Patents

Literature

11356results about How to "Meet the use requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Premixing mortar with high moisture retention and production method thereof

The invention discloses pre-stirring mortar with high moisture retention and a production method thereof. The premixing mortar comprises the following components by weight ratio: 100 parts of cement with the high moisture retention, 1 to 900 parts of fine aggregate and 30 to 200 parts of water, wherein the cement with the high moisture retention contains a cellulose ether component and has the moisture retention above 90 percent; and the fine aggregate is natural sand or artificial sand obtain through screen sizing or removing harmful components, and has the maximum grain diameter of 1.18 mm to 2.36 mm. The production method comprises the following steps: arranging a mortar stirring machine on a construction site or nearby; adopting the cement with the high moisture retention and the fine aggregate to automatically meter and stir, enable mortar to be usable while stirring, and the like to ensure the mortar quality; and adopting a closed stirring mode, a dust-collecting mode and the like to reduce dust raise. The pre-stirring mortar can effectively improve and ensure the qualities of the mortar buildings, obviously improves the construction environment, greatly decreases the production cost of the pre-stirring mortar and solves the difficult problems that the prior pre-stirring mortar has over-high cost and are difficult to popularize and apply.

Owner:SOUTH CHINA UNIV OF TECH

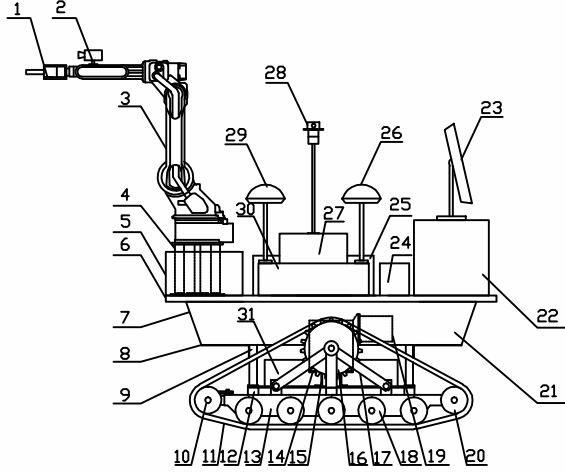

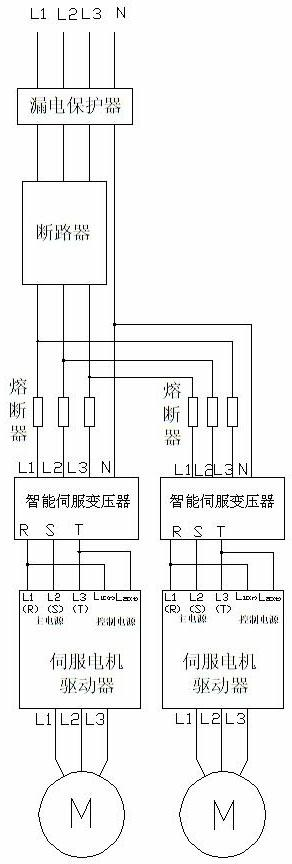

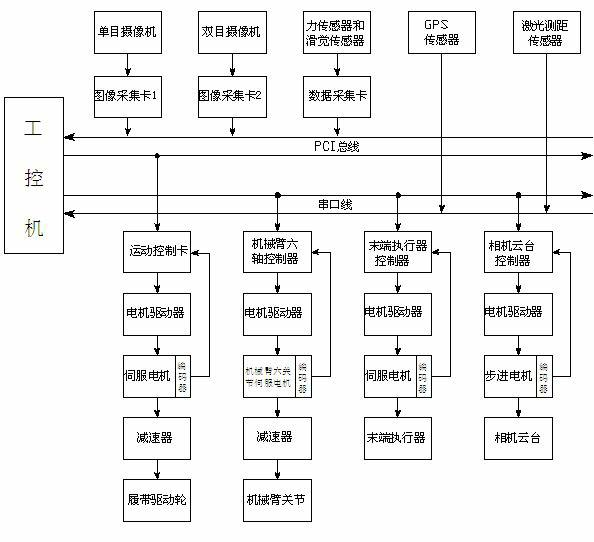

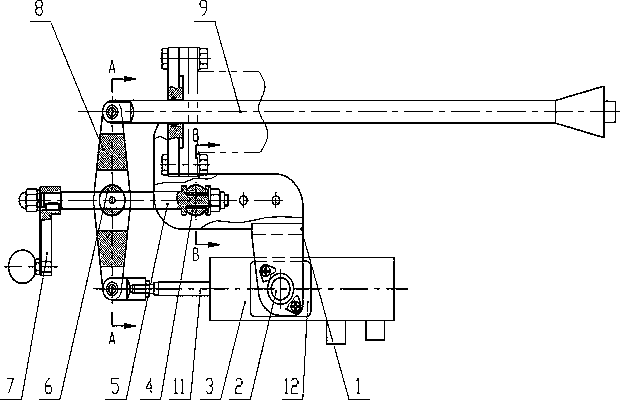

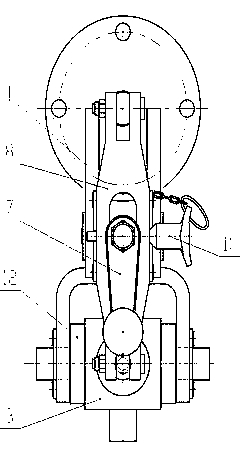

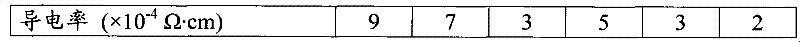

Automatic-navigation crawler-type mobile fruit picking robot and fruit picking method

InactiveCN102165880AFully automated pickingSimple structureProgramme-controlled manipulatorPicking devicesSimulationActuator

The invention discloses an automatic-navigation crawler-type mobile fruit picking robot which comprises a mechanical execution system and a control system and is characterized in that the mechanical execution system comprises an intelligent movable platform, a fruit picking mechanical arm and a two-finger type manipulator, wherein the intelligent movable platform comprises two crawler assemblies, an experimental facility fixing rack, a supporting stand column, a cross beam, a speed reducer and the like; and the control system comprises an industrial personal computer, a motion control card, a data collecting card, an image collecting card, an encoder, a GPS (global position system), a monocular zooming camera assembly, a binocular camera, a laser ranging sensor, a control circuit and the like. The automatic-navigation crawler-type mobile fruit picking robot integrates the fruit picking mechanical arm, the two-finger type manipulator, the intelligent movable platform and the sensor system, integrates multiple key technologies such as fruit identification, motion of the picking mechanical arm, grabbing of a tail-end executer, automatic navigation and obstacle avoidance of the movable platform, and the like, and really realizes automatic and humanized fruit picking.

Owner:NANJING AGRICULTURAL UNIVERSITY

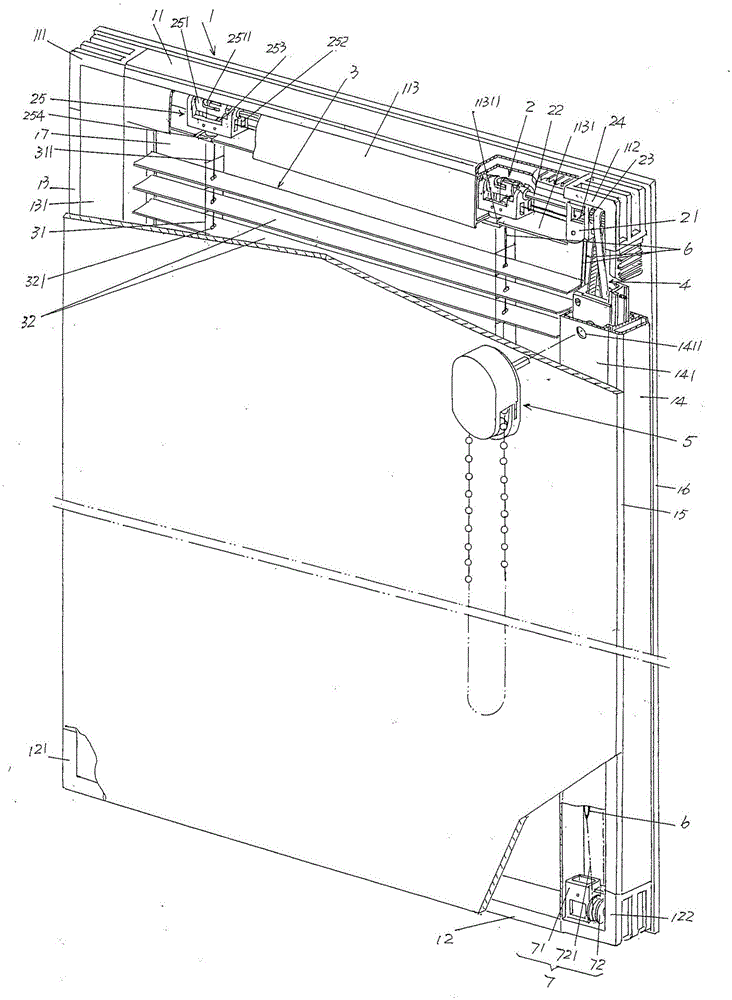

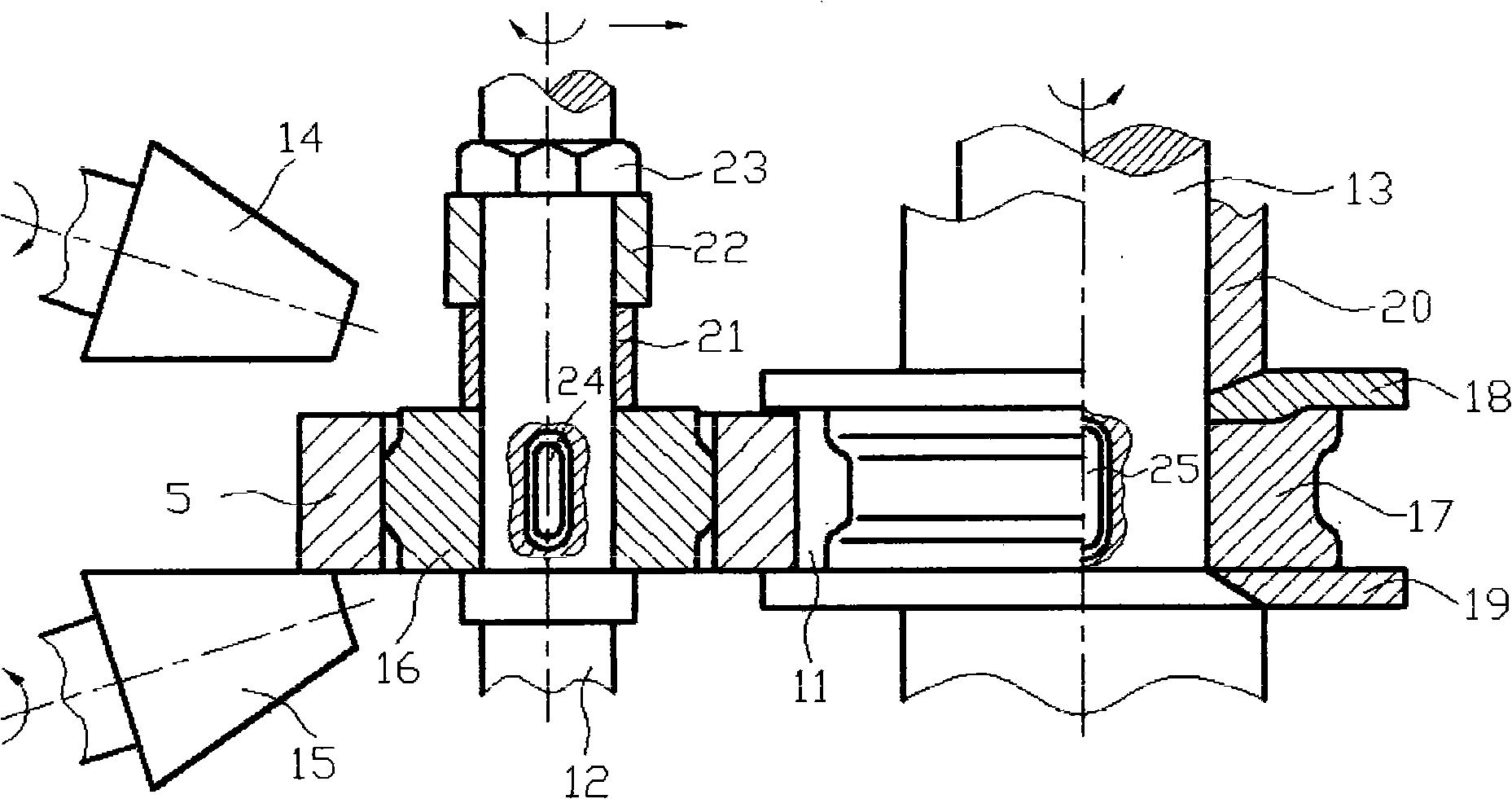

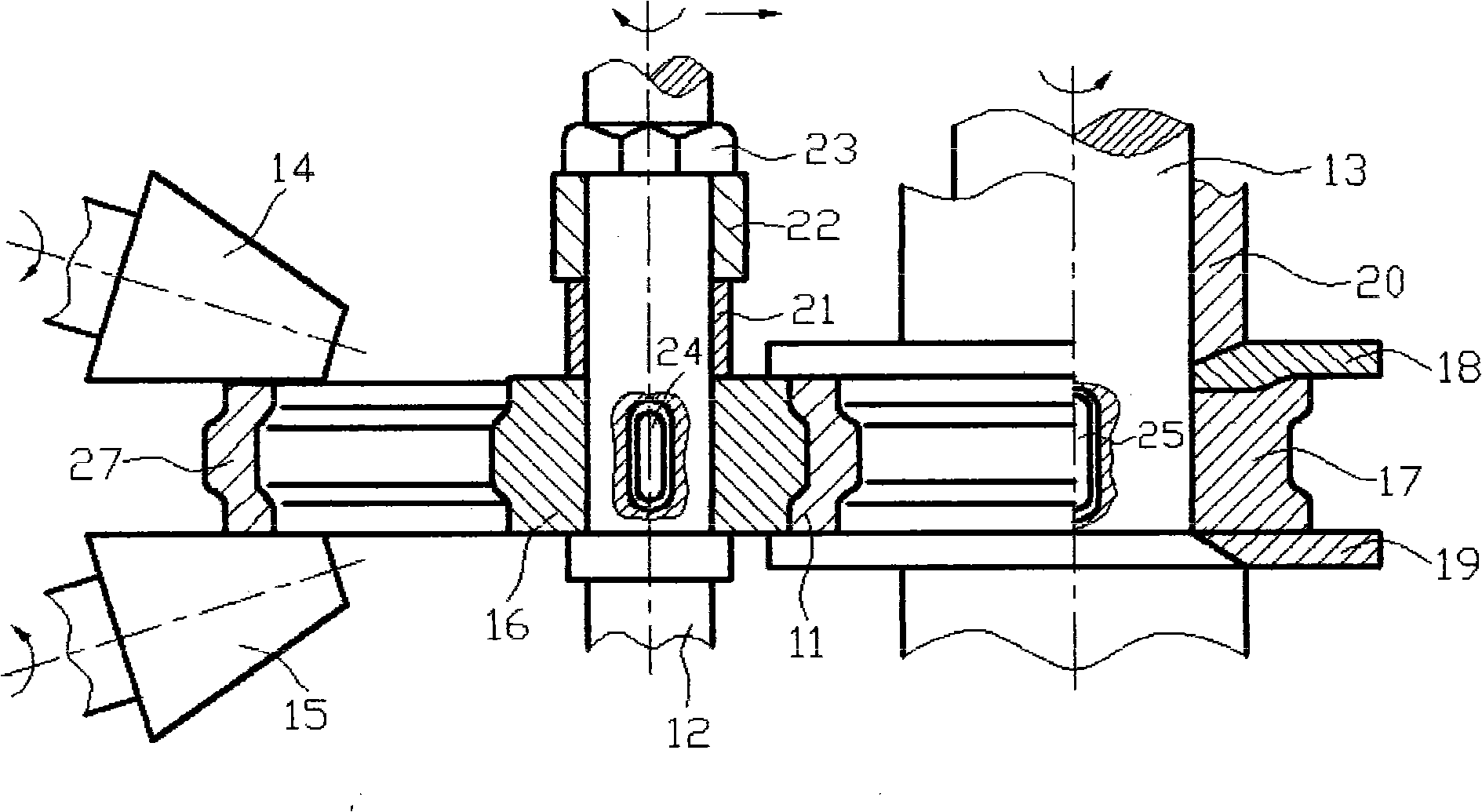

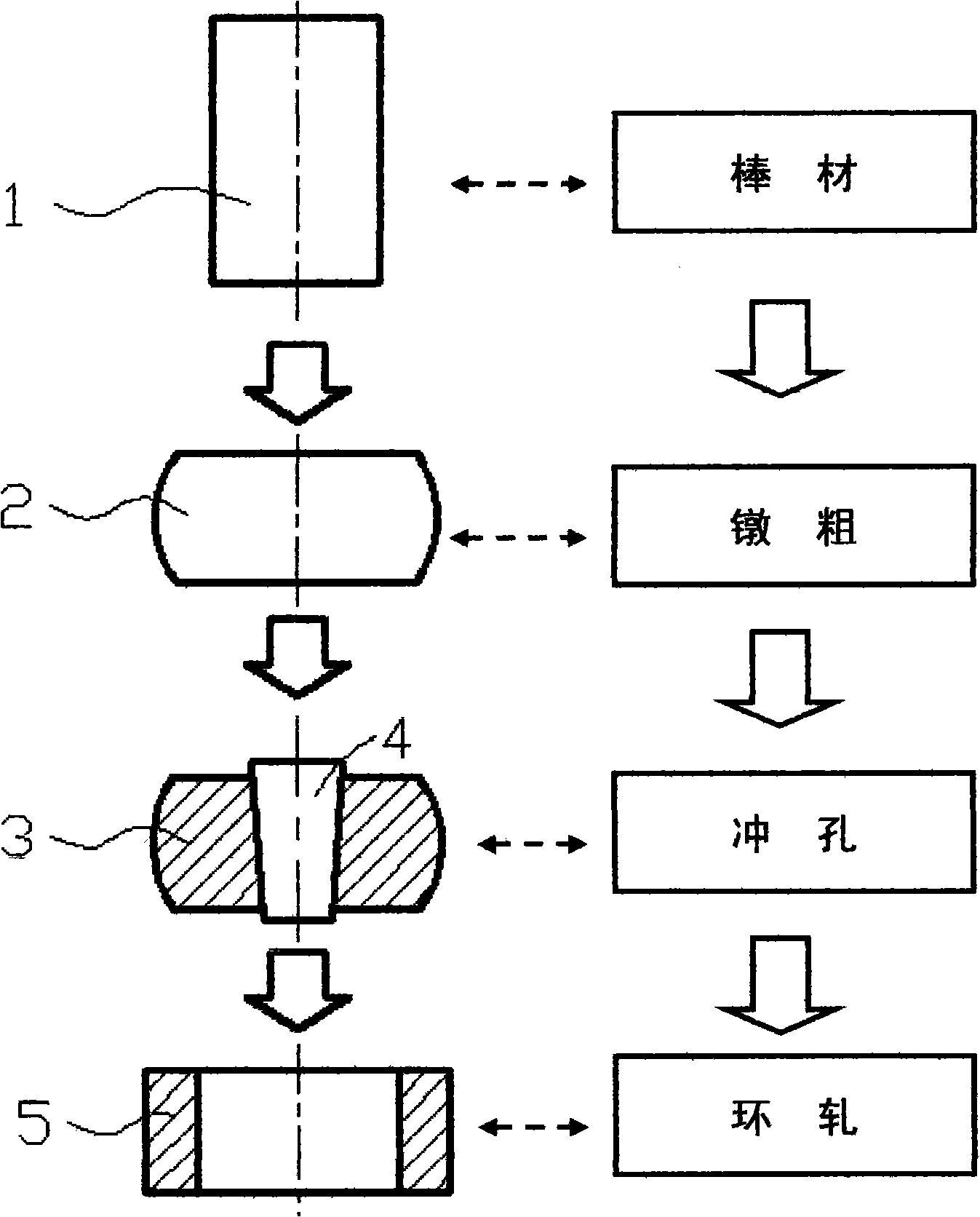

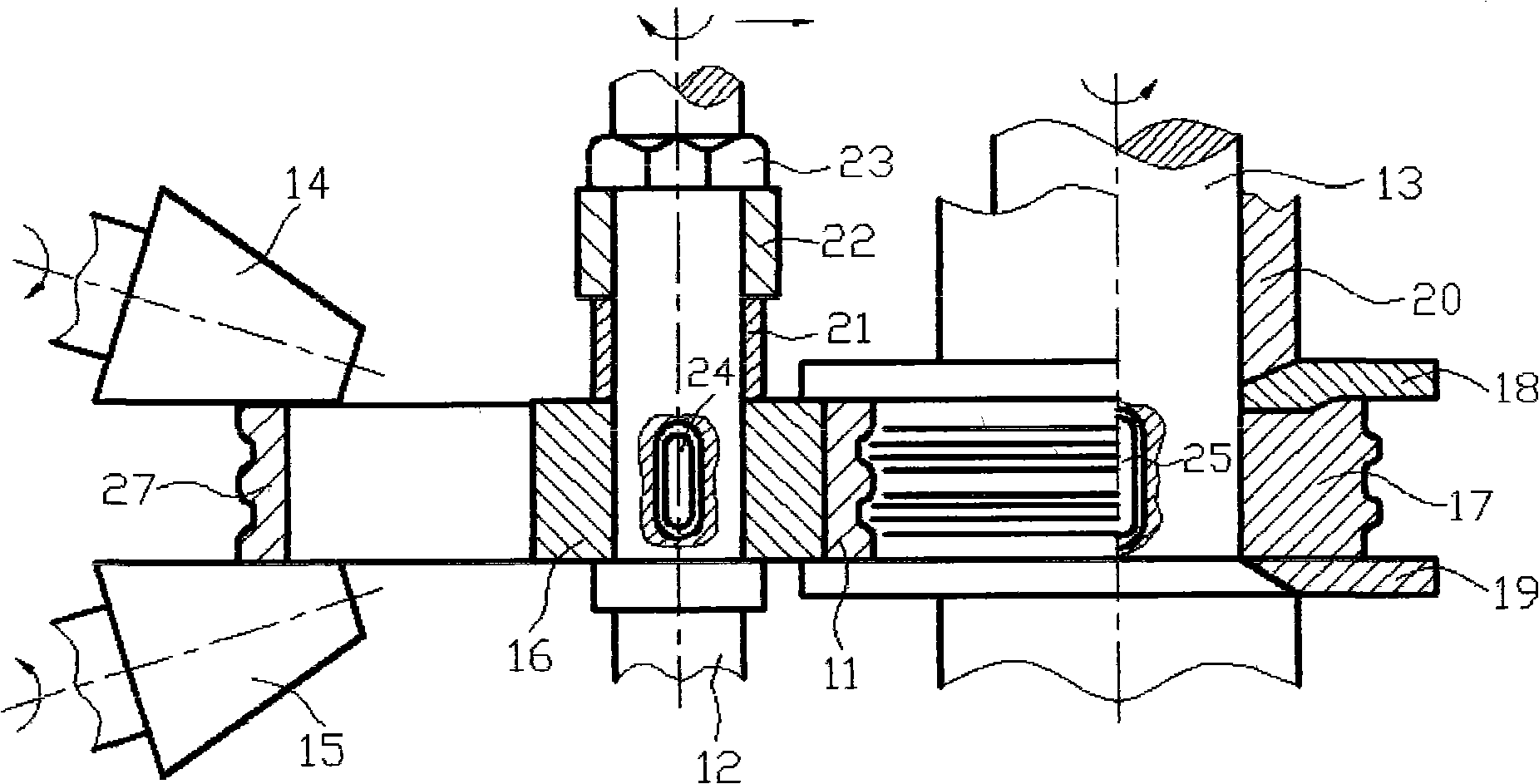

Non-magnet driven double-glazed built-in shutters

ActiveCN105041170BMeet the use requirementsSave resourcesLight protection screensWindow shutterEngineering

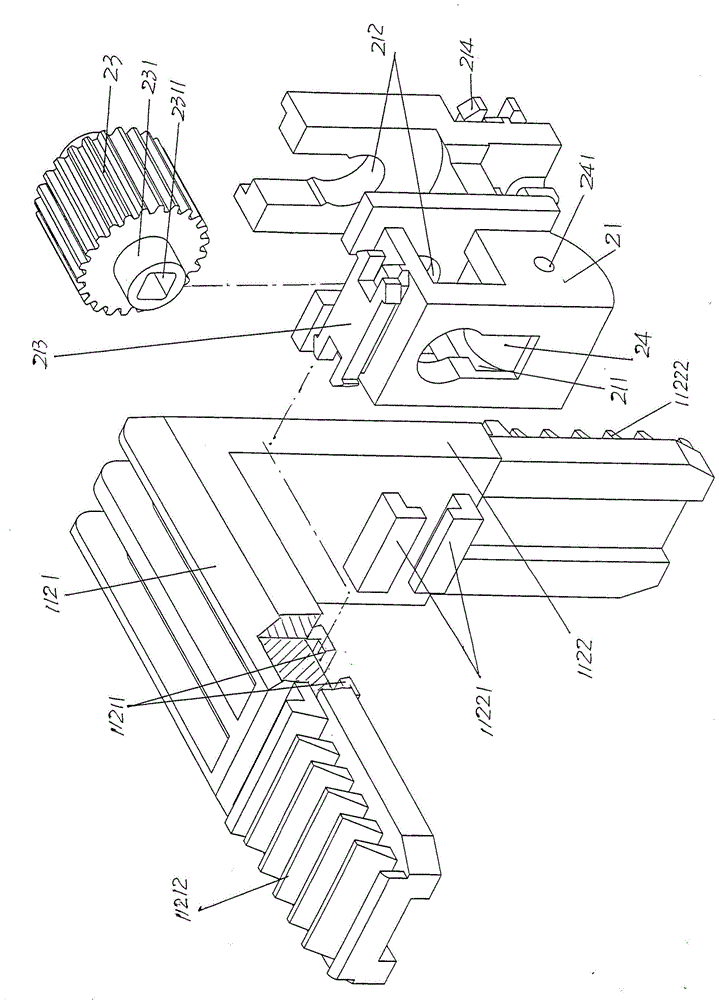

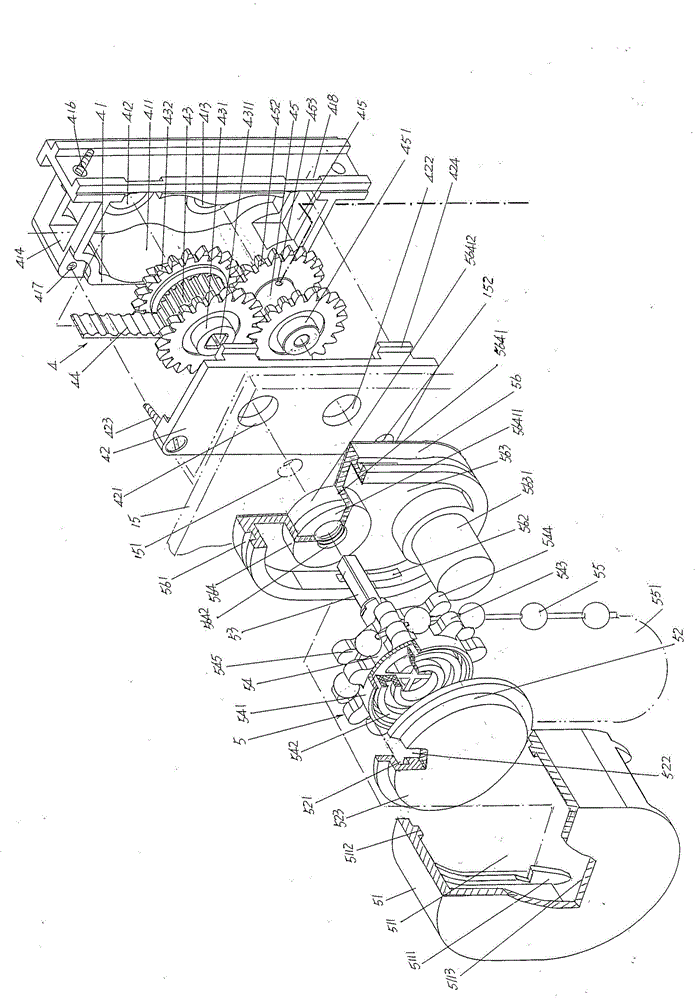

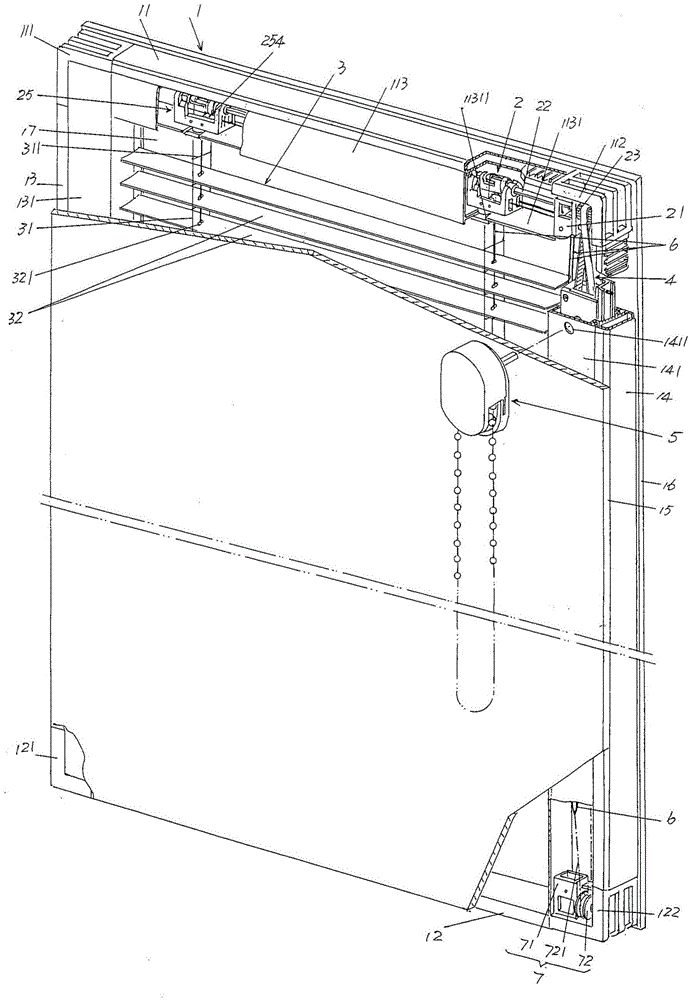

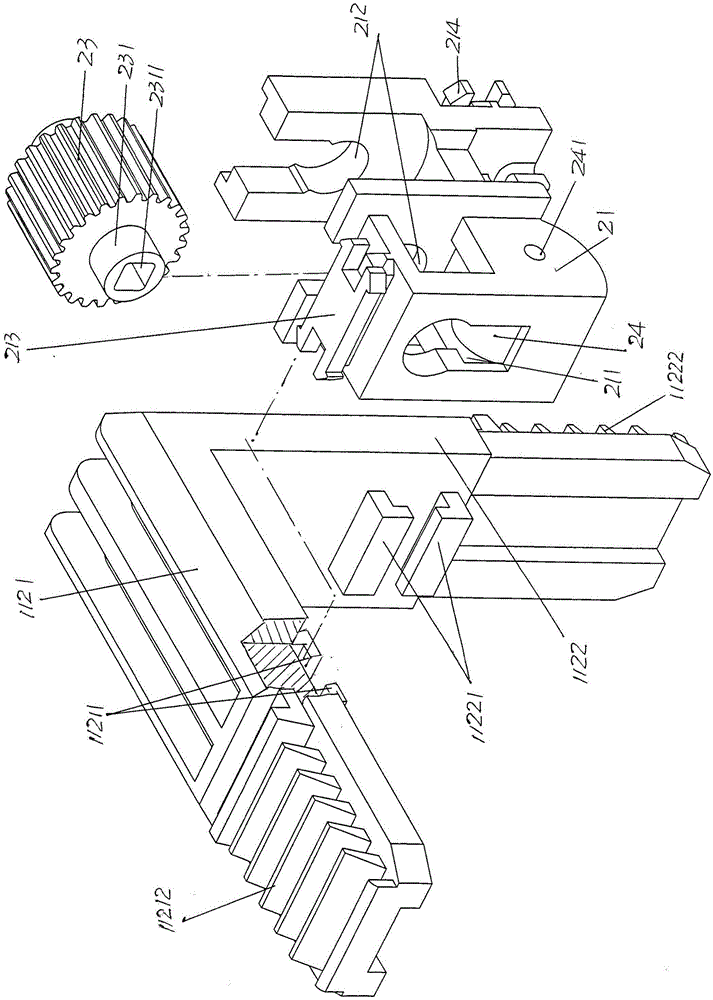

The invention discloses a non-magnetic driven type blind window with internally-installed double-layer hollow glass, and belongs to the technical field of sunshade hollow glass products. The non-magnetic driven type blind window with the internally-installed double-layer hollow glass comprises a window body which comprises inner glass and outer glass, a blind sheet turning mechanism, a venetian blind, an internal manipulation mechanism, an external manipulation mechanism and a venetian blind lifting pulling rope. The non-magnetic driven type blind window with the internally-installed double-layer hollow glass is characterized in that the internal manipulation mechanism comprises a case body, a case cover, a synchronous pulley, a synchronous belt and a lifting pulling rope driving wheel, the case body is arranged in a hollow cavity and fixed with the window body, the synchronous pulley is located above the case body cavity, one end of a synchronous pulley shaft is supported on the case cover, and the other end of the synchronous pulley shaft is supported on the cavity bottom wall of the case body cavity; one end of the synchronous belt is arranged on the blind sheet turning mechanism in a sleeving mode, and the other end of the synchronous belt is arranged on the synchronous pulley in a sleeving mode; the lifting pulling rope driving wheel is arranged in the case body cavity of the case body and located on the lower portion of the case body cavity; the external manipulation mechanism comprises a shield, a friction disc, a bead chain wheel shaft, a bead chain wheel hub, a bead chain and a bead chain wheel shaft seat; one end of the lifting pulling rope of the venetian blind is connected with the lifting pulling rope driving wheel. Therefore, resources are saved, the cost is reduced, and the labor is saved in operation.

Owner:CHANGSHU ZHONGQIN BUILDING MATERIAL

Bead-chain driven double-glazed built-in shutters

ActiveCN105041172BMeet the use requirementsReduce manufacturing costLight protection screensManufacturing cost reductionWindow shutter

The invention discloses a bead chain driving type double-layer hollow glass built-in louver and belongs to the technical field of sunshade hollow glass products. The louver comprises a window body, a curtain piece turning mechanism, a venetian blind, an inner control mechanism, an outer control mechanism and a venetian blind lifting traction rope. The window body comprises an upper window body transverse tube, a lower window body transverse tube, a left window body longitudinal tube, a right window body longitudinal tube, inner glass and outer glass. The louver is characterized in that the inner control mechanism comprises a box body, a box cover, a synchronous belt pulley, a synchronous belt and a lifting traction rope driving wheel. The outer control mechanism comprises a protective cover, a friction plate, a bead chain wheel shaft, a bead chain wheel shaft hub, a bead chain and a bead chain wheel shaft base. The protective cover forms a protective cover cavity. The friction plate is arranged in the protective cover cavity. The bead chain wheel shaft hub is supported by a shaft hub cavity. The bead chain wheel shaft is arranged in the middle of the bead chain wheel shaft hub. One end of the bead chain is arranged on the bead chain wheel shaft hub in a sleeving mode. The other end of the bead chain forms a suspending end. The bead chain wheel shaft base is matched with the protective cover. One end of the venetian blind lifting traction rope is in driving connection with a lifting traction rope driving wheel. Manufacturing cost is reduced; labor is saved during operation; service life is long, and the using effect is good; resource-saving economy is reflected.

Owner:CHANGSHU ZHONGQIN BUILDING MATERIAL

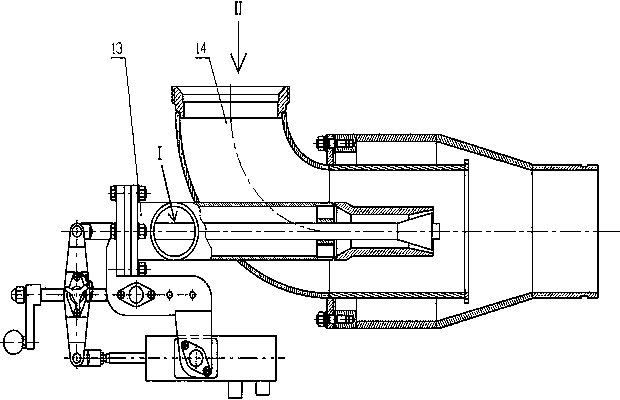

Clear water controlling device for high-energy mixer and high-energy mixer

ActiveCN102729335BControl openingAccurate opening controlFlow mixersTransportation and packagingHigh energyEngineering

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Composite polypropylene material and its preparing method

The composite polypropylene material is prepared with polypropylene 10-100 weight portions, polyethylene 1-50 weight portions, inorganic rigid grain 1-50 weight portions, toughener 1-50 weight portions, coupling agent 0.01-10 weight portions and grafting compatilizer 1-50 weight portions. The composite polypropylene material has high rigidity, high impact strength and balanced rigidity and toughness, and compared with common automobile bumper material, it has 15-30 % higher bending modulus.

Owner:吴永刚

Automatic sorting system for household refuse

Disclosed is an automatic sorting system for household refuse. The system comprises a refuse target identification unit, a refuse sorting control unit, a mechanical arm and a sampling camera which is mounted at the fixed position of a conveying belt for conveying household refuse; the sampling camera shoots the household refuse on the conveying belt in real time and transmits obtained optical images to the refuse target identification unit; the refuse target identification unit receives the optical images in real time and displays the images, according to the characteristics of presorted target refuse, the optical images are treated, targets in the images are identified, and target posture information frames are obtained, and are input into the refuse sorting control unit; and the refuse sorting control unit judges whether a target enters the working section of the leisure mechanical arm or not according to the input target posture information frames and the opposite position of the mechanical arm and the conveying belt, the posture information of the target entering the working section of the mechanical arm is converted into a mechanical arm coordinate system and sent to the corresponding mechanical arm, and the corresponding mechanical arm is controlled to grab the corresponding target.

Owner:BEIJING XINCHANGZHENG TIANGAO INTELLIGENT MACHINE TECH CO LTD

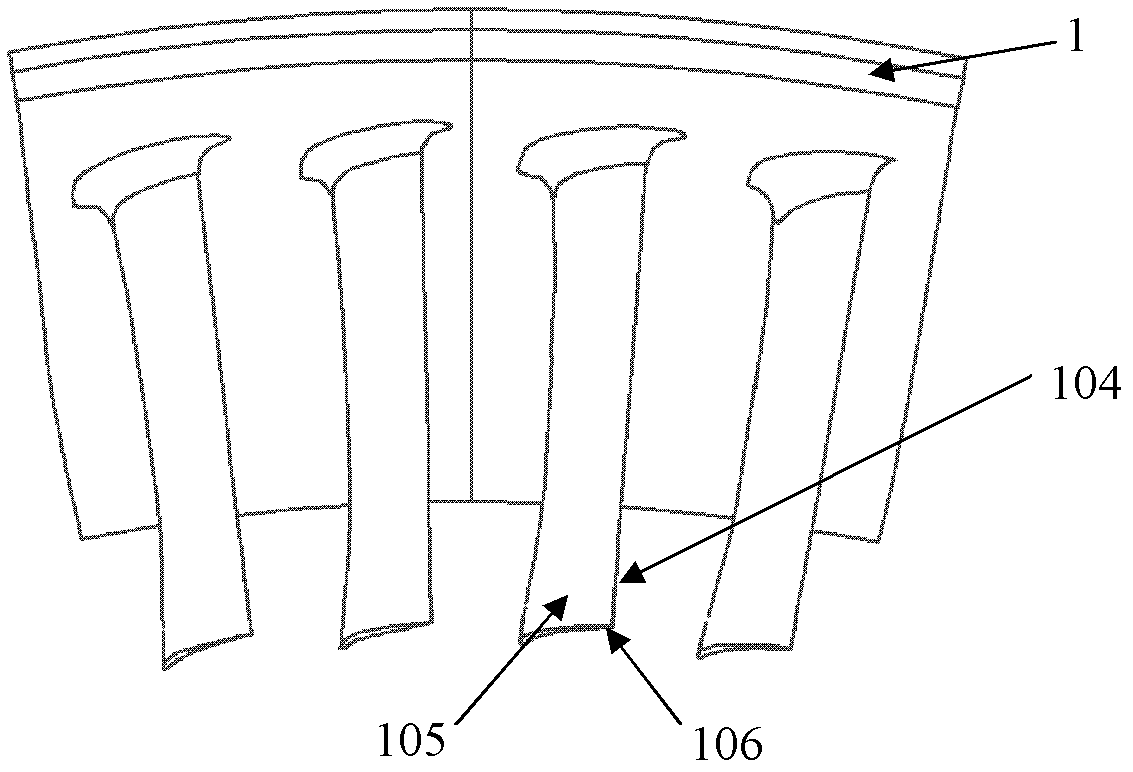

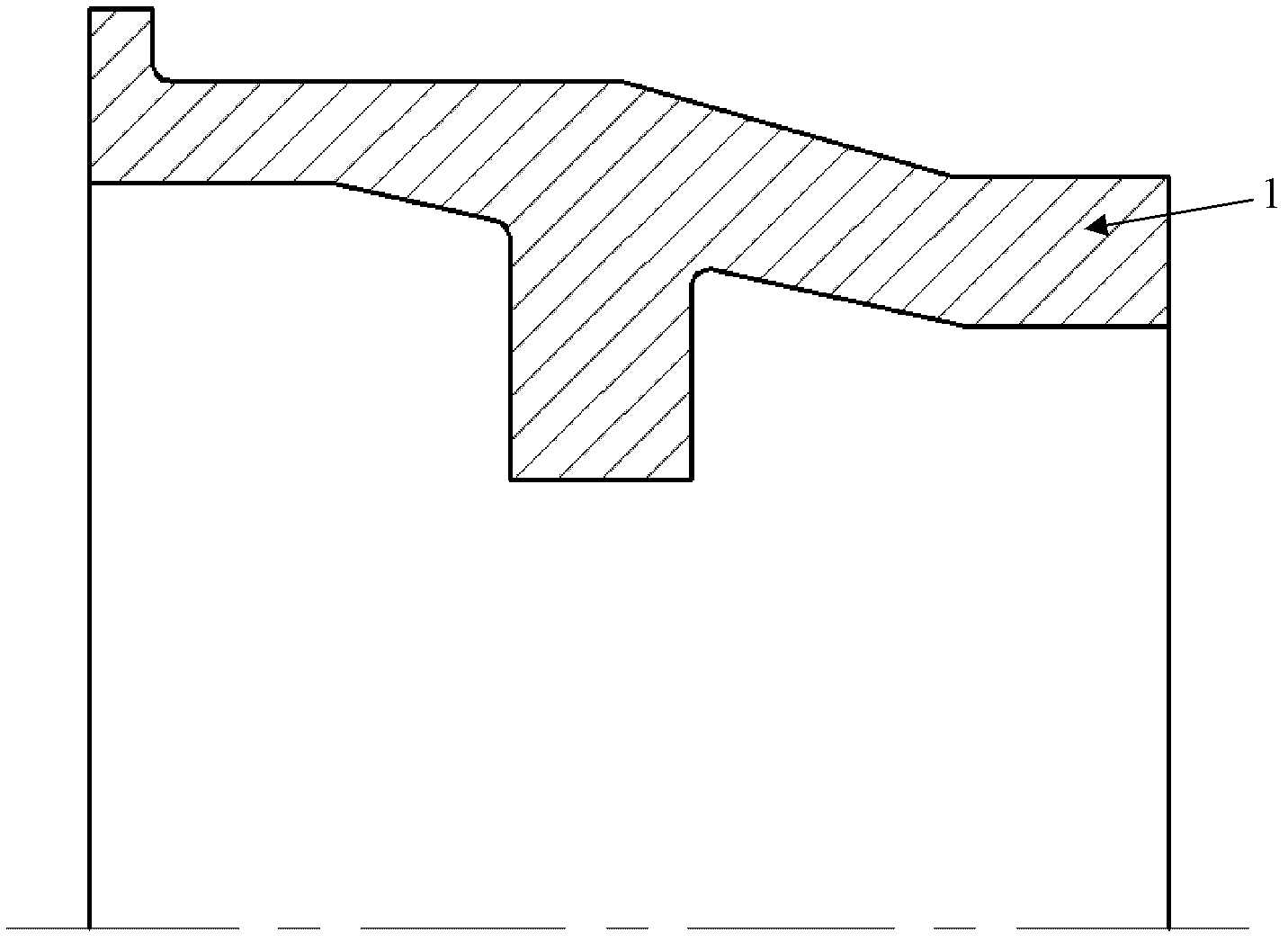

Method for processing integral casing of engine

The invention relates to a method for processing an integral casing of an engine, which is characterized by mainly comprising the steps of: inspecting blanks, carrying out rough turning on inner and outer shapes of the casing, carrying out numerical control milling on the outer shape of the casing and engraving lines for trisection, carrying out wire cutting and trisecting on the casing on the basis of the trisection lines, carrying out aging and stress-relieving treatments, grinding upper and lower end faces and processing two dowel holes in the lower end face, carrying out blade slot treatment and processing a faying surface and a flange hole, carrying out finish milling on the outer shape of the casing, carrying out the aging treatment again, assembling the trisected modules and establishing a benchmark again, carrying out finish turning on the inner surface of the casing, disassembling the modules of the casing, carrying out the finish milling on blades and assembling the modules of the casing, wherein a fillet variable-axis plunge milling method, a blade spacing processing method and a flexible supporting method are adopted in the blade finish milling process. The method provided by the invention has the advantages: the technical process is simple; the produced integral casing has higher precision; the advantages of good consistency, little deformation and high efficiencyare provided in the blade processing; the technical problem that the integral casing is difficult in numerical control is solved by means of the trisection processing method; and the process method can also be used for the development of multilevel integral casings.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Polyhydroxylkanoates as well as blending modification for copolymer thereof and polylactic acid

The invention discloses a PHBV with good performance and a copolymer of PHBV and PLA and the preparation technique method. The invention is characterized in that 1 per cent to 99 per cent of PHAs, 1 per cent to 99 per cent of PLA1 and other additives 0-40 per cent are put in a mixer for 1 to 30 minutes, and then put in an electricity hot blast drying oven a temperature ranging from 40 to 100 DEG C for 2 to 48 hours after being mixed equally. The dried compound is plastified in a double screw extruder, the highest temperature of the double screw extruder is between 90 and 180 DEG C according to the the different content of PHAs and the temperature of the mouth mold is between110 to 170 DEG C. The material extruded from a die head is cooled, stretched and grained to form the complete biodegradation aggregate. The resin consisting of PHBV and copolymer of PHBV and PLA is able to be used for producing the thin films, plates and sheet materials and injected mold to plastic materials. The compound has biological degradability and good machining performance. The target product of the compound has excellent mechanical properties and can be used for replacing the petroleum base plastic to be widely used for packing, agriculture, medical material, electron, chemical industry concerning products for daily use, etc.

Owner:深圳市奥贝尔科技有限公司

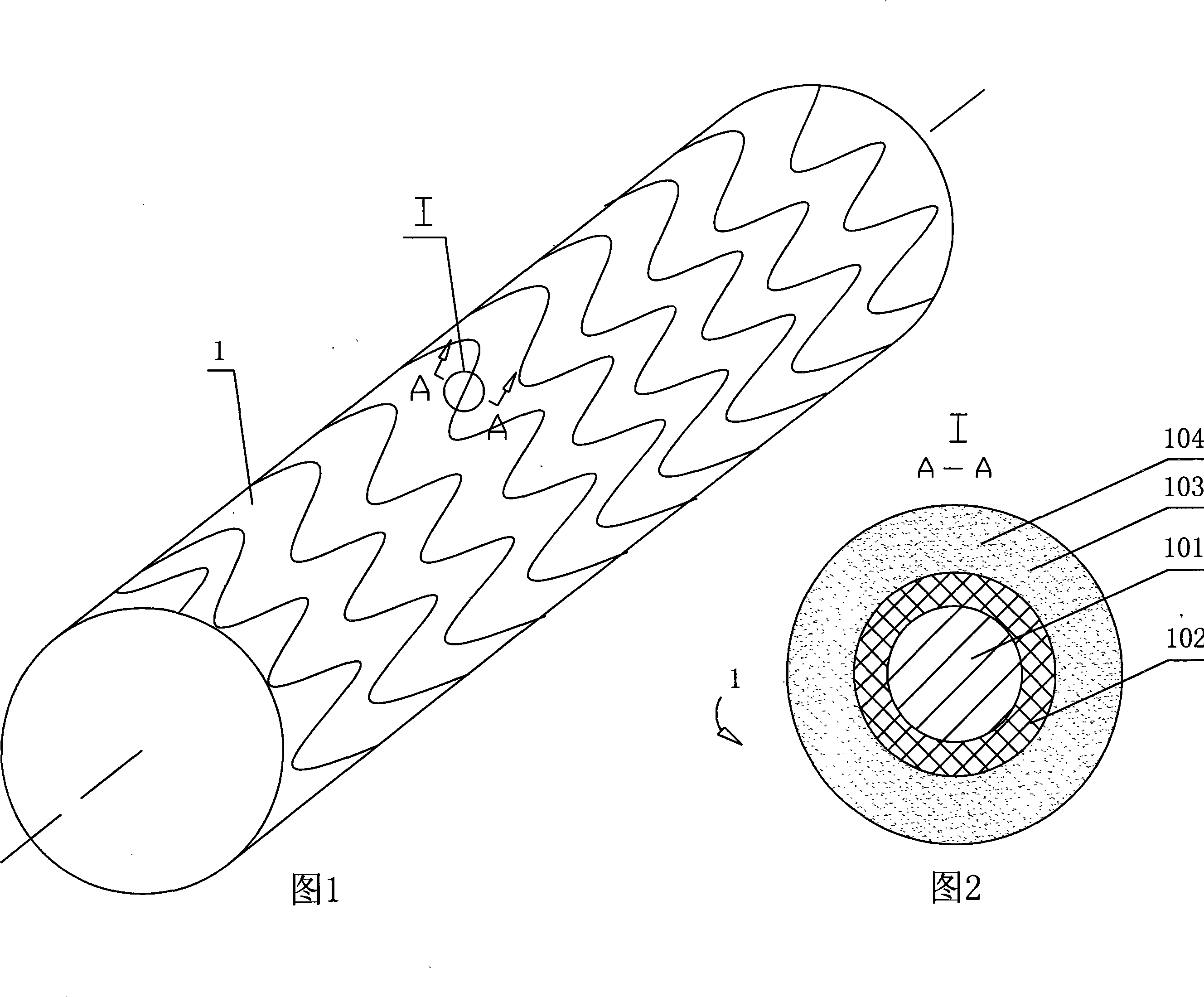

Controlled degradation magnesium alloy coating bracket and preparation thereof

InactiveCN101214396AImprove mechanical propertiesExcellent pharmacological propertiesAnodisationStentsSurface cleaningPolymer chemistry

The invention relates to a controlled degradation magnesium alloy coating stent and a preparation method. The stent body is made of medical high purity magnesium or magnesium alloy by mechanical processing or laser carving; the stent body is provided with a drug-loading coating which bears curative drug; the surface of the stent body is provided with an anti-corrosive coating; the surface of the anti-corrosive coating is provided with a degradable polymer film drug-loading coating; the preparation method includes surface cleaning, preparation of the degradable polymer film drug-loading coating, and application of curative drug; through (1)surface cleaning, (2)preparation of the degradable polymer film drug-loading coating, and (3)application of curative drug, an oxide film is formed on the surface; different drugs and dosage can be fixed by regulating the molecular weight and the thickness of the polymer layer, the drug-loading quantity is more than 30 percent, which improves the fixed stability of the drug, greatly reduces the degradation speed of the magnesium alloy and controls release of the drug, delays corrosion of the magnesium alloy, extends the service life of the stent, is safe in use, and meets the clinical requirement.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

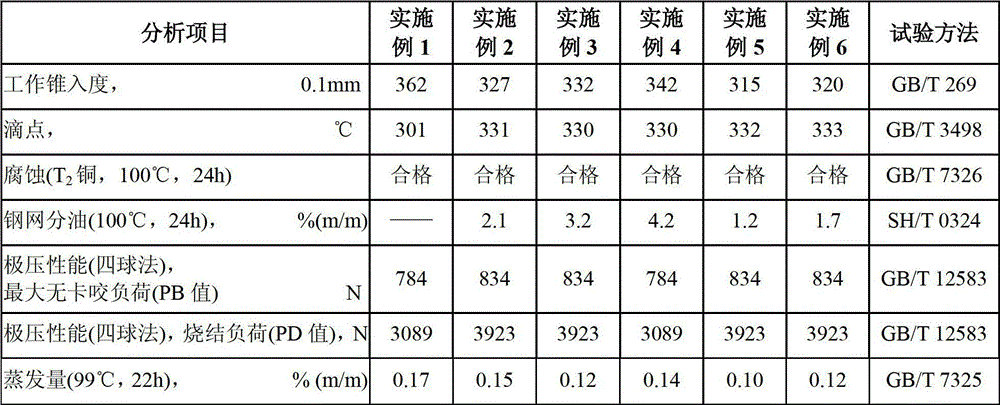

High-temperature-resistant extreme pressure type lubricating grease composition and preparation method

The invention relates to a high-temperature-resistant extreme pressure type lubricating grease composition and a preparation method of the high-temperature-resistant extreme pressure type lubricating grease composition. The preparation method comprises steps as follows: mixing high-base-value calcium naphthenate, high-base-value sulfoacid calcium, and 35 to 65% of base oil; agitating; then adding a transforming agent; heating to reach 75 to 105 DEG C; maintaining the temperature for 40 to 120 minutes until the materials are thick; continuously heating the material until the temperature reaches more than 200 DEG C; removing the water completely, wherein the rest base oil is added during heating; continuously heating the materials until the temperature reaches 220 to 240 DEG C; agitating for 5 to 30 minutes at constant temperature until the materials are thick; and cooling and homogenizing to obtain the product as requirements. The lubricating grease prepared by the preparation method is high in comprehensive performance, excellent in high-temperature resistance, and high in extreme-pressure wear resistance, and can be used for lubricating high-temperature equipment with high load; and the requirements on use in high-temperature and high-load lubricating situations in the ferrous metallurgy industry can be met.

Owner:CHINA PETROLEUM & CHEM CORP

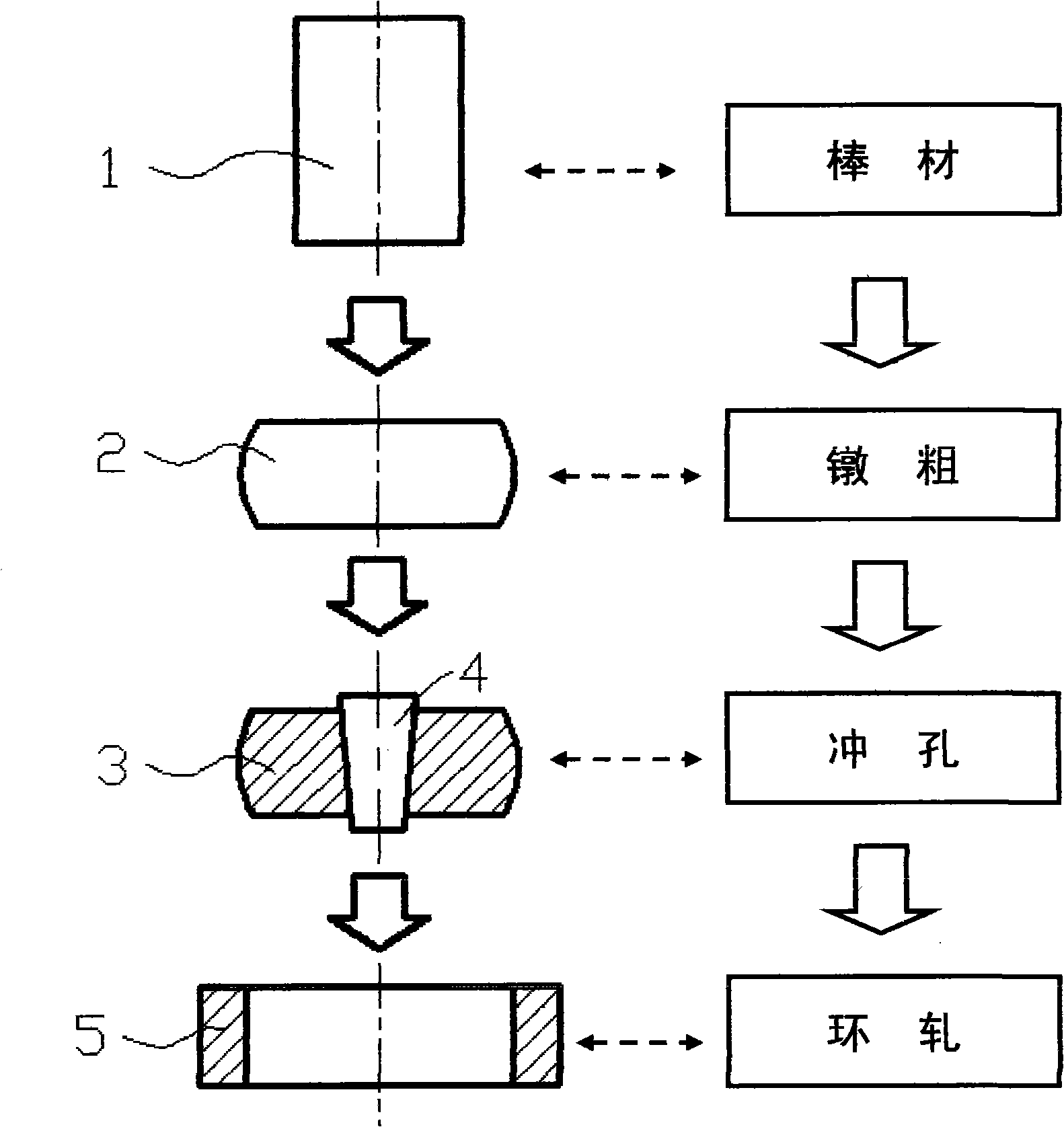

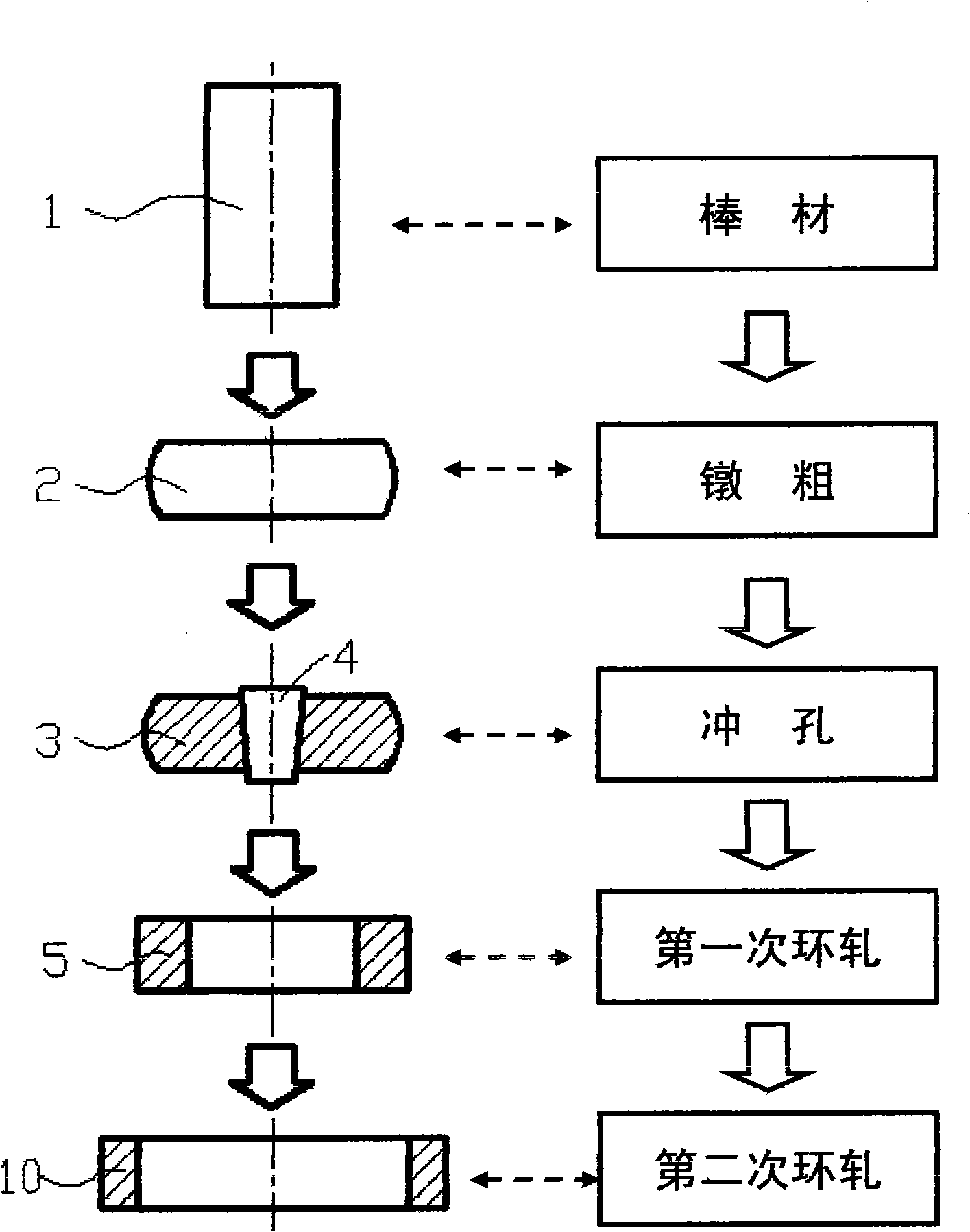

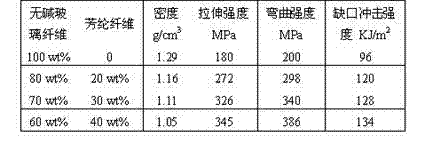

Method for rolling and shaping stainless steel special-shaped ring forging

The invention discloses a rolling and shaping method for a stainless steel heterotypic ring forging in order to obtain the alloy heterotypic ring forgings with excellent tissues and properties as well as realize accurate rolling. The method includes the following steps: alloy bar material is heated, carried out continuous upsetting and deformed by 50 to 55 percent, so as to be made into a solid cake and then is punched again to lead the alloy bar material to be made into a hollow round cake after the aperture dimension of the alloy bar material is 30 to 35 percent of the dimension of the outer diameter thereof; a rectangle pre-rolling blank is obtained after the hollow round cake is heated, rolled circularly and deformed by 40 to 45 percent; the pre-rolling blank is heated and arranged in a rolling die of a ring rolling machine and forms a heterotypic ring forging after being rolled and deformed by 50 to 55 percent in a section groove. When in expansion, the broadening speed of the pre-rolling blank along the radial direction is 2mm / s to 15mm / s with radial rolling force of 20000kg to 120000kg. The method is mainly used for the shaping of the heterotypic ring forging of an aeroengine. The method can be adopted to obtain the heterotypic ring forging that is arranged in a flow line along the outline of a part.

Owner:GUIZHOU ANDA AVIATION FORGING

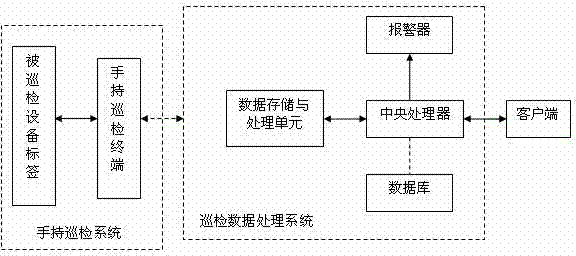

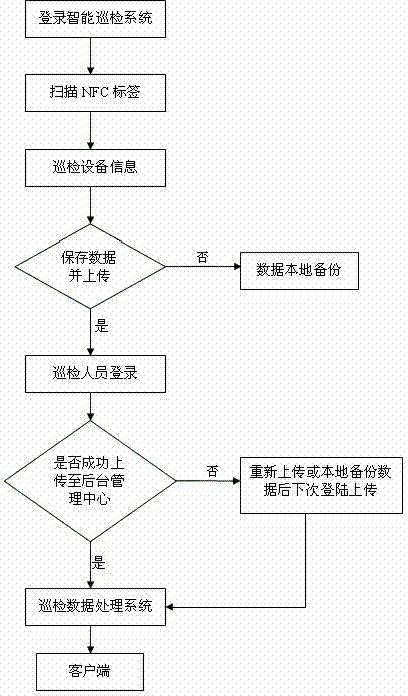

Intelligent mobile phone routing inspection system and intelligent mobile phone routing inspection method based on near field communication (NFC)

InactiveCN103093511AMeet the use requirementsRealize paperless operationRegistering/indicating working of machinesData informationPaperless office

The invention discloses an intelligent mobile phone routing inspection system and an intelligent mobile phone routing inspection method based on near field communication (NFC). The routing inspection system comprises a handheld routing inspection system and a background management center, wherein the background management center comprises a routing inspection data processing system and a client; the handheld routing inspection terminal can communicate with the routing inspection data processing system through a mobile Internet in real time; and the routing inspection data processing system exchanges data with the client through a local network. The routing inspection method comprises the following steps that a routing inspector scans an NFC label of equipment subjected to routing inspection by an NFC intelligent mobile phone, automatically records the routing inspection time through a cloth arranged in the mobile phone, directly types state information of the routing inspection equipment into the mobile phone, selects a state information storage or sending button, confirms information of the inspector and uploads data information to the background management center and the routing inspection data processing system for processing through the mobile Internet. According to the system and the method, paper-free work for routing inspection and intelligent management can be realized; the cost is reduced; the routing inspection efficiency and the responsibility of a worker are improved; and the mistake probability is reduced.

Owner:成都宇泰达科技有限公司

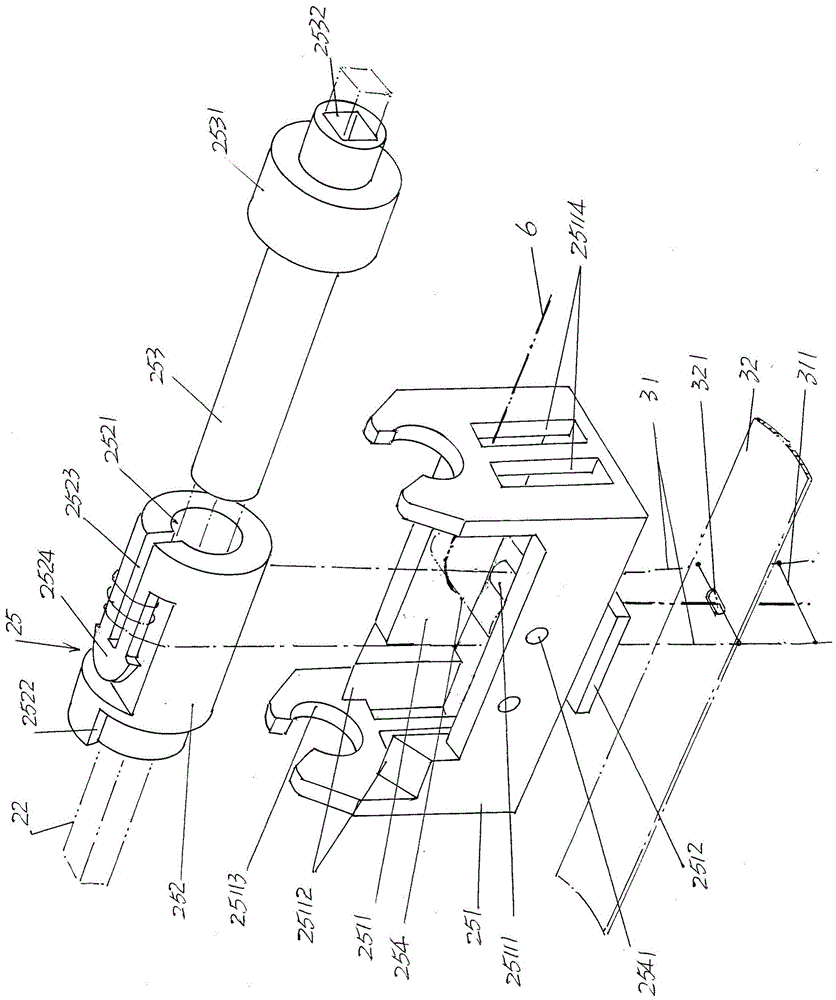

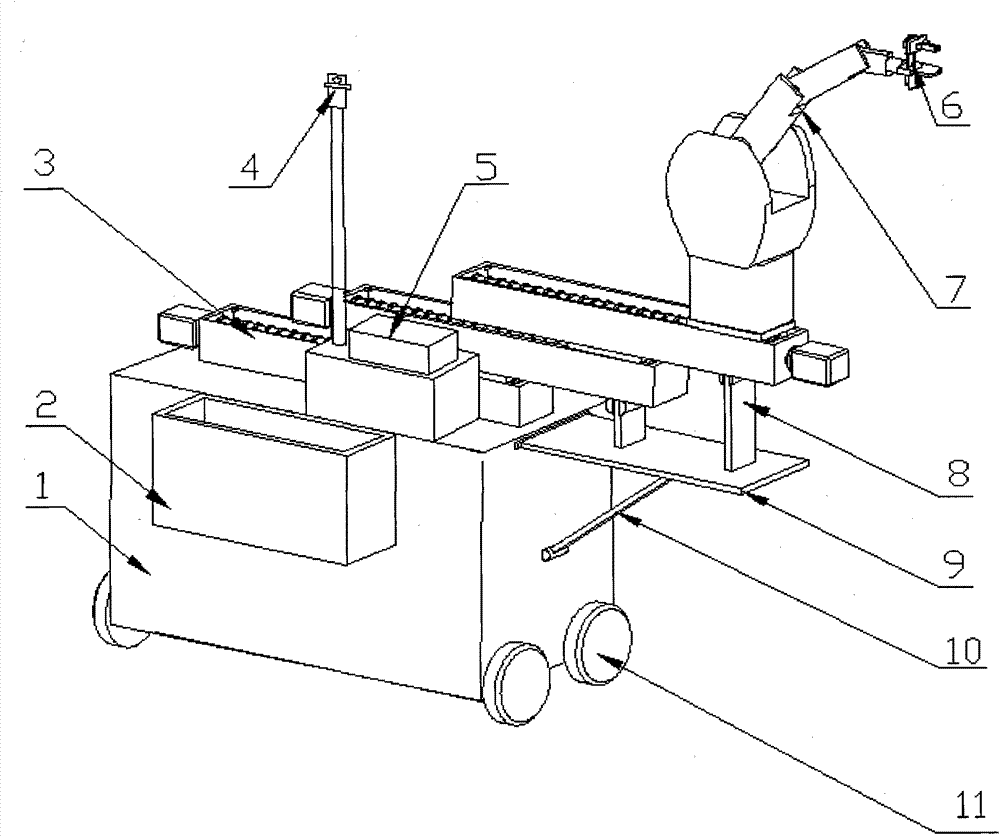

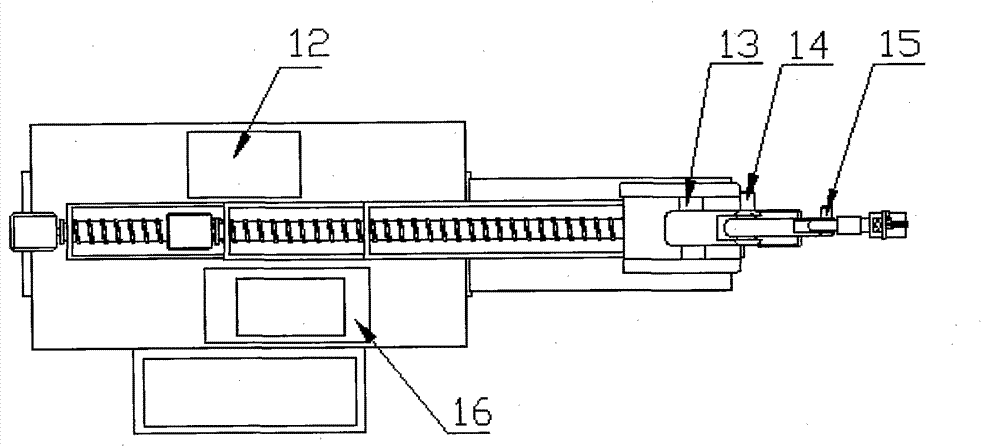

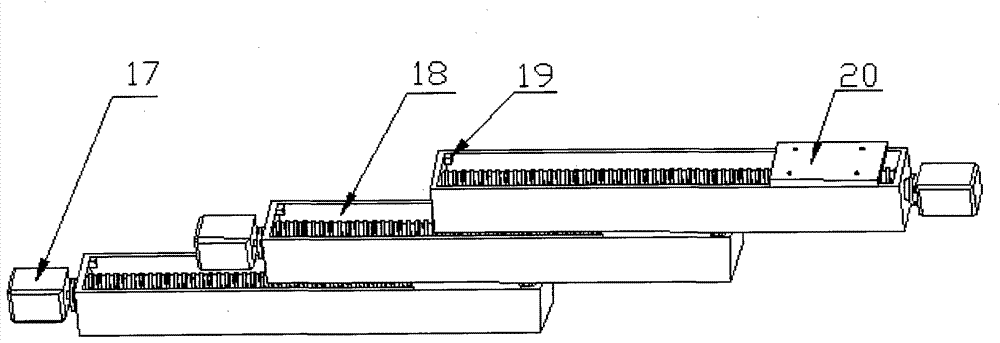

Picking robot and picking method for kiwi fruits

InactiveCN103749094AImprove environmental adaptabilityImprove work efficiencyPicking devicesActinidiaData acquisition

The invention discloses a picking robot and a picking method for kiwi fruits. The picking robot for the kiwi fruits comprises a machinery execution system and a control system, and is characterized in that the machinery execution system comprises a car body, a telescopic slide platform, a five freedom degree picking robot arm and a two finger type end actuator, and the control system comprises an industrial personal computer, a motion control card, a data acquisition card, an image acquisition card, a servo motor driver, a binocular video camera, an infrared sensor, a pressure sensor, an electric control cabinet and a control circuit. The picking robot and the picking method for the kiwi fruits use a building block design philosophy to integrate the two finger type end actuator, the five freedom degree picking robot arm, the telescopic slide platform and a sensor system together and integrate image acquisition and feature extraction of fruits and barriers, intelligent mobility of the telescopic slide platform, counterguard and fruit positioning of the five freedom degree picking robot arm and grab motions of the two finger type end actuator together, and therefore achieve mechanization and automation of picking of the kiwi fruits, improve labor productivity, reduce production cost, and guarantee harvest quality of the kiwi fruits.

Owner:NORTHWEST A & F UNIV

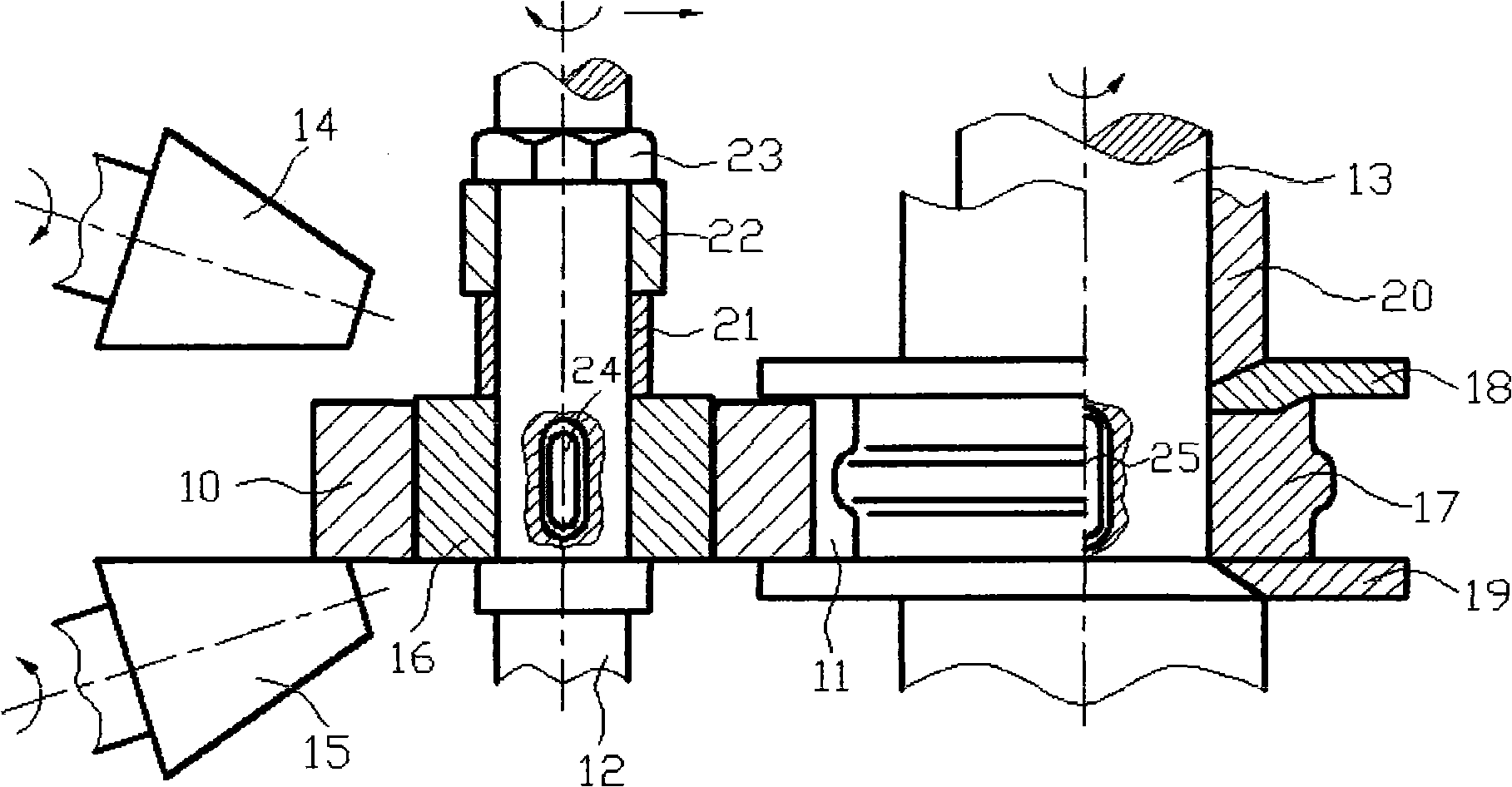

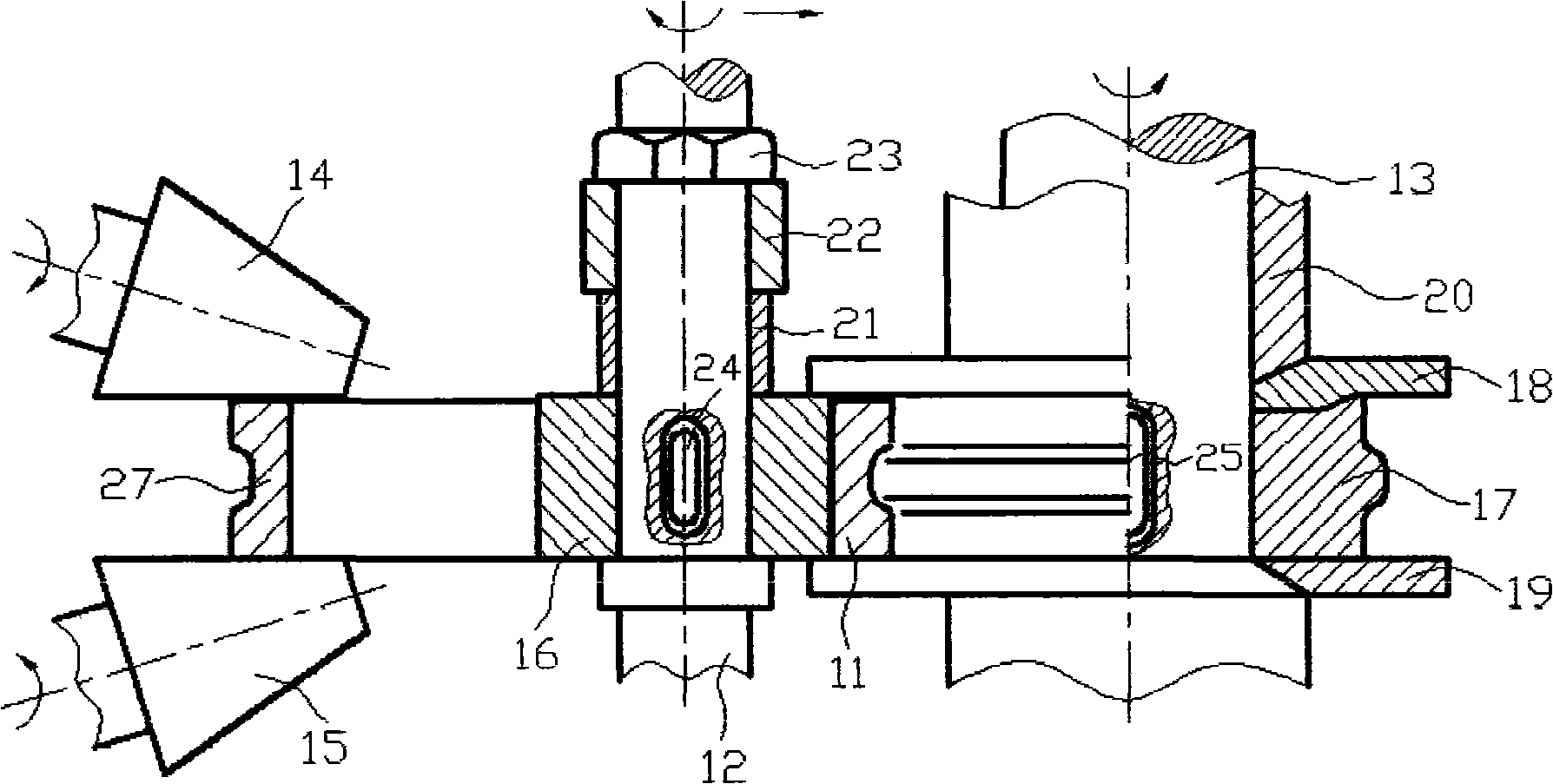

Method for rolling and shaping titanium alloy special-shaped ring forging

ActiveCN101279345AReduce manufacturing costHigh dimensional accuracyMetal rollingTitanium alloyAbnormal shaped

The invention discloses a rolling and shaping method for a titanium alloy heterotypic ring forging in order to obtain the alloy heterotypic ring forgings with excellent tissues and properties as well as realize accurate rolling. The method includes the following steps: alloy bar material is heated, carried out continuous upsetting and deformed by 65 to 70 percent, so as to be made into a solid cake and then is punched again to lead the alloy bar material to be made into a hollow round cake after the aperture dimension of the alloy bar material is 30 to 35 percent of the dimension of the outer diameter thereof; a rectangle ring blank is obtained after the hollow round cake is heated, rolled circularly and deformed by 25 to 30 percent; a rectangle pre-rolling blank is obtained after the rectangle ring blank is heated, rolled circularly and deformed by 25 to 30 percent again; the pre-rolling blank is heated and arranged in a rolling die of a ring rolling machine and becomes a heterotypic ring forging after being rolled and deformed by 40 to 45 percent in a section groove of the die. When in expansion, the broadening speed of the pre-rolling blank along the radial direction is 2mm / s to 15mm / s with a radial rolling force of 40000kg to 220000kg. The method is mainly used for the shaping of the heterotypic ring forging of an aeroengine or a gas turbine. The method can be adopted to obtain the heterotypic ring forging that is arranged in a flow line along the outline of a part.

Owner:GUIZHOU ANDA AVIATION FORGING

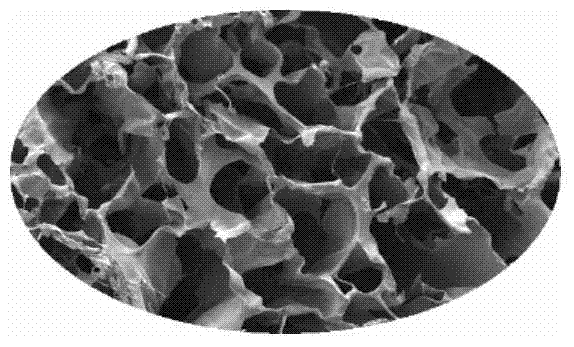

Porous complex gel-nanofiber oxygen permeation dressing and preparation method thereof

ActiveCN104491914AHigh oxygen permeabilityImprove antibacterial propertiesAbsorbent padsBandagesWound dressingFreeze-drying

The invention discloses a porous complex gel-nanofiber oxygen permeation dressing and a preparation method thereof. The method comprises the following steps: obtaining a collagen nanofiber membrane by adopting a collagen solution by virtue of an electrostatic spinning method; performing chemical crosslinking on two natural and non-toxic macromolecule polysaccharides such as chitosan and alginic acid, and preparing complex gel; and preparing the porous sponge-nanofiber double-layer composite material in a freeze-drying mode, wherein the upper gel layer of the dressing is in a sponge state during drying and is in a gel state after moisture absorption. The biological wound dressing is prepared under the condition that any toxic chemical crosslinking agent is not added, the process is simple, and the safety is high. The prepared biological wound dressing disclosed by the invention has the characteristics of excellent oxygen permeation performance, water-absorbing quality, water permeability, moisture penetrability and high biocompatibility, a physiological wet environment of the wound surface can be maintained, wound healing and effective haemostasis are promoted, wound infection can be avoided, the recovery is accelerated, the wound surface can be effectively recovered, and the dressing is applied to multiple wound surfaces such as trauma, burns and ulceration.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

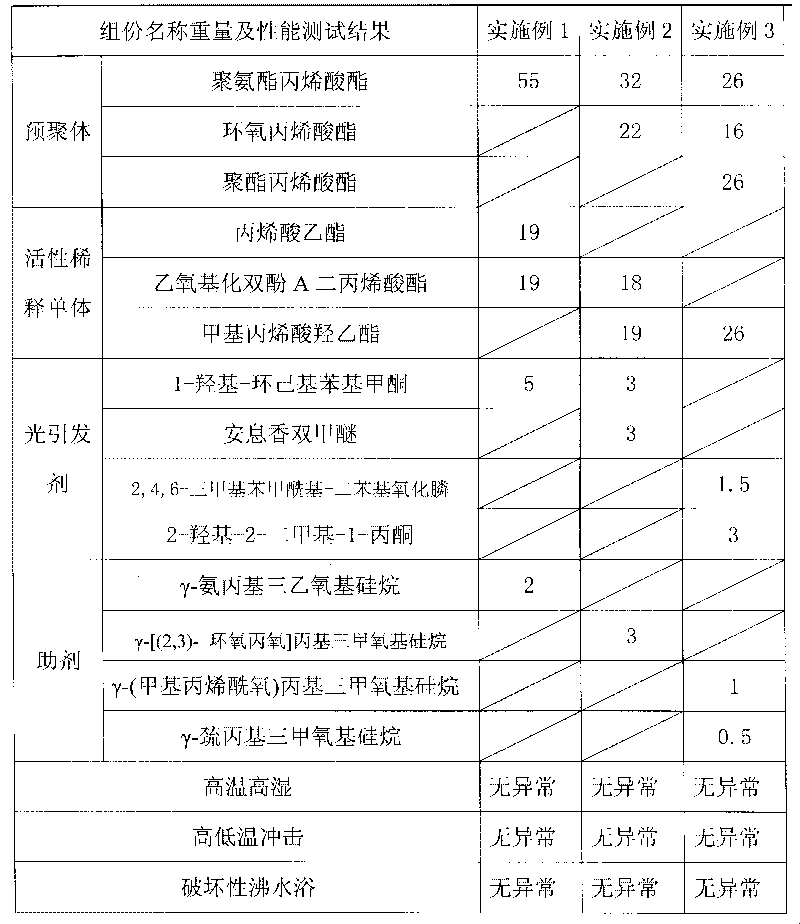

UV curing packaging adhesive for liquid crystal display

InactiveCN101724374AFast curingCuring shrinkage is smallOther chemical processesPolyureas/polyurethane adhesivesPrepolymerPhotoinitiator

The invention provides a UV curing packaging adhesive for a liquid crystal display. Based on 100 weight parts, the adhesive consists of following components: 40 to 70 parts of prepolymer, 20 to 50 parts of active diluent monomer, 1 to 8 parts of photoinitiator, and 0.1 to 5 parts of assistant. The prepolymer is one or a mixture of more of the urethane acrylate, epoxy acrylate and polyster acrylate. The UV curing packaging adhesive for the liquid crystal display has the characteristics of high curing speed, low shrinkage rate and excellent damp heat resistance.

Owner:BEIJING HYSTIC NEW MATERIALS

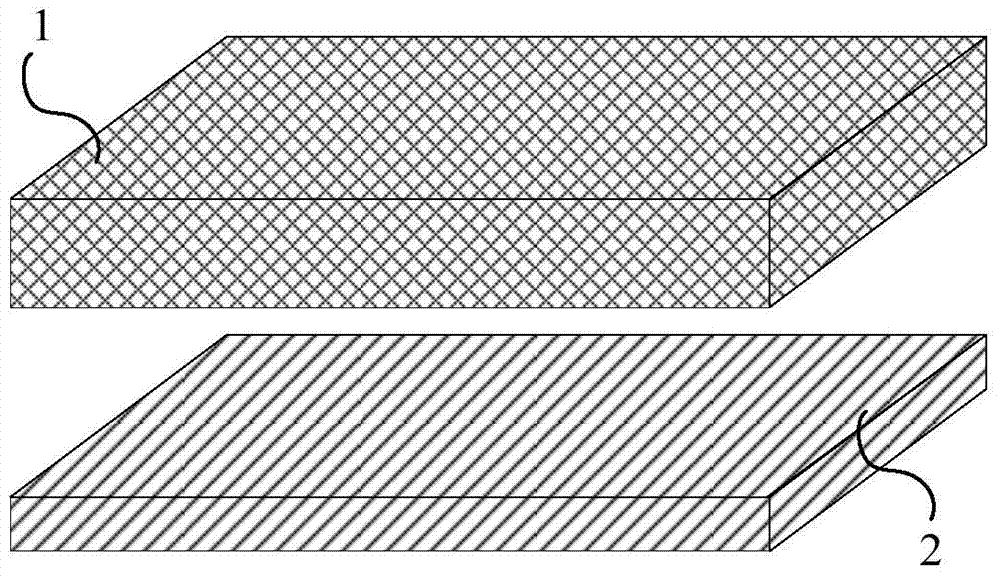

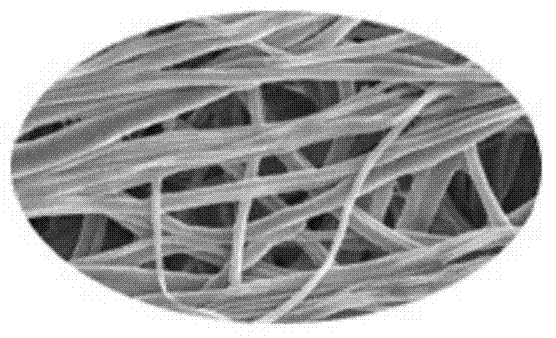

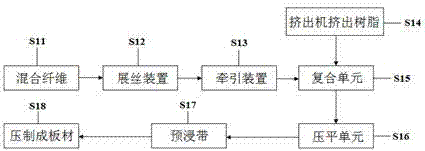

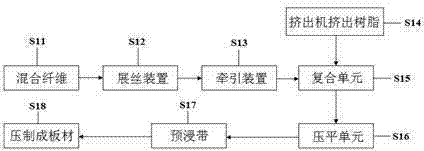

High-performance continuous synthetic fiber reinforced thermoplastic composite and preparation method thereof

The invention discloses a high-performance continuous synthetic fiber reinforced thermoplastic composite and a preparation method thereof. The composite comprises the following components including, by weight, 35-60 parts of reinforcing filler, 35-60 parts of thermoplastic resin and 0.5-5 parts of aids, wherein the reinforcing filler includes synthetic fibers which include, by weight, 55-95% of inorganic fibers and 5-45% of organic fibers. The continuous inorganic fibers and the high-performance organic fibers are mixed to reinforce the thermoplastic resin so as to improve the performance of the composite, and advantages of various fibers are integrated to obtain the continuous fiber reinforced thermoplastic composite which is light in weight, high in strength and high in modulus while impact resistance and fatigue resistance are particularly improved. Mixing a small quantity of expensive high-performance organic fibers with the inorganic fibers can achieve better enhancing effect while cost is effectively reduced, so that higher using requirements of materials can be met.

Owner:LIAONING LIAOJIE SCI & TECH

Method for rolling and shaping aluminum alloy special-shaped ring forging

InactiveCN101279344AReduce manufacturing costHigh dimensional accuracyMetal rollingAbnormal shapedAero engine

The invention discloses a rolling and shaping method for an aluminum alloy heterotypic ring forging in order to obtain the alloy heterotypic ring forgings with excellent tissues and properties as well as realize accurate rolling. The method includes the following steps: alloy bar material is heated, carried out continuous upsetting and deformed by 50 to 55 percent, so as to be made into a solid cake and then is punched again to lead the alloy bar material to be made into a hollow round cake after the aperture dimension of the alloy bar material is 30 to 35 percent of the dimension of the outer diameter thereof; a rectangle pre-rolling blank is obtained after the hollow round cake is heated, rolled circularly and deformed by 40 to 45 percent; the pre-rolling blank is heated and arranged in a rolling die of a ring rolling machine and forms a heterotypic ring forging after being rolled and deformed by 50 to 55 percent in a section groove. When in expansion, the broadening speed of the pre-rolling blank along the radial direction is 2mm / s to 15mm / s with a radial rolling force of 20000kg to 120000kg. The method is mainly used for the shaping of the heterotypic ring forging of an aeroengine. The method can be adopted to obtain the heterotypic ring forging that is arranged in a flow line along the outline of a part.

Owner:GUIZHOU ANDA AVIATION FORGING

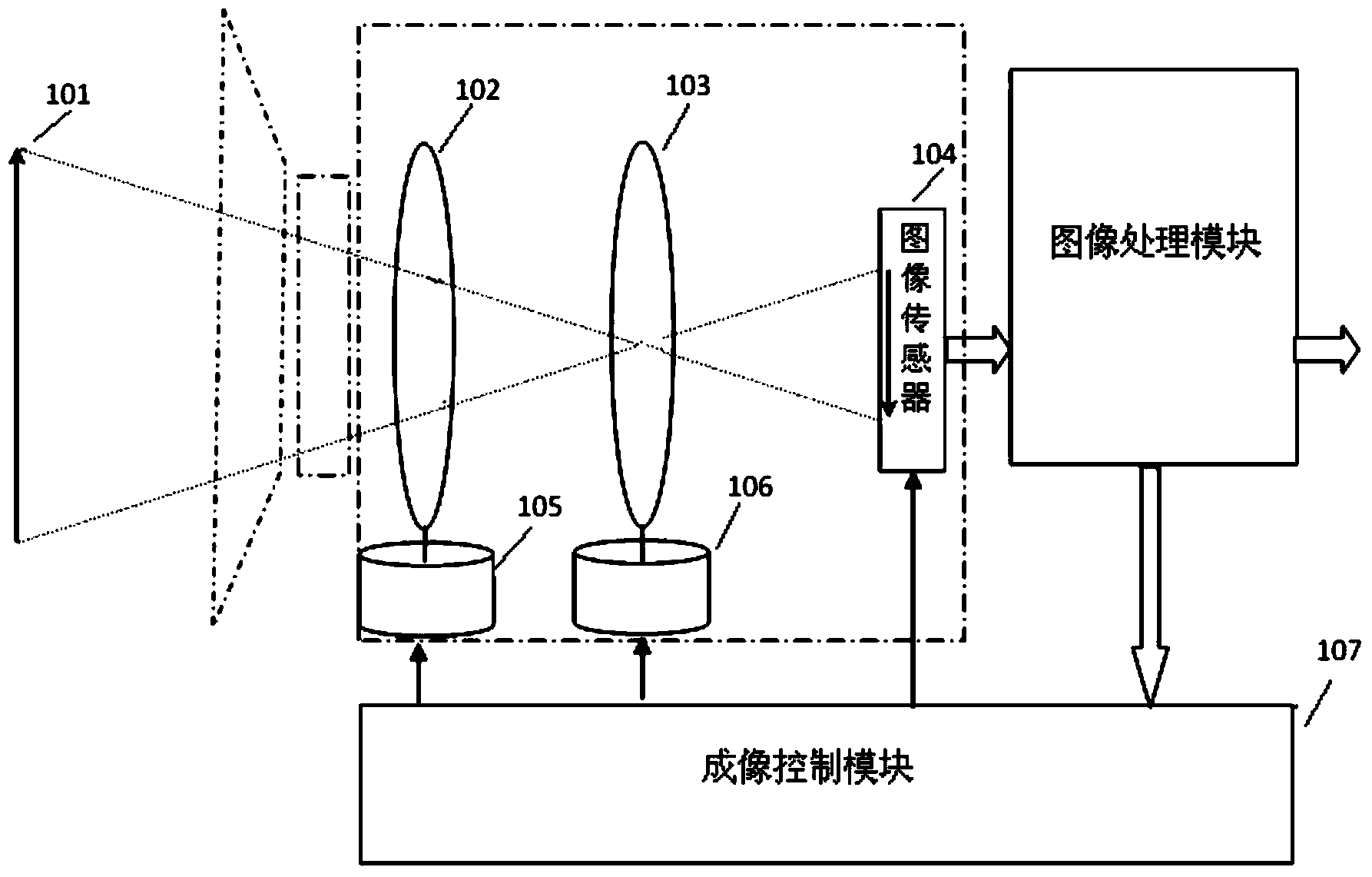

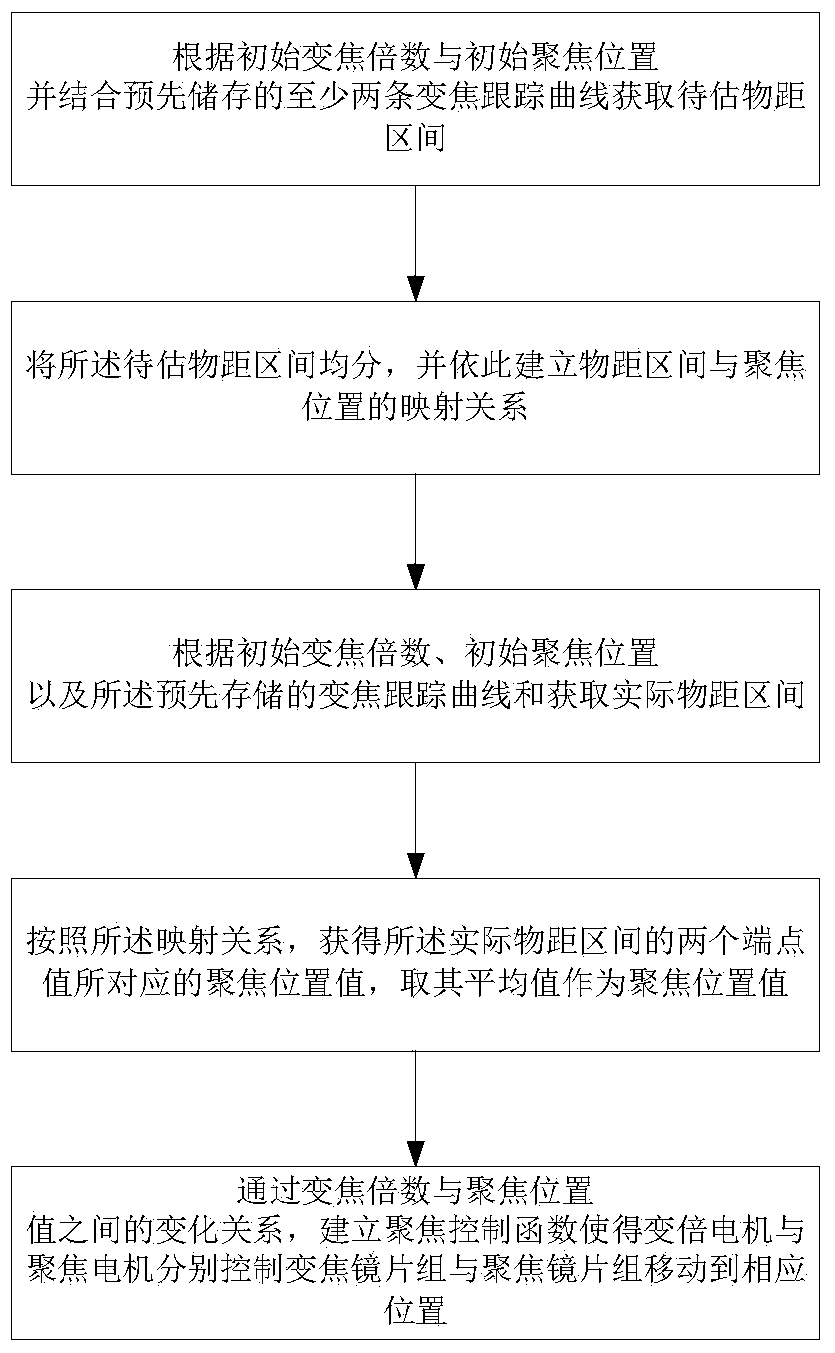

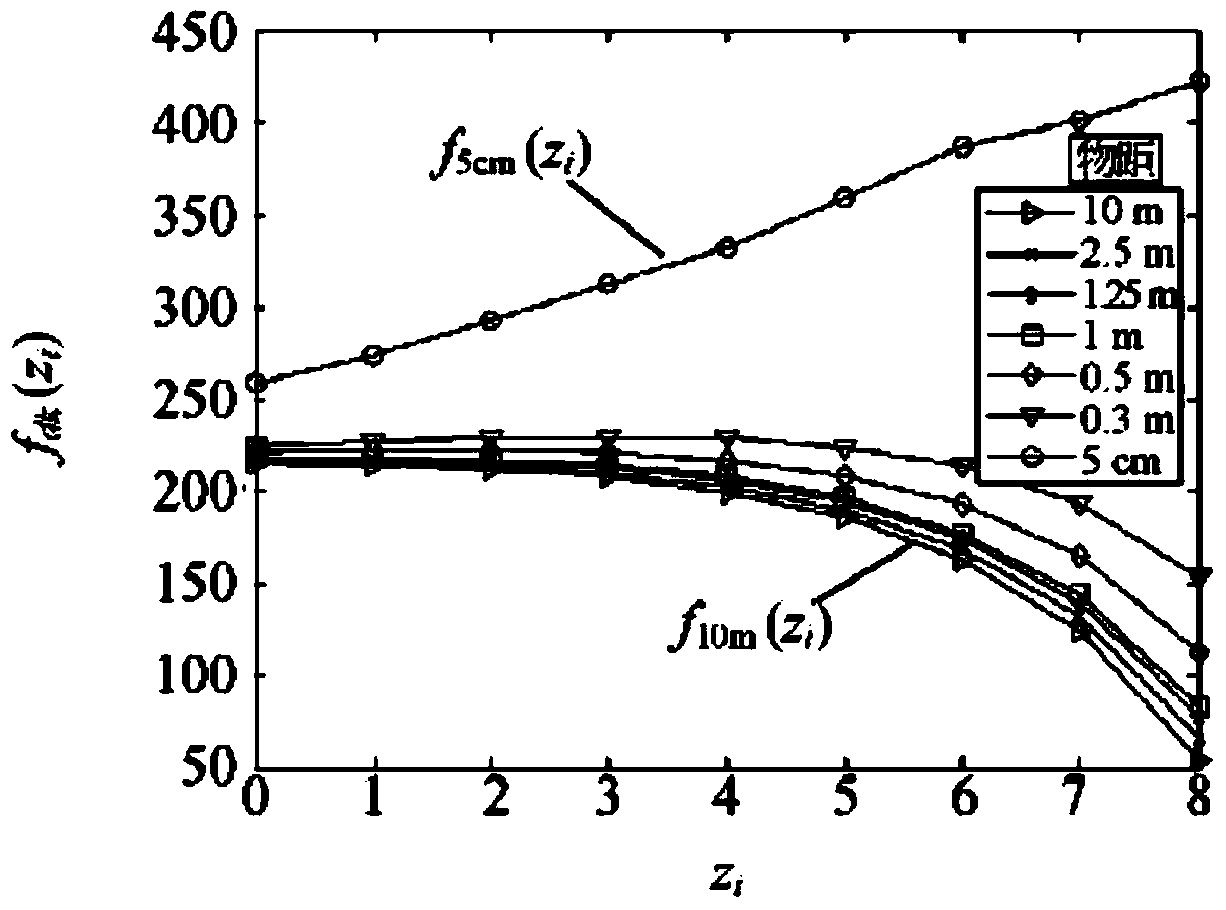

Method and system achieving integrated camera automatic focusing

InactiveCN103546692AImplement mobile controlMeet real-time requirementsTelevision system detailsColor television detailsComputer scienceMobility control

The invention provides a method and system for achieving integrated camera automatic focusing, and provides a zooming tracking method based on a relationship type, namely for a shot object at a fixed object distance, according to the initial zooming multiple, the value of an initial focusing position and a plurality of zooming tracking curves stored in advance, the mapping relation between the object distance interval and the focusing position is constructed, and the position to be focused is calculated in real time. Then, a gradient control function obtained by the combination of the statistical law of a lot of experimental data is utilized to achieve mobility control over a zooming motor and a focusing motor, the value of the position to be focused is improved and amended to a certain degree, the value of the position to be focused is closer to a real zooming tracking curve, and an automatic focusing effect is more accurate. Meanwhile, the zooming tracking curves are not needed to be stored in advance, all the zooming tracking curves corresponding to different object distances are not needed to be calculated point by point, an algorithm is simple, it is possible that the zooming speed meets a real-time property, and the focusing effect can meet the requirement for clearness in the whole process.

Owner:SUZHOU KEDA TECH

High magnetic induction and high grad non-orientation electrical steel and its making process

InactiveCN1888112AReduce the amount of solid solutionReduce precipitationFurnace typesHeat treatment furnacesElectrical steelGrain structure

The present invention is high magnetic induction and high grade non-orientation electrical steel and its making process. The high magnetic induction and high grade non-orientation electrical steel consists of C not more than 0.0050 wt%, N not more than 0.0030 wt%, Si 1.50-2.50 wt%, Al 0.80-1.30 wt%, Mn 0.20-0.50 wt%, P not more than 0.030 wt%, S not more than 0.005 wt%, Sb 0.03-0.10 wt% or Sn 0.05- 0.12 wt%, and B 0.0005-0.0040 wt%, except Fe and inevitable impurities. Its making process includes initial rolling and high temperature winding to obtain ideal hot rolled steel belt structure; cold rolling to provide the energy for crystal grain growth in re-crystallizing annealing, and re-crystallizing annealing in controlled temperature to obtain ideal crystal grain structure. It has excellent surface quality, high magnetic induction and low iron loss, and is suitable for use in high efficiency motor iron core.

Owner:BAOSHAN IRON & STEEL CO LTD

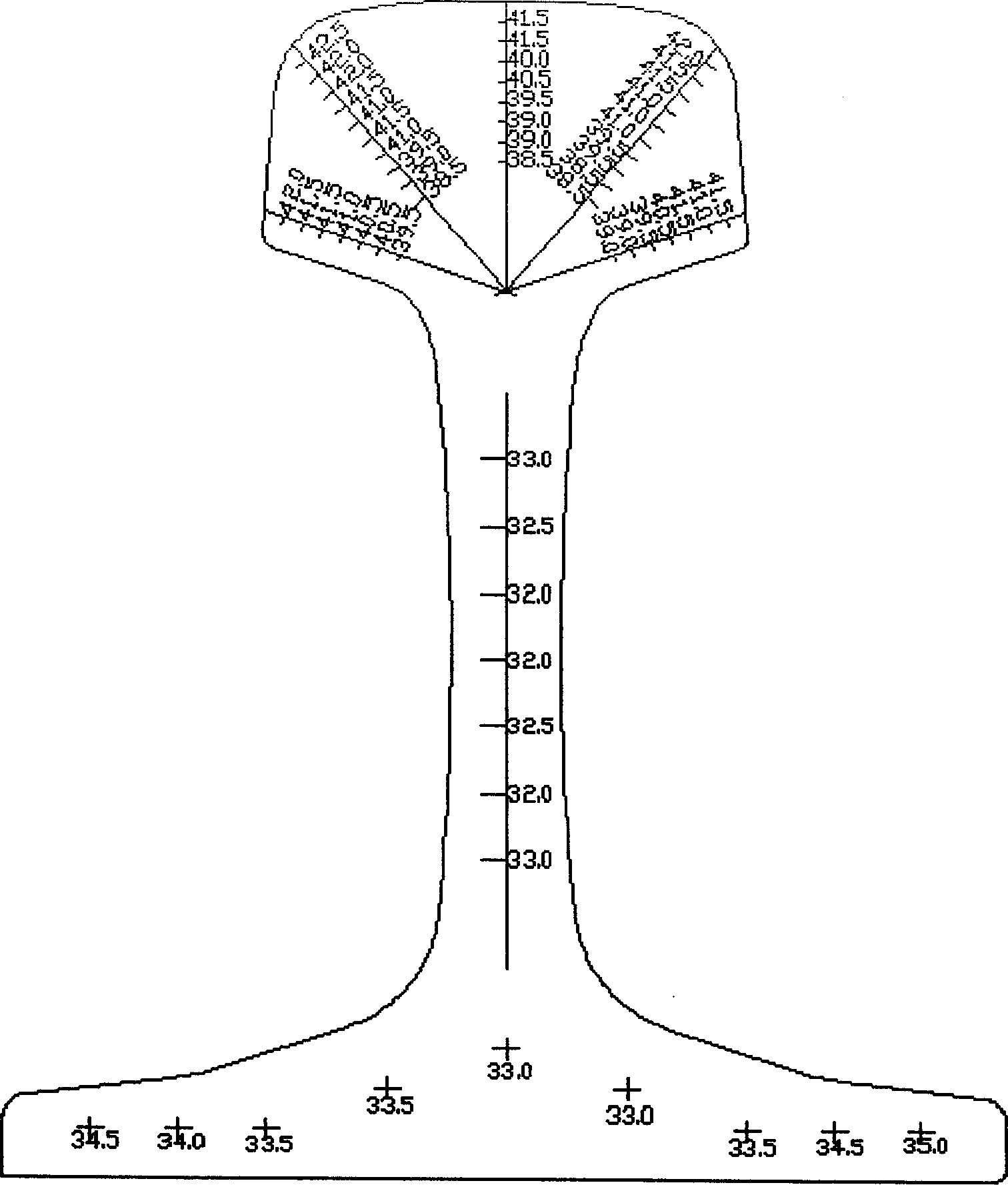

Pealite like thermal treating steel rail and producing method thereof

ActiveCN1793403AMeet the use requirementsImprove wear resistanceFurnace typesHeat treatment furnacesChemical compositionFree cooling

The invention relates to pearly heat-treated steel rail and its manufacturing method. Its chemical composition percentage by weight includes: C:0.70%-0.95%, Si:0.20%-1.10%, Mn:0.50%-1.50%, V:0.01%-0.20%, Cr:0.15%-1.20%, P: not less than 0.035%, S:not less than 0.035%, and Al: not less than 0.005%. The method includes the following steps: smelting; casting; rolling; cooling from 650-880 centigrade degree to 400-500 centigrade degree or room temperature with 1-10 centigrade degree per second; heating to 850-1100 centigrade degree; natural cooling to 650-880 centigrade degree; cooling to 400-500 centigrade degree with 1-10 centigrade degree per second than stop cooling; and natural laying. The formed steel rail has good wear resistance.

Owner:PANZHIHUA IRON AND STEEL

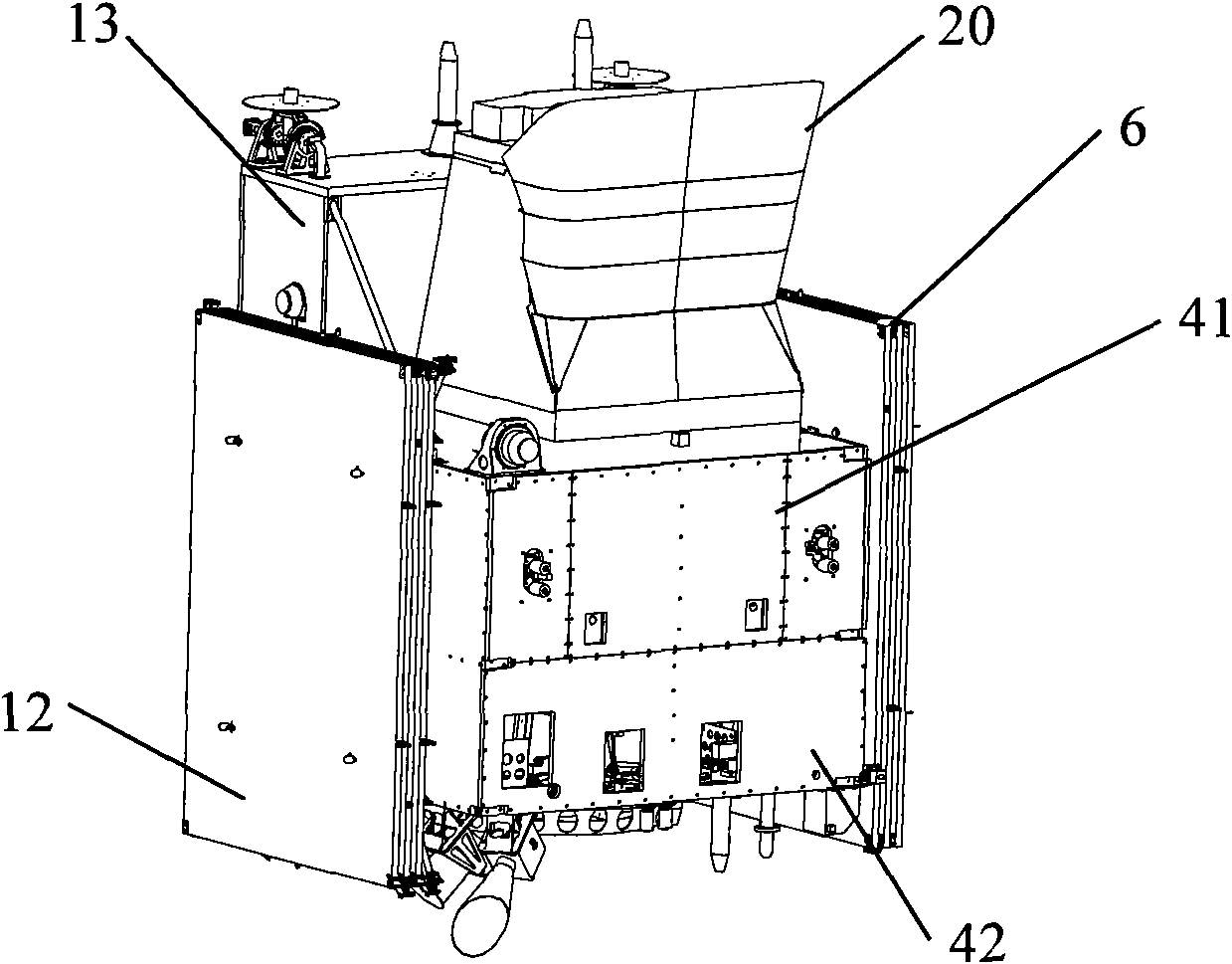

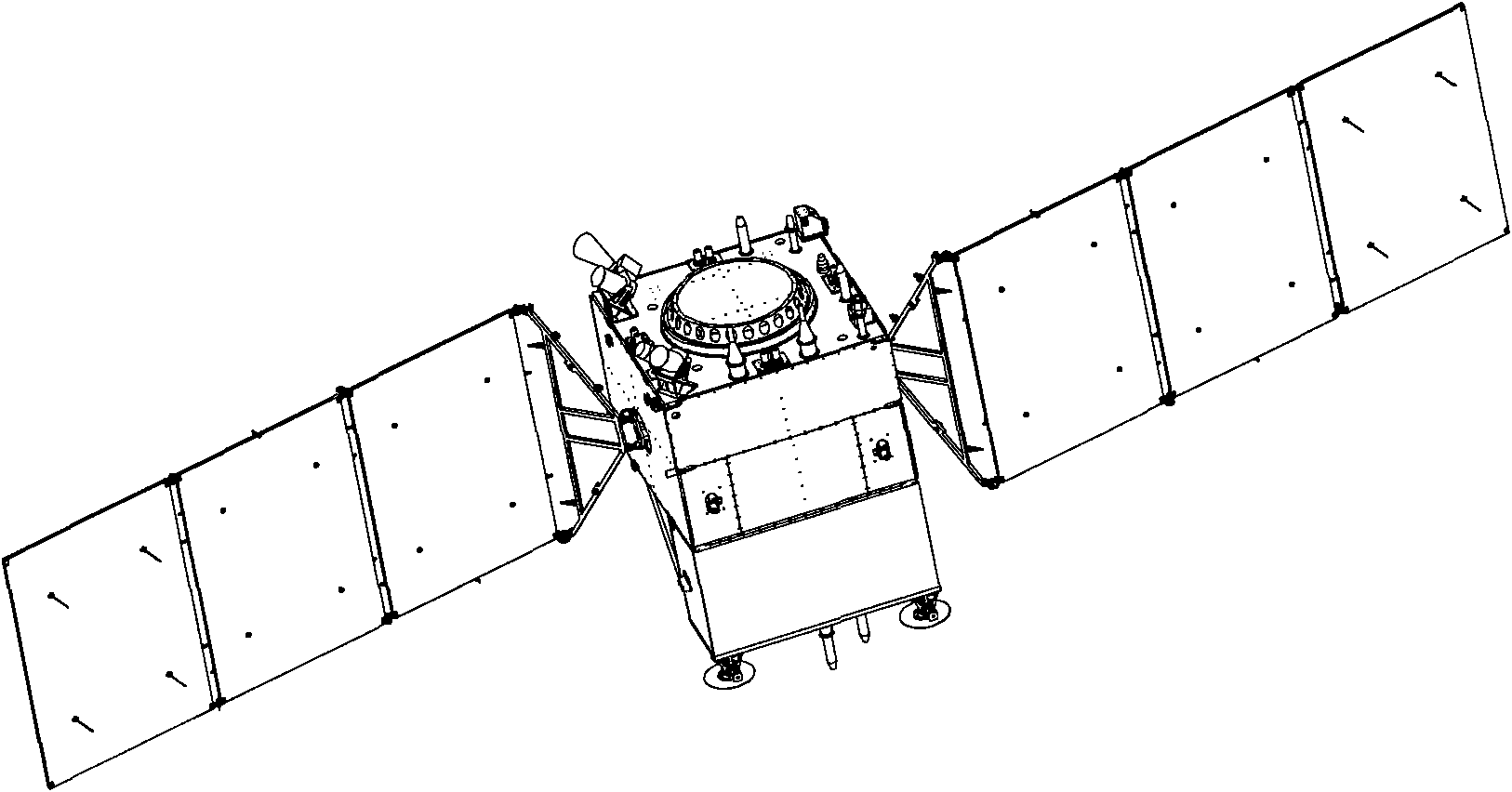

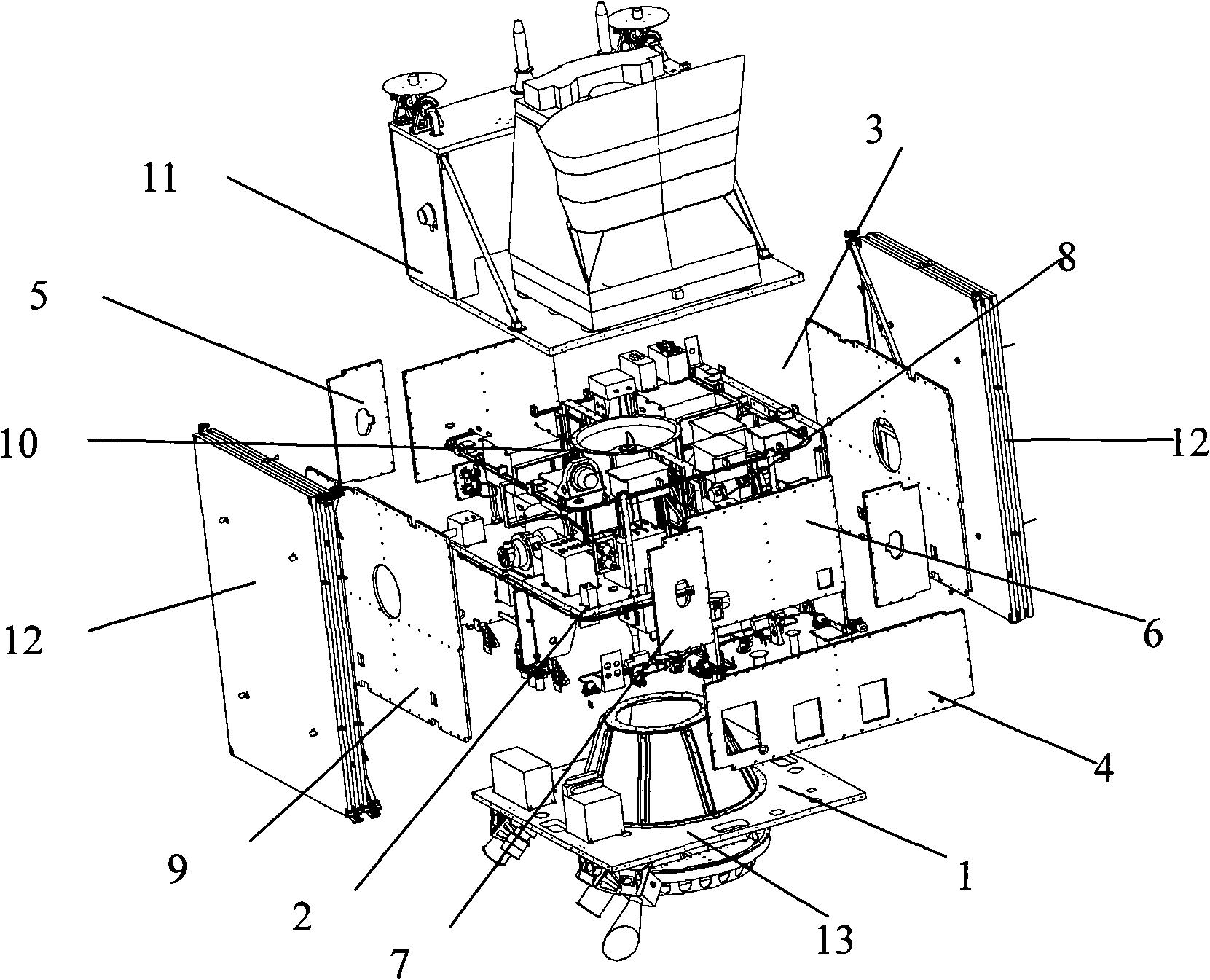

Configuration for low-earth-orbit remote sensing satellite and mounting method thereof

InactiveCN102372092AStable structureHigh precision requirementsArtificial satellitesCentral forceLow earth orbit

The invention provides a configuration for a low-earth-orbit remote sensing satellite, which comprises a base plate, a middle plate, a top plate, a plurality of transverse lateral plates and upright lateral plates, wherein the base plate, the middle plate and the top plate are enclosed into a sealed space by the transverse lateral plates and the upright lateral plates; a central force-bearing cylinder is arranged in the sealed space; corresponding solar cell arrays are arranged on the two sides of the sealed space; a supporting rod is connected between the base plate and the middle plate; four isolating plates are uniformly distributed and are arranged between the middle plate and the top plate; a payload bay is connected above the top plate; and an overskirt is connected to the bottom of the base plate. The configuration for the low-earth-orbit remote sensing satellite has a stable structure, is capable of carrying a large-size and large-mass load, and is high in adaptability for the characteristics of large volume, heavy weight, high precision demand and difficulty in mounting of the present payload.

Owner:SHANGHAI SATELLITE ENG INST

Special material for antistatic impact fire resistant polyethylene pipe

InactiveCN1657561AImprove antistatic performanceMeet the use requirementsTubular articlesPolymer scienceAntistatic agent

An antistatic, anti-impact and flame-retarded polyethene used for pipeline is proportionally prepared from high-density polyethene, antistatic agent, flame retarder, flame-retarded synergist, toughening agent, optical stabilizer and antioxidizing agent through mixing part of polyethene with others, extruding out to become particles, mixing with rest of polyethene, dual-screw extruding out, cooling, drying and cutting to become particles.

Owner:QINGDAO UNIV OF SCI & TECH

Folium artemisiae argyi incense

InactiveCN101601866AGood mosquito repellentStrong enoughBiocidePest repellentsChemistryPotassium nitrate

The invention provides folium artemisiae argyi incense with excellent effect of repelling mosquitoes. 50 to 95 weight percent of folium artemisiae argyi powder, 4 to 47 weight percent of debregeasia orientalis skin powder and 0.5 to 3 weight percent of potassium nitrate are evenly mixed with water, and then the mixed solution is formed and dried to prepare the folium artemisiae argyi incense. Preferably, no more than 20 weight percent of starch is also contained. The incense adopting the formula has the advantages of good mosquito repellent effect, air sterilization, enough strength, low raw material consumption and convenient production.

Owner:曾阳平

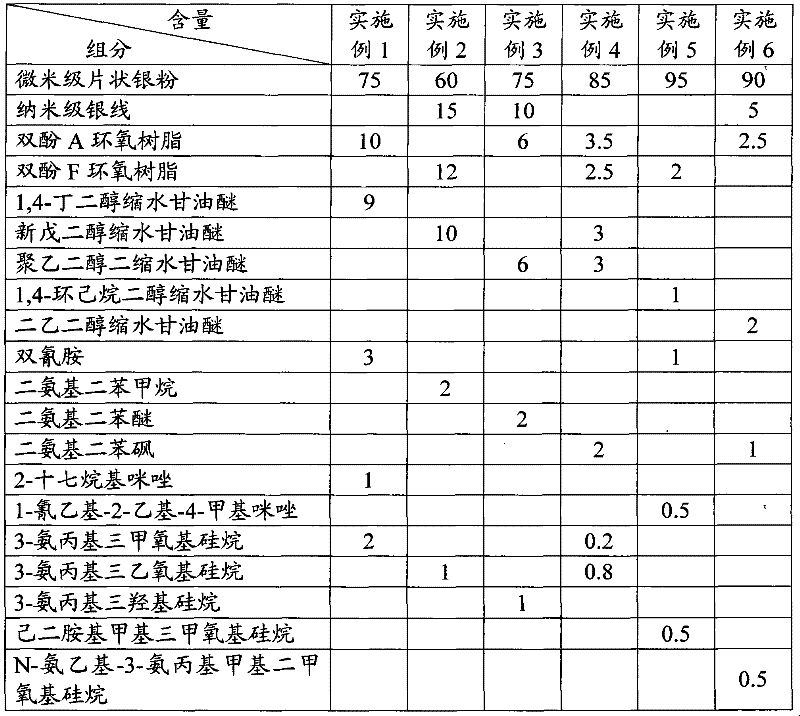

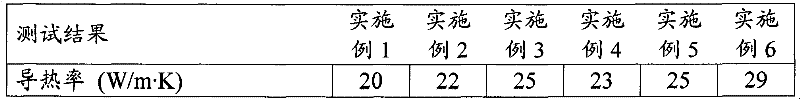

Conductive adhesive for LED (light emitting diode) packaging and preparation method of conductive adhesive

InactiveCN102174306ASuperior performanceGood thermal conductivityModified epoxy resin adhesivesSemiconductor devicesChemistryAdhesive

The invention discloses a conductive adhesive for LED (light emitting diode) packaging. The conductive adhesive consists of the following raw materials in percentage by weight: 75 to 95 percent of conductive powder, 2 to 12 percent of epoxy resin, 1 to 10 percent of epoxy diluting agent, 1 to 3 percent of curing agent, 0 to 1 percent of curing accelerator, and 0.5 to 2 percent of coupling agent. The LED conductive adhesive provided by the invention has superior performance and good heat conduction and electric conduction effects and can fully meet operating requirements of a high-brightness high-power LED chip.

Owner:YANTAI DARBOND TECH

Creep-resistant polypropylene composition and preparation method and application thereof

ActiveCN102344609AIncrease the interfacial bonding areaPerfect crystallinityElastomerPolymer science

The invention belongs to the field of material engineering and discloses a creep-resistant polypropylene composition and a preparation method and application thereof. The creep-resistant polypropylene composition is prepared from 40-80 percent by weight of polypropylene resin, 5-30 percent by weight of elastomer, 10-40 percent by weight of high-aspect-ratio (HAR) inorganic filler and 0.01-0.5 percent by weight of nucleating agent, wherein the nucleating agent is an alpha-crystal nucleating agent. In the invention, the polypropylene composition modified by the HAR inorganic filler and the alpha-crystal nucleating agent has high creep resistance; and an injection molding piece prepared from the polypropylene composition has stable size and small deformation under practical use conditions, and can fully meet the using requirements of relevant industries such as automobiles, home appliances and the like.

Owner:KINGFA SCI & TECH CO LTD +2

Construction material produced by utilizing industrial residue

The invention discloses a construction material produced from industrial residue, aims to provide a construction material having the advantages of light weight, sound insulation, heat insulation, low cost, fire resistance, dense products, high rigidity and the like, and solves the problems with land occupation and pollute environment of phosphate slag and phosphogypsum at the same time. the invention is realized through the following technical scheme: phosphate slag and phosphogypsum are used as raw materials for producing the construction material, which comprises the following components by the weight part: 35 to 65 parts of phosphate slag, 10 to 40 parts of phosphogypsum, 5 to 15 parts of lime, 15 to 28 parts of cement, 0.1 to 0.4 part of light aggregate, 0.02 to 0.05 part of soluble glass, 0.02 to 0.05 part of water-reducing agent, 0 to 0.004 part of retarding agent, 0 to 0.005 part of early-strength admixture, and 0 to 0.008 part of foam killer; the components are weighed by the formula weight part and added to a blender; water is added to the blender with the water-to-material proportion being 4 to 10 and mixed evenly with the materials; and the solution is cast into a die and natural air dried after molding. Dies with different structures can be used according to purposes to conduct cast molding. The construction materials such as wall plates, guardrail decoration pillars, door and window sleeves, vase sleeves and the like can be produced.

Owner:张勇飞

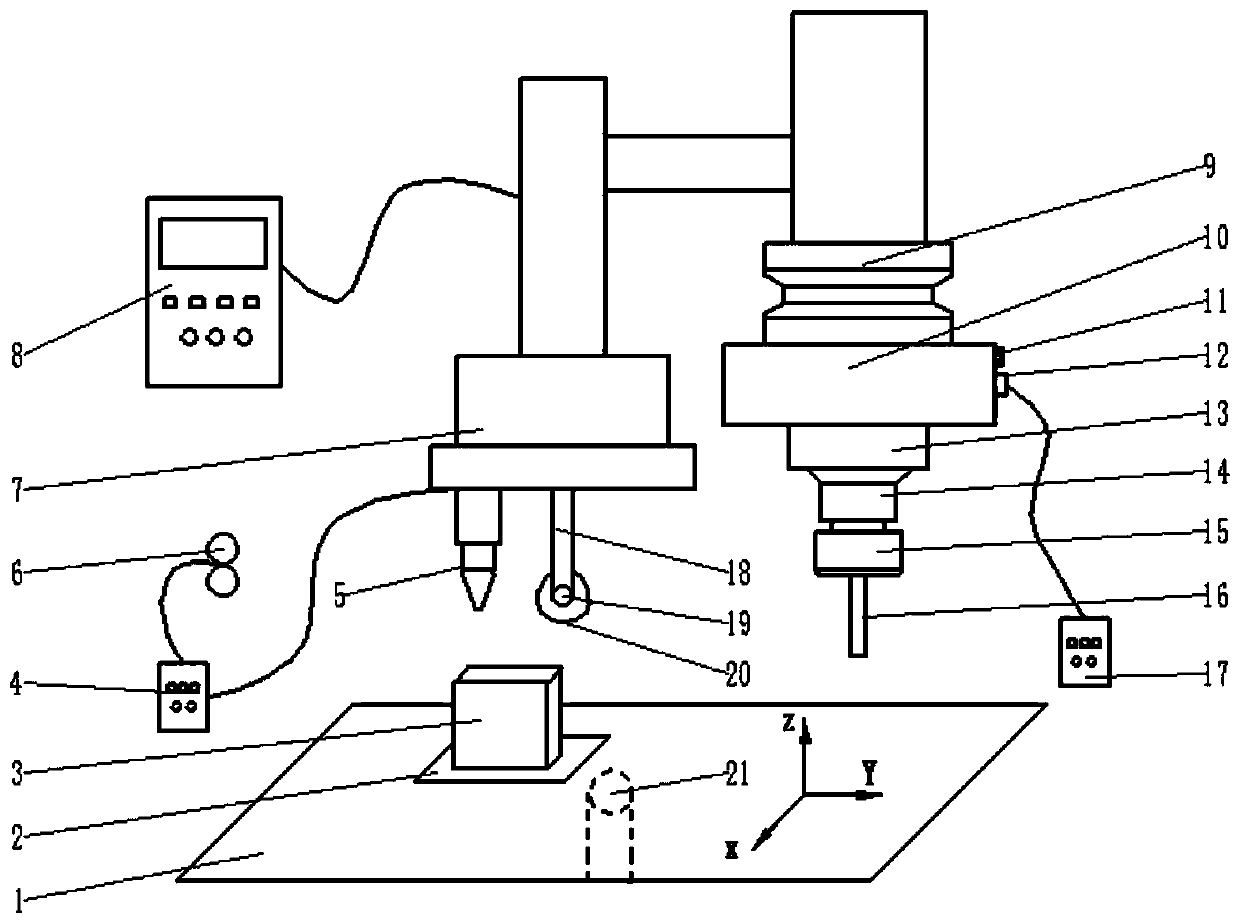

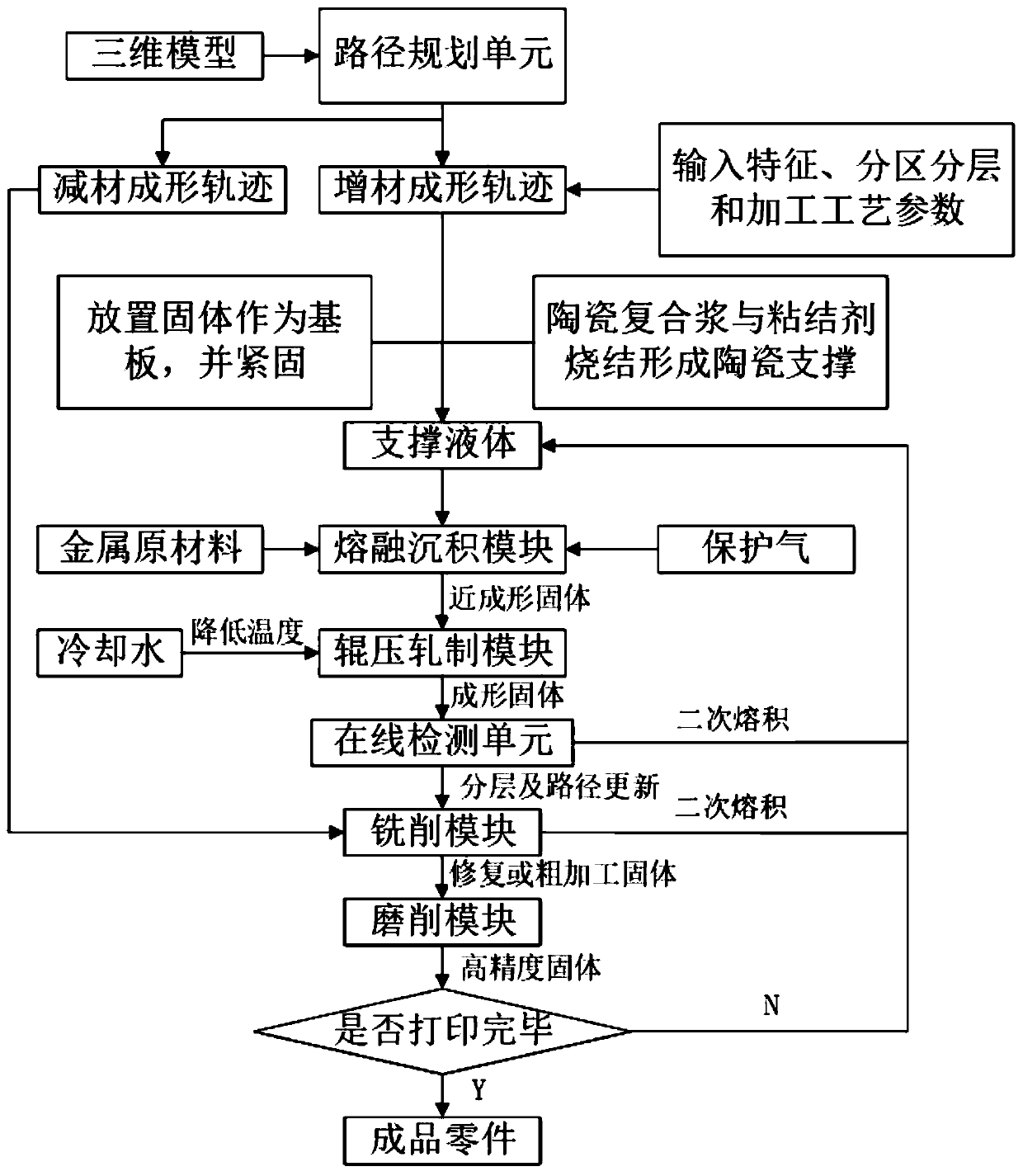

Metal part manufacturing system and method adopting micro-casting-forging and milling-grinding in-situ composite

InactiveCN110076566AImprove tissue mechanical propertiesImprove processing efficiencyAdditive manufacturing apparatusOther manufacturing equipments/toolsEngineeringManufacturing systems

The invention belongs to the field of metal part manufacturing, and particularly discloses a metal part manufacturing system and method adopting the micro-casting-forging and milling-grinding in-situcomposite. The system involves a micro-casting-forging module, a milling module, a five-axis linkage workbench and a control device, wherein the micro-casting-forging module is connected with the milling module and comprises a fusion deposition sub-module and a roller-pressing rolling sub-module, the five-axis linkage workbench is positioned below the micro-casting-forging module and the milling module, and is used for containing metal parts to be formed, and the control device is connected with the fusion deposition sub-module, the roller-pressing rolling sub-module, the milling module and the five-axis linkage workbench. According to the system and method, micro-casting-forging and a milling process are composited to process and manufacture the metal parts, so that the problems that whenthe metal parts are made through the additive manufacturing, the structure is not uniform, the deformation is serious, the residual stress is large, the structure performance is poor, and the surfacequality is poor are solved, and the system and method is especially suitable for processing a high-performance complicated special-shaped element.

Owner:HUAZHONG UNIV OF SCI & TECH

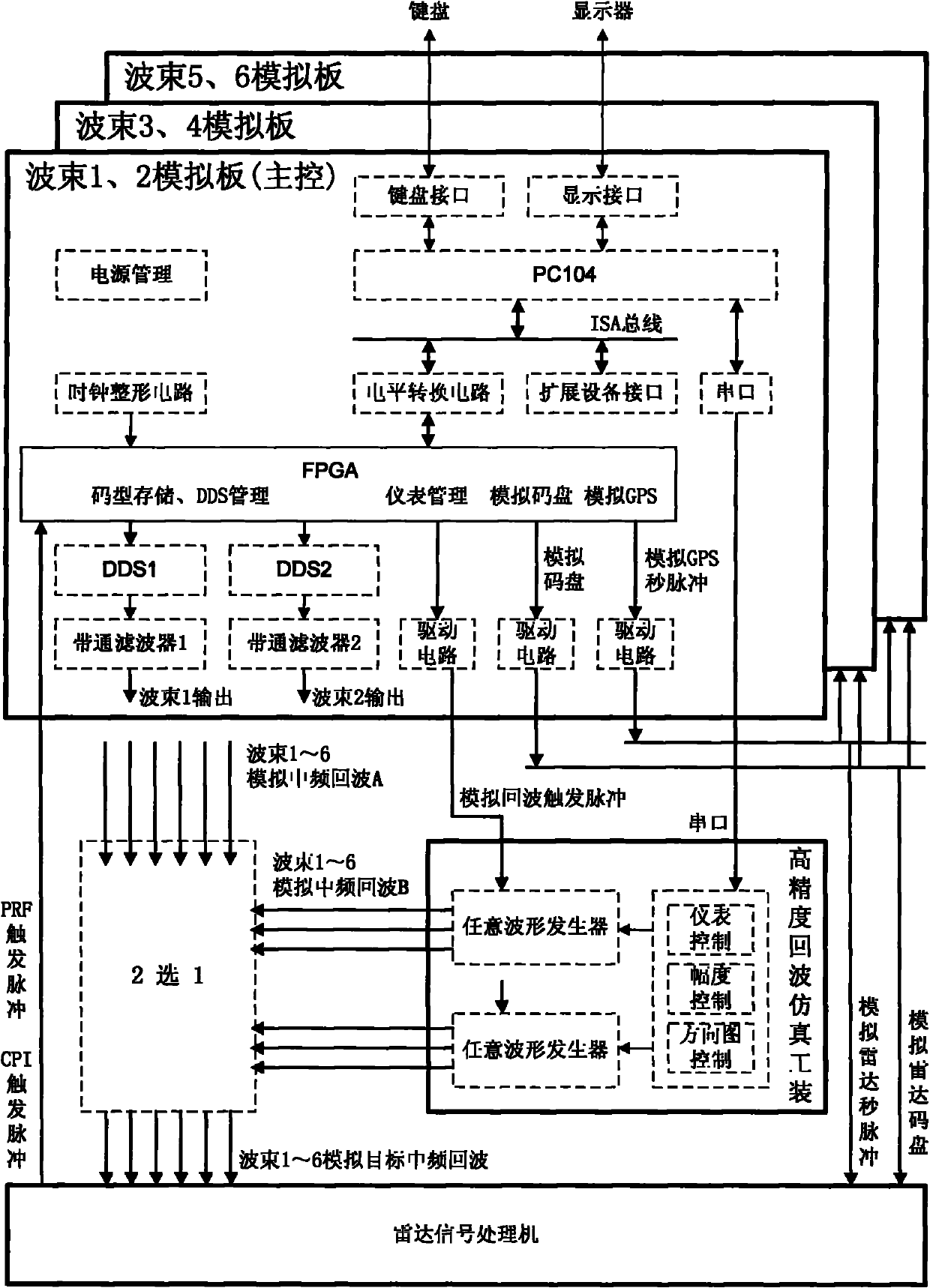

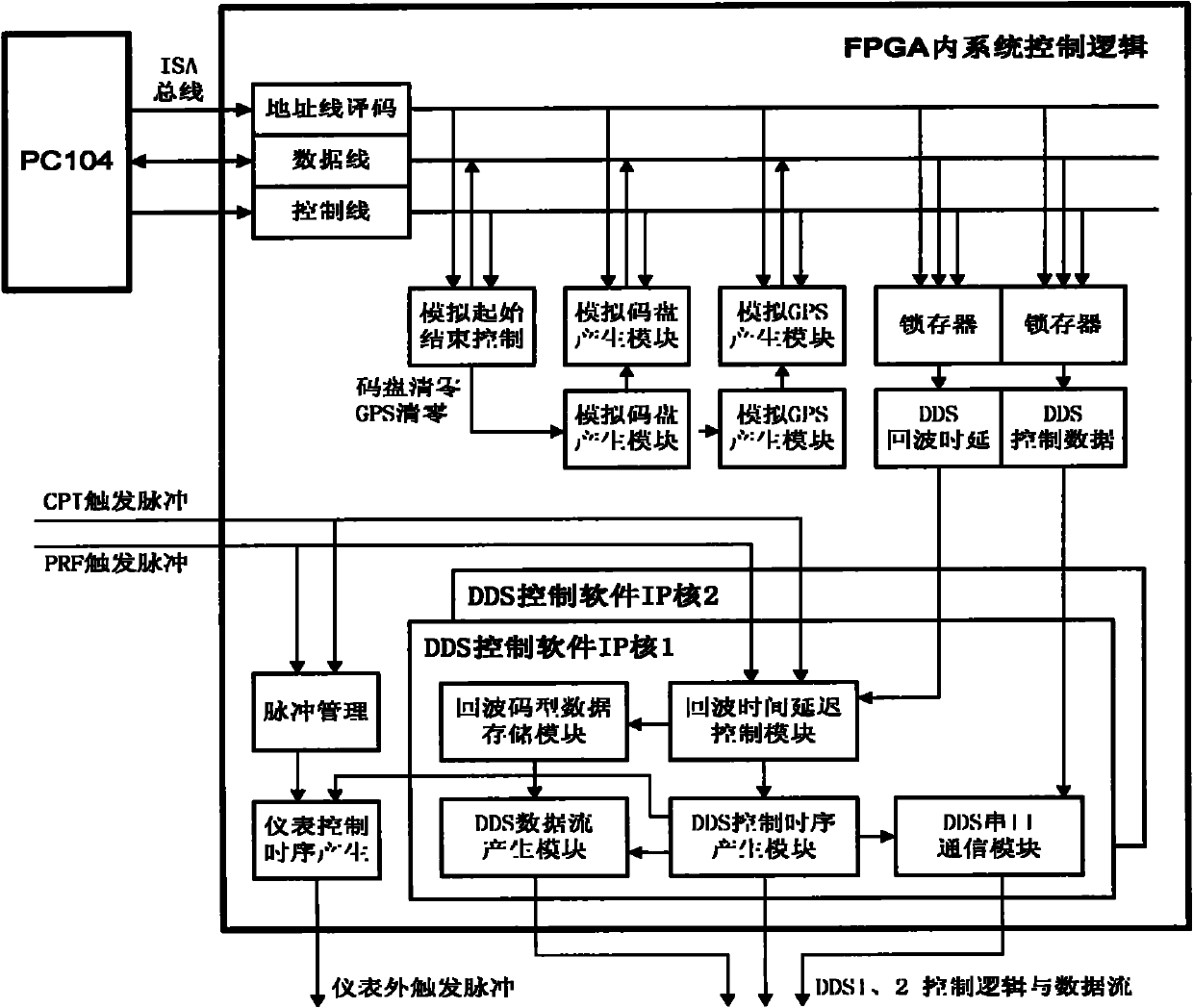

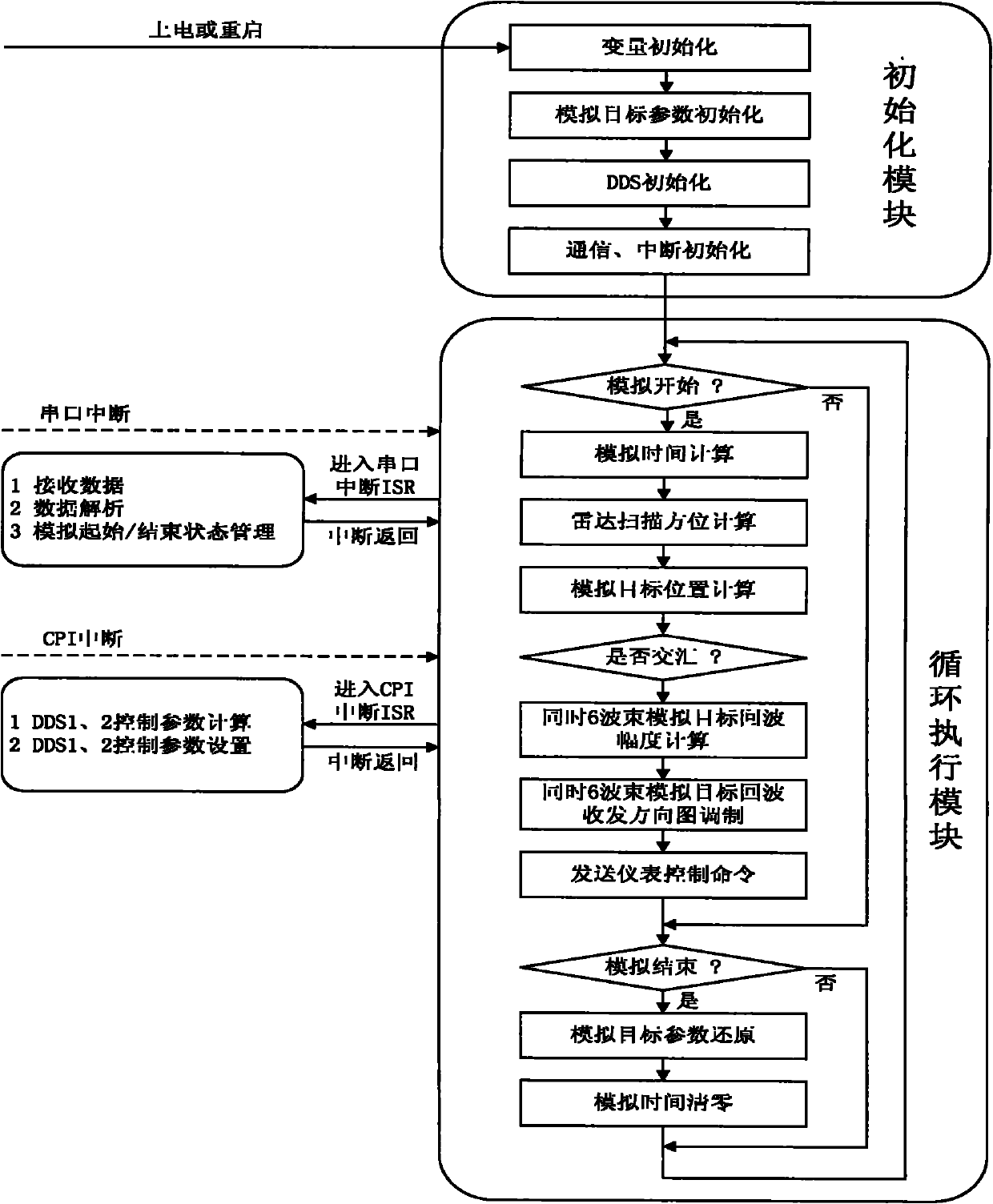

Radar target intermediate frequency (IR) echo simulation system based on multi-beam amplitude-comparison angle measurement and control method thereof

InactiveCN102023293AEasy to controlDensity controllableWave based measurement systemsIntermediate frequencyRadar signal processing

The invention relates to a radar target intermediate frequency (IR) echo simulation system based on multi-beam amplitude-comparison angle measurement and a control method thereof, relating to the field of radar target echo simulation. The system comprises three target echo simulation boards and an arbitrary waveform generator instrument fixture, wherein the echo simulation boards are designed with a computer module PC104, a field programmable gate array (FPGA), direct digital synthesis (DDS) technique and a simulation circuit as cores; and the arbitrary waveform generator instrument fixture is designed with instrument programming control as the core. According to the invention, simultaneous 6-channel simulated target IR echo simulation of the radar of the multi-beam amplitude-comparison angle measurement system is realized, parameters of the simulated target echo such as distance, delay, echo amplitude, Doppler shift, pattern, direction pattern modulation, noise superposition and the like can be controlled, single-channel switching and output of dual-beam echo is realized, and the test use requirement of the radar signal processor of the system is met. In the invention, the arbitrary waveform generator instrument frock is utilized, thus improving the amplitude precision of the output echo signals; and the control program in the FPGA in the target echo simulation boards is designed by the soft IP core, thus providing convenience for hardware transplanting and clipping.

Owner:中国兵器工业第二0六研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com