Patents

Literature

51results about How to "Avoid peel damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

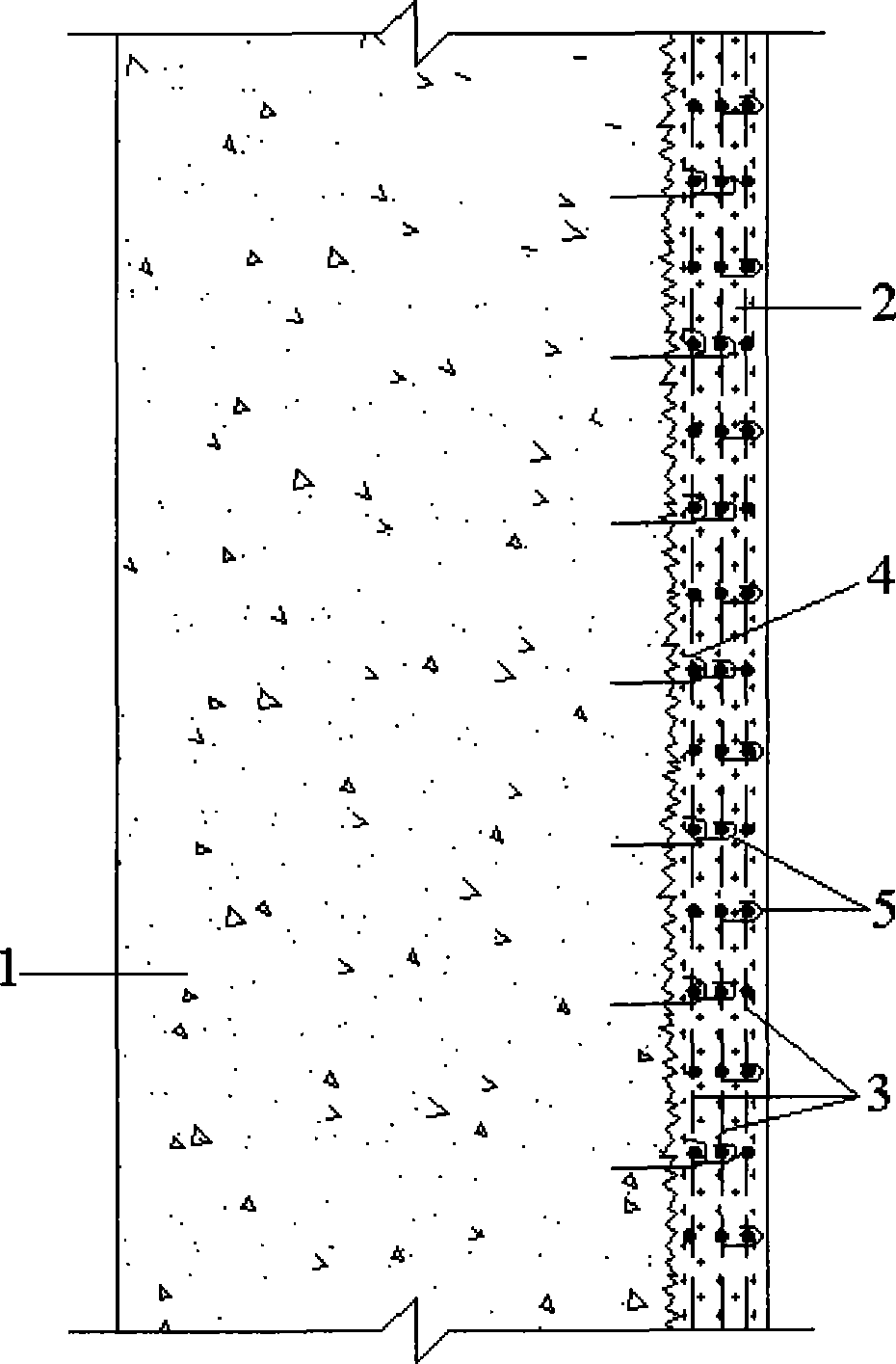

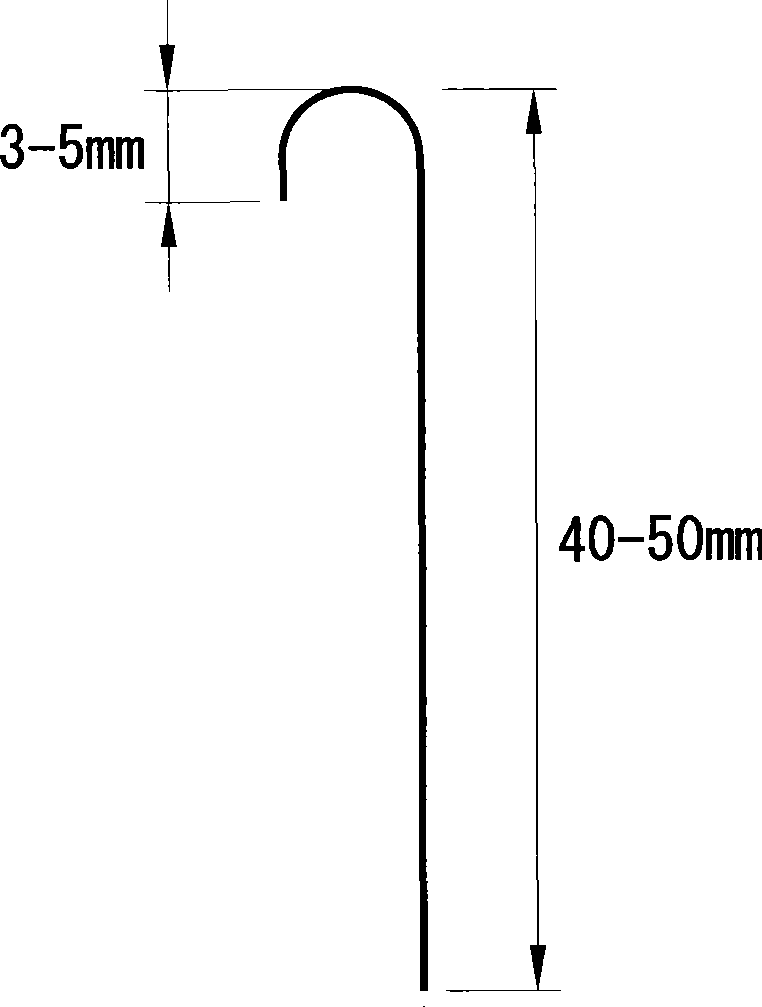

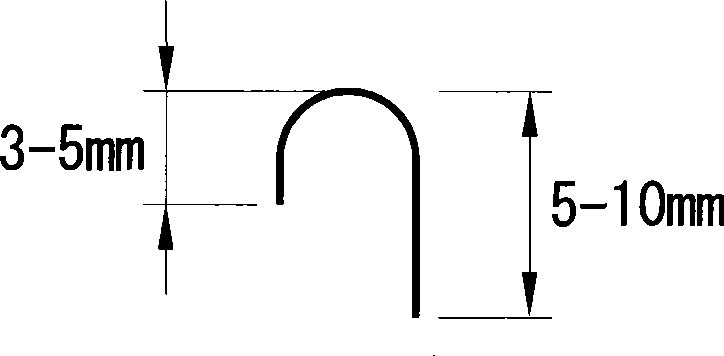

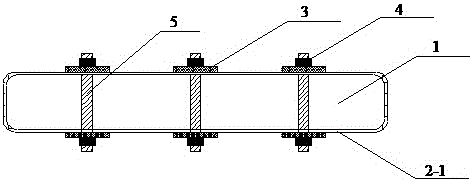

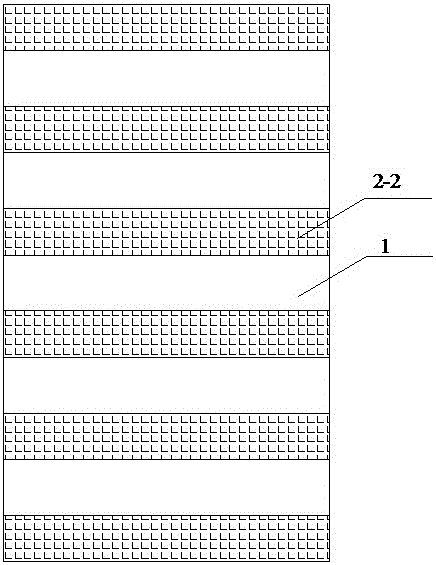

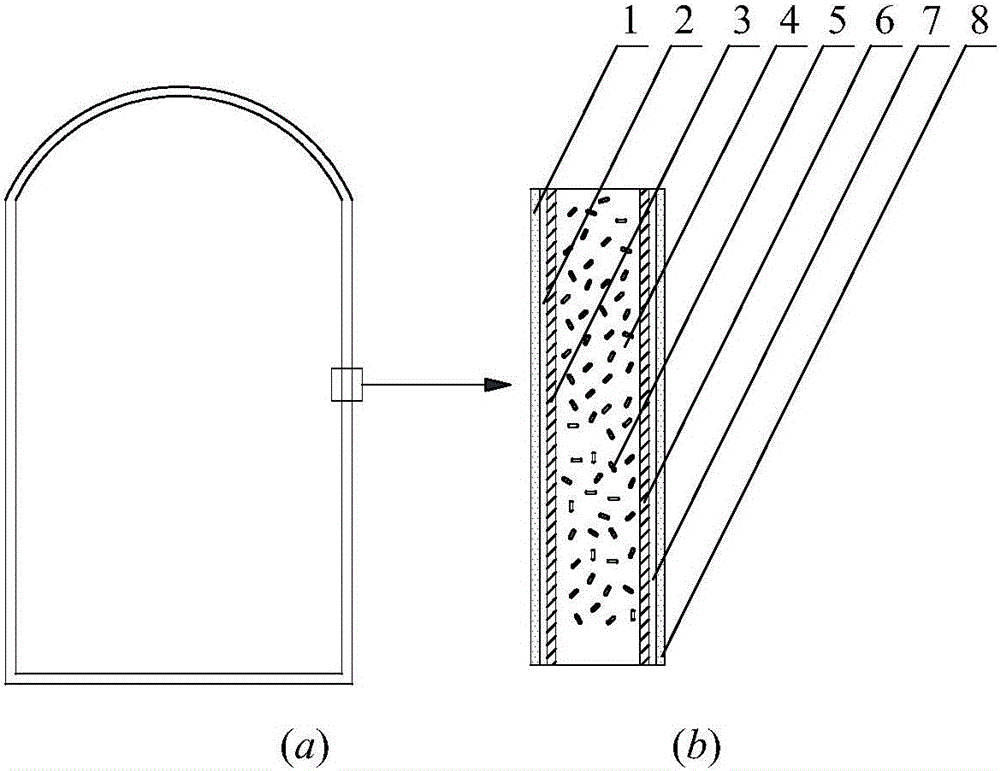

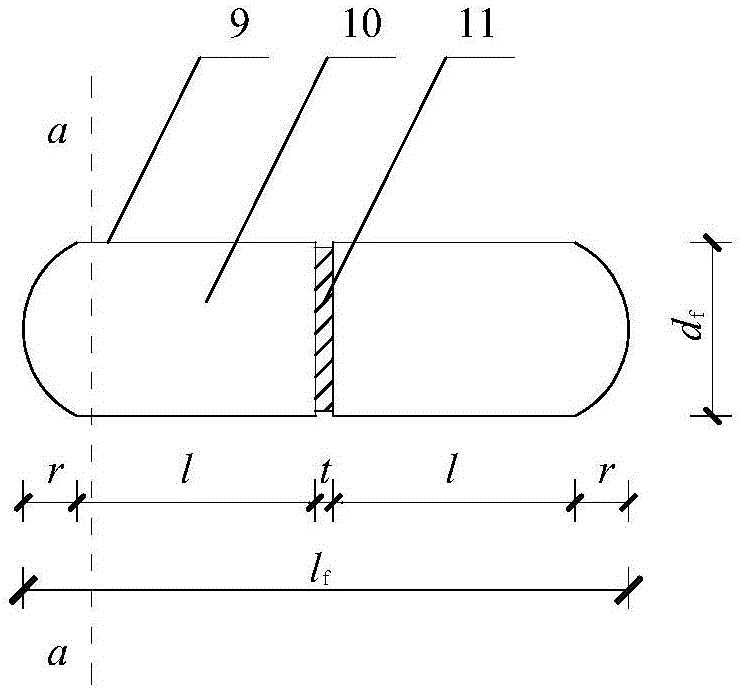

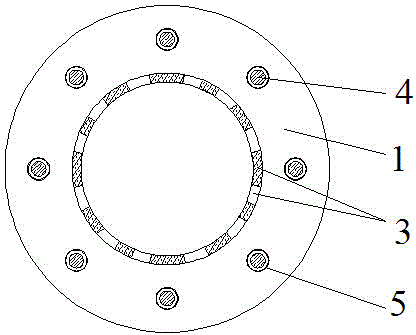

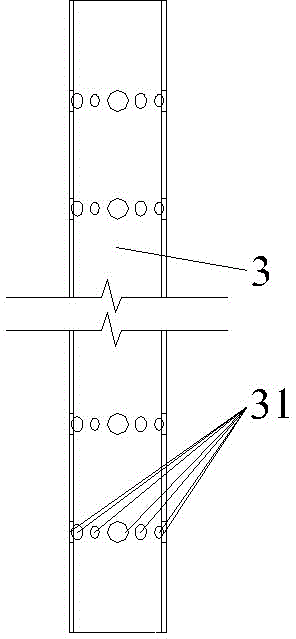

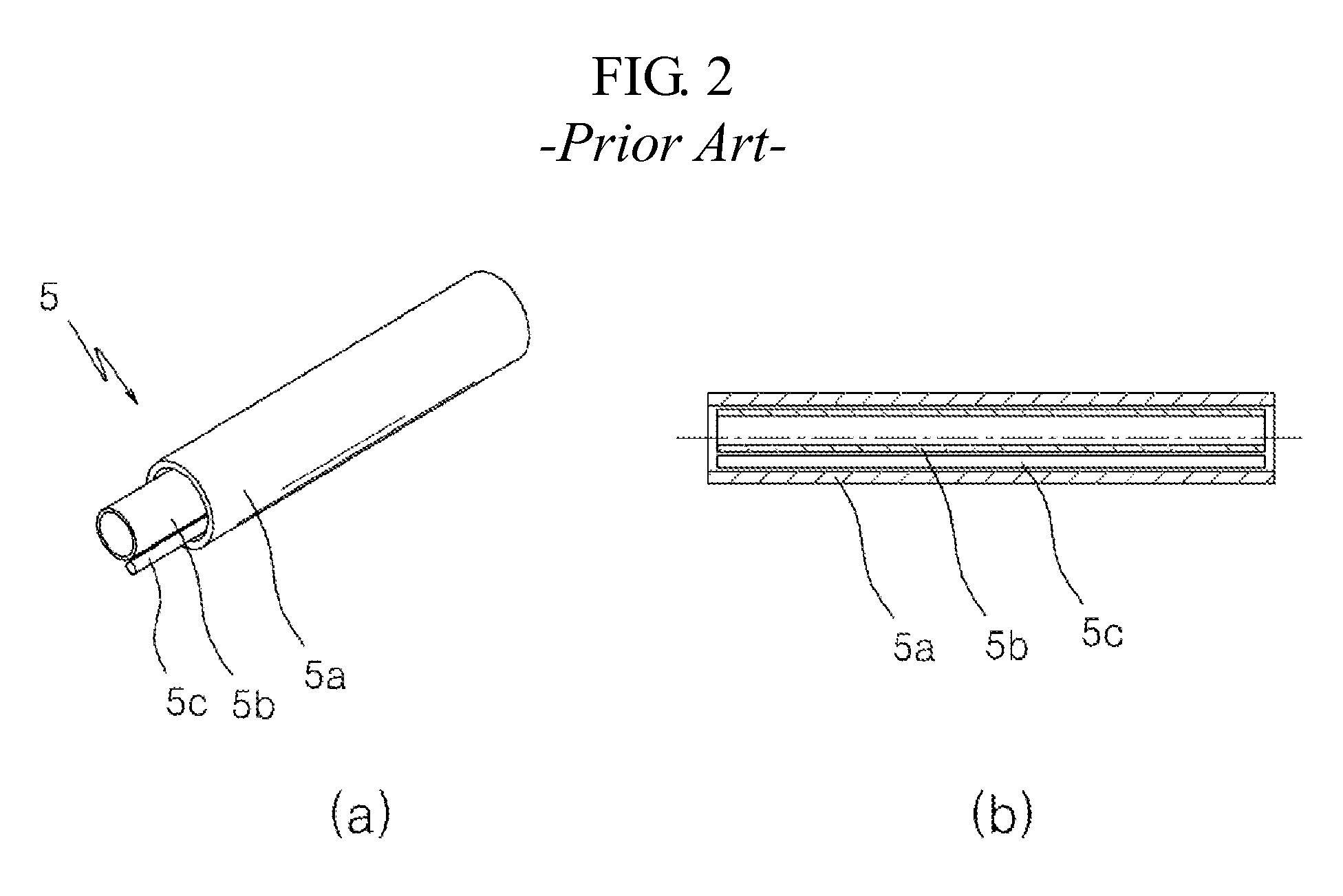

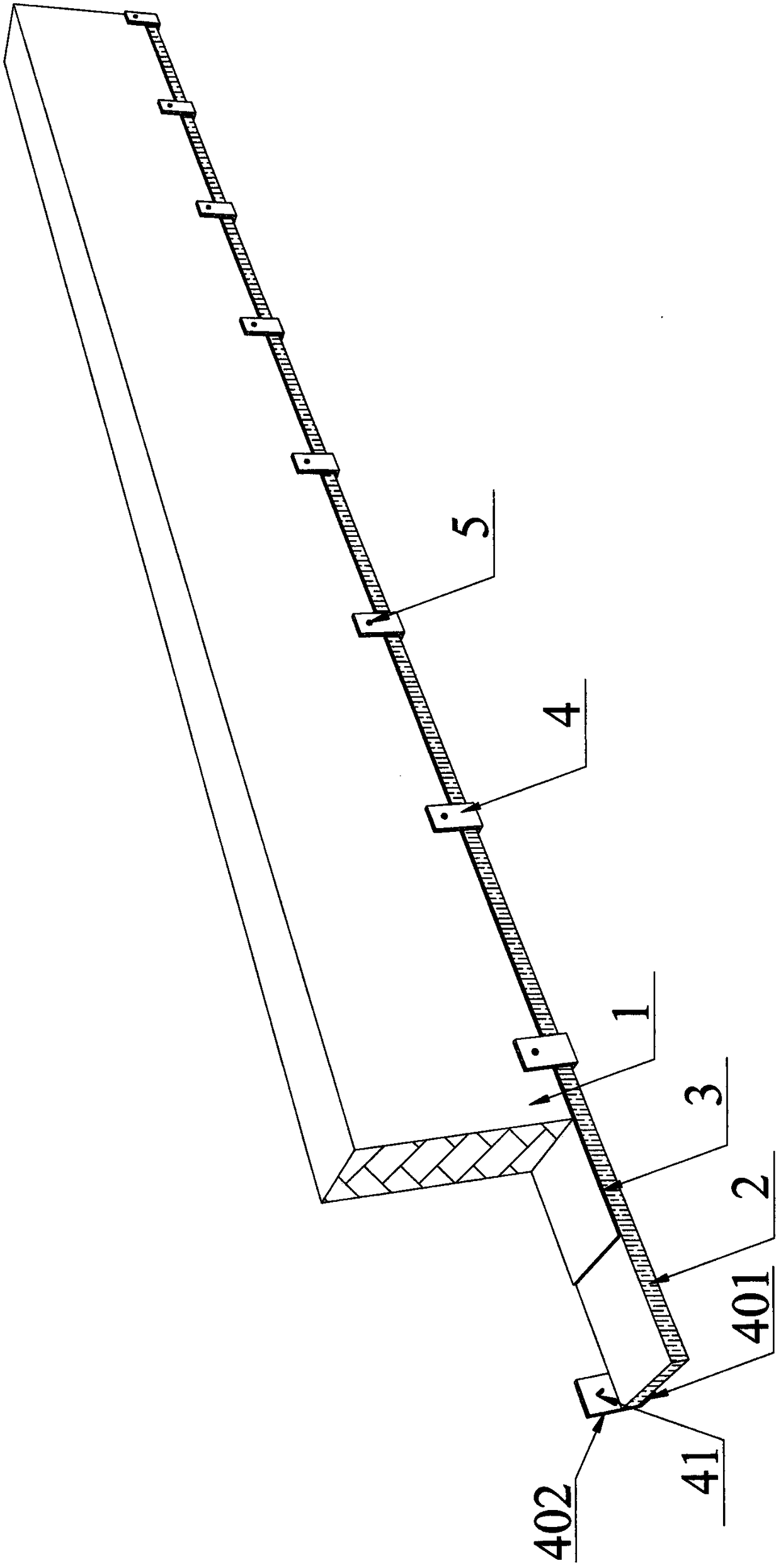

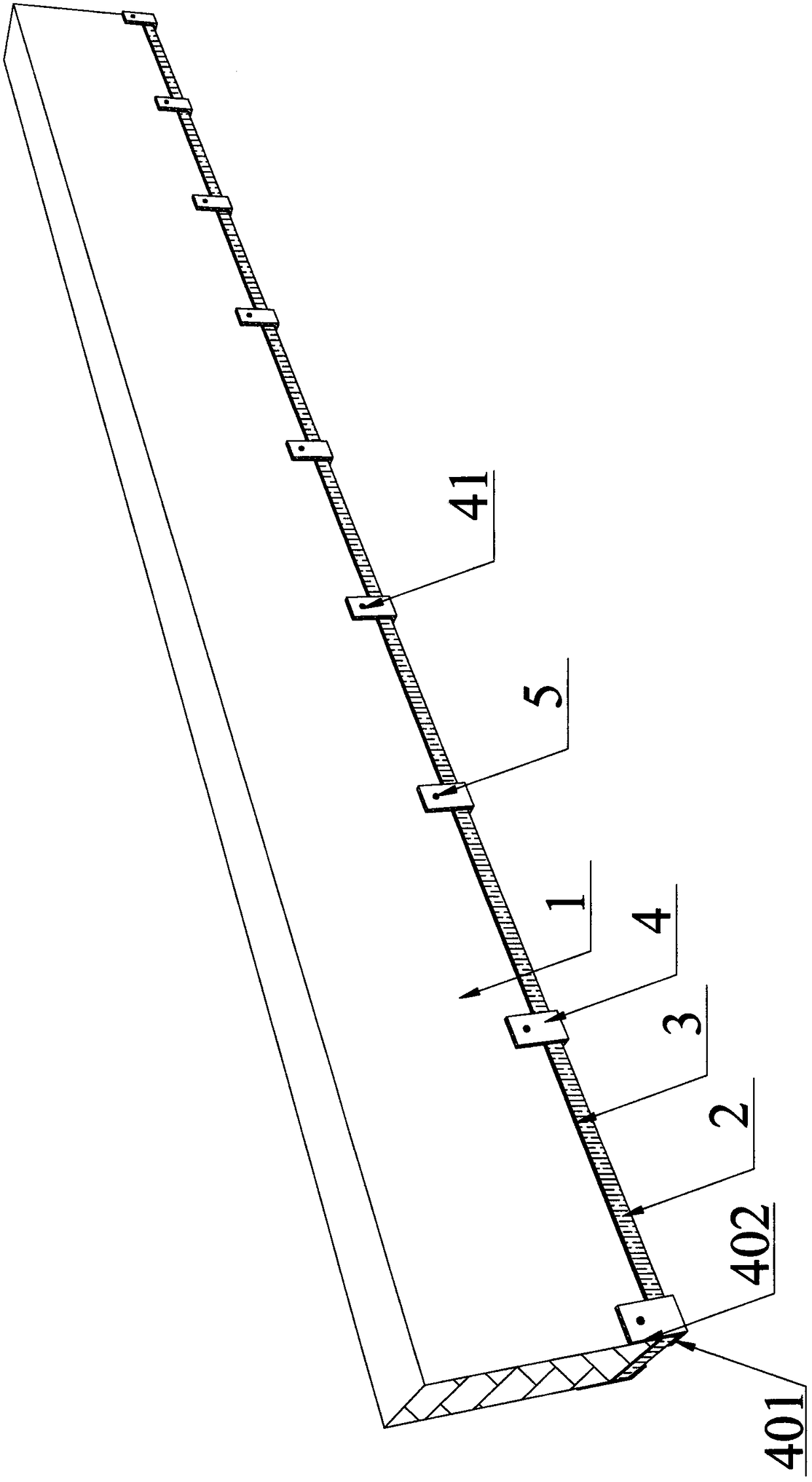

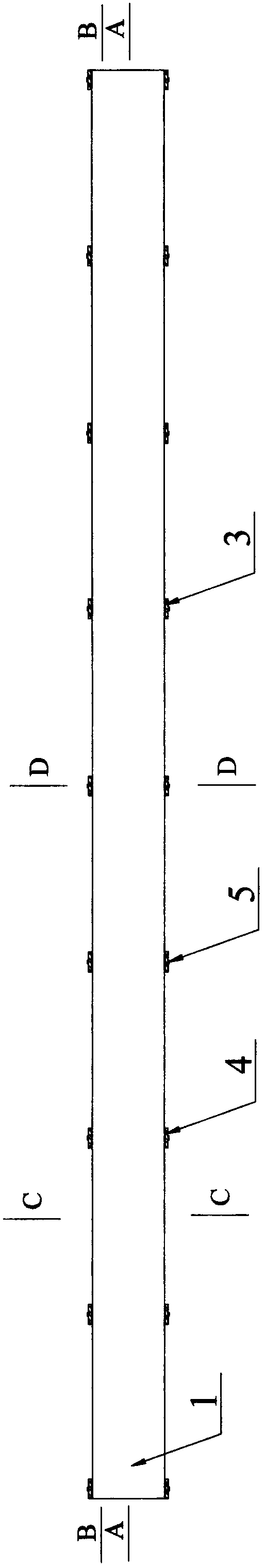

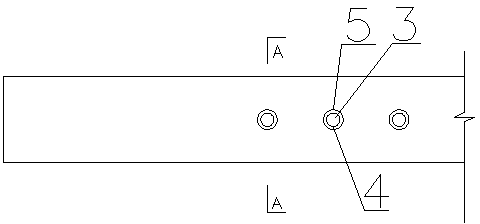

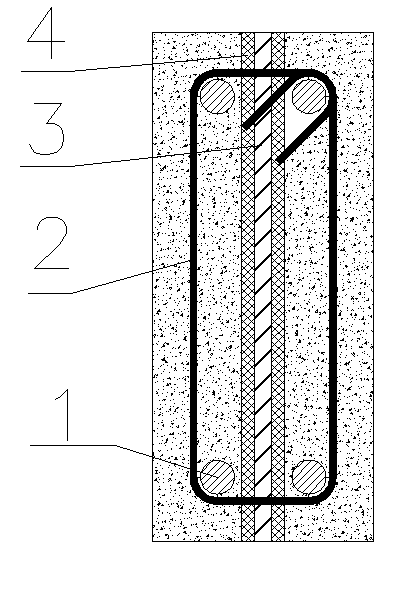

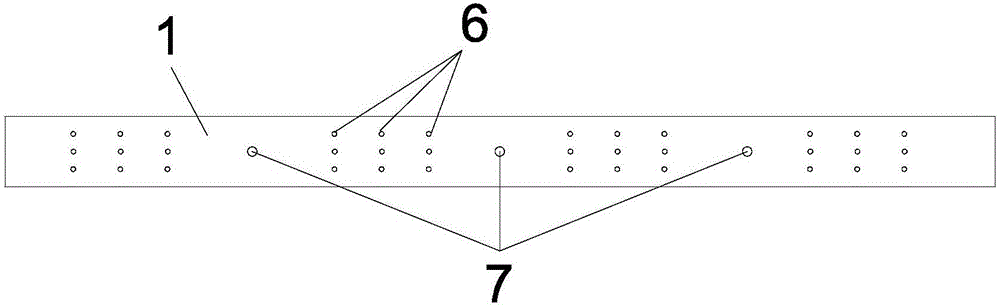

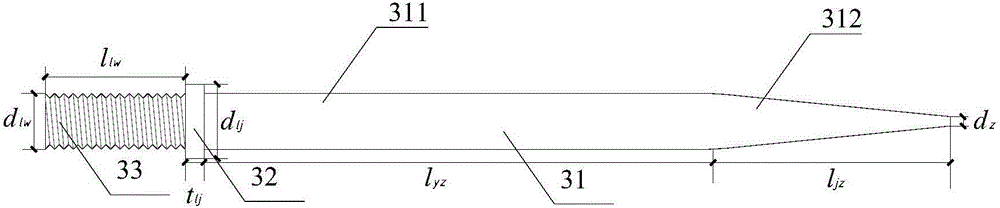

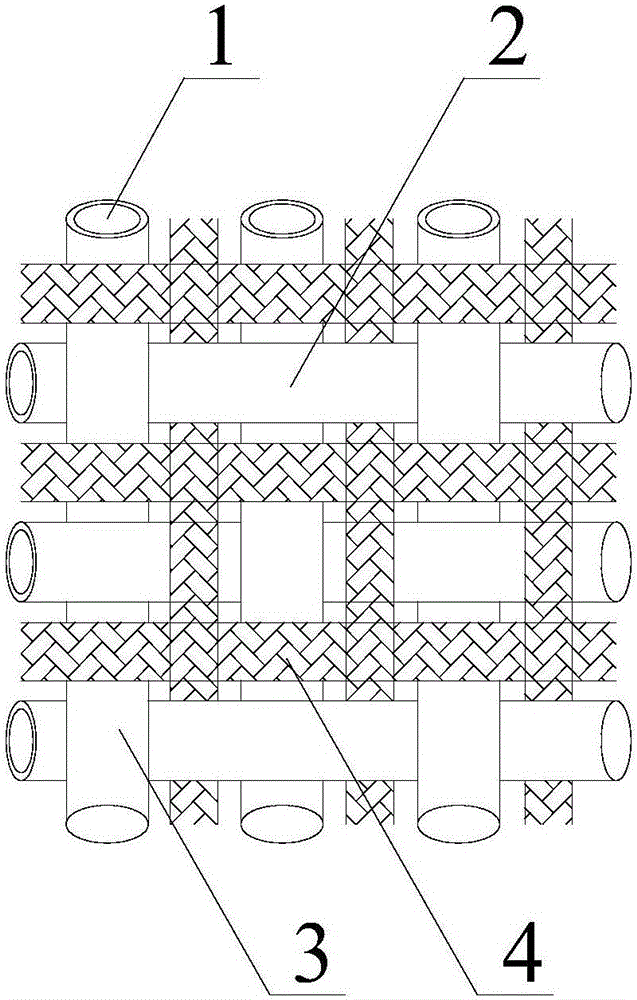

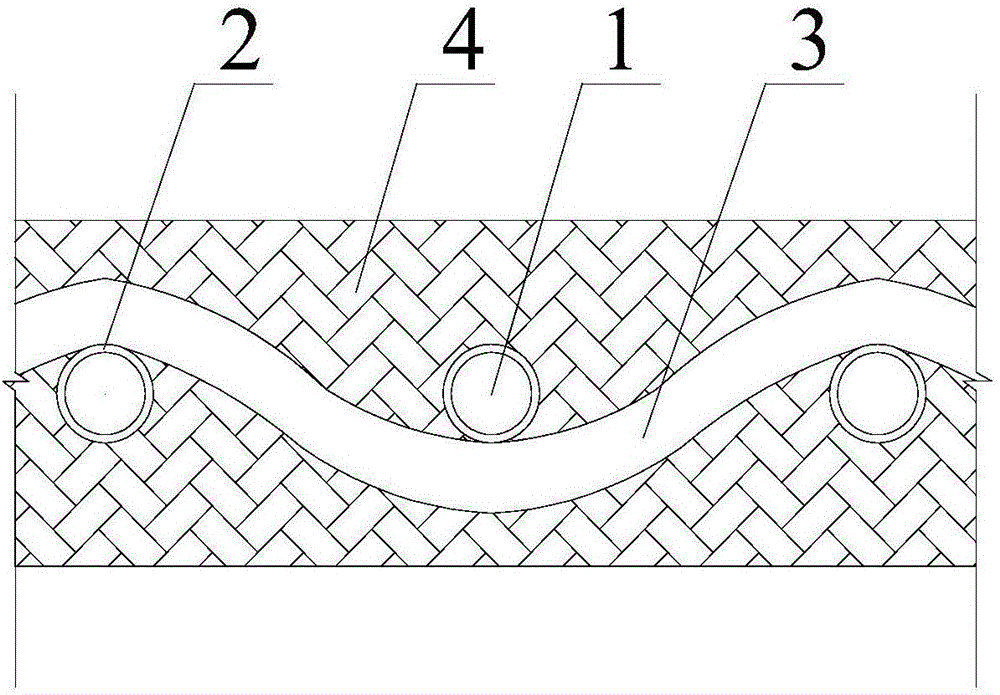

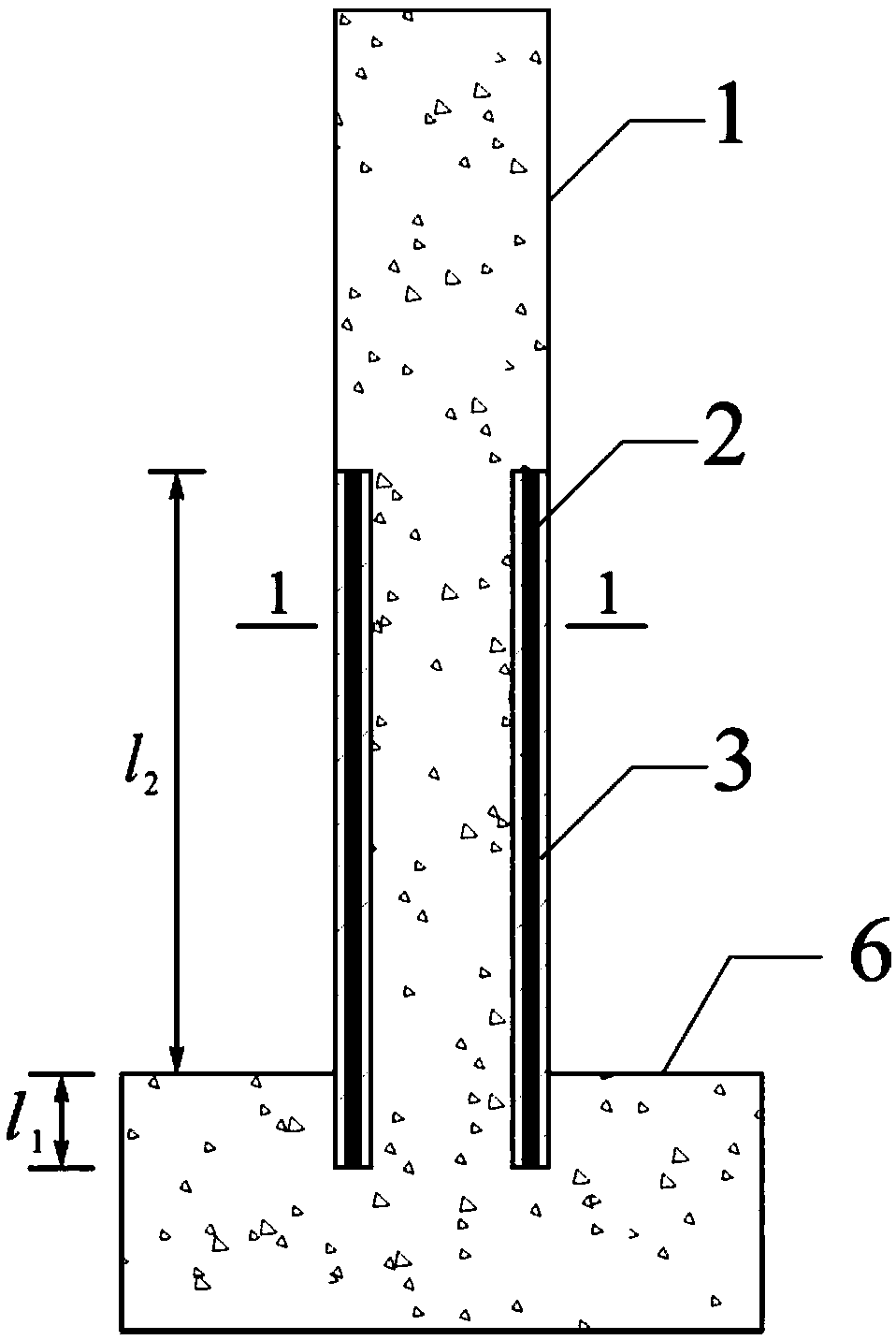

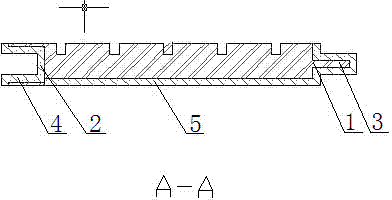

Method for reinforcing construction structure by fiber knitted net and fine concrete

ActiveCN101476396AImprove adhesionAvoid peel damageSolid waste managementMixing operation control apparatusFiberReinforced concrete

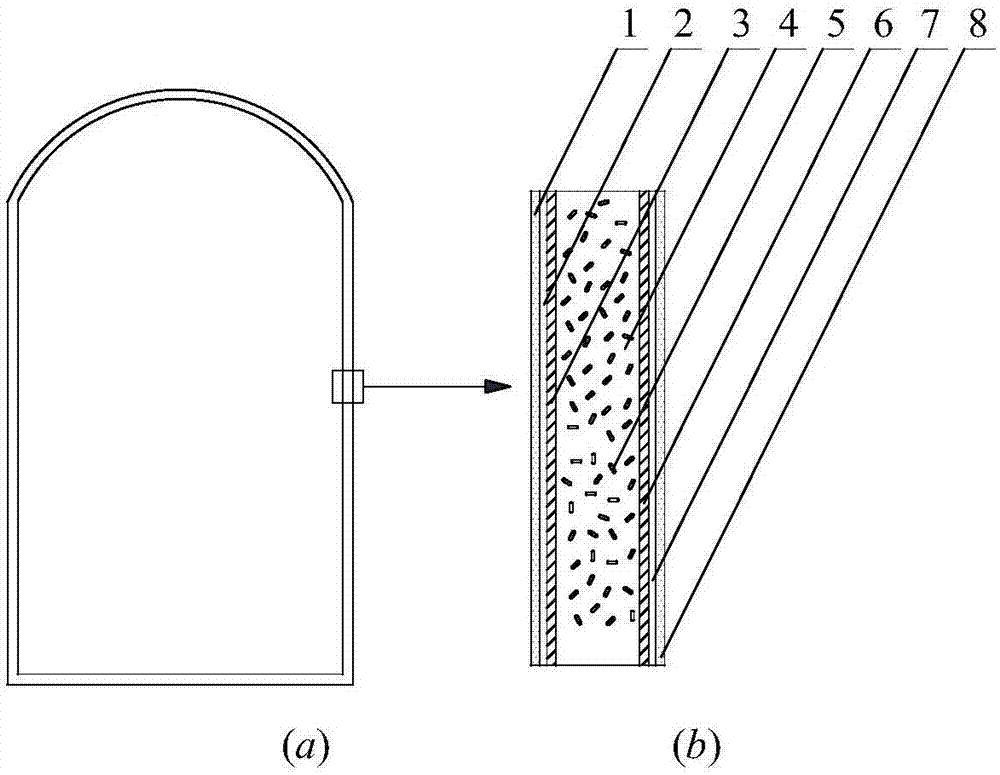

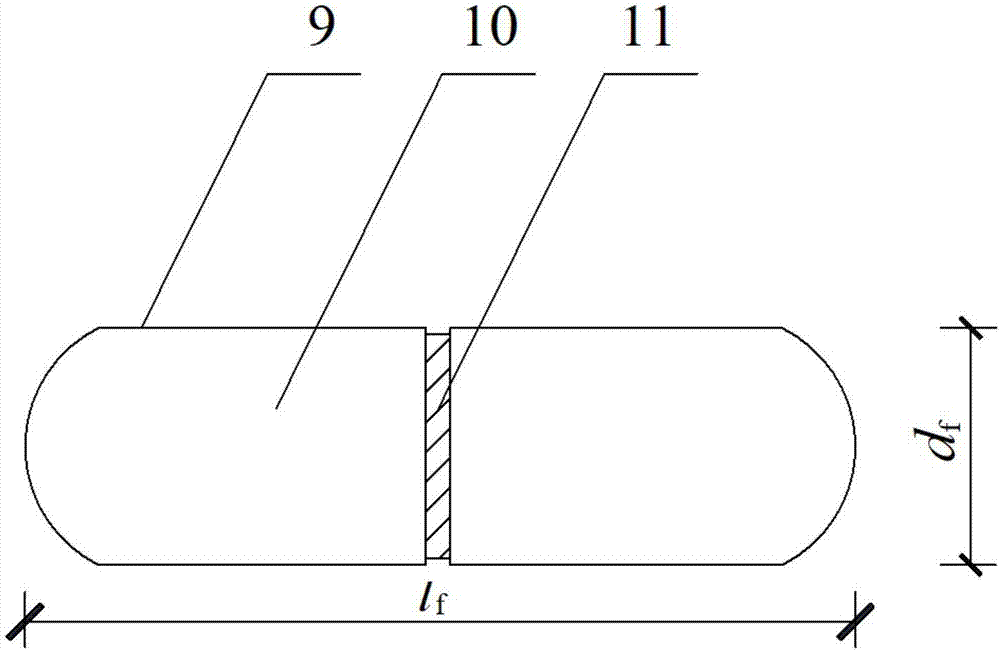

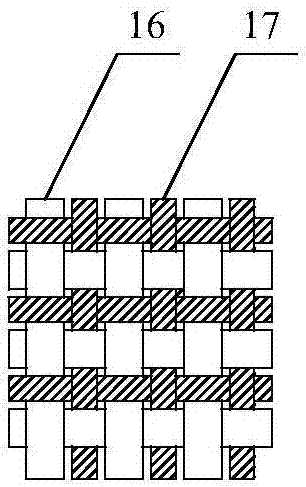

The invention belongs to the technical field of concrete reinforcement and relates to a method for reinforcing concrete with a fibrage net and a cement-based material. The method is to pour the fibrage net the total thickness of which is between 10 and 20 millimeters and fine concrete on the outer surface of a structure, and is characterized by comprising the following steps that: drilling holes on the surface of the structure in the process of construction; using the short end foot of a U-shaped shear resistant pin of which the two end feet have different lengths to hook the fibrage net, and inserting the long end foot thereof into the hole after a building structural adhesive is smeared on the long end foot; spraying the fine concrete after the adhesive is solidified; using the short end foot of a U-shaped hook of which the two end feet have different lengths to hook a second layer fibrage net, and inserting the long end foot thereof to the fine concrete; and spraying the fine concrete. The method can avoid the generation of interface micro cracks at high stress, effectively prevent interface peeling damages, reinforces building structures reliably, simply, efficiently and environmental protection, and is applicable to reinforcing and repairing various types of structures.

Owner:浙江固邦新材料有限公司

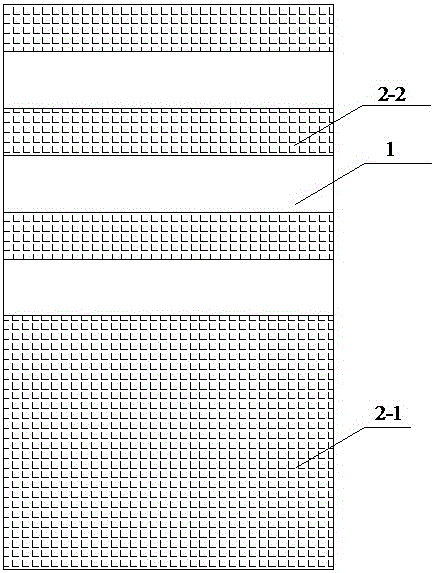

Device and method for reinforcing concrete shear wall by FRP (fiber reinforced plastics)

The invention relates to the technical field of civil engineering structure reinforcement, in particular to a device and a method for reinforcing a concrete shear wall by FRP (fiber reinforced plastics). The device comprises the concrete shear wall, epoxy resin layers, a first FRP strip belt and second FRP strip belts, wherein the epoxy resin layers coat two wall surfaces of the concrete shear wall; the first FRP strip belt is fully and transversely bonded on the surface of the oxygen resin layer of the lower part of the concrete shear wall; a plurality of second FRP strip belts are uniformly and transversely bonded at equal intervals at the upper part of the first FRP strip belt; a plurality of through holes are uniformly formed in the lower part of the concrete shear wall; the device for reinforcing the concrete shear wall by FRP also comprises steel plates, a screw rod and a screw nut; installing holes are formed in the steel plate; the steel plates cover the two ends of the through holes, and the installing holes and the through holes are opposite; the screw rod simultaneously passes through the concrete shear wall, the epoxy resin layers, the first FRP strip belt and the steel plate; screw nuts are arranged at the two ends of the steel plate. The quake-proof capability of the concrete shear wall can be improved; the FRP peeling damage can be prevented.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

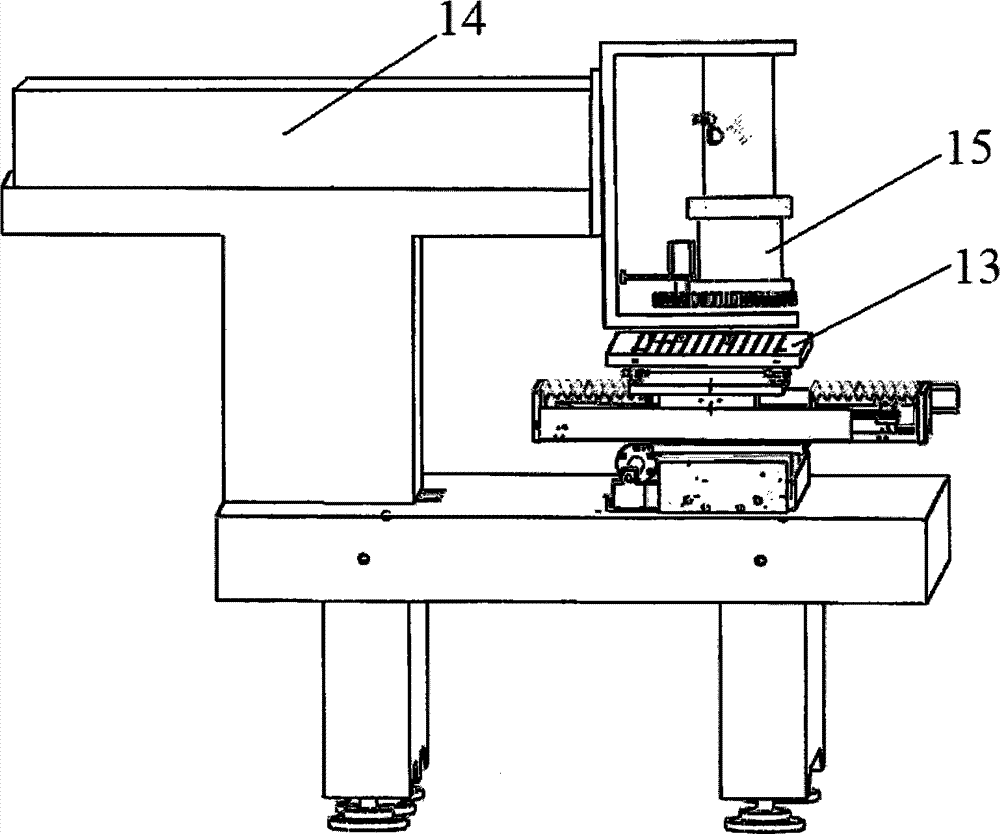

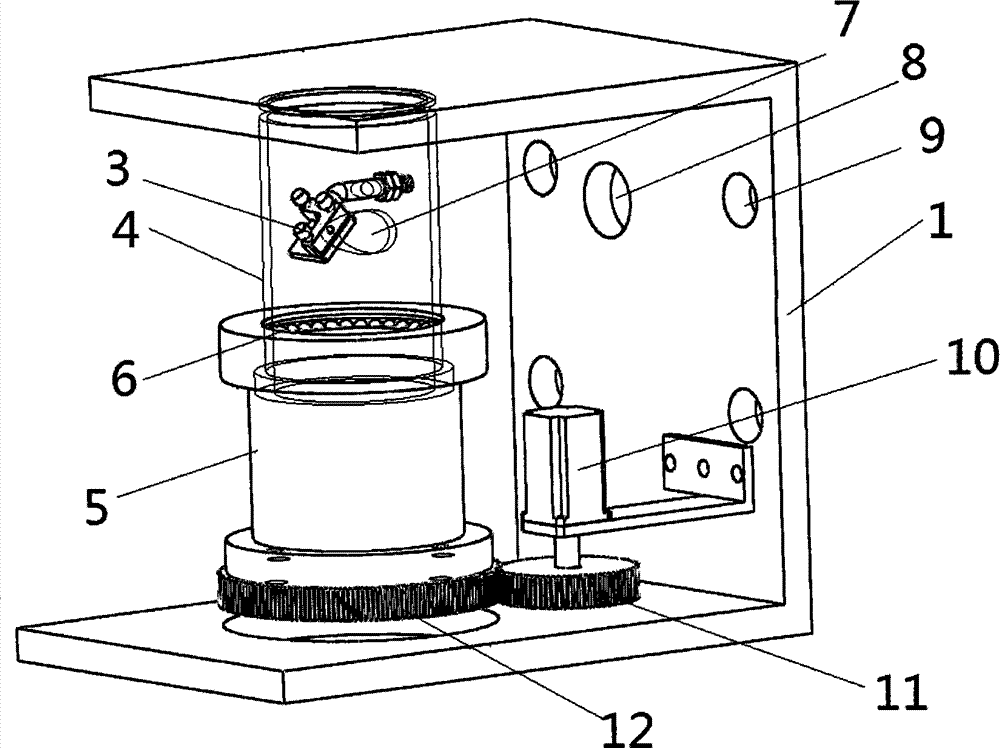

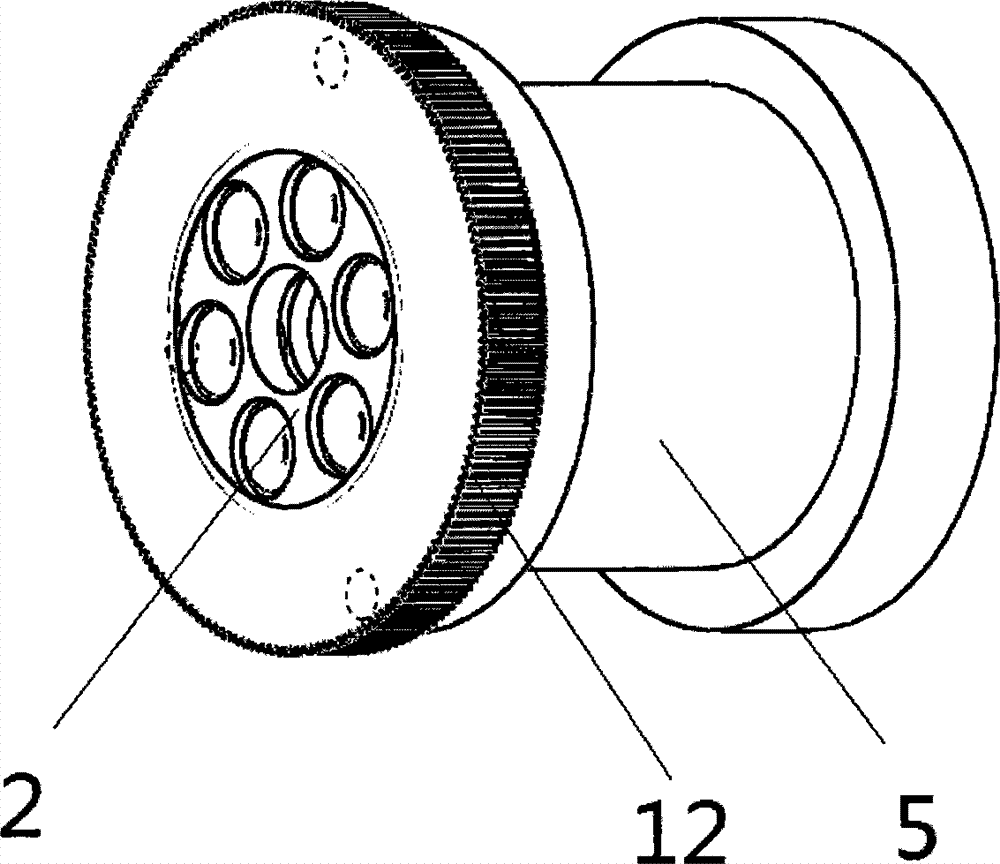

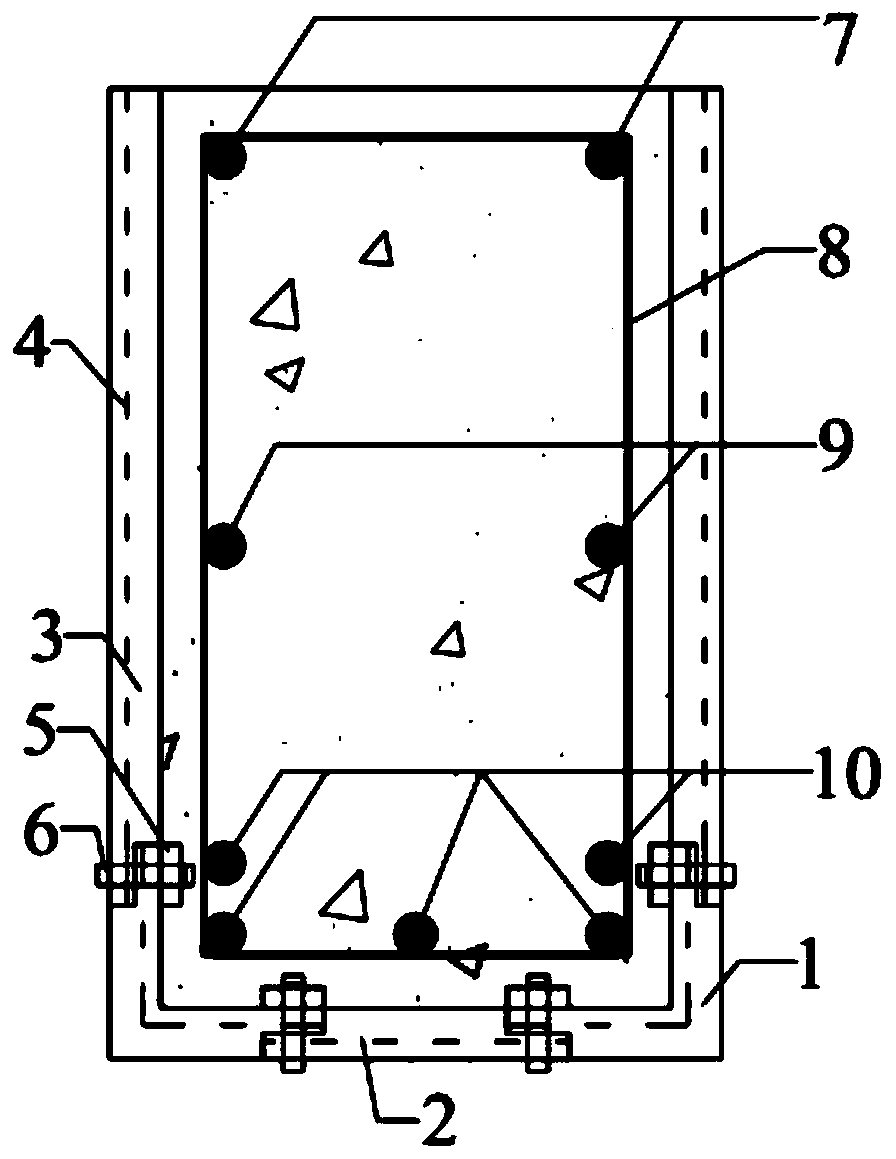

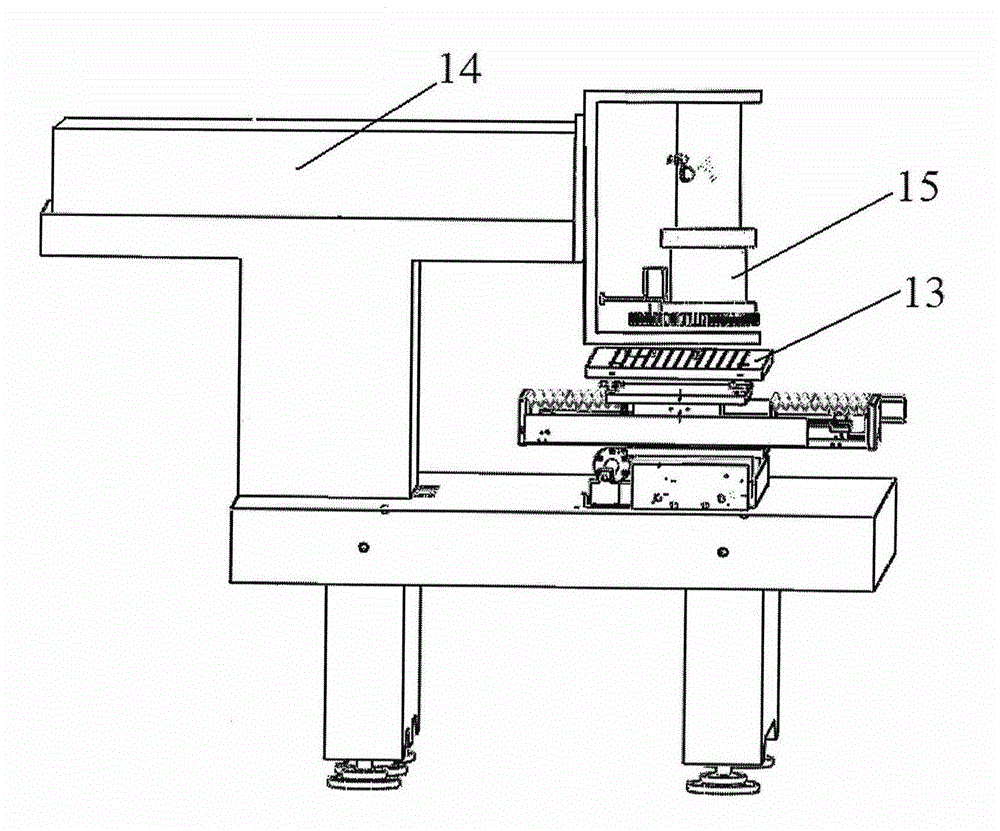

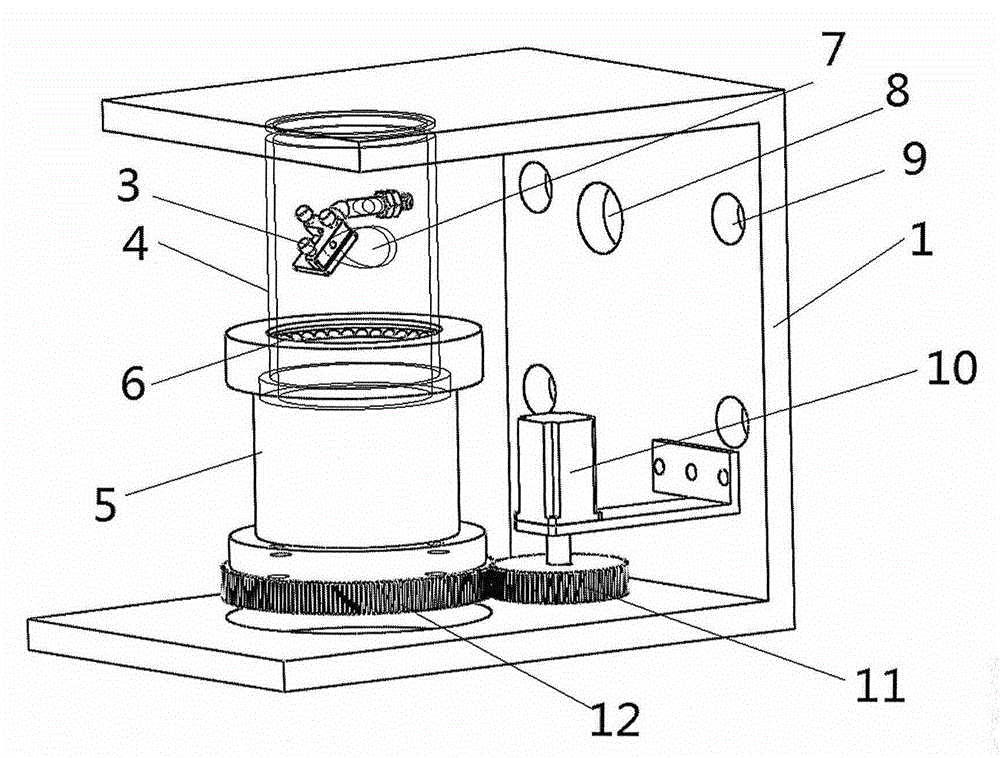

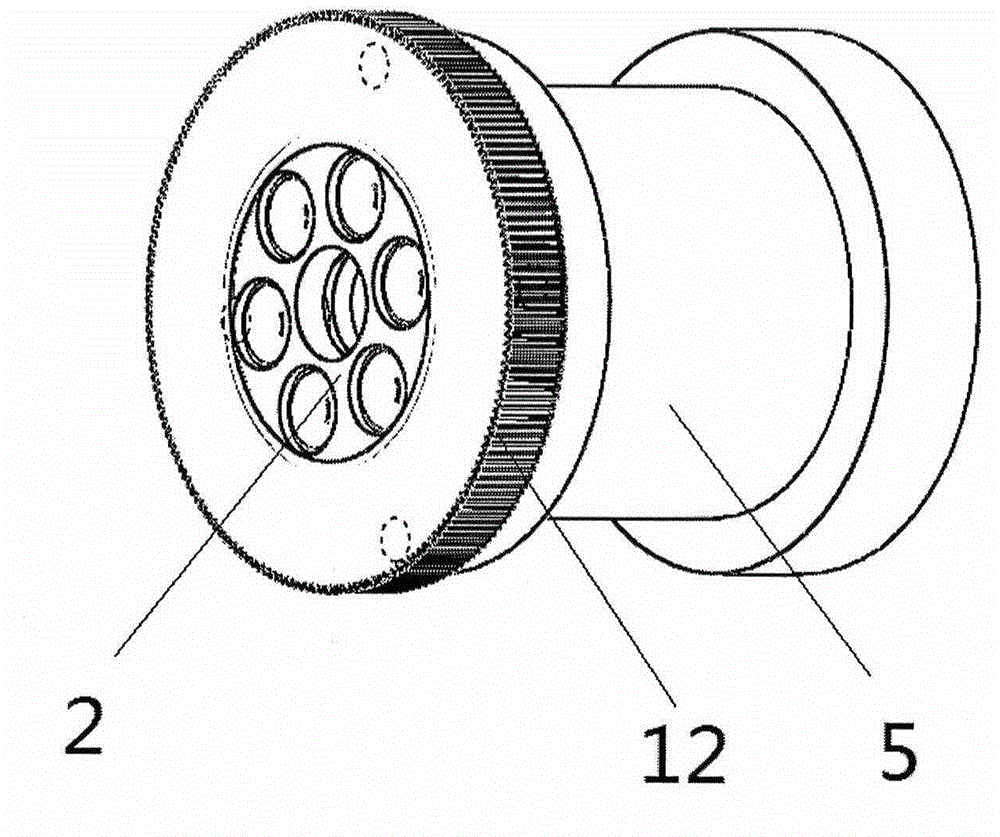

Method and device for precisely machining deep groove and deep hole by varifocal lasers

InactiveCN103878495AEnergy concentrationLarge hole depthLaser beam welding apparatusEngineeringDeep hole

The invention provides a method for precisely machining a deep groove and a deep hole by varifocal lasers. The method comprises the steps that a plurality of focusing lenses with different focal lengths and workpieces are clamped; if deep groove machining is carried out, a laser beam is continuously output; laser etching machining is completed once; if deep hole machining is carried out, N laser pulses are output; the lasers are closed, and a working table moves to the original position; whether machining meets the requirements or not is detected; if machining meets the requirements, machining is finished; if machining does not meet the requirements, a focusing lens base is rotated, the next focusing lens is moved to the position of the current focusing lens, and laser machining is carried out again until machining meets the requirements. The pulse laser beam sequentially penetrates through the focusing lenses with the different focal lengths by rotating the focusing lens base, the focal lengths are progressively changed, the lasers are focused on the new exposed surface in the laser etching or punching process all the time, energy is more concentrated, the punching deep is larger, and the efficiency is higher. The invention provides a device for precisely machining the deep groove and the deep hole by the varifocal lasers at the same time.

Owner:WENZHOU UNIVERSITY +1

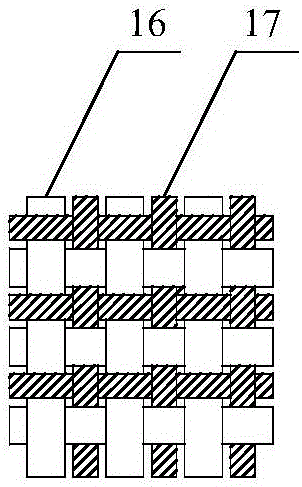

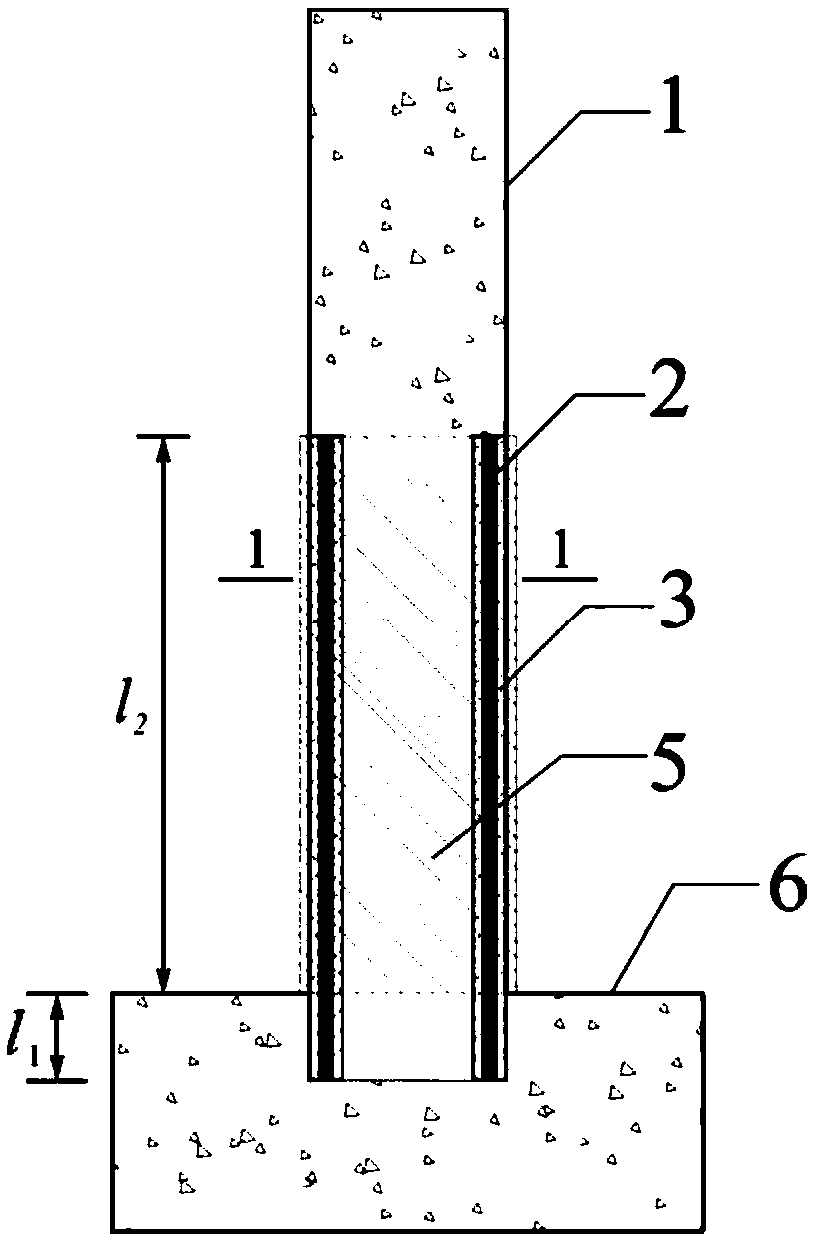

Assembled permanent formwork overlapped FRP rib seawater sea sand recycled concrete beam and manufacturing method thereof

ActiveCN110318495AGive Full Play to the "Hoop Effect"Give full play to the "ring effect"MouldsClimate change adaptationConcrete beamsLong term durability

The invention discloses an assembled permanent formwork overlapped FRP rib seawater sea sand recycled concrete beam and a manufacturing method thereof. The assembled permanent formwork overlapped FRPrib seawater sea sand recycled concrete beam comprises a prefabricated assembled permanent formwork and an FRP rib seawater sea sand recycled concrete beam. The prefabricated assembled permanent formwork is formed by assembling corer strip assembly blocks, first panels, second panels and positioning connecting parts, and the formwork is manufactured from an engineering cement-based composite (ECC)and a fiber woven mesh. The FRP rib seawater sea sand recycled concrete beam comprises seawater sea sand recycled concrete poured into the prefabricated assembled permanent formwork and an FRP rib framework fixedly arranged in the seawater sea sand recycled concrete. As the TRE formwork and the FRP rib seawater sea sand recycled concrete are compounded, the engineering manufacturing cost of the formwork is effectively reduced, the ductility of the FRP rib seawater sea sand recycled concrete beam is improved, the long-time durability of FRP ribs is guaranteed, and meanwhile the problems that an existing integral formwork is large in occupied space and not easy to transport are solved.

Owner:CHINA UNIV OF MINING & TECH

Prestress-steel-wire-rope-bending-shearing-reinforced concrete T beam and reinforcing method thereof

InactiveCN105937307AEasy constructionImprove construction efficiencyBuilding repairsBuilding material handlingHysteresisT-beam

The invention discloses a prestress-steel-wire-rope-bending-shearing-reinforced concrete T beam. The prestress-steel-wire-rope-bending-shearing-reinforced concrete T beam comprises a reinforcing system arranged on the concrete T beam. The reinforcing system comprises steel wire ropes, a plurality of bending-resistant reinforcing steel plates arranged at the bottom of the concrete T beam and a plurality of angle steels horizontally fixed to the two sides of a web plate of the concrete T beam; a plurality of bolt holes are formed in the other edges of all the angle steels in the length direction of the angle steels, adjustable bolts are arranged in all the bolt holes, circular rings are arranged at one ends of the adjustable bolts, and after the steel wire ropes are wound around the beam bottom, the two ends penetrate through corresponding circular rings respectively and are tensioned; a protection system is further arranged on the outer side of the reinforcing system. In the reinforcing process, prestress is applied to the steel wire ropes through the adjustable bolts, a specially-made tensioning apparatus does not need to be adopted, construction is convenient and fast, construction efficiency is greatly improved, the prestress is applied to the steel wire ropes, the stress hysteresis effect is avoided, and the reinforcing effect and the whole bearing capacity are improved; construction cost is low, construction is easy and convenient, the influence on structure weight is small, and the excellent structural performance and economic benefits are achieved.

Owner:JIANGXI GANYUE EXPRESSWAY +2

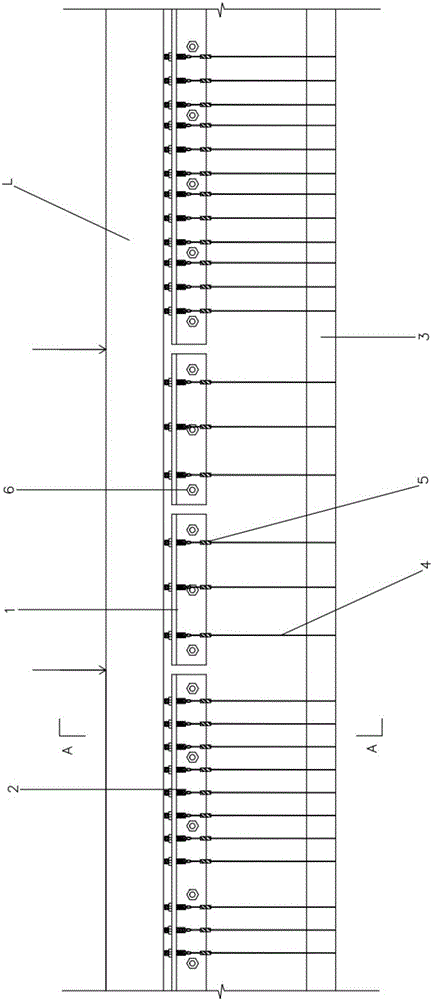

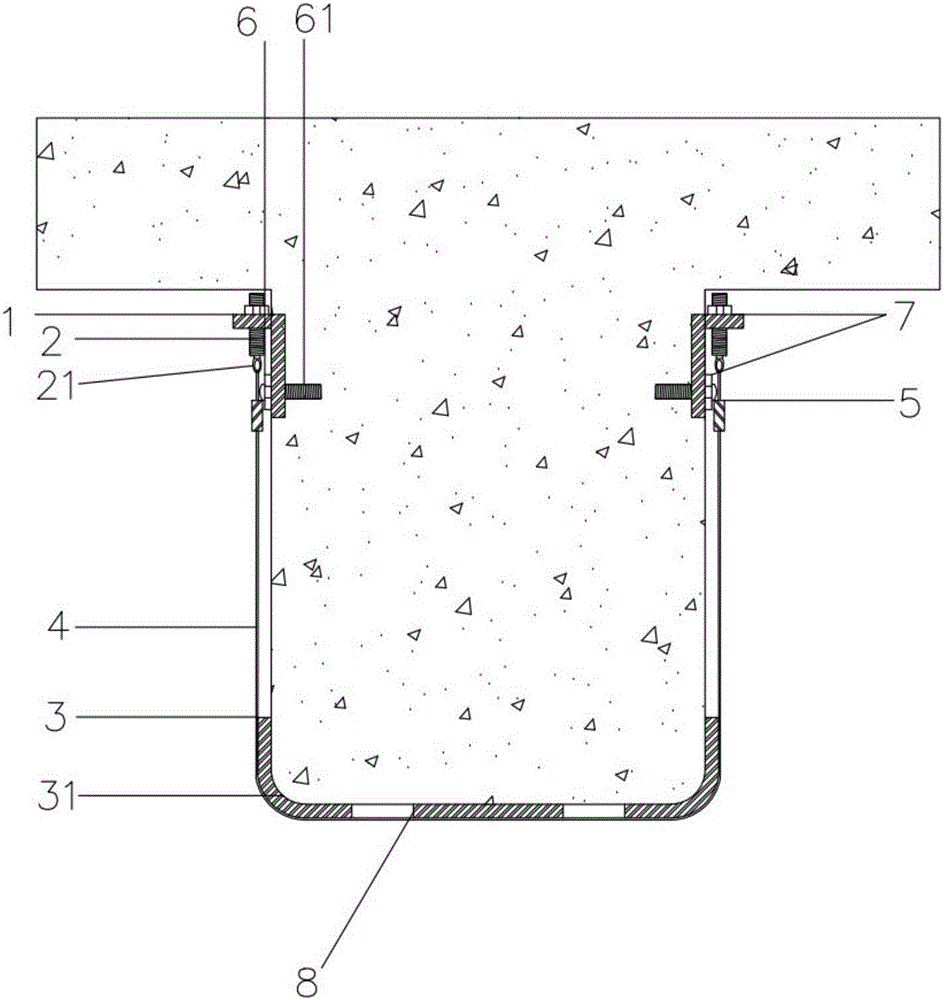

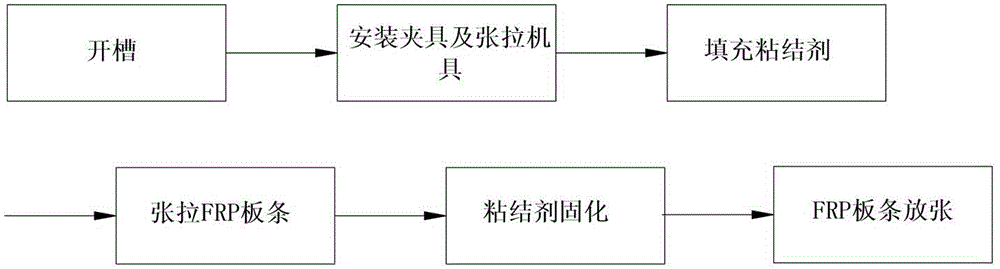

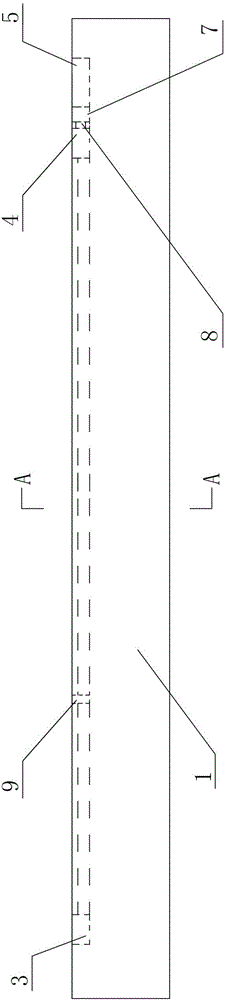

Concrete structure reinforcing method based on near surface mounted prestressed FRP (Fiber Reinforced Polymer)

ActiveCN102425311BAchieve anchoringGive full play to high-strength performanceBuilding repairsFiberSurface mounting

The invention discloses a concrete structure reinforcing method based on near surface mounted prestressed FRP (Fiber Reinforced Polymer), which comprises the steps of: 1, slotting, arranging more than one preformed groove on a concrete structure to be reinforced; 2, installing a tensioning tool of an FRP strip and an FRP strip clamp; 3, tensioning internal FRP strips in the tensioning tool and the FRP strip tool so that the internal FRP strips are tensioned, placing the internal FRP strips in the preformed groove, filling an adhesive, keeping a clamping and anchoring state for a period of time and then curing; and 4, relaxing: when adhesive resin is cured completely to reach the strength, dismantling the FRP strip clamp. The concrete structure has the advantages of low cost, convenience for construction, long service life, good reliability and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

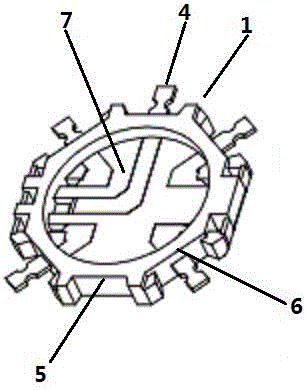

Device for precisely processing deep groove and deep hole by variable-focus laser

ActiveCN104907704AEnergy concentrationLarge hole depthLaser beam welding apparatusLaser etchingPunching

The invention provides a method for precisely machining a deep groove and a deep hole by varifocal lasers. The method comprises the steps that a plurality of focusing lenses with different focal lengths and workpieces are clamped; if deep groove machining is carried out, a laser beam is continuously output; laser etching machining is completed once; if deep hole machining is carried out, N laser pulses are output; the lasers are closed, and a working table moves to the original position; whether machining meets the requirements or not is detected; if machining meets the requirements, machining is finished; if machining does not meet the requirements, a focusing lens base is rotated, the next focusing lens is moved to the position of the current focusing lens, and laser machining is carried out again until machining meets the requirements. The pulse laser beam sequentially penetrates through the focusing lenses with the different focal lengths by rotating the focusing lens base, the focal lengths are progressively changed, the lasers are focused on the new exposed surface in the laser etching or punching process all the time, energy is more concentrated, the punching deep is larger, and the efficiency is higher. The invention provides a device for precisely machining the deep groove and the deep hole by the varifocal lasers at the same time.

Owner:WENZHOU UNIVERSITY

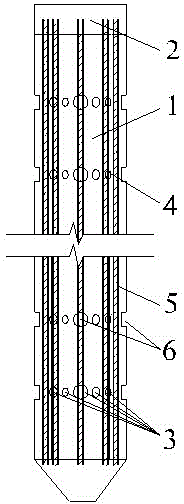

Nuclear radiation resistant self-healing concrete containment vessel

InactiveCN105835466AHigh strengthIncrease elasticityNuclear energy generationSynthetic resin layered productsNuclear radiationSelf-healing

The invention discloses a nuclear radiation resistant self-healing concrete containment vessel. The containment vessel body is composed of a first steel deck, a first structural adhesive layer, a first compound fabric layer, a leaded steel capsule concrete layer, a second compound fabric layer, a second structural adhesive layer and a second steel deck successively from inside out, wherein the leaded steel capsule concrete layer is prepared by mixing concrete and leaded steel capsules. The product can effectively absorb rays so as to raise radiation resistance of the containment vessel. In addition, leakage of radioactive substances can be prevented, and strength and toughness of the product are also enhanced so as to further raise anti-seismic property.

Owner:WUHAN UNIV

Fiber reinforced composite material rib concrete drainage pipe pile

ActiveCN104372790AExtend your lifeExtend the service lifeBulkheads/pilesSoil preservationSteel tubeRebar

The invention discloses a fiber reinforced composite material rib concrete drainage pipe pile which comprises a pile body, an end plate and inner sleeves. The pile body is internally provided with fiber reinforced composite material ribs. Carbon fiber is adopted for the material ribs to serve as the reinforcing materials, and unsaturated polyester or epoxy resin or phenolic resin serves as the base body. The material ribs are sleeved with steel pipes. The inner wall of the pile body is evenly provided with concrete protrusions, and the pipe pile body is evenly provided with a certain number of drainage holes. According to the fiber reinforced composite material rib concrete drainage pipe pile, steel ribs are replaced by the fiber reinforced composite material ribs, the problem that ordinary reinforced concrete piles are prone to crack after being pulled is effectively solved by the adoption of the advantages of the high-elasticity modulus, corrosion resistance and the like of carbon fiber ribs, and the service life of the permeable pipe pile is prolonged. Meanwhile, the fiber ribs are sleeved with the steel pipes, and the fiber ribs are separated from the concrete, so that the situation that a concrete structure interface is stripped and damaged due to insufficient fiber rib-concrete interface strength is avoided, and the inner wall of the pile body is creatively provided with the concrete protrusions so that the permeable pipe pile can be pulled out in the future demolition conveniently to rebuild the building foundation.

Owner:宏盛建业投资集团有限公司

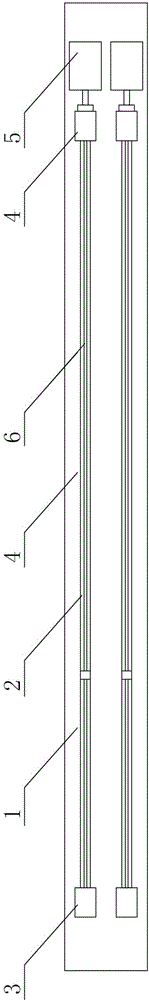

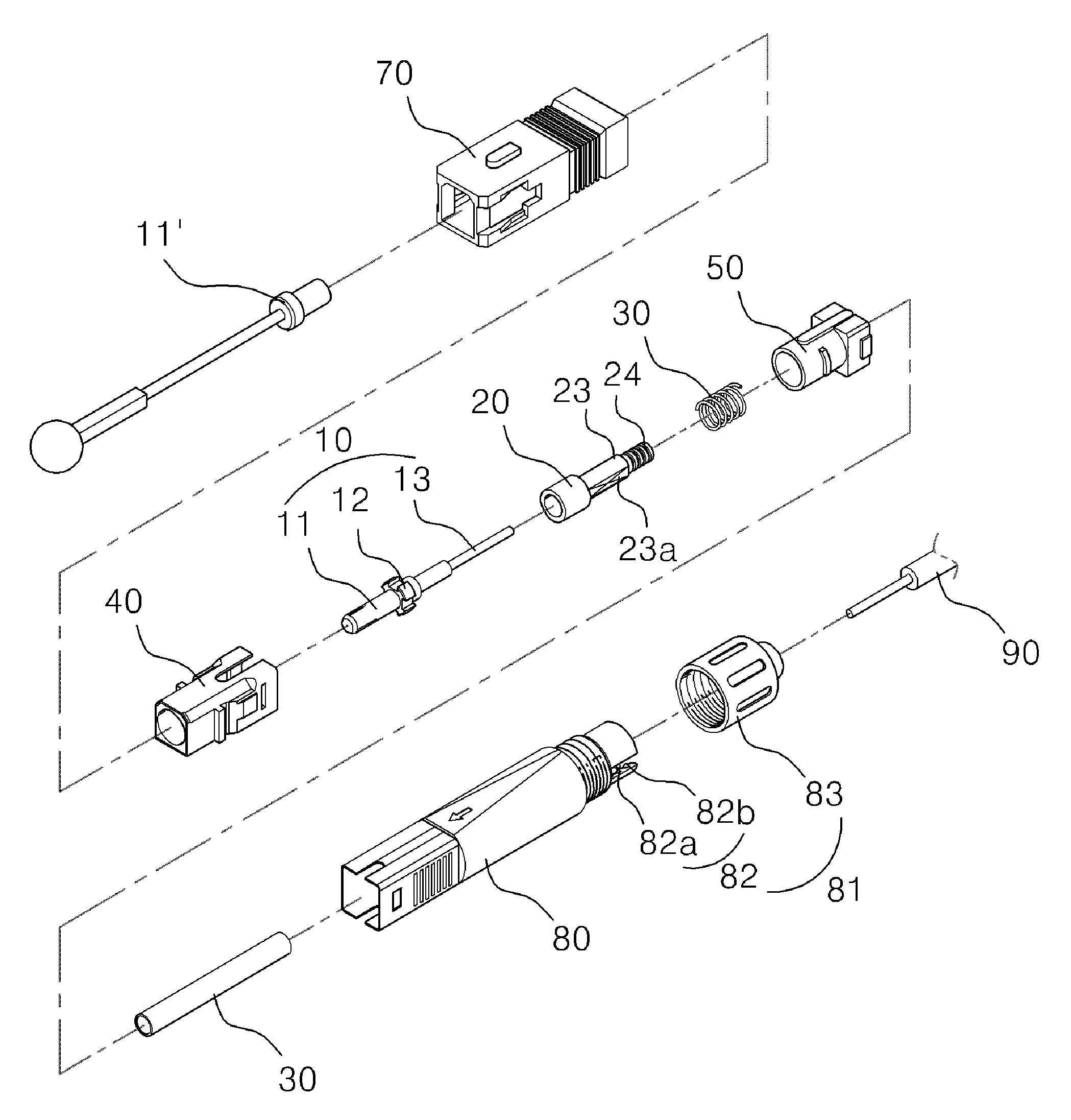

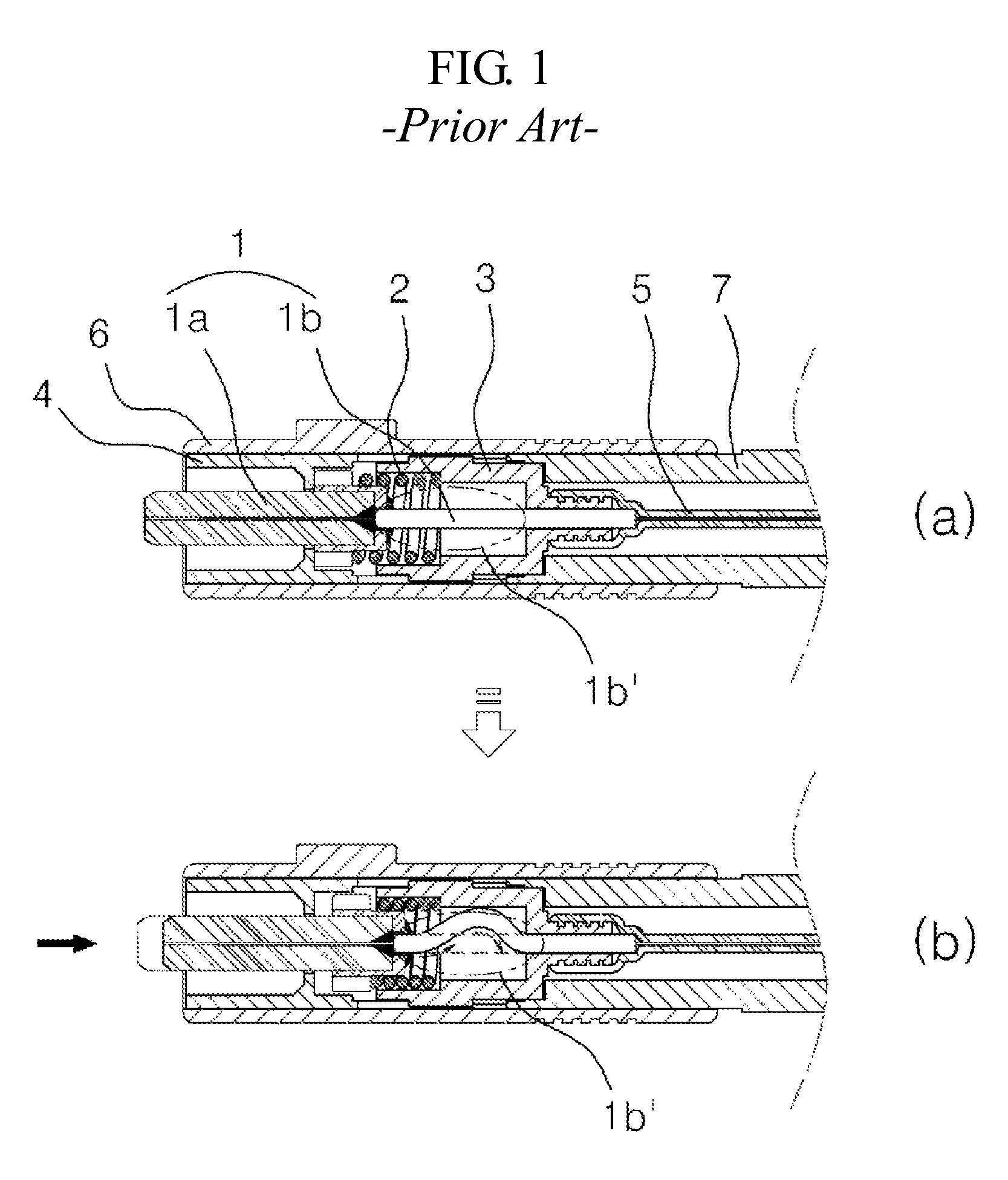

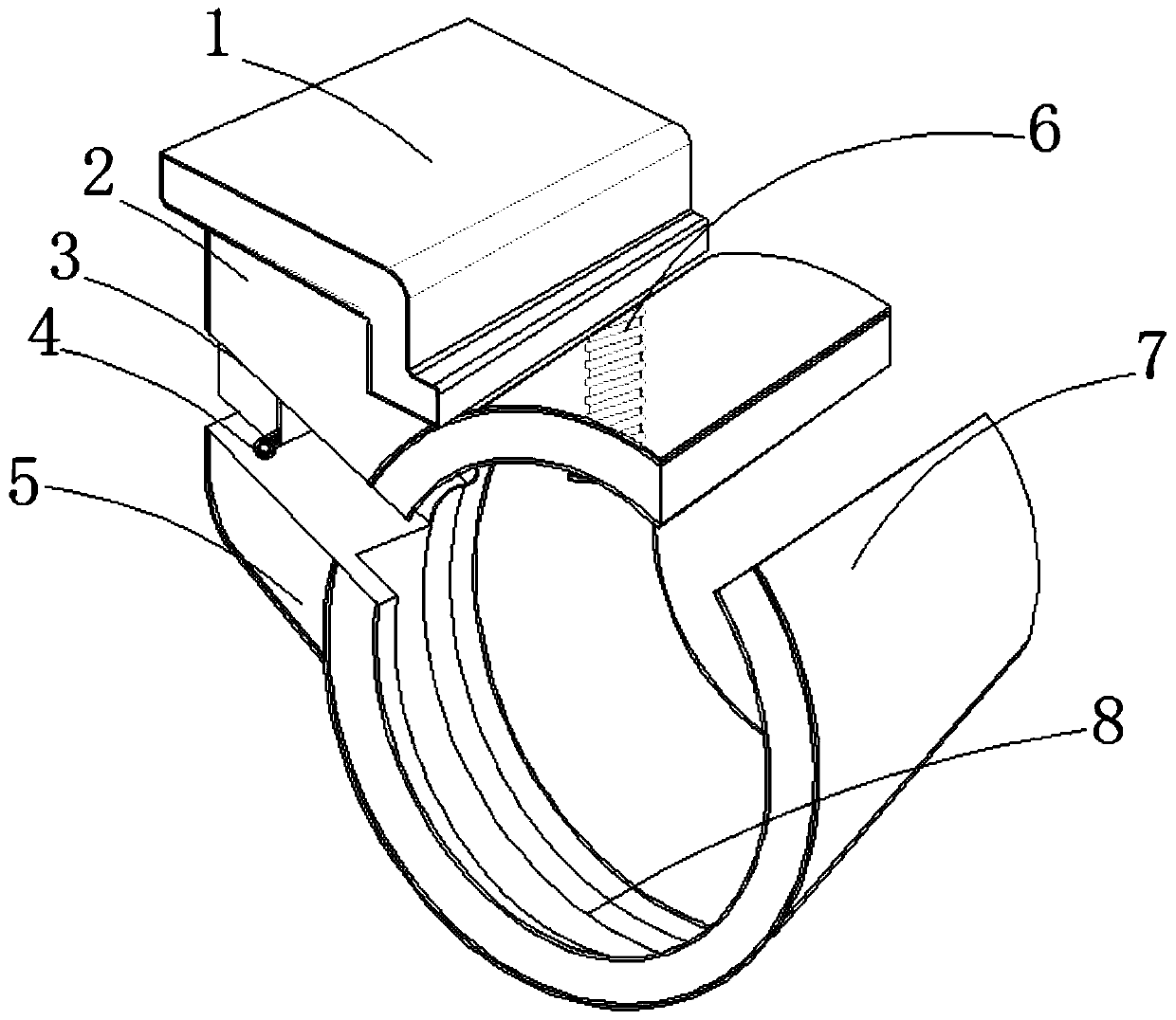

Optical fiber connector and an assembly method for the same

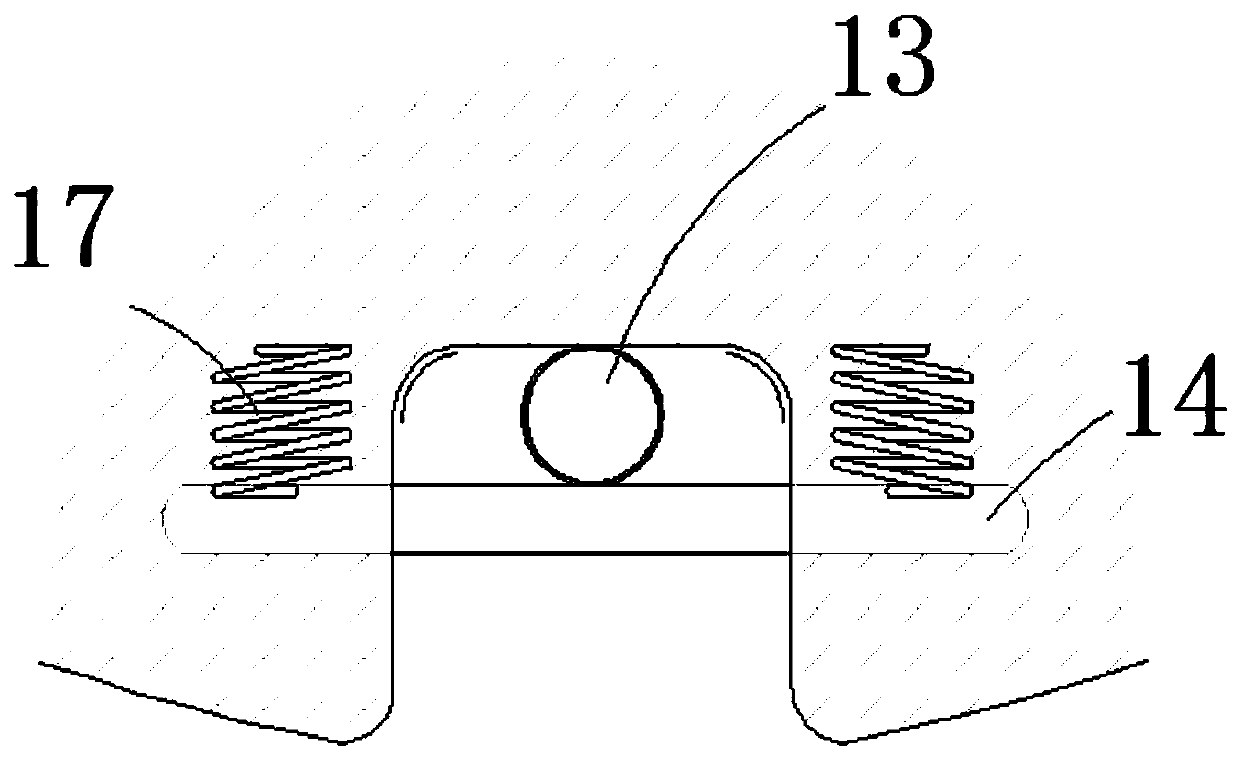

ActiveUS9057849B2Avoid damagePossible to performCoupling light guidesMetal working apparatusCoil springEngineering

The present invention relates to an optical fiber connector whereby an operator can easily couple optical fibers on site, and to an assembly method for the same. More specifically the invention relates to: an optical fiber connector wherein a guide ferrule bush is provided between a ferrule and a coil spring so as to be able to solve a problem whereby a ferrule optical fiber between a ferrule body and a reinforcing sleeve is bent, and a problem whereby contact between the ferrule body and the ferrule optical fiber is broken due to frequent movement, when the ferrule moves within a range of movement provided for by a resilient member due to the resilient member; and to an assembly method for the same.

Owner:ILSIN OTS

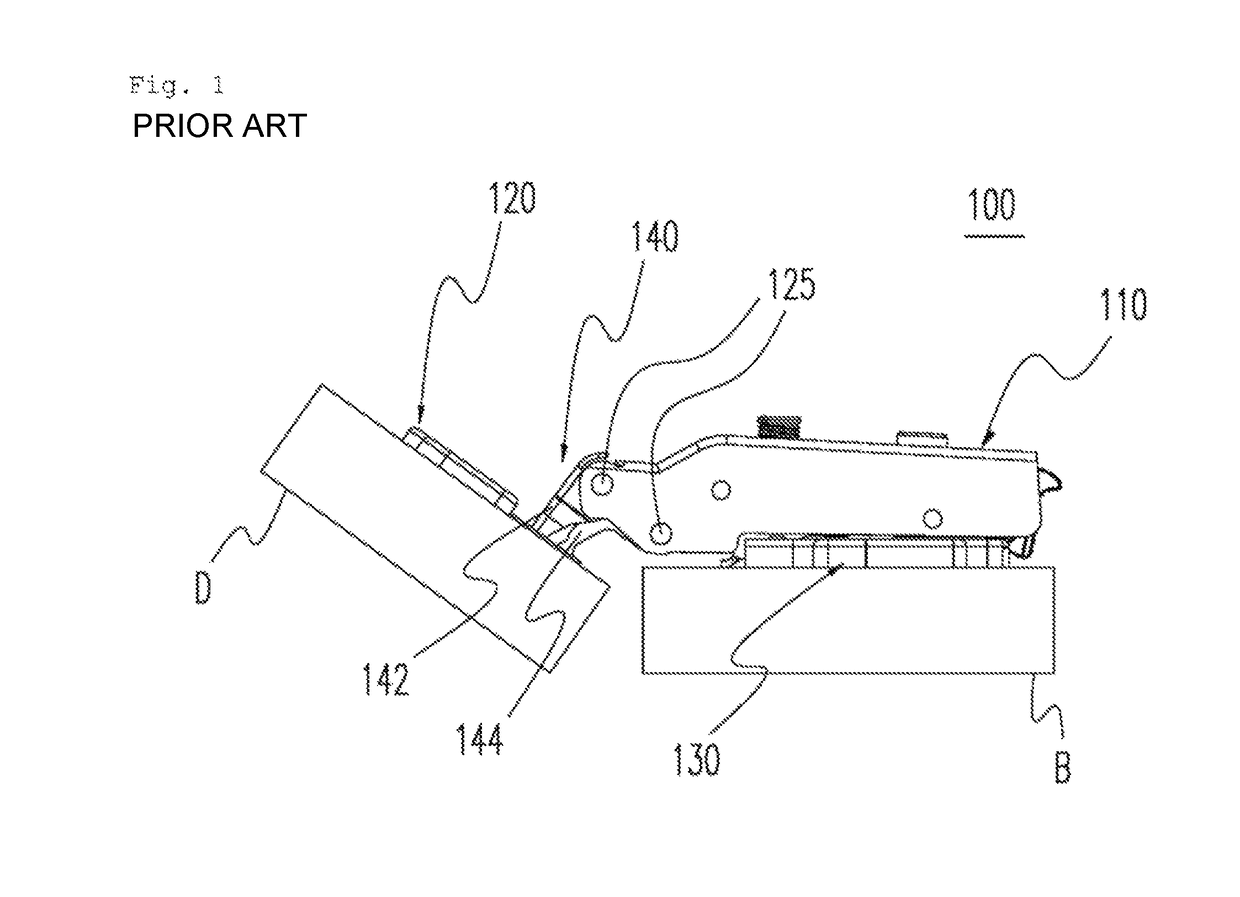

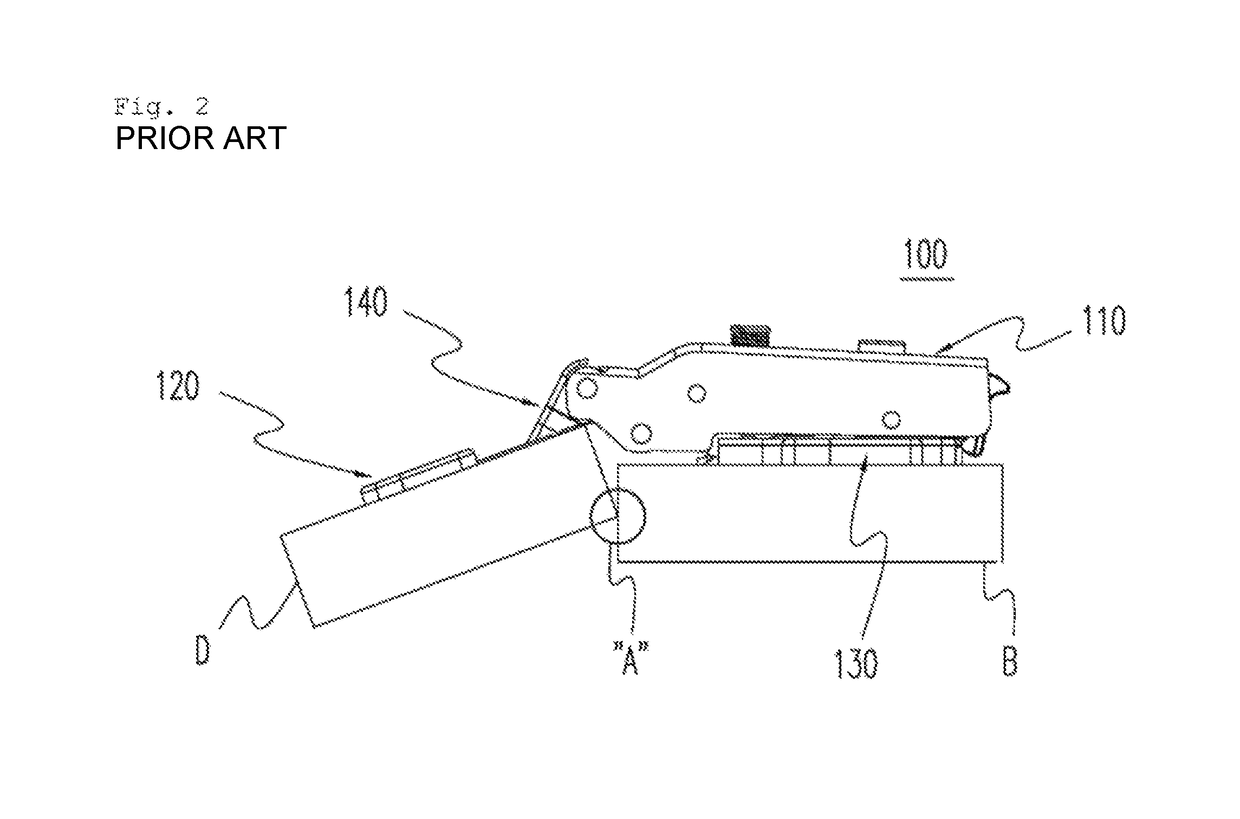

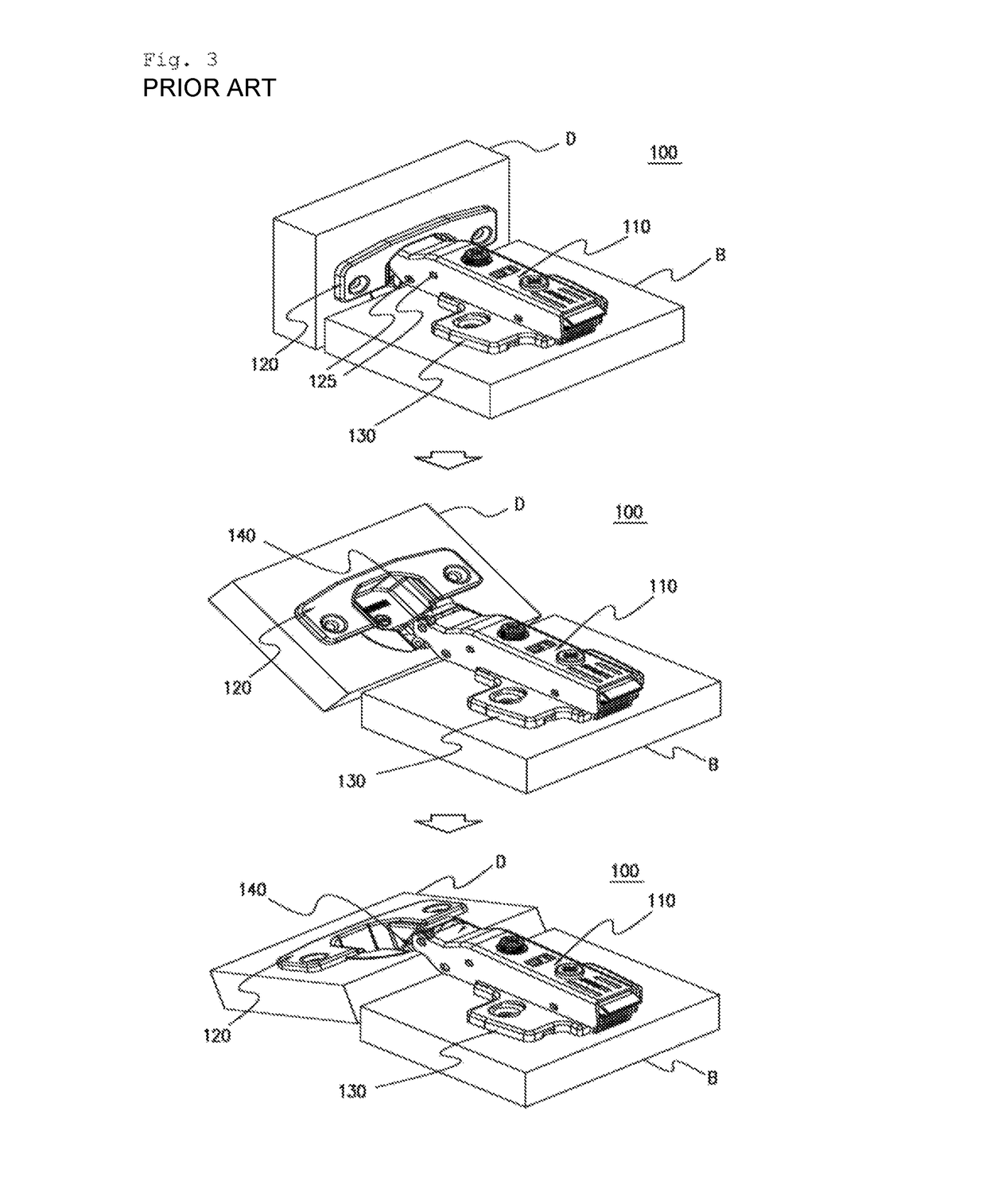

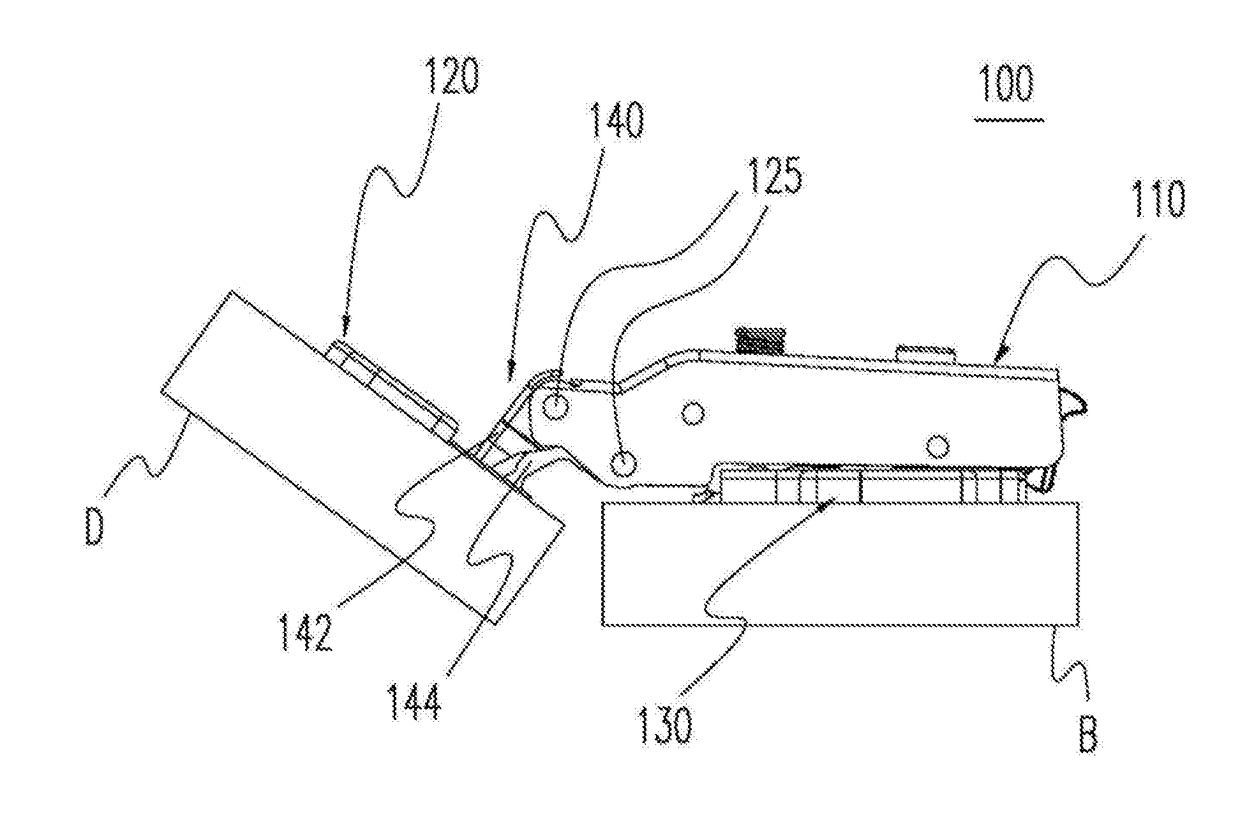

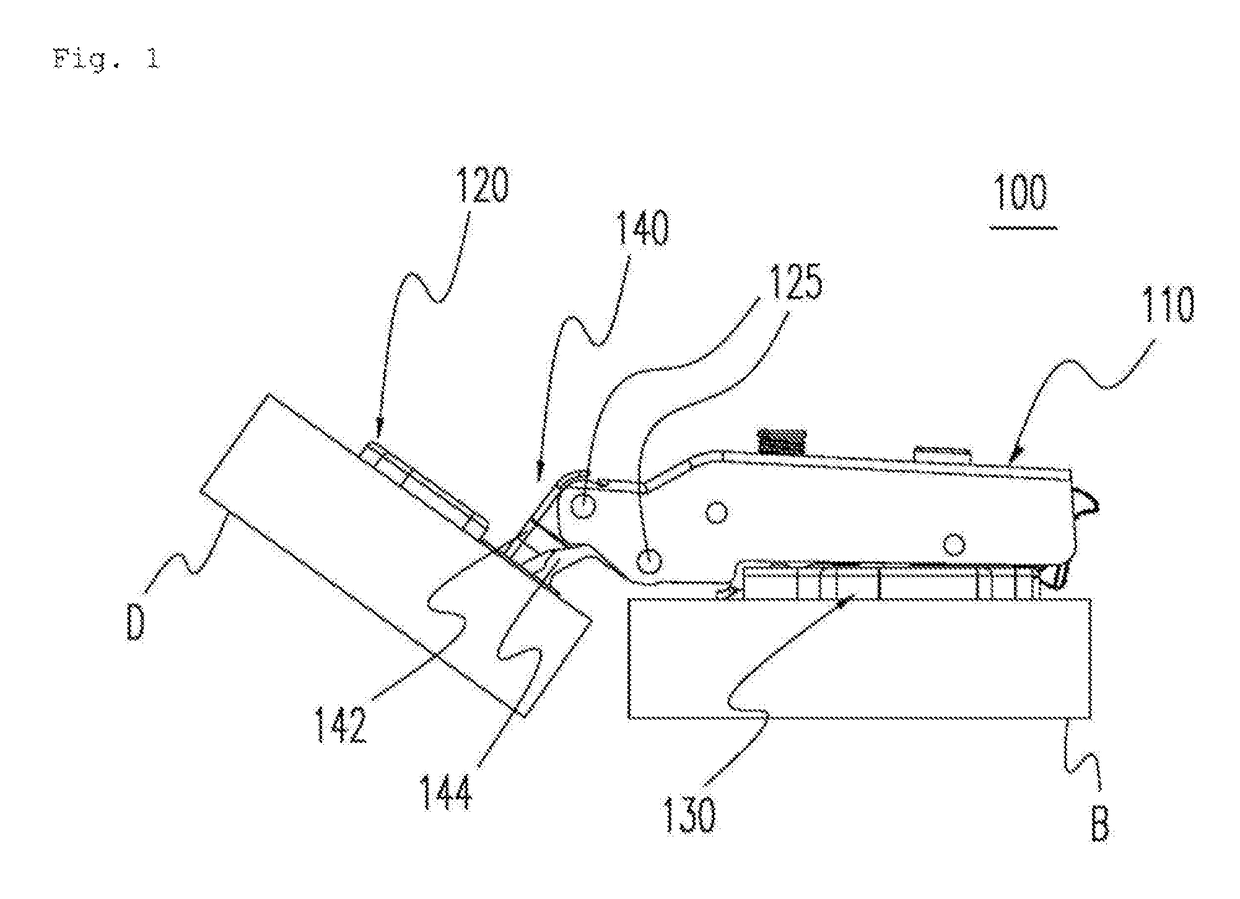

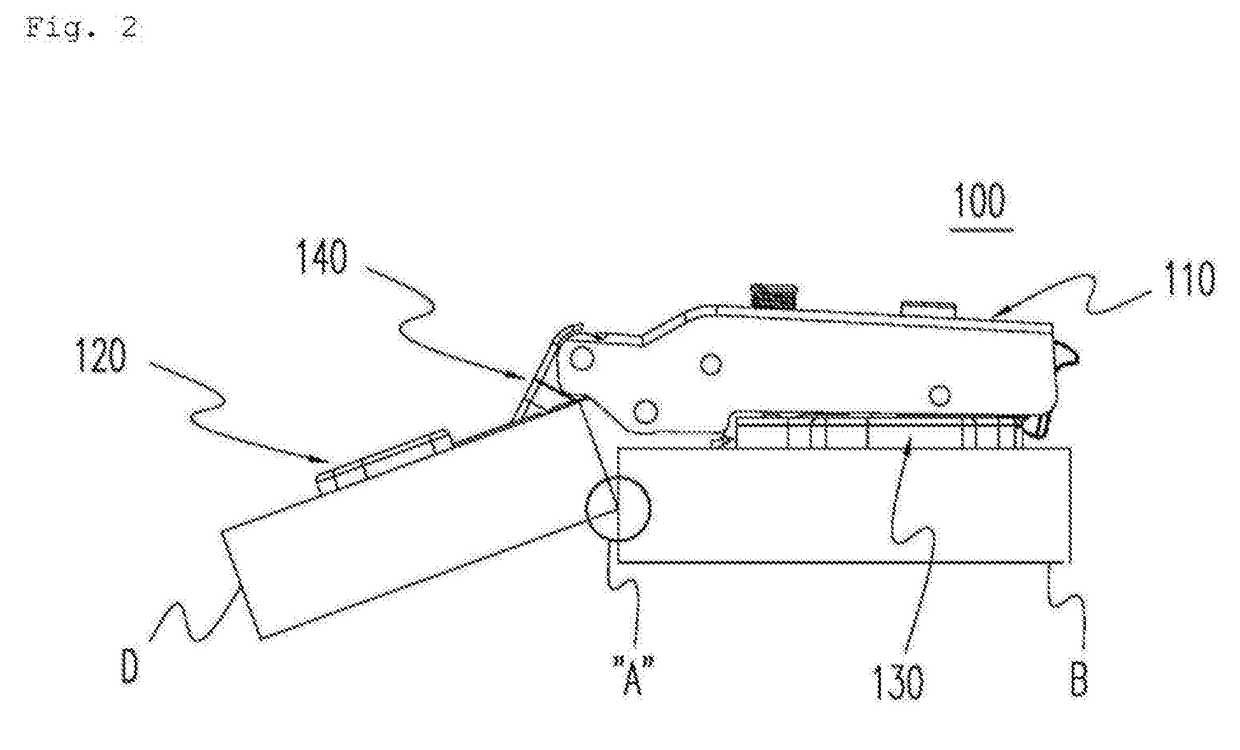

Furniture hinge for increasing jumping length of furniture door

ActiveUS10233684B2Increase the lengthAvoid damageFurniture joining partsWing accessoriesEngineeringMechanical engineering

Owner:SAMSUNG PRECISION IND

Bending member for bamboo reinforced wood beam and manufacture method thereof

PendingCN108979197AGive full play to the strength of the materialGuaranteed reinforcement effectBuilding repairsAdhesiveEngineering

Provided is a bending member for a bamboo reinforced wood beam. The member is composed of a wood beam, a bamboo board, an adhesive, angular fasteners sand anchor bolts. The bamboo board is closely bonded on the bottom surface of the wood beam through the adhesive. The angular fasteners are arranged on angle positions where the bottom surface intersects with side surfaces of the wood beam along thevertical direction of the wood beam at spaced intervals. Bottom flanges of the angular fasteners are fixed on the bottom surface of the bamboo board. Flanges on the side surfaces of the angular fasteners are fixed on the side surface of the wood beam in order to form a member body. Through the angular fasteners, the reinforced wood board is anchored multiple times. The member enjoys following advantages of effectively preventing separation between the bamboo board and the wood beam, improving anti-bending performance of the wood beam and fully leveraging high anti-pulling strength of the bamboo material.

Owner:NANJING FORESTRY UNIV

Shear strengthening method of concrete beam

InactiveCN103452331AAvoid damageImprove use valueBuilding repairsBridge erection/assemblyEpoxyPre stress

The invention relates to a shear strengthening method of a concrete beam. The method comprises the following steps of: selecting a fiber reinforcement with a diameter of 8mm-25mm according to the shear span area length of the concrete beam and the strength of concrete; drilling corresponding holes in a shear span area of the beam, wherein the diameter of the holes is 1.5 to 1.5 times larger than the diameter of the fiber reinforcement, the distance between adjacent holes is 1 to 2 times larger than the distance between hoop reinforcements in the shear span area, and the holes are positioned in the midpoints of the cross beam of the beam in the width direction; filling epoxy resin glue in the holes; applying prestress on the selected fiber reinforcement; and inserting the fiber reinforcements with prestress into the holes to form a shear system formed by longitudinal reinforcements, the hoop reinforcements, the fiber reinforcements, and epoxy resin glue and the concrete. The method has the beneficial effects that the damage to a concrete protecting layer limited to the concrete beam itself is avoided, the middle of the beam is provided with the holes, and the fiber reinforcements are fully wrapped by epoxy resin and concrete, so that a greater anchoring force is generated, the material utilization rate is improved, and the debonding failure of the fiber reinforcements and the concrete is also prevented, and thus the utilization value of the fiber reinforcements is increased.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Furniture Hinge for Increasing Jumping Length of Furniture Door

ActiveUS20180016825A1Eliminate contactImprove satisfactionFurniture joining partsWing accessoriesEngineeringMechanical engineering

A furniture hinge mounted between a furniture wall and a furniture door so as to be used as an opening and closing mechanism of the furniture door, in which, by using the movement part provided on the body part of the furniture hinge and the adjustment part provided at the movement path of the movement part, the entire length of the furniture hinge is changed by advancing and returning the movement part in the opening and closing process of the furniture door such that, since the furniture wall and the furniture door do not come into contact with each other even though the furniture door is completely opened, the peeling damage to the exterior of the furniture is prevented and contact noise is eliminated, thereby improving the satisfaction of consumers.

Owner:SAMSUNG PRECISION IND

Metal surface gradient coating cladding method

InactiveCN106435442AAdapt to wideLower technical barriersMolten spray coatingSurface gradientPlasma generator

The invention discloses a metal surface gradient coating cladding method, and belongs to the technical field of metal surface heat treatment. The metal surface gradient coating cladding method comprises four steps of matrix surface pretreatment, coating material setting, coating cladding treatment and coating inspection; and in the coating cladding process, through specific setting of coating cladding equipment, a laminar flow plasma generator and a cladding spraying gun are adopted to provide a heat source to laminar flow plasma to perform gradient treatment for a metal surface. After at least two times of classing treatment, a coating layer with a gradient is formed, so that the cracking or stripping damage in an ultrahard coating layer is prevented, and the application range of the coating layer is wider; the laminar flow plasma is fast in heating speed, and the matrix temperature is convenient to control, and is not higher to prevent generation of annealing deformation; and meanwhile, as the laminar flow plasma continuously works to cause relatively slow cooling of a machine body, and a formed transition area is higher, the stress release is better for hard surface material cladding.

Owner:CHENGDU PLASMAJET SCI & TECH

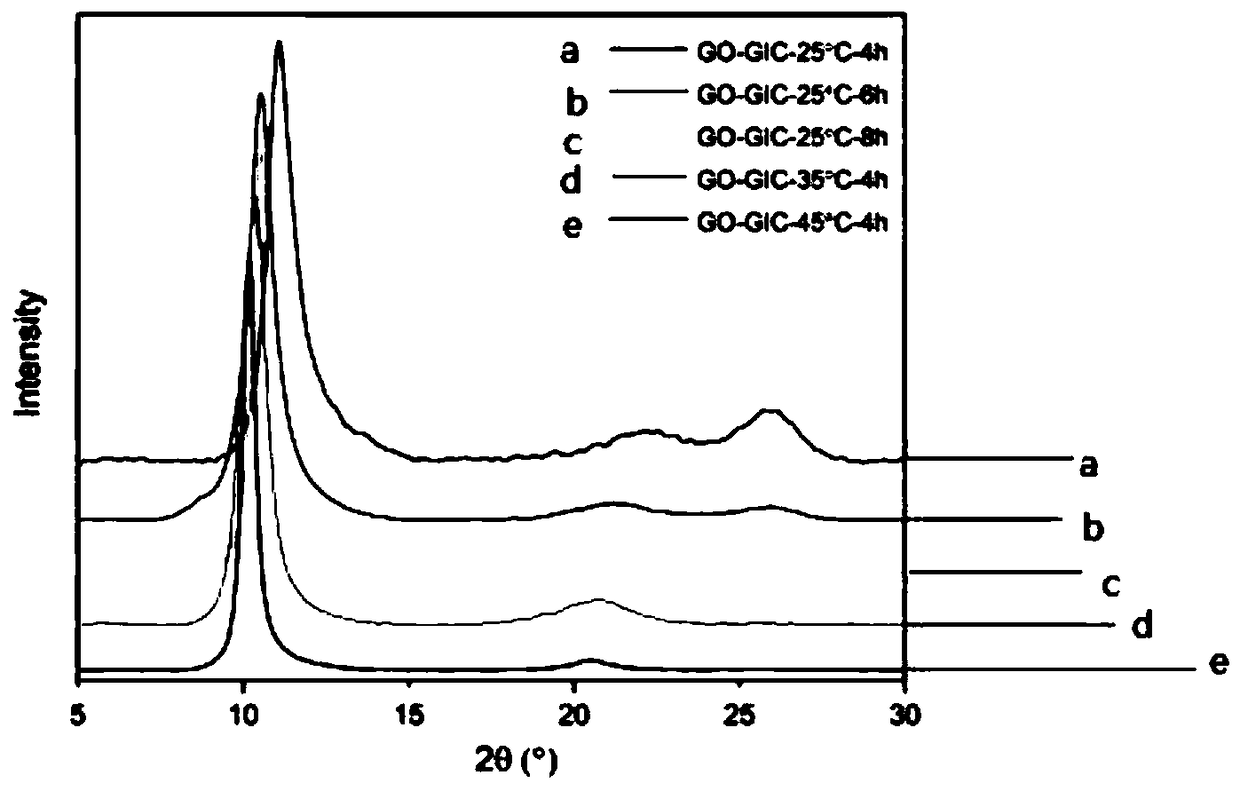

Preparation method of graphene

The invention discloses a preparation method of graphene. The method comprises the following steps: using novel expanded graphite as a raw material, oxidizing the expanded graphite at low temperatureof 45 DEG C by using a strong oxidization solution, and then reducing graphene oxide at the temperature of 200 DEG C, cooling to collect high-quality graphene. The expanded graphite is taken as the raw material in the invention, so that an expanded graphite sheet provided with an expanded graphite layer is beneficial to infiltration of an acid solution and the subsequent oxidation reaction. The synthesis process uses strong acid and performs a redox reaction at low temperature, and an ultrasonic stripping process is eliminated, so that the prepared graphene oxide has a large size, and the production of conductive graphene is facilitated.

Owner:珠海市扬程玻璃制品有限公司

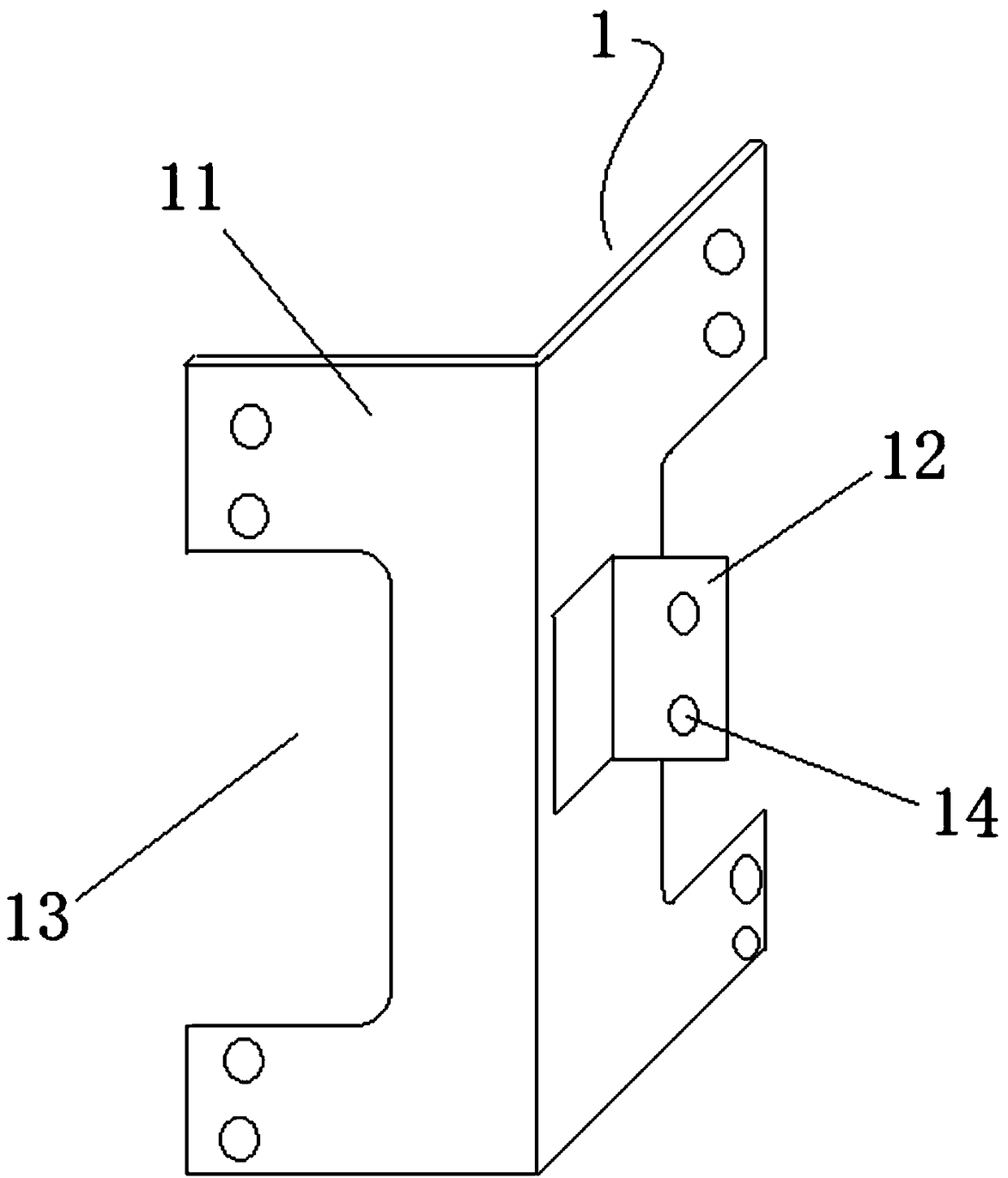

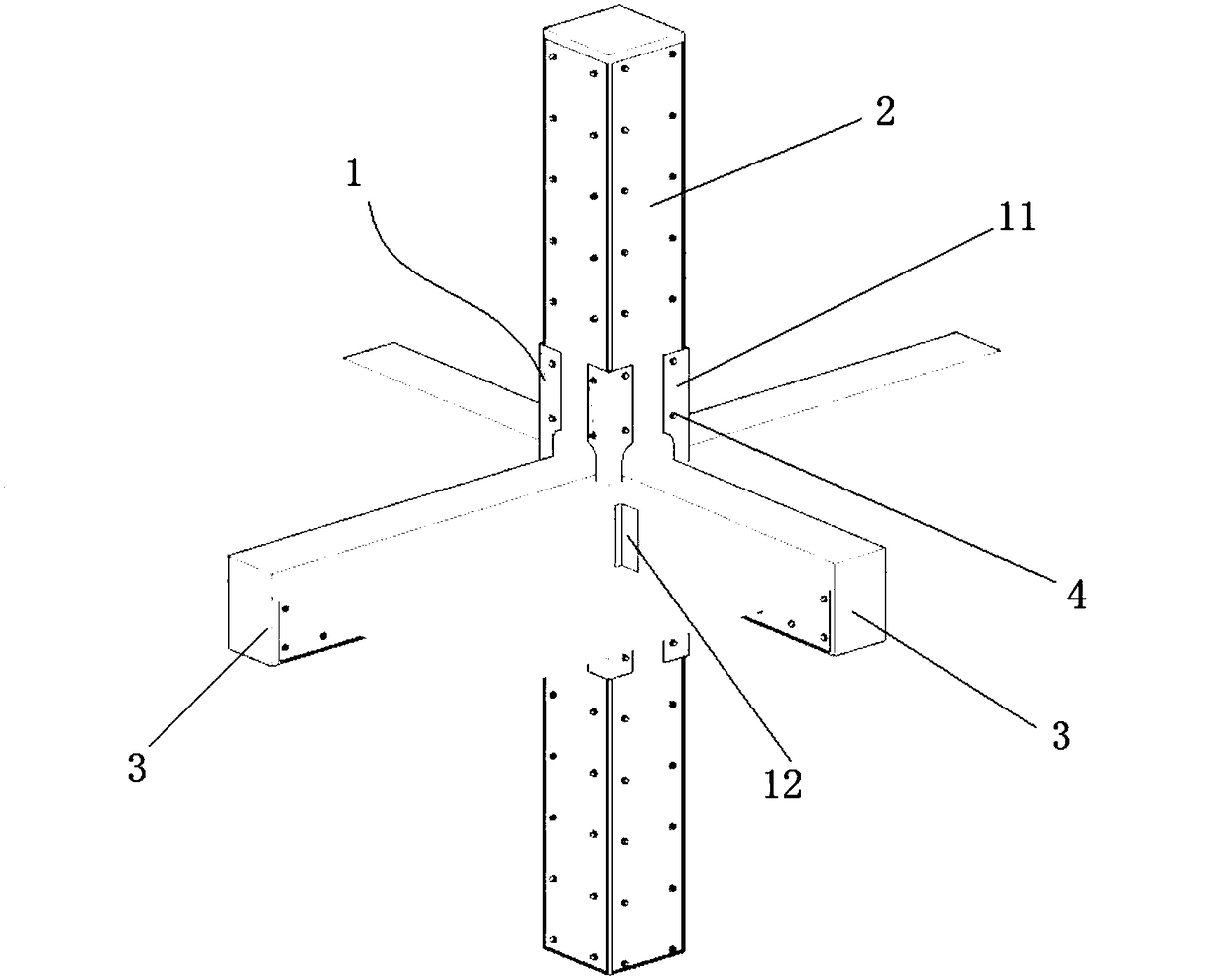

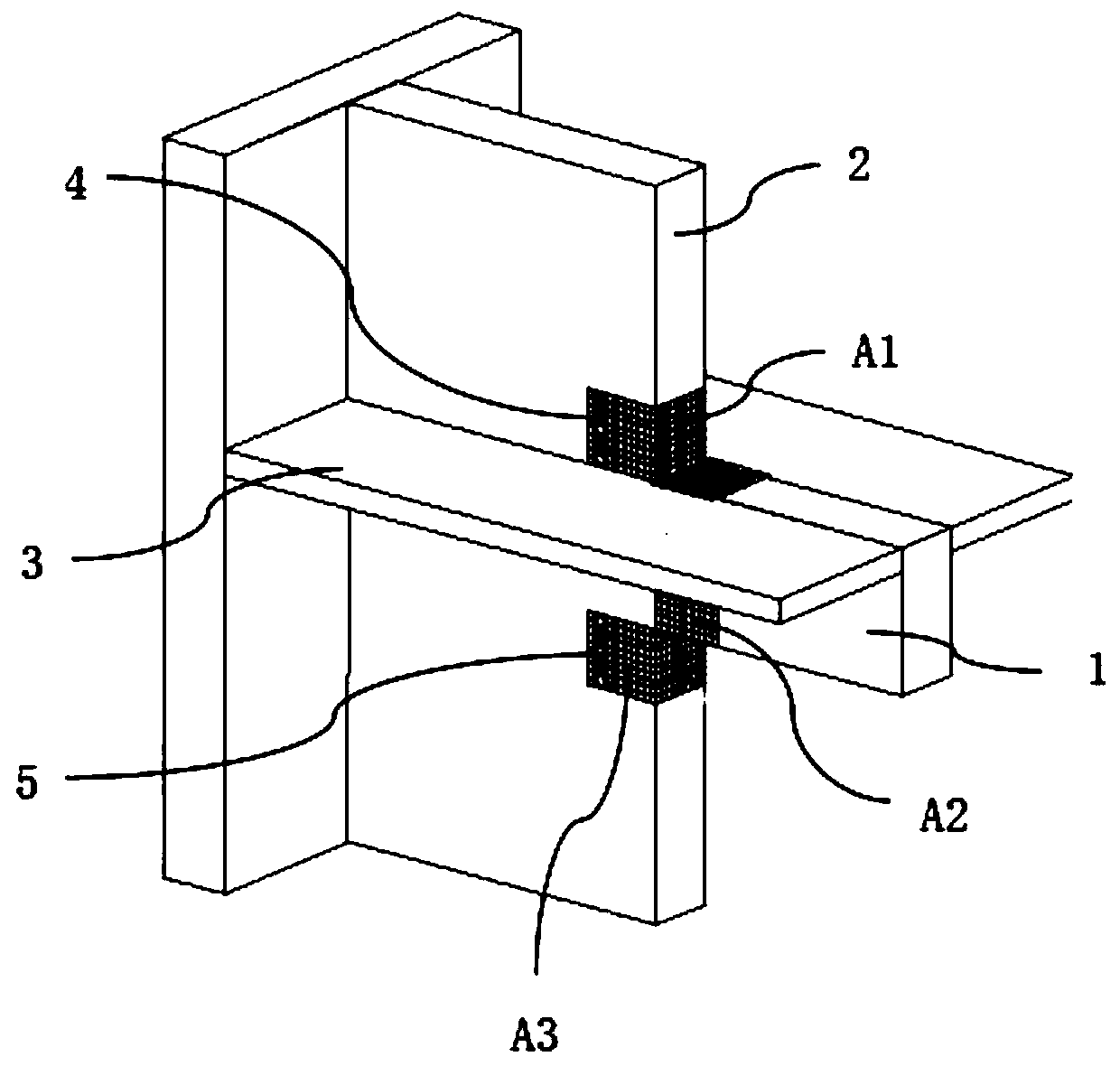

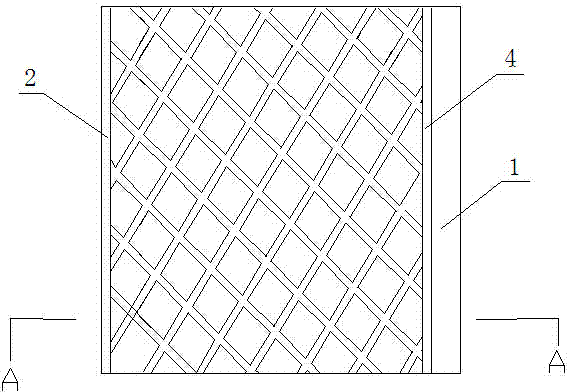

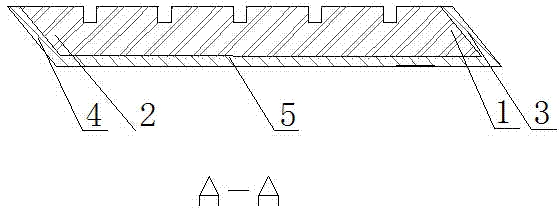

Externally-wrapped anchor steel reinforcement structure for concrete beam and column joint

ActiveCN108643602AAvoid peel damageSolve the problem of transferring weak points to nodesBuilding repairsFloor slabSheet steel

The invention discloses an externally-wrapped anchor steel reinforcement structure for a concrete beam and a column joint. The externally-wrapped anchor steel reinforcement structure is composed of penetration steel angles, beam side steel angles, beam side steel plates and column side steel plates, wherein the penetration steel angles, the beam side steel angles, the beam side steel plates and the column side steel plates are connected in a planting bar type post-installed fastening mode. The penetration steel angles penetrate through floors and are connected with the column side steel plates, the beam side steel plates are connected with the penetration steel angles by the beam side steel angle, and therefore a complete set of reinforcement scheme with reasonable force transmission is formed. When the bearing capacity of beams and columns is improved, the problem that a core area of the joint is relatively weak caused by beam and column reinforcement is solved, and brittle shear failure in the core area is avoided; and internal force transmitted to the core area of the joint through the penetration steel angles is evenly distributed onto bolts and steel plates, so that shearing resistance and energy dissipation performance of the core area are greatly improved.

Owner:TONGJI UNIV

Concrete simply-supported beam based on carbon fiber grid composite boards and manufacturing method

InactiveCN106760190AEliminate the problem of reduced bearing capacityImprove bearing capacityGirdersJoistsCarbon fibersCement board

The invention discloses a concrete simply-supported beam based on carbon fiber grid composite boards and a manufacturing method and belongs to the technical field of building structure engineering. The concrete simply-supported beam comprises a side board, a bottom board, an end board, a U-shaped steel hoop and concrete. The side board and the bottom board are the carbon fiber grid composite boards. The bottom board is a common cement board. The side board and the bottom board are connected through the U-shaped steel hoop. The end board is located at the end in a groove-shaped structure composed of the side board and the bottom board. The side board is clamped at the end through a G-shaped clamp. Shear-resistant connection parts are embedded in the side board and the bottom board so as to enhance the adhesive force of the concrete and the carbon fiber grid composite boards. Concrete is poured in the space formed by the side board, the bottom board and the end board in a surrounded mode and is subjected to curing, and a simply-supported flexural member is formed. The concrete simply-supported beam has the advantages of being free of template, small in dead weight, good in durability, high in integrality and simple to construct.

Owner:HUNAN UNIV

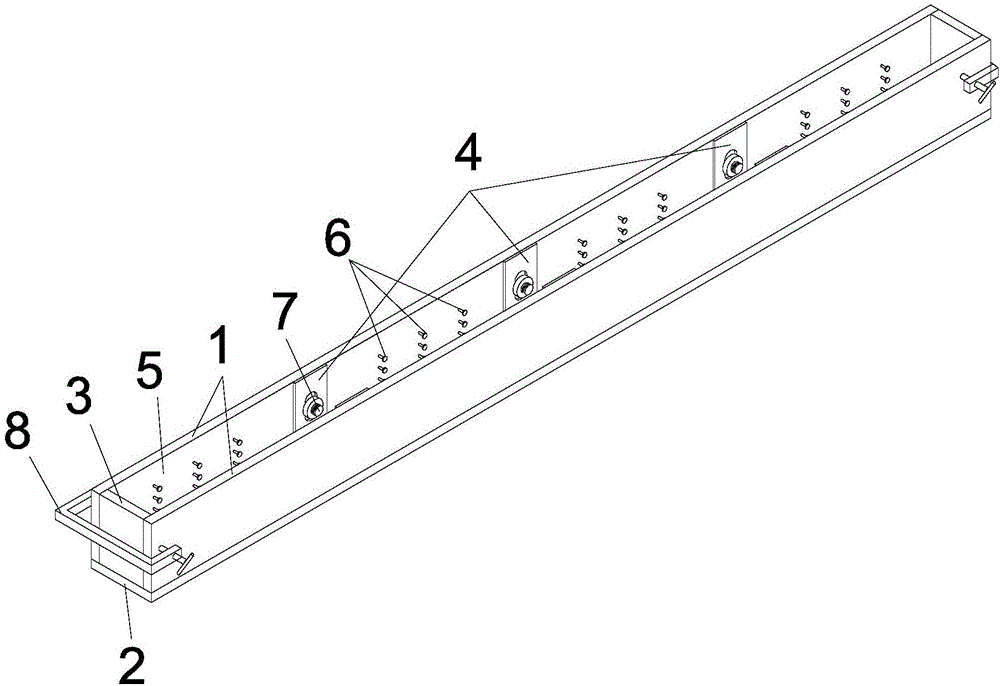

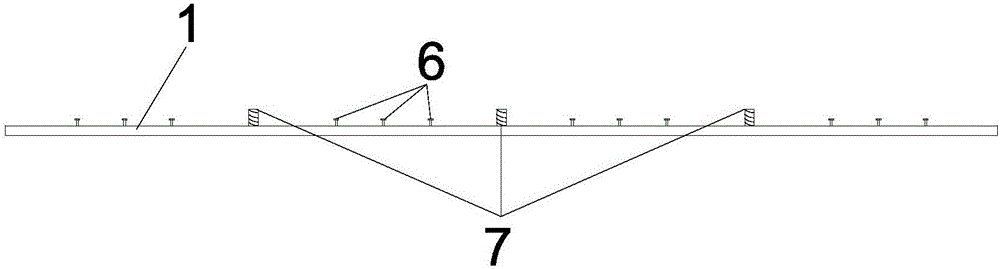

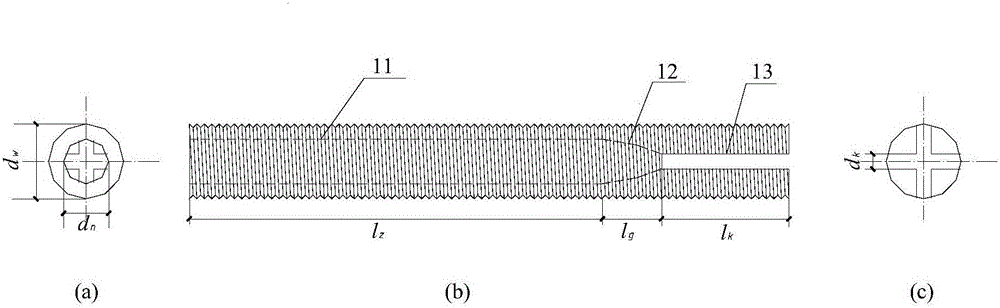

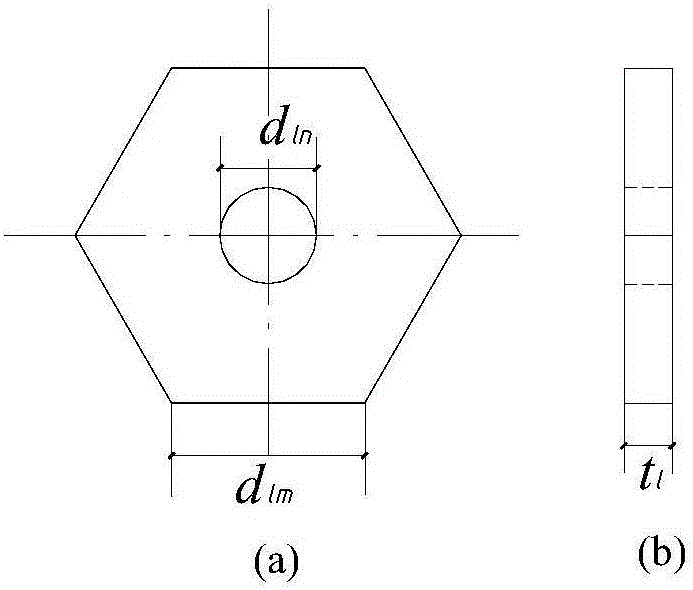

Composite anchor rod device and method for fastening cross section by using anchor rod device in anchoring manner

InactiveCN105863294AControl implant depthAvoid peel damageBuilding repairsInsertion depthEngineering

The invention relates to a composite anchor rod device and a method for fastening a cross section by using the anchor rod device in an anchoring manner. The composite anchor rod device comprises an anchor rod, a positioning screw nut, a fixing cone, a fixing sleeve, a pressing plate and a fastening screw nut, wherein an inner threaded hole is formed inside the anchor rod; a partitioning groove which is communicated with the threaded hole is formed in an inserting end of the anchor rod; the partitioning groove is used for dividing a rod body into a plurality of deformation parts which are expanded outwards under the action of extrusion; the positioning screw nut is arranged on the anchor rod in a sleeving manner and is used for adjusting the insertion depth of the anchor rod; the fixing cone is inserted into the anchor rod, a sharp part has a conical surface for extruding the deformation part, and outer threads are fixed at a rear part; and one end of the fixing sleeve is connected with the fixing cone in a sleeving manner, and the pressing plate and the fastening screw nut for fixing the pressing plate are arranged at the other end of the fixing sleeve in a sleeving manner. By adopting the composite anchor rod device, the insertion depth of the anchor rod can be effectively controlled, on one hand, a part to be fastened can be prevented from a phenomenon that a concrete protecting layer is peeled and damaged, and on the other hand, a reinforced layer and the part to be fastened can be prevented from a damage phenomenon of interface peeling. The invention further discloses a method for fastening the cross section by using the anchor rod device in the anchoring manner.

Owner:ZHEJIANG UNIV

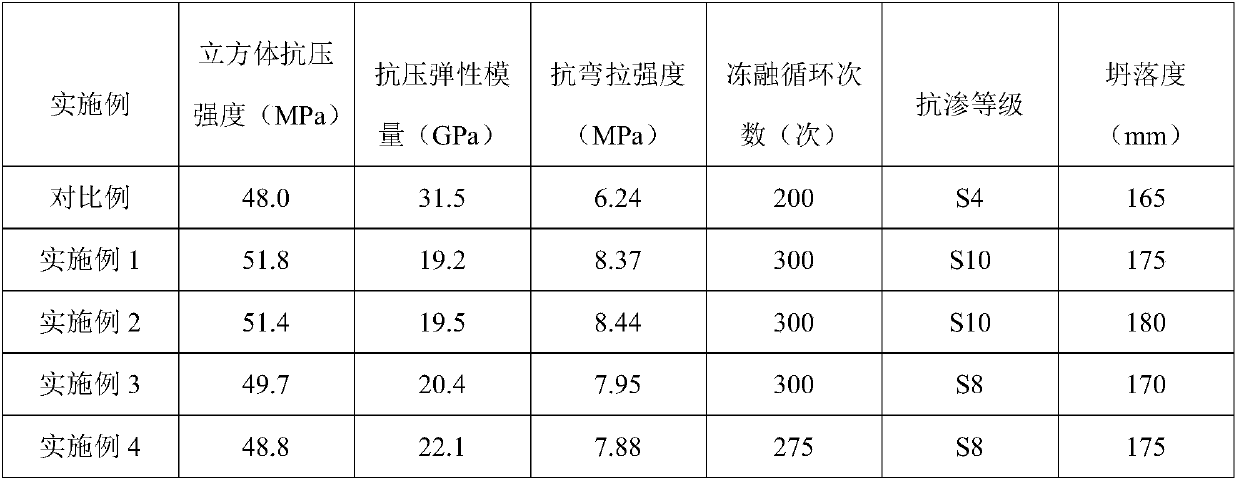

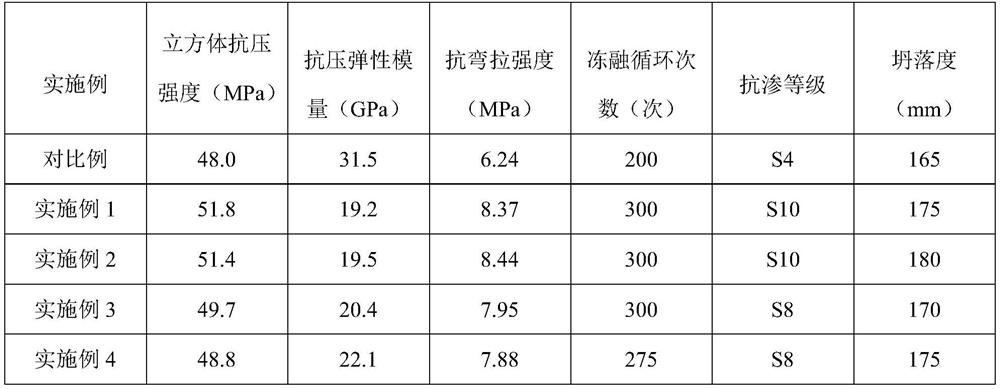

High-performance sulfur concrete and preparation method thereof

The invention discloses high-performance sulfur concrete and a preparation method thereof. The high-performance sulfur concrete comprises the following raw materials in percentage by mass: 30%-37% ofcement, 38%-43% of river sand, 11%-17% of water, 0.4%-0.8% of a water reducer, 8%-15% of sulfur powder, 0.1-0.5% of an emulsifying dispersant and 0.8-1.2% of resin emulsion. By the high-performance sulfur concrete provided by the invention, sulfur can be recycled, furthermore, the bending resistance, the seepage resistance and the frost resistance of the concrete can be improved, and the durability of the concrete and the service capability of the concrete under extreme condition are improved effectively.

Owner:CHANGAN UNIV

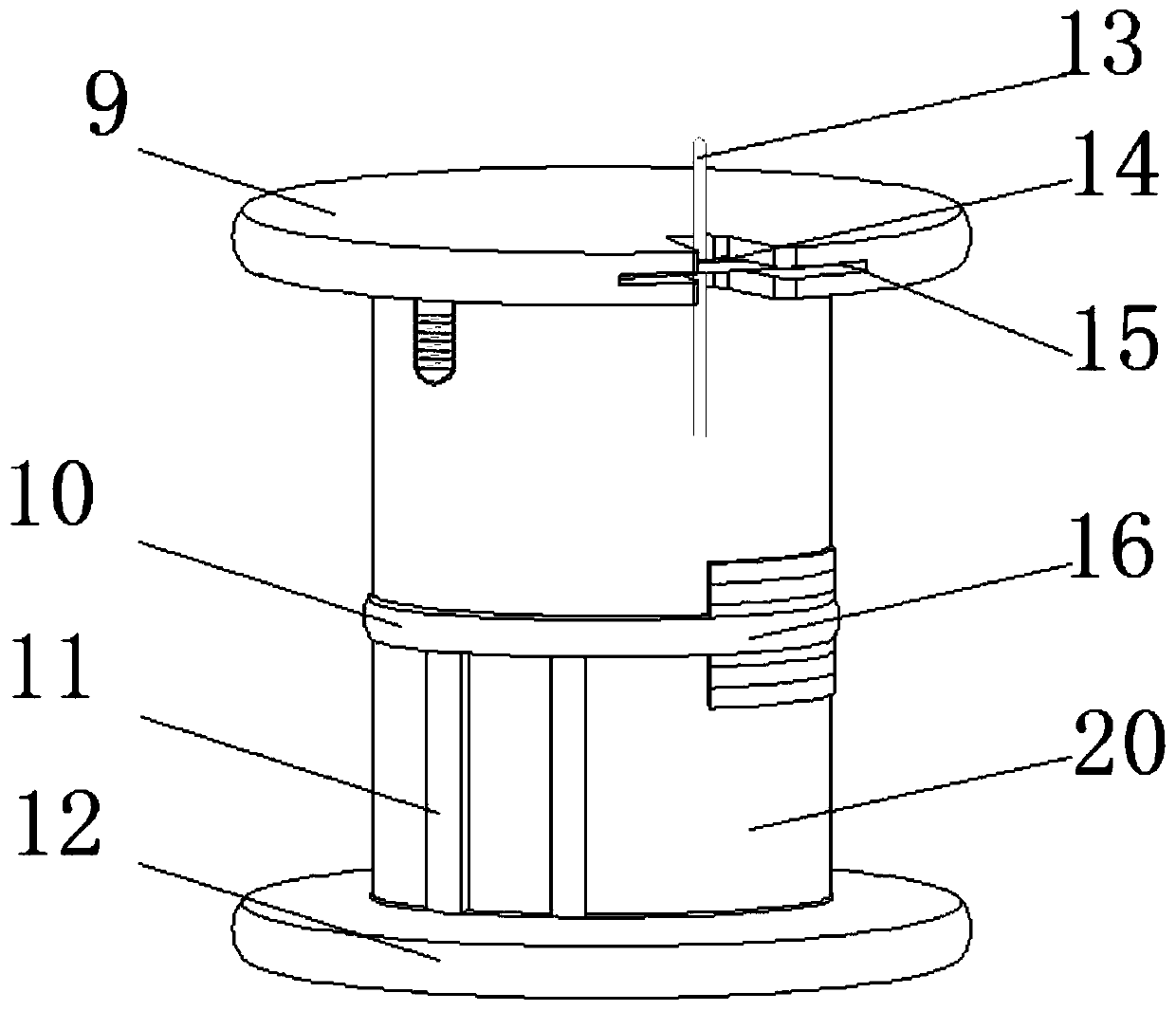

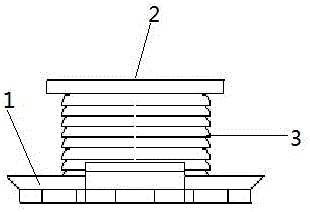

Microelectronic hollow inductor winding shaft

ActiveCN110364354ATime-consuming and laborious to solveImprove efficiencyInductances/transformers/magnets manufactureInductor windingsInductance

The invention relates to the technical field of winding shafts, and discloses a microelectronic hollow inductor winding shaft. The side surface of an upper baffle, located on the outer ring of a rotating roller, is provided with a bayonet; the side surface middle part of the upper baffle, located at the bayonet, is provided with a clamping groove; the inner part of the clamping groove, located atthe bayonet, is fixedly connected to the inner end of a tension spring; the outer ends of the tension springs are elastically connected to the inner sides of two ends of a gear lever; an extension rodA is fixed by the gear lever, an extension rod B passes through a rotating ring and is slidably connected between two elastic support rods, the rotating roller passes through from the front surface of a casing, the extension rod A is bent and clamped between a fixing block and a supporting platform, a blocking block is buckled, a bottom baffle is clamped to the bottom end of the winding roller, the extension rod B passes through a clamping hole arranged in the bottom baffle, the bottom baffle is rotated, waste time and energy during a manual operation process can be avoided, and the efficiency in the production process is facilitated.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD +1

Internal viscous damper geotechnical cloth and method for structure reinforcement by cloth

The invention discloses an internal viscous damper geotechnical cloth and a method for structure reinforcement by the cloth. An outer layer of the internal viscous damper geotechnical cloth is a woven geotechnical cloth, and crisscrossed PVC (polyvinyl chloride) hoses are arranged inside the internal viscous damping geotechnical cloth and filled with viscous dampers. The internal viscous damper geotechnical cloth is arranged between a steel tube and concrete, clings to the inner wall of the steel tube, is connected with the inner wall of the steel tube through structural adhesives and wraps the whole length of the steel tube concrete. The seismic resistance of the steel tube concrete is improved by the aid of excellent energy dissipation capability of the viscous dampers and high tensile strength of the woven geotechnical cloth, epoxy resin in the PVC hoses flows out and can serve as an adhesive for adhering cracks of a steel tube concrete column, so that the structure has a certain self-healing property, and the strength of the structure is greatly enhanced. Besides, the geotechnical cloth can prevent the steel tube and the concrete from stripping.

Owner:WUHAN UNIV

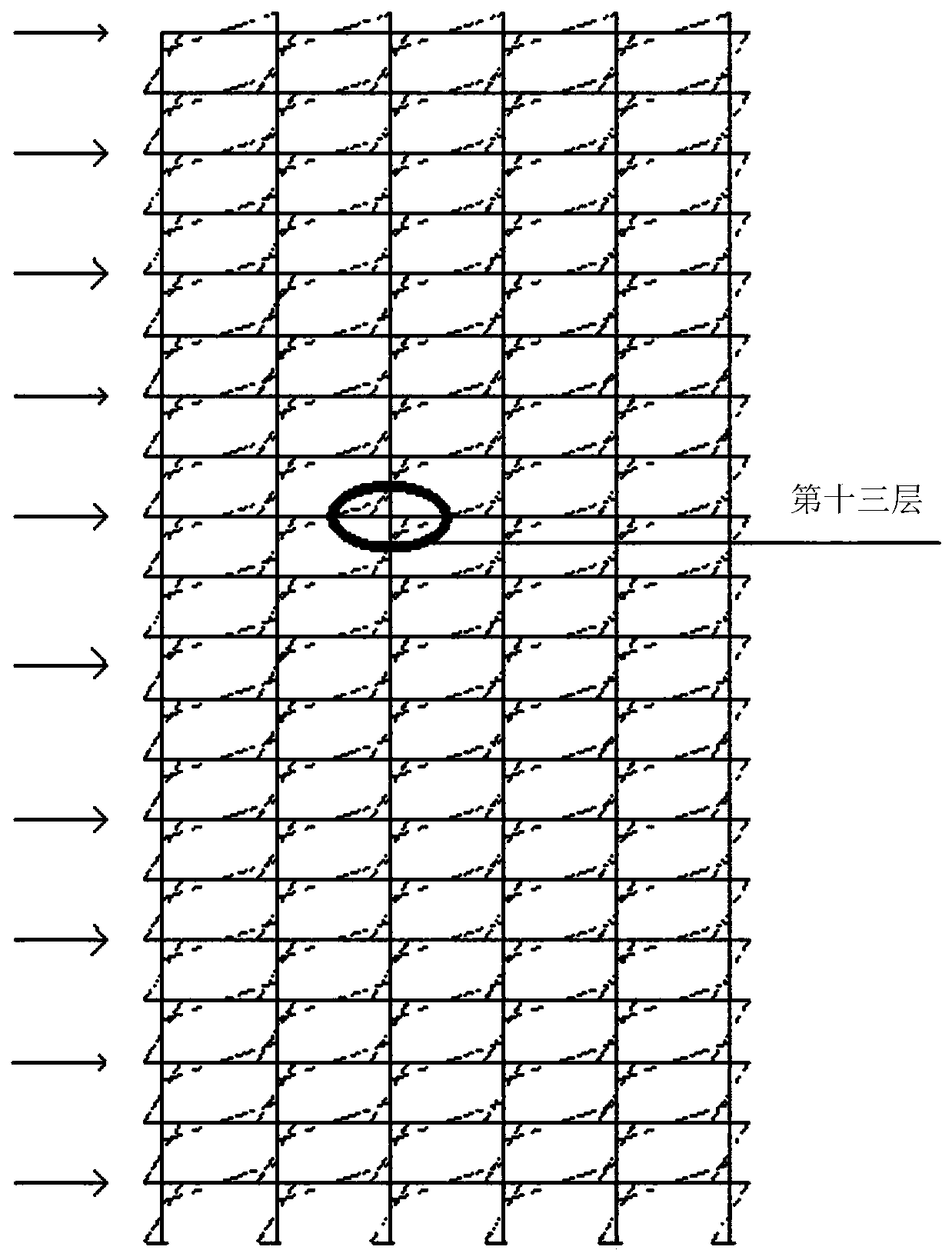

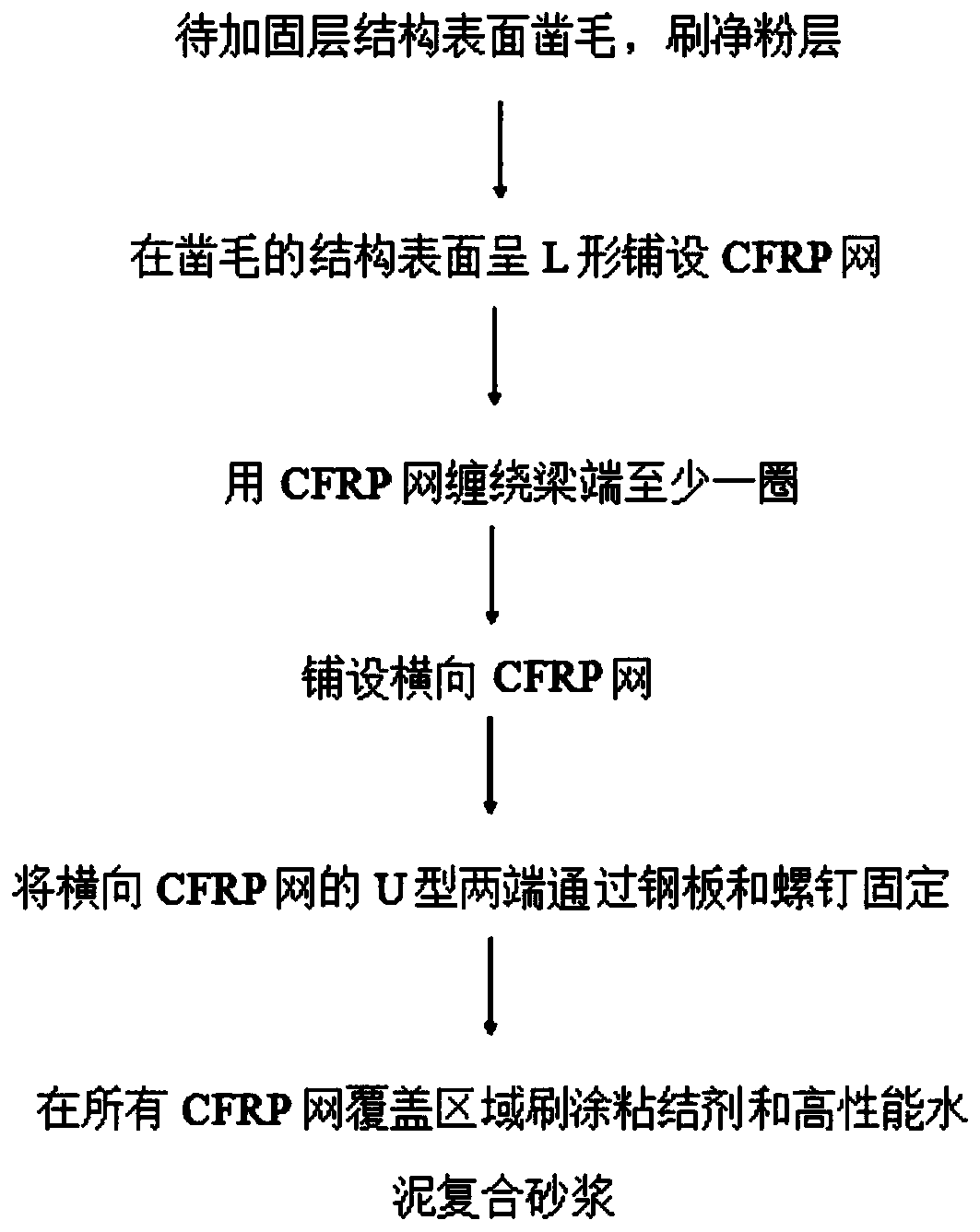

Method for anti-bending reinforcement of beam end with floor

The invention belongs to the technical field of seismic reinforcement and discloses a method for anti-bending reinforcement of a beam end with a floor, wherein a wall or a pillar is disposed at the beam end; the floor is in perpendicular connection to a beam, the wall or the pillar; and composite mortar reinforced by a CFRP mesh is paved to an L-shaped connecting surface between the beam and the wall or the pillar for reinforcement. The method disclosed by the invention has the beneficial effects that based on characteristics of the CFRP mesh that the mesh is light, high in strength and modulus, flexible and easy in construction, easy in anchoring, overlapping and positioning, durable, anti-corrosion, anti-fatigue, anti-magnetic, anti-shielding, and anti-stripping and can reduce thicknessof a reinforcement layer, the CFRP mesh is built in the high-performance cement composite mortar for reinforcement of parts with complicated structures, so various adverse factors of reinforcement with various composite materials which take a traditional rebar mesh as a reinforcement phase can be remedied. The high-strength CFRP mesh is paved to the L-shaped connecting surface between the beam andthe wall or the pillar in an L-shaped manner, so the reinforcement layer formed through combination of the CFRP mesh and the subsequent cement composite mortar can give full play to an anti-tension effect.

Owner:HUNAN UNIV OF TECH

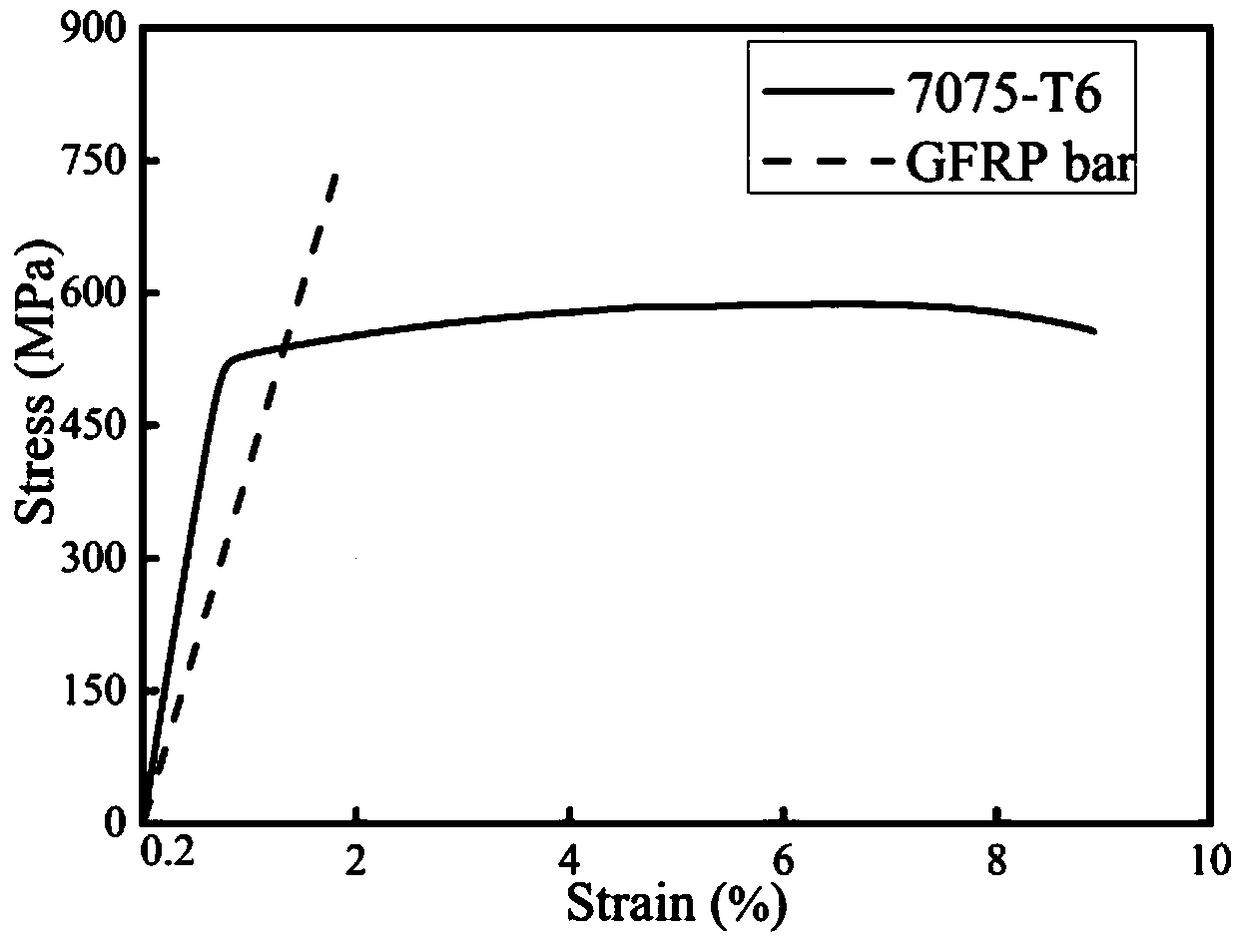

Reinforcing system and method for reinforced concrete column

InactiveCN108824225AAchieving semi-active controlImprove energy consumptionBuilding repairsBridge erection/assemblyReinforced concrete columnResidual deformation

The invention discloses a reinforcing system and method for a reinforced concrete column. A reinforcing groove is vertically formed in a side wall protective layer on the to-be-reinforced reinforced concrete column, and the interior of the reinforcing groove is coated with a filling material; the clean reinforcing groove is half filled with the filling material, then an aluminum alloy rib is placed into the clean reinforcing groove, and the reinforcing groove is pressed into the filling material; then the reinforcing groove is filled with a filling material and compacted and leveled, so that the reinforced concrete column and the aluminum alloy rib form a whole. A near-surface reinforcing method is adopted, so that the bonding area of the reinforcing rib and the concrete is increased, thepossibility of bonding stripping damage is reduced, and the bonding performance of the reinforcing rib and the concrete is improved. The characteristics of the aluminum alloy rib are utilized so thatthe energy consumption capability of the reinforcing column can be remarkably improved, the residual deformation generated after stress of the concrete column is reduced, and the damage self-repairingcapability of a component is improved.

Owner:CHANGAN UNIV

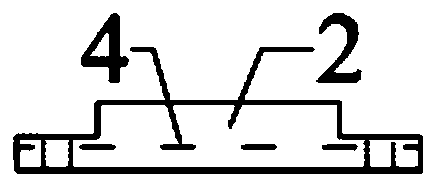

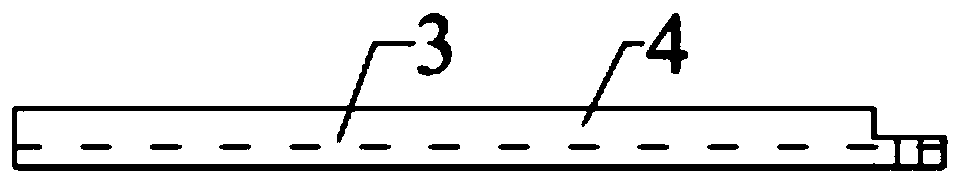

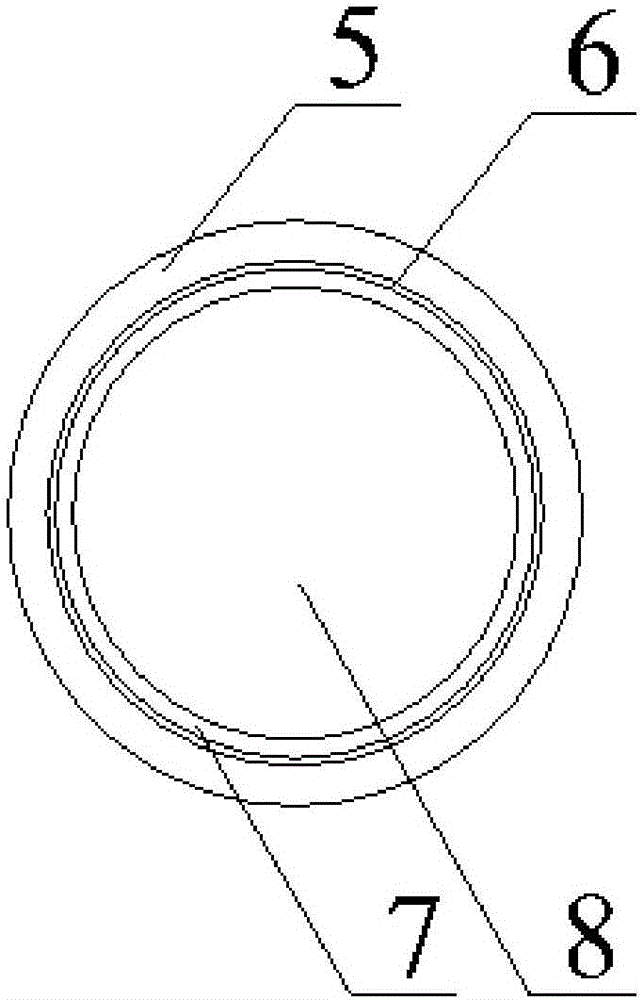

Modular rubber plate for roller rubber coating

InactiveCN104724461ADecrease stockHigh bonding strengthRollersMechanical engineeringComposite material

The invention discloses a modular rubber plate for roller rubber coating. Mutually-matched socket and spigot joints are arranged at two ends of a rubber plate head (1) and two ends of a rubber plate tail (2). The length of the working face between the rubber plate head and the rubber plate tail is 157 mm+ / -20 mm, 314 mm+ / -20 mm, 471+ / -20 mm, 628+ / -20 mm, 785+ / -20 mm or 942+ / -20 mm. The socket and spigot joint (3) at the rubber plate head portion is wedge-shaped, or step-shaped or convex, and the socket and spigot joint (4) at the rubber plate tail portion is inverted-wedge-shaped, or inverted-step-shaped or concave and is matched with the socket and spigot joint at the head portion. A soft rubber layer (5) is arranged on the bonding face of the rubber plate. The anti-stripping performance of the roller rubber plate is improved, cutting is not needed, construction is convenient, and quick roller rubber coating in a field can be achieved.

Owner:贵州优拓材料有限公司

Novel surface-mounted inductor

InactiveCN106158253AImprove product qualityIncrease contact areaTransformers/inductances casingsTransformers/inductances magnetic coresSurface mountingInductor

The invention discloses a novel surface-mounted inductor which comprises a base, an I-shaped magnetic core located on the upper surface of the base, and a coil winding arranged on the magnetic core, wherein one end of the magnetic core is adhered to the upper surface of the base with pins PIN; the pins PIN of the base are welded with the terminals of the coil winding; gaps are formed in black plastic positions at the pin-free ends of the base; and electric spark lines are formed on the surface, bonded with the magnetic core, of the base. By the adoption of the structure, the product quality and the production efficiency of the surface-mounted inductor are improved.

Owner:临沂市乐盈电子科技有限公司

Rubber-metal bonding quality detection method and bonding strength quality determination method

ActiveCN111521651ARealize non-destructive testingAvoid scrappingMaterial electrochemical variablesAdhesive cementPhysical chemistry

The invention discloses a rubber-metal bonding quality detection method. The method is characterized by comprising the following steps: 1, preparing a bath solution with metal cations and anions, 2, soaking a rubber-metal part into the bath solution, polarizing the cations and anions in the bath solution under the action of current according to a metal electroplating method within specified time,extruding the cations and anions into a rubber-metal bonding interface to destroy the stability of adhesive and metal bonding chemical bonds; and 3, taking out the rubber-metal part, checking the stripping damage condition of the bonding edges of rubber and metal, and judging whether the bonding quality of the rubber-metal part is qualified or not according to the bonding quality requirement of the product. Nondestructive testing of the rubber-metal bonding quality is achieved, product scrapping after detection is avoided, and the method is suitable for batch detection of rubber metal parts. The invention further provides a rubber-metal bonding strength quality judgment method.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

A Self-healing Concrete Containment Shell Against Nuclear Radiation

InactiveCN105835466BHigh strengthIncrease elasticityNuclear energy generationSynthetic resin layered productsNuclear radiationSelf-healing

Owner:WUHAN UNIV

A kind of high-performance sulfur concrete and its preparation method

The invention discloses high-performance sulfur concrete and a preparation method thereof. The high-performance sulfur concrete comprises the following raw materials in percentage by mass: 30%-37% ofcement, 38%-43% of river sand, 11%-17% of water, 0.4%-0.8% of a water reducer, 8%-15% of sulfur powder, 0.1-0.5% of an emulsifying dispersant and 0.8-1.2% of resin emulsion. By the high-performance sulfur concrete provided by the invention, sulfur can be recycled, furthermore, the bending resistance, the seepage resistance and the frost resistance of the concrete can be improved, and the durability of the concrete and the service capability of the concrete under extreme condition are improved effectively.

Owner:CHANGAN UNIV

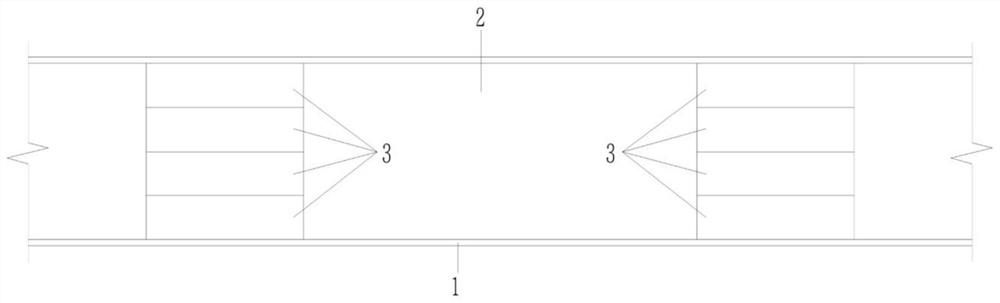

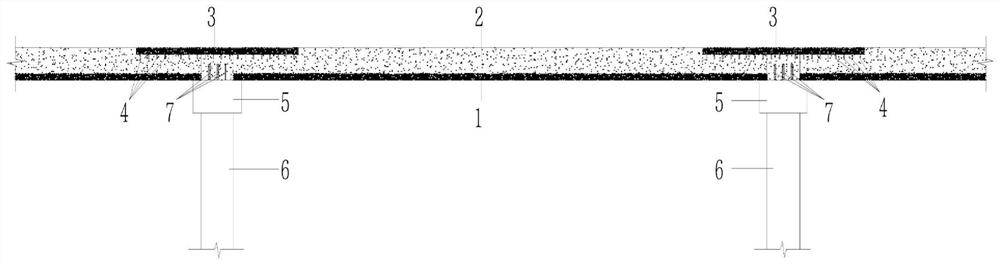

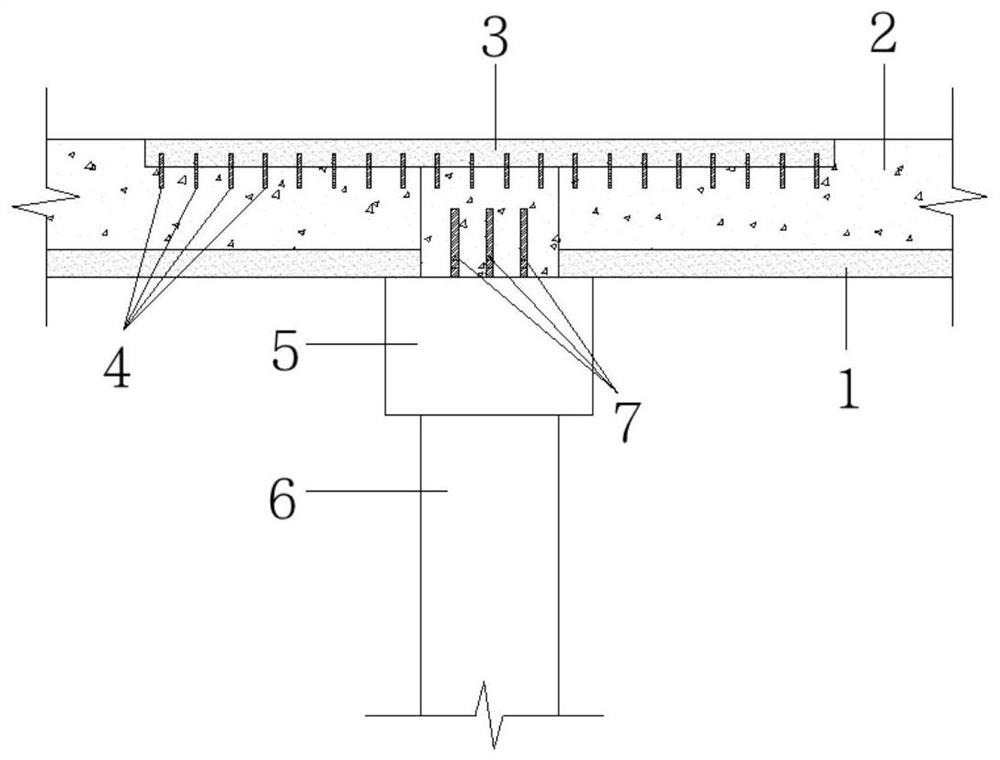

UHPC board and concrete combined type frame slab bridge and construction method thereof

PendingCN114277671AImprove crack resistanceImprove mechanical propertiesBridge structural detailsBridge erection/assemblyArchitectural engineeringPier

The invention discloses a UHPC (Ultra High Performance Concrete) board and concrete combined type frame slab bridge and a construction method thereof, the structure part of the UHPC board and concrete combined type frame slab bridge comprises a plurality of groups of bridge piers arranged at equal intervals, cover beams are arranged on the bridge piers, UHPC board trusses are erected among the cover beams, concrete is poured on the UHPC board trusses, and the UHPC board trusses are connected with the cover beams through the concrete. The ends of the adjacent UHPC plate trusses are correspondingly provided with hogging moment area UHPC prefabricated slabs, and the two ends of each hogging moment area UHPC prefabricated slab are connected with concrete at the ends of the UHPC plate trusses on the two sides respectively. Compared with a cast-in-place common concrete structure, the UHPC board concrete combined continuous frame slab bridge designed by the invention is better in stress performance, better in durability, more convenient in construction process and lower in construction cost, has very remarkable advantages, and has relatively high applicability to construction of bridges in coastal splash zones.

Owner:福建省交通规划设计院有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com