Patents

Literature

1794 results about "Micro cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro cracks are often a result of mechanical forces or thermal stress. In the production process, micro cracks most frequently occur during lamination of the panel, especially when using certain EVA films with weak moisture impermeability.

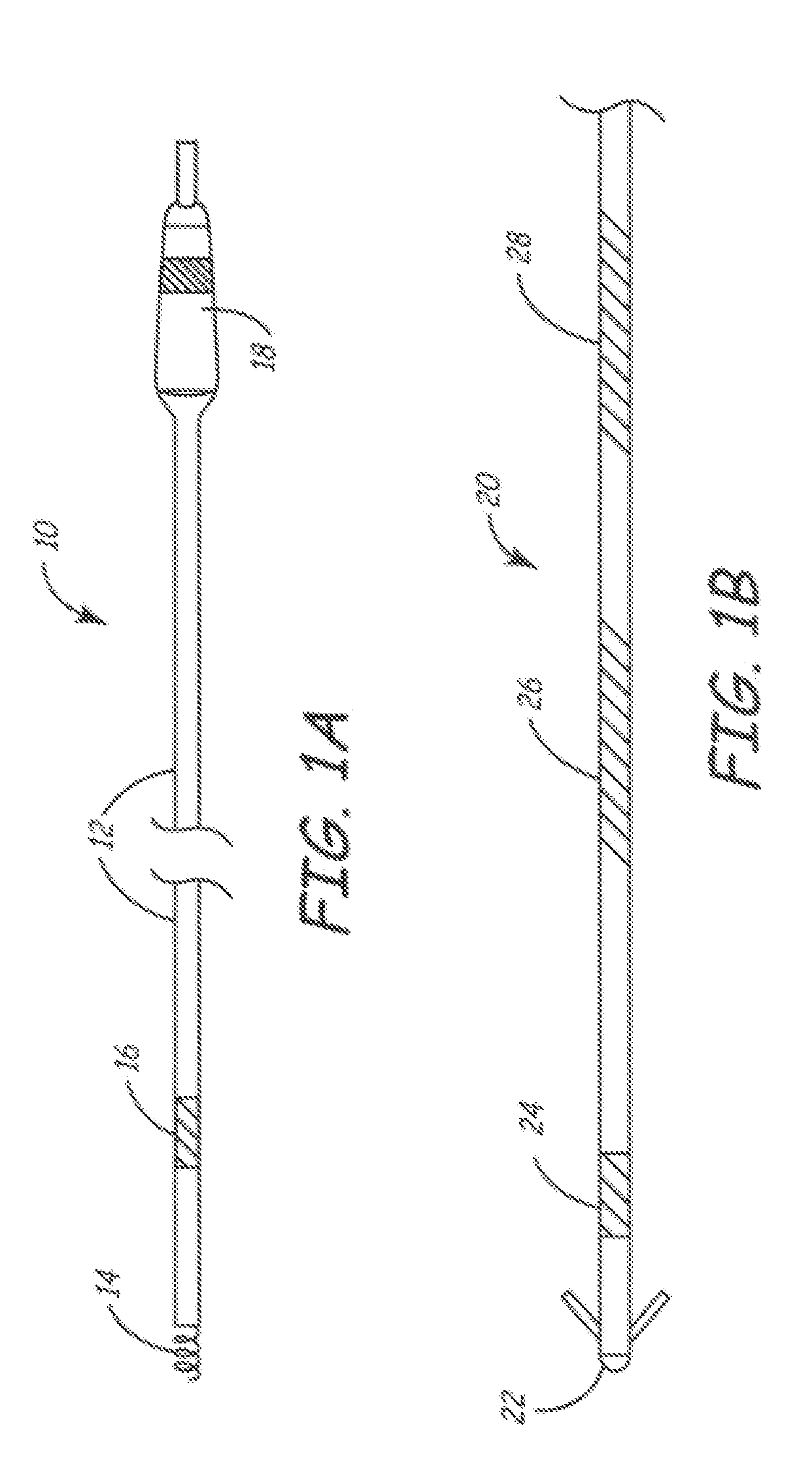

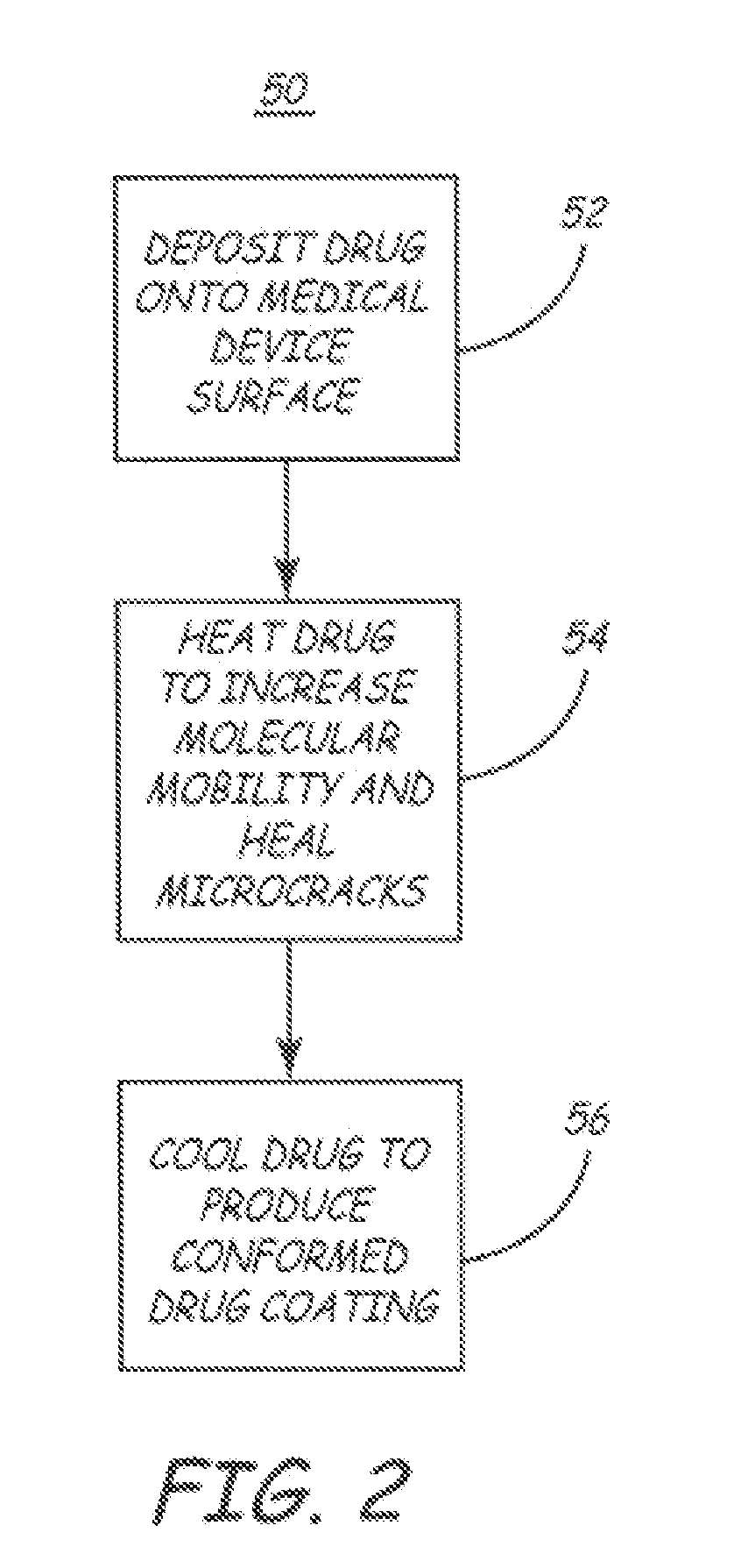

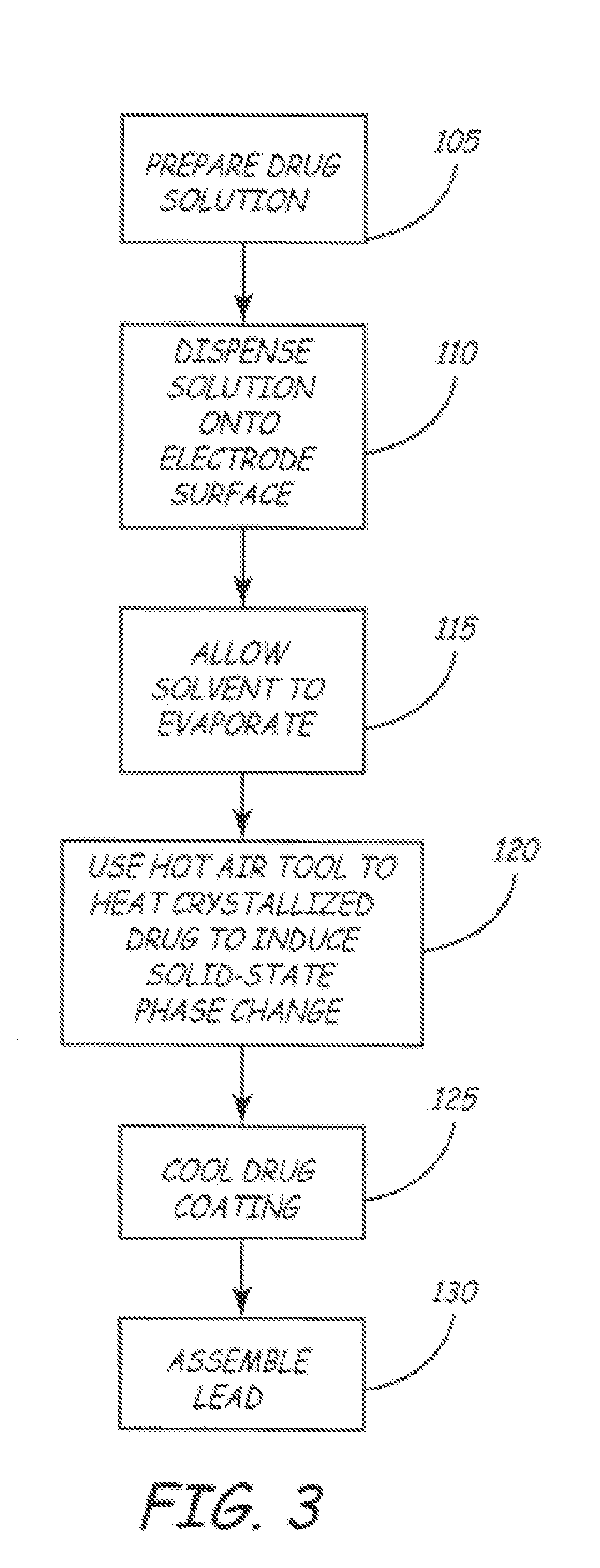

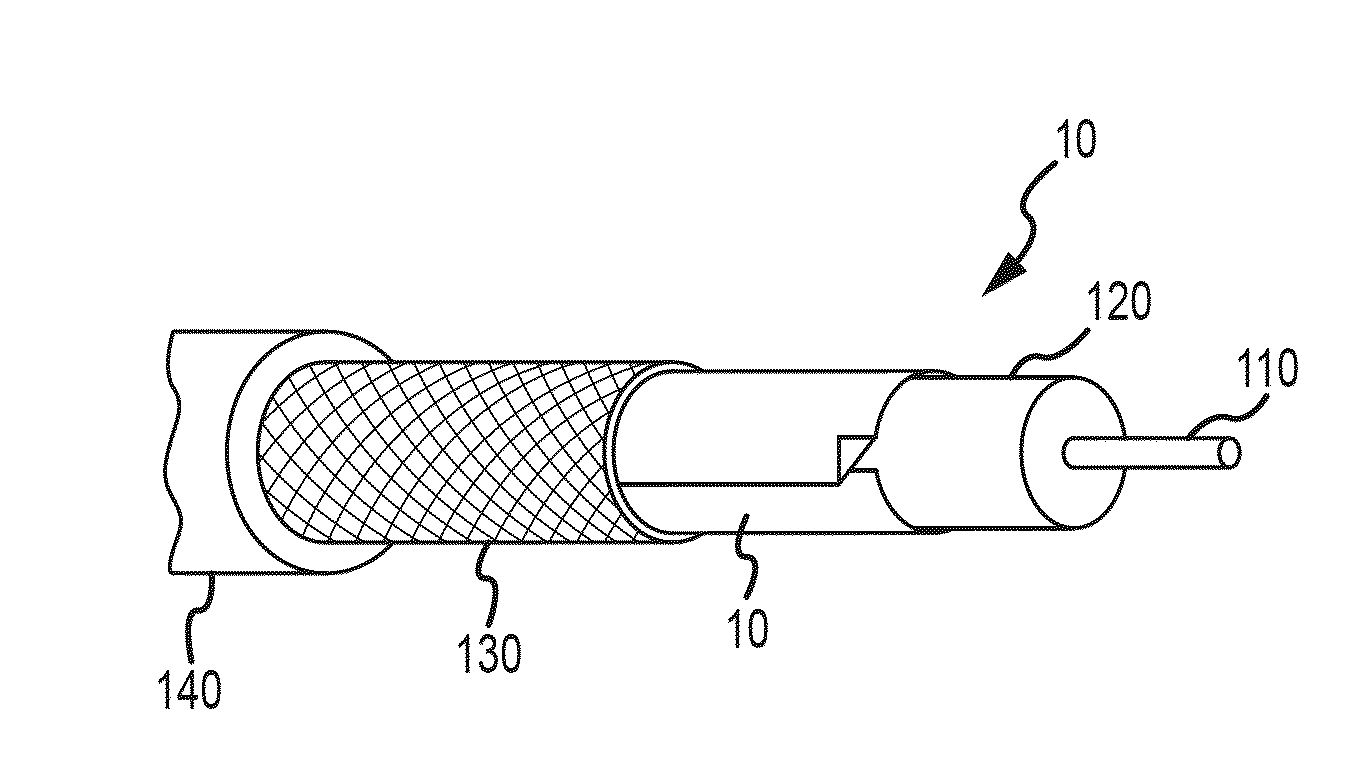

Method for applying a drug coating to a medical device

A method for coating a medical device with a drug is provided. Energy, preferably thermal energy, is applied to a crystalline deposit of a drug on the surface of a medical device to increase the molecular mobility and form a conformable drug coating with a low density of micro-cracks and other mechanical defects that can degrade the coating toughness and effective adhesion to the device surface. In a preferred embodiment, solution evaporation methods are used to deposit a crystalline coating of an anti-inflammatory steroid on a medical electrode. Heat applied at a controlled temperature, for a predetermined amount of time, induces a solid-state phase change of the drug coating providing a smooth, uniform, well-attached, conformable coating to form a layer that will elute from the electrode over time when implanted in a patient's body.

Owner:MEDTRONIC INC

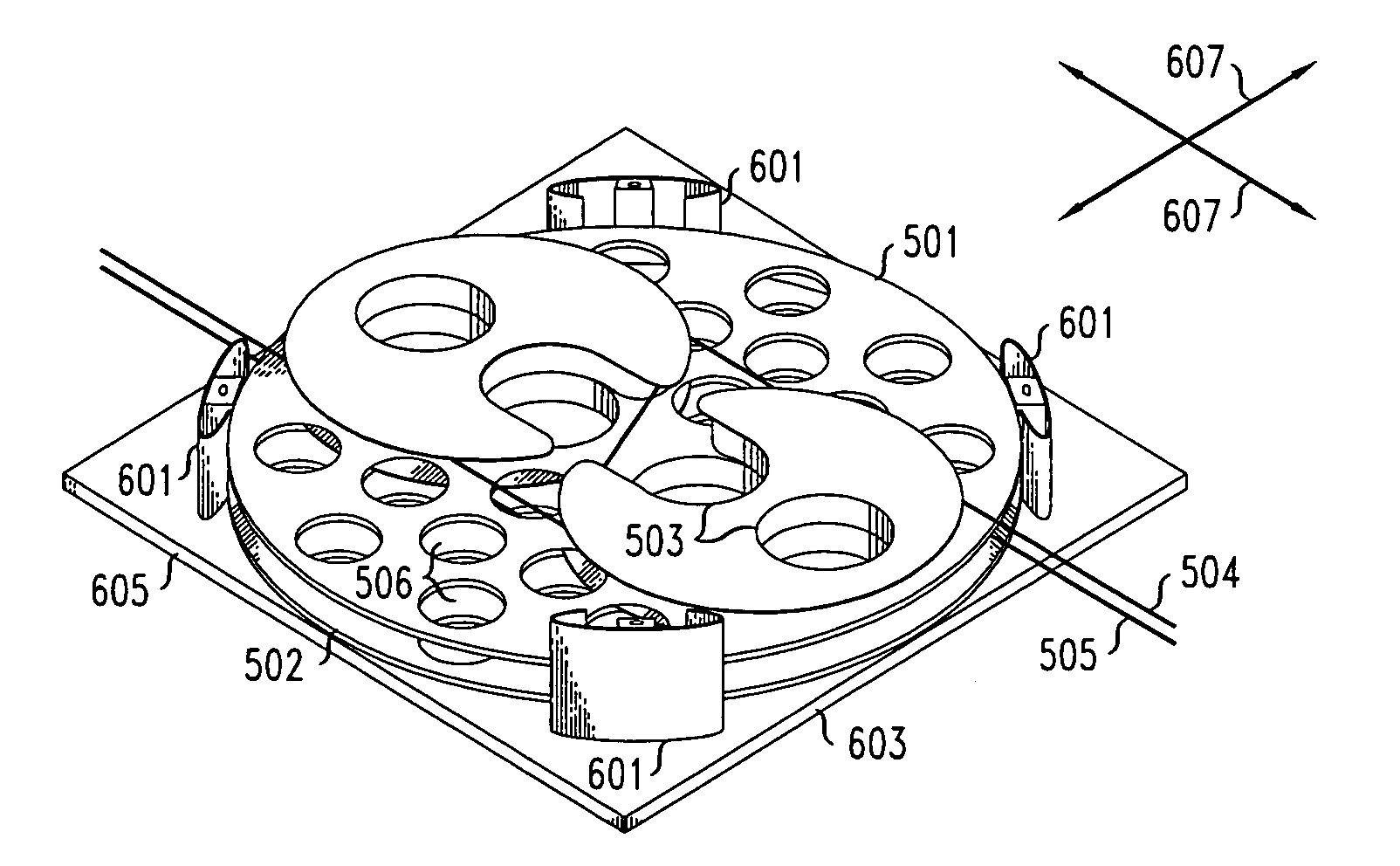

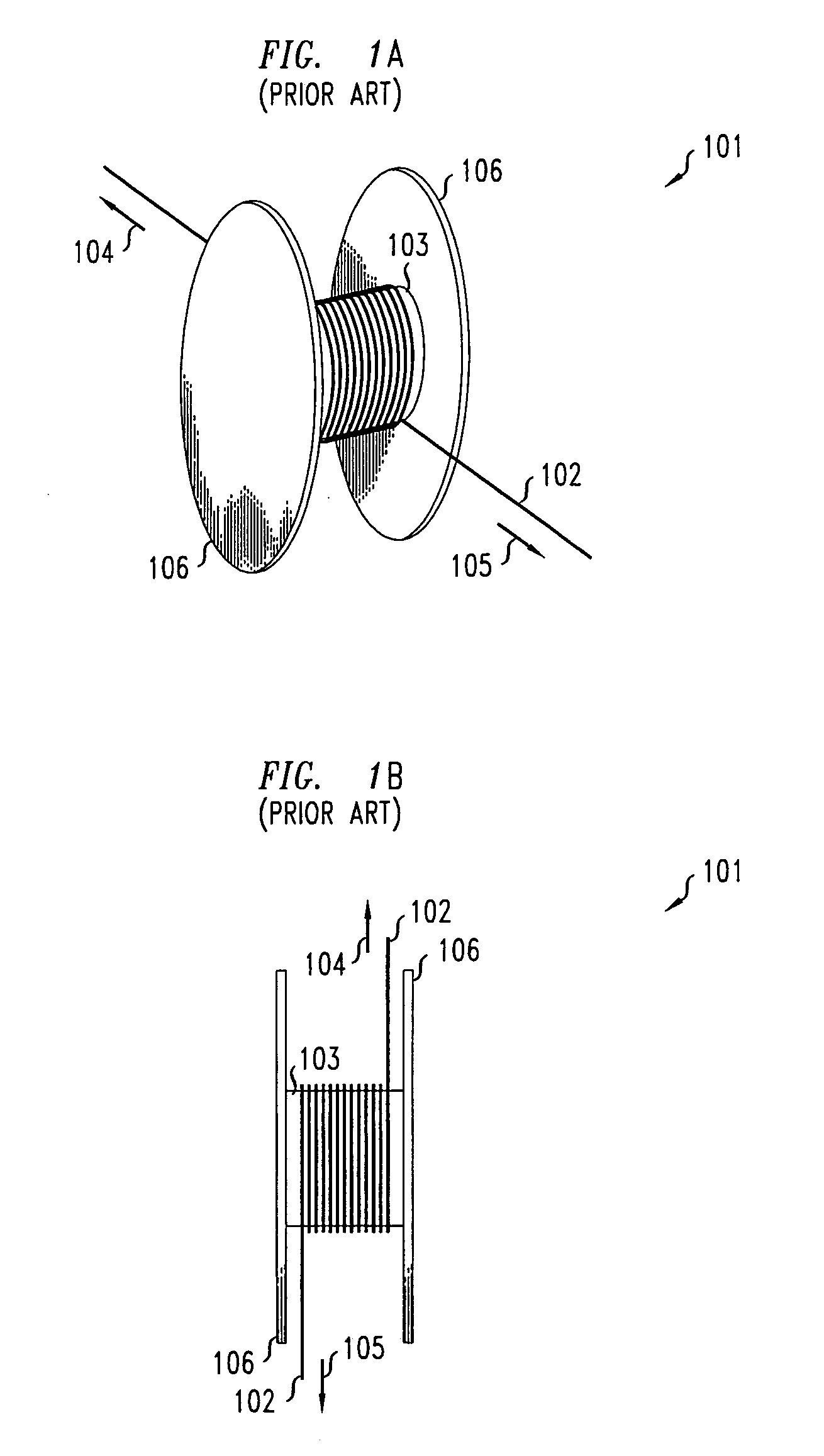

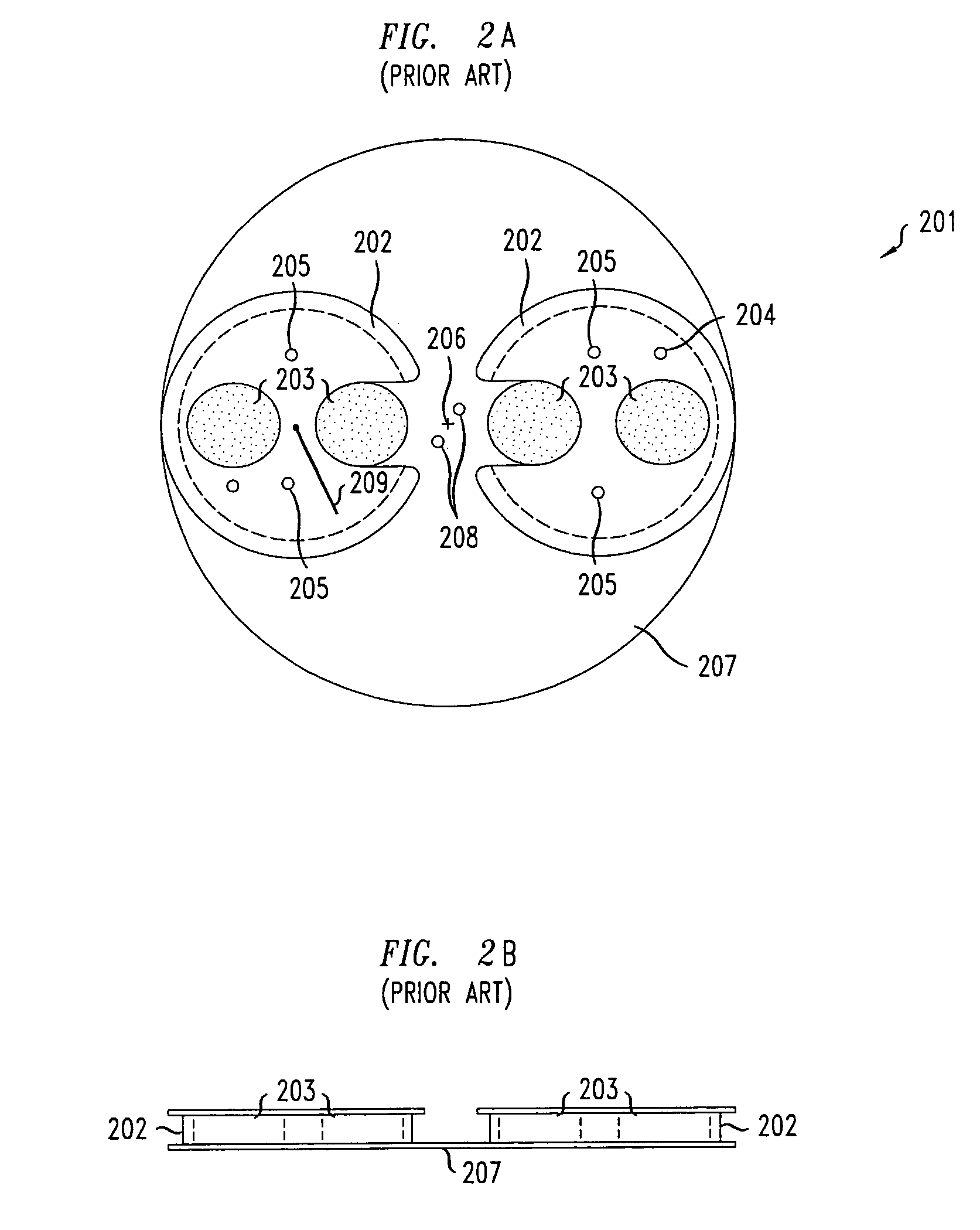

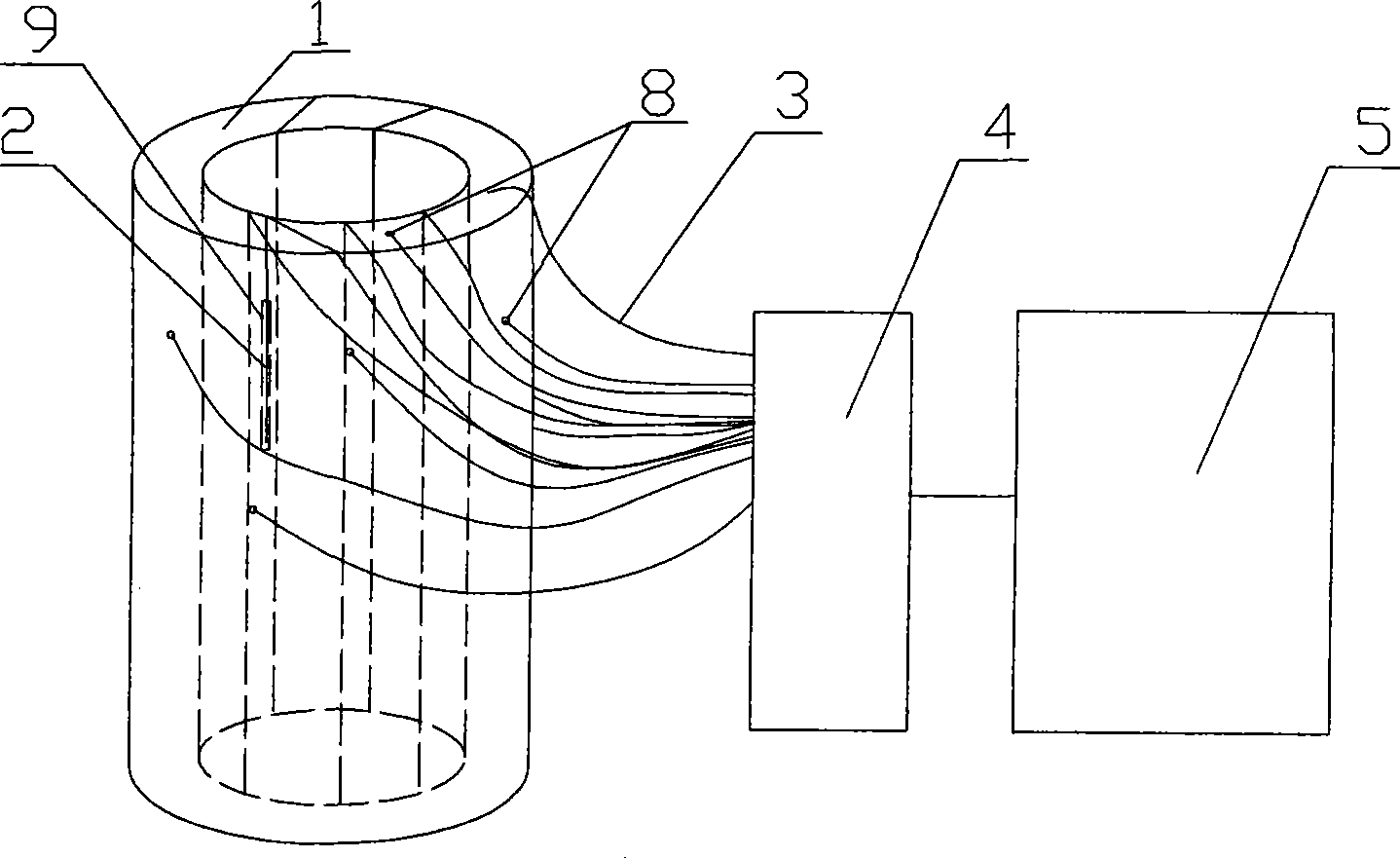

Method and apparatus for operational low-stress optical fiber storage

A reel for storing optical fiber is disclosed that significantly reduces the torsional force applied to optical fiber as the fiber is being wound onto the reel for storage. The optical fiber reel comprises two spindles that are offset with respect to the rotational center of the reel. Such an arrangement causes the fiber to be wound onto the reel in a substantially linear fashion, thus preventing the torsional force and resulting twisting that cause micro-cracks to develop. The spindles are of a sufficiently large diameter to facilitate operational use of the fiber while stored on the spindle without increasing the attenuation of signals that could result from the use of a smaller diameter spindle.

Owner:LUCENT TECH INC

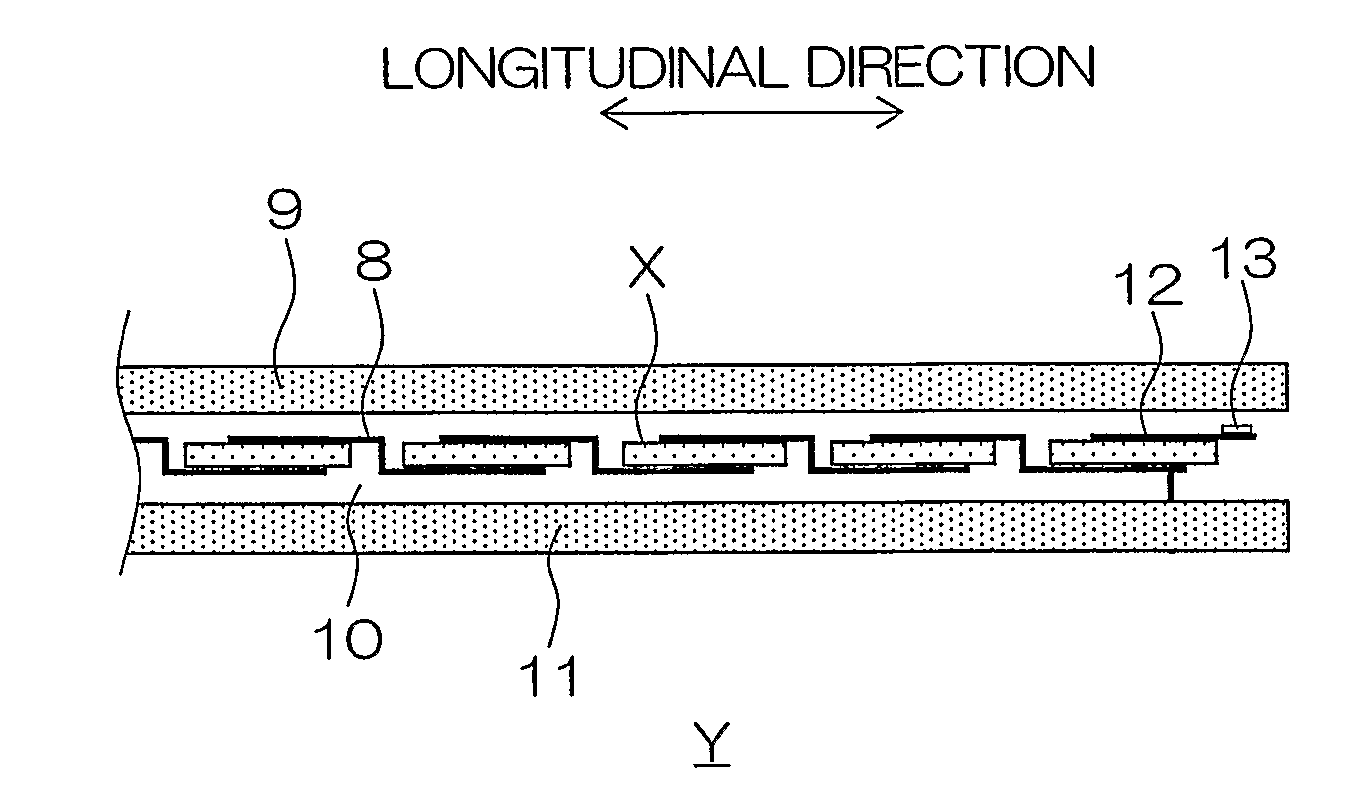

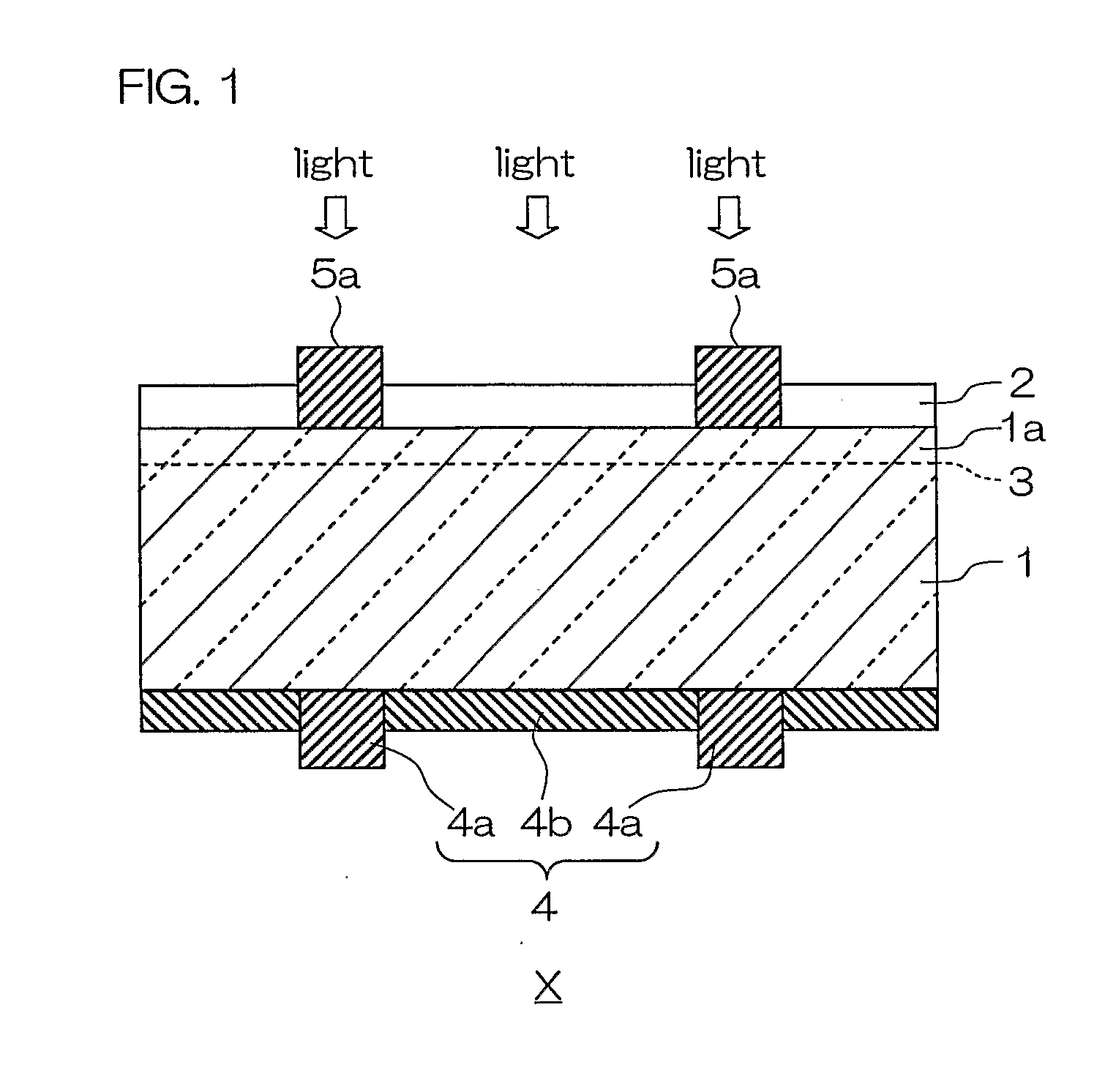

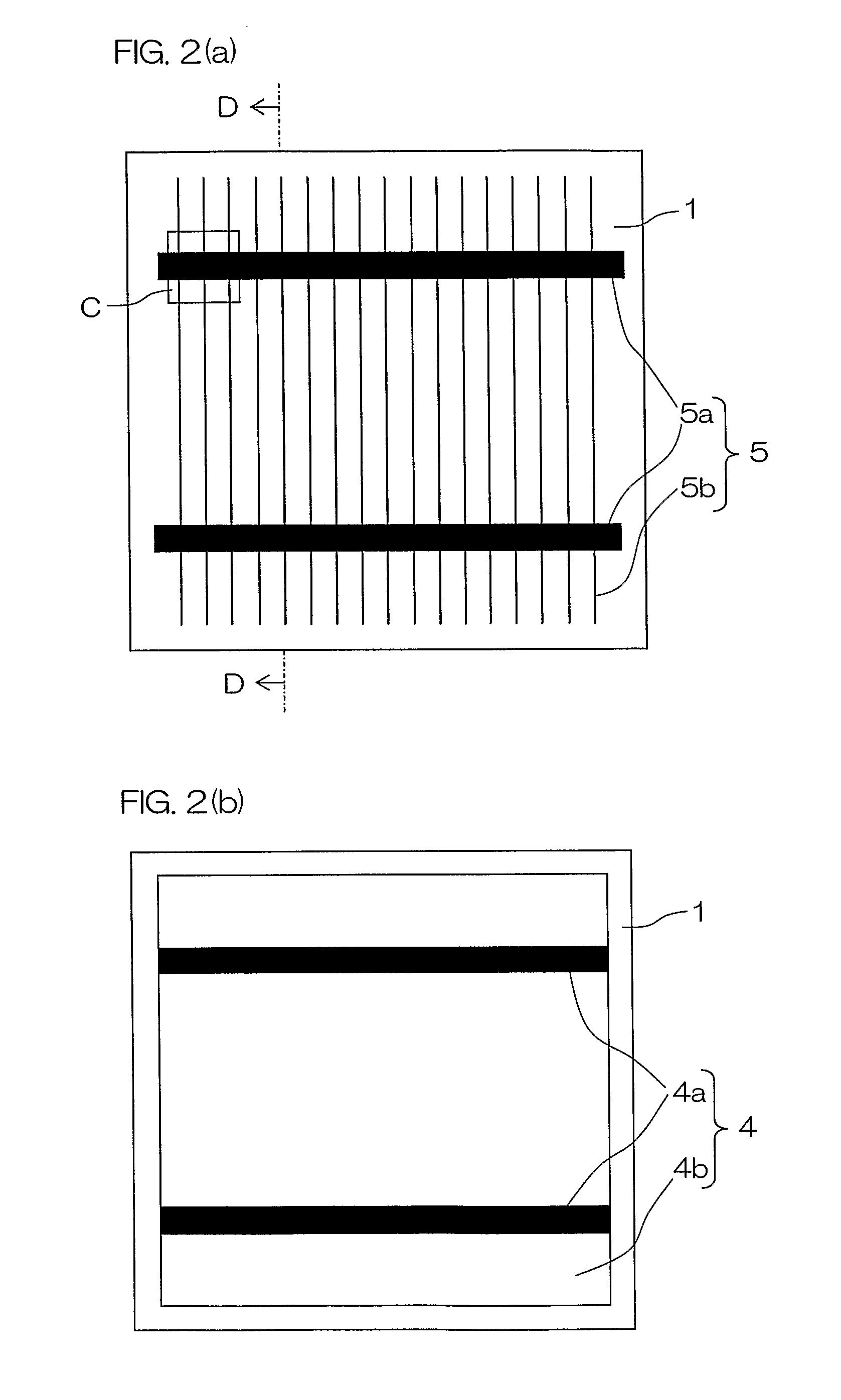

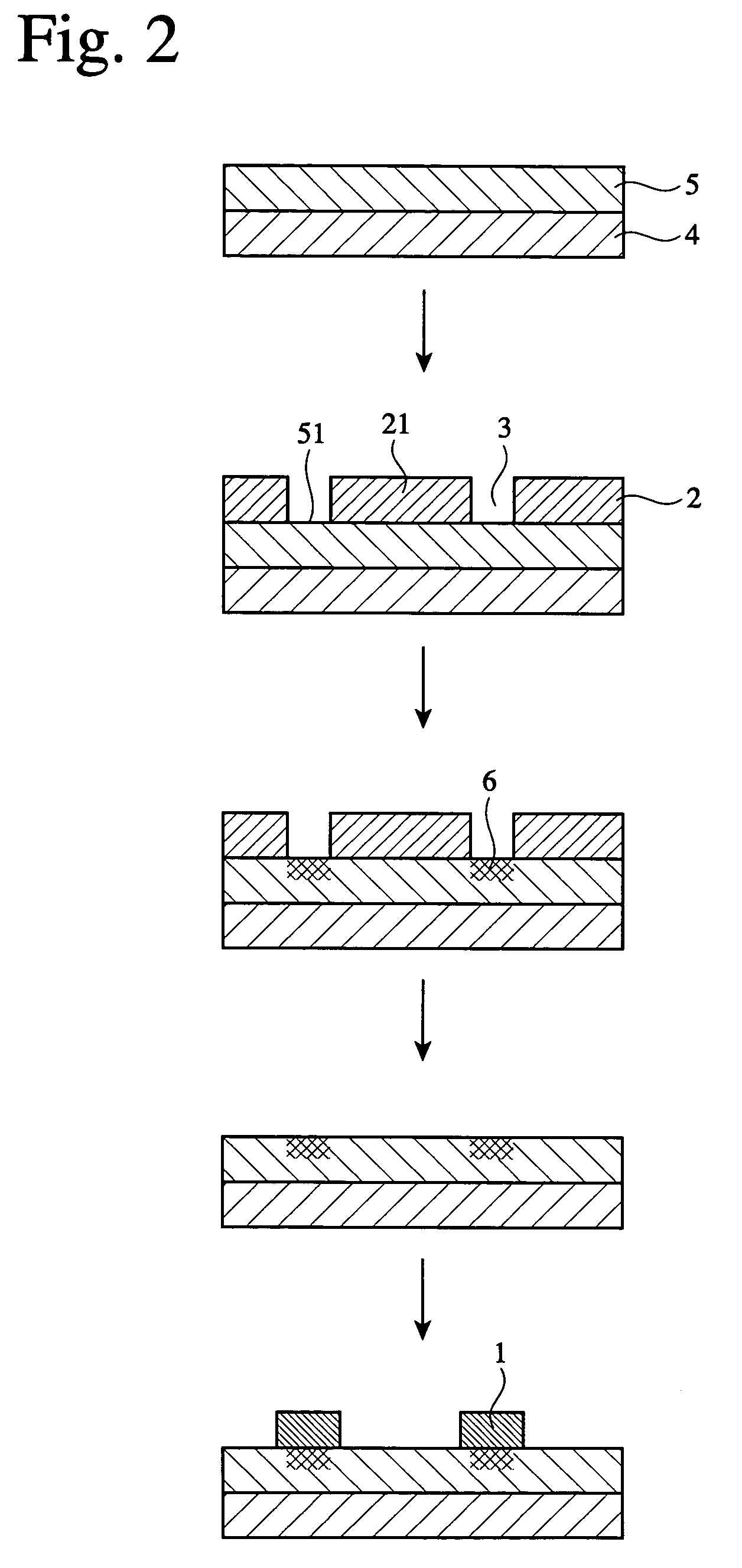

Solar cell module

InactiveUS20070095387A1Confirm effectHigh breaking strengthPV power plantsPhotovoltaic energy generationSolar cellSemiconductor

The largest stress is created in the vicinity of the boundary between an edge of a bus bar electrode in a solar cell and a surface of a semiconductor substrate, and stress are easily concentrated. Accordingly, defects such as micro cracks occur in the semiconductor substrate, which develop into a large craze with the defects as its starting point. In connecting bus bar electrodes 4a and 5a in the solar cell by an inner lead 8, therefore, a solder 6 is not brought into contact with edges along the longitudinal direction if the bus bar electrodes 4a and 5a and portions F from the edges to a predetermined distance a inward therefrom, and is brought into direct contact with a filler 10.

Owner:KYOCERA CORP

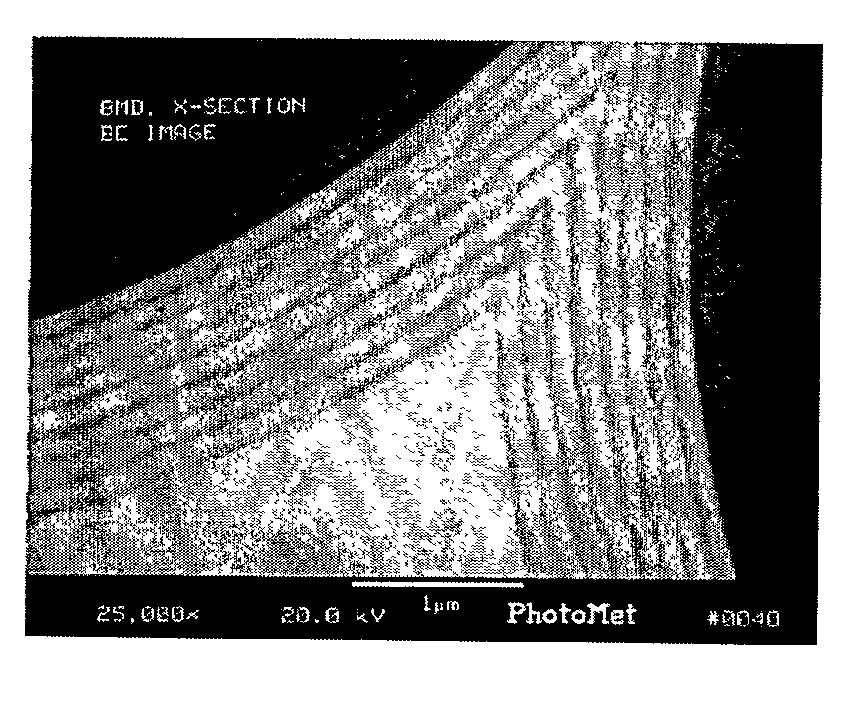

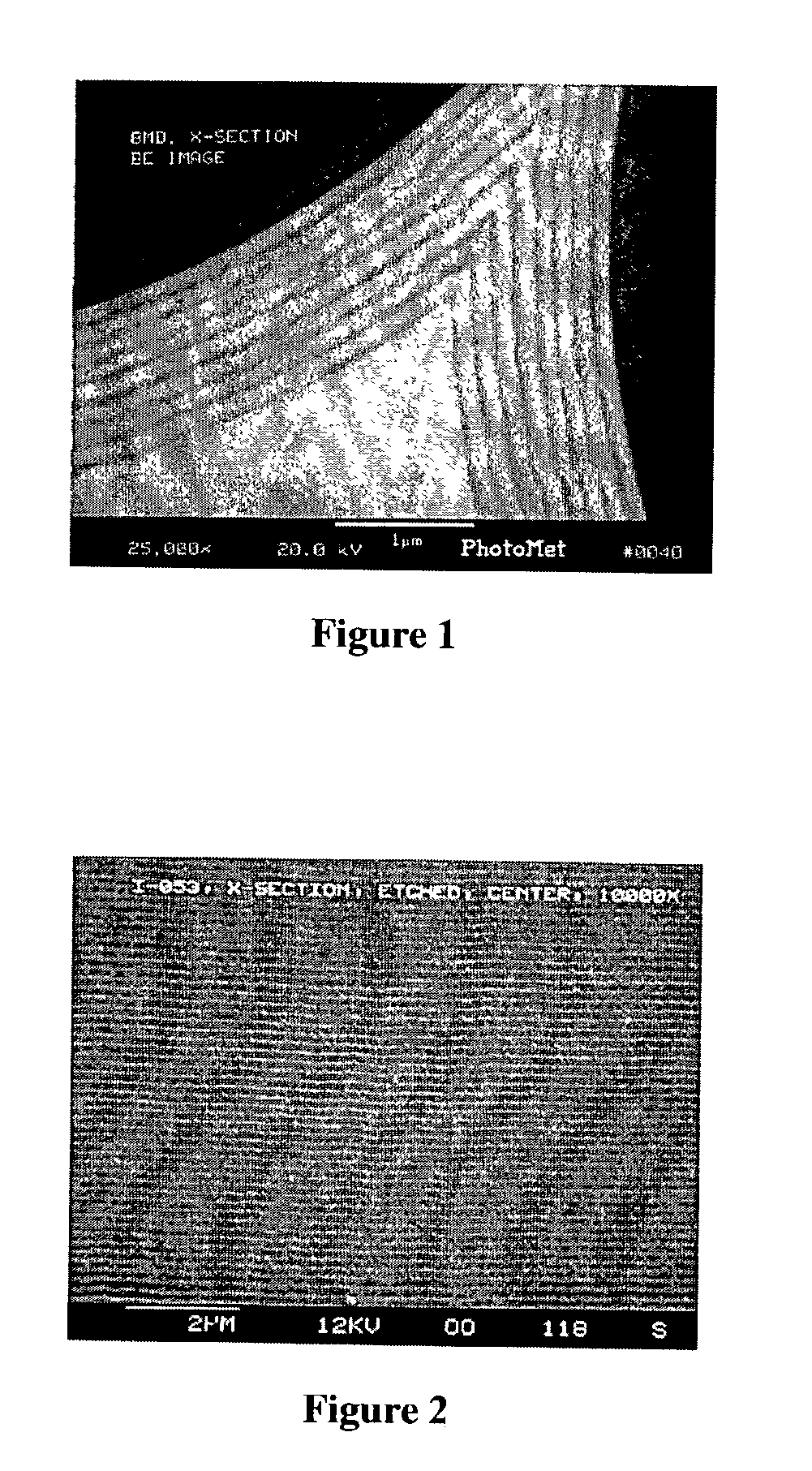

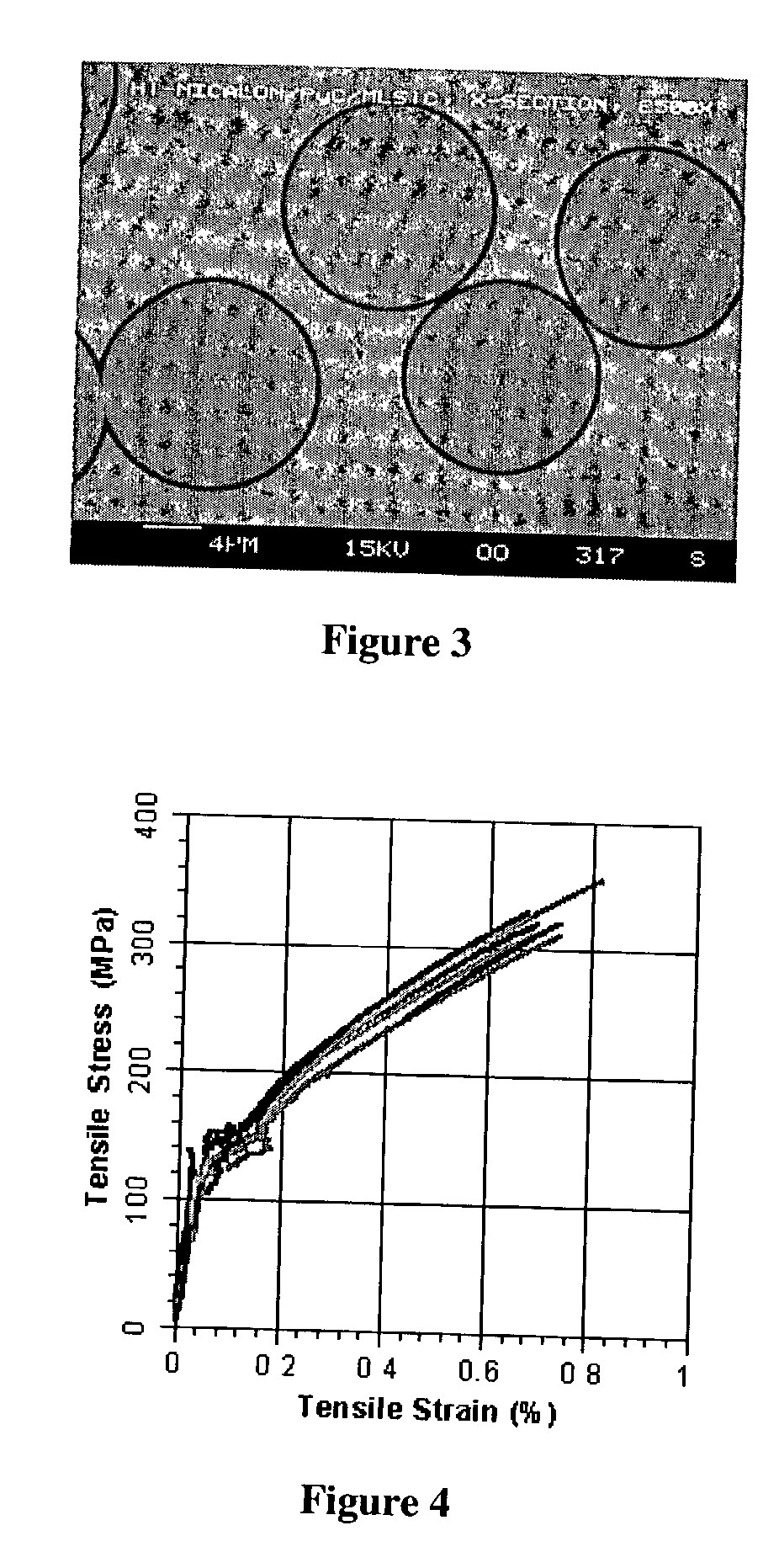

Fiber-reinforced ceramic composite material comprising a matrix with a nanolayered microstructure

InactiveUS20050181192A1Improve the immunityHigh strengthSynthetic resin layered productsCeramic layered productsCeramic compositeToughening

A fiber-reinforced ceramic matrix composite material exhibiting increased matrix cracking strength and fracture toughness is produced by sequentially depositing a plurality of 5-500 nanometer-thick layers of a primary ceramic matrix material phase periodically separated by 1-100 nanometer-thick intermediate layers of a secondary matrix material phase onto the reinforcing fibers upon their consolidation. The resultant nanolayered matrix enhances the resistance to the onset of matrix cracking, thus increasing the useful design strength of the ceramic matrix composite material. The nanolayered microstructure of the matrix constituent also provides a unique resistance to matrix crack propagation. Through extensive inter-layer matrix fracture, debonding and slip, internal matrix microcracks are effectively diverted and / or blunted prior to their approach towards the reinforcing fiber, thus increasing the apparent toughness of the matrix constituent. This unique toughening mechanism serves to dampen energetic co-planar macrocrack propagation typically observed in conventionally manufactured ceramic matrix composites wherein matrix cracks are usually deflected at the fiber / matrix interphase region.

Owner:ROLLS ROYCE HIGH TEMPERATURE COMPOSITES INC

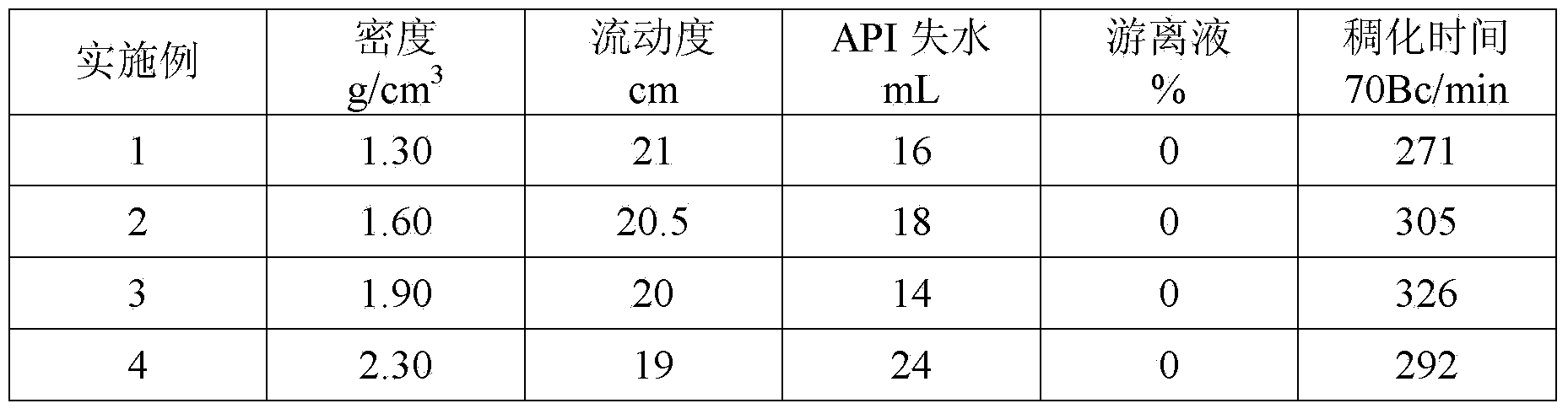

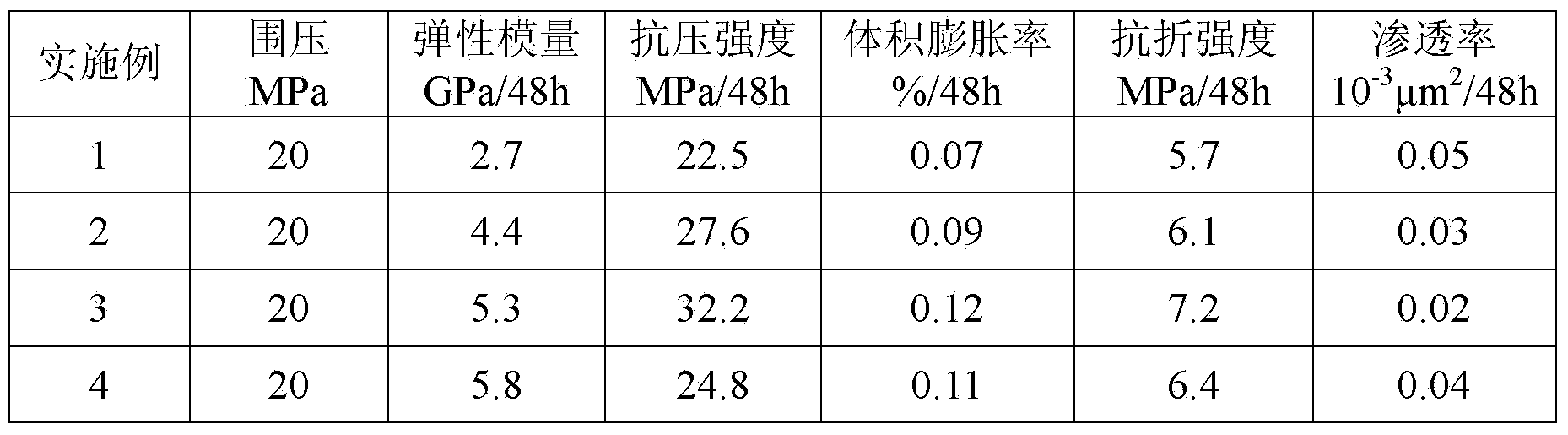

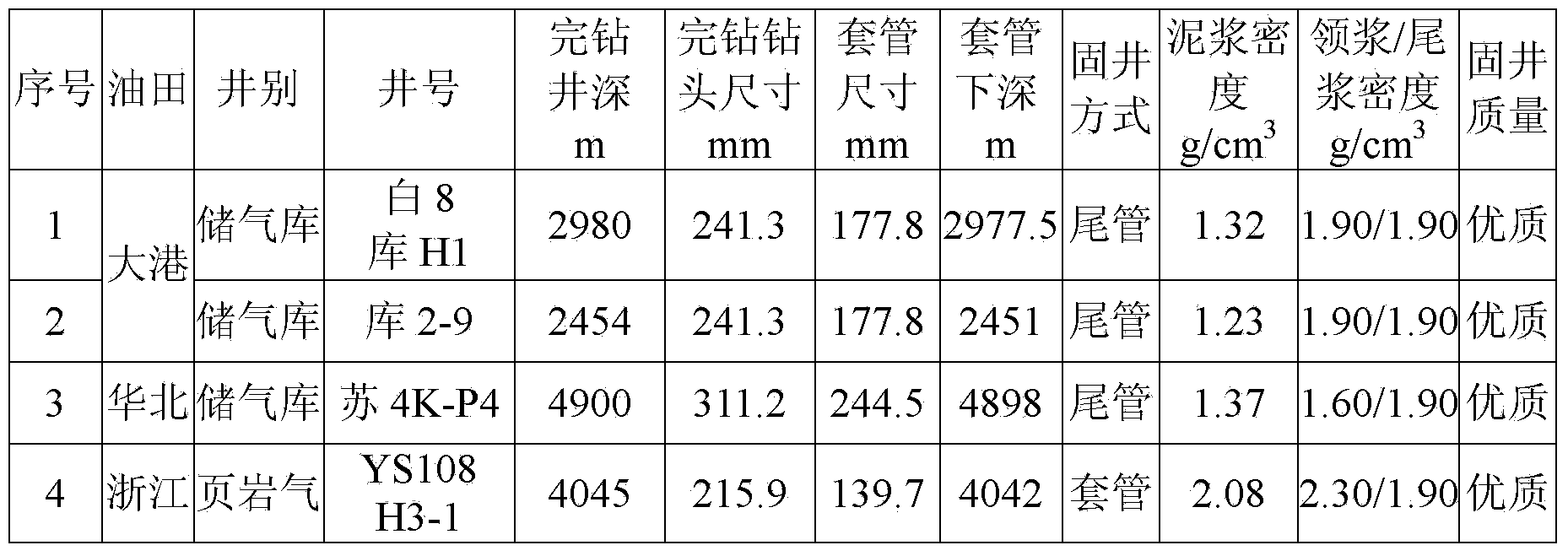

Expanded flexible well cementing grout and preparation method thereof

ActiveCN104371678ALow elastic modulusLower transfer coefficientDrilling compositionHorizontal wellsVolumetric Mass Density

The invention provides an expanded flexible well cementing grout and a preparation method thereof. The grout comprises the following components in parts by weight: 100 parts of cement, 6-14 parts of toughening material, 3-80 parts of reinforcing material, 8-120 parts of density modifier, 0.5-2.5 parts of suspension stabilizer, 20-40 parts of high-temperature stabilizer, 35-100 parts of distilled water, 0.5-2 parts of dispersant, 0.5-4 parts of fluid loss agent, 0.3-4 parts of retarder, 0.1-2 parts of foam inhibitor and 0.1-2 parts of defoamer. The invention further provides a preparation method of the expanded flexible well cementing grout. The grout has good sedimentation stability; and the set cement has the characteristics of micro expansion, high strength and low elasticity modulus, and can avoid the phenomena of micro cracks, micro annuluses, even fracture and the like caused by cement sheaths in subsequent operation of gas storage wells, shale gas wells, dense oil-gas horizontal wells and the like, thus realizing good zonal isolation and providing a technical support for long-term, safe and effective operation of oil-gas wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

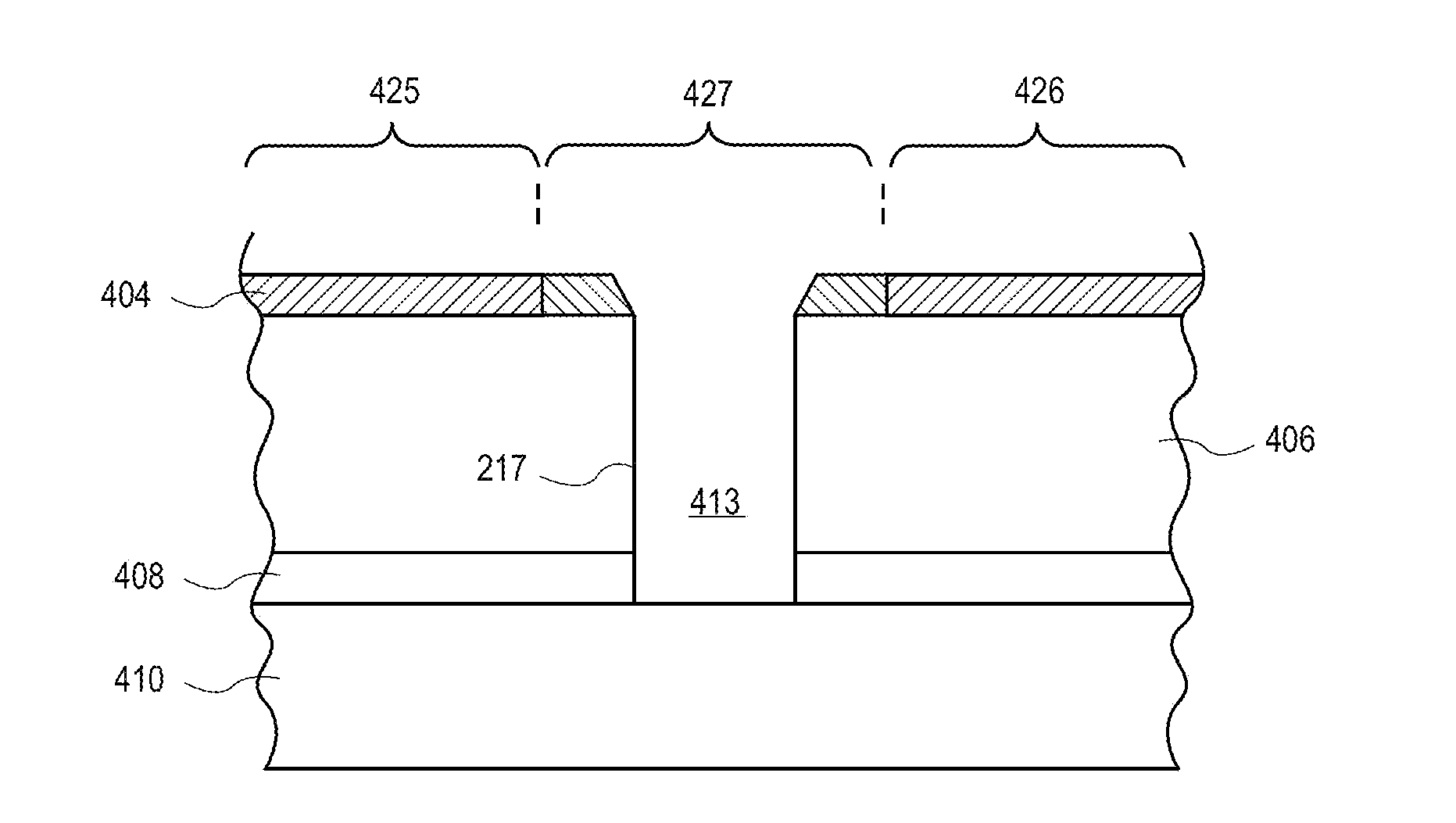

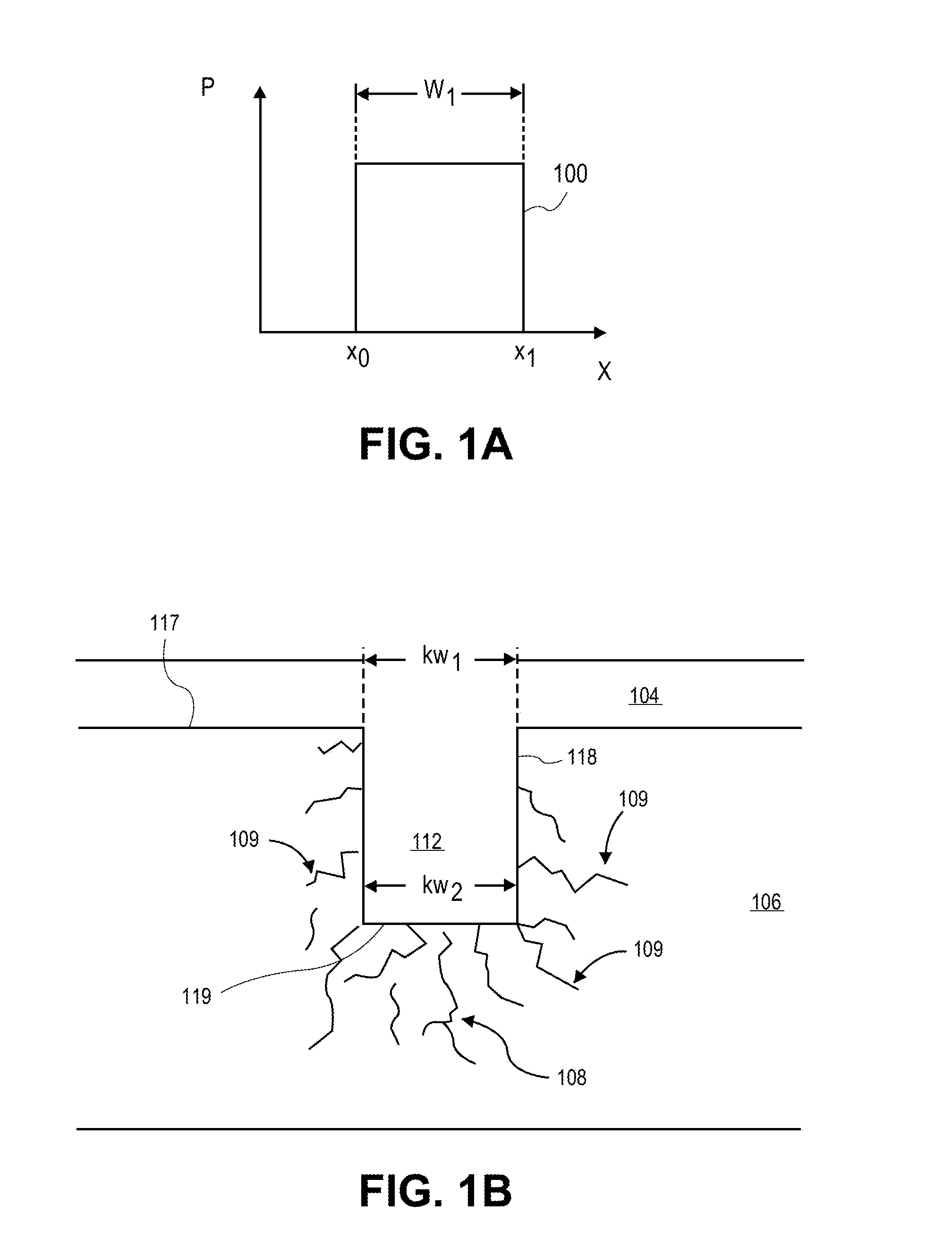

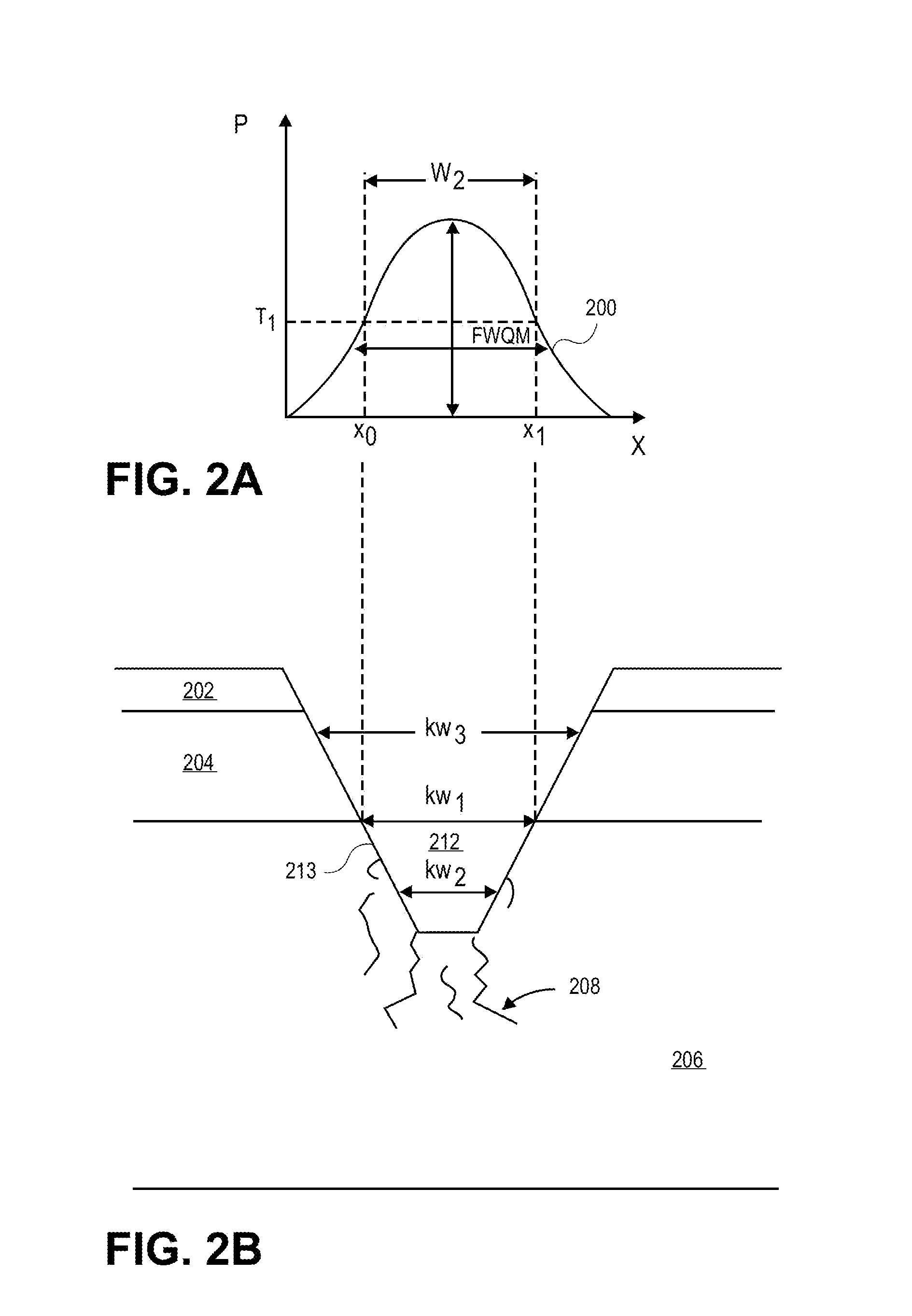

Damage isolation by shaped beam delivery in laser scribing process

ActiveUS20120322240A1Electric discharge tubesSemiconductor/solid-state device manufacturingShaped beamOptoelectronics

Owner:APPLIED MATERIALS INC

Micro-crack self-repairing microcapsule and preparation method thereof

ActiveCN102702838ARealize automatic curingFill crack voidsAnti-corrosive paintsMicroballoon preparationCyclohexanoneSolvent

The invention discloses a micro-crack self-repairing microcapsule, which comprises a capsule core and a capsule wall, wherein the capsule core comprises the following ingredients in part by weight: 10 to 60 parts of isocyanate derivative, 0.1 to 10 parts of capsule core diluent and 2 to 40 parts of cosolvent; and the capsule wall comprises ingredients with the following mol ratio: urea: formaldehyde solution, prepolymer=1: (1.0-4.0): (2.0-6.0), wherein the prepolymer is formed from the ingredients with the mol ratio: isocyanate derivative: cyclohexanone: chain extender=1: (2.0-5.0): (0.3-3.0). The invention also discloses a micro-crack self-repairing anti-corrosion coating utilizing the capsule. The micro-crack self-repairing microcapsule is free from additionally adding a repairing catalyst or an initiator, can realize completely automatic repairing function, can be widely applied to the protection field of a metal surface coating in a wet environment, and solves the problems that the contact probability between functional filling material flowing into cracks in the intelligent anticorrosion coating and the catalyst or the initiator is small.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

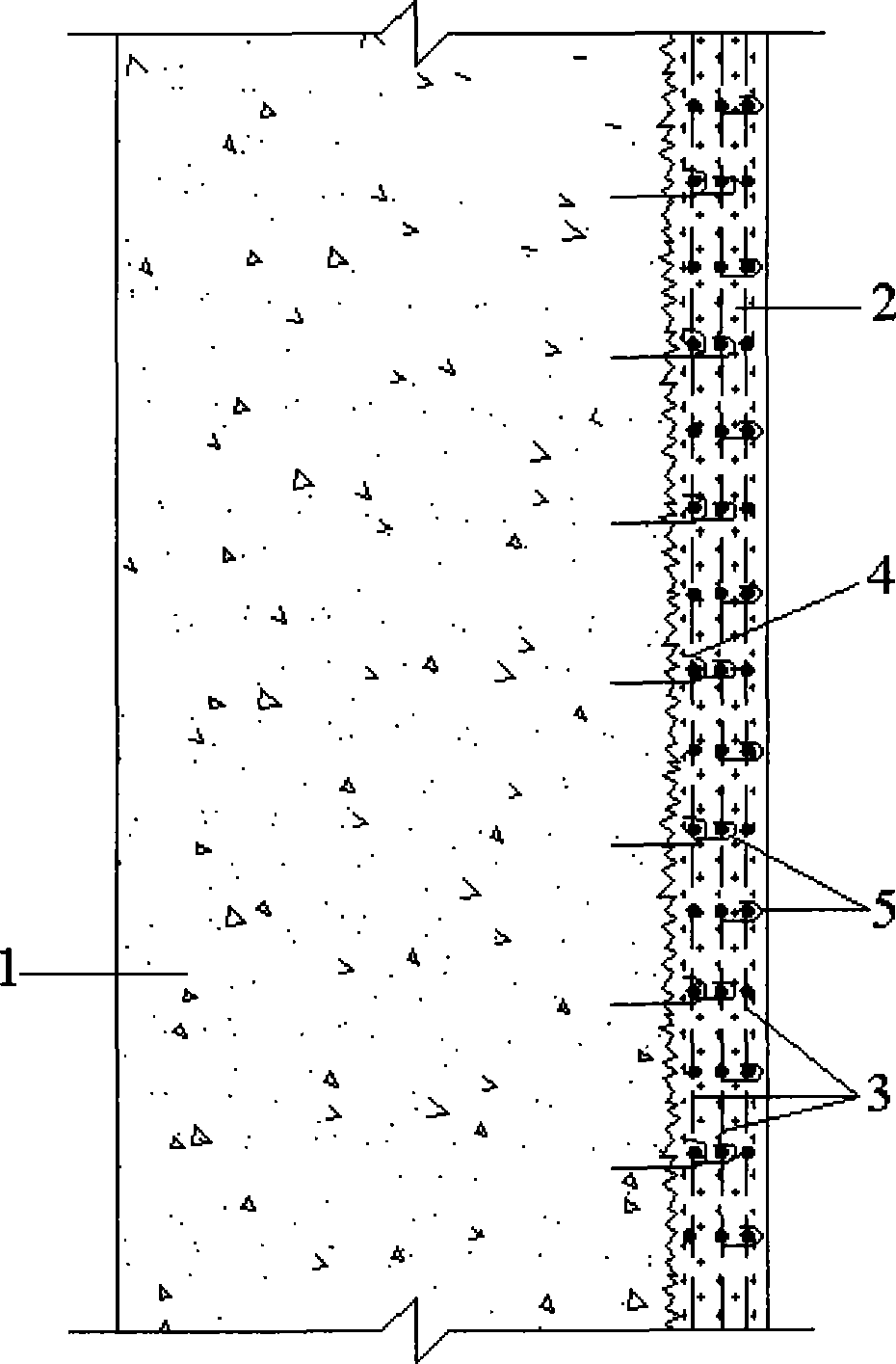

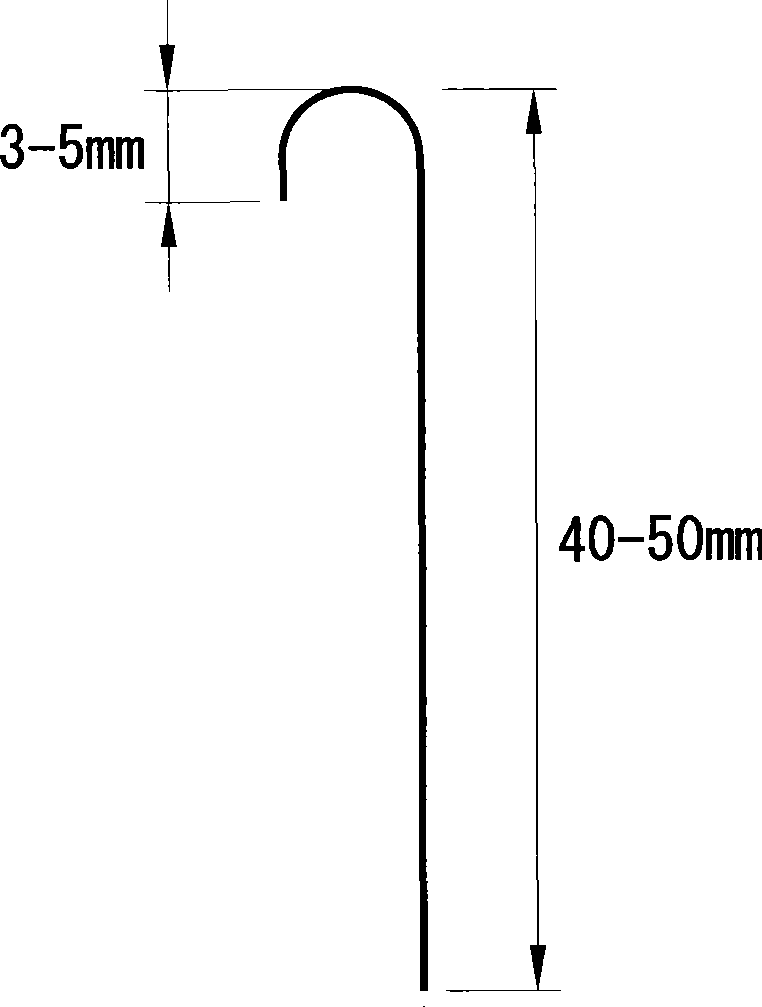

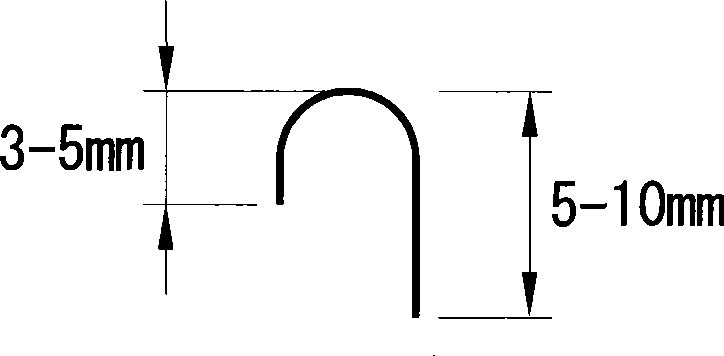

Method for reinforcing construction structure by fiber knitted net and fine concrete

ActiveCN101476396AImprove adhesionAvoid peel damageSolid waste managementMixing operation control apparatusFiberReinforced concrete

The invention belongs to the technical field of concrete reinforcement and relates to a method for reinforcing concrete with a fibrage net and a cement-based material. The method is to pour the fibrage net the total thickness of which is between 10 and 20 millimeters and fine concrete on the outer surface of a structure, and is characterized by comprising the following steps that: drilling holes on the surface of the structure in the process of construction; using the short end foot of a U-shaped shear resistant pin of which the two end feet have different lengths to hook the fibrage net, and inserting the long end foot thereof into the hole after a building structural adhesive is smeared on the long end foot; spraying the fine concrete after the adhesive is solidified; using the short end foot of a U-shaped hook of which the two end feet have different lengths to hook a second layer fibrage net, and inserting the long end foot thereof to the fine concrete; and spraying the fine concrete. The method can avoid the generation of interface micro cracks at high stress, effectively prevent interface peeling damages, reinforces building structures reliably, simply, efficiently and environmental protection, and is applicable to reinforcing and repairing various types of structures.

Owner:浙江固邦新材料有限公司

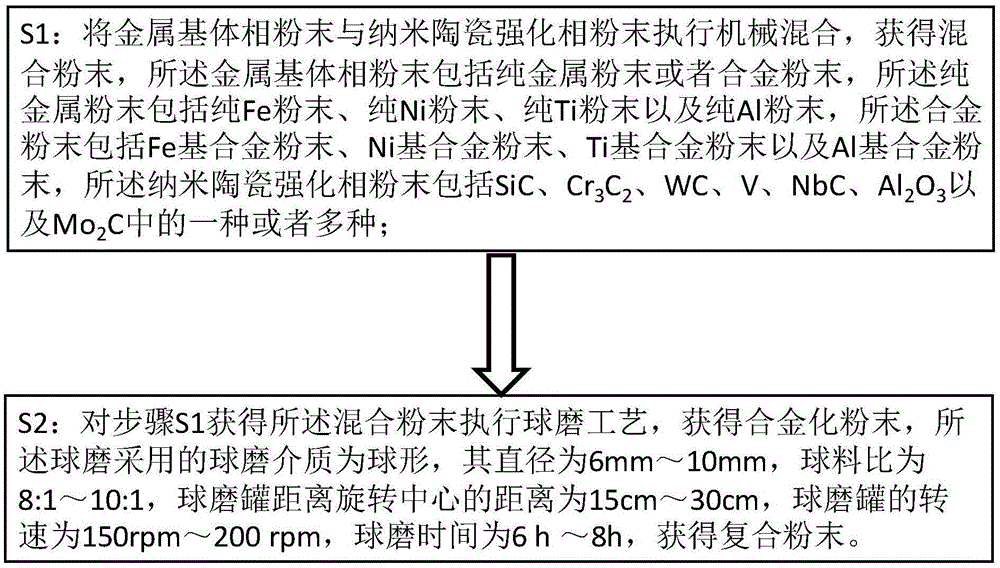

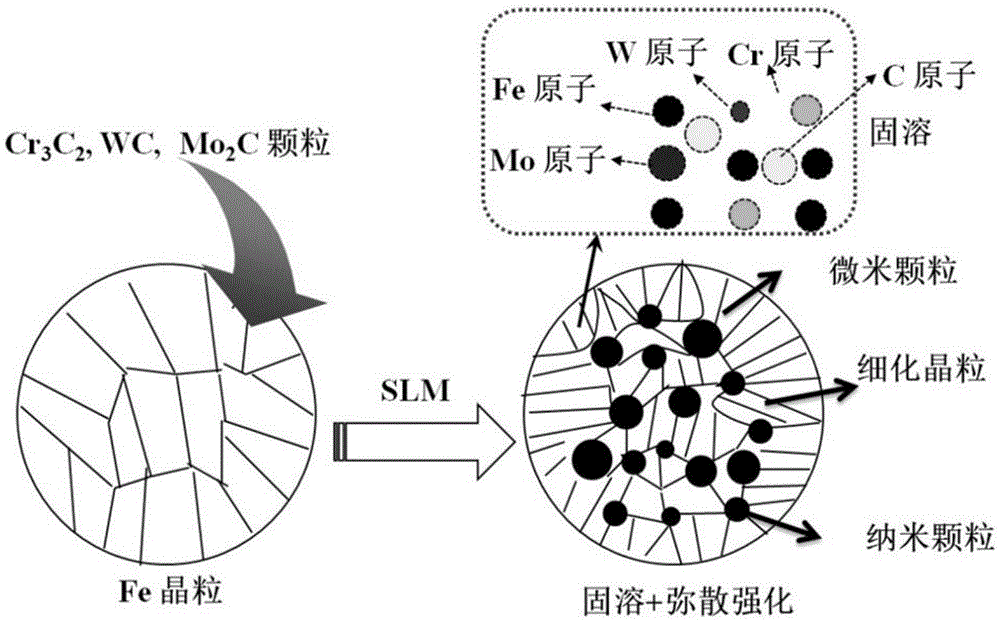

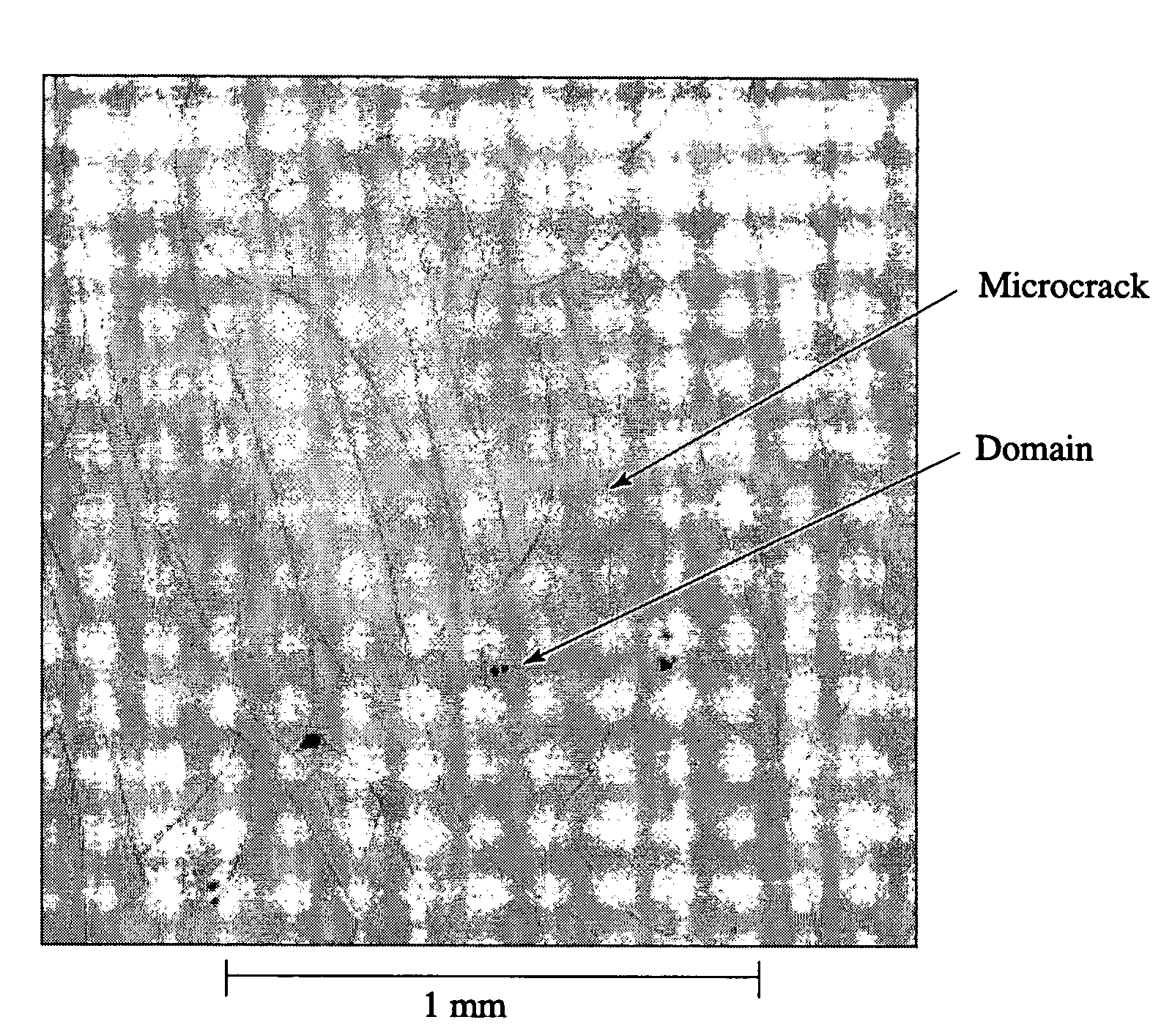

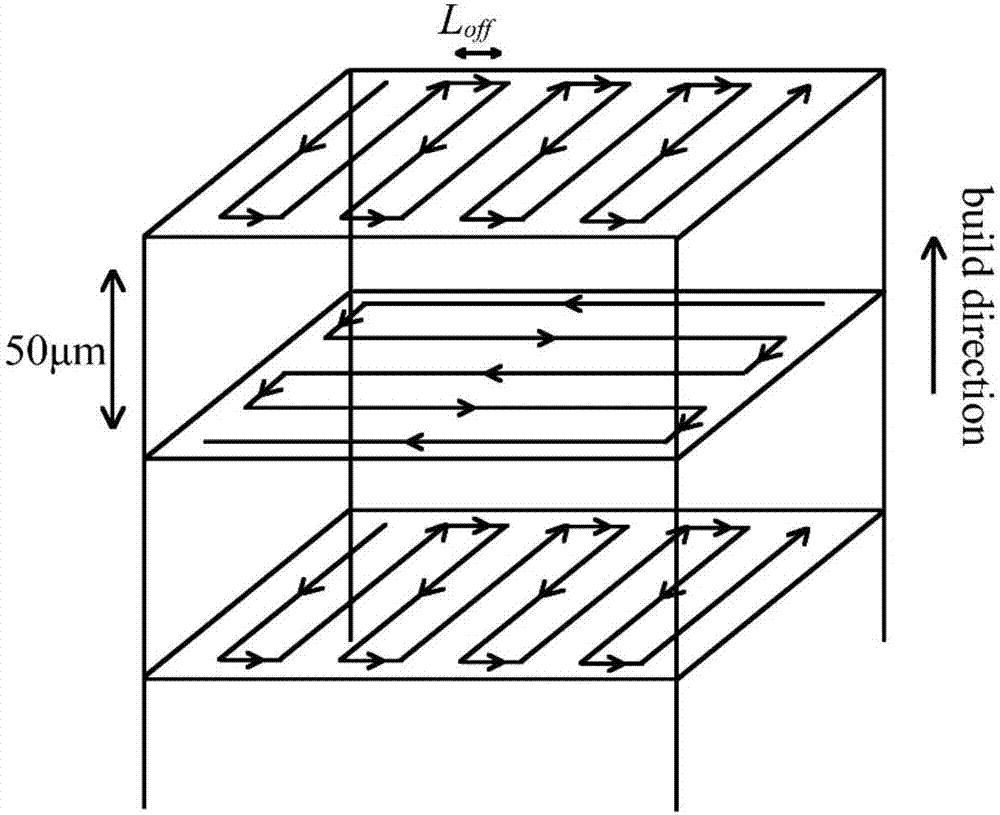

Method for preparing composite powder for 3D printing, product and application

ActiveCN105583401ANo microscopic cracksSuper full noAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSupersaturated solid solution

The invention discloses a method for preparing a composite powder for 3D printing, and belongs to the technical field of material additive manufacturing. The method comprises the following steps: S1, executing mechanical mixing on a metal matrix phase powder and a nano-ceramic strengthening phase powder to obtain a mixed powder; and S2, executing a ball-milling process on the mixed powder to obtain an alloyed powder, wherein a ball-milling medium used in ball-milling is spherical and has a diameter of 6-10mm, a ball-to-powder ratio is 8: 1 to 10: 1, a distance from a ball-milling tank to a rotary centre is 15-30cm, a rotational speed is 150-200rpm, a ball-milling time is 6-8h, and the composite powder is obtained. The invention further provides a method for using the composite powder prepared by the above-mentioned method for 3D printing forming for parts. The composite powder prepared by the method disclosed by the invention is free from micro-cracks and the problem of supersaturated solid solution, and has no high internal stress; and the parts prepared by virtue of the composite powder disclosed by the invention through a selective laser melting forming method have good comprehensive performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Network conductor and its production method and use

ActiveUS7172822B2Maintain good propertiesLow resistivityConductive layers on insulating-supportsSolid-state devicesNetwork structureConductive materials

Owner:FUJIFILM CORP +1

Strong-inhibition strong-blocking drilling fluid

InactiveCN102863947AReduce harmNo pollution in the processDrilling compositionHigh concentrationAbsorption capacity

The invention relates to the technical field of drilling fluid for petroleum drilling, particularly to high-inhibition strong-blocking drilling fluid. The drilling fluid comprises, by weight, 0.5%-15% of a strong inhibitor, 0.5%-7% of a strong blocking agent, 0.5%-5% of bentonite and 0.2%-6% of a fluid loss agent. The drilling fluid has strong inhibiting effect on hydration of strong water-sensitive mud shales through high concentration K+ generated after dissolution of the strong inhibitor; simultaneously, anions generated after the dissolution of the strong inhibitor take the absorption action with the surface of clay through the absorption capacity so as to form protective films on the surface of the clay, and therefore the hydration of the clay is prevented; and the strong blocking agent can achieve strong blocking to strong water-sensitive mud shale stratums with micro-cracks to form isolating films in the real sense, and therefore instability of well walls of the strong water-sensitive mud shale stratums is prevented. The drilling fluid has the advantages of being good in blocking, strong in inhabitation, good in lubricity, stable in high temperature property, small in damage to reservoir stratums, free of pollution and capable of improving the production efficiency.

Owner:CNPC XIBU DRILLING ENG

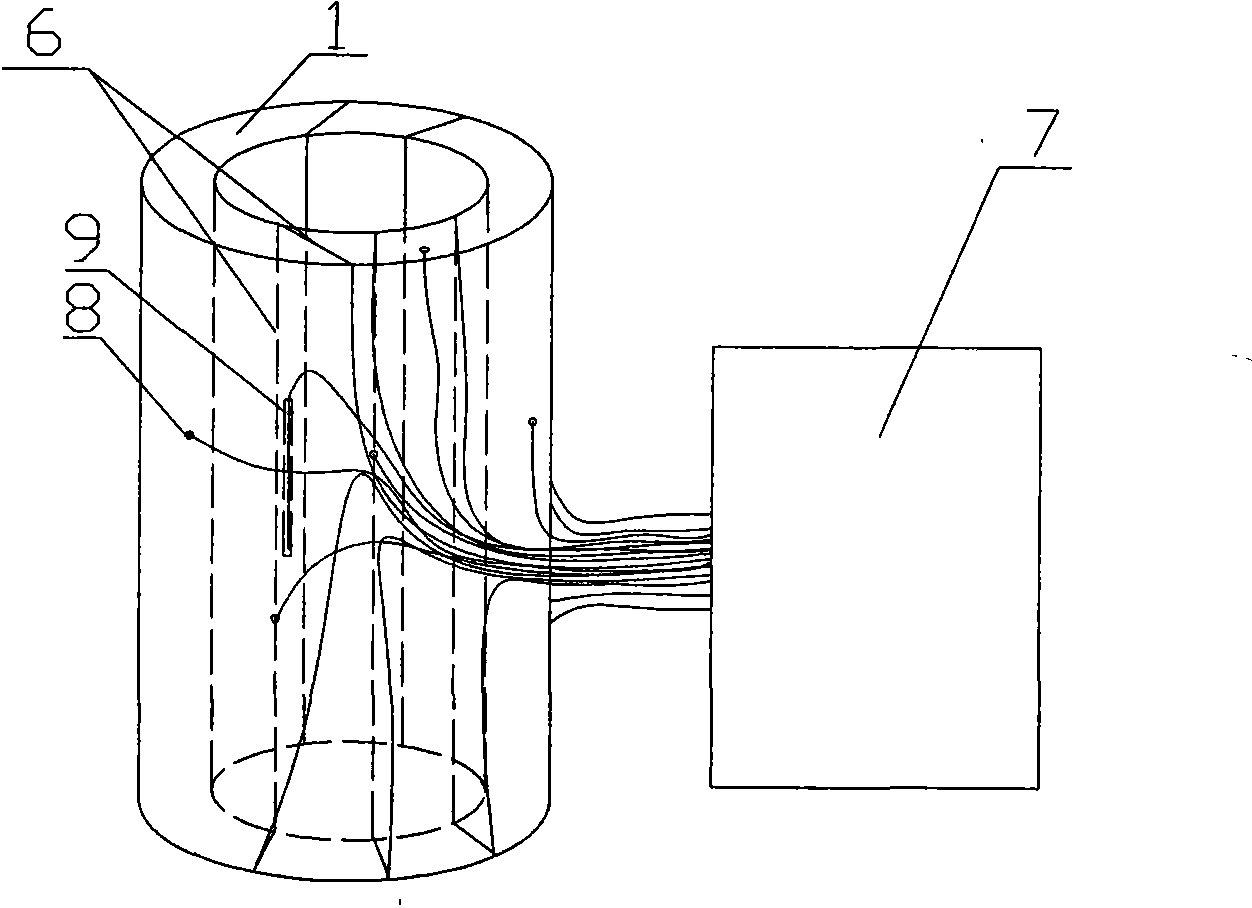

Rock deforming and cracking three-dimensional dynamic testing system based on fiber strain sensing

InactiveCN101520317AIncrease space positionMaterial strength using tensile/compressive forcesUsing optical meansFiber strainInstability

The invention relates to a rock deforming and cracking three-dimensional dynamic testing system based on fiber strain sensing, which comprises a testing piece, wherein the testing piece is laid with a fiber sensor encapsulated with a plurality of testing strains; the fiber sensor is connected with a signal demodulation processing device through a connecting fiber; and demodulated data signals can build three-dimensional testing data of the testing piece and can form a three-dimensional dynamic strain field of the testing piece after interpolation. The system can effectively lay out the fiber sensor inside and on the surface of the real rock testing piece under the pressure of a three-axis presser, enters the rock inside to detect the rock dynamic strain under the premise of not influencing the rock structure and the stress, and can really test the rock dynamic cracking process to obtain the crack initial and expended spatial positions inside the testing piece. The system continuously monitors the generation and expansion of tiny cracks inside brittle materials under the loading action in real time at the same time, and can be widely applied to researching cracking instability mechanisms of materials, such as rocks, concrete and the like.

Owner:SHANDONG UNIV

Inorganic powder capillary crystalline waterproof coating material

InactiveCN101362867AImprove impermeabilityImprove permeabilityAntifouling/underwater paintsPaints with biocidesWater reducerQuartz

The invention discloses an inorganic powder infiltration crystalline water-proof material which consists of 45 to 55 portions of 600#silicate cement, 20 to 25 portions of ultra-thin quartz sands, 25 to 30 portions of master batches, 1 to 5 portions of effective retarding water reducers and 1 to 5 portions of macromolecular tougheners and is manufactured by feeding the materials into a stirrer to be uniformly stirred. The inorganic powder infiltration crystalline water-proof material is characterized by having the advantages of secondary anti-permeability capacity, durable water-proof performance, high sticking performance, acid resistance and alkali matter resistance; besides, the inorganic powder infiltration crystalline water-proof material have the capacity of growing an insoluble crystal in the pores and the micro cracks of a concrete substrate to plug the pores and the micro cracks, thereby improving the anti-permeability capacity of the concrete and achieving the goals of anti-permeability and anti-leakage. The inorganic powder infiltration crystalline water-proof material can be broadly applied to the water-proof projects of railways, roads, ports and docks, culverts, dams and pools as well as large underground projects.

Owner:天津市耀新科技发展有限公司

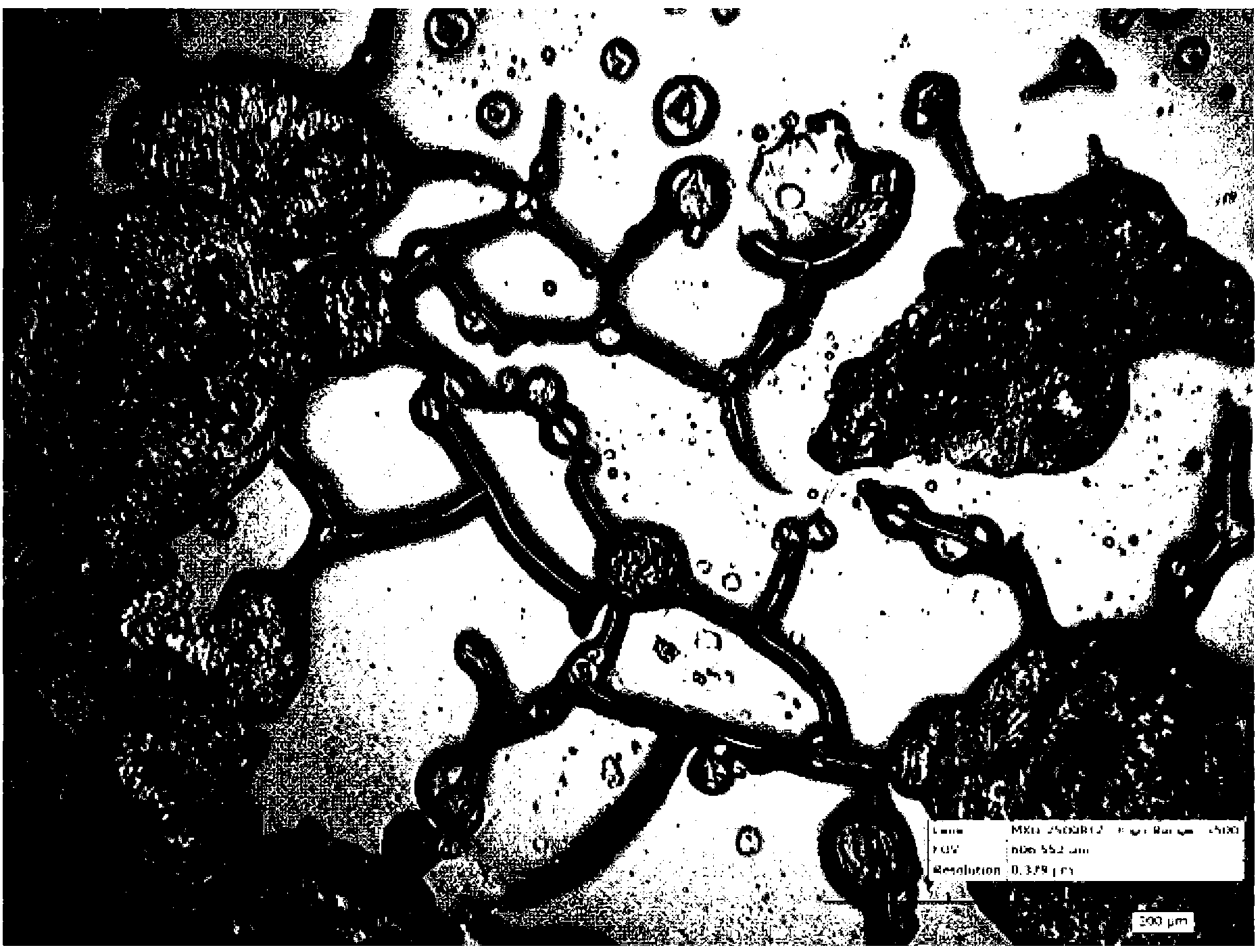

Visual simulation shale micro-crack plugging capacity test system and method

ActiveCN103485762AIntuitive visual macro analysisImprove general applicabilityConstructionsBorehole/well accessoriesMicroscopic observationMicroscopic scale

The invention relates to a visual simulation shale micro-crack plugging capacity test system and a visual simulation shale micro-crack plugging capacity test method. Displacement evaluation experiment is performed on a single or combined micro-crack rock sample by a solution or a drilling fluid which contains the plugging agents with different concentrations and different types at different experiment conditions, such as pressure differences and times, indexes, such as the invasion depth, are compared, the formation conditions of inner mud cakes in drilling are directly described, and microscopic observation and analysis are performed on percolation substances invade into the micro-cracks by utilizing amplification imaging instruments, such as a high-definition microscope, so that the plugging mechanisms and the effects of various drilling fluid plugging agents and drilling fluids are analyzed and researched intuitively and microscopically, a proper drilling fluid plugging agent is selected preferably, a drilling fluid system formula is optimized, the problem about the experimental conditions that the visual simulation evaluation cannot be performed on shale micro-crack plugging in the past is solved, and a new evaluation experimental research means is provided for related research and production in the technical field of fractured shale strata borehole wall stability in petroleum engineering.

Owner:CHINA PETROLEUM & CHEM CORP +1

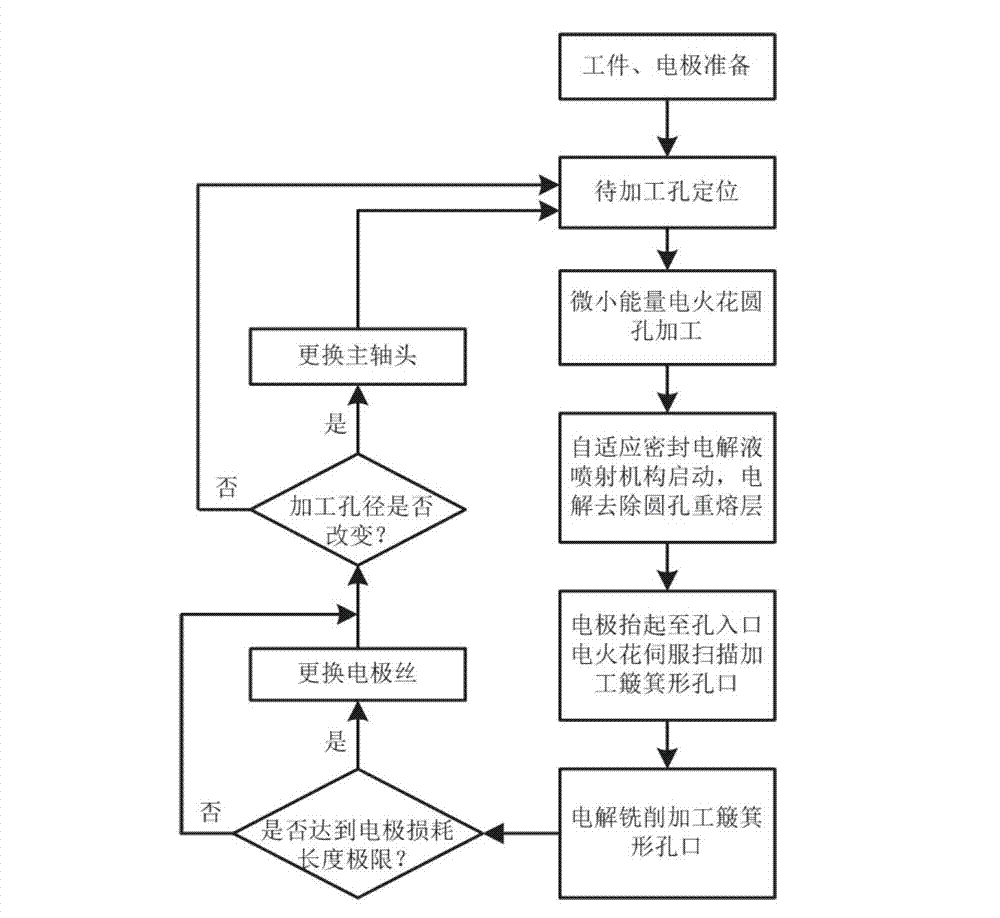

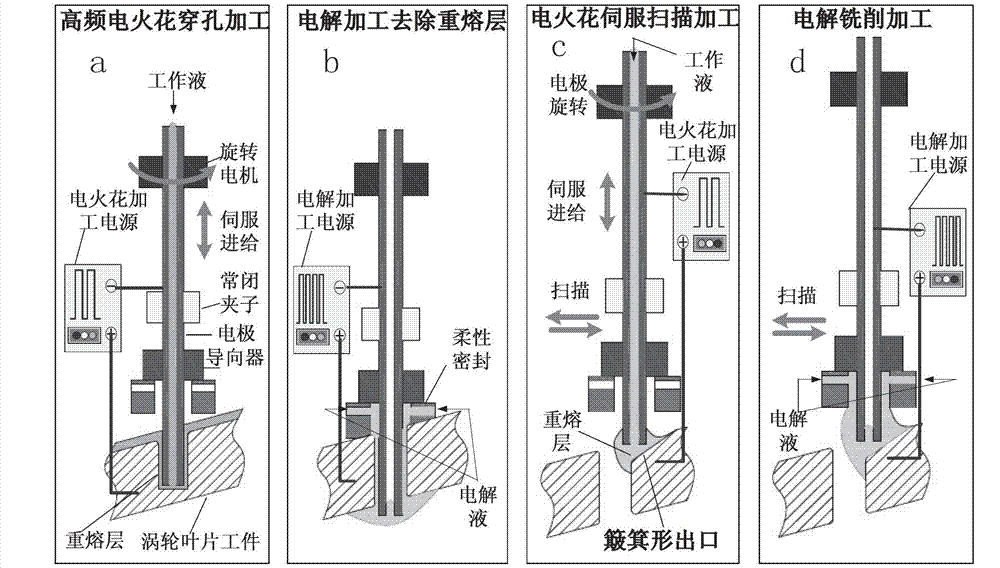

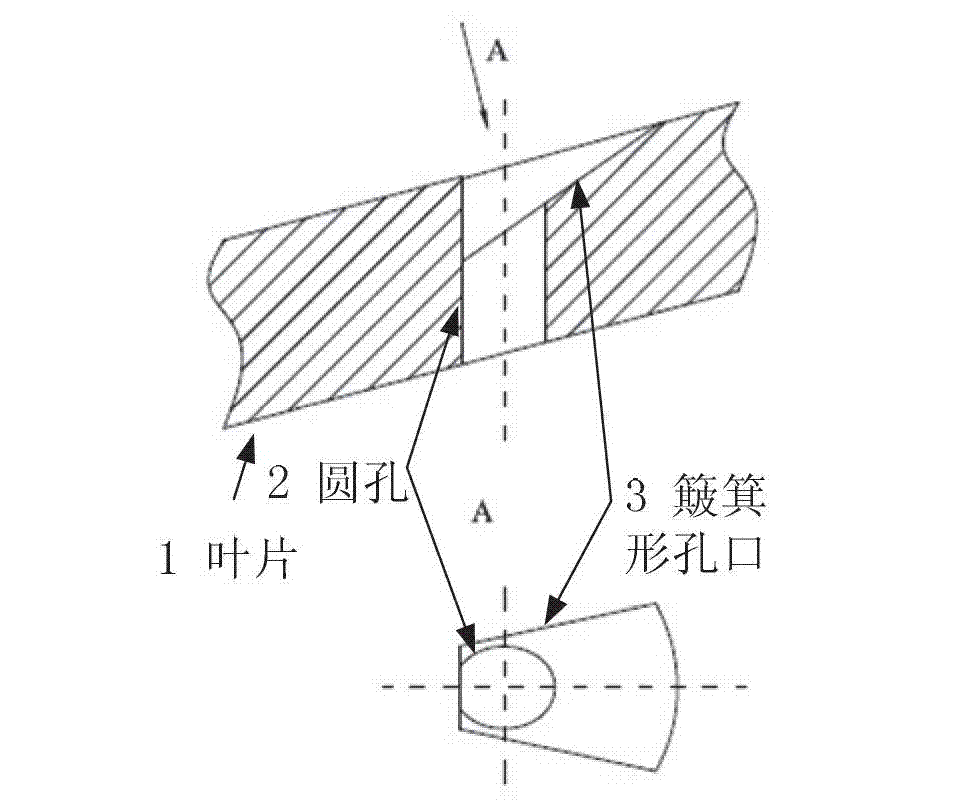

Machining method of gravity-free smelting layer air membrane hole of aviation engine turbine blade

InactiveCN102861956AReduce manufacturing difficultyShorten the manufacturing cycleAviationEngineering

The invention belongs to the technical field of small hole electric machining and particularly relates to a machining method of a gravity-free smelting layer air membrane hole of an aviation engine turbine blade. The machining method comprises four steps: firstly, machine a circular hole with a needed size a nickel-based high-temperature alloy blade on a gas turbine by utilizing washing liquid electric sparks in a hollow electrode according to a design requirement; then utilizing the same electrode to electrolyze the machined circular hole in an electrolyte environment of an outer washing solution to remove a re-smelted layer; then, raising the electrode and utilizing an electric spark servo scanning and milling and machining process to machine a dustpan-shaped hole opening of the air membrane hole; and finally, utilizing the end part of the electrode to carry out electrolytic milling machining on the dustpan-shaped hole opening to remove the re-smelted layer of the hole opening so as to improve the surface quality. According to the machining method disclosed by the invention, the problem of a residual re-smelted layer and small cracks of the air membrane hole machined by the electric sparks can be solved, a secondary clamping and positioning error is avoided and the machining efficiency is improved.

Owner:TSINGHUA UNIV

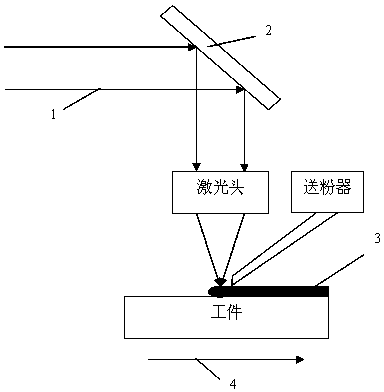

Method for prolonging life of pump shells and blades by carrying out laser strengthening micro-cracks

InactiveCN103409758AExtended service lifeImprove fatigue strengthMetallic material coating processesHeat-affected zoneLaser processing

The invention discloses a method for prolonging life of pump shells and blades by carrying out laser strengthening, which relates to the technical fields of machinery manufacturing and laser processing application. The method adequately combines the characteristics of laser cladding with laser shock strengthening, i.e., the method comprises the steps of performing laser cladding repair on micro-cracks at first, and then performing laser shock strengthening treatment on a cladding layer, thus effectively solving the problem that the pump shells and blades are easy to generate internal defects such as cracks and air holes in the laser cladding repair process, and avoiding the problems of welding deformation, large heat influence area, easy generation of heat cracks and the like in a conventional processing method; the method disclosed by the invention is capable of generating a high-amplitude residual compressive stress on the surface of a material, effectively improving the fretting fatigue resistance of the material, comprehensively improving the mechanical properties of the material, and greatly prolonging the fatigue life of the material, thus achieving the purposes of prolonging the life and improving the reliability and safety.

Owner:JIANGSU UNIV

Aerated concrete building block and preparation technology thereof

ActiveCN102206095AHigh tensile strengthHigh impact strengthCeramicwarePhosphogypsumUltimate tensile strength

The invention discloses an aerated concrete building block. The aerated concrete building block comprises, by weight, 65-72 parts of fly ash, 15-20 parts of quick lime, 5-10 parts of cement, 2.83-3.83 parts of phosphogypsum, 0.1 parts of aluminum powers, 0.05 parts of a foam stabilizer and 0.02 parts of a polypropylene fibre. The modified polypropylene fiber is added to the concrete structure material, such that tensile strength and anti-impact strength of the concrete structure material are improved, a drying shrinkage value of the concrete structure material is reduced, and cracks are prevented from formation and extension during cement solidification. During a green body structural strength formation, a plurality of microcracks are generated due to a plastic shrinkage of the green body, such that during a later autoclaved process, larger cracks are easily generated from the microcracks when the aerated concrete structure extends; meanwhile, because a gradient variation of humidity of the aerated concrete material is large, cracks in the aerated concrete material are easily generated during humidity changing. Therefore, the internal structure of the aerated concrete provided by the present invention can enable improving the disadvantages of generation of aerated concrete wall cracks through an enhancement of the polypropylene fibre.

Owner:俞华贵

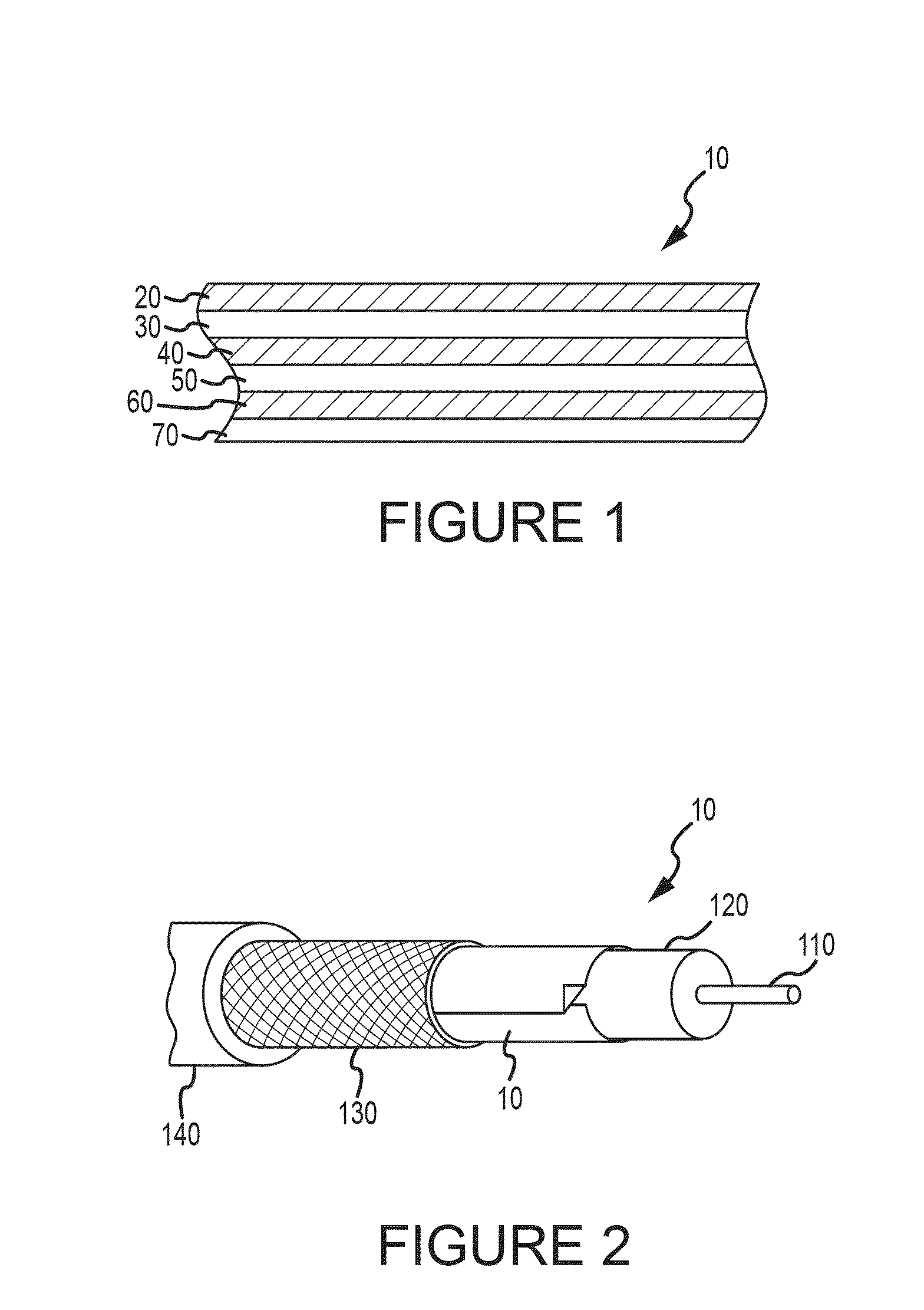

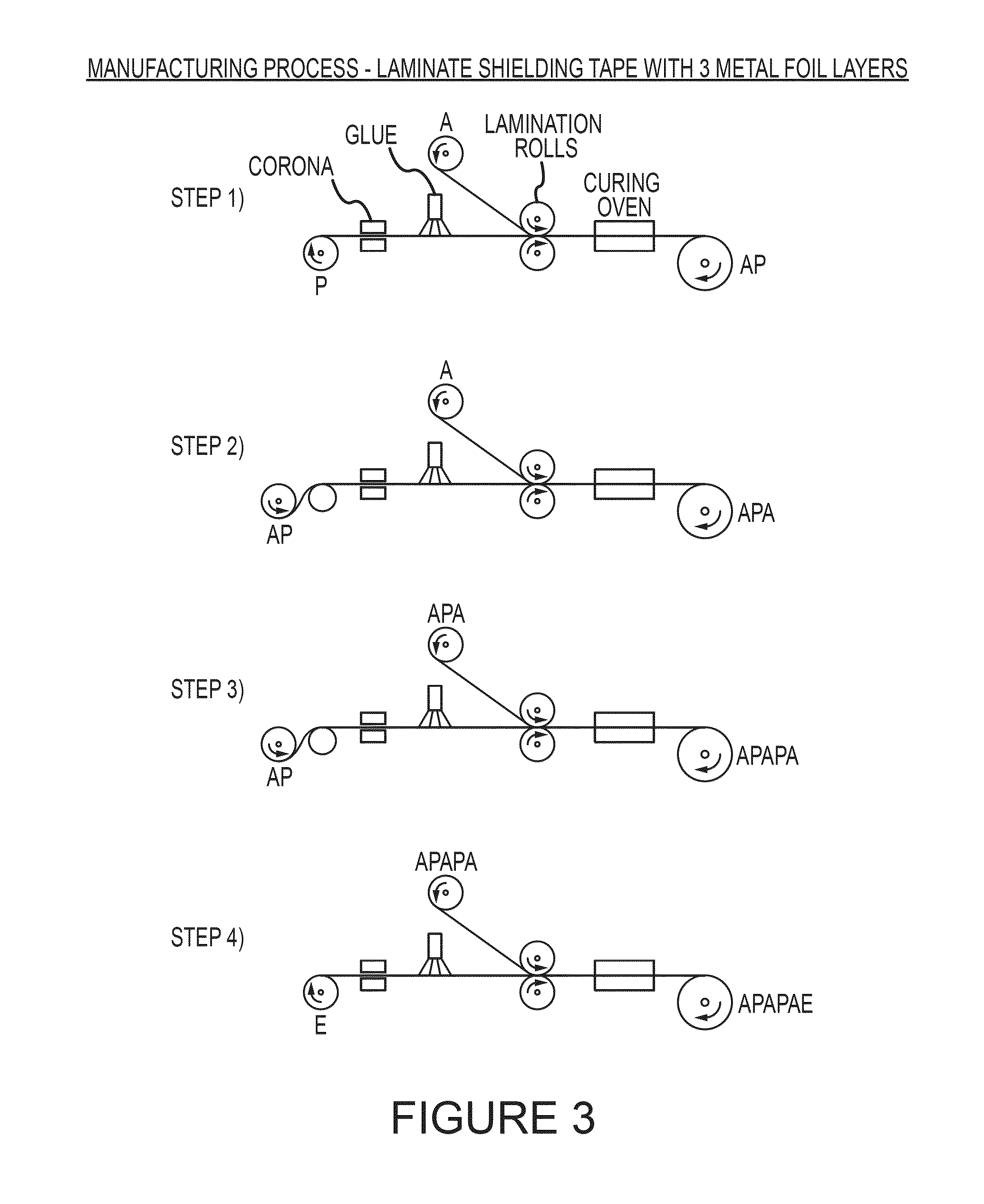

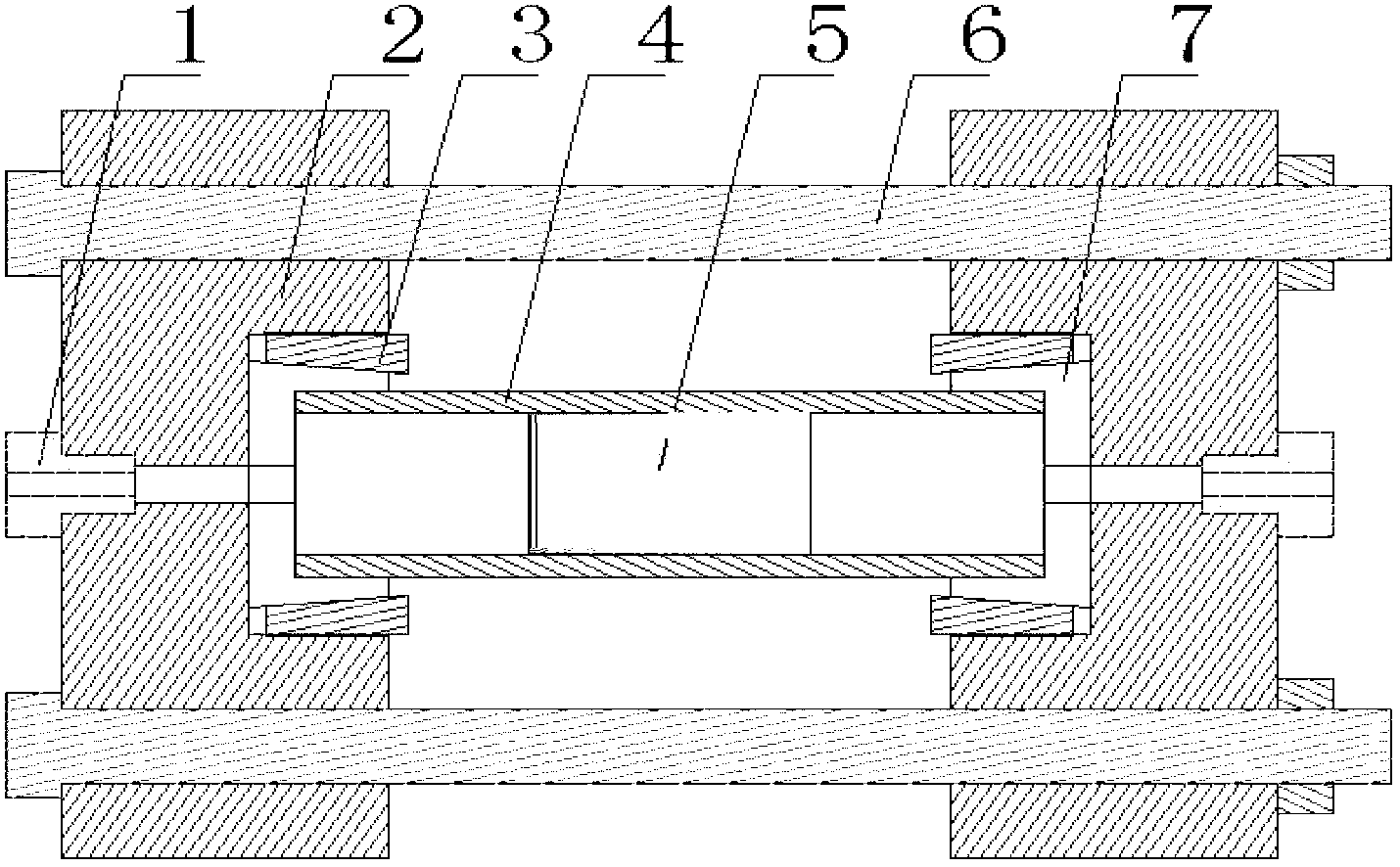

Shielding tape with multiple foil layers

ActiveUS20110011639A1Extend elastic lifeReducing signal egressCable conductor constructionMagnetic/electric field screeningDielectricCoaxial cable

A coaxial cable of the present invention comprises a center conductor, a dielectric surrounding the center conductor, a shielding tape surrounding the dielectric, a braided metal surrounding the shielding tape, and an outer jacket surrounding the braided metal. The shielding tape comprises: (i) a first shielding layer bonded to a first separating layer; (ii) a second shielding layer bonded to the first separating layer and a second separating layer; and (iii) a third shielding layer bonded to the second separating layer. The present invention eliminates the potential problem of the outer shielding structures separating and interfering with connector attachment. Furthermore, the use of three or more shielding layers in the shielding tape of the present invention improves the flex life of the shield tape by covering micro-cracks in the metal layers with additional shielding layers, thus reducing signal egress or ingress. Accordingly, the present invention provides cost savings and / or an improvement in shielding performance.

Owner:PCT INT

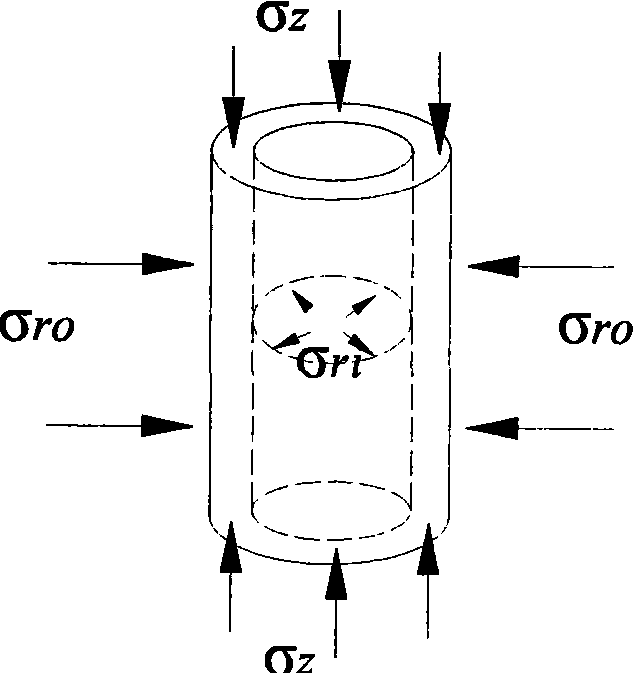

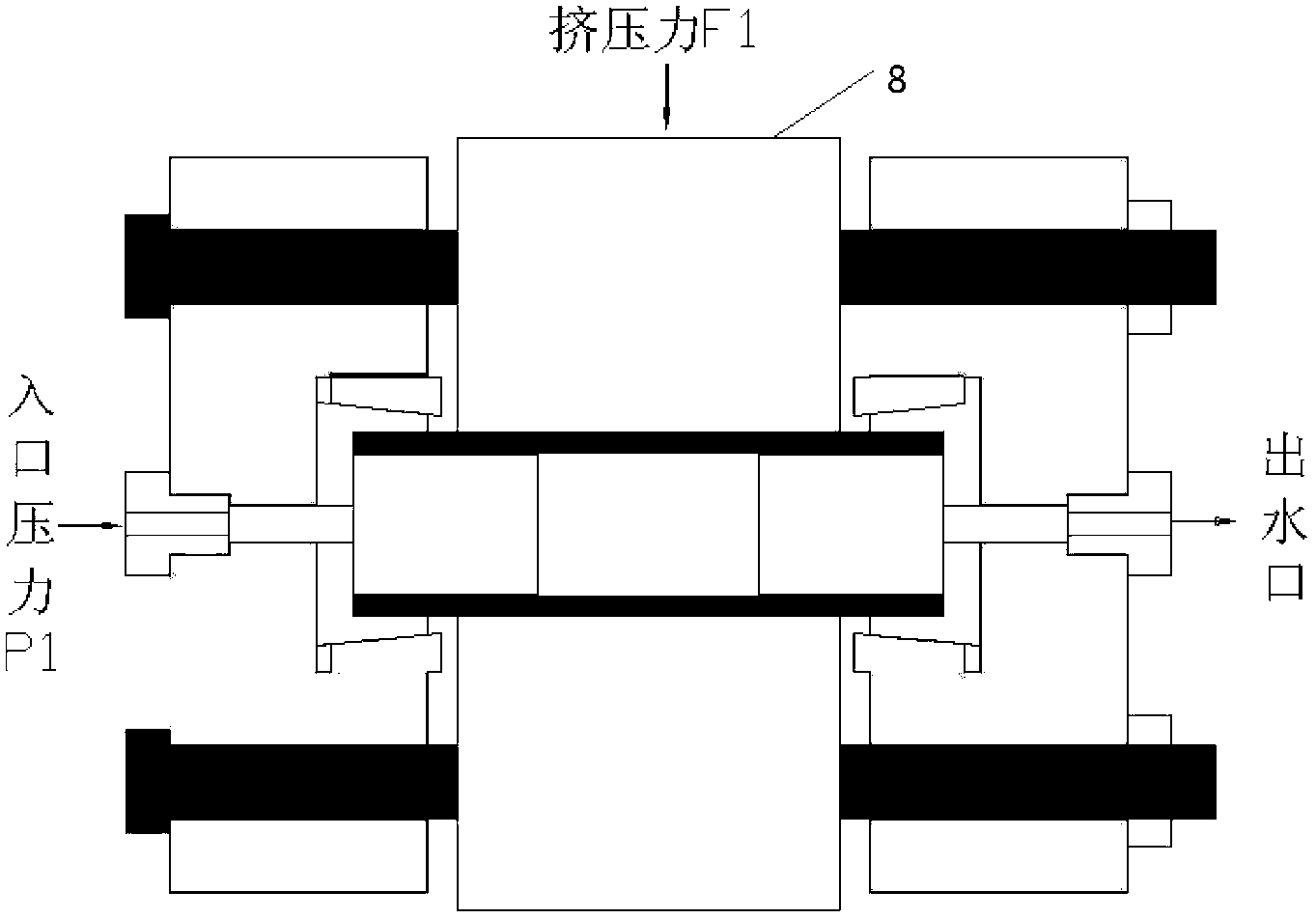

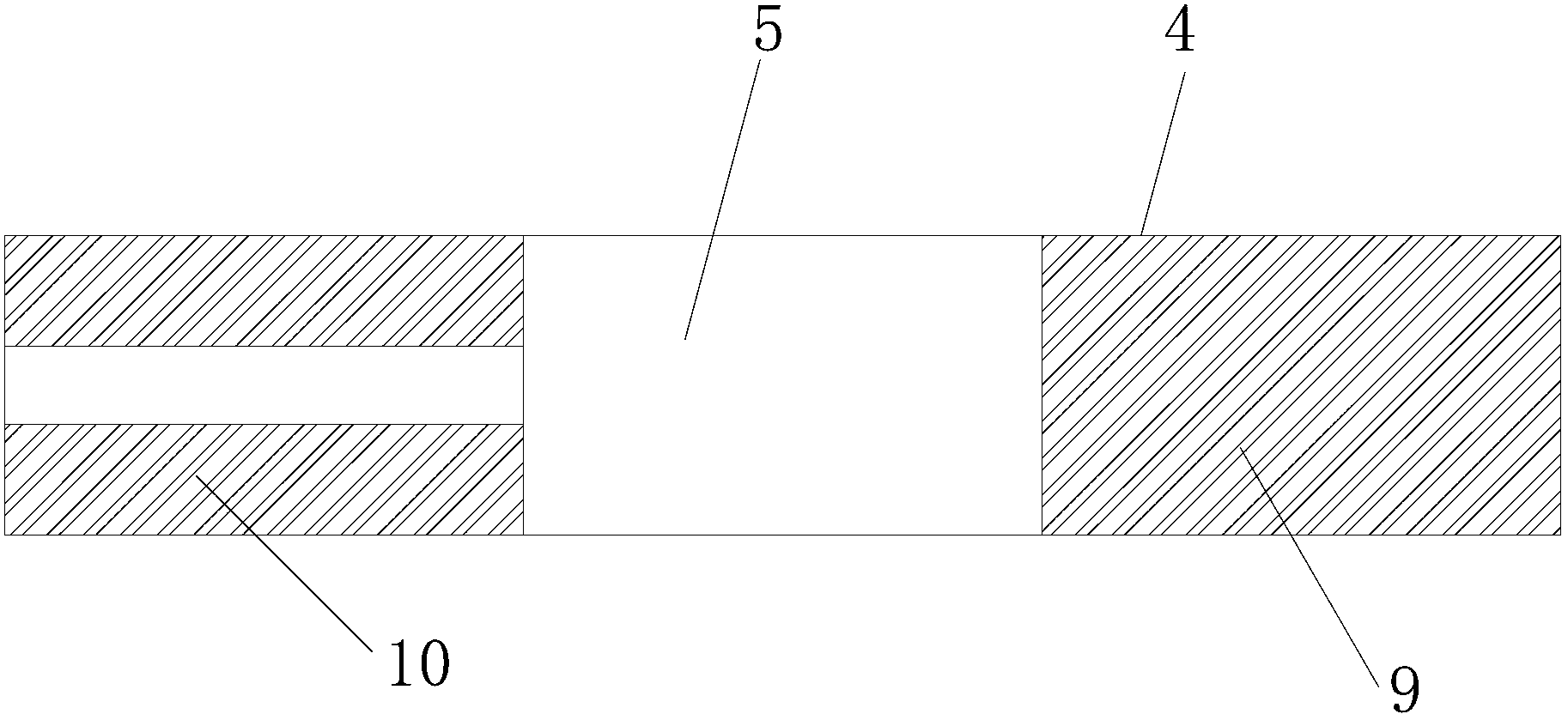

Well cementation cement sheath integrity simulation and evaluation tester

A well cementation cement sheath integrity simulation and evaluation tester includes pressing joints, wherein the pressing joints are arranged on compress packings; screwing compression rings are connected with compress discs through screw threads, and fix trapezoid rubber seal rings onto the compress discs and a steel tube; the steel tube containing a well cementation cement solidified body test sample is clamped tightly by screw rod and screw nut connecting assemblies and connected with the screw rod and screw nut connecting assemblies into a whole; pressing blocks and a mechanical pressure device are connected together to exert mechanical extrusion force to simulate the process that underground pressure variation causes damage and micro cracks to an oil well cement sheath; the pressing joints and a fluid pressing device are connected, so as to exert fluid pressure, simulate fluid pressure of the formation fluid on the well cementation cement sheath, and test and evaluate anti-channeling strength of the well cementation cement sheath; cured samples are placed in the well cementation cement sheath mechanical property simulation tester for test and analysis; and the tester can detect variation situations of the anti-channeling strength of the well cementation cement sheath under different conditions, so that impacting ductility and packing reliability of the well cementation cement sheath can be evaluated accurately.

Owner:XI'AN PETROLEUM UNIVERSITY

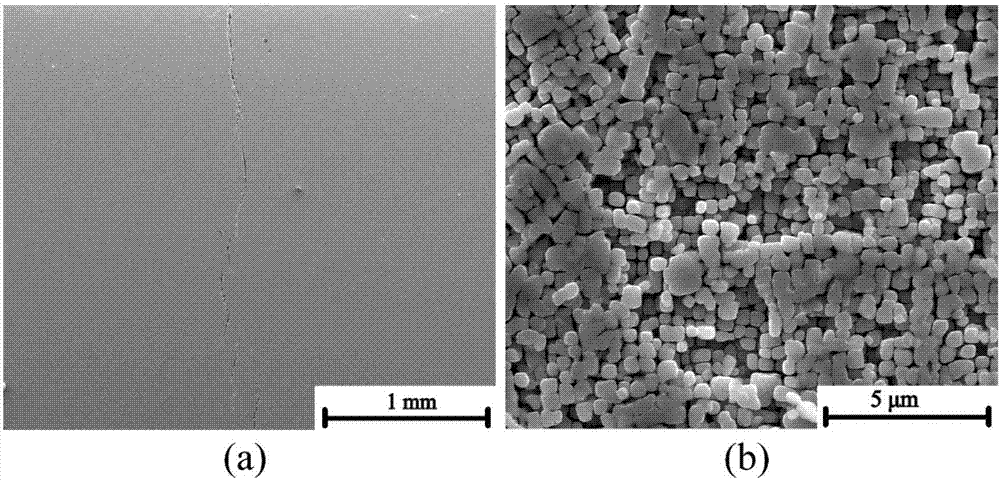

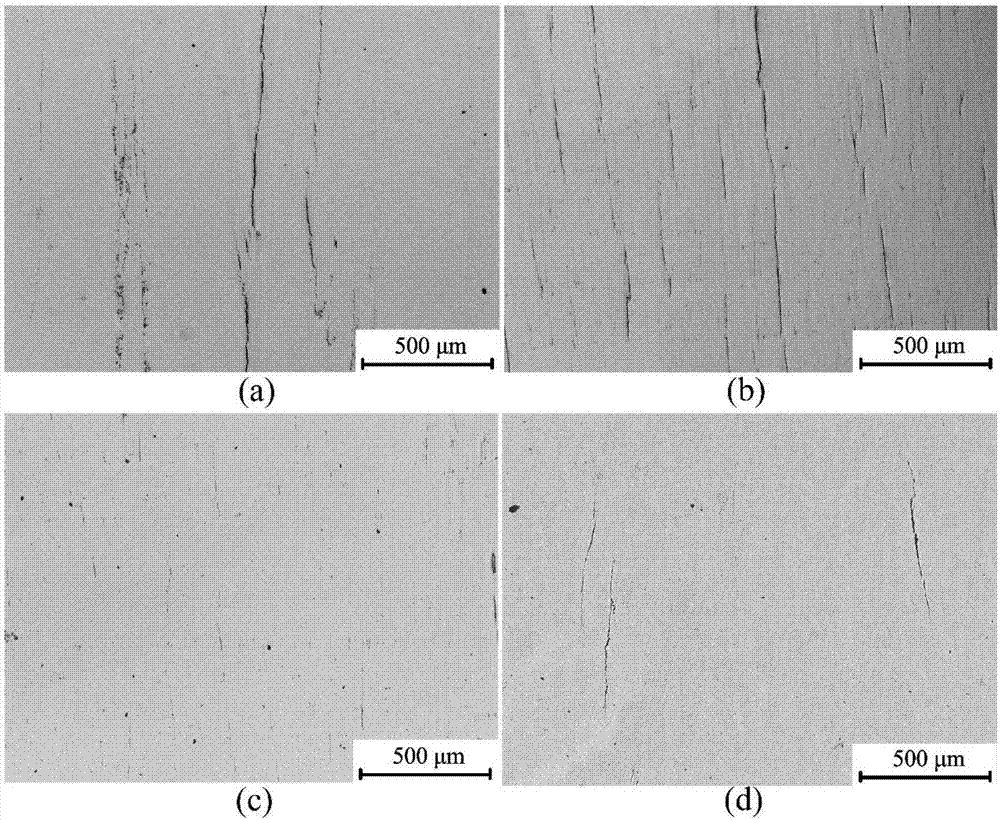

Method for removing microcracks from additive manufacturing nickel-base high-temperature alloy components manufactured by electron beam selective melting

InactiveCN107971491ASimple structureImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencySolution treatmentSolid solution

The invention discloses a method for removing microcracks from additive manufacturing nickel-base high-temperature alloy components manufactured by electron beam selective melting, and belongs to thetechnical field of high-temperature alloy and additive manufacturing. According to the method disclosed by the invention, additive manufacturing nickel-base high-temperature alloy is treated with heattreatment technologies, including hot isostatic pressing treatment, solid solution treatment and aging treatment in sequence, and compact additive manufacturing nickel-base high-temperature alloy materials without the microcracks can be prepared with the heat treatment technologies, and have excellent microstructure and mechanical properties.

Owner:BEIHANG UNIV

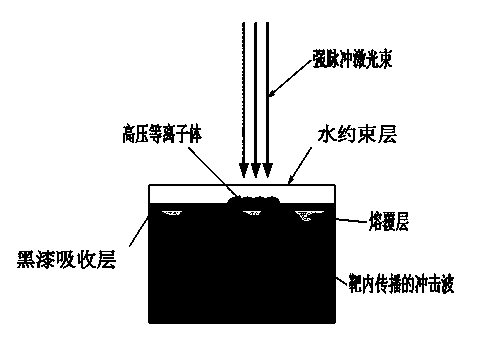

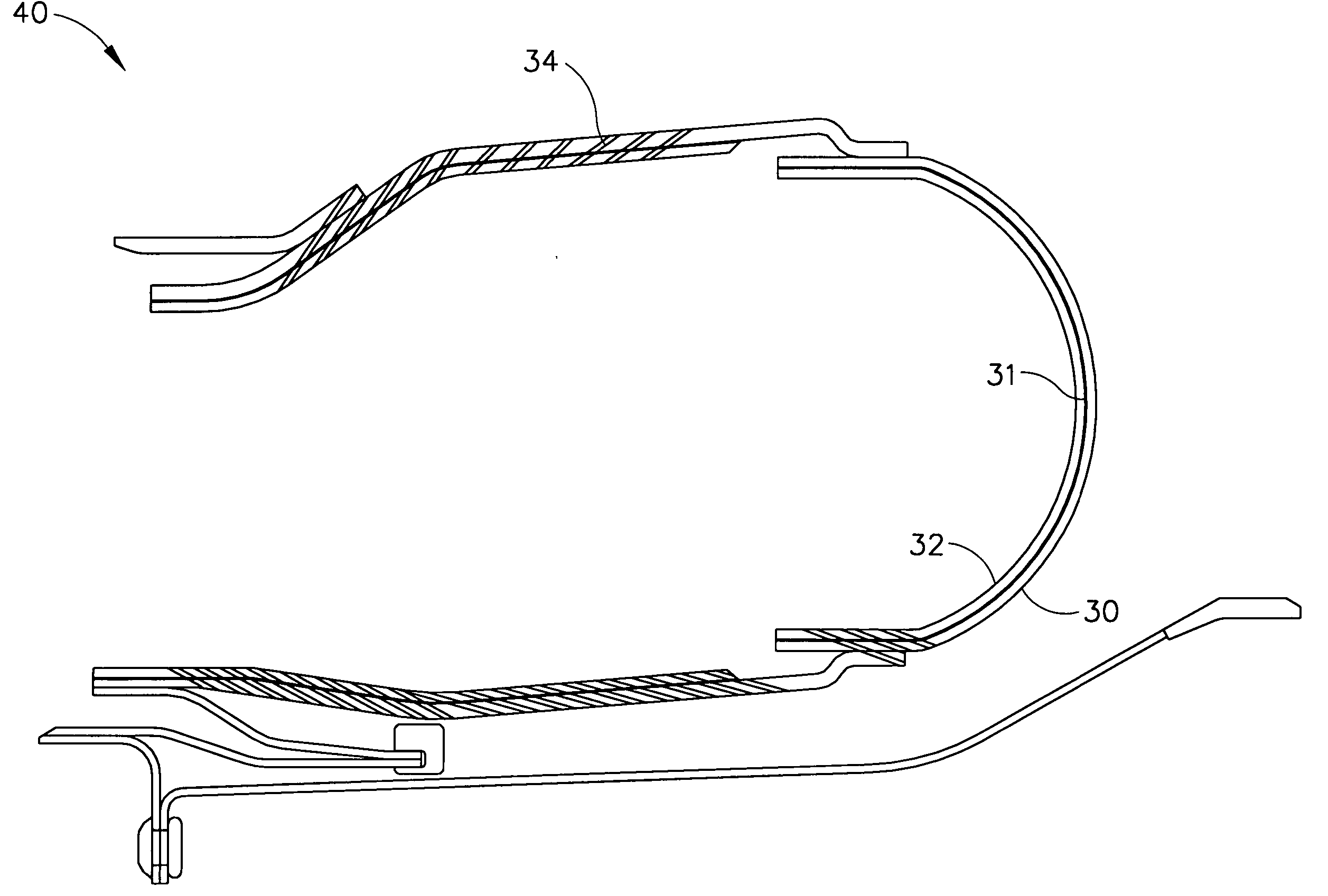

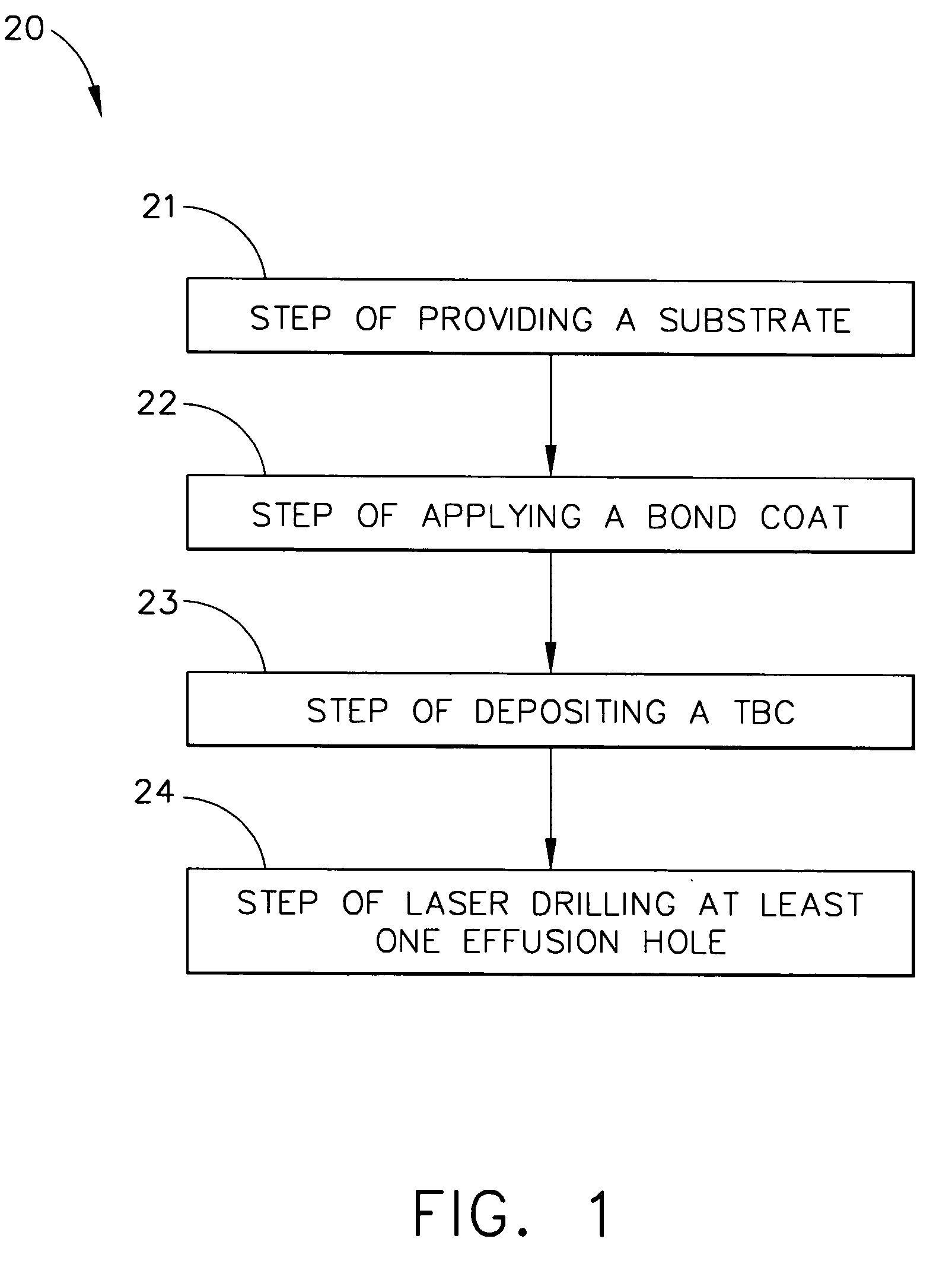

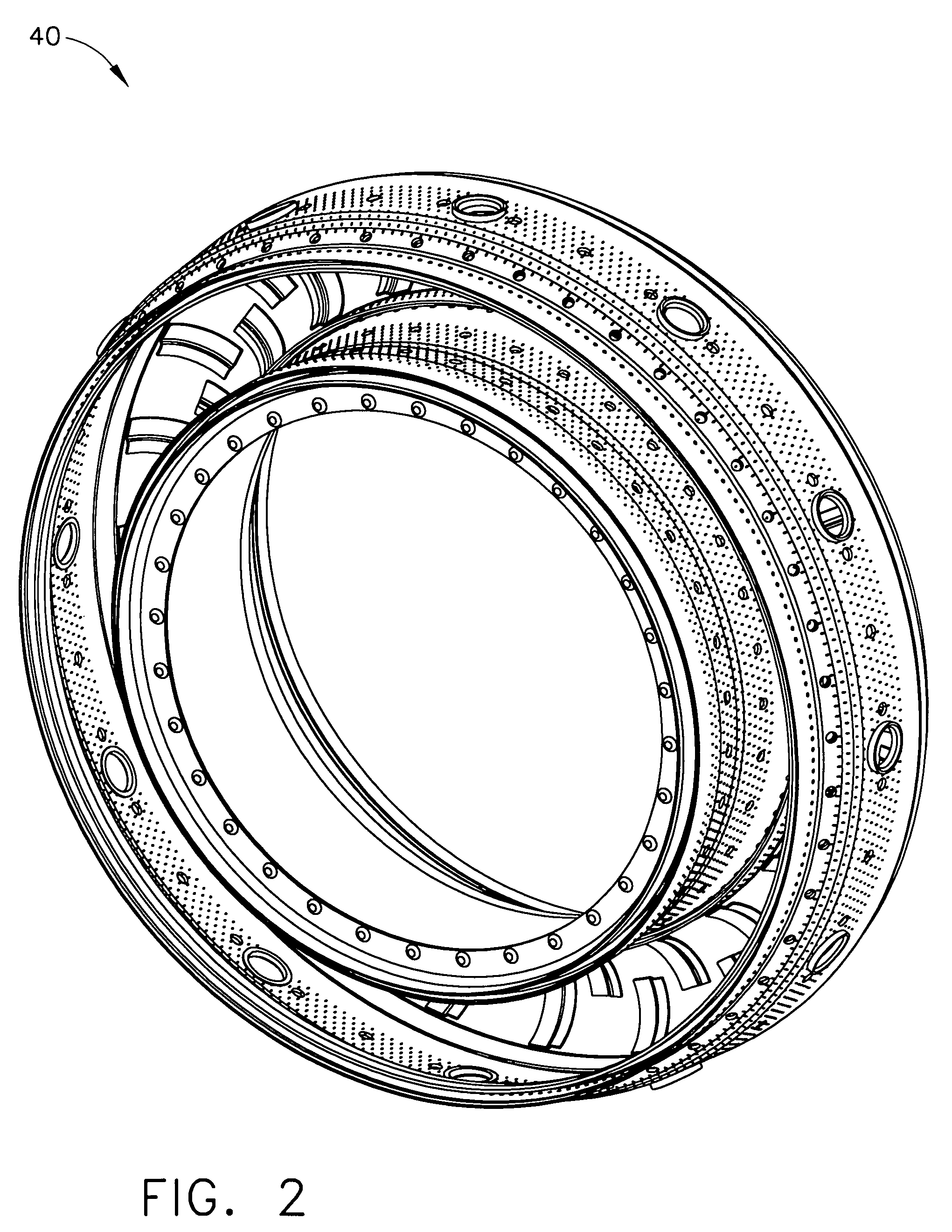

Combined effusion and thick TBC cooling method

A method for combined effusion and thick TBC cooling comprises a providing a substrate, depositing a thick TBC onto the substrate and laser drilling an array of effusion holes through the TBC coated substrate. The thick TBC has a columnar crack structure, which gives compliance and spall resistance. The microstructure of the segmentation microcracked TBC reduces cracking and chipping of the TBC during effusion hole laser drilling.

Owner:HONEYWELL INT INC

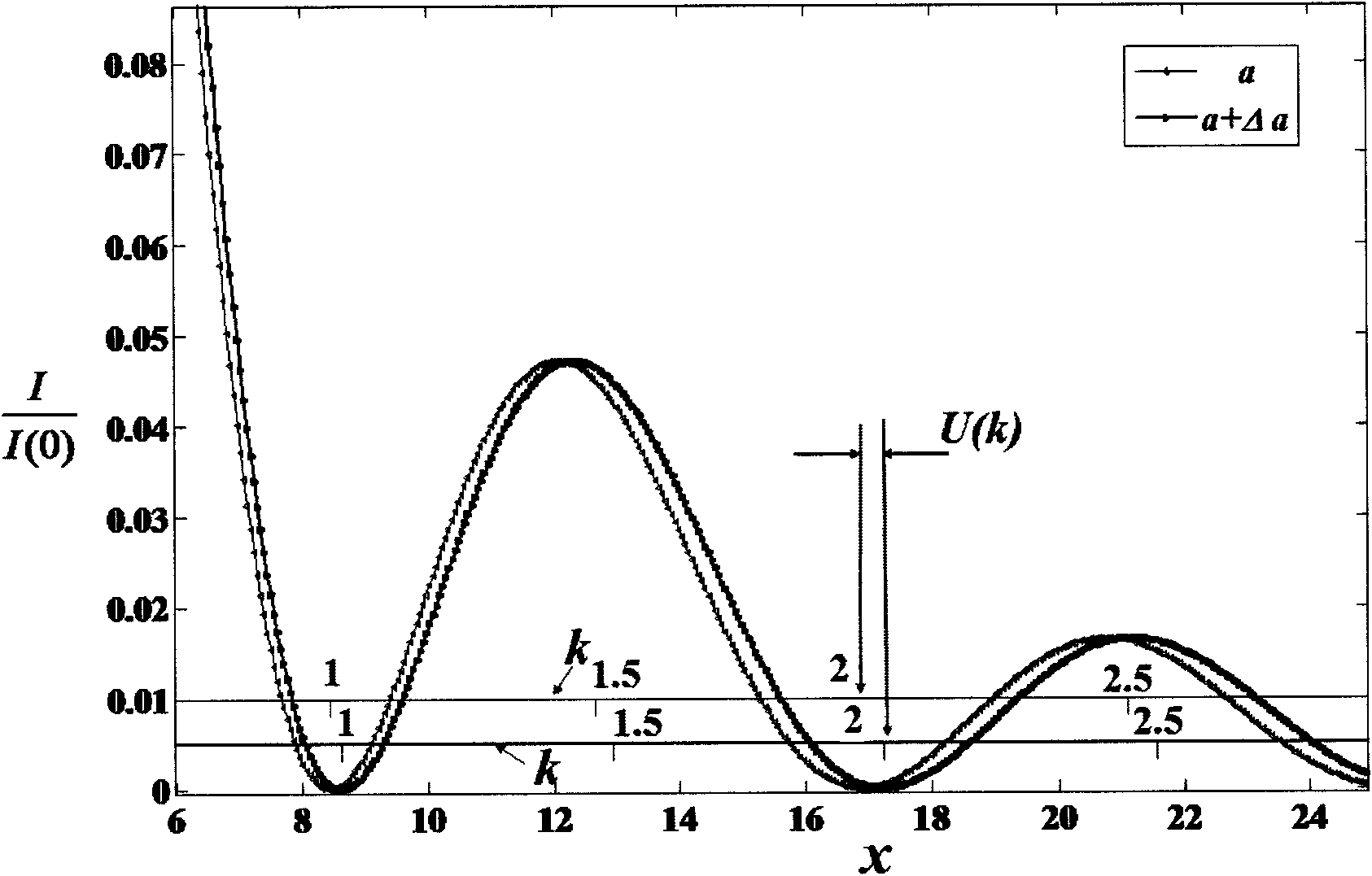

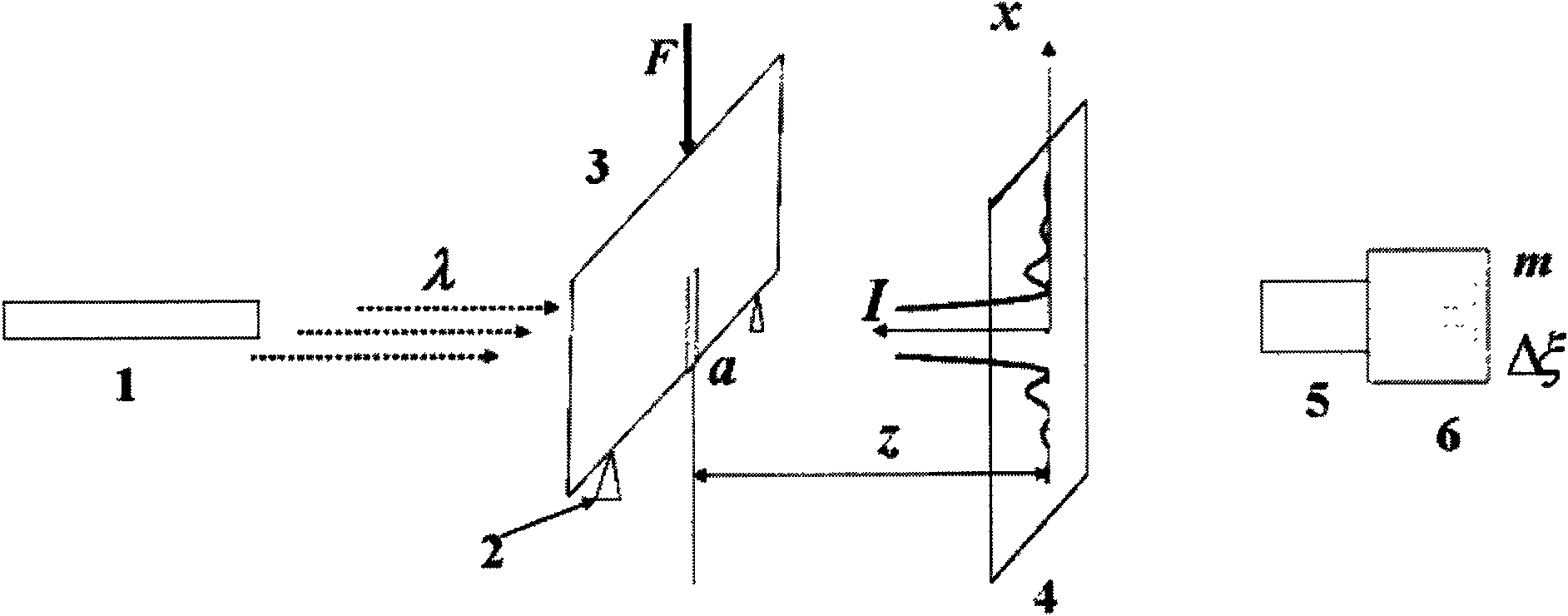

Measuring method of little opening displacement of microcrack

InactiveCN101608905AHigh measurement accuracyMeet different measurement needsUsing optical meansStrength propertiesLength waveMeasurement precision

The invention discloses a measuring method of little opening displacement of microcrack, belonging to the technical fields of photo mechanics, structural member deformation, displacement measurement and the like. The invention adopts a measuring system mainly consisting of a laser device, a loading device, a test specimen with a microcrack, a light intensity receiving screen and a pattern collecting system. During measurement, laser sends out light with a wave length of lambda; a Fraunhofer diffraction fringe pattern is formed on the receiving screen by the microcrack; an initial light intensity pattern of the microcrack is obtained by the pattern collecting system; the loading device is used for slowly loading the test specimen to open the microcrack; the pattern collecting system is used for recording multiple slit diffraction light intensity patterns of the microcrack on the receiving screen under different loads; digital pattern analysis and relative operation are carried out according to a light intensity pattern so as to finally obtain the little opening displacement amount of the microcrack under different loads. The method has the characteristics of convenient use, high measurement precision and the like. The deformation amount measurement of the microcrack can reach 100 mu epsilon magnitude, and the displacement measurement sensitivity can reach wavelength magnitude.

Owner:TSINGHUA UNIV

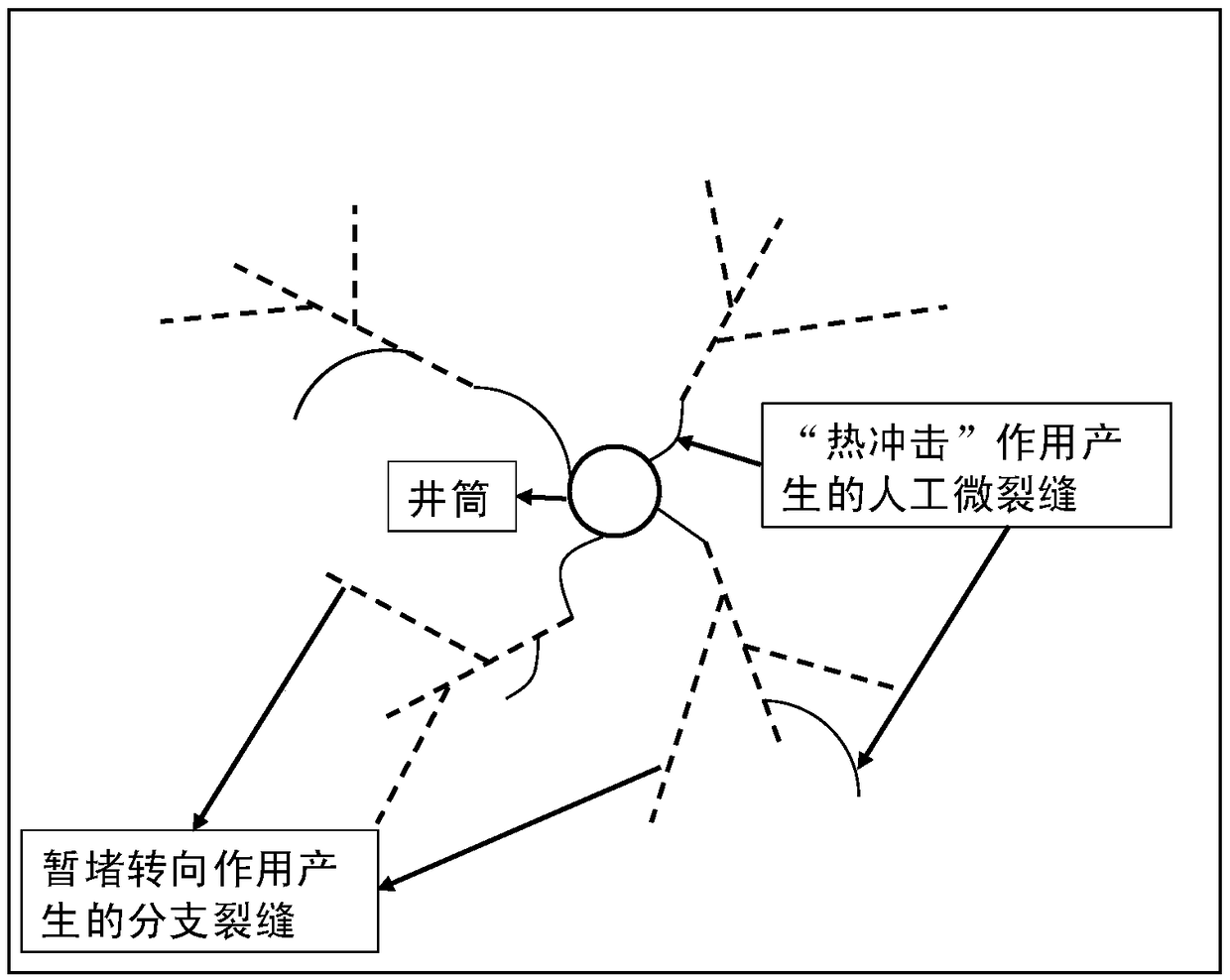

Fracturing method for increasing complexity of high-temperature stratum artificial crack net

ActiveCN108661617AReduce construction pressureIncrease the complexity of artificial fracturesFluid removalHorizontal wellsFracturing fluid

The invention discloses a fracturing method for increasing the complexity of a high-temperature stratum artificial crack net and belongs to the technical field of petroleum and natural gas engineeringexploitation. The method comprises the following steps that low-temperature work liquid is injected into a high-temperature stratum, a strong cold-hot stress impacting effect is generated through thehigh-temperature difference between the low-temperature work liquid and the high-temperature stratum, rock around a well is induced to generate micro cracks, then fracturing liquid is injected to enable the micro cracks to continue to expand forwards, finally temporary plugging steering liquid is injected to conduct bridge plugging on the artificial cracks to force the cracks to steer to form multi-branch cracks, and the steps are executed at least once. Through the fracturing method, the multiple artificial cracks can be formed, the seepage area is enlarged, the single-well yield and economic benefits are increased, the bursting pressure can be lowered, the fracturing construction risk caused by high temporary plugging steering pressure in the high-temperature stratum is avoided, and safe construction is ensured. The fracturing method is suitable for the high-temperature strata such as hot dry rock, deep-layer shale gas and deep-layer compact oil gas, can be used for vertical well fracturing construction and can also be applied to fracturing construction of horizontal wells, oblique wells and the like.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

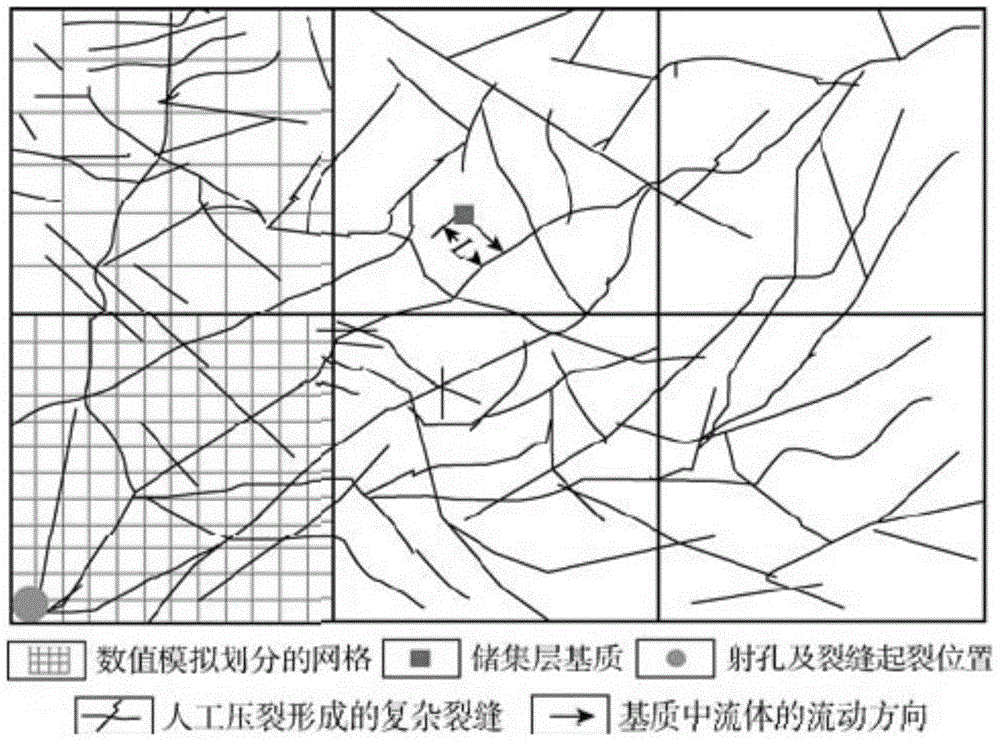

Reservoir modifying method through forming crack network by temporary plugging turning in cracks

ActiveCN105089603AReduce seepage distanceImprove seepage capacityFluid removalDrilling compositionTight oilEngineering

The invention provides a reservoir modifying method through forming a crack network by temporary plugging turning in cracks. The method comprises the following steps: injecting a temporary plugging turning material liquid into a reservoir man-made crack and forming a bridge plug in the deep part of the crack, forcing the crack to turn and form a plurality of cracks, using an active fluid or an acid fluid to activate reservoir micro-cracks, and forming the crack network. The method can form the man-made crack network in unconventional oil-gas reservoirs such as low-permeability, ultra low permeability oil-gas reservoirs, tight oil reservoirs and shale oil-gas reservoirs, so as to increase the contact area to the reservoirs and greatly shorten the seepage distance and the seepage resistance of the oil and gas in the reservoirs towards the cracks in the arbitrary directions, and furthermore the single well yield and the final recovery efficiency are increased.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +2

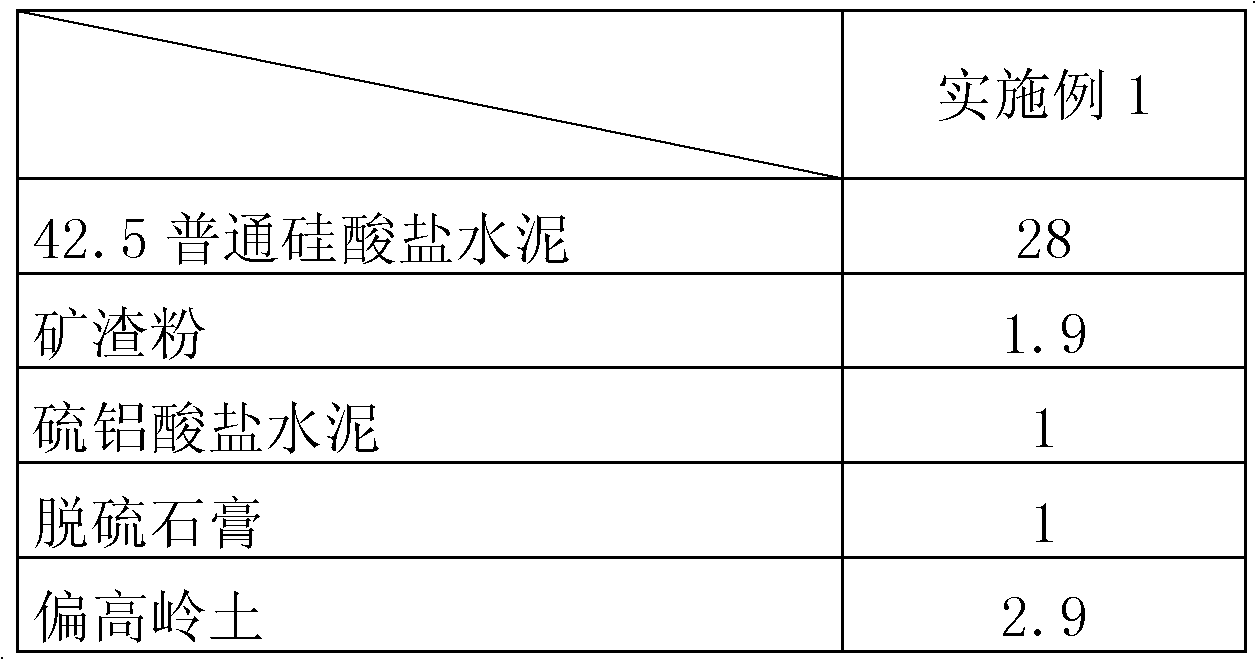

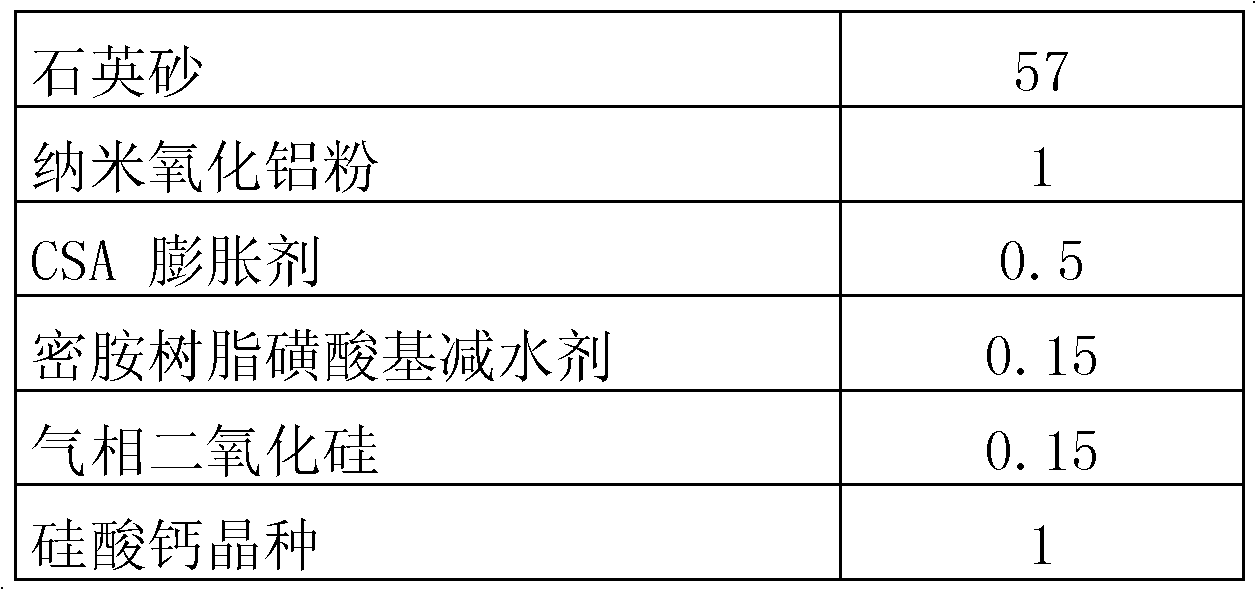

Wear-resistant cement mortar, wear-resistant floor and preparation method thereof

InactiveCN102910885AHas high strengthNon-shrinkableIn situ pavingsFlooringCalcium silicateWear resistant

The invention discloses wear-resistant cement mortar, a wear-resistant floor and a preparation method thereof, wherein the wear-resistant cement mortar is composed by mixing the following components according to a normal method, by weight, 22-40 parts of ordinary portland cement, 1.9-7.5 parts of slag powder, 1-5 parts of special cement, 1-5 parts of metakaolin, 1-5 parts of gypsum, 40-60 parts of quartz sand, 1-3 parts of calcium silicate seed crystal; 1-7 parts of nano alumina powder and 0.1-0.3 part of a water reducing agent, wherein the special cement is sulphoaluminate cement or aluminate cement. The wear-resistant cement mortar has the advantages of excellent hardness and strength. The wear-resistant floor prepared by the wear-resistant cement mortar has no micro-cracks on the surface after being grinded; good smoothness and various fresh brilliant colors can be obtained; color ordonnance can be realized on the surface with extremely high compactness; and aesthetic patterns with paint effects can be obtained.

Owner:MINGLUN BUILDING MATERIALS IND SUZHOU CO LTD

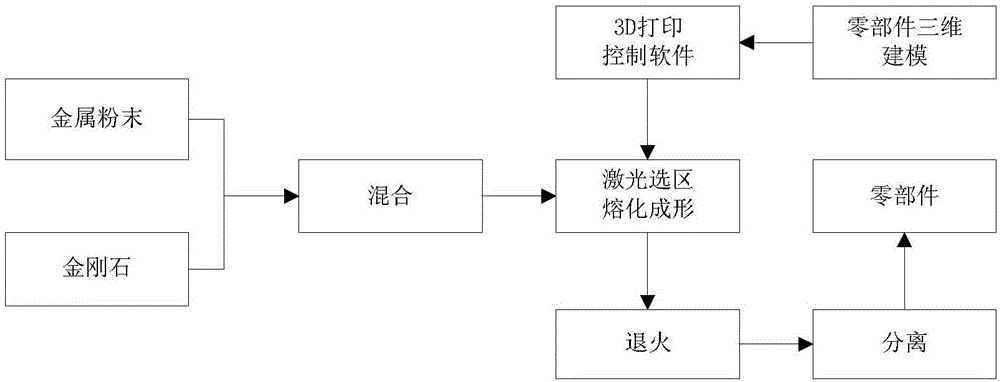

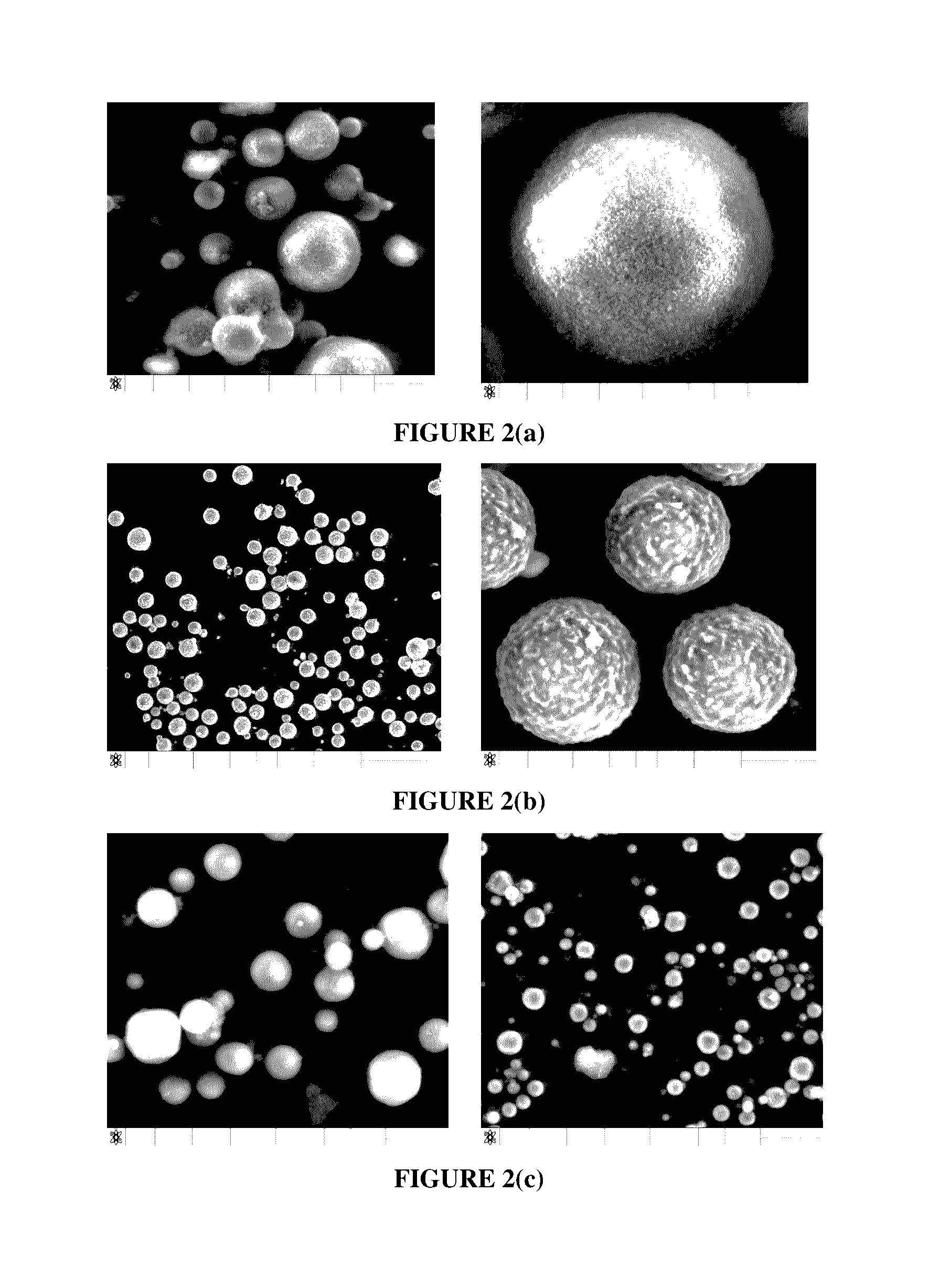

Metal-matrix diamond composite material and 3D (three dimensional) printing manufacturing method of parts of metal based diamond composite material

InactiveCN106825568AHigh hardnessImprove wear resistanceAdditive manufacturing apparatusIncreasing energy efficiencyStress relievingHardness

The invention discloses a metal-matrix diamond composite material and a 3D (three dimensional) printing manufacturing method of parts of the metal-matrix diamond composite material. The composite material is made from, by weight, 2%-3% of diamond and the balance of metal powder; the metal powder is 15umm-65umm in grain size; the grade of the diamond is above SMD 30, and the diamond is 35-18 meshes in particle size; the diamond is evenly mixed with metal matrix powder prior to being put in a feeding device of a melting unit in a selective laser region to perform three-dimensional printing to form the parts on a substrate; the parts are subjected to stress-relieving annealing treatment after formation is completed, microcrack healing is promoted, structure defect is removed, and the performance is controlled. By the arrangement, metal matrix alloying can be realized, the diamond is effectively embedded, the metal-matrix diamond composite material with ideal hardness and abrasion performance is obtained, and the metal-matrix diamond composite material parts with the complex structure are manufactured.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Process for preparation of self healing microcapsules

The present invention disclosed a process for the preparation of microcapsules containing epoxy resin which comprises water-insoluble and / or water-soluble components prepared by in-situ polymerization using non-aqueous continuous phase which acts as healing agents for the micro-cracks when embedded in composite structures.

Owner:COUNCIL OF SCI & IND RES

Plating liquid for plating micro-crack nickel and use thereof

InactiveCN101705508AImprove anti-corrosion performanceImprove corrosion resistanceAcetic acidCopper plating

The invention discloses plating liquid for plating micro-crack nickel and use thereof. One liter of the plating liquid mainly comprises the following components: 180 to 260 grams of nickel chloride, 20 to 60 milliliters of acetic acid, 80 to 120 milliliters of ELPELYT MR and 1 to 5 milliliters of 62A. In the invention, the plating liquid is used for plating micro-crack nickel on the surface of a plastic piece, and the plating process uses the plastic piece as a substrate and comprises the following steps: A, plastic surface metallization; B, bright copper plating; C, semibright nickel plating; bright nickel plating; E, washing with water; F, micro-crack nickel plating; G, washing with water; bright chromium plating; I, washing; J, washing with hot water; and K, drying. The invention provides a novel formula for the liquid plating. According to the formula, the plastic piece can generate micro cracks in a nickel bath, the anticorrosion performance of the plastic piece is improved obviously, the product does not decay in a cold environment, and the service life of the plastic piece is prolonged.

Owner:NINGBO SWELL IND CO LTD

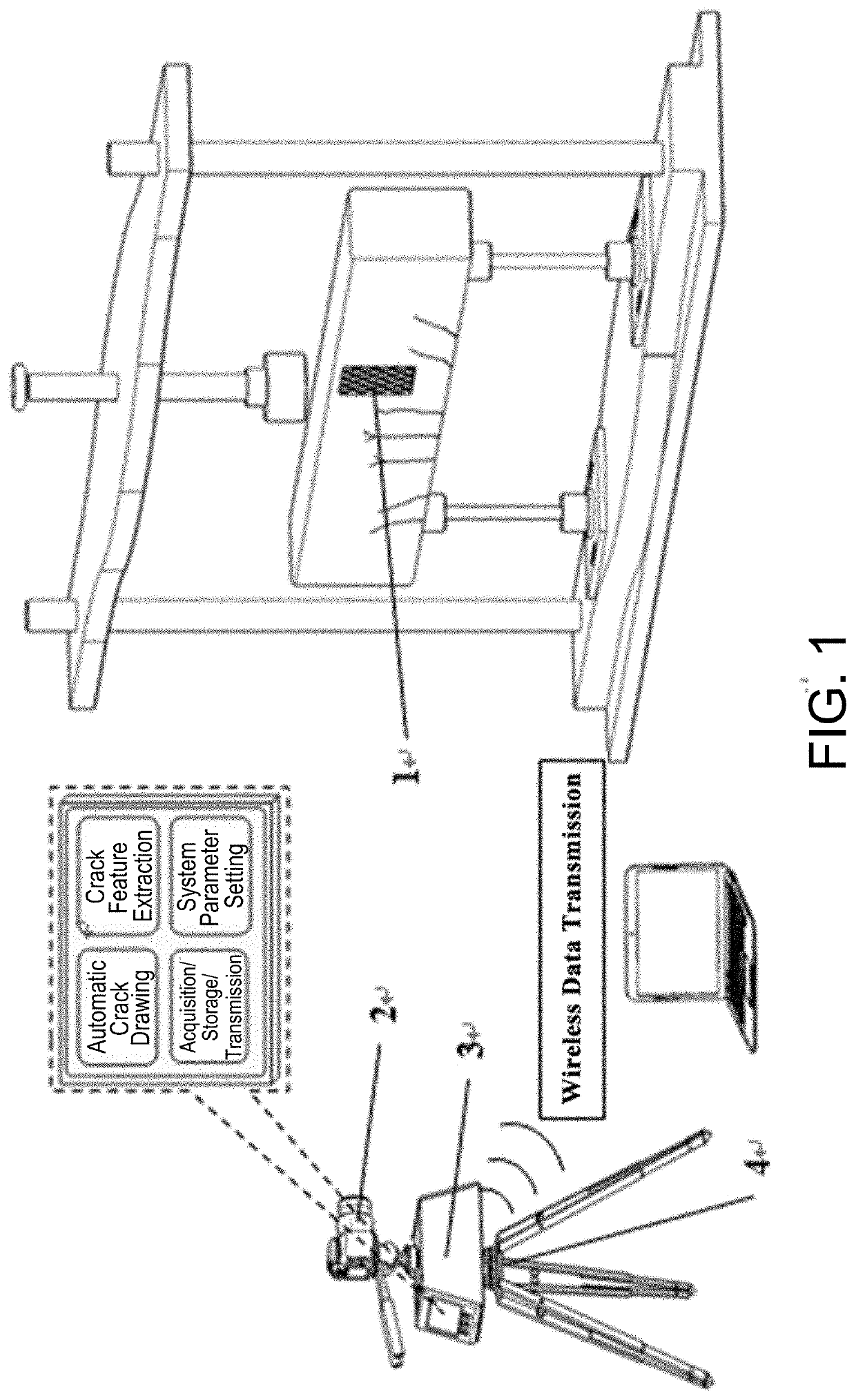

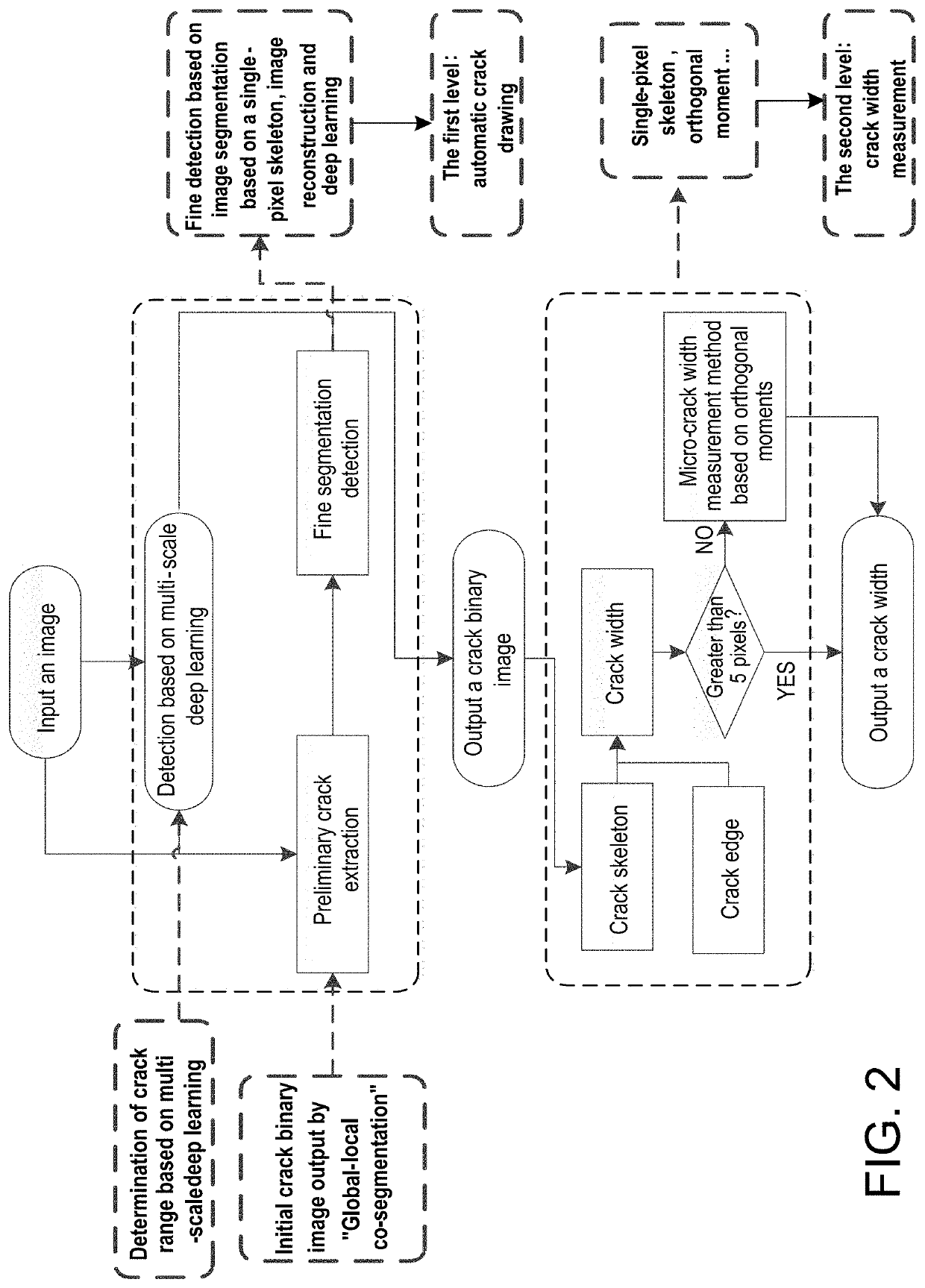

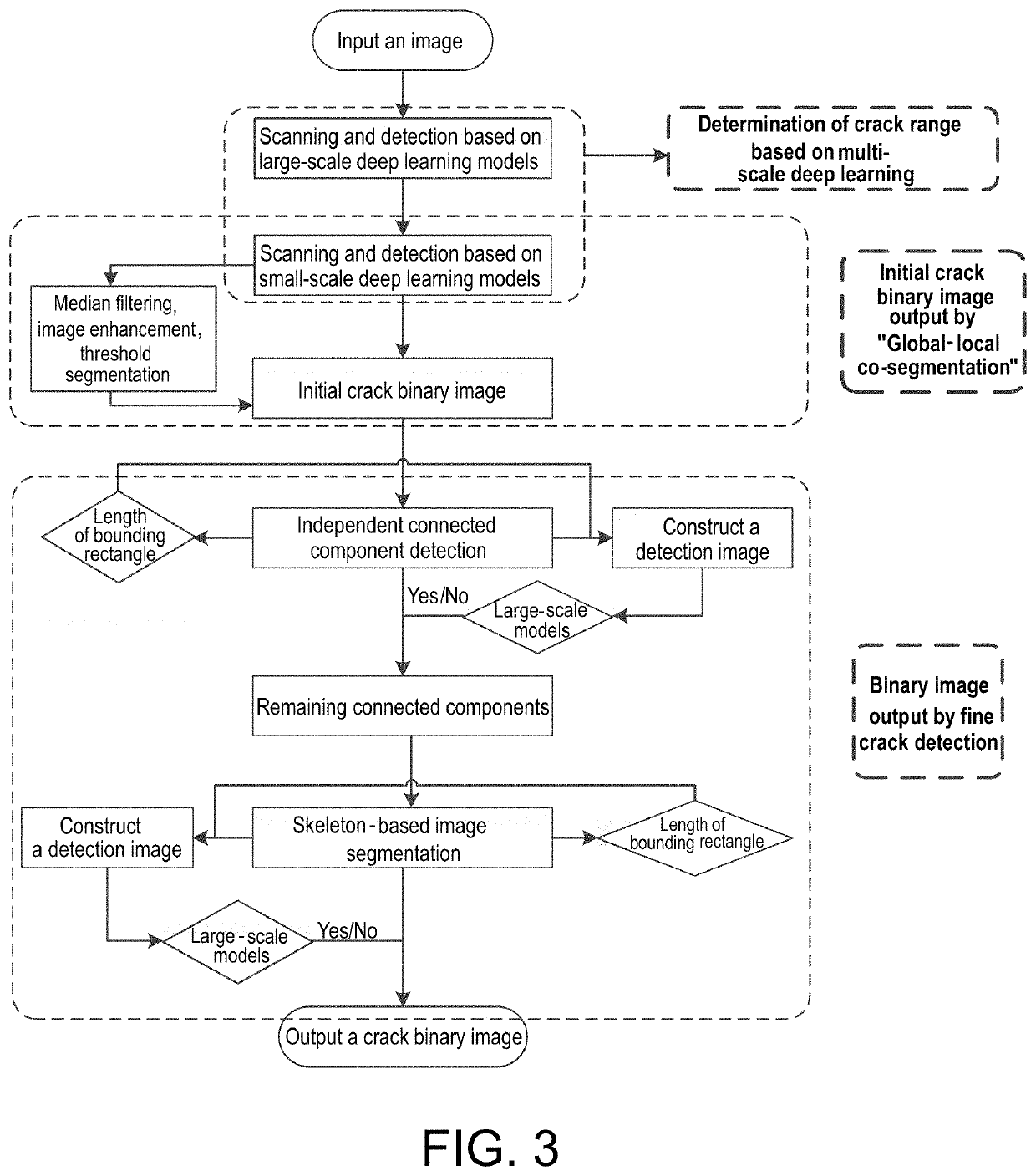

Method and device for automatically drawing structural cracks and precisely measuring widths thereof

ActiveUS20200364849A1Improve accuracyHigh recallImage enhancementImage analysisStructural engineeringMechanical engineering

The present invention discloses a method and device for automatically drawing structural cracks and precisely measuring widths thereof. The method comprises a method for automatically drawing cracks and a method for calculating widths of these cracks based on a single-pixel skeleton and Zernike orthogonal moments, wherein the method for automatically drawing cracks is used to rapidly and precisely draw cracks in the surface of a structure, and the method for calculating widths of these cracks based on a single-pixel skeleton and Zernike orthogonal moments is used to calculate widths of macro-cracks and micro-cracks in an image in a real-time manner.

Owner:SOUTHEAST UNIV

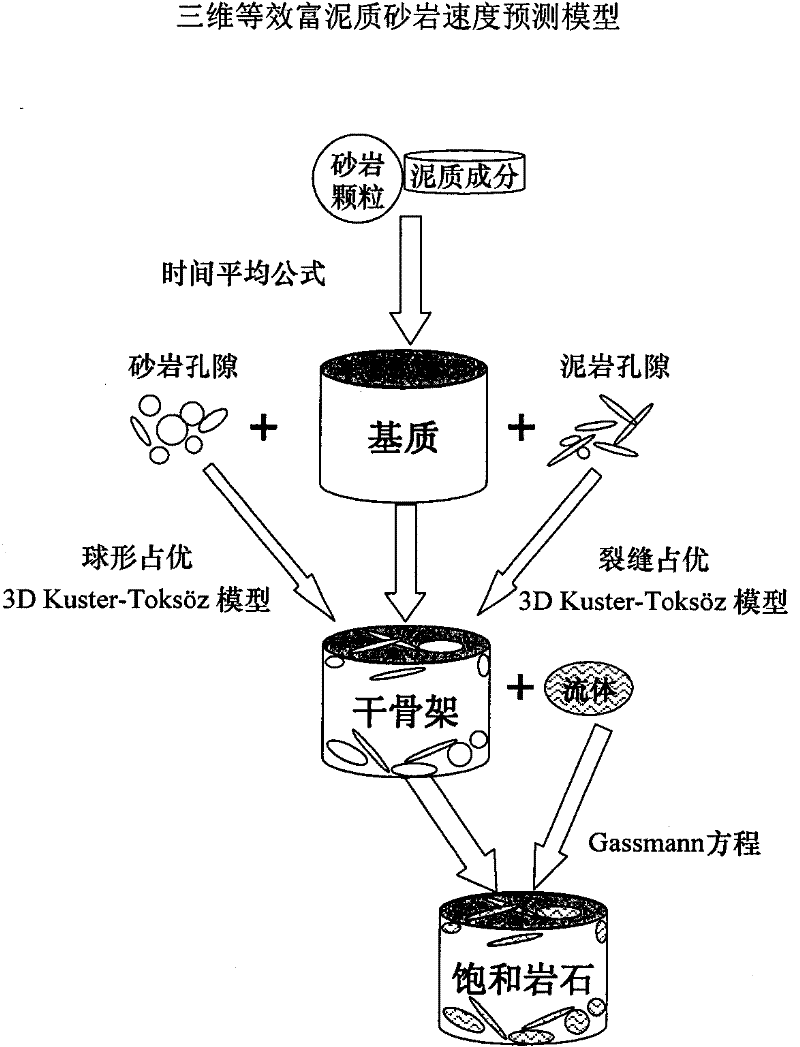

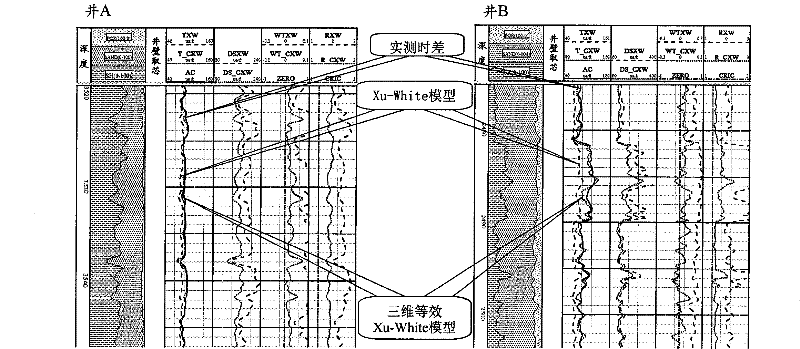

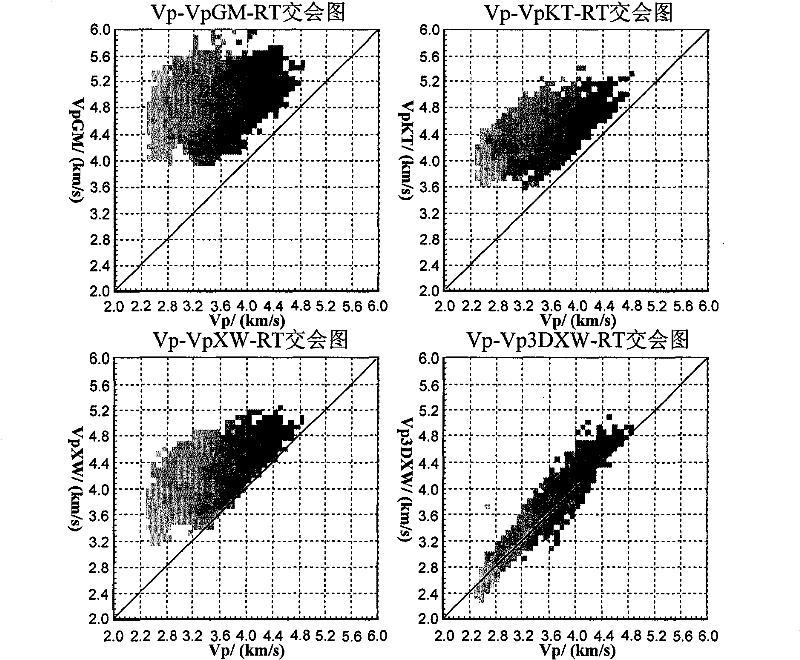

Rich argillaceous sand stone three-dimension equivalent speed prediction model

The invention relates to a rich argillaceous sand stone three-dimension equivalent speed prediction model which is deduced by improving a method of calculating elastic modulus of dry rocks in a Xu-White speed prediction model. The model calculates the elastic modulus of dry rocks by replacing the aspect ratio of a fixed pore in the Xu-White model by four three-dimension shape (spherical shape, needle shape, tray shape and crack shape) pores which are raised by Berryman (1955) according to a statistic pore distribution spectrum, the improved model can simulate the geometric size which is more close to argillaceous micro cracks in rich argillaceous sand stone by freely adjusting the pore aspect ratio, thereby directly and truly reflecting the shape of underground reservoir space and ensuring the coincidence of a predicted result and the actual measuring result.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com