Patents

Literature

2056results about How to "Ensure safe production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

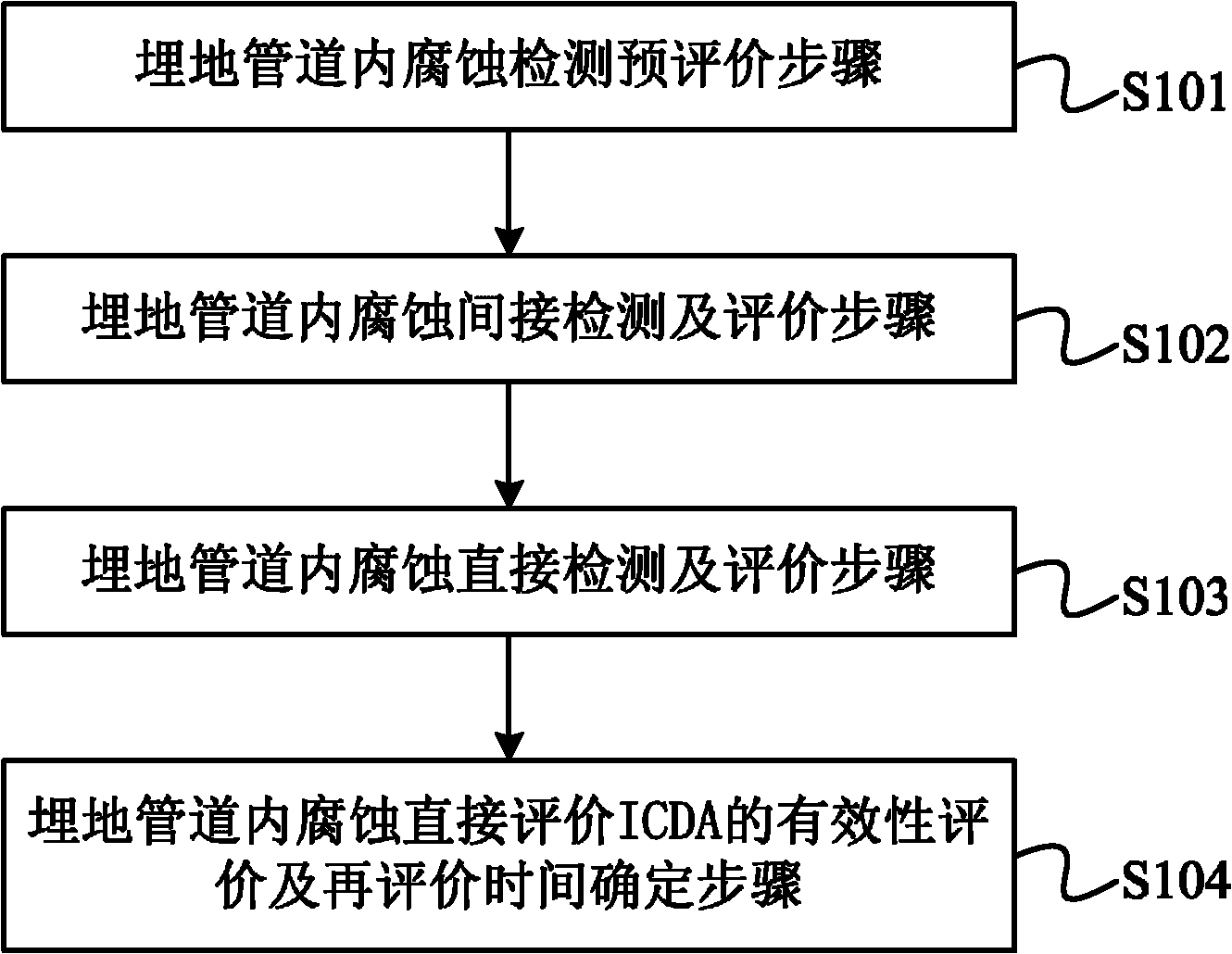

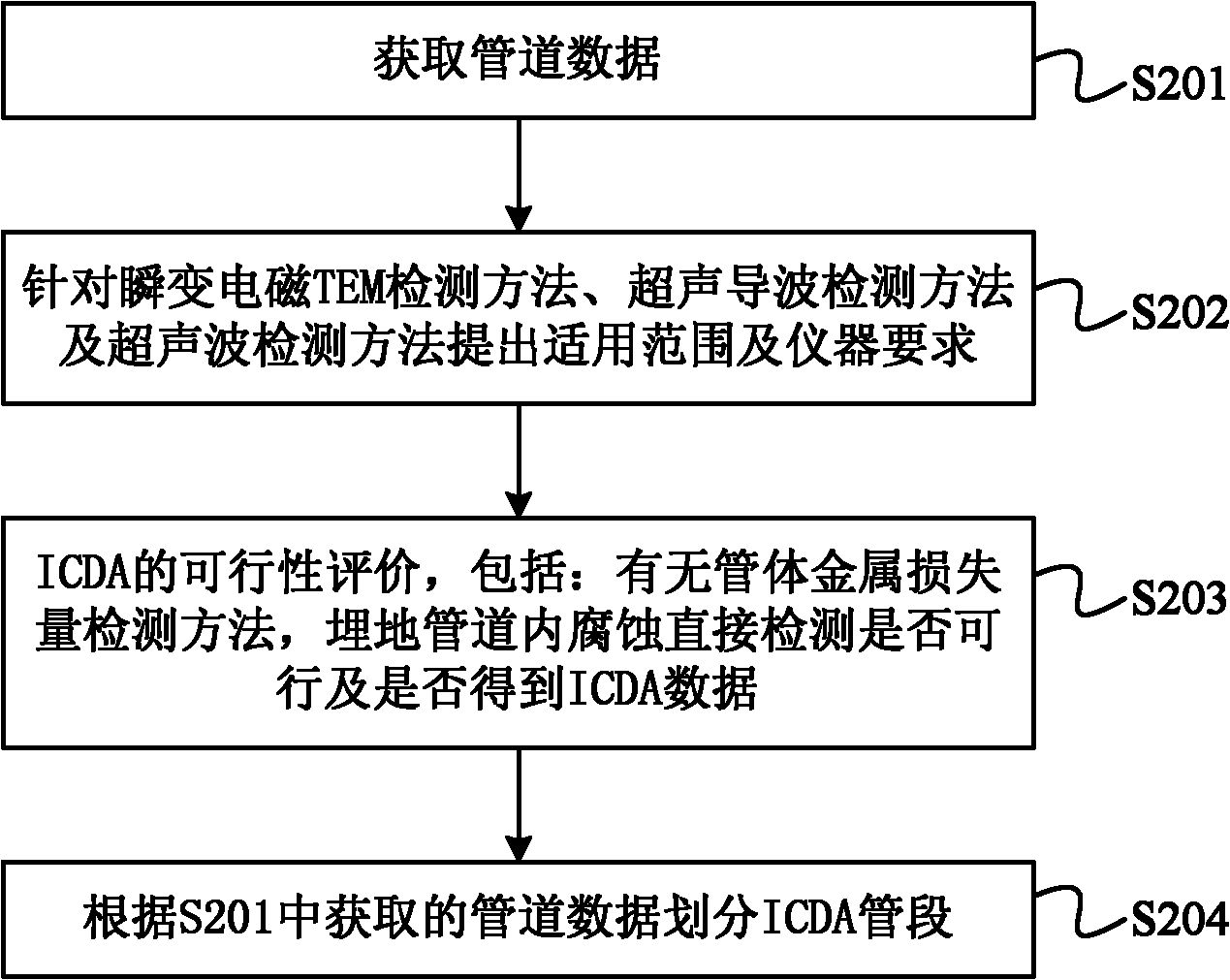

Method for evaluating corrosion in buried pipeline

ActiveCN102156089AReduce economic lossUnleash the full potential of your applicationWeather/light/corrosion resistanceDirect evaluationSafe operation

The invention provides a method for evaluating corrosion in a buried pipeline. The method for evaluating the corrosion in the buried pipeline comprises the following steps of: preliminary evaluation of corrosion detection in the buried pipeline, indirect detection and evaluation of the corrosion in the buried pipeline, direct detection and evaluation of the corrosion in the buried pipeline, and validity evaluation of direct evaluation ICDA of the corrosion in the buried pipeline and reevaluation time determination. At present, many in-service pipelines of petroleum enterprises sequentially enter a frequent accident period and an important stage of maintenance and update. By the method for evaluating the corrosion in the buried pipeline, levels of safe operation management and technology of the buried pipeline are improved, economic loss of personnel and facilities due to sudden accidents can be reduced, and safe production is ensured; the application potential of the in-service old pipelines is fully exerted, and the service life of the pipelines is prolonged; reliability and economical efficiency of pipeline engineering construction and operation are improved, and petroleum production and engineering costs are reduced; and environmental destruction caused by the sudden accidents is slowed down.

Owner:PETROCHINA CO LTD +1

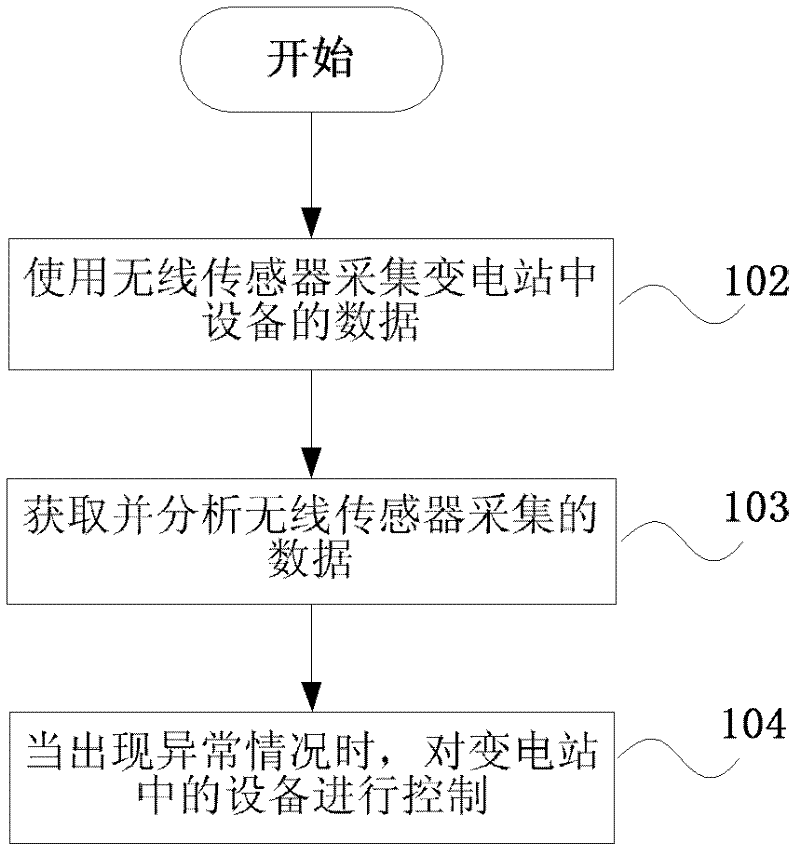

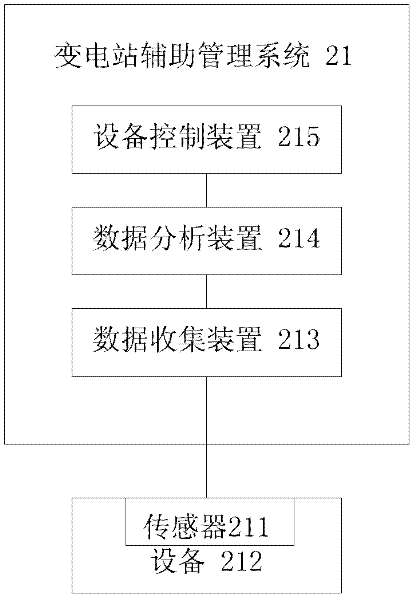

Transformer substation assisting management system and method

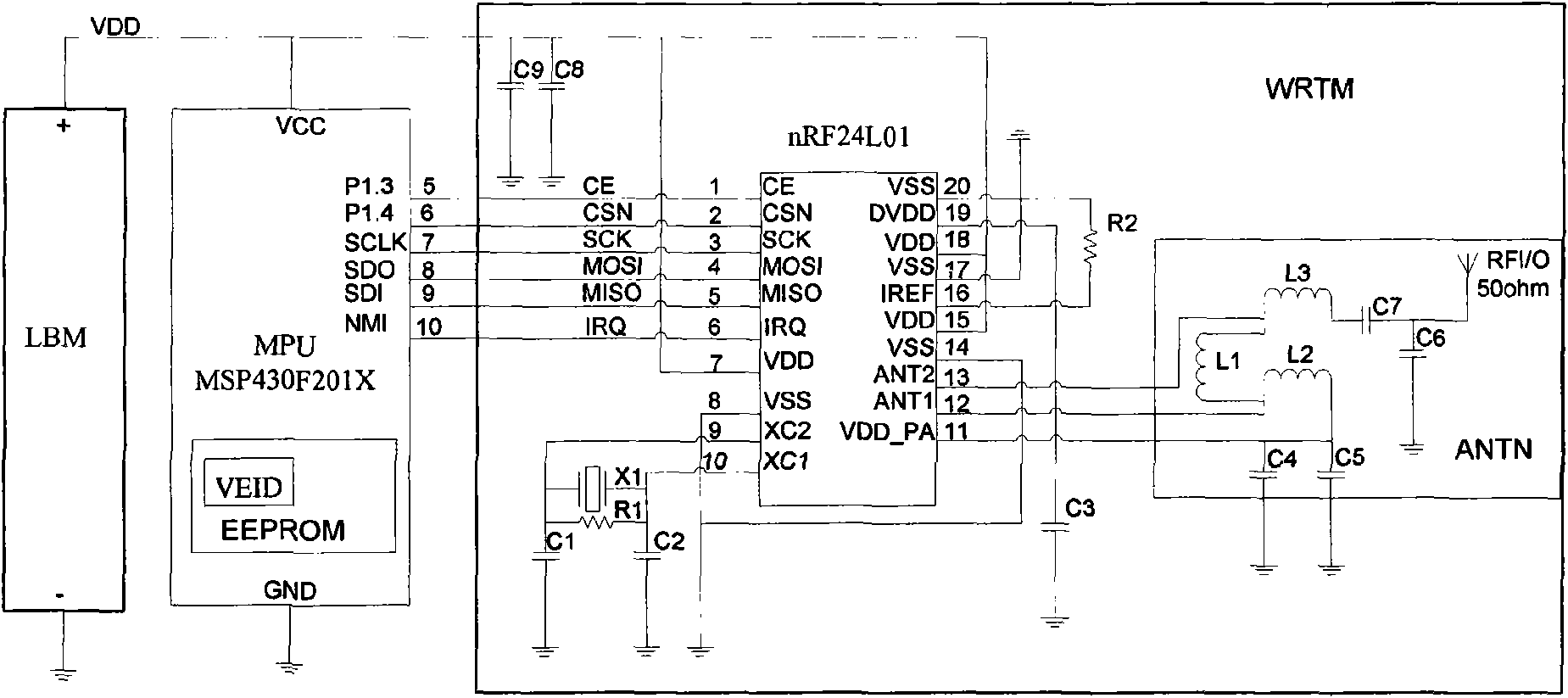

ActiveCN102591275AAutomate managementComprehensive Condition MonitoringCircuit arrangementsTotal factory controlWireless dataCondition monitoring

The invention discloses a transformer substation assisting management system and method, relating to the field of automatic management. Data in equipment of the transformer substation is collected by a wireless sensor and the data collected by the wireless data is obtained and analyzed. When an abnormal condition happens, the equipment of the transformer substation is controlled. The method and the system, disclosed by the invention, realize the automatic management to the transformer substation and can carry out all-around stat monitoring and property and personnel management, so as to provide guarantees to safety production.

Owner:STATE GRID CORP OF CHINA +2

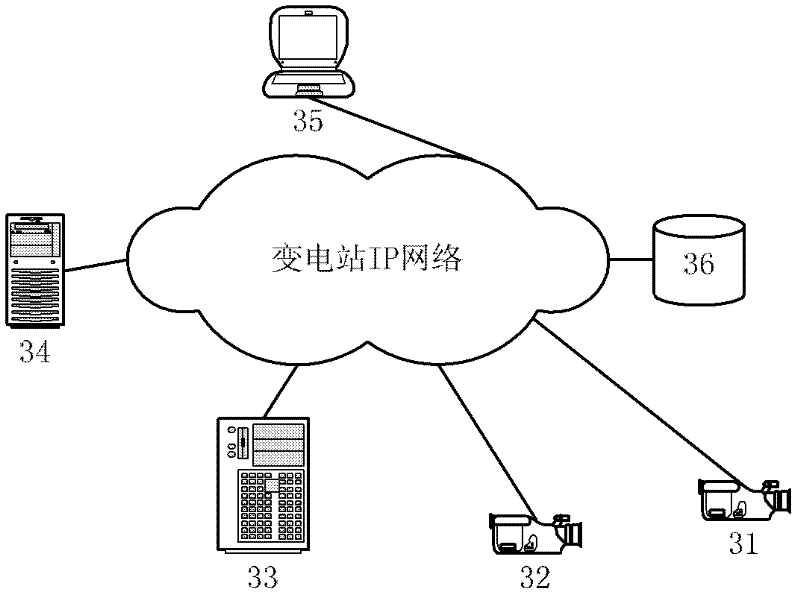

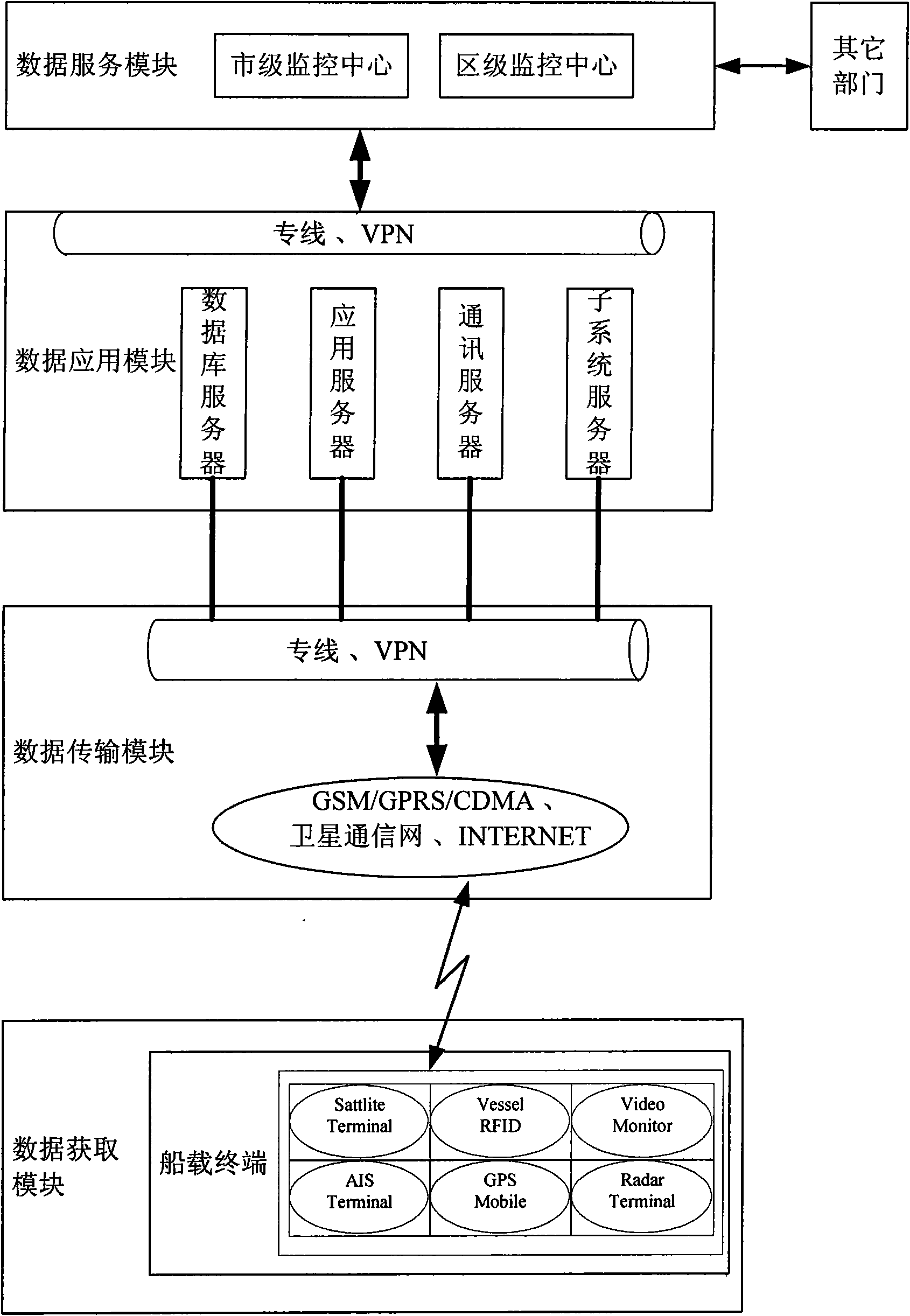

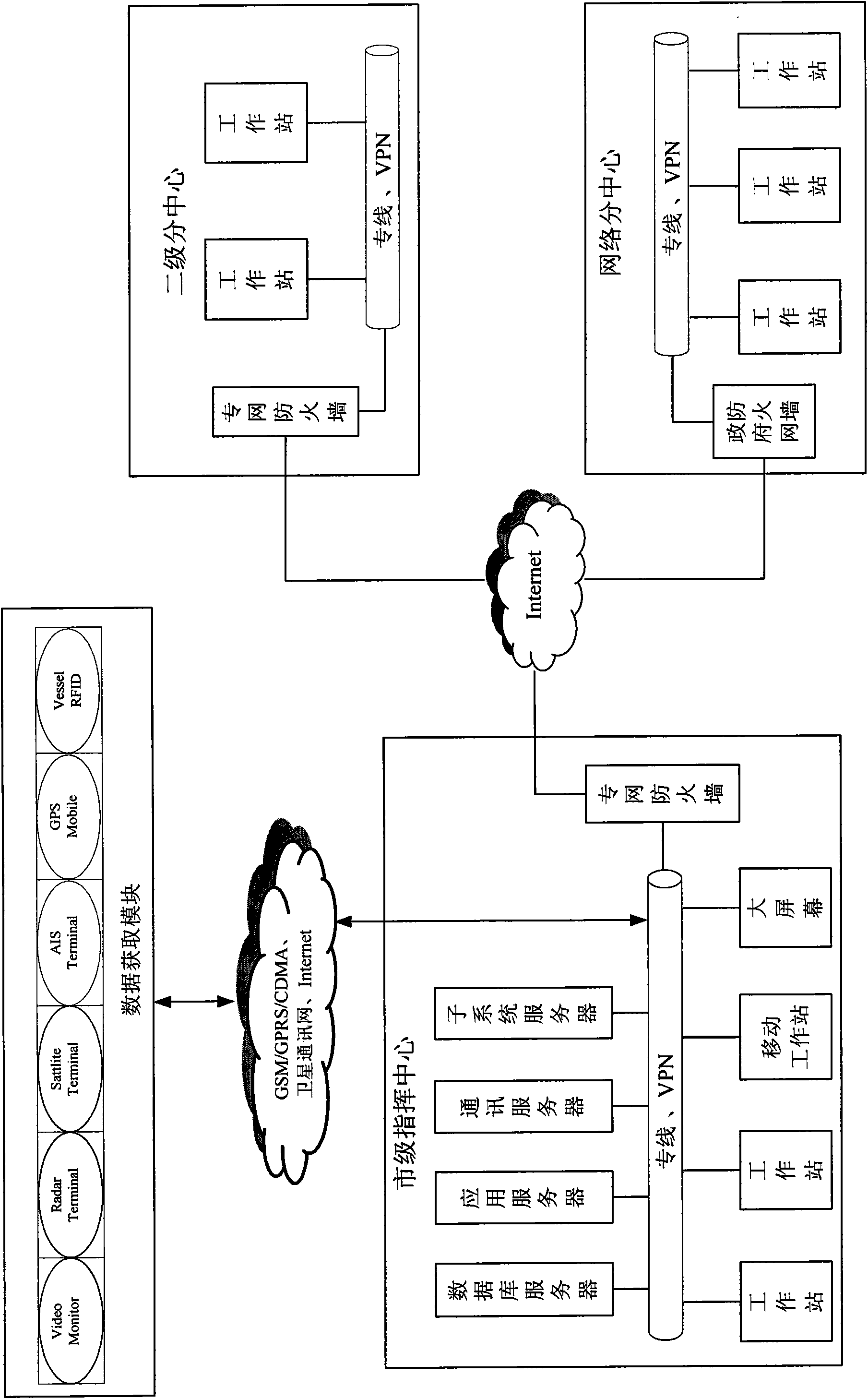

Ship rescue information system and realization method thereof

InactiveCN101551946AImprove regulatory capacityReal-time positioningData switching by path configurationMarine craft traffic controlWirelessAlarm message

The invention relates to a ship rescue information system and realization method thereof. In the system, ship related information is obtained by each subsystem of a data obtaining module, and the information is transmitted to a data application module through wireless or network transmission by a data transmission module, the data application module checks, analyzes and stores data, the ship related information is obtained and operation recording or warning information is formed, the information is transmitted to a data service module as real-time displaying or warning processing, and simultaneously the data service module also can response the command issued by monitor staff for the system, thereby realizing related management operation. The invention has the following beneficial effect: real-time, efficient and accurate ship positioning and tracking position information, operation state and work condition are provided for ship management department and user, thereby improving ship supervision ability, further analyzing obtained ship information, realizing statistical analysis, early warning and warning functions of ship information, and further perfecting ship safety rescue system.

Owner:上海普适导航科技股份有限公司

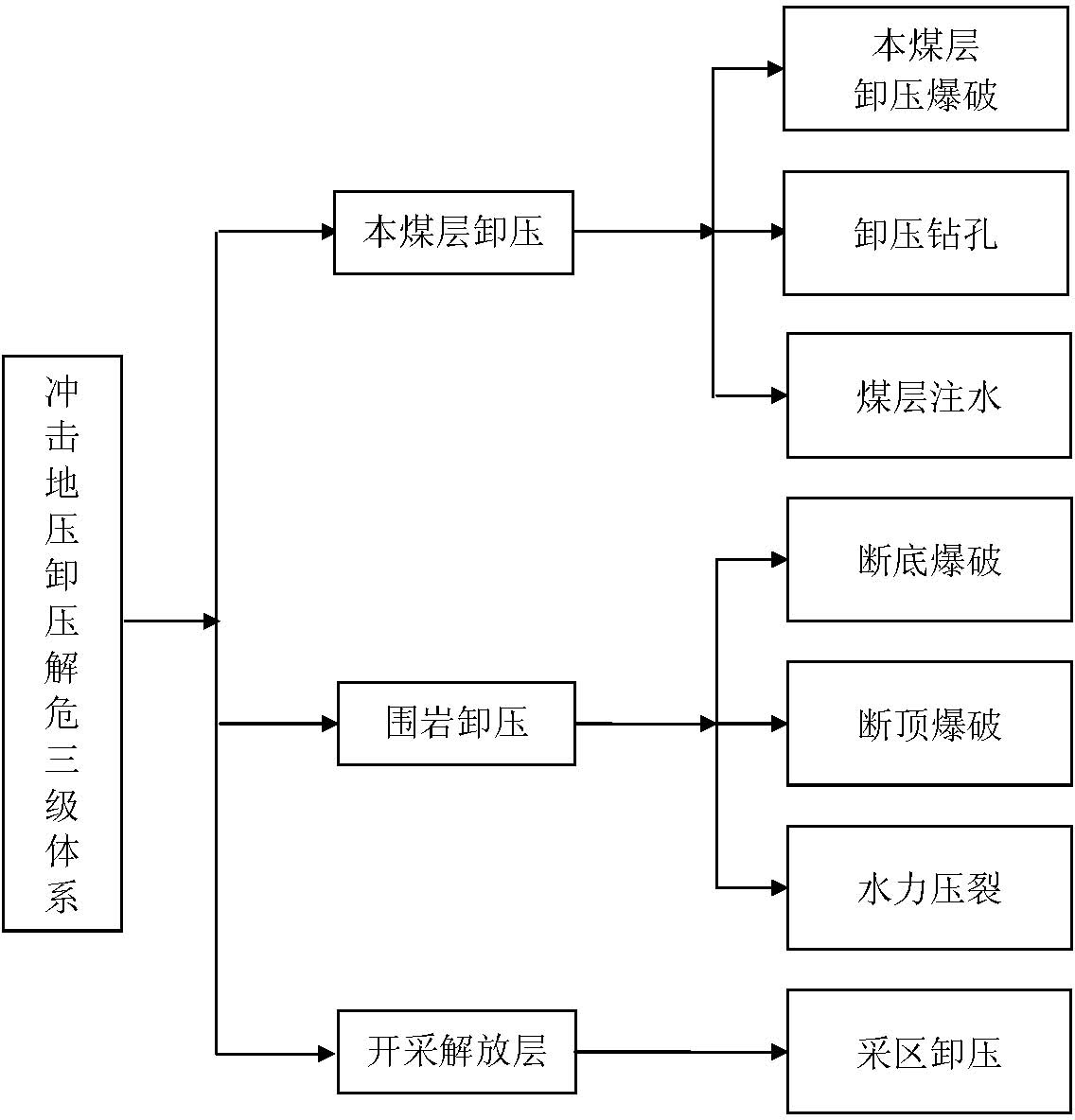

Method for releasing pressure and removing danger of rock burst

InactiveCN102678120AGood effectEnsure safe productionUnderground miningSurface miningWater contentCoal

The invention relates to a method for releasing pressure and removing danger of rock burst. The effects of releasing pressure and removing danger of rock burst and ensuring the safety of a coal mine can be effectively realized. The method comprises the following steps of: releasing pressure and bursting a coal bed; because of higher inner stress in the coal bed, drilling a roadway wall to form a free space, so that the stress is re-distributed; drilling to enable pressure and water solution to enter a coal body and increase water content; bursting a top plate of the coal bed; bursting a bottom plate of the coal bed; through high pressure, filling fracturing fluid into cracks and slots which are formed in the coal body before fracturing and after fracturing; expanding, extending and dredging the cracks; increasing the slots of the coal bed; changing the magnitude and the direction of the stress on the coal body; transmitting the stress to the deep part of a coal-rock mass; and selecting the safe coal bed or coal body to exploit, wherein after a goaf area and a natural caving arch are formed, an unloading effect is achieved, the rock burst and roof collapse are prevented or relieved. The method is stable and reliable, good in pressure-releasing and danger-removing effects, and high in economic and social benefits, prevention and control on the rock burst are realized, and the safe production of the coal mine is effectively protected.

Owner:HENAN DAYOU ENERGY

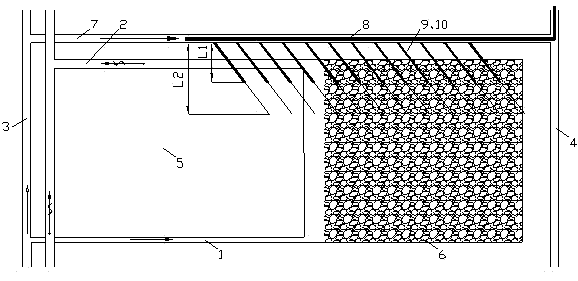

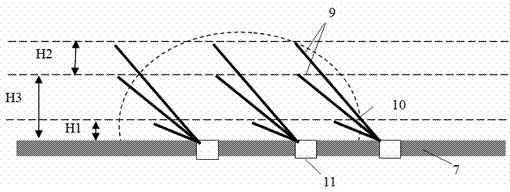

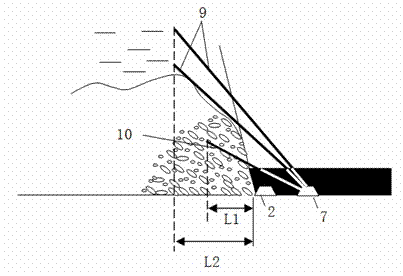

Gas extraction method of cross hole drilling area of gas discharge laneway

ActiveCN102226413AEffective interceptionEffective gush controlDirectional drillingGas removalDrill siteOblique angle

The invention discloses a gas extraction method of a cross hole drilling area of a gas discharge laneway, comprising the following steps: tunnelling an mining area return airway parallel to a mining area track roadway at the tail part of the gas discharge laneway; arranging drill sites on the gas discharge laneway along the roof of a coal seam at intervals; respectively constructing multiple high-level drilling holes with different oblique angles and different lengths and a low-level hole in a worked out area direction in the middle and upper part of each drill site; arranging an extraction pipe after hole drilling construction in each drill site is finished; sealing the holes; and connecting the drilling holes in each drill site into the extraction pipe of the gas discharge laneway through an upper confluence pipe and a lower confluence pipe for extraction, thus realizing the safe production of a gas coal seam group. The method is safe and reliable, can effectively intercept pressure relief gas at an upper neighbor layer, effectively controls the gas from flowing out from a stope face, lowers the gas concentration of an upper corner, and ensures the safe production of the stope face.

Owner:CHINA UNIV OF MINING & TECH

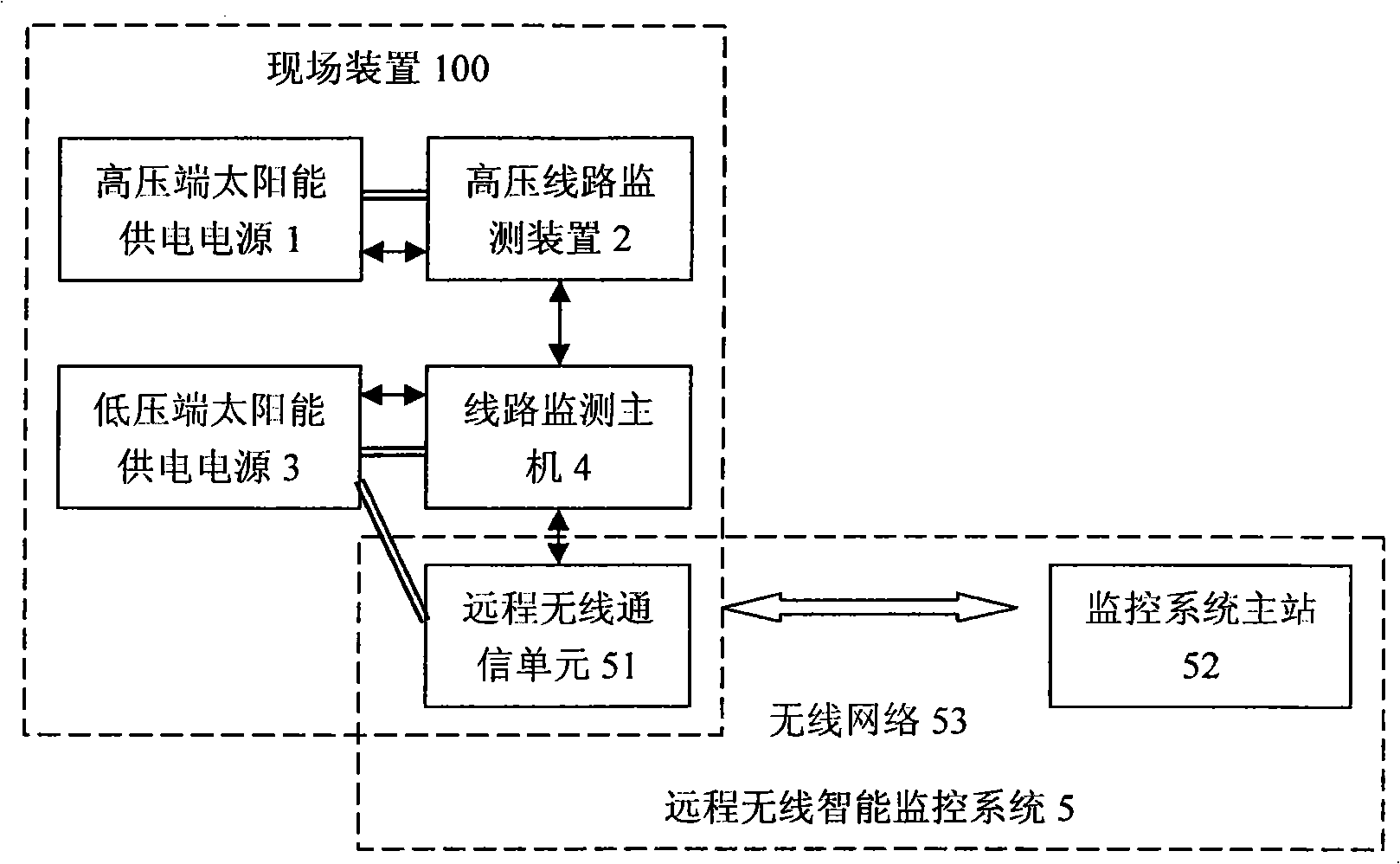

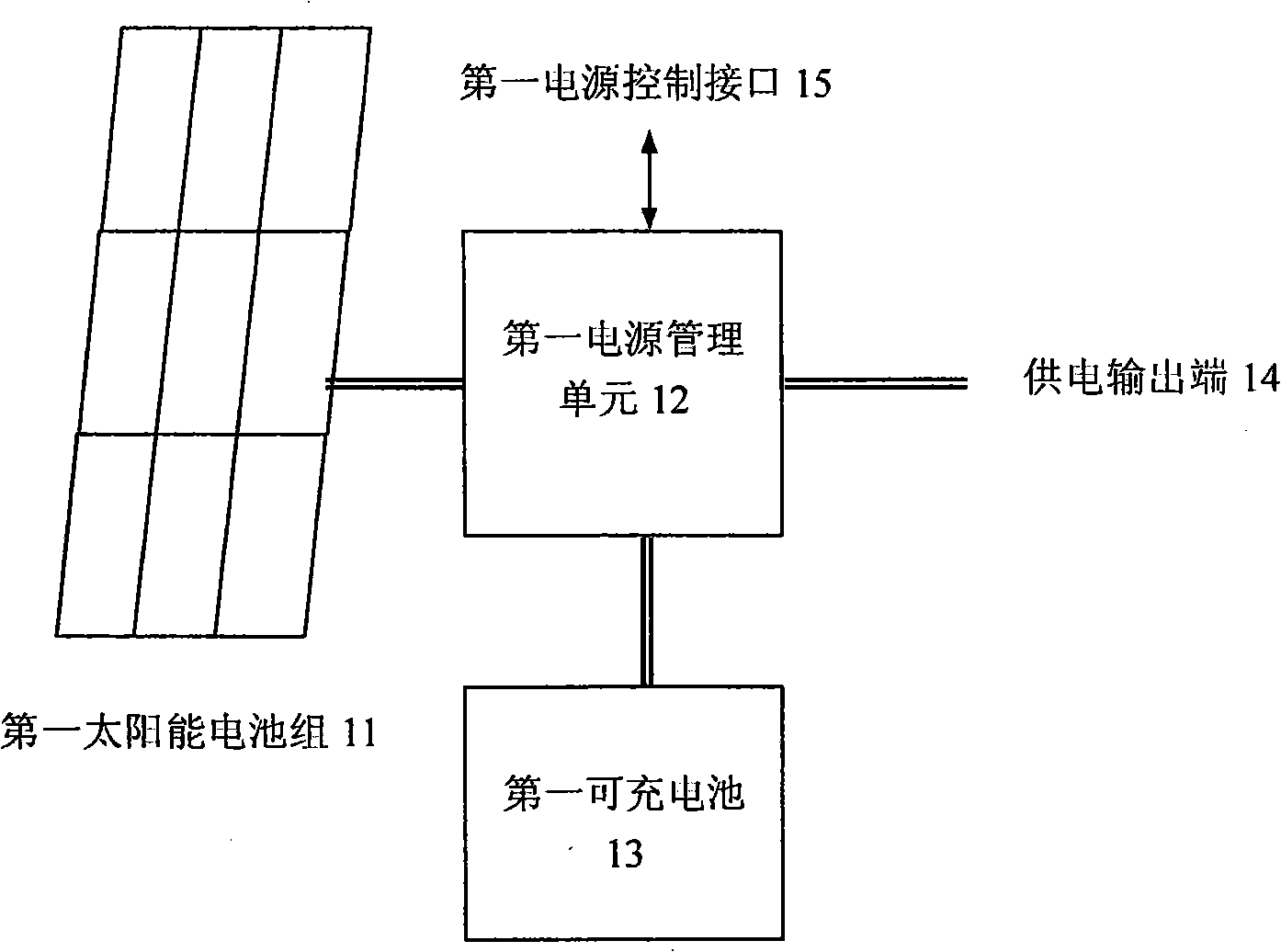

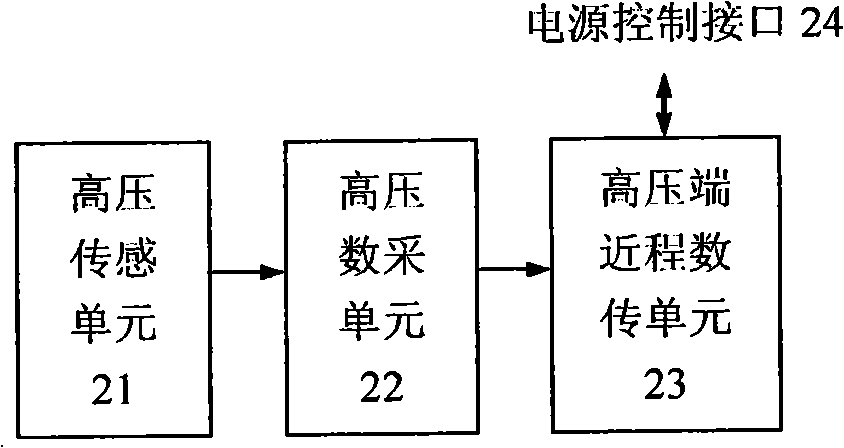

Ultra-high pressure circuit monitoring system for solar power generation

InactiveCN101359022ARealize long-term online operationSolve power problemsData switching by path configurationFault locationTime informationUltra high pressure

The invention relates to a solar-powered ultra-high voltage line monitoring system, comprising a high-voltage side solar power supply, a high voltage line monitoring device, a low-voltage side solar power supply, a line monitoring host computer and a remote wireless intelligent monitoring system. The high-voltage side solar power supply and the low-voltage side solar power supply comprise solar batteries, rechargeable batteries and power management units; the high voltage line monitoring device and the line monitoring host computer comprise sensing units as well as data acquisition and recording units for detecting and processing field parameters of various lines; and the remote wireless intelligent monitoring system comprises a wireless communication unit and a monitoring system master station. The high-voltage side solar power supply, the high voltage line monitoring device, the low-voltage side solar power supply, the line monitoring host computer and the remote wireless intelligent monitoring system compose a field device which collects and records the running status and fault information of high-voltage lines through solar power and transmits the running status and fault information to the monitoring system master station through the remote wireless communication unit so as to provide real-time information for power line monitoring.

Owner:SOUTHEAST UNIV +2

Carbon-based fertilizer potentiating agent and application thereof

InactiveCN102675001ASimple production processRaw materials are easy to getClimate change adaptationFertilising methodsNitrification inhibitorsPollution

Owner:SHENYANG AGRI UNIV

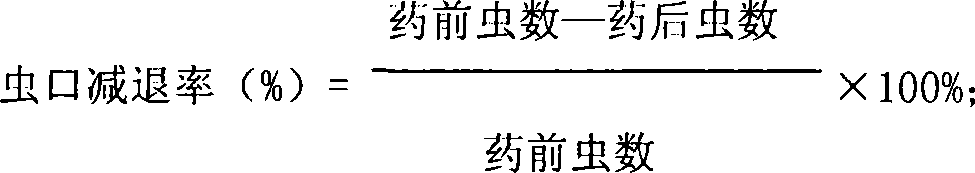

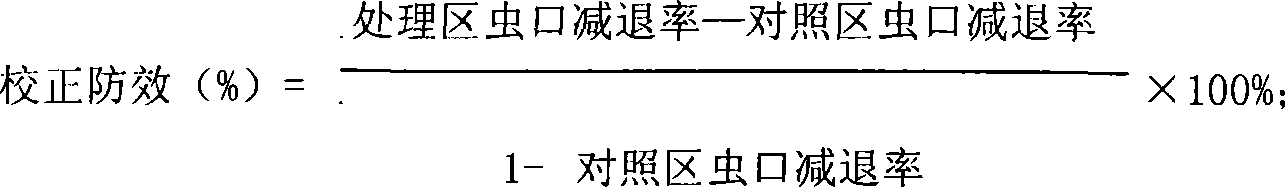

Insecticidal composition containing indoxacarb

InactiveCN101243798AEnsure safe productionReduce the frequency of sprayingBiocideAnimal repellantsChlorpyrifosPhoxim

The invention relates to a pesticide composition containing indoxacarb, mainly used in crops disinfestation, which comprises emulsifiable concentrate, wettable powder and suspension agent. The active ingredients of the pesticide composition are indoxacarb and active ingredient B which is any one or composition of more than one with any proportion of Methylamino abamectin benzoate, hexaflumuron, nitenpyram, avermectin, fipronil, chlorfenapyr, acetamiprid, profenofos, phoxim, high-efficiency cypermethrin, cyhalothrin, triazophos and chlorpyrifos. The pesticide composition has the advantages of enlarging the application range, having strong contact toxicity and stomach poisoning action, having low mammalian toxicity and better compatibility of environment, being effective to the pest of every growth period, increasing the effect of every component of the composition significantly, reducing the production cost and agricultural cost of the pesticide, having wide insecticidal spectrum and high efficiency, delaying the occurrence of the drug resistance of the pests, prolonging the service life of the pesticide agent, enabling the high yield and high quality of the crops, having strong activity, long persistent period and stable drug efficacy to the pests.

Owner:湖南万家丰科技有限公司

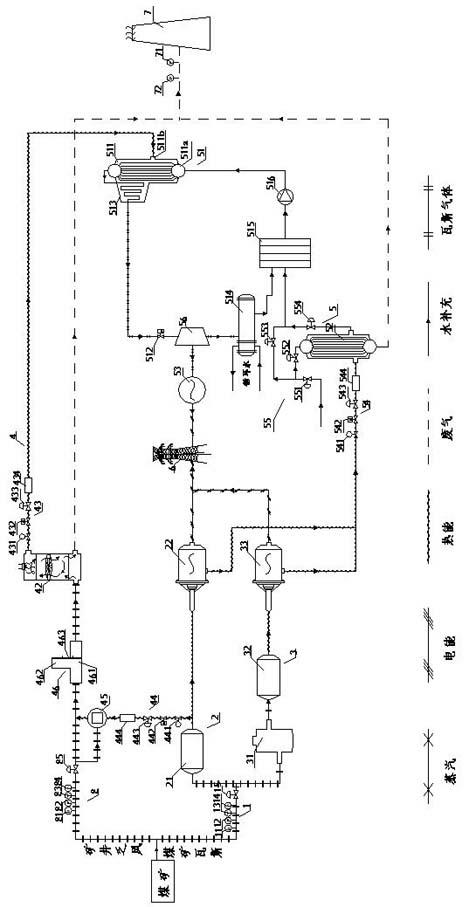

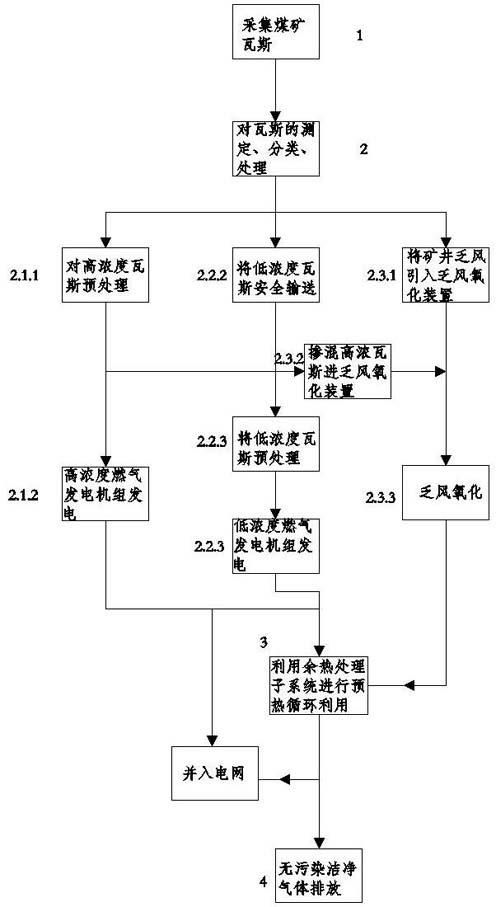

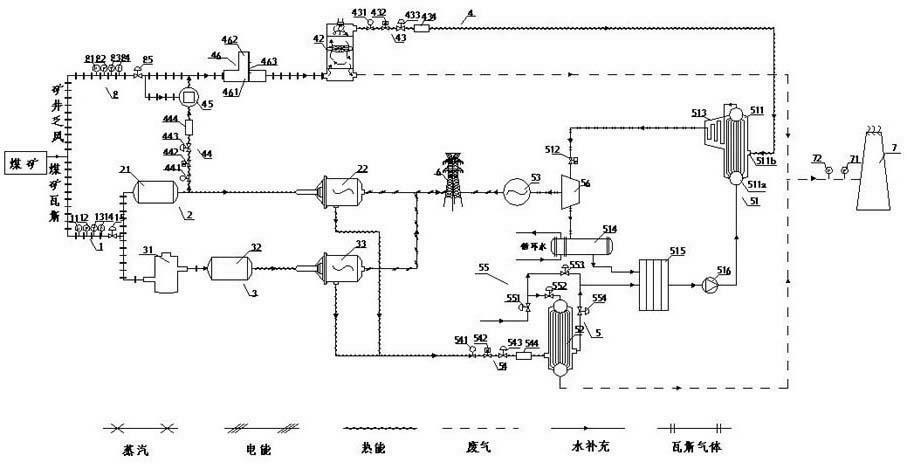

Coal mine gas comprehensive application system and application method thereof

ActiveCN102562131AHigh extraction rateEnsure safe productionMining devicesInternal combustion piston enginesHigh concentrationEngineering

The invention discloses a coal mine gas comprehensive application system and an application method thereof. The system comprises a coal mine ventilation air measuring component, a coal mine gas measuring component, a high-concentration gas treatment subsystem, a low-concentration gas treatment subsystem, a coal mine ventilation air treatment subsystem and an afterheat treatment subsystem, wherein a high-concentration gas pre-treatment device and a high-concentration gas generator set are connected via a pipeline to form the high-concentration gas treatment subsystem, a safe conveying device, a low-concentration gas pre-treatment device and a low-concentration gas generator set are connected via pipelines to form the low-concentration gas treatment subsystem, the high-concentration gas generator set and the low-concentration gas generator set are respectively connected with a power grid via cables, a ventilation air delivering connecting device, a mixing device and a ventilation air oxidization device are connected via pipelines to form the coal mine ventilation air treatment subsystem, and the afterheat treatment subsystem is respectively connected with the high-concentration gas treatment subsystem, the low-concentration gas treatment subsystem and the coal mine ventilation air treatment subsystem. The coal mine gas comprehensive application system and the application method can be used for comprehensively applying gas with different concentrations, utilization rate of the gas is the highest, emission of greenhouse gas is reduced, and comprehensive recycling of energy is realized.

Owner:SHANGHAI PANGEA INVESTMENT

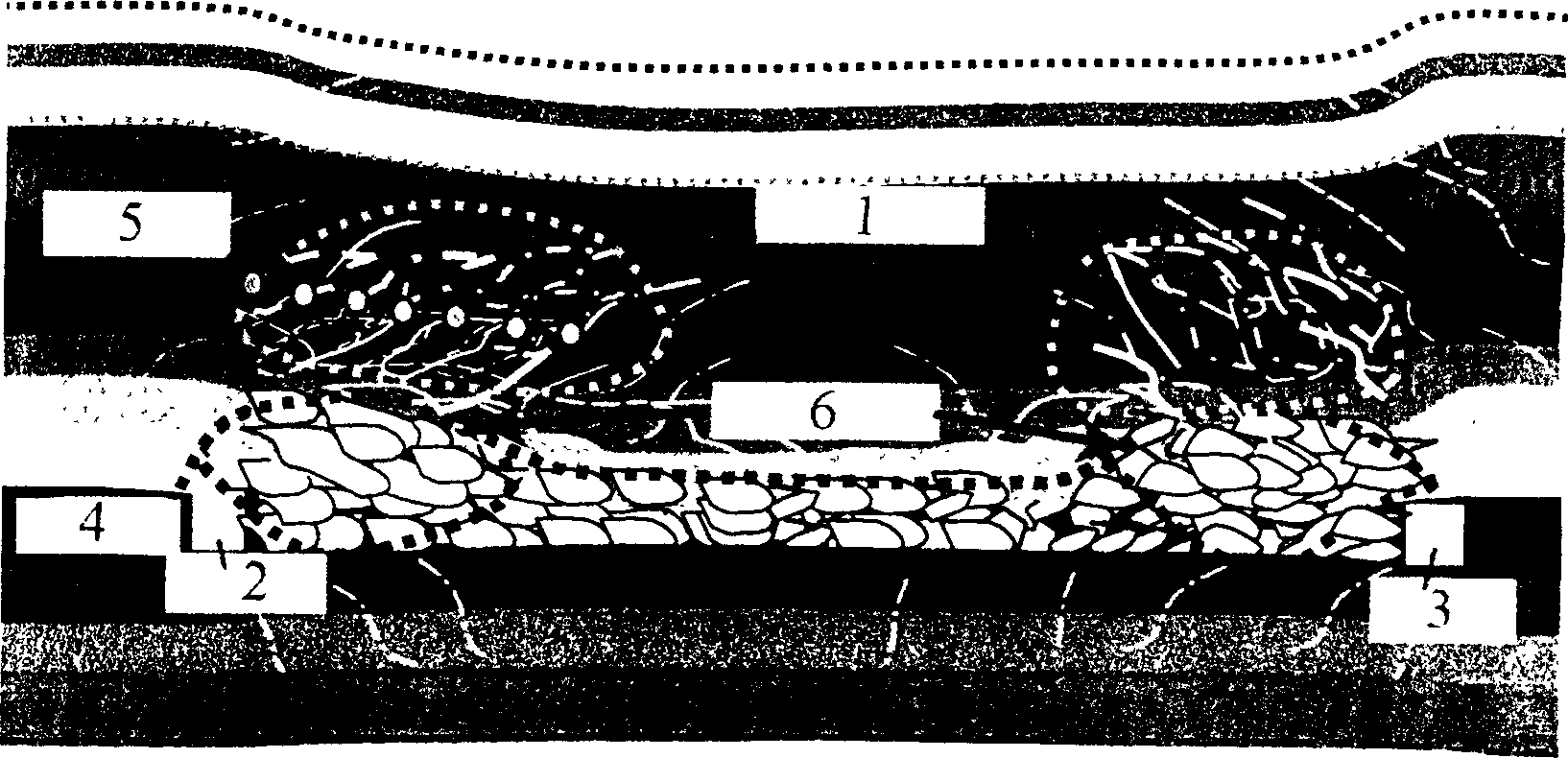

Method for pumping out gas from mining coal layer roof

The gas pumping out method during mining cliff features that during mining cliff, the desorbed gas from the mined and released coal layers to the 'annular crack circle' via crack channel formed through mining is pumped via the drilled holes or tunnel in the 'annular crack circle'. The 'annular crack circle' is located in the stratafugic crack band over the stoped out cliff inbreak band near return airway and intake airway in the coal mining face. The present invention solves the problem of overrunning gas in stoping working face to ensure safe production.

Owner:HUAINAN MINING IND GRP +1

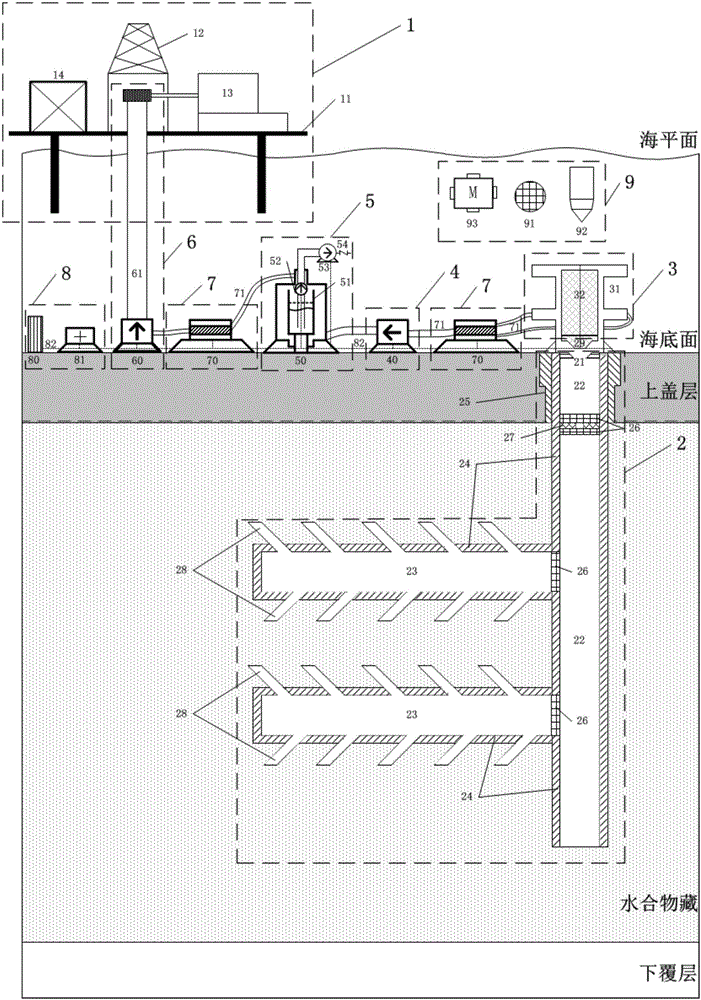

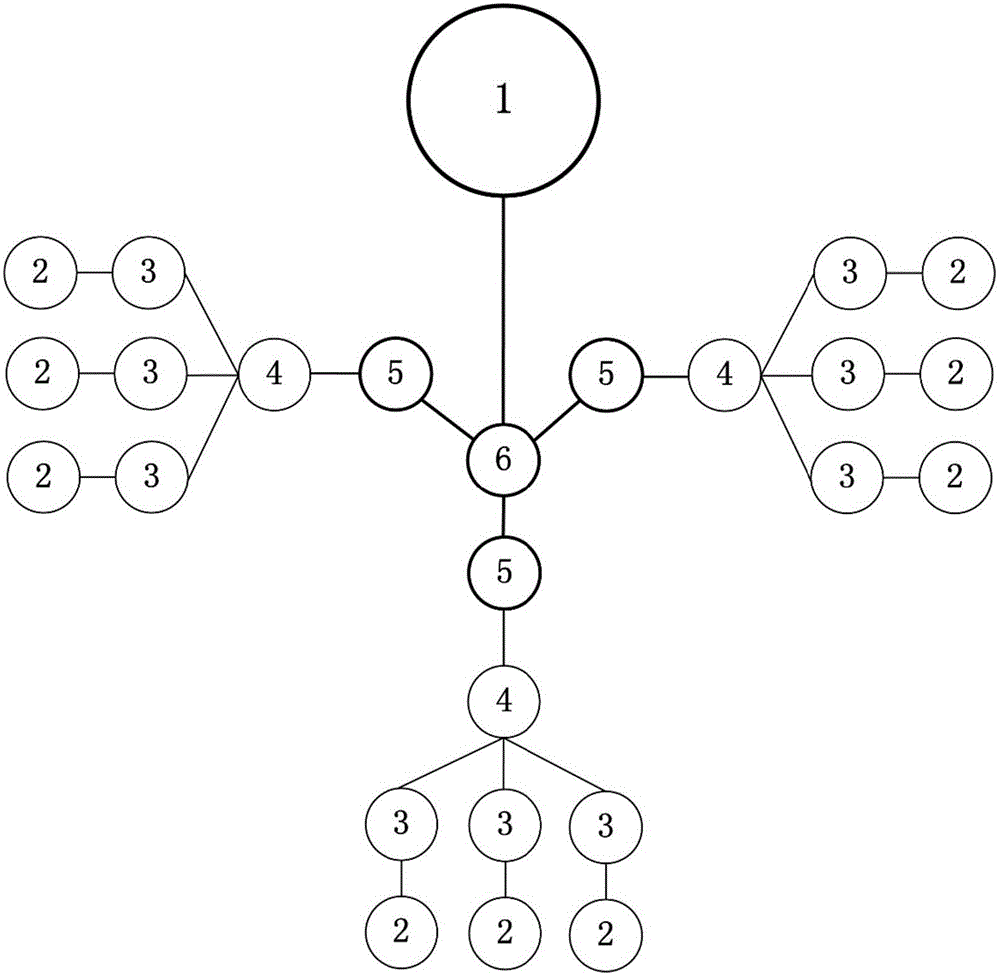

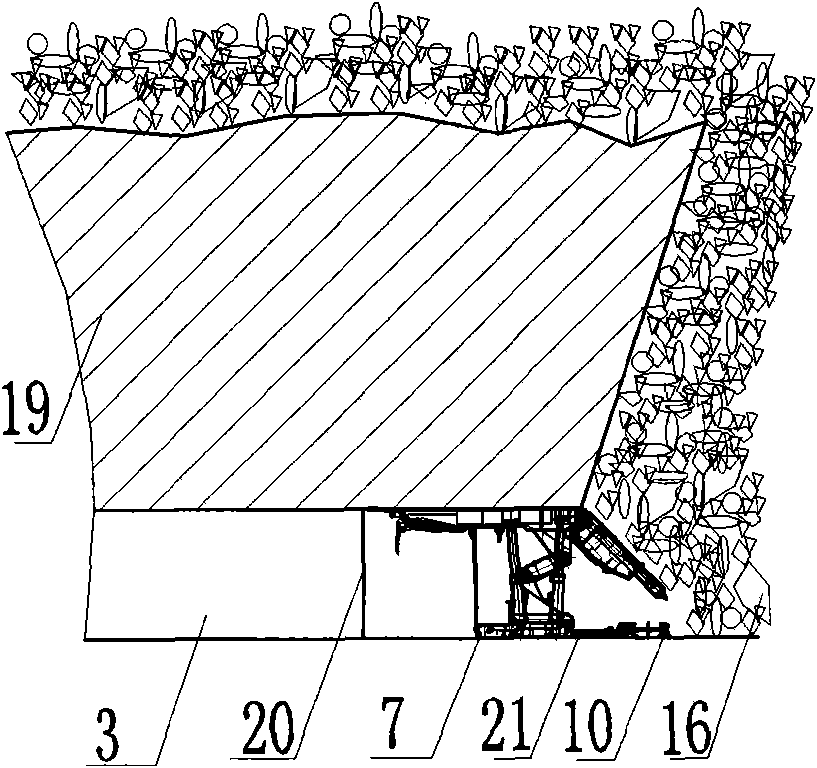

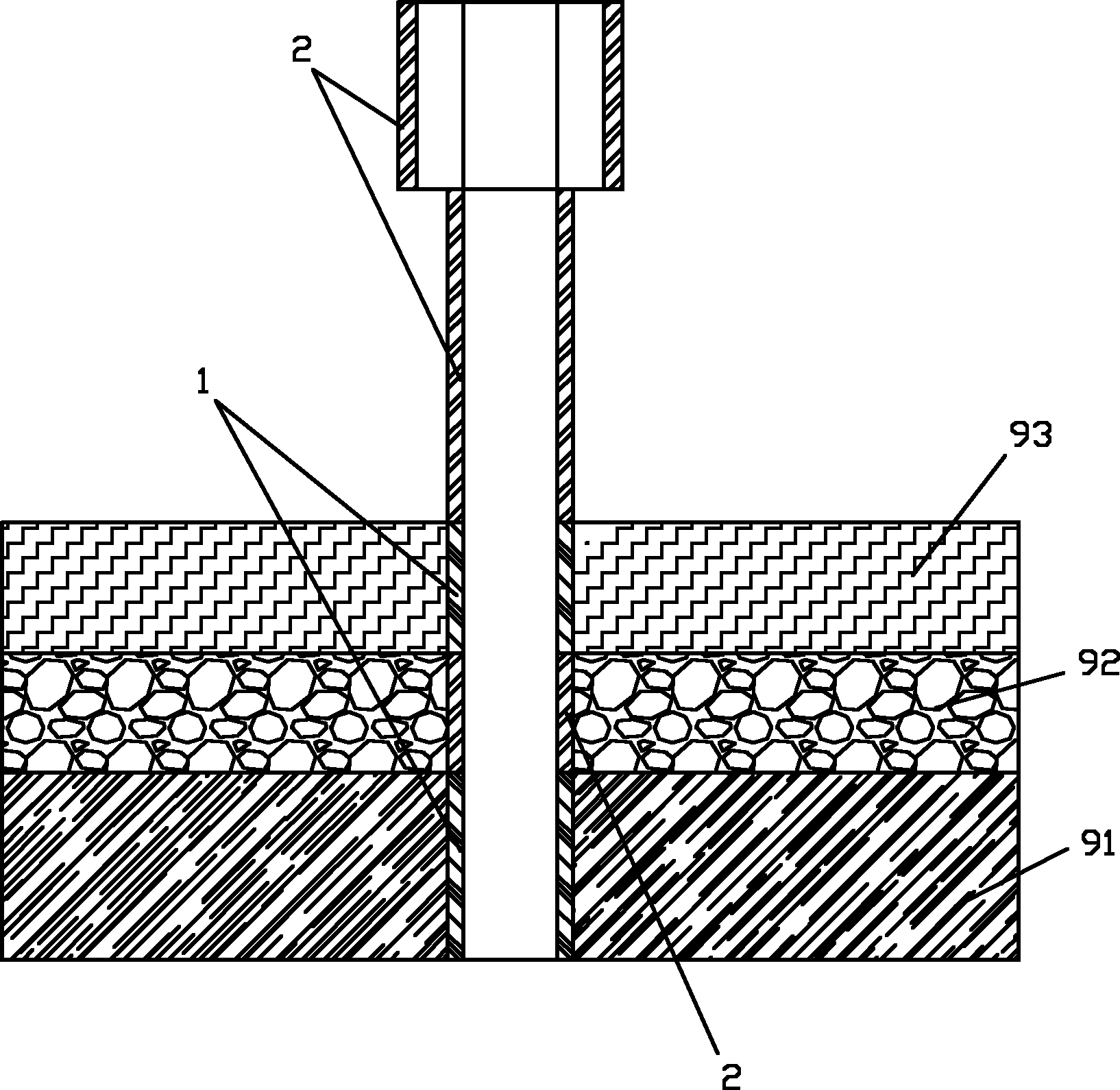

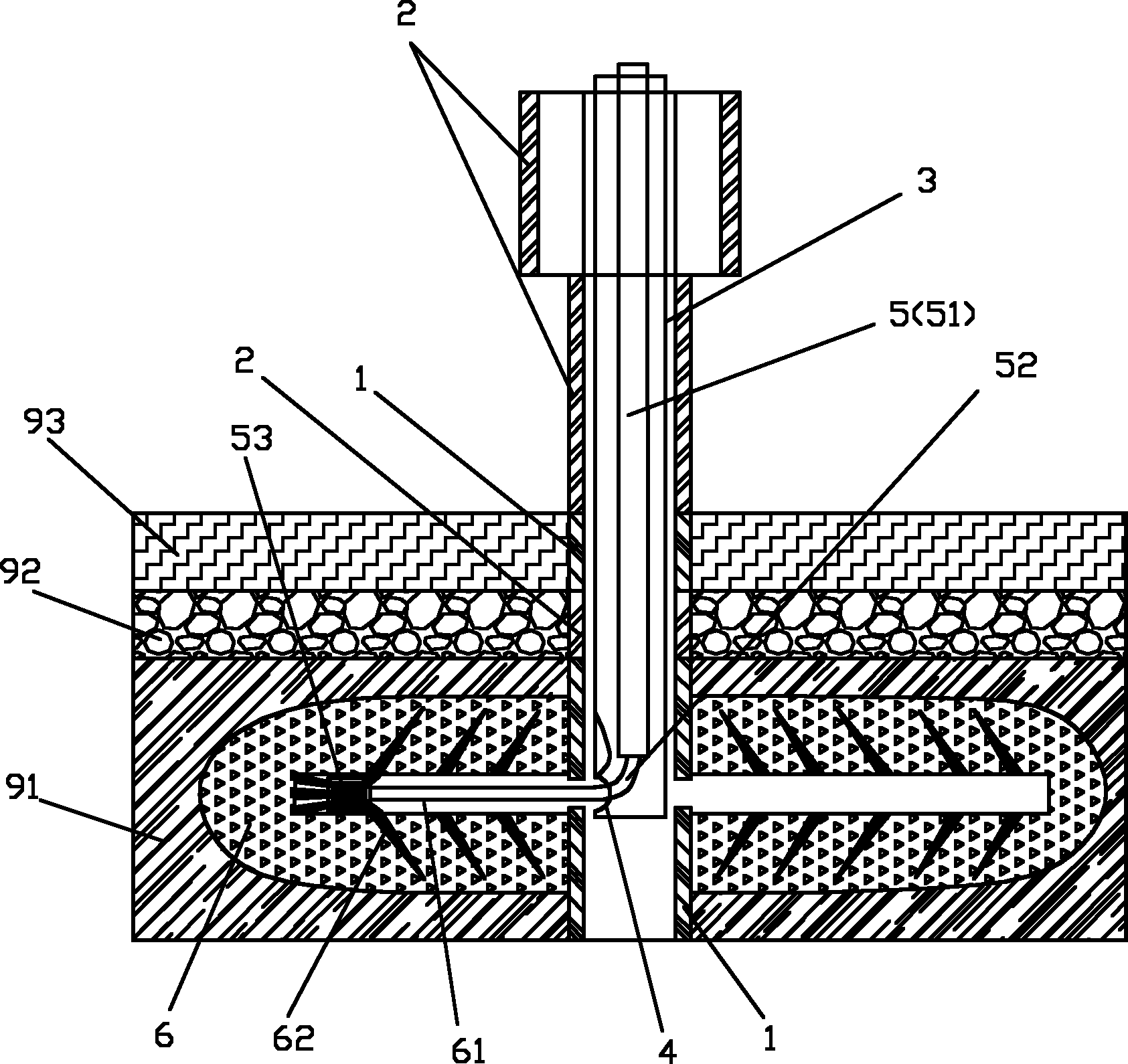

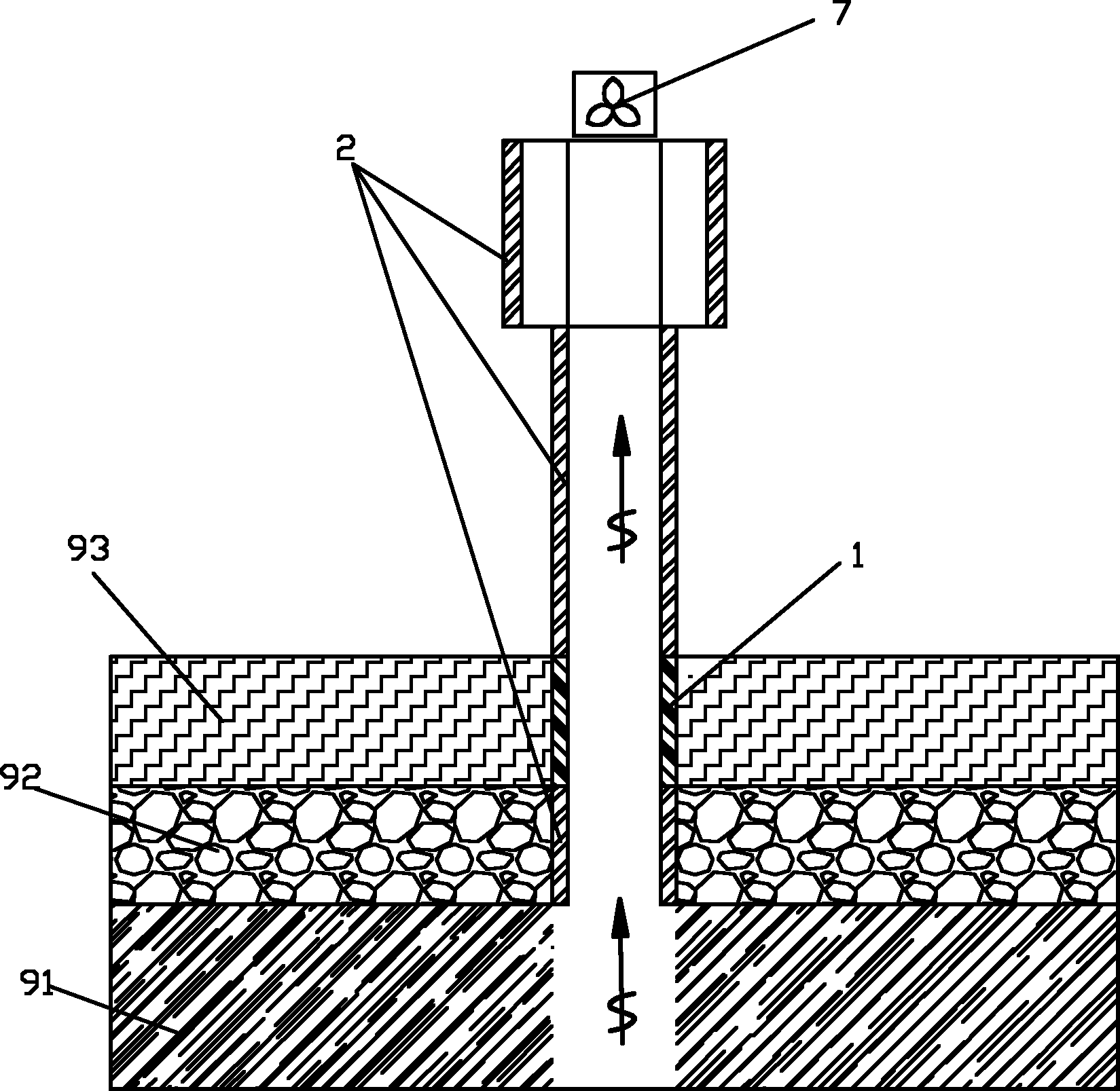

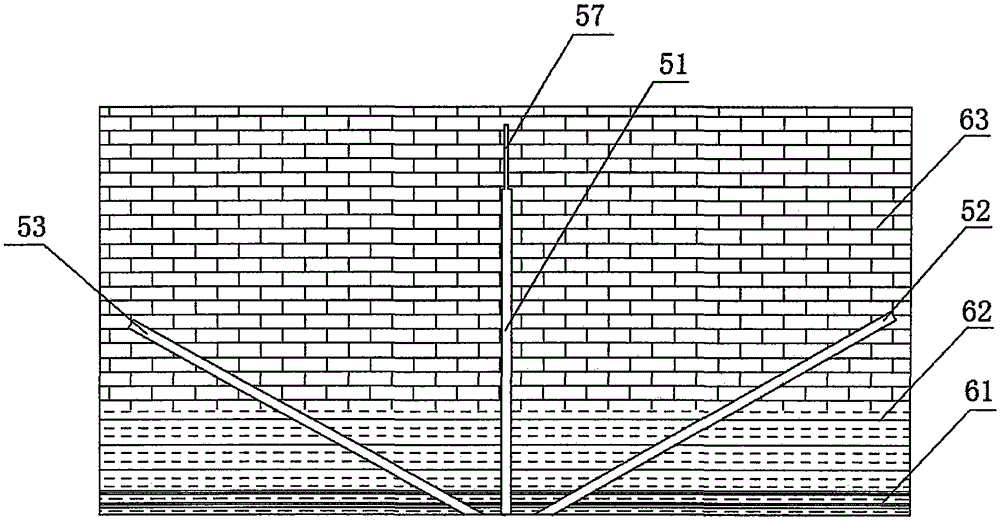

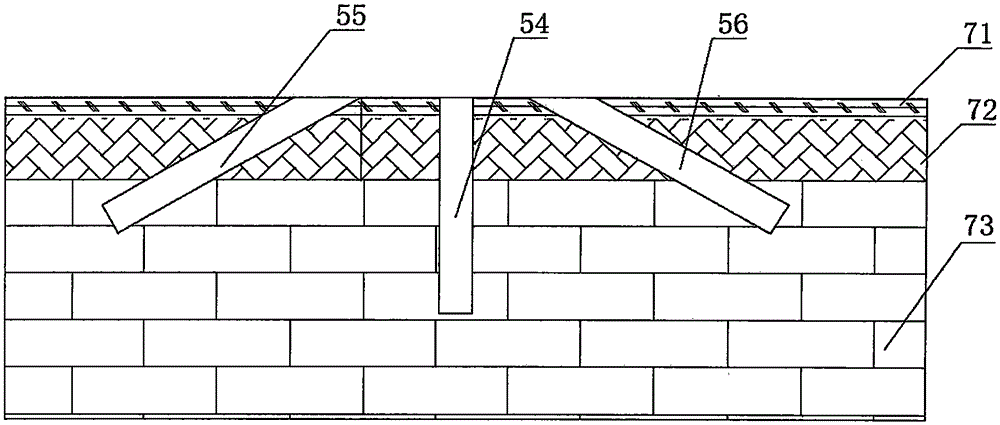

Decompression marine natural gas hydrate mining method and submarine mining system

The invention relates to a decompression marine natural gas hydrate mining method and a submarine mining system. The submarine mining system comprises a semi-submersible offshore platform, a mining well with multiple shower holes, a wellhead gas and water acquisition tree, a gas and water mixed delivery system, a submarine gas and water separating device, a gas delivery system, a pipeline system, a power and communication system and an auxiliary device. The decompression marine natural gas hydrate mining method and the submarine mining system have the advantages that submarine natural gas hydrate reservoirs can be safely, efficiently and economically mined; the submarine mining system is complete, and various portions of the submarine mining system are high in modularization, low in manufacturing cost and short in manufacturing cycle and can be reused; most devices are positioned in submarine environments and are controlled via the offshore platform, only natural gas is delivered offshore, and accordingly the submarine mining system is low in extra energy consumption; owing to a technology for forming the multiple shower holes in the mining well, missed mining regions can be effectively reduced, and the gas yield can be effectively increased owing to multiple horizontal wells; the submarine mining system has functions of well blocking prevention, well blowout prevention, hydrate secondary generation and the like, and accordingly safety production can be guaranteed; various main devices can flexibly move and are used with one another, and accordingly movable regional production operation can be implemented.

Owner:DALIAN UNIV OF TECH

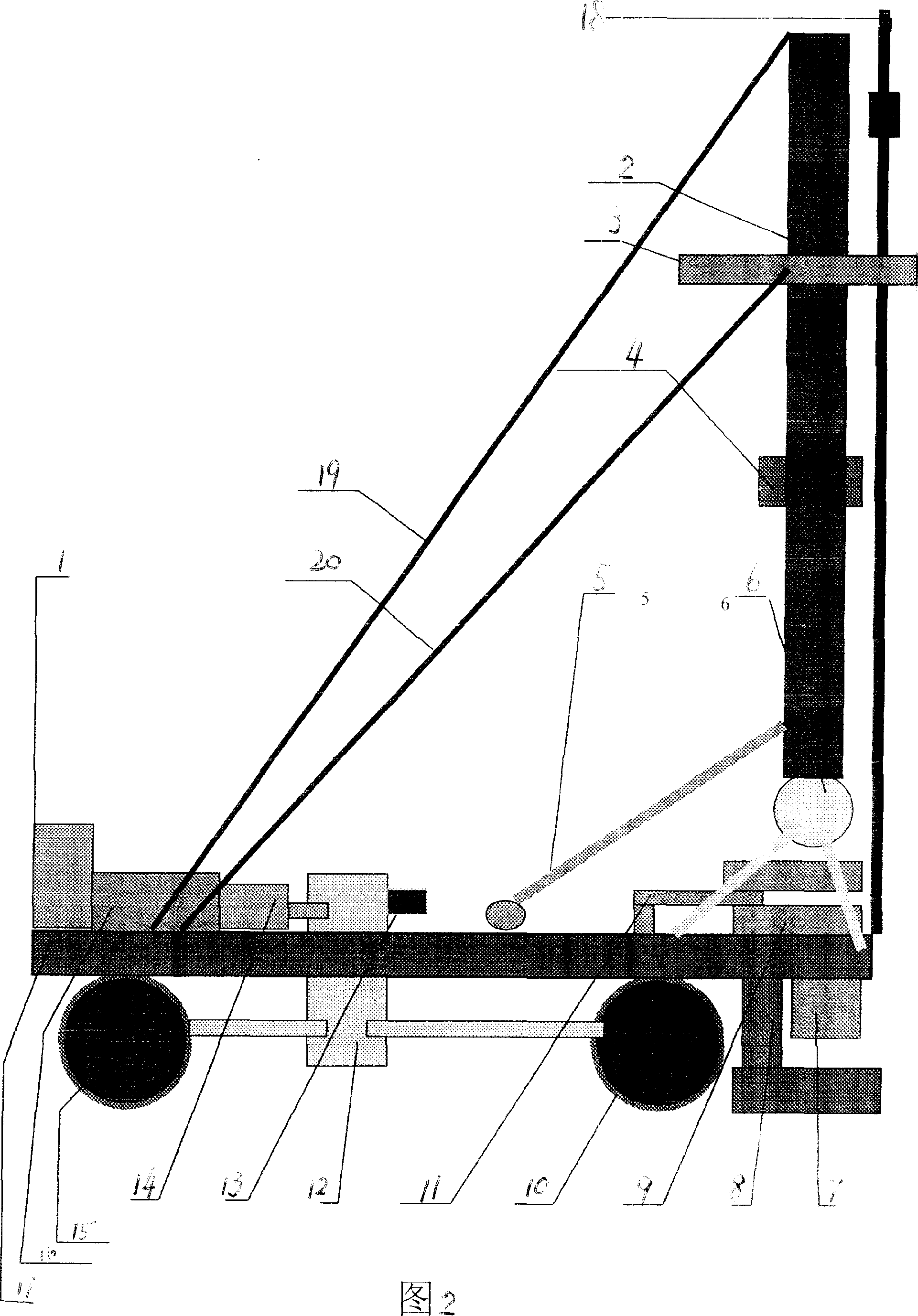

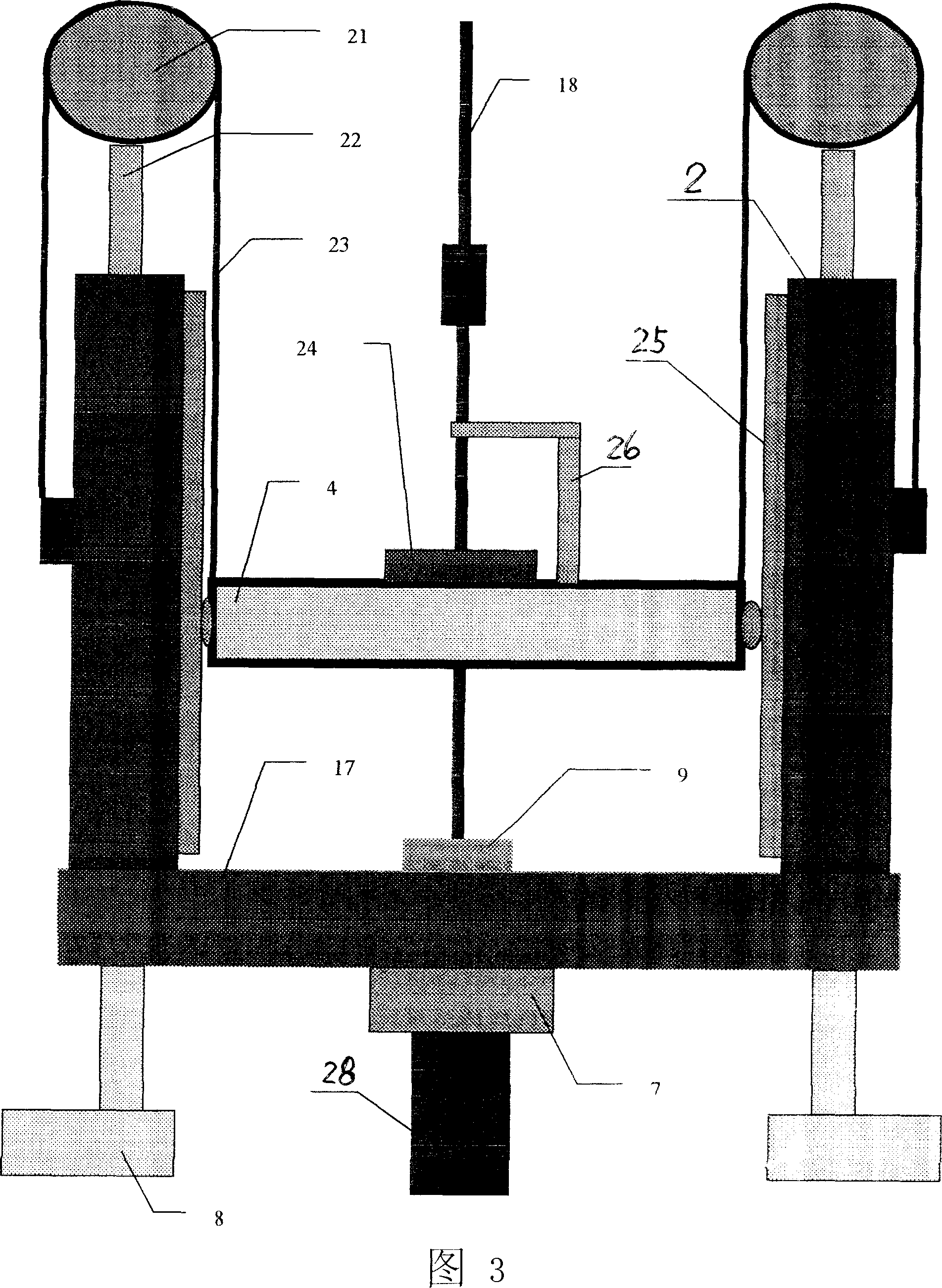

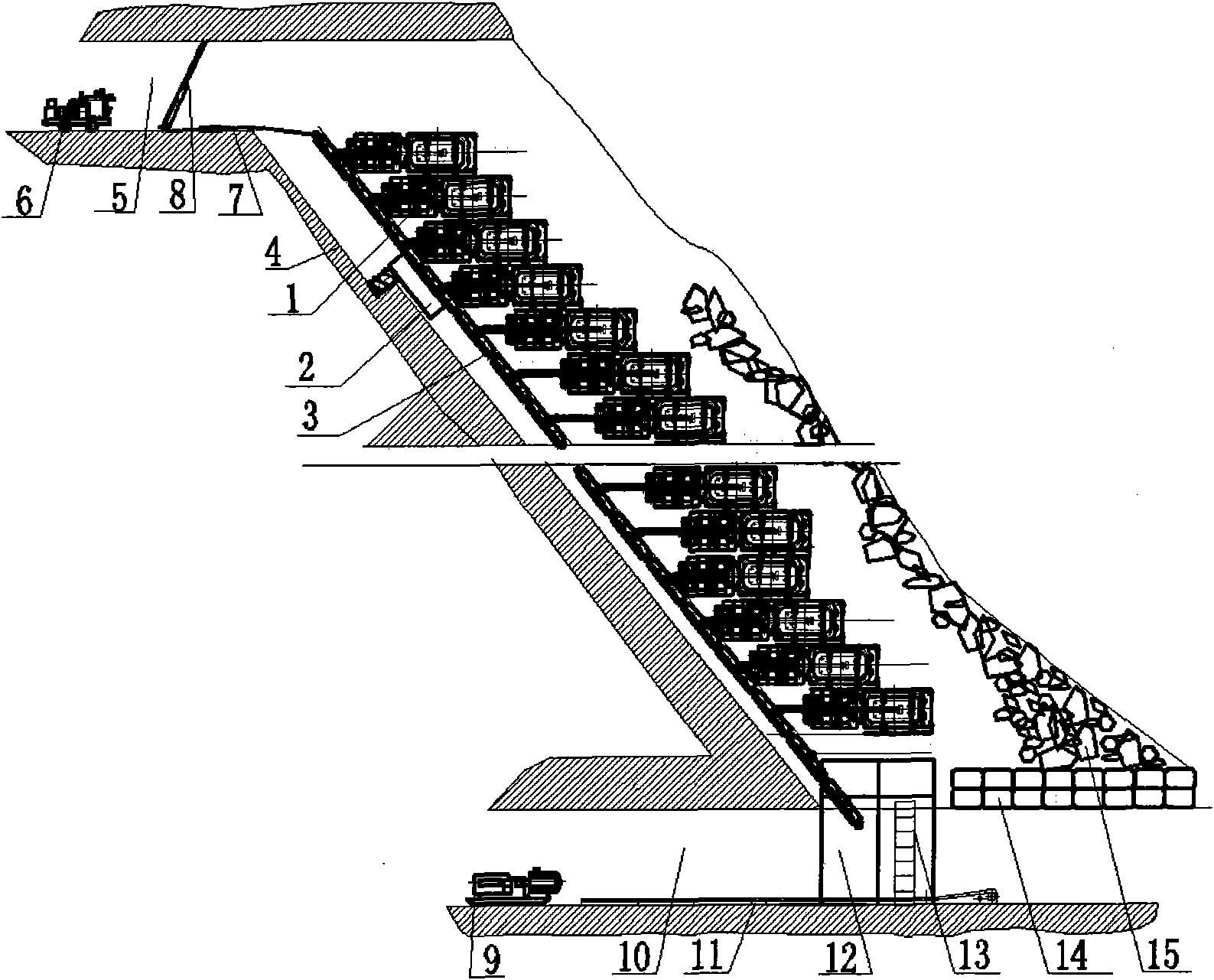

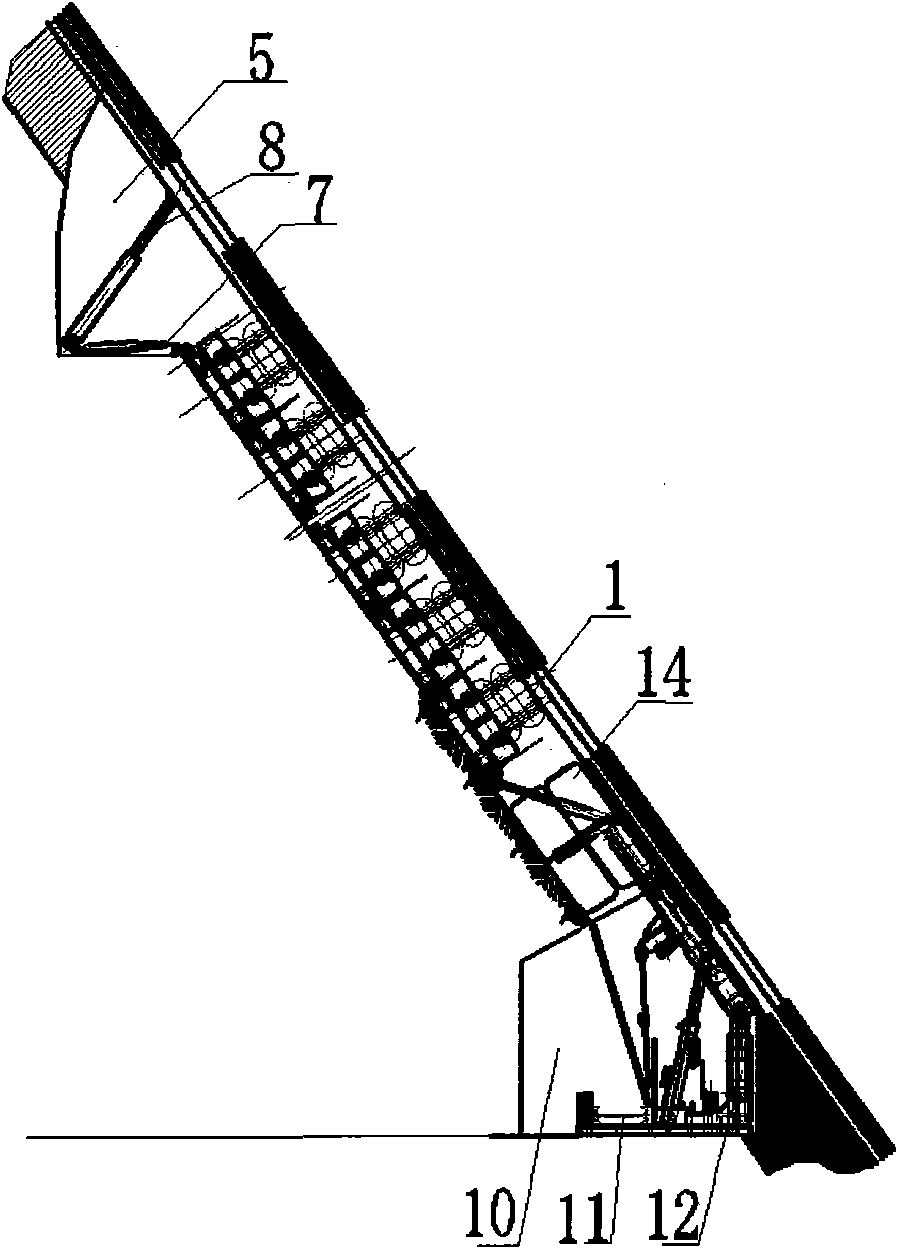

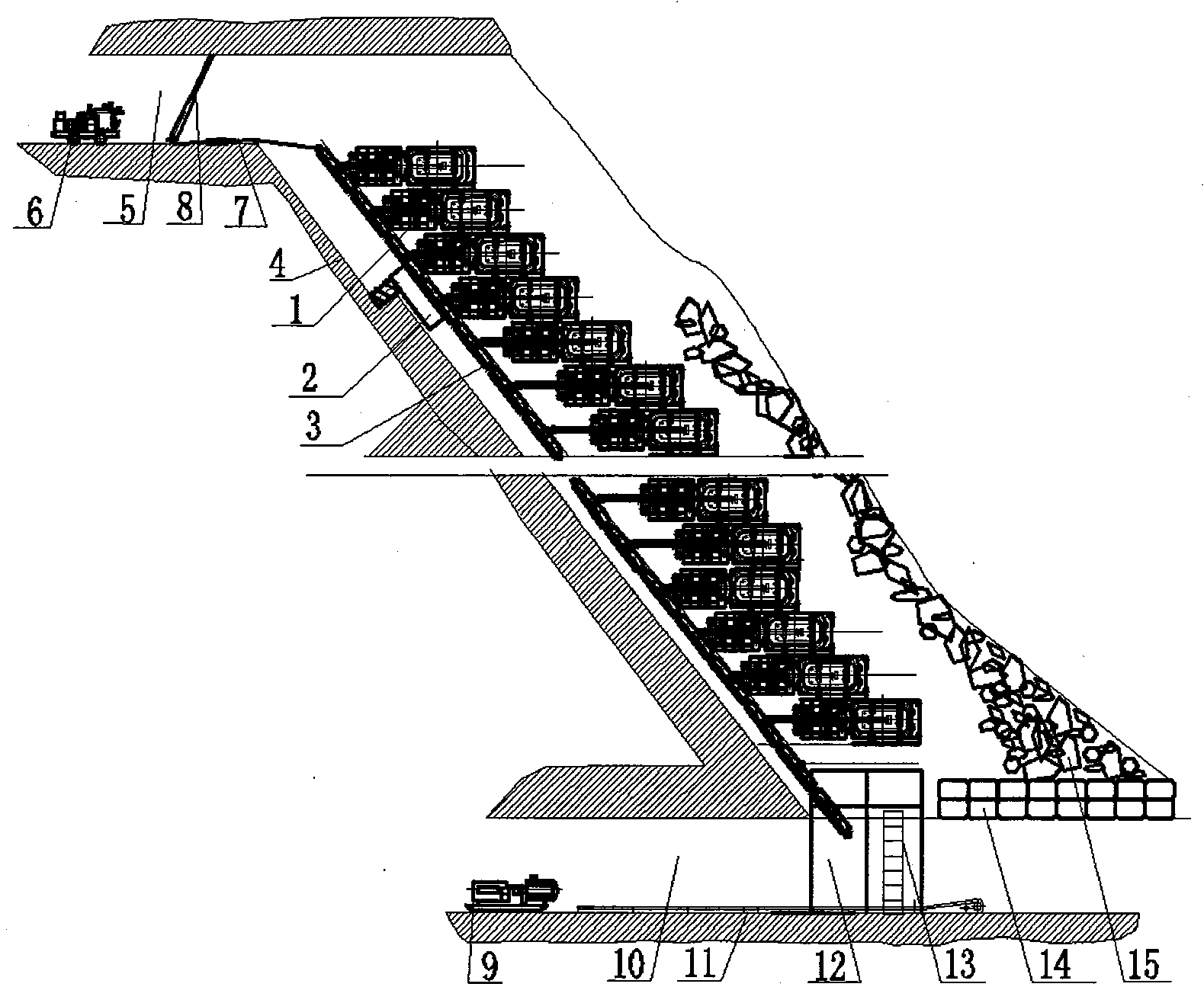

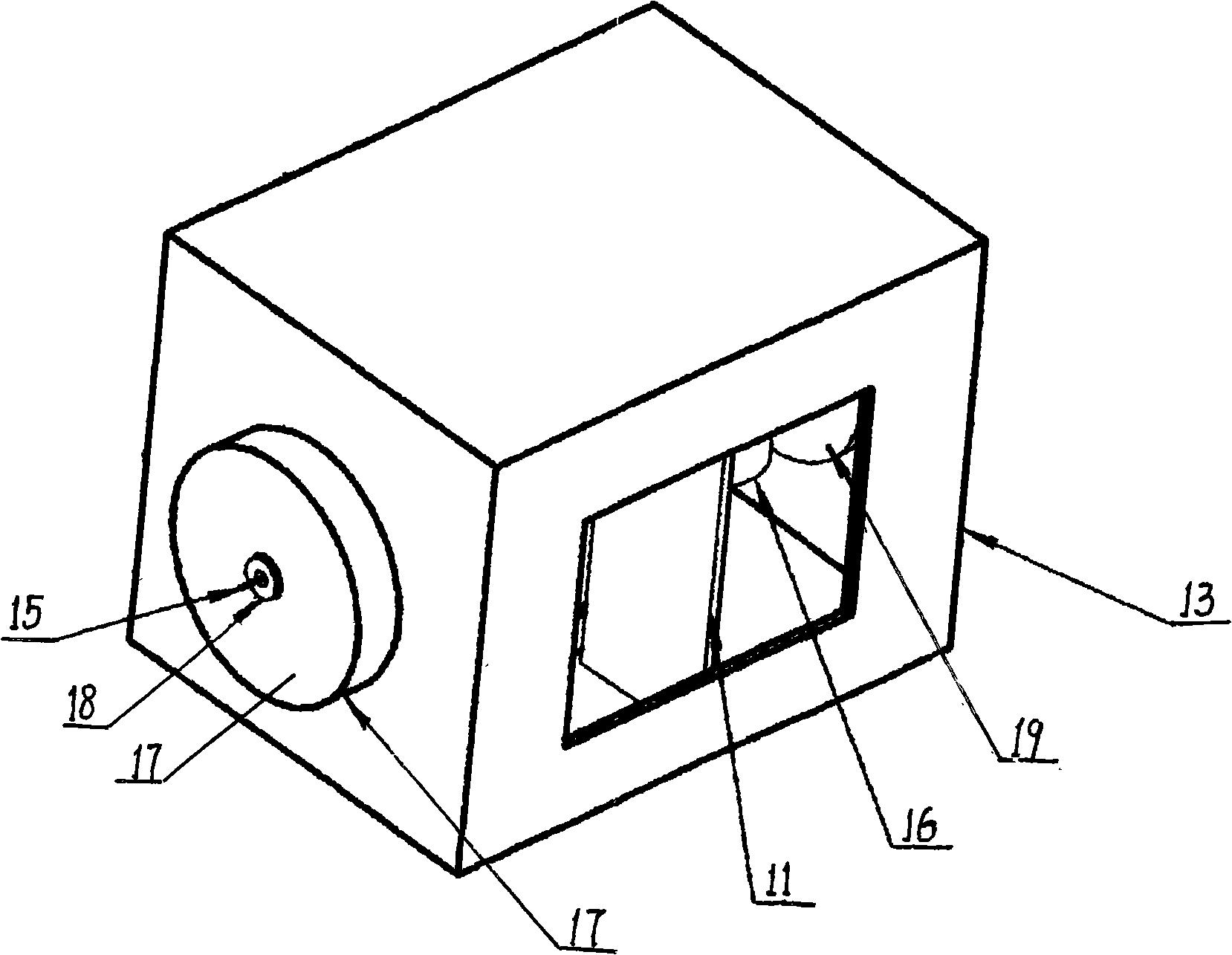

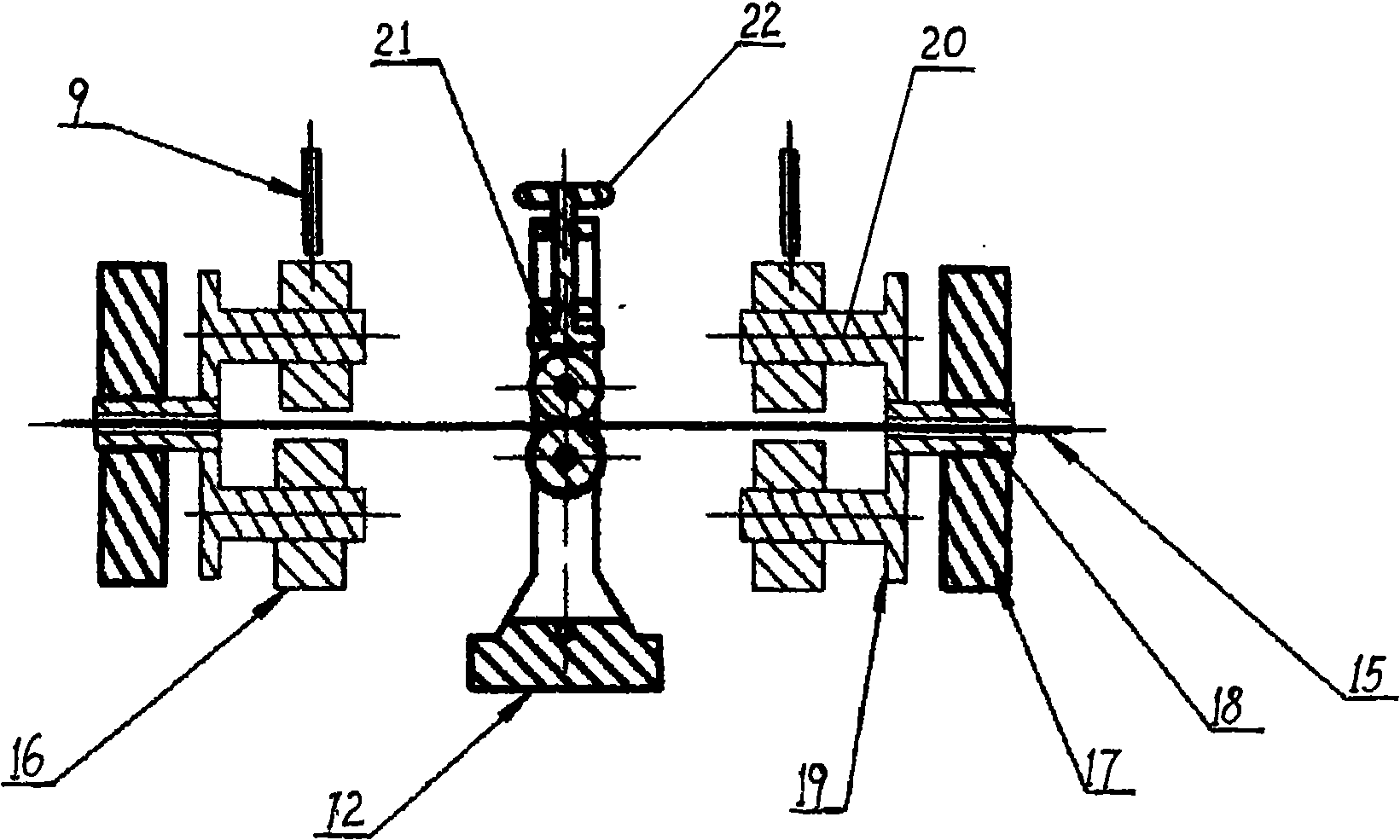

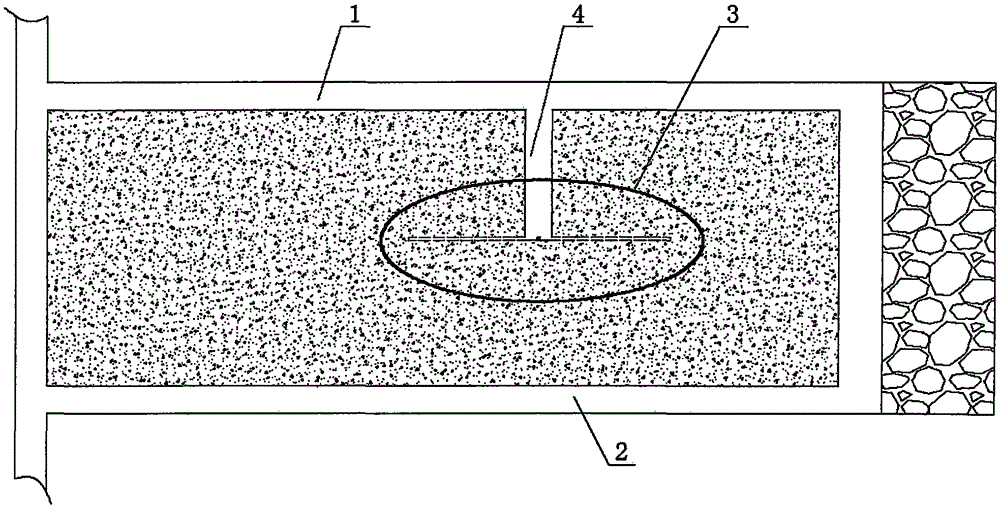

Drill floor well repairing machine without manual operation in well mouth

InactiveCN1920239AReduce labor intensityImprove workover efficiencyDrilling rodsDrilling casingsHydraulic cylinderVehicle frame

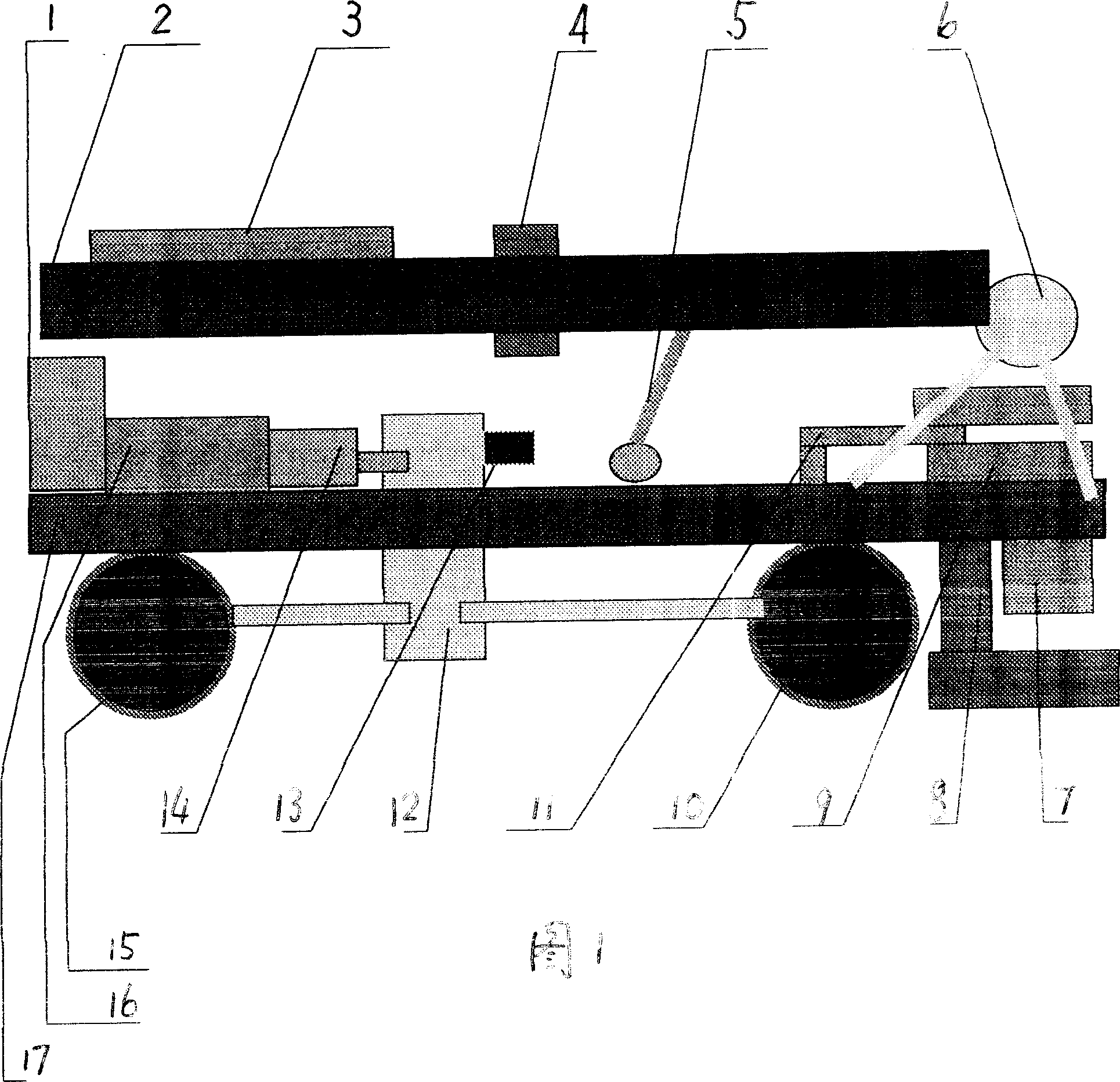

The invention relates to a workover device in drill floor type, used in non-manned operation under the oil well, wherein it is formed by driving control room 1, thick support post 2, discharge tube 3, lifter 4, amplitude-variable hydraulic cylinder 5, support post base 6, well-open hydraulic blowout preventer 7, drill floor hydraulic base 8, fixing hydraulic clamp disc 9, back tyre, back driving bridge 10, hydraulic clamper 11 with flexible sliding channel 11, hydraulic gear box 12, high-pressure gear pump 13, hydraulic torque converter 14, front tyre, front driving bridge 15, engine 16, frame and drill floor 17; the front part of frame 17 is arranged with driving control room 1, engine 16, hydraulic torque converter 14, hydraulic gear box 12 and high-pressure gear pump 13, while the back part has fixing hydraulic clamp disc 19, support post base 6, and hydraulic clamper 11; the support post base 6 is mounted with thick support post 2, discharge tube 3 and lifter 4. The invention can automatically set discharge tube and improve the working efficiency.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

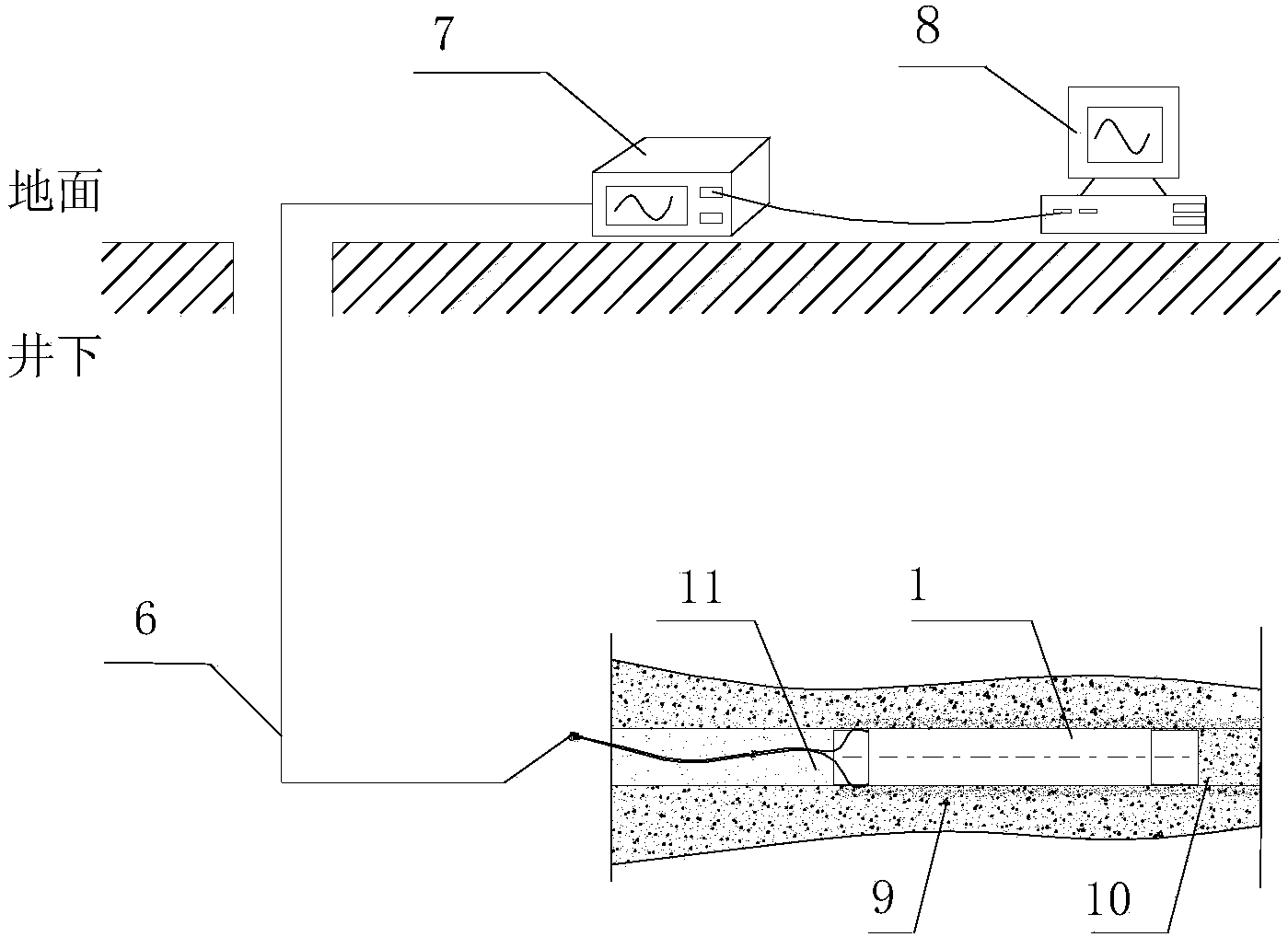

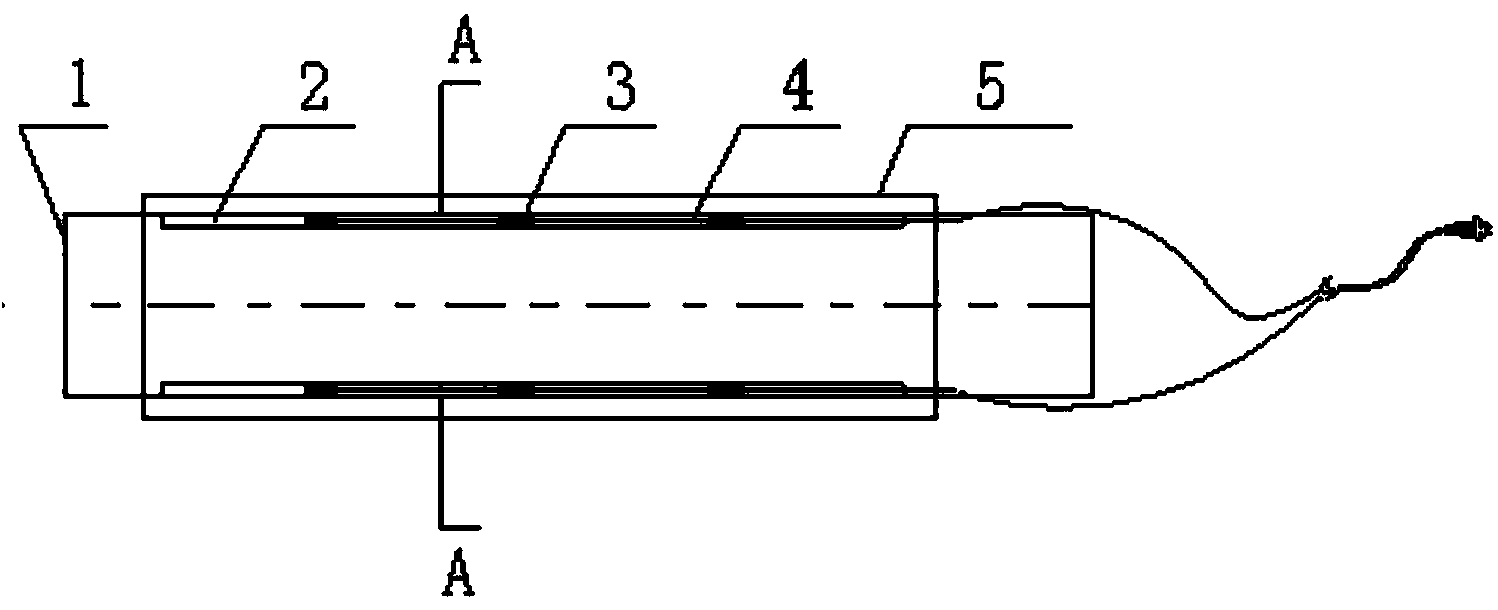

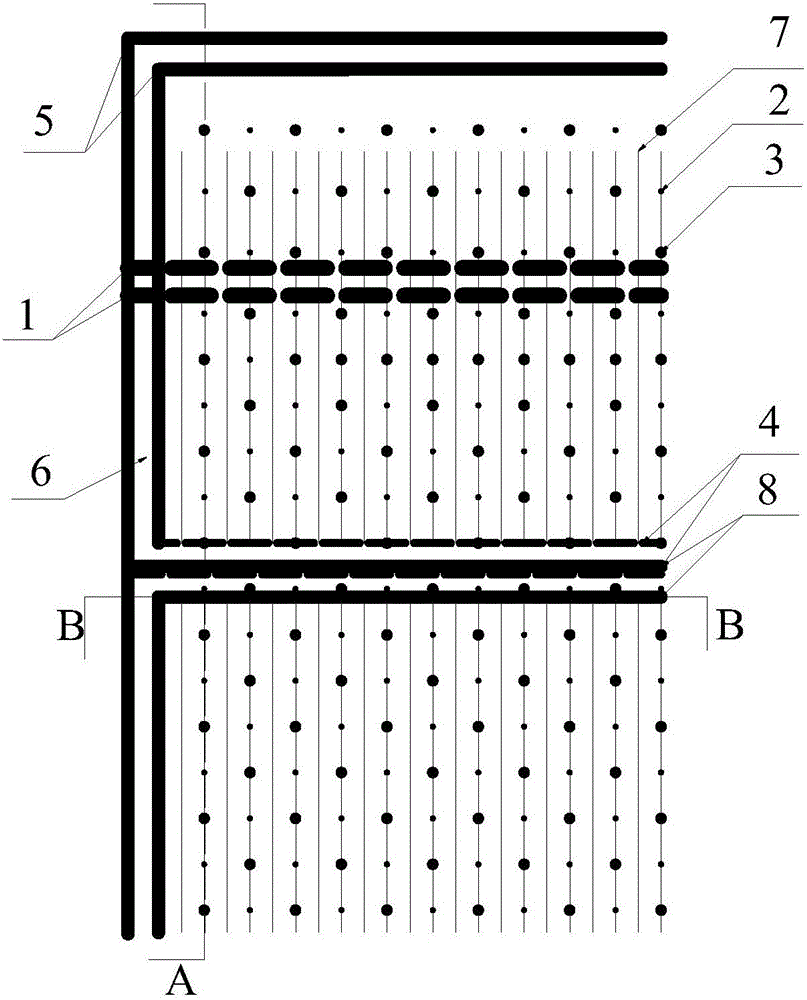

Roadway surrounding rock stress monitoring device based on fiber bragg grating sensing

ActiveCN103454021AUnderstanding Stress SituationsImprove stabilityForce measurement by measuring optical property variationUsing optical meansGratingFiber Bragg grating

The invention discloses a roadway surrounding rock stress monitoring device based on fiber bragg grating sensing. Grooves are symmetrically carved in a metal rod along the axial center, an FBG set is fixedly installed inside each groove, FBGs serve as sensitive elements, when roadway surrounding rock is deformed, the stress of the surrounding rock will be changed, therefore, force is generated through the metal rod, surface micro-deformation is generated, the grating distances of the FBGs attached to the metal rod are changed along with the metal rod, the center reflection wavelength of the FBGs can be caused to generate drifting, wavelength signals are demodulated into electrical signals through an FBG interrogator, and the stress situations of different sites can be obtained. The roadway surrounding rock stress monitoring device has the advantages that installation is easily achieved, and the roadway surrounding rock stress monitoring device is suitable for wide popularization; power is not required to be supplied to the working face end, and site safety is guaranteed; all-optical measurement and fiber transmission are adopted, and influences of electromagnetic interference are effectively avoided; the temperature error is compensated, and the accuracy is improved; the surrounding rock stress monitoring results can be timely and accurately provided, and guidance on site production and scientific research is facilitated.

Owner:CHINA UNIV OF MINING & TECH

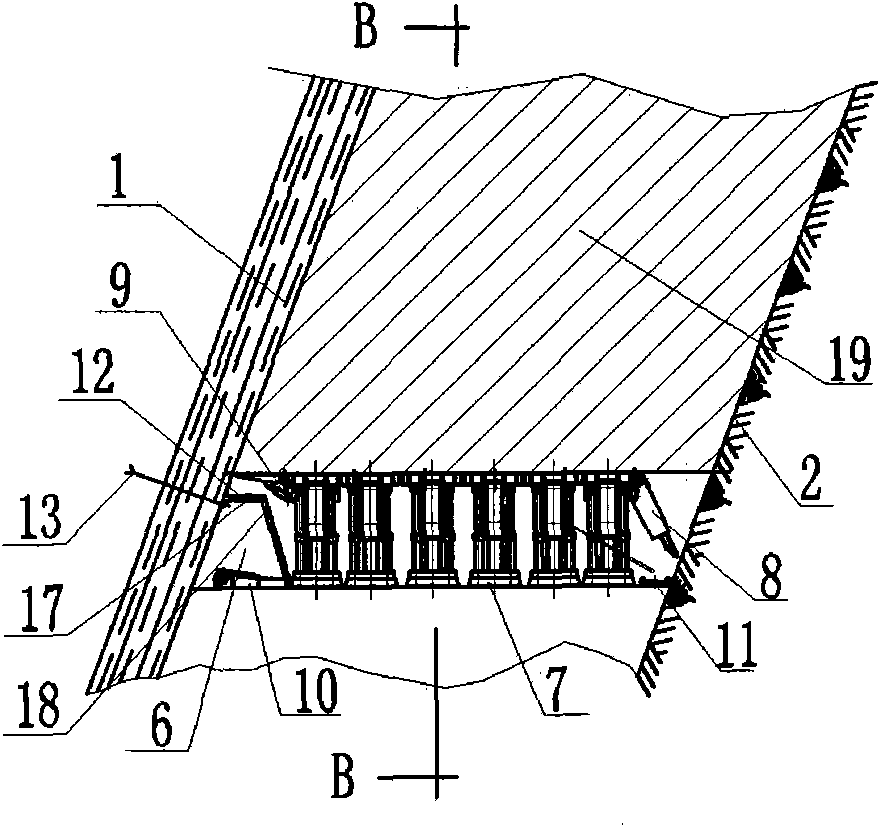

Coal mining method for high-dipping low seam

InactiveCN101942999AAchieve mechanical propertiesIncrease productionUnderground miningSurface miningLongwall miningMining engineering

The invention relates to a coal mining method for a high-dipping low coal seam by long-wall mining. The method comprises the following steps of: supporting a roof by a self-advancing air bag support; arranging a working surface in a mode of advancing to the dip; mining coal by drilling and blasting or using an off-pan shearer; transporting the coal in a mode of gravity haulage; filling a goaf with gangue or sand; and filling a lower end with gangue bags, precast concrete blocks or solidified macromolecular foaming slurry. The coal mining method has the advantages of realizing mechanical coal mining for the high-dipping low coal seam, improving the yield per unit and efficiency of the working surface, effectively protecting the exploited ground, improving the recovery rate of mines, and guaranteeing the coal seam mining safety.

Owner:TIANDI SCI & TECH CO LTD

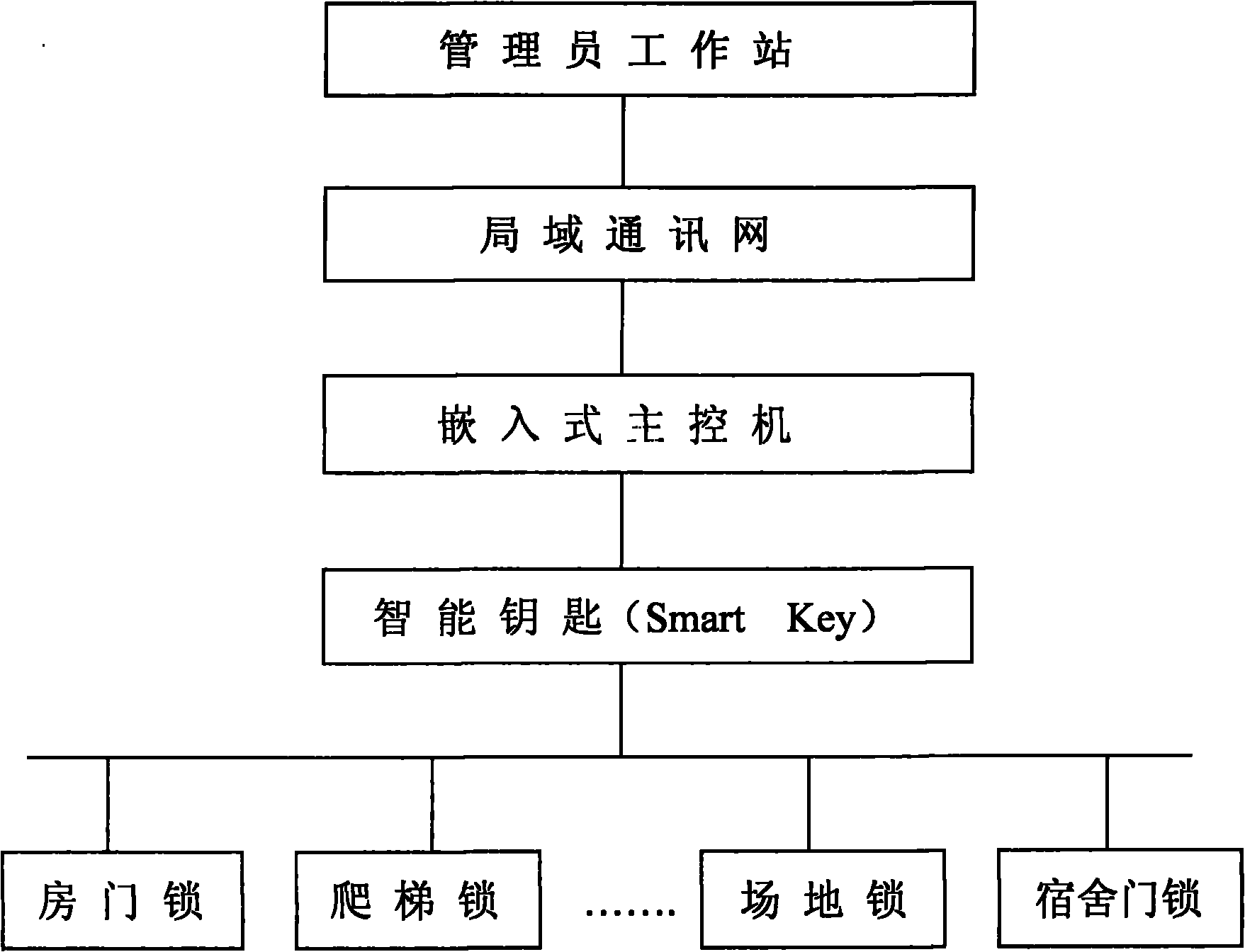

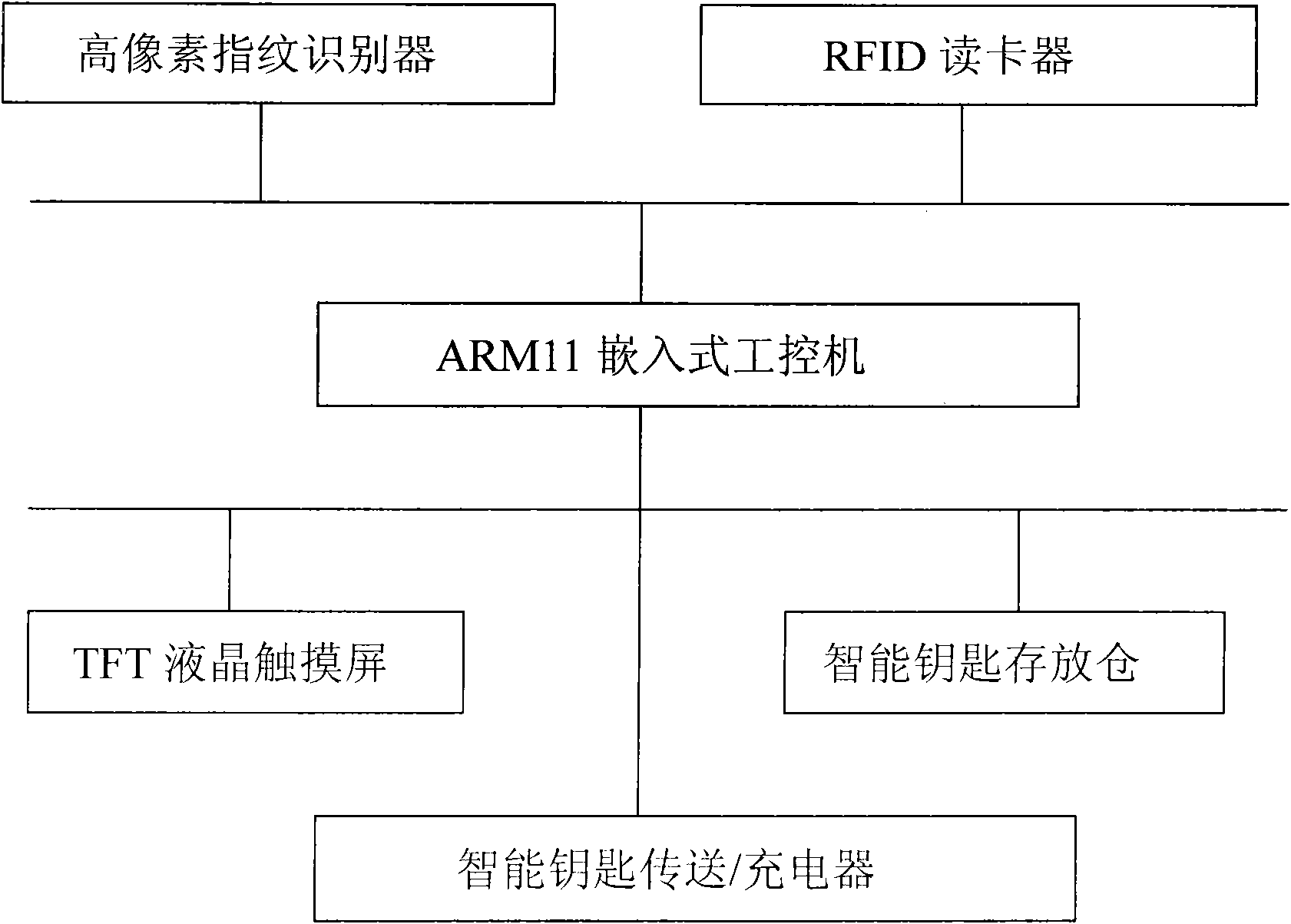

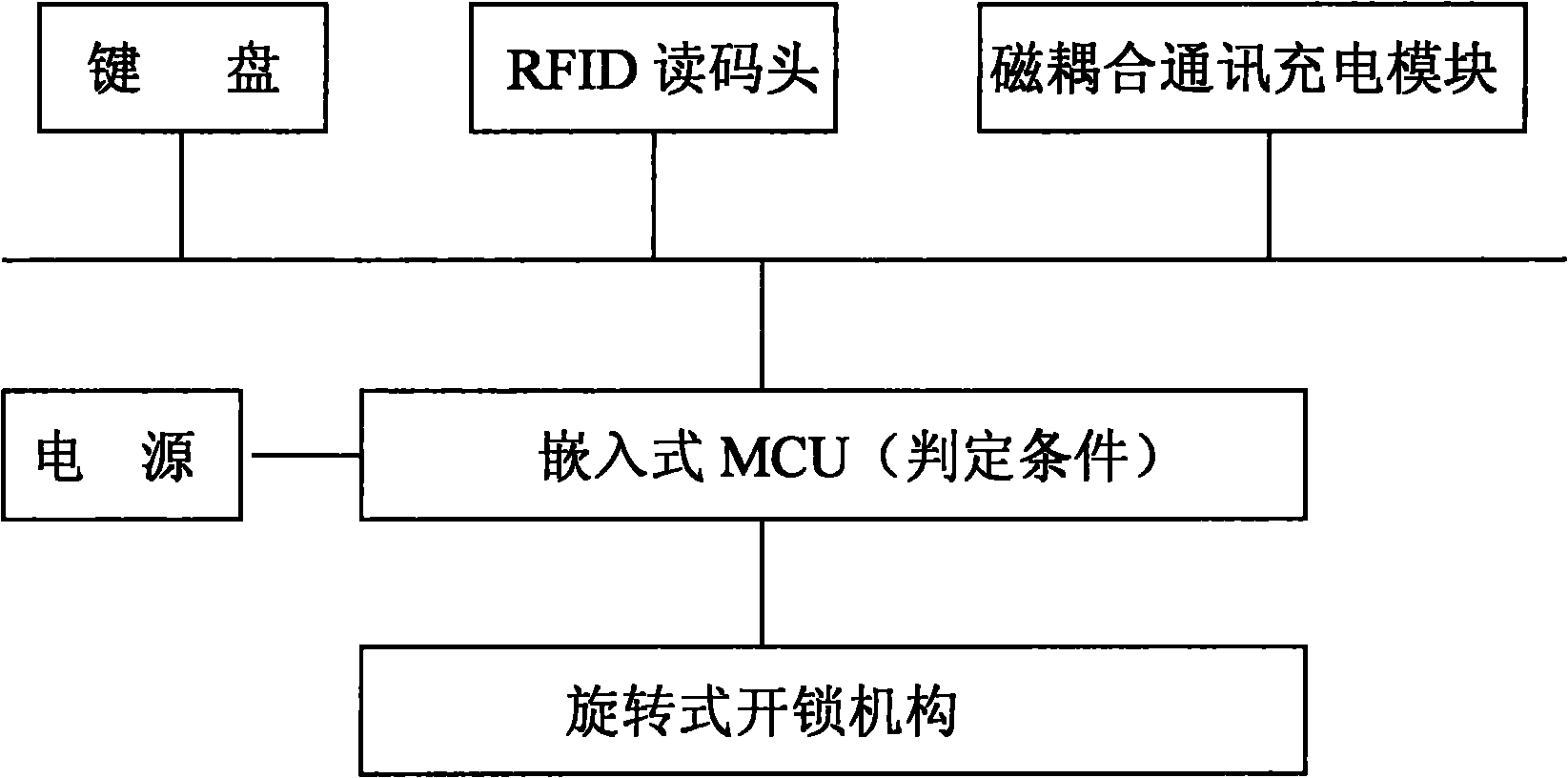

Intelligent lock-control system for electric power safety

InactiveCN102044100AReasonable structurePerfect processIndividual entry/exit registersEmbedded systemPower station

The invention discloses an intelligent lock-control system for electric power safety, which has the advantages of reasonable structure, safety, reliability, and high work efficiency. The system comprises an administrator workstation, a master control machine communicated with the administrator workstation through a local communication network, an intelligent key and locksets arranged on terminal places, wherein unlocking scope data of different rank personnel is stored in the master control machine, the unlocking scope data comprises the scope of opening locksets and RFID (Radio Frequency Identification Device) code value corresponding to an RFID code piece in each lockset; and before the unlocking personnel takes away the intelligent key, the personnel needs to affirm identity on the master control machine, then the master control machine transfers the set unlocking scope data to the intelligent key, at last, the intelligent key judges whether to unlock through distinguishing the RFID code value in the lockset. The system can provide an effective technical method for strengthening personnel access management and equipment using management of a transformer station and a power station, improving work efficiency, and ensuring safe production.

Owner:ZHUHAI LIXIANG TECH

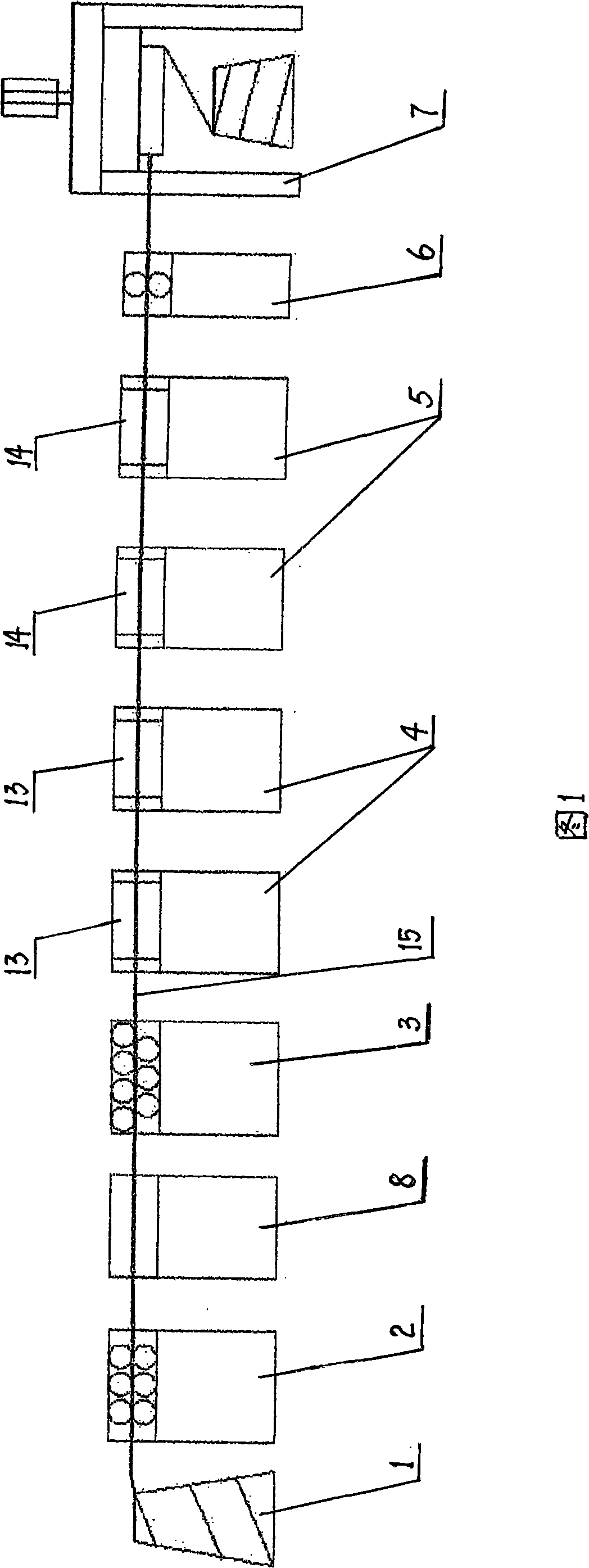

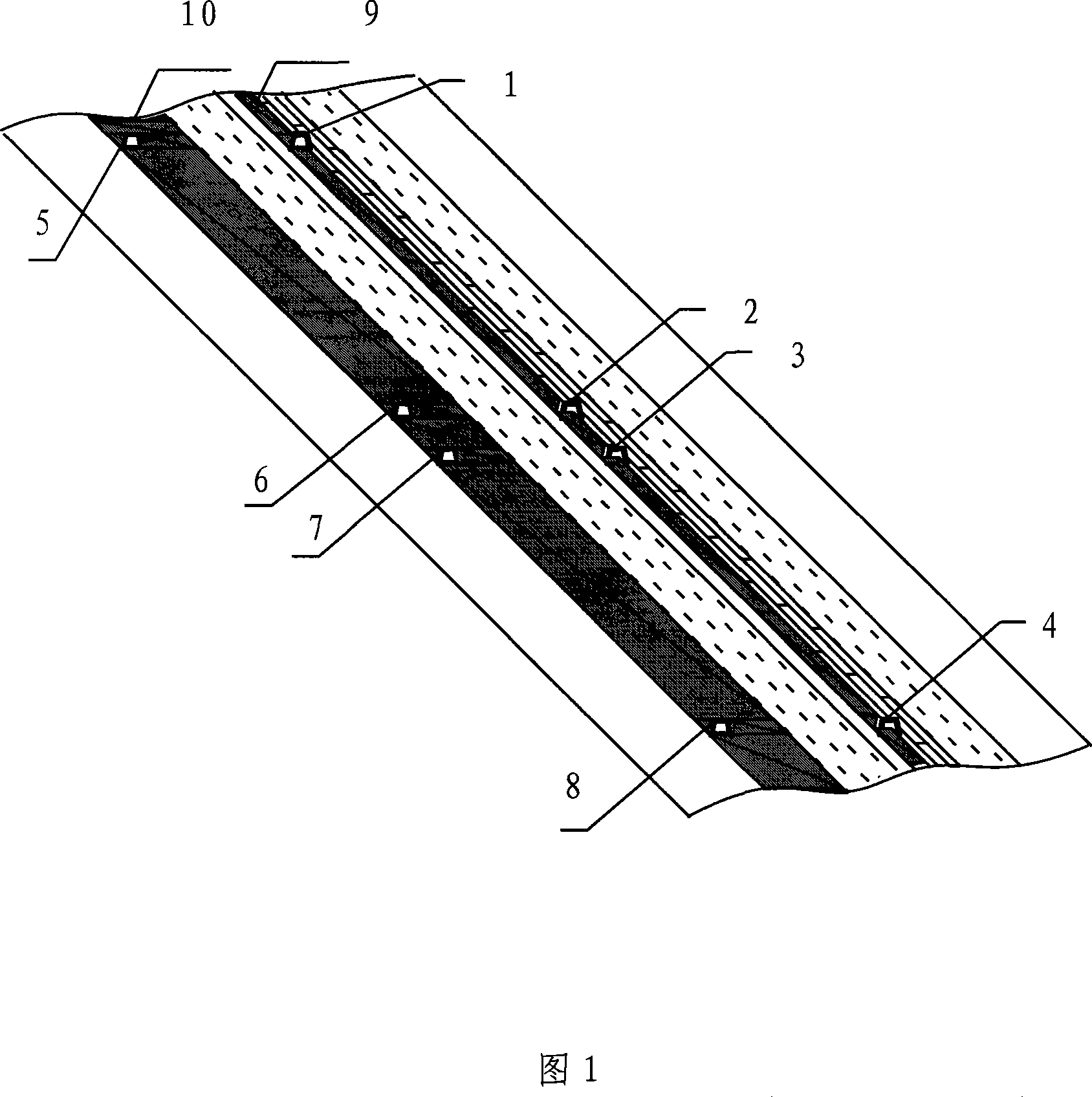

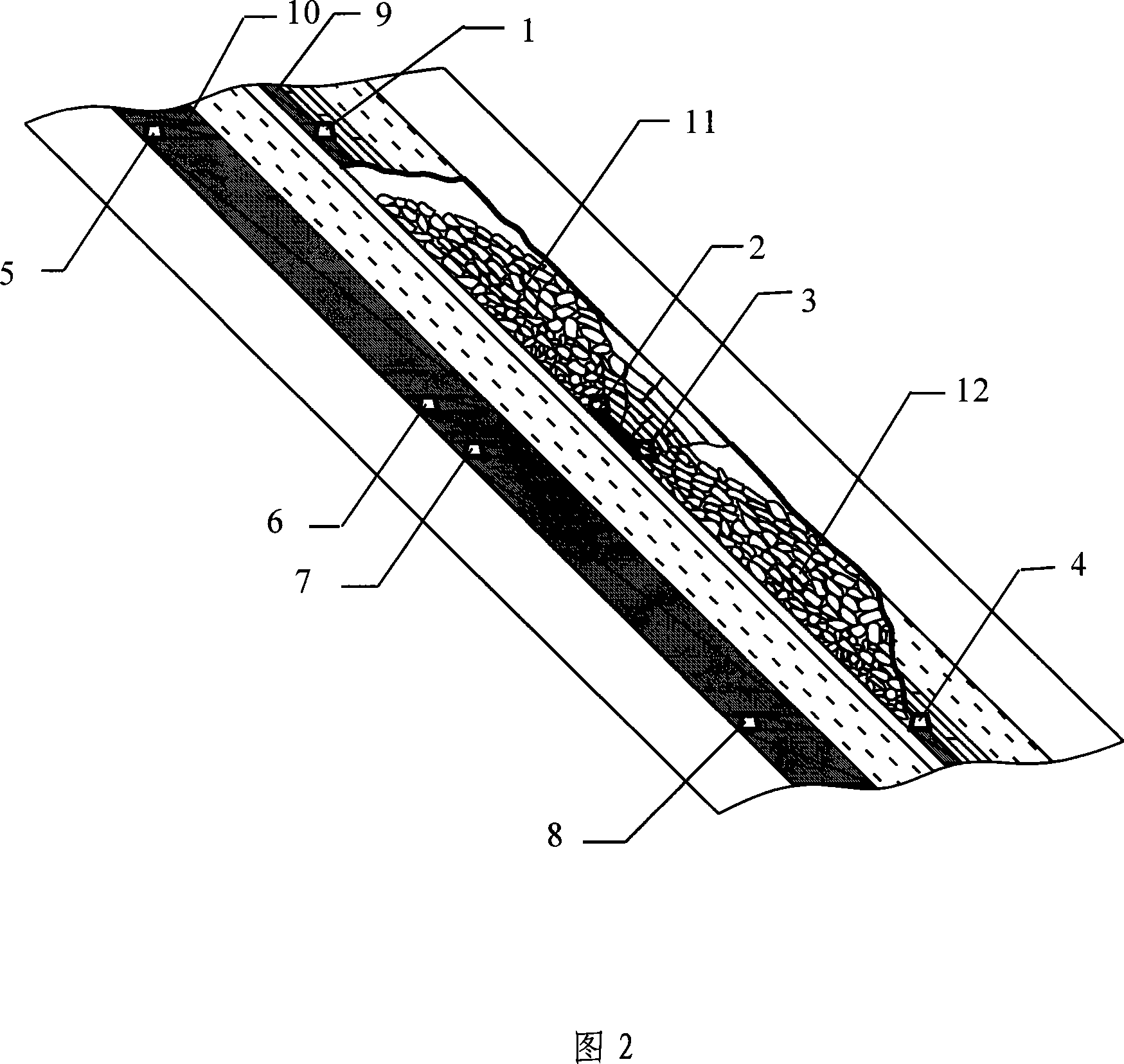

Method and equipment for removing oxidizing layer of titanium and titanium alloy wire material

ActiveCN101269397AEnsure consistencyGuaranteed uniformityWire articlesBurnishing machinesProduction lineTitanium

The invention relates to a method for removing an oxidation layer on titanium and titanium alloy wires and a device thereof. The method includes the following steps: 1. straightening: a straightening machine is used for straightening the titanium and titanium alloy wires; 2. phosphorus removal: a steel wheel phosphorus removal machine is used for removing the oxidation layer on the surface of the titanium and titanium alloy wires; 3. polishing: a sand belt wheel polisher is used for polishing the surface of the titanium and titanium alloy wires. The device is sequentially provided from left to right with a pay-off stand (1), a clamping device (2), a heating device (8), a straightening device (3), two steel wheel phosphorus removal machines (13), sand belt wheel polishers (14), a guide and guard (6) and a vertical down drawing machine (7). On the basis of the present steel wheel phosphorus removal machine, the method is additionally provided with a heating device, a phosphorus removing and polishing machine, a cooling device, a dust removing device and a tension device, thereby forming a production line for removing the oxidation layer on a large and heavy titanium alloy wire, so as to reach the purpose of removing the oxidation layer and polishing.

Owner:BAOJI TITANIUM IND

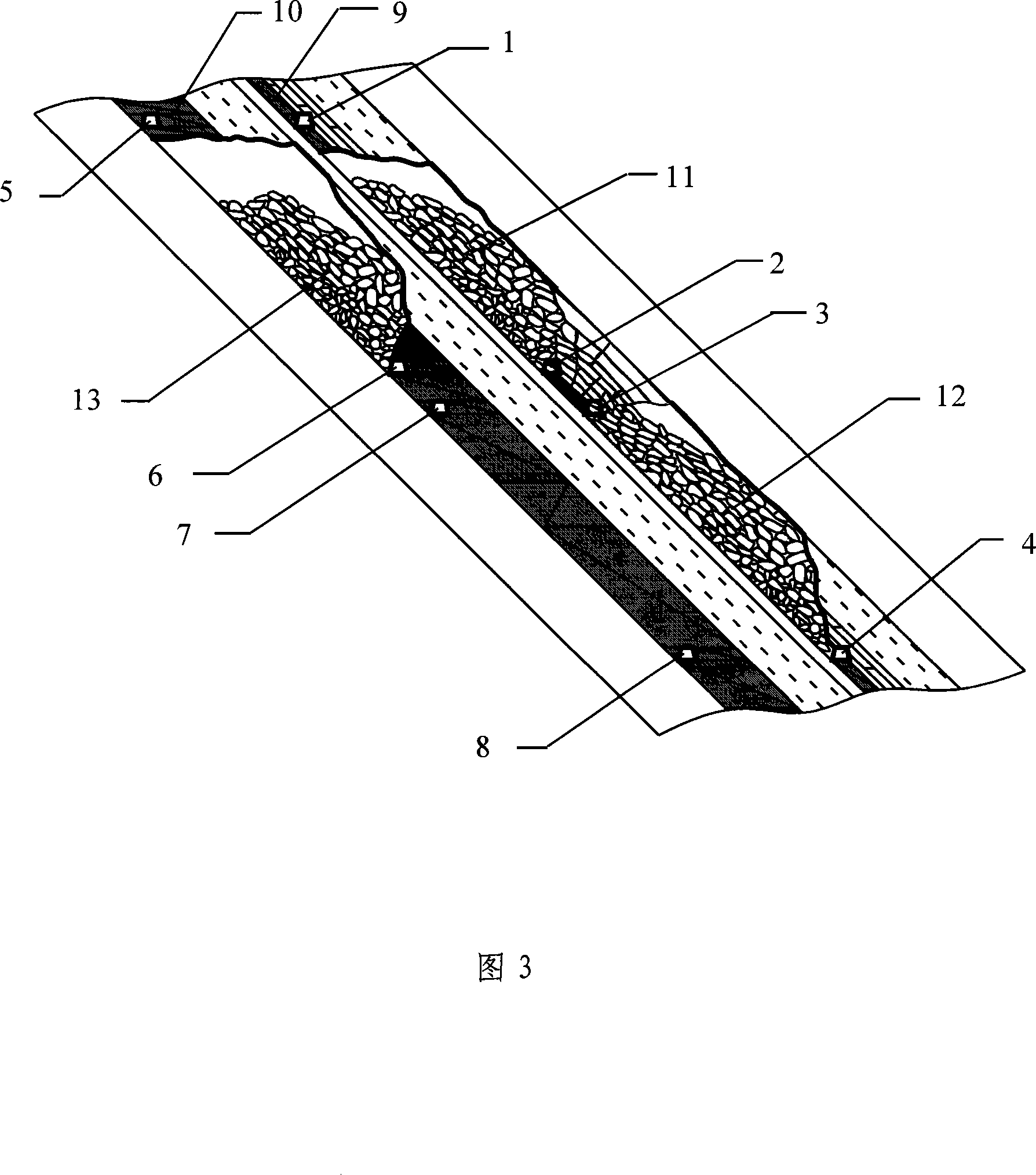

Fully mechanized top coal roof multiple segment control exploration method for deeply inclined coal seam

InactiveCN101169039AIncrease the lengthIncrease release rateUnderground miningSurface miningMining engineeringCoal pillar

The invention provides a head-plate multi-section control mining method for the high inclination-angle coal seam comprehensive top-coal caving. The method is characterized in that two or more sections / working faces are arranged on the same stage of the coal seam, protective or isolating coal pillars are arranged between the sections / working faces; the upper sections / working faces on the same stage is mined firstly when mining the single coal seam; the upper layer of coal is mined firstly when mining the coal seam group; the upper sections / working faces on the same stage of a same coal seam is mined first, and the top-coal is not caved or is caved in control during the mining process; the normal top-coal caving stopping procedure begins mining from the second or lower section / working face; in the course of mining the second or lower section / working face, the protective or isolating pillars on the section / working face of the recovery part can ensure that the gangue slips or rolls into the space formed after the top-coal on the middle or upper areas of the section / working face is caved. The method can improve the top-coal recovering rate of the high inclination-angle coal seam top-coal caving and the output of the working face, and can ensure safe production.

Owner:XIAN UNIV OF SCI & TECH

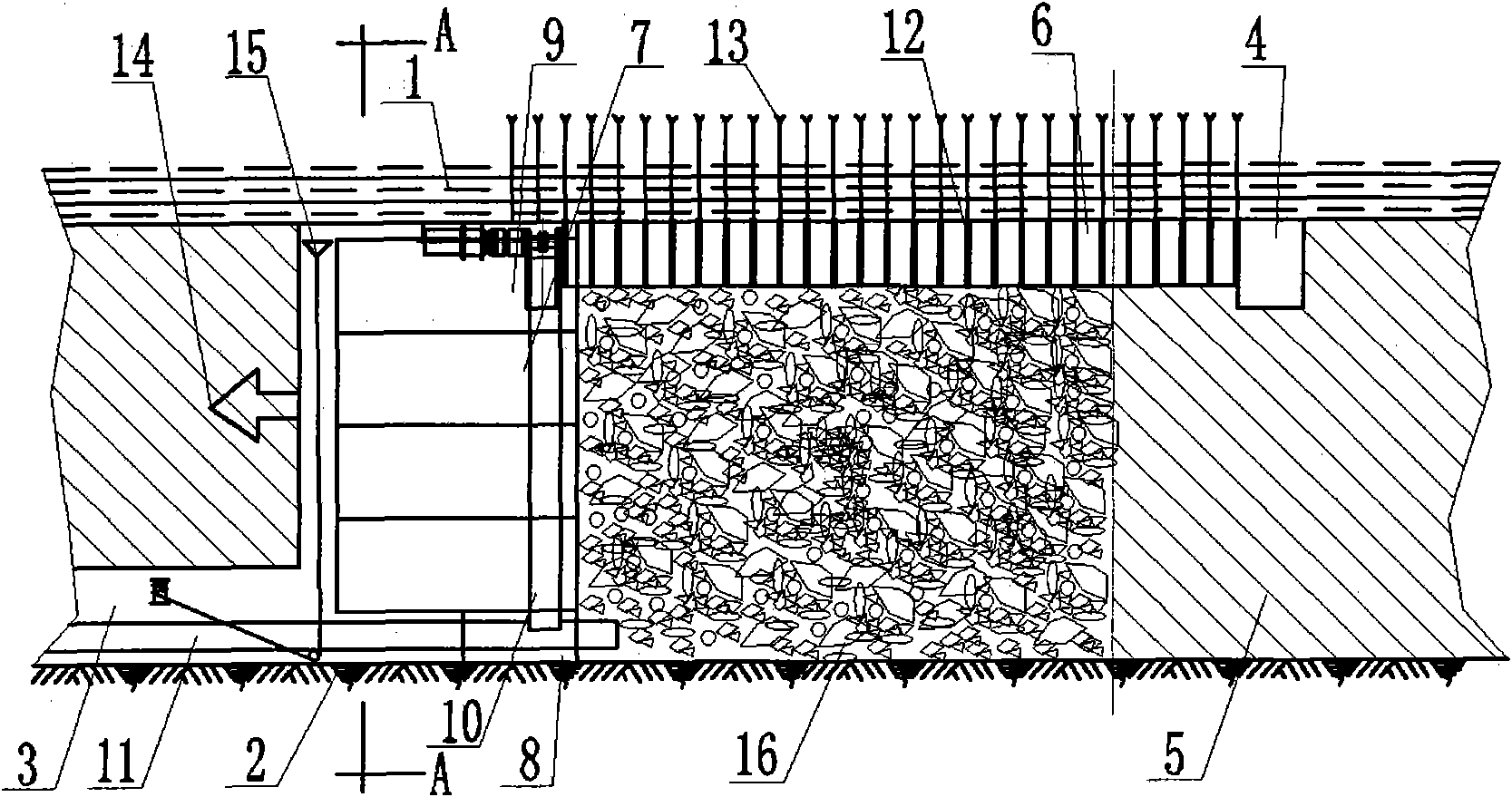

Method of mining coal from heavy pitch thick coal seam

ActiveCN101915101AIncrease productionImprove efficiencyUnderground miningSurface miningEngineeringCoal mining

The invention provides a method for mining coal from a heavy pitch thick coal seam in a horizontal and segmental short wall manner. The method comprises the following steps of: supporting and caving coal by using a top coal caving hydraulic support in a work surface; drilling holes, blasting coal, and conveying the coal with a scraper conveyor; performing gob-side entry retaining by using a prefabricated metal shed or a plastic bucket. The coal-mining method can realize mechanical mining of the heavy pitch thick coal seam, greatly improves yield and efficiency of the working face and ensures safe production.

Owner:TIANDI SCI & TECH CO LTD

Method for extracting coal bed gas by negative pressure on ground through gas-coal simultaneous extraction

InactiveCN102080519AReduce concentrationEnsure safe productionUnderground miningLiquid/gas jet drillingWell drillingNew energy

The invention provides a method for extracting coal bed gas by negative pressure on the ground through gas-coal simultaneous extraction aiming at a waterless coal bed in an ore field. The extraction of the coal bed gas sequentially comprising three stages, namely pre-extraction before coal mining, extraction during coal mining, and extraction after coal mining; and in the method, in the well drilling process, nonmetal sleeves are descended into an old top section and a coal bed section of a vertical well, steel sleeves are descended in other layers, the nonmetal sleeves arranged in the coal bed section avoid hidden danger of sparkles caused by collision of a coal cutter and metal sleeves in subsequent coal mining, and the nonmetal sleeves arranged in the old top section reserve channels for extraction in a worked out section after the rock and shaft below the old top section are collapsed. In the method for extracting the coal bed gas, one well has three purposes, namely gas is pre-extracted in the coal bed section before coal mining, air return and exhaust are performed in the coal mining process and gas in the worked out section is extracted by negative pressure after coal mining, and the utilization rate of a coal bed gas well is improved; and the gas-coal simultaneous extraction is realized, the safety production of a coal mine is ensured, and multi-win effects of efficiently extracting the coal bed gas, utilizing new energy, protecting environment and the like are achieved.

Owner:中矿瑞杰(北京)科技有限公司

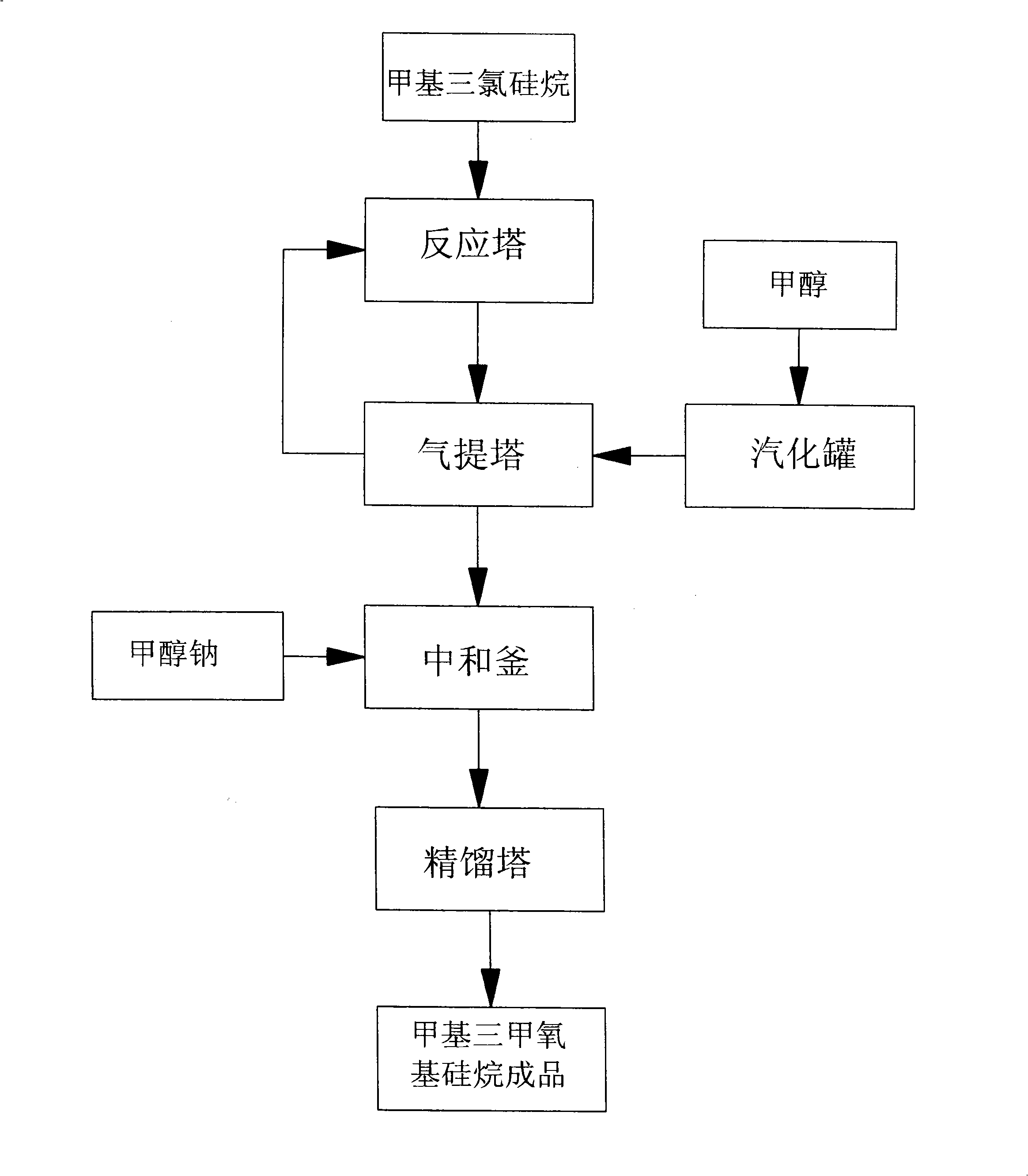

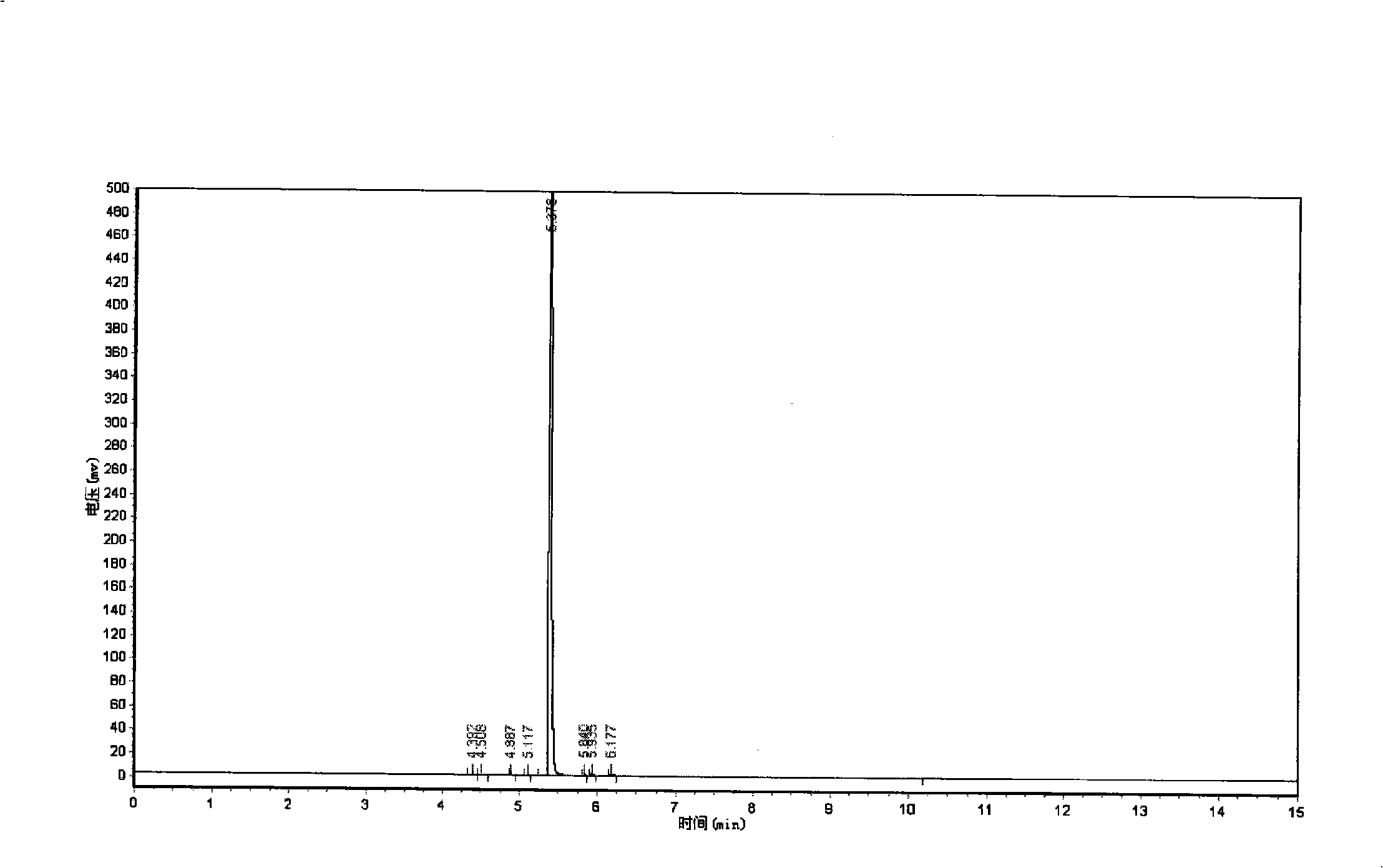

Preparation technique of methyl trimethoxysilane

ActiveCN101348497AEfficient removalAvoid it happening againGroup 4/14 element organic compoundsMethyltrichlorosilaneSilanes

The invention provides a process for preparing methyltrimethoxy silane. The process comprises the following steps that: a. methanol is subjected to vaporization by a vaporizing cylinder and passes through a stripping tower, and enters the bottom part of a reaction tower, methyl trichlorosilane enters the reaction tower from the top and is sprayed downward, and methanol reacts with methyl trichlorosilane by counter current contact; b. a primary product is pumped in the top part of the stripping tower and subjected to steam stripping by methanol gases passing by the stripping tower, after falling onto the bottom part of the stripping tower, the primary product is pumped in a neutralization kettle, and the saturated sodium methylate solution is added in the neutralization kettle for neutralization; c. the coarse product of methyltrimethoxy silane is pumped in a rectification tower for rectification. The process has the characteristics of high working efficiency, stable process and big output, etc. Because the process of the invention is continuously carried out, the process has the advantages of having few operators, ensuring safe production and being capable of easily realizing the control of DCS computers; moreover, the product yield is 90 percent, the effective content of the product is high, and the content of methyltrimethoxy silane is more than 99 percent.

Owner:湖北新蓝天新材料股份有限公司

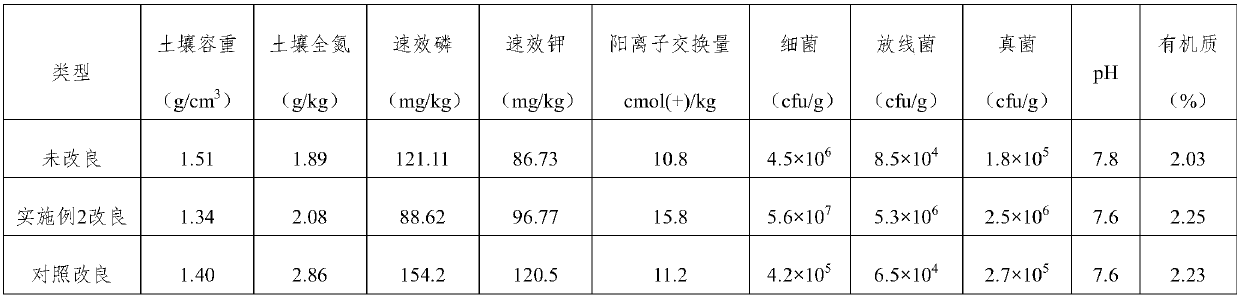

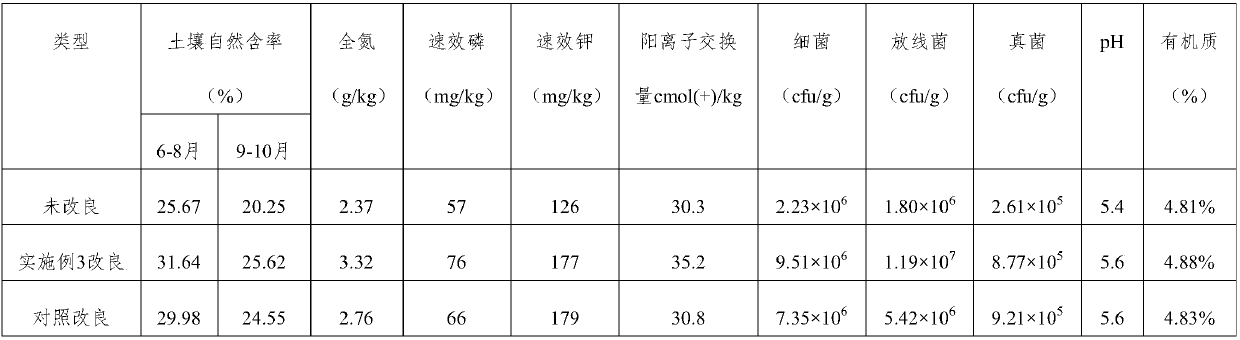

Improver applicable to soil of different soil fertility levels and improvement method

InactiveCN109679662AImprove abilityImprove the poor status quoOther chemical processesOrganic fertilisersMicrobial agentBiology

The embodiment of the invention discloses an improver applicable to soil of different soil fertility levels and an improvement method and relates to the technical field of soil improvement. The improver is prepared from an organic fertilizer, active organic matters, inert organic matters, mineral fertilizers, microbial agents and biological stimulators. The improver is capable of improving barrensoil of different soil fertility degradation levels, and organic matters of soil can be rapidly enriched, soil structures can be improved, soil microorganisms can be activated, microbial flora structures of the soil can be balanced, healthy ecological systems of crop roots can be rapidly established, safe production of crops can be ensured, food security can be ensured, field returning and recycling of organic wastes in cities and rural areas can be achieved, and multiple purposes can be achieved by one stroke.

Owner:BEIJING GOLDENWAY BIO TECH +1

Rock burst prevention method through deep hole blasting and depressurizing

The invention provides a rock burst prevention method through deep hole blasting and depressurizing. The rock burst prevention method comprises the steps that 1, rock burst monitoring signals are detected in an upper roadway and in a lower roadway of a working face of a coal bed with the risk of rock bursts and are compared with the normal value and the obvious characteristics of rock bursts occurring in adjacent regions, field detection is conducted on the hypocenter location and the drilling quantity of coal bodies, a highly-concentrated stressed zone is divided, and a dangerous zone is delineated; 2, a guide depressurizing roadway is dug along the upper roadway towards the center of the dangerous zone of the rock bursts, blasting and depressurizing holes are drilled in the guide depressurizing roadway in the direction of top plate surrounding rock and bottom plate surrounding rock, after explosives are installed, the blasting and depressurizing holes are sealed through yellow mud, and secure detonation is conducted in the guide depressurizing roadway outside the blasting and depressurizing holes; and 3, after blasting and depressurizing danger relieving is conducted in the dangerous zone of the rock bursts, the depressurizing effect is analyzed and detected, and when the depressurizing effect does not reach the detection standard, secondary danger relieving is conducted through the same method till the depressurizing effect reaches the standard. According to the rock burst prevention method through deep hole blasting and depressurizing, the depressurizing danger relieving effect can be improved, the risk of the rock bursts and the anti-burst cost are reduced, and coal mine safety production is ensured.

Owner:LIAONING TECHNICAL UNIVERSITY

Image data base and inspection robot-based equipment trouble detection method

InactiveCN104253482AFacilitate the unattended processReduce labor intensityRadiation pyrometryCircuit arrangementsFeature extractionMultimodality image registration

The invention discloses an image data base and inspection robot-based equipment trouble detection method. According to the image data base and inspection robot-based equipment trouble detection method, an image data base is established, equipment is calibrated manually, a visible light camera and a thermal imaging camera which are installed on an inspection robot are used for shooting, and detection and alarming of equipment with abnormal temperature are achieved only through rectification between a real-time visible light image and the corresponding image data base, so that problems of complex and uncontrollable multi-modal image registration, equipment characteristic extraction, mode recognition and the like are converted to be the problem of single-modal image registration, steps are simplified, and the detection accuracy is improved.

Owner:UNIV OF JINAN

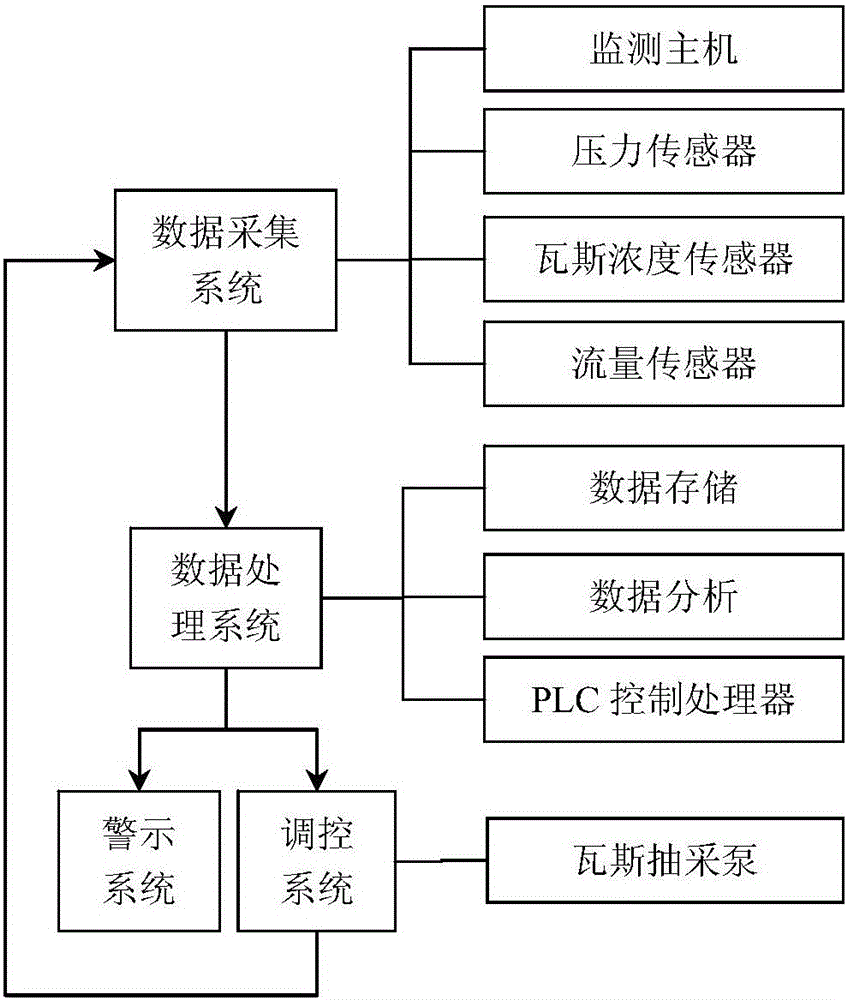

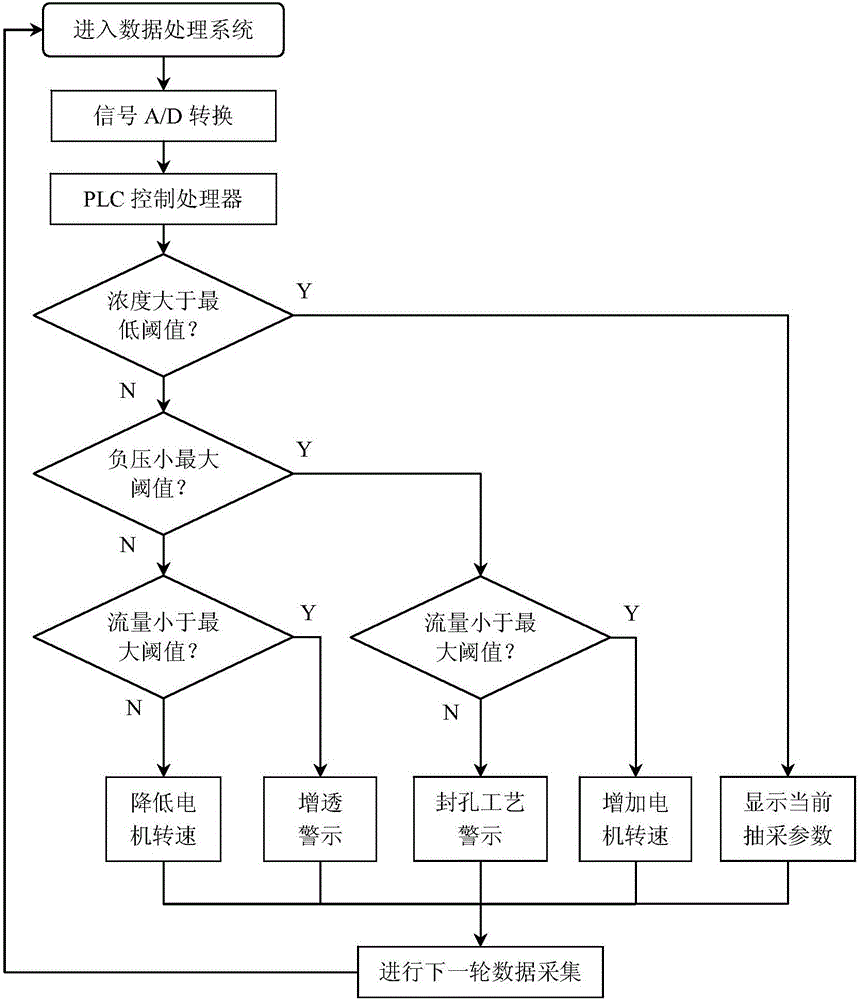

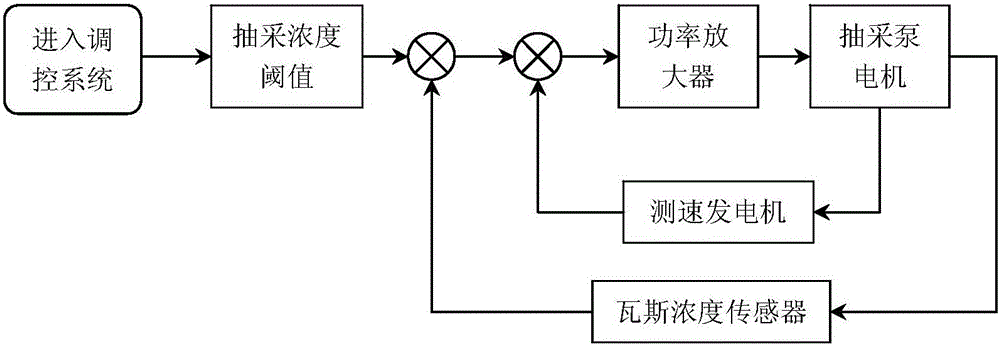

Coal mine gas extraction parameter automatic regulating and controlling system and coal mine gas extraction parameter automatic regulating and controlling method

ActiveCN105065057AImprove extraction efficiencyEnsure safe productionMining devicesGas removalTraffic volumeMonitoring data

The invention discloses a coal mine gas extraction parameter automatic regulating and controlling system and a coal mine gas extraction parameter automatic regulating and controlling method. The regulating and controlling system comprises a data collecting system, a data processing system, a regulating and controlling system and a warning system, wherein the data collecting system is in charge of collecting and displaying monitoring data such as the gas concentration, the flow rate and the extraction negative pressure in a gas extraction pipeline; the data processing system is in charge of receiving and storing the monitoring data, analyzing the data and providing a response signal for the regulating and controlling system and the warning system; the regulating and controlling system is in charge of regulating the operation parameters of a gas extraction pump arranged on the extraction pipeline according to the received response signal; and the warning system is used for warning the unreasonable extraction parameters and extraction states in a sound and light mode according to the received response signal. The operation state parameters of the extraction pump are changed in a mode of automatically regulating the extraction pump; the effects of effectively monitoring the pipeline gas extraction parameter and automatically regulating the work state of the extraction pump are achieved; the warning is achieved on the defective extraction condition; and the gas extraction efficiency is improved.

Owner:SHAANXI COAL & CHEM TECH INST

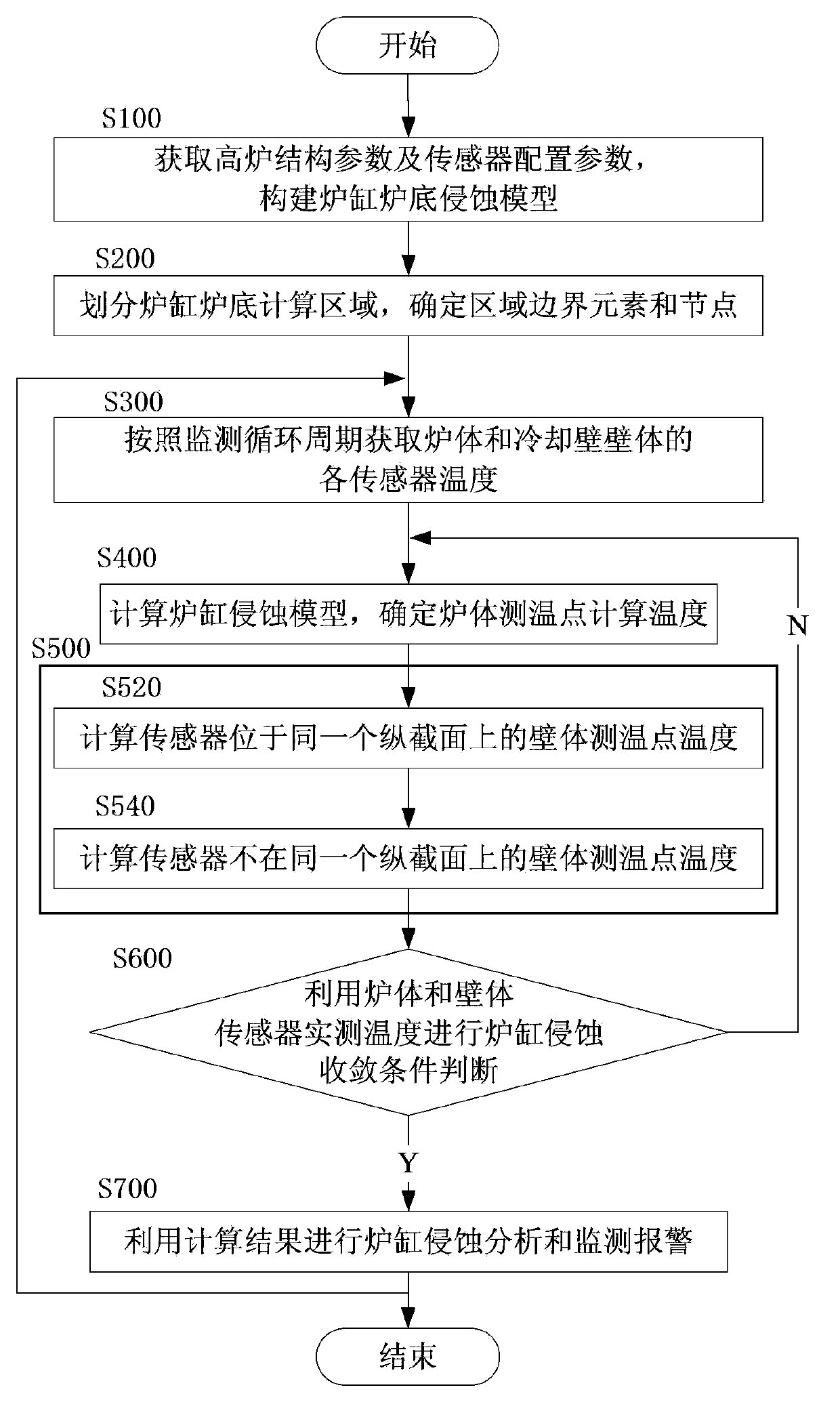

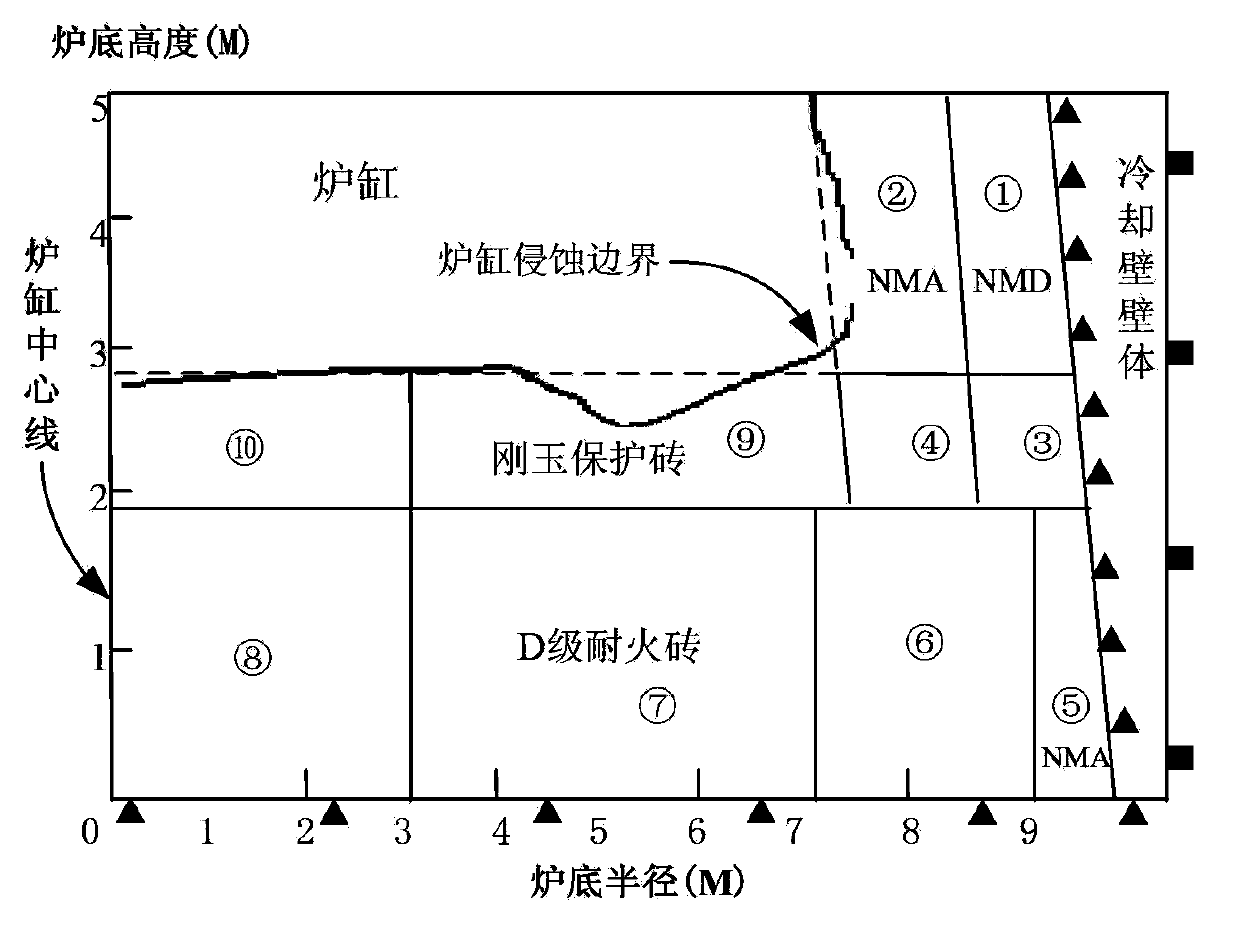

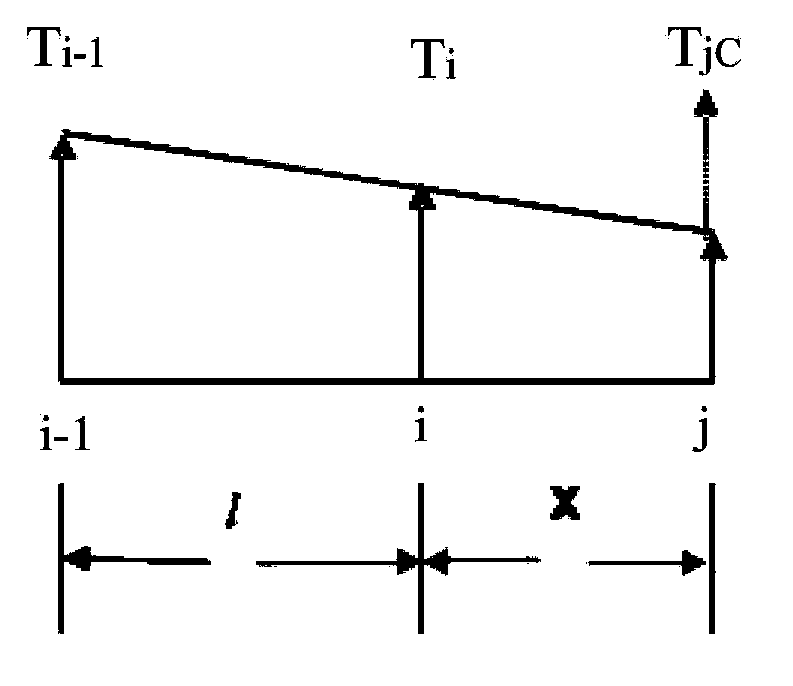

Method for monitoring erosion deviation of blast furnace hearth

ActiveCN103866061ASolve the problem of calculation failureExtend your lifeBlast furnace detailsChecking devicesHearthErosion

The invention discloses a method for monitoring erosion deviation of a blast furnace hearth, relates to online monitoring of erosion of an iron and steel smelting blast-furnace lining, and particularly relates to a method for monitoring erosion deviation of the blast furnace hearth by using computer program. The method comprises the following steps: building a blast furnace model; dividing a computational domain of the hearth bottom according to the material and the shape of the furnace wall; obtaining the temperature of sensors on the furnace wall and a cooling wall; calculating an erosion model at the hearth bottom, and determining the computation temperature of a temperature measuring point of the furnace body; calculating the temperature of a boundary node of the furnace body; carrying out hearth erosion convergence condition judgment by using the really measured temperature of the furnace wall and the cooling wall; carrying out hearth erosion analysis and monitoring alarming by using the computation result. The furnace body temperature sensor and the cooling wall body temperature sensor are comprehensively utilized to monitor the deviation, and the problems of a computation failure easily caused by the damage to the furnace wall temperature sensor, and a large error in the computation result caused by erosion computation by directly utilizing the cooling wall temperature sensor in the existing erosion monitoring computation method can be solved.

Owner:BAOSHAN IRON & STEEL CO LTD

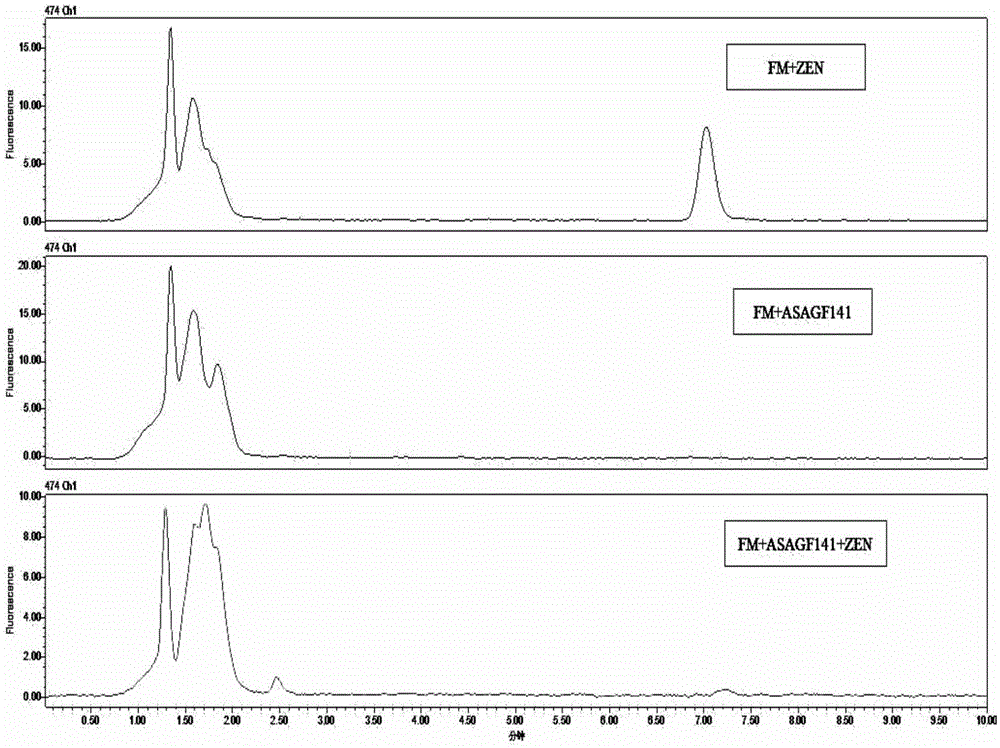

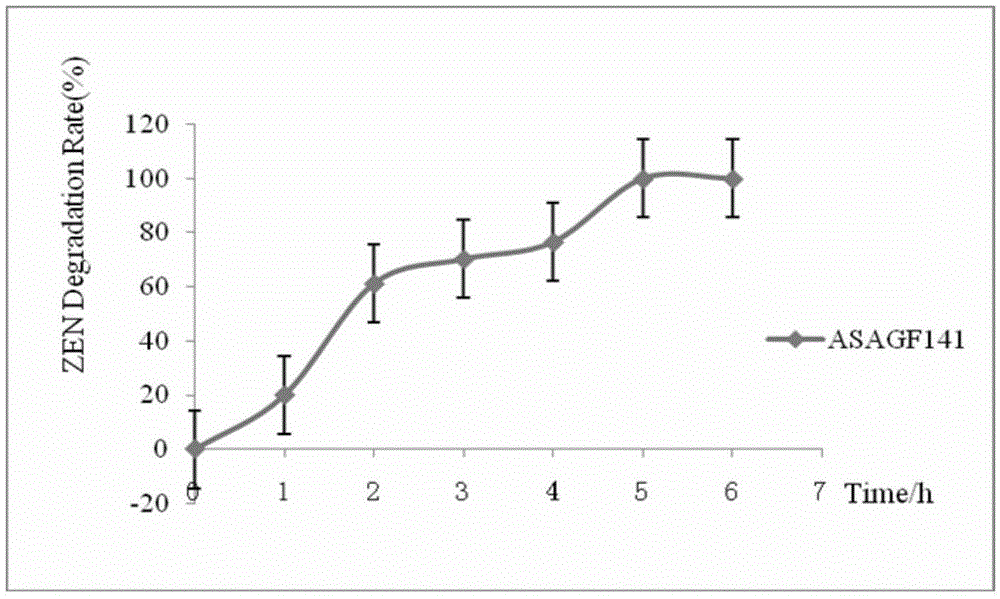

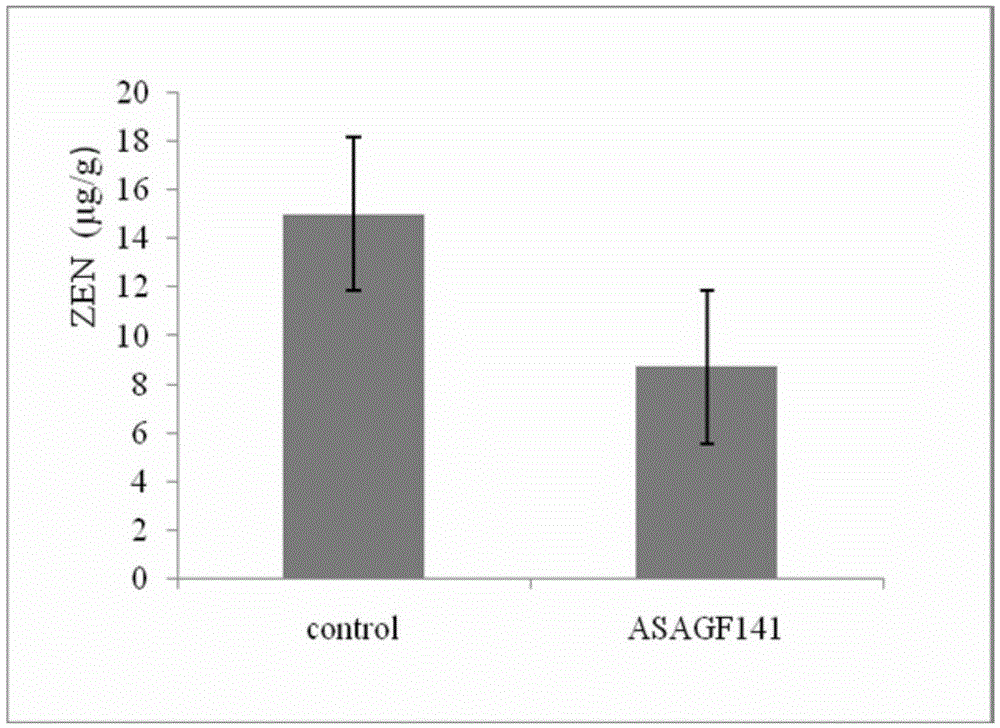

Bacillus subtilis for effectively degrading zearalenone and application thereof

ActiveCN105385616AEfficient degradationEfficient production and degradationBacteriaMicroorganism based processesMicrobiologyVirgibacillus species

The invention discloses Bacillus subtilis for effectively degrading zearalenone and application thereof. The preservation serial number of the Bacillus subtilis ASAGF141 is CGMCC No.9463. The invention further provides bactericide containing preserved strains and a preparation method of the bactericide; besides, the invention further provides application of the strains or the bactericide to degradation of the zearalenone. According to the Bacillus subtilis for effectively degrading zearalenone and application thereof, the trains can completely degrade the 20 microgram / ml zearalenone within a short time, and the degradation rate is 10%.

Owner:ACAD OF NAT FOOD & STRATEGIC RESERVES ADMINISTRATION

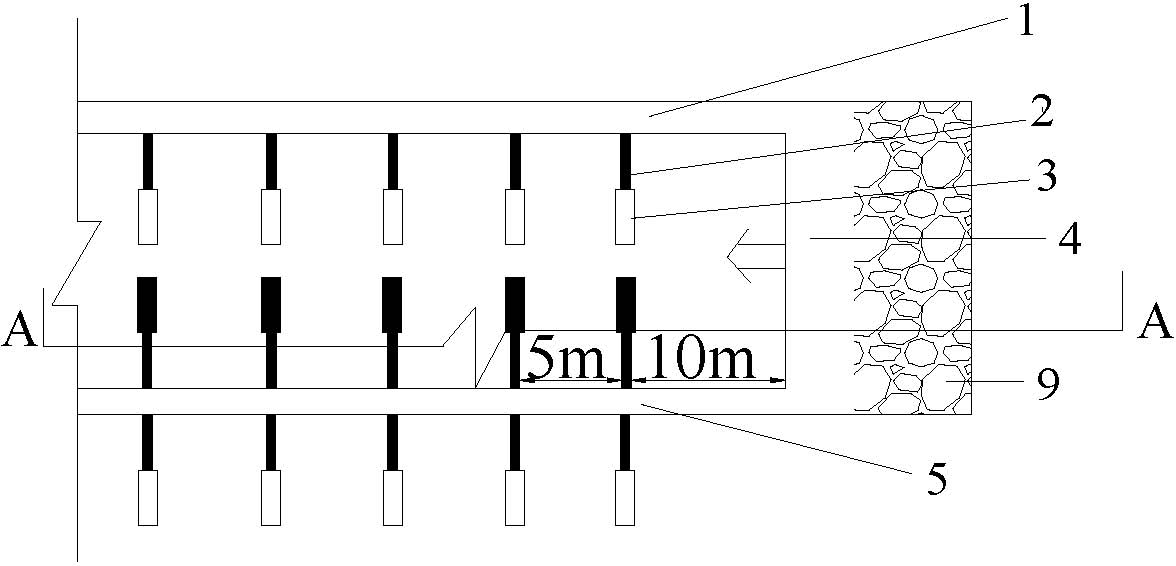

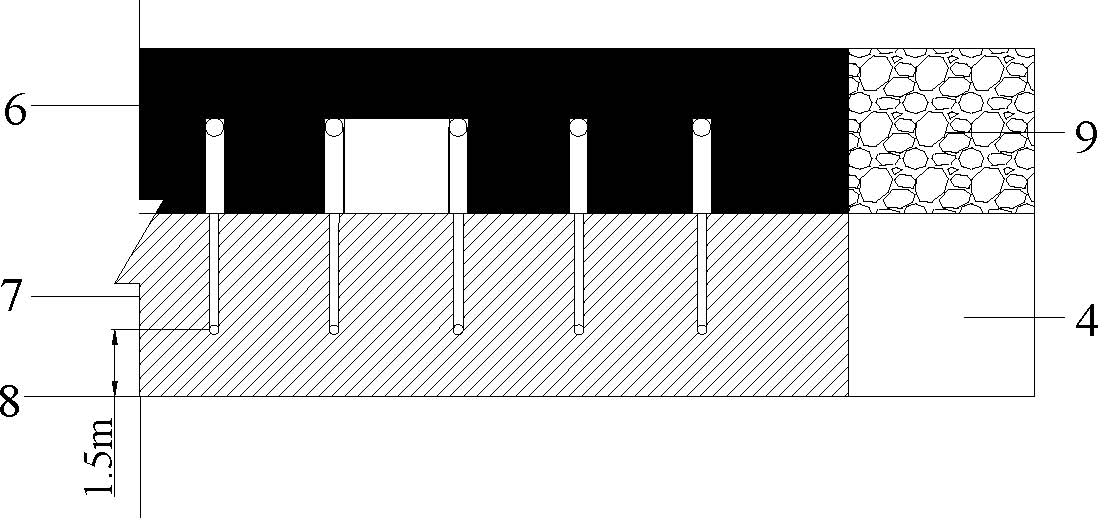

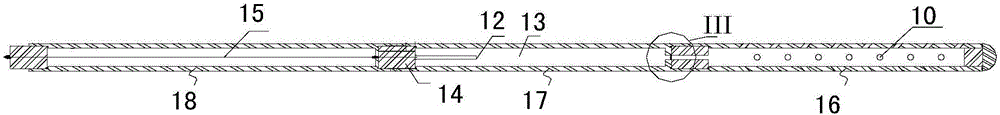

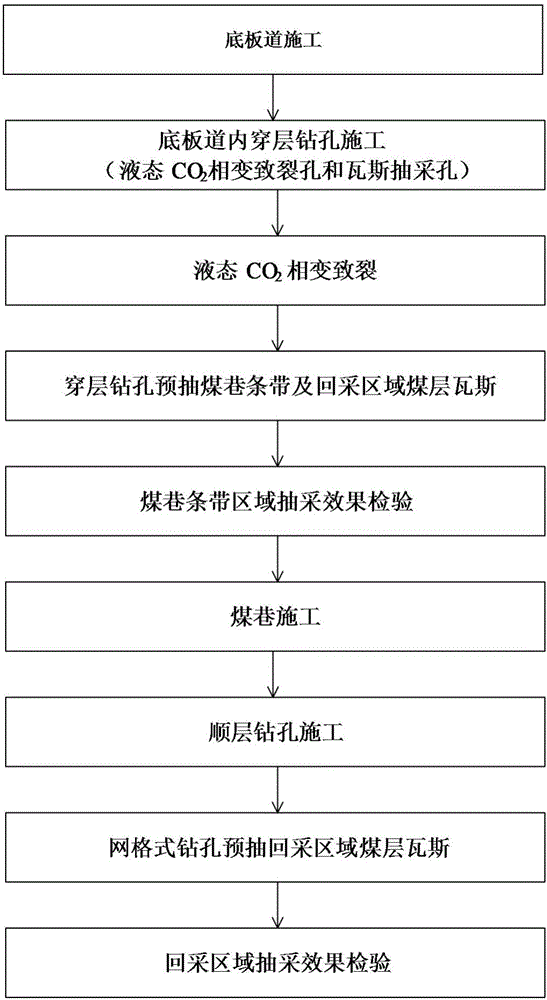

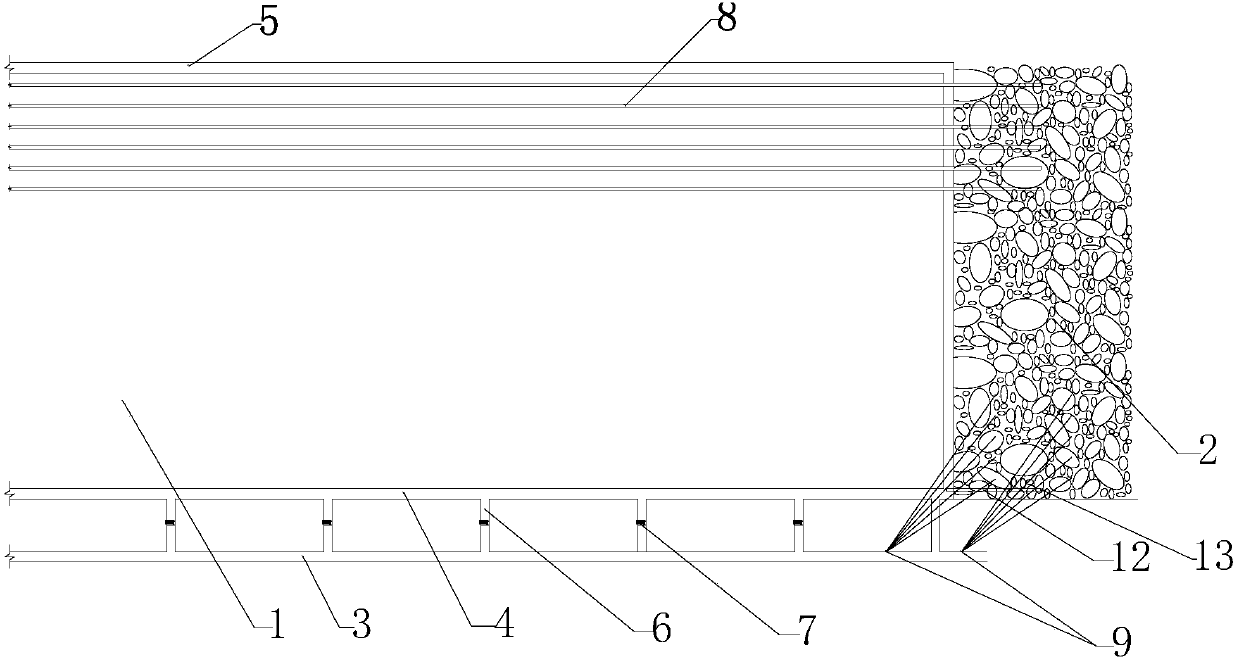

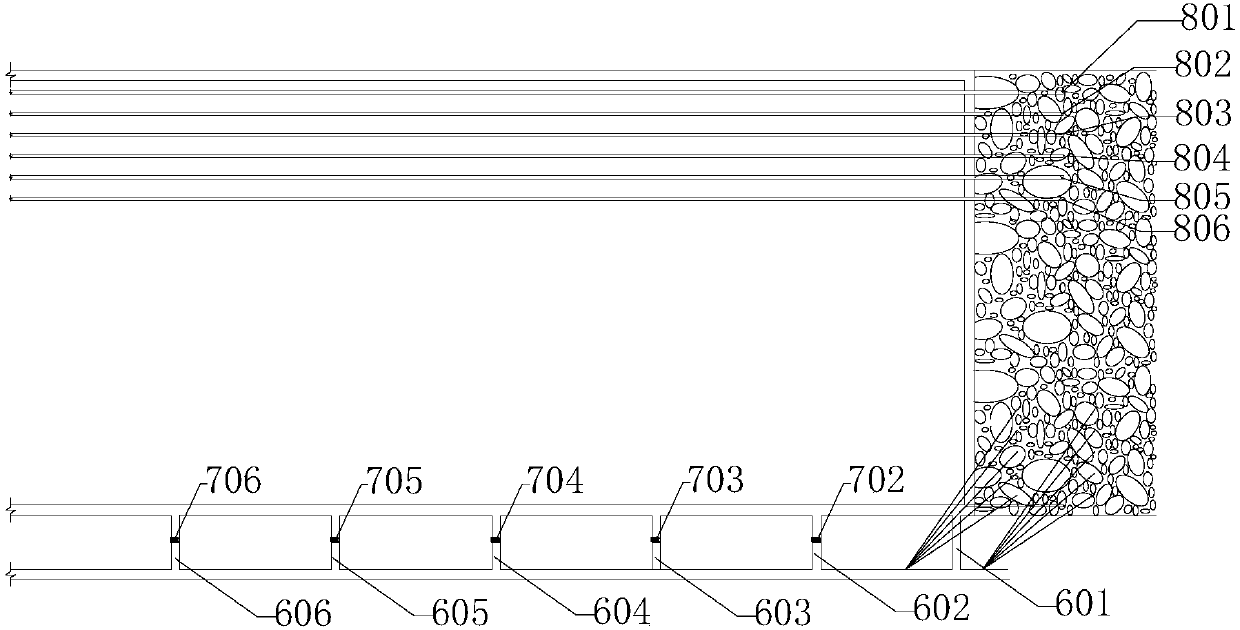

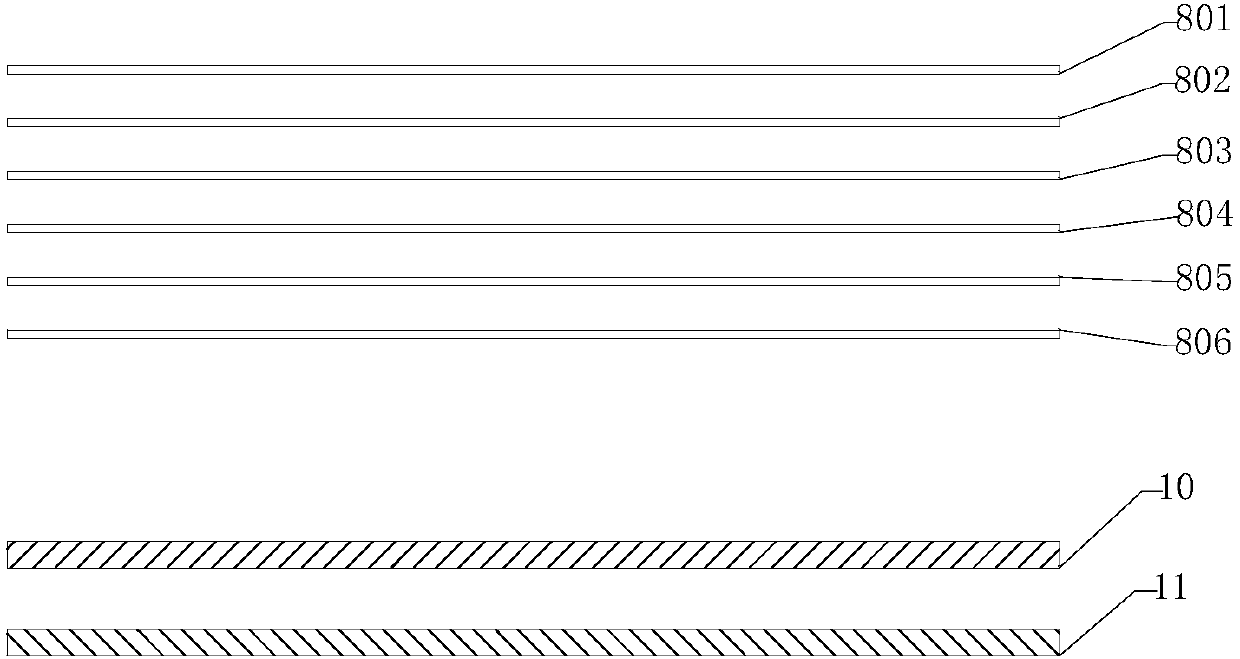

Liquid-phase CO2 phase change cracking permeability-increasing grid type gas extraction method for low-permeable coal seam

ActiveCN106194244AIncrease gas extractionEliminate outstanding hazardsFluid removalGas removalDrill holeProcess engineering

The invention discloses a liquid-phase CO2 phase change cracking permeability-increasing grid type gas extraction method for a low-permeable coal seam. The method comprises the following steps that (1) a bottom board passage is constructed; (2) crossing drilling construction is carried out in the bottom board passage; (3) liquid CO2 phase change cracking is carried out; (4) gas of coal seams of a coal roadway strip and a recovery area is pre-drained with crossing drill holes; (5) the extraction effect of the coal roadway strip area is detected; (6) coal roadway construction is carried out; (7) hole drilling down the seam is carried out; (8) gas of the coal seam in the recovery area is pre-drained with grid type drill holes; and (9) the extraction effect of the recovery area is detected. The method can improve the quantity of drainage of gas of underground coal mine, achieve the purpose of rapidly eliminating danger of outburst for high-gas low-permeable outburst coal seams, prevent coal and gas outburst accidents and guarantee safety production of the underground coal mine.

Owner:CHONGQING UNIV

Joint treatment method for gas and coal spontaneous combustion in night distance seam mining

InactiveCN107859530APrevent overrunningLow costDust removalFire preventionCoal spontaneous combustionControl system

The invention discloses a joint treatment method for gas and coal spontaneous combustion in night distance seam mining. Gas gushing out of a stope working face is treated through a 'two intakes and one return' working face ventilation system, long drill holes in the trend of a fissure zone are utilized to replace a high pumping lane to extract gas gushing out of residual coal of night distance seams and a coal seam, thus corner gas overflow on the stope working face is avoided, and the gas extraction project cost is reduced. Gas injecting pipelines are arranged on a belt gate roadway of the stope working face to continuously inject liquid carbon dioxide into a goaf to restrain spontaneous combustion of the residual coal of the coal seam, low-position drill holes are formed in a track gateroadway of the stope working face to inject nitrogen to prevent spontaneous combustion of the coal of the night distance seams after extraction collapse, thus a coal spontaneous combustion three-dimensional preventing and control system of the goaf is formed, float coal spontaneous combustion in the goaf is accurately prevented and treated, finally, the purpose of joint treatment for gas and coalspontaneous combustion in night distance seam mining is achieved, the coal recovery rate of coal and the working face stoping continuous speed are increased, and safe production of the tope working face is guaranteed.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Fireproof high-molecular compound colloid material for coal mines

ActiveCN101993574AStrong targetingStrong adhesionDust removalFire preventionSpontaneous combustionSodium Bentonite

The invention discloses a fireproof high-molecular compound colloid material for coal mines, which belongs to fireproof materials. The fireproof high-molecular compound colloid material is compounded from 40-100 portions of high-molecular compound and 52-98 portions of an inorganic material, wherein the high-molecular compound is polyacrylate, or is composed of 40-55 portions of polyacrylate, 0-30 portions of carboxymethyl cellulose and 0-15 portions of polyacrylamide; the inorganic material is composed of 30-50 portions of bentonite, 12-18 portions of alumina shale powder, 10-20 portions of kaolin, 0-5 portions of attapulgite and 0-5 portions of clay; and the fineness of each raw material is less than 120 um. The preparation method of the colloid material comprises the following steps: mixing the high-molecular compound for 3-5 minutes; and after respectively spraying the inorganic material on a dry mixer, sufficiently and uniformly mixing the 8 materials for 8-10 minutes. The colloid material has the advantages of high water content, high moisture retention, high heat absorption capacity, quick fireproof effect taking, favorable effect, low possibility of afterburning and low composite cost, and is suitable for preventing and controlling fire for the spontaneous combustion and inflammation laws of different types of coal; and the downhole operation is simple and safe.

Owner:徐州意创化工科技有限公司

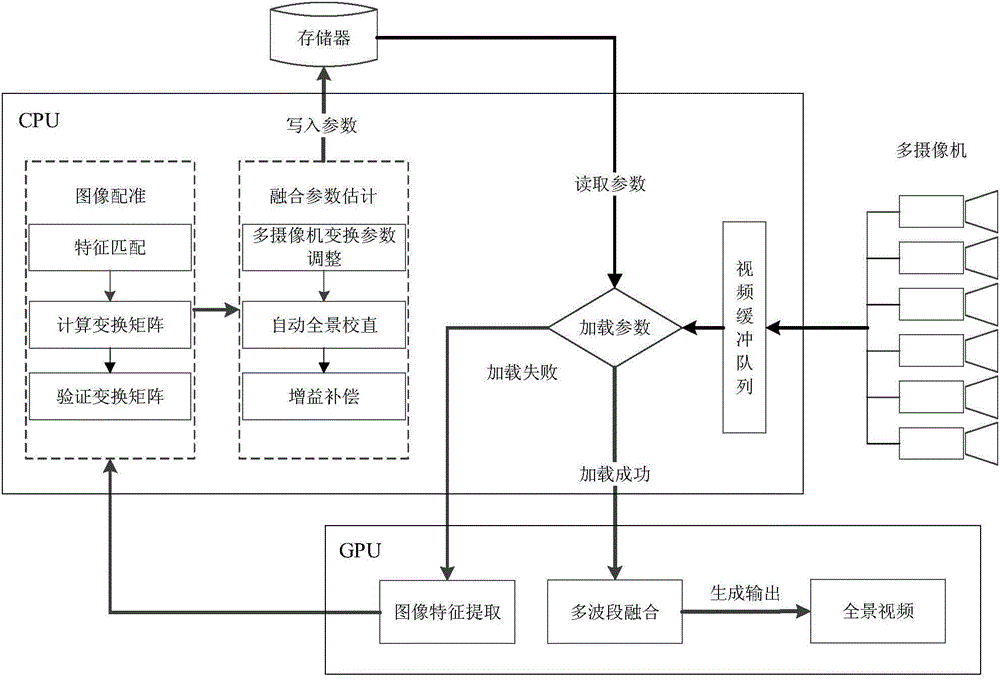

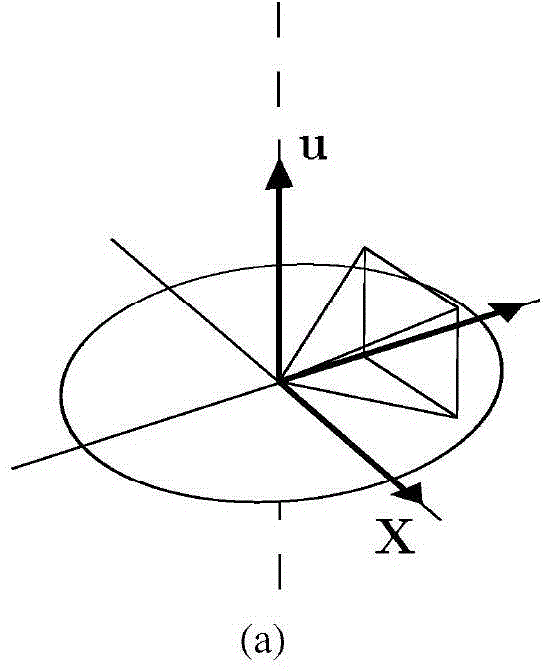

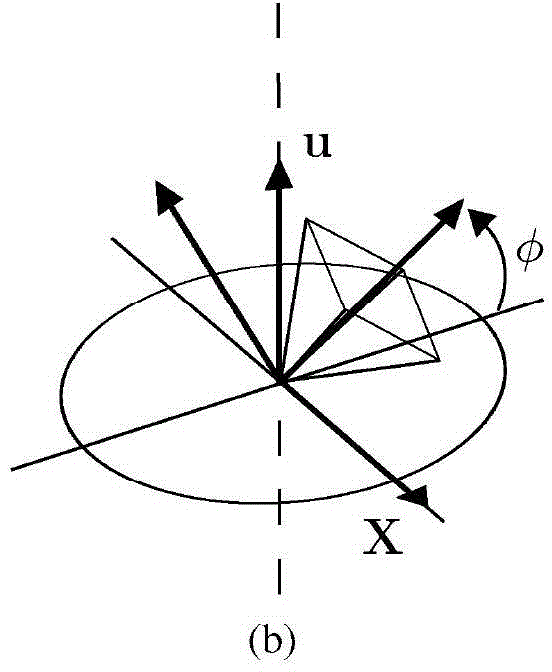

Mine multi-camera video fusion method based on GPU and CPU cooperative computing

InactiveCN104966063AAlleviate the status quo of poor real-time performanceSolve the deformationImage enhancementImage analysisMulti cameraUltrahigh resolution

The invention discloses a mine multi-camera video fusion method based on GPU and CPU cooperative computing and belongs to the mine multi-camera video fusion method. The method is characterized in that a GPU and CPU cooperative computing model is established, and thus current situation of poor real-time performance of an existing video fusion method is relieved; automatic matching is carried out by utilizing features of overlapped regions between adjacent video sources to determine relative position relation of the video sources, so that positions of cameras do not need to be assigned in advance, and automatic integration is realized; camera parameter bundle adjustment estimation and automatic alignment are carried out, so that the problem of deformation of panorama images after fusion is solved; and an exposure compensation and multiband fusion method is adopted, and finally, an ultrahigh-resolution large-visual angle mine mining (extraction) working face large-scale scene real-time integral video is generated, so that the method plays an important role for improving coal mining work efficiency and guaranteeing coal mine safety production. The advantages are that the multi-camera video fusion method utilizes the existing cameras of a coal mine fully to generate the mine mining (extraction) working face panorama video, thereby reducing equipment investment and improving safety of coal mine production.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com