Patents

Literature

274 results about "Saggar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A saggar is a type of kiln furniture. It is a ceramic boxlike container used in the firing of pottery to enclose or protect ware being fired inside a kiln. Traditionally, saggars were made primarily from fireclay. Saggars have been used to protect, or safeguard, ware from open flame, smoke, gases and kiln debris: the name may be a contraction of the word safeguard. Their use is widespread, including in China, Korea, Japan and the United Kingdom. Saggars are still used in the production of ceramics to shield ware from the direct contact of flames and from damage by kiln debris. Modern saggars are made of alumina ceramic, cordierite ceramic, mullite ceramic silicon carbide and in special cases from zirconia.

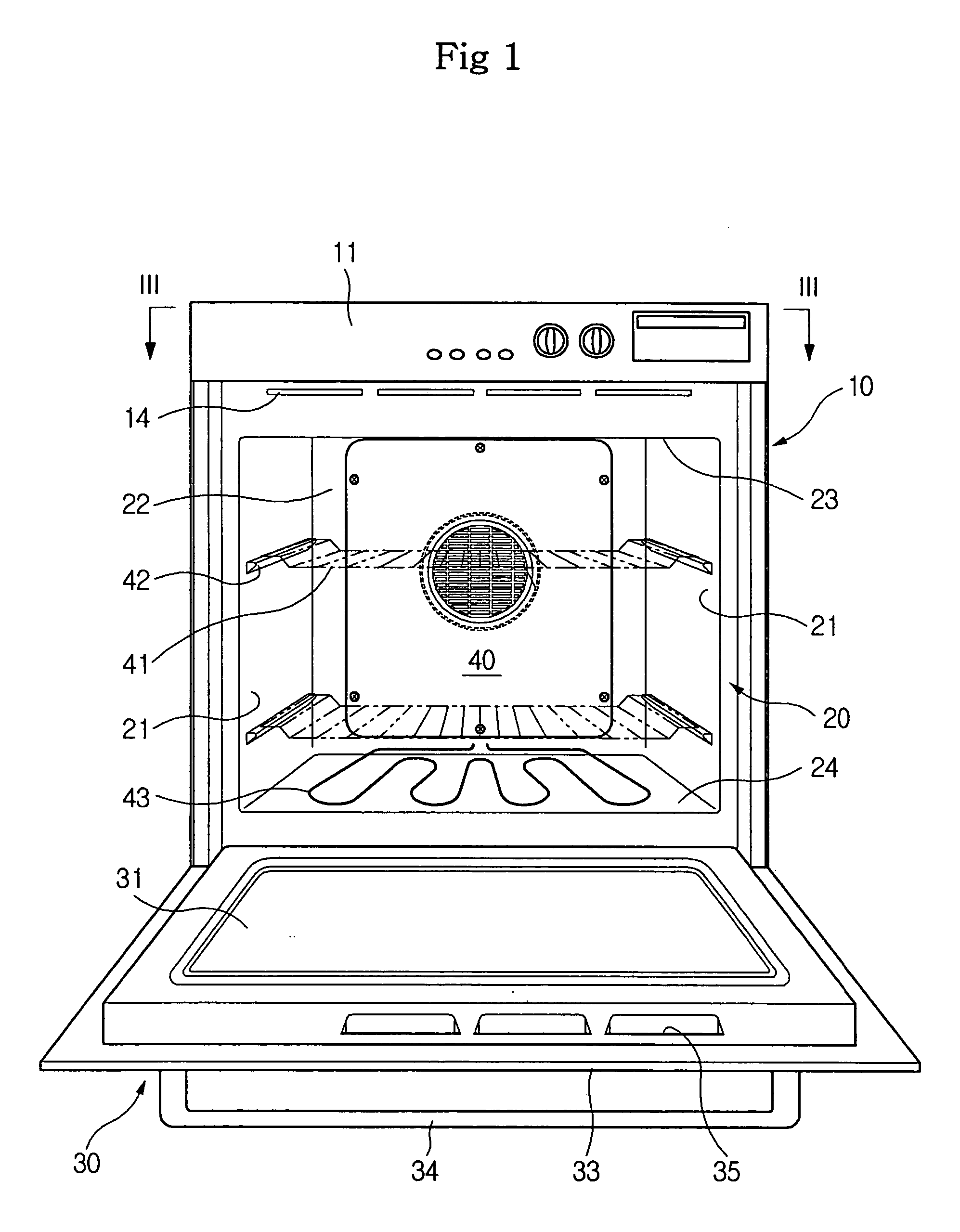

Oven

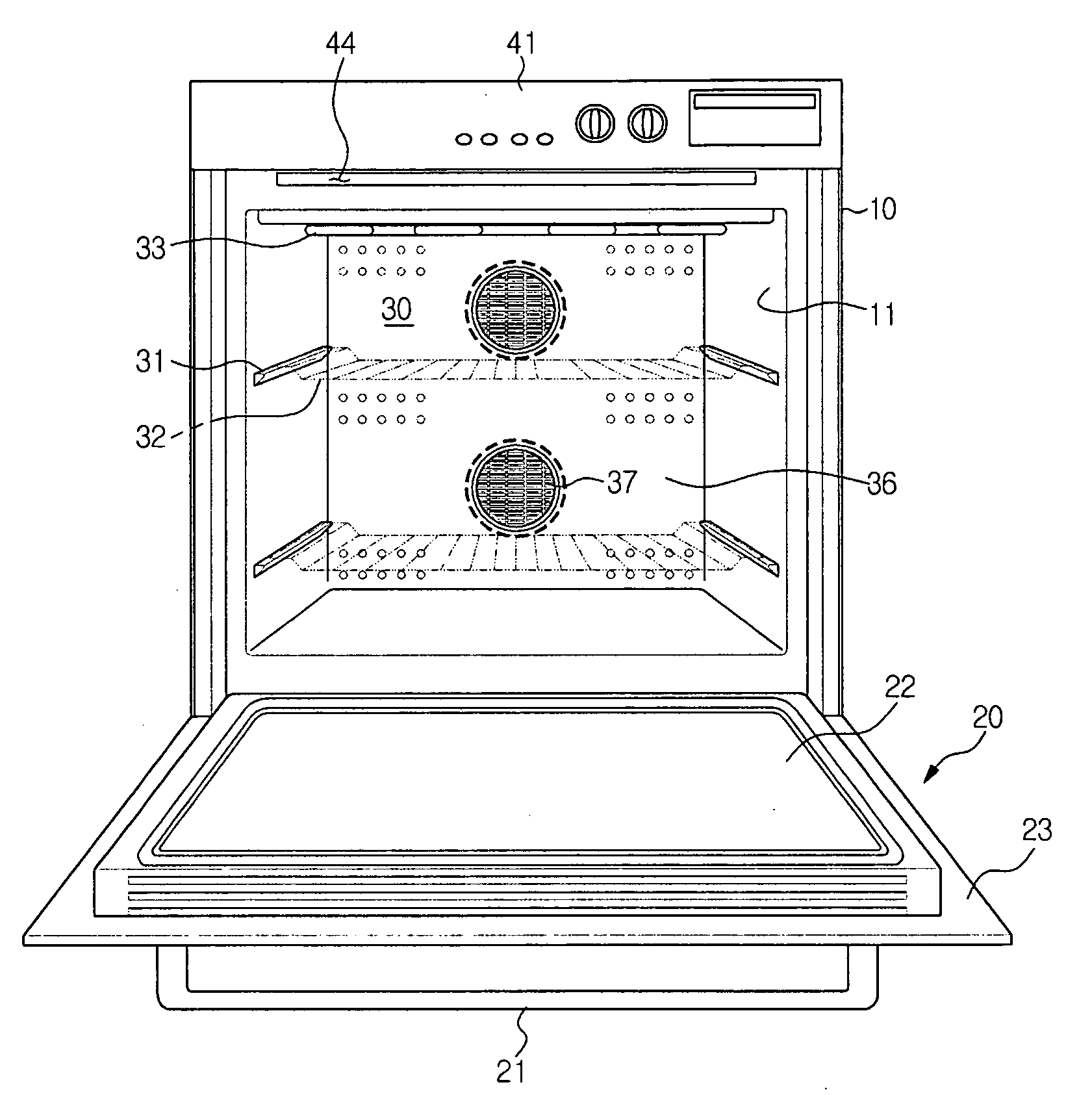

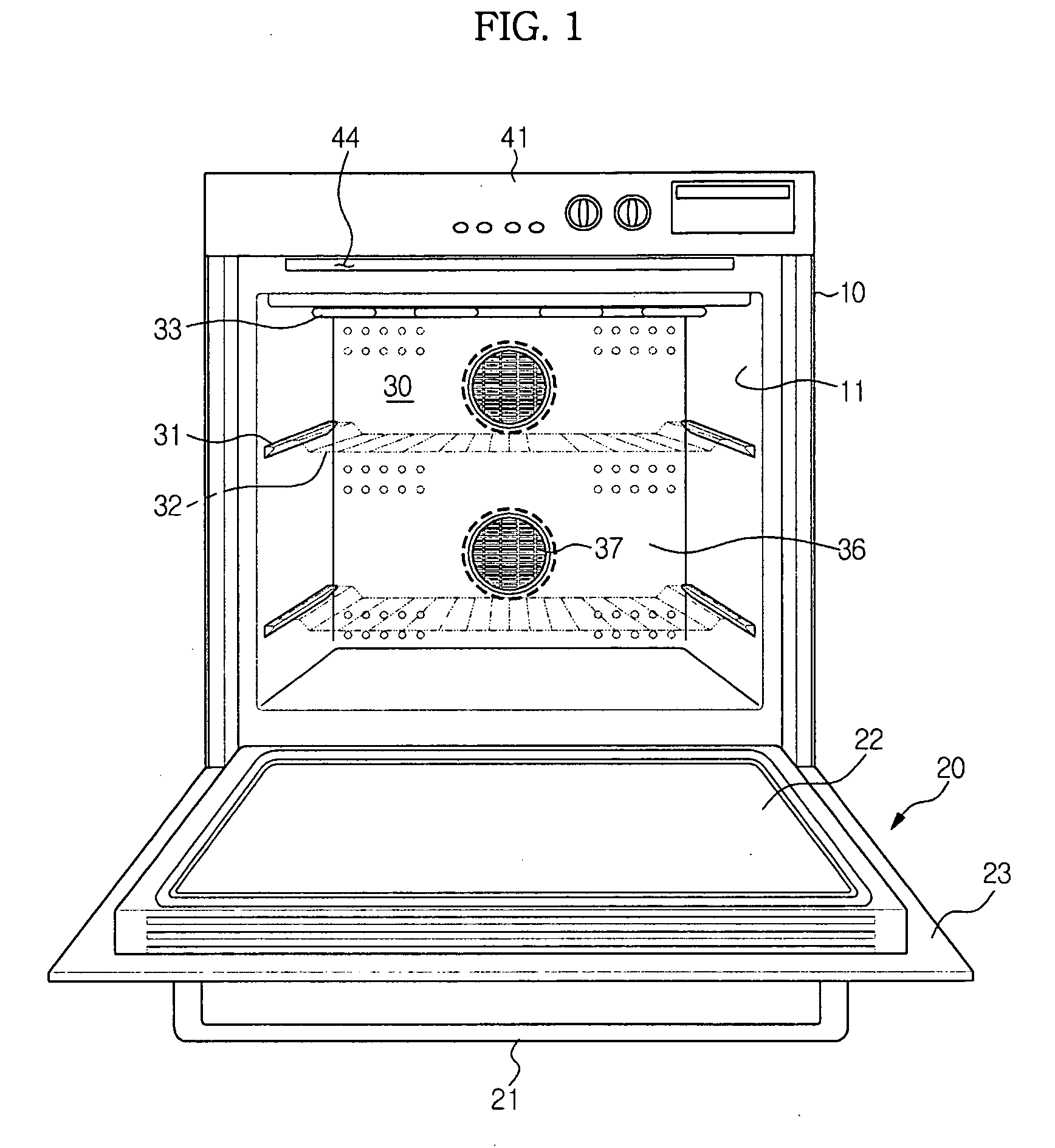

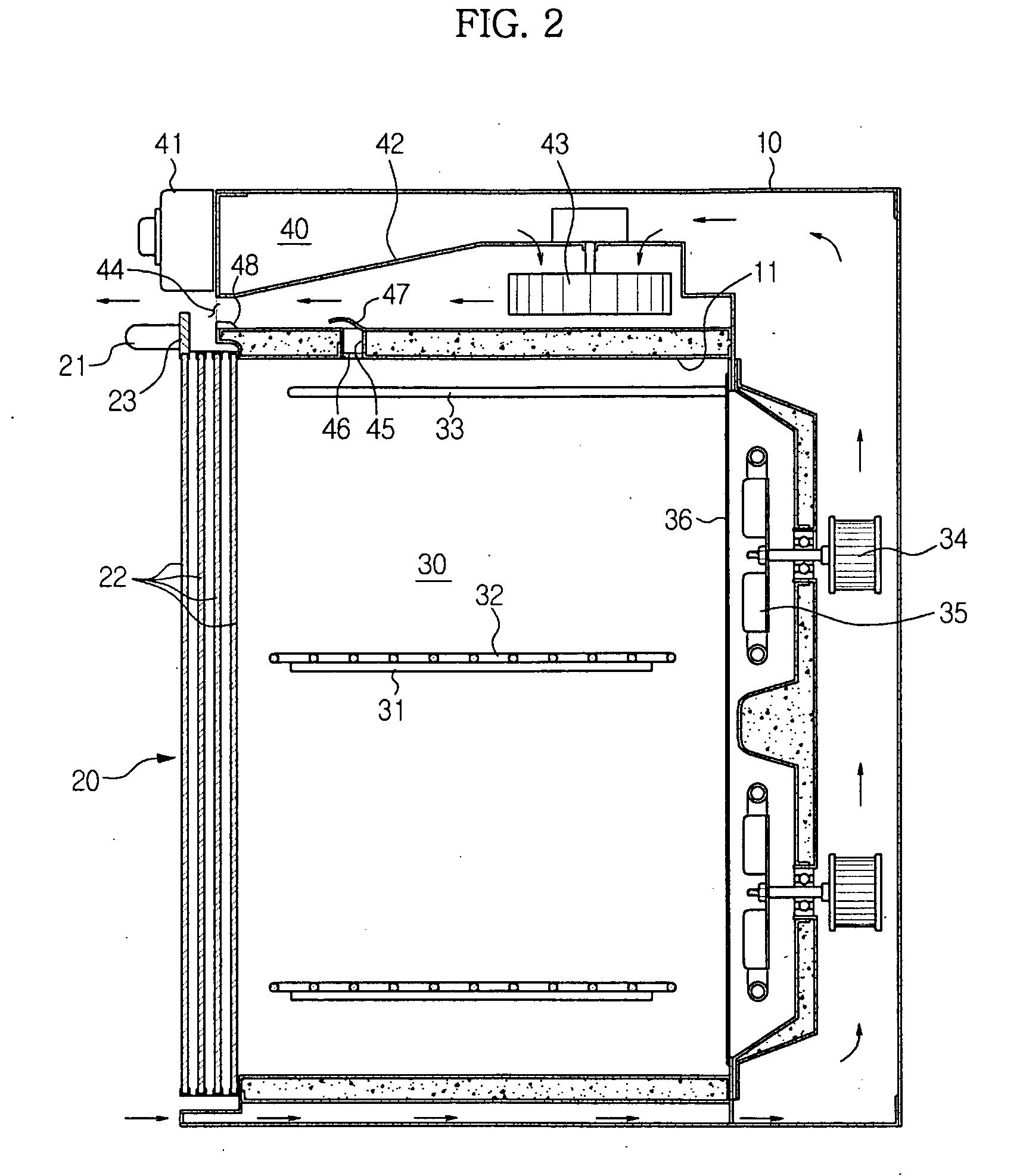

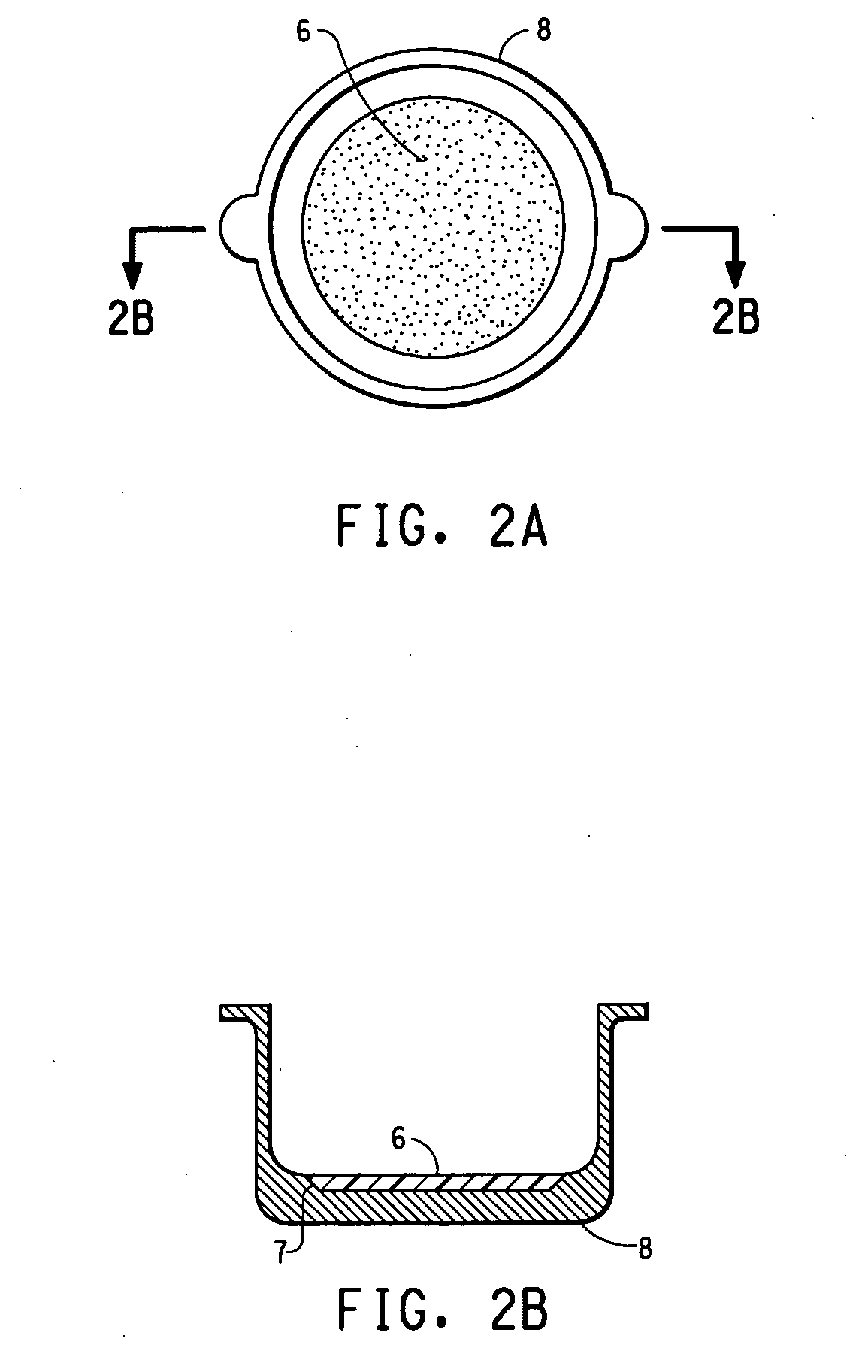

ActiveUS20090194090A1Domestic stoves or rangesDoors for stoves/rangesSaggarElectrical and Electronics engineering

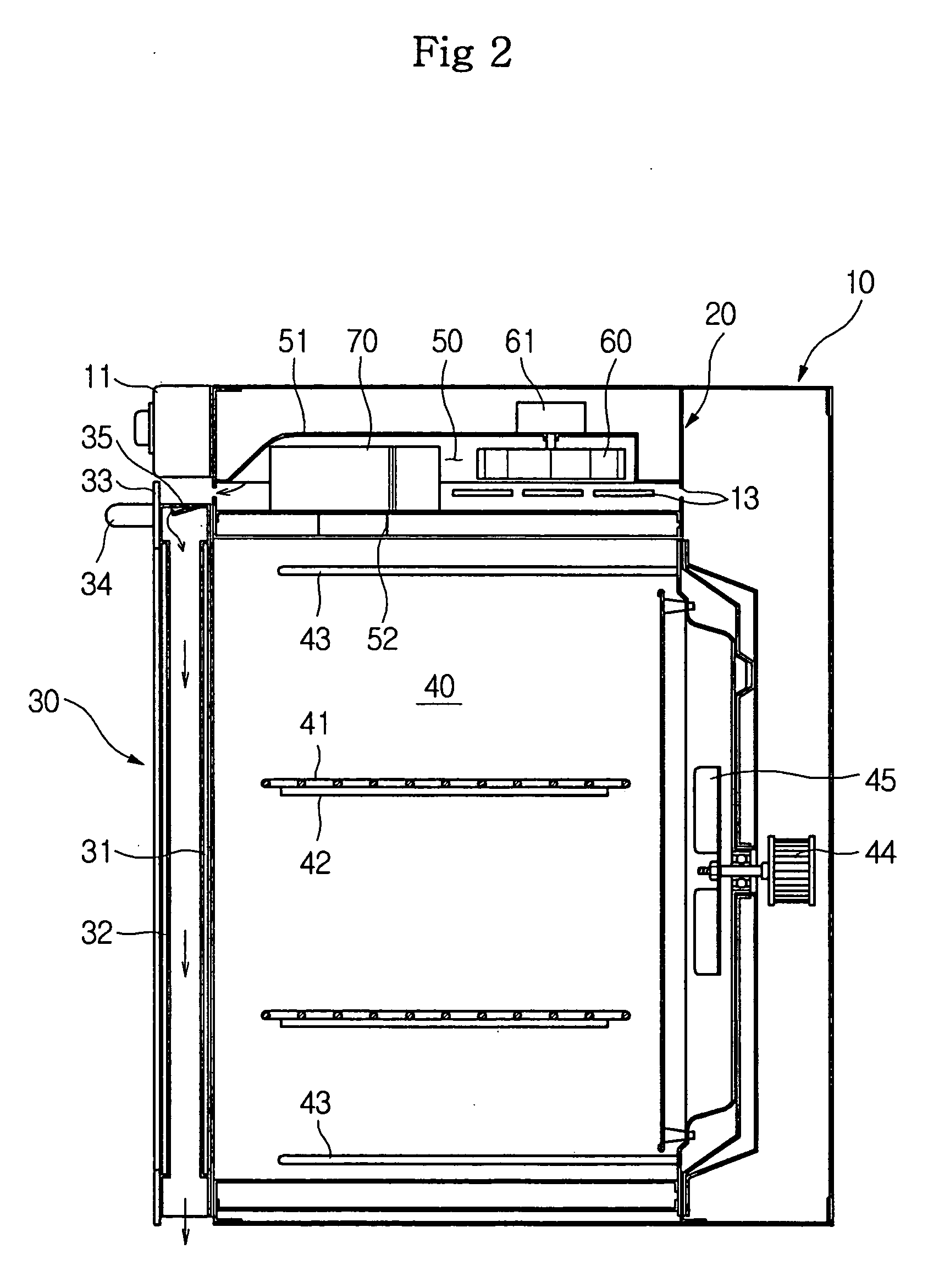

An oven, which both satisfies heat insulating and cooling of a door by adjusting an air flow in channels formed in the door. The oven includes a plurality of channels provided in a door, into which external air flows, accompanied with air discharged by a discharge duct, such that the air flows in the plurality of the channels, and a flow conversion part formed above at least one of the plurality of the channels for stagnating the flow of air. Since the door insulates a cooking chamber from heat and is cooled using a difference of pressures between upper and lower portions of the door, the oven concurrently satisfies conflicting two requirements, such as heat insulating and cooling of the door.

Owner:SAMSUNG ELECTRONICS CO LTD

Pizza oven for grill

Owner:DRISCOLL JAMES P JR

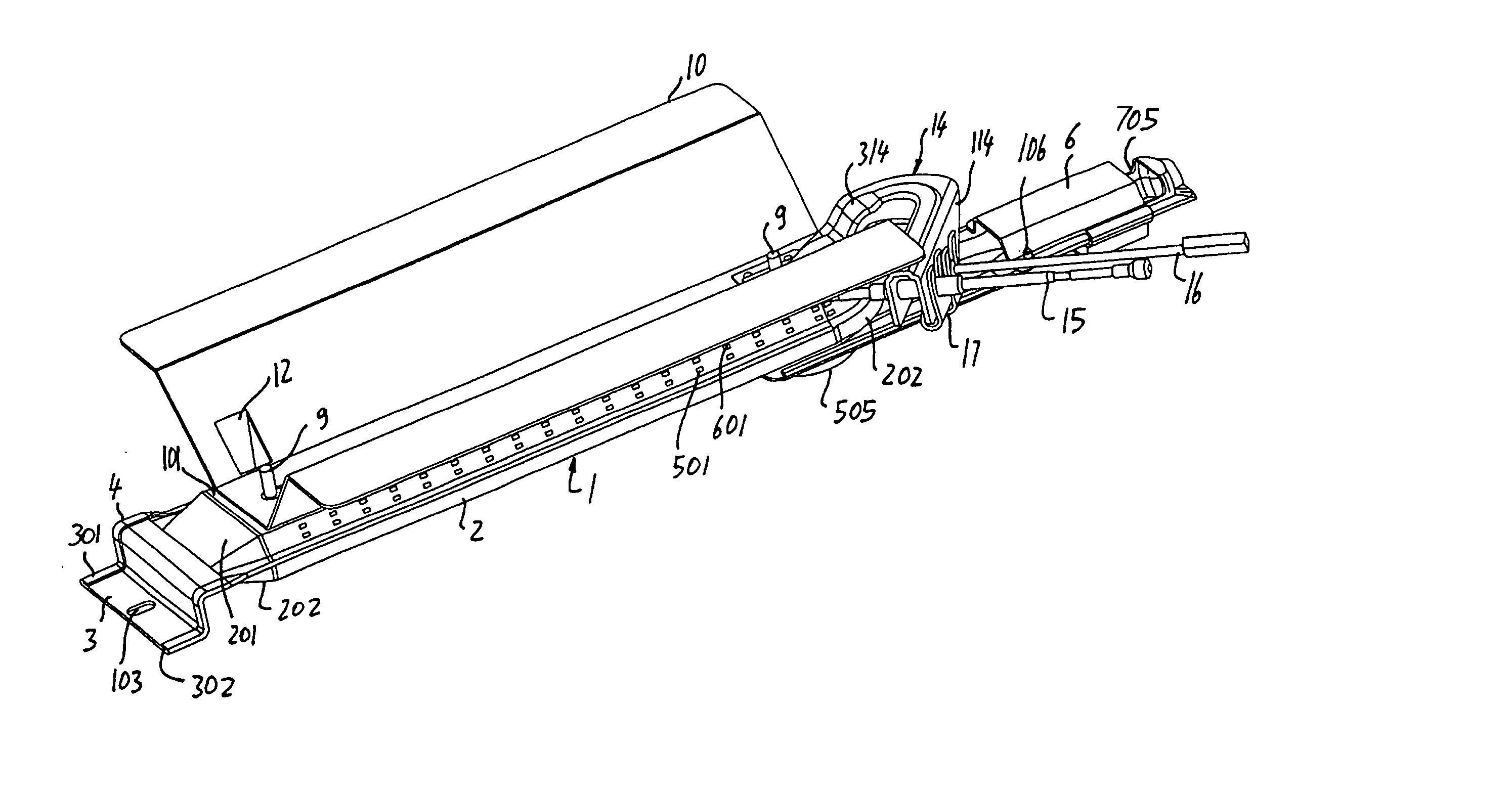

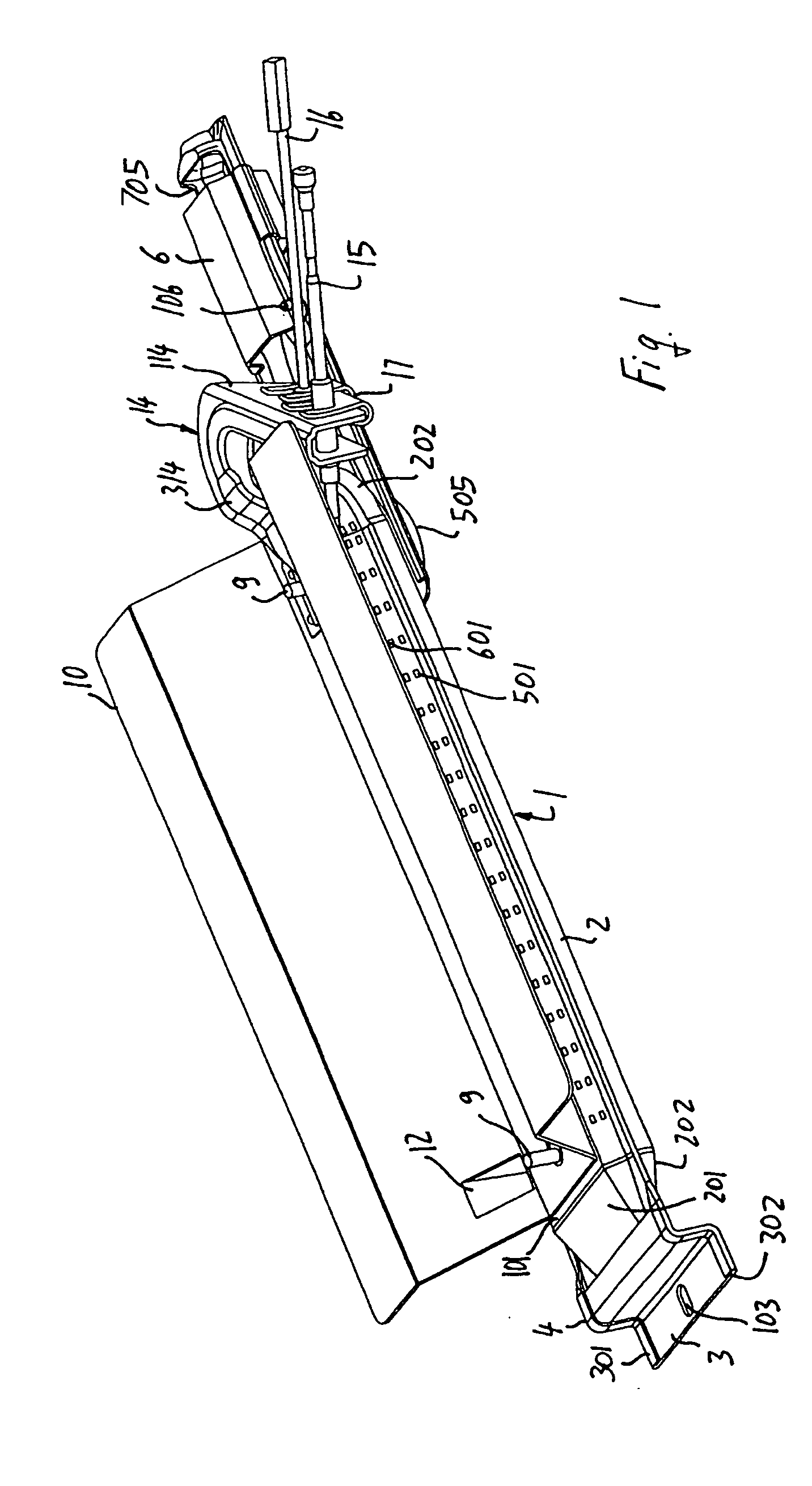

Oven or grill burner, venturi tube, mounting for a thermocouple and/or an igniter, and process for fabricating said burner

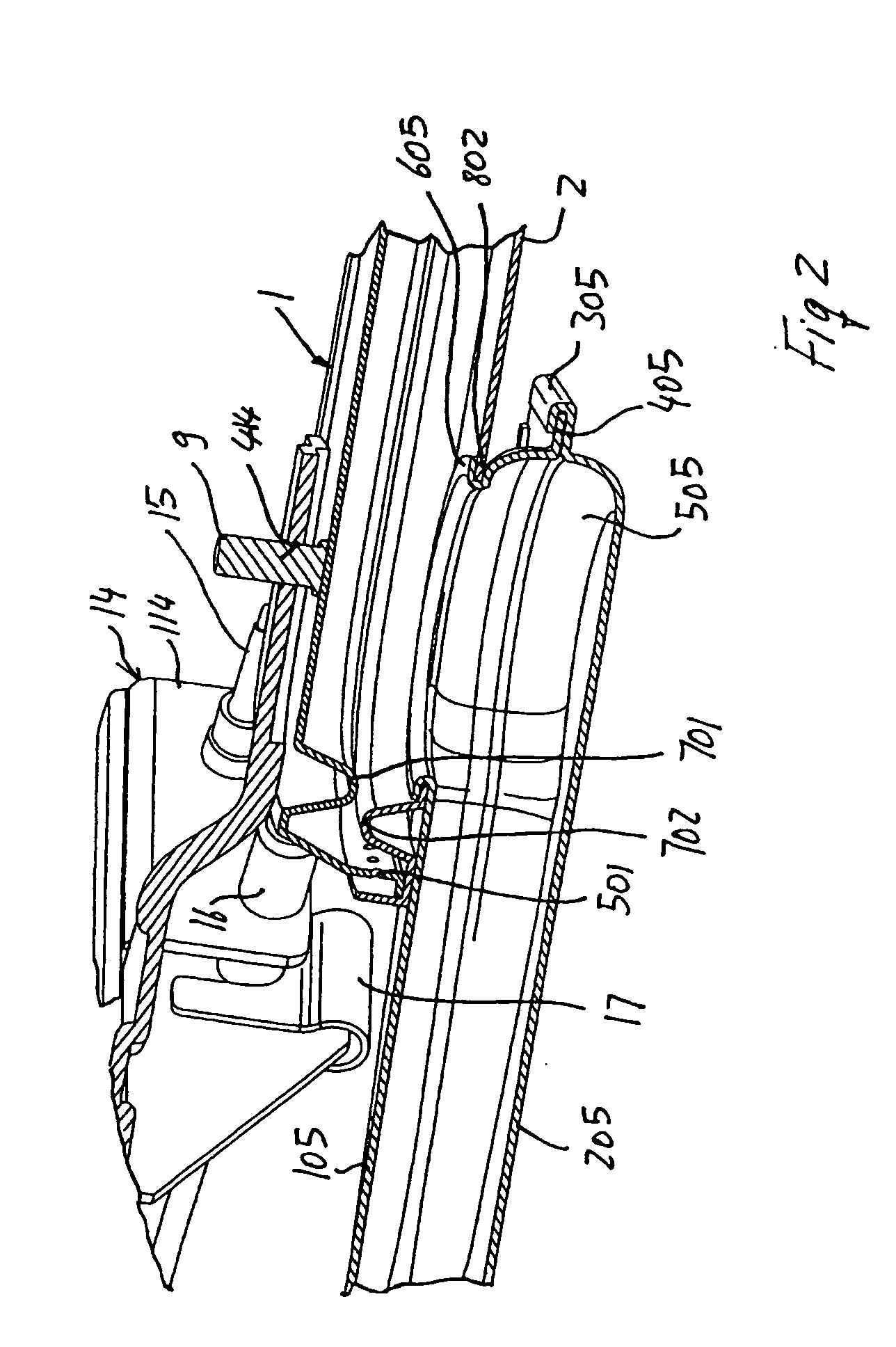

ActiveUS20050138789A1Function increaseStrong construction adaptabilityDomestic stoves or rangesBurner manufactureCombustorCoupling

The invention relates to a burner comprising two half shells, one of which is perforated, that are tightly joined together along at least a portion of their edges, so as to form a tubular body communicating with a venturi tube. At least two corresponding ends of the two half shells have a truncated profile, providing the tubular body has at least one truncated end. The invention also relates to a venturi tube for said burner that is composed of two half shells The invention further relates to a mounting for a thermocouple and for an igniter of said burner, the mounting having coupling means that cause mutual contact surfaces to be oriented in at least three non-parallel planes and that prevent mounting rotation, so that the position thereof is accurately defined. The invention also relates to a process for fabricating said burner.

Owner:CAST SPA

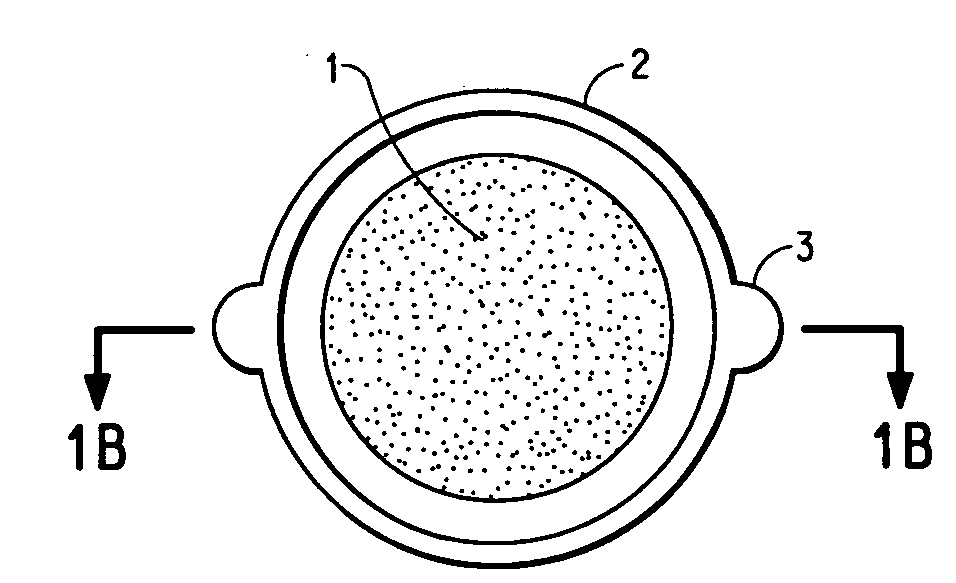

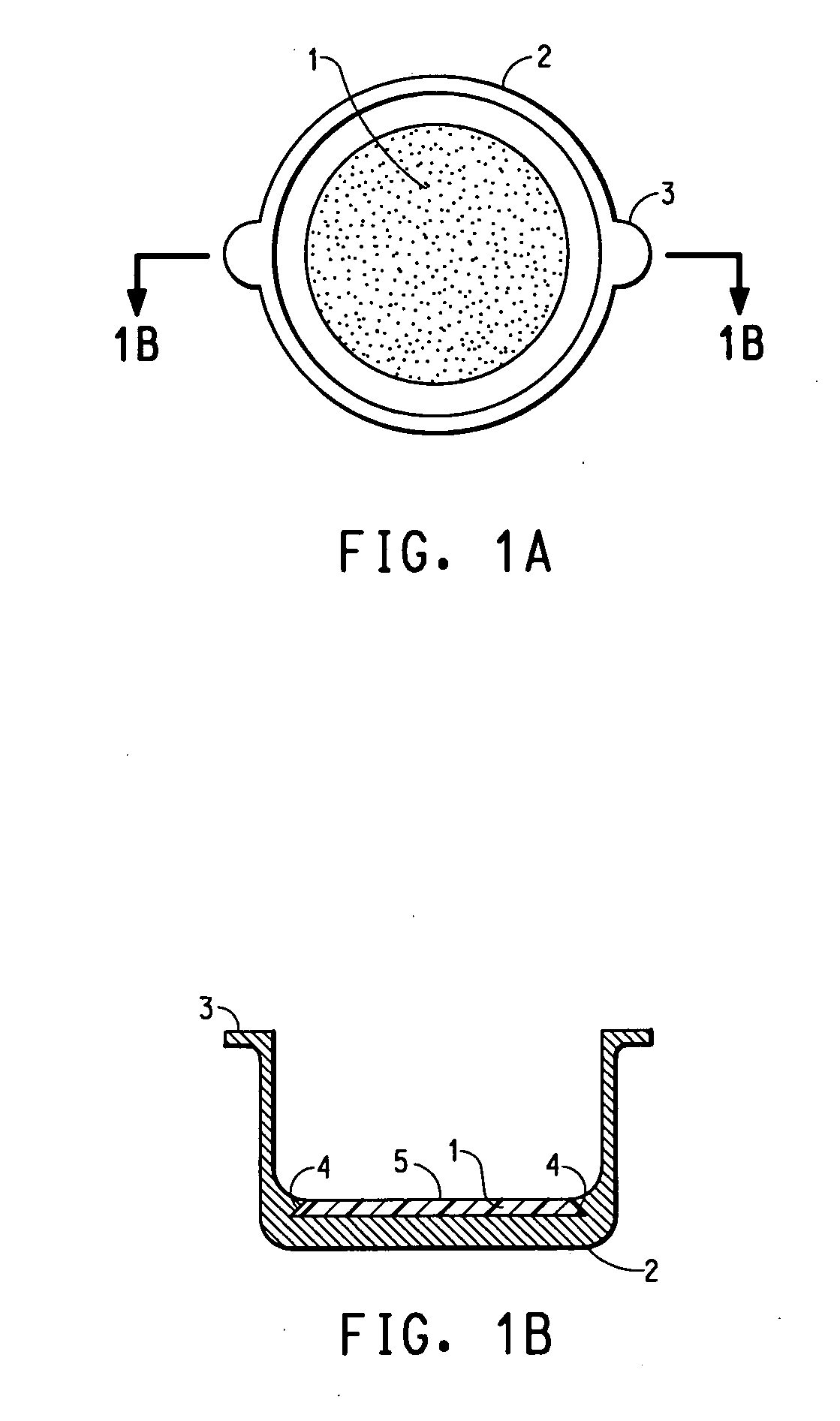

Ovenware for microwave oven

Ovenware for microwave ovens which contain a composition comprising a susceptor which has a Curie point temperature of about 100° C. to about 300° C. and a thermoplastic or thermoset polymer are improved and said composition is in contact with the food or drink to be heated or cooked, and / or composition has a thermal conductivity of about 0.7 W / m° K. or more. Heat generated by absorption of microwave radiation by the susceptor is more readily conducted to the food being cooked when the thermal conductivity of the composition is high, particularly when the part containing the susceptor is relatively thick. The relatively low Curie point of the susceptor prevent overheating of the ovenware and food being cooked. Also described are designs for various pieces of ovenware containing this composition.

Owner:TICONA LLC

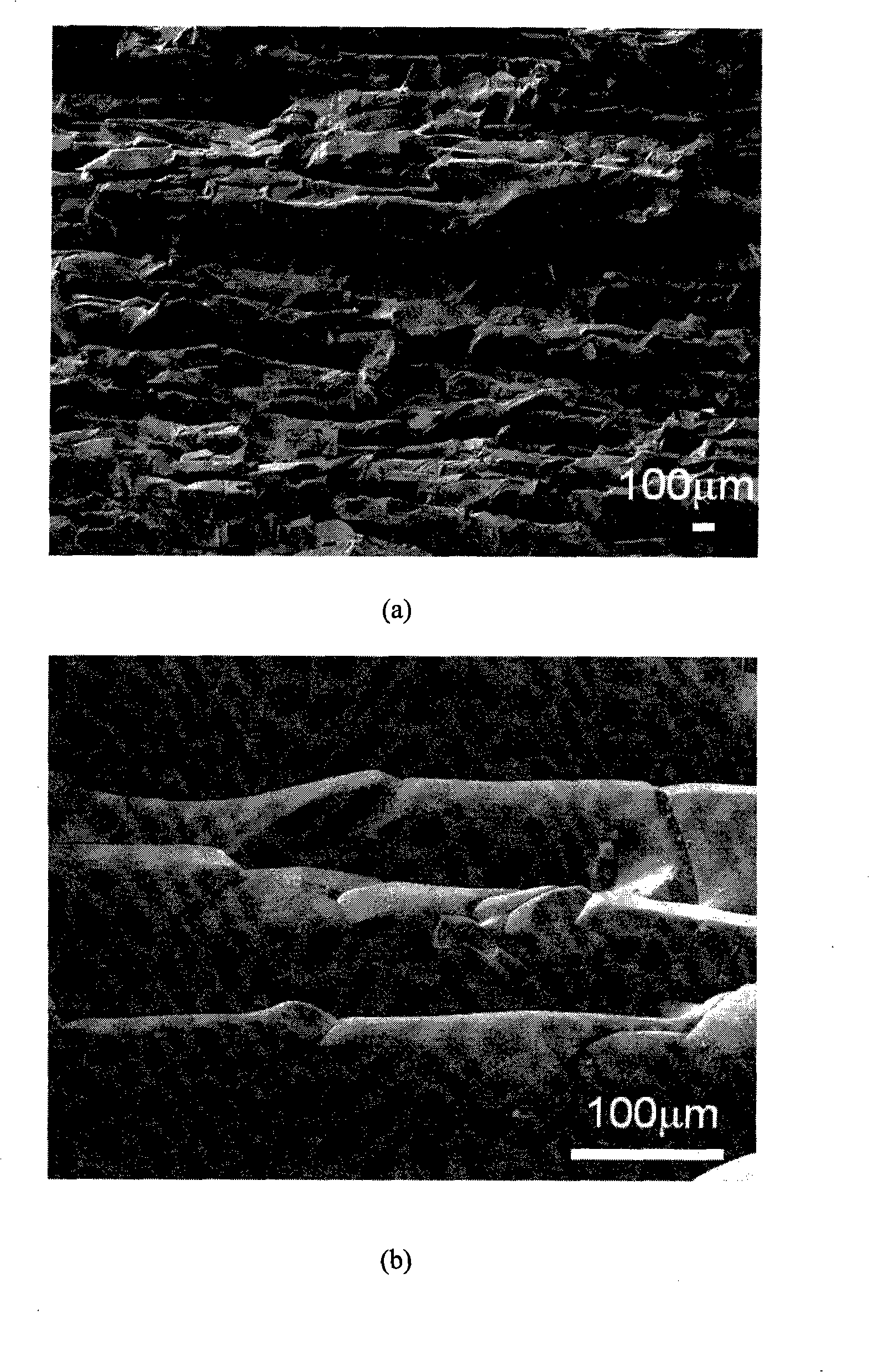

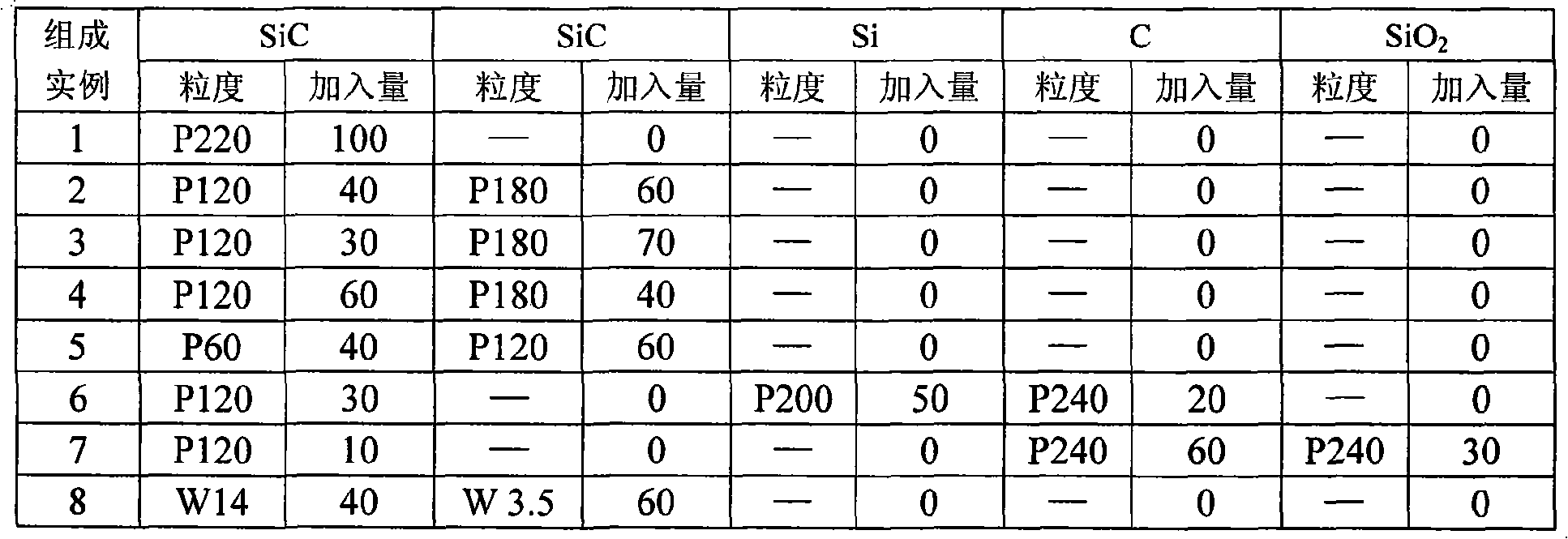

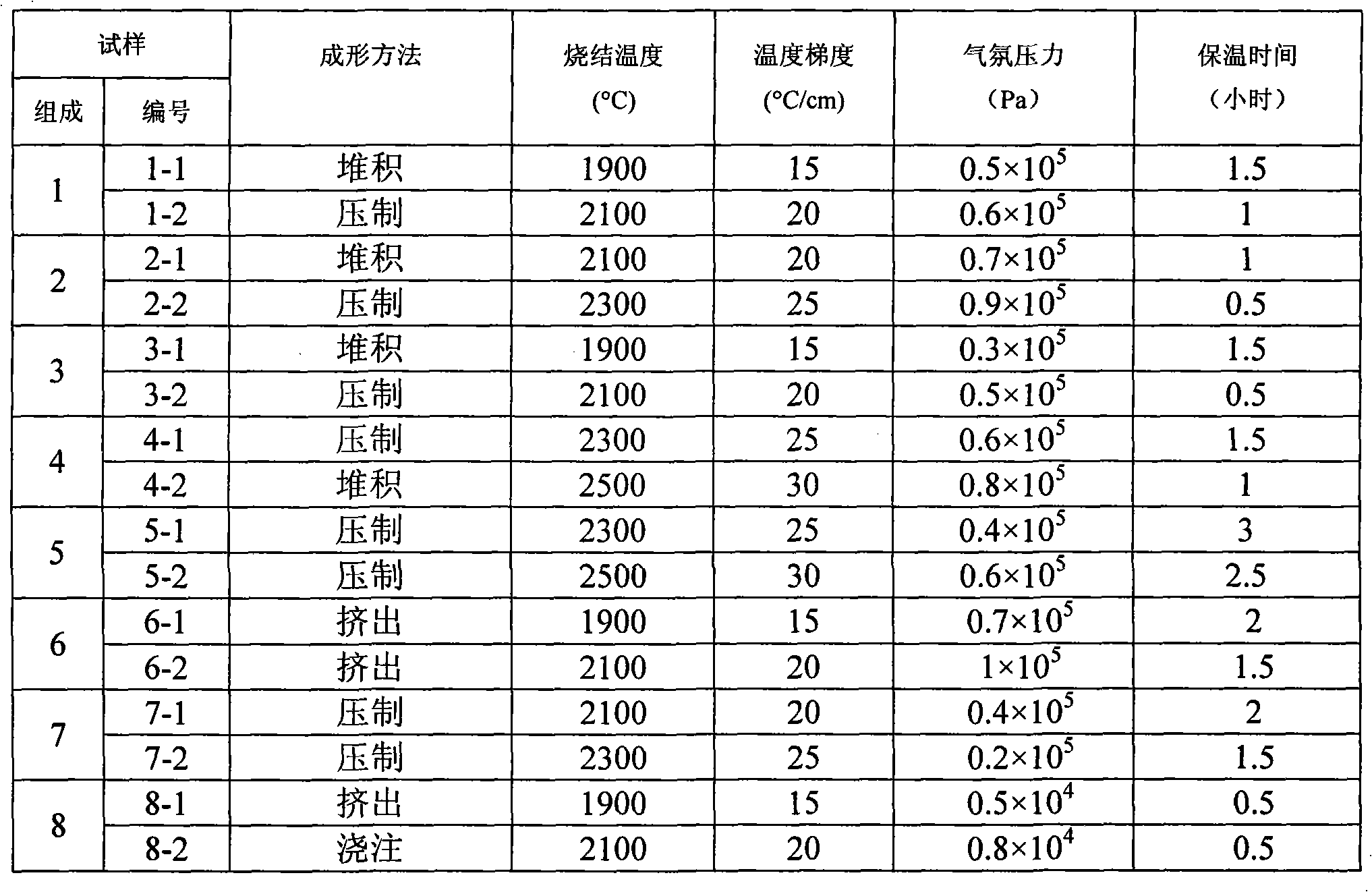

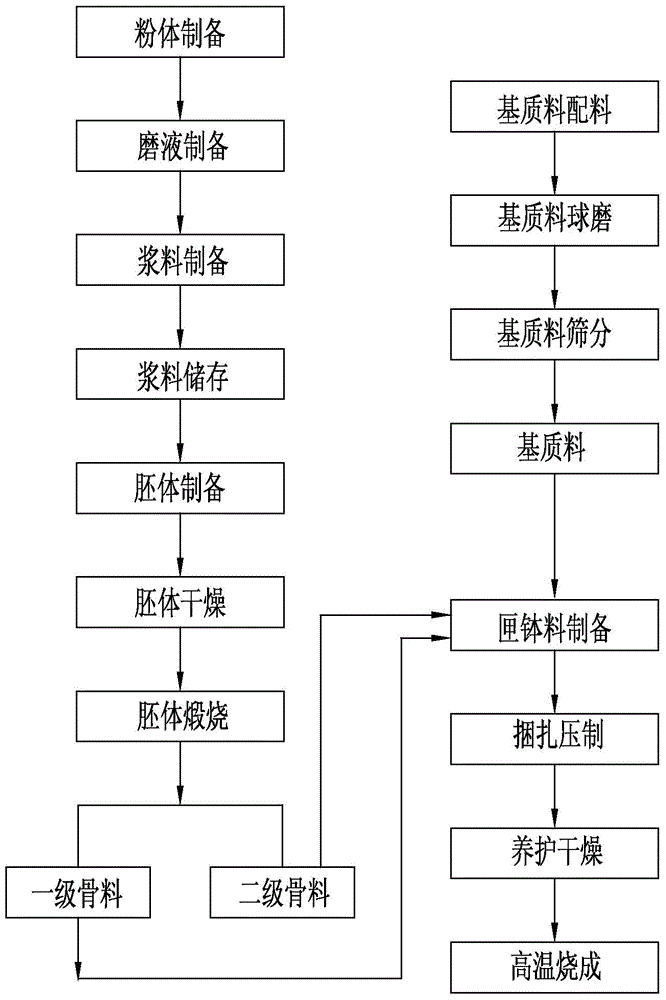

Preparation of oriented hole silicon carbide porous ceramic

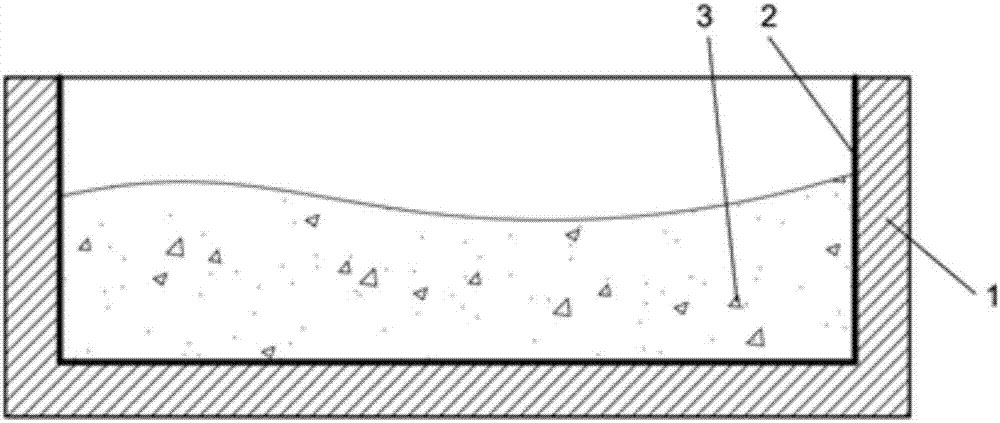

InactiveCN101323524AControl evaporation-condensation directionAdjust evaporation-condensation rateCeramicwareGranularitySaggar

The invention discloses a preparation method of a porous silicon-carbide ceramic provided with oriented pores. Firstly, according to weight percentage, 0 to 30 percent of carbon powder, 0 to 50 percent of silicon powder and 0 to 60 percent of silica are added into the 10 to 100 percent of the basic material of silicon-carbide; wherein, the granularity of the silicon-carbide is W3.5 to P220, and one granularity or two granularities are adopted for graduation; then the equally mixed materials are processed through powder accumulation or normal ceramic forming process to obtain a green compact which is put into a graphite crucible or a saggar; the graphite crucible or saggar is placed into a vacuum sintering furnace provided with a temperature field with a temperature grade from 15 to 30 DEG C / cm, and then the temperature is raised to 1900 to 2500 DEG C in an argon environment and with pressure of 0.2 to 1 multipliedby 10 <5>Pa, and the insulation work for the graphite crucible or saggar is preserved for 0.5 to 3 hours; finally the temperature naturally falls down under air protection and the sintered body is taken out, namely, the recrystallization porous silicon-carbide ceramic provided with oriented pores is obtained.

Owner:XI AN JIAOTONG UNIV

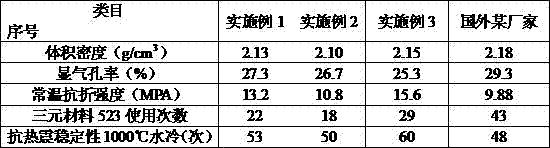

Preparation process for anticorrosion saggar for calcination of lithium battery cathode material

The invention discloses a preparation process for an anticorrosion saggar for calcination of a lithium battery cathode material. The preparation process includes the steps of primary aggregate preparation, secondary aggregate preparation, matrix material preparation and saggar preparation. The steps of primary aggregate preparation and secondary aggregate preparation sequentially comprise the procedures of powder preparation, ball milling slurry preparation, slurry preparation, slurry storage, blank preparation, blank drying and blank calcination. The step of matrix material preparation sequentially includes the procedures of matrix material burdening, matrix material ball milling and matrix material screening. The step of saggar preparation sequentially includes the procedures of saggar material preparation, bundling pressing, maintenance drying and high-temperature firing. Primary aggregates, secondary aggregates and a matrix material are mixed according to the process ratio to form a saggar material. The anticorrosion saggar has the alkali-resistant and anti-corrosion functions, and pure magnesium hydrate, aluminum oxide and silicon dioxide are calcinated to obtain high-purity cordierite material aggregates; magnesium-aluminum-rich spinel powder is added for preparing the matrix material, and the saggar is small in heat expansion coefficient, high in heat impact resistance and long in service life.

Owner:SUZHOU RUIBANG CERAMIC NEW MATERIAL

A low-cost long-service-lifetime ceramic saggar and a preparing method thereof

The invention relates to a low-cost long-service-lifetime ceramic saggar and a preparing method thereof. The ceramic saggar is used for sintering powder of a lithium compound. Raw materials of a matrix of the ceramic saggar include, by weight, 20-25% of talcum, 15-20% of bauxitic rock, 5-35% of magnesium aluminate spinel having a size of 60-65 meshes, 15-45% of magnesium aluminate spinel having a size of 100-120 meshes, and 5-15% of cordierite. Some natural ore materials which are the talcum and the bauxitic rock are adopted as raw materials to prepare the ceramic saggar, and the cost is saved by 1 / 3 or above. The ceramic saggar prepared by the method can bear 50 times of thermal shock cycles without cracks, and has good thermal shock resistance. The ceramic saggar does not react with synthetic raw materials of lithium ion battery cathode materials at 1000 DEG C, and has good corrosion resistance. The service lifetime of the ceramic saggar can be 50 times or above.

Owner:WUHAN UNIV OF TECH

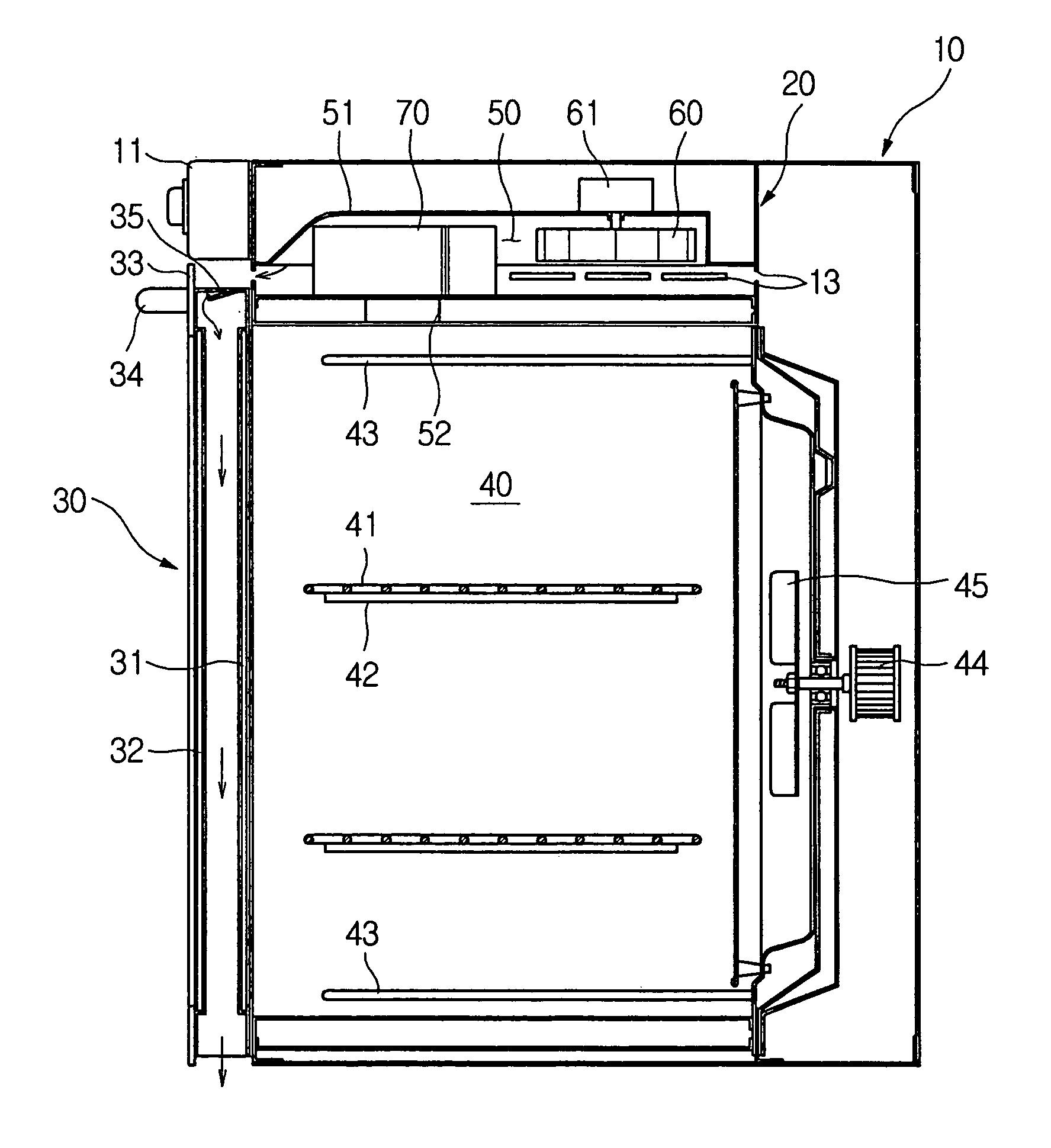

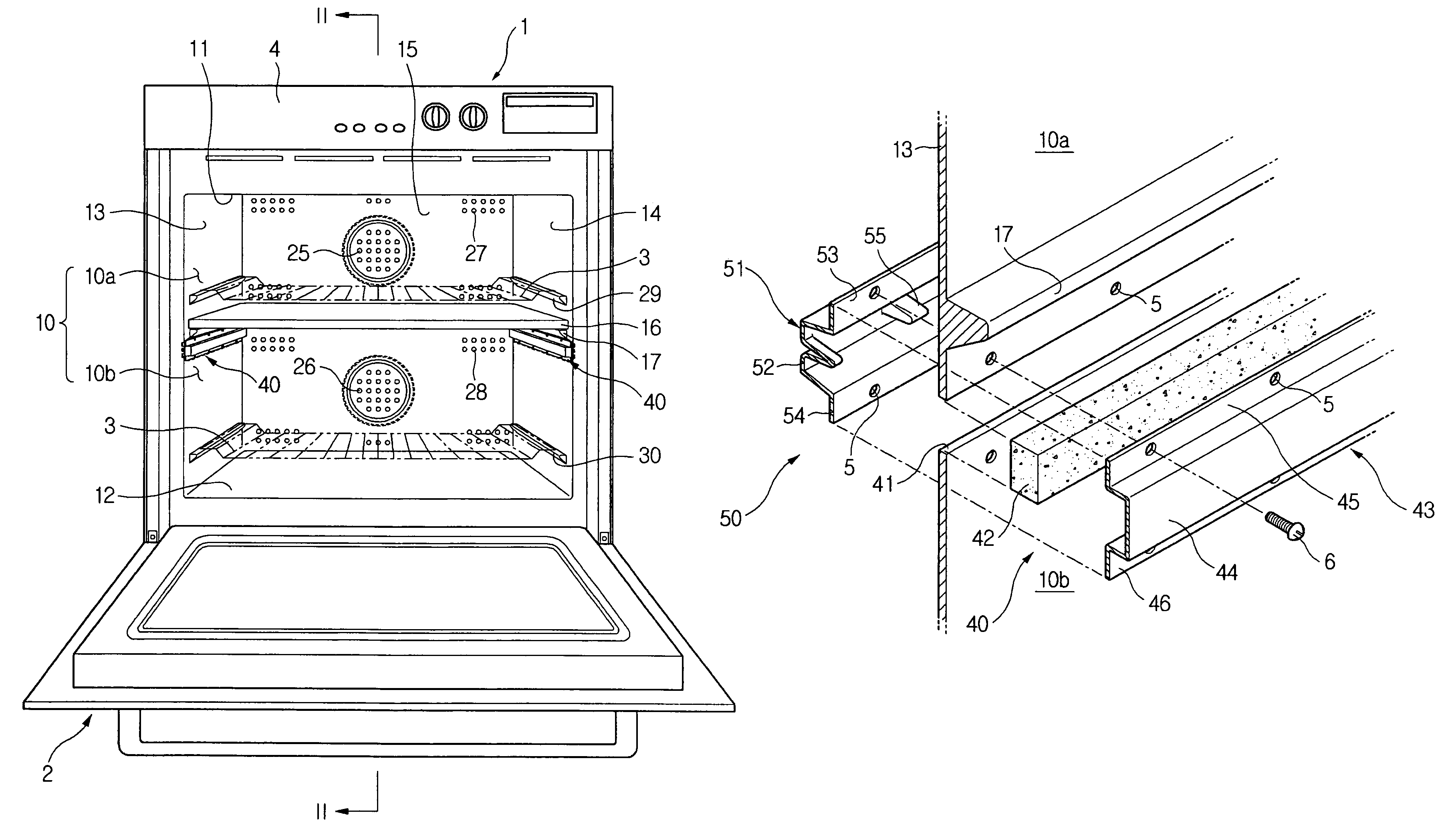

Oven

ActiveUS20060196495A1Effectively and rapidly coolingAvoid dischargeSelf-cleaning stoves/rangesDoors for stoves/rangesEngineeringAir blower

Owner:SAMSUNG ELECTRONICS CO LTD

Lightweight saggar for roasting positive electrode material of lithium battery and preparation method thereof

ActiveCN108373324AHigh bonding strengthImprove corrosion resistanceCobalt compoundsMulliteLithium-ion battery

The invention relates to a lightweight saggar for roasting a positive electrode material of a lithium battery and a preparation method thereof. The invention adopts the technical scheme which is characterized in that the preparation method comprises the following steps: firstly adopting 30-45wt% of spodumene, 30-40wt% of azorite, 10-20wt% of Suzhou soil and 5-10wt% of titanium dioxide as raw materials, adding 4-6wt% of water, and uniformly mixing to prepare glaze; then adopting 45-65wt% of mullite lightweight aggregate, 15-20wt% of kyanite, 10-20wt% of aluminium oxide micropowder and 10-20wt%of Suzhou soil as a mixture, adding a bonding agent with the amount being 10-15wt% of the amount of the mixture, uniformly mixing, and mechanically pressing and molding to obtain a saggar matrix; uniformly distributing the glaze onto the working surface of the bottom part of the saggar matrix, mechanically pressing again, drying, and insulating thermal for 3-10 hours under the condition with the temperature of 1,330-1,400 DEG C to prepare the lightweight saggar for roasting the positive electrode material of the lithium battery. The lightweight saggar and the preparation method have the beneficial effects that the production cost is low and the preparation process is simple; the prepared lightweight saggar for roasting the positive electrode material of the lithium battery is excellent inthermal shock stability, good in erosion resistance and long in service life.

Owner:广东山摩新材料科技有限公司

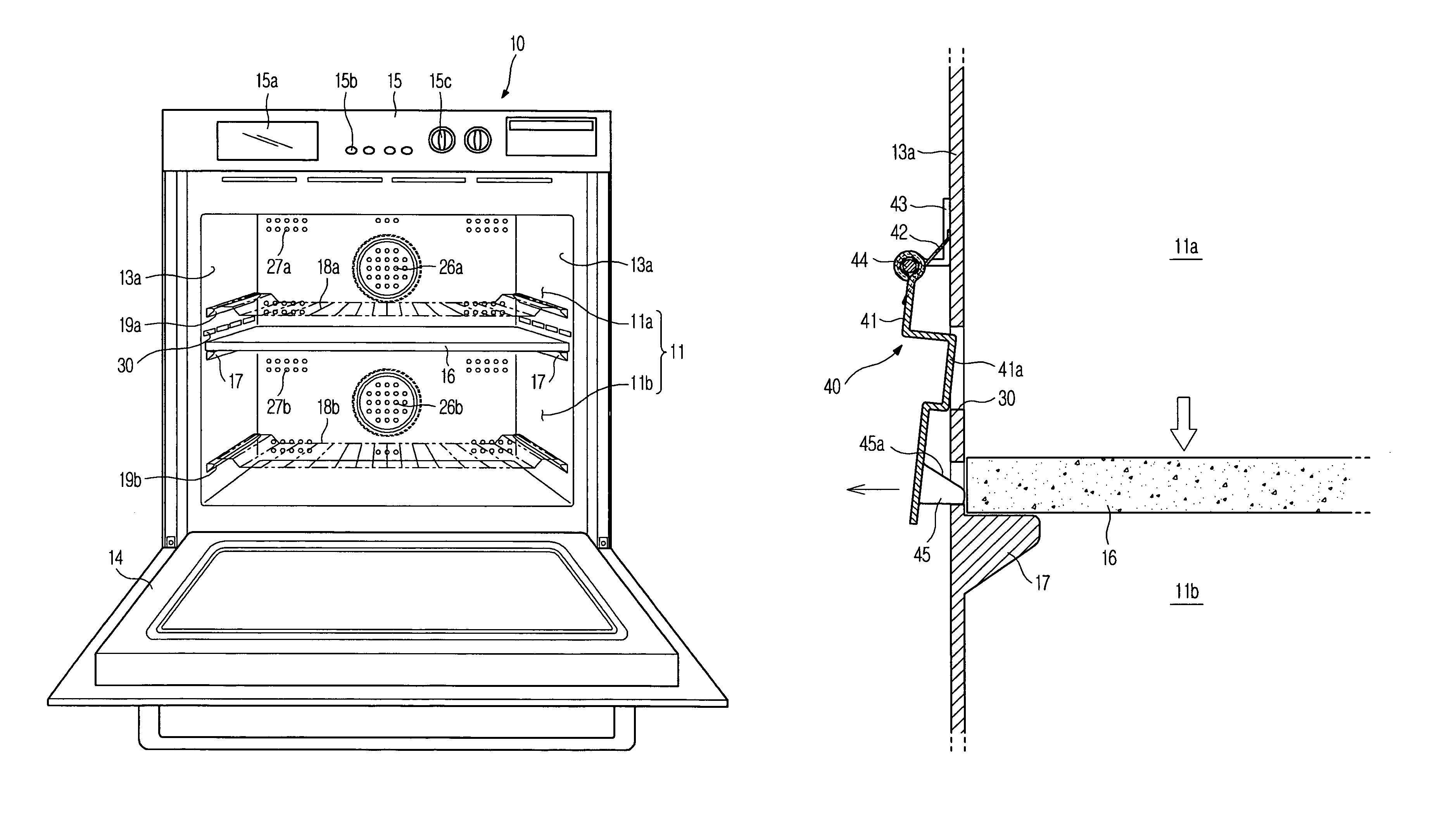

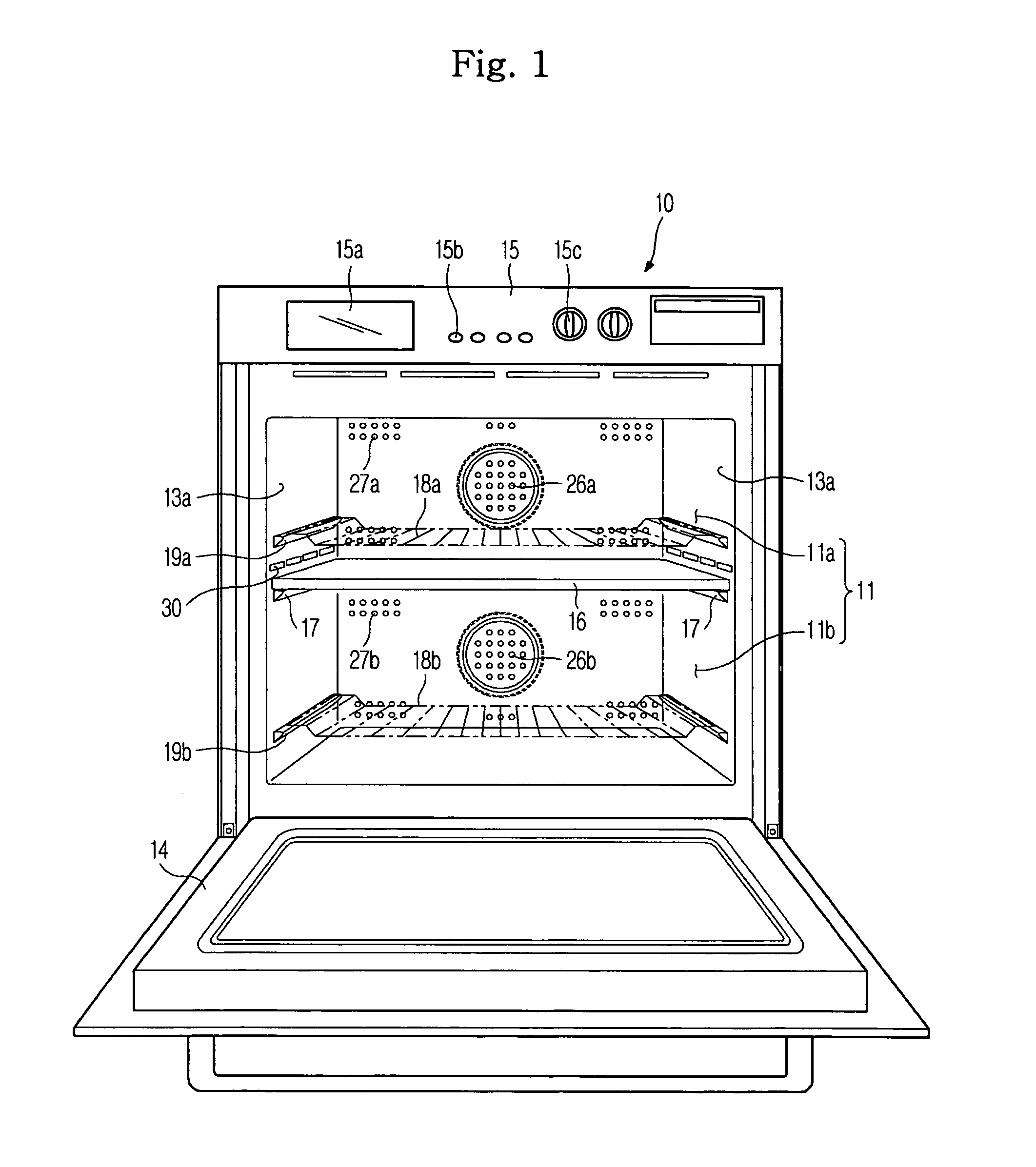

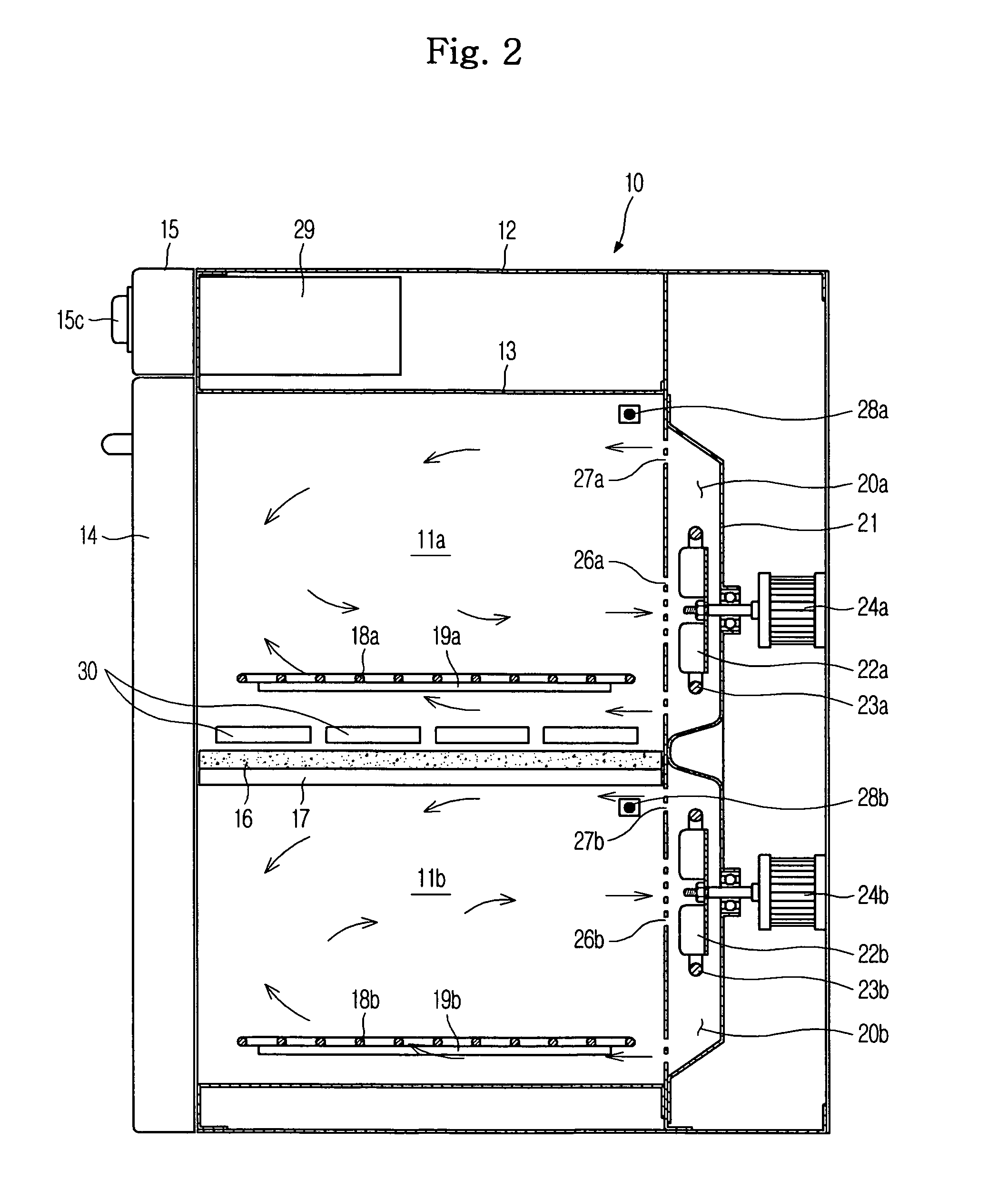

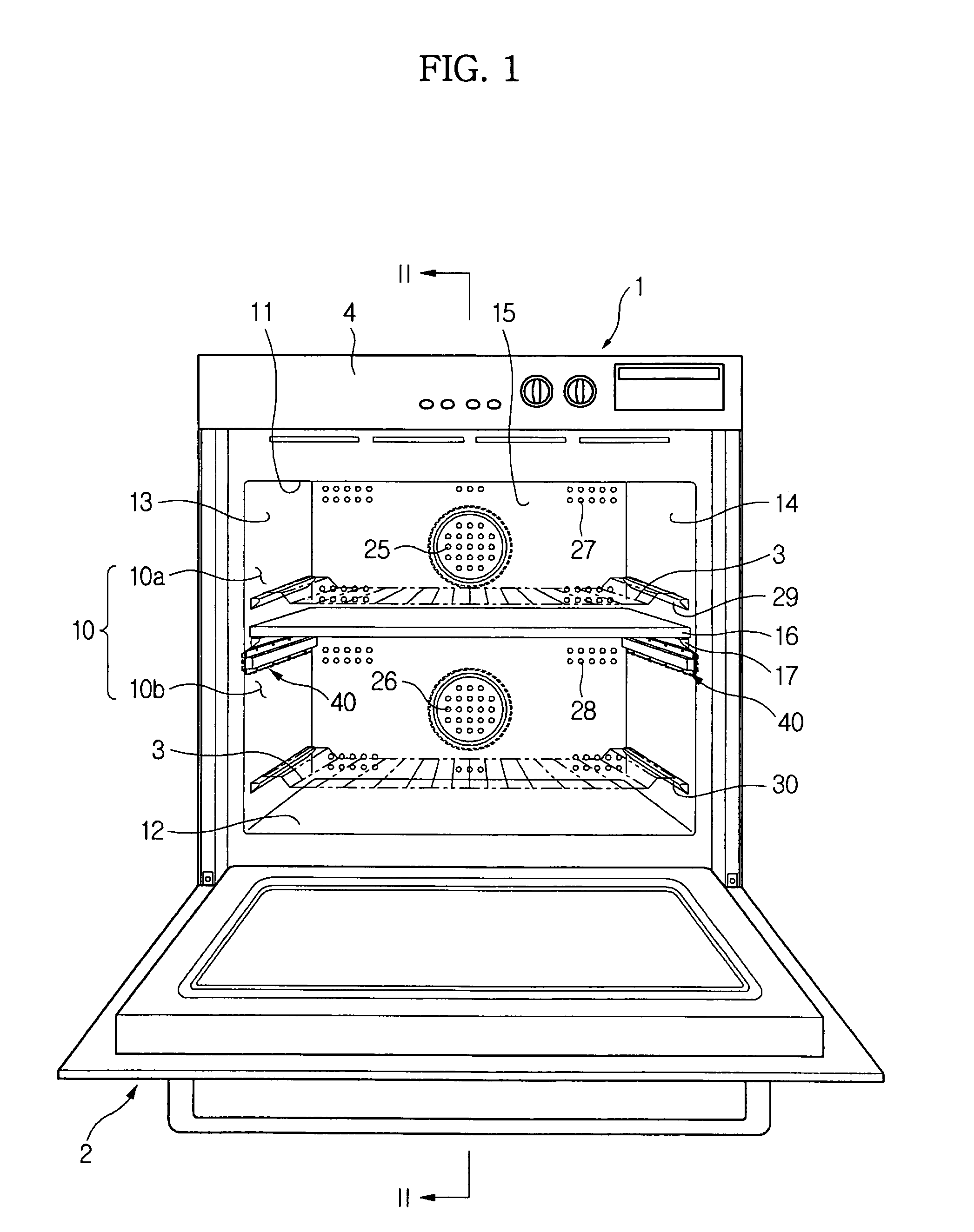

Oven

InactiveUS7183520B2Minimize heat transferDomestic stoves or rangesStoves/ranges shelves or racksProcess engineeringSaggar

An oven that is capable of minimizing heat transfer between adjacent cooking spaces along the wall of a cooking chamber. The oven includes an oven body having a cooking chamber, a partition to partition the cooking chamber into a plurality of cooking spaces, and insulating grooves formed at a wall of the cooking chamber to minimize heat transfer between the cooking spaces.

Owner:SAMSUNG ELECTRONICS CO LTD

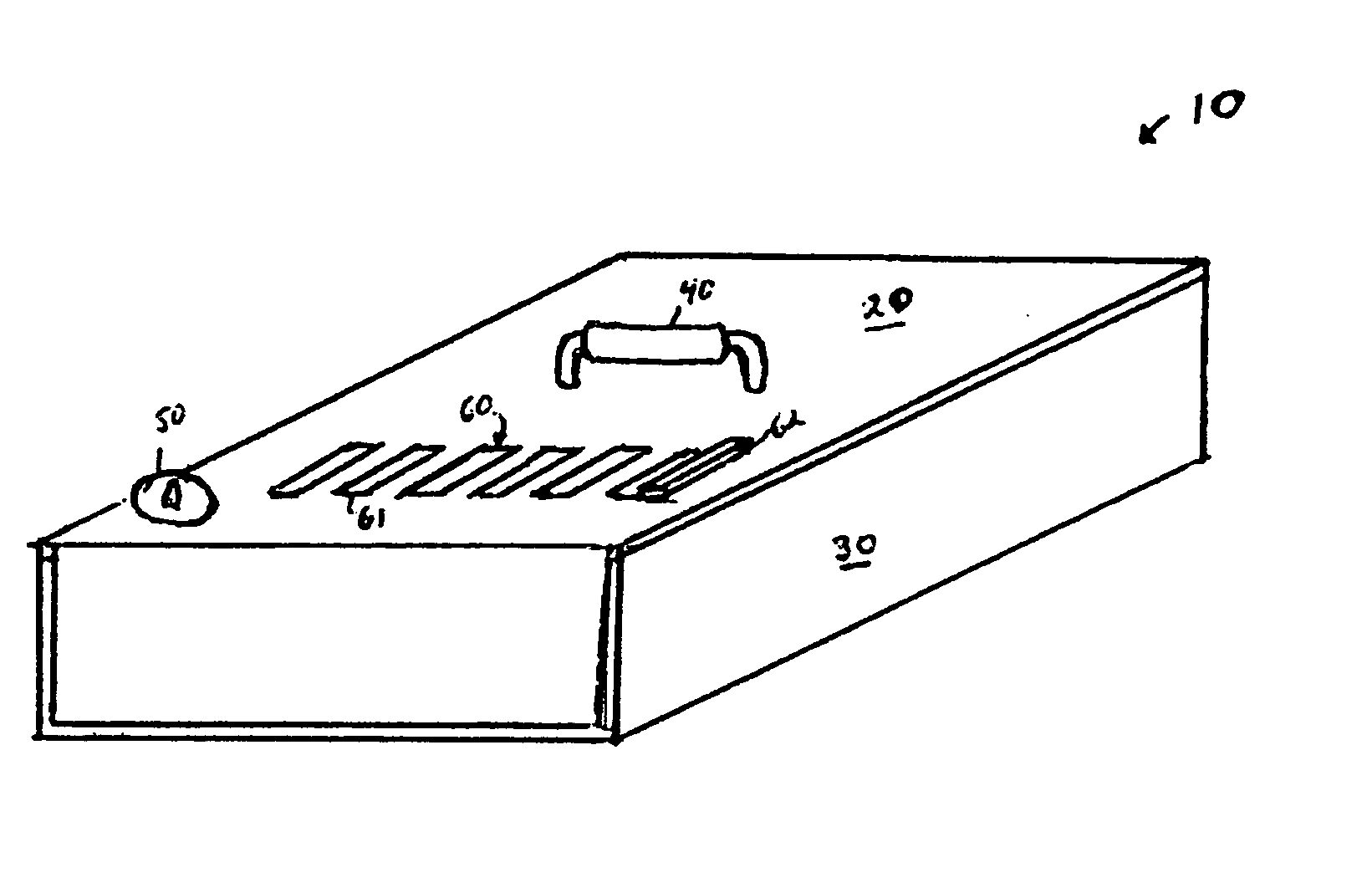

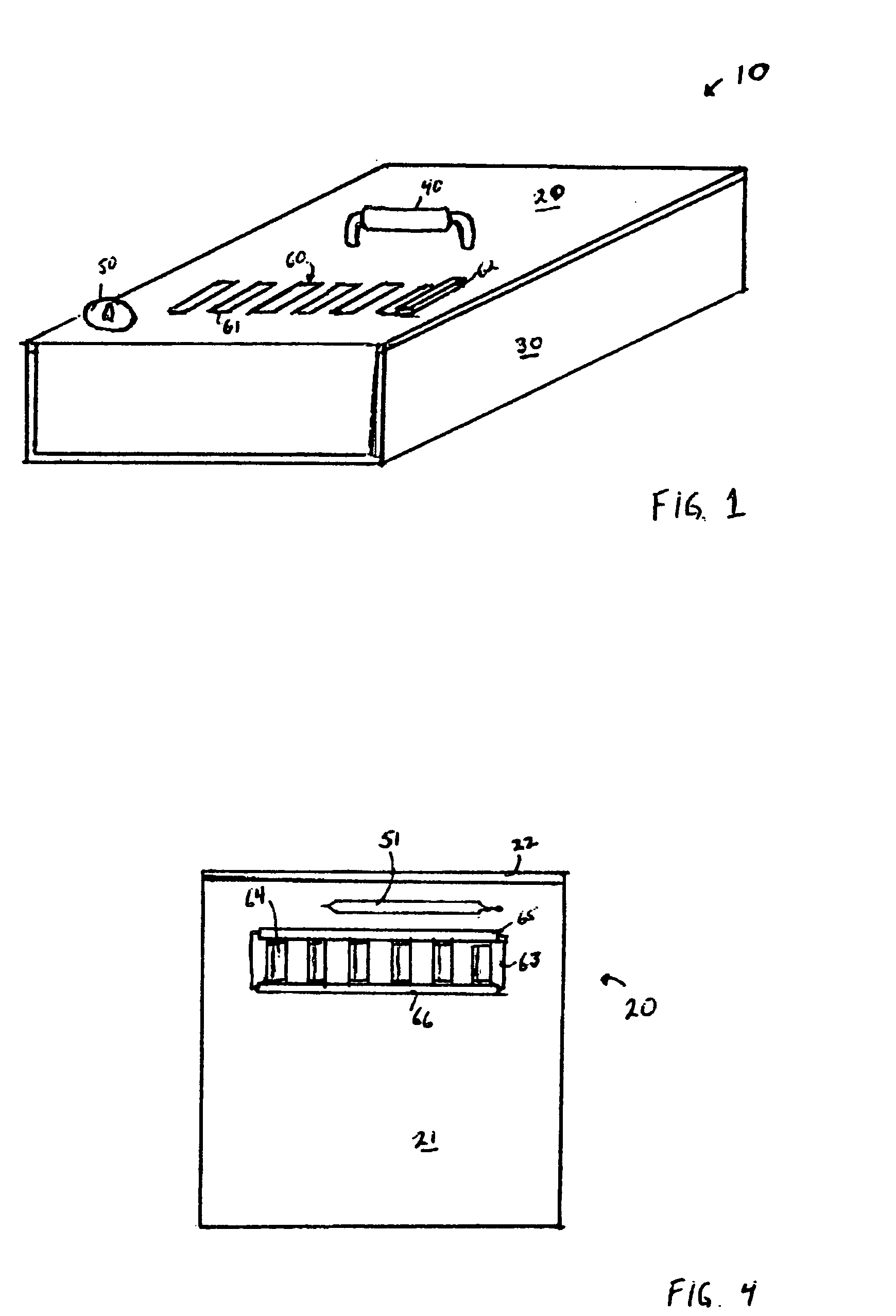

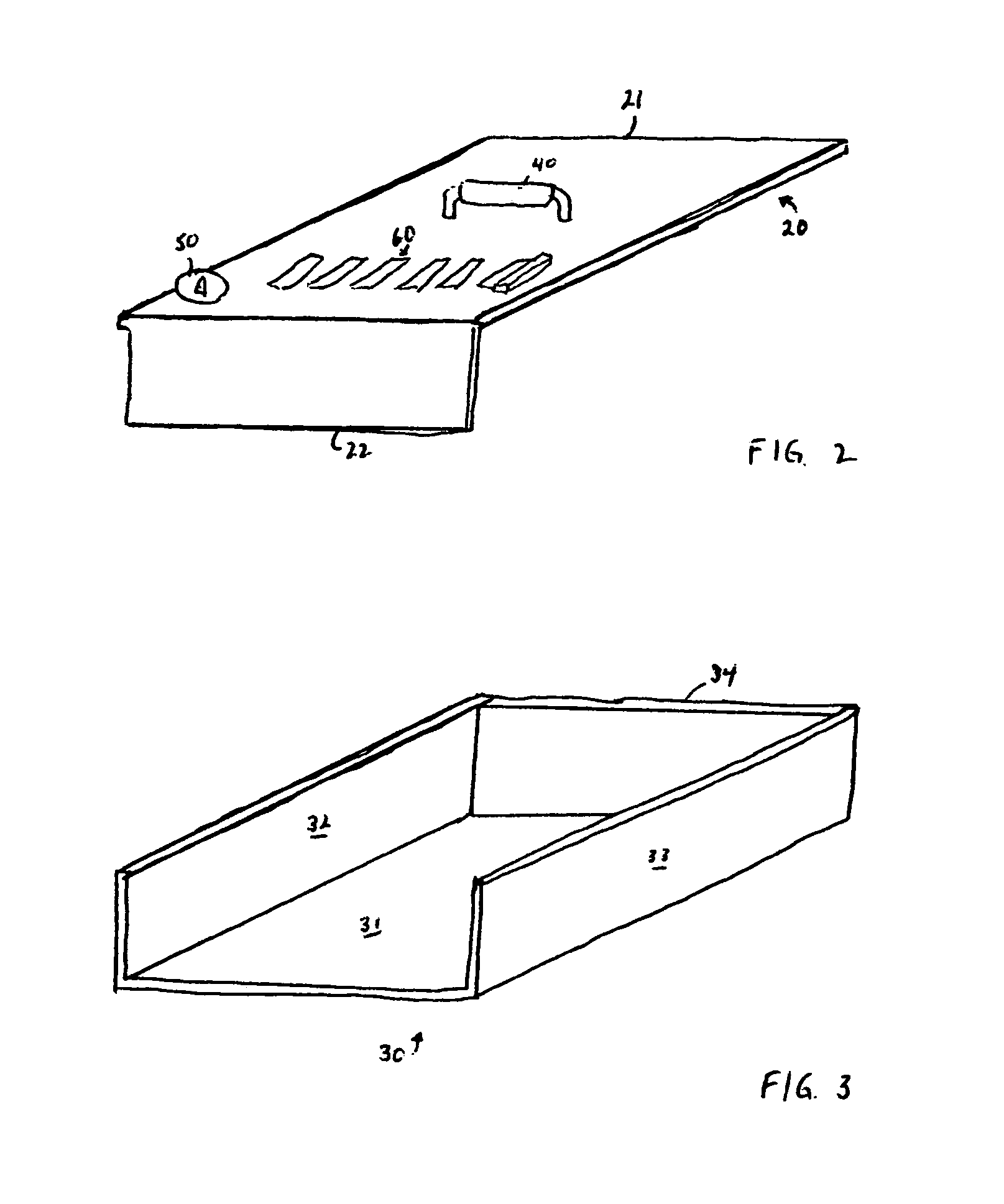

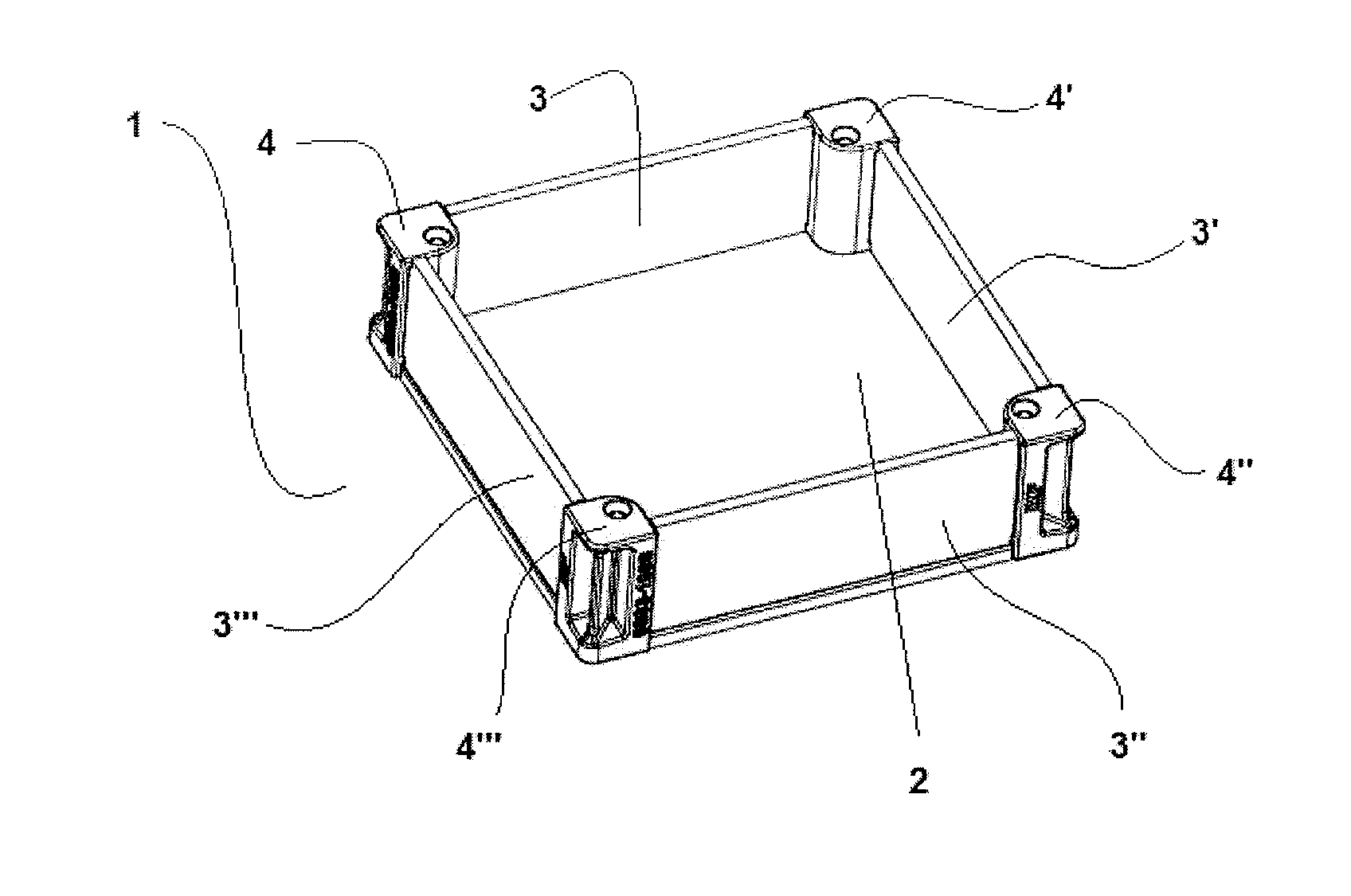

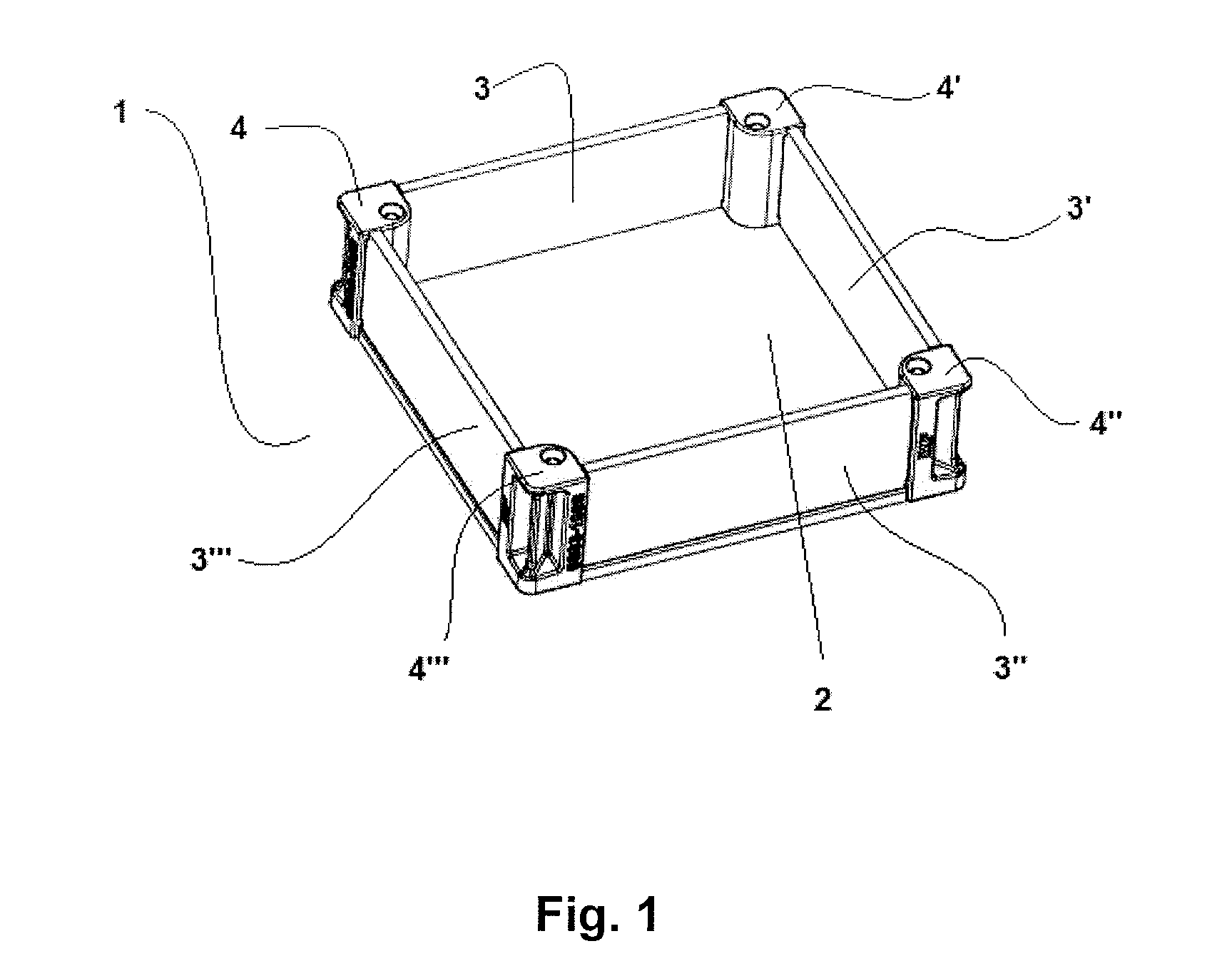

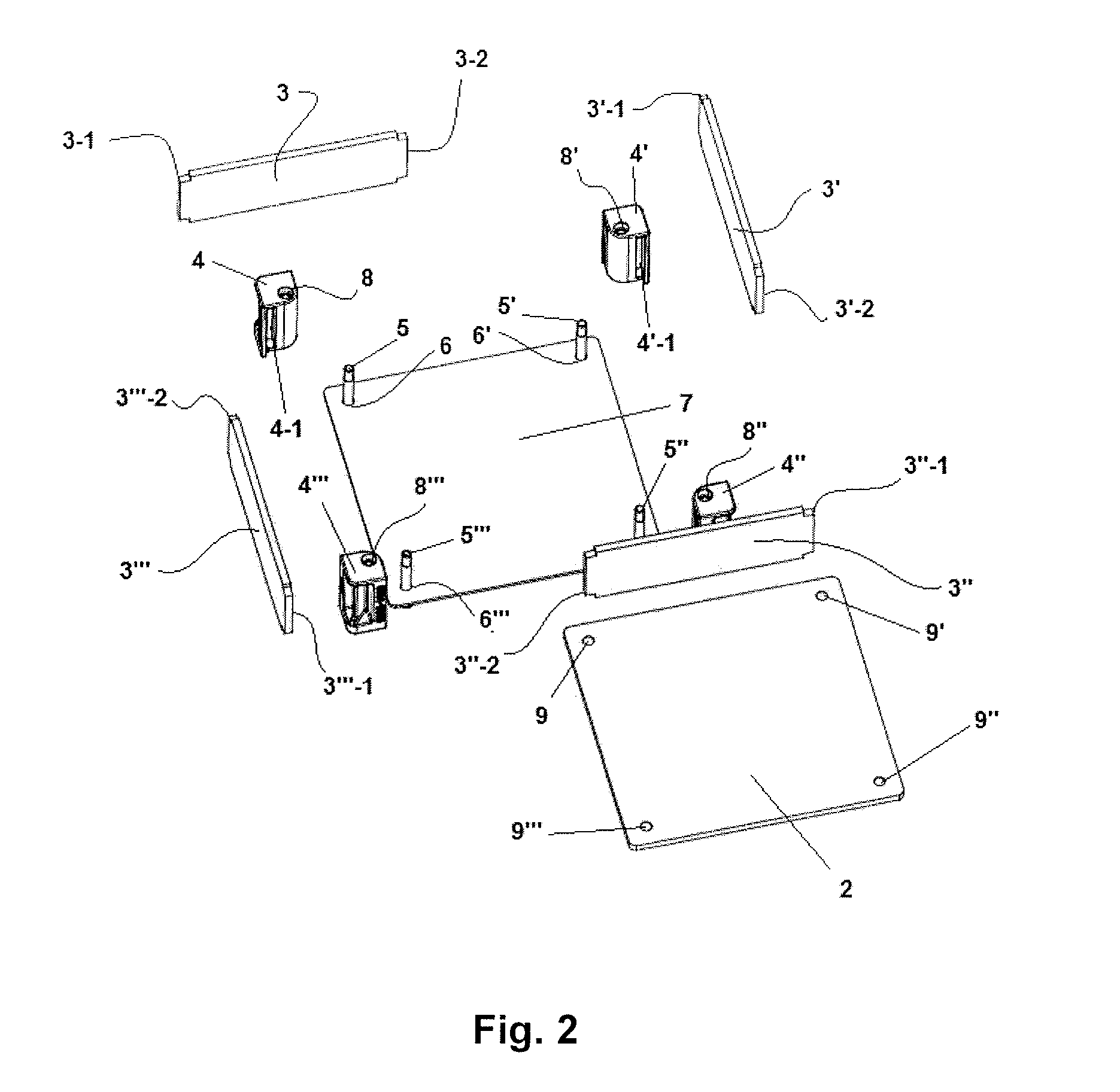

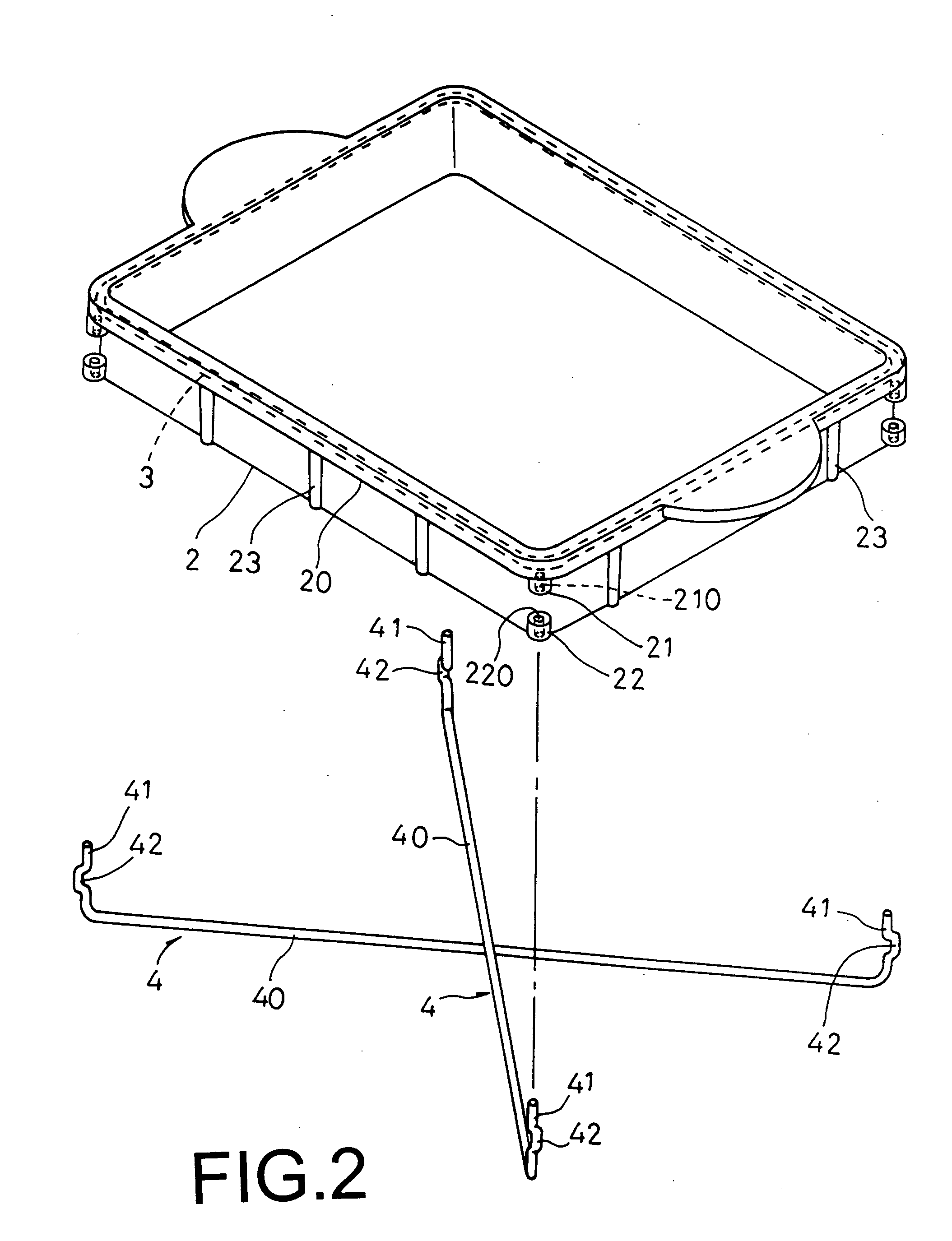

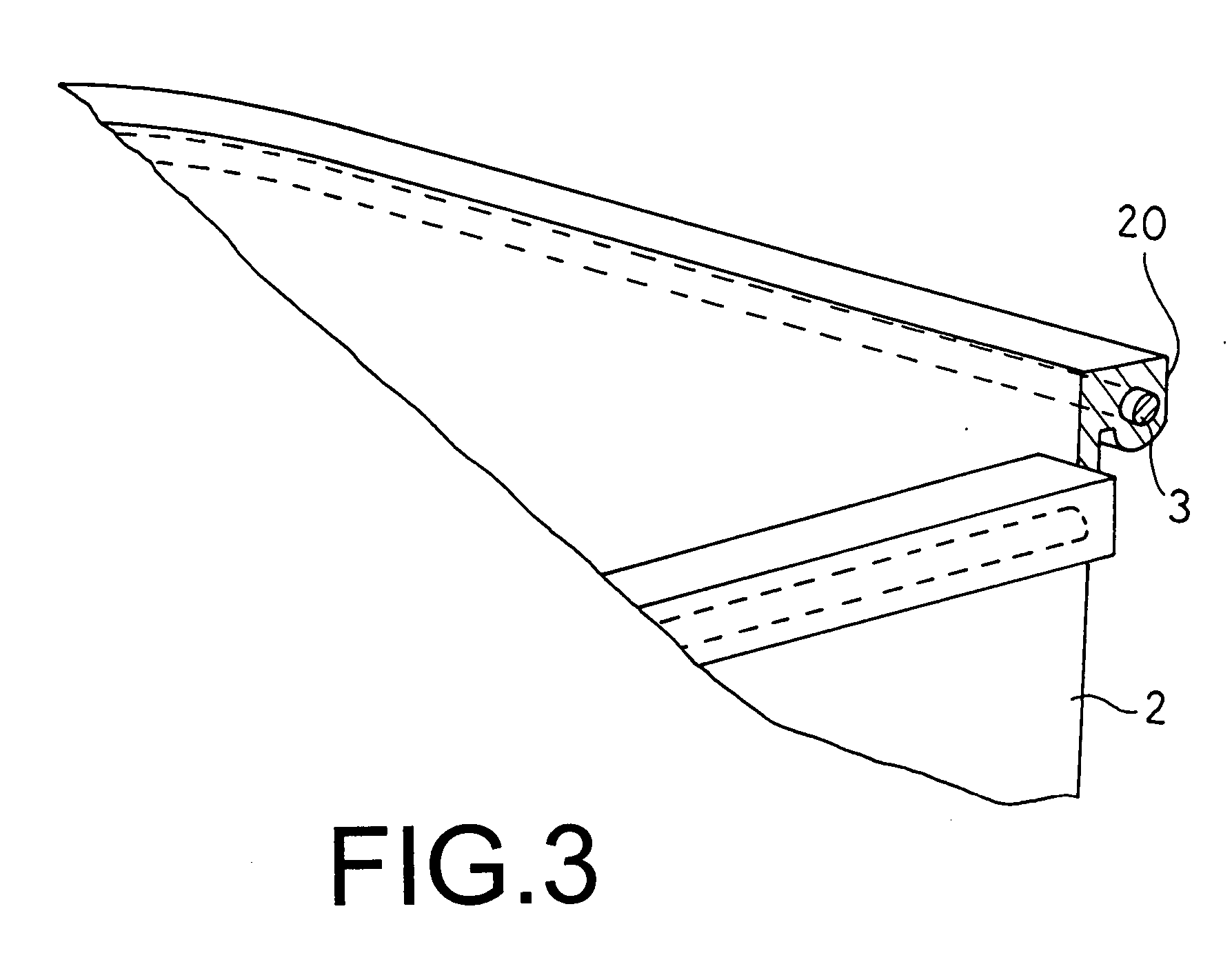

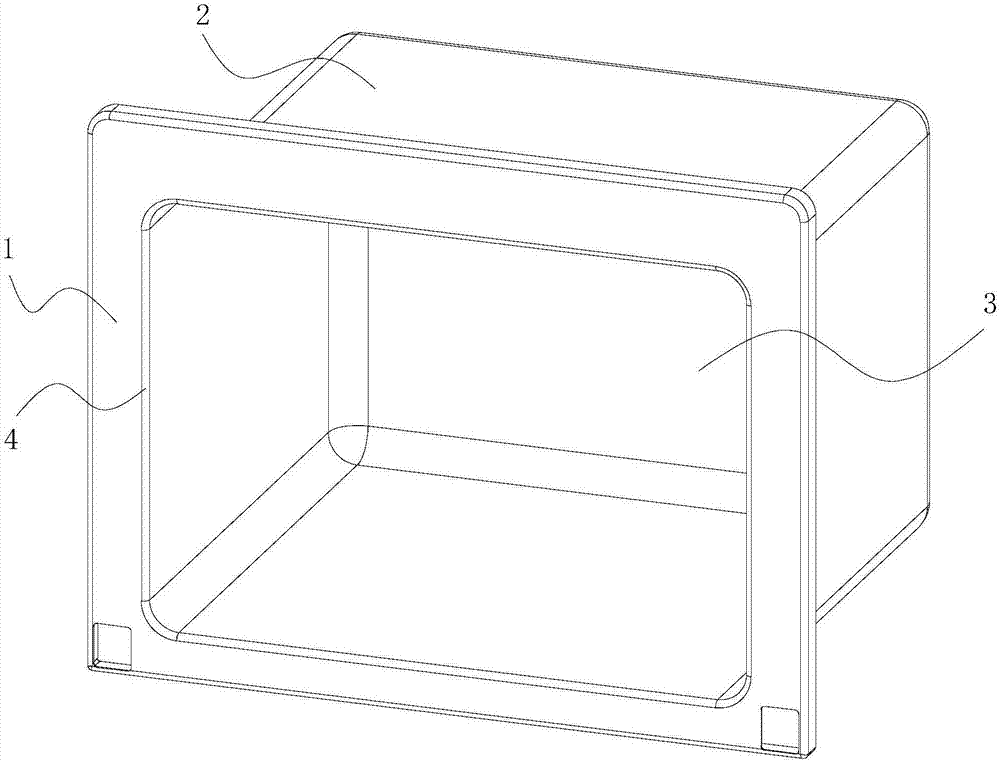

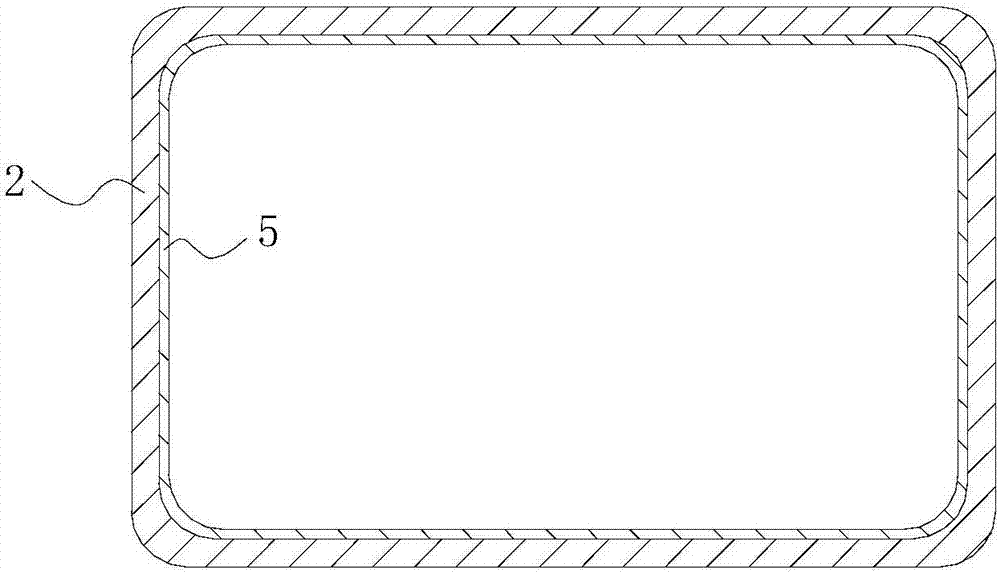

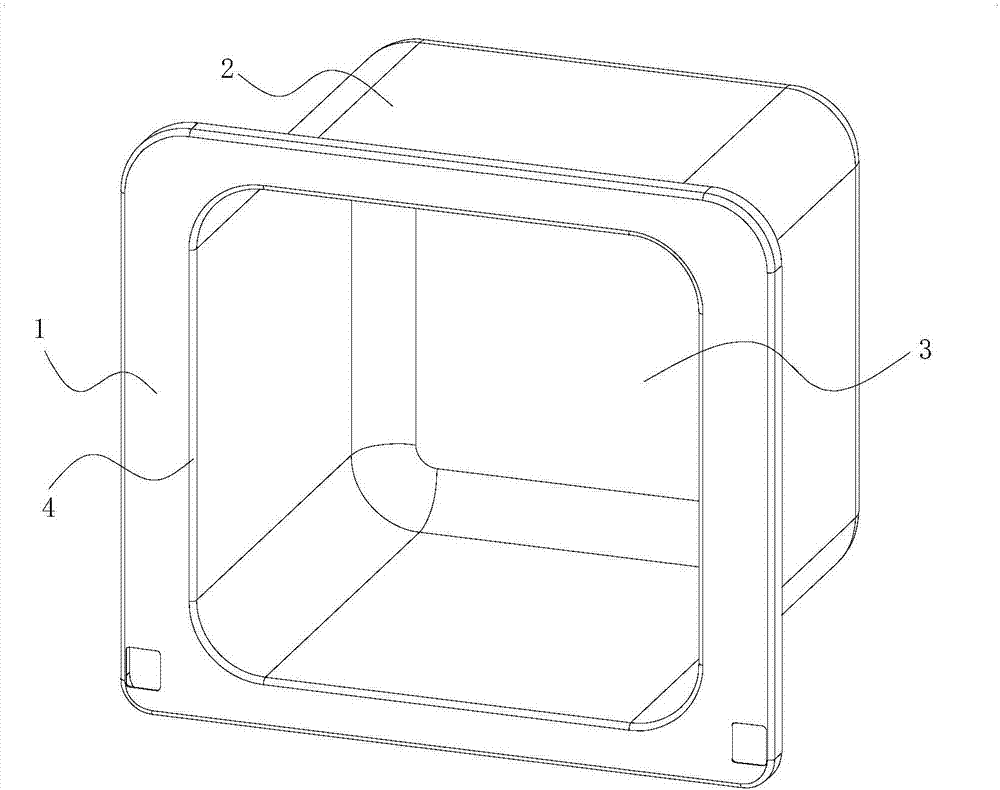

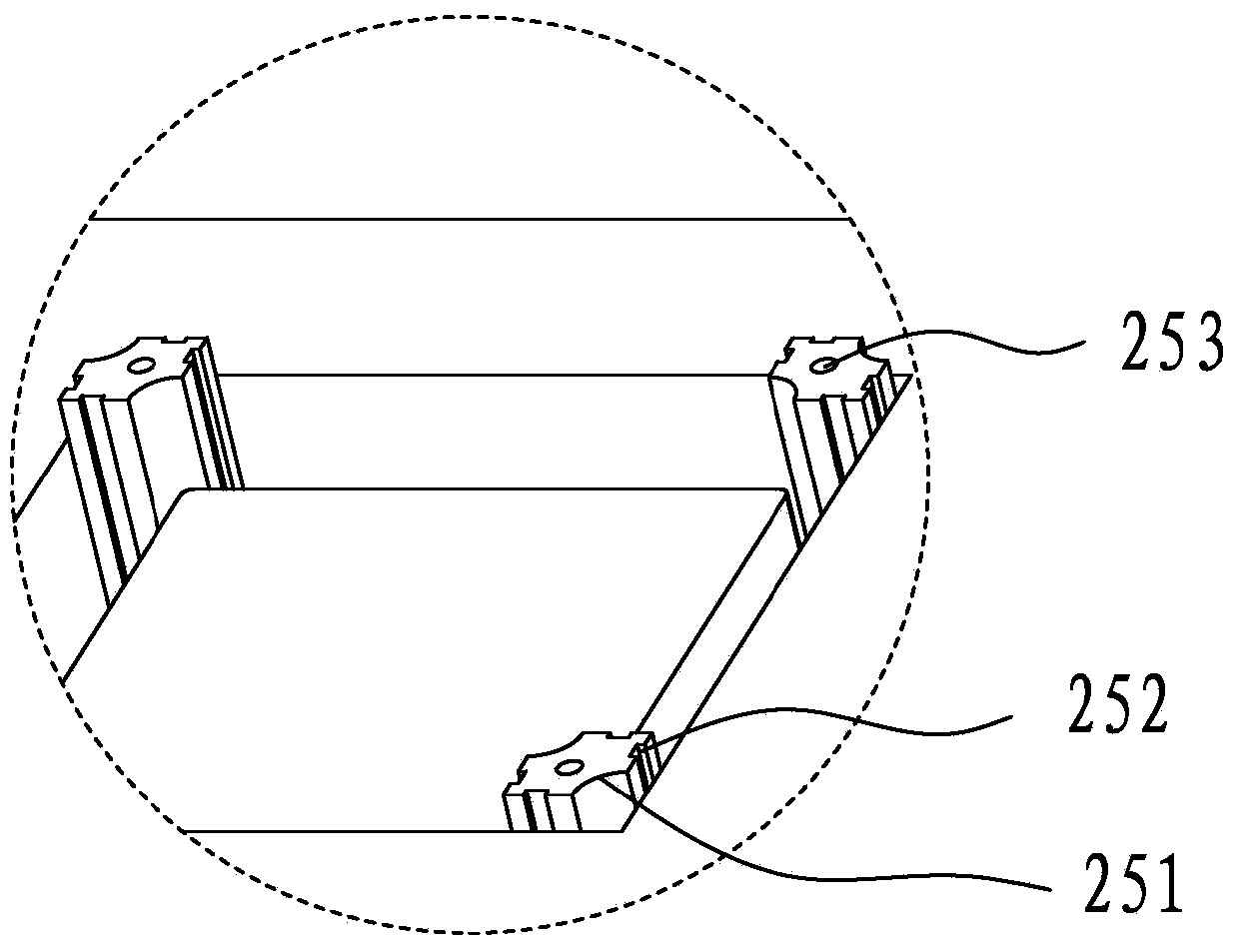

Saggar assembly

An assembly for providing a saggar for use in high temperature applications, may include a first substantially rectangular base element and two sets of two substantially rectangular side elements, wherein the side elements of each set of side elements have at least one dimension corresponding to dimensions of first and second opposite edges of the base element. The assembly may also include four corner elements and fasteners, wherein the base element and the side elements are configured to be assembled into a box-shaped saggar and secured to one another using the corner elements and the fasteners, and wherein the first base element is made of a corrosion resistant material.

Owner:IMERTECH SAS

Silicone-rubber plate used in an oven

A silicone-rubber plate used in an oven includes an plate body, a projecting circumferential edge formed around the plate body and containing a metal bar therein, two pairs of upper ears and of lower ears formed on the outer vertical surface of the plate body and facing each other and respectively having a through hole, and plural U-shaped support bars crossing each other and propping the lower side of the plate body and respectively having two ends inserting firmly in the through holes of the upper and the lower ears of the plate body. Then the plate is supported by the support bars and the metal bars so that the plate may not disfigure when held up, keeping intact its flat shape, preventing soup therein from overflowing and keeping intact the appearance of baked food thereon and to hamper food from falling off.

Owner:LIU I WEN

Case corrugated zirconium dioxide electric ceramic burning plate and manufacturing method thereof

InactiveCN101767991AApplicable sintering processHighlight substantiveElectricityElectrical performance

The invention discloses a case corrugated zirconium dioxide electric ceramic burning plate and a manufacturing method thereof, belongs to ceramic molded products using the zirconium dioxide as base materials, in particular to a bracket and a screen board for charging a sintering furnace special for ultra-thin zirconium dioxide electric ceramic products. The case corrugated zirconium dioxide electric ceramic burning plate comprises the following raw material components in mol percentage: 87 to 96 mol percent of zirconium dioxide ZrO2 and 4 to 13 mol percent of yttrium oxide Y2O3; and the manufacturing method for the case corrugated zirconium dioxide electric ceramic burning plate comprises the following steps: (1) preparing yttrium oxide stabilized zirconium dioxide ceramic materials; (2) performing dry pressing molding; and (3) sintering. The invention provides the case corrugated zirconium dioxide electric ceramic burning plate in which a plurality of V-shaped strips are connected and compounded with a saggar into a whole, and the manufacturing method thereof. The process for putting the V-shaped strips is saved; the work force is reduced; and the labor intensity of workers is lowered. The sintering space is enlarged without the matching of the saggar; the production capacity of the sintering furnace is improved, and the sintered product rate is improved. The electrical performance and physical performance of the products are greatly improved.

Owner:临沂临虹无机材料有限公司

Sagger for calcining battery material and preparation method thereof

InactiveCN107382298ALower firing temperatureLow melting pointCharge supportsCharge treatment typeCordieriteAssembly line

The invention relates to a sagger for calcining a battery material and a preparation method thereof, and belongs to the technical field of lithium batteries. The sagger comprises the following raw materials in parts by weight: 10-50 parts of cordierite with a particle size of 2 to 1, 10-40 parts of cordierite with a particle size of 1 to 0, 1-20 parts of 200-mesh cordierite fine powder, 1-25 parts of 325-mesh fused magnesia-alumina spinel fine powder, 1-5 parts of sintering-promoting micro powder, 1-30 part of clay and 0.1-2 parts of an organic binding agent. The sagger uses the sintering-promoting micro powder, the sintering-promoting micro powder comprises of a plurality of kinds of lithium fine powder, and has low melting point and small thermal expansion coefficient so as to reduce the firing temperature of the saggar; and a roller kiln is used for firing, after forming, the saggar is spread out and put into the roller kiln for sintering, after the firing, the bottom flatness effect of the sagger is better than that of the sagger which is sintered by vertically placed in a shuttle kiln, and a fully automated assembly line production mode of a user can be met.

Owner:宜兴市锦泰耐火材料有限公司

Pyrolytic self-cleaning oven

InactiveUS20010052515A1Quick changeAccurate and reliable processSelf-cleaning stoves/rangesOven air-treatment devicesCombustionSelf-cleaning oven

A pyrolytic self-cleaning oven having a catalytic composition positioned in the oven cavity or exhaust gas passage in order to complete the combustion and / or the oxidation of gases produced by a process carried out inside the oven. The catalytic composition is supported by a ceramic coating on a metal wire. The metal wire is electrically connected to a control system of the oven for controlling the cooking and / or pyrolytic cleaning process. The catalytic composition carried on the metal wire may be part of a net-shaped catalytic element.

Owner:WHIRLPOOL CORP

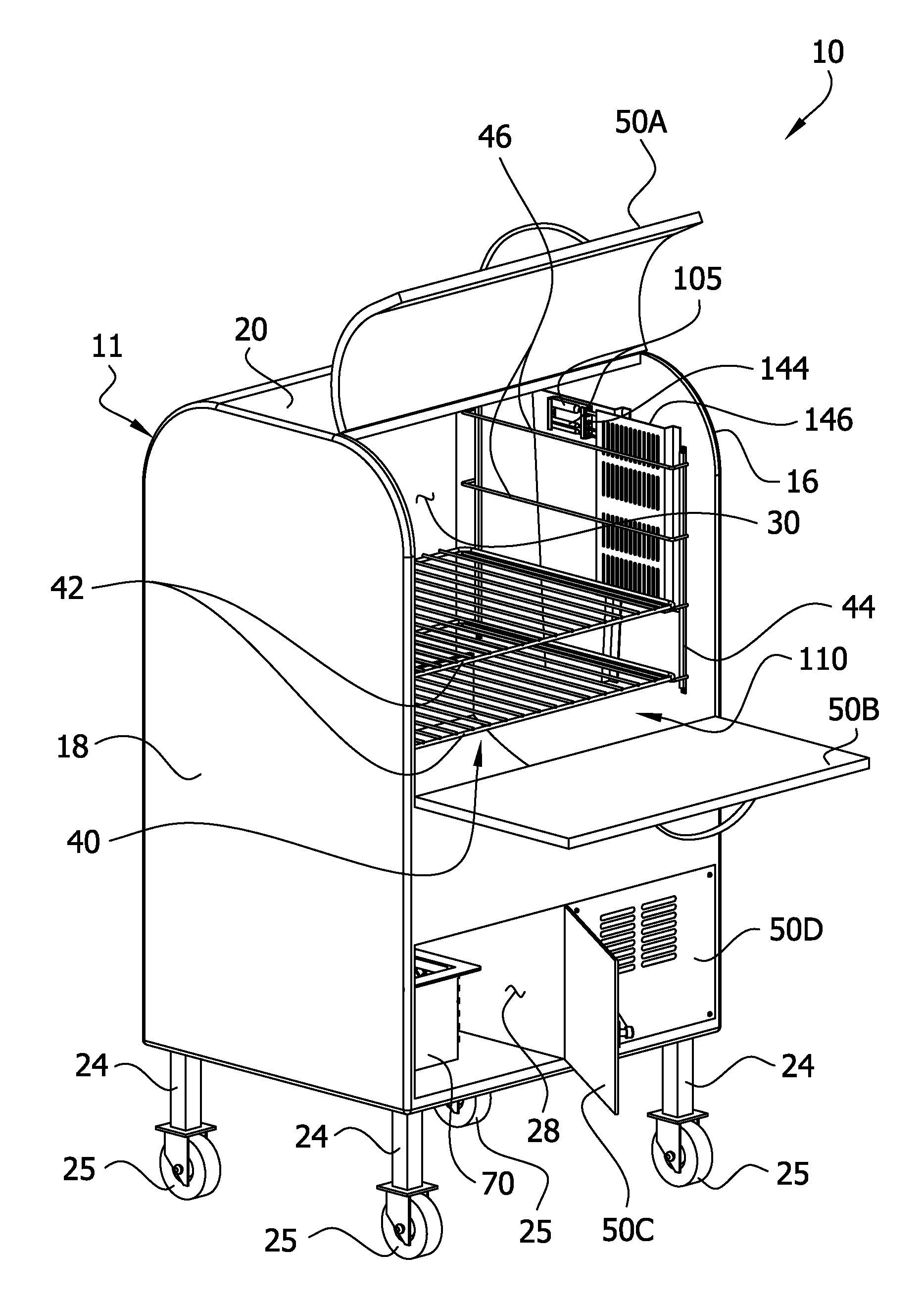

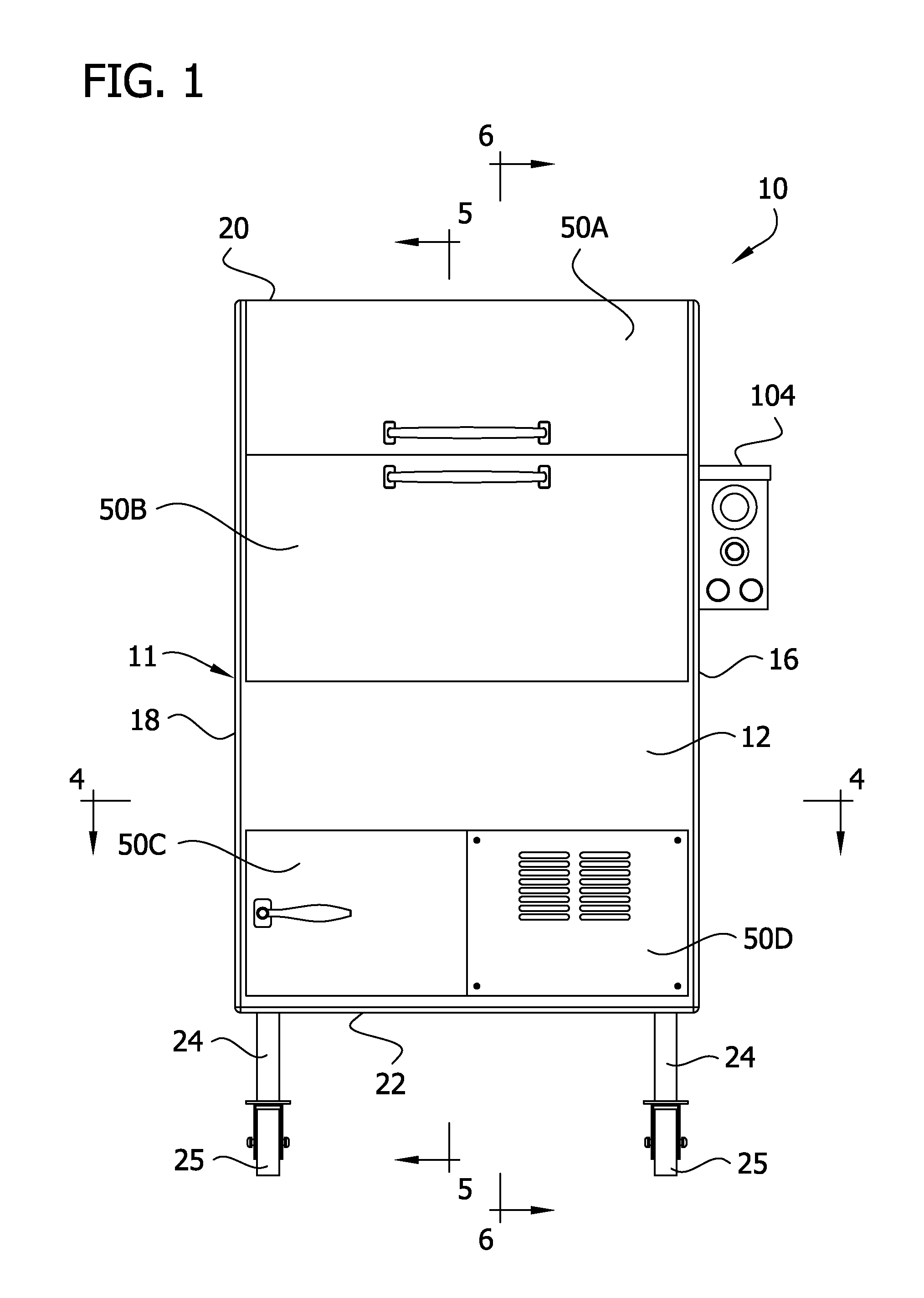

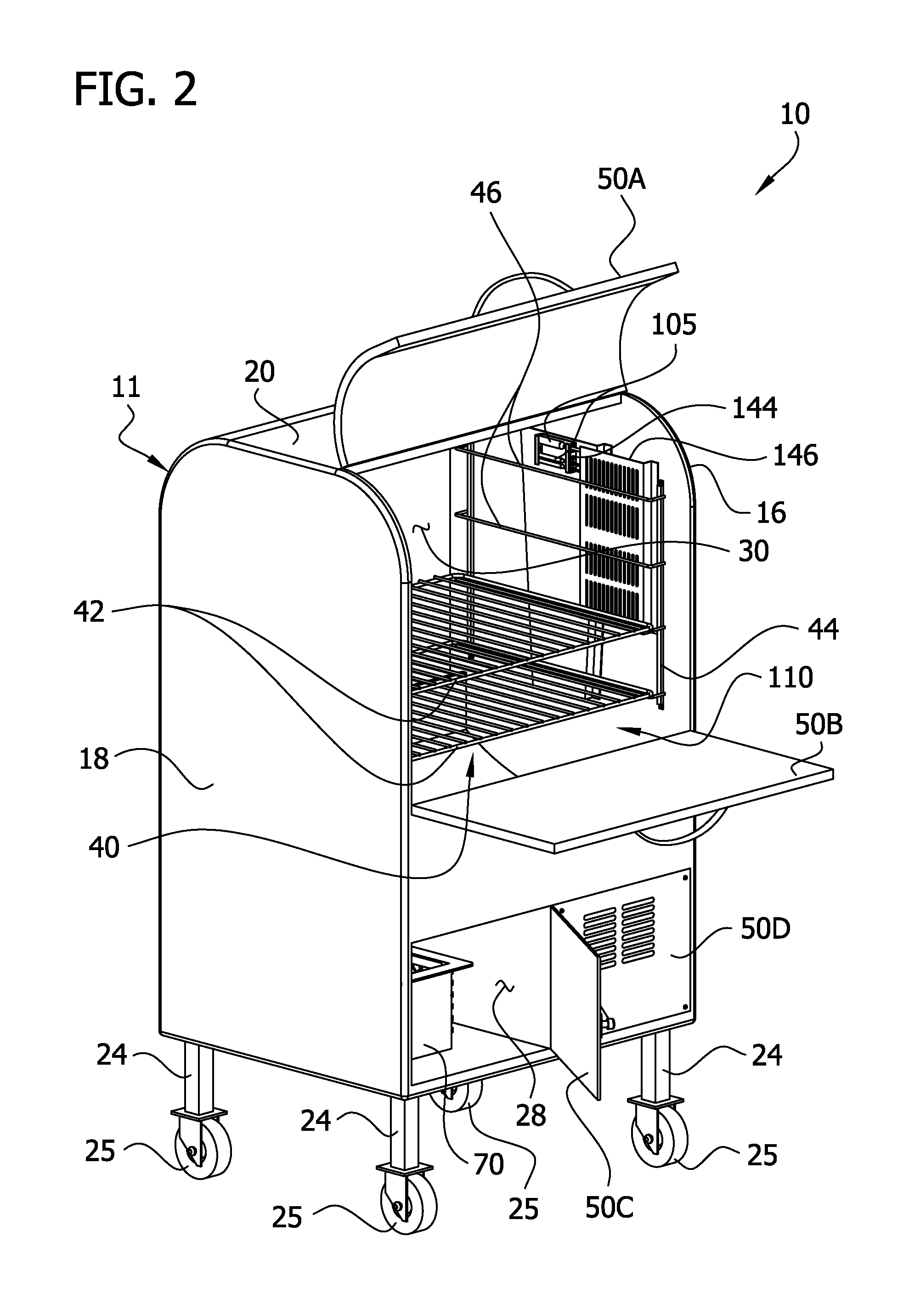

Barbeque oven

An oven for cooking foods includes a housing having a front, a back, a top, a bottom and opposing first and second sides. The oven further includes a vessel for holding solid fuel for cooking. A fire chamber in the housing is adapted for holding the solid fuel vessel. The housing includes a first movable closure at a location on the front of the housing mounted for opening and closing at a location to permit selective access to the solid fuel vessel in the fire chamber. A cooking chamber in the housing is adapted for holding food to be cooked by the oven. The housing further includes a second movable closure on the front of the housing mounted for opening and closing at a location to permit access to the cooking chamber.

Owner:DAVID B KNIGHT & ASSOCS

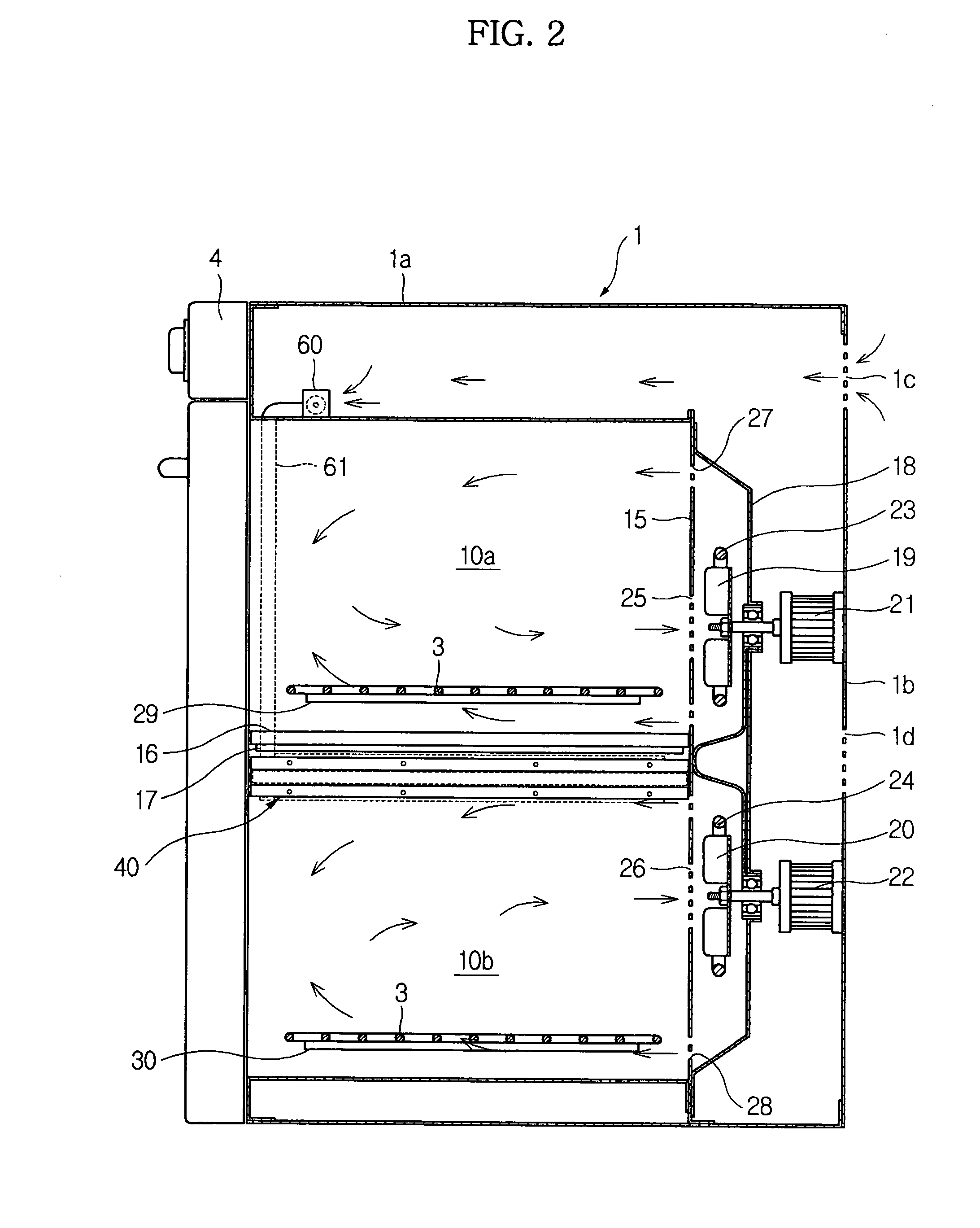

Oven

InactiveUS7087863B1Prevent heat transferIncrease temperatureStoves/ranges foundationsDomestic stoves or rangesEngineeringSaggar

An oven capable of preventing heat transfer from one cooking space having relatively high temperature to another cooking space having relatively low temperature along each side plate of a cooking chamber having a plurality of partitioned cooking spaces. The oven includes an insulating unit and a cooling unit mounted at each side plate to prevent heat transfer between first and second cooking spaces along each side plate. The insulating unit includes a slit formed right under the partition, an insulating member fitted in the slit, and a supporting member attached to the inside of each side plate. The cooling unit includes an air guide member attached to the outside of each side plate to cover the insulating member, and a blowing fan connected to the air guide member to forcibly blow outside air to the air guide member.

Owner:SAMSUNG ELECTRONICS CO LTD

Metal aluminum/silicon carbide-combined complex phase material and preparation method thereof

The invention discloses a metal aluminum / silicon carbide-combined complex phase material and a preparation method thereof. The complex phase material is prepared by mixing and sintering powder and a binder. The powder is composed of the following components in percentage by weight: 90-95% of silicon carbide powder and 5-10% of aluminum powder. The metal aluminum used as the combination phase has plastic deformation capacity at normal temperature, and is capable of enhancing the forming density and reducing the porosity. The complex phase material can react with resin carbon residues at high temperature to generate high-melting-point aluminum carbide, or can be oxidized to generate aluminum oxide and silicon carbide and oxidized to generate silicon oxide so as to form a mullite phase, thereby improving the properties of the interface and preventing the silicon carbide inside the particles from being further oxidized. The complex phase material has the advantages of high melting point, high heat conductivity, low thermal expansivity, high thermal shock stability and high wear resistance. The material can be used as heat treatment furnace guide rails, liners, flame insulation plates, slabs, saggars and other ceramic kiln tools. The method has the characteristics of simple technique, favorable comprehensive properties of the product and the like. The product has the advantages of higher application temperature, high heat conductivity, high wear resistance, favorable thermal shock stability and favorable oxidation resistance.

Owner:唐山贝斯特高温材料有限公司

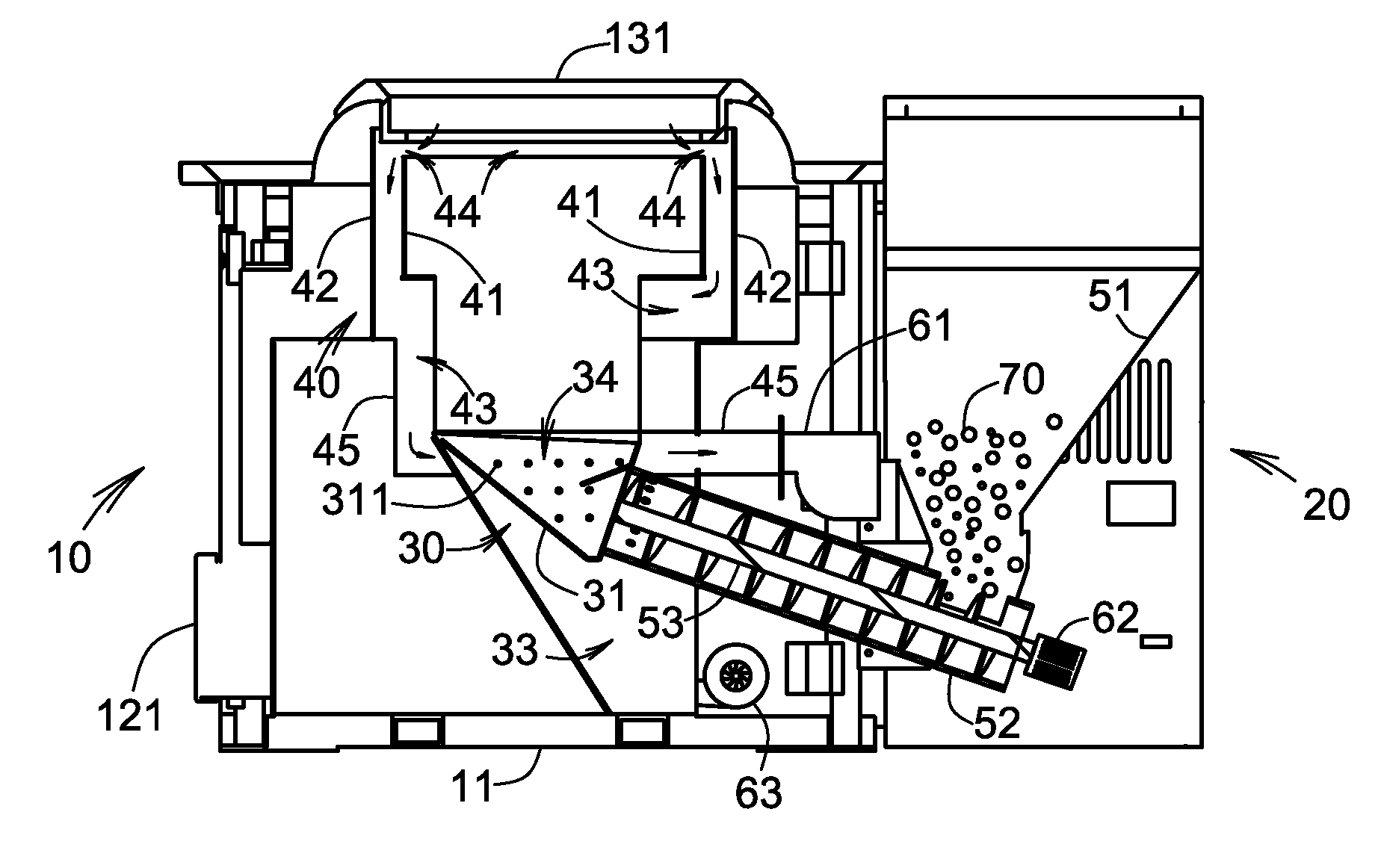

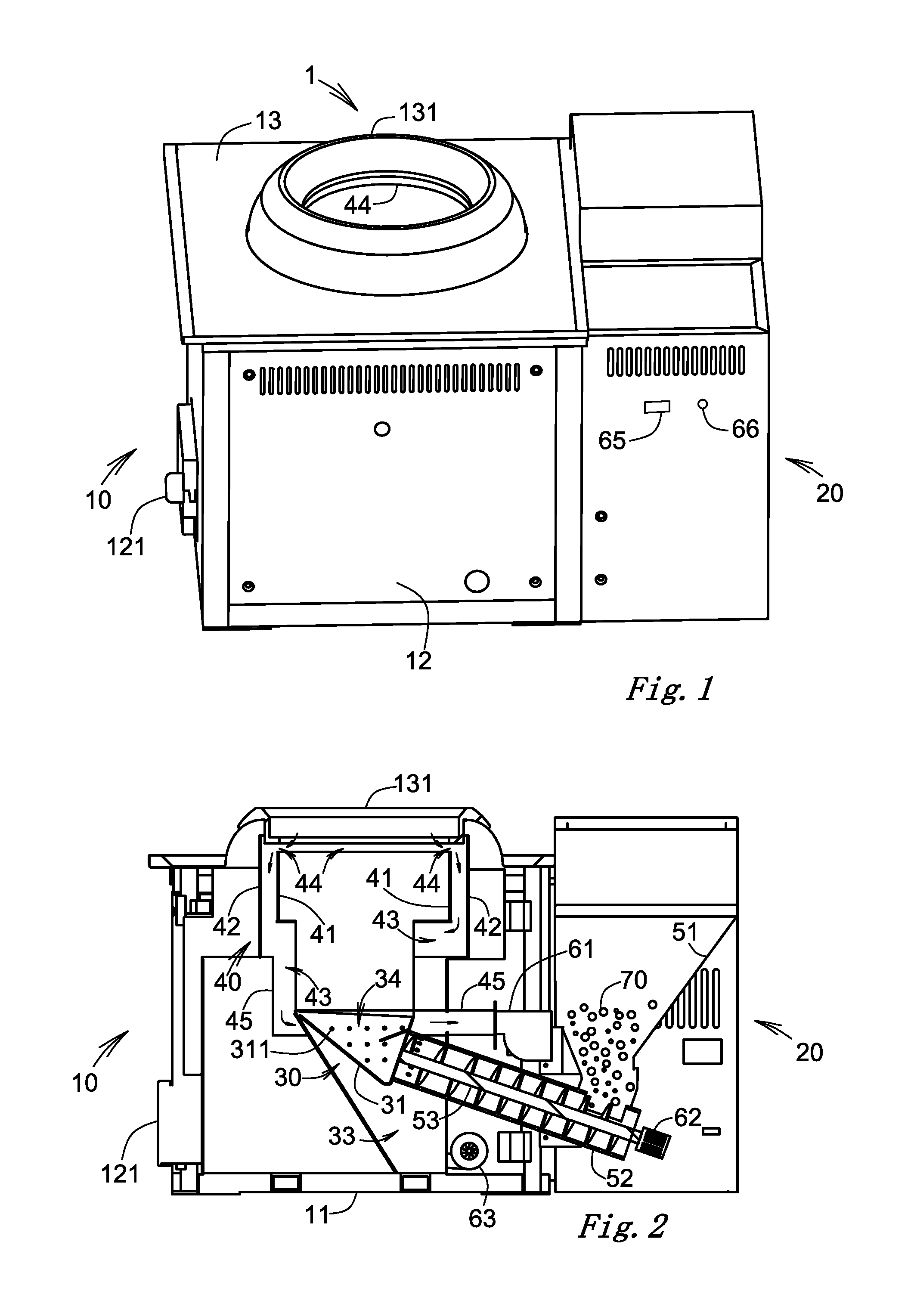

Oven without dust rise

InactiveUS20140373827A1Not always easyReduce pollutionStoves/ranges foundationsStoves/ranges with convection heatingCombustion chamberCombustor

Owner:ZHU HONGFENG

Special sagger for sintering lithium battery positive electrode material and preparation method of sagger

PendingCN110540418AIncrease production costIncrease usageCharge supportsCeramic shaping apparatusRefractorySpinel

The invention provides a special sagger for sintering a lithium battery positive electrode material and a preparation method of the sagger, and belongs to the technical field of refractory materials.The special sagger for sintering the lithium battery positive electrode material comprises a sagger main body; a corrosion-resistant layer which is integrally formed by pressing together with the sagger main body is arranged on the bottom layer of the sagger main body; the thickness of the corrosion-resistant layer is 2-3mm; the corrosion-resistant layer comprises aluminum-magnesium spinel, fusedalumina, zirconia powder, kaolin powder, alumina powder, a binder and water; and the sagger main body comprises cordierite, sintered mullite, alumina powder, the kaolin powder, the binder and the water. According to the special sagger, the corrosion-resistant layer is additionally arranged at the inner bottom layer of an ordinary sagger, so that compared with the ordinary saggar, the production cost of the special sagger is only increased by 10-15%, and the use frequency of the special saggar can be improved by more than two times.

Owner:湖南金铠新材料科技股份有限公司

Cavity applying steam oven and steam oven

InactiveCN107485304AImprove air tightnessImprove rust resistanceCooking-vessel materialsSteam cooking vesselsSS - Stainless steelSilica gel

The invention discloses a cavity applying a steam oven. The cavity is formed by stretching and forming whole metal. The cavity comprises a front installation plate, a U-shaped frame and a rear plate, the cavity is formed by stretching and forming the front installation plate, the U-shaped frame and the rear plate at a time, the inner surface of the cavity formed by integrated stretching and forming is coated with an inorganic glassy material, and a metallic matrix of the cavity and the inorganic glassy material are used for coating and sticking through an enameling technology. The invention further provides the steam oven with the cavity. The cavity obtained by integrated stretching and forming is low in mold cost, no splicing gap exists, the consumption of sealing silica gel can be lowered, the sealing performance is good, the surface of the cavity can be completely covered with the inorganic glassy material, the rusting problem is eliminated, an enameled pressed steel plate is adopted for replacing expensive 304 stainless steel, the whole oven cost can be lowered, meanwhile the problems of yellowing and not resisting high temperature can be solved, the 400 DEG C or more high-temperature self-cleaning function can be achieved, and the problem that an existing steam oven is hard to clean is solved.

Owner:广东天倬智能家居有限公司

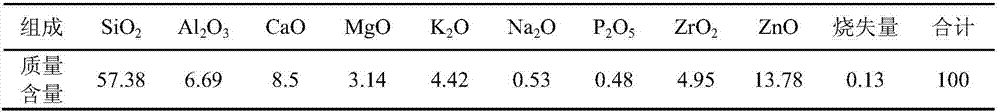

Foaming stone insulation board and preparation method thereof

InactiveCN101985403AImprove insulation effectFeldspar Chemical CompositionCeramicwareClaywaresTunnel kilnBrick

The invention discloses a foaming stone insulation board and a preparation method thereof, wherein the insulation board comprises the following components in percentage by weight: 90%-97% of feldspar, 2%-8% of mineralizer and 0.4%-2% of foaming agent. The preparation method comprises the following steps: firstly, mixing and grinding materials; then adopting a silicon carbide material for manufacturing a box body saggar; coating a clay anti-cohesion layer on the inner surface of the saggar; putting the mixed materials into the saggar and foaming and sintering the mixed materials in a tunnel kiln, wherein the sintering and foaming temperature is 1200-1250 DEG C; slowly cooling the mixed materials to obtain large blocky foaming stones; and cutting and processing the foaming stones into various blocky foaming stones. The foaming stone insulation board of the invention has the chemical composition and superior properties of the feldspar, the volume density is less than that of a light-weight insulating brick, the mechanical strength is higher than that of the light-weight insulating brick, the heat-insulating property is better than that of the light-weight insulating brick, the usage temperature is higher than that of foaming glass and foaming ceramics, and the foaming stone insulation board can be used for insulation of an outer layer of high-temperature equipment such as high-temperature kiln and the like, and can obviously improve the insulation effect.

Owner:WUXI INST OF ARTS & TECH +1

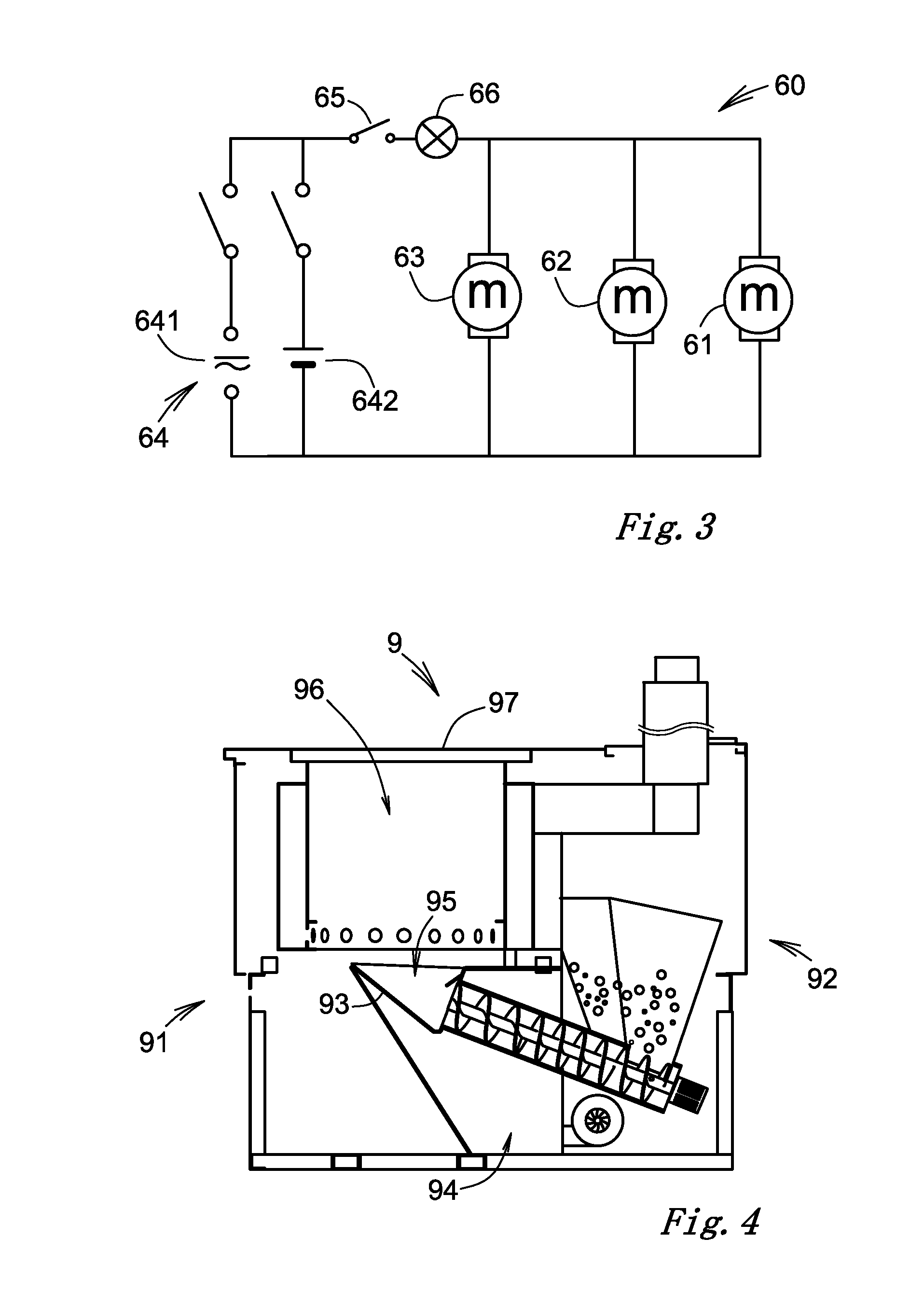

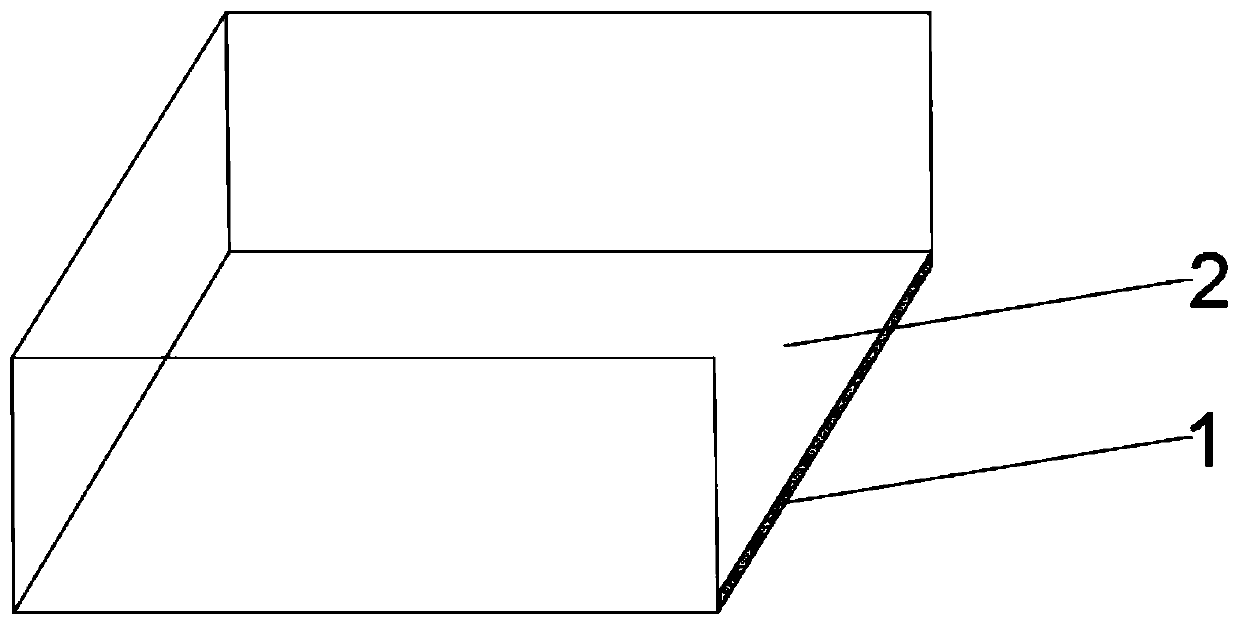

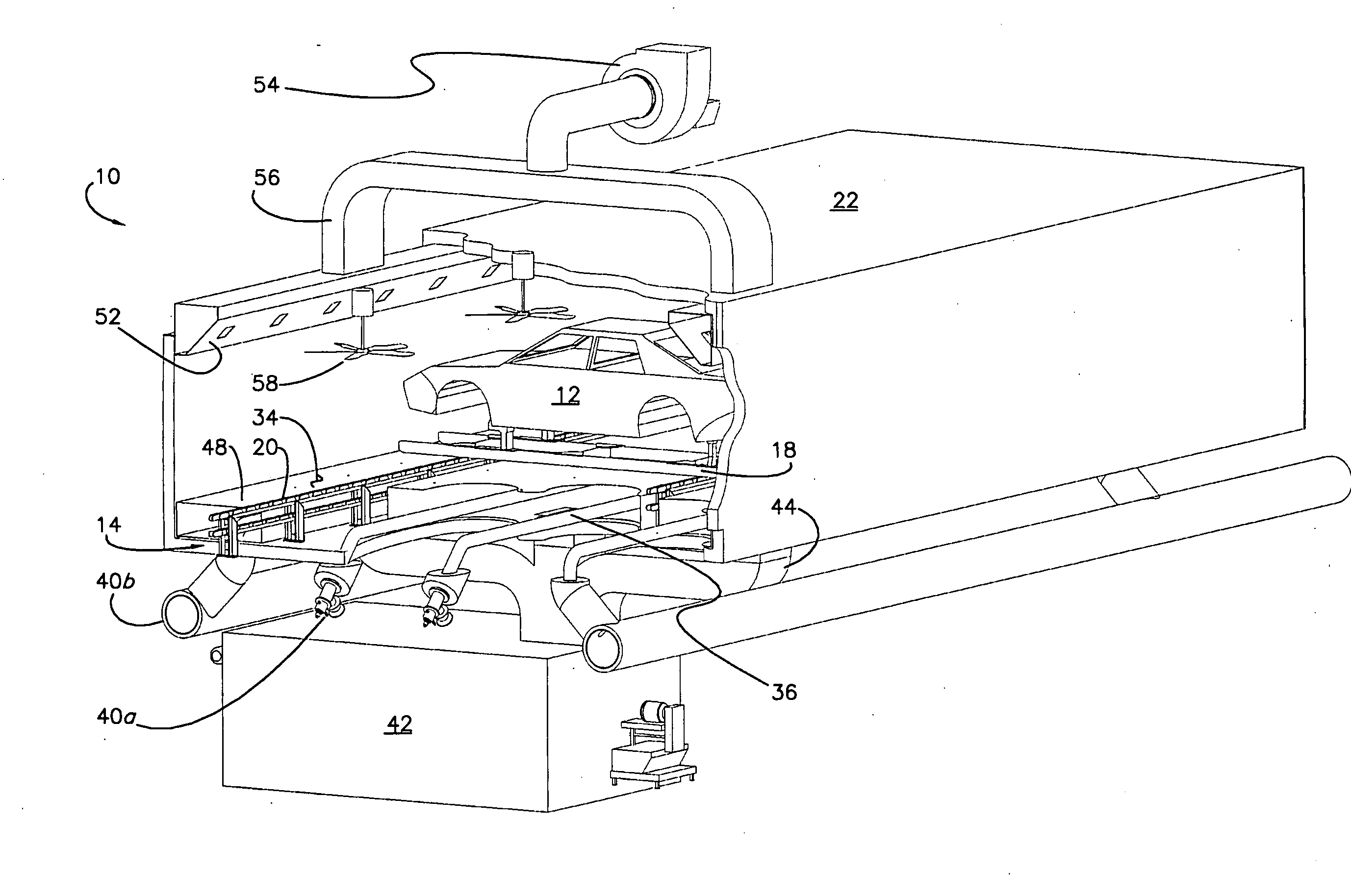

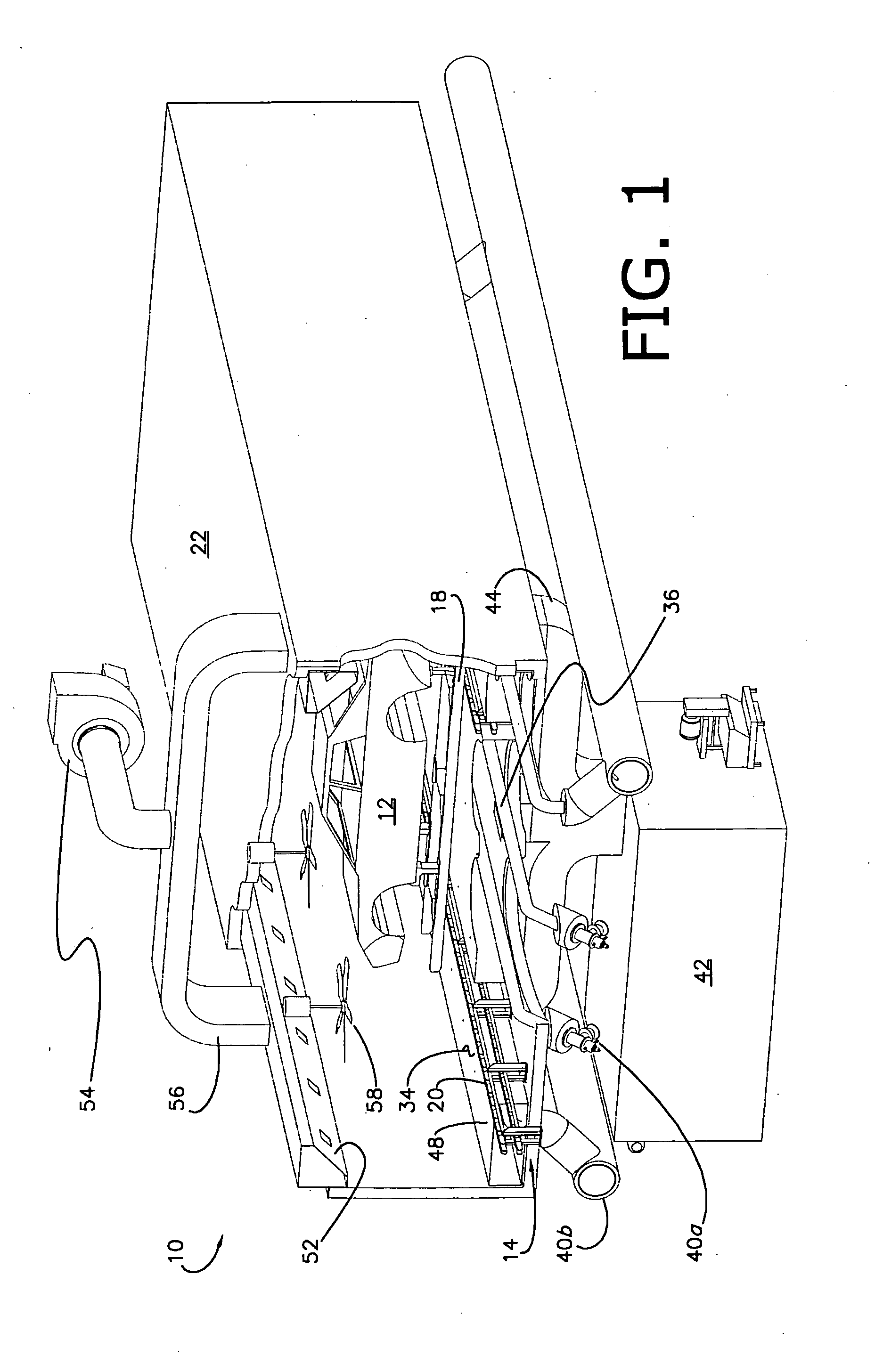

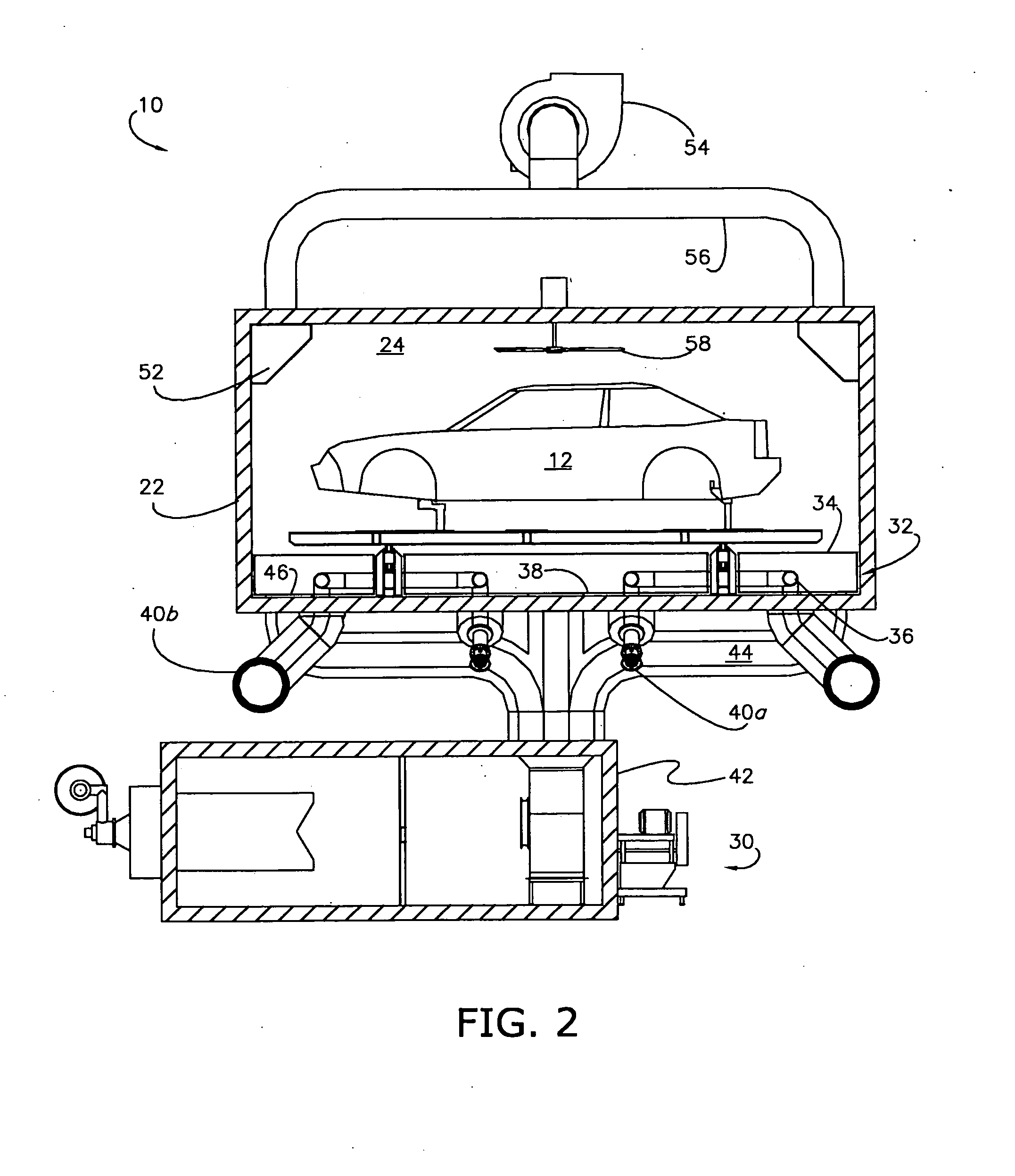

Transverse oven and method of baking workpieces

InactiveUS20100038353A1Increase widthFacilitates transverse bakingDrying solid materials with heatMuffle furnacesCooking & bakingCeiling fan

A manufacturing oven for and a method of baking a workpiece presenting a transverse orientation relative to the oven, includes dual radiant and convection heating sources operable to uniformly heat the workpiece by focusing convection heating air towards desirous parts of the workpiece, and preferably includes a chamber, a high emissivity false floor, at least one radiant heating element beneath the floor, at least one reflector beneath each element and configured to redirect radiant heat energy towards the floor, a fresh air heater for delivering fresh heated air into the chamber, an exhaust system for removing heated air and evaporated paint solvents from the chamber, and at least one ceiling fan operable to cause lighter heated air to flow from the ceiling of the chamber and towards the workpiece.

Owner:GM GLOBAL TECH OPERATIONS LLC

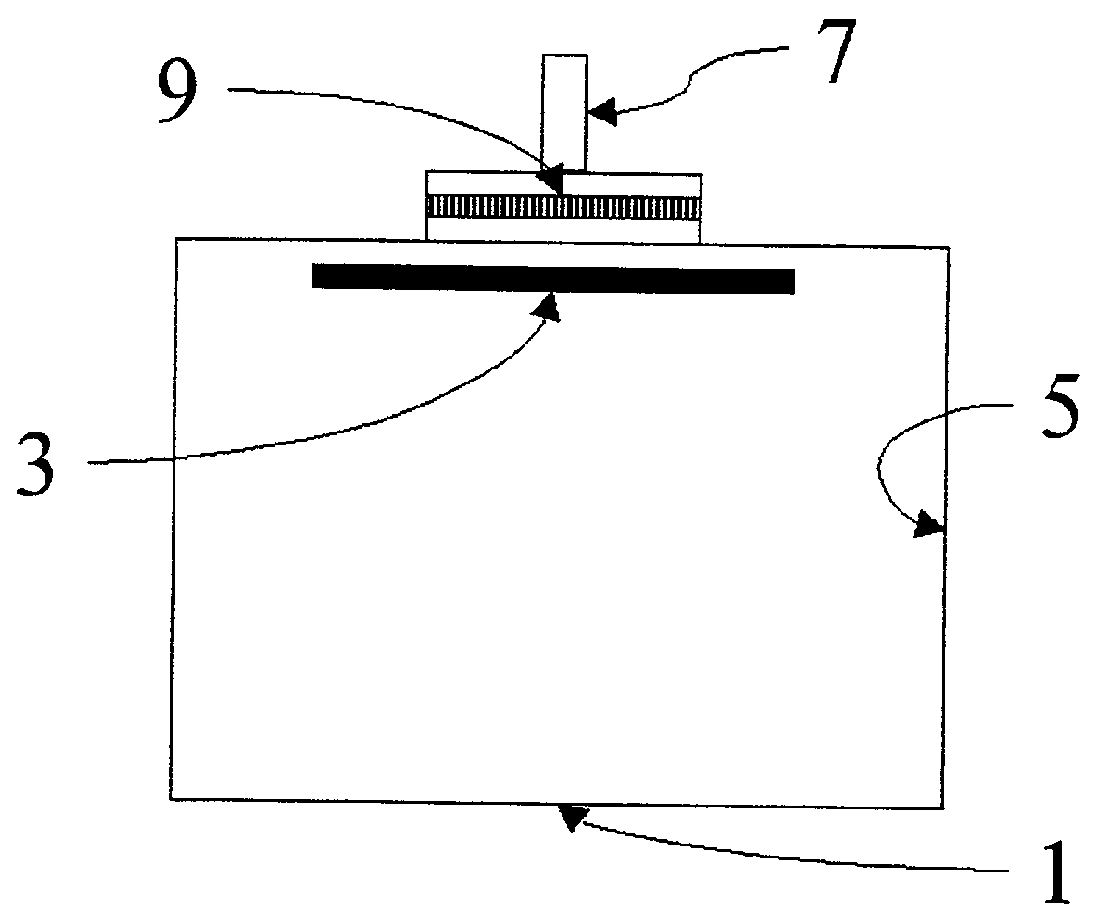

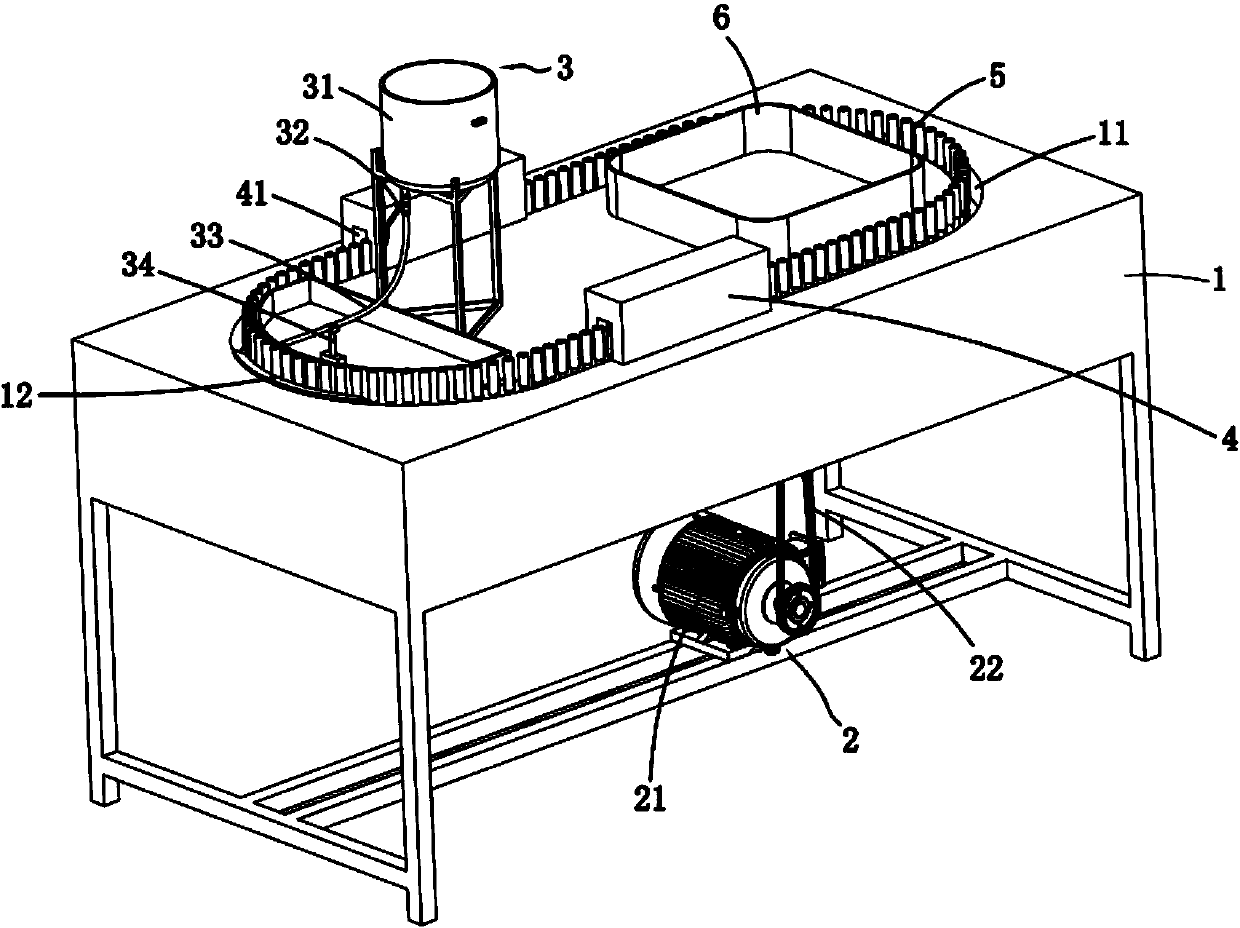

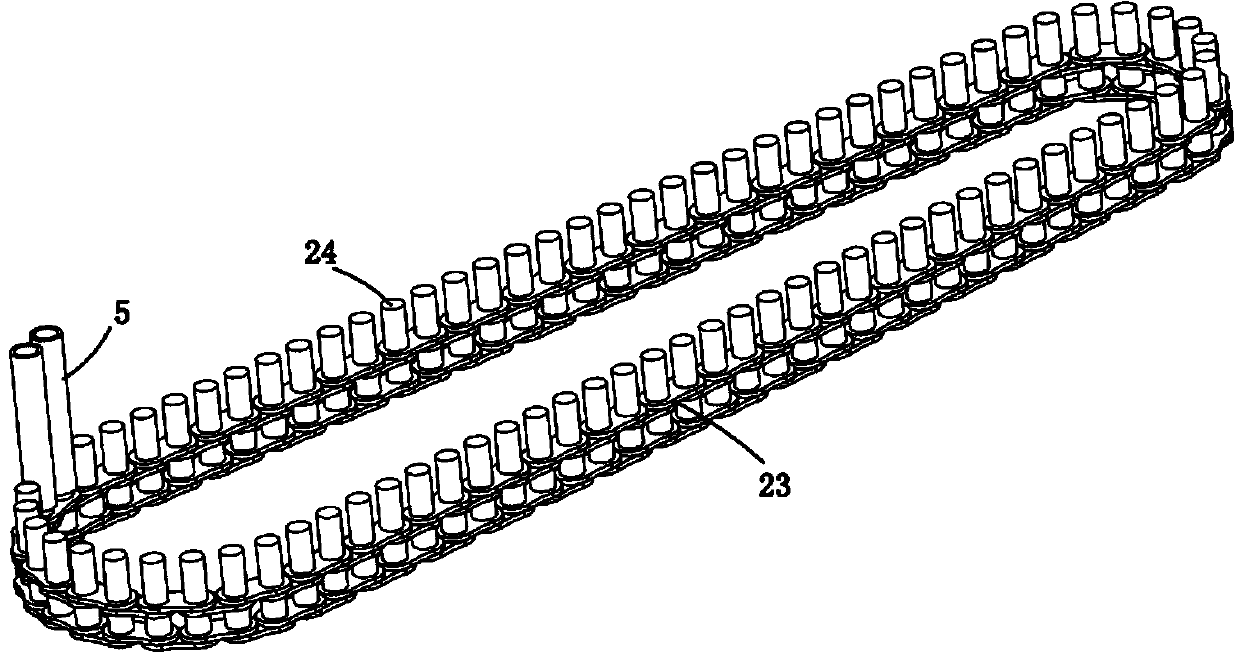

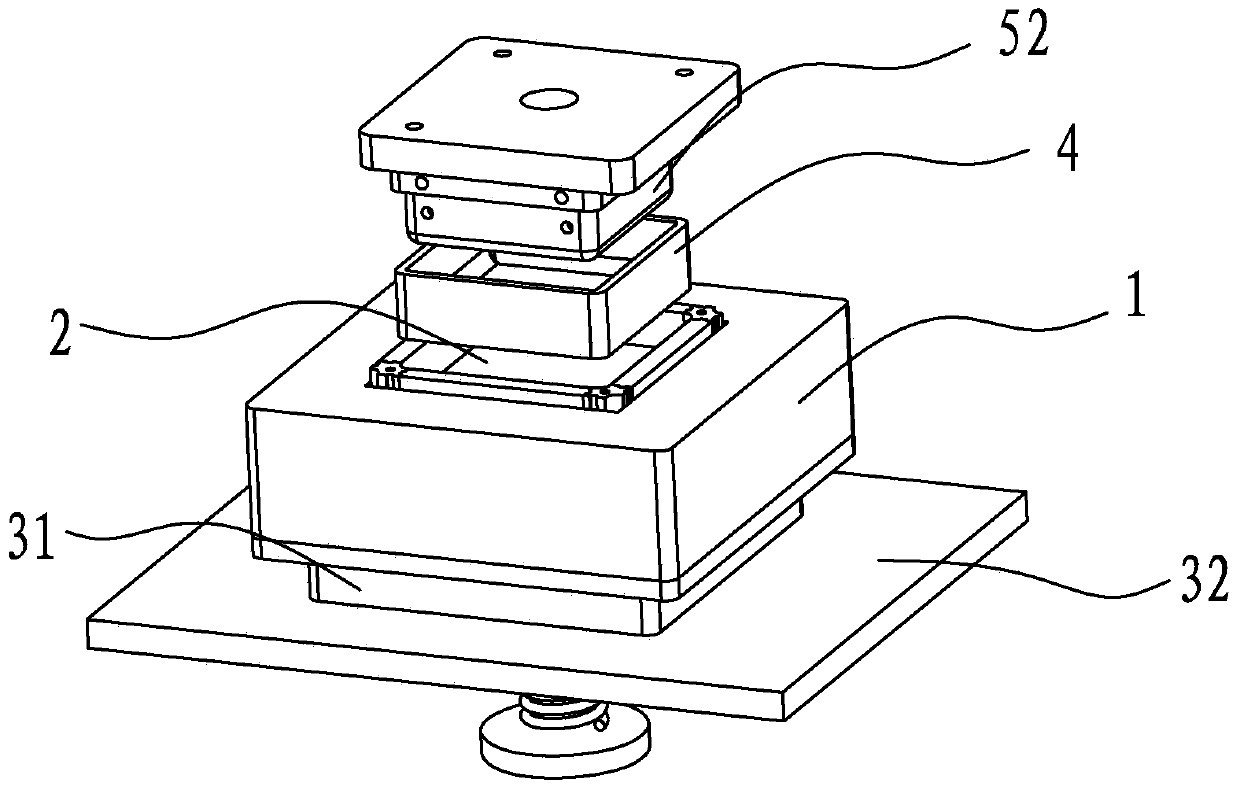

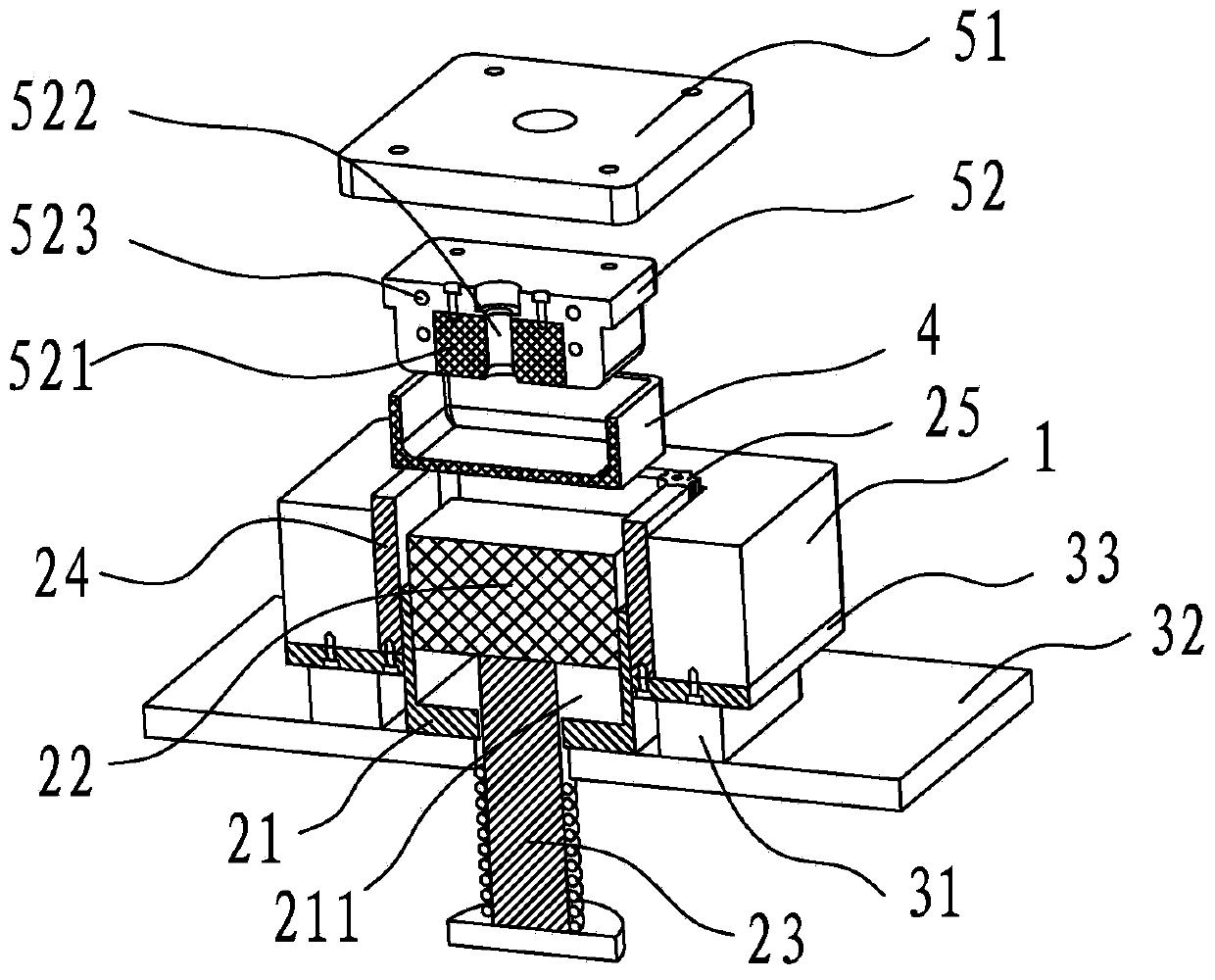

Ceramic spark plug blank glazing device

The invention relates to a ceramic spark plug blank glazing device which comprises a machine frame, a transmission mechanism, a glazing unit, heaters and a plurality of cylindrical brackets for placing spark plug blanks, wherein the transmission mechanism comprises a motor, a belt pulley transmission gear and a chain; the machine frame is provided with an annular track; the chain is provided with rollers and driven by the motor to circularly rotate in the track through the belt transmission gear; the chain is vertically provided with a plurality of rotating shafts; each shaft is sheathed with one cylindrical bracket; and the machine frame is also provided with a saggar for placing the blanks to be glazed. The annular track is provided with the two heaters; the spark plug blank is heated and dried before glaze spraying, so that the blank surface can not easily suspend the glaze, and the glaze surface is uniform; and while the blank is driven to revolve by the chain, the blank also rotates under the extrusion and friction actions of the rubber pad and cylindrical bracket arranged on the inner side of the track, thereby ensuring the uniform thickness of the blank surface glaze layer. The ceramic spark plug blank glazing device is simple in structure and easy to operate and implement.

Owner:芜湖市科邦新能源科技有限公司

Combined manufacturing method of building exterior-wall thermal-insulation material

ActiveCN103570328AControllable sizeDeformation controllableClimate change adaptationPassive housesPumice dustThermal insulation

The invention relates to a building exterior-wall thermal-insulation material obtained by a combined manufacturing method and the combined manufacturing method. Raw materials of the building exterior-wall thermal-insulation material comprise an aggregate, a high-temperature binder and a low-temperature binder. The aggregate comprises expanded perlite, expanded vermiculite, pumice, expanded clay, expanded shale, expanded volcanic ash and expanded raw materials having a large amount of pores. The high-temperature binder comprises 45-60wt% of SiO2, 4-8wt% of Al2O3, 10-15wt% of CaO, 5-12wt% of B2O3, 1-8wt% of Na2O, 1-8wt% of K2O and 1-4wt% of ZnO. The low-temperature binder comprises water glass and bentonite. The combined manufacturing method has the characteristics that 1, in plate manufacture, the size and deformation can be controlled easily and the building exterior-wall thermal-insulation material is superior to foam light thermal-insulation materials; 2, compared with the foam thermal-insulation material manufacturing method utilizing a series of technological parameters such as a sintering temperature to control a heat conduction coefficient, the combined manufacturing method provided by the invention realizes heat conduction coefficient control only by raw material selection; 3, a sintering temperature is controlled in a range of 700-900 DEG C; and 4, in plate production, a roller kiln direct firing technology is utilized and kiln tools such as a base plate and a saggar are avoided so that a sintering heat utilization rate is high.

Owner:咸阳陶瓷研究设计院有限公司

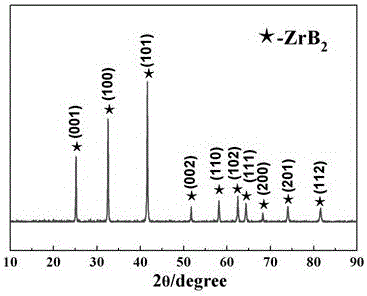

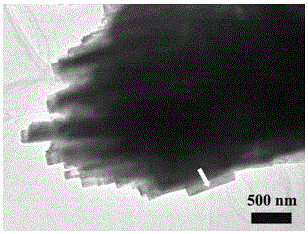

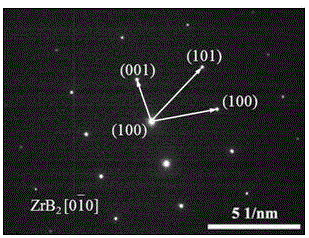

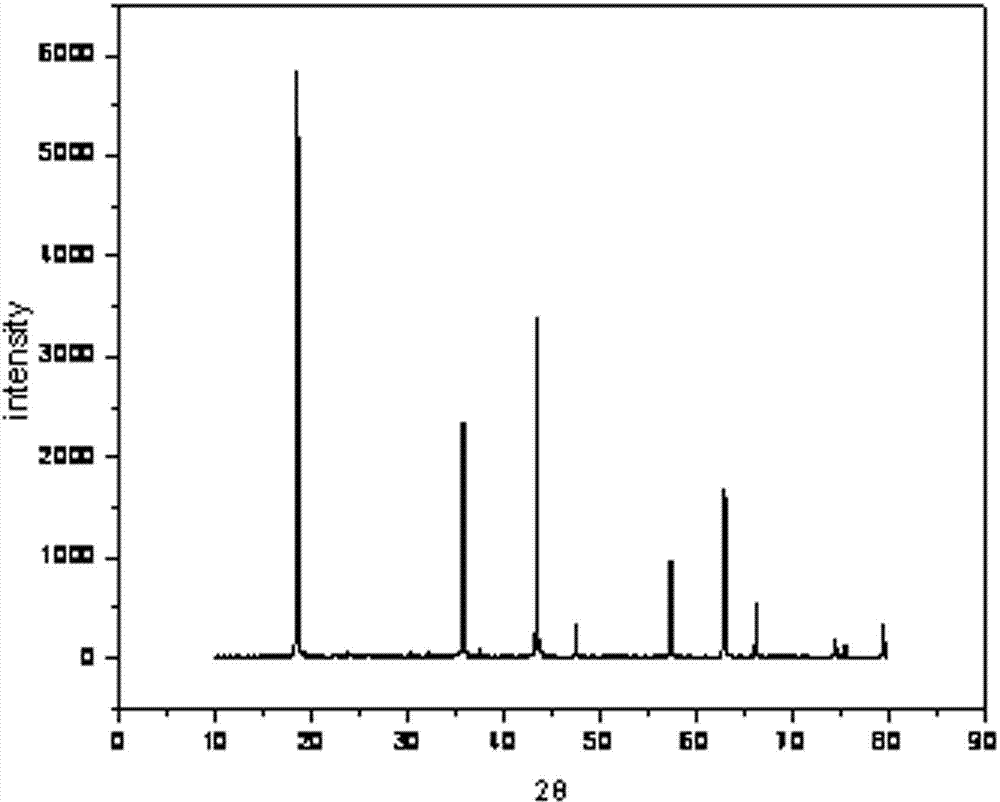

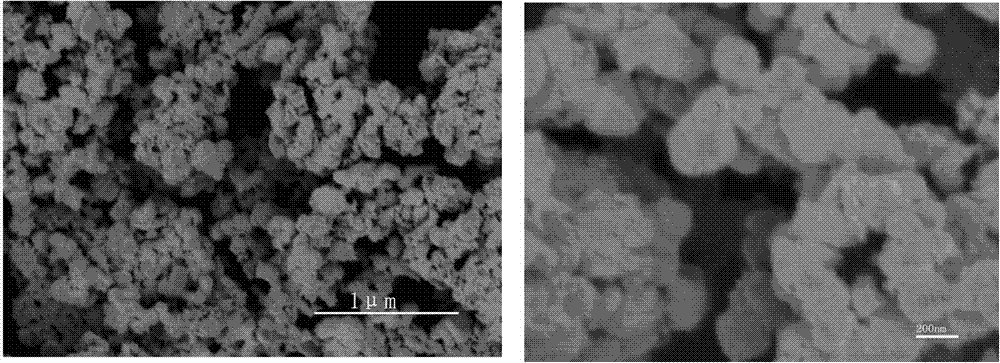

Nano rodlike zirconium boride powder and preparation method thereof

The invention relates to nano rodlike zirconium boride powder and a preparation method thereof. According to the technical scheme, the preparation method comprises the step of uniformly mixing, by weight, 27-39% of zirconium oxide powder, 8-16% of boron carbide powder, 4-8% of non-formalized carbon powder, 12-26% of sodium chloride powder and 24-36% of potassium chloride powder, so that a mixture is obtained; putting a crucible containing the mixture into a saggar, then placing the saggar in a microwave oven, preserving the temperature for 20-40 minutes under the conditions that the vacuum degree is 10-50 Pa, argon atmosphere is provided, and the temperature ranges from 1000 DEG C to 1200 DEG C, conducting natural cooling, then conducting cleaning with deionized water, and preserving the temperature for 6-12 hours at the temperature of 65-80 DEG C in a vacuum drying box, so that the nano rodlike zirconium boride powder is obtained. The preparation method has the advantages of being low in cost, simple in process, low in reaction temperature, high in reaction velocity, suitable for industrialized production and environmentally friendly, and the obtained nano rodlike zirconium boride powder is high in purity, of a uniform rodlike structure, controllable in dimension, large in specific surface area and good in sintering property.

Owner:WUHAN UNIV OF SCI & TECH

Manufacturing process for die-casting saggars with refractory materials

InactiveCN104175389ALow costReduce the number of poresDischarging arrangementCeramic shaping mandrelsRefractoryDie casting

The invention discloses a manufacturing process for die-casting saggars with refractory materials. A method that a mold is die-cast by a press is adopted. The mold comprises an upper mold core, wherein the upper mold core is provided with a cooling water channel and an exhaust pipeline, a lower mold core matched with the upper mold core is arranged below, and the lower mold core adopts a floating structure. During mold opening, the lower mold core rises to the highest position, and the refractory materials are evenly placed onto the floating mold core of a lower mold; a switch of the press is pressed to press the upper mold core downwards, when the upper mold core is pressed downwards to the floating mold core of the lower mold, the floating mold core of the lower mold drops along with the upper mold core, the bottom surface of the floating mold core of the lower mold is stopped from dropping when being pressed downwards to a working table surface of the press, the upper mold core drops continuously at the moment, the refractory materials distributed on the lower mold core are compacted, after compaction, the upper mold core rises, and the floating mold core of the lower mold returns to the initial position. The manufacturing process is convenient in blanking and can solve problems that a lot of air holes exist in the pressed saggars and the saggars are uneven in thickness.

Owner:浙江立鑫高温耐火材料有限公司

Preparation method of nanocarbon coated lithium titanate cathode material

ActiveCN103682278AImprove particle activityGranularityMaterial nanotechnologyCell electrodesFiltrationShielding gas

A preparation method of a nanocarbon coated lithium titanate cathode material comprises the following steps of: (1) preparing a strongly alkaline solution, weighing titanium dioxide, adding into an autoclave for reaction for 3-5h at 160-180 DEG C, cleaning a precipitate in a polyethene lining of the autoclave with hydrochloric acid for several times, performing filtration washing with distilled water, then putting in vacuum drying equipment for drying, (2) weighing a lithium source and pretreated titanium dioxide powder material according to an Li:Ti mole ratio, putting in a ball milling tank, then weighing a soluble carbon source, adding a little distilled water, dissolving at room temperature or under a heating condition, transferring all into a mixing tank, (3) quickly drying slurry with a spray dryer, transferring all materials into a corundum crucible or a saggar, putting in a muffle furnace for sintering in shielding gas, and (4) grinding and sieving an obtained material, and obtaining the carbon coated lithium titanate cathode material.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Technique for firing spinel-type black ceramic material with tunnel kiln

The invention discloses a technique for firing a spinel-type black ceramic material with a tunnel kiln, which comprises the following steps: 1) uniformly mixing 25-40 wt% of chrome oxide green, 30-45 wt% of iron oxide red, 2-25 wt% of cobalt oxide, 10-20 wt% of nickel protoxide and 0-20 wt% of dopant; 2) filling the mixture obtained in the step 1) into a saggar by 70-80% full, calcining in a tunnel kiln, and naturally cooling the calcining product, wherein the technological conditions for calcination are as follows: the temperature of the preheating region is 1170-1250 DEG C, the temperature of the high-temperature region is 1200-1300 DEG C, and the transmission speed is 12-20 hours from charging to discharging; 3) pulverizing and grinding the cooled calcining product; and 4) adding concentrated hydrochloric acid to wash the calcining substance powder obtained in the step 3), stirring to sufficiently react, stirring, washing with water until the pH value is 7, drying and screening. The ceramic pigment has the advantages of high color development capacity and low cost.

Owner:佛山市南海万兴材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com