Patents

Literature

7443results about How to "High dimensional accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

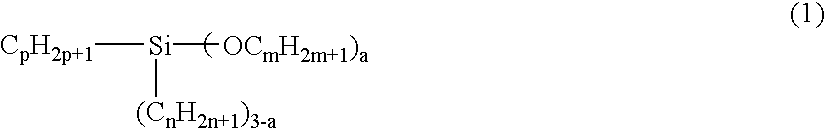

Method for protecting layer by forming hydrocarbon-based extremely thin film

ActiveUS10043661B2Improve concentrationGood chemical resistanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNoble gasProtection layer

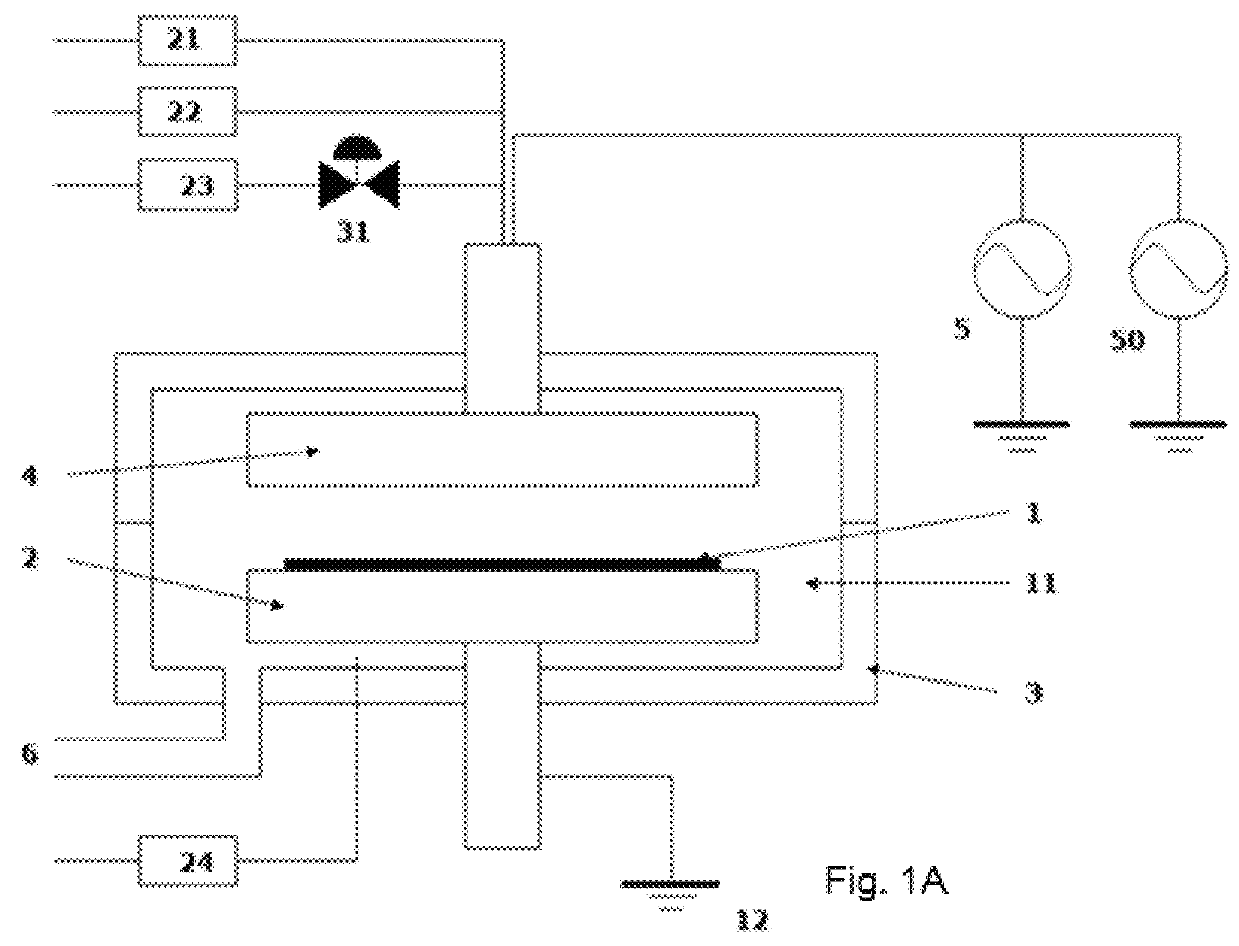

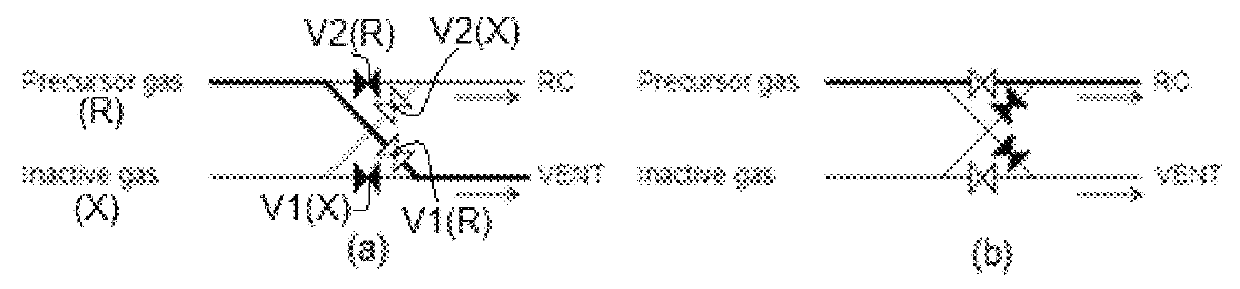

A method for protecting a layer includes: providing a substrate having a target layer; depositing a protective layer on the target layer, which protective layer contacts and covers the target layer and is constituted by a hydrocarbon-based layer; and depositing an oxide layer on the protective layer so that the protective layer in contact with the oxide layer is oxidized. The hydrocarbon-based layer is formed by plasma-enhanced atomic layer deposition (PEALD) using an alkylaminosilane precursor and a noble gas without a reactant.

Owner:ASM IP HLDG BV

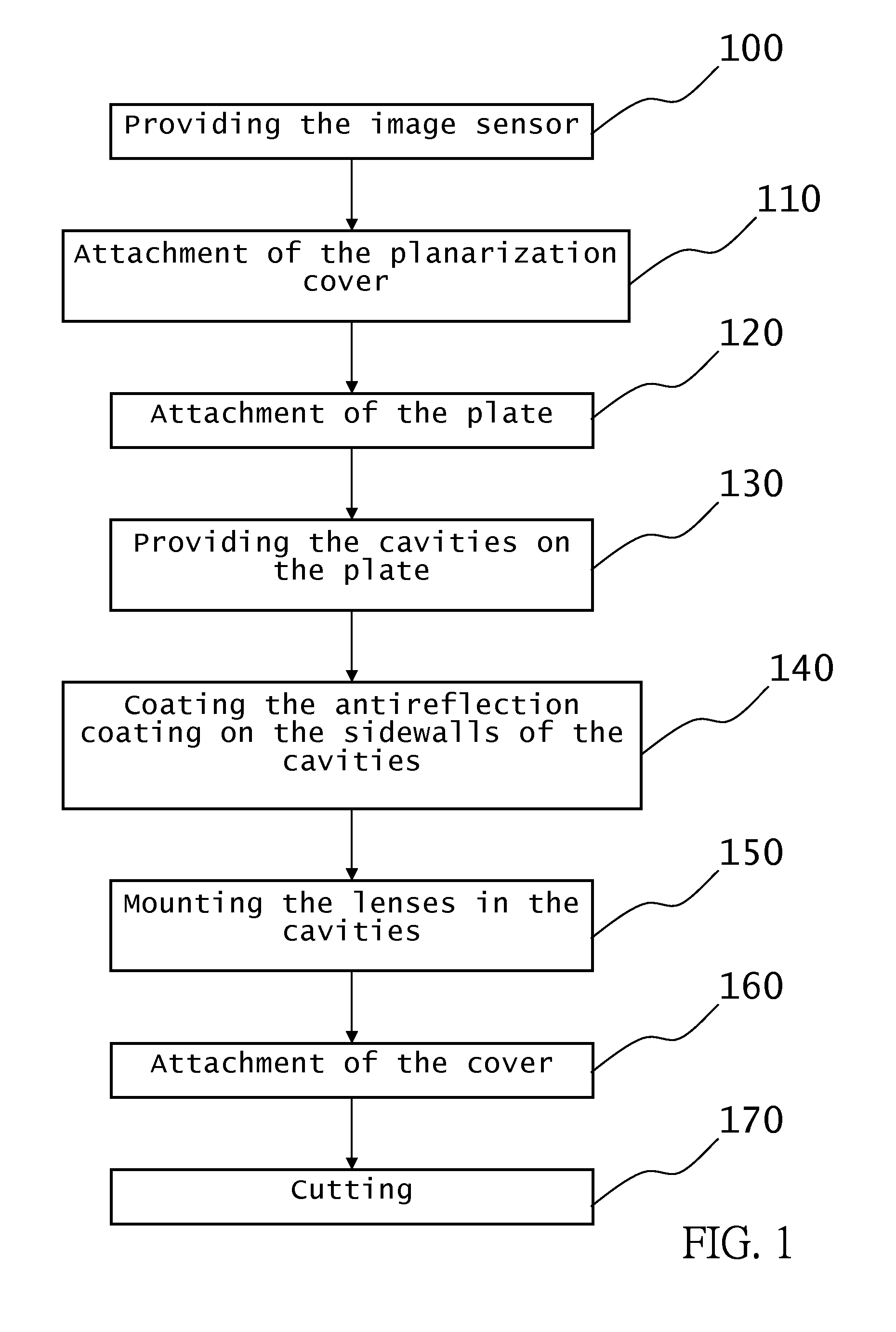

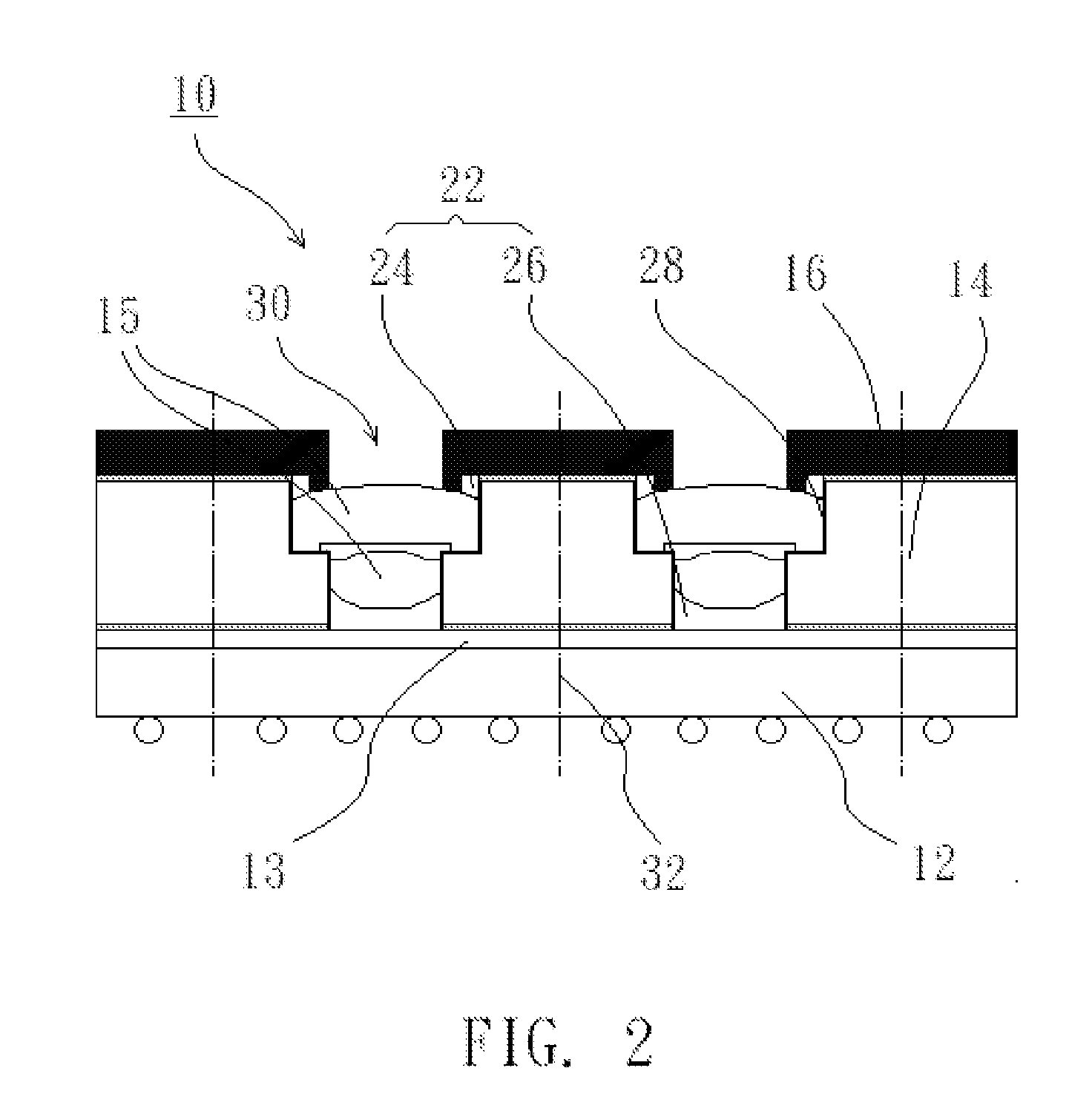

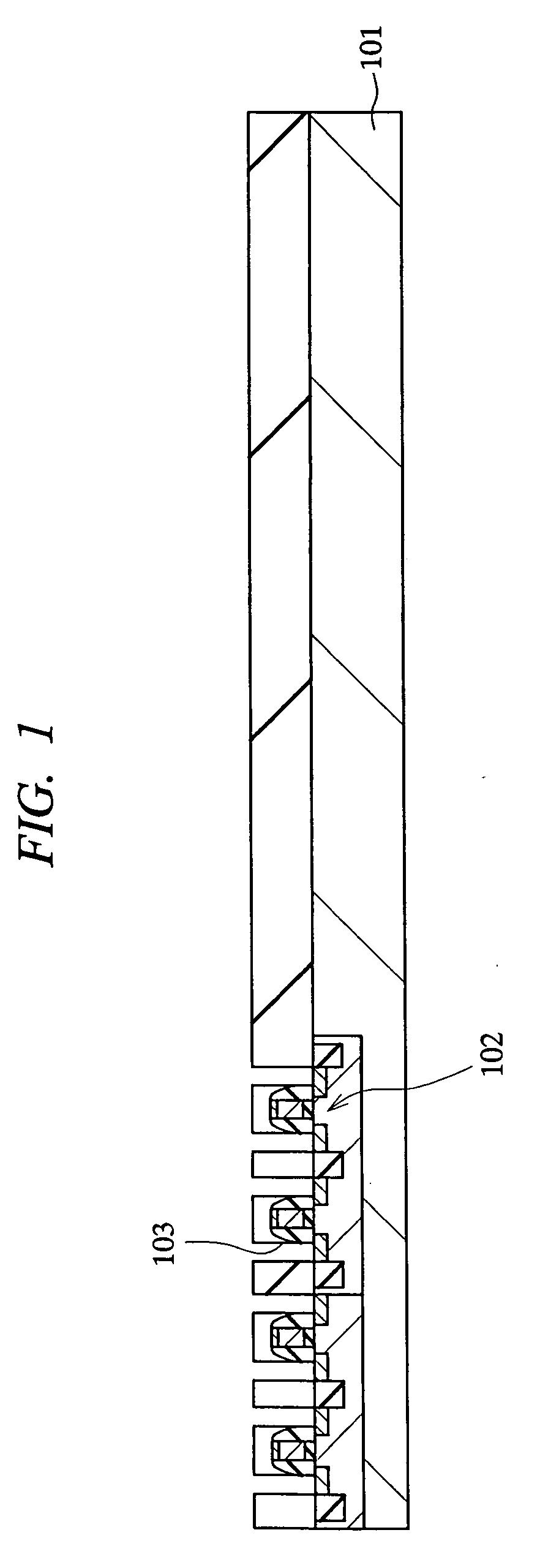

Method of making image capture unit

InactiveUS20070296847A1Image be preventAvoid dustTelevision system detailsSolid-state devicesImage sensorEdge region

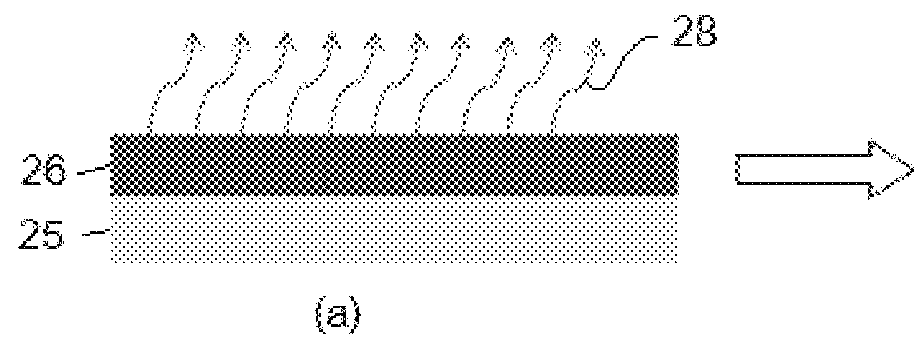

The present invention provides a method of making an image capture unit, which includes the steps of: providing an image sensor; attaching a plate on the image sensor; providing at least one cavity on the plate aligned with the image sensor; mounting lenses in the cavity of the plate, and attaching a cover on the plate to shield a margin region of each of the lenses.

Owner:ETHER PRECISION

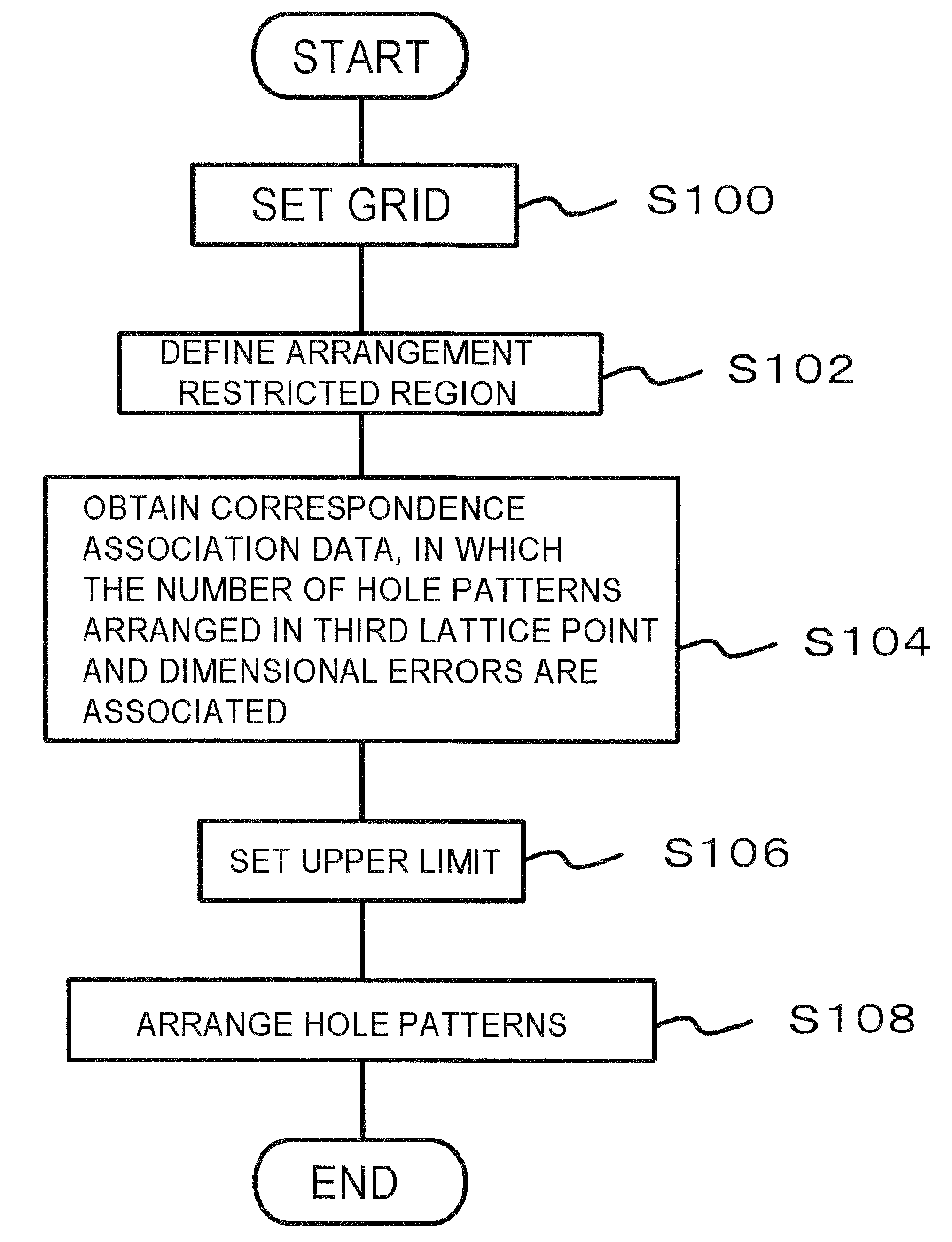

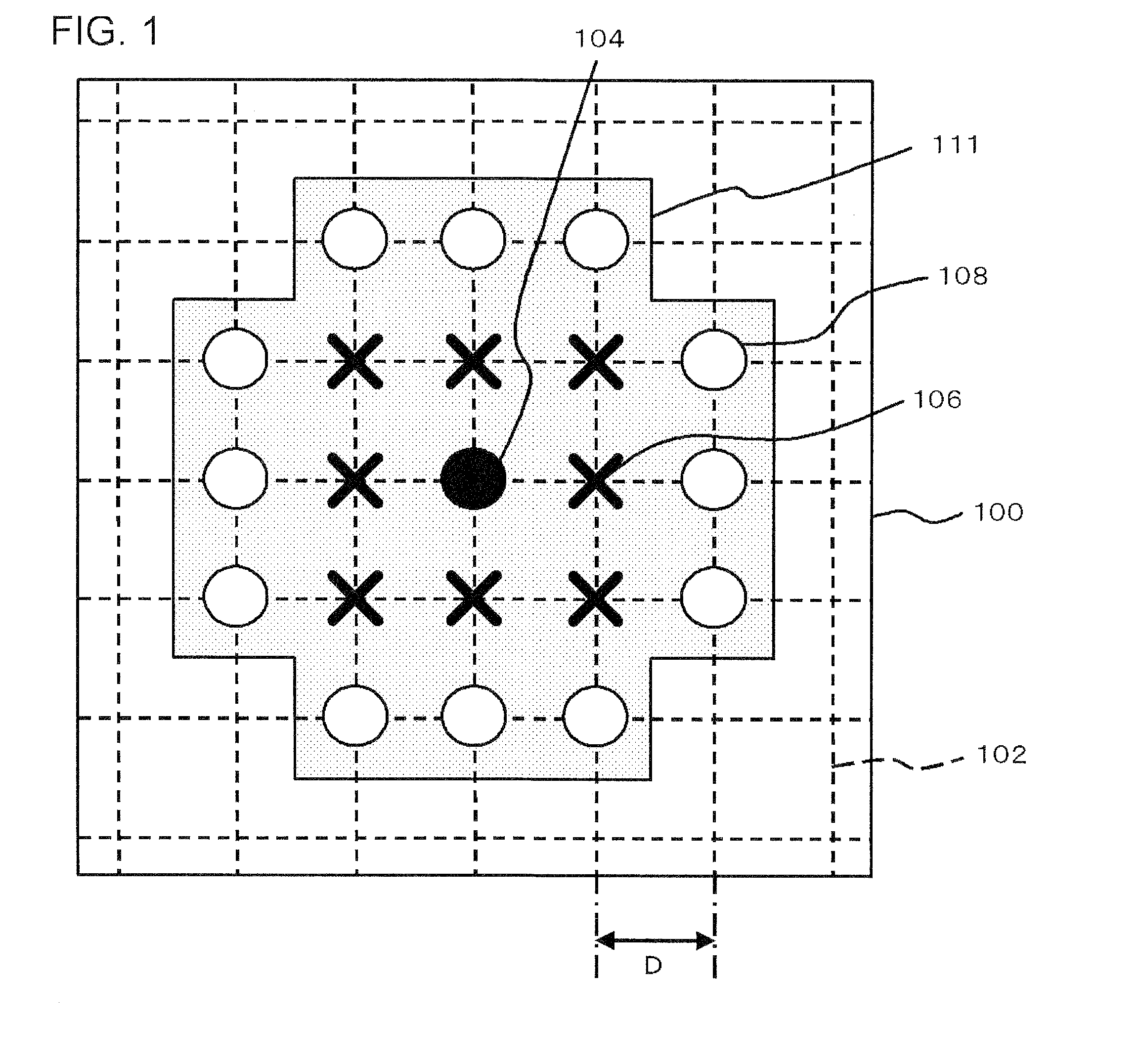

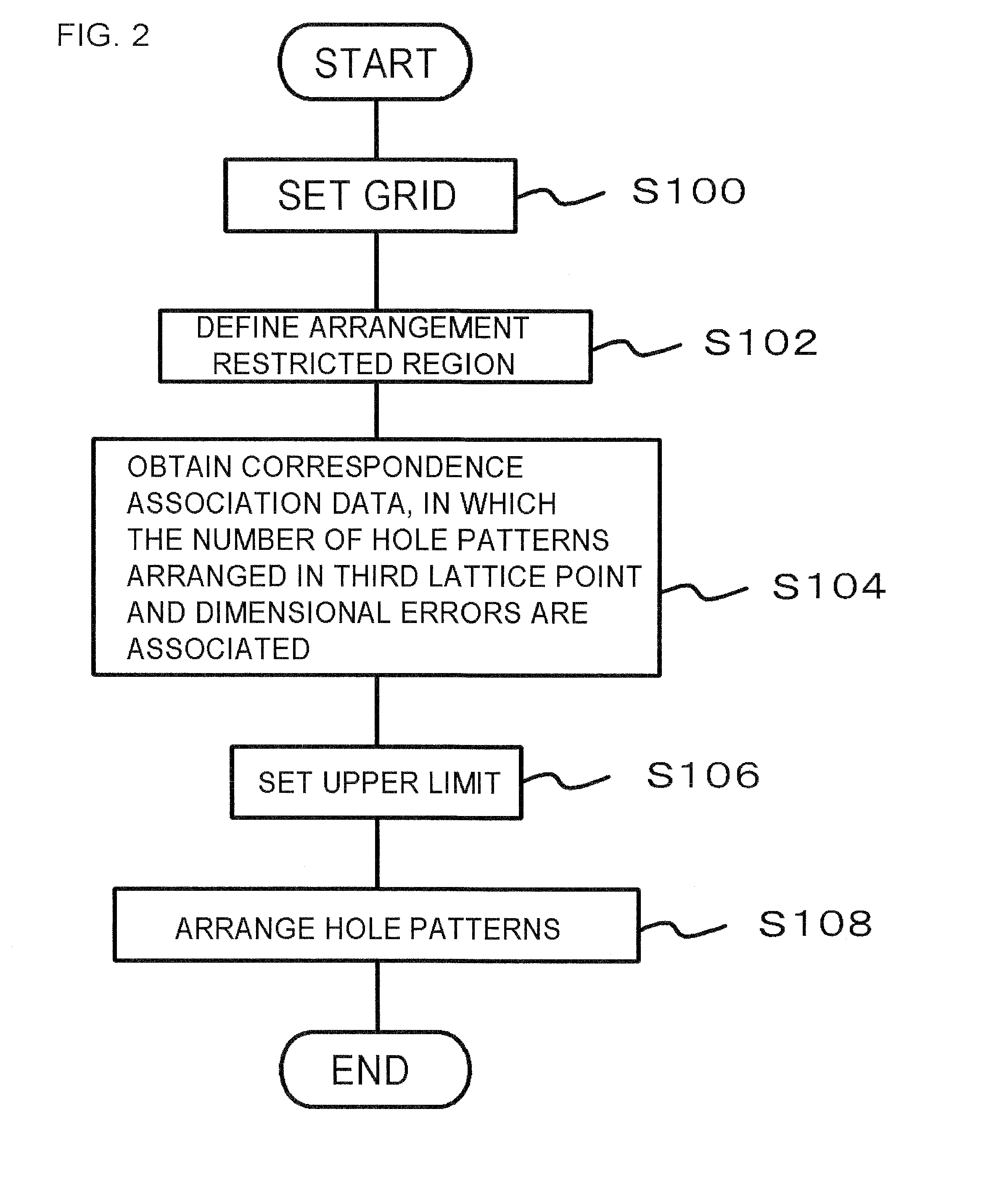

Method of designing a pattern

ActiveUS20080086712A1Reduce areaSmall size errorSemiconductor/solid-state device manufacturingCAD circuit designEngineeringSemiconductor

A method of designing a pattern of a hole pattern having a configuration, in which grid of interval smaller than a minimum permissible pitch according to a design rule for a semiconductor integrated circuit is provided in a pattern drawing, a hole pattern is arranged on a first lattice point which is an intersection of the grid, and, at the same time, other hole patterns are not arranged on a second lattice point group which is on the periphery of the first lattice point, and is adjacent to the first lattice point is provided. And, the number of hole patterns, which may be arranged in a third lattice point group of a plurality of lattice points which are on the periphery of a second lattice point group and are within a predetermined distance from the first lattice point, is controlled.

Owner:RENESAS ELECTRONICS CORP

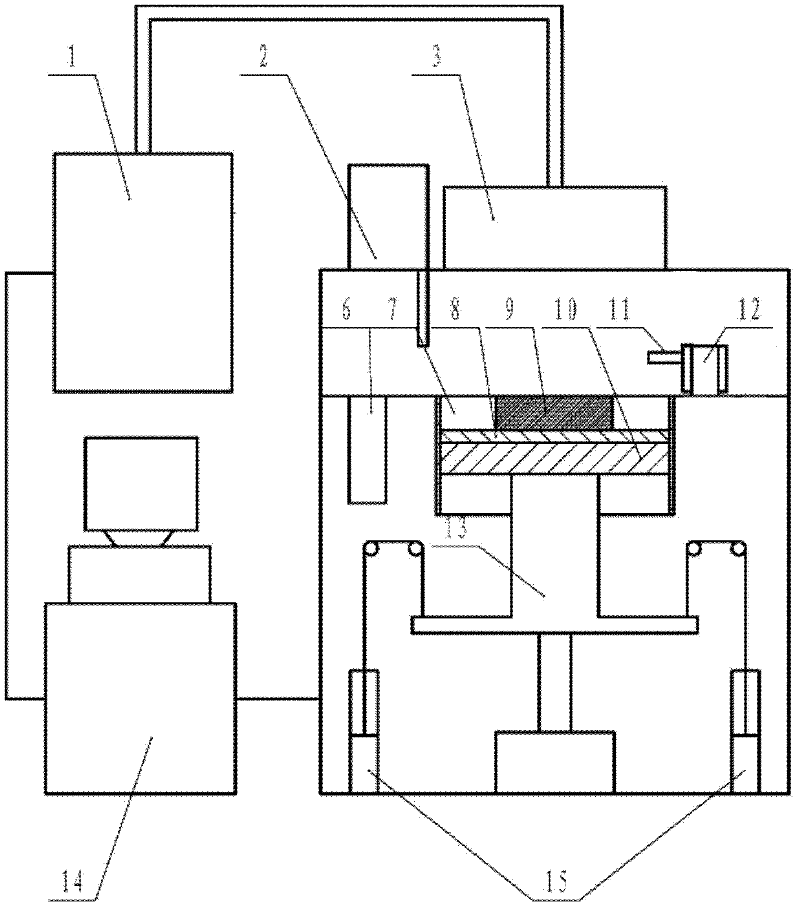

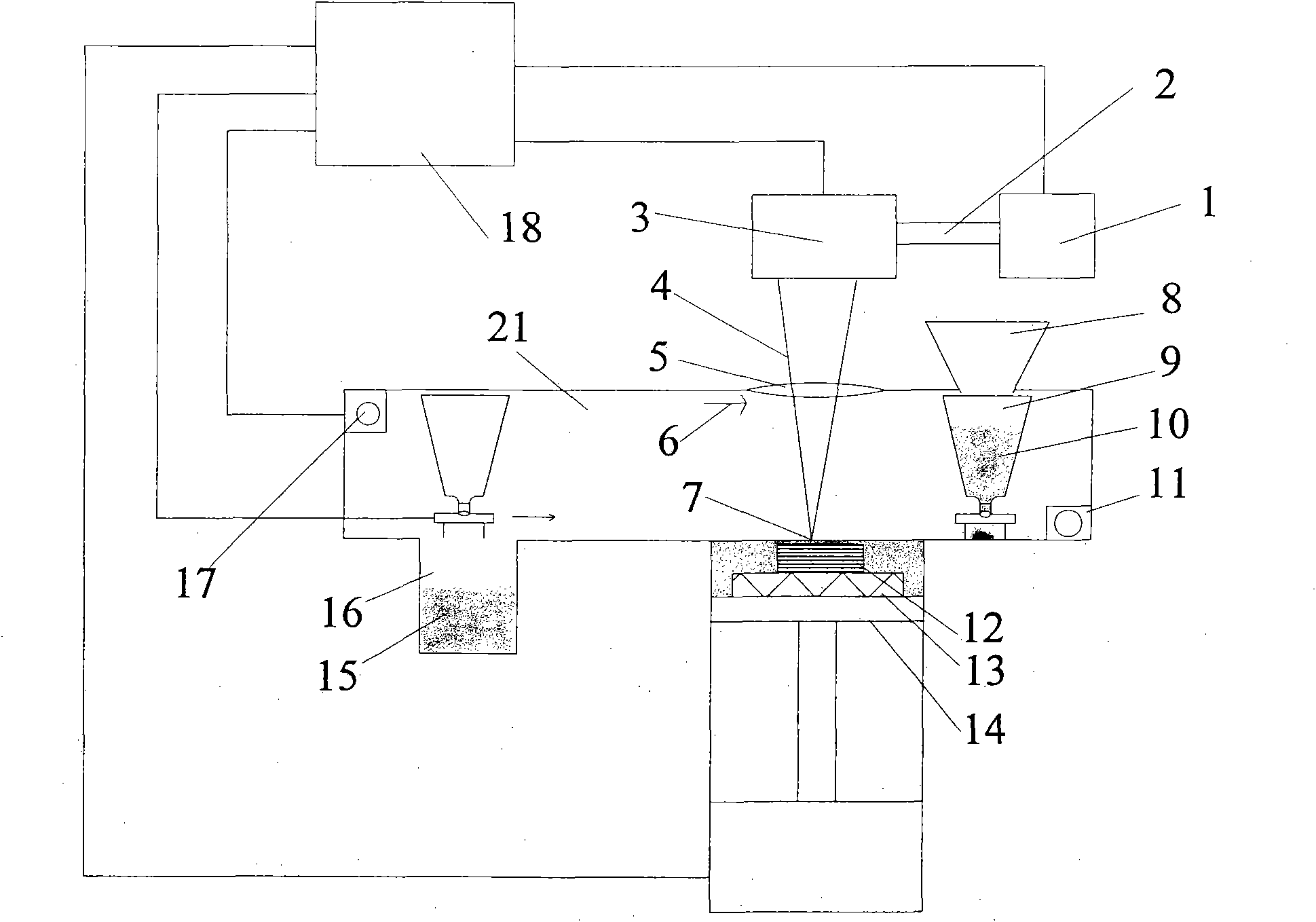

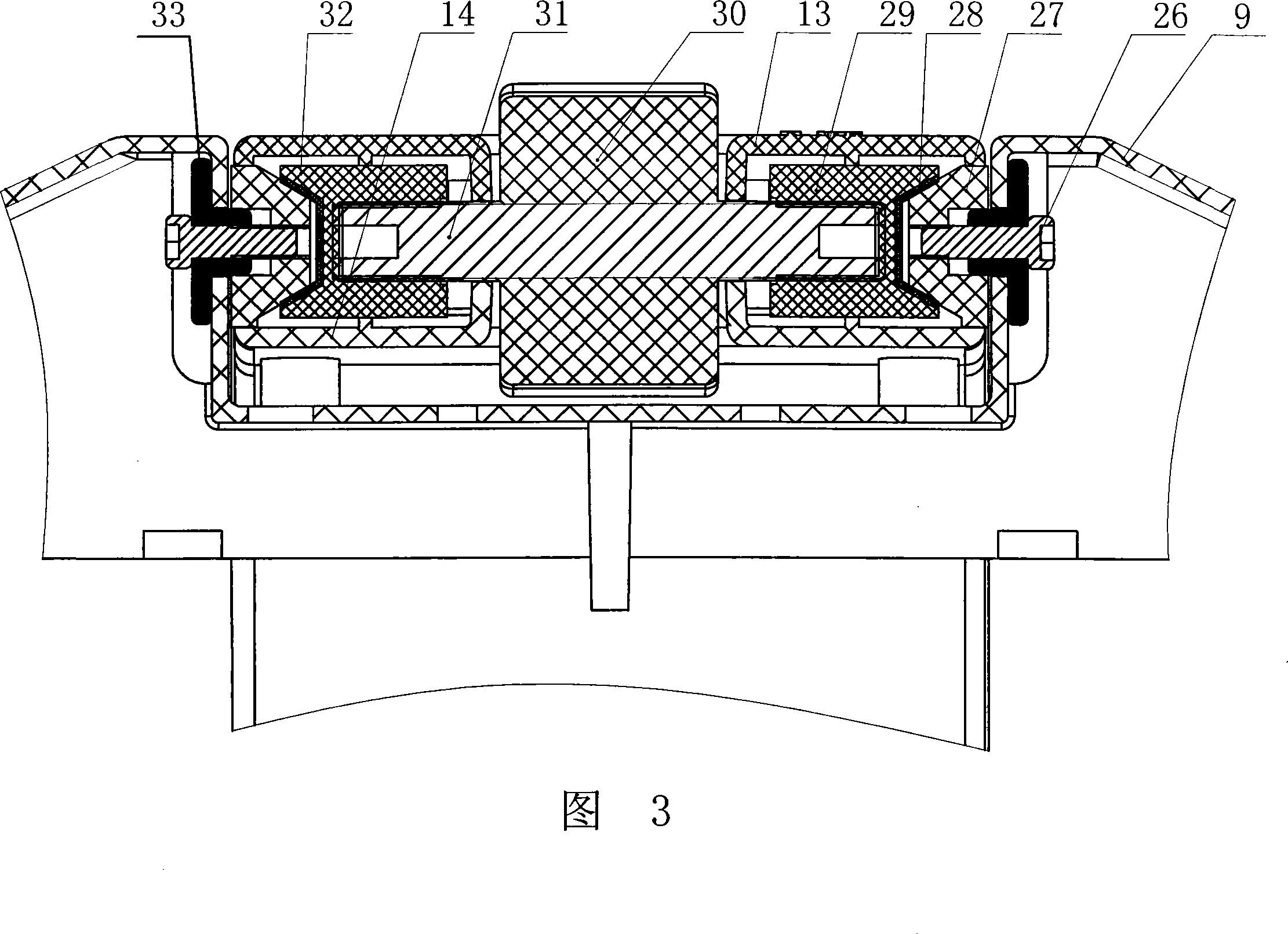

Selective laser melting rapid prototyping equipment for direct manufacturing of large parts

ActiveCN102266942AMeet the process requirementsReduce construction costsIncreasing energy efficiencySelective laser meltingLaser array

The invention discloses a selective laser melting rapid forming device for directly manufacturing large-size compact parts, which mainly comprises a laser array, an optical system array, a forming cylinder, a forming cylinder vertical sectional heating thermal-insulation structure, a forming cylinder weight balancing system, a substrate leveling device, a double-recovering cylinder, a double powder storing box, a double quantitative powder sending and discharging device, a powder paving device, a protective atmosphere cover, a gas purifying system and a control system, wherein an adopted optical system is composed of a plurality of optical system units and a mechanical moving platform, and the coverage area of the optical system can be randomly expanded or reduced. The size of the parts manufactured by using the selective laser melting rapid forming device provided by the invention is more than the size of the parts manufactured by using the existing national and foreign selective laser melting processes. The forming efficiency is multiplied while the forming precision, the parts complexity and the mechanical property are not changed.

Owner:TECH LASER TECH SHANGHAI CO LTD

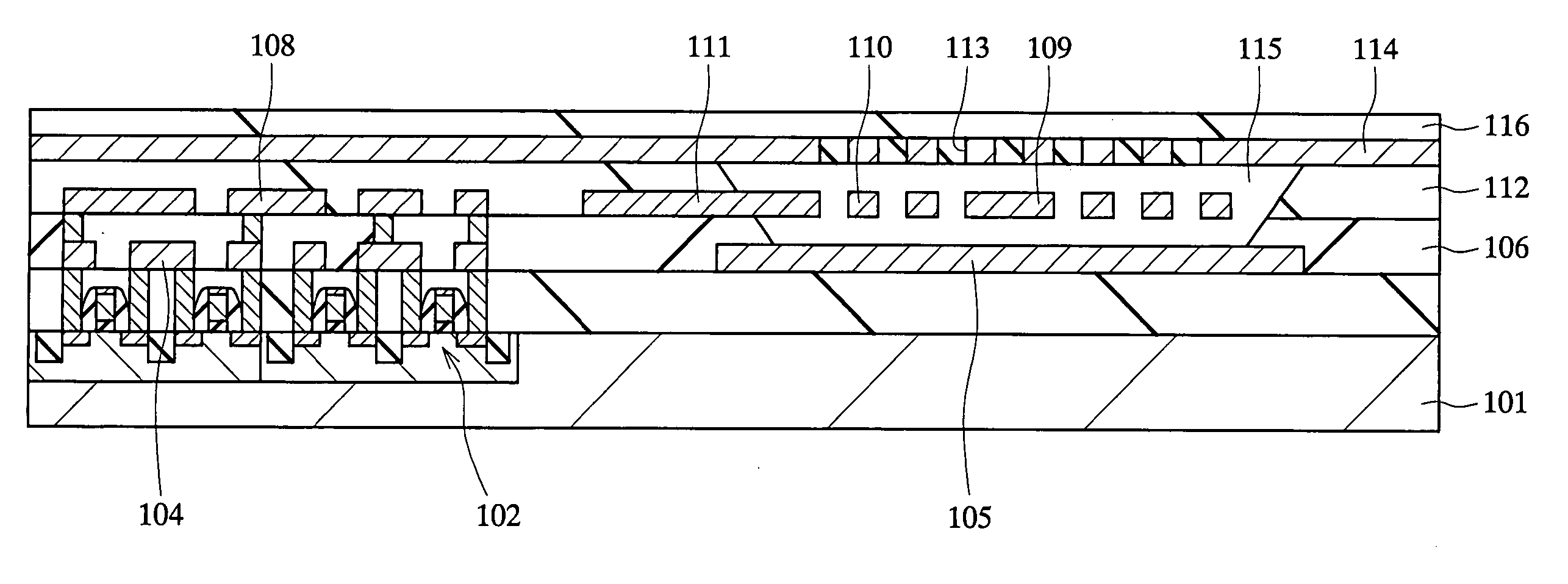

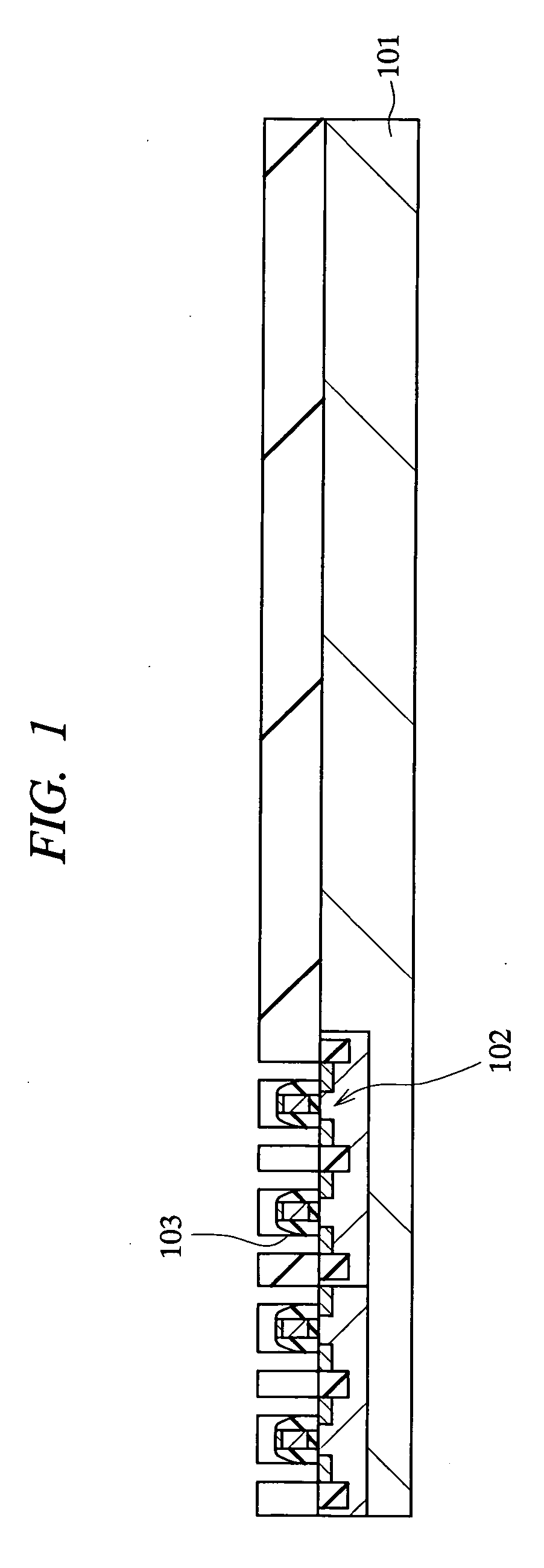

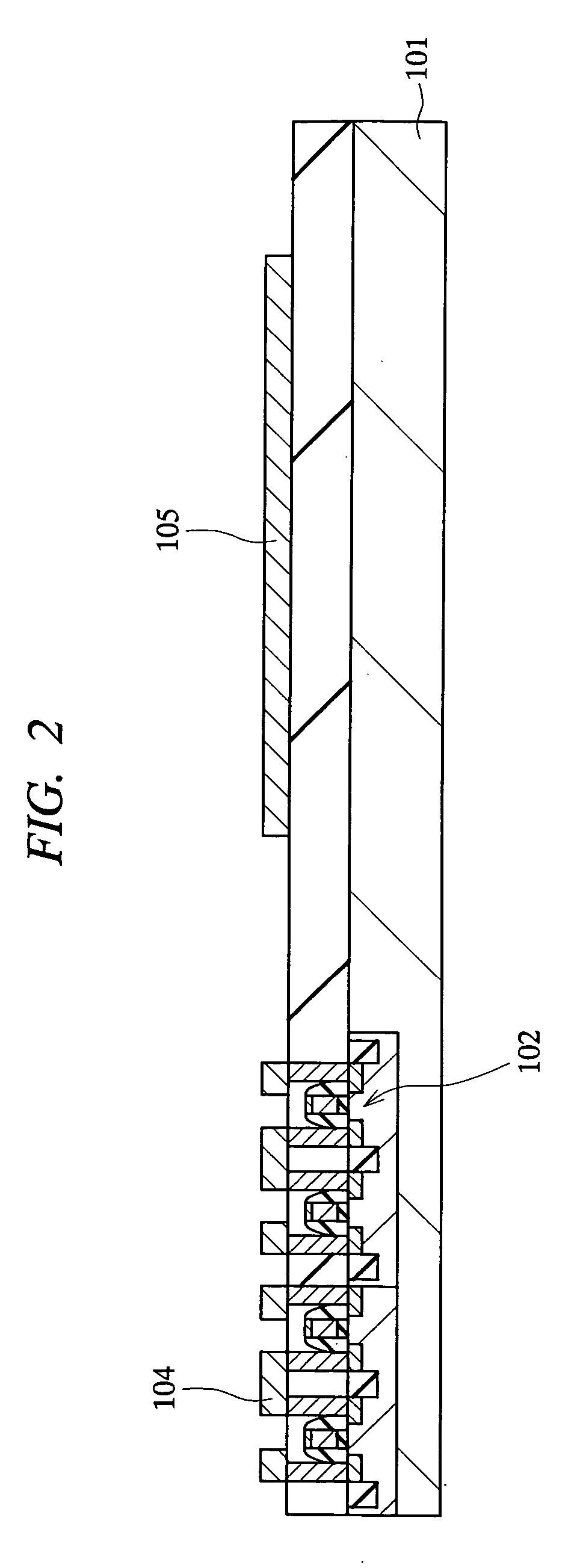

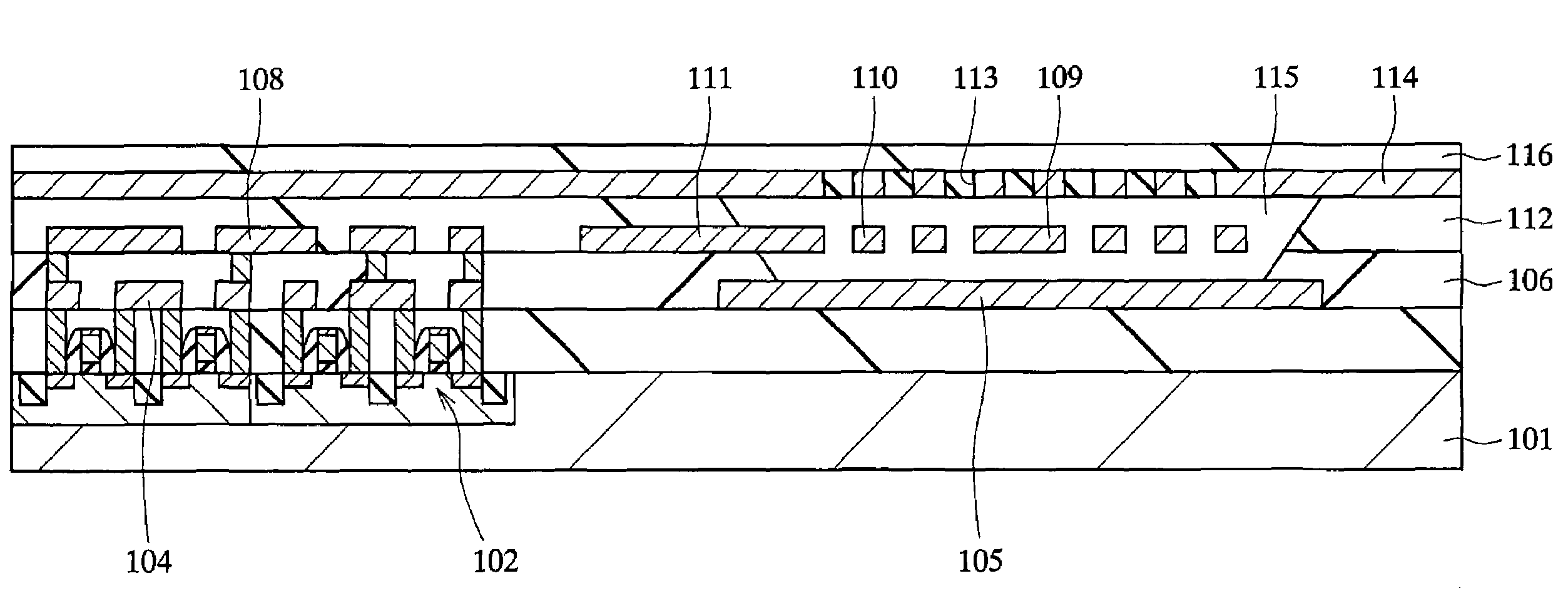

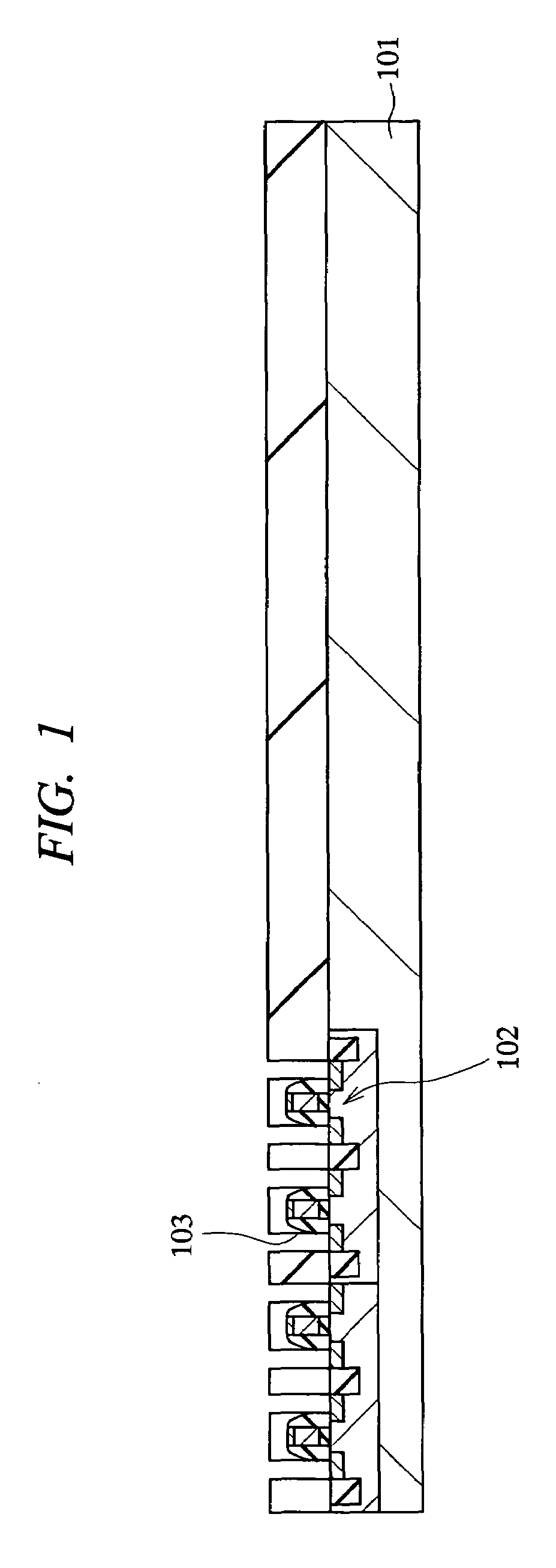

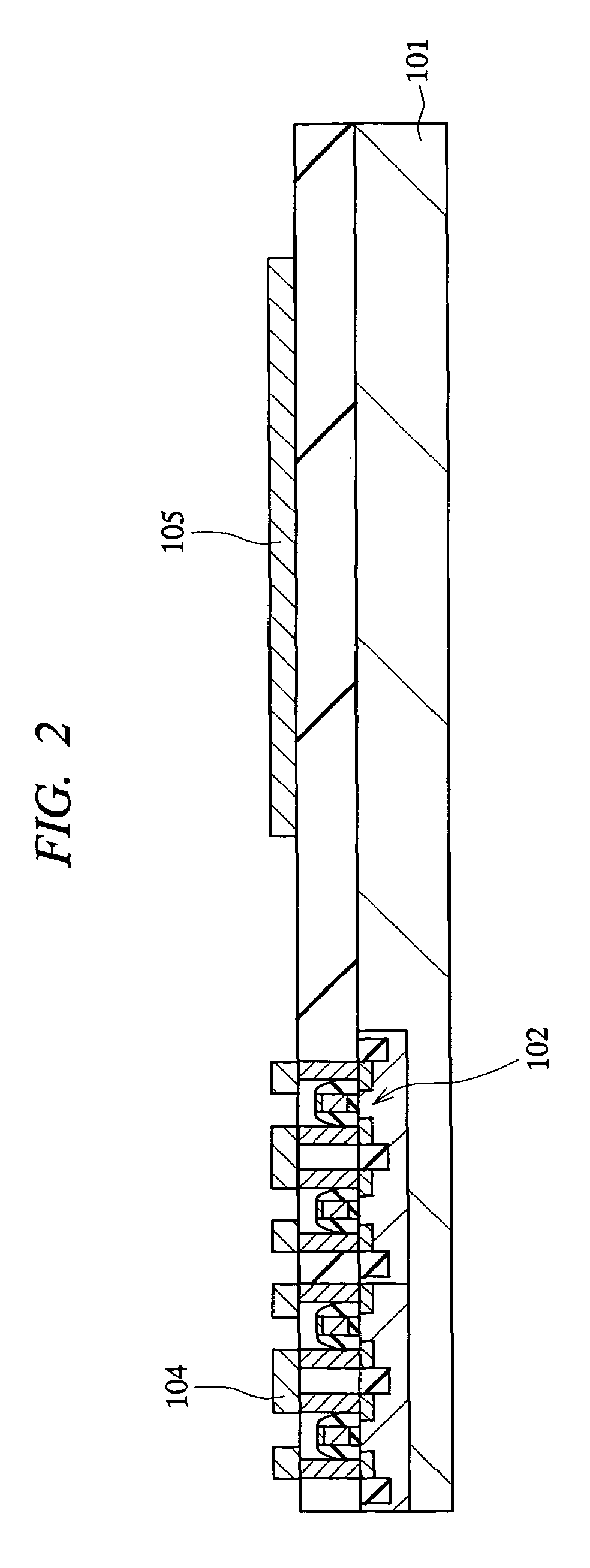

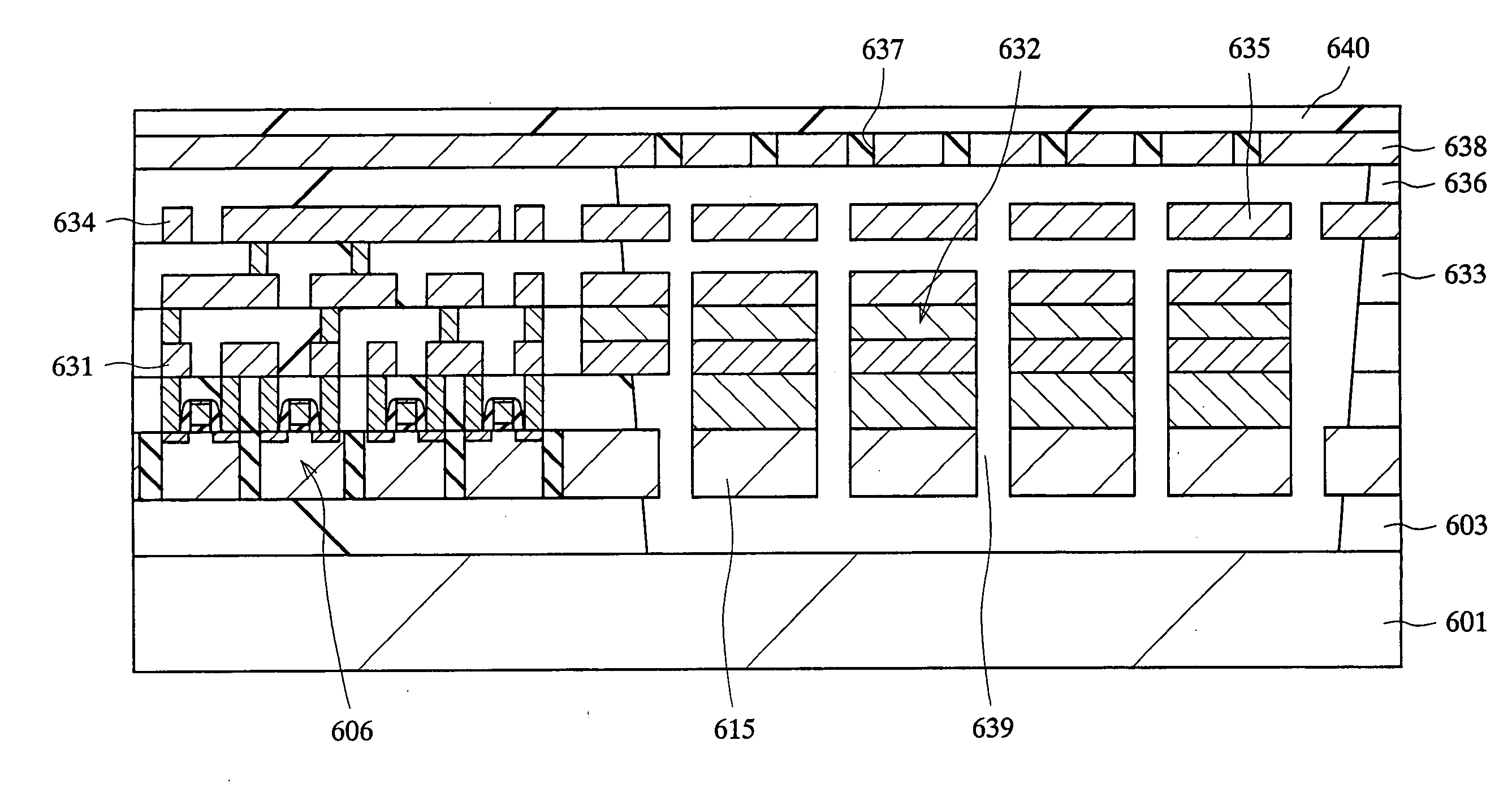

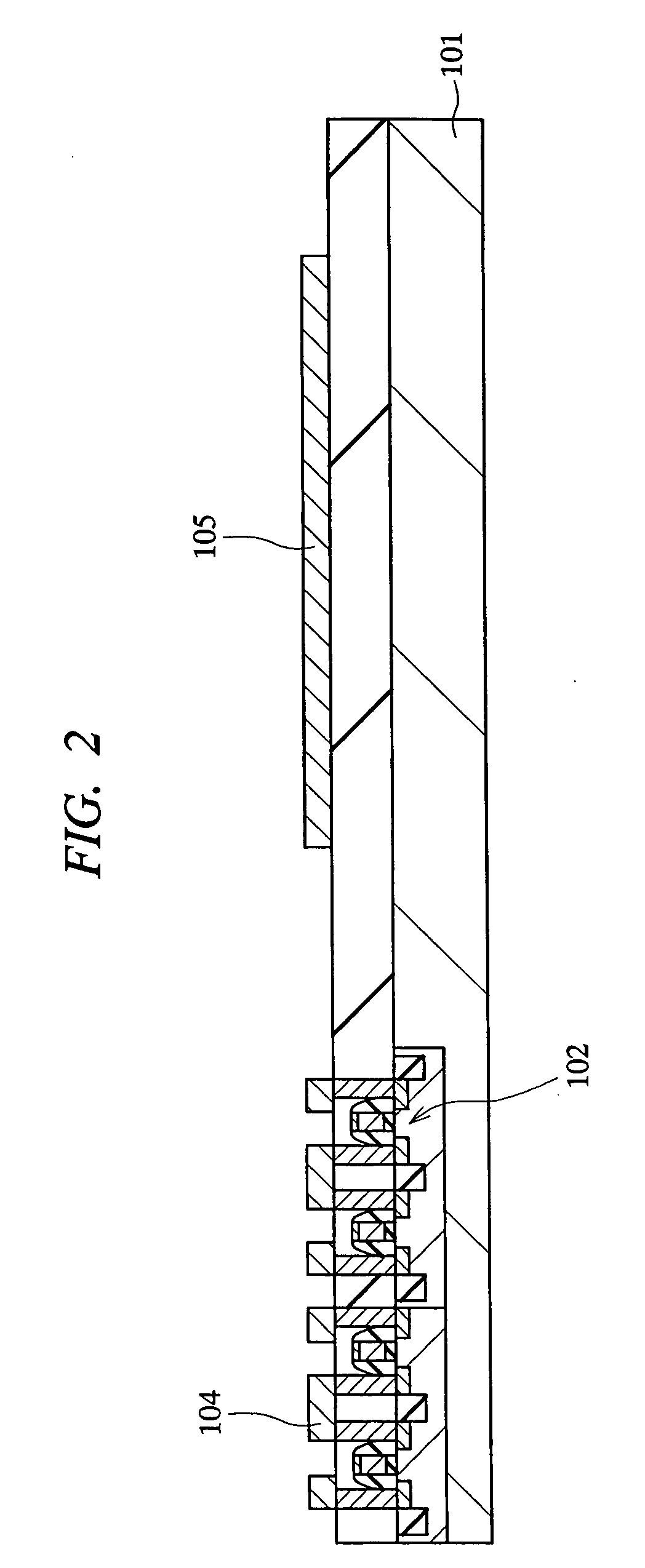

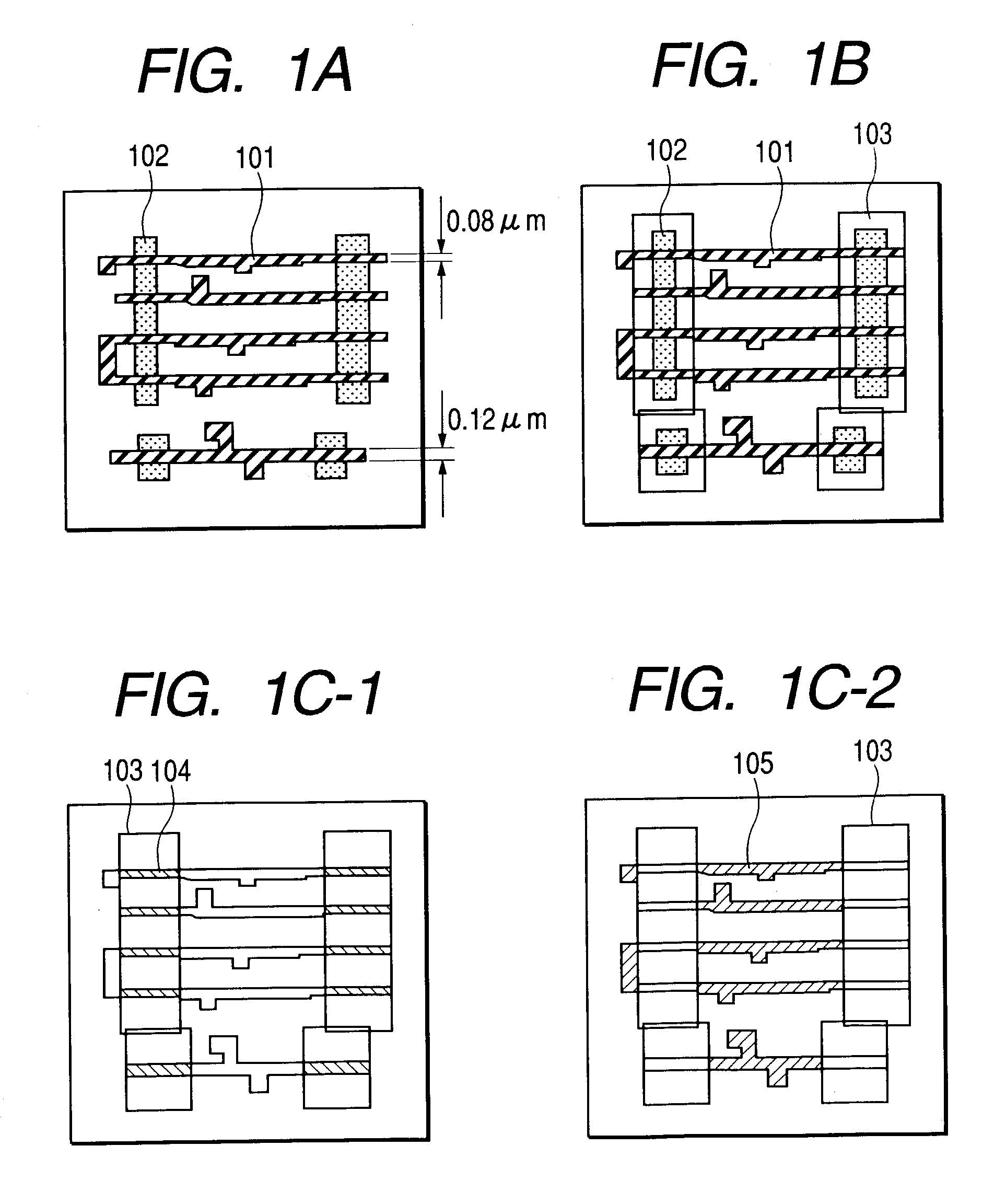

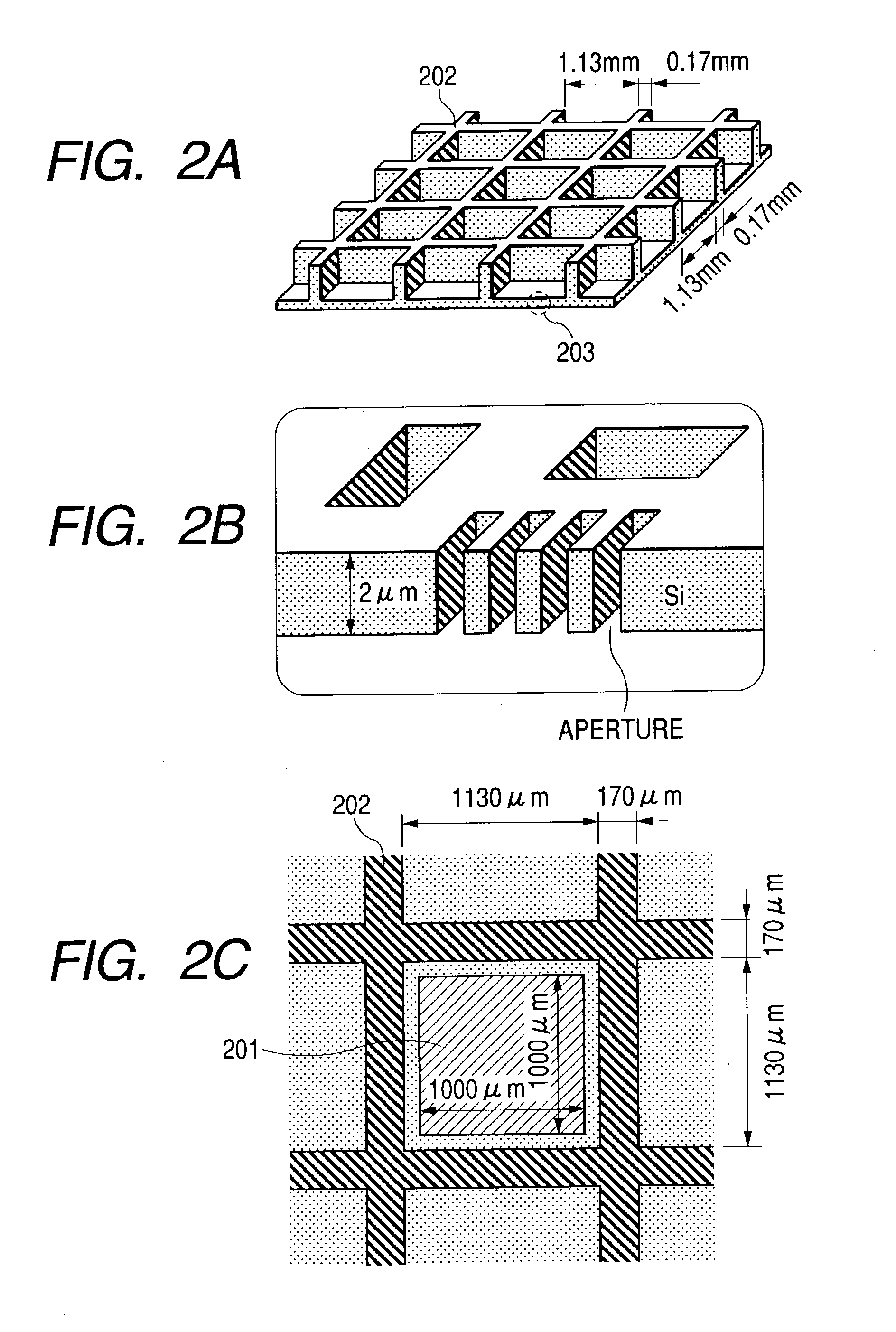

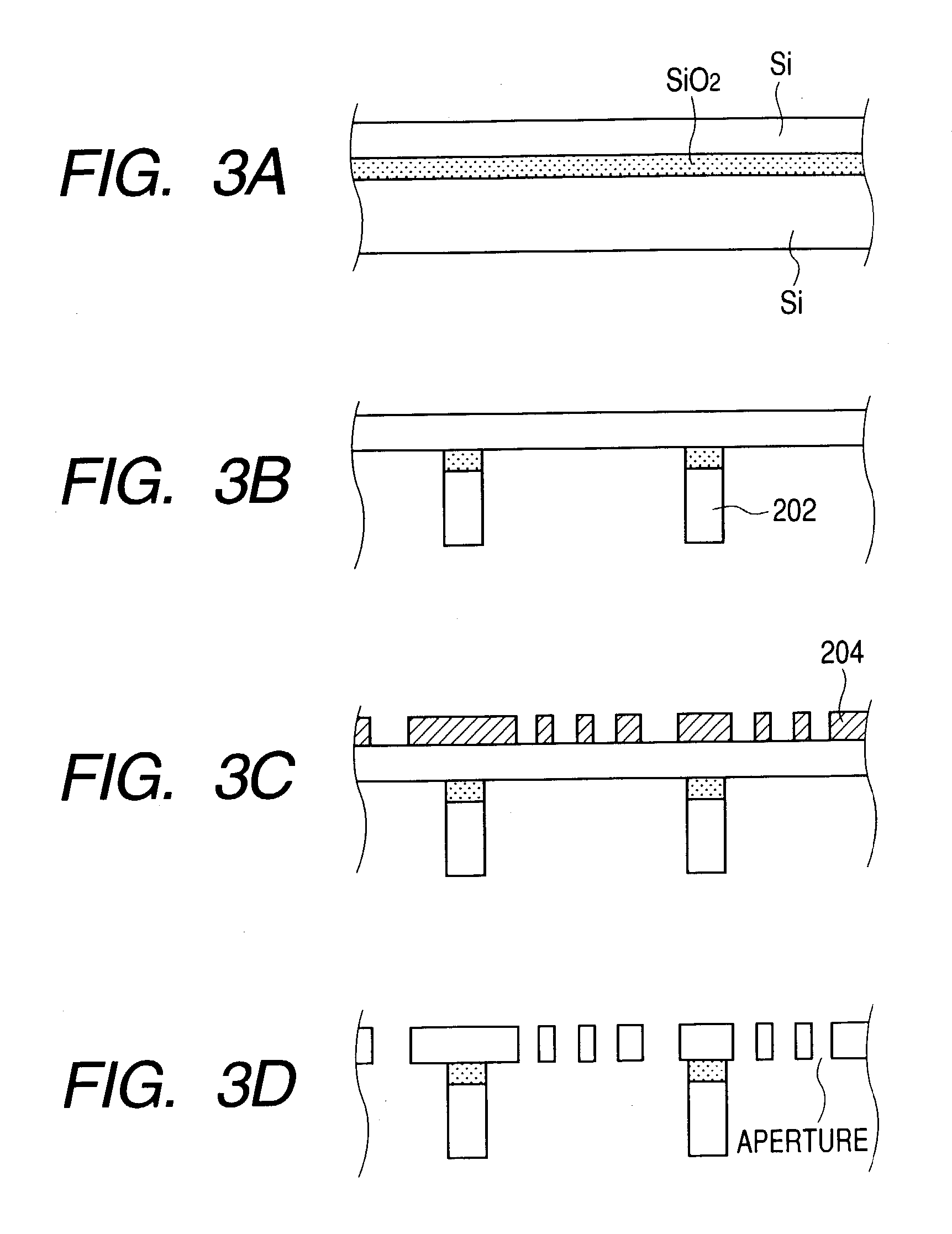

Integrated micro electro-mechanical system and manufacturing method thereof

ActiveUS20060205106A1Accurate representationHigh dimensional accuracyTelevision system detailsInflated body pressure measurementDielectricEtching

In the manufacturing technology of an integrated MEMS in which a semiconductor integrated circuit (CMOS or the like) and a micro machine are monolithically integrated on a semiconductor substrate, a technology capable of manufacturing the integrated MEMS without using a special process different from the normal manufacturing technology of a semiconductor integrated circuit is provided. A MEMS structure is formed together with an integrated circuit by using the CMOS integrated circuit process. For example, when forming an acceleration sensor, a structure composed of a movable mass, an elastic beam and a fixed beam is formed by using the CMOS interconnect technology. Thereafter, an interlayer dielectric and the like are etched by using the CMOS process to form a cavity. Then, fine holes used in the etching are sealed with a dielectric.

Owner:HITACHI ASTEMO LTD

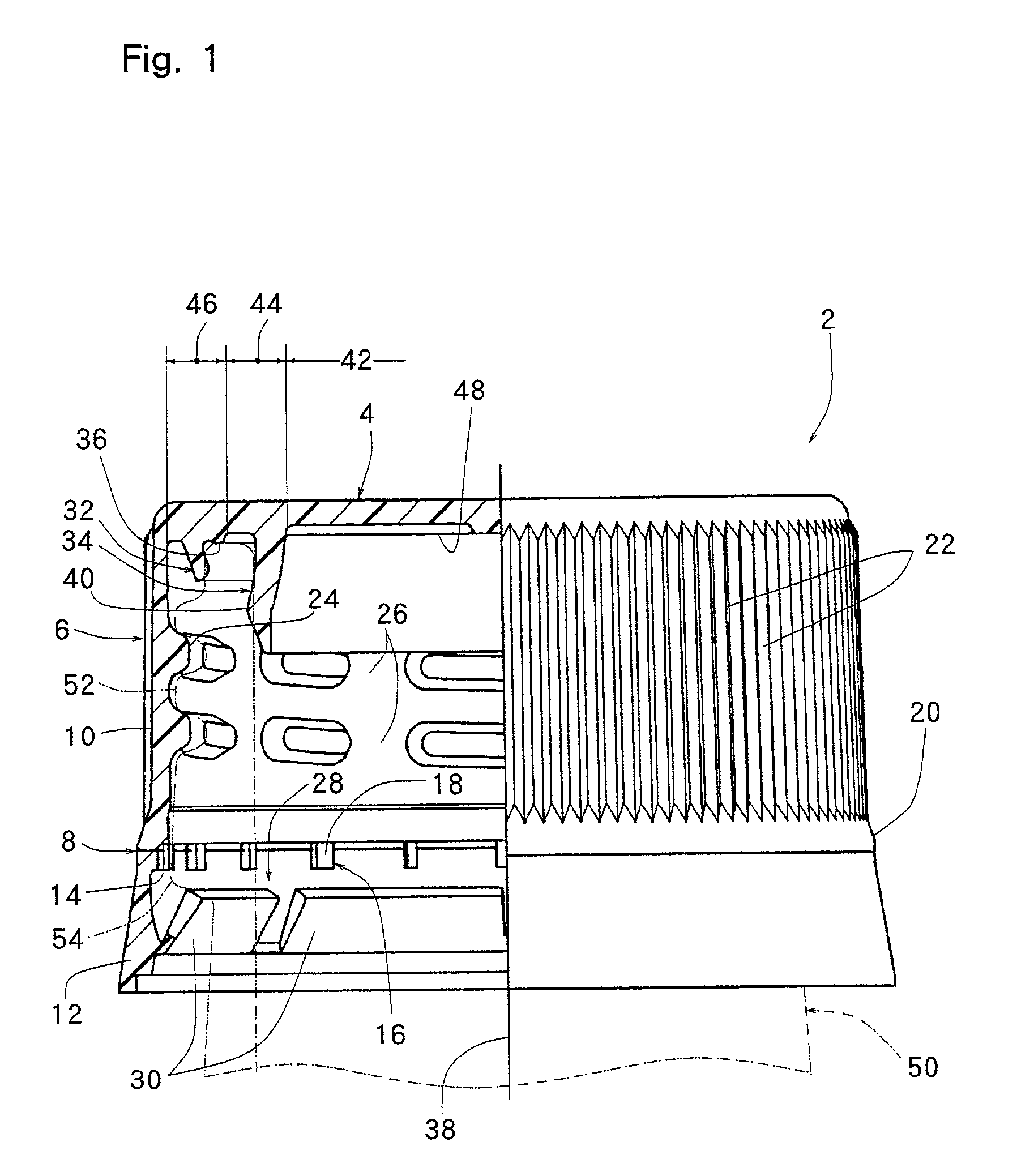

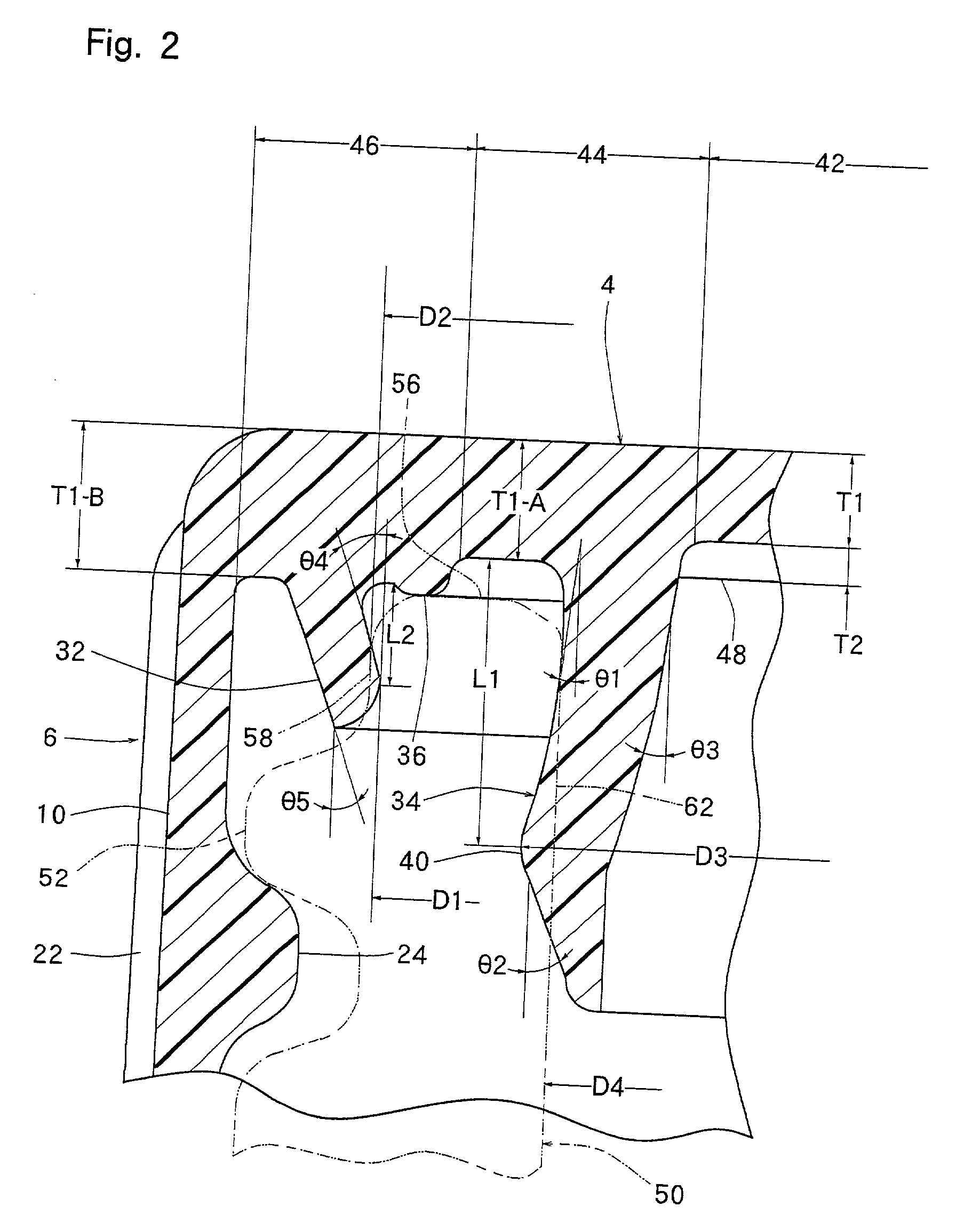

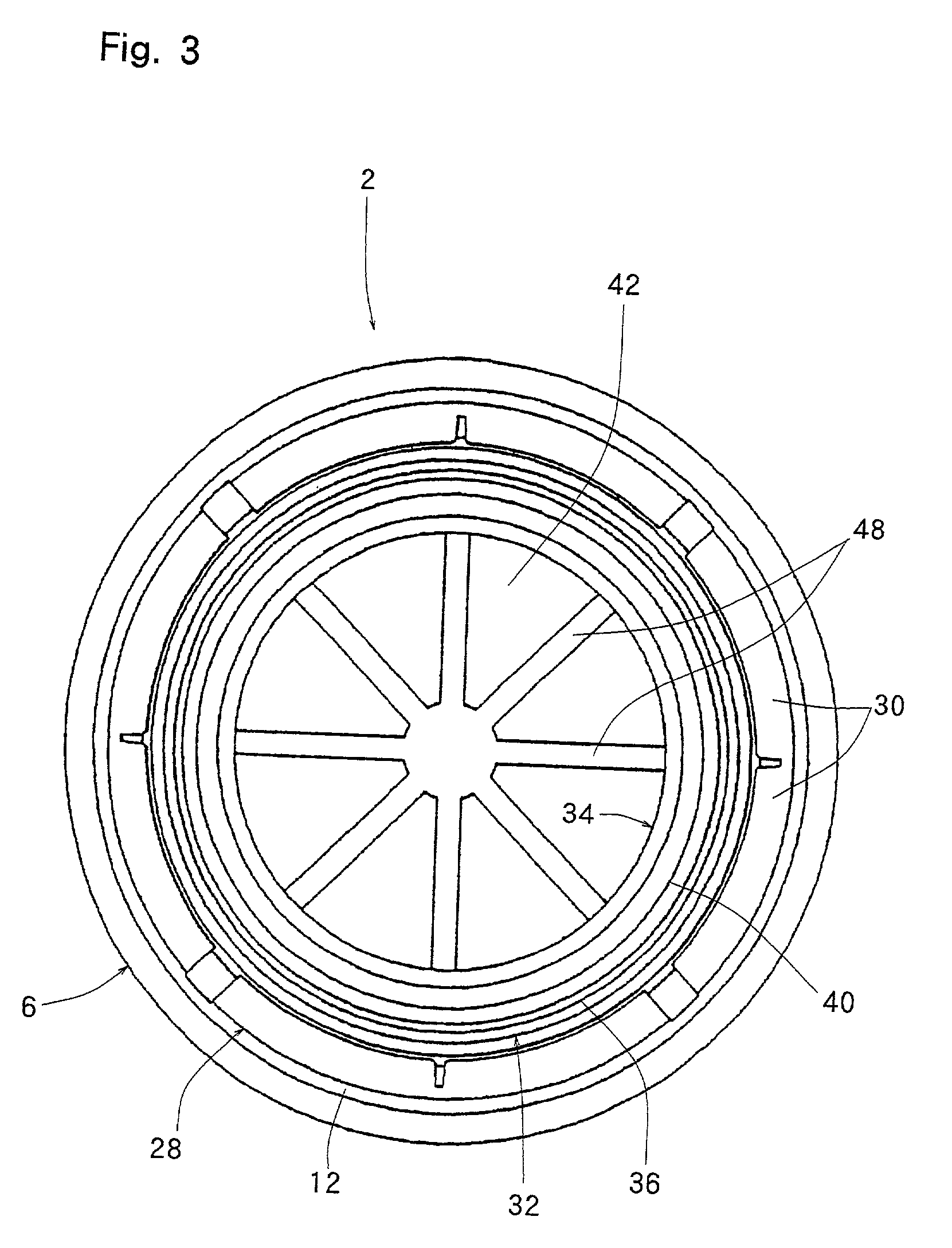

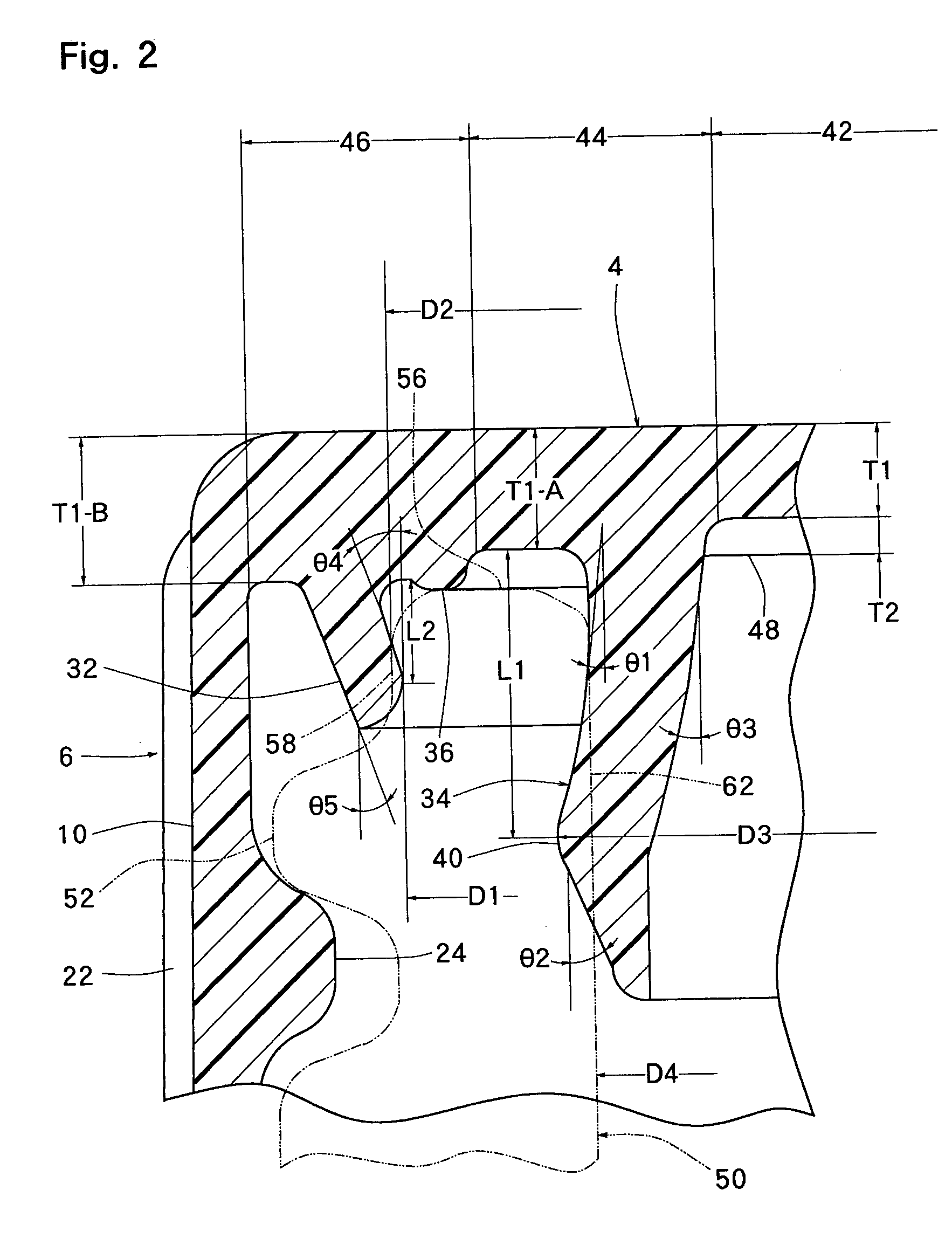

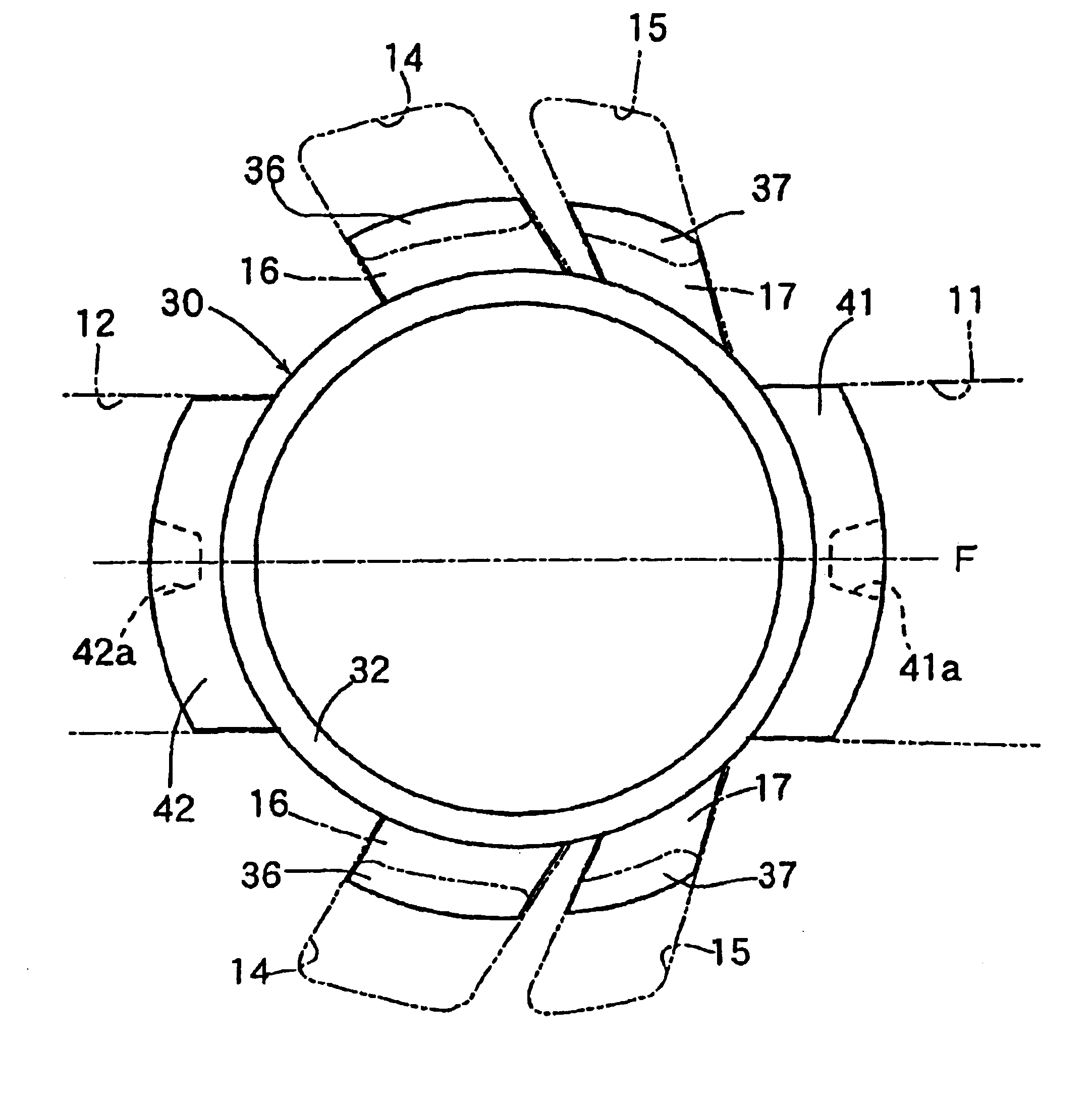

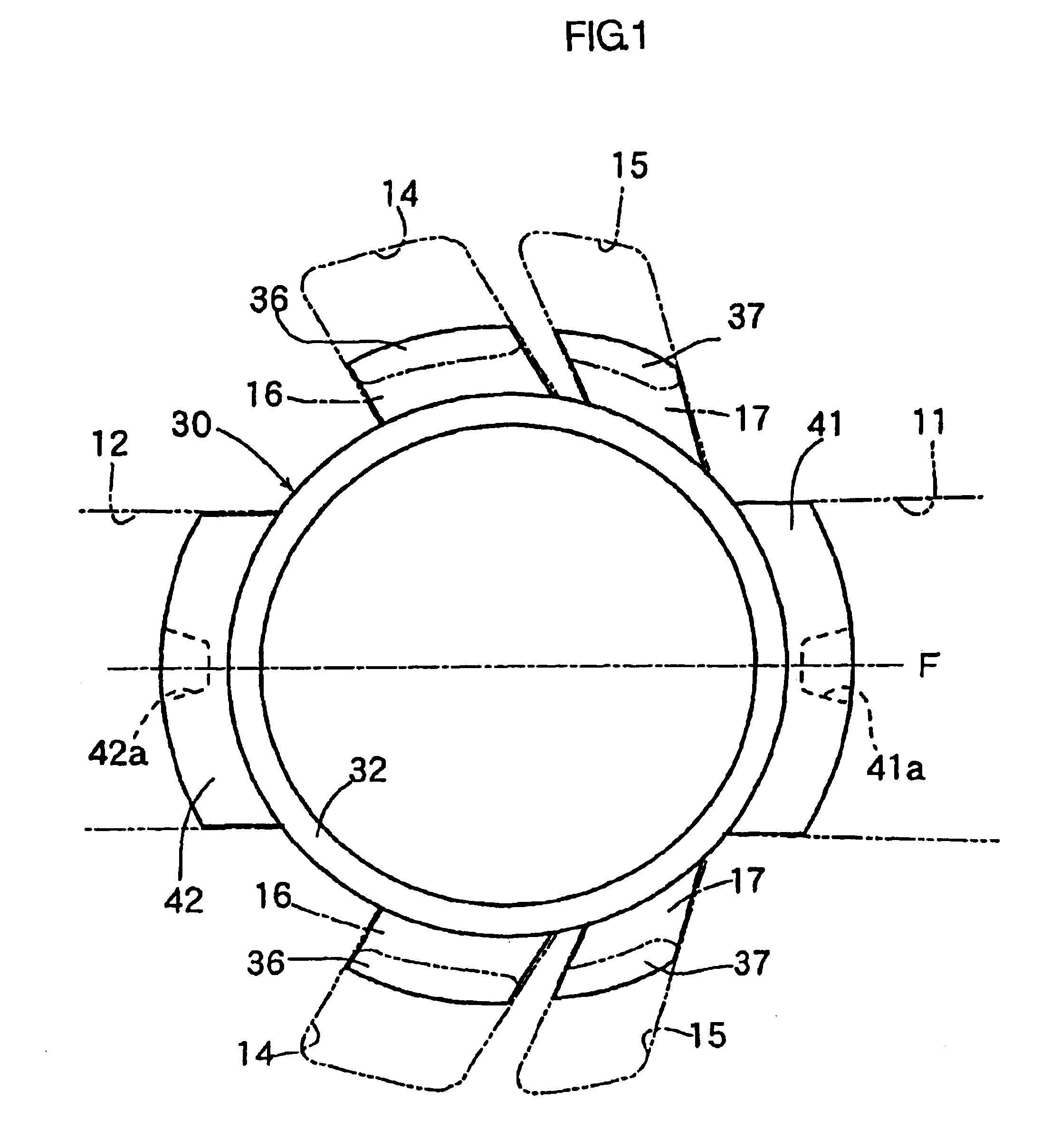

Synthetic resin container closure

InactiveUS20010027957A1Reduce compressionReduce injectionCapsClosure using stoppersEngineeringMechanical engineering

A container closure formed from a synthetic resin as a single unit has a circular top panel wall and a cylindrical skirt wall extending downwardly from the peripheral edge of the top panel wall. An outer cylindrical sealing protrusion, inner cylindrical sealing protrusion and annular sealing ridge arranged therebetween, all having a predetermined shape and a predetermined size, are formed on the inner surface of the top panel wall. The thickness of the center portion of the top panel wall is reduced to a predetermined range and a plurality of ribs having a predetermined thickness are formed on the inner surface of the center portion of the top panel wall.

Owner:JAPAN CROWN CORK CO LTD

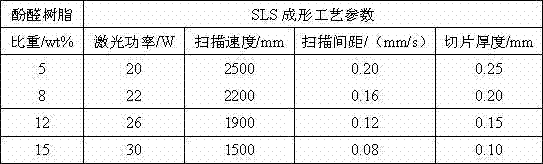

Method for preparing complexly shaped biomedical porous titanium molybdenum alloy implant body

InactiveCN102335742ADesign personalizationHigh dimensional accuracyIncreasing energy efficiencyProsthesisNatural boneMetallic materials

The invention provides a method for preparing a complexly shaped biomedical porous titanium molybdenum alloy implant body and belongs to the technical field of biomedical porous metallic material preparation. The method comprises the following steps of: taking a mixture of titanium and molybdenum metallic element powder and organic polymer powder as raw materials, and then preparing the biomedical porous titanium molybdenum alloy implant body by adopting the processes, such as three-dimensional modeling, selective laser-firing rapid forming, thermal de-greasing, vacuum sintering, and the like. The processing steps are simple, the period is short, the use ratio of materials is high, the cost is low, any complexly shaped porous titanium alloy implant body can be conveniently manufactured, and the method has efficiency and economic advantages in individual design and rapid manufacturing of the implant body. A titanium molybdenum alloy material prepared by using the method has the advantages that pore space is uniform, adjustment scopes of porosity, aperture ratio and aperture are wide, elasticity modulus and compression strength are in close proximity to natural bone, and the demand on biomechanical compatibility required by a biomedical material is met.

Owner:UNIV OF SCI & TECH BEIJING

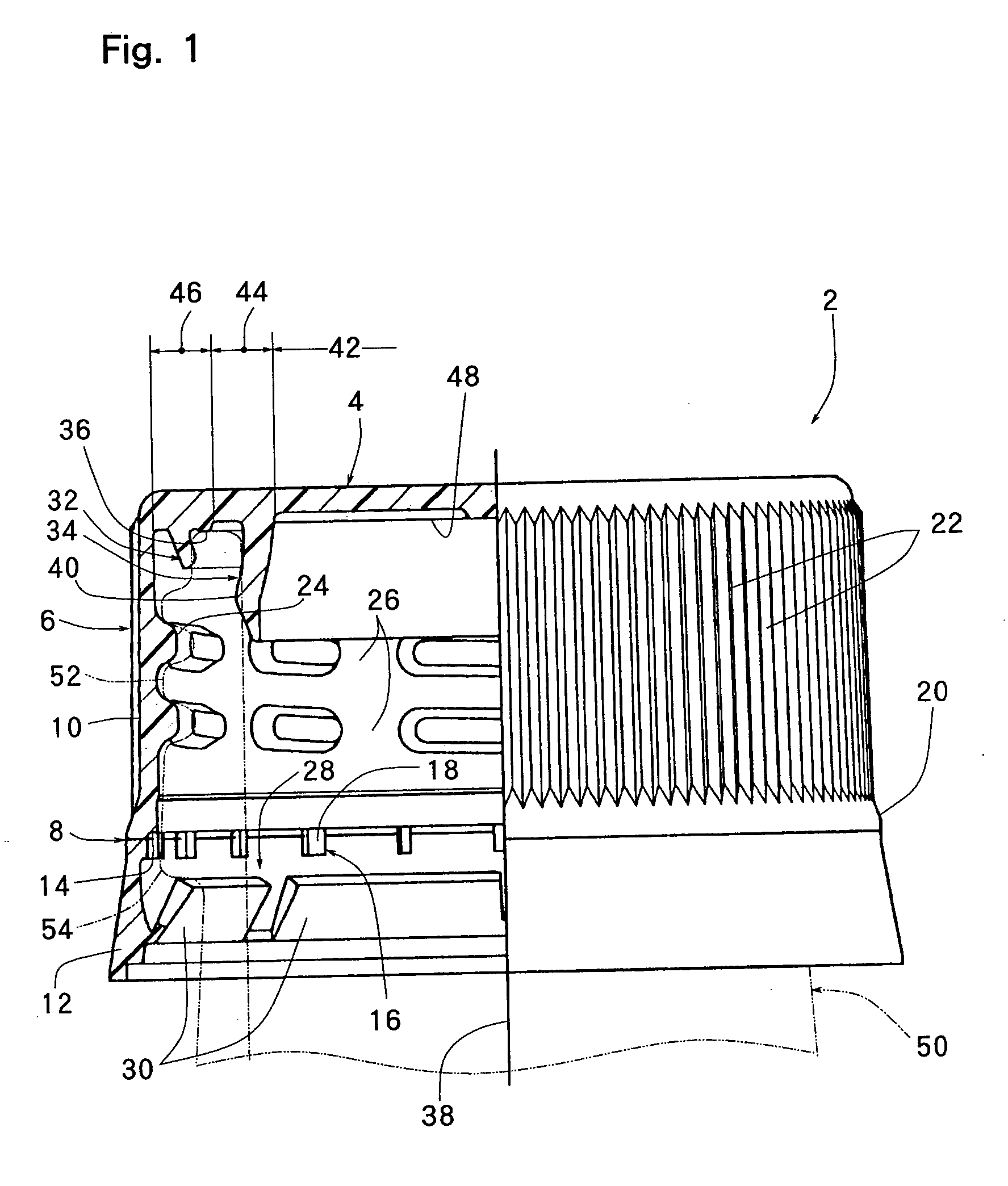

Integrated micro electro-mechanical system and manufacturing method thereof

ActiveUS7402449B2Easy to manufactureSufficient massTelevision system detailsInflated body pressure measurementDielectricEtching

In the manufacturing technology of an integrated MEMS in which a semiconductor integrated circuit (CMOS or the like) and a micro machine are monolithically integrated on a semiconductor substrate, a technology capable of manufacturing the integrated MEMS without using a special process different from the normal manufacturing technology of a semiconductor integrated circuit is provided. A MEMS structure is formed together with an integrated circuit by using the CMOS integrated circuit process. For example, when forming an acceleration sensor, a structure composed of a movable mass, an elastic beam and a fixed beam is formed by using the CMOS interconnect technology. Thereafter, an interlayer dielectric and the like are etched by using the CMOS process to form a cavity. Then, fine holes used in the etching are sealed with a dielectric.

Owner:HITACHI ASTEMO LTD

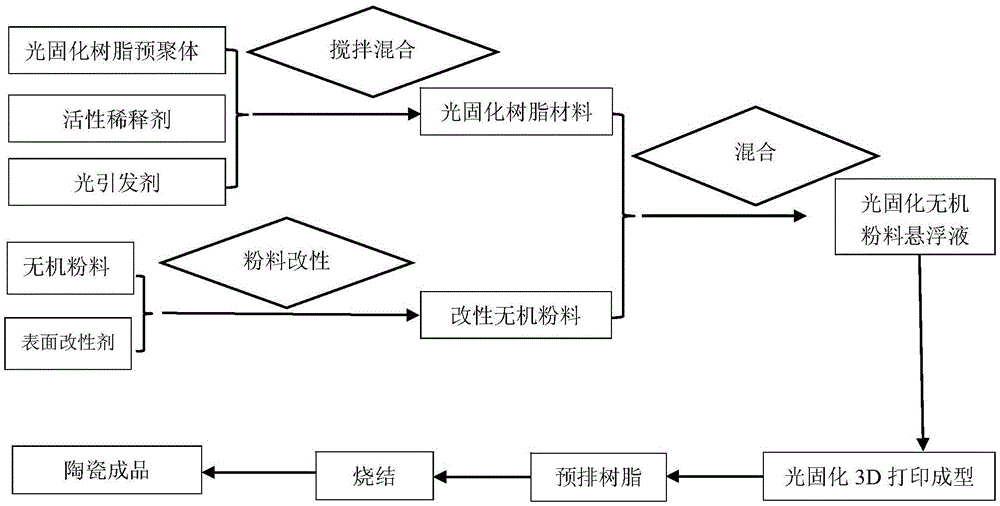

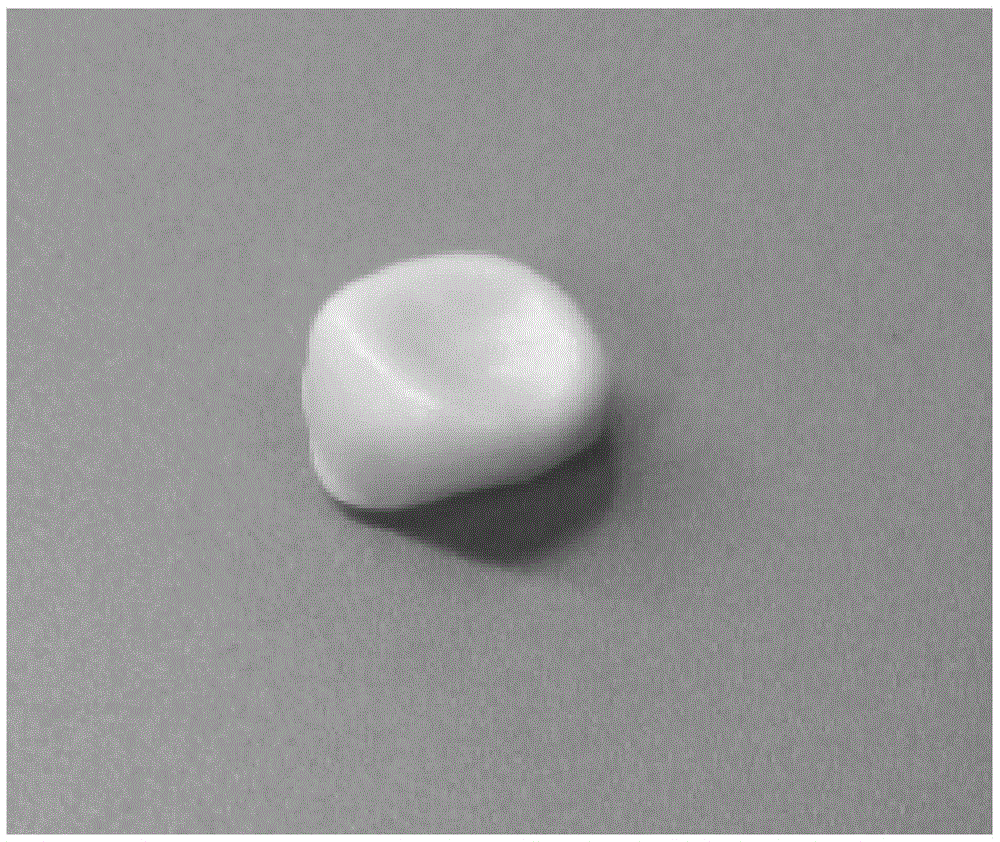

Ceramic material for 3D (three-dimensional) light curing forming printing and preparation method thereof

The invention provides a ceramic material for 3D (three-dimensional) light curing forming printing. The ceramic material is prepared from the following ingredients in percentage by weight: 25 to 85 weight percent of light curing resin and 15 to 75 weight percent of modified inorganic powder. The invention also further provides a preparation method and a use method of the ceramic material for 3D light curing forming printing. The ceramic material for 3D light curing forming printing provided by the invention is applicable to the preparation of a ceramic product by 3D light curing forming technologies such as the light curing laser fast forming and digital-based light processing projection curing forming. The defect of the current condition that the light curing forming technology in the prior art is not used for producing the ceramic product is overcome; the dimension precision of the obtained ceramic product is high; the 3D printing forming of various ceramic elements in complicated shapes can be realized; the ceramic material can be applied to aviation and aerospace industry, the medical field and the industrial field.

Owner:SHANGHAI UNION TECH

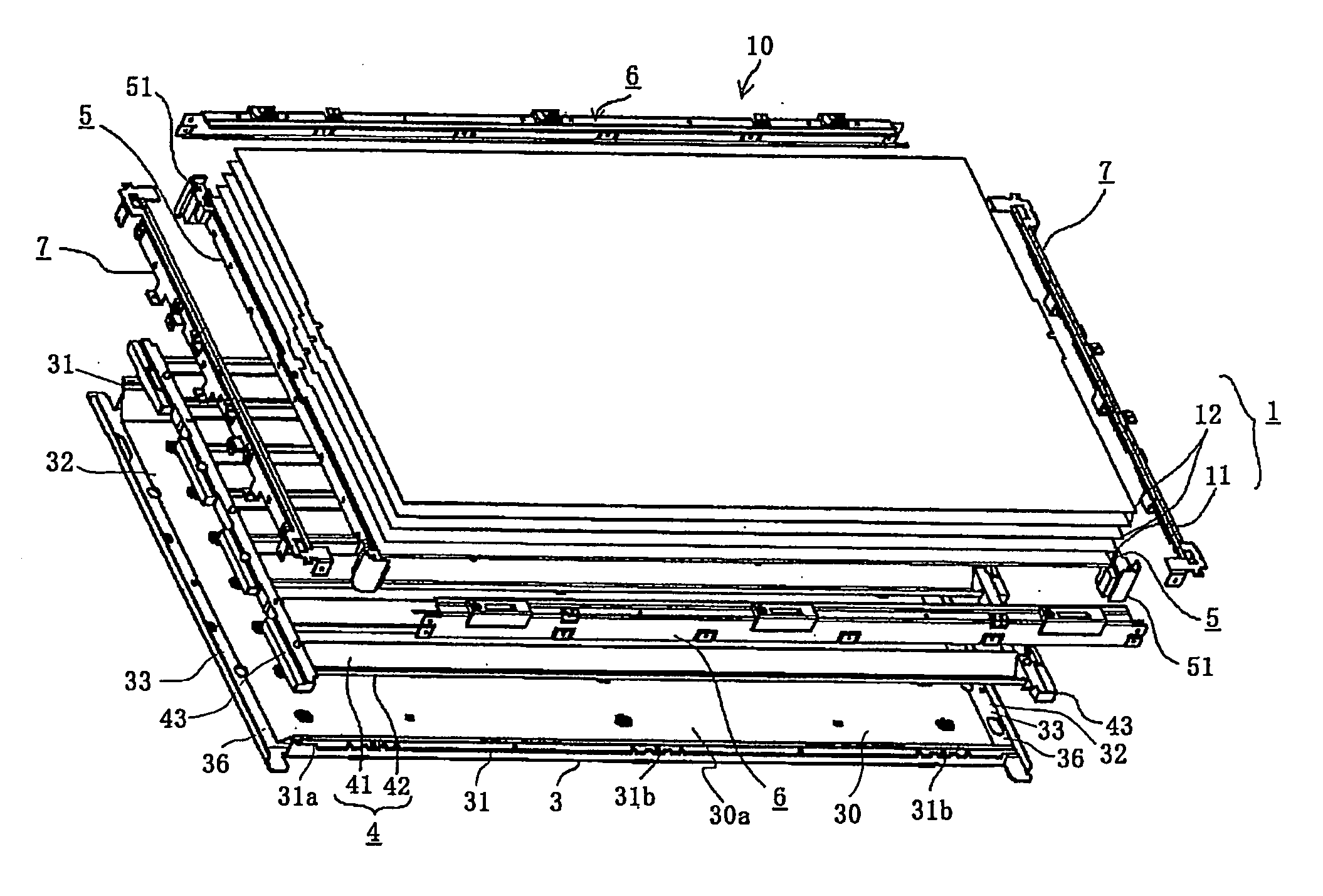

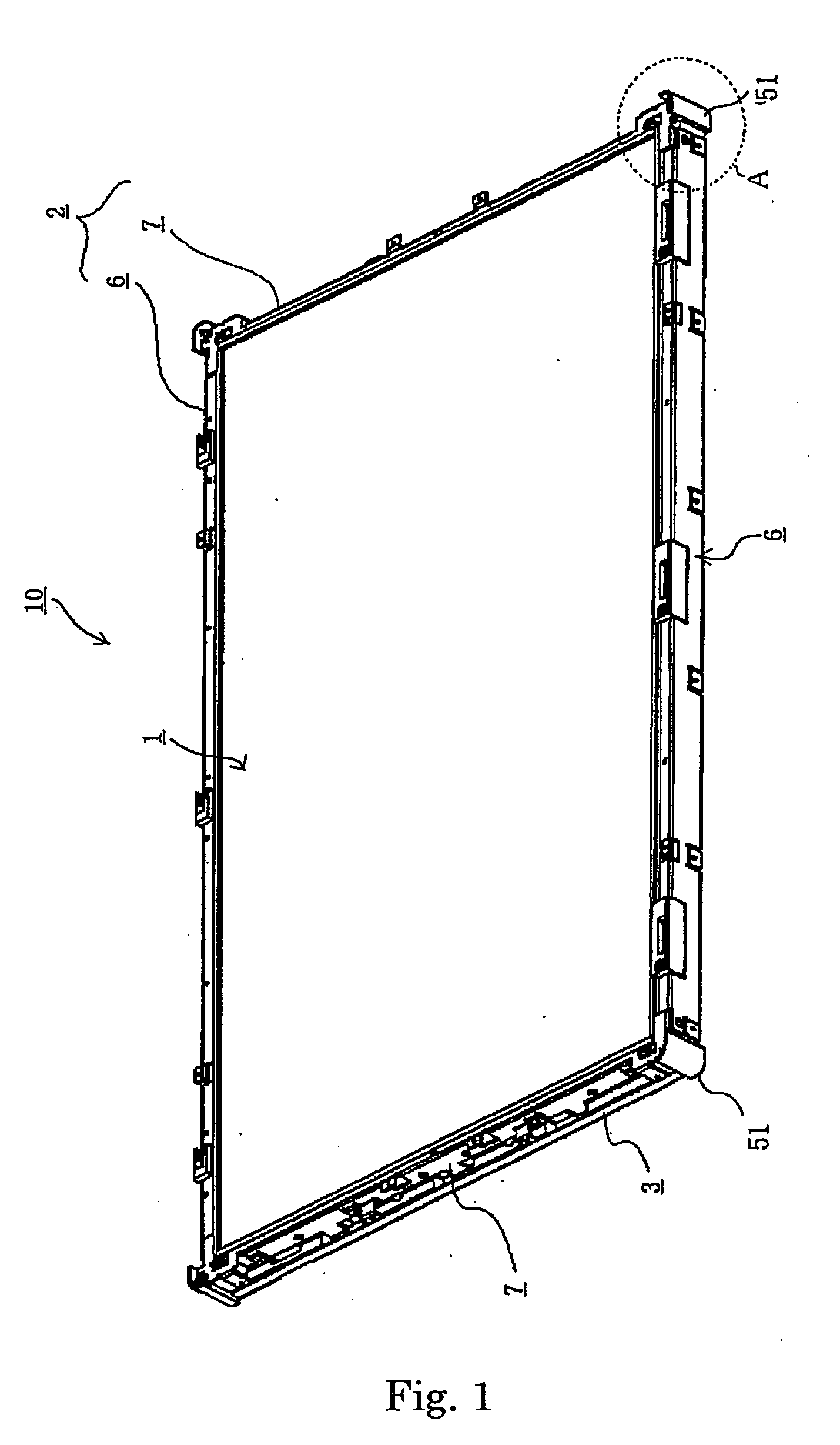

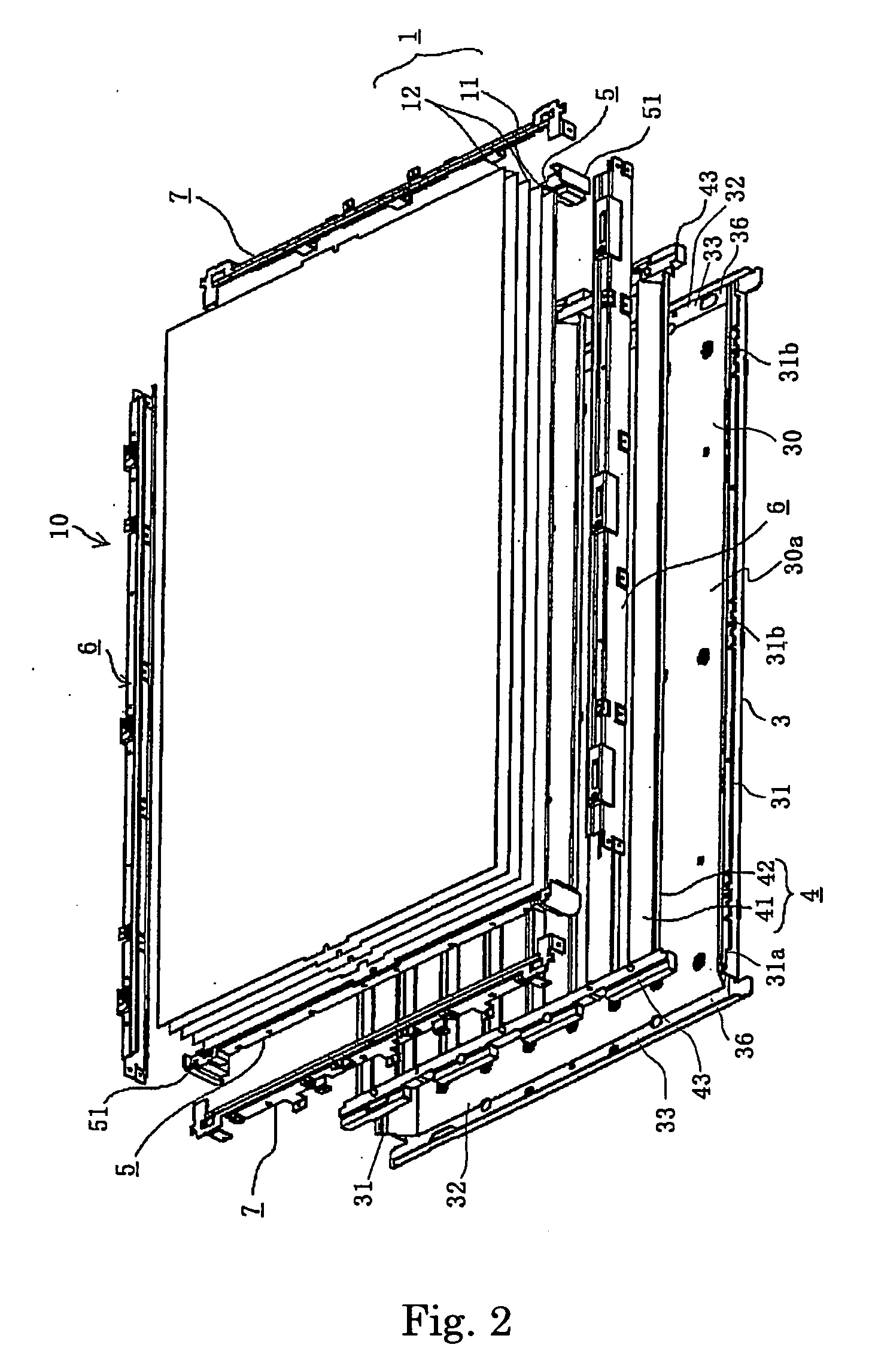

Liquid crystal display device

InactiveUS20060055839A1Easy to disassembleLow unit priceNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display device comprising a main body case 3 having opposing side walls 31, 31 and other open portions 32, 32 and a relatively wide U-shaped bottom wall 30, a backlight unit 4 housed in the main body case 3, and an optical member 1 placed on the surfaces of both side walls 31, 31 of the main body case 3 while covering the backlight unit 4, and whose outer periphery is encased by reinforcing frames 6, 7 that are joined at the corners to form a picture frame.

Owner:SANYO ELECTRIC CO LTD +1

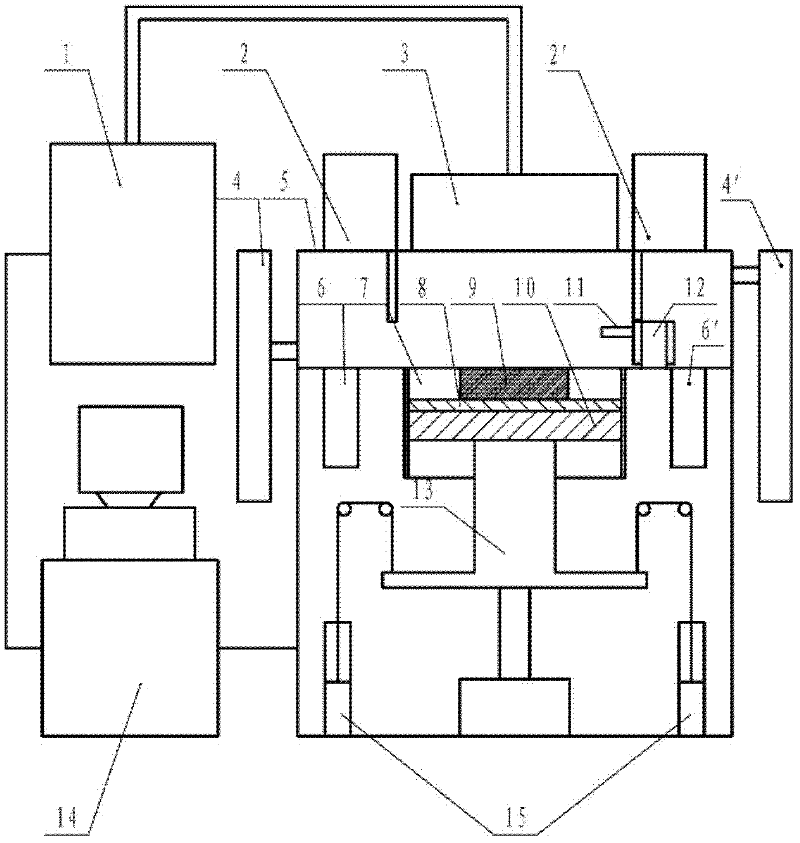

Selective laser melting forming device and method of medical magnesium alloy metal part

ActiveCN101856724ASatisfies complex spatial shape requirements with high degrees of freedomMeet complex space shape requirementsSelective laser meltingOptoelectronics

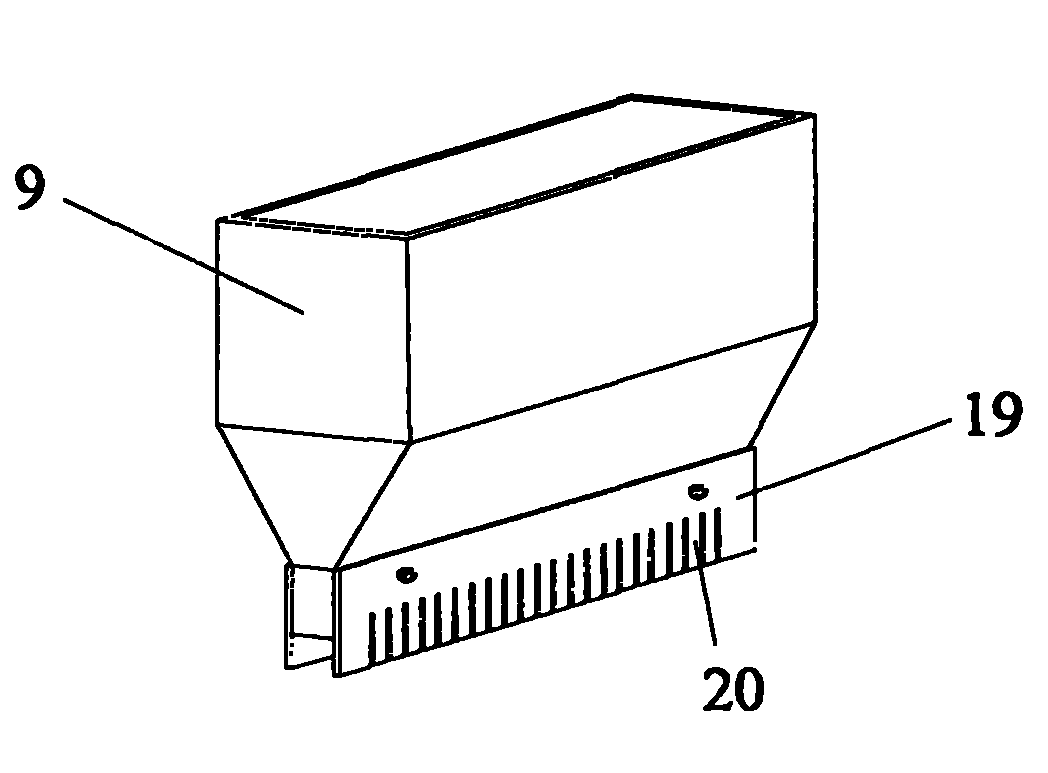

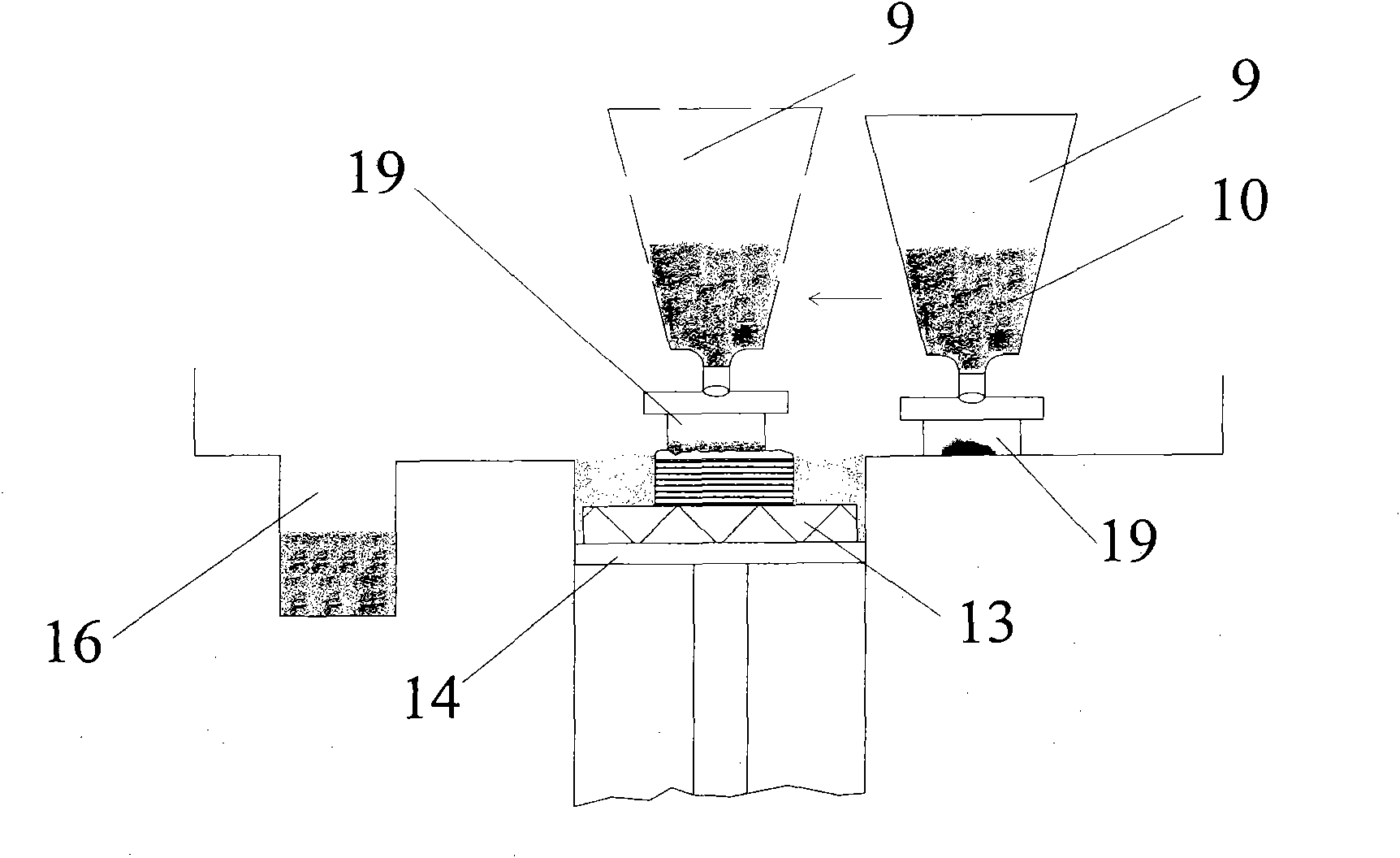

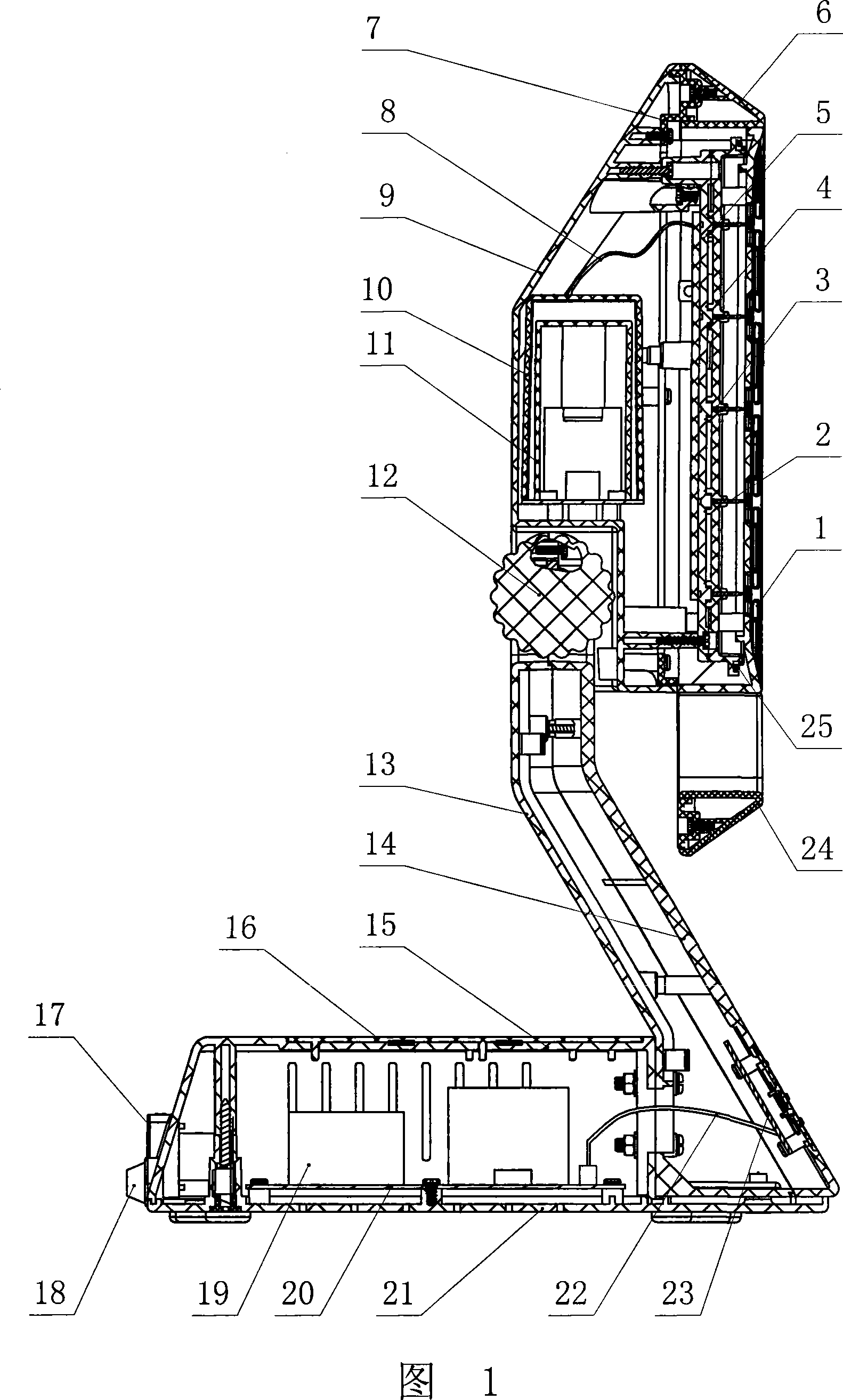

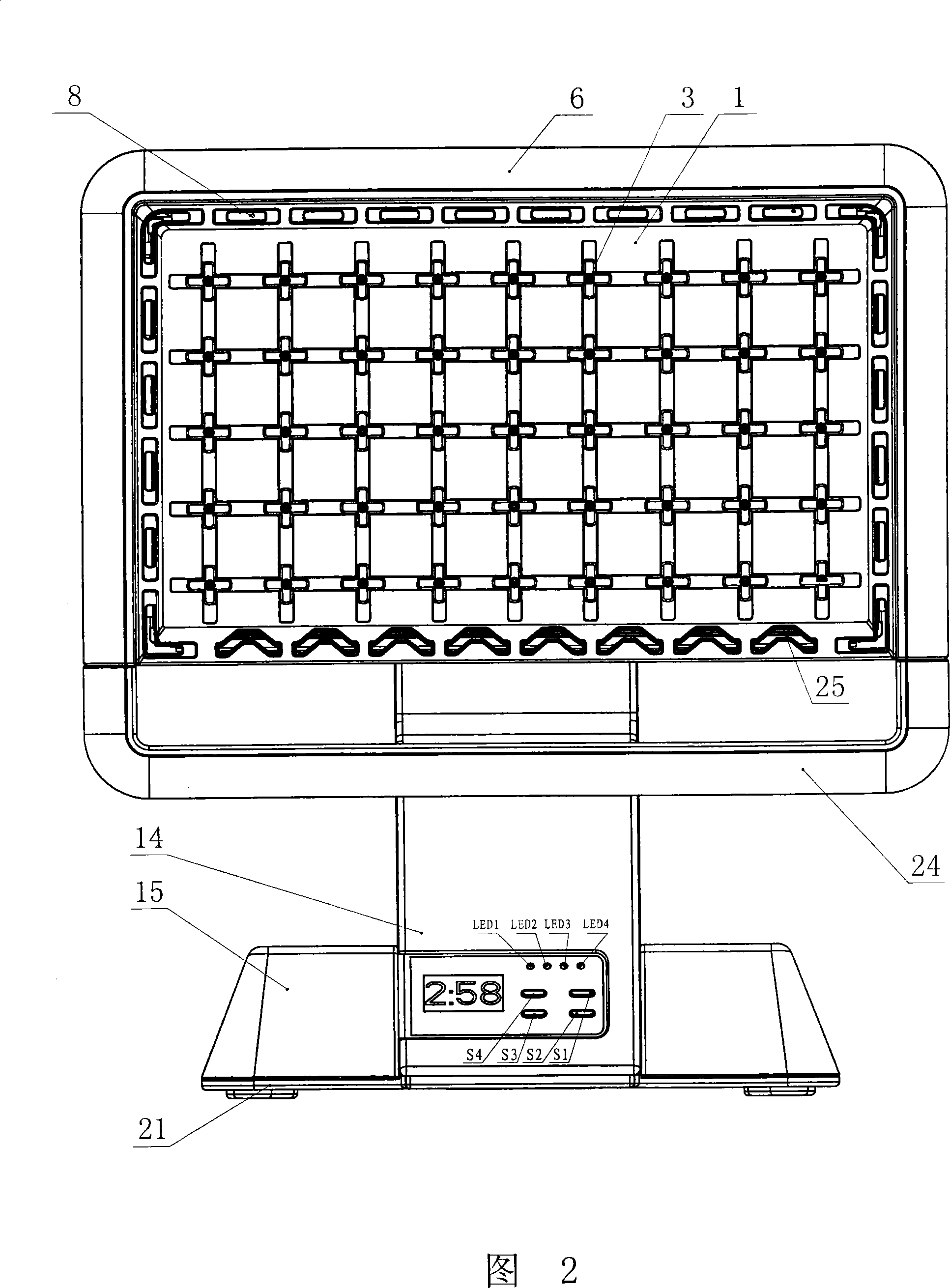

The invention provides a selective laser melting forming device of a medical magnesium alloy metal part, which comprises a control device, a powder delivering and spreading device, a laser transmission mechanism, an air purification device and a closed forming chamber, wherein the powder delivering and spreading device comprises a hopper and powder spreading brushes arranged on two sides below the hopper, the upper part of the hopper is arranged in a way of corresponding to a feeding opening on the upper part of the forming chamber, and the lower parts of the powder spreading brushes horizontally correspond to the upper surface of a forming cylinder; the laser transmission mechanism is arranged outside and above the forming chamber and is arranged in a way of corresponding to the forming cylinder; the side wall of the forming chamber is provided with an air inlet and an air outlet, and the air purification device is connected with the air inlet and the air outlet respectively; and the control device is connected with the powder delivering and spreading device, the laser transmission mechanism, the forming cylinder and the air purification device respectively. The invention also provides a selective laser melting forming method of the medical magnesium alloy metal part. The device and the method can manufacture parts which have complex shapes required in the medical field directly, and have the advantages of high forming efficiency and the like.

Owner:SOUTH CHINA UNIV OF TECH

Negative ion generating device

ActiveCN101214390AQuality improvementLarge particle sizeDeodrantsCorona dischargeFiberHigh concentration

An anion generator includes a base and a shell assembled on the base, needle stripes of homopolar spray points vertically lined with equal spacing fixed between a partition plate and a window grating, and a control circuit. The technical proposal is that the shell consists of a rear shell and a front shell; the window grating is moveably connected with the rear shell; the homopolar tungsten alloy spray points vertically lined with equal spacing are fixed between the needle stripes and press plates through the one-off sealing and packaging technique; the carbide fibre fixed on the needle stripes is communicated with the small high voltage blocks; a closed carbide fibre ring is arranged in a circular slot on the circumference of the needle stripes; the high voltage block assembly components fixed in the shell are sealed and packaged in a shield screen; the base and the shell are hinged together by a rotary positioning device. The invention has the advantages of reasonable structure design, convenience in adjustment and positioning, good transmission direction of the anion, high concentration and small grain size of the generated anion, large output quantity within unit time and obvious improvement of the air quality, thus obviously improving the curative effect of diseases and the air purification efficiency, and obviously extending the service life.

Owner:柏学红

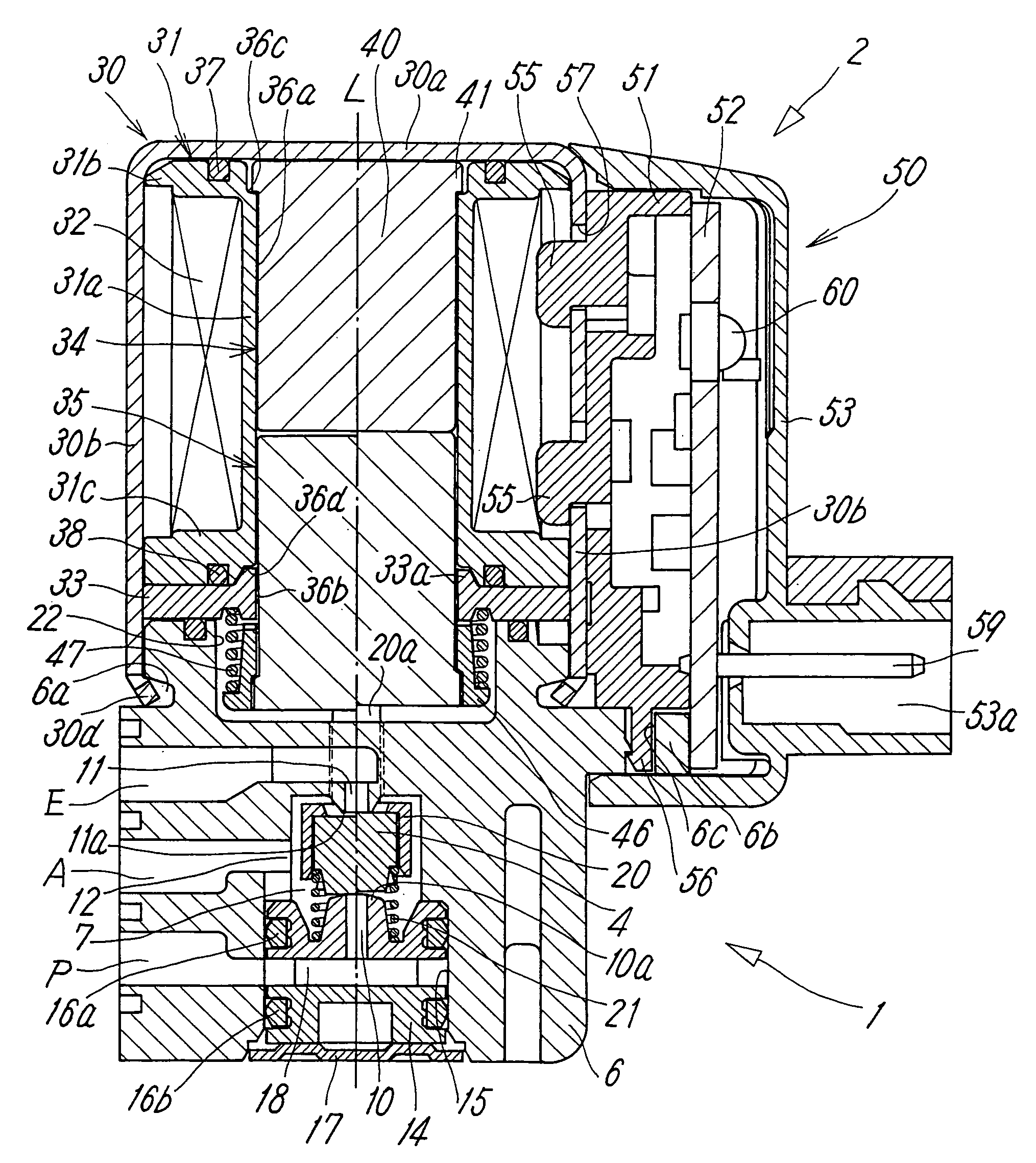

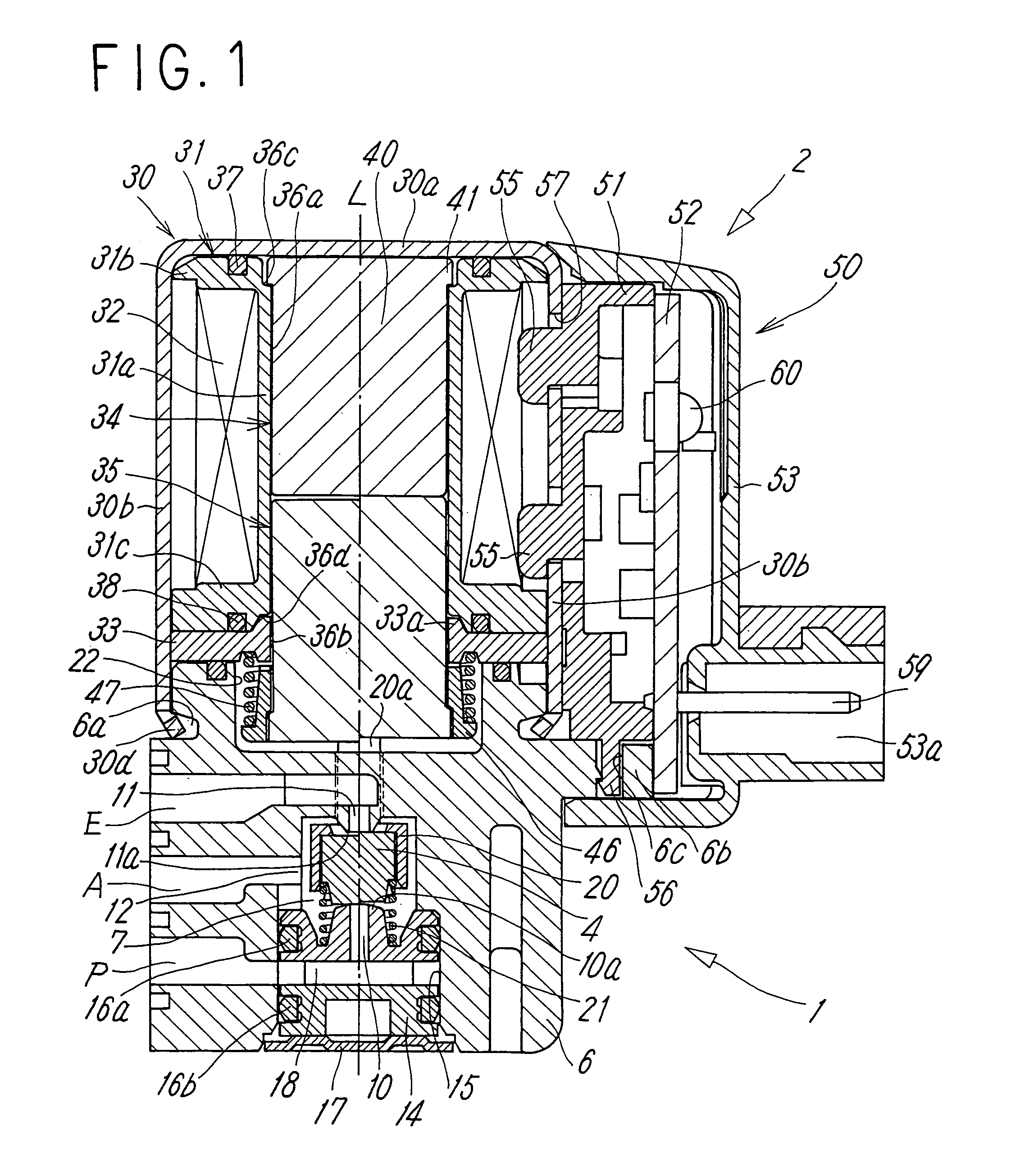

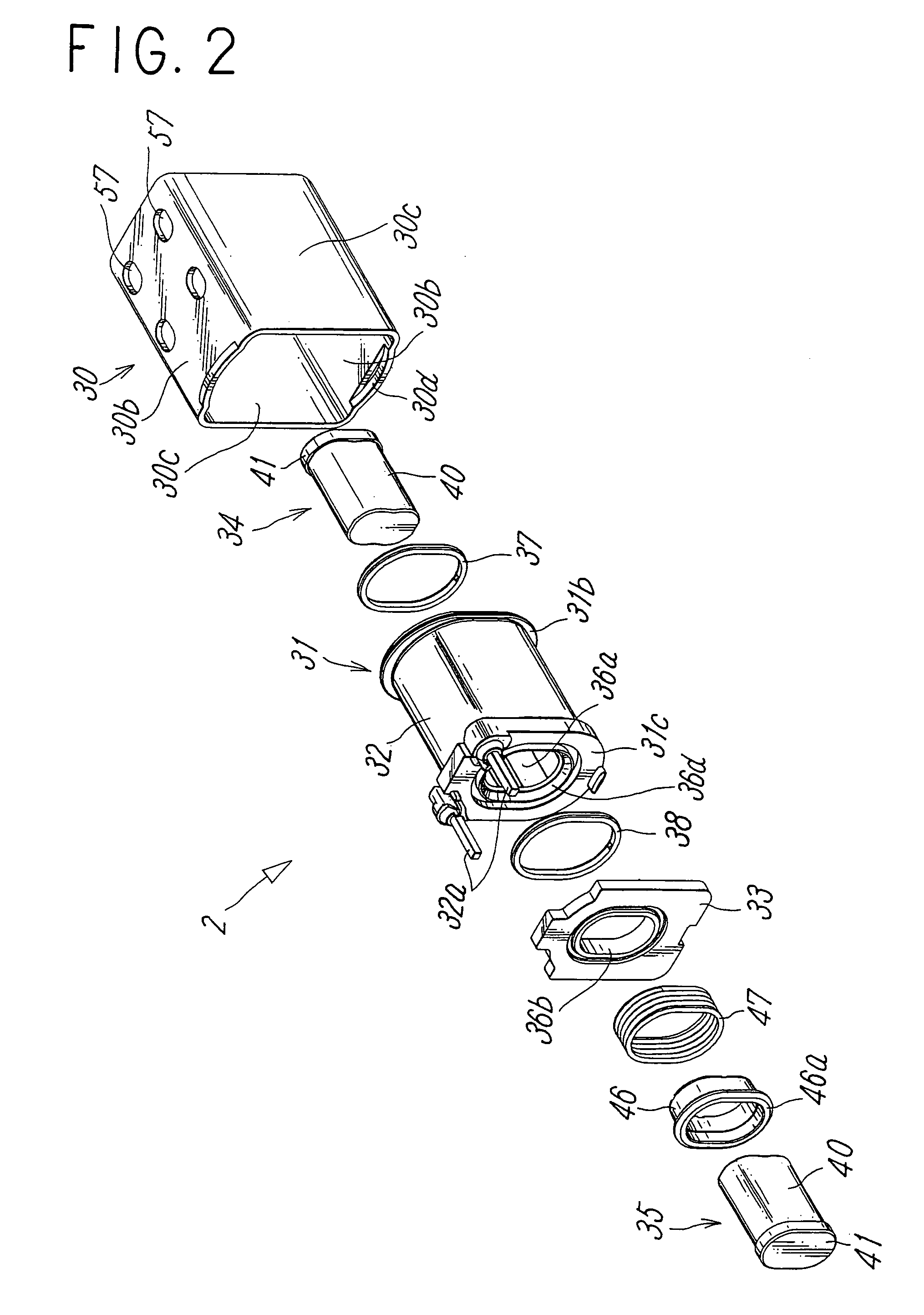

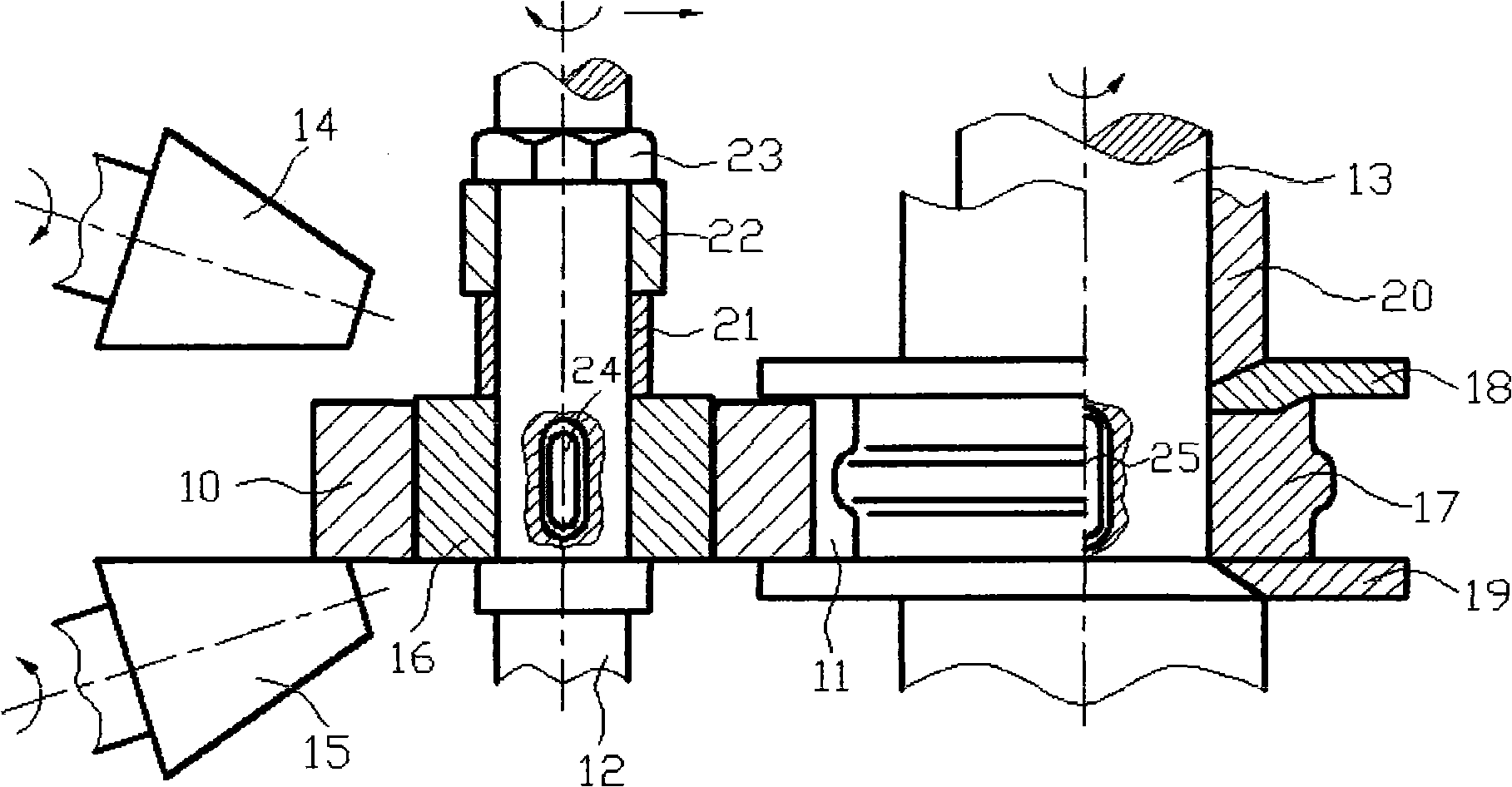

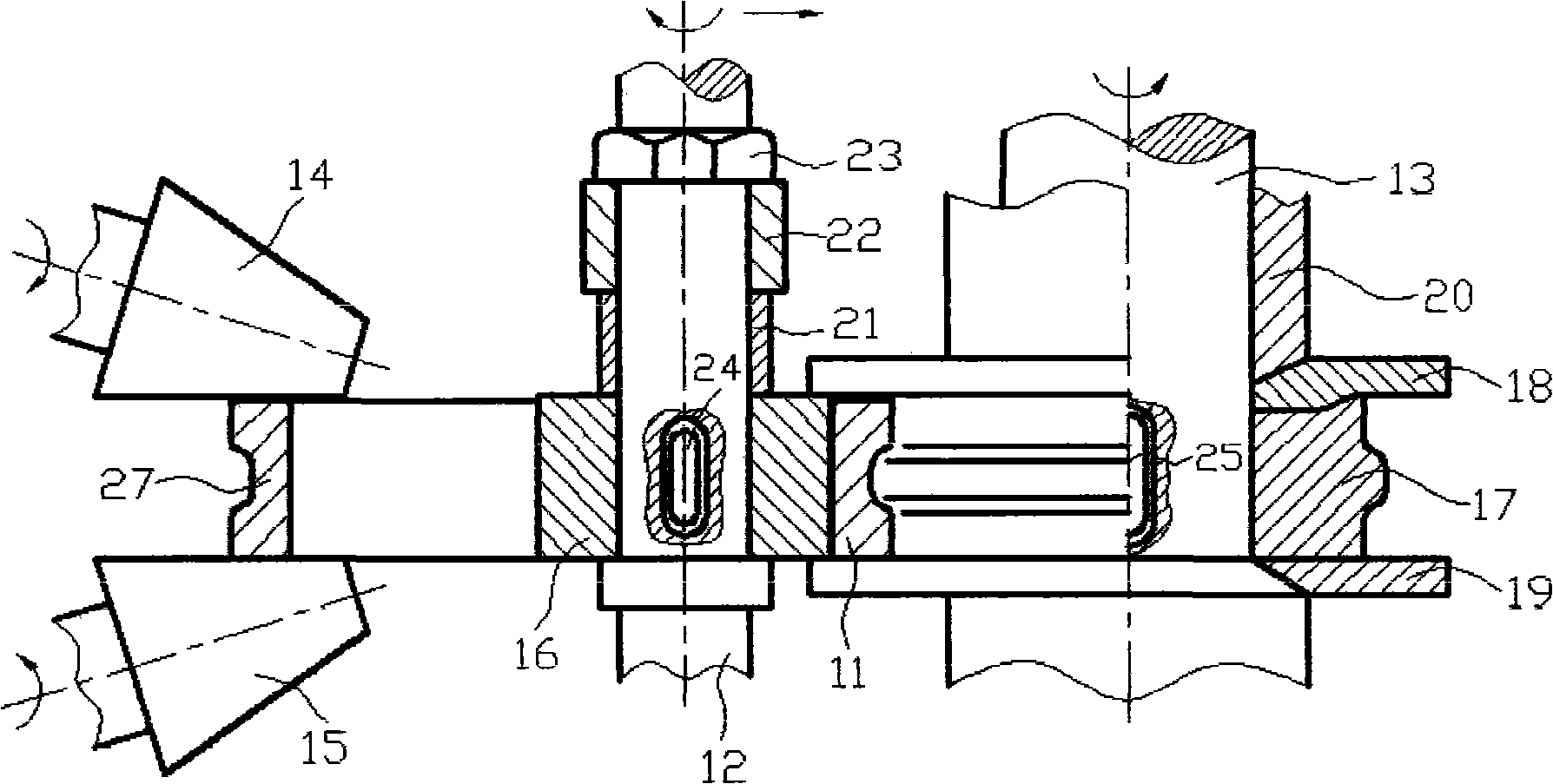

Electromagnetic valve

ActiveUS7273206B2Simple structureReduce manufacturing costOperating means/releasing devices for valvesMultiple way valvesBobbinNuclear engineering

An electromagnetic manipulating portion of an electromagnetic valve includes a fixed iron core fixedly disposed in the inside hole of a bobbin and a movable iron core movably disposed in the inside hole and attracted to the fixed iron core by a magnetic attraction force. The fixed iron core and the movable iron core are composed of the same normally magnetic material in the same shape and in the same size and have compatibility each other.

Owner:SMC CORP

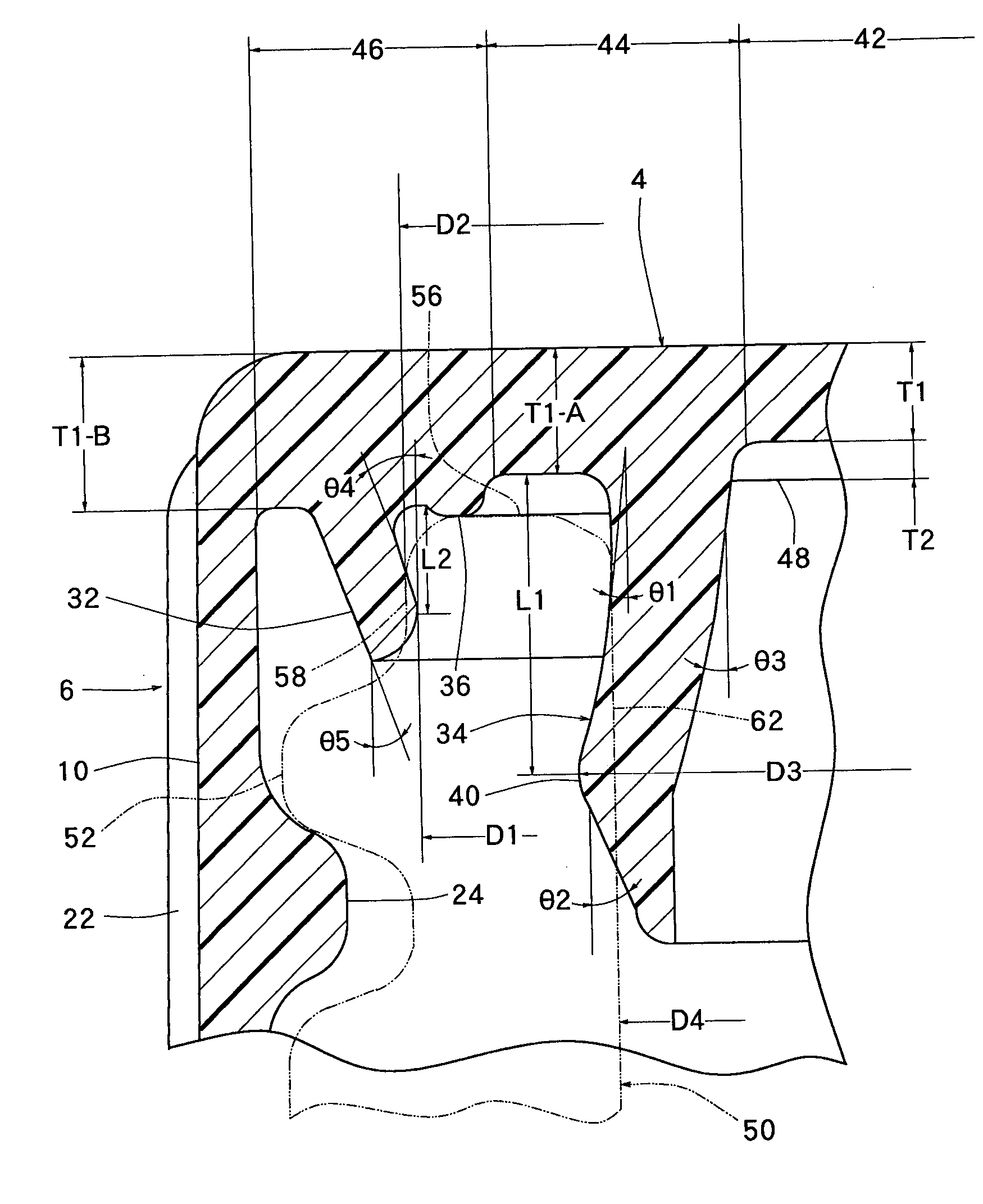

Synthetic resin container closure

InactiveUS20040060893A1Reduce compressionReduce injectionCapsClosure using stoppersEngineeringSynthetic resin

A container closure formed from a synthetic resin as a single unit has a circular top panel wall and a cylindrical skirt wall extending downwardly from the peripheral edge of the top panel wall. An outer cylindrical sealing protrusion, an inner cylindrical sealing protrusion, and annular sealing ridge, all having a predetermined shape and a predetermined size, are formed on the inner surface of the top panel wall. In one embodiment, the thickness of the center portion of the top panel wall is reduced to a predetermined range and a plurality of ribs having a predetermined thickness are formed on the inner surface of the center portion of the top panel wall.

Owner:JAPAN CROWN CORK CO LTD

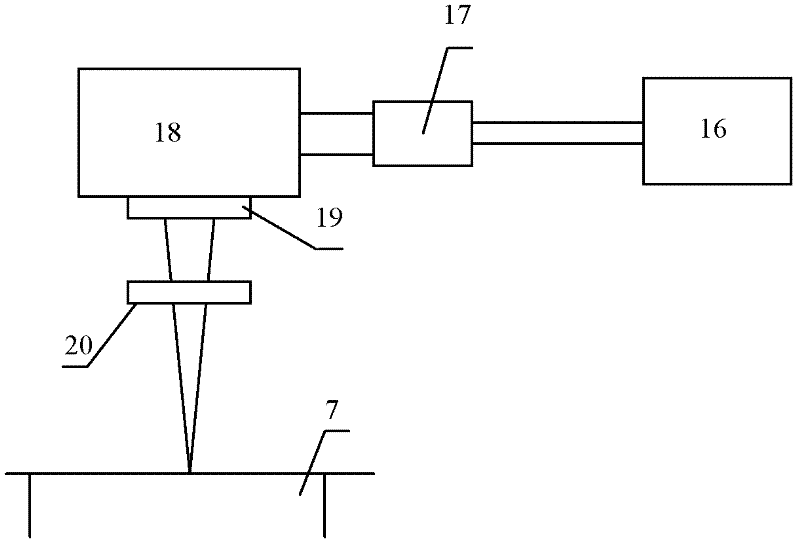

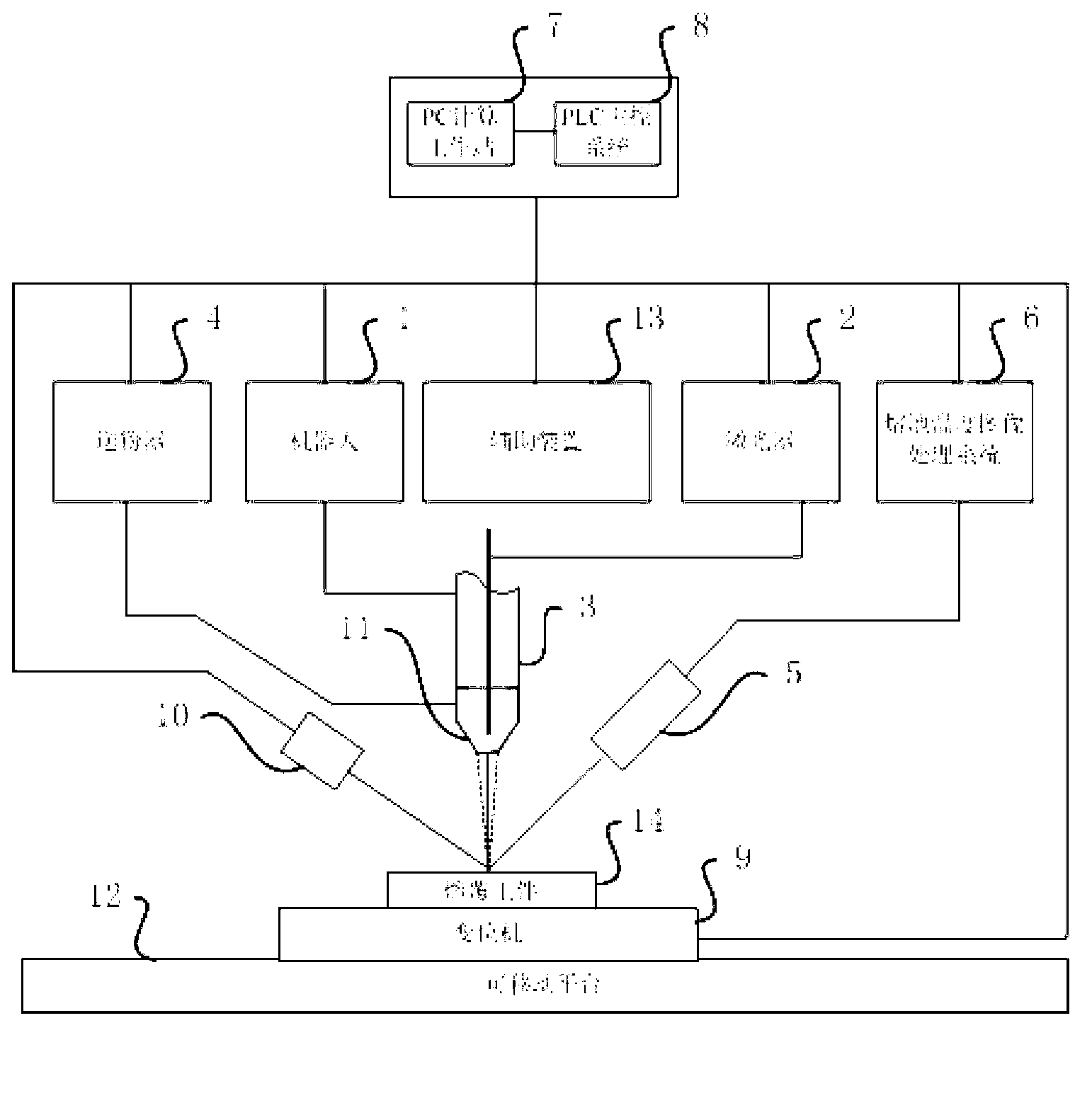

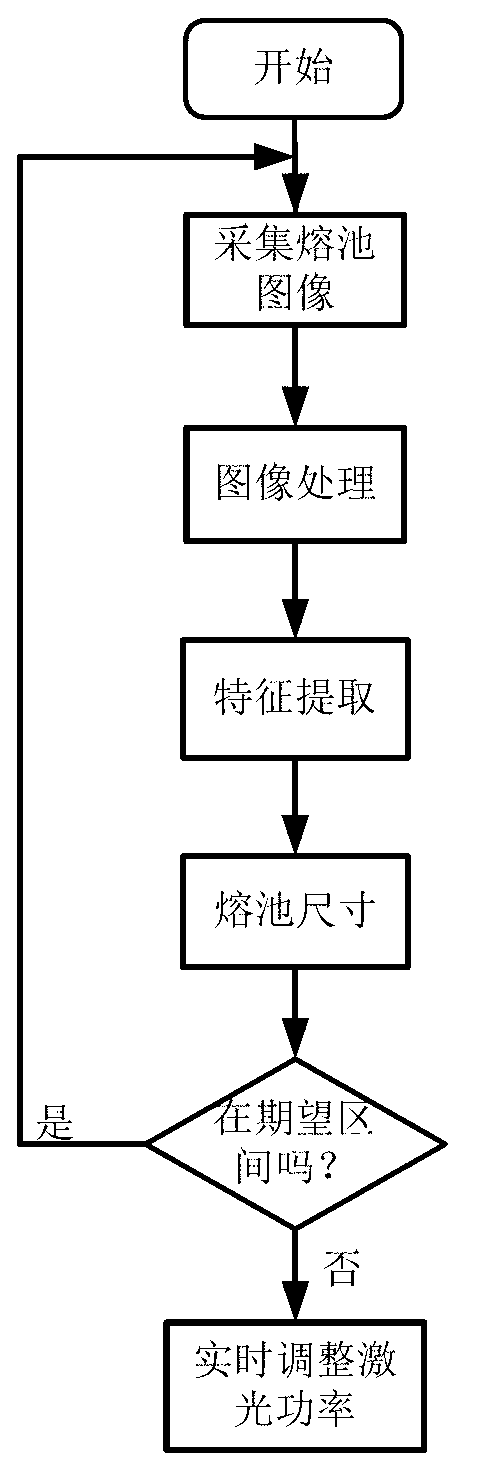

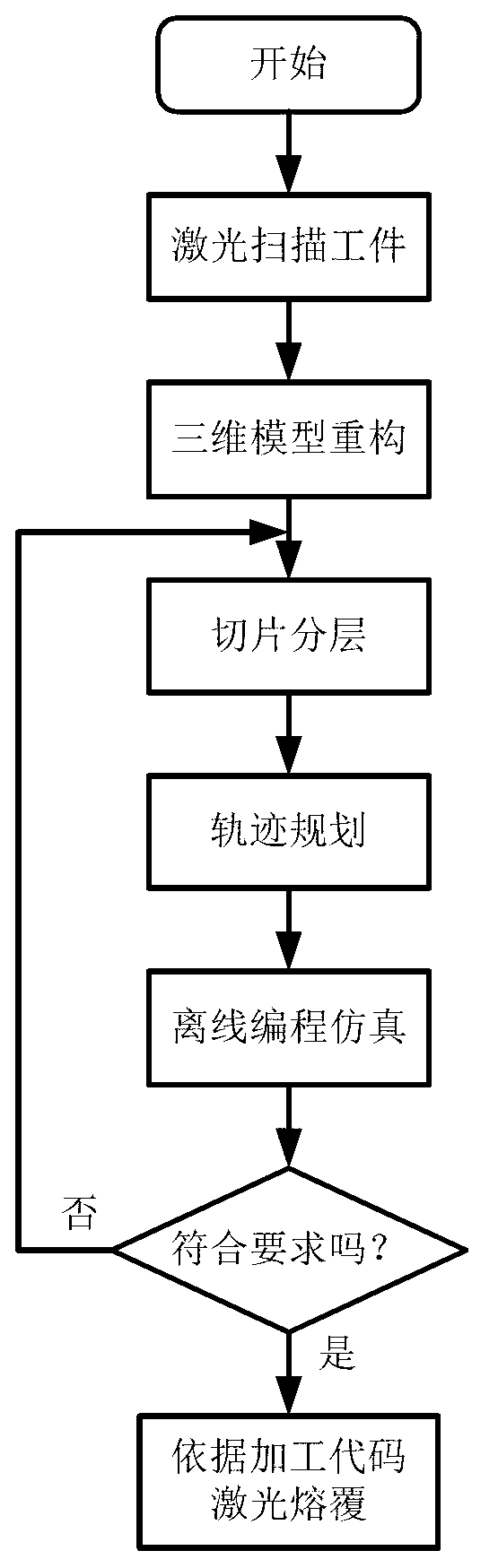

Movable laser cladding and repairing system

ActiveCN103074625AAchieve claddingAchieve fixMetallic material coating processesLaser scanningLaser sensor

The invention provides a movable laser cladding and repairing system in the field of laser cladding and repairing. The movable laser cladding and repairing system comprises a movable platform, wherein a laser, a robot, a position changing machine, a powder feeder, an image processing system, a control system (comprises a PLC (programmable logic controller) main control system, a PC (personal computer) computing workstation), a video camera, a three-dimensional laser scanning sensor, a laser processing head and a coaxial powder feeding head are fixedly arranged on the movable platform. The movable laser cladding and repairing system takes the robot as a moving body, controls the clad pool size, the temperature and other information by using an image acquiring and processing system, and scans a workpiece to slice, stratify and automatically clad a three-dimensional workpiece model based on the three-dimensional laser sensor; the movable laser cladding and repairing system is convenient and flexible, simplifies a repairing process, achieves precision and self-adaptive control of a cladding process, effectively improves the cladding quality, and facilitates field application of a large component through the movable platform.

Owner:SHANGHAI JIAO TONG UNIV

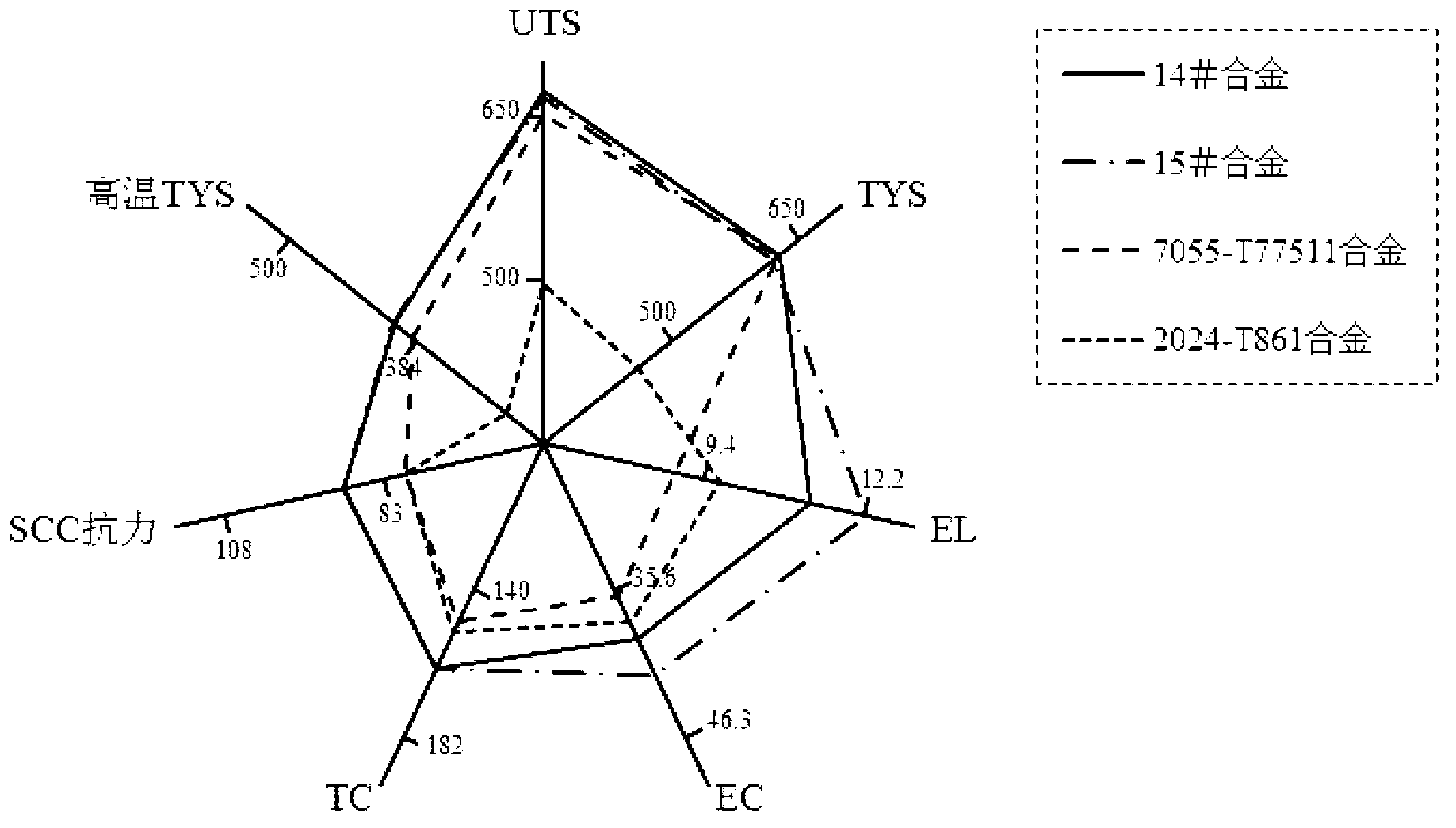

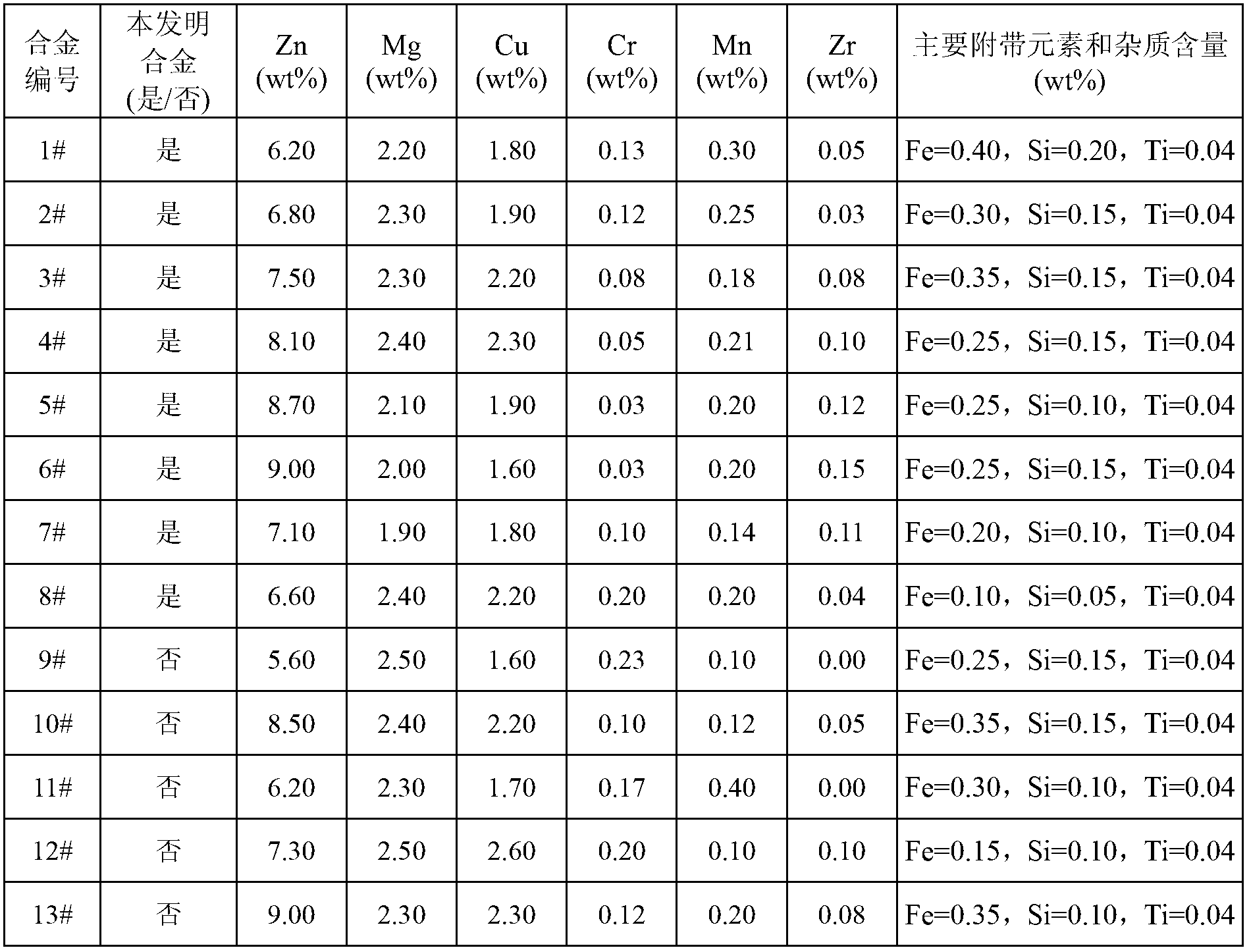

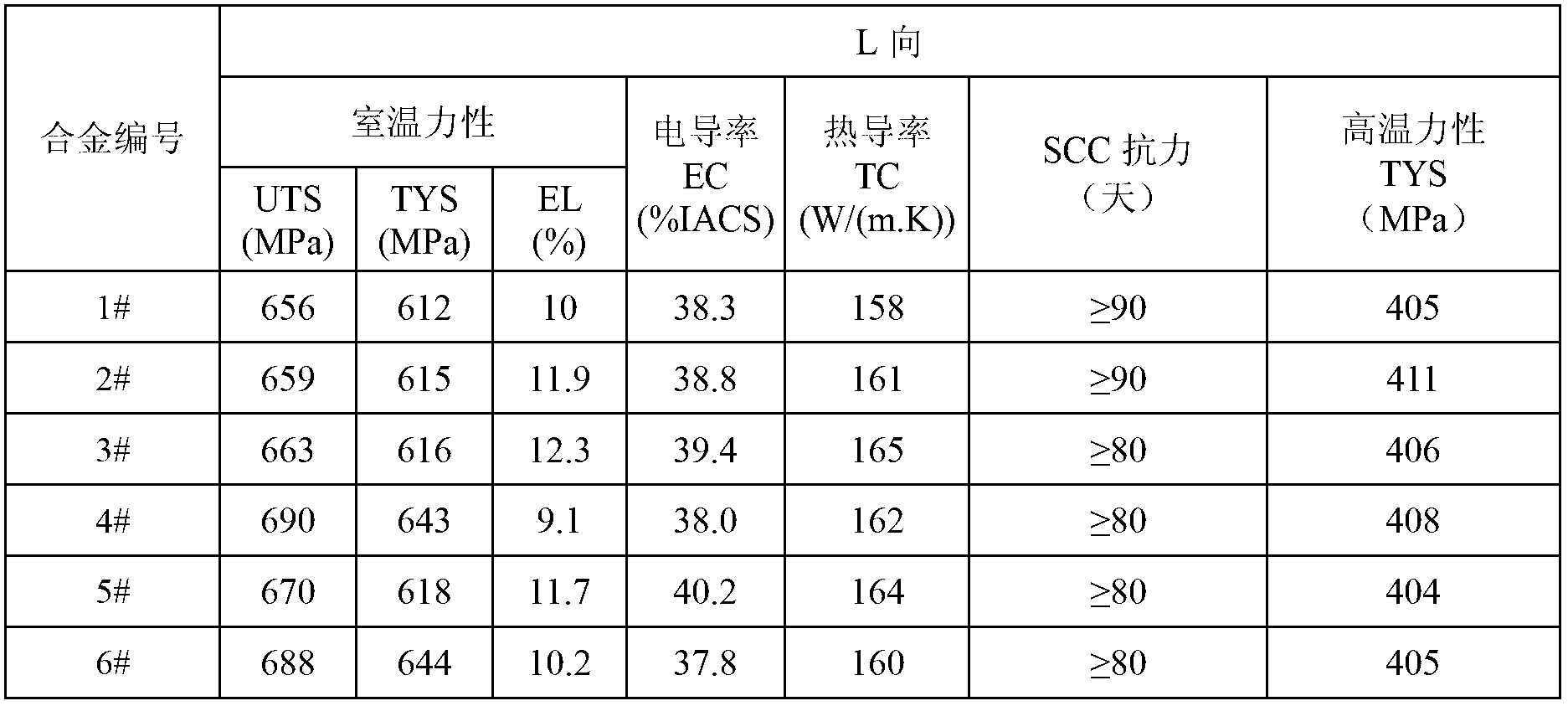

Aluminum alloy product suitable for structure and function integration, and preparation method thereof

The invention relates to an aluminum alloy product suitable for structure and function integration, and a preparation method thereof. The aluminum alloy product comprises the components of, by weight, 5.5-10.0% of Zn, 1.5-2.8% of Mg, 1.5-2.5% of Cu, 0.01-0.50% of Cr, 0.05-0.50% of Mn, 0.01-0.20% of Zr, and balance of of Al and incidental elements and impurities. In the aluminum alloy product: (a) Zn+Mg+Cu is no lower than 10.0% and no higher than 14.0%; (b) (Zn / Mg)+Cu is no lower than 4.4 and no higher than 6.5; (c) Cr+Mn+Zr is no lower than 0.10 and no higher than 0.60; and (d) the content of Cr is no higher than that of Mn, and content of Mn is no higher than that of Cr+0.20. The aluminum alloy product has high strength, high electric conductivity, and good thermal conductivity. Also, the aluminum alloy product has low residual stress, good surface quality, and good dimensional precision. The invention also relates to a preparation method of the aluminum alloy product.

Owner:GRIMAT ENG INST CO LTD

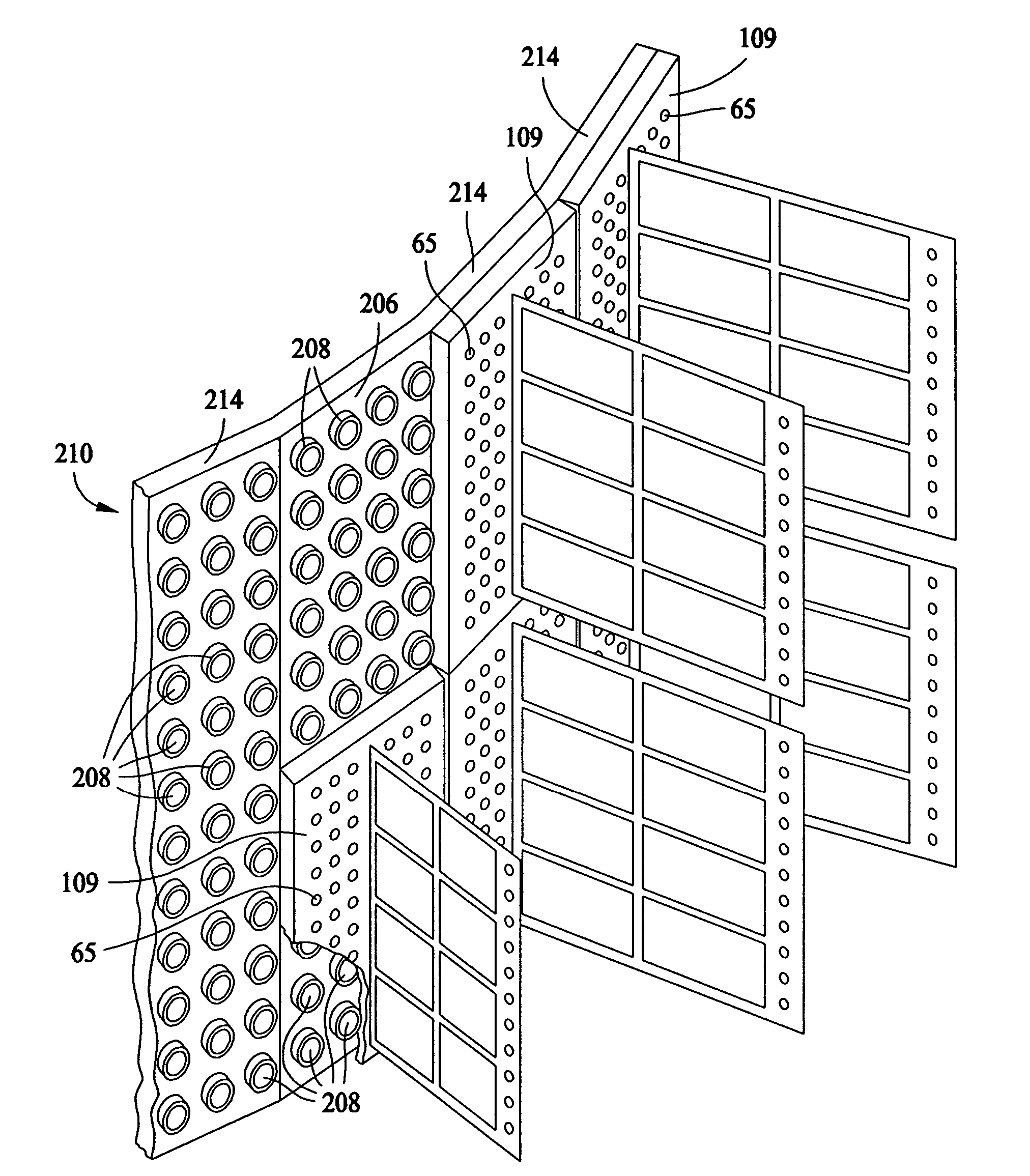

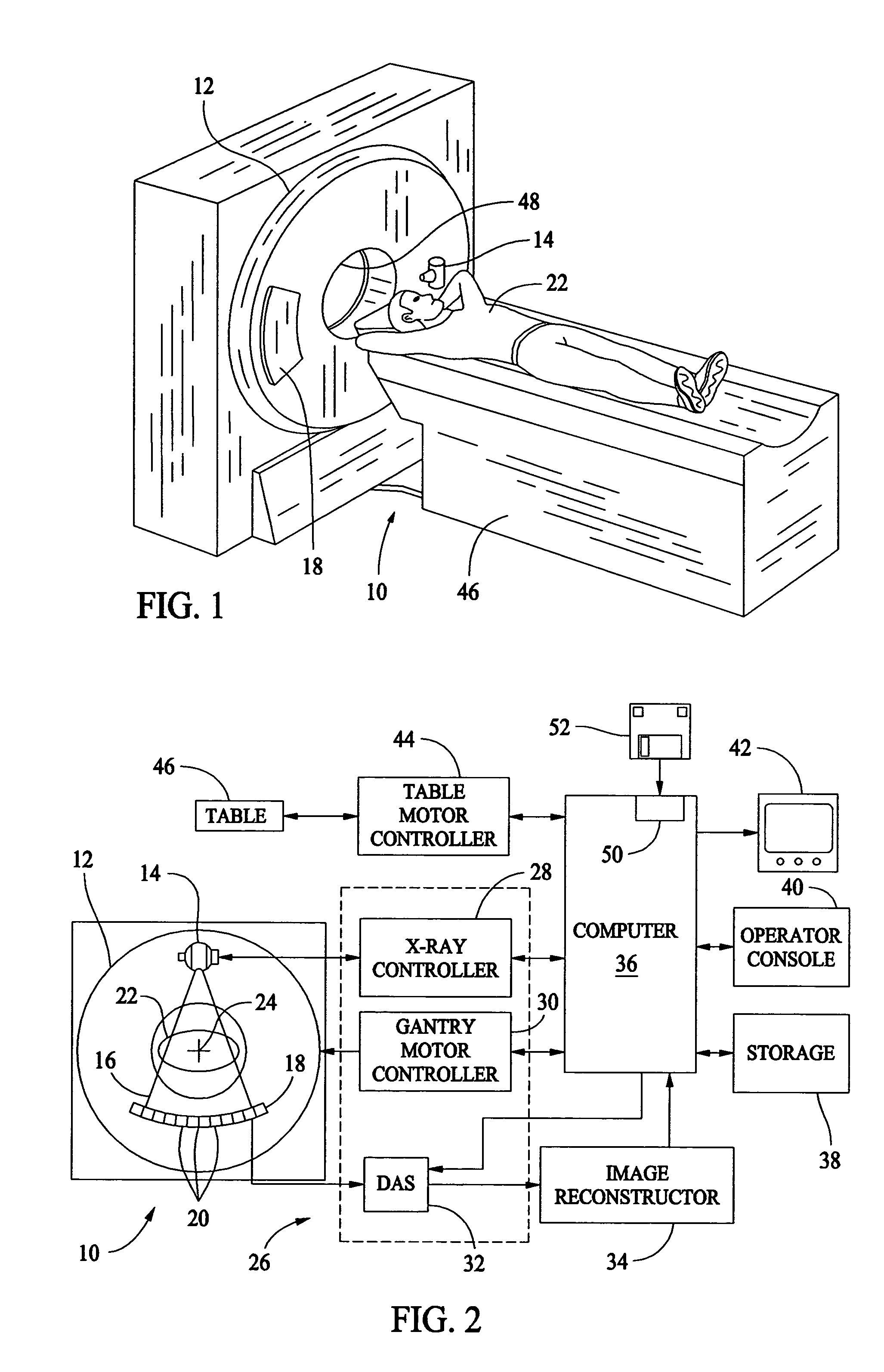

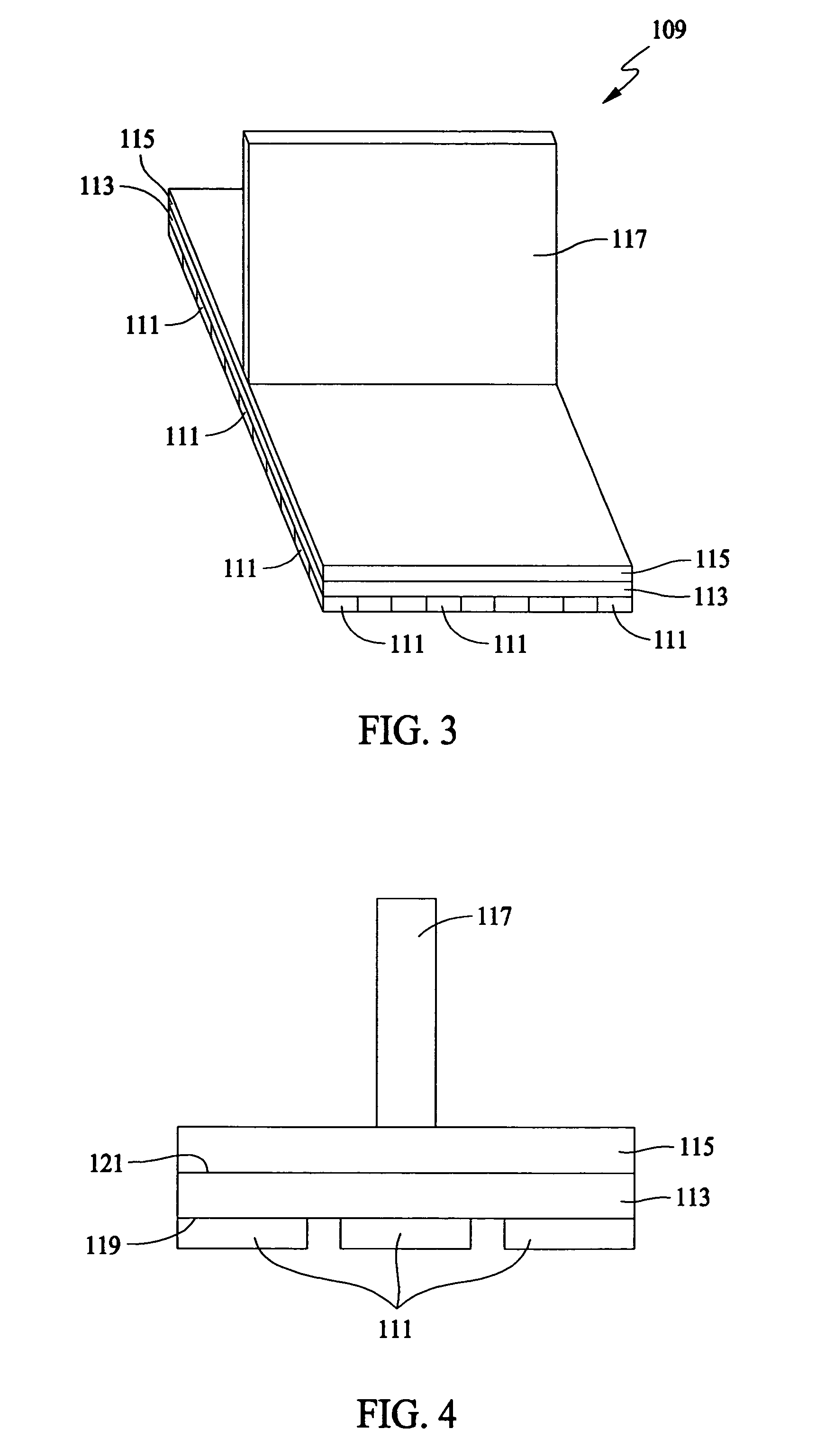

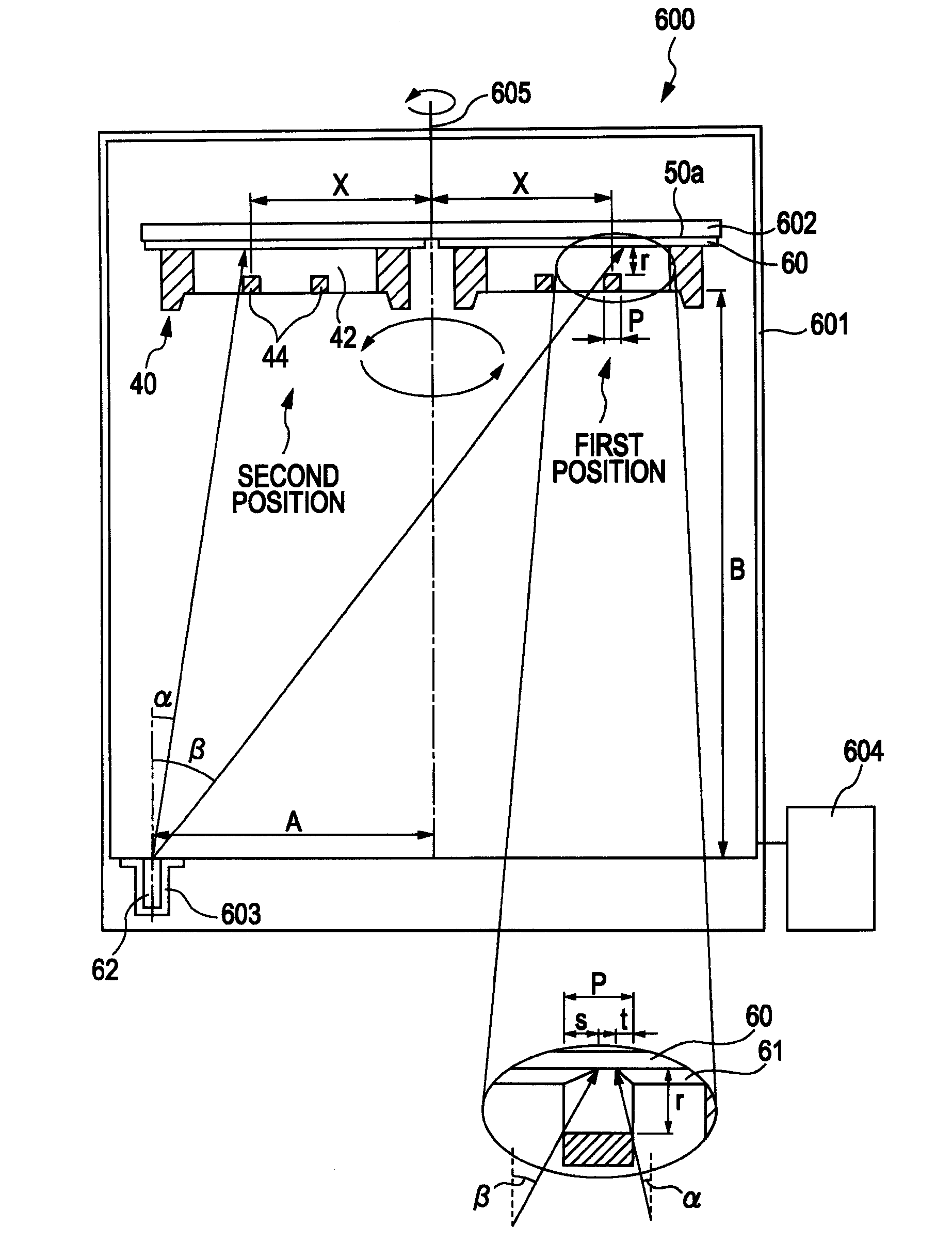

Methods and apparatus for tileable sensor array

ActiveUS6990176B2Facilitate insertion and extraction and field replacementHigh dimensional accuracyMaterial analysis using wave/particle radiationSolid-state devicesSensor arrayForms of energy

A detector array kit that includes at least one sensor array. The sensor array has an active side at least one sensor on the flat active side configured to detect a particular form of energy. The sensor array active side has a positioning structure on the active side that is essentially transparent to the particular form of energy. The positioning structure includes a plurality of spaced compressible posts or tubes configured to compressively and frictionally engage with a complementary mounting structure. The detector kit further includes a complementary mounting structure essentially transparent to the particular form of energy.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

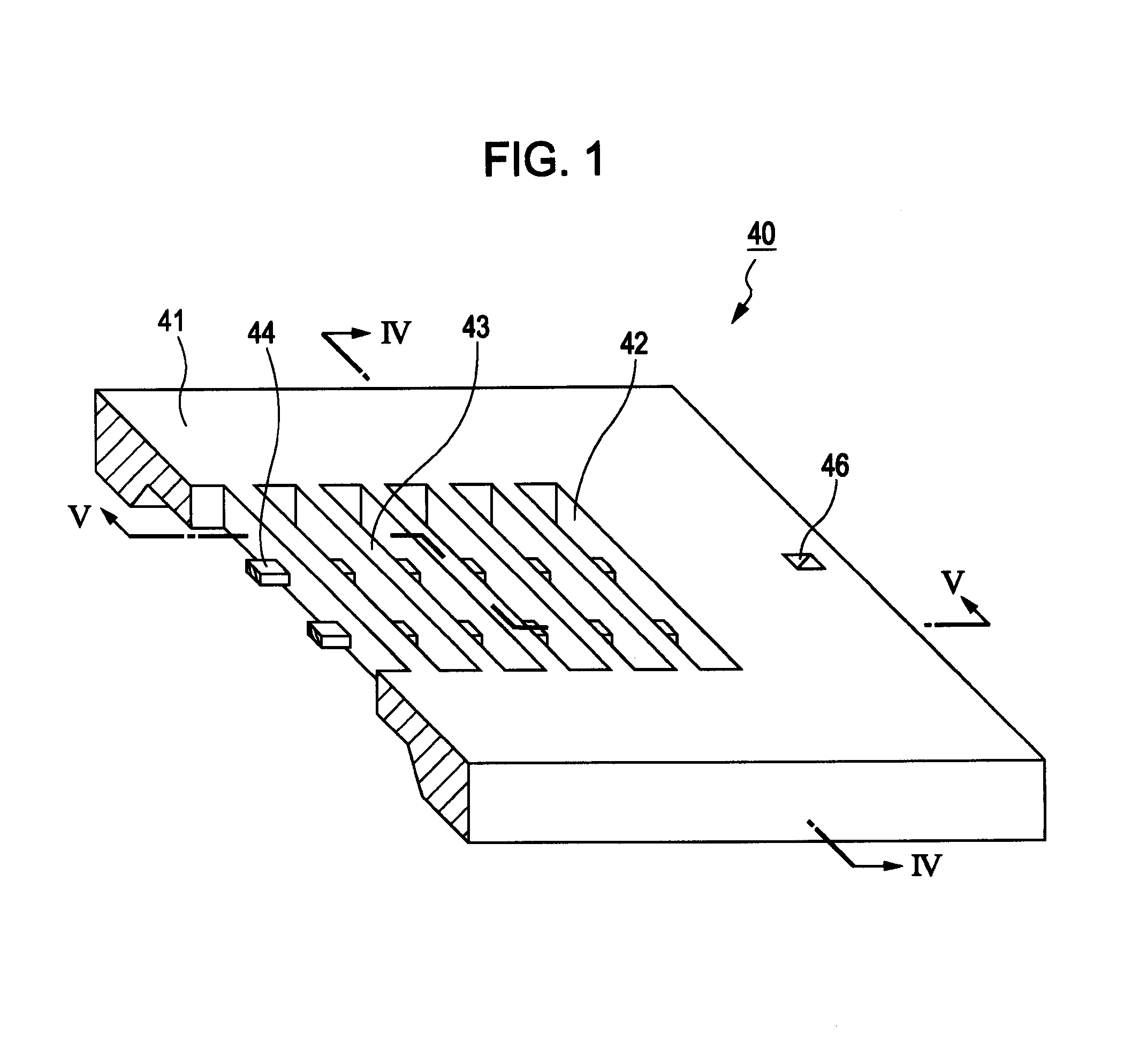

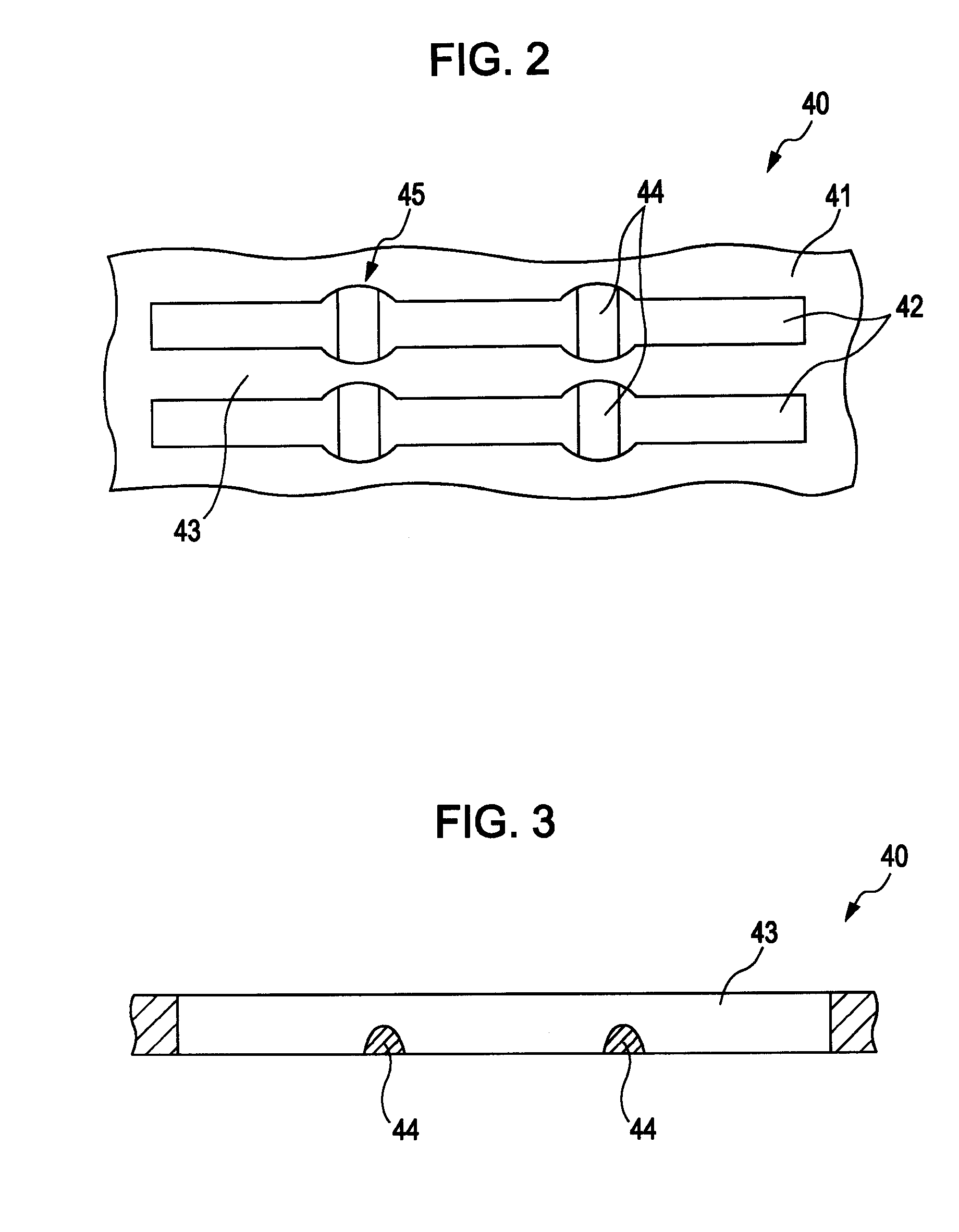

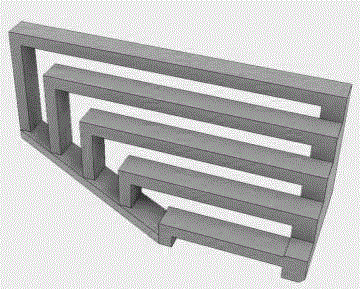

Mask, film forming method, light-emitting device, and electronic apparatus

InactiveUS20070157879A1High dimensional accuracyImprove featuresLiquid surface applicatorsElectroluminescent light sourcesLight emitting deviceFilm material

Provided is a mask which is used to form on the surface of a substrate a plurality of linear film members disposed in parallel to each other by fixing one surface of the mask to the substrate and supplying a film material through the other surface of the mask by the use of a vapor process. The mask includes: a mask body having a plurality of openings corresponding to patterns of the linear film members; and reinforcement ribs which are disposed to cross the openings and which have a function of preventing deformation of the mask body due to the weight thereof. Here, the reinforcement ribs are disposed close to the other surface of the mask in the thickness direction of the openings.

Owner:SEIKO EPSON CORP

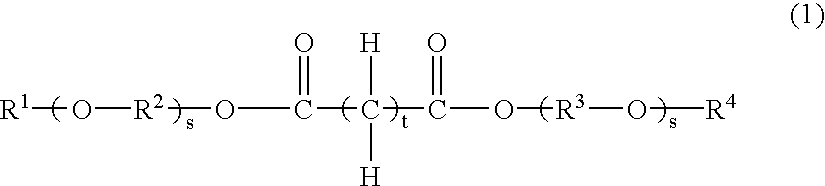

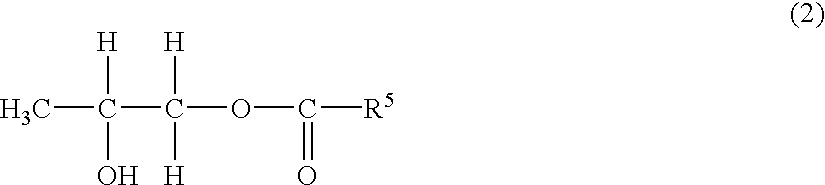

Composite particle for dielectrics, ultramicroparticulate composite resin particle, composition for forming dielectrics and use thereof

InactiveUS20030151032A1High dielectric constantSmall dielectric loss tangentSemiconductor/solid-state device detailsSolid-state devicesInorganic particleResin-Based Composite

The dielectric-forming composition according to the invention is characterized by consisting of: composite particles for dielectrics in which part or all of the surfaces of inorganic particles with permittivity of 30 or greater are coated with a conductive metal or a compound thereof, or a conductive organic compound or a conductive inorganic material; and (B) a resin component constituted of at least one of a polymerizable compound and a polymer. In addition, another dielectric-forming composition according to the invention is characterized by containing: ultrafine particle-resin composite particles composed of (J) inorganic ultra fine particles with the average particle size of 0.1 mum or smaller, and (B) a resin component constituted of at least one of a polymerizable compound and a polymer, wherein part or all of the surfaces of the inorganic ultrafine particles (J) are coated with the resin component (B), and the ultrafine particle-resin composite particles contain 20% by weight or more of the inorganic ultrafine particles (J); and inorganic particles with the average particle size of 0.1 to 2 mum and permittivity of 30 or greater, or inorganic composite particles in which a conductive metal or a compound thereof, or a conductive organic compound or a conductive inorganic material is deposited on the part or all of the surfaces of the inorganic particles.

Owner:JSR CORPORATIOON

Integrated micro electro-mechanical system and manufacturing method thereof

InactiveUS20090049911A1Easy to manufactureSufficient massTelevision system detailsInflated body pressure measurementDielectricEtching

In the manufacturing technology of an integrated MEMS in which a semiconductor integrated circuit (CMOS or the like) and a micro machine are monolithically integrated on a semiconductor substrate, a technology capable of manufacturing the integrated MEMS without using a special process different from the normal manufacturing technology of a semiconductor integrated circuit is provided. A MEMS structure is formed together with an integrated circuit by using the CMOS integrated circuit process. For example, when forming an acceleration sensor, a structure composed of a movable mass, an elastic beam and a fixed beam is formed by using the CMOS interconnect technology. Thereafter, an interlayer dielectric and the like are etched by using the CMOS process to form a cavity. Then, fine holes used in the etching are sealed with a dielectric.

Owner:HITACHI LTD

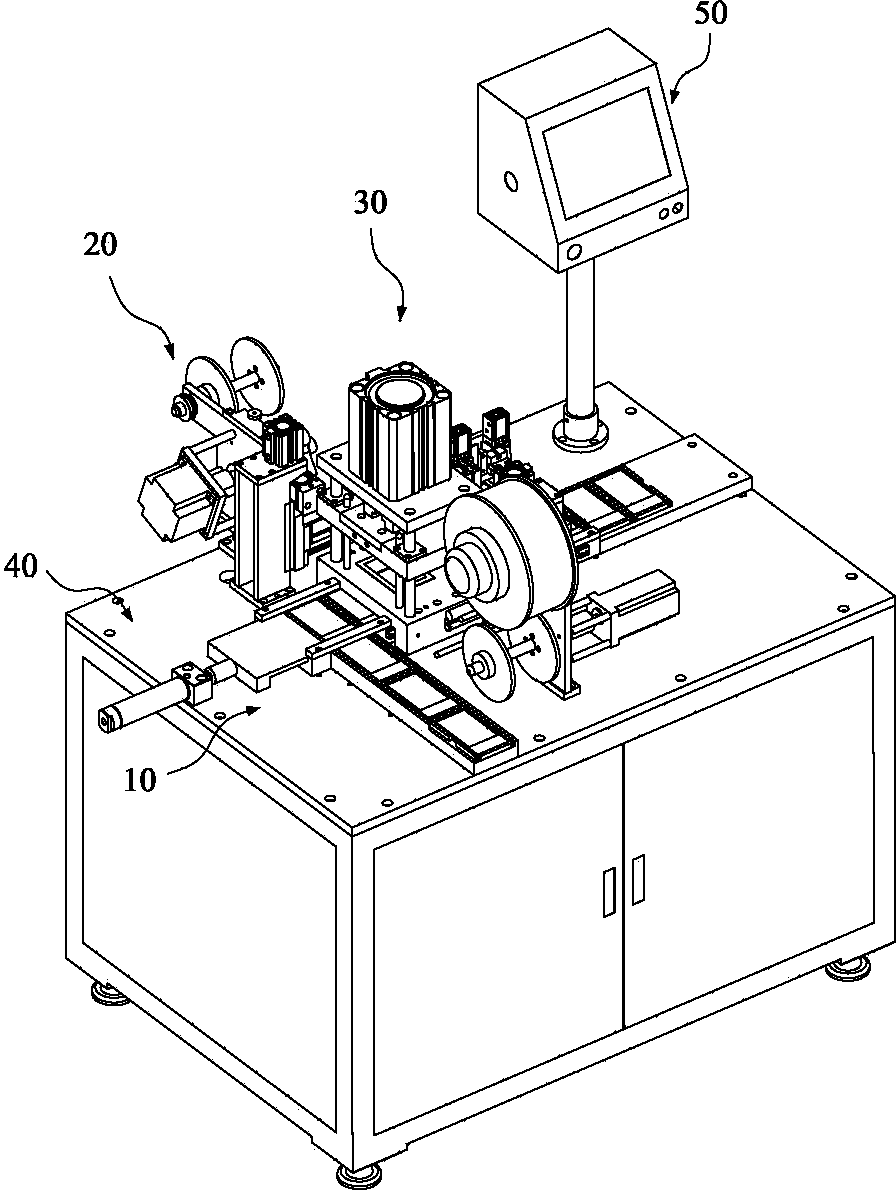

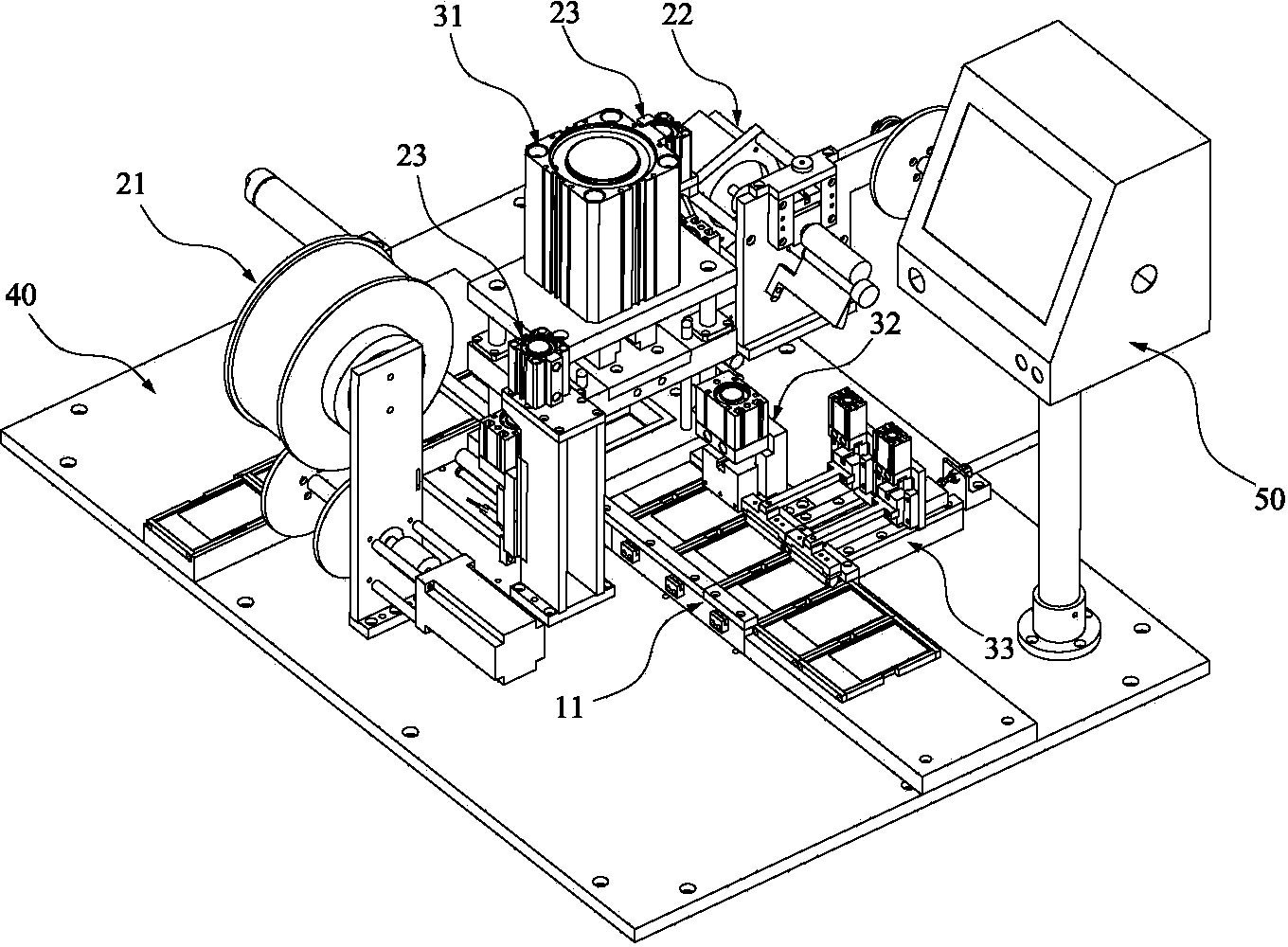

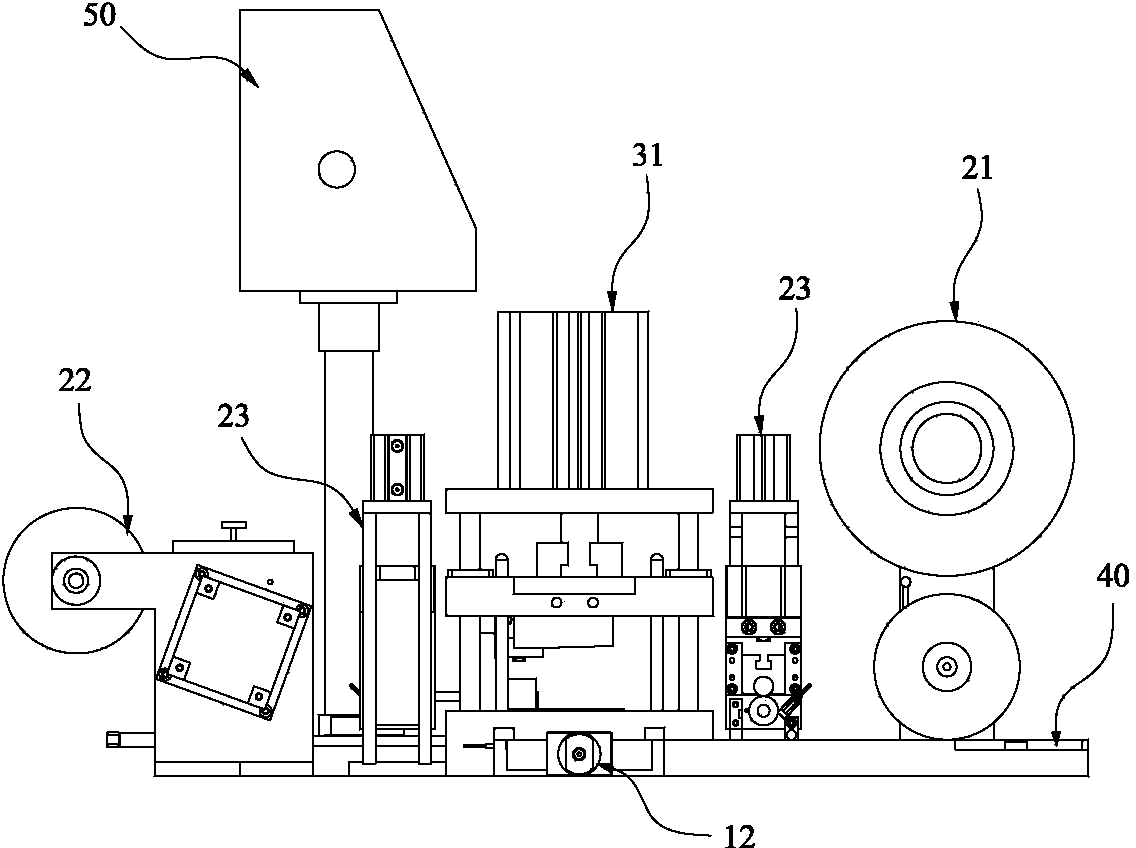

Automatic coating machine

InactiveCN103359313ARealize automatic feeding processImprove positionPackagingCoating systemEngineering

The invention discloses an automatic coating machine which comprises a work platform as well as a product conveying system, a coating system and a protection film conveying and recycling system which are arranged on the work platform, wherein the protection film conveying and recycling system comprises an adhesive tape conveying part and a protection film residue recovering part. When the machine runs, the product conveying system is used for automatically conveying a product and a protection film to a coating station, the coating system is used for cutting the protection film and applying the cut protection film to the surface of the product, production film residues generated during cutting of the production film are automatically recycled after the coating action is finished, and the product is automatically conveyed out, wherein the two-time rolling operation is performed to completely squeeze out air in the protection film to enable the protection film to completely cling to the product before the product is conveyed out. According to the automatic coating machine, the automatic coating operation is finished instead of a manual coating operation, the coating efficiency can be effectively improved, the manpower cost is reduced, the coating operation is simpler and easy, air bubbles in the protection film are squeezed out to enable the protection film to completely cling to the product, and the coating effect is ideal.

Owner:DONGGUAN KECHENDA ELECTRONICS TECH

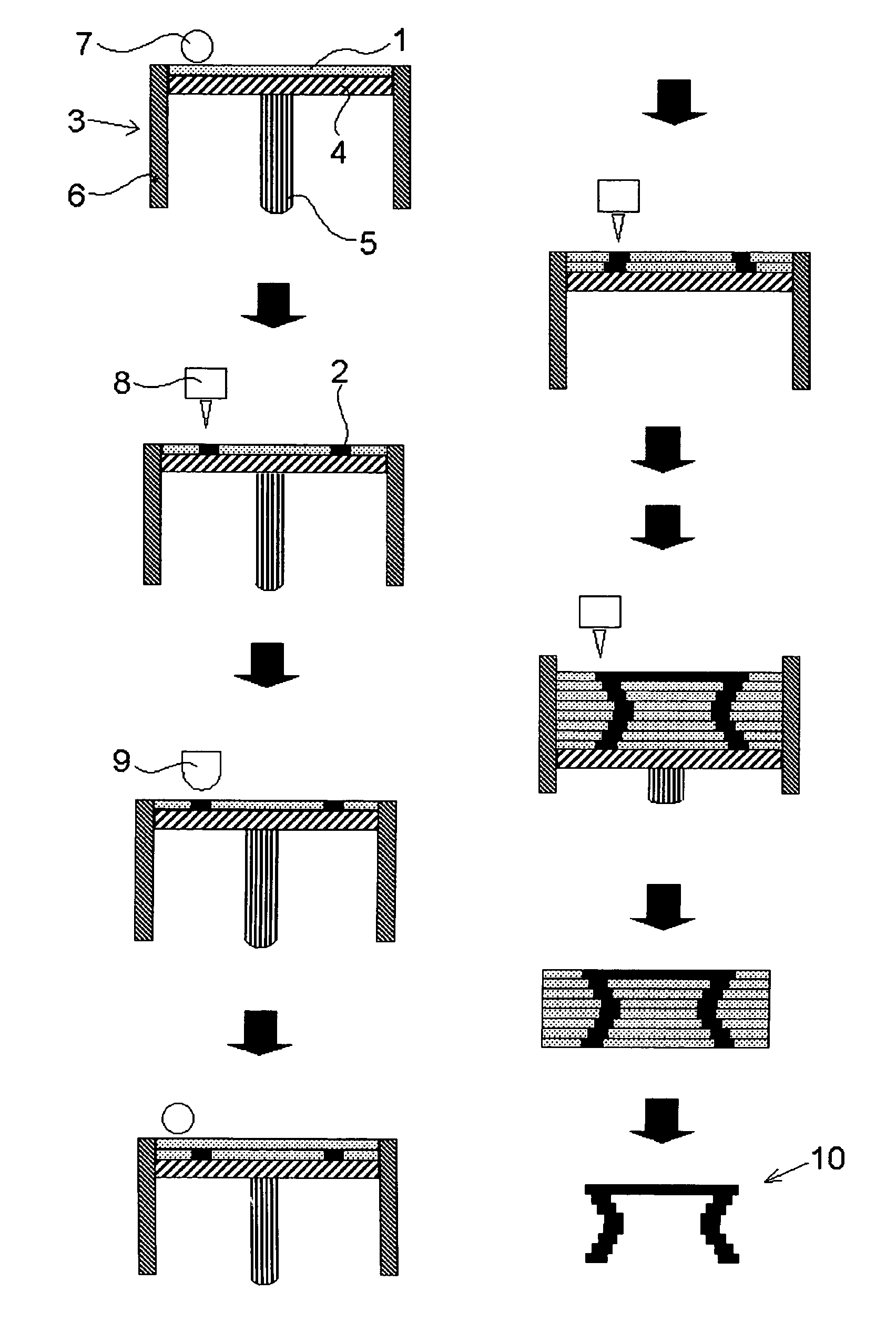

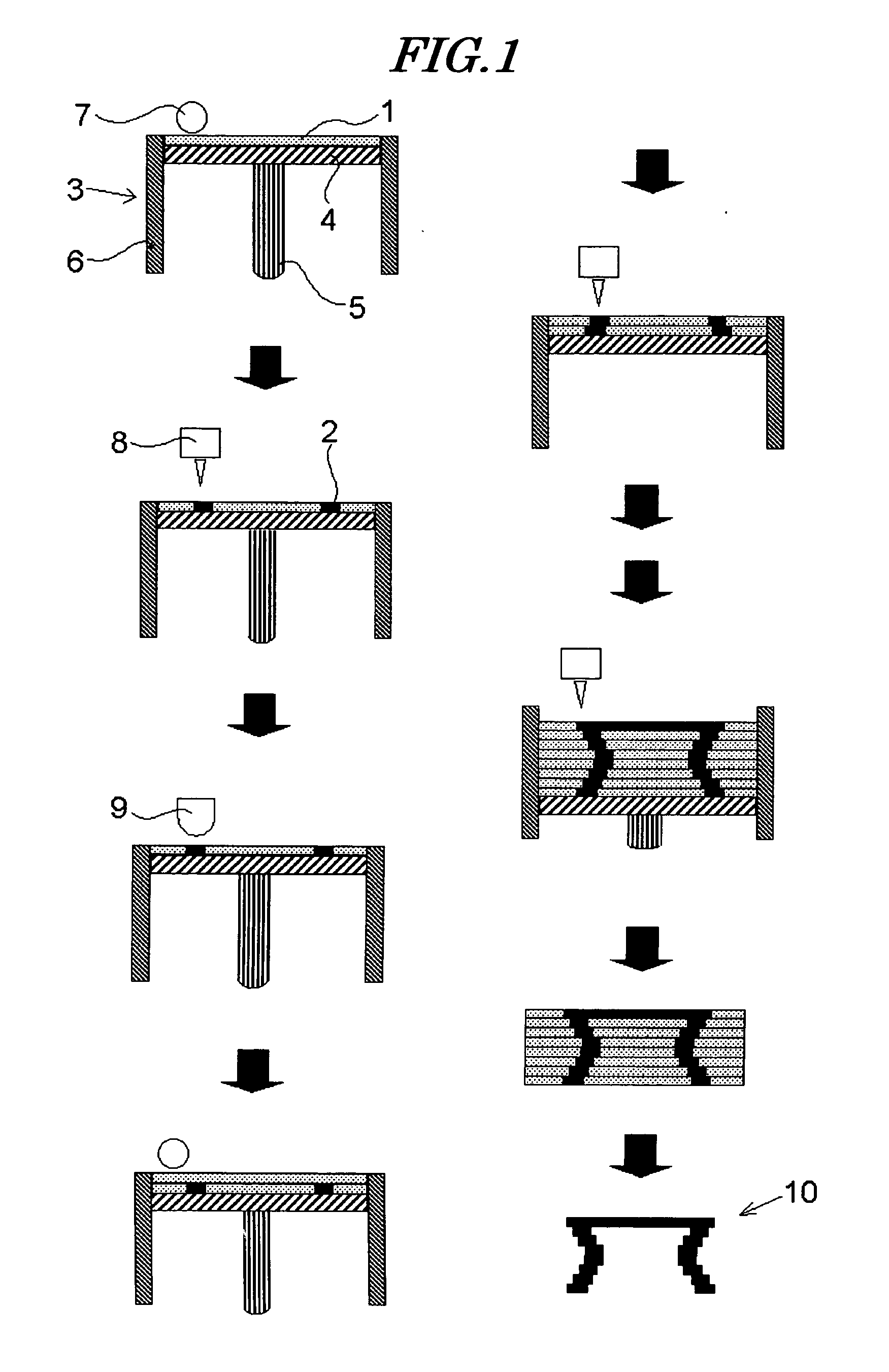

Method of producting three-dimensional model

InactiveUS20070007698A1Improve discharge performanceImprove curing effectNon-woven fabricsAdditive mnaufacturing with solid and fluidViscosityShape formation

The present invention relates to a process for producing a three-dimensional model in which a binder has good discharge properties and curability. The process for producing a three-dimensional model is a process for producing a three-dimensional model that includes a step (layer formation step) of forming above a support a layer of a powder material, the layer having a predetermined thickness, a step (cross-sectional shape formation step) of imagewise bonding the powder material layer by a binder according to sliced cross-sectional data of a modeled object so as to give a cross-sectional shape, and sequentially repeating the above steps, the binder having a viscosity at 25° C. of 5 to 100 mPa·s.

Owner:FUJIFILM CORP +1

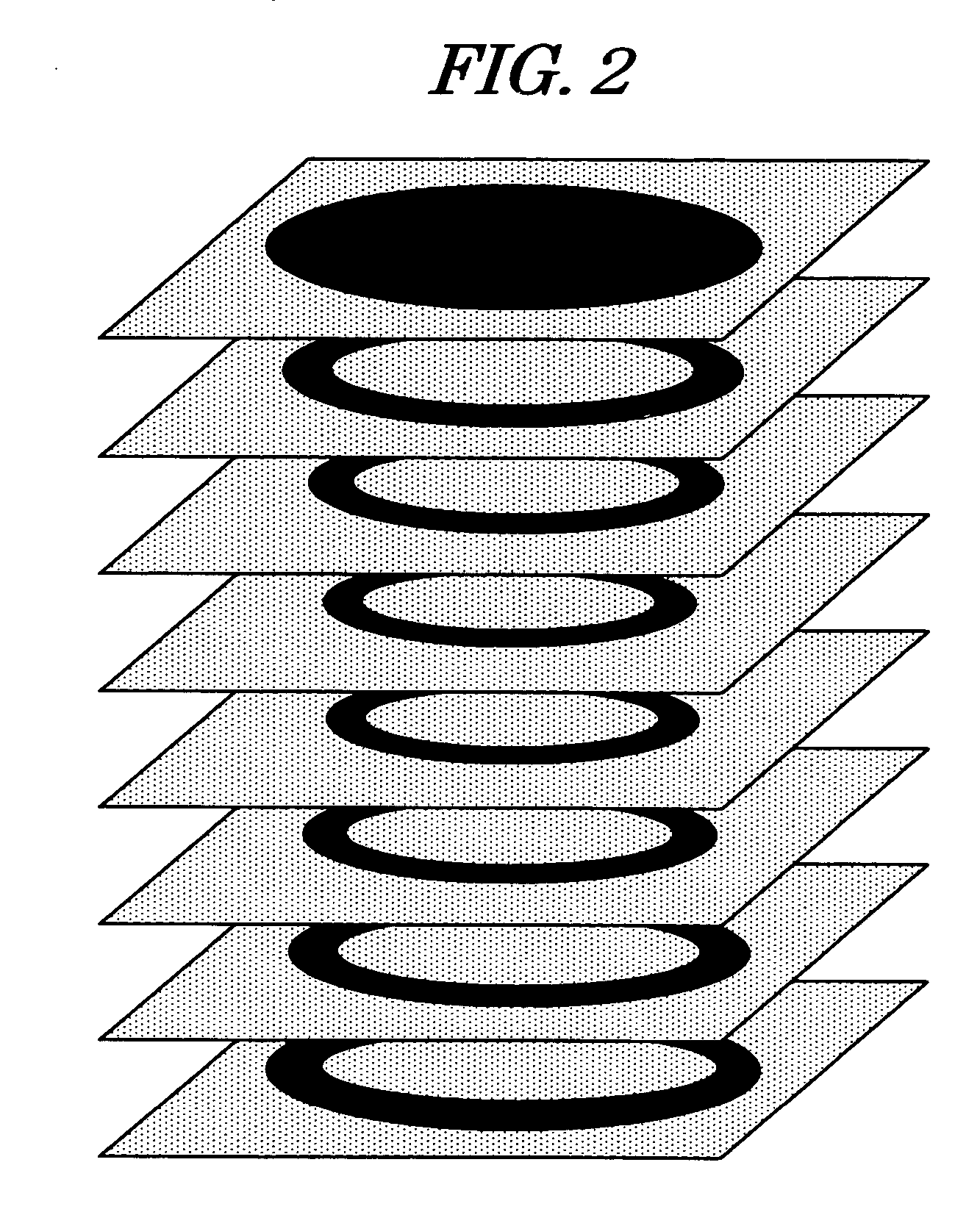

Adjustable laser coaxial powder feeding nozzle

The invention discloses an adjustable coaxial laser nozzle for sending powder, comprising a laser head, a protection lens, a water-cooling sleeve for the protection lens and a column laser cavity arranged on the upper part, a coaxial conical laser cavity which is formed by the inner layer of a laser sleeve and arranged in the middle part, wherein a powder cavity, a secondary external protective cavity and an external water-cooling cavity are arranged on the lower part of the external part of the laser sleeve; the powder cavity is formed between the laser sleeve and a power cavity sleeve screwed together; the secondary external protective cavity is formed between the powder cavity and a protective air casing screwed together; the powder cavity and the protective sir casing are screwed together and adjustable between 1mm to 3mm; 4 to 6 power transmitting pipes and 4 to 6 air tubes are respectively positioned around the top parts of the cones of the powder cavity and the protective air cavity. The adjustable coaxial laser nozzle for sending powder has the advantages that the focus length of the focus lamp fit for the coaxial powder-sending nozzle is between 100mm to 300mm, which ensures convenient assembly and disassembly, even velocity, flexible adjustment of the powder converge diameter, convenient changeable lower coaxial conical parts (the powder cavity, the air casing and the water cavity).

Owner:XI AN JIAOTONG UNIV

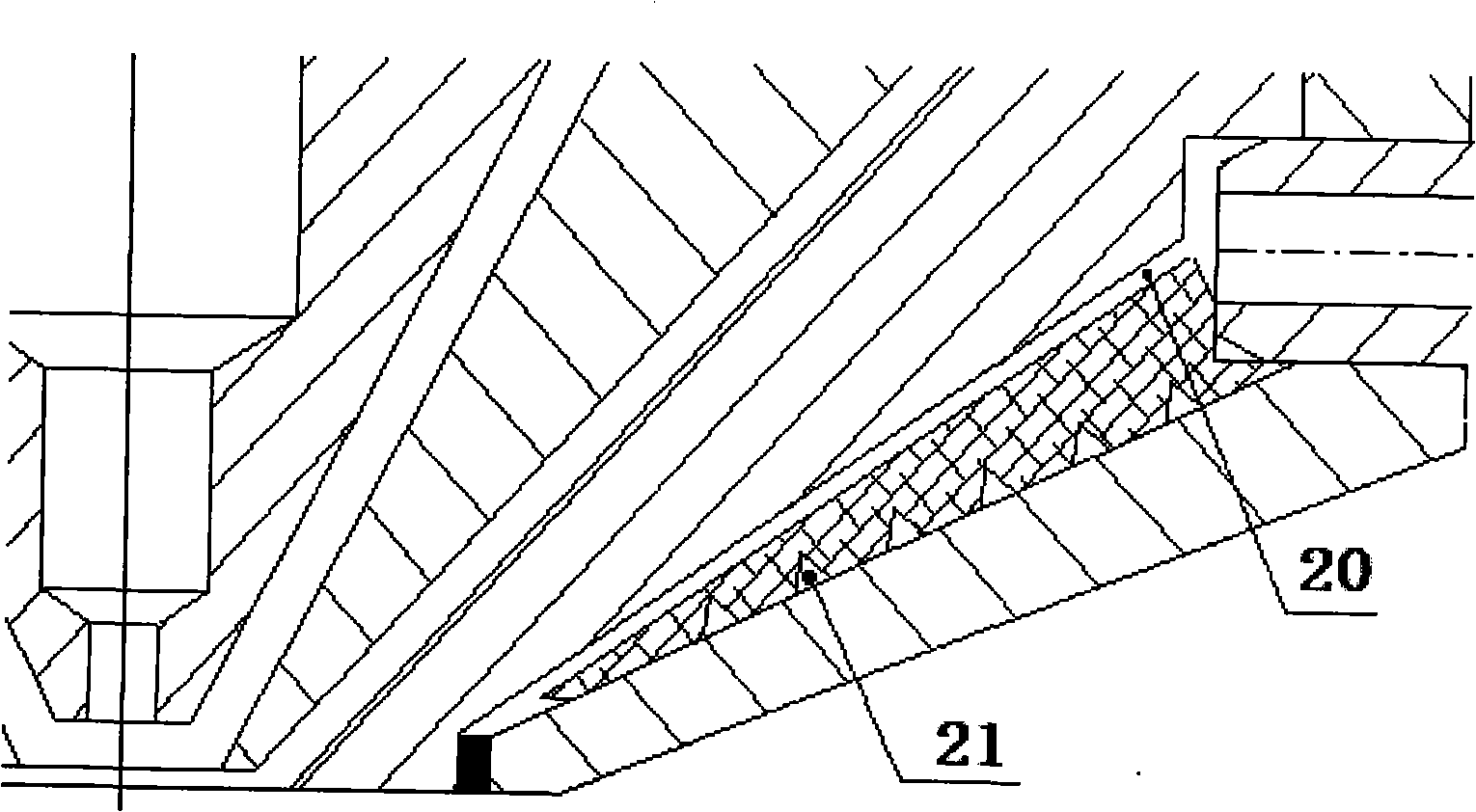

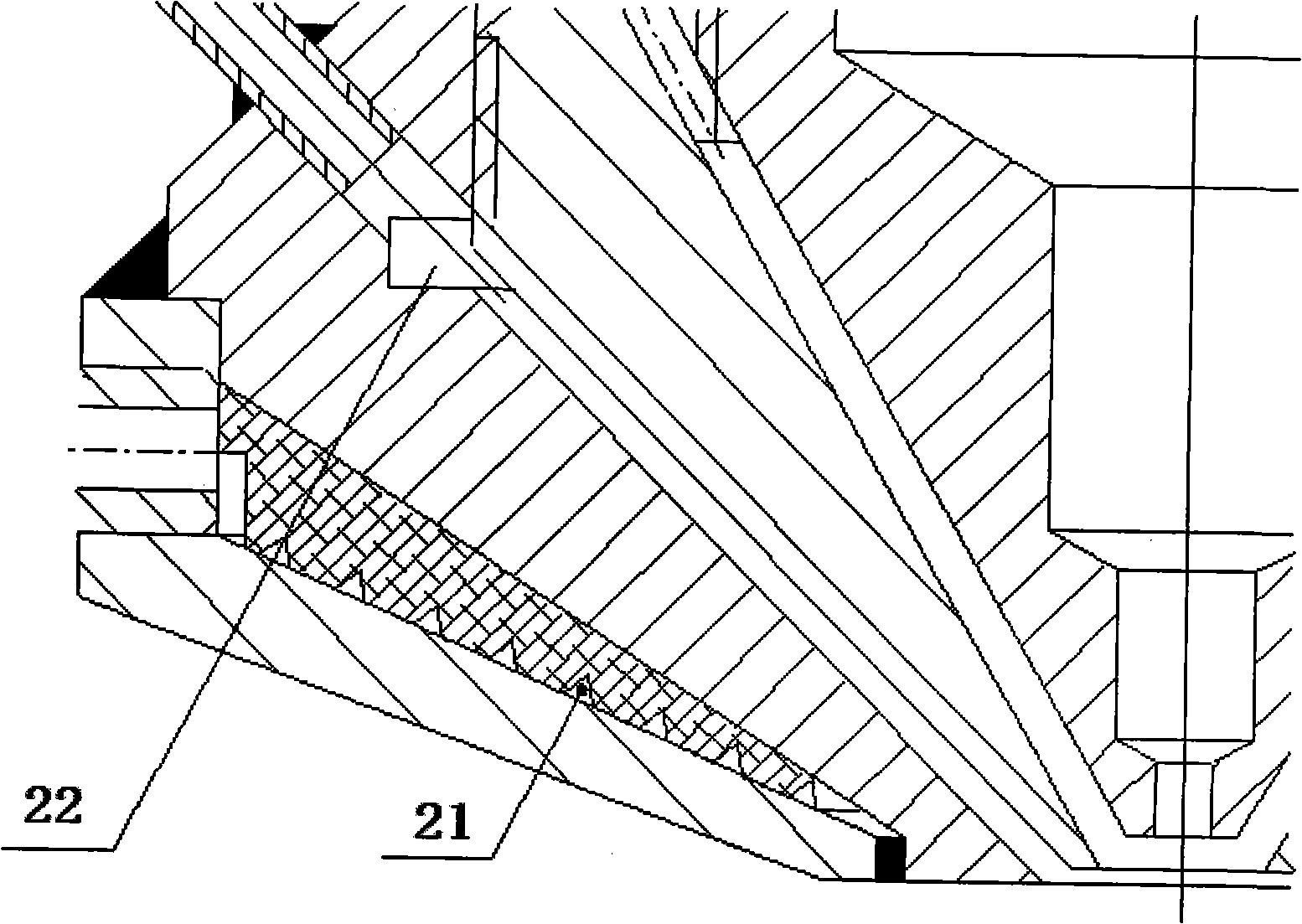

Insert core and method for manufacturing a cylinder for internal combustion engine by making use of the insert core

There is provided a method for manufacturing a cylinder for an internal combustion engine by making use of an insert core, which makes it possible to manufacture the cylinder by a die casting method such as a high-pressure die casting method at low cost and in high accuracy. The insert core to be employed herein includes: a cylindrical body having substantially the same outer diameter as the diameter of bore of the cylinder to be obtained; a scavenging port-forming portion projecting radially outward from the cylindrical body and having substantially the same cross-sectional configuration as that of the scavenging port; a suction port-forming portion projecting radially outward from the cylindrical body and having substantially the same cross-sectional configuration as that of at least the cylinder bore-side end portion of a suction port; and an exhaust port-forming portion projecting radially outward from the cylindrical body and having substantially the same cross-sectional configuration as that of at least the cylinder bore-side end portion of an exhaust port.

Owner:KIORITZ

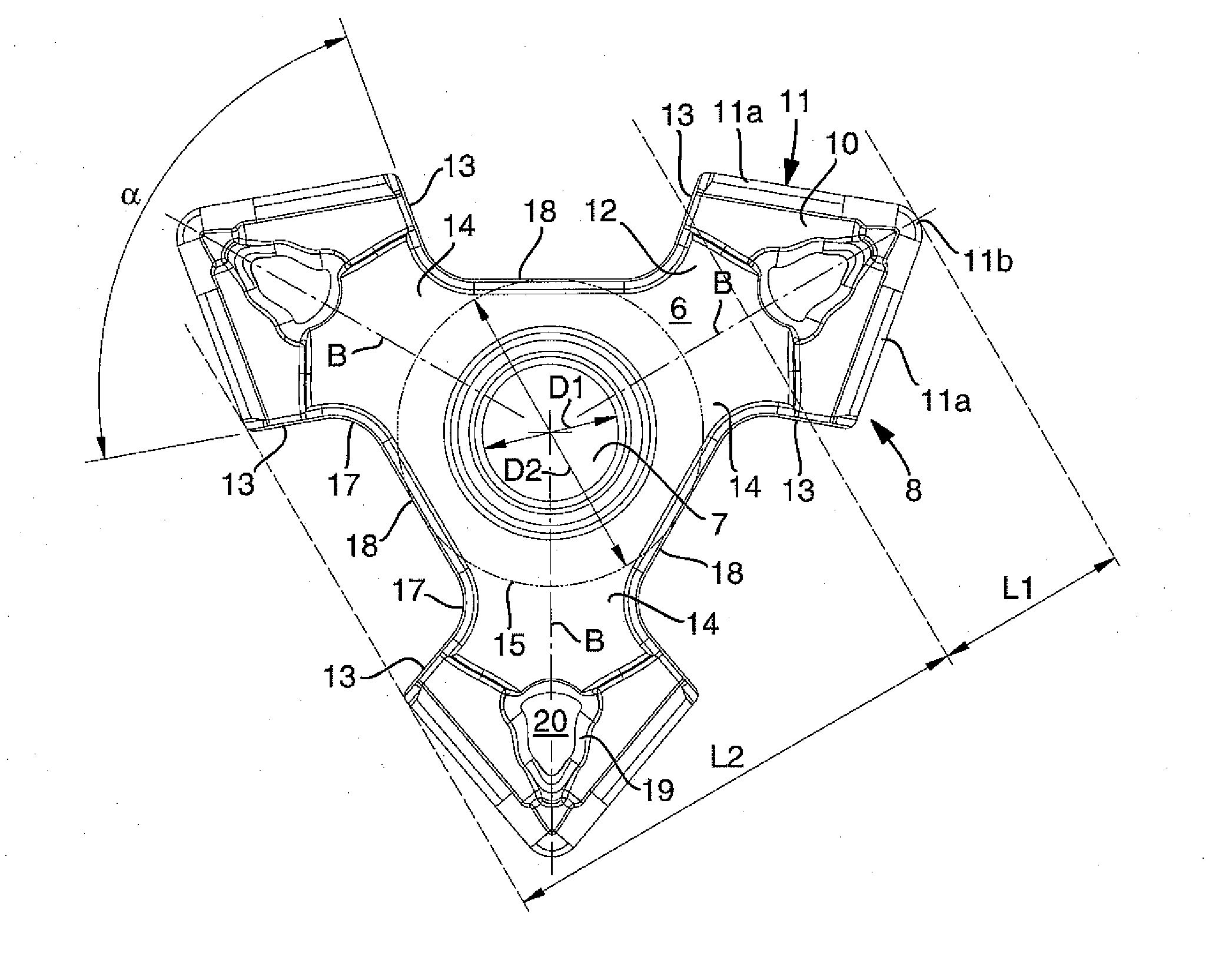

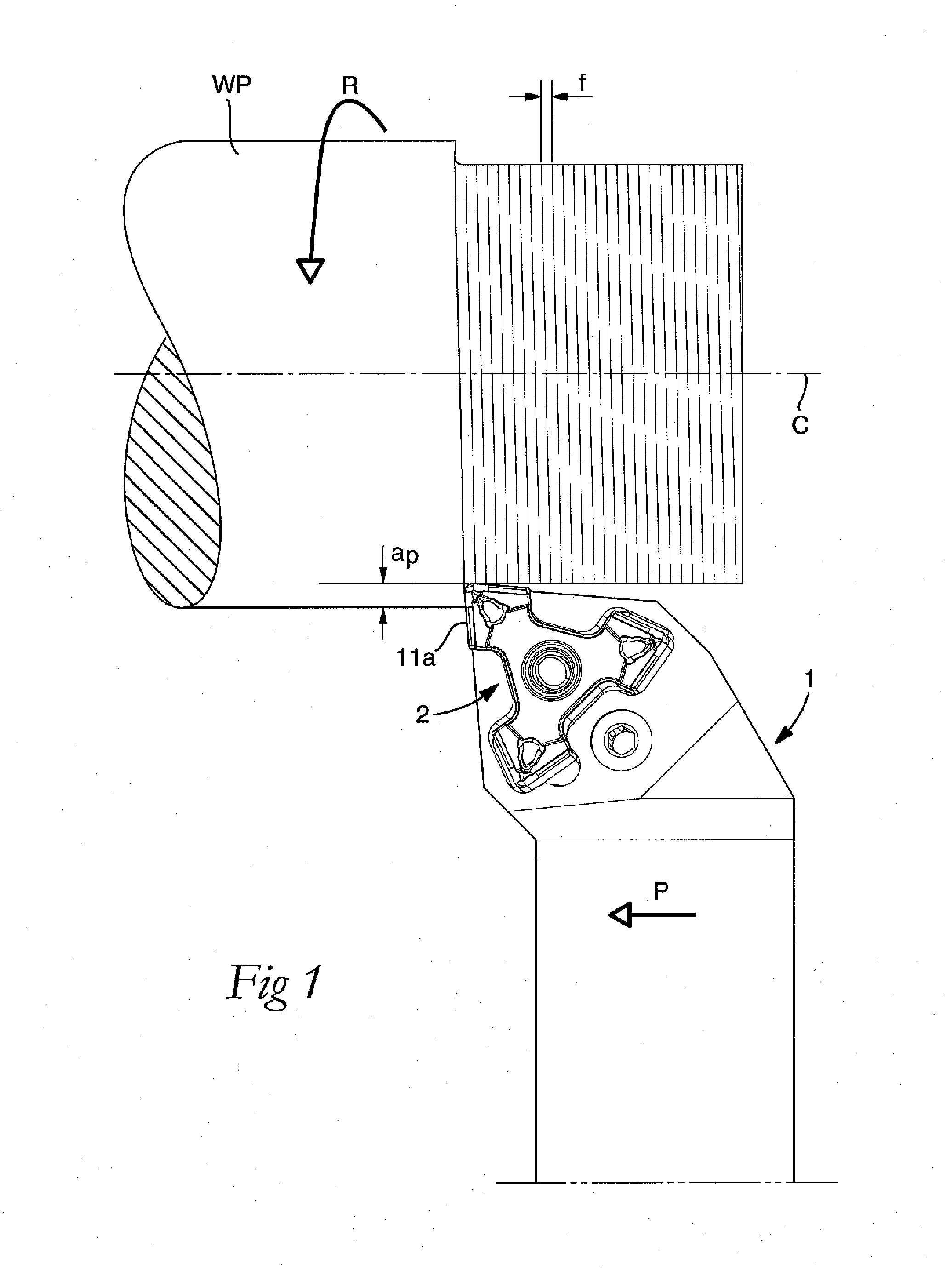

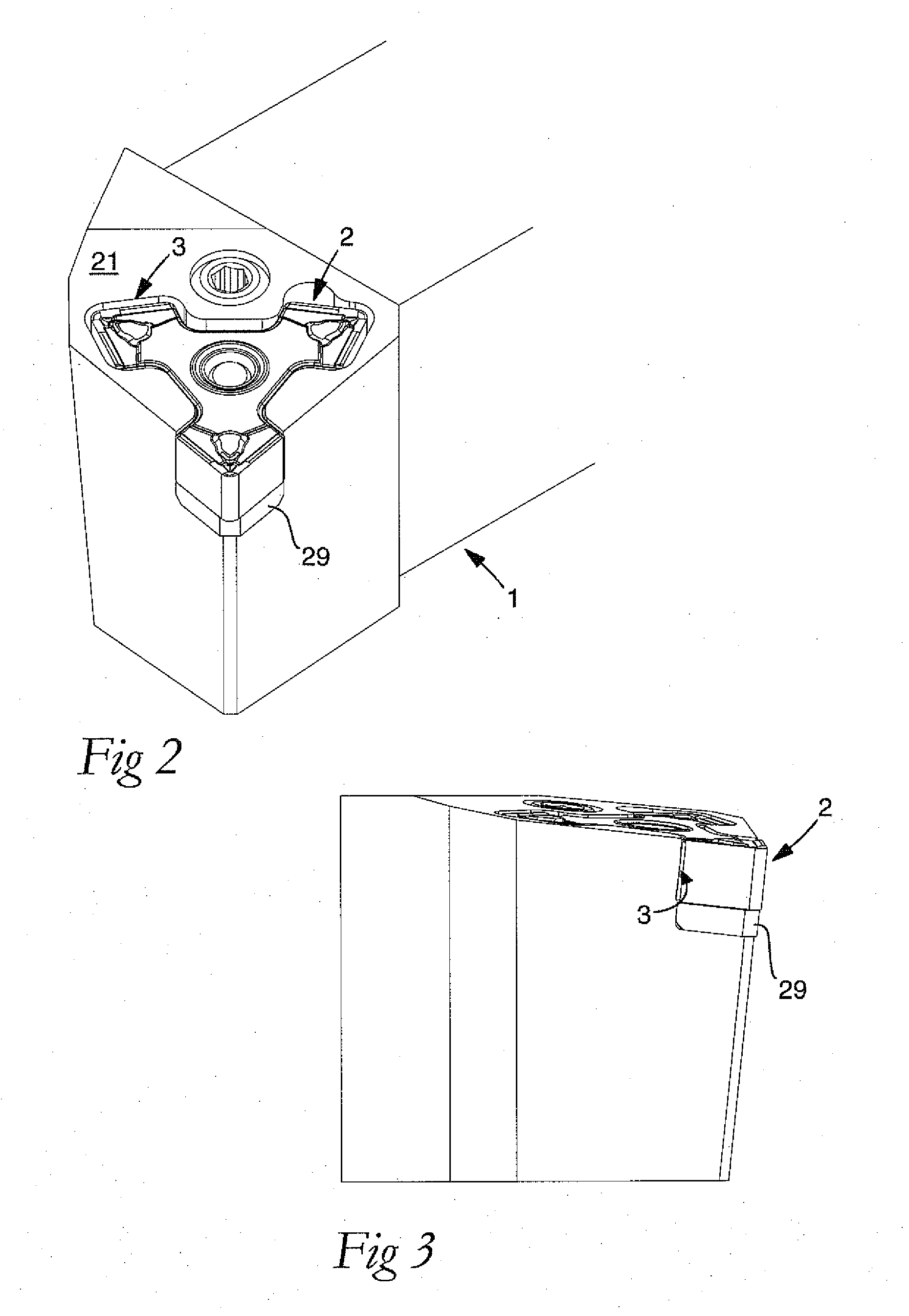

Tool for chip removing machining as well as a solid indexable cutting insert and a solid basic body therefor

ActiveUS20100329800A1Reduce manufacturing costGood precisionMilling cuttersCutting insertsHardnessEngineering

A tool for chip removing machining, including a basic body having an insert seat, and an indexable cutting insert fixed in the seat. The insert includes an upperside, an underside, a pair of side contact surfaces, two cutting edges that individually extend along a chip surface included in one of the upperside and underside, at least two heads that are spaced-apart via an intermediate part and individually include a front portion having at least one cutting edge and a rear portion along which the pair of side contact surfaces are formed. The insert seat of the basic body includes a central hollow space, and a front cavity and at least one rear cavity in which the heads of the cutting insert are housed, the front cavity including a pair of side support surfaces against which the pair of side contact surfaces of the cutting insert are pressed when a tightening element pulls the head rearward toward the side support surfaces. The basic body is solid by being formed integrally of steel material. The seat is countersunk in the basic body such that the side support surfaces are integrated in the steel material. The cutting insert is formed integrally from a second, hard-wearing material having at least the same hardness as cemented carbide, the pair of side contact surfaces of the insert being integrated in the second material.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Semiconductor device and manufacturing method thereof

InactiveUS6964832B2Beam blur is preventedImprove accuracyElectric discharge tubesRadiation applicationsHigh dimensionalSemiconductor

A method is provided for solving a problem that the fine processing property is degraded by an increase of a current applied to complementarily divided masks in an electron beam projection process. In the method, the complementarily divided masks used for electron projection are used whereby one mask is used for patterns requiring high dimensional accuracy and another is used for other patterns. Consequently, it is possible to lower the current applied to the patterns requiring high dimensional accuracy to realize high printing accuracy. In addition, the highly accurate patterns can be formed at a high throughput.

Owner:HITACHI LTD

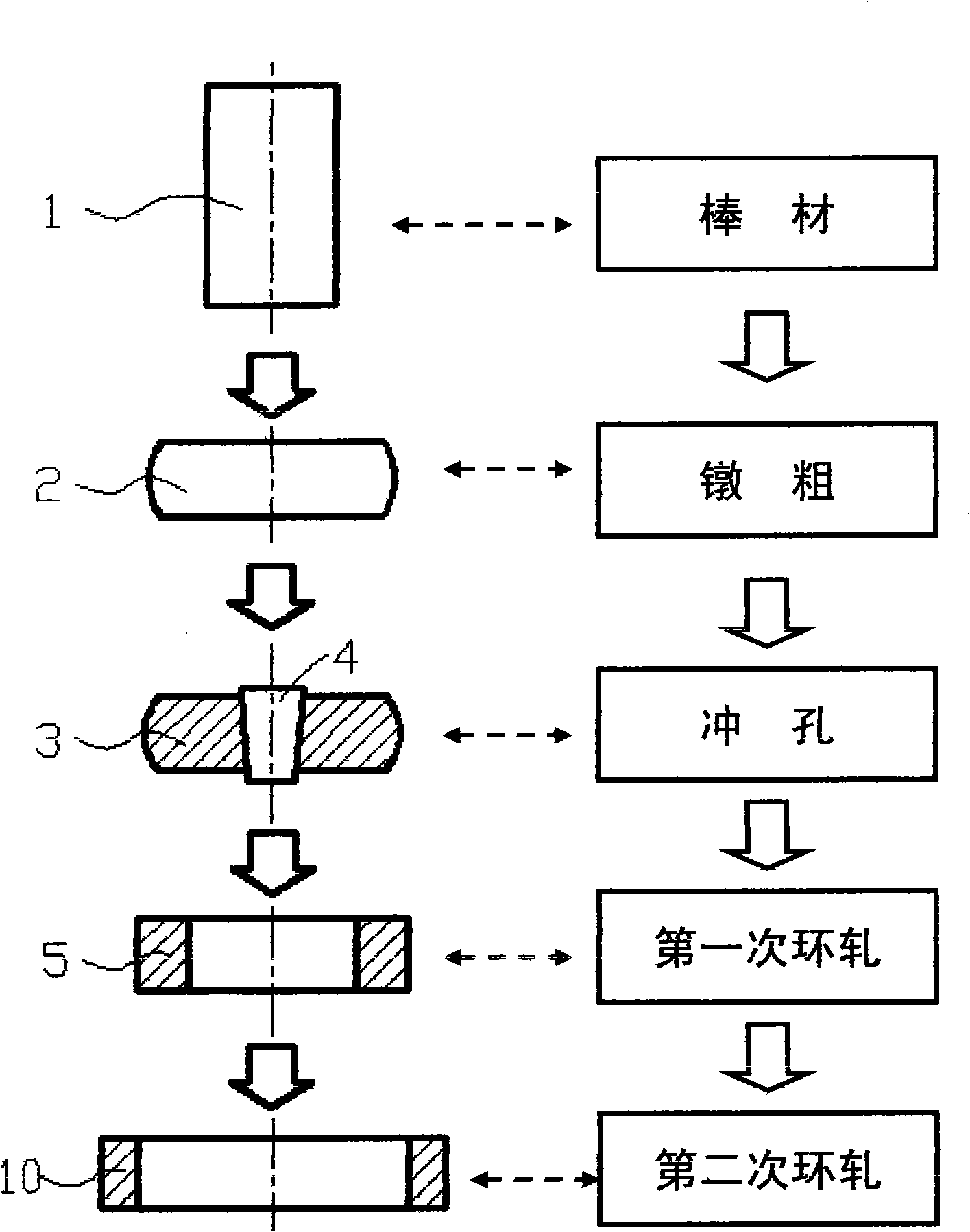

Method for rolling and shaping titanium alloy special-shaped ring forging

ActiveCN101279345AReduce manufacturing costHigh dimensional accuracyMetal rollingTitanium alloyAbnormal shaped

The invention discloses a rolling and shaping method for a titanium alloy heterotypic ring forging in order to obtain the alloy heterotypic ring forgings with excellent tissues and properties as well as realize accurate rolling. The method includes the following steps: alloy bar material is heated, carried out continuous upsetting and deformed by 65 to 70 percent, so as to be made into a solid cake and then is punched again to lead the alloy bar material to be made into a hollow round cake after the aperture dimension of the alloy bar material is 30 to 35 percent of the dimension of the outer diameter thereof; a rectangle ring blank is obtained after the hollow round cake is heated, rolled circularly and deformed by 25 to 30 percent; a rectangle pre-rolling blank is obtained after the rectangle ring blank is heated, rolled circularly and deformed by 25 to 30 percent again; the pre-rolling blank is heated and arranged in a rolling die of a ring rolling machine and becomes a heterotypic ring forging after being rolled and deformed by 40 to 45 percent in a section groove of the die. When in expansion, the broadening speed of the pre-rolling blank along the radial direction is 2mm / s to 15mm / s with a radial rolling force of 40000kg to 220000kg. The method is mainly used for the shaping of the heterotypic ring forging of an aeroengine or a gas turbine. The method can be adopted to obtain the heterotypic ring forging that is arranged in a flow line along the outline of a part.

Owner:GUIZHOU ANDA AVIATION FORGING

A 3D printing polymer material and a preparing method thereof

ActiveCN105524399AGood dimensional stabilityGood bridgingAdditive manufacturing apparatusAntioxidantTactile sensation

The invention relates to the technical field of resin composition preparation and particularly relates to a 3D printing polymer material with special beautifying effects and a preparing method thereof. The polymer material comprises following raw materials by weight: 60-90 parts of matrix resin, 4.0-10 parts of a compatilizer, 0-30 parts of an inorganic filler, 0.3-2.0 parts of white oil, 0.4-0.6 part of an antioxidant, 0.5-1.0 part of a processing auxiliary agent and 1.0-5 parts of a toner. The polymer material is good in dimension stability, good in bridging effect and excellent in draping performance. The appearance of the polymer material is strong in metallic tactile sensation and pearl effects. The polymer material has one or a plurality of effects selected from heat discoloration, photochromic effects, effects of color changing when sensing water, and the like, and is of great significance for promoting material diversification and functionalization of 3D printing. The preparing method is simple, improves shearing and dispersion for the inorganic filler and the toner to the utmost, and improves properties of the polymer material.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

Copolyamide powder and its preparation, use of copolyamide powder in a shaping process and mouldings produced from this copolyamide powder

ActiveUS20090236775A1Low viscosityHigh dimensional accuracyAdditive manufacturing apparatusElectric discharge heatingLaurolactamPolyamide

A task often encountered in very recent times is the rapid provision of prototypes. Particularly suitable processes are those based on pulverulent materials and in which the desired structures are produced layer-by-layer through selective melting and solidification. The invention provides the constitution, production and use of a copolyamide powder which was produced using the following monomer units: a) laurolactam or ω-aminoundecanoic acid, and also b) dodecanedioic acid, and either c) decanediamine or dodecanediamine, in shaping processes, and also to mouldings produced through a layer-by-layer process which selectively melts regions of a powder layer, using this specific powder. Once the regions previously melted layer-by-layer have been cooled and solidified, the moulding can be removed from the powder bed. The mouldless layer-by-layer processes for the production of components using the copolyamide powder result in simplified and more reliable conduct of the process and better recyclability.

Owner:EVONIK OPERATIONS GMBH

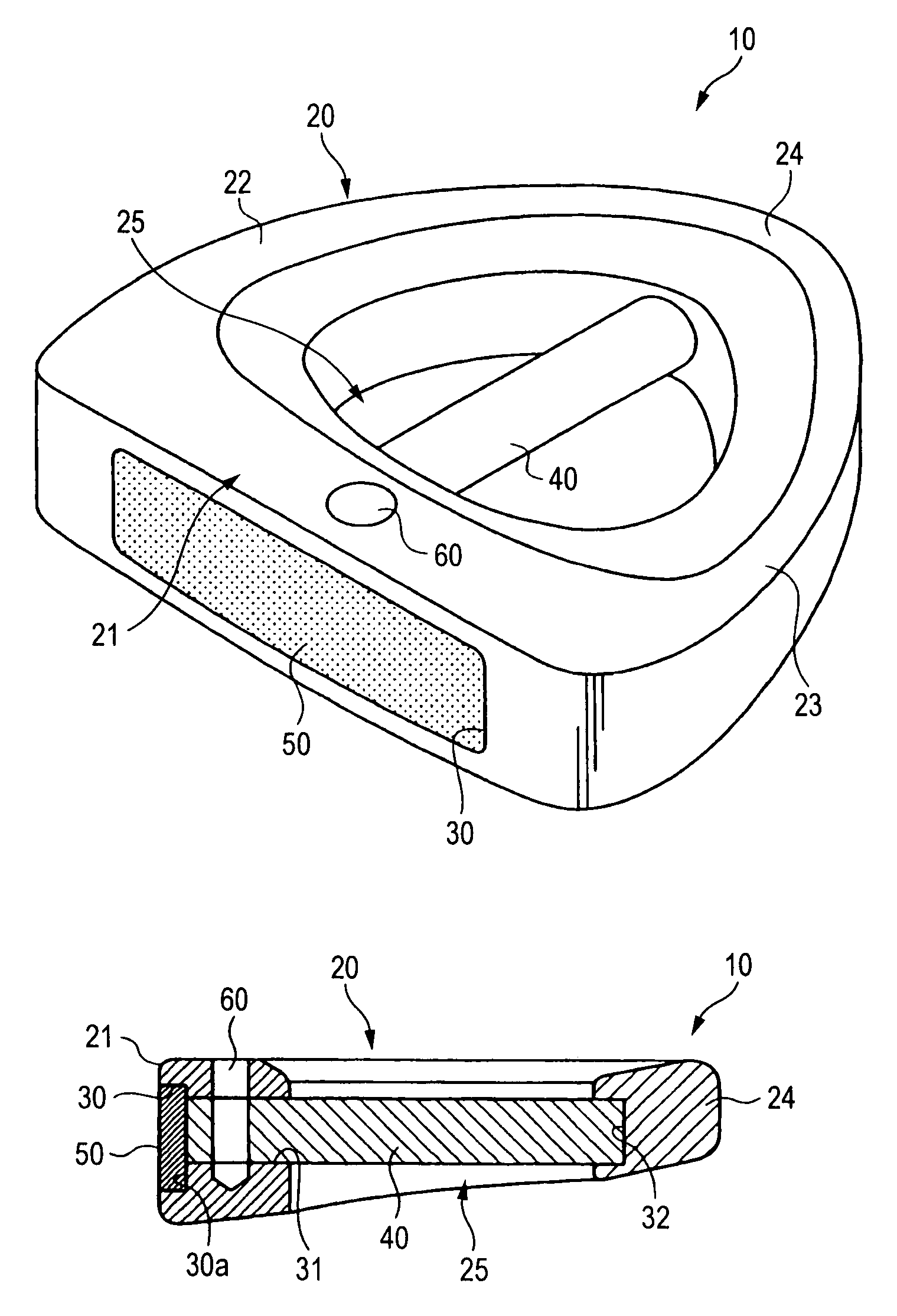

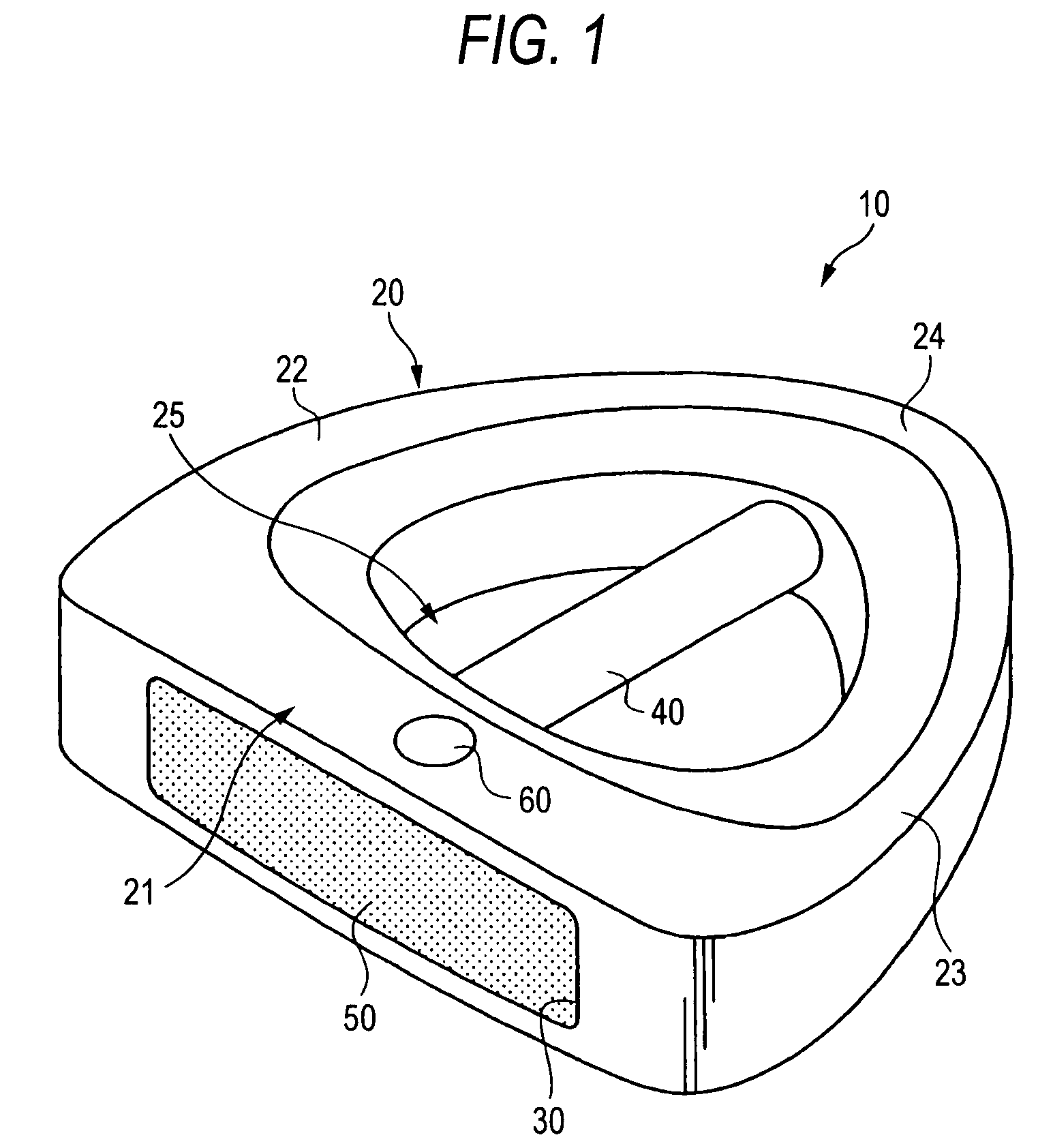

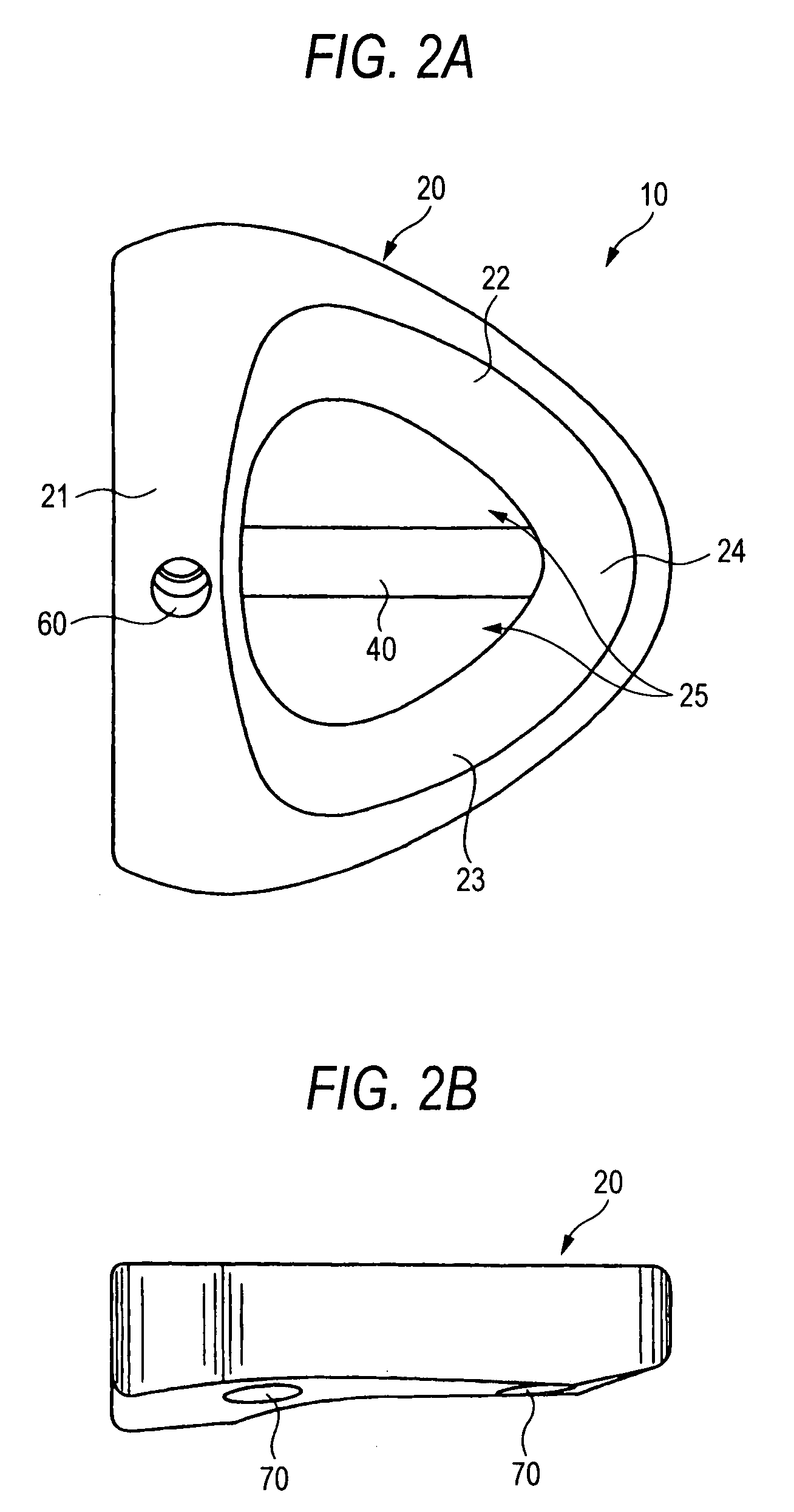

Putter head

InactiveUS7588499B2High dimensional accuracyEasy to manufactureGolf clubsRacket sportsAdhesiveEngineering

A putter head includes a head main body that defines a periphery of the putter head, and a bar that crosses a void space of the head main body in a forward-backward direction. The bar is inserted into insertion holes and fixed thereto by an adhesive. A face member is mounted on a recess. A shaft fixing hole is provided to pass through the bar from the top surface of a front portion of the head main body. A shaft is inserted into the shaft fixing hole and fixed thereto by an adhesive.

Owner:BRIDGESTONE SPORTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com