Preparation of oriented hole silicon carbide porous ceramic

A technology of directional arrangement and porous ceramics, which is applied in ceramic products, other household utensils, household utensils, etc., can solve the problems of difficult to obtain materials with high porosity, material use temperature limitation, and the excellent performance of silicon carbide cannot be fully utilized, etc. Achieve the effect of wide application field, wide temperature range and stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

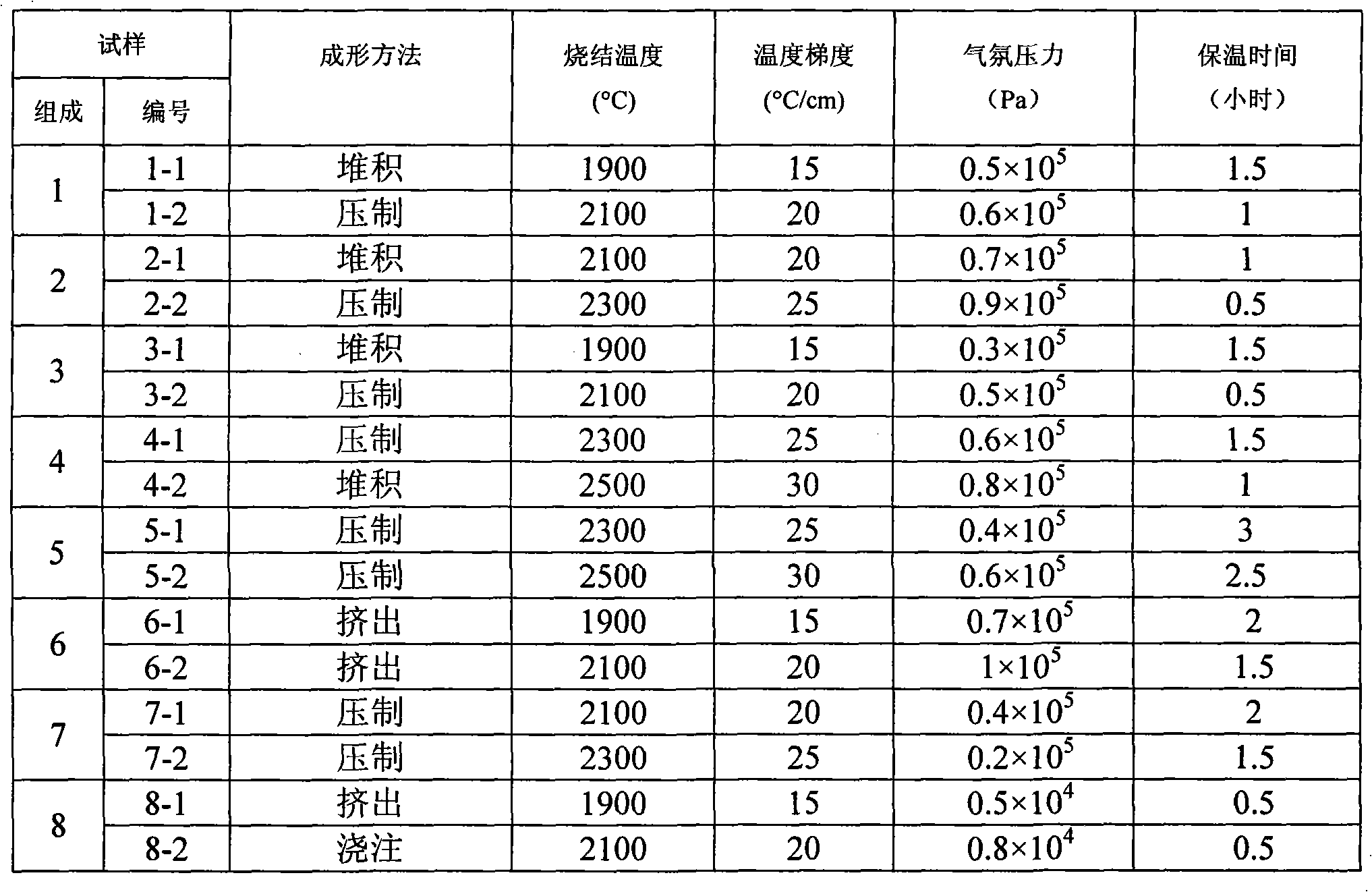

[0024] The present invention has done 8 embodiments altogether, and the raw material composition of embodiment 1~8 is listed in table 1.

[0025] The raw material composition (WT%) of porous silicon carbide ceramics of the present invention of table 1

[0026]

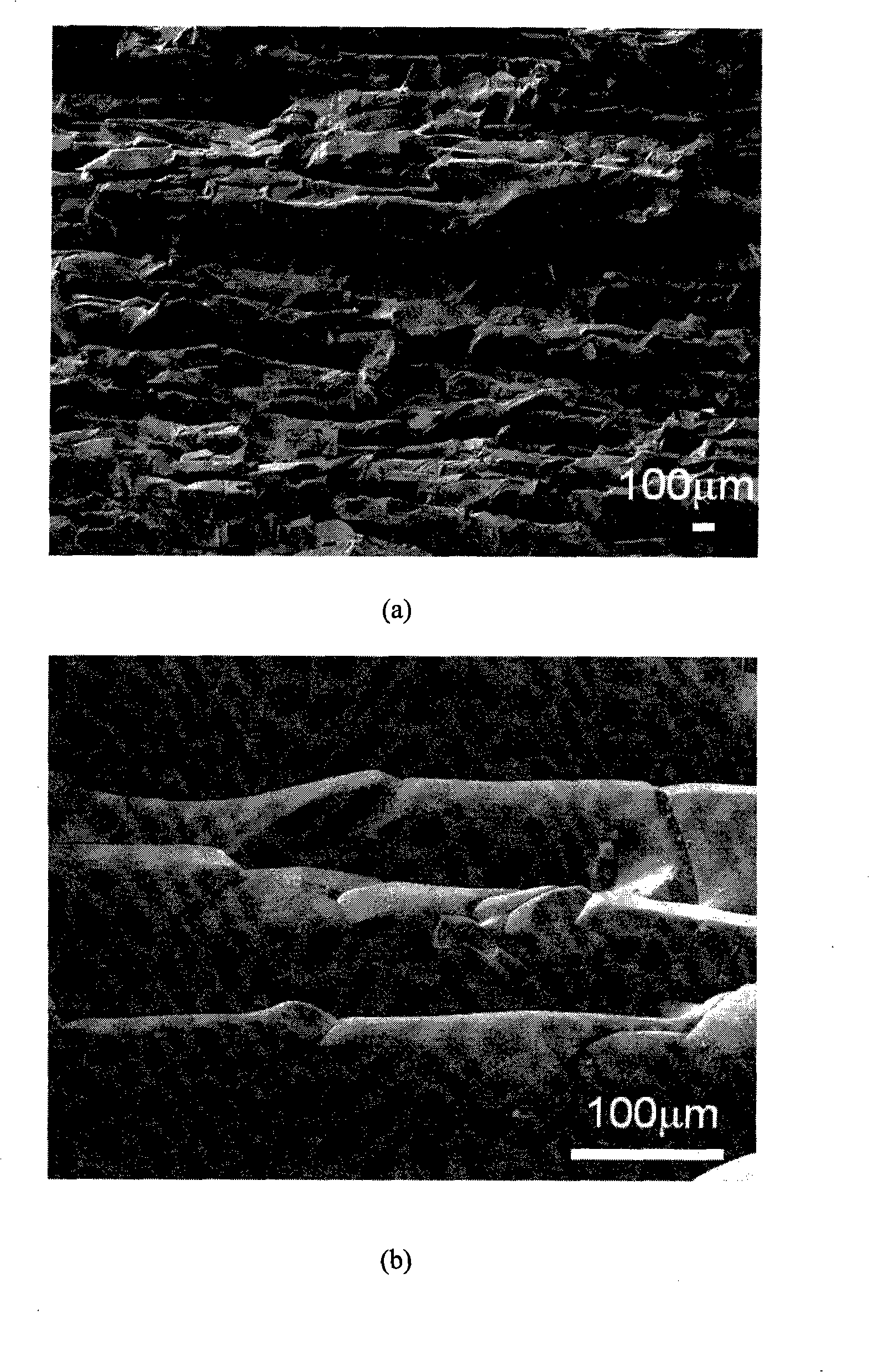

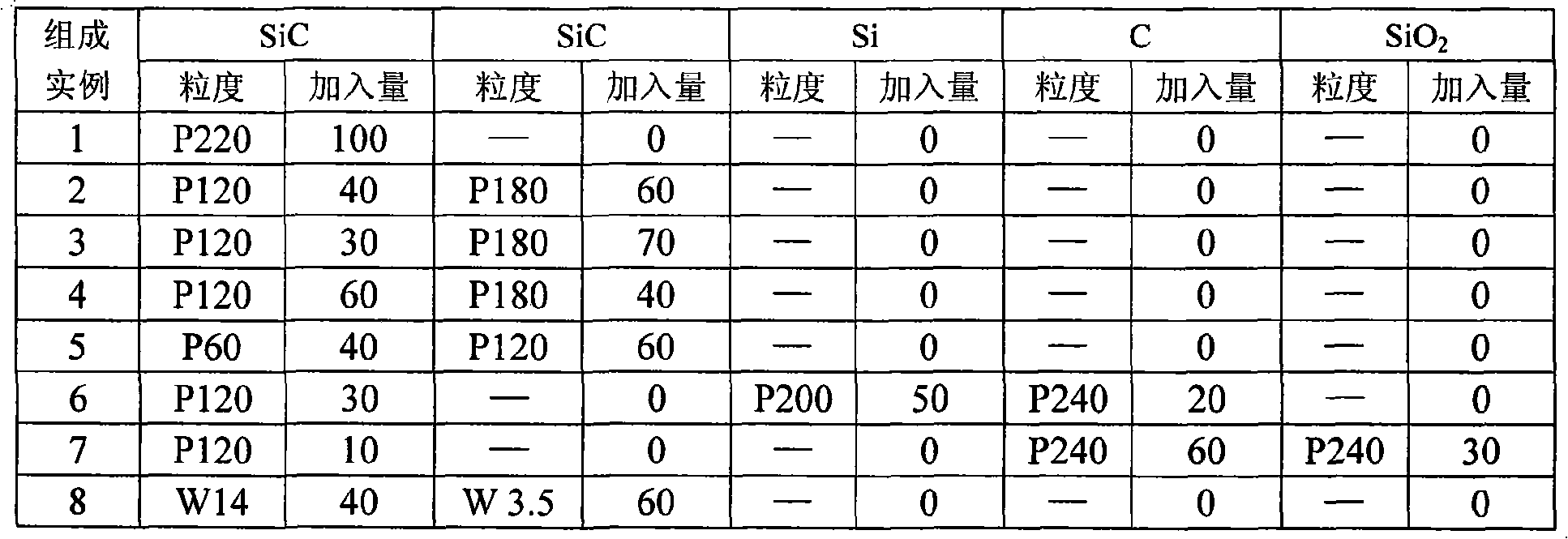

[0027] According to the formulations of Examples 1 to 8 in Table 1, common adhesives for ceramics are added to the raw materials, and phenolic resins with high carbon-fixing content can also be used as adhesives, and conventional forming methods are used to mix the raw materials and adhesives evenly; into green bodies of different densities; after drying, put them into graphite crucibles or saggars; you can also directly shake the mixed powder into graphite crucibles or saggars with required shape products without using binders. Put the crucible or sagger into a high-temperature vacuum atmosphere sintering furnace, and create a vertical or radial temperature gradient in the furnace body through the design of the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com