New method used for realizing powder melting and forming based on laser scanning

A laser scanning and new method technology, applied in the field of laser melting molding, can solve the problems of easy deformation of parts, cracks, and difficult thermal stress, etc., and achieve the effect of reducing distortion, improving molding efficiency, and not easy to warp deformation and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

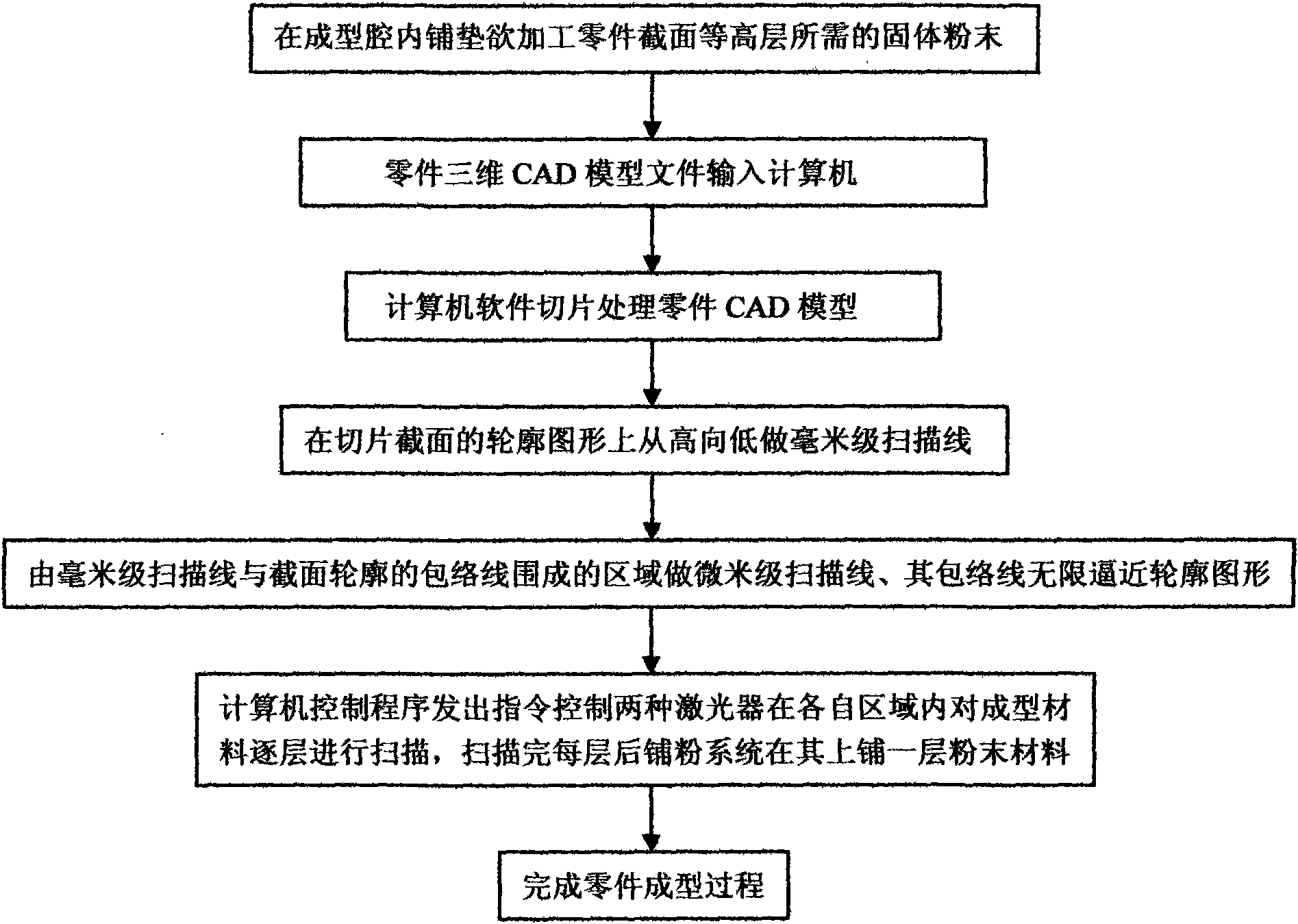

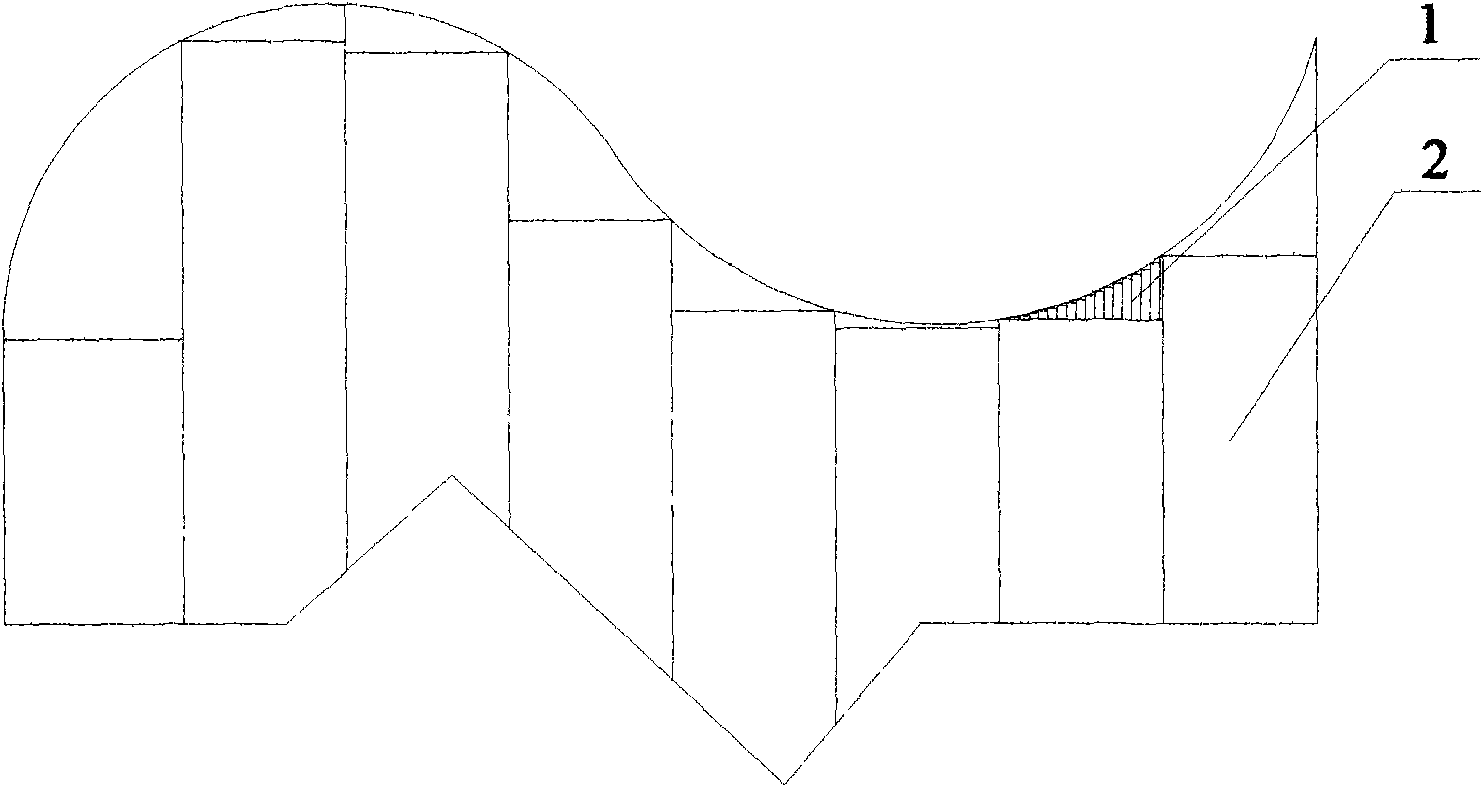

[0011] see figure 1 , a new method based on laser scanning to realize powder melting molding. This method scans and melts sintered materials by means of lasers, vibrating mirror systems and supporting computer control software programs. For solid powder, the cross-section information of the processed parts is extracted by software. With the help of computer control, the laser scans layer by layer according to the cross-section information of the part model. After each layer of solid powder is melted and formed under laser scanning, the next layer of solid powder is laid for the next layer Prepare for the first laser scan, and scan layer by layer until the entire molding process is completed. The above method uses two types of lasers and a matching galvanometer system to scan the area of each layer of solid powder synchronously according to the contour graphics of the section section. Each area is scanned layer by layer to complete the powder fusion molding. The above-mention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com