Method for modifying styrene-acrylic emulsion through organic silicon

A styrene-acrylic emulsion and silicone technology, applied in the chemical industry, can solve the problems of low coating strength, high film-forming temperature, poor water resistance and weather resistance of ordinary styrene-acrylic emulsions, etc. Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

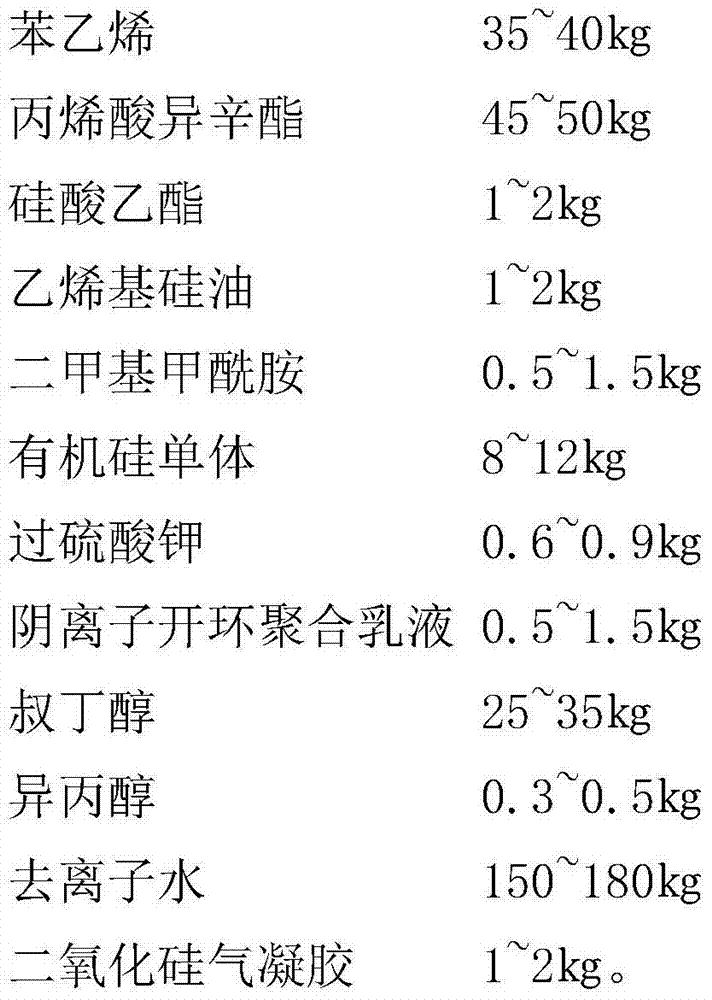

[0022] A silicone-modified styrene-acrylic emulsion, consisting of the following components by weight,

[0023]

[0024] The anionic ring-opening polymerization emulsion is the emulsion synthesized by ring-opening emulsion polymerization of cyclosiloxane in the presence of an anionic catalyst.

[0025] The preparation method of silicone acrylic emulsion printing adhesive of the present invention is as follows:

[0026] 1) Weigh each component according to the above formula, first put deionized water, tert-butanol and isopropanol into the reaction kettle, stir and mix evenly, heat to 60-70°C, and prepare solution a for use;

[0027] 2) Dissolve styrene, isooctyl acrylate, ethyl silicate, silicone monomer and anionic ring-opening polymerization emulsion into solution a, stir well, heat while stirring, until the temperature reaches 80-90°C and keep warm for 2 Hour, make solution b stand-by;

[0028] 3) Put vinyl silicone oil, silica airgel and dimethylformamide into solution...

Embodiment 2

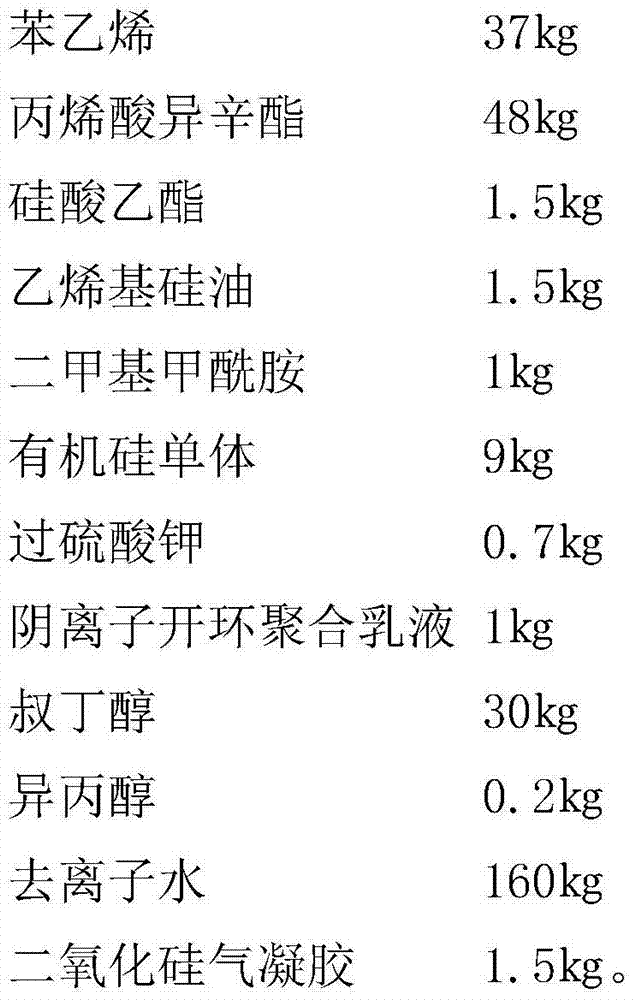

[0032] A silicone-modified styrene-acrylic emulsion, consisting of the following components by weight,

[0033]

[0034] The anionic ring-opening polymerization emulsion is the emulsion synthesized by ring-opening emulsion polymerization of cyclosiloxane in the presence of an anionic catalyst.

[0035] The preparation method of silicone acrylic emulsion printing adhesive of the present invention is as follows:

[0036] 1) Weigh each component according to the above formula, first put deionized water, tert-butanol and isopropanol into the reaction kettle, stir and mix evenly, heat to 60-70°C, and prepare solution a for use;

[0037] 2) Dissolve styrene, isooctyl acrylate, ethyl silicate, silicone monomer and anionic ring-opening polymerization emulsion into solution a, stir well, heat while stirring, until the temperature reaches 80-90°C and keep warm for 2 Hour, make solution b stand-by;

[0038] 3) Put vinyl silicone oil, silica airgel and dimethylformamide into solution...

Embodiment 3

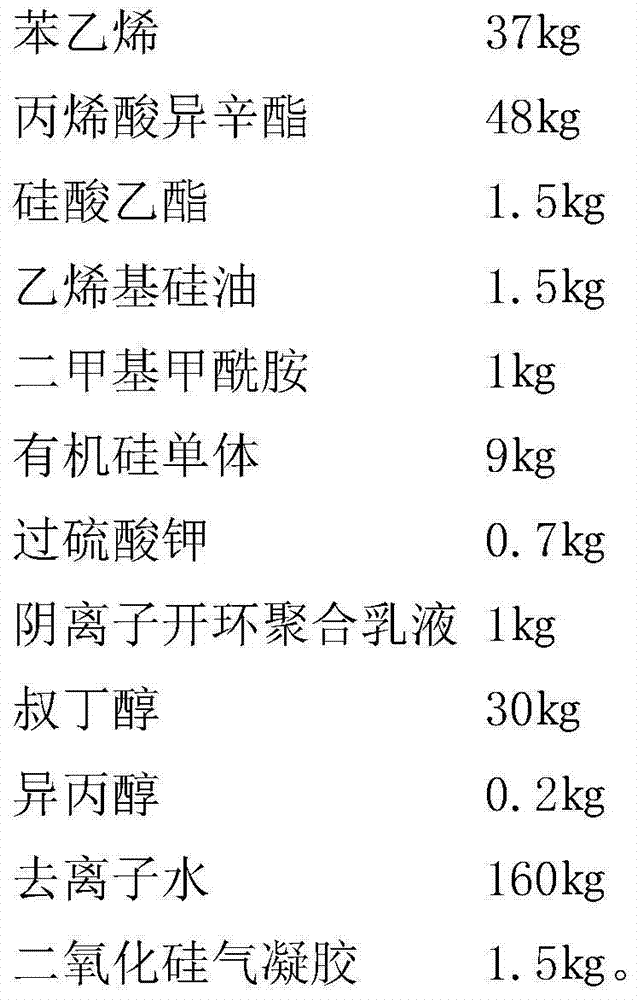

[0042] A silicone-modified styrene-acrylic emulsion, consisting of the following components by weight,

[0043]

[0044] The anionic ring-opening polymerization emulsion is the emulsion synthesized by ring-opening emulsion polymerization of cyclosiloxane in the presence of an anionic catalyst.

[0045] The preparation method of silicone acrylic emulsion printing adhesive of the present invention is as follows:

[0046] 1) Weigh each component according to the above formula, first put deionized water, tert-butanol and isopropanol into the reaction kettle, stir and mix evenly, heat to 60-70°C, and prepare solution a for use;

[0047] 2) Dissolve styrene, isooctyl acrylate, ethyl silicate, silicone monomer and anionic ring-opening polymerization emulsion into solution a, stir well, heat while stirring, until the temperature reaches 80-90°C and keep warm for 2 Hour, make solution b stand-by;

[0048] 3) Put vinyl silicone oil, silica airgel and dimethylformamide into solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com