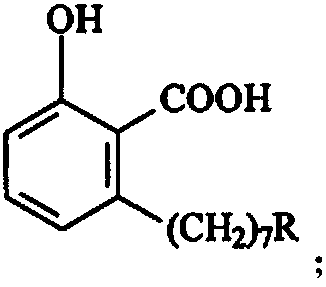

A kind of polycarboxylate water-reducer modified by gingkgolic acid grafting and preparation method thereof

A graft modification, polycarboxylic acid technology, applied in the field of cement admixtures, can solve problems such as water quality and environmental pollution, and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

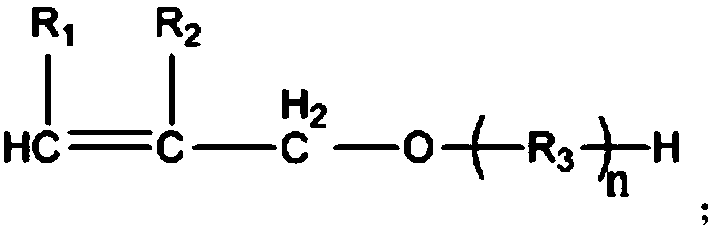

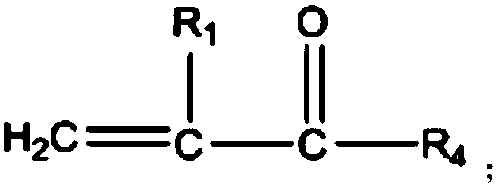

Method used

Image

Examples

Embodiment 1

[0030] In the glass reaction equipment equipped with thermometer, stirrer, constant pressure dropping funnel, nitrogen conduit and reflux condenser, add the water of the isobutylene polyoxyethylene ether of 95 mass parts, the ginkgolic acid of 1 mass part and 60 mass parts, While stirring, purging the interior of the reaction device with nitrogen, when the temperature rose to 20 degrees, uniformly added dropwise a solution of 4 parts by mass of acrylic acid and 50 parts by mass of water to the reaction device for 2 hours, while A solution of 0.1 parts by mass of ammonium persulfate, 0.05 parts by mass of mercaptopropionic acid and 60 parts by mass of water was added dropwise at a constant speed to the reaction device, and the dropping time was 3.5 hours.

[0031] After the aqueous solution of ammonium persulfate and mercaptopropionic acid has been added dropwise, keep it warm at 20°C for 1 hour, add a sodium hydroxide solution with a mass fraction of 32%, and neutralize the sys...

Embodiment 2

[0038] In the glass reaction equipment equipped with thermometer, stirrer, constant pressure dropping funnel, nitrogen conduit and reflux condenser, add the water of the isobutylene polyoxyethylene ether of 65 mass parts, the ginkgolic acid of 15 mass parts and 60 mass parts, While stirring, purging the interior of the reaction equipment with nitrogen, when the temperature rose to 80 degrees, uniformly added dropwise a solution of 20 parts by mass of acrylic acid and 50 parts by mass of water to the reaction device, and the dropping time was 2.5 hours. At the same time, a solution of 10 parts by mass of ammonium persulfate, 5 parts by mass of thioglycolic acid and 60 parts by mass of water was added dropwise at a constant speed to the reaction device, and the dropping time was 3 hours.

[0039] After the ammonium persulfate aqueous solution was added dropwise, keep it warm at 80°C for 1 hour, add 32% sodium hydroxide solution, neutralize the system until the pH value is 6-7, an...

Embodiment 3

[0044] In glass reaction equipment equipped with thermometer, stirrer, constant pressure dropping funnel, nitrogen conduit and reflux condenser, add 85 mass parts of isopentenyl polyoxyethylene ether, 5 mass parts of ginkgolic acid and 60 mass parts of Water, while stirring, purging the interior of the reaction equipment with nitrogen, when the temperature rises to 60 degrees, uniformly add a solution of 10 parts by mass of acrylic acid and 50 parts by mass of water to the reaction device dropwise, and the dropping time is 2.5 hours , At the same time, a solution of 0.5 mass parts of ammonium persulfate, 1 mass part of mercaptopropionic acid and 60 mass parts of water was added dropwise at a constant speed in the reaction equipment, and the dropping time was 3.5 hours.

[0045] After the ammonium persulfate aqueous solution was added dropwise, keep it warm at 60°C for 1 hour, add 32% sodium hydroxide solution to neutralize the system until the pH value is 6-7, and the obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com