Novel iron runner castable with waste refractory as main material

A technology of castable and refractory materials for iron troughs, which is applied in the field of uncertain refractory materials, can solve the problems of a large increase in the amount of water added to castables and cement, a low utilization rate of waste refractory materials, and a single application type of waste refractory materials. Comprehensive cost, good field use effect, and the effect of breaking through the limit of thermal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

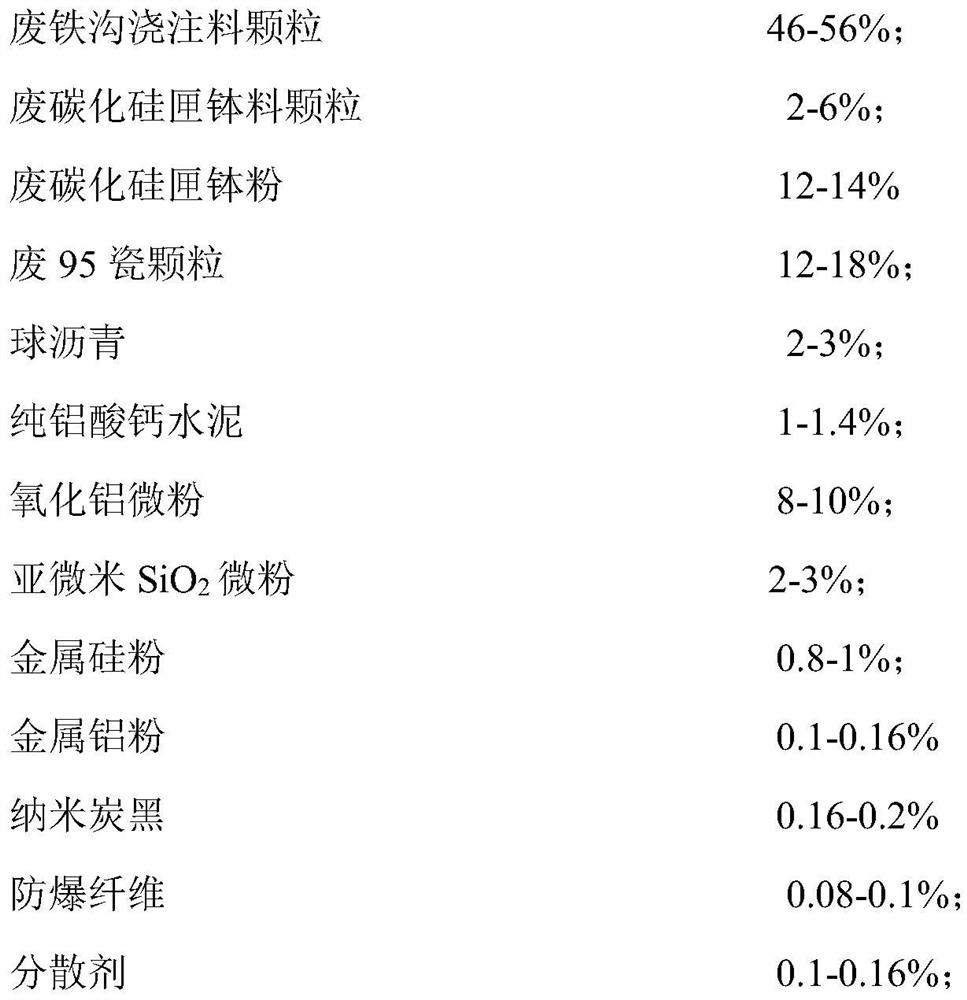

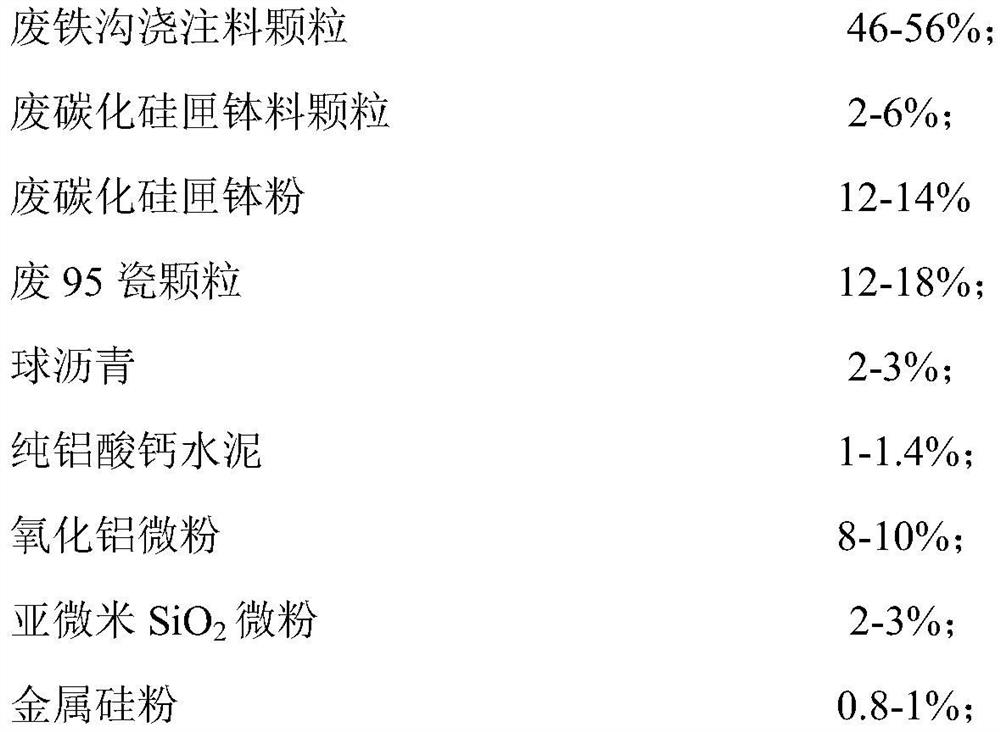

Embodiment 1

[0044] A new iron ditch castable material based on waste and old refractory materials, 46% (weight percentage, the same below) scrap iron ditch castable particles, 6% waste silicon carbide sagger material particles, 12% waste silicon carbide saggar Bowl powder, 18% waste 95 porcelain particles, 3% ball pitch, 1% pure calcium aluminate cement, 9.44% alumina micropowder, 3% submicron SiO 2 Micropowder, 1% metal silicon powder, 0.16% metal aluminum powder, 0.1% explosion-proof fiber, 0.2% nano carbon black, 0.1% dispersant are fully mixed; then add water (the quality of water is iron ditch castable 5% of the mass) and vibrated after stirring evenly. The molded samples were dried naturally for 24 hours, and then heat-treated at 110°C for 24 hours to obtain iron trough castable samples containing 82% waste refractory materials.

[0045]A sample of a new type of iron trench castable made of waste refractory material as the main material prepared in Example 1 was tested, and the tes...

Embodiment 2

[0049] A new iron ditch castable material based on waste and old refractory materials, 56% (weight percentage, the same below) scrap iron ditch castable particles, 2% waste silicon carbide sagger material particles, 12.46% waste silicon carbide saggar Bowl powder, 115% waste 95 porcelain particles, 2% ball pitch, 1.2% pure calcium aluminate cement, 8% alumina micropowder, 2% submicron SiO 2 Micropowder, 0.8% metal silicon powder, 0.1% metal aluminum powder, 0.08% explosion-proof fiber, 0.16% nano-carbon black, and 0.2% dispersant are fully mixed; then add water (the quality of water is iron ditch castable 5% of the mass) and vibrated after stirring evenly. The molded samples were dried naturally for 24 hours, and then heat-treated at 110°C for 24 hours to obtain iron trough castable samples containing 80.46% waste refractories.

[0050] A sample of a new type of iron trench castable made of waste refractory material as the main material prepared in Example 2 was tested, and t...

Embodiment 3

[0054] A new iron ditch castable material based on waste and old refractory materials, 51% (weight percentage, the same below) scrap iron ditch castable particles, 4% waste silicon carbide sagger material particles, 14% waste silicon carbide sagger Bowl powder, 13.31% waste 95 porcelain particles, 2.5% ball pitch, 1.4% pure calcium aluminate cement, 10% alumina micropowder, 2.5% submicron SiO 2 Micropowder, 0.9% metal silicon powder, 0.12% metal aluminum powder, 0.09% explosion-proof fiber, 0.18% nano-carbon black, and 0.15% dispersant are fully mixed; then add water (the quality of water is iron trench castable 5% of the mass) and vibrated after stirring evenly. The molded samples were dried naturally for 24 hours, and then heat-treated at 110°C for 24 hours to obtain iron trench castable samples containing 82.33% waste refractory materials.

[0055] A sample of a new type of castable iron trench made of waste refractory material as the main material prepared in Example 3 wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com