Method for extracting coal bed gas by negative pressure on ground through gas-coal simultaneous extraction

A coalbed methane and ground technology, which is applied in ground mining, drilling equipment and methods, and mining fluids, etc., can solve the problem of large and short engineering volume (limited by the replacement time of coal mining, 3-6 months after the construction of the extraction hole). In order to improve the utilization rate, the problem of coal mining and large investment in the

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

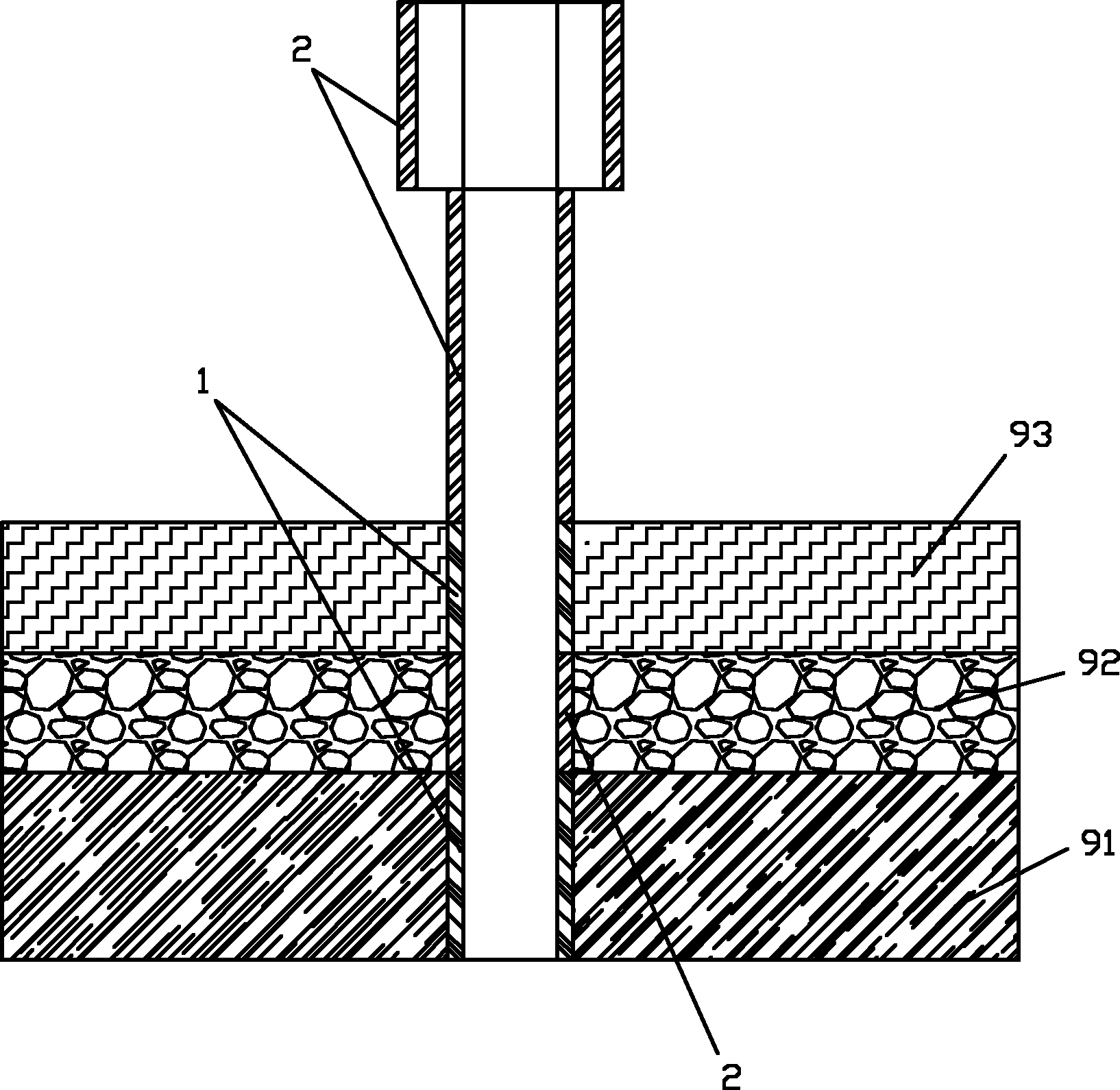

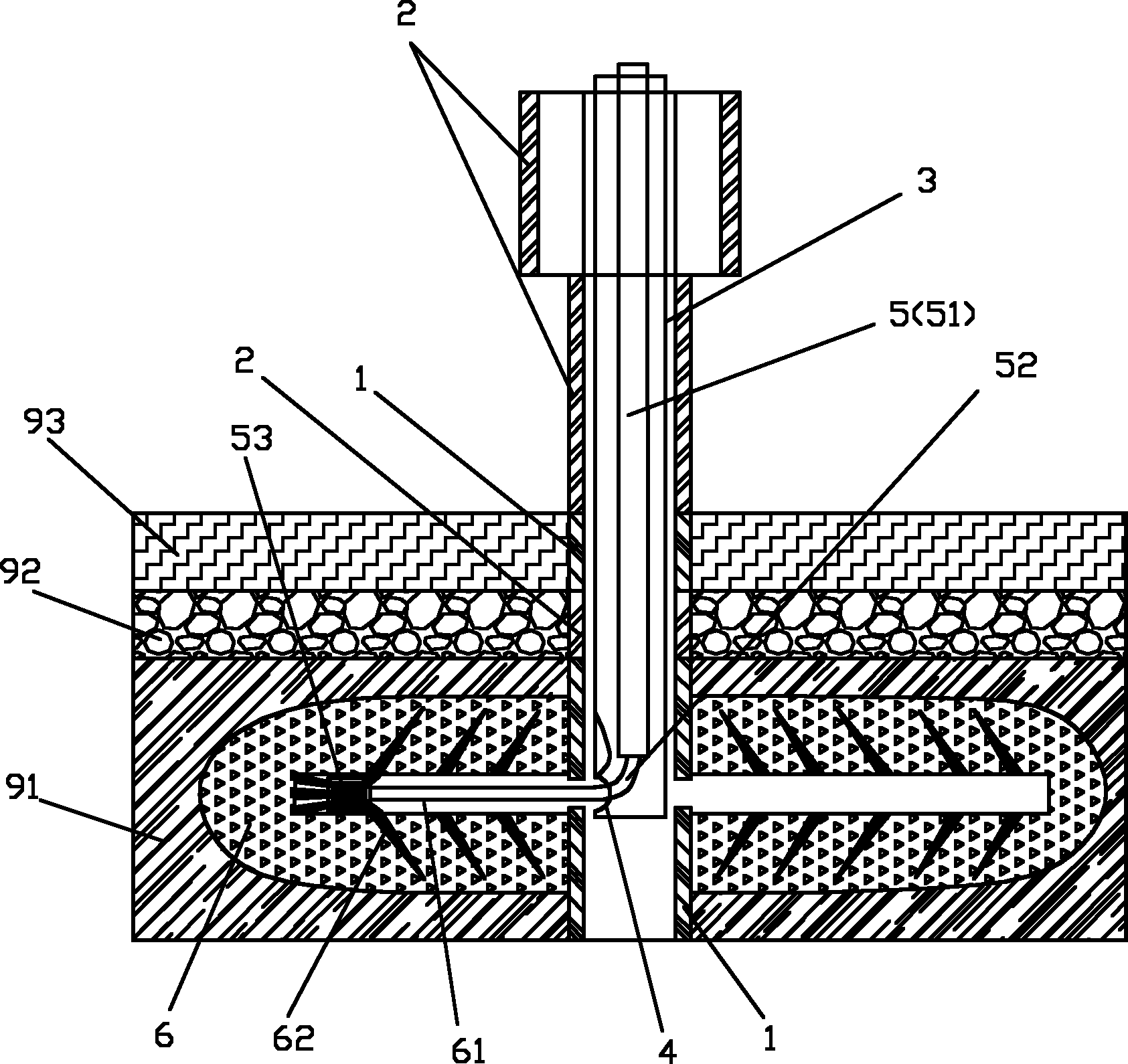

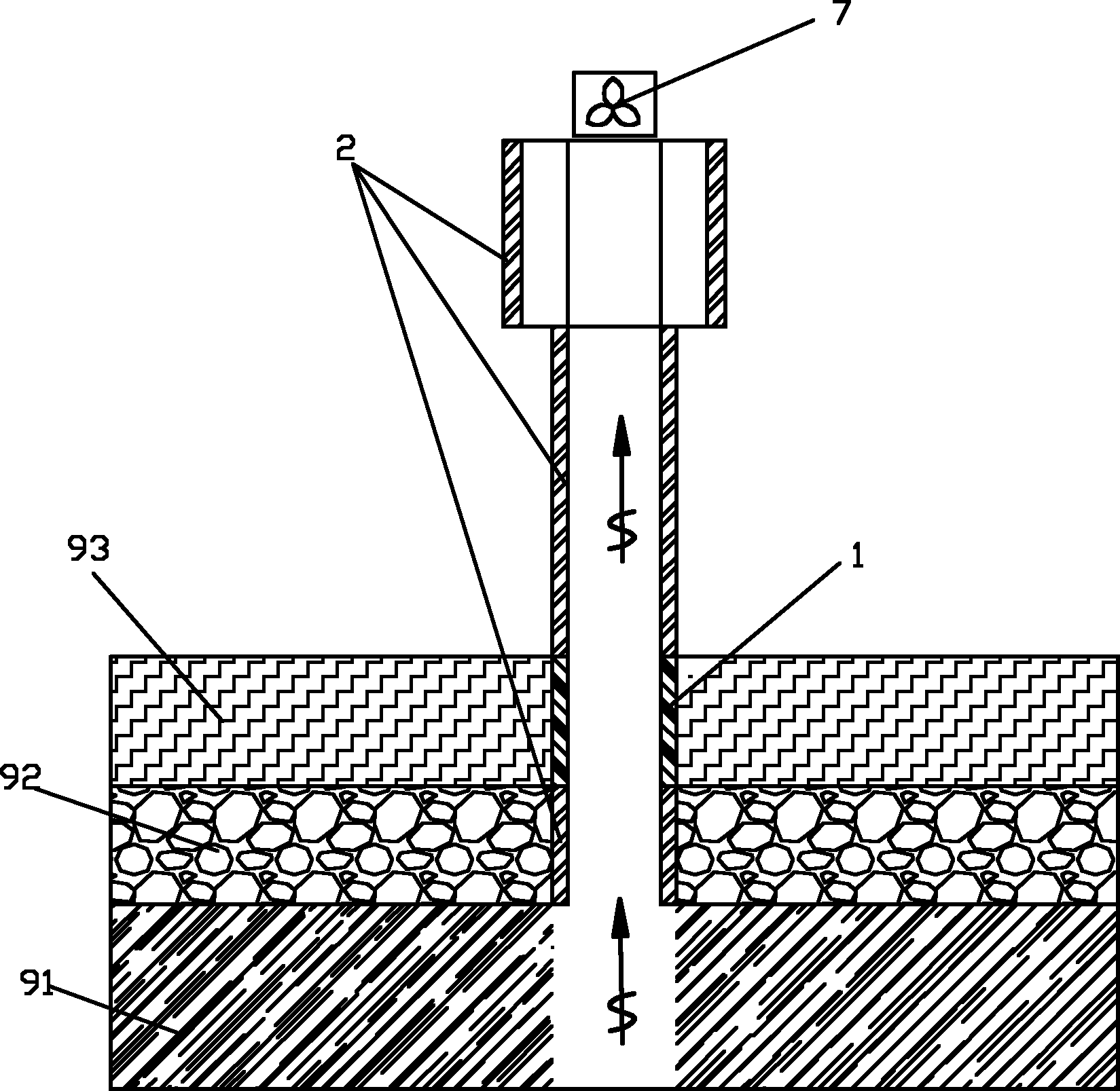

[0023] The present invention proposes a method of ground negative pressure extraction of coalbed methane in gas-coal co-extraction, such as figure 1 As shown, after drilling, set non-metallic casing 1 for cementing in the old top section 93 wellbore and coal seam section 91 wellbore, and use steel casing 2 for cementing in other intervals (such as: immediate top section 92, upper side of the old top section, etc.) . Using non-metallic casing 1 to cement the coal seam section 91 wellbore avoids the hidden danger of sparks caused by the collision between the coal cutter and the metal casing during subsequent coal mining; After the lower rock mass and wellbore collapsed, a channel was reserved for gas pumping in the goaf. In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com