Patents

Literature

976results about How to "High degree of polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of making a photopolymer printing plate

ActiveUS20050266349A1High degree of polymerizationImage deteriorationPhotosensitive materialsDuplicating/marking methodsPhotopolymerEngineering

A method of making a lithographic printing plate comprising the steps of: a) providing a lithographic printing plate precursor comprising (i) a support having a hydrophilic surface or which is provided with a hydrophilic layer, (ii) a photopolymerizable coating on said support, b) image-wise exposing said coating in a plate setter, c) developing the precursor, thereby removing the non-exposed areas of the coating from the support, whereby the developing step is carried out off-press in a gumming unit by treating the coating of the precursor with a gum solution.

Owner:AGFA OFFSET BV

Method of making a lithographic printing plate

ActiveUS8232043B2High degree of polymerizationQuality improvementPlaten pressesPhotosensitive materialsInter layerEngineering

A method of making a lithographic printing plate includes the steps of a) providing a lithographic printing plate precursor including (i) a support having a hydrophilic surface or which is provided with a hydrophilic layer, (ii) a coating on the support including a photopolymerizable layer, and, optionally, an intermediate layer between the photopolymerizable layer and the support, b) image-wise exposing the coating in a plate setter, c) optionally, heating the precursor in a preheating unit, and d) developing the precursor off-press in a gumming unit by treating the coating of the precursor with a gum solution, thereby removing the non-exposed areas of the coating from the support, wherein the coating further includes a compound capable of interacting with the support, the compound being present in the photopolymerizable layer and / or in the intermediate layer.

Owner:AGFA OFFSET BV

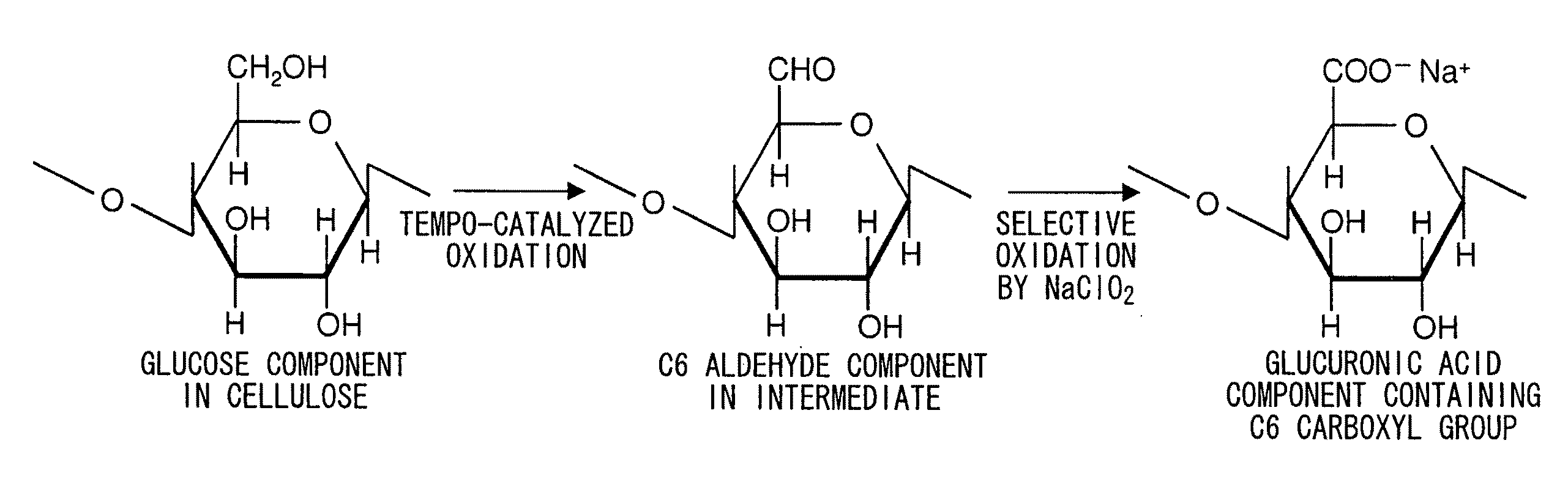

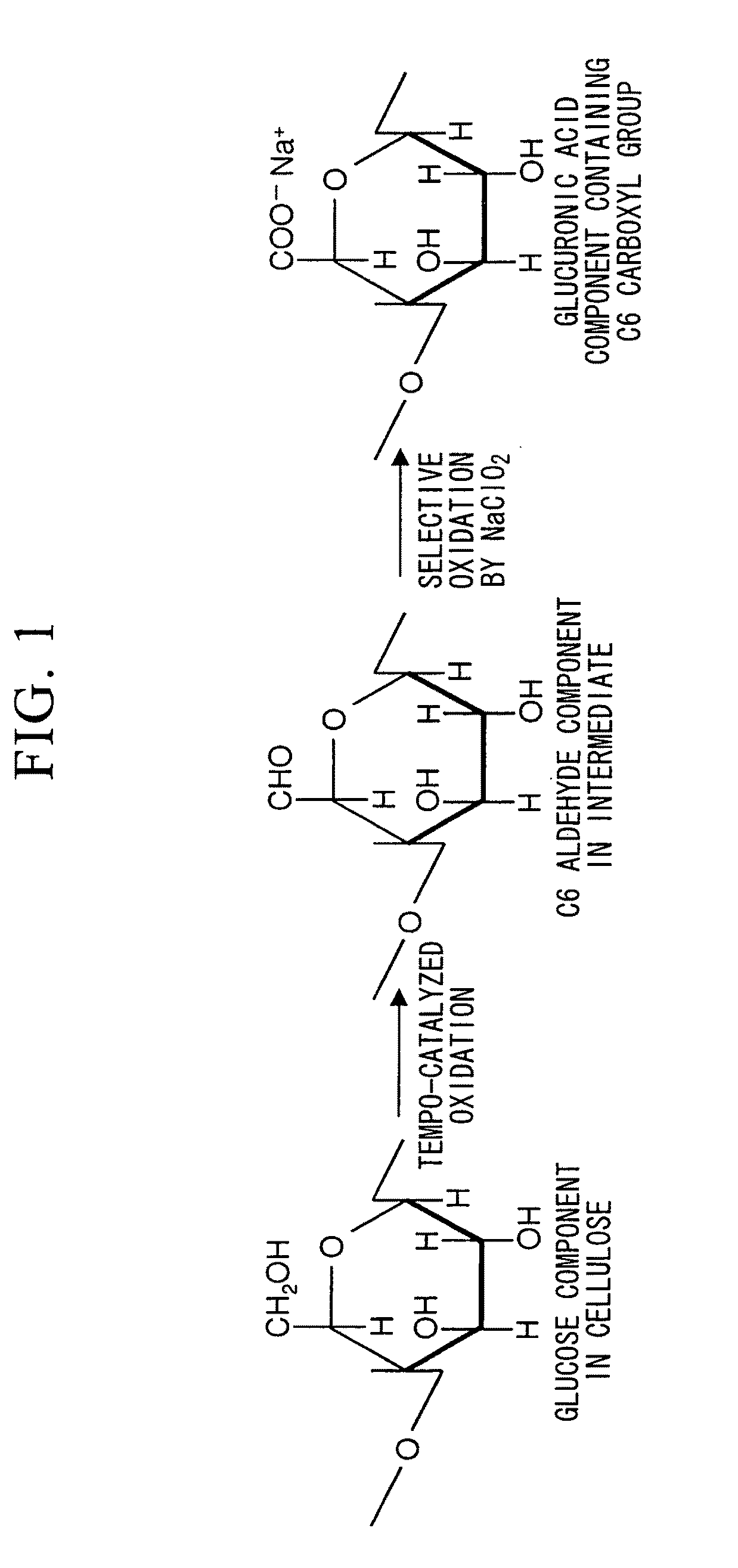

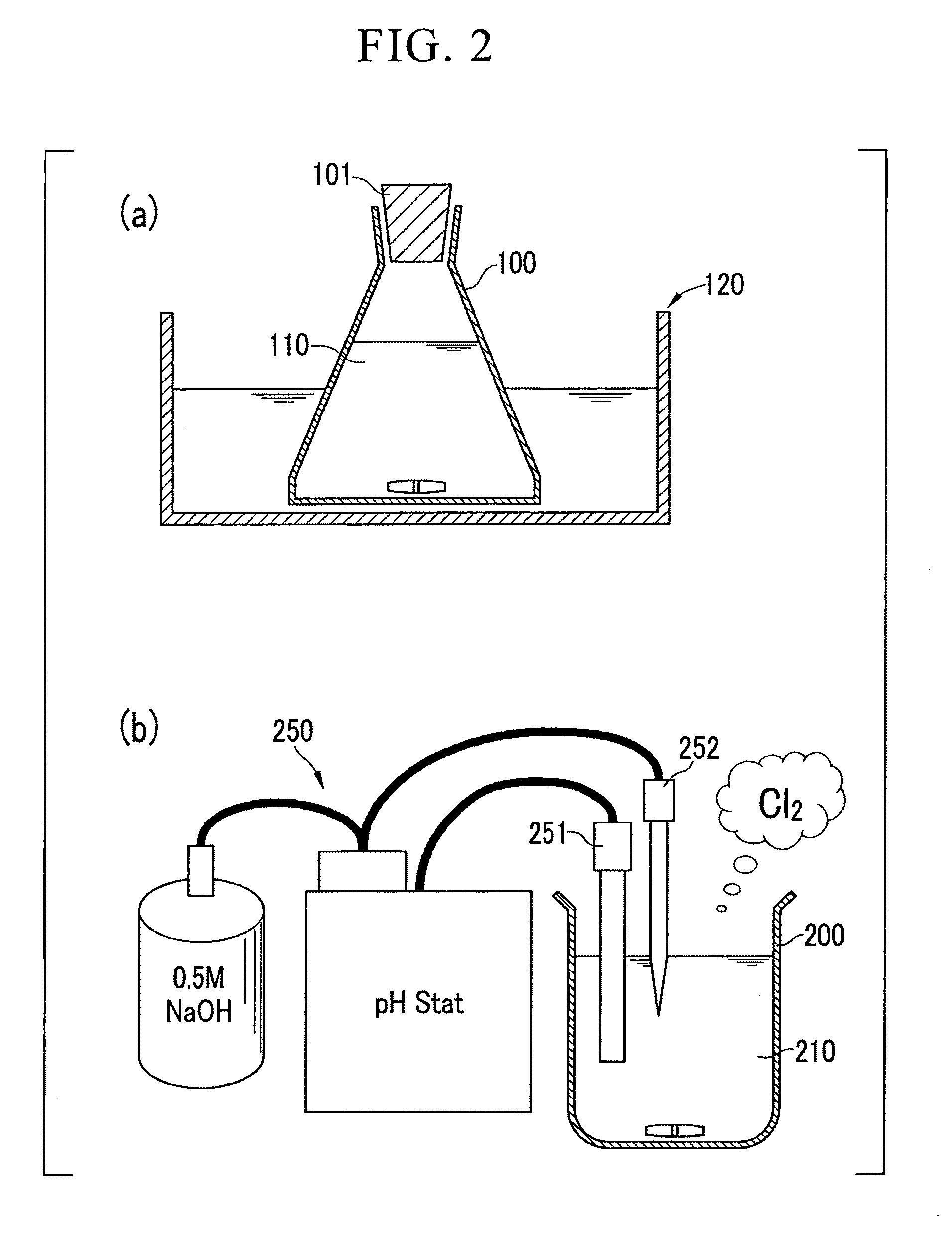

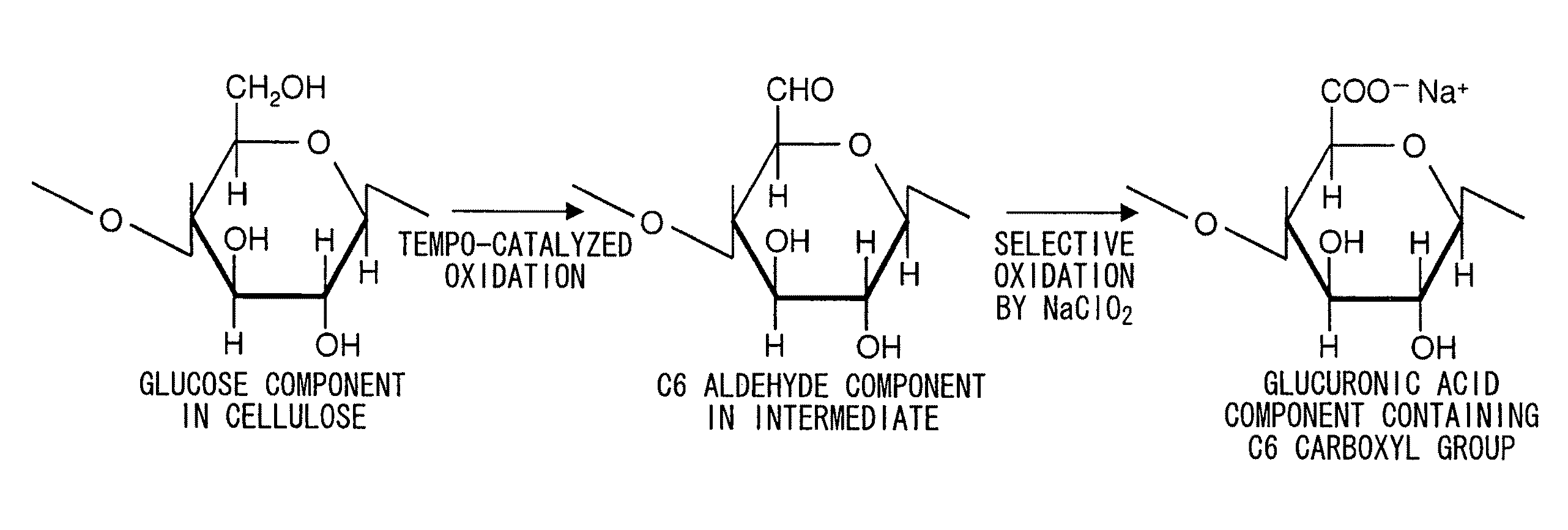

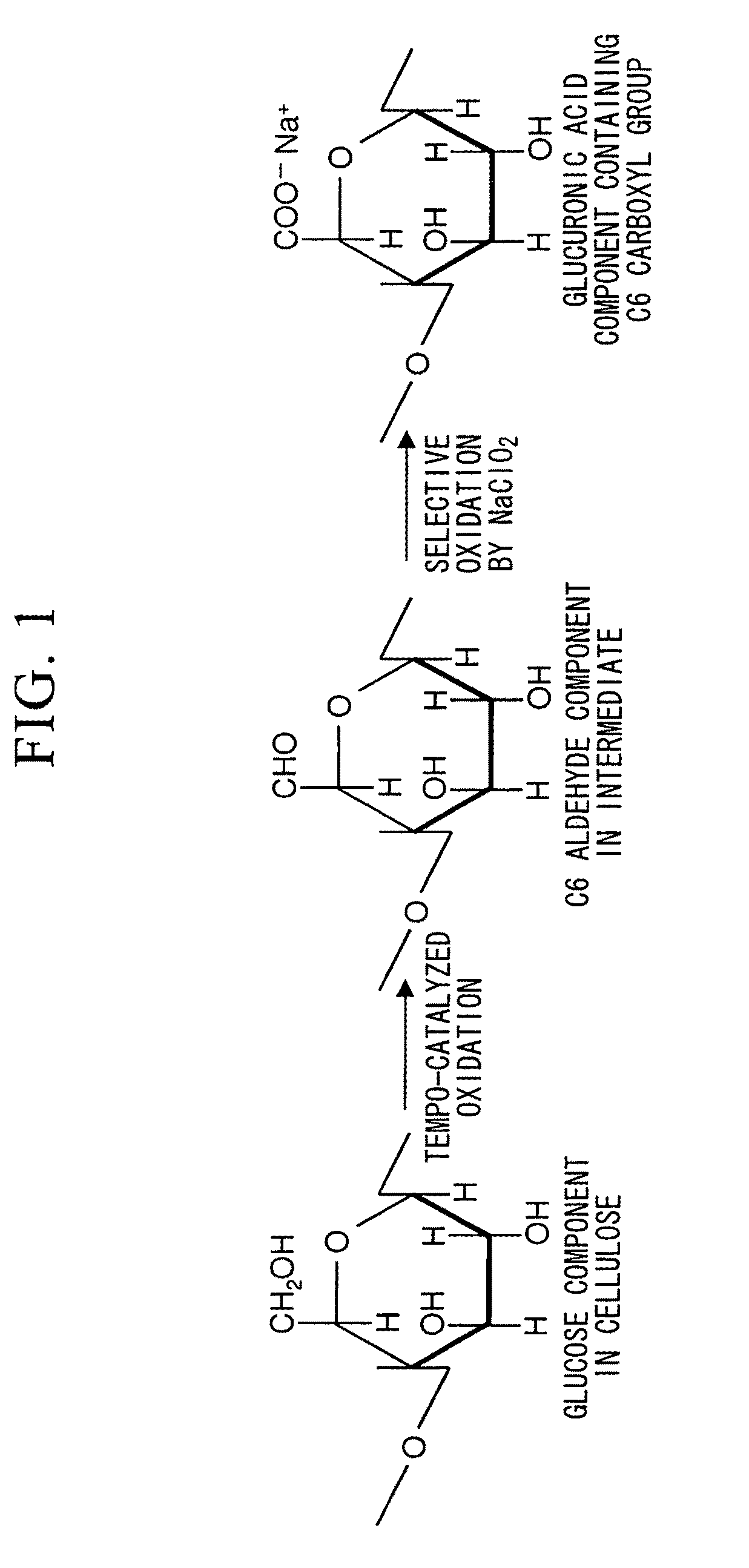

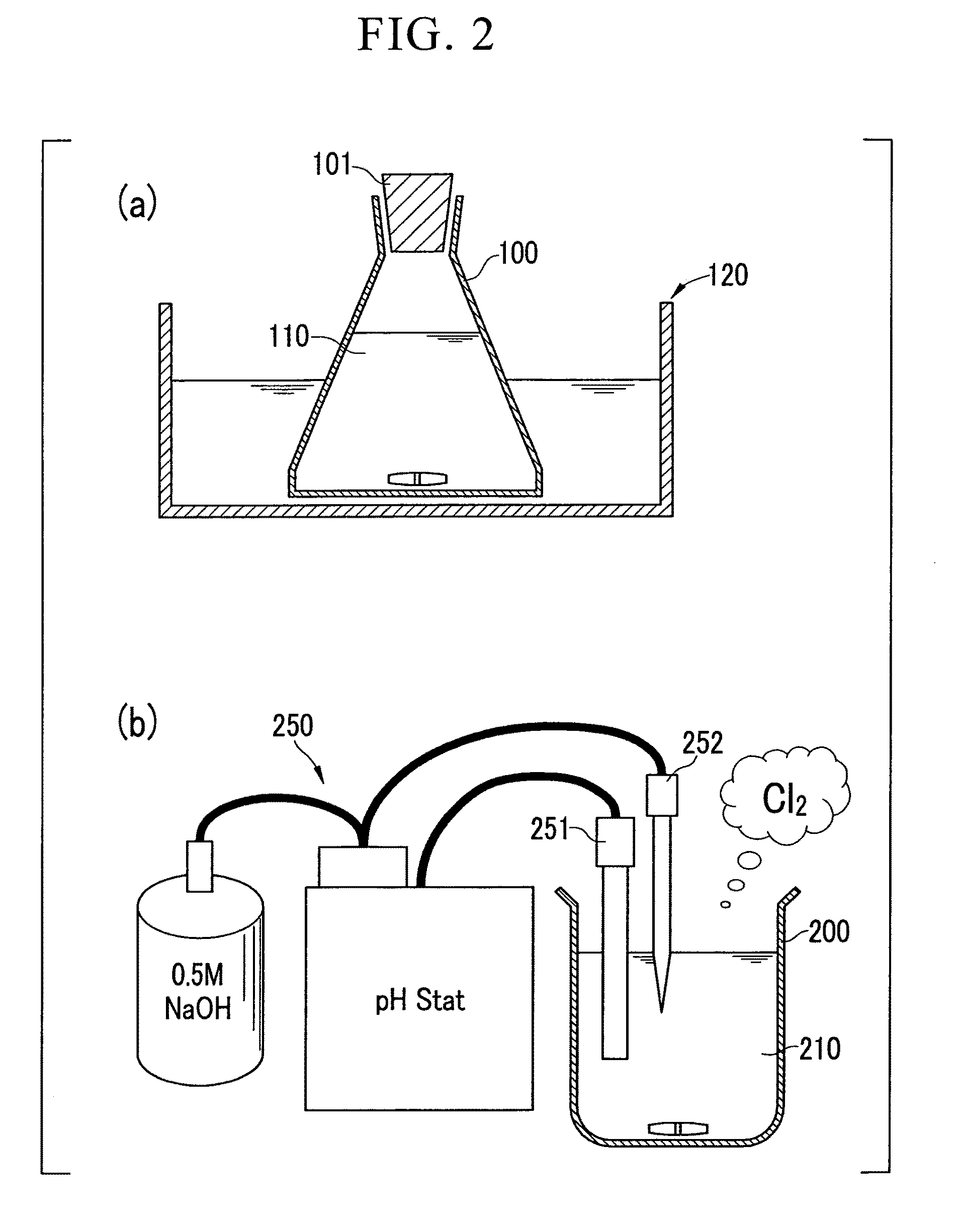

Cellulose nanofiber production method of same and cellulose nanofiber dispersion

InactiveUS20100233481A1High degree of polymerizationHigh strengthNanotechPulp properties modificationCelluloseFiber

The cellulose nanofiber production method of the present invention comprises an oxidation treatment step for oxidizing native cellulose in a neutral or acidic reaction solution containing an N-oxyl compound and an oxidizing agent that oxidizes aldehyde groups, and a dispersion step for dispersing the native cellulose in a medium following the oxidation treatment step. According to the production method of the present invention, a cellulose nanofiber is provided that has long fibers and demonstrates high strength.

Owner:THE UNIV OF TOKYO

Method for producing polyether polyol

The object of the present invention is to provide a method for producing a polyether polyol which is little colored and has a high degree of polymerization in high yield by a dehydration-condensation of a polyol. In the present invention, a dehydration-condensation reaction is carried out in the presence of a catalyst composed of an acid and a base.

Owner:MITSUBISHI CHEM CORP

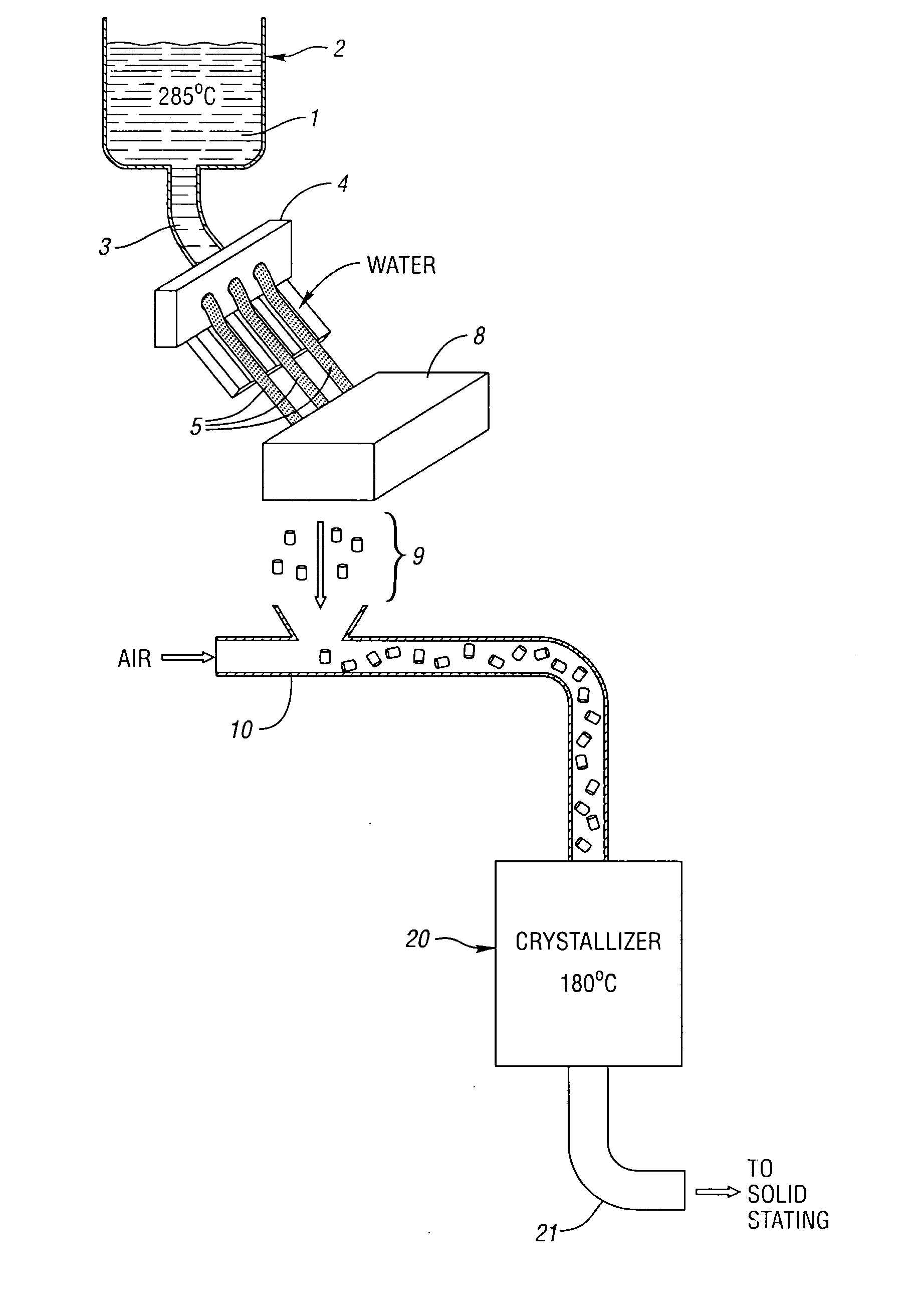

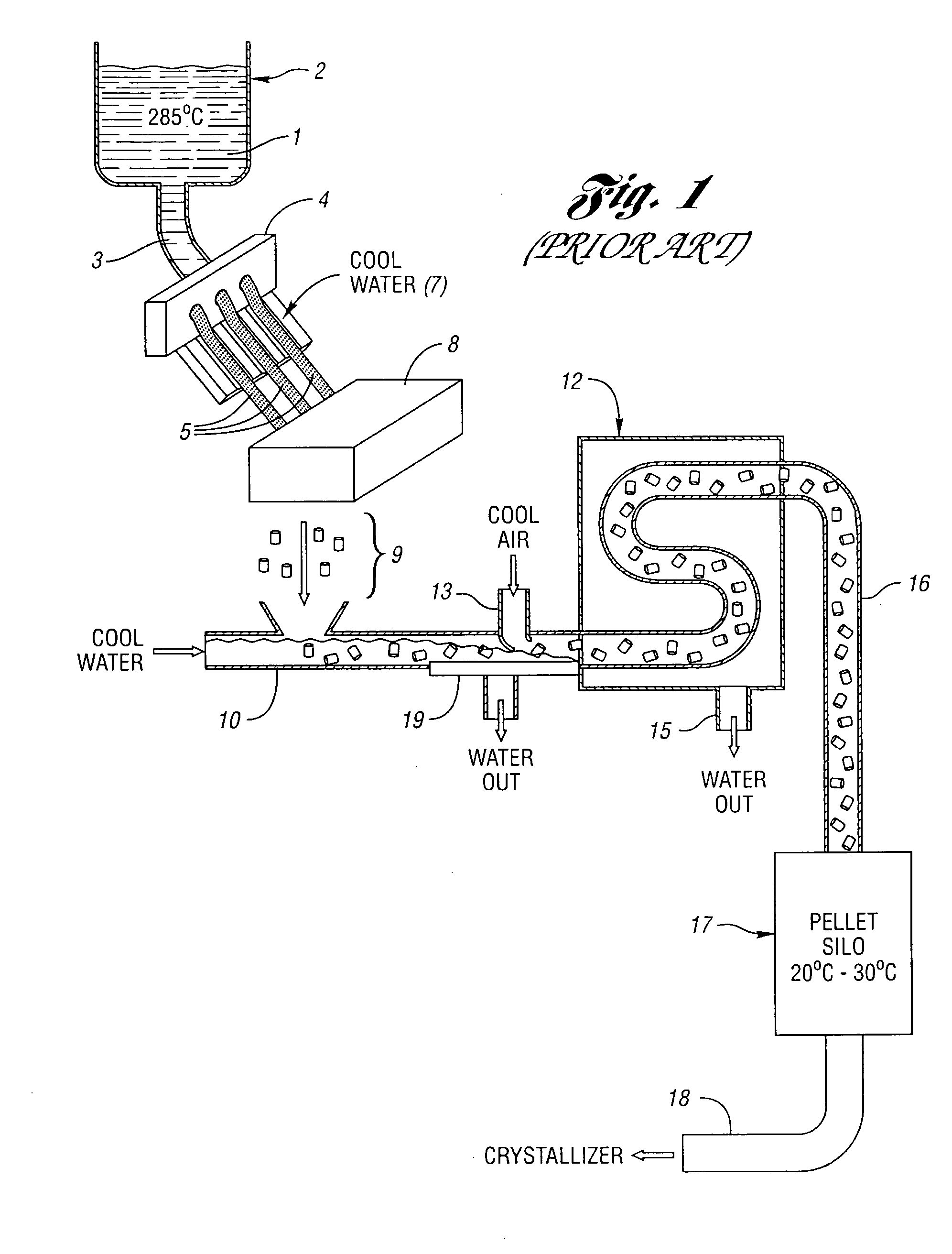

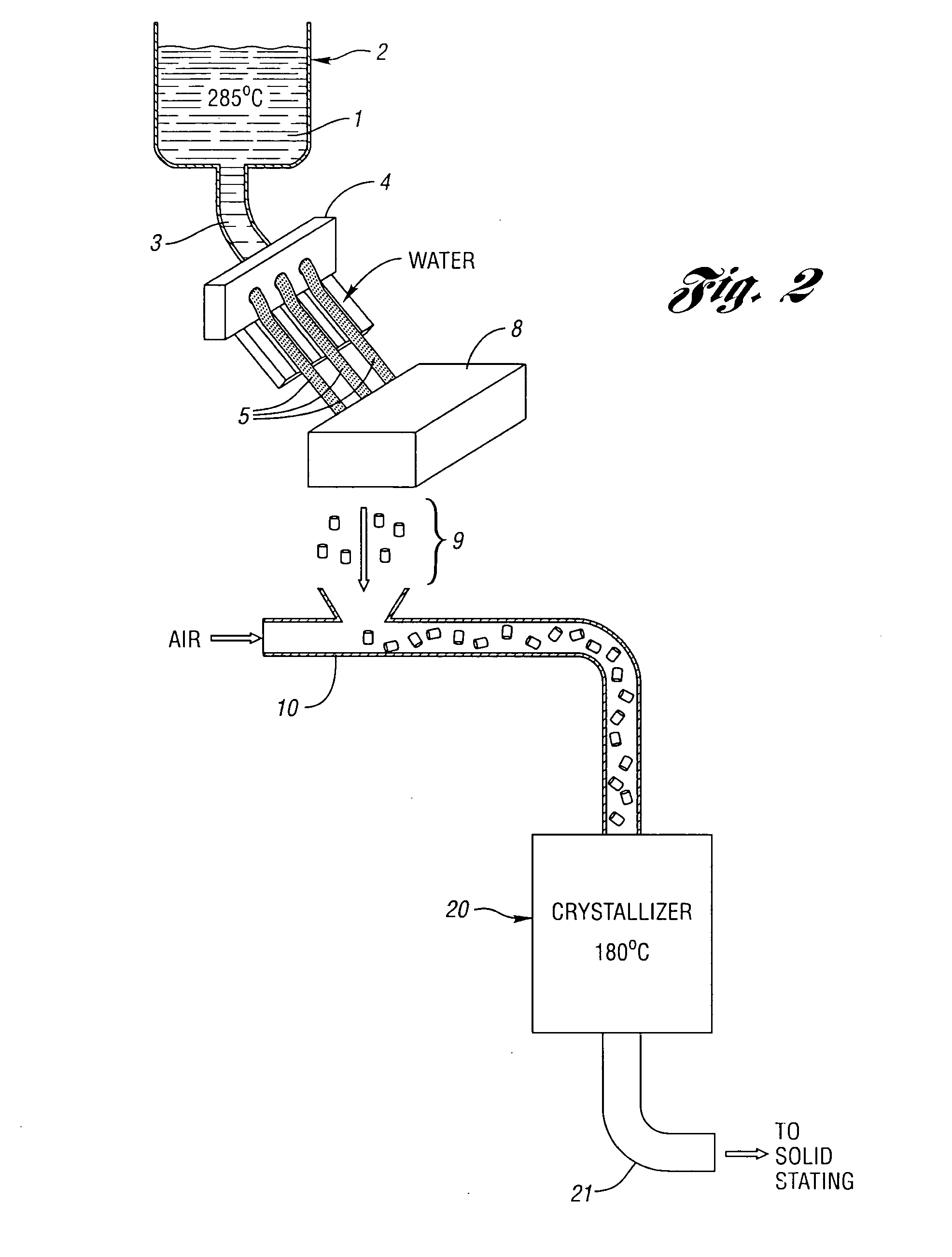

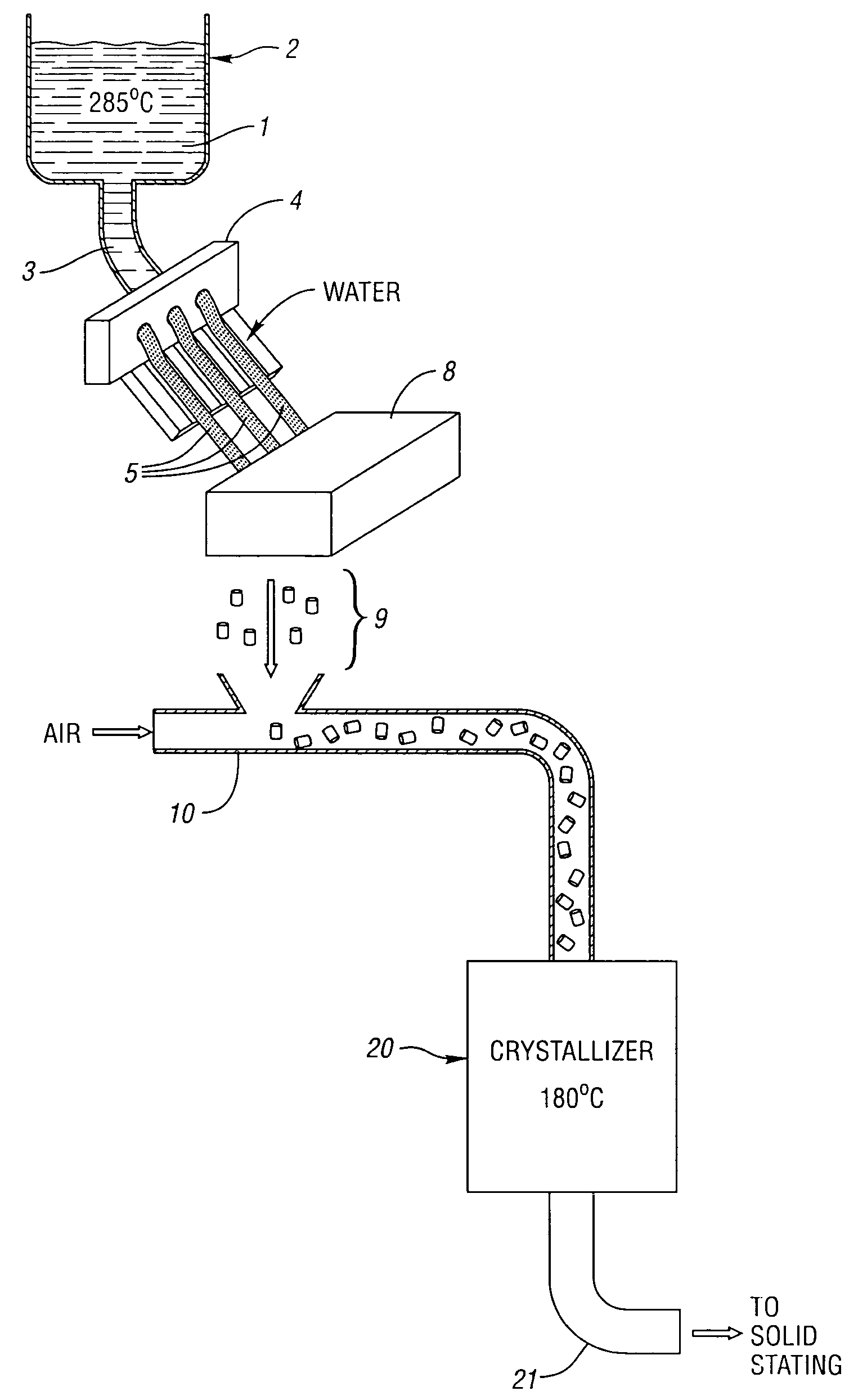

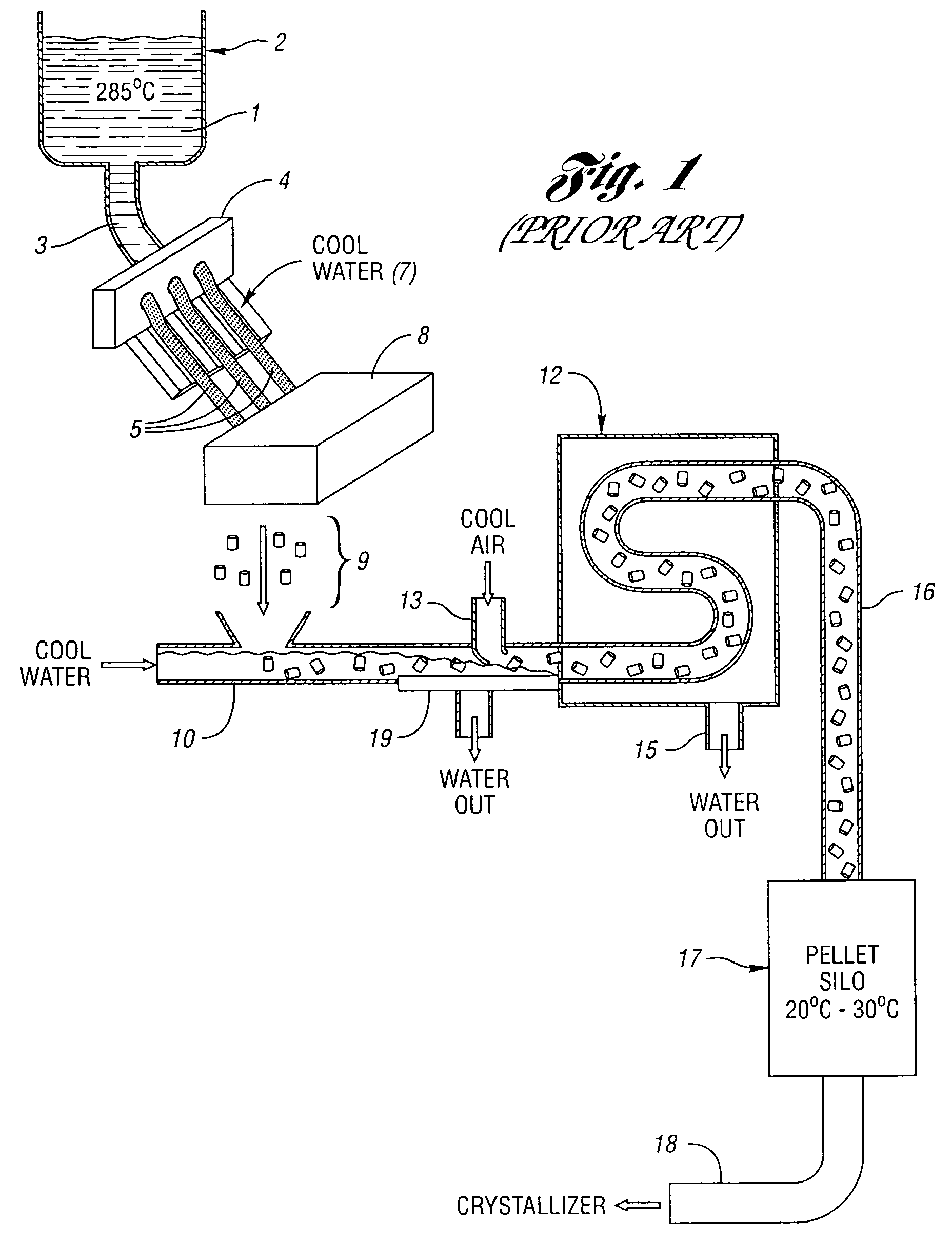

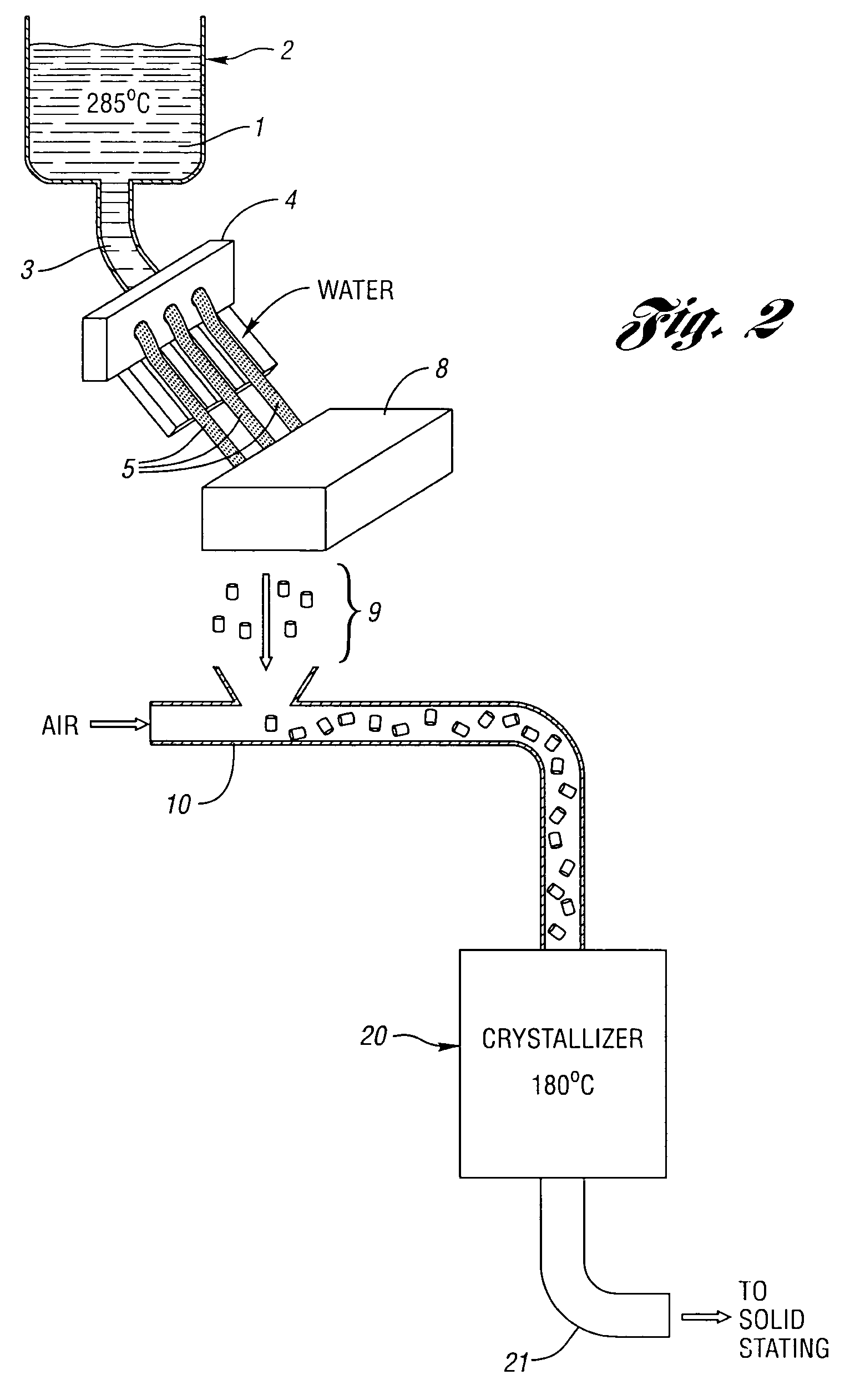

Direct coupling of melt polymerization and solid state processing for PET

ActiveUS20050056961A1Increase temperatureReduce molecular weightWood working apparatusBuilding constructionsPolyethylene terephthalate glycolPolyethylene terephthalate

Strands of molten polyethylene terephthalate (PET) from a PET polycondensation reactor are solidified, pelletized, and cooled only to a temperature in the range of 50° C. to a temperature near the polymer Tg by contact with water. The still hot pellets are conveyed, optionally followed by drying to remove water, to a PET crystallizer. By avoiding cooling the amorphous pellets to room temperature with water and cool air, significant savings of energy are realized.

Owner:ALPEK POLYESTER SA DE CV

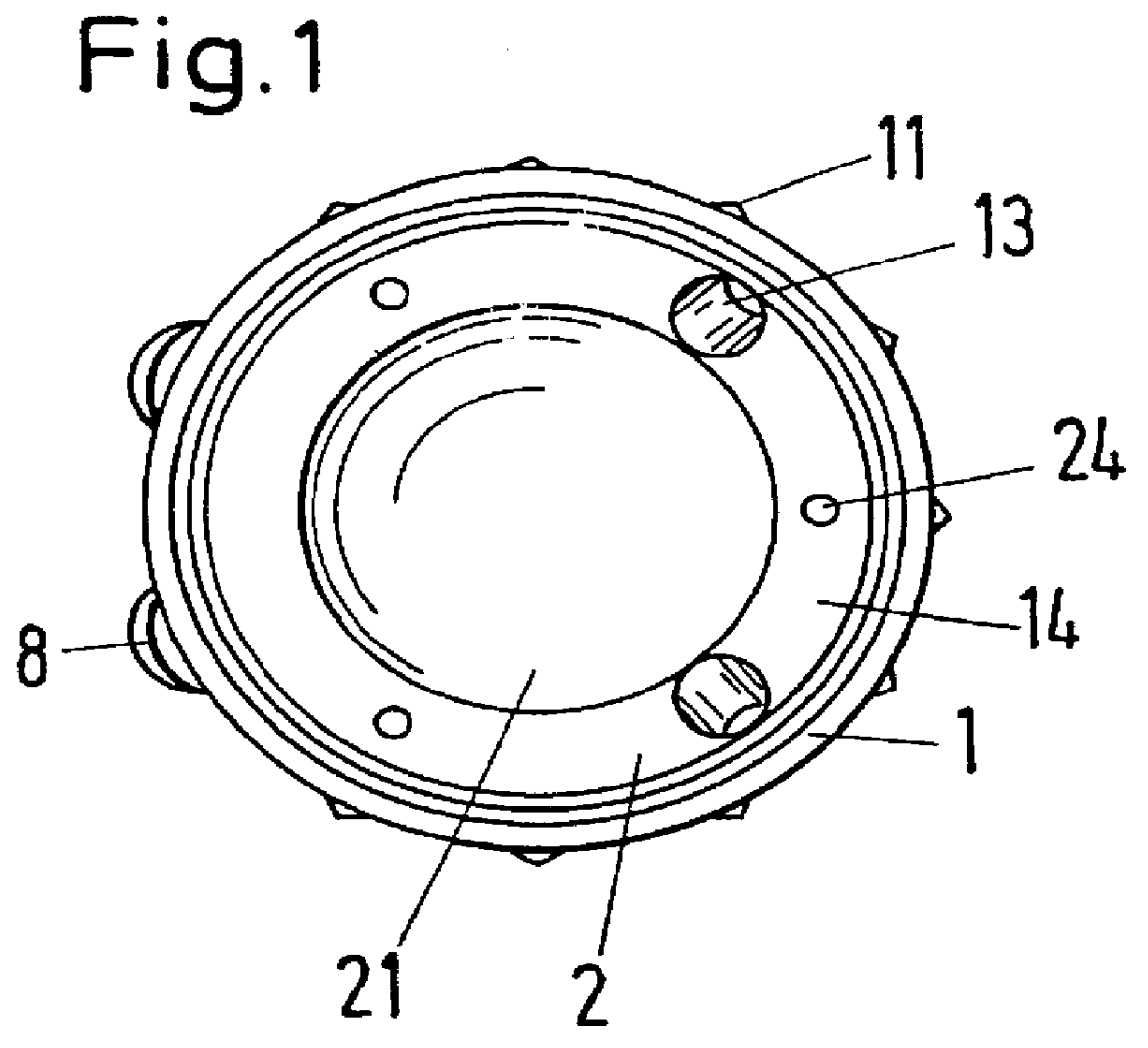

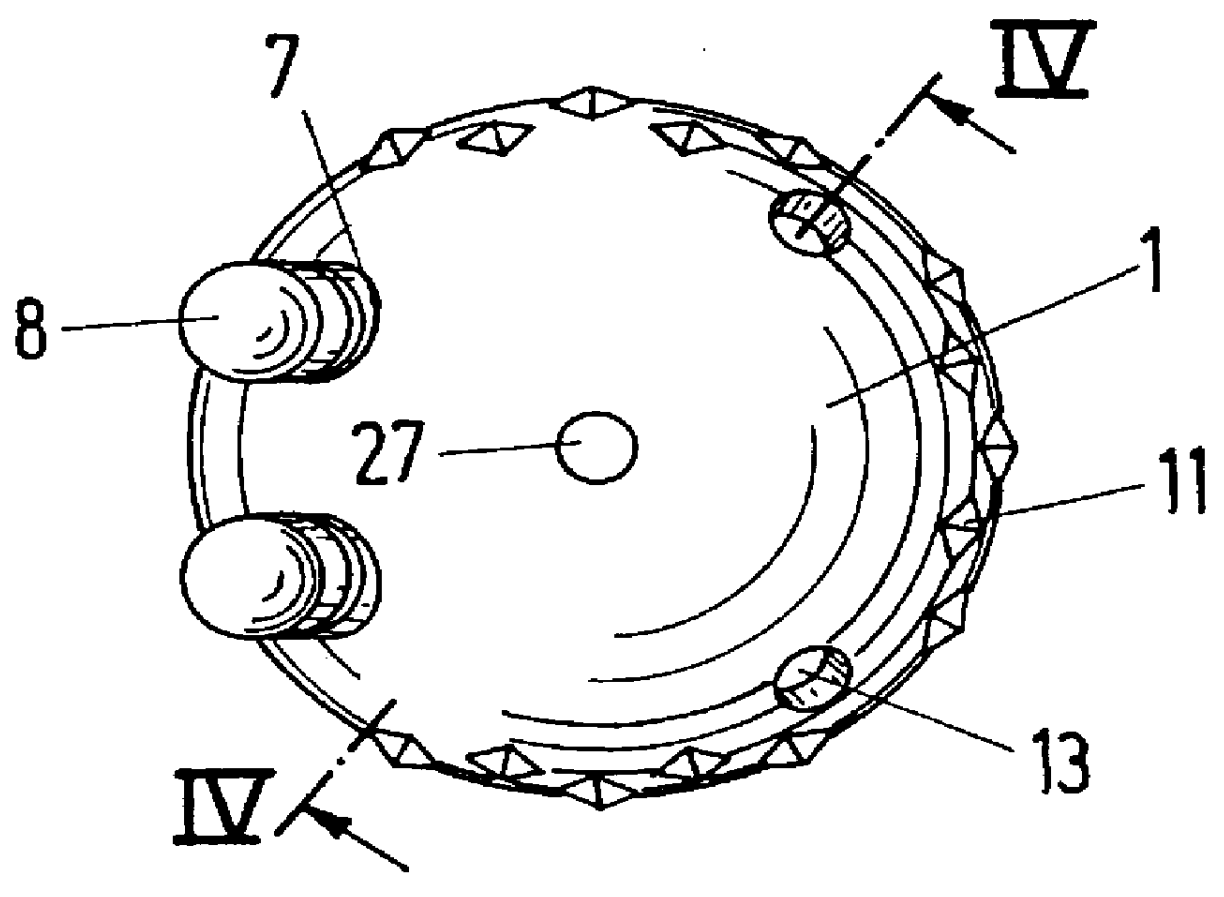

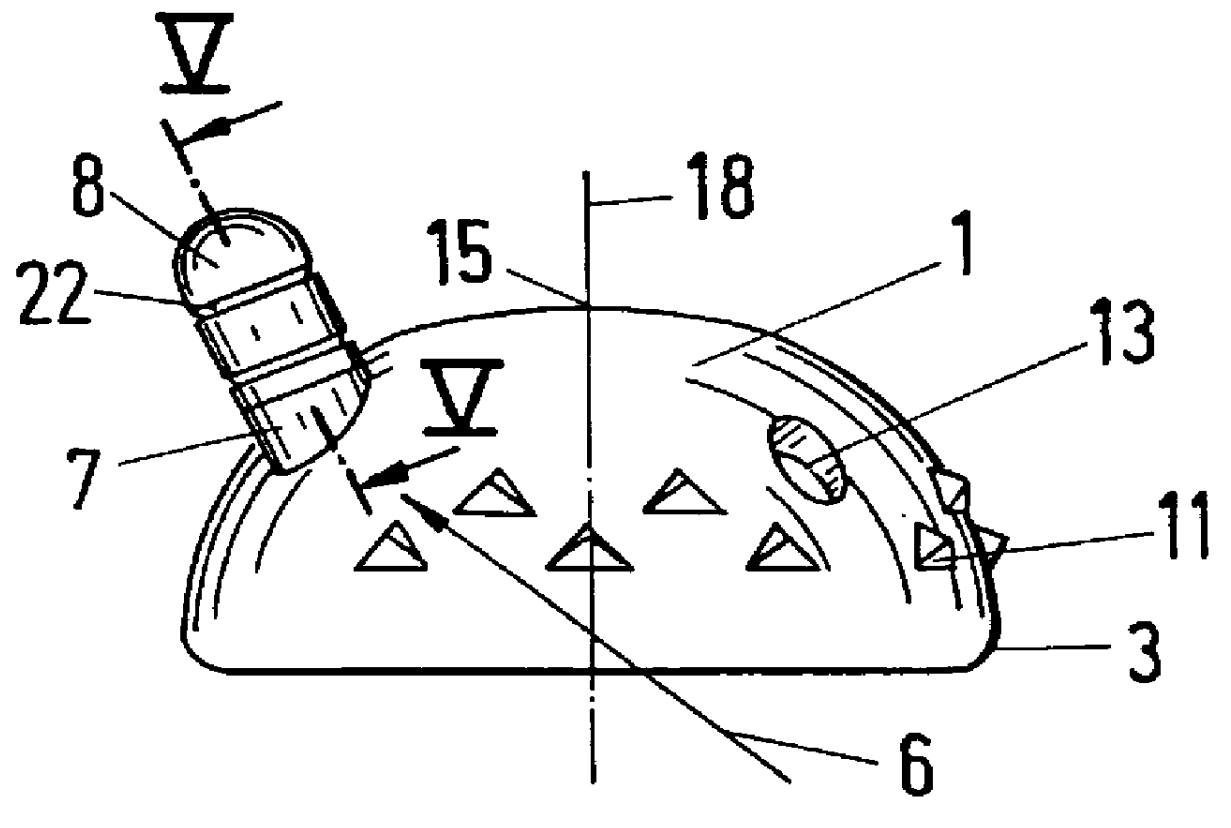

Twin-shelled artificial hip joint and its manufacture

InactiveUS6045583AHigh degree of polymerizationReduce wear rateJoint implantsCoatingsArtificial hip jointsCoxal joint

The invention shows a hip joint socket and its manufacture, with the hip joint socket including a thin walled metallic outer shell with anchoring pins which is firmly connected to an inner shell of plastic. Since the bearing surface of the inner shell is not produced until after the assembly, a high accuracy of shape of the bearing surface results together with a relatively elastic outer shell and with good anchoring aids for a primary anchoring.

Owner:SULZER ORTHOPAEDIC

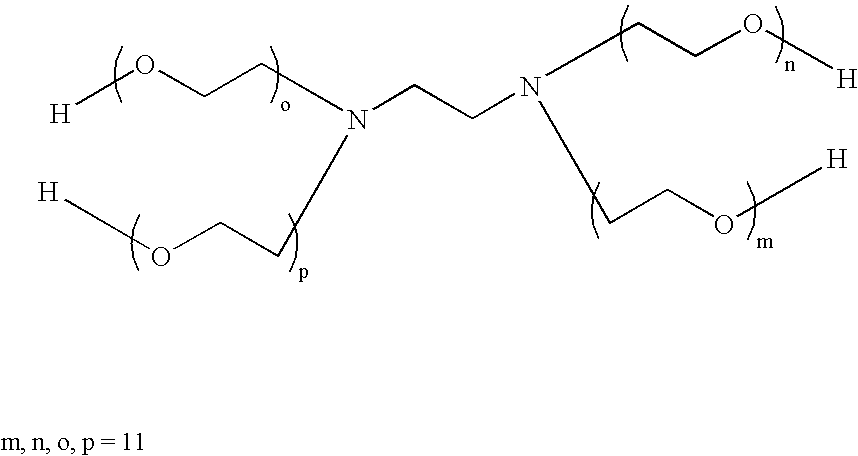

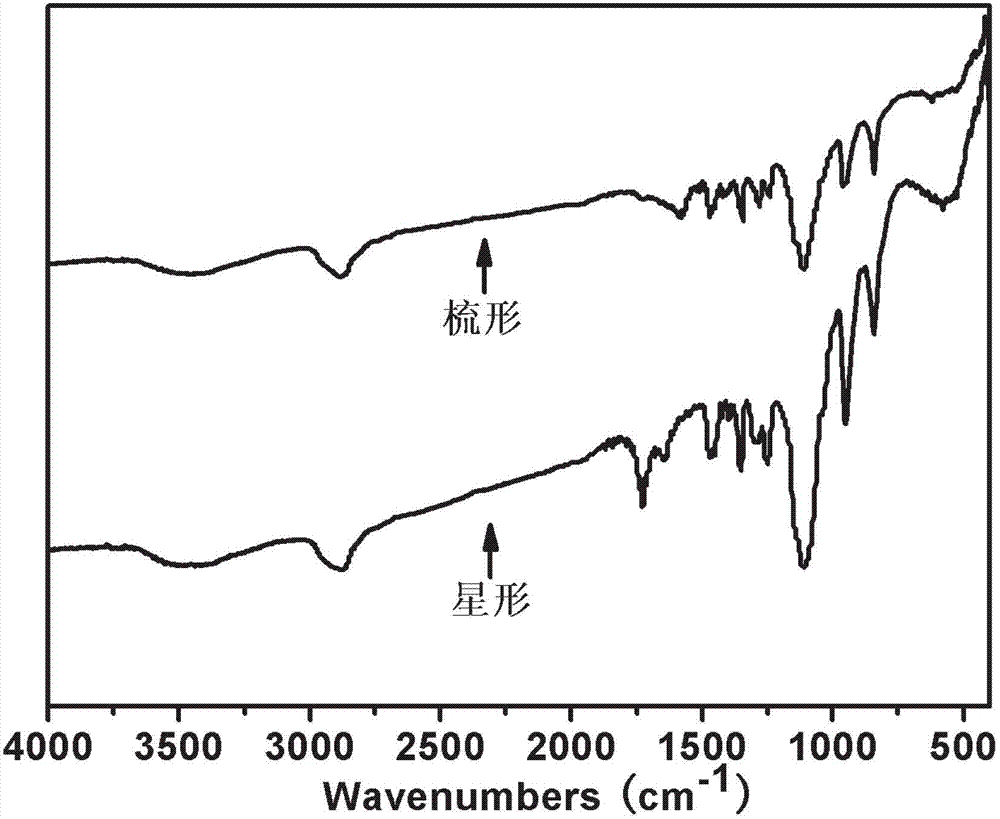

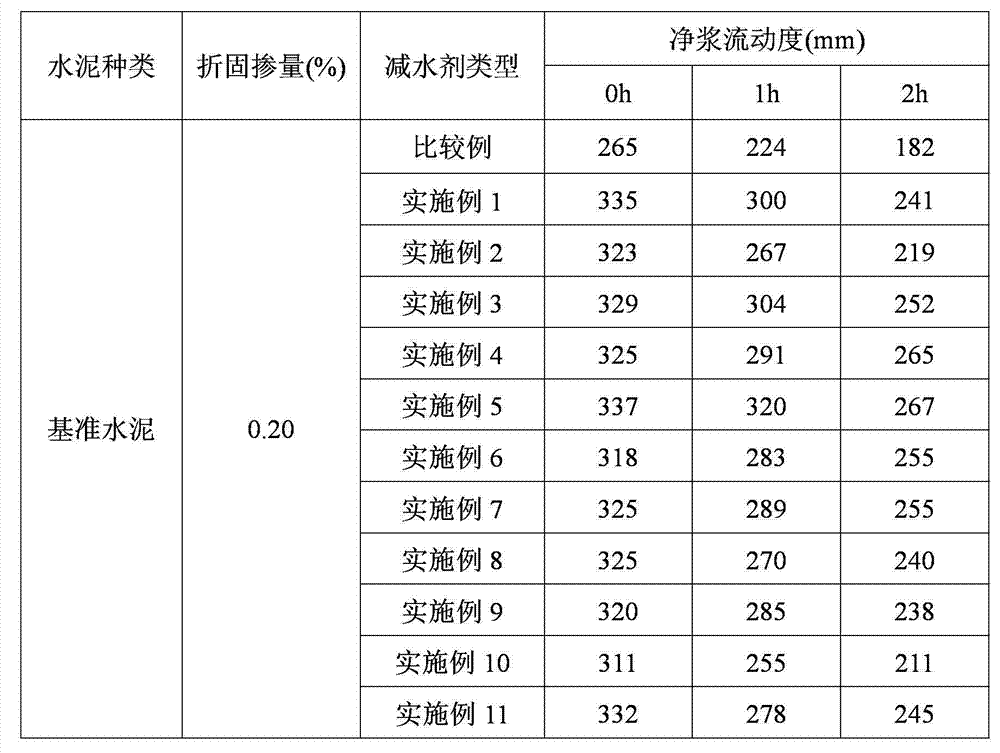

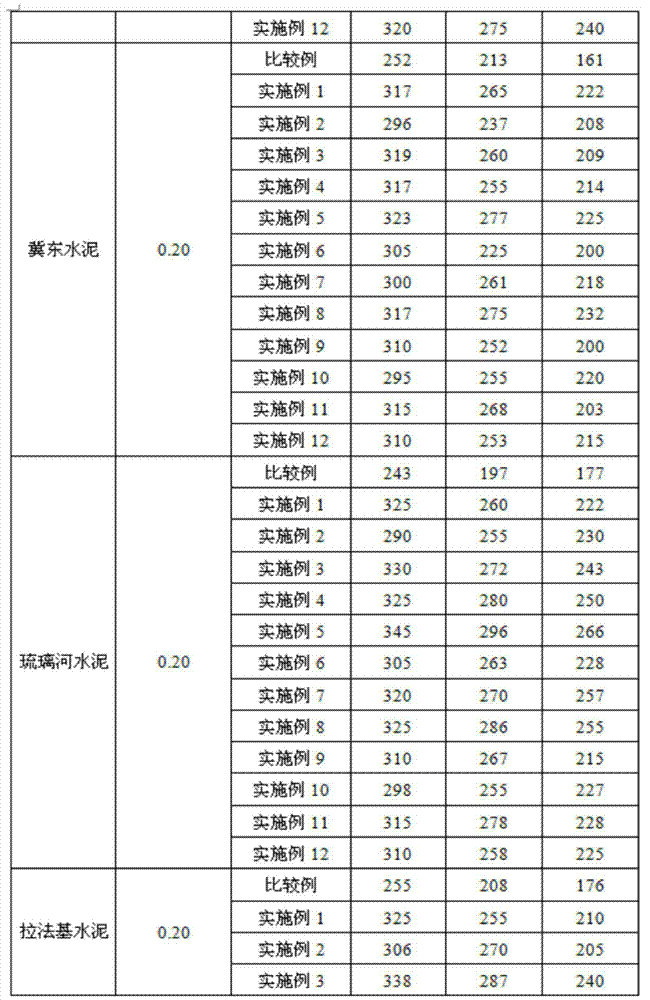

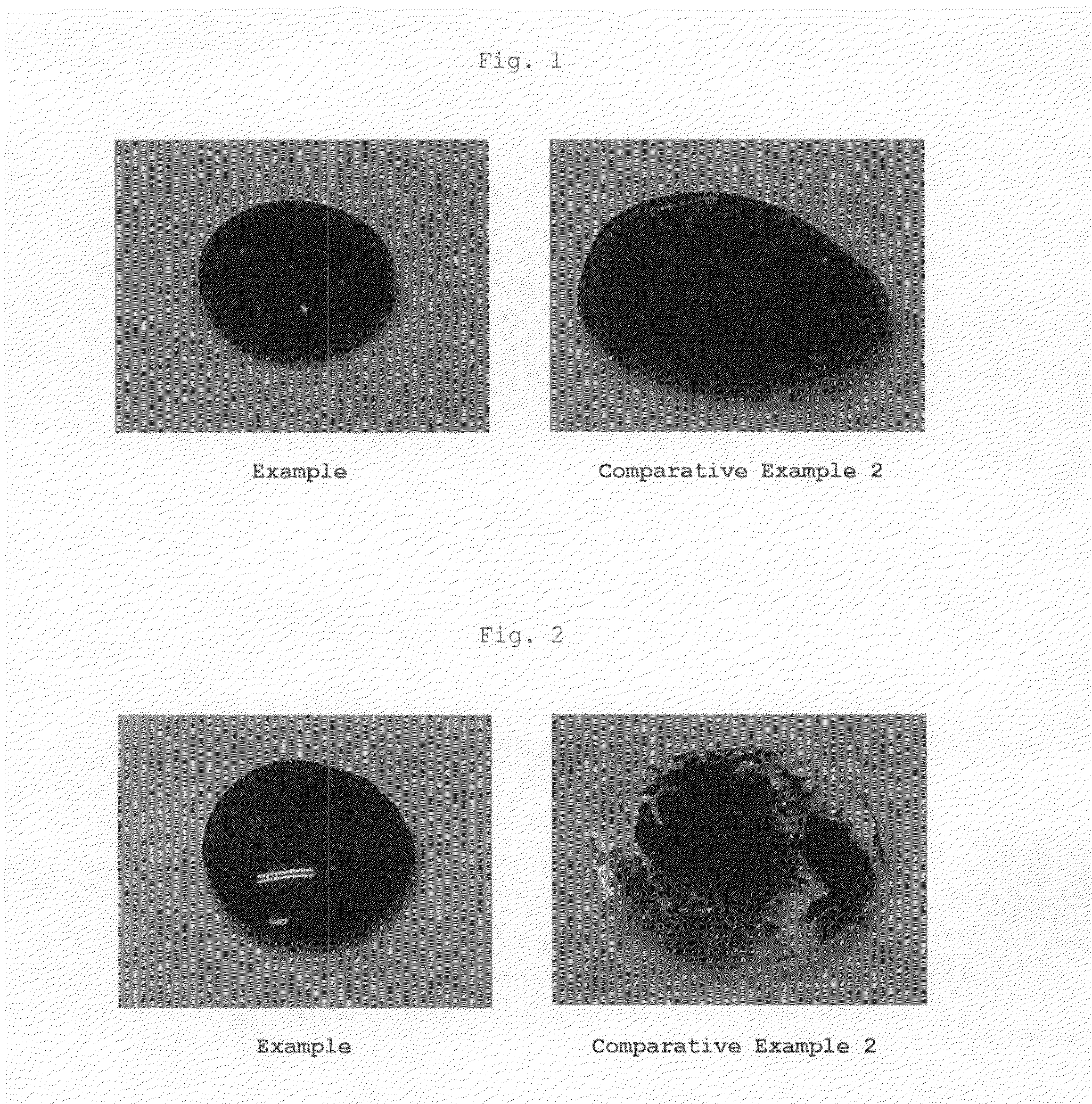

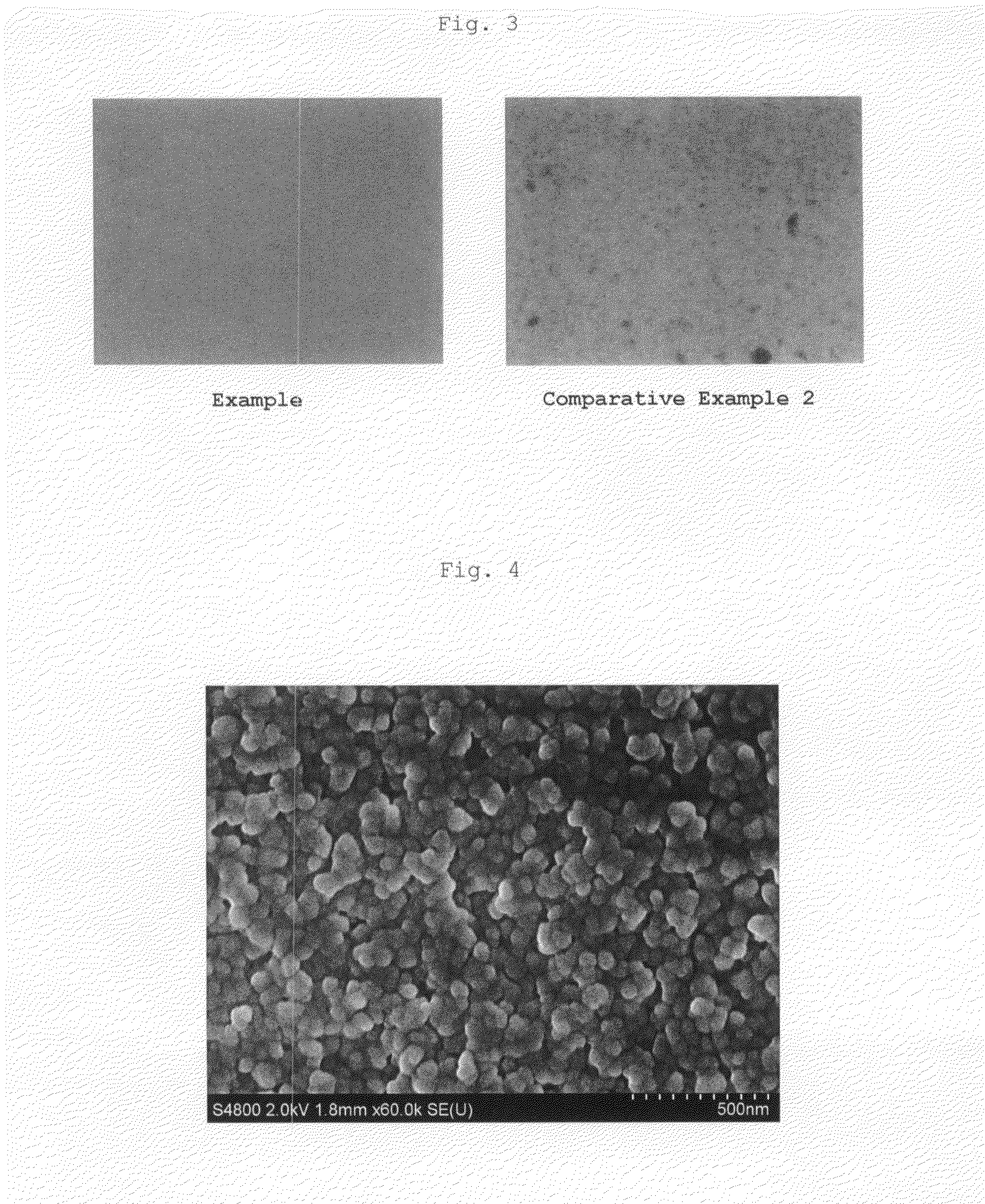

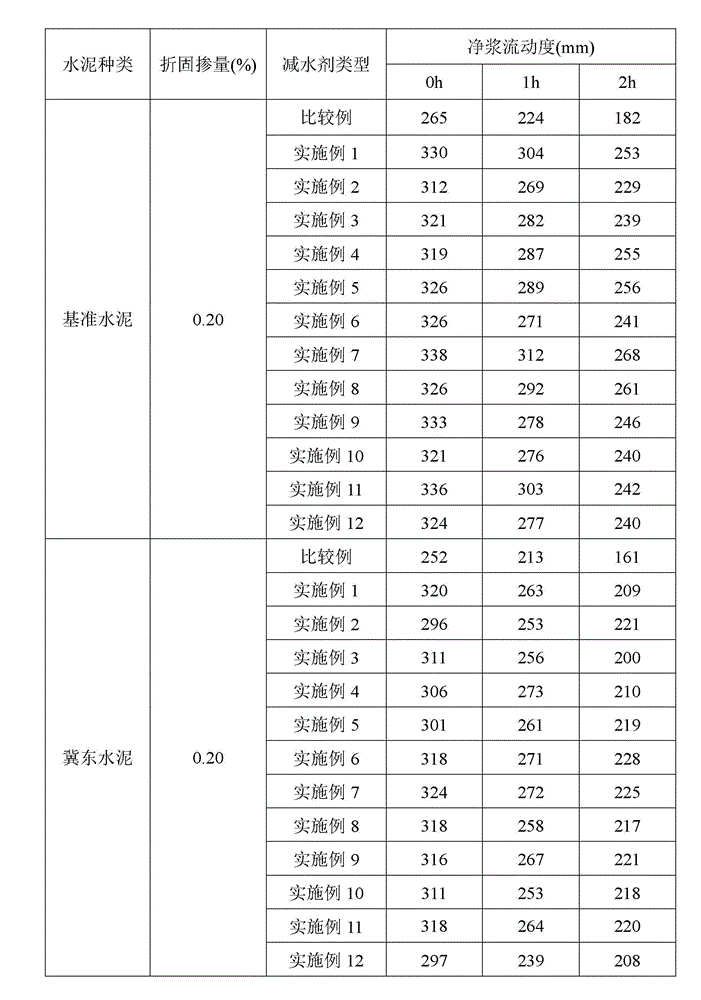

Preparation method of star polycarboxylic acid high-performance water reducing agent

ActiveCN102887979AExtended Dionon Design-Structure-PropertyExpanding the theoretical connotation of the design-structure-performance of moleculesWater reducerPollution

The invention relates to a preparation method of a star polycarboxylic acid high-performance water reducing agent. Polybasic alcohol and (methyl) acrylic acid used as main raw materials for esterification are esterified and polymerized to prepare the star polycarboxylic acid high-performance water reducing agent material: the (methyl) acrylic acid and polybasic alcohol used as reactants are esterified under the action of a catalyst to firstly prepare a star polymerizable active terminal, and free-radical polymerization reaction is carried out with unsaturated polyethenoxy ether, molecular weight regulator and unsaturated carboxylic acid monomer under the action of an initiator to prepare the star polycarboxylic acid high-performance water reducing agent. The invention is easy to control, and has the advantages of high polymerization degree, low cost and no pollution; the esterification reaction is carried out form an active core, and the free-radical polymerization is carried out to generate the chain arm, thereby implementing the polycarboxylic acid high-performance water reducing agent in a star molecular structure; and under the condition of common doping amount and low doping amount, the star polycarboxylic acid high-performance water reducing agent has better cement paste flowability and holding capacity than the traditional linear and comb polycarboxylic acid water reducing agents, and has favorable cement adaptability and concrete application performance.

Owner:GUIZHOU DR SHI TECH

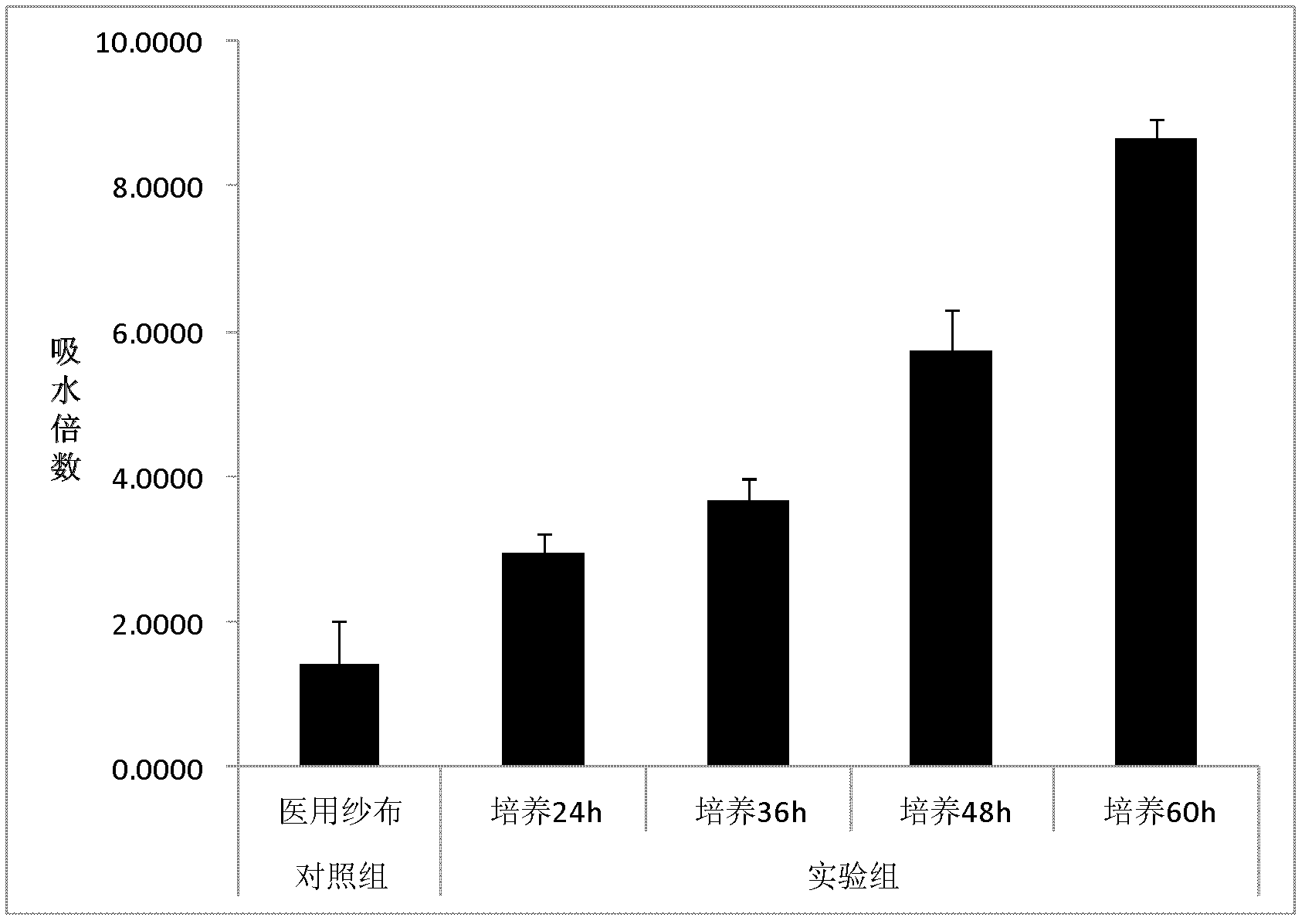

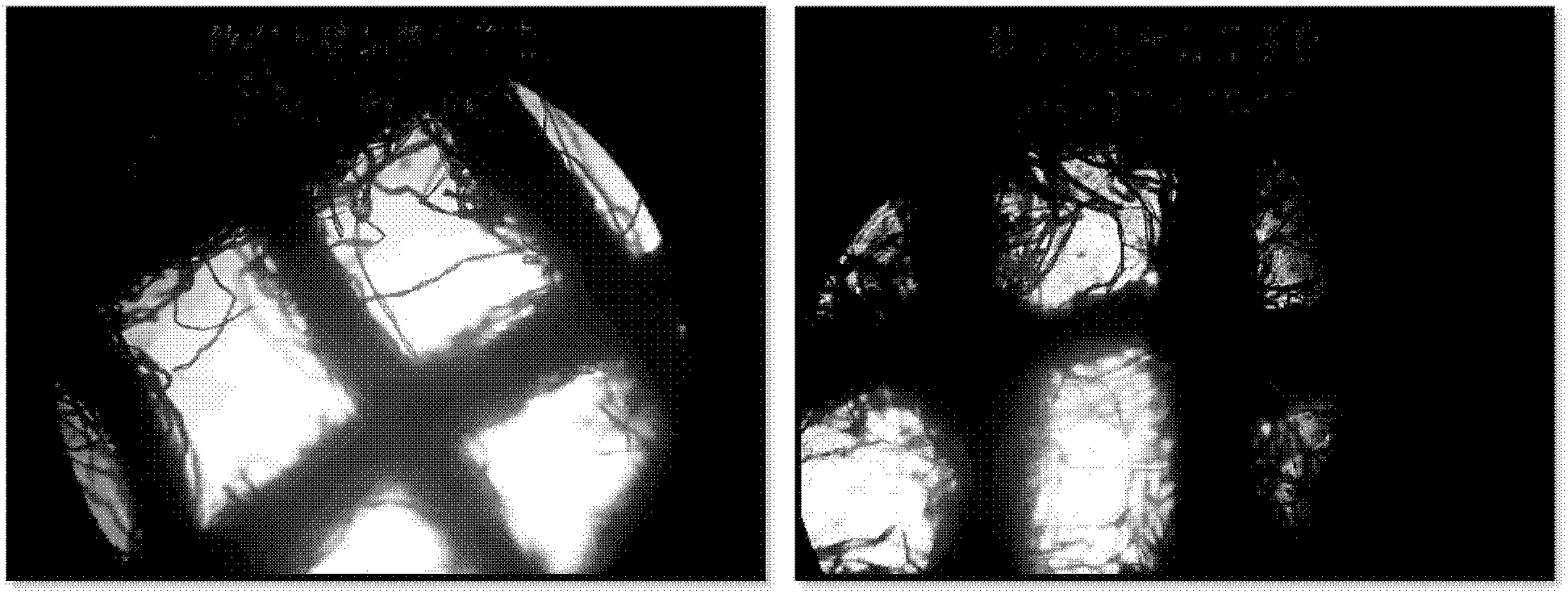

Method for preparing nano-cellulose antibacterial composite material through on-line culture

ActiveCN102552965ARealize fermentation productionImprove continuityCosmetic preparationsBacteriaWater bathsFiber

The invention relates to a method for preparing a nano-cellulose antibacterial composite material through on-line culture. The method comprises the following steps of: (1) inoculating an activated bacterial cellulose producing strain into a liquid culture medium, performing amplification culture, transferring the liquid culture medium into a bioreactor, culturing, adding an antibacterial material into the liquid culture medium, and continuing to culture to obtain an unpurified antibacterial bacterial cellulose composite material; and (2) peeling a bacterial cellulose membrane from a framework or directly soaking the composite material in a NaOH solution, treating in water bath, and washing until an obtained product is neutral to obtain the nano-cellulose antibacterial composite material. The preparation efficiency is high, and the method is simple, convenient, feasible and low in cost; and the surface of the bacterial cellulose composite material has a nanoscale three-dimensional fibrous mesh-shaped structure, the tensile strength of the material is greatly improved compared with that of a pure bacterial cellulose membrane, and the material can be widely applied to products such as facial masks, wound dressings, plasters, artificial skins and the like.

Owner:DONGHUA UNIV

Direct coupling of melt polymerization and solid state processing for PET

InactiveUS7204945B2Reduce molecular weightReduce the degree of polymerizationWood working apparatusDomestic articlesPolyethylene terephthalatePolyethylene terephthalate glycol

Strands of molten polyethylene terephthalate (PET) from a PET polycondensation reactor are solidified, pelletized, and cooled only to a temperature in the range of 50° C. to a temperature near the polymer Tg by contact with water. The still hot pellets are conveyed, optionally followed by drying to remove water, to a PET crystallizer. By avoiding cooling the amorphous pellets to room temperature with water and cool air, significant savings of energy are realized.

Owner:ALPEK POLYESTER SA DE CV

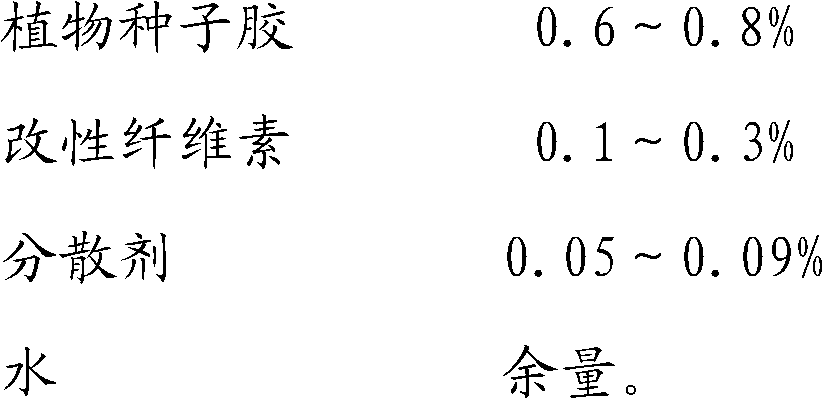

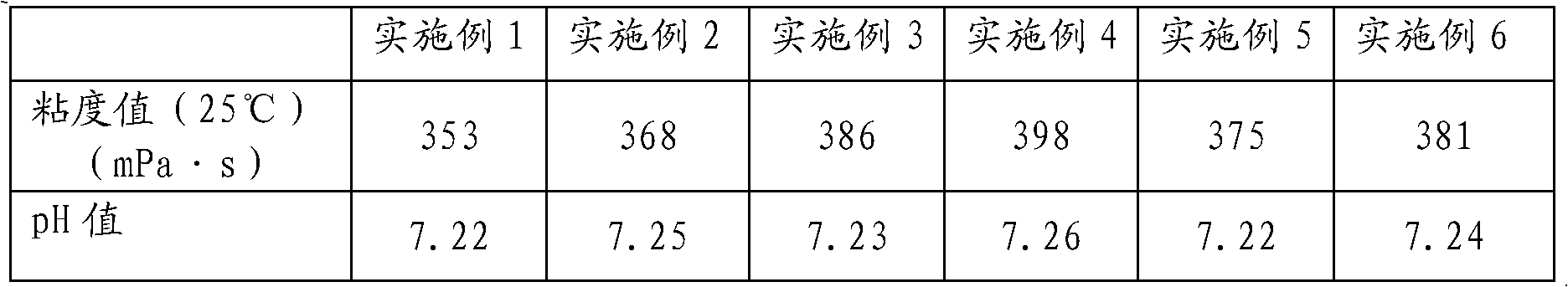

dust suppressant

The invention discloses a dust inhibitor, which comprises the following raw material in percentage by weight: 0.6 to 0.8 percent of plant seed colloid, 0.1 to 0.3 percent of modified cellulose, 0.05 to 0.09 percent of dispersant and the balance of water. The dust inhibitor can be prepared at normal temperature in a common mixing equipment from mixed aqueous solution of plant seed colloid, modified cellulose, crosslinking agent, dispersant and reinforcing agent; and after being prepared, the dust inhibitor can be sprayed onto the surface of coal in carriages to allow the coal to form a layer of cured film on the surface, the viscosity of the film is high, the wind corrosion rate of the film is low, so that the dust pollution along railways in railway transportation of the coal and the dust loss of the coal are avoided. Besides, dust inhibition in railway coal transportation, the dust inhibitor can be used for dust inhibition on roads in mining areas, urban roads, constructions sites, stations, ports and the like so that the dust inhibitor can be used almost without being limited by fields, and the dust inhibitor can be widely used.

Owner:北京中盛益世环保科技有限公司

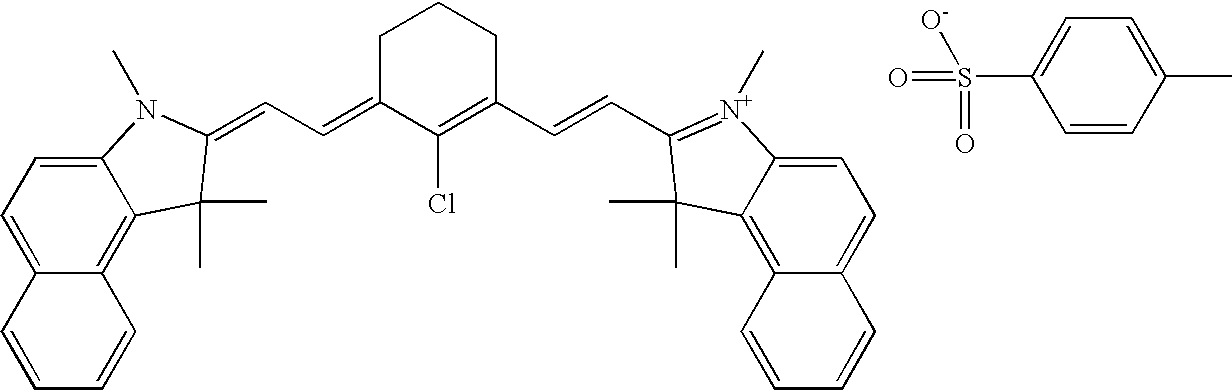

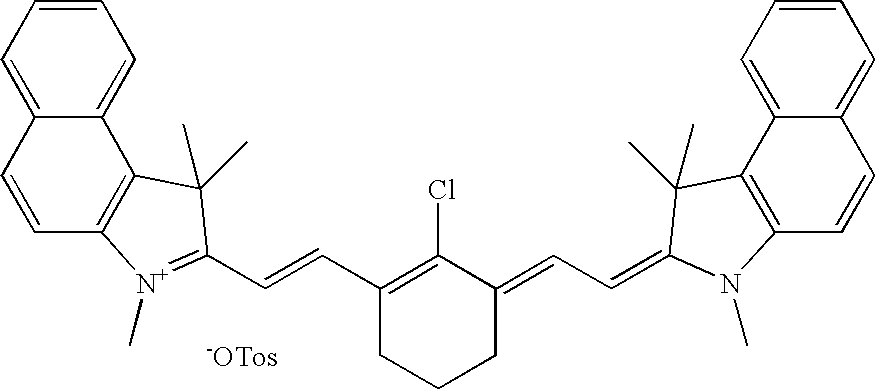

Aqueous pigment dispersion and applications thereof

InactiveUS20110223529A1Readily dissolved in waterGood dispersionTransportation and packagingInksPolymer sciencePigment dispersion

Disclosed are an aqueous pigment dispersion containing at least a pigment, water, a high-molecular dispersant, and an alkali. The high-molecular dispersant is a diblock polymer having a formula (1) of A-B or a triblock polymer having a formula (2) of A-B-C. The diblock or triblock polymer is a diblock or triblock polymer obtained by polymerizing addition-polymerizable monomers with a radical generator while using an organic iodide as a polymerization initiating compound and an organic phosphorus compound, organic nitrogen compound or organic oxygen compound as a catalyst. Also disclosed are a production method and use of the aqueous pigment dispersion. With the high-molecular dispersant obtained by a simple living radical polymerization process free of the problems of conventional living radical polymerization and having a precisely-controlled molecular structure, the aqueous pigment dispersion can be obtained with the pigment dispersed in it.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD +1

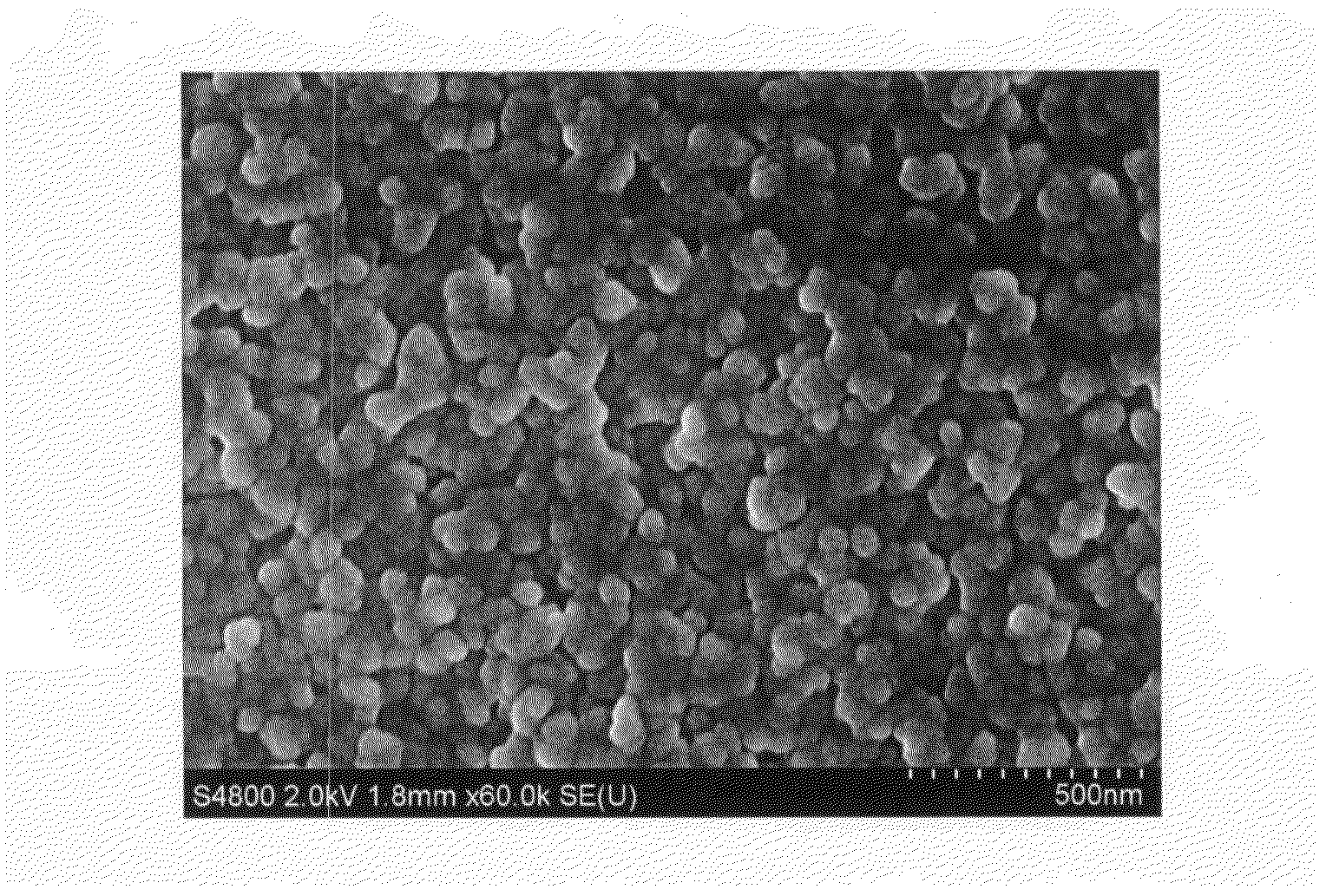

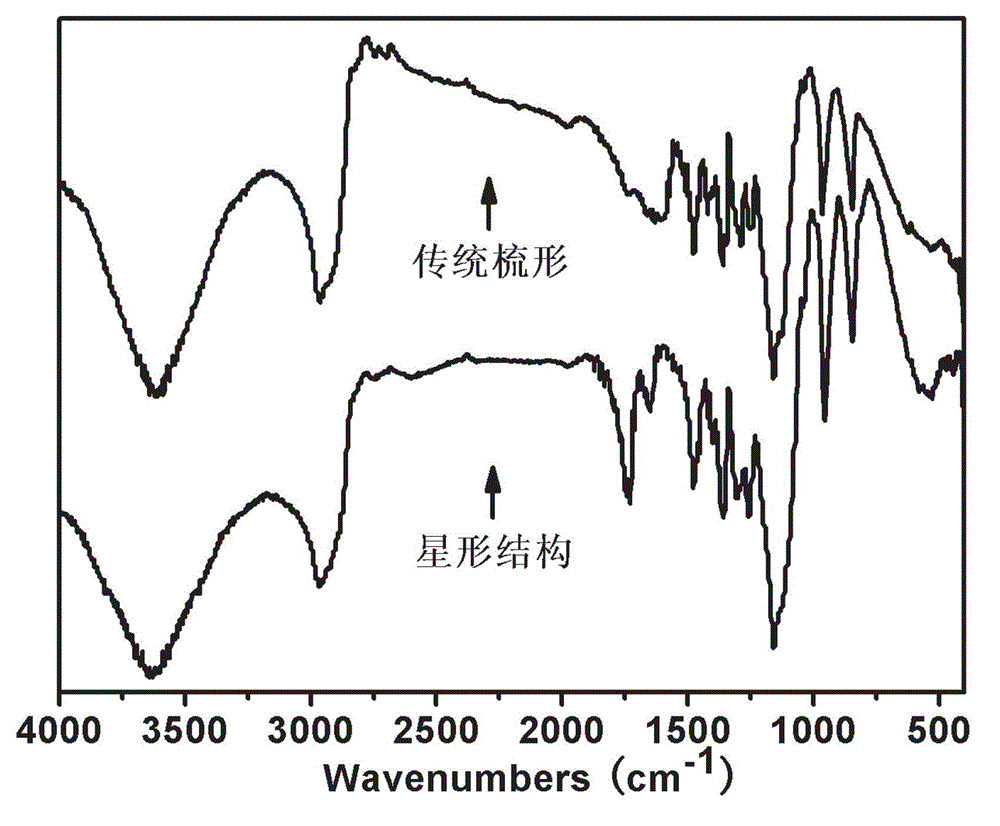

Synthesis method of polycarboxylic acid high-performance water reducing agent of star-like structure

ActiveCN102911322AExtended Dionon Design-Structure-PropertyExpanding the theoretical connotation of the design-structure-performance of moleculesSynthesis methodsPolyethylene glycol

The invention discloses a synthesis method of a polycarboxylic acid high-performance water reducing agent of a star-like structure, belonging to the field of a water reducing agent. According to the synthesis method, polybasic alcohol, (methyl) acrylic acid, a polyethylene glycol compound and the like are used as esterification raw materials, and the polycarboxylic acid high-performance water reducing agent of the star-like structure is prepared through a sequential esterification and polymerization method, i.e., the (methyl) acrylic acid and the polybasic alcohol are used as reactants, a star-like polymerizable active end is prepared through esterification reaction under the action of a catalyst, and then the polycarboxylic acid high-performance water reducing agent is prepared from the star-like polymerizable active end and esterification macromolecule, a molecular weight regulator and an unsaturated carboxylic acid monomer under the action of an initiator through free radical polymerization reaction. The synthesis method has the advantages of simplicity, easiness in control, high polymerization degree, low cost, no pollution, capability of realizing the polycarboxylic acid high-performance water reducing agent of the star-like structure connected with a plurality of polycarboxylic acid molecules, and more superior cement paste fluidity and holding capacity, good cement adaptability and concrete application performance compared with the conventional linear and comb-shaped polycarboxylic acid water reducing agent in the case of normal and low added amount.

Owner:GUIZHOU DR SHI TECH

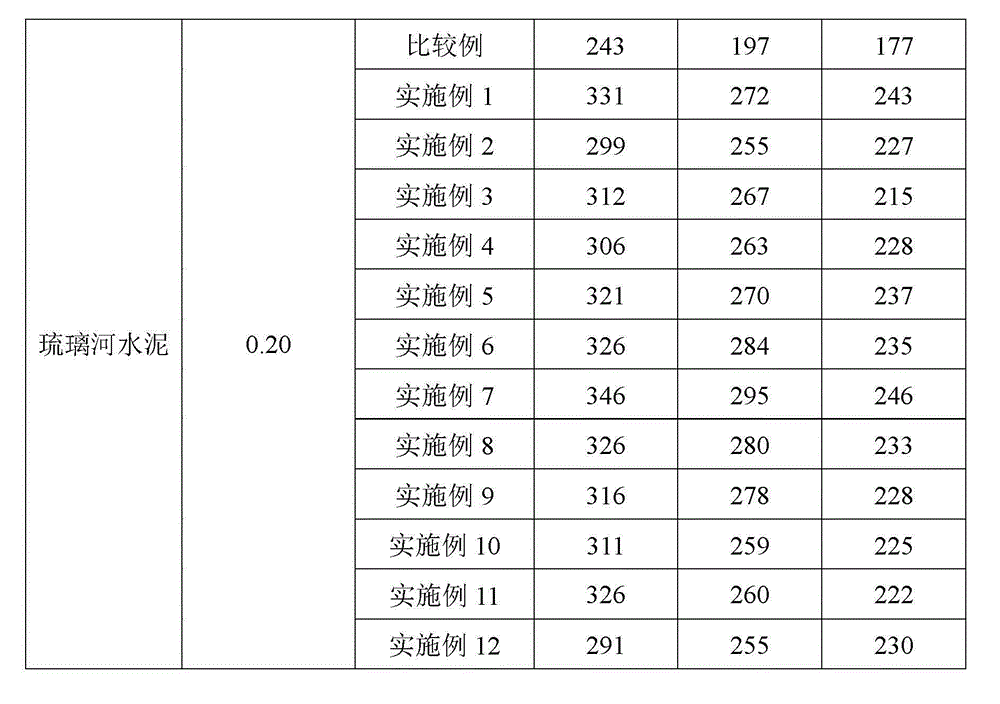

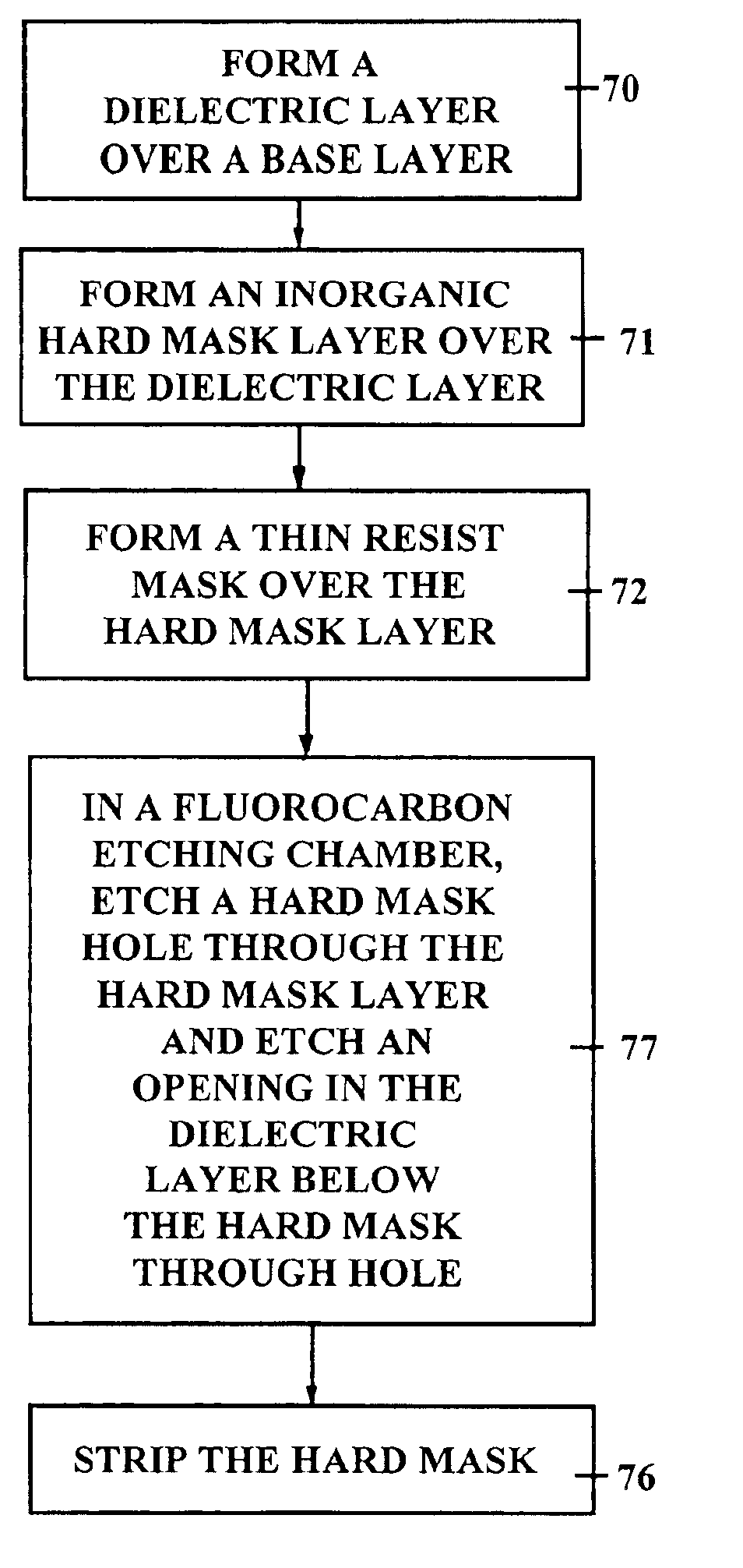

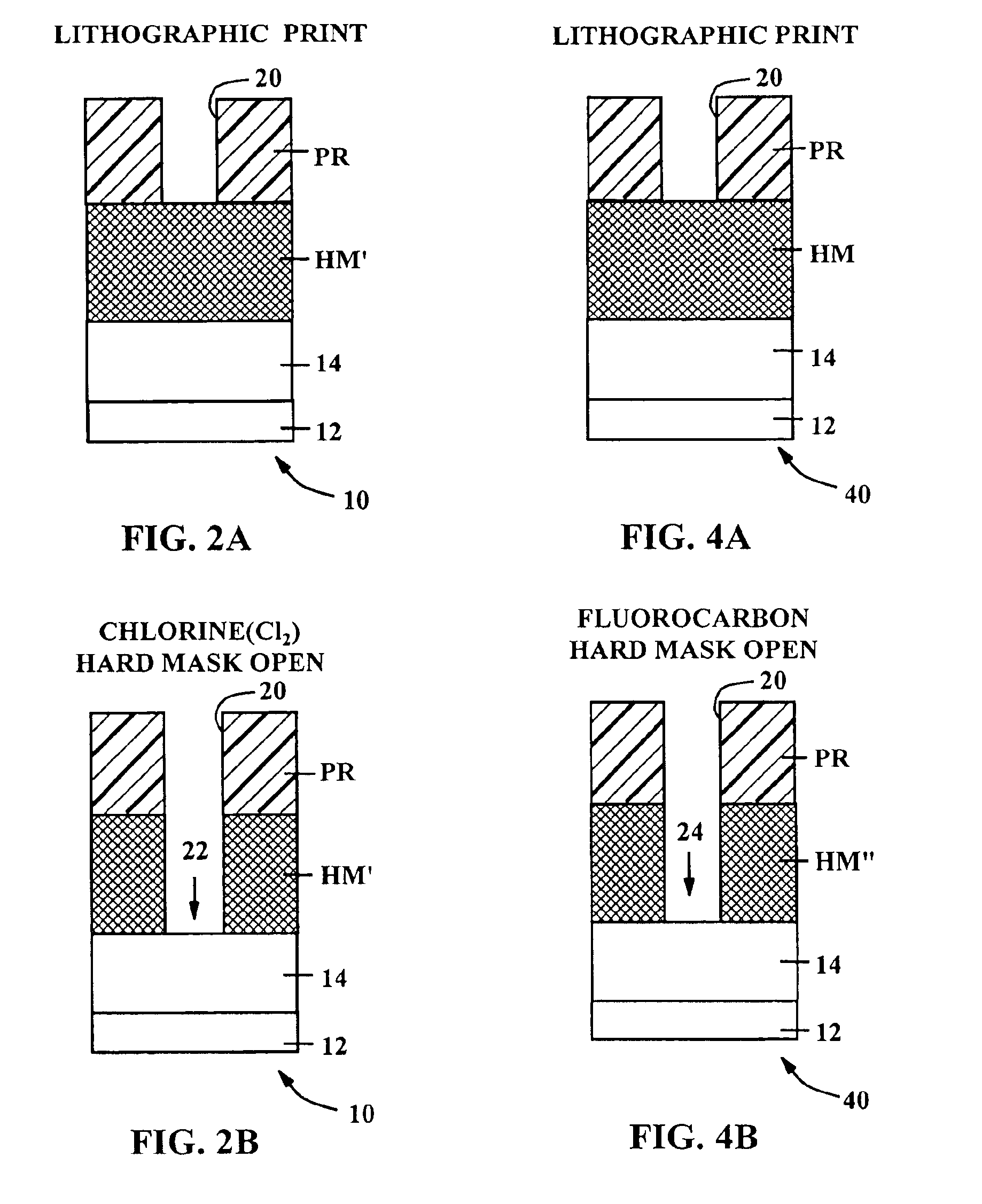

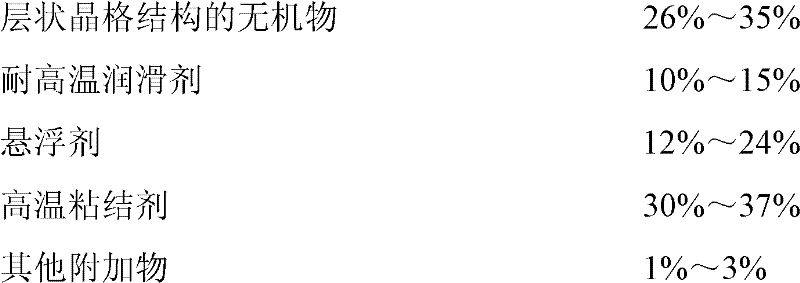

Hard mask integrated etch process for patterning of silicon oxide and other dielectric materials

InactiveUS6869542B2High degree of polymerizationRaise the ratioDecorative surface effectsSemiconductor/solid-state device manufacturingMetallurgyDiluent

Form an opening in a dielectric layer formed on a substrate comprises depositing a hard mask composed of an etch resistant material over a dielectric layer, e.g. a silicon oxide. Use a photoresist mask to expose the hard mask. Use a fluorocarbon plasma to etch through the window to form an opening through the hard mask. Then etch through the hard mask opening to pattern the dielectric layer. The hard mask comprises an RCH / RCHX material with the structural formula R:C:H or R:C:H:X, where R is selected from Si, Ge, B, Sn, Fe, Ti and X is selected from O, N, S and F. The plasma etching process employs a) a gas mixture comprising N2; fluorocarbon (CHF3, C4F8, C4F6, CF4, CH2F2, CH3F); an oxidizer (O2, CO2), and a noble diluent (Ar, He); b) a high DC bias (500-3000 Volts bias on the wafer); 3) medium pressure (20-100 mT.; and d) moderate temperatures (−20 to 60°).

Owner:IBM CORP

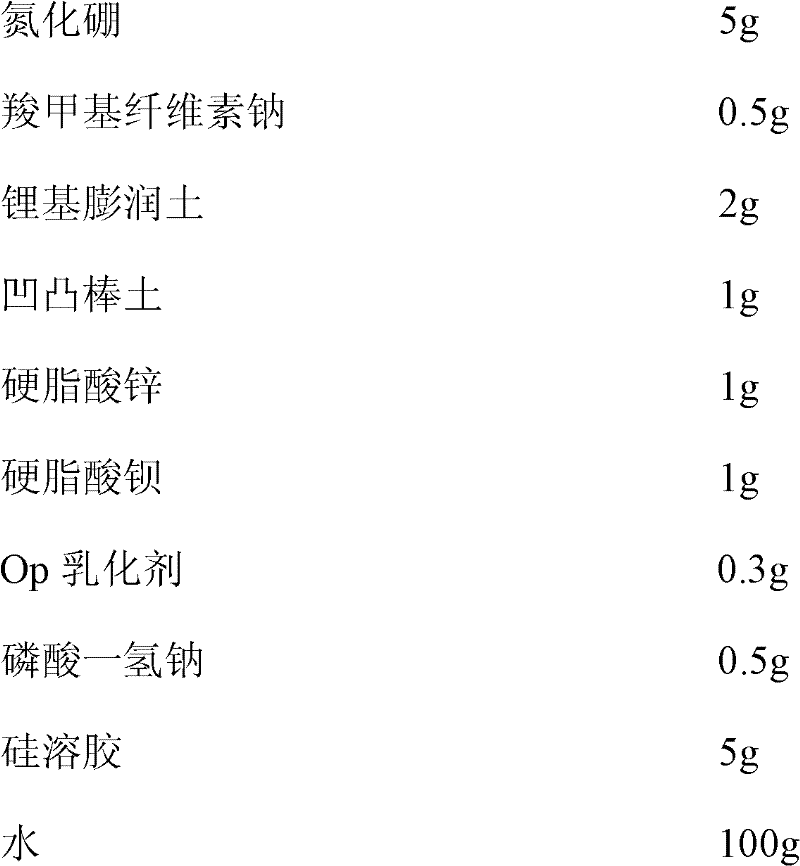

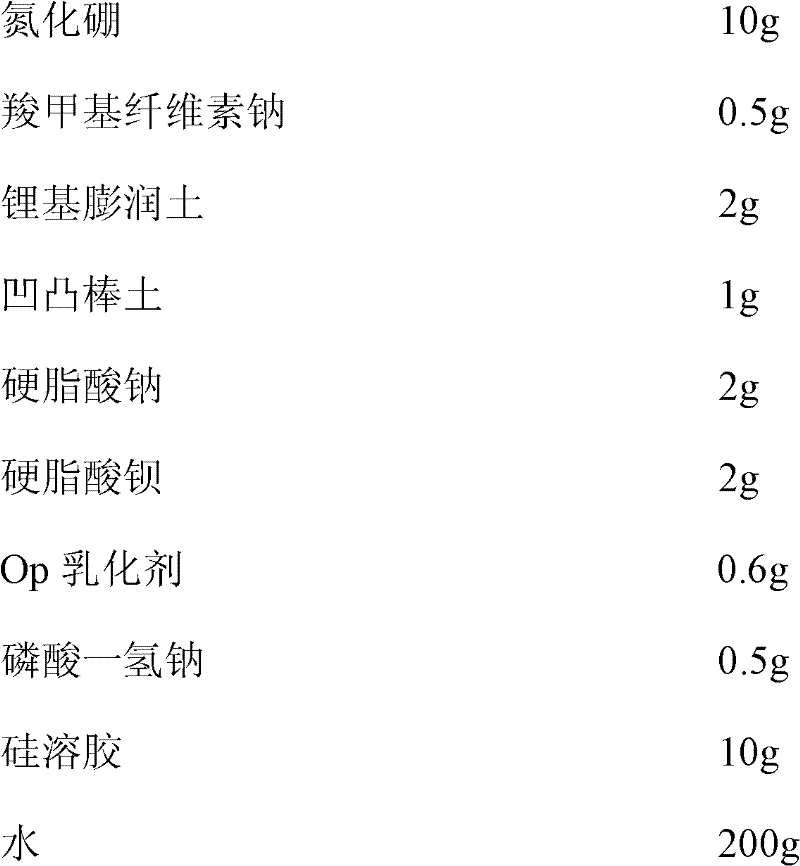

Non-graphite type lubricant for hot die forging of metal and preparation method of non-graphite type lubricant

The invention discloses a water-based non-graphite type lubricant, which is characterized by comprising the following ingredients in percentage by weight: 26%-35% of inorganic substance with layered lattice structures, 10%-15% of high-temperature-resistant lubricant, 12%-24% of suspending agent, 30%-47% of high-temperature adhesive and 1%-3% of adjuvant. The water-based non-graphite type lubricant is an environment-friendly lubricant for hot die forging, can replace a graphite type lubricant, and is especially suitable for the hot die forging of metal, in particular, for the hot die forging of large-sized aluminum pieces. The invention further discloses a preparation method of the water-based non-graphite type lubricant. The preparation method has the advantages of simple preparation process and excellent film-forming performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Phenolic resin-based adhesives and methods of using same in preparing laminated veneer lumber (LVL)

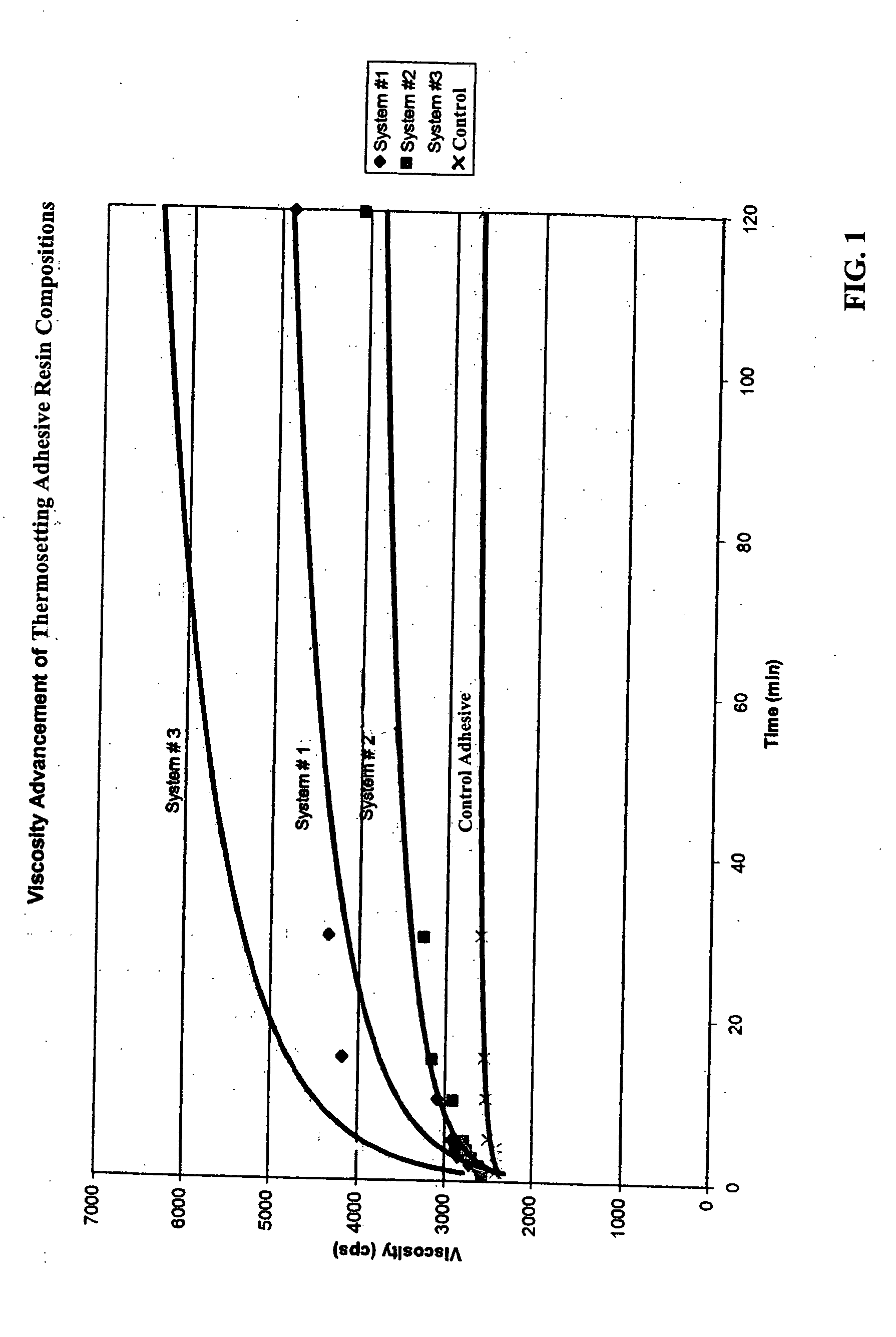

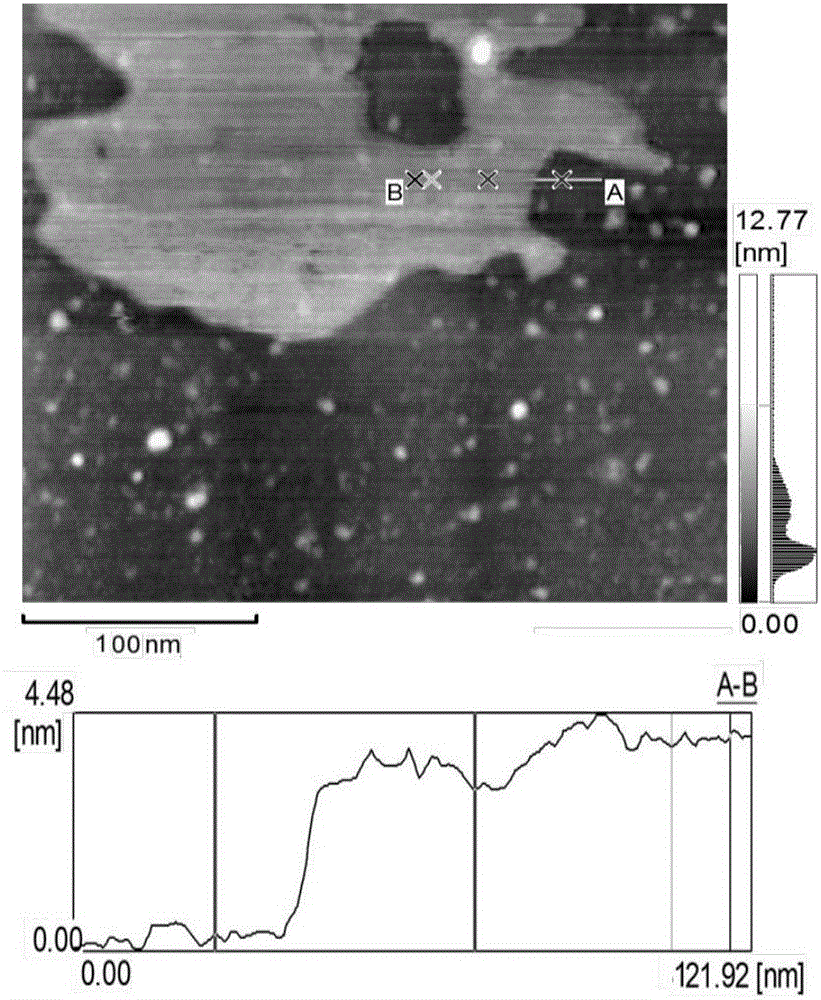

InactiveUS20050257888A1Fast tack build and curingGood bonding characteristicLaminationAdhesive processes with adhesive heatingPHENOL LIQUIDKetone

Adhesive compositions and methods of using the compositions in the production of laminated veneer lumber (LVL) are disclosed. The adhesive compositions comprise a thermosetting phenol-aldehyde resin having at least one of (A) a number average molecular weight (Mn) of at least about 450, (B) a weight average molecular weight (Mw) of at least about 2000, and (C) a Z-average molecular weight (Mz) of at least about 6000, wherein said Mn, Mw, and Mz are measured using gel permeation chromatography (GPC), a ketone-aldehyde resin cure promoter, and optionally other components (e.g., a tack-promoter or a catalyst). The adhesive compositions minimize or eliminate the art-recognized problems of glue line dryout and steam blowout, associated with LVL manufacture from both low-moisture veneers and high-moisture veneers, respectively. Furthermore, the adhesive compositions provide fast tack-build and curing as well as ultimately good bonding characteristics.

Owner:GEORGIA PACIFIC CHEM LLC

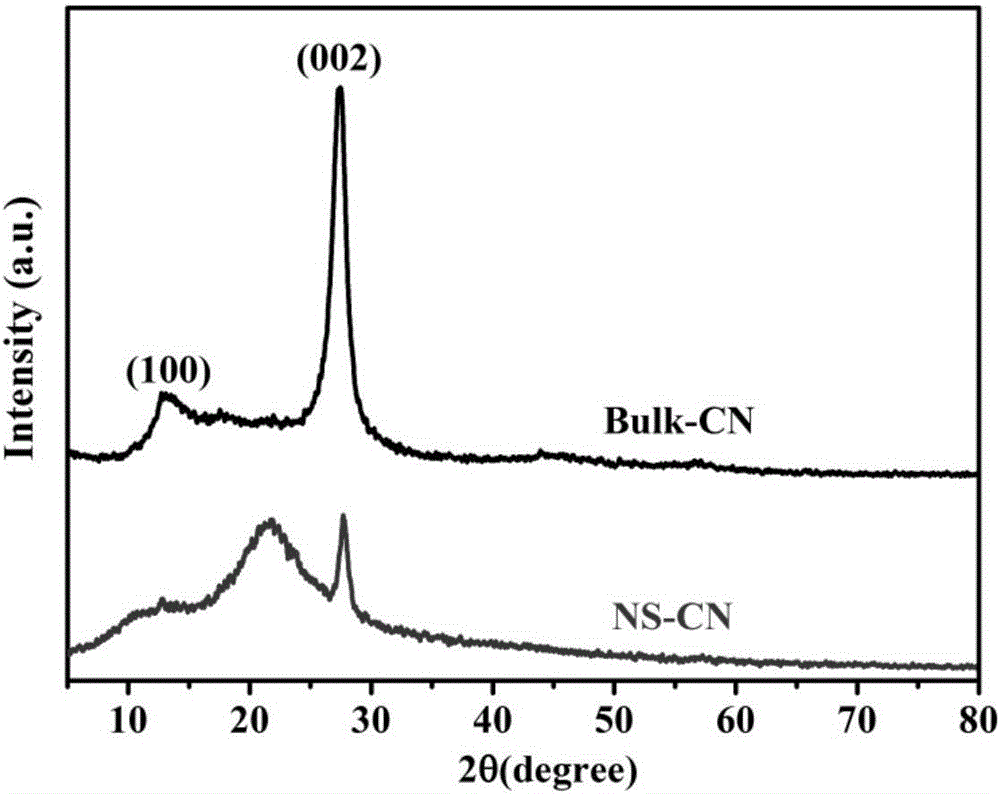

Ammoniated ultrathin graphite-phase carbonitride photocatalyst and preparation method thereof

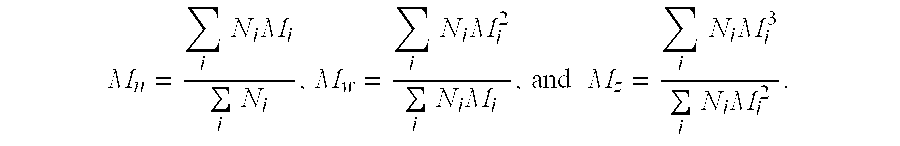

ActiveCN106563481AScattering effect is smallEasy to separateCatalyst activation/preparationTube furnaceGraphite

The invention discloses an ammoniated ultrathin graphite-phase carbonitride photocatalyst material and a preparation method thereof. The ammoniated ultrathin graphite-phase carbonitride photocatalyst material resembles wrinkled tulle, is in the shape of tulle with wrinkles and has a uniform thickness of 3 to 5 nm; and the surface of the material is smooth and contains rich amino groups. The preparation method comprises the following steps: acidifying melamine so as to obtain a protonated melamine supermolecular structure crystal, carrying out calcining in an inert protective atmosphere so as to prepare a graphite-phase carbonitride material and carrying out uniformization so as to obtain ultrafine powder of a graphite-phase carbonitride photocatalyst material; and placing the ultrafine powder of the graphite-phase carbonitride photocatalyst material and an ammonia-source substance capable of producing ammonia gas through thermal decomposition into a tubular furnace, introducing inert gas for deoxygenation and then carrying out gradient calcining in the inert protective atmosphere, i.e., carrying out heating to 500 to 540 DEG C at first, maintaining the temperature for 2 to 4 h, then carrying out heating to 560 to 600 DEG C, maintaining the temperature for 2 to 3 h and then carrying out cooling. The ammoniated ultrathin graphite-phase carbonitride photocatalyst material has substantially improved photocatalysis efficiency and present excellent photocatalysis performance when applied to catalytic reduction of CO2.

Owner:WUHAN UNIV OF TECH

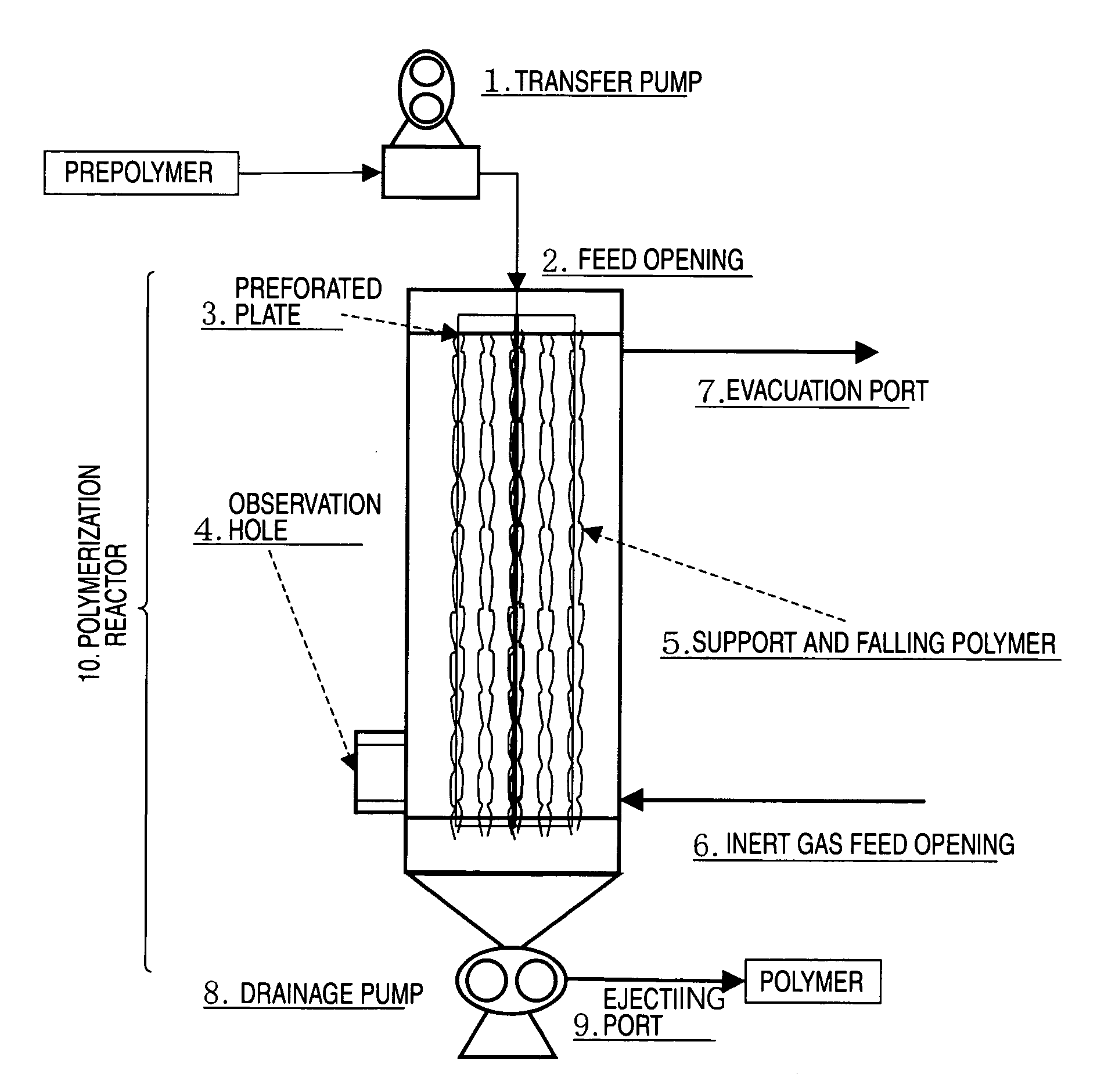

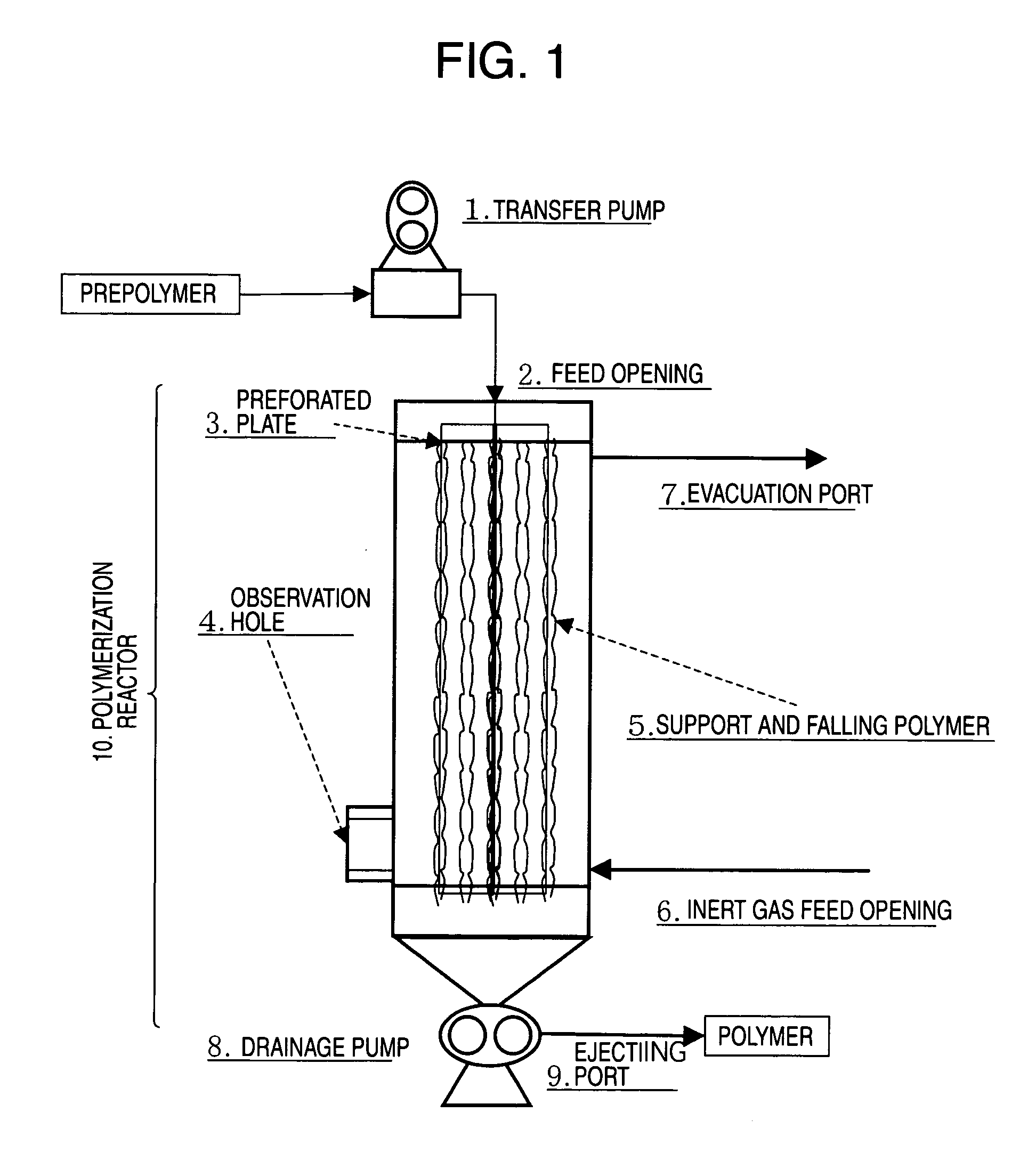

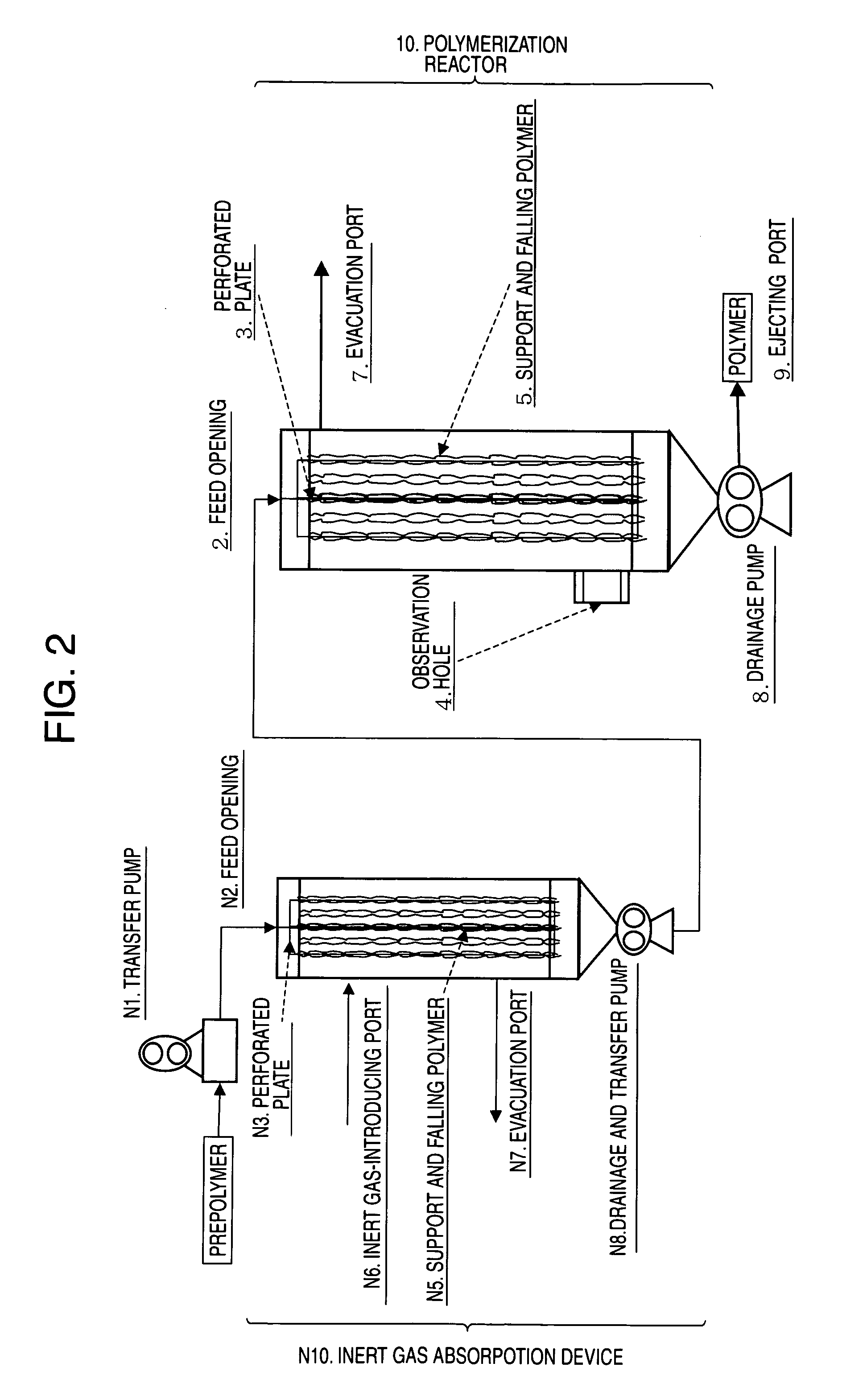

Process for Producing Polyalkylene Terephthalate, Process for Producing Polyalkylene Terephthalate Molding and Polyalkylene Terephthalate Molding

ActiveUS20080274320A1Low costIncrease production capacitySuture equipmentsLayered productsMolten statePolymer science

The present invention provides a method of producing polyalkylene terephthalate, which comprises: introducing a prepolymer of polyalkylene terephthalate that is in a molten state comprising 70 mol % or more of ethylene terephthalate or 1,4-butylene terephthalate repeating units and having an intrinsic viscosity [η] between 0.2 and 2 dl / g through a feed opening to a polymerization reactor; discharging the introduced prepolymer from holes of a perforated plate; and polymerizing the prepolymer under reduced pressure, while allowing the prepolymer to fall along the surface of a support that is open towards the outside at a temperature between the [crystalline melting point−10° C.] of the prepolymer or higher and the [crystalline melting point+30° C.] of the prepolymer or lower under the conditions represented by a formula S1 / S2>1, wherein S1 is the surface area of falling polyalkylene terephthalate, and S2 is the area where the support is in contact with polyalkylene terephthalate.

Owner:ASAHI KASEI CHEM CORP

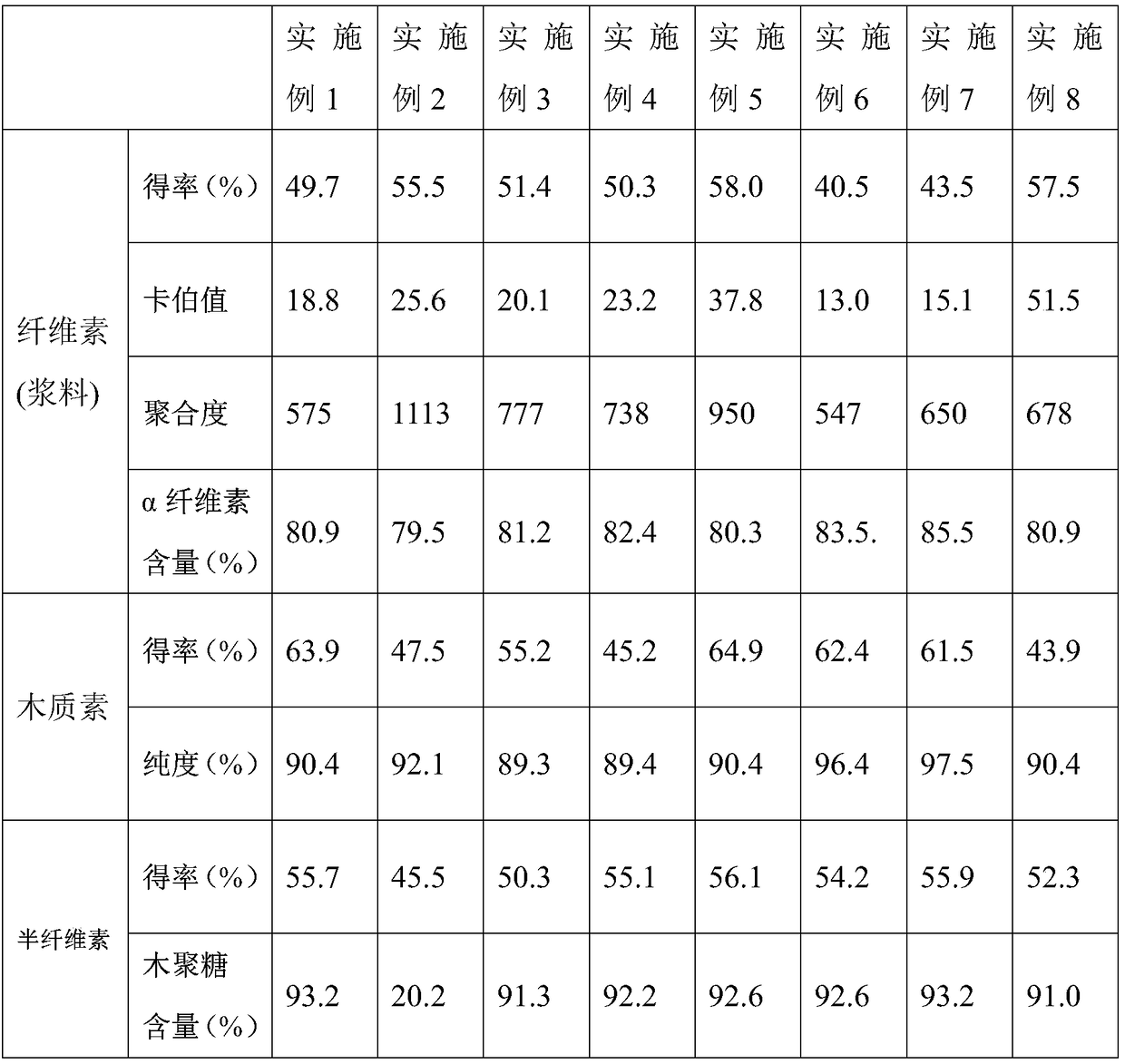

Method for separating three components of cellulose, hemicellulose and lignin in plant fiber raw materials

The invention discloses a method for separating three components of cellulose, hemicellulose and lignin in plant fiber raw materials. The method comprises the following steps of heating, steaming andboiling the plant fiber raw materials by a lactic acid / choline chloride low-eutectic solvent in a pressurizing or normal-pressure way, selectively dissolving out the lignin and hemicellulose, and washing the remaining insoluble matters, so as to obtain the cellulose; adding water into a dissolution solution of the low-eutectic solvent containing lignin and hemicellulose, the lignin is separated out, washing and separating, so as to obtain the lignin; separating the remaining water solution of low-eutectic solvent containing the hemicellulose in a nanofiltration way, so as to obtain the hemicellulose; concentrating and dewatering the water solution of the low-eutectic solvent, so as to recycle. The method has the advantages that the components of the plant fiber raw materials can be fully separated, so as to obtain the cellulose with content of alpha-cellulose greater than 79.5% and polymerizing degree of 1,113, the lignin with purity greater than 89%, and the hemicellulose with yield rate greater than 45%; the production energy consumption is low, the property of the obtained slurry is excellent, and the industrialized application prospect is realized.

Owner:NANJING FORESTRY UNIV

Waterproof and anti-corrosion repair mortar for polymer cement-based concrete structure

The invention relates to a waterproof and anti-corrosion repair mortar for a polymer cement-based concrete structure, in particular to a cement concrete repair material for a cement concrete structure, which is used for carrying out bonding reinforcement and repair on defects of municipal roads, municipal services, bridges and water conservancy projects (dams and gates). The waterproof and anti-corrosion repair mortar is prepared by mixed materials and water, and the mixed materials comprise the following components in parts by weight: 20-30 parts of portland cement, 0.01-0.05 part of high-performance water-reducing agent, 1-5 parts of high-aluminum cement, 15-30 parts of quartz sand, 25-60 parts of gravel and 1-3 parts of acrylic adhesive powder, 1-3 parts of fiber material, while the using amount of water accounts for 5-14% of the total parts of the mixed materials. Due to the adoption of the technical scheme, the waterproof and anti-corrosion repair mortar has the characteristics of good pressure resistance, high flexural strength, high bonding strength, good durability, convenient and fast construction, fast setting and early strength shrinkage control, and can greatly shorten the repair time and quickly resume the traffic in particular to roads.

Owner:卢建华

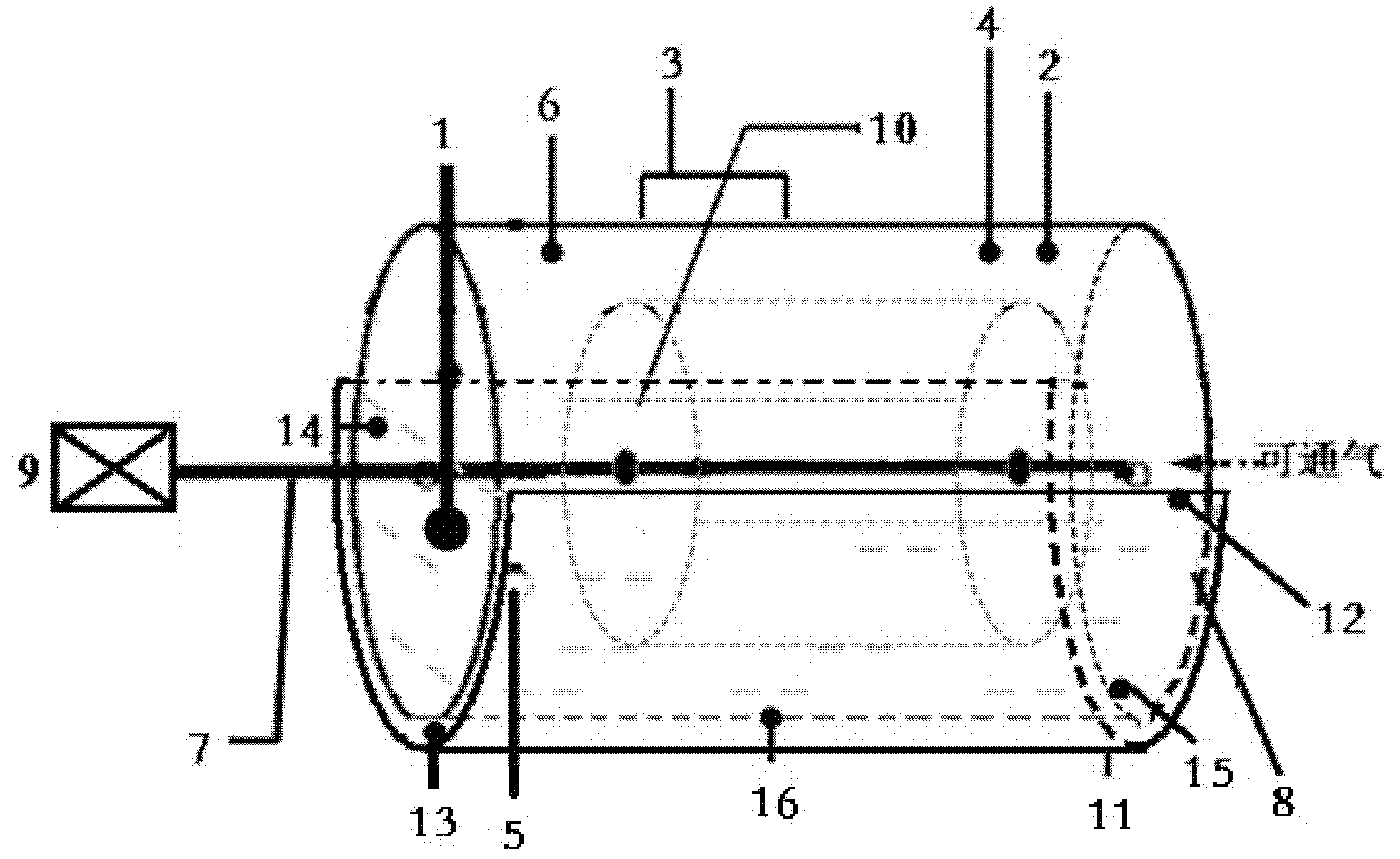

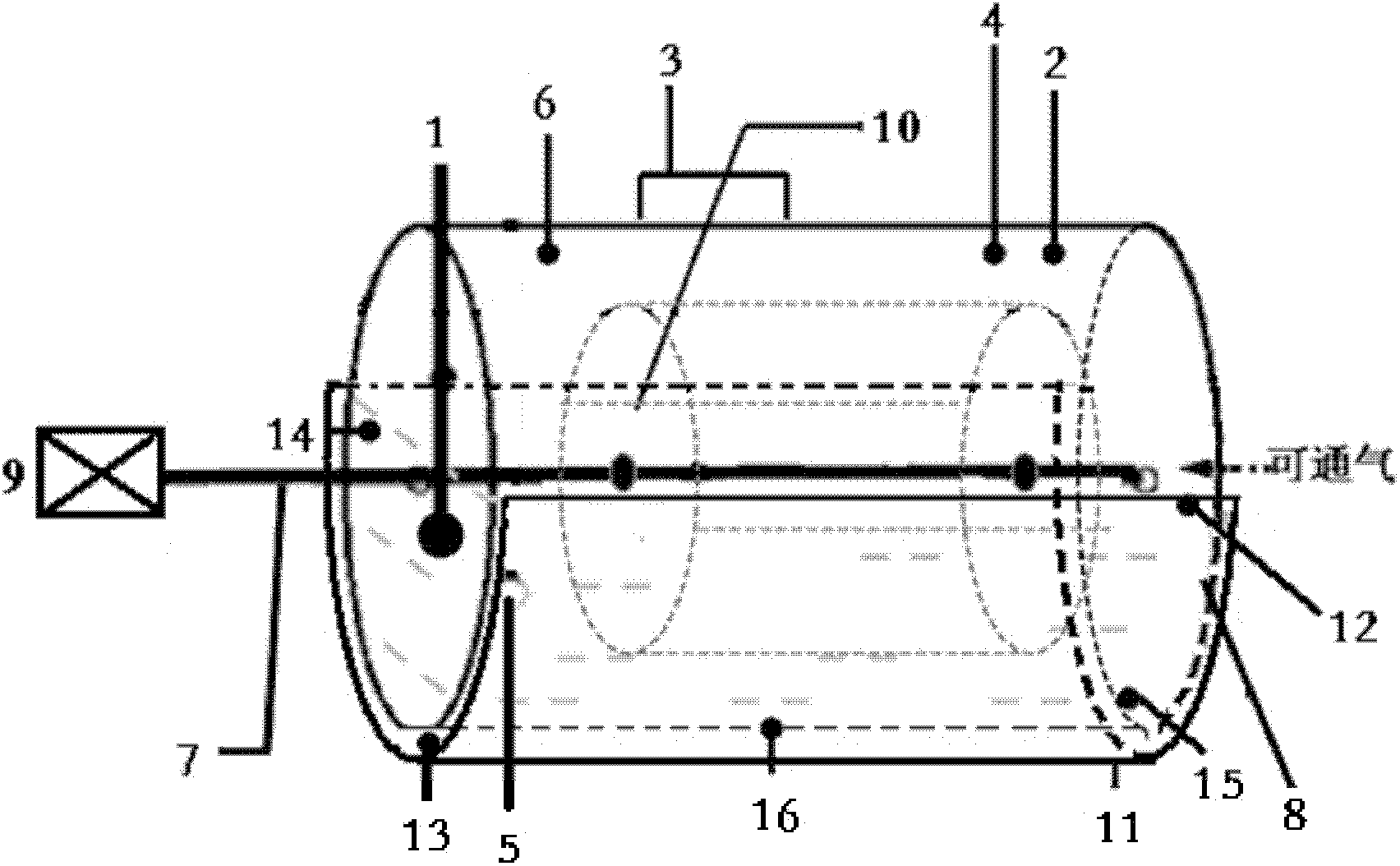

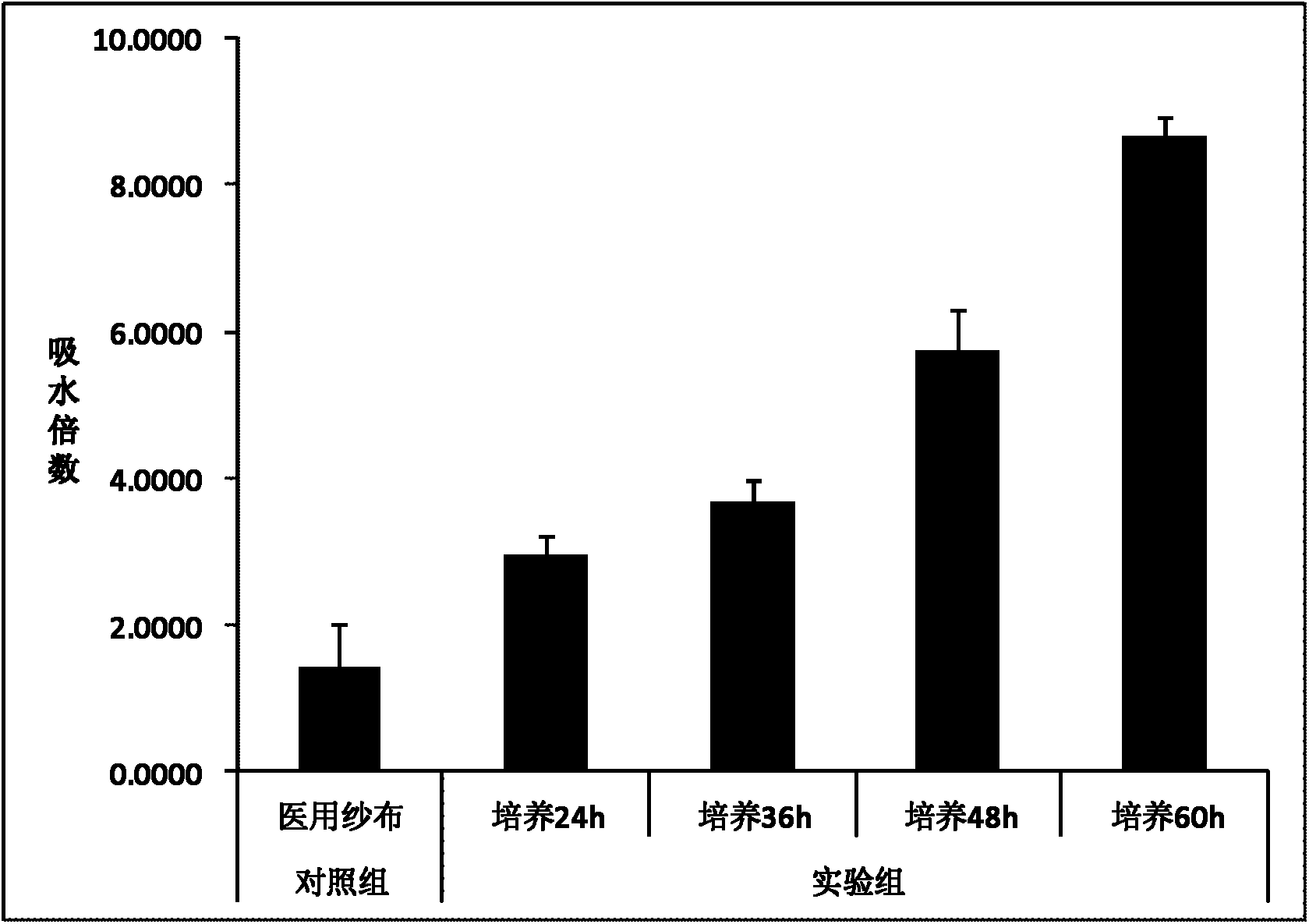

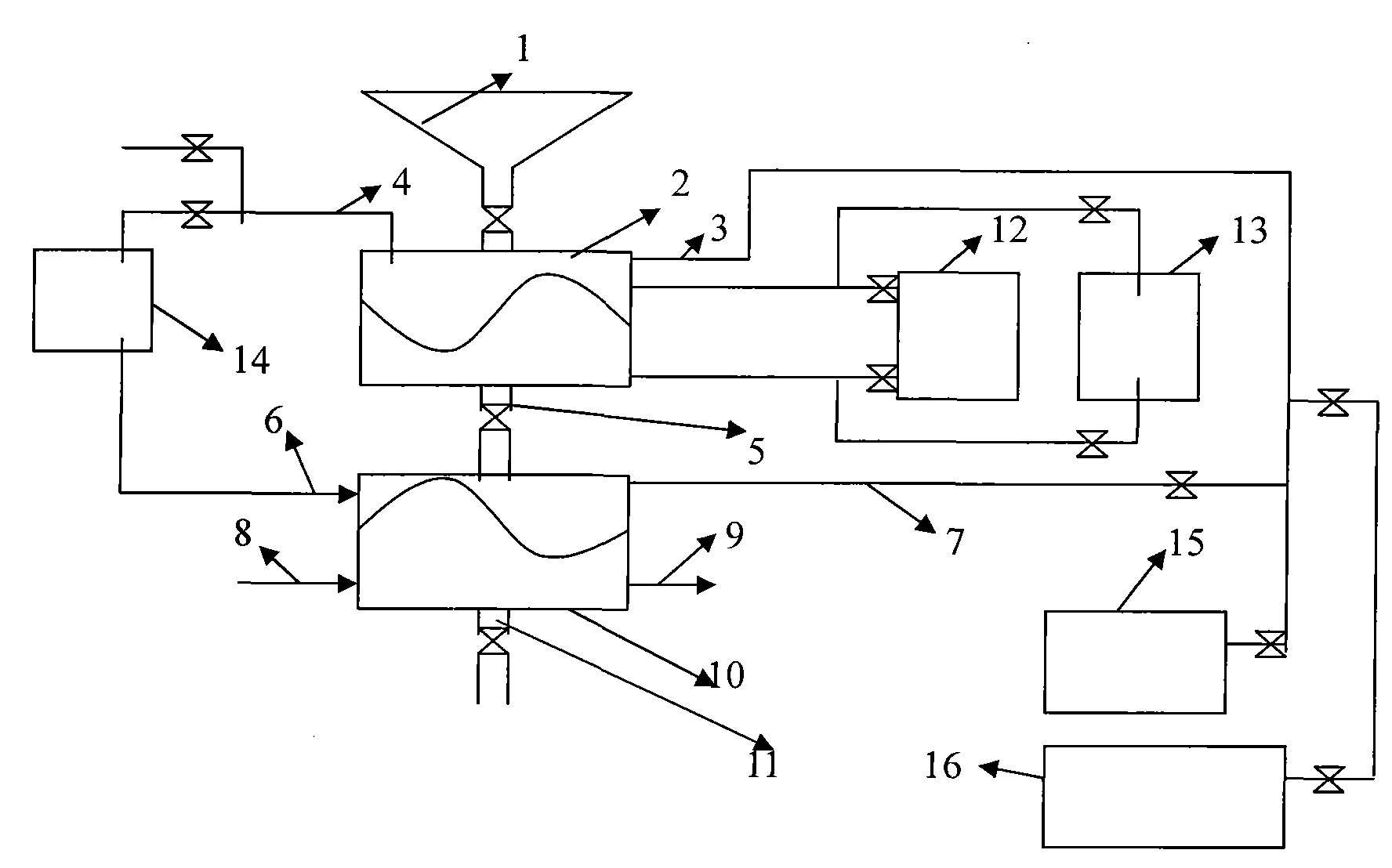

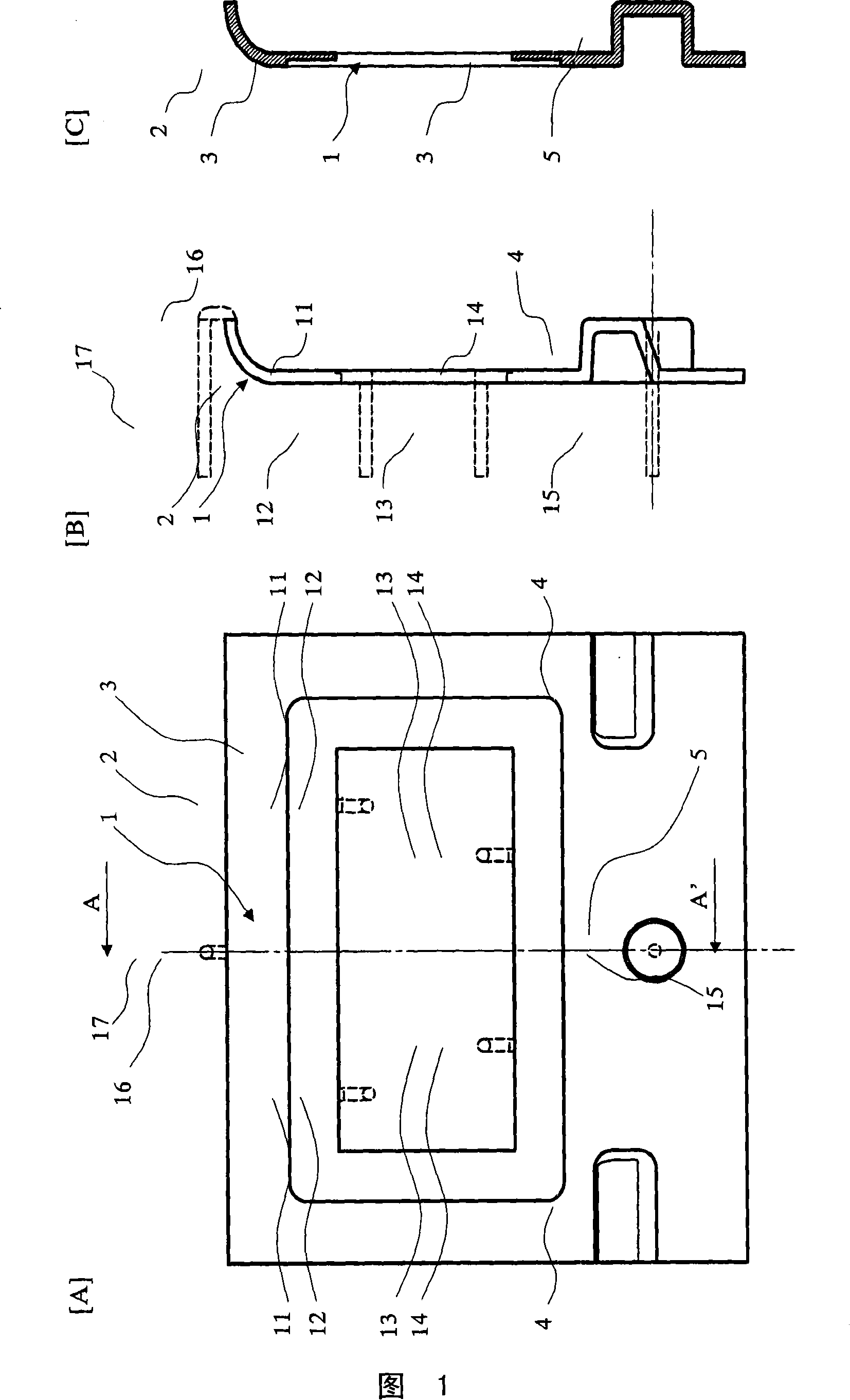

Method and device for preparing bacterial cellulose composite material quickly on large scale

ActiveCN102533904AReduce dosageGuaranteed StrengthBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumFermentation

The invention relates to a method and device for preparing bacterial cellulose composite materials quickly on a large scale. The method comprises the steps as follows: (1) a bacterial cellulose producing strain is inoculated in liquid medium for propagation and then transferred into a biological reactor containing framework material for perturbation cultivation, so that bacterial cellulose composite material can be obtained; and (2) bacterial cellulose of the bacterial cellulose composite material is peeled off from the framework material or the cellulose composite material is soaked in NaOH solution to be washed. The device comprises a thermometer opening, an acid liquor and alkali liquor feeding opening, a handle, an air vent, a pH meter opening, a nutrition feeding opening, a rotating shaft, a fermentation tank, a motor, a rotating drum, a fermentation tank jacket, a circulating water inlet, a circulating water outlet, a nutrient fluid inlet, a nutrient fluid outlet and a condensed water outlet. The rotating drum is fixed on the rotating shaft in the fermentation tank. The device provided by the invention has the advantages of simplicity, convenience, detachable die, low cost, high production efficiency and high degree of automation; and the obtained bacterial cellulose composite material can be widely applied.

Owner:DONGHUA UNIV

Process for biologically pulping

InactiveCN1616758AReduce pollution loadQuality improvementNon-woody plant/crop pulpCellulose material pulpingFiberPre treatment

The biologically pulping process includes the following steps: pre-treating cotton fiber material with polyxylose enzyme to obtain pulp material; and normal pressure and low temperature steaming and rinsing of the pre-treated pulp material with alkali and H2O2. The said pulping process has low cost of eliminating impurity from the material, lowered bleaching chemical liquid consumption and raised paper pulp quality.

Owner:CHINA BANKNOTE PRINTING & MINTING

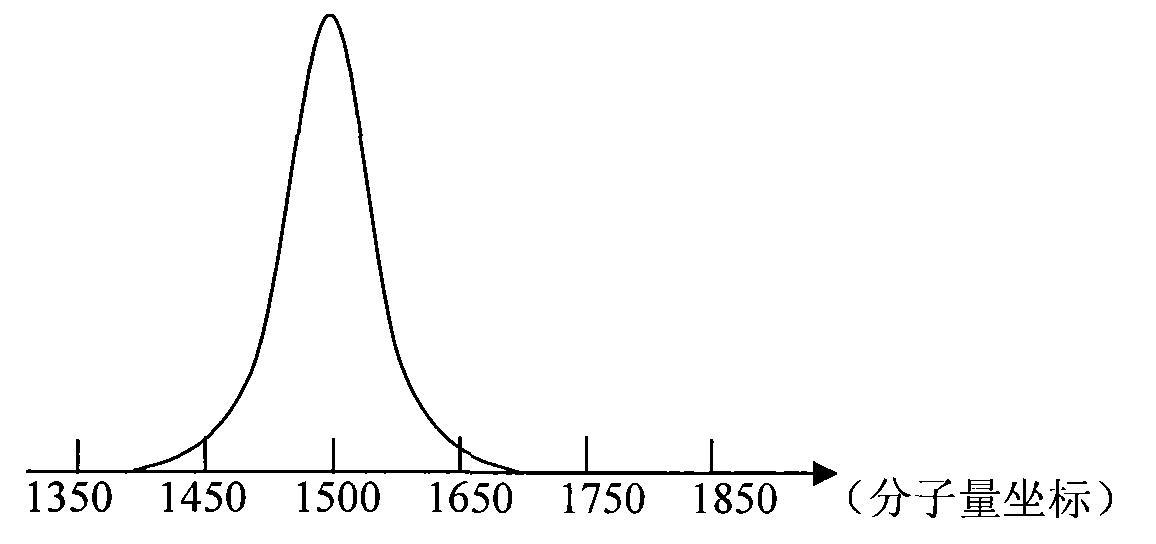

Method for preparing crystal II-type ammonium polyphosphate with distribution of high polymerization degree and narrow molecular weight

ActiveCN101597044AEliminate the effects ofTemperature controlPhosphorus compoundsSolubilityPolymerization

The invention discloses a method for preparing crystal II-type ammonium polyphosphate with distribution of high polymerization degree and narrow molecular weight. The method comprises the following steps: putting phosphorus pentoxide and diammonium phosphate which have equal molar ratio into a malaxator which can accurately control a temperature and heated by conducting oil for mixing; under the protection of inert gas, heating the materials in the malaxator to between 100 and 250 DEG C through the circulatory conducting oil; stopping introducing the inert gas; performing ammonification on the materials and heating the materials under an atmosphere of ammonia gas till the materials are totally molten down; stopping introducing the ammonia gas; after homogenization, introducing the ammonia gas again and heating the materials; throwing a surface treating agent into the malaxator; after material throwing is completed, continuously introducing the ammonia gas, keeping warm and mixing the materials; after reaction is finished, transferring the materials to a closed vessel and reducing the temperature; simultaneously, continuously introducing the ammonia gas till the temperature of the materials is below 100 DEG C; and obtaining a finished product. The method can prepare the crystal II -type ammonium polyphosphate with the distribution of the high polymerization degree and the narrow molecular weight; and the product has the characteristics of uniform granularity shape, small water-solubility, good heat resistance, high polymerization degree, narrow distribution of molecular weight and high crystal II-type purity.

Owner:GUANGDONG JUSHI CHEM CO LTD

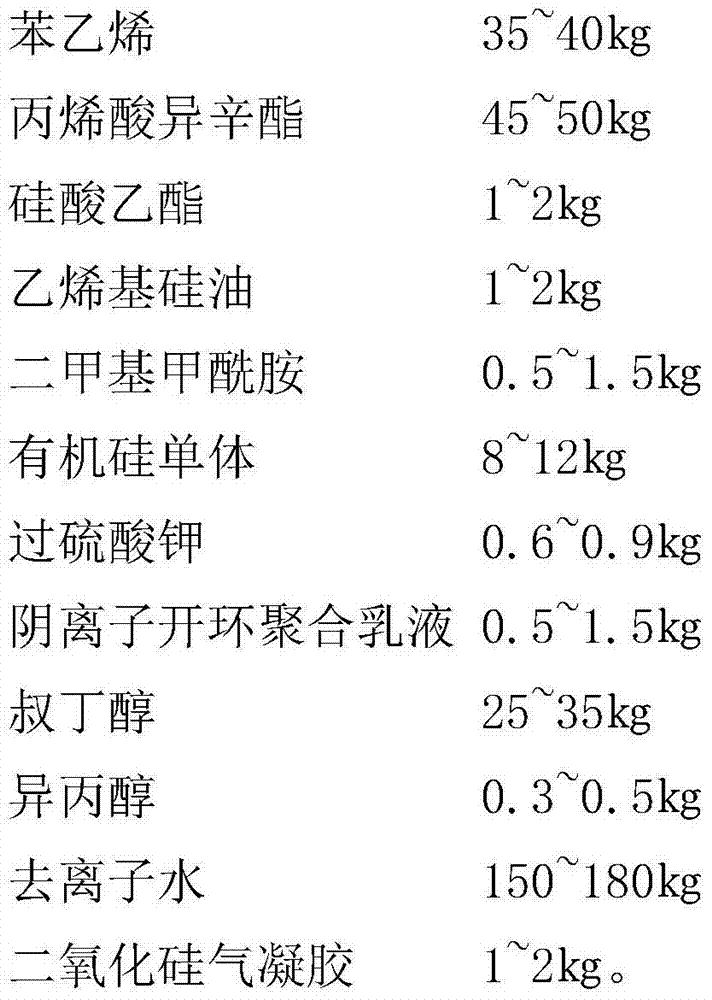

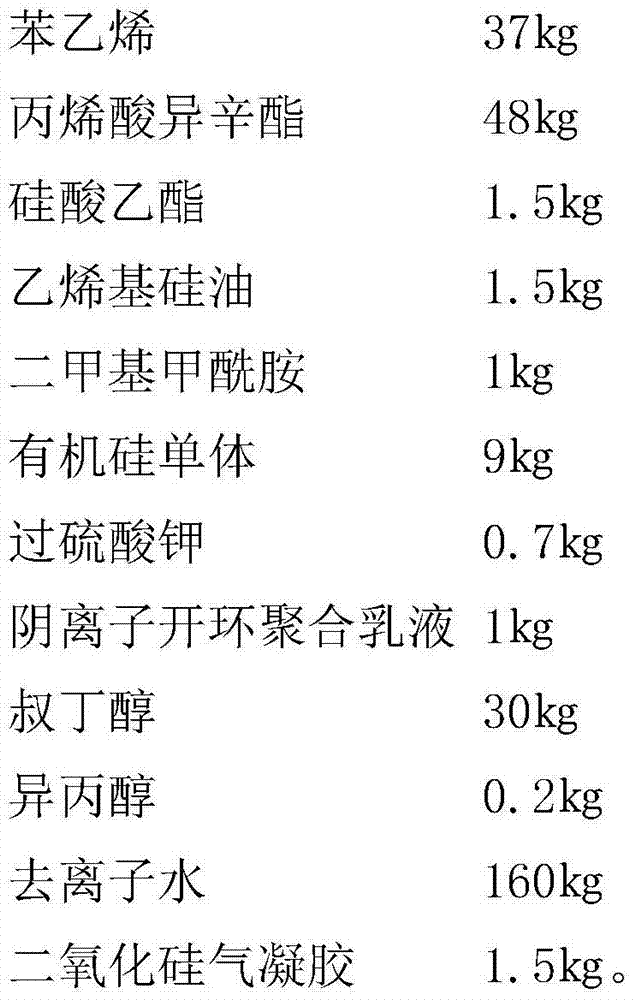

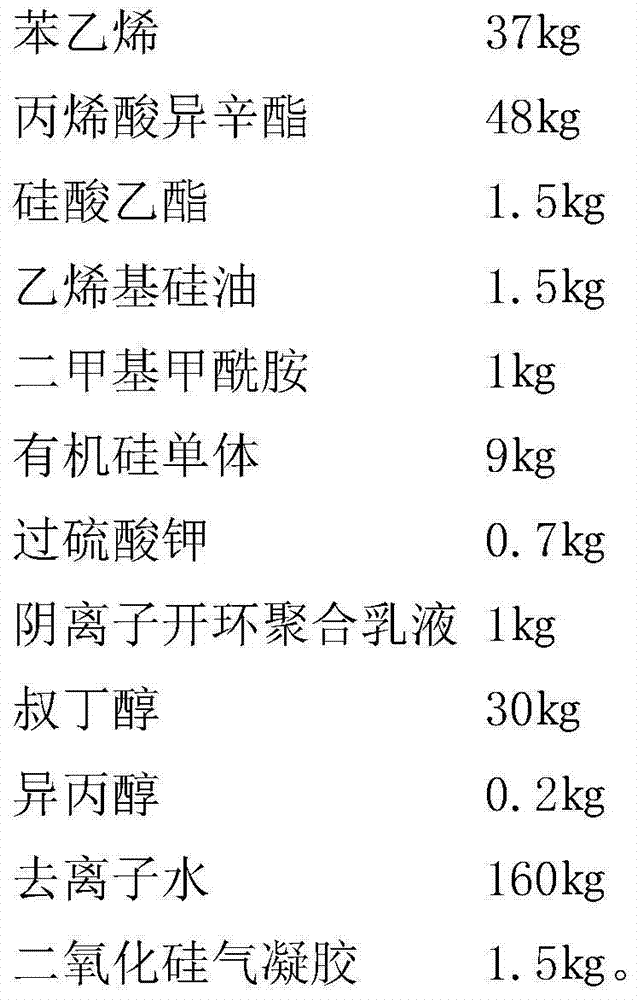

Method for modifying styrene-acrylic emulsion through organic silicon

ActiveCN103923271AHigh degree of polymerizationImprove water resistanceIsooctyl acrylatePotassium peroxodisulfate

The invention provides a method for modifying styrene-acrylic emulsion through organic silicon, relating to the field of chemical engineering technologies. The method comprises steps of (1) firstly putting deionized water, tertiary butanol and isopropanol into a reaction kettle and mixing uniformly through stirring, and heating up to 60-70DEG C, so as to prepare a solution a; (2) dissolving styrene, 2-ethylhexyl acrylate, ethyl silicate, organosilicone monomer and anion ring opening polymerization emulsion into the solution a, fully mixing through stirring till the temperature rises up to 80-90DEG C, and preserving heat for 2 hours, so as to prepare a solution b; (3) putting vinyl silicone oil, silicon dioxide aerogel and dimethyl formamide into the solution b, stirring for 30 minutes to be mixed uniformly to prepare a solution c; (4) controlling the temperature of the solution c at 60-65 DEG C, then dripping potassium peroxodisulfate for 0.5 hour, and cooling to room temperature, so as to prepare a solution d; (5) regulating the pH value of the solution d to be neutral with ammonia water, filtering the discharged material so as to prepare the styrene-acrylic emulsion. Due to the addition of organic silicon monomer, ethyl silicate and the like, the degree of crosslinking of a latex film is improved, and the weather fastness of the styrene-acrylic emulsion is greatly improved.

Owner:DONGZHI OASIS ENVIRONMENTAL PROTECTION CHEM

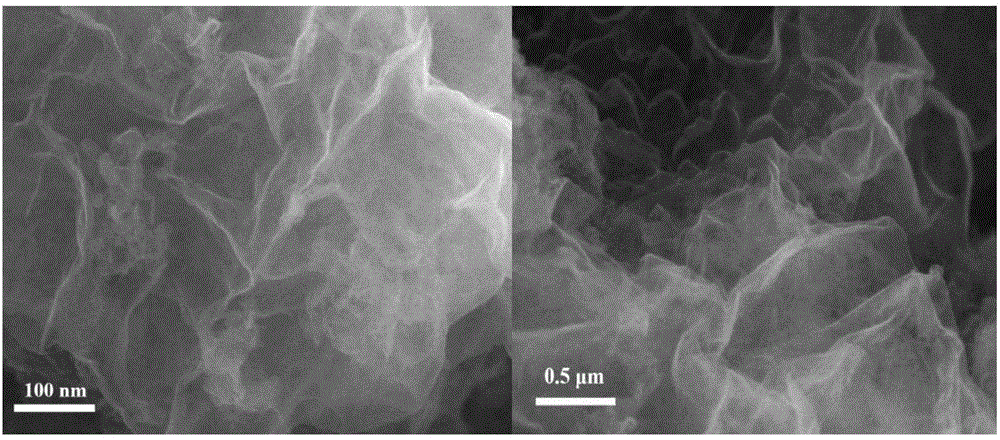

Cellulose nanofiber, production method of same and cellulose nanofiber dispersion

InactiveUS8992728B2High degree of polymerizationHigh strengthNon-fibrous pulp additionNanotechCellulosePolymer science

The cellulose nanofiber production method of the present invention comprises an oxidation treatment step for oxidizing native cellulose in a neutral or acidic reaction solution containing an N-oxyl compound and an oxidizing agent that oxidizes aldehyde groups, and a dispersion step for dispersing the native cellulose in a medium following the oxidation treatment step. According to the production method of the present invention, a cellulose nanofiber is provided that has long fibers and demonstrates high strength.

Owner:THE UNIV OF TOKYO

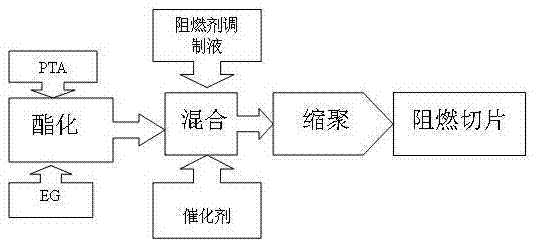

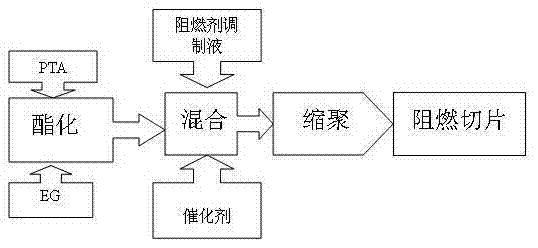

Method for producing phosphorus copolymerized flame-retarding terylene high-strength industrial yarns

ActiveCN102199807ADoes not affect the molecular skeleton structureImprove hydrolytic stabilityArtificial filament heat treatmentMonocomponent copolyesters artificial filamentYarnHigh intensity

The invention discloses a method for producing phosphorus copolymerized flame-retarding terylene high-strength industrial yarns, which is characterized by comprising the following steps: pumping ethylene glycol (EG) and purified terephthalic acid (PTA) into a pulping kettle according to a molar ratio of 1.15 for pulping; after uniform pulping, transferring the uniform pulp into an esterification kettle for esterification; after the esterification is accomplished, adding blended liquid of a flame retardant, uniformly mixing, and adding the mixture into a polymerization kettle; after the polymerization is accomplished, discharging and cutting to obtain flame-retarding polyester chips with a viscosity of 0.61; feeding the prepared flame-retarding polyester chips into a solid-phase polymerization system, and improving the viscosity to 0.90 to 1.10; and melting at a high temperature into molten spinning solution in a screw extruder, spinning by a spinning component, drawing, and thermally setting to obtain phosphorus copolymerized flame-retarding terylene high-strength industrial yarns. In the invention, a copolymerized flame-retarding modification process is used for flame-retarding modification of the polyester, and the obtained terylene industrial yarns have high strength and a permanent flame-retarding property.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

Stimuli-responsive textile fabric and method for preparing same

The invention relates to an environment-response intelligent weave fabric and relative preparation. Wherein, adding the fabric which is induced by argon microwave low-temperature plasma to generate free group on surface, into the dual monomer solution of 2-acrylamide-2-methanesulfonic acid and N-isopropyl acrylamide that contains N and N'-methylene dual acrylamide cross linker to process graft polymerization reaction, while the bath ratio is 1:40, to graft the dual intelligent gel on the fiber macromolecule of fabric, to attain said inventive product. When the invention is dry, it has no difference from general fabric, but when it is wet, the gel will adsorb water to expand and block the slits between fibers, to reduce the water and gas permeability of fabric, and avoid outer penetrating into the inner layer of fabric to stop heat emission. The invention can be used to produce army waterproof clothes, heat-accumulation temperature adjustable special clothes, etc.

Owner:TIANJIN POLYTECHNIC UNIV

Lignose and process for modifying phenolic resin with derivates thereof

The invention discloses a lignin and a method for modifying a phenolic resin which is a ramification thereof. The method that the polymerization is performed for a plurality of times and the extent of polymerization is deepened gradually is adopted to improve the uniform stability, the inoxidability, the toughness and the intensity of the product, effectively recycle the wasted resources, lower the cost and make the industrialization easier. The invention is realized by the technical proposal which is as follows: the phenolic resin low polymer is prepared firstly; the lignin or a ramification thereof is added to polymerize in order to obtain a preformed polymer secondly; finally, phenol and formaldehyde are added to polymerize in order to obtain the high polymer. A molding material prepared by the phenolic resin can be widely applied to the manufacture of a low-voltage apparatus, an insulating structure and a product for daily life.

Owner:JILIN UNIV

Resin composition

ActiveCN101142277ALow intrinsic viscosityHigh degree of polymerizationPolyethylene terephthalateFilling materials

Disclosed is a resin composition comprising an aromatic polycarbonate and a polyethylene terephthalate, which has high chemical resistance and is excellent in impact resistance, heat resistance, stiffness and thermal stability while maintaining good fluidability. Also disclosed is a molded article produced from the resin composition. Further disclosed is a process for production of a vehicle exterior material. The resin composition comprises 50 to 100 wt% of a resin component and 0 to 50 wt% of an inorganic filler (component D), the resin component comprising (i) an aromatic polycarbonate having a specified viscosity average molecular weight (component A) and (ii) a polyethylene terephthalate having a specified inherent viscosity (IV), a specified terminal carboxyl group content and a specified ratio of a weight average molecular weight (Mw) to a number average molecular weight (Mn) (Mw / Mn) (component B), provided that (iii) the ratio by weight of the total amount of the components A and D to the amount of the component B [(A+D) / B] falls within the range from 60 / 40 to 85 / 15.

Owner:TEIJIN KASEK KK

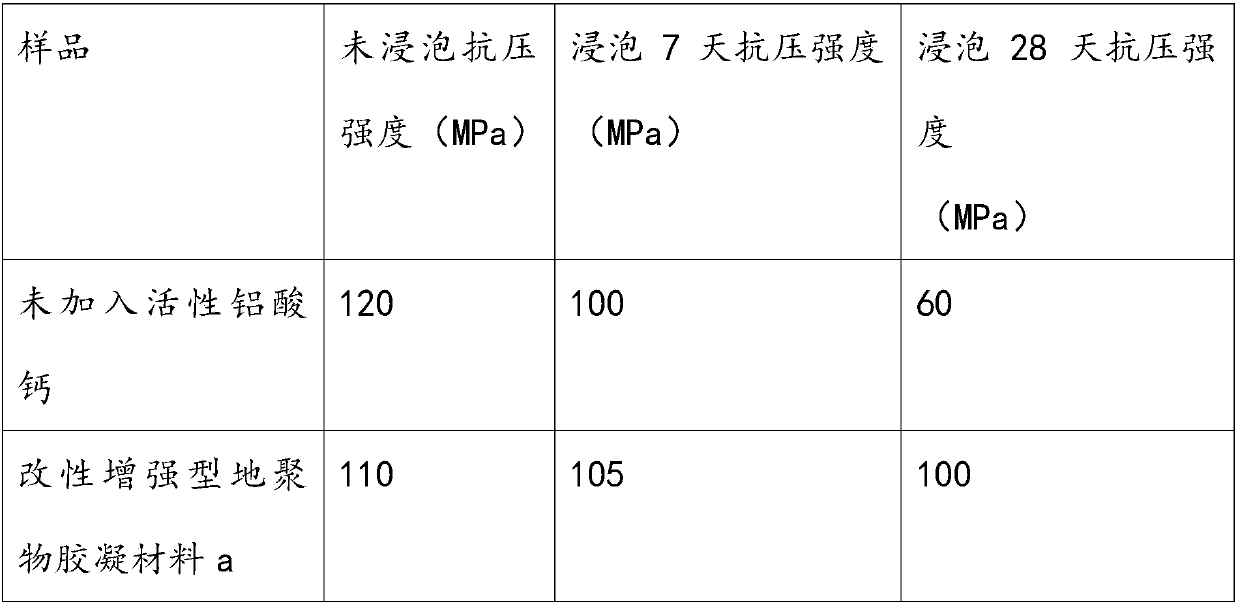

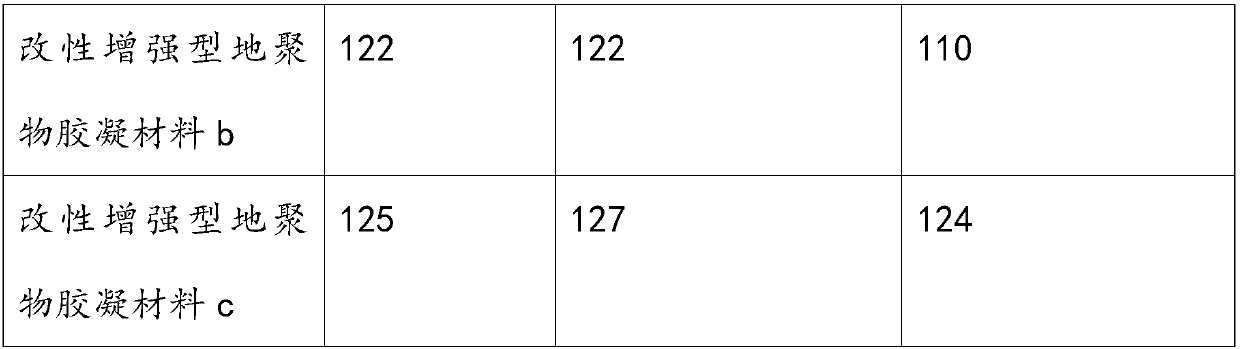

Modified reinforced geopolymer gelling material and preparation method thereof

The invention discloses a modified reinforced geopolymer gelling material. The modified reinforced geopolymer gelling material comprises 40-60 parts of compounded silicon-aluminum powder, 70-90 partsof a compounded alkali activator, 5-15 parts of a modifier and 2-6 parts of a condensed phosphate promoter, and the compounded silicon-aluminum powder includes 20-30 parts of metakaolin, 10-20 parts of fly ash, 5-10 parts of mineral slag, 5-10 parts of steel slag, 4-6 parts of silica fume and 1-2 parts of nano-silica. The invention also discloses a preparation method of the modified reinforced geopolymer gelling material. The above product has a high chemical stability and a high mechanical strength in an acid and alkali erosion environment.

Owner:ZHEJIANG UNIV

PVC (Polyvinyl Chloride) paste resin and preparation method thereof

The invention discloses PVC (Polyvinyl Chloride) paste resin and a preparation method thereof, belonging to the technical field of polymer chemical industry. Weighted in 100 parts by weight of vinyl chloride, the PVC paste resin with the average grain diameter of 0.5-2mum, the average degree of polymerization of 1600-1900 and the paste viscosity of 1500-3500mPa.s is prepared from the following components: 70-120 parts of deionized water, 0.5-5 parts of mixed emulsifier, 0.005-0.02 part of oil-soluble compound initiating agent, 0.05-0.5 part of pH value regulator and 0-0.1 part of chain extender through microsuspension polymerization. The paste resin prepared according to the invention has the advantages of high degree of polymerization, low paste viscosity, rapidness in plasticization, good transparency and favorable defoaming performance.

Owner:SHENYANG CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com