Patents

Literature

390results about How to "Easy to peel off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous casting slab high-temperature oxidation resistant coatings and preparation process thereof

InactiveCN101693791AGood anti-oxidation effect at high temperatureRaw materials are easy to getCoatingsOxidation resistantSuspending Agents

The invention relates to a preparation process of continuous casting slab high-temperature oxidation resistant coatings, which is characterized in that less than 120 meshes of powder, reductant containing carbon, inorganic binders, surfactants, suspending agents and the like with the compositions such as 25-55 wt% SiO2, 10-20 wt% Al203, 11-23 wt% MgO and the like are respectively grinded and mixed evenly, then water is used to be mixed and stirred sufficiently evenly, and finally the density of the coatings are adjusted within 1200-1500 kg / m3. The coatings can not only be sprayed onto continuous casting slabs at normal temperature, but also be sprayed onto high-temperature casting slabs, form continuous whole protective coating layers under the action of high temperature, effectively reduce temperature drop of the casting slabs and oxidation burning loss in even heating process of a heating furnace without changing original performance of matrixes, and effectively decrease dilution of alloying elements on the surfaces of the casting slabs. After the casting slabs are out of the heating furnace, natural spalling capability of the coating layers is strong, and oxidation matrixes of the casting slabs are smooth. Raw materials of the oxidation resistant coatings are easy to be obtained, and the coatings have low cost and simple preparation process and are adaptable to oxidation resistance for various steels when being heated at 700-1300 DEG C / 2-8 hours.

Owner:UNIV OF SCI & TECH BEIJING

Green multifunctional detergent and its prepn process

InactiveCN1847381AHigh decontamination efficiencyOperational securityOrganic detergent compounding agentsSurface-active detergent compositionsSemiconductor materialsLiquid-crystal display

The present invention discloses one kind of green multifunctional detergent comprising surfactants, detergency promoter, permeating agent, chelating agent, defoaming agent and water in certain weight proportion. The green multifunctional detergent is used in cleaning ferrous metals, non-ferrous metals and stainless steel, as well as semiconductor material and device, LCD glass plate, coated glass, LCD box and electronic circuit board. The present invention has the advantages of compounding and use at normal temperature, powerful detergency, high cleaning efficiency, no ODS matter contained, no phosphate contained, no inflammability, no explosion, no pollution, and direct exhaust and reuse of used waste liquid.

Owner:BEIJING XINLI MACHINERY

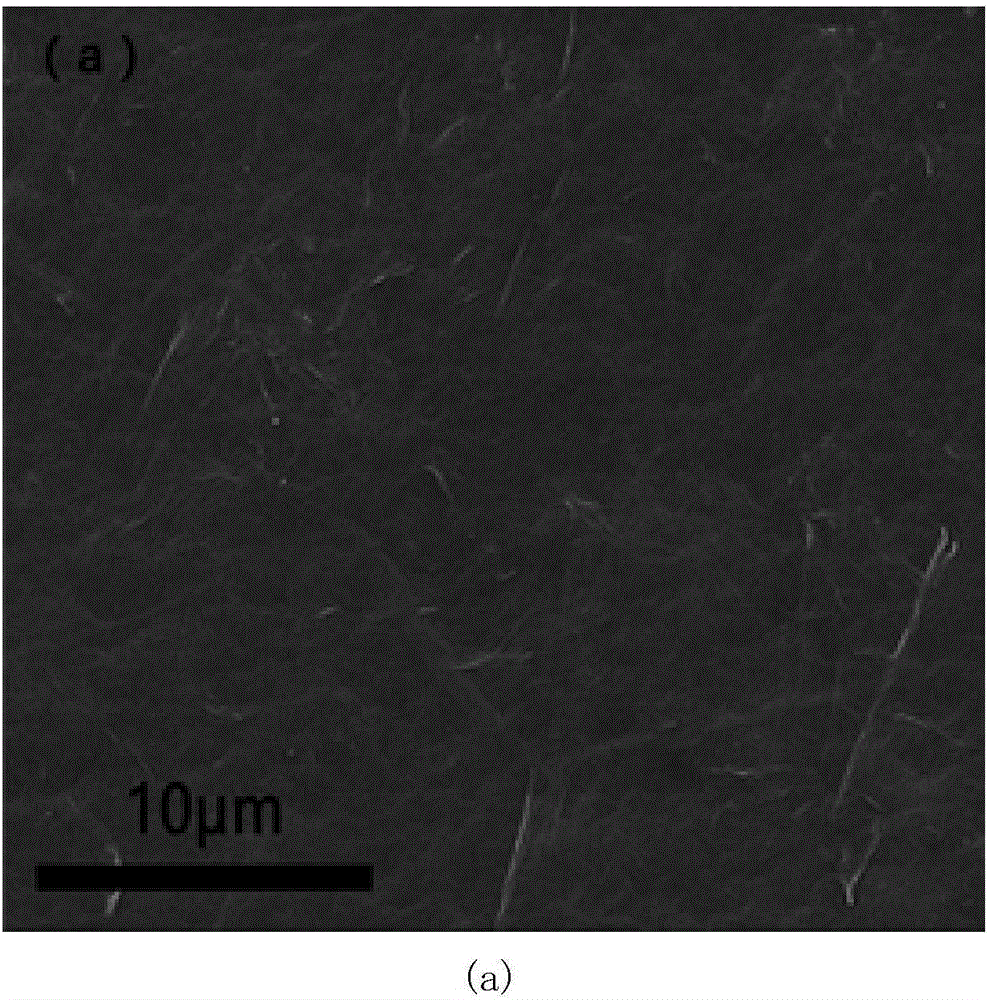

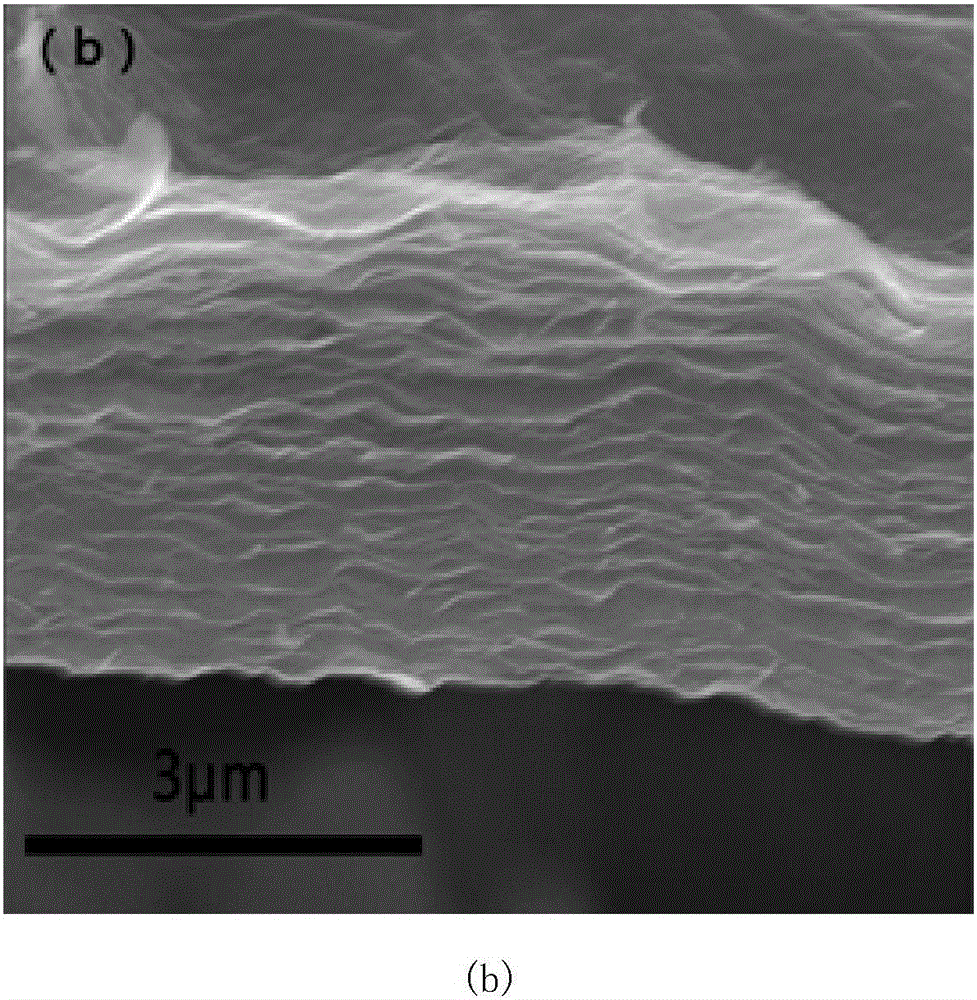

Preparation method of high-heat-conduction flexible graphene film

The invention provides a preparation method of a high-heat-conduction flexible graphene film. Oxidized graphene powder is frozen, dried and dispersed in a solvent, and an oxidized graphene dispersion liquid with the concentration being 0.1-10 mg / ml is obtained; the oxidized graphene dispersion liquid is added to a spraying device and sprayed on a substrate, the substrate is heated at the temperature of 50-150 DEG C for 0.5-5 h, and the oxidized graphene film is formed on the substrate after the dispersion liquid is evaporated; the oxidized graphene film is peeled off and rolled; hot-pressing carbonization and high-temperature graphitization are performed under the protection of a protective atmosphere, and the heat-conduction graphene film is obtained. With the adoption of the method, the high-heat-conduction flexible graphene film with the size and the thickness being controllable can be effectively prepared to meet requirements of different heat dissipation devices and can be applied to various wearable equipment, smart phones, smart televisions and LEDs on a large scale to improve the heat dissipation effect.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

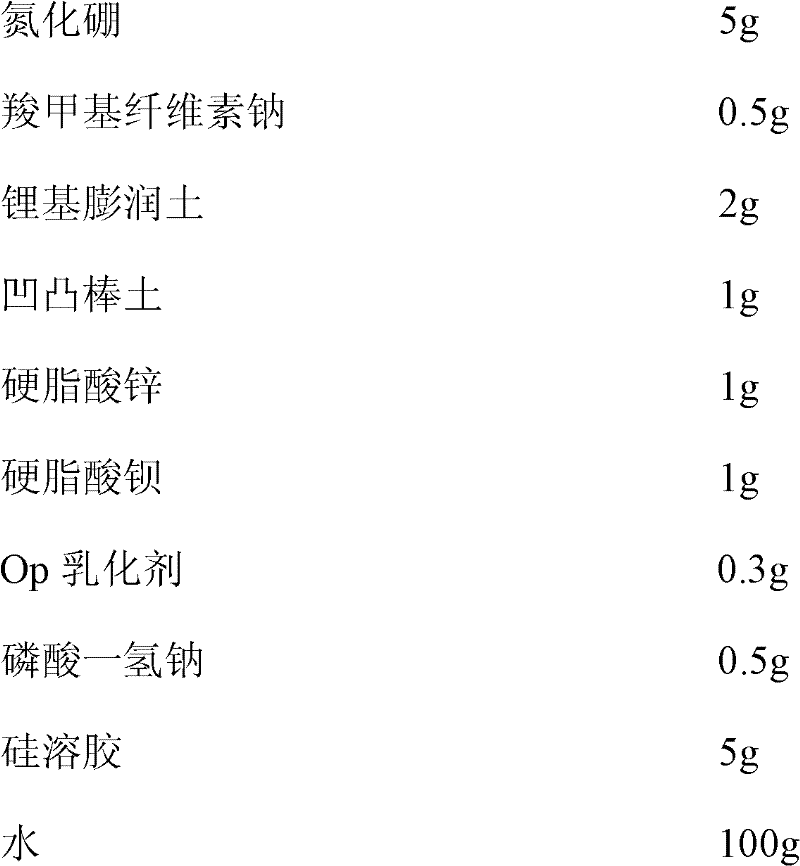

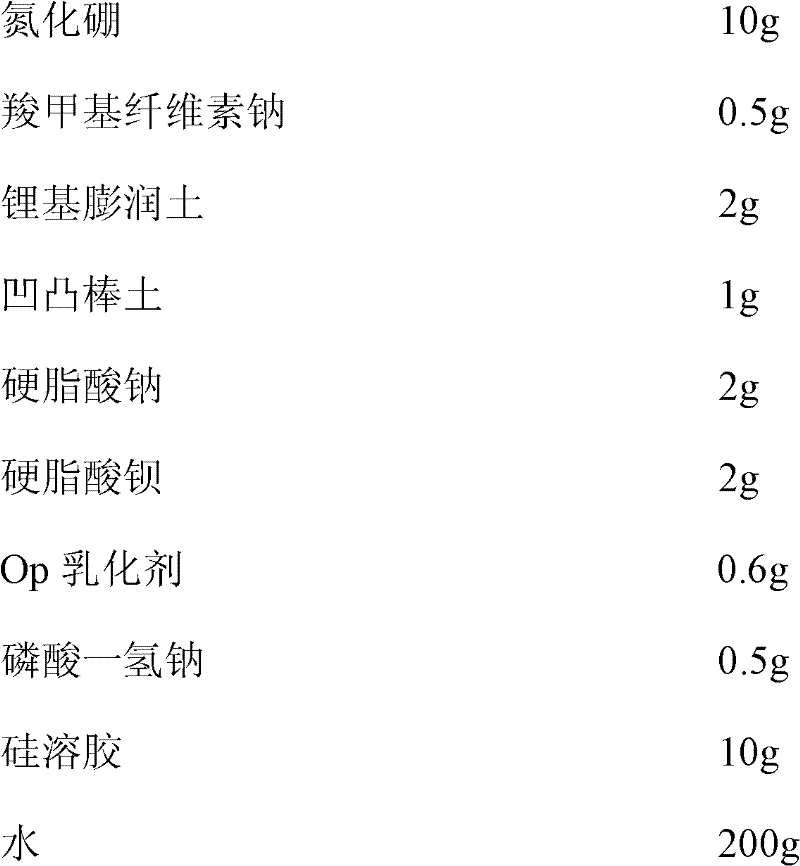

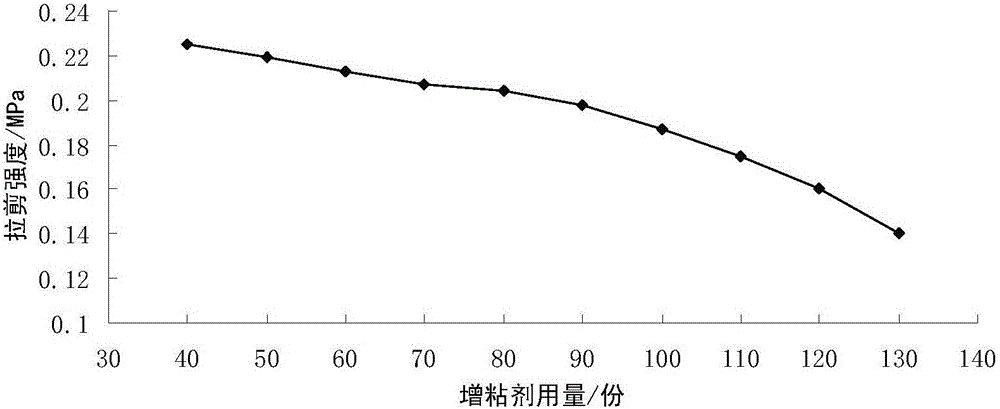

Non-graphite type lubricant for hot die forging of metal and preparation method of non-graphite type lubricant

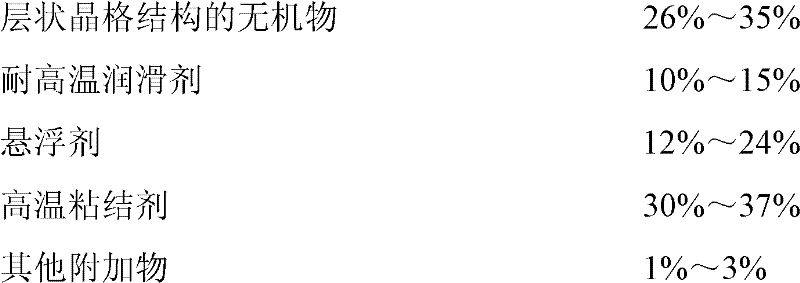

The invention discloses a water-based non-graphite type lubricant, which is characterized by comprising the following ingredients in percentage by weight: 26%-35% of inorganic substance with layered lattice structures, 10%-15% of high-temperature-resistant lubricant, 12%-24% of suspending agent, 30%-47% of high-temperature adhesive and 1%-3% of adjuvant. The water-based non-graphite type lubricant is an environment-friendly lubricant for hot die forging, can replace a graphite type lubricant, and is especially suitable for the hot die forging of metal, in particular, for the hot die forging of large-sized aluminum pieces. The invention further discloses a preparation method of the water-based non-graphite type lubricant. The preparation method has the advantages of simple preparation process and excellent film-forming performance.

Owner:HUAZHONG UNIV OF SCI & TECH

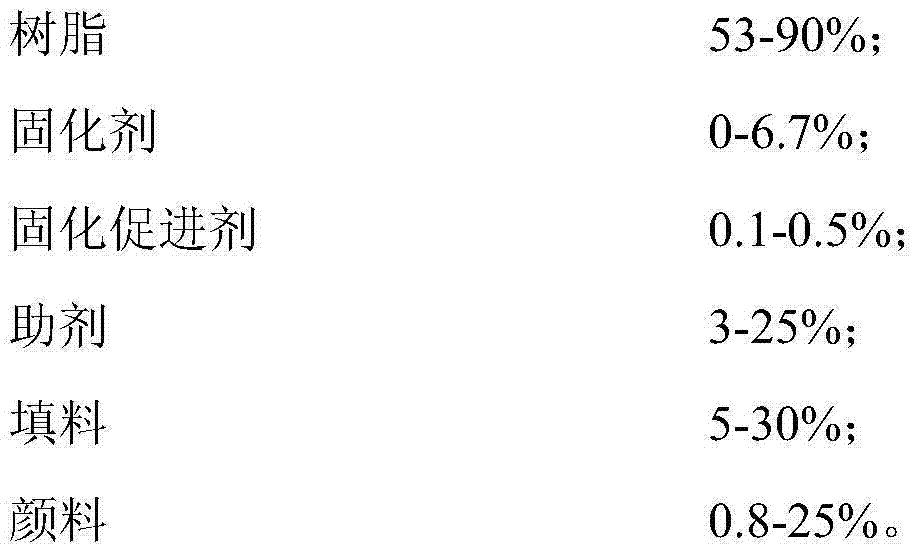

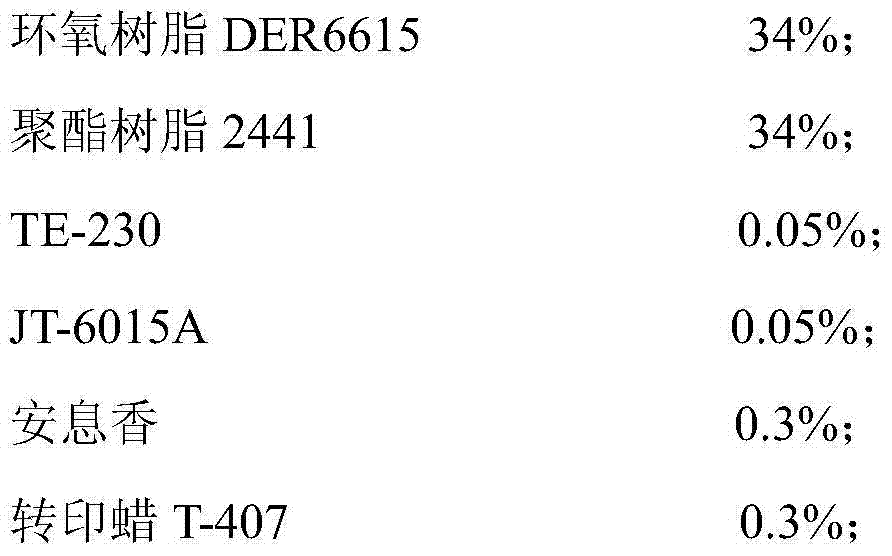

Powder coating for MDF transfer printing and application method of powder coating

PendingCN104497808AImprove texture clarityEasy to tear offDuplicating/marking methodsPowdery paintsWeather resistanceWear resistance

The invention relates to powder coating and particularly relates to powder coating for MDF transfer printing and an application method of the powder coating. The powder coating is prepared from the following raw materials in percentage by weight: 53-90% of resin, 0-6.7% of a curing agent, 0.1-0.5% of a curing accelerant, 3-25% of auxiliaries, 5-30% of filler and 0.8-25% of pigment. After the powder coating is used for transfer printing, the texture is clear, the penetration is deep, the third dimension is strong, the transfer printing paper can be easily uncovered, the thermal transfer printing product is durable in use, and the patterns are not dropped, cracked or faded; moreover, the thermal transfer printing only achieves a surface decoration effect without changing the characteristics of the original glossiness, the wear resistance, the weather resistance, the acid and alkali resistance, and the like of the product. The invention also provides an application method of the powder coating.

Owner:山东朗法博粉末涂装科技有限公司

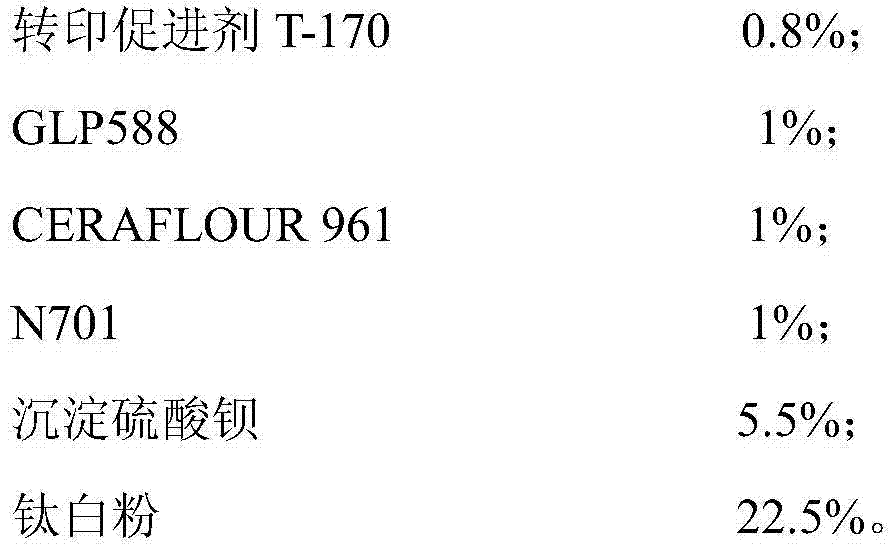

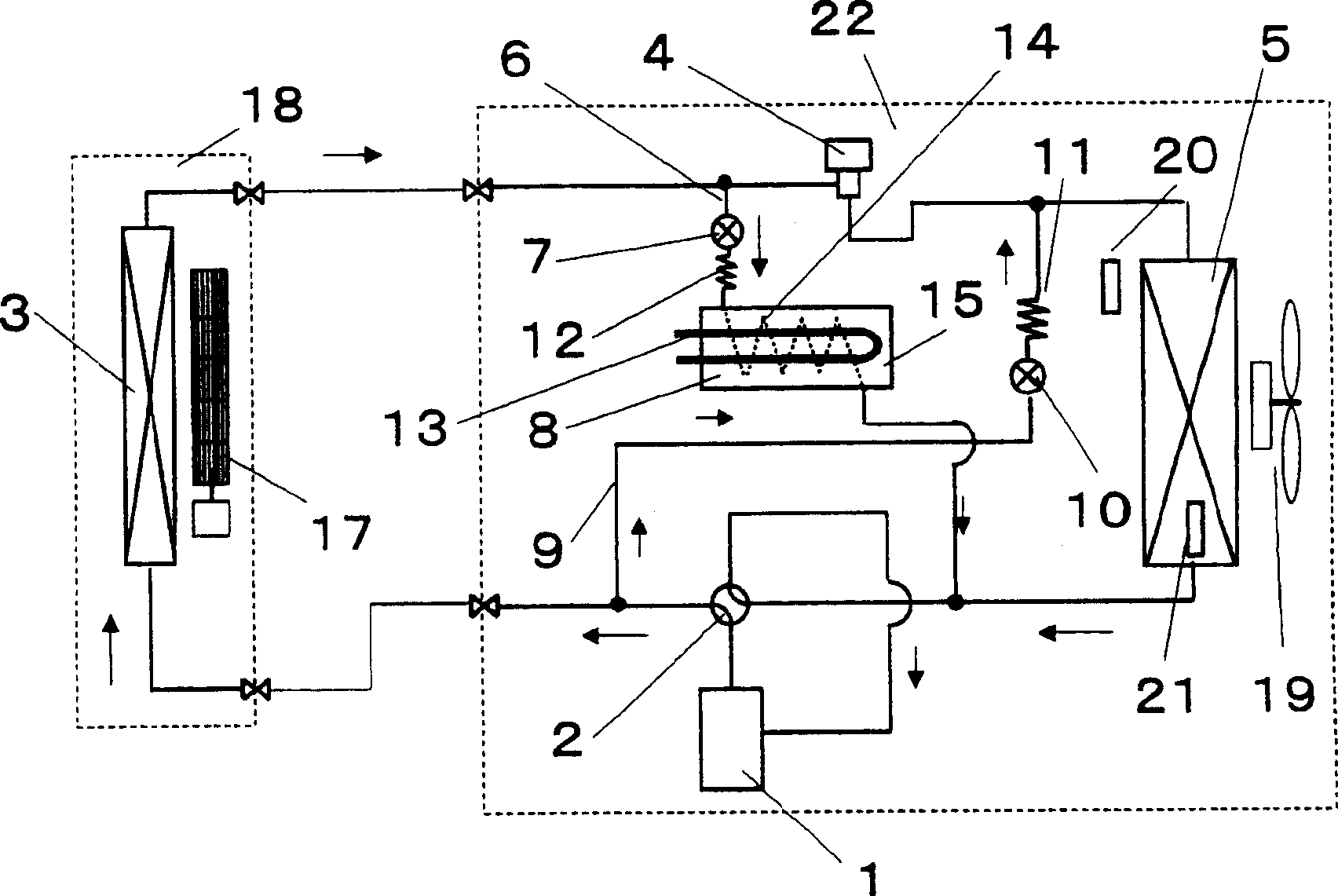

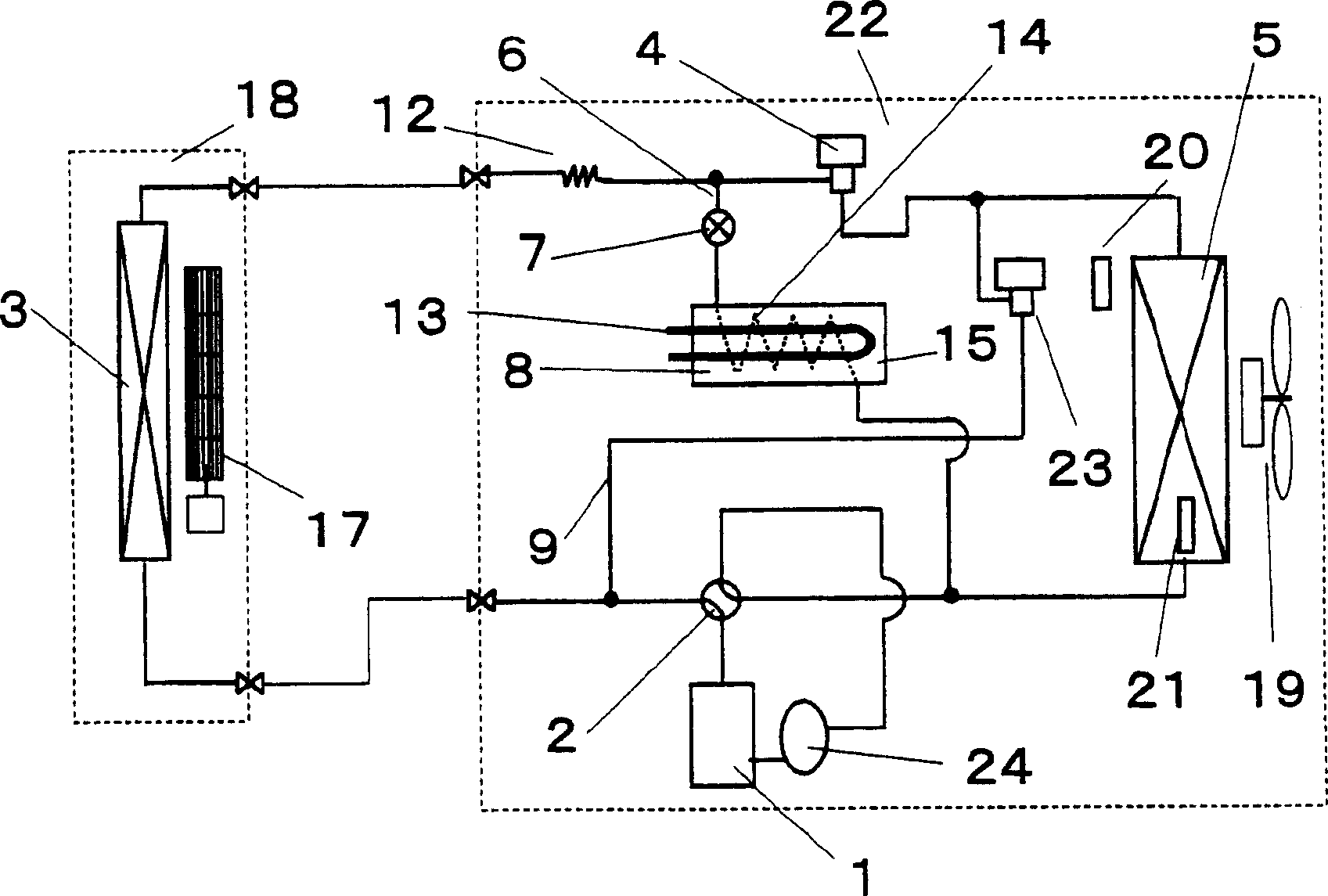

Air conditioner device

InactiveCN1916538ANo noiseSmall oil changeCorrosion preventionCompression machines with reversible cycleFour-way valveEngineering

This invention provides an air-conditioner that continues a heating operation while performing a defrosting operation. A first bypass circuit 6 is provided for connecting the portion of a heat-pump-type refrigerating cycle between an indoor heat exchanger 3 and a decompressor 4 to the suction side of a compressor 1. The first bypass valve 6 is provided with a two-way valve 7 and a refrigerant heater 8. Further, a second bypass circuit 9 is provided for connecting the portion between a four-way valve 2 and the indoor heat exchanger 3 to the portion between the decompressor 4 and an outdoor heat exchanger 5. The second bypass circuit 9 is provided with a defrosting two-way valve 10. To defrost the outdoor heat exchanger 5, the decompressor 4 and the defrosting two-way valve 10 are closed according to outside air temperature and a fan 19 is rotated to perform a first defrosting operation. When the temperature detected by the temperature means of the outdoor heat exchanger is less than a predetermined value while the first defrosting operation is within a preset period of time, the two-way valve of the second bypass circuit is opened and an outdoor fan is stopped to perform a second defrosting operation.

Owner:PANASONIC CORP

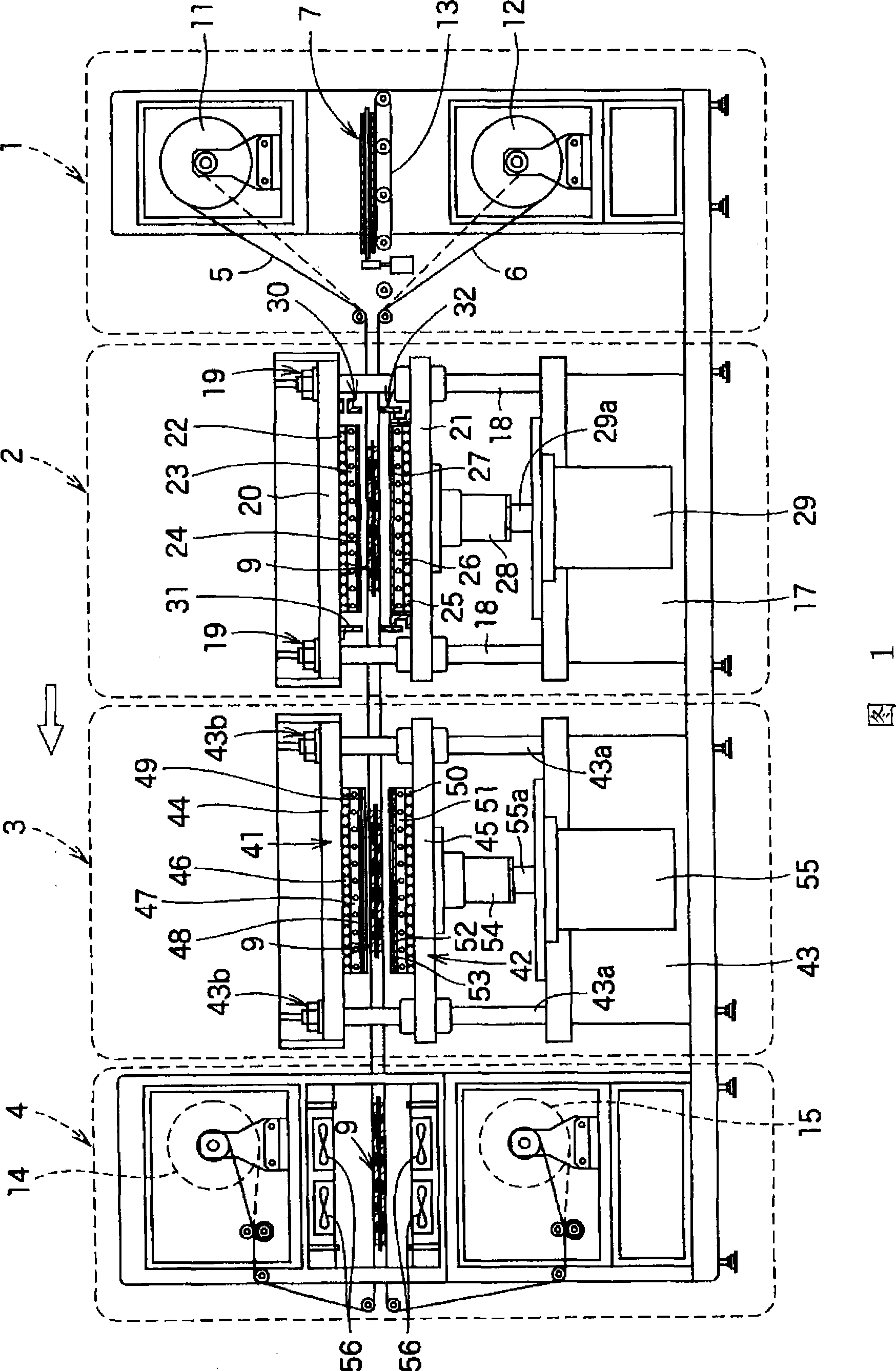

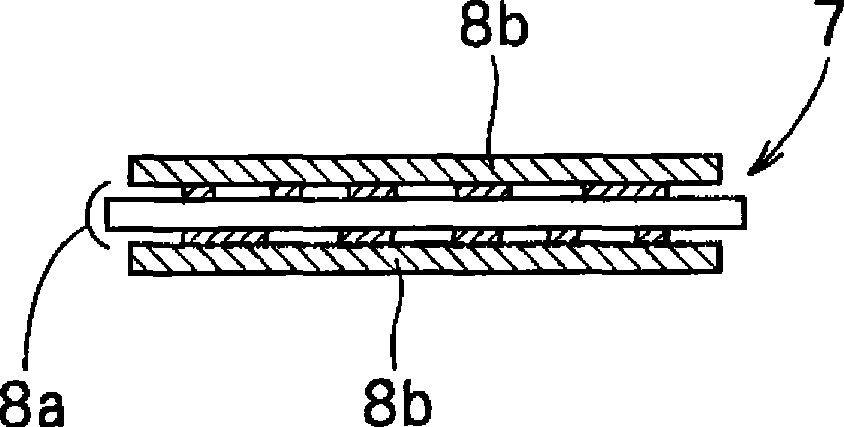

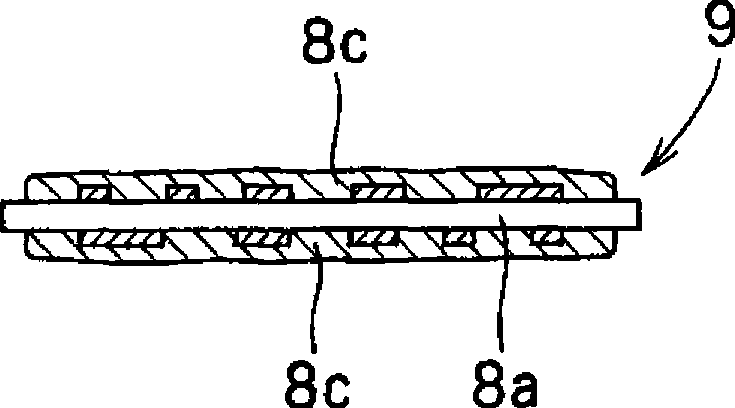

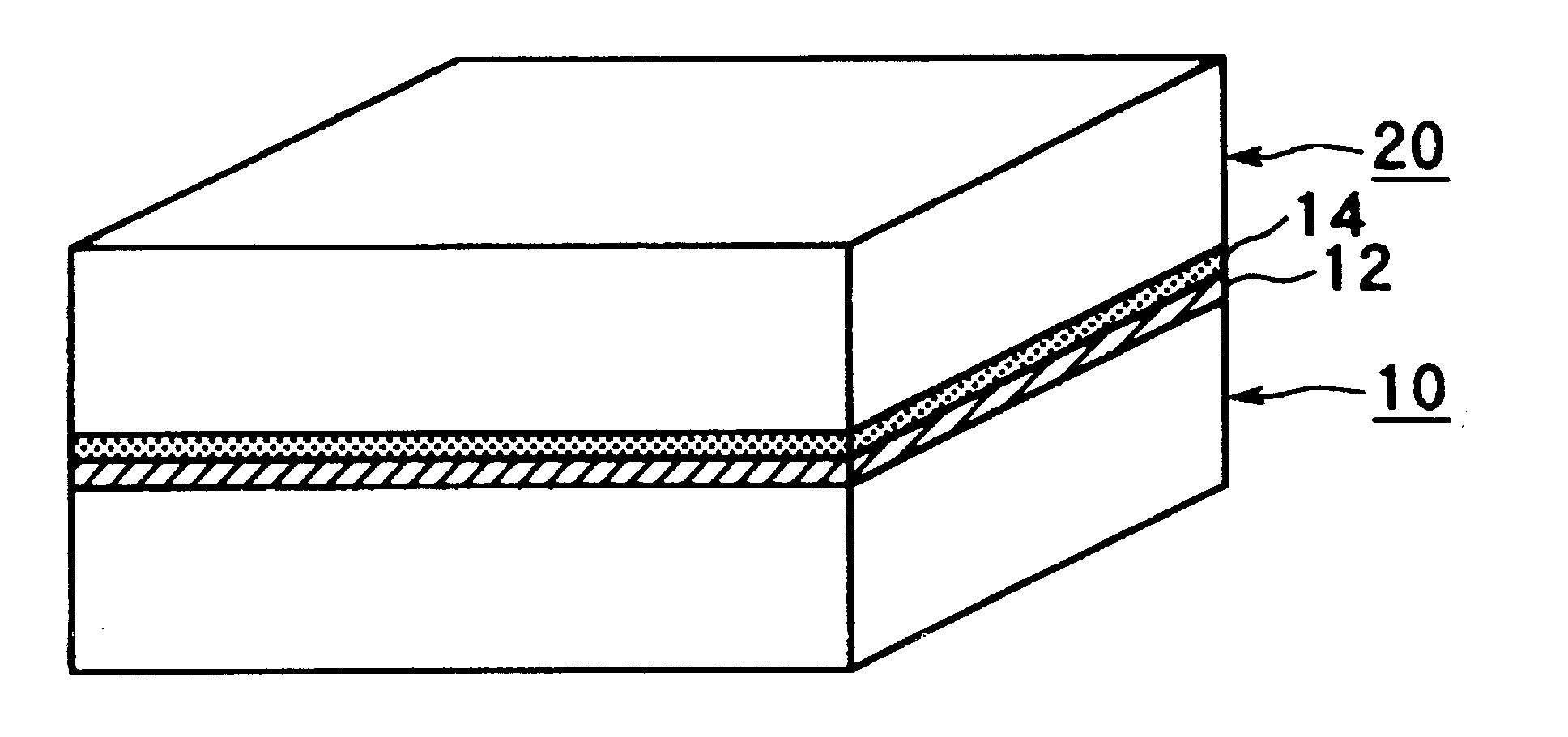

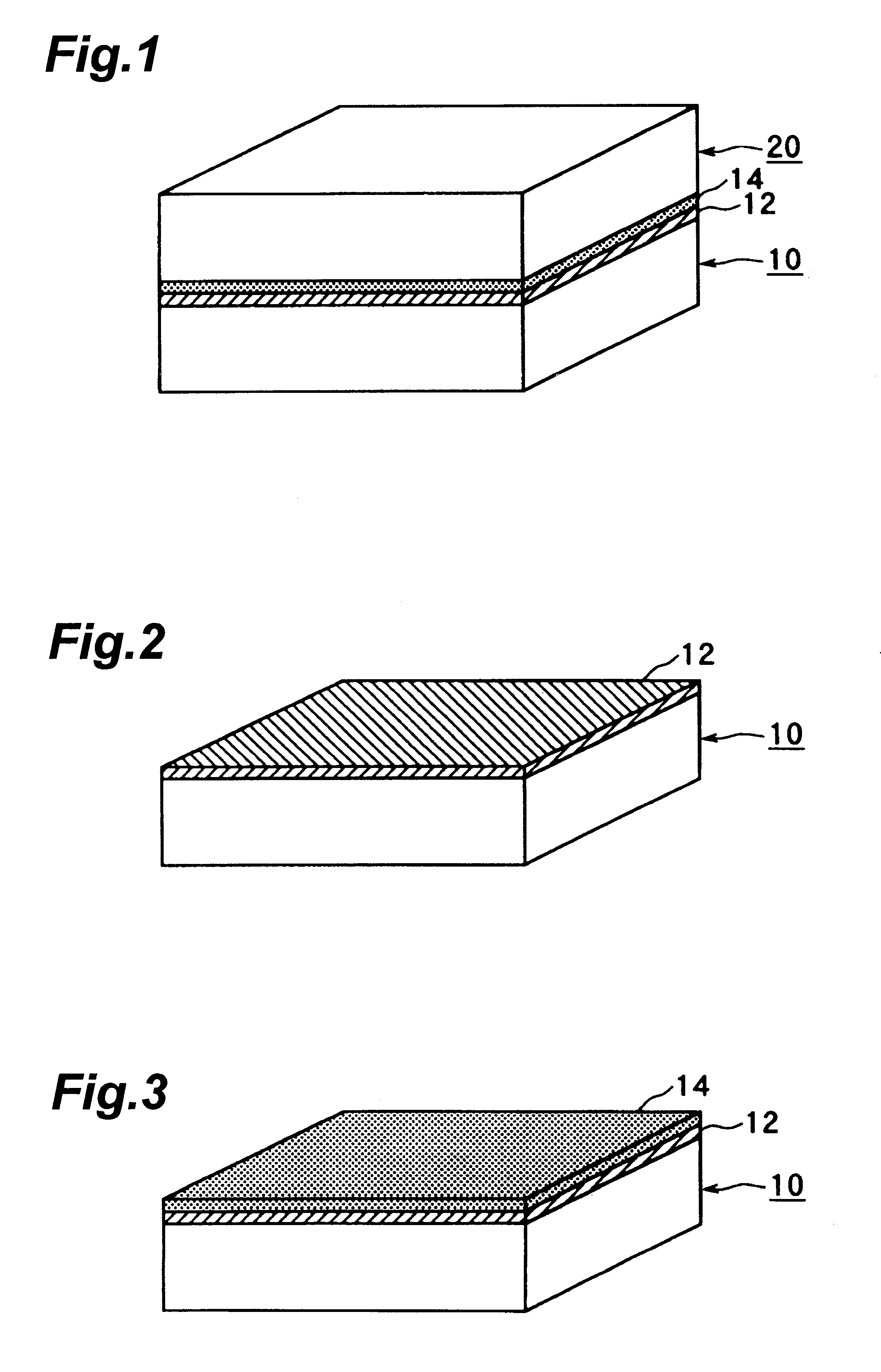

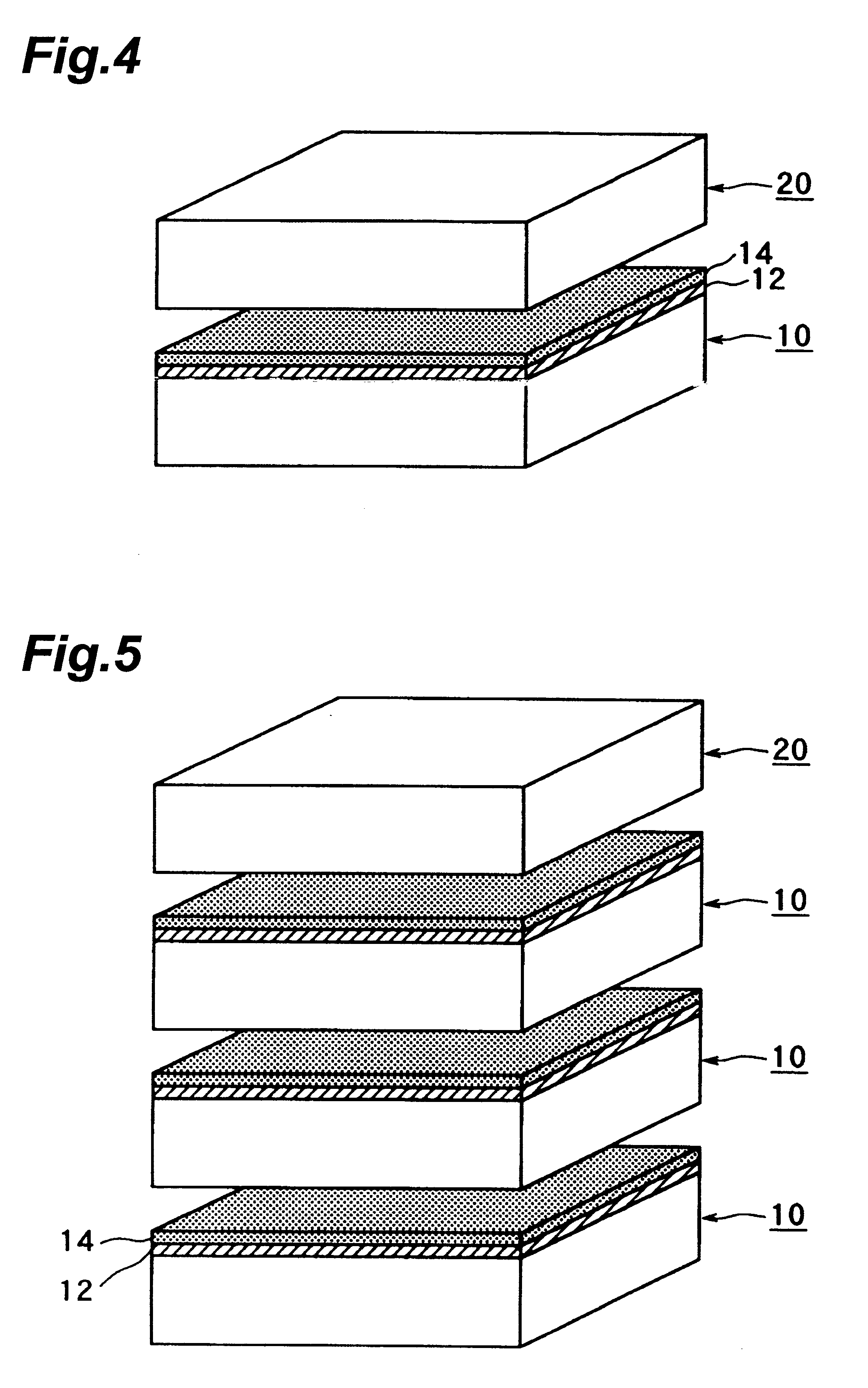

Laminating apparatus, and laminating method using it

ActiveCN101384416AGood heat resistanceImproves closeness and followabilityLamination plant layoutLayered product treatmentEngineering

Owner:NIKKO MATERIALS CO LTD

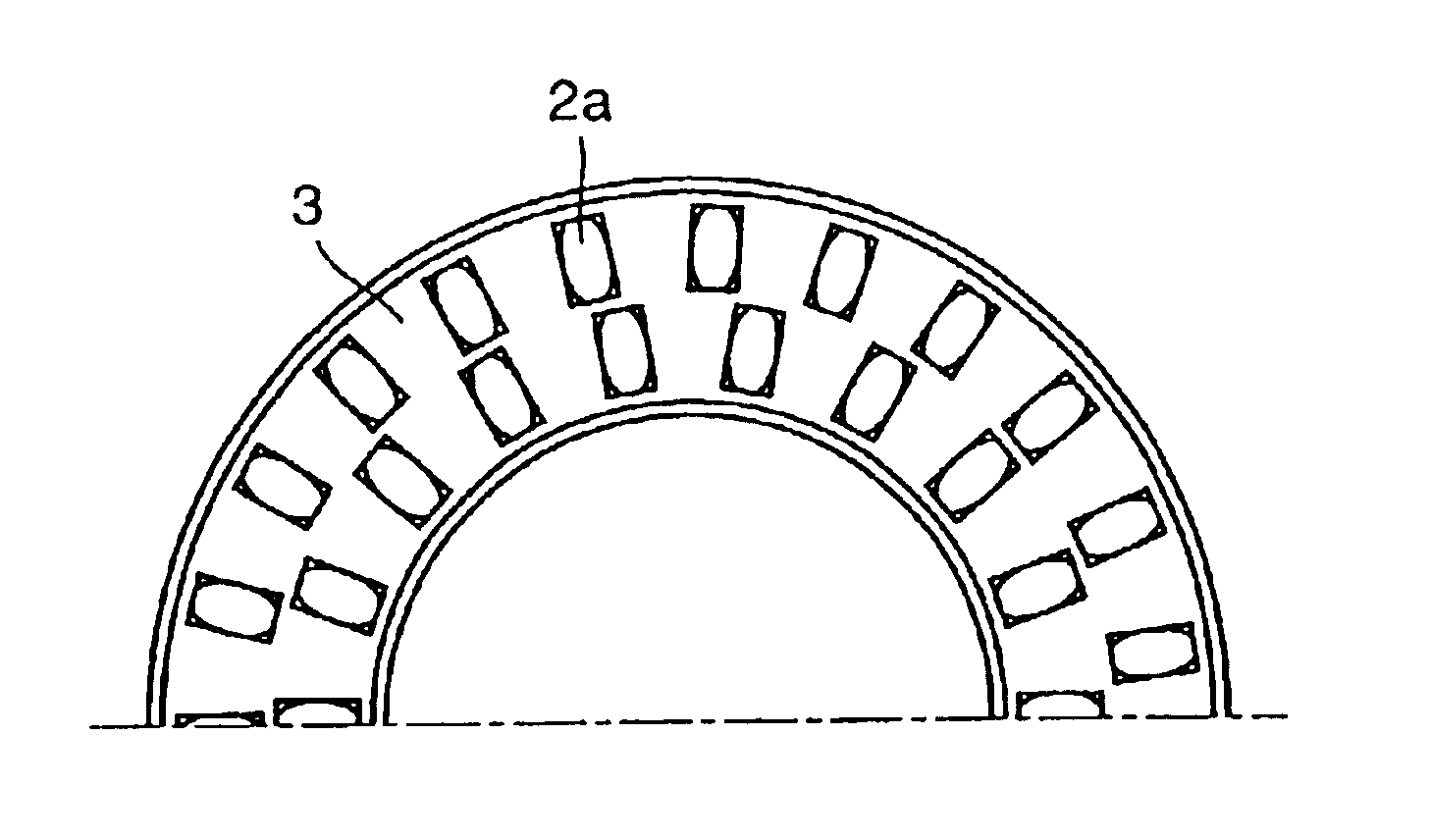

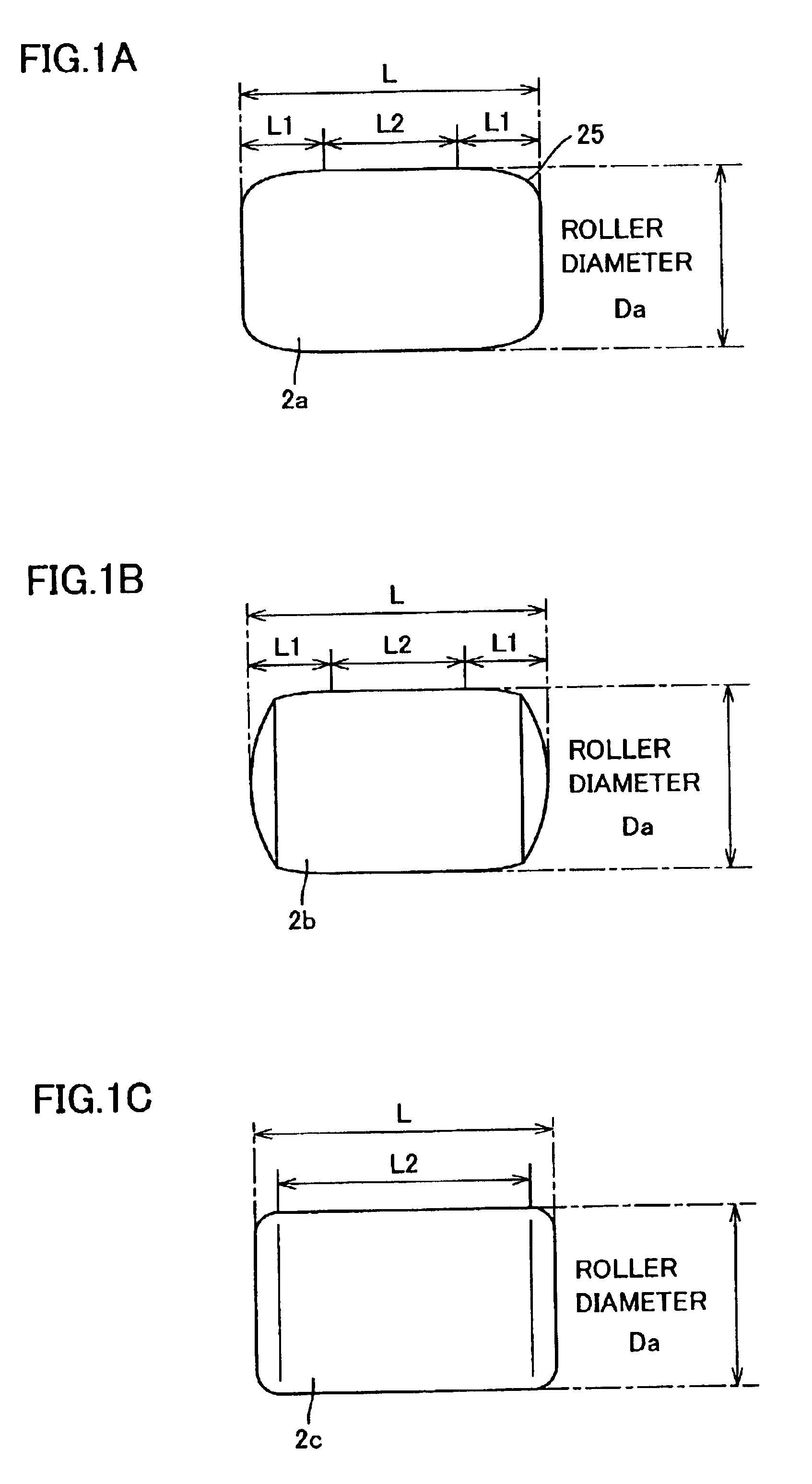

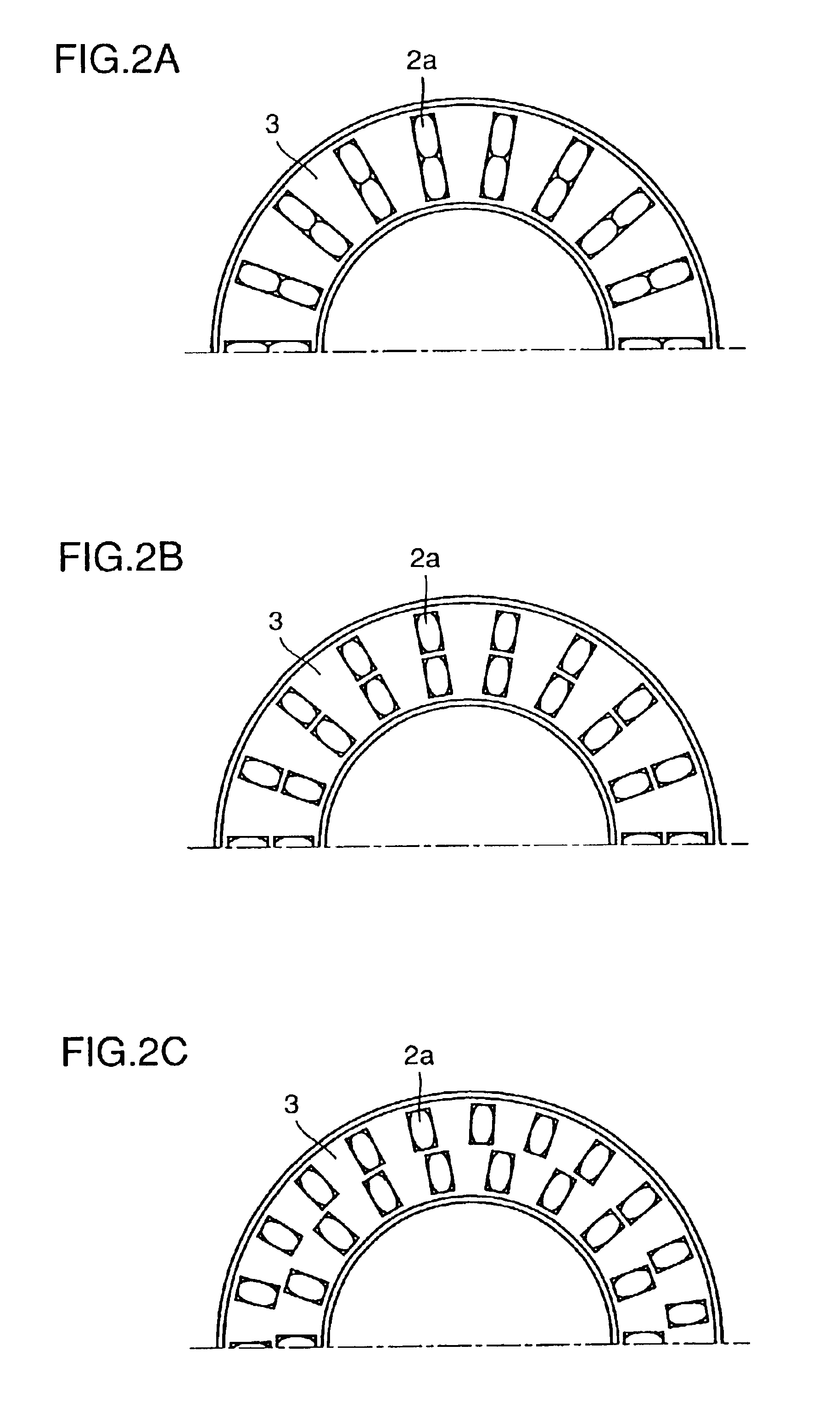

Roller thrust bearing

InactiveUS6843605B2Reducing a differential slipImprove the immunityRoller bearingsShaftsThrust bearingAerospace engineering

There is provided a roller thrust bearing providing reduced differential slip, free of significant friction and wear, and providing increased longevity against flaking. The present invention provides a thrust bearing in the form of a roller thrust bearing including at least two radially arranged rows of rollers and a cage holding the rollers, the rollers including at least one roller crowned.

Owner:NTN CORP

Composition for strechable film

ActiveUS20110318987A1Satisfactory formabilityEasy to peel offSynthetic resin layered productsLaminationPolymer scienceThin membrane

Provided is a composition for a stretchable film, which achieves a high-level balance between a high elastic modulus and a small permanent set, and can be formed into a stretchable film with satisfactory formability. A composition for a stretchable film comprises a block copolymer composition containing a block copolymer A represented by the following general formula (A) and a block copolymer B represented by the following general formula (B), and a tackifier resin:Ar1a-Da-Ar2a (A)(Arb-Db)n-X (B),in the general formulas (A) and (B), Ar1a and Arb each represent an aromatic vinyl polymer block having a weight average molecular weight of 6,000 to 20,000; Ar2a represents an aromatic vinyl polymer block having a weight average molecular weight of 40,000 to 400,000; Da and Db each represent a conjugated diene polymer block having a vinyl bond content of 1 mol % to 20 mol %; X represents a single bond or a residue of a coupling agent; and n represents an integer of 2 or greater.

Owner:ZEON CORP

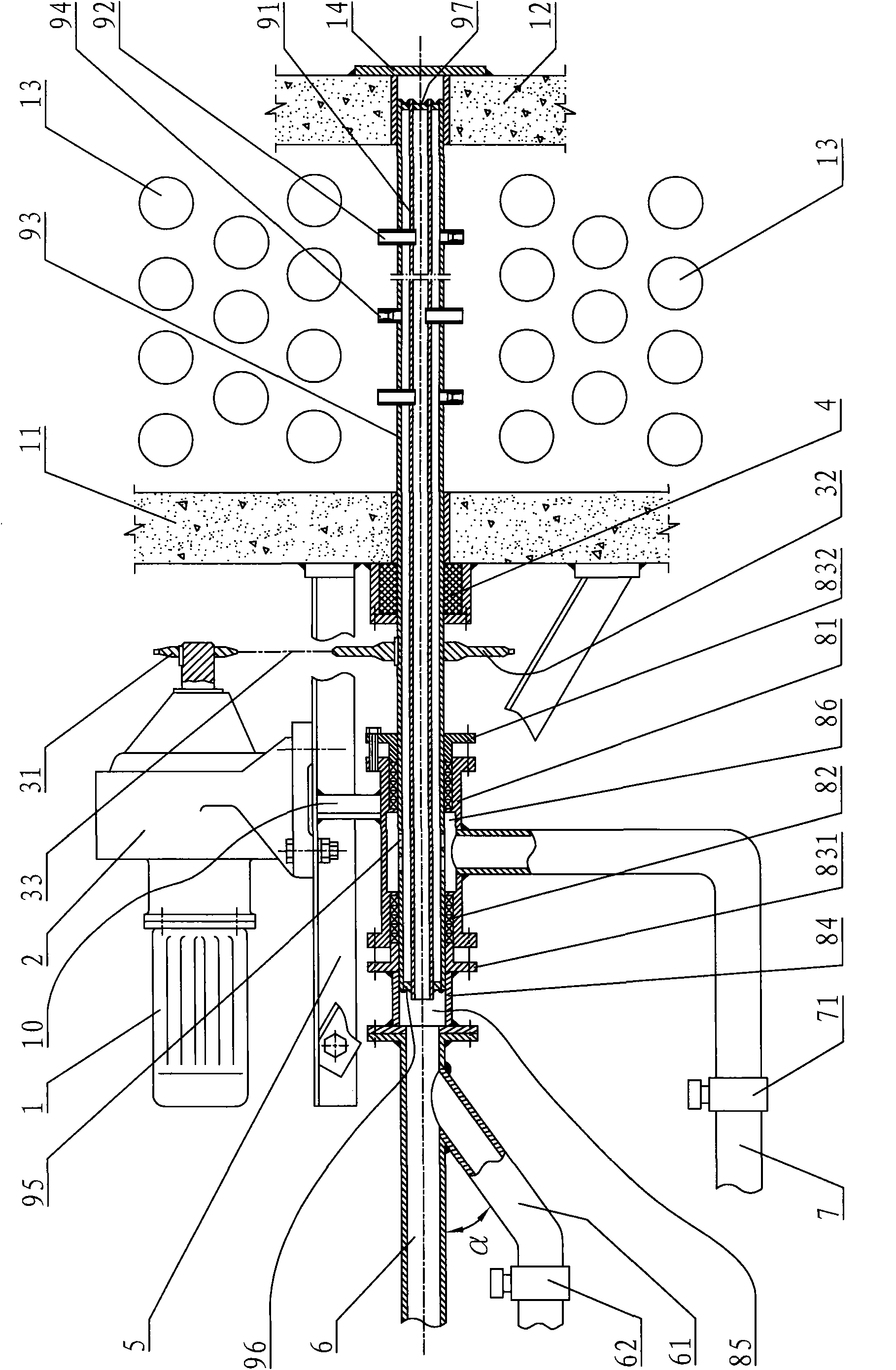

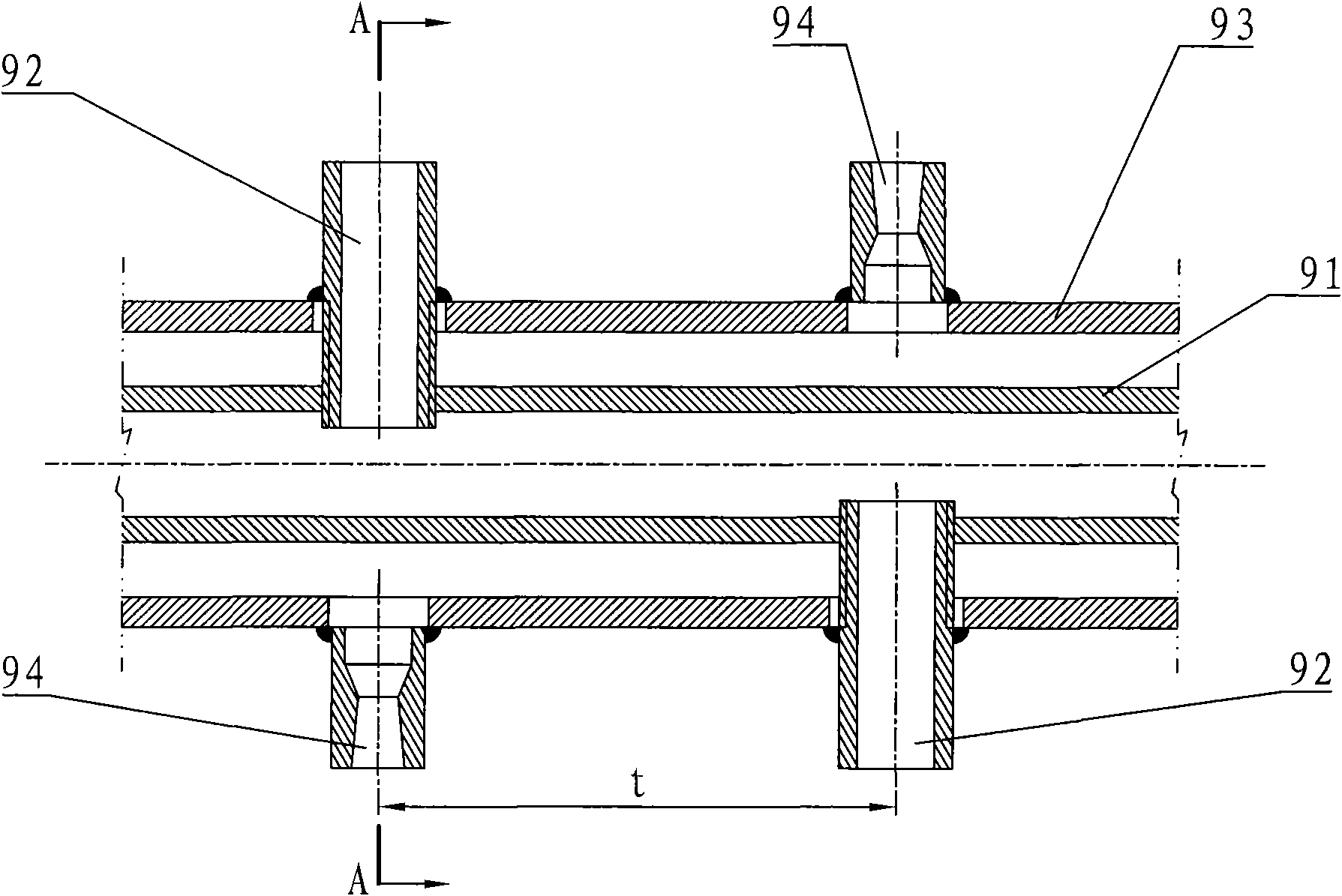

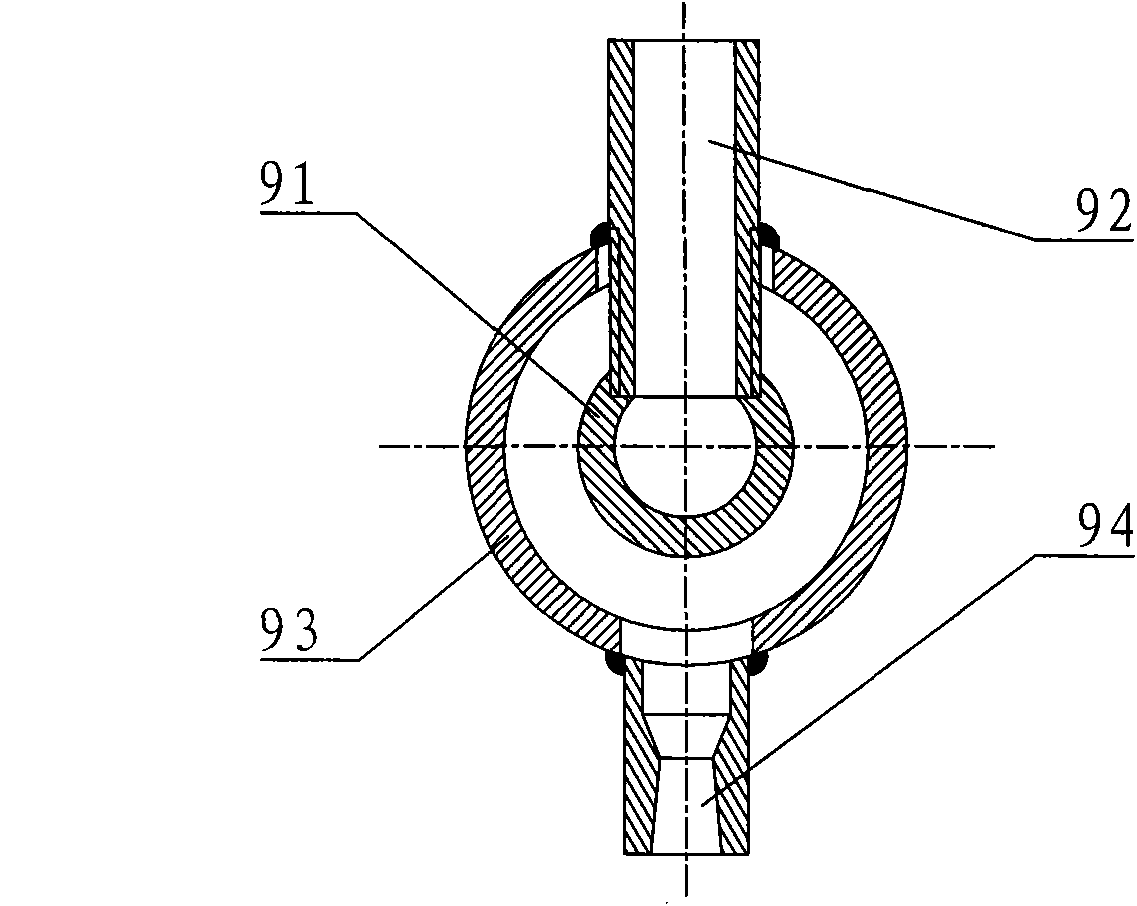

Soot blower

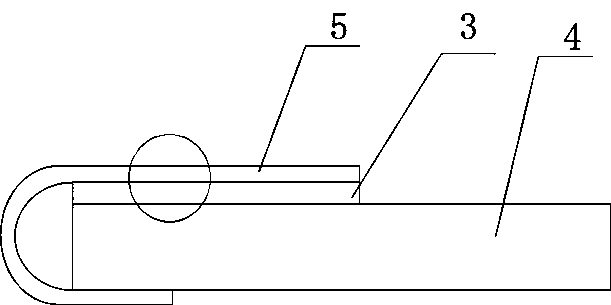

ActiveCN101876447AEasy to peel offReduce the degree of cohesive dust accumulationSolid removalAir preheaterEngineering

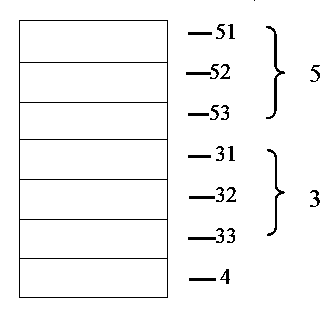

The invention discloses a soot blower. The invention aims to solve the problem that the existing soot blower and soot remover spray system can not well clean adhesive soot deposited on furnace tubes in a convection section of a tube heating furnace and heat exchange tubes in an air preheater. The soot blower of the invention is provided with an air intake system, a transmission system, a soot blowing tube (93) and a bracket (5), wherein the soot blowing tube is provided with two rows of soot blowing nozzles (94) in the axial direction, and a soot remover spray tube (91) is coaxially arranged in the soot blowing tube; the soot remover spray tube is axially provided with two rows of soot remover nozzles (92), and the upper part of each soot remover nozzle extends out of the wall of the soot blowing tube; each soot remover nozzle row and the corresponding soot blowing nozzle row are in the same row, and the soot blowing nozzles and soot remover nozzles in each row are alternately arranged; and the air inlet section of the soot blowing tube is provided with an air inlet (95). The invention is mainly used in tube heating furnaces in the fields of petroleum refining and petrochemical industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

Strippable protective polyvinyl butyral coating film and its production process

The strippable protective polyvinyl butyral coating is produced with polyvinyl butyral, ethanol, methanol, ethyl acetate, butyl acetate, n-butanol and butanone as material. Modified polyvinyl butylral liquid is painted to the surface of automobile, furniture, electric appliance and other objects to form protective coating at normal temperature. The coating is continuous, homogeneous, tough and transparent and can be stripped for recovery. The coating is sun-proof, water, oil, alkali, salt solution and dilute acid resistant, and has wide application and no environmental pollution.

Owner:JILIN AOJIE SCI & TECH

Positive electrode material recovering method for waste lithium ionic cell

InactiveCN101499547ASuitable for large-scale recyclingEasy to peel offSolid waste disposalWaste accumulators reclaimingCurrent collectorAqueous solution

The invention provides a method of recycling the anode material of a waste lithium-ion battery. The method comprises the following steps: the anode plate is separated from the waste lithium-ion battery and dipped in an organic solvent to separate the anode material from a current collector; the current collector is taken out; and the anode material can be obtained by filtering. The method of separating the anode plate from the waste lithium-ion battery comprises the steps: the waste lithium-ion battery is dipped in the aqueous solution of the electrolyte; the shell of the battery is stripped; and the anode plate is separated from the cathode plate. The content of the electrolyte in the aqueous solution of the electrolyte is 10 to 50 weight percent. The invention has the advantages of simple recycling method and low cost, and is applicable to the large-scale recycling treatment of lithium-ion batteries.

Owner:BYD CO LTD

60% high solid content pressure-sensitive adhesive and preparation method thereof

InactiveCN101676347AImprove bindingEasy to peel offEster polymer adhesivesTectorial membraneEmulsion polymerization

The invention relates to a 60% high solid content pressure-sensitive adhesive and a preparation method thereof, and discloses a way for obtaining environment-friendly pressure-sensitive adhesive whichis applicable to manufacturing a surface protective film of building materials, electrical and electronic products, machines, furniture and the like. The pressure-sensitive adhesive is prepared by adopting a semi-continuous seed emulsion polymerization, taking butyl acrylate, methyl methacrylate, hydroxy-ethyl acrylate and acrylic acid as monomers, synchronously adding mixed emulsifying agent formed by anionic emulsifying agent and nonionic emulsifying agent as well as mixed liquid formed by initiating agent and ammonium persulphate, and having polymerization reaction in subacid deionized water. The pressure-sensitive adhesive has no emission of noxious and harmful substances when in production and use, so as to purify the environment. Meanwhile, the protective film and base material produced by the pressure-sensitive adhesive has better combination, do not damage the surface of the protected object, and can be torn off from the surface of the protected object so as to leave no residual trace.

Owner:成都航天明江科技实业有限公司 +1

Natural mineral-based high-temperature anti-oxidation decarbonization coating

InactiveCN102786822AGood dispersionImprove high temperature resistanceCoatingsPhysical chemistrySlurry

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Waterborne peelable protective paint

InactiveCN102850923ALow priceEasy to peel offRosin coatingsPolyurea/polyurethane coatingsCellulosePolymer science

The invention discloses a waterborne peelable protective paint which is composed of the components of, by weight: 60-100 parts of polyurethane emulsion, 30-40 parts of organosiloxane, 15-30 parts of modified polyacrylate, 10-20 parts of silicone, 20-40 parts of hydroxyethyl cellulose, 10-15 parts of rosin, 2-8 parts of a peeling accelerant, and balance of a water solvent. The waterborne peelable protective paint provided by the invention is green, environment-friendly, and low in cost. When a film is formed by using the paint, the film is aging-resisting, and is easy to peel. The film has good weatherability.

Owner:南通博宇机电有限公司

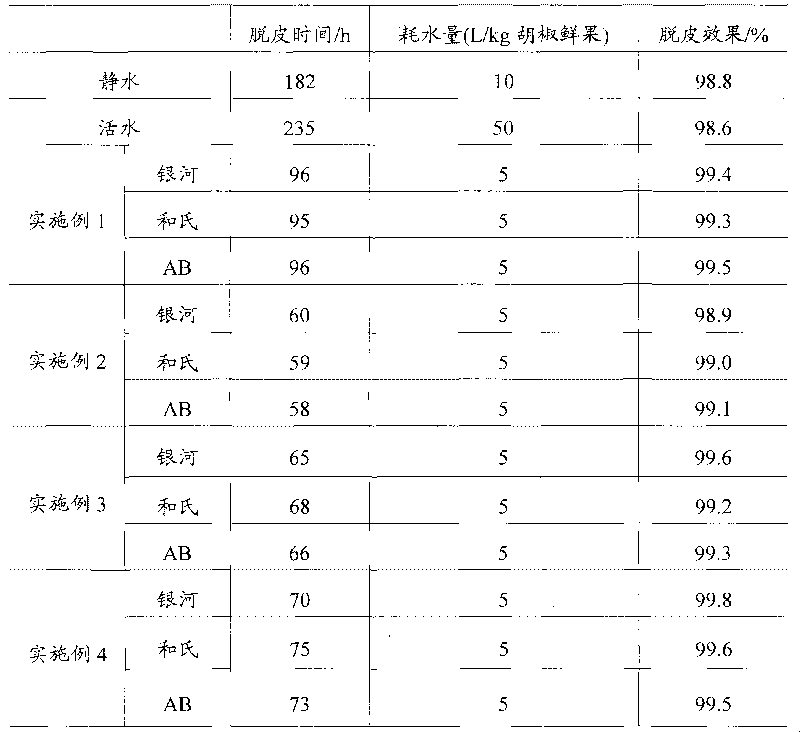

Dehulling method of fresh pepper fruit

The invention discloses a dehulling method of fresh pepper fruit, which comprises the follow steps: (1) selecting fresh pepper fruit; (2) soaking: soaking the fresh pepper fruit spikes in pectinase liquid with the volume concentration of 1-5 per thousand till the peel is corrupted, wherein the weight ratio of the fresh pepper fruit spikes to the pectinase liquid is 1-2:2-3; and (3) dehulling and washing: fishing out the soaked pepper fruit, and removing the peels and pedicles, thus obtaining pepper corns. The whole process is simple, the treatment is easy, the period is short (about 3-4 days), and the high-quality white peppers can be processed in a short period, the difficulties of long process period, low efficiency and poor quality of the white pepper are solved, the production quality of the white pepper is improved, the water resource is saved, sewage discharge amount is decreased, the production cost is reduced, standardizing and large-scale production is realized, technical support is provided for China to build a safe, high-efficiency, energy-saving and environment protective processing technique system, the upgrade of pepper industry is promoted, and the market competitiveness of Chinese pepper products is further strengthened.

Owner:SPICE & BEVERAGE RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Silicon fluoride super-amphiphobic non-stick coating material

The invention relates to a non-sticking paint containing fluorine-silicon materials, which comprises a coating material portion and a curing agent portion, wherein the amount of the curing agent is 6.5-12% of the coating material portion, the coating material portion mainly comprises fluorocarbon resin, 10-20% of organosilicon resin, 3-30% of color filler, 1-5% of silicon micronized quartz powder and 3-10% of fluorine micronized powder, the curing agent is at least one of biuret, HDI trimer and organotin, the fluorocarbon resin is prepared from perfluoroethylene monomer, alkyl vinyl ester and functional monomers through copolymerization, wherein the fluorine content is greater than 35wt%, the solid content is greater than 50%, the organosilicon resin is end monohydric organosilicon resin.

Owner:ZIBO YINGQIANG CHEM TECH

Preparation method of metallic lithium strip and metallic lithium strip prepared by the same

ActiveCN104993094AAdvantages of preparation methodFacilitate strippingElectrode rolling/calenderingMetallic lithiumBond Force

Belonging to the technical field of metal lithium, the invention particularly relates to a preparation method of a metallic lithium strip. The method includes: firstly selecting a substrate, then treating the substrate with a lubricant, placing a lithium source cloth between two layers of treated substrates, and then performing rolling to obtain a composite lithium strip, selecting the radius ratio of the rolling rollers and adjusting the speed of the double rollers in the rolling process to make the bonding force between the lithium strip and the two layers of substrates different, and finally peeling the substrate with small bonding force to the lithium layer in the composite lithium strip, thus obtaining a single side self-supported metallic lithium strip. The method for preparation of metallic lithium strip is simple, and the prepared lithium strip has good thickness uniformity.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

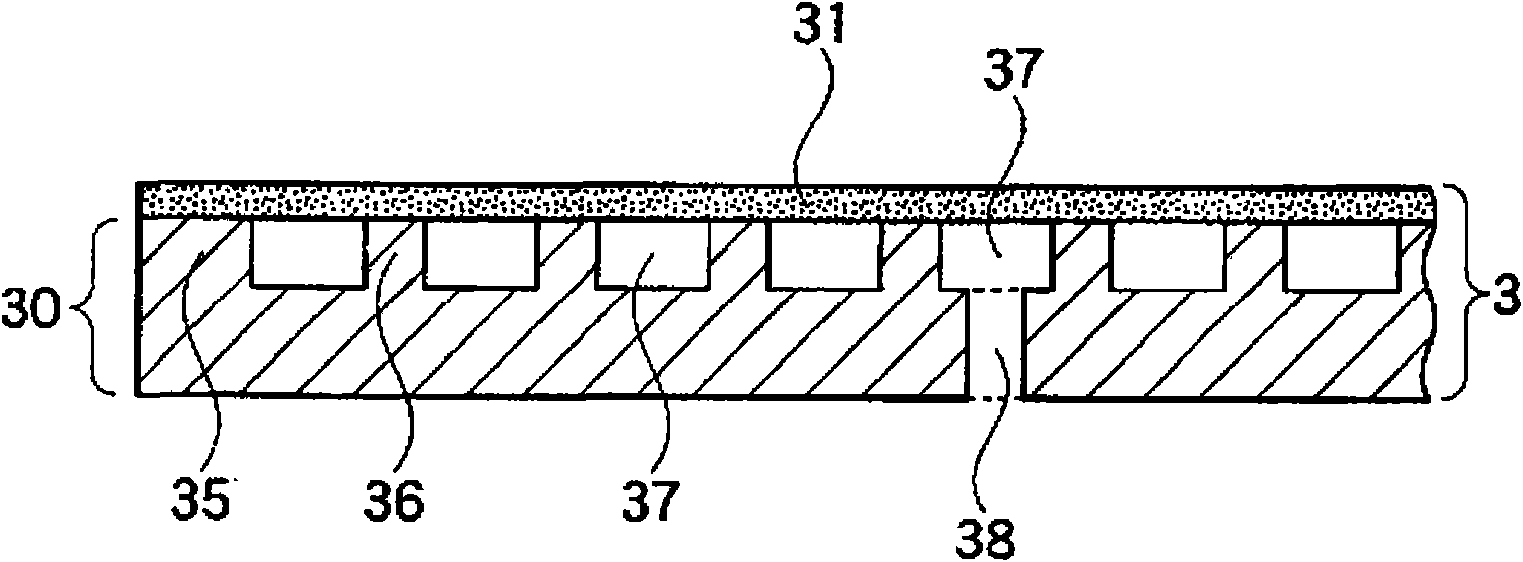

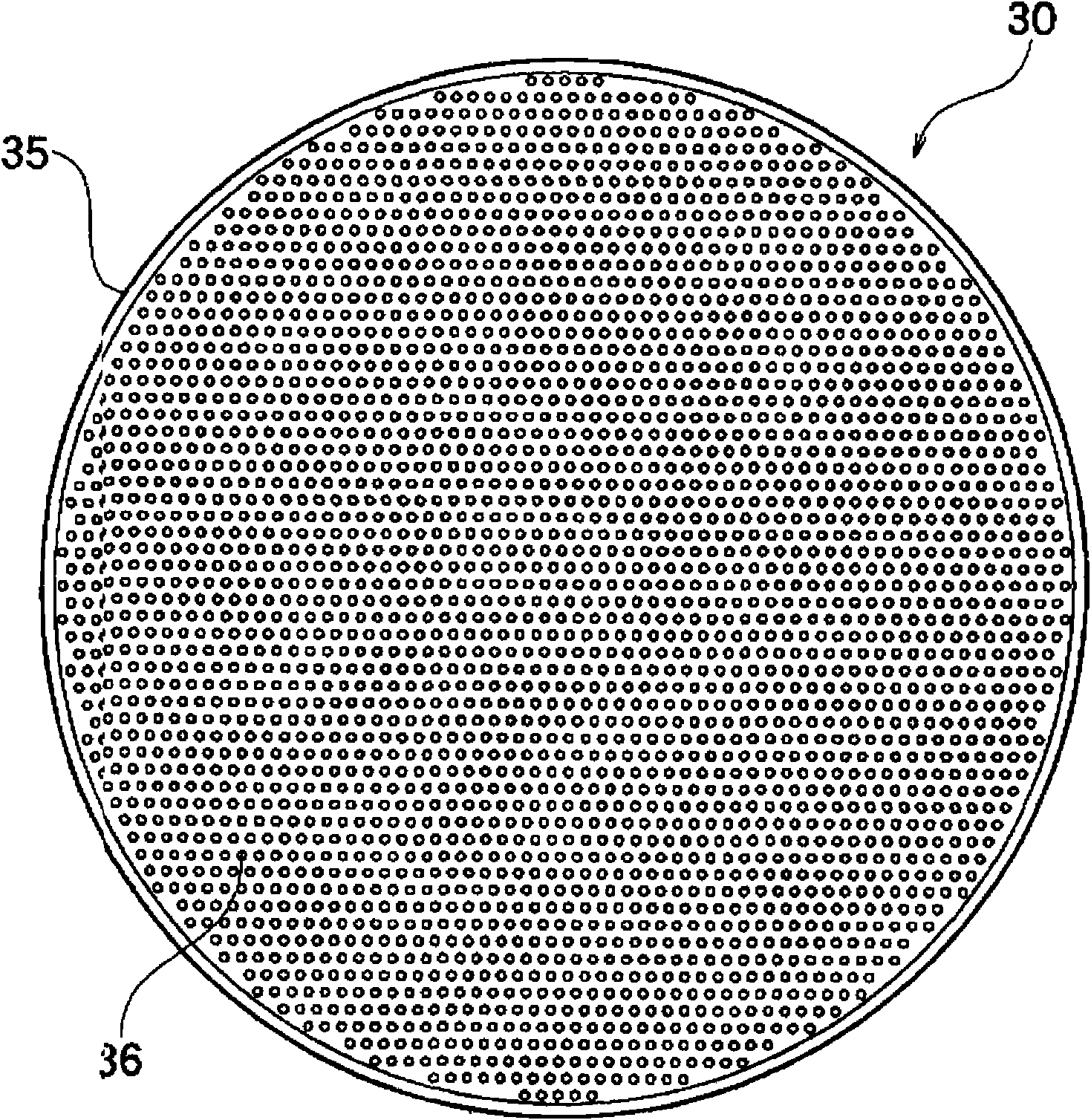

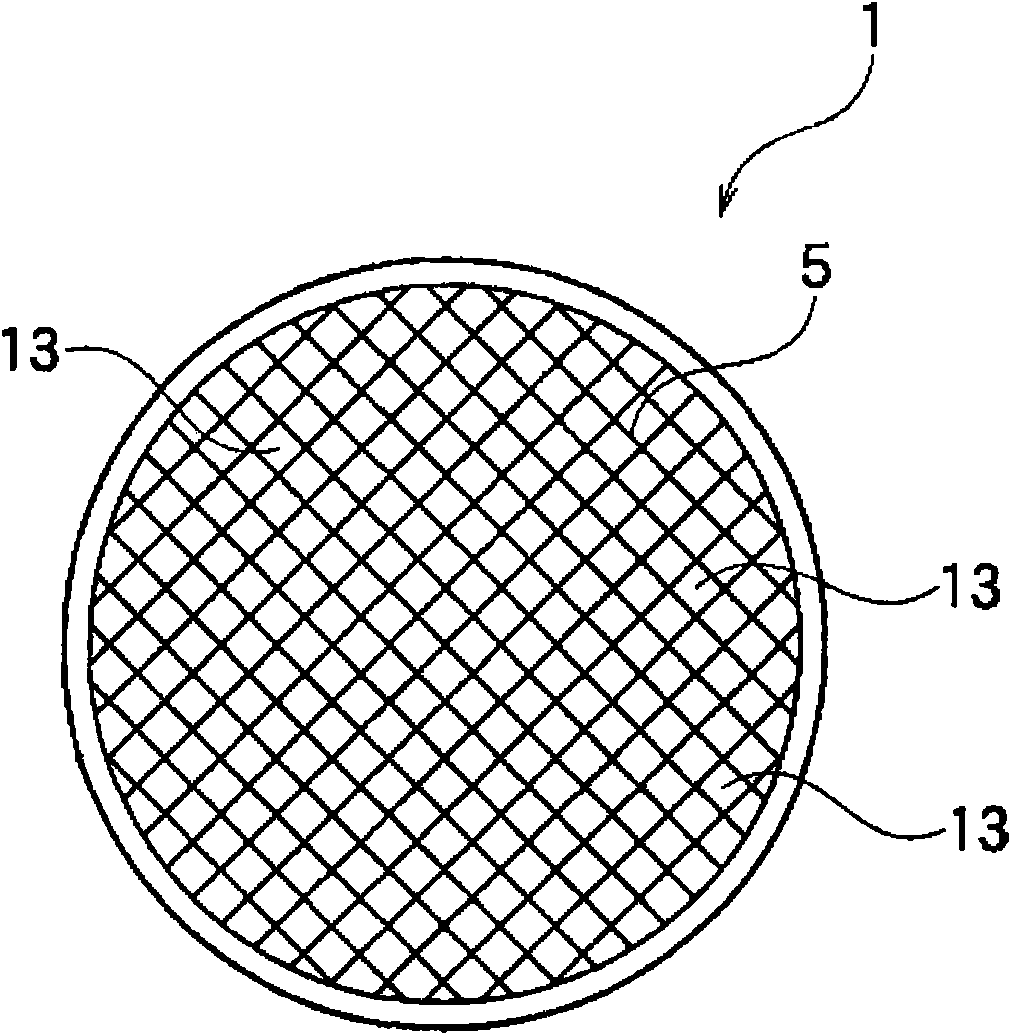

Chip pickup method and chip pickup apparatus

InactiveCN101529575AEx situ implementation of pickup methodsFacing the idealSemiconductor/solid-state device manufacturingElectrical componentsEngineeringElectrical and Electronics engineering

The present invention provides a pickup method and a pickup apparatus wherein pushing up of a chip is not required and a force for holding a chip which is not picked up is not varied as pickup progresses. A method is provided for picking up a chip (13) from a fixed jig (3) to which the chip (13) is fixed. The fixed jig (3) consists of a jig base (30) having a plurality of protrusions (36) on one side and a sidewall (35) of substantially the same height as that of the protrusion (36) at the outer circumference of the one side, and an adhesion layer (31) laminated on the surface of the jig base (30) having the protrusions (36) and bonded on the upper surface of the sidewall (35). A section space (37) is formed on the surface of the jig base (30) having the protrusions by the adhesion layer (31), the protrusions (36) and the sidewall (35), and at least one through hole (38) penetrating the outside and the section space (37) is provided in the jig base (30). The pickup method comprises a step for fixing a chip, a step for deforming the adhesion layer (31) by sucking air in the section space (37) through the through hole (38), and a step for picking up the chip (13) completely from the adhesion layer (31) by sucking the chip (13) from the upper surface side of the chip (13) by means of a suction collet (70).

Owner:LINTEC CORP

Method of bonding glass members

InactiveUS6314759B1Easy to peel offNot to damageGlass/slag layered productsOptical partsMetalFirst glasses

After a film made of SiO2 is formed on at least a part of a bonding surface of a first glass member, a part of or the whole bonding surface being formed with a metal film, a second glass member is hot-pressed against the bonding surface at a predetermined pressure and a predetermined temperature. As the second glass member is hot-pressed by way of the SiO2 film against the bonding surface of the first member made of glass or the like having its bonding surface formed with a metal film, the two glass members are firmly bonded together, the bonding surface would be less likely to peel off, and the metal film would not be damaged.

Owner:HAMAMATSU PHOTONICS KK

Method for quickly repairing concrete pavement defects

InactiveCN108755334AAdhesive strength hasIncrease elasticityPaving detailsRoads maintainenceEpoxyEngineering

The invention relates to a method for quickly repairing concrete pavement defects. The method comprises the following steps: (1) opening a groove in a crack needing to be repaired, wherein the grooveis 2-3 mm in width and 3-5 cm in depth, blowing accumulated water in the groove, injecting epoxy slurry in the crack, covering the upper part of the groove filled with the slurry with strip-shaped plastic cloth, drilling inclined holes in one side of the crack along the length direction of the crack, pouring the epoxy slurry in each drilled inclined hole and plugging the drilled inclined holes after pouring the epoxy slurry in the inclined holes; and (2) cleaning and polishing hollow parts needing to the repaired until the hollow part is lower than the concrete surface outside the hollow partby 3-4 mm, performing epoxy slurry injection treatment on the crack on the concrete surface of the repaired part, pouring the prepared epoxy bituminous grout or epoxy bituminous mortar in the hallow part to be repaired, beating packing by using a rubber hammer until the packing is flush with the concrete surface of a pavement, covering with the strip-shaped plastic cloth after finishing leveling,and repairing after curing. The invention provides the method for quickly repairing concrete pavement defects which has the advantages that on the basis of not damaging or using the undamaged concreteon an original pavement as far as possible, the pavement repairing treatment quantity is reduced, the impact and wear resistance is high, and the repairing speed is high.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

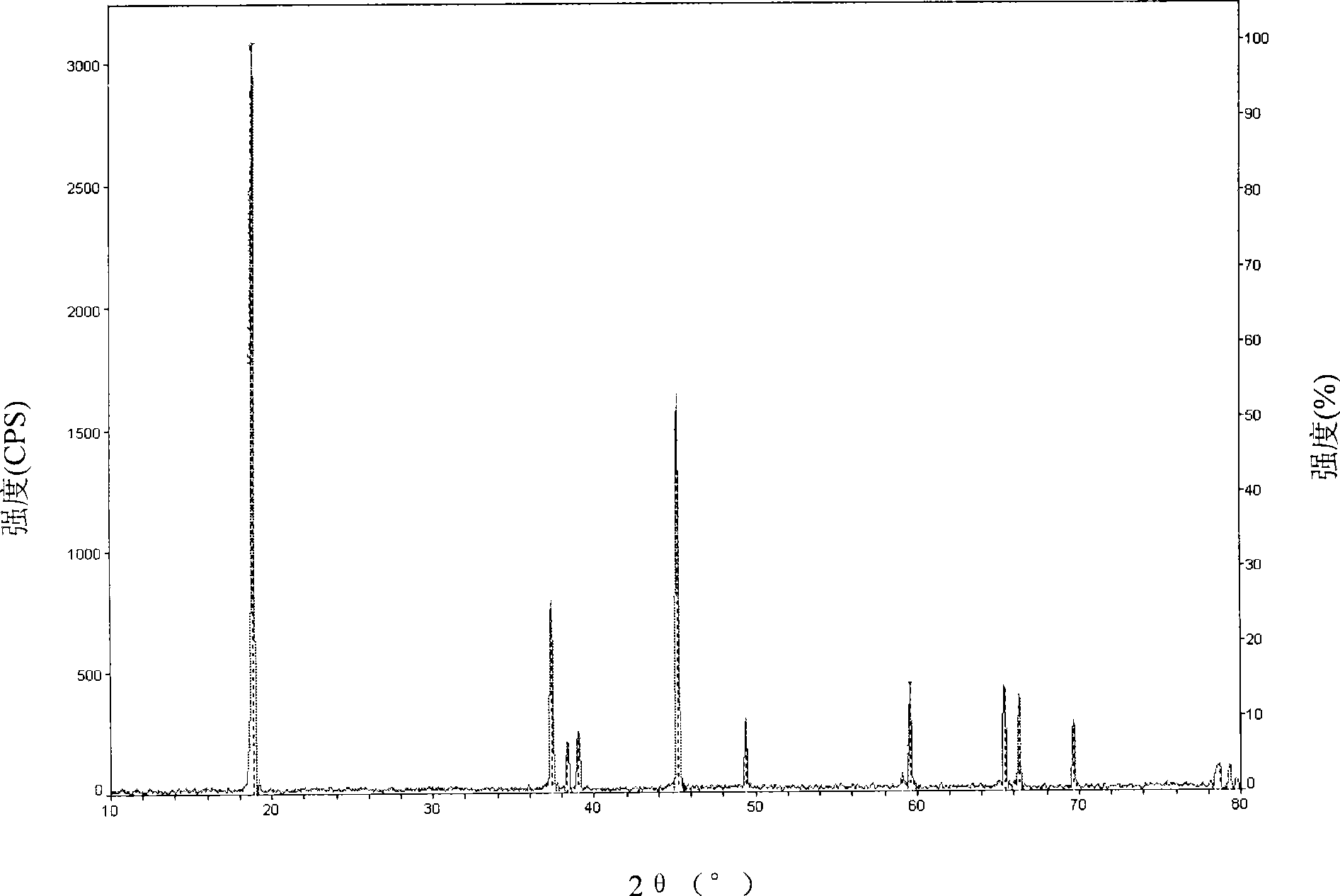

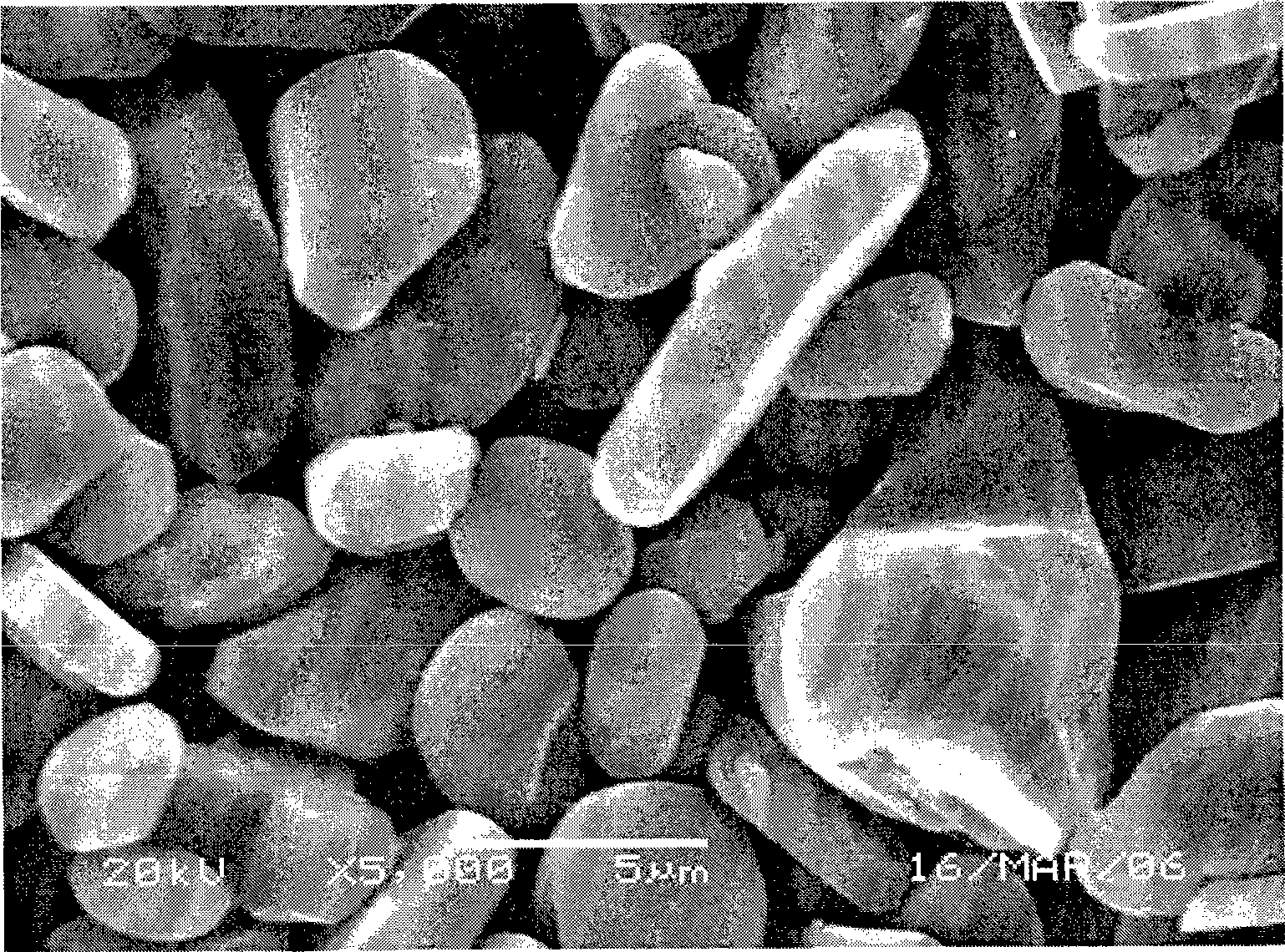

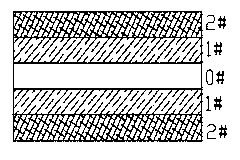

Process for preparing layered silicon nitride ceramic with high strength and high toughness by utilizing component gradient design

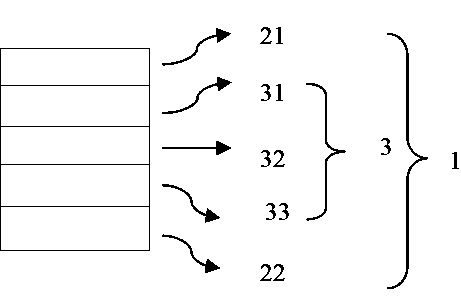

The invention aims to provide a process for preparing layered silicon nitride ceramic with high strength and high toughness by utilizing component gradient design, which comprises the following steps: (1), selecting alpha-Al2O3 and Y2O3 as sintering aids; (2), burdening, respectively weighing commercially available alpha-Si3N4, alpha-Al2O3 and Y2O3 powder according to the proportion of a burden sheet, taking absolute ethyl alcohol as a dispersion medium and a silicon nitride ball with the diameter of 2-3 mm as a grinding medium, ball-milling and uniformly mixing in a nylon tank, and controlling the granularity of a mixed material at about D50=0.2 mu m; (3), forming, adding a 5-9 wt% of polyving akohol (PVA) solution with the concentration of 3 wt% as a temporary binder into the mixed powder, adding various materials with corresponding numbers according to the charging sequence in the picture 1, pressing into blocky structures by using an isostatic pressing machine below 100 MPa, and controlling the thickness of each layer after being pressed at about 2 mm; and (4), sintering.

Owner:SHANDONG UNIV OF TECH

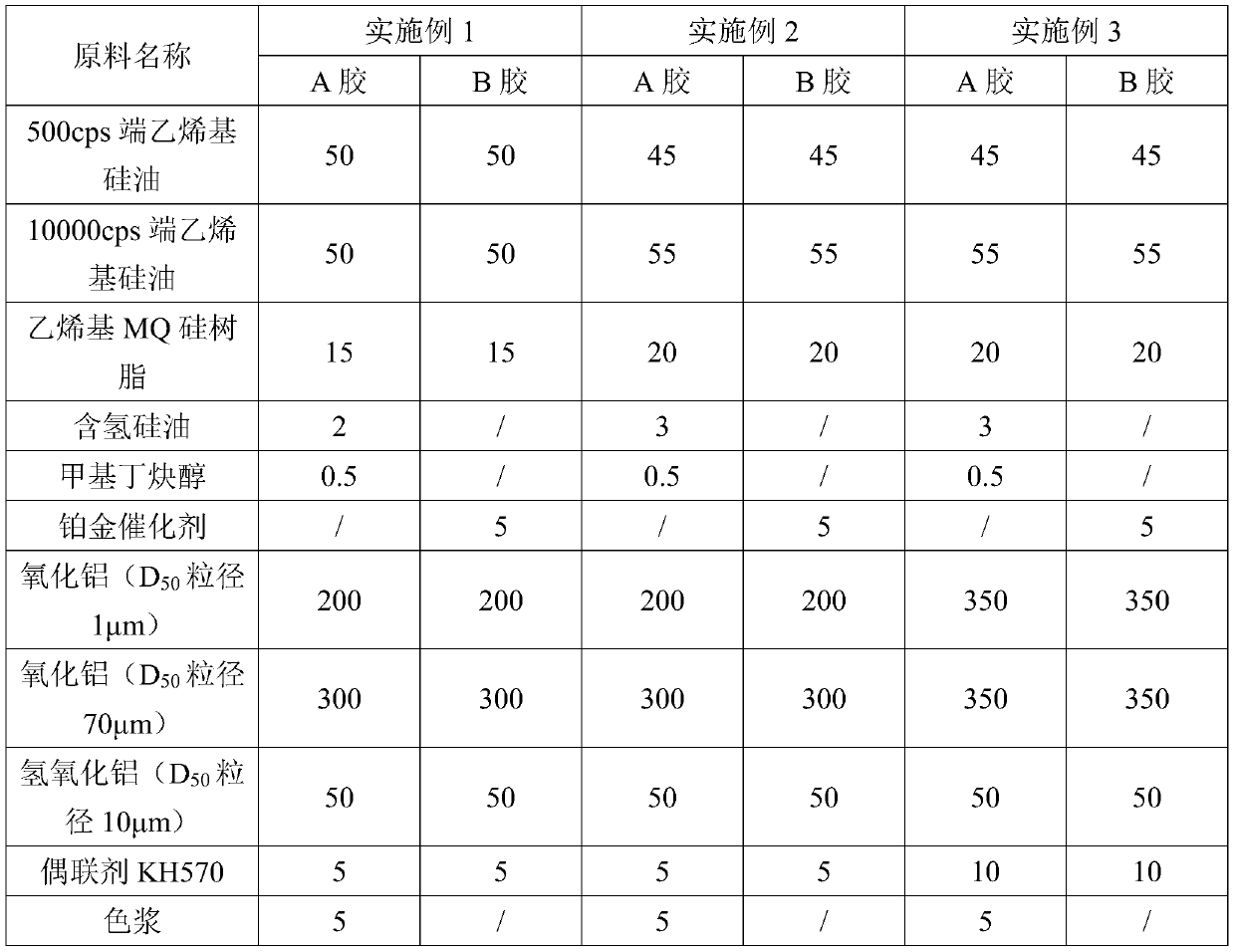

Heat-conducting silica gel as well as preparation method and application thereof

InactiveCN111004510ANot easy to settleHigh thermal conductivityHeat-exchange elementsSilicone resinPolymer chemistry

The invention provides heat-conducting silica gel as well as a preparation method and application thereof. The heat-conducting silica gel comprises an adhesive A and an adhesive B according to a massratio of (0.5-1.5): 1; wherein the adhesive A comprises the following components in parts by weight: 100 parts of vinyl silicone oil, 10-30 parts of vinyl MQ silicone resin, 0.5-5 parts of hydrogen-containing silicone oil, 0.1-2 parts of an inhibitor, 300-1500 parts of a heat-conducting filler and 1-10 parts of a coupling agent; the adhesive B is prepared from 100 parts of vinyl silicone oil, 10 to 30 parts of vinyl MQ silicon resin, 1 to 20 parts of a catalyst, 300 to 1500 parts of a heat-conducting filler and 1 to 10 parts of a coupling agent; and the vinyl silicone oil is prepared from vinyl silicone oil with the viscosity of 1 to 2000 cps and vinyl silicone oil with the viscosity of 5000 to 65000cps. The heat-conducting silica gel provided by the invention has good storage stability, and a cured product of the heat-conducting silica gel has relatively high strength and toughness and is easy to integrally peel off.

Owner:CYBRID TECHNOLOGIES INC

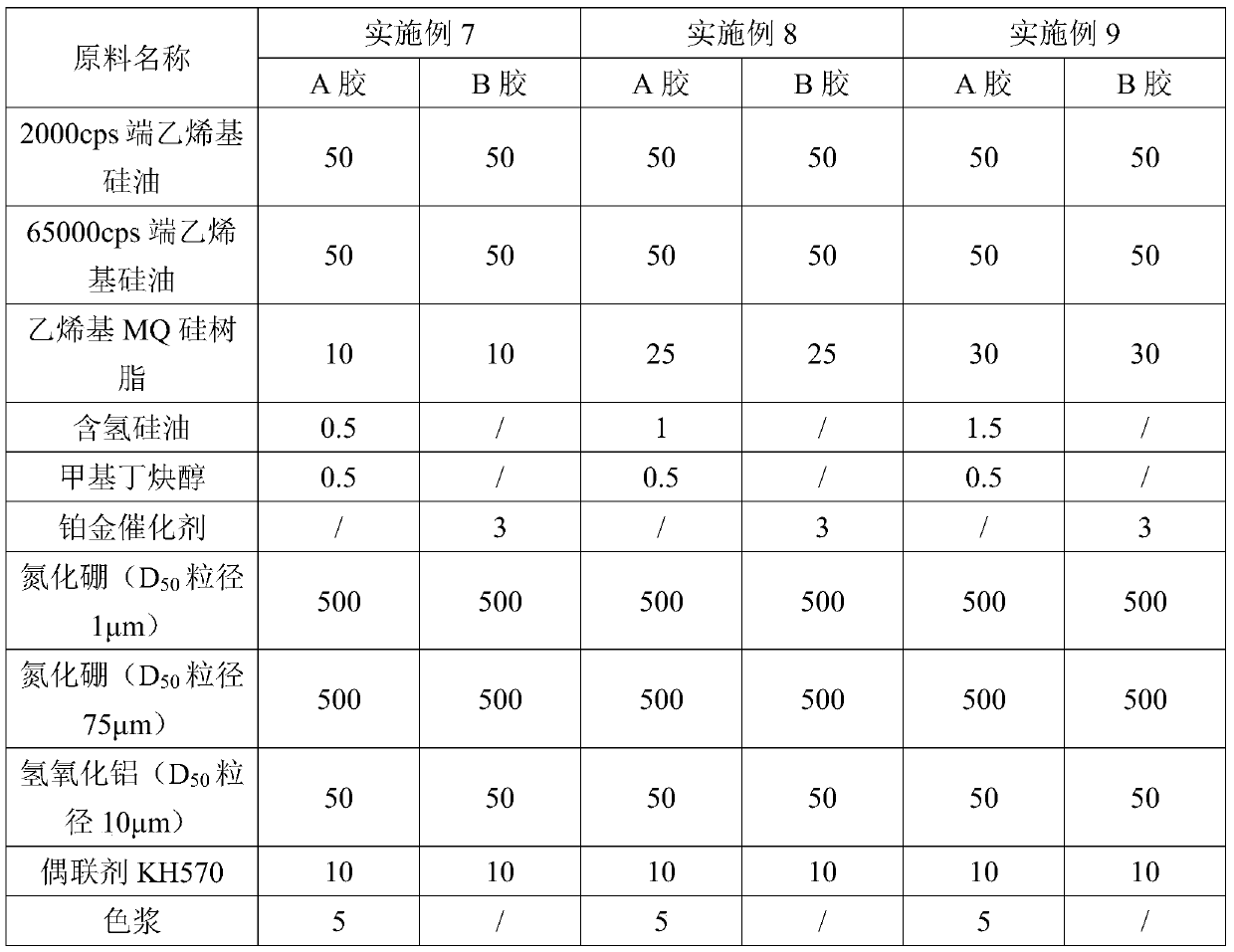

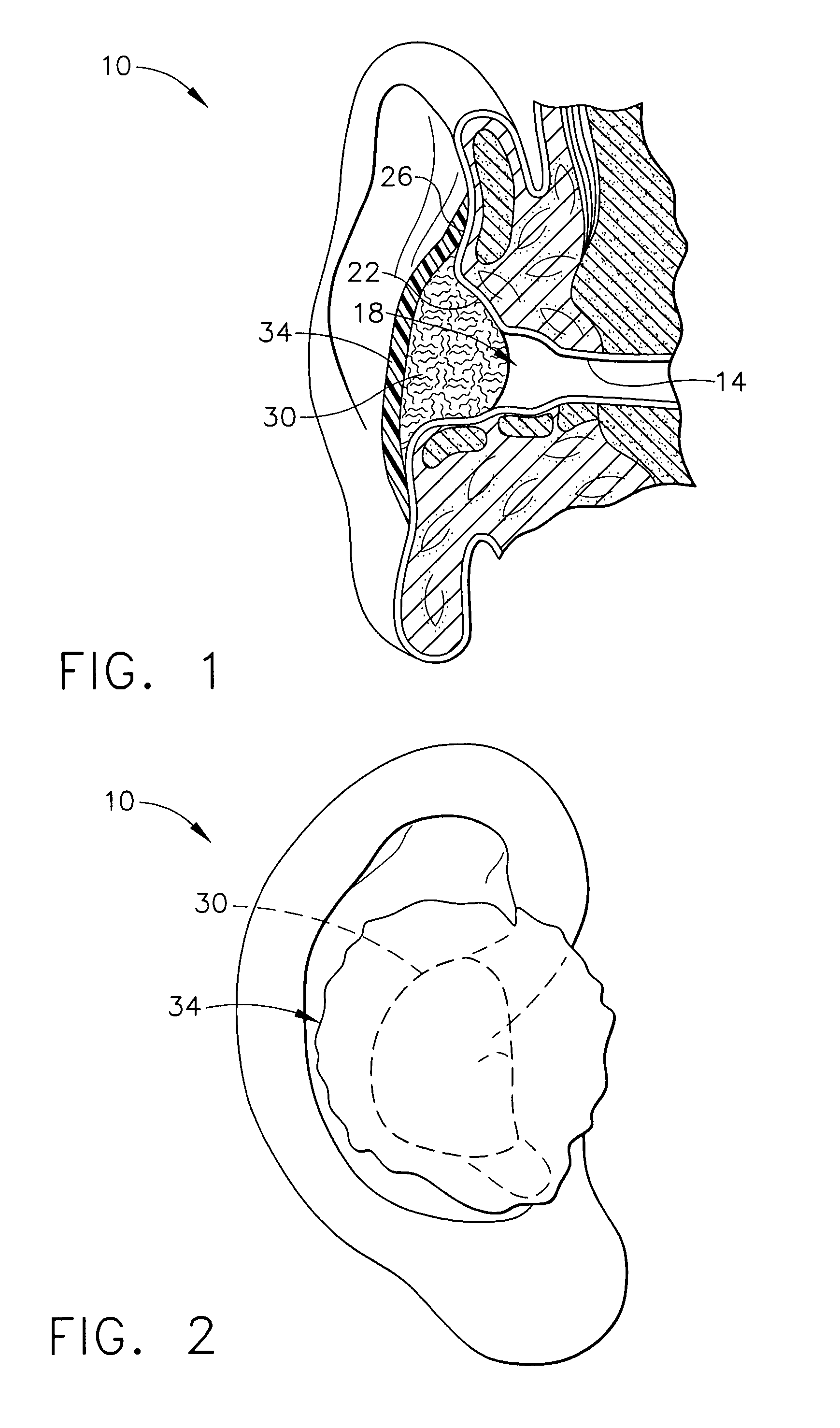

Method for forming occlusive barrier over ear canal and kit for providing same

A method for forming an occlusive, typically temporary barrier over the entrance of the ear canal of a user. The method comprises the steps of: (a) without entering the ear canal, covering the entrance of the ear canal of the user with a substrate capable of supporting the formation of an occlusive barrier that substantially covers the entrance to the ear canal while preventing the occlusive barrier from entering the ear canal; (b) applying to the substrate a composition capable of forming in situ a occlusive barrier thereon; and (c) allowing the applied composition to form the occlusive barrier on the substrate in a manner such that the occlusive barrier substantially prevents the entry of solid or liquid foreign matter into the ear canal. A kit can be provided that comprises (1) at least one component selected from: (a) a source of the substrate; and (b) a source of the composition for in situ formation of the occlusive barrier on the substrate; and (2) instructions associated with the at least one component which describe the method for forming the occlusive barrier on the substrate.

Owner:JOHNSON ARTHUR ALAN

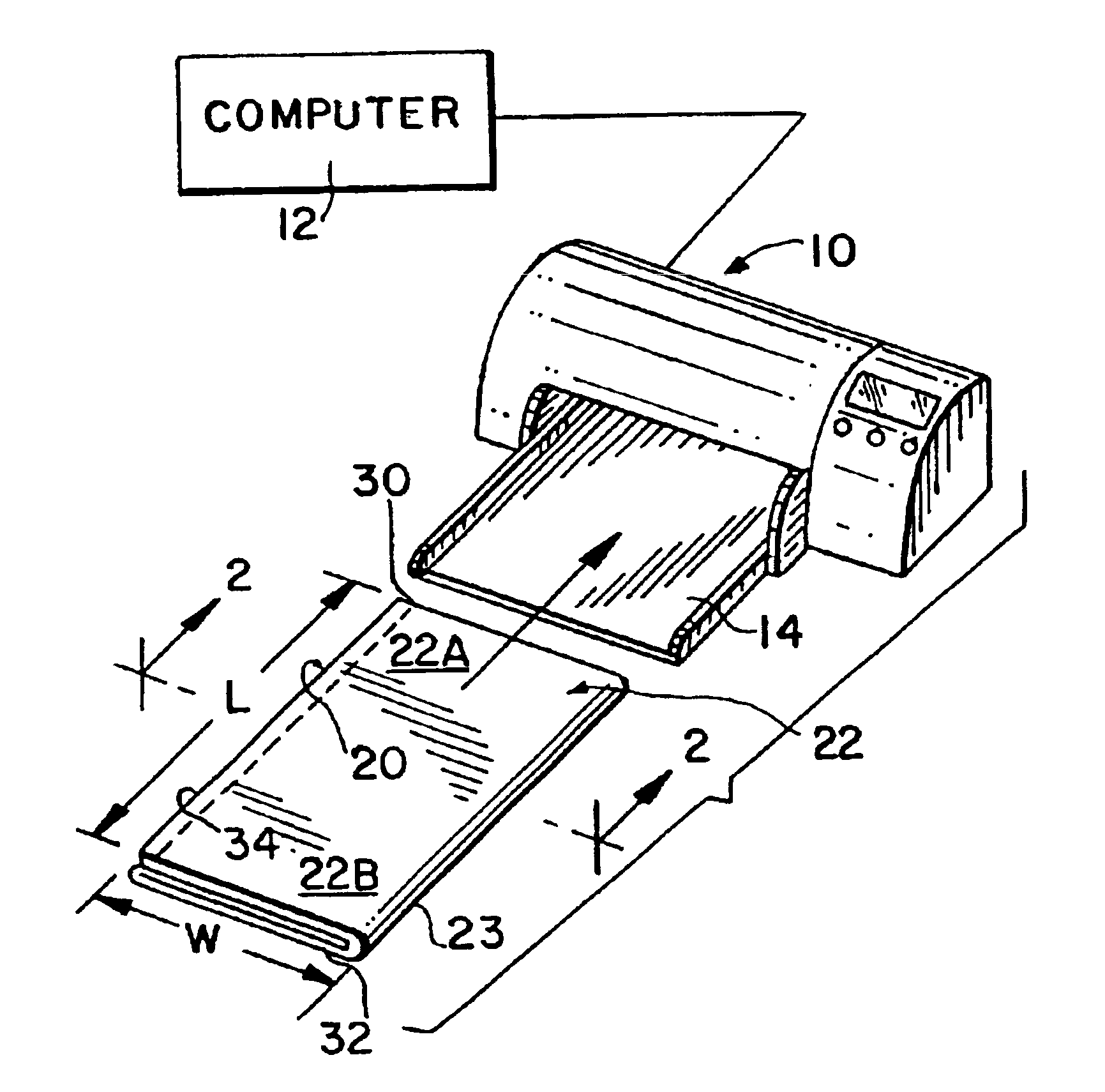

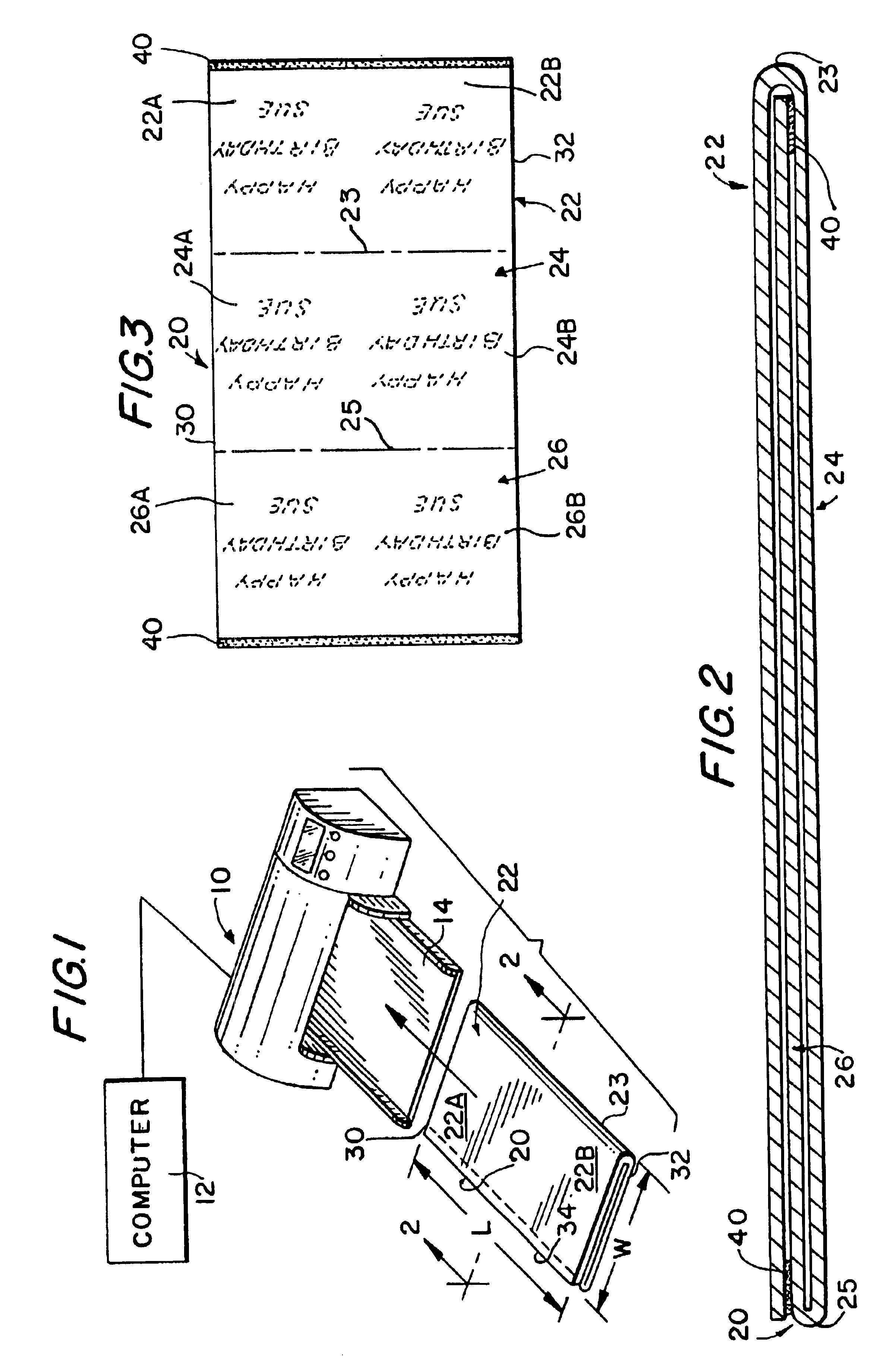

Custom-decorated giftwrap, kit, and method of and system for custom-decorating the giftwrap

InactiveUS6886309B2Simple designEasy to useEnvelopes/bags making machineryWrappersEngineeringSheet material

A custom-decorated giftwrap is made by feeding a folded sheet into a printer, while avoiding paper jams therein by holding together sheet portions of the sheet.

Owner:PHILLIPS CHARLES

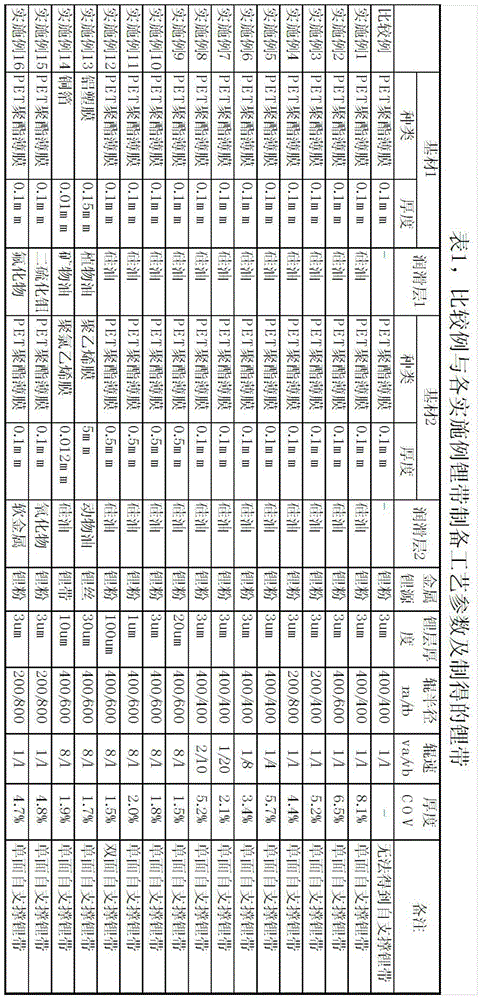

Re-peel-off type special double-faced adhesive sheet for fixing flexible printed circuit board

InactiveCN103834320AImprove yieldEasy to peel offFilm/foil adhesivesEster polymer adhesivesPolyesterAdhesive

The invention provides a re-peel-off type special double-faced adhesive sheet for fixing flexible printed circuit board. The double-faced adhesive sheet for fixing a flexible printed circuit board comprises a first core material layer, a first adhesive layer and a second adhesive layer, wherein the core material layer is arranged between the inner side of the first adhesive layer and the inner side of the second adhesive layer, the core material of the core material layer is a polyester film with thickness not more than 12 microns, the first adhesive layer is a re-peel-off layer, the second adhesive layer is a permanent fixing layer, the initial adhesive force of the first adhesive layer is not more than 700g / 20mm, and the adhesive force after being fixed is not less than 900g / 20mm, and the adhesive force of the second adhesive layer is not less than 900g / 20mm. The double-faced adhesive sheet is prepared by adopting special acrylic acid adhesive and can be re-peeled off within short time, and the re-work performance is good, the permanent adhesion and fixation after re-working and fixing can be satisfied, and the adhesive sheet cannot warp and deform after aging within a certain environment.

Owner:新纶电子材料(常州)有限公司

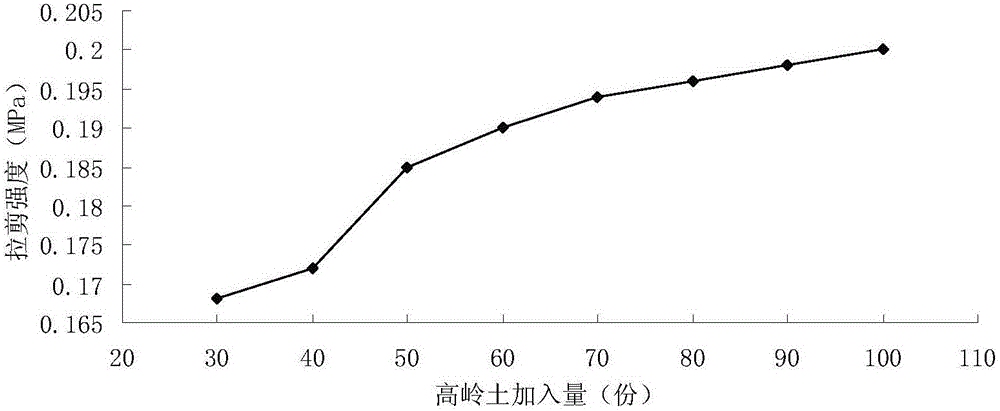

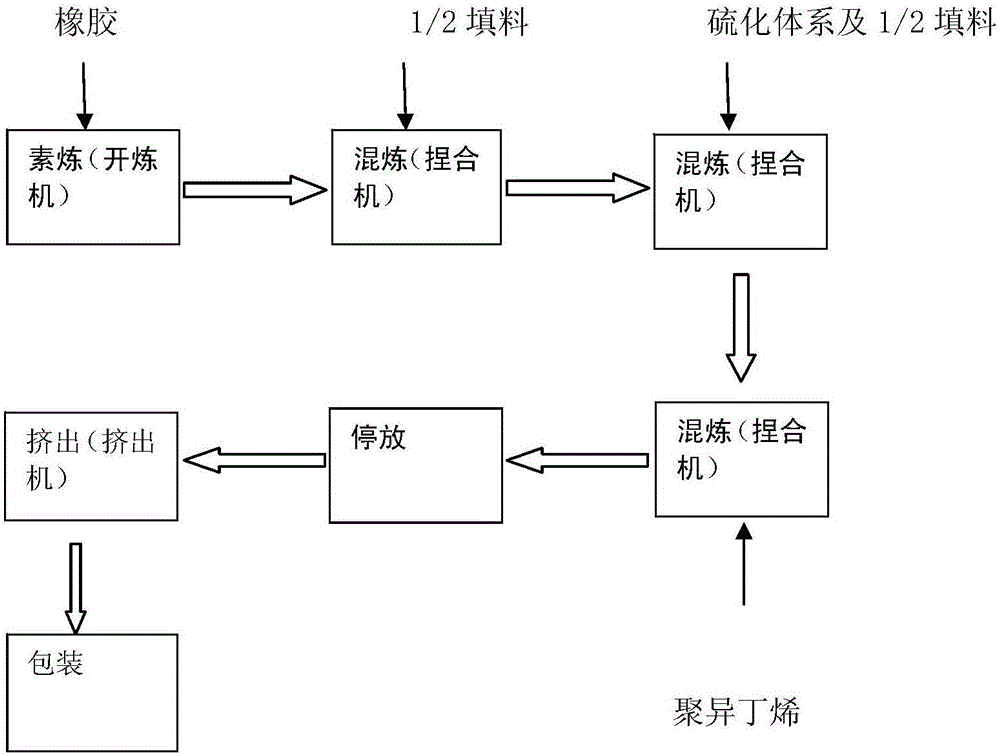

Vacuum bag sealing adhesive tape applicable under room temperature to 220 DEG C, and preparation method thereof

The invention relates to a pressure sensitive vacuum bag sealing adhesive tape applicable under room temperature to 220 DEG C. Chlorinated butyl rubber is adopted as the base adhesive material of the sealing adhesive tape. Tackifying resin, a filler, a vulcanizing agent, an activator, a scorch retarder, a water-absorbing agent, and a coupling agent are added to the base adhesive material. The adhesive tape has the following advantage: the air permeation of chlorinated butyl rubber is the lowest among all general rubbers, such that chlorinated butyl rubber has good air tightness; the sealing adhesive tape has good heat resistance, wherein phenolic resin vulcanized chlorinated butyl rubber has as an application temperature range from room temperature to 220 DEG C; the sealing adhesive tape is pressure sensitive, such that sealing can be realized with finger pressure, wherein the pressure sensitivity is provided by polyisobutylene; the sealing adhesive tape has good adhesiveness on various sealing films and molds. A vacuum bag prepared with the sealing adhesive tape can provide pressure close to 1atm. With the sealing adhesive tape, long-time sealing can be realized under room temperature to 220 DEG C, and leakage is prevented. The sealing adhesive tape is convenient to use.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

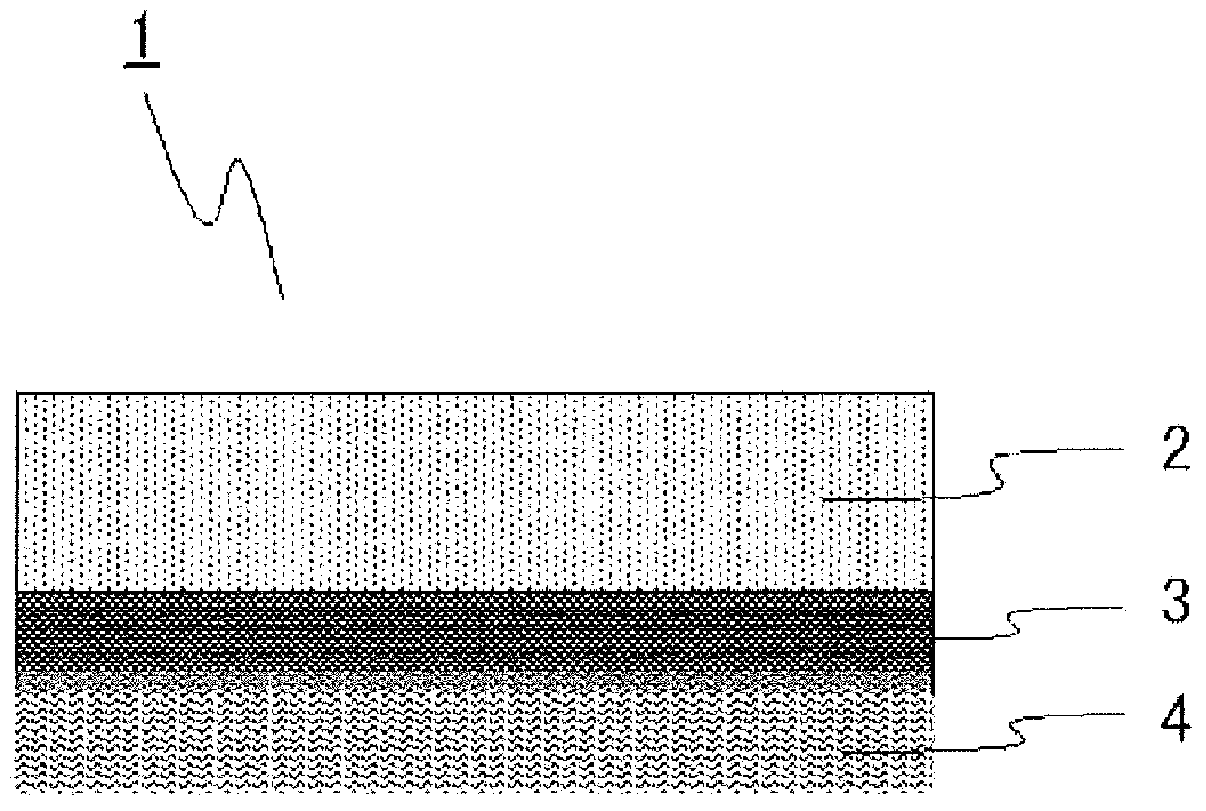

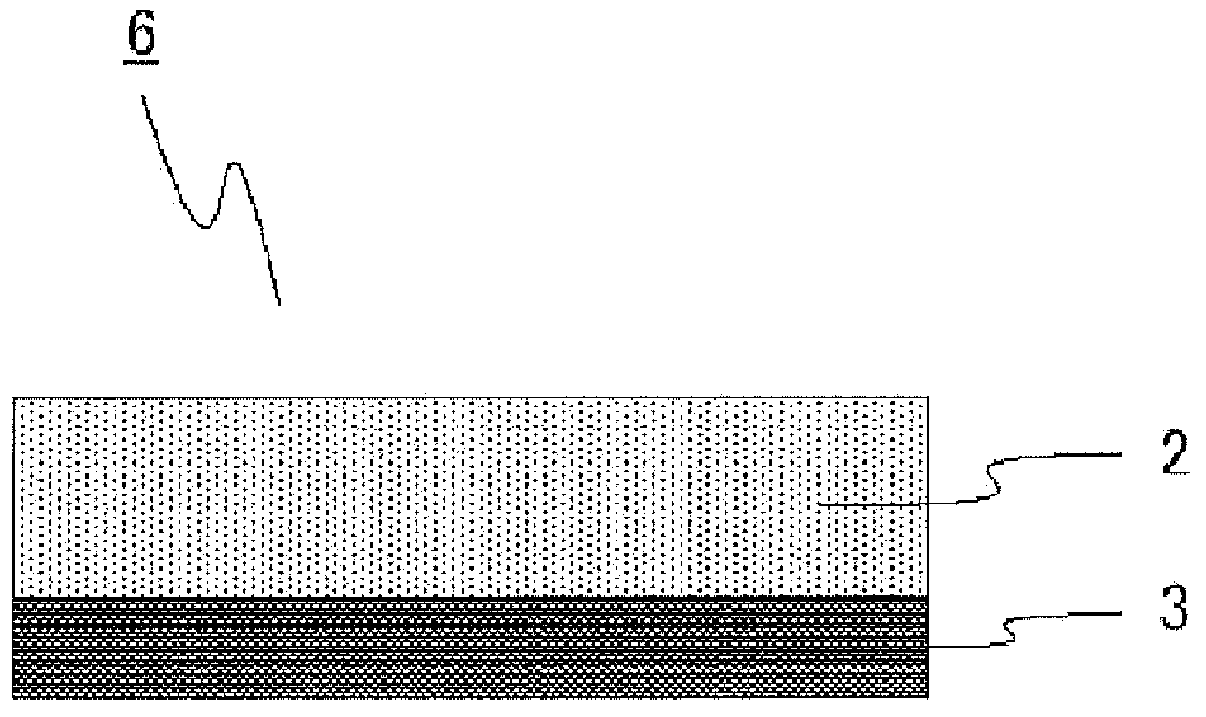

Water-activated sheet, water-activated label using said sheet, production method for said label, label adhering device using said label, and adherend for said label

Provided is a water-activated sheet (1) which has a porous water-absorbing layer (3) on at least one surface thereof, the liquid absorbing capacity of the water-absorbing layer being in the range of 1-10ml / m2. In the water-activated sheet (1), an adhesive layer (4) formed by coating and then drying solid a water-based adhesive is provided on top of the water-absorbing layer of a paper material. When used in a label, the water-activated sheet resolves the problems of conventional glued labels, such as creases in the labels and seepage of the glue of the labels due to condensation, the labour required to attach labels, the residual glue on the adherend after peeling off the labels, and pollution in the water used to remove the residual glue.

Owner:YUPO CORP

Composition of binder used for negative electrode of lithium ion secondary battery and preparation method thereof

ActiveCN107868160AExcellent battery characteristicsHas a rigid natureCell electrodesSecondary cellsLithiumMicroparticle

The invention relates to a composition of a binder used for a negative electrode of a lithium ion secondary battery and a preparation method thereof. The binder is a polymer microparticle emulsion binder, specifically a dispersion type polymer microparticle emulsion, wherein an emulsion dispersion is polymer microparticles; a dispersion medium is water; the dispersion polymer microparticles is a polymer which has a glass transition temperature of minus 50 to 50 DEG C and is copolymerized from a monomer containing conjugated diene, a monomer containing an aromatic vinyl group and an unsaturatedmonomer containing an epoxy group; and the polymer microparticle emulsion binder has a particle size of 50 to 300 nm, a gel content of 20 to 90% and a pH value of 4.0 to 7.0. The binder provided by the invention can be used for manufacturing of the negative electrode of the lithium ion secondary battery, and has an effect of binding an electrode active material, a conductive agent and a current collector.

Owner:NANJING TECH UNIV

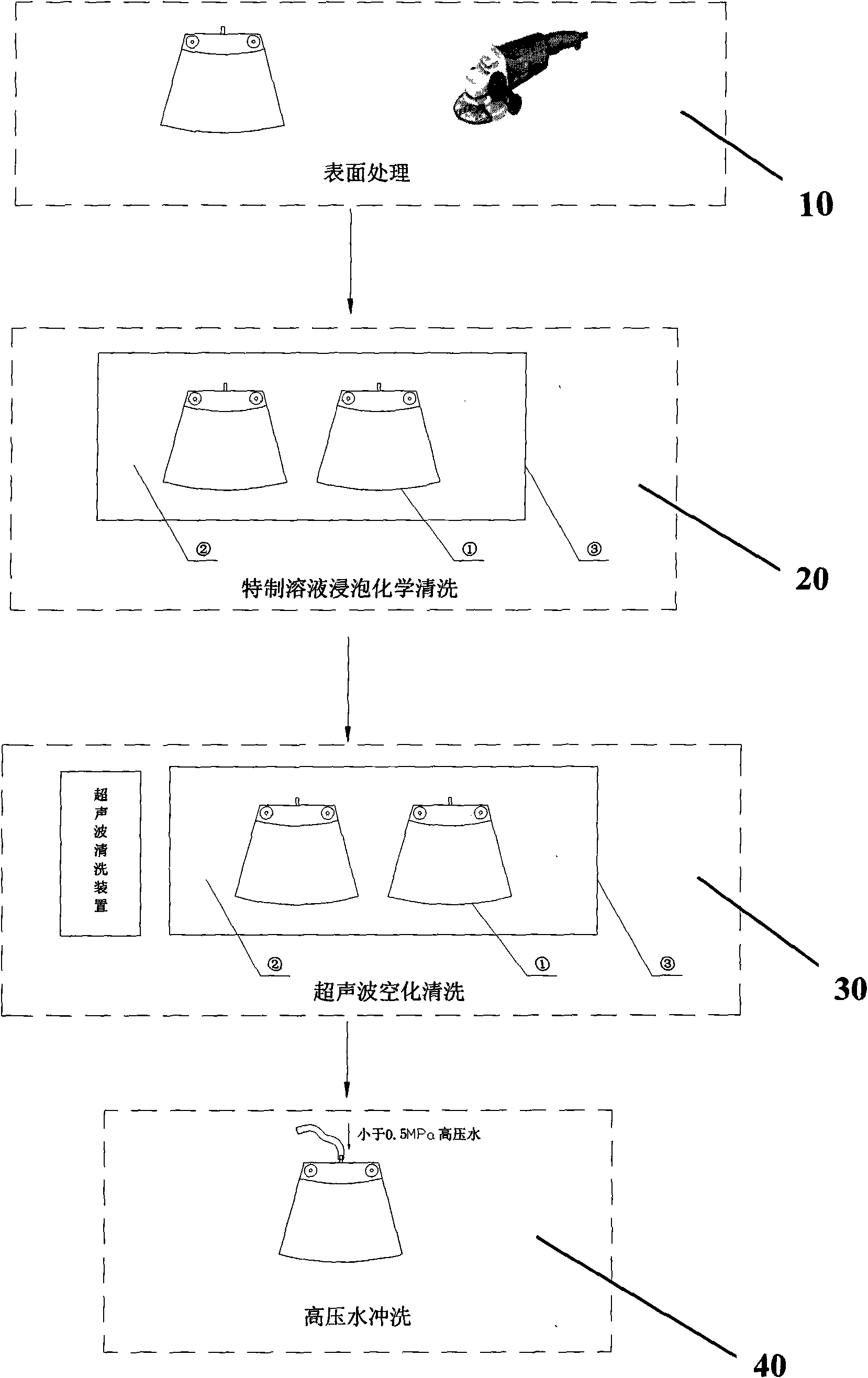

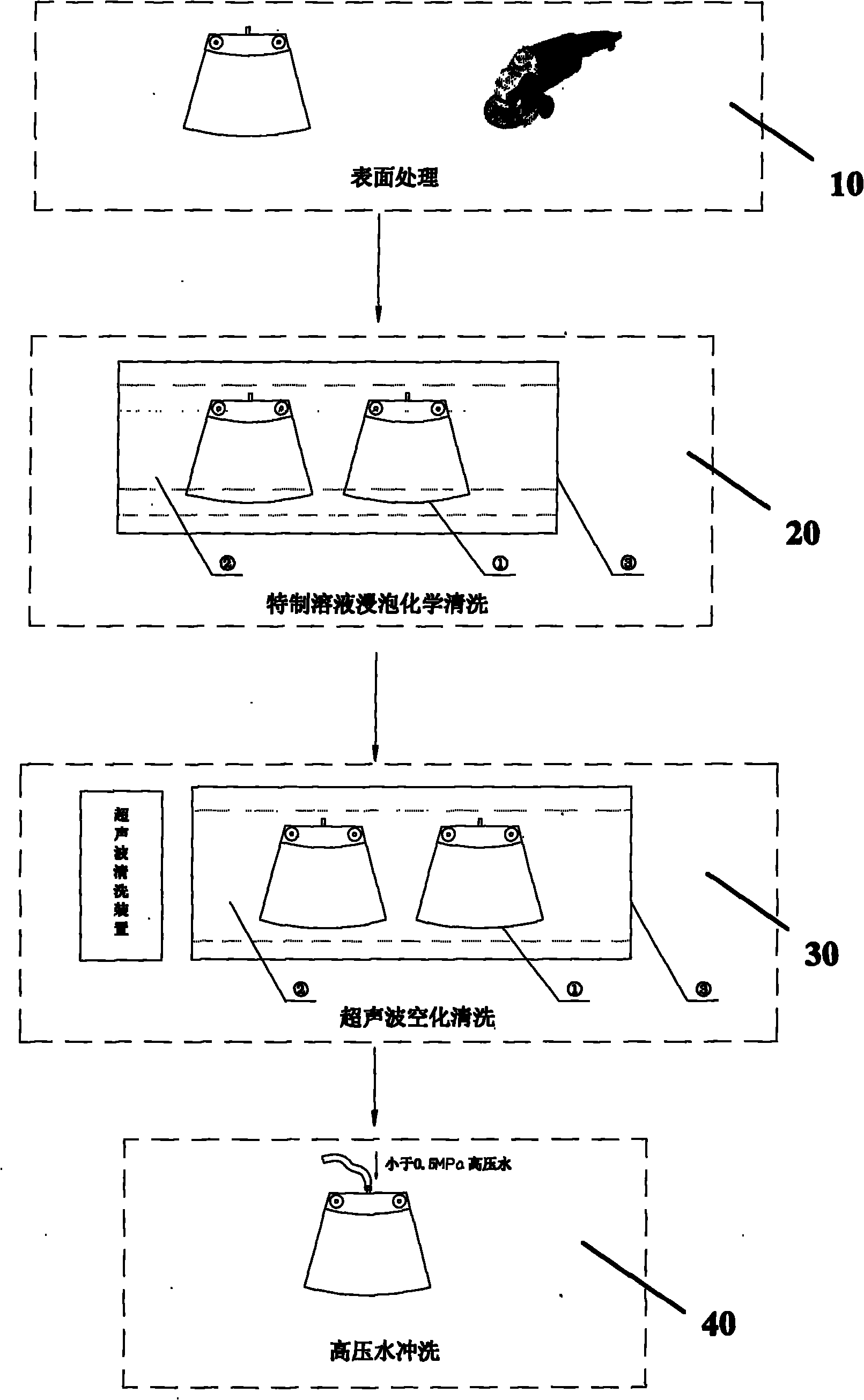

Method for cleaning ceramic filter plate of ceramic filter

InactiveCN101954226ASolve dirty cleaningExtended service lifeFilter regenerationVacuum ceramic filterMegasonic cleaning

The invention relates to a method for cleaning a ceramic filter plate of a ceramic filter. The cleaning method comprises a surface treatment step of the ceramic filter plate, wherein the surface treatment is surface polishing treatment of the ceramic filter plate. The cleaning method also comprises a chemical cleaning step, an ultrasonic cleaning step and a high-pressure water flushing step. The method has the advantages of simpleness in operation of the four steps and low cost, and greatly prolongs the service life of the ceramic filter plate; and the cleaning method can be reused, greatly reduces the operation cost of the ceramic filter, and can be popularized and applied to the filter plate of the ceramic filter.

Owner:宝钢集团上海梅山有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com