Patents

Literature

32results about How to "Guaranteed contour accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

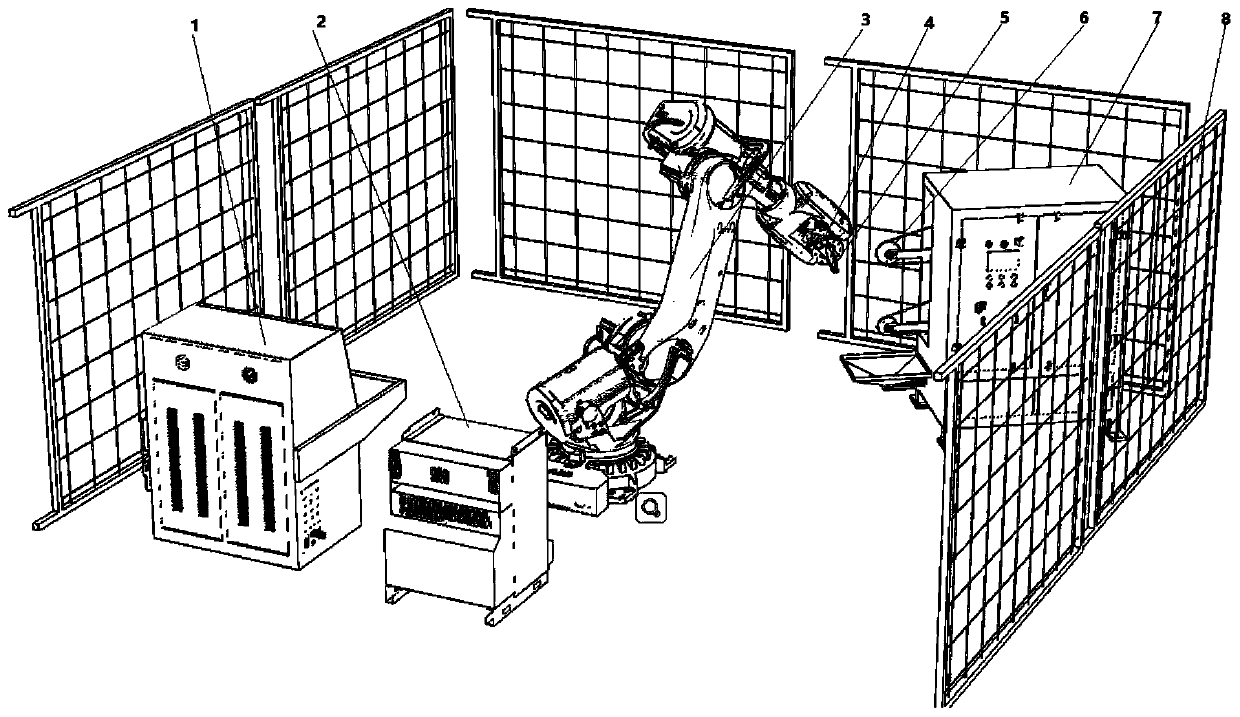

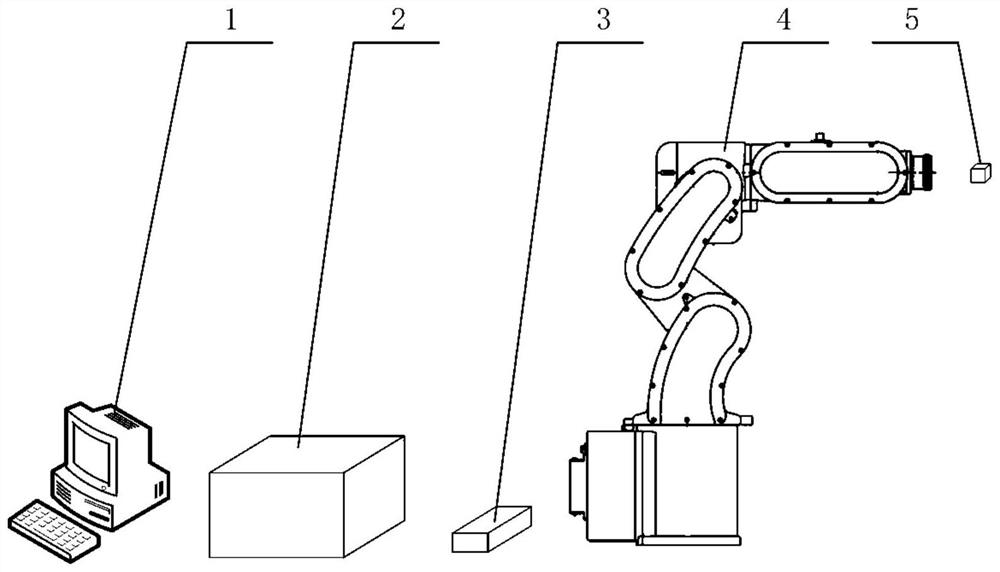

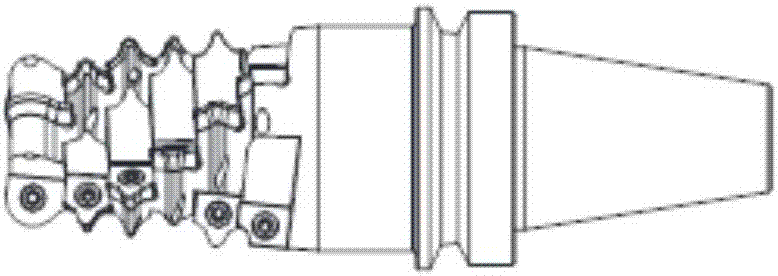

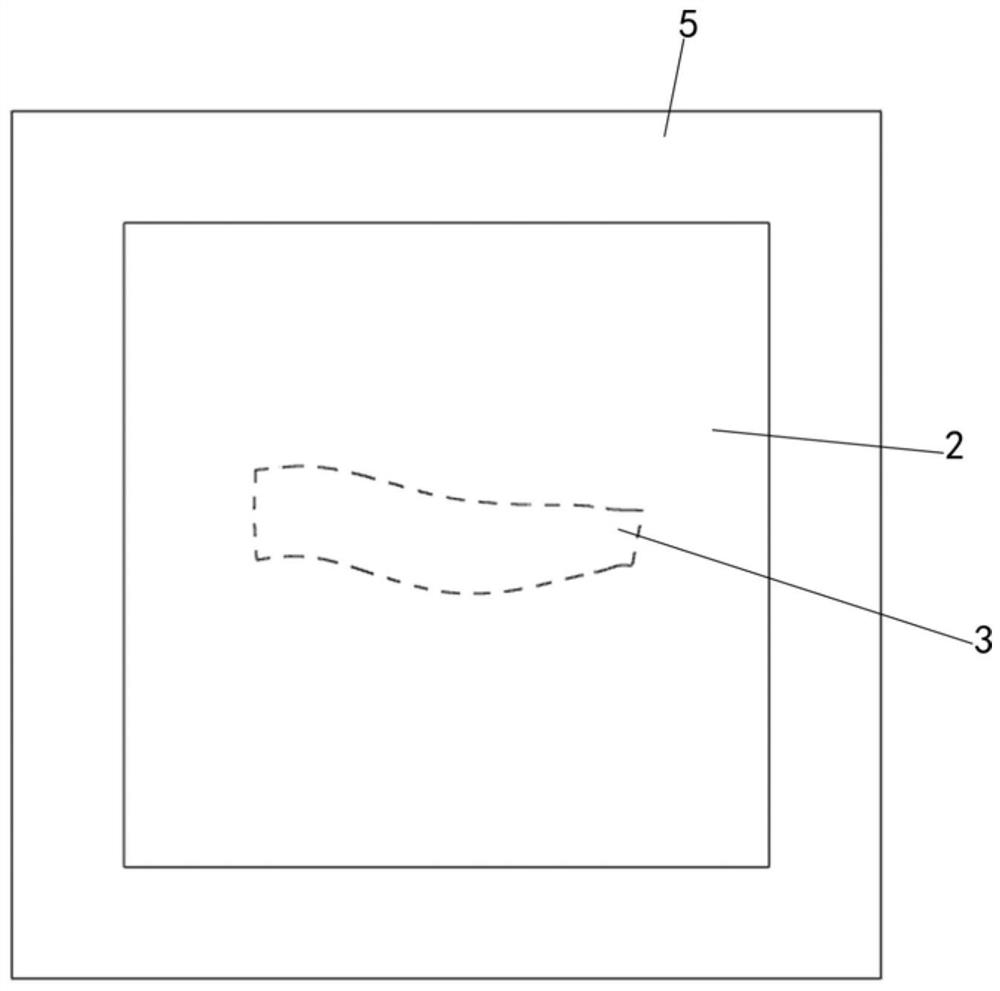

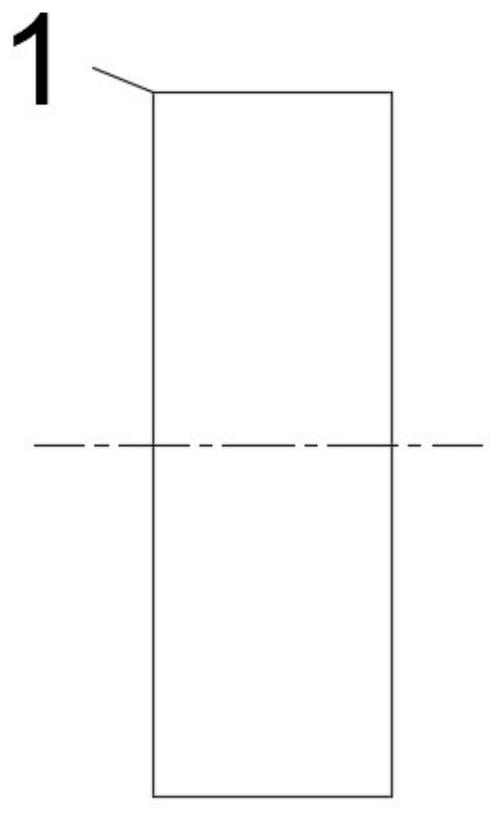

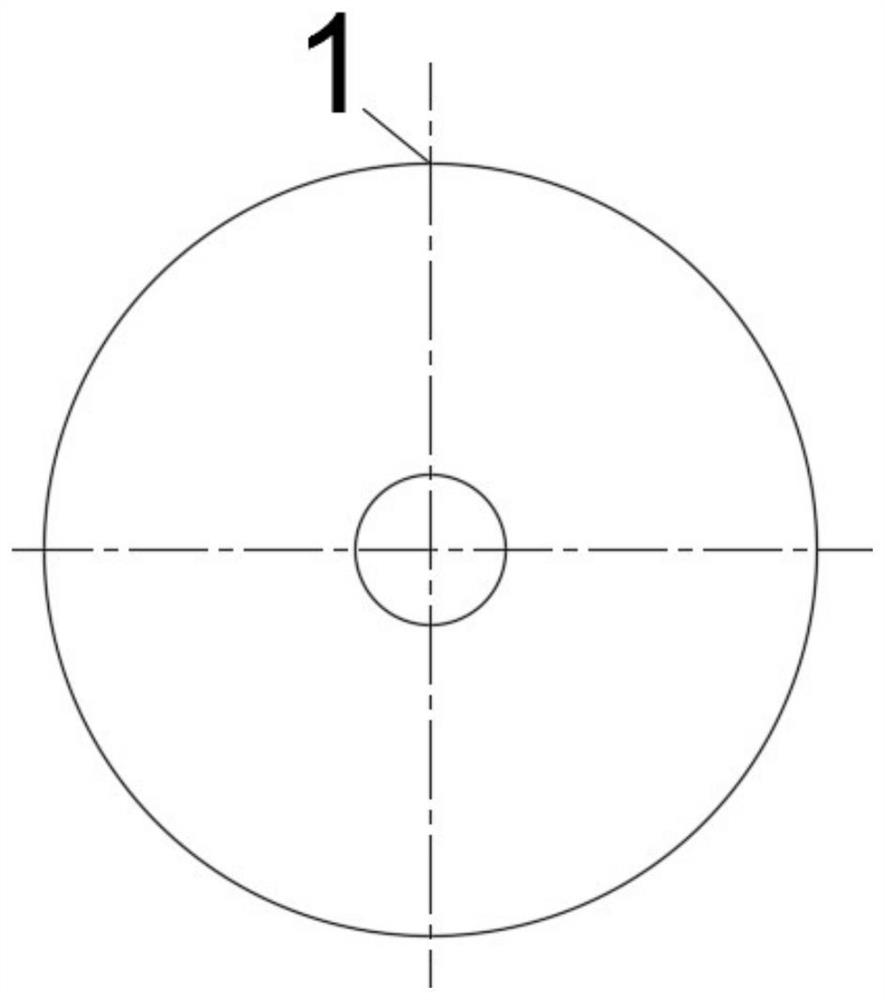

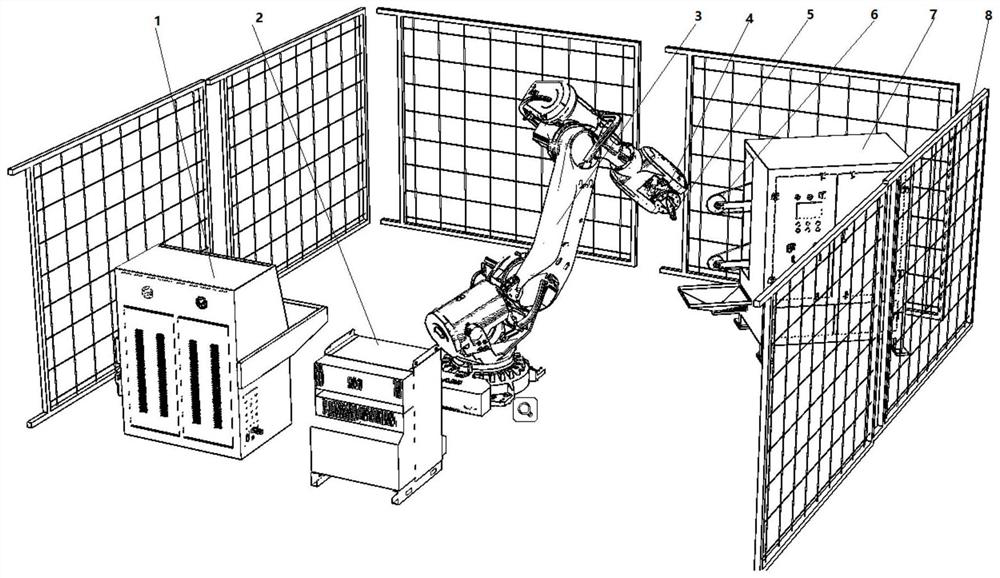

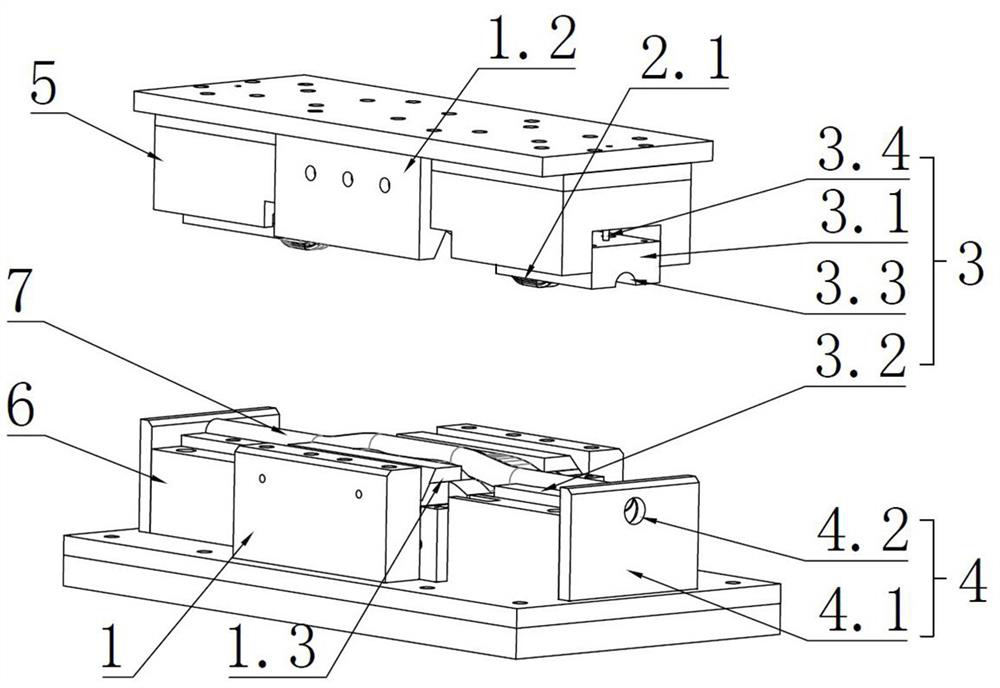

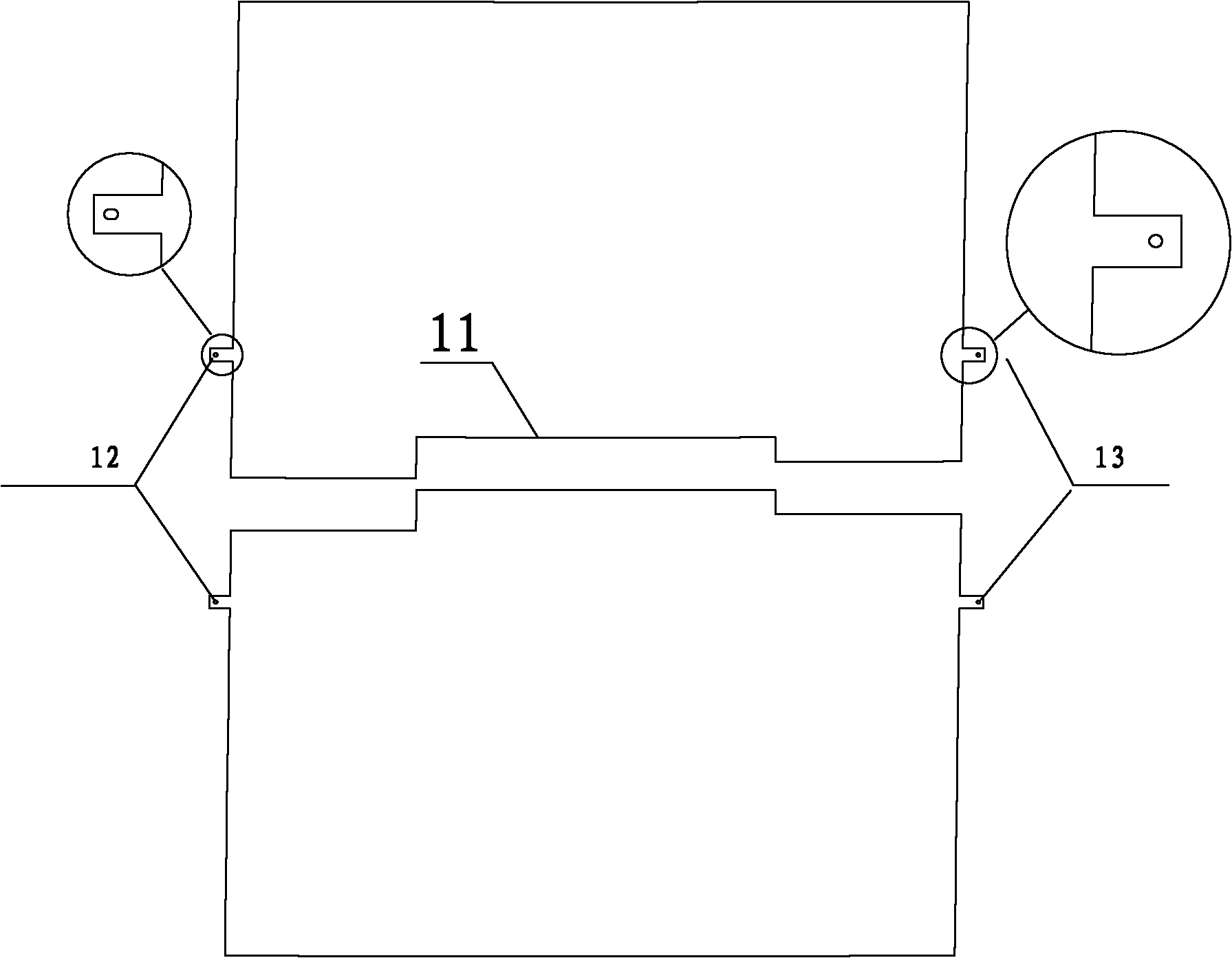

Wire additive and reductive combination machining equipment and application thereof

ActiveCN106425490AGuaranteed contour accuracyGuaranteed forming accuracyOther manufacturing equipments/toolsNumerical controlThree dimensional measurement

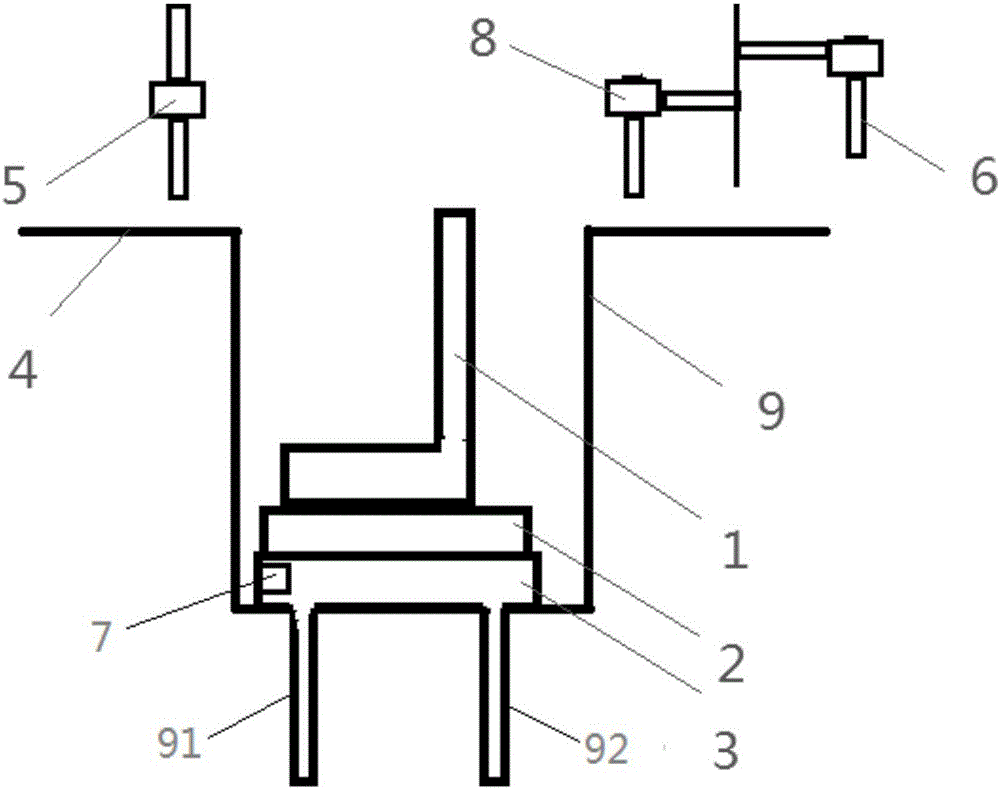

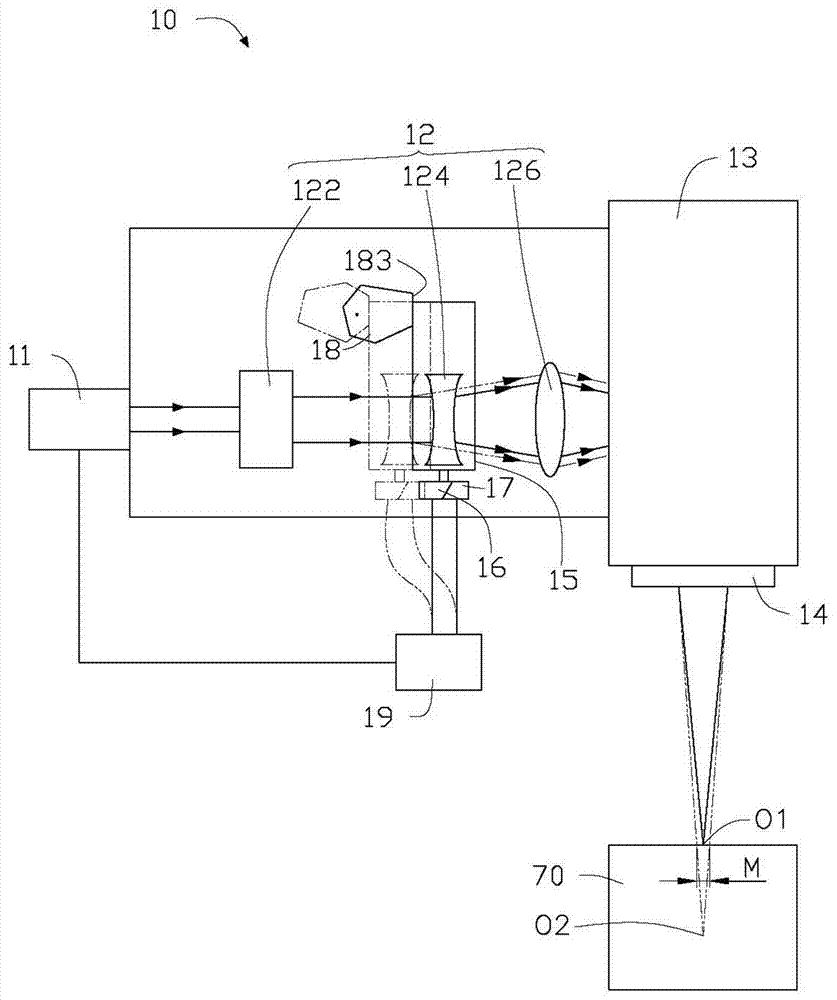

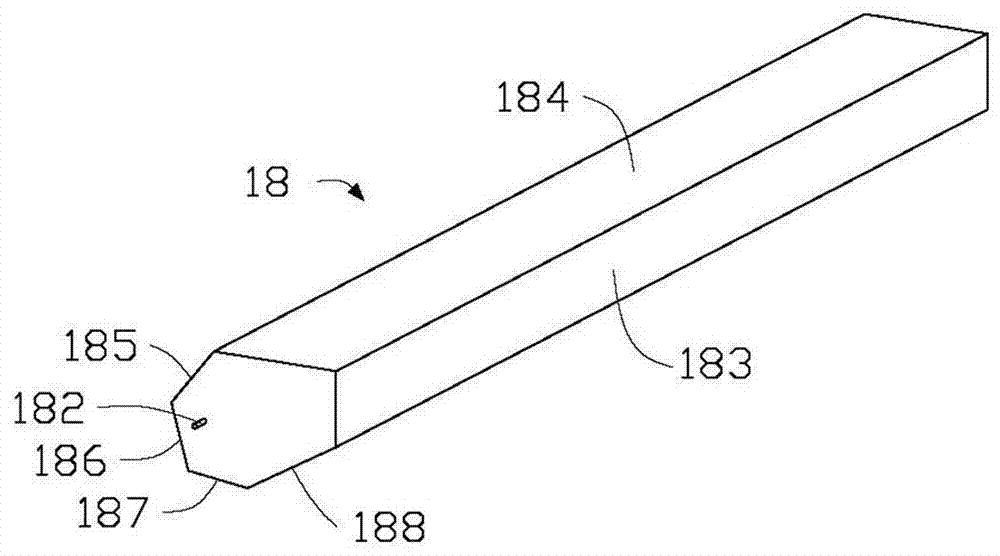

The invention discloses wire additive and reductive combination machining equipment. The wire additive and reductive combination machining equipment comprises an on-line metal arc welding wire additive manufacture device and a numerical control multi-axis linkage machining device, wherein the on-line metal arc welding wire additive manufacture device comprises a welding robot and a welder system; the welder system is arranged on the welding robot; the multi-axis linkage machining system comprises a three-dimensional measurement device and a multi-axis linkage precise machining system; the three-dimensional measurement device is used for measuring the outline information of a part and transmits the information to a computer; the computer is used for obtaining the real outline of the part through the received outline information, then compares the real outline with a theoretical three-dimensional model to obtain an error; and the multi-axis linkage precise machining system is used for performing wire reductive machining on the part, so that the error between the real outline and the theoretical three-dimensional model is controlled in a preset range. By adopting the wire additive and reductive combination machining equipment, the problem of a current precise machining method that a part with a complex shape can hardly be machined automatically is solved; and the advantages of arc welding wire additive manufacture of high efficiency, low energy consumption and high environment adaptability can be fully exerted.

Owner:HUAZHONG UNIV OF SCI & TECH

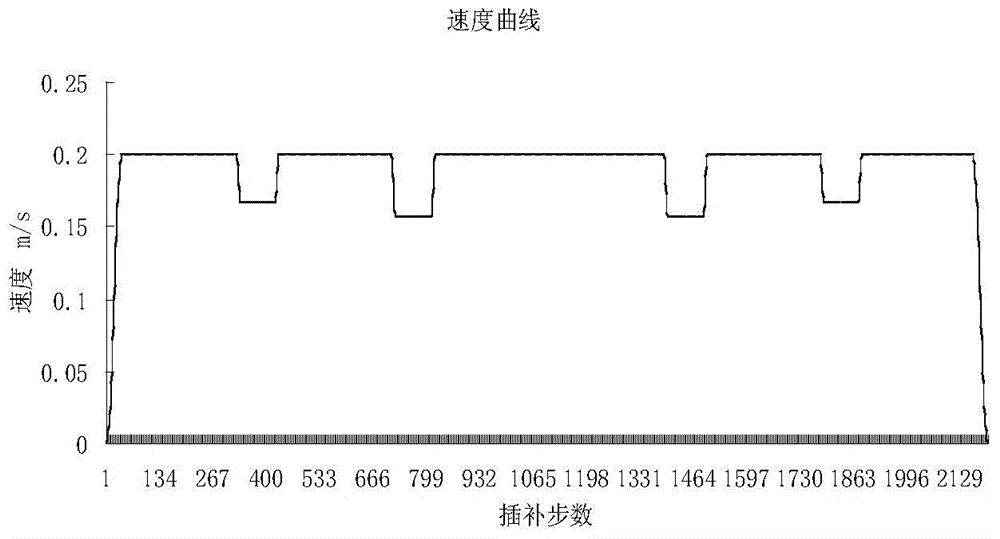

Quartic polynomial speed planning algorithm for spline interpolation

ActiveCN103801981AImprove machining accuracyGuaranteed machining accuracyAutomatic control devicesFeeding apparatusNumerical controlMachining process

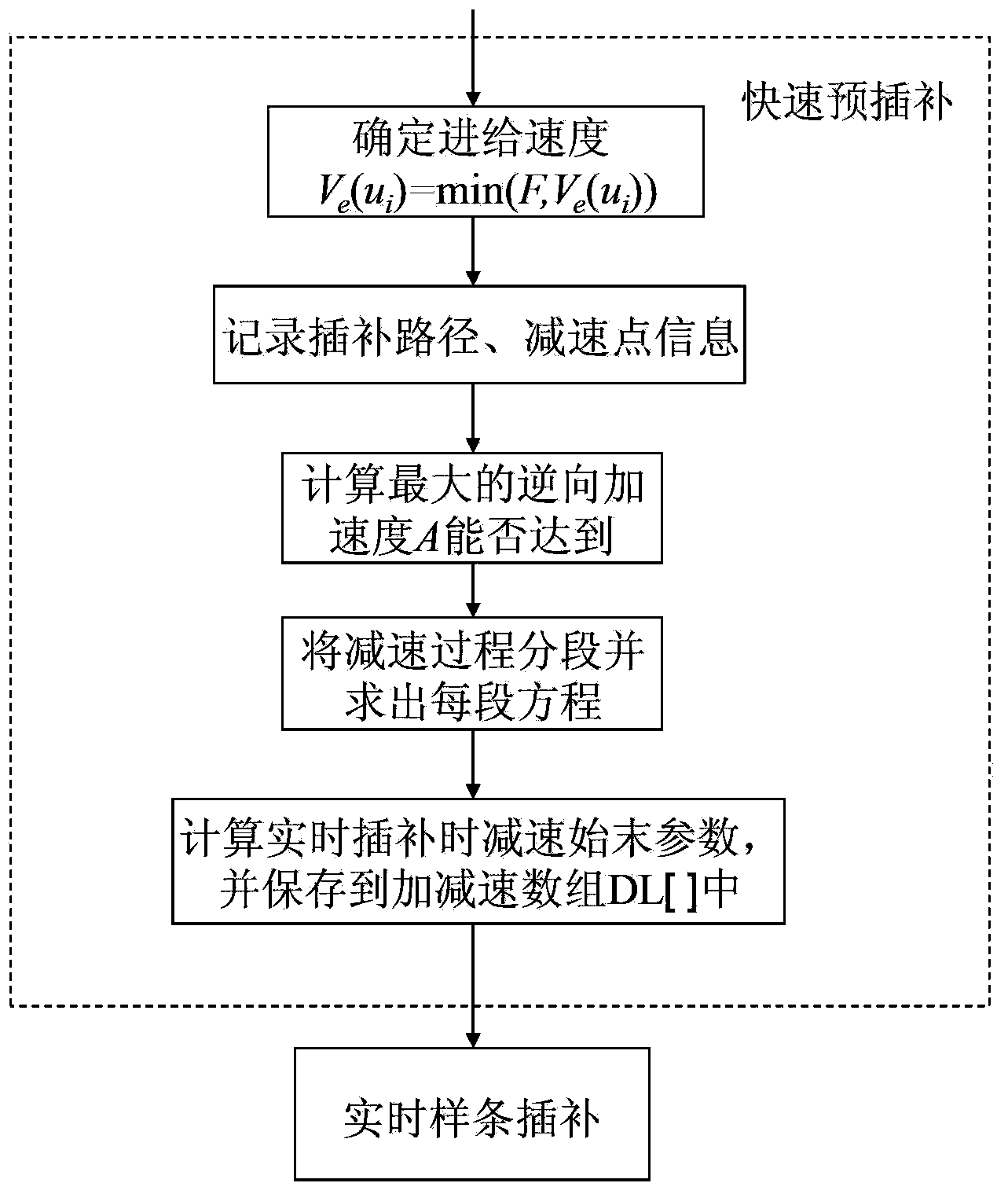

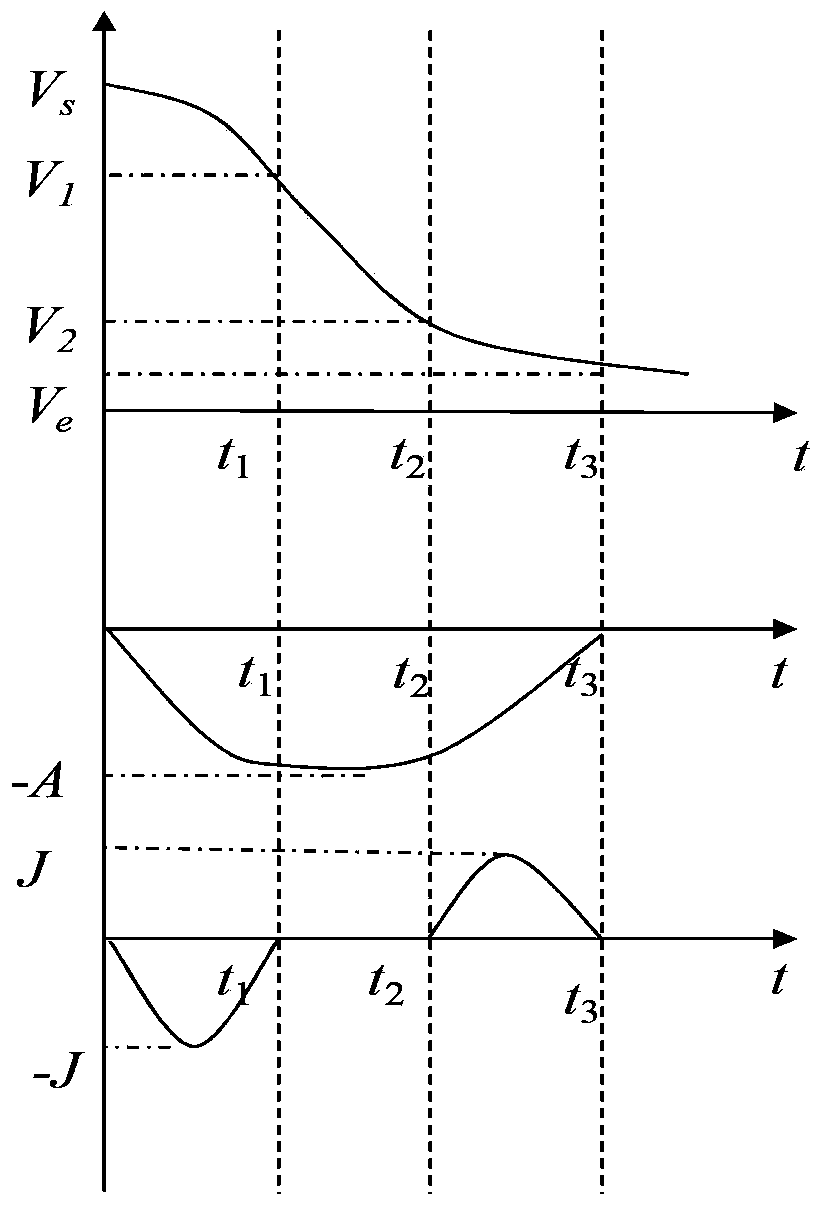

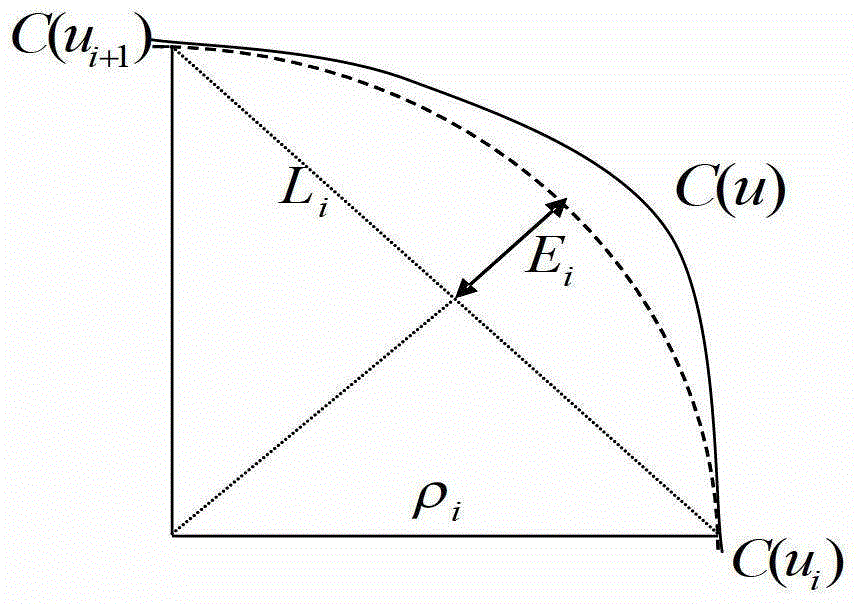

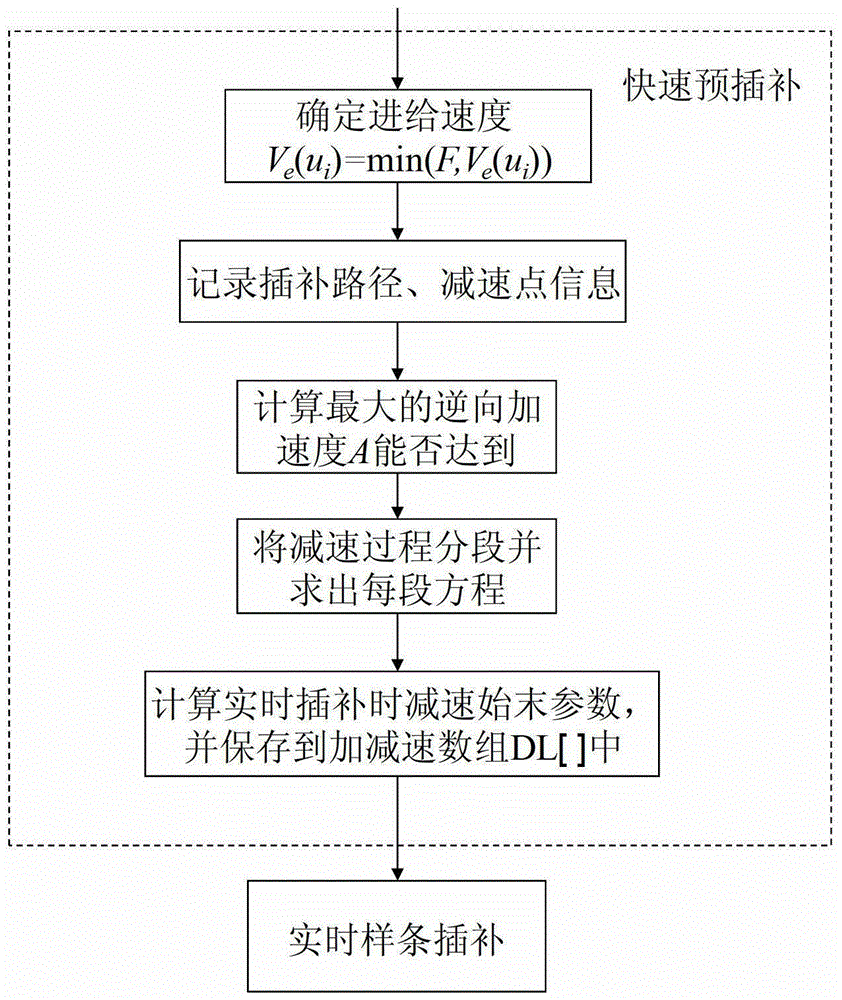

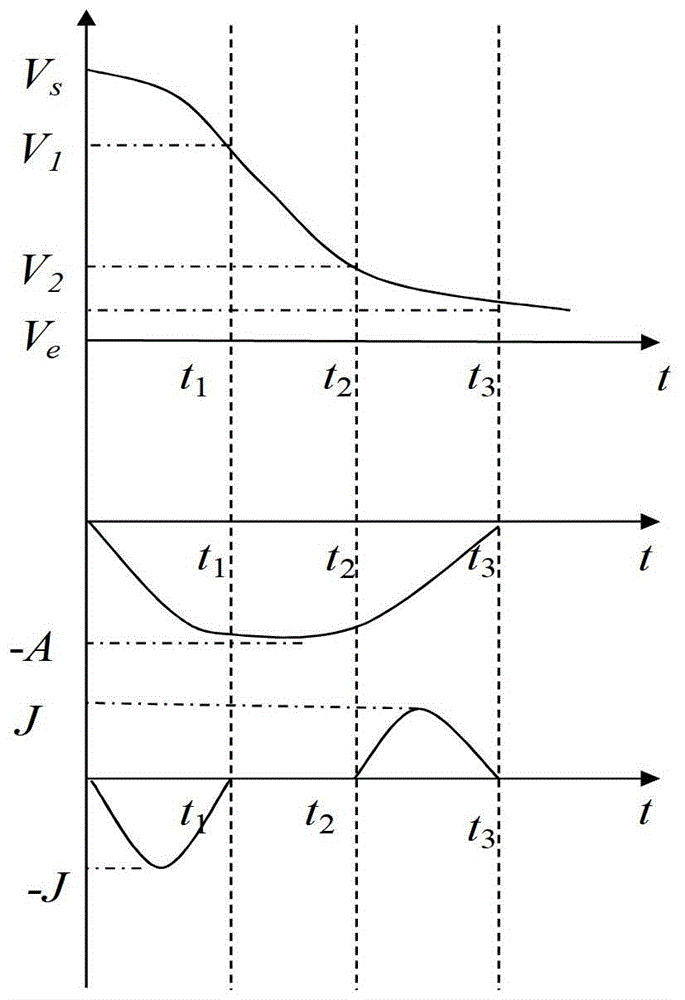

The invention discloses a quartic polynomial speed planning algorithm for spline interpolation. For example, at a deceleration section, the algorithm comprises the following steps: performing fast pre-interpolation on a numerical control machining curve, recording the length of an interpolation path, as well as a deceleration starting point and a speed minimum point which meet the machining accuracy requirements, calculating to judge whether the maximum reverse acceleration A can be reached or not, segmenting the deceleration process, and calculating quartic polynomial speed equations of all segments; then determining the needed theoretical distance from the deceleration starting point to the speed minimum point according to the speed equations, and calculating interpolation parameters corresponding to the theoretical distance; finally performing real-time spline interpolation according to the speed equations obtained in the pre-interpolation stage and the interpolation parameters at the starting and ending moments of acceleration and deceleration. By adopting the method, the continuous change of the speed, acceleration and acceleration change rate of a numerical control machine tool in a high-speed machining process can be realized, overshoot caused by high-speed machining is reduced, and thus smooth and flexible acceleration and deceleration control on a servo shaft is realized.

Owner:中国科学院沈阳计算技术研究所有限公司

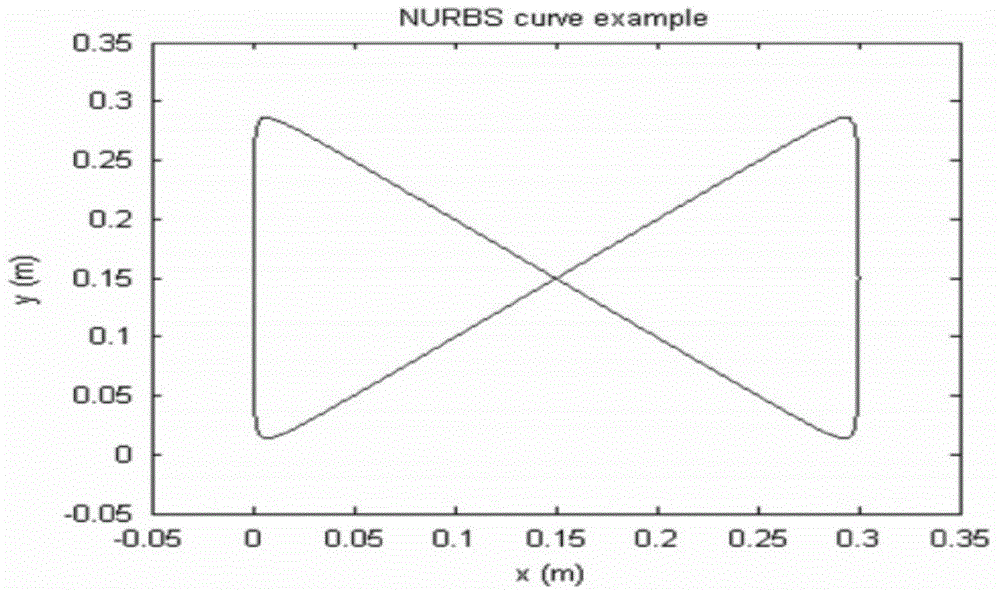

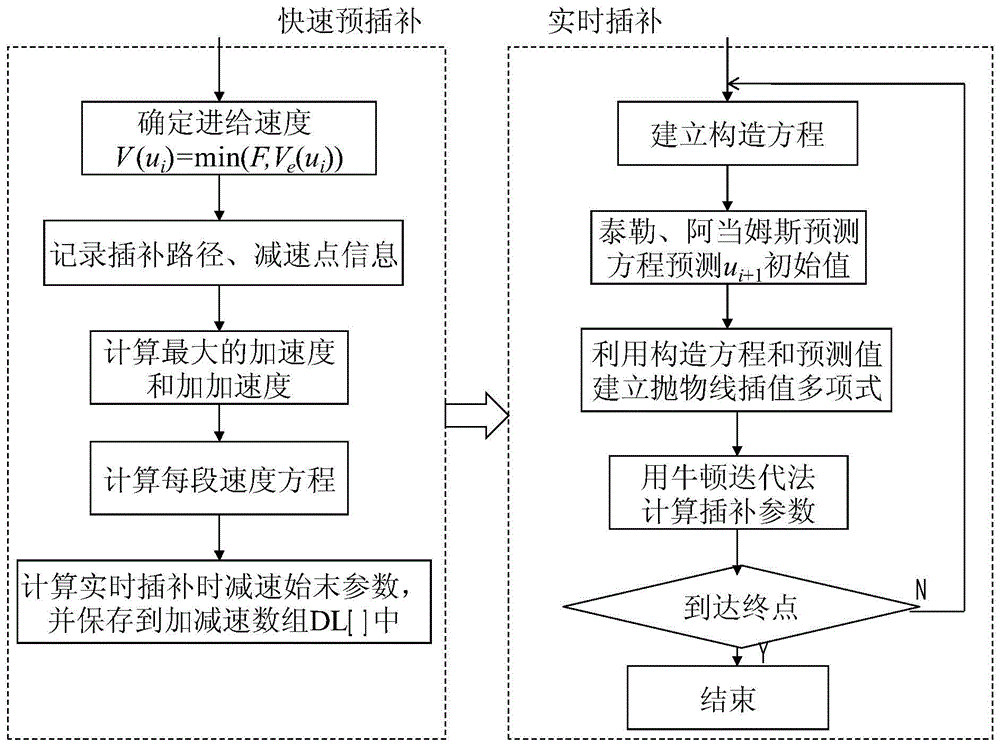

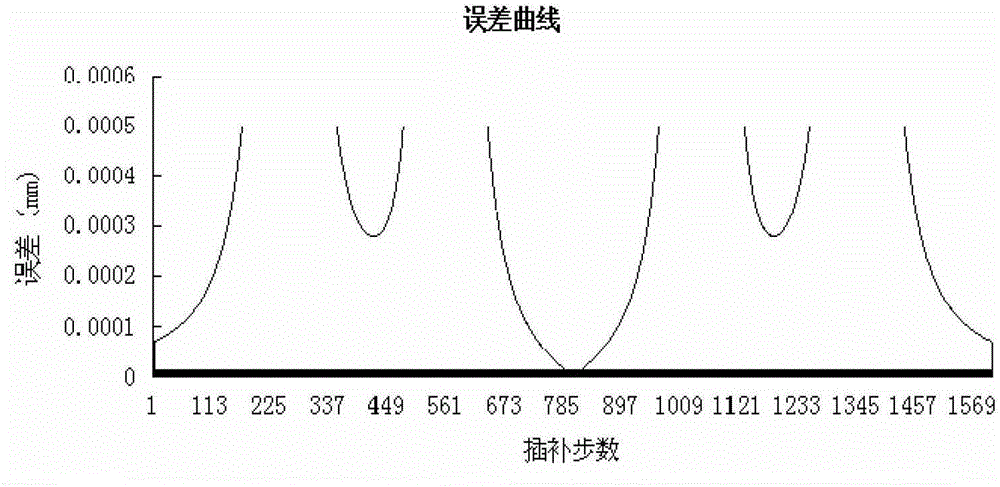

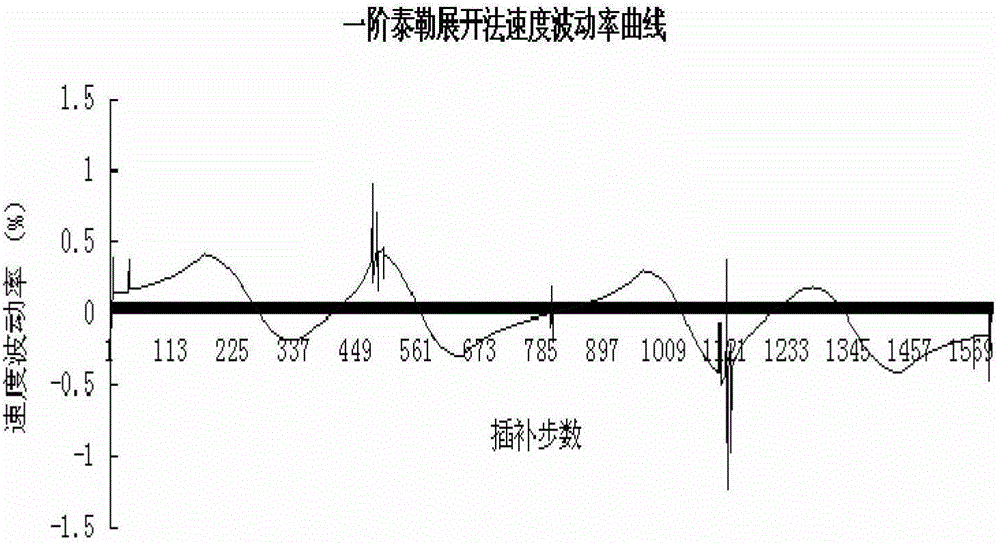

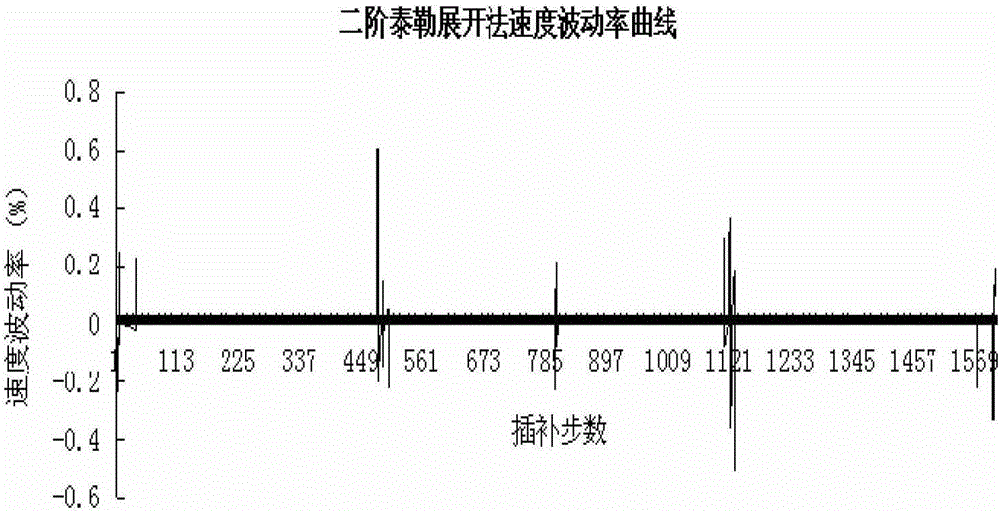

Spline curve interpolation algorithm for high quality processing

InactiveCN104597845AImprove machining accuracyGuaranteed contour accuracyNumerical controlNumerical controlAlgorithm

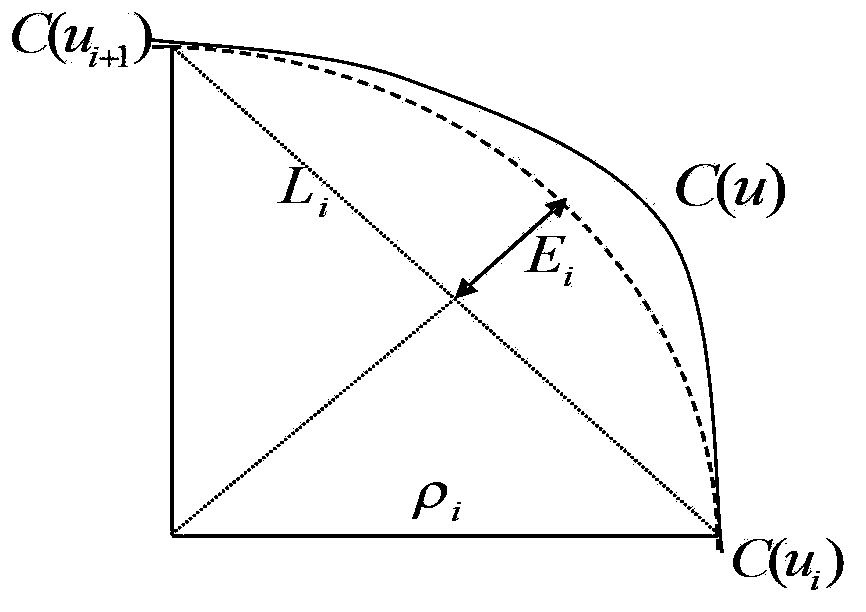

The invention discloses a spline curve interpolation algorithm for high quality processing, and the spline curve interpolation algorithm for high quality processing comprises the following steps: quickly pre-interpolating the numerical control machining curve, recording the length of the interpolation path and the maximum / minimum value of the acceleration / deceleration process; calculating the maximum acceleration and most much acceleration of the acceleration / deceleration process, having subsection on the acceleration / deceleration process, calculating quadratic polynomial speed equations of each section; obtaining the speed equation according to the pre-interpolating stage at the real time interpolating stage, adopting the strategy that the theory chord length is close to the practical chord length for building the construction function, estimating the initial value of the interpolation parameter and building the parabolic interpolation polynomial, using the Newton iteration method for exactly calculating the interpolation parameter. The speed plan adopts five-section S curve acceleration / deceleration control algorithm for guaranteeing continuous change of the speed and accelerated speed, the bounded change of the accelerated acceleration speed and the running stability of the machine tool; the calculation of the interpolation parameter adopts the combination of parabolic interpolation method and Newton iteration method for controlling the feeding speed fluctuation of the real time interpolation in the ideal level and satisfying the high quality processing requirement.

Owner:中国科学院沈阳计算技术研究所有限公司

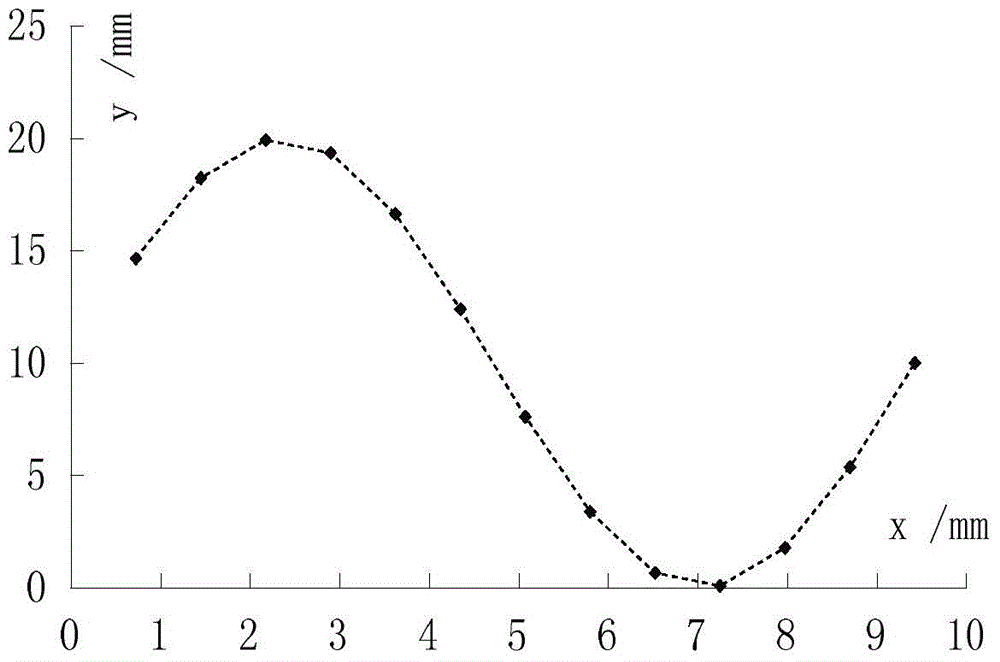

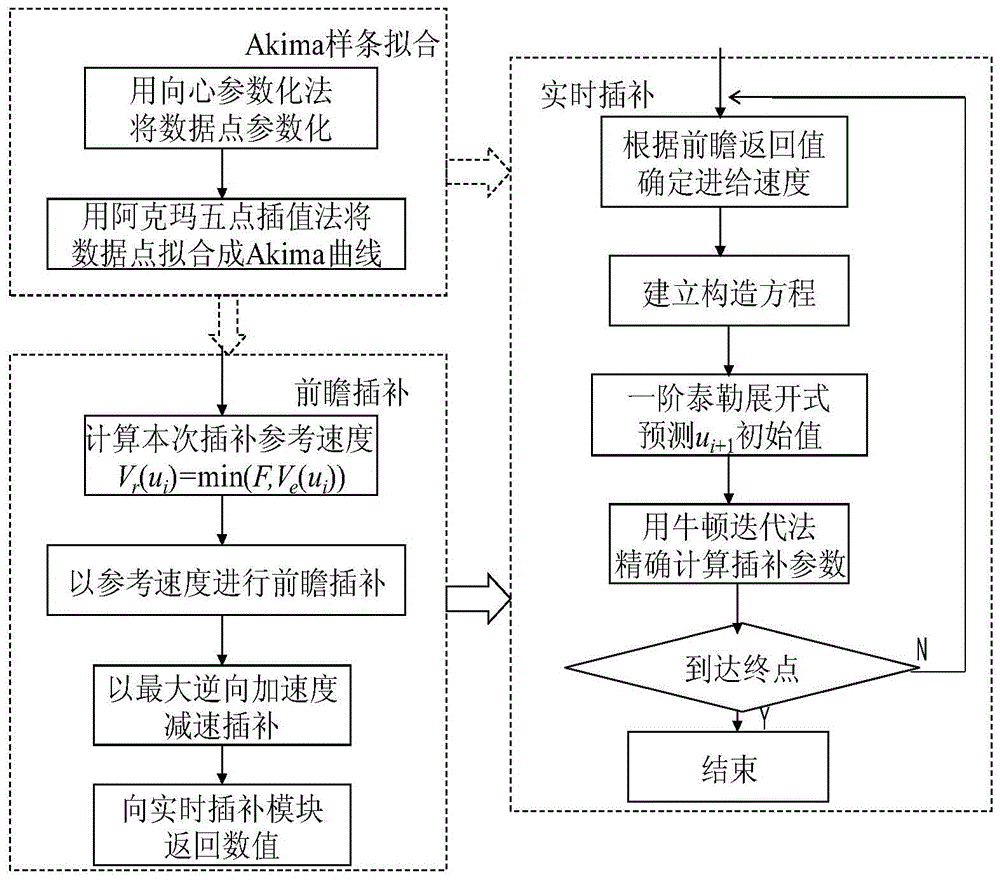

Akima spline fitting based look-ahead interpolation method

InactiveCN104597847APrecisely throughImprove fitting accuracyNumerical controlCurve fittingComputer science

The invention provides an Akima spline fitting based look-ahead interpolation method. The method is characterized in that the Akima spline fitting is that the parameters corresponding to each interpolation point are calculated by the centripetal parameterization method, and then the data points are fitted into a smooth Akima spline by the Akima five-point interpolation method; the look-ahead interpolation is that different values are returned for real-time interpolation by the look-ahead interpolation calculation according to the processing precision requirement, the programming speed of a numerical control system and the maximum speed information; the real-time interpolation is that the real-time feeding speed is adjusted according to the look-ahead interpolation returning value, then a structural equation is created according to the known Akima spline equation and interpolation cycle and other information, then the primary iteration value of the next interpolation method is predicated, and finally the interpolation parameters are accurately calculated by the newton iteration method. According to the method, the data points to be processed are fitted through the Akima spline, so that the actuating efficiency is increased, the smoothness is high, the fitting precision is improved while the interpolation real-time performance is ensured, the accuracy and flexibility are improved, and the actual state of a workpiece can be restored to the maximum.

Owner:中国科学院沈阳计算技术研究所有限公司

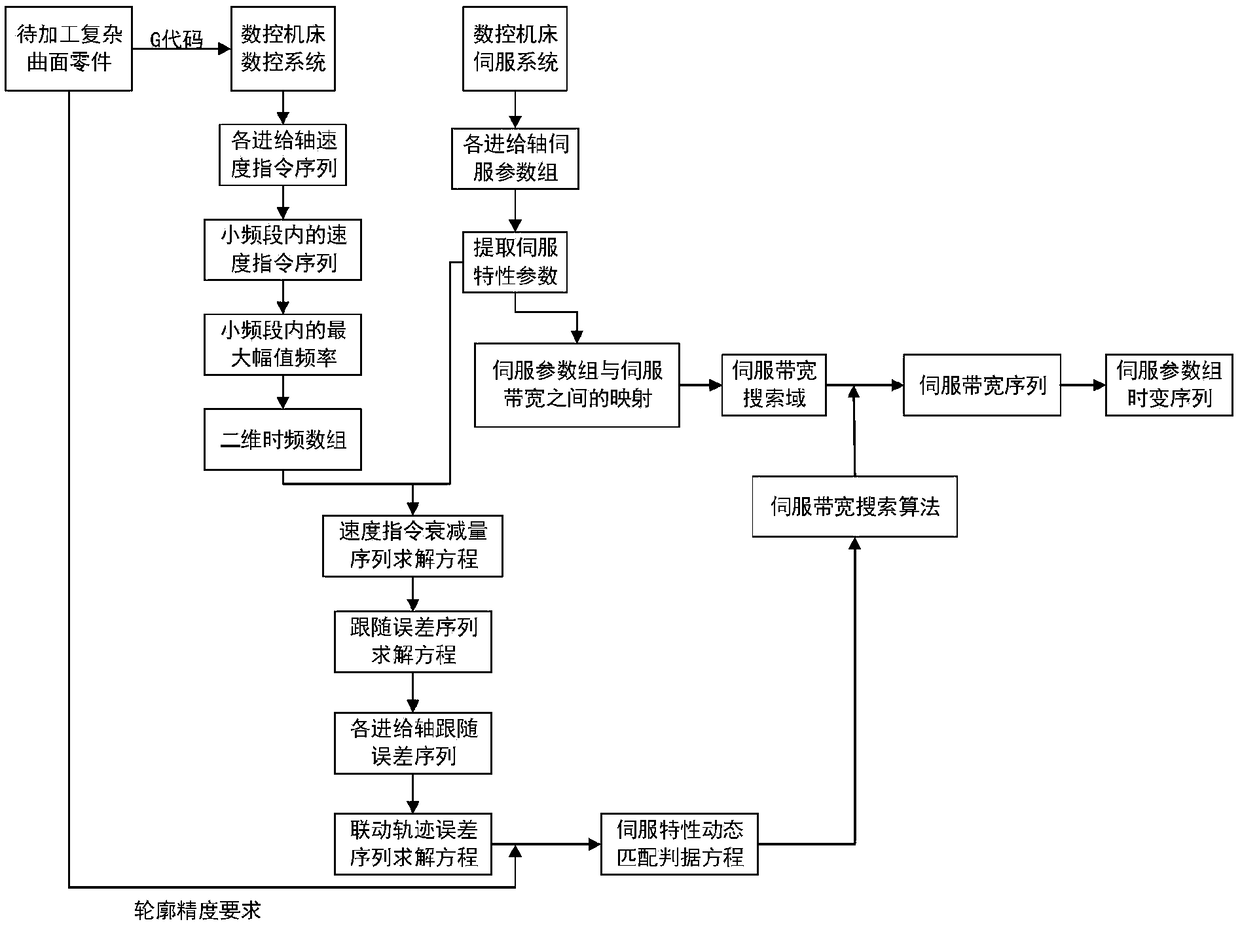

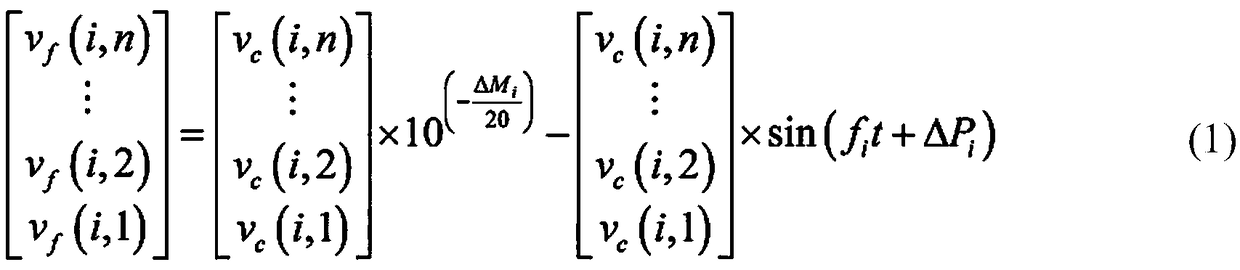

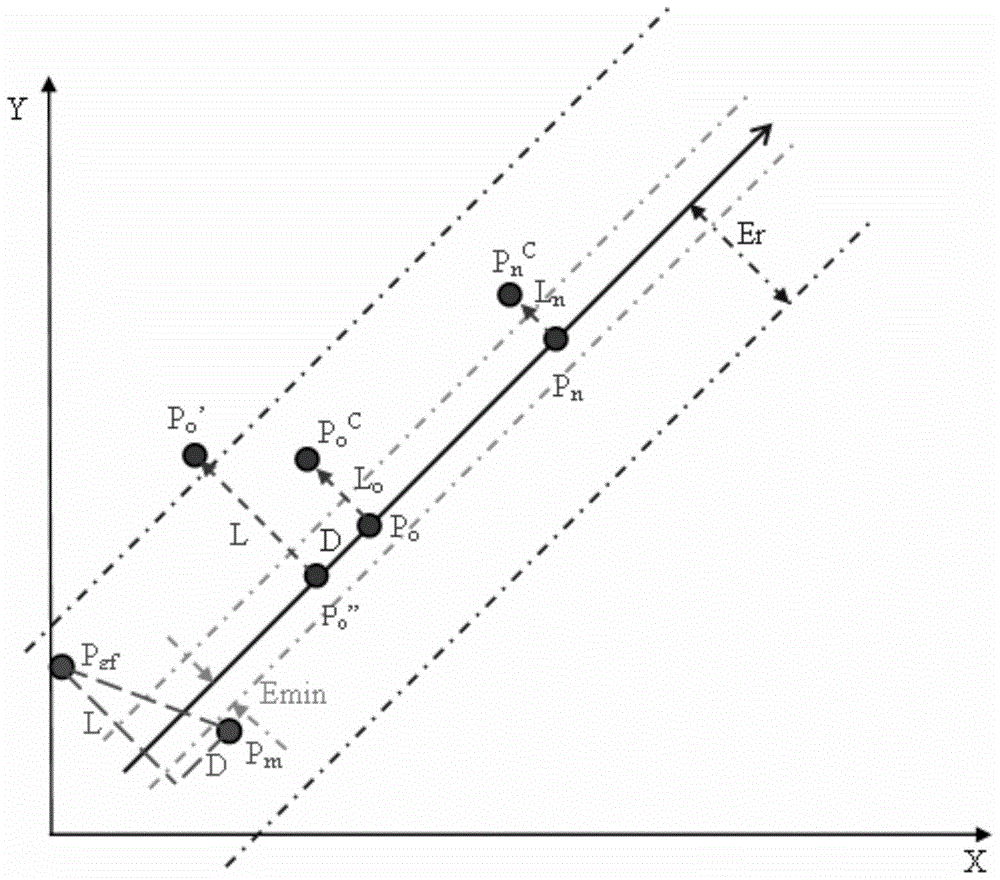

Intelligent method for automatically regulating servo parameters for numerical control machine tool

ActiveCN109100987AReal-timeGuaranteed contour accuracyProgramme controlComputer controlUltrasound attenuationNumerical control

The invention relates to an intelligent method for automatically regulating servo parameters for a numerical control machine tool. The method comprises the steps of collecting a speed instruction sequence of each feed shaft, creating a speed instruction sequence in a small band, extracting a maximum amplitude frequency of each band, and creating a two-dimensional time-frequency array based on timepoint and maximum amplitude frequency of the speed instruction sequence; then creating a servo parameter group of each feed shaft, extracting a servo characteristic parameter, creating a mapping of aservo parameter group and servo bandwidth; then creating a speed instruction attenuation sequence solving equation, a following error sequence solving equation of each feed shaft, a linkage trajectory error sequence solving equation, and a servo characteristic dynamic matching determining equation in sequence; and then searching each sampling position of the speed instruction sequence of each feed shaft, acquiring a servo bandwidth sequence of each feed shaft, converting the servo bandwidth sequence into a servo parameter group time-varying sequence of each feed shaft, and regulating the servo parameter of each feed shaft by the numerical control machine tool automatically according to the servo parameter group time-varying sequence. Through adoption of the method, a complex curve part isguaranteed to have an accurate outline at high feed speed.

Owner:XI AN JIAOTONG UNIV

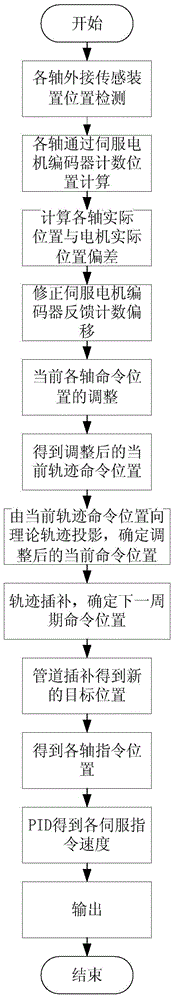

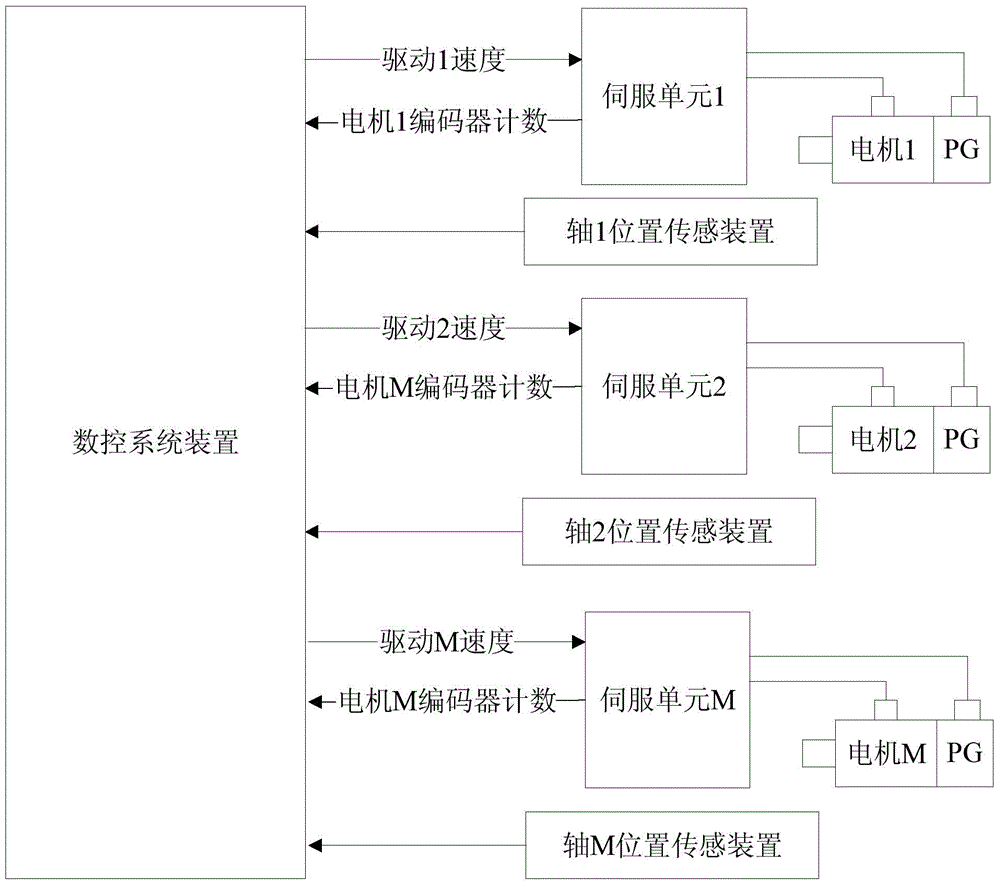

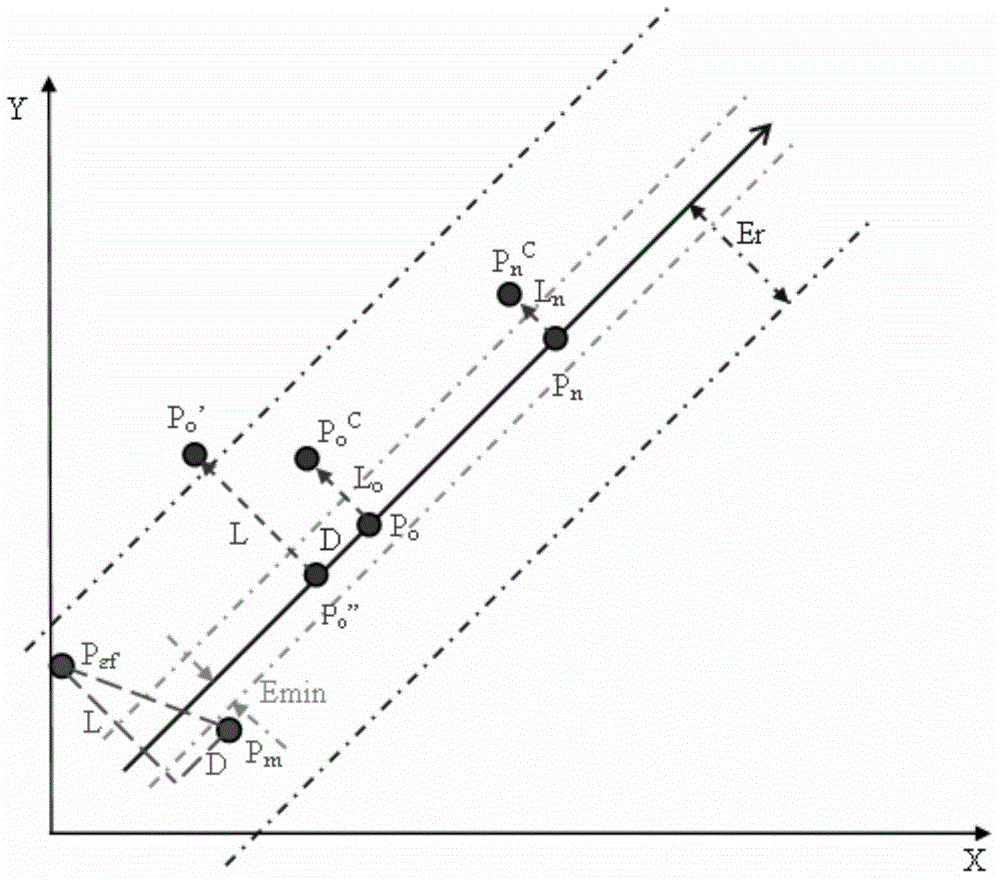

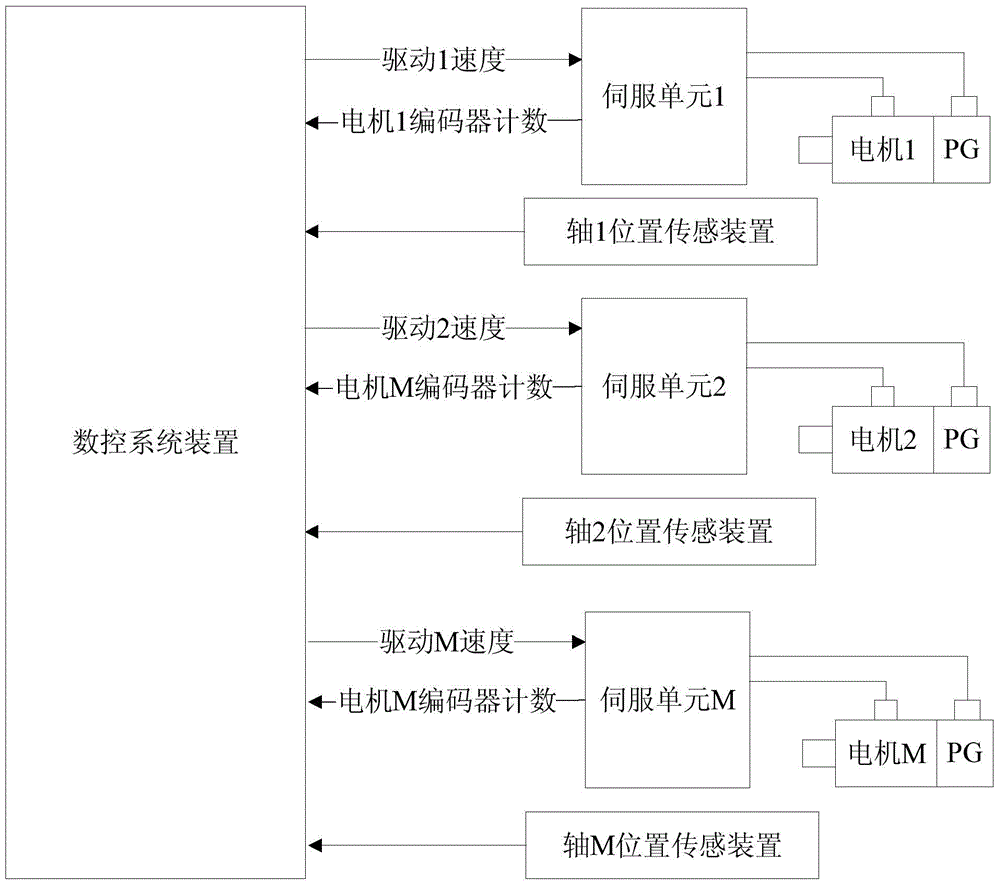

Lull-closed-loop motion control method for interpolation of multi-shaft coupling pipeline

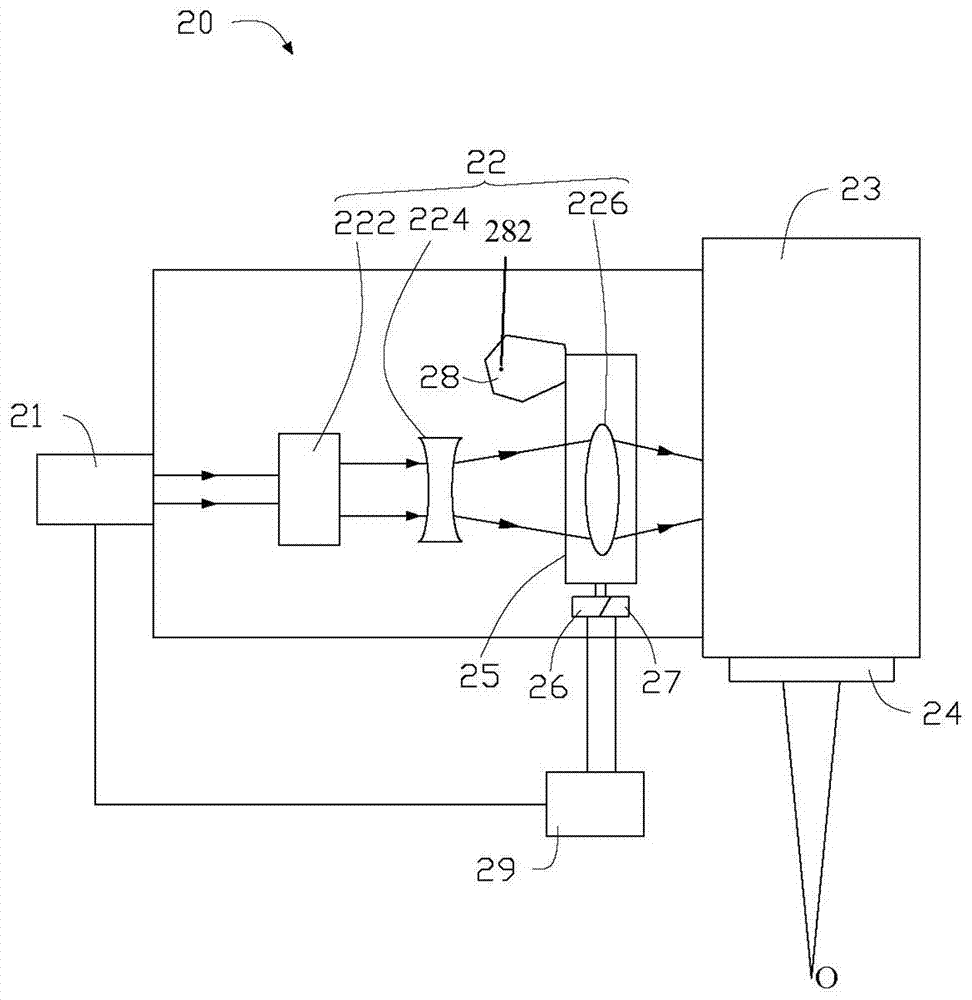

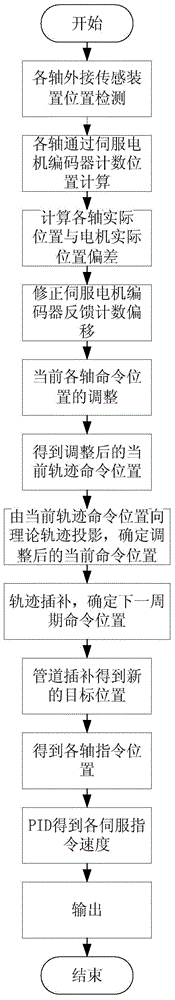

ActiveCN104597846AAdaptableExcellent mechanical transmission performanceNumerical controlNumerical controlCoupling

The invention relates to the field of control of numerical control machine tools, and specifically provides method for adding pipeline interpolation on the basis of dynamically correcting motion track interpolation position according to the feedback of a grating ruler and other external connecting position sensing devices as well as a servo motor encoder so as to dynamically plan the motion tracks. The method is suitable for two-shaft and three-shaft coupling linear interpolation, two-shaft coupling arc-shaped interpolation and hybrid configuration of full-closed-loop feedback, full-closed-hoop feedback and semi-closed-hoop feedback. With the adoption of the method, the multi-shaft coupling contour precision, positioning precision and repeated positioning precision can be met, a servo motor can run stably, the processing precision of a workpiece can be ensured, and the service life of a machine can be prolonged. The method is high in adaptability, high in processing route contour precision, high in speed smoothness, high in dynamic performance and high in motion safety.

Owner:中国科学院沈阳计算技术研究所有限公司

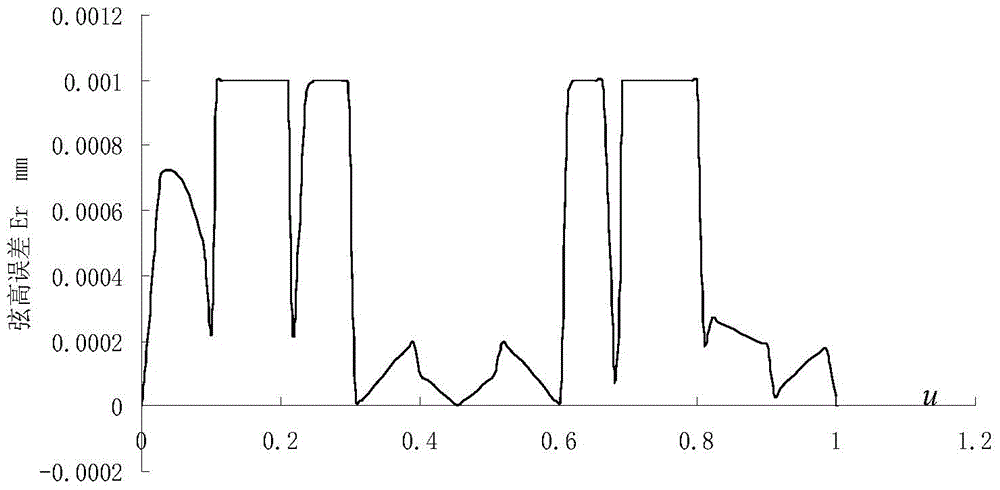

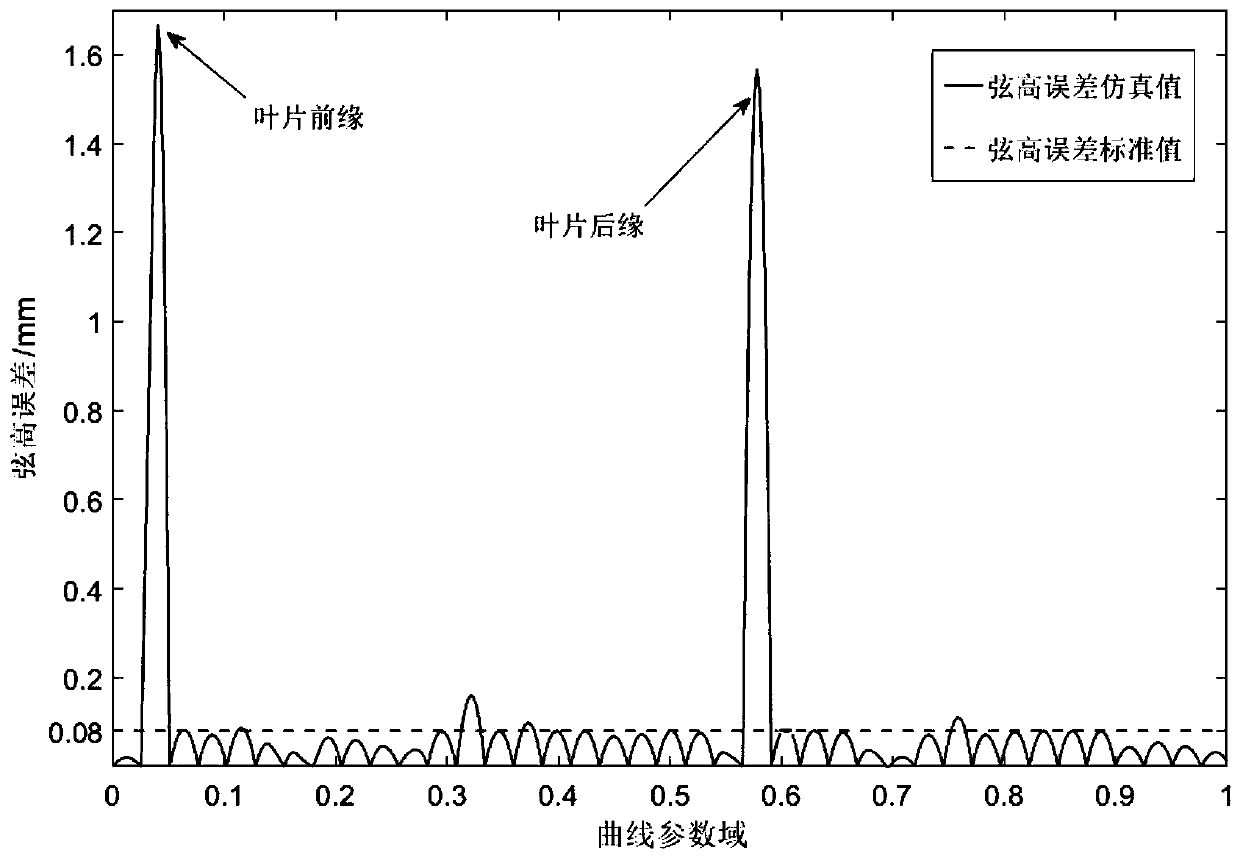

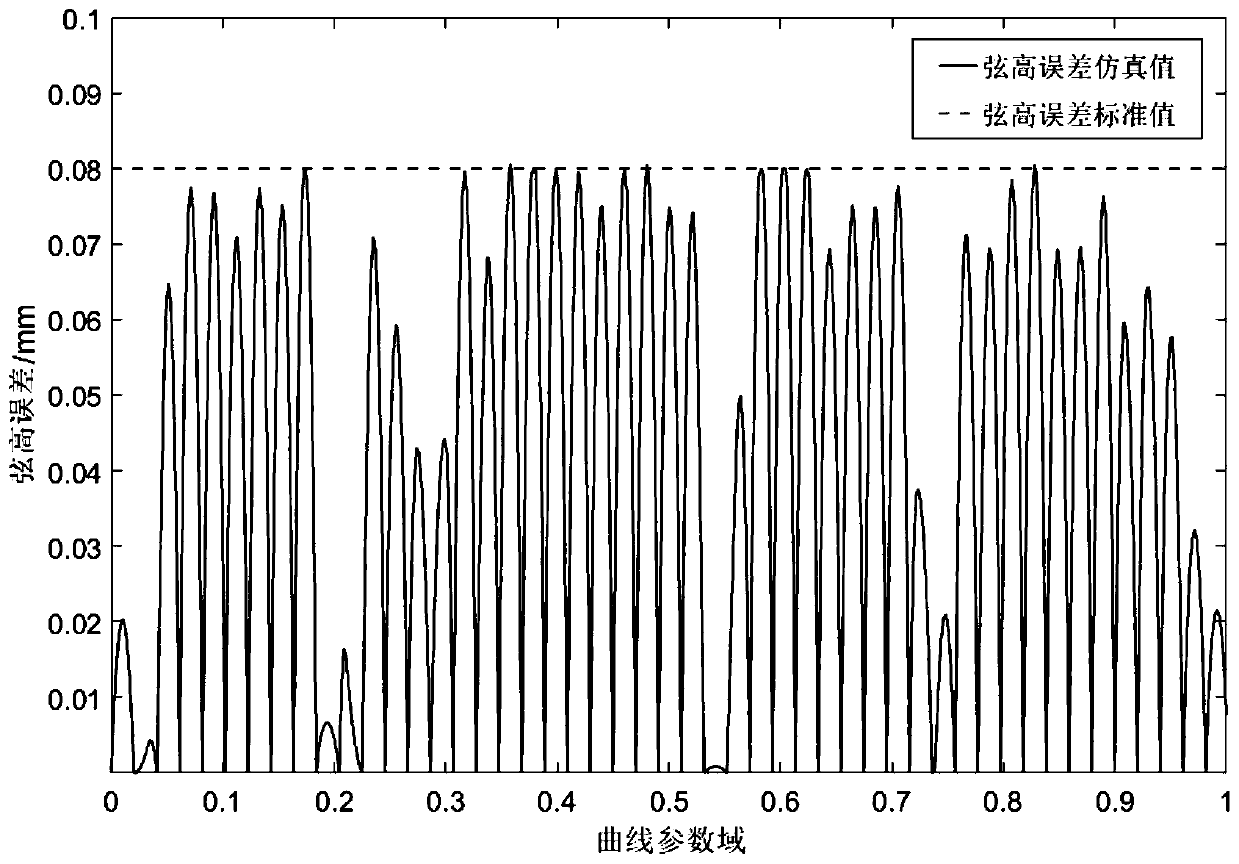

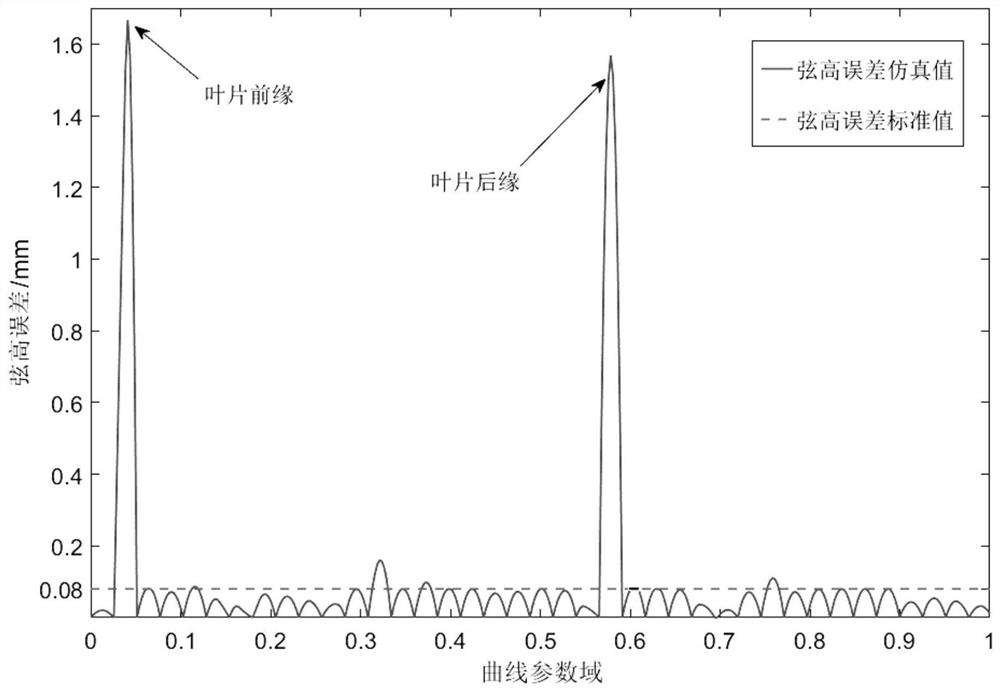

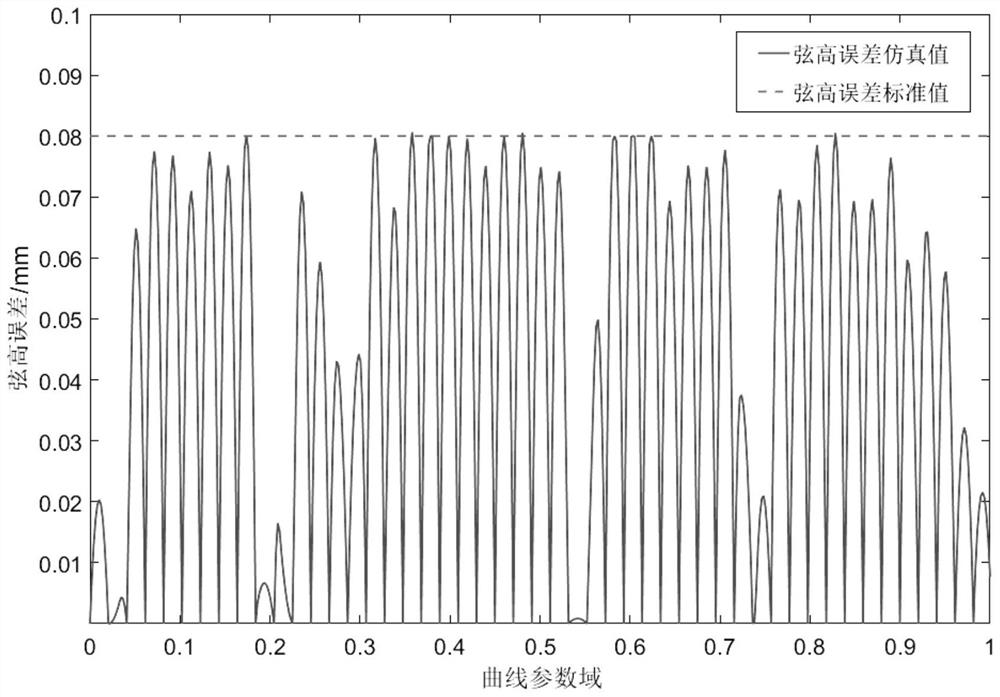

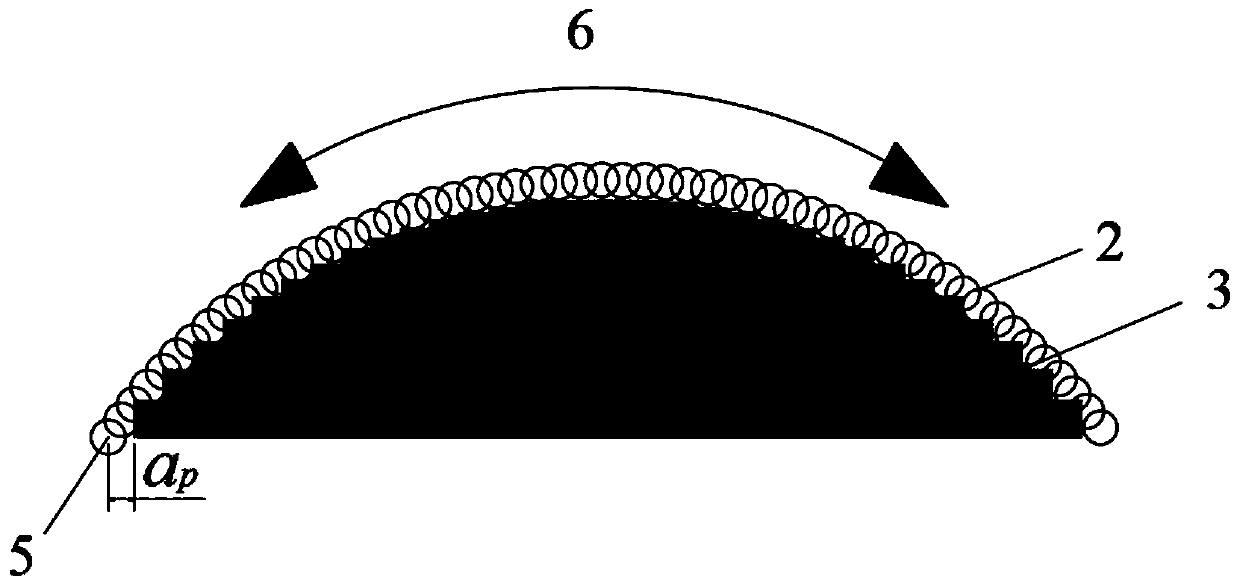

Front and rear blade edge robot abrasive belt grinding and polishing step optimization method

ActiveCN110116353AImprovements in the situation where the chord height error is out of toleranceGuaranteed contour accuracyBelt grinding machinesDistance from a point to a linePoint density

The invention discloses a front and rear blade edge robot abrasive belt grinding and polishing step optimization method. The method comprise the steps that firstly, a machining step is calculated based on an equal-chord-height error step method; secondly, the machining step is converted into a corresponding difference value in a curve parameter domain, and accordingly, the position of the next cutter location point is determined; thirdly, a practical chord height error is calculated based on a principle of distance from a point to a line and compared with a standard value, and whether chord height error deviation occurs or not is judged; and fourthly as well as finally, as for a curve segment with the deviation phenomenon, the current cutter location point curvature radius and the machining step are calculated all over again, the position of the next cutter location point is updated, and circulation is performed thus until path planning is completed. According to the front and rear blade edge robot abrasive belt grinding and polishing step optimization method, the situation of the chord height error deviation occurring when the equal-chord-height error step method is applied to cutter location point planning of a blade complex curved surface part is improved mainly, and particularly, in blade front and rear edge curvature large variation areas, the machining profile precision is guaranteed by increasing the cutter location point density in a self-adaption mode; and in blade smooth areas, cutter location points are kept sparse while the machining efficiency is also taken into consideration.

Owner:WUHAN UNIV OF TECH

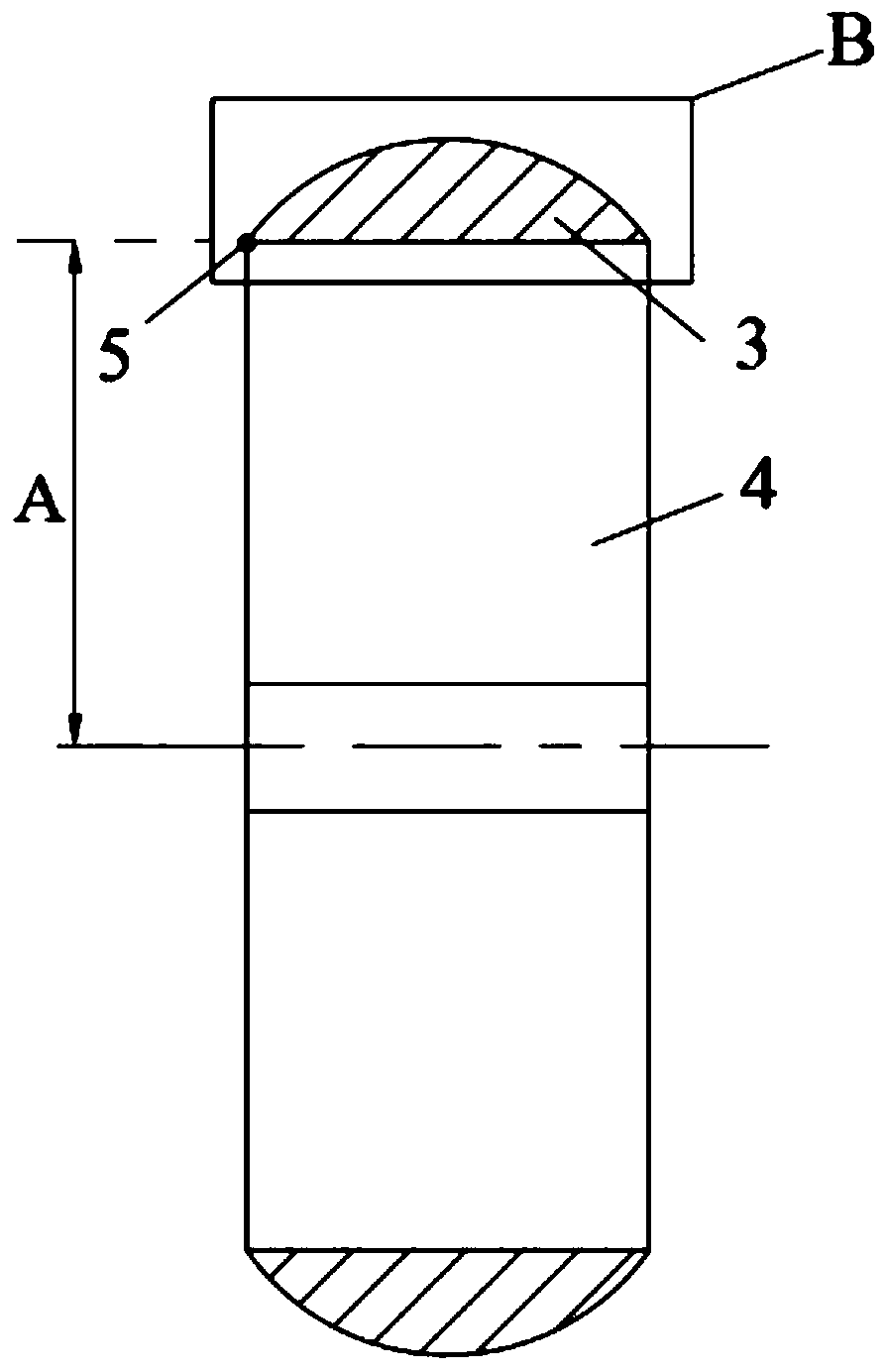

Circular-arc-shaped diamond grinding wheel dressing method

ActiveCN110202478AImprove dressing efficiencyImprove surface conditionAbrasive surface conditioning devicesLaser beam welding apparatusDiamond grindingHigh energy

A circular-arc-shaped diamond grinding wheel dressing method comprises the steps that 1, micro water guide laser parameters are set, and tool setting is conducted; 2, radial rough modification is conducted, specifically, the working surface of a grinding wheel is equally divided into a plurality of cross sections which are L wide in the axial direction of a parallel grinding wheel, according to the different depths of feeding, in the axial direction of the grinding wheel, of the laser water beam, different depths H of abrasive layers are removed from the cross sections in sequence, and finally, the parallel grinding wheel is formed into a circular-arc-shaped grinding wheel through rough modification; 3, the surface profile precision of the grinding wheel is detected, height information ofall points on the surface is obtained, and tool setting is conducted; 4, cutting direction precise shaping is conducted; 5, micro water guide laser technology parameters are set, and tool setting is conducted; and 6, radial sharpening is conducted. According to the method, the high-energy high-density laser beam is guided through the water beam to remove the grinding wheel material in the fusion and gasification modes, a laser water beam variable rate scanning mathematic model is disclosed, the abrasive particle exposure height consistency is ensured, the dressed grinding wheel is good in surface appearance, the dressing precision is high, in addition, the dressing quality is ensured through water beam cooling, and energy saving and environmental protection are achieved.

Owner:HUNAN UNIV OF SCI & TECH

Method for manufacturing cylindrical titanium alloy parts with two ends flanged inwards through forced supplementing

ActiveCN104493436ASolve the problem of serious thickness reductionUniform thickness distributionEngineeringHigh pressure

The invention discloses a method for manufacturing cylindrical titanium alloy parts with two ends flanged inwards through forced supplementing. The method includes determining structure and size of an initial blank and feeding; rolling edges, welding longitudinal seams and correcting; sealing tubing and welding a vent pipe; placing the blank and a superplastic forming die into a superplastic forming machine, heating and assembling the die; injecting inertia high-pressure gas of certain pressure into a closed space of the tubing and keeping pressure; axially and forcefully supplementing the tubing; forming superplastically after supplementing; cooling to discharge the parts and removing allowance. By the method, the cylindrical parts with two ends flanged inwards are realized by equal-thickness plates, the parts are uniform in integral thickness distribution, the blank can be fed and the parts can be taken at the high temperature, continuous production is realized, production efficiency can be greatly improved and production cost is reduced.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

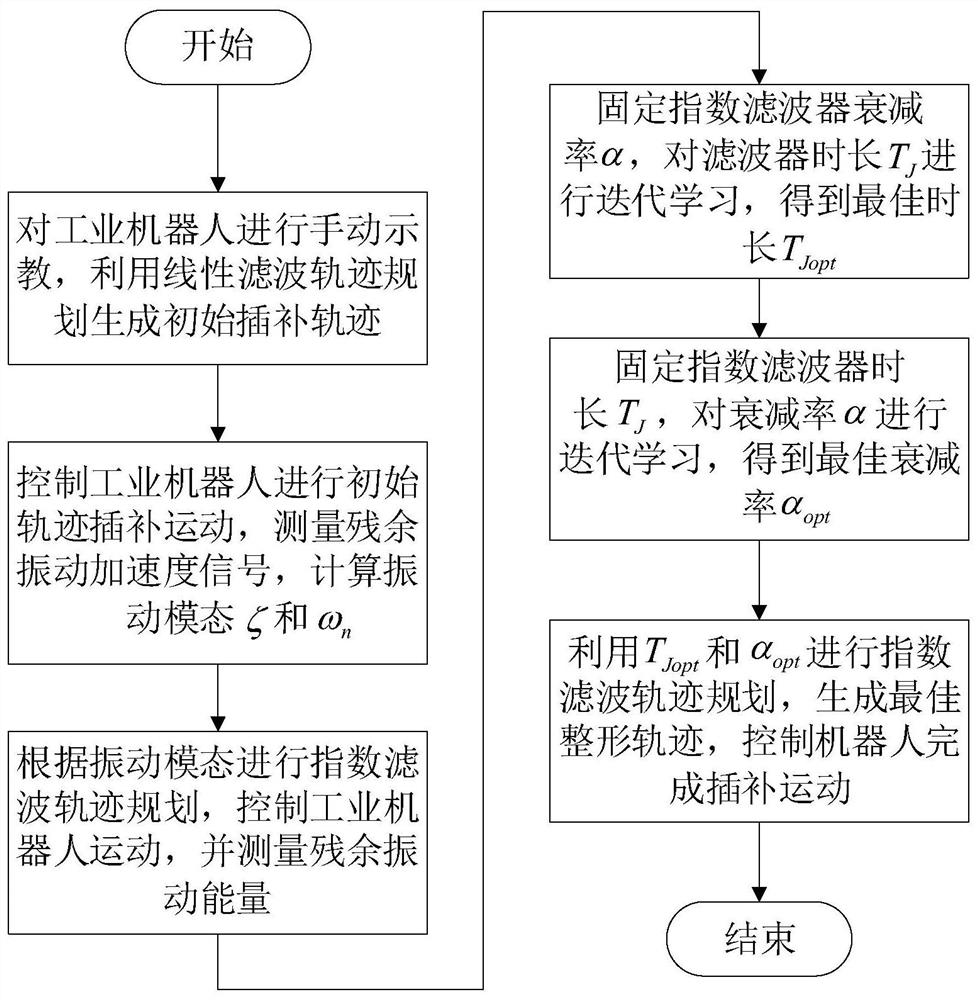

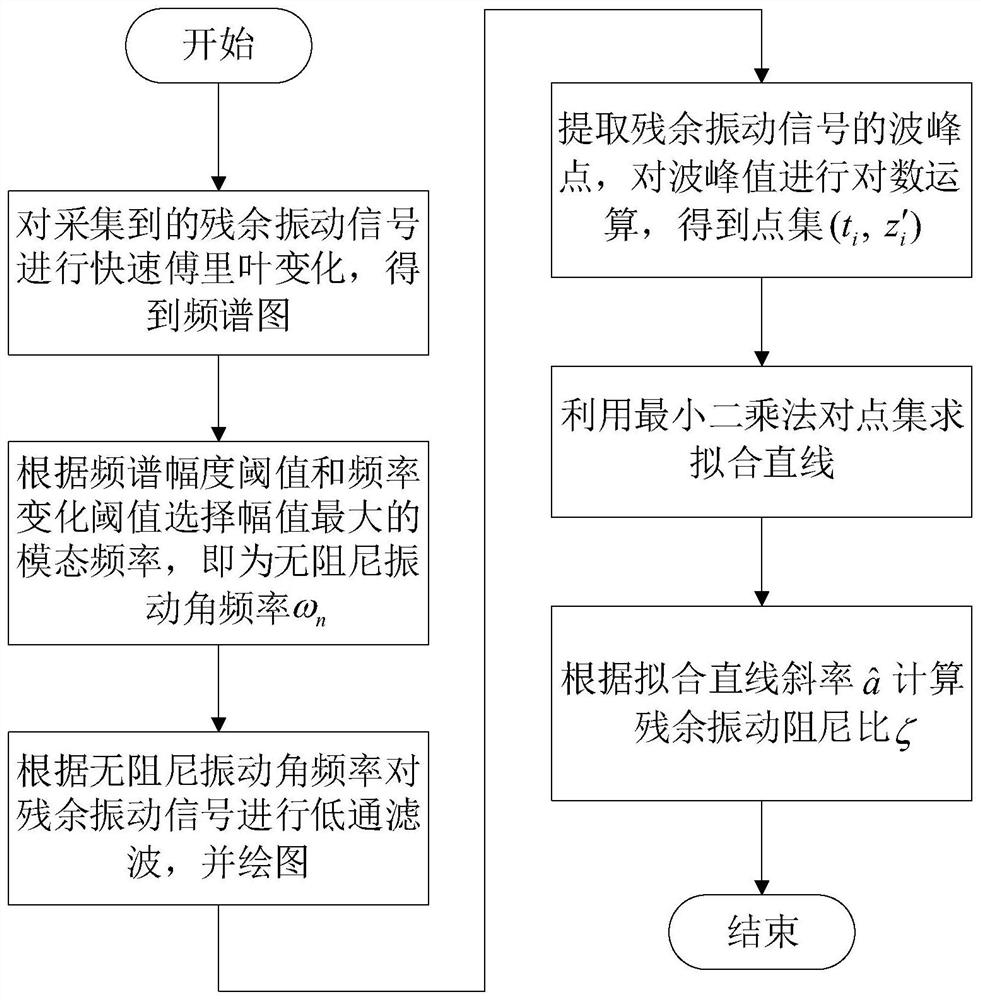

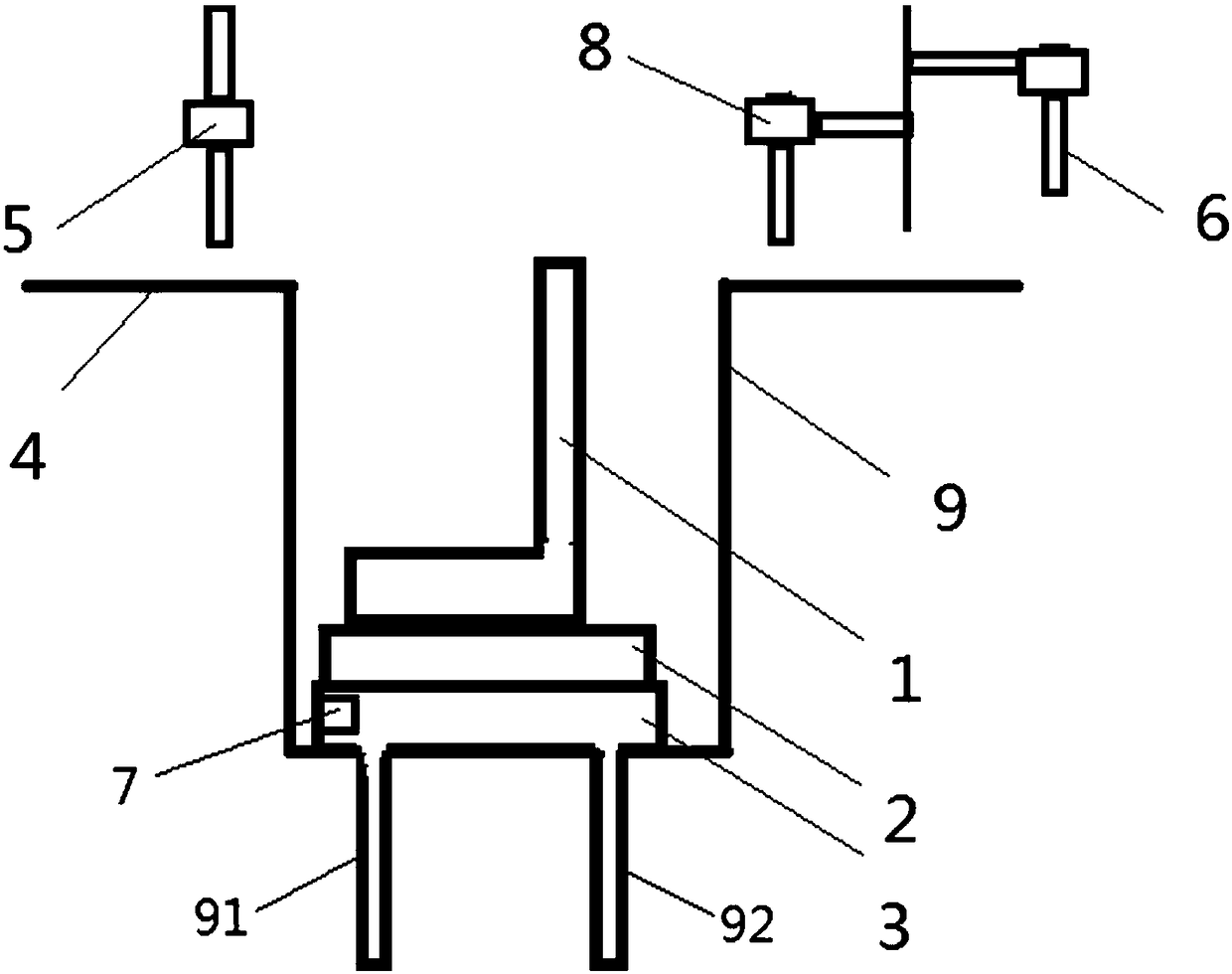

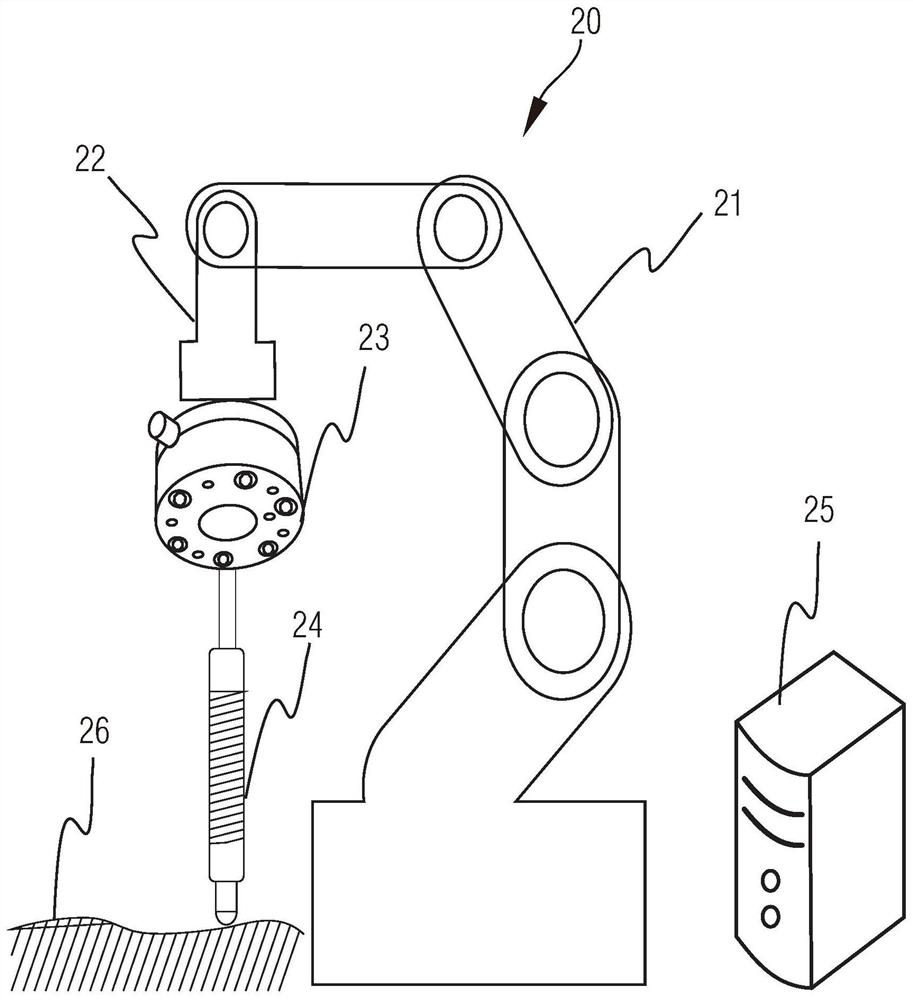

Residual vibration suppression system and method for industrial robot

ActiveCN114505844ALow technical costHigh technical feasibilityProgramme-controlled manipulatorTotal factory controlIndustrial EthernetResidual vibration

The invention discloses a residual vibration suppression system and method for an industrial robot, and the system comprises an embedded industrial control computer with a real-time control function, an acceleration sensor, an acceleration signal transmission device, the industrial robot, and a servo controller of the industrial robot. The acceleration sensor is installed at the tail end of the industrial robot through an acceleration sensor fixing element, collected acceleration signals are connected into a servo driver of the industrial robot through an acceleration signal transmission device, and the servo driver is connected with the embedded industrial personal computer through a gigabit industrial Ethernet interface. The residual vibration suppression system provided by the invention is relatively simple and relatively low in cost, the industrial robot control platform has a real-time function, and the residual vibration suppression method provided by the invention can further improve the smoothness of track operation and reduce the impact on the motor in the operation process while realizing the maximum suppression of the residual vibration, so that the reliability of the system is improved. And the contour precision of the interpolation track is ensured.

Owner:SOUTH CHINA UNIV OF TECH

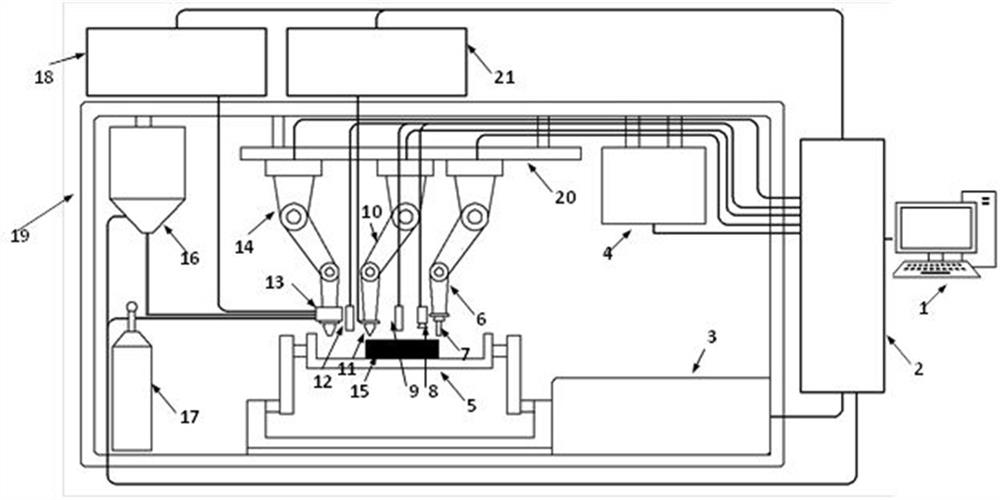

A compound processing equipment for adding and subtracting materials and its application

ActiveCN106425490BGuaranteed contour accuracyGuaranteed forming accuracyOther manufacturing equipments/toolsNumerical controlThree dimensional measurement

The invention discloses wire additive and reductive combination machining equipment. The wire additive and reductive combination machining equipment comprises an on-line metal arc welding wire additive manufacture device and a numerical control multi-axis linkage machining device, wherein the on-line metal arc welding wire additive manufacture device comprises a welding robot and a welder system; the welder system is arranged on the welding robot; the multi-axis linkage machining system comprises a three-dimensional measurement device and a multi-axis linkage precise machining system; the three-dimensional measurement device is used for measuring the outline information of a part and transmits the information to a computer; the computer is used for obtaining the real outline of the part through the received outline information, then compares the real outline with a theoretical three-dimensional model to obtain an error; and the multi-axis linkage precise machining system is used for performing wire reductive machining on the part, so that the error between the real outline and the theoretical three-dimensional model is controlled in a preset range. By adopting the wire additive and reductive combination machining equipment, the problem of a current precise machining method that a part with a complex shape can hardly be machined automatically is solved; and the advantages of arc welding wire additive manufacture of high efficiency, low energy consumption and high environment adaptability can be fully exerted.

Owner:HUAZHONG UNIV OF SCI & TECH

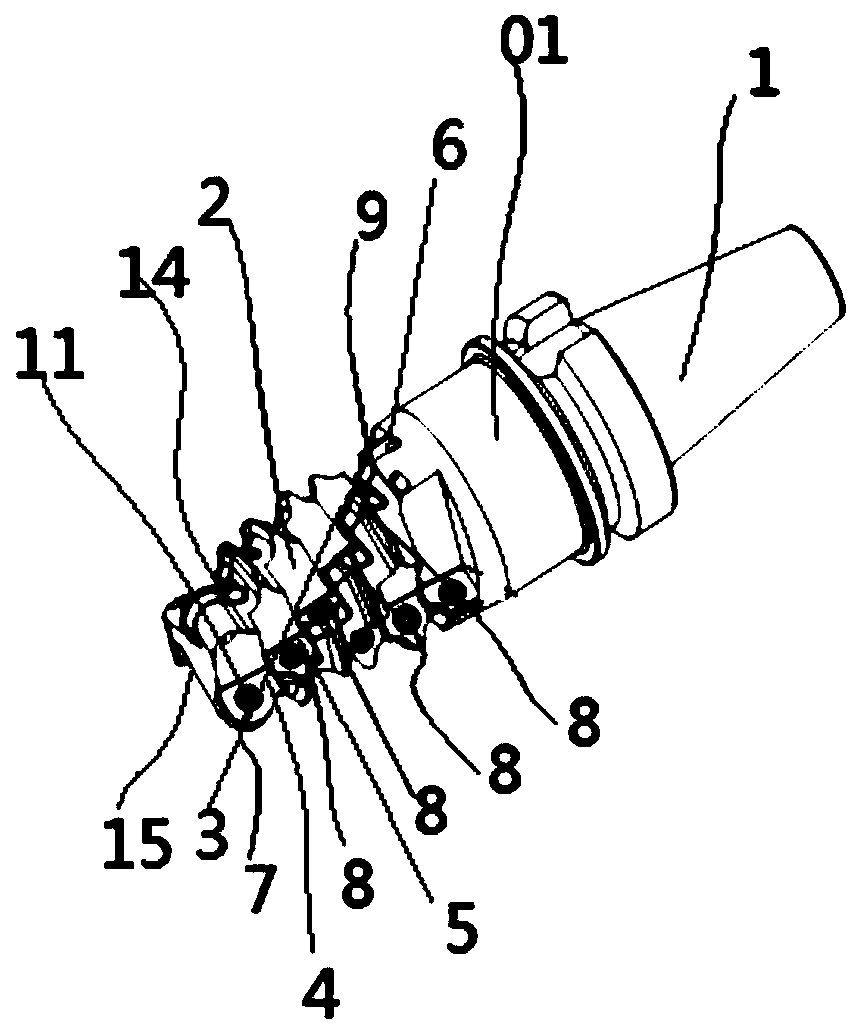

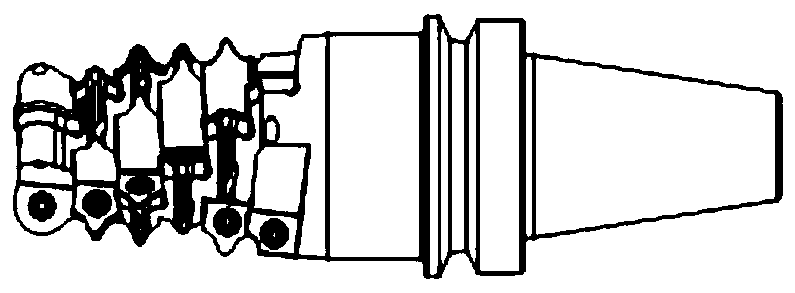

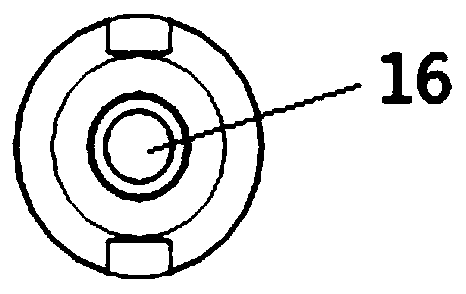

Forming milling cutter and manufacturing method thereof

InactiveCN107234285ASimple preparation processEasy to processMilling cuttersMilling cutterTree shaped

The embodiment of the invention discloses a forming milling cutter and a manufacturing method of the forming milling cutter, and relates to the field of machining tool manufacturing. The forming milling cutter has the advantages that the manufacturing process is simple, and machining is easy. The forming milling cutter comprises a cutting part of a cutter body and a cutting edge arranged on the cutting part. The edge shape of the cutting edge is formed by overlapping edges of at least two blades in the axial direction. The method comprises the steps that the blades in the preset edge shape are machined; the cutter body with the preset contour is machined; and the blades are installed to the cutter body to overlap at least one cutting edge with the same contour as a part to be machined. The forming milling cutter is applicable to machining tool manufacturing and workpiece machining manufacturing, and particularly applicable to machining workpieces with complex contours such as turbine disc fir-tree-shaped blade roots and blades.

Owner:HEZHOU UNIV

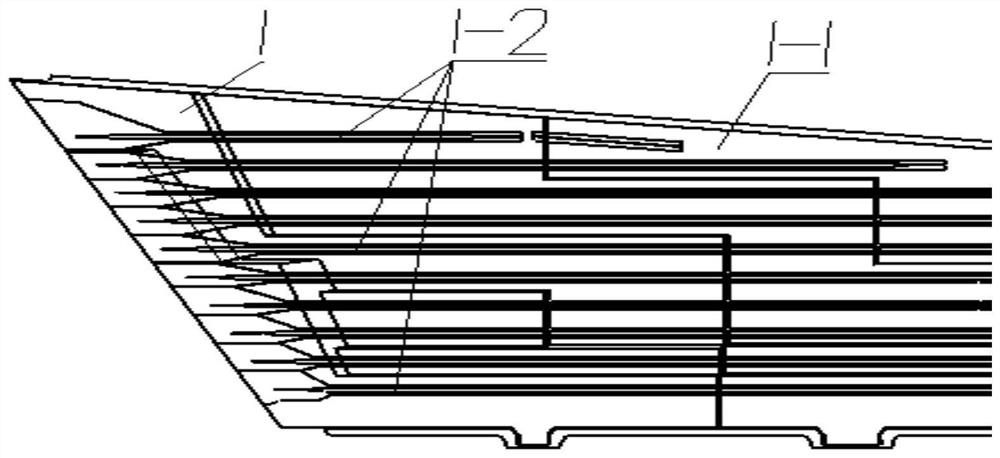

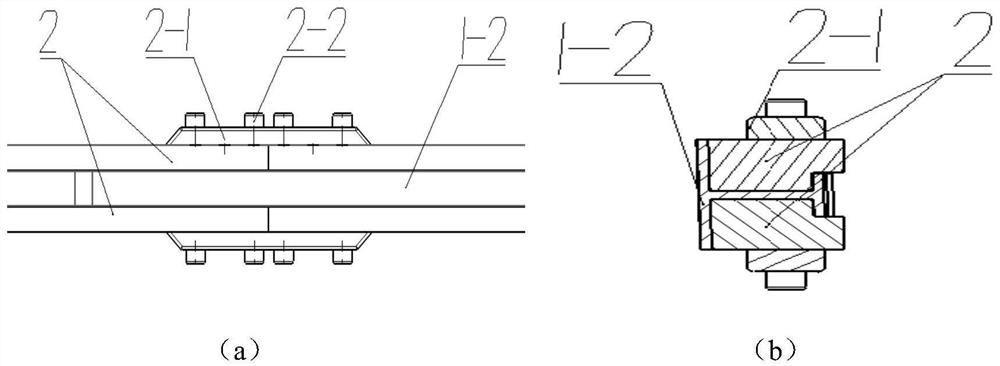

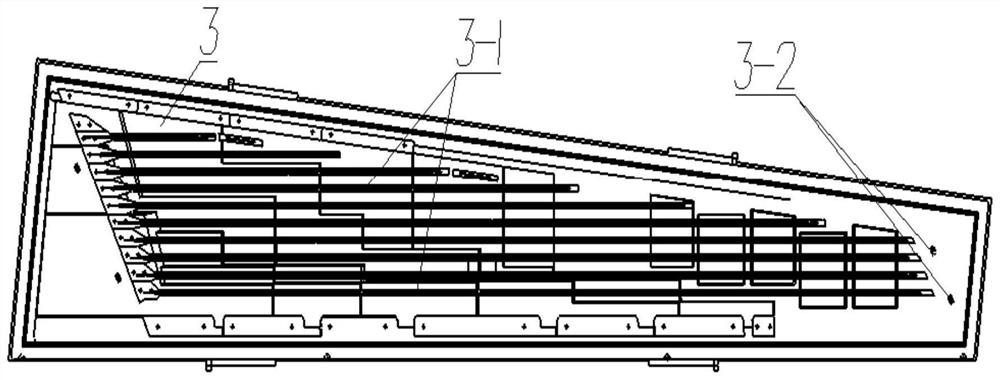

Composite material large wing surface I-shaped stringer wallboard forming tool

InactiveCN111958884AGuaranteed contour accuracyNo offsetDomestic articlesStringerMechanical engineering

The invention discloses a composite material large wing surface I-shaped stringer wallboard forming tool, and belongs to the field of composite material wallboard and I-shaped stringer forming. The tool comprises a stringer laying and forming die, a cover plate forming die, a stringer pre-compaction die and a wallboard forming die. According to the tool structure form, manufacturing of the large wing surface I-shaped stringer wallboard is divided into the following steps that stringers and wallboards are separately laid; a set of soft film forming die is formed and used for ensuring the contour precision of the wallboards; and a group of stringer positioning structures is used, so that the stringers are accurately positioned in a combined state, and the positions of the stringers are not deviated in a curing process.

Owner:SHENYANG AIRCRAFT CORP

Form milling cutter and manufacturing method thereof

InactiveCN107234285BGuaranteed contour accuracyMilling cuttersManufacturing technologyMilling cutter

The embodiment of the invention discloses a forming milling cutter and a manufacturing method thereof, which relate to the field of machining tool manufacturing and have the characteristics of simple manufacturing process and easy processing. The profiled milling cutter includes: a cutting part including a cutter body and a cutting edge arranged on the cutting part, the cutting edge shape is formed by overlapping the cutting edges of at least two inserts in the axial direction. The method includes: processing a blade with a predetermined edge shape; processing a cutter body with a predetermined contour; installing the blade on the cutter body to form at least one cutting edge consistent with the contour of the part to be processed. The invention is suitable for the manufacture of machining tools and workpieces, and is especially suitable for machining workpieces with complex contours, such as the processing of fir-tree-shaped blade roots and blades of turbine discs.

Owner:HEZHOU UNIV

A Quaternary Polynomial Speed Planning Algorithm for Spline Interpolation

ActiveCN103801981BImprove machining accuracyGuaranteed machining accuracyAutomatic control devicesFeeding apparatusNumerical controlMachining process

The invention discloses a quartic polynomial speed planning algorithm for spline interpolation. For example, at a deceleration section, the algorithm comprises the following steps: performing fast pre-interpolation on a numerical control machining curve, recording the length of an interpolation path, as well as a deceleration starting point and a speed minimum point which meet the machining accuracy requirements, calculating to judge whether the maximum reverse acceleration A can be reached or not, segmenting the deceleration process, and calculating quartic polynomial speed equations of all segments; then determining the needed theoretical distance from the deceleration starting point to the speed minimum point according to the speed equations, and calculating interpolation parameters corresponding to the theoretical distance; finally performing real-time spline interpolation according to the speed equations obtained in the pre-interpolation stage and the interpolation parameters at the starting and ending moments of acceleration and deceleration. By adopting the method, the continuous change of the speed, acceleration and acceleration change rate of a numerical control machine tool in a high-speed machining process can be realized, overshoot caused by high-speed machining is reduced, and thus smooth and flexible acceleration and deceleration control on a servo shaft is realized.

Owner:中国科学院沈阳计算技术研究所有限公司

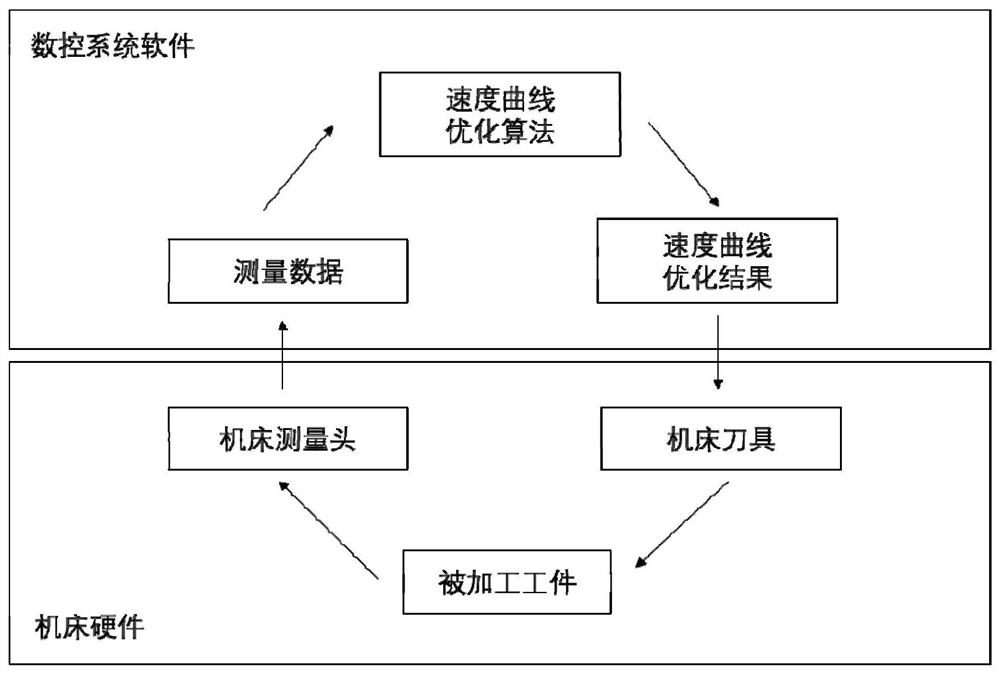

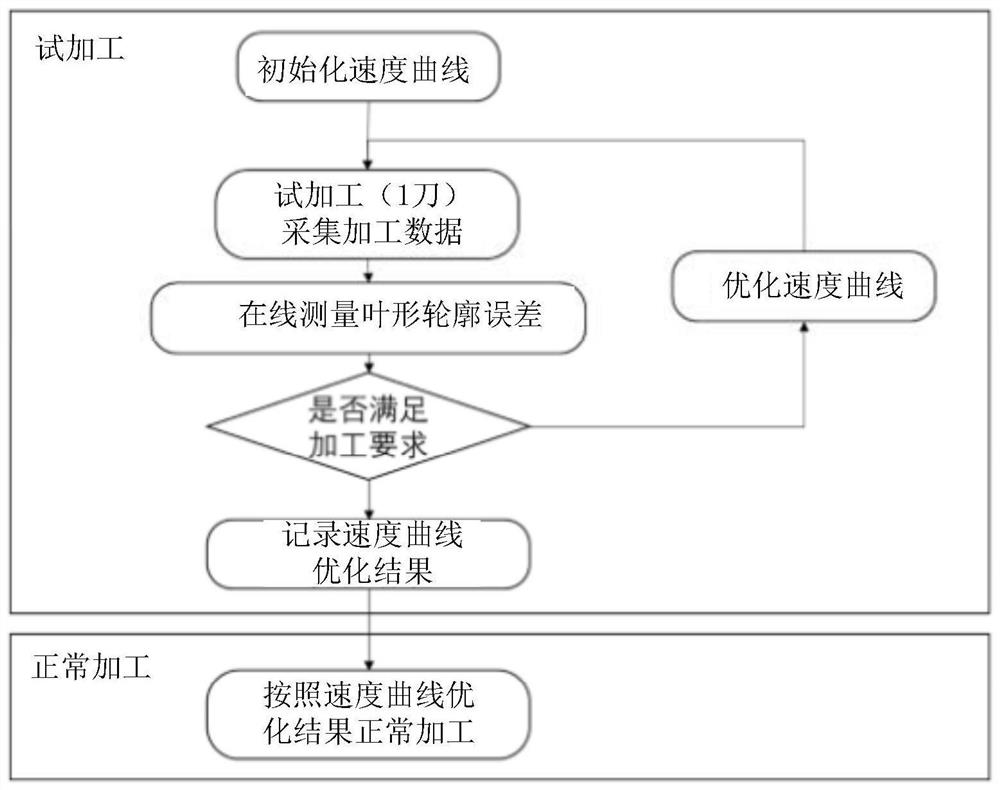

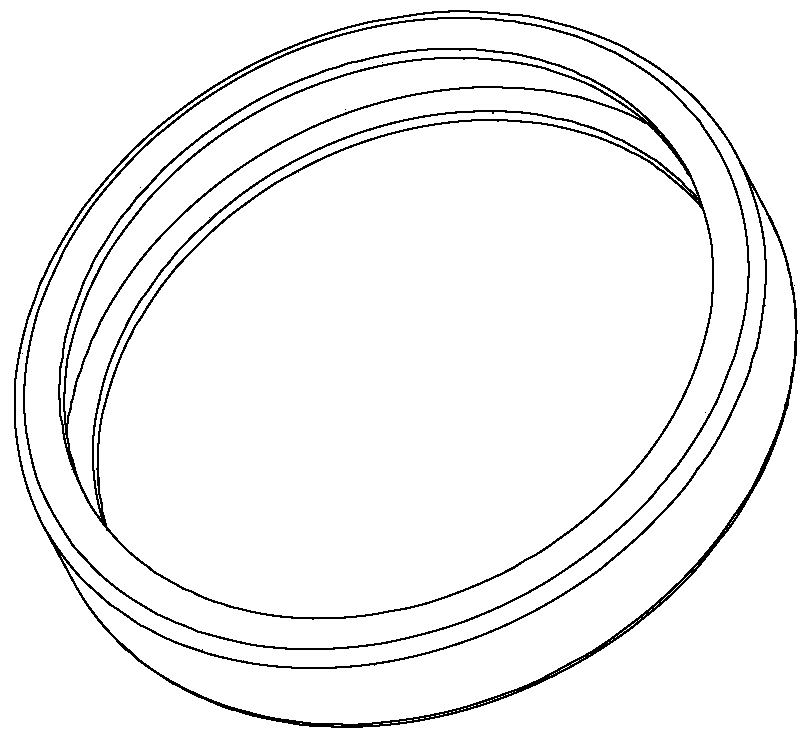

Numerically-controlled machine tool acceleration and deceleration intelligent optimization method and device using online measurement

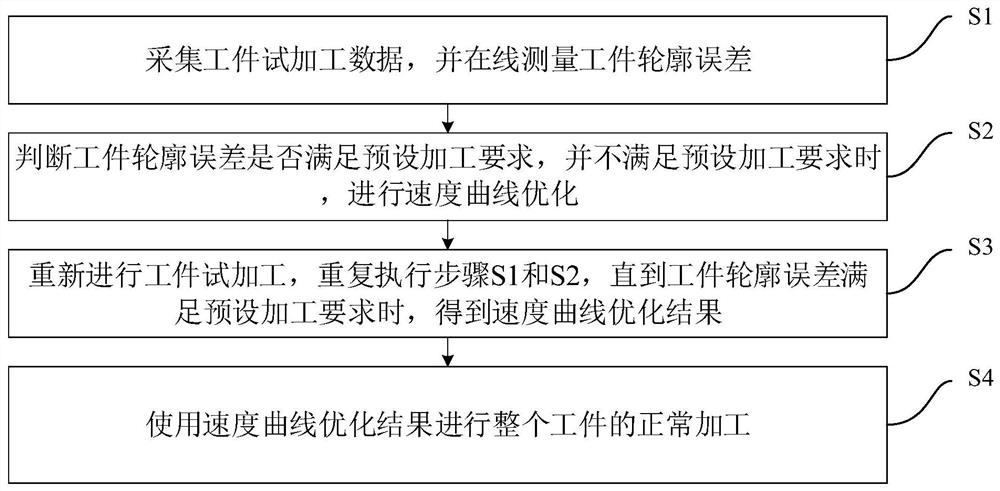

InactiveCN112327757AImprove optimization efficiencyImprove machining accuracyProgramme controlComputer controlControl engineeringContour error

The invention discloses a numerically-controlled machine tool acceleration and deceleration intelligent optimization method and device using online measurement. The method is applied to a CNC platformso as to achieve the closed-loop optimization of the interior of a CNC, and comprises the following steps of: S1, collecting the trial machining data of a workpiece, and carrying out online measurement of the contour error of the workpiece; S2, judging whether the contour error of the workpiece meets a preset machining requirement or not, and conducting speed curve optimization under the condition that the contour error of the workpiece does not meet the preset machining requirement; S3, conducting trial machining on the workpiece again, repeatedly executing the step S1 and the step S2 till the contour error of the workpiece meets the preset machining requirement, thereby obtaining a speed curve optimization result; and S4, using the speed curve optimization result to perform normal machining on the whole workpiece. According to the method, the reliability and stability of the final machining quality of the machined workpiece can be guaranteed, data do not need to be imported into theCAM and the tool path does not need to be recalculated, and the speed planning optimization efficiency is improved on the premise that the contour precision is guaranteed.

Owner:TSINGHUA UNIV

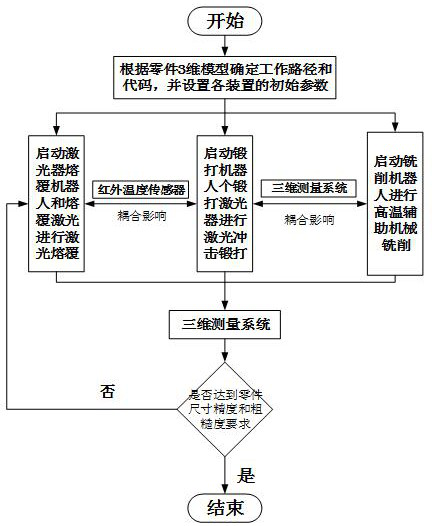

Coaxial powder feeding and laser forging composite addition and subtraction material manufacturing method and device

ActiveCN108746616BHigh precisionGuaranteed contour accuracyAdditive manufacturing apparatusIncreasing energy efficiencySurface roughnessCw laser

The present invention relates to the technical field of additive and subtractive material manufacturing, more specifically, to a method and device for manufacturing additive and subtractive materials combined with coaxial powder feeding and laser forging. Based on the three-dimensional model of the part, after slicing and planning the path, the cladding robot is started The continuous laser is used for layered forming of the parts, and the forging robot is started at the same time to use short pulses to laser forge the cladding area within the forging temperature range, and the milling system is started to mill the cladding area at the same time, the two-beam laser system and The milling system interacts with each other through the real-time feedback data, and the parts obtained have high precision and almost no defects inside the parts. And through the coaxial powder feeding of the robot, the problem of cladding stability caused by the environment, powder shape, and uniformity of the powder feeding process is solved; the pores and micro cracks in the cladding area are solved by laser shock forging, and the distribution of residual stress is improved. ;By milling each layer in the cladding area, the dimensional accuracy of the part is increased and the surface roughness is reduced.

Owner:GUANGDONG UNIV OF TECH

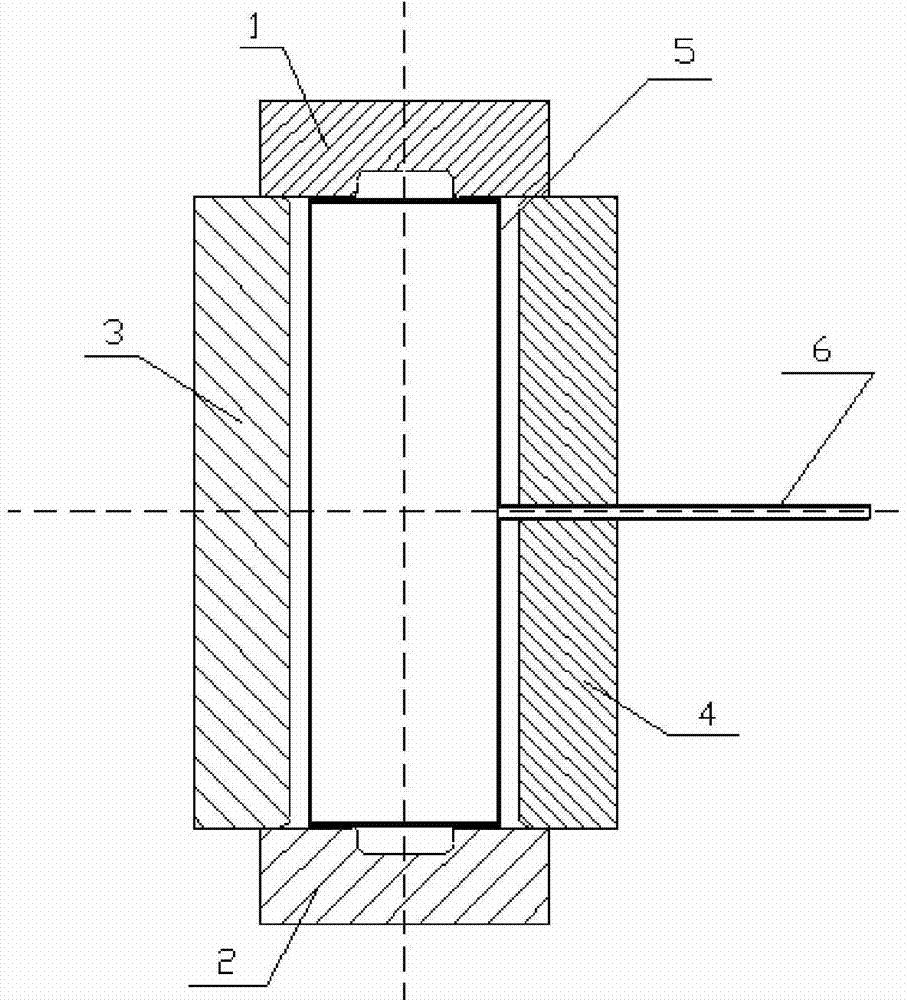

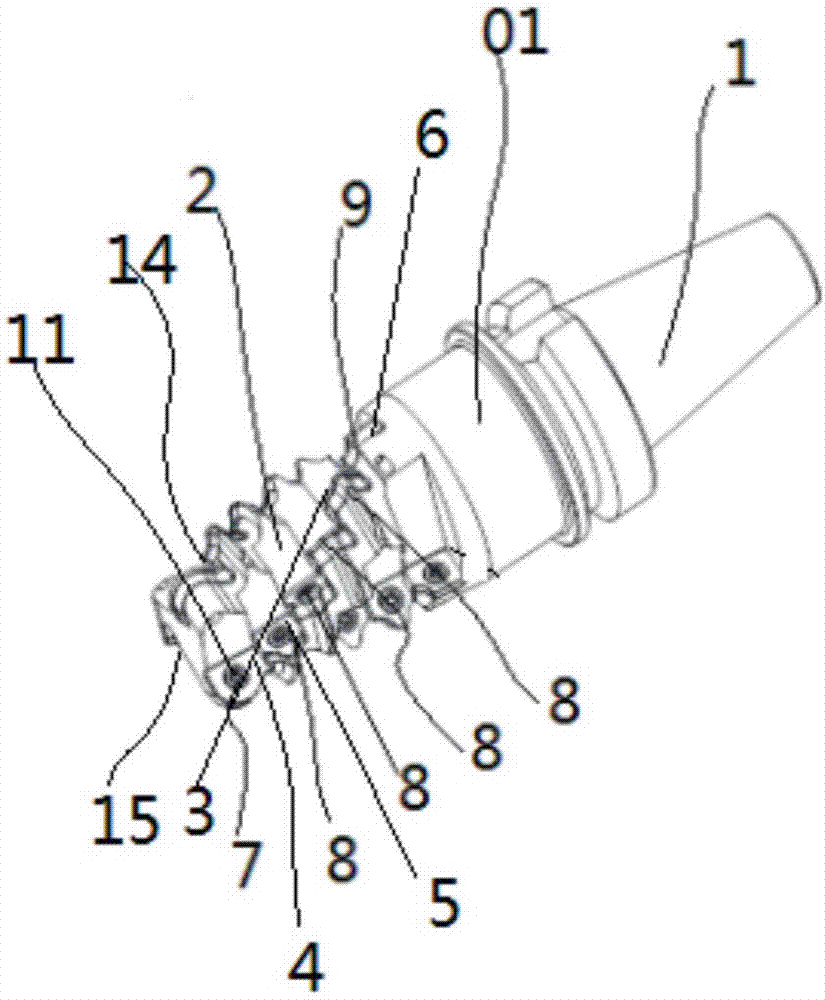

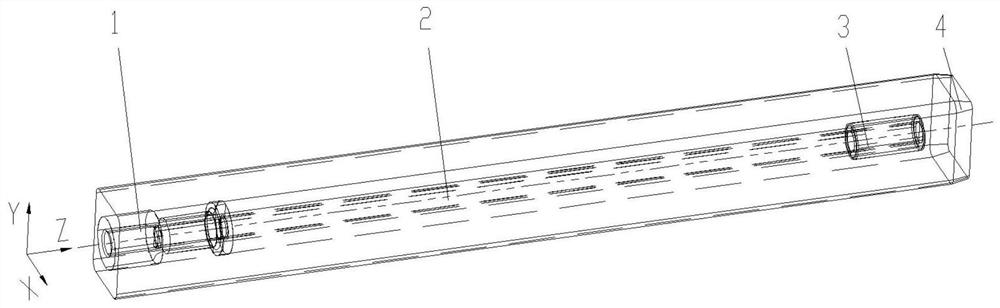

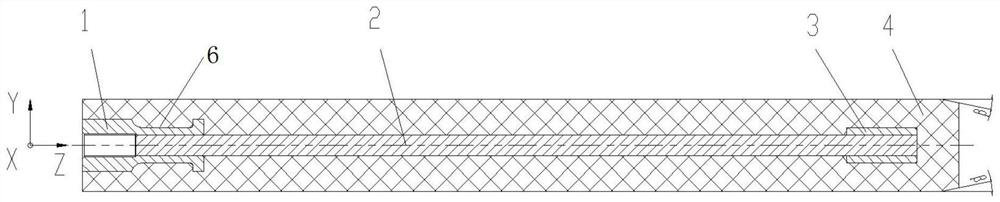

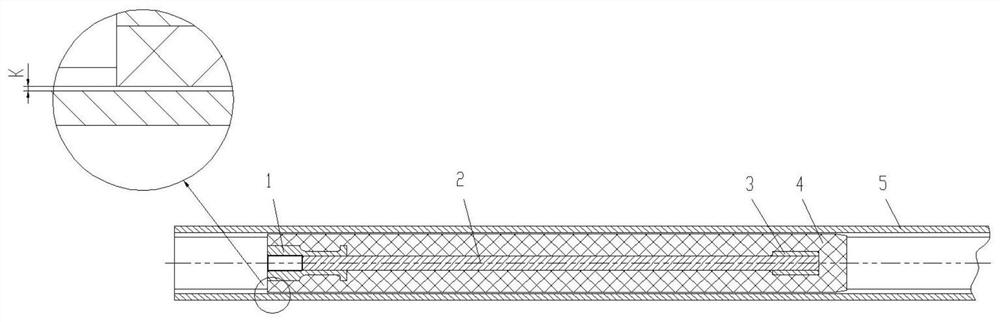

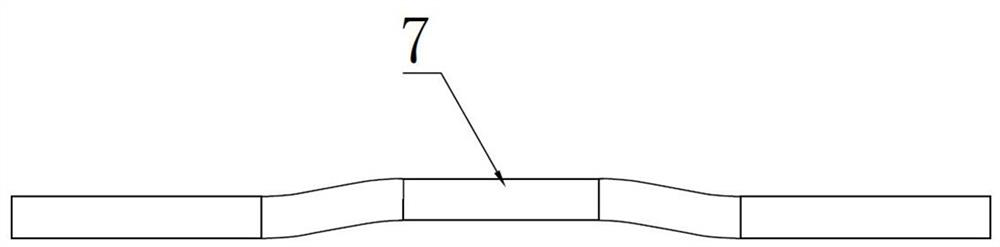

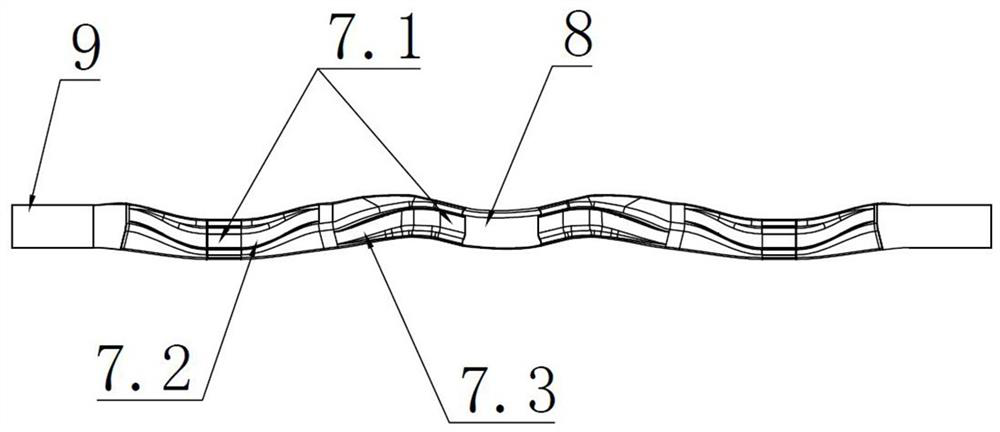

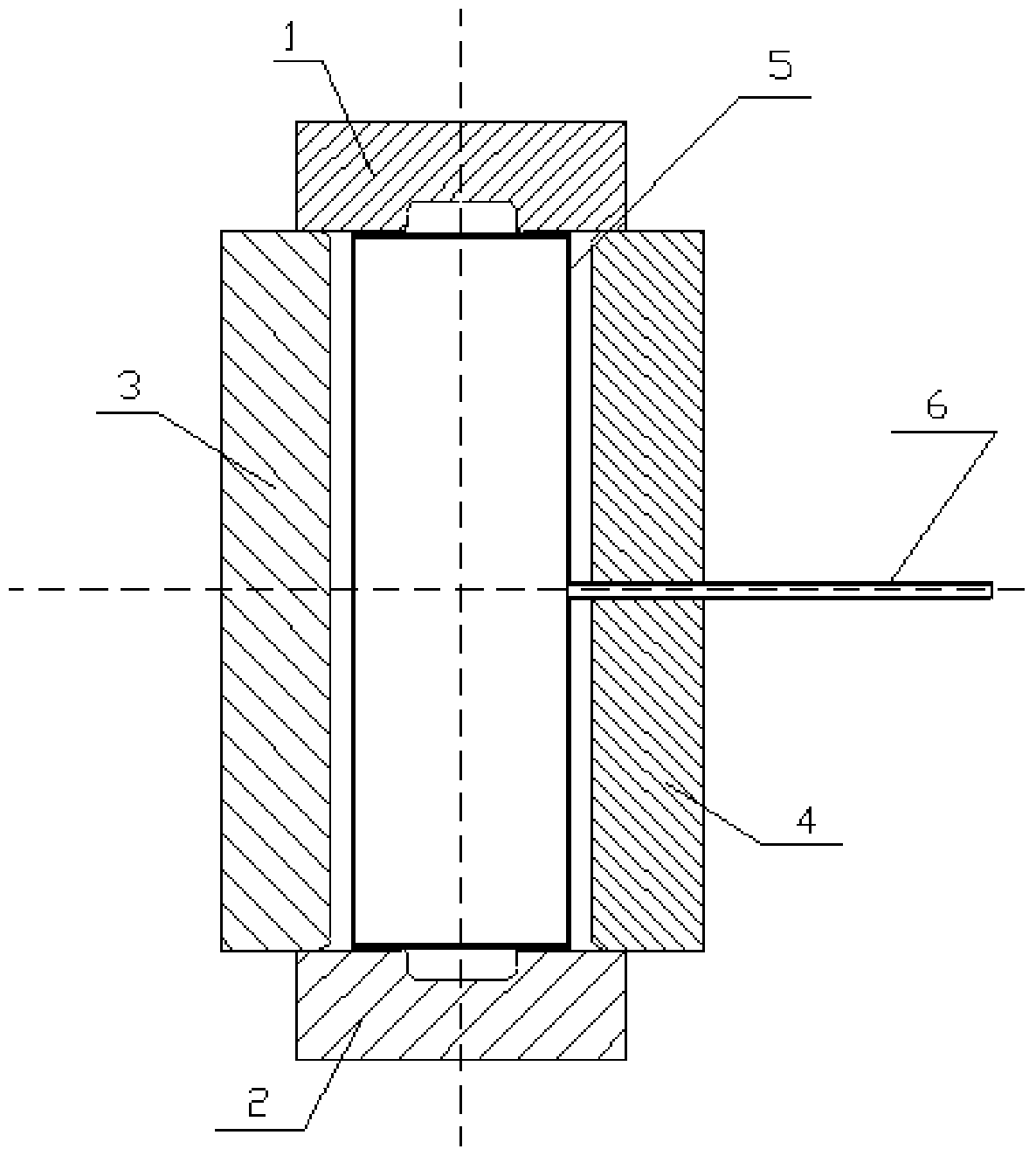

Integrally cast core mechanism with built-in steel wire rope coated with polyurethane

The invention relates to an integrally cast core mechanism with a built-in steel wire rope coated with polyurethane. The integrally cast core mechanism comprises a built-in flexible framework and a polyurethane outer layer, the outer side of the flexible framework is coated with the polyurethane outer layer, the built-in flexible framework comprises a transition joint, the steel wire rope and a buckle, the head end of the steel wire rope is fixedly connected with the transition joint in a buckling manner, and the tail end of the steel wire rope is fixedly connected with the buckle in a buckling manner; the buckle is embedded into the polyurethane outer layer; the transition joint is of a tubular structure, and an internal thread structure is machined at the head end of the transition joint; a U-shaped groove is machined in the outer contour of the tail end of the transition joint along the Z axis, and the polyurethane outer layer can be embedded into the U-shaped groove in the casting process to connect the transition joint and the U-shaped groove; and the buckle can be embedded into the polyurethane outer layer in the casting process. The structure that the steel wire rope metal framework is arranged in the middle and coated with polyurethane is adopted, under the condition that the requirement for the bending angle of any position of a product is met, the axial rigidity of the core is greatly improved, and the stability of the production process is improved.

Owner:LINGYUN INDAL CORP

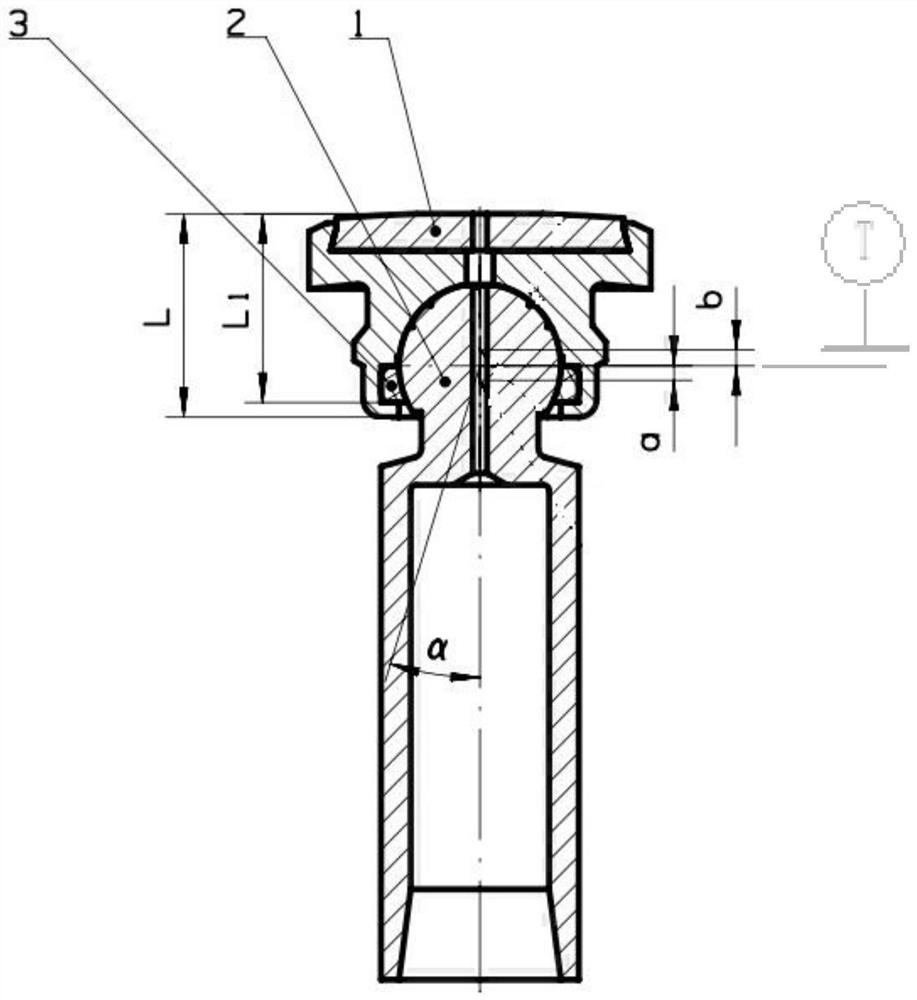

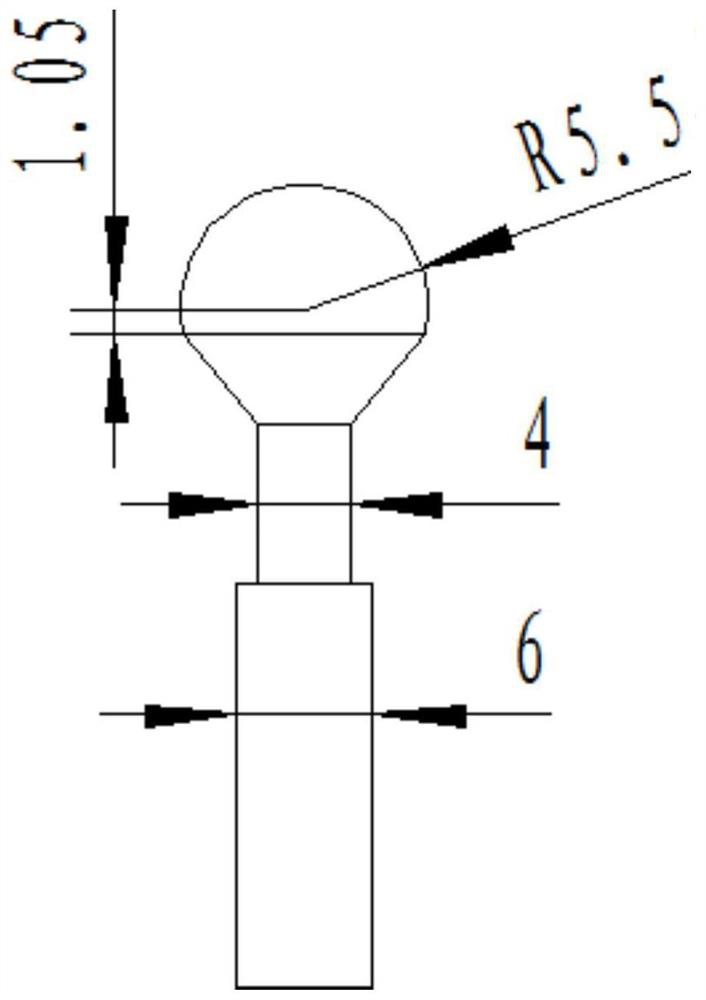

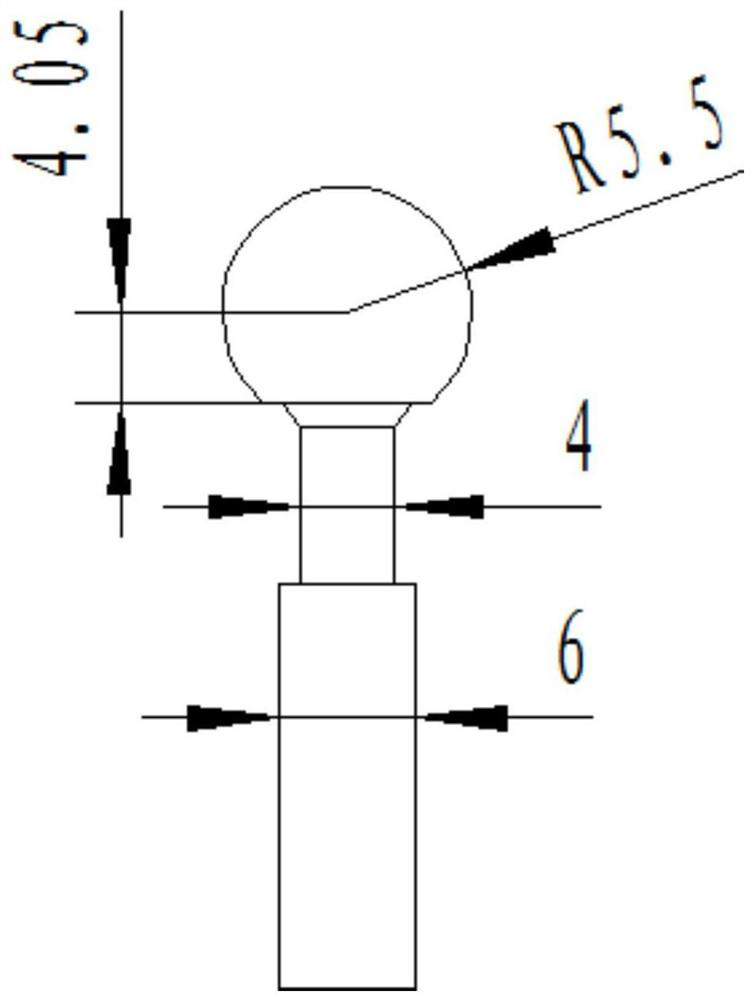

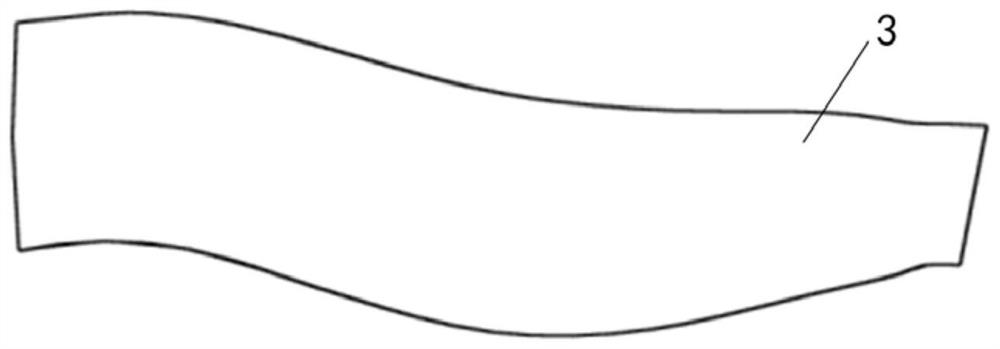

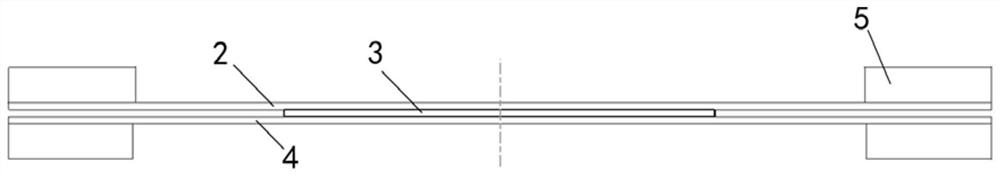

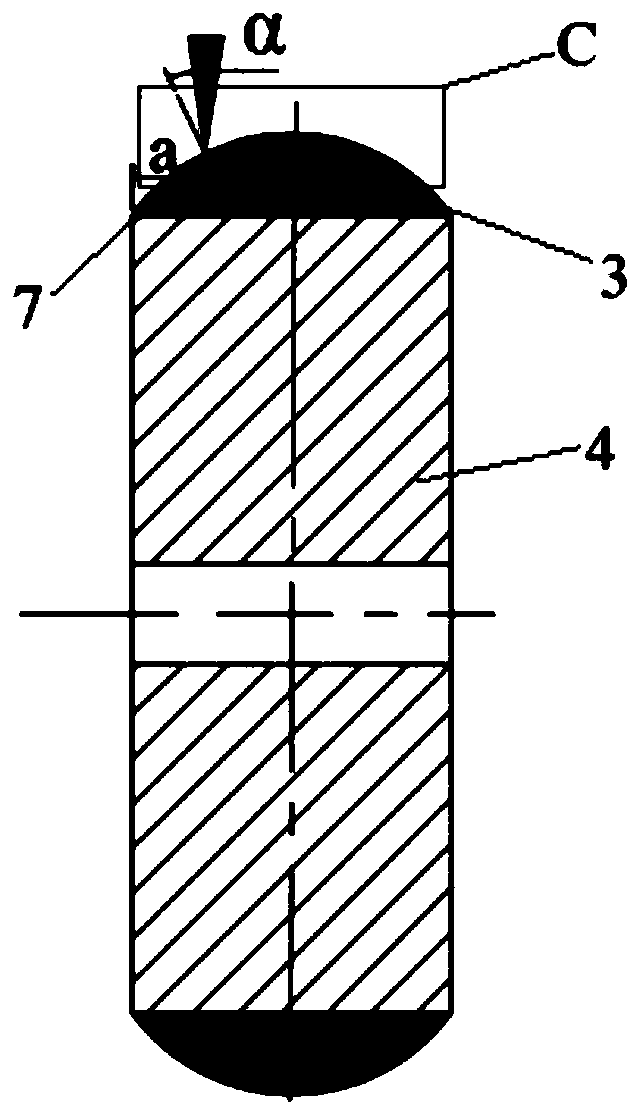

Selecting and matching method for plunger assembly with check ring

PendingCN114382671AImprove processing efficiencyDimensional and shape error stableLapping machinesLapping toolsStructural engineeringMechanical engineering

The invention relates to a matching method for a plunger assembly with a check ring. The matching method comprises the steps that (1) a sliding shoe, the check ring and a plunger are prepared; (2) the inner spherical surface of the sliding shoe is machined, and the size of the inner spherical surface of the sliding shoe is measured; (3) the sliding shoes are grouped according to the measurement size; (4) plunger outer spherical surfaces are machined according to the grouping condition of the sliding shoes, and grouping is conducted according to the sizes of the plunger outer spherical surfaces; 5) coloring the inner spherical surface of the matched sliding shoe by using the outer spherical surface of the plunger; (6) the inner spherical surfaces of the check rings are selected and machined according to the size b of the selected sliding shoes, and it is ensured that the a + b value of each set of check rings and sliding shoes meets the requirement and the difference value of each set is not larger than 0.01; and 7) polishing the outer spherical surface of the plunger, the inner spherical surface of the sliding shoe and the inner spherical surface of the check ring to finish matching. The plunger assembly can be efficiently selected and matched, and the service life of the plunger assembly can be effectively prolonged.

Owner:XIAN AERO ENGINE CONTROLS

A method for incremental forming of sheet metal parts with non-cavity geometric features

ActiveCN112845832BImprove stress statusIncremental forming process realizationShaping toolsMetal-working feeding devicesLamellar structureFormability

The invention relates to a method for progressive forming of sheet metal parts with non-cavity geometric features. The base material is clamped between the upper auxiliary material and the lower auxiliary material to form a three-layer structure, and the base material, upper auxiliary material, Lubricating oil is filled between the lower and auxiliary materials, and the surroundings of the upper and lower auxiliary materials are clamped and fixed by fixtures; the tool head is used to apply deformation force to the base material through the upper and auxiliary materials, and the incremental forming process is performed; the base material is formed into the After the components of the desired shape are removed, the upper and lower auxiliary materials are removed. Compared with the prior art, the present invention has the advantages of realizing progressive forming of materials with poor formability, realizing processing of sheet metal parts with non-cavity geometric features, and the like.

Owner:SHANGHAI JIAO TONG UNIV

A kind of dressing method of arc-shaped diamond grinding wheel

ActiveCN110202478BQuick removalUniform removalAbrasive surface conditioning devicesLaser beam welding apparatusLaser technologyHigh energy

A circular-arc-shaped diamond grinding wheel dressing method comprises the steps that 1, micro water guide laser parameters are set, and tool setting is conducted; 2, radial rough modification is conducted, specifically, the working surface of a grinding wheel is equally divided into a plurality of cross sections which are L wide in the axial direction of a parallel grinding wheel, according to the different depths of feeding, in the axial direction of the grinding wheel, of the laser water beam, different depths H of abrasive layers are removed from the cross sections in sequence, and finally, the parallel grinding wheel is formed into a circular-arc-shaped grinding wheel through rough modification; 3, the surface profile precision of the grinding wheel is detected, height information ofall points on the surface is obtained, and tool setting is conducted; 4, cutting direction precise shaping is conducted; 5, micro water guide laser technology parameters are set, and tool setting is conducted; and 6, radial sharpening is conducted. According to the method, the high-energy high-density laser beam is guided through the water beam to remove the grinding wheel material in the fusion and gasification modes, a laser water beam variable rate scanning mathematic model is disclosed, the abrasive particle exposure height consistency is ensured, the dressed grinding wheel is good in surface appearance, the dressing precision is high, in addition, the dressing quality is ensured through water beam cooling, and energy saving and environmental protection are achieved.

Owner:HUNAN UNIV OF SCI & TECH

A method for optimizing the step size of abrasive belt grinding and polishing of the leading and trailing edges of blades

ActiveCN110116353BImprovements in the situation where the chord height error is out of toleranceGuaranteed contour accuracyBelt grinding machinesCutter locationMachining

The invention discloses a front and rear blade edge robot abrasive belt grinding and polishing step optimization method. The method comprise the steps that firstly, a machining step is calculated based on an equal-chord-height error step method; secondly, the machining step is converted into a corresponding difference value in a curve parameter domain, and accordingly, the position of the next cutter location point is determined; thirdly, a practical chord height error is calculated based on a principle of distance from a point to a line and compared with a standard value, and whether chord height error deviation occurs or not is judged; and fourthly as well as finally, as for a curve segment with the deviation phenomenon, the current cutter location point curvature radius and the machining step are calculated all over again, the position of the next cutter location point is updated, and circulation is performed thus until path planning is completed. According to the front and rear blade edge robot abrasive belt grinding and polishing step optimization method, the situation of the chord height error deviation occurring when the equal-chord-height error step method is applied to cutter location point planning of a blade complex curved surface part is improved mainly, and particularly, in blade front and rear edge curvature large variation areas, the machining profile precision is guaranteed by increasing the cutter location point density in a self-adaption mode; and in blade smooth areas, cutter location points are kept sparse while the machining efficiency is also taken into consideration.

Owner:WUHAN UNIV OF TECH

A compression-expansion composite internal high-pressure forming device and process for torsion parts

Owner:浙大宁波理工学院

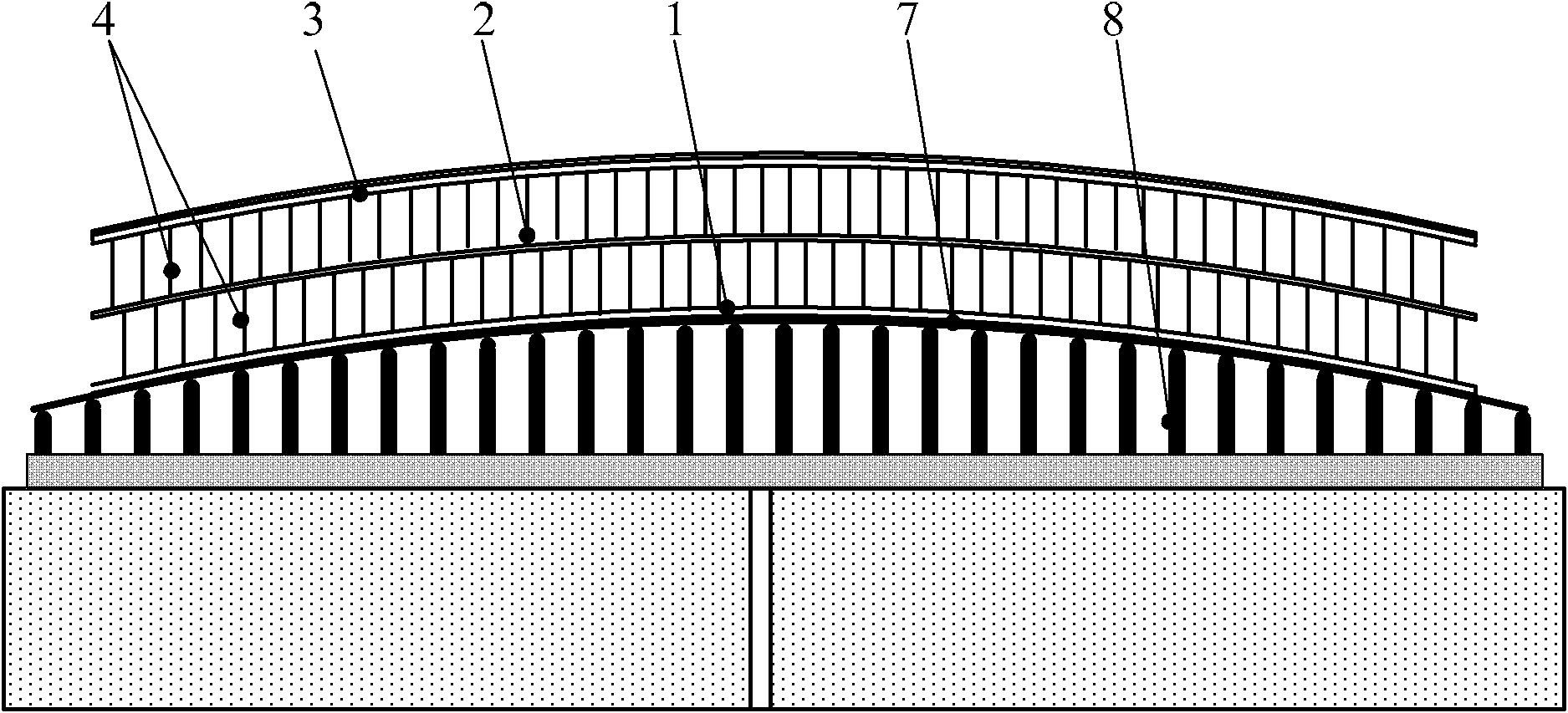

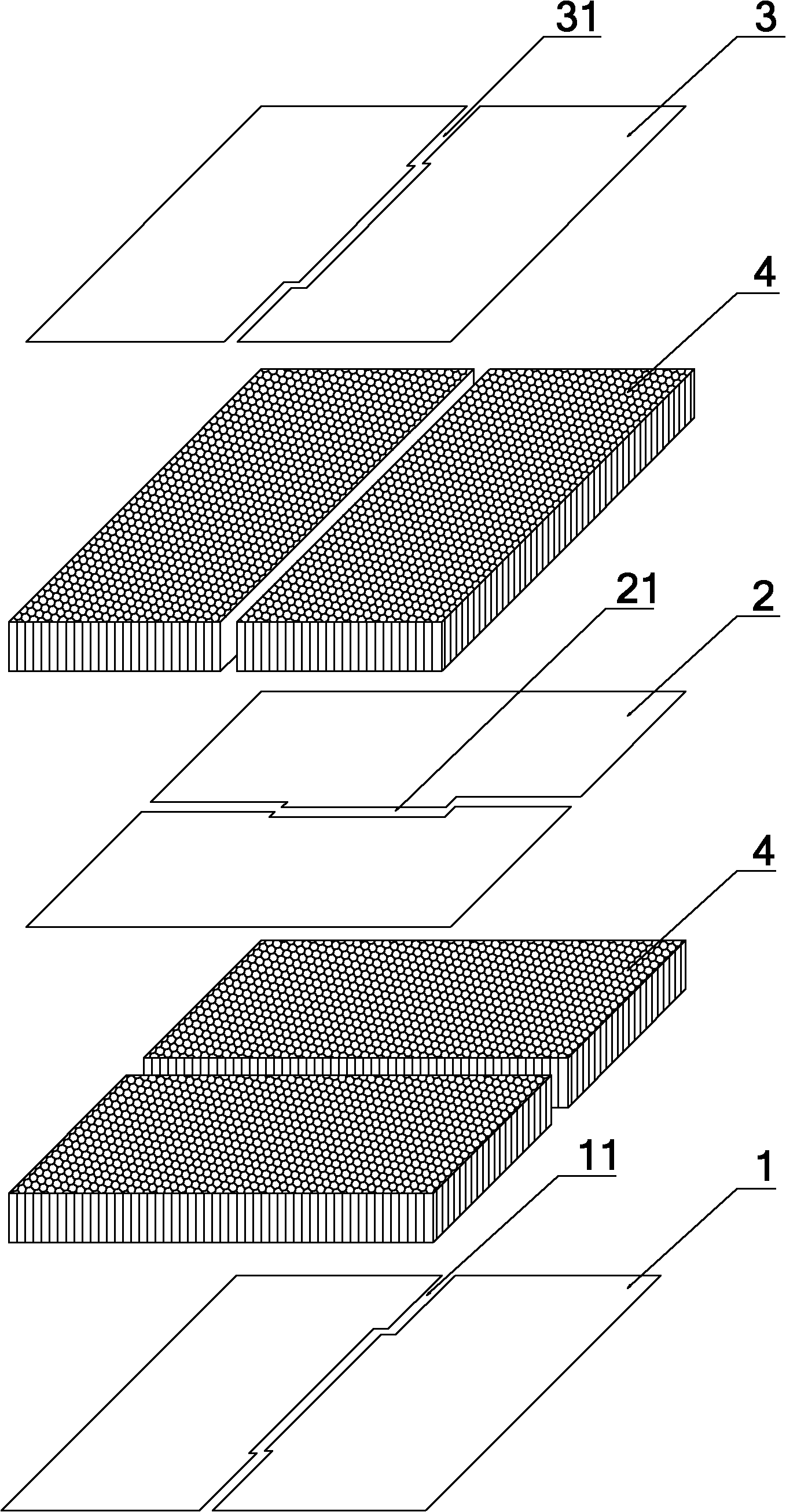

Splicing method for reflection panel in honeycomb sandwich structure

ActiveCN102270782BGuaranteed stiffnessGuaranteed contour accuracyAntennasEngineeringUltimate tensile strength

The invention relates to a splicing method for a reflection panel in a honeycomb sandwich structure. The method provided by the invention comprises the following steps: determining the shape and positioning mode of splicing seams of an aluminum plate, splicing and laying the sandwich structure layer by layer and repairing the splicing seams, wherein the splicing seams of the aluminum plate in a sandwich plate are in a Great Wall shape; after modeling, blanking figures are respectively obtained through expanding splicing curved surfaces; after the layout processing, a production blank is obtained; the sandwich structure which is spliced and laid side by side is the core course of manufacturing a sandwich plate; and the repairing of the splicing seams comprises the repairing for the splicing seams of a working plate and the simple shear splicing of a back plate. The method provided by the invention solves the problem that the manufacturing dimension of the panel is limited by the dimension of a raw material and can ensure that the profile accuracy of the working surface of the sandwich plate fully meets the design requirements; the rigidness of the panel can be maintained to the maximum limit through the transverse-longitudinal intersection of the splicing seams; and the repairing of the splicing seams can effectively repair the discontinuity of the working plate because the seams exist, ensures the electric properties of a reflection surface and improves the splicing intensity and tightness of the seams of the back plate.

Owner:BEIHANG UNIV

A kind of sharpening method of arc-shaped diamond grinding wheel

ActiveCN110293482BImprove surface conditions with large runout errorsImprove sharpening efficiencyAbrasive surface conditioning devicesHigh energyLaser beams

The invention provides a sharpening method of a circular arc diamond grinding wheel. The method comprises the following radially sharpening steps of enabling a laser water beam to incident upon the surface of the shaped circular arc grinding wheel along a radial direction of the grinding wheel, enabling the laser water beam to scan at the variable-rate scanning speed along an axial direction of the grinding wheel, and uniformly removing a binding agent material so as to realize uniform protrusion of abrasive particles. According to the sharpening method of the circular arc diamond grinding wheel provided by the invention, a high-energy-density laser beam is guided by the water beam, a grinding wheel material is removed by adopting melting and gasifying as principal manners, and a mathematic model for laser water beam variable-rate scanning is provided, so that the uniformity in removing the grinding wheel surface binding agent and the consistency of the protrusion heights of the abrasive particles are ensured, the sharpened grinding wheel is good in surface appearance and high in sharpening accuracy, the sharpening quality is ensured through the cooling and scouring actions of thewater beam, and energy conservation and environment friendliness are realized.

Owner:HUNAN UNIV OF SCI & TECH

Laser output device and 3D printer

ActiveCN105799176BGuaranteed contour accuracyMeet different printing needsAdditive manufacturing apparatusIncreasing energy efficiencyLaser scanningGalvanometer

Owner:GUANGDONG HANBANG 3D TECH CO LTD +1

A multi-axis linkage pipeline interpolation full-closed-loop motion control method

ActiveCN104597846BAdaptableExcellent mechanical transmission performanceNumerical controlNumerical controlCoupling

The invention relates to the field of control of numerical control machine tools, and specifically provides method for adding pipeline interpolation on the basis of dynamically correcting motion track interpolation position according to the feedback of a grating ruler and other external connecting position sensing devices as well as a servo motor encoder so as to dynamically plan the motion tracks. The method is suitable for two-shaft and three-shaft coupling linear interpolation, two-shaft coupling arc-shaped interpolation and hybrid configuration of full-closed-loop feedback, full-closed-hoop feedback and semi-closed-hoop feedback. With the adoption of the method, the multi-shaft coupling contour precision, positioning precision and repeated positioning precision can be met, a servo motor can run stably, the processing precision of a workpiece can be ensured, and the service life of a machine can be prolonged. The method is high in adaptability, high in processing route contour precision, high in speed smoothness, high in dynamic performance and high in motion safety.

Owner:中国科学院沈阳计算技术研究所有限公司

A method for manufacturing titanium alloy tubular parts with inward flanging at both ends with forced feeding

ActiveCN104493436BSolve the problem of serious thickness reductionUniform thickness distributionMetallurgyHigh pressure

The invention discloses a method for manufacturing cylindrical titanium alloy parts with two ends flanged inwards through forced supplementing. The method includes determining structure and size of an initial blank and feeding; rolling edges, welding longitudinal seams and correcting; sealing tubing and welding a vent pipe; placing the blank and a superplastic forming die into a superplastic forming machine, heating and assembling the die; injecting inertia high-pressure gas of certain pressure into a closed space of the tubing and keeping pressure; axially and forcefully supplementing the tubing; forming superplastically after supplementing; cooling to discharge the parts and removing allowance. By the method, the cylindrical parts with two ends flanged inwards are realized by equal-thickness plates, the parts are uniform in integral thickness distribution, the blank can be fed and the parts can be taken at the high temperature, continuous production is realized, production efficiency can be greatly improved and production cost is reduced.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Interpolation method of spline curve based on chord intercept method

ActiveCN103809521BAvoid derivative operationsImprove execution efficiencyProgramme controlComputer controlComputer scienceSecant method

The invention relates to a spline curve interpolation method based on a secant method. The spline curve interpolation method is applied to spline curve interpolation of a numerical control system. The spline curve interpolation method comprises the steps of establishing a structure equation according to the cutter feeding speed during processing, a spline curve equation and an interpolation cycle, and enabling the equation root to be an interpolation parameter; utilizing the structure equation and applying a secant iteration method to solve the interpolation parameter, and predicting an initial value of the interpolation parameter by adopting a Taylor prediction equation and a Bill Adams prediction equation; substituting the solved interpolation parameter into the spline curve equation, and obtaining the actual cutter feeding amount of every movement axis. The method is small in calculation amount, and execution efficiency of a numerical control machine tool is high; limitation of chord height errors is considered, and processing contour precision is guaranteed; the secant method has superlinear convergence, so that when the method is utilized to calculate the interpolation parameter, the convergence rate is high, the calculation amount is small, and the stability is good.

Owner:中国科学院沈阳计算技术研究所有限公司

Method, device and system for determining three-dimensional model of object to be measured

PendingCN114445548AGuaranteed Contour AccuracyDetails involving processing stepsImage enhancementComputer visionThree dimensional model

The embodiment of the invention discloses a method, device and system for determining a three-dimensional model of a to-be-detected object. The method comprises the following steps: enabling an elastic detection element arranged on an end effector to keep a predetermined contact force or contact moment to move on each surface of an object to be detected based on adjusting the position of the end effector of the robot; determining contour data of each surface based on the position adjustment amount of the end effector in the movement process of the elastic detection element on each surface; and determining a three-dimensional model of the to-be-measured object based on the contour data of each surface. According to the embodiment of the invention, the three-dimensional model of the to-be-measured object can be determined without laser scanning equipment, the cost is saved, and the method is also suitable for large-size to-be-measured objects. In addition, the embodiment of the invention has no special requirement on the photosensitive attribute of the to-be-detected object.

Owner:SIEMENS CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com