Patents

Literature

2303results about How to "Improve molding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic slurry preparation and 3D (three dimensional) printing light curing molding method

ActiveCN106810215ALow viscosityHigh solid contentAdditive manufacturing apparatusCeramic shaping apparatusFlexural strengthVolumetric Mass Density

The invention provides a ceramic slurry preparation and 3D (three dimensional) printing light curing molding method. 25-85vol% of ceramic powder and 15-75vol% of an optical resin premix solution are mainly involved, and the method includes: A), preparation of the optical resin premix : namely stirring a low polymer, a reactive diluent, a photoinitiator, a dispersing agent, a photosensitizer and a sensitizer according to a certain proportion under intermediate speed for 0.5-3 hours to enable the components to be mixed evenly; B), placing the premix solution and the ceramic powder in a ball mill according to certain volume for ball-milling for 5-15 hours to prepare the ceramic slurry high in solid content and low in viscosity; subjecting the ceramic slurry to curing molding layer by layer gradually on a 3D light curing molding machine to obtain a ceramic green body prior to aftertreatment of drying, degreasing, sintering and the like to obtain ceramic part. The method is high in preparation molding precision and free of molds to prepare complex structure parts, the ceramic product can reach more than 92% in density, 320-1750MPa in flexural strength and 1800-4500MPa in compression strength.

Owner:重庆摩方科技有限公司

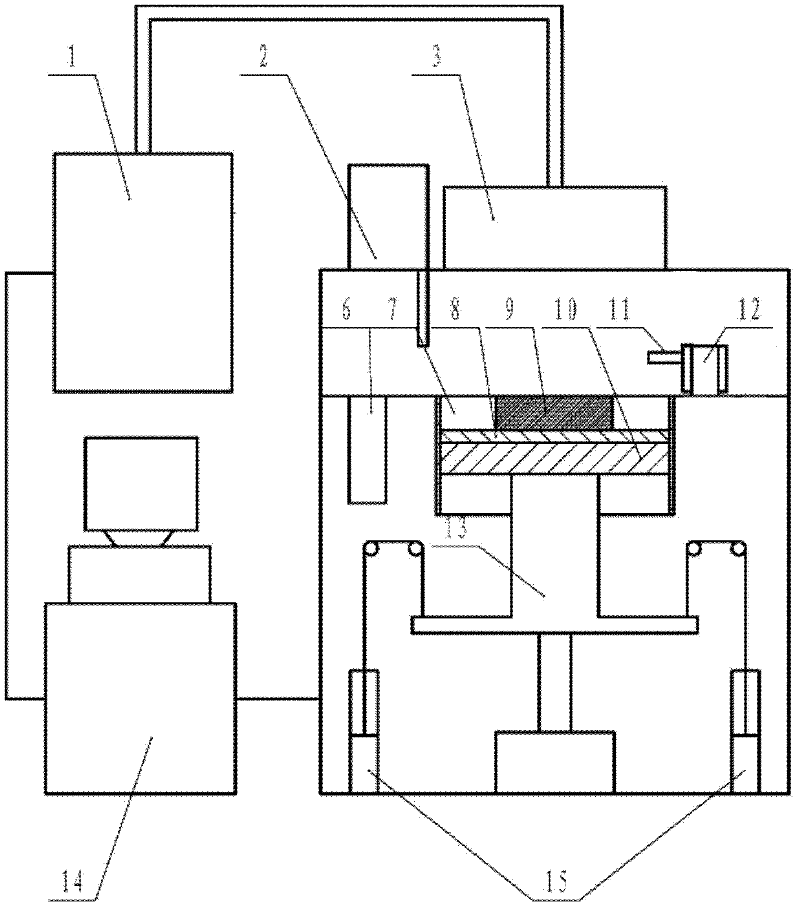

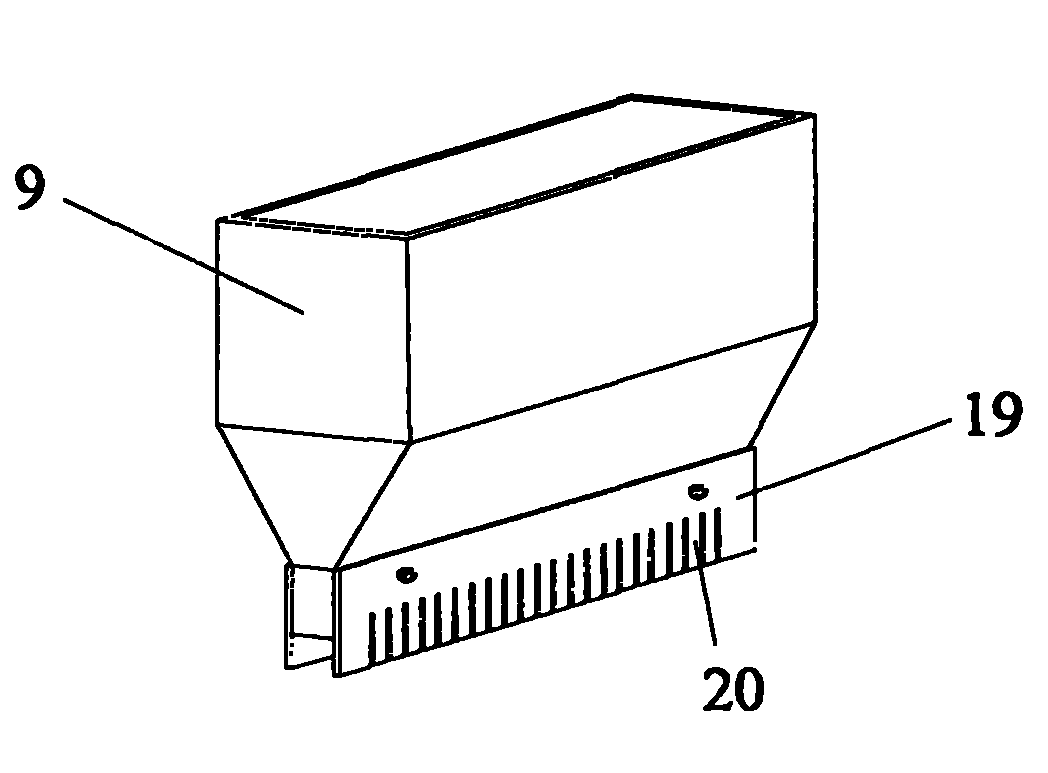

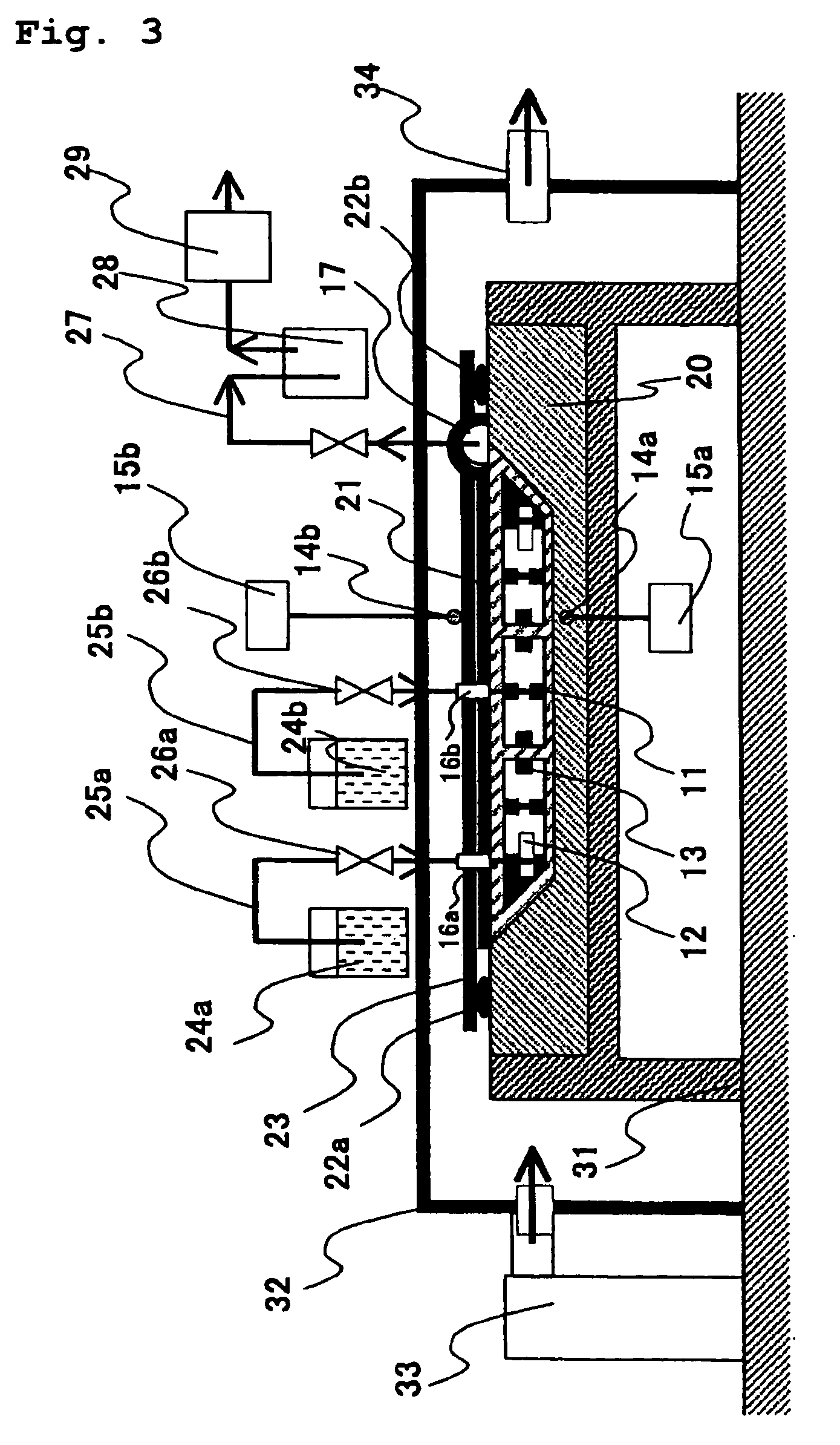

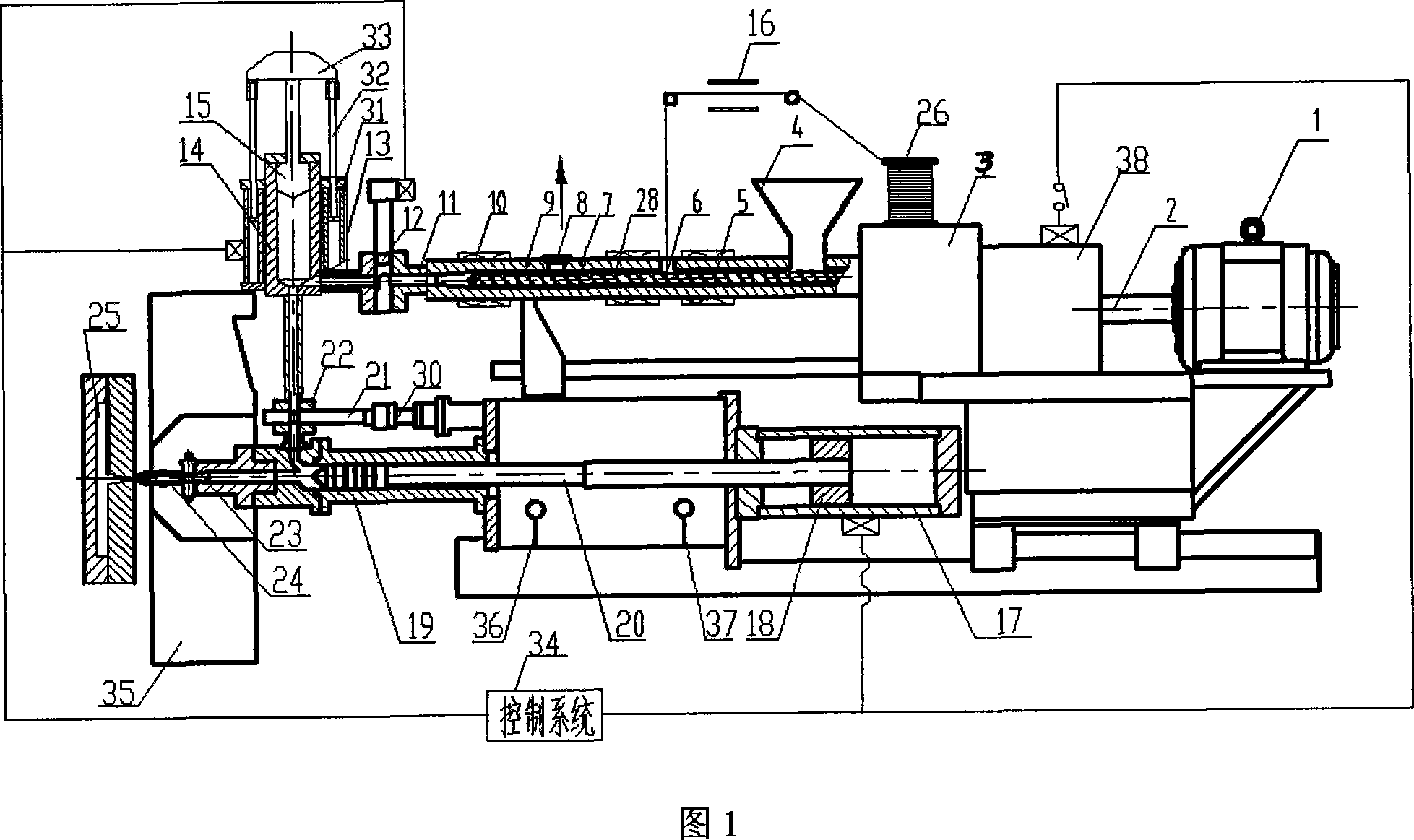

Selective laser melting rapid prototyping equipment for direct manufacturing of large parts

ActiveCN102266942AMeet the process requirementsReduce construction costsIncreasing energy efficiencySelective laser meltingLaser array

The invention discloses a selective laser melting rapid forming device for directly manufacturing large-size compact parts, which mainly comprises a laser array, an optical system array, a forming cylinder, a forming cylinder vertical sectional heating thermal-insulation structure, a forming cylinder weight balancing system, a substrate leveling device, a double-recovering cylinder, a double powder storing box, a double quantitative powder sending and discharging device, a powder paving device, a protective atmosphere cover, a gas purifying system and a control system, wherein an adopted optical system is composed of a plurality of optical system units and a mechanical moving platform, and the coverage area of the optical system can be randomly expanded or reduced. The size of the parts manufactured by using the selective laser melting rapid forming device provided by the invention is more than the size of the parts manufactured by using the existing national and foreign selective laser melting processes. The forming efficiency is multiplied while the forming precision, the parts complexity and the mechanical property are not changed.

Owner:TECH LASER TECH SHANGHAI CO LTD

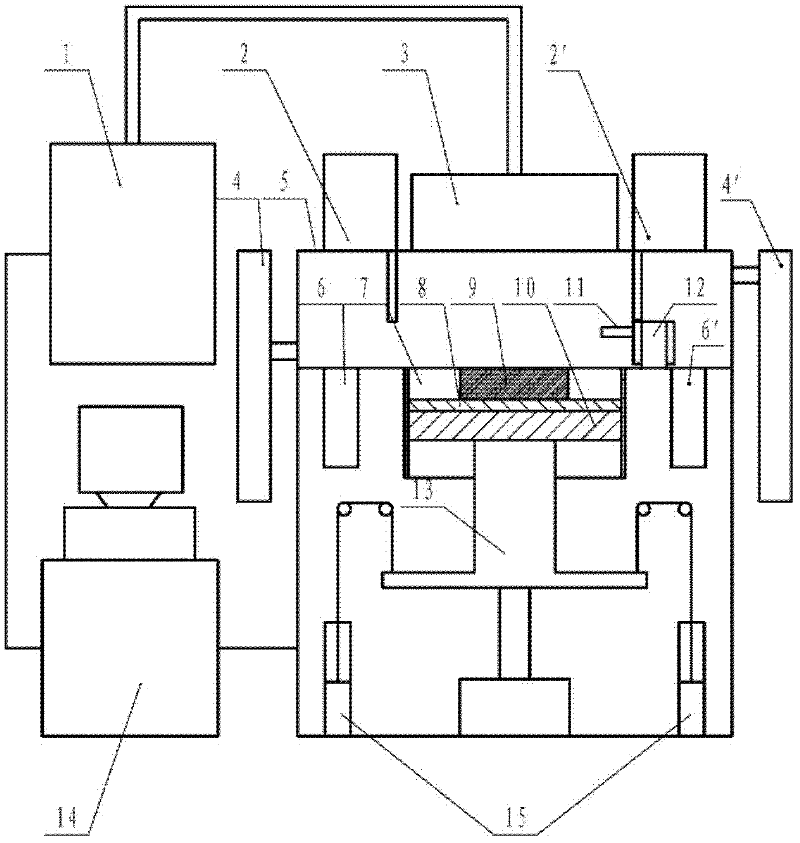

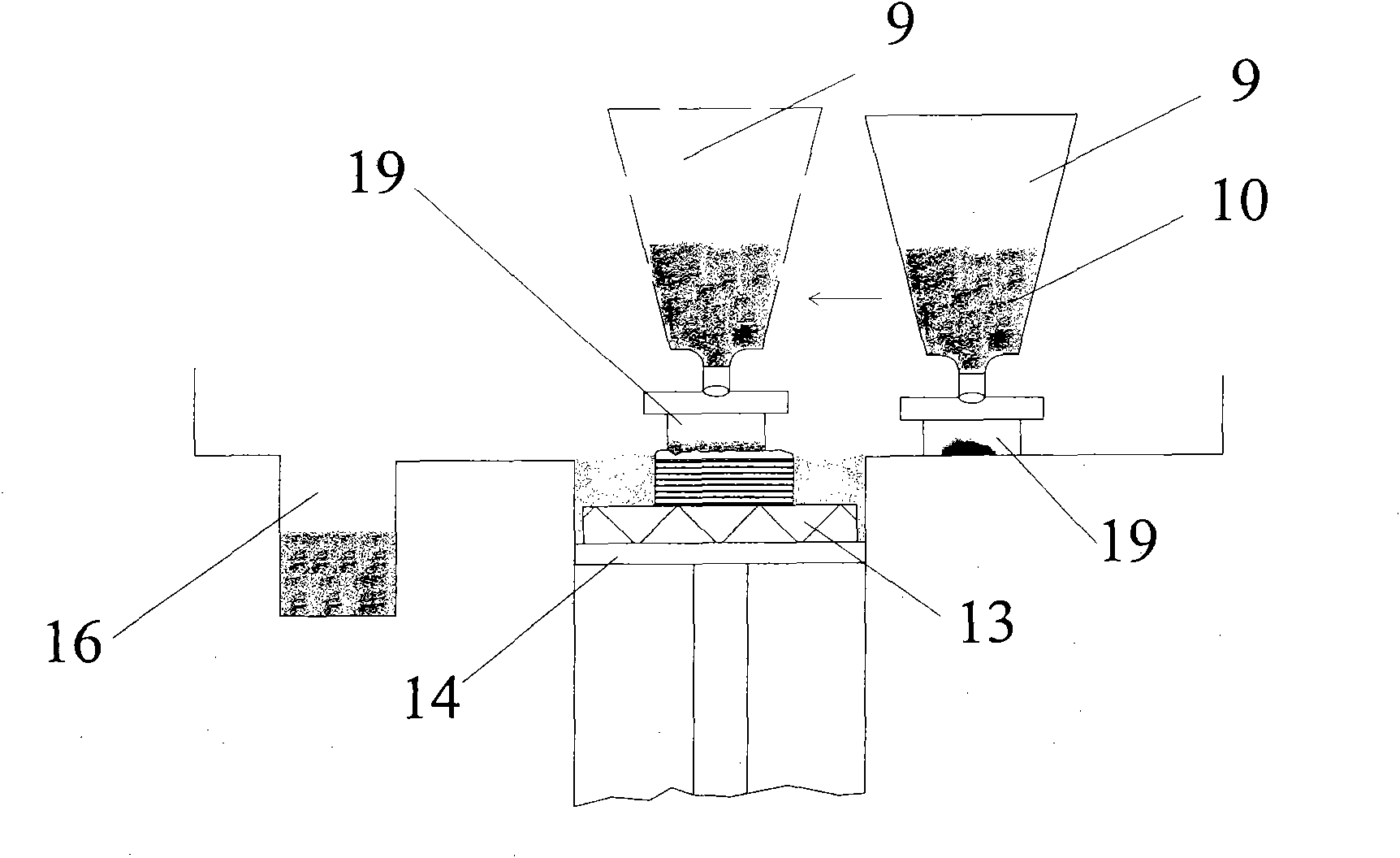

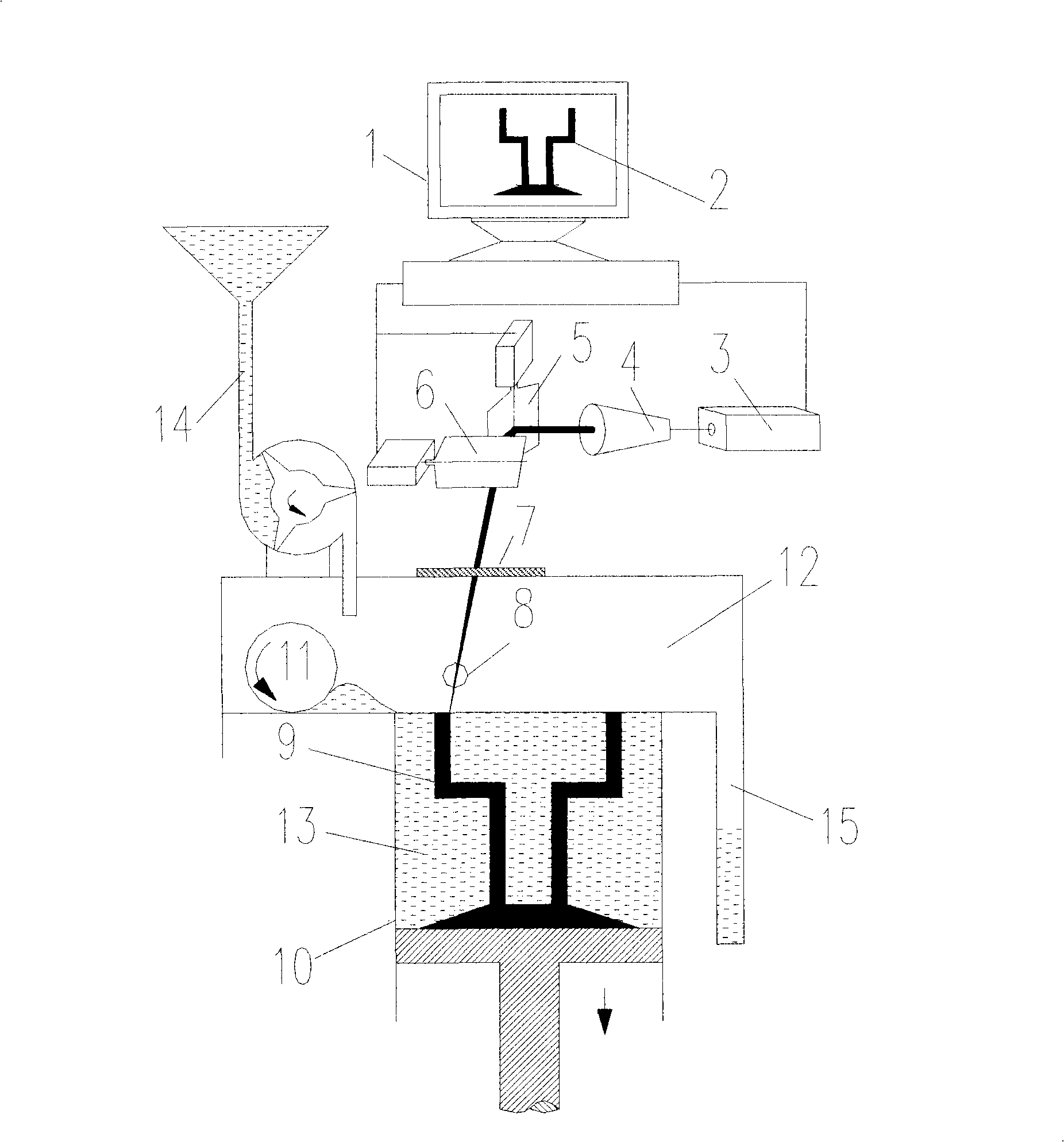

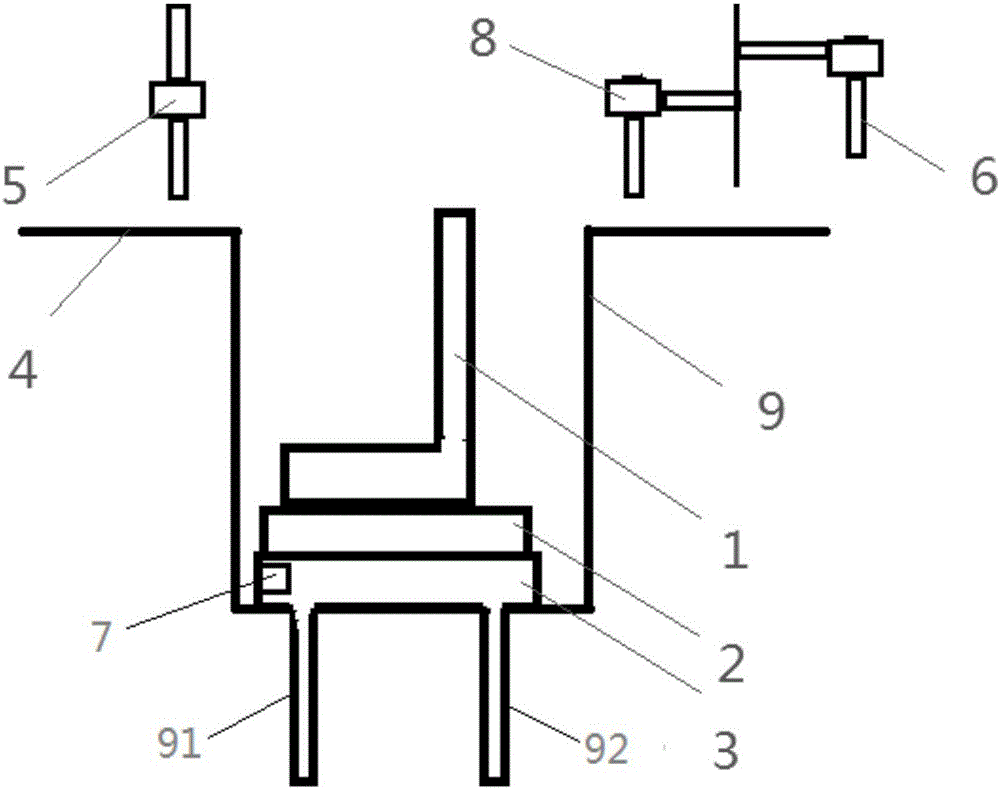

Selective laser melting forming device and method of medical magnesium alloy metal part

ActiveCN101856724ASatisfies complex spatial shape requirements with high degrees of freedomMeet complex space shape requirementsSelective laser meltingOptoelectronics

The invention provides a selective laser melting forming device of a medical magnesium alloy metal part, which comprises a control device, a powder delivering and spreading device, a laser transmission mechanism, an air purification device and a closed forming chamber, wherein the powder delivering and spreading device comprises a hopper and powder spreading brushes arranged on two sides below the hopper, the upper part of the hopper is arranged in a way of corresponding to a feeding opening on the upper part of the forming chamber, and the lower parts of the powder spreading brushes horizontally correspond to the upper surface of a forming cylinder; the laser transmission mechanism is arranged outside and above the forming chamber and is arranged in a way of corresponding to the forming cylinder; the side wall of the forming chamber is provided with an air inlet and an air outlet, and the air purification device is connected with the air inlet and the air outlet respectively; and the control device is connected with the powder delivering and spreading device, the laser transmission mechanism, the forming cylinder and the air purification device respectively. The invention also provides a selective laser melting forming method of the medical magnesium alloy metal part. The device and the method can manufacture parts which have complex shapes required in the medical field directly, and have the advantages of high forming efficiency and the like.

Owner:SOUTH CHINA UNIV OF TECH

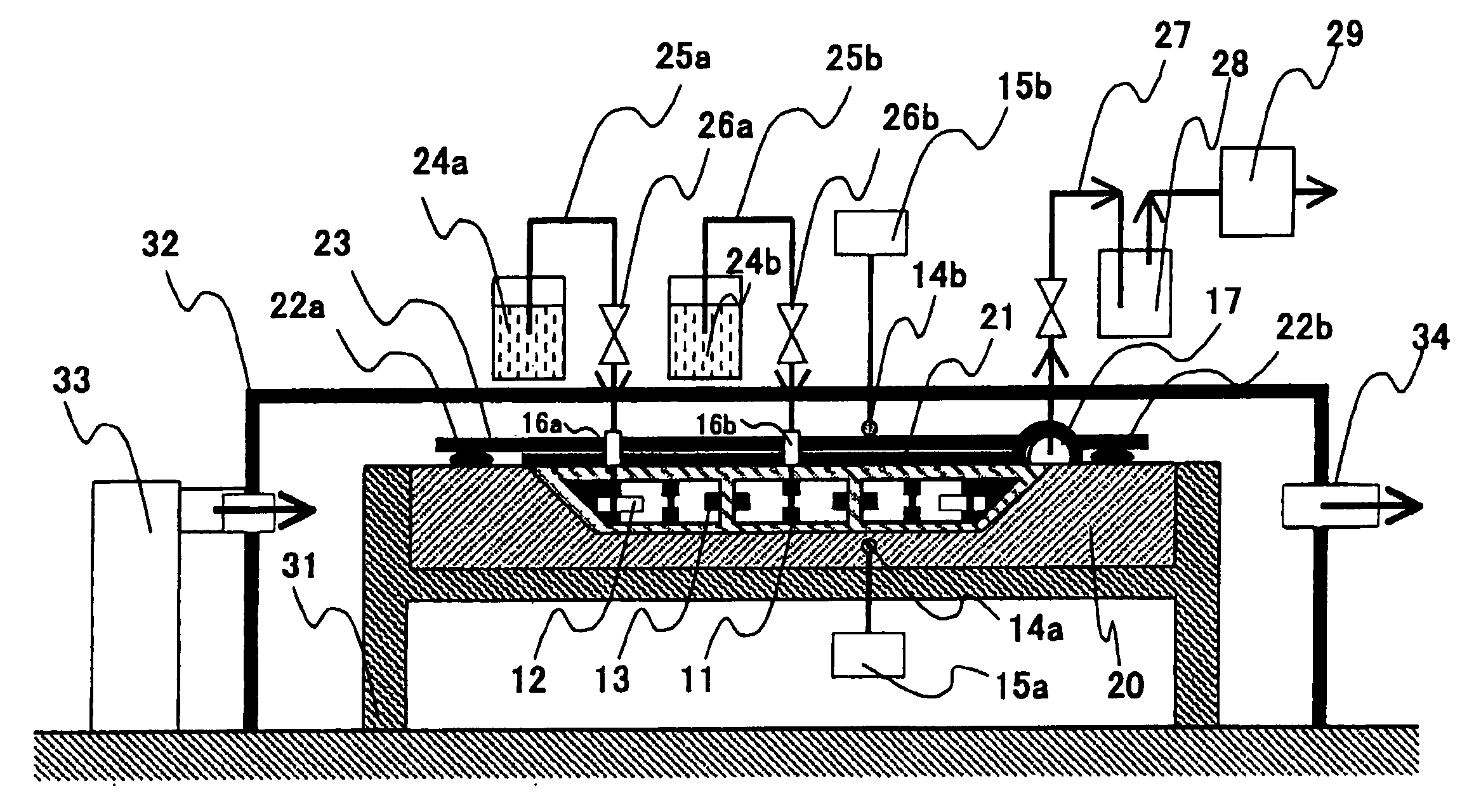

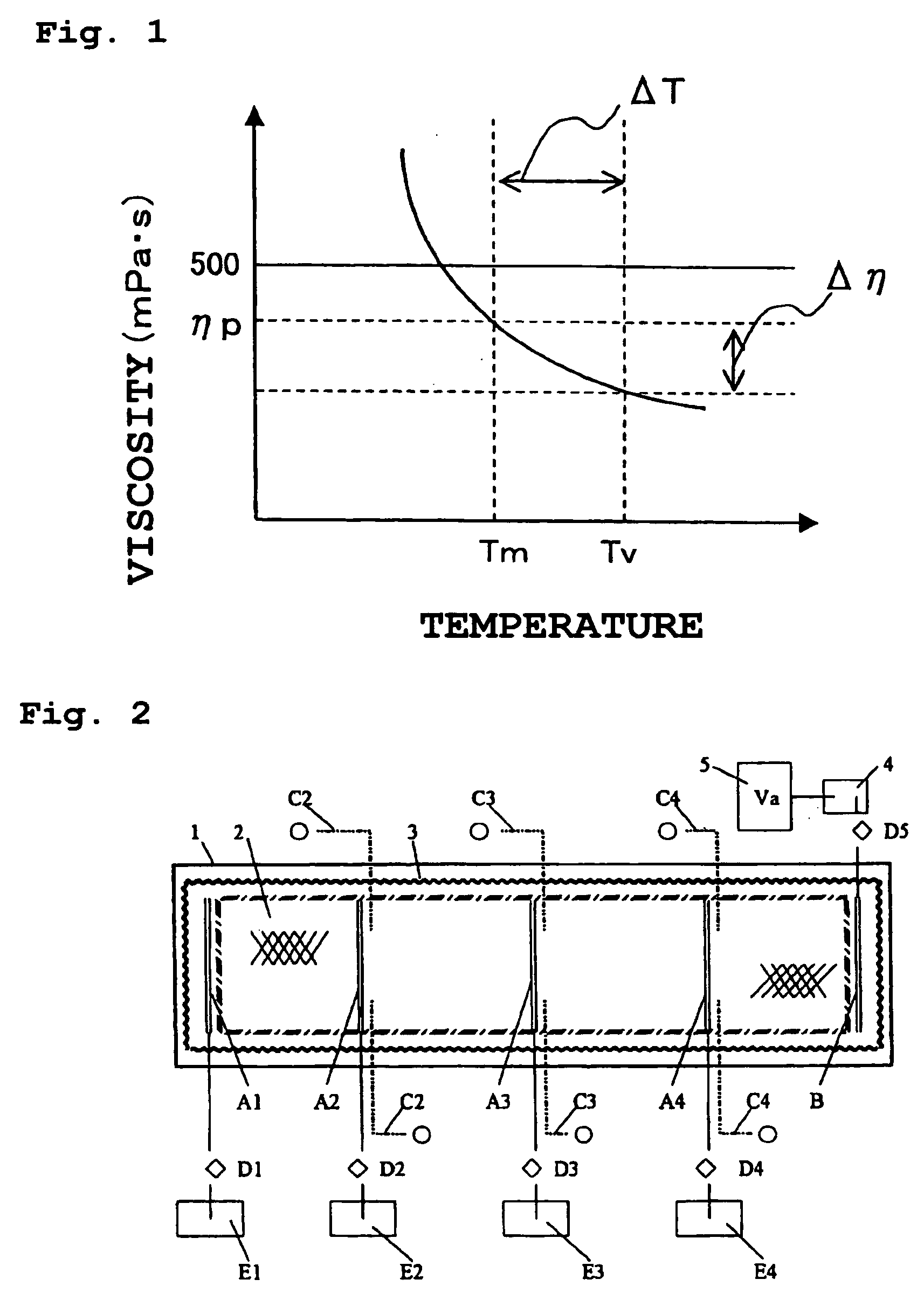

Method for producing upsized frp member

InactiveUS20040130072A1Improve mass productionReduce manufacturing costLamination ancillary operationsLaminationAir cycleFiber

The present invention relates to a method for manufacturing a large FRP member and has the following structure. The method for manufacturing a large FRP member, comprising the following steps (A) to (F). They are: setting step (A) of disposing a preform containing a reinforcing fiber base material on a surface of a molding die; sealing step (B) of covering a molding portion with a bagging material or a mold and providing at least one suction port and at least one resin injection port for sealing; evacuating step (C) of evacuating the molding portion through the suction port; hot-air heating step (D) of heating the molding portion by hot air; resin injection step (E) of injecting a thermosetting resin from the resin injection port for impregnating the reinforcing fiber base material with the resin while a temperature Tm of the molding die and a temperature Tv of the bagging material or the mold are both set to room temperature or more, and a difference DeltaT in temperature between the Tm and the Tv is set to 10° C. or less; and curing step (F) of curing the resin by maintaining the molding portion at a predetermined temperature Tpc which is equal to or more than room temperature. Preferably, the preform described above includes the reinforcing fiber base material and a resin distribution medium. In addition, it is preferable that in the hot-air heating step (D), the molding die be placed in a sealed chamber which is heat insulated with a heat insulating material, the hot air be circulated and supplied, and timing of starting the injection of the resin from a plurality of the resin injection ports be controlled in accordance with signals supplied from resin detection sensors provided in the molding die. The present invention provides a method for manufacturing a large FRP member having superior quality at an inexpensive cost and with high production yield, in which non-impregnated portions and voids are unlikely to be formed.

Owner:TORAY IND INC

Scratch-resistance French white filled polypropylene composition and its preparing method

InactiveCN1580115AImprove scratch resistanceImproves UV resistanceProcedure AgentsSilicone Elastomers

This invention refers to a kind of component of nick resistant talcum-powder-filling polypropylene, is characterized with strengthened toughness through latex and is composed of the following materials in amounts of weight: between 50 and 80 of polypropylene, between 5 and 35 of filler, between 5 and 25 of latex, between 0.5 and 5 of high molecular silicone elastomer, between 0.05 and 0.5 of nucleater, between 0.1 and 1.0 of stabilizer, between 0.2 and 1.5 of talcum powder surface passiation agent, between 0.05 and 1.0 of processing agent and between 0.3 and 2.0 of toner. The manufacturing method is to weigh the materials in amounts of weight, to mix polypropylene, filler, latex, high molecular silicone elastomer, nucleater, stabilizer, talcum powder surface passiation agent, processing agent and toner in homo mixer, then put them into double-screwed extruder for melting and extruding. After cooling, drying and pelleting, we can get the turnoff. The invention improves the nick resistance of polypropylene, ultraviolet radiation endurance and thermal endurance and the toughness and rigidity of the material reach good balance. It can meet the requirements of the material of automobile limbs. It can demold at a relatively high temperature, improves the moulding efficiency greatly and reduces the processing cost.

Owner:SHANGHAI PRET COMPOSITES

Ceramic material for 3D light curing formation printing and preparation method of ceramic element

InactiveCN109400177AHigh ceramic contentEasy to printAdditive manufacturing apparatusOligomerAgent Combination

The invention relates to a ceramic material for 3D light curing formation printing and a preparation method of a ceramic element. The ceramic material is prepared from 30 to 70 vol percent of ceramicpowder and 30 to 70 vol percent of photosensitive resin premixed liquid, wherein the photosensitive resin premixed liquid is prepared from 37 to 50 weight percent of oligomers, 30 to 60 weight percentof reactive diluents, 0.1 to 5 weight percent of photoinitiators, 1 to 5 weight percent of dispersing agents, 0.1 to 0.6 weight percent of ultraviolet blocking agents, 0 to 0.05 weight percent of polymerization inhibitors, 1 to 4 weight percent of anti-foaming agents, 0.5 to 2.35 weight percent of anti-settling agents and 0.3 to 3 weight percent of leveling agents. In the degreasing and sinteringpost-treatment work procedures, specific parameters are used, so that a sintering element can reach good sintering density and mechanical performance. By optimizing the composition and the proportionof light curing ceramic resin, and selecting the excellent dispersing agent combination and the reasonable consumption, the ceramic powder can be better dispersed in the resin; the problems that theexisting light curing ceramic resin has poor flowability and low formation precision, and that a finally prepared ceramic product can easily generate cracks or deformation, and the like are solved.

Owner:西安点云生物科技有限公司

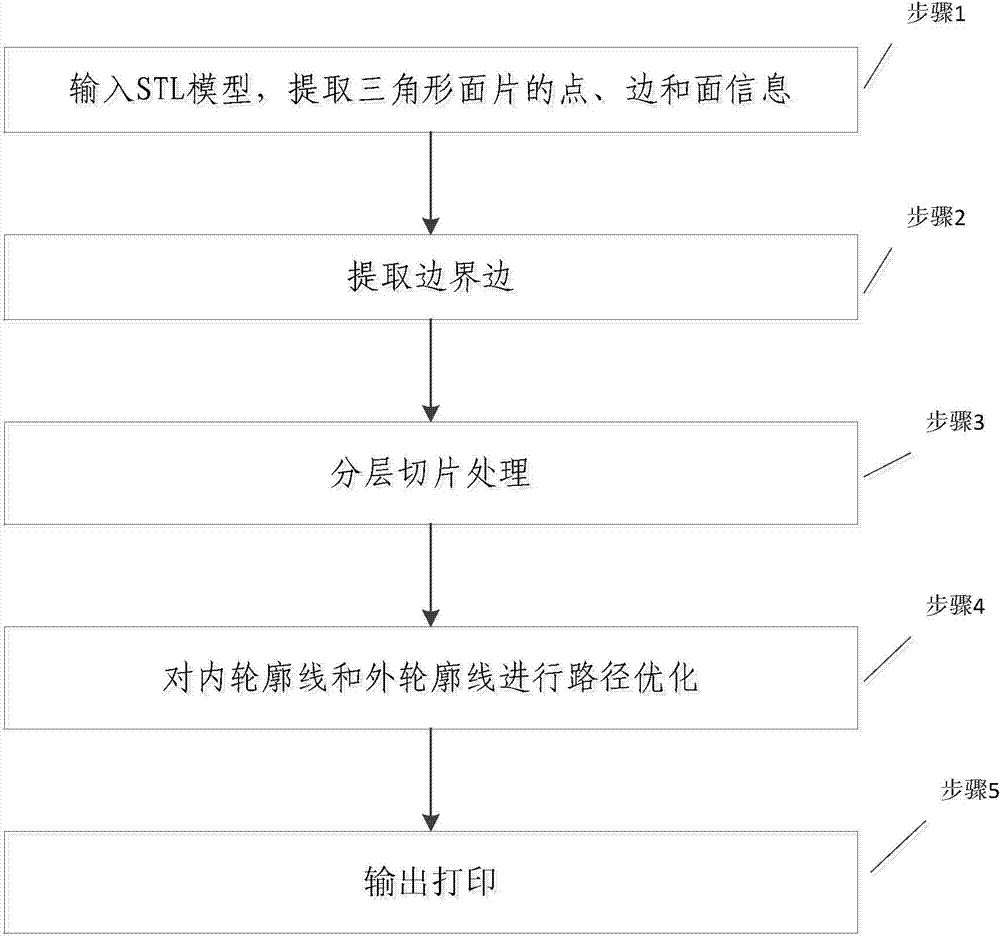

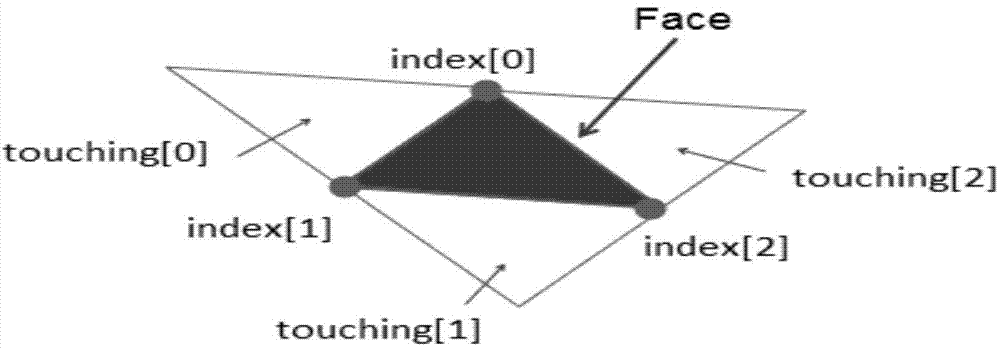

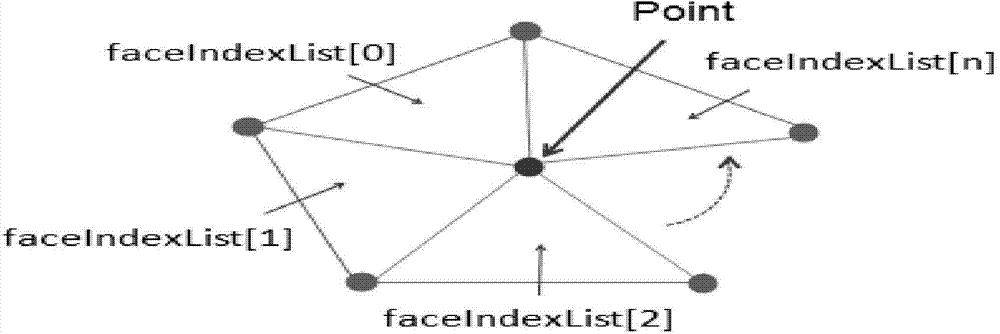

Slicing processing method aiming at non-closed STL model with boundaries

InactiveCN104331555ATroubleshoot slice handling issuesImprove molding efficiencySpecial data processing applicationsComputer graphics (images)3d printer

The invention discloses a slicing processing method aiming at a non-closed STL model with boundaries for a 3D (three-dimensional) printer. The method comprises the following steps that point, edge and surface information of triangles in an STL model are extracted, and in addition, the topology relationship among the point, edge and surface information is built; all boundary edges are extracted according to the boundary edge judging rule; lamination slicing processing is carried out on non-closed lattices to obtain non-closed 2D polygons; printable inner and outer contour lines obtained after the deflection processing on the polygons are subjected to path optimization for reducing idle strokes; a slicing file is used for outputting universal Gcode files which are read and printed by the 3D printer. The invention provides the slicing method aiming at non-closed STL model input from the boundary extraction aspect for the first time, and breaks through the limitation that the traditional 3D printer can only carry out the slicing processing on the closed STL model, and the slicing processing on the non-closed STL model with the boundaries is realized, so that the non-closed STL model can be directly printed and formed.

Owner:上海极臻三维设计有限公司

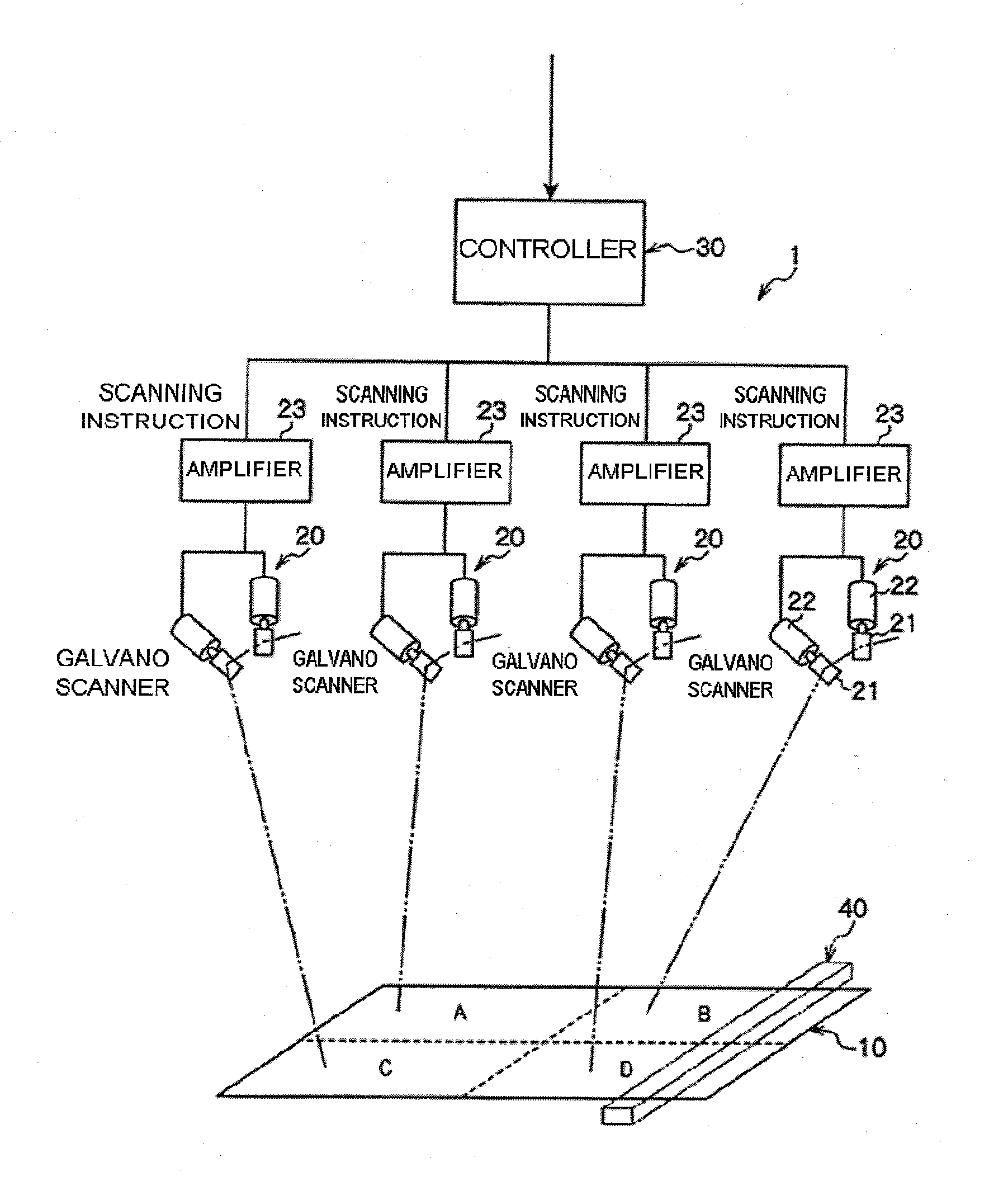

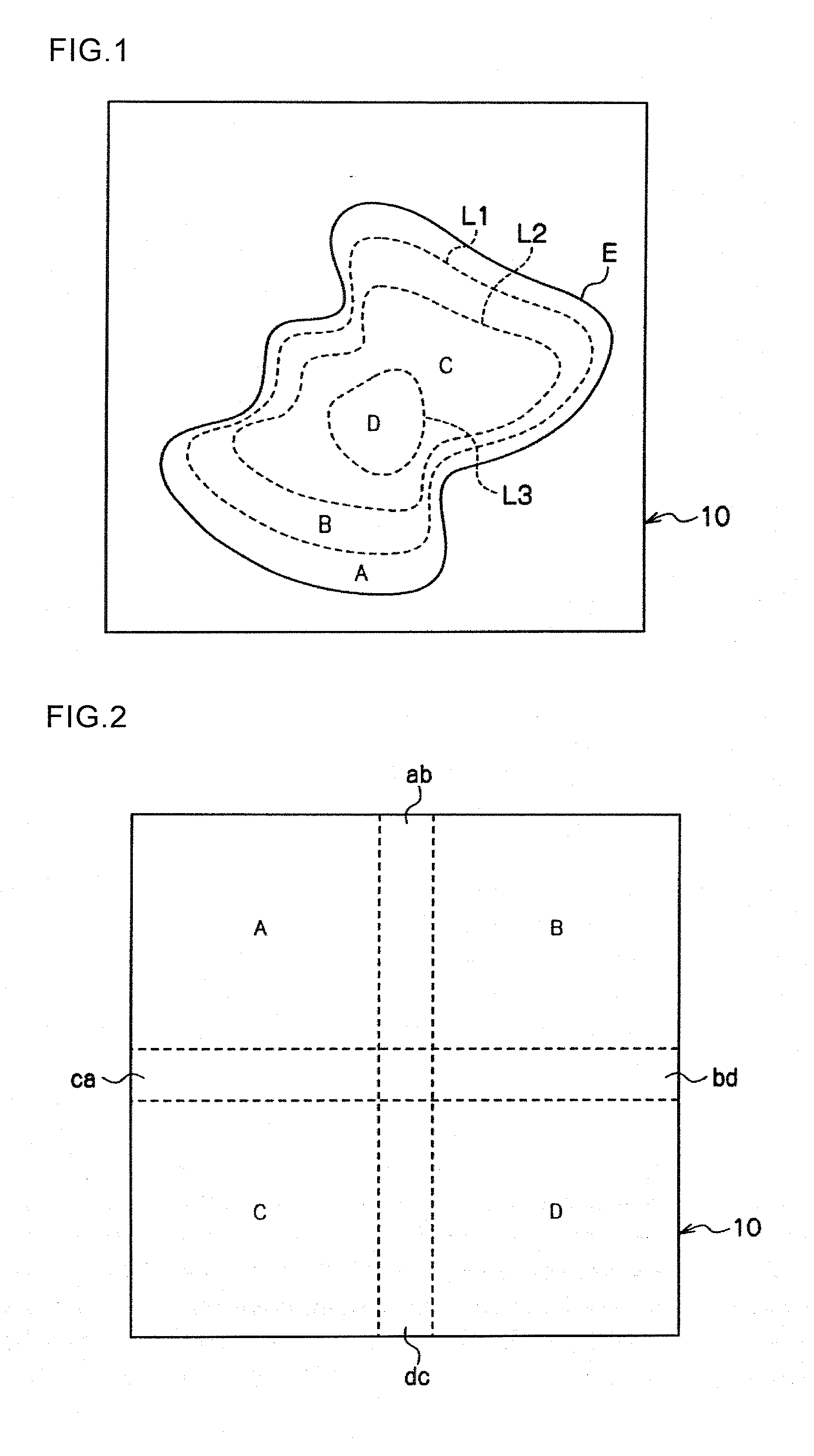

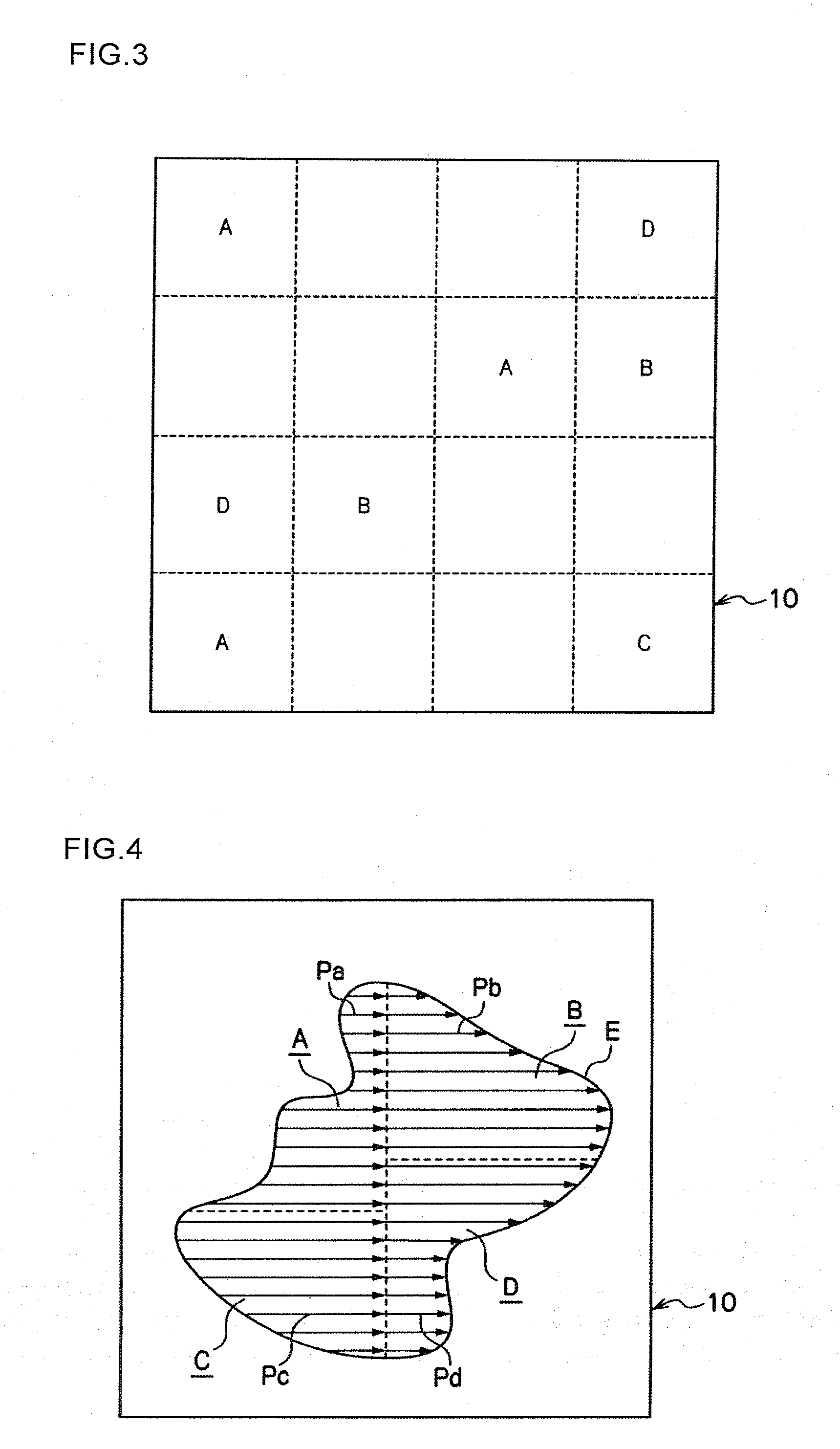

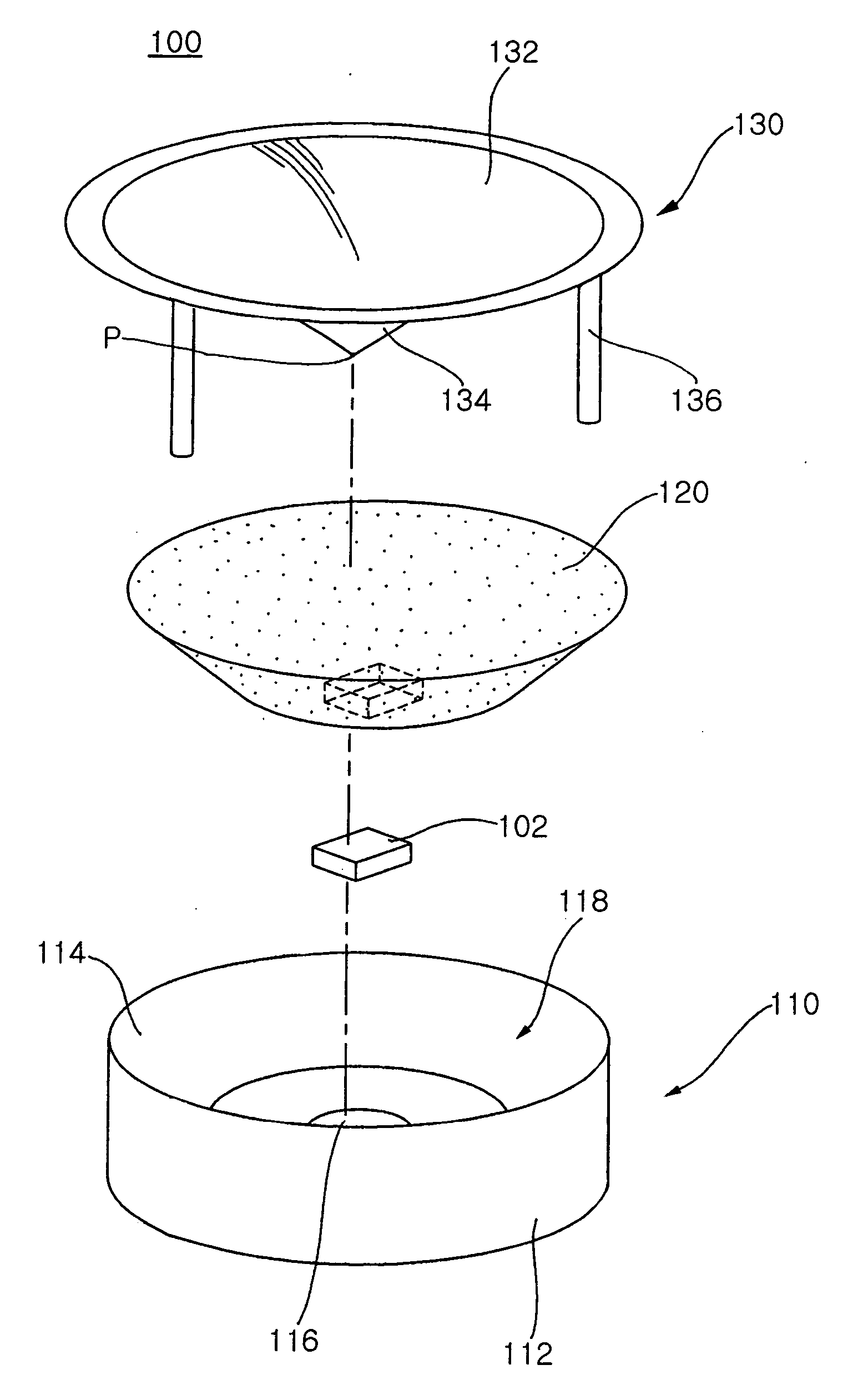

Three-dimensional molding equipment

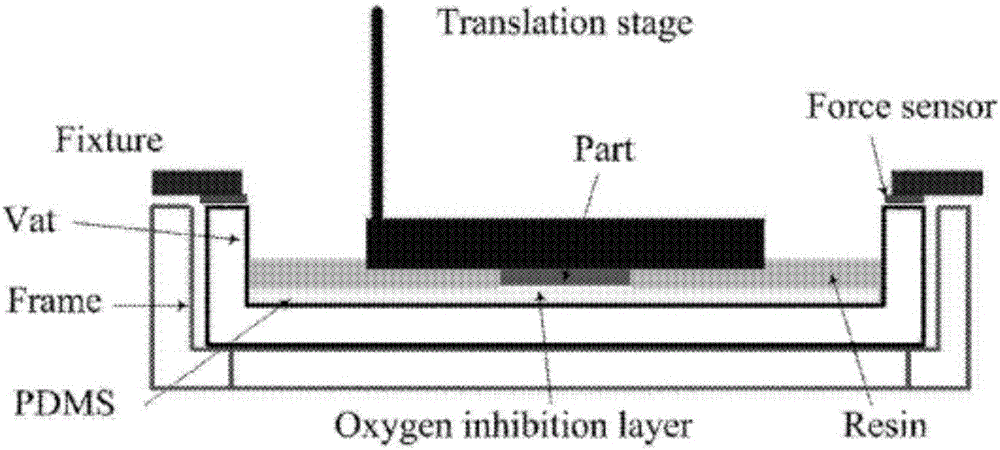

ActiveUS20150283611A1Improve molding efficiencyAdditive manufacturing apparatusAuxillary shaping apparatusLight beamMaterials science

Three-dimensional molding equipment includes powder supply equipment configured to supply powder material and form a powder layer, and a light beam scanning unit configured to radiate a light beam to the powder layer and move a radiated location thereof, where a three-dimensional shaped molding object is manufactured by alternately repeating processes of forming the powder layer and sintering the powder layer with light beam radiation. A region used for manufacturing the three-dimensional shaped molding object is divided into a plurality of divided regions such that respective divided regions have an equal-length molding path which is to be a scanning route of the beam such as having unequal-length molding parts by a scanning route of the beam, and radiation is executed by a plurality of the light beam scanning units to the respective plurality of divided regions to improve molding efficiency.

Owner:MATSUURA MACHINERY

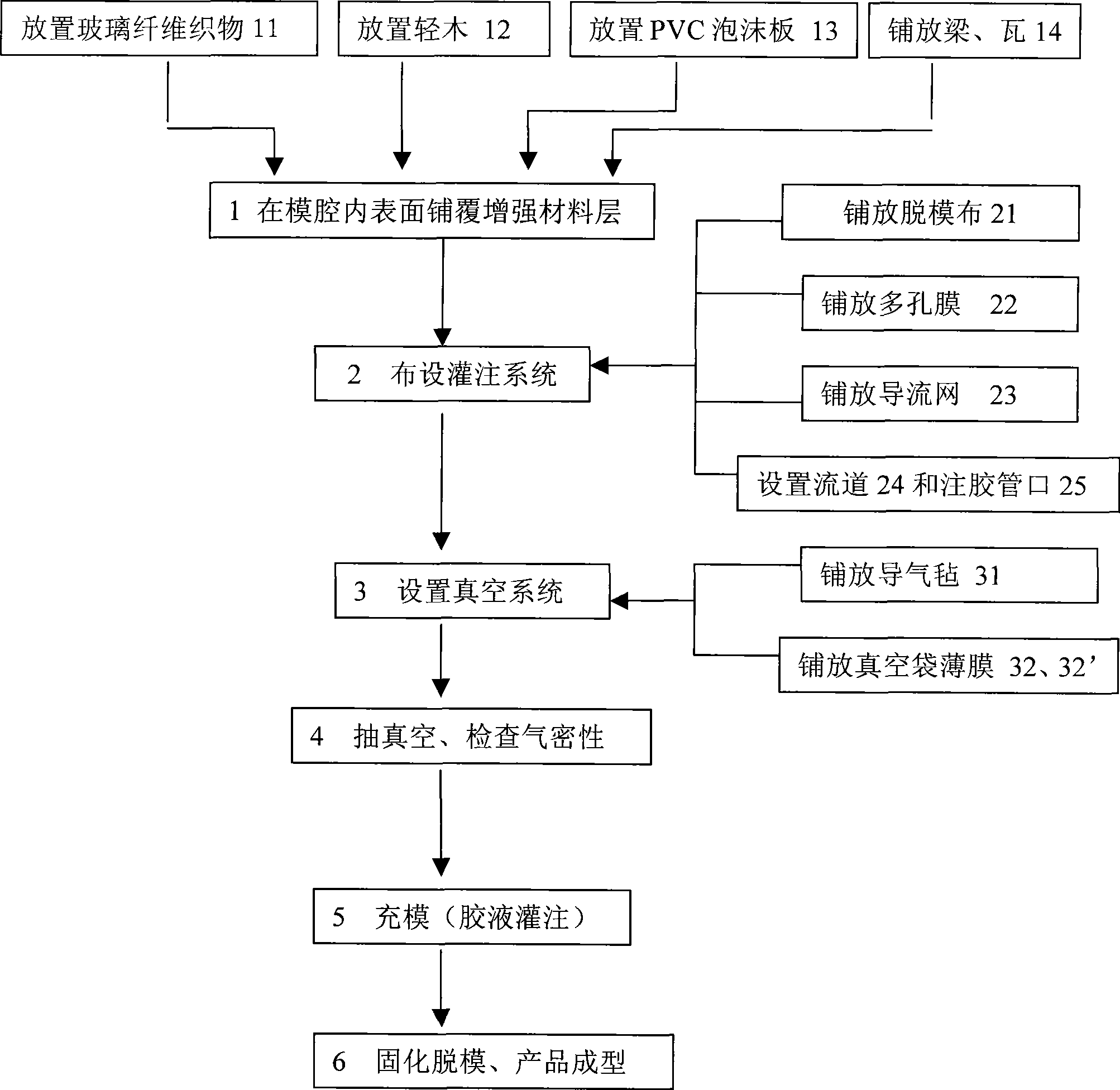

Megawatt level composite material wind electricity blade vacuum guiding and forming technique

ActiveCN101456256AHarm reductionImprove molding efficiencyFinal product manufactureDomestic articlesElectricityTurbine blade

The invention discloses a vacuum infusion forming process for a megawatt grade composite material wind turbine blade. The process comprises a step of spreading and cladding reinforced material layers in an upper mold cavity and a lower mold cavity of a mould of the blade respectively and a step of solidification, demoulding and product forming, and is characterized by comprises the following steps between the two steps: 1)distributing injection systems on the surfaces of the reinforced material layers; 2) distributing vacuum systems on the outer surface of the injection systems spread and covered with flow channels in the step 1); 3) checking the airtight performance of an vacuumizing opening; 4) mould filling ( filling rubber liquid); and 5), solidification, demoulding and product forming. The vacuum infusion process can complete mould filling in 1.5 hours, improves the forming efficiency of large blades, saves special equipment and achieves low production costs. Products formed by the process are uniform in quality distribution and good in process repeatability, and can reduce volatilization of harmful gases and environmental pollution and ensure heath of operators and are easy to promote and use compared with a hand lay up process and a wet spreading process.

Owner:SINOMATECH WIND POWER BLADE

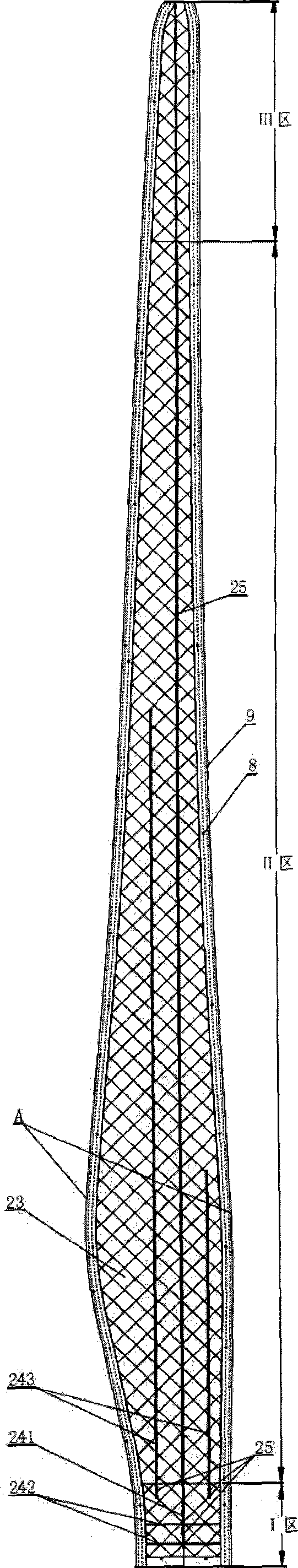

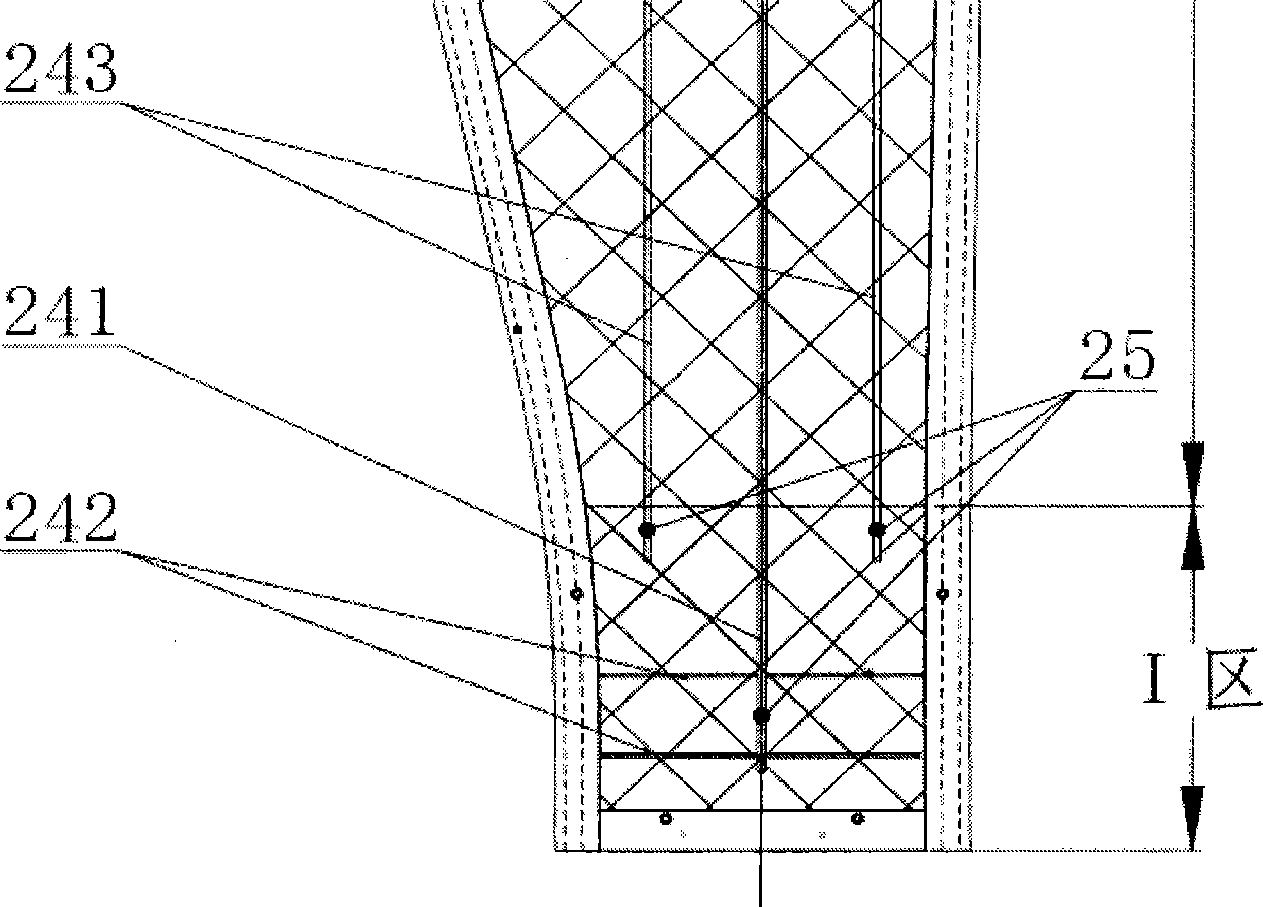

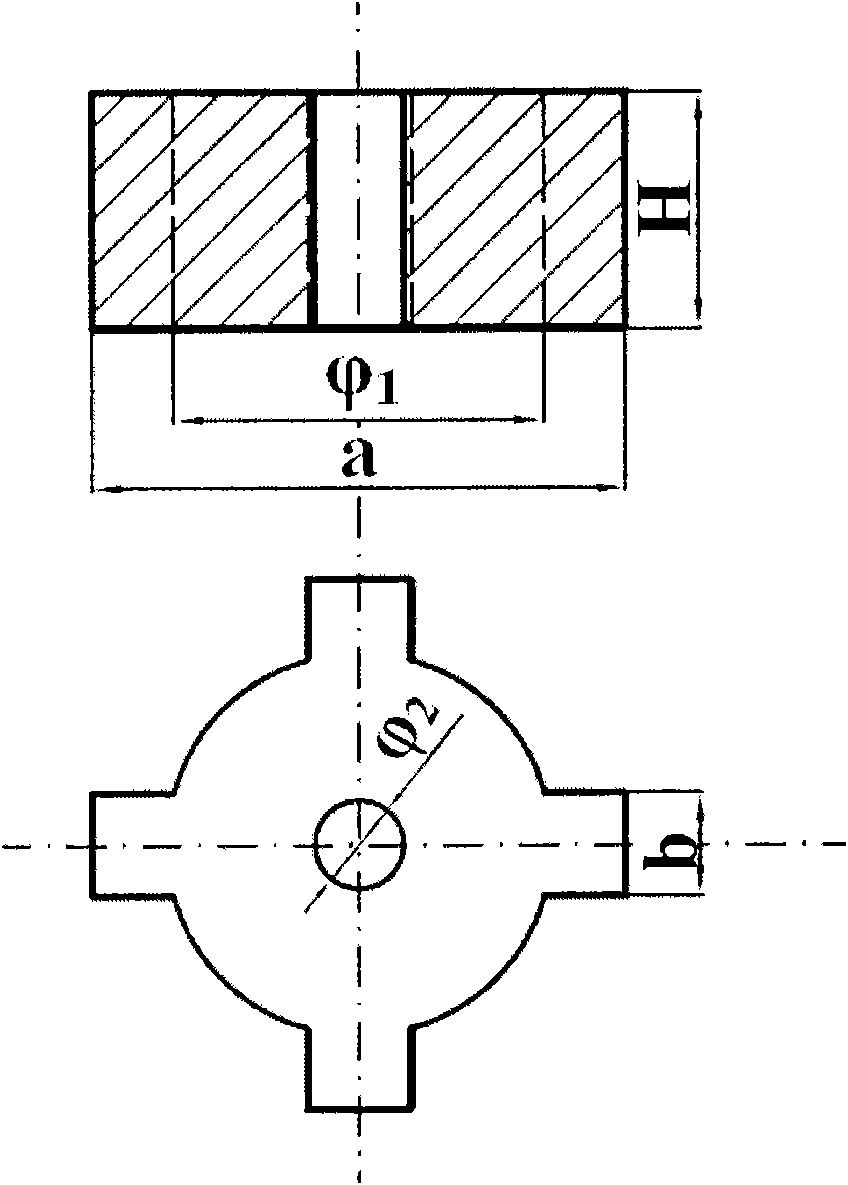

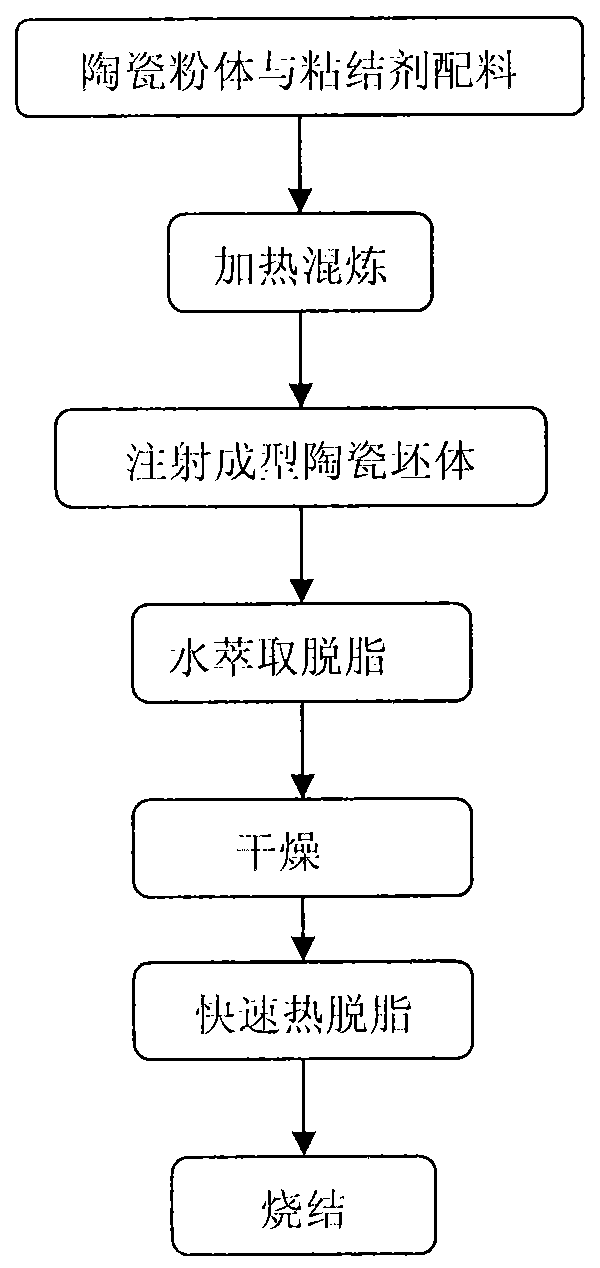

Method for manufacturing dentate special-shaped ceramic components by injection molding

InactiveCN101643360AEfficient preparationHigh precision manufacturingCeramic shaping apparatusSurface finishHigh dimensional

The invention discloses a method for manufacturing dentate special-shaped ceramic components by injection molding, belonging to the technical field of high-performance ceramic preparation. The methodcomprises the following steps: evenly mixing 81wt% to 90wt% of ceramic powder and 10wt% to 19wt% of organic binders by weight percentage to obtain an injection-molding mixture, injection-molding the injection-molding mixture on an injection-molding machine with the injection temperature being 175 to 195 DEG C, to obtain a green body, and de-molding within 2 minutes after the injection, so as to obtain a molded green body; and then, subjecting the molded green body to water-extraction degreasing and thermal degreasing, sintering the degreased green body at 1,350 to 1,550 DEG C, holding for 1 to4 hours and furnace-cooling to obtain the ceramic components. The invention has the advantages of high automation degree, high molding and degreasing efficiencies, even green body, high dimensional accuracy and surface smoothness of sintered products, and environment-friendly and energy-saving manufacture.

Owner:TSINGHUA UNIV +1

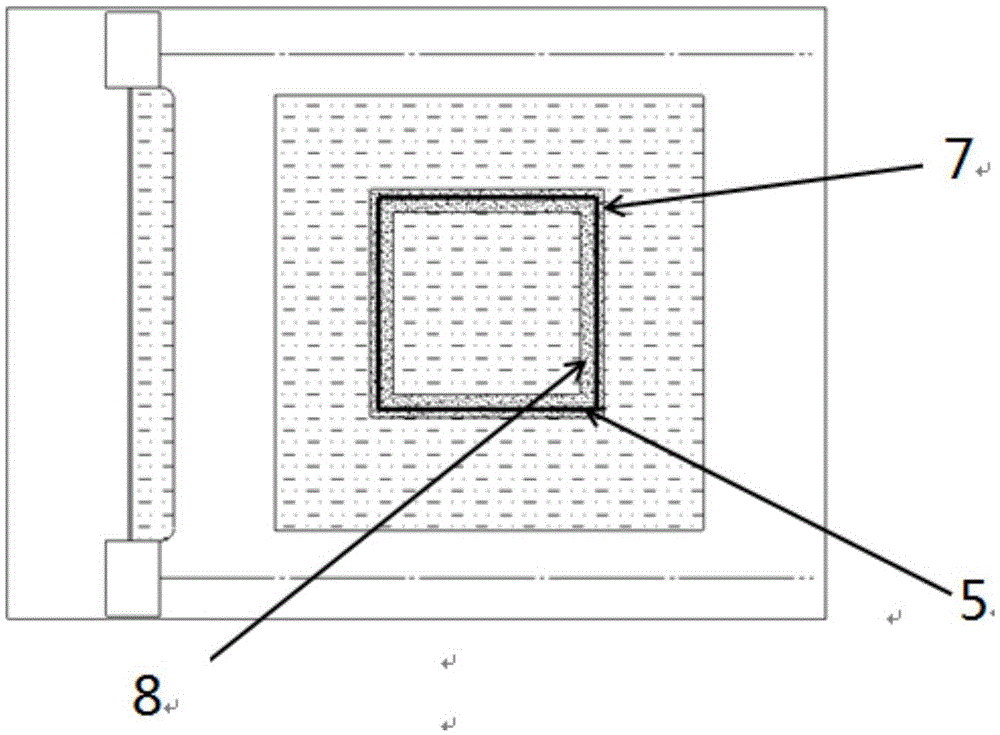

Scanning/molding method for improving additive manufacturing/molding quality of metal part

ActiveCN105903961AHigh precisionImprove surface roughnessAdditive manufacturing apparatusIncreasing energy efficiencyComputer scienceAdditive layer manufacturing

The invention discloses a scanning / molding method for improving additive manufacturing / molding quality of a metal part. According to the scanning / molding method, a scanning method is divided into support scanning and entity scanning; during the support scanning, an interlayer scanning manner is adopted; the entity scanning comprises profile offset scanning of a shell and square block partition scanning of an interior part; after the profile shell scanning of an entity is completed, layer-by-layer offset partition scanning is carried out on the interior part; according to the size of the part, square blocks which are 5*5mm to 10*10mm are filled in the interior part; the scanning line directions between every two adjacent square blocks are 90-degree orthogonal to each other; during the entity scanning in the inner part of the part, the focusing spot diameter is improved through optical path adjustment so as to improve the processing efficiency. The partition square blocks in the interlayer sections are rotated 60 degrees layer by layer, so that the square blocks at the upper and lower layers are prevented from being overlapped so as to possibly eliminate the edge embossing defect, and the stress accumulation defect generated in the multi-layer stacking process can be prevented. The scanning / molding method can be widely applied to the field of additive manufacturing.

Owner:SOUTH CHINA UNIV OF TECH

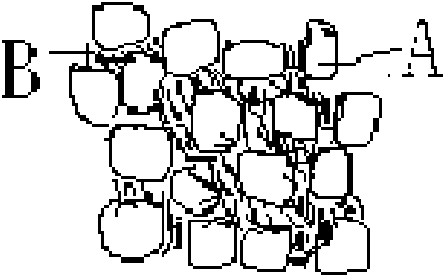

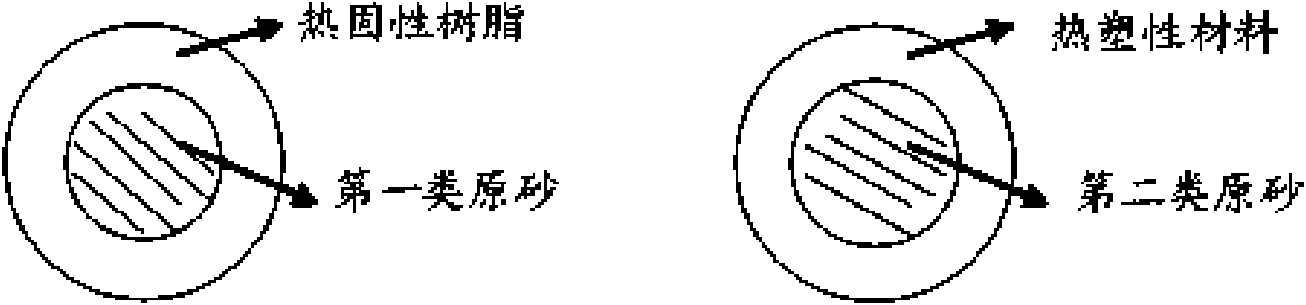

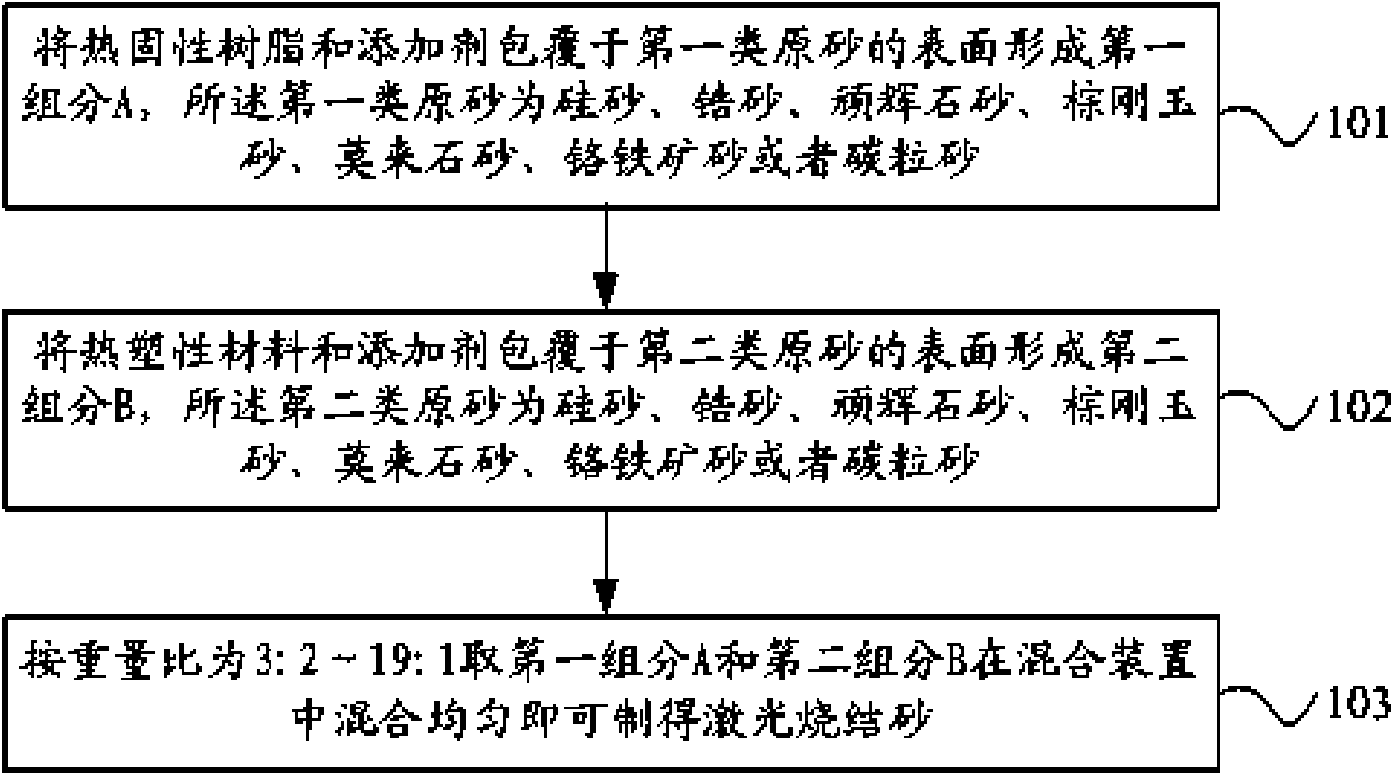

Laser sintering sand, preparation method thereof, sand core and preparation method thereof

ActiveCN101837427AHigh sintered initial strengthMeet the intensityFoundry mouldsFoundry coresGenerating capacityMetal

The invention relates to a laser sintering sand, a preparation method thereof, a sand core and the preparation method thereof. The laser sintering sand consists of a first component and a second component which are evenly mixed, the first component consists of a first type of raw sand with the coefficient of angularity of less than 1.3, thermosetting resin and additives, wherein the thermosetting resin and the additives are coated on the surface of the first type of the raw sand; and the second component consists of a second type of raw sand with the coefficient of angularity of less than 1.1, a thermoplastic material and the additives, wherein the thermoplastic material and the additives are coated on the surface of the second type of the raw sand. The adoption of the laser sintering sand does not need to add an auxiliary support structure during the laser sintering process, thereby improving the molding efficiency and reducing the manual intervention; and the any complex sand core can be manufactured without using a mold, and the sand core simultaneously has high sintering initial strength and can meet the requirements on the thermal strength and the gas-generating capacity of the sand core during the metal casting process.

Owner:安徽隆源成型科技有限公司

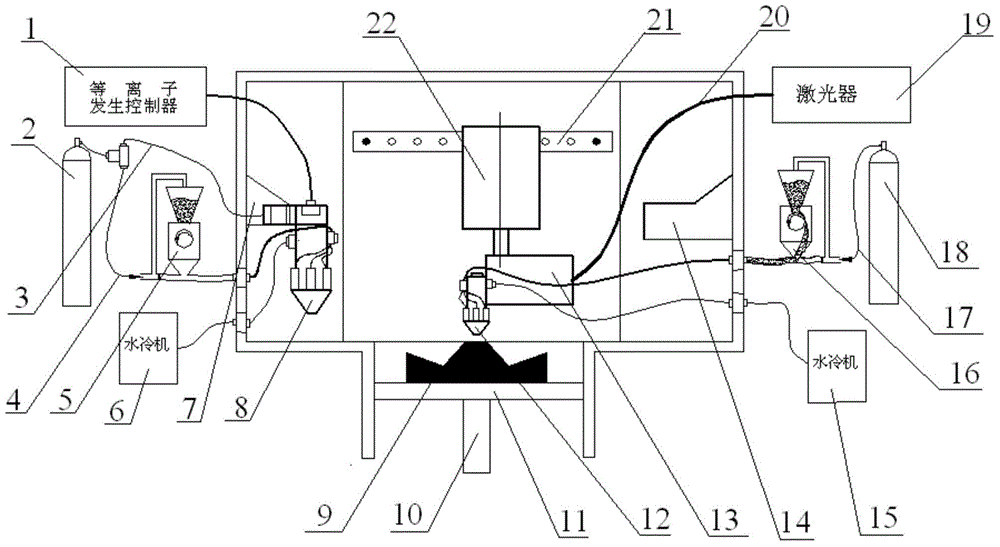

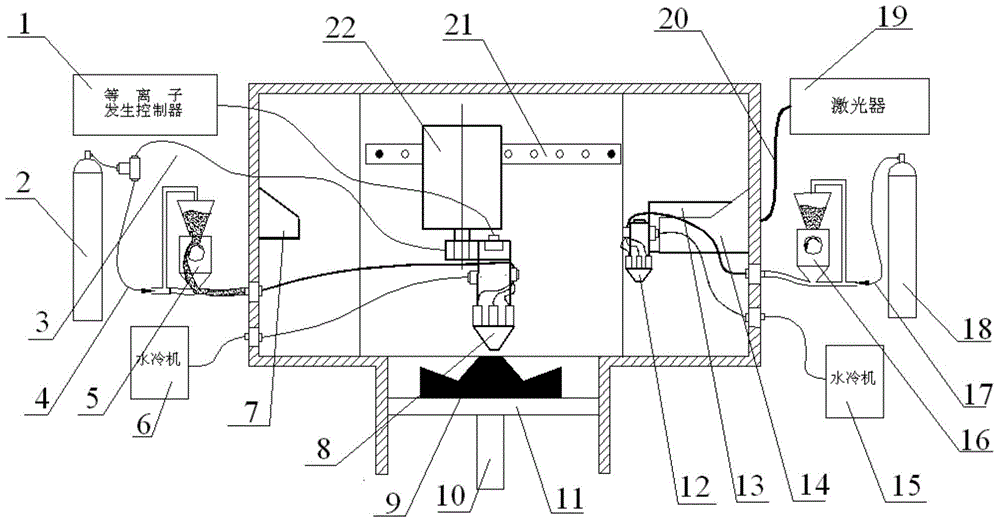

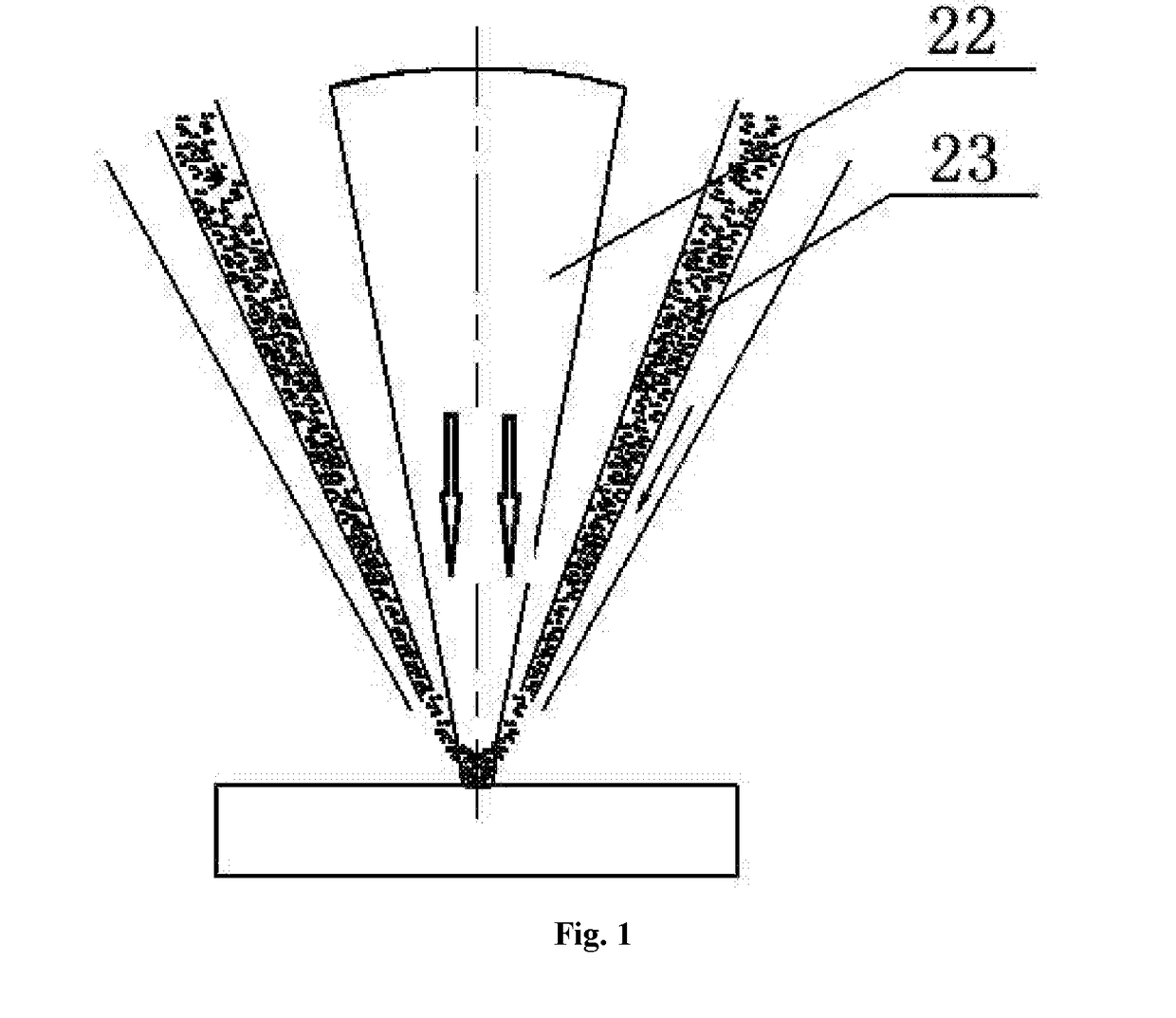

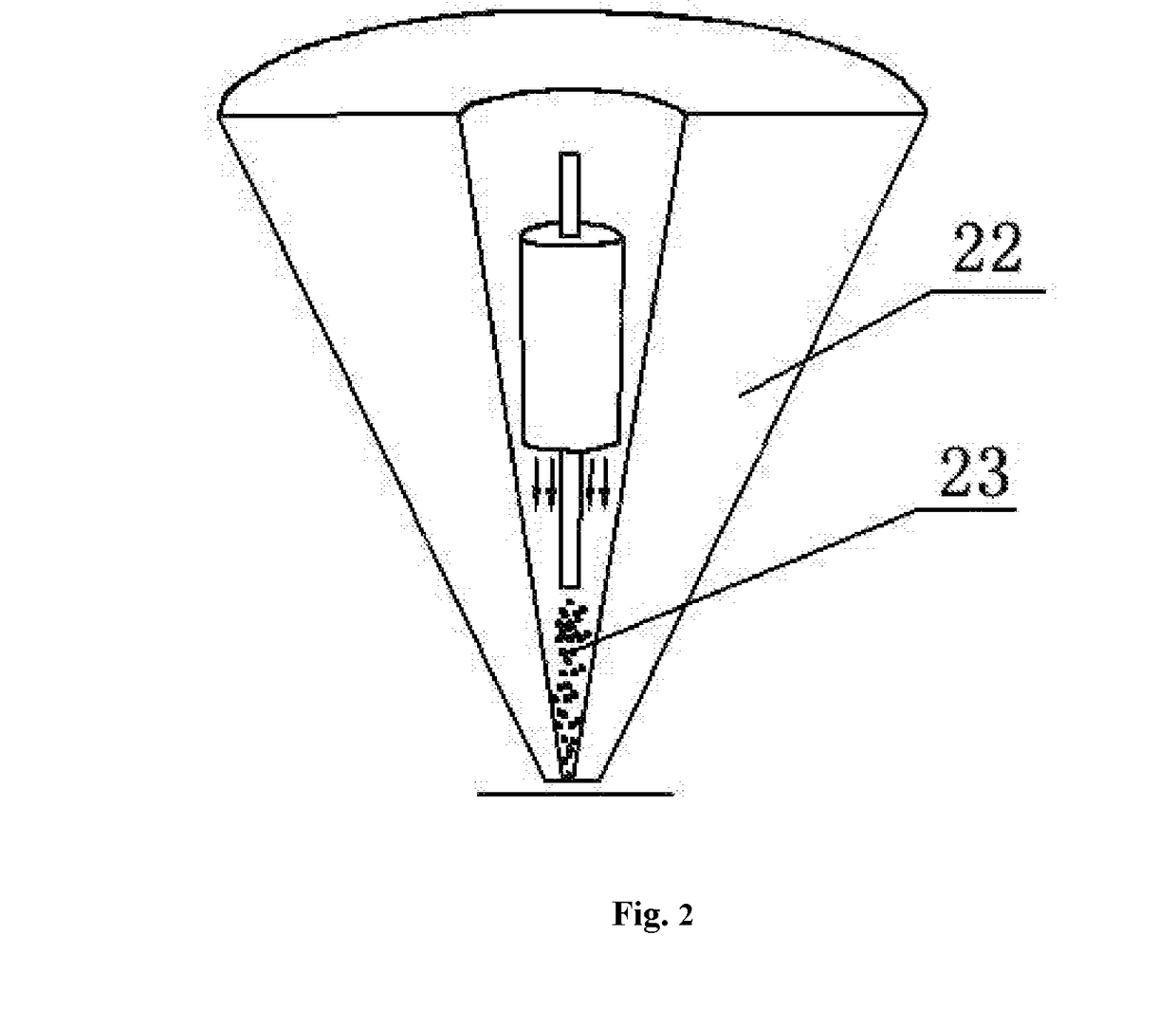

Laser and microbeam plasma composite 3D (3-dimensional) printing equipment and method

ActiveCN104801712ASolve efficiency problemsSolve the accuracy problemAdditive manufacturing apparatusNumerical controlControl system

The invention discloses a laser and microbeam plasma composite 3D (3-dimensional) printing equipment and method. The equipment comprises a central control system, a sealing forming chamber, a laser forming device and a plasma processing device, wherein a laser forming spray head and a plasma gun are correspondingly put on a support frame arranged at the left and right side inner walls of the sealing forming chamber, and the laser forming spray head or the plasma gun is clamped through a co-work numerical control main shaft, so that the laser forming spray head or the plasma gun moves in the Z, X and Y directions in the sealing forming chamber. The central control system controls the co-work numerical control main shaft for conveying back the laser forming spray head back to the support frame, then, the co-work numerical control main shaft clamps the plasma gun for filling the inside of the profile of a formed metal part, and the work is alternately carried out in such a way until the part manufacturing is completed, so that the scanning time is reduced to a great degree. The laser fast forming is combined with the plasma, the problem of conflict between the efficiency and the precision of a metal 3D printing technology is solved, and in addition, the plasma is adopted for replacing the laser to be used as a heat source, so that the high-efficiency and low-cost industrial level metal 3D printing equipment is obtained.

Owner:SOUTH CHINA UNIV OF TECH

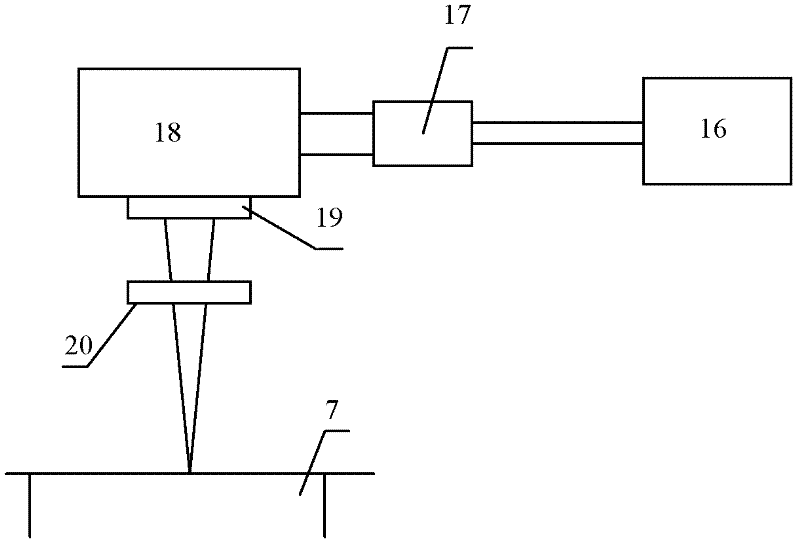

Precinct laser fusion rapid molding method and device of medical implantation material wax mould

InactiveCN101310964ADense tissueSimplify the manufacturing processComputerised tomographsTomographyWaxOriginal data

The invention provides a method for laser-melting and fast forming of a choosing area of a medical implant moulage, which refers to measuring an organ of a patient to obtain the original data for a medical implant; three-dimensional CAD software is adopted to transform the original data into a three-dimensional CAD model for secondary processing and then for slicing processing so as to obtain a multi-layer-slice two-dimensional CAD data model of the medical implant; scanning path planning is carried out to the two-dimensional CAD data model of each slice to obtain scanning path data which is guided into a host computer of a choosing area laser-melting and fast forming device, and a layer-to-layer fast scanning method is adopted to carry out the choosing area laser-melting and fast forming to paraffin powder so as to prepare and obtain the medical implant moulage; the medical implant moulage is taken out to clear redundant paraffin power on the surface. The slicing processing of the invention does not relate to STL format data; the formed moulage has dense tissue, thus no more processing is needed after infiltration of the paraffin, small scale forming equipment can be realized, equipment producing cost can be reduced and forming time is shortened.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing zirconium oxide ceramic by 3D (Three Dimensional) printing based on photo-curing molding

InactiveCN106673646AHigh surface finishHigh precisionAdditive manufacturing apparatusSurface finishPolymer science

The invention belongs to the technical field of 3D (Three Dimensional) printing and particularly relates to a method for preparing zirconium oxide ceramic by 3D printing based on photo-curing molding. The invention provides a composition which is prepared from the following raw materials: ceramic powder, a pre-mixed solution, a photoinitiator and a dispersant. The invention further provides a preparation method for preparing the zirconium oxide ceramic by utilizing the composition; and the preparation method comprises the following steps: preparing slurry, molding, curing, drying, degreasing and sintering. According to the technical scheme provided by the invention, the molding efficiency is high, and ceramic particles are uniformly dispersed; a prepared blank body is not cracked or deformed, is dense and uniform and has good surface gloss finish, high precision and excellent blank body performances; and meanwhile, the method also has the advantage of high preparation efficiency. According to the technical scheme provided by the invention, the technical defects of a zirconium oxide ceramic molding method in the prior art that the dependence on a mold is too great and a complicated and precise structure cannot be prepared are overcome.

Owner:GUANGDONG UNIV OF TECH

Flush toilet

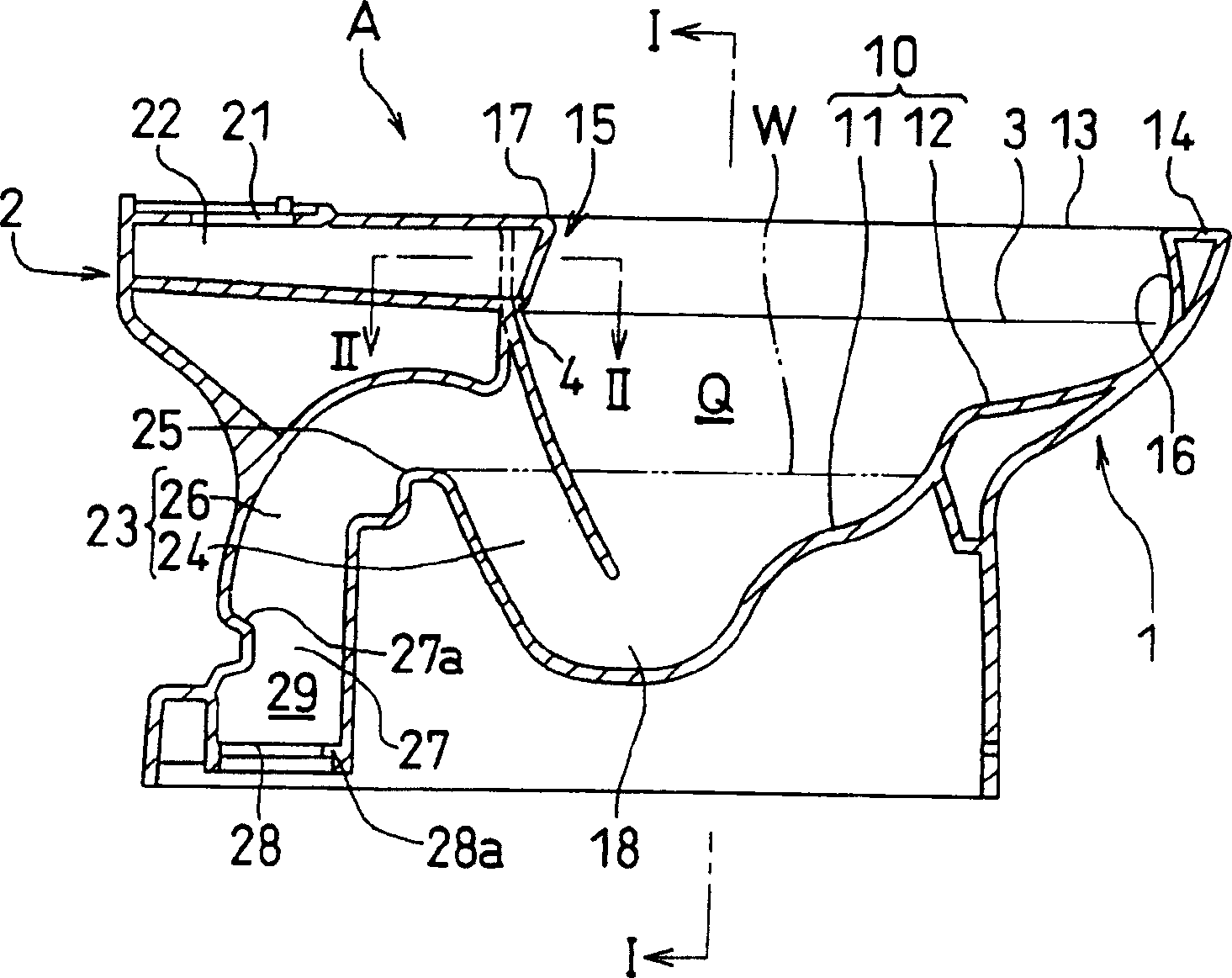

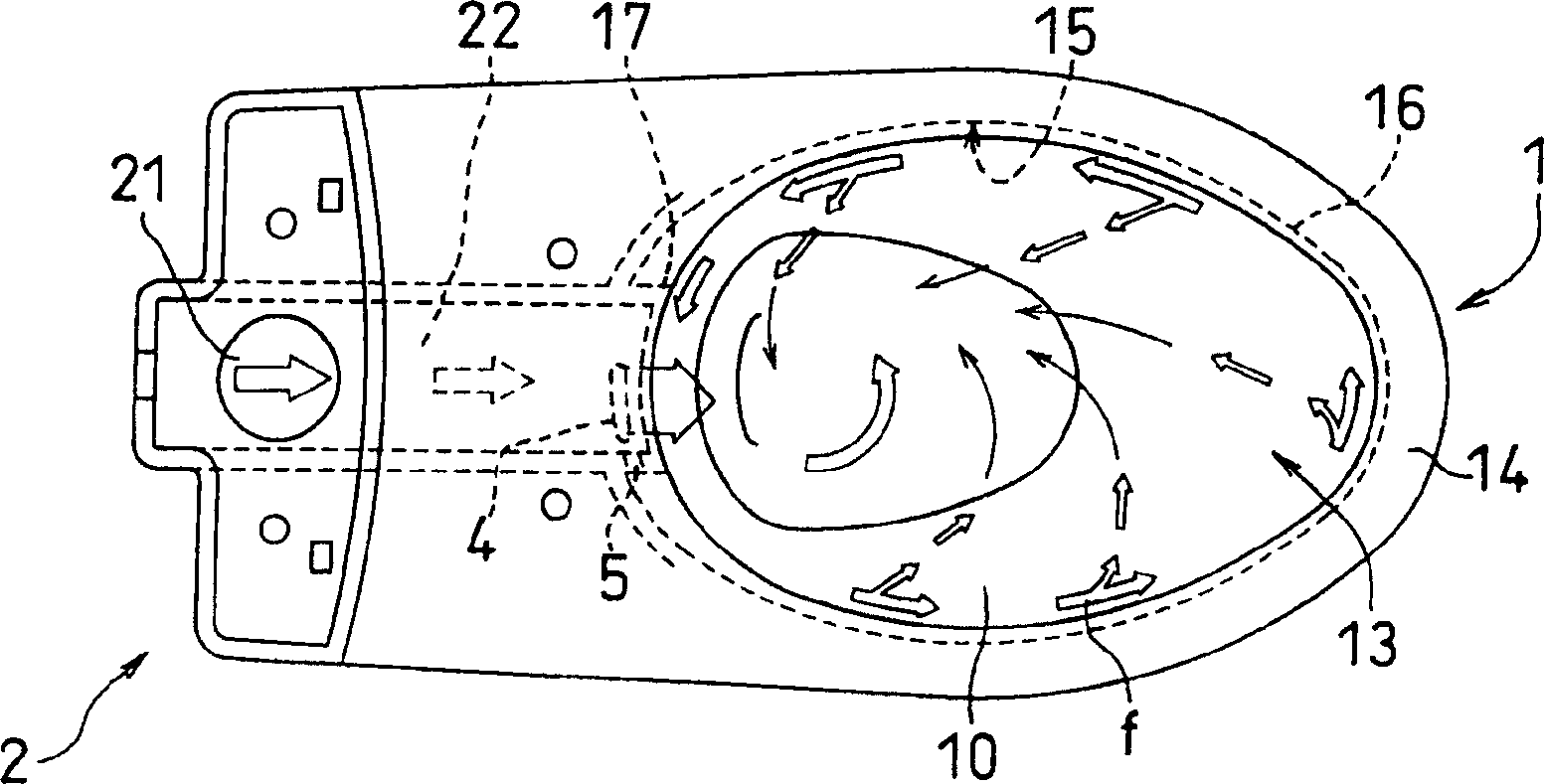

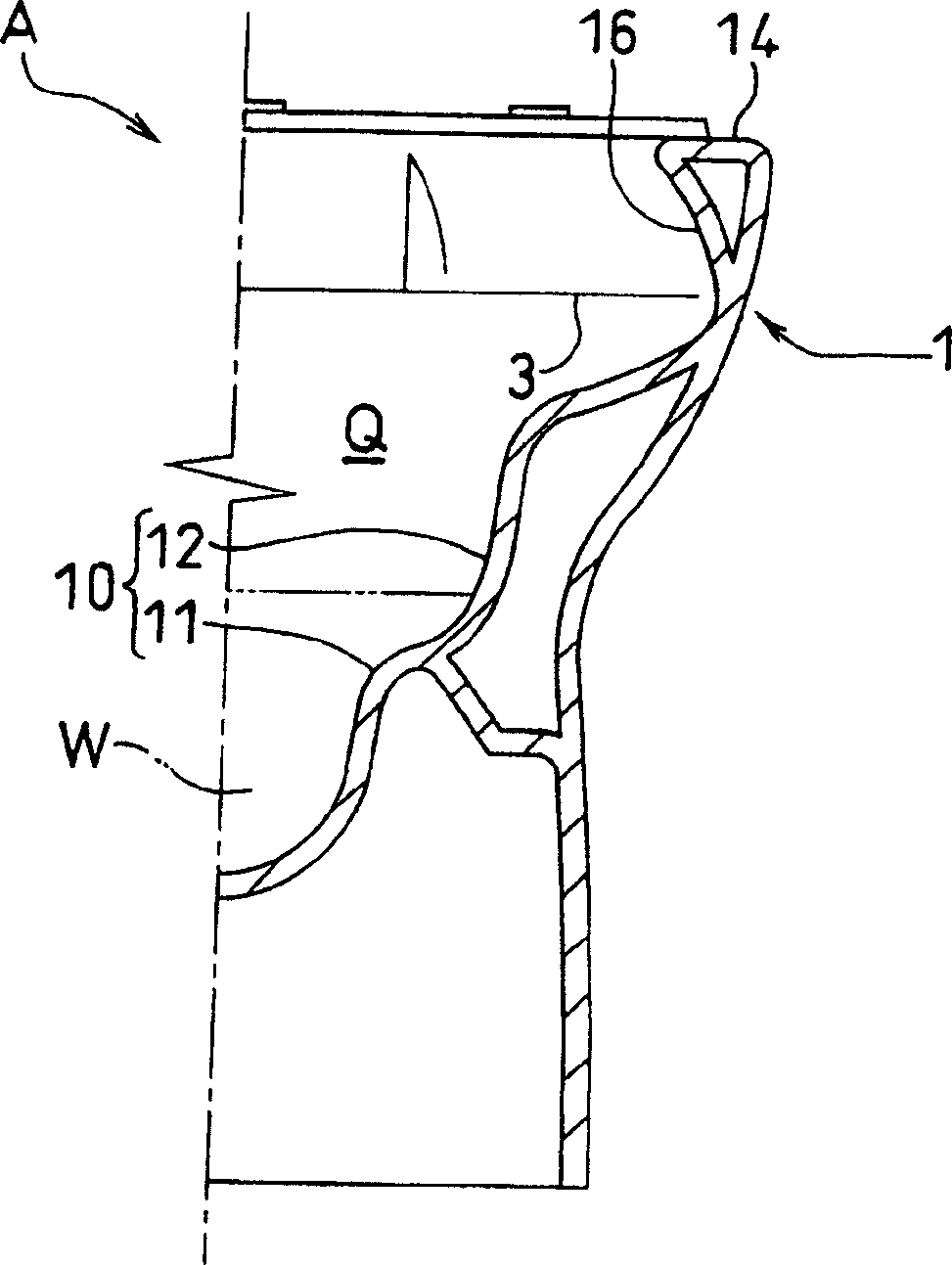

InactiveCN1576473AImprove cleanlinessWon't splashUrinalsWater closetsFlush toiletMechanical engineering

The flush toilet has a waste receipt surface section (10) of a bowl section (1) formed continuously integrally with an inner rim wall surface section (15) of the rim portion disposed at a peripheral edge of an upper opening (13) of the bowl section (1) as a curved surface; and the inner rim wall surface section (15) of the rim portion acts as a flush water passage (16) of the bowl section. The flush water passage (16) of the bowl section is further configured such that the inner rim wall surface section (15) of the rim portion is shaped in an overhanging form inclining so as to hang over inside of the bowl section (1). The flush toilet of this configuration can be cleaned with ease and kept clean in sanitation.

Owner:TOTO LTD

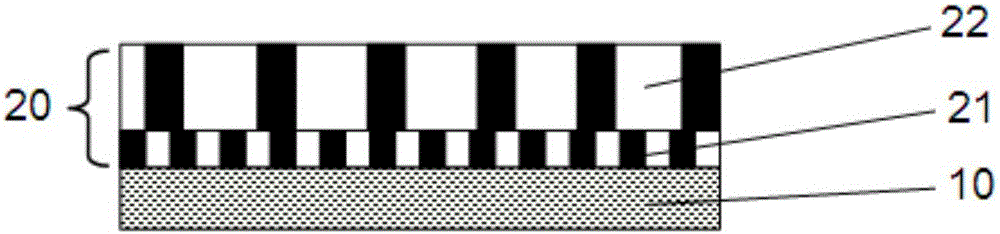

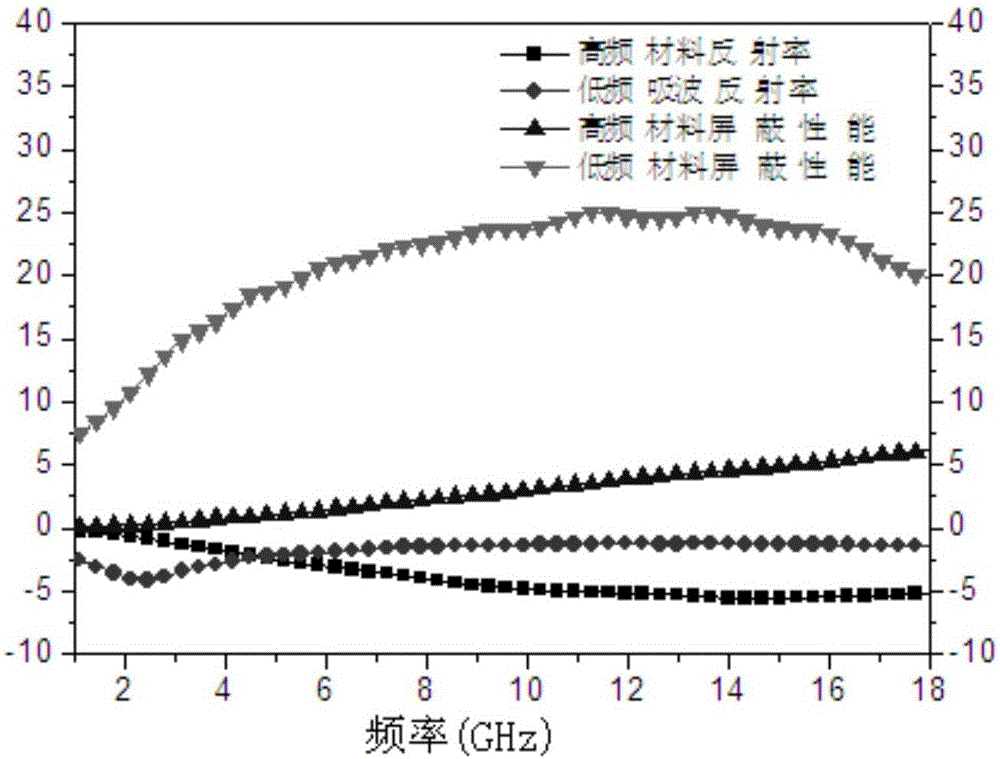

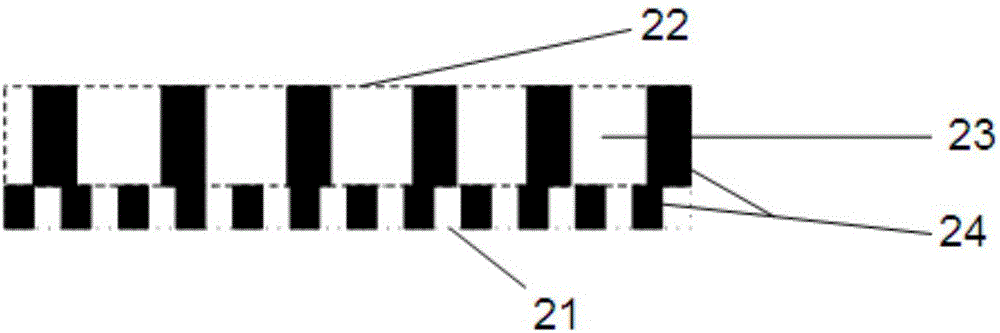

Broadband wave-absorbing material and preparation method thereof

The invention discloses a broadband wave-absorbing material and a preparation method thereof. The broadband wave-absorbing material is composed of a low frequency wave-absorbing material bottom layer and a high frequency wave-absorbing material surface layer. The high frequency wave-absorbing material surface layer comprises a plurality of high frequency wave-absorbing layers with different concentrations. FeSi or FeSiAl particles are taken as the additive of the low frequency wave-absorbing material, and carbonyl iron particles are taken as the additive of the high frequency wave-absorbing material. A rolling method is adopted to prepare the low frequency wave-absorbing material bottom layer, and a three-dimensional moulding technology is adopted to prepare the high frequency wave-absorbing material surface layer. The multilayer lamination manufacturing method combines a multi-rolling technology and three-dimensional moulding together and has the advantages that the binding force between layers can be ensured, multiple repeated mould pressing is avoided, the thickness of each layer, the internal structure, and particle distribution can be adjusted so as to satisfy the predetermined electromagnetic property requirements; the broadband wave-absorbing performance of the wave-absorbing material and designable performance of a shielding material can be realized; the integrated manufacturing of space structure of the wave-absorbing material is achieved, and the preparation cost is low at the same time.

Owner:SHANGHAI RADIO EQUIP RES INST

Pulse type shock processing on-line compound injection molding method and its equipment

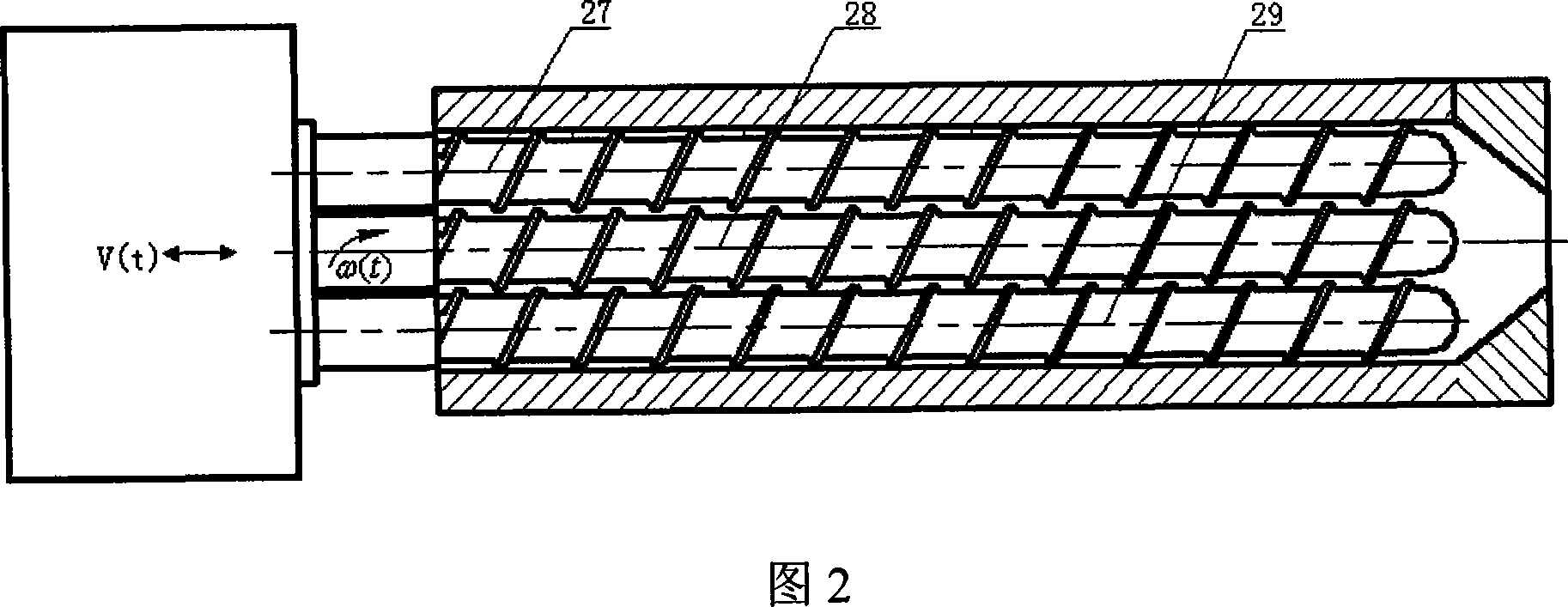

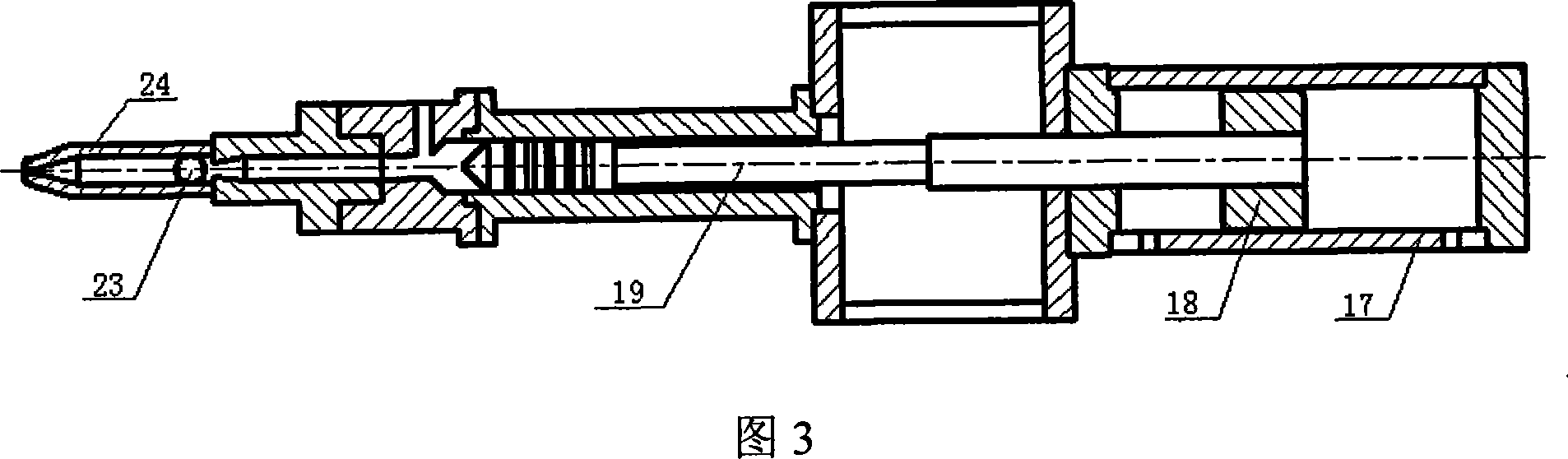

InactiveCN101077611AIncrease fill ratioImprove interface compatibilityEngineeringFiber-reinforced composite

The present invention discloses pulse type shock reinforced in-line mixing and injecting forming method and apparatus. Pulse type shock is introduced into the whole in-line mixing and injecting forming process of producing fiber reinforced composite polymer material. The apparatus includes one plasticizing extruder with three screws arranged in one line and including one main screw capable of generating periodical axial pulse shock, one buffering storing device, and one pulse type shock pressure reinforcing plunger injecting device. The present invention can lower melt viscosity, raise mixing and homogenizing effect, raise the compatibility between fiber and polymer, lower the processing power consumption and raise product quality.

Owner:SOUTH CHINA UNIV OF TECH

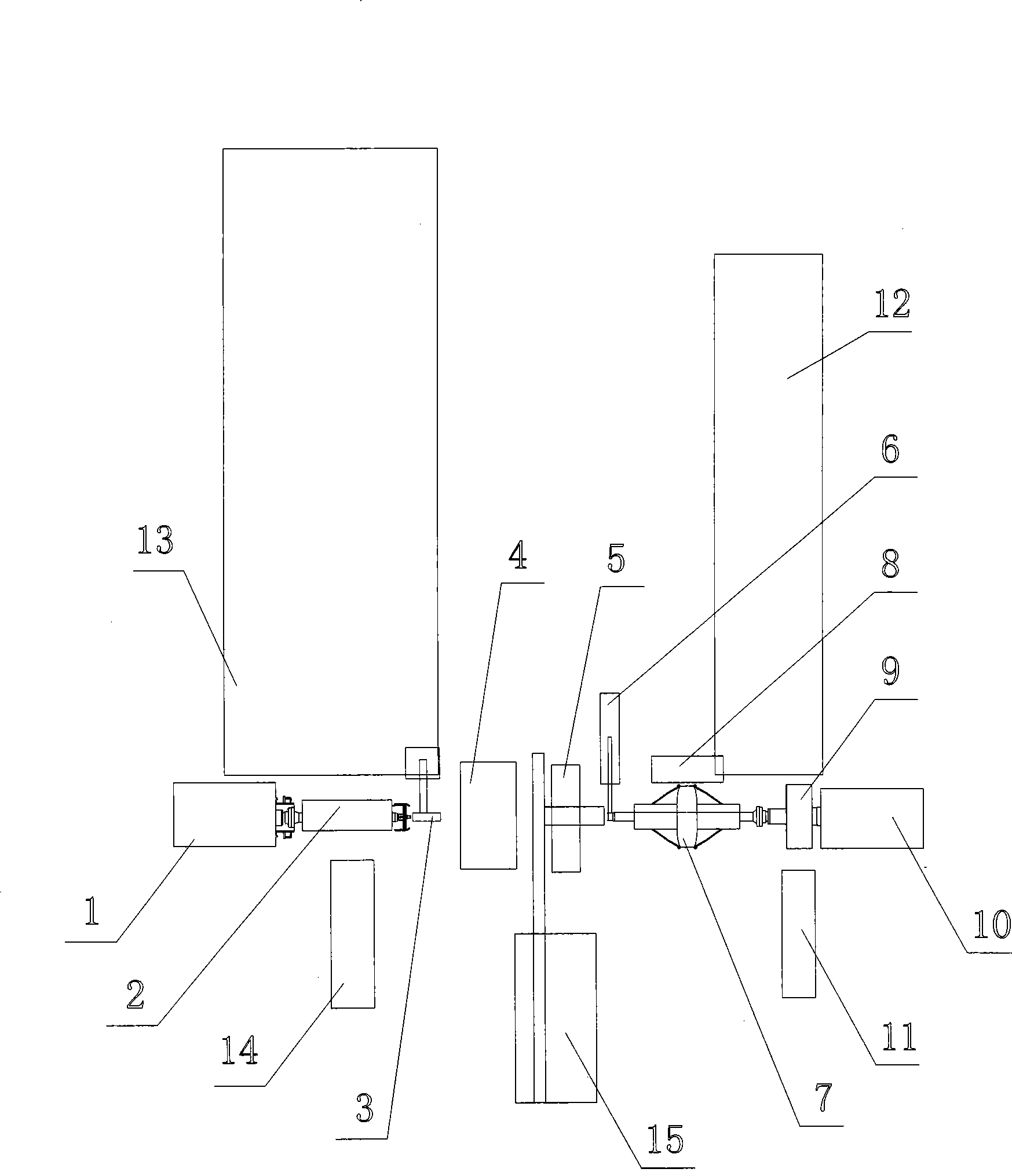

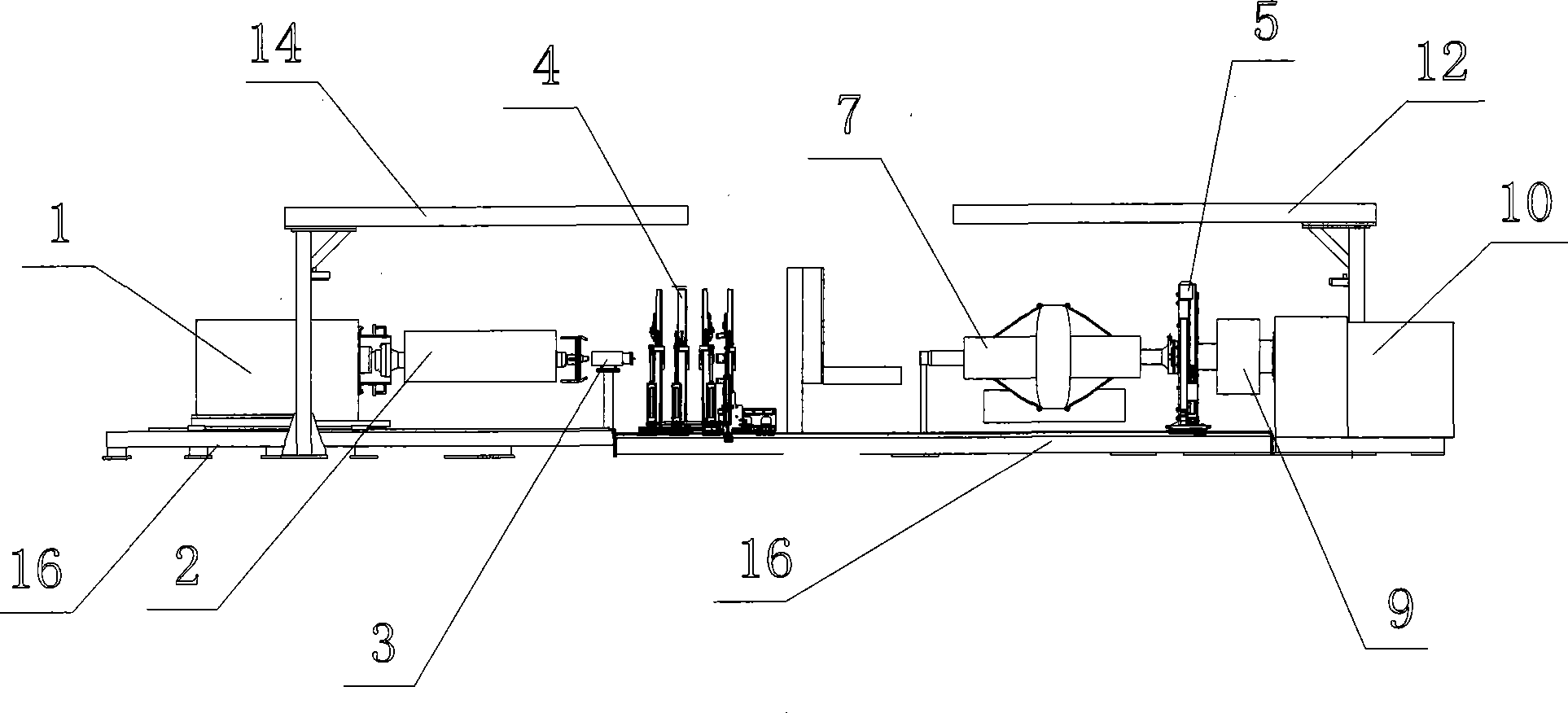

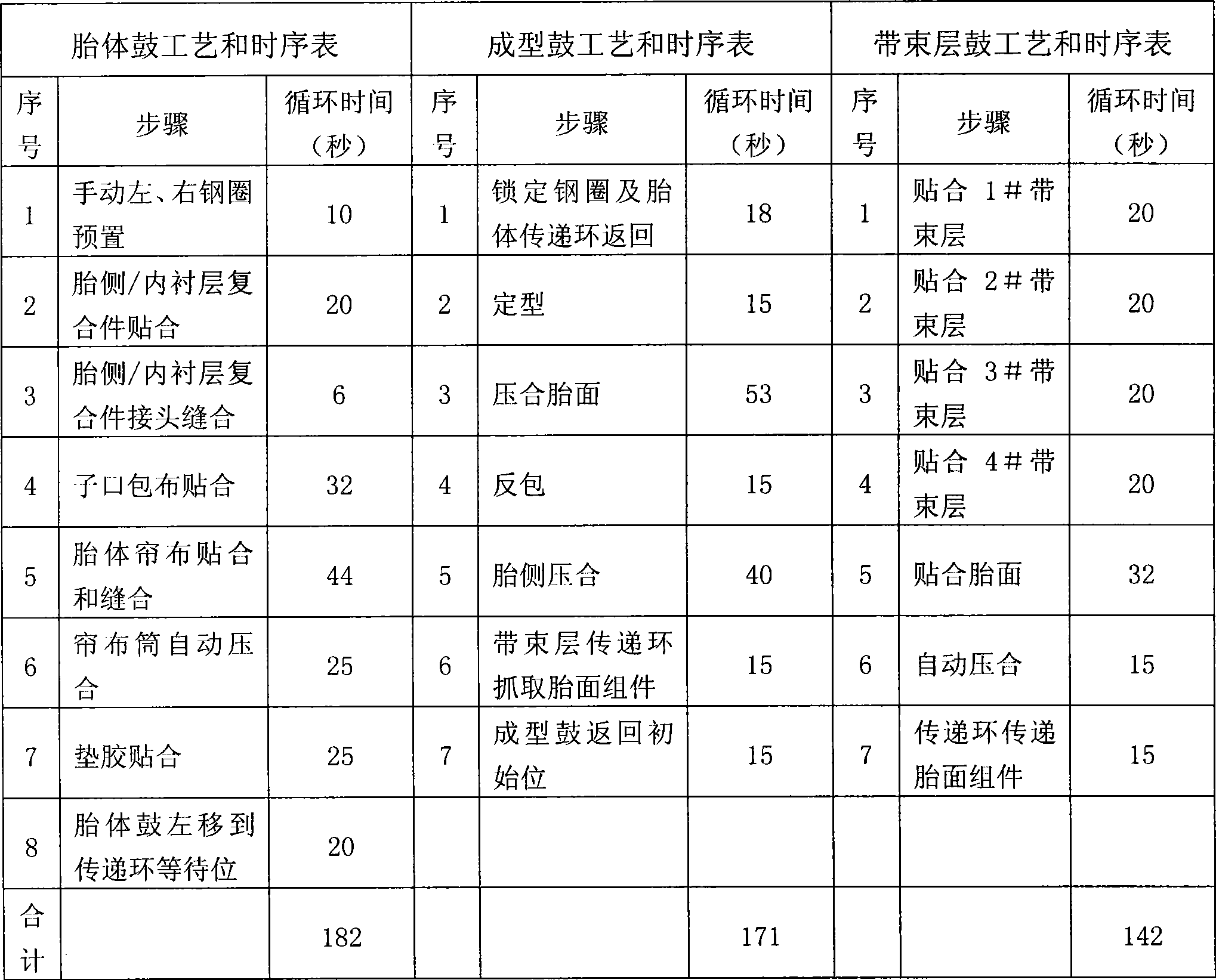

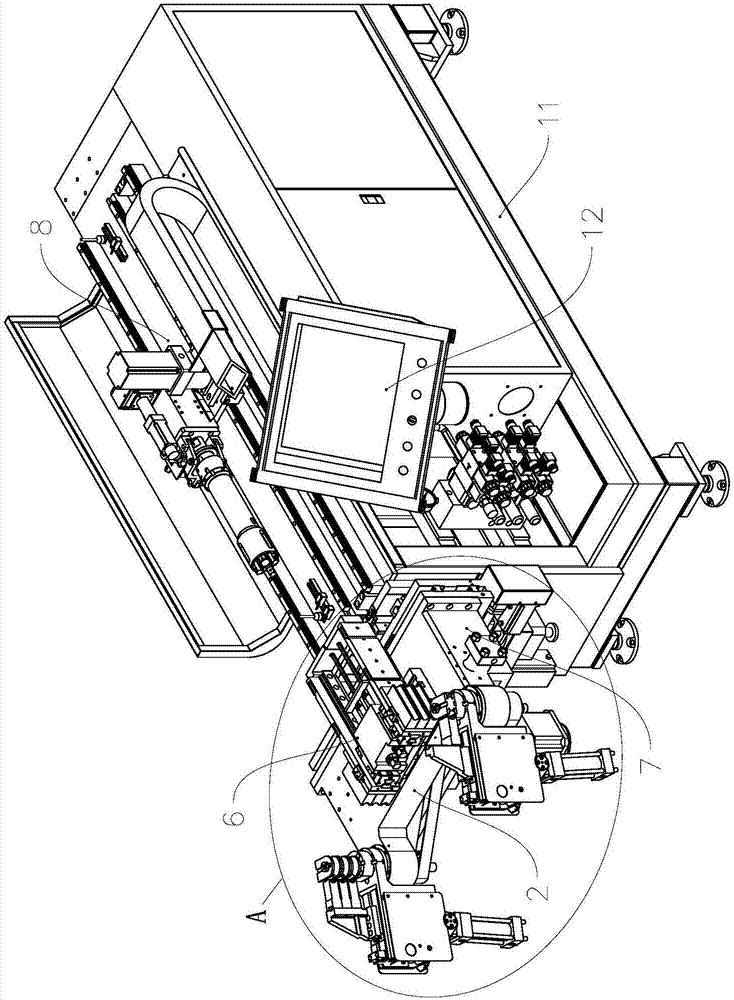

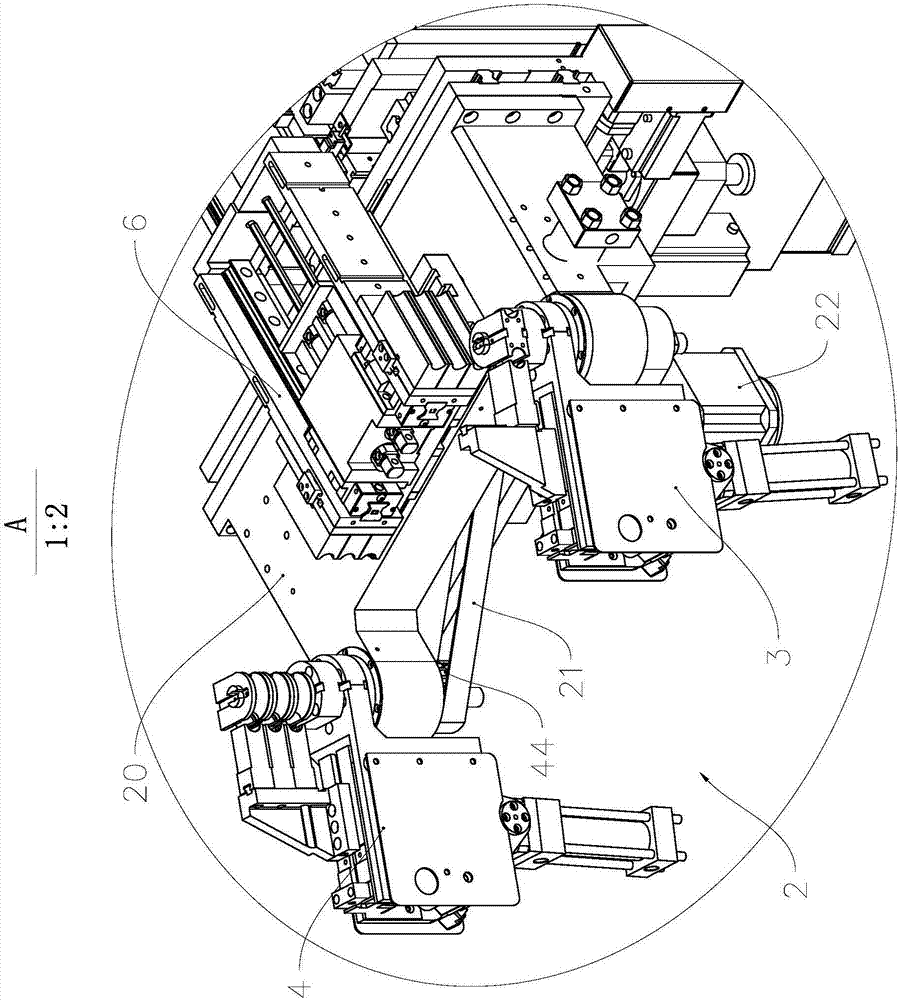

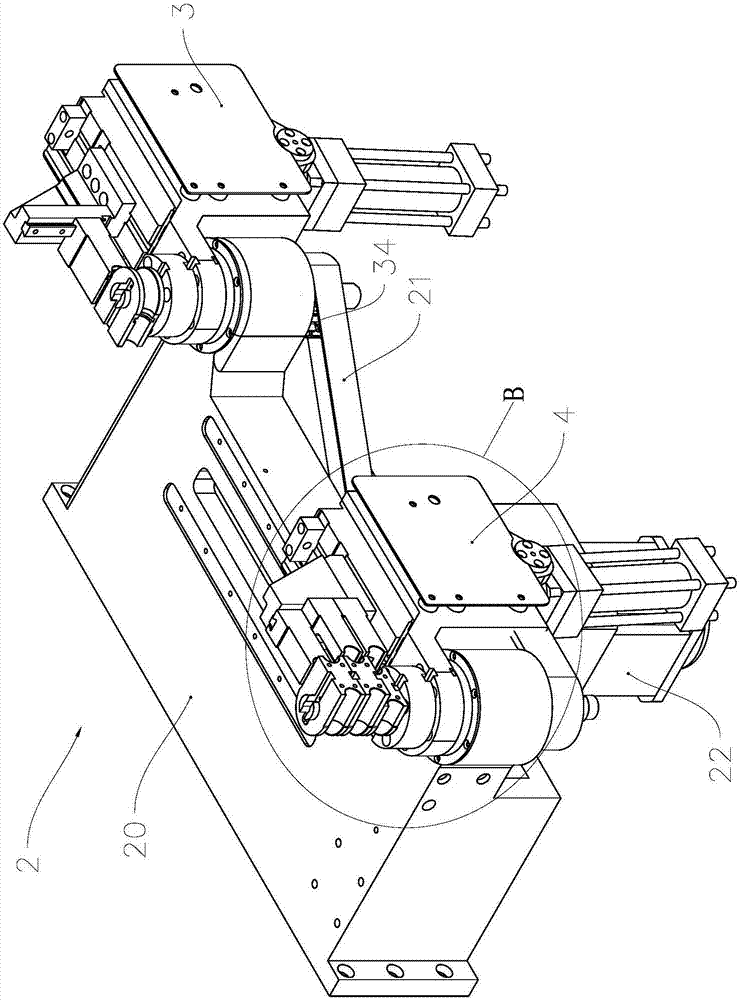

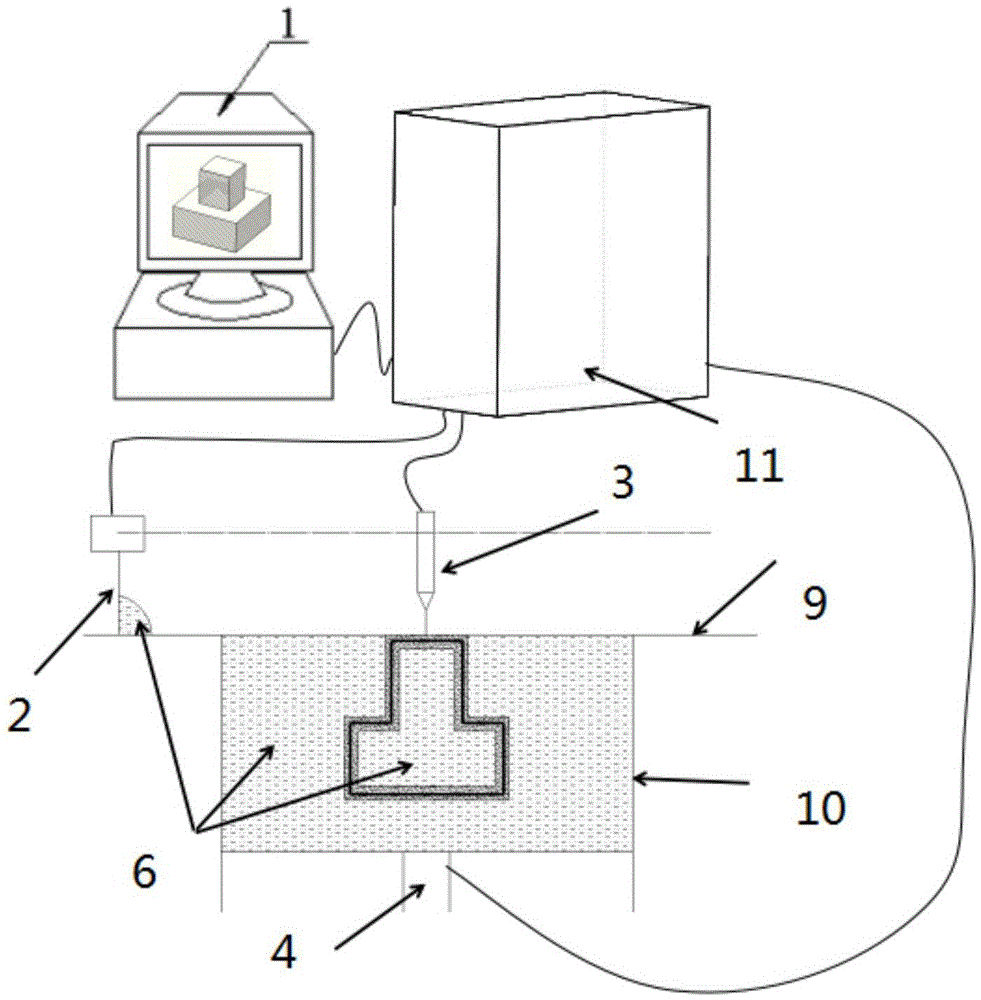

Three-drum forming machine for producing green tyre and method thereof

The invention discloses a three-drum shaping machine for manufacturing a tire blank and a method thereof. A time planning method is adopted to respectively realize and simultaneously carry out the preparation and conveying techniques of a tire component and a belt beam layer-tire surface component, thus being beneficial to simplifying the production technique, shortening the production time of a single tire blank as well as effectively improving the uniformity and the shaping efficiency of the tire. The three-drum shaping machine includes a tire body drum, a belt beam layer drum and a shaping drum; besides, the three drums are arranged on the same horizontal shaft; the tire body drum is loaded by a tire body drive unit; the belt beam layer drum and the shaping drum are loaded by the same drive unit of the shaping drum. The drive unit of the shaping drum and the drive unit of the tire body drum are oppositely and coaxially arranged on the same bottom lead rail; a tire body component conveying device used for conveying the prepared tire body component into the shaping drum is arranged between the tire body drum and the shaping drum; the conveying device of the belt beam layer-tire surface component used for conveying the prepared belt beam layer-tire surface component into the shaping drum is arranged at one side of the shaping drum.

Owner:MESNAC

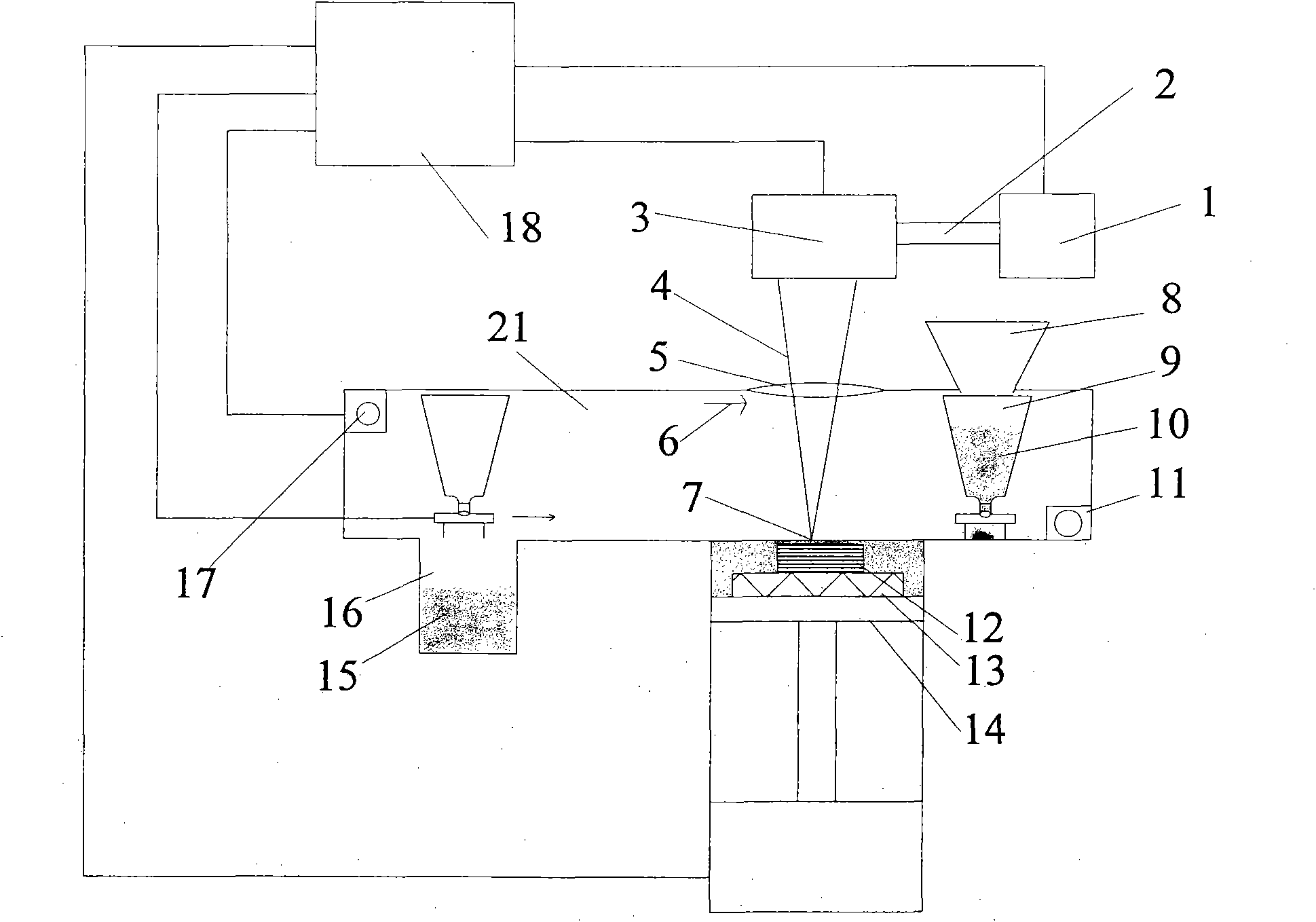

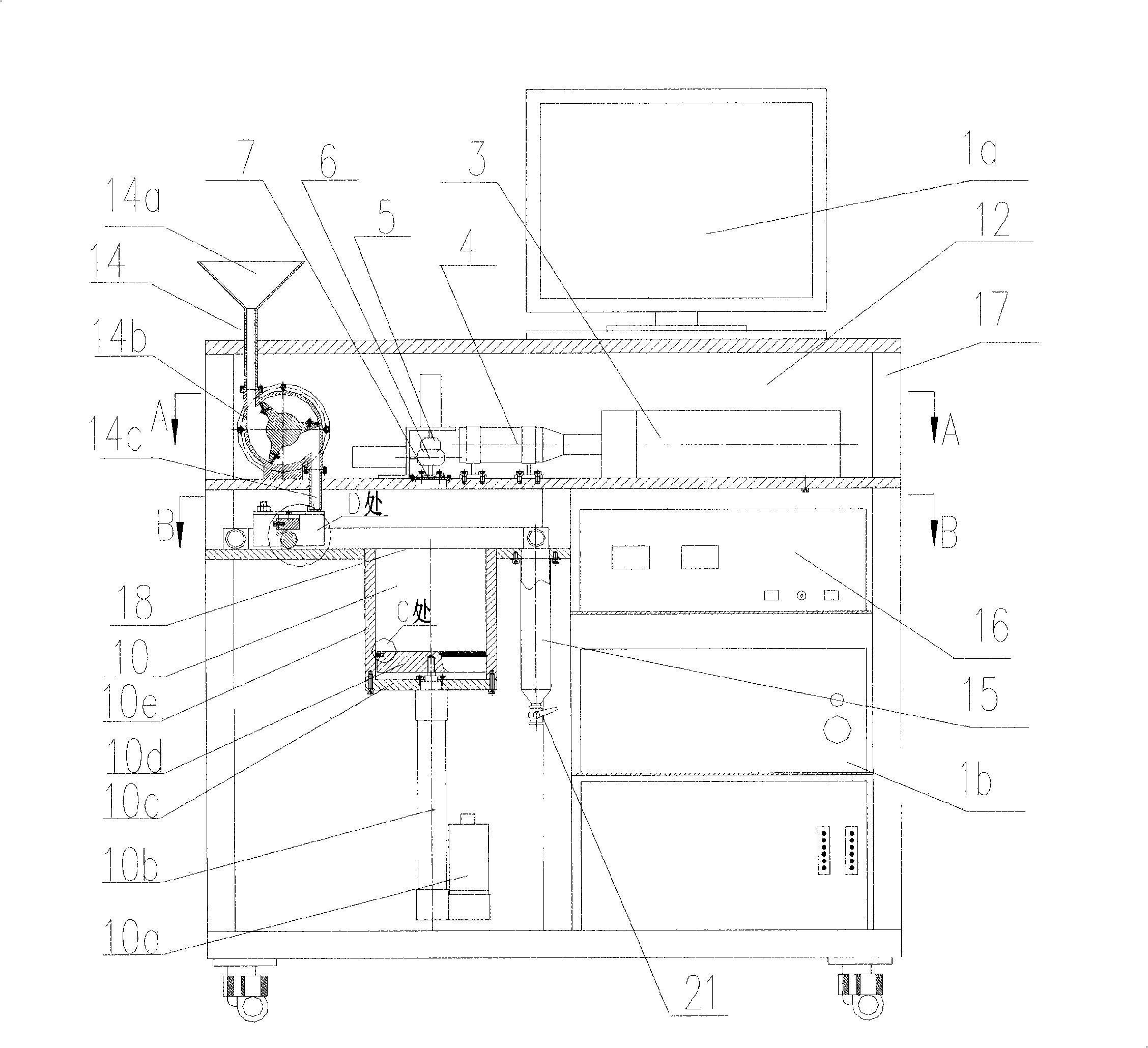

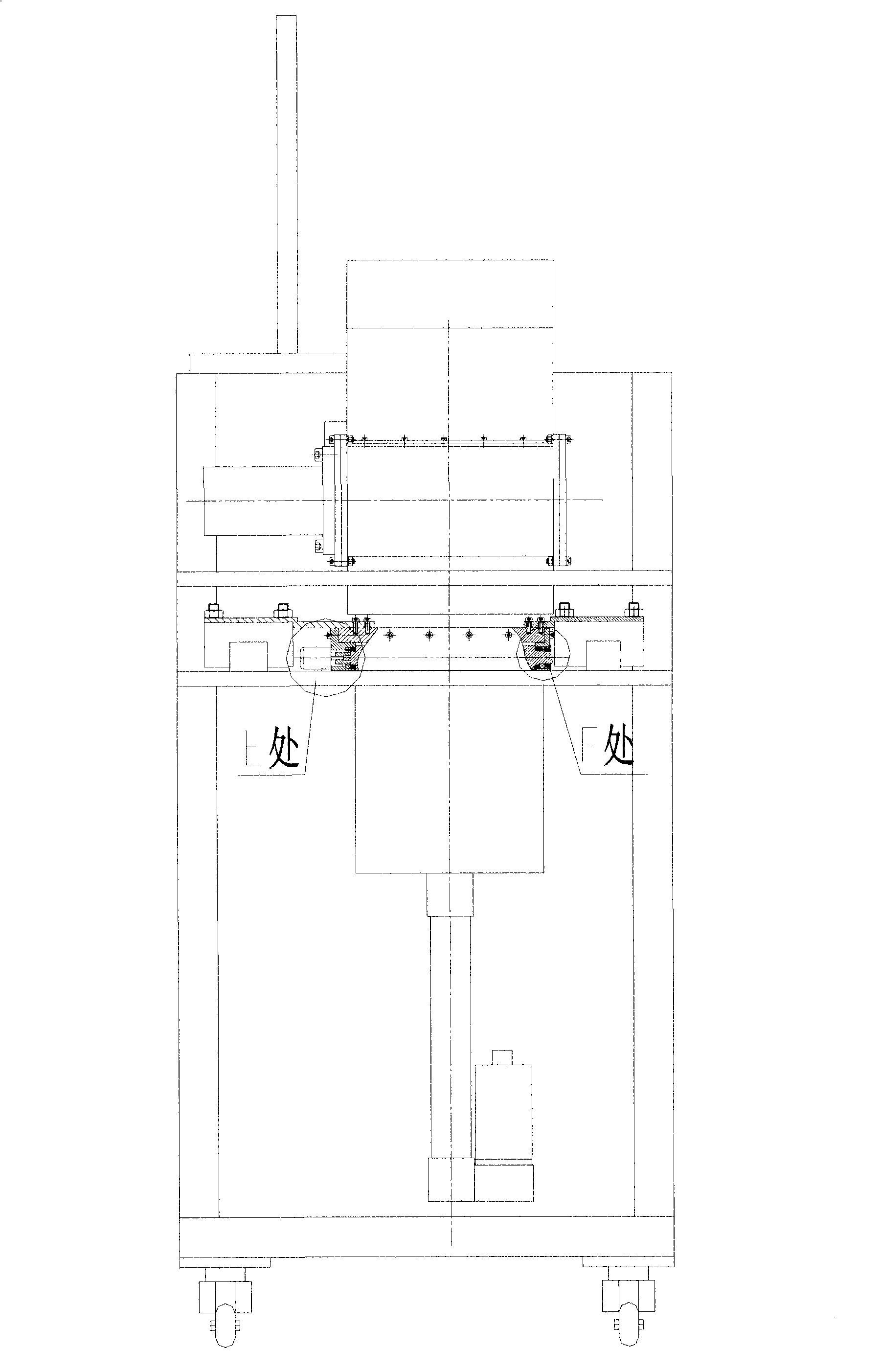

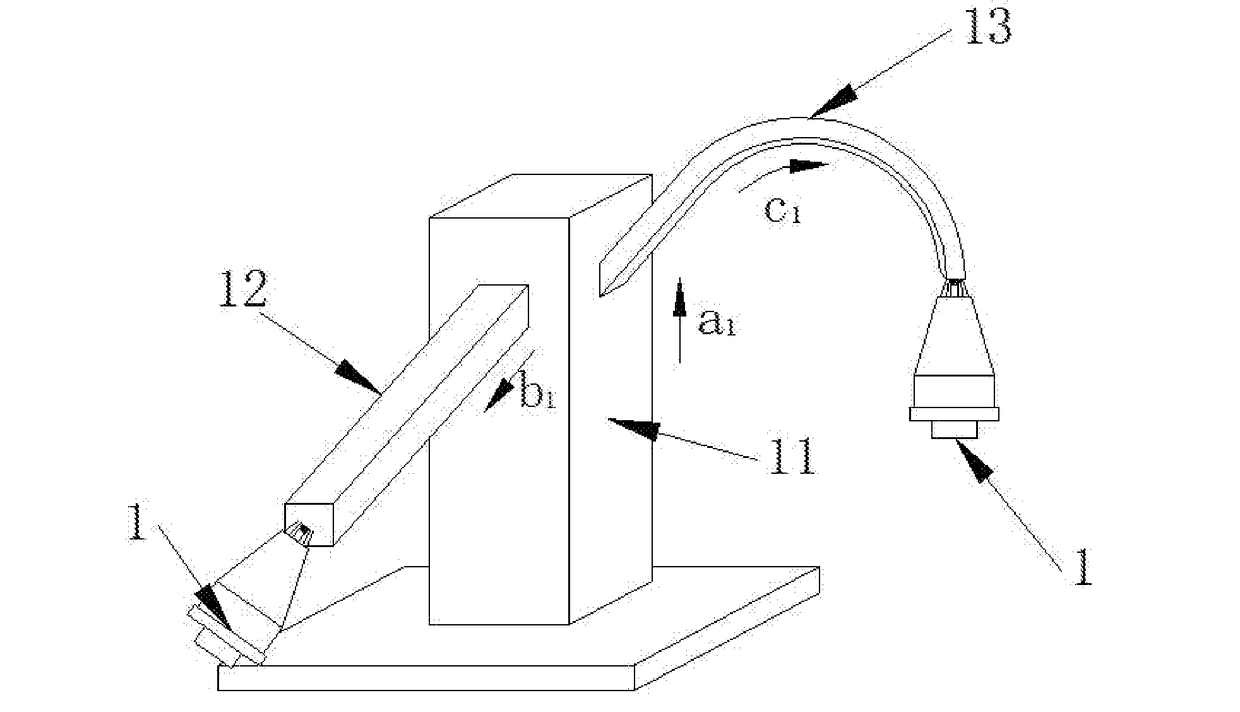

Synchronous powder-feeding space laser machining and three-dimensional forming method and device

InactiveUS20170232518A1Simple trackEasy to controlAdditive manufacturing apparatusIncreasing energy efficiencyLight beamLaser

A method for synchronous powder-feeding space laser cladding and three-dimensional forming includes: dividing a three-dimensional solid into a plurality of forming units according to a form simplification and nozzle cladding scanning accessibility principle, and dividing each forming unit into a plurality of layers; employing a single-beam gas-carried power-feeding mode in a hollow annular laser; controlling a mechanical arm (7) to drive an in-laser powder-feeding nozzle (1) to move and scan along a predetermined trajectory in a filling area and a boundary area of the layer; and sequentially conducting cladding and stacking formation of the layer for the entire unit. A device includes an inside-laser powder-feeding nozzle (1), a laser generator (6), a mechanical arm (7), a control module (4), a transmission optical fiber (5), a gas-carried powder feeder (3) and a gas source (2).

Owner:SUZHOU UNIV

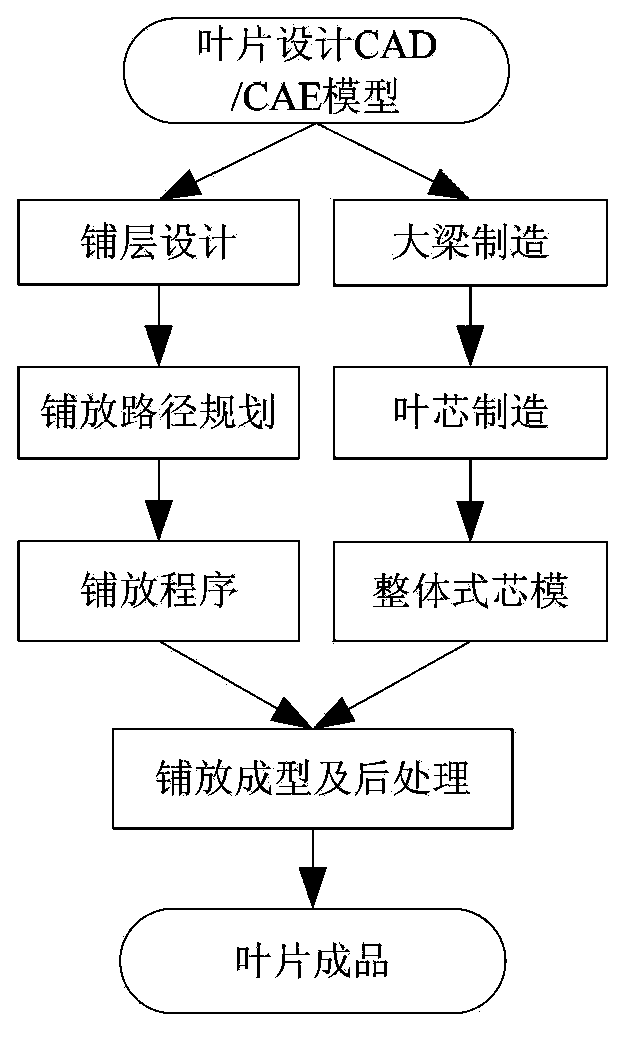

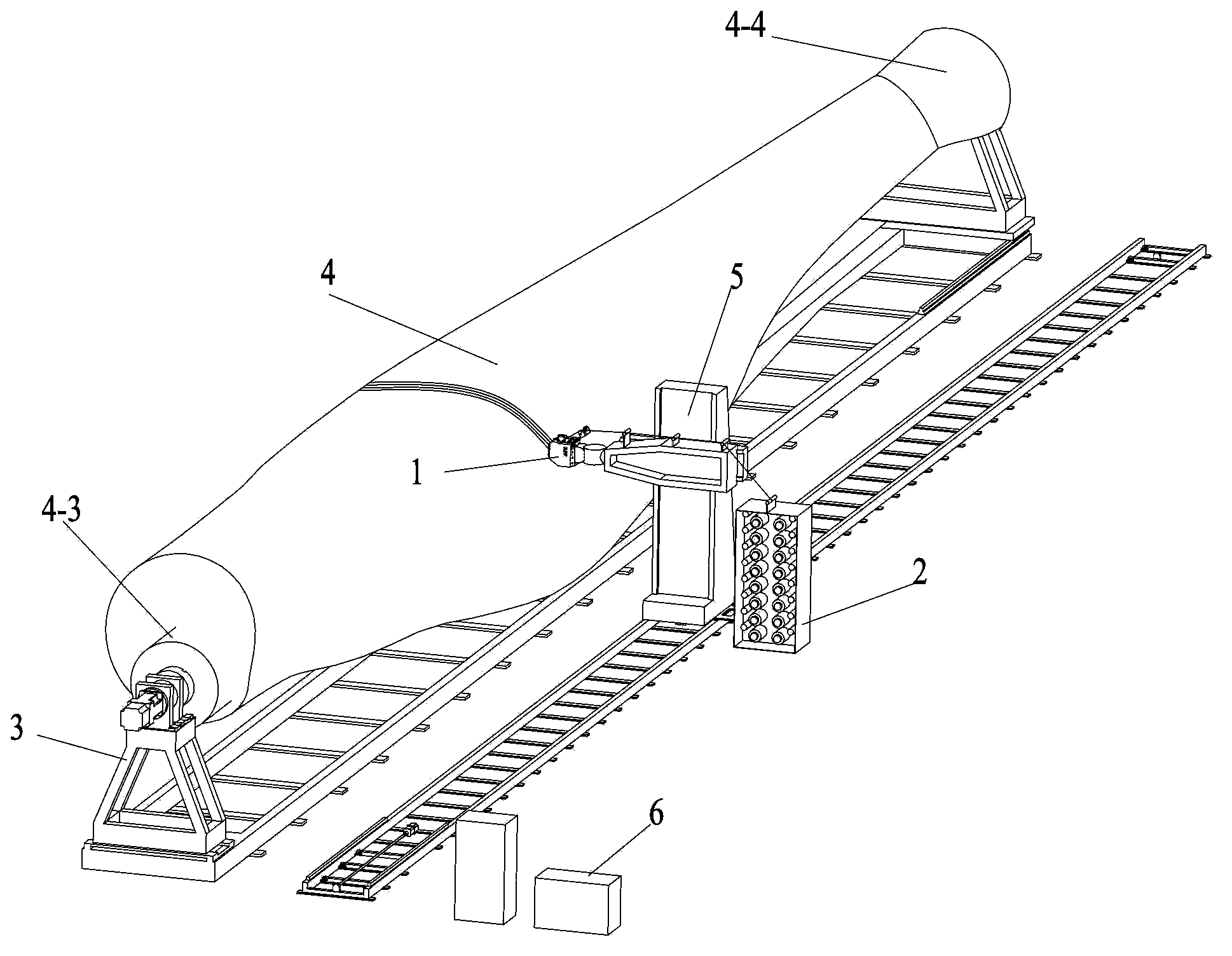

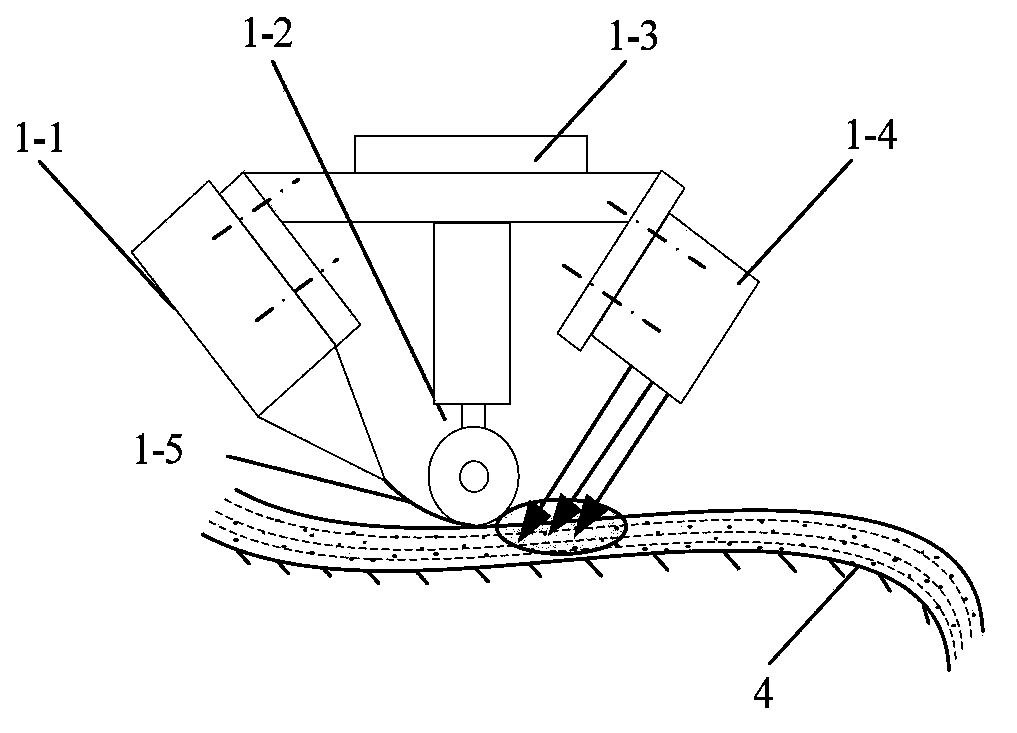

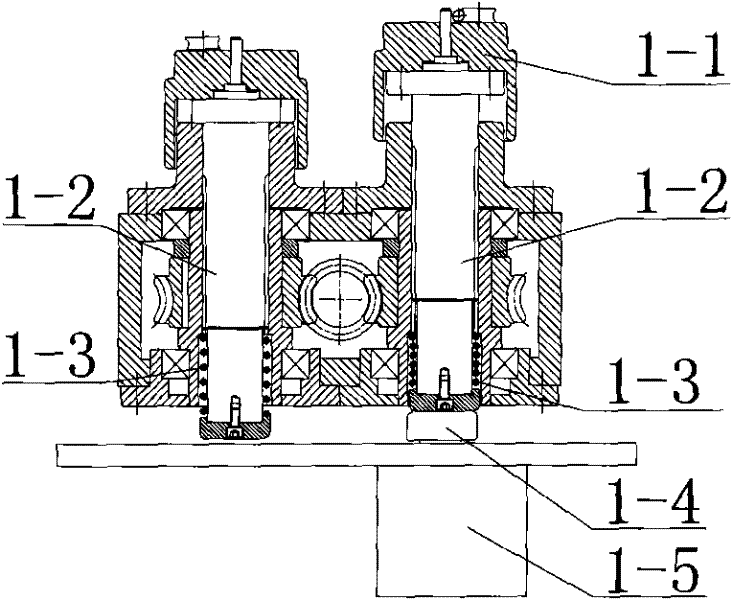

Integral wind-power blade ultraviolet light/electron beam in situ curing fiber laying forming device and integral wind-power blade ultraviolet light/electron beam in situ curing fiber laying forming method

InactiveCN103358564AImprove curing efficiencyEfficient automated manufacturingBonding strengthMachine tool

The invention discloses an integral wind-power blade ultraviolet light / electron beam in situ curing fiber laying forming device and an integral wind-power blade ultraviolet light / electron beam in situ curing fiber laying forming method, which can be applied to the automatic manufacturing field of large-scale composite material wind-power blades. Aiming at the problems that a perfusion and mold-splitting type wind-power blade manufacturing process has low degree of automation, high labor intensity and unstable quality, a two-piece type wind-power blade has low bonding strength, integral strength and stiffness, blade laying cannot be optimally designed, and a large-scale wind-power blade is difficultly manufactured and the like, the invention adopts the ultraviolet light in situ curing fiber laying manufacturing method and the ultraviolet light in situ curing fiber laying manufacturing device. According to the method, an ultraviolet light / electron beam in situ curing process is utilized for completing the forming and curing processes of the large-scale wind-power blade one time, the large-scale wind-power blade is integrally formed, and the curing efficiency and the overall performance of the blade are improved. Meanwhile, a large-scale wind-power blade fiber laying manufacturing system is combined and comprises an ultraviolet light / electron beam in situ curing fiber laying head, a presoaking belt conveying system, a core mold supporting device, an integral wind-power blade core mold, a horizontal or vertical multi-freedom machine tool system and a laying control system so as to realize the automatic manufacturing of the integral large-scale wind-power blade.

Owner:XI AN JIAOTONG UNIV

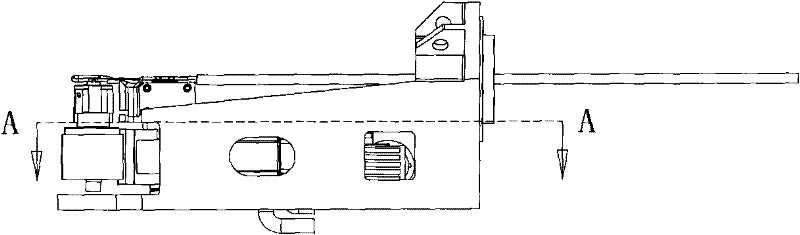

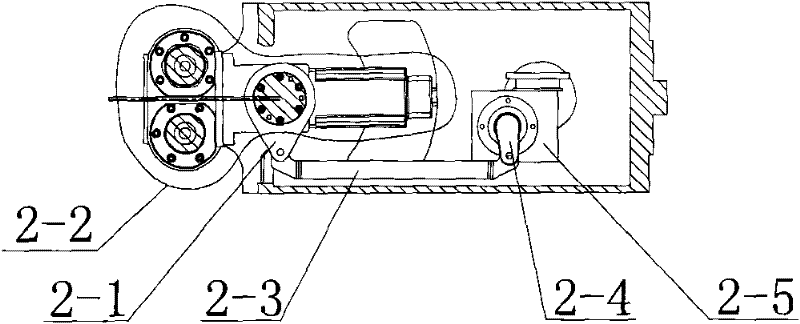

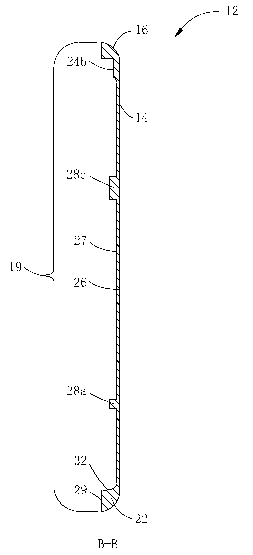

Working handpiece of numerical control wire bending machine

InactiveCN101733344BImprove molding efficiencyImprove molding processing efficiencyAxial displacementNumerical control

The invention relates to a working handpiece of a numerical control wire bending machine, which comprises the working handpiece of the numerical control wire bending machine. Two die heads in the die-changing and die head steering lifting position-hiding mechanism in the numerical control wire bending machine are connected with two spline shafts without relative displacement; the bottom parts of the spline shafts are contacted with the lower end of a pressure spring; the upper end of the pressure spring is contacted with the inner step of a main shaft and drives the spline shafts to move downwards; a swing arm of the position changing and swinging mechanism of the bending die head in the numerical control wire bending machine is connected with a wire bending power driving device without relative displacement; one end of a connecting rod is moveably connected with the swing arm, while the other end is moveably connected with the swing arm; the swing arm is connected with a rotating shaft of a numerical angle graduator without relative displacement; a driving device takes a worm-gear case as a main body; a worm is supported by a bearing without axial displacement, and at the same time drives two worm gears which are connected with the main shaft without relative displacement; splines are arranged in the main shaft; the spline shafts are connected with the splines in the main shaft; the main shaft and the worm-gear case are supported by the bearing without axial displacement; and two bending die heads are connected with the two spline shafts respectively without relative displacement.

Owner:浙江博雷重型机床制造有限公司

Forging mould and molding method of metal casing applied to electronic device

ActiveCN103231002AImprove molding efficiencyReduce manufacturing costForging/hammering/pressing machinesMachining timeMetal

The invention provides a forging mould and a molding method of a metal casing applied to an electronic device. A metal plate can be molded in a forging and pressing mode into a blank of the metal casing with less following machining quantity through the mould, and the blank of the casing is subjected to a small amount of machining to form the metal casing. The mould and the method solve the problem in the prior art that the metal casing of the electronic device is long in machining time, the blank of the casing with less following machining quantity cannot be molded, production cost is high, material utilization rate is low and the like.

Owner:亚超特工业有限公司

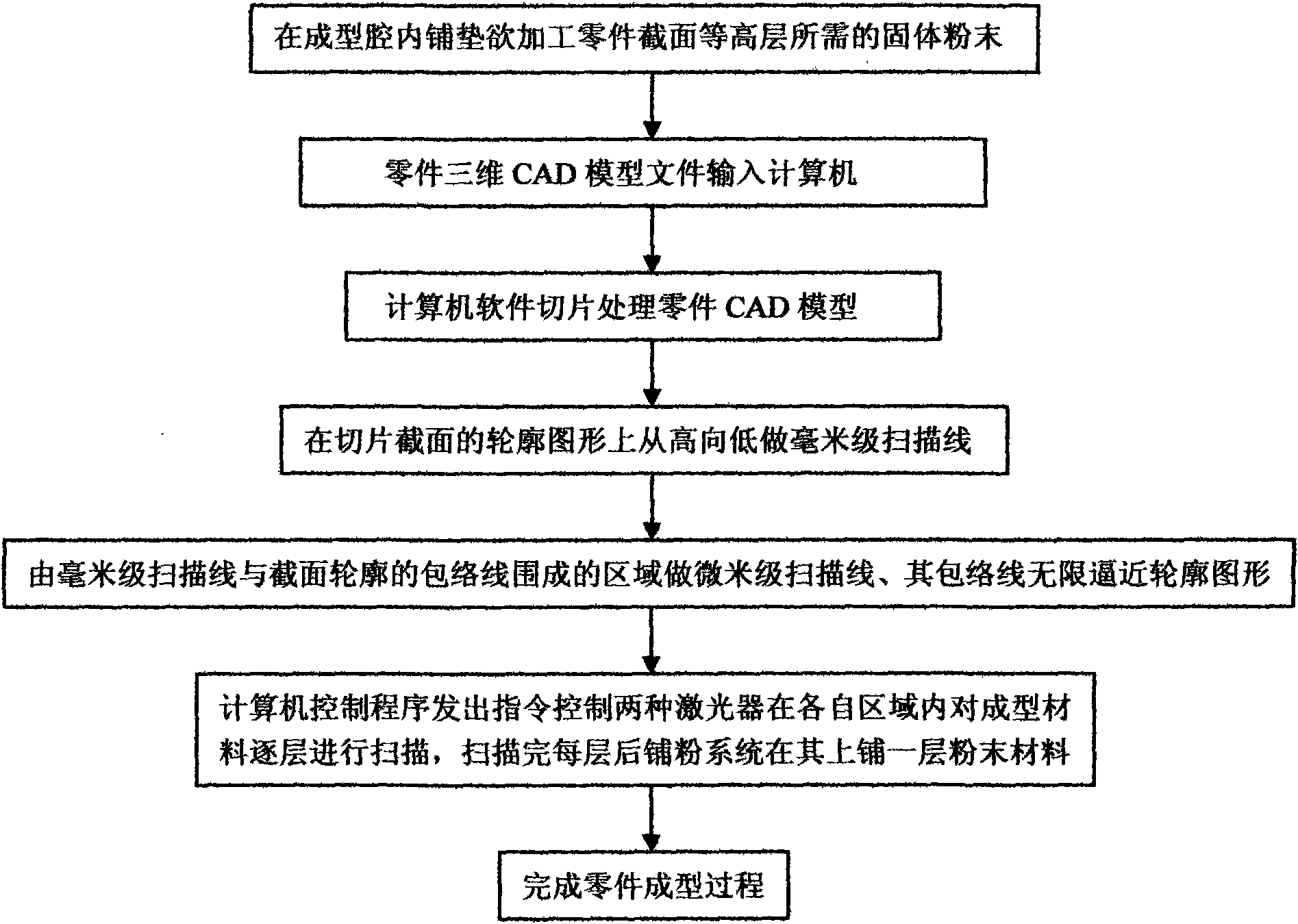

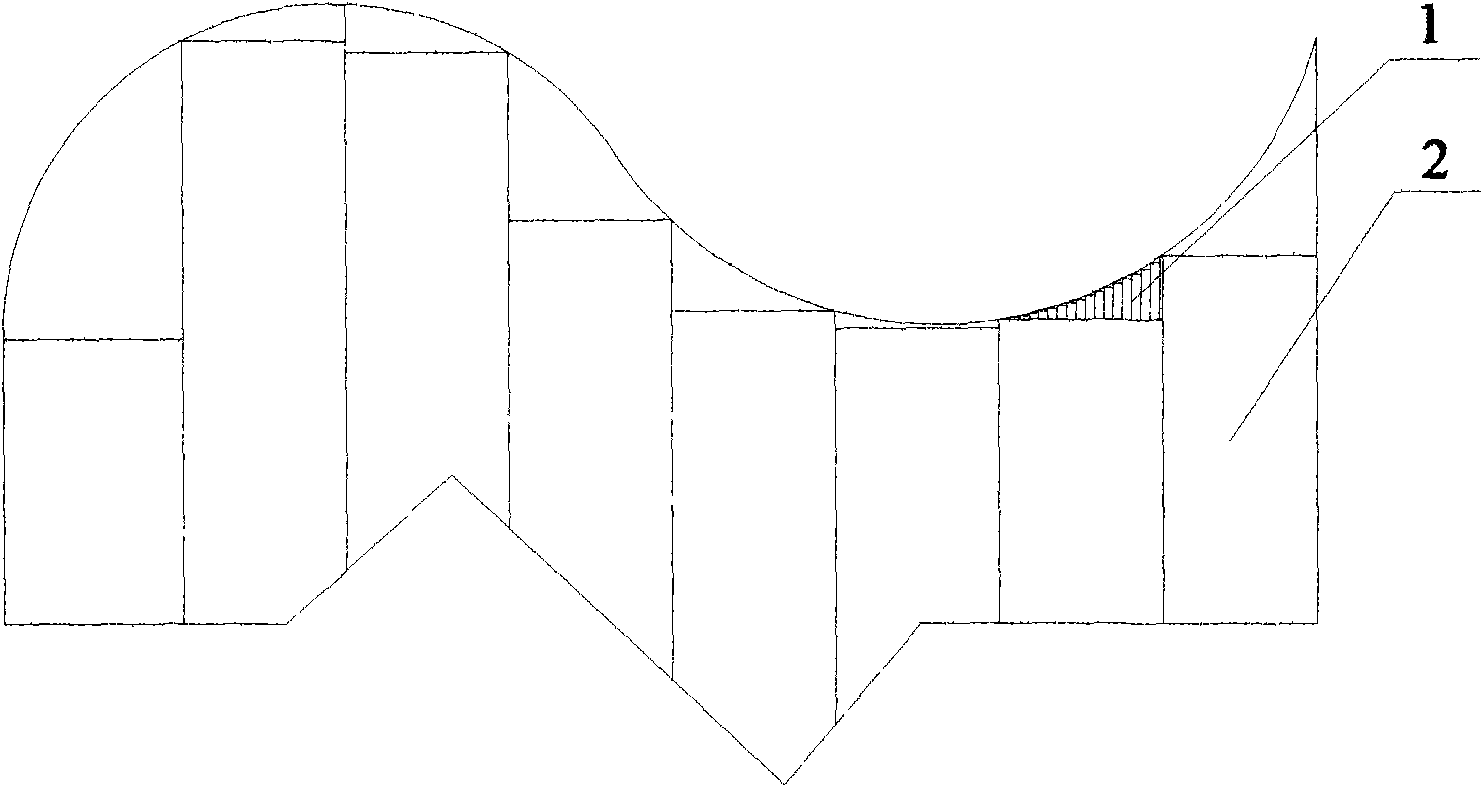

New method used for realizing powder melting and forming based on laser scanning

The invention relates to a new method used for realizing powder melting and forming based on laser scanning, aiming at solving the technical problems that the efficiency is low by adopting single beamof laser for melting and forming, parts are easy to be deformed and cracked after forming, and the thermal stress is difficult to be controlled. A technical scheme is adopted as follows: two types oflasers and matched vibration mirror systems are adopted; according to a contour pattern of a cross-section of a slice, each layer of solid powder is subjected to area scanning synchronously; and scanning is carried out layer by layer by the two types of lasers in each area so as to finish the powder melting and forming, wherein an area dividing method comprises the steps of respectively scanningand dividing parallelly a cross-section image by scanning lines in millimetre and micrometer so as to form a rectangular fast scanning area in millimetre and a curve edge fine scanning area in micrometer and lead the envelope curve pattern of the curve edge fine scanning area in micrometer to be approximate to the contour pattern infinitely. The method has the advantages that two lasers are adopted for compound scanning; the time is saved; the part forming efficiency is improved; and the part is not easy to be buckled and deformed and cracked.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing toughened aluminum oxide ceramic based on stereo lithography appearance namely 3D printing

InactiveCN106673627ASolve technical defects of uneven structureInhibit productionAdditive manufacturing apparatusCeramic shaping apparatusPhotoinitiatorMicrostructure

The invention belongs to the technical field of 3D printing, and particularly relates to a method for preparing toughened aluminum oxide ceramic based on stereo lithography appearance namely 3D printing. The invention provides a composition. The composition comprises the following raw materials: aluminum oxide ceramic powder, a liquid premix, a photoinitiator, a dispersant and a surfactant. The invention further provides a preparation method for preparing zirconium oxide-toughened aluminum oxide ceramic by using the composition. The preparation method comprises the following steps: preparing a slurry, moulding, drying and degreasing, wherein a blank is dried primarily, degreased and post-treated. According to the technical scheme provided by the invention, the ceramic blank is prepared by stereo lithography appearance, so that the moulding efficiency is high and the dimensional accuracy of the product is high; through optimization of parameters in the degreasing step, the blank does not deform and does not crack in the degreasing process; by an infiltrating step, the growth of aluminum oxide crystal grains is inhibited, and through electronic microscopic observation on the product structure, the microstructure of the product is uniform; the technical defect that in the prior art, the structure of the zirconium oxide-toughened aluminum oxide ceramic is nonuniform is overcome.

Owner:GUANGDONG UNIV OF TECH

Wire additive and reductive combination machining equipment and application thereof

ActiveCN106425490AGuaranteed contour accuracyGuaranteed forming accuracyOther manufacturing equipments/toolsNumerical controlThree dimensional measurement

The invention discloses wire additive and reductive combination machining equipment. The wire additive and reductive combination machining equipment comprises an on-line metal arc welding wire additive manufacture device and a numerical control multi-axis linkage machining device, wherein the on-line metal arc welding wire additive manufacture device comprises a welding robot and a welder system; the welder system is arranged on the welding robot; the multi-axis linkage machining system comprises a three-dimensional measurement device and a multi-axis linkage precise machining system; the three-dimensional measurement device is used for measuring the outline information of a part and transmits the information to a computer; the computer is used for obtaining the real outline of the part through the received outline information, then compares the real outline with a theoretical three-dimensional model to obtain an error; and the multi-axis linkage precise machining system is used for performing wire reductive machining on the part, so that the error between the real outline and the theoretical three-dimensional model is controlled in a preset range. By adopting the wire additive and reductive combination machining equipment, the problem of a current precise machining method that a part with a complex shape can hardly be machined automatically is solved; and the advantages of arc welding wire additive manufacture of high efficiency, low energy consumption and high environment adaptability can be fully exerted.

Owner:HUAZHONG UNIV OF SCI & TECH

Leftward and rightward double-bending type numerical-controlled pipe bending machine

ActiveCN107282720AAvoid shakingQuality improvementMetal-working feeding devicesPositioning devicesAviationPipe fitting

The invention relates to a leftward and rightward double-bending type numerical-controlled pipe bending machine, and belongs to the technical field of pipe processing. The leftward and rightward double-bending type numerical-controlled pipe bending machine comprises a rack, a control unit, a pipe bending device and a feeding vehicle which are mounted on the rack and controlled by the control unit, wherein the pipe bending device comprises a machine head, a die guide unit and a die changing unit; the machine head comprises a mounting seat, a leftward pipe bending unit and a rightward pipe bending unit which are mounted on the mounting seat and driven by a same pipe bending motor; each of the leftward and rightward pipe bending units comprises a circular die, a swing arm and a clamping die mounted on the swing arm; the die changing unit is controlled by the control unit to drive the machine head to move in transverse and vertical directions being perpendicular to the axial direction of a pipe to be bent relative to the rack, so that the numerical-controlled pipe bending machine can switch between a leftward bending working mode and a rightward bending working mode. According to the leftward and rightward double-bending type numerical-controlled pipe bending machine, the same pipe bending motor drives the leftward pipe bending unit and the rightward pipe bending unit simultaneously, at the same time the switching between the leftward pipe bending unit and the rightward pipe bending unit is realized through the die changing unit, not only is the pipe bending quality effectively improved, but also the compactness of the integrated layout is improved, and therefore the leftward and rightward double-bending type numerical-controlled pipe bending machine can be extensively applied to fields such as air conditioning and aviation.

Owner:浙江和良智能装备有限公司

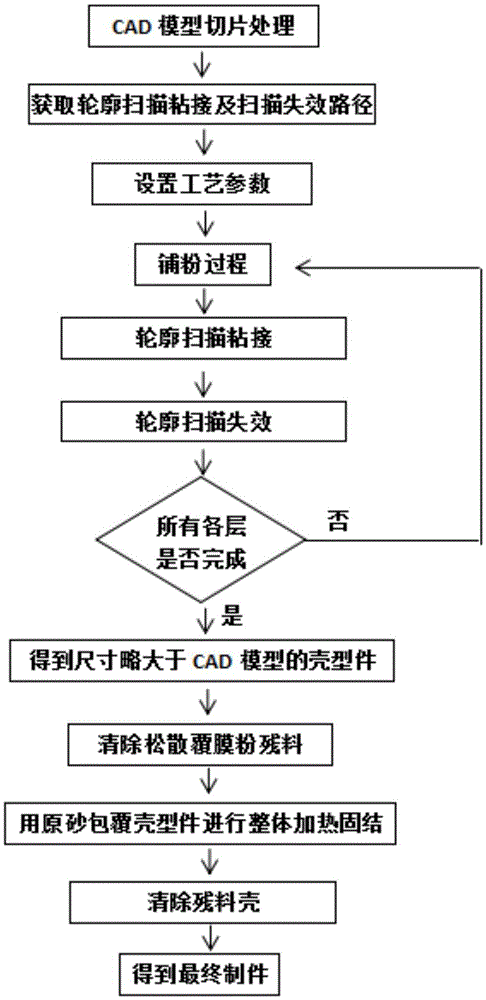

3D printing method adopting laser hybrid profile scanning

ActiveCN105538712AConsolidation without radiative heatingImprove complex structureAdditive manufacturing apparatusHigh energyLight beam

The invention discloses a laser hybrid profile scanning method used for 3D laser printing. In the 3D laser printing process, by utilizing adjustment and changes of spot diameters and energy densities of laser beams, light beams with different light beam diameters are obtained, namely the small-spot light beams with the high energy density are obtained. Large-spot light beams with the low energy density are used for carrying out hybrid scanning on the model profile, large spots with the low energy density are used for achieving bonding and curing of profile scanning, small spots with the high energy density are used for achieving profile scanning invalidation, and finally manufacturing of shell molds meeting the requirements for size precision and strength is completed.

Owner:DALIAN UNIV OF TECH

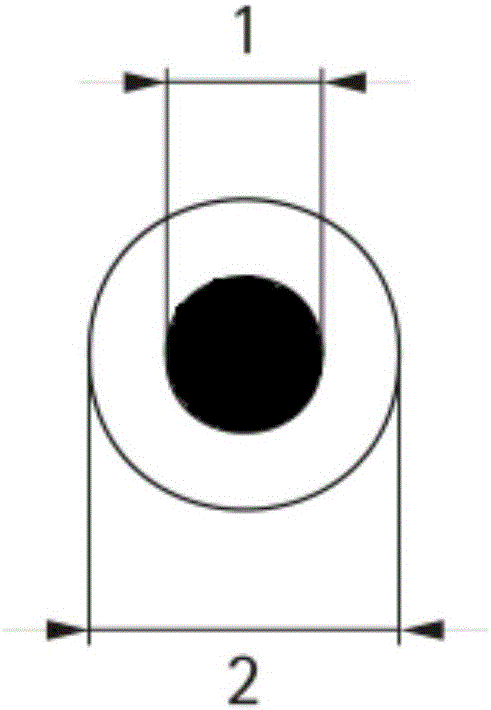

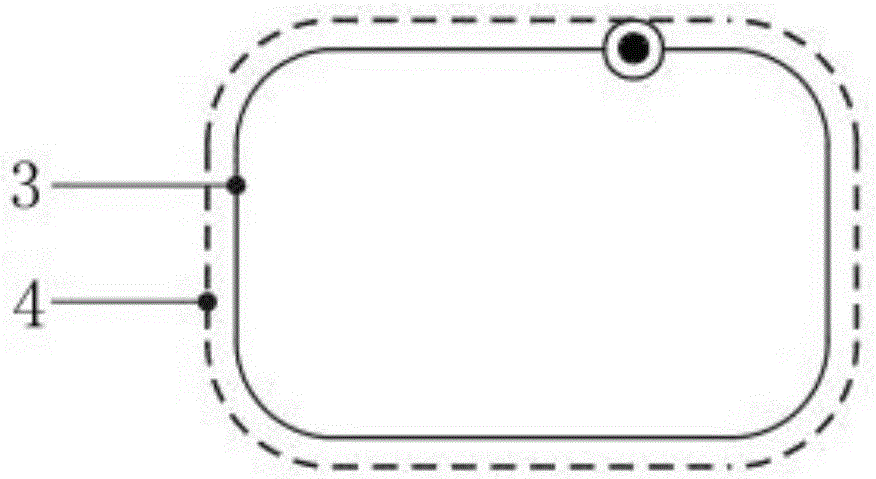

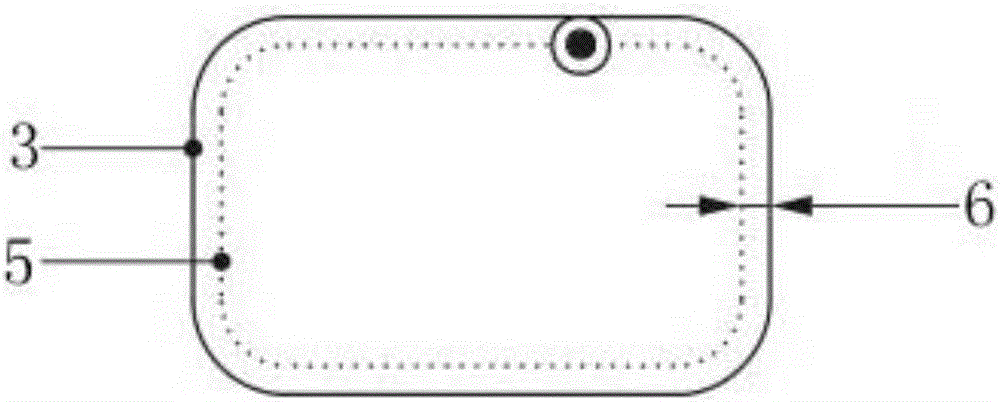

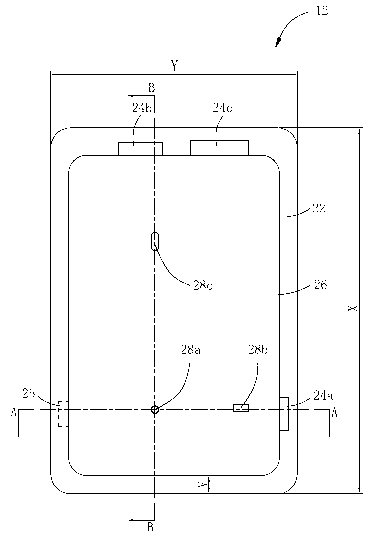

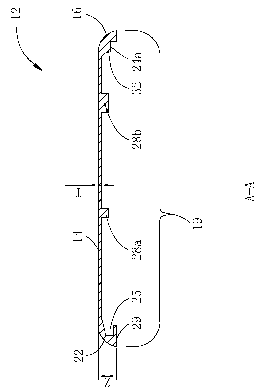

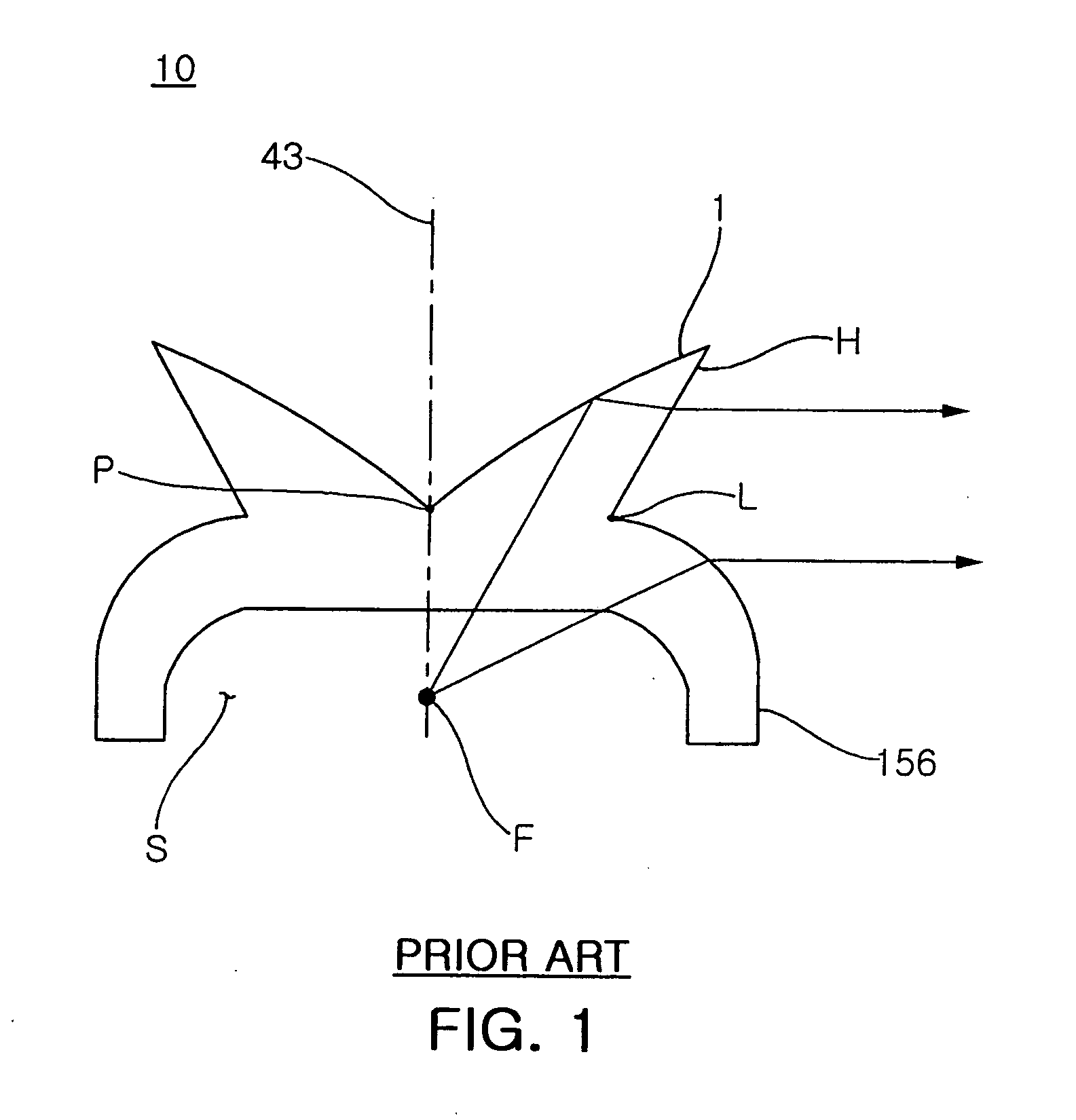

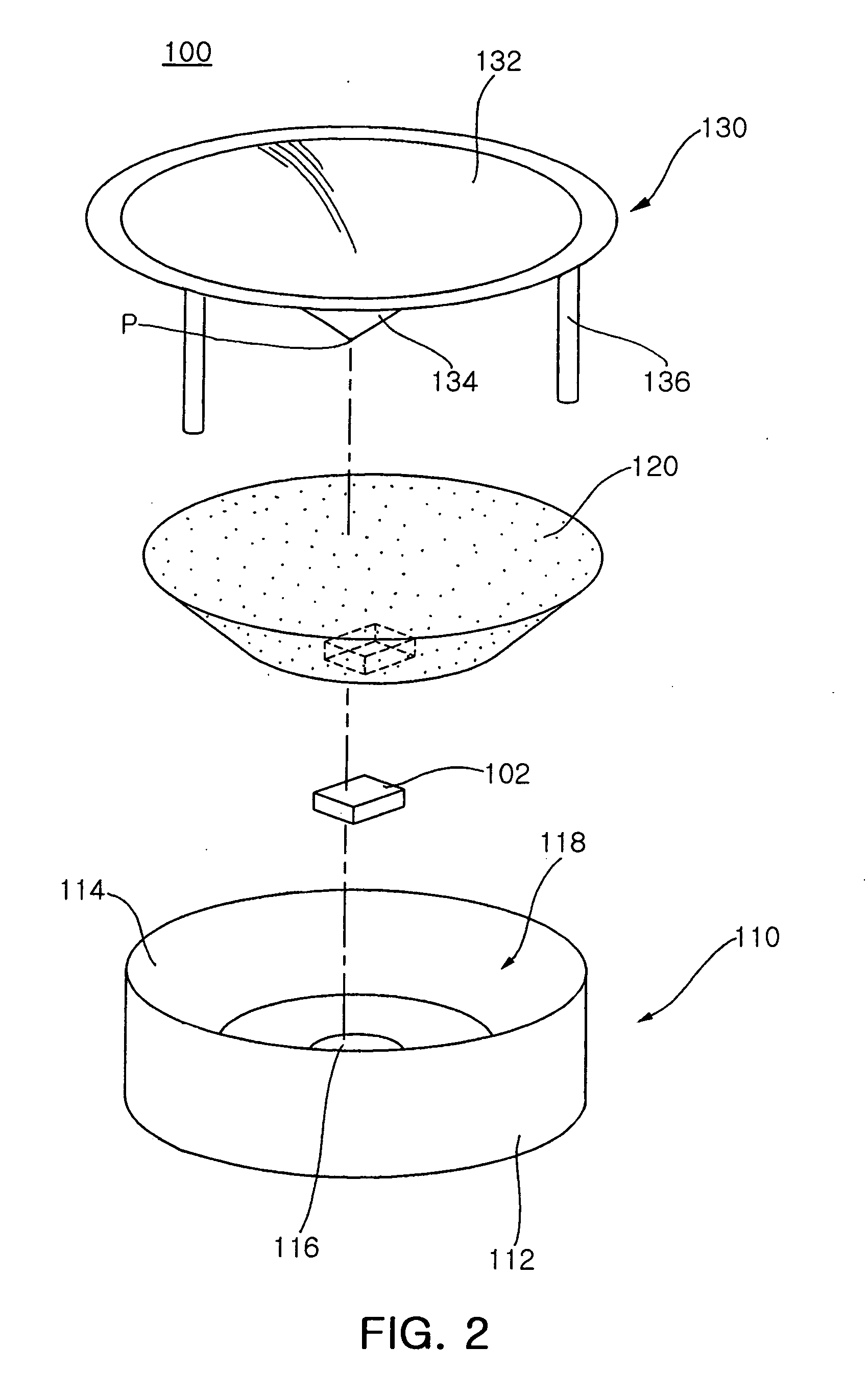

Side-emission typy LED package

ActiveUS20060171151A1Improve molding efficiencyImprove production efficiencySemiconductor devices for light sourcesRefractorsEngineeringLed packaging

A side-emission type LED package is provided. The LED package includes an LED chip, a lower structure, and an upper structure. The lower structure has a lower mirror and a transparent sealing member. The lower structure supports the LED chip. The lower mirror is extended upward and outward@ from the LED chip so as to reflect light from the LED chip upward. The transparent sealing member is formed around the LED chip inside the lower mirror. The upper structure is combined to an upper portion of the lower structure so as to reflect the light reflected upward by the lower structure to a radial lateral direction. As described above, the lower structure and the upper structure are separately provided and combined with each other, whereby molding efficiency of the sealing member is improved and the side-emission type LED package can be manufactured in an easy manner.

Owner:SAMSUNG ELECTRONICS CO LTD

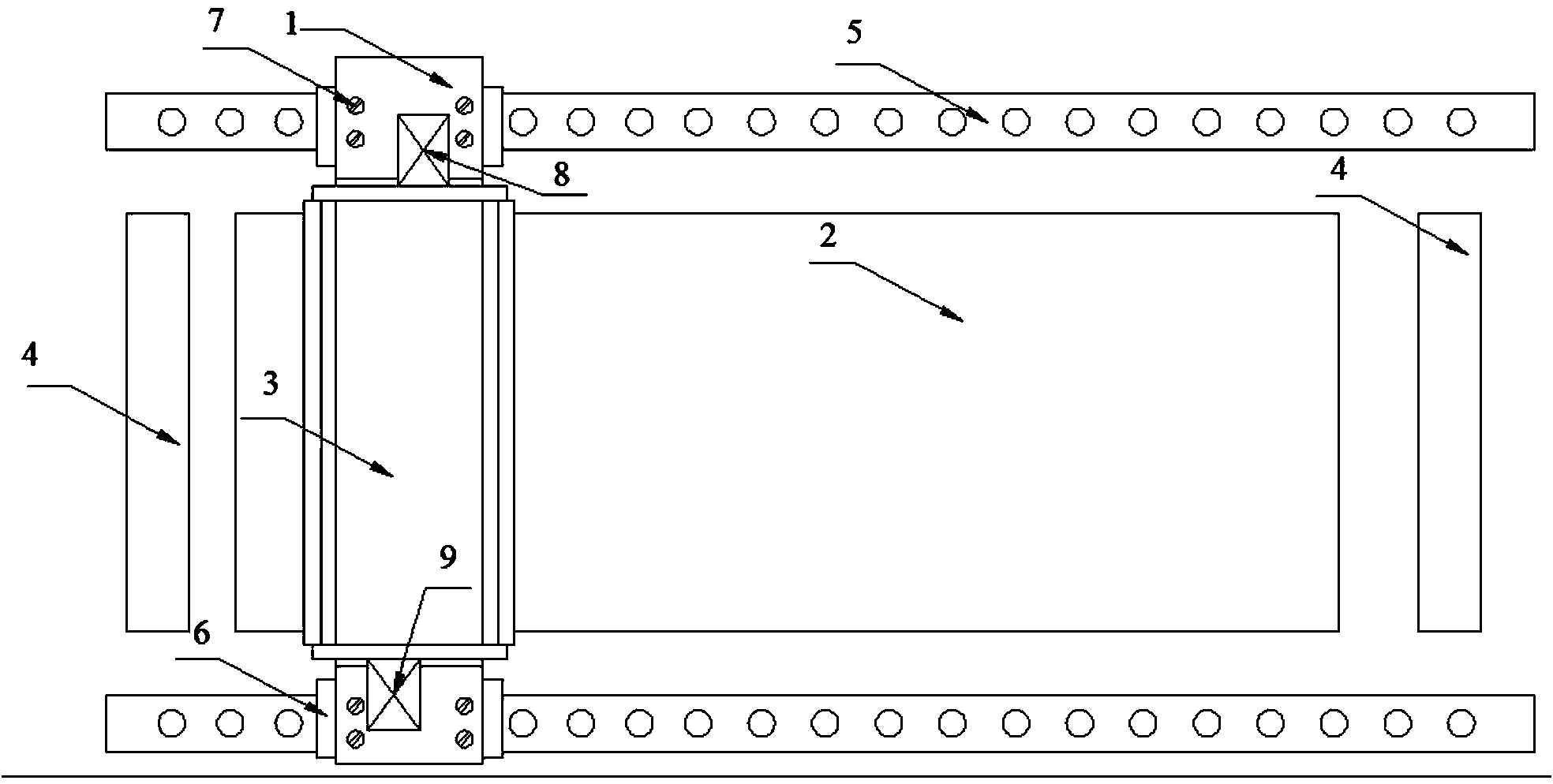

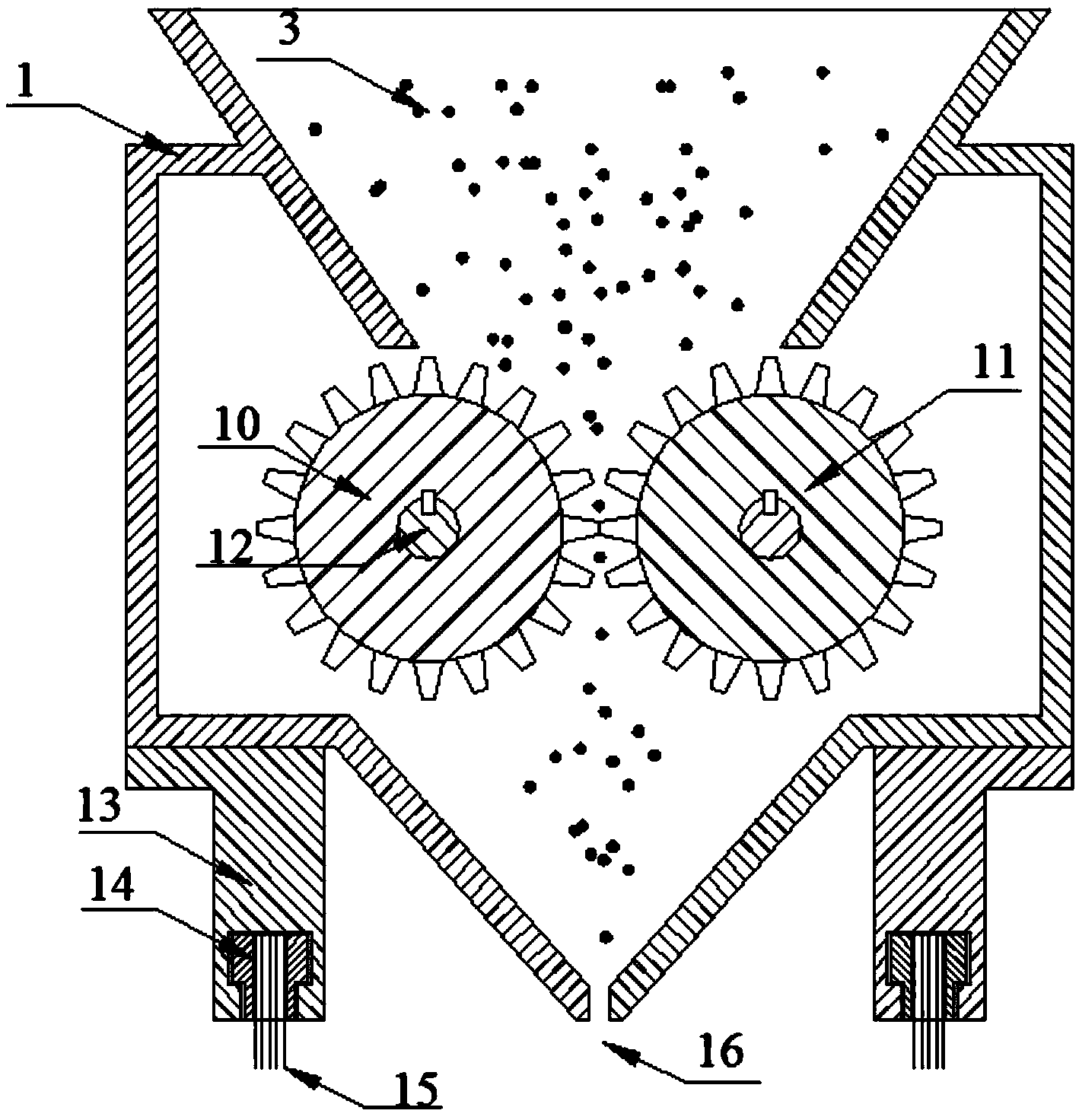

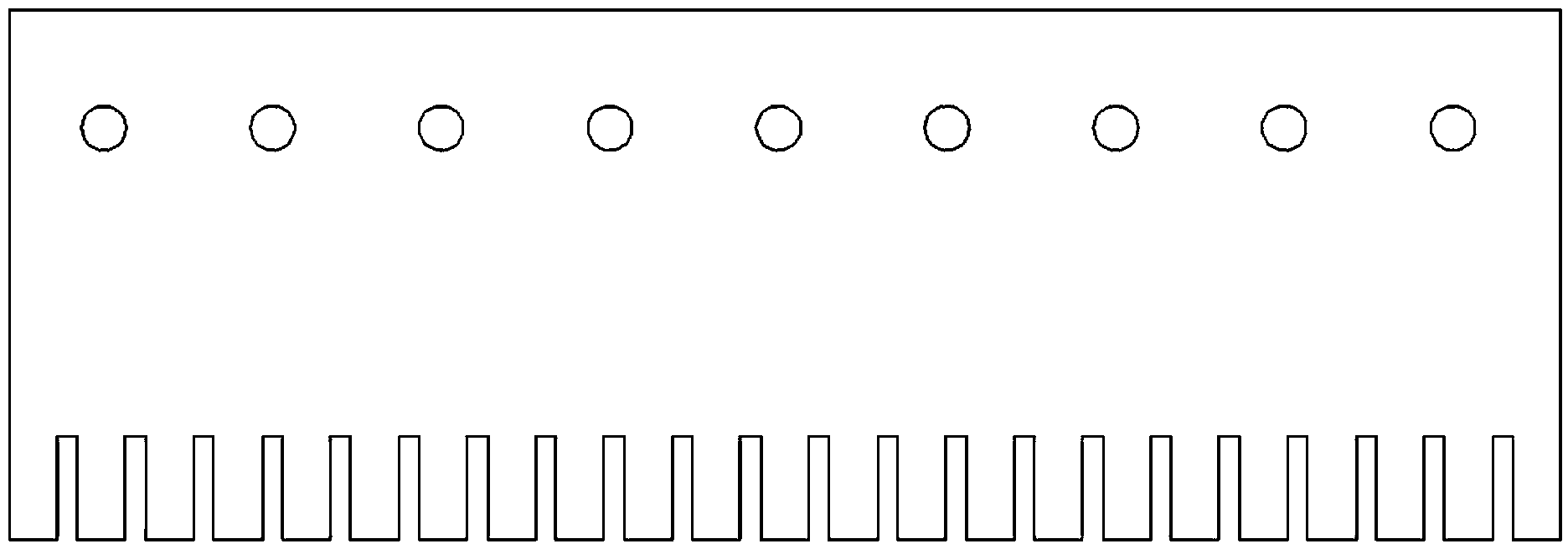

Two-way powder spreading device of SLM equipment and powder spreading method

ActiveCN103658646AGuaranteed uniformityGuaranteed flatnessIncreasing energy efficiencyDrive shaftInstability

The invention discloses a two-way powder spreading device of SLM equipment and a powder spreading method. The powder spreading device comprises a powder spreading device body, two parallel auxiliary linear motor guide rails and two parallel linear motor movable sliding blocks, wherein the linear motor movable sliding blocks are arranged on the auxiliary linear motor guide rails; the powder spreading device body is arranged on the linear motor movable sliding blocks in an erecting mode and comprises a powder carrying device and two powder supply gears arranged inside the powder carrying device; the circle center position of each powder supply gear is provided with a servo motor transmission shaft; the two powder supply gears are arranged at the equal altitude; the gear top circles of the two powder supply gears are tangent in the radial direction; flexible powder scraping brushes are arranged on the two sides of the powder carrying device. By means of the powder spreading device, the redundant steps in the powder spreading process are reduced, powder is spread in the back and forth direction, the evenness and flatness of the spread powder are ensured through the flexible powder scraping brushes on the two sides, and the good repairing function is achieved on the process instability.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com