Shear strengthening method of concrete beam

A technology of concrete beams and concrete, applied in bridge reinforcement, bridge, bridge maintenance, etc., can solve the problems of reducing the net height of buildings, accelerated wear and tear of materials, and poor durability, so as to improve the utilization rate of materials, prevent peeling damage, and increase the use value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] As shown in the figure, the steps of the present invention are as follows:

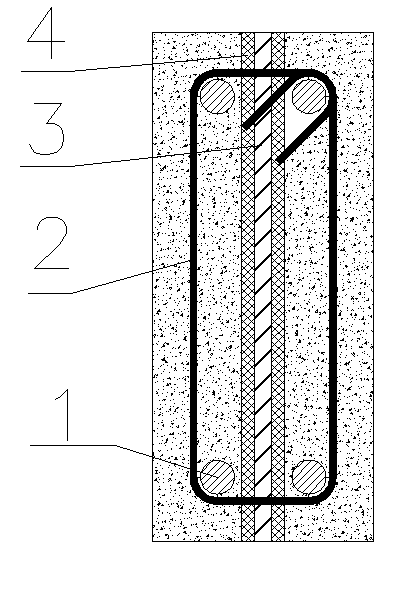

[0017] 1. Select fiber bars with a diameter of 10mm according to the length of the shear span of the concrete beam with longitudinal reinforcement 1 and stirrup 2 and the strength of the concrete.

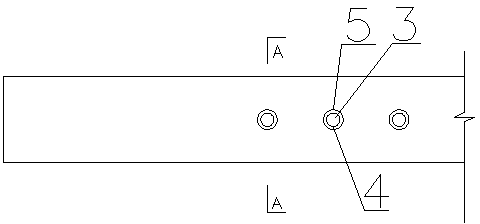

[0018] 2. According to the calculation requirements of shear reinforcement design, drill corresponding holes 5 in the shear span area of the beam and according to the width of the shear span area. The diameter of the hole 5 is 1.5 times the diameter of the fiber reinforcement, and the distance between adjacent holes 5 Equal to the spacing of the stirrups 3 in the shear span area, the position of the hole 5 is at the midpoint of the width of the beam cross section, that is, the middle of the cross section;

[0019] 3. Then pour epoxy resin glue 4 into the hole 5;

[0020] 4. Apply prestress to the selected fiber reinforcement 3, the applied prestress is 50% of its ultimate strength, and the method...

Embodiment 2

[0023] As shown in the figure, the steps of the present invention are as follows:

[0024] 1. According to the length of the shear span of the concrete beam with longitudinal reinforcement 1 and stirrup 2 and the strength of the concrete, select a fiber reinforcement with a diameter of 16mm.

[0025] 2. Drill corresponding holes 5 in the shear span area of the beam according to the calculation requirements of the shear reinforcement design and according to the width of the shear span area. The diameter of the hole 5 is 1.8 times the diameter of the fiber reinforcement 3. The distance is equal to twice the distance between the stirrups 3 in the shear span area, and the hole 5 is located at the midpoint of the width of the beam cross section, that is, the middle of the cross section;

[0026] 3. Then pour epoxy resin glue 4 into the hole 5;

[0027] 4. Apply prestress to the selected fiber reinforcement 3, and the applied prestress is 70% of its ultimate strength. The method ...

Embodiment 3

[0030] As shown in the figure, the steps of the present invention are as follows:

[0031] 1. According to the length of the shear span of the concrete beam with longitudinal reinforcement 1 and stirrup 2 and the strength of the concrete, a fiber reinforcement with a diameter of 20mm is selected.

[0032] 2. Drill corresponding holes 5 in the shear span area of the beam according to the calculation requirements of the shear reinforcement design and according to the width of the shear span area. The diameter of the hole 5 is 1.6 times the diameter of the fiber reinforcement 3. The distance is equal to 1.5 times the distance between the stirrups 3 in the shear span area, and the position of the hole 2 is at the midpoint of the width of the beam cross section, that is, the middle of the cross section;

[0033] 3. Then pour epoxy resin glue 4 into the hole 5;

[0034] 4. Apply prestress to the selected fiber reinforcement 3, and the applied prestress is 60% of its ultimate stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com