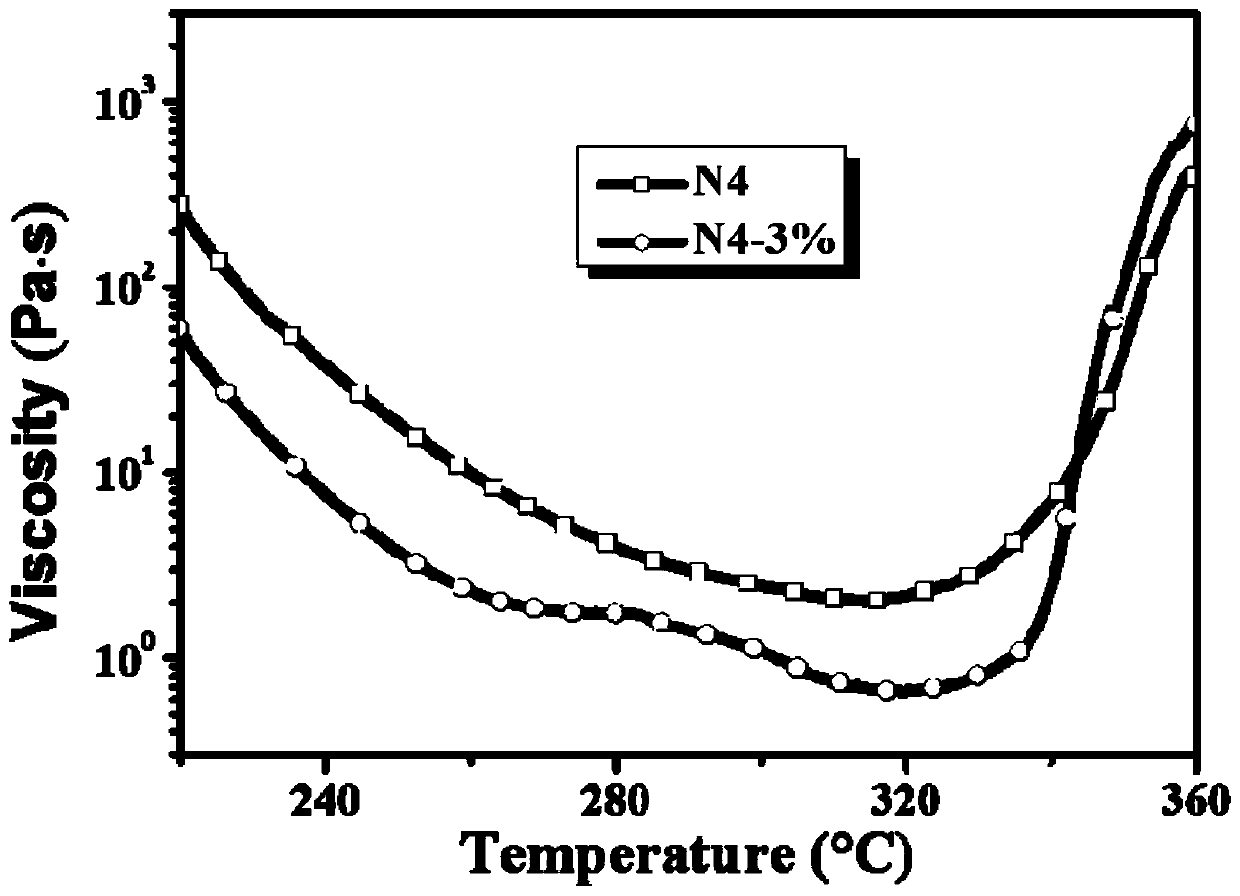

Hollow microsphere composite modified thermosetting polyimide material and preparation method thereof

Owner:SHANGHAI JIAOTONG UNIV

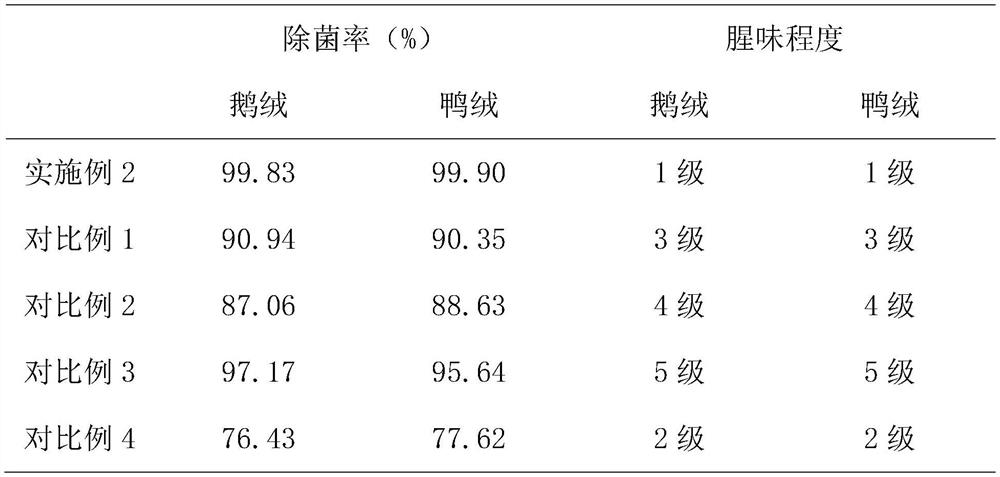

Down jacket deodorant containing marine biological components

ActiveCN113718530AGood flow dispersionEfficient removalBiochemical fibre treatmentAir quality improvementAntimicrobial actionFiber

The invention relates to the technical field of down feather deodorization, and particularly discloses a down jacket deodorant containing marine biological components. The down jacket deodorant is prepared from the following raw materials: a marine active agent, a plant active agent, an organic solvent, an aromatic and a conditioner, wherein the marine active agent is algal polysaccharides and chitosan; and the plant active agent is formed by mixing coumarin and lignan according to the mass ratio of 5: (1 to 2). The deodorant disclosed by the invention is added with the marine biological components consisting of the algal polysaccharides and the chitosan, so that bacteria and viruses bred on the surface of a down jacket can be effectively removed; in addition, the flow dispersibility of the deodorant can be improved by adding the chitosan, so that stable release of biological activity is promoted; the coumarin and the lignan are adopted as the plant active agents, so that a good deodorization effect can be achieved, especially for the fishy smell of down feather keratin fibers; and meanwhile, the algal polysaccharides can be matched,so that a good antibacterial effect is achieved, and generation of the fishy smell is avoided from the source.

Owner:ANHUI GUIGU E COMMERCE

A kind of early-strength polycarboxylate water reducer and preparation method thereof

Owner:JIANGSU OXIRANCHEM CO LTD

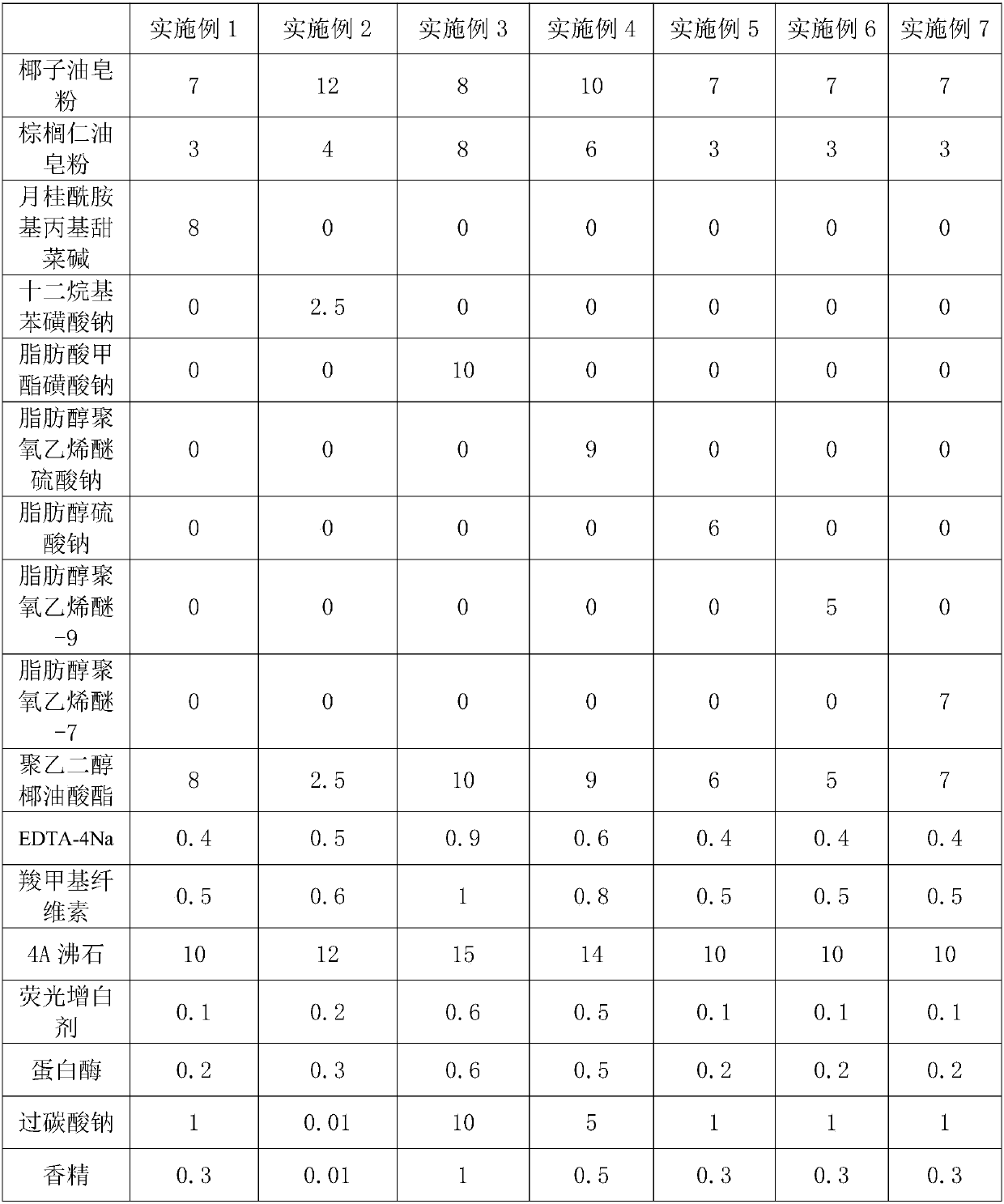

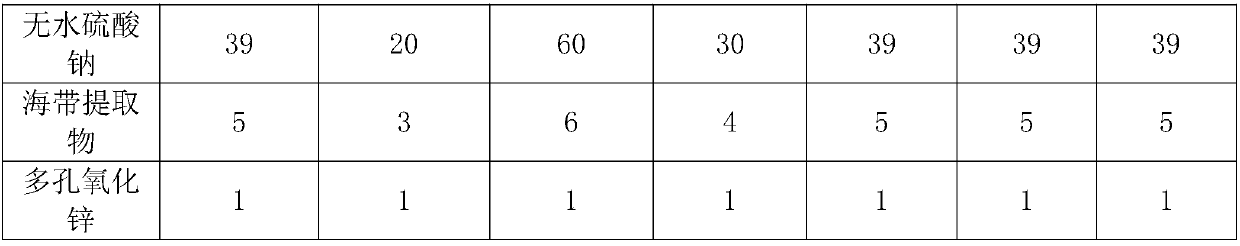

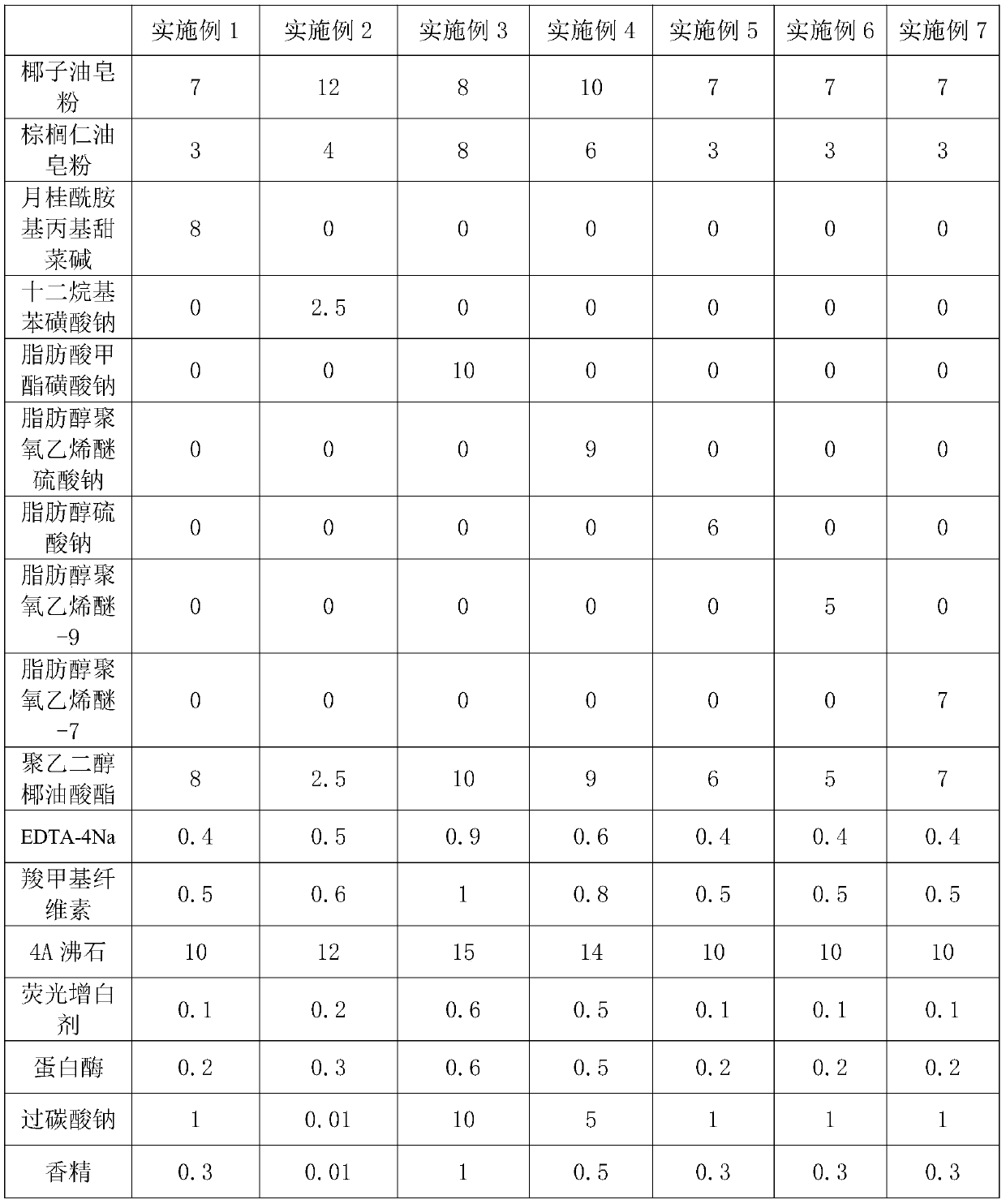

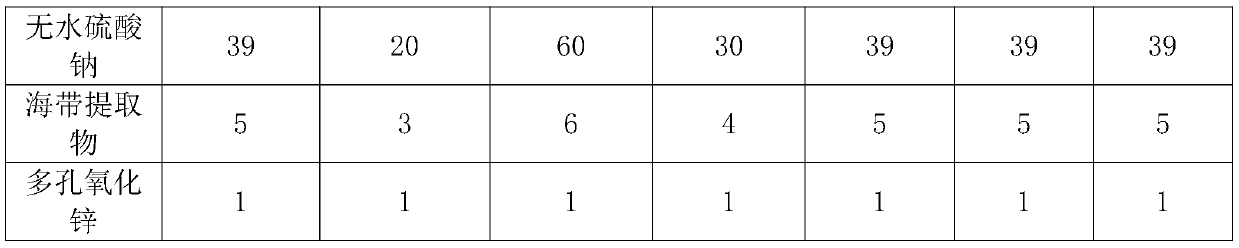

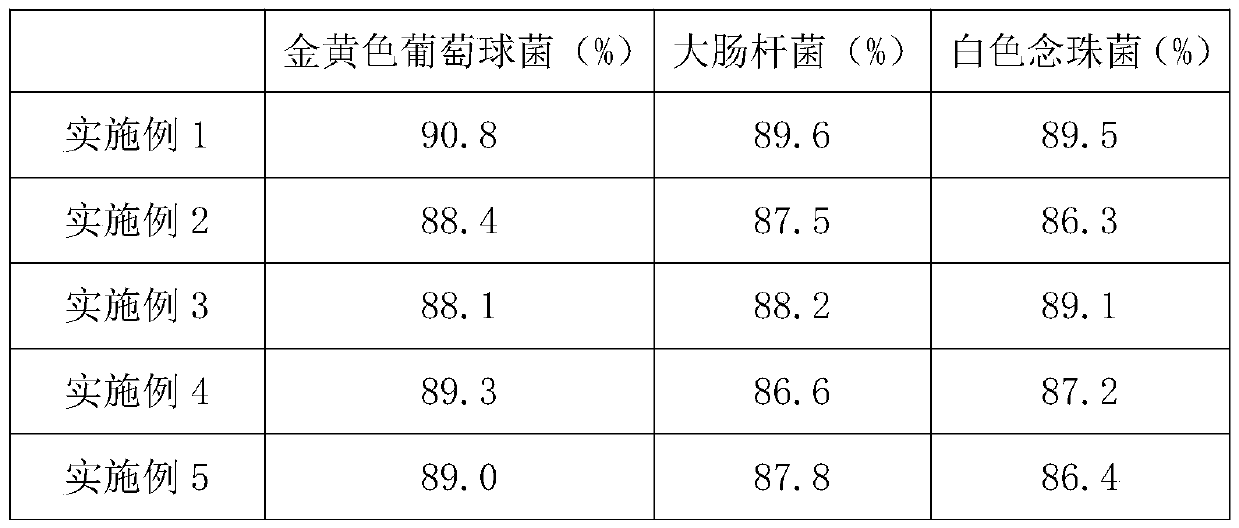

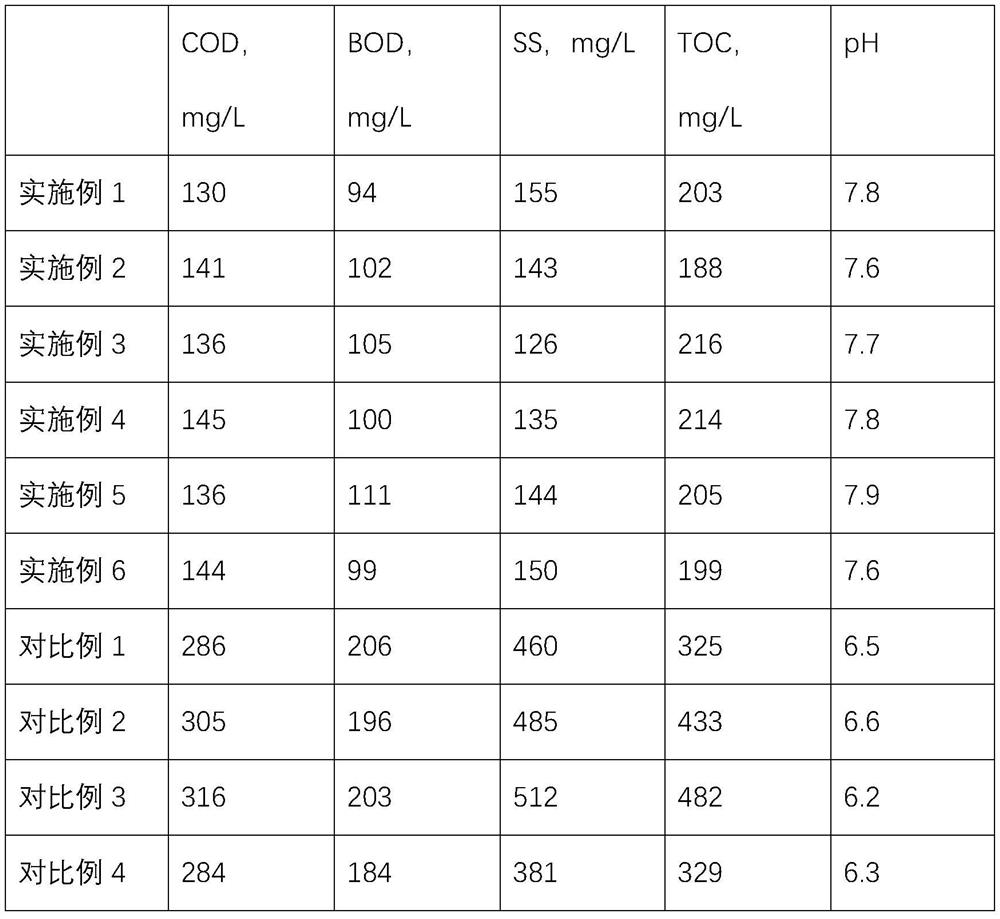

Aerobic powdered soap composition having degerming function and preparation method of aerobic powdered soap composition

ActiveCN107937181AGood antibacterial effectGood flow dispersionSurface-active non-soap compounds and soap mixture detergentsAmpholytes/electroneutral surface-active compoundsCarboxymethyl cellulosePalm kernel oil

The invention provides an aerobic powdered soap composition having a degerming function. The aerobic powdered soap composition comprises, by weight, 7-12 parts of coconut oil powdered soap, 3-8 partsof palm kernel oil powdered soap, 5-20 parts of a surfactant, 0.4-0.9 part of EDTA-4Na, 0.5-1 part of carboxymethyl cellulose, 10-15 parts of 4A zeolite, 0.1-0.6 part of a fluorescent brightener, 0.2-0.6 part of protease, 0.01-10 parts of sodium percarbonate, 0.01-1 part of essence, 20-60 parts of a filler, 3-6 parts of a kelp extract, and 1 part of porous zinc oxide. The invention further provides a preparation method of the powdered soap composition. The provided powdered soap composition is excellent in degerming performance, washing performance and flow dispersibility.

Owner:WALCH GUANGZHOU COMMODITY

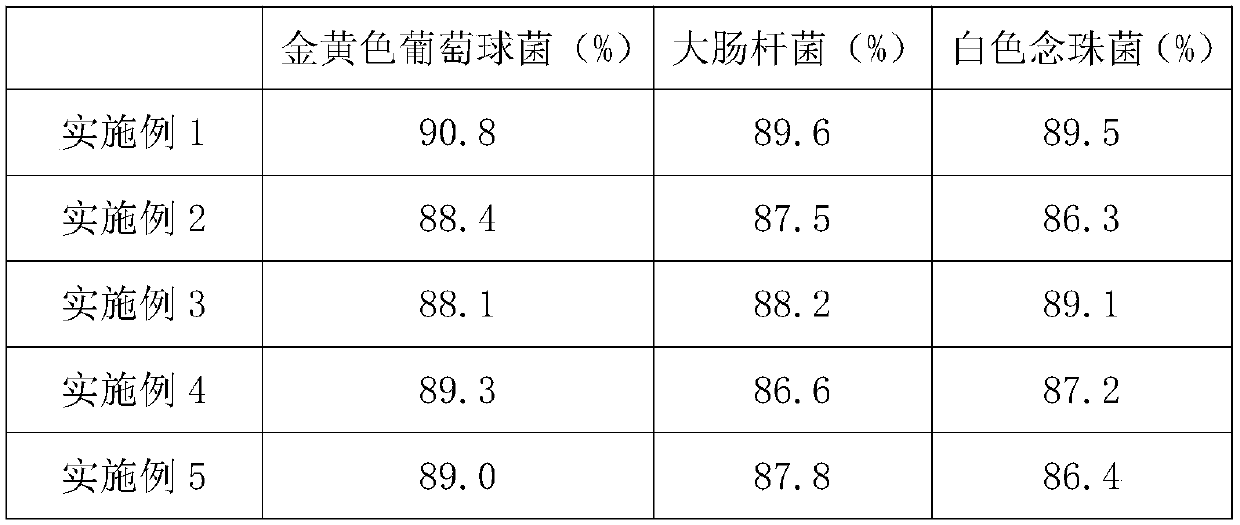

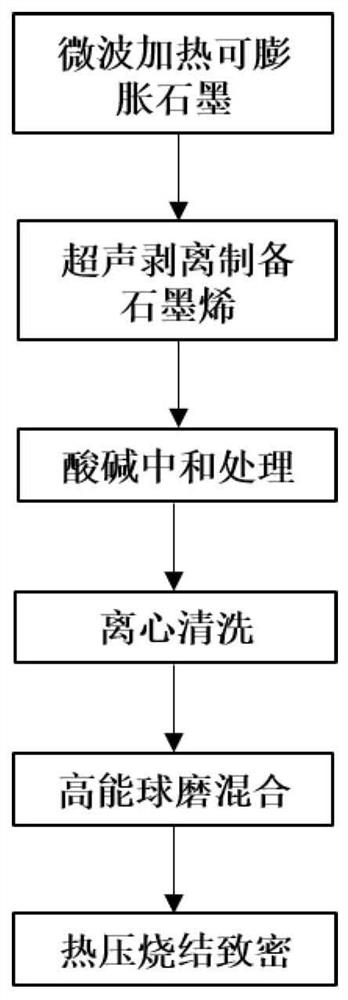

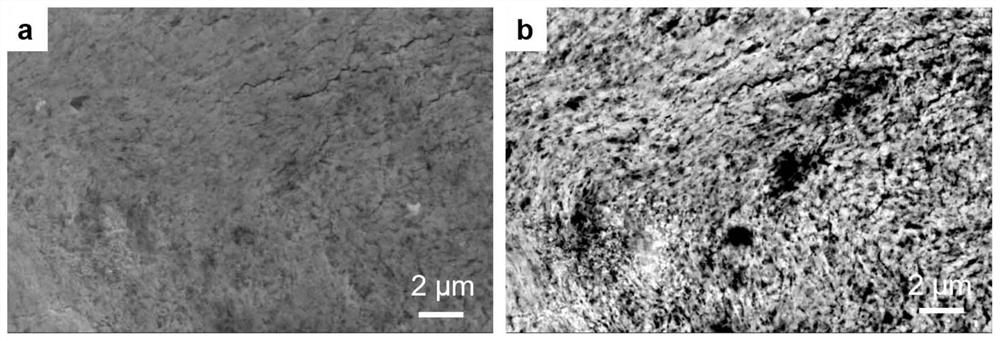

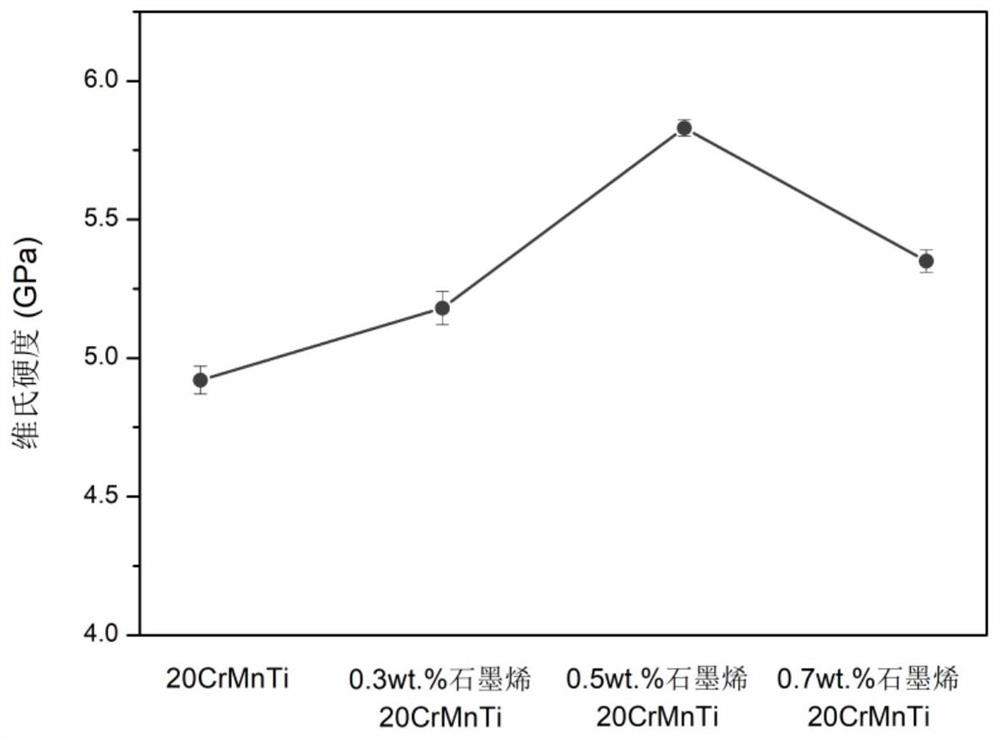

A kind of graphene-enhanced 20crmnti alloy steel and preparation method thereof

Owner:BEIJING NAT INNOVATION INST OF LIGHTWEIGHT LTD +1

Powder metallurgy material for preparing synchronizer gear hub

PendingCN113649563AGood pressing uniformityUniform and dense structureIncreasing energy efficiencyPowder metallurgyMechanical properties of carbon nanotubes

The invention provides a powder metallurgy material for preparing a synchronizer gear hub. The powder metallurgy material comprises the following components: nanoscale prefabricated alloy powder, molybdenum powder, graphite powder, metal carbide powder, an additive and iron powder; the nanoscale prefabricated alloy powder is Cu-Ni-Si-RE prefabricated alloy powder; and the metal carbide powder is Co / Ti carbide. Powder metallurgy compositions are reasonably compounded, raw material selection is optimized, powder materials have excellent dispersity, the pressing uniformity is good, the structure is uniform and compact, mechanical properties are stable and improved, the surface is free of cracks and spots, the precision grade can reach level IT5-7, comprehensive benefits are higher, and the material is worthy of application and popularization.

Owner:浙江迅达工业科技股份有限公司

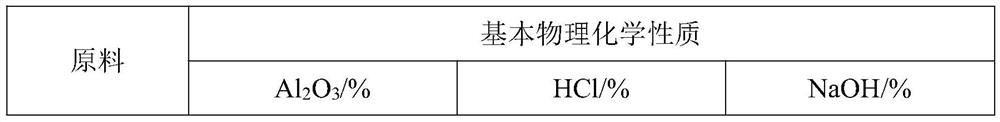

Degradable antibacterial functional master batch special for polylactic acid and preparation method of degradable antibacterial functional master batch

The invention relates to the technical field of plastic modification processing, in particular to a special degradable antibacterial functional master batch for polylactic acid and a preparation method of the special degradable antibacterial functional master batch, and the antibacterial functional master batch comprises the following components in percentage by mass: 75.0-85.0% of low-molecular-weight polylactic acid; 10.0 to 20.0 wt.% of an inorganic antibacterial agent; 1.0 to 3.0 wt.% of nano cerium dioxide; 1.0 to 3.0 wt.% of mesoporous zirconium hydrogen phosphate; 0.1 to 0.3 wt.% of a thermo-oxidative aging resistant auxiliary agent; and 2.5-3.0 wt.% of a dispersing aid. According to the antibacterial functional master batch provided by the invention, a powder antibacterial agent of a silver-zinc ion inorganic substance carrier is adopted, and mesoporous zirconium hydrogen phosphate is introduced into the antibacterial functional master batch, so that the antibacterial performance of a modified polylactic acid special material adopting the antibacterial functional master batch can be remarkably improved, and the action period of the antibacterial function of modified biodegradable plastic is prolonged; the processing efficiency is improved.

Owner:江苏万纳普新材料科技有限公司

Preparation process of polyaluminum chloride solution as water purifying agent

PendingCN114014347AGood flow dispersionImprove the coagulation effectAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorideAluminium chlorohydrate

The invention discloses a preparation process of a polyaluminum chloride solution as a water purifying agent, which comprises the following steps of: S1, well mixing polyaluminum chloride and crystalline dextrose as raw materials in a mass ratio of (5: 2)-(2.3: 0.8), adding a sodium hydroxide solution, and reacting at normal temperature; and S2, after the reaction is completed, adding the reaction product into a high-speed homogeneous dispersion machine for high-speed dispersion, adding an HCL solution in batches, and controlling the basicity (OH / Al ratio) of the reaction solution to be 2.5 + / -0.2, so as to obtain polyaluminum chloride mother liquor. According to the invention, the high-saturation sodium carbonate solution is added into the polyaluminum chloride mother liquor and stirred, so that the water purifying agent polyaluminum chloride solution has the advantages of high aluminum content, high basicity, high flow dispersity, wider pH application range and better coagulation effect, is suitable for treating various environmental water quality, and has the COD removal rate of 65% or more and the TP removal rate of about 99%.

Owner:吉林省益能科技有限公司

A special adhesive for stone paper and its preparation method

ActiveCN104559897BGood flow dispersionImprove adhesion strengthNon-macromolecular adhesive additivesAlginic acid adhesivesPolymer scienceAdhesive

The invention provides a special adhesive for stone paper and a preparation method thereof. It is characterized in that: the adhesive contains microfibers, and the components are calculated in parts by weight: 40-55 parts of seaweed glue powder, 15-20 parts of alkyd resin, 10-25 parts of reinforcing fiber, and 0.5-parts of organic silicon 1 part, 0.5‑1 part of dispersant, appropriate amount of water; use the penetration of alkyd resin and the thickening of seaweed glue powder to make the stone paper bond quickly through the connection of fine fibers, especially the adhesive can be used in hot water Dispersion, to realize the bonding process of stone paper on traditional paper product processing equipment.

Owner:山东润耀环保科技有限公司

Novel polyaluminum chloride water purifier and preparation method thereof

ActiveCN109678232BSolve the defect of limited adjustment of polymerization degreeGood flow dispersionWater/sewage treatment by flocculation/precipitationAluminium chlorideAluminium chlorohydrate

The invention discloses a novel polyaluminum chloride water purifying agent and a preparation method thereof. The aluminum oxide of the polyaluminum chloride is 10-12wt%, the basicity is 70-95wt%, the water-insoluble matter is ≤0.1wt%, and the pH (10g / L aqueous solution) value is 4.5-5.0, and its preparation method includes the following Steps: preparing aluminum-containing mother liquor, high-speed dispersion and homogenization to obtain a homogenized mother liquor, adding an alkaline regulator under high-speed dispersion conditions to adjust the degree of polymerization, and continuing the reaction to obtain a polyaluminum chloride water purifying agent. The new polyaluminum chloride water purifying agent of the present invention has high aluminum, high basicity, high flow dispersibility, wider pH application range, better coagulation effect, COD removal rate can reach more than 50%, and TP removal rate can reach About 99%, in the preparation method of the present invention, the high-speed dispersion technology is used to homogenize the aluminum-containing mother liquor and the polymerization degree adjustment reaction process, which overcomes the limitation of the polymerization degree adjustment of the traditional alkali adjustment system and realizes the high polymerization degree water purifier Completely slag-free continuous production.

Owner:CHANGZHOU WUJIN YOUBANG WATER PURIFICATION MATERIALS

A kind of aerobic soap powder composition with antibacterial function and preparation method thereof

ActiveCN107937181BGood antibacterial effectGood flow dispersionSurface-active non-soap compounds and soap mixture detergentsAmpholytes/electroneutral surface-active compoundsCelluloseActive agent

The invention provides an aerobic powdered soap composition having a degerming function. The aerobic powdered soap composition comprises, by weight, 7-12 parts of coconut oil powdered soap, 3-8 partsof palm kernel oil powdered soap, 5-20 parts of a surfactant, 0.4-0.9 part of EDTA-4Na, 0.5-1 part of carboxymethyl cellulose, 10-15 parts of 4A zeolite, 0.1-0.6 part of a fluorescent brightener, 0.2-0.6 part of protease, 0.01-10 parts of sodium percarbonate, 0.01-1 part of essence, 20-60 parts of a filler, 3-6 parts of a kelp extract, and 1 part of porous zinc oxide. The invention further provides a preparation method of the powdered soap composition. The provided powdered soap composition is excellent in degerming performance, washing performance and flow dispersibility.

Owner:WALCH GUANGZHOU COMMODITY

Coated purification deodorant for sewage treatment and preparation process thereof

PendingCN113087034AHigh efficiencyGood effectSpecific water treatment objectivesWater/sewage treatment by flocculation/precipitationEnvironmental chemistryCeramic particle

The invention relates to the field of water treatment, and provides a coated purification deodorant for sewage treatment and a preparation process thereof. A slow-release cementing material comprises an inner core, a transition layer and an outer coating layer which are sequentially arranged from inside to outside, wherein the inner core is honeycomb ceramic particles doped with water treatment agent; the transition layer is polyacrylamide gel doped with water treatment agent supported inorganic fibers, the outer coating layer is silica-alumina gel doped with water treatment agent supported composite fibers, the water treatment agent is reasonably coated and designed in a multi-layer mode, multiple purification effects of biological purification and chemical purification are achieved, the sewage treatment efficiency is greatly improved through sequential progressive cooperation, the purifying and deodorizing effects are good, the effect taking is fast, the lasting effect is long, the comprehensive benefits are obviously improved, and the process is worthy of popularization and application.

Owner:南京金湖环保科技有限公司

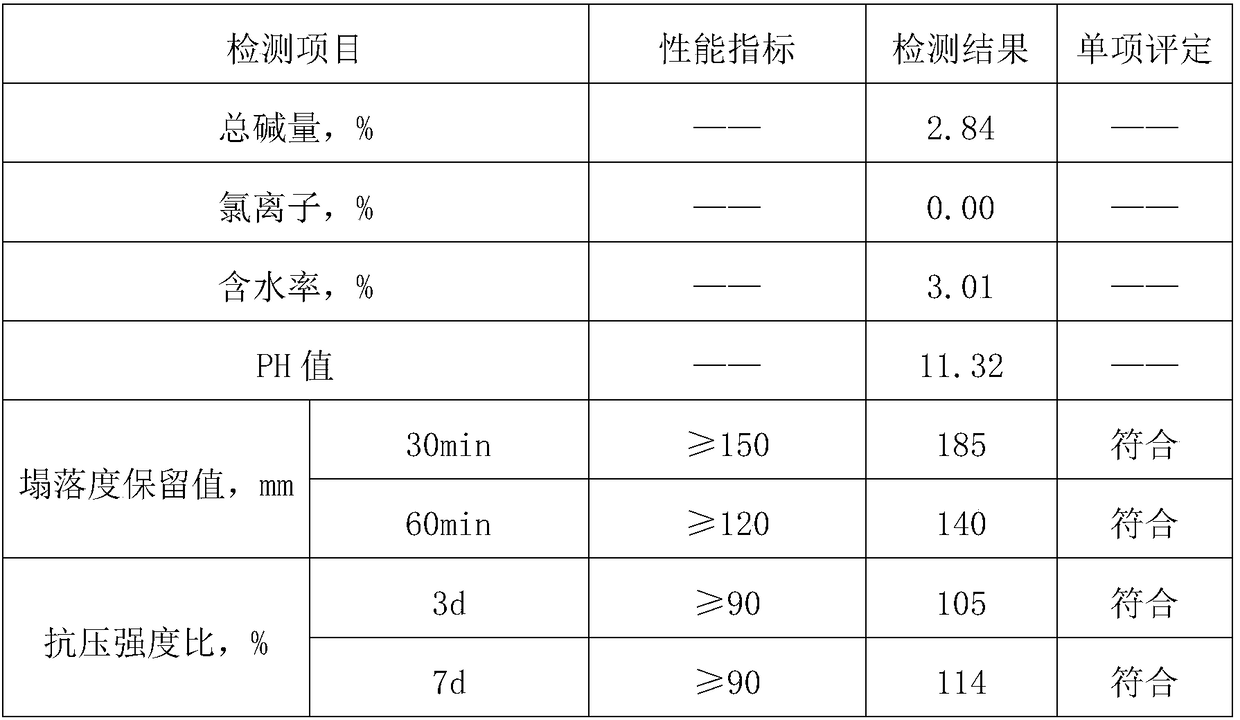

A high-efficiency permeable reinforced concrete preservative

The invention relates to an efficient permeating reinforced concrete preservative which comprises an anti-corrosion component, an anti-rust component and a high-molecular polymer component. The efficient permeating reinforced concrete preservative comprises, by mass percentage, 50-70% of anti-corrosion component, 10-30% of anti-rust component and 8-20% of high-molecular polymer component. The sum of the mass percentages of all the components is 100%. The preservative remarkably improves concrete capability of preventing corrosive mediums from permeating the inside to lead to structural damage and anti-permeating performance; a passive film and an absorption film are formed on the surface of a steel bar, and the corrosion to the steel bar caused by chloride ions can be effectively restrained for a long term; a special net-shaped anti-permeating film is generated in the strong-basic environment of cement slurry, and the speed of most of acid ions migrating into the concrete is delayed.

Owner:SHANDONG HUAAN TOWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com