One well three-purpose mash gas harnessing method for ground well drilling and ground well drilling

A surface drilling and gas technology, applied in coal mine gas control methods and drilling fields, can solve the problems that are not enough to ensure safe production in deep coal seams, can not completely avoid blowhole phenomenon, and imperfect anti-drilling blowhole measures, etc., to achieve improvement Mine economic benefits, saving treatment costs, and reducing the effect of gas drainage roadways

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

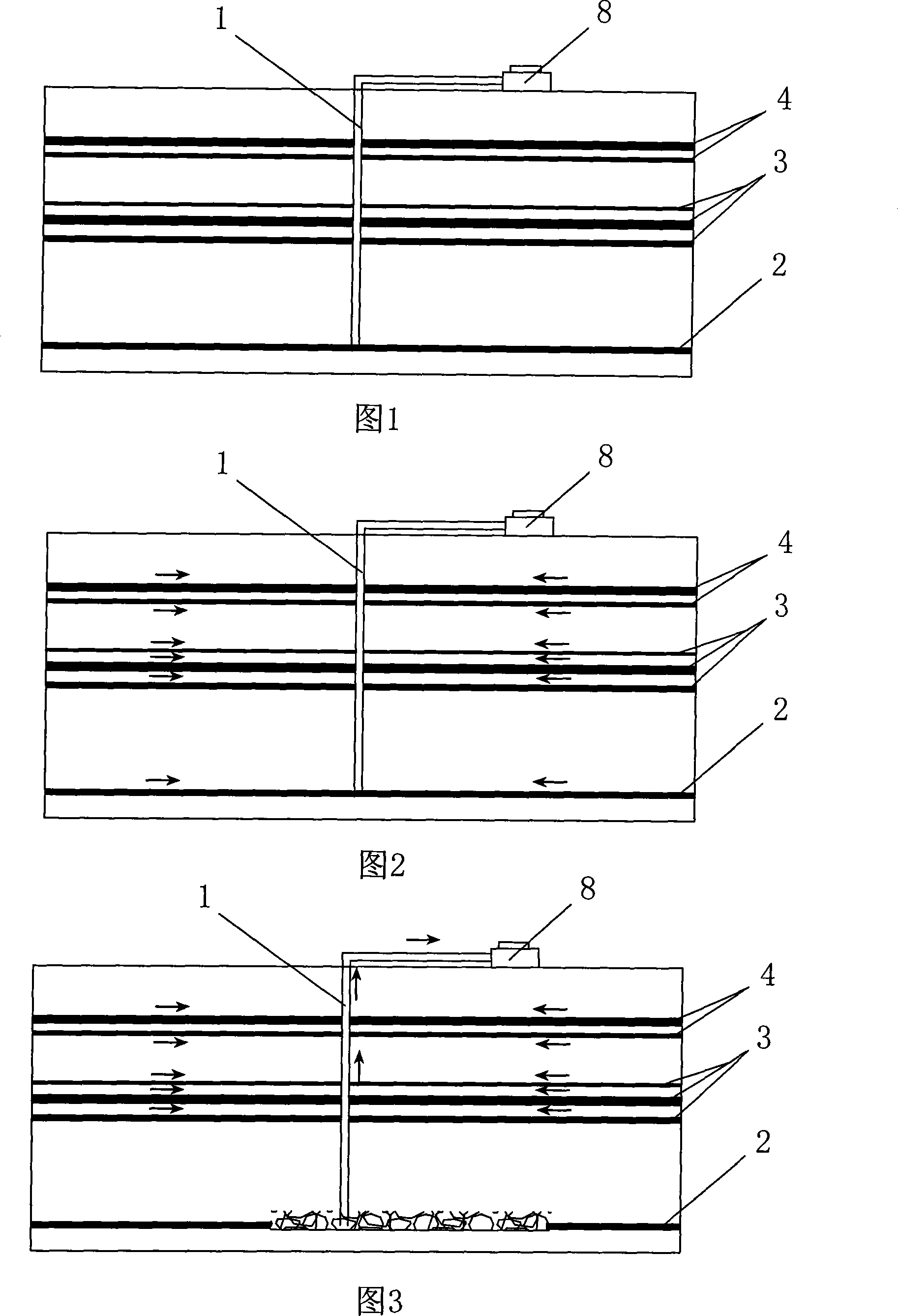

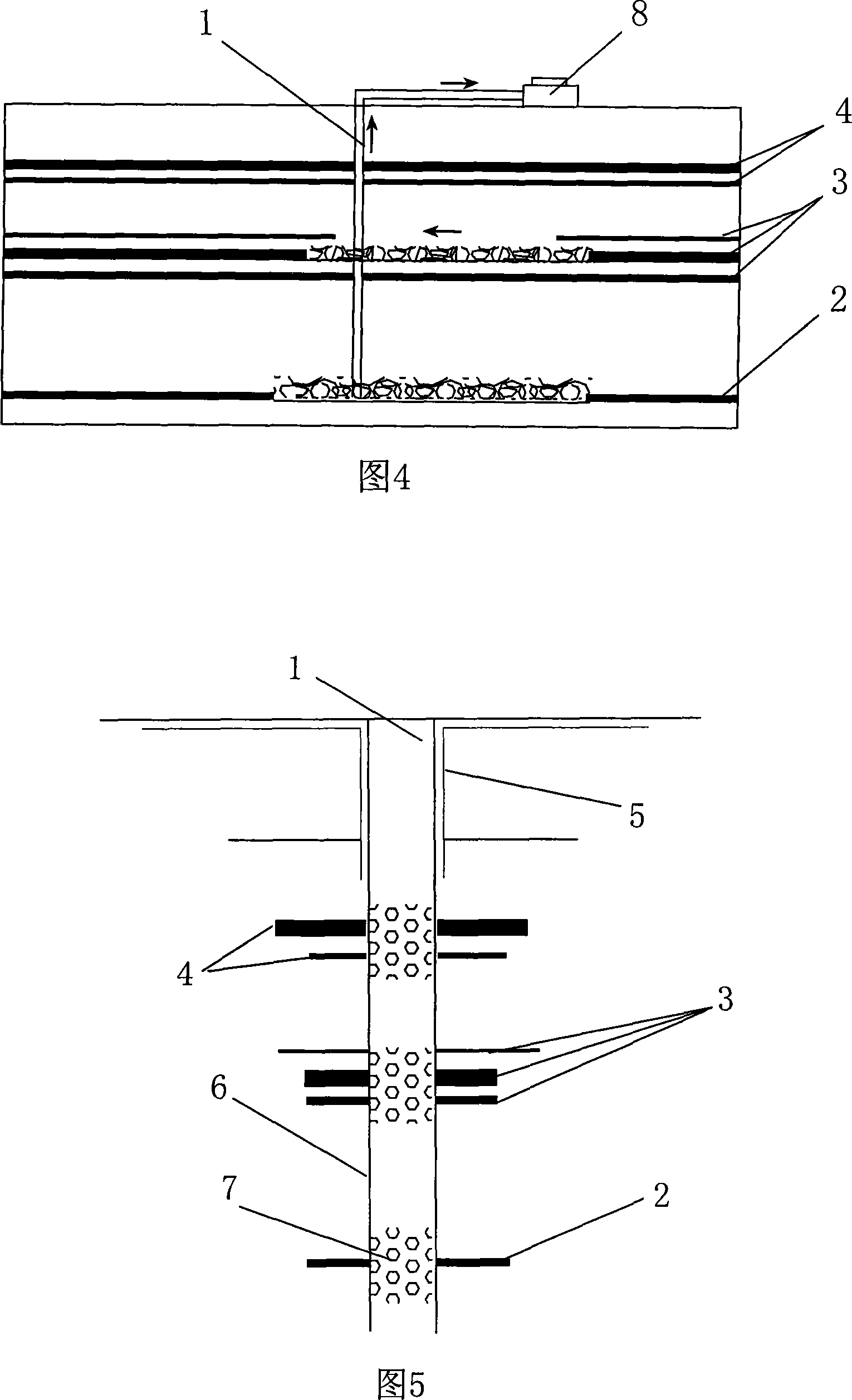

[0031] Refer to Figure 1. Multiple surface drilling wells 1 are arranged on the ground to form a well network. Through fracturing and drainage, the water level will be lowered in a large area, forming coal seam pressure relief, and releasing gas. It can reach 40%, basically realize outburst elimination; then when mining in the 10th coal seam working face, the overlying 7, 8, 9 coal seams, that is, the middle coal formation 3 and the rock formation, cause pressure relief and expansion, greatly improve the air permeability of the coal seam, and use ground drilling 1 negative pressure Drain pressure relief gas; when mining at the 3rd working face of the middle coal group, the ground drilling 1 is used again to drain the gas in the gob area of the working face, and finally realize the "one well with three purposes" repeated drainage of coal seam gas to achieve the goal of eradicating gas , the extracted gas can be directly sent to the gas utilization equipment 8 to enter the gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com