Patents

Literature

688 results about "Surface bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing registration template

InactiveUS20140096369A1Precise alignmentShorten the timeDiagnostic markersInstruments for stereotaxic surgeryTomographyOptical tracking

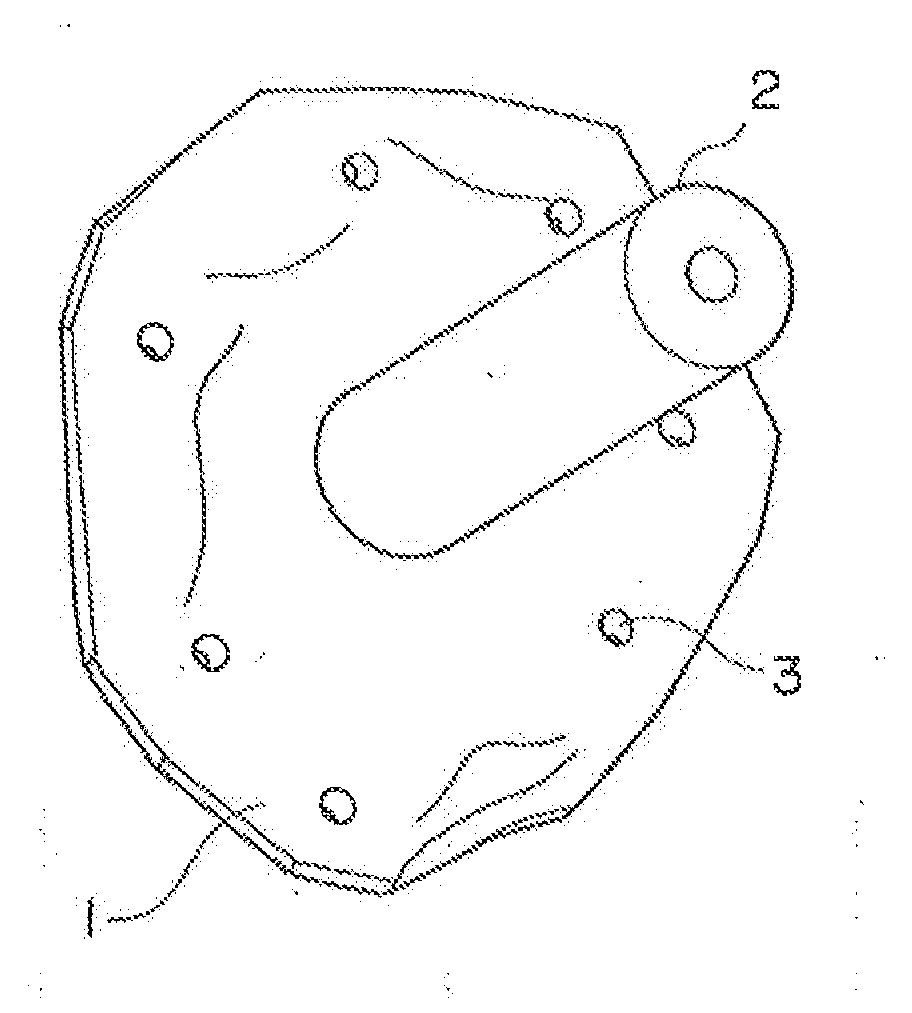

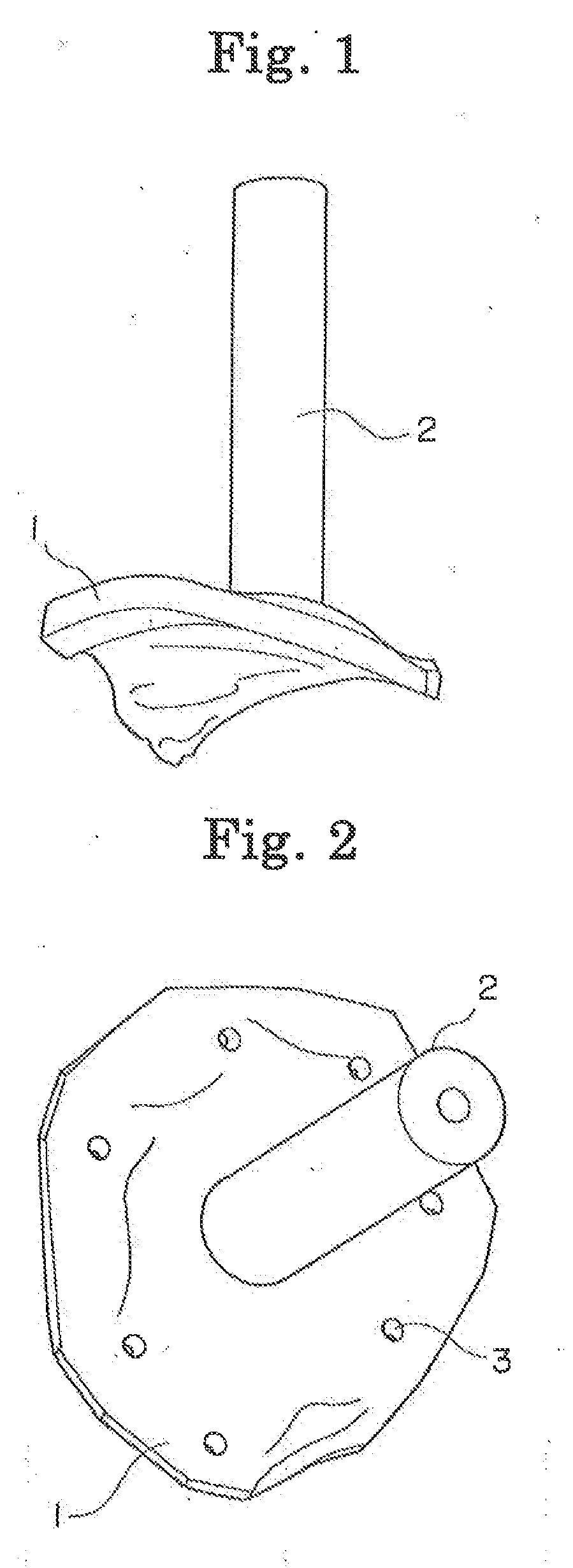

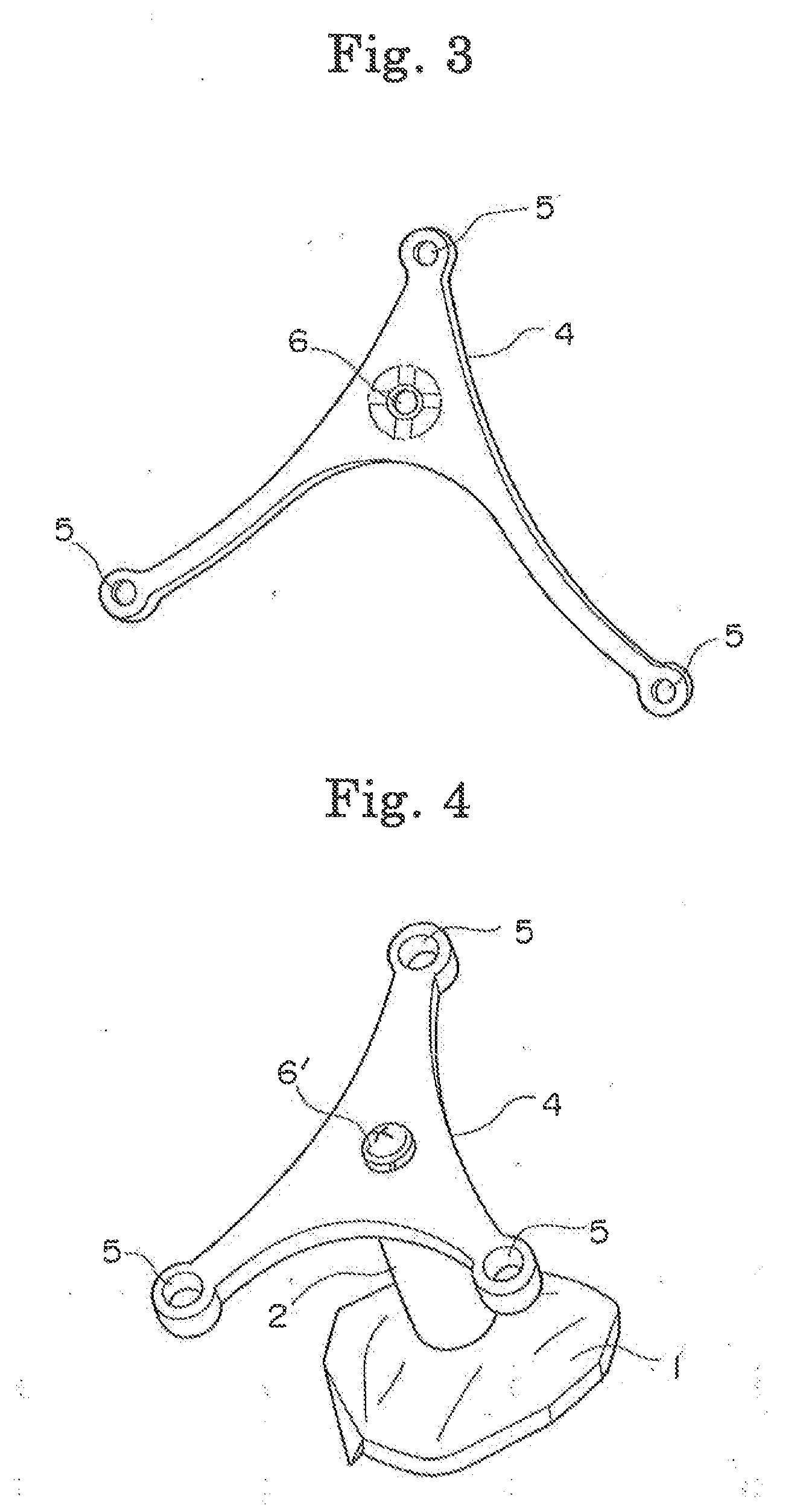

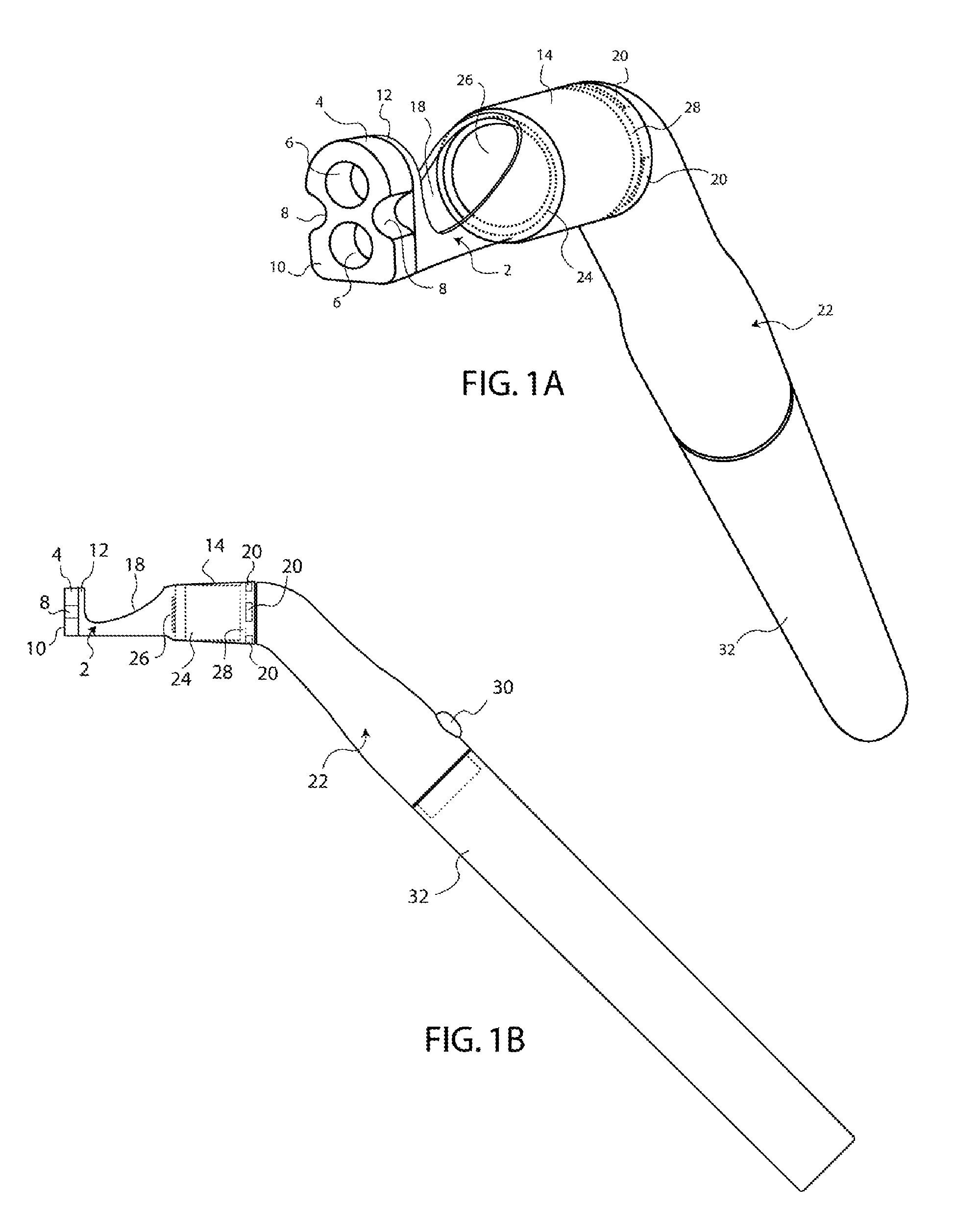

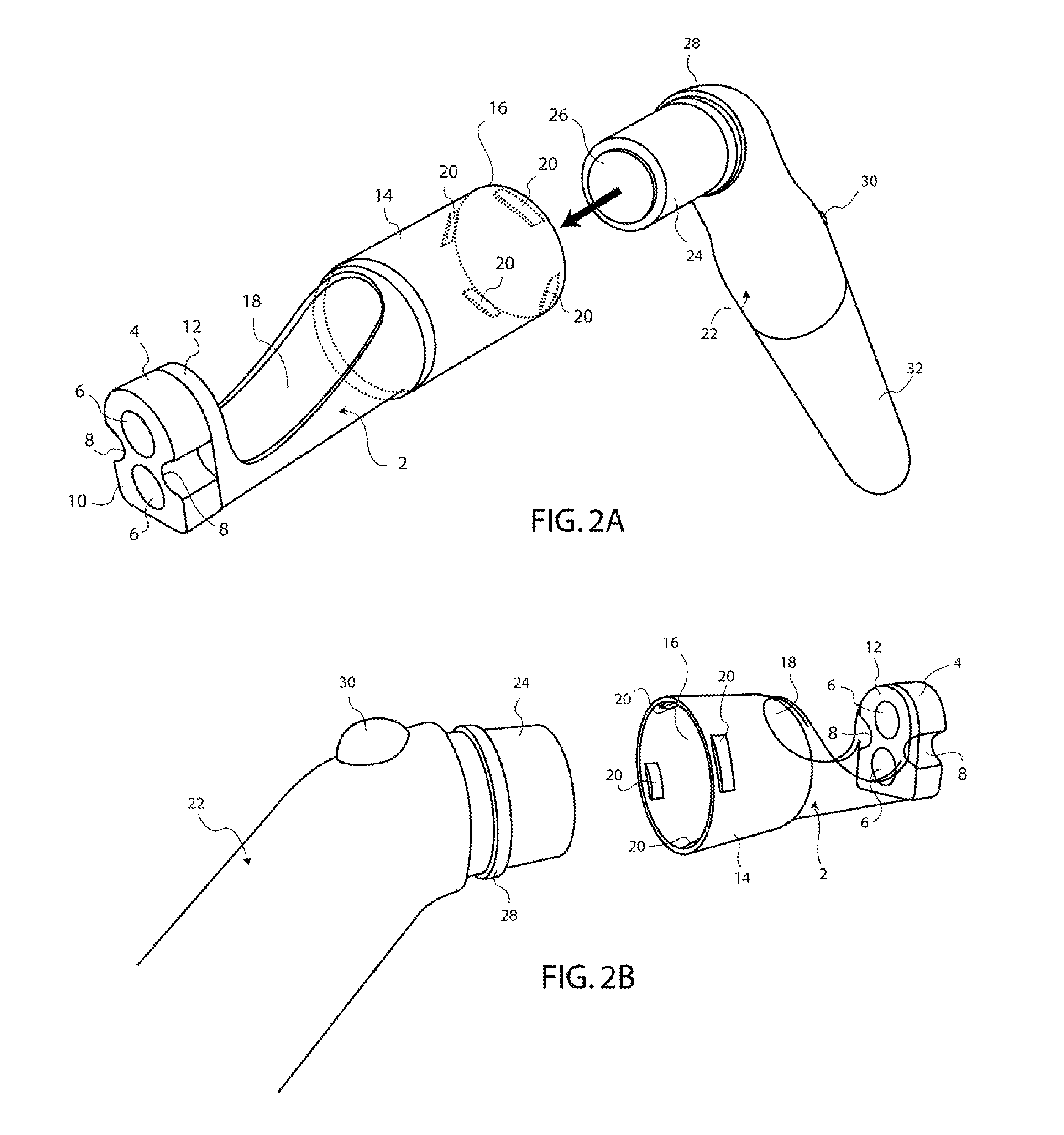

A method for manufacturing a registration template for use in medical navigation system-guided surgery, comprising: producing a registration template having a surface, which precisely surface-bonds to a surface of a bone at a surgical target site of a patient, and having three or more registration points, from stereoscopic surface data ensuring precise surface bonding to the surface of the bone at the surgical target site of the patient, based on stereoscopic surface data created from tomography information on the bone of the surgical target site of the patient; and providing a pedestal (4) for mounting optical tracking balls (7), which are used for three-dimensional position detection for a medical navigation system, at the center of the registration points. By using the template having curves surfaces which three-dimensionally precisely and intimately contact the bone surface of the patient, high-precision registration can be performed, and an operator's man-hours immediately before surgery in an operating room can be reduced to shorten the surgery time.

Owner:ONO

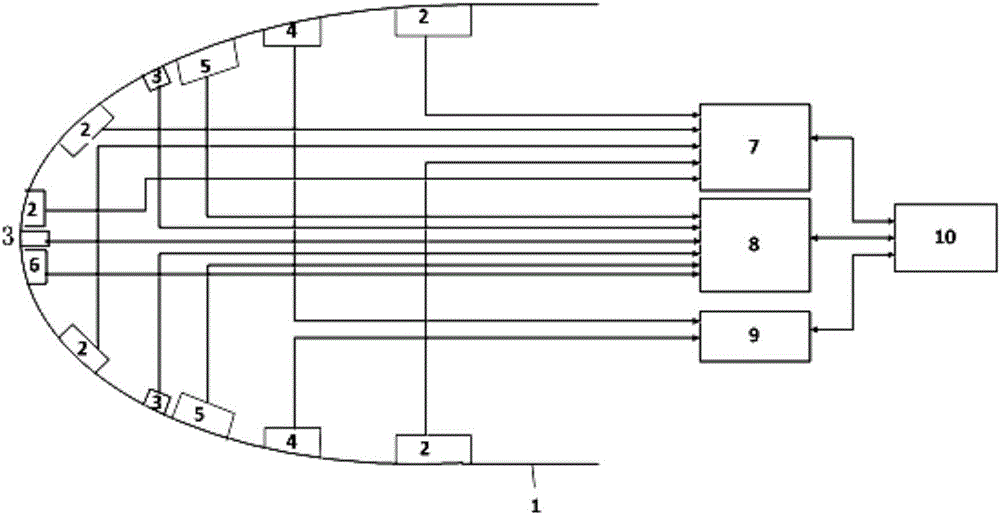

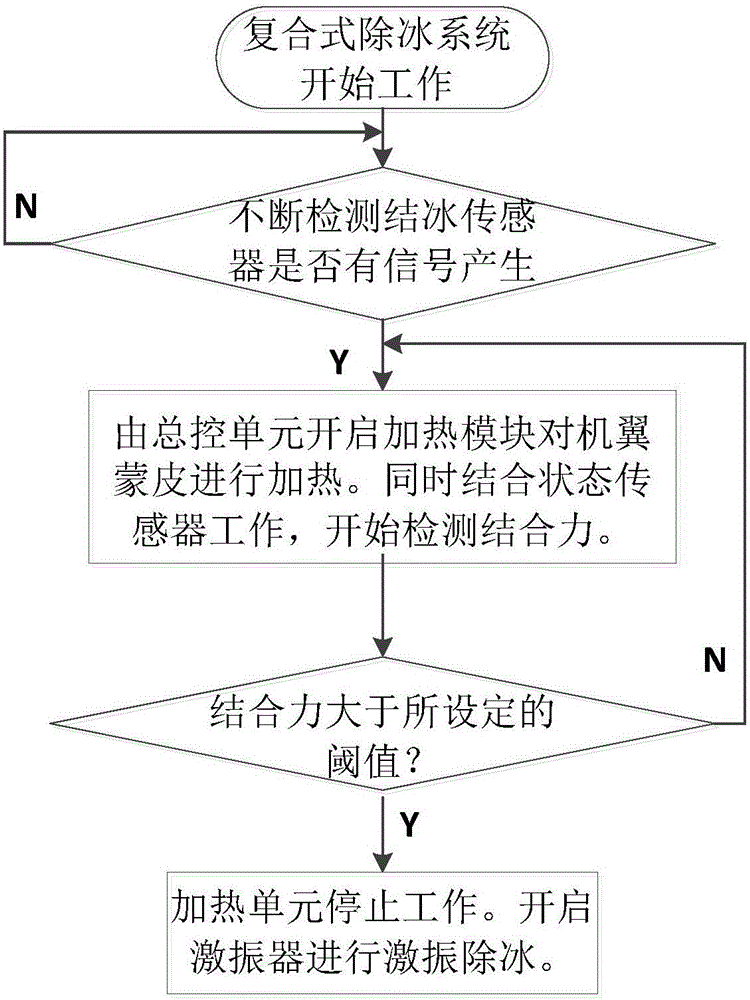

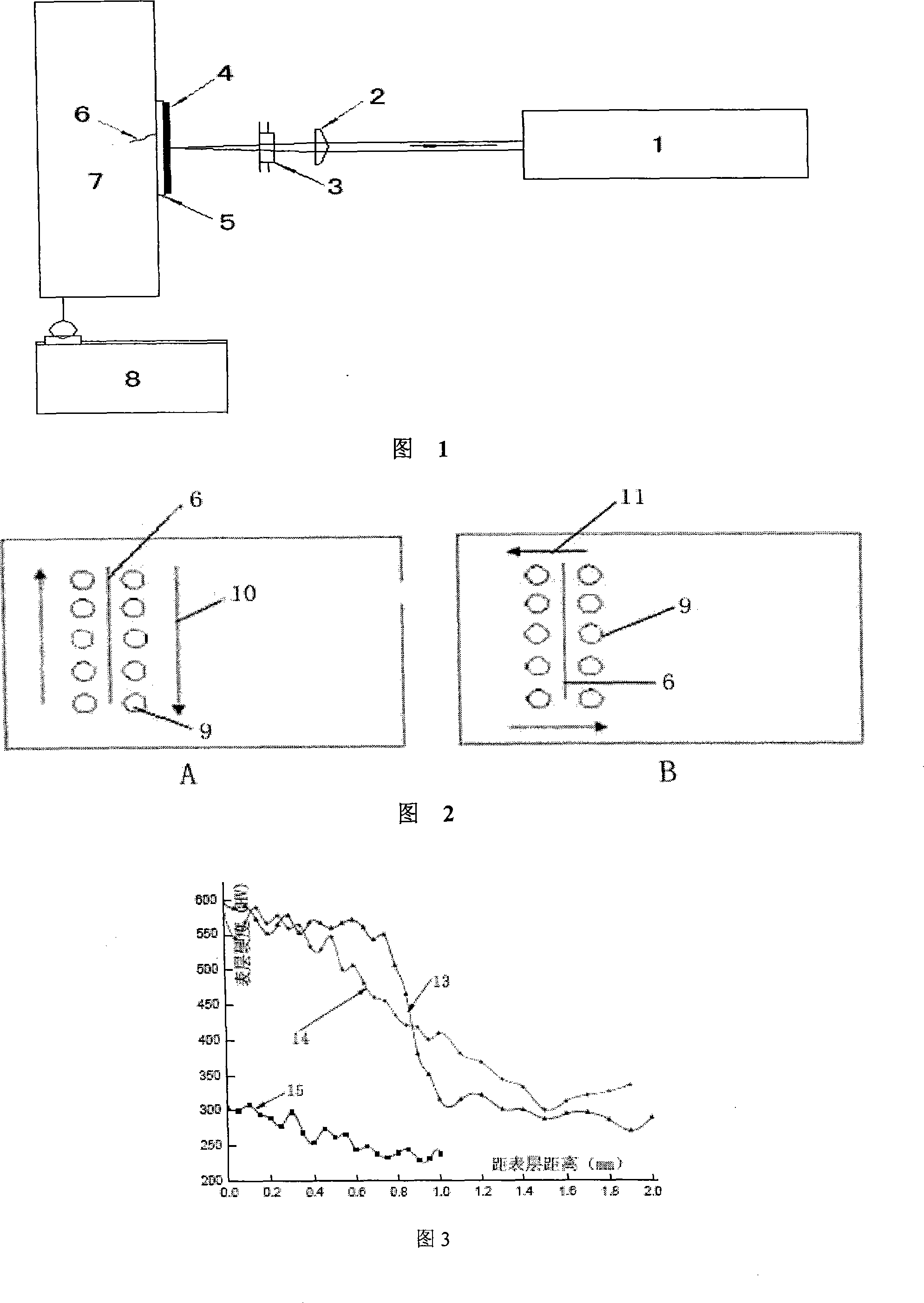

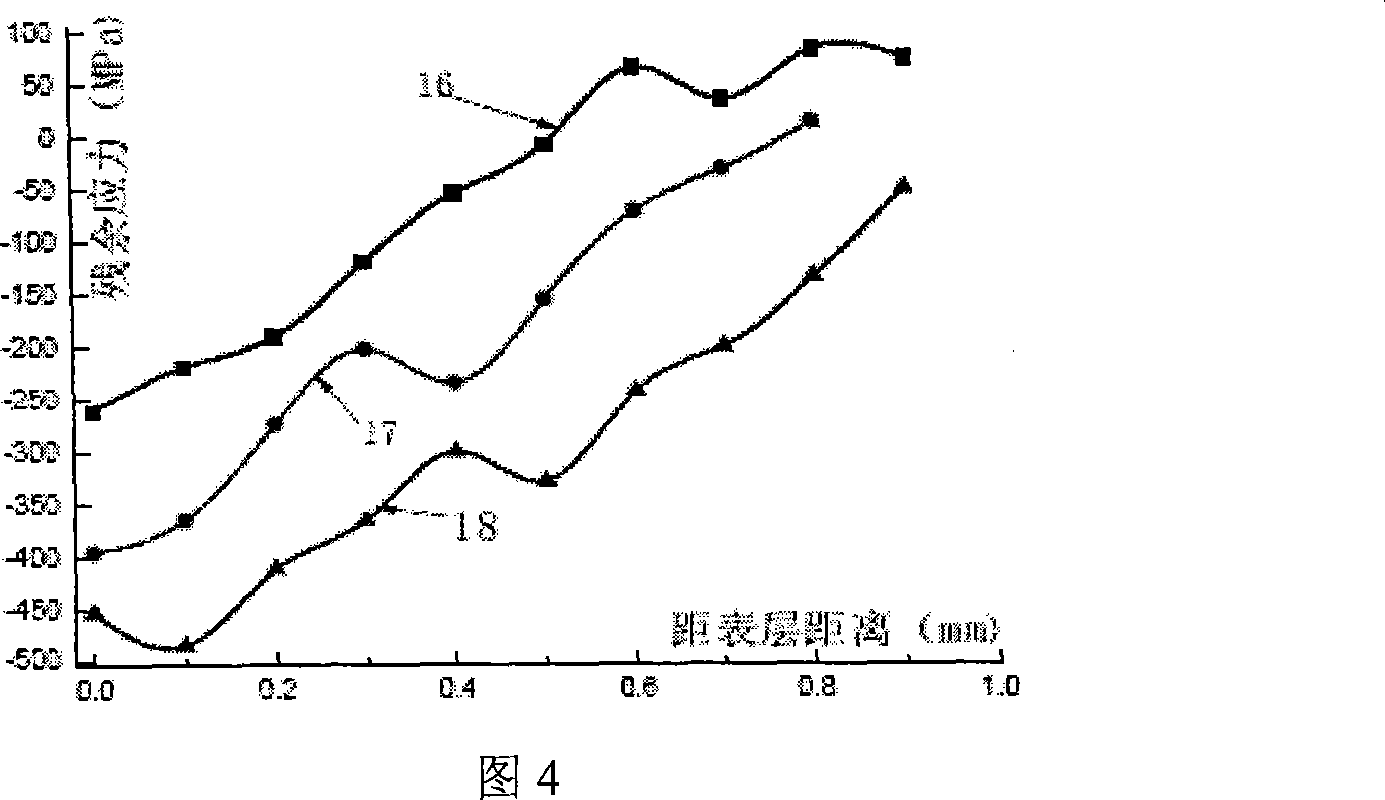

Combined deicing system based on detection of ice layer-skin surface bonding state

ActiveCN106741968AReduce energy consumptionAvoid damageDe-icing equipmentsSignal conditioningEngineering

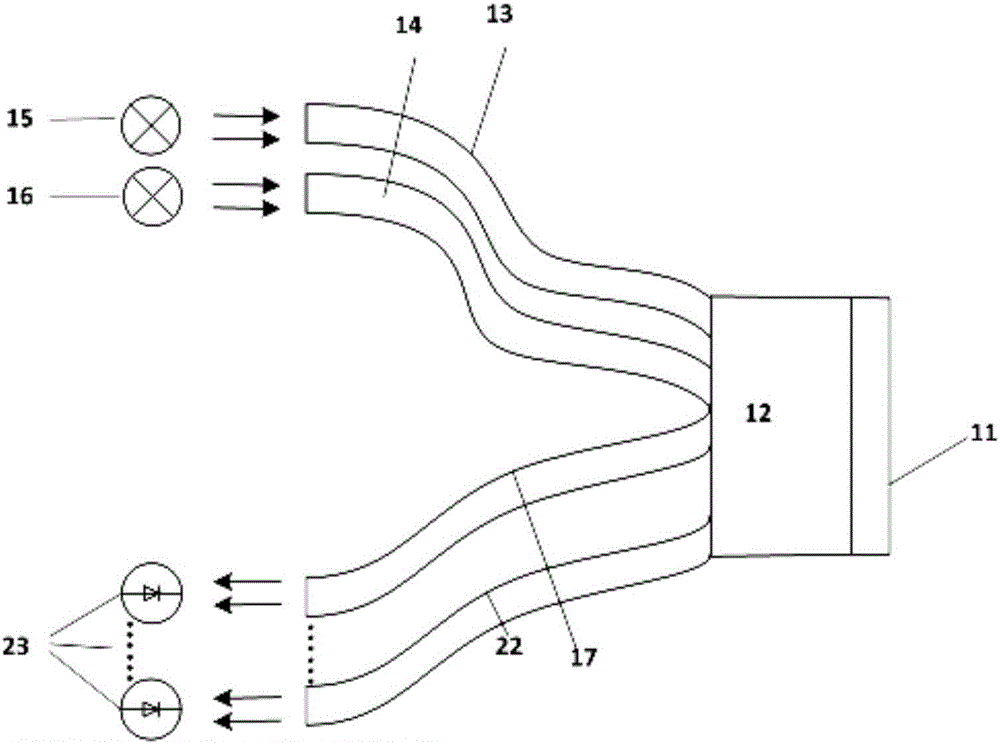

The invention discloses combined deicing system and method based on detection of ice layer-skin surface bonding state. The combined deicing system and method based on detection of ice layer-skin surface bonding state are used for removing ice accumulated on the surfaces of aircraft wings. The combined deicing system bonding state sensors arranged on inner skin of wings, heating units, an icing sensor and excitation modules and correspondingly comprises, a heating control unit, a signal conditioning unit, an excitation control unit and the like. According to signals from the bonding state sensors and temperature sensors, the information of the ice layer-skin surface bonding state can be obtained, and the appropriate deicing time can be mastered according. By adopting the method combining heating and excitation, a safe and efficient deicing with low energy consumption is achieved. Compared with a pure electric-heating deicing method, energy consumption is low, and the exciting force for exciting deicing is smaller than the exciting force of pure exciting deicing, therefore, damage to wing skin materials is small, and the effect on the aircraft aerodynamic shape is smaller.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Transparent laminate

InactiveUS6387477B1Synthetic resin layered productsRecord information storageVitrificationSurface layer

The present invention provides a transparent laminate comprising a laminate substrate obtained by bonding a Second substrate composed of a polycarbonate-based resin to a first surface of a first substrate composed of an acrylic resin via a first bonding layer composed of a resin having a glass transition temperature(Tg) of about 50° C. or less, and a surface layer composed of a polycarbonate-based resin bonded via a surface bonding layer composed of an acrylic resin to a second surface of the first substrate, which laminate is light and excellent in transparency and excellent in impact resistance when it repeatedly receives an impact.

Owner:SUMITOMO CHEM CO LTD

Method of improving surface cohesion performance of relative molecular weight polyethylene

InactiveCN1693544AGood adhesionImprove surface adhesionFilament-forming treatmentStretch-spinning methodsPolymer scienceUltimate tensile strength

The invention discloses a method for improving surface bonding performance of ultrahigh molecular polyethylene filter (UHMWPE), including the steps as follows: (1) dissolving polar polymer in a routine extractant of ultrahigh weight-average relative molecular weight polyethylene jelly glue filter with a relative molecular weight of 1,000,000-5,000,000 to make a composite extractant, where the polar polymer accounts for 0.1wt%-10wt% (weight percent); (2) extracting the said jelly glue fiber at 0.4-5 atmospheres at 0-80 deg.C in the composite extractant for 0.1-20 min, and then by the postprocessing procedures, such as stretching, making an ultrahigh relative molecular weight polyethylene fiber with the surface bonding performance has been improved to a higher extent. The advantages of the invention are that it maximumly holds original fiber strength and the surface bonding performance of UHMWPE has a relatively outstanding improved effect.

Owner:DONGHUA UNIV

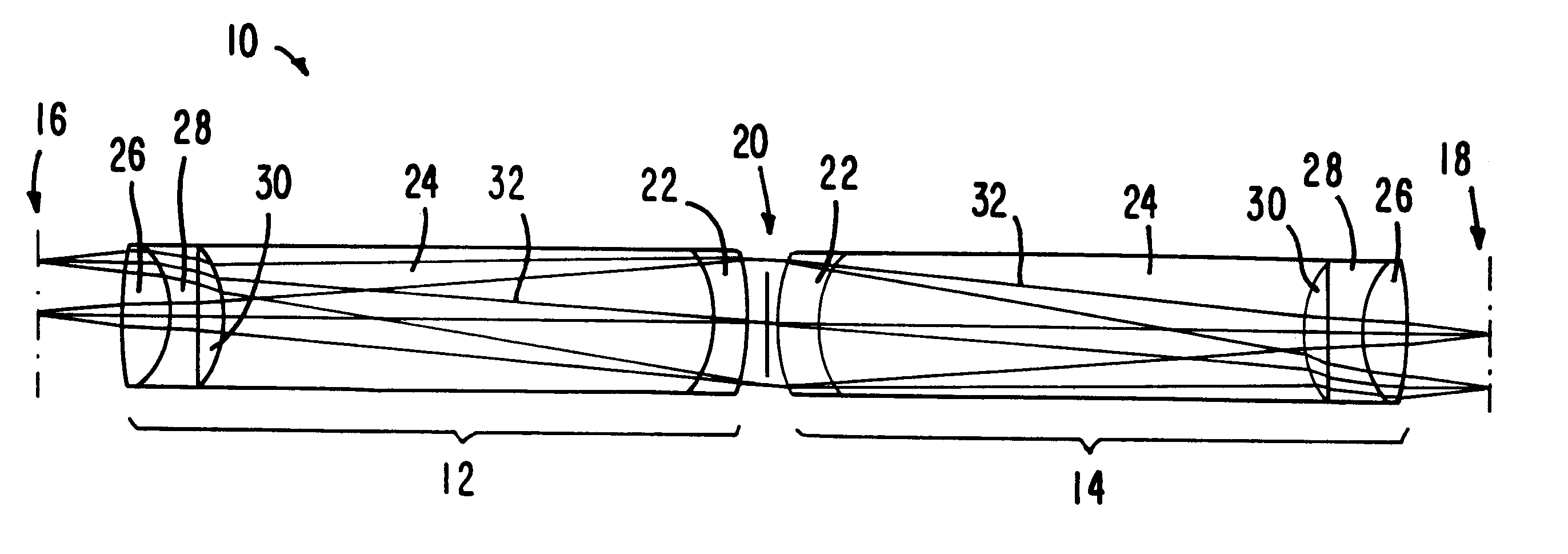

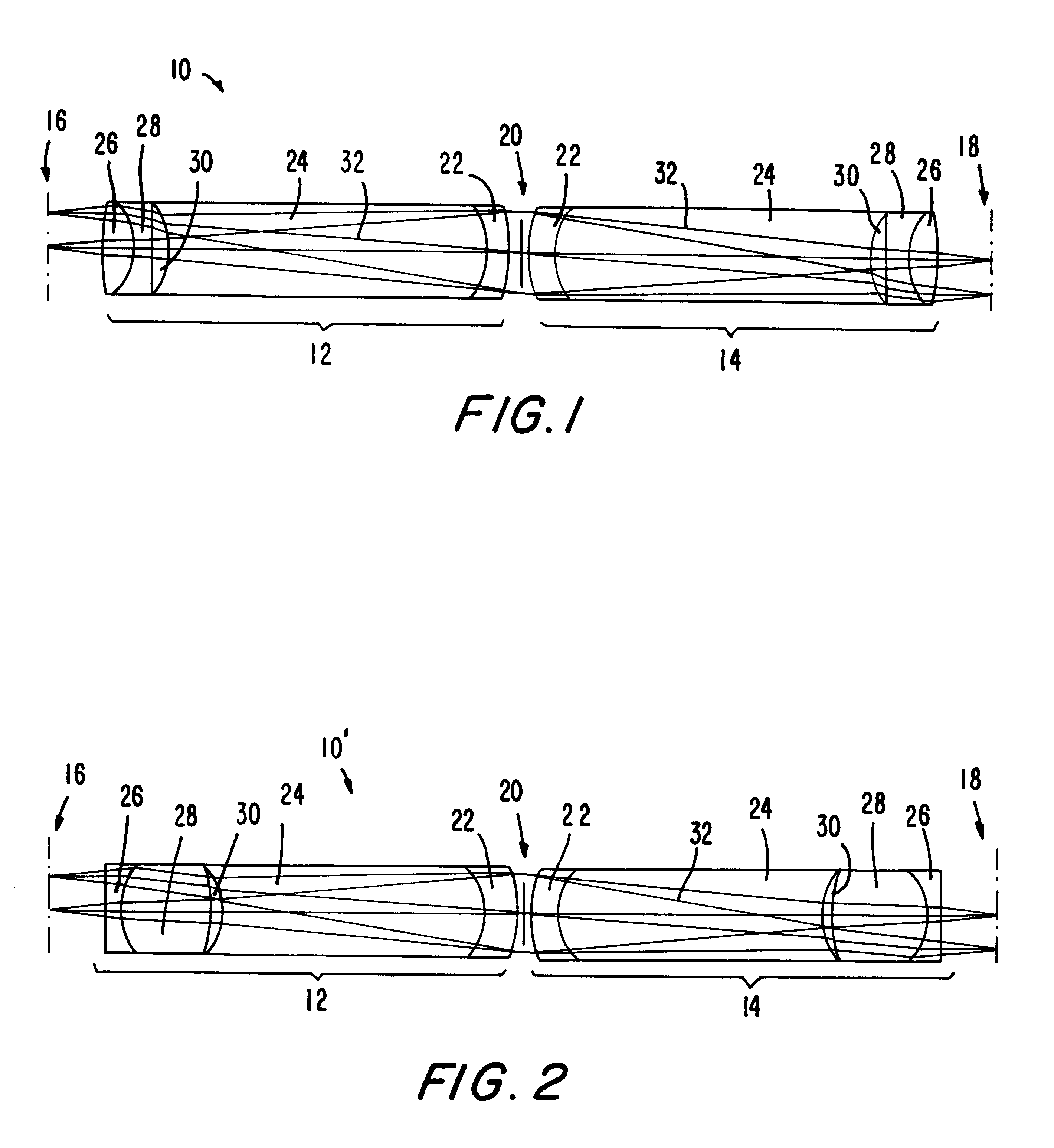

Symmetric anastigmatic endoscope relay system

InactiveUS6490085B1Reduce the secondary spectrumIncrease the number ofTelescopesIntermediate imageEngineering

A symmetric relay system for endoscopes includes an optically-aligned pair of elongated concavo-convex rod-type lenses formed from crown glass, to the convex end surface of each of which a meniscus-shaped flint lens is cemented. The concave ends of the rod lenses are disposed to face the intermediate images of the relay system, and the convex ends to face the aperture of the relay system. A pair of achromatic lenses, each formed of a pair of lens elements x, y, are disposed adjacent and in optical alignment with the respective concave ends of the rod lenses between the concave rod ends and the intermediate images. Each achromatic lens fulfills the condition n x / ny=vx / vy. Apochromatic glass combinations may be used in the rod lenses to significantly reduce the secondary spectrum.

Owner:RICHARD WOLF GMBH

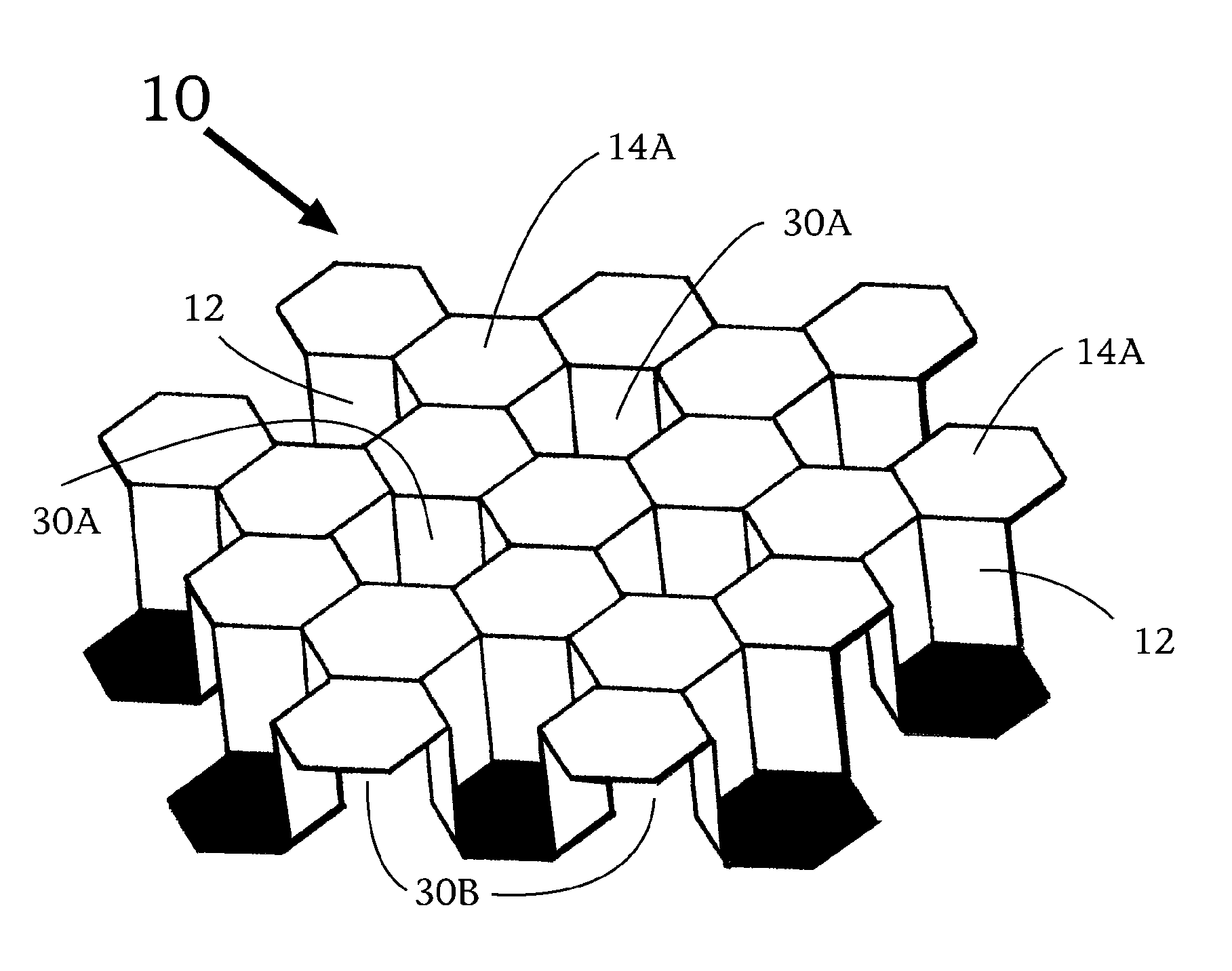

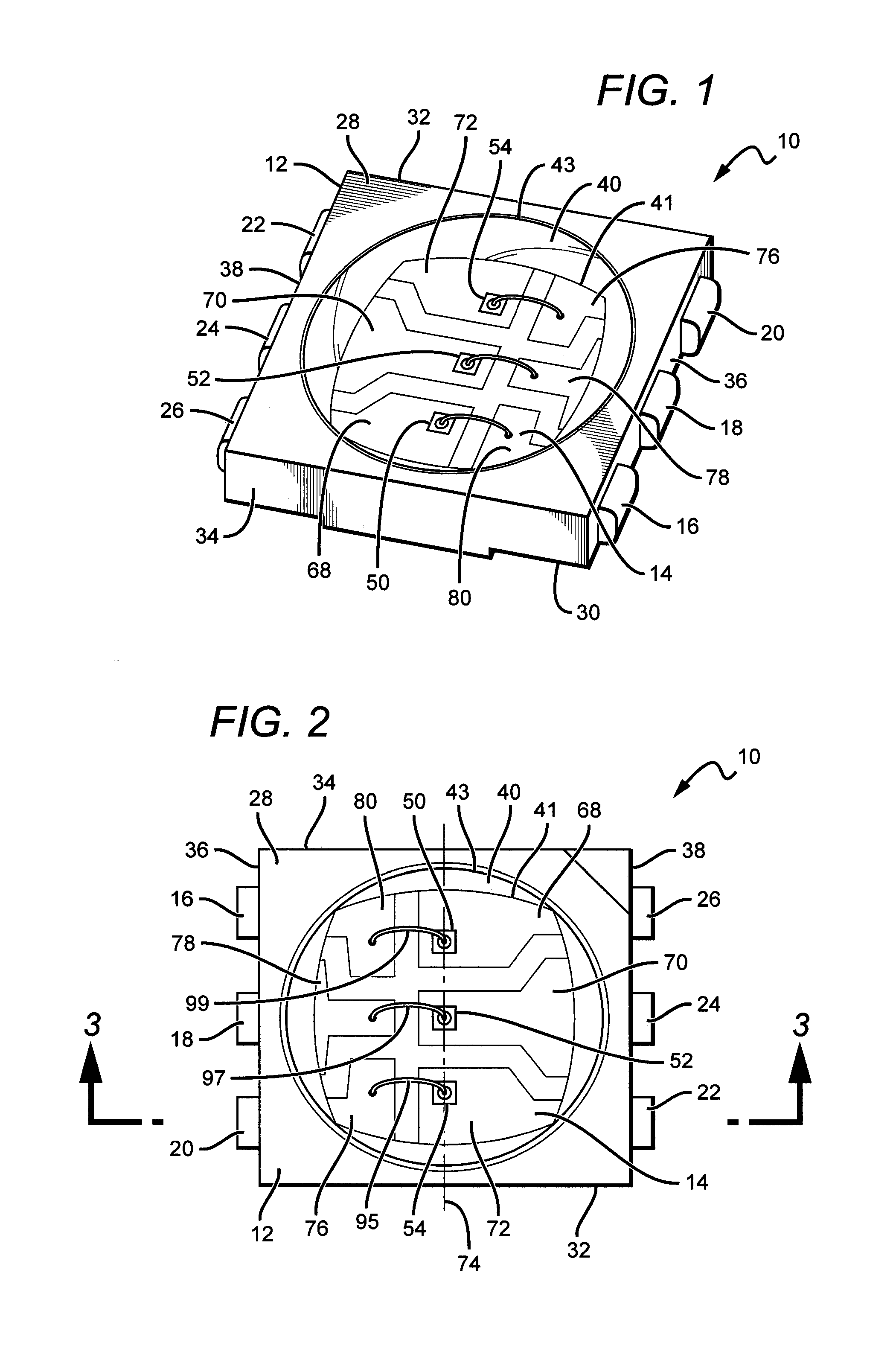

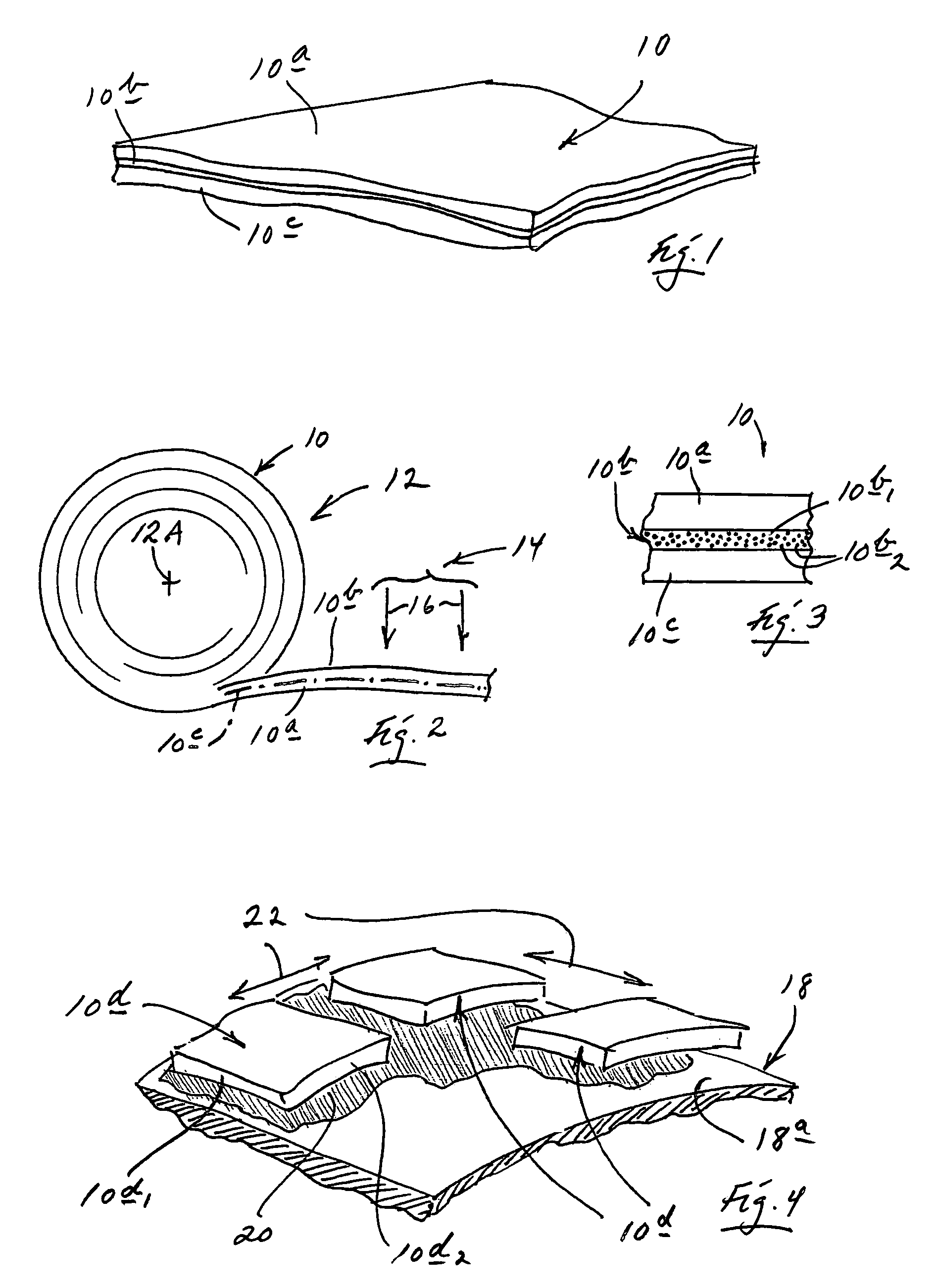

Flexible construction element with large bonding surface area and method of manufacture

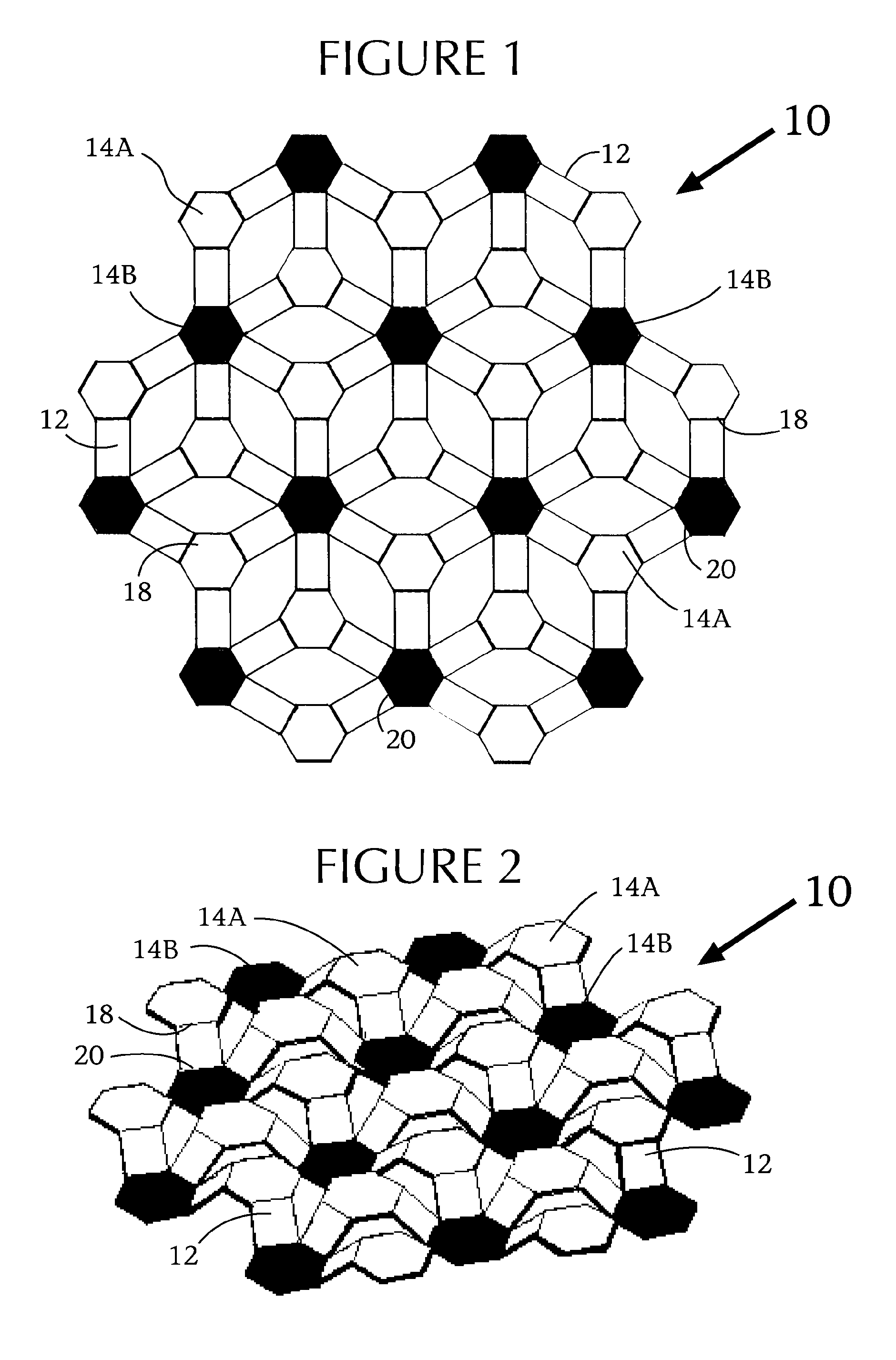

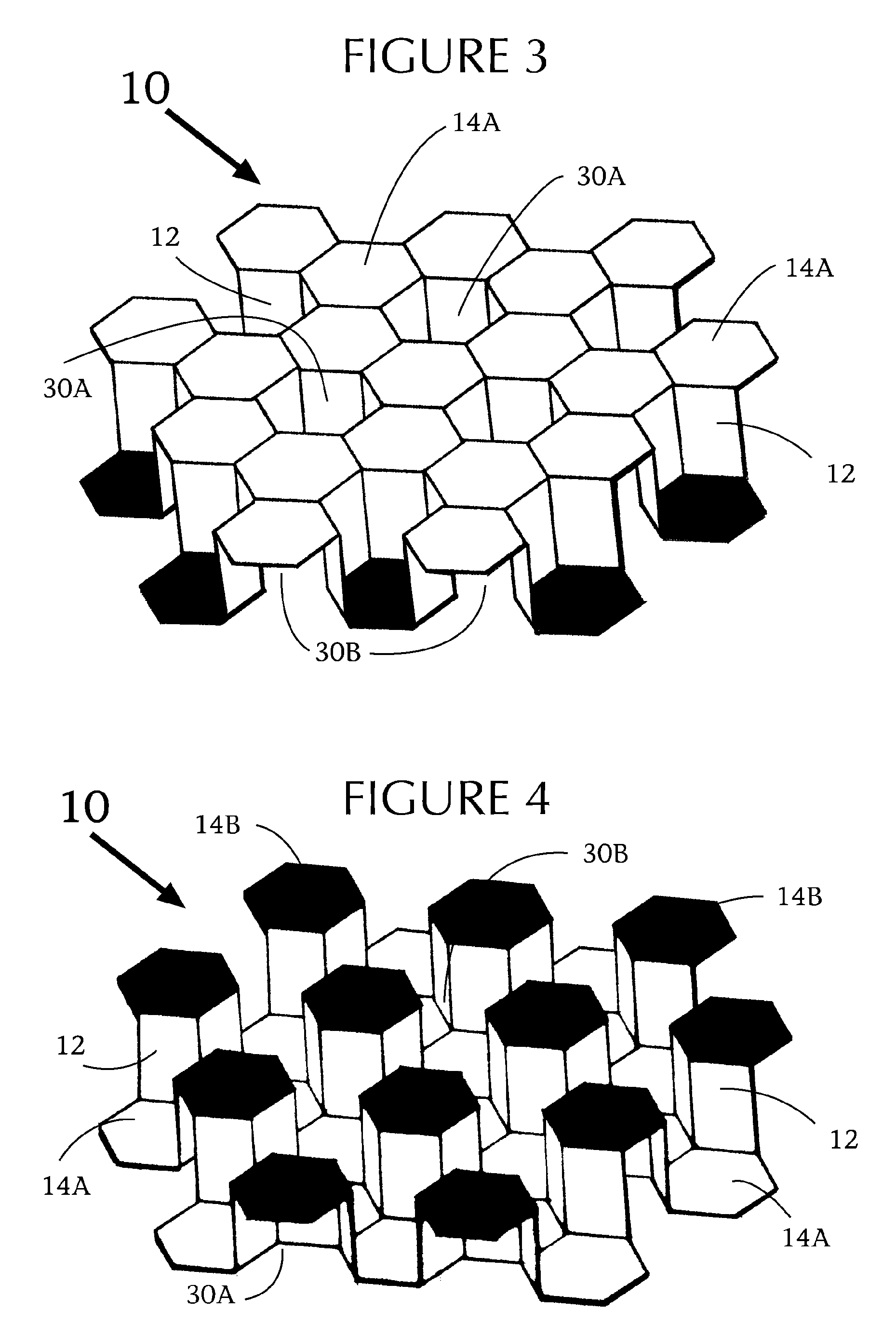

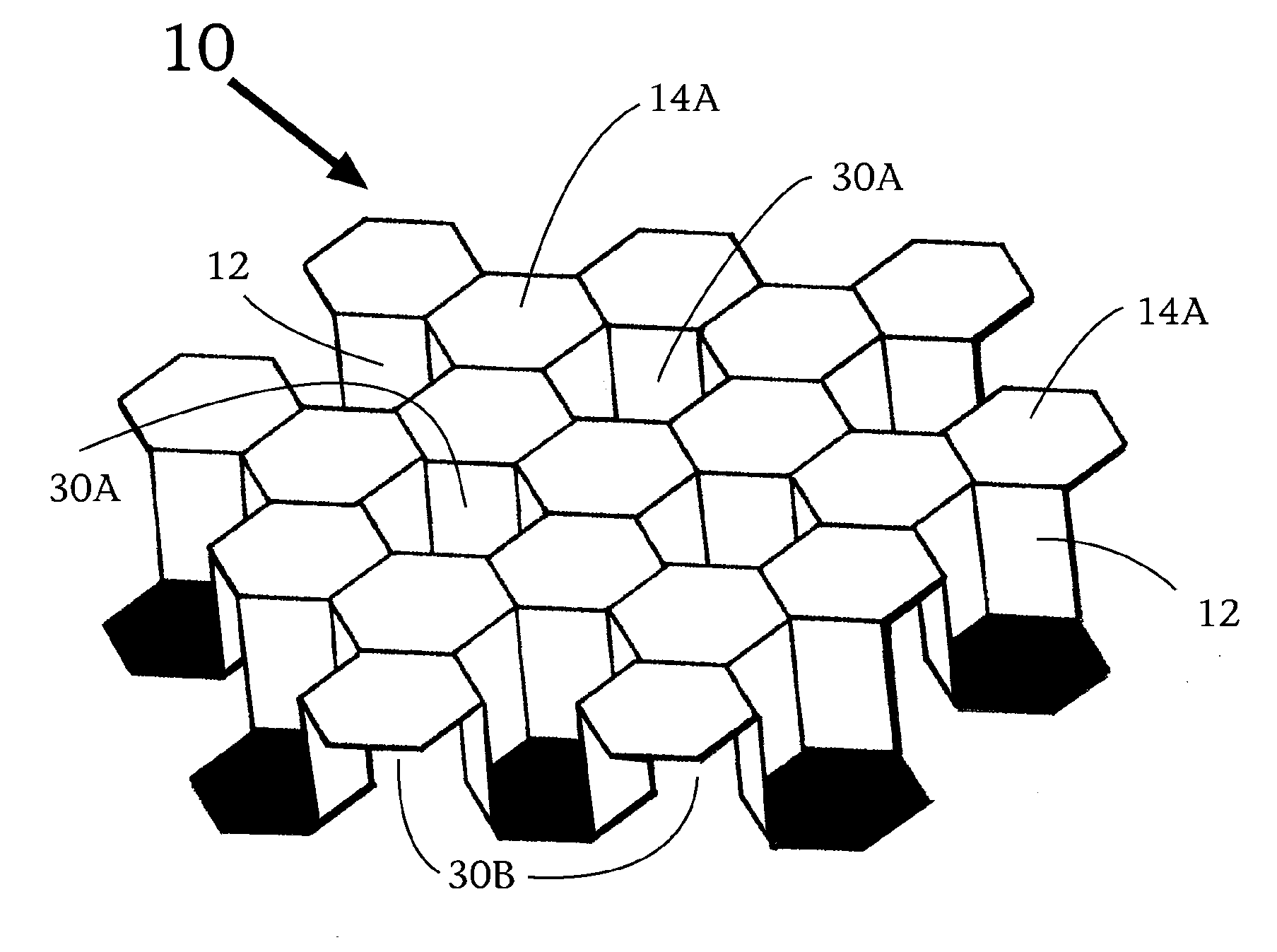

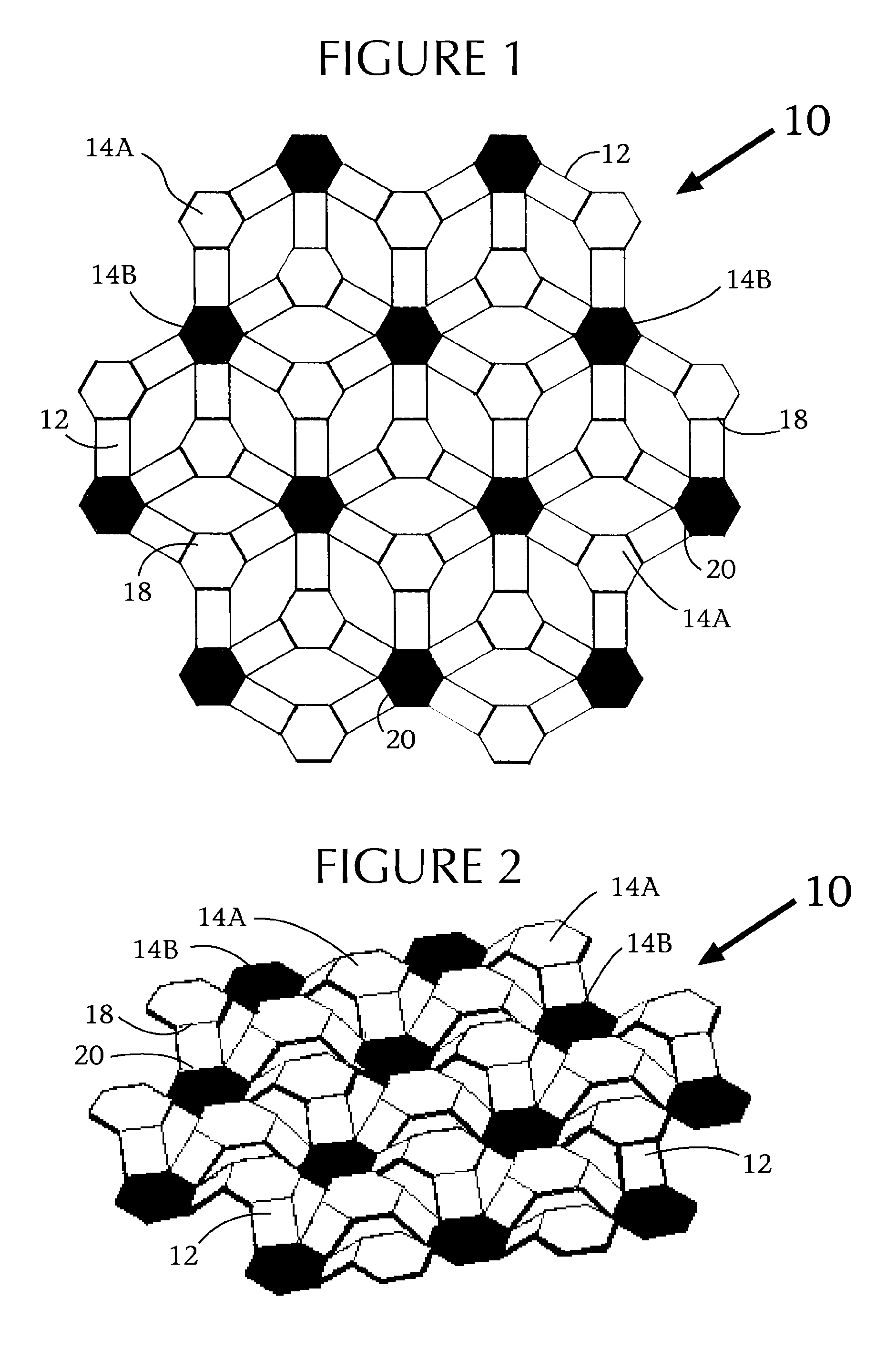

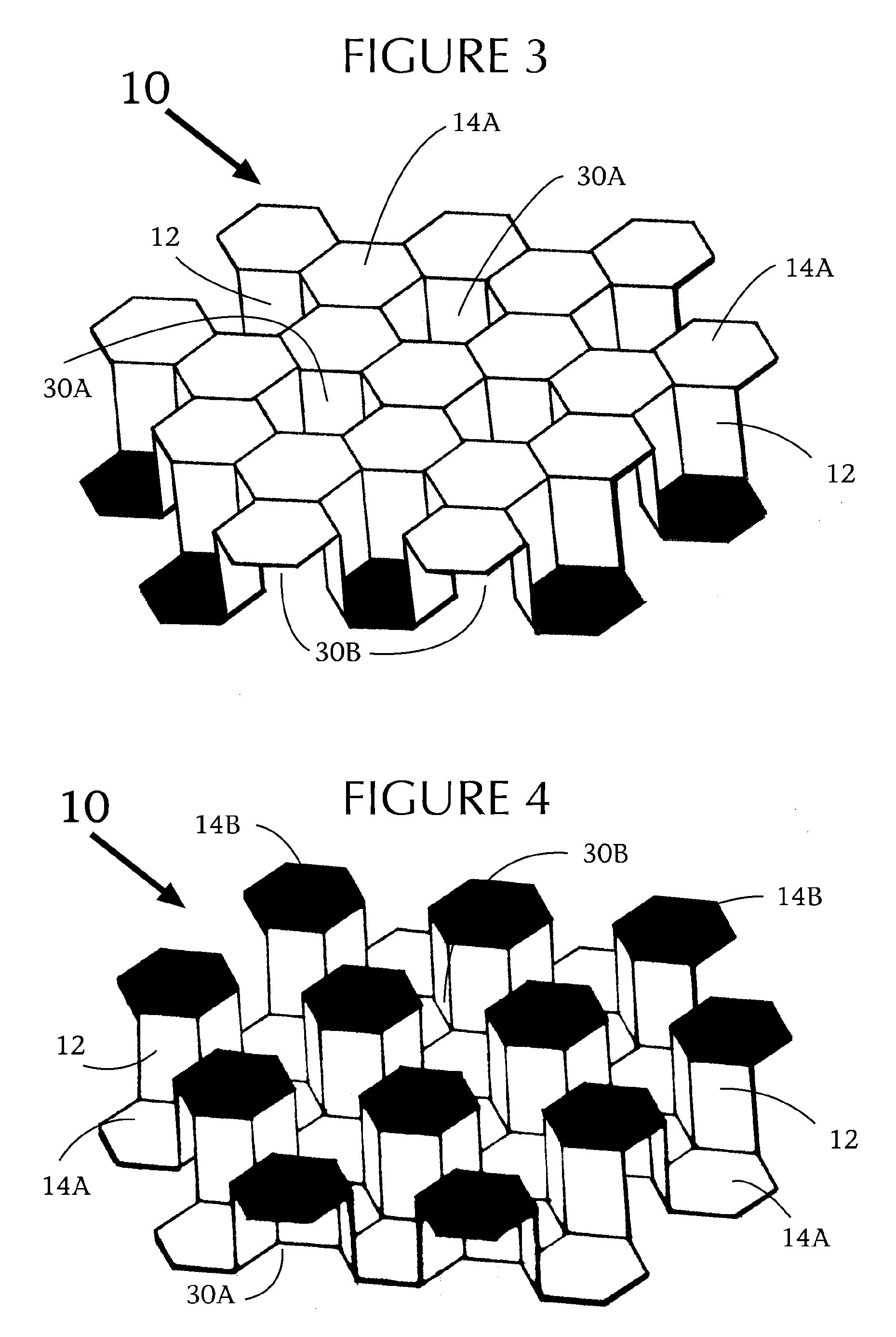

ActiveUS7541085B2Increase the areaIncreased shear strengthPaper/cardboard articlesLaminationHexagonal cellGeometric design

A flexible core element having a large bonding surface area suitable for sandwich type construction comprising a plurality of first hexagonal nodes defining a first surface, a plurality of second hexagonal nodes defining a second surface spaced apart from and parallel to the first surface, and a plurality of rectangular wall members which interconnect said first hexagonal nodes to said second hexagonal nodes and define the depth of the core element. Each hexagonal node corresponds to an open hexagonal cell on its obverse surface and serves as a bonding surface. The core element is fabricated from a continuous sheet of material that has been die-cut with a repeating geometrical design, creased and folded, concertina style, in upon itself to make a double-sided core material that is flexible, able to vent, exhibits good bend and shear strength, and has a large surface bonding area rendering it suitable in the construction of lightweight sandwich panels and offering a wide array of other applications.

Owner:BURDON ROBERT L J

Flexible construction element with large bonding surface area and method of manufacture

ActiveUS20070015000A1Large surface bonding areaEasy to bendPaper/cardboard articlesLaminationHexagonal cellGeometric design

A flexible core element having a large bonding surface area suitable for sandwich type construction comprising a plurality of first hexagonal nodes defining a first surface, a plurality of second hexagonal nodes defining a second surface spaced apart from and parallel to the first surface, and a plurality of rectangular wall members which interconnect said first hexagonal nodes to said second hexagonal nodes and define the depth of the core element. Each hexagonal node corresponds to an open hexagonal cell on its obverse surface and serves as a bonding surface. The core element is fabricated from a continuous sheet of material that has been die-cut with a repeating geometrical design, creased and folded, concertina style, in upon itself to make a double-sided core material that is flexible, able to vent, exhibits good bend and shear strength, and has a large surface bonding area rendering it suitable in the construction of lightweight sandwich panels and offering a wide array of other applications.

Owner:BURDON ROBERT L J

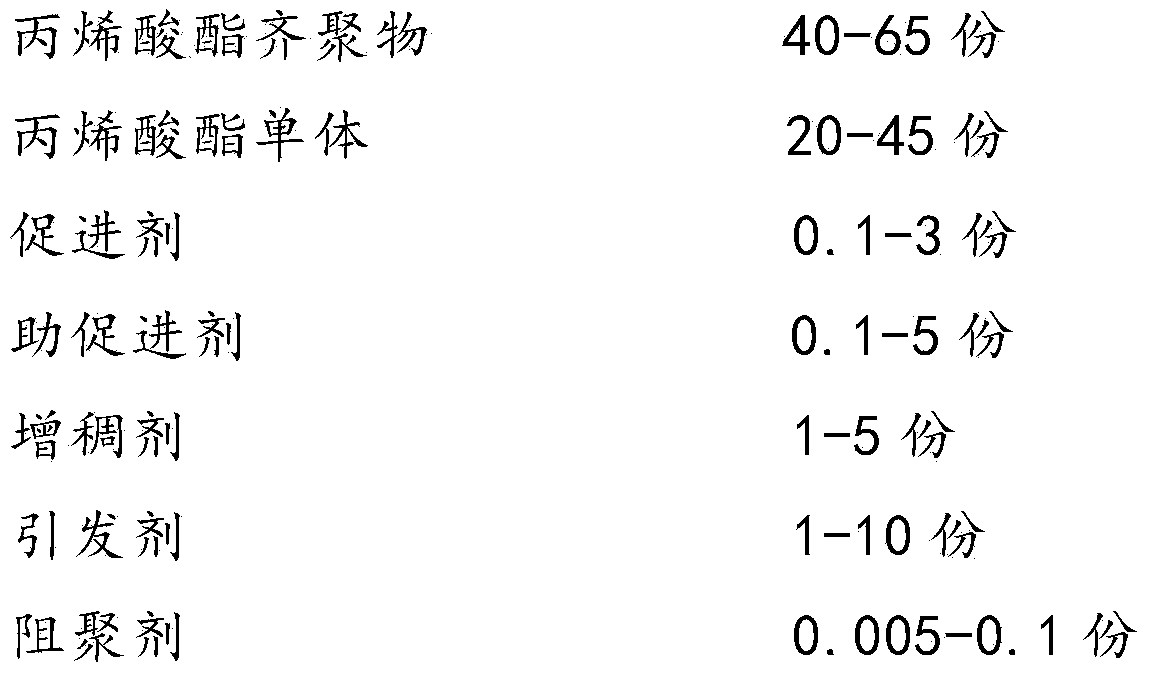

Anaerobic adhesive for surface bonding of inert metal

ActiveCN103725243AFast curingImprove safety and reliabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveAccelerant

The invention discloses an anaerobic adhesive for surface bonding of an inert metal. A preparation method comprises the following steps: firstly, adding an acrylate oligomer, an acrylate monomer and a chelating agent which are weighed according to weight part into a reaction flask; stirring at 20 DEG C to 40 DEG C; adding an accelerant, a cure activating agent, a polymerization inhibitor, a lubricant and a thickening agent which are weighed according to weight part into a solution; evenly stirring; and finally, adding an initiating agent which is weighed according to weight part into the solution, stirring at 35 DEG C and discharging. The anaerobic adhesive has the beneficial effects that the inert metal can be rapidly cured at a normal temperature without being treated by a primer coating; the anaerobic adhesive has the high bonding strength. Thus, the work efficiency and the safe reliability of a workpiece are improved; meanwhile, the threat of the primer coating on the health of a worker and the pollution of the primer coating on atmosphere are avoided.

Owner:山东禹王和天下新材料有限公司

Manufacturing technique of digitally customizing orthopedic implants

InactiveCN103150442AFit closelyReduced chance of internal fixation failureSpecial data processing applicationsGraphicsBond properties

The invention discloses a manufacturing technique of digitally customizing an orthopedic implant, which comprises the steps of scanning a fracture part of a fracture patient, obtaining injured fracture data, introducing the injured fracture data into 3D (three dimensional) medical finite element simulation software for processing, obtaining a 3D figure of the fracture part, reconstructing and resetting fracture part, introducing 3D figure data after medical 3D reconstruction and resetting into 3D industrial design software, designing a primary orthopedic implant according to a surgical requirement and experience, obtaining 3D figure data of the primary orthopedic implant, introducing the 3D figure data of the primary orthopedic implant into the 3D medical finite element simulation software to conduct virtual assembly with the fracture part after the medical 3D reconstruction and resetting, confirming a position and a direction of a screw hole of the primary orthopedic implant according to a resetting condition of the fracture part, introducing 3D figure data of a final orthopedic implant into a quick forming machine to accumulate to a practical orthopedic implant, and obtaining the finished orthopedic implant. The manufacturing technique can design specially and achieve high-precision resetting and internal fixation according to different fracture shapes, and the manufactured orthopedic implant is good in surface bonding property and reasonable in thickness.

Owner:CHANGZHOU WASTON MEDICAL APPLIANCE CO LTD

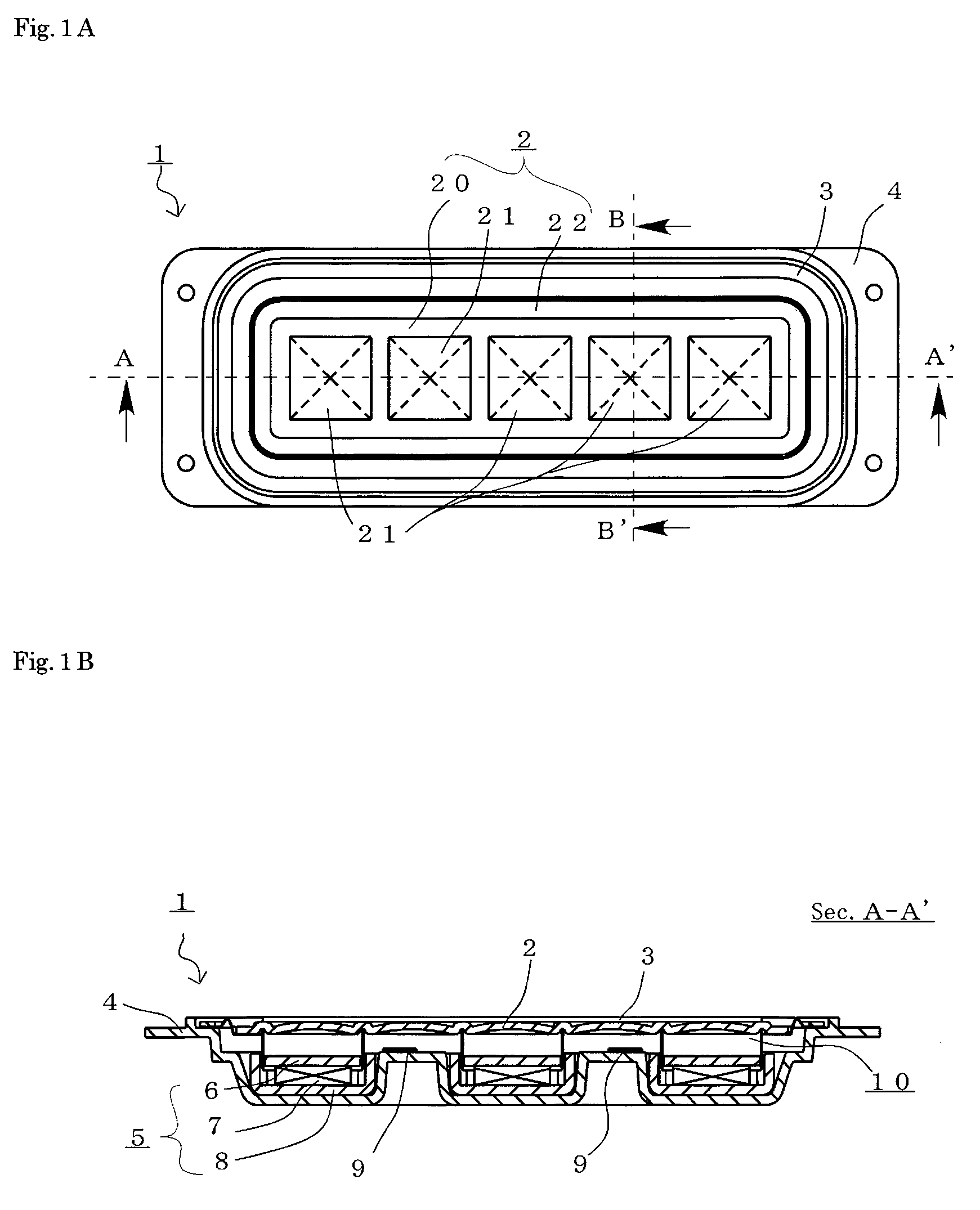

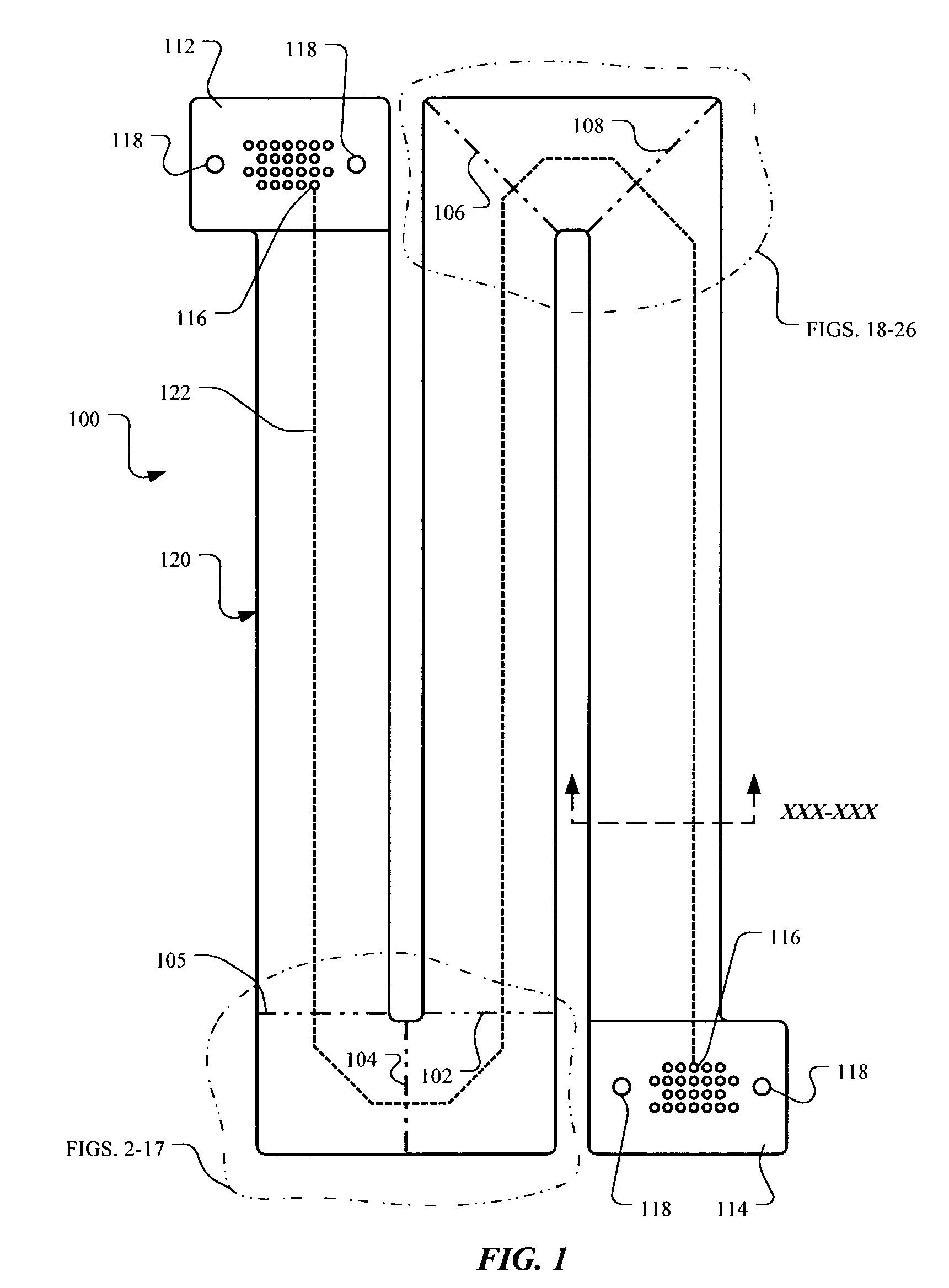

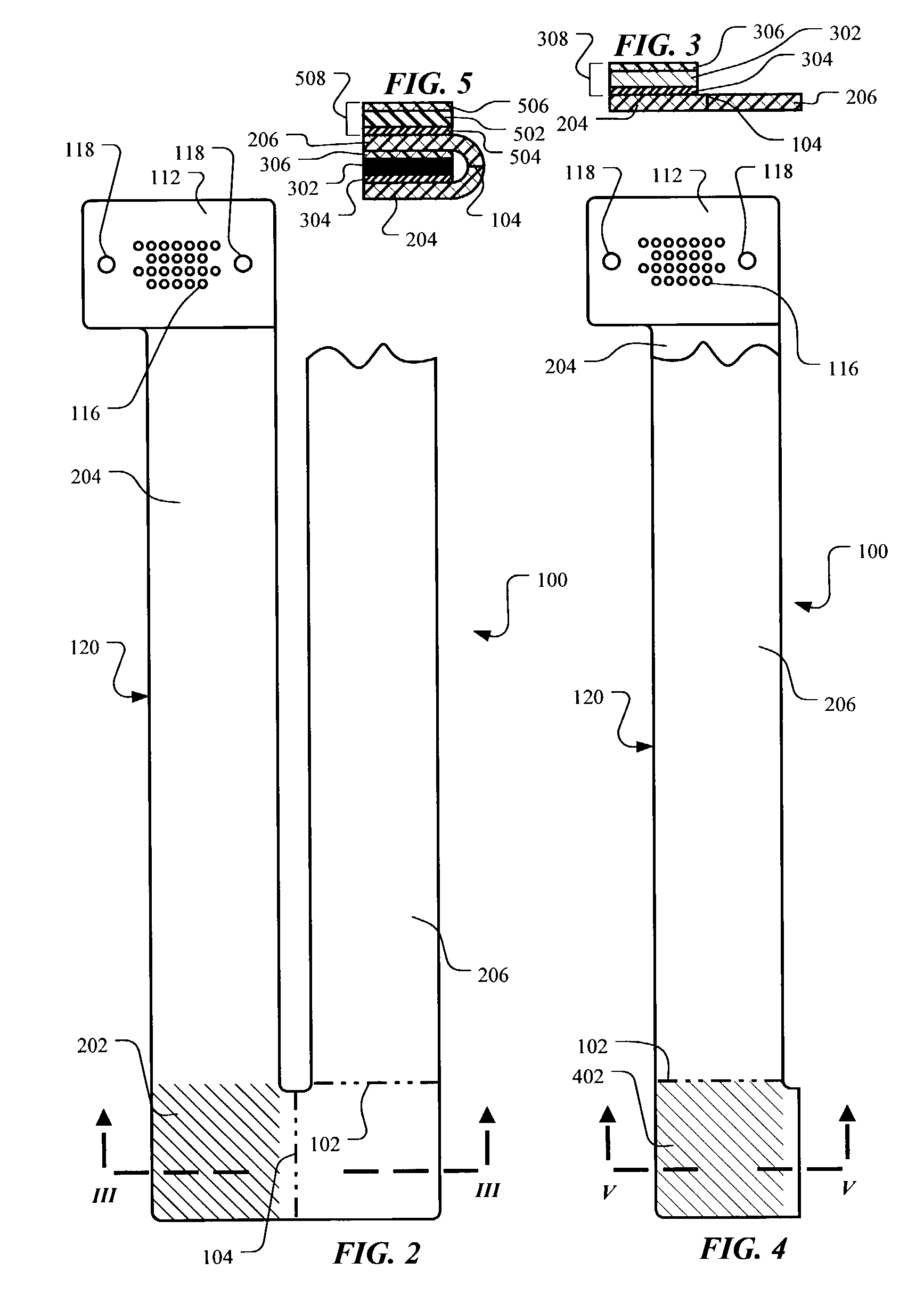

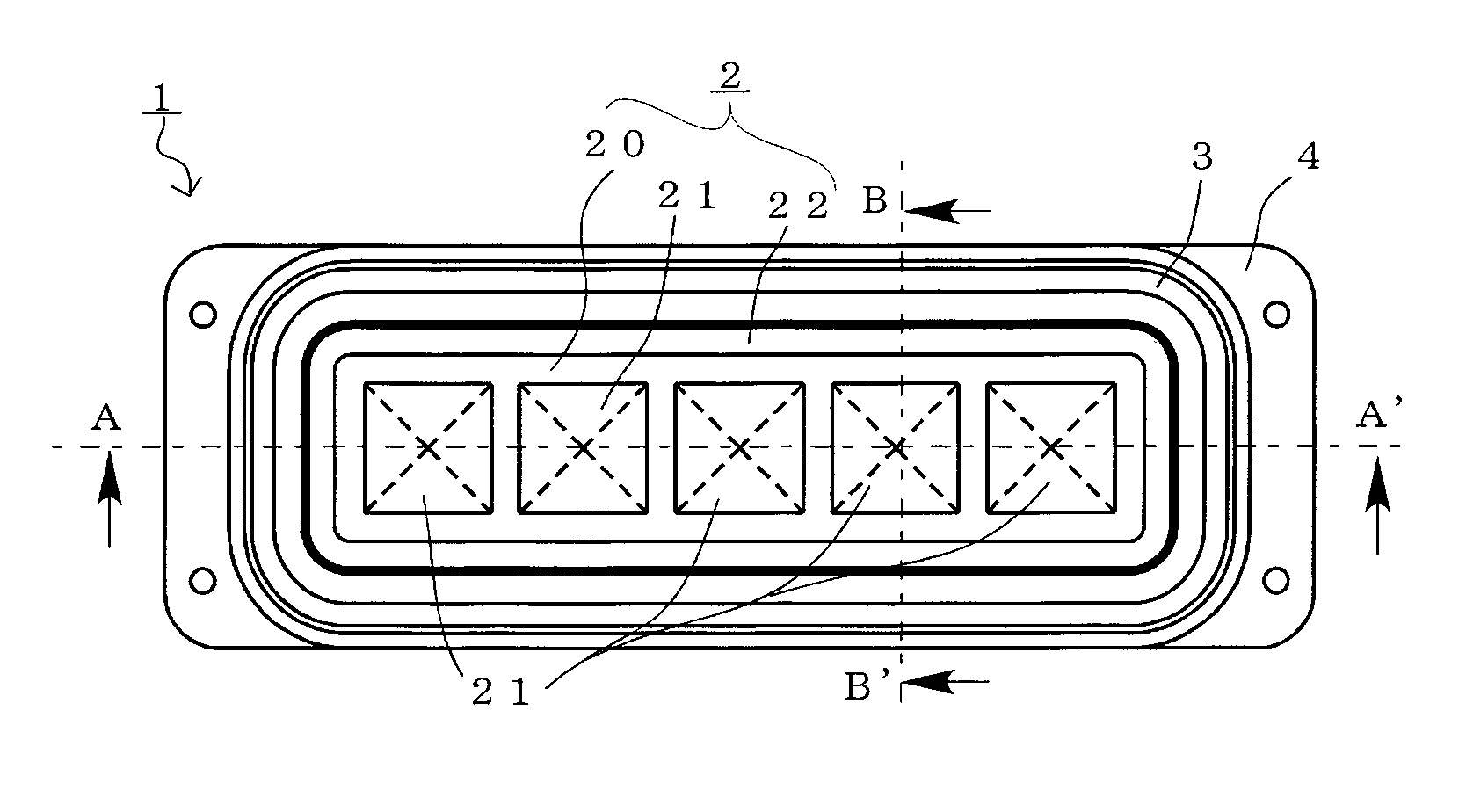

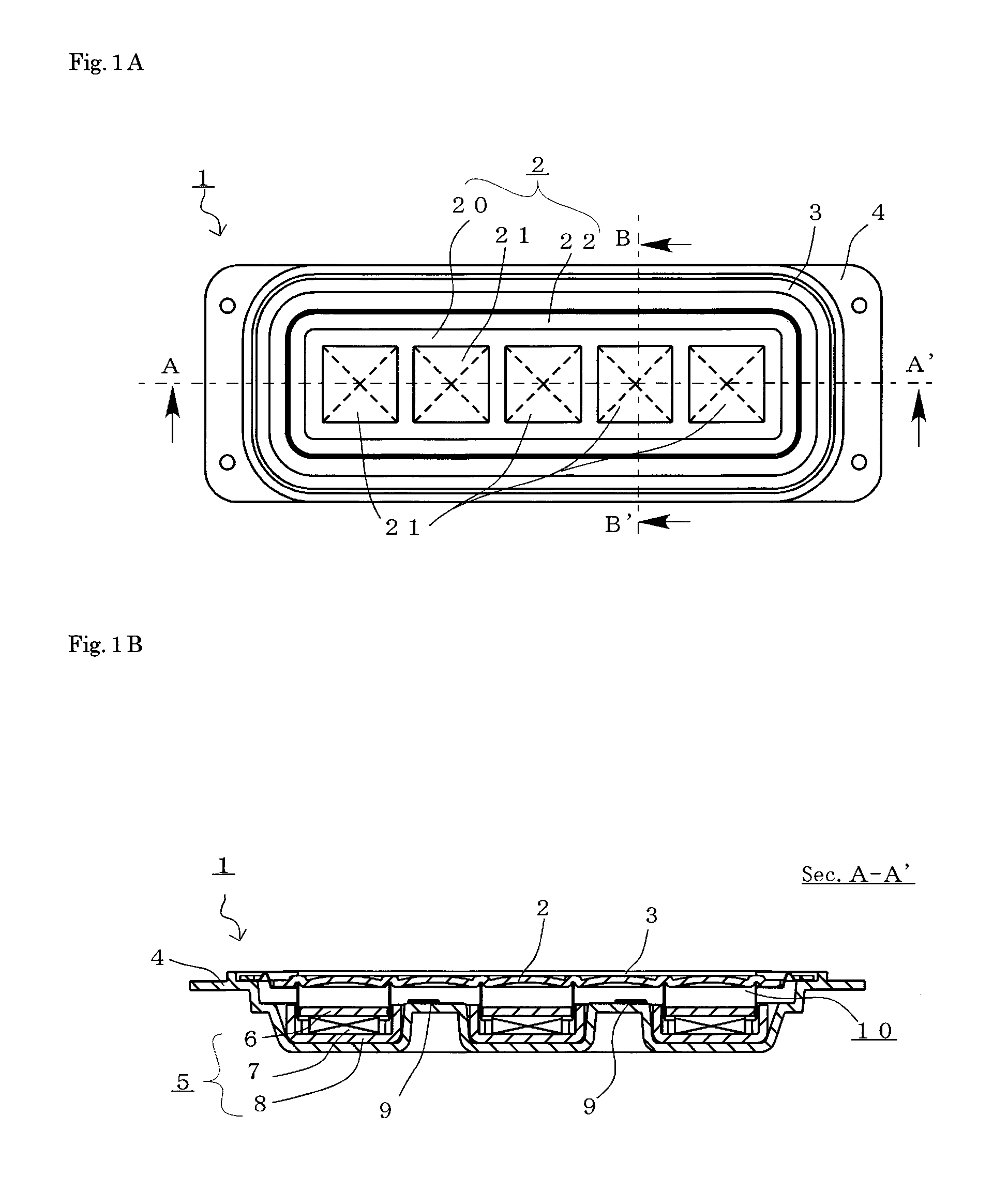

Voice coil assembly and loudspeaker using the same

InactiveUS7864977B2High strengthSmooth frequency characteristicTransducer detailsPlane diaphragmsManufacturing cost reductionGrid pattern

According to the invention, a whole-surface driven, flat thin loudspeaker that brings about smooth frequency characteristics with split vibration hardly caused is realized, and a voice coil assembly that has high reproduction efficiency and fewer operation failures, and brings about favorable work efficiency in manufacturing and further reduced manufacturing cost, and a loudspeaker using the same are manufactured. The voice coil assembly includes a rectangular voice coil including a rectangular bobbin formed with a rectangular cross section and a rectangular coil bonded to the rectangular bobbin, and a rectangular reinforcing member coupling the plurality of rectangular voice coils to one another in a grid pattern, wherein a portion of inner wall surfaces of the rectangular reinforcing member is bonded to any of outer wall surfaces of the rectangular bobbins of the plurality of rectangular voice coils, and the outer wall surfaces of the rectangular bobbins, to which the inner wall surfaces of the rectangular reinforcing member are not bonded, and portions of the inner wall surfaces of the rectangular reinforcing member, which are not bonded to the outer wall surfaces of the rectangular bobbins define a rectangular space between a pair of the adjacent rectangular voice coils.

Owner:ONKYO KK

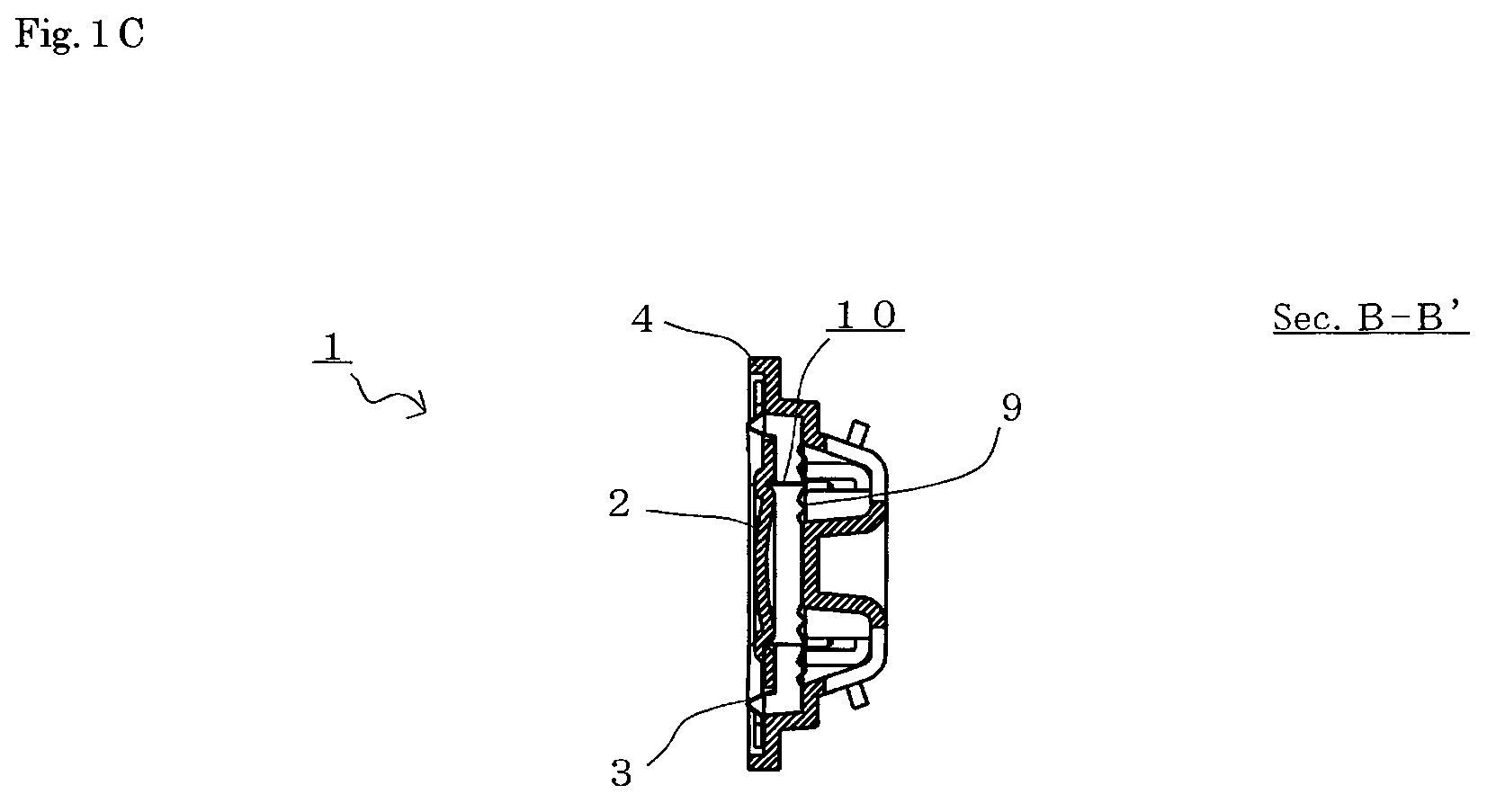

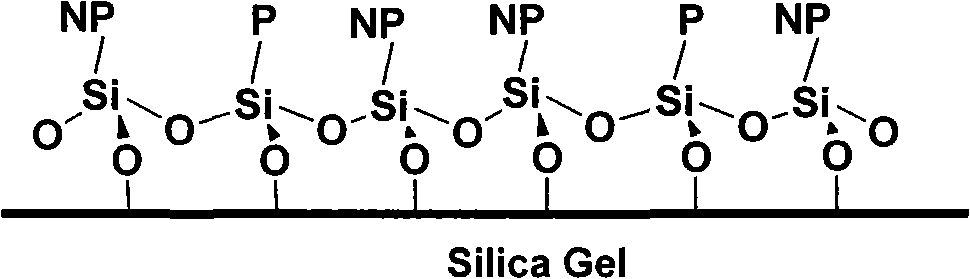

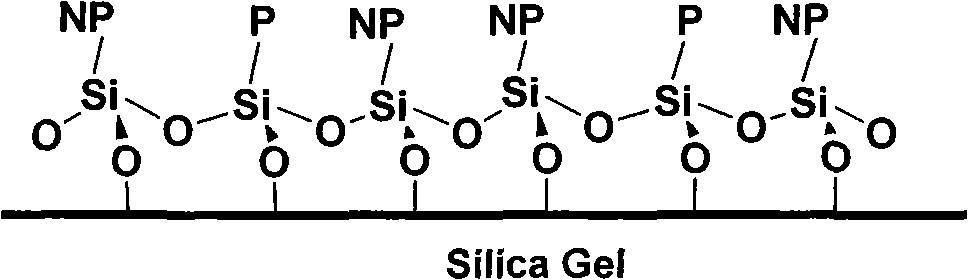

Chromatographic separation material based on copolymerization on silica gel surface and preparation thereof

ActiveCN101987293ANovel structureHigh selectivityOther chemical processesSolid sorbent liquid separationChromatographic separationSilanes

The invention relates to a silica gel matrix separation material, wherein two or more silane reagents form nonpolar / polar copolymerization stationary phase through the copolymerization on silica gel surface. The structural formula of the nonpolar / polar copolymerization stationary phase is as follows: FORMULA, wherein Silica Gel is silica gel; NP stands for nonpolar group, which is one or more of C1 to C30 normal chain alkyl and phenyl; and P stands for polar group, which is one or more kinds of C1 to C12 normal chain alkyl whose tail end has the functional group such as chlorine atom, bromineatom, cyan, amido, benzenesulfonic acid group, sulfo group, carboxyl, quaternary ammonium group and alcohol group. The bonded phase of the separation material has novel structure, and simultaneously has nonpolar group and polar group, thereby being capable of providing hydrophobic force and polymorphic polar acting force, and greatly improving the selectivity of the inverse and efficient liquid chromatogram. The stationary phase prepared with the preparation method provided by the invention has the advantages of even and stable surface bonding group, large bonding quantity, and the like.

Owner:浙江华谱新创科技有限公司

Crack arrest method of alloy surface fine crack crack arrest method and device thereof

InactiveCN101239432AImprove efficiencyRaise the Fatigue ThresholdLaser beam welding apparatusLacquerPulse energy

A crack arrest process and device thereof for removing fine cracks on alloy surfaces, relates to laser impulse processing application technique field. Oxide layers and pollutants on alloy surfaces which affect surface bonding force are removed to obtain good glue-joint strength and permanent stability; a flexible film is adhered to the alloy surface as a crack arrest patch, and a layer of black lacquer coating is applied on the crack arrest patch; laser pulse with following parameters: pulse energy of 15-40J, pulse width of 20-30ns, light spot size of 4-10mm, repetition frequency of 0.5-10Hz is selected to performing laser impact crack arrest according to damage status of the cracks; laser crack arrest is performed by selecting crack arrest route, and crack effects are inspected by using no-damage technique during crack arrest process. The invented method and device can increase alloy surface fatigue threshold value, the existing of residual compressive stress on metal surface after laser impulse enhances fatigue threshold stress on material surface greatly.

Owner:JIANGSU UNIV

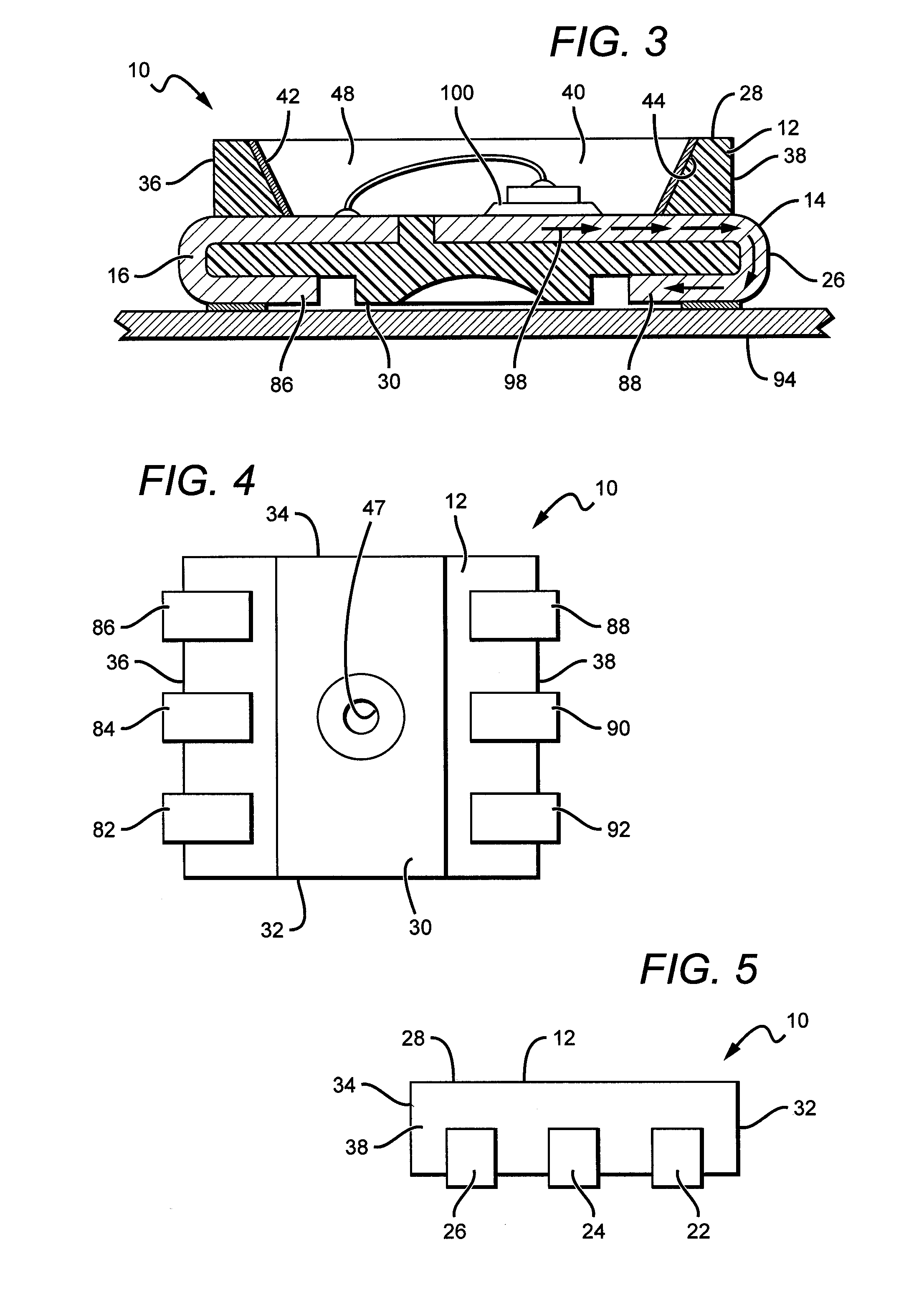

Surface mount device thin package

ActiveUS20110248293A1Improved color emission uniformityImproves Structural IntegritySolid-state devicesSemiconductor devicesSurface bondingEngineering

The present invention is directed to LED packages and LED displays utilizing thin / low profile LED packages with improved structural integrity, emission characteristics, and customizable attributes. In some embodiments the improved structural integrity is provided by various features in the lead frame that cooperate with the casing for a stronger package. Moreover, in some embodiments the improved emission characteristics are provided by cavity features such as shape and depth, which provide for increased surface bonding area for multiple LED chips and increased viewing angle, respectively. Some embodiments also provide for gradated packages having customizable top portions for applications using smaller packages, with bottom portions comprising dimensions compatible with customary mechanical / electrical supports.

Owner:CREE HUIZHOU SOLID STATE LIGHTING

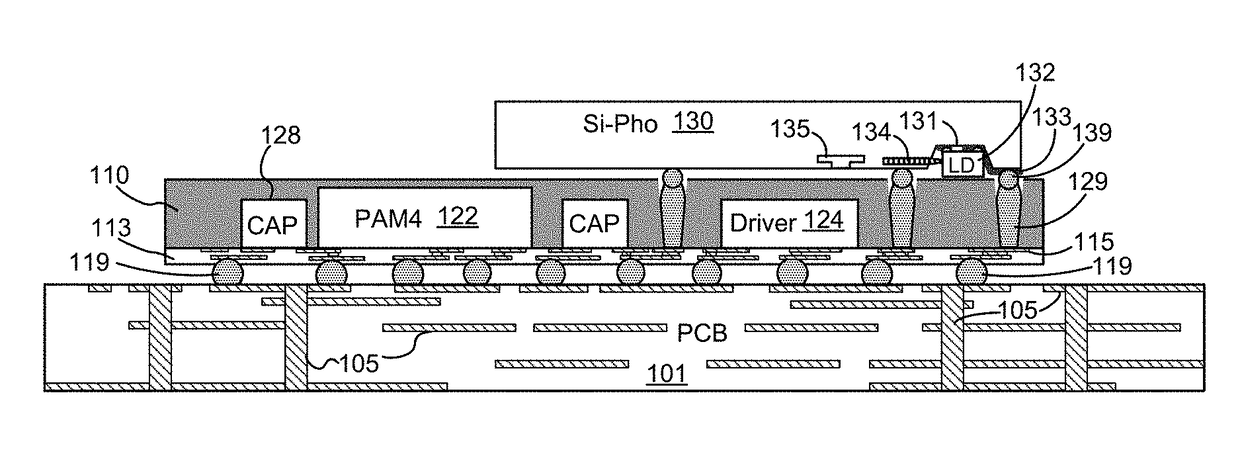

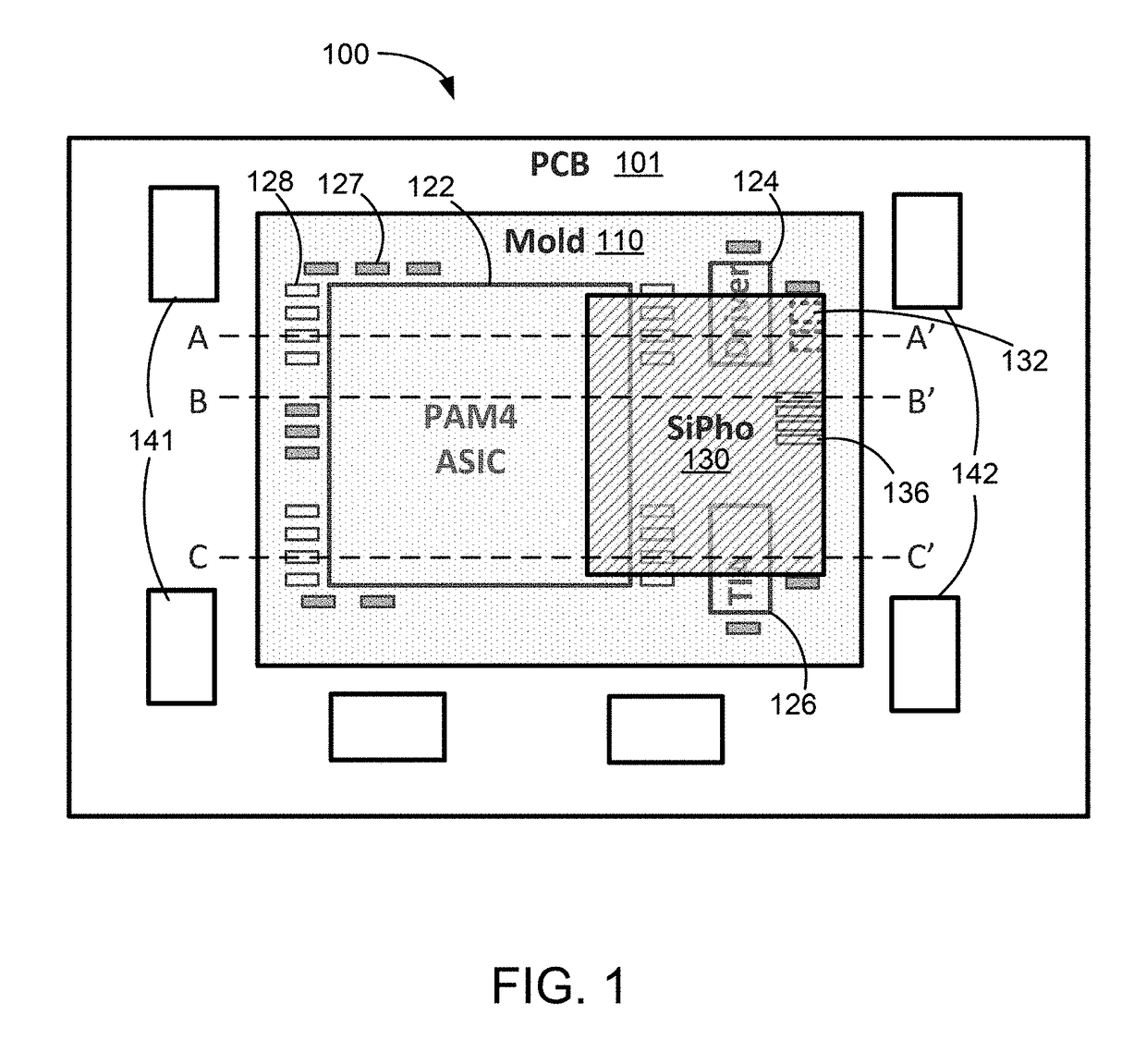

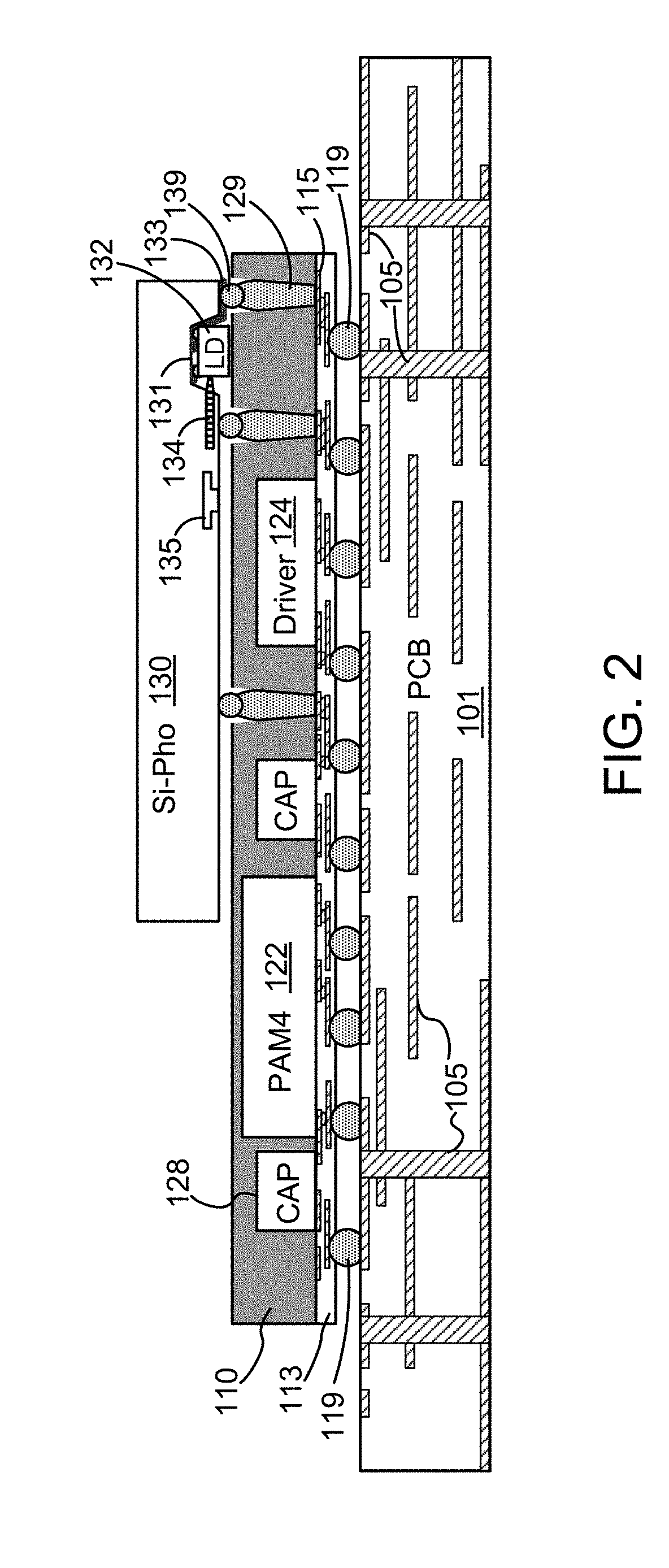

Optical transceiver by fowlp and dop multichip integration

ActiveUS20170254968A1High yieldSmall sizeSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerTransceiver

An optical transceiver by hybrid multichip integration. The optical transceiver includes a PCB with a plurality of prefabricated surface bonding sites. A first chip includes a FOWLP package of multiple electronics devices embedded in a dielectric molding layer overlying a dielectric redistribution layer is disposed on the PCB by respectively bonding a plurality of conductor balls between the dielectric redistribution layer and the plurality of prefabricated surface bonding sites while exposing soldering material filled in multiple through-mold vias (TMVs) in the dielectric molding layer. The optical transceiver further includes a second chip configured as a Sipho die comprising photonics devices embedded in a SOI wafer substantially free from any electronics device process. The second chip is stacked over the first chip with multiple conductor bumps being bonded respectively to the soldering material in the multiple TMVs.

Owner:MARVELL ASIA PTE LTD

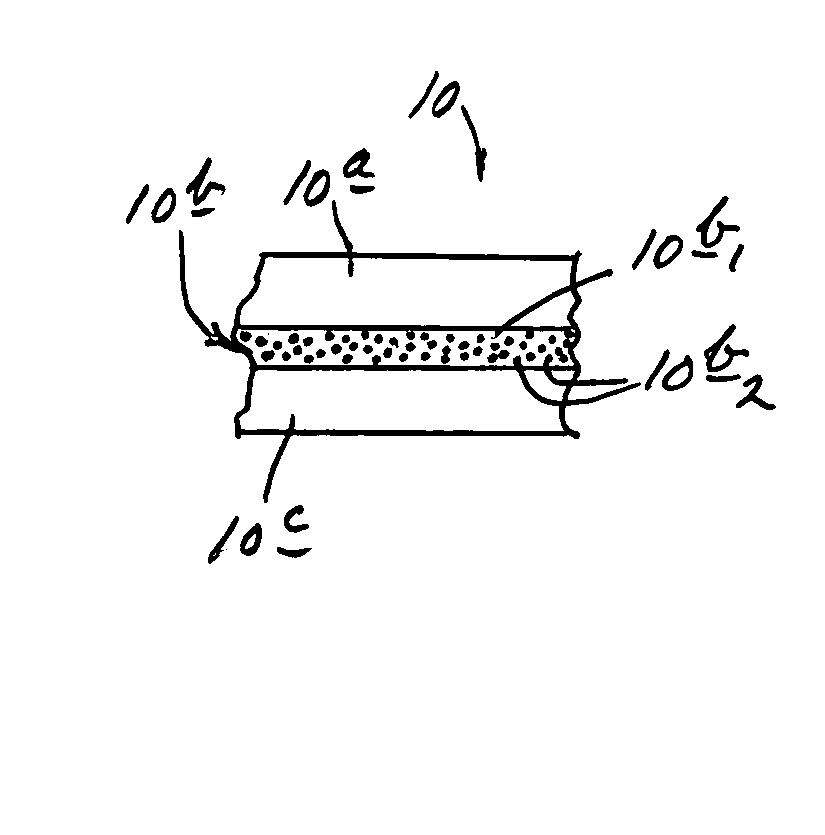

Adhereable, pre-fabricated, self-healing, anti-puncture coating for liquid container and methodology

A bulk, generally elastomeric and pliable, layered mat formed to permit selective trimming into size-chosen mat trims / tiles, each of which is structured to perform as a self-puncture(wound)-sealing, defined-liquid-reactive, anti-puncture-leakage coating element applicable bondedly to the outside surface of a selected wall in a container holding the defined-liquid. Also disclosed is a method for protecting against liquid leakage from a puncture wound in such a wall including: (a) preparing a generally elastomeric, pliable, layered coating mat of a self-puncture-healing, defined-liquid-reactive, anti-puncture-leakage material; (b) in relation to a selected container wall, selectively removing, by trimming, from the prepared mat one or more mat trims / tiles shaped for specific use on the outside surface of that wall; and (c) applying and surface-bonding the one or more trims / tiles to the outside surface of the selected wall.

Owner:HIGH IMPACT TECH

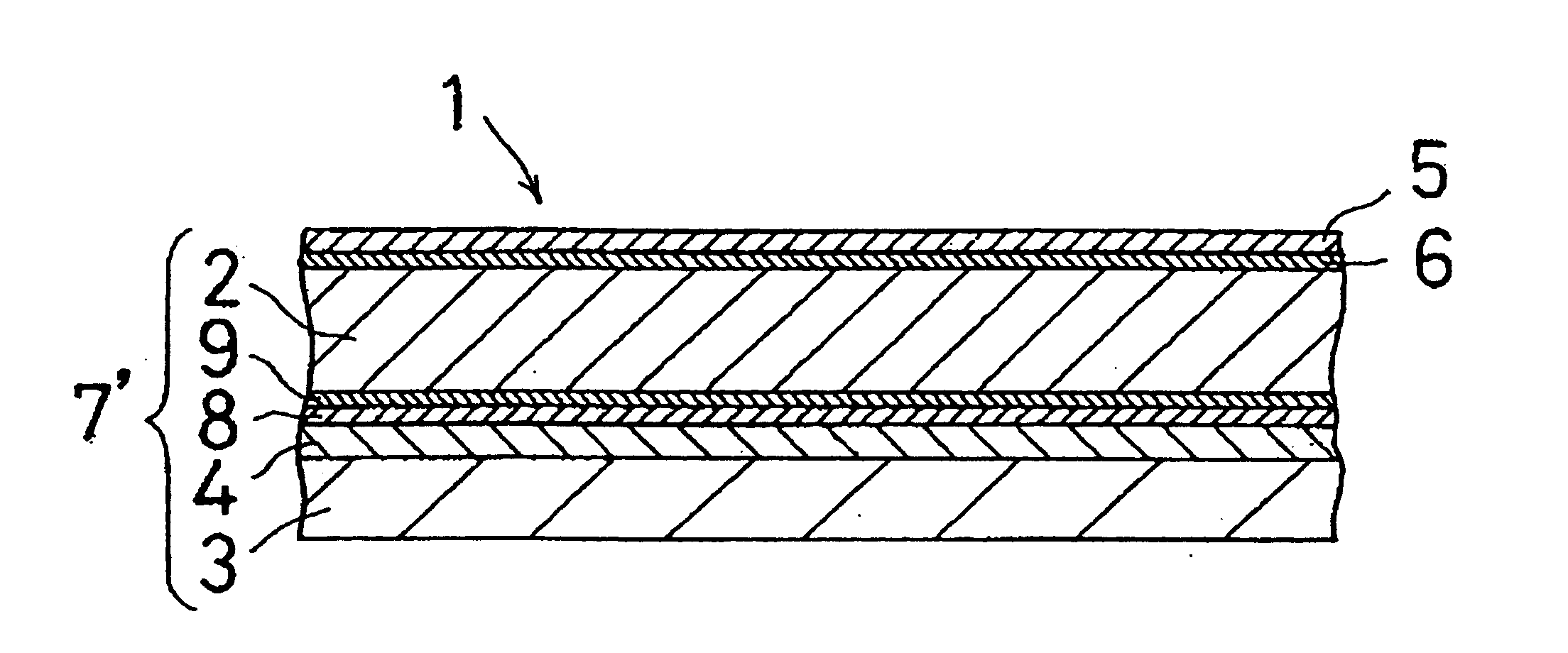

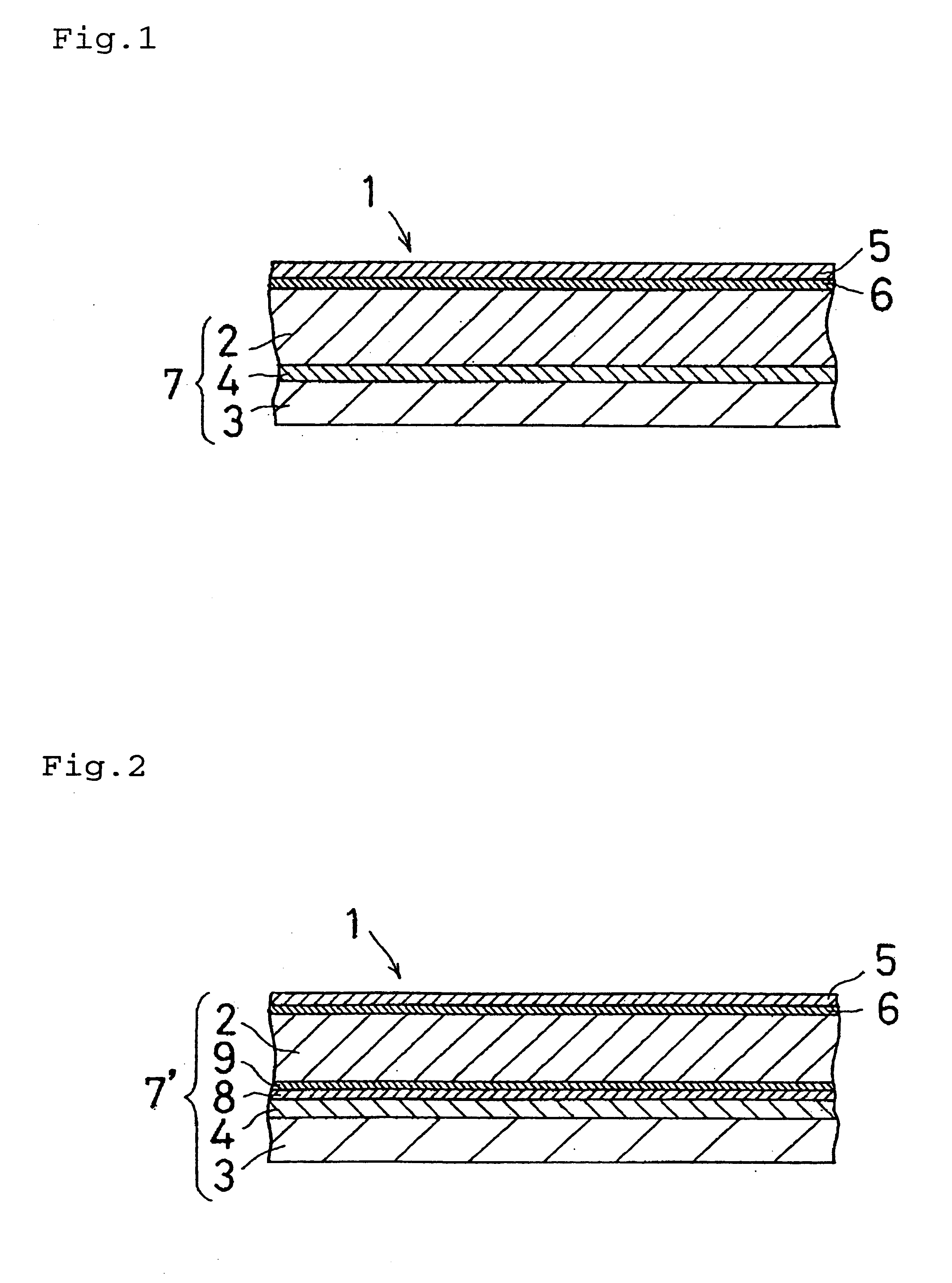

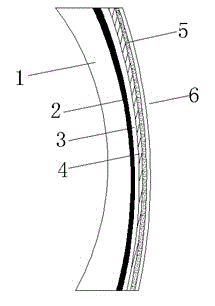

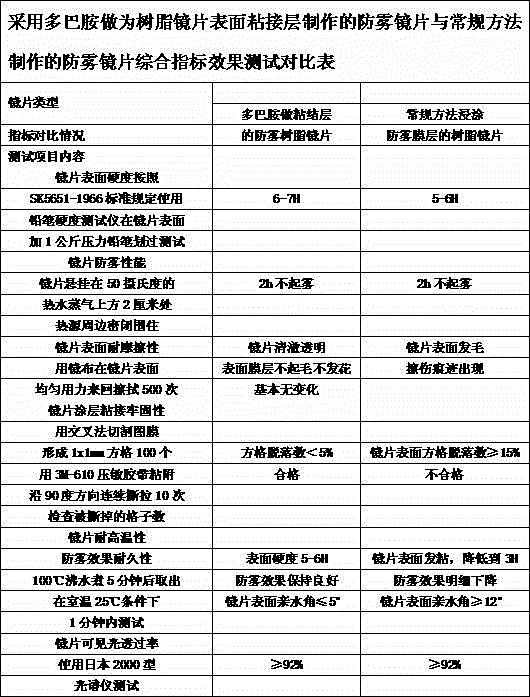

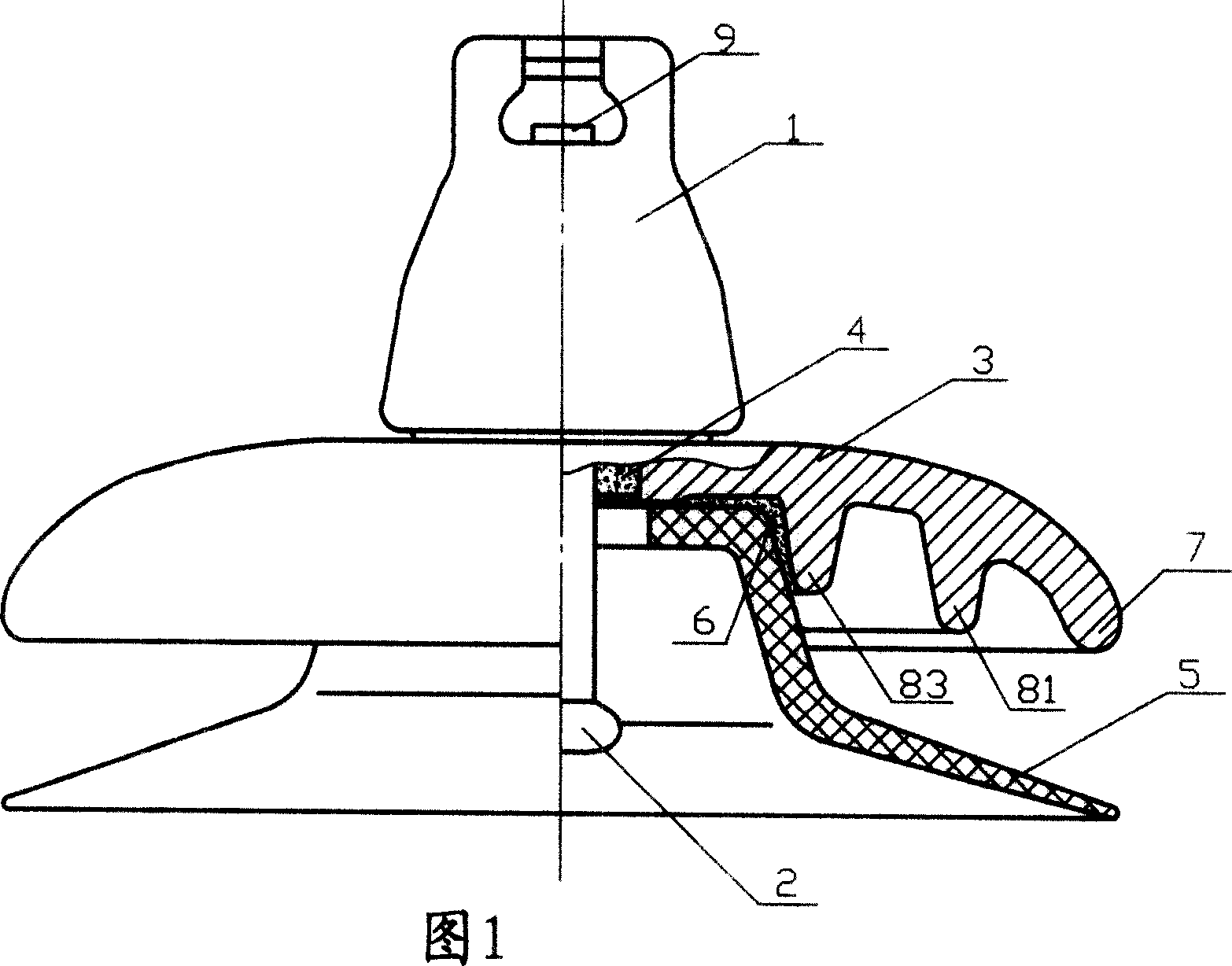

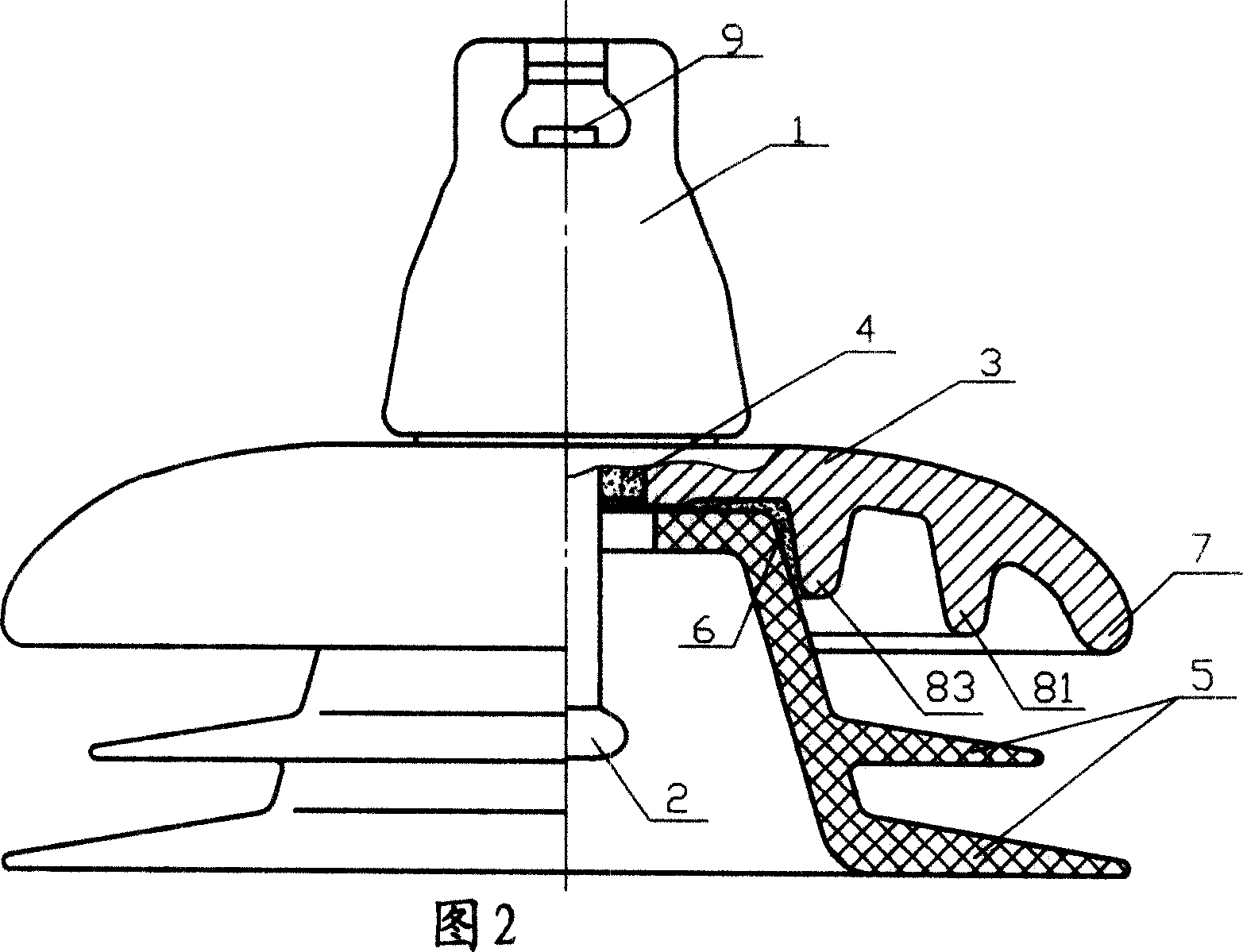

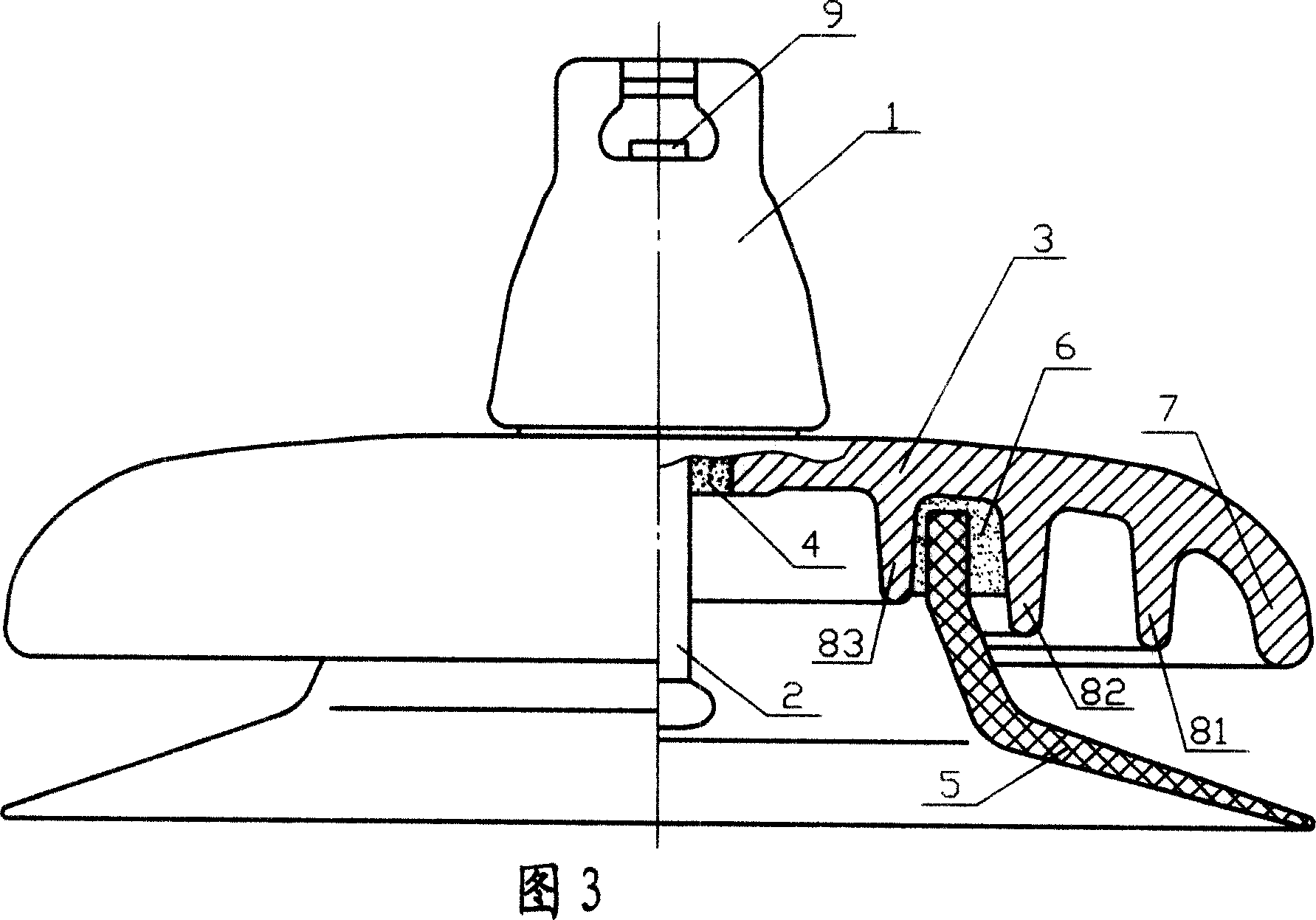

Anti-fog lens with dopamine as surface bonding layer, and technological process thereof

ActiveCN104898189AAchieve long-term anti-fog functionNot easy to fall offOptical partsOptical elementsOptoelectronicsDopamine

The invention provides an anti-fog lens with dopamine as a surface bonding layer, and a technological process thereof. The anti-fog lens is composed of a substrate (1), a stiffened film layer (2), an anti-reflecting film layer (3), a waterproof film layer (4), the dopamine bonding layer (5) and an anti-fog film layer (6). The anti-fog lens is characterized in that the dopamine bonding layer (5) is adhered on the surface of the waterproof film layer (4) through dipping; and the hydrophilic anti-fog film layer (6) is bonded with the surface of the dopamine bonding layer (5) through dipping. According to the anti-fog lens, an anti-fog paint is combined with the surface of a resin lens for realizing no easy falling, thereby forming the firm anti-fog film layer after heat-curing, and realizing long-term anti-fog function of eyeglasses. The anti-fog lens has advantages of high novelty, simple process, high adhesion firmness and high practicability.

Owner:DANYANG JINGTONG GLASSES TECH INNOVATION SERVICE CENT

Composite insulator

This invention is concerned with the technique project that the bottom surface of single-layer umbrella cap and pin insulator of the glass or the porcelain with umbrella arris splices the composed umbrella shed made of the silicon rubber polymers and gets double-layer umbrella-hanging insulator. The structure is: the middle hole of the compound umbrella shed extends upwards by drum shape, the top part of the drum shape and the umbrella cap bottom surface of the hanging insulator splices with each other. The invention can improve the anti fouling of the insulator without reducing its performance in un / installation.

Owner:王淑兰

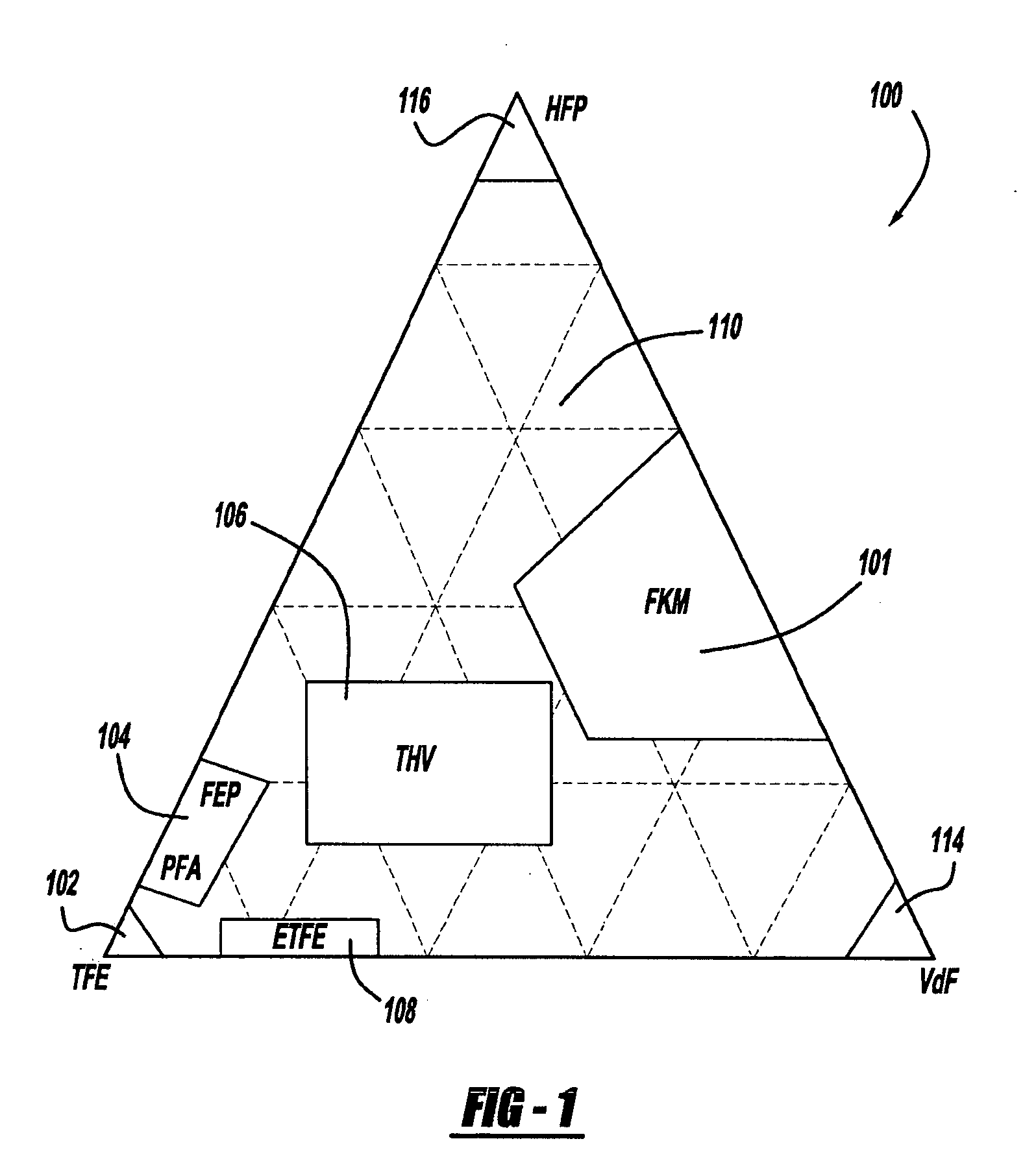

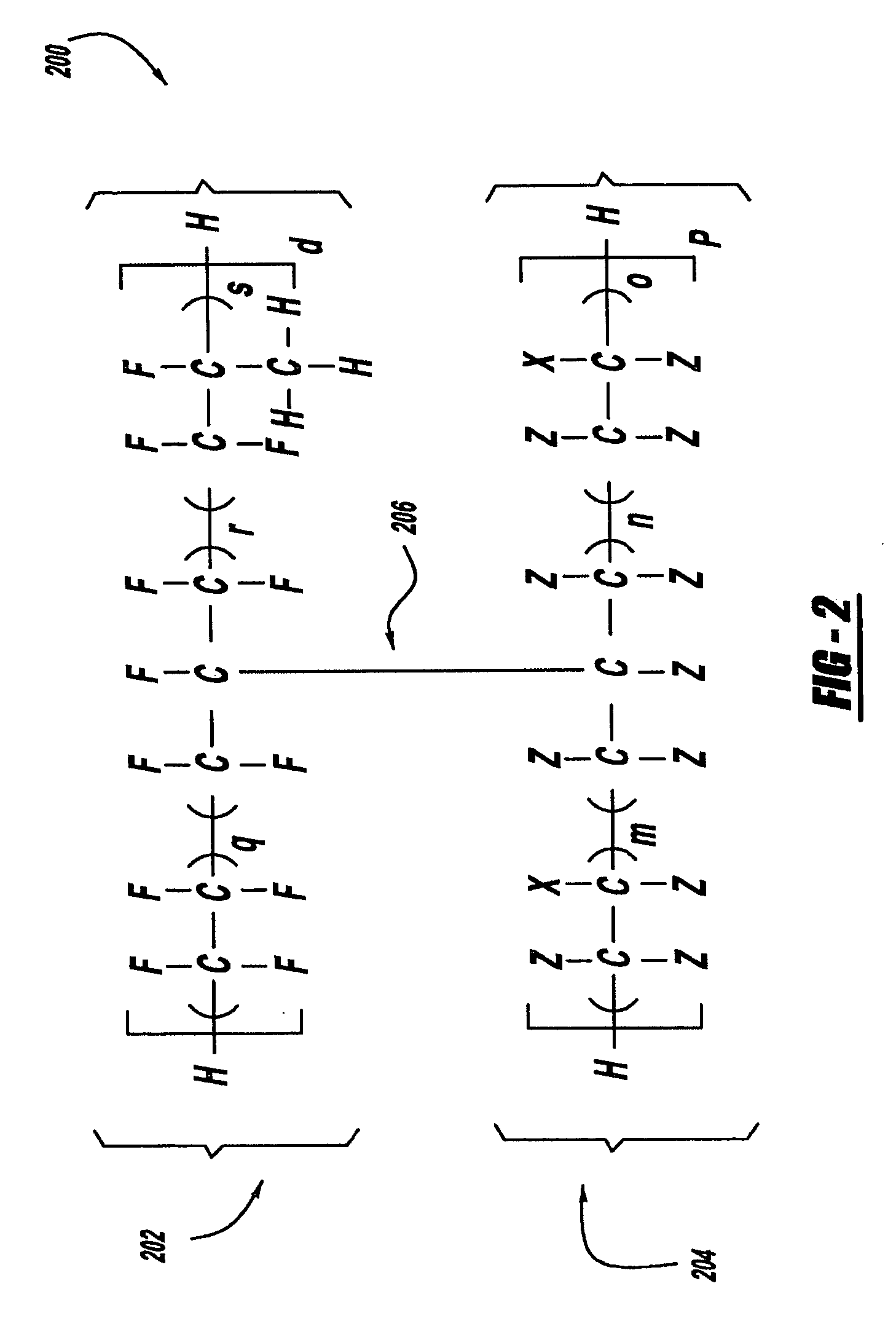

Surface bonding in halogenated polymeric components

Etching the surface (activating the surface) of a halogenated polymer component with an electron beam generates a set of free radical sites in polymeric chains of the surface that sustain for at least 4 hours in an inert environment. The inert environment is provided by a noble gas, nitrogen, a static free space, and / or a vacuum. Items such as dynamic seals, static seals, gaskets, pump diaphragms, hoses, and o-rings all benefit from precursors made according to the technique.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

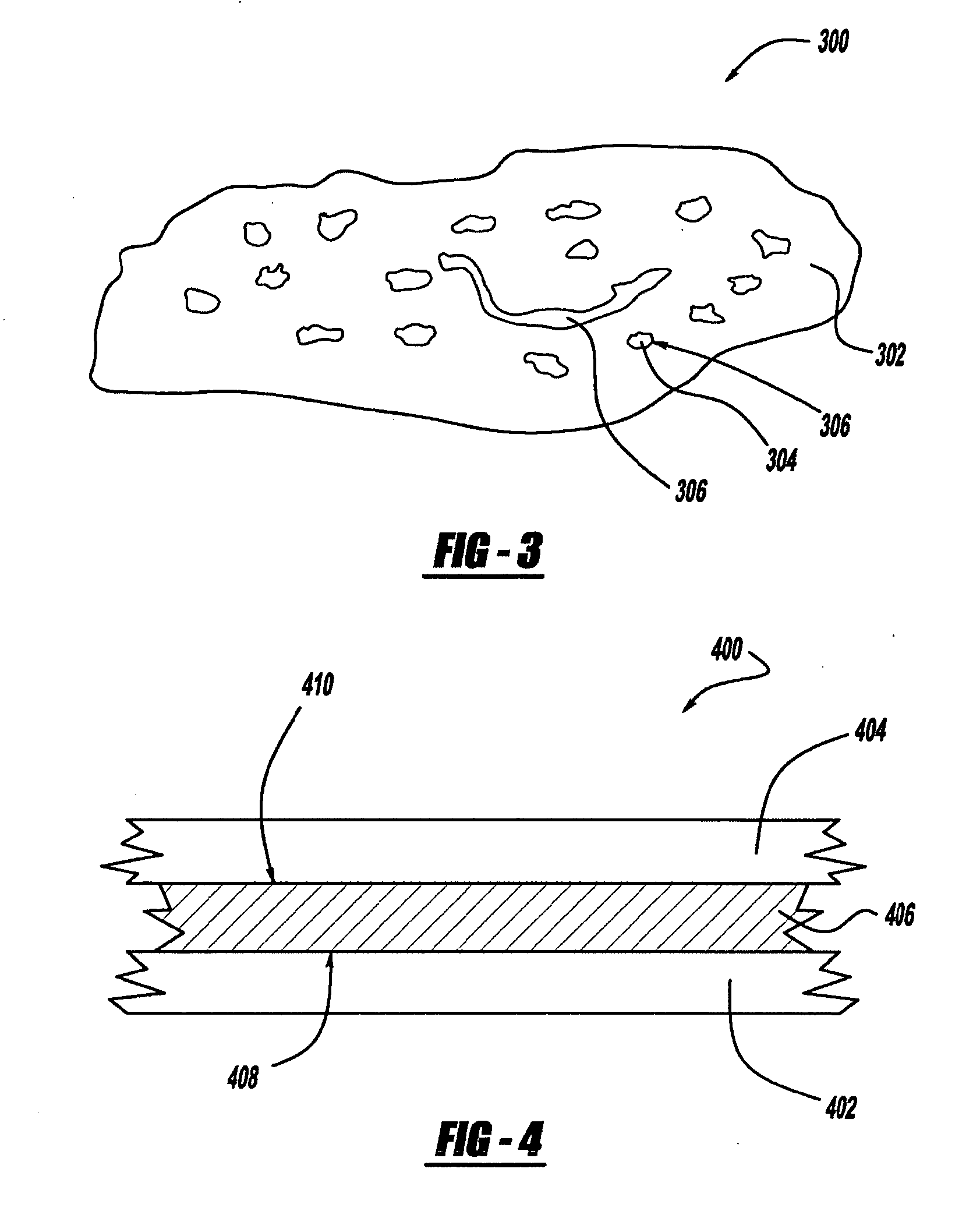

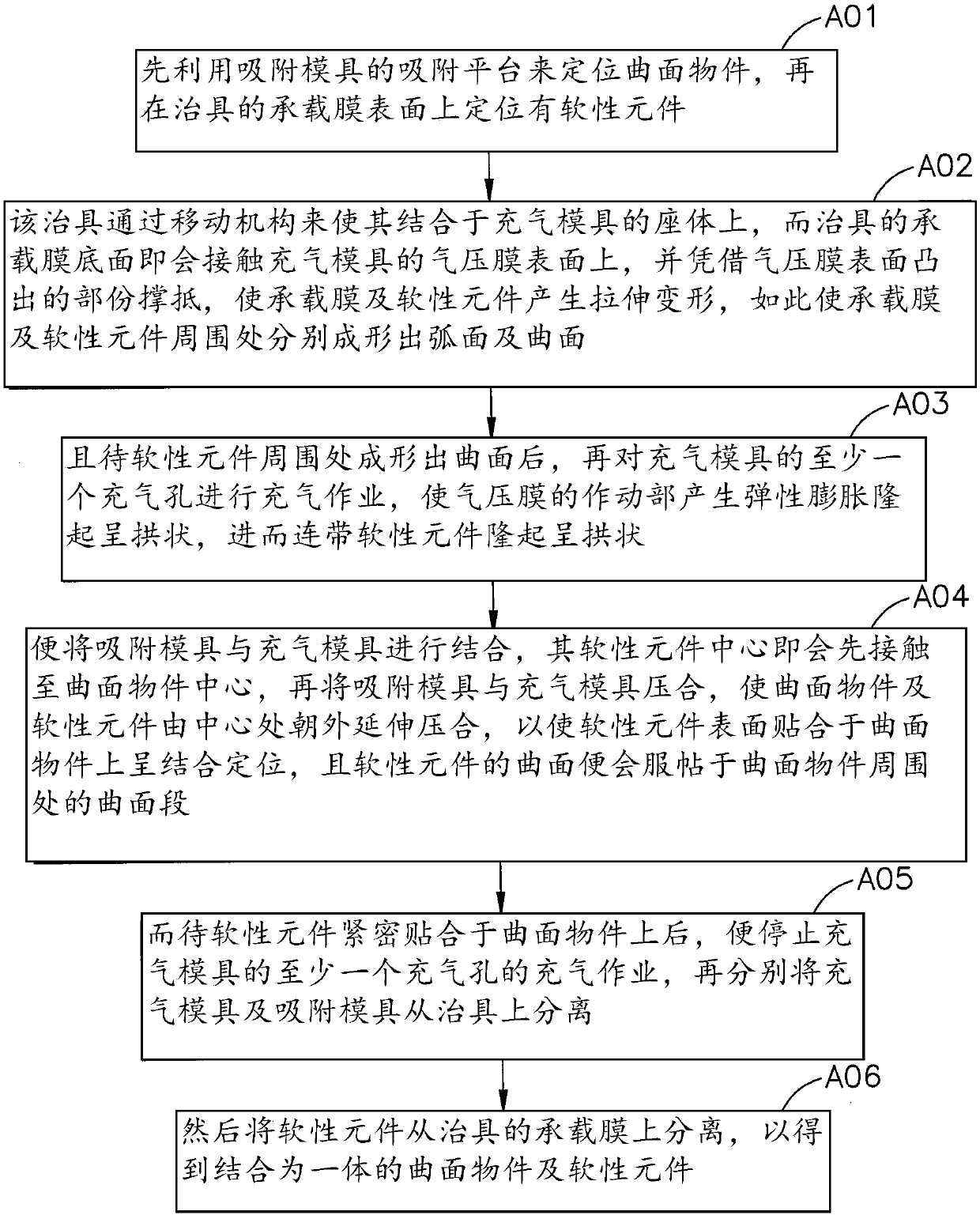

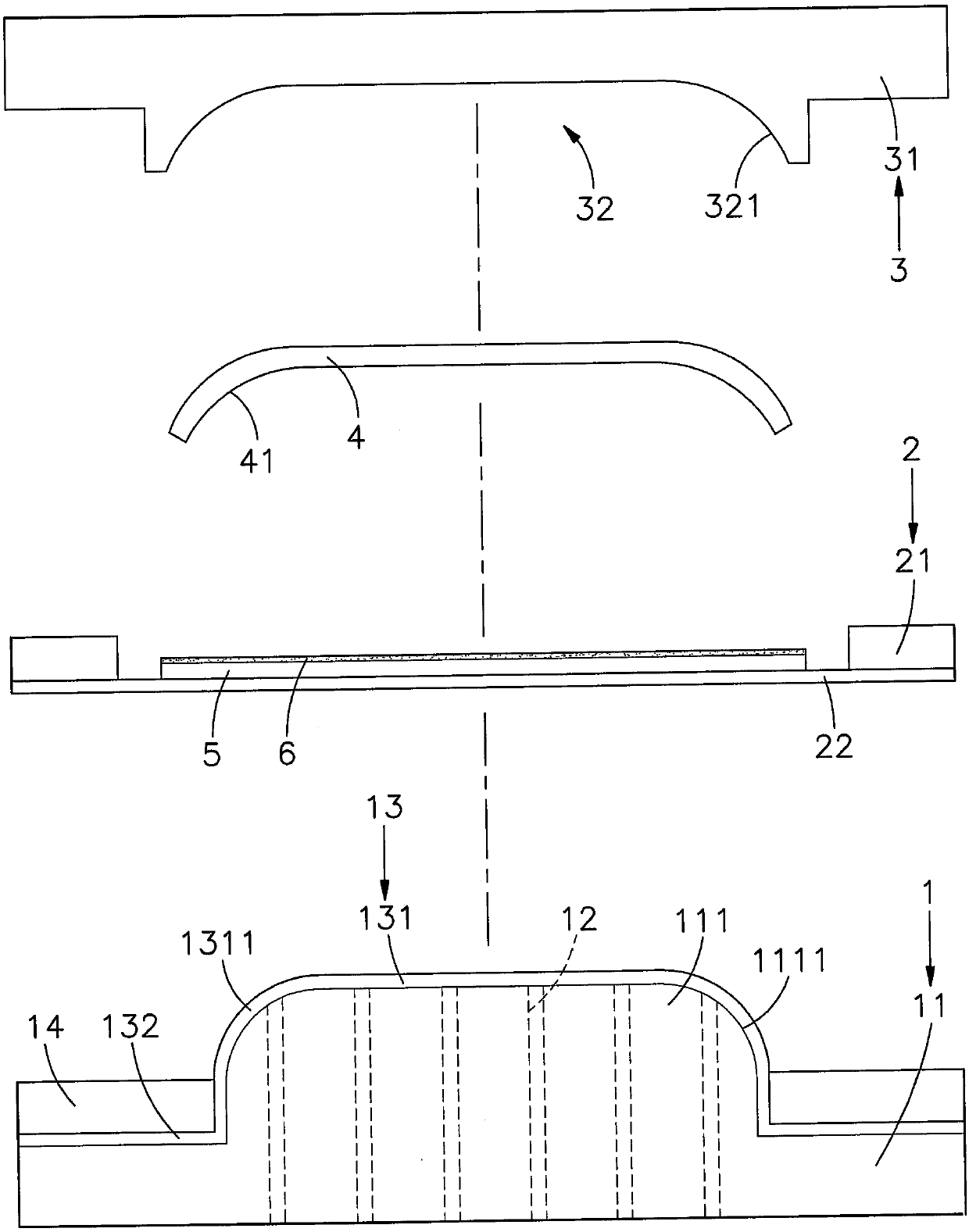

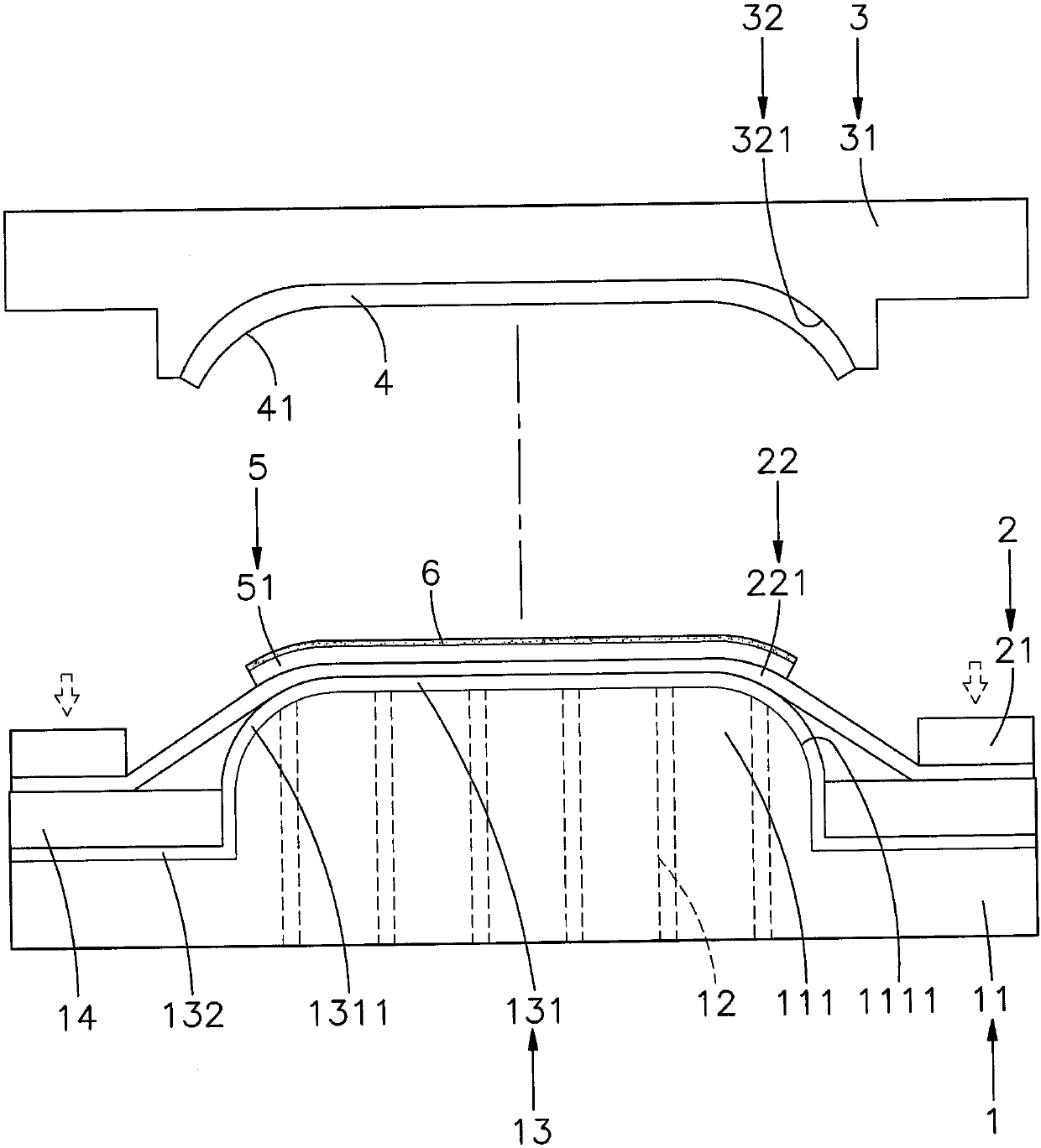

Curved surface bonding apparatus and bonding method thereof

ActiveCN110014717AAvoid wrinklesPrecise and tight fitLaminationLamination apparatusWrinkle skinBonding process

The invention provides a curved surface bonding apparatus and a bonding method thereof. An inflation mold can use at least one inflation hole to inflate an air pressure film to drive the central position of a soft component to be ridged to be arch-shaped, when the soft component and a curved surface object adsorbed by an adsorption mold are bonded to each other, the ridged center of the soft component can be used to really contact the center of the curved surface object, and then the outward extending and pressing is carried out from the center for close bonding and positioning to ensure thatgas between the curved surface object and the soft component is completely extruded outwards, so that no air bubbles are generated between the curved surface object and the soft component, and no optical refraction problem is caused due to the air bubbles. At the same time, the soft component can be prevented from generating wrinkles during the bonding process, and can be accurately and closely bonded to the curved surface object, so that the purpose of improving the producing process and the product qualification rate is achieved.

Owner:USUN TECH CO LTD

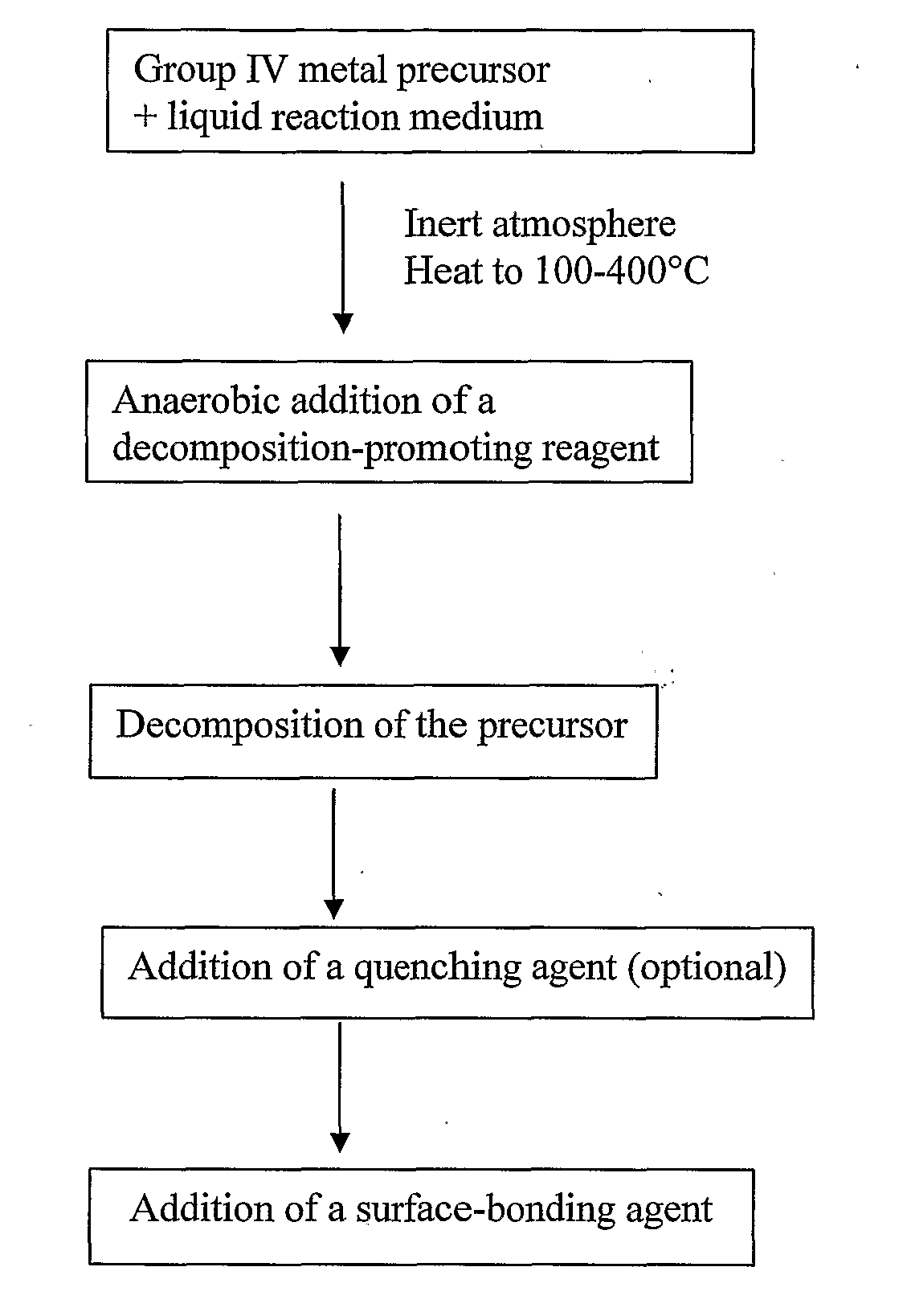

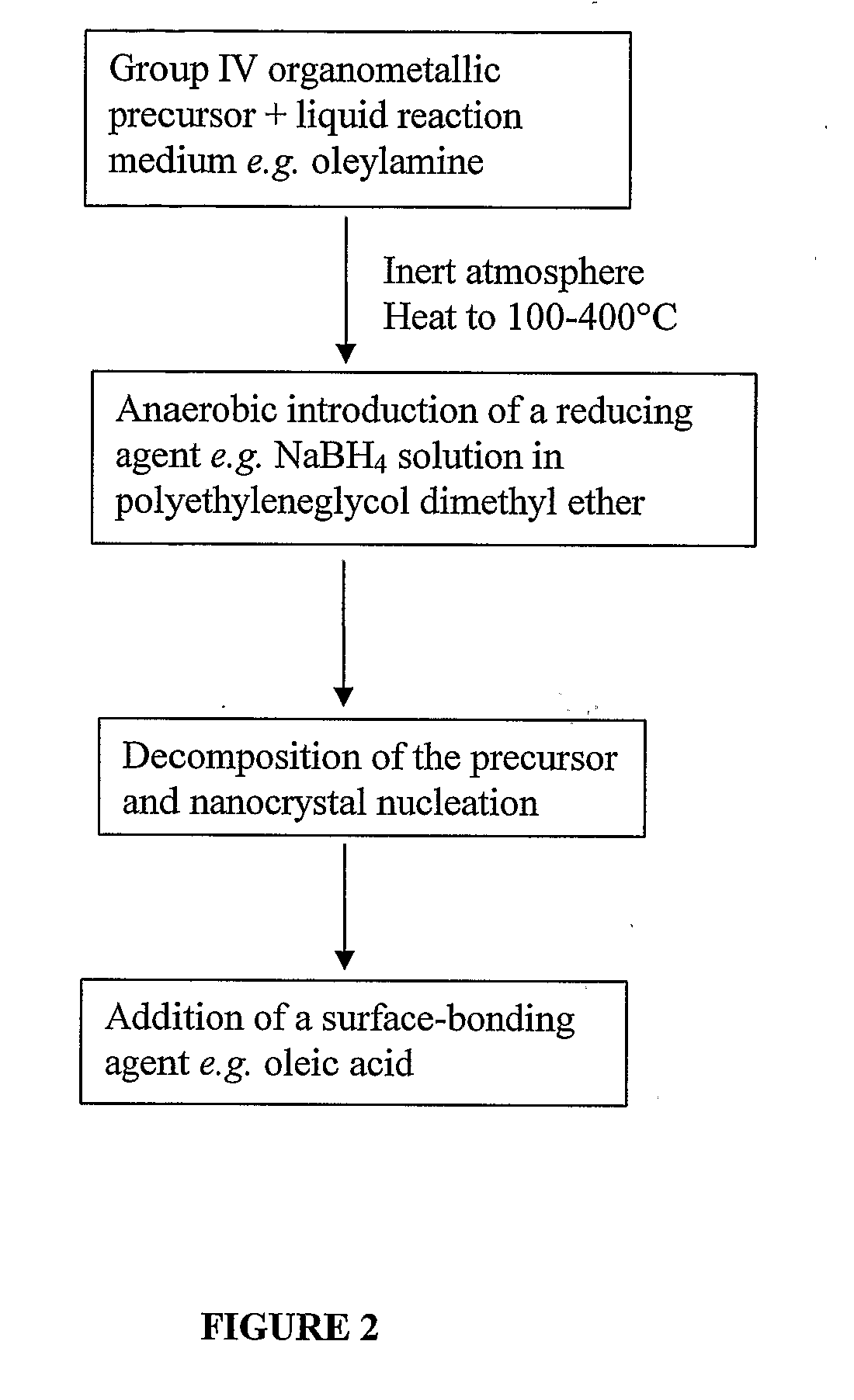

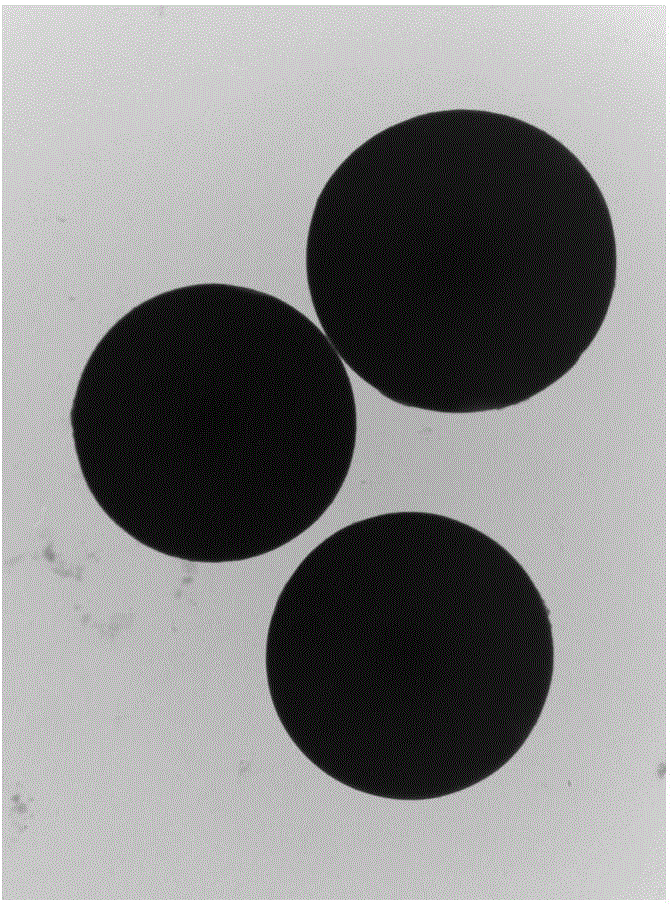

Methods of Forming Nanoparticles

InactiveUS20100139455A1Inhibit aggregationMaterial nanotechnologyTransportation and packagingDecompositionNanoparticle

The present invention provides a method for preparing nanoparticles of group IV elements, particularly nanoparticles of Si, Ge and Sn, and binary and ternary alloys of these elements. The method comprises the solution-phase decomposition of one or more group IV metal precursors at elevated temperature and under an inert atmosphere at atmospheric pressure, using a decomposition-promoting reagent. A surface-bonding agent is added to the reaction mixture to form an organic layer surrounding the nanoparticles and prevent aggregation.

Owner:VICTORIA LINK LTD

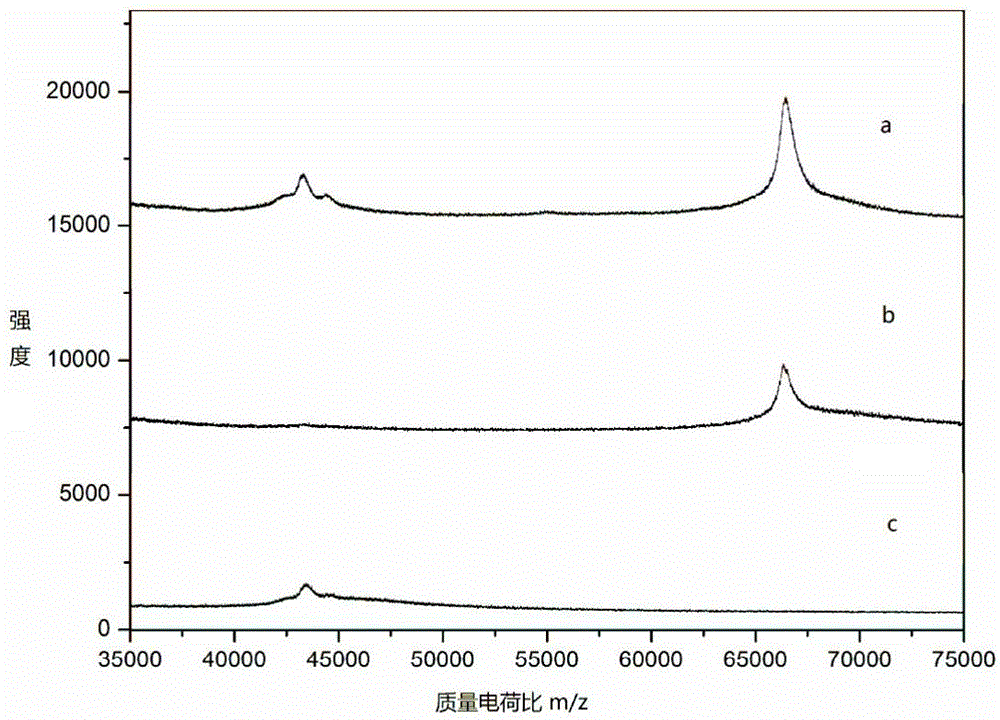

Organic and inorganic hybrid microsphere particle, preparation and application thereof

ActiveCN104418990AImprove hydrophilicityHigh bonding capacityPreparing sample for investigationCross-linkMicrosphere

The invention belongs to the technical fields of polymer materials and analysis, relates to a monodispersed organic and inorganic hybrid microsphere particle with core-shell structure and preparation and application thereof. Inorganic silica particles as the core are modified by a silanizing agent, and then 3-acetylaminophenylboronic acid and polyene cross-linking monomer coat on the click nuclear surface through a mercaptan-alkene click chemistry technology to form organic and inorganic hybrid nano / micron particles with core-shell structure, smooth surface and boric acid functional groups. According o the invention, introduction of the phenyl boronic acid functional group to the material surface by a mercaptan-alkene method not only overcomes the shortcomings of complex procedure and low reaction efficiency in a post modification method but also allows stable polymerization of APBA, increases surface bonding amount of boric acid and hydrophilic property of the material, and reduces the nonspecific adsorption of proteins. The microsphere particles of the invention can be used in separation or enrichment of glycoprotein with 1,2-cis diol structure, and has good practical value and application prospect in the field of proteomics.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

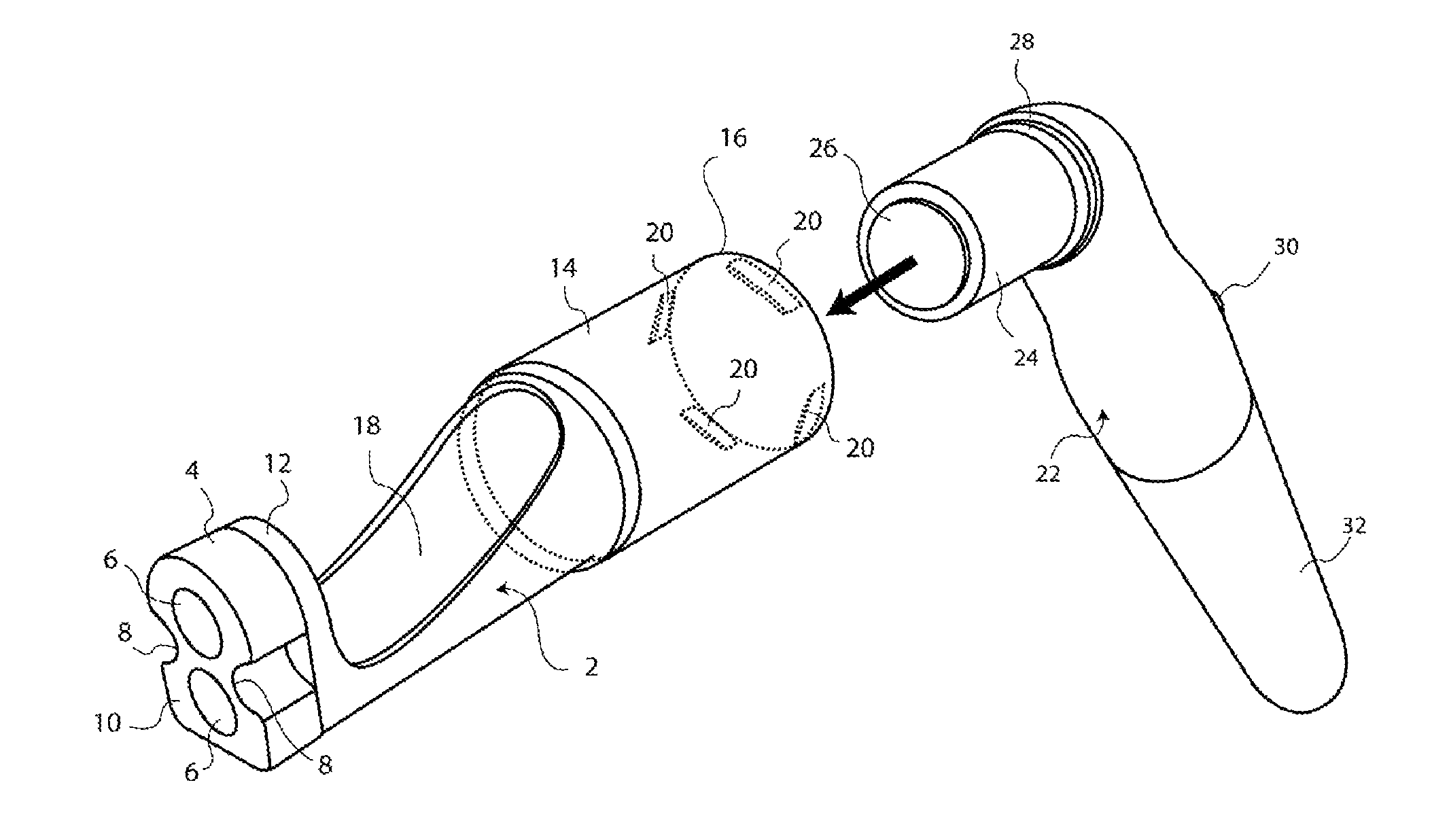

Cure through laminate veneer applicator with cure light

A veneer applicator to compressively place and photo cure a restorative covering to a tooth to include a photo transmissible insert (2) having a compressible applicator (4) with at least one traversing aperture (6) and a photo transmissible insert shaft (14) to dock with an LED device (22). Docking the insert shaft (14) with the LED device (22) permits a photo curing spectrum to traverse the shaft (14) and compressible applicator (4) at least one aperture (6). This allows for direct surface bonding during veneer application.

Owner:VISCOMI BRIAN D

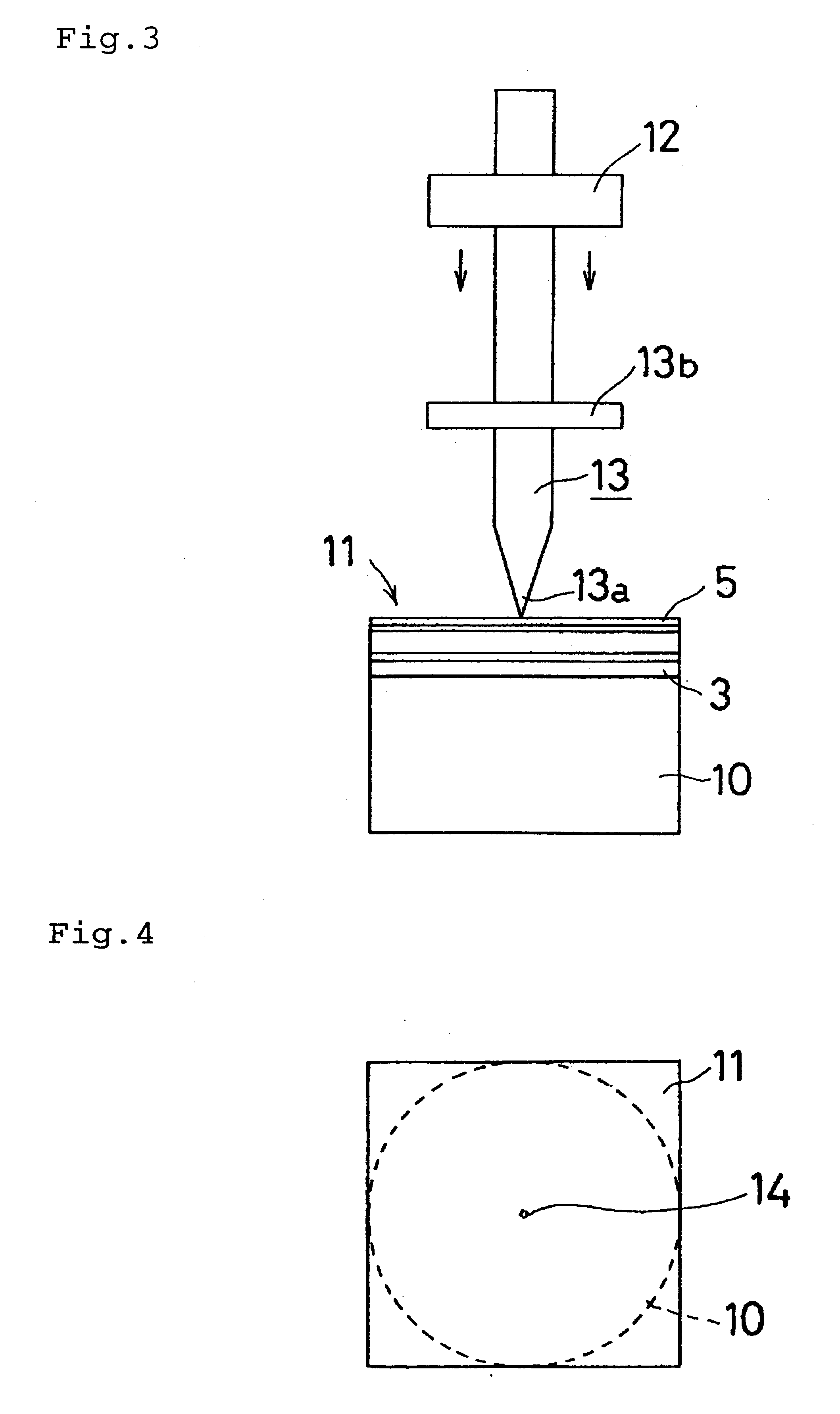

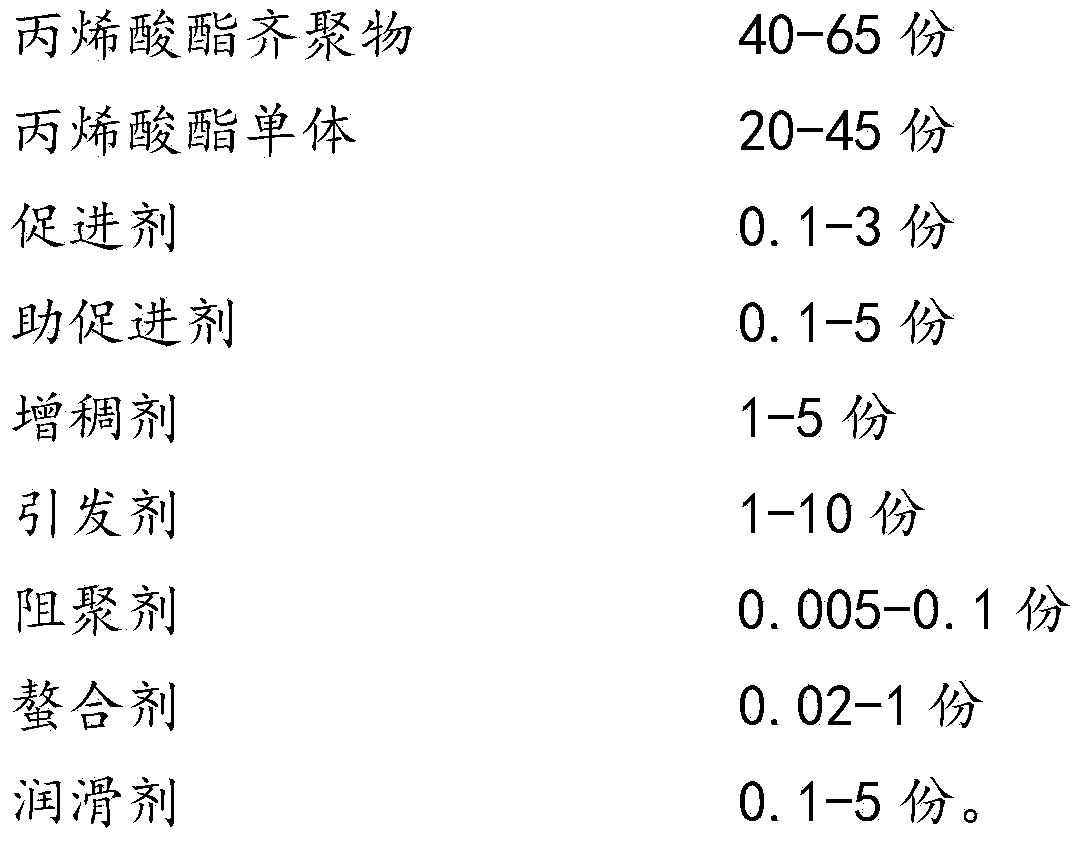

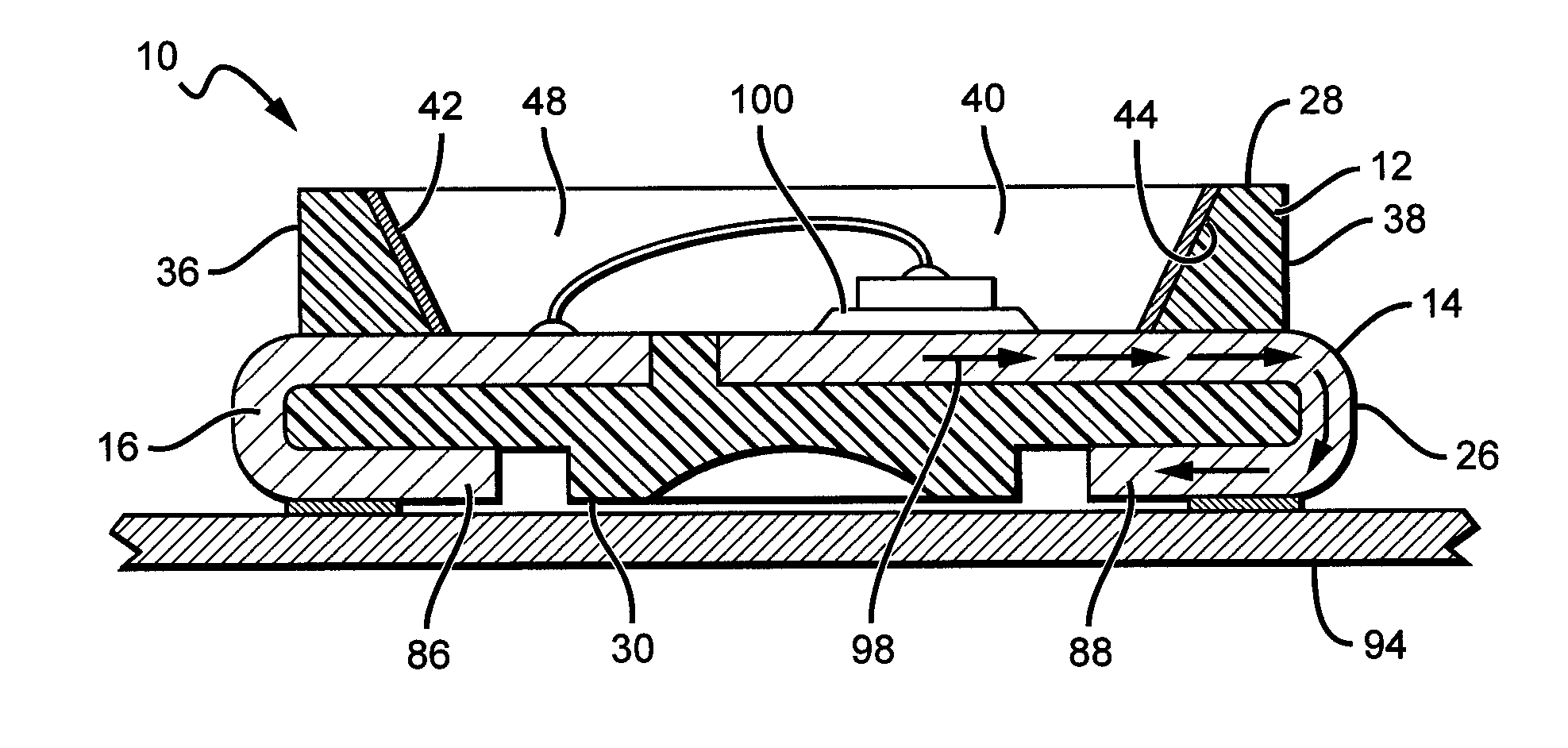

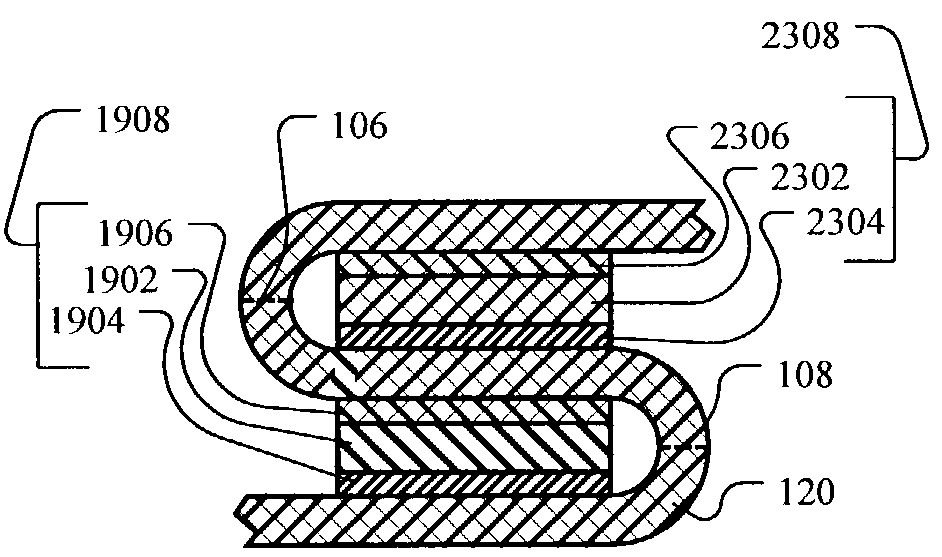

Chip pickup method and chip pickup apparatus

InactiveCN101529575AEx situ implementation of pickup methodsFacing the idealSemiconductor/solid-state device manufacturingElectrical componentsEngineeringElectrical and Electronics engineering

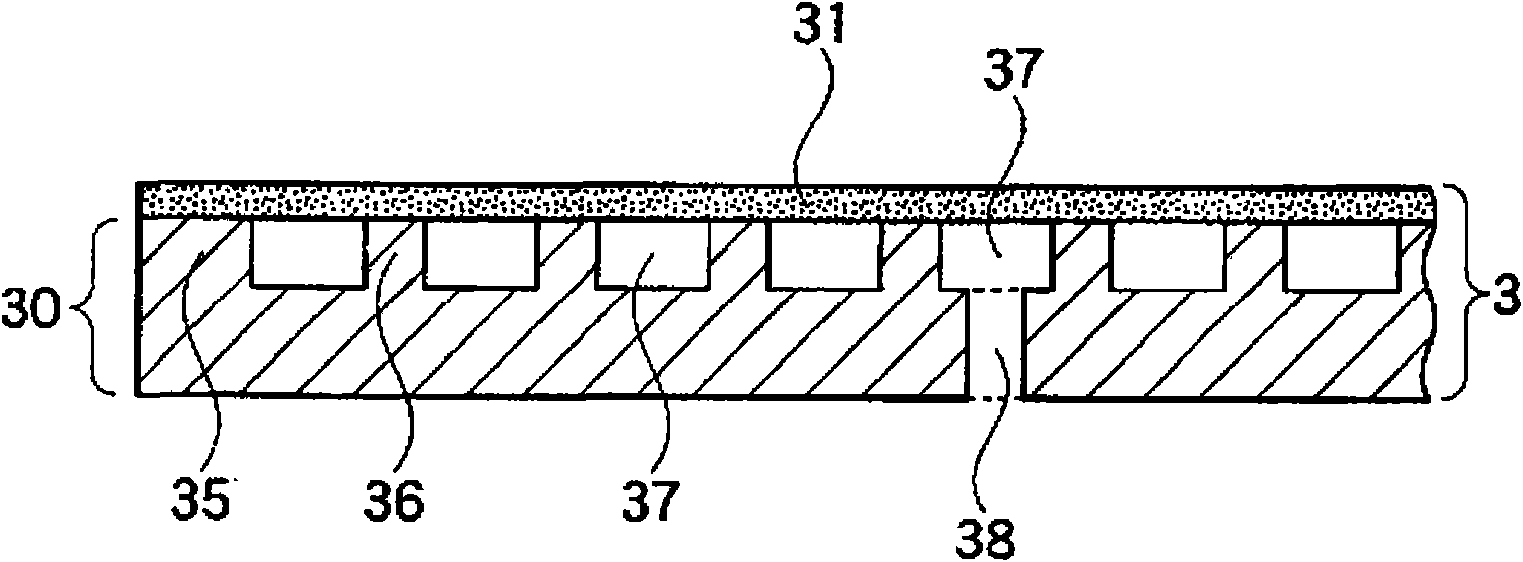

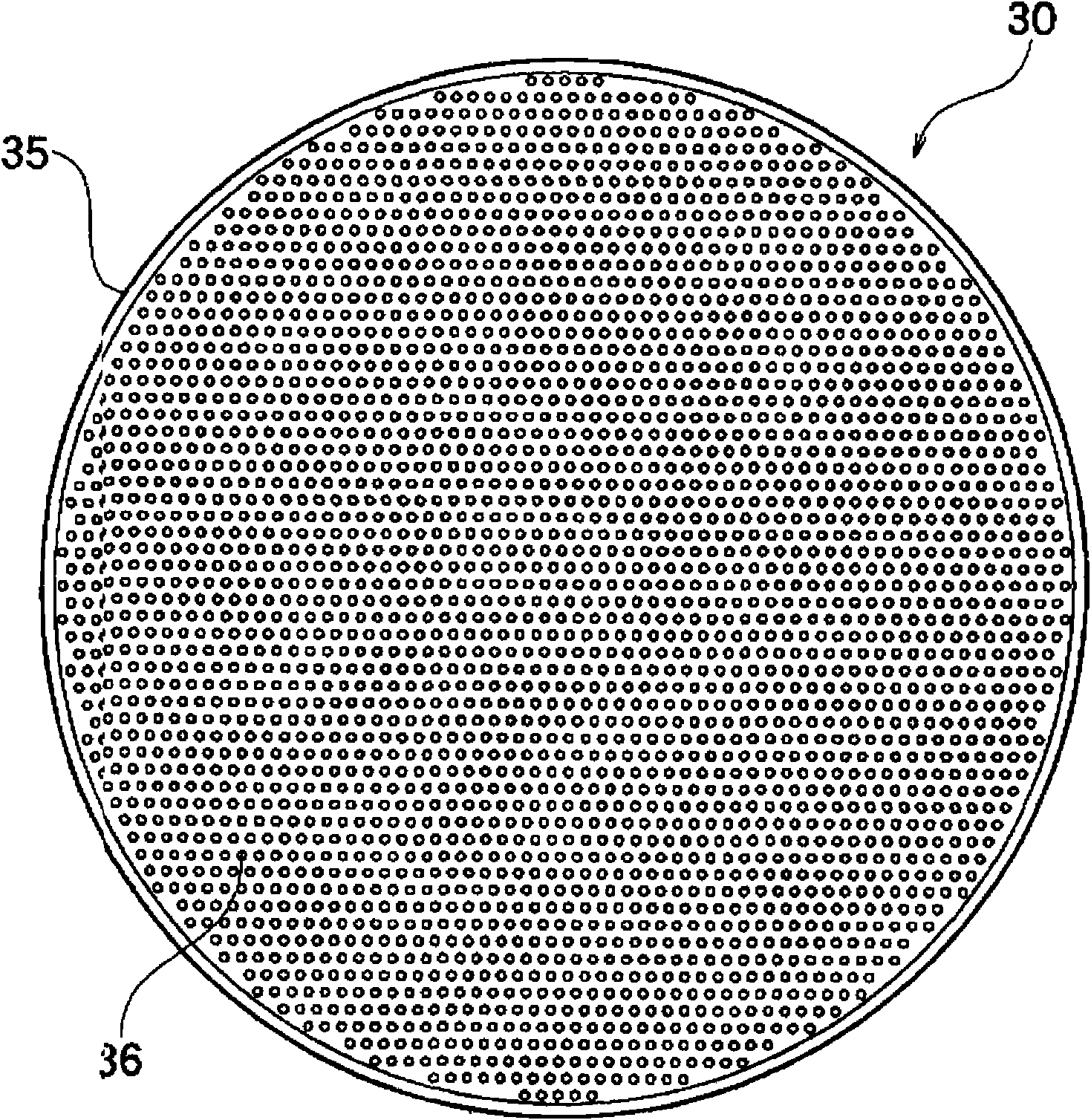

The present invention provides a pickup method and a pickup apparatus wherein pushing up of a chip is not required and a force for holding a chip which is not picked up is not varied as pickup progresses. A method is provided for picking up a chip (13) from a fixed jig (3) to which the chip (13) is fixed. The fixed jig (3) consists of a jig base (30) having a plurality of protrusions (36) on one side and a sidewall (35) of substantially the same height as that of the protrusion (36) at the outer circumference of the one side, and an adhesion layer (31) laminated on the surface of the jig base (30) having the protrusions (36) and bonded on the upper surface of the sidewall (35). A section space (37) is formed on the surface of the jig base (30) having the protrusions by the adhesion layer (31), the protrusions (36) and the sidewall (35), and at least one through hole (38) penetrating the outside and the section space (37) is provided in the jig base (30). The pickup method comprises a step for fixing a chip, a step for deforming the adhesion layer (31) by sucking air in the section space (37) through the through hole (38), and a step for picking up the chip (13) completely from the adhesion layer (31) by sucking the chip (13) from the upper surface side of the chip (13) by means of a suction collet (70).

Owner:LINTEC CORP

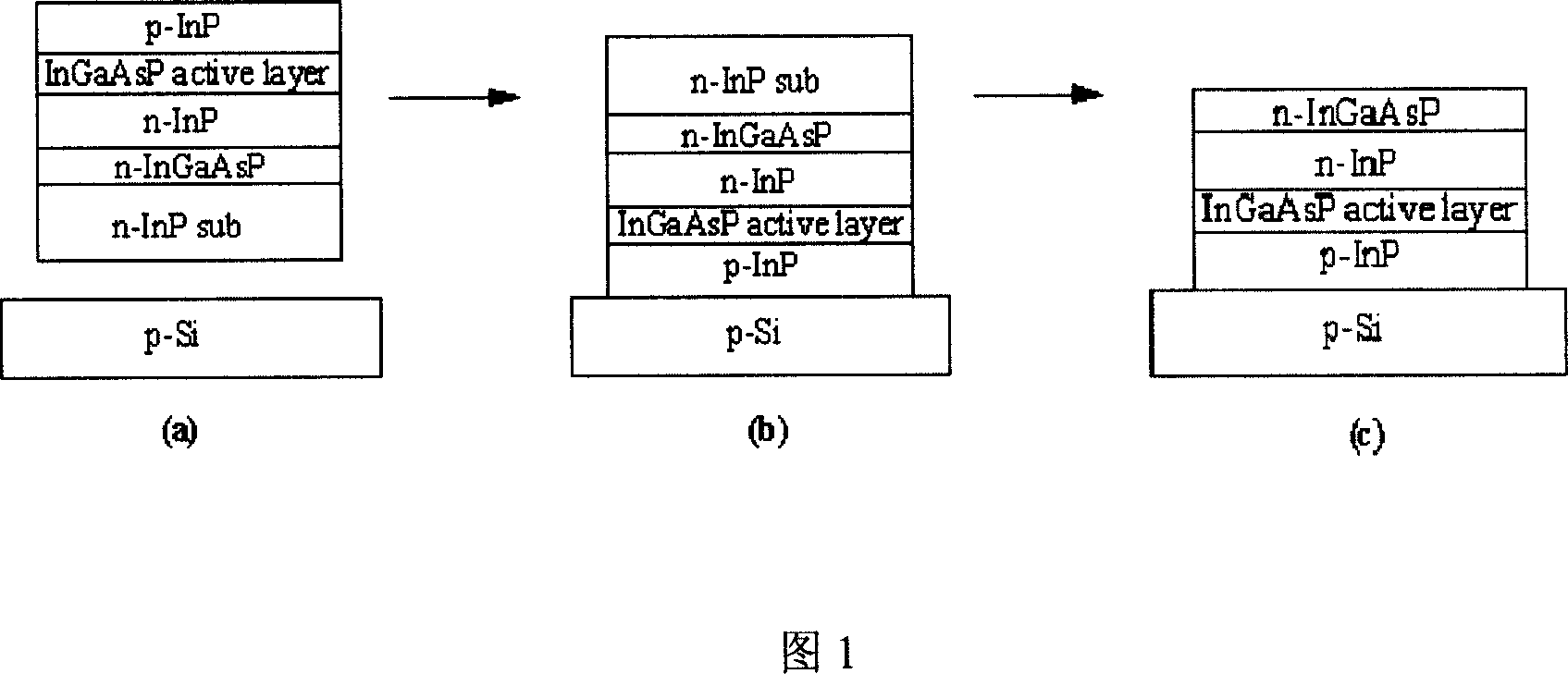

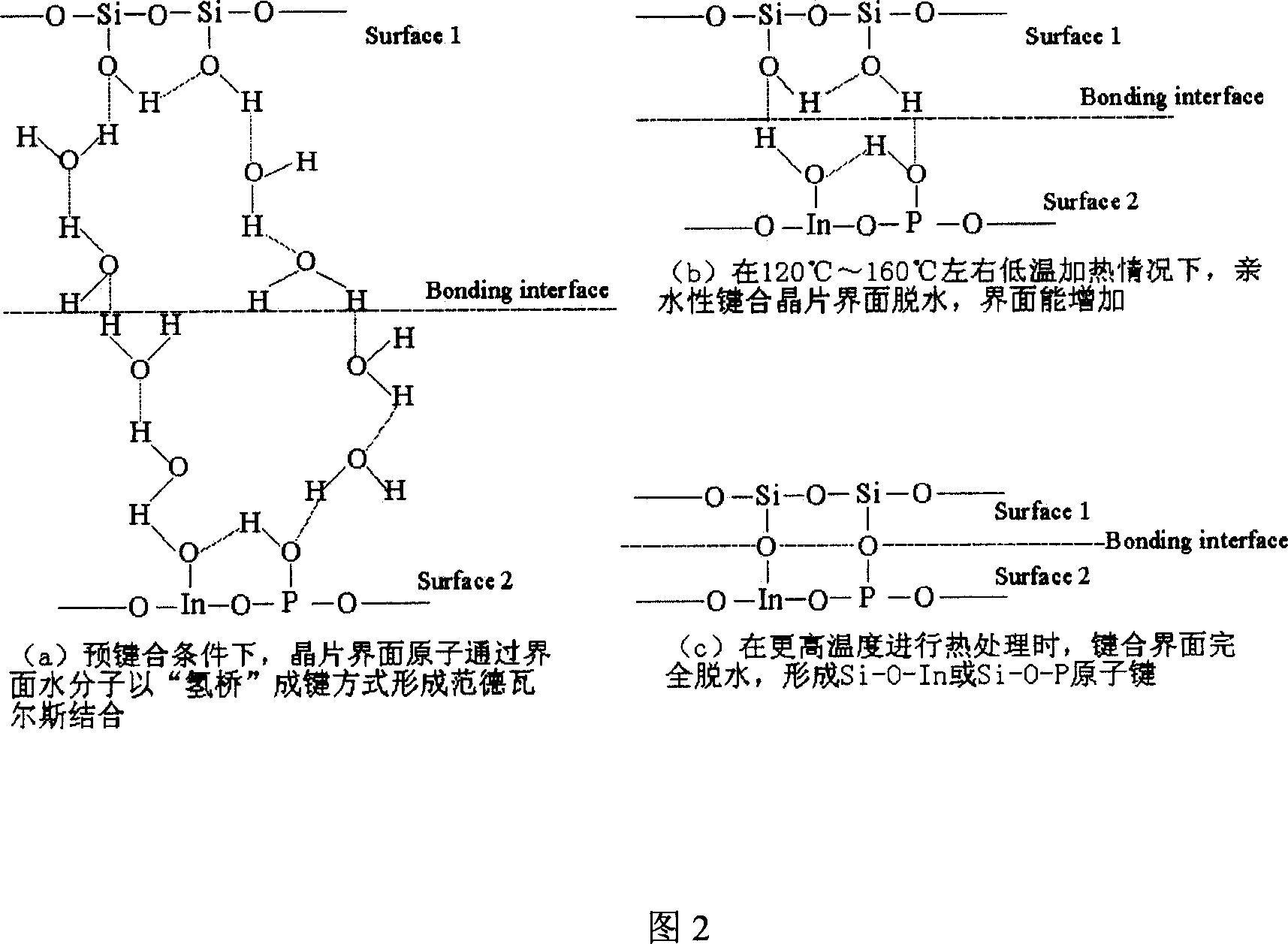

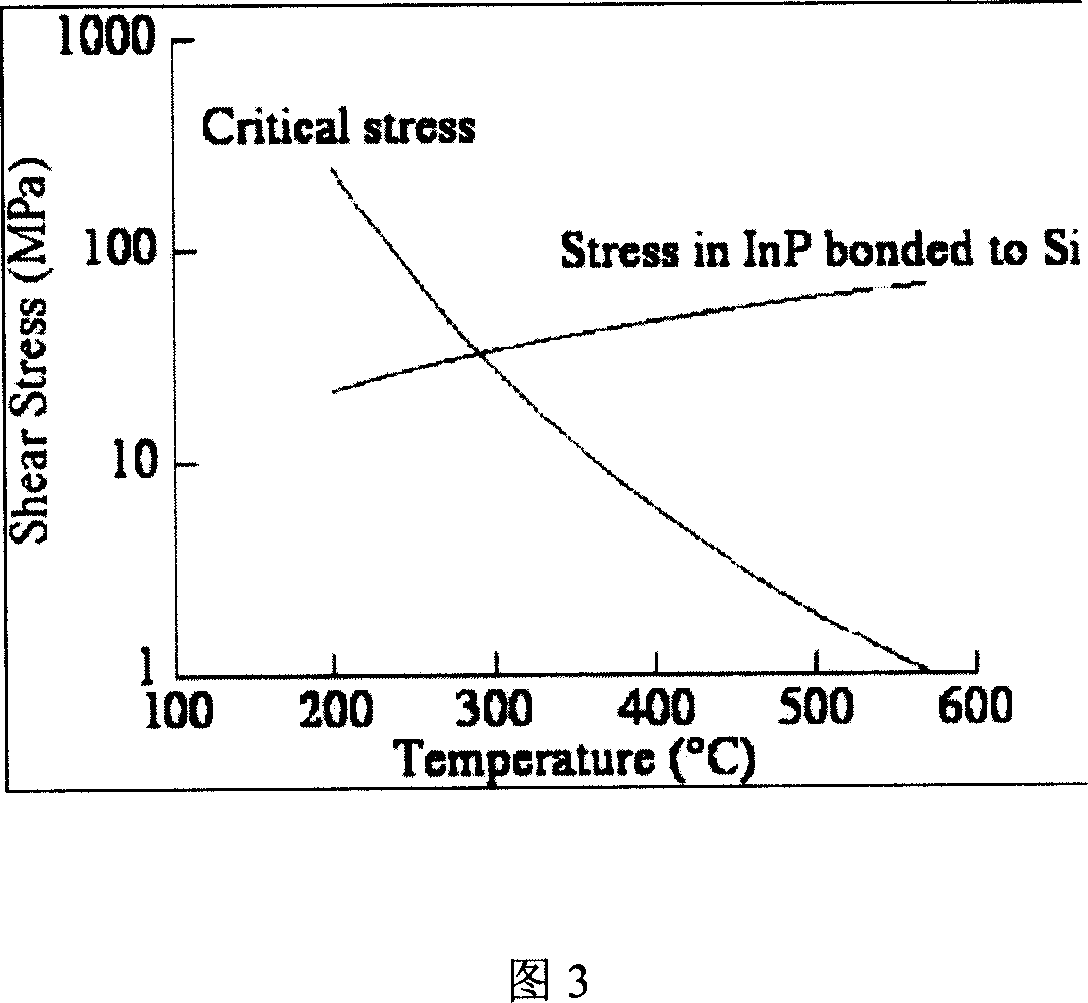

Low-temperature chip direct bonding method

InactiveCN1933096AMeet the production process requirementsSemiconductor/solid-state device manufacturingOrganic solventImpurity ions

A method relates to wafer straight bonding technology field and uses low temperature bonding technology to bond InP group stuff on Si surface. Remove one layer hydrophobic organic on surface of single polishing Si and InP wafers by organic solvent, remove impurity ion and carbon and surface rinsing dispose to them, then carry the pretreatment. Put the pretreatment wafers into one vacuum furnace system with temperature controller to adding temperature and pressure, then carry heating dispose with proper temperature and pressure to remove hydrosphere of bonding surface. Carry thinner dispose for bonding piece and heat treatment of removing left gas to surface without pressure to make heat treatment at higher temperature for enhance surface bonding ability. At last, carry InP underlay cauterization with bonding piece. It uses for micro-electronics and silicon-base photoelectron field.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

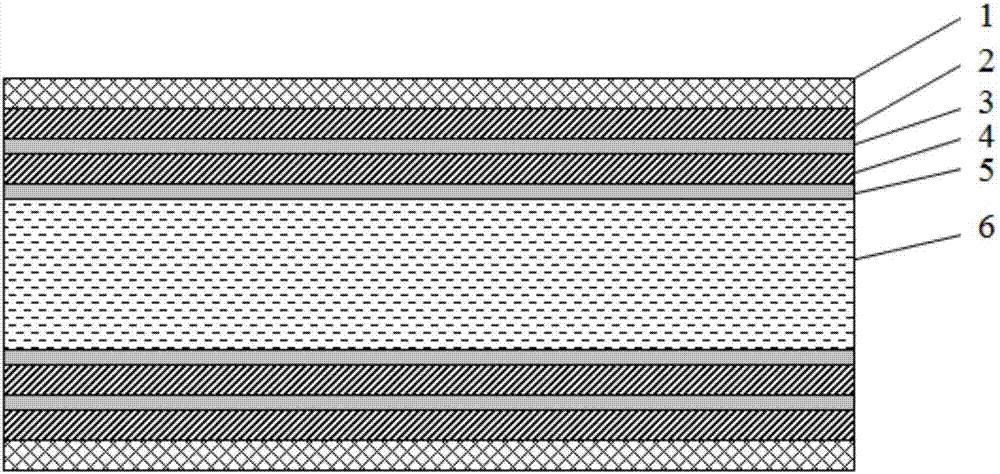

Cracking-resistant multifunctional impregnated bond paper decorative face artificial board and manufacturing method thereof

InactiveCN107053374AHigh tensile strengthTightly gluedOther plywood/veneer working apparatusSynthetic resin layered productsFiberCarbon fibers

The invention provides a cracking-resistant multifunctional impregnated bond paper decorative face artificial board and a manufacturing method thereof. The artificial board at least comprises a base material and an impregnated bond paper layer. At least one layer of carbon fiber material layer is arranged between the base material and the impregnated bond paper layer. The upper structure and the lower structure of the base material are arranged symmetrically. According to the cracking-resistant multifunctional impregnated bond paper decorative face artificial board and the manufacturing method thereof, carbon fiber materials are adopted for enhancing tensile strength of solidified impregnated bond paper and the overall structure stability of the decorative face board, the problem that board face cracking is liable to appear during usage is solved, the surface bonding strength, bending resistant strength, impact resistance and other mechanical properties are enhanced, and the decorative face quality is improved by the carbon fiber material layer with the flat surface and a certain buffer function and a wood buffer layer cooperatively. Especially a conducting layer is formed under the impregnated bond paper, and meanwhile, good electrostatic resistance and reflection loss electromagnetic radiation performance are achieved. According to the manufacturing method, the manufacturing efficiency is improved while the decorative face performance is improved effectively, and industrialization production is convenient.

Owner:GUANGXI UNIV

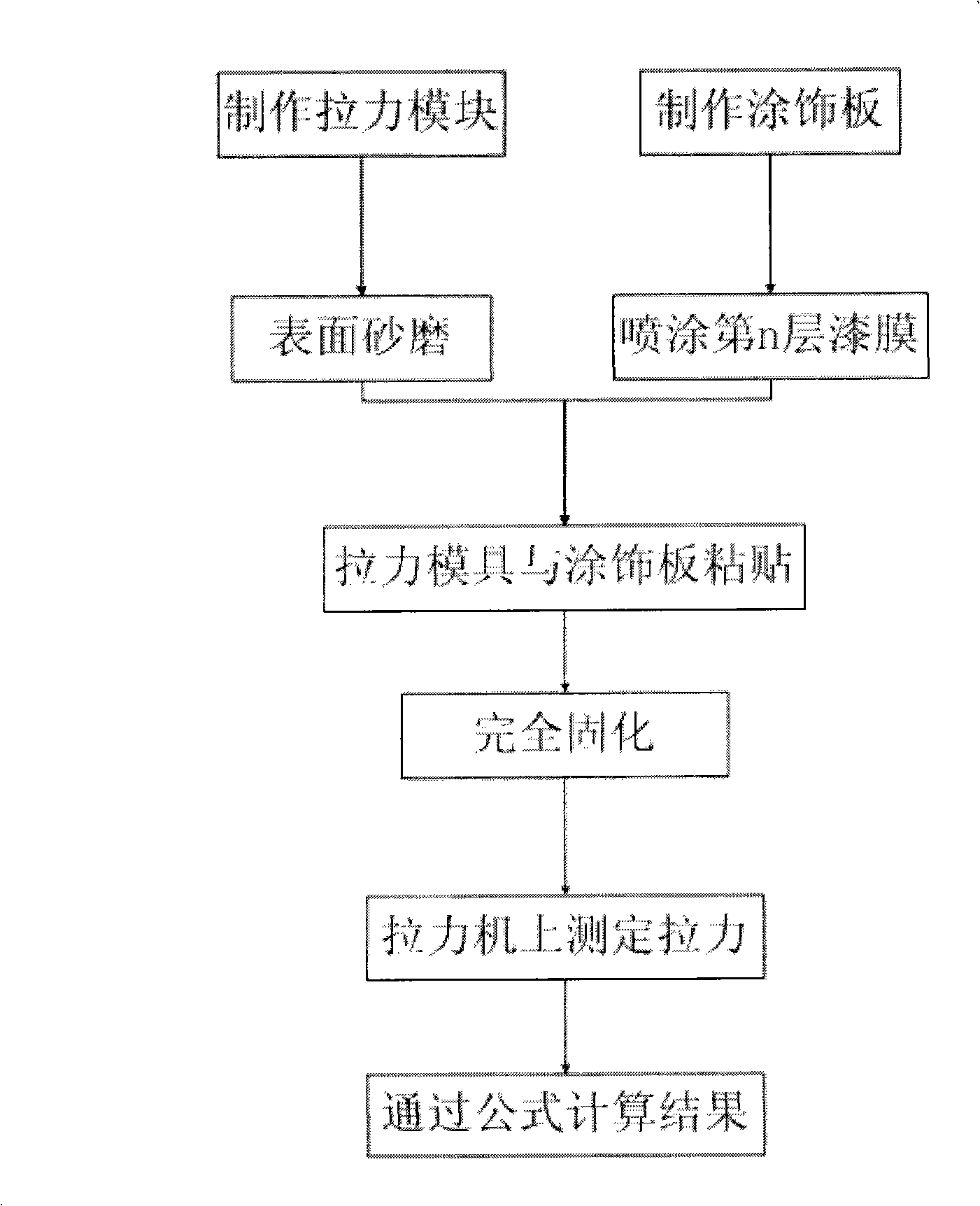

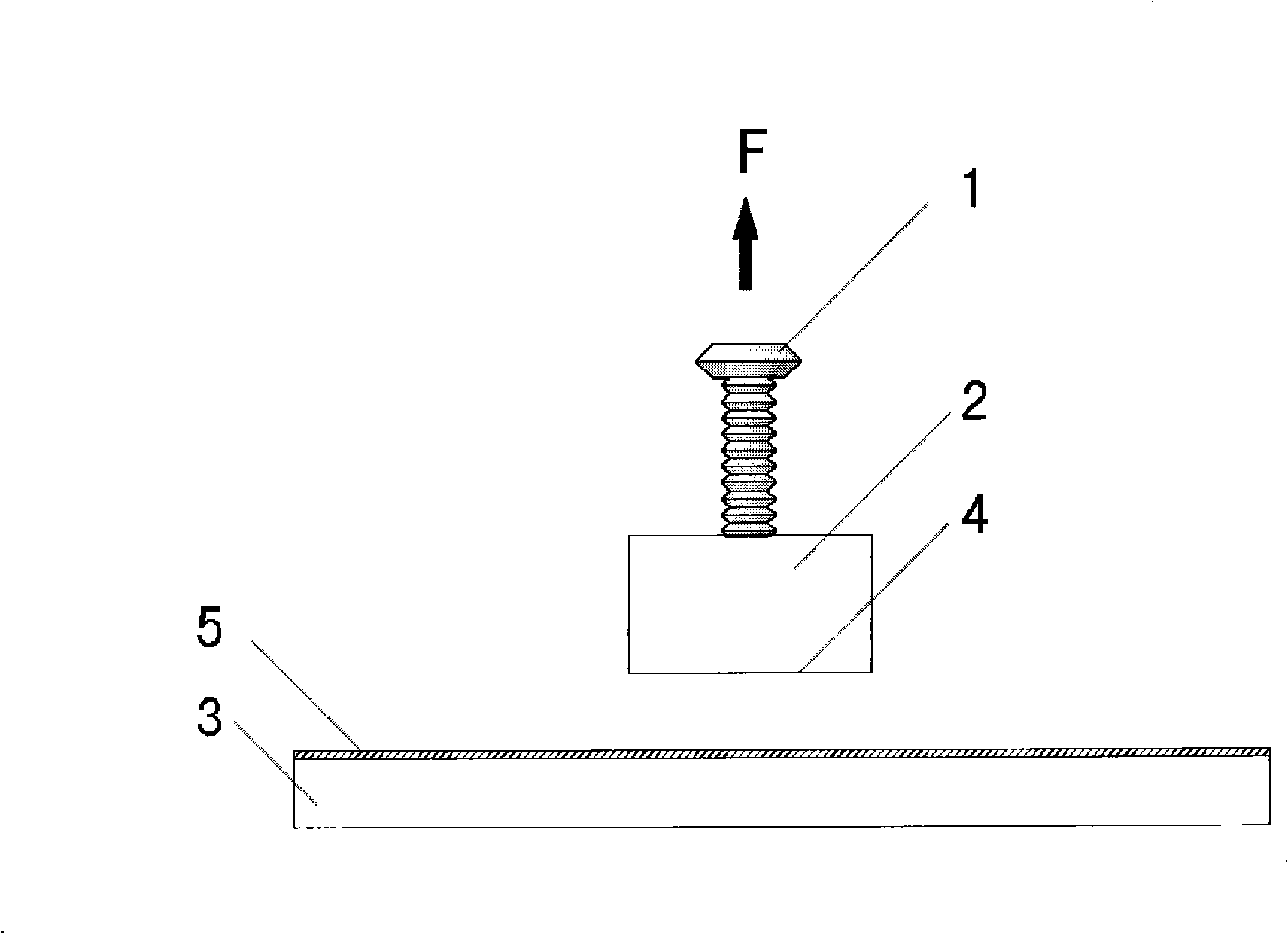

Method for determining wooden furniture lacquerfilm coatings adhesive force

The invention discloses a novel method which can be used for testing the cohesive force of paint film coating of wood furniture. The method combines the cohesive force testing method of the coating and the method of testing the surface bonding strength of the artificial plate of a decorative veneer. In the method, a wet paint film is used as adhesive; a special wood mould is used as a tension module; a finishing plate is adhered to the bottom of the tension module after being painted; after the finishing plate is completely solidified, a tensile tester is used for determining the tension between the tension module and the finishing plate; thus the cohesive force of the paint film can be determined. The novel method can quantitatively and accurately determine the cohesive force of the coating of the paint film, and can provide evidence for choosing a better technology in various types of finishing technology.

Owner:夏玉国 +2

Cable and method

InactiveUS6969806B2Electrically conductive adhesive connectionsFlat/ribbon cablesEngineeringElectrical and Electronics engineering

Owner:LOCKHEED MARTIN CORP

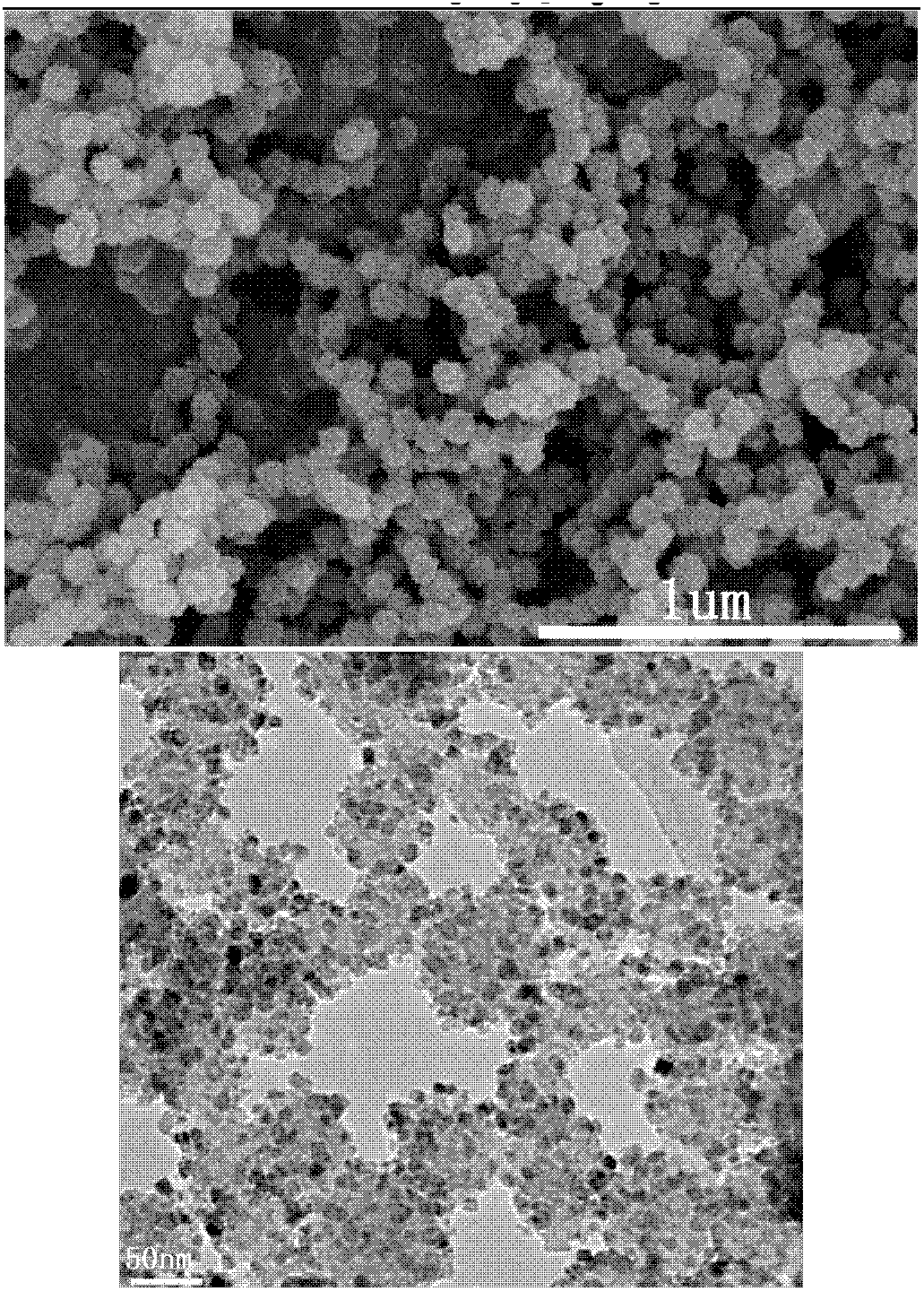

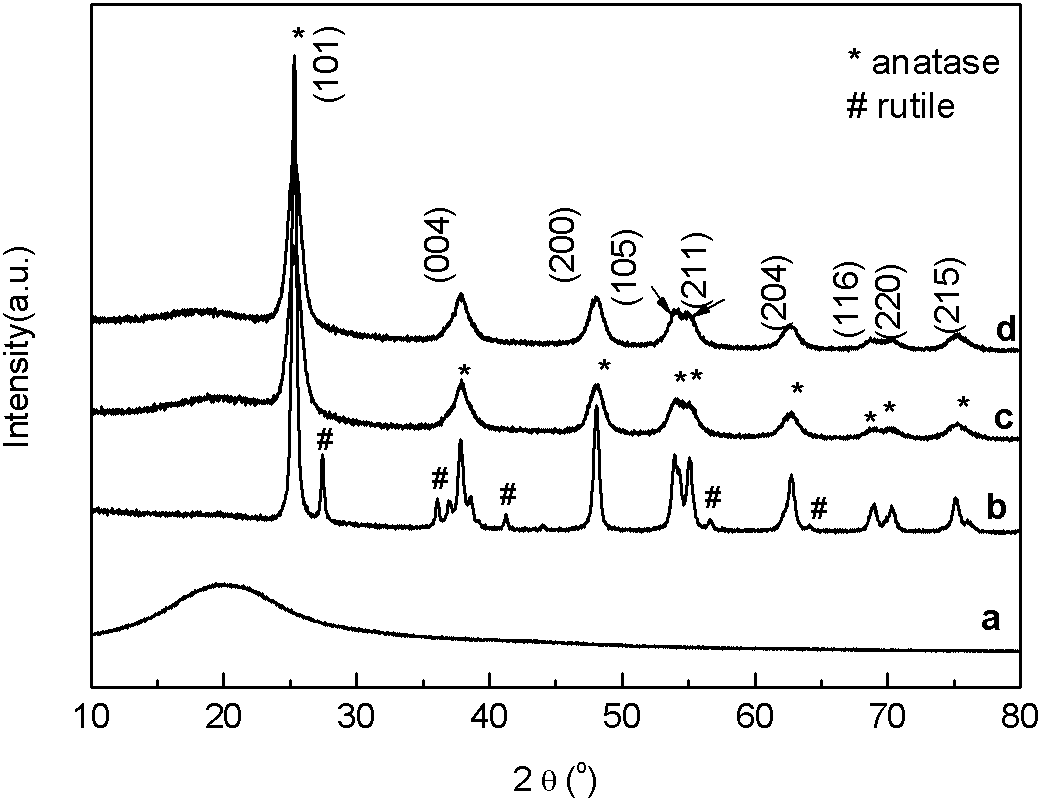

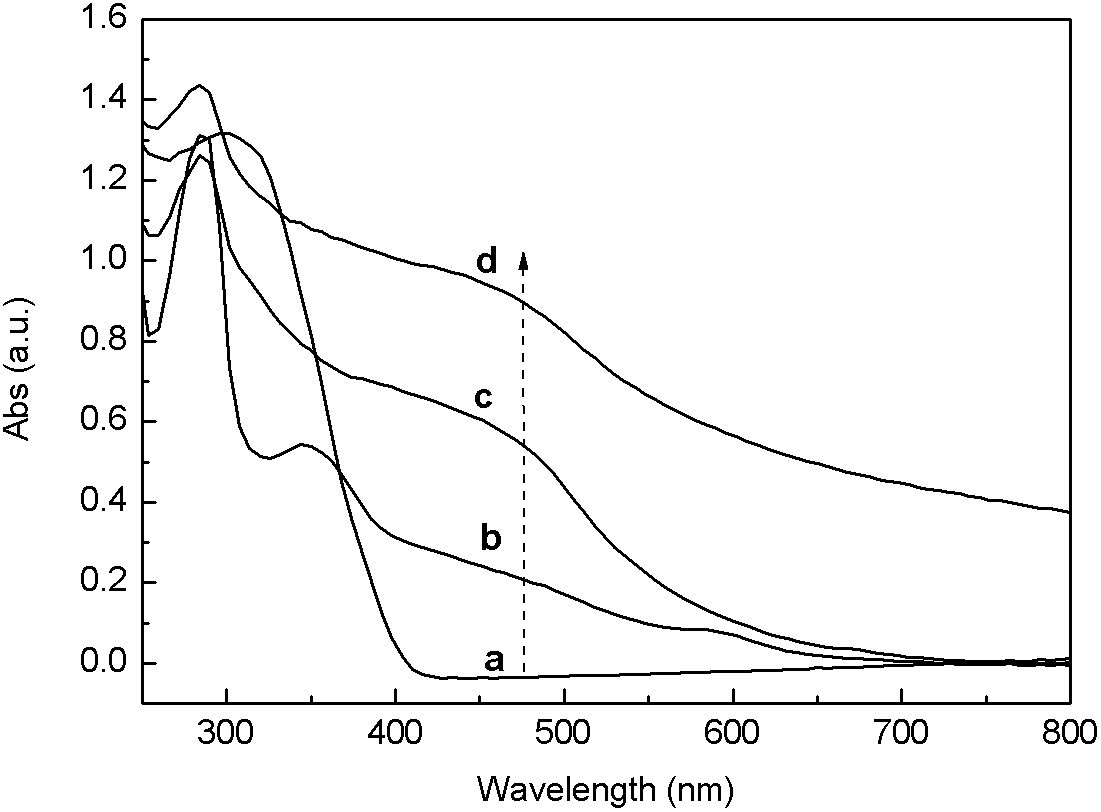

Photocatalyst for visible light transformation and preparation method of same

ActiveCN102553648AHigh catalytic activityImproved visible light responseWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsSolventThermal treatment

The invention relates to the field of environment and energy and in particular relates to a photocatalyst with nano-heterostructure for visible light transformation and a preparation method of the photocatalyst. The photocatalyst for visible light transformation has a nano-heterostructure which is formed by loading TiO2 precursor on the surface of phenolic resin by means of surface bonding, wherein the mass ratio of phenolic resin / TiO2 precursor is 1: (100 to 0.1). According to the invention, titanium oxide is loaded on the surface of phenolic resin particles by low temperature hydrothermal treatment or solvent thermal treatment, to form TiO2 / phenolic resin heterostructure on the surface of phenolic resin; and the heterostructure has high visible light catalytic activity under visible light conditions. The catalyst provided by the invention has the advantages of high visible light response, high catalytic activity and stable structure.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Voice coil assembly and loudspeaker using the same

InactiveUS20100215208A1Reduce thicknessHigh strengthTransducer detailsPlane diaphragmsManufacturing cost reductionBobbin

According to the invention, a whole-surface driven, flat thin loudspeaker that brings about smooth frequency characteristics with split vibration hardly caused is realized, and a voice coil assembly that has high reproduction efficiency and fewer operation failures, and brings about favorable work efficiency in manufacturing and further reduced manufacturing cost, and a loudspeaker using the same are manufactured. The voice coil assembly includes a rectangular voice coil including a rectangular bobbin formed with a rectangular cross section and a rectangular coil bonded to the rectangular bobbin, and a rectangular reinforcing member coupling the plurality of rectangular voice coils to one another in a grid pattern, wherein a portion of inner wall surfaces of the rectangular reinforcing member is bonded to any of outer wall surfaces of the rectangular bobbins of the plurality of rectangular voice coils, and the outer wall surfaces of the rectangular bobbins, to which the inner wall surfaces of the rectangular reinforcing member are not bonded, and portions of the inner wall surfaces of the rectangular reinforcing member, which are not bonded to the outer wall surfaces of the rectangular bobbins define a rectangular space between a pair of the adjacent rectangular voice coils.

Owner:ONKYO KK

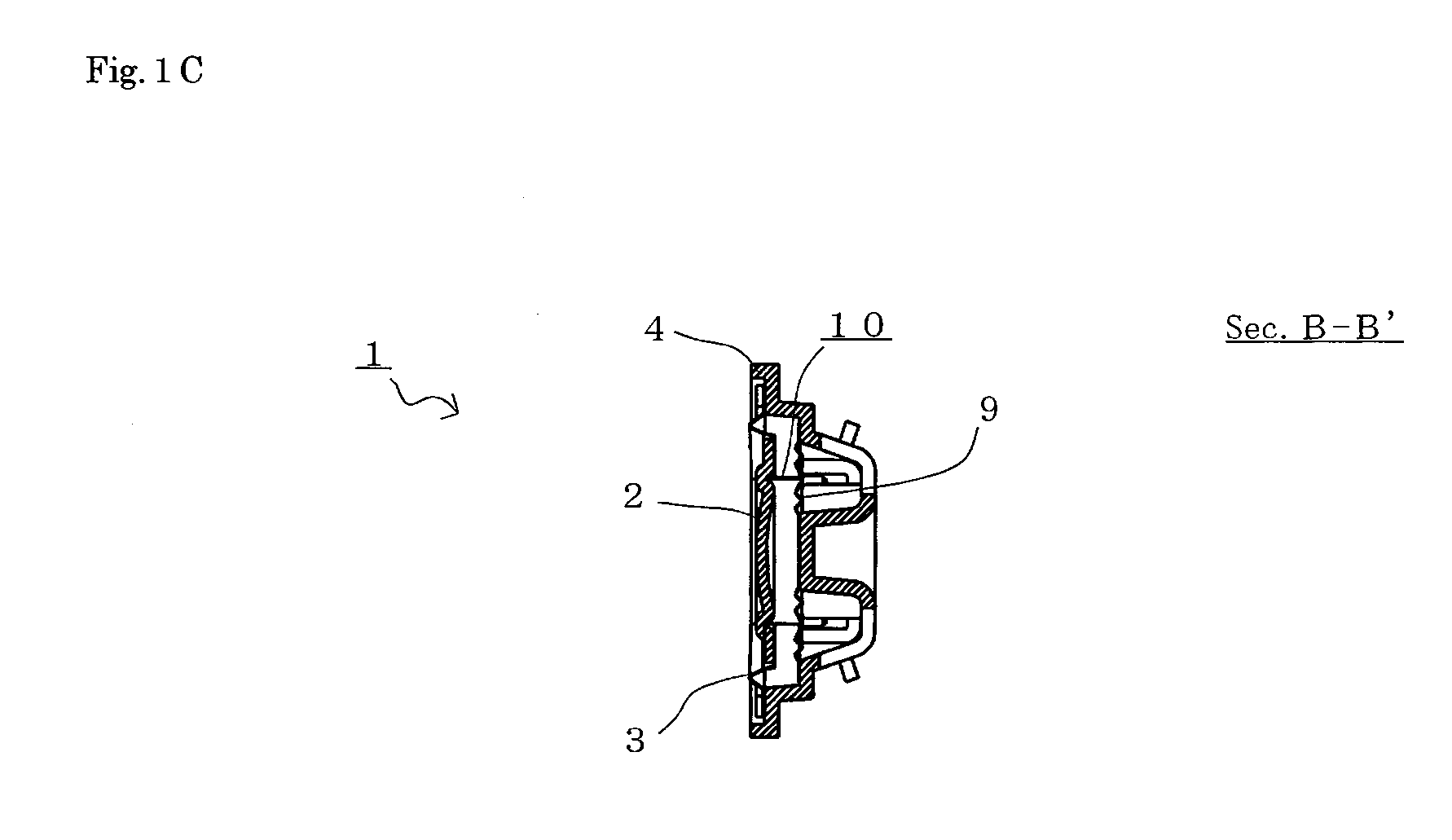

High pressure nitrogen storage bottle made of PBO fiber and carbon fiber composite material and its preparation method

InactiveCN1948816ATo achieve the purpose of structural optimizationSatisfy air tightnessPressure vesselsGlass fiberNeoprene

The invention relates to a nitrogen cylinder and its preparation method, in which, on the outside surface of the neoprene lining is bonded an adhesive layer and the outside surface of the adhesive layer is bonded to the inside surface of the inner structure layer of carbon fibre composite; the inside surface of the outer structure layer of PBO fibre composite is wound on the outside surface of carbon fibre composite inner structure layer and on the outside surface of the outer structure layer of PBO fibre composite is wound an outer protective covering of glass fibre composite. The method consists in: coating an adhesive layer on the outside surface of the lining; overlying a spiral and toroidal wound inner structure layer, an outer structure layer and an outer protective covering; curing and then getting the preset inventive nitrogen cylinder.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com