Patents

Literature

878results about How to "Reduce air permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

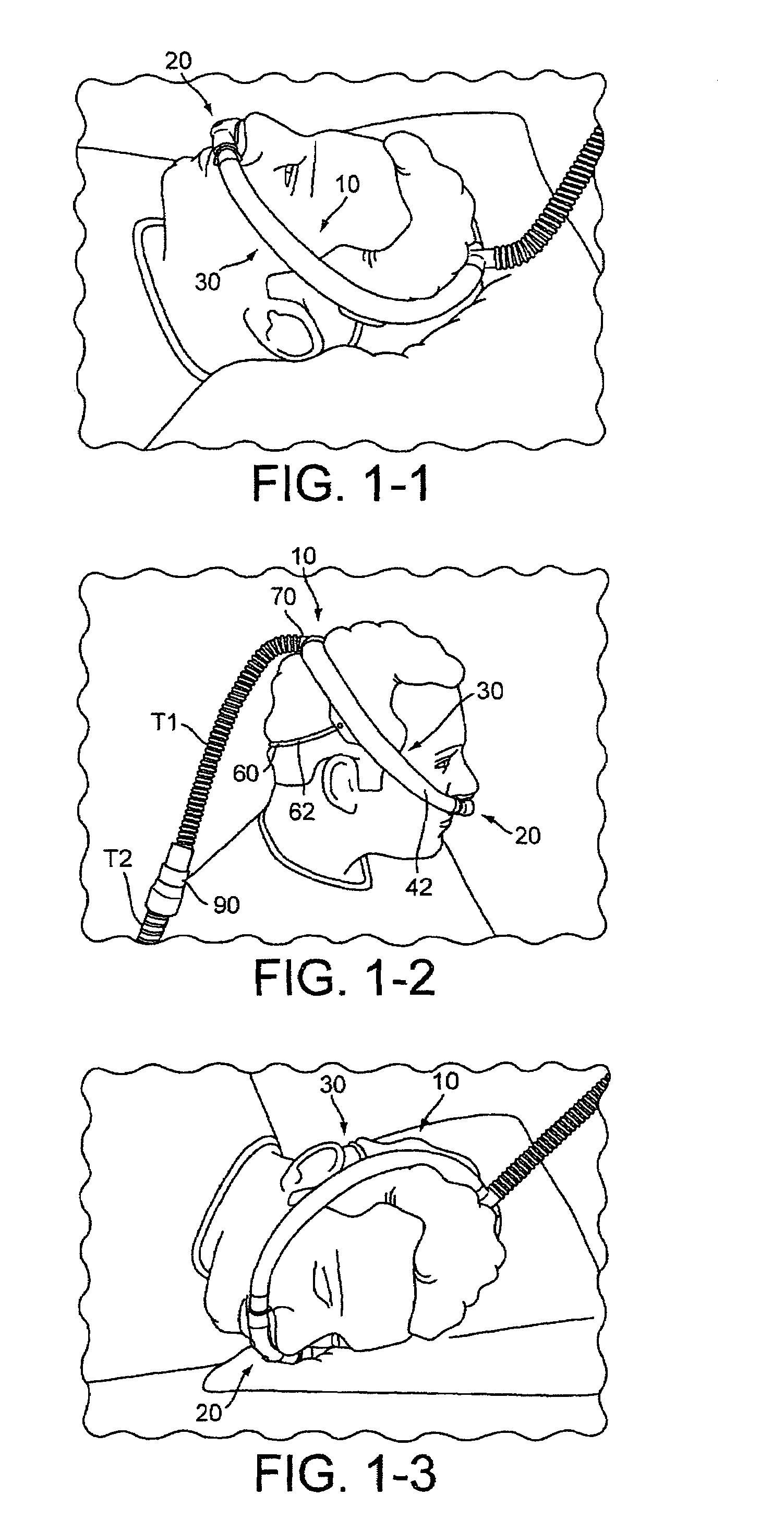

Delivery of respiratory therapy

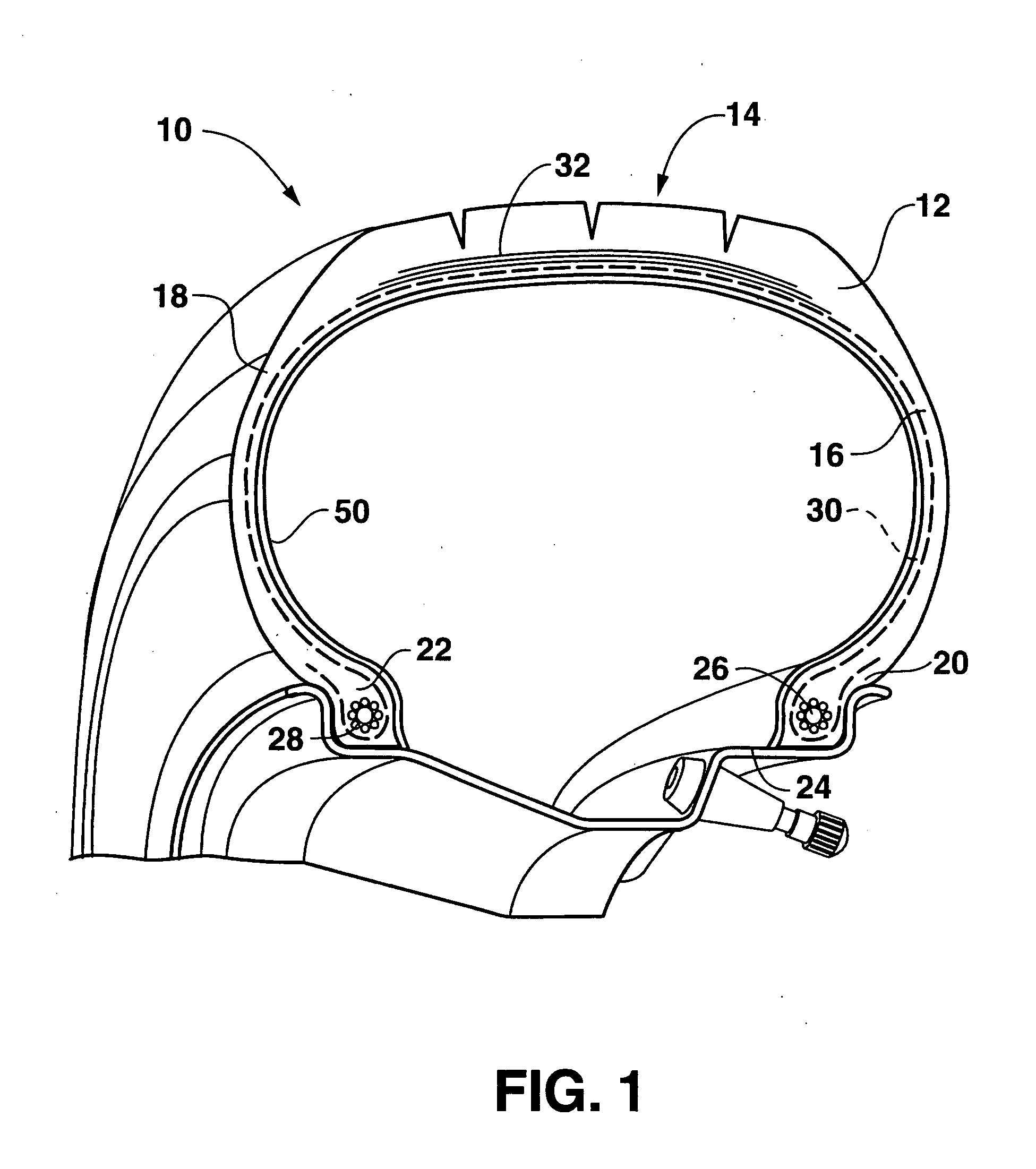

ActiveUS20100018534A1Sleep comfortablyImprove comfortBreathing masksRespiratory masksPositive airway pressureRespiratory mask

A respiratory mask for continuous positive airway pressure treatment includes a cushion adapted to be positioned against the face of a patient. The cushion is configured in a gasket arrangement around an entrance to the airways of the patient. The cushion is constructed from a polyurethane foam and has a thickness of greater than about 5 mm.

Owner:RESMED LTD

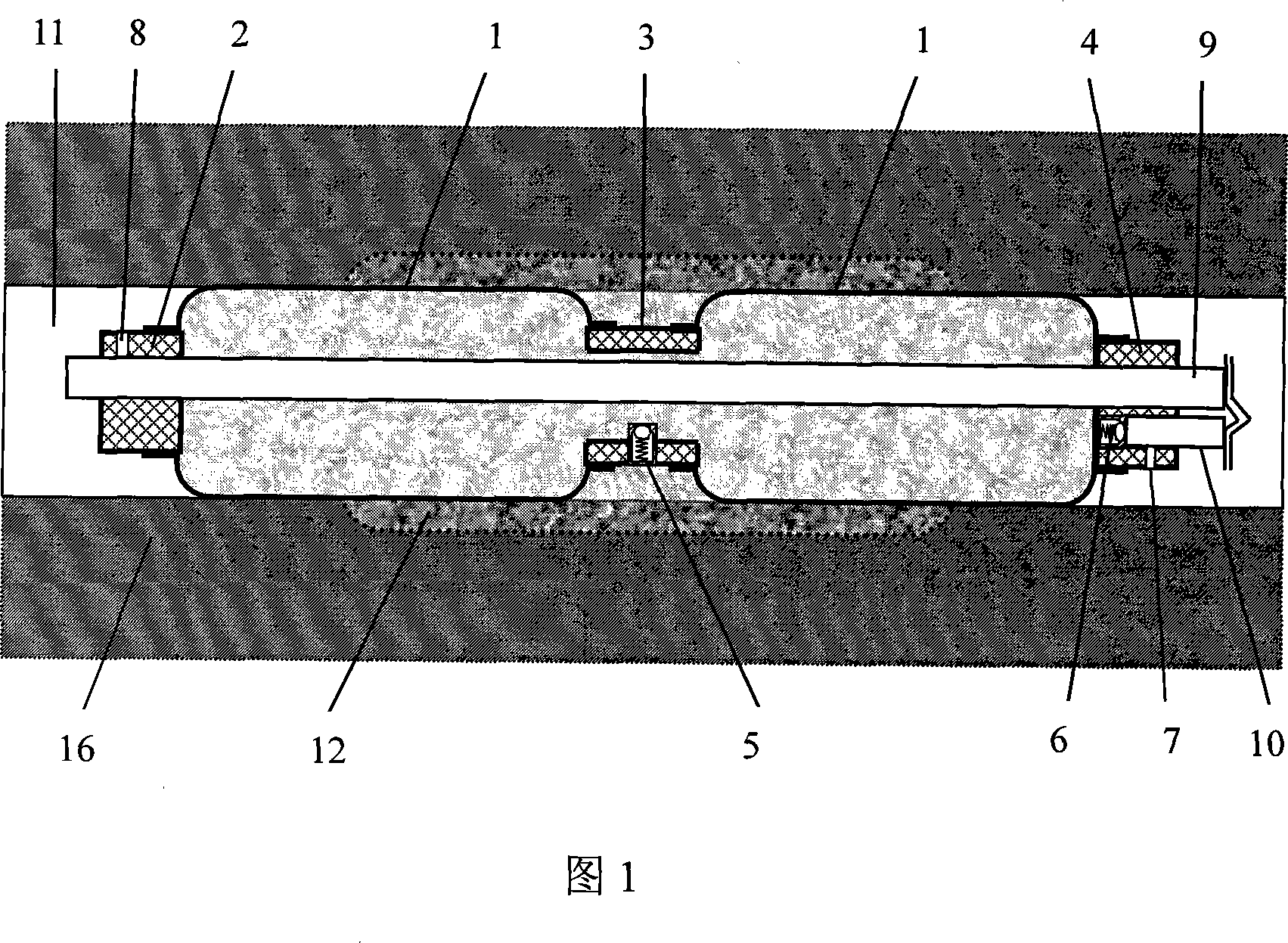

Bag type paste injection hole sealing device and its hole sealing method

InactiveCN101050696AGrouting and sealing are effectiveReduce air permeabilityGas removalSealing/packingSlurryControl valves

The present invention relates to a bag type paste-injecting hole-sealing equipment and its hole-sealing method. Said bag type paste-injecting hole-sealing equipment includes the following several portions: bag, internal end supporting component, middle portion supporting component, external end supporting component, paste injection control valve, reverse check valve and pressure control pin. Besides, said invention also provides the concrete steps of said hole-sealing method.

Owner:HENAN POLYTECHNIC UNIV

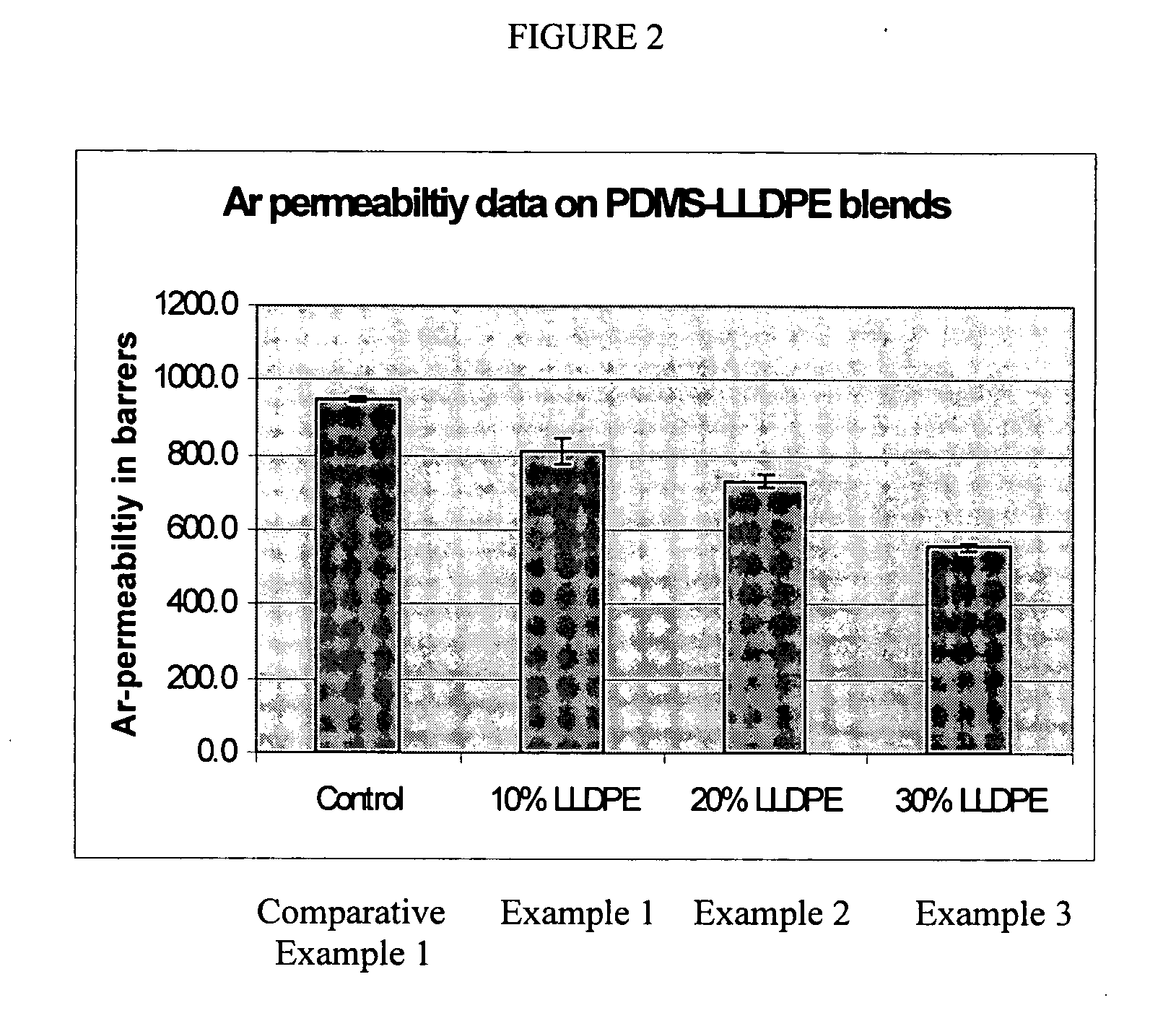

Insulated glass unit possessing room temperature-cured siloxane sealant composition of reduced gas permeability

InactiveUS20070116907A1Easy to useReduce air permeabilityAdhesivesUnits with parallel planesPolymer scienceInsulated glazing

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Wet crepe throughdry process for making absorbent sheet and novel fibrous products

InactiveUS20020148584A1Big cost advantageReduce air permeabilityNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

An improved process for making sheet from a fibrous furnish includes: depositing the furnish on a foraminous support; compactively dewatering the furnish to form a nascent web; drying the web on a heated cylinder; creping the web therefrom and throughdrying the web to a finished product. The microstructure of the web is controlled so as to facilitate throughdrying. The product exhibits a characteristic throughdrying coefficient of from 4 to 10 when the airflow through the sheet is characterized by a Reynolds Number of less than about 1. The novel products of the invention are characterized by wet springback ratio, hydraulic diameter and an internal bond strength parameter.

Owner:GPCP IP HLDG LLC

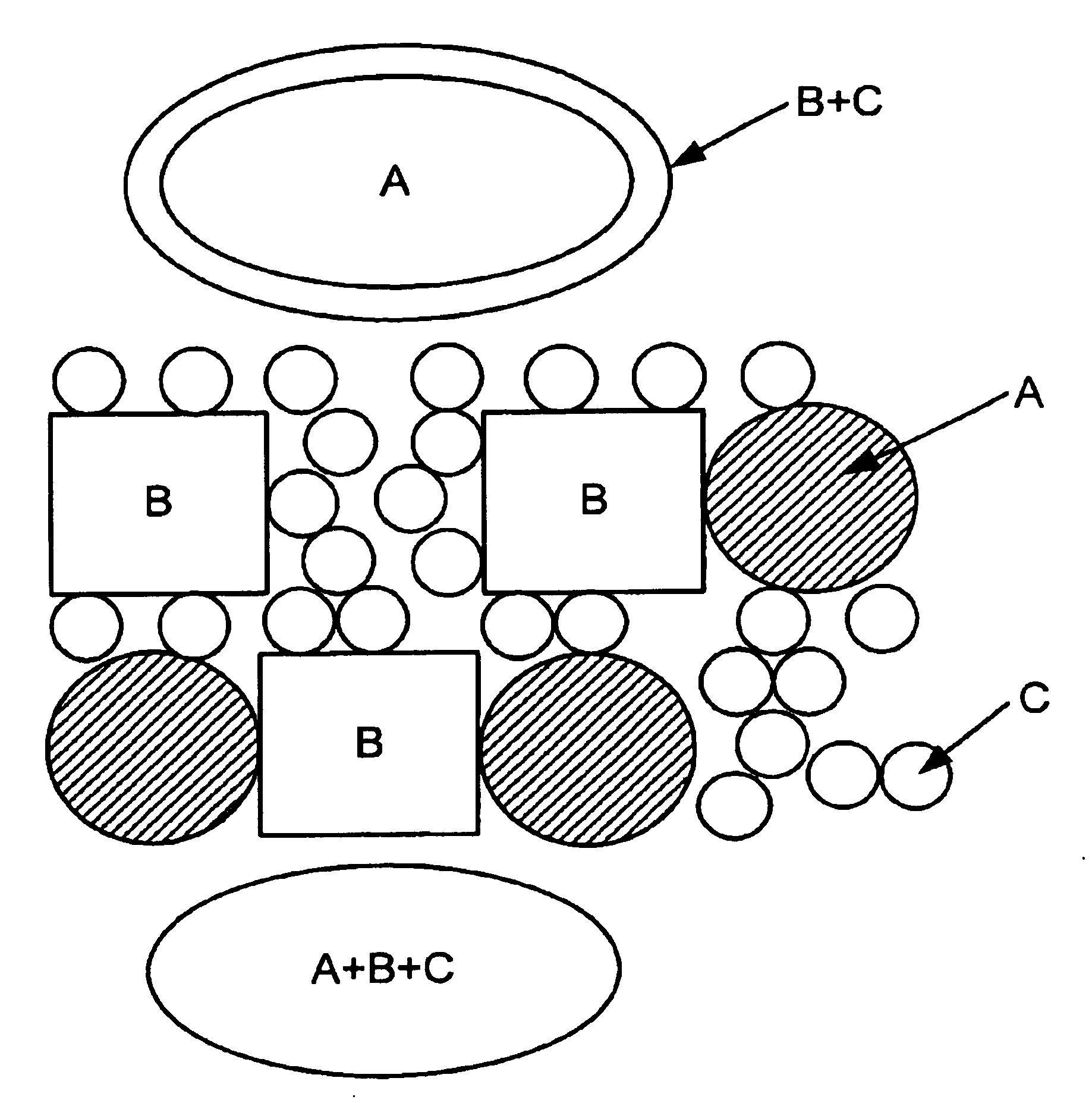

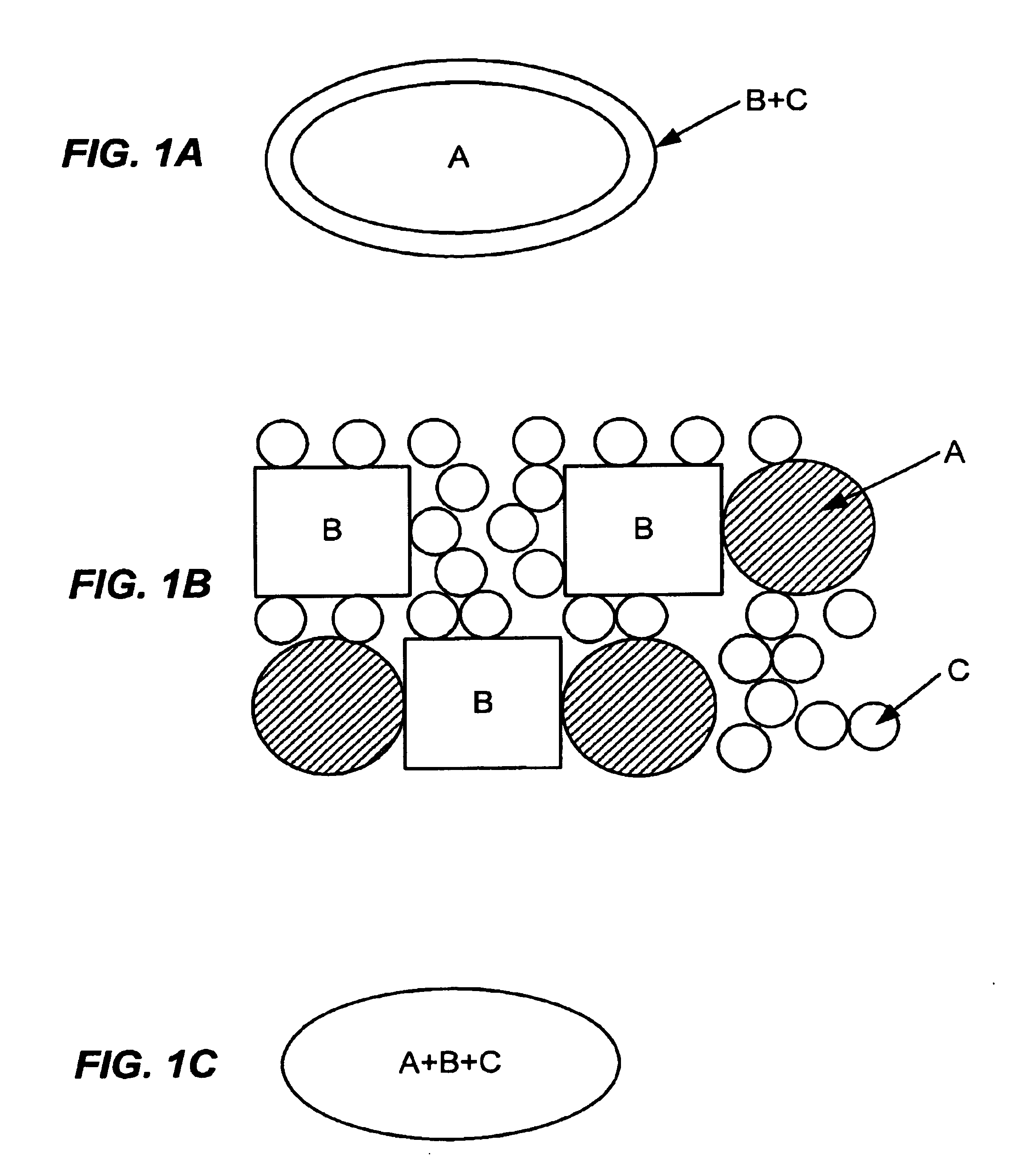

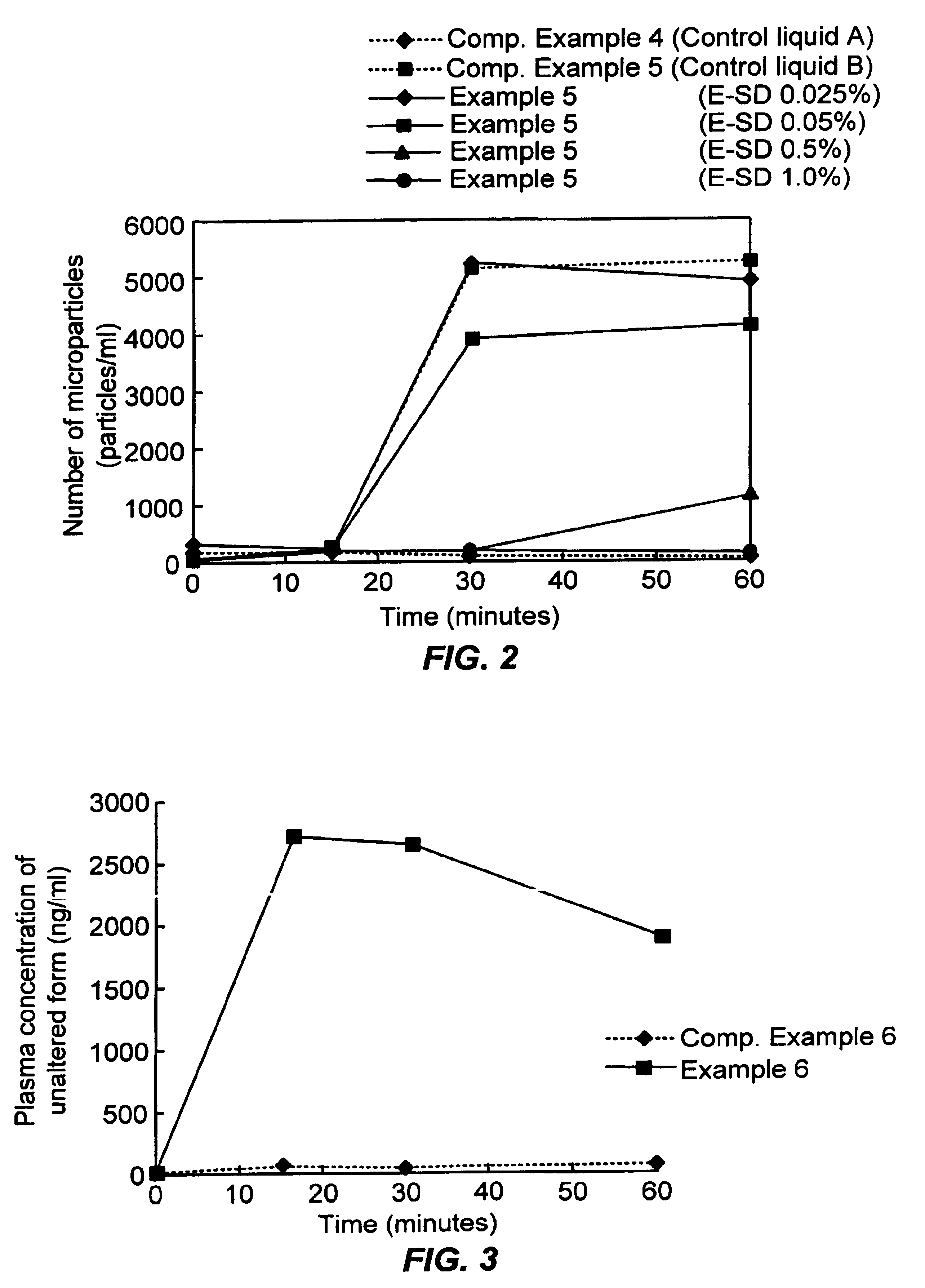

Pharmaceutical composition for oral use with improved absorption

InactiveUS7008640B2Promote absorptionDifficult to absorbBiocideNervous disorderBULK ACTIVE INGREDIENTAcid substances

The present invention presents a pharmaceutical composition for oral use with improved absorption, which comprises drug, aminoalkyl methacrylate copolymer E, and acidic substance and is obtained by bringing said 3 components together and uniformly mixing at least this polymer and this acidic substance, and a method of improving oral absorption by using this pharmaceutical composition. Moreover, the present invention presents an agent for improving oral absorption that increases drug permeability of the digestive tract mucous membrane and / or mucous layer present on the surface of this membrane, whose active ingredient is aminoalkyl methacrylate copolymer E. In addition, the present invention presents an oral agent for improving absorption by increasing drug permeability of the digestive tract mucous membrane and / or the mucous layer distributed over this mucous membrane, whose effective component is aminoalkyl methacrylate copolymer E.

Owner:ASTELLAS PHARMA INC

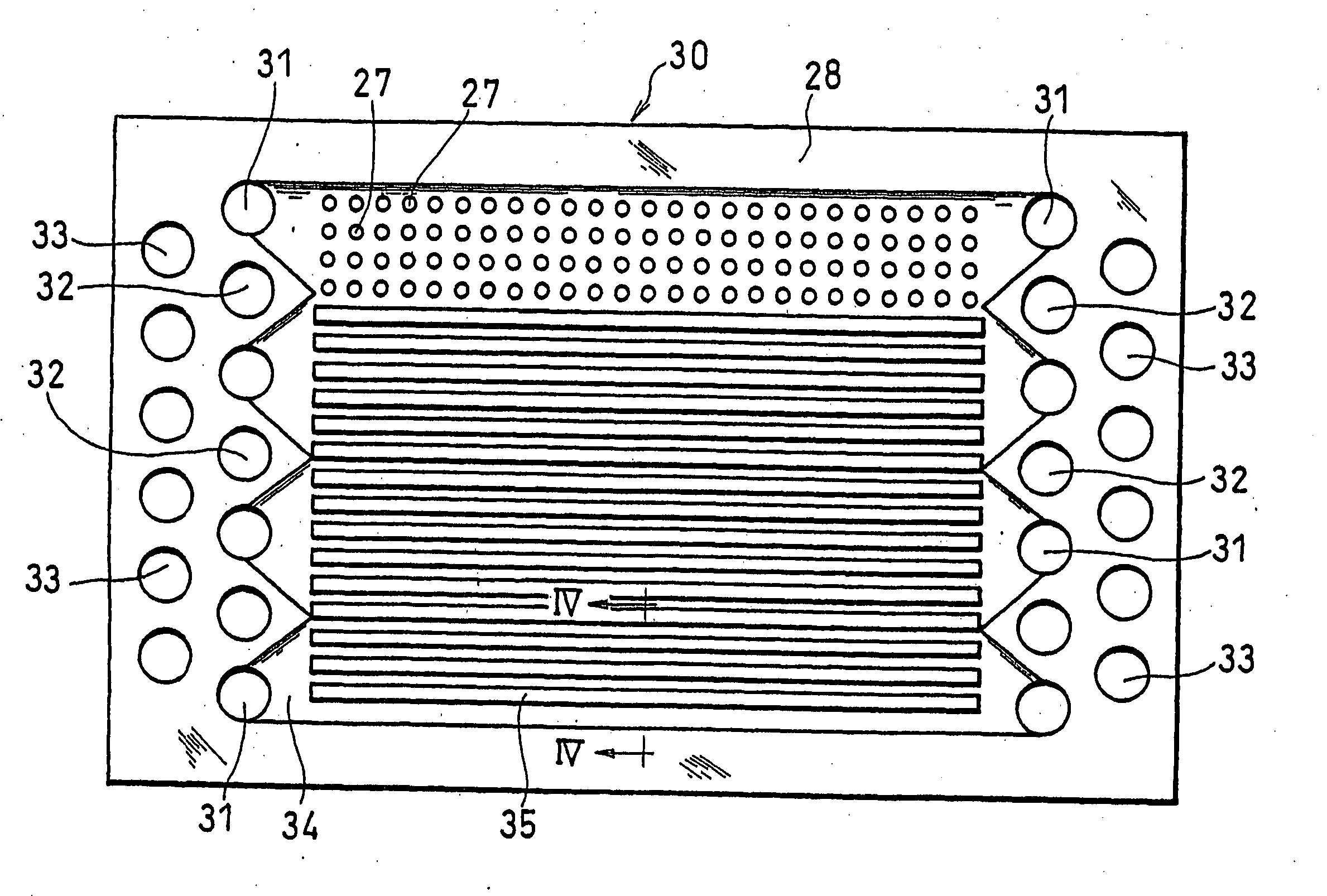

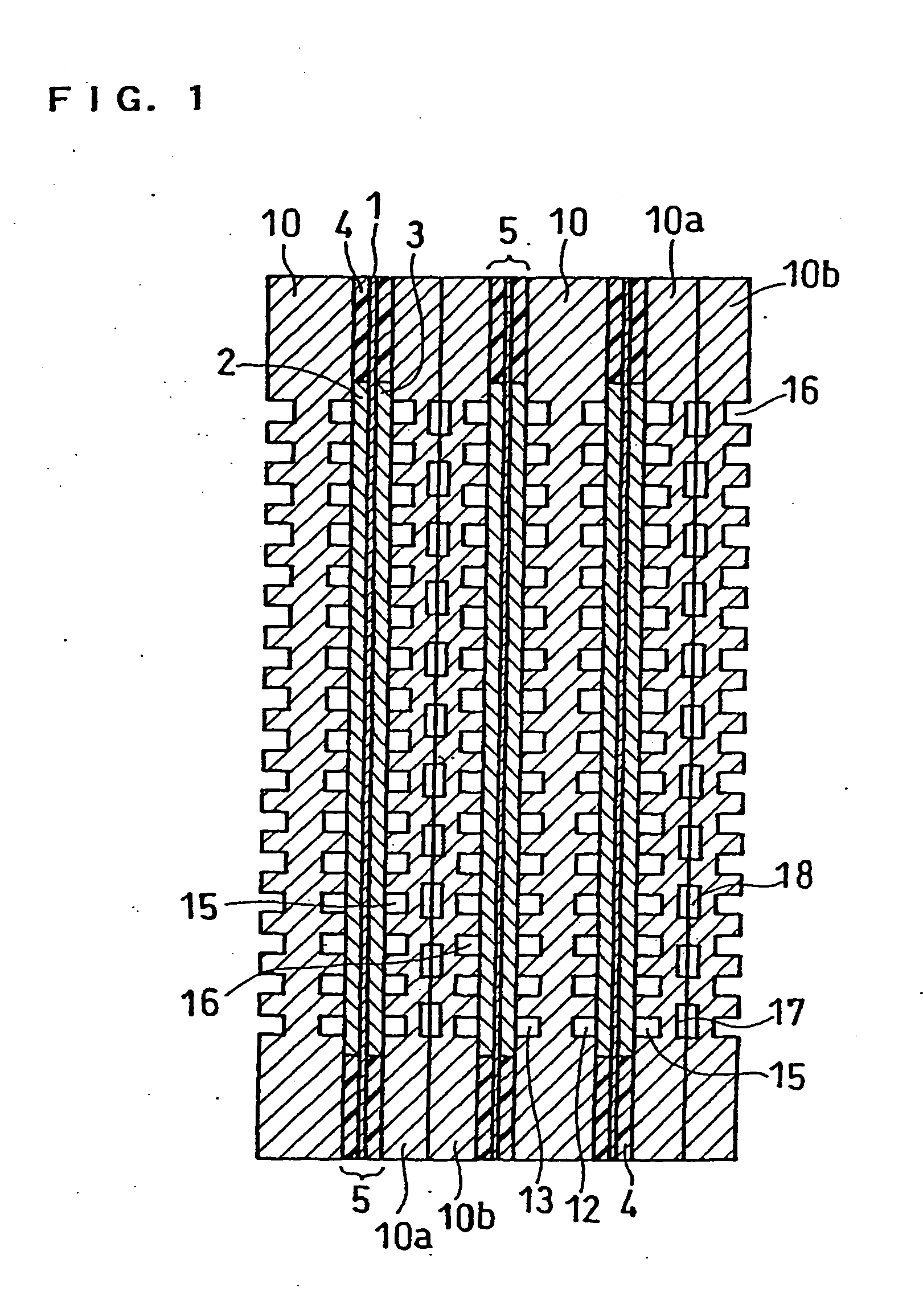

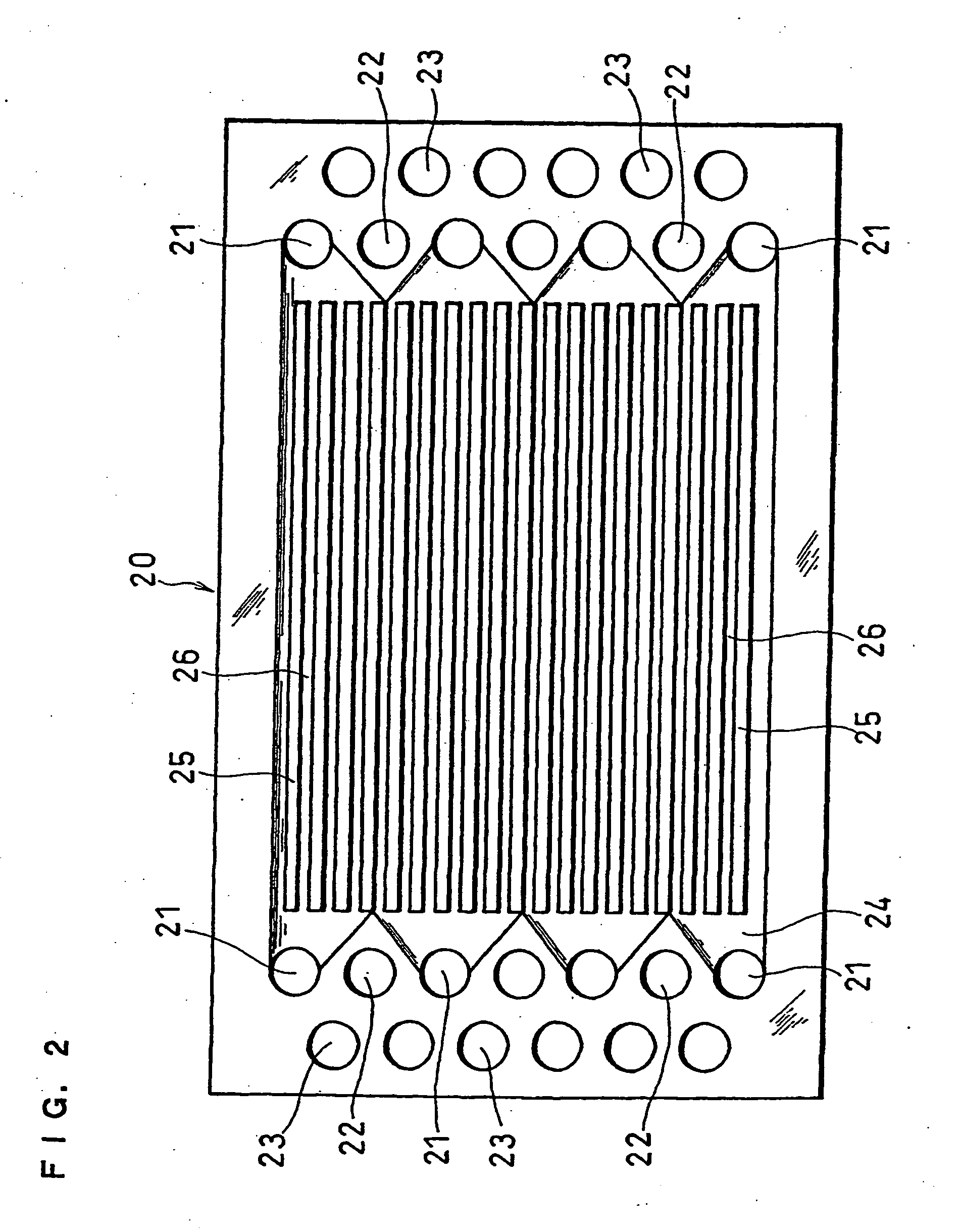

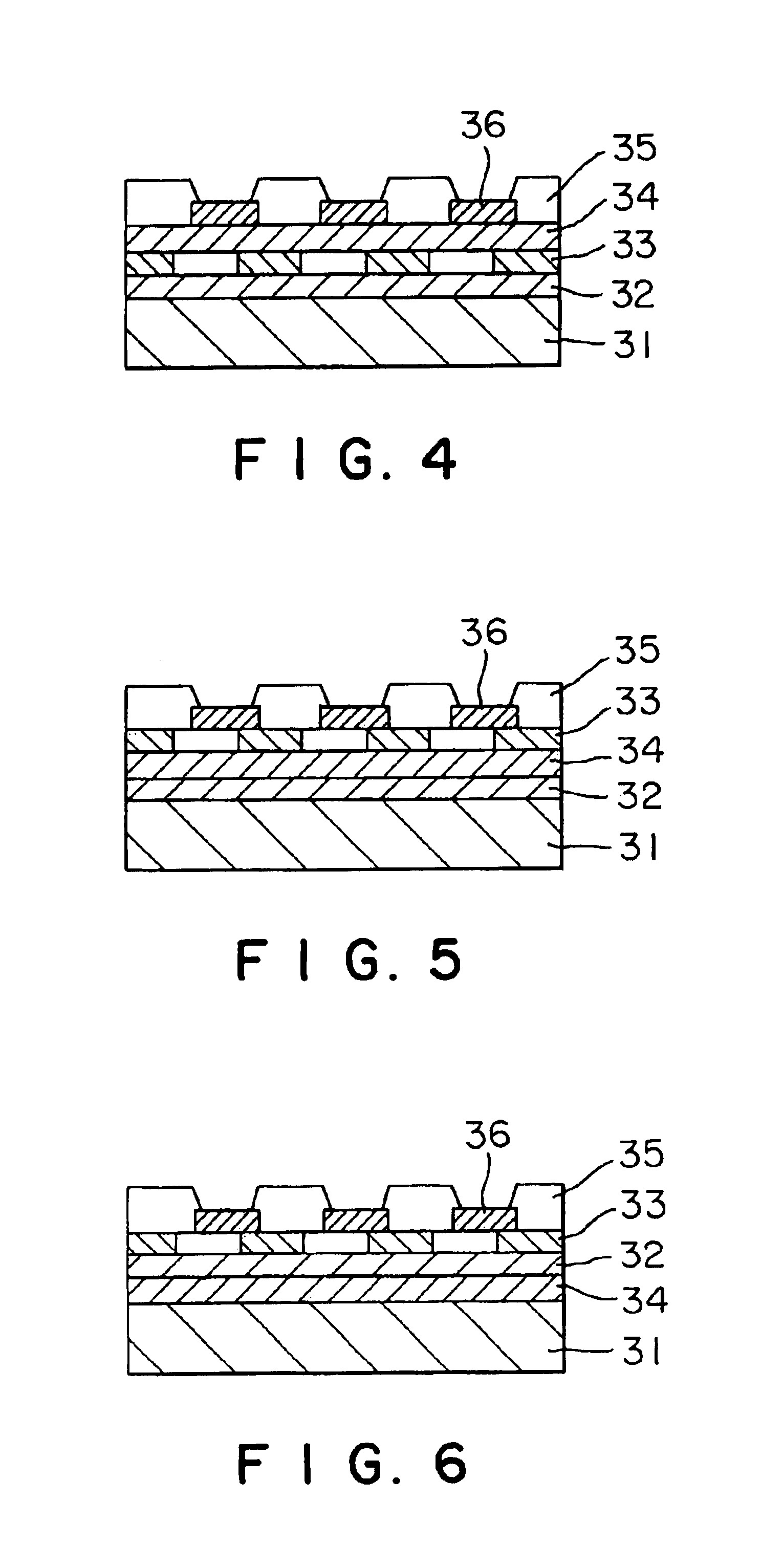

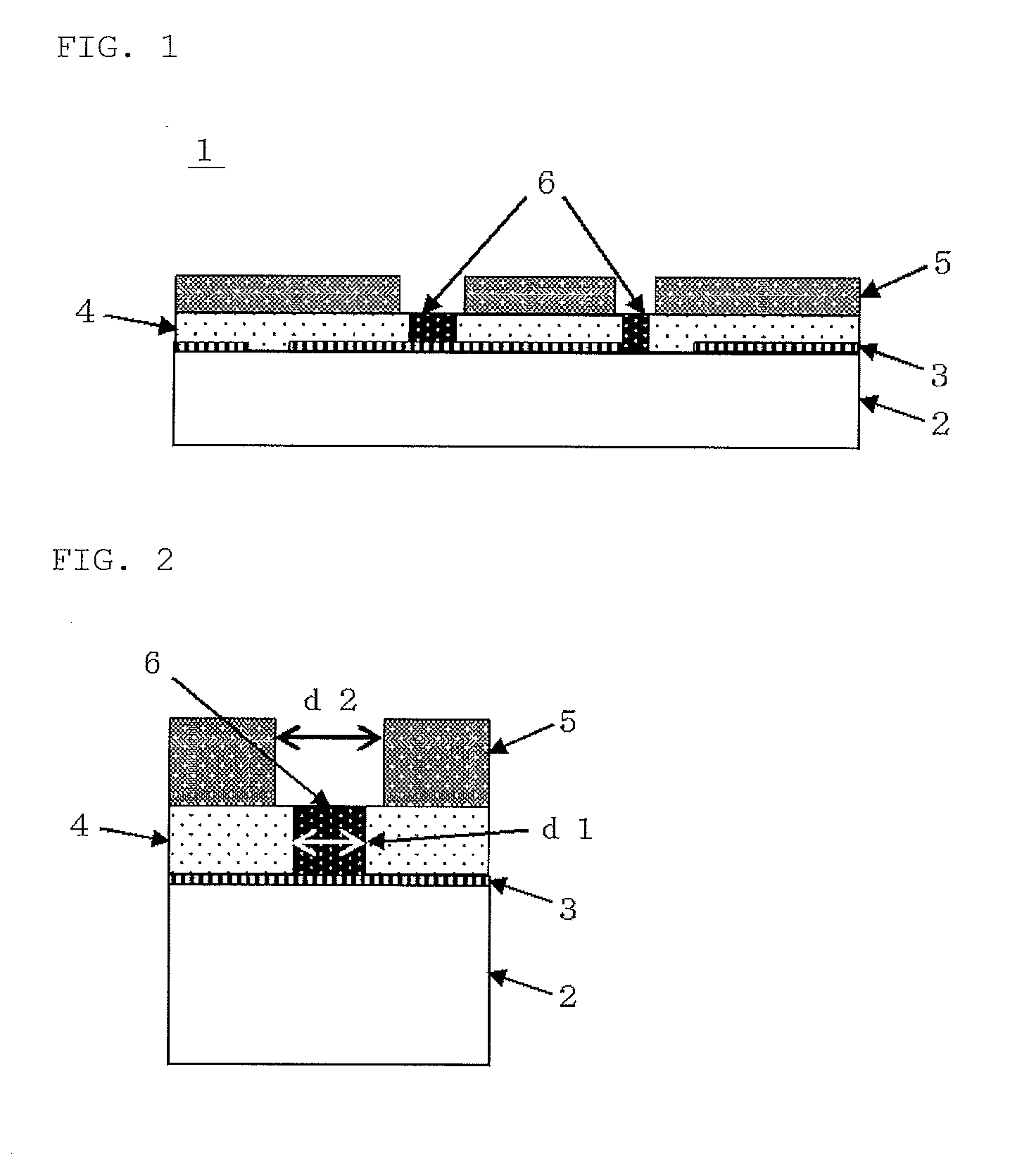

Polymer electrolyte fuel cell and method of manufacturing the same

InactiveUS20040197633A1Improves product water-removal efficiencyEvenly distributedFuel cell heat exchangeFinal product manufacturePolymer electrolytesFuel cells

The present invention relates to a polymer electrolyte fuel cell comprising: an electrolyte membrane-electrode assembly including an anode, a cathode and a polymer electrolyte membrane interposed therebetween; an anode-side conductive separator plate having a gas flow channel for supplying a fuel gas to the anode; and a cathode-side conductive separator plate having a gas flow channel for supplying an oxidant gas to the cathode. A conductive separator plate made of carbon has poor wettability with water. This has posed the disadvantage that variations in performance are induced by nonuniform gas distribution among cells due to the accumulation of product water or humidifying water in the gas flow channel on the surface of the separator plate. The present invention employs a conductive separator plate comprising a conductive carbon having a hydrophilic functional group, at least in a portion of the gas flow channels, thereby preventing water from accumulating in the gas flow channels.

Owner:PANASONIC CORP

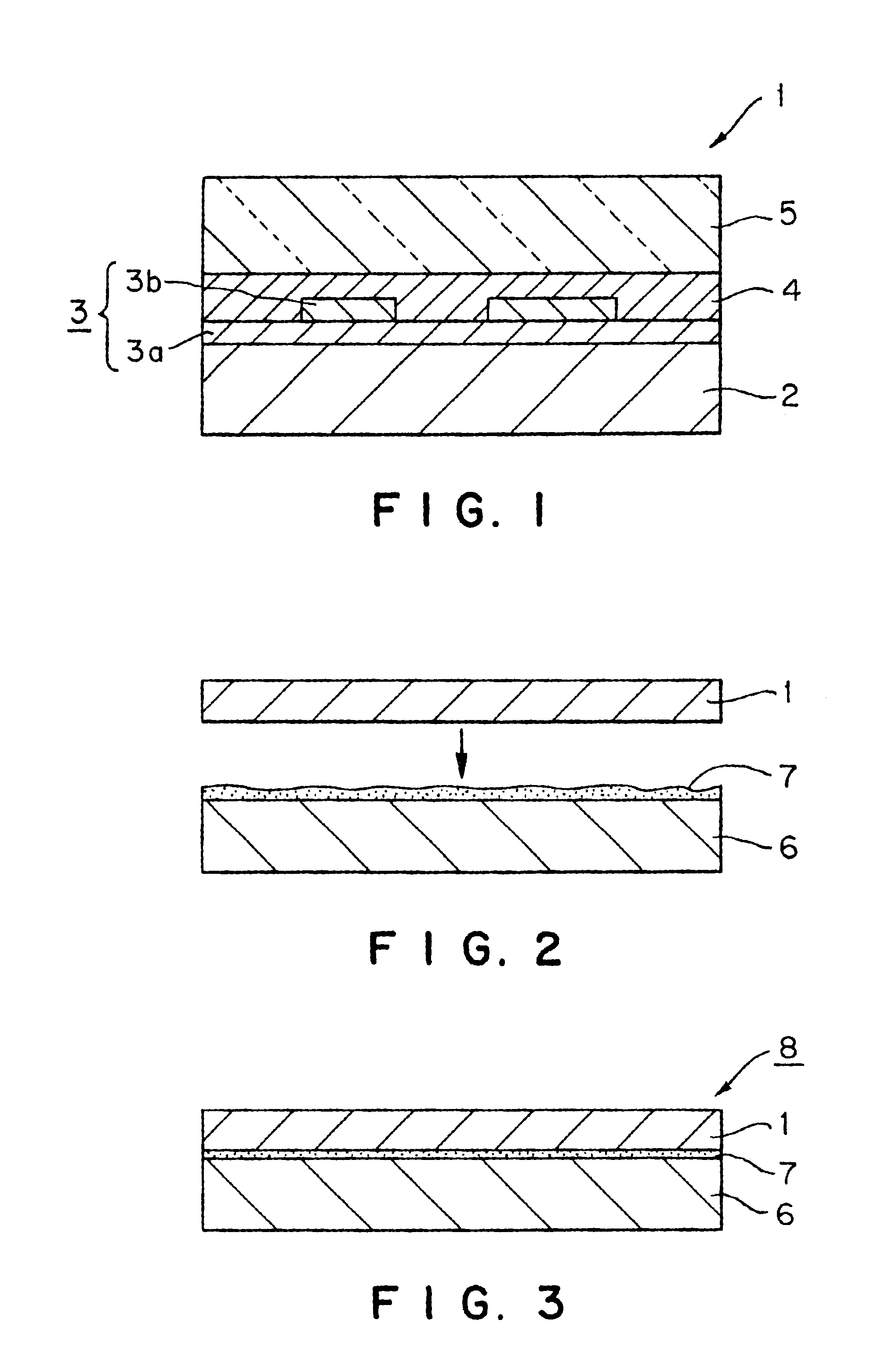

Decorative material

InactiveUS6852399B2Reduce air permeabilityIncrease resistanceNon-fibrous pulp additionPretreated surfacesProtection layerIonizing radiation

A decorative material is provided which particularly possesses excellent adhesion properties. The decorative material comprises: a substrate; a print layer provided on the substrate; a protective layer provided on the print layer, the protective layer comprising an ionizing radiation-cured resin; and a stress relaxing layer as a primer layer provided between the print layer and the protective layer, for relaxing shrinkage stress caused at the time of curing of an ionizing radiation-curable resin for the formation of the ionizing radiation-cured resin constituting the protective layer.

Owner:DAI NIPPON PRINTING CO LTD

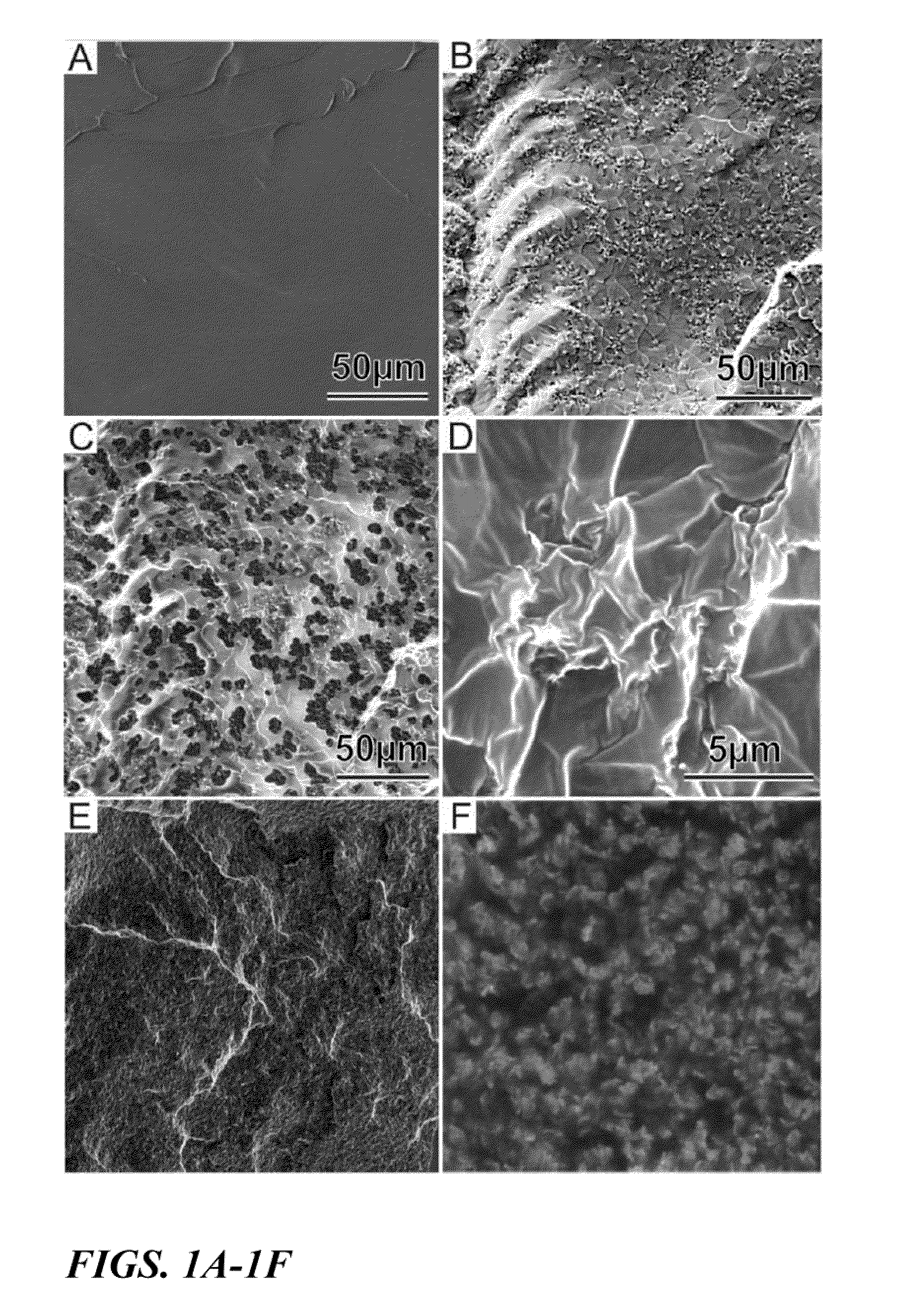

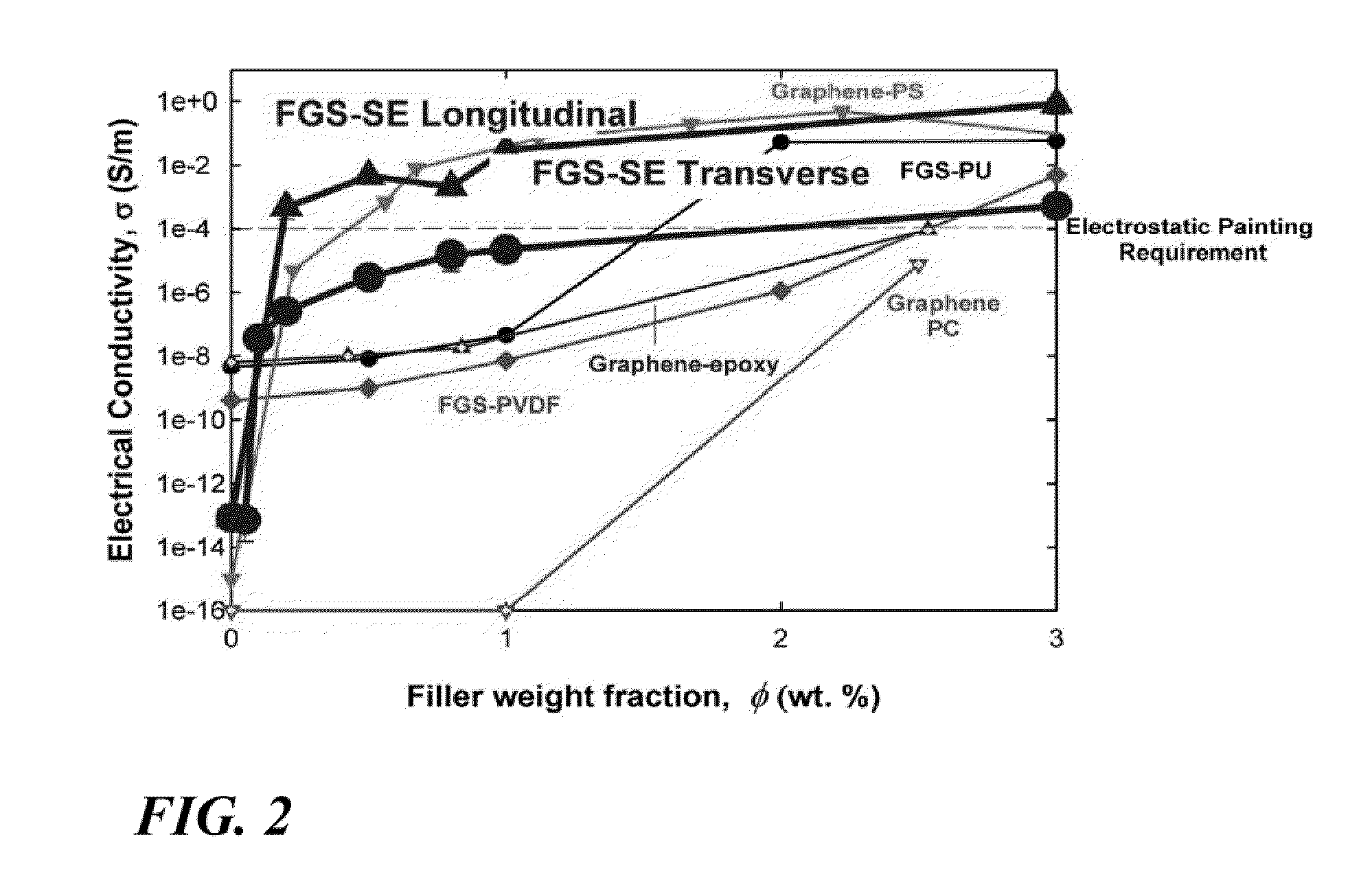

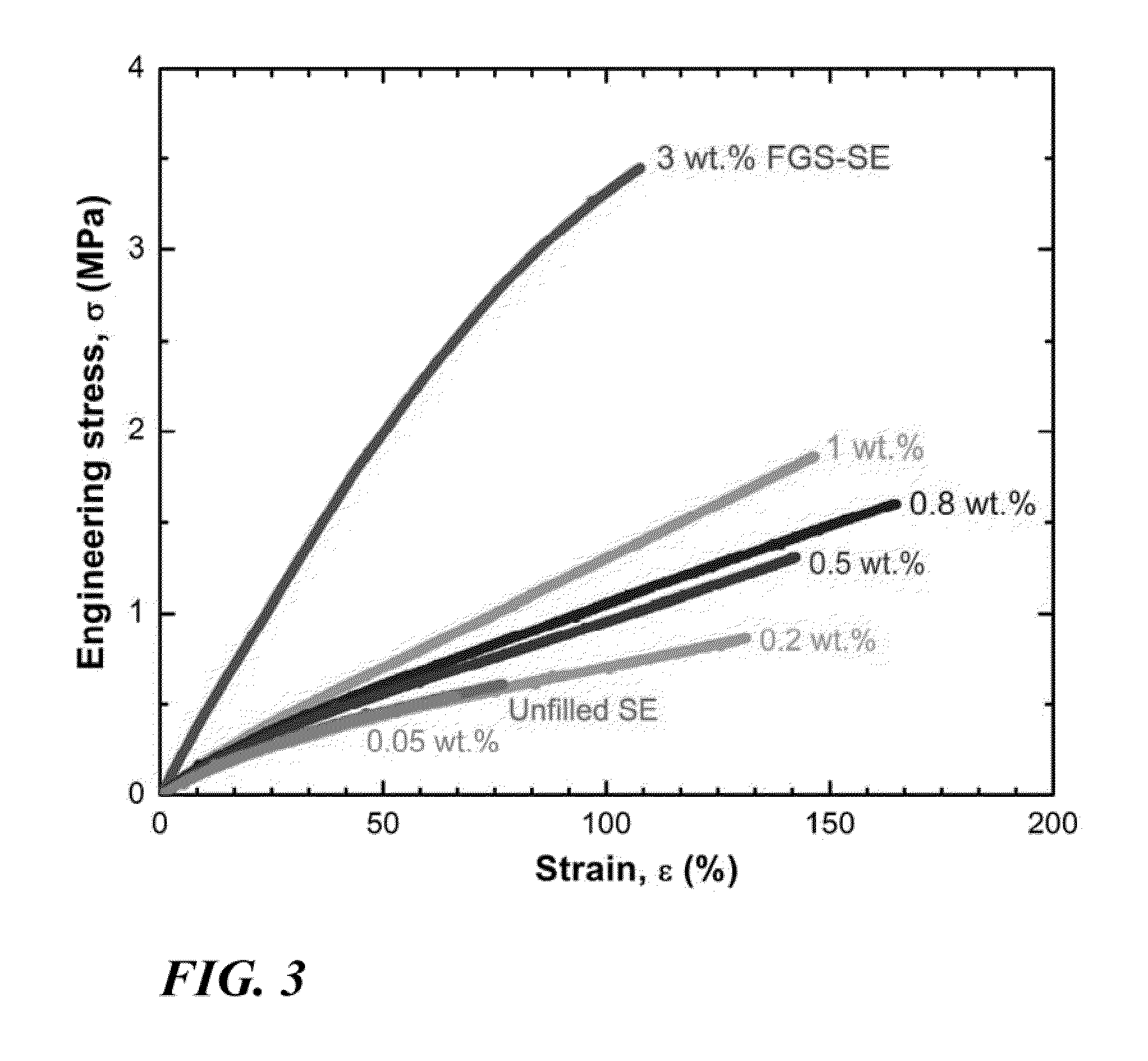

Multifunctional graphene-silicone elastomer nanocomposite, method of making the same, and uses thereof

ActiveUS20110178224A1Reduce air permeabilityMaterial nanotechnologySpecial tyresSilicone ElastomersGraphene

A nanocomposite composition having a silicone elastomer matrix having therein a filler loading of greater than 0.05 wt %, based on total nanocomposite weight, wherein the filler is functional graphene sheets (FGS) having a surface area of from 300 m2 / g to 2630 m2 / g; and a method for producing the nanocomposite and uses thereof.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Barrier layer for elastomeric articles

InactiveUS20070161735A1Improve performanceAvoid flowWithout separate inflatable insertsWith separate inflatable insertsVitrificationElastomer

A composition well suited to forming gas barrier layers in elastomeric articles is described. The barrier layer may be incorporated into, for instance, inflatable articles that are intended to contain a gas, such as air, under pressure. For example, in one embodiment, the barrier layer may be incorporated into a tire for preventing oxygen or other gaseous components from migrating through the tire. In general, the barrier layer is made from an elastomer that is combined with permeability reducing particles, such as a silicate, and a terpene hydrocarbon resin having a relatively high glass transition temperature. The terpene hydrocarbon resin can improve the processability of the composition and, in one embodiment, can even serve to improve the permeability characteristics of the barrier layer.

Owner:MICHELIN RECH & TECH SA +1

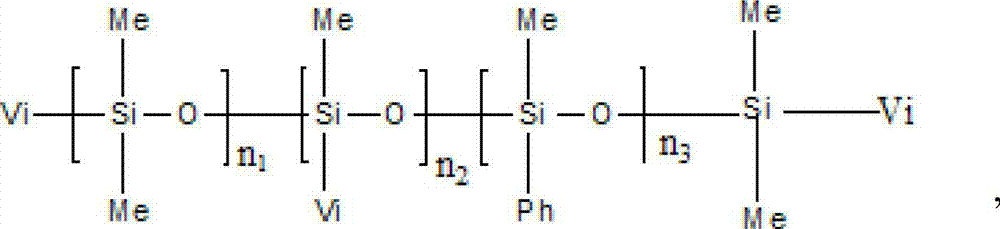

Vulcanization-proof LED (light-emitting diode) packaging silica gel

InactiveCN102965069AStrong adhesionIncrease dosageNon-macromolecular adhesive additivesMacromolecular adhesive additivesVulcanizationAdhesive

The invention relates to an LED (light-emitting diode) packaging silica gel, and in particular relates to a vulcanization-proof LED packaging silica gel, belonging to the technical field of adhesives. The vulcanization-proof LED packaging silica gel comprises a component A and a component B, wherein the weight ratio of the component A to the component B is 1: 1; the component A comprises raw materials based on parts by weight: 50-60 parts of methyl phenyl vinyl silicone oil, 30-60 parts of methyl vinyl MQ resin, 0.1-0.3 part of platinum catalyst and 3-5 parts of bonding agent; and the component B comprises raw materials based on parts by weight: 40-50 parts of methyl phenyl vinyl silicone oil, 30-50 parts of methyl vinyl MQ resin, 5-15 parts of cross-linking agent and 0.1-0.3 part of inhibitor. The vulcanization-proof LED packaging silica gel has excellent adhesive force for silver, phenyl-propanolamine (PPA), glass and the like, and has the light transmittance of more than 98%; and phenyl-containing functional groups and branched chain type vinyl are introduced into the LED packaging silica gel, and the dosage of the vinyl MQ resin is increased, so that the crosslinking density and the curing handness are improved, and therefore, the vulcanization resistance of a packaging adhesive layer can be improved.

Owner:YANTAI DEBANG ADVANCED SILICON MATERIALS

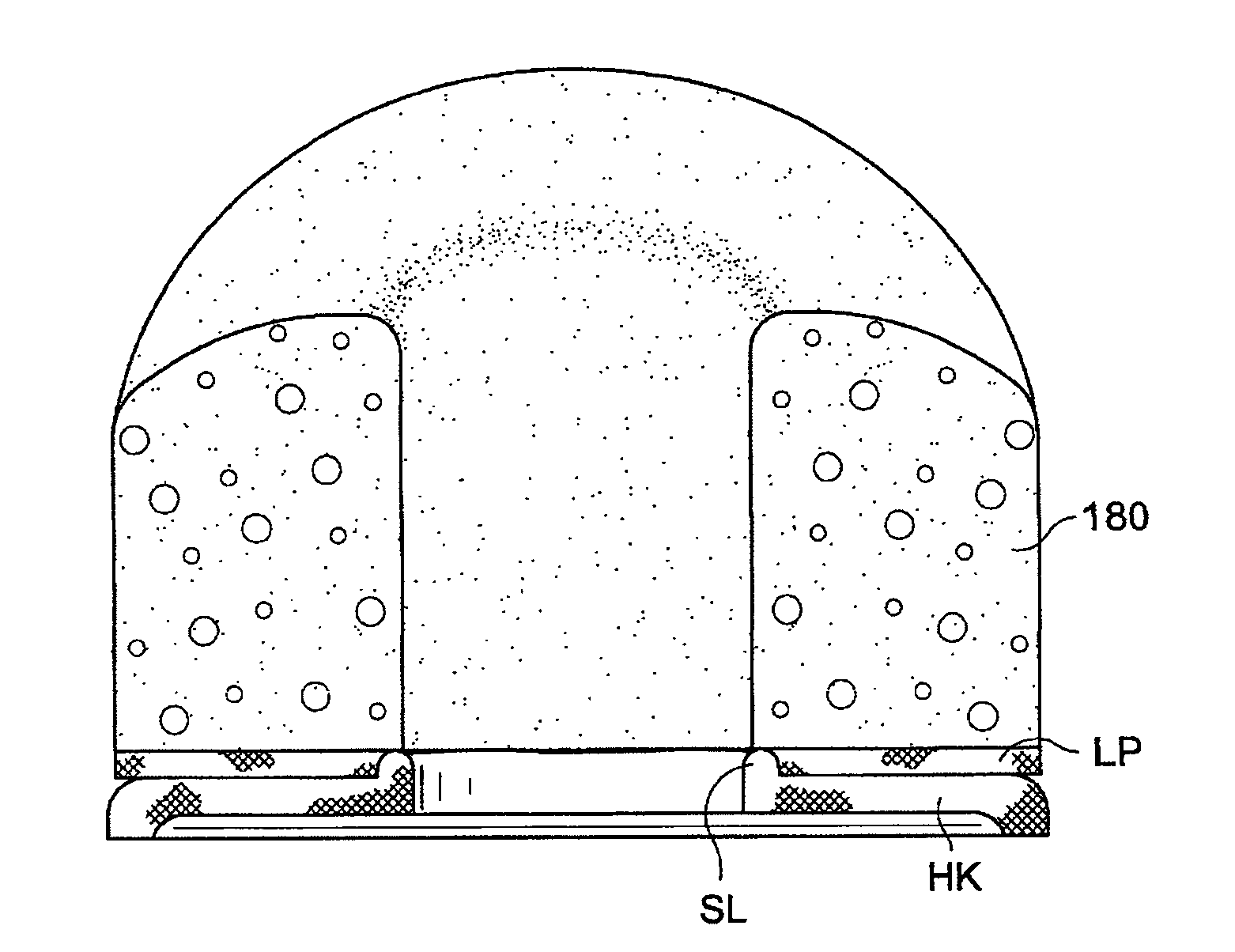

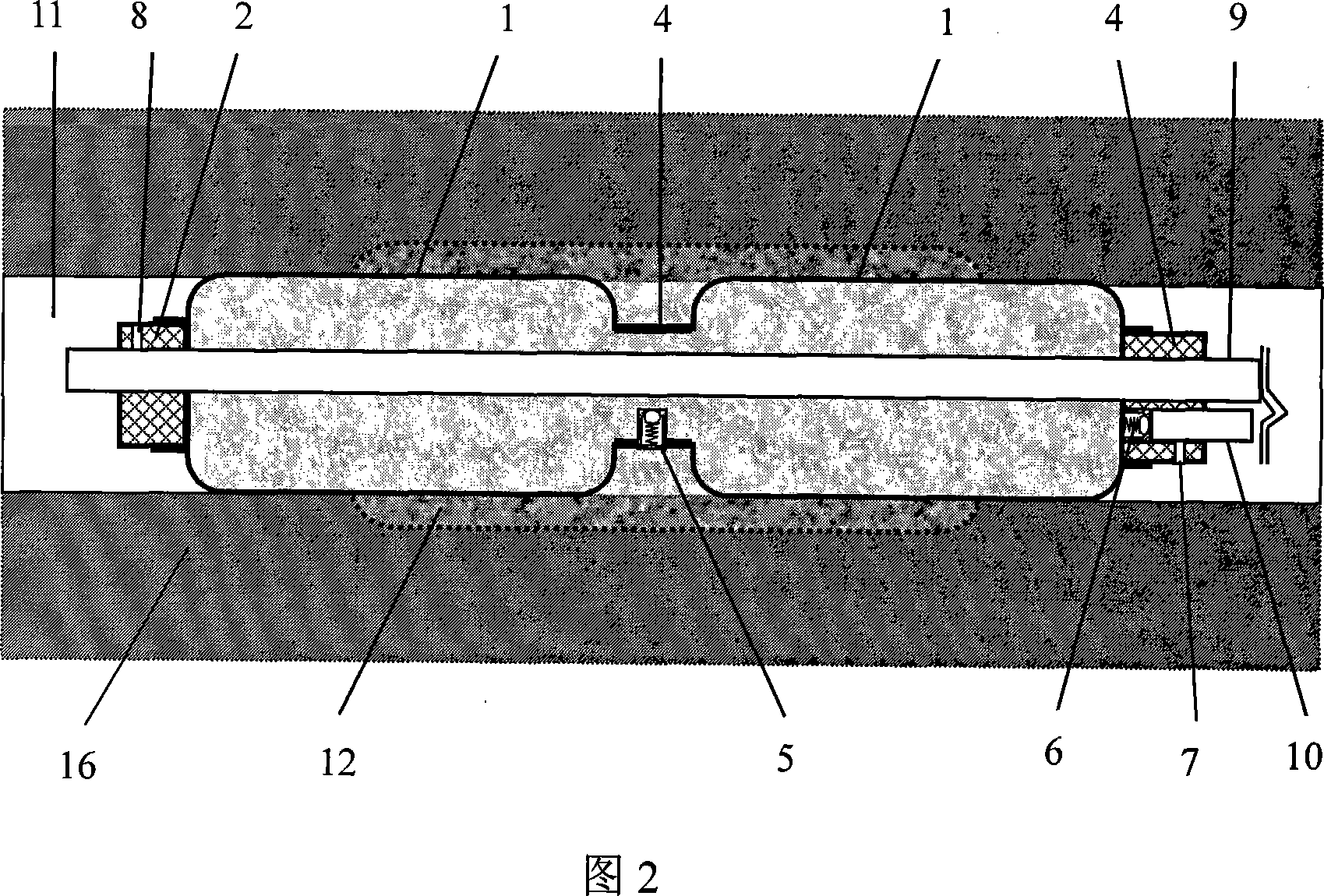

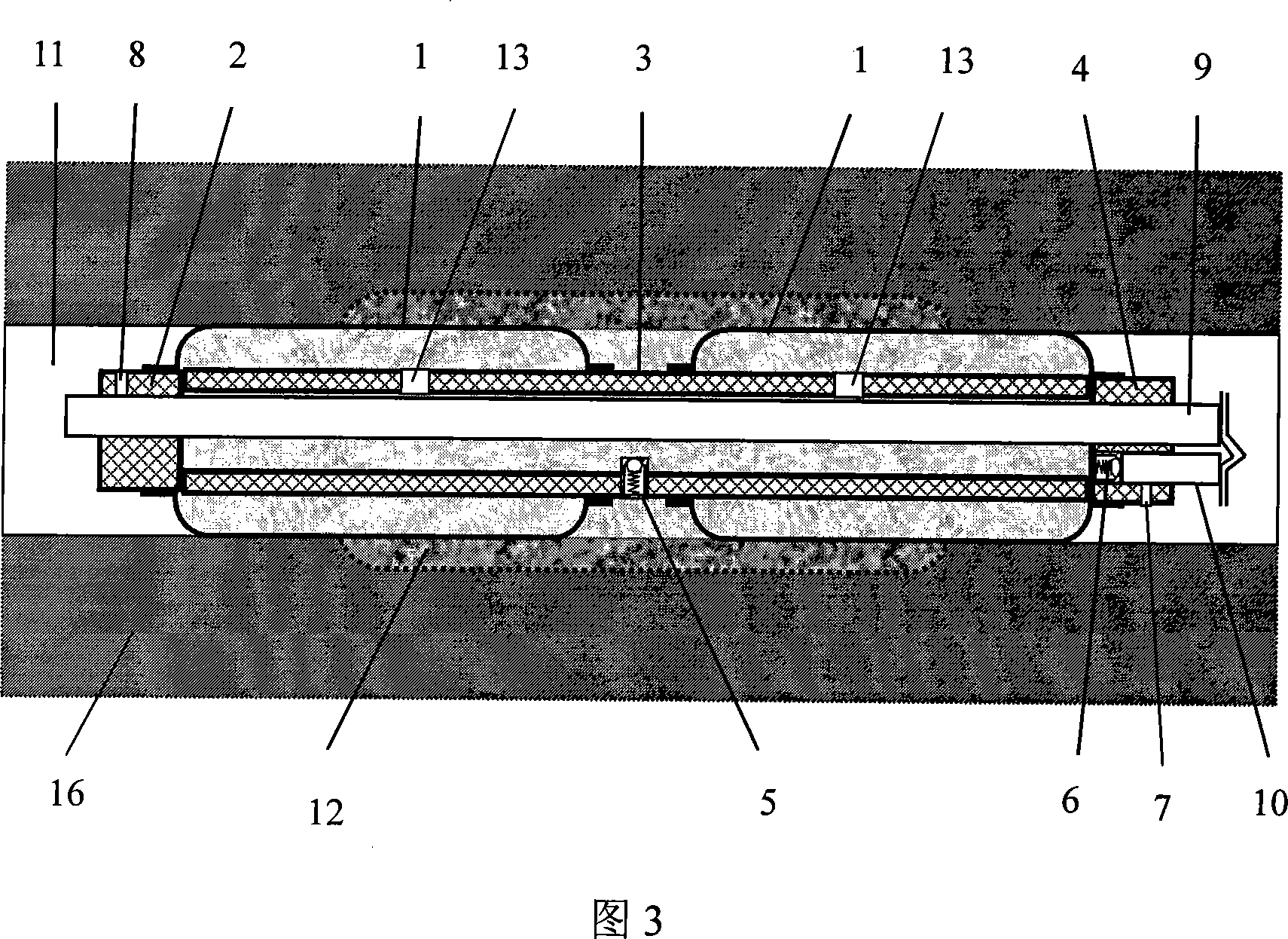

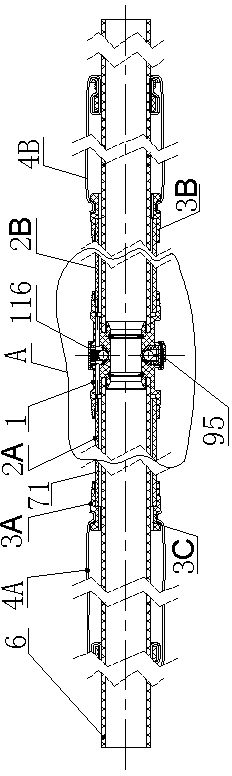

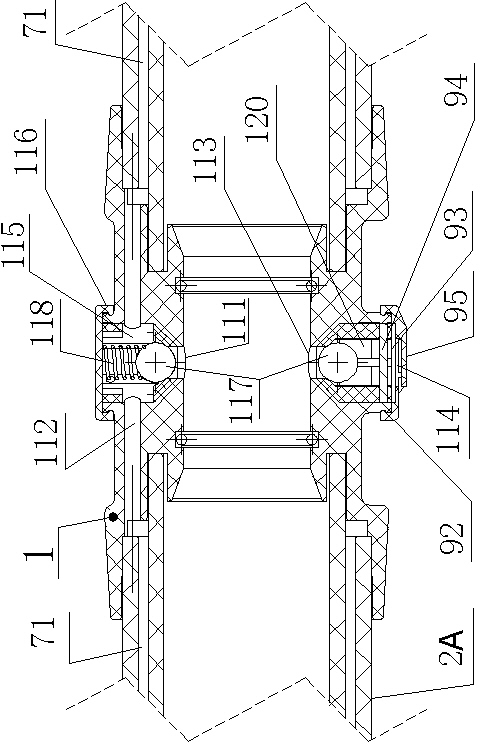

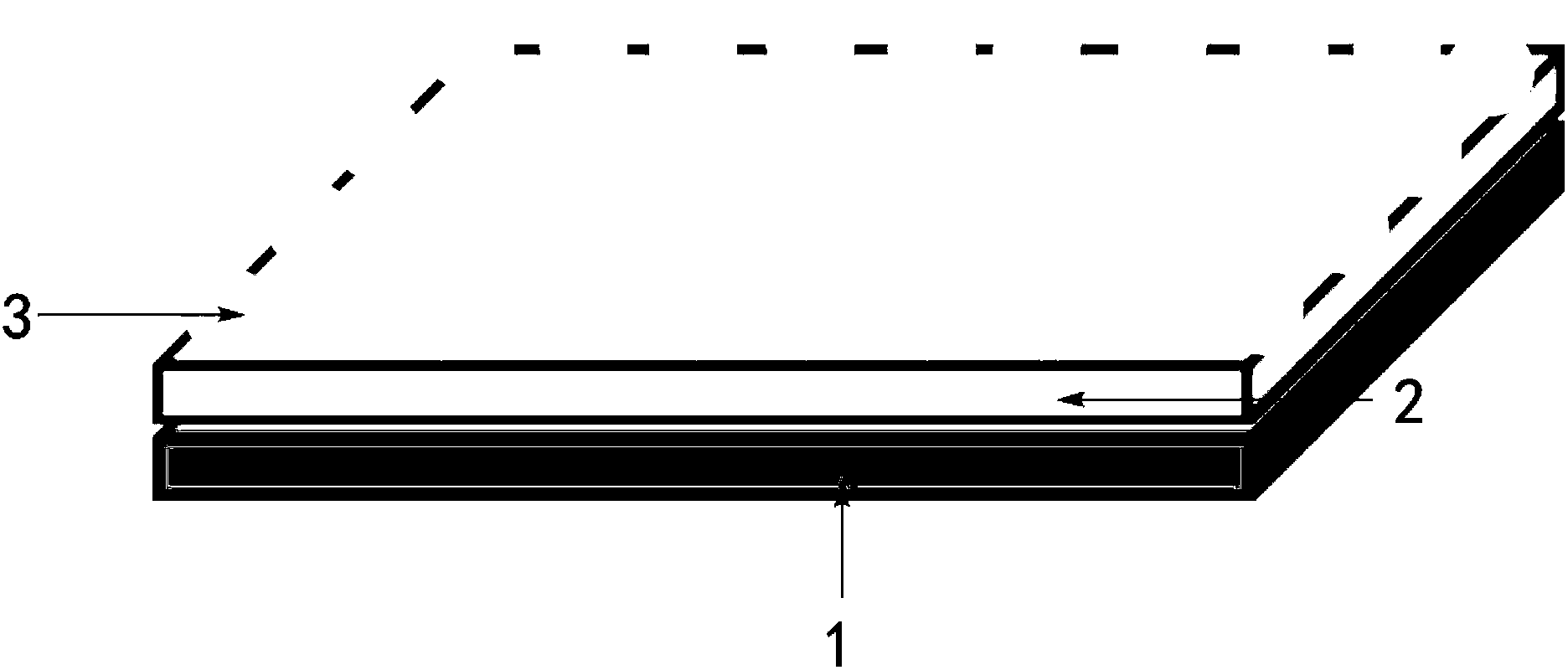

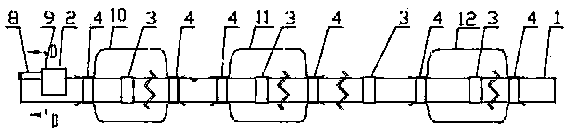

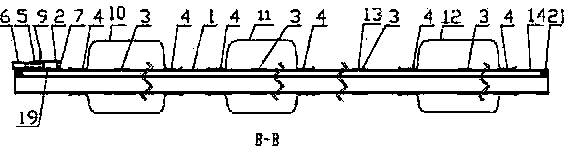

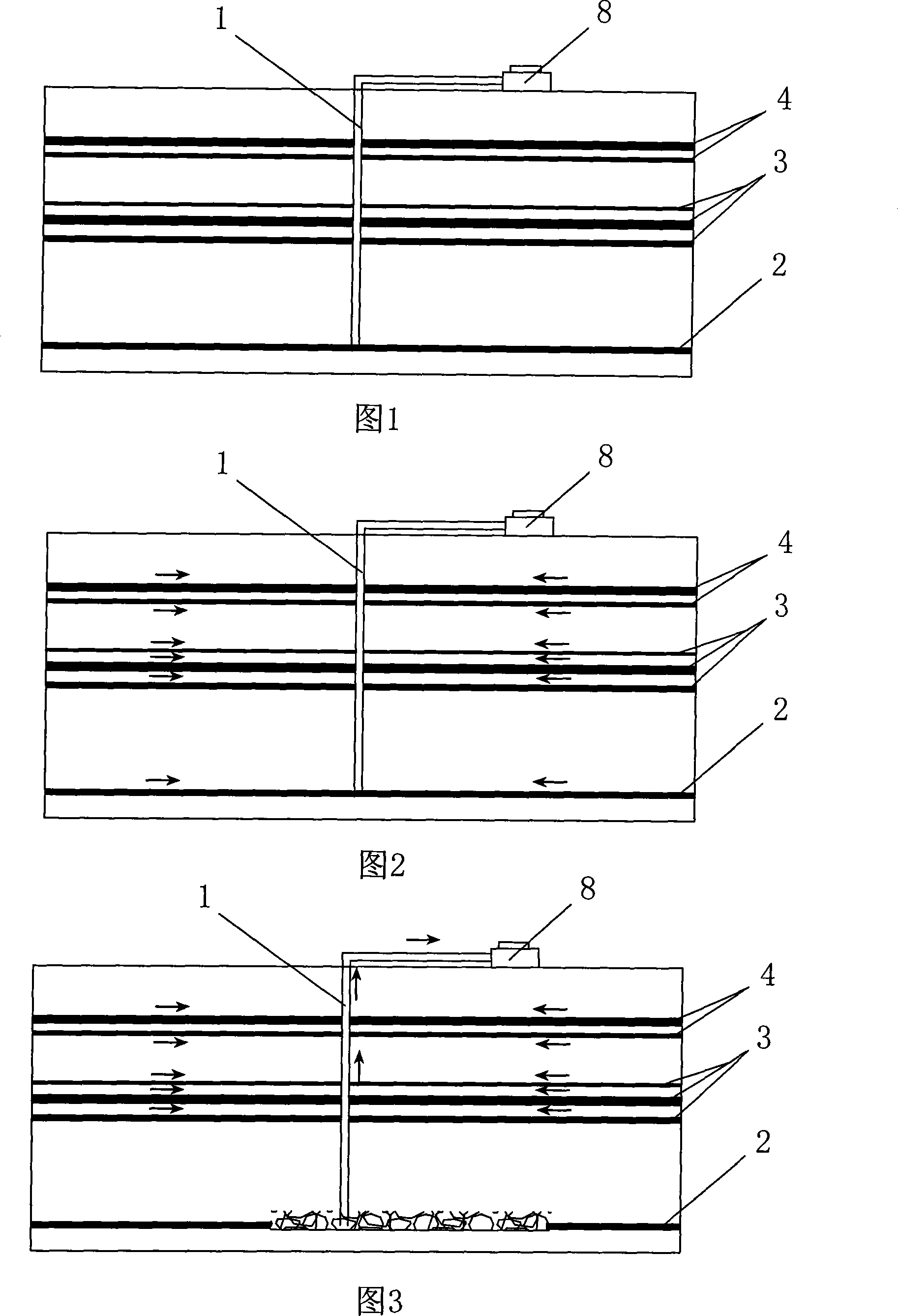

Gas extraction center divided-flow type grouting and hole sealing device and hole sealing method

InactiveCN102200024AReduced pumping resistanceQuality improvementGas removalSealing/packingEngineeringSlurry

The invention discloses a gas extraction center divided-flow type grouting and hole sealing device which comprises an extraction pipe, a grouting plug, a left bag and a right bag, wherein the extraction pipe penetrates through the left bag and the right bag, a multifunctional valve is arranged in the extraction pipe, and the left side and the right side of the multifunctional valve are respectively connected with a left flow division pipe and a right flow division pipe; the left flow division pipe and the right flow division pipe are both sheathed on the extraction pipe, and the inner diameter of the left flow division pipe and that of the right flow division pipe are both greater than that of the extraction pipe so as to form a slurry passage among the left flow division pipe, the right flow division pipe and the extraction pipe; and a grouting insertion pipe is inserted into the extraction pipe. Through the gas extraction center divided-flow type grouting and hole sealing device, more effective grouting and hole sealing of drilling holes in the hole sealing section can be realized, and the generation and the propagation of leakage cracks around the drilling holes can be better prevented. The invention also provides a hole sealing method by using the gas extraction center divided-flow type grouting and hole sealing device. Through the method, high stress regions are produced around the drilling holes in the hole sealing section, the permeability of coal around the drilling holes in the hole sealing section is reduced, and the purpose of effectively grouting and sealing the drilling holes in the hole sealing section is realized.

Owner:HENAN POLYTECHNIC UNIV

High-density fabric

Provided is a fabric that is favorably used for a side cloth of a down wear, a down jacket, a futon, a sleeping bag or some other, and that is light, thin and high in tear strength and can further keep a low air permeability after washed. The high-density fabric of the present invention that can attain the purpose is a fabric including a synthetic fiber that has a fineness of 28 dtex or less, and having a total cover factor ranging from 1700 to 2200. In this fabric, multifilaments are present in each of which monofilaments are arranged in the form of two layers in at least one direction of warp and weft directions. Furthermore, the fabric has a cover factor ranging from 700 to 900 in at least one direction of the warp and weft directions which has the multifilaments present.

Owner:TOYOBO SPECIALTIES TRADING

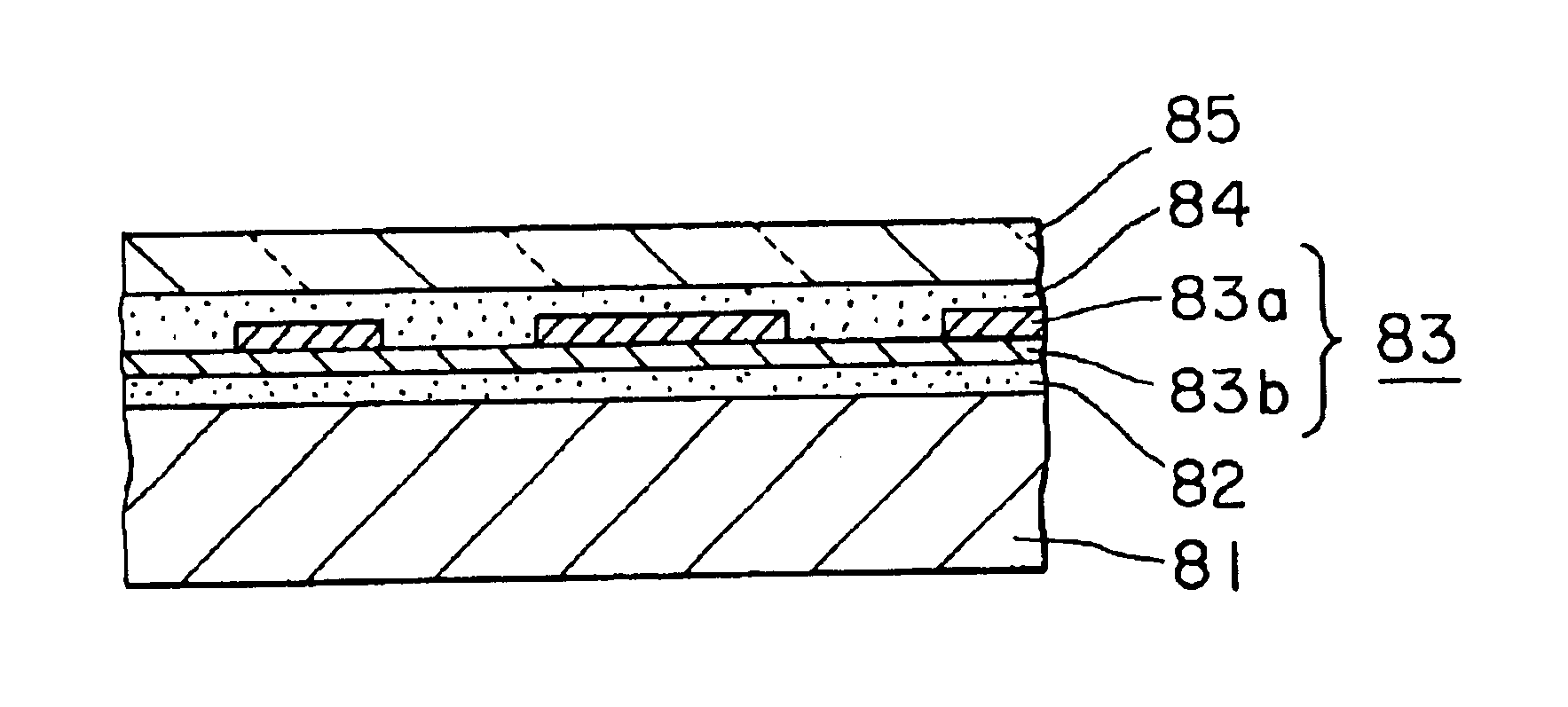

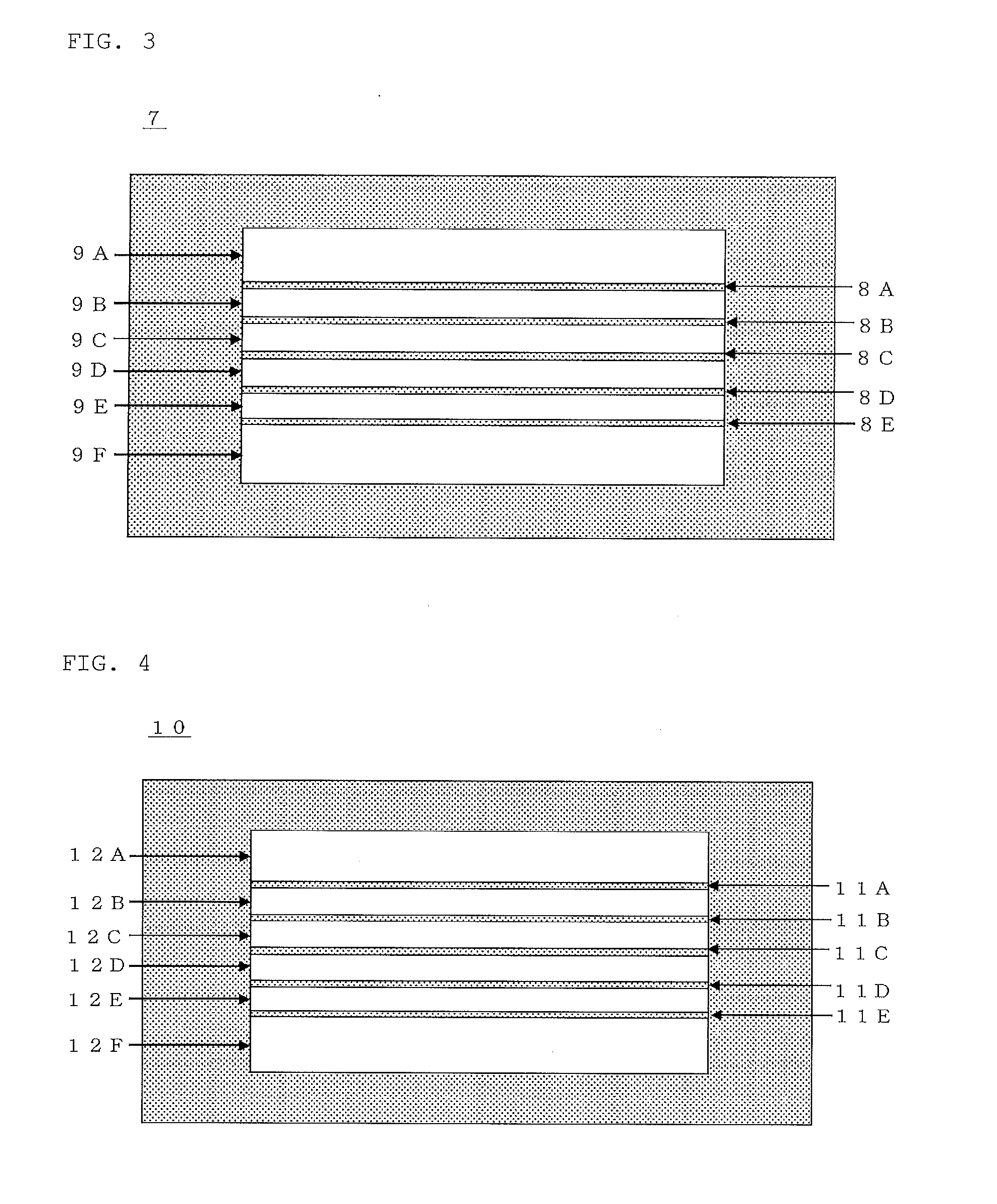

Transparent Conductive Film, Method For Producing Transparent Conductive Film and Organic Electroluminescent Device

InactiveUS20080226924A1Improve abilitiesReduce air permeabilityElectroluminescent light sourcesSolid-state devicesRefractive indexTransparent conducting film

A transparent conductive film comprising at least a transparent plastic film, a gas barrier layer and a transparent conductive layer is characterized in that the refractive index thereof is so regulated as to decrease continuously or stepwise from the side having the transparent conductive layer to the other side. Also disclosed are a method for producing such a film efficiently, and an organic EL device which is characterized by comprising an organic electroluminescent element-forming layer on such a transparent conductive film and having a high luminance (namely emission luminance).

Owner:KONICA MINOLTA INC

Coated ceramic catalyst supports and method

ActiveUS7166555B2Reduce penetrationReduce porosityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyvinyl alcoholMetallurgy

Porous ceramic catalyst supports are pre-coated with a passivation layer prior to applying a catalyst or catalyst support coating, the passivation layer consisting of a coating of a liquid mixture comprising at least one coating material selected from the group of polyvinyl alcohol / vinyl amine copolymer, polyvinyl alcohol / vinyl formamide copolymer, and gelatin.

Owner:CORNING INC

Printed wiring board, method for producing printed wiring board and semiconductor device

InactiveUS20160322293A1Efficient productionHigh hardnessSecond resist patternSemiconductor/solid-state device detailsResistElectrical conductor

The present invention provides a printed wiring board comprising: a conductor circuit on an insulating substrate, a white solder resist layer which is composed of a photosensitive resin composition on the insulating substrate having the conductor circuit, and a protective layer which is composed of a silicone resin composition on the white solder resist layer. The inventive printed wiring board shows superior thermo-discoloration resistivity and excellent patterning resolution.

Owner:SHIN ETSU CHEM IND CO LTD

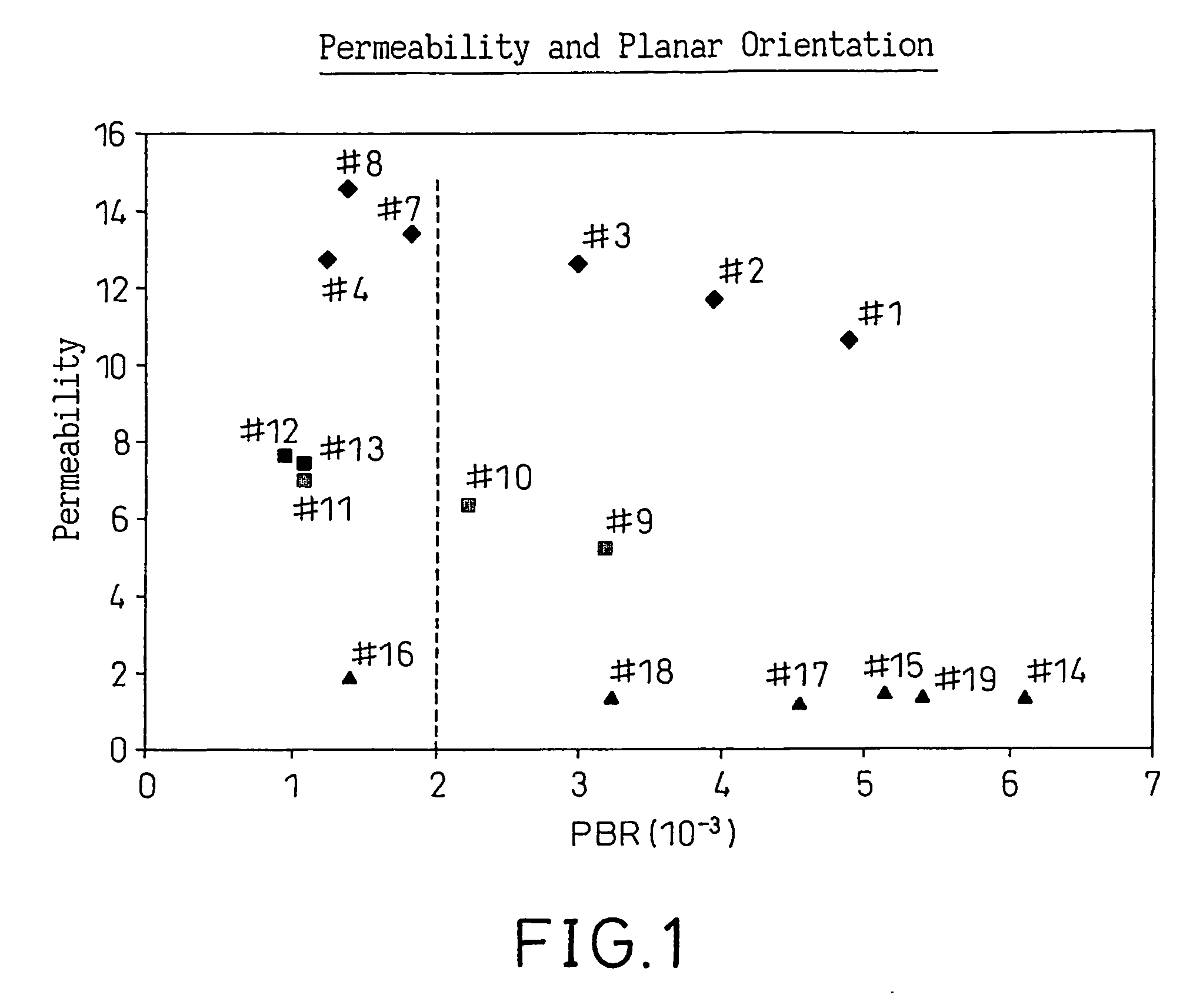

Oriented thermoplastic elastomer film and process for producing the same

InactiveUS20060241244A1Reduce air permeabilityImprove fatigue resistanceThin material handlingElastomerPolymer science

An oriented thermoplastic elastomer film having reduced permeability and improved fatigue resistance comprising a dynamically vulcanized polymer blend of (A) a halogenated isobutylene elastomer and (B) polyamide, the film is produced by C casting or blowing the above polymer blend under the condition such that a shear rate at a die lip for casting or blowing is regulated to control the molecular arrangement in the film, whereby the planar birefringemence (PBR) of the resultant film becomes greater or equal to 0.002 and a production process of the same.

Owner:EXXONMOBIL CHEM PAT INC +1

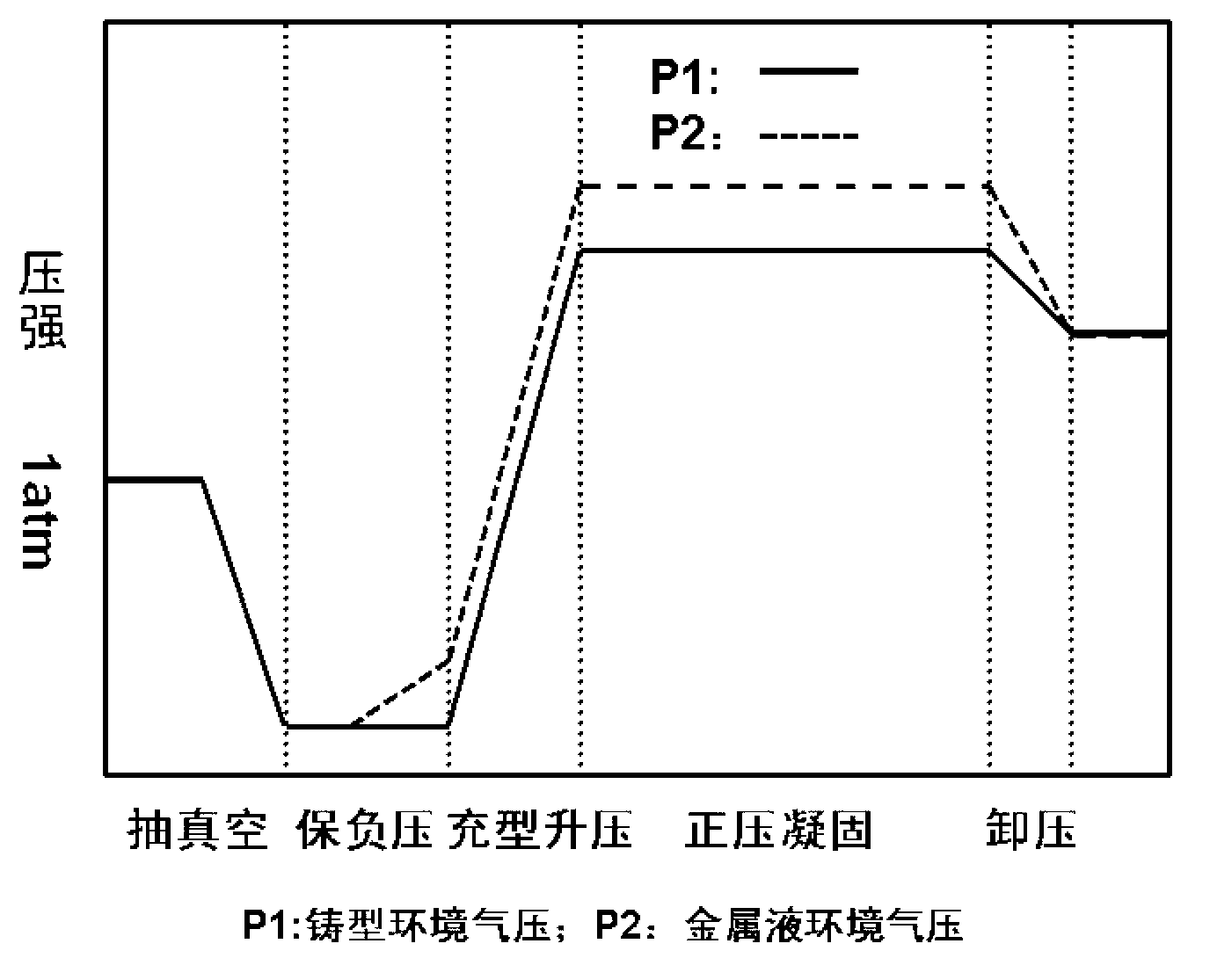

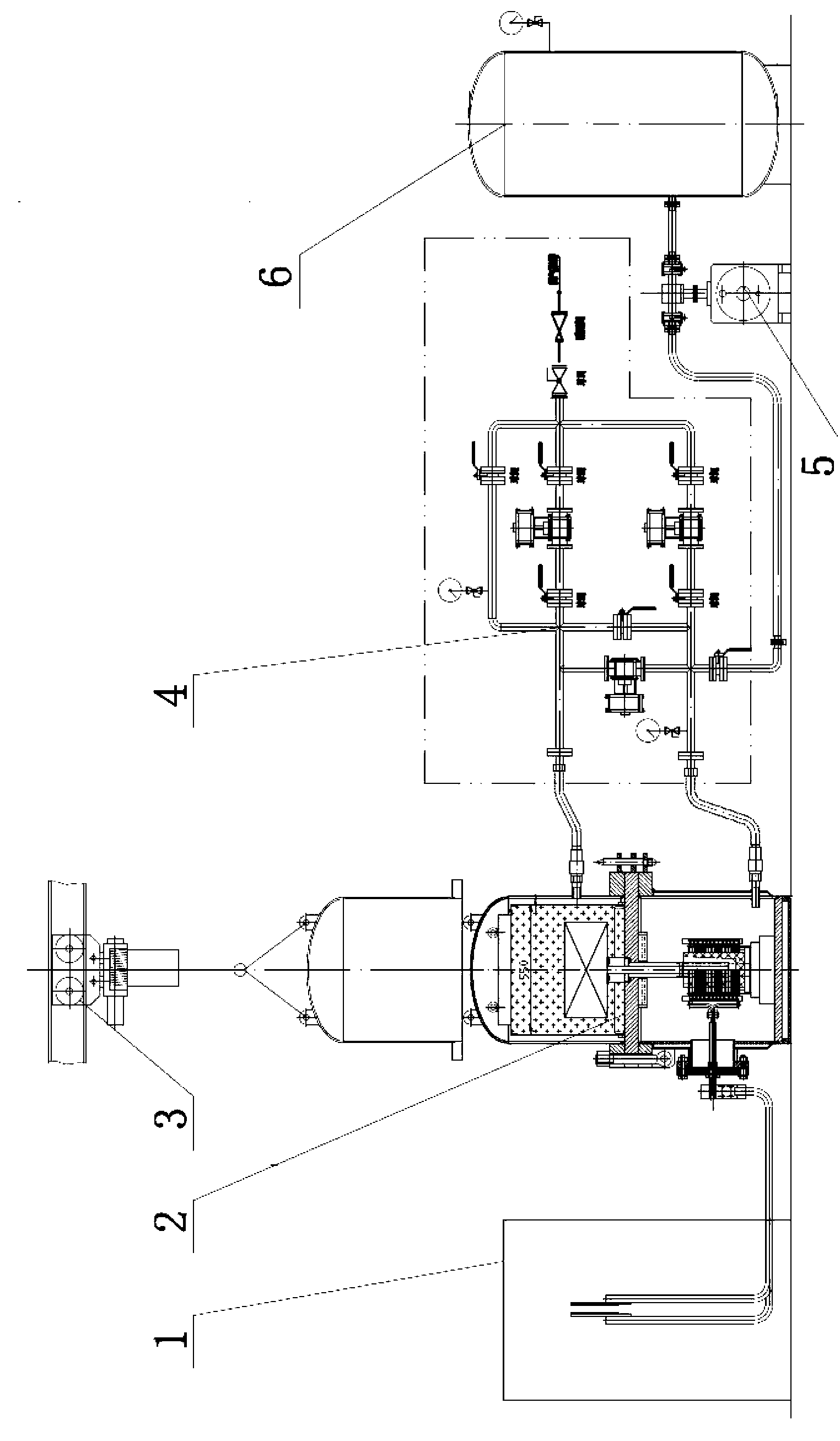

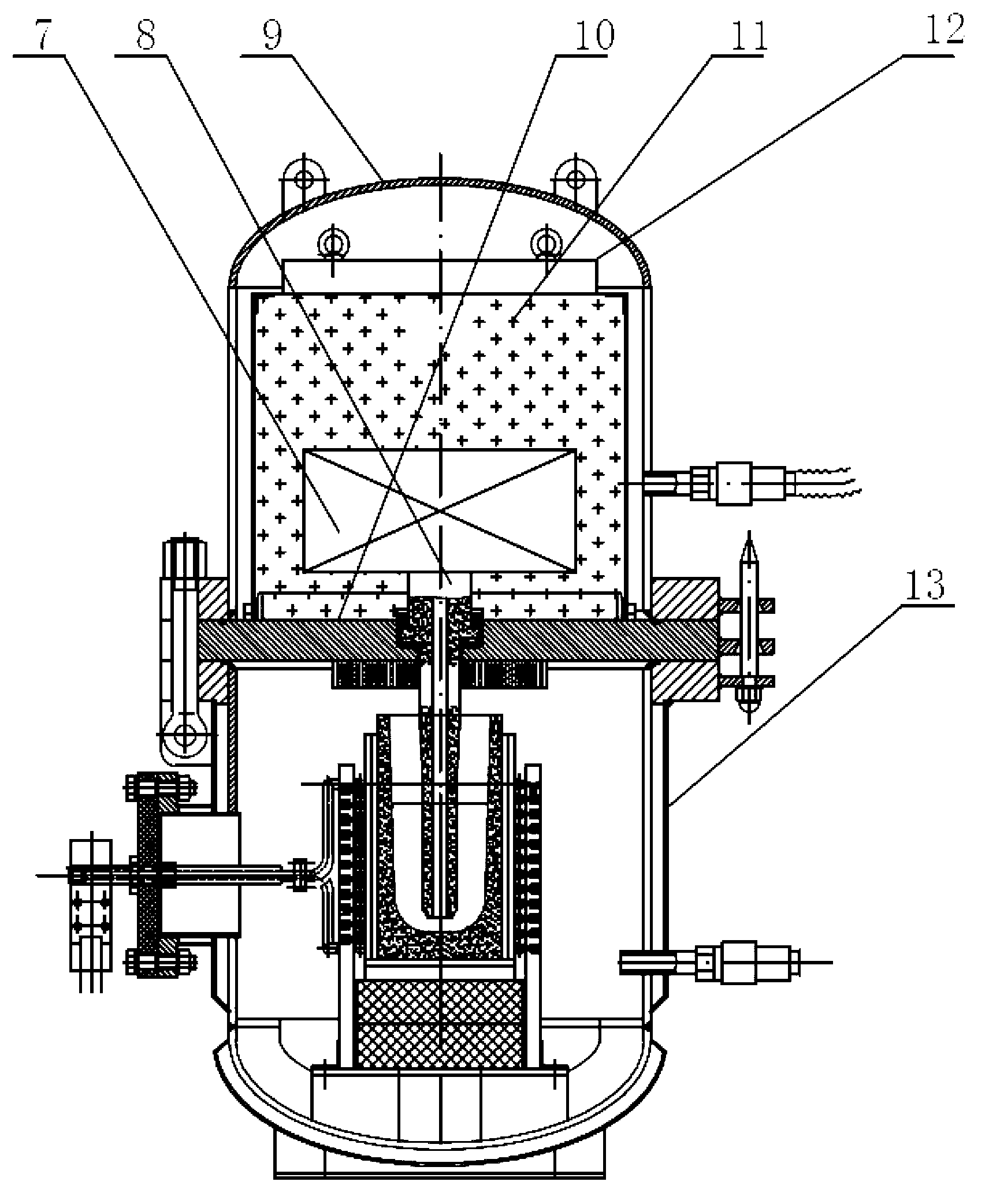

Precesion casting method for high temperature alloy complex thin-walled castings

ActiveCN102699311ASolve filling problemsReduce air permeabilityFoundry mouldsFoundry coresIntermediate frequencyMold filling

The invention discloses a precision casting method for high temperature alloy complex thin-walled castings. The method comprises the following steps of: utilizing a medium frequency induction heating power supply to melt the alloy, utilizing a medium baffle to separate an upper tank and a lower tank, and utilizing an electric hoist to elevate the upper tank when a casting mold and a liquid rising tube are installed; after the installation is completed, utilizing a gas circuit control pipeline, a vacuum system and a gas tank to realize vacuum and pressure regulation in a pressure regulating furnace. By adopting the method disclosed by the invention, stable and efficient mold filling is realized, the castings is solidified sequentially, utilization efficiency of the material can be effectively improved, and the space for near-end net shape casting can be supplied; the complex, thin-walled and integral metal castings which are difficult to cast through other molding methods can be produced, so as to solve the filling problem in the pouring process of the complex thin-walled castings, and in particular, the filling capacity for the thin-walled castings with the wall thickness of less than 3mm is greatly improved. Accurate castings with high dimensional accuracy can be obtained through high temperature alloy pressure regulating investment precision casting, and the accuracy of the casting can reach between CT4 and CT6.

Owner:SHANGHAI JIAO TONG UNIV

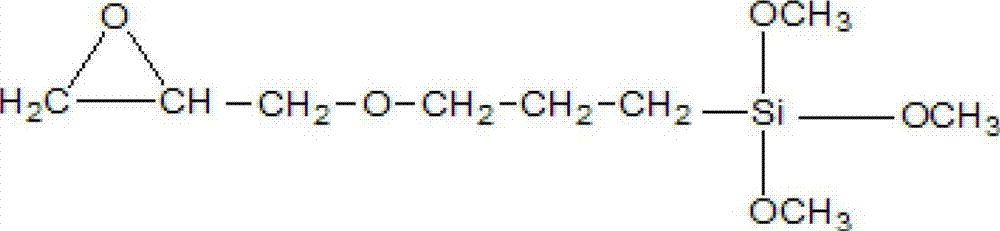

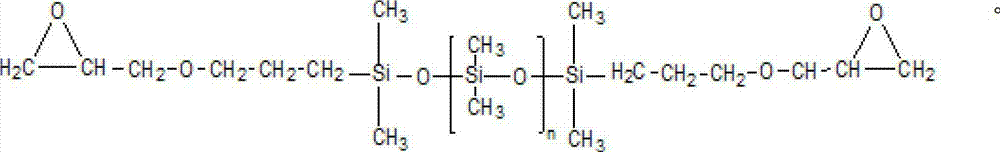

High refraction and high adhesion large power LED packaging organosilicon material and preparation method thereof

ActiveCN102936414ASolve the problem of incomplete hydrolysis and condensationReduce air permeabilitySemiconductor devicesChemical synthesisPtru catalyst

The present invention relates to a high refraction and high adhesion large power LED packaging organosilicon material and a chemical synthesis method thereof. The organosilicon packaging material is prepared by carrying out mixing matching on a component A and a component B according to a mass ratio of 1:1, wherein the component A comprises vinyl phenyl polysiloxane, vinyl phenyl silicone oil, a platinum-containing polysiloxane catalyst and a tackifier, the component B comprises hydrogen-containing phenyl polysiloxane, dihydrideterminated phenyl polysiloxane, vinyl phenyl polysiloxane and an inhibitor, the tackifier is prepared by carrying out addition on isocyanate, methoxy silane and epoxy silane, and provides strong adhesion for PPA and a silver surface, the curing agent is prepared by compounding hydrogen-containing phenyl polysiloxane and dihydrideterminated phenyl polysiloxane, and a compounding mass ratio is preferably 4:1-2, such that the packaging material has moderate hardness and flexibility after curing so as to effectively solve contradiction of strength and cracking of the cured adhesive. With the present invention, the organosilicon packaging material with characteristics of refraction of 1.54, suitability for industrialization and fully meeting of large power LED packaging requirements can be obtained.

Owner:湖北环宇化工有限公司

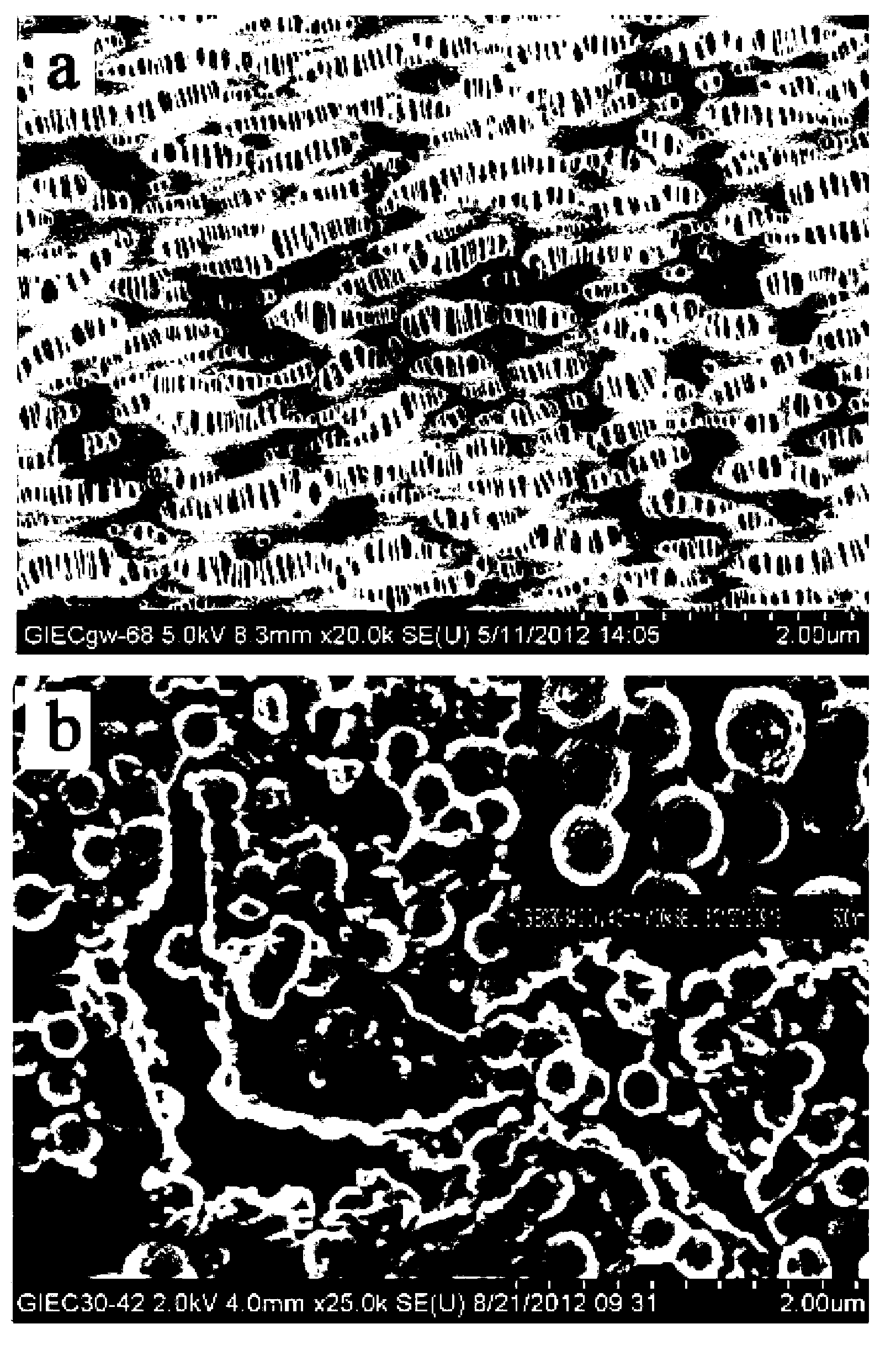

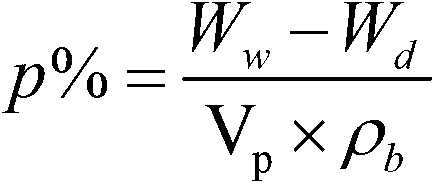

Method for preparing high temperature resistant composite separator by lithium ion battery

ActiveCN103066231AImprove lyophilicityImprove cycle performanceCell component detailsPolyolefinTemperature resistance

The invention discloses a method for preparing a high temperature resistant composite separator by a lithium ion battery, and belongs to the field of lithium ion battery separators. The method comprises the following steps: active groups are introduced into the surface of a polyolefin microporous film and a micropore through the surface pretreatment of a substrate film, silica sol is prepared by a sol-gel method, and a silica coating is introduced, and is bonded with the substrate film by a chemical bond. The method is simple in preparation process, low in requirement on equipment, and easy to realize the industrialization; the prepared composite separator has the advantages of high mechanical strength, good air permeability, good high temperature resistance, high ionic conductivity, and good adhesion property of silica coating and polyolefin microporous film, and the silica coating is not easy to fall off, so that the safety performance and the comprehensive property of the separator are improved.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

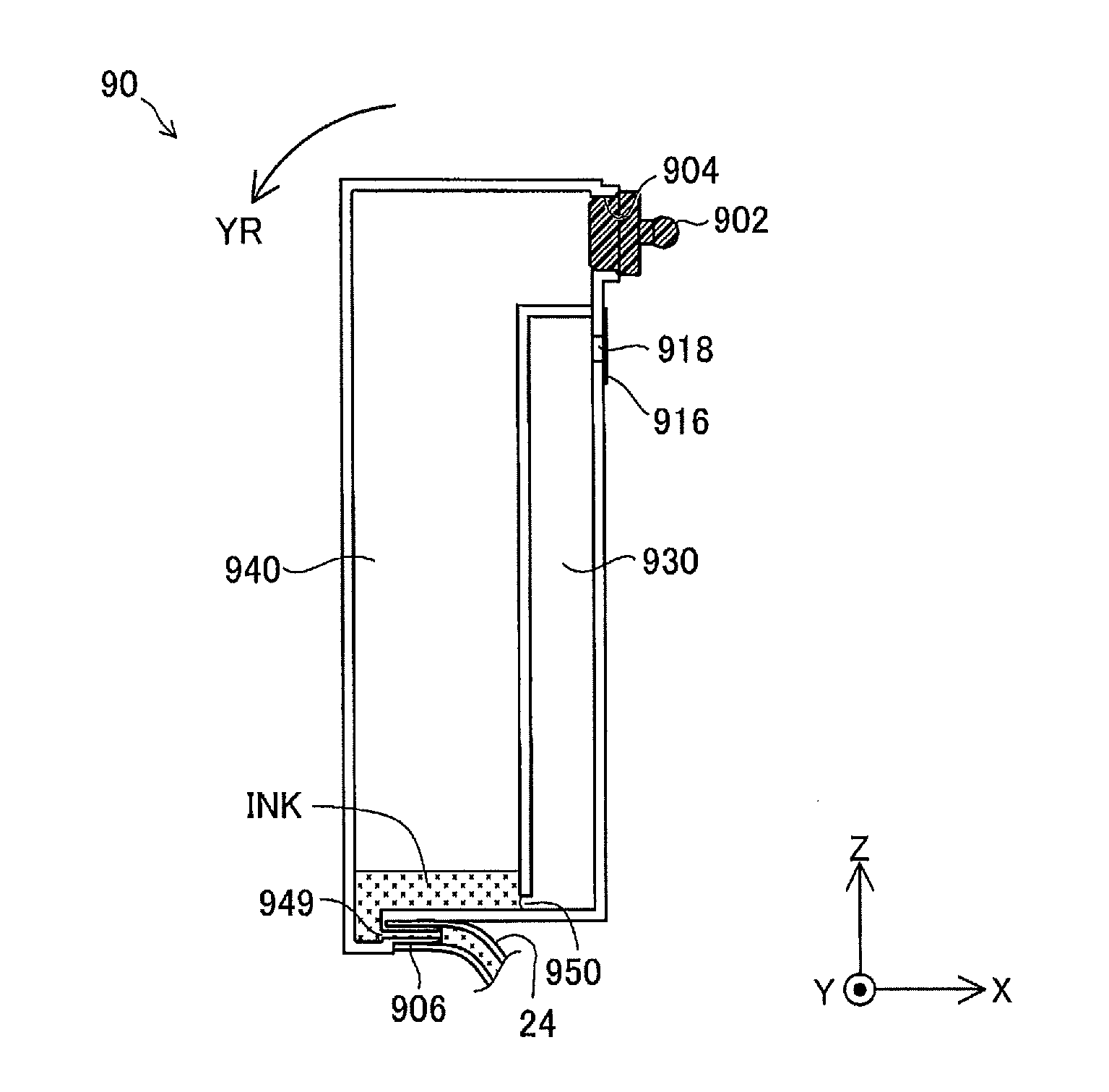

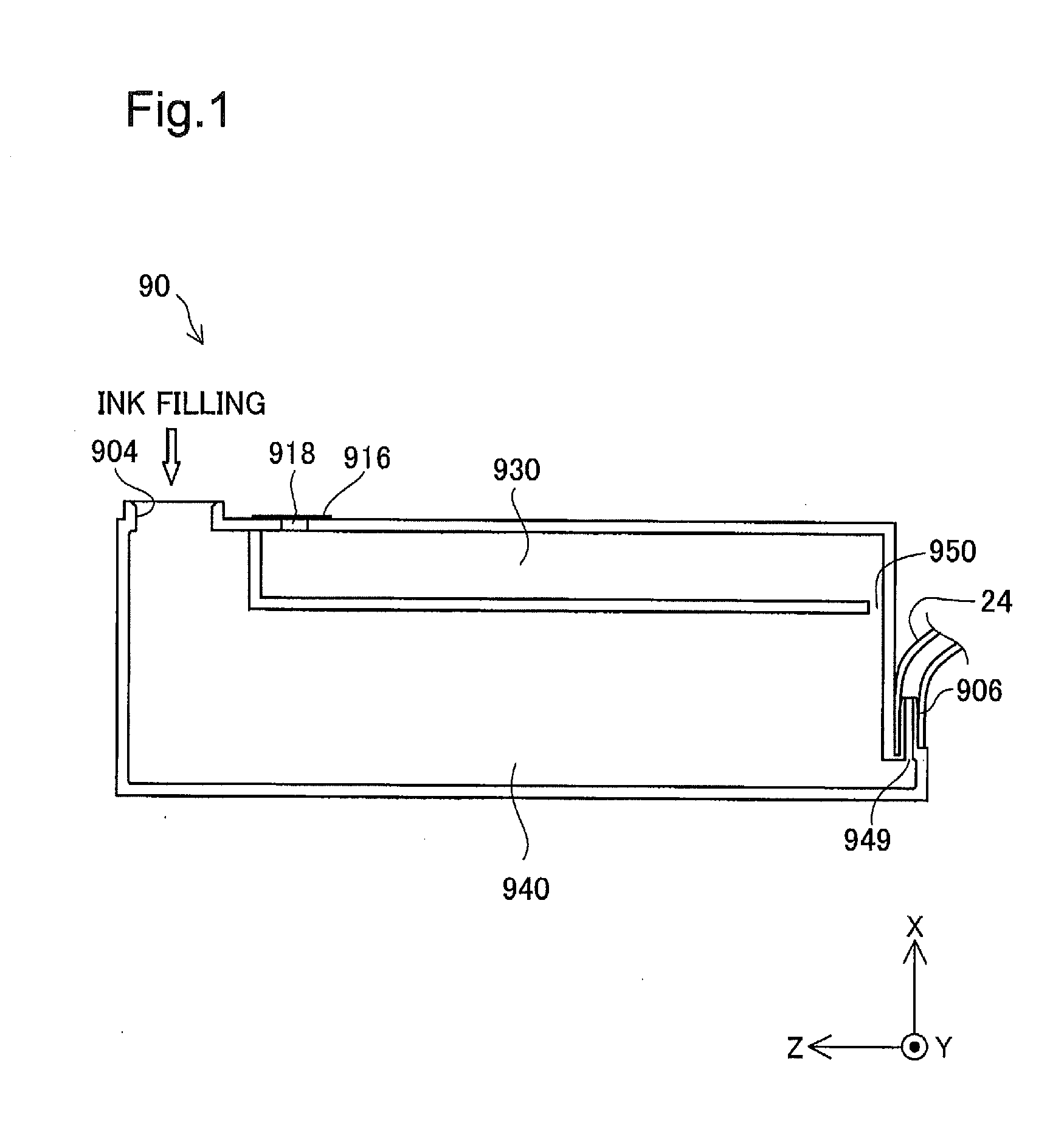

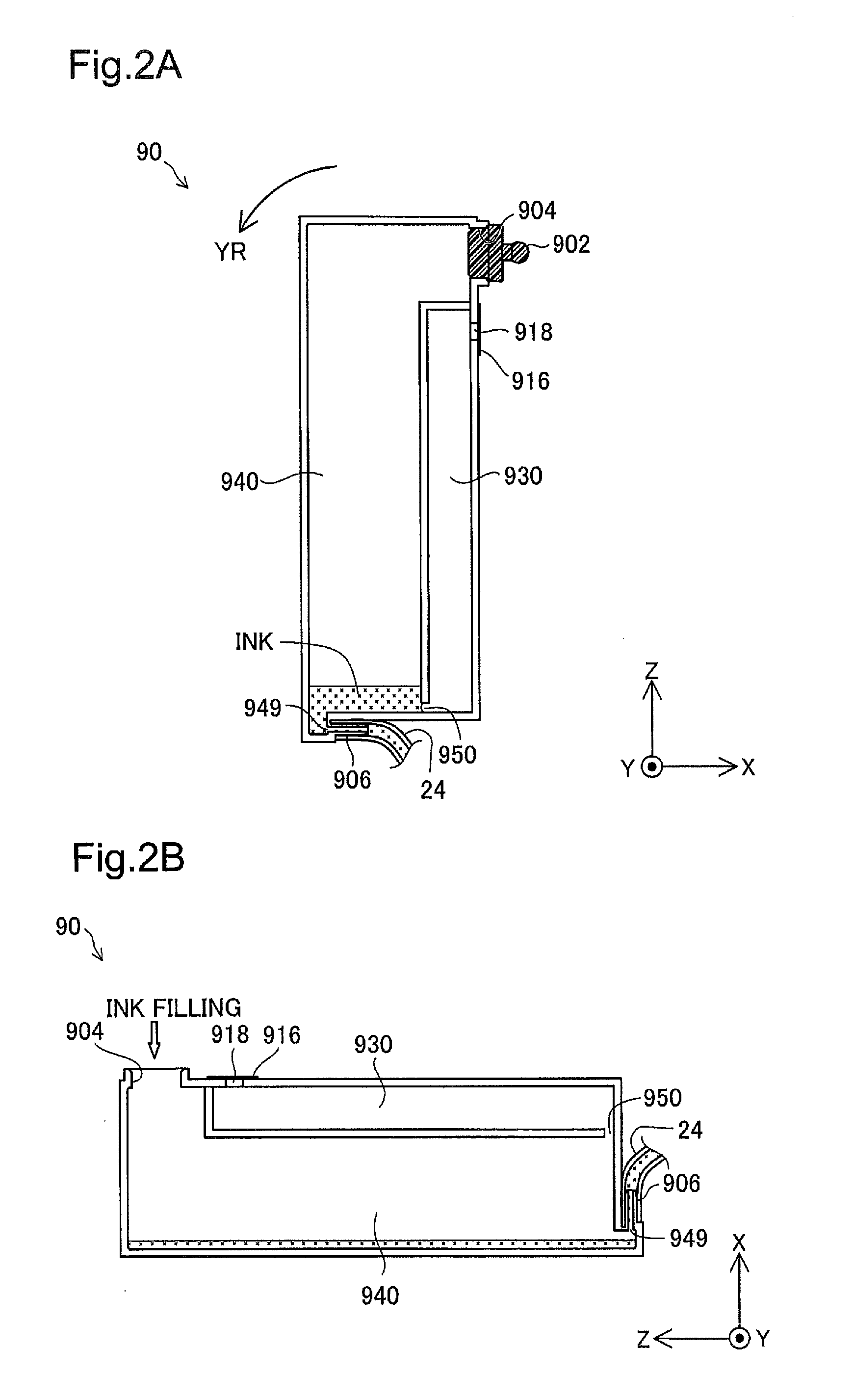

Liquid container and liquid ejection system

A liquid container for supplying a liquid to a liquid ejection apparatus comprises: a liquid chamber provided to store the liquid; an air chamber connected with the liquid chamber to introduce the outside air into the liquid chamber with consumption of the liquid in the liquid chamber; an open-air hole provided to introduce the outside air into the air chamber; and a liquid inlet provided to fill the liquid into the liquid chamber, wherein the liquid inlet is located at a lower position than the open-air hole, in a filling attitude of the liquid container in which the liquid is filled into the liquid chamber.

Owner:SEIKO EPSON CORP

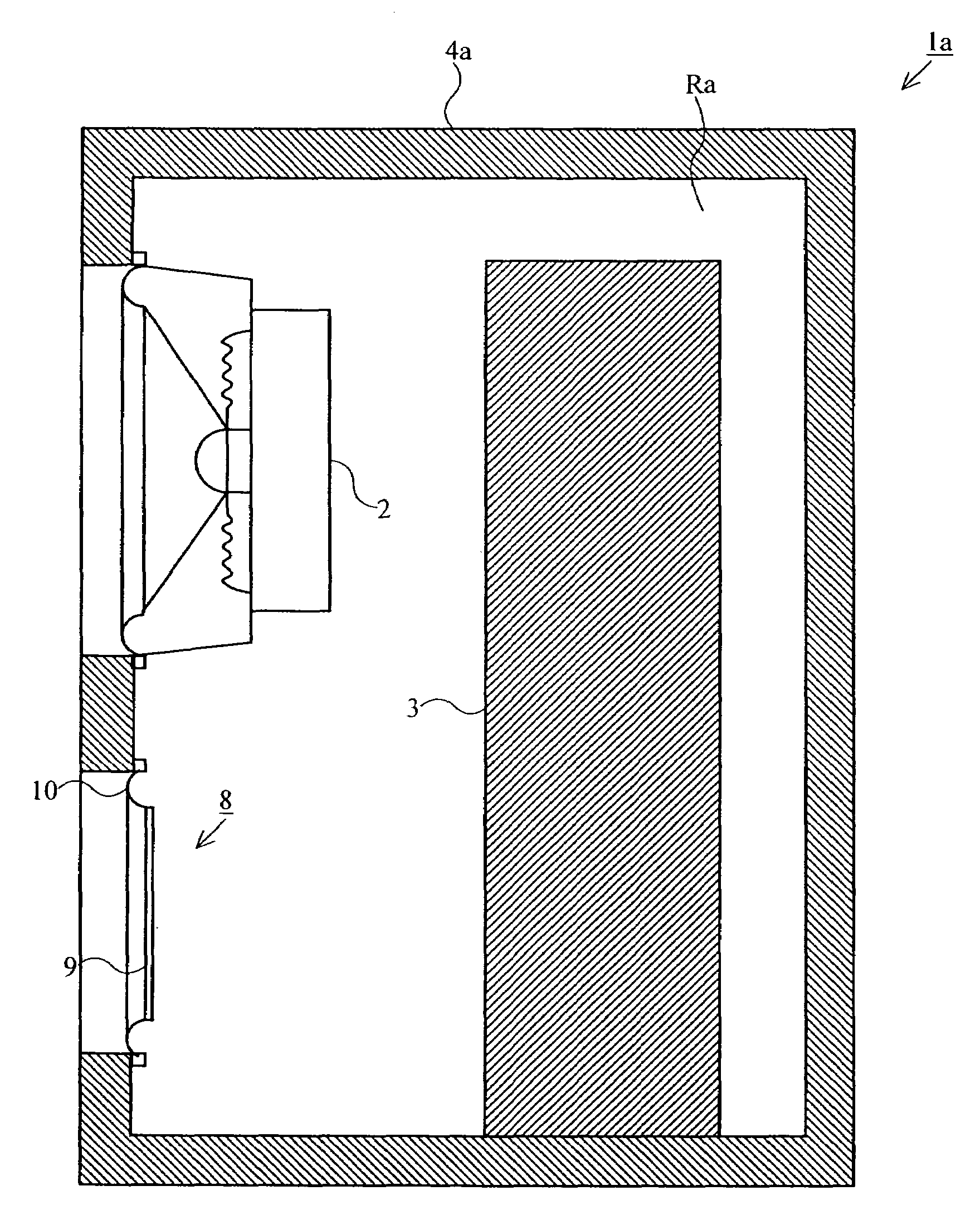

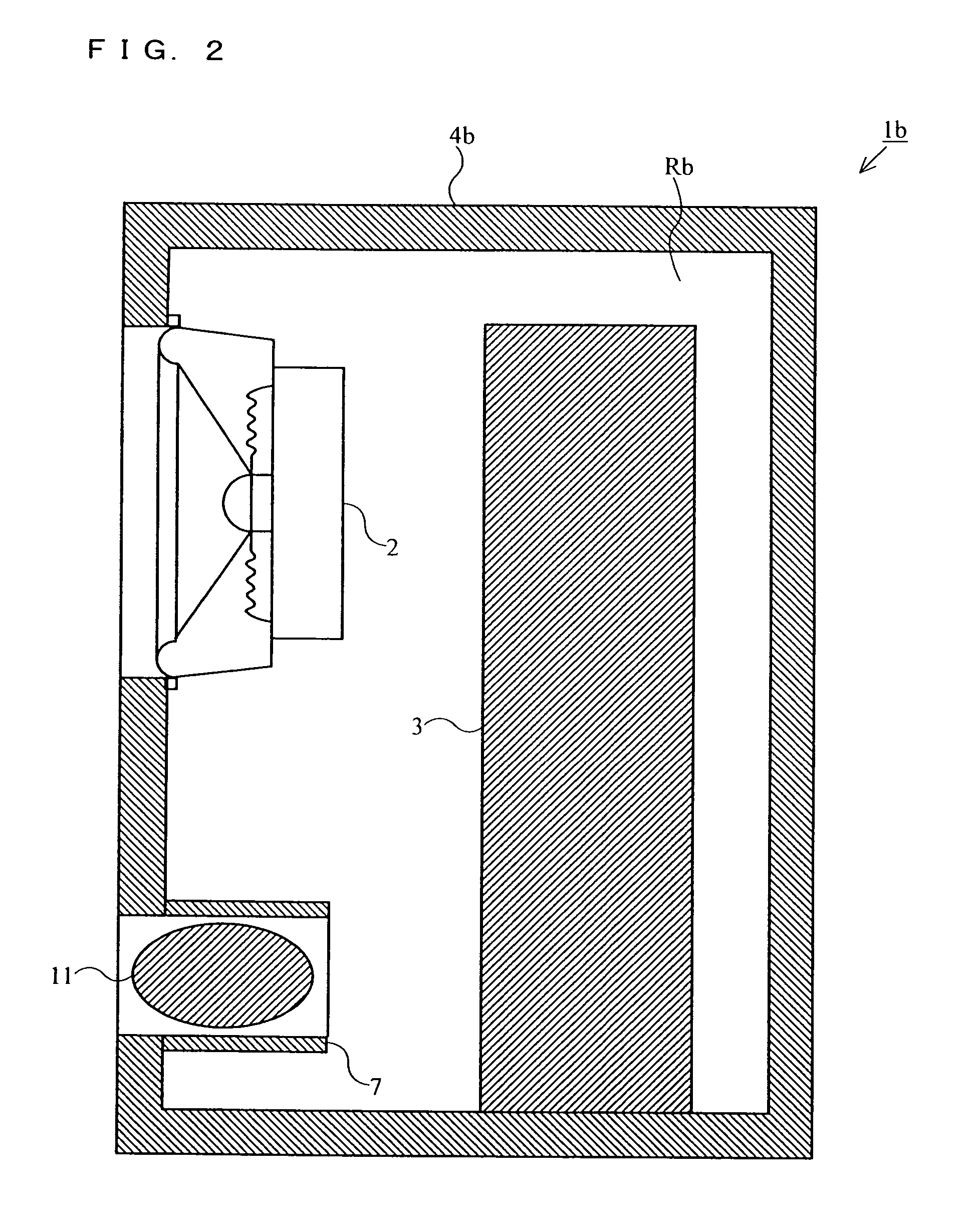

Loudspeaker system

ActiveUS7463747B2Large capacityPrevent intrusionFrequency/directions obtaining arrangementsTransducer casings/cabinets/supportsEngineeringLoudspeaker

A loudspeaker unit (2) of a loudspeaker system (1) is fitted to a cabinet (4). An absorbent (3) is disposed in a hollow chamber (R) inside the cabinet (4) and absorbs a gas inside the hollow chamber (R). A phase inverting mechanism (8) inverts the phase by resonating with a sound of a specific frequency radiated from the loudspeaker unit (2) into the hollow chamber (R) and radiates this sound to outside. The watertight means of the phase inverting mechanism (8) prevents invasion of moisture into inside the hollow chamber (R) from outside the cabinet (4) through the phase inverting mechanism (8).

Owner:PANASONIC CORP

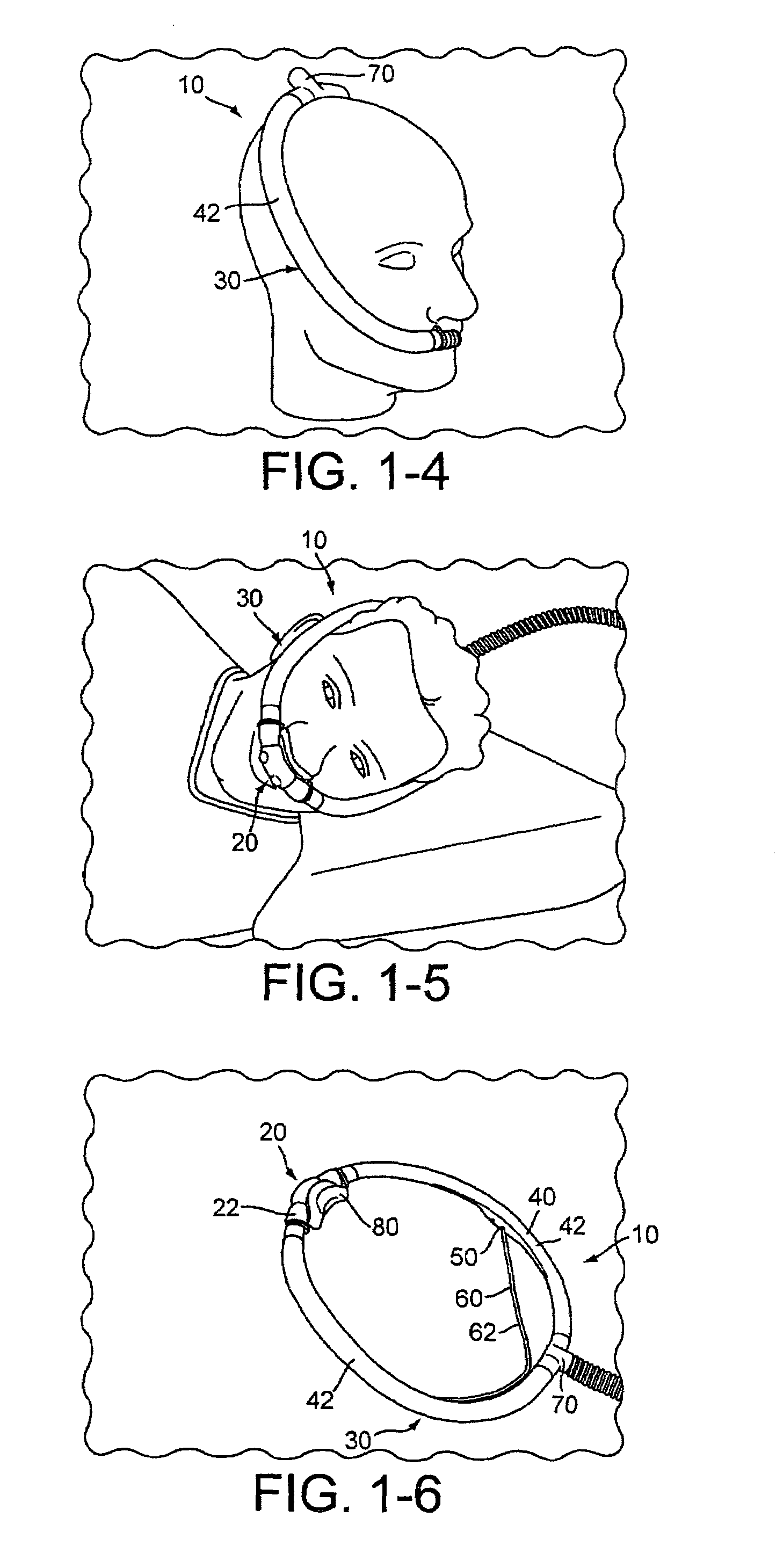

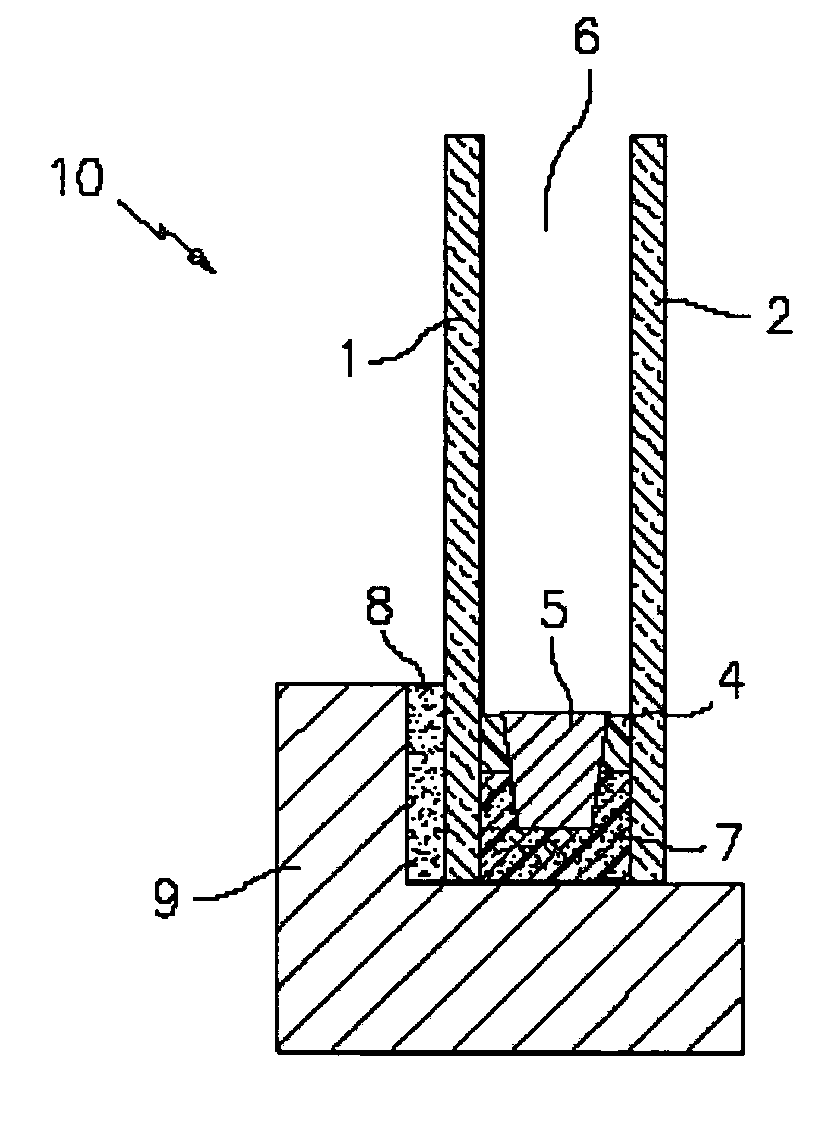

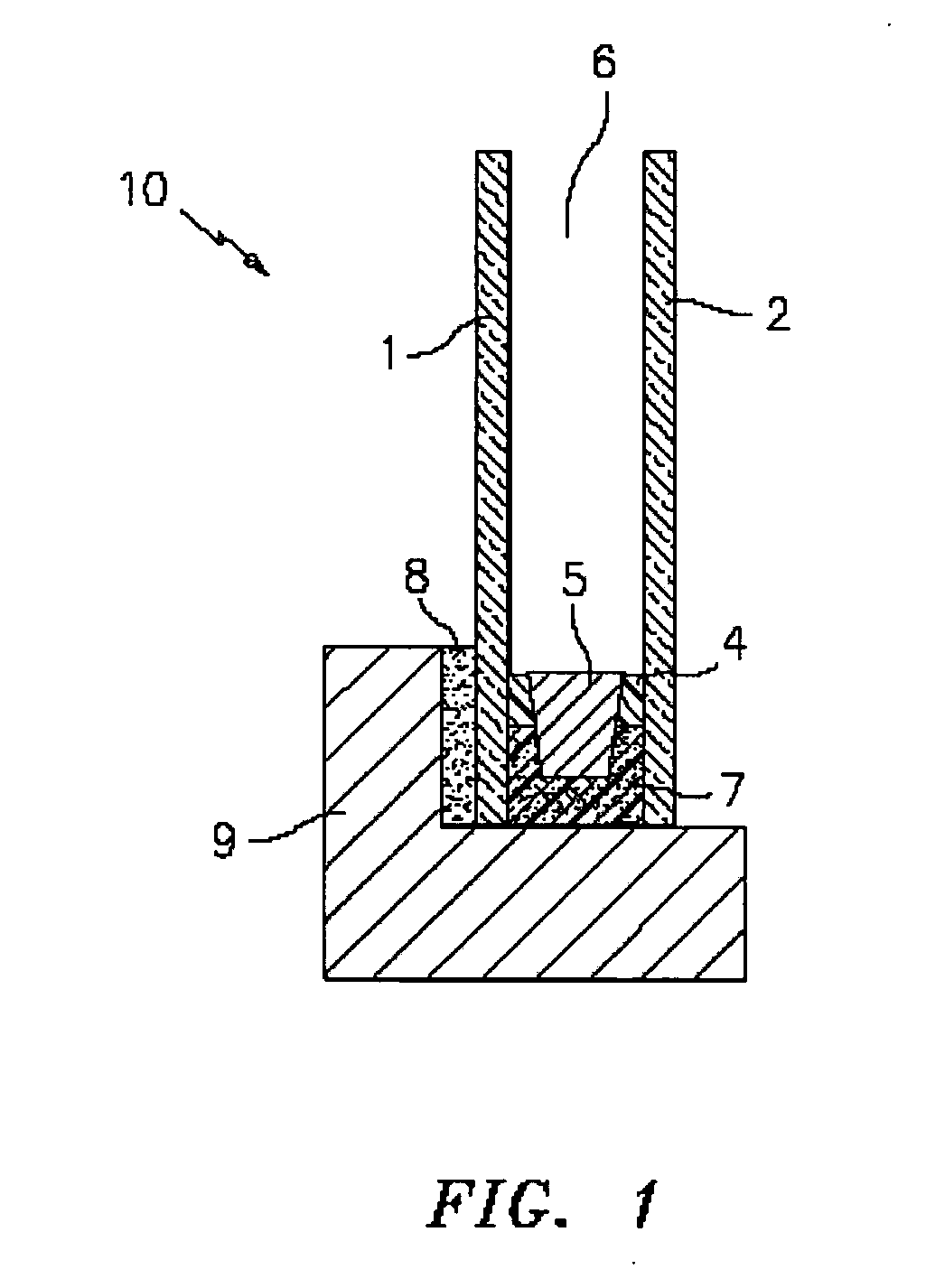

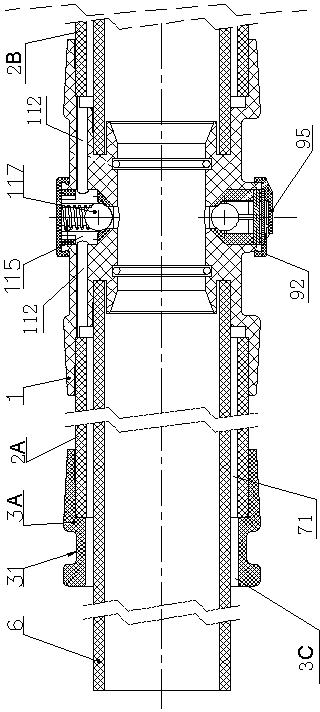

Gas pumping fixing occluder and use method thereof

ActiveCN103452525AEffective blocking purposeAvoid it happening againGas removalSealing/packingGas leakPipe

The invention discloses a gas pumping fixing occluder and a use method thereof. A three-hole pipe penetrates through three bags, a recyclable grouting pipe is communicated with a grouting channel of the three-hole pipe by a drainage device; a gas leaking handling pipe is communicated with a gas leaking handling channel of the three-hole pipe by a drainage device; a grouting hole of the drainage device and a grouting communicating small hole of the three-hole pipe are coaxial by a grouting small hole; a gas leaking handling hole of the drainage device and a gas leaking handling communicating small hole of the three-hole pipe are coaxial by a gas leaking handling small hole; check valves are arranged at the grouting channel in the three bags; a pressure check valve is mounted on the grouting channel between the No.2 bag and the No.3 bag. According to the gas pumping fixing occluder and the use method thereof, more effective grouting sealing can be realized on drill holes of a hole sealing section, generation of coal wall seams around drill holes at the hole sealing section can be more effectively avoided, and the occluder can also fill extremely small coal seams, so the hole sealing effect is optimal.

Owner:HENAN POLYTECHNIC UNIV

Preparation method of acrylate modified water-borne polyurethane emulsion for synthetic leather

The invention discloses a preparation method of acrylate modified water-borne polyurethane emulsion for synthetic leather. The preparation method comprises the following steps of: 1) preparing water-borne acrylate emulsion; 2) preparing water-borne polyurethane emulsion; and 3) physically blending the water-borne acrylate emulsion obtained in the step 1) and the water-borne polyurethane emulsion obtained in the step 2) to obtain the acrylate modified water-borne polyurethane emulsion for synthetic leather. The preparation method disclosed by the invention has the advantages that: by introducing a natural reproducible polyhydric alcohol compound namely castor oil, the water resistance of the water-borne polyurethane material can be improved, and good flexibility, cold resistance and warping strength of the coating are obtained at the same time; meanwhile, by adding a silane coupling agent, good air permeability and flexibility of the material can be obtained, and the water-borne polyurethane emulsion can be spread on the surface of a base material (particularly a non-polar base material) better so as to improve the adhesive force and water repellency; and moreover, by modifying with the thermoplastic material namely water-borne acrylate, the embossing stability of the water-borne polyurethane leather can be improved.

Owner:福建宝利特新材料科技有限公司 +1

One well three-purpose mash gas harnessing method for ground well drilling and ground well drilling

InactiveCN101240715AGood drilling safetyIncrease concentrationUnderground miningSurface miningWell drillingPositive pressure

Mash gas treating method of floor well drilling having three functions and floor well drilling are disclosed, the character of it is that gas is token out by using the same floor well drilling in ground with the following steps; First, before exploiting , mounting fracturing well formal floor well drilling, forming artificial slit and gas producing channel with fracturing method in coal seam, collecting gas using positive-pressure released by gas burning-self, eliminating projection of lower coal and gas; Second exploiting lower coal group, pressure relief and stress releasing of upper coal group and middle coal group when lower coal group is exploited, and gas of upper coal group and middle coal group in bending subsiding belt is exploited by negative-pressure type in the same floor well drilling; Finally, when exploiting upper coal group and middle coal group, once more the same floor well drilling negative-pressure exploits the exploited region gas in middle coal group or upper coal group working surface. Gas exploiting ratio of the method is high, ratio between cost and efficiency is good, and exploited gas concentration is high.

Owner:HUABEI MINING GRP

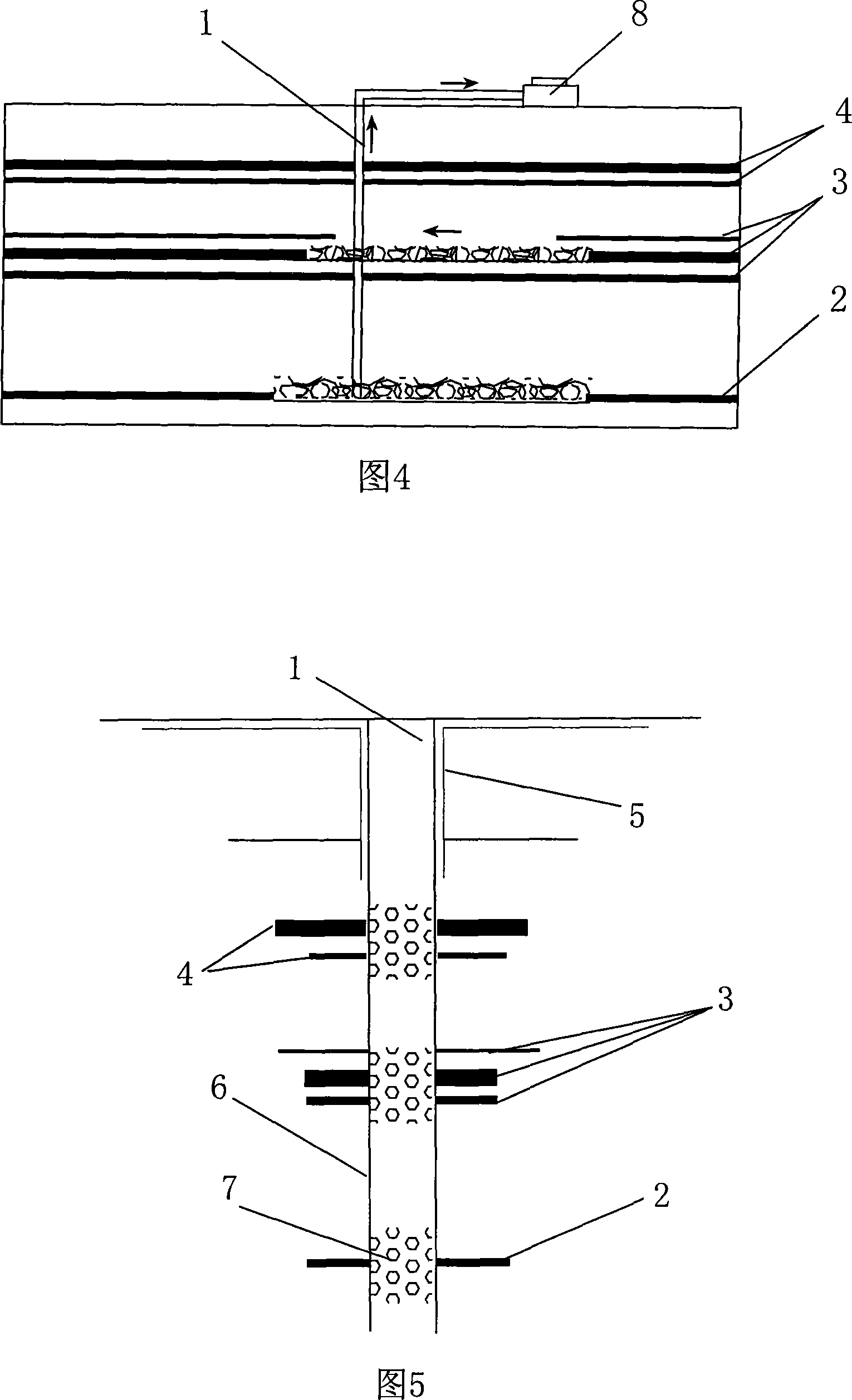

Preparation method of expanding microporous poly tetrafluoroethylene

InactiveCN101007242AImprove uniformityEnhanced tensile breaking strengthSemi-permeable membranesTetrafluoroethylenePolymer science

An expanded micropore polytetrafluoroethylene film (it is named ePTFE film briefly) Preparation is an improved method of the existing polytetrafluoroethylene film preparation. It includes mixing materials, striking adobe, squeezing, pulling longitudinally and pulling horizontally, it is characterized by: using the mold head of flat finish mold in squeezing procedure; adding glazing procedure between the squeezing procedure and pulling longitudinally procedure. The ePTFE film prepared by the technology can balance two important physics properties of permeability and stretching splitting strong force of ePTFE film and gain the ePTFE film with high permeability, high stretching splitting strong force, high uniformity and good appearance. The invention can be uses for produce mass ePTFE film with stabilizing appearance and property and improve the products property of the ePTFE film effectively.

Owner:SINOMA SCI & TECH

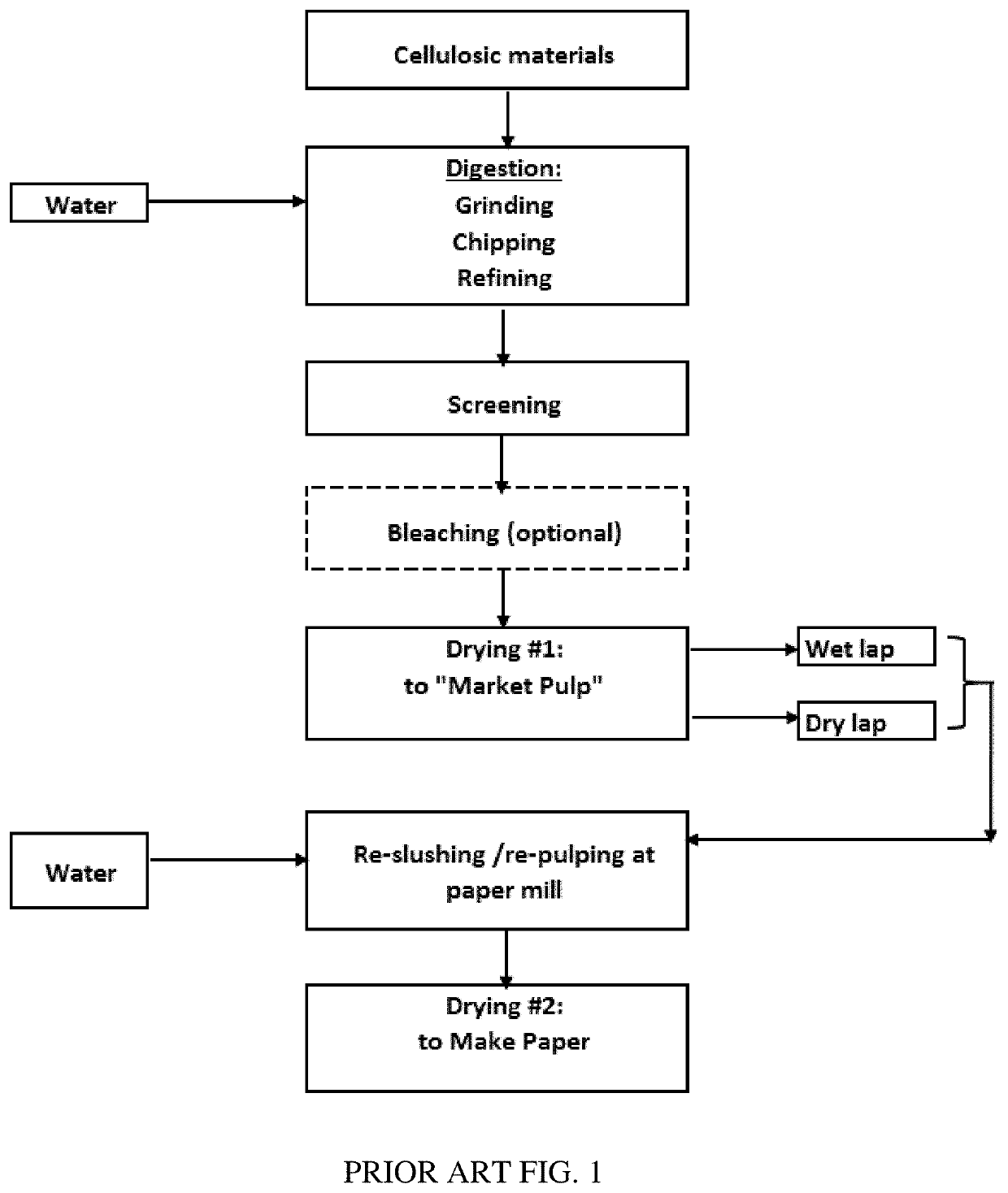

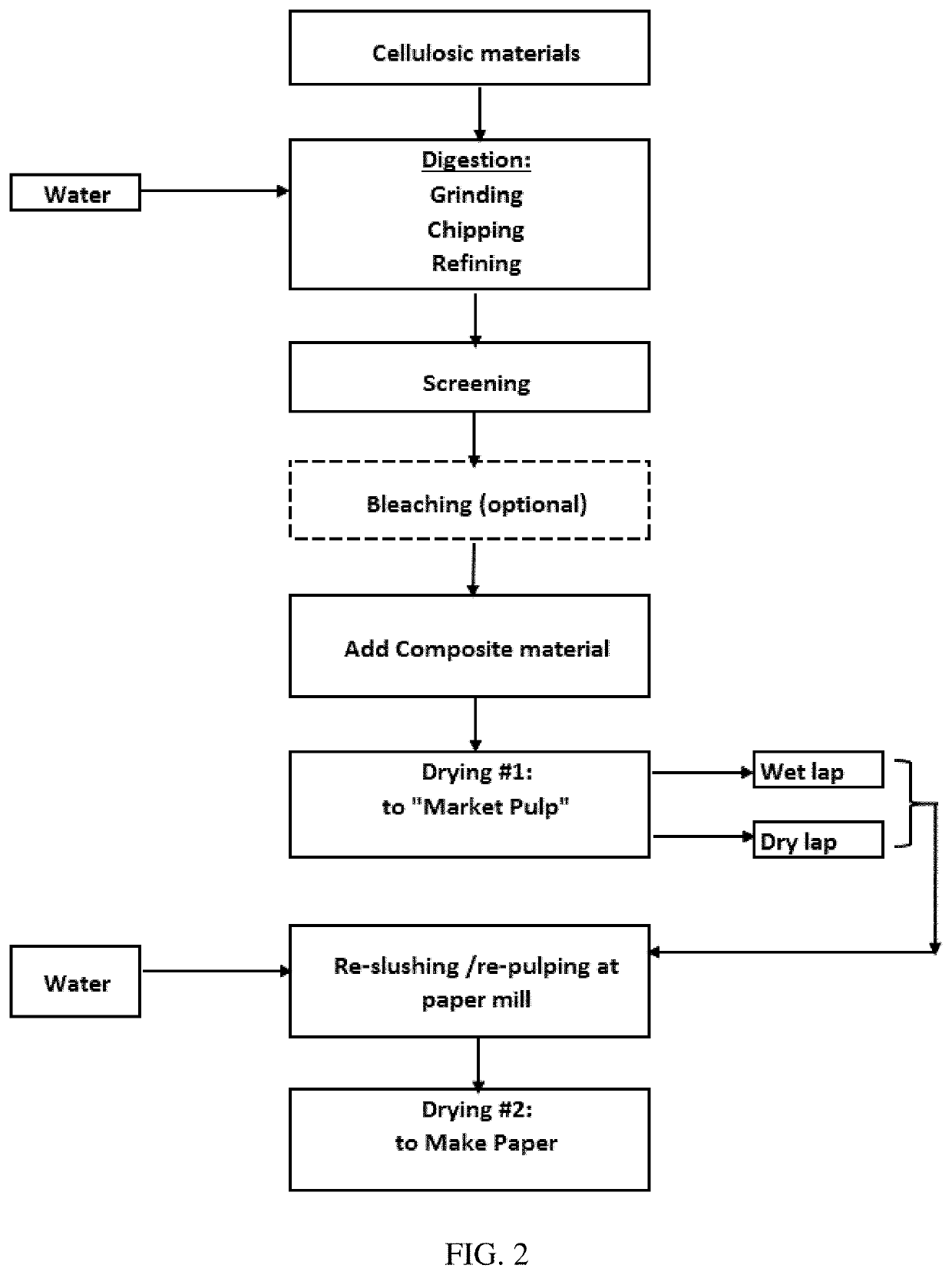

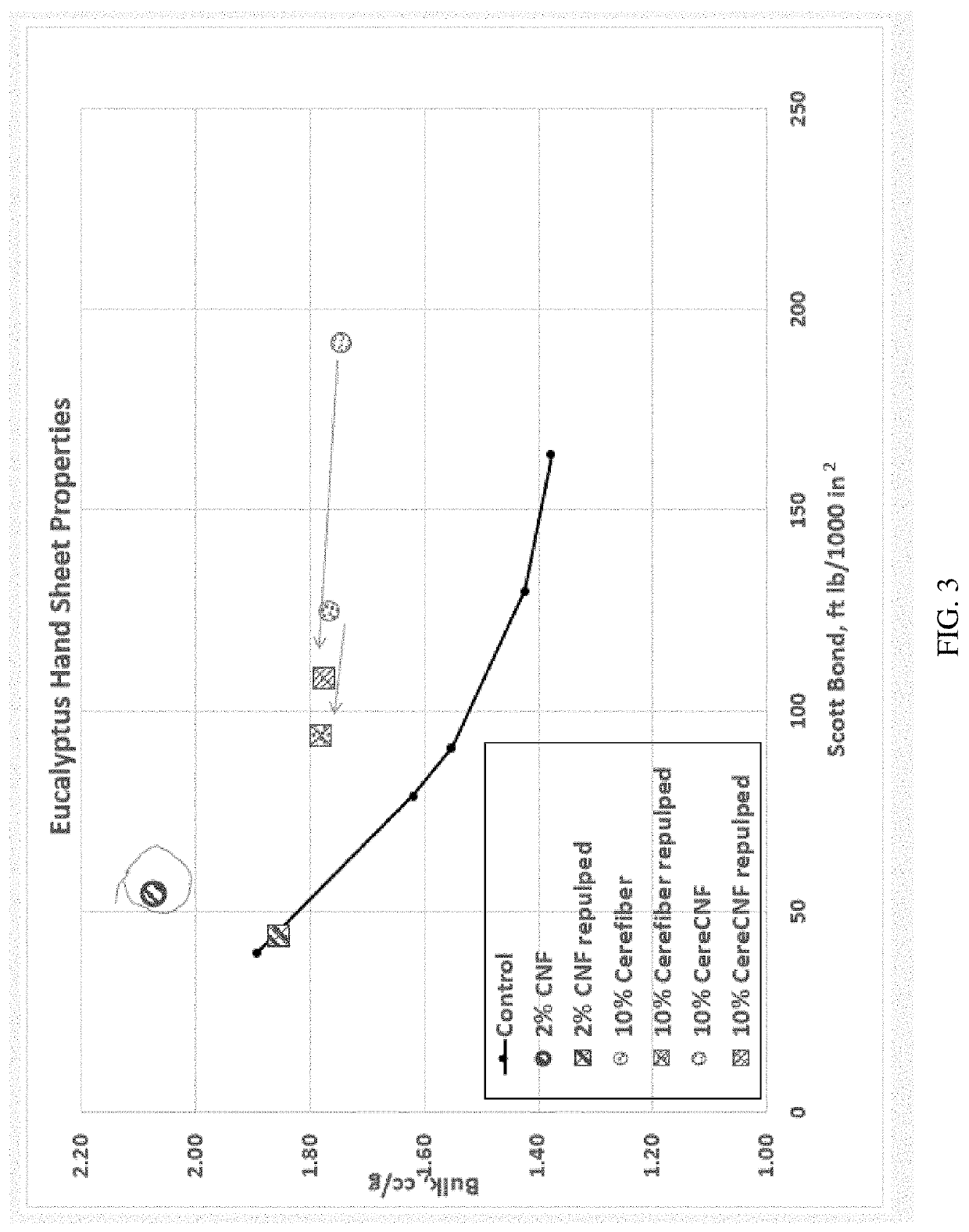

Method to Produce Composite-Enhanced Market Pulp and Paper

ActiveUS20200347549A1Enhanced market pulpHigh freenessPulp properties modificationNon-macromolecular organic additionFiberPolymer science

An improved market pulp and process for making the same by adding a composite material are described. The composite material includes cellulose nanocrystals, cellulose nanofibers, or another high aspect ratio, high surface area cellulose material (or a starch, or both) and a crosslinking compound that crosslinks a portion of the surface hydroxyl groups to form a 3-D matrix. Adding the composite material to market pulp has been shown to improve the strength of twice-dried paper products, made from such an enhanced market pulp. By crosslinking a portion of the surface hydroxyl groups in the market pulp to form a 3-D matrix, a first drying step may be accomplished without loss of benefits afforded when the market pulp is later re-pulped to make a paper product.

Owner:UNIVERSITY OF MAINE

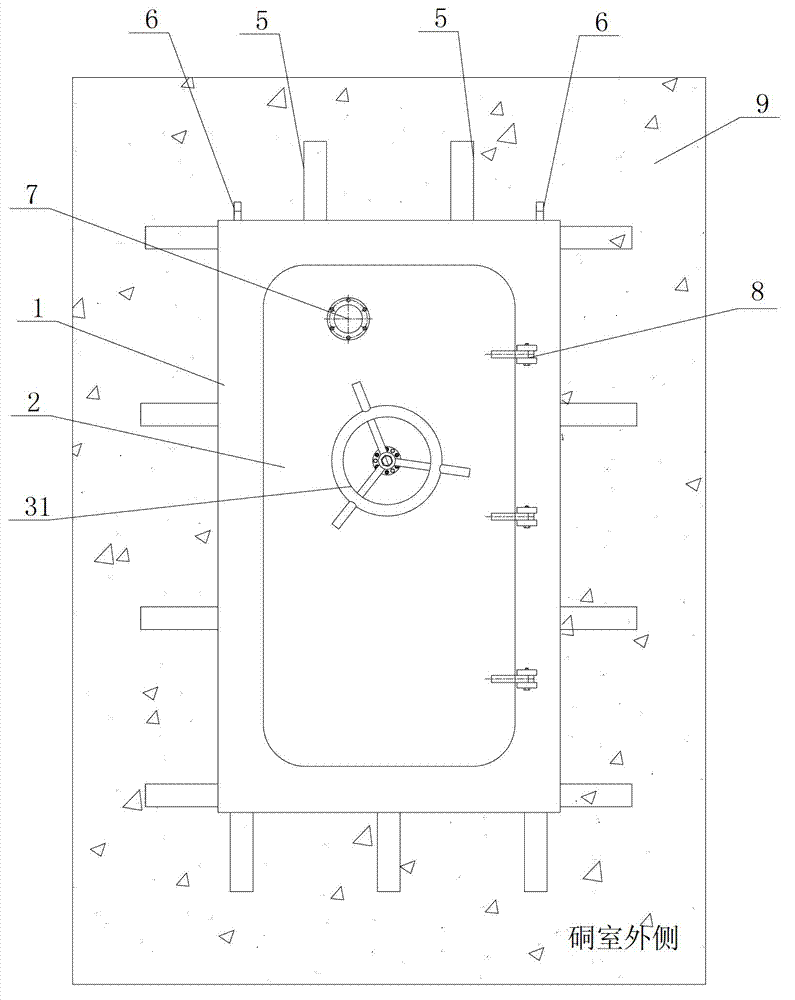

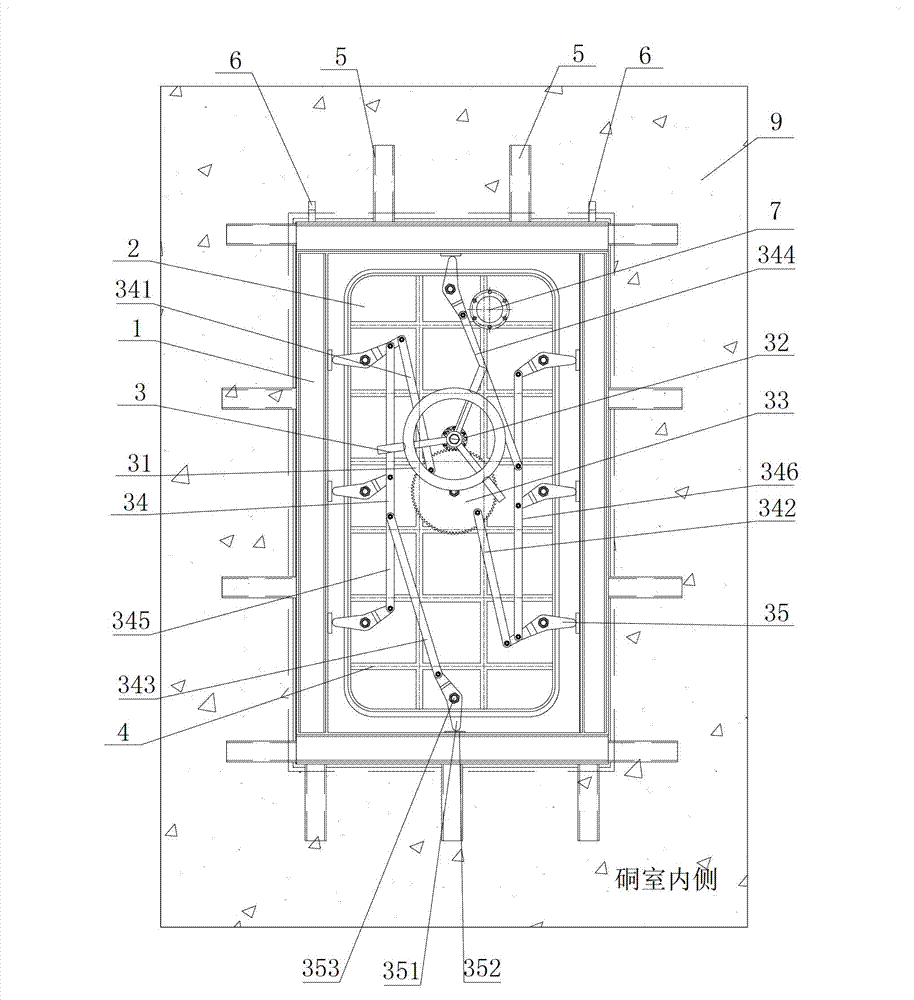

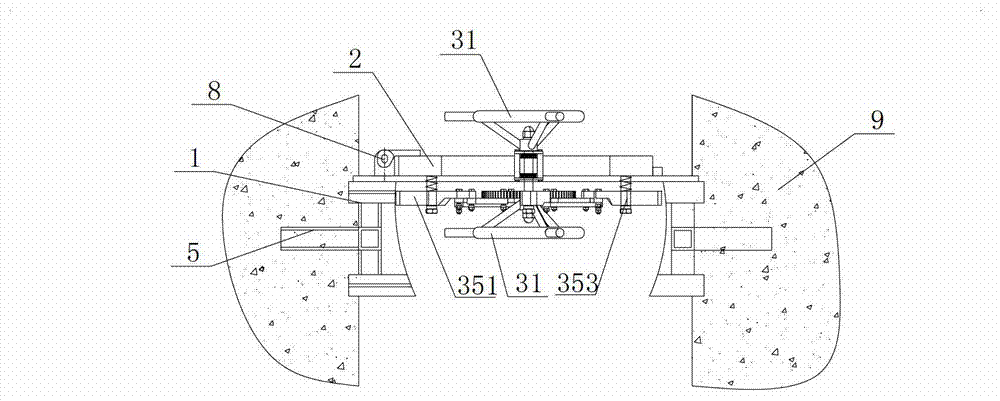

Protective sealing door for underground refuge chamber

ActiveCN102900335AImprove toughnessImprove bindingFireproof doorsConstruction fastening devicesLocking mechanismEngineering

The invention discloses a protective sealing door for an underground refuge chamber. The protective sealing door comprises a door frame and a door plate, wherein the door plate is arranged on the door frame through a rotation shaft; a locking mechanism for locking the door plate on the door frame is arranged on the door plate, a plurality of first reinforcing ribs for reinforcing the strength of the door plate are arranged in the door plate; heat-insulating materials, namely aerogel heat-insulating felts are filled among the reinforcing ribs; at least two annular sealing rings, namely flame-resisting sealing rings are arranged at the joint of the door plate and the door frame; and the periphery of the door plate is locked by the locking mechanism. According to the protective sealing door, the aerogel heat-insulating felts which can bear the temperature of 1,400 DEG C to the maximum are filled in the door plate, so that the door plate can resist high temperature generated during explosion, and the high temperature is insulated out of the refuge chamber; at least two sealing rings which are made of flame-resisting, anti-static, high temperature-resisting and oil-resisting materials are arranged on the contact surface of the door plate and the door frame, so that the protective sealing door has a good sealing effect.

Owner:CCTEG CHINA COAL RES INST

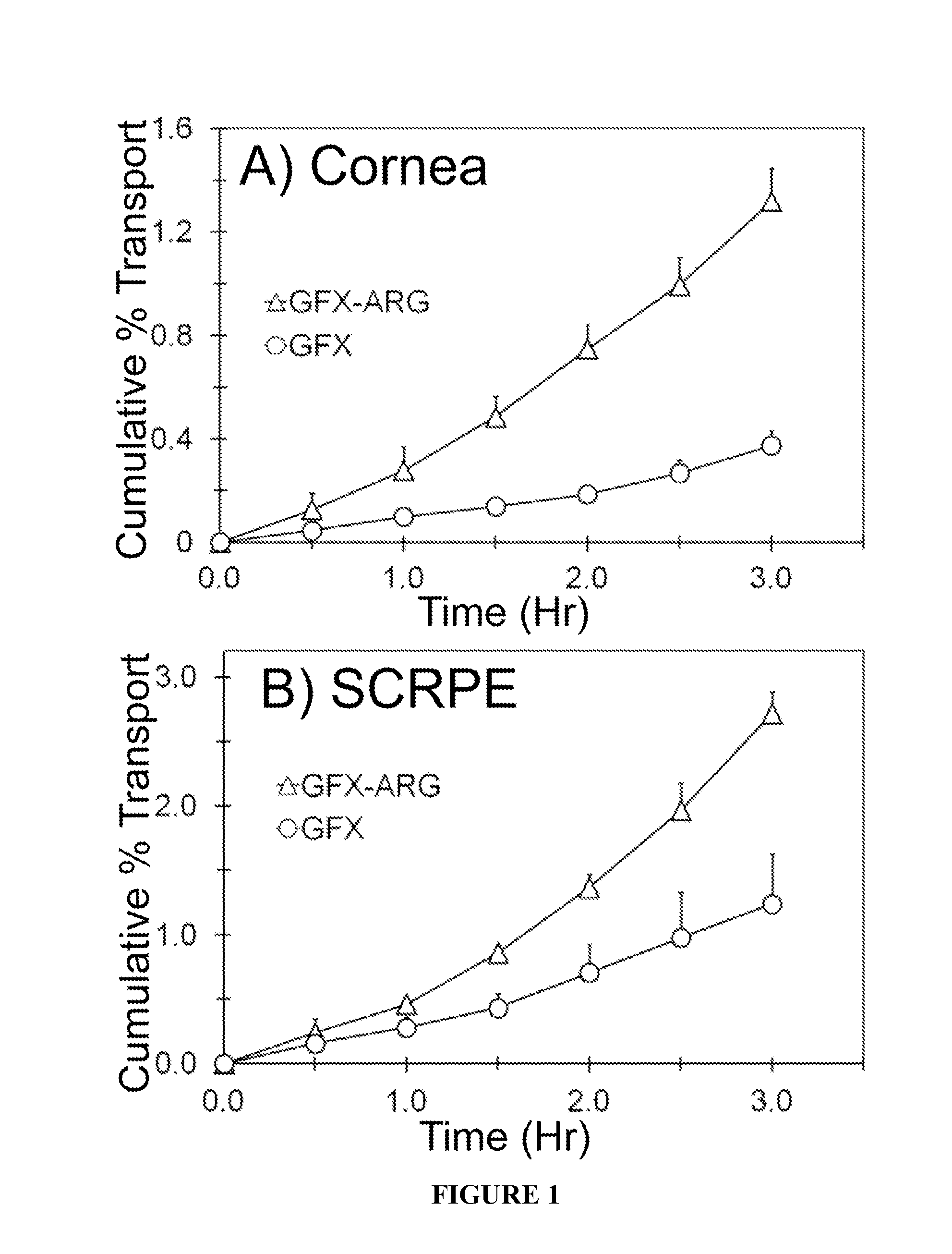

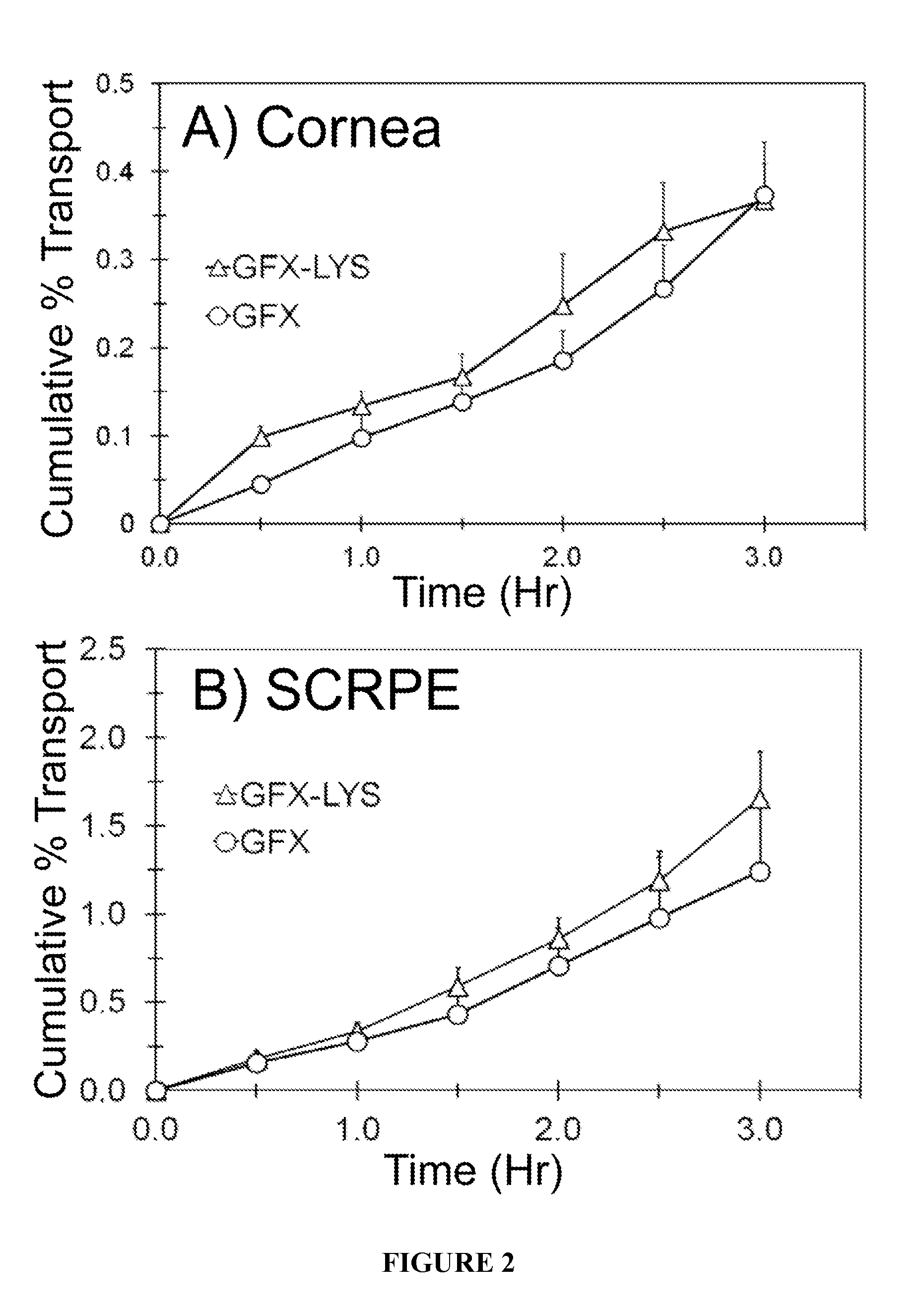

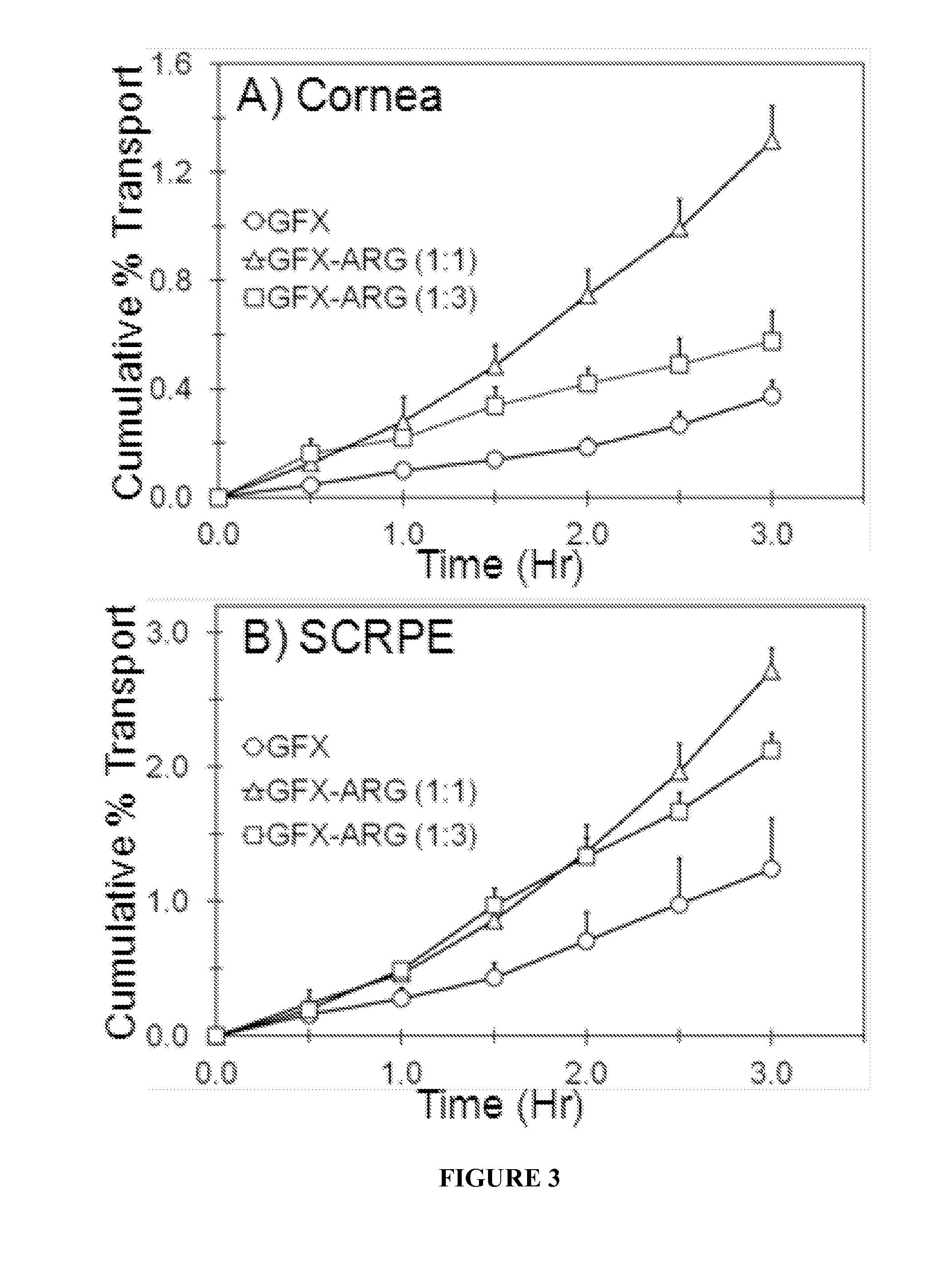

Topical ocular drug delivery

InactiveUS20130190324A1Increased transporter mediated delivery of drugReduce penetrationBiocideOrganic active ingredientsMembrane TransportersBioavailability

The present invention provides compositions and methods for increasing the delivery (i.e., bioavailability) of a compound to an ocular cell. Such compositions and methods can be used to treat an ocular clinical condition. Typically, increased bioavailability or delivery of the compound to ocular cells is achieved by utilizing a membrane transporter.

Owner:UNIV OF COLORADO THE REGENTS OF

Woven or Knitted Fabric and Clothes Containing Crimped Composite Filaments and Having an Air Permeability Which Increases When the Fabric is Wetted With Water

InactiveUS20080132133A1Improve breathabilityReduce air permeabilityGarment special featuresWeft knittingFiberPolyamide

A woven or knit fabric containing crimped composite fibers having its air permeability enhanced by water wetting and being useful in clothes such as outerwear, which woven or knit fabric contains 10 to 100 mass % of composite fibers of side-by-side type or eccentric core sheath type composed of polyester resin component and polyamide resin component whose thermal shrinkages are different from each other, the composite fibers having crimps developed by heat treatment. The composite fibers exhibit humid crimp factor HCF (%), as measured through a procedure comprising immersing the same in water of 30° C. for 2 hr, pulling them up, interposing them between a pair of filter papers at 30° C. in a humidity of 90% RH within 60 sec of the pulling up and applying a pressure of 0.69 mN / cm2 for 5 sec, of ≧10% lower than the dry crimp factor DCF (%) after dying by allowing them to stand still at 20° C. in a humidity of 65% RH for 24 hr, so that the woven or knit fabric exerts of the effect of air permeability enhancement by water wetting.

Owner:TEIJIN FRONTIER CO LTD

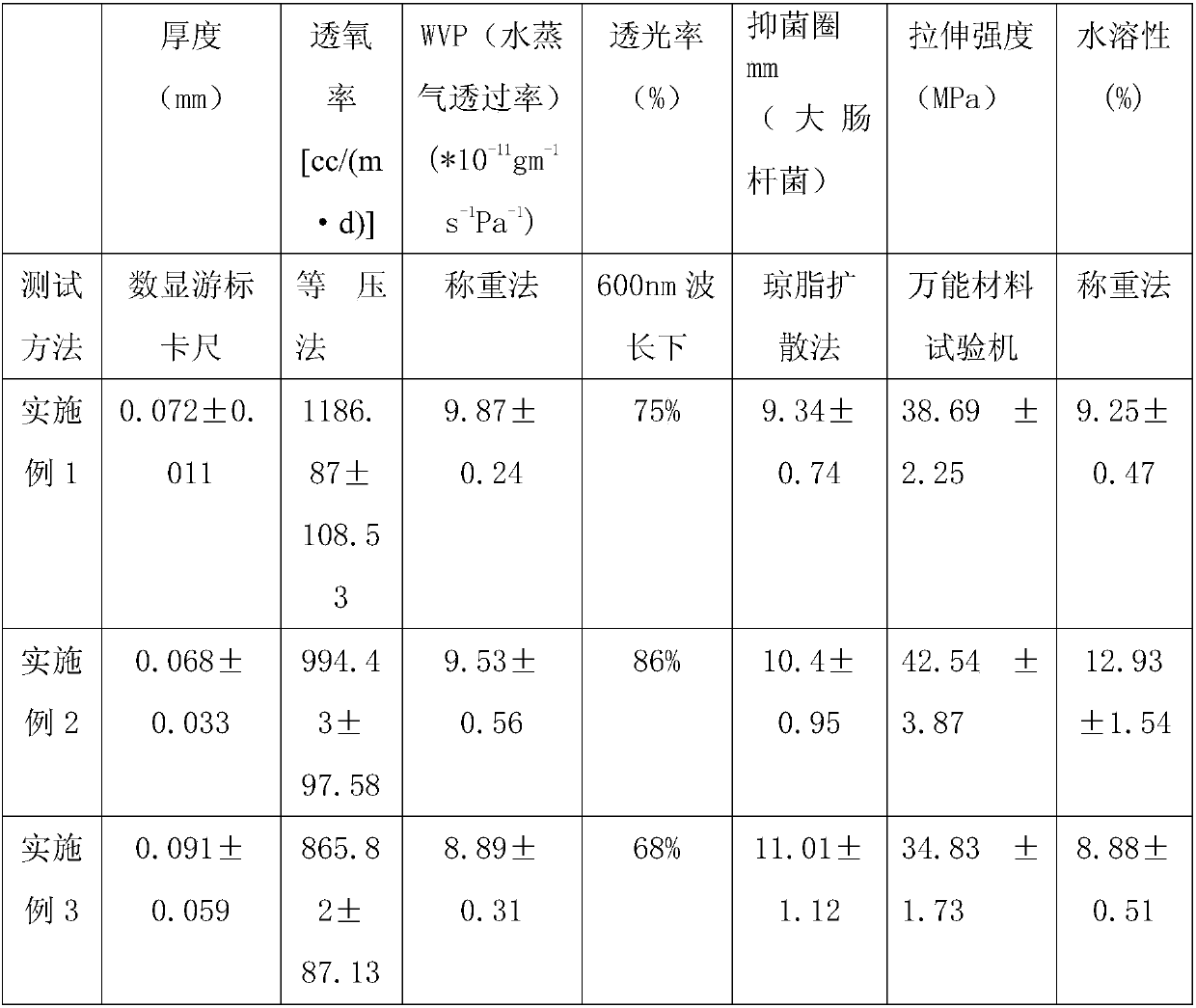

Sodium alginate-chitosan double-layer edible membrane as well as preparation method and application thereof

InactiveCN107840981AImprove food safetyExtensive sources of raw materialsFlexible coversWrappersChemistryFruits and vegetables

The invention discloses a sodium alginate-chitosan double-layer edible membrane as well as a preparation method and an application thereof. The sodium alginate-chitosan double-layer edible membrane isprepared from a sodium alginate membrane and a chitosan membrane through cross-linking compounding. The sodium alginate-chitosan double-layer edible membrane is prepared from a safe and non-toxic material, wide in raw material source, low in production cost and good in membrane forming property, the eating security of an edible inner packaging membrane is improved, through synergetic promotion ofthe components, the air permeability of the membrane is remarkably degraded, the oxygen permeation rate of the membrane is remarkably reduced, the tension property and the transparency of the membrane are remarkably improved, and the membrane is easy to degrade; due to addition of a natural antibacterial agent, microorganism pollution can be very well prevented; the thickness of the membrane canbe controlled by changing the proportioning of the sodium alginate to the chitosan, and then the mechanical properties, the dissolution degree and the antibacterial agent release speed of the membraneare controlled; and the membrane is simple in preparation step, and by adopting the preservative membrane made from the membrane disclosed by the invention, moisture loss and microorganism pollutionin the transportation, storage and processing process of fruits and vegetables can be reduced.

Owner:HAINAN NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com