Chip pickup method and chip pickup apparatus

A chip and chip technology, applied in the direction of electrical components, electrical components, circuits, etc., can solve problems such as air leakage, decreased chip retention, and increased leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the present invention will be described below with reference to the drawings.

[0052]

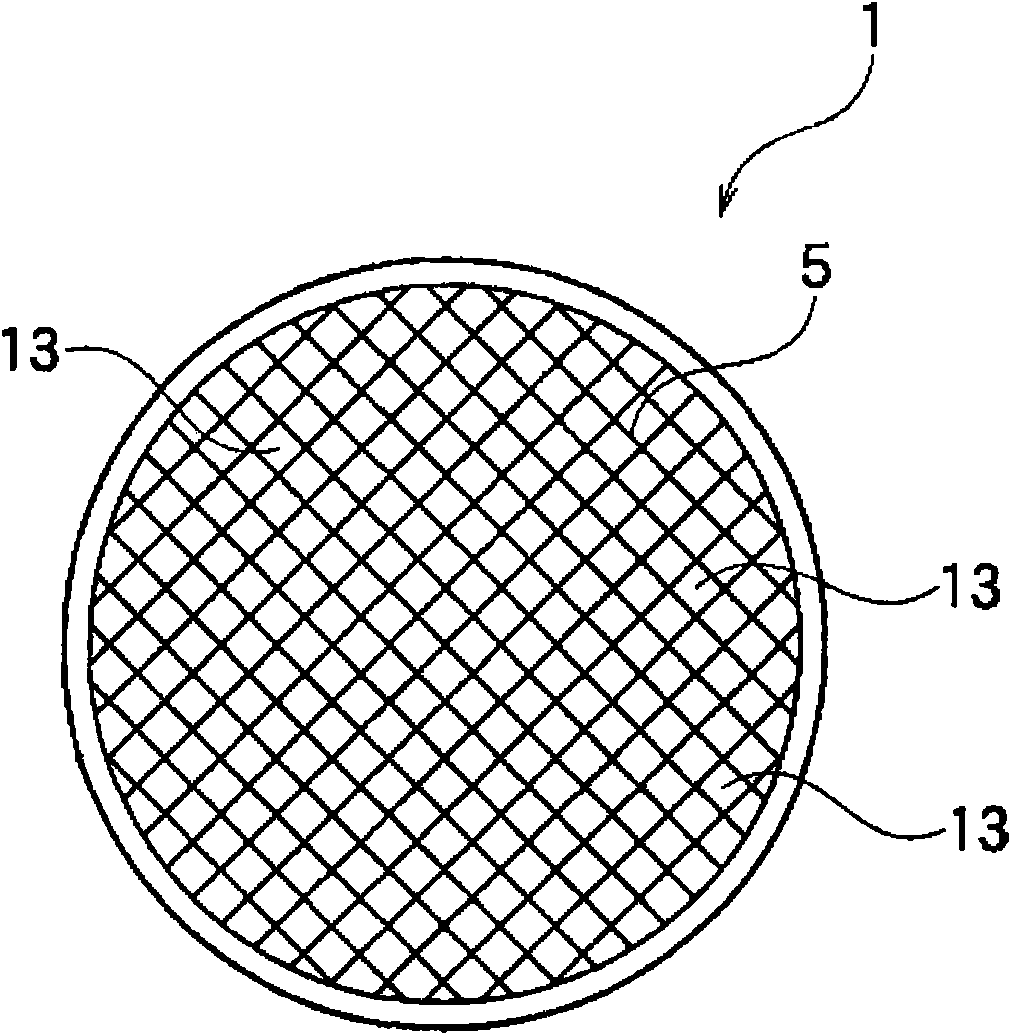

[0053] First, the fixing jig used in the present invention will be described. figure 1 The fixing fixture of the present invention is loaded into the pickup device of the present invention for use.

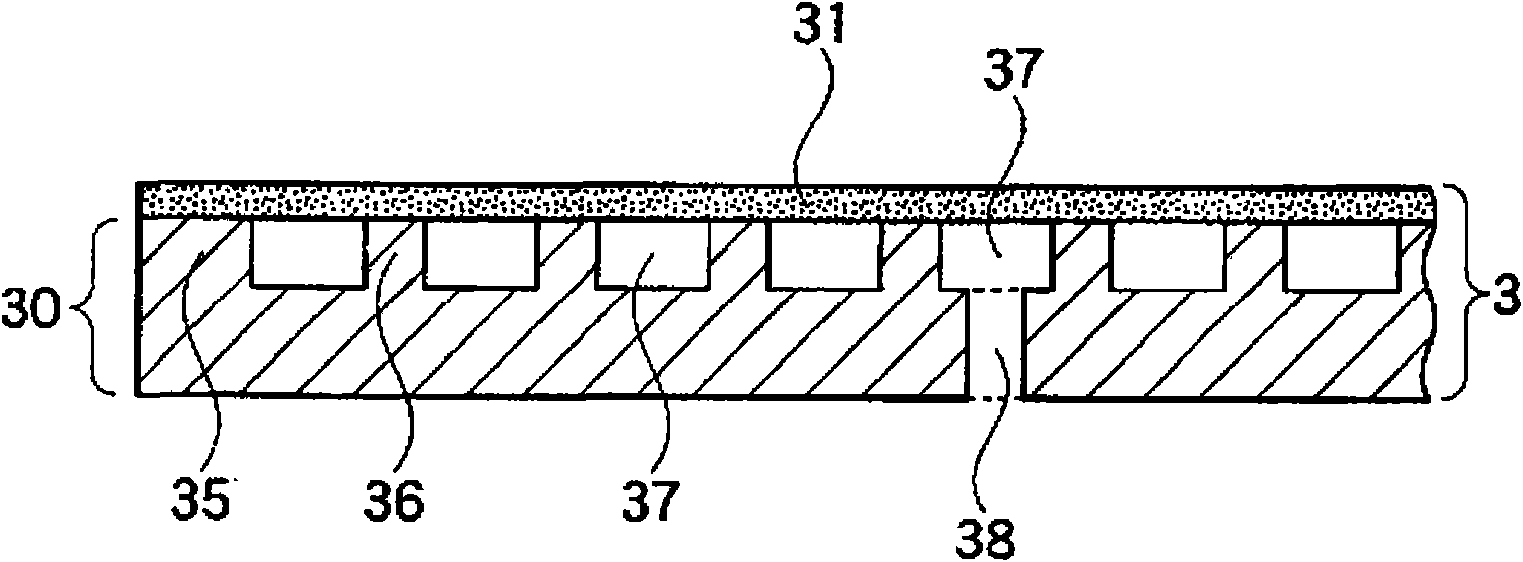

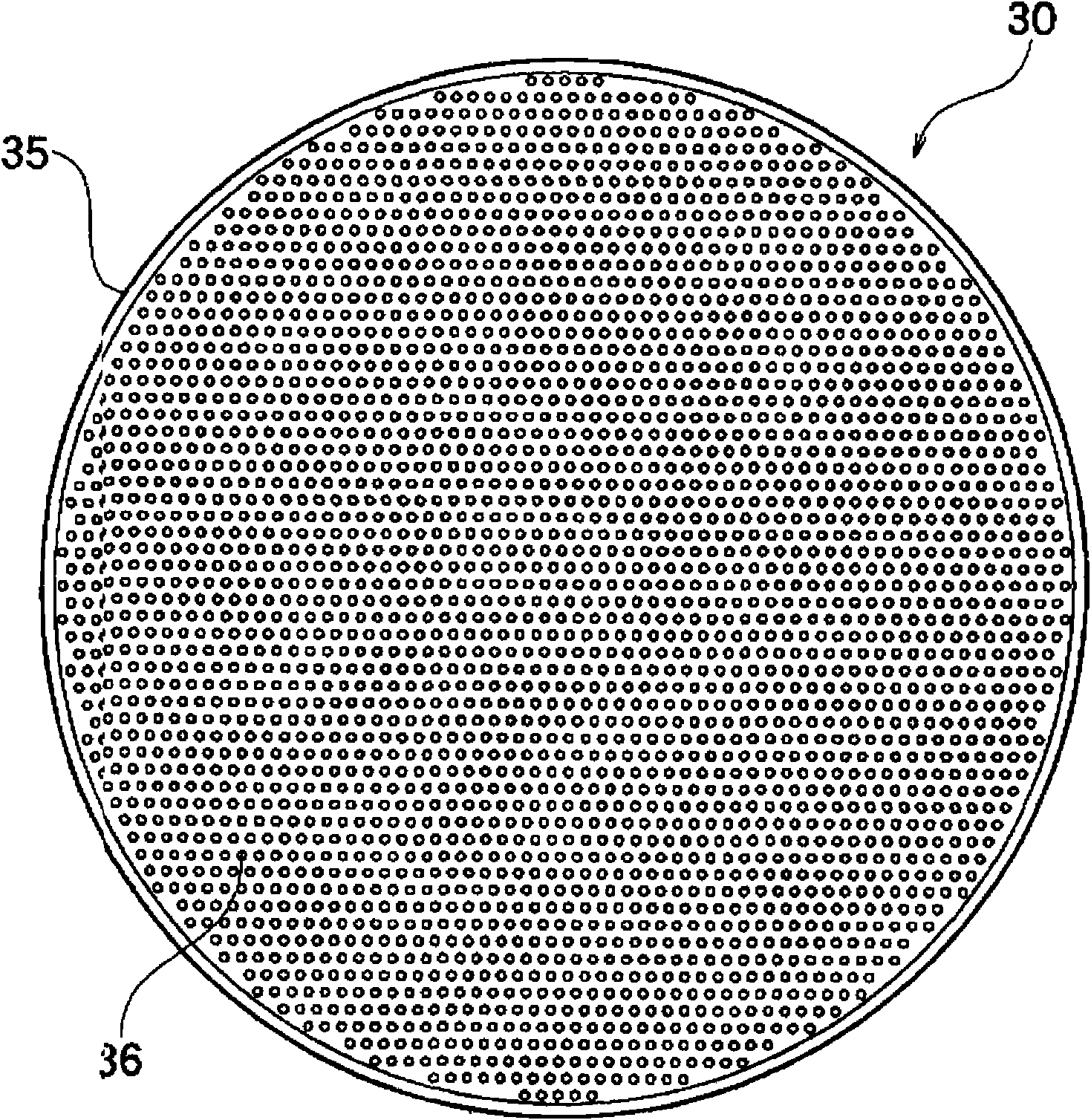

[0054]Such as figure 1 As shown, the fixing fixture 3 used in the present invention is composed of a fixture base 30 and an adhering layer 31 . As the shape of the jig base 30, a substantially circular shape, a substantially elliptical shape, a substantially rectangular shape, and a substantially polygonal shape may be mentioned, and a substantially circular shape is preferable. On one face of the jig base 30, such as figure 1 and figure 2 As shown, a plurality of protrusions 36 are formed to protrude upward at intervals. The shape of the protrusion 36 is not particularly limited, but a cylindrical shape or a truncated cone shape is ideal. In addition, a side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com